Page 1

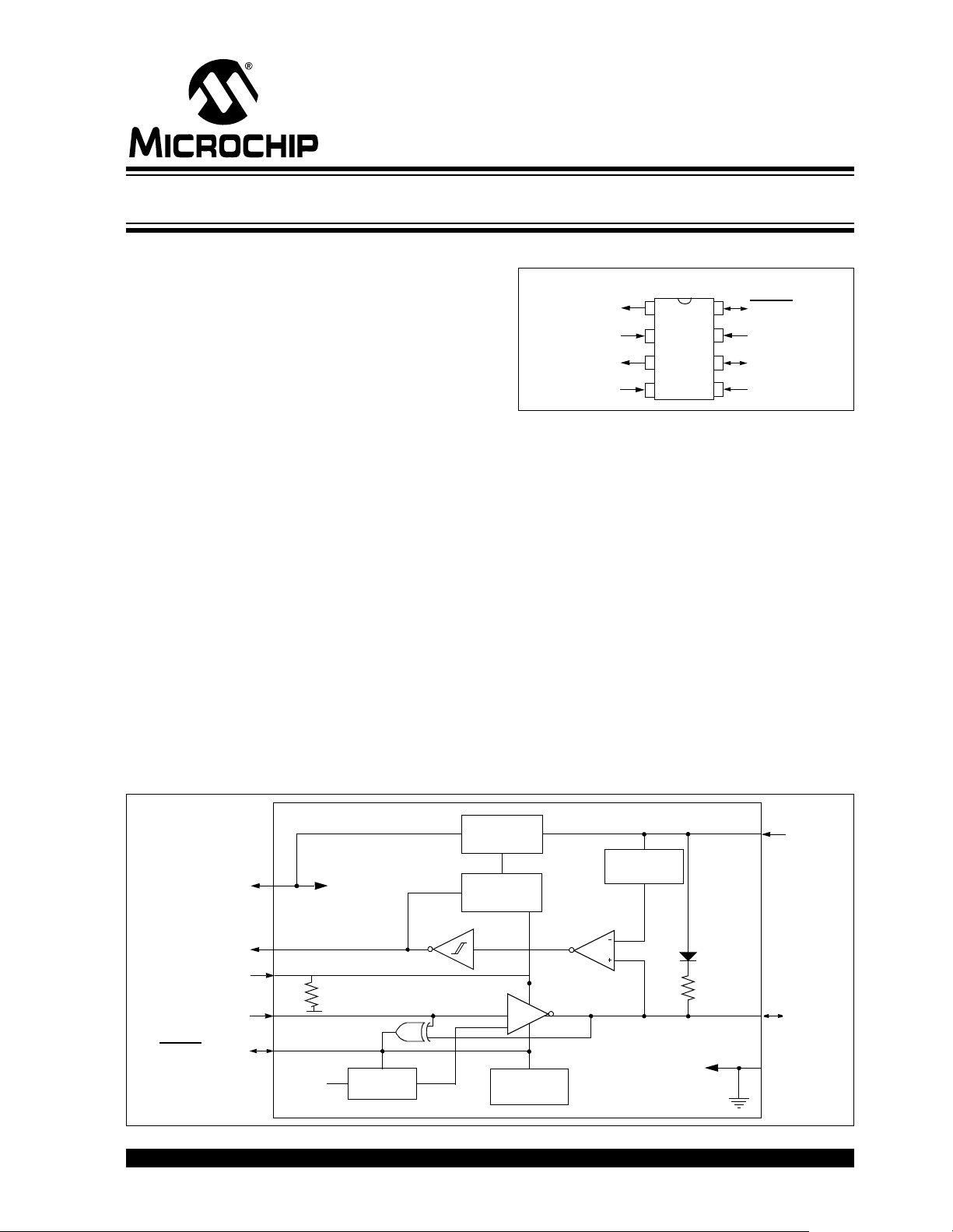

MCP201

LIN Transceiver with Voltage Regulator

Features

• Supports baud rates up to 20 Kbaud

• 40V load dump protected

• Wide supply voltage, 6.0 – 18.0V, continuous

- Maximum input voltage of 30V

• Extended Temperature Range: -40°C to +125°C

• Interfa ce to standard USARTs

• Compati ble with LIN Spec 1.3

• Local Interconnect Network (LIN) Line pin:

- Internal pull-up resistor and diode

- Protected against ground shorts (LIN pin to

ground)

- Protected against LIN pin loss of ground

- High current drive, 40 mA ≤ I

• Automatic thermal shutdown

• On-board Voltage Regulator:

- Output voltage of 5V with ±5% tolerances

over temperature range

- Maximum output current of 50 mA

- Able to drive an external series-pass

transistor for increased current supply

capability

- Internal thermal overload protection

- Internal short-circuit current limit

- External components limited to filter capacitor

only and load capacitor

OL ≤ 200 mA

Package Types

PDIP, SOIC, DFN

RXD

CS/WAKE

V

REG

TXD

1

2

3

4

8

7

6

MCP201

5

FAULT/SLPS

VBAT

LIN

SS

V

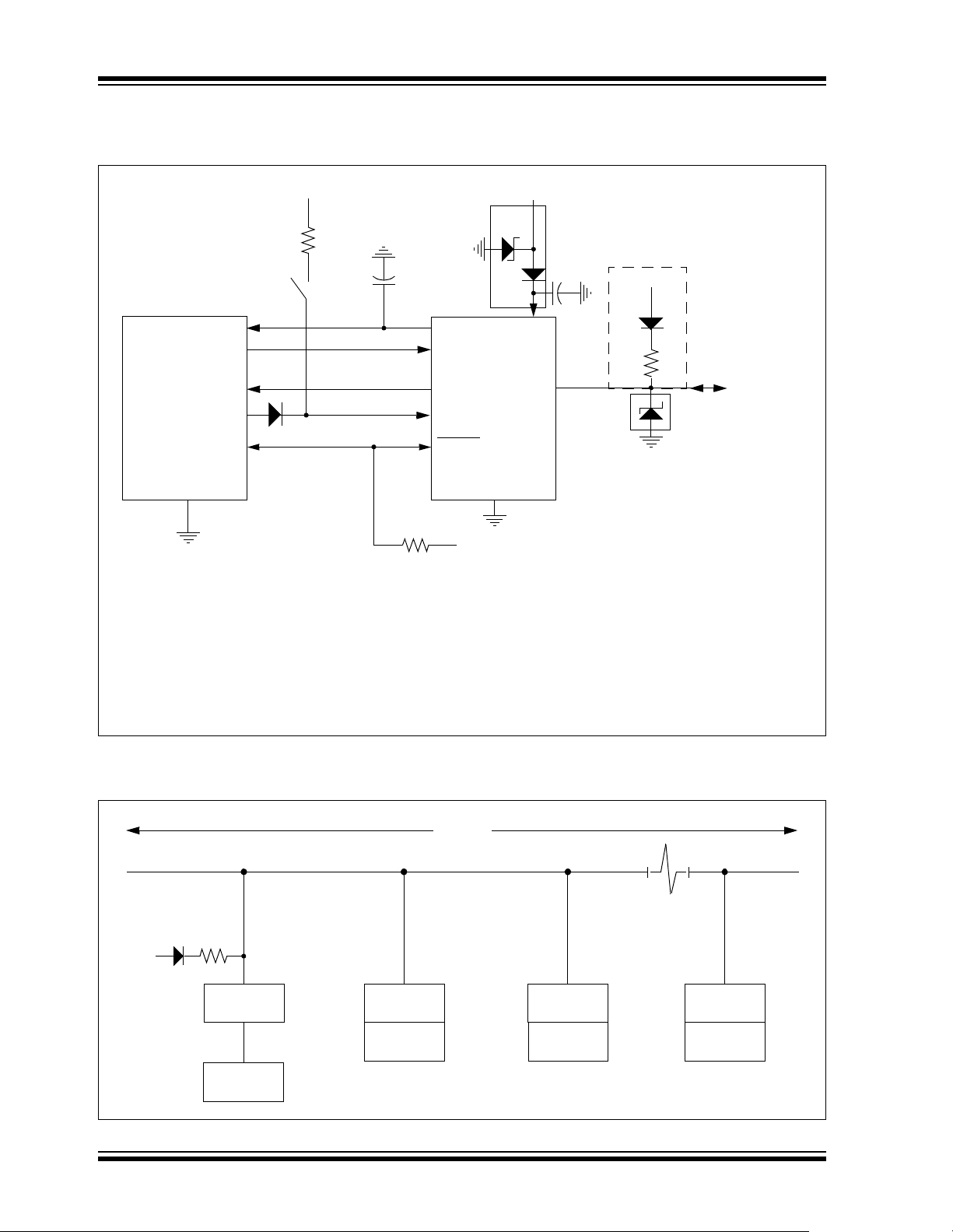

Block Diagram

Voltage

Regulator

Ratiometric

VREG

RXD

CS/WAKE

TXD

FAULT/SLPS

© 2007 Microchip Technology Inc. DS21730F-page 1

Internal Circuits

POR

Slope

Control

Wake-Up

Logic

OC

Thermal

Protection

Reference

approx.

30 kΩ

Vss

V

BAT

LIN

Page 2

MCP201

NOTES:

DS21730F-page 2 © 2007 Microchip Technology Inc.

Page 3

MCP201

1.0 DEVICE OVERVIEW

The MCP201 provides a physical interface between a

microcontroller and a LIN half-du plex bus. It is i ntended

for automotive and industrial applications with serial

bus speeds up to 20 Kbaud.

The MCP201 provides a half-duplex, bidirectional

communications interface between a microcontroller

and the serial network bus. This device will translate

the CMOS/TTL logic levels to LIN level logic, and vice

versa.

The LIN specification 1.3 requires that the transceiver

of all nodes in the system be connected via the LIN pin,

referenced to ground and with a maximum external

termination resistance of 510Ω from LIN bus to battery

supply. The 510Ω corresponds to 1 Master and 16

Slave nodes.

The MCP201 pro vides a +5V 50 mA regulate d power

output. The regulator uses a LDO design, is shortcircuit-protected and will turn the regulator output off if

it falls below 3.5V. The MCP201 also includes thermal

shutdown protec tion. The regulator has been specifically designed to operate in the automotive environment and will survive reverse battery connections,

+40V load dump transients and double-battery jumps

(see Section 1.6 “Internal Voltage Regulator”).

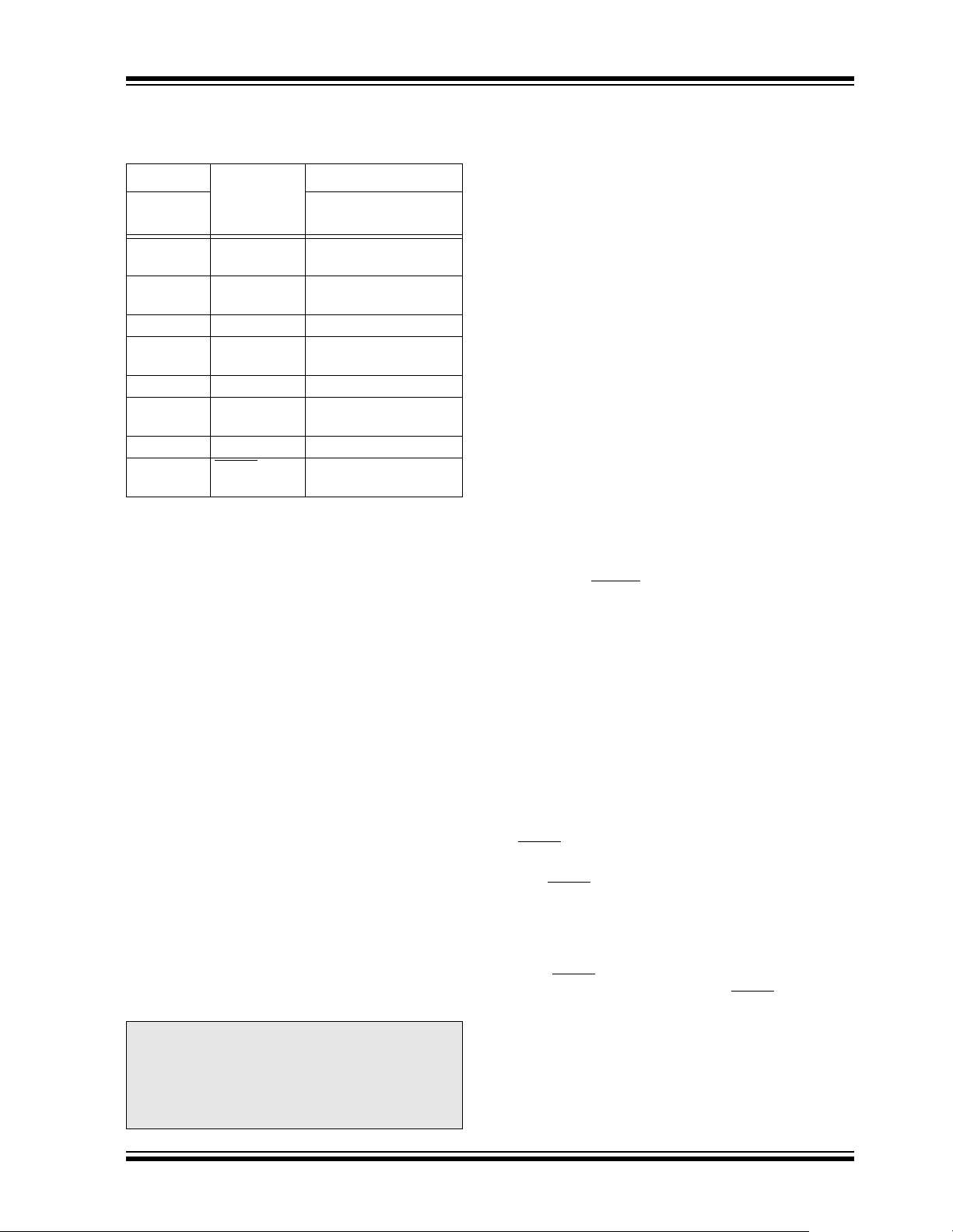

1.1 Optional External Protection

1.1.1 TRANSIENT VOLTAGE PROTECTION (LOAD DUMP)

An external 27V transient suppressor (TVS) diode,

between V

with the battery supply and the V

tect the device from power transients (see Figure 1-2)

and ESD events. While this protection is optional, it

should be considered as good engineering practice.

BAT and ground, with a 50Ω resistor in series

BAT pin, serves to pro-

1.2 Internal Protection

1.2.1 ESD PROTECTION

For component-level ESD ratings, please refer to the

maximum operation specifications.

1.2.2 GROUND LOSS PROTECTION

The LIN bus specification states that the LIN pin must

transition to the recessive state when ground is

disconnected. Therefore, a loss of ground effectively

forces the LIN line to a hi-impedance level.

1.2.3 THERMAL PROTECTION

The thermal protection circuit monitors the die

temperature and is able to shut down the LIN

transmitter and voltage regulator. Refer to T able 1-1 for

details.

There are three causes for a thermal overload. A

thermal shut down can be triggered by any one, or a

combination of, the following thermal overload

conditions.

• Volt a ge regu lator overload

• LIN bus output overload

• Increase in die temperature due to increase in

environment temperature

Driving the TXD and checking the RXD pin makes it

possible to determi ne whether there is a bus co ntention

(Rx = low, Tx = high) or a thermal overload condition

(Rx = high, Tx = low).

Note: After recovering from a thermal, bus or

voltage regulator overload condition, the

device will be in the Ready1 mode. In order

to go into Operational mode, the CS/

WAKE pin has to be toggled.

1.1.2 REVERSE BATTERY PROTECTION

An external reverse-battery-blocking diode can be

used to provide polarity protection (see Figure 1-2).

This protection is opt ional, but shoul d be considered as

good engineering practice.

TABLE 1-1: SOURCES OF THERMAL OVERLOAD

TXD RXD Comments

L H LIN transmitter shutdown, receiver and voltage regulator active, thermal overload

condition.

H L Regulator shutdown, rece iv er active, bus contention.

Legend: x = Don’t care, L = Low, H = High

Note 1: LIN transceiver overload current on the LIN pin is 200 mA.

2: Voltage regulator overload current on voltage regulator greater than 50mA.

© 2007 Microchip Technology Inc. DS21730F-page 3

(1,2)

Page 4

MCP201

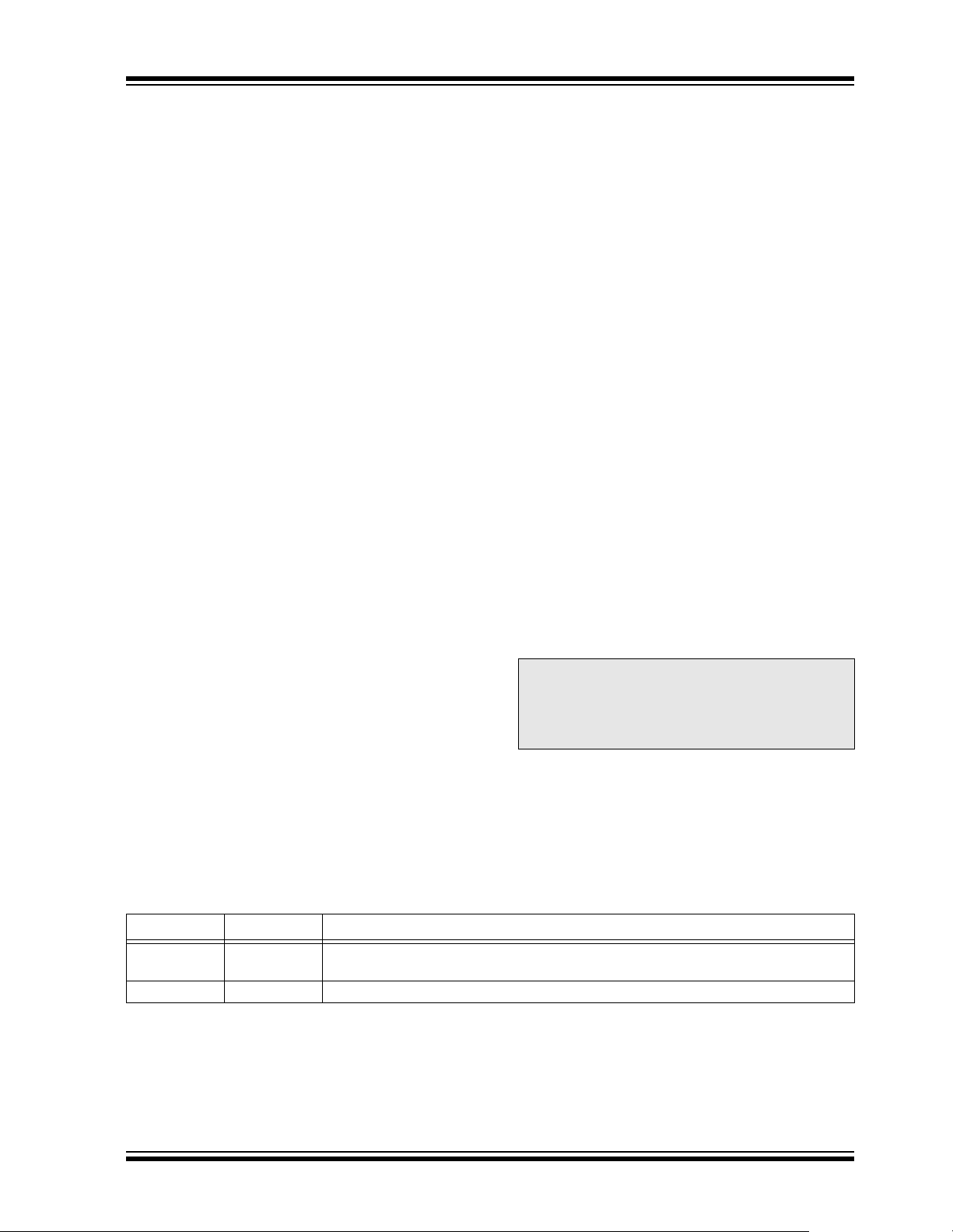

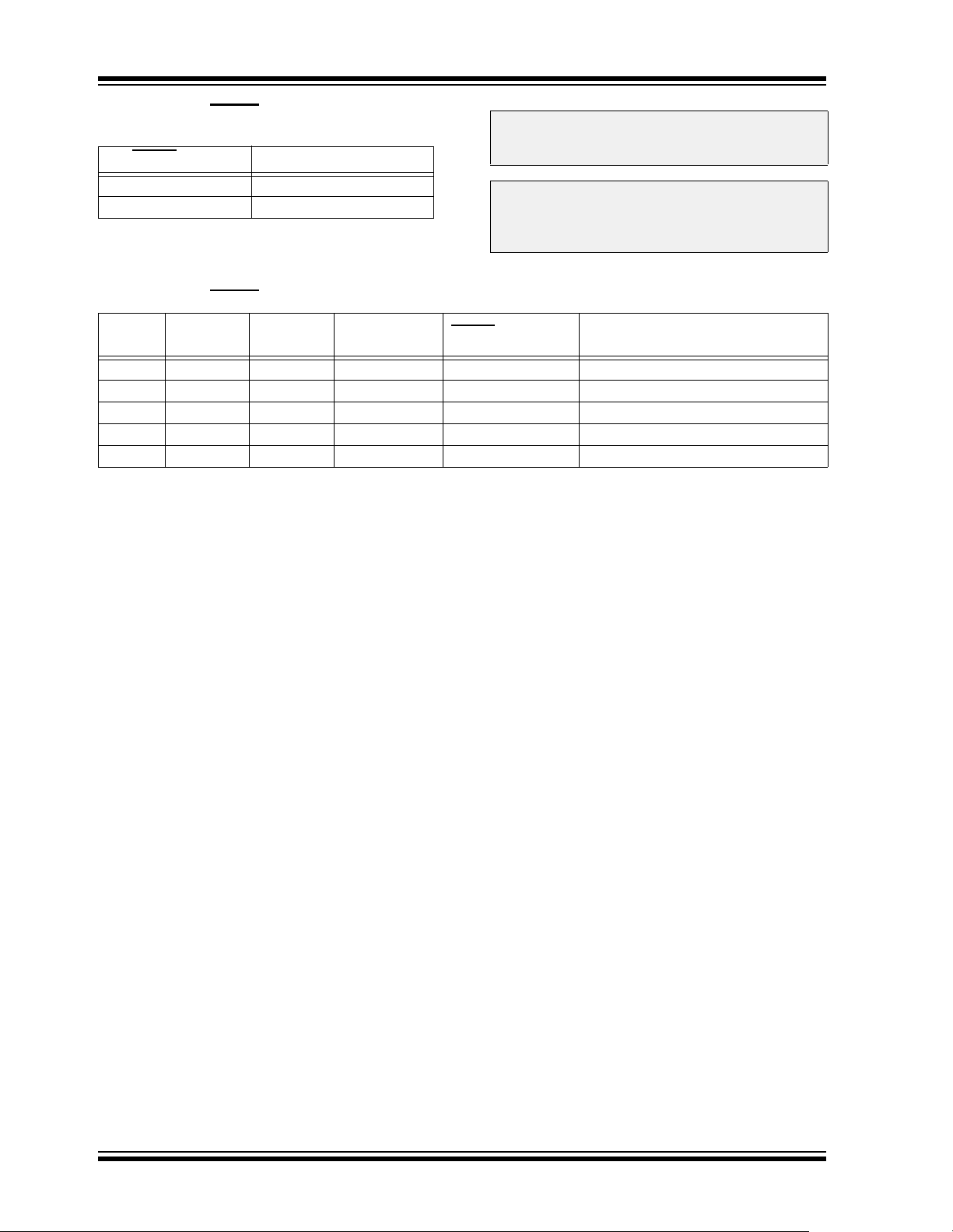

1.3 Modes of Operation

For an overview of all operational modes, please refer

to Table 1-2.

1.3.1 POWER-DOWN MODE

In the Power-down mode, the transmitter and the

voltage regulat or are both off . Only the rec eiver sectio n

and the CS/WAKE pin wake-up circuits are in

operation. This is the lowest power mode.

If any bus activity (e.g., a BREAK character) should

occur during Power-down mode, the device will

immediately enable the voltage regulator. Once the

output has stabilized, the device will enter Ready

mode.

The part will ente r the Operation mod e, if the CS/W AKE

pin should become active-high (‘1’).

1.3.2 READY AND READY1 MODES

There are two states for the Ready mode. The only

difference be tween these states is the transitio n d uring

start-up. The state Ready1 mode ensures that the

transition from Read y to Opera tion mode (once a risin g

edge of CS/WAKE) occurs without disrupting bus

traffic.

Immediately upon entering either Ready1 or Ready

mode, the voltage regulator will turn on and provide

power. The transmitter portion of the circuit is off, with

all other circuit s (in cluding the re ceive r) of the MCP20 1

being fully operational. The LIN pin is kept in a

recessive state.

If a microcontroller is being driven by the voltage

regulator output, it will go through a power-on re set and

initialization sequ enc e. All o ther circuits, other than the

transmitter, are fully operational. The LIN pin is held in

the recessive state.

The device will stay in R eady mode unt il the CS/W AKE

pin transitions high (‘1’). After CS/WAKE is active, the

transmitter is enabled and the device enters Operation

mode.

The device may only enter Power-down mode after

going through the Operation mode step.

At power-on of the V

in either Ready or Ready1 mode, waiting for a

CS/WAKE rising edge.

The MCP201 will stay in either mode for 600 µs as the

regulator powers it s i nternal circuitry and wait s u ntil th e

CS/WAKE pin transitions high. During the 600 µs

delay, the MCP201 will not recognize a CS/WAKE

event. The CS/W AKE transition from low to high should

not occur until after this delay.

• The CS input is edge, no t level, sensitive.

• The CS pin is not monitored until approximately

600 µs after V

• The transistion f rom R eady 1 to Rea dy is made on

the falling edge of CS.

• The transition from Ready mode to Operational

mode is on the rising edge of CS.

BAT supply pin, the component is

REG has stabized.

1.3.3 OPERATION MODE

In this mode, all internal modules are operational.

The MCP201 will go into Power-down mode on the

falling edge of CS/WAKE.

FIGURE 1-1: OPERATIONAL MODES

STATE DIAGRAMS

CS/WAKE = t rue

Operation

Mode

Note: After power-on, CS will not be sampled

Note: While the MCP201 is in shutdown, TXD

Power-down

Mode

CS/WAKE = false

T

L

F

CS/WAKE = t rue

Ready1

Mode

until V

REG has stabized and an additional

Bus Activity

T

L

F

Ready

Mode

CS/WAKE = false

CS/WAKE = true

CS/WAKE = false

POR

Start

600 µs has elapsed. The microcontroller

should toggle CS approx imately 1mS after

RESET to ensure that CS will be recognized.

should not be actively driven high. If TXD

is driven high actively, it may power

internal logic.

1.3.4 DESCRIPTION OF BROWNOUT CONDITIONS

As VBAT decreases VREG is regulated to 5.0 VDC (see

REG in Section 2.2 “DC Specifications”) while VBAT

V

is greater than 5.5 - 6.0 VDC.

BAT decreases further VREG tracks VBAT (VREG =

As V

BAT - (0.5 to 1.0) VDC.

V

The MCP201 monitors V

not fall below V

ifications”), V

BAT increases VREG will continue to track VBAT

As V

SD (see VSD in Section 2.2 “DC Spec-

REG will remain powered.

until VREG reaches 5.0 VDC.

REG falls below VSD, VREG is turned off and the

If V

MCP201 powers itself down.

The MCP201 will remain powered down until V

increases above VON (see VON in Section 2.2 “DC

Specifications”.

REG and as long as V REG does

BAT

DS21730F-page 4 © 2007 Microchip Technology Inc.

Page 5

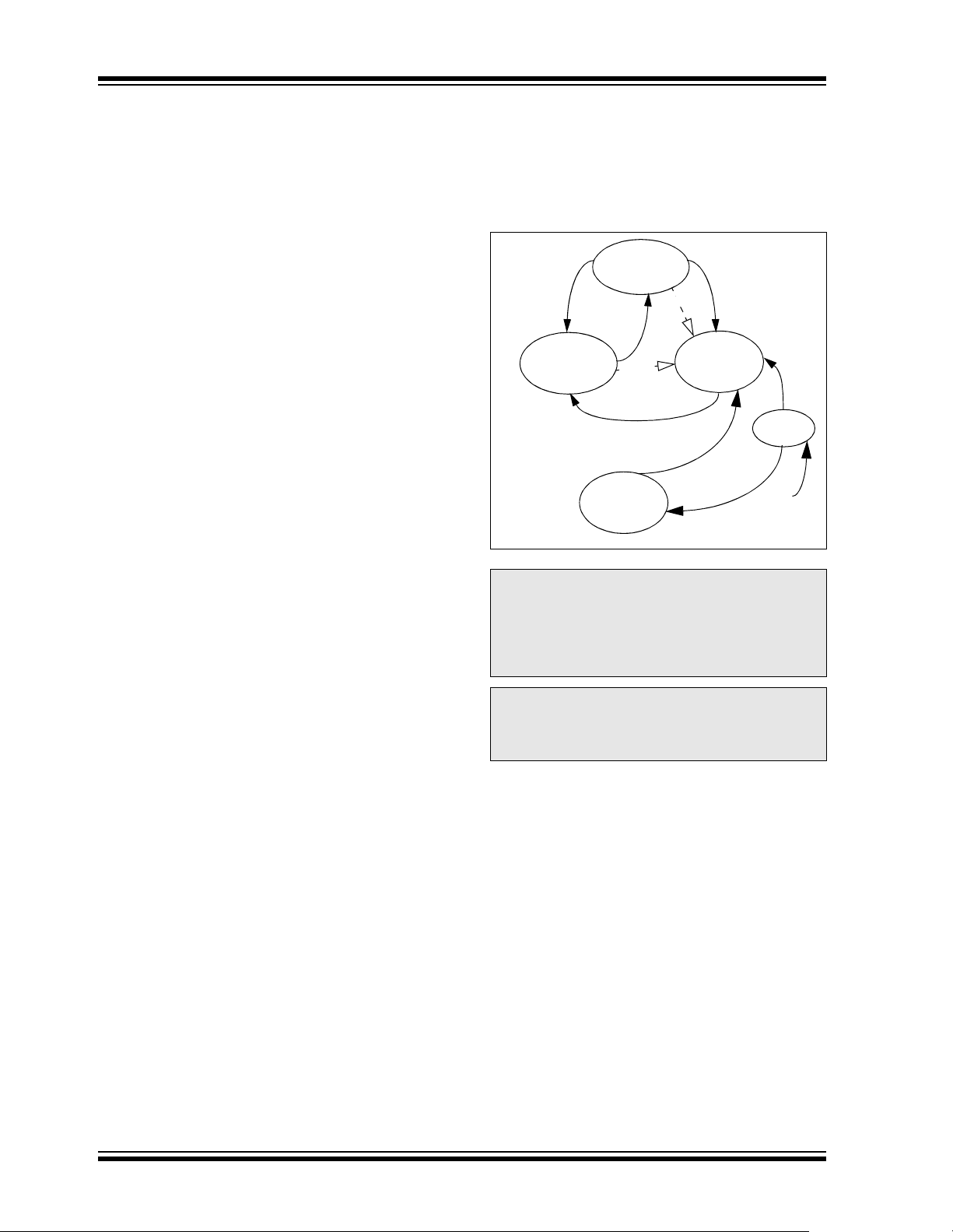

TABLE 1-2: OVERVIEW OF OPERATIONAL MODES

State Transmitter Voltage Regulator Operation Comments

POR OFF OFF Read CS/WAKE.

If low, then READY.

If high, READY1 mode.

Ready OFF ON If CS/WAKE rising edg e, then

Operation mode.

Ready1 OFF ON If CS/WAKE falling edge,

then READY mode.

Operation ON ON If CS/WAKE falling edge,

then Power down.

Power-down OFF OFF On LIN bus falling, go to

READY mode.

On CS/WAKE rising edg e, go

to Operational mode

Note: After power-on, CS w ill no t be sa mpled until V

microcontroller should toggle CS approximately 1mS after RESET to ensure that CS will be recognized.

REG has sta bized and an addit ion al 600µs has elap sed . The

Sample FAULT/SLPS and

select slope

Bus Off state

Bus Off state

Normal Operation mode

Low-Power mode

MCP201

© 2007 Microchip Technology Inc. DS21730F-page 5

Page 6

MCP201

1.4 Typical Applications

FIGURE 1-2: TYPICAL MCP201 APPLICATI ON

+12V

10 kΩ

WAKE-UP

VDD

TXD

®

PIC

MCU

Note 1: The load capacitor, CG, should be a ceramic or t ant alum ra ted for e xtend ed temp erature s and b e in

RXD

I/O

I/O

VSS

the range of 1.0 - 22 µF with an ESR 0.4Ω - 5Ω..

F if the filter capacitor for the external voltage supply.

2: C

3: This diode is only needed if CS/WAKE is connected to 12V supply.

4: Transient suppressor diode. Vclamp L = 40V.

5: These components are for load dump protection.

D1

(3)

CG

+5V

100 kΩ

(1,2)

27V

REG

V

TXD

MCP201

RXD

CS/WAKE

FAULT/SLPS

SS

V

VREG or VSS

+12V

Optional components

Master Node Only

CF

10 uF

VBAT

LIN

1kΩ

(5)

+12V

(4)

D2

24V

Optional components

LIN bus

FIGURE 1-3 : TYPICAL LIN NETWORK C O NF I GUR AT ION

40m

+ Return

LIN bus

BAT

V

DS21730F-page 6 © 2007 Microchip Technology Inc.

1kΩ

LIN bus

MCP201

Master

µC

LIN bus

MCP201

Slave 1

µC

LIN bus

MCP201

Slave 2

µC

LIN bus

MCP201

Slave n <16

µC

Page 7

MCP201

1.5 Pin Descriptions

TABLE 1-3: MCP201 PINOUT OVERVIEW

Devices

8-Pin PDIP/

SOIC/DFN

1 RXD Receive Data Output

2 CS/WAKE Chip Select (TTL-HV

3V

4 TXD Transmit Data Input

5V

6 LIN LIN bus (bidirectional-

7V

8FAULT/SLPS Fault Detect Output,

Legend: TTL = TTL input buffer,

Bond Pad

Name

REG Power Output

SS Ground

BAT Battery

HV = High Voltage (VBAT)

1.5.1 RECEIVE DATA OUTP UT (RX D)

The Receive Data Output pin is a standard CMOS

output and follows the state of the LIN pin.

The LIN receiver monitors the state of the LIN pin and

generates the output signal RXD.

1.5.2 CS/WAKE

Chip Select Input pin. This pi n controls whether the part

goes into READY1 or READY mode at power-up. The

internal pull-down resistor will keep the CS/WAKE pin

low. This is done to ensure that no disruptive data will

be present on the bus while the microcontroller is

executing a Power-on Reset and I/O initialization

sequence. The pin must see a low-to-high transition to

activate the transmitter.

After CS/WAKE transitions to ‘1’, the transmitter is

enabled. If CS/WAKE = ‘0’, the device is in Ready1

mode on power-up or in Low-Power mode. In LowPower mode, the voltage regulator is shut down, the

transmitter driver is disabled and the receiver logic is

enabled.

An external switch (see Figure 1-2) can then wake up

both the transceiver and the microcontroller. An

external-blocking di ode and current-limiti ng resistor are

necessary to protect the microcontroller I/O pin.

Note: On POR, the MCP201 enters Ready or

Ready1 mode (see Figure 1-1). In order to

enter Operational mode, the MCP201 has

to see one rising edge on CS/WAKE

600 µs after the voltage regulator reaches

5V.

Function

Normal Operation

(CMOS output)

input)

(TTL)

HV)

Slope Select Input

1.5.3 POWER OUTPUT (VREG)

Positive Supply Voltage Regulator Output pin.

1.5.4 TRANSMIT DATA INPUT (TXD)

The Transmit Data Input pin has an internal pull-up to

REG. The LIN pi n i s lo w (do m in an t) wh en T XD is l ow,

V

and high (recessive) when TXD is high.

In case the thermal protection detects an over-temperature condition while the signal TXD is low, the

transmitter is shut do wn. The r ecove ry fr om the therma l

shutdown is equal to adequate cooling time.

1.5.5 GROUND (VSS)

Ground pin.

1.5.6 LIN

The bidirectiona l L IN bus Interface pin is the driver unit

for the LIN pin and is contro lle d by the signal T XD. LIN

has an open collector output with a current limitation.

To reduce EMI, the edges during the signal changes

are slope-controlled.

1.5.7 BATTERY (VBAT)

Battery Positive Supply Voltage pin. This pin is also the

input for the internal voltage regulator.

1.5.8 FAULT/SLPS

FAULT Detect Output, Slope Select Input.

This pin is usually in Output mode. Its state is defined

as shown in Table 1-5.

The state of this pin is internally sample d during power-

on of V

(approximately 6 VDC) and V

5.25 VDC, the state of this pin selects which slew rate

profile to apply to the LIN output. It is only during this

time that the pin is used as an input (the output driver

is off during this t ime). The sl ope wil l st ay s electe d unti l

the next V

less of any power-down, wake-up or SLEEP events.

Only a V

FAULT

irrespective of the state of any other pin.

The FAULT

V

the slope selection. This large resistance allows the

FAULT indication function to overdrive the resistor in

normal operation mode.

If the FAULT

ing is selected (dv/dt = 2 V/µs). If FAULT

(‘0’) during this time, the alternate slope-shaping is

selected (dv/dt = 4 V/µs). This mode can be used if a

user desires to run at a faster slope. This mode is not

LIN compliant.

BAT. Once VBAT has reached a stable level,

REG is stable at 4.75 to

BAT power-off/power-on sequence, regard-

BAT rising state will cause a sampling of the

/SLPS pin. The Slope selection will be made

/SLPS pin is connected to either VREG or

SS through a resistor (app roximately 100 kΩ) to make

/SLPS is high (‘1’), the normal slo pe shap-

/SLPS is low

© 2007 Microchip Technology Inc. DS21730F-page 7

Page 8

MCP201

TABLE 1-4: FAULT / SLPS SLOPE

SELECTION DURING POR

/SLPS Slope Shaping

FAULT

HNormal

LAlternate

Note 1: This mode does not conform to LIN bus

specification version 1.3, but might be

(1)

Note: This pin is ‘0’ whenever the internal circuits

have detected a short or thermal excursion

and have disabled the LIN output driver.

Note: Every time TX is togg led , a Fault condition

will occur for the length of time, depending

on the bus load. The Fault time is equal to

the propagation delay.

used for K-line applications.

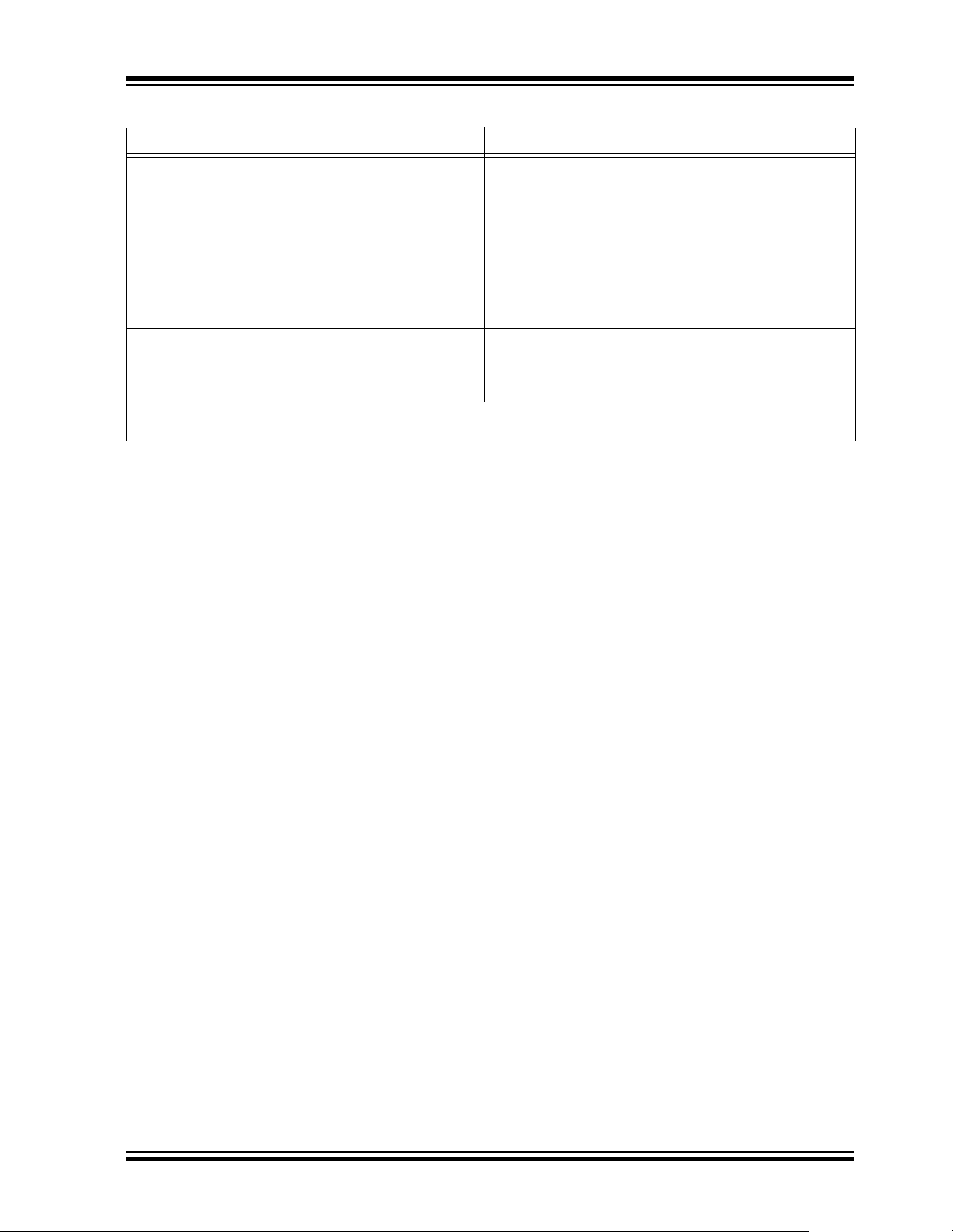

TABLE 1-5: FAULT

TXD In RXD Out LIN Bus I/O

LHV

/ SLPS TRUTH TABLE

Thermal

Override

BAT OFF L Bus shorted to battery

/ SLPS Out Comments

FAULT

HHVBAT OFF H Bus recessive

L L GND OFF H Bus dominant

H L GND OFF L Bus shorted to ground

xxV

BAT ON L Thermal excursion

Legend: x = don’t care

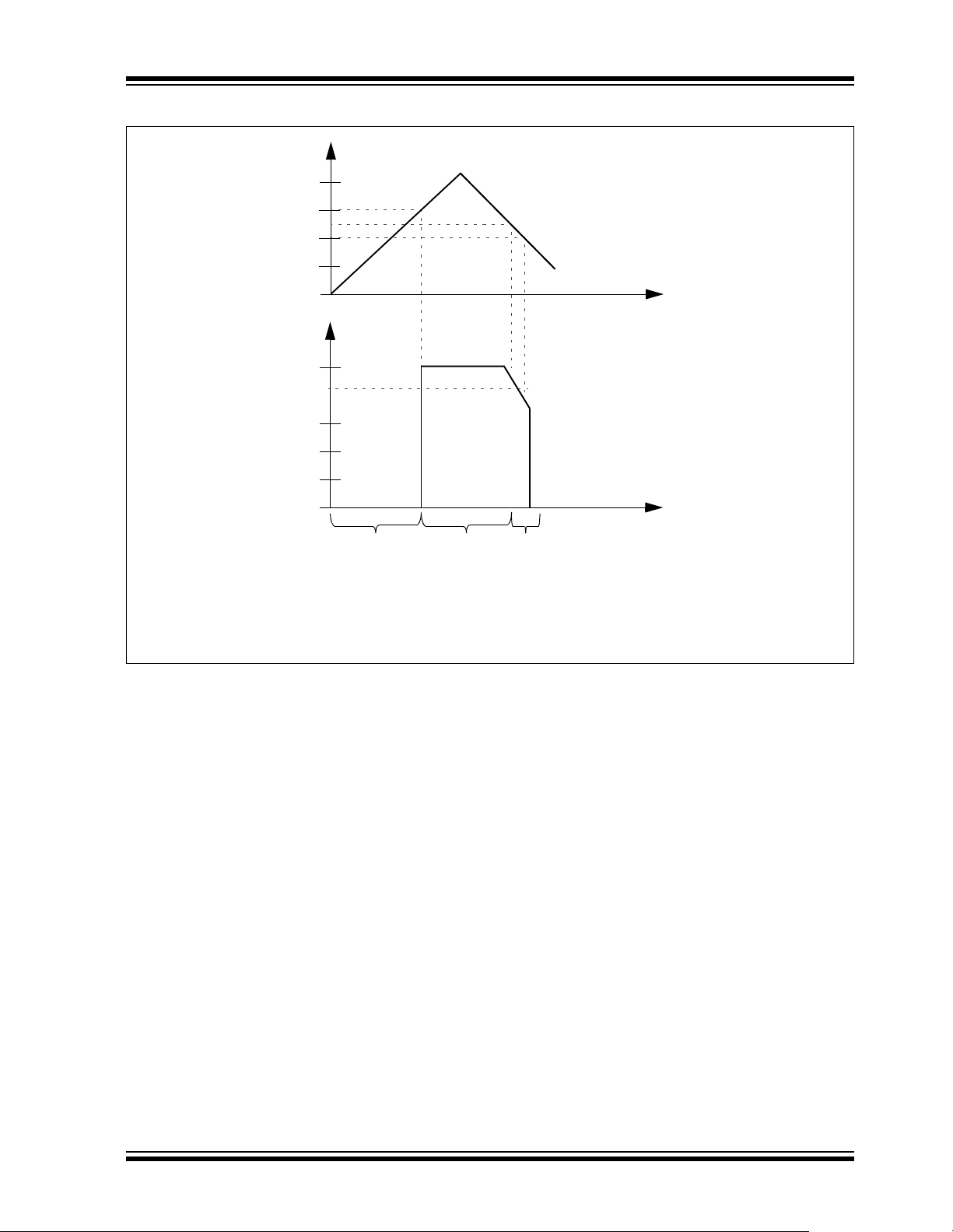

1.6 Internal Voltage Regulator

6.0V. The device will come up in either READY1 or

READY mode and will have to be transitioned to

The MCP201 has a low drop-out voltage, positive

regulator c apabl e of supp lyin g 5. 00 VDC ±5% at up to

50 mA of load current over the entire operating

temperature range. With a load current of 50 mA, the

minimum input-to-output voltage differential required

for the output to remain in regulation is typically +0.5V

(+1V maximum over the full operating temperature

range). Quiescent current is less than 1.0 mA, with a

full 50 mA load current, when the input-to-output

voltage differential is greater than +2V.

The regulator requires an external output bypass

capacitor for stability. The capacitor should be either a

ceramic or tantalum for stable operation over the

extended temperature range. The compensation

capacitor shou ld ra nge from 1.0 µf – 22 µf and have a

ESR or CSR of 0.4Ω – 5.0Ω. The input capaci tor, C

F, in

Figure 1.4 should be on the order of 8 t o 10 times larger

than the output capacitor, C

G.

Designed for automoti ve applica tions, the reg ulator will

protect itself from rev ers e b atte ry c on nec tio ns, doublebattery jum ps and up to +40V load dump transien ts.

The voltage regulator has both short-circuit and

Operational mode to re-enable data transmission.

In the start phase, V

BAT must be at least 6.0V

(Figure 1-4) to initiate operation during power-up. In

Power-down mode, the VBAT monitor will be turned of f.

The regulator has a thermal shutdown. If the thermal

protection circuit det ects an overtemperature condition

caused by an overcurrent condition (Figure1-6) of the

regulator, it will shut down.

The regulator has an overload current limiting. During

a short-circuit, V

REG is monitored. If VREG is lower than

3.5V , t he regu lator will t urn of f. After a thermal re covery

time, the VREG will be checked again. If there is no

short-circuit (V

REG > 3.5V), the regulator will be

switched back on. The MCP201 will come up in either

READY1 or READY mode and will have to be

transitioned to Operational mode to re-enable data

transmission.

The accuracy of the voltage regulator, when using a

pass transistor, will degrade due to the extra external

components needed. All performance characteristics

should be evaluated on every design.

thermal shutdown protection built-in.

Regarding the correlation between V

BAT, VREG and IDD,

please refer to Figure 1-4 through 1-6. Whe n the input

voltage (V

provide stable regulation, the output V

BAT) drops below the differential neede d to

REG will track the

input down to approxima tely 3.5V, at which po int the

regulator will turn off. This will allow microcontrollers

with internal POR circuits to generate a clean arming of

the Power-on Reset trip poi nt. The MCP201 will then

monitor V

BAT and turn on th e regulator when VBAT is

DS21730F-page 8 © 2007 Microchip Technology Inc.

Page 9

FIGURE 1-4: VOLTAGE REGULATOR OUTPUT ON POWER-ON RESET

VBAT

------------- -

8

6

4

2

V

MCP201

0

VREG

--------------V

5.5

3.5

3

0

(1) (2) (3)

Note 1: Start-up, VBAT < 6.0V, regulator off.

2: VBAT > 6.0V, regulator on.

3: V

BAT ≤ 5.5V, regulator tracks VBAT, regulator will turn

off when V

REG < 3.5V.

t

t

© 2007 Microchip Technology Inc. DS21730F-page 9

Page 10

MCP201

FIGURE 1-5: VOLTAGE REGULATOR OUTPUT ON POWER DIP

VBAT

------------- -

12

8

6

4

3.5

2

V

0

VREG

---------------

5

4

3.5

3

0

Note 1: Voltage regulator on.

2: V

3: VREG < 3. 5V, regulator is of f. If th e volt ag e regu lator shoul d shut

4: V

V

(1) (2) (3)

REG ≤ 5.5V, regulator tracks VBAT until VREG < 3.5V.

off due to V

turn V

REG > 4.0V, voltage regulator tracks VDD, when VREG > 4.0V.

REG falling below 3 .5V, the VBAT must rise to 6.0V to

REG back on.

(4)

t

t

DS21730F-page 10 © 2007 Microchip Technology Inc.

Page 11

MCP201

FIGURE 1-6: VOL TAGE REGULATOR OU TP UT O N OV ER CU RR E N T SI TU AT I O N

IREG

------------mA

50

0

VRE G

-------------- -

6

5

3.5

3

0

Note 1: I

REG less than 50 mA, regulator on.

2: After IREG exceeds IREGmax, voltage regulator output will be reduced

until V

V

(1) (2)

REGoff is reached.

1.7 ICSP™ Considerations

The following should be considered when the MCP201

is connected to pins sup porting in-c ircuit progra mming:

• Power used for programming the microcontroller

should be supplied from the progra mmer , not from

the MCP201

• The MCP201 should be left unpowered

• The voltage on V

maximum output voltage of V

• The TXD pin should not be brought high during

programming

REG should not exceed the

REG

t

t

© 2007 Microchip Technology Inc. DS21730F-page 11

Page 12

MCP201

NOTES:

DS21730F-page 12 © 2007 Microchip Technology Inc.

Page 13

MCP201

2.0 ELECTRICAL CHARACTERISTICS

2.1 Absolute Maximum Ratings†

VIN DC Voltage on Logic pins except CS/WAKE.................................................................................-0.3 to VREG+0.3V

IN DC Voltage on CS/WAKE...............................................................................................................-0.3 to VBAT+0.3V

V

BAT Battery Voltage, non-operating (LIN bus recessive, no regulator load, t < 60s)....................................-0.3 to +40V

V

BAT Battery Voltage, transient (Note 1)........................................................................................................-0.3 to +40V

V

BAT Battery Voltage, continuous ..................................................................................................................-0.3 to +30V

V

LBUS Bus Voltage, continuous.......................................................................................................................-18 to +30V

V

LBUS Bus Voltage, transient (Note 1)............................................................................................................-27 to +40V

V

LBUS Bus Short Circuit Current Limit....................................................................................................................200 mA

I

ESD protection on LIN, V

ESD protection on all other pins (Human Body Model) (Note 2).............................................................................>2 kV

Maximum Junction Temperature.............................................................................................................................150°C

Storage Temperature ..................................................................................................................................-55 to +150°C

Note 1: ISO 7637/1 load dump compliant (t < 500 ms).

2: According to JESD22-A114-B.

BAT (Human Body Model) (Note 2)..................................................................................>4 kV

† NOTICE: Stresse s a bov e th os e l ist ed u nd er “M ax im um R atin gs ” ma y c au se perm an ent dam ag e to the device. This

is a stress rating only and func ti ona l op eration of the device at those or any other conditio ns abo ve those indicated in

the operational li stings of thi s specificati on is not im plied. Expos ure to maximum rat ing cond itions for extend ed periods

may affect device reliability.

© 2007 Microchip Technology Inc. DS21730F-page 13

Page 14

MCP201

2.2 DC Specifications

Electrical Characteristics:

Unless otherwise indicated, all limits are specified for:

DC Specifications

Sym. Parameter Min. Typ. Max. Units Conditions

Power

I

BATQ VBAT Quiescent Operating

Current (voltage regulator

without load and transceiver)

IBAT VBAT Power-down Current

transceiver only

DDQ VREG Quiesce nt Op er at ing

I

Current

VREG VREG maximum output

I

current

Microcontroller Interface

V

IH High-level Input Volta ge

(TXD, FAULT

V

IL Low-level Input Voltage

(TXD, FAULT

I

IHTXD High-level Output Current

/SLPS)

/SLPS)

(TXD)

ILTXD Low-level Output Current

I

(TXD)

V

IHCS/

WAKE

ILCS/

V

WAKE

IHCS/

I

WAKE

I

ILCS/

WAKE

V

OHRXD High-level Output Voltage

High-level Input Voltage

(CS/WAKE)

Low-level Input Voltage

(CS/WAKE)

High-level Input Current

(CS/WAKE)

Low-level Input Current

(CS/WAKE)

(RXD)

OLRXD Low-level Output Voltage

V

(RXD)

Note 1: Internal current limited. 2.0 ms typical recovery time (R

25C. Recovery time highly dependent on ambient temperature, package and thermal resistance).

2: For design guidance only, not tested.

3: This current is at the V

BAT pin.

4: The maximum power dissipation is a function of T

allowable power dissipation at an ambient temperature is P

exceeded, the die temperature will rise above 150°C and the MCP201 will go into thermal shutdown.

VBAT = 6.0V to 18.0V

AMB = -40°C to +125°C

T

LOADREG = 10 µF

C

— 0.45 1.0 mA IVREG = 0 mA, LIN bus pin

recessive, (Note 3)

— 23 50 µA CS/WAKE = High, voltage

regulator disabled

—500 — µA(Note 2)

—— 50 mA(Note 4)

2.0 — V

-0.3 — 0.15 x V

REG + 0.3 V

REG V

-90 — +30 µA Input voltage = 4V

-150 — -10 µA Input voltage = 1V (though

> 50 kΩ internal pull-up)

3.0 — VBAT V Through an external currentlimiting resistor (10 kΩ)

-0.3 — 1.0 V

-10 — +80 µA Input voltage = 4V (though

>100 kΩ internal pull-down)

5 — 30 µA Input voltage = 1V

V

0.8

REG

—— IOH = -4 mA

——0.2 VREG IOL = 4 mA

LBUS = 0Ω, TX = 0.4 VREG, VLBUS = VBAT, TAMB =

JMAX, ΘJA and ambient temperature TA. The maximum

D = (TJMAX - TA)ΘJA. If this dissipation is

DS21730F-page 14 © 2007 Microchip Technology Inc.

Page 15

MCP201

2.2 DC Specifications (Continued)

Electrical Characteristics:

Unless otherwise indicated, all limits are specified for:

DC Specifications

Sym. Parameter Min. Typ. Max. Units Conditions

Bus Interface

VIHLBUS High-level Input Voltage

BUS)

(L

V

ILLBUS Low-level Input Voltage

BUS)

(L

HYS Input Hysteresis 0.05

V

IOL Low-level Output Current

BUS)

(L

O High-level Output Current

I

BUS)

(L

P Pull-up Current on Input

I

(L

BUS)

ISC Short-circuit Current-Limit 50 — 200 mA (Note 1)

VOH High-level Output Vo ltage

(L

BUS)

V

OL Low-level Output Voltage

BUS)

(L

Voltage Regulator

V

REG Output Voltage 4.75 — 5.25 V 0 mA > IOUT > 50 mA,

REG1 Output Voltage 4.4 — 5.25 V 0 mA > IOUT > 50 mA,

V

ΔVREG1 Line Regulation — 1 0 50 mV IOUT = 1 mA, 7.0V < VBAT < 18V

REG2 Load Regulation — 1 0 50 mV 5 mA < IOUT < 50 mA,

ΔV

VN Output Noise Voltage — — 400 µVRMS 1VRMS @ 10 Hz - 100 kHz

SD Shutdown Voltage

V

(monitoring V

V

ON Input Voltage to Turn On

Output (monitoring V

REG)

BAT)

Note 1: Internal current limited. 2.0 ms typical recovery time (R

25C. Recovery time highly dependent on ambient temperature, package and thermal resistance).

2: For design guidance only, not tested.

3: This current is at the V

BAT pin.

4: The maximum power dissipation is a function of T

allowable power dissipation at an ambient temperature is P

exceeded, the die temperature will rise above 150°C and the MCP201 will go into thermal shutdown.

VBAT = 6.0V to 18.0V

AMB = -40°C to +125°C

T

LOADREG = 10 µF

C

0.6 V

BAT — 18 V Recessive state

-8 — 0.4 V

BAT V Dominant state

— 0.1 VBAT VVIH - VIL

V

BAT

40 — 200 mA Output voltage = 0.1 V

BAT = 12V

V

-20 — 20 µA V

BUS ≥ VBAT, VLBUS < 40V

BAT,

-180 — -60 µA Approx. 30 kΩ internal pull-up

@ VIH = 0.7 VBAT

BAT —— V

0.8 V

——0.2 V

BAT V

7.0V < V

6.0V < V

V

BAT < 18V

BAT < 7.0V

BAT = Constant

3.5 — 4.0 V See Figure 1-4

5.5 — 6.0 V

LBUS = 0Ω, TX = 0.4 VREG, VLBUS = VBAT, TAMB =

JMAX, ΘJA and ambient temperature TA. The maximum

D = (TJMAX - TA)ΘJA. If this dissipation is

© 2007 Microchip Technology Inc. DS21730F-page 15

Page 16

MCP201

2.3 AC Specifications

Electrical Characterist ics:

AC Specifications

Symbol Parameter Min Typical Max Units Conditions

Bus Interface

|dV/dt| Slope Rising and Falling Edges 1.0 2.0 3.0 V/

|dV/dt| Slope Rising and Falling edges

ALTERNATE

t

TRANSPD

t

RECPD

t

RECSYM

Propagation Delay of Transmitter — — 6.0 µst

Propagation Delay of Receiver — — 6.0 µs(t

Symmetry of Propagation Delay of

Receiver Rising Edge with Respect

to Falling Edge

t

TRANSSYM

Symmetry of Propagation Delay of

Transmitter Rising Edge with

Respect to Falling Edge

Voltage Regulator

t

BACTVE

Bus Activity to Voltage Regulator

Enabled

t

VEVR

Voltage Regulator Enabled to

Ready

t

R Voltage Regulator Enabled to

VREGPO

Ready after POR

t

CSOR

t

CSPD

t

SHUTDOWN

t

SCREC Short-Circuit Recovery Time — 2.0 — ms Characterized but not

Chip Select to Operation Ready 0 50 200 µs (Note 2)

Chip Select to Power-down 0 — 40 µs (Note 2) No CLOAD

Short-Circuit to Shutdown — 450 — µs Characterized but not

Note 1: The mode does not conform to LIN Bus specification version 1.3.

2: Time depends on external capacitance and load.

3: Internal current limited. 2.0 ms typical recovery time (R

25C. Recovery time highly dependent on ambient temperature, package, and thermal resistance).

Unless otherwise indicated, all limits are specified for:

BAT = 6.0V to 18.0V

V

T

AMB = -40°C to +125°C

µs (40% to 60%), No Load

2.0 4.0 6.0 V/µs(Note 1), No Load

= max

RECPD

RECPDR

-2.0 — 2.0 µst

-2.0 — 2.0 µst

RECSYM

TRANSSYM

(t

TRANSPDF

or t

= max

= max

- t

10 — 40 µs Bus debounce time

—50200µs (Note 2)

——2.5ms(Note 2) CLOAD = 25 nF

tested

tested (Note 3)

LBUS = 0Ω, TX = 0.4 VREG, VLBUS = VBAT, TAMB =

RECPDF

RANSPDR

)

)

TABLE 2-1: MCP201 THERMAL SPECIFICATIONS

Sym Parameter Min Typical Max Units Test Conditions

θ

RECOVERY

θ

SHUTDOWN

t

THERM

Note 1: Internal current limited. 2.0 ms typical recovery time (R

DS21730F-page 16 © 2007 Microchip Technology Inc.

Recovery Temperature

(junction temperature)

Shutdown Temperature

(junction temperature)

Thermal Recovery Time

(after Fault condition removed)

—+135— °C Characterized but not

tested

—+155— °C Characterized but not

tested

— 2.0 — ms Characterized but not

tested (Note 1)

LBUS = 0Ω, TX = 0.4 VREG, VLBUS = VBAT, TAMB =

25C. Recovery time highly dependent on ambient temperature, package, and thermal resistance).

Page 17

2.4 Timing Diagrams and Specifications

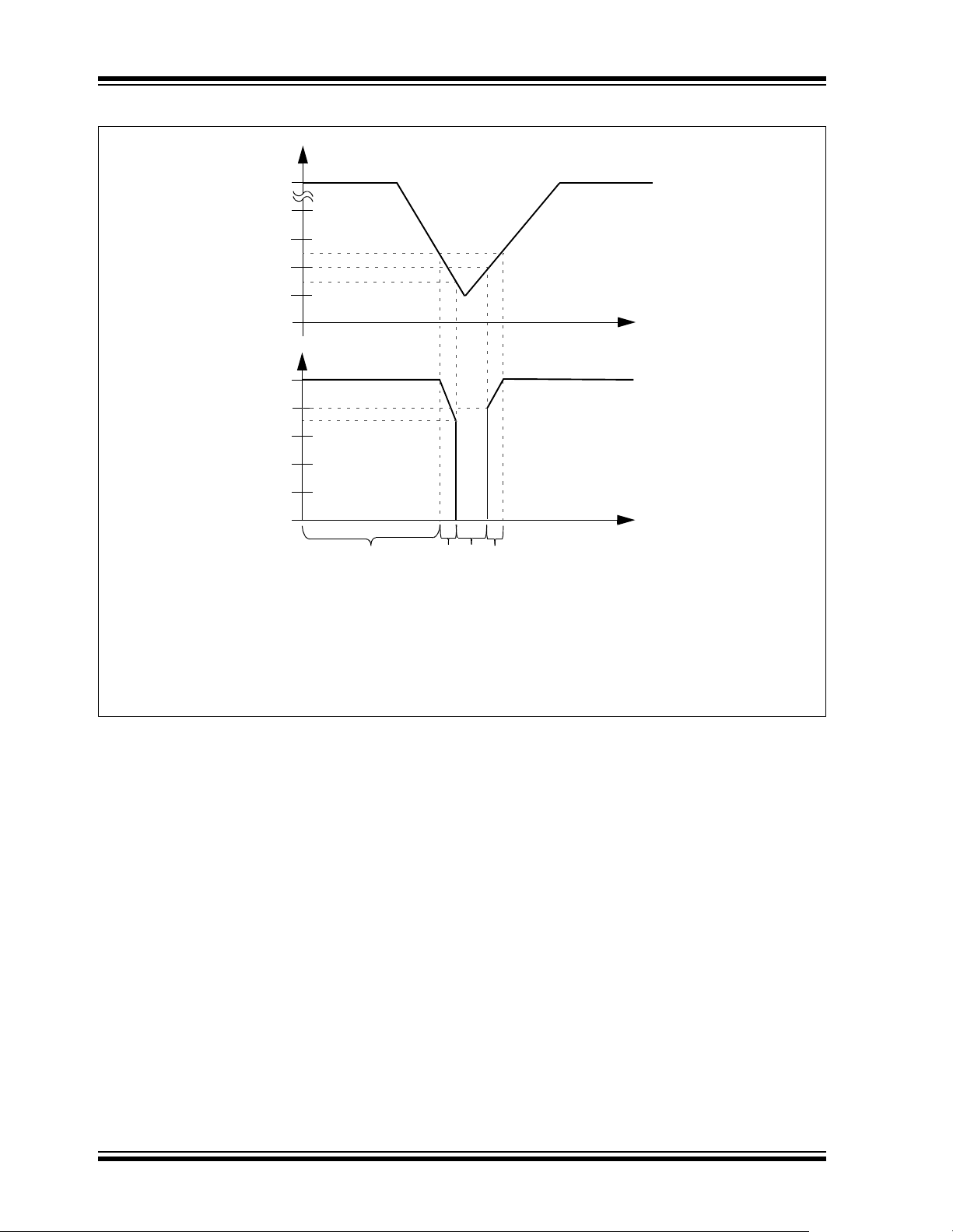

FIGURE 2-1: BUS TIMING DIAGRAM

TXD

L

BUS

MCP201

.6 VBAT

.4 VBAT

TTRANSPDF

TRECPDF

RXD

FIGURE 2-2: REGULATO R T IMI NG DIAG RAM ON CS /WAKE SIGNAL

CS/WAKE

TCSOR

VREG

TCSPD

TTRANSPDR

TRECPDR

Regulator Stable

© 2007 Microchip Technology Inc. DS21730F-page 17

Page 18

MCP201

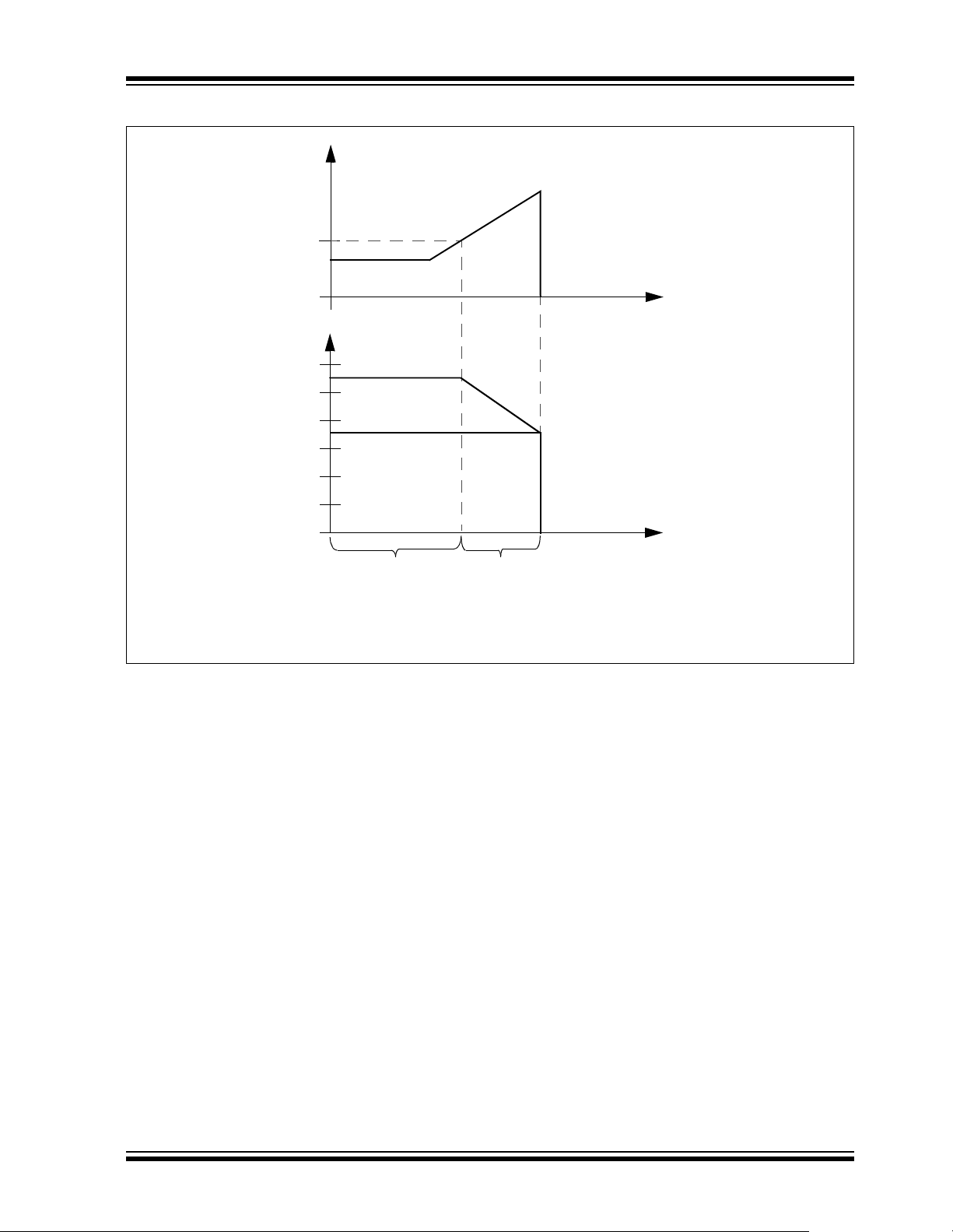

FIGURE 2-3: REGULA TOR TIMI NG DI AGR AM ON BU S ACTI VI TY

Regulator Stable

VREG

TVEVR

TBACTVE

LBUS

.4 VBAT

FIGURE 2-4: POR DIAGRAM

VBAT

VREG

6V

5.0V

tVREGPOR

DS21730F-page 18 © 2007 Microchip Technology Inc.

Page 19

3.0 CHARACTERIZATION GRAPHS

FIGURE 3-1: IDD(mA) vs. VBAT

t

CSPD

(µs) vs. V

700

600

500

400

(µs)

300

CSPD

t

200

100

0

4 6 8 10 12 14 16 18 20

V

BAT

(v)

BAT

(V)

MCP201

t

CSPD

(µs) -40(C)

t

CSPD

(µs) 25(C)

t

CSPD

(µs) 125(C)

dap/jx 3/5/03

30 parts Y1004 B2

© 2007 Microchip Technology Inc. DS21730F-page 19

Page 20

MCP201

FIGURE 3-2: REGULATOR VOLTAGE (V) VS. REGULATOR CURRENT

Regulator Voltage (V) vs. Regulator Current (A)

5.25

5.15

5.05

4.95

4.85

4.75

4.65

4.55

Regulator Voltage (V)

4.45

4.35

4.25

0 102030405060

VREGOUT (V) VBAT 18(V) -40(C)

V

REGOUT (V) VBAT 14.4(V) -40(C)

REGOUT (V) VBAT 8(V) -40(C)

V

REGOUT (V) VBAT 6(V) -40(C)

V

REGOUT (V) VBAT 18(V) 25(C)

V

V

REGOUT (V) VBAT 14.4(V) 25(C)

REGOUT (V) VBAT 8(V) 25(C)

V

V

REGOUT (V) VBAT 6(V) 25(C)

V

REGOUT (V) VBAT 18(V) 125(C)

V

REGOUT (V) VBAT 14.4(V) 125(C)

V

REGOUT (V) VBAT 8(V) 125(C)

REGOUT (V) VBAT 6(V) 125(C)

V

dap/jx

2/28/03

30 parts

Y1004 B2

Regulator Current (mA)

DS21730F-page 20 © 2007 Microchip Technology Inc.

Page 21

FIGURE 3-3: REGULA TOR CHANGE (V) VS. LI NE VOL T AGE CHAN GE

Line Regulation

Regulator Change (V) vs Line Voltage Change (mV)

5

Regulator Change (mV) -40(C) Load = 50(mA)

0

-5

-10

-15

-20

-25

Regulator Change (mV)

-30

-35

-40

0 2 4 6 8 10 12 14

Line Voltage Change (V)

dap/jx

3/3/03

30 parts

Y1004 B2

Regulator Change (mV) -40(C) Load = 25(mA)

Regulator Change (mV) -40(C) Load = 5(mA)

Regulator Change (mV) -40(C) Load = 1(mA)

Regulator Change (mV) 25(C) Load = 50(mA)

Regulator Change (mV) 25(C) Load = 25(mA)

Regulator Change (mV) 25(C) Load = 5(mA)

Regulator Change (mV) 25(C) Load = 1(mA)

Regulator Change (mV) 125(C) Load = 50(mA)

Regulator Change (mV) 125(C) Load = 25(mA)

Regulator Change (mV) 125(C) Load = 5(mA)

Regulator Change (mV) 125(C) Load = 1(mA)

MCP201

© 2007 Microchip Technology Inc. DS21730F-page 21

Page 22

MCP201

g

)

FIGURE 3-4: LOAD REGULATION REGULATOR CHANGE VS. REGULATOR LOAD CHANGE

Load Regulation

Regulator Change (mV) vs. Regulator Load Change (mA)

70

BAT = 18V

BAT = 14.4V

BAT = 8.0V

BAT = 6.0V

BAT = 18V

BAT = 14.4V

BAT = 8.0V

BAT = 6.0V

BAT = 18V

BAT = 14.4V

BAT = 8.0V

BAT = 6.0V

60

50

40

30

Regular Charge (mV)

20

Regulator Change (mV) -40C V

Regulator Change (mV) -40C V

Regulator Change (mV) -40C V

Regulator Change (mV) -40C V

Regulator Change (mV) 25C V

Regulator Change (mV) 25C V

Regulator Change (mV) 25C V

Regulator Change (mV) 25C V

Regulator Change (mV) 125C V

Regulator Change (mV) 125C V

Regulator Change (mV) 125C V

Regulator Change (mV) 125C V

10

0

0 102030405060

ular Load Current Change (mA

Re

dap/jx

3/3/03

30 parts

Y1004 B2

DS21730F-page 22 © 2007 Microchip Technology Inc.

Page 23

FIGURE 3-5: FALLING EDGE NORMAL DV/ D T VS . VBAT

Falling Edge Normal dVdT (V/µs) vs. VBAT(v)

2.40

2.35

2.30

2.25

2.20

2.15

2.10

2.05

2.00

Falling Edge Normal dVdT (V/µs)

1.95

1.90

4 6 8 10 12 14 16 18 20

VBAT(v)

MCP201

Falling Edge Normal

dVdT (V/µs) -40(C)

Falling Edge Normal

dVdT (V/µs) 25(C)

Falling Edge Normal

dVdT (V/µs) 125(C)

dap/jx

3/6/03

30 parts

Y1004 B2

© 2007 Microchip Technology Inc. DS21730F-page 23

Page 24

MCP201

FIGURE 3-6: RISING EDG E NOR MAL DV /D T VS. VBA T

Rising Edge Normal dV/dT (V/µs) vs. VBAT(V)

2.2

2.1

2.0

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

Rising Edge Normal dV/dT (V/µs)

1.0

0.9

4 6 8 101214161820

VBAT(V)

Rising Edge Normal

dVdT (V/µs) -40(C)

Rising Edge Normal

dVdT (V/µs) 25(C)

Rising Edge Normal

dVdT (V/µs) 125(C)

dap/jx 3/6/03

30 parts Y1004 B2

DS21730F-page 24 © 2007 Microchip Technology Inc.

Page 25

FIGURE 3-7: BUS ACTIVE VS. VBAT

tBACTIVE (µs) vs. VBAT(V)

55

50

45

40

tBACTIVE (µs)

35

30

MCP201

tBACTIVE (µs) -40(C)

tBACTIVE (µs) 25(C)

tBACTIVE (µs) 125(C)

dap/jx 3/6/03

30 parts Y1004 B2

201816141210864

VBAT(V)

© 2007 Microchip Technology Inc. DS21730F-page 25

Page 26

MCP201

FIGURE 3-8: VOLTAGE REGULATOR ACTIVE TIME VS. VBAT

tVEVR (µs) vs. VBAT(V)

10000

1000

tVEVR (µs)

100

10

10

4 6 8 10 12 14 16 18 20

VBAT(v)

tVEVR (µs) -40(C)

tVEVR (µs) 25(C)

tVEVR (µs) 125(C)

dap/jx 3/6/03

30 parts Y1004 B2

DS21730F-page 26 © 2007 Microchip Technology Inc.

Page 27

FIGURE 3-9: CHIP SELECT TO OPERATION READY

tCSOR (µs) vs. VBAT(V)

MCP201

14

13

12

11

10

9

8

tCSOR (µs)

7

6

5

4

tCSOR (µs) -40(C)

tCSOR (µs) 25(C)

tCSOR (µs) 125(C)

dap/jx 3/5/03

30 parts Y1004 B2

201816141210864

VBAT(v)

© 2007 Microchip Technology Inc. DS21730F-page 27

Page 28

MCP201

FIGURE 3-1 0: CHIP SELECT TO POW E R DOW N

tCSPD (µs) vs. VBAT(V)

700

600

500

400

300

tCSPD (µs)

200

100

0

4 6 8 10 12 14 16 18 20

VBAT(v)

tCSPD (µs) -40(C)

tCSPD (µs) 25(C)

tCSPD (µs) 125(C)

dap/jx 3/5/03

30 parts Y1004 B2

DS21730F-page 28 © 2007 Microchip Technology Inc.

Page 29

FIGURE 3-11: PROPAGATION DELAY OF TRANSMITT ER

tTRANSPD (µs) Rising Edge Normal vs. VBAT(V)

MCP201

2.5

2.4

2.3

2.2

2.1

2

1.9

tTRANSPD (µs)

1.8

Rising Edge Normal

1.7

1.6

1.5

4 6 8 10 12 14 16 18 20

tTRANSPD (µs) Rising Edge

Normal -40(C)

tTRANSPD (µs) Rising Edge

Normal 25(C)

tTRANSPD (µs) Rising Edge

Normal 125(C)

dap/jx 3/6/03

30 parts Y1004 B2

VBAT(v)

© 2007 Microchip Technology Inc. DS21730F-page 29

Page 30

MCP201

FIGURE 3-12: PROPAGATION DELAY OF RECEIVER

t

RECPD

(µs) Falling Edge Normal vs. V

BAT

(V)

3.3

3.1

2.9

2.7

2.5

(µs)

2.3

RECPD

t

2.1

Falling Edge Normal

1.9

1.7

1.5

4 6 8 10 12 14 16 18 20

V

BAT

(v)

t

RECPD

(µs) Falling Edge

Normal -40(C)

t

RECPD

(µs) Falling Edge

Normal 25(C)

t

RECPD

(µs) Falling Edge

Normal 125(C)

dap/jx 3/6/03

30 parts Y1004 B2

DS21730F-page 30 © 2007 Microchip Technology Inc.

Page 31

4.0 PACKAGING INFORMATION

4.1 Package Marking Information

MCP201

8-Lead DFN-S

XXXXXXXX

XXXXXXXX

YYWW

NNN

8-Lead PDIP (300 mil)

XXXXXXXX

XXXXXNNN

YYWW

8-Lead SOIC (150 mil)

XXXXXXXX

XXXXYYWW

NNN

Example

MCP201

E/MF

Example:

MCP201

E/P256

Example:

MCP201

E/SN0715

:

0715

256

0715

256

3

e

3

e

3

e

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

3

e

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note: In the event the full Microc hip p art numb er cann ot be mark ed on one line, it wil l

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

© 2007 Microchip Technology Inc. DS21730F-page 31

3

e

Page 32

MCP201

8-Lead Plastic Dual Flat, No Lead Package (MF) – 6x5 mm Body [DFN-S]

P

N

1

2

3

B

UNCH SINGULATED

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.m icrochip.com/packaging

D

NOTE 1

A

A1

N

1

TOP VIEW

φ

D1

E

E1

EXPOSED

2

A2

A3

b

PAD

2

D2

BOTTOM VIEW

NOTE 2

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 8

Pitch e 1.27 BSC

Overall Height A – 0.85 1.00

Molded Package Thickness A2 – 0.65 0.80

Standoff A1 0.00 0.01 0.05

Base Thickness A3 0.20 REF

Overall Length D 4.92 BSC

Molded Package Length D1 4.67 BSC

Exposed Pad Length D2 3.85 4.00 4. 15

Overall Width E 5.99 BSC

Molded Package Width E1 5.74 BSC

Exposed Pad Width E2 2.16 2.31 2.46

Contact Width b 0.35 0.40 0.47

Contact Length L 0.50 0.60 0.75

Contact-to-Exposed Pad K 0.20 – –

Model Draft Angle Top φ – – 12°

otes:

. Pin 1 visual index feature may vary, but must be located within the hatched area.

. Package may have one or more exposed tie bars at ends.

. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

DS21730F-page 32 © 2007 Microchip Technology Inc.

e

N

E2

1

L

K

NOTE 1

Microchip Technology Drawing C04-113

Page 33

8-Lead Plastic Dual In-Line (P) – 300 mil Body [PDIP]

N

1

2

3

4

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

N

NOTE 1

MCP201

E1

12

A

A1

b1

b

Number of Pins N 8

Pitch e .100 BSC

Top to Seating Plane A – – .210

Molded Package Thickness A2 .115 .130 .195

Base to Seating Plane A1 .015 – –

Shoulder to Shoulder Width E .290 .310 .325

Molded Package Width E1 .240 .250 .280

Overall Length D .348 .365 .400

Tip to Seating Plane L .115 .130 .150

Lead Thickness c .008 .010 .015

Upper Lead Width b1 .040 .060 .070

Lower Lead Width b .014 .018 .022

Overall Row Spacing § eB – – .430

otes:

. Pin 1 visual index feature may vary, but must be located with the hatched area.

. § Significant Characteristic.

. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010" per side.

. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

© 2007 Microchip Technology Inc. DS21730F-page 33

3

D

E

A2

L

e

eB

Units INCHES

Dimension Limits MIN NOM MAX

c

Page 34

MCP201

8-Lead Plastic Small Outline (SN) – Narrow, 3.90 mm Body [SOIC]

N

1

2

3

4

B

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

D

N

e

E

E1

NOTE 1

12 3

b

φ

A

A1

A2

Units MILLMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 8

Pitch e 1.27 BSC

Overall Height A – – 1.75

Molded Package Thickness A2 1.25 – –

Standoff

§

A1 0.10 – 0.25

Overall Width E 6.00 BSC

Molded Package Width E1 3.90 BSC

Overall Length D 4.90 BSC

Chamfer (optional) h 0.25 – 0.50

Foot Length L 0.40 – 1.27

Footprint L1 1.04 REF

Foot Angle φ 0° – 8°

Lead Thickness c 0.17 – 0.25

Lead Width b 0.31 – 0.51

Mold Draft Angle Top α 5° – 15°

Mold Draft Angle Bottom β 5° – 15°

otes:

. Pin 1 visual index feature may vary, but must be located within the hatched area.

. § Significant Characteristic.

. Dimens ions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15 mm per side.

. Dimens ioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

h

L

L1

h

α

c

β

Microchip Technology Drawing C04-057

DS21730F-page 34 © 2007 Microchip Technology Inc.

Page 35

APPENDIX A: REVISION HISTORY

Revision F (January 2007)

This revision includes updates to the packaging

diagrams.

MCP201

© 2007 Microchip Technology Inc. DS21730F-page 35

Page 36

MCP201

NOTES:

DS21730F-page 36 © 2007 Microchip Technology Inc.

Page 37

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

MCP201

PART NO. X /XX

Device

Device: MCP2 01: LIN Transceiver with Voltage Regulator

Temperature Range: I = -40°C to +85°C

Package: MF = Dual Flatpack, No-Lead (6x5 mm Body), 8-lead

Range

MCP201T: LIN Transceiver with Voltage Regulator

E = -40°C to +125°C

P = Plastic DIP (300 mil Body), 8-lead

SN = Plastic SOIC (150 mil Body), 8-lead

PackageTemperature

(Tape and Reel)

Examples:

a) MCP201-E/SN: Extended Temperature,

SOIC package.

b) MCP201-E/P: Extended Temperature,

PDIP package.

c) MCP201-I/SN: Industrial Temperature,

SOIC package.

d) MCP201-I/P: Industrial Temperature,

PDIP package.

e) MCP201T-I/SN: Tape and Reel,

Industrial Temperature,

SOIC package.

f) MCP201T-E/SN: Tape and Reel,

Extended Temperature,

SOIC package.

g) MCP201-E/MF: Extended Temperature,

DFN package.

h) MCP201T-E/MF: Tape and Reel,

Extended Temperature,

DFN package.

© 2007 Microchip Technology Inc. DS21730F-page 37

Page 38

MCP201

NOTES:

DS21730F-page 38 © 2007 Microchip Technology Inc.

Page 39

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are com mitted to continuously improving the code protect ion f eatures of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Mill ennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by updat es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Linear Active

Thermistor, Mindi, MiWi, MPASM, MPLIB, MPLINK, PIC kit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, Pow e rTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology I ncorporat ed in the U.S.A. and other

countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporated, Pr inted in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

MCUs and dsPIC DSCs, KEELOQ

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial

© 2007 Microchip Technology Inc. DS21730F-page 39

®

Page 40

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Techn ical Su pport:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-67 33

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2 100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5 511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750- 3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502- 7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5 533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2 829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203- 2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5 300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7 250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53 -63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

12/08/06

DS21730F-page 40 © 2007 Microchip Technology Inc.

Loading...

Loading...