Page 1

查询MP111-195E/LB供应商

MCP111/112

Micropower Voltage Detector

Features

• Ultra-low supply current: 1.75 µA (max.)

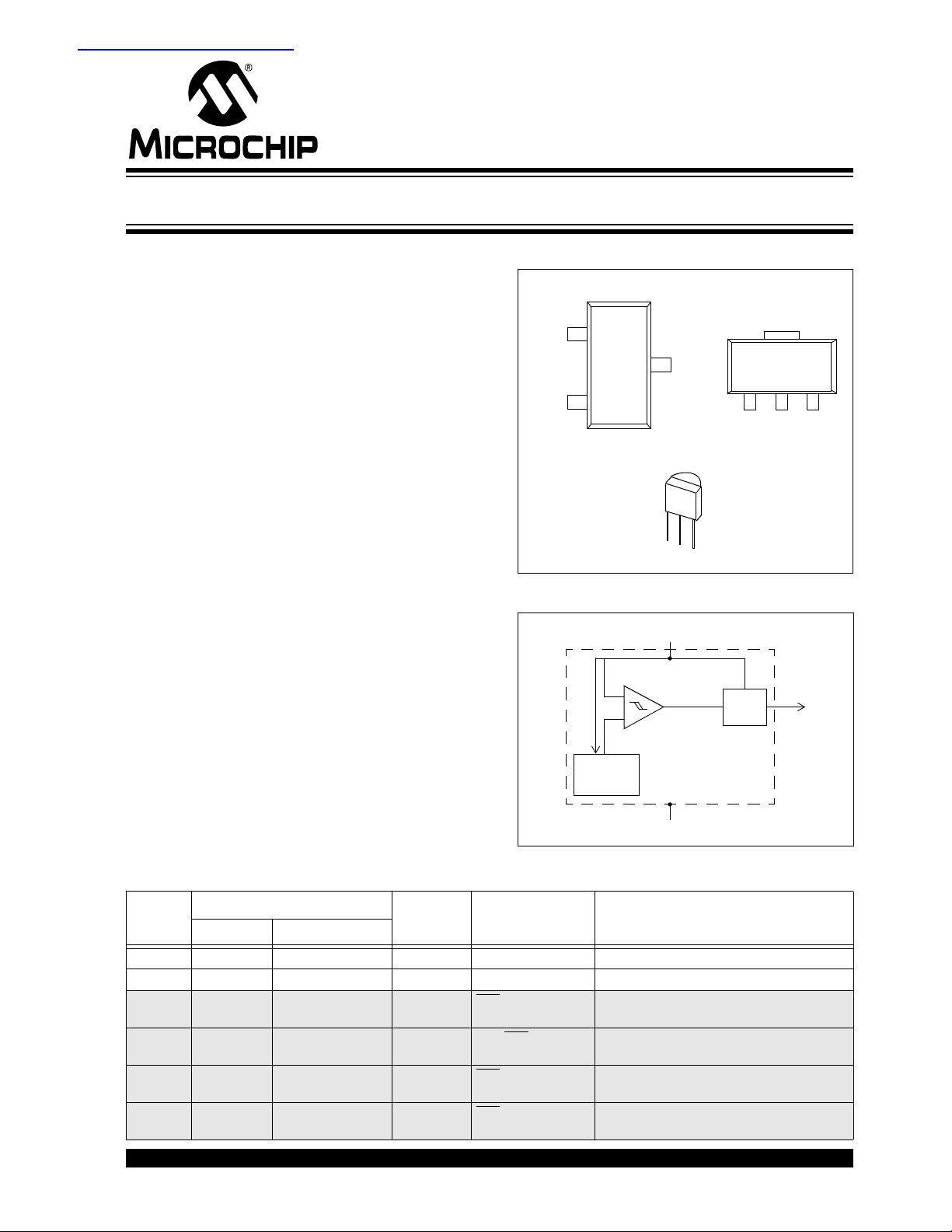

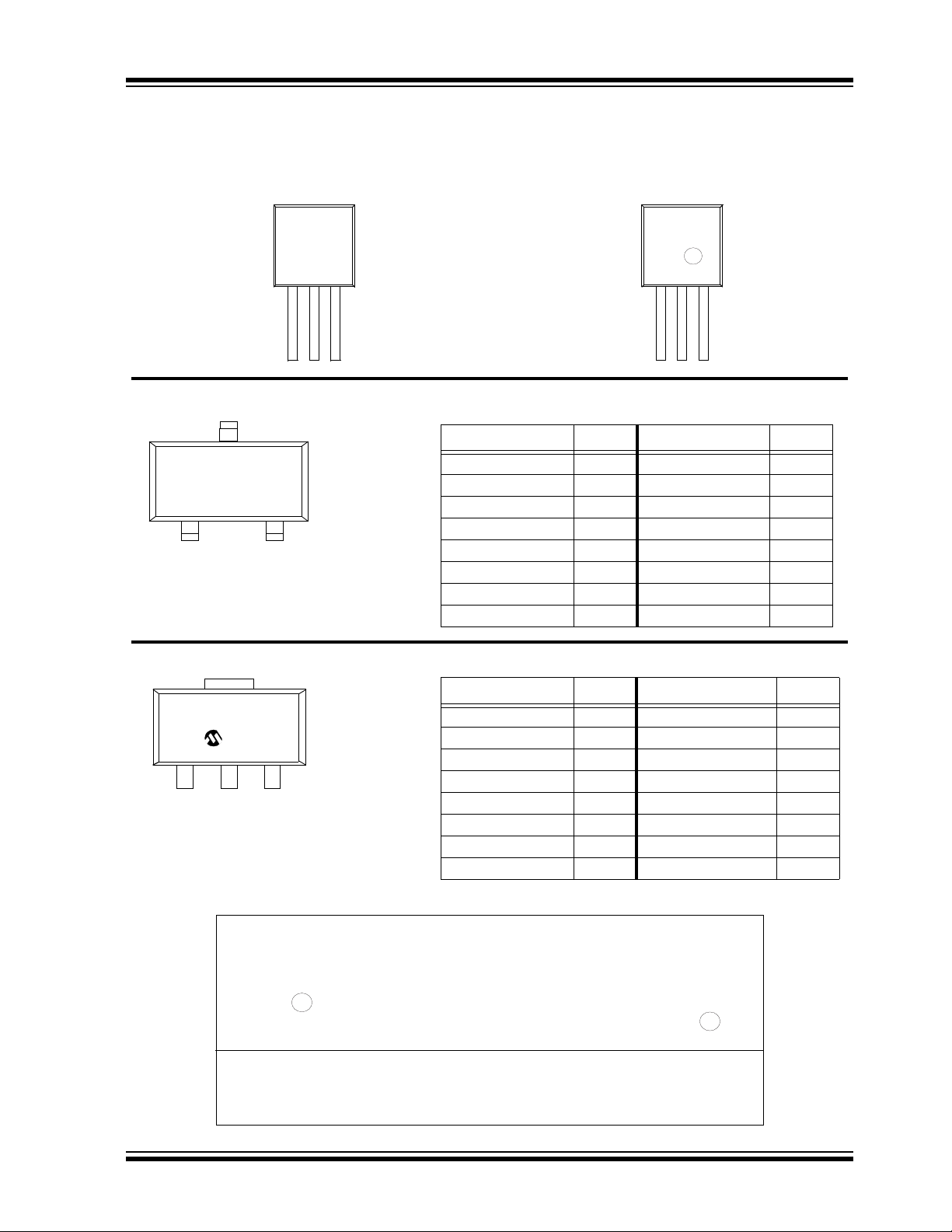

Package Types

3-Pin SOT23-3/SC-70

3-Pin SOT-89

• Precision monitoring options of:

V

- 1.90V, 2.32V, 2.63V, 2.90V, 2.93V, 3.08V,

4.38V and 4.63V

• Resets microcontroller in a power-loss event

•Active-low V

OUT

pin:

- MCP111 active-low, open-drain

- MCP112 active-low, push-pull

V

OUT

V

SS

1

V

3

DD

2

MCP111/112

DD

MCP111/112

1 32

V

V

OUT

• Available in SOT23-3, TO-92, SC-70 and

SOT-89-3 packages

3-Pin TO-92

• Temperature Range:

- Extended: -40°C to +125°C

(except MCP1XX-195)

- Industrial: -40°C to +85°C (MCP1XX-195 only)

• Pb-free devices

V

OUT

V

V

SS

DD

Applications

• Critical Microcontroller and Microprocessor

Power-Monitoring Applicati ons

• Computers

• Intelligent Instruments

• Portable Battery-Powered Equipm en t

Description

The MCP111/112 are voltage-detecting devices

designed to keep a microcontroller in reset until the

system voltage has stabilized at the appropriate level

for reliable system operation. These devices also

operate as protection from brown-out conditions when

the system supply voltage drops below the specified

threshold voltage level. Eight different trip voltag es a re

available.

TABLE 1: DEVICE FEATURES

Device

Output

Type Pull-up Resistor

MCP111 Open-drain External No V

MCP112 Push-pull No No V

MCP102 Push-pull No 120 ms RST, VDD, VSS See MCP102/103/121/131 Data Sheet

MCP103 Push-pull No 120 ms VSS, RST, VDD See MCP102/103/121/131 Data Sheet

MCP121 Open-drain External 120 ms RST, VDD, VSS See MCP102/103/121/131 Data Sheet

MCP131 Open-Drain Internal (~95 kΩ) 120 ms RST, VDD, VSS See MCP102/103/121/131 Data Sheet

Reset Delay

(typ)

Block Diagram

Package Pin Out

(Pin # 1, 2, 3)

, VSS, V

OUT

OUT

, VSS, V

DD

DD

Band Gap

Reference

(DS21906)

(DS21906)

(DS21906)

(DS21906)

V

Comparator

+

–

V

DD

SS

Output

Driver

Comment

V

DD

OUT

V

SS

© 2005 Microchip Technology Inc. DS21889D-page 1

Page 2

MCP111/112

1.0 ELECTRICAL

CHARACTERISTICS

† Notice: Stresses above those listed under “Maximum

Ratings” may cause permanent damage to the device. This is

a stress rating only and functional operation of the device at

those or any other conditions above those indicated in the

Absolute Maximum Ratings†

operational listings of this specification is not implied.

Exposure to maximum rating conditions fo r ext ended pe riods

VDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.0V

Input current (V

Output current (RST

Rated Rise Time of V

All inputs and outputs (except RST

) . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 mA

DD

) . . . . . . . . . . . . . . . . . . . . . . . . . .10 mA

. . . . . . . . . . . . . . . . . . . . . . 100V/µs

DD

) w.r.t. V

SS

may affect device reliability.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0 . 6 V to (VDD + 1.0V)

output w.r.t. VSS . . . . . . . . . . . . . . . . . . . -0.6 V to 1 3 .5 V

RST

Storage temperature. . . . . . . . . . . . . . . . . . .65°C to + 150°C

Ambient temp. with power applied . . . . . . . -40°C to + 125°C

Maximum Junction temp. with power applied . . . . . . . .150°C

ESD protection on all pins. . . . . . . . . . . . . . . . . . . . . . . . . ≥ 2kV

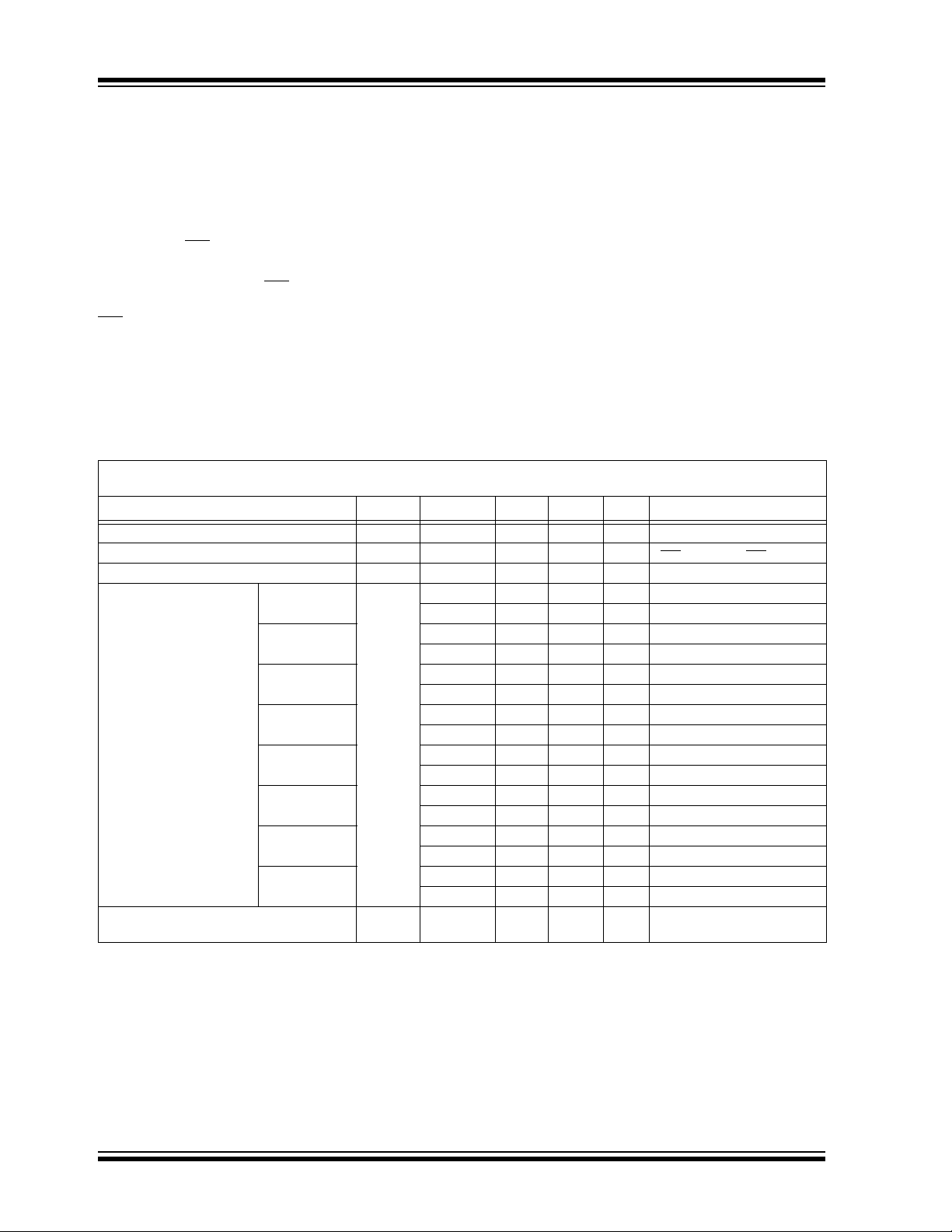

DC CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, all limits are specified for VDD = 1V to 5.5V, RPU = 100 kΩ (only MCP111),

T

= -40°C to +125°C.

A

Parameters Sym Min Typ Max Units Conditions

Operating Voltage Range V

Specified V

Value to V

DD

low V

OUT

Operating Current I

V

Trip Point MCP1XX-195 V

DD

DD

DD

DD

TRIP

MCP1XX-240 2.285 2.320 2.355 V T

MCP1XX-270 2.591 2.630 2.670 V T

MCP1XX-290 2.857 2.900 2.944 V T

MCP1XX-300 2.886 2.930 2.974 V T

MCP1XX-315 3.034 3.080 3.126 V T

MCP1XX-450 4.314 4.380 4.446 V T

MCP1XX-475 4.561 4.630 4.700 V T

Trip Point Tempco T

V

DD

TPCO

Note 1: Trip point is ±1.5% from typical value.

2: Trip point is ±2.5% from typical value.

3: This specification allows this device to be used in PICmicro

Serial Programming™ (ICSP™) feature (see device-specific programming specifications for voltage requirements).

This specification DOES NOT allow a continuous high voltage to be present on the open-drain output pin (V

total time that the V

V

pin should be limited to 2 mA. It is recommended that the device operational temperature be maintained between

OUT

pin can be above the maximum device operational voltage (5.5V) is 100 sec. Current into the

OUT

0°C to 70°C (+25°C preferred). For additional information, please refer to Figure 2-28.

4: This parameter is established by characterization and is not 100% tested.

1.0 — 5.5 V

1.0 — V I

= 10 µA, V

RST

RST

—< 11.75µA

1.872 1.900 1.929 V TA = +25°C (Note 1)

1.853 1.900 1.948 V T

= -40°C to +85°C (Note 2)

A

= +25°C (Note 1)

A

2.262 2.320 2.378 V Note 2

= +25°C (Note 1)

A

2.564 2.630 2.696 V Note 2

= +25°C (Note 1)

A

2.828 2.900 2.973 V Note 2

= +25°C (Note 1)

A

2.857 2.930 3.003 V Note 2

= +25°C (Note 1)

A

3.003 3.080 3.157 V Note 2

= +25°C (Note 1)

A

4.271 4.380 4.490 V Note 2

= +25°C (Note 1)

A

4.514 4.630 4.746 V Note 2

— ±100 — ppm/°

C

®

microcontroller applications that require the In-Circuit

< 0.2V

). The

OUT

DS21889D-page 2 © 2005 Microchip Technology Inc.

Page 3

MCP111/112

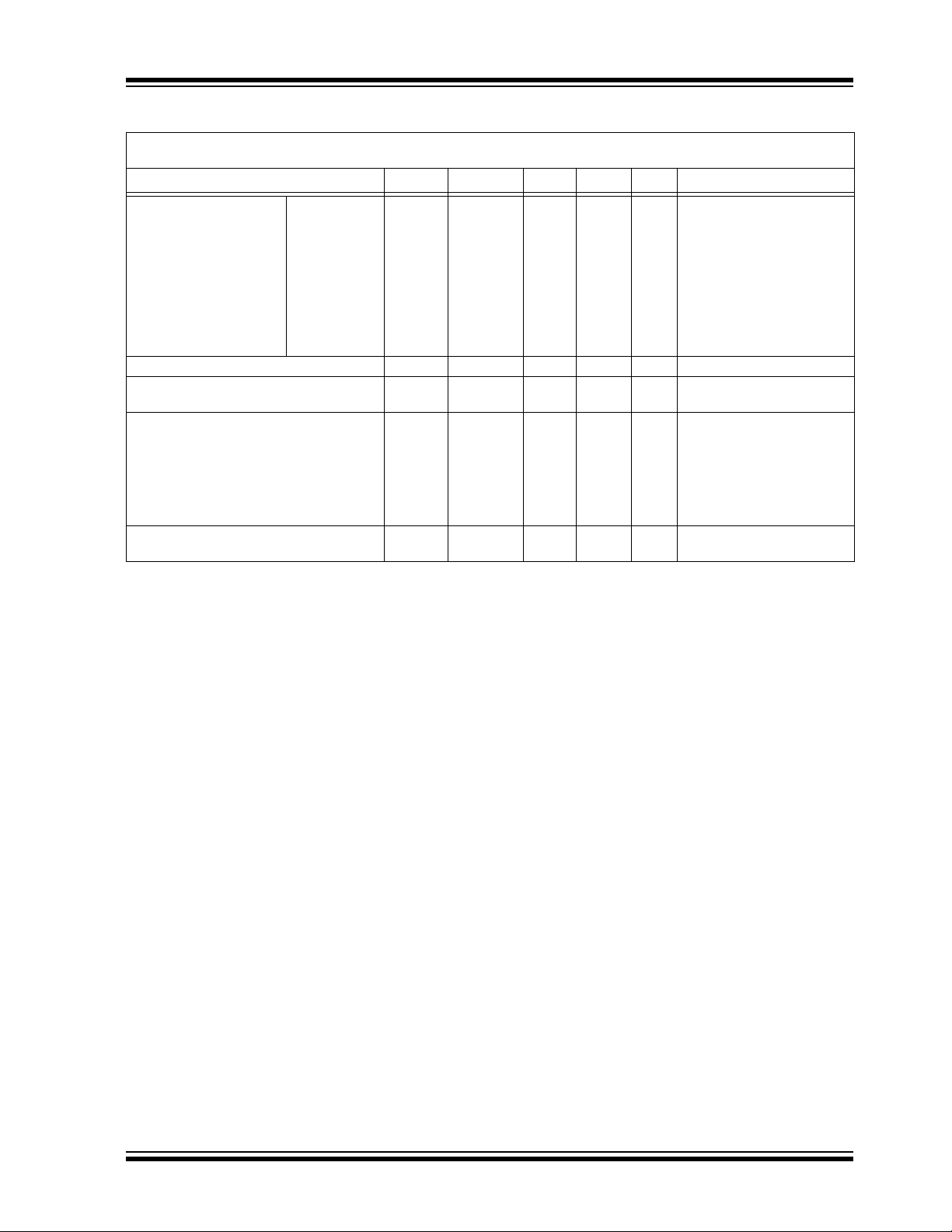

DC CHARACTERISTICS (CONTINUED)

Electrical Specifications: Unless otherwise indicated, all limits are specified for VDD = 1V to 5.5V, RPU = 100 kΩ (only MCP111),

= -40°C to +125°C.

T

A

Parameters Sym Min Typ Max Units Conditions

Threshold Hysteresis

(min. = 1%, max = 6%)

Low-level Output Voltage V

V

OUT

V

High-level Output Voltage V

OUT

Open-drain High Voltage on Output V

Open-drain Output Leakage Current

(MCP111 only)

Note 1: Trip point is ±1.5% from typical value.

2: Trip point is ±2.5% from typical value.

3: This specification allows this device to be used in PICmicro

Serial Programming™ (ICSP™) feature (see device-specific programming specifications for voltage requirements).

This specification DOES NOT allow a continuous high voltage to be present on the open-drain output pin (V

total time that the V

V

pin should be limited to 2 mA. It is recommended that the device operational temperature be maintained between

OUT

0°C to 70°C (+25°C preferred). For additional information, please refer to Figure 2-28.

4: This parameter is established by characterization and is not 100% tested.

MCP1XX-195 V

HYS

0.019 — 0.114 V TA = +25°C

MCP1XX-240 0.023 — 0.139 V

MCP1XX-270 0.026 — 0.158 V

MCP1XX-290 0.029 — 0.174 V

MCP1XX-300 0.029 — 0.176 V

MCP1XX-315 0.031 — 0.185 V

MCP1XX-450 0.044 — 0.263 V

MCP1XX-475 0.046 — 0.278 V

OL

OH

——0.4VI

VDD – 0.6 — — V IOH = 1 mA, For only MCP112

= 500 µA, V

OL

DD

(push-pull output)

— — 13.5

ODH

(3)

VMCP111 only,

= 3.0V, Time voltage >

V

DD

5.5V applied ≤ 100s,

current into pin limited to

2 mA , +25°C operation

recommended

Note 3, Note 4

I

OD

pin can be above the maximum device operational voltage (5.5V) is 100 sec. Current into the

OUT

—0.1—µA

®

microcontroller applications that require the In-Circuit

= V

OUT

TRIP(MIN)

). The

© 2005 Microchip Technology Inc. DS21889D-page 3

Page 4

MCP111/112

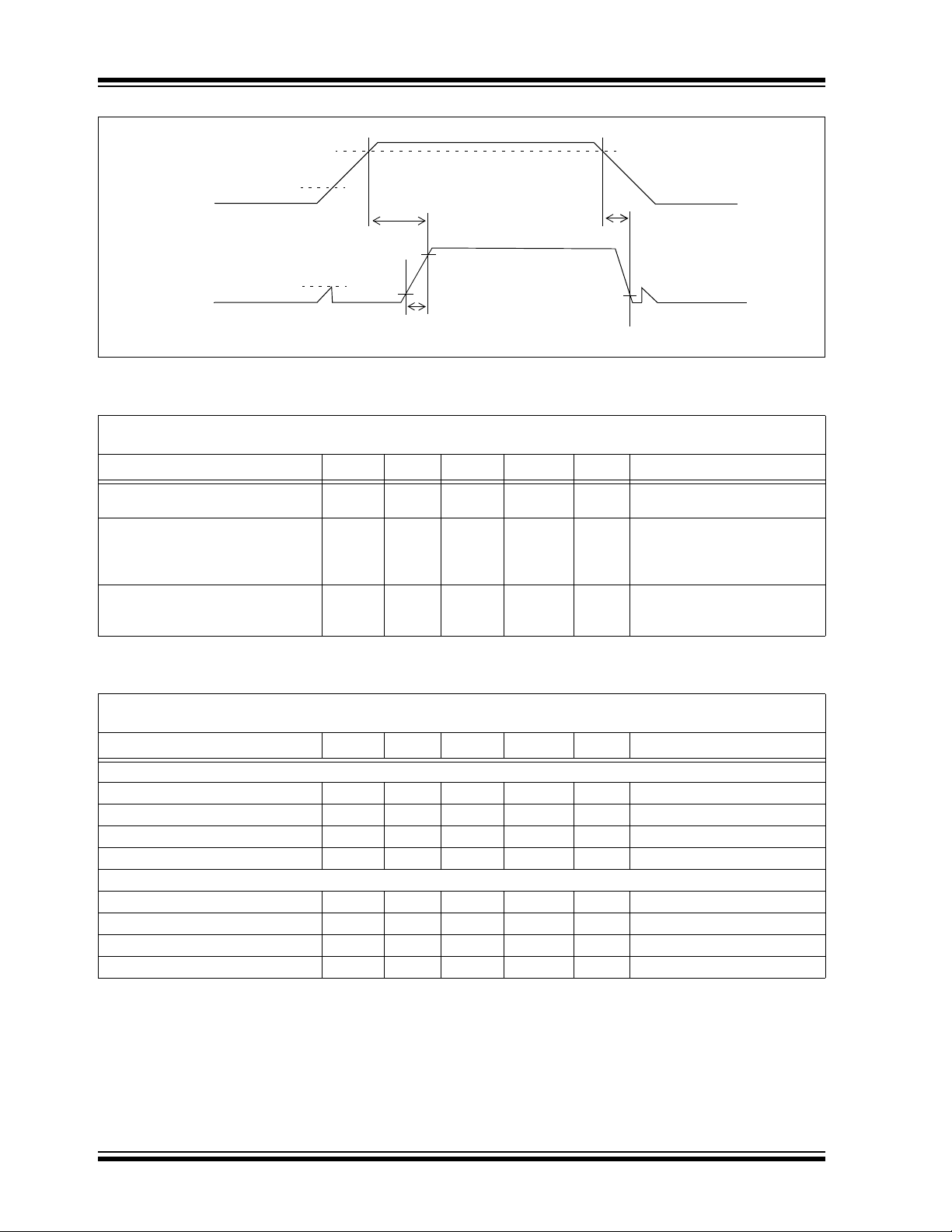

V

TRIP

1V

V

V

OUT

DD

1V

t

RPU

t

RPD

V

OH

V

OL

t

RT

FIGURE 1-1: Timing Diagram.

AC CHARACTERISTICS

Electrical Specifications: Unless otherwise indicated, all limits are specified for VDD = 1V to 5.5V, RPU = 100 kΩ

(only MCP111), T

VDD Detect to V

Detect to V

V

DD

Rise Time After V

V

OUT

Note 1: These parameters are for design guidance only and are not 100% tested.

= -40°C to +125°C.

A

Parameters Sym Min Typ Max Units Conditions

Inactive t

OUT

Active

OUT

Active t

OUT

RPU

t

RPD

RT

—90 — µs

— 130 — µs

—5 —µs

Figure 1-1 and C

(Note 1)

V

ramped from V

DD

250 mV down to V

250 mV, per Figure 1-1,

C

= 50 pF (Note 1)

L

For V

value per Figure 1-1, C

(Note 1)

10% to 90% of final

OUT

= 50 pF

L

TRIP(MAX)

TRIP(MIN)

–

= 50 pF

L

+

TEMPERATURE CHARACTERISTICS

Electrical Specifications: Unless otherwise noted, all limits are specified for V

(only MCP111), T

Temperature Ranges

Specified Temperature Range T

Specified Temperature Range T

Maximum Junction Temperature T

Storage Temperature Range T

Package Thermal Resistances

Thermal Resistance, 3L-SOT23 θ

Thermal Resistance, 3L-SC-70 θ

Thermal Resistance, 3L-TO-92 θ

Thermal Resistance, 3L-SOT-89 θ

= -40°C to +125°C.

A

Parameters Sym Min Typ Max Units Conditions

A

A

J

A

JA

JA

JA

JA

-40 — +85 °C MCP1XX-195

-40 — +125 °C Except MCP1XX-195

——+150°C

-65 — +150 °C

— 336 — °C/W

— 340 — °C/W

—131.9 — °C/W

—110 —°C/W

= 1V to 5.5V, RPU = 100 kΩ

DD

DS21889D-page 4 © 2005 Microchip Technology Inc.

Page 5

MCP111/112

0

0

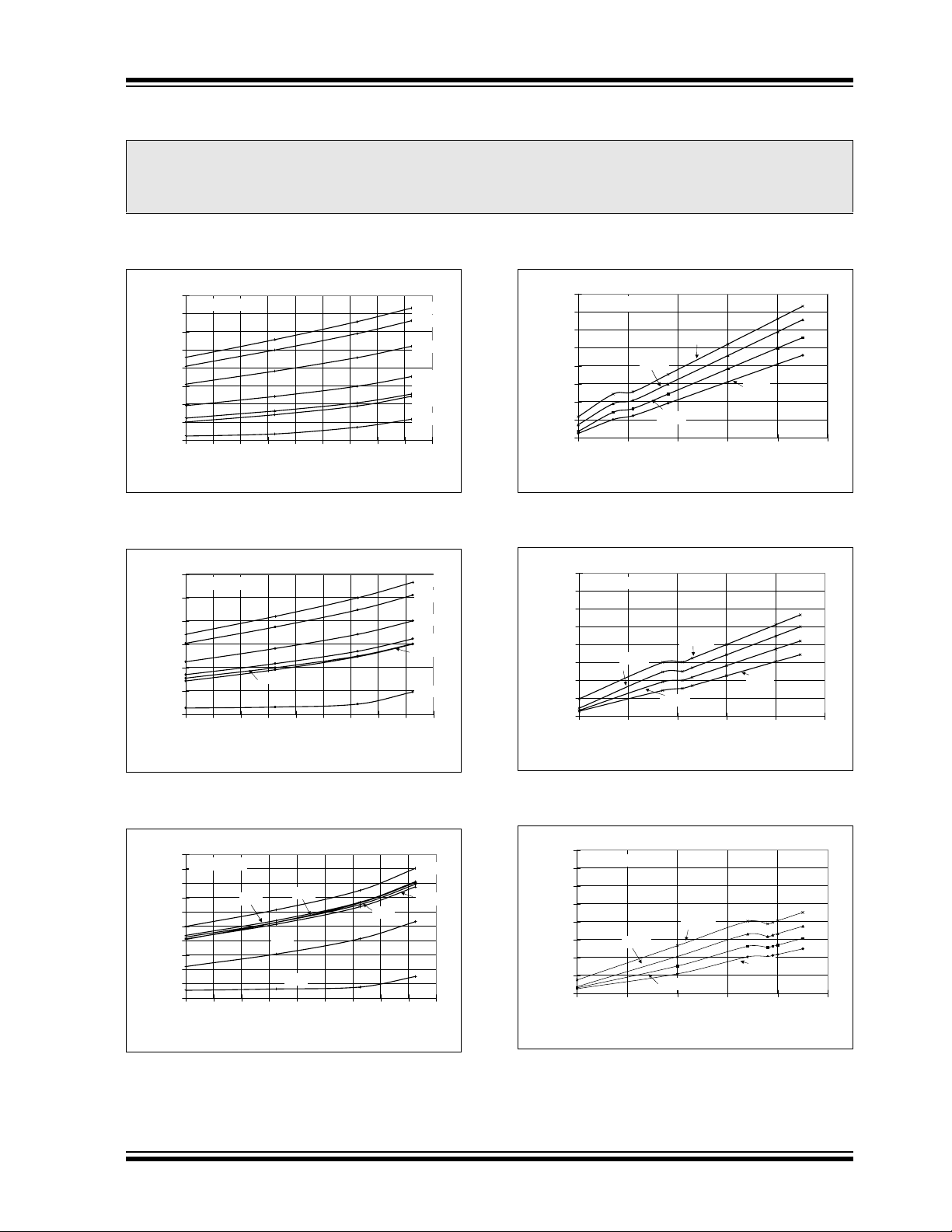

2.0 TYPICAL PERFORMANCE CURVES

Note: The graphs and tables provided fol lowi ng this note are a st a tis tic al s umm ary based on a lim ite d n um ber of

samples and are provided for informational purposes only. The performance characteristics listed herein

are not tested or guaranteed. In some graphs or tables, the data presented may be outside the specified

operating range (e.g., outside specified power supply range) and therefore outside the warranted range.

Note: Unless otherwise indicated, all limits are specified for VDD = 1V to 5.5V, RPU = 100 kΩ (only MCP111;

see Figure 4-1), T

= -40°C to +125°C.

A

1.6

MCP111-195

1.4

1.2

1

0.8

(uA)

DD

I

0.6

0.4

0.2

0

-40

-20

0

FIGURE 2-1: I

(MCP111-195).

1.2

MCP112-300

1

0.8

0.6

(uA)

DD

I

0.4

0.2

0

-40

-20

0

20

40

60

Temperature (°C)

vs. Temperature

DD

2.1V

20

40

60

Temperature (°C)

1.6

5.5V

5.0V

4.0V

2.8V

2.1V

1.7V

1.0V

80

100

120

140

FIGURE 2-4: I

5.5V

5.0V

4.0V

2.8V

1.7V

1.0V

80

100

120

140

MCP111-195

1.4

1.2

1

0.8

(uA)

DD

I

0.6

0.4

0.2

0

1.02.03.04.05.06.

1.6

MCP112-300

1.4

1.2

1

0.8

(uA)

DD

I

0.6

0.4

0.2

0

1.0 2.0 3.0 4.0 5.0 6.0

+85°C

+125°C

+85°C

-40°C

+25°C

V

(V)

DD

vs. VDD (MCP111-195).

DD

+125°C

-40°C

+25°C

V

(V)

DD

FIGURE 2-2: I

vs. Temperature

DD

FIGURE 2-5: I

vs. VDD (MCP112-300).

DD

(MCP112-300).

1

MCP112-475

0.9

0.8

0.7

0.6

0.5

(uA)

DD

0.4

I

0.3

0.2

0.1

0

-40

-20

5.0V

0

FIGURE 2-3: I

4.0V

1.7V

1.0V

20

40

60

Temperature (°C)

vs. Temperature

DD

5.5V

2.1V

2.8V

80

100

120

140

1.6

MCP112-475

1.4

1.2

1

0.8

(uA)

DD

I

0.6

0.4

0.2

0

1.0 2.0 3.0 4.0 5.0 6.

+85°C

FIGURE 2-6: I

+125°C

-40°C

+25°C

V

(V)

DD

vs. VDD (MCP112-475).

DD

(MCP112-475).

© 2005 Microchip Technology Inc. DS21889D-page 5

Page 6

MCP111/112

Note: Unless otherwise indicated, all limits are specified for VDD = 1V to 5.5V, RPU = 100 kΩ (only MCP111;

see Figure 4-1), T

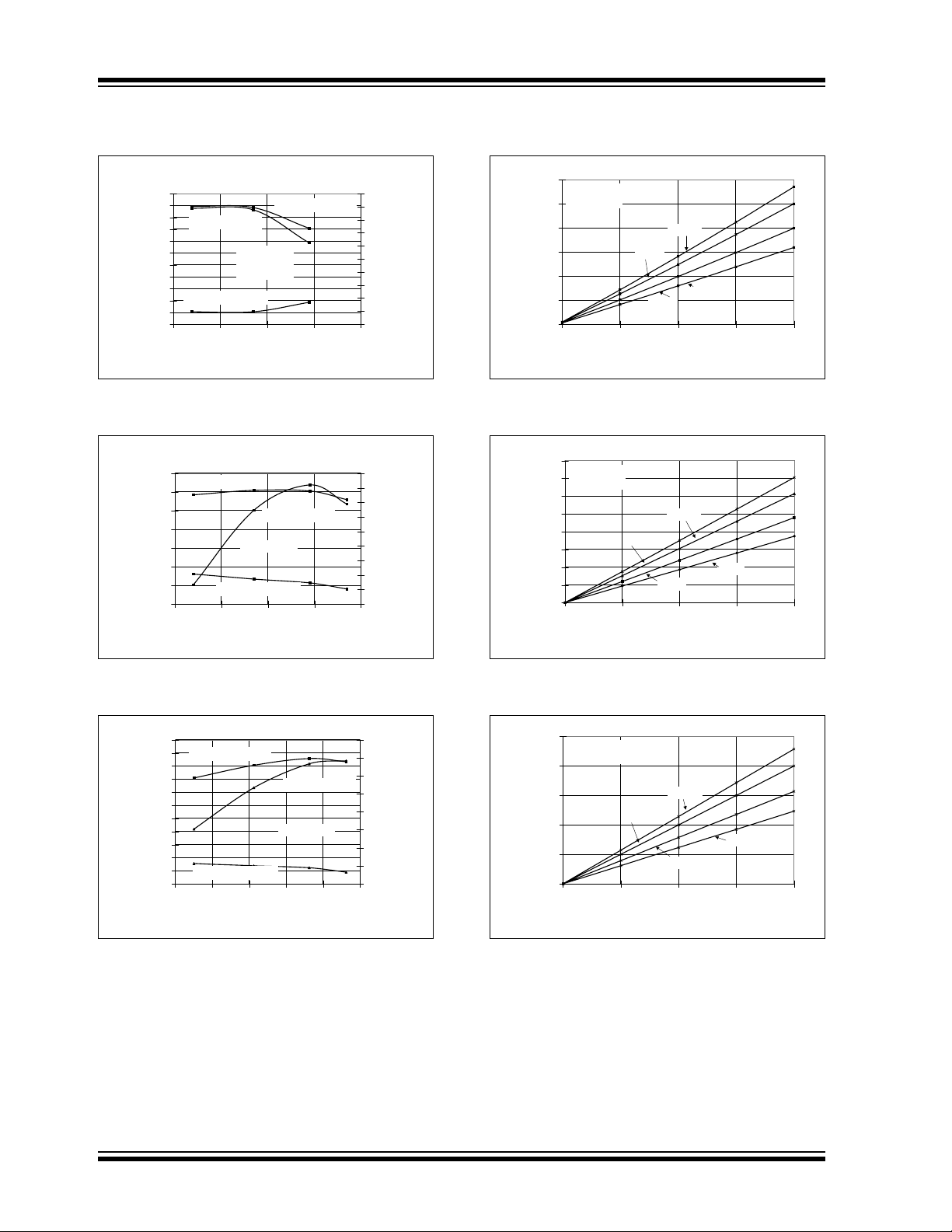

1.950

1.945

1.940

1.935

1.930

(V)

1.925

1.920

TRIP

V

1.915

1.910

1.905

1.900

1.895

-60 -10 40 90 140

= -40°C to +125°C.

A

V

, Hysteresis

HYS

MCP111-195

max temp is

+85°C

V

, V decreasing

TRIP

Temperature (°C)

V

, V increasing

TRIP

0.050

0.045

0.040

0.035

0.030

0.025

0.020

0.015

0.010

0.005

0.000

0.120

MCP111-195

= 1.7V

V

0.100

0.080

(V)

0.060

OL

Hyst (V)

V

0.040

0.020

DD

+125°C

+85°C

-40°C

+25°C

0.000

0.00 0.25 0.50 0.75 1.00

I

(mA)

OL

FIGURE 2-7: V

TRIP

and V

Temperature (MCP111-195).

3.040

V

, V increasing

TRIP

MCP112-300

V

, V decreasing

TRIP

V

, Hysteresis

HYS

(V)

TRIP

V

3.020

3.000

2.980

2.960

2.940

2.920

2.900

-60 -10 40 90 140

Temperature (°C)

FIGURE 2-8: V

TRIP

and V

Temperature (MCP112-300).

4.800

4.780

4.760

4.740

4.720

(V)

4.700

4.680

TRIP

V

4.660

4.640

4.620

4.600

4.580

V

, V increasing

TRIP

MCP112-475

V

, V decreasing

TRIP

-60 -20 20 60 100 140

Temperature (°C)

V

, Hysteresis

HYS

HYST

HYST

vs.

0.100

0.098

0.096

0.094

0.092

0.090

0.088

0.086

0.084

0.082

vs.

0.180

0.170

0.160

0.150

0.140

0.130

0.120

0.110

0.100

FIGURE 2-10: V

(MCP111-195 @V

0.080

MCP112-300

0.070

V

DD

= 2.7V

OL

= 1.7V).

DD

vs. IOL

0.060

0.050

(V)

0.040

OL

V

Hyst (V)

0.030

0.020

0.010

+125°C

+85°C

-40°C

+25°C

0.000

0.00 0.25 0.50 0.75 1.00

I

(mA)

OL

FIGURE 2-11: V

(MCP112-300 @V

0.050

MCP112-475

= 4.4V

V

0.040

0.030

(V)

OL

V

Hyst (V)

0.020

0.010

DD

OL

= 2.7V).

DD

+85°C

vs. IOL

+125°C

-40°C

+25°C

0.000

0.00 0.25 0.50 0.75 1.00

(mA)

I

OL

FIGURE 2-9: V

TRIP

and V

Temperature (MCP112-475).

HYST

vs.

FIGURE 2-12: V

(MCP112-475 @V

DD

vs. IOL

OL

= 4.4V).

DS21889D-page 6 © 2005 Microchip Technology Inc.

Page 7

MCP111/112

0

Note: Unless otherwise indicated, all limits are specified for VDD = 1V to 5.5V, RPU = 100 kΩ (only MCP111;

see Figure 4-1), T

= -40°C to +125°C.

A

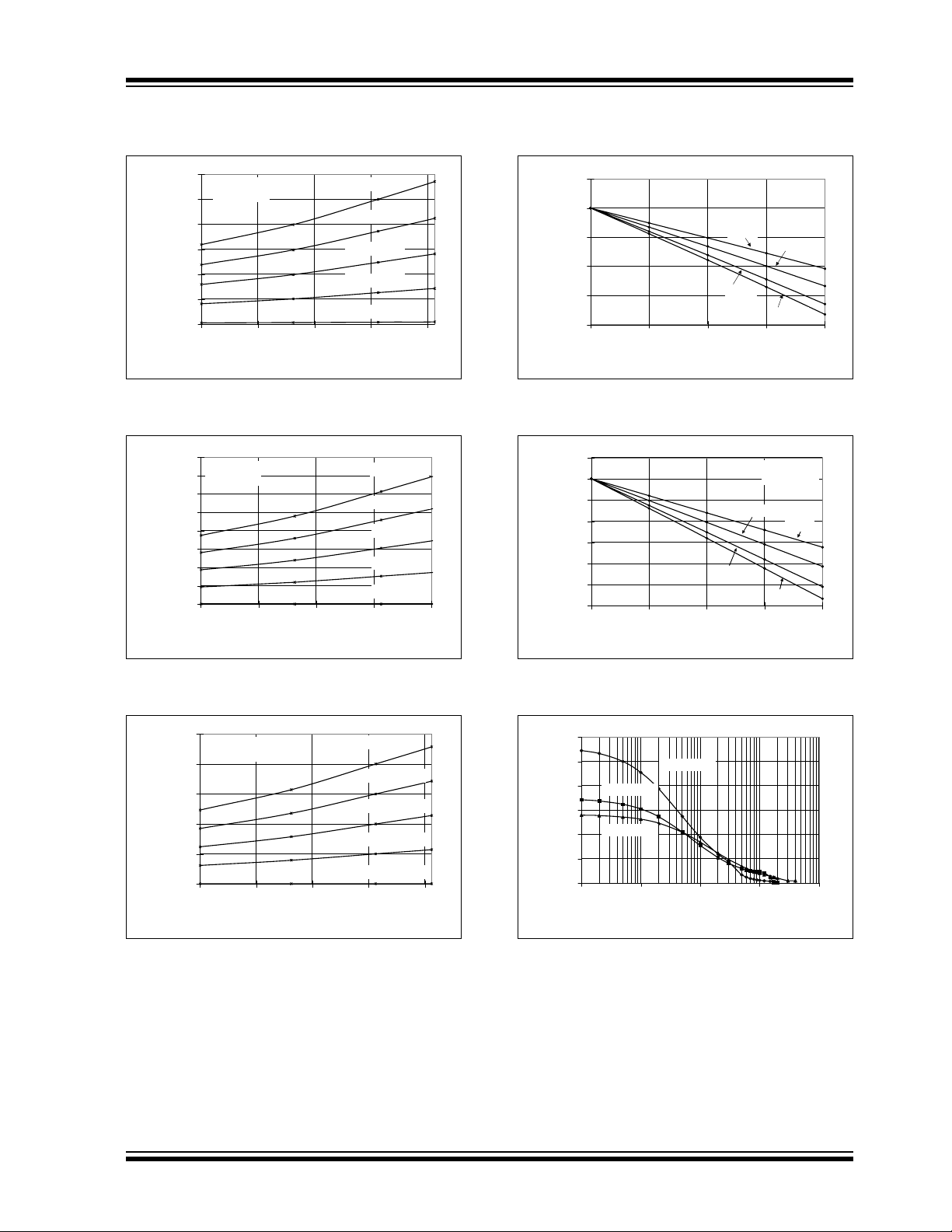

(V)

OL

V

0.120

0.100

0.080

0.060

0.040

0.020

0.000

MCP111-195

= 1.7 V

V

DD

-40 0 40 80 120

Temperature (°C)

IOL = 1.00 mA

IOL = 0.75 mA

IOL = 0.50 mA

IOL = 0.25 mA

IOL = 0.00 mA

FIGURE 2-13: VOL vs. Temperature

(MCP111-195 @ V

0.080

MCP112-300

(V)

OL

V

0.070

0.060

0.050

0.040

0.030

0.020

0.010

0.000

= 2.7V

V

DD

-40 0 40 80 120

= 1.7V).

DD

Temperature (°C)

IOL = 1.00 mA

I

= 0.75 mA

OL

IOL = 0.50 mA

IOL = 0.25 mA

IOL = 0.00 mA

(V)

OH

V

3.150

3.100

3.050

3.000

2.950

2.900

MCP112-300

= 3.1V

V

DD

0.00 0.25 0.50 0.75 1.0

FIGURE 2-16: V

(MCP112-300 @ V

4.820

4.800

4.780

4.760

(V)

OH

4.740

V

4.720

4.700

4.680

0.00 0.25 0.50 0.75 1.00

DD

IOL (mA)

vs. IOH

OH

= 3.1V).

(mA)

I

OL

-40 °C

+85 °C

+25 °C

+85 °C

+25 °C

+125 °C

MCP112-475

V

= 4.8V

DD

-40 °C

+125 °C

FIGURE 2-14: V

(MCP112-300 @ V

0.050

MCP112-475

V

0.040

0.030

(V)

OL

V

0.020

0.010

0.000

-40 0 40 80 120

DD

DD

= 4.4V

FIGURE 2-15: V

(MCP112-475 @ V

DD

vs. Temperature

OL

= 2.7V).

IOL = 1.00 mA

Temperature (°C)

vs. Temperature

OL

= 4.4V).

IOL = 0.75 mA

IOL = 0.50 mA

IOL = 0.25 mA

IOL = 0.00 mA

FIGURE 2-17: V

(MCP112-475 @ V

600

500

400

300

200

100

Transient Duration (µs)

MCP112-300

MCP112-475

0

0.001 0.01 0.1 1 10

OH

= 4.8V).

DD

MCP111-195

V

TRIP

vs. IOH

(min) - V

DD

FIGURE 2-18: Typical Transient Response

(25 °C).

© 2005 Microchip Technology Inc. DS21889D-page 7

Page 8

MCP111/112

Note: Unless otherwise indicated, all limits are specified for VDD = 1V to 5.5V, RPU = 100 kΩ (only MCP111;

see Figure 4-1), T

= -40°C to +125°C.

A

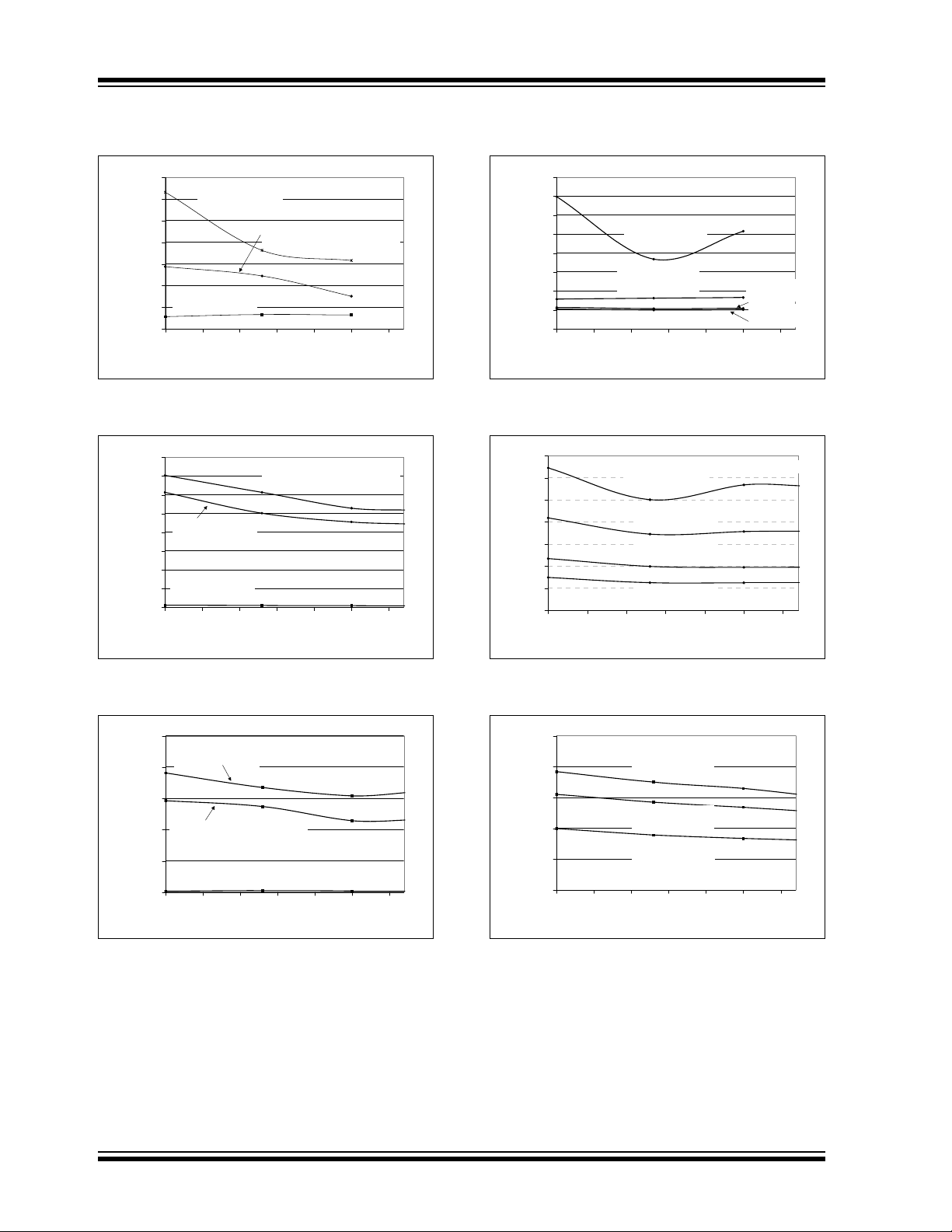

350

300

VDD decreasing from:

5V - 1.7V

250

200

(µs)

150

RPD

t

100

VDD decreasing from:

5V - 0V

50

0

-40 -15 10 35 60 85 110

FIGURE 2-19: t

(MCP111-195).

160

MCP112-300

140

120

100

VDD decreasing from:

(µs)

5V - 2.7V

80

RPD

t

60

40

VDD decreasing from:

20

5V - 0V

0

-40 -15 10 35 60 85 110

VDD decreasing from:

V

+ 0.25V to V

TRIP(max)

Temperature (°C)

vs. Temperature

RPD

VDD decreasing from:

V

+ 0.25V to V

TRIP(max)

Temperature (°C)

MCP111-195

- 0.25V

TRIP(min)

- 0.25V

TRIP(min)

400

350

300

250

(µs)

200

RPU

t

150

100

VDD increasing from:

0V - 2.8V

50

0

-40 -15 10 35 60 85 110

FIGURE 2-22: t

(MCP111-195).

140

120

100

80

(µs)

60

RPU

t

40

20

0

-40 -15 10 35 60 85 110

VDD increasing from:

0V - 2.1V

Temperature (°C)

vs. Temperature

RPU

VDD increasing from:

0V - 3.1V

VDD increasing from:

0V - 3.3V

VDD increasing from:

0V - 4.0V

VDD increasing from:

0V - 5.5V

Temperature (°C)

MCP111-195

VDD increasing

from: 0V - 4.0V

VDD increasing

from: 0V - 5.5V

MCP112-300

FIGURE 2-20: t

(MCP112-300).

250

VDD decreasing from:

5V - 4.4V

200

150

(µs)

VDD decreasing from:

RPD

t

100

50

0

+ 0.25V to V

V

TRIP(max)

VDD decreasing from:

5V - 0V

-40 -15 10 35 60 85 110

FIGURE 2-21: t

(MCP112-475).

vs. Temperature

RPD

- 0.25V

TRIP(min)

Temperature (°C)

vs. Temperature

RPD

MCP112-475

FIGURE 2-23: t

(MCP112-300).

250

200

150

(µs)

RPU

100

t

50

0

-40 -15 10 35 60 85 110

FIGURE 2-24: t

(MCP112-475).

vs. Temperature

RPU

VDD increasing from:

0V - 4.9V

VDD increasing from:

0V - 5.0V

VDD increasing from:

0V - 5.5V

Temperature (°C)

vs. Temperature

RPU

MCP112-475

DS21889D-page 8 © 2005 Microchip Technology Inc.

Page 9

MCP111/112

Note: Unless otherwise indicated, all limits are specified for VDD = 1V to 5.5V, RPU = 100 kΩ (only MCP111;

see Figure 4-1), T

= -40°C to +125°C.

A

60

55

50

45

40

(µs)

RT

t

35

30

25

20

-40 -15 10 35 60 85 110

VDD increasing from:

0V - 2.1V

VDD increasing from:

0V - 5.5V

Temperature (°C)

MCP111-195

VDD increasing

from: 0V - 4.0V

VDD increasing from:

0V - 2.8V

FIGURE 2-25: tRT vs. Temperature

(MCP111-195).

0.4

0.35

VDD increasing from:

0V - 3.3V

0.3

0.25

0.2

(µs)

RT

t

0.15

VDD increasing from:

0.1

0V - 4.0V

0.05

0

-40 -15 10 35 60 85 110

VDD increasing from:

0V - 3.1V

MCP112-300

Temperature (°C)

VDD increasing from:

0V - 5.5V

0.1500

0.1400

0.1300

VDD increasing from:

0V - 4.9V

0.1200

(µs)

RT

t

0.1100

0.1000

0.0900

0.0800

VDD increasing from:

0V - 4.8V

-40 -15 10 35 60 85 110

FIGURE 2-27: t

(MCP112-475).

1.E-02

10m

1.E-03

1m

1.E-04

100µ

1.E-05

10µ

1.E-06

1µ

1.E-07

100n

1.E-08

10n

1.E-09

1n

1.E-10

100p

1.E-11

10p

Open-Drain Leakage (A)

1.E-12

1p

1.E-13

100f

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

VDD increasing from:

0V - 5.0V

VDD increasing from:

0V - 5.5V

Temperature (°C)

vs. Temperature

RT

125°C

25°C

Pull-Up Voltage (V)

MCP112-475

- 40°C

FIGURE 2-26: t

(MCP112-300).

vs. Temperature

RT

FIGURE 2-28: Open-Drain Leakage

Current vs. Voltage Applied to V

OUT

Pin

(MCP111-195).

© 2005 Microchip Technology Inc. DS21889D-page 9

Page 10

MCP111/112

3.0 PIN DESCRIPTION

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

Pin No.

SOT-23-3

SC-70

SOT-89-3 T0-92

111V

223VSSGround reference

332V

—4—VDDPositive power supply

Symbol Function

OUT

Output State

Falling:

V

DD

H = V

DD

> V

L = VDD < V

VDD Rising:

DD

> V

H = V

L = VDD < V

Positive power supply

DD

TRIP

TRIP

TRIP

TRIP

+ V

+ V

HYS

HYS

DS21889D-page 10 © 2005 Microchip Technology Inc.

Page 11

MCP111/112

r

4.0 APPLICATION INFORMATION

For many of today’s microcontroller applicat ions, care

must be taken to prevent low-power conditions that can

cause many different system problems. The most

common causes are brown-out condition s, where the

system supply drops below the operating level momentarily. The second most common cause is when a slowly

decaying power supply causes the microcontroller to

begin executing instructions without sufficient voltage to

sustain SRAM, thus producing indeterminate results.

Figure 4-1 shows a typical application circuit.

V

DD

3

V

0.1

µF

DD

MCP11X

V

V

SS

OUT

R

PU

(1)

1

2

Note 1: RPU may be required with the MCP111

due to the open-drain output. Resisto

RPU is not required with the MCP112.

V

DD

PICmicro

®

Microcontroller

MCLR

(Reset Input)

GND

4.1 V

The voltage trip point (V

edge of V

be between the minimum trip point (V

maximum trip point (V

Operation

TRIP

) is determined on the falling

. The actu al vol tage tr ip point (V

DD

TRIP

). There is a hysteresis on

TRIPMAX

TRIPMIN

) will

TRIPAC

) and the

this trip point to remove any “jitter” that would occur on

the V

Figure 4-2 shows the state of the V

determined by the V

is for falling V

rising, the V

V

pin when the device VDD is at the trip point.

OUT

voltage. The V

DD

voltages. When the VDD voltage is

DD

pin will not be drive n h igh unt il VDD is at

OUT

+ V

HYS

.

TRIP

pin as

OUT

specification

TRIP

FIGURE 4-1: Typical Application Circuit.

VDD

V

TRIPMAX

V

TRIPMIN

1V

V

OUT

FIGURE 4-2: V

Operation as Determined by the V

OUT

< 1 V is outside the

device speci fications

V

TRIPAC

+ V

HYSAC

TRIP

V

and V

TRIPAC

HYS

V

TRIPAC

.

© 2005 Microchip Technology Inc. DS21889D-page 11

Page 12

MCP111/112

4.2 Negative Going VDD Transients

The minimum pulse width (time) required to cause a

reset may be an important criteria in the implementation of a Power-on Reset (POR) circuit. This time is

referred to as transient dur ation, defined as the amount

of time needed for these supervisory devices to

respond to a drop in V

dependant on the magnitu de of V

speaking, the transient duration decreases with

increases in V

TRIP

Figure 4-3 shows a typ ical tran sient dur ation vs . reset

comparator overdrive for which the MCP111/112 will

not generate a reset pulse. It shows that the farther

below the trip point the transient pulse goes, the

duration of the pulse required to cause a reset gets

shorter. Figure 2-18 shows the transient response

characteristics for the MCP111/112.

A 0.1 µF bypass capacitor, mounted as close as

possible to the V

immunity (refer to Figure4-1).

5V

Supply Voltage

0V

FIGURE 4-3: Example of Typical

Transient Duration Waveform.

. The transient du ration tim e is

DD

– VDD. Generally

TRIP

– VDD.

pin, provides additional transient

DD

V

TRIP(MAX)

V

TRIP(MIN)

t

TRANS

Time (µs)

V

TRIP(MIN)

- V

DD

4.3 Effect of Temperature on Time-ou t

Period (t

The time-out period (t

device remains in the reset condition. This is affected

by both VDD and temperature. The graph shown in

Figures 2-22, 2-23 and 2-24 show the typical respo nse

for different VDD values and temperatures.

)

RPU

) determines how long the

RPU

4.4 Using in PICmicro®

Microcontroller ICSP™

Applications (MCP111 only)

Figure 4-4 shows the typical application circuit for using

the MCP111 for voltage supervisory function when the

PICmicro mi crocontroller will be programmed via the

In-Circuit Serial Programming™ (ICSP)

feature. Additional information is available in TB087,

“Using Voltage Supervisors with PICmicro

troller Systems which Implement In-Circuit Serial

Programming™”, DS91087.

Note: It is recommend ed that th e current into the

pin be current limited by a 1kΩ

RST

resistor.

VDD/V

0.1 µF

R

V

DD

PU

MCP111

RST

V

SS

1kΩ

®

Microcon-

PP

V

DD

PICmicro

MCU

MCLR

(reset input)

(Active-Low)

V

SS

®

FIGURE 4-4: Typical Application Circuit

for PICmicro

®

Microcontroller with the ICSP™

feature.

DS21889D-page 12 © 2005 Microchip Technology Inc.

Page 13

5.0 PACKAGING INFORMATION

5.1 Package Marking Information

MCP111/112

3-Pin SOT-23

XXNN

3-Lead TO-92

XXXXXX

XXXXXX

XXXXXX

YWWNNN

Example:

MCP111

290E

TO^^

3

e

547256

Example:

Part Number SOT-23 Part Number SOT-23

MCP111T-195I/TT MPNN MCP112T-195I/TT MRNN

MCP111T-240ETT MQNN MCP112T-240ETT MSNN

MCP111T-270E/TT MGNN MCP112T-270E/TT MANN

MCP111T-290E/TT NHNN MCP112T-290E/TT MBNN

MCP111T-300E/TT MJNN MCP112T-300E/TT MCNN

MCP111T-315E/TT MKNN MCP112T-315E/TT MDNN

MCP111T-450E/TT MLNN MCP112T-450E/TT MENN

MCP111T-475E/TT MMNN MCP112T-475E/TT MFNN

3-Pin SOT-89

Part Number SOT-89 Part Number SOT-89

XXYYWW

NNN

Legend: XX...X Customer-specific information

Y Year code (last digit of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

3

e

Pb-free JEDEC designator for Matte Tin (Sn)

* This package is Pb-free. T he Pb-free JEDEC designator ( )

can be found on the outer packaging for this package.

Note: In the event the full Microchip part nu mber ca nnot be m arked o n one lin e, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

MCP111T-195I/MB MP MCP112T-195I/MB MR

MCP111 T-240EMB MQ MCP112T-240EMB MS

MCP111T-270E/MB MG MCP112T-270E/MB MA

MCP111T-290E/MB NH MCP112T-290E/MB MB

MCP111T-300E/MB MJ MCP112T-300E/MB MC

MCP111T-315E/MB MK MCP112T-315E/MB MD

MCP111T-450E/MB ML MCP112T-450E/MB ME

MCP111T-475E/MB MM MCP112T-475E/MB MF

Example:

3

e

© 2005 Microchip Technology Inc. DS21889D-page 13

Page 14

MCP111/112

Package Marking Information (Continued)

3-Pin SC-70

XXN

Top Side

OR

XXNN

Top Side

Example:

Part Number SC-70 Part Number SC-70

MCP111T-195I/LB EPN MCP112T-195I/LB ERN

MCP111T-240E/LB EQN MCP112T-240E/LB ESN

MCP111T-270E/LB EGN MCP112T-270E/LB EAN

MCP111T-290E/LB EHN MCP112T-290E/LB EBN

MCP111T-300E/LB EJN MCP112T-300E/LB ECN

MCP111T-315E/LB EKN MCP112T-315E/LB EDN

MCP111T-450E/LB ELN MCP112T-450E/LB EEN

MCP111T-475E/LB EMN MCP112T-475E/LB EFN

Example:

Part Number SC-70 Part Number SC-70

MCP111T-195I/LB EPNN MCP112T-195I/LB ERNN

MCP111T-240E/LB EQNN MCP112T-240E/LB ESNN

MCP111T-270E/LB EGNN MCP112T-270E/LB EANN

MCP111T-290E/LB EHNN MCP112T-290E/LB EBNN

MCP111T-300E/LB EJNN MCP112T-300E/LB ECNN

MCP111T-315E/LB EKNN MCP112T-315E/LB EDNN

MCP111T-450E/LB ELNN MCP112T-450E/LB EENN

MCP111T-475E/LB EMNN MCP112T-475E/LB EFNN

DS21889D-page 14 © 2005 Microchip Technology Inc.

Page 15

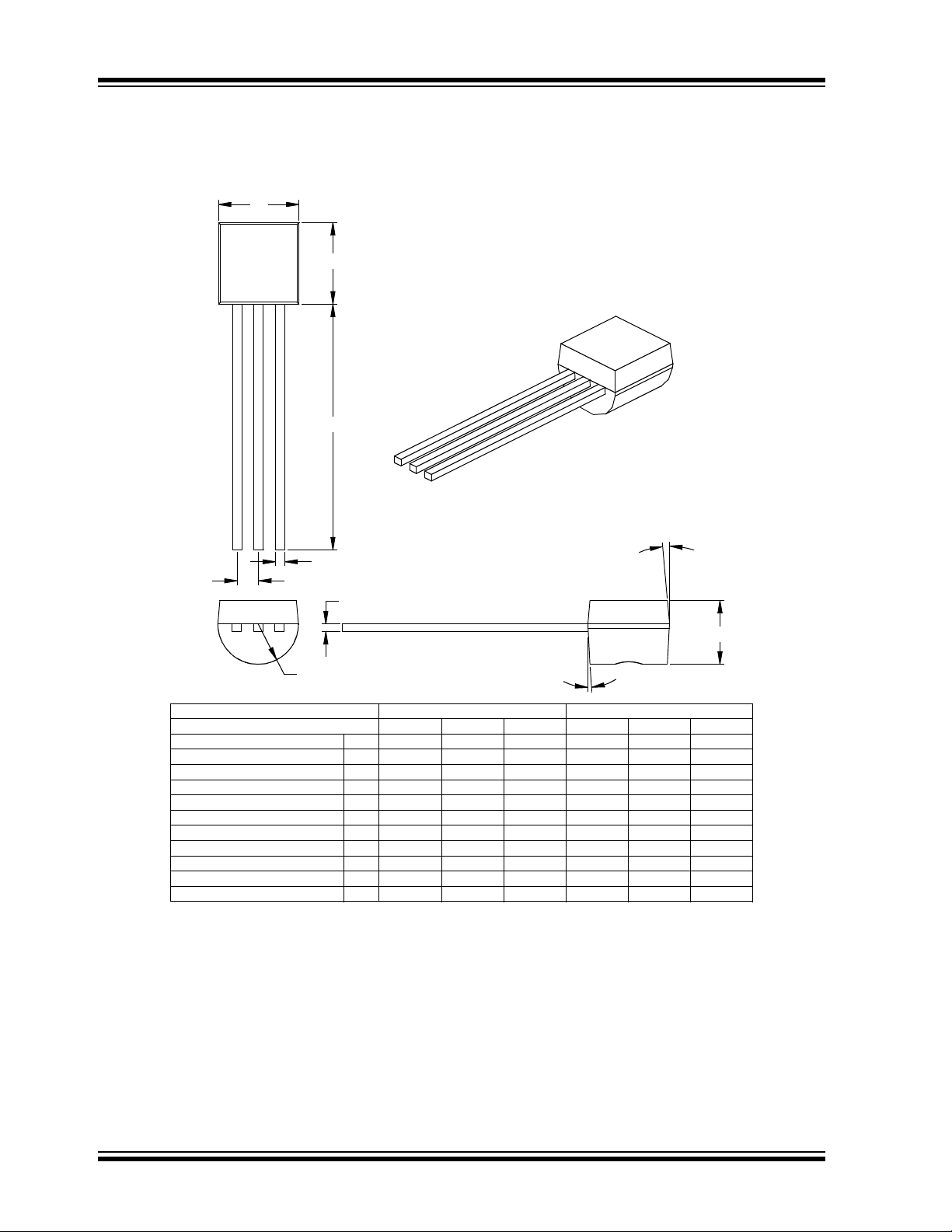

3-Lead Plastic Small Outline Transistor (MB) (SOT89)

H

E

B1

3

B

MCP111/112

D1

D

2

R

1

B1

L

E1

A

C

Pitch

Outside lead pitch (basic)

Molded Package Width at Base

Molded Package Width at Top

Tab Corner Radii R 0.254.010

Foot Length L .035 .047 0.89 1.20

Lead Thickness

Leads 1 & 3 Width B1 .014 .019 0.36 0.48

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold or flash protrusions. Mold flash or protrusions

shall not exceed .005" (0.127mm) per side.

JEDEC Equivalent: TO-243

Drawing No. C04-29

p1

p

MILLIMETERS*INCHESUnits

p

p1

E .090 .102 2.29 2.60

c

Revised 07-24-03

MAXMINMAXMINDimension Limits

1.50 BSC.059 BSC

3.00 BSC.118 BSC

1.601.40.063.055AOverall Height

4.253.94.167.155HOverall Width

2.292.13.090.084E1

4.604.40.181.173DOverall Length

1.831.62.072.064D1Tab Length

0.440.35.017.014

0.560.43.022.017BLead 2 Width

© 2005 Microchip Technology Inc. DS21889D-page 15

Page 16

MCP111/112

3-Lead Plastic Small Outline Transistor (TT) (SOT-23)

E

E1

2

B

n

1

c

β

Number of Pins

Pitch

Outside lead pitch (basic)

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: TO-236

Drawing No. C04-104

n

p

p1

φ

c

α

β

p1

D

p

A

.038

A1

MILLIMETERSINCHES*Units

0.96

1.92.076

φ

L

α

A2

MAXNOMMINMAXNOMMINDimension Limits

33

1.121.010.89.044.040.035AOverall Height

1.020.950.88.040.037.035A2Molded Package Thickness

0.100.060.01.004.002.000A1Standoff §

2.642.372.10.104.093.083EOverall Width

1.401.301.20.055.051.047E1Molded Package Width

3.042.922.80.120.115.110DOverall Length

0.550.450.35.022.018.014LFoot Length

10501050

0.180.140.09.007.006.004

0.510.440.37.020.017.015BLead Width

10501050

10501050

DS21889D-page 16 © 2005 Microchip Technology Inc.

Page 17

3-Lead Plastic Small Outline Transistor (LB) (SC-70)

E

E1

MCP111/112

B

3

2

p1 D

p

1

a

c

b

Pitch

Outside lead pitch (basic)

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions

shall not exceed .005" (0.127mm) per side.

L

p

p1

c

a

b

A

.026 BSC.

.051 BSC.

A2

A1

MILLIMETERS*INCHESUnits

MAXMINMAXMINDimension Limits

33Number of Pins

0.65 BSC.

1.30 BSC.

1.100.80.043.031AOverall Height

1.000.80.039.031A2Molded Package Thickness

.0100.00.0004.000A1Standoff

2.401.80.094.071EOverall Width

1.351.15.053.045E1Molded Package Width

2.251.80.089.071DOverall Length

0.410.10.016.004LFoot Length

0.250.08.010.003

0.400.15.016.006BLead Width

12°8°12°8°

12°8°12°8°

JEITA (EIAJ) Equivalent: SC70

Drawing No. C04-104

© 2005 Microchip Technology Inc. DS21889D-page 17

Page 18

MCP111/112

3-Lead Plastic Transistor Outline (TO) (TO-92)

E1

D

1

Number of Pins

Pitch

Tip to Seating Plane L .500 .555 .610 12.70 14.10 15.49

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: TO-92

Drawing No. C04-101

n

L

1

2

3

B

p

c

R

n

p

c

α

β

β

MILLIMETERSINCHES*Units

α

A

MAXNOMMINMAXNOMMINDimension Limits

33

1.27.050

3.943.623.30.155.143.130ABottom to Package Flat

4.954.714.45.195.186.175E1Overall Width

4.954.644.32.195.183.170DOverall Length

2.412.292.16.095.090.085RMolded Package Radius

0.510.430.36.020.017.014

0.560.480.41.022.019.016BLead Width

654654

432432

DS21889D-page 18 © 2005 Microchip Technology Inc.

Page 19

MCP111/112

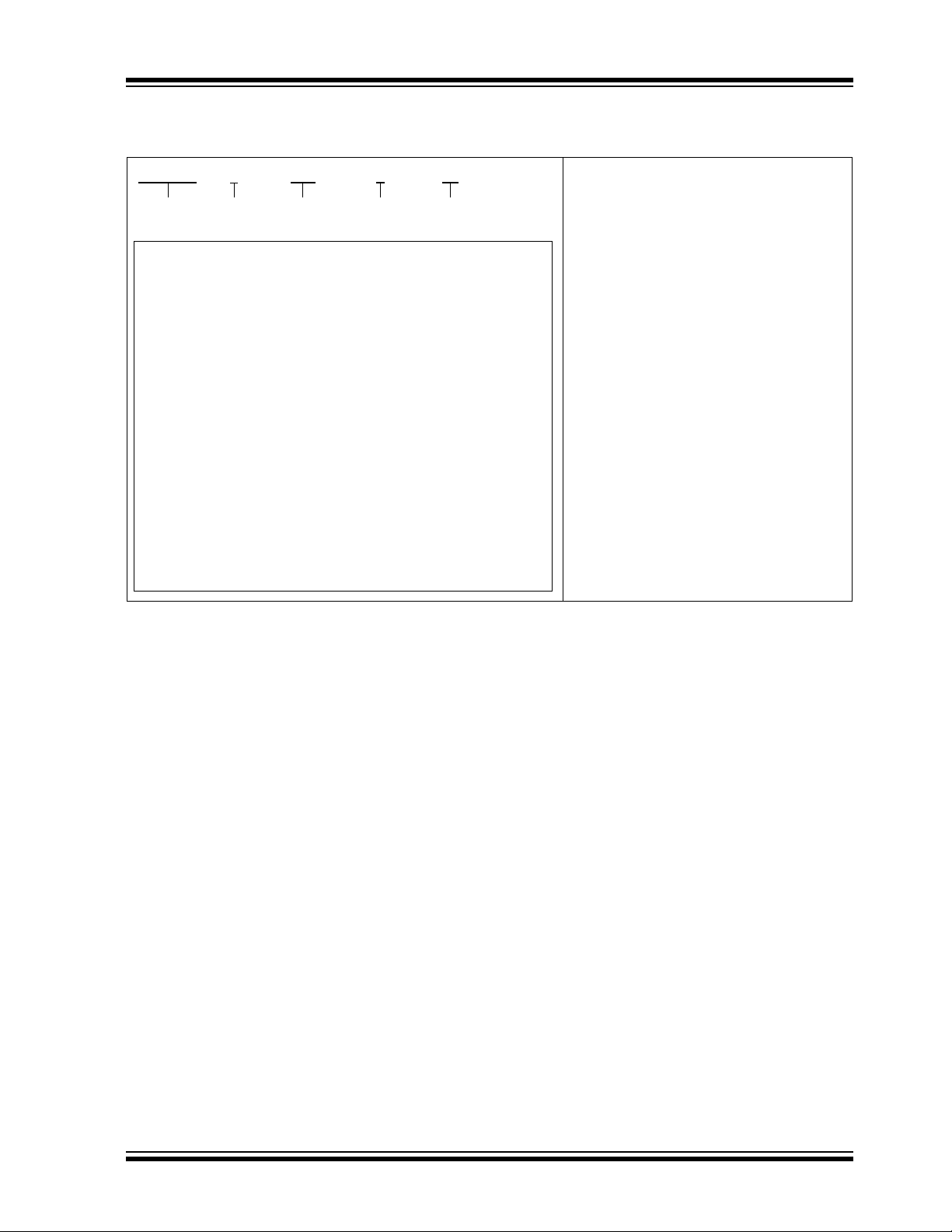

5.2 Product Tape and Reel Specifications

FIGURE 5-1: EMBOSSED CARRIER DIMENSIONS (8, 12, 16 AND 24 MM TAPE ONLY)

Top

Cover

Tape

A

0

W

K

0

B

0

P

TABLE 1: CARRIER TAPE/CAVITY DIMENSIONS

Carrier

Case

Outline

Package

Type

Dimensions

W

mm

P

mmA0mmB0mm

TT SOT-23B 3L 8 4 3.15 2.77 1.22 3000 180

LB SC-70 3L 8 4 2.4 2.4 1.19 3000 180

Cavity

Dimensions

K0

mm

Output

Quantity

Units

FIGURE 5-2: 3-LEAD SOT-23/SC70 DEVICE TAPE AND REEL SPECIFICATIONS

User Direction of Feed

Device

Marking

W

PIN 1

Standard Reel Component Orientation

P

Reel

Diameter in

mm

© 2005 Microchip Technology Inc. DS21889D-page 19

Page 20

MCP111/112

Pin 1

P, Pitch

W, Width

of Carrier

Tape

Pin 1

FIGURE 5-3: TO-92 DEVICES

Device

Marking

Seal

Tape

Back

Tape

Note: Bent leads are for Tape and Reel only.

MARK

FACE

MARK

FACE

MARK

FACE

User Direction of Feed

P

W

FIGURE 5-4: SOT-89 DEVICES

Standard Reel Component Orientation

User Direction of Feed

Reverse Reel Component Orientation

DS21889D-page 20 © 2005 Microchip Technology Inc.

Page 21

APPENDIX A: REVISION HISTORY

Revision D (June 2005)

1. Added SOT-89-3 package information

throughout.

Revision C (March 2005)

The following is the list of modifications:

1. Added Section 4.4 “Using in PICmicro®

Microcontroller ICSP™ Applications

(MCP111 only)” on using the MCP111 in

PICmicro microcontroller ICSP applications.

2. Added V

“Electrical Characteristics” (for ICSP

applications).

3. Added Figure 2-28.

4. Added devices features table to page 1.

5. Updated SC-70 package markings and added

Pb-free marking information to Section 5.0

“Packaging information”.

6. Added Appendix A: “Revision History”.

specifications in Section 1.0

ODH

MCP111/112

Revision B (August 2004)

1. Corrected package marking information in

Section 5 .0 “Packaging information”

Revision A (May 2004)

• Original Release of this Document.

© 2005 Microchip Technology Inc. DS21889D-page 21

Page 22

MCP111/112

NOTES:

DS21889D-page 22 © 2005 Microchip Technology Inc.

Page 23

MCP111/112

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. XXX X

Device

Device: MCP111: MicroPo w er Voltage Detector, open-drain

Monitoring Options: 195 = 1.90V

Temperature Range: I = -40°C to +85°C (MCP11X-195 only)

Package: LB = SC-70, 3-lead

X

Tape/Reel

Option

Monitoring

Options

MCP111T: MicroPo w er Voltage Detector, open-drain

MCP112: MicroPower Voltage Detector, push-pull

MCP112T: MicroPo wer Voltage Detector, push-pull

240 = 2.32V

270 = 2.63V

290 = 2.90V

300 = 2.93V

315 = 3.08V

450 = 4.38V

475 = 4.63V

E = -40°C to +125°C (Except MCP11X-195 only)

MB = SOT-89, 3-lead

TO = TO-92, 3-lead

TT = SOT-23B, 3-lead

Temperature

Range

(Tape and Reel)

(Tape and Reel)

X

X

Package

Examples:

a) MC P111T-195I/TT: Tape and Reel,

b) MC P111T-315E/LB: Tape and Reel,

c) MCP111-300E/TO: 3.00V option, open-drain,

d) MCP111-315E/MB: 3.15V option, open-drain,

a) MC P112T-290E/TT: Tape and Reel,

b) MC P112T-475E/LB: Tape and Reel,

c) MCP112-450E/TO: 4.5V option, push-pull,

d) MCP112-315E/MB: 3.15V option, push-pull,

1.95V option, open-drain,

-40°C to +85°C,

SOT-23B package.

3.15V option, open-drain,

-40°C to +125°C,

SC-70-3 package.

-40°C to +125°C,

TO-92-3 package.

-40°C to +125°C,

SOT-89-3 package.

2.90V option, push-pull, 40°C to +125°C,

SOT-23B-3 package.

4.75V option, push-pull,

-40°C to +125°C,

SC-70-3 package.

-40°C to +125°C,

TO-92-3 package.

-40°C to +125°C,

SOT-89-3 package.

© 2005 Microchip Technology Inc. DS21889D-page 23

Page 24

MCP111/112

NOTES:

DS21889D-page 24 © 2005 Microchip Technology Inc.

Page 25

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are com mitted to continuously improving the code protect ion f eatures of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Mill ennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of M icrochip’s prod ucts as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro,

PICSTART, PRO MATE, PowerSmart, rfPIC, a nd

SmartShunt are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor,

MPASM, MPLIB, MPLINK, MPSI M, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, rfLAB, rfPICDEM, Select Mode,

Smart Serial, SmartTel, Total Endurance and WiperLock are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2005, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

© 2005 Microchip Technology Inc. DS21889D-page 25

Page 26

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Qingdao

Tel: 86-532-502-7355

Fax: 86-532-502-7205

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-2229-0061

Fax: 91-80-2229-0062

India - New Delhi

Tel: 91-1 1-5160-8631

Fax: 91-11-5160-8632

Japan - Kanagawa

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel:011-604-646-8870

Fax:011-604-646-5086

Philippines - Manila

Tel: 01 1-632-634-9065

Fax: 011-632-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Taiwan - Hsinchu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

EUROPE

Austria - Weis

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Ballerup

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Massy

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Ismaning

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

England - Berkshire

Tel: 44-118-921-5869

Fax: 44-118-921-5820

04/20/05

DS21889D-page 26 © 2005 Microchip Technology Inc.

Loading...

Loading...