Page 1

MCP19035

Power Module 8A

Reference Design

User’s Guide

2019 Microchip Technology Inc. DS50002840A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIE DBYDNV

== ISO/TS16949==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

QUALITYMANAGEMENTS

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, AVR Freaks, BitCloud, chipKIT, chipKIT logo,

CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo,

JukeBlox, KeeLoq, Kleer, LANCheck, LINK MD, maXStylus,

maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip

Designer, QTouch, SAM-BA, SpyNIC, SST, SST Logo,

SuperFlash, tinyAVR, UNI/O, and XMEGA are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMOS,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity,

JitterBlocker, KleerNet, KleerNet logo, memBrain, Mindi, MiWi,

motorBench, MPASM, MPF, MPLAB Certified logo, MPLIB,

MPLINK, MultiTRAK, NetDetach, Omniscient Code Generation,

PICDEM, PICDEM.net, PICkit, PICtail, PowerSmart, PureSilicon,

QMatrix, REAL ICE, Ripple Blocker, SAM-ICE, Serial Quad I/O,

SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2019, Microchip Technology Incorporated, All Rights Reserved.

ISBN: 918-1-5224-4099-4

DS50002840A-page 2 2019 Microchip Technology Inc.

Page 3

MCP19035 POWER MODULE

8A REFERENCE DESIGN

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 4

Introduction............................................................................................................ 4

Document Layout .................................................................................................. 4

Conventions Used in this Guide ............................................................................ 5

Recommended Reading........................................................................................ 6

The Microchip WebSite ......................................................................................... 6

Customer Support ................................................................................................. 6

Document Revision History ................................................................................... 6

Chapter 1. Product Overview

1.1 Introduction ..................................................................................................... 7

1.2 MCP19035 Overview ..................................................................................... 7

1.3 What is the MCP19035 Power Module 8A Reference Design? ..................... 8

1.4 What the MCP19035 Power Module 8A Reference Design Kit Contains ...... 8

Chapter 2. Installation and Operation

2.1 Introduction ..................................................................................................... 9

2.2 Getting Started ............................................................................................... 9

Appendix A. Schematic and Layouts

A.1 Introduction .................................................................................................. 12

A.2 Board – Schematic ....................................................................................... 13

A.3 Board – Top Silk .......................................................................................... 14

A.4 Board – Top Copper and Silk ....................................................................... 14

A.5 Board – Top Copper .................................................................................... 14

A.6 Board – Bottom Copper ............................................................................... 15

A.7 Board – Bottom Copper and Silk ................................................................. 15

A.8 Board – Bottom Silk ..................................................................................... 15

Appendix B. Bill of Materials (BOM)

Appendix C. Reference Design Waveforms

C.1 Typical Performance Data, Curves and Waveforms .................................... 17

Worldwide Sales and Service .................................................................................... 20

2019 Microchip Technology Inc. DS50002840A-page 3

Page 4

MCP19035 POWER MODULE

8A REFERENCE DESIGN

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics, to open a list of available online help files.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP19035 Power Module 8A Reference Design. Items discussed in this chapter

include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip WebSite

• Customer Support

• Document Revision History

®

IDE online help.

DOCUMENT LAYOUT

This document describes how to use the MCP19035 Power Module 8A Reference

Design as a development tool to emulate and debug firmware on a target board. The

manual layout is as follows:

• Chapter 1. “Product Overview” – Important information about the MCP19035

Power Module 8A Reference Design.

• Chapter 2. “Installation and Operation” – Includes instructions on installing and

starting the MCP19035 Power Module 8A Reference Design.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the MCP19035 Power Module 8A Reference Design.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

MCP19035 Power Module 8A Reference Design.

• Appendix C. “Reference Design Waveforms” – Lists the typical performance

data, curves and waveforms.

2019 Microchip Technology Inc. DS50002840A-page 4

Page 5

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

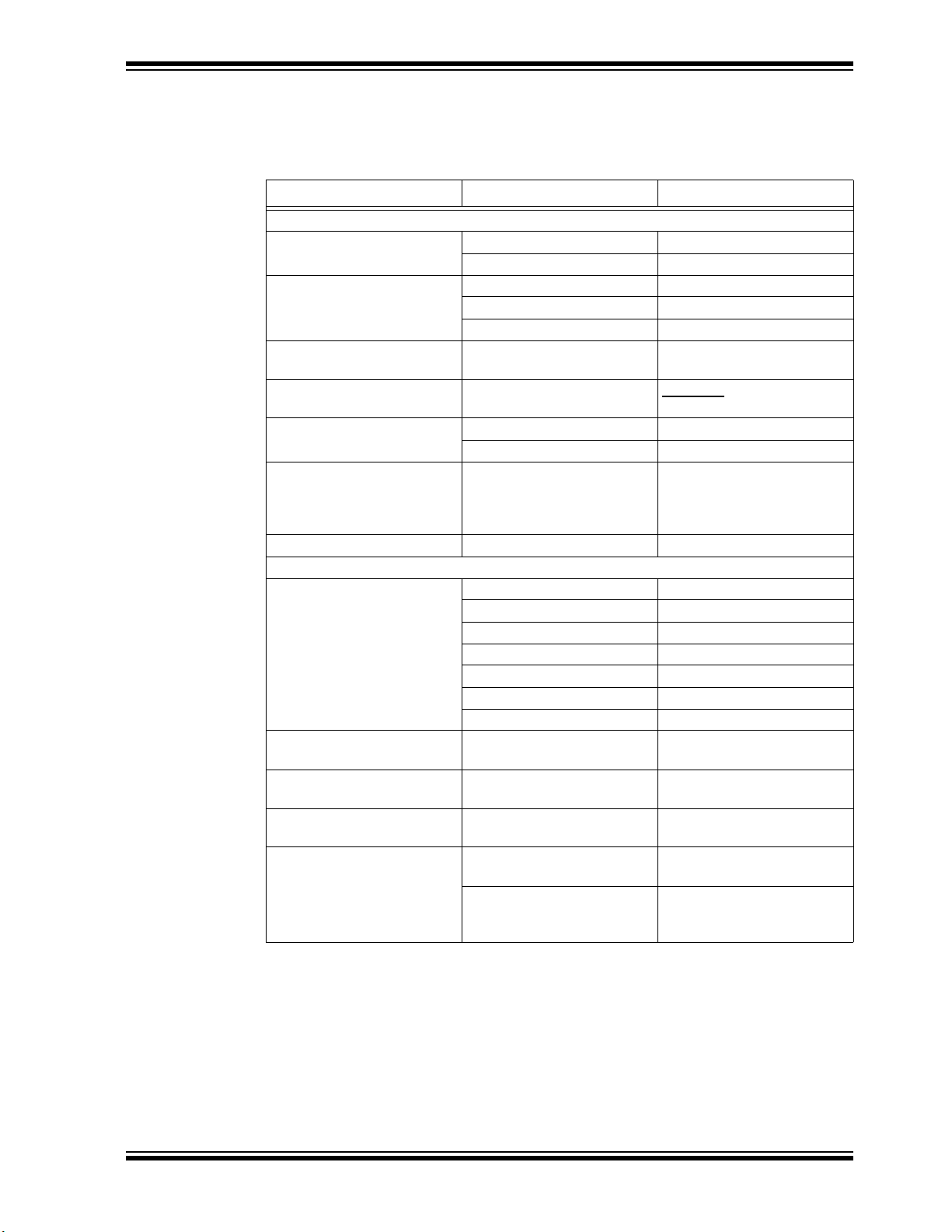

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Initial caps A window the Output window

Quotes A field name in a window or

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

Preface

®

IDE User’s Guide

Emphasized text ...is the only compiler...

A dialog the Settings dialog

A menu selection select Enable Programmer

“Save project before build”

dialog

A menu path File>Save

A tab Click the Power tab

4‘b0010, 2‘hF1

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

any valid filename

[options]

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

2019 Microchip Technology Inc. DS50002840A-page 5

Page 6

RECOMMENDED READING

This user’s guide describes how to use the MCP19035 Power Module 8A Reference

Design. Other useful documents are listed below. The following Microchip documents

are available and recommended as supplemental reference resources:

• MCP19035 Data Sheet – “High-Speed Synchronous Buck Controller”

(DS20002326)

• MCP19035 User’s Guide – “MCP19035 600 kHz High-Voltage Synchronous

Buck Controller Reference Design User’s Guide” (DS50002228)

• MCP19035 Design Analyzer v1.0

THE MICROCHIP WEBSITE

Microchip provides online support via our website at www.microchip.com. This website

is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the website contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the website at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (January 2019)

• Initial release of this document

2019 Microchip Technology Inc. DS50002840A-page 6

Page 7

Chapter 1. Product Overview

C

IN

C

OUT

MCP19035

HDRV

LDRV

PHASE

BOOT

+VCC

C

BOOT

C

VCC

+V

OUT

SHDN

V

IN

PWRGD

COMP

FB

+VIN

ON

OFF

1.1 INTRODUCTION

This chapter provides an overview of the MCP19035 Power Module 8A Reference

Design and covers the following topics:

• MCP19035 Overview

• What is the MCP19035 Power Module 8A Reference Design?

• What the MCP19035 Power Module 8A Reference Design Kit Contains

1.2 MCP19035 OVERVIEW

The MCP19035 is a highly-featured, highly-integrated, synchronous buck controller in

a space-saving 10-pin DFN 3x3 package that operates from input voltage sources up

to 30V. Integrated features include high and low-side MOSFET drivers, fixed-frequency

voltage mode control, internal oscillator and reference voltage generator, overcurrent

protection circuit for both sides, Power Good (PG) circuit and overtemperature protection. A minimal number of external components are necessary to develop a complete,

high-performance synchronous buck converter power supply.

The MCP19035 Synchronous Buck Controller is intended to be used for applications

requiring medium-to-high output currents (up to 20A) and input voltages up to 30V.

Typical applications include: medium currents Point-of-Load converters, FPGA/DSP

power supplies, USB power ports, digital Set-Top boxes, industrial 24V rails converters,

high-power LED drivers.

The internal high-current linear voltage regulator (LDO) allows low-current loads (ex.

®

PIC

microcontrollers) to be powered directly from this controller without any additional

components.

MCP19035 POWER MODULE

8A REFERENCE DESIGN

USER’S GUIDE

FIGURE 1-1: Typical Application.

2019 Microchip Technology Inc. DS50002840A-page 7

Page 8

1.3 WHAT IS THE MCP19035 POWER MODULE 8A REFERENCE DESIGN?

The MCP19035 Power Module 8A Reference Design is a compact, highly efficient,

step-down voltage circuit that will convert the input voltage rail (typically 12V) to 5V regulated output voltage. The maximum output current for this step-down converter is 8A.

The board demonstrates the capabilities of the MCP19035 600 kHz Synchronous Buck

Converter Controller in a typical high-voltage input step-down application. The

MCP19035 Power Module 8A Reference Design can be modified to support output

voltages from 3.3V to 5.5V by changing a single resistor.

1.4 WHAT THE MCP19035 POWER MODULE 8A REFERENCE DESIGN KIT CONTAINS

The MCP19035 Power Module 8A Reference Design includes the following items:

• MCP19035 Power Module 8A Reference Design (ADM00987)

• Important Information Sheet

2019 Microchip Technology Inc. DS50002840A-page 8

Page 9

Chapter 2. Installation and Operation

2.1 INTRODUCTION

The MCP19035 Power Module 8A Reference Design was developed to provide a

compact, low-cost and highly efficient step-down conversion for low to medium output

currents.

The key features of this board include:

• Input Voltage Range: 6V to 18V

• Output Voltage: 5V (can be adjusted by changing one resistor between 3.3V and

5V)

• Maximum Output Current: 8A

• 95% Typical Efficiency at 5V/8A Output and 12V Input

• 600 kHz Fixed Switching Frequency

• Over-Current Protection for High and Low-Side MOSFETs

• Shutdown Input for Placing the Converter in Low-Power Standby Mode

• Under Voltage Lockout (UVLO) with 4.5V and 3.9V (typical) Thresholds

MCP19035 POWER MODULE

8A REFERENCE DESIGN

USER’S GUIDE

2.2 GETTING STARTED

The MCP19035 Power Module 8A Reference Design is fully assembled and tested to

evaluate and demonstrate the MCP19035 capabilities.

2.2.1 Necessary Instruments and Tools

• Adjustable DC Power Supply with 0V-30V/5ADC range output capability

• Electronic Load with at least 8A current capability and load stepping capability

• Digital Oscilloscope with a minimum bandwidth of 50 MHz

• Digital Voltmeter/Ammeter

• Wires for connections; these wires must sustain high currents, 8A for the connection between adjustable DC Power Supply and board, 8A for the connection

between board and the Electronic Load

2.2.2 Setup Procedure

To power-up the MCP19035 Power Module 8A Reference Design, the following steps

must be completed:

1. Connect the Electronic Load to the J1 connector of the reference design; the

positive (+) and negative (-) connector pins are the 2, 3 and 4 pins, for positive,

respectively 5, 6,10 pins, for negative, off the J1 connector.

2. Connect the Adjustable DC Power Supply to the J1 connector of the reference

design; the positive (+) and negative (-) connector pins are the 7 and 8 pins, for

positive, respectively 5, 6,10 pins, for negative, off the J1 connector.

3. The DC voltage supplied by the Adjustable DC Power Supply must be 12V.

2019 Microchip Technology Inc. DS50002840A-page 9

Page 10

Installation and Operation

2.2.3 Board Testing

The typical application is shown in Figure 2-1 and the 3D view of the board with the J1

connector pins numbered is shown in Figure 2-2. For more details, see Appendix

A. “Schematic and Layouts”.

The user can connect various instruments at the listed pins of the J1 connector to evaluate the parameters of the converter. The typical performance data, curves and waveforms are presented in Section C.1 “Typical Performance Data, Curves and

Waveforms”.

The user also has two ways to connect the R4 to the circuit. First is to mount the resistor

on the silk footprint on the board, and the second is to connect the R4 to the pins.

FIGURE 2-1: Schematic.

FIGURE 2-2: 3D View of the Board.

2019 Microchip Technology Inc. DS50002840A-page 10

Page 11

Installation and Operation

R

4

R3V

REF

V

OUTVREF

–

------------------------------- -=

Where:

V

REF

= 0.6V

R

3

= 20 kΩ

2.2.4 Adjusting the Output Voltage

The output voltage can be modified by changing the value of R4 from the feedback

divider. The output voltage is set according to Equation 2-1.

EQUATION 2-1:

Do not modify the value of the R3 resistor (20 kΩ), as this will affect the loop compensation of the system.

Some parameters, such as the efficiency, the overcurrent protection thresholds and the

input and output voltage ripples can be affected by the modification of the output voltage. Do not exceed 6V for the output voltage or permanent damage of the board can

occur.

Ta bl e 2 -1 shows the standard values of the R4 resistor for a few usual output voltages.

TABLE 2-1: OUTPUT VOLTAGE VS. R4 VALUE

V

OUT

3.3 4.42 4.3

5 2.74 2.7

R4 (kΩ)

calculated

R4 (kΩ)

E24 standard

2.2.5 Testing Procedure

In the testing procedure, measurements are made on a testing board to help get better

results, as the parameters are at 12V voltage on input and 8A current on output.

2019 Microchip Technology Inc. DS50002840A-page 11

Page 12

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the following schematics and layouts for the MCP19035 Power

Module 8A Reference Design - ADM00995:

• Board – Schematic

• Board – Top Silk

• Board – Top Copper and Silk

• Board – Top Copper

• Board – Bottom Copper

• Board – Bottom Copper and Silk

• Board – Bottom Silk

MCP19035 POWER MODULE

8A REFERENCE DESIGN

USER’S GUIDE

2019 Microchip Technology Inc. DS50002840A-page 12

Page 13

DS50002840A-page 13 2019 Microchip Technology Inc.

*1'

*1'

*1'

*1' *1'

*1'

*1' *1'

0.33uF

16V

&

100k

1%

5

2.7k

1%

YES

5

20k

5%

5

750R

1%

5

9LQ

9RXW

6+'1

2XWSXW7ULP

3+$6(

MCP19035-BAABE/MF

6+'1

)%

&203

9,1

3:5*'

9&&

/'59

%227

3+$6(

+'59

(3

8

*1'

+'59

/'59

MCP87055T

1,2,3

5,6,7,8

4

MCP87055T

1,2,3

5,6,7,8

4

6+'1

2XWSXW7ULP

*1'

47pF

50V

&

5600pF

50V

&

&203

100k

1%

5

9&&

9&&

3:5*'

73

73

9LQ 99

,RXWPD[ $

5IE

5IE 9UHI[5IE N

9RXW9UHI

5 9RXW

N 9

N 9

5IE

2XWSXW7ULP

9RXW

([WHUQDO7ULP5HVLVWRU

9RXW9

'13

GHWHUPLQHG

E\5IE

HDR-2 Male 2x5

-

9RXW

9LQ

4.7uF

35V

&

4.7uF

35V

&

2.2uH

XAL7070-222MEC

/

2.7k

0402 1%

5

680pF

50V

0402

&

22uF

10V

1206

&

22uF

10V

1206

&

1uF

25V

0603

&

1uF

25V

0603

&

5IE

A.2 BOARD – SCHEMATIC

MCP19035 Power Module 8A Reference Design User’s Guide

Page 14

A.3 BOARD – TOP SILK

A.4 BOARD – TOP COPPER AND SILK

Schematic and Layouts

A.5 BOARD – TOP COPPER

2019 Microchip Technology Inc. DS50002840A-page 14

Page 15

A.6 BOARD – BOTTOM COPPER

A.7 BOARD – BOTTOM COPPER AND SILK

Schematic and Layouts

A.8 BOARD – BOTTOM SILK

2019 Microchip Technology Inc. DS50002840A-page 15

Page 16

MCP19035 POWER MODULE

8A REFERENCE DESIGN

USER’S GUIDE

Appendix B. Bill of Materials (BOM)

TABLE B-1: BILL OF MATERIALS (BOM)

Qty. Reference Description Manufacturer Part Number

2 C1, C2 Capacitor Ceramic, 4.7 µF, 35V, 10%, X7R,

SMD, 0805

1 C3 Capacitor Ceramic, 5600 pF, 50V, 10%, X7R,

SMD, 0402

1 C4 Capacitor Ceramic, 0.33 µF, 16V, 10%, X7R,

SMD, 0603

1 C5 Capacitor Ceramic, 47 pF, 50V, 5%, NP0,

SMD, 0402

2 C6, C9 Capacitor Ceramic, 1 µF, 25V, 10%, X7R,

SMD, 0603, AEC-Q200

2 C7, C8 Capacitor Ceramic, 22 µF, 10V, 10%, X7R,

SMD, 1206, AEC-Q200

1 C10 Capacitor Ceramic, 680 pF, 50V, 10%, X7R,

SMD, 0402

1 J1 Connector Header-2, Male, 2x5, Gold, TH, RASamtec, Inc. TMM-105-01-L-D-RA

TDK Corporation C2012X7R1V475K125AE

Samsung ElectroMechanics America, Inc

Murata Electronics® GRM188R71C334KA01D

Murata Electronics® GRM1555C1H470JA01D

Samsung ElectroMechanics America, Inc.

Taiyo Yuden Co., Ltd. LMJ316BB7226KLHT

Wurth Elektronik 885012205060

CL05B562KB5NNNC

CL10B105KA8VPNC

1 L1 Inductor 2.2 µH, 17.8A, 20%, SMD,

L7.5W7.2D7

1 PCB1 Printed Circuit Board Microchip Technology

2 Q1, Q2 Microchip Analog MOSFET N-CH, 25V, 60A,

MCP87055T-U/LC PDFN-8

2 R1, R6 Resistor, TKF, 100k, 1%, 1/10W, SMD, 0402 Panasonic

1 R2 Resistor, TKF, 2.7k, 1%, 1/10W, SMD, 0402 Panasonic

1 R3 Resistor, TKF, 20k, 5%, 1/10W, SMD, 0402 Panasonic® - ECG ERJ-2GEJ203X

0 R4 Do Not Populate – Resistor, TKF, 2.7k, 1%,

1/10W, SMD, 0402

1 R5 Resistor, TKF, 750R, 1/10W, 1%, SMD, 0402 Panasonic® - ECG ERJ-2RKF7500X

1 U1 Microchip Analog PWM Controller, 600 kHz,

MCP19035-BAABE/MF DFN-10

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Coilcraft XAL7070-222MEC

04-10880-R1

Inc.

Microchip Technology

Inc.

®

- ECG ERJ-2RKF1003X

®

- ECG ERJ-2RKF2701X

Panasonic

Microchip Technology

Inc.

®

- ECG ERJ-2RKF2701X

MCP87055T-U/LC

MCP19035-BAABE/MF

2019 Microchip Technology Inc. DS50002840A-page 16

Page 17

MCP19035 POWER MODULE

(IILFLHQF\

,

287

$

(II9

(IIY

(II9

(II9

(II9

(II 9

8A REFERENCE DESIGN

USER’S GUIDE

Appendix C. Reference Design Waveforms

C.1 TYPICAL PERFORMANCE DATA, CURVES AND WAVEFORMS

This chapter shows some of the typical performance parameters and curves of the

MCP19035 Power Module 8A Reference Design.

TABLE C-1: CONVERTER PARAMETERS

Parameter Value Comments

Input Voltage Range (V) 6 - 18

Output Voltage (V) 5 ±1.5% Tolerance

Maximum Output Current (A) 8 Steady state output current

Output Voltage Ripple (mV) < 25 V

Input Voltage Ripple (mV) < 300 VIN = 12V, I

Output Voltage Overshoot during

Step Load (mV)

Switching Frequency (kHz) 550 - 650 Typical 600 kHz

< 200 Step Load 0A to 8A

= 12V, I

IN

OUT

OUT

= 8A

= 8A

FIGURE C-1: Efficiency vs. I

OUT

(A).

2019 Microchip Technology Inc. DS50002840A-page 17

Page 18

MCP19035 Power Module 8A Reference Design User’s Guide

9

287

9

,

287

$

FIGURE C-2: Load Regulation (VIN=12V).

FIGURE C-3: Output Voltage Ripple/Noise (V

BW = 20MHz).

2019 Microchip Technology Inc. DS50002840A-page 18

=12V, I

IN

OUT

=8A,

Page 19

MCP19035 Power Module 8A Reference Design User’s Guide

FIGURE C-4: Input Voltage Ripple/Noise (VIN=12V, I

FIGURE C-5: Step Load (VIN=12V, I

= 0A to 8A).

OUT

= 8A, BW = 20MHz).

OUT

2019 Microchip Technology Inc. DS50002840A-page 19

Page 20

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

China - Beijing

Tel: 86-10-8569-7000

China - Chengdu

Tel: 86-28-8665-5511

China - Chongqing

Tel: 86-23-8980-9588

China - Dongguan

Tel: 86-769-8702-9880

China - Guangzhou

Tel: 86-20-8755-8029

China - Hangzhou

Tel: 86-571-8792-8115

China - Hong Kong SAR

Tel: 852-2943-5100

China - Nanjing

Tel: 86-25-8473-2460

China - Qingdao

Tel: 86-532-8502-7355

China - Shanghai

Tel: 86-21-3326-8000

China - Shenyang

Tel: 86-24-2334-2829

China - Shenzhen

Tel: 86-755-8864-2200

China - Suzhou

Tel: 86-186-6233-1526

China - Wuhan

Tel: 86-27-5980-5300

China - Xian

Tel: 86-29-8833-7252

China - Xiamen

Tel: 86-592-2388138

China - Zhuhai

Tel: 86-756-3210040

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

India - New Delhi

Tel: 91-11-4160-8631

India - Pune

Tel: 91-20-4121-0141

Japan - Osaka

Tel: 81-6-6152-7160

Japan - Tokyo

Tel: 81-3-6880- 3770

Korea - Daegu

Tel: 82-53-744-4301

Korea - Seoul

Tel: 82-2-554-7200

Malaysia - Kuala Lumpur

Tel: 60-3-7651-7906

Malaysia - Penang

Tel: 60-4-227-8870

Philippines - Manila

Tel: 63-2-634-9065

Singapore

Tel: 65-6334-8870

Taiwan - Hsin Chu

Tel: 886-3-577-8366

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Taiwan - Taipei

Tel: 886-2-2508-8600

Thailand - Bangkok

Tel: 66-2-694-1351

Vietnam - Ho Chi Minh

Tel: 84-28-5448-2100

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

Finland - Espoo

Tel: 358-9-4520-820

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-67-3636

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Israel - Ra’anana

Tel: 972-9-744-7705

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-7288-4388

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

2019 Microchip Technology Inc. DS50002840A-page 20

08/15/18

Loading...

Loading...