Page 1

HCS512

KEELOQ® Code Hopping Decoder

FEATURES

Security

• Secure storage of Manufacturer’s Code

• Secure sto rage of transmitter’s keys

• Up to four transmitters can be learned

•K

• Normal and secure learning mechanisms

Operating

• 4.0V – 6.0V operation

• 4 MHz external RC oscillator

• Learning indication on LRNOUT

• Auto baud rate detection

• Power saving SLEEP mode

Other

• Stand-alone decoder

• On-chip EEPROM for transmitter storage

• Four binary function outputs–15 functions

• 18-pin DIP/SOIC package

Typical Applications

• Automotive remote entry systems

• Automotive alarm systems

• Automotive immobilizers

• Gate and garage openers

• Electronic door locks

• Identity t okens

• Burglar alarm systems

Compatible Encoders

All KEELOQ encoders and transponders configured for

the following setting:

• PWM modulation format (1/3-2/3)

•T

•10 x TE Header

• 28-bit Serial Number

• 16-bit Synchronization counter

• Discrimination bit s equal to Serial Num ber 8 LSbs

• 66- to 69-bit length code word.

EELOQ

E in the range from 100 µs to 400 µs

code hopping technology

DESCRIPTION

The Microchip Technology Inc. HC S51 2 is a c od e ho pping decoder designed for secure Remote Keyless

Entry (RKE) systems. The HCS512 utilizes the patented K

EELOQ code hopping system and high security

learning mechanisms to make this a canned solution

when used with the HCS en co ders to i mp lem en t a un idirectional remote keyless entry system.

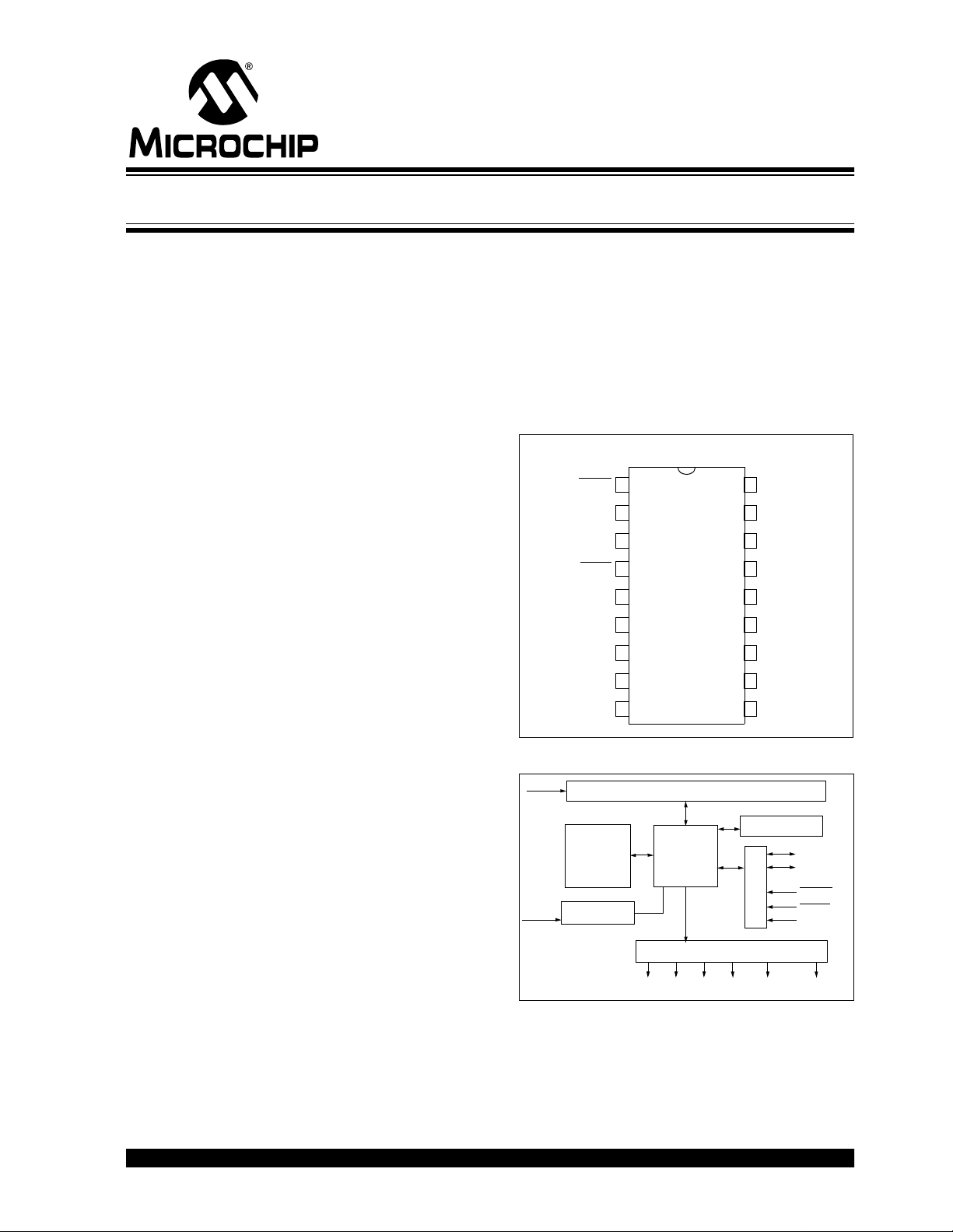

PACKAGE TYPE

PDIP, SOIC

NC

S0

S1

S2

S3

1

2

3

4

5

6

7

8

9

18

RFIN

NC

17

OSCIN

16

HCS512

15

14

13

12

11

10

OSC

VDD

DATA

CLK

SLEEP

V

LOW

OUT

LRNIN

LRNOUT

MCLR

GND

BLOCK DIAGRAM

RFIN

EEPROM CONTROL

OSCIN

OSCILLATOR

The Manufacturer’s Code, transmitter keys, and synchronization information are stored in protected onchip EEPROM. The HCS512 uses the DATA and CLK

inputs to load the Manufacturer’s Code which cannot

be read out of the device.

Reception Register

DECRYPTOR

OUTPUT

S0 S1 S3S2VLOW

CONTROL

DATA

CLK

LRNIN

MCLR

SLEEP

LRNOUT

2002 Microchip Technology Inc. DS40151D-page 1

Page 2

HCS512

The HCS512 operates over a wide voltage range of

3.0 volts to 6.0 volts. The decoder employs automatic

baud rate detection which allows it to compensate for

wide variations in transmitter data rate. The decoder

contains sophisticated error checking algorithms to

ensure only valid codes are accepted.

1.0 SYSTEM OVERVIEW

Key Terms

The following is a l ist of key te rms us ed thro ughout this

data sheet. For additional information on K

Code Hopping, refer to Technical Brief 3 (TB003).

• RKE - Remote Keyless Entry

• Button Status - Indicates what button input(s)

activated the transmission. Encompasses the 4

button status bits S3, S2, S1 and S0 (Figure8-2).

• Code Hopping - A method by which a code,

viewed externally to the system, appears to

change unpredictably each time it is transmitted.

• Code word - A block of data that is repeatedly

transmitted upon button activation (Figure8-1).

• Transmission - A data stream consisting of

repeating code words (Figure 8-1).

• Crypt key - A unique and secret 64-bit number

used to encrypt and decrypt data. In a symmetrical block cipher such as the K

the encryption and de cry pti on k ey s a re equal and

will therefore be refer red to generally as the crypt

key.

• Encoder - A device that generates and encodes

data.

• Encryption Algorithm - A recipe whereb y data i s

scrambled using a crypt k ey . The dat a can only be

interpreted by the respe ctive dec ryptio n algo rithm

using the same crypt key.

• Decoder - A device that decodes data received

from an encoder.

• Decryption algorithm - A recipe whereby data

scrambled by an encryption algorithm can be

unscrambled using the same crypt key.

• Learn – Learning invol ves the recei ver calcula ting

the transmitter’s app ropr i ate crypt key, decrypting

the received hopping code and storing the serial

number, synchronization counter value and crypt

key in EEPROM. The K

itates several learning strategies to be implemented on the decoder. The following are

examples of what can be done.

- Simple Learning

The receiver uses a fixed crypt key, common

to all components of all system s by the s am e

manufacturer, to decrypt the received code

word’s encrypted portion.

- Normal Learning

The receiver uses information transmitted

EELOQ algorithm,

EELOQ product family fa cil-

EELOQ and

during normal operation to derive the crypt

key and decrypt the received code word’s

encrypted portion.

- Secure Learn

The transmitter is activated through a special

button combinat ion to t ransmit a stored 60-bit

seed value used to generat e the trans mitter’s

crypt key. The receiver uses this seed value

to derive the same crypt key and decrypt the

received code word’s encrypted portion.

• Manufacturer’s code – A unique and secret 64-

bit number used to generate un ique encoder crypt

keys. Each encoder is programmed with a crypt

key that is a function of the manufacturer’s code.

Each decoder is programmed with the manufacturer code itself.

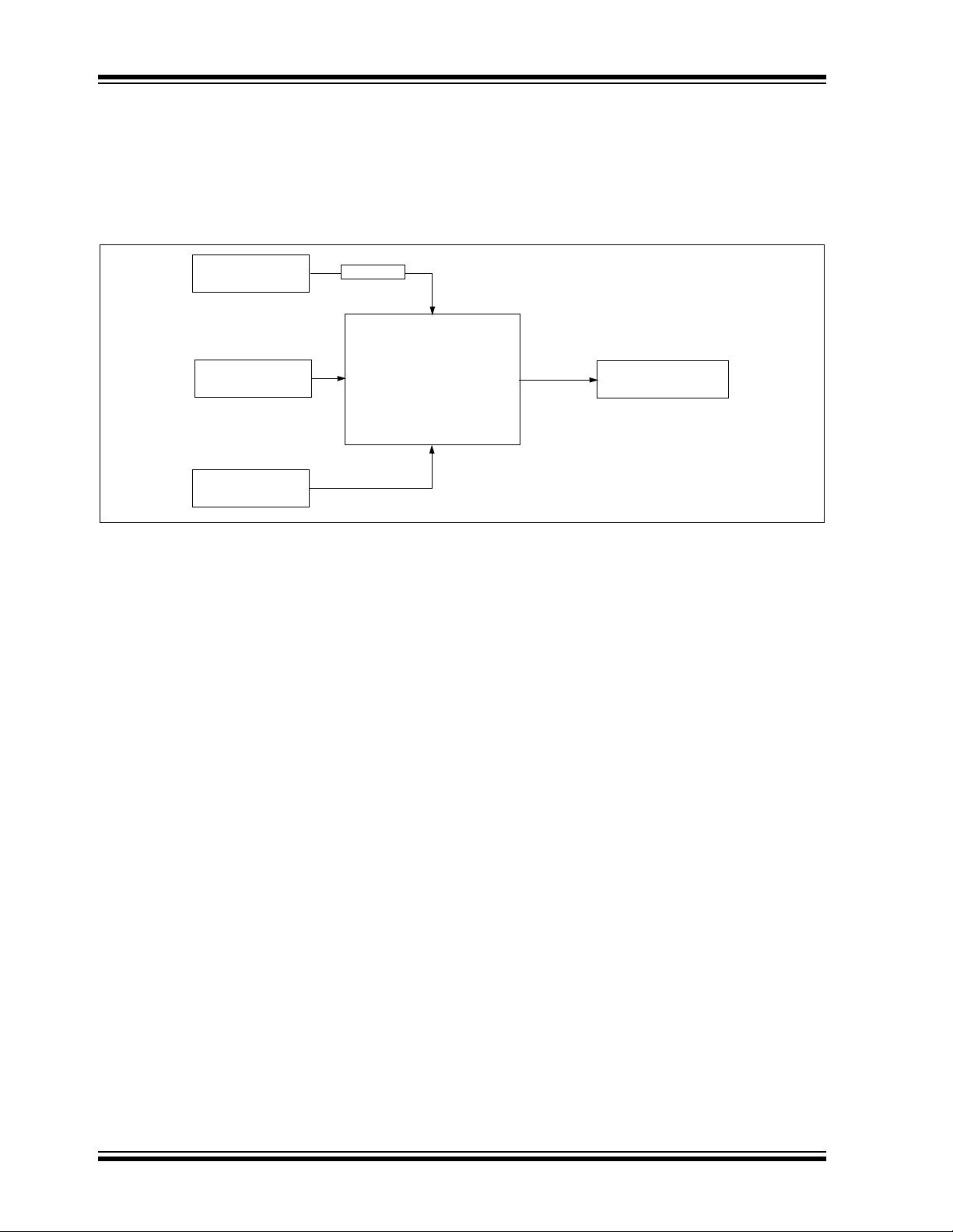

1.1 HCS Encoder Overview

The HCS encoders have a small EEPROM array wh ich

must be loaded with several parameters before use.

The most important of these values are:

• A crypt key that is generated at the time of production

• A 16-bit sy nchronizati on counter value

• A 28-bit serial number w hich is meant to be

unique for every encoder

The manufacturer program s the serial nu mber for eac h

encoder at the time of production, while the ‘Key Generation Algorithm’ generat es the crypt k ey (Figure 1-1).

Inputs to the key generation algorithm typically consist

of the encoder’s serial number and a 64-bit manufacturer’s code, which the manufacturer creates.

Note: The manufact urer co de is a pivo tal part of

the system’s overall security. Consequently, all possible precautions must be

taken and maintained for this code.

DS40151D-page 2 2002 Microchip Technology Inc.

Page 3

HCS512

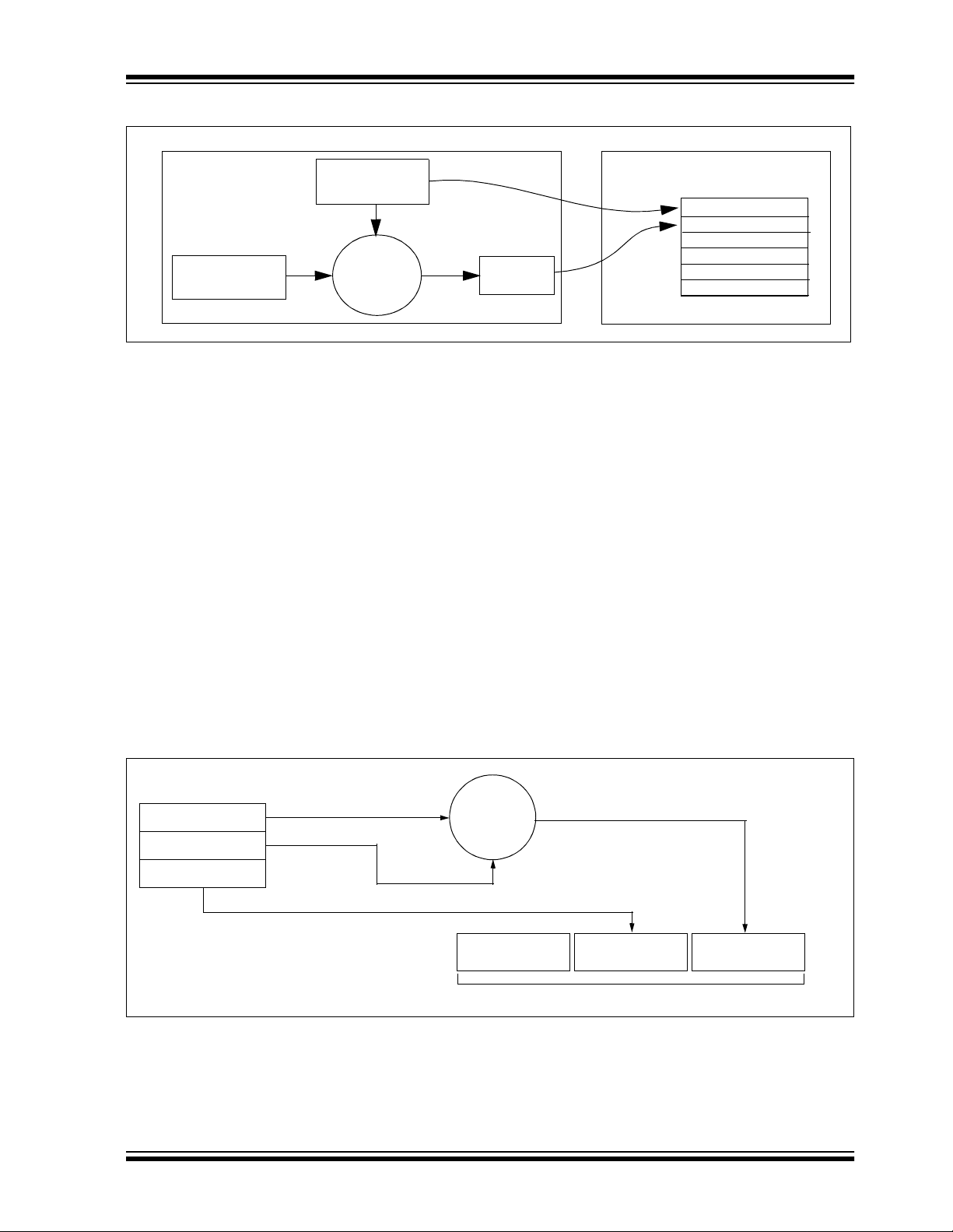

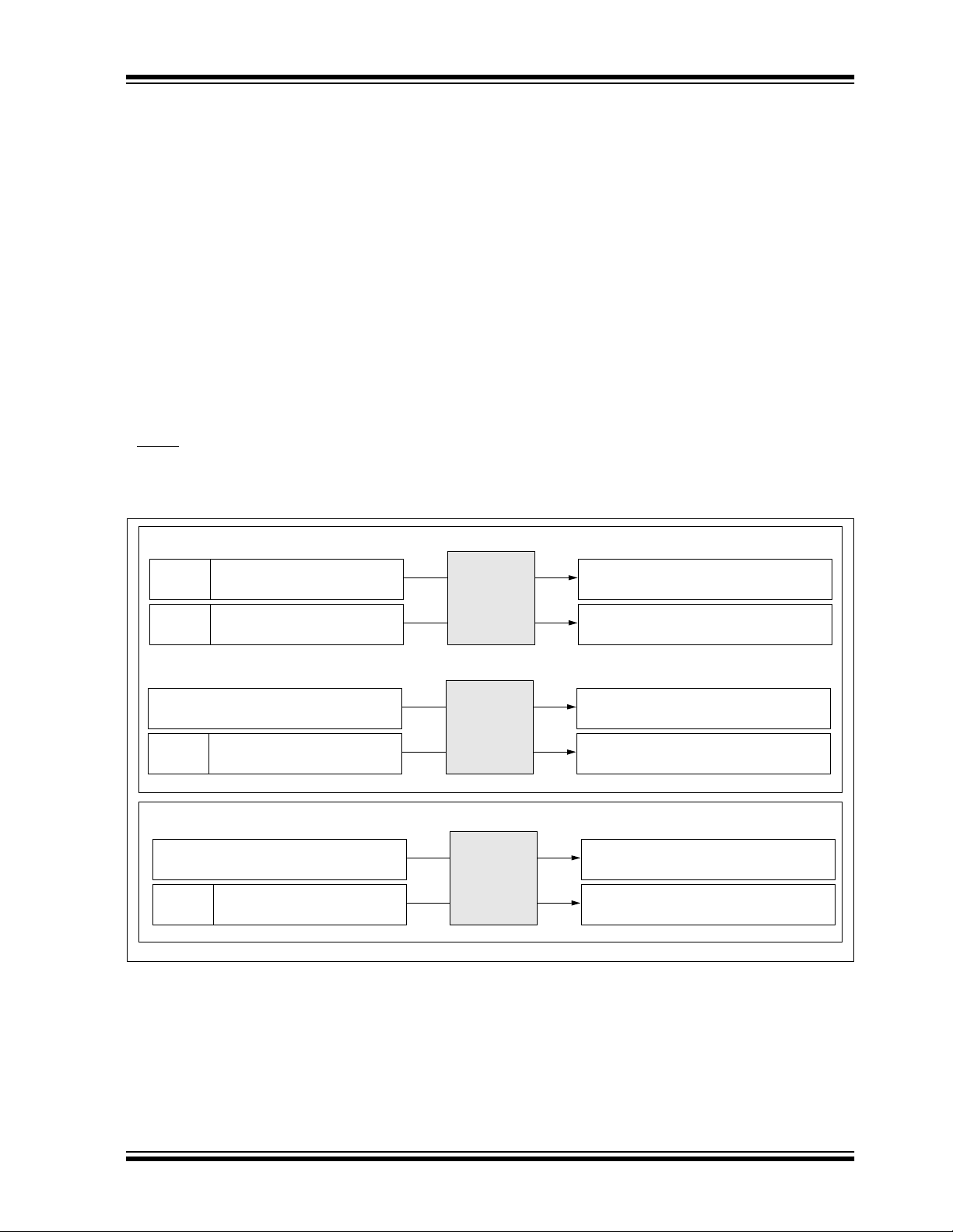

FIGURE 1-1: CREATION AND STORAGE OF CRYPT KEY DURING PRODUCTION

Production

Programmer

Manufacturer’s

Code

The 16-bit synchronization counter is the basis behind

the transmitted code word changing for each transmission; it increments each time a button is pressed. Due

to the code hoppin g algorith m’s complex ity, each increment of the synchronization value results in greater

than 50% of the bits changing in the transmitted code

word.

Figure 1-2 shows how the key values in EEPROM are

used in the encoder . O nce the encoder dete cts a button

press, it reads the button inputs and updates the synchronization counter. The synchronization co unter and

crypt key are input to the encryption algorithm and the

output is 32 bits of encrypted information. This data will

change with every button press, its value appearing

externally to ‘ran domly h op aroun d’, hence it is re ferred

to as the hopping portion of the code word. The 32-bit

hopping code is combined with the button information

and serial numb er to fo rm the code word transm itted to

the receiver. The code word format is explained in

greater detail in Section 8.2.

Transmitter

Serial Number

Key

Generation

Algorithm

HCS512

EEPROM Array

Serial Number

Crypt Key

Sync Counter

Crypt

Key

A receiver may use any type of controller as a decoder,

but it is typically a microcontroller with compatible firmware that allows the decoder to operate in conjunction

with an HCS512 based transmitter. Section 5.0

provides detail on integrating the HCS512 into a system.

A transmitter must first be ‘learned’ by the receiver

before its use is allowed in the system. Learning

includes calculating the transmitter’s appropriate crypt

key, decrypting the received hopping code and storing

the serial number, synchronization counter value and

crypt key in EEPROM.

In normal operation, each received message of valid

format is evaluated. The serial number is used to determine if it is from a learned transmitter. If from a learned

transmitter, the message is decrypted and the synchronization counter is verified. Finally, the button status is

checked to see what operation is requested. Figure 1-3

shows the relationship between some of the values

stored by the receiver and the values received from

the transmitter.

.

.

.

FIGURE 1-2: BUILDING THE TRANSMITTED CODE WORD (ENCODER)

EEPROM Array

Crypt Key

Sync Counter

Serial Number

2002 Microchip Technology Inc. DS40151D-page 3

KEELOQ

Encryption

Algorithm

Button Press

Information

Serial Number

Transmitted Information

Encrypted Data

32 Bits

Page 4

HCS512

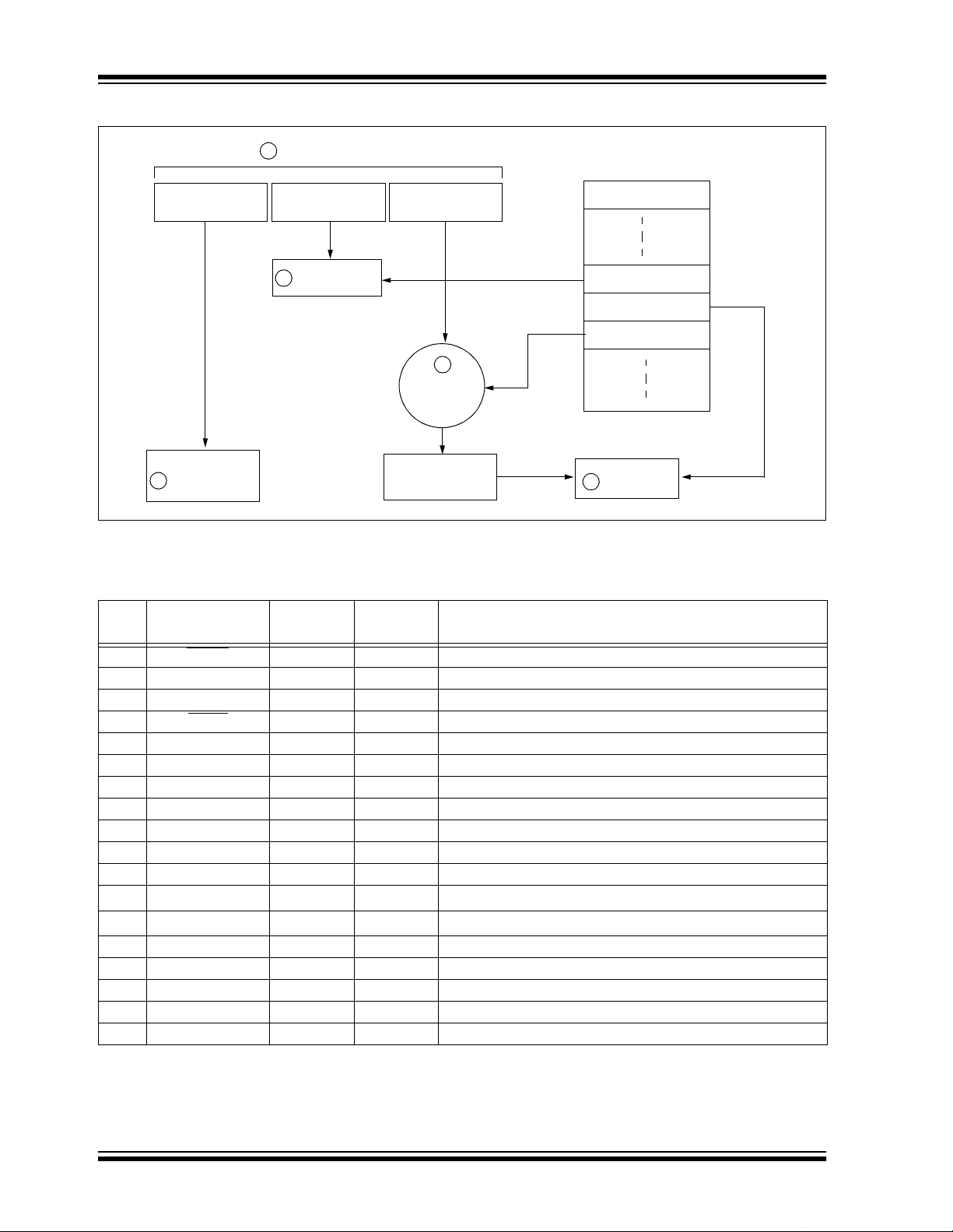

FIGURE 1-3: BASIC OPERATION OF RECEIVER (DECODER)

1

Received Information

Button Press

Information

Serial Number

32 Bits of

Encrypted Data

EEPROM Array

Manufacturer Code

Check for

2

Match

KEELOQ

Decryption

Algorithm

Perform Function

Indicated by

5

button press

NOTE: Circled numbers indicate the order of execution.

Decrypted

Synchronization

Counter

3

Serial Number

Sync Counte r

Crypt Key

Check for

4

Match

2.0 PIN ASSIGNMENT

PIN

1 LRNIN

2 LRNOUT O TTL Learn output - indicates learning

3NC — TTL Do not connect

4MCLR

5 Ground P — Ground connection

6S0 OTTL Switch 0

7S1 OTTL Switch 1

8S2 OTTL Switch 2

9S3 OTTL Switch 3

10 V

11 SLEEP I TTL Connect to RFIN to allow wake-up from SLEEP

12 CLK I/O

13 DATA I/O

14 V

15 OSCOUT (1MHZ) O TTL Oscillator out (test point)

16 OSC

17 NC — —

18 RFIN I TTL RF input from receiver

Note 1: P = power, I = in, O = out, and ST = Schmitt Trigger input.

Decoder

Function

LOW O TTL Battery low indication output

DD P — Power connection

IN (4MHz) I ST Oscillator in – recommended values 4.7 kΩ and 22 pF

2: Pin 12 and Pin 13 have a dual purpose. After RESET, these pins are used to determine if Programming

mode is selected in which case they are the clock and data lines. In normal operation, they are the clock

and data lines of the synchronous data output stream.

(1)

I/O

I TTL Learn input - initiates learning, 10K pull-up required on input

I ST Master clear input

Buffer

Type

TTL/ST

TTL/ST

(1)

(2)

(2)

Description

Clock in Programming mode and Synchronous mode

Data in Programming mode and Synchronous mode

DS40151D-page 4 2002 Microchip Technology Inc.

Page 5

HCS512

3.0 DESCRIPTION OF FUNCTIONS

3.1 Parallel Interface

The HCS512 activates the S3, S2, S1 & S0 outputs

when a new valid code is received. The outputs will be

activated for approxi mat ely 50 0 ms. I f a repeated code

is received during this time, the output extends for

approximately 500 ms.

3.2 Serial Interface

The decoder has a PWM/Synchronous interface connection to microcontrol lers with l imited I/O. An output

data stream is generated when a valid transmission is

received. The data stream consists of one START bit,

four function bits, one bit for battery status, one bit to

indicate a repeated transmission, two status bits, and

one STOP bit. (Table 3-1). The DA T A and CLK line s are

used to send a synchronous event message.

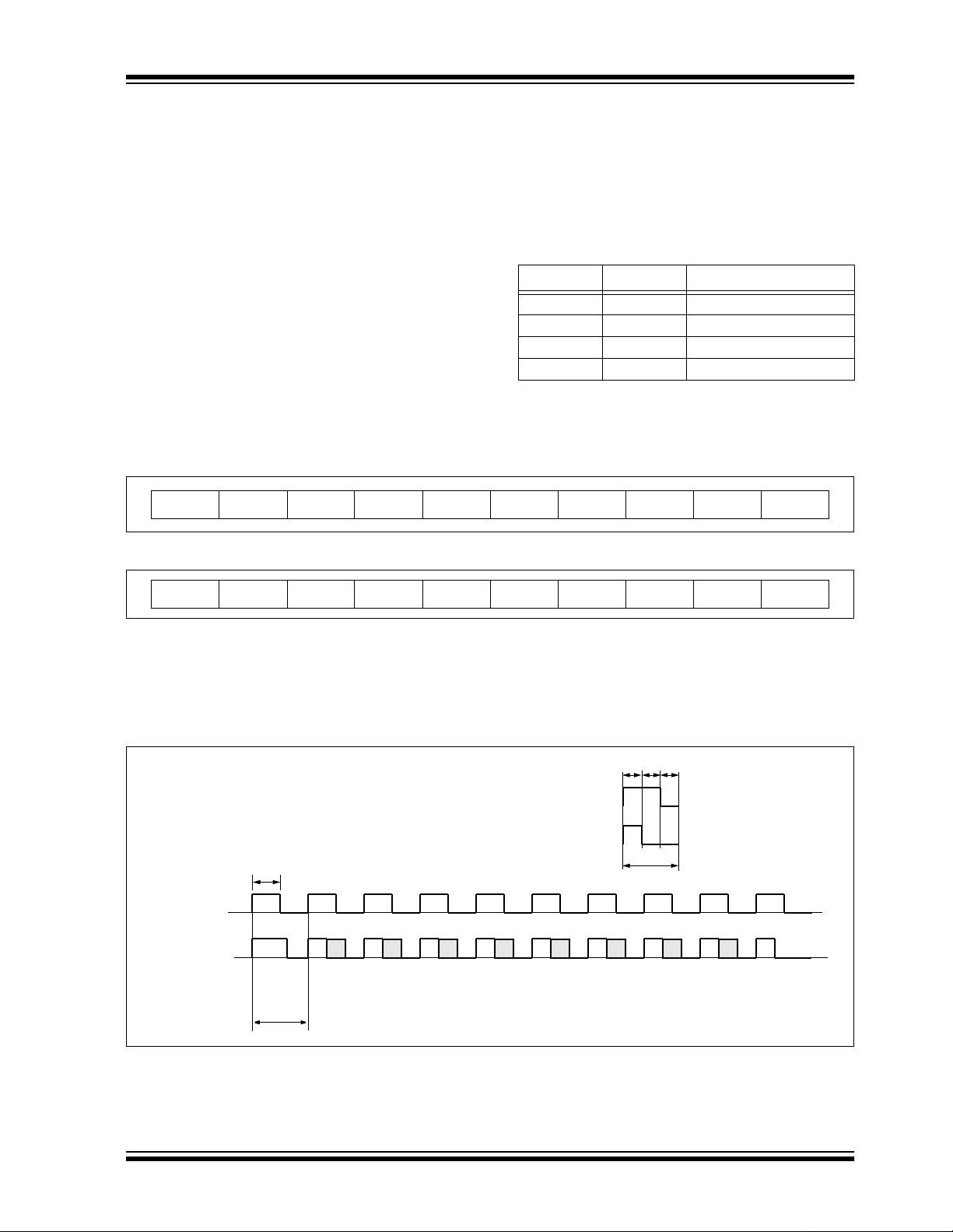

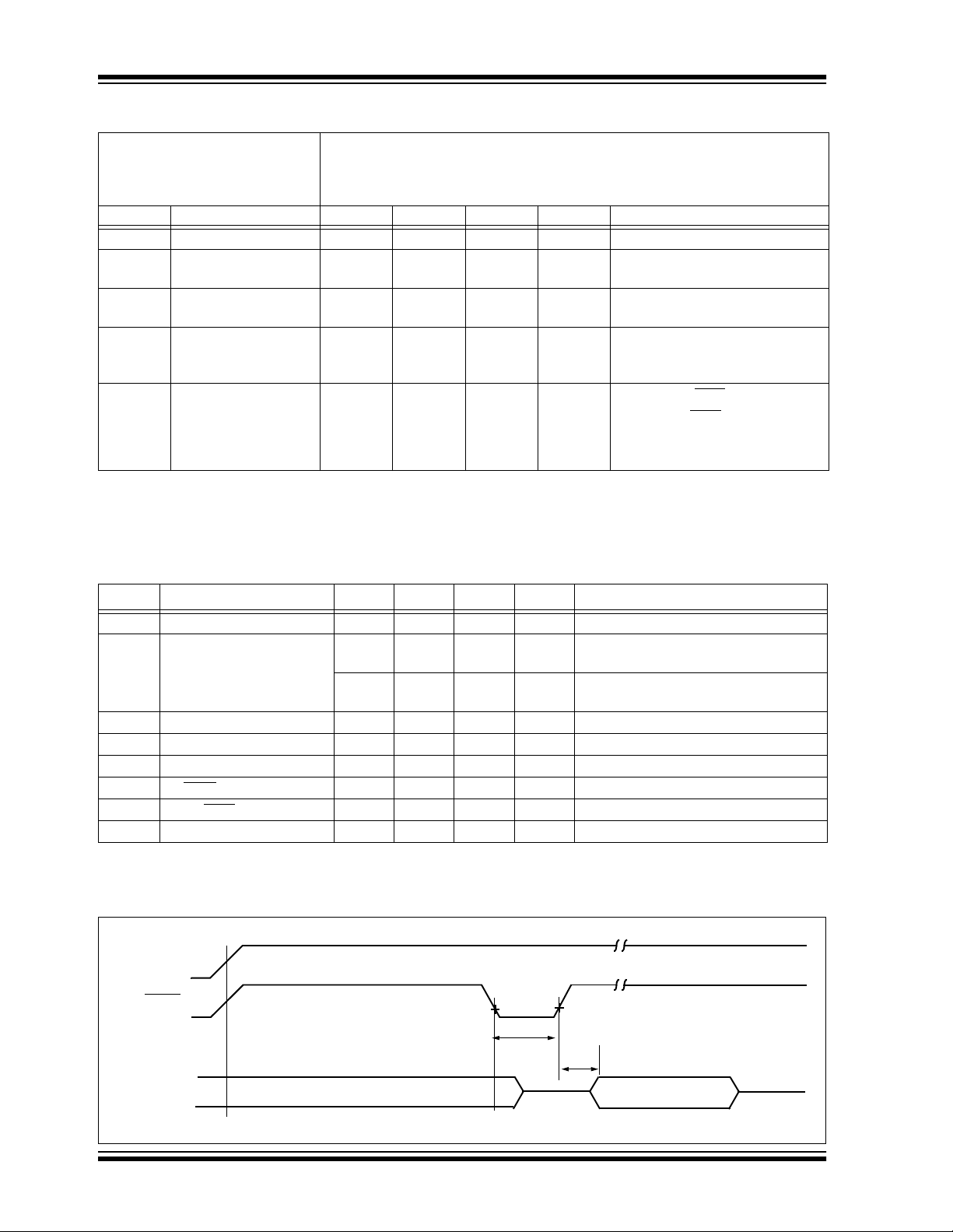

FIGURE 3-1: DATA OUTPUT FORMAT

STARTS3S2S1S0

FIGURE 3-2: STATUS MESSAGE FORMAT

A special statu s mess age is transmitted on the sec on d

pass of learn. Th is al lows th e cont rollin g mic rocont roller to determine if the learn w as successful (R esult = 1)

and if a previous transmitte r was overwritten (Overwri te

= 1). The status message is shown in Figure 3-2.

Table 3-1 show the values for TX1:0 and th e number of

transmitters learned.

TABLE 3-1: STATUS BITS

TX1 TX0 Number of Transmitters

00 One

01 Two

10 Three

11 Four

VLOW

TX1 TX0 STOPREPEAT

START0000

A 1-wire PWM or 2-wire synchronous interface can be used.

In 1-wire mode, the data is transmitted as a PWM signal with a basic pulse width of 400 µs.

In 2-wire mode, Synchronou s mode PWM bit s sta rt on the rising edg e of the clock, an d the bits must be sampl ed on the

falling edge. The START bit is a ‘1’ and the STOP bit is ‘0’.

FIGURE 3-2: PWM OUTPUT FORMAT

600 µs

CLK

DATA

S3START S2 S1 S0 VLOW RPT Reserved Reserved STOP

1200 µs

(1)

RESUL T

TX1 TX0 STOPOVRWR

1/31/31/3

LOGIC “1”

LOGIC “0”

1200 µs

Note: The Decoder output PWM format logic (“1” / “0”) is reversed with respe ct of the Encoder modulat ion format.

2002 Microchip Technology Inc. DS40151D-page 5

Page 6

HCS512

4.0 DECODER OPERATION

4.1 Learning a Transmitter to a

Receiver

Either the serial number-based learning method or the

seed-based learning method can be selected. The

learning method is s elected in t he config uration byte. In

order for a transmitter to be used with a decoder, the

transmitter must f irst be ‘learn ed’. When a transmitte r is

learned to a decoder, the decoder stores the crypt key,

a check value of the serial number and current synchronization value in EEPROM. The decoder must

keep track of these values for every transmitter that is

learned. The maxim um numbe r of trans mitters that can

be learned is four. The decoder must also contain the

Manufacturer’s Code in order to learn a transmitter.

The Manufacturer’s Code will typically be the same for

all decoders in a system.

The HCS512 has four memory slots. After an “erase

all” procedure, all the memory slots will be cleared.

Erase all is activated by taking LRNIN

mately 10 seconds . When a new transm itter is lea rned,

the decoder searches for an empty memory slot and

stores the transmitter’s informati on in that memory slo t.

When all memory slots are full, the decoder randomly

overwrites existing transmitters.

4.1.1 LEARNING PROCEDURE

Learning is activated by taking the LRNIN input low for

longer than 64 ms. Thi s inp ut req uire s an external pullup resistor.

To learn a new transmitter to the HCS512 decoder, the

following sequence is required:

1. Enter Learning mode by pulling LRNIN

longer than 64 ms. The LRNOUT output will go

high.

2. Activate the transmitter until the LRNOUT out-

put goes low indic ating re cepti on of a v alid code

(hopping message).

3. Activate the transmitter a second time until the

LRNOUT toggles for 4 seconds (in Secure

Learning mode, the seed transmission must be

transmitte d dur in g the s eco nd sta ge o f le arn by

activatin g the ap propria te butt ons on t he trans mitter).

If LRNIN

learn status indication, the indication will be terminated. Onc e a succe ssful l earning sequen ce

is detected, the indication can be terminated

allowing quick learning in a manufacturing

setup.

4. The transmitter is no w lea r ned in to t he d ec oder.

5. Repeat steps 1-4 to learn up to four tran smitters.

6. Learning will be terminated if two non-sequential

codes were received or if two acceptable codes

were not decoded within 30 seconds.

is taken low momentarily during the

low for approxi-

low for

The following checks are performed on the decoder to

determine if the transmission is valid during learn:

• The first code word is checked for bit integrit y.

• The second code word is c hec ke d f or b it i nte grit y.

• The hopping code is decrypted.

• If all the checks pass, the serial number and synchronization counters are stored in EEPROM

memory.

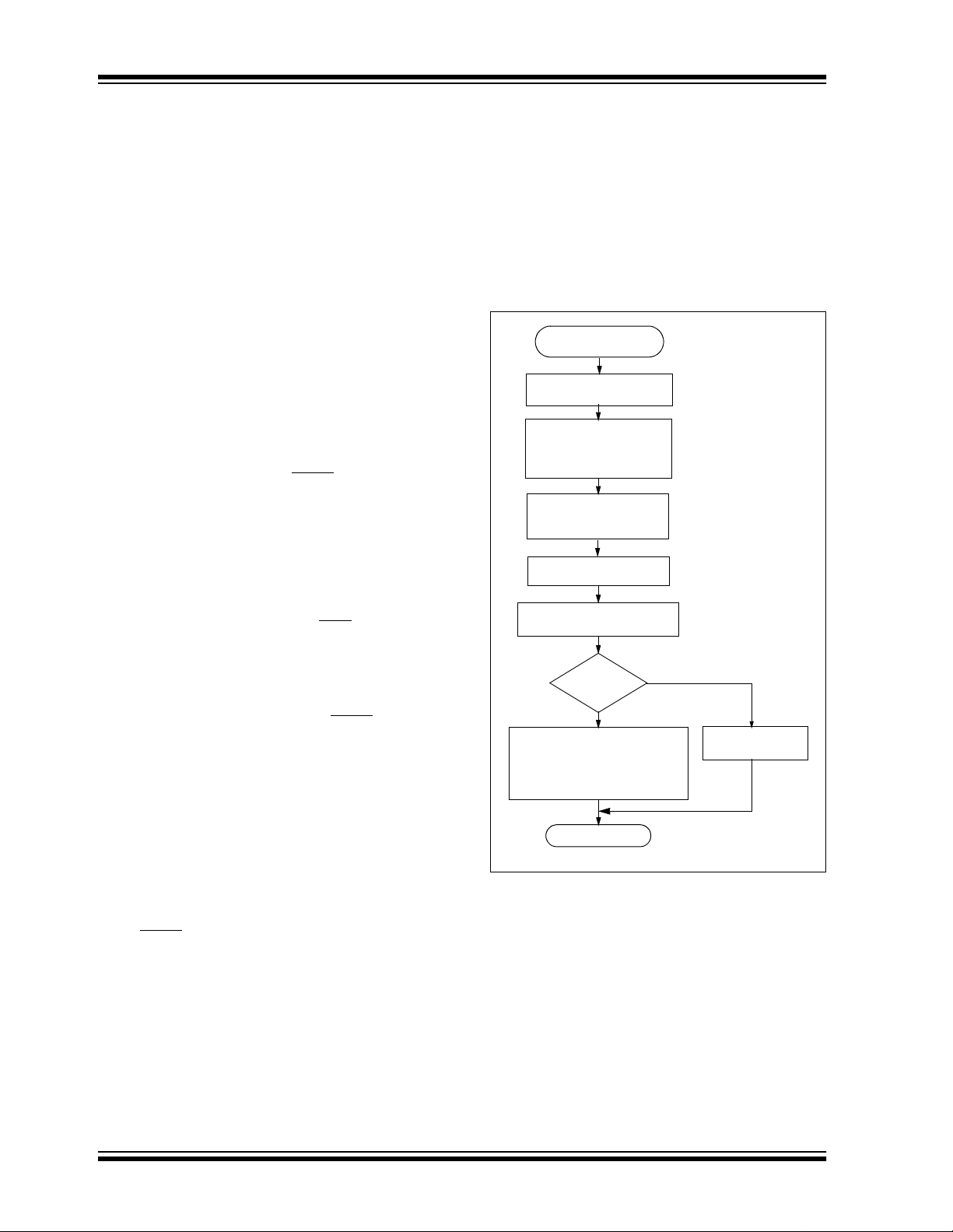

Figure 4-1 shows a flow chart of the learn sequence.

FIGURE 4-1: LEARN SEQUENCE

Enter Learn

Mode

Wait for Reception

of a Valid Code

Wait for Reception

of Second

Non-Repeated

V alid Code

Generate Key

from Serial Number

or Seed Value

Use Generated Key

to Decrypt

Compare Discrimination

Value with Serial Number

Equal

?

Yes

Learn successful. Store:

Serial number check value

Synchronization counter

crypt key

Exit

No

Learn

Unsuccessful

DS40151D-page 6 2002 Microchip Technology Inc.

Page 7

HCS512

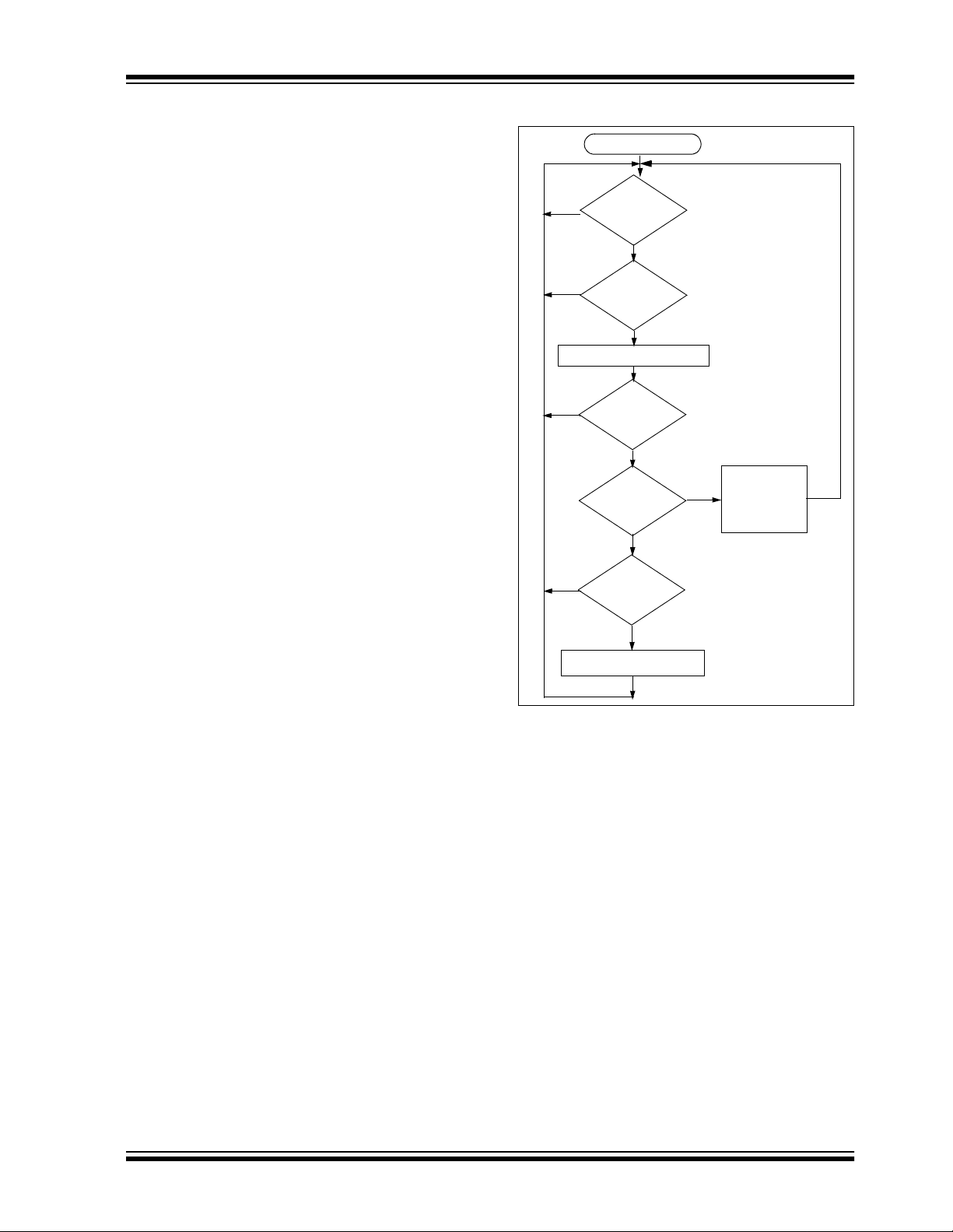

4.2 Validation of Codes

The decoder waits for a transmission and checks the

serial number to determine if the transmitter has been

learned. If learned, the decoder decryp ts the en crypted

portion of t he t rans mis sio n us ing t he cr ypt k ey. It uses

the discrimination bits to determine if the decryption

was valid. If everything up to this point is valid, the

synchronization value is evaluated.

4.3 Validation Steps

Validation consists of the following steps:

• Search EEPROM to find the Serial Number

Check Value Match

• Decrypt the Hopping Code

• Compare the 10 bits of discrimination value with

the lower 10 bits of serial number

• Check if the synchronization counter falls within

the first synchronization window.

• Check if the synchronization counter falls within

the second synchronization window.

• If a valid transmission is found, update the synchronization coun ter , el se use the next t ransmi tter

block and repeat the tests.

FIGURE 4-2: DECODER OPERATION

Start

No

Transmission

Received

?

Yes

No

Decrypt Transmission

No

No

Does

Ser # Check Val

Match

?

Yes

Is

Decryption

Valid

?

Yes

Is

Counter

Within 16

?

No

Is

Counter

Within 32K

?

Yes

Execute

Command

and

Update

Counter

Yes

Save Counter

in Temp Location

2002 Microchip Technology Inc. DS40151D-page 7

Page 8

HCS512

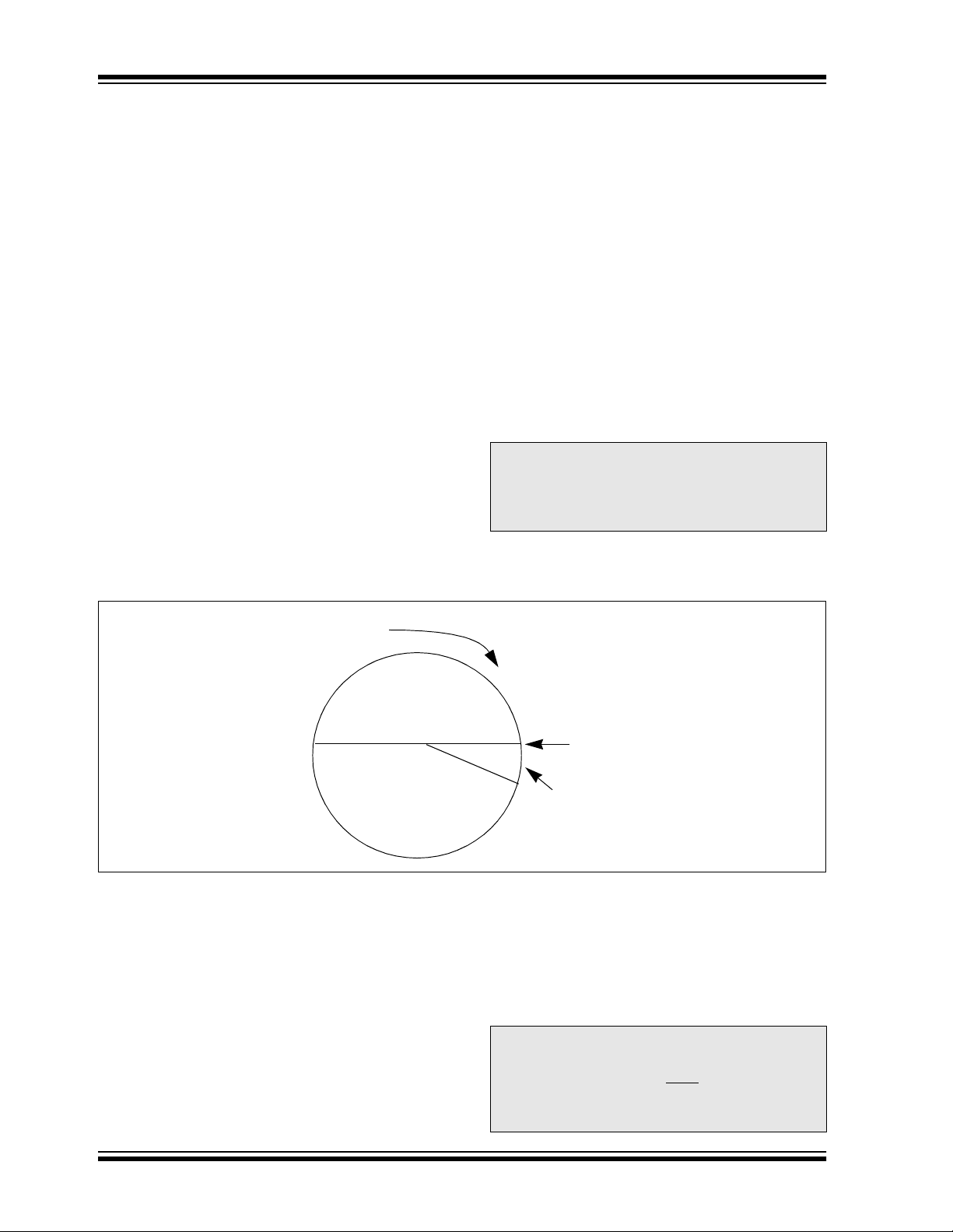

4.4 Synchronization with Decoder

(Evaluating the Counter)

The KEELOQ technology patent scope includes a

sophisticated synchronization technique that does not

require the calculation and s torage of future codes. The

technique sec urely blocks inva lid transmission s while

providing transparent resynchronizat ion to t r ans mi tte rs

inadvertently activated away from the receiver.

Figure 4-3 shows a 3-partition, rotating synchronization

window. The size of each window is optional but the

technique is fundamental. Each time a transmission is

authenticated, the intended function is executed and

the transmission’s synchronization counter value is

stored in EEPROM. From the currently stored counter

value there is an initial "Single Operation" forward window of 16 codes. If the difference between a received

synchronization counter and the last stored counter is

within 16, the intended fun ction wi ll be ex ecuted on the

single button press and the new synchronization

counter will be st ored. Stori ng the new s y nch ron iz atio n

counter value ef fectively rot ates the entire synchronization window.

A "Double Operation" (resynchronization) window further exists from the Si ngle Ope ration wind ow up to 3 2K

codes forward of the currently stored counter value. It

is referred to as "Double Operation" because a transmission with synchronization counter value in this window will require an additional, sequential counter

transmissi on prior to execut ing the intended function.

Upon receiving the sequential transmission the

decoder executes the intended function and stores the

synchroniz ation co unter va lue. Th is resy nchroniz ation

occurs transparently to the user as it is human nature

to press the button a second t ime if the first was un successful.

The third window is a "Blocked Window" ranging from

the double operation window to the currently stored

synchroniz ation counter value. An y transmission with

synchronization counter value within this window will

be ignored. This window excludes previously used,

perhaps code-grabbed transmissions from accessing

the system.

Note: The synchronization method described in

this section is only a typic al implement ation

and because it is usually implemented in

firmware, it can be altered to fit the needs

of a particular system.

FIGURE 4-3: SYNCHRONIZATION WINDOW

Entire Window

rotates to eliminate

use of previously

used codes

Blocked

Window

(32K Codes)

Double Operation

(resynchronization)

Window

(32K Codes)

4.5 SLEEP Mode

The SLEEP mode of the HCS512 is used to reduce

current consumption when no RF input signal is

present. SLEEP mode will only be effective in systems

where the RF re ceiver is relat ively q uiet when no si gnal

is present. During SLEEP, the clock stops, thereby significantly reducing the operating current. SLEEP mode

is enabled by the SLEEP bit in the configuration byte.

The HCS512 will enter SLEEP mode when:

• The RF line is low

• After a function output is switched off

• Learn mode is terminated (time-out reached)

Stored

Synchronization

Counter Value

Single Operation

Window

(16 Codes)

The device will not enter SLEEP mode when:

• A function output is active

• Learn sequence active

• Device is in Programming mode

The device will wake-up from SLEEP when:

• The SLEEP input pin changes state

• The CLOCK line changes state

Note: During SLEEP mode the CLK line will

change from an output line to an input line

that can be used to wake-up the device.

Connect CLK to

to reliably enter the Learn mode whenever

SLEEP mode is active.

LRNIN via a 100K resistor

DS40151D-page 8 2002 Microchip Technology Inc.

Page 9

HCS512

5.0 INTEGRATING THE HCS512 INTO A SYSTEM

The HCS512 can act as a stand-alone decoder or be

interfaced to a microcontroller. Typical stand-alone

applications include garage door openers and electronic door locks. In stand-alone applications, the

HCS512 will handle learning, reception, decryption,

and validation of the received code; and generate the

appropriate output. For a garage door opener, the

HCS512 input will be conne cted t o an RF recei ver, and

the output, to a relay driver to connect a motor controller.

Typical systems where the HCS512 will be connected

to a microcontroller include vehicle and home security

systems. The HCS51 2 input wil l be connect ed to an RF

receiver and the function outputs to the microcontroller.

The HCS512 will hand le all the decod ing fun ctions an d

the microcontroller, all the system functi ons. T he Seria l

Output mode with a 1- or 2-wire interface can be used

if the microcontroller is I/O limited.

6.0 DECODER PROGRAMMING

The PG306001 production programmer will allow easy

setup and programming of the configuration byte and

the manufacturer’s code.

6.1 Configuration Byte

The configuration b yte is used to set sys tem c onfigu ration for the decoder. The LRN bits determine which

algorithm (Decrypt or XOR ) is used for th e key g eneration. SC_LRN determines whether normal learn (key

derived from serial number) or secure learn (key

derived from seed value) is used.

TABLE 6-1: CONFIGURATION BYTE

Bit Name Description

0 LRN0 Learn algorithm select

1 LRN1 Not used

2 SC_LRN Secure Learn enable (1 = enabled)

3 SLEEP SLEEP enable (1 = enabled)

4 RES1 Not used

5 RES2 Not used

6 RES3 Not used

7 RES4 Not used

TABLE 6-2: LEARN METHOD LRN0, LRN1

DEFINITIONS

LRN0 Description

0 Decrypt algorithm

1 XOR algorithm

2002 Microchip Technology Inc. DS40151D-page 9

Page 10

HCS512

6.2 Programming the Manufacturer’s

Code

The manufacturer’s code must be programmed into

EEPROM memory through the synchronous programming interface using the DA T A and CLK lines. Provi sion

must be made for connections to these pins if the

decoder is going to be programmed in circuit.

Programming mode is activated if the CLK is low for at

least 1 ms and then goes high within 64 ms after powerup, stays high for longer than 8 ms but not longer than

128 ms. After entering Programming mode the 64-bit

manufacturer’s code, 8-bit c onfigu rati on byte, and 8-bit

checksum is sent to the device using the synchronous

interface. After receiv ing the 80-bit message th e checksum is verified and the information is written to

EEPROM. If the programming operation was successful, the HCS512 will respond with an Acknowledge

pulse.

After programming the manufacturer’s code, the

HCS512 decoder will automatically activate an

Erase All function, removing all transmitters from the

system.

6.3 Download Format

The manufacturer’s code and configuration byte must

be downloaded Least Significant Byte, Least Significant bit first as shown in Table 6-3.

6.4 Checksum

The checksum is used by the HCS512 to check that the

data downloaded was correctly received before programming the dat a. The check sum is calcul ated so that

the 10 bytes added together (discarding the overflow

bits) is zero. The checksum can be calculated by adding the first 9 bytes of dat a togethe r and sub tracting th e

result from zero. Throughout the calculation the overflow is discarded.

Given a manufacturer’s code of 0123456789ABCDEF

checksum is calculated as shown in Figure 6-1. The

checksum is 3F16.

and a Configuration Word of 116, the

16

6.5 Test Transmitter

The HCS512 decoder will automatically add a test

transmitter each time an Erase All Function is done. A

test transmitter is defined as a transmitter with a serial

number of zero. After an Erase All, the test transmitter

will always work without l earning and will not c heck th e

synchronization counter of the transmitter. Learning of

any new transmitters will erase the test transmitter.

Note 1: A transmitter with a serial number o f ze ro

cannot be learned. Learn will fail after the

first transmission.

2: Always learn at least one transmitter aft er

an Erase All sequence. This ensures that

the test transmitter is erased.

TABLE 6-3: DOWNLOAD DATA

Byte 9 Byte 8 Byte 7 Byte 6 Byte 5 Byte 4 B yte 3 Byte 2 Byte 1 Byte 0

Check-

sum

Config

Man

Key_7

Man

Key_6

Man

Key_5

Man

Key_4

Man

Key_3

Byte 0, right-most bit downloaded first.

Man

Key_2

Man

Key_1

FIGURE 6-1: CHECKSUM CALCULATION

0116 + 2316 = 24

2416 + 4516 = 69

6916 + 6716 = D0

D016 + 8916 = 159

5916 + AB16 = 10416 (Carry is discarded)

+ CD16 = D116 (Carry is discarded)

04

16

+ EF16 = 1C0

D1

16

C016 + 116 = C116 (Carry is discarded)

- C116) + 116 = 3F

(FF

16

6

16

16

16

16

16

Man

Key_0

DS40151D-page 10 2002 Microchip Technology Inc.

Page 11

FIGURE 6-2: PROGRAMMING WAVEFORMS

MCLR

T

CKL

Bit1Bit0 Bit78 Bit79

CLK

(Clock)

DAT

(Data)

T

PS

T

PH1

Enter Program Mode

T

PH2

T

CKH

80-bit Data Package

T

ACK

Acknowledge

HCS512

T

ACKH

Ack

pulse

TABLE 6-4: PROGRAMMING TIMING REQUIREMENTS

Parameter Symbol Min. Max. Units

Program mode setup time TPS 1 64 ms

Hold time 1 TPH1 8 128 ms

Hold time 2 TPH2 0.05 320 ms

Clock High Time TCKH 0.05 32 0 ms

Clock Low Time TCKL 0.050 320 ms

Acknowledge Time TACK —80ms

Acknowledge duration TACKH 1 — ms

Note: FOSC equals 4 MHz.

2002 Microchip Technology Inc. DS40151D-page 11

Page 12

HCS512

7.0 KEY GENERATION SCHEMES

The HCS512 decode r h as tw o k ey g ene rati on sc he me s. N orm al l earn ing u se s the tra ns mitter’s serial number to de riv e

two input seeds which are used as inputs to the key generation algorithm. Secure learning uses the seed transmission

to derive the two input seeds. Two key generation algorithms are available to convert the inputs seeds to secret keys.

The appropriate scheme is selected in the Configuration Word.

FIGURE 7-1:

Serial

Number

Manufacturer’s

Key

Seed

Patched

Key Generation

Algorithms

------------------Decrypt

XOR

Encoder

Key

7.1 Normal Learning (Serial Number Derived)

The two input seeds are composed from the serial number in two ways, depending on the encoder type. The encoder

type is determine d from th e numb er of bit s in the inc oming tran smis sion. SourceH is used to calc ulate the upp er 32 bits

of the crypt key, and SourceL, for the lower 32 bits.

For 28-bit serial number encoders (66 / 67-bit transmissions):

SourceH = 6H + 28 bit Serial Number

SourceL = 2H + 28 bit Serial Number

7.2 Secure Learning (Seed Derived)

The two input seeds are c om pos ed fr om the s eed val ue th at is tran sm itted during secure lear ni ng. Th e lo w er 32 b it s of

the seed transmission is used to compose the lower seed, and the upper 32 bits, for the upper seed. The upper 4 bits

(function code) are set to zero.

For 32-bit seed encoders:

SourceH = Serial Number

SourceL = Seed

32 bits

Lower 28 bits

(with upper 4 bits always zero)

For 48-bit seed encoders:

SourceH = Seed

SourceL = Seed

Upper 16 bits

Lower 32 bits

+ Serial Number

Upper 16 bits

(with upper 4 bits always zero) << 16

For 60-bit seed encoders:

SourceH = Seed

SourceL = Seed

DS40151D-page 12 2002 Microchip Technology Inc.

Upper 28 bits

Lower 32 bits

(with upper 4 bits always zero)

Page 13

HCS512

7.3 Key Generation Algorithms

There are two key generation algorithms implemented in the HCS512 decoder. The KEELOQ decryption algorithm provides a higher level of s ecurity th an the XOR alg orithm. Section 6.1 describes the se lectio n of the algo rithms in th e configuration byte.

7.3.1 KEELOQ DECRYPT ALGORITHM

This algorithm uses the KEELOQ decryption algorithm and the manufacturer’s code to derive the crypt key as follows:

Key

Upper 32 bits

Key

Lower 32 bits

7.3.2 XOR WITH THE MANUFACTURER’S CODE

The two 32-bits seeds are XOR with the manufacturer’s code to form the 64 bit crypt key.

Key

Upper 32 bits

Key

Lower 32 bits

After programming the manufacturer’s code, the HCS512 decoder will automatically activate an Erase All function,

removing all transmitters from the system.

If LRNIN

learning sequence is detected, the indication can be terminated, allowing quick learning in a manufacturing setup.

FIGURE 7-2: HCS512 KEY GENERATION

= Decrypt (SourceH)

= Decrypt (SourceL)

= SourceH XOR Manufacturers Code

= SourceL XOR Manufacturers Code

64 Bit Manufacturers Code

64 Bit Manufacturers Code

Upper 32 bits

Lower 32 bits

is taken low moment arily du ring the learn st atus indica tion, the indica tion will be term inated. Once a su ccessful

Normal Learn (SC_LRN = 0)

Padding

2

Padding

6

Padding

0000b

Padding

0000b

28-bit Serial Number

28-bit Serial Number

Secure Learn (SC_LRN = 1)

LS 32 bits of Seed Transmission

MS 28 bits of Seed Transmission

Secure Learn XOR (SC_LRN = 1)

LS 32 bits of Seed Transmission

MS 28 bits of Seed Transmission

LRN0 = 0

KEELOQ

Decryption

Algorithm

LRN0 = 0

KEELOQ

Decryption

Algorithm

LRN0 = 1

XOR

LS 32 bits of crypt key

MS 32 bits of crypt key

LS 32 bits of crypt key

MS 32 bits of crypt key

LS 32 bits of crypt key

MS 32 bits of crypt key

2002 Microchip Technology Inc. DS40151D-page 13

Page 14

HCS512

8.0 KEELOQ ENCODERS

8.1 Transmission Format (PWM)

The KEELOQ encoder transmission is made up of sev-

eral parts (Figure 8-1). Each transmission begins with

a preamble and a header, followed by the encrypted

and then the fixed data. The actual data is 66/69 bits

which consists of 32 bits of encrypted data and 34/37

bits of non-enc rypted data. Each transmis sion is followed by a guard period before another transmission

can begin. The encrypted portion provides up to four

billion changing code combinations and includes the

button status bits (based on which buttons were activated) along with the synchronization counter value

and some discrimination bits. The non-encrypted portion is comprised of the status bits, the function bits,

FIGURE 8-1: TRANSMISSION FORMAT (PWM)

and the 28-bit serial number. The encrypted and nonencrypted combined sections increase the number of

combinations to 7.38 x 10

19

.

8.2 Code Word Organization

The HCSXXX encoder transmit s a 66/69- bit co de word

when a button is pressed. The 66/69-bit word is constructed from an encryption portion and a nonencrypted code portion (Figure 8-2).

The Encrypted Data is gen erated from four button bit s,

two overflow counter bits, ten discrimination bits, and

the 16-bit synchronization value.

The Non-encrypted Data is made up from 2 status

bits, 4 function bits, and the 28/32-bit serial number.

TETET

LOGIC "0"

LOGIC "1"

E

T

BP

Preamble

50%

10xTE

Header

FIGURE 8-2: CODE WORD ORGANIZATION

34 bits of Fixe d Portion 32 bits of Encrypted Portion

MSb

MSb

Repeat

(1-bit)

Repeat

(1-bit)

VLOW

(1-bit)

Button

Status

S2 S1 S0 S3

V

LOW

(1-bit)

Button

Status

1 1 1 1

SEED replaces Encrypted Portion when all button inputs are activated at the same time.

Serial Number

(28 bits)

Serial Number

(28 bits)

Encrypted

Portion

Button

Status

S2 S1 S0 S3

Portion

OVR

(2 bits)

Fixed Code

DISC

(10 bits)

SEED

(32 bits)

Guard

Time

Sync Counter

(16 bits)

66 Data bits

Transmitted

LSb first.

LSb

LSb

DS40151D-page 14 2002 Microchip Technology Inc.

Page 15

HCS512

9.0 ELECTRICAL CHARACTERISTICS FOR HCS512

Absolute Maximum Ratings †

Ambient temperature under bias.............................................................................................................-55°C to +125°C

Storage temperature...............................................................................................................................-65°C to +150°C

Voltage on any pin with respect to

Voltage on

VDD with respect to Vss...................................... ...... ...... ..... ...... ..... ........................................ ..........0 to +7.5V

Total power dissipation (Note 1) ..........................................................................................................................800 mW

Maximum current out of

Maximum current into

Input clamp current, Iik (

VSS pin.............................................................................................................................150 mA

VDD pin................................................................................................................................100 mA

VI < 0 or VI > VDD).................................................. ..... ...... ...... ....................................... ..± 20 mA

Output clamp current, IOK (V

Maximum output current sunk by any I/O pin..........................................................................................................25 mA

Maximum output current sourced by any I/O pin....................................................................................................20 mA

Note: Power dissipation is calculated as follows: Pdis = V

† NOTICE: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stress rating only and functional operation of the device at those or any other conditions above

those indicated in the ope ration listi ngs of this speci fication is not implied. Exposure to maxim um rating co nditions for

extended periods may affect device reliability.

VSS (except VDD) ............................................................................ -0.6V to VDD +0.6V

O < 0 or VO >VDD) ........................................................................... ...... ...................± 20 mA

DD x {IDD - ∑ IOH} + ∑ {(VDD–VOH) x IOH} + ∑(VOl x IOL)

2002 Microchip Technology Inc. DS40151D-page 15

Page 16

HCS512

TABLE 9-1: DC CHARACTERISTICS

Standard Operating Conditions (unless otherwise stated)

Operating temperature

Commercial (C): 0°C ≤ TA ≤ +70°C for commercial

Industrial (I): -40°C ≤ T

Symbol Characteristic Min Typ

DD Supply Voltage 4.0 —6.0V

V

VPOR VDD start voltage to

—VSS —V

(†)

ensure RESET

S

VDD VDD rise rate to

0.05* — — V/ms

ensure RESET

DD Supply Current —

I

—

1.8

7.3

15

VIL Input Low Voltage VSS —0.16 VDD Vexcept MCLR = 0.2 VDD

VIH Input High Voltage 0.48 VDD —VDD Vexcept MCLR = 0.85 VDD

VOL Output Low Voltage — — 0.6 V IOL = 8.5 mA, VDD = 4.5V

VOH Output High Voltage VDD-0.7 — — V IOH = -3.0 mA, VDD = 4.5V

† Data in “Typ” column is at 5.0V, 25°C unless otherwise stated. These parameters are for design guidance only

and are not tested.

* These parameters are characterized but not tested.

Note: Negative current is defined as coming out of the pin.

A ≤ +85°C for industrial

Max U nits Conditions

4.5

10

32

mA

mA

µA

FOSC = 4 MHz, VDD = 5.5V

(During EEPROM programming)

In SLEEP mode

TABLE 9-2: AC CHARACTERISTICS

Symbol Characteristic Min Typ Max Units Conditions

OSC Oscillator frequency 2.7 4 6.21 MHz REXT = 10K, CEXT = 10 pF

F

65 — 1080 µs 4.5V < VDD < 5.5V

E

T

PWM elemental

pulse width

130 — 1080 µs 3V < V

Oscillator components tolerance < 6%.

DD < 6V

Oscillator components tolerance <10%

T

OD Output delay 70 90 115 ms

TA Output activation time 322 500 740 ms

RPT REPEAT activation time 32 50 74 ms

T

TLRN LRNIN activation time 21 32 — ms

TMCLR MCLR low time 150 — — ns

OV Time output valid — 150 222 ms

T

* These parameters are characterized but not tested.

FIGURE 9-1: RESET WATCHDOG TIMER, OSCILLATOR START-UP TIMER AND POWER-UP

TIME R TIMI NG

VDD

MCLR

TMCLR

TOV

I/O Pins

DS40151D-page 16 2002 Microchip Technology Inc.

Page 17

2002 Microchip Technology Inc. DS40151D-page 17

RFIN

S[3,2,1,0]

1 Code Word 50 ms

TOD

FIGURE 9-2: OUTPUT ACTIVATION

Note 1

TA

VLOW

TA

LRNOUT

0s 1s 2s 3s 4s 5s

Note 2

Note 1: Output is activated as long as code is received.

2: Output is activated if battery low (

VLOW) is detected.

HCS512

Page 18

DS40151D-page 18 2002 Microchip Technology Inc.

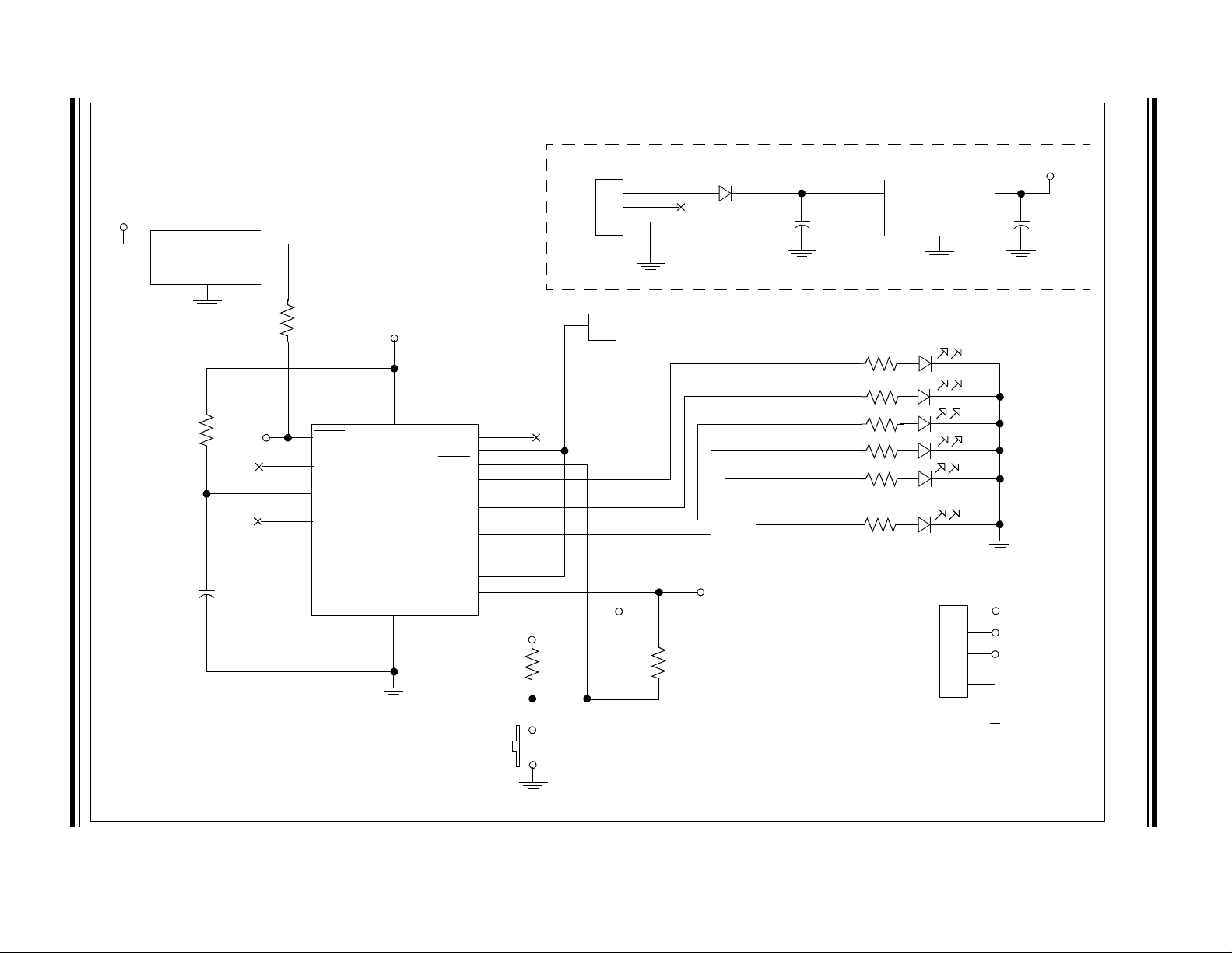

FIGURE 9-3: TYPICAL DECODER APPLICATION CIRCUIT

HCS512

MCP100-450

V

DD

LOW VOLTAGE DETECTOR—DO NOT OMIT

G

VI

VO

N

D

10K

P2

4.7K

4

MCLR

3

NC

16

OSC

15

OSCOUT

IN

22 pF

HCS512

VDD

V

G

VDD

100 µF

12V

GND

LM7805

1

2

3

1N4004/7

100 µF

VI

VO

G

N

D

POWER SUPPLY

RECEIVE DATA INPUT

1

1K

1K

14

17

NC

18

D

D

N

D

5

RFIN

LRNIN

LRNOUT

S0

S1

S2

S3

VLOW

SLEEP

CLK

DAT

1

2

6

7

8

9

10

11

12

13

DD

10K

P4

100K

V

P3

1K

1K

1K

1K

DATA

CLOCK

RESET

LRNOUT

S0

S1

S2

S3

VLOW

P4

P3

P2

GND P1

LEARN

BUTTON

In-Circuit

Programming Pads

Page 19

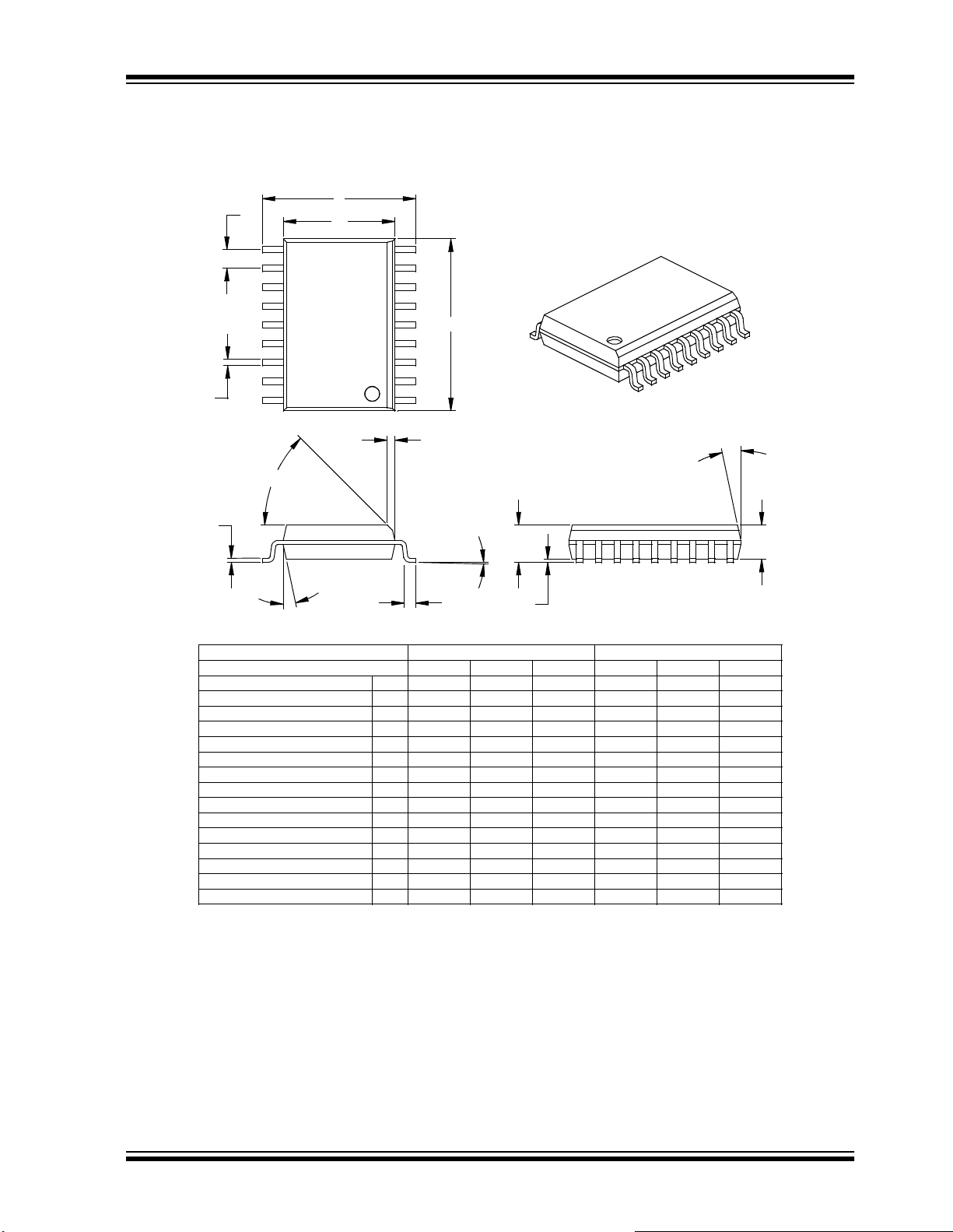

10.0 PACKAGING INFORMATION

10.1 Package Marking Information

18-Lead PDI P (300 mil) Example

HCS512

XXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXX

YYWWNNN

18-Lead SOIC (300 mil) Example

XXXXXXXXXXXX

XXXXXXXXXXXX

XXXXXXXXXXXX

YYWWNNN

Legend: XX...X Customer specific information*

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

HCS512

HCS512

/SO

0110017

01 10 017

Note: In the event the full Microchip part number can not be ma rked on one line, it will

be carried over to the next l ine thus lim it ing t he nu mb er of av ai lab le cha r ac ters

for customer specific information.

* Standard PICmicro device marking consists of Microchip part number, year code, week code, and

traceability code. For PICmicro device marking beyond this, certain price adders apply. Please check

with your Microchip Sales Office. For QTP devices, any special marking adders are included in QTP

price.

2002 Microchip Technology Inc. DS40151D-page 19

Page 20

HCS512

10.2 Package Details

18-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

D

2

n

1

α

E

A

c

A1

β

eB

Number of Pins

Pitch

Lead Thickne ss

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-007

n

p

c

α

β

B1

B

0.38.015A1Base to Seating Plane

p

MILLIMETERSINCHES*Units

2.54.100

A2

L

MAXNOMMINMAXNOMMINDimension Limits

1818

4.323.943.56.170.155.140ATop to Seating Plane

3.683.302.92.145.130.115A2Molded Package Thickness

8.267.947.62.325.313.300EShoulder to Shoulder Width

6.606.356.10.260.250.240E1Molded Package Width

22.9922.8022.61.905.898.890DOverall Length

3.433.303.18.135.130.125LTip to Seating Plane

0.380.290.20.015.012.008

1.781.461.14.070.058.045B1Upper Lead Width

0.560.460.36.022.018.014BLower Lead Width

10.929.407.87.430.370.310eBOverall Row Spacing §

1510515105

1510515105

DS40151D-page 20 2002 Microchip Technology Inc.

Page 21

18-Lead Plastic Small Outline (SO) – Wide, 300 mil (SOIC)

HCS512

p

B

n

°

45

c

β

E1

E

D

2

1

h

A

φ

L

A1

α

A2

MILLIMETERSINCHES*Units

A2

n

p

φ

c

α

β

048048

1.27.050

Number of Pins

Pitch

Molded Package Thickness

Foot Angle

Lead Thickne ss

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-013

Drawing No. C04-051

MAXNOMMINMAXNOMMINDimension Limits

1818

2.642.502.36.104.099.093AOverall Height

2.392.312.24.094.091.088

0.300.200.10.012.008.004A1Standoff §

10.6710.3410.01.420.407.394EOverall Width

7.597.497.39.299.295.291E1Molded Package Width

11.7311.5311.33.462.454.446DOverall Length

0.740.500.25.029.020.010hChamfer Distance

1.270.840.41.050.033.016LFoot Length

0.300.270.23.012.011.009

0.510.420.36.020.017.014BLead Width

1512015120

1512015120

2002 Microchip Technology Inc. DS40151D-page 21

Page 22

HCS512

ON-LINE SUPPORT

Microchip provides on-line support on the Microchip

World Wide Web (WWW) site.

The web site is used b y Micr ochip as a means to mak e

files and information easily available to customers. To

view the site, the use r must hav e access to the Intern et

and a web browser, such as Netscape or Microsoft

Explorer. Files are also available for FTP download

from our FTP site.

Connecting to the Microchip Internet Web Site

The Microchip web site is available by using your

favorite Internet browser to attach to:

www.microchip.com

The file transfer site is available by using an FTP service to connect to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of

services. Users may download files for the latest

Development Tools, Data Sheets, Application Notes,

User’s Guides, Articles and Sample Programs. A variety of Micr ochip specific bu siness informati on is also

available, including listings of Microchip sales offices,

distributors and factory representatives. Other data

available for consideration is:

• Latest Microchip Press Releases

• Technical Support Section with Frequently Asked

Questions

• Design Tips

• Device Errata

• Job Postings

• Microchip Consultant Program Member Listing

• Links to other useful web sites related to

Microchip Products

• Conferences for products , Development System s,

technical information and more

Listing of seminars and events

Systems Information and Upgrade Hot Line

The Systems Information and Upgrade Line provides

system users a listing of the latest versions of all of

Microchip's development systems software products.

Plus, this line provides information on how customers

can receive any currently available upgrade kits.The

Hot Line Numbers are:

1-800-755-2345 for U.S. and most of Canada, and

1-480-792-7302 for the rest of the world.

DS40151D-page 22 2002 Microchip Technology Inc.

Page 23

HCS512

READER RESPONSE

It is our intentio n t o provide you with the bes t doc um entation possible to en sure successful use of y our Microchip product. If you wish to pro vide your comm ents on org aniza tion, c larity, subject matter, and ways in which our doc umenta tion

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this Data Sheet.

To:

RE: Reader Response

From:

Application (optional):

Would you like a reply? Y N

Device:

Questions:

1. What are the best features of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this data sheet easy to follow? If not, why?

Technical Publications Manager

Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________

HCS512

Literature Number:

Total Pages Se nt

FAX: (______) _________ - _________

DS40151D

4. What additions to the data sheet do you think would enhance the structure and subject?

5. What deletions from the data sheet could be made without affecting the ov erall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

8. How would you improve our software, systems, and silicon products?

2002 Microchip Technology Inc. DS40151D-page 23

Page 24

HCS512

HCS512 PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

HCS512 — /P

Package:

P = Plastic DIP (300 mil Body), 18-lead

SO = Plastic SOIC (300 mil Body), 18-lead

Temperature

Range:

Device:

Blank = 0°C to +70°C

I =-40°C to +85°C

HCS512 Code Hopping Decoder

HCS512T Code Hopping Decoder (Tape and Reel)

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

DS40151D-page 24 2002 Microchip Technology Inc.

Page 25

Microchip’s Secure Data Products are covered by some or all of the following patents:

Code hopping encoder patents issued in Europe, U.S.A., and R.S.A. — U.S.A.: 5,517,187; Europe: 0459781; R.S.A.: ZA93/4726

Secure learning patents issued in the U.S.A. and R.S.A. — U.S.A.: 5,686,904; R.S.A.: 95/5429

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, FilterLab,

K

EELOQ, MPLAB, PIC, PICmicro, PICMASTER, PICSTART,

PRO MATE, SEEVAL and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

dsPIC, ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, microID,

microPort, Migratable Memory, MPASM, MPLIB, MPLINK,

MPSIM, MXDEV, PICC, PICDEM, PICDEM.net, rfPIC, Select

Mode and Total Endurance are trademarks of Microchip

Technology Incorporated in the U.S . A.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwid e head qu art ers,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999. The

Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs and microperipheral

products. In addition, Microchip’s quality

system for the design and manufacture of

development systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hoppin g

2002 Microchip Technology Inc. DS40151D - page 25

Page 26

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640 -03 07

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692 -38 21

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818 -29 24

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263 -13 38

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273 -53 35

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436 -79 55

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-6766200 Fax: 86-28-6766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Of fice

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1315, 13/F, Shenzhen Kerry Centre,

Renminnan Lu

Shenzhen 518001, China

Tel: 86-755-2350361 Fax: 86-755-2366086

Hong Kong

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama- shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-334- 8870 Fax: 65-334-8850

Taiwan

Microchip Technology Taiwan

11F-3, No. 207

Tung Hua North Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Denmark

Microchip Technology Nordic ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Microchip Technology GmbH

Gustav-Heinemann Ring 125

D-81739 Munich, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

United Kingdom

Arizona Microchip Technology Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG41 5TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

01/18/02

DS40151D-page 26 2002 Microchip Technology Inc.

Loading...

Loading...