Page 1

HCS360

KEELOQ® Code Hopping Encoder

FEATURES

Security

• Programmable 28/32-bit serial number

• Programmable 64-bit encryption key

• Each transmission is unique

• 67-bit transmission code length

• 32-bit hopping code

• 35-bit fixed code (28/32-bit serial number,

4/0-bit function code, 1-bit status, 2-bit CRC)

• Encryption keys are read protected

Operating

• 2.0-6.6V operation

• Four but ton inputs

- 15 functions available

• Selectable baud rate

• Automatic code word co mpletion

• Battery low signal transmitted to receiver

• Nonvolatile synchronization data

• PWM and Manchester modulation

Other

• Easy-to-use programming interface

• On-chip EEPROM

• On-chip oscillator and timing components

• Button inputs have inte rnal pull-down resistors

• Current limiting on LED

• Minimum component count

Enhanced Features Over HCS300

• 48-bit seed vs. 32-bit seed

• 2-bit CRC for error detection

• 28/32-bit serial number select

• Two seed transmission methods

• PWM and Manchester modulation

• IR Modulation mode

output

DESCRIPTION

The HCS360 is a code hopping encoder designed for

secure Remote Keyless Entry (RKE) systems. The

HCS360 utilizes the KEELOQ c ode ho pping techno logy,

which incorporates high security, a small package

outline and low cost, to make this device a perfect

solution for unidirectional remote keyless entry systems and access control systems.

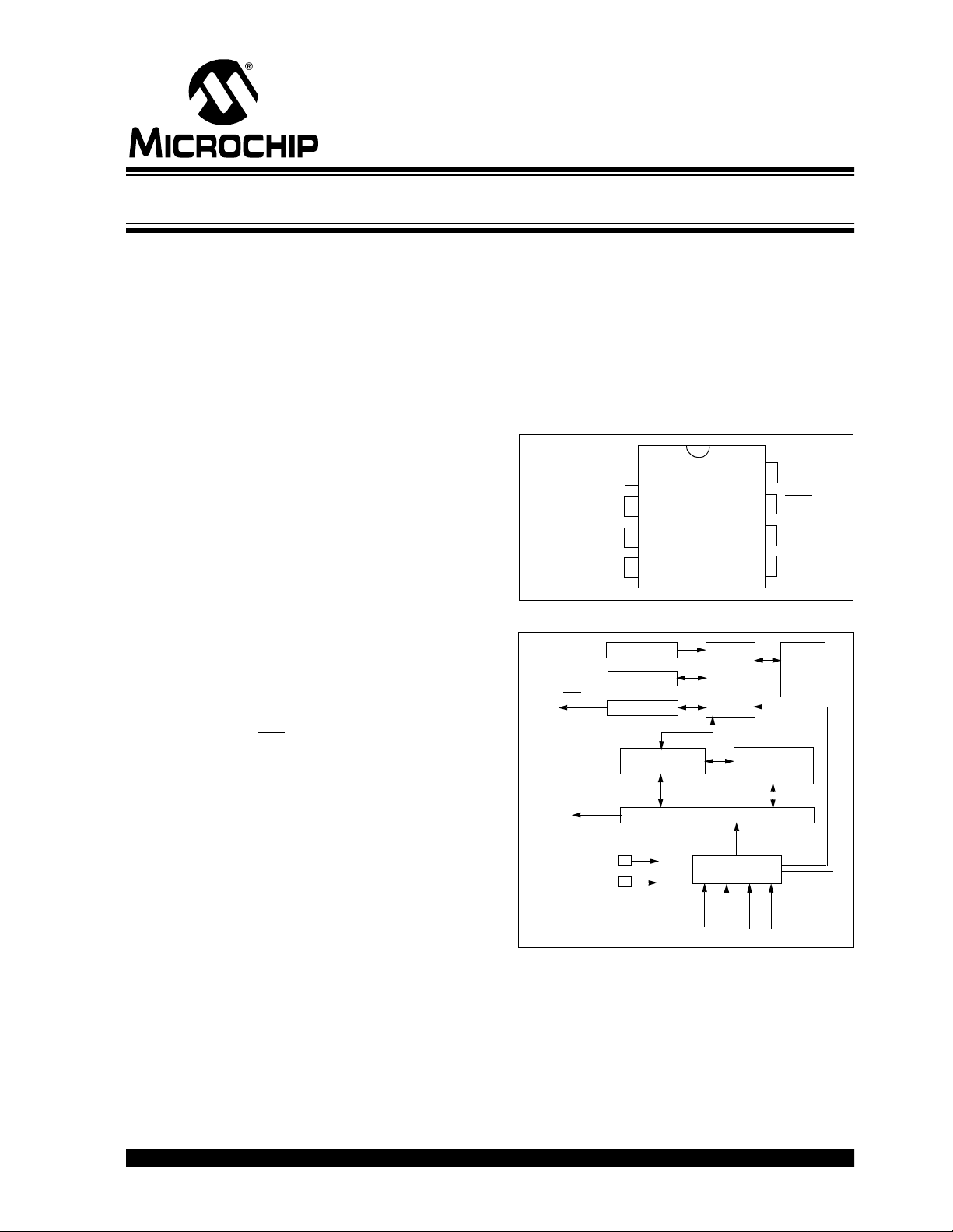

PACKAGE TYPES

PDIP, SOIC

8

V

S0

S1

S2

S3

1

HCS360

2

3

4

DD

LED

7

6

DATA

V

SS

5

BLOCK DIAGRAM

LED

DATA

RESET circuit

VSS

VDD

Oscillator

Controller

LED driver

EEPROM

32-bit shift register

Button input port

Encoder

Power

latching

and

switching

Typical Applications

The HCS360 is ideal for Remote Keyless Entry (RKE)

applications. These applications include:

• Automotive RKE systems

• Automotive alarm systems

The HCS360 combines a 32-bit hopping code

generated by a nonlinear encryption algorithm, with a

28/32-bit serial number and 7/3 status bits to create a

67-bit transmission stream.

S

S

S1S

2

3

0

• Automotive immobilizers

• Gate and garage door openers

• Identity t okens

• Burglar alarm systems

2002 Microchip Technology Inc. DS40152E-page 1

Page 2

HCS360

The crypt key, serial number and conf iguration d ata are

stored in an EEPROM array which is n ot accessible via

any external connection. The EEPROM data is programmable but read-protected. The data can be verified only after an automatic erase and programming

operation. This protects against attempts to gain

access to keys or manipulate synchronizat ion values.

The HCS360 provides an easy-to-use serial interface

for programming the necessary keys, system parameters and configuration data.

1.0 SYSTEM OVERVIEW

Key Terms

The following is a l ist of key te rms us ed thro ughout this

data sheet. For additional information on K

Code Hopping, refer to Technical Brief 3 (TB003).

• RKE - Remote Keyless Entry

• Button Status - Indicates what button input(s)

activated the transmission. Encompasses the 4

button status bits S3, S2, S1 and S0 (Figure 3-1).

• Code Hopping - A method by which a code,

viewed externally to the system, appears to

change unpredictably each time it is transmitted.

• Code word - A block of data that is repeatedly

transmitted upon button activation (Figure3-1).

• Transmission - A data stream consisting of

repeating code words (Figure 8-1).

• Crypt key - A unique and secret 64-bit number

used to encrypt and decrypt data. In a symmetrical block cipher such as the K

the encryption and de cry pti on k ey s a re equal and

will therefore be referred to generally as the crypt

key.

• Encoder - A device that generates and encodes

data.

• Encryption Algorithm - A recipe wher eby data i s

scrambled using a cryp t key . The dat a can only be

interpreted by the respe ctive dec ryptio n algo rithm

using the same crypt key.

• Decoder - A device that decodes data received

from an encoder.

• Decryption algorithm - A recipe whereby data

scrambled by an encryption algorithm can be

unscrambled using the s ame crypt key.

EELOQ algorithm,

EELOQ and

• Learn – Learning involves the receive r calculatin g

the transmitter’s appropriate crypt ke y, d ec rypting

the received hopping code and storing the serial

number, synchronization counter value and crypt

key in EEPROM. The K

itates several learning strategies to be implemented on the decoder. The following are

examples of what can be done.

- Simple Learning

The receiver uses a fixed crypt key, common

to all compone nts of al l s y ste ms b y the same

manufacturer, to decrypt the received code

word’s encrypted portion.

- Normal Learning

The receiver uses information transmitted

during normal operation to derive the crypt

key and decrypt the received code word’s

encrypted portion.

- Secure Learn

The transmitter is activated through a special

button combinat ion to t ransmit a stored 60-bit

seed value used to generat e the trans mitter’s

crypt key. The receiver uses this seed value

to derive the same crypt key and decrypt the

received code word’s encrypted portion.

• Manufacturer’s code – A unique and secret 64-

bit number used to generate un ique encoder crypt

keys. Each encoder is programmed with a crypt

key that is a function of the manufacturer’s code.

Each decoder is programmed with the manufacturer code itself.

The HCS360 code hopping encode r is designed sp ecifically for keyless entry systems; primarily vehicles and

home garage door openers. The encoder portion of a

keyless entry system is integrated into a transmitter,

carried by the user and operated to gain access to a

vehicle or restricted area. The HCS360 is meant to be

a cost-effective yet secure solution to such systems,

requiring very few external components (Figure 2-1).

Most low-end keyless entry transmitters are given a

fixed identificati on code that is transmitted ever y time a

button is pushed. The number of unique identification

codes in a low-end system is usually a relatively small

number. These shortcomings provide an opportunity

for a soph istic ated t hief to crea te a d evice that ‘grab s’

a transmission and retransmits it later, or a device that

quickly ‘scans ’ all pos sible identi ficati on c odes un til the

correct one is found.

The HCS360, on the other hand, employs the K

code hopping technology coupled with a transmission

length of 66 bits to virtually eliminate the use of code

‘grabbing’ or code ‘scann ing’. The hig h security le vel of

the HCS360 is ba sed on the p ate nted K

ogy. A block cipher based on a block length of 32 bits

and a key length of 64 bits is used. The algorithm

obscures the informati on i n such a way that even if th e

transmission informati on (before c oding) dif fers b y only

one bit from that of the previous transmission, the next

EELOQ product family facil-

EELOQ

EELOQ

technol-

DS40152E-page 2 2002 Microchip Technology Inc.

Page 3

HCS360

coded transmission will be completely different. Statistically, if only one bit in the 32-bit string of information

changes, greater than 50 percent of the coded transmission bits will change.

As indicated in the block diagram on page one, the

HCS360 has a small EEPROM array which must be

loaded with several p arameters before use; mos t ofte n

programmed by the manufacturer at the time of production. The most important of these are:

• A 28-bit serial number, typically unique for every

encoder

• A crypt key

• An initial 16-bit synchronization value

• A 16-bit configuration value

The crypt key generatio n typically input s the transmitter

serial number and 64-bit manufact urer ’s code into t he

key generation algorithm (Figure 1-1). The manufacturer’s code is chosen by the system manufacturer and

must be carefully controlled as it is a pivotal part of the

overall system security.

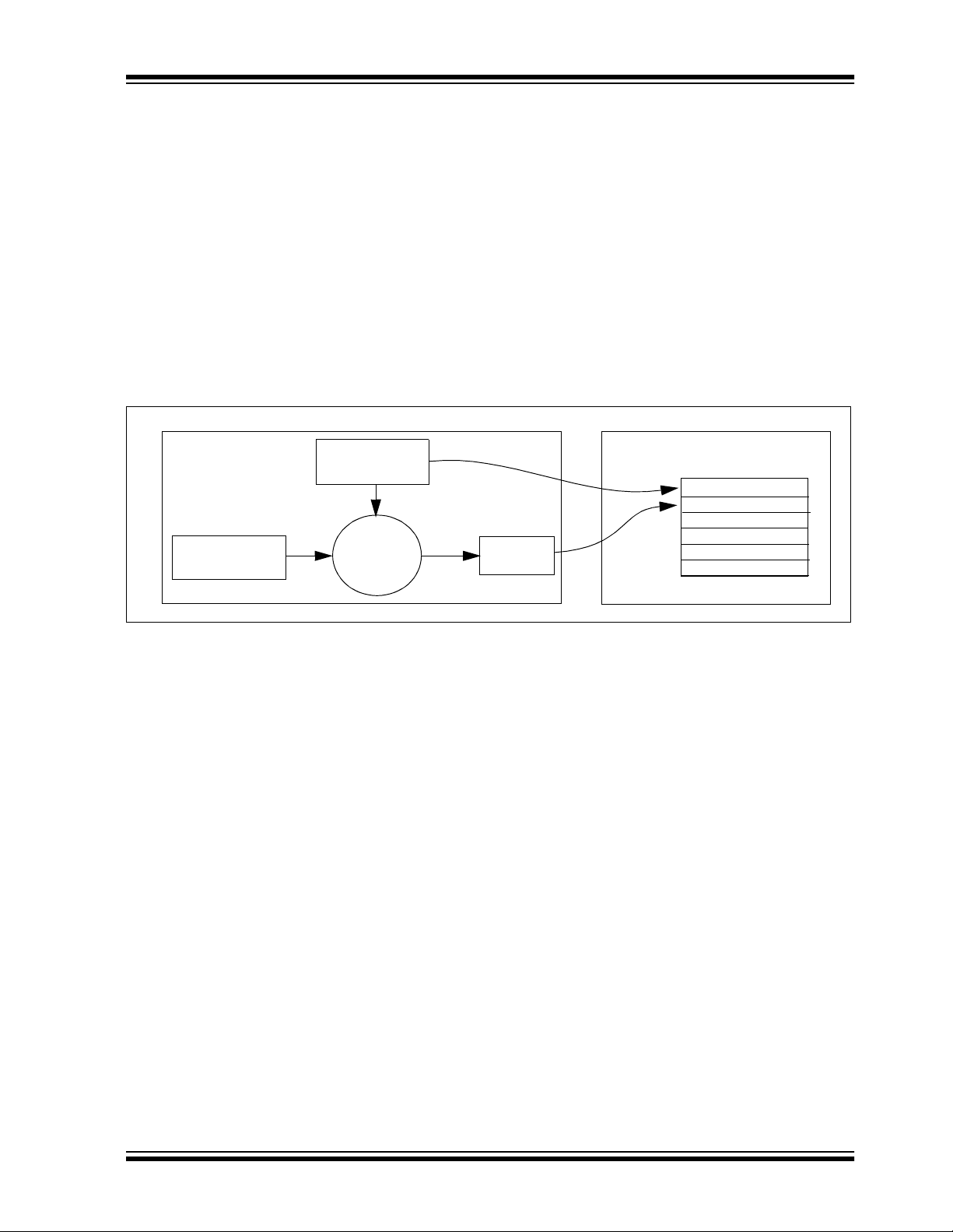

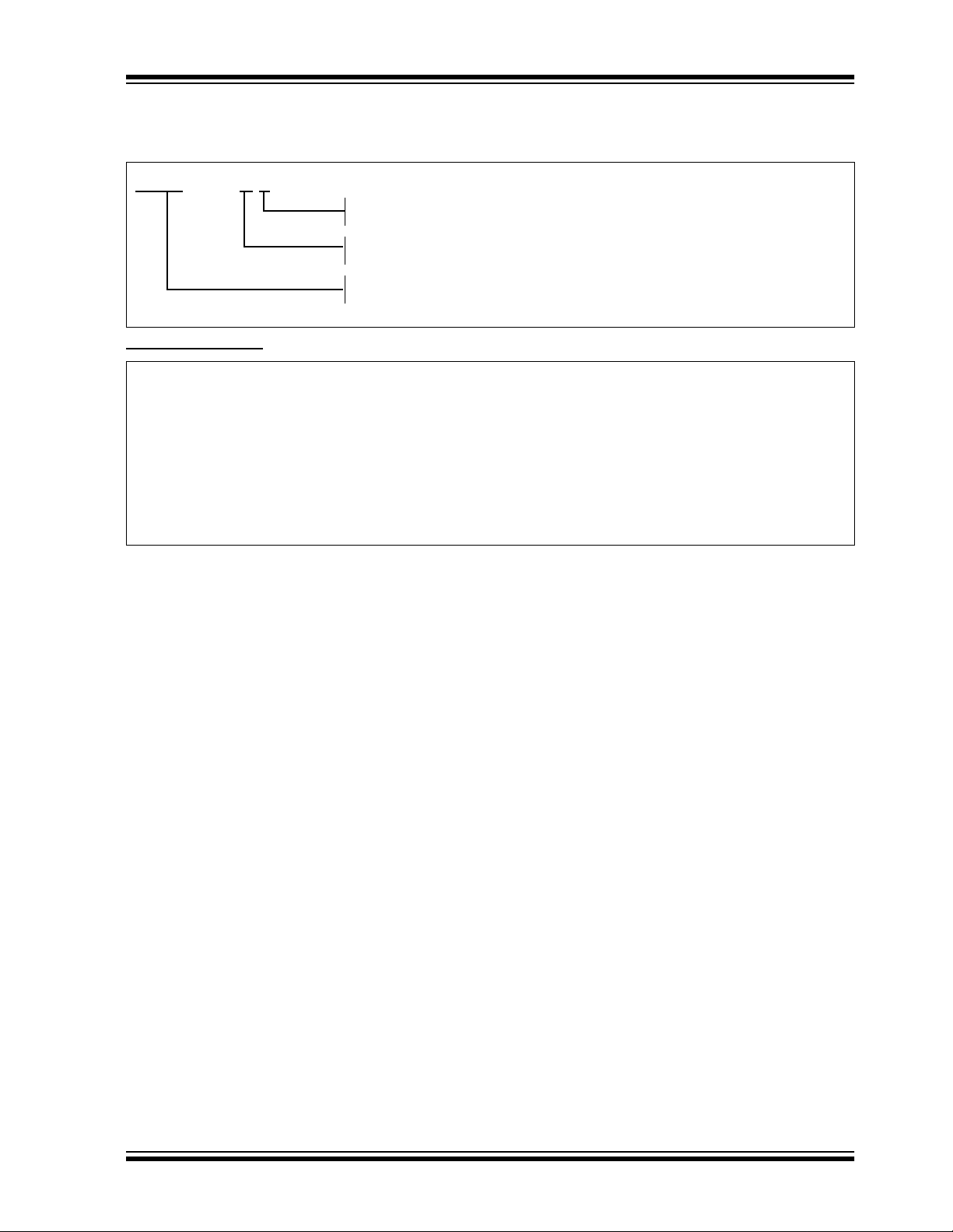

FIGURE 1-1: CREATION AND STORAGE OF CRYPT KEY DURING PRODUCTION

Production

Programmer

Manufacturer’s

Code

Transmitter

Serial Number

Key

Generation

Algorithm

Crypt

Key

HCS360

EEPROM Array

Serial Number

Crypt Key

Sync Counter

.

.

.

The 16-bit synchronization counter is the basis behind

the transmitted code word changing for each transmission; it increments each time a button is pressed. Due

to the code hoppin g algorith m’s complex ity, each i ncrement of the synchronization value results in greater

than 50% of the bits changing in the transmitted code

word.

Figure 1-2 shows how the key values in EEPROM are

used in the encoder . O nce the encoder dete cts a button

press, it reads the button inputs and updates the synchronization counter. The synchronization counter and

crypt key are input to the encryption algorithm and the

output is 32 bits of encrypted information. This data will

change with every button press, its value appearing

externally to ‘ran domly h op aroun d’, hence it is re ferred

to as the hopping portion of the code word. The 32-bit

hopping code is combined with the button information

and serial numb er to fo rm the code word transm itted to

the receiver. The code word format is explained in

greater detail in Section 4.2.

A receiver may use any type of controller as a decoder,

but it is typically a microcontroller with compatible firmware that allows the decoder to operate in conjunction

with an HCS360 based transmitter. Section 7.0

provides detail on integrating the HCS360 into a system.

A transmitter must first be ‘learned’ by the receiver

before its use is allowed in the system. Learning

includes calculating the transmitter’s appropriate crypt

key, decrypting the received hopping code and storing

the serial number, synchronization counter value and

crypt key in EEPROM.

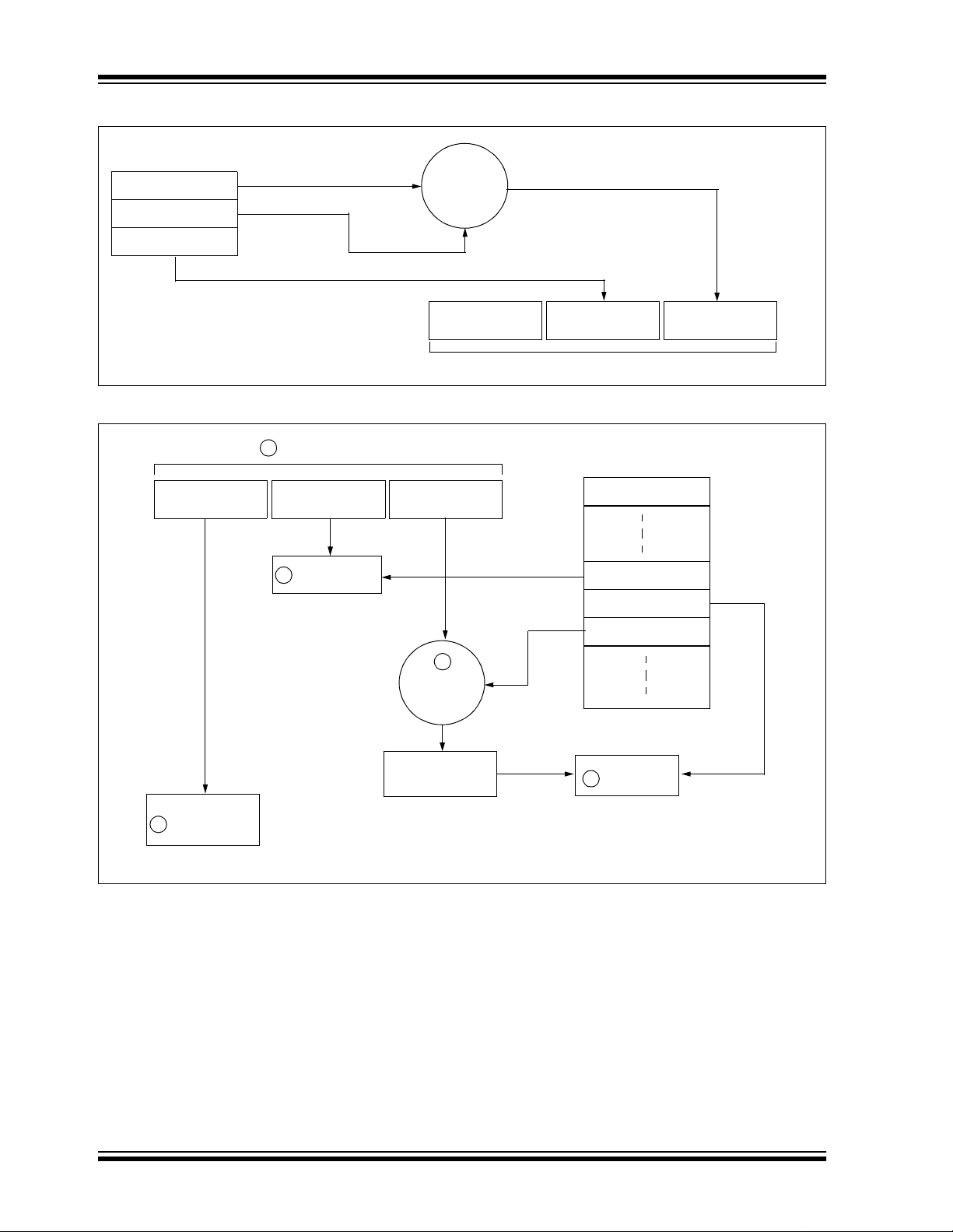

In normal operation, each received message of valid

format is evaluated. The serial number is used to determine if it is from a learned transmitter. If from a learned

transmitter, the message is decrypted and the synchronization counter is verified. Finally, the button status is

checked to see what operation is requested. Figure 1-3

shows the relationship between some of the values

stored by the receiver and the values received from

the transmitter.

2002 Microchip Technology Inc. DS40152E-page 3

Page 4

HCS360

FIGURE 1-2: BUILDING THE TRANSMITTED CODE WORD (ENCODER)

EEPROM Array

Crypt Key

Sync Counter

Serial Number

KEELOQ

Encryption

Algorithm

Button Press

Information

Serial Number

Transmitted Information

FIGURE 1-3: BASIC OPERATION OF RECEIVER (DECODER)

1

Received Information

Button Press

Information

Serial Number

Check for

2

Match

32 Bits of

Encrypted Data

32 Bits

Encrypted Data

EEPROM Array

Manufacturer Code

Serial Number

Sync Counte r

KEELOQ

Decryption

Algorithm

Decrypted

Synchronization

Counter

Perform Function

Indicated by

5

button press

NOTE: Circled numbers indicate the order of execution.

Crypt Key

3

Check for

4

Match

DS40152E-page 4 2002 Microchip Technology Inc.

Page 5

HCS360

2.0 DEVICE OPERATION

As shown in the typical a pplication circ uits (Figu re 2-1),

the HCS360 is a simple device to use. It requires only

the addition of buttons and RF circuitry for use as the

transmitter in your security applic ation. A descripti on of

each pin is described in Table2-1.

FIGURE 2-1: TYPICAL CIRCUITS

VDD

B0

B1

S0

S1

S2

S3

Two button remote control

VDD

LED

DATA

V

SS

Tx out

discrimination value and button information will be

encrypted to form the hopping code. The hopping code

portion will change every transmission, even if the

same button is pushed again. A code word that has

been transmitted will not repeat for more than 64K

transmissions. Thi s provides mo re than 18 years of use

before a code is repeated; based on 10 operations per

day . Overflow inform ation sent from the enc oder can be

used to extend the number of unique transmissions to

more than 192K.

If in the tr an smit proc ess it i s de tec ted t hat a n ew b utton(s) has been pressed, a RESET will immediately

occur and the current cod e word will no t be compl eted.

Please note that buttons removed will not have any

effect on the code word unless no buttons remain

pressed; in which c ase the code word will be compl eted

and the power-down will occur.

FIGURE 2-2: ENCODER OPERATION

TABLE 2-1: PIN DESCRIPTIONS

Name

S0 1 Switch input 0

S1 2 Switch input 1

S2 3 Switc h input 2 / Clock pin when in

S3 4 Switch input 3

SS 5 Ground reference

V

DATA 6 Data output pin /Data I/O pin for

LED

VDD 8 Positive supply voltage

The HCS360 will wake-up upon detecting a button

press and delay approximately 10 ms for button

debounce (Figure 2-2). The synchronization counter,

2002 Microchip Technology Inc. DS40152E-page 5

Pin

Number

Description

Programming mode

Programming mode

7 Cathode connection for LED

Page 6

HCS360

3.0 EEPROM MEMORY ORGANIZATION

The HCS360 contains 192 bits (12 x 16-bit words) of

EEPROM memory (Table 3-1). This EEPROM array is

used to store the crypt key information, synchronization

value, etc . Fu r t he r d es cr i pti o ns of t h e m e mory array is

given in the following sections.

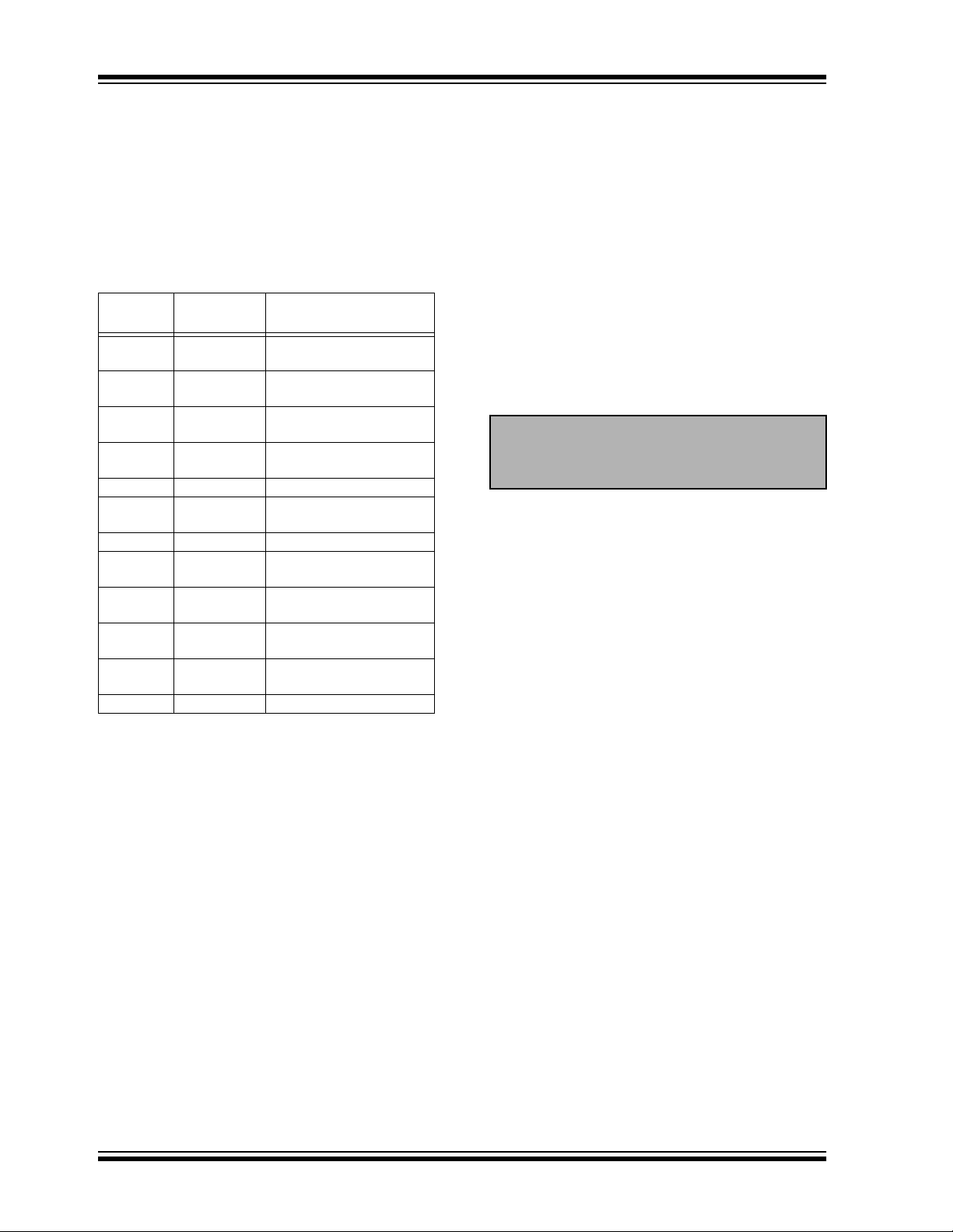

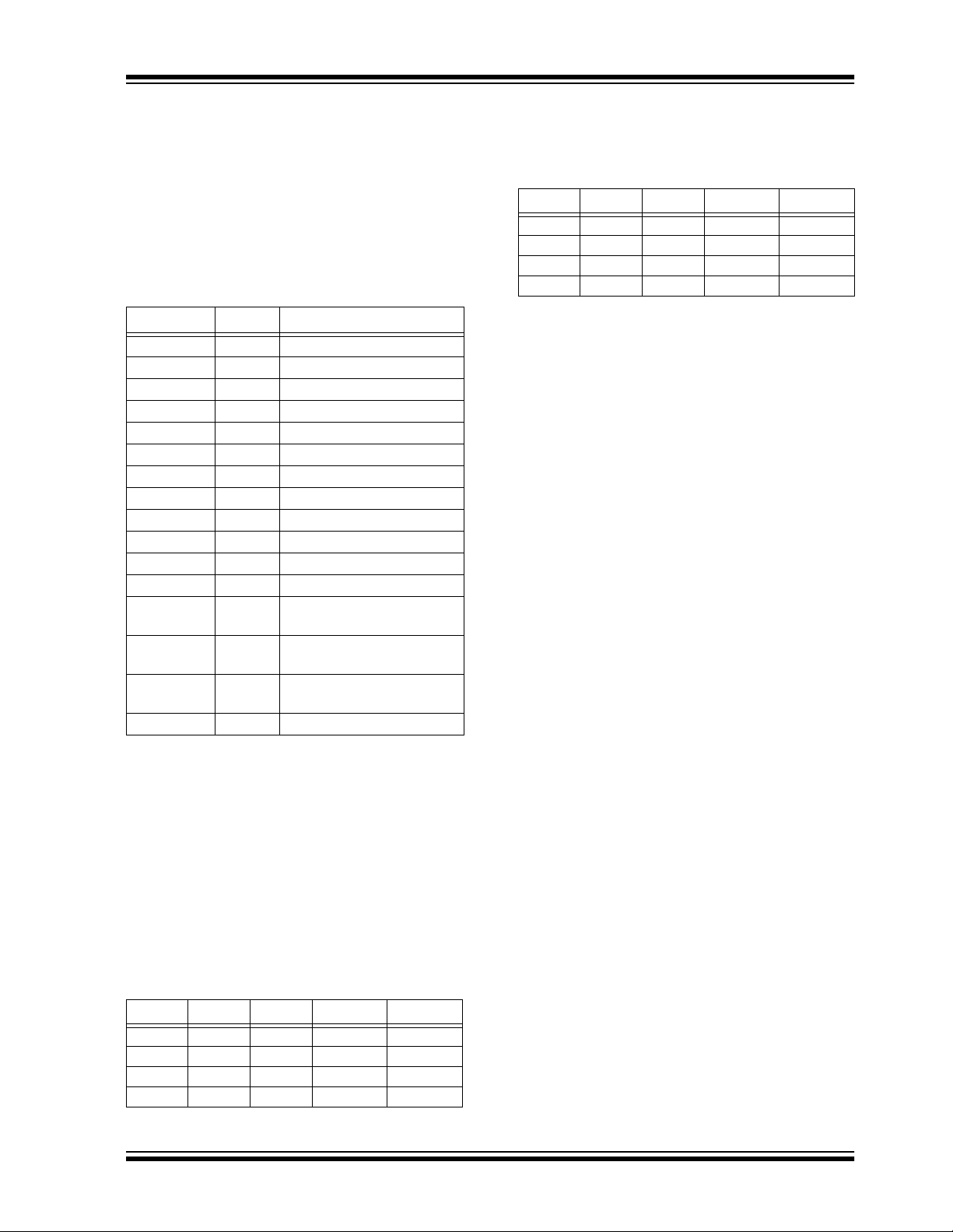

TABLE 3-1: EEPROM MEMORY MAP

WORD

ADDRESS

0 KEY_0 64-bit crypt key

1 KEY_1 64-bit crypt key

2 KEY_2 64-bit crypt key

3 KEY_3 64-bit crypt key

4 SYNC_A 16-bit synch counter

5 SYNC_B/

6 RESERVED Set to 0000H

7SEED_0Seed Value

8SEED_1Seed Value

9SER_0Device Serial Number

10 SER_1 Device Serial Number

11 CONFIG Configuration Word

MNEMONIC DESCRIPTION

(word 0) LSb’s

(word 1)

(word 2)

(word 3) MSb’s

16-bit synch counter B

SEED_2

or Seed value (word 2)

(word 0) LSb’s

(word 1) MSb’s

(word 0) LSb’s

(word 1) MSb’s

3.2 SYNC_A, SYNC_B

(Synchronization Counter)

This is th e 16 -bit syn chr oni zatio n va lue th at is used to

create the hopping code for trans missio n. This value is

incremented after every transmission. Separate synchronization counters can be used to stay synchronized with different receivers.

3.3 SEED_0, SEED_1, and SEED_2

(Seed Word)

The three word (48 bits) seed code will be transmitted

when seed transmission is selected. This allows the system designer to implement the Secure Learn feature or

use this fixed code word as part of a different key generation/tracking process or purely as a fixed code transmission.

Note: Since SEED2 and SYNC_B share the

same memory location, Secure Learn and

Independent mod e trans miss ion (inclu ding

IR mode) are mutually exclusive.

3.4 SER_0, SER_1

(Encoder Serial Number)

SER_0 and SER_1 are the lower and upper words of

the device serial number, respectively. There are 32

bits allocated for the Serial Number and a selectable

configuration bit determines whether 32 or 28 bits will

be transmitted. The serial number is meant to be

unique for every transmitter.

3.1 KEY_0 - KEY_3 (64-Bit Crypt Key)

The 64-bit crypt key is used to create the encrypted

message transmitted to the receiver. This key is calculated and programmed during production using a key

generation algorithm. The key generation algorithm

may be different from the K

the key generation algorithm are typically the transmit-

ter’s serial number and the 64 -bit manufa cturer’s cod e.

While the key generation algorithm supplied from

Microchip is the typical method used, a user may elec t

to create their own m ethod of key gene ration. This ma y

be done providing that the deco der is program med with

the same means of creating the key for

decryption purposes.

DS40152E-page 6 2002 Microchip Technology Inc.

EELOQ

algorithm. Inputs to

Page 7

HCS360

3.5 CONFIG

(Configuration Word)

The Configuration Word is a 16-bit word stored in

EEPROM array that is used by the device to store

information used during the enc ryption proce ss, as well

as the status of option configurations. Further

explanations of each of the bits are described in the

following sections.

TABLE 3-2: CONFIGURATION WORD.

Bit Number Symbol Bit Description

0 LNGRD Long Guard Tim e

1 BSEL 0 Baud Rate Selection

2 BSEL 1 Baud Rate Selection

3 NU Not Used

4 SEED Seed Transmission enable

5 DELM Delay mode enable

6 TIMO Time-out enable

7 IND Independent mode enable

8 USRA0 User bit

9 USRA1 User bit

10 USRB0 User bit

11 USRB1 User bit

12 XSER Extended serial number

enable

13 TMPSD Temporary seed transmis-

sion enable

14 MOD Manchester/PWM modula-

tion selection

15 OVR Overflow bit

3.5.1 MOD: MODULATION FORMAT

MOD selects between Manchester code modulation

and PWM modulation.

If MOD = 1, Manchester modulation is selected:

If MOD = 0, PWM modulation is selected.

BSEL 1 and BSEL 0 determine the baud rate according

to Table3-4 when Manchester modulation is selected.

TABLE 3-4: BAUD RATE SELECTION

MOD BSEL 1 BSEL 0 TE Unit

100800us

101400us

110400us

111200us

3.5.3 OVR: OVERFLOW

The overflow bit is u sed to exten d the nu mber o f poss ible synchronization values. The synchronization

counter is 16 bits in length, yielding 65,536 values

before the cycle repeats. Under typical use of

10 operations a day, this will provide n ea rly 18 years of

use before a repeated value will be used. Should the

system designer conclude that is not adequate, then

the overflow bit can be utiliz ed to exte nd the numbe r of

unique values. This can be do ne by pr ogramming O VR

to 1 at the time of production. The encoder will automatically clear OVR the first time that the transmitted

synchronization value wraps from 0xFFFF to 0x0000.

Once cleared, OVR cannot be set again, thereby crea ting a permanent record of the counter overflow. This

prevents fast cycling of 64K counter . If the dec oder system is programmed to track the overflow bits, then the

effective number of unique synchronization values can

be extended to 128K. If programmed to zero, the system will be compatible with old encoder devices.

3.5.4 LNGRD: LONG GUARD TIME

LNGRD = 1 selects the encoder to extend the guard

time between code words adding ≈50 ms. This can be

used to reduce the average power transmitted over a

100 ms window and thereby transmit a higher peak

power.

3.5.2 BSEL 1, 0

BAUD RATE SELECTION

BSEL 1 and BSEL 0 determin e the baud rate according

to Table 3-3 when PWM mo dulation is selected.

TABLE 3-3: BAUD RATE SELECTION

MOD BSEL 1 BSEL 0 T

000400us

001200us

010200us

011100us

2002 Microchip Technology Inc. DS40152E-page 7

E Unit

Page 8

HCS360

3.5.5 XSER: EXTENDED SERIAL

NUMBER

If XSER = 0, the four Most Significant bits of the Serial

Number are substituted by S[3:0] and the code word

format is co mpatible with the HCS200/300/301.

If XSER = 1, the full 32-bit Serial Number [SER_1,

SER_0] is transmitted.

Note: Since the button status S[3:0] is used to

detect a Seed transmission, Extended

Serial Number and Secure Learn are

mutually exclusive.

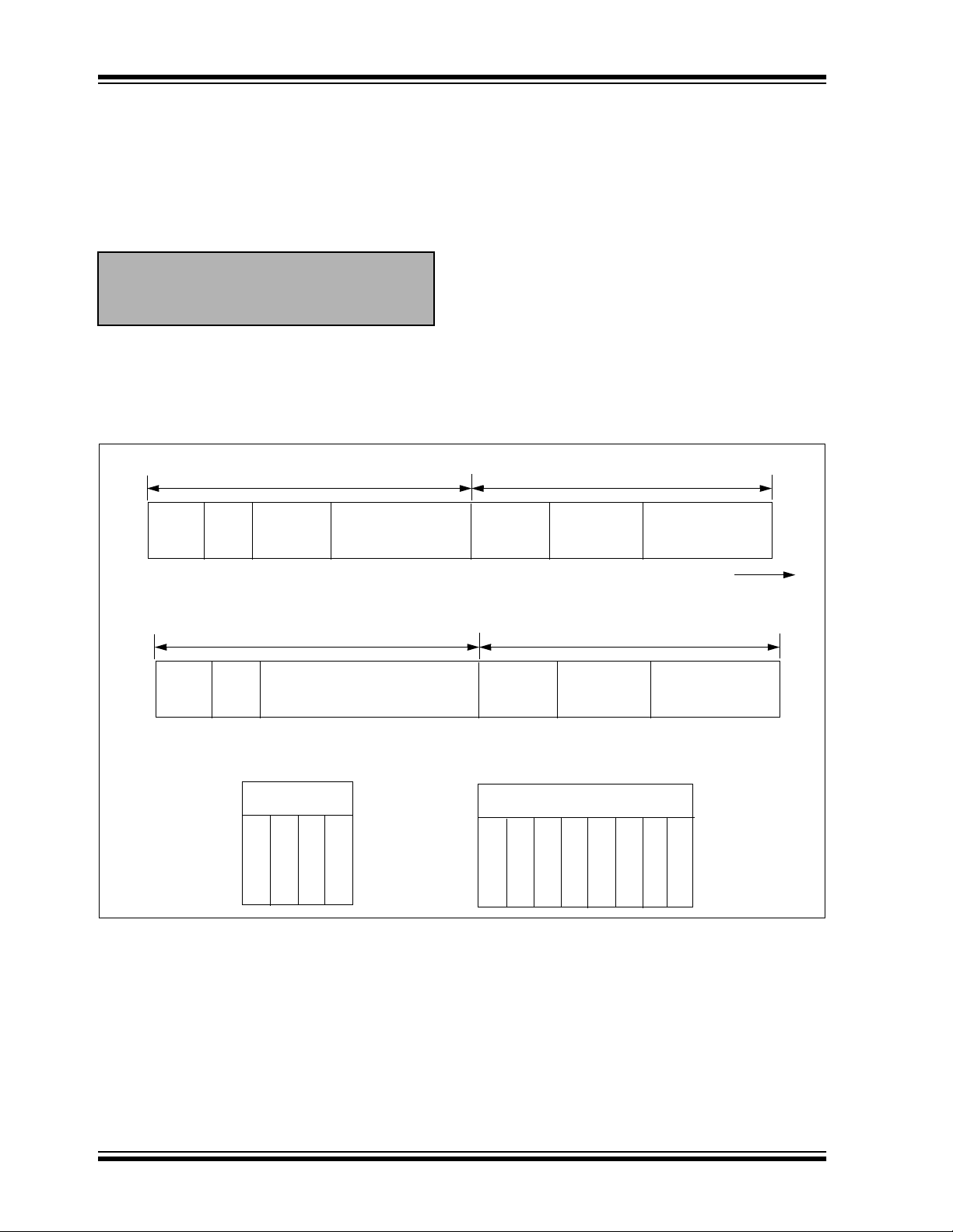

FIGURE 3-1: CODE WORD ORGANIZATION

XSER=0

Fixed Code Portion of Transmission Encrypted Portion of Transmission

Button

Status

(4 bits)

28-bit

Serial Number

MSB

CRC

(2-bit)

VLOW

(1-bit)

3.5.6 DISCRIMINATION VALUE

While in other KEELOQ encoders its value is user

selectable, the HCS360 uses directly the 8 Least Significant bits of the Se rial N umber a s part of t he info rmation that form the encrypted portion of the

transmission (Figure 3-1).

The discrimination value aids the post-decryption

check on the decoder end. After the receiver has

decrypted a transmiss ion, the discrimination b its are

checked against the e ncoder Serial Number to verif y

that the decryp tion process was valid.

3.5.7 USRA,B: USER BITS

User bits form part of the discrimi nation valu e. The user

bits together with the IND bit can be used to identify the

counter that is used in Independent mode.

Button

Status

(4 bits)

Discrimination

bits

(12 bits)

16-bit

Sync Value

LSB

XSER=1

MSB

Fixed Code Portion of Transmission Encrypted Portion of Transmission

CRC

(2-bit)

VLOW

(1-bit)

Button Status

(4 bits)

SSSS

2103

Extended Serial Number

32-bit

Button

Status

(4 bits)

I O U U S S ... S

N V S S E E ... E

Discrimination

bits

(12 bits)

Discrimination Bits

(12 bits)

D R R R R R ... R

1 0 7 6 ... 0

67 bits

of Data

Transmitted

16-bit

Sync Value

LSB

DS40152E-page 8 2002 Microchip Technology Inc.

Page 9

HCS360

3.5.8 SEED: ENABLE SEED

TRANSMISSION

If SEED = 0, seed transmission is disabled. The Independent Counter mode can only be used with seed

transmission disable d since SEED_2 i s shared with th e

second synchronization counter.

With SEED = 1, seed transmission is enabled. The

appropriate button code(s) must be activated to transmit the seed information. In this mode, the seed infor-

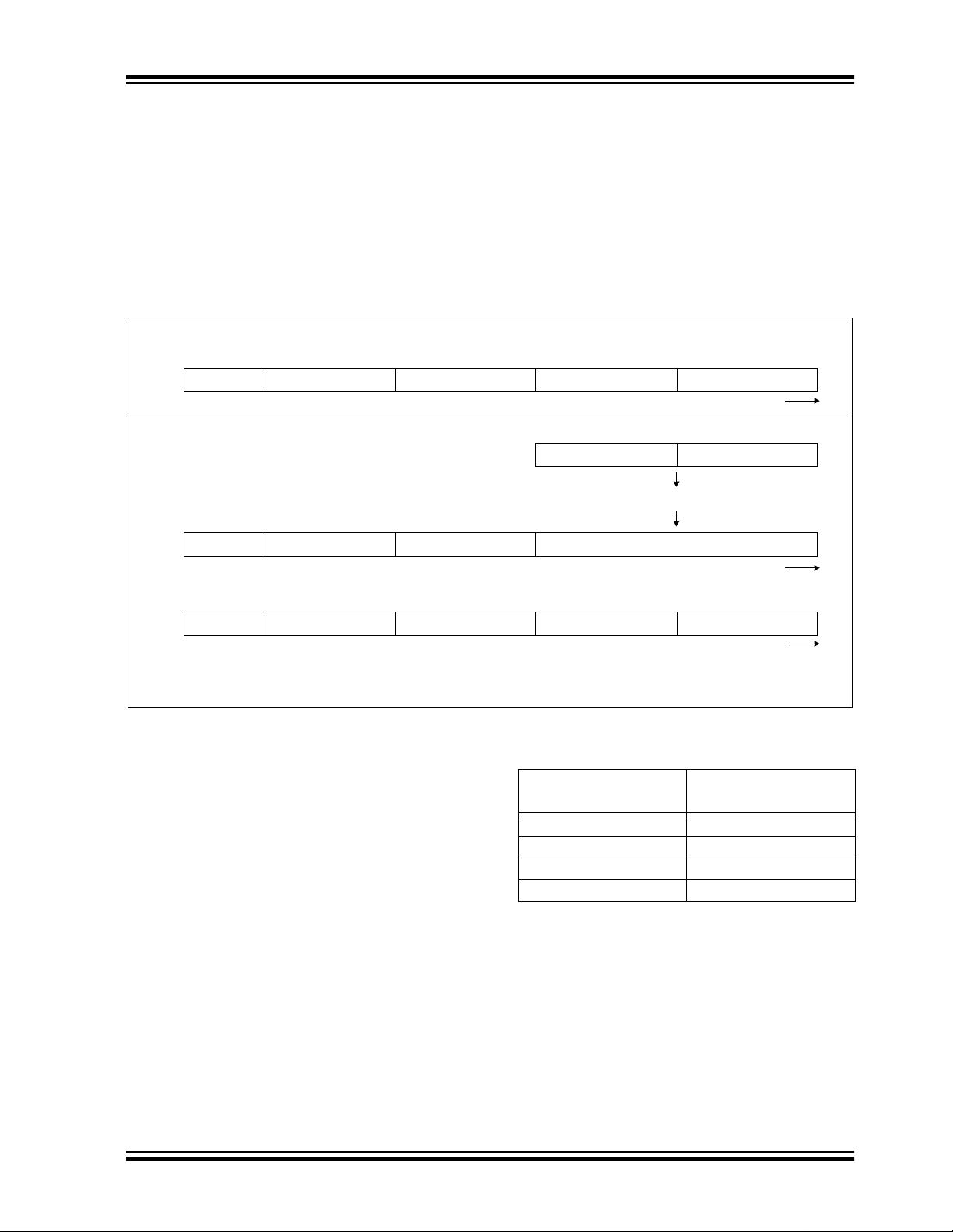

FIGURE 3-2: Seed Transmission

All examples shown with XSER = 1, SEED = 1

When S[3:0] = 1001, delay is not acceptable.

CRC+VLOW SER_1 SEED_2 SEED_1 SEED_0

For S[3:0] = 0x3 before delay:

CRC+VLOW SER_1 SER_0 Encrypted Data

mation (SEED_0, SEED_1, and SEED_2) and the

upper 12 or 16 bits of the serial number (SER_1) are

transmitted instead of the hop code.

Seed transmission is available for function codes

(Table 3-9) S[3:0] = 1001 and S[3:0] = 0011(delayed).

This takes place regardless of the setting of the IND bit.

The two seed transmissions are shown in Figure 3-2.

Data transmission direction

16-bit Data Word 16-bit Counter

Encrypt

Data transmission direction

For S[3:0] = 0011 after delay (Note 1, Note 2):

CRC+VLOW SER_1 SEED_2 SEED_1 SEED_0

Note 1 : For Seed Transmission, SEED_2 is transmitted instead of SER_0.

2: For Seed Transmission, the setting of DELM has no effect.

3.5.9 TMPSD: TEMPORARY SEED

TRANSMISSION

The temporary seed transmission can be used to disable learning after the transmitter has been used for a

programmable number of operations. This feature can

be used to implemen t very secu re systems. After learning is disabled, the seed information cannot be

accessed even if physical access to the transmitter is

possible. If TMPSD = 1 the seed transmission will be

disabled after a number of code hopping transmissions. The number of tra nsmiss ions be fore see d transmission is disabl ed, can be programmed by setting th e

synchronization counter (SYNC_A, SYNC_B) to a

value as shown in Table 3-5.

Data transmission direction

TABLE 3-5: SYNCHRONOUS COUNTER

INITIALIZATION VALUES

Synchronous Counter

Value s

0000H 128

0060H 64

0050H 32

0048H 16

Number of

Transmissions

2002 Microchip Technology Inc. DS40152E-page 9

Page 10

HCS360

3.5.10 DELM: DELAY MODE

If DELM = 1, delay transmission is enabled. A delayed

transmissi on is indic ated by in verting th e lower nib ble

of the discrimination value. The Delay mode is primarily

for compatibil ity with pre vious K

not recommended for new designs.

EELOQ devices and is

TABLE 3-6: TYPICAL DELAY TIMES

Number of Code

BSEL 1 BSEL 0

00 28 ≈ 2.9s ≈ 5.1s

01 56 ≈ 3.1s ≈ 6.4s

10 28 ≈ 1.5s ≈ 3.2s

11 56 ≈ 1.7s ≈ 4.5s

Words before Delay

Mode

3.5.11 TIMO: TIME-OUT

OR AUTO-SHUTOFF

If TIMO = 1, the time-out is enabled. Time-out can be

used to terminate accid ental c ontinuous tran smissions.

When time-out occurs, the PWM output is set low and

TABLE 3-7: TYPICAL TIME-OUT TIMES

If DELM = 0, delay transmission is disabled (Table 3-

6).

Time Before Delay Mode

(MOD = 0)

the LED is turned off. Current consumption will be

higher than in Standby mode since current will flow

through the activated input resistors. This state can be

exited only after al l in put s are taken low. TIMO = 0, will

enable continuous transmission (Table 3-7).

Time Before Delay Mode

(MOD = 1)

Maximum Number of

BSEL 1 BSEL 0

00 256 ≈ 26.5s ≈ 46.9

01 512 ≈ 28.2s ≈ 58.4

10 256 ≈ 14.1s ≈ 29.2

11 512 ≈ 15.7s ≈ 40.7

Code Words

Transmitted

Time Before Time-out

(MOD = 0)

Time Before Time-out

(MOD = 1)

DS40152E-page 10 2002 Microchip Technology Inc.

Page 11

HCS360

3.5.12 IND: INDEPENDENT MODE

The Independent mode can be used where one

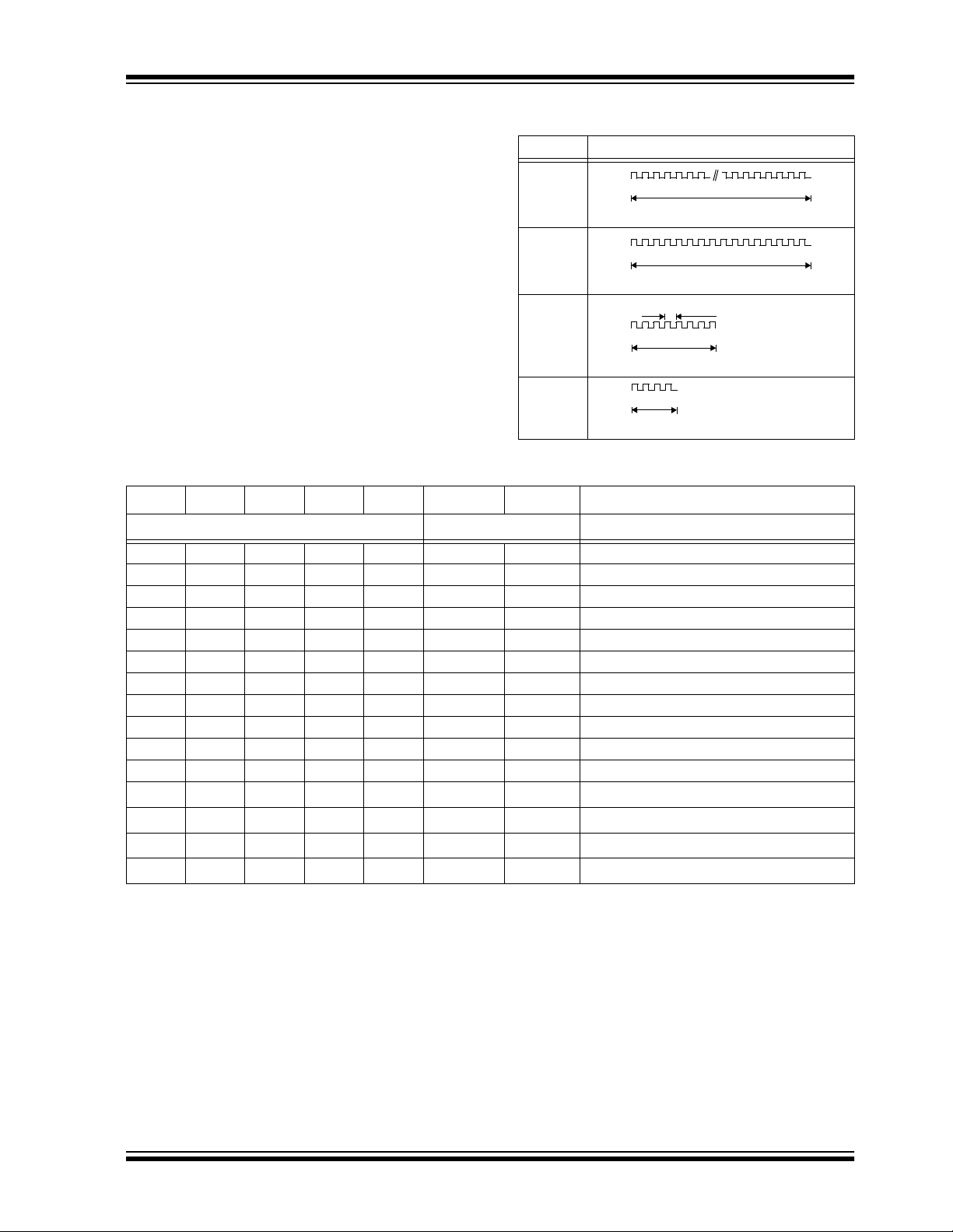

TABLE 3-8: IR MODULATION

T

E Basic Pulse

encoder is used to co ntro l tw o re ce iv ers . Two counters

(SYNC_A and SYNC_B) are used in Independent

mode. As indicated in Table 3-9, function codes 1 to 7

use SYNC_A and 8 to 15 SYNC_B.

800us

(800µs)

(32x)

3.5.13 INFRARED MODE

The Independent mode also selects IR mode. In IR

400us

mode functi on codes 12 to 15 will use SYNC_B. T he

PWM output signal is modulated with a 40 kHz carrier

(see Table 3-8). It must be pointed out that the 40 kHz

is derived from the inte rnal cloc k and wil l therefore vary

200us

(200µs)

with the same percentage as the baud rate. If IND = 0,

SYNC_A is used for all fun ction code s. If IND = 1, Independent mode is enabled and counters for functions

are used according to Table 3-9.

TABLE 3-9:

FUNCTION CODES

100us

(100µs)

(4x)

S3 S2 S1 S0 IND = 0 IND = 1 Comments

Counter

10001 A A

20010 A A

3 0 0 1 1 A A If SEED = 1, transmit seed after delay.

40100 A A

50101 A A

60110 A A

70111 A A

81000 A B

9 1 0 0 1 A B If SEED = 1, transmit seed immediately.

101010 A B

111011 A B

121100 A

131101 A

141110 A

151111 A

(1)

B

(1)

B

(1)

B

(1)

B

Note 1: IR mode

(400µs)

(16x)

Period = 25µs

(8x)

2002 Microchip Technology Inc. DS40152E-page 11

Page 12

HCS360

4.0 TRANSMITTED WORD

4.1 Transmission Format (PWM)

The HCS360 code word is made up of several parts

(Figure 4-1 and Figure 4-2). Each code word contains

a 50% duty cycle preamble, a header, 32 bits of

encrypted data and 35 bits of fixed data followed by a

guard period before another code word can begin.

Refer to T able8-3 and Table 8-5 for code word timing.

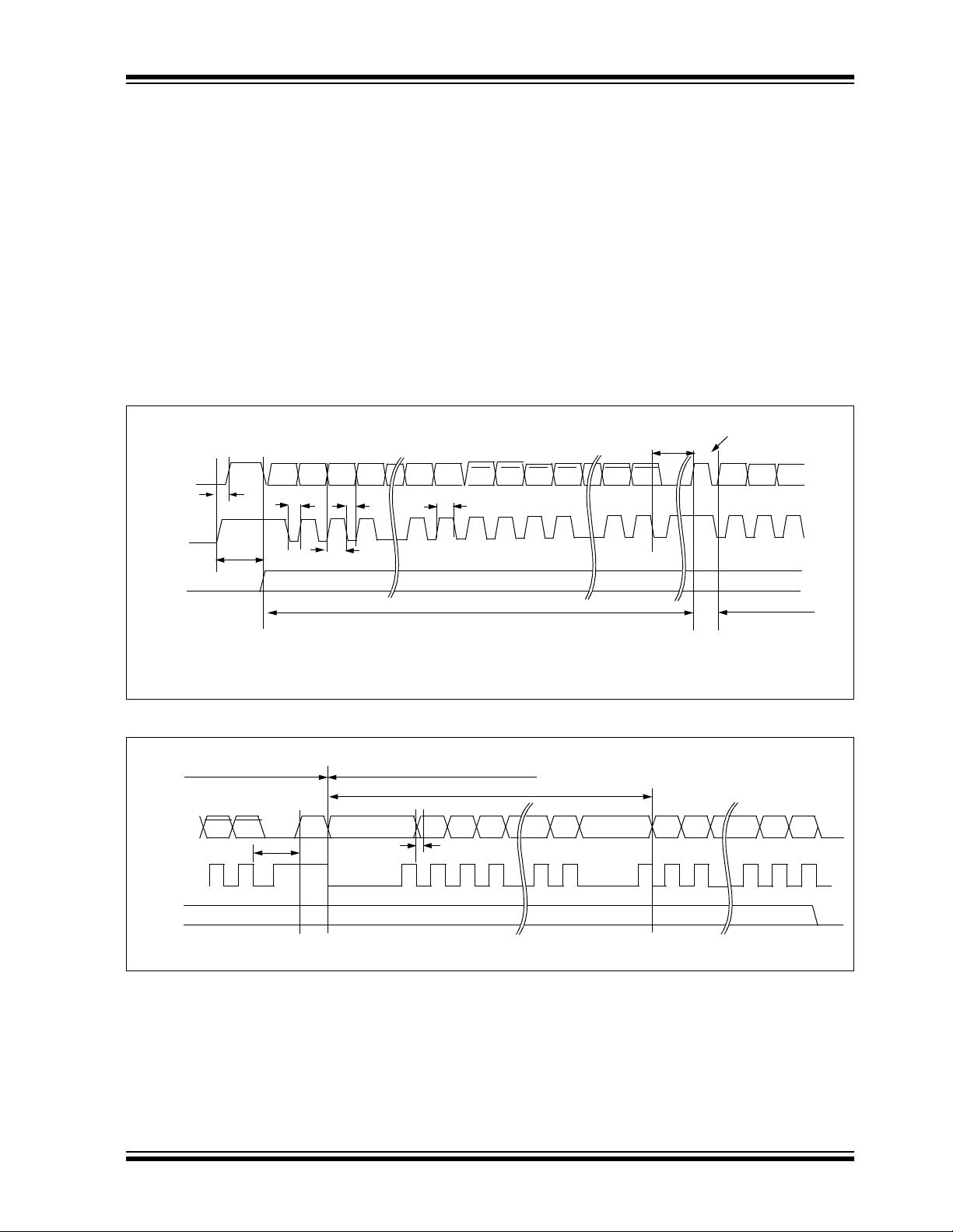

FIGURE 4-1: CODE WORD FORMAT (PWM)

50% Duty Cycle

Preamble

1

16

4.2 Code Word Organization

The HCS360 transmit s a 67 -bit code word when a button is pressed. The 67-bit word is constructed from a

Fixed Code portion and an Encrypted Code portion

(Figure 3-1).

The Encrypted Data is generated from 4 function bits,

2 user bits, overflow bit, Independent mode bit, and 8

serial number bits, and the 16-b it synchronization value

(Figure 3-1). The encrypted portion alone provides up

to four billion changing code combinations.

The Fixe d Code Data is made up of a V

bits, 4 function bits, and the 28-bit serial number. If the

extended serial numb er (32 bits) is s elected, the 4 func tion code bits will not be transmitted. The fixed and

encrypted sections combined increase the number of

code combinations to 7.38 x 10

LOGIC "0"

LOGIC "1"

19

LOW bit, 2 CRC

TETET

E

31XTE Encrypted Portion Fixed Portion

Preamble

10xTE

Header

of Transmission

FIGURE 4-2: CODE WORD FORMAT (MANCHESTER)

50% Duty Cycle

Preamble

1

2

31XTE

Preamble

START bit

16

4XTE

Header

bit 0

bit 2

bit 1

Encrypted Portion Fixed Portion

of Transmission of Transmission

of Transmission

LOGIC "0"

LOGIC "1"

Guard

STOP bit

Time

T

E

Guard

Time

TE

DS40152E-page 12 2002 Microchip Technology Inc.

Page 13

HCS360

5.0 SPECIAL FEATURES

5.1 Code Word Completion

Code word completion is an automatic feature that

ensures th at th e en tire cod e wor d i s tran smi tte d, e ven

if the button is rel eased before the transmissi on is complete and that a minimum of two words are completed.

The HCS360 encode r powers i tself up when a button is

pushed and powers itself down after two complete

words are transmitted if the user has already released

the button. If the button is held down beyond the time

for one transmission, then multiple transmissions will

result. If another button is activated during a

transmission, the active transmission will be aborted

and the new code will be generated using the new

button information.

5.2 Long Guard Time

Federal Communications Commission (FCC) part 15

rules specify the limits on fundamental power and

harmonics that can be transmitted. Power is calculated

on the worst case average power transmitted in a 100

ms window. It is therefore advantageous to minimize

the duty cycle of the transmitted word. This can be

achieved by minimizing the duty cycle of the individual

bits or by extending the guard time between transmissions. Long guard time (LNGRD) is used for reducing

the average power of a transmission. This is a selectable feature. Using the LNGRD allows the user to

transmit a higher amplitude transmission if the

transmission time pe r 10 0 m s is shorter. The FCC puts

constraints on the average power that can be

transmitted by a device, and LNGRD effectively

prevents continuous transmission by only allowing the

transmission of every seco nd word. This reduces the

average power transmitted and hence, assists in FCC

approval of a transmitter device.

5.3 CRC (Cycle Redundancy Check)

Bits

The CRC bits are calcul ated on the 65 previously trans mitted bits. The CRC bits can be used by the receiver

to check the dat a integrity before processi ng start s. The

CRC can detect all single bit and 66% of double bit

errors. The CRC is computed as follows:

EQUATION 5-1: CRC Calculation

CRC 1[]

and

CRC 0[]

with

and

Di

the nth transmission bit 0 ≤ n ≤ 64

n

Note: The CRC may be wrong when the battery

. Work around: If the CRC calculation is incor-

n 1+

CRC 10,[]

voltage is around either of the V

points. This may happen because V

sampled twice each transmission, once for

the CRC calculation (PWM is low) and once

when V

V

sion which could lead to a different value for

V

and the transmission

rect, recalculate for the opposite value of

V

LOW is transmitted (PWM is high).

DD tends to move sligh tly during a transmis -

LOW being used for the CRC calculation

LOW.

CRC 0[]nDin∧=

n 1+

CRC 0[]nDin∧()CRC 1[]

0

∧=

0=

n

LOW trip

LOW is

2002 Microchip Technology Inc. DS40152E-page 13

Page 14

HCS360

5.4 Auto-shutoff

The Auto-shutoff function automatically stops the

device from transmitting if a button inadvertently gets

pressed fo r a lo ng p eri od of tim e. Th is w ill prev ent the

device from draining the battery if a button gets

pressed whil e the transmitte r is in a pocket or purse .

This function can be enabled or disabled and is

selected by setting or clearing the time-out bit

(Section 3.5.1 1). Setti ng this bit wil l enab le the f unctio n

(turn Auto-shutoff function on) and clearing the bit will

disable the function. Time-out period is approx imately

25 seconds.

5.5 VLOW: Voltage LOW Indicator

The VLOW bit is transmitted with every transmission

(Figure 3-1) and will be transmitted as a one if the

operating voltage has dropped below the low voltage

trip point, typically 3.8V at 25°C. This V

LOW signal is

transmitted so the receiver c an give an indicati on to the

user that the transmitter battery is low.

5.6 LED Output Operation

During normal transmission the LED output is LOW

while the data is being transmitted and high during the

guard time. Two voltage indications are combined into

one bit: V

of V

LOW. Table 5-1 indicates the operation value

LOW while data is being transmitted.

FIGURE 5-1: VLOW Trip Point VS.

Temperature

4.5

V

3.5

2.5

1.5

LOW=0

4

LOW=1

3

2

-40

V

LOW=0

V

Nominal Trip Point

3.8V

Nominal Trip

Point

25 85

3.5

2V

If the supply voltage drops below the low voltage trip

point, the LED

output will be toggl ed at appr oximate ly

1Hz during the transmission.

TABLE 5-1: VLOW AND LED VS. VDD

Approximate

Supply Voltage

Max → 3.8V 0 Normal

3.8V → 2.2V 1 Flashing

2.2V → Min 0 Normal

LOW Bit LED Operation*

V

*See also FLASH operating modes.

DS40152E-page 14 2002 Microchip Technology Inc.

Page 15

HCS360

6.0 PROGRAMMING THE HCS360

When using the HCS360 in a s ystem, the user will have

to program some parameters into the device including

the serial number and the secret key before it can be

used. The programming allows the user to input all 192

bits in a serial dat a stre am, whi ch are then stored internally in EEPROM. Programming will be initiated by

forcing the PWM line high, after the S3 line has been

held high for the appropriate length of time. S0 should

be held low during the entir e program cycle . The S1

line on the HCS360 part needs to be set or cleared

depending on the LS bit of the memory map (Key 0)

before the ke y is clocked in to the HCS360. S1 must

remain at this l evel for the duratio n of the p rogramm ing

cycle. The device can the n be programmed by clocking

FIGURE 6-1: Programming Waveforms

Enter Program

Mode

DATA

(Data)

S2/S3

(Clock)

S1

T

2

T

1

Bit 1 Bit 2 Bit 3 Bit 14 Bit 15

Bit 0

TCLKL

TDH

TDS

Bit 0 of Word0

Data for Word 0 (KEY_0)

TCLKH

Repeat for each word

in 16 bits a t a ti me , followed by the wo rd’s compleme nt

using S3 or S2 as the clock line and PWM as the data

in line. After each 16-b it word is load ed, a programm ing

delay is require d f or t he internal program cy c le to c om plete. The Acknowledge can read back after the programming delay (T

WC). After the first word and its

complement have been downloaded, an automatic

bulk write is performed. This delay can take up to Twc.

At the end of the programming cycl e, the device can be

verified (Figure 6-1) by reading back the EEPROM.

Reading is done by clocking the S3 line and reading the

data bits on PWM . For security reasons, i t is no t possible to execute a Verify function without first programming the EEPROM. A Verify operation can only be

done once, immediately following the Program

cycle.

Acknowledge Pulse

TWC

Bit 0 Bit 1 Bit 2 Bit 3 Bit 14 Bit 15

Bit 16

Data for Word 1

Bit 17

Note 1: Unused button inputs to be held to ground during the entire programming sequence.

The VDD pin must be taken to ground after a program/verify cycle.

2: The V

DD pin must be taken to ground after a Program/Verify cycle.

FIGURE 6-2: Verify Waveforms

End of Programming Cycle Beginning of Verify Cycle

Data from Word0

DATA

(Data)

S2/S3

(Clock)

S1

Ack

Bit 0Bit191Bit190

TWC

Note: A Verify sequence is performed only once immediately after the Program cycle.

Bit 1 Bit 2 Bit 3 Bit 15Bit 14 Bit 16 Bit 17 Bit190 Bit191

TDV

2002 Microchip Technology Inc. DS40152E-page 15

Page 16

HCS360

TABLE 6-3: PROGRAMMING/VERIFY TIMING REQUIREMENTS

DD = 5.0V ± 10%

V

25° C ± 5 °C

Parameter Symbol Min. Max. Units

Program mode setup time T

Hold time 1 T

Program cycle time T

Clock low time T

Clock high time T

Data setup time T

2

1

WC 50 — ms

CLKL 50 — µs

CLKH 50 — µs

DS 0—

Data hold time TDH 30 —

Data out valid time TDV —30

Note 1: Typical values - not tested in production.

04.0ms

9.0 —ms

µs

µs

µs

(1)

(1)

(1)

DS40152E-page 16 2002 Microchip Technology Inc.

Page 17

HCS360

7.0 INTEGRATING THE HCS360 INTO A SYSTEM

Use of the HCS360 in a system requires a compatible

decoder . This decoder is typically a microco ntroller with

compatible firmware. Microchip will provide (via a

license agreement) firmware routines that accept

transmissions from the HCS360 and decrypt the

hopping code portion of the data stream. These

routines provide system designers the means to

develop their own decoding system.

7.1 Learning a Transmitter to a

Receiver

A transmitter must first be ’ learned’ by a decoder before

its use is allowed in the system. Several learning strategies are possible, Figure 7-1 details a typical learn

sequence. Core to each, the decoder must minimally

store each learned trans mitter’ s seri al nu mber and c urrent synchronization counter value in EEPROM. Additionally, the decoder typically stores each transmitter’s

unique crypt key. The maximum number of learned

transmitters will therefore be relative to the available

EEPROM.

A transmitter’s serial number is transmitted in the clear

but the synchronization counter only exists in the code

word’s encrypted portion. The decoder obtains the

counter value by decrypting using the same key used

to encrypt the information. The K

symmetrical block cipher so the e ncryption and decryption keys are identical and referred to generally as the

crypt key. The encoder receives its crypt key during

manufacturing. The decoder is programmed with the

ability to generate a crypt key as well as all but one

required input to the key generation routine; typically

the transmitter’s serial number.

Figure 7-1 summarizes a typical learn sequence. The

decoder receives and authenticates a first transmission; first button press. Authentication involves generating the ap propriate crypt ke y, decrypting, va lidating

the correct key usage via the discrimination bits and

buffering th e counter v alue. A seco nd transmi ssion is

received and authenticated. A final check verifies the

counter values were sequential; consecutive button

presses. If the learn sequence is successfully complete, the decoder stores the learned transmitter’s

serial number, current synchronization counter value

and appropriate crypt key. From now on the crypt key

will be retrieved from EEPROM during normal operation instead of recalculating it for each transmission

received.

Certain learning strategies have been patented and

care must be taken not to infringe.

EELOQ algorithm is a

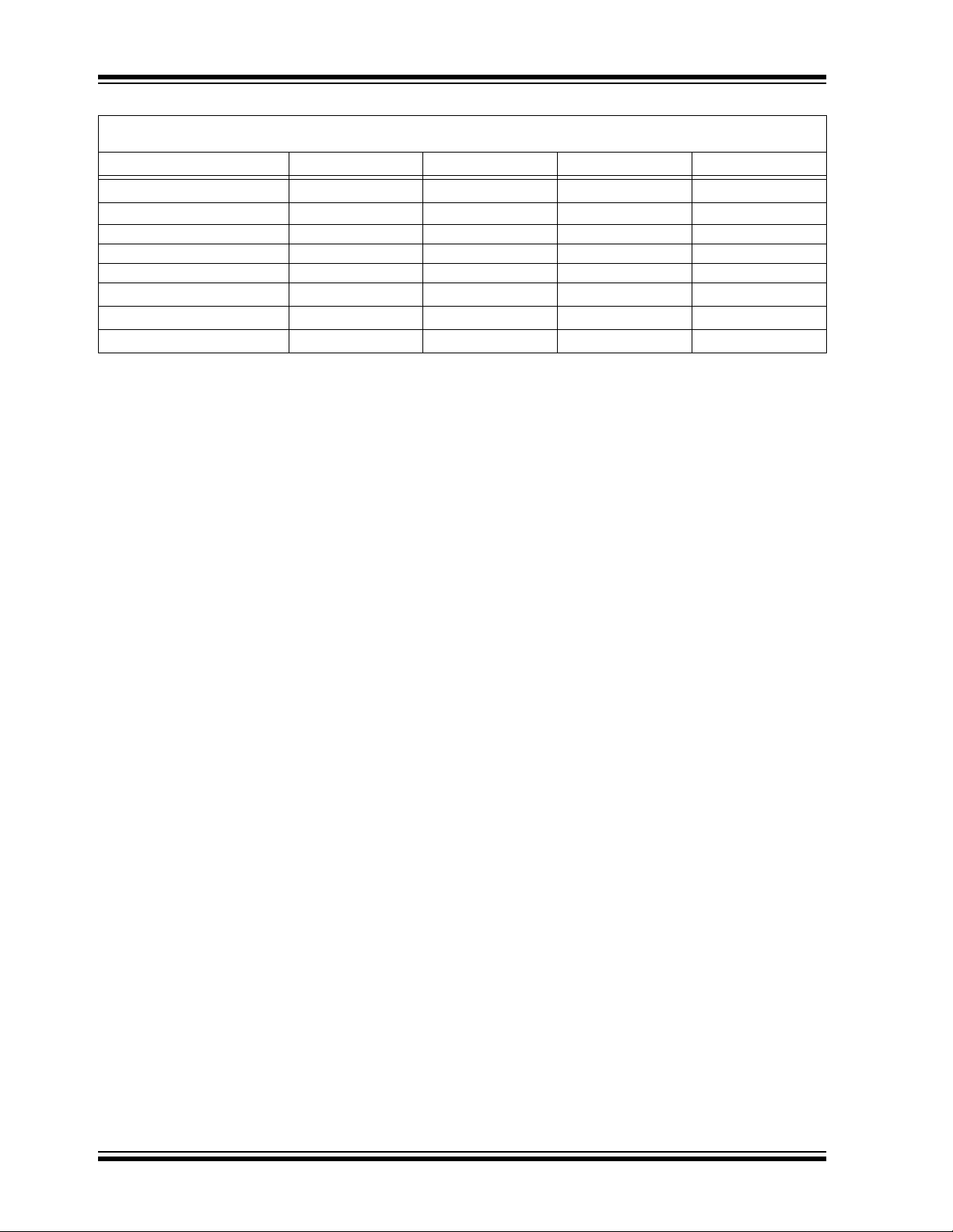

FIGURE 7-1: TYPICAL LEARN

SEQUENCE

Enter Learn

Mode

Wait for Reception

of a Valid Code

Generate Key

from Serial Number

Use Generated Key

to Decrypt

Compare Discrimination

Value with Fixed Value

Equal

?

Yes

Wait for Reception

of Second Valid Code

Use Generated Key

to Decrypt

Compare Discrimination

Value with Fixed Value

Equal

?

Yes

Counters

Sequential

?

Yes

Learn successful Store:

Serial number

Encryption key

Synchronization counter

Exit

No

No

No

Learn

Unsuccessful

2002 Microchip Technology Inc. DS40152E-page 17

Page 18

HCS360

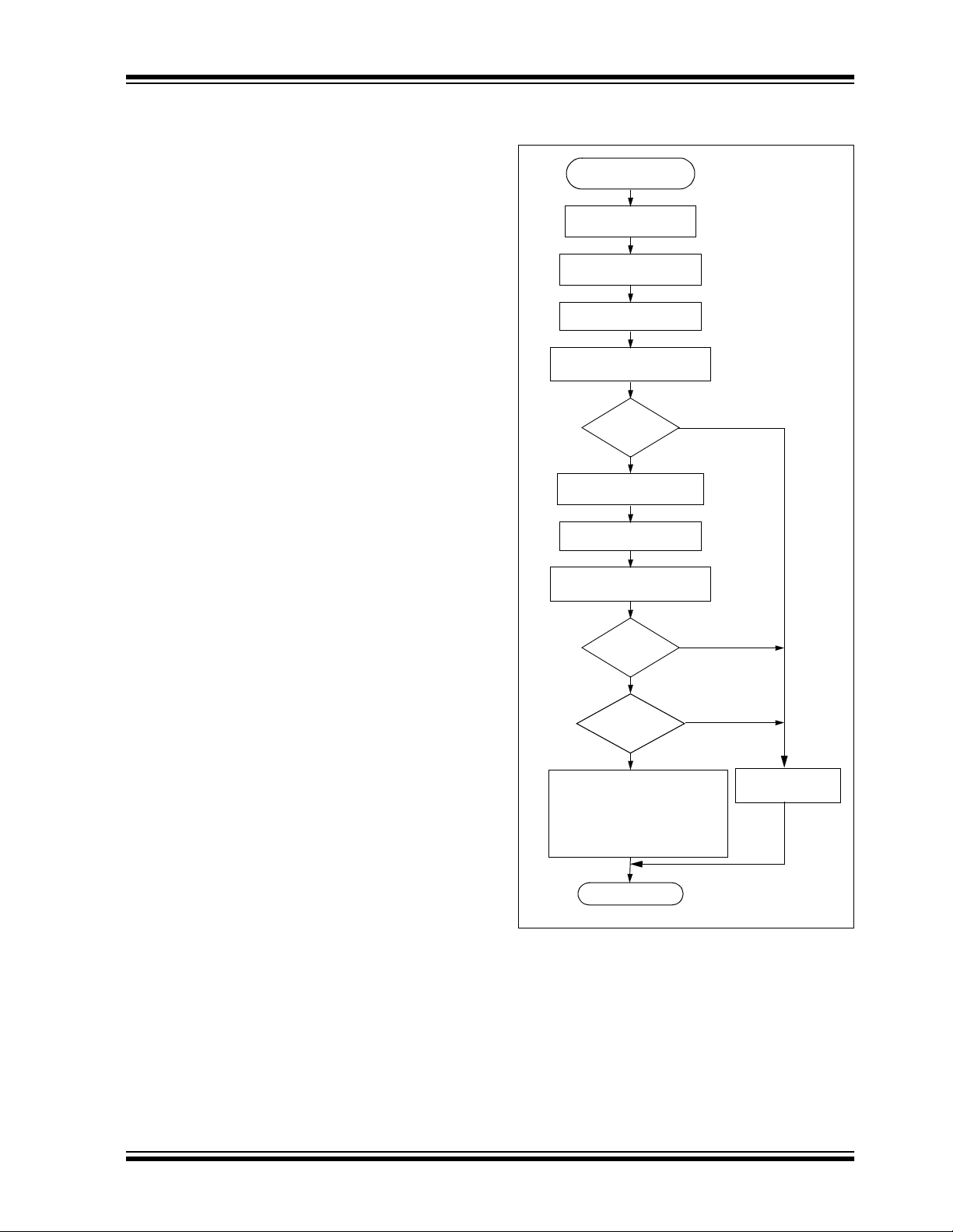

7.2 Decoder Operation

Figure 7-2 summarizes normal d ecoder op eration . The

decoder waits until a transmission is received. The

received serial number is compared to the EEPROM

table of learned transmitters to first determine if this

transmitter’s use is allowed in the system. If from a

learned transmitter, the transmission is decrypted

using the stored crypt key and authenticated via the

discrimination bits for appropriate crypt key usage. If

the decryption was valid the synchronization value is

evaluated.

FIGURE 7-2: TYP ICAL DECODER

OPERATION

Start

No

Transmission

Received

?

Yes

No

Decrypt Transmission

No

No

No

Does

Serial Number

Match

?

Yes

Is

Decryption

Valid

?

Yes

Is

Counter

Within 16

?

No

Is

Counter

Within 32K

?

Yes

Save Counter

in Temp Location

Yes

Execute

Command

and

Update

Counter

7.3 Synchronization with Decoder

(Evaluating the Counter)

The KEELOQ technology patent scope includes a

sophisticated synchronization technique that does not

require the calculation an d storage of future codes. Th e

technique securely blocks invalid transmissions while

providing transparent resynchro niz at ion to transmitters

inadvertently activated away from the receiver.

Figure 7-3 shows a 3-partitio n, rotatin g synchroniza tion

window. The size of each window is optional but the

technique is fundamental. Each time a transmission is

authenticated, the intended function is executed and

the transmission’s synchronization counter value is

stored in EEPROM. From the currently stored counter

value ther e is an initial "Single Operation" forward window of 16 codes. If the difference between a received

synchronization counter and the last stored counter is

within 16, the intended functi on wil l be execu ted on the

single button press and the new synchronization

counter will be sto r ed . Storing the new synchronization

counter value ef fectively rot ates the entire sy nchronization window.

A "Double Operation" (resynchronization) window further exists from the Si ngle Ope ration windo w up to 3 2K

codes forward of the currently stored counter value. It

is referred to as "Double Operation" because a transmission with synchronization counter value in this window will require an additional, sequential counter

transmissi on prior to execut ing the intended function.

Upon receiving the sequential transmission the

decoder executes the intended function and stores the

synchroniz ation co unter va lue. Th is resy nchroniz ation

occurs transparently to the user as it is human nature

to press the button a second t ime if the first was un successful.

The third window is a "Blocked Window" ranging from

the double operation window to the currently stored

synchroniz ation counter value. An y transmission with

synchronization counter value within this window will

be ignored. This window excludes previously used,

perhaps code-grabbed transmissions from accessing

the system.

Note: The synchronization method described in

this section is only a typic al implement ation

and because it is usually implemented in

firmware, it can be altered to fit the needs

of a particular system.

DS40152E-page 18 2002 Microchip Technology Inc.

Page 19

FIGURE 7-3: SYNCHRONIZATION WINDOW

Entire Window

rotates to eliminate

use of previously

used codes

Blocked

Window

(32K Codes)

Double Operation

(resynchronization)

Window

(32K Codes)

HCS360

Stored

Synchronization

Counter Value

Single Operation

Window

(16 Codes)

2002 Microchip Technology Inc. DS40152E-page 19

Page 20

HCS360

8.0 ELECTRICAL CHARACTERISTICS

TABLE 8-1: ABSOLUTE MAXIMUM RATINGS

Symbol Item Rating Units

V

DD Supply voltage -0.3 to 6.9 V

VIN Input voltage -0.3 to VDD + 0.3 V

VOUT Output voltage -0.3 to VDD + 0.3 V

OUT Max output current 25 mA

I

TSTG Storage temperature -55 to +125 °C (Note)

TLSOL Lead soldering temp 300 °C (Note)

ESD ESD rating 4000 V

V

Note: Stresses above those lis ted under “ABSOLUTE MAXIMUM RATINGS” may cause permanent damage to the

device.

TABLE 8-2: DC CHARACTERISTICS

Commercial (C): Tamb = 0°C to +70°C

Industrial (I): Tam b = -40°C to +85°C

2.0V < V

Parameter Sym. Min

Operating current

I

CC 0.3 1.2

(avg)

Standby current I

Auto-shutoff

2,3

current

High level input

CCS 0.1 1.0 0.1 1.0 µA

ICCS 40 75 160 350 µA

V

IH 0.55 VDD VDD+0.3 0.55VDD VDD+0.3 V

voltage

Low level input

V

IL -0.3 0.15 VDD -0.3 0.15VDD V

voltage

High level output

V

OH 0.7 VDD 0.7 V DD VIOH = -1.0 mA, VDD = 2.0V

voltage

Low level output

VOL 0.08 VDD 0.08VDD VIOL = 1.0 mA, VDD = 2.0V

voltage

LED sink current ILED 0.15 1.0 4.0 0.15 1.0 4.0 mA

Pull-Down

S0-34060 80 406080kΩ VDD = 4.0V

R

Resistance; S0-S3

Pull-Down

R

PWM 80 120 160 80 120 160 kΩ VDD = 4.0V

Resistance; DAT A

Note 1: Typical values are at 25°C.

2: Auto-shutoff current specification does not include the current through the input pull-down resistors.

3: Auto-shutoff current is periodically sampled and not 100% tested.

4: VLED is the voltage between the VDD pin and the LED pin.

DD < 3.3 3.0 < VDD < 6.6

1

Typ

Max Min

Typ

0.7 1.6

1

Max Unit Conditions

mA VDD = 3.3V

I

OH = -2.0 mA, VDD = 6.6V

I

OL = 2.0 mA, VDD = 6.6V

4

V

LED

= 1.5V, VDD = 6.6V

DD = 6.6V

V

DS40152E-page 20 2002 Microchip Technology Inc.

Page 21

HCS360

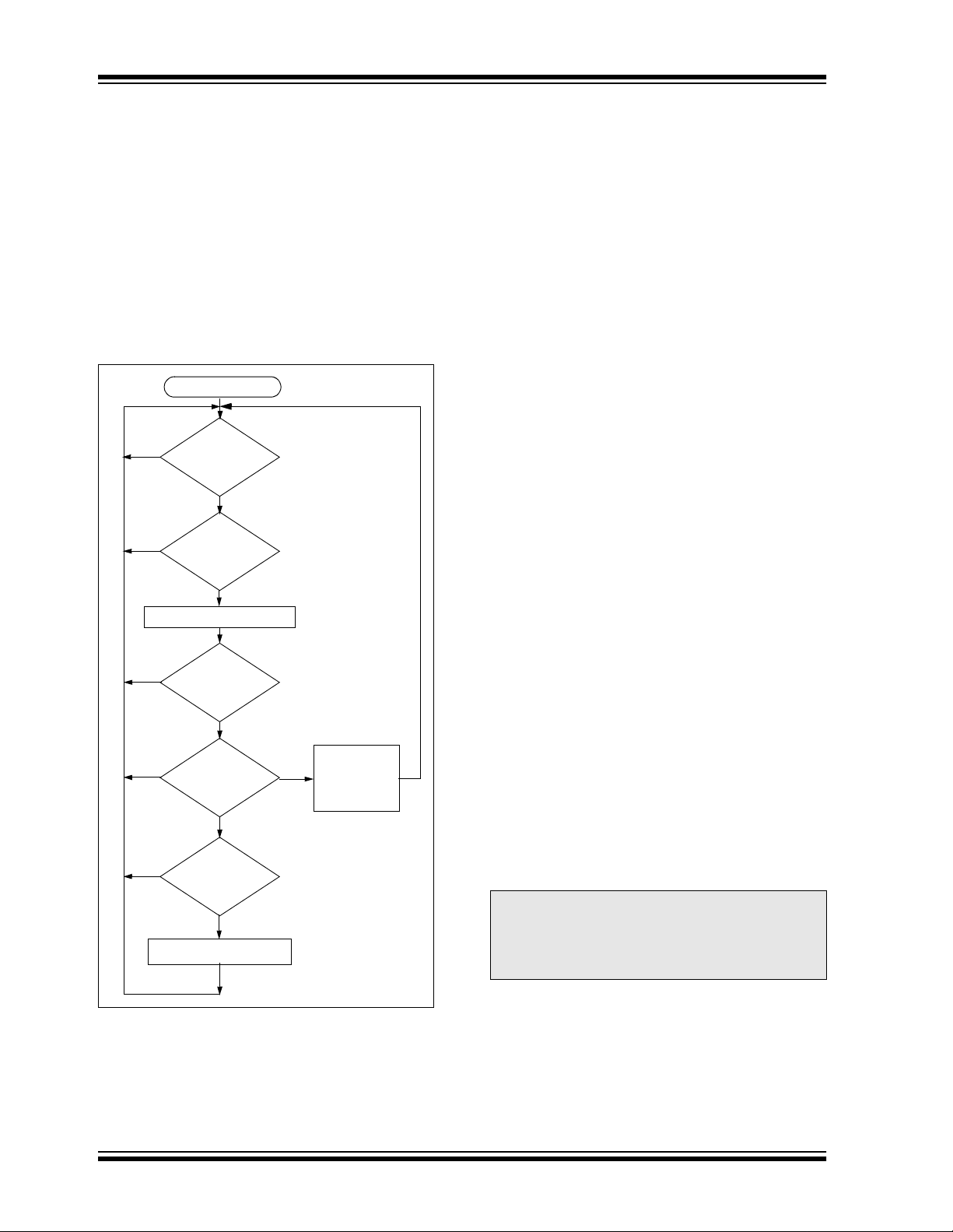

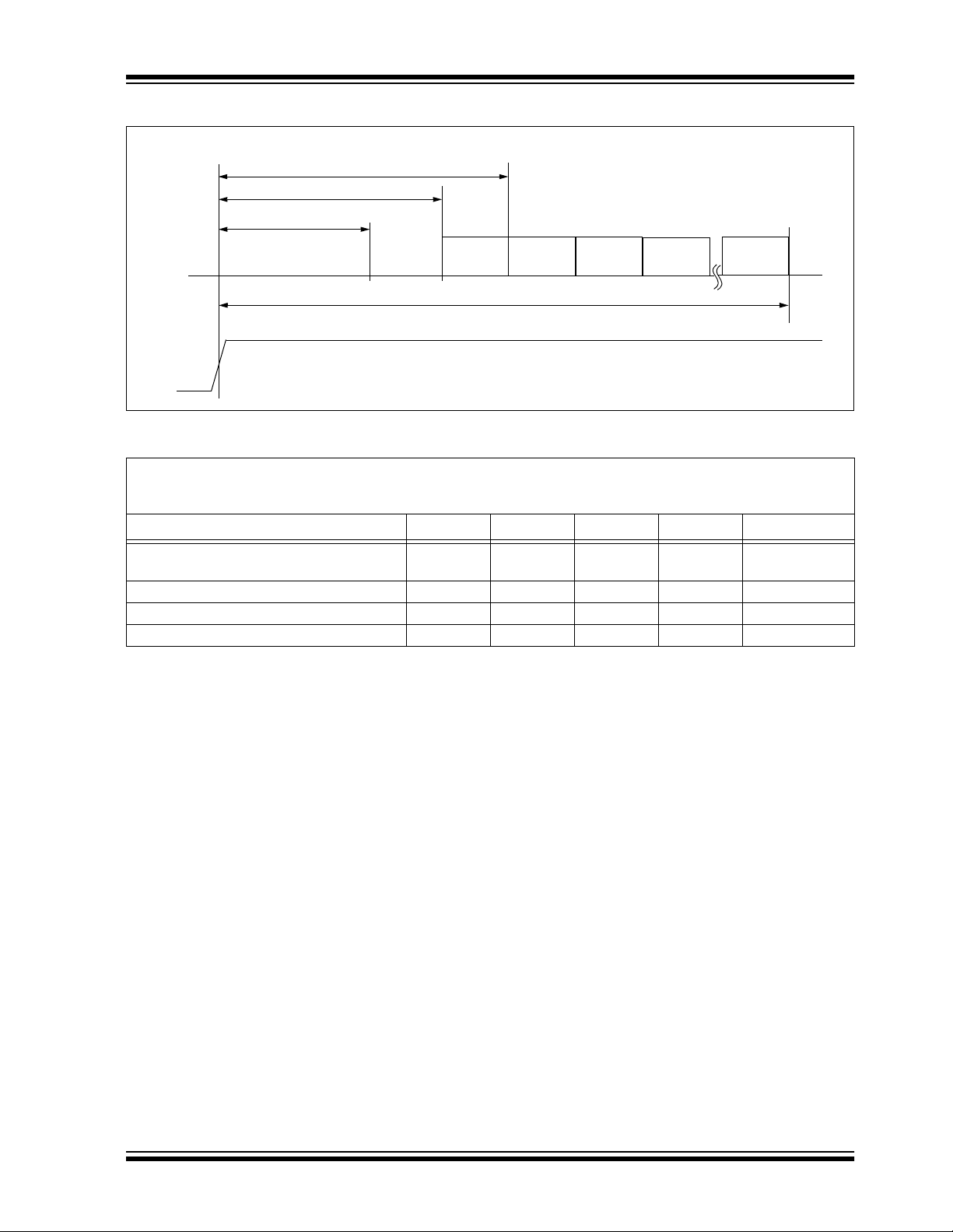

FIGURE 8-1: POWER-UP AND TRANSMIT TIMING

Button Press

PWM

Output

Button

Input

Sn

Detect

T

DB

TTD

BP

T

Code

Word

1

FIGURE 8-2: POWER-UP AND TRANSMIT TIMING REQUIREMENTS

VDD = +2.0 to 6.6V

Commercial (C): T amb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Parameter Symbol Min Max Unit Remarks

Time to second button press TBP 10 + Code

Transmit delay from button detect T

Debounce delay T

Auto-shutoff time-out period TTO 15.0 35 s (Note 3)

Note 1: TBP is the time in which a second button can be pressed without completion of the first code word and the

intention was to press the combination of buttons.

2: Transmit delay maximum value if the previous transmission was successfully transmitted.

3: The Auto-shutoff time-out period is not tested.

TD 4.5 26 ms (Note 2)

DB 4.0 13 ms

Multiple Code Word Transmission

Code

Word

2

TTO

Word Time

Code

Word

3

26 + Code

Word Time

Code

Word

4

Code

Word

n

ms (Note 1)

2002 Microchip Technology Inc. DS40152E-page 21

Page 22

HCS360

DS40152E-page 22 2002 Microchip Technology Inc.

Page 23

FIGURE 8-6: MANCHESTER FORMAT SUMMARY (MOD=1)

LOGIC "0"

LOGIC "1"

HCS360

TPB

TE

TE

1

2

50% Duty Cycle

Preamble

31XTE

Preamble

START bit

16

4XTE

Header

bit 0

bit 2

bit 1

Encrypted Portion Fixed Portion

of Transmission of Transmission

FIGURE 8-7: MANCHESTER PREAMBLE/HEADER FORMAT (MOD=1)

50% Duty Cycle

P1

FIGURE 8-8: HCS360 NORMALIZED T

TE

Preamble

31 x TE

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

-50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

Preamble

E VS. TEMP

TE Max.

TE Min.

Temperature °C

P16

4 x TE

Header

Typical

STOP bit

Bit 0 Bit 1

Data Word

Transmission

VDD LEGEND

= 2.0V

= 3.0V

= 6.0V

Guard

Time

2002 Microchip Technology Inc. DS40152E-page 23

Page 24

HCS360

TABLE 8-3:

VDD = +2.0V to 6.6V

Commercial (C):Tamb = 0°C to +70°C

Industrial (I):Tamb = -40°C to +85°C

Symbol Characteristic Min. Typ. Max. Min. Typ. Max. Units

T

E Basic pulse element 260 400 620 130 200 310 µs

TBP PWM bit pulse width 3 3 TE

TP Preamble duration 31 31 TE

TH Header duration 10 10 TE

THOP Hopping code duration 96 96 TE

TFIX Fixed code duration 105 105 TE

TG Guard Time (LNGRD = 0) 17 33 TE

— Total transmit time 259 275 TE

— Total transmit time 67.3 103.6 160.6 35.8 55.0 85.3 ms

— PWM data rate 1282 833 538 2564 1667 1075 bps

Note: The timing parameters are not tested but derived from the oscillator clock.

TABLE 8-4:

VDD = +2.0V to 6.6V

Commercial (C):Tamb = 0°C to +70°C

Industrial (I):Tamb = -40°C to +85°C

Symbol Characteristic Min. Typ. Max. Min. Typ. Max. Units

TE Basic pulse element 130 200 310 65 100 155 µs

T

BP PWM bit pulse width 33TE

TP Preamble duration 31 31 TE

TH Header duration 10 10 TE

THOP Ho pping code dur ation 96 96 TE

TFIX Fixed code duration 105 105 TE

TG Guard Time (LNGRD = 0) 33 65 TE

— Total transmit time 275 307 TE

— Total transmit time 35.8 55.0 85.3 20.0 30.7 47.6 ms

— PWM data rate 2564 1667 1075 5128 3333 2151 bps

Note: The timing parameters are not tested but derived from the oscillator clock.

CODE WORD TRANSMISSION TIMING PARAMETERS—PWM MODE

Code Words Transmitted

BSEL1 = 0

BSEL0 = 0

BSEL1 = 0

BSEL0 = 1

CODE WORD TRANSMISSION TIMING PARAMETERS—PWM MODE

Code Words Transmitted

BSEL1 = 1,

BSEL0 = 0

BSEL1 = 1,

BSEL0 = 1

DS40152E-page 24 2002 Microchip Technology Inc.

Page 25

HCS360

TABLE 8-5: CODE WORD TRANSMISSION TIMING PARAMETERS—MANCHESTER MODE

VDD = +2.0V to 6.6V

Commercial (C):Tamb = 0°C to +70°C

Industrial (I):Tamb = -40°C to +85°C

Symbol Characteristic Min. Ty p. Max. Min. Typ. Max. Units

T

E Basic pulse element 520 800 1240 260 400 620 µs

TP Preamble duration 31 31 TE

TH Header duration 4 4 TE

TSTART START bit 2 2 TE

THOP Hopping code duration 64 64 TE

TFIX Fixed code duration 70 70 TE

TSTOP STOP bit 2 2 TE

TG Guard Time (LNGRD = 0) 9 17 TE

— Total transmit time 182 190 TE

— Total transmit time 94.6 145.6 223.7 49.4 76.0 117.8 ms

— Manchester data rate 1923 1250 806 3846.2 2500 1612.9 bps

Note: The timing parameters are not tested but derived from the oscillator clock.

BSEL1 = 0,

BSEL0 = 0

Code Words Transmitted

BSEL1 = 0.

BSEL0 = 1

TABLE 8-6: CODE WORD TRANSMISSION TIMING PARAMETERS—MANCHESTER MODE

VDD = +2.0V to 6.6V

Commercial (C):Tamb = 0°C to +70°C

Industrial (I):Tamb = -40°C to +85°C

BSEL1 = 1,

BSEL0 = 0

Code Words Transmitted

BSEL1 = 1.

BSEL0 = 1

Symbol Characteristic Min. Typ. Max. Min. Typ. Max. Units

T

E Basic pulse element 260 400 620 130 200 310 µs

TP Preamble duration 32 32 TE

TH Header duration 44TE

TSTART START bit 22TE

THOP Hopping code duration 64 64 TE

TFIX Fixed code duration 70 70 TE

TSTOP STOP bit 22TE

TG Guard Time (LNGRD = 0) 16 32 TE

— Total transmit time 190 206 TE

— Total transmit time 49.4 76.0 1 17.8 26.8 41.2 63.4 ms

— Manchester data rate 3846.2 2500.0 1612.9 7692.3 5000.0 3225.8 bps

Note: The timing parameters are not tested but derived from the oscillator clock.

2002 Microchip Technology Inc. DS40152E-page 25

Page 26

HCS360

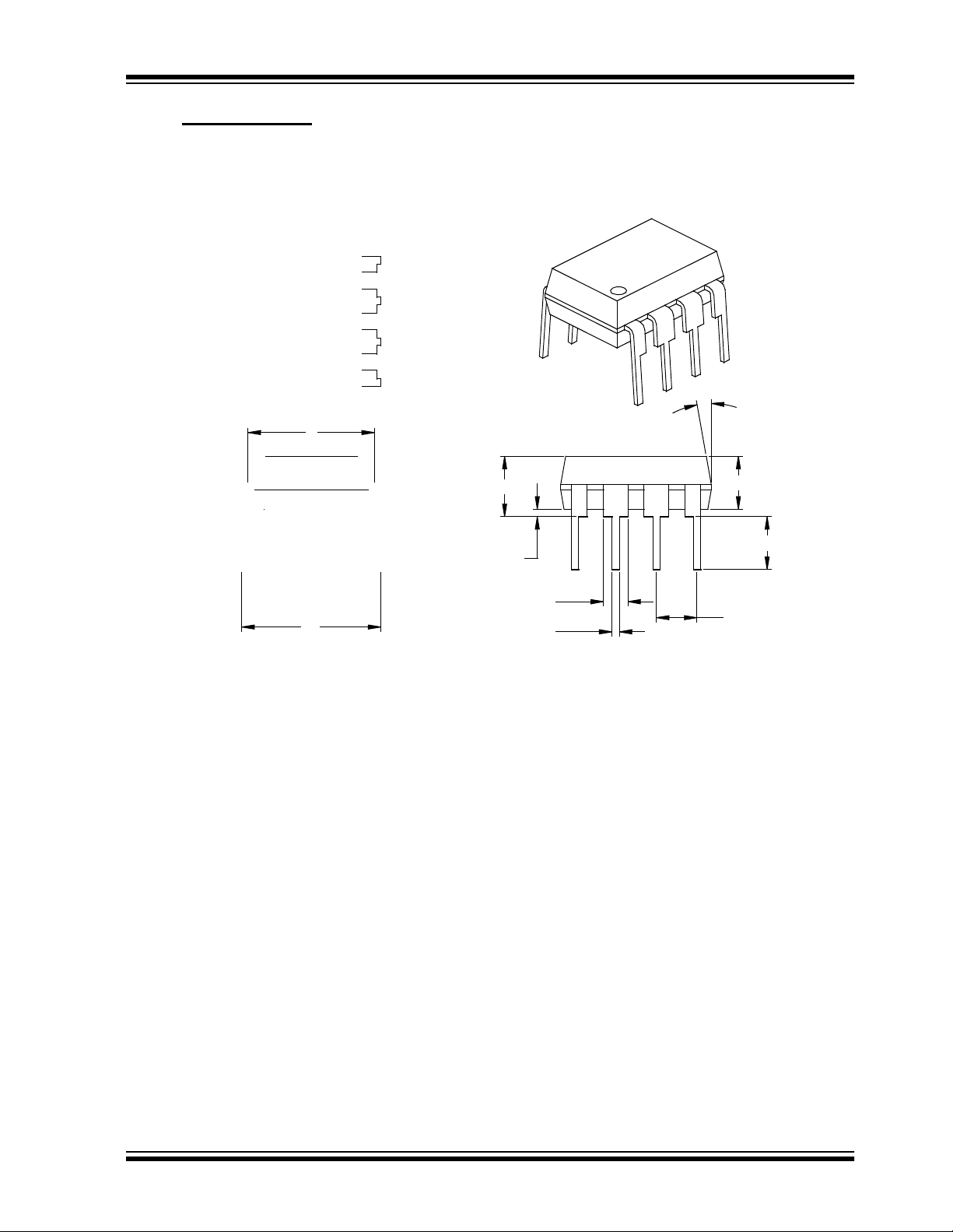

9.0 PACKAGING INFORMATION

9.1 Package Marking Information

DS40152E-page 26 2002 Microchip Technology Inc.

Page 27

9.2 Package Details

8-Lead Plastic Dual In-line (P) - 300 mil (PDIP)

E

HCS360

α

eB

A

A1

B1

B

A2

L

p

2002 Microchip Technology Inc. DS40152E-page 27

Page 28

HCS360

8-Lead Plastic Small Outline (SN) - Narrow, 150 mil (SOIC)

E

E1

p

D

2

B

Number of Pins

Pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-057

n

°

45

c

β

n

p

φ

c

α

β

1

h

A

φ

L

048048

A1

MILLIMETERSINCHES*Units

1.27.050

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004A1Standoff §

6.206.025.79.244.237.228EOverall Width

3.993.913.71.157.154.146E1Molded Package Width

5.004.904.80.197.193.189DOverall Length

0.510.380.25.020.015.010hChamfer Distance

0.760.620.48.030.025.019LFoot Length

0.250.230.20.010.009.008

0.510.420.33.020.017.013BLead Width

1512015120

1512015120

DS40152E-page 28 2002 Microchip Technology Inc.

Page 29

HCS360

ON-LINE SUPPORT

Microchip provides on-line support on the Microchip

World Wide Web (WWW) site.

The web site is used b y Micr ochip as a means to mak e

files and information easily available to customers. To

view the site, the use r must hav e access to the Intern et

and a web browser, such as Netscape or Microsoft

Explorer. Files are also available for FTP download

from our FTP site.

Connecting to the Microchip Internet Web Site

The Microchip web site is available by using your

favorite Internet browser to attach to:

www.microchip.com

The file transfer site is available by using an FTP service to connect to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of

services. Users may download files for the latest

Development Tools, Data Sheets, Application Notes,

User’s Guides, Articles and Sample Programs. A variety of Micr ochip specific bu siness informati on is also

available, including listings of Microchip sales offices,

distributors and factory representatives. Other data

available for consideration is:

• Latest Microchip Press Releases

• Technical Support Section with Frequently Asked

Questions

• Design Tips

• Device Errata

• Job Postings

• Microchip Consultant Program Member Listing

• Links to other useful web sites related to

Microchip Products

• Conferences for products , Development System s,

technical information and more

• Listing of seminars and events

Systems Information and Upgrade Hot Line

The Systems Information and Upgrade Line provides

system users a listing of the latest versions of all of

Microchip's development systems software products.

Plus, this line provides information on how customers

can receive any currently available upgrade kits.The

Hot Line Numbers are:

1-800-755-2345 for U.S. and most of Canada, and

1-480-792-7302 for the rest of the world.

2002 Microchip Technology Inc. DS40152E-page 29

Page 30

HCS360

READER RESPONSE

It is our intentio n t o provide you with the best documentati on possible to ensu re s uc ce ss ful us e of your Microchip product. If you wish to pro vide your comm ents on org aniza tion, c larity, subject matter , and w ays in whi ch ou r doc umenta tion

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this Data Sheet.

To:

RE: Reader Response

From:

Application (optional):

Would you like a reply? Y N

Device:

Questions:

1. What are the best features of this docume nt?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this data sheet easy to follow? If not, why?

Technical Publications Manager

Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________

HCS360

Literature Number:

Total Pages Sent

FAX: (______) _________ - _________

DS40152E

4. What additions to the data sheet do you think would enhance the structure and subject?

5. What delet ions from the data sheet could be made without affecti ng the overal l usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

8. How would you improve our software, systems, and silicon products?

DS40152E-page 30 2002 Microchip Technology Inc.

Page 31

HCS360

HCS360 PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

HCS360 — /P

Package: P = Plastic DIP (300 mil Body), 8-lead

Temperature Blank = 0°C to +70°C

Range: I = –40°C to +85°C

Device: HCS360 Code Hopping Encoder

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

SN = Plastic SOIC (150 mil Body), 8-lead

HCS360T Code Hopping Encoder (Tape and Reel)

2002 Microchip Technology Inc. DS40152E-page 31

Page 32

HCS360

NOTES:

DS40152E-page 32 2002 Microchip Technology Inc.

Page 33

Microchip’s Secure Data Products are covered by some or all of the following patents:

Code hopping encoder patents issued in Europe, U.S.A., and R.S.A. — U.S.A.: 5,517,187; Europe: 0459781; R.S.A.: ZA93/4726

Secure learning patents issued in the U.S.A. and R.S.A. — U.S.A.: 5,686,904; R.S.A.: 95/5429

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, FilterLab,

K

EELOQ, MPLAB, PIC, PICmicro, PICMASTER, PICSTART,

PRO MATE, SEEVAL and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

dsPIC, ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, microID,

microPort, Migratable Memory, MPASM, MPLIB, MPLINK,

MPSIM, MXDEV, PICC, PICDEM, PICDEM.net, rfPIC, Select

Mode and Total Endurance are trademarks of Microchip

Technology Incorporated in the U.S .A .

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwid e head qu art ers,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999. The

Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs and microperipheral

products. In addition, Microchip’s quality

system for the design and manufacture of

development systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hoppin g

2002 Microchip Technology Inc. DS40152E - page 33

Page 34

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640 -03 07

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692 -38 21

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818 -29 24

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263 -13 38

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273 -53 35

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436 -79 55

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

DS40152E-page 34 2002 Microchip Technology Inc.

Loading...

Loading...