Page 1

查询HCS473供应商

HCS473

Data Sheet

Code Hopping Encoder and Transponder

2002 Microchip Technology Inc. Preliminary DS40035C

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, K

EELOQ,

MPLAB, PIC, PICmicro, PICSTART and PRO MATE are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

FilterLab, microID, MXDEV, MXLAB, PICMASTER, SEEVAL

and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

dsPIC, dsPICDEM.net, ECONOMONITOR, FanSense,

FlexROM, fuzzyLAB, In-Circuit Serial Programming, ICSP,

ICEPIC, microPort, Migratable Memory, MPASM, MPLIB,

MPLINK, MPSIM, PICC, PICDEM, PICDEM.net, rfPIC, Select

Mode and Total Endurance are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

DS40035C - page ii Preliminary 2002 Microchip Technology Inc.

Page 3

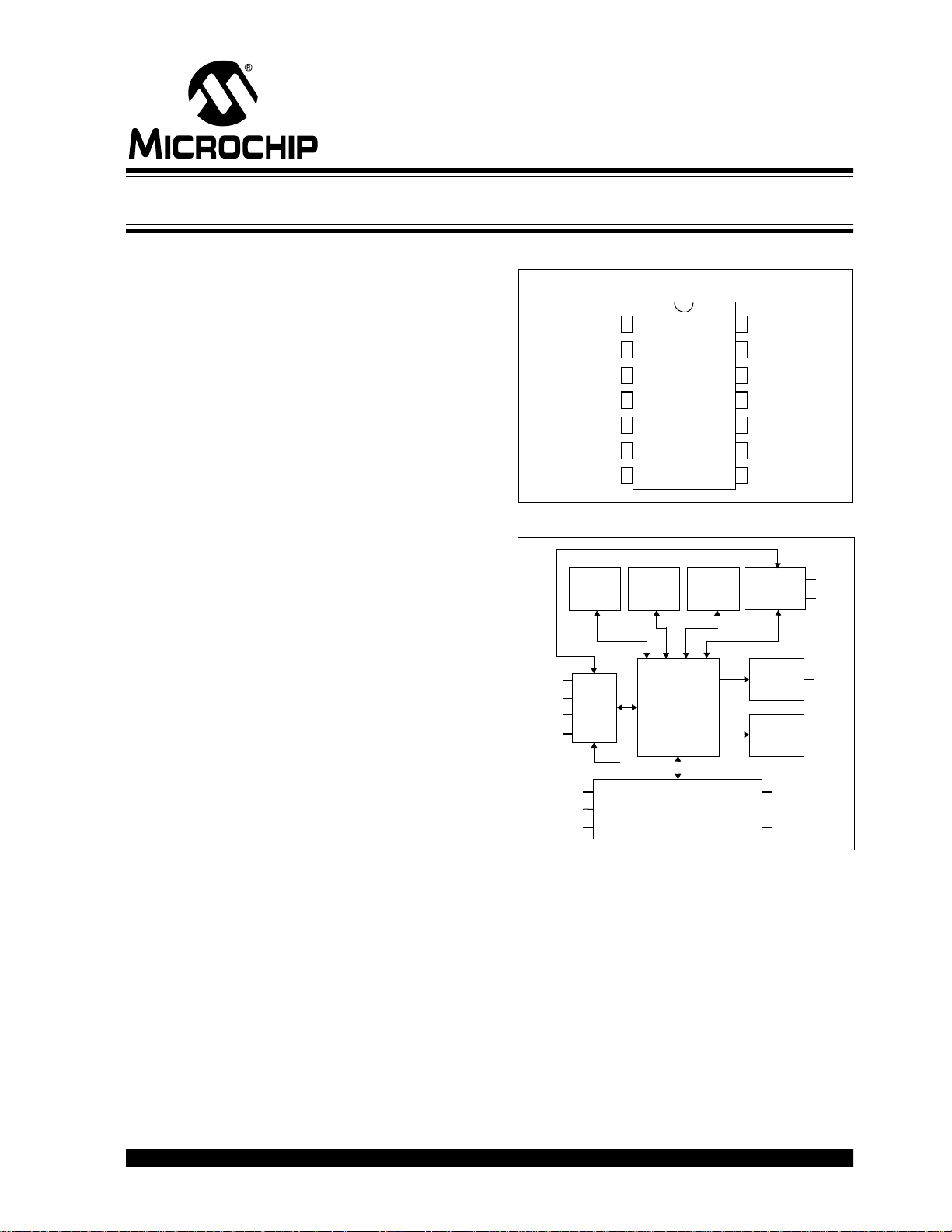

HCS473

KEELOQ® 3-Axis Transcoder

FEATURES

Encoder Security

• Read protected 64-bit encoder key

• 69-bit transmission length

• 60-bit, read protected seed for secure learning

• Programmable 32-bit serial number

• Non-volatile 16/20-bit synchronization counter

Encoder Operation

• 2.05V to 5.5V operation

• Four switch inputs – up to 15 functions codes

• PWM or Manchester modulation

• Selectable Baud Rate (416 - 5,000 bps)

• Transmissions include button queuing information

• PLL interface

Transponder Security

• 2 read protected 64-bit Challenge/Response keys

• Two IFF encryption algorithms

• 16/32-bit Challenge/Response

• Separate Vehicle ID and Token ID

• 2 vehicles supported

• CRC on all communication

Transponder Operation

Package Types

PDIP, SOIC

S0

S1

S2

S3/RFEN

VDDT

LCX

LCY

Block Diagram

Low

Voltage

Detector

S0

S1

Wake-up

Control

S2

S3/

RFEN

1

2

3

4

5

6

7

Internal

Oscillator

Control

HCS473

Logic

14

13

12

11

10

9

8

EEPROM

V

DD

LED

DATA

V

SS

V

SST

LCCOM

LCZ

RESET and

Power

Control

LED

Driver

Data

Output

V

DD

V

SS

LED

DATA

• Three sensitive transponder inputs

• Bi-directional transponder communication

• Transponder in/RF out operation

LCX

LCY

LCZ

3 Input Transponder

Circuitry

V

DDT

LCCOM

V

SST

• Anticollision of multiple transponders

• Intelligent damping for high Q-factor LC-circuits

• Low battery operation

• Passive proximity activation

• 64-bit secure user EEPROM

• Fast reaction time

Typical Applications

• Passive entry systems

• Automotive remote entry systems

• Automotive alarm systems

• Automotive immobilizers

Peripherals

• Low Voltage Detector

• On-board RC oscillator with ±10% variation

• Gate and garage openers

• Electronic door locks (Home/Office/Hotel)

• Burglar alarm systems

• Proximity access control

• Passive proximity authentication

2002 Microchip Technology Inc. Preliminary DS40035C-page 1

Page 4

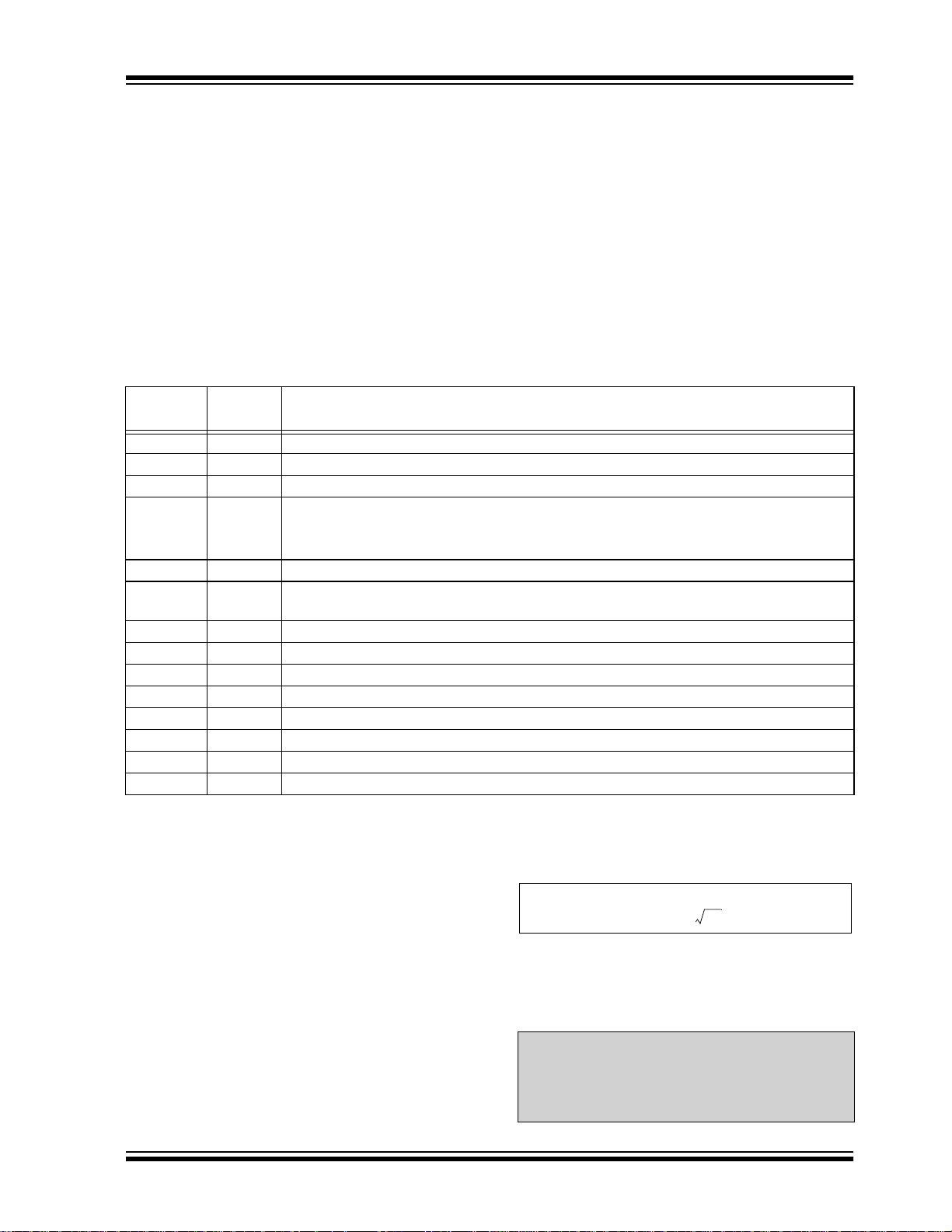

HCS473

Table of Contents

1.0 General Description ..................................................................................................................................................................... 3

2.0 Device Description ...................................................................................................................................................................... 5

3.0 Device Operation ....................................................................................................................................................................... 11

4.0 Programming Specification ....................................................................................................................................................... 37

5.0 Integrating the HCS473 Into A System ..................................................................................................................................... 39

6.0 Development Support................................................................................................................................................................. 43

7.0 Electrical Characteristics ........................................................................................................................................................... 49

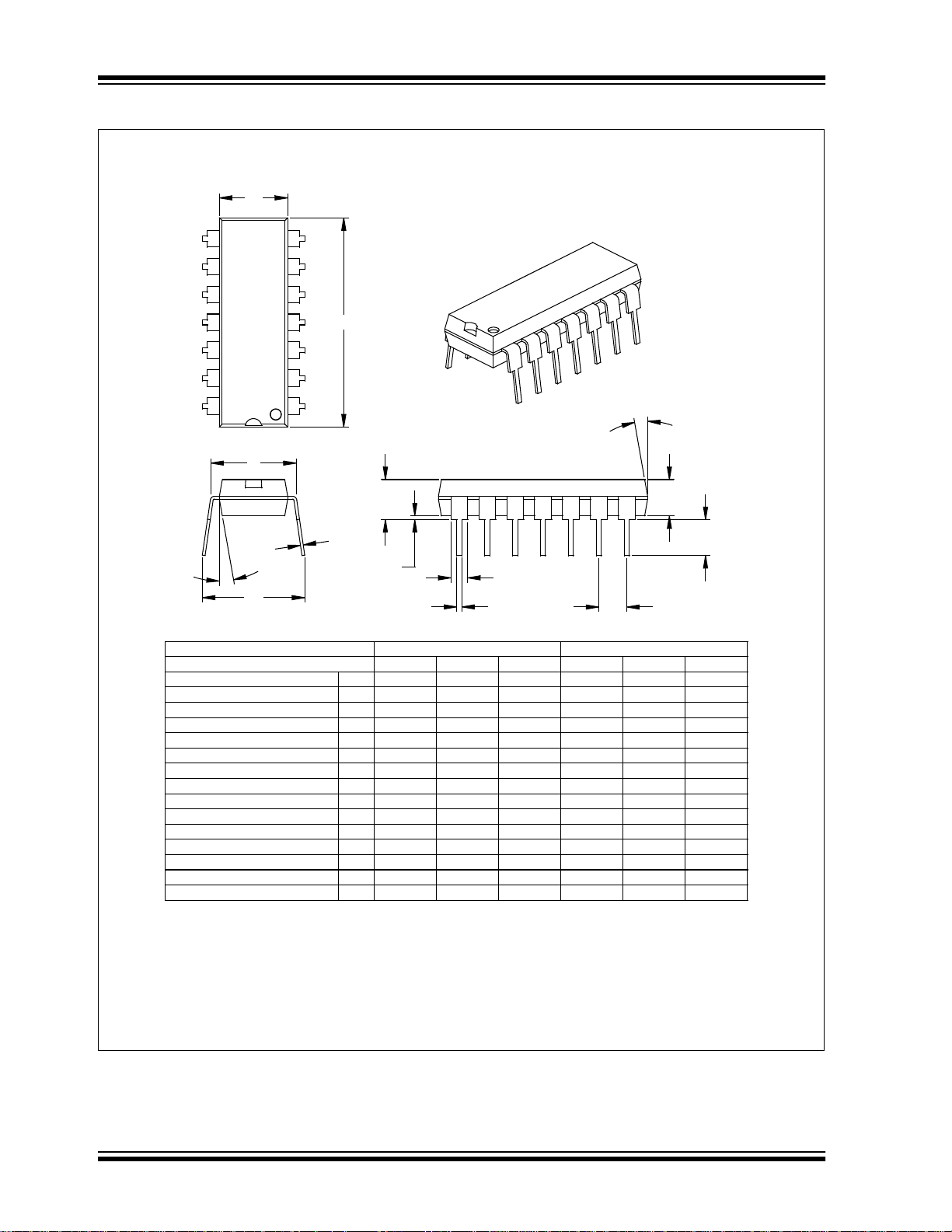

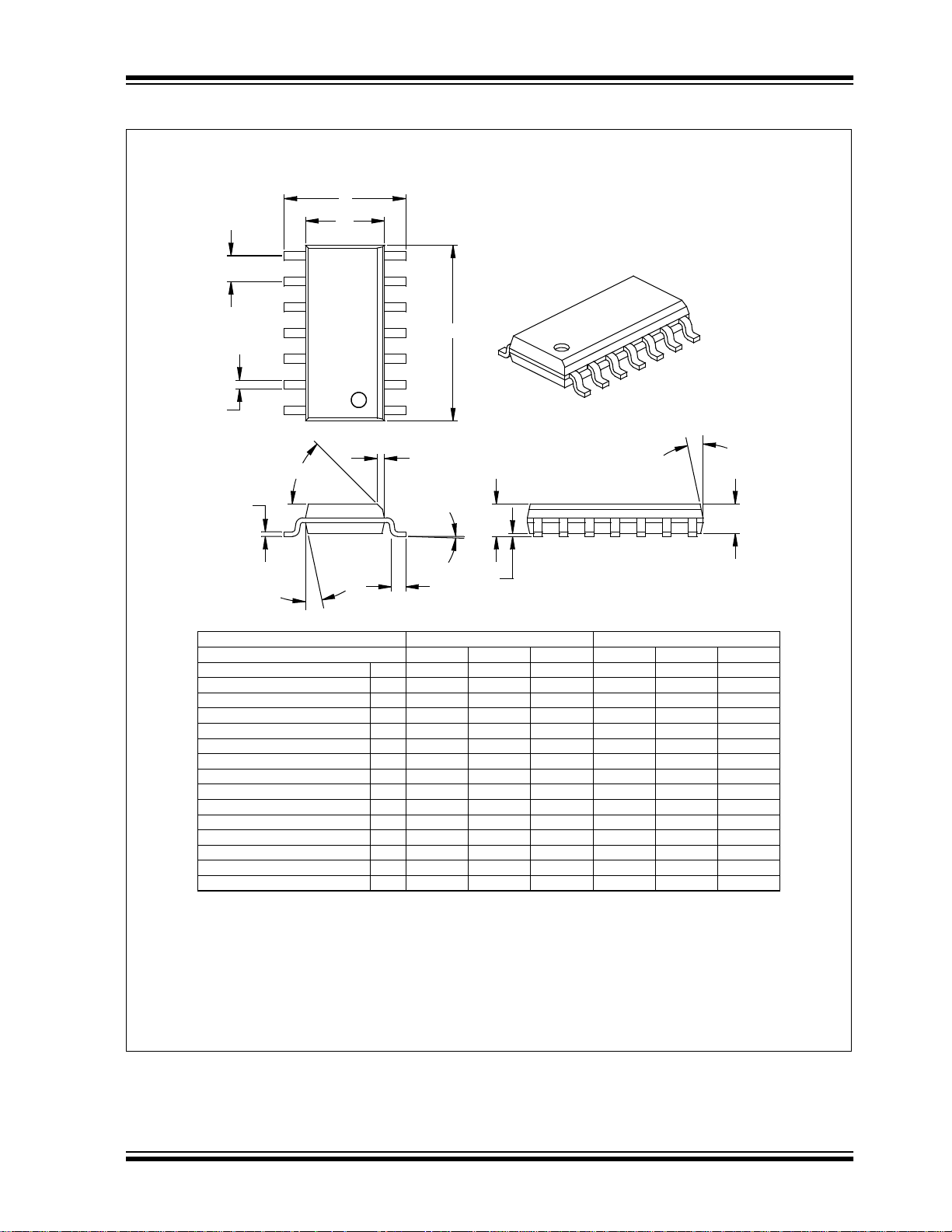

8.0 Packaging Information................................................................................................................................................................ 57

INDEX .................................................................................................................................................................................................. 61

On-Line Support................................................................................................................................................................................... 62

Systems Information and Upgrade Hot Line ........................................................................................................................................ 62

Reader Response ................................................................................................................................................................................ 63

Product Identification System............................................................................................................................................................... 64

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@mail.microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150.

We welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

• The Microchip Corporate Literature Center; U.S. FAX: (480) 792-7277

When contacting a sales office or the literature center, please specify which device, revision of silicon and data sheet (include liter-

ature number) you are using.

Customer Notification System

Register on our web site at www.microchip.com/cn to receive the most current information on all of our products.

DS40035C-page 2 Preliminary 2002 Microchip Technology Inc.

Page 5

HCS473

1.0 GENERAL DESCRIPTION

The HCS473 combines the patented KEELOQ code

hopping technology and bi-directional transponder

challenge-and-response security into a single chip

solution for logical and physical access control.

The three-input transponder interface allows the combination of three orthogonal transponder antennas,

eliminating the directionality associated with traditional

single antenna transponder systems.

When used as a code hopping encoder, the HCS473 is

well suited to keyless entry systems; vehicle and

garage door access in particular. The same HCS473

can also be used as a secure bi-directional transponder

for contactless authentication. These capabilities make

the HCS473 ideal for combined secure access control

and identification applications, dramatically reducing

the cost of hybrid transmitter/transponder solutions.

1.1 System Overview

1.1.1 KEY TERMS

The following is a list of key terms used throughout this

data sheet. For additional information on terminology,

please refer to the K

(TB003).

• AGC - Automatic Gain Control.

• Anticollision - A scheme whereby transponders

in the same field can be addressed individually,

preventing simultaneous response to a command

(Section 3.2.1.4).

• Button Status - Indicates what button input(s)

activated the transmission. Encompasses the 4

button status bits S3, S2, S1 and S0 (Figure 3-2).

• Code Hopping - A method by which a code,

viewed externally to the system, appears to

change unpredictably each time it is transmitted

(Section 1.2.3).

• Code word - A block of data that is repeatedly

transmitted upon button activation (Figure 3-2).

• Crypto key - A unique and secret 64-bit number

used to encrypt and decrypt data. In a symmetrical block cipher such as the K

the encryption and decryption keys are equal and

will therefore be referred to generally as the

crypto key.

• Decoder - A device that decodes data received

from an encoder.

• Decryption algorithm - A recipe whereby data

scrambled by an encryption algorithm can be

unscrambled using the same crypto key.

• Device Identifier - 16-bit value used to uniquely

select one of multiple transponders for communication.

• Encoder - A device that generates and encodes

data.

EELOQ introductory Technical Brief

EELOQ algorithm,

• Encryption Algorithm - A recipe whereby data is

scrambled using a crypto key. The data can only

be interpreted by the respective decryption algorithm using the same crypto key.

• IFF - Identify Friend or Foe, a classic authentication method (Section 3.2.3.3).

• Learn - Learning involves the receiver calculating

the transmitter’s appropriate crypto key, decrypting the received hopping code and storing the

serial number, synchronization counter value and

crypto key in EEPROM (Section 5.1). The

EELOQ product family facilitates several learning

K

strategies to be implemented on the decoder. The

following are examples of what can be done.

• Simple Learning

The receiver uses a fixed crypto key, common to

all components of all systems by the same manufacturer, to decrypt the received code word’s

encrypted portion.

• Normal Learning

The receiver uses information transmitted during

normal operation to derive the crypto key and

decrypt the received code word’s encrypted portion.

• Secure Learn

The transmitter is activated through a special button combination to transmit a stored 60-bit seed

value used to derive the transmitter’s crypto key.

The receiver uses this seed value to calculate the

same crypto key and decrypt the received code

word’s encrypted portion.

• LF - Low Frequency. For HCS473 purposes, LF

refers to a typical 125 kHz frequency.

• Manufacturer’s code – A unique and secret 64bit number used to generate unique encoder

crypto keys. Each encoder is programmed with a

crypto key that is a function of the manufacturer’s

code. Each decoder is programmed with the manufacturer code itself.

• Proximity Activation - A method whereby an

encoder automatically initiates a transmission in

response to detecting an inductive field

(Section 3.1.1.2).

• PKE - Passive Keyless Entry.

• RKE - Remote Keyless Entry.

• Transmission - A data stream consisting of

repeating code words.

• Transcoder - Device combining unidirectional

transmitter capabilities with bi-directional authentication capabilities.

• Transponder - A transmitter-receiver activated

for transmission by reception of a predetermined

signal.

2002 Microchip Technology Inc. Preliminary DS40035C-page 3

Page 6

HCS473

• Transponder Reader (Reader, for short) - A

device that authenticates a transponder using bidirectional communication.

• Transport code - An access code, ‘password’

known only by the manufacturer, allowing write

access to certain secure device memory areas

(Section 3.2.3.2).

1.2 Encoder Overview

The HCS473 code hopping transcoder is designed

specifically for passive entry systems; particularly vehicle access. The transcoder portion of a passive entry

system is integrated into a fob, carried by the user and

operated to gain access to a vehicle or restricted area.

The HCS473 is meant to be a cost-effective yet secure

solution to such systems, requiring very few external

components (Figure 2-1).

1.2.1 LOW-END SYSTEM SECURITY

RISKS

Most low-end keyless entry transmitters are given a

fixed identification code that is transmitted every time a

button is pushed. The number of unique identification

codes in a low-end system is usually a relatively small

number. These shortcomings provide an opportunity

for a sophisticated thief to create a device that ‘grabs’

a transmission and retransmits it later, or a device that

quickly ‘scans’ all possible identification codes until the

correct one is found.

1.2.2 HCS473 SECURITY

The HCS473, on the other hand, employs the KEELOQ

code hopping technology coupled with a transmission

length of 69 bits to virtually eliminate the use of code

‘grabbing’ or code ‘scanning’. The high security level of

the HCS473 is based on the patented K

ogy. A block cipher based on a block length of 32 bits

and a key length of 64 bits is used. The algorithm

obscures the information in such a way that even if the

transmission’s pre-encrypted information differs by

only one bit from that of the previous transmission, statistically greater than 50 percent of the transmission’s

encrypted result will change.

EELOQ

technol-

1.2.3 HCS473 HOPPING CODE

The 16-bit synchronization counter is the basis behind

the transmitted code word changing for each transmission; it increments each time a button is pressed.

Once the device detects a button press, it reads the

button inputs and updates the synchronization counter.

The synchronization counter and crypto key are input

to the encryption algorithm and the output is 32 bits of

encrypted information. This encrypted data will change

with every button press, its value appearing externally

to ‘randomly hop around’, hence it is referred to as the

hopping portion of the code word. The 32-bit hopping

code is combined with the button information and serial

number to form the code word transmitted to the

receiver. The code word format is explained in greater

detail in Section 3.1.2.

1.3 Identify Friend or Foe (IFF)

Overview

Validation of a transponder first involves an authenticating device sending a random challenge to the

device. The transponder then replies with a calculated

response that is a function of the received challenge

and its stored crypto key. The authenticating device,

transponder reader, performs the same calculation and

compares it to the transponder’s response. If they

match, the transponder is identified as valid and the

transponder reader can take appropriate action.

The HCS473’s IFF response is generated using one of

two possible crypto keys. The authenticating device

precedes the challenge with a three bit field dictating

which key to use in calculating the response.

The bi-directional communication path required for IFF

is typically inductive for short range (<10cm) transponder applications with an inductive challenge and inductive response. Longer range (~1.5m) passive entry

applications still transmit using the LF inductive path

but the response is transmitted RF.

DS40035C-page 4 Preliminary 2002 Microchip Technology Inc.

Page 7

HCS473

2.0 DEVICE DESCRIPTION

The HCS473 is designed for small package outline,

cost-sensitive applications by minimizing the number of

external components required for RKE and PKE applications.

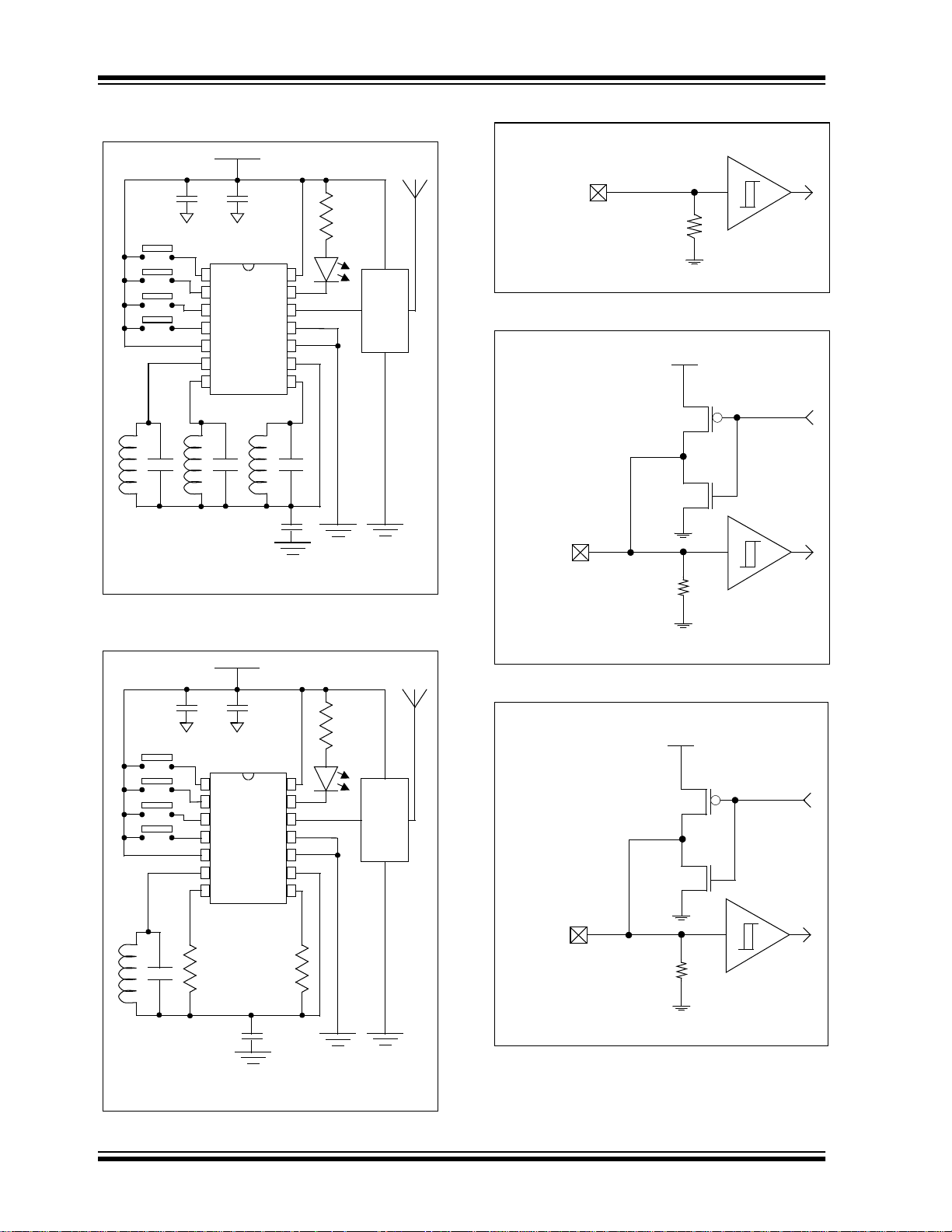

Figure 2-1 shows a typical 3-axis HCS473 RKE/PKE

application.

• The switch inputs have internal pull-down resistors and integrated debouncing allowing a switch

to be directly connected to the inputs.

The transponder circuitry requires only the addition of

external LC-resonant circuits for inductive communication capability.

• The open-drain LED output allows an external

resistor for customization of LED brightness - and

current consumption.

• The DATA output can be directly connected to the

RF circuit or connected in conjunction with S3/

RFEN to a PLL.

2.1 Pinout Overview

A description of pinouts for the HCS473 can be found

in Table 2-1.

TABLE 2-1: PINOUT SUMMARY

Pin Name

S0 1 Button input pin with Schmitt Trigger detector and internal pull-down resistor (Figure 2-3).

S1 2 Button input pin with Schmitt Trigger detector and internal pull-down resistor (Figure 2-3).

S2 3 Button input pin with Schmitt Trigger detector and internal pull-down resistor (Figure 2-3).

S3/RFEN 4 Multi-purpose input/output pin (Figure 2-4).

DDT 5 Transponder supply voltage. Regulated voltage output for strong inductive field.

V

LCX 6 Sensitive transponder input X (Figure 2-7). A strong signal on this pin is internally regulated

LCY 7 Sensitive transponder input Y (Figure 2-7)

LCZ 8 Sensitive transponder input Z (Figure 2-7)

LCCOM 9 Transponder bias output (Figure 2-7)

SST 10 Transponder ground reference, must be connected to VSS.

V

SS 11 Ground reference

V

DATA 12 Transmission data output (Figure 2-5)

LED 13 Open drain LED output (Figure 2-6)

DD 14 Positive supply voltage

V

Pin

Number

Description

• Button input pin with Schmitt Trigger detector and internal pull-down resistor.

• RFEN output driver.

and supplied on V

DD for low-battery operation/recharging.

2.2 LF Antenna Considerations

A typical magnetic low frequency sensor (receiving

antenna) consists of a parallel inductor-capacitor circuit

that is sensitive to an externally applied magnetic signal. This LC circuit is tuned to resonate at the source

signal's base frequency. The real-time voltage across

the sensor represents the presence and strength of the

surrounding magnetic field. By amplitude modulating

the source's magnetic field, it is possible to transfer

data over short distances. This communication

approach is successfully used with distances up to 1.8

meters, depending on transmission strengths and sensor sensitivity. Two key factors that greatly affect communication range are:

1. Sensor tuning

2. A properly tuned sensor's relative sensitivity

2002 Microchip Technology Inc. Preliminary DS40035C-page 5

An LC antenna’s component values may be initially calculated using the following equation. “Initially” because

there are many factors affecting component selection.

1

2π F

It is not this data sheet’s purpose to present in-depth

details regarding LC antenna and their tuning. Please

refer to “Low Frequency Magnetic Transmitter Design

Application Note”, AN232, for appropriate LF antenna

design details.

Note: Microchip also has a confidential Applica-

tion Note on Magnetic Sensors (AN832C).

Contact Microchip for a Non-Disclosure

Agreement in order to obtain this application note.

-----------

=

LC

Page 8

HCS473

FIGURE 2-1: HCS473 3-AXIS

APPLICATION

DD

V

1µF 100nF

HCS473

Y

DDT

LCCOM

L

Z

V

LED

DATA

V

VSST

LCZ

680pF

DD

SS

Circuit

C

Z

S0

S1

S2

S3/RFEN

V

LCX

LCY

L

C

L

X

X

Note: The 680pF capacitor prevents device instability - self

C

Y

resonance.

FIGURE 2-3: S0/S1/S2 PIN DIAGRAM

S0, S1, S2

Inputs

RPD

RF

FIGURE 2-4: S3/RFEN PIN DIAGRAM

VDD

RFEN

PFET

NFET

S3 Input/

RFEN Output

RPD

FIGURE 2-2: HCS473 1-AXIS

APPLICATION

V

DD

1µF 100nF

HCS473

DDT

LCCOM

V

DD

LED

DATA

SS

V

VSST

LCZ

100Ω

S0

S1

S2

S3/RFEN

V

LCX

LCY

L

C

X

X

100Ω

660 pF

Circuit

RF

Note: RPD is disabled when driving RFEN.

FIGURE 2-5: DATA PIN DIAGRAM

VDD

PFET

NFET

DATA

RDATA

Note: RDATA is disabled when the DATA line is driven.

DATA OUT

Note: Connect unused LC antenna inputs to LCCOM

through a 100Ω resistor for proper bias conditions.

DS40035C-page 6 Preliminary 2002 Microchip Technology Inc.

Page 9

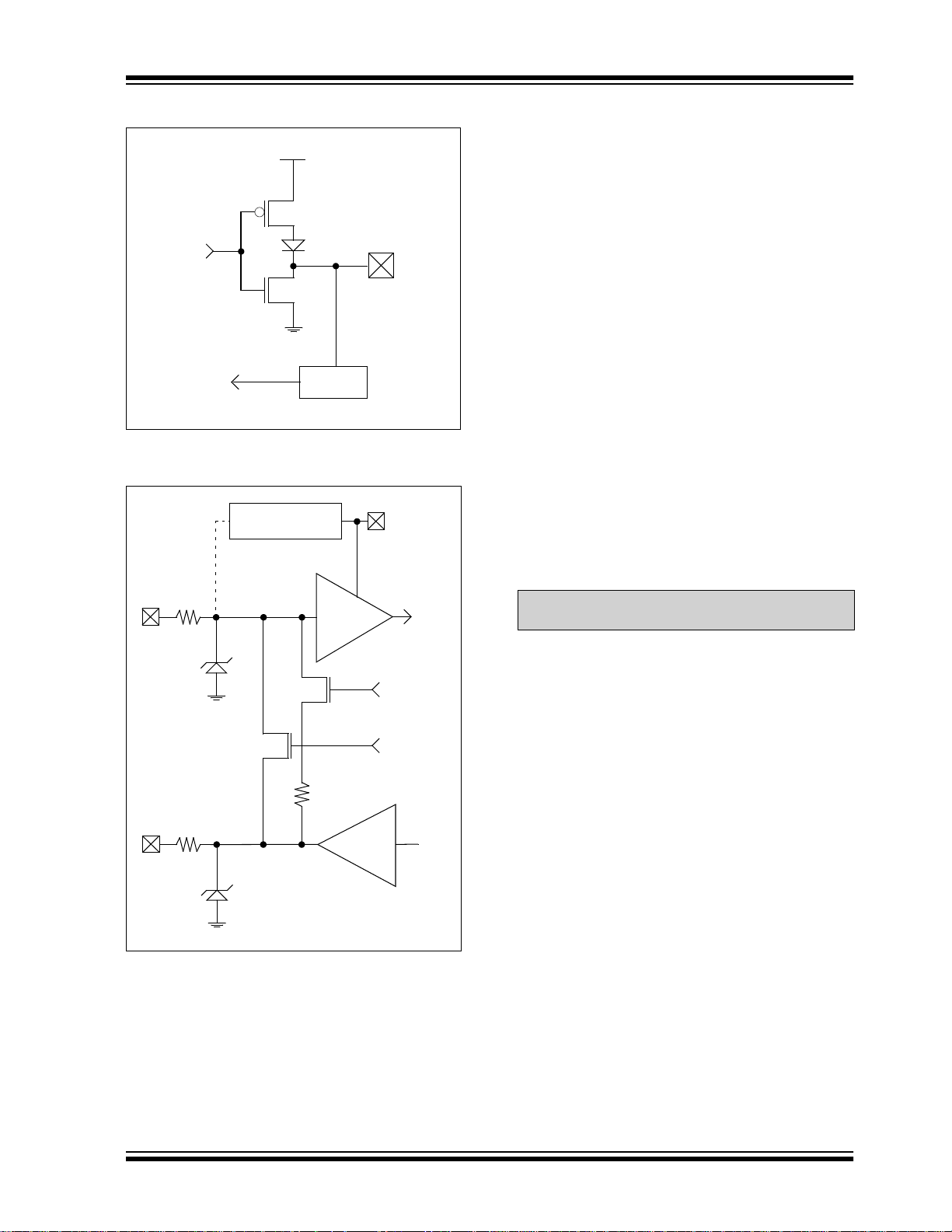

HCS473

FIGURE 2-6: LED PIN DIAGRAM

VDD

Weak

LED

LED

Program

Mode

HV

Detect

FIGURE 2-7: LCCOM/LCX/LCY/LCZ/

VSST PIN DIAGRAM

LCX

only

LCX/LCY/

LCZ Inputs

100Ω

RECTIFIER and

REGULATOR

AMP

and

DET

VSST

LC

Input

2.3 Architectural Overview

2.3.1 WAKE-UP LOGIC

The HCS473 automatically goes into a low-power

Standby mode once connected to a supply voltage.

Power is supplied to the minimum circuitry required to

detect a wake-up condition; button activation or LC signal detection.

The HCS473 will wake from Low-power mode when a

button input is pulled high or a signal is detected on a

LC low frequency antenna input pin. Waking involves

powering the main logic circuitry that controls device

operation. The button and transponder inputs are then

sampled to determine which input activated the device.

A button input activation places the device into Encoder

mode. A signal detected on the transponder input

places the device into Transponder mode. Encoder

mode has priority over Transponder mode such that

communication on the transponder input would be

ignored or perhaps interrupted if it occurred simultaneously to a button activation; ignored until the button

input is released.

2.3.2 ENCODER INTERFACE

Using the four button inputs, up to 15 unique control

codes may be transmitted.

Note: S3 may not be used as a button input if the

RFEN option is enabled.

LCCOM

100Ω

10V

10V

R

DAMP

CURRENT

DAMP

CLAMP

BIAS

2002 Microchip Technology Inc. Preliminary DS40035C-page 7

Page 10

HCS473

2.3.3 TRANSPONDER INTERFACE

The transponder interface on the HCS473 consists of

the following:

• The internal transponder circuitry has separate

power supply (V

tions.

- The V

DDT pin supplies power to the transpon-

der circuitry and also outputs a regulated voltage if the LCX antenna input is receiving a

strong signal; transponder is placed in a

strong LF field.

- The V

SST pin supplies the ground reference

to the transponder circuitry and must be connected to the V

• LF input amplifier and envelope detector to detect

and shape the incoming low frequency excitation

signal.

• Three sensitive transponder inputs with over-voltage protection (LCX, LCY, LCZ).

• Incoming LF energy rectification and regulation on

the LCX input to supplement the supply voltage in

low-battery transponder instances.

• 10V zener input protection from excessive

antenna voltage resulting when proximate to very

strong magnetic fields.

• LCCOM pin used to bias the transponder resonant circuits for best sensitivity.

• LF antenna clamping transistors for inductive

responses back to the transponder reader. The

antenna ends are shorted together, ‘clamped’,

dissipating the oscillatory energy. The reader

detects this as a momentary load on its excitation

antenna.

• Damping transistors to increase LF communication reliability when using high Q-factor LC antennae.

The LCCOM pin functions to bias the LCX, LCY, and

LCZ AGC amplifier inputs. The amplifier gain control

sets the optimum level of amplification in respect to the

incoming signal strength. The signal then passes

through an envelope detector before interpretation in

the logic circuit.

A block diagram of the transponder circuit is shown in

Figure 2-8.

DDT) and ground (VSST) connec-

SS pin.

FIGURE 2-8: HCS473 TRANSPONDER

CIRCUIT

LCX

LCY

LCZ

LCCOM

Rectifier/

Regulator

Noise

Filter

CCT

V

Signal In

Damp/Clamp

Control

2.3.4 INTERNAL EEPROM

The HCS473 has an on-board non-volatile EEPROM

which is used to store:

• configuration options

- encryption keys

- serial number

- vehicle ID’s

- baud rates

- ... see Section 3.1.4 and Section 3.2.1

• 64 bits of user memory

• synchronization counter.

All options are programmable during production, but

many of the security related options are programmable

only during production and are further read protected.

The user area allows storage of general purpose information and is accessible only through the transponder

communication path.

During every EEPROM write, the device ensures that

the internal programming voltage is at an acceptable

level prior to performing the EEPROM write.

DS40035C-page 8 Preliminary 2002 Microchip Technology Inc.

Page 11

2.3.5 INTERNAL RC OSCILLATOR

The HCS473 runs on an internal RC oscillator. The

internal oscillator may vary ±10% over the device’s

rated voltage and temperature range for commercial

temperature devices. A certain percentage of industrial temperature devices vary further on the slow side,

-20%, when used at higher voltages (V

cold temperature. The LF and RF communication

timing values are subject to these variations.

DD > 3.5V) and

2.3.6 LOW VOLTAGE DETECTOR

The HCS473’s battery voltage detector detects when

the supply voltage drops below a predetermined value.

The value is selected by the Low Voltage Trip Point

Select (VLOWSEL) configuration option (Section 3.3).

The low voltage detector result is included in encoder

transmissions (VLOW) allowing the receiver to indicate

when the transmitter battery is low (Section 3.1.4.6).

The HCS473 also indicates a low battery condition by

changing the LED operation (Section 3.1.5).

2.3.7 THE S3/RFEN PIN

HCS473

The S3/RFEN pin may be used as a button input or RF

enable output to a compatible PLL. Select between S3

button input and RFEN functionality with the RFEN

configuration option (Table 2-2).

TABLE 2-2: RFEN OPTION

RFEN Resulting S3/RFEN Configuration

0 S3 button input pin with Schmitt Trigger

detector and internal pull-down resistor.

1 RFEN output driver.

S3 may not be used as a button input if the

RFEN option is enabled

2002 Microchip Technology Inc. Preliminary DS40035C-page 9

Page 12

HCS473

NOTES:

DS40035C-page 10 Preliminary 2002 Microchip Technology Inc.

Page 13

HCS473

3.0 DEVICE OPERATION

HCS473 operation depends on how the device is activated. The device exits Low-power mode either when a

switch input is pulled high or when a signal is detected

on an LC antenna input pin. Once activated, the device

determines the source of the activation and enters

Encoder mode or Transponder mode.

A button input activation places the device into Encoder

mode. A signal detected on the transponder input

places the device into Transponder mode. Encoder

mode has priority over Transponder mode such that

communication on the transponder input would be

ignored or perhaps interrupted if it occurred simultaneously to a button activation; ignored until the button

input is released.

3.1 Encoder mode

3.1.1 ENCODER ACTIVATION

3.1.1.1 Button Activation

The main way to enter Encoder mode is when the

wake-up circuit detects a button input activation; button

input transition from GND to V

logic wakes and delays a nominal switch debounce

time (T

DB) prior to sampling the button inputs. The but-

ton input states, cumulatively called the button status,

determine whether the HCS473 transmits a code hopping or seed transmission.

The transmission begins a time T

consists of a stream of code words transmitted as long

as the switch input is held high or until a selectable

TSEL timeout occurs (see Section 3.1.4.16 for TSEL

options). A timeout returns the device to Low-power

mode, protecting the battery in case a button is stuck.

Additional button activations during a transmission will

immediately reset the HCS473, perhaps leaving the

current code word incomplete. The device will start a

new transmission which includes the updated button

status value.

Buttons removed during a transmission will have no

effect unless no buttons remain activated. If no button

activations remain, the minimum number of complete

code words will be completed (see Section 3.1.4.15 for

MTX options) and the device will return to Low Power

mode.

DD. The HCS473 control

PU after activation. It

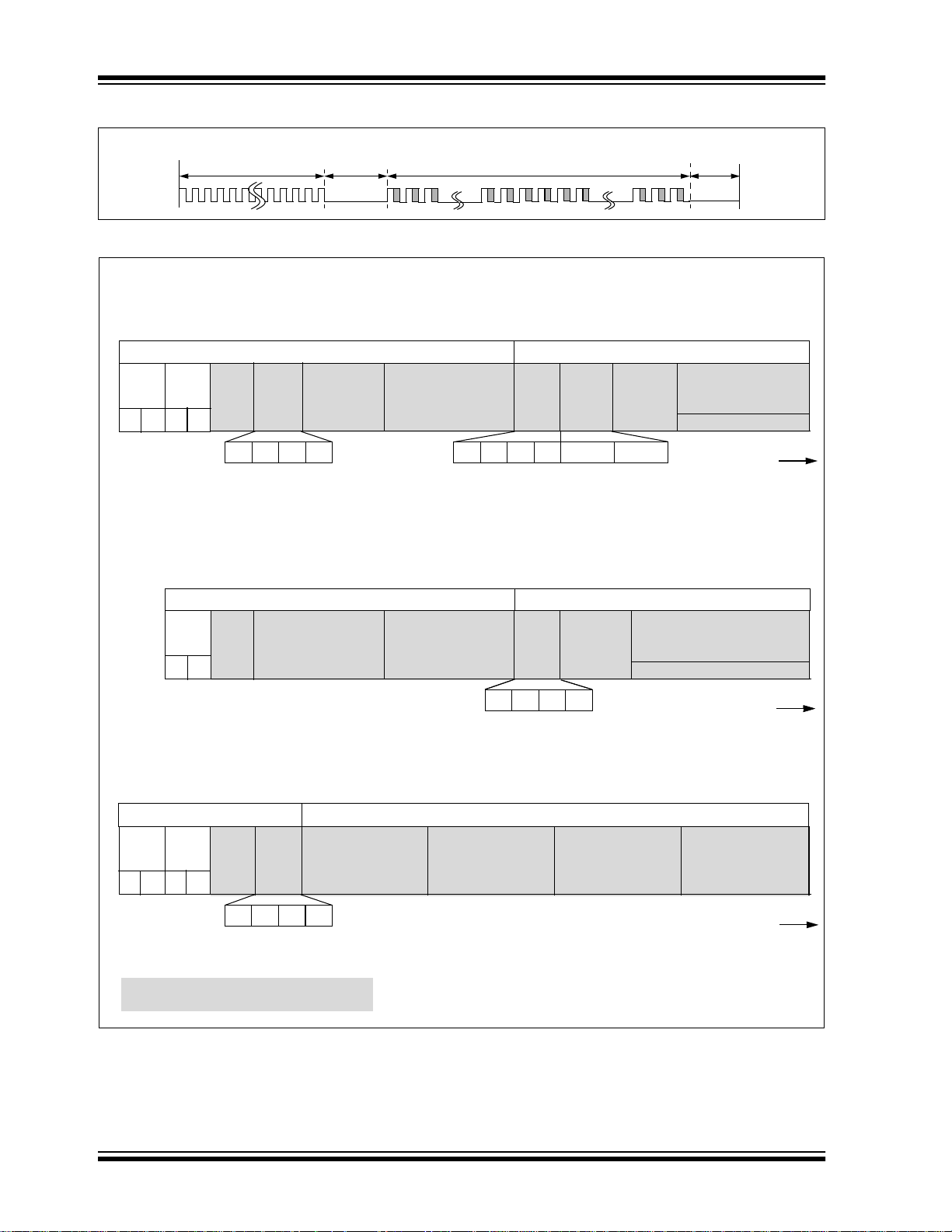

3.1.2 TRANSMITTED CODE WORD

The HCS473 transmits a 69-bit code word in response

to a button activation or proximity activation, Figure 3-

1. The code word content varies with the two unique

transmission types; Hopping or Seed.

3.1.2.1 Hopping Code Word

Hopping code words are those transmitted during normal operation. Each Hopping code word contains a

preamble, header, 32 bits of encrypted data and up to

37 bits of fixed value data followed by a guard period

before another code word begins.

• The 32 bits of Encrypted Data include button status bits, discrimination bits and the synchronization counter value. The inclusion/omission of

overflow bits and size of both synchronization

counter and discrimination bit fields vary with the

CNTSEL option, Figure 3-2 and Section 3.1.4.5.

• The 37 bits of Fixed Code Data include queue

bits (if enabled), CRC bits, low voltage status and

serial number. The inclusion/omission of button

status and size of the serial number field vary with

the XSER option, Figure 3-2 and Section 3.1.4.3.

3.1.2.2 Seed Code Word

Seed code words are required when the system implements secure key generation. Seed transmissions are

activated when the button inputs match the value specified by the seed button code configuration option

(SDBT), Section 3.1.4.9.

Each Seed code word contains a preamble, header

and up to 69 bits of fixed data followed by a guard

period before another code word begins.

• The 69 bits of Fixed Code Data include queue

bits (if enabled), CRC bits, low voltage status, button status and the 60-bit seed value, Figure 3-2.

.

Note: For additional information on KEELOQ the-

ory and implementation, please refer to the

KEELOQ introductory Technical Brief

(TB003).

3.1.1.2 Proximity Activation

A second way to enter Encoder mode is if the proximity

activation option (PXMA) is enabled and the wake-up

circuit detects a wake-up sequence on an LC antenna

input pin. This form of activation is called Proximity

Activation as a code hopping transmission would be initiated when the device was proximate to a LF field.

2002 Microchip Technology Inc. Preliminary DS40035C-page 11

Page 14

HCS473

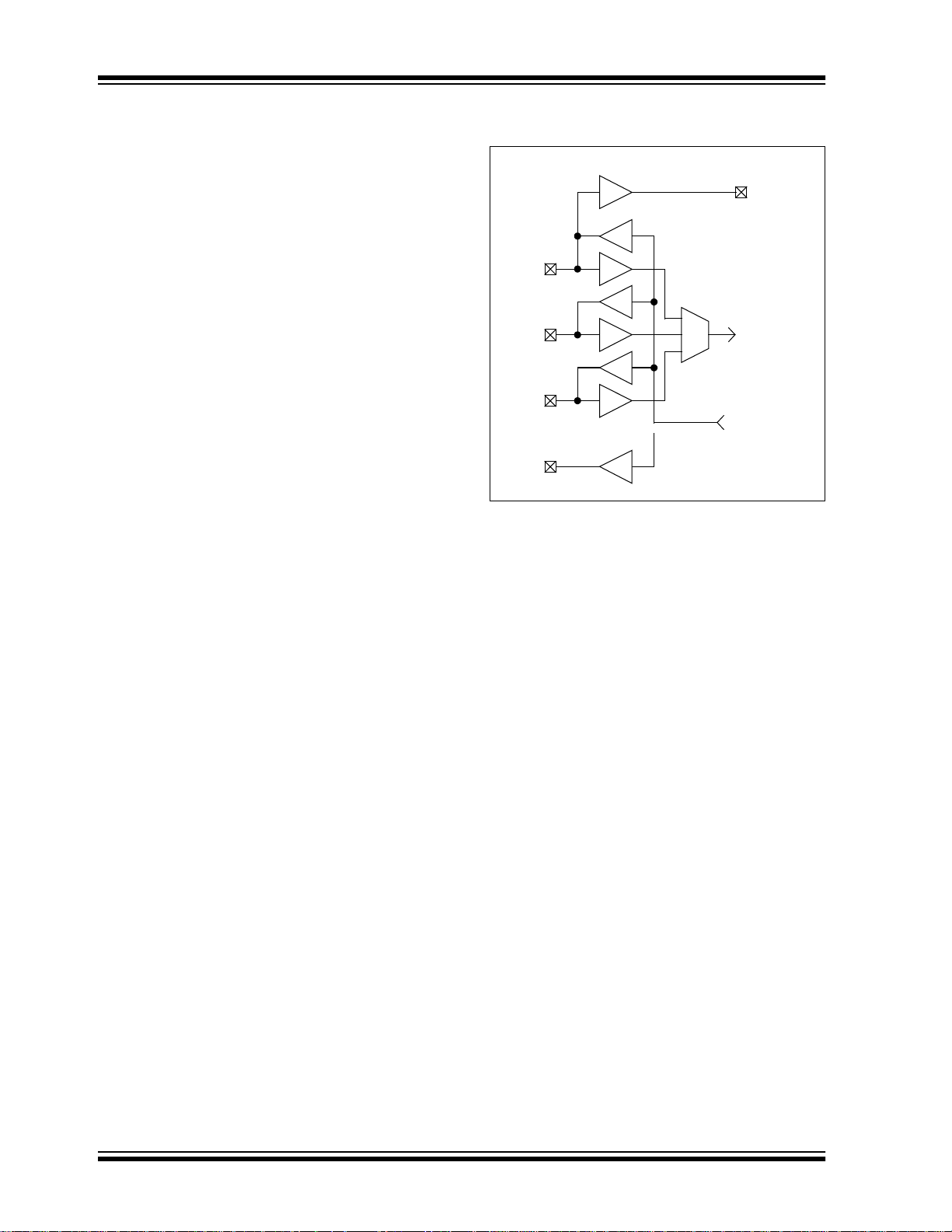

FIGURE 3-1: GENERAL CODE WORD FORMAT

Preamble

Header

FIGURE 3-2: CODE WORD ORGANIZATION

Hopping Code:

CRC

QUE

2 Bits

2 Bits

Q1 Q0 C1 C0

MSb

Hopping Code:

28-bit Serial Number (XSER = 0)

16-bit Synchronization Counter (CNTSEL=0)

Button Queuing enabled (QUEN=1)

Fixed Code Portion (37 Bits)

VLOW

BUT

4 Bits

1-Bit

S2 S1 S0 S3

SER 1

12 MSb’s

SER 0

Least Sig16 Bits

32-bit Serial Number (XSER = 1)

20-bit Synchronization Counter (CNTSEL=1)

Button Queuing disabled (QUEN=0)

Data Bits

Hopping Code Portion Message (32 Bits)

Counter

BUT

Overflow

4 Bits

S2 S1 S0 S3 OVR1 OVR0

2 Bits

DISCRIM

10 Bits

Guard

Time

Synchronization

Counter

16 Bits

15

LSb

69 Data bits

Transmitted LSb first.

0

Fixed Code Portion (35 Bits)

CRC

2 Bits

C1 C0

V

LOW

1-Bit

SER 1

Most Sig 16 Bits

MSb

Seed Code:

Fixed Code Portion (9 Bits) Seed Value (60 Bits)

QUE

CRC

2 Bits

2 Bits

Q1 Q0

C1 C0

Shaded 65 bits included in CRC calculation

Queuing enabled (QUE = 1)

LOW

V

BUT

1-Bit

4 Bits

111 1

SDVAL3

12 Most Sig Bits

SER 0

Least Sig 16 Bits

SDVAL2

16 Bits

BUT

4 Bits

S2 S1 S0 S3

S2 S1 S0 S3

Hopping Code Portion Message (32 Bits)

Synchronization

Synchronization

Counter

DISCRIM

8 Bits

20

Counter

20 Bits

67 Data bits

Transmitted LSb first.

SDVAL1

16 Bits

SDVAL0

16 Least Sig Bits

69 Data bits

Transmitted LSb first.

0

LSb

LSbMSb

DS40035C-page 12 Preliminary 2002 Microchip Technology Inc.

Page 15

HCS473

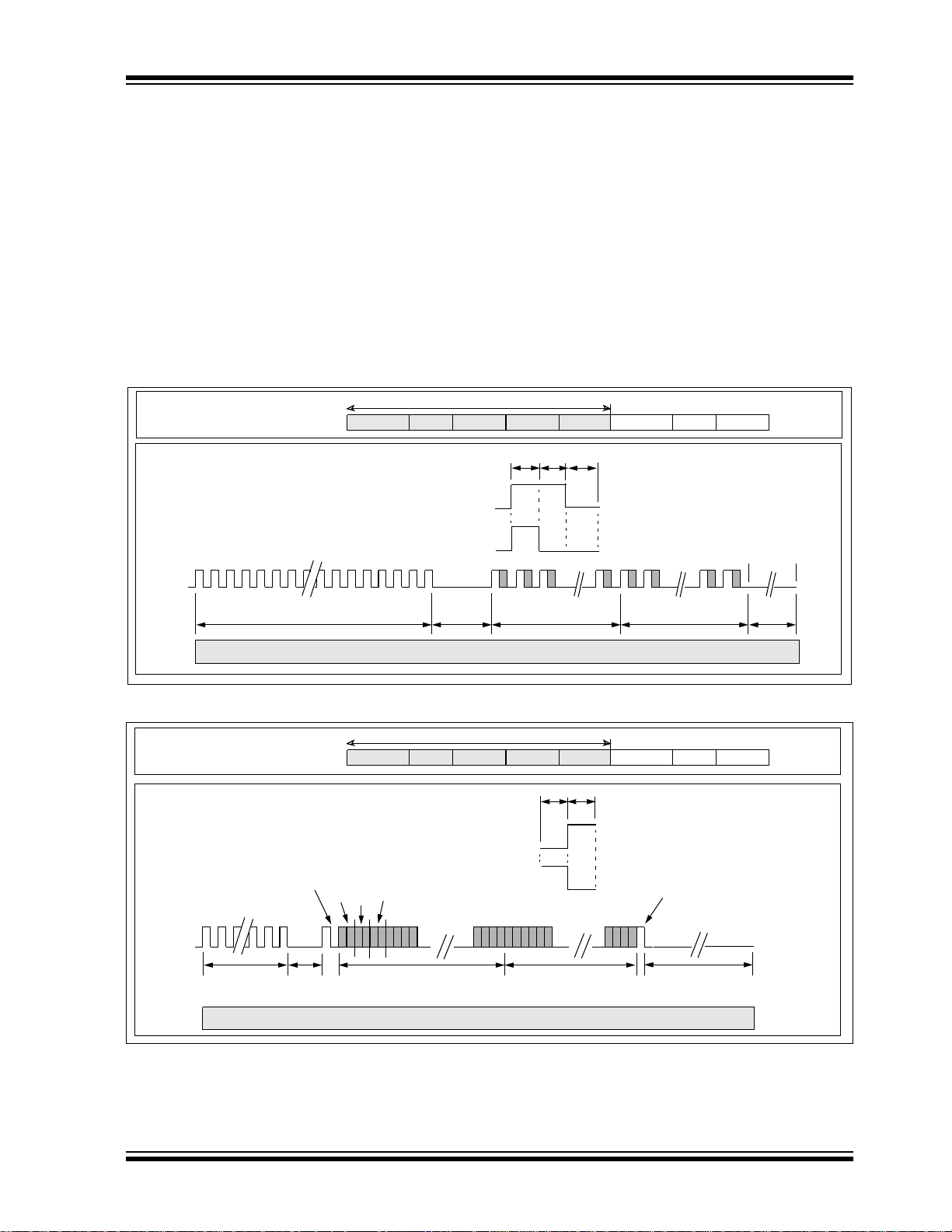

3.1.3 CODE HOPPING MODULATION

FORMAT

The data modulation format is selectable between

Pulse Width Modulation (PWM) and Manchester using

the modulation select (MSEL) configuration option.

Regardless of the modulation format, each code word

contains a leading preamble and a synchronization

header to wake the receiver and provide synchronization events for the receive routine. Each code word also

contains a trailing guard time to separate code words.

The same code word repeats as long as the same input

pins remain active, until a timeout occurs or a delayed

seed transmission is activated.

The modulated data timing is typically referred to in

multiples of a basic Timing Element (RFT

because the DATA pin output is typically sent through a

RF transmitter to the decoder or transponder reader.

E may be selected using the RF Transmission

RFT

Baud Rate (RFBSL) configuration option

(Section 3.1.4.13).

Manchester encoding further includes a leading data ‘1’

START pulse and closing 1 RFT

E STOP pulse around

each data block.

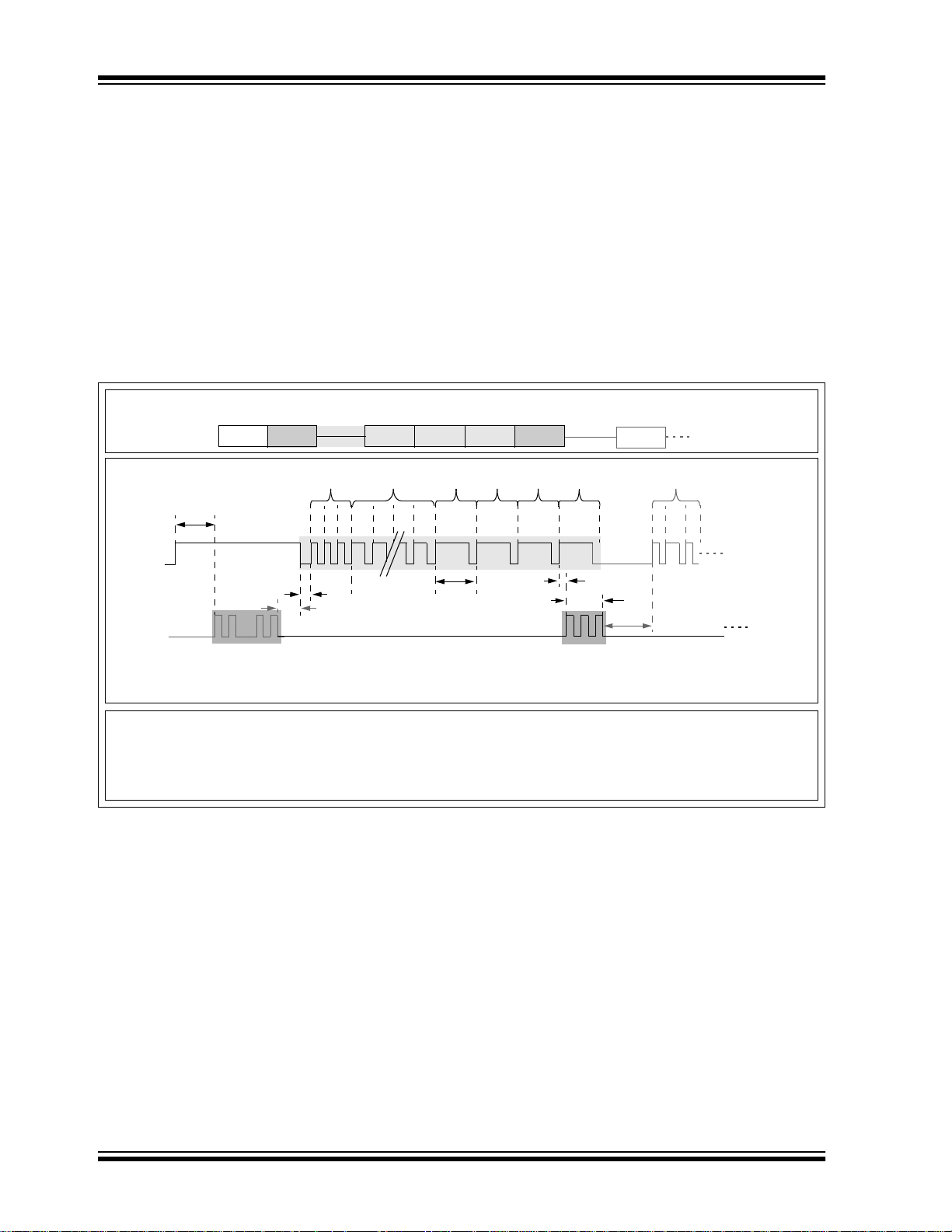

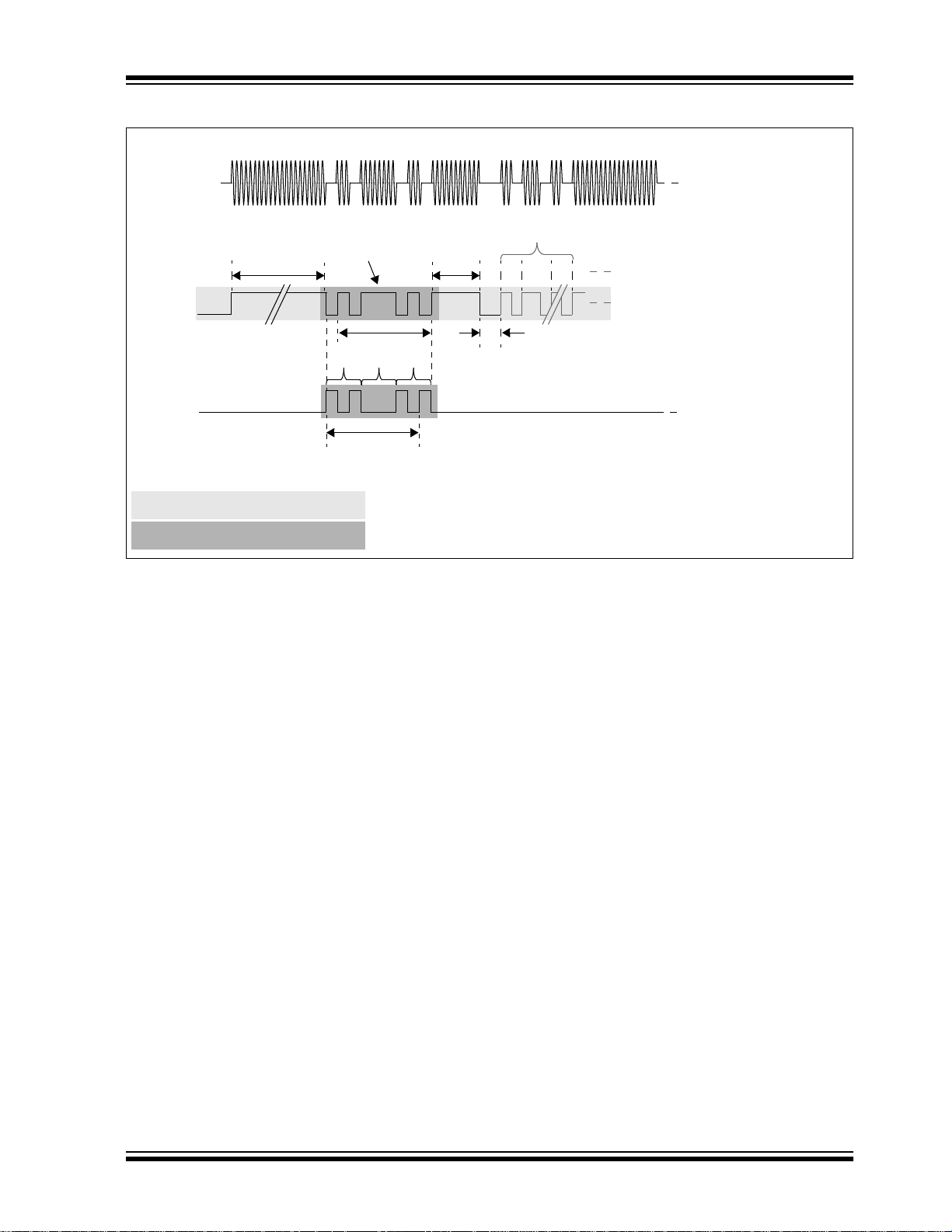

FIGURE 3-3: PWM TRANSMISSION FORMAT (MSEL = 0)

TOTAL TRANSMISSION:

Preamble Sync Encrypt Fixed Guard

1 CODE WORD

TETET

LOGIC "0"

LOGIC "1"

E). ‘RF’ TE

Preamble Sync Encrypt

E

Preamble

Header

Encrypted

Portion

CODE WORD

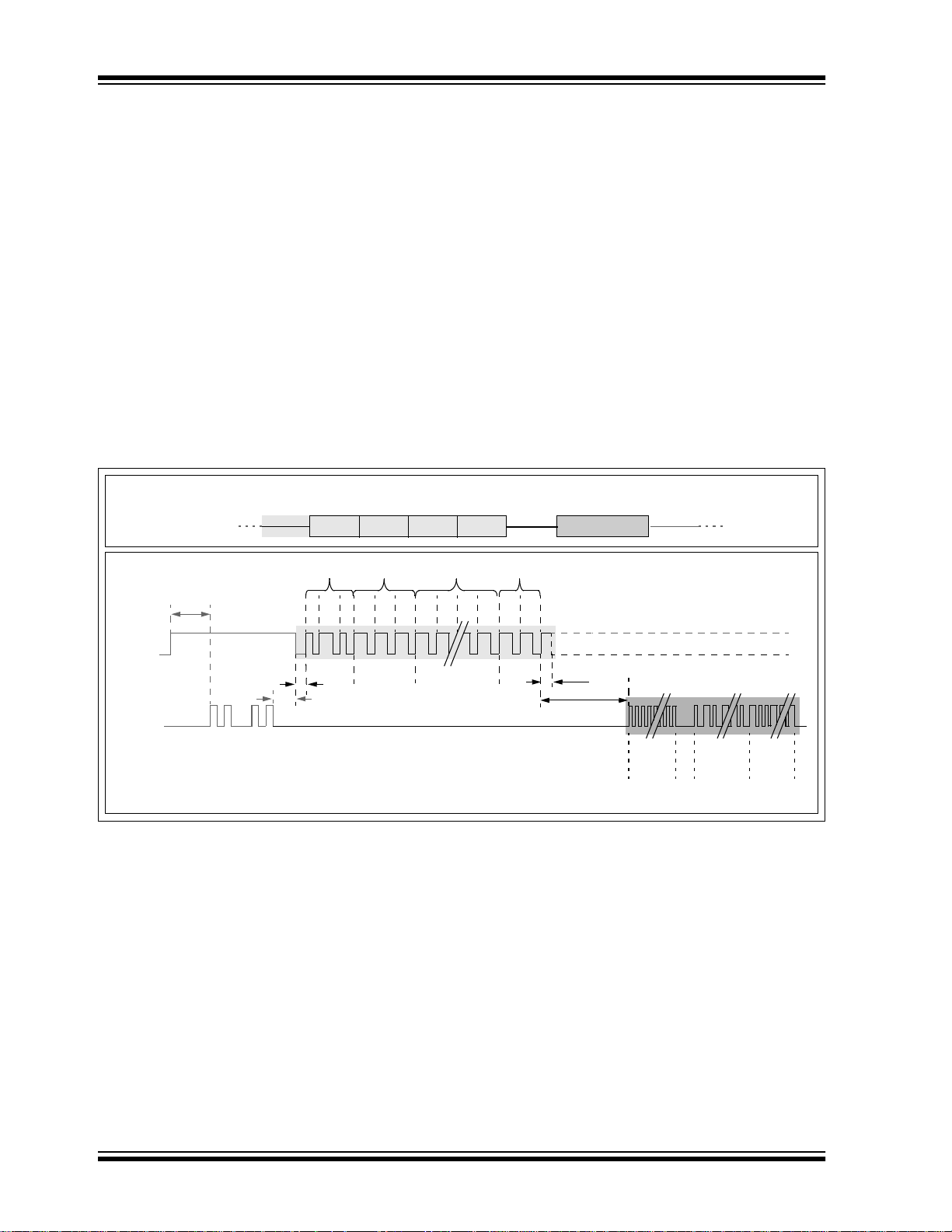

FIGURE 3-4: MANCHESTER TRANSMISSION FORMAT (MSEL = 1)

1 CODE WORD

TOTAL TRANSMISSION:

START bit

Preamble

Preamble Sync Encrypt Fixed Guard

LOGIC “0”

bit 0

bit 1

bit 2

LOGIC “1”

CODE WORD

Preamble Sync Encrypt

TE

T

E

Fixed Code

Portion

STOP bit

GuardHeader Encrypted Fixed Code

TimePortion Portion

Guard

Time

2002 Microchip Technology Inc. Preliminary DS40035C-page 13

Page 16

HCS473

3.1.4 ENCODER MODE OPTIONS

The following HCS473 configuration options configure

transmission characteristics of the information exiting

the DATA pin:

• Modulation select (MSEL)

• Header select (HSEL)

• Extended serial number (XSER)

• Queue counter enable (QUEN)

• Counter select (CNTSEL)

• Low voltage trip point (VLOWSEL)

• PLL interface select (AFSK)

• RF enable output (RFEN)

• Seed button code (SDBT)

• Time before Seed (SDTM)

• Limited Seed (SDLM)

• Seed mode (SDMD)

• RF baud rate select (RFBSL)

• Guard time select (GSEL)

• Minimum code words (MTX)

• Timeout select (TSEL)

• Long preamble enable (LPRE)

• Long preamble length (LPRL)

• Preamble duty cycle (PRD)

The following sections detail each configuration’s avail-

able options. All timing values specified are subject to

the specified oscillator variation.

3.1.4.1 Modulation Format (MSEL)

The Modulation format option selects the modulation

format for data output from the DATA pin; most often

transmitted via RF.

MSEL options:

• Pulse Width Modulation (PWM), Figure 3-3

• Manchester Modulation, Figure 3-4

3.1.4.2 Header Select (HSEL)

The synchronization header is typically used by the

receiver to adjust bit sampling appropriate to the transmitter’s current speed; as the transmitter’s RC oscillator varies with temperature and voltage, so will the

transmission’s timing.

HSEL options:

TE

•4 RF

• 10 RFTE

3.1.4.3 Extended Serial Number (XSER)

The Extended Serial Number option determines

whether the HCS473 transmits a 28 or 32-bit serial

number.

When configured for a 28-bit serial number, the Most

Significant nibble of the 32 bits reserved for the serial

number is replaced with a copy of the 4-bit button status, Figure 3-2.

XSER options:

• 28-bit serial number

• 32-bit serial number

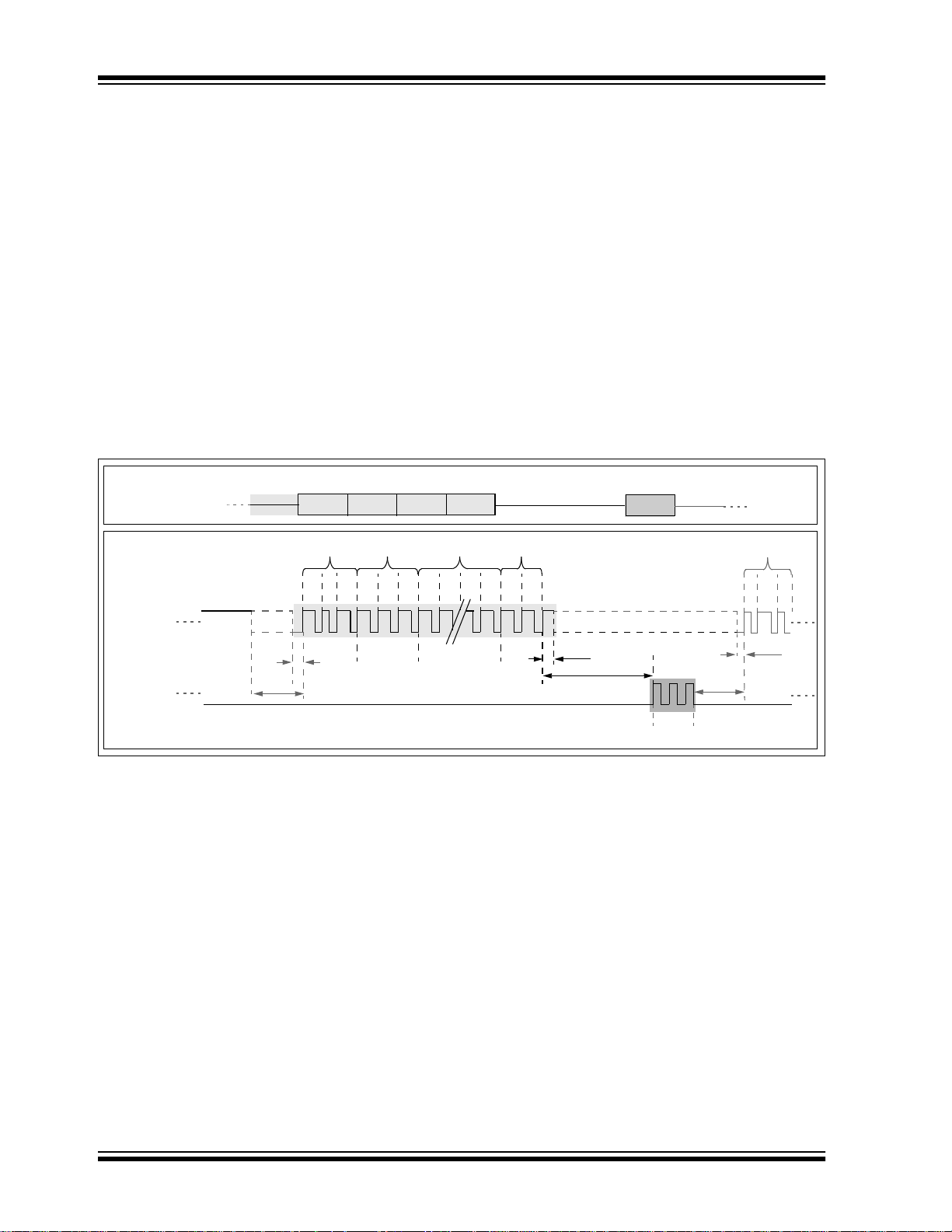

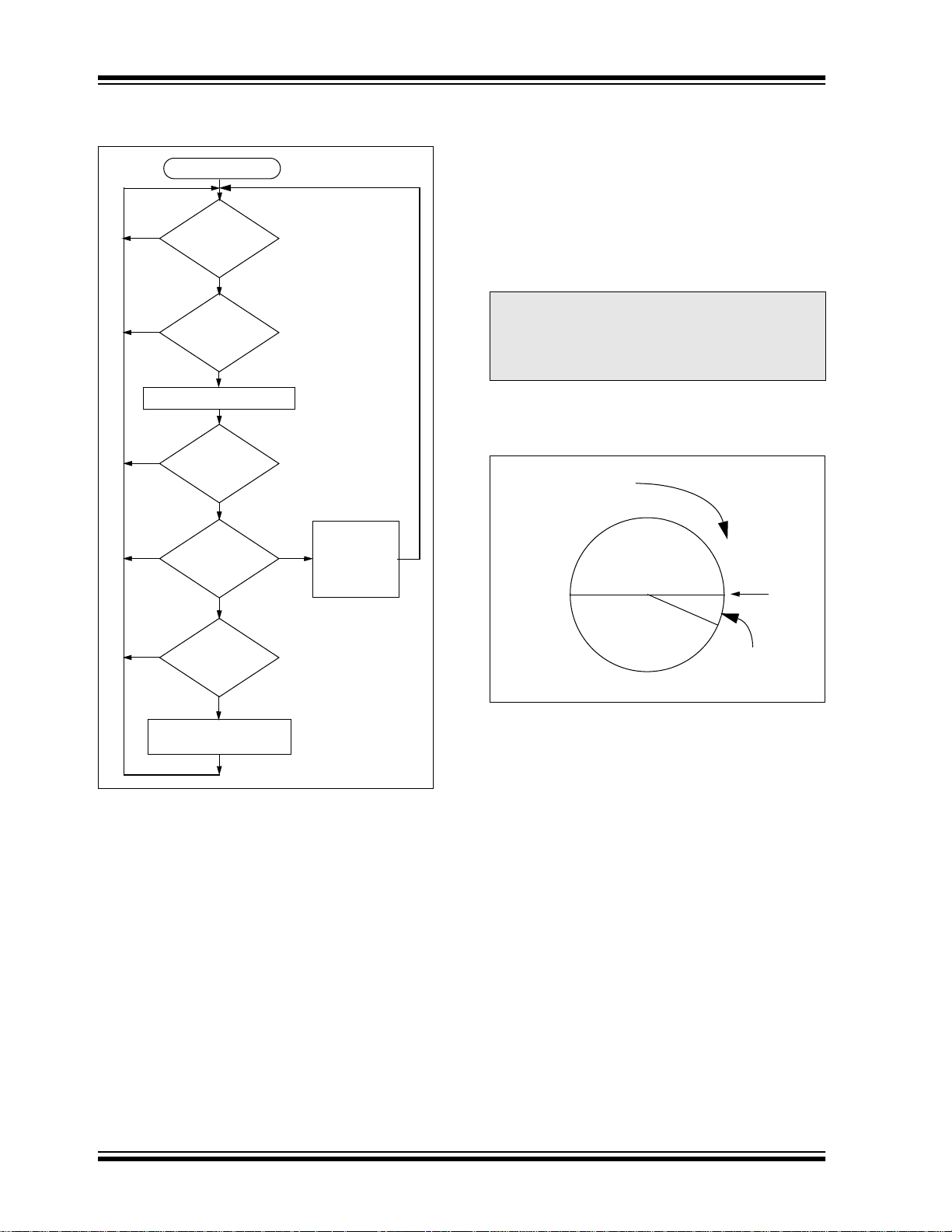

3.1.4.4 Queue Counter (QUEN)

The QUE counter can be used to request secondary

decoder functions using only a single transmitter button. Typically a decoder must keep track of incoming

transmissions to determine when a double button press

occurs, perhaps an unlock all doors request. The QUE

counter removes this burden from the decoder by

counting multiple button presses and including the

QUE counter value in the last two bits of the 69-bit code

word, (Figure 3-2). If QUEN is disabled, the transmission will consist only of 67 bits as the QUE bits field is

not transmitted.

Que counter functionality is enabled with the QUEN

configuration option. The 2-bit QUE counter is incremented each time an active button input is released for

at least the Debounce Time (T

(button pressed again) within the Queue Time (T

Figure 3-5. The counter increments up from 0 to a maximum of 3, returning to 0 only after a different button

activation or after button activations spaced greater

than the Queue Time (T

The current transmission aborts, after completing the

minimum number of code words (Section 3.1.4.15),

when the active button inputs are released. A button reactivation within the queue time (T

new transmission (new synchronization counter,

encrypted data) using the updated QUE value. Button

combinations are queued the same as individual buttons.

QUE) apart.

DB), then re-activated

QUE),

QUE) then initiates a

DS40035C-page 14 Preliminary 2002 Microchip Technology Inc.

Page 17

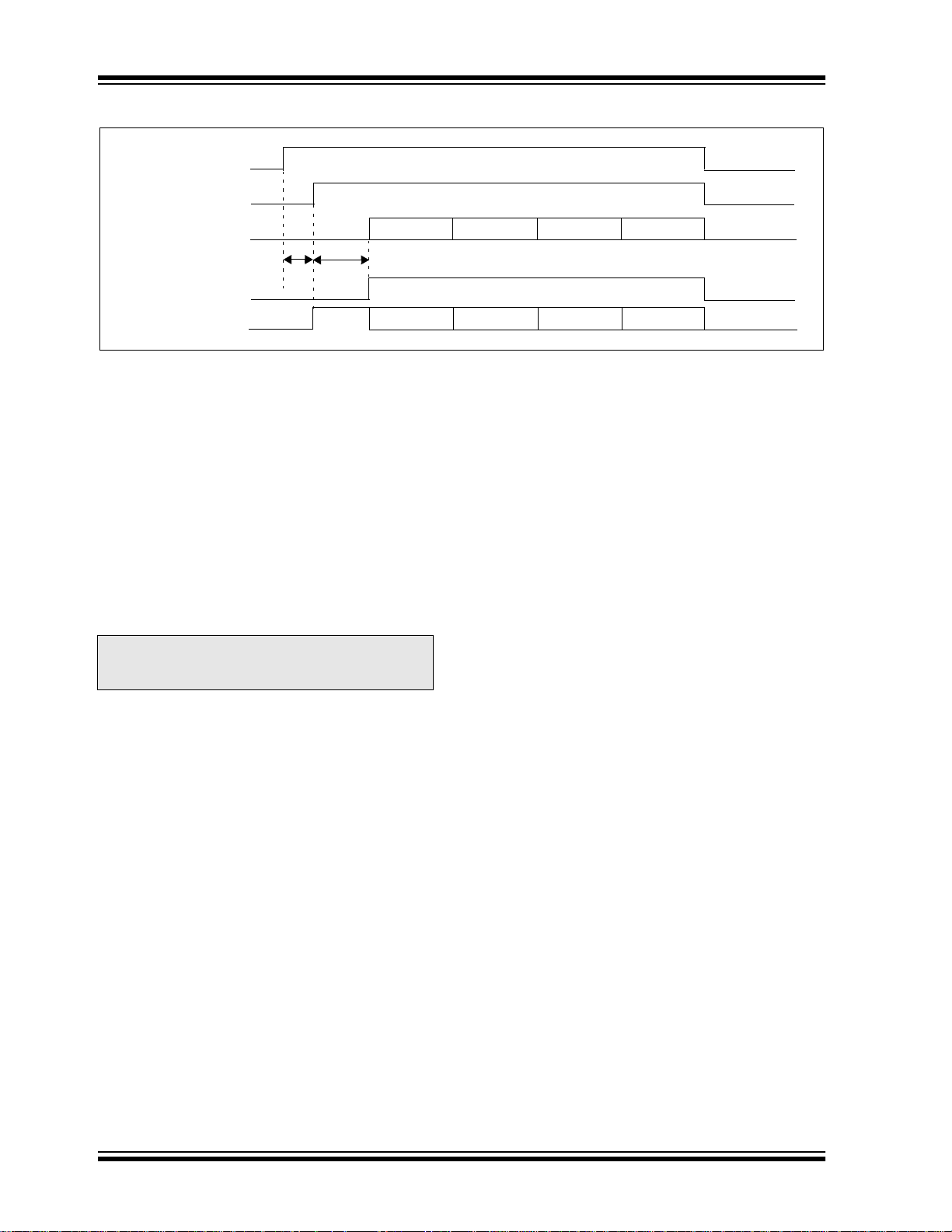

FIGURE 3-5: QUE COUNTER TIMING DIAGRAM

HCS473

Button Input

Sx

Code Words

Transmitted

1st Button Press All Buttons Released 2nd Button Press

Transmission: QUE1:0 = 01

t ≥ TDB

QUE1:0 = 00

Synch CNT = X

2

TDB

3.1.4.5 Counter Select (CNTSEL)

The counter select option selects between a 16-bit or

20-bit counter. This option changes the way the 32-bit

hopping portion is constructed, as indicated in

Figure 3-2. The 16-bit counter format additionally

includes two overflow bits for increasing the synchronization counter range, see Section 3.1.7.

CNTSEL options:

• 16-bit synchronization counter

• 20-bit synchronization counter

3.1.4.6 Low Voltage Trip Point Select

(VLOWSEL)

The HCS473’s battery voltage detector detects when

the supply voltage drops below a predetermined value.

The value is selected by the Low Voltage Trip Point

Select (VLOWSEL) configuration option (Table 3-6).

VLOWSEL options:

• 2.2V trip point

• 3.3V trip point

The low voltage detector result (VLOW) is included in

Hopping code transmissions allowing the receiver to

indicate when the transmitter battery is low (Figure 3-

2). The HCS473 also indicates a low battery condition

by changing the LED operation (Section 3.1.5).

The HCS473 samples the internal low voltage detector

at the end of each code word’s first preamble bit. The

transmitted VLOW status will be a ‘0’ as long as the low

voltage detector indicates V

low voltage trip point. VLOW will change to a ‘1’ if V

drops below the selected low voltage trip point.

DD is above the selected

DD

Transmission:

Synch CNT = X+1

TDB ≤ t ≤ TQUE

2

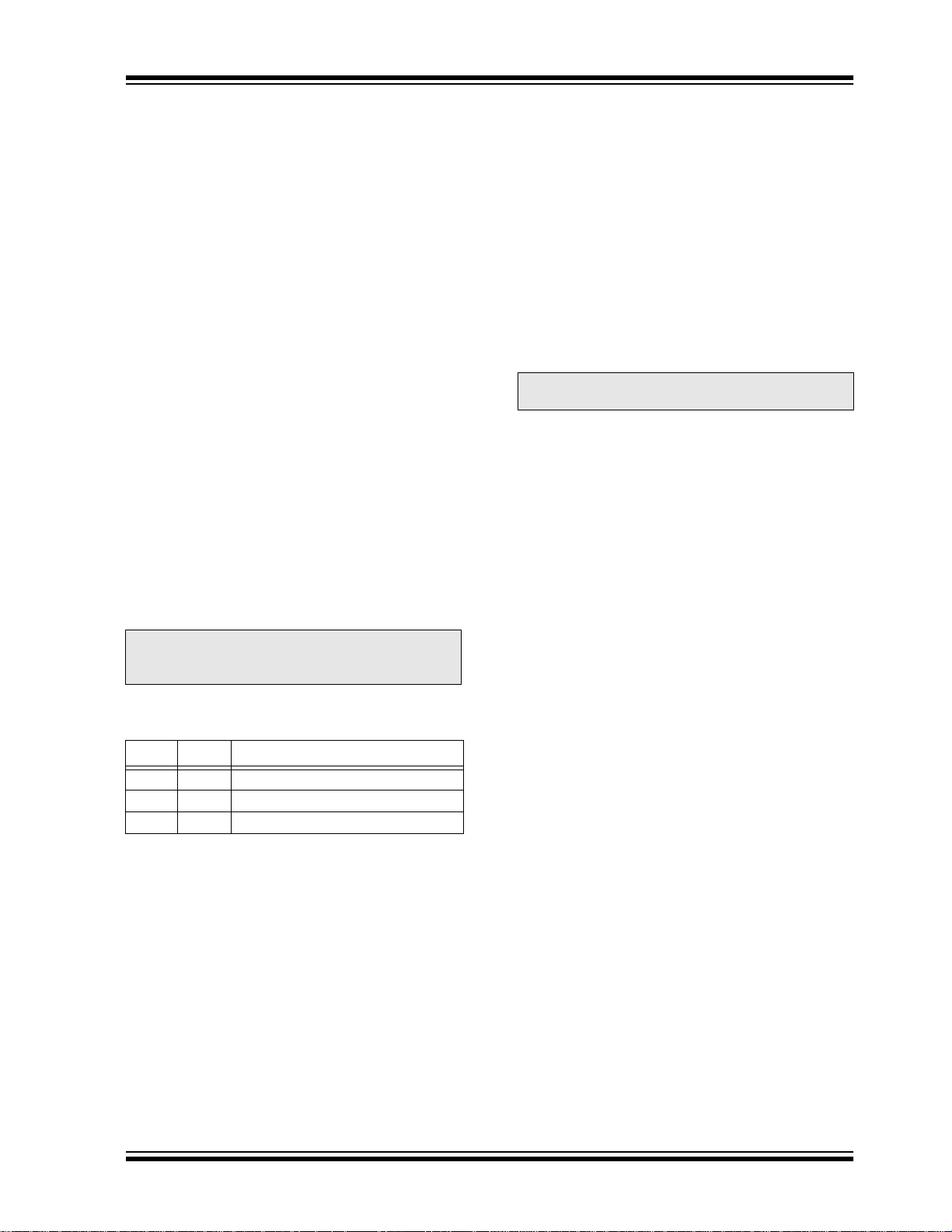

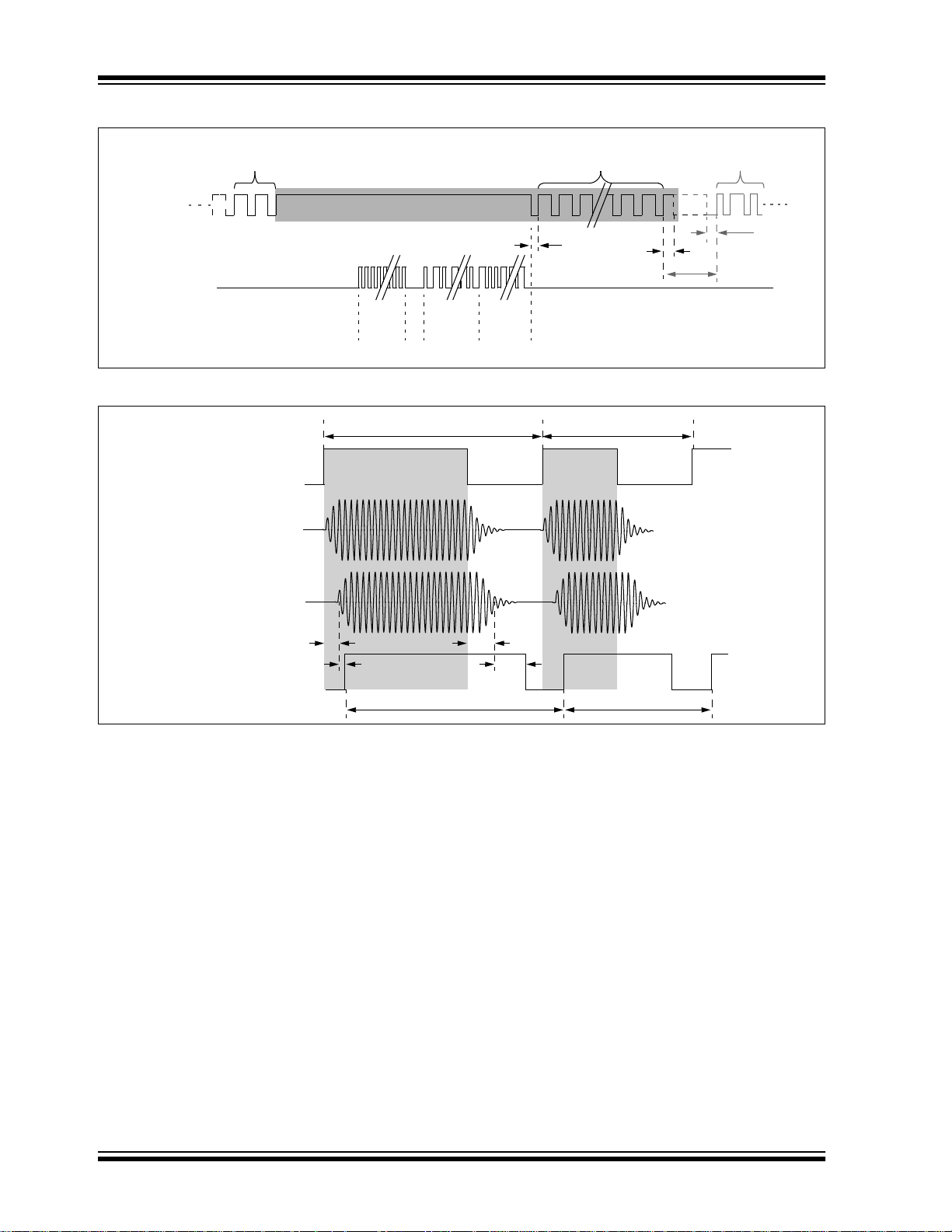

3.1.4.7 PLL Interface Select (PLLSEL)

The S3/RFEN pin may be configured as an RF enable

output to an RF PLL. The pin’s behavior is coordinated

with the DATA pin to activate a typical PLL in either

ASK or FSK mode.

The PLL Interface (PLLSEL) configuration option controls the output as shown for Encoder operation in

Figure 3-6. Please refer to Section 3.2.8 for RFEN

behavior during LF communication.

PLLSEL options:

• ASK PLL Setup

• FSK PLL Setup

3.1.4.8 RF Enable Output (RFEN)

The S3/RFEN pin of the HCS473 can be configured to

function as an RF enable output signal. When enabled,

the pin is driven high whenever data is transmitted

through the DATA pin; the S3/RFEN pin can therefore

not be used as an input in this configuration. The RF

enable option bit functions in conjunction with the PLL

interface select option, PLLSEL.

RFEN options:

• S3/RFEN pin functions as S3 switch input only

• S3/RFEN pin functions as RFEN output only

TABLE 3-1: VLOW STATUS BIT

VLOW Description

0 V

1 V

2002 Microchip Technology Inc. Preliminary DS40035C-page 15

DD is above selected trip voltage

DD is below selected trip voltage

Page 18

HCS473

FIGURE 3-6: ENCODER OPERATION: RF ENABLE/ASK/FSK OPTIONS

SWITCH

ASK:

FSK:

S3/RFEN

DATA

S3/RFEN

DATA

TPU

Code Word Code Word Code Word

T

PLL

Code Word Code Word Code Word

3.1.4.9 SEED Button Code (SDBT)

SDBT selects which switch input(s) activate a seed

transmission. Seed transmissions are disabled by

clearing all 4 bits. If a button combination is pressed

that matches the 4-bit SDBT value, a seed code word

is transmitted as configured by the SDTM, SDLM and

SDMD options (see following sections).

The binary bit order is S3-S2-S1-S0. For example, if

you want the combination of S2 and S0 to activate a

seed transmission, use SDBT=0101

2.

SDBT options:

• Seed is transmitted when SDBT flags match the

button input flags

• SDBT = 0000

disables seed capability.

2

Note: Configuring S3/RFEN as RFEN (see

Section 3.1.4.8) prevents the use of S3 to

trigger a seed transmission.

3.1.4.10 Time Before Seed (SDTM)

The time before seed option selects the delay from

device activation until the seed code words are transmitted. If the delay is not zero, the HCS473 transmits

hopping code words until the selected time, then transmits seed code words.

As code words are always completed, the seed code

word begins the first code word after the specified time.

SDTM options:

• 0s - seed code words begin immediately

•0.8s

•1.6s

•3.2s

Code Word

Code Word

3.1.4.11 Limited Seed (SDLM)

The limited seed option may be used to disable seed

transmission capability after a configurable number of

transmitter activations; limiting a transmitter’s ability to

be learned into a receiver. Specifically, seed transmissions are disabled when the synchronization counter’s

LSB increments from 7Fh to 80h.

SDLM options:

• unlimited seed capability

• limited seed capability - counter value dependent

3.1.4.12 SEED Mode (SDMD)

The Seed mode option selects between User and Production seed modes. Production mode functions as a

special time before seed case (SDTM).

With Production mode enabled, a seed button code

activation triggers MTX hopping code words followed

by MTX seed code words. Production mode functionality is disabled when the synchronization counter’s LSB

increments from 7Fh to 80h.

SDMD options:

•User

• Production

3.1.4.13 RF Baud Rate Select (RFBSL)

The timing of code word data modulated on the DATA

pin is referred to in multiples of a basic Timing Element

RFT

E. ‘RF’ TE

sent through a RF transmitter to the decoder or transponder reader.

E may be selected using the RF Baud Rate Select

RFT

(RFBSL) configuration option. RF

ject to the oscillator variation over temperature and

voltage.

RFBSL options:

•100 µs RFT

•200 µs RFTE

•400 µs RFTE

•800 µs RFTE

because the DATA pin output is typically

TE accuracy is sub-

E

DS40035C-page 16 Preliminary 2002 Microchip Technology Inc.

Page 19

HCS473

3.1.4.14 Guard Time Select (GSEL)

The guard time (TG) select option determines the time

between consecutive code words when no data is

transmitted. The guard time may be selected in conjuction with the RF baud rate and preamble duty cycle to

control time-averaged power output for transmitter certification.

GSEL options:

TE

•3 RF

• 6.4 ms

•51.2 ms

• 102.4 ms

3.1.4.15 Minimum Code Words (MTX)

The Minimum Code Words (MTX) configuration option

determines the minimum number of code words transmitted when a momentary switch input is taken high for

more than T

MTX options:

•1 code word

•2 code words

•4 code words

•8 code words

PU, or when a proximity activation occurs.

3.1.4.18 Long Preamble Length (LPRL)

The long preamble length option selects the first code

word’s preamble length when the long preamble option

(LPRE) is enabled. Only the first code word begins with

the long preamble, subsequent code words begin with

the standard 16 high pulses preamble.

LPRL options:

•75 ms

• 100 ms

3.1.4.19 Preamble Duty Cycle (PRD)

The preamble duty cycle can be set to either 33% or

50% to limit the average power transmitted, Figure 3-7.

PRD options:

• 50% Duty Cycle

• 33% Duty Cycle

FIGURE 3-7: PREAMBLE FORMATS

50% Duty Cycle

33% Duty Cycle

TE TE

TE 2TE

3.1.4.16 Timeout Select (TSEL)

The HCS473’s Timeout function prevents battery drain

should a switch input remain high (stuck button) longer

than the selectable TSEL time. After the TSEL time, the

device will return to Low-power mode.

The device will stop transmitting in Low-power mode

but there will be leakage across the stuck button input’s

internal pull-down resistor. The current draw will therefore be higher than if no button were stuck.

TSEL options:

•4s

•8s

•16s

•32s

3.1.4.17 Long Preamble Enable (LPRE)

Enabling the Long Preamble configuration option

extends the first code word’s preamble to a ‘long’ preamble time LPRL

wake and bias before the data bits arrive. The longer

preamble will be a square wave at the selected RFT

Subsequent code words begin with the standard preamble length.

LPRE options:

• Standard 16 high pulse preamble

• Long preamble, duration defined by LPRL

; allowing the receiver more time to

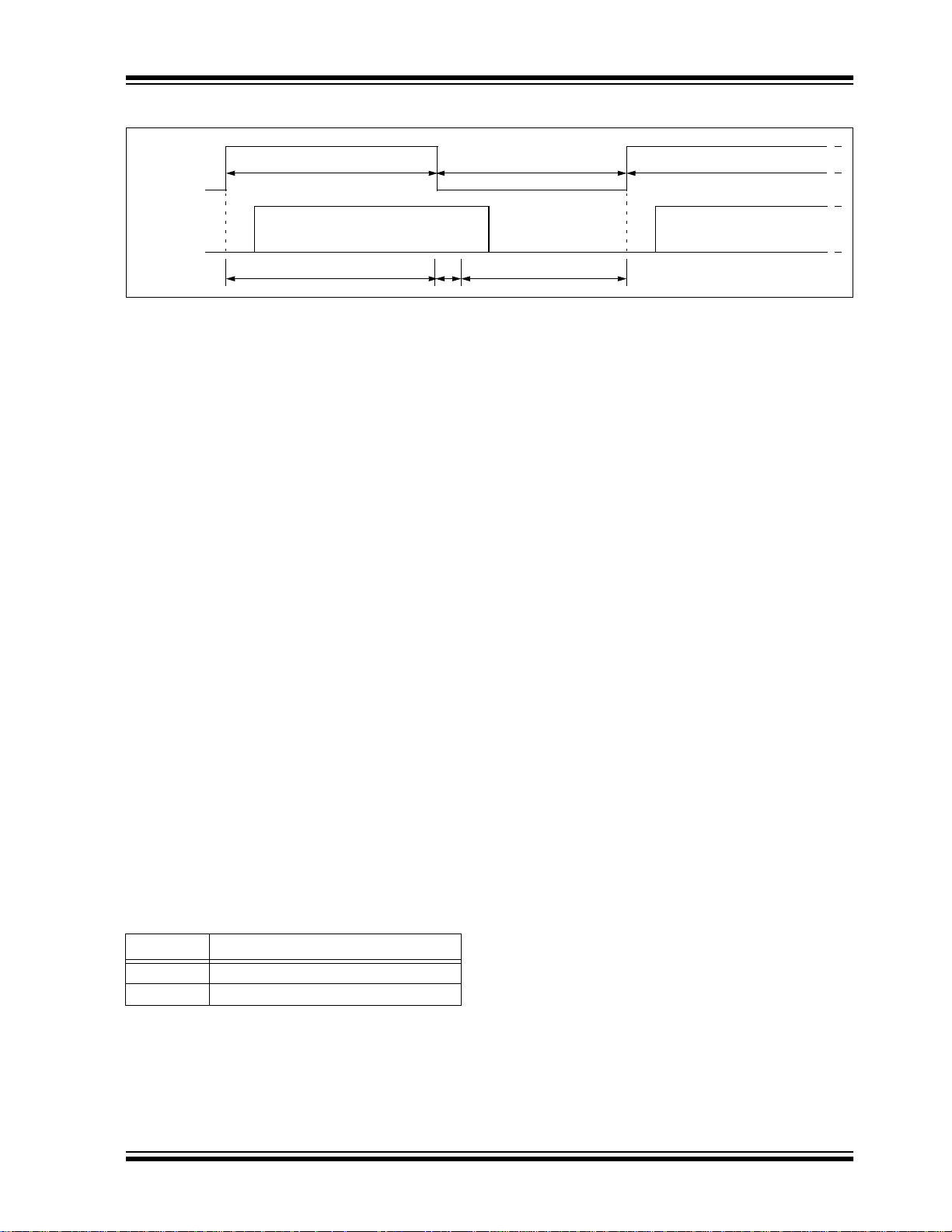

3.1.5 LED OPERATION

The LED pin output varies depending on whether the

device V

below V

The LED pin will periodically be driven low as long as

the device is transmitting and the battery is good. If the

supply voltage drops below the specified V

point, the LED pin will be driven low only once for any

given device activation so long as the low battery condition remains (Figure 3-8). If the battery voltage recovers during the transmission, the LED will begin blinking

again.

E.

DD is greater than VLOWSEL (a good battery) or

LOWSEL (a flat battery).

LOWSEL trip

2002 Microchip Technology Inc. Preliminary DS40035C-page 17

Page 20

HCS473

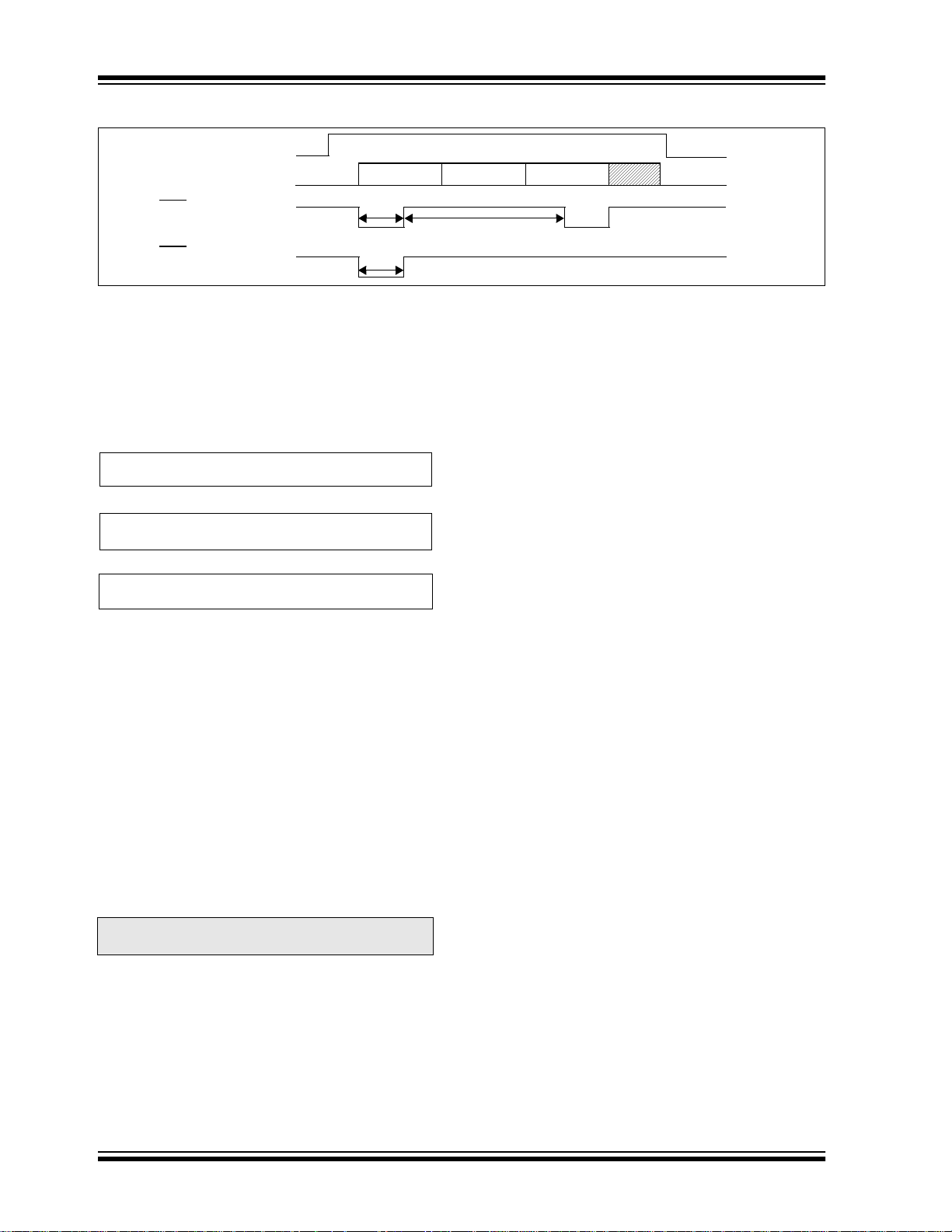

FIGURE 3-8: LED OPERATION

SWITCH Sx

Code Word Code Word Code Word

TLEDON

TLEDON

LED

LED

-

-

DATA

VDD>VLOWSEL

(good battery)

V

DD≤VLOWSEL

(flat battery)

3.1.6 CYCLE REDUNDANCY CHECK

(CRC)

The decoder can use the CRC bits to check the data

integrity before processing begins. The CRC is calculated on the previously transmitted bits (Figure 3-2),

detecting all single bit and 66% of all double bit errors.

EQUATION 3-1: CRC CALCULATION

CRC 1[]

and

CRC 0[]

with

and Di

the nth transmission bit 0 ≤ n ≤ 64

n

n1+

n1+

CRC 1 0,[]00=

CRC 0[]nDin⊕=

CRC 0[]nDin⊕()CRC 1[]

⊕=

n

3.1.7 COUNTER OVERFLOW BITS

(OVR1, OVR0)

The Counter Overflow Bits may be utilized to increase

the 16-bit synchronization counter range from the nominal 65,535 to 131,070 or 196,605. The bits do not exist

when the device is configured for 20-bit counter operation.

The bits must be programmed during production as ‘1’s

to be utilized. OVR0 is cleared the first time the synchronization counter wraps from FFFFh to 0000h.

OVR1 is cleared the second time the synchronization

counter wraps to zero. The two bits remain at ‘0’ after

all subsequent counter wraps.

Note: See Section 4.0, Programming Specs, for

information on programming OVR bits.

TLEDOFF

3.1.8 DISCRIMINATION VALUE (DISC)

The Discrimination Value is typically used by the

decoder in a post-decryption check. It may be any

value, but in a typical system it will be programmed

equal to the Least Significant bits of the serial number.

The discrimination bits are part of the information that

form the encrypted portion of the transmission

(Figure 3-2). After the receiver has decrypted a transmission, the discrimination bits are checked against the

receiver’s stored value to verify that the decryption process was valid; appropriate decryption key was used. If

the discrimination value was programmed as the LSb’s

of the serial number then it may merely be compared to

the respective bits of the received serial number.

The discrimination bit field size varies with the counter

select (CNTSEL) option (Figure 3-2).

3.2 Transponder Mode

The HCS473’s Transponder mode allows it to function

as a bi-directional communication transponder. Commands are received on the LC pins, responses may be

returned on either the LC pins or DATA pin for short

range LF or long range RF responses, respectively.

Transponder mode capabilities include:

• A bi-directional challenge and response sequence

for IFF validation.

• Read selected EEPROM areas.

• Write selected EEPROM areas.

• Request a code hopping transmission.

• Proximity Activation of a code hopping transmission.

• Address an individual transponder when multiple

units are within the LF field; device selection for

anticollision communication purposes.

DS40035C-page 18 Preliminary 2002 Microchip Technology Inc.

Page 21

HCS473

3.2.1 TRANSPONDER OPTIONS

The following HCS473 configuration options influence

the device behavior when in Transponder mode:

• Preamble length select (TPRLS)

• LF Demodulator (LFDEMOD)

• LF Baud rate select (LFBSL)

• Anticollision (ACOL)

• Proximity Activation (PXMA)

• Intelligent Damping (DAMP)

• LC response Enable (LCRSP)

• RF response Enable (RFRSP)

• Skip Field Acknowledge (SKIPACK)

The following sections describe these options in detail.

3.2.1.1 Transponder Preamble Length

Select (TPRLS)

Data responses through the DATA pin use the format

determined by the Encoder mode options, with one

exception/option to shorten the response time. The

response’s preamble can be reduced to 4 high pulses

by setting the transponder preamble length select

option. This only affects the responses as a result of

transponder communication (proximity activation transmissions included), not responses resulting from button input activations. The 4 high pulse short preamble

will be at the same duty cycle defined by the preamble

duty cycle Encoder mode option (PRD).

Note: The long preamble enable Encoder mode

option (LPRE) holds priority over the transponder preamble length option.

The demodulated signal on the LED pin is accurate to

within +/-10µs of the signal on the LC pins. The injected

signal will have baud rate limitations based on the

HCS473’s internal filter charge and discharge times,

Section 3.2.6.

The filter times discussed in Section 3.2.6 will be easily

seen in Demodulator mode. The internal filter delay

may be isolated by communicating to the HCS473

inputting the digital signal into LCX and observing the

signal plus internal filter delays on the LED pin.

LFDEMOD options:

• Disabled - device functions normally

• Enabled - device demodulates signal on LC pins,

outputting digital result on the LED pin.

Note: Damping is disabled when in Demodulator

mode.

3.2.1.3 LF Baud Rate Select (LFBSL)

The LF Baud rate select option allows the user to adjust

the basic pulse width element (LF

sponder communication.

TE) used for tran-

LFBSL options:

• 100 µs LFTE

• 200 µs LFTE

• 400 µs LFTE

• 800 µs LFTE

All communication to and from the HCS473 through the

LC transponder pins will use the selected LF

acknowledges to LF communication, through the DATA

pin, will also use the selected LF

TE.

TE. RF

TABLE 3-2: TRANSPONDER PREAMBLE

LENGTH SELECT (TPRLS)

TPLS LPRE Description

00Normal - 16 high pulses

X1Long - LPRL determines length

10Short - 4 high pulses

3.2.1.2 LF Demodulator (LFDEMOD)

The HCS473 has a LF Demodulator mode useful for

debugging antenna hardware.

Enabling LFDEMOD limits the device to demodulator

only mode. After receiving an appropriate wake-up

sequence, the device enters a loop demodulating the

signal on the LC pins and outputting the resulting digital

representation on the LED pin. The HCS473 remains in

this mode until no edges are detected on the LC pins

DEMOD, upon which it will return to Low-power

for T

mode; requiring another wake-up sequence to further

demodulate data.

3.2.1.4 Anticollision (ACOL)

Multiple transponders in the same inductive field will

simultaneously respond to inductive commands.

Enabling anticollision prevents multiple HCS473

responses from 'colliding'. Hence the term ‘anticollision.’

When anticollision (ACOL) is enabled, the first command received after the device wakes must be either

the SELECT TRANSPONDER or ANTICOLLISION

OFFcommand before the HCS473 will respond to any

other command.

The ANTICOLLISION OFF command may be used to

temporarily bypass anticollision requirements for a single communication sequence. It allows communication

with an anticollision enabled HCS473 if the VID and

TID are not known (perhaps during a learning

sequence). See Section 3.2.3.7 for further anticollision

off details.

The SELECT TRANSPONDER command allows the

addressing of and communication to an individual

HCS473, regardless if multiple devices are in the field

(Section 3.2.3.1).

2002 Microchip Technology Inc. Preliminary DS40035C-page 19

Page 22

HCS473

The HCS473 anticollision method is that all devices

trained to a given vehicle will have the same 12-bit

vehicle identifier (VID); Most Significant 12 bits of the

device identifier, Table 3-3. The device identifier of up

to 16 transponders trained to access a given vehicle

will differ only in the 4 LSb’s. These 4 bits are referred

to as the token identifier (TID).

TABLE 3-3: DEVICE ID

16-bit Device ID (DEVID)

1514131211109876543210

VID TID

11109 8 7 6 5432103210

The vehicle ID associates the HCS473 with a given

vehicle and the token ID makes it a uniquely addressable (selectable) 1 of 16 possible devices authorized to

access the vehicle.

Two unique device identifiers are available allowing the

HCS473 to be used with two different vehicles. The

HCS473 responds if the presented VID and TID match

either of the two programmed identifiers.

SELECT TRANSPONDER may still be performed on

devices not configured to require anticollision; communication can still be isolated to one of multiple devices

in the field. Equally, the same devices will respond to all

command sequences not preceded by the SELECT

TRANSPONDER sequence.

3.2.1.6 Intelligent Damping (DAMP)

A high Q-factor LC antenna circuit connected to the

HCS473 will continue to resonate after a strong LF field

is removed, slowly decaying. The slow decay makes

fast communication near the reader difficult as the

resulting extended high time makes the following low

time disappear.

The Intelligent damping option enables a pulsed, resistive short from the LC pins to LCCOM when the

HCS473 is expecting the incoming LC signal level to go

low. These pulses damp the antenna, dissipating resonant energy for a quicker decay time when the field is

switched off.

The damping pulses are applied between the LCCOM

pin and the individual LC pins, starting 1.2 LF

detecting the bit’s rising edge and repeating until the

LC input goes low. Damp pulse width is 6 µs, beginning

every 44 µs as shown in Figure 3-9.

Note: Damping will not reduce the HCS473 inter-

nal LF analog filter discharge time, T

(Section 3.2.6).

TE from

FILTF

FIGURE 3-9: INTELLIGENT DAMPING

No Damping With Damping

Field on

LC pins

3.2.1.5 Proximity Activation (PXMA)

Enabling the Proximity Activation configuration option

allows the HCS473 to transmit a hopping code transmission in response to detecting an appropriate wakeup pulse on an LC input pin.

The HCS473 sends a wake-up sequence Acknowledge in response to detecting the LF field (Figure 3-

11). The device then waits T

edge followed by the normal T

transponder command to begin. If no command is

received, a code hopping transmission is generated

and the minimum code words (set with MTX option) are

transmitted. When the transmission completes, the

HCS473 waits a T

begin. If no command is received the device returns to

SLEEP.

Proximity activations are not repeatedly activated when

the device is in the presence of a continuous LF field

(computer monitor, tv,...). The HCS473 must receive an

appropriate wake-up sequence to activate each transmission.

The button status used in the proximity activated code

hopping transmission clears the S0, S1, S2 and S3 button status flags.

CMD window for a new command to

CMD for the LF field’s falling

CMD window waiting for a

LC Output

Level

Signal

TDAMP

Damping Pulses

3.2.1.7 Response Options (RFRSP,

LCRSP)

HCS473 responses may optionally be returned on the

DATA pin for long-range RF responses and/or LC pins

for short-range LF responses (Table 3-4). Responses

include both Acknowledge sequences and data

responses.

The options controlling the response path are:

• LC response option (LCRSP)

• RF response option (RFRSP)

If both RF and LF responses are enabled, Acknowledge pulses will occur simultaneously on the DATA and

LC pins; using the LF

Figure 3-19). Data responses will not occur simultaneously. The RF response on the DATA pin will occur

first (following the designated Encoder mode format),

immediately followed by the LF response on the LC

pins (Figure 3-20).

TE baud rate (Figure 3-11,

DS40035C-page 20 Preliminary 2002 Microchip Technology Inc.

Page 23

HCS473

TABLE 3-4: HCS473 RESPONSE OPTIONS

RFRSP LCRSP Description

00No response

01Response over the LC pins

10Response through the DATA pin

11Response through the DATA pin

first and then the LC pins

3.2.1.8 Skip Field Acknowledge (SKIPACK)

The initial Field Acknowledge sequence, occurring during the wake-up pulse, may be disabled by enabling the

Skip Field Acknowledge configuration option (SKIPACK=1). Omitting the ACK slightly minimizes a

HCS473’s average communication current draw, but

conversely will increase average authentication time as

the wake-up pulse must then be the maximum start-up

SF

filter charge time, T

MAX

.

3.2.2 TRANSPONDER COMMUNICATION

Data to and from the HCS473 is always sent Least Significant bit first. The data length and modulation format

vary with the particular command sequence and the

transmission path.

3.2.2.1 LC Communication Format

Commands from the transponder reader to the

HCS473 as well as the responses from the HCS473

over the low frequency path (LC pins) are Pulse Position Modulated (PPM) according to Figure 3-10.

Communication from the transponder reader to a

HCS473 is via the reader amplitude shifting a 125kHz

low frequency (LF) field.

LF responses back to the transponder reader are

achieved by the HCS473 applying a low-resistance

short from the LC pins to LCCOM (configuration option

LCRSP enables LF talkback). This short across the

antenna inputs is detected by the reader as a load on

its 125kHz transmitting antenna.

See Section 5.4 for further details on inductive communication principles.

FIGURE 3-10: LC PIN PULSE POSITION

MODULATION (PPM)

‘0’

125kHz

1LF

TE

1LF

TE

Digital

Representation

START or

previous bit

‘1’

125kHz

Digital

Representation

2LF

TE

1LF

TE

3.2.2.2 RF DATA Communication Format

The RF responses on the DATA pin vary with the information being returned.

• Acknowledge responses are based on the LF

• Data code words responses are based on the

RF

TE, using the format determined by the

Encoder mode options, Section 3.1.4.

TE.

3.2.2.3 Wake-up Sequence

The transponder reader initiates each communication

sequence by turning on the low frequency field, then

waits for a HCS473 to Acknowledge the field.

The HCS473 enters Transponder Mode after detecting

a signal on any LC low frequency antenna input pin that

has remained high for at least the start-up filter time

SF, Table 7-5. The device then responds with a Field

T

Acknowledge sequence indicating that it has detected

the LF field, is in Transponder Mode and is ready to

receive commands (Figure 3-11). The wake-up pulse’s

falling edge must then occur within T

the Field Acknowledge sequence.

The Field Acknowledge sequence may optionally be

disabled by enabling the Skip Field ACK configuration

option, Section 3.2.1.8.

In both cases, the first command bit must begin within

CMD of the wake-up pulse’s falling edge or the

T

HCS473 will return to Low Power mode.

CMD of the end of

2002 Microchip Technology Inc. Preliminary DS40035C-page 21

Page 24

HCS473

FINH should be appropriately adjusted to receive con-

3.2.2.4 Command Sequence

The transponder reader follows the HCS473’s Field

Acknowledge by sending the desired 3-bit command,

3-bit option or address, associated data and CRC;

each as required. LF commands are Pulse Position

Modulated (PPM) as shown in Figure 3-10. The last bit

(CRC bit) should be followed by leaving the field on for

FINH.

T

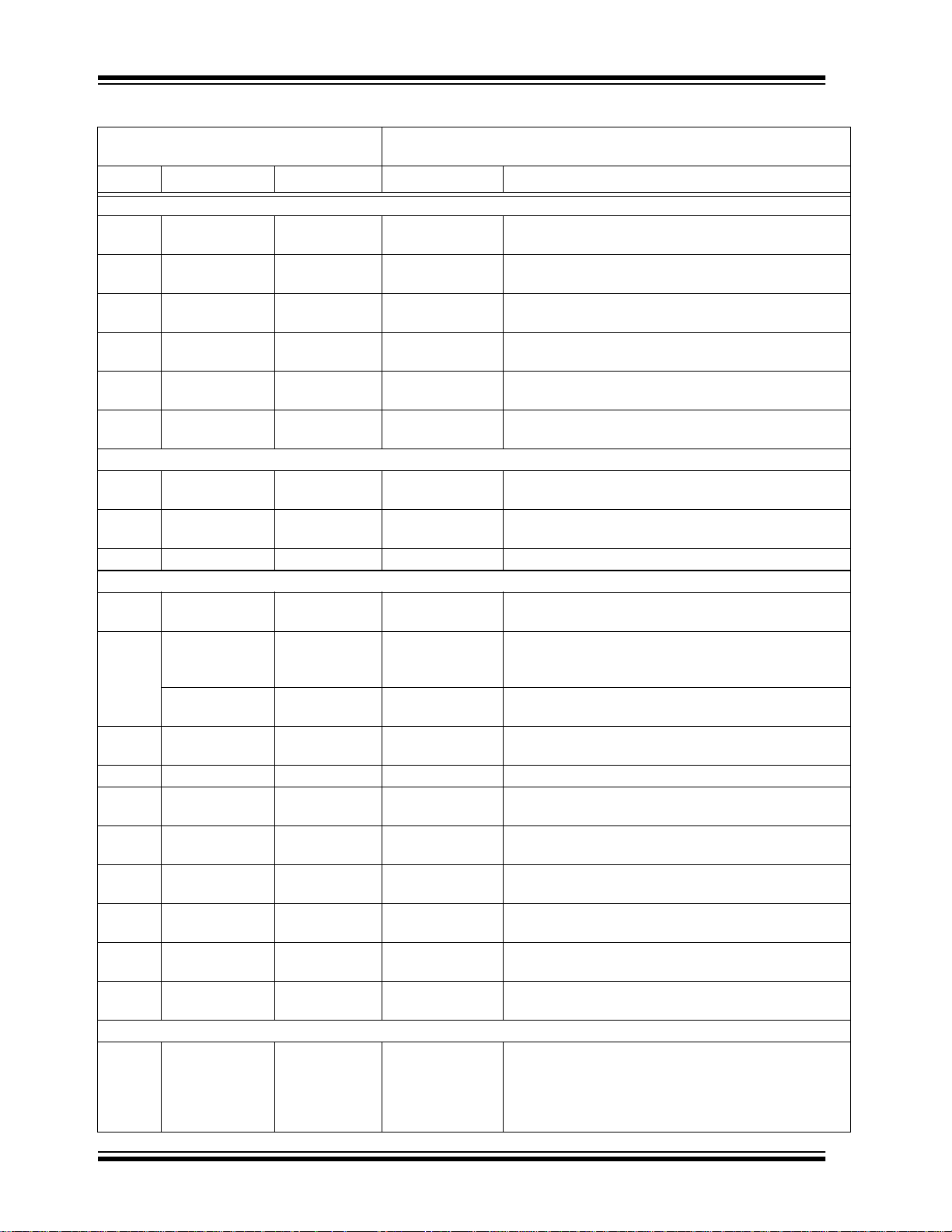

FIGURE 3-11: HCS473 TRANSPONDER WAKE-UP SEQUENCE

SKIPACK = 0 - Field Acknowledge sent when device wakes

T

secutive commands or LF responses. See

Section 3.2.4 and Section 3.2.5 for LF response and

consecutive command considerations.

125kHz Field

(on LC pins)

Simultaneous LF

Acknowledge

(LFRSP=1)

TSF

Inductive

(LC)

3LFTE 3LFTE3LFTE 3LFTE

RF

Response

(DATA)

RF Acknowledge

(RFRSP=1)

SKIPACK = 1 - Field Acknowledge is not sent

Inductive

(LC)

TCMD

TSF

MAX

Command

bit0

bit1

TCMD

bit2

Command

bit0

bit1

TCMD

bit2

Communication from reader to HCS473

Communication from HCS473 to reader

DS40035C-page 22 Preliminary 2002 Microchip Technology Inc.

Page 25

3.2.3 TRANSPONDER COMMANDS

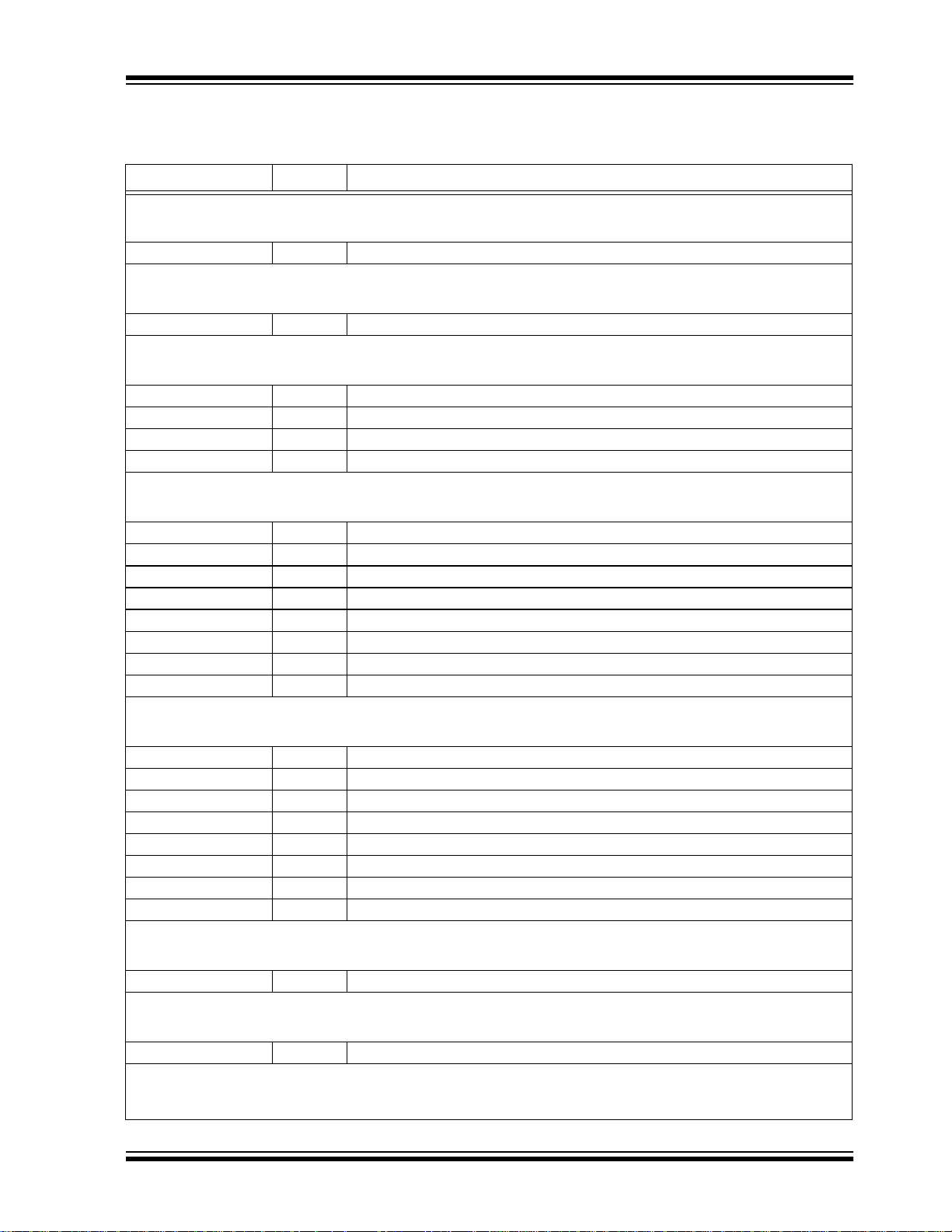

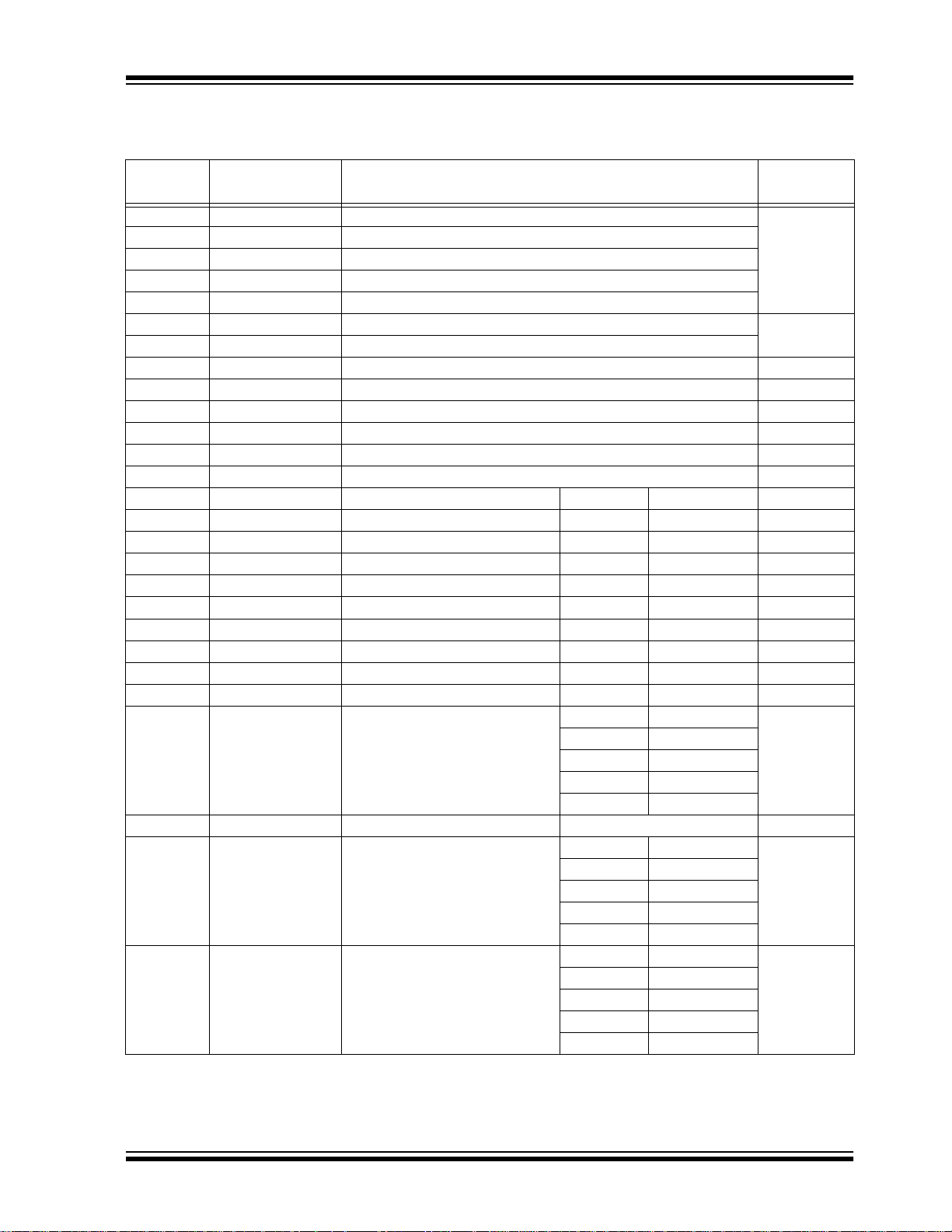

TABLE 3-5: LIST OF AVAILABLE TRANSPONDER COMMANDS

Command Option Description

Select Transponder

(Section 3.2.3.1)

000

2

Present Transport Code

(Section 3.2.3.2)

001

2

Identify Friend or Foe (IFF)

(Section 3.2.3.3)

010

2

Read EEPROM

(1)

(Section 3.2.3.4)

100

2

Write EEPROM

(1) (2)

(Section 3.2.3.5)

101

2

Request Hopping Code

(Section 3.2.3.6)

110

2

- Select HCS473, used to isolate communication to a single HCS473

(1)

- Used to gain write access to the device EEPROM memory locations

(1)

000

001

010

011

000

001

010

011

100

101

110

111

000

001

010

011

100

101

110

111

(1)

32-bit IFF using the Transponder Key

2

16-bit IFF using the Transponder Key

2

32-bit IFF using the Encoder Key

2

16-bit IFF using the Encoder Key

2

Read 16-bit User EEPROM 0

2

Read 16-bit User EEPROM 1

2

Read 16-bit User EEPROM 2

2

Read 16-bit User EEPROM 3

2

Read Most Significant 16 bits of the Serial Number

2

Read Least Significant 16 bits of the Serial Number

2

Read 16-bit Device Identifier #1 (12-bit Vehicle ID #1 and 4-bit Token ID #1)

2

Read 16-bit Device Identifier #2 (12-bit Vehicle ID #2 and 4-bit Token ID #1)

2

Write 16-bit User EEPROM 0

2

Write 16-bit User EEPROM 1

2

Write 16-bit User EEPROM 2

2

Write 16-bit User EEPROM 3

2

Write Most Significant 16 bits of the Serial Number

2

Write Least Significant 16 bits of the Serial Number

2

Write 16-bit Device Identifier #1 (12-bit Vehicle ID #1 and 4-bit Token ID #1)

2

Write 16-bit Device Identifier #2 (12-bit Vehicle ID #2 and 4-bit Token ID #1)

2

- Request Hopping Code transmission

HCS473

Anticollision OFF

(Section 3.2.3.7)

111

2

- Temporarily bypass a HCS473’s anticollision requirements.

Note 1: Command must be preceded by successful Select Transponder or Anticollision Off sequence if anticolli-

sion is enabled.

2: A successful Present Transport Code sequence must first occur to gain write access.

2002 Microchip Technology Inc. Preliminary DS40035C-page 23

Page 26

HCS473

3.2.3.1 SELECT TRANSPONDER

The SELECT TRANSPONDER sequence must immediately follow the HCS473 wake-up. A 12-bit Vehicle ID

(VID) follows the 3-bit command. The 4-bit Token ID

(TID) is sent by pulsing the field to identify which transponder should respond.

The HCS473 counts each time the field is pulsed (6

TE period), the first pulse setting the counter equal to

LF

0. If the VID matched, the HCS473 will send an

Acknowledge when the TID matches the counter. Any

further TID pulses after the Acknowledge occurs will

Any HCS473 that did not match both the presented VID

and TID will return to SLEEP, unselected, remaining

that way until the next wake-up pulse occurs.

The next command must begin T

Acknowledge. If the LC input is high a point T

after the Acknowledge ends, the HCS473 will return to

SLEEP, unselected, assuming the transponder reader

is sending additional TID pulse(s) to select a different

device. A device of any TID value may therefore be

uniquely selected, regardless if a device with lower TID

has already acknowledged.

deselect the device, putting it back to SLEEP - again

requires a wake-up sequence to communicate.

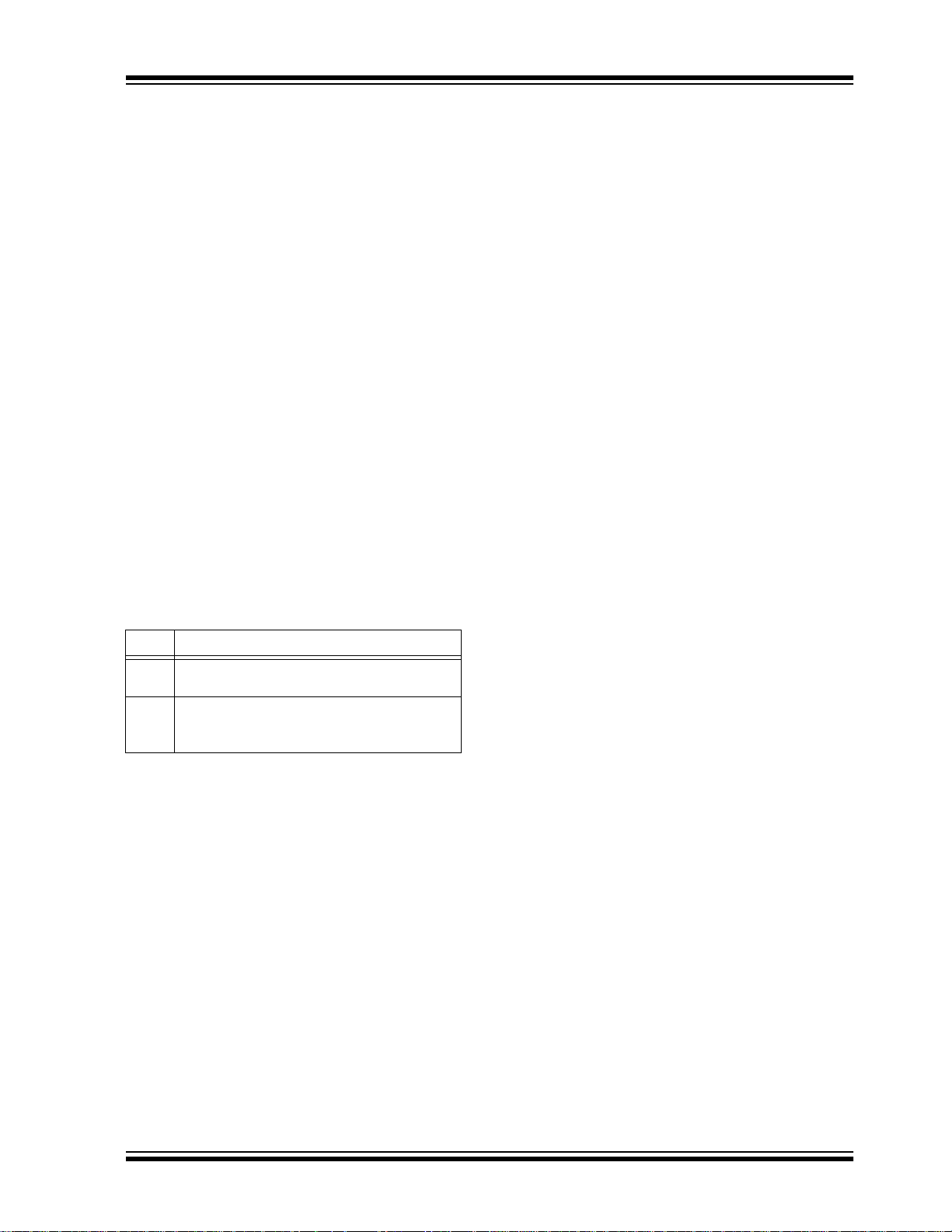

FIGURE 3-12: TRANSPONDER SELECT SEQUENCE (RF RESPONSE EXAMPLE)

1-16

Pulses

TID

TID=0

TID=1 TID=2 TID=3

6 LF

TE

T

TSCMD

ACK

T

TSACK

5 LF

TE

T

TSCMD

Transponder Select ACK

Example for TID=’0011’

‘XXX’

CMD

Next

Command

bit0

bit1

bit2

Inductive In

(LC Pins)

RF Response

(DATA Pin)

T

SF

WAKE ACK

T

CMD

ACK

T

CMD

Command

‘0’

‘0’

LSb

T

CMD

‘0002’

CMD VID

12-Bit

‘0’

bit0

LSb

MSb

VID

bit1

12 bits

bit10

bit11

MSb

TSCMD after the

TSCMD

MIN

16-bit Device Identifier = [ 12-bit Vehicle ID ] [ 4-bit Token ID ]

bit5

bit6

bit7

bit8

bit9

bit10

bit11

bit12

bit13

bit14

bit15

MSb

DID

bit4

bit3

bit2

bit1

bit0

LSb

bit11

MSb

bit10

bit5

bit6

bit7

bit8

bit9

bit1

bit2

bit3

bit4

bit0

LSb

bit3

TIDVID

MSb

bit2

bit1

bit0

LSb

DS40035C-page 24 Preliminary 2002 Microchip Technology Inc.

Page 27

HCS473

3.2.3.2 PRESENT TRANSPORT CODE

Prior to modifying the device EEPROM, the correct 32bit transport code (password) must be presented to

gain write access. This is done with the PRESENT

TRANSPORT CODE command followed by the 32-bit

transport code and CRC calculated on the 3-bit command and 32 bits of data.

The HCS473 will return an Acknowledge if the transport code matches the value programmed in production; write access has been granted.

The next command (usually a write) must begin T

CMD

after the Acknowledge, Figure 3-13.

FIGURE 3-13: PRESENT TRANSPORT CODE SEQUENCE (RF RESPONSE EXAMPLE)

The present transport code sequence must precede a

write sequence but not necessarily immediately. Perhaps all four user memory locations will be written and

verified. The present transport code sequence must

precede only the first write to gain write access. The

system may then alternately write and read (verify)

multiple memory locations. Write access remains until

the next time the device returns to Low Power mode communication error or T

CMD time out without receiving

another command.

Wake Sequence

Previous Command

Inductive In

(LC Pins)

RF Response

(DATA Pin)

or

Response

T

SF

ACK

T

CMD

T

CMD

Command

T

CMD

‘0012’

32 bits

CMD TCODE

32-Bit

Transport

‘1’