1

3

2

V

IN

GND V

OUT

MCP1702

1

2

3

V

IN

GND V

OUT

MCP1702

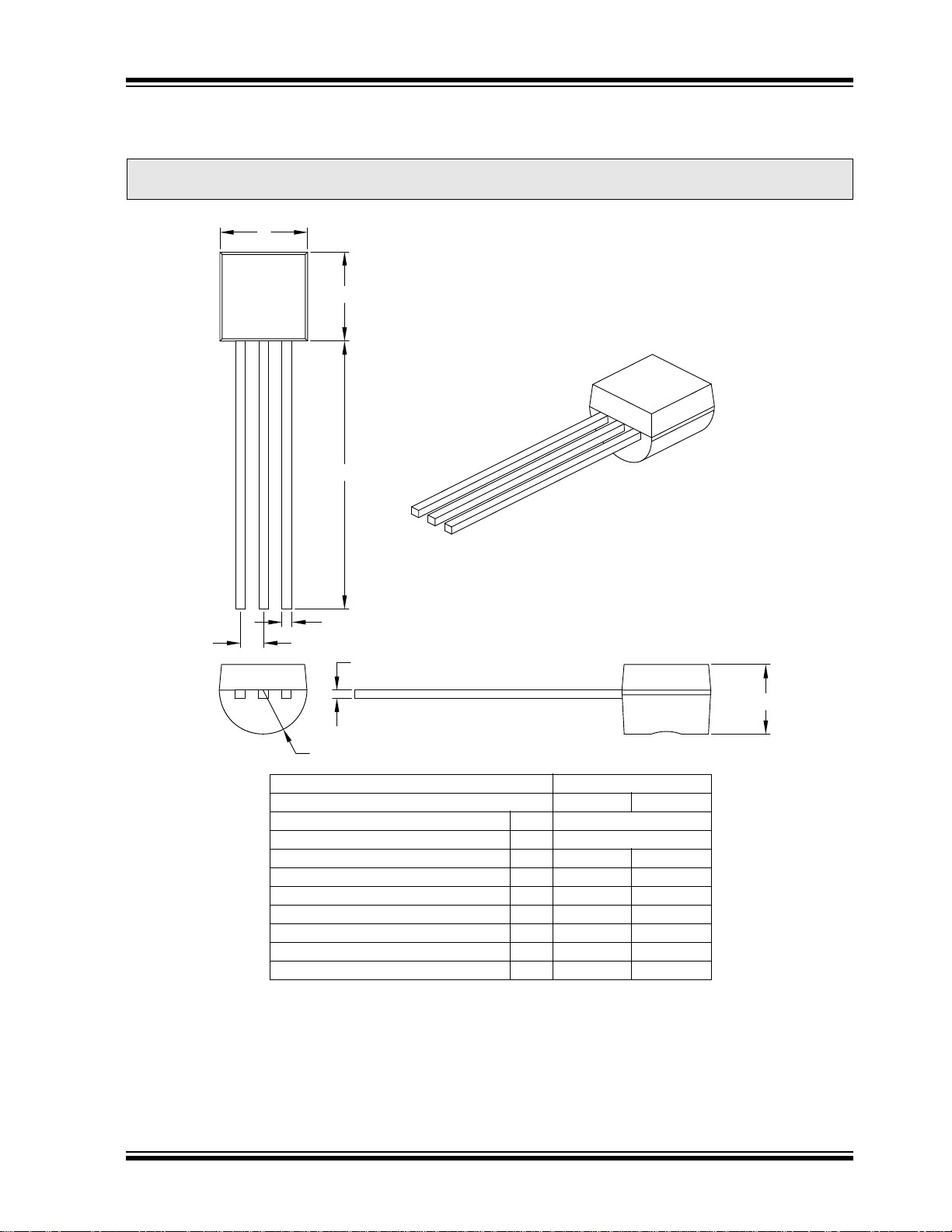

3-Pin SOT-23A

3-Pin SOT-89

V

IN

3-Pin TO-92

12

V

OUT

V

IN

GND

Bottom

View

3

查询MCP1702T-1202E/CB供应商

250 mA Low Quiescent Current LDO Regulator

MCP1702

Features

• 2.0 µA Quiescent Current (typical)

• Input Operating Voltage Range: 2.7V to 13.2V

• 250 mA Output Current for Output Voltages ≥ 2.5V

• 200 mA Output Current for Output Voltages < 2.5V

• Low Dropout (LDO) voltage

• 0.4% Typical Output Voltage Tolerance

• Standard Output Voltage Options:

• Output voltage range 1.2V to 5.5V in 0.1V

• Stable with 1.0 µF to 22 µF Output Capacitor

• Short-Circuit Protection

• Overtemperature Protection

Applications

• Battery-powered Devices

• Battery-powered Alarm Circuits

• Smoke Detectors

•CO

• Pagers and Cellular Phones

• Smart Battery Packs

• Low Quiescent Current Voltage Reference

•PDAs

• Digital Cameras

• Microcontroller Power

• Solar-Powered Instruments

• Consumer Products

• Battery Powered Data Loggers

Related Literature

• AN765, “Using Microchip’s Micropower LDOs”,

• AN766, “Pin-Compatible CMOS Upgrades to

• AN792, “A Method to Determine How Much

- 625 mV typical @ 250 mA (V

- 1.2V, 1.5V, 1.8V, 2.5V, 2.8V,

3.0V, 3.3V, 4.0V, 5.0V

Increments (50 mV increments available upon

request)

2

Detectors

OUT

= 2.8V)

DS00765, Microchip Technology Inc., 2002

BiPolar LDOs”, DS00766,

Microchip Technology Inc., 2002

Power a SOT-23 Can Dissipate in an Application”,

DS00792, Microchip Technology Inc., 2001

Description

The MCP1702 is a family of CMOS low dropout (LDO)

voltage regulators that can deliver up to 250 mA of

current while consuming only 2.0 µA of quiescent

current (typical). The input operating range is specified

from 2.7V to 13.2V, making it an ideal choice for two to

six primary cell battery-powered applications, 9V

alkaline and one or two cell Li-Ion-powered

applications.

The MCP1702 is capable of delivering 250 mA with

only 625 mV (typical) of input to output voltage

differential (V

of the MCP1702 is typically ±0.4% at +25°C and ±3%

maximum over the operating junction temperature

range of -40°C to +125°C. Line regulation is ±0.1%

typical at +25°C.

Output voltages available for the MCP1702 range from

1.2V to 5.0V. The LDO output is stable when using only

1 µF of output capacitance. Ceramic, tantalum or

aluminum electrolytic capacitors can all be used for

input and output. Overcurrent limit and

overtemperature shutdown provide a robust solution

for any application.

Package options include the SOT-23A, SOT-89-3, and

TO-92.

= 2.8V). The output voltage tolerance

OUT

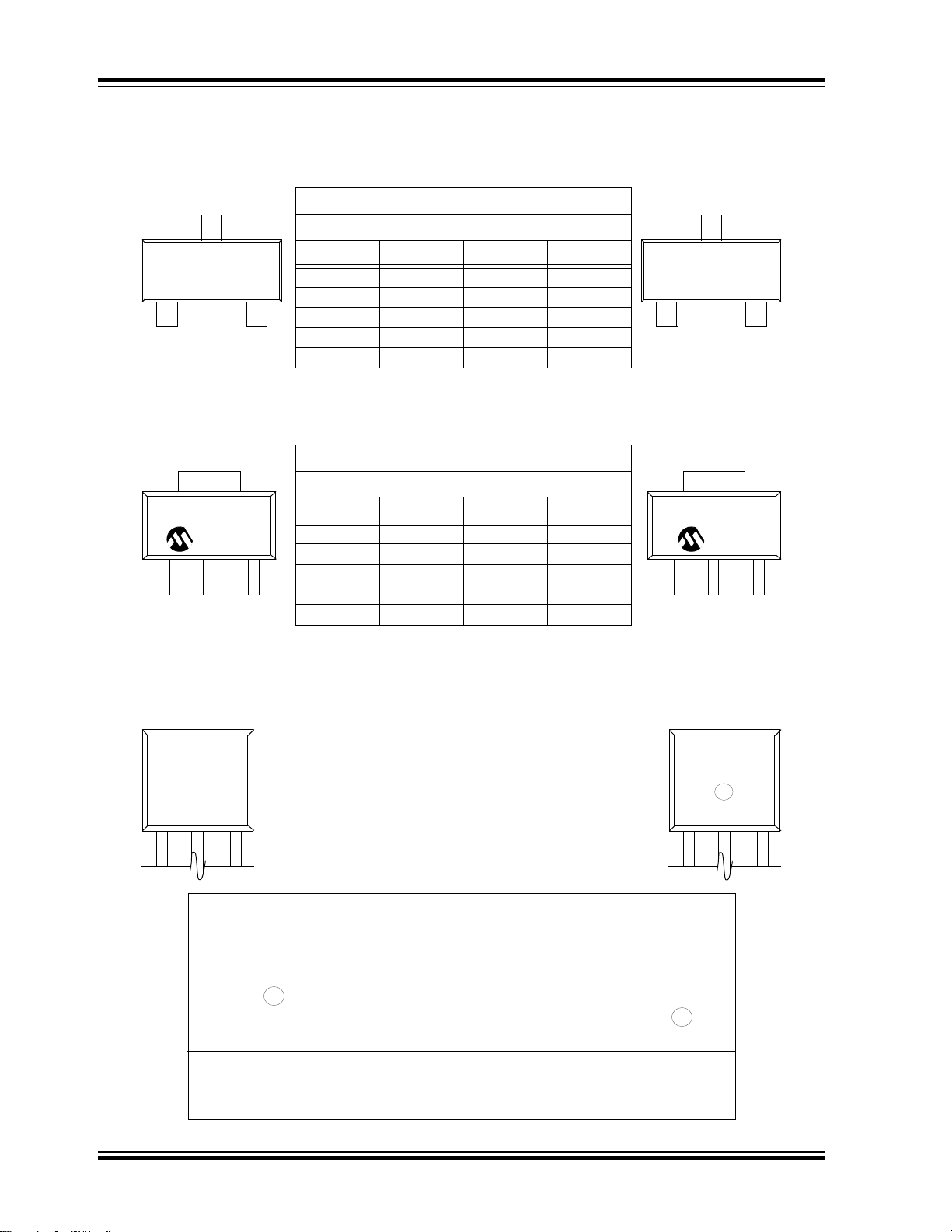

Package Types

© 2007 Microchip Technology Inc. DS22008B-page 1

MCP1702

+

-

MCP1702

V

IN

V

OUT

GND

+V

IN

Error Amplifier

Voltage

Reference

Overcurrent

Overtemperature

MCP1702

V

IN

C

IN

1µF Ceramic

C

OUT

1 µF Ceramic

V

OUT

V

IN

3.3V

I

OUT

50 mA

GND

V

OUT

9V

Battery

+

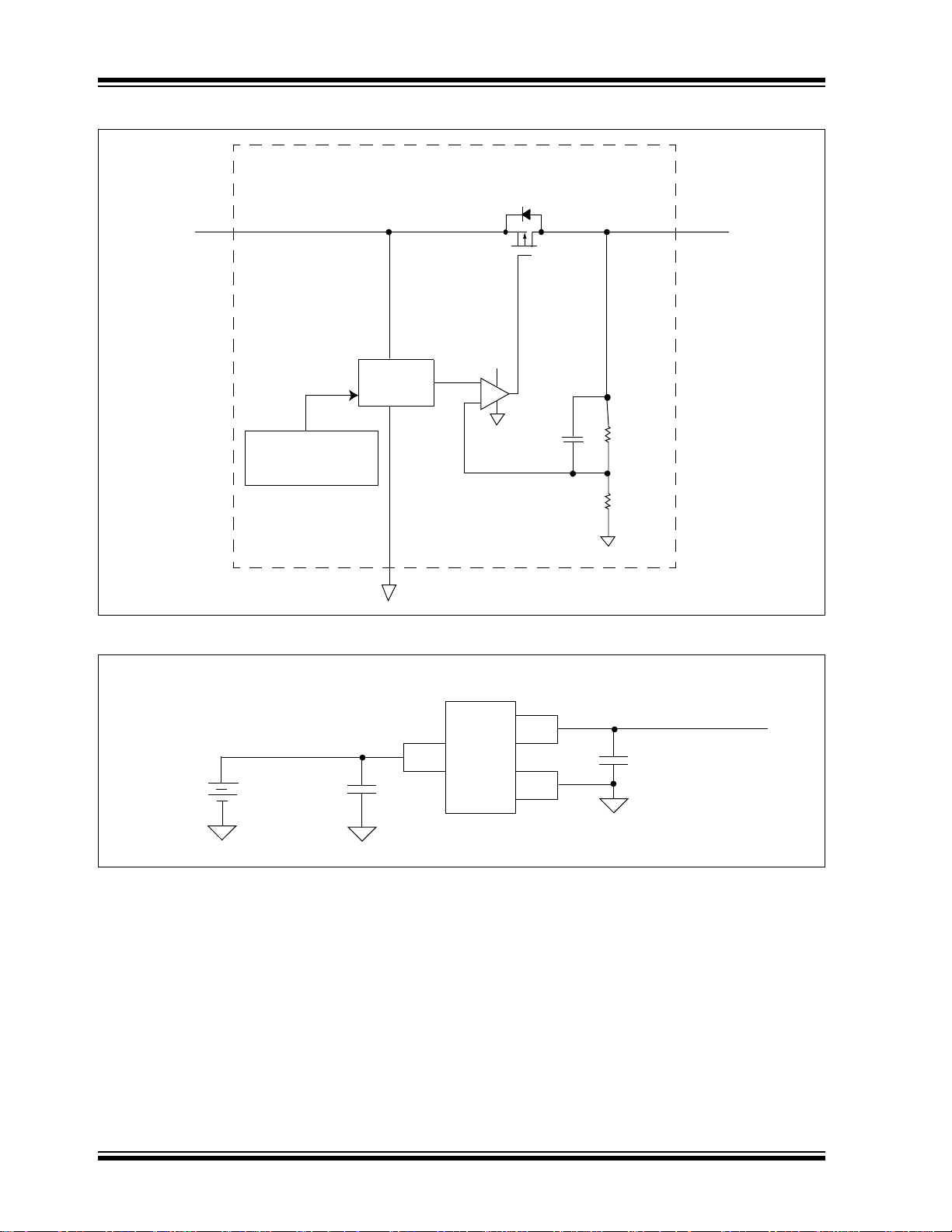

Functional Block Diagrams

Typical Application Circuits

DS22008B-page 2 © 2007 Microchip Technology Inc.

MCP1702

1.0 ELECTRICAL

CHARACTERISTICS

† Notice: Stresses above those listed under “Maximum Rat-

ings” may cause permanent damage to the device. This is a

stress rating only and functional operation of the device at

those or any other conditions above those indicated in the

Absolute Maximum Ratings †

VDD...............................................................................+14.5V

All inputs and outputs w.r.t. .............(V

-0.3V) to (VIN+0.3V)

SS

operational listings of this specification is not implied. Exposure to maximum rating conditions for extended periods may

affect device reliability.

Peak Output Current ...................................................500 mA

Storage temperature .....................................-65°C to +150°C

Maximum Junction Temperature...................................150°C

Operating Junction Temperature...................-40°C to +125°C

ESD protection on all pins (HBM;MM)............... ≥ 4kV; ≥ 400V

DC CHARACTERISTICS

Electrical Specifications: Unless otherwise specified, all limits are established for VIN = V

I

= 100 µA, C

LOAD

Boldface type applies for junction temperatures, T

= 1 µF (X7R), CIN = 1 µF (X7R), TA = +25°C.

OUT

of -40°C to +125°C. (Note 7)

J

OUT(MAX)

Parameters Sym Min Typ Max Units Conditions

Input / Output Characteristics

Input Operating Voltage V

Input Quiescent Current I

Maximum Output Current I

OUT_mA

IN

q

2.7 — 13.2 V Note 1

—2.0 5 µA IL = 0 mA

250 —— mAFor V

50 100 — mA For V

100 130 — mA For V

150 200 — mA For V

200 250 — mA For V

Output Short Circuit Current I

OUT_SC

Output Voltage Regulation V

Temperature Coefficient TCV

V

OUT

Line Regulation ΔV

(V

OUT

Load Regulation

Note 1: The minimum V

2: V

is the nominal regulator output voltage. For example: VR = 1.2V, 1.5V, 1.8V, 2.5V, 2.8V, 3.0V, 3.3V, 4.0V, or 5.0V.

R

The input voltage V

3: TCV

OUT

= (V

temperature range. V

ΔV

OUT/VOUT

must meet two conditions: VIN ≥ 2.7V and VIN ≥ V

IN

= V

IN

OUT-HIGH

- V

OUT-LOW

OUT

OUT

/

OUT

XΔVIN)

OUT(MAX)

OUT-LOW

= lowest voltage measured over the temperature range.

— 400 — mA VIN = V

VR-3.0%

V

-2.0%

R

±0.4%VR+3.0%

V

R

V

+2.0%

R

V Note 2

—50150 ppm/°C Note 3

-0.3 ±0.1 +0.3 %/V (V

-2.5 ±1.0 +2.5 %IL = 1.0 mA to 250 mA for VR ≥ 2.5V

+ V

= highest voltage measured over the

+ V

DROPOUT(MAX)

or VIN = 2.7V (whichever is greater); I

) *106 / (VR * ΔTemperature), V

OUT(MAX)

OUT-HIGH

4: Load regulation is measured at a constant junction temperature using low duty cycle pulse testing. Changes in output

voltage due to heating effects are determined using thermal regulation specification TCV

5: Dropout voltage is defined as the input to output differential at which the output voltage drops 2% below its measured

value with an applied input voltage of V

OUT(MAX)

+ V

DROPOUT(MAX)

or 2.7V, whichever is greater.

6: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable junction

temperature and the thermal resistance from junction to air (i.e., T

dissipation will cause the device operating junction temperature to exceed the maximum 150°C rating. Sustained

, TJ, θJA). Exceeding the maximum allowable power

A

junction temperatures above 150°C can impact the device reliability.

7: The junction temperature is approximated by soaking the device under test at an ambient temperature equal to the

desired Junction temperature. The test time is small enough such that the rise in the Junction temperature over the

ambient temperature is not significant.

+ V

DROPOUT(MAX)

≥ 2.5V

R

< 2.5V, VIN ≥ 2.7V

R

< 2.5V, VIN ≥ 2.95V

R

< 2.5V, VIN ≥ 3.2V

R

< 2.5V, VIN ≥ 3.45V

R

(Note 1), V

IN(MIN)

Current (average current) measured

10 ms after short is applied.

OUT(MAX)

≤ V

I

= 1.0 mA to 200 mA for VR < 2.5V,

L

V

IN

DROPOUT(MAX)

+ V

≤ 13.2V, (Note 1)

IN

DROPOUT(MAX)

= 3.45V Note 4

.

= 100 µA.

OUT

.

OUT

, Note 1,

= GND,

OUT

)

© 2007 Microchip Technology Inc. DS22008B-page 3

MCP1702

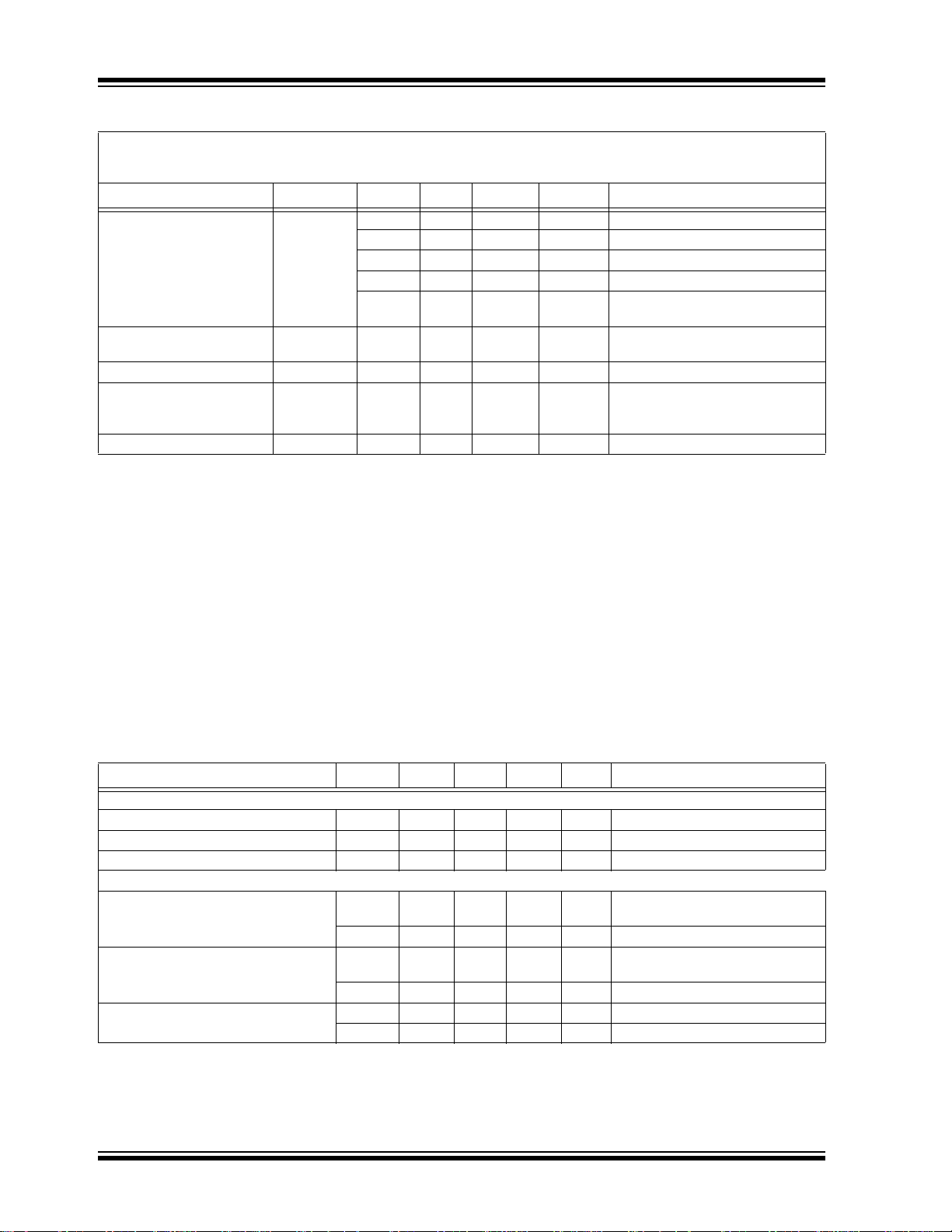

DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise specified, all limits are established for VIN = V

I

= 100 µA, C

LOAD

Boldface type applies for junction temperatures, T

= 1 µF (X7R), CIN = 1 µF (X7R), TA = +25°C.

OUT

of -40°C to +125°C. (Note 7)

J

OUT(MAX)

Parameters Sym Min Typ Max Units Conditions

Dropout Voltage

(Note 1, Note 5)

V

DROPOUT

— 330 650 mV IL = 250 mA, VR = 5.0V

— 525 725 mV I

— 625 975 mV I

— 750 1100 mV I

——— mV V

Output Delay Time T

Output Noise e

Power Supply Ripple

PSRR — 44 — dB f = 100 Hz, C

DELAY

N

— 1000 — µs VIN = 0V to 6V, V

—8 µV/(Hz)

1/2

Rejection Ratio

Thermal Shutdown Protection T

Note 1: The minimum V

2: V

is the nominal regulator output voltage. For example: VR = 1.2V, 1.5V, 1.8V, 2.5V, 2.8V, 3.0V, 3.3V, 4.0V, or 5.0V.

R

The input voltage V

3: TCV

= (V

OUT

temperature range. V

must meet two conditions: VIN ≥ 2.7V and VIN ≥ V

IN

= V

IN

OUT-HIGH

- V

OUT-LOW

SD

OUT(MAX)

OUT-LOW

= lowest voltage measured over the temperature range.

— 150 — °C

+ V

DROPOUT(MAX)

or VIN = 2.7V (whichever is greater); I

) *106 / (VR * ΔTemperature), V

OUT(MAX)

OUT-HIGH

+ V

= highest voltage measured over the

4: Load regulation is measured at a constant junction temperature using low duty cycle pulse testing. Changes in output

voltage due to heating effects are determined using thermal regulation specification TCV

5: Dropout voltage is defined as the input to output differential at which the output voltage drops 2% below its measured

value with an applied input voltage of V

OUT(MAX)

+ V

DROPOUT(MAX)

or 2.7V, whichever is greater.

6: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable junction

temperature and the thermal resistance from junction to air (i.e., T

dissipation will cause the device operating junction temperature to exceed the maximum 150°C rating. Sustained

, TJ, θJA). Exceeding the maximum allowable power

A

junction temperatures above 150°C can impact the device reliability.

7: The junction temperature is approximated by soaking the device under test at an ambient temperature equal to the

desired Junction temperature. The test time is small enough such that the rise in the Junction temperature over the

ambient temperature is not significant.

+ V

DROPOUT(MAX)

= 250 mA, 3.3V ≤ VR < 5.0V

L

= 250 mA, 2.8V ≤ VR < 3.3V

L

= 250 mA, 2.5V ≤ VR < 2.8V

L

< 2.5V, See Maximum Output

R

Current Parameter

R

= 50Ω resistive

L

OUT

IL = 50 mA, f = 1 kHz, C

= 1 µF, IL = 50 mA,

V

INAC

V

=1.2V

R

DROPOUT(MAX)

OUT

= 100 mV pk-pk, CIN = 0 µF,

.

= 100 µA.

OUT

.

OUT

, Note 1,

= 90% VR

= 1 µF

OUT

TEMPERATURE SPECIFICATIONS (NOTE 1)

Parameters Sym Min Typ Max Units Conditions

Temperature Ranges

Specified Temperature Range T

Operating Temperature Range T

Storage Temperature Range T

J

J

A

Thermal Package Resistance

Thermal Resistance, 3L-SOT-23A

Thermal Resistance, 3L-SOT-89

Thermal Resistance, 3L-TO-92 θ

θ

JA

θ

JC

θ

JA

θ

JC

JA

θ

JC

Note 1: The maximum allowable power dissipation is a function of ambient temperature, the maximum allowable junction

temperature and the thermal resistance from junction to air (i.e., T

dissipation will cause the device operating junction temperature to exceed the maximum 150°C rating. Sustained

junction temperatures above 150°C can impact the device reliability.

DS22008B-page 4 © 2007 Microchip Technology Inc.

-40 +125 °C

-40 +125 °C

-65 +150 °C

—336—°C/W

EIA/JEDEC JESD51-7

FR-4 0.063 4-Layer Board

—110—°C/W

—52—°C/W

EIA/JEDEC JESD51-7

FR-4 0.063 4-Layer Board

—10—°C/W

— 131.9 — °C/W

— 66.3 — °C/W

, TJ, θJA). Exceeding the maximum allowable power

A

MCP1702

0.00

1.00

2.00

3.00

4.00

5.00

2468101214

Input Voltage (V)

Quiescent Current (µA)

V

OUT

+25°C

+130°C

-45°C

0°C

+90°C

0.00

1.00

2.00

3.00

4.00

5.00

3 5 7 9 11 13

Input Voltage (V)

Quiescent Current (µA)

V

OUT

+25°C

+130°C

-45°C

0°C

+90°C

1.00

2.00

3.00

4.00

5.00

67891011121314

Input Voltage (V)

Quiescent Current (µA)

V

OUT

+25°C

+130°C

-45°C

0°C

+90°C

0.00

20.00

40.00

60.00

80.00

100.00

120.00

0 40 80 120 160 200

Load Current (mA)

GND Current (µA)

Temperature = +25°C

V

OUT

= 1.2V

V

IN

= 2.7V

0.00

20.00

40.00

60.00

80.00

100.00

120.00

0 50 100 150 200 250

Load Current (mA)

GND Current (µA)

Temperature = +25°C

V

OUT

= 5.0V

V

IN

= 6.0V

V

OUT

= 2.8V

V

IN

= 3.8V

0.00

0.50

1.00

1.50

2.00

2.50

3.00

-45-20 5 305580105130

Junction Temperature (°C)

Quiescent Current (µA)

I

OUT

V

OUT

= 5.0V

V

IN

= 6.0V

V

OUT

= 1.2V

V

IN

= 2.7V

V

OUT

= 2.8V

V

IN

= 3.8V

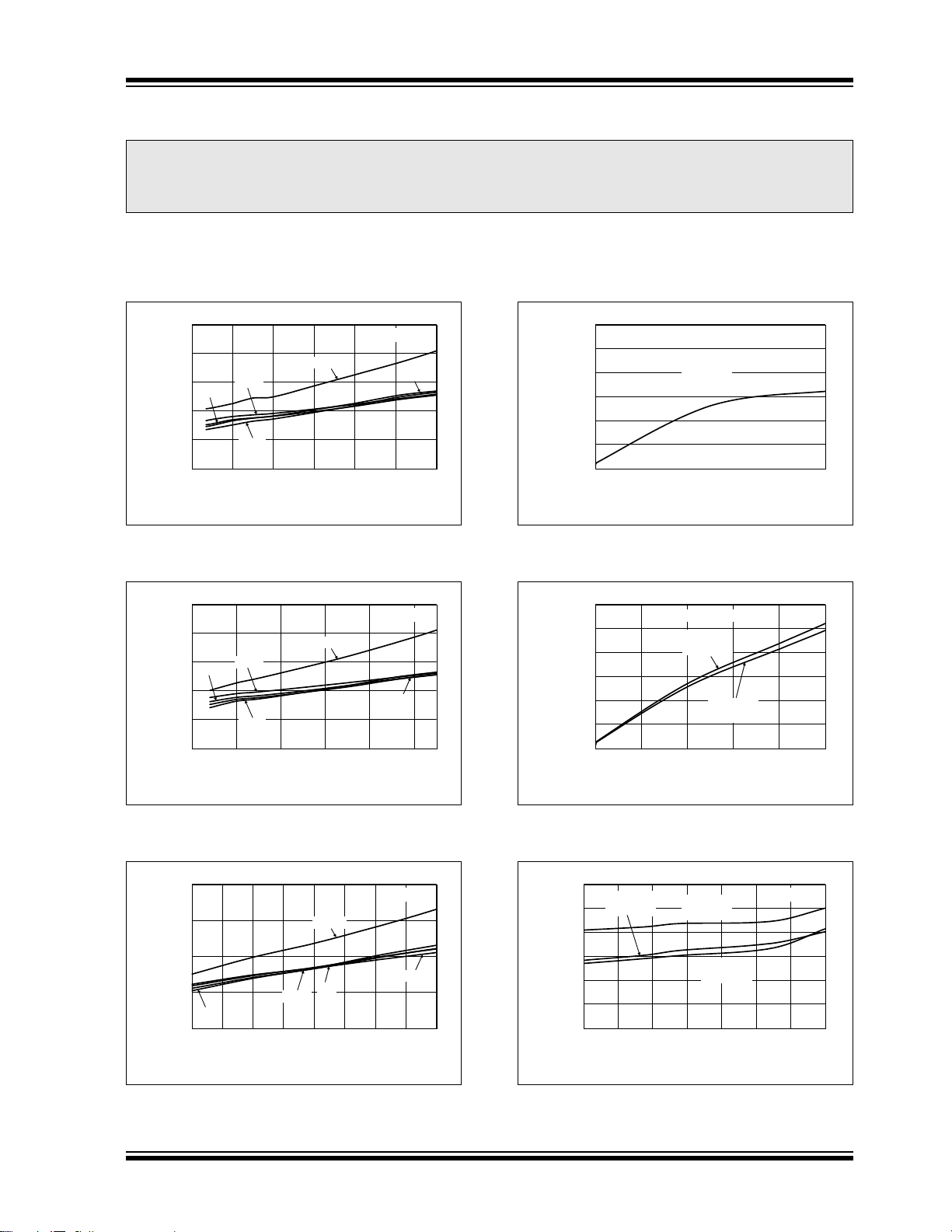

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided following this note are a statistical summary based on a limited number of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated: VR = 2.8V, C

TA = +25°C, VIN = V

OUT(MAX)

+ V

DROPOUT(MAX)

= 1 µF Ceramic (X7R), CIN = 1 µF Ceramic (X7R), IL = 100 µA,

OUT

.

Note: Junction Temperature (TJ) is approximated by soaking the device under test to an ambient temperature equal to the desired junction

temperature. The test time is small enough such that the rise in Junction temperature over the Ambient temperature is not significant.

= 1.2V

FIGURE 2-1: Quiescent Current vs. Input

Voltage.

= 2.8V

FIGURE 2-4: Ground Current vs. Load

Current.

FIGURE 2-2: Quiescent Current vs.Input

Voltage.

FIGURE 2-3: Quiescent Current vs.Input

Voltage.

© 2007 Microchip Technology Inc. DS22008B-page 5

= 5.0V

FIGURE 2-5: Ground Current vs. Load

Current.

= 0 mA

FIGURE 2-6: Quiescent Current vs.

Junction Temperature.

MCP1702

1.18

1.19

1.20

1.21

1.22

1.23

1.24

2468101214

Input Voltage (V)

Output Voltage (V)

V

OUT

I

LOAD

+25°C

+130°C

-45°C

0°C

+90°C

2.77

2.78

2.79

2.80

2.81

2.82

2.83

2.84

2.85

3 4 5 6 7 8 9 1011121314

Input Voltage (V)

Output Voltage (V)

V

OUT

= 2.8V

I

LOAD

= 0.1 mA

+25°C

+130°C

-45°C

0°C

+90°C

4.96

4.98

5.00

5.02

5.04

5.06

6 7 8 9 10 11 12 13 14

Input Voltage (V)

Output Voltage (V)

V

OUT

= 5.0V

I

LOAD

= 0.1 mA

+25°C

+130°C

-45°C

0°C

+90°C

1.18

1.19

1.20

1.21

1.22

1.23

0 20406080100

Load Current (mA)

Output Voltage (V)

V

OUT

+25°C

+130°C

-45°C

0°C

+90°C

2.77

2.78

2.79

2.80

2.81

2.82

2.83

0 50 100 150 200 250

Load Current (mA)

Output Voltage (V)

V

OUT

+25°C

+130°C

-45°C

0°C

+90°C

4.96

4.97

4.98

4.99

5.00

5.01

5.02

5.03

5.04

0 50 100 150 200 250

Load Current (mA)

Output Voltage (V)

V

OUT

+25°C

+130°C

-45°C

0°C

+90°C

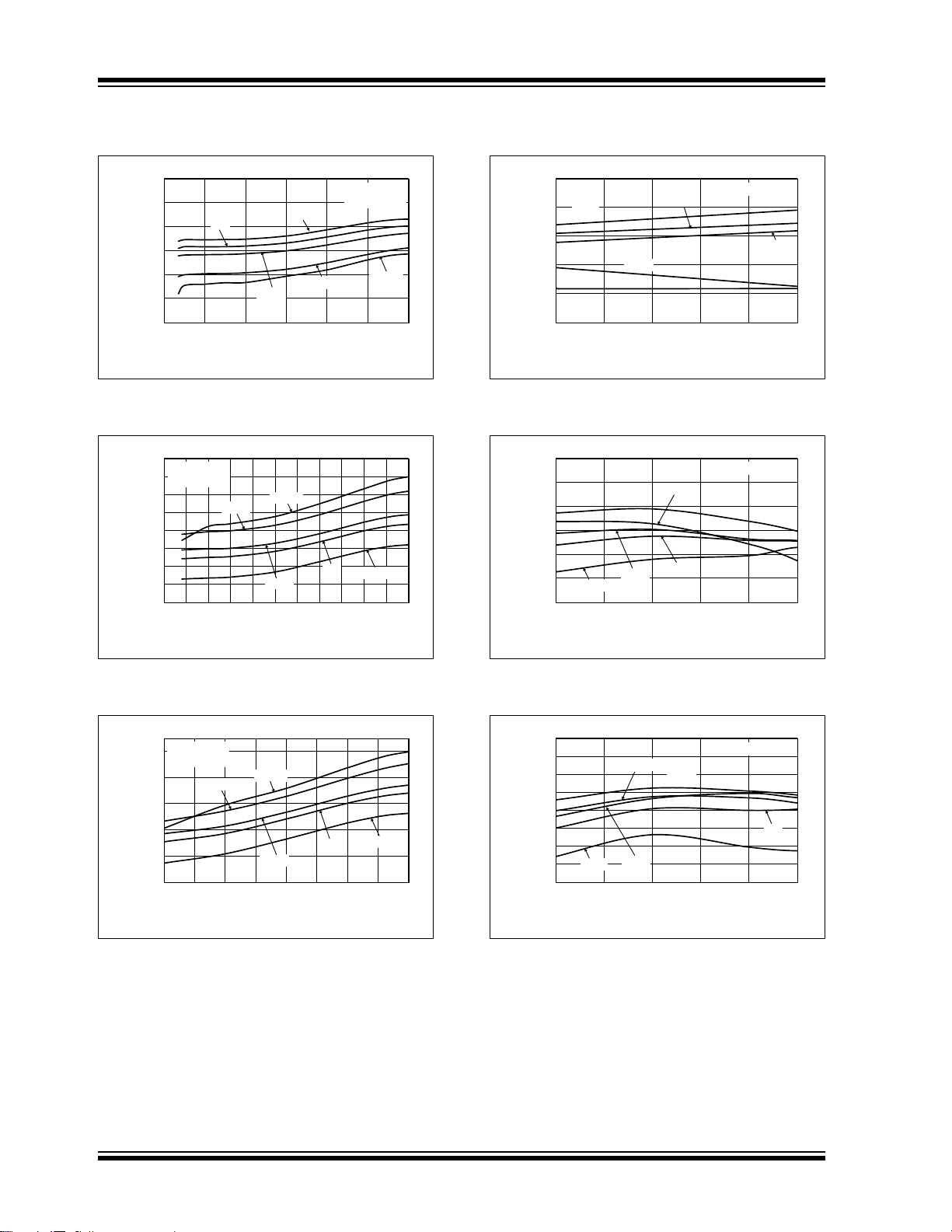

Note: Unless otherwise indicated: VR = 2.8V, C

TA = +25°C, VIN = V

OUT(MAX)

+ V

DROPOUT(MAX)

OUT

.

= 1.2V

= 0.1 mA

FIGURE 2-7: Output Voltage vs. Input

Voltage.

= 1 µF Ceramic (X7R), CIN = 1 µF Ceramic (X7R), IL = 100 µA,

= 1.2V

FIGURE 2-10: Output Voltage vs. Load

Current.

= 2.8V

FIGURE 2-8: Output Voltage vs. Input

Voltage.

FIGURE 2-9: Output Voltage vs. Input

Voltage.

DS22008B-page 6 © 2007 Microchip Technology Inc.

FIGURE 2-11: Output Voltage vs. Load

Current.

= 5.0V

FIGURE 2-12: Output Voltage vs. Load

Current.

MCP1702

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

1.40

100 120 140 160 180 200

Load Current (mA)

Dropout Voltage (V)

V

OUT

= 1.8V

+25°C

+130°C

-45°C

0°C

+90°C

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

0 25 50 75 100 125 150 175 200 225 250

Load Current (mA)

Dropout Voltage (V)

V

OUT

= 2.8V

+25°C

+130°C

+0°C

-45°C

+90°C

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0 25 50 75 100 125 150 175 200 225 250

Load Current (mA)

Dropout Voltage (V)

V

OUT

= 5.0V

+25°C

+130°C

+0°C

-45°C

+90°C

0.00

100.00

200.00

300.00

400.00

500.00

600.00

4 6 8 10 12 14

Input Voltage (V)

Short Circuit Current (mA)

V

OUT

= 2.8V

R

OUT

< 0.1

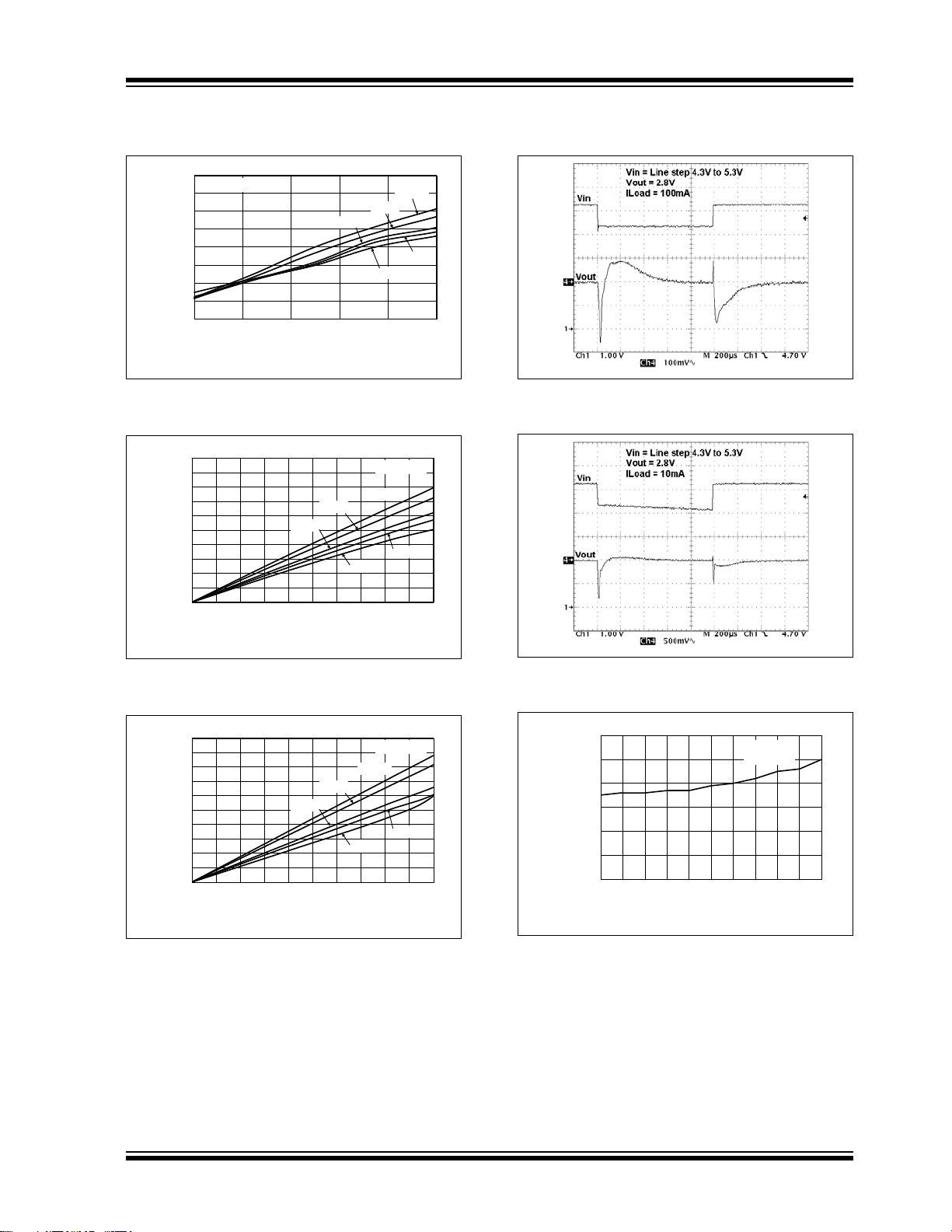

Note: Unless otherwise indicated: VR = 2.8V, C

TA = +25°C, VIN = V

OUT(MAX)

+ V

DROPOUT(MAX)

OUT

.

FIGURE 2-13: Dropout Voltage vs. Load

Current.

= 1 µF Ceramic (X7R), CIN = 1 µF Ceramic (X7R), IL = 100 µA,

FIGURE 2-16: Dynamic Line Response.

FIGURE 2-14: Dropout Voltage vs. Load

Current.

FIGURE 2-15: Dropout Voltage vs. Load

Current.

© 2007 Microchip Technology Inc. DS22008B-page 7

FIGURE 2-17: Dynamic Line Response.

FIGURE 2-18: Short Circuit Current vs.

Input Voltage.

MCP1702

-0.30

-0.25

-0.20

-0.15

-0.10

-0.05

0.00

0.05

0.10

0.15

0.20

-45-20 5 305580105130

Temperature (°C)

Load Regulation (%)

V

OUT

= 1.2V

I

LOAD

= 0.1 mA to 200 mA

VIN = 4V

VIN = 13.2V

VIN = 6V

VIN = 12VVIN = 10V

-0.60

-0.50

-0.40

-0.30

-0.20

-0.10

0.00

0.10

0.20

0.30

0.40

-45-20 5 305580105130

Temperature (°C)

Load Regulation (%)

V

OUT

I

LOAD

= 1 mA to 250 mA

VIN = 3.8V

VIN = 13.2V

VIN = 10V

VIN = 6V

-0.10

0.00

0.10

0.20

0.30

0.40

-45-20 5 305580105130

Temperature (°C)

Load Regulation (%)

V

OUT

I

LOAD

VIN = 6V

VIN = 13.2V

VIN = 8V

VIN = 10V

0.00

0.04

0.08

0.12

0.16

0.20

-45-20 5 305580105130

Temperature (°C)

Line Regulation (%/V)

V

OUT

V

IN

1 mA

100 mA

0 mA

0.00

0.04

0.08

0.12

0.16

0.20

-45-20 5 305580105130

Temperature (°C)

Line Regulation (%/V)

V

OUT

= 2.8V

V

IN

= 3.8V to 13.2V

200 mA

100 mA

0 mA

250 mA

0.06

0.08

0.10

0.12

0.14

0.16

-45-20 5 305580105130

Temperature (°C)

Line Regulation (%/V)

V

OUT

= 5.0V

V

IN

= 6.0V to 13.2V

200 mA

100 mA

0 mA

250 mA

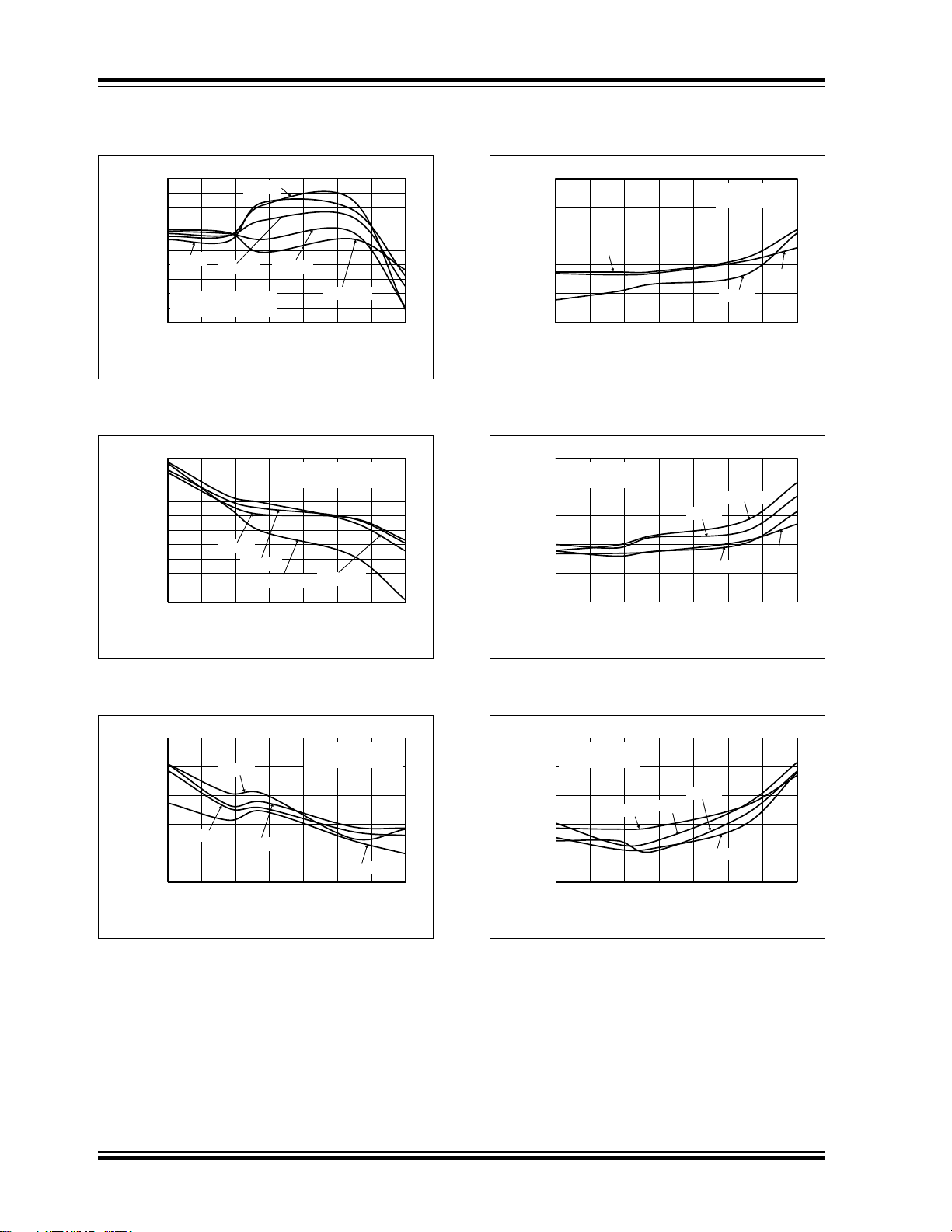

Note: Unless otherwise indicated: VR = 2.8V, C

TA = +25°C, VIN = V

OUT(MAX)

+ V

DROPOUT(MAX)

FIGURE 2-19: Load Regulation vs.

Temperature.

= 2.8V

= 1 µF Ceramic (X7R), CIN = 1 µF Ceramic (X7R), IL = 100 µA,

OUT

.

= 2.7V to 13.2V

FIGURE 2-22: Line Regulation vs.

Temperature.

= 1.2V

FIGURE 2-20: Load Regulation vs.

Temperature.

FIGURE 2-21: Load Regulation vs.

Temperature.

DS22008B-page 8 © 2007 Microchip Technology Inc.

= 1 mA to 250 mA

= 5.0V

FIGURE 2-23: Line Regulation vs.

Temperature.

FIGURE 2-24: Line Regulation vs.

Temperature.

MCP1702

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

0.01 0.1 1 10 100 1000

Frequency (kHz)

PSRR (dB)

VR=1.2V

C

OUT

=1.0 μF ceramic X7R

V

IN

=2.7V

C

IN

=0 μF

I

OUT

=1.0 mA

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

0.01 0.1 1 10 100 1000

Frequency (kHz)

PSRR (dB)

VR=5.0V

C

OUT

=1.0 μF ceramic X7R

V

IN

=6.0V

C

IN

=0 μF

I

OUT

=1.0 mA

0.001

0.01

0.1

1

10

100

0.01 0.1 1 10 100 1000

Frequency (kHz)

Noise (μV/ ¥Hz)

VR=5.0V, VIN=6.0V

I

OUT

=50 mA

VR=2,8V, VIN=3.8V

VR=1.2V, VIN=2.7V

Note: Unless otherwise indicated: VR = 2.8V, C

TA = +25°C, VIN = V

OUT(MAX)

+ V

DROPOUT(MAX)

FIGURE 2-25: Power Supply Ripple

Rejection vs. Frequency.

= 1 µF Ceramic (X7R), CIN = 1 µF Ceramic (X7R), IL = 100 µA,

OUT

.

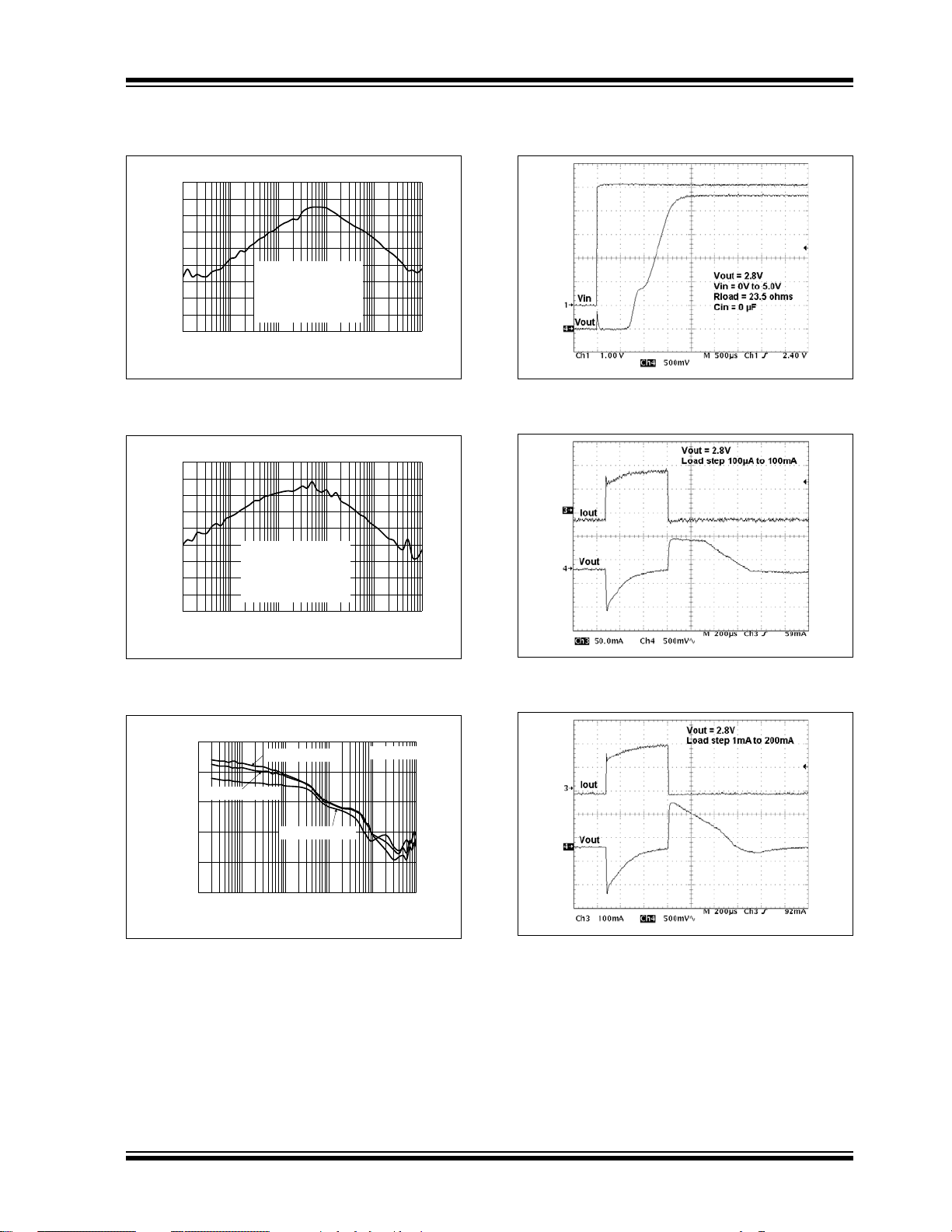

FIGURE 2-28: Power Up Timing.

FIGURE 2-26: Power Supply Ripple

Rejection vs. Frequency.

FIGURE 2-27: Output Noise vs. Frequency.

© 2007 Microchip Technology Inc. DS22008B-page 9

FIGURE 2-29: Dynamic Load Response.

FIGURE 2-30: Dynamic Load Response.

MCP1702

3.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

Pin No.

SOT-23A

1 1 1 GND Ground Terminal

233V

32, Tab2 V

– – – NC No connection

Pin No.

SOT-89

Pin No.

TO-92

Symbol Function

OUT

IN

Regulated Voltage Output

Unregulated Supply Voltage

3.1 Ground Terminal (GND)

Regulator ground. Tie GND to the negative side of the

output and the negative side of the input capacitor.

Only the LDO bias current (2.0 µA typical) flows out of

this pin; there is no high current. The LDO output

regulation is referenced to this pin. Minimize voltage

drops between this pin and the negative side of the

load.

3.2 Regulated Output Voltage (V

Connect V

positive terminal of the output capacitor. The positive

side of the output capacitor should be physically

located as close to the LDO V

The current flowing out of this pin is equal to the DC

load current.

to the positive side of the load and the

OUT

pin as is practical.

OUT

OUT

)

3.3 Unregulated Input Voltage Pin

)

(V

IN

Connect VIN to the input unregulated source voltage.

Like all LDO linear regulators, low source impedance is

necessary for the stable operation of the LDO. The

amount of capacitance required to ensure low source

impedance will depend on the proximity of the input

source capacitors or battery type. For most

applications, 1 µF of capacitance will ensure stable

operation of the LDO circuit. For applications that have

load currents below 100 mA, the input capacitance

requirement can be lowered. The type of capacitor

used can be ceramic, tantalum or aluminum

electrolytic. The low ESR characteristics of the ceramic

will yield better noise and PSRR performance at highfrequency.

DS22008B-page 10 © 2007 Microchip Technology Inc.

4.0 DETAILED DESCRIPTION

+

-

MCP1702

V

IN

V

OUT

GND

+V

IN

Error Amplifier

Voltage

Reference

Overcurrent

Overtemperature

MCP1702

4.1 Output Regulation

A portion of the LDO output voltage is fed back to the

internal error amplifier and compared with the precision

internal bandgap reference. The error amplifier output

will adjust the amount of current that flows through the

P-Channel pass transistor, thus regulating the output

voltage to the desired value. Any changes in input

voltage or output current will cause the error amplifier

to respond and adjust the output voltage to the target

voltage (refer to Figure 4-1).

4.2 Overcurrent

The MCP1702 internal circuitry monitors the amount of

current flowing through the P-Channel pass transistor.

In the event of a short-circuit or excessive output

current, the MCP1702 will turn off the P-Channel

device for a short period, after which the LDO will

attempt to restart. If the excessive current remains, the

cycle will repeat itself.

4.3 Overtemperature

The internal power dissipation within the LDO is a

function of input-to-output voltage differential and load

current. If the power dissipation within the LDO is

excessive, the internal junction temperature will rise

above the typical shutdown threshold of 150°C. At that

point, the LDO will shut down and begin to cool to the

typical turn-on junction temperature of 130°C. If the

power dissipation is low enough, the device will

continue to cool and operate normally. If the power

dissipation remains high, the thermal shutdown

protection circuitry will again turn off the LDO,

protecting it from catastrophic failure.

FIGURE 4-1: Block Diagram.

© 2007 Microchip Technology Inc. DS22008B-page 11

MCP1702

5.0 FUNCTIONAL DESCRIPTION

The MCP1702 CMOS LDO linear regulator is intended

for applications that need the lowest current consumption while maintaining output voltage regulation. The

operating continuous load range of the MCP1702 is

from 0mA to 250mA (V

voltage range is from 2.7V to 13.2V, making it capable

of operating from two or more alkaline cells or single

and multiple Li-Ion cell batteries.

5.1 Input

The input of the MCP1702 is connected to the source

of the P-Channel PMOS pass transistor. As with all

LDO circuits, a relatively low source impedance (10Ω)

is needed to prevent the input impedance from causing

the LDO to become unstable. The size and type of the

capacitor needed depends heavily on the input source

type (battery, power supply) and the output current

range of the application. For most applications (up to

100 mA), a 1 µF ceramic capacitor will be sufficient to

ensure circuit stability. Larger values can be used to

improve circuit AC performance.

≥ 2.5V). The input operating

R

5.2 Output

The maximum rated continuous output current for the

MCP1702 is 250 mA (V

where VR < 2.5V, the maximum output current is

200 mA.

A minimum output capacitance of 1.0 µF is required for

small signal stability in applications that have up to

250 mA output current capability. The capacitor type

can be ceramic, tantalum or aluminum electrolytic. The

esr range on the output capacitor can range from 0Ω to

2.0Ω.

≥ 2.5V). For applications

R

5.3 Output Rise time

When powering up the internal reference output, the

typical output rise time of 500 µs is controlled to

prevent overshoot of the output voltage. There is also

a startup delay time that ranges from 300 µs to 800 µs

based on loading. The startup time is separate from

and precedes the Output Rise Time. The total output

delay is the Startup Delay plus the Output Rise time.

DS22008B-page 12 © 2007 Microchip Technology Inc.

MCP1702

MCP1702

GND

V

OUT

V

IN

C

IN

1µF Ceramic

C

OUT

1µF Ceramic

V

OUT

V

IN

(2.8V to 3.2V)

1.8V

I

OUT

150 mA

P

LDO

V

IN MAX)()VOUT MIN()

–()I

OUT MAX )()

×=

Where:

P

LDO

= LDO Pass device internal

power dissipation

V

IN(MAX)

= Maximum input voltage

V

OUT(MIN)

= LDO minimum output voltage

T

JMAX()PTOTAL

RθJA× T

AMAX

+=

Where:

T

J(MAX)

= Maximum continuous junction

temperature

P

TOTAL

= Total device power dissipation

Rθ

JA

Thermal resistance from

junction to ambient

T

AMAX

= Maximum ambient temperature

P

DMAX()

T

JMAX()TAMAX()

–()

Rθ

JA

---------------------------------------------------=

Where:

P

D(MAX)

= Maximum device power

dissipation

T

J(MAX)

= Maximum continuous junction

temperature

T

A(MAX)

Maximum ambient temperature

RθJA= Thermal resistance from

junction to ambient

T

JRISE()PDMAX()RθJA

×=

Where:

T

J(RISE)

= Rise in device junction

temperature over the ambient

temperature

P

TOTAL

= Maximum device power

dissipation

Rθ

JA

Thermal resistance from

junction to ambient

TJT

JRISE()TA

+=

Where:

T

J

= Junction Temperature

T

J(RISE)

= Rise in device junction

temperature over the ambient

temperature

T

A

Ambient temperature

6.0 APPLICATION CIRCUITS AND

ISSUES

6.1 Typical Application

The MCP1702 is most commonly used as a voltage

regulator. It’s low quiescent current and low dropout

voltage makes it ideal for many battery-powered

applications.

FIGURE 6-1: Typical Application Circuit.

6.1.1 APPLICATION INPUT CONDITIONS

Package Type = SOT-23A

Input Voltage Range = 2.8V to 3.2V

V

maximum = 3.2V

IN

V

typical = 1.8V

OUT

I

= 150 mA maximum

OUT

EQUATION 6-2:

The maximum power dissipation capability for a

package can be calculated given the junction-toambient thermal resistance and the maximum ambient

temperature for the application. The following equation

can be used to determine the package maximum

internal power dissipation.

EQUATION 6-3:

6.2 Power Calculations

6.2.1 POWER DISSIPATION

The internal power dissipation of the MCP1702 is a

function of input voltage, output voltage and output

current. The power dissipation, as a result of the

quiescent current draw, is so low, it is insignificant

(2.0 µA x V

calculate the internal power dissipation of the LDO.

EQUATION 6-1:

The maximum continuous operating junction

temperature specified for the MCP1702 is +125

estimate the internal junction temperature of the

MCP1702, the total internal power dissipation is

multiplied by the thermal resistance from junction to

ambient (Rθ

ambient for the SOT-23A pin package is estimated at

°C/W.

336

© 2007 Microchip Technology Inc. DS22008B-page 13

). The following equation can be used to

IN

). The thermal resistance from junction to

JA

EQUATION 6-4:

EQUATION 6-5:

°C. To

MCP1702

PIC

®

MCP1702

GND

V

IN

C

IN

1µF

C

OUT

1µF

Bridge Sensor

V

OUT

V

REF

ADO

AD1

Ratio Metric Reference

2 µA Bias

Microcontroller

6.3 Voltage Regulator

Internal power dissipation, junction temperature rise,

junction temperature and maximum power dissipation

are calculated in the following example. The power

dissipation, as a result of ground current, is small

Junction Temperature Estimate

To estimate the internal junction temperature, the

calculated temperature rise is added to the ambient or

offset temperature. For this example, the worst-case

junction temperature is estimated below.

enough to be neglected.

T

6.3.1 POWER DISSIPATION EXAMPLE

Package

Package

Input Voltage

LDO Output Voltages and Currents

V

Maximum Ambient Temperature

T

A(MAX)

Internal Power Dissipation

Internal Power dissipation is the product of the LDO

output current times the voltage across the LDO

(VIN to V

OUT

P

LDO(MAX)

P

P

=SOT-23A

Type

V

= 2.8V to 3.2V

IN

=1.8V

OUT

I

=150mA

OUT

= +40°C

).

=(V

I

OUT(MAX)

= (3.2V - (0.97 x 1.8V)) x 150 mA

LDO

= 218.1 milli-Watts

LDO

IN(MAX)

- V

OUT(MIN)

) x

=T

J

TJ=113.3°C

Maximum Package Power Dissipation at +40°C

Ambient Temperature

SOT-23 (336.0°C/Watt = RθJA)

P

D(MAX)

P

D(MAX)

= (125°C - 40°C) / 336°C/W

= 253 milli-Watts

SOT-89 (52°C/Watt = RθJA)

P

D(MAX)

P

D(MAX)

= (125°C - 40°C) / 52°C/W

= 1.635 Watts

TO92 (131.9°C/Watt = RθJA)

P

D(MAX)

P

D(MAX)

= (125°C - 40°C) / 131.9°C/W

= 644 milli-Watts

6.4 Voltage Reference

The MCP1702 can be used not only as a regulator, but

also as a low quiescent current voltage reference. In

many microcontroller applications, the initial accuracy

of the reference can be calibrated using production test

equipment or by using a ratio measurement. When the

JRISE

+ T

A(MAX)

initial accuracy is calibrated, the thermal stability and

Device Junction Temperature Rise

line regulation tolerance are the only errors introduced

by the MCP1702 LDO. The low-cost, low quiescent

The internal junction temperature rise is a function of

internal power dissipation and the thermal resistance

from junction to ambient for the application. The thermal

resistance from junction to ambient (Rθ

) is derived

JA

current and small ceramic output capacitor are all

advantages when using the MCP1702 as a voltage

reference.

from an EIA/JEDEC standard for measuring thermal

resistance for small surface mount packages. The EIA/

JEDEC specification is JESD51-7, “High Effective

Thermal Conductivity Test Board for Leaded Surface

Mount Packages”. The standard describes the test

method and board specifications for measuring the

thermal resistance from junction to ambient. The actual

thermal resistance for a particular application can vary

depending on many factors, such as copper area and

thickness. Refer to AN792, “A Method to Determine

How Much Power a SOT-23 Can Dissipate in an

Application”, (DS00792), for more information regarding

this subject.

T

J(RISE)

T

T

DS22008B-page 14 © 2007 Microchip Technology Inc.

=P

= 218.1 milli-Watts x 336.0°C/Watt

JRISE

= 73.3°C

JRISE

x Rq

TOTAL

JA

FIGURE 6-2: Using the MCP1702 as a

voltage reference.

6.5 Pulsed Load Applications

For some applications, there are pulsed load current

events that may exceed the specified 250 mA

maximum specification of the MCP1702. The internal

current limit of the MCP1702 will prevent high peak

load demands from causing non-recoverable damage.

The 250 mA rating is a maximum average continuous

rating. As long as the average current does not exceed

250 mA, pulsed higher load currents can be applied to

the MCP1702

MCP1702 is 500 mA (T

. The typical current limit for the

+25°C).

A

MCP1702

© 2007 Microchip Technology Inc. DS22008B-page 15

MCP1702

3-Pin SOT-23A

XXNN

Standard

Extended Temp

Symbol Voltage * Symbol Voltage *

HA 1.2 HF 3.0

HB 1.5 HG 3.3

HC 1.8 HH 4.0

HD 2.5 HJ 5.0

HE 2.8 — —

* Custom output voltages available upon request.

Contact your local Microchip sales office for more

information.

Example:

HANN

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. The Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

Standard

Extended Temp

Symbol Voltage * Symbol Voltage *

HA 1.2 HF 3.0

HB 1.5 HG 3.3

HC 1.8 HH 4.0

HD 2.5 HJ 5.0

HE 2.8 — —

* Custom output voltages available upon request.

Contact your local Microchip sales office for more

information.

3-Lead SOT-89

XXXYYWW

NNN

Example

HA0619

256

3-Lead TO-92

XXXXXX

XXXXXX

XXXXXX

YWWNNN

Example

1702

1202E

TO^^

619256

7.0 PACKAGING INFORMATION

7.1 Package Marking Information

3

e

3

e

DS22008B-page 16 © 2007 Microchip Technology Inc.

3

e

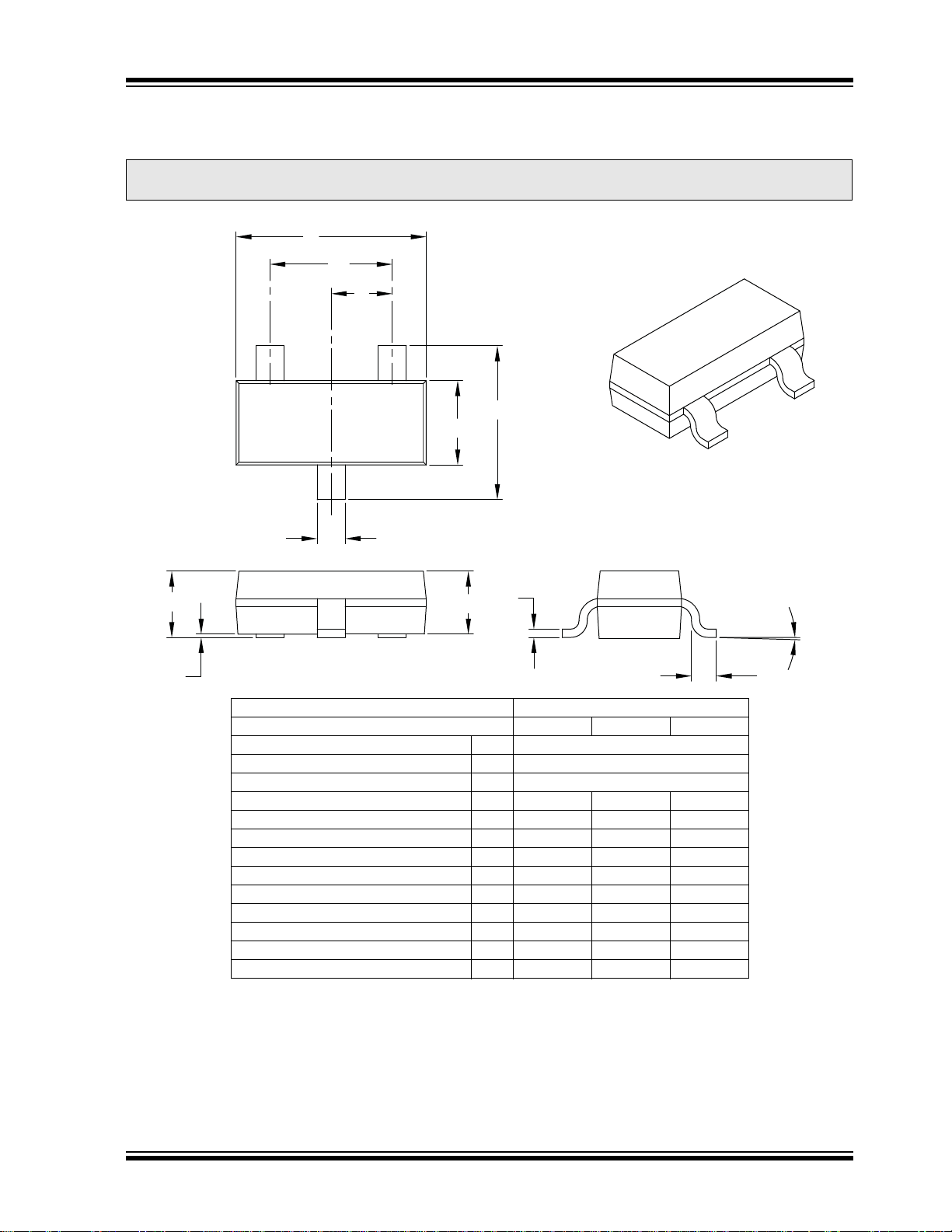

3-Lead Plastic Small Outline Transistor (CB) [SOT-23A]

Notes:

1. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.127 mm per side.

2. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

Units MILLIMETERS

Dimension Limits MIN NOM M AX

Number of Pins N 3

Lead Pitch e 0.95 BSC

Outside Lead Pitch e1 1.90 BSC

Overall Height A 0.89 – 1.45

Molded Package Thickness A2 0.90 – 1 .30

Standoff A1 0.00 – 0.15

Overall Width E 2.10 – 3.00

Molded Package Width E1 1.20 – 1 .80

Overall Length D 2.70 – 3.10

Foot Length L 0.15 – 0.60

Foot Angle φ 0° – 30°

Lead Thickness c 0.09 – 0.26

Lead Width b 0.30 – 0.51

D

e

e1

2

1

E

E1

N

b

A

A1

A2

c

L

φ

Microchip Technology Drawing C04-130B

MCP1702

© 2007 Microchip Technology Inc. DS22008B-page 17

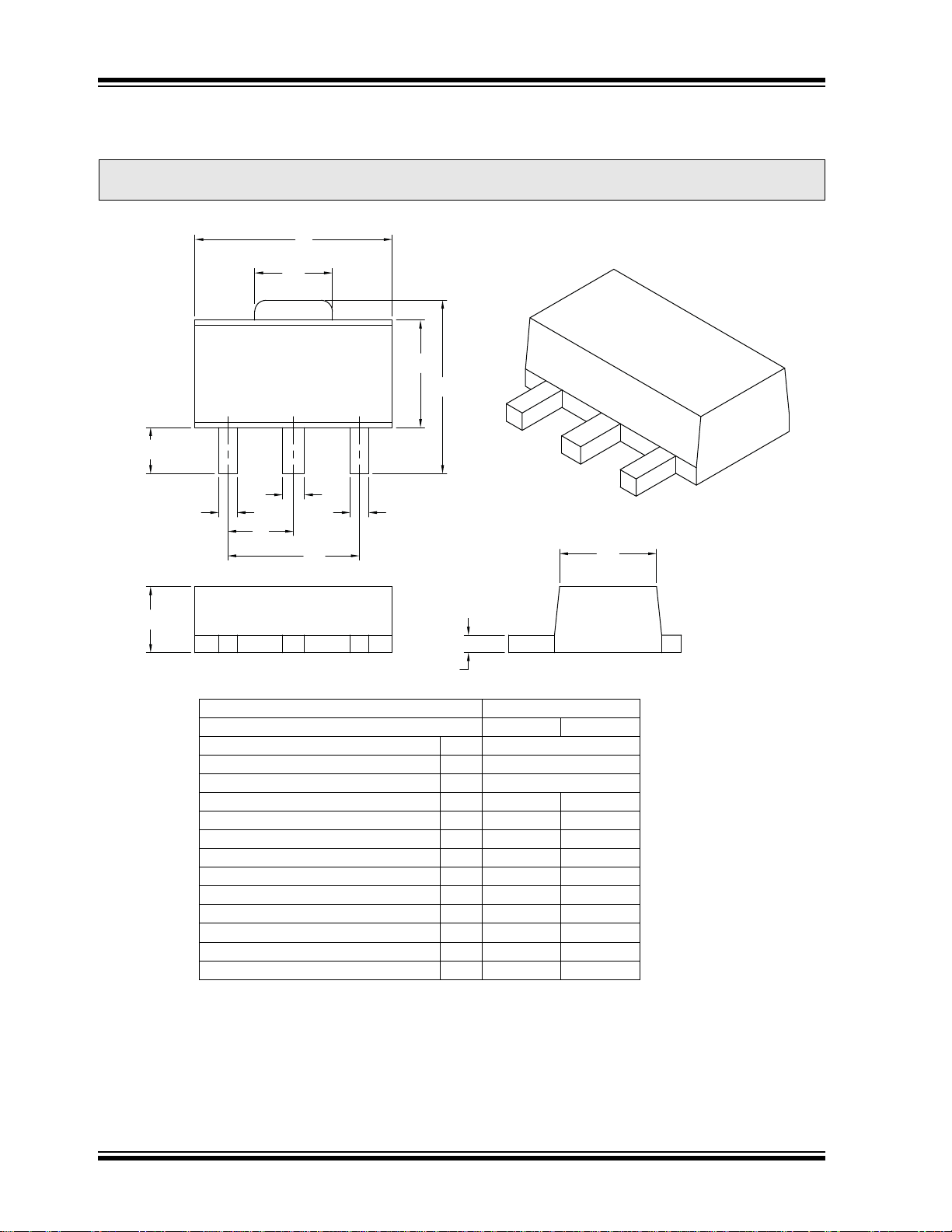

MCP1702

3-Lead Plastic Small Outline Transistor Header (MB) [SOT-89]

Notes:

1. Dimensions D and E do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.127 mm per side.

2. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

Units MILLIMETERS

Dimension Limits MIN MAX

Number of Leads N 3

Pitch e 1.50 BSC

Outside Lead Pitch e1 3.00 BSC

Overall Height A 1.40 1.60

Overall Width H 3.94 4.25

Molded Package Width at Base E 2.29 2.60

Molded Package Width at Top E1 2.13 2.29

Overall Length D 4.39 4.60

Tab Length D1 1.40 1.83

Foot Length L 0.79 1.20

Lead Thickness c 0.35 0.44

Lead 2 Width b 0.41 0.56

Leads 1 & 3 Width b1 0.36 0.48

D

D1

E

H

N

b1

e1

b

21

e

b1

L

A

C

E1

Microchip Technology Drawing C04-029B

DS22008B-page 18 © 2007 Microchip Technology Inc.

3-Lead Plastic Transistor Outline (TO) [TO-92]

Notes:

1. Dimensions A and E do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .005" per side.

2. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

Units INCHES

Dimension Limits MIN MAX

Number of Pins N 3

Pitch e .050 BSC

Bottom to Package Flat D .125 .165

Overall Width E .175 .205

Overall Length A .170 .210

Molded Package Radius R .080 .105

Tip to Seating Plane L .500 –

Lead Thickness c .014 .021

Lead Width b .014 .022

E

A

N

1

L

b

e

c

R

D

1

2

3

Microchip Technology Drawing C04-101B

MCP1702

© 2007 Microchip Technology Inc. DS22008B-page 19

MCP1702

NOTES:

DS22008B-page 20 © 2007 Microchip Technology Inc.

APPENDIX A: REVISION HISTORY

Revision B (May 2007)

• All Pages: Corrected minor errors in document.

• Page 4: Added junction-to-case information to

Temperature Specifications table.

• Page 16: Updated Package Outline Drawings in

Section 7.0 “Packaging Information”.

• Page 21: Updated Revison History.

• Page 23: Corrected examples in ”Product Identi-

fication System”.

Revision A (September 2006)

• Original Release of this Document.

MCP1702

© 2007 Microchip Technology Inc. DS22008B-page 21

MCP1702

NOTES:

DS22008B-page 22 © 2007 Microchip Technology Inc.

PRODUCT IDENTIFICATION SYSTEM

Device: MCP1702: 2 µA Low Dropout Positive Voltage Regulator

Tape and Reel: T = Tape and Reel

Output Voltage *: 12 = 1.2V “Standard”

15 = 1.5V “Standard”

18 = 1.8V “Standard”

25 = 2.5V “Standard”

28 = 2.8V “Standard”

30 = 3.0V “Standard”

33 = 3.3V “Standard”

40 = 4.0V “Standard”

50 = 5.0V “Standard”

*Contact factory for other output voltage options.

Extra Feature Code: 0 = Fixed

Tolerance: 2 = 2.0% (Standard)

Temperature: E = -40°C to +125°C

Package Type: CB = 3-Pin SOT-23A (equivalent to EIAJ SC-59)

MB = 3-Pin SOT-89

TO = 3-Pin TO-92

PART NO. XXX

Output Feature

Code

Device

Vol tag e

X

Tol era nceX/Tem p.XXPackage

X-

Tap e

and Reel

Examples:

a) MCP1702T-1202E/CB: 1.2V LDO Positive

Voltage Regulator,

SOT-23A-3 pkg.

b) MCP1702T-1802E/MB: 1.8V LDO Positive

Voltage Regulator,

SOT-89-3 pkg.

c) MCP1702T-2502E/CB: 2.5V LDO Positive

Voltage Regulator,

SOT-23A-3 pkg.

d) MCP1702T-3002E/CB: 3.0V LDO Positive

Voltage Regulator,

SOT-23A-3 pkg.

e) MCP1702T-3002E/MB: 3.0V LDO Positive

Voltage Regulator,

SOT-89-3 pkg.

f) MCP1702T-3302E/CB: 3.3V LDO Positive

Voltage Regulator,

SOT-23A-3 pkg.

g) MCP1702T-3302E/MB: 3.3V LDO Positive

Voltage Regulator,

SOT-89-3 pkg.

h) MCP1702T-4002E/CB: 4.0V LDO Positive

Voltage Regulator,

SOT-23A-3 pkg.

i) MCP1702-5002E/TO: 5.0V LDO Positive

Voltage Regulator,

TO-92 pkg.

j) MCP1702T-5002E/CB: 5.0V LDO Positive

Voltage Regulator,

SOT-23A-3 pkg.

k) MCP1702T-5002E/MB: 5.0V LDO Positive

Voltage Regulator,

SOT-89-3 pkg.

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

MCP1702

© 2007 Microchip Technology Inc. DS22008B-page 23

MCP1702

NOTES:

DS22008B-page 24 © 2007 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, microID, MPLAB, PIC,

PICmicro, PICSTART, PRO MATE, PowerSmart, rfPIC, and

SmartShunt are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

AmpLab, FilterLab, Linear Active Thermistor, Migratable

Memory, MXDEV, MXLAB, PS logo, SEEVAL, SmartSensor

and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, Mindi, MiWi,

MPASM, MPLAB Certified logo, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

MCUs and dsPIC® DSCs, KEELOQ

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial

© 2007 Microchip Technology Inc. DS22008B-page 25

®

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Habour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

12/08/06

DS22008B-page 26 © 2007 Microchip Technology Inc.

Loading...

Loading...