Page 1

HCS301

KEELOQ® Code Hopping Encoder

FEATURES

Security

•Programmable 28-bit serial number

•Programmable 64-bit encryption key

•Each transmission is unique

•66-bit transmission code length

•32-bit hopping code

•34-bit fixed code (28-bit serial number,

4-bit button code, 2-bit status)

•Encryption keys are read protected

Operating

•3.5V - 13.0V operation

•Four button inputs

•No additional circuitry required

•15 functions available

•Selectable baud rate

•Automatic code word completion

•Battery low signal transmitted to receiver

•Battery low indication on LED

•Non-volatile synchronization data

Other

•Functionally identical to HCS300

•Easy-to-use programming interface

•On-chip EEPROM

•On-chip oscillator and timing components

•Button inputs have internal pull-down resistors

•Current limiting on LED

•Low external component cost

Typical Applications

output

DESCRIPTION

The HCS301 from Microchip Technology Inc. is a code

hopping encoder designed for secure Remote Keyless

Entry (RKE) systems. The HCS301 utilizes the KEELOQ

code hopping technology, which incorporates high

security, a small package outline and low cost, to make

this device a perfect solution for unidirectional remote

keyless entry systems and access control systems.

PACKAGE TYPES

PDIP, SOIC

8

S0

S1

S2

S3

1

2

3

4

HCS301

VDD

LED

7

6

PWM

V

SS

5

HCS301 BLOCK DIAGRAM

LED

PWM

Oscillator

RESET circuit

LED

VSS

VDD

Controller

driver

EEPROM

32-bit shift register

Button input port

Power

latching

and

switching

Encoder

The HCS301 is ideal for Remote Keyless Entry (RKE)

applications. These applications include:

•Automotive RKE systems

•Automotive alarm systems

•Automotive immobilizers

•Gate and garage door openers

•Identity tokens

•Burglar alarm systems

2001 Microchip Technology Inc. DS21143B-page 1

The HCS301 combines a 32-bit hopping code,

generated by a nonlinear encryption algorithm, with a

28-bit serial number and 6 information bits to create a

66-bit code word. The code word length eliminates the

threat of code scanning and the code hopping mechanism makes each transmission unique, thus rendering

code capture and resend schemesuseless.

S3

S2

S1 S0

Page 2

HCS301

The crypt key, serial number and conf iguration dat a are

stored in an EEPROM array which is n ot accessible via

any external connection. The EEPROM data is programmable but read-protected. The data can be verified only after an automatic erase and programming

operation. This protects against attempts to gain

access to keys or manipulate synchronizat ion values.

The HCS301 provides an easy-to-use serial interface

for programming the necessary keys, system parameters and configuration data.

1.0 SYSTEM OVERVIEW

Key Terms

The following is a l ist of key te rms us ed thro ughout this

data sheet. For additional information on K

Code Hopping, refer to Technical Brief 3 (TB003).

• RKE - Remote Keyless Entry

• Button Status - Indicates what button input(s)

activated the transmission. Encompasses the 4

button status bits S3, S2, S1 and S0 (Figure 4-2).

• Code Hopping - A method by which a code,

viewed externally to the system, appears to

change unpredictably each time it is transmitted.

• Code word - A block of data that is repeatedly

transmitted upon button activation (Figure4-1).

• Transmission - A data stream consisting of

repeating code words (Figure 8-2).

• Crypt key - A unique and secret 64-bit number

used to encrypt and decrypt data. In a symmetrical block cipher such as the K

the encryption and de cry pti on k ey s a re equal and

will therefore be referred to gene rally as the crypt

key.

• Encoder - A device that generates and encodes

data.

• Encryption Algorithm - A recipe whereb y data i s

scrambled using a crypt k ey . The dat a can only be

interpreted by the respe ctive dec ryptio n algo rithm

using the same crypt key.

• Decoder - A device that decodes data received

from an encoder.

• Decryption algorithm - A recipe whereby data

scrambled by an encryption algorithm can be

unscrambled using the same crypt key.

EELOQ algorithm,

EELOQ and

• Learn – Learning inv olves the recei ver calcula ting

the transmitter’s appropriate crypt key, d ec ryp ting

the received hopping code and storing the serial

number, synchronization counter value and crypt

key in EEPROM. The K

itates several learning strategies to be implemented on the decoder. The following are

examples of what can be done.

- Simple Learning

The receiver uses a fixed crypt key, common

to all components of all system s by the same

manufacturer, to decrypt the received code

word’s encrypted portion.

- Normal Learning

The receiver uses information transmitted

during normal operation to derive the crypt

key and decrypt the received code word’s

encrypted portion.

- Secure Learn

The transmitter is activated through a special

button combinat ion to t ransmit a stored 60-bit

seed value used to generat e the trans mitter’s

crypt key. The receiver uses this seed value

to derive the same crypt key and decrypt the

received code word’s encrypted portion.

• Manufacturer’s code – A unique and secret 64-

bit number used to generate un ique encoder crypt

keys. Each encoder is programmed with a crypt

key that is a function of the manufacturer’s code.

Each decoder is programmed with the manufacturer code itself.

The HCS301 code hopping encode r is designed sp ecifically for keyless entry systems; primarily vehicles and

home garage door openers. The encoder portion of a

keyless entry system is integrated into a transmitter,

carried by the user and operated to gain access to a

vehicle or restricted area. The HCS301 is meant to be

a cost-effective yet secure solution to such systems,

requiring very few external components (Figure 2-1).

Most low-end keyless entry transmitters are given a

fixed identificati on code that is transmitted ever y time a

button is pushed. The number of unique identification

codes in a low-end system is usually a relatively small

number. These shortcomings provide an opportunity

for a soph istic ated t hief to crea te a d evice that ‘grab s’

a transmission and retransmits it later, or a device that

quickly ‘scans ’ all pos sible identi ficati on c odes un til the

correct one is found.

The HCS301, on the other hand, employs the K

code hopping technology coupled with a transmission

length of 66 bits to virtually eliminate the use of code

‘grabbing’ or code ‘scann ing’. The hig h security le vel of

the HCS301 is base d on the p atented K

ogy. A block cipher based on a block length of 32 bits

and a key length of 64 bits is used. The algorithm

obscures the informati on i n such a way that even if the

transmission informati on (before c oding) dif fers b y only

one bit from that of the previous transmission, the next

EELOQ product family facil-

EELOQ

EELOQ

technol-

DS21143B-page 2 2001 Microchip Technology Inc.

Page 3

HCS301

coded transmission will be completely different. Statistically, if only one bit in the 32-bit string of information

changes, greater than 50 percent of the coded transmission bits will change.

As indicated in the block diagram on page one, the

HCS301 has a small EEPROM array which must be

loaded with several p arameters before use; most often

programmed by the manufacturer at the time of production. The most important of these are:

• A 28-bit serial number, typically unique for every

encoder

• A crypt key

• An initial 16-bit synchronization value

• A 16-bit configuration value

The crypt key generatio n typically input s the transmitter

serial number and 64-bit manufact urer ’s code into t he

key generation algorithm (Figure 1-1). The manufacturer’s code is chosen by the system manufacturer and

must be carefully controlled as it is a pivotal part of the

overall system security.

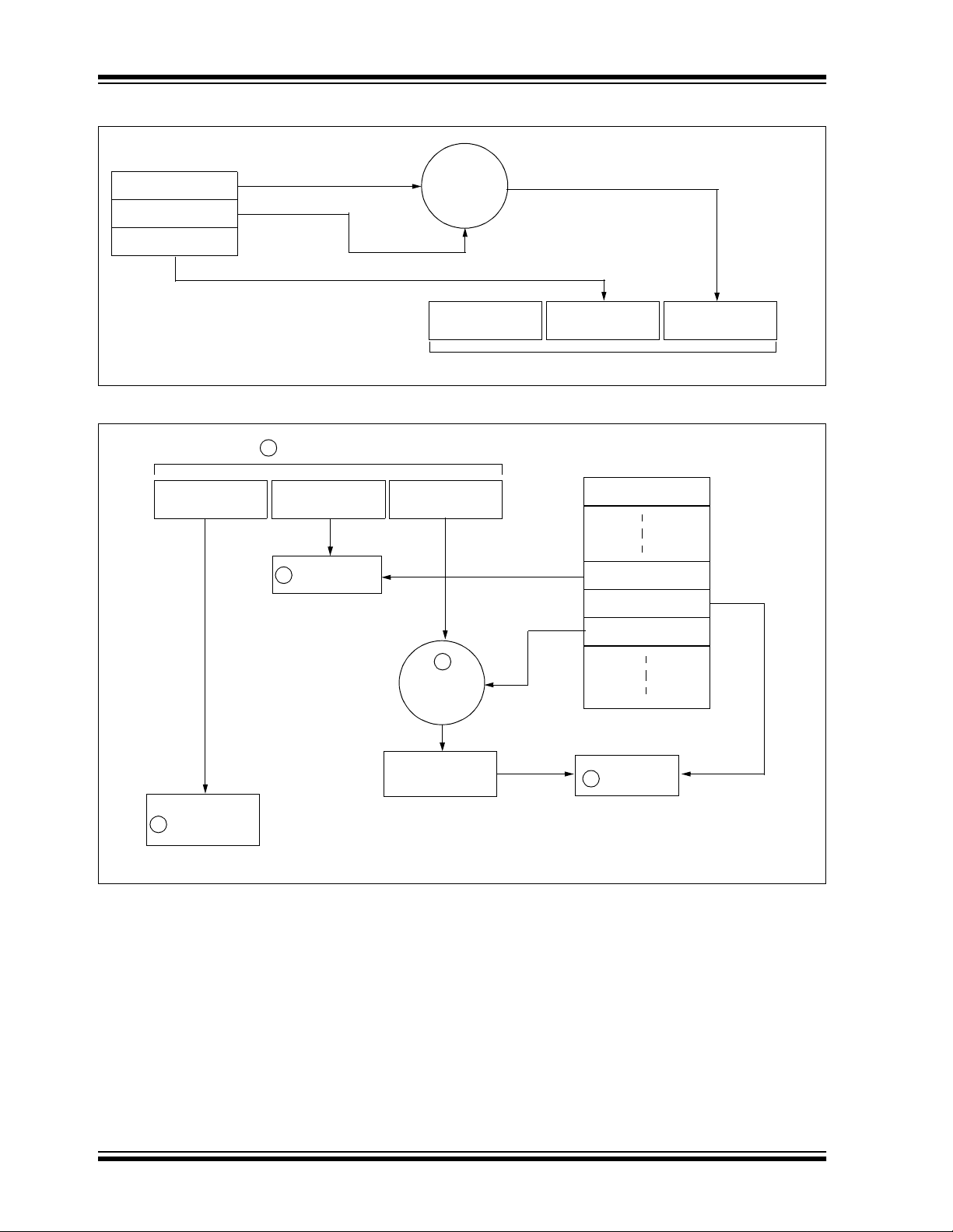

FIGURE 1-1: CREATION AND STORAGE OF CRYPT KEY DURING PRODUCTION

Production

Programmer

Manufacturer’s

Code

Transmitter

Serial Number

Key

Generation

Algorithm

Crypt

Key

HCS301

EEPROM Array

Serial Number

Crypt Key

Sync Counter

.

.

.

The 16-bit synchronization counter is the basis behind

the transmitted code word changing for each transmission; it increments each time a button is pressed. Due

to the code hoppin g algorith m’s complex ity, each inc rement of the synchronization value results in greater

than 50% of the bits changing in the transmitted code

word.

Figure 1-2 shows how the key values in EEPROM are

used in the encoder . O nce the encoder dete cts a button

press, it reads the button inputs and updates the synchronization counter. The synchronization counter and

crypt key are input to the encryption algorithm and the

output is 32 bits of encrypted information. This data will

change with every button press, its value appearing

externally to ‘ran domly h op aroun d’, hence it is re ferred

to as the hopping portion of the code word. The 32-bit

hopping code is combined with the button information

and serial numb er to fo rm the code word transm itted to

the receiver. The code word format is explained in

greater detail in Section 4.0.

A receiver may use any type of controller as a decoder,

but it is typically a microcon troller with compatible firmware that allows the decoder to operate in conjunction

with an HCS301 based transmitter. Section 7.0

provides detail on integrating the HCS301 into a system.

A transmitter must first be ‘learned’ by the receiver

before its use is allowed in the system. Learning

includes calculating the transmitter’s appropriate crypt

key, decrypting the received hopping code and storing

the serial number, synchronization counter value and

crypt key in EEPROM.

In normal operation, each received message of valid

format is evaluated. The serial number is used to determine if it is from a learned transmitter. If from a learned

transmitter, the message is decrypted and the synchronization counter is verified. Finally, the button status is

checked to see what operation is requested. Figure 1-3

shows the relationship between some of the values

stored by the receiver and the values received from

the transmitter.

2001 Microchip Technology Inc. DS21143B-page 3

Page 4

HCS301

FIGURE 1-2: BUILDING THE TRANSMITTED CODE WORD (ENCODER)

EEPROM Array

Crypt Key

Sync Counter

Serial Number

KEELOQ

Encryption

Algorithm

Button Press

Information

Serial Number

Transmitted Information

FIGURE 1-3: BASIC OPERATION OF RECEIVER (DECODER)

1

Received Information

Button Press

Information

Serial Number

Check for

2

Match

32 Bits of

Encrypted Data

32 Bits

Encrypted Data

EEPROM Array

Manufacturer Code

Serial Number

Sync Counte r

KEELOQ

Decryption

Algorithm

Decrypted

Synchronization

Counter

Perform Function

Indicated by

5

button press

NOTE: Circled numbers indicate the order of execution.

Crypt Key

3

Check for

4

Match

DS21143B-page 4 2001 Microchip Technology Inc.

Page 5

HCS301

2.0 DEVICE OPERATION

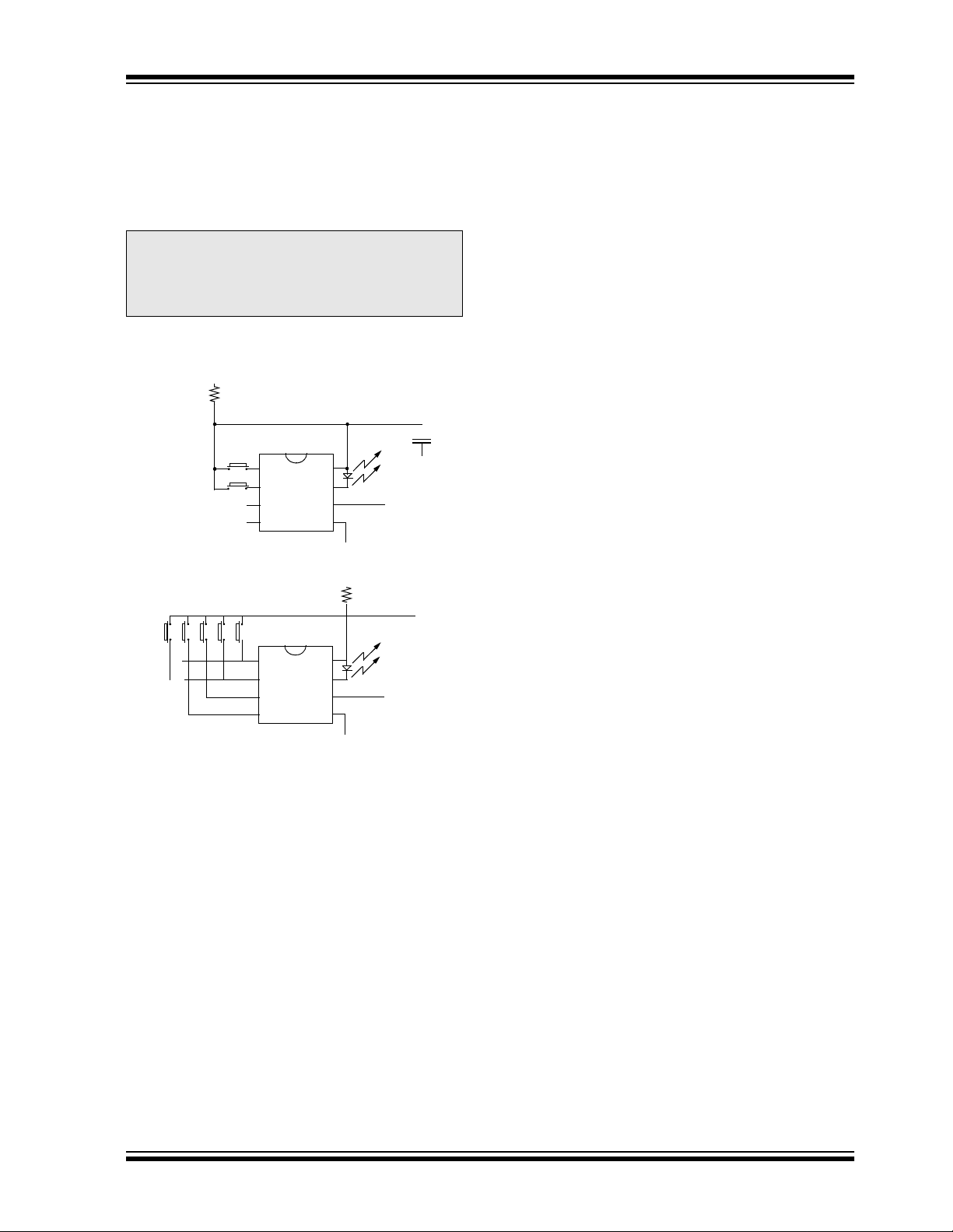

As shown in the typical a pplication circ uits (Figu re 2-1),

the HCS301 is a simple device to use. It requires only

the addition of buttons and RF circuitry for use as the

transmitter in your security applic ation. A descripti on of

each pin is given in Table 2-1.

Note: When VDD > 9.0V and driving low capaci-

tive loads, a res ist or wi th a minimum value

of 50Ω should be used in line with V

This prevents clamping of PWM at 9.0V in

the event of P WM overshoot .

FIGURE 2-1: TYPICAL CIRCUITS

+12V

R

B0

B1

2 button remote control

B4 B3 B2 B1 B0

5 button remote control

Note 1: Up to 15 functions can be implemented by pressing

more than one button si multaneously or by usi ng a

suitable diode array.

2: Resistor R is recommended for current limiting.

S0

S1

S2

S3

S0

S1

S2

S3

(1)

V

DD

LED

PWM

SS

V

DD

V

LED

PWM

V

SS

Tx out

Tx out

DD.

TABLE 2-1: PIN DESCRIPTIONS

The HCS301 will wake-up upon detecting a button

press and delay approximately 10 ms for button

debounce (Figure 2-2). The synchronization counter,

discrimination value and button information will be

encrypted to form the hopping code. The hopping code

portion will change every transmission, even if the

same button is pushed again. A code word that has

been transmitted will not repeat for more than 64K

transmissions. Thi s provides mo re than 18 years of use

before a code is repeated; based on 10 operations per

day . Overflow inform ation sent from the enc oder can be

used to extend the number of unique transmissions to

more than 192K.

If in the tr an smit proc ess it i s de tec ted t hat a n ew b utton(s) has been pressed, a RESET will immediately

occur and the current cod e word will no t be compl eted.

Please note that buttons removed will not have any

effect on the code word unless no buttons remain

pressed; in which c ase the code word will be compl eted

and the power-down will occur.

2001 Microchip Technology Inc. DS21143B-page 5

Page 6

HCS301

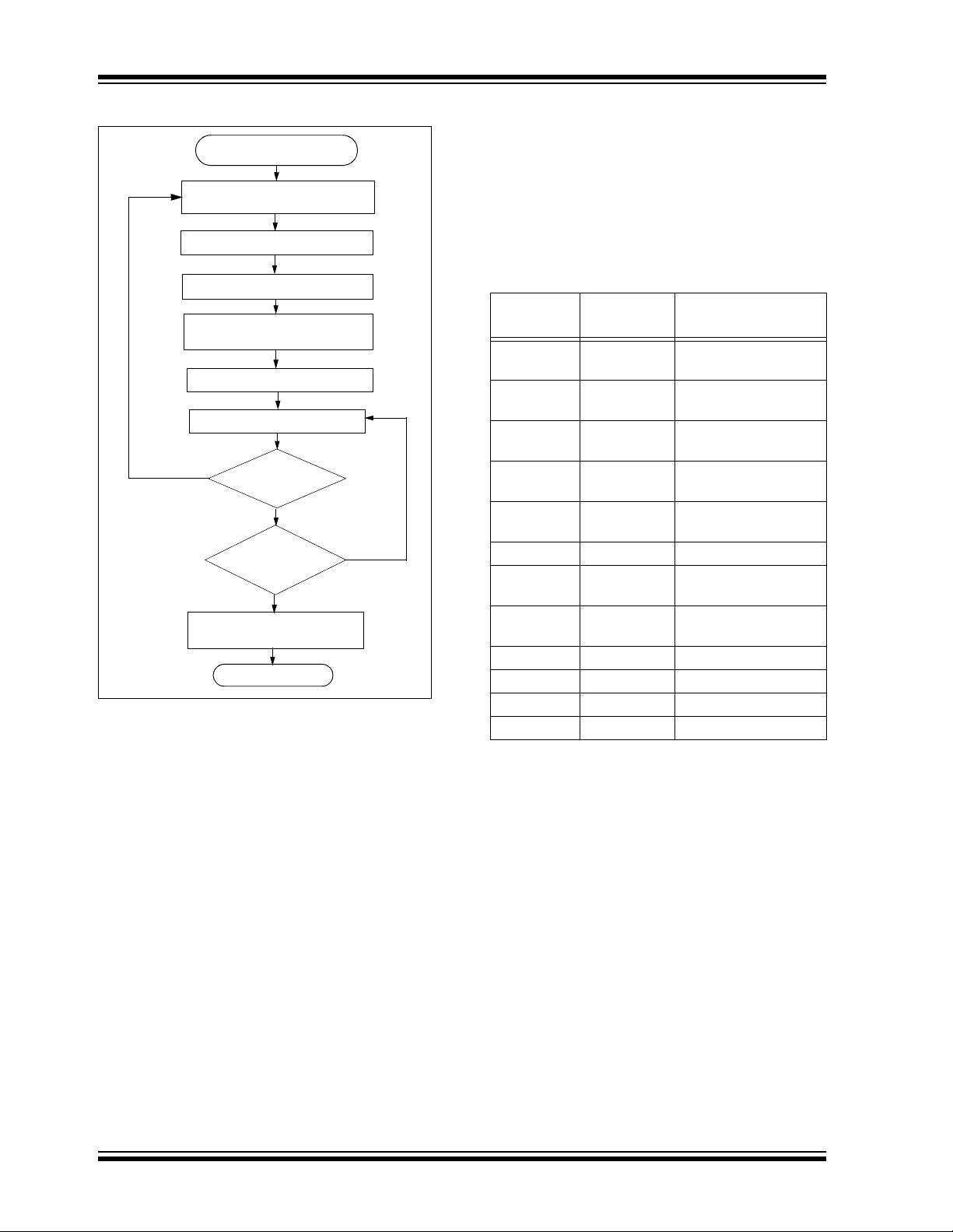

FIGURE 2-2: ENCODER OPERATION

Power-Up

(A button has been pressed)

RESET and Debounce Delay

(10 ms)

Sample Inputs

Update Sync Info

Encrypt With

Crypt Key

Load Transmit Register

Transmit

Yes

Buttons

Added

?

No

All

Buttons

Released

?

Yes

Complete Code

Word Transmission

Stop

No

3.0 EEPROM MEMORY ORGANIZATION

The HCS301 contains 192 bits (12 x 16-bit words) of

EEPROM memory (Table 3-1). This EEPROM array is

used to store the encryption key information,

synchroniz ation v alue, etc. Fur ther de scripti ons of the

memory array is given in the following sections.

T ABLE 3-1: EEPROM MEMORY MAP

WORD

ADDRESS

0 KEY_0 64-bit encryption key

1 KEY_1 64-bit encryption key

2 KEY_2 64-bit encryption key

3 KEY_3 64-bit encryption key

4 SYNC 16-bit synchronization

5 RESERVED Set to 0000H

6 SER_0 Device Serial Number

7 SER_1(Note) Device Serial Number

8 SEED_0 Seed V al ue (word 0)

9 SEED_1 Seed V al ue (word 1)

10 RESERVED Set to 0000H

11 CONFIG Config Word

Note: The MSB of the serial nu mber con tains a bit

MNEMONIC DESCRIPTION

(word 0) LSb’s

(word 1)

(word 2)

(word 3) MSb’s

value

(word 0) LSb’s

(word 1) MSb’s

used to select the Auto-shutoff timer.

3.1 KEY_0 - KEY_3 (64-Bit Crypt Key)

The 64-bit crypt key is used to create the encrypted

message tra nsmitted to the receiver. This ke y is calculated and programmed during production using a key

generation algorithm. The key generation algorithm

may be different from the K

the key generation algorithm are typically the transmit-

ter’s serial numbe r and the 64-bit man ufactu rer’s cod e.

While the key generation algorithm supplied from

Microchip is the typical method used, a user may elect

to create their ow n method of key g eneration. This ma y

be done providing that the deco der is program med with

the same means of creating the key for

decryption purposes.

DS21143B-page 6 2001 Microchip Technology Inc.

EELOQ

algorithm. Inputs to

Page 7

HCS301

3.2 SYNC (Synchronization Counter)

This is the 16-bit synchronization value that is used to

create the hopping code for transmission. This value

will increment after every transmission.

3.3 Reserved

Must be initialized to 0000H.

3.4 SER_0, SER_1

(Encoder Serial Number)

SER_0 and SER_1 are the lower and upper words of

the device serial number, respectively. Although there

are 32 bits allocated for the serial number, only the

lower order 28 bits are transmitted. The serial number

is meant to be unique for every transmitter.

3.4.1 AUTO-SHUTOFF TIMER ENABLE

The Most Sign ificant bit of the serial number (Bit 31) is

used to turn the Auto-shutoff timer on or off. This timer

prevents the transmitter from draining the battery

should a bu tton get stuck in the on positi on for a l ong

period of time. The time period is approximately

25 seconds, after which the device will go to the Timeout mode. When in the Time-out mo de, t he devi ce w ill

stop transmitting, although since some circuits within

the device a re still acti ve, the curre nt draw within the

Shutoff mode will be higher than Standby mode. If the

Most Signifi can t bi t i n the s eri al n umb er i s a o ne, t hen

the Auto-shutoff timer is enabled, and a zero in the

Most Significant bit will disable the timer. The length of

the timer is not selectable.

3.5 SEED_0, SEED_1 (Seed Word)

The 2-word (32-bit) seed c ode will be tr ansmitte d when

all three buttons are pressed at the same time (see

Figure 4-2). This allows the system designer to implement the secu re learn feature or u se this fixed code

word as part of a different key generation/tracking process.

3.6 CONFIG (Configuration Word)

The Configuration Word is a 16-bit word stored in

EEPROM array that is used by the device to store

information used duri ng the encryp tion process, as w ell

as the status of option configurations. The following

sections further explain these bits.

TABLE 3-2: CONFIGURATION WORD

Bit Number Bit Description

0 Discrimination Bit 0

1 Discrimination Bit 1

2 Discrimination Bit 2

3 Discrimination Bit 3

4 Discrimination Bit 4

5 Discrimination Bit 5

6 Discrimination Bit 6

7 Discrimination Bit 7

8 Discrimination Bit 8

9 Discrimination Bit 9

10 Overflow Bit 0 (OVR0)

11 Overflow Bit 1 (OVR1)

12 Low Voltage Trip Poi nt Select

(V

LOW SEL)

13 Baud rate Select Bit 0 (BSL0)

14 Baud rate Select Bit 1 (BSL1)

15 Reserved, set to 0

3.6.1 DISCRIMINATION VALUE

(DISC0 TO DISC9)

The discrimination value aids the post-decryption

check on the decoder end. It may be any value, but in

a typical system it will be programmed as the 10 Least

Significant bits of the serial number. Values other than

this must be separately stored by the receiver when a

transmitter is learned. The discrimination bits are part

of the information tha t form the encrypte d portion o f the

transmission (Figure 4-2). After the receiver has

decrypted a transmission, the discrimination bits are

checked against the receiver’s stored value to verify

that the decryption proc ess was v alid. If the discrim ination value was programmed as the 10 LSb’s of the

serial number then it may merely be compared to the

respectiv e bits of the received se rial number; saving

EEPROM space.

3.6.2 OVERFLOW BITS

(OVR0, OVR1)

The overflow bits are used to extend the number of

possible synchronization values. The synchronization

counter is 16 bits in length, yielding 65,536 values

before the cycle repeats. Under typical use of

10 operations a day , th is will provi de nea rly 18 year s of

use before a repeated value will be used. Should the

system designer conclude that is not adequate, then

the overflow bits can be utilized to extend the number

2001 Microchip Technology Inc. DS21143B-page 7

Page 8

HCS301

of unique values. This can be done by programming

OVR0 and OVR1 to 1s at the time of production. The

encoder will automatica lly clear OVR0 the first time that

the synchronization value wraps from 0xFFFF to

0x0000 and clear OVR1 the second time the counter

wraps. Once cleared, OVR0 and OVR1 cannot be set

again, thereby creating a permanent record of the

counter overflow. This prevents fast cycling of 64K

counter. If the decoder system is programmed to track

the overflow bits, then the effective number of unique

synchronization values can be extended to 196,608.

3.6.3 BAUD RATE SELECT BITS

(BSL0, BSL1)

BSL0 and BSL1 select the speed of transmission and

the code word blanking. Table 3-3 shows how the bits

are used to select the different baud rates and

Section 5.7 provides detailed explanation in code word

blanking.

TABLE 3-3: BAUD RATE SELECT

BSL1 BSL0

Basic Pulse

Element

0 0 400 µsAll

0 1 200 µs 1 out of 2

1 0 100 µs 1 out of 2

1 1 100 µs 1 out of 4

Code Words

Transmitted

3.6.4 LOW VOLTAGE TRIP POINT

SELECT

The low voltage trip point select bit is used to tell the

HCS301 what

VDD level is being used. This information

will be used by the device to determine when to send the

voltage low signal to the receiver. When this bit is set to

a one, the

9V or 12V

VDD level is assumed to be operating from a

VDD level. If the bit is set low, then the VDD le vel

is assumed to be 6.0 volts. Refer to Figure 3-1 for voltage trip point.

FIGURE 3-1: VOLTAGE TRIP POINTS

BY CHARACTERIZATION

Volts (V)

5.5

5.0

4.5

4.0

3.5

3.0

2.5

9.0

8.5

8.0

7.5

7.0

VLOW sel = 0

VLOW sel = 1

V

LOW

Max

Min

Max

Min

-40 20 40 100

-20 0 60 80

Temp (C)

DS21143B-page 8 2001 Microchip Technology Inc.

Page 9

HCS301

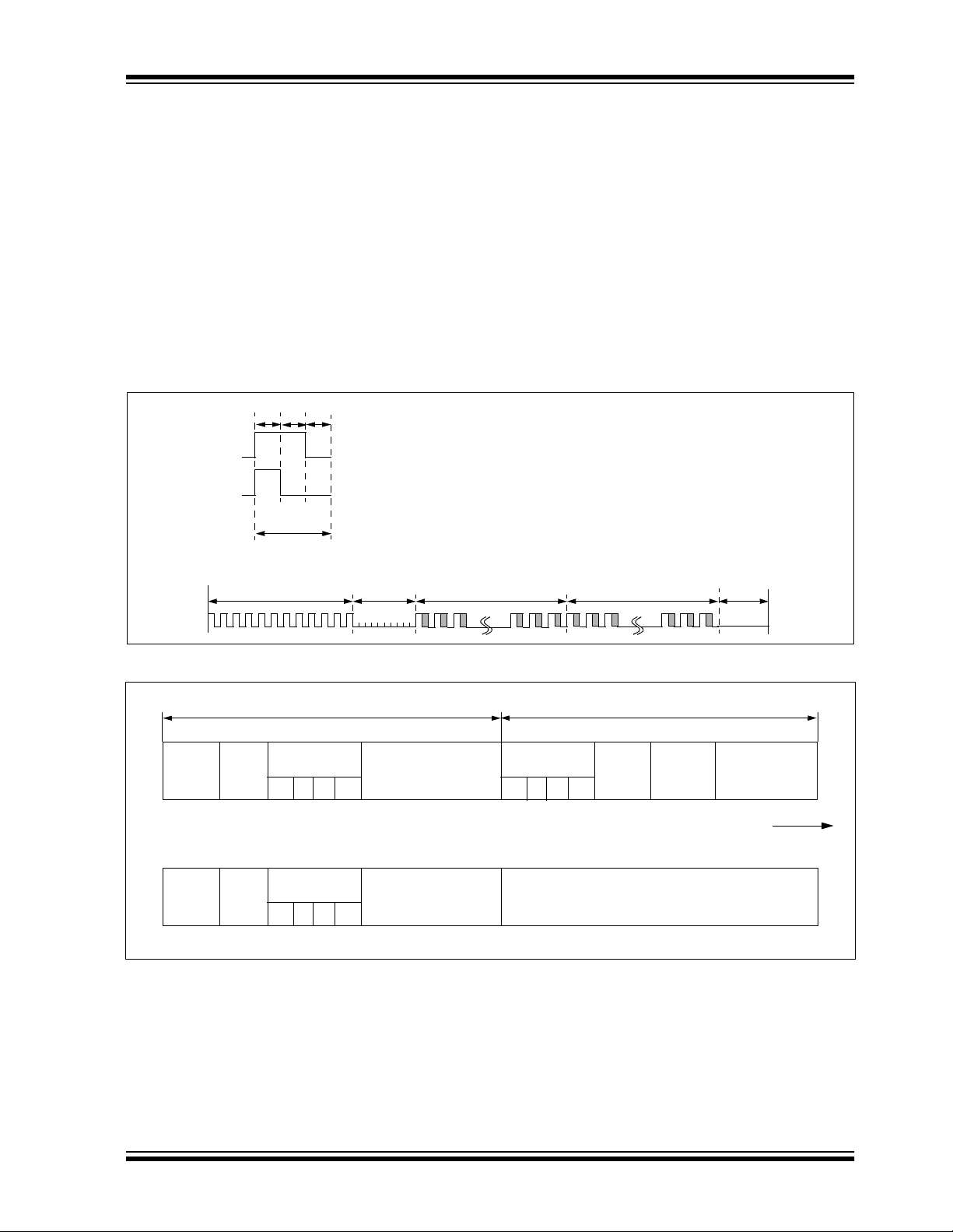

4.0 TRANSMITTED WORD

4.1 Code Word Format

The HCS301 code word is made up of several parts

(Figure 4-1). Each code word contains a 50% duty

cycle preamble, a hea der , 32 bits of en crypted data an d

34 bits of fixed data followed by a guard period before

another code word can begin. Refer to Table 8-4 for

code word timing.

FIGURE 4-1: CODE WORD FORMAT

TE

TE

TE

LOGIC ‘0’

LOGIC ‘1’

Bit

Period

50% Duty Cycle

Preamble

TP

Header

TH

Encrypted Portion

of Transmission

4.2 Code Word Organization

The HCS301 transmits a 66-bit code word when a

button is pressed. The 66-bit word is constructed from

a Fixed Code portion and an Encrypted Code portion

(Figure 4-2).

The 32 bits of Encrypted Data are generated from 4

button bits, 12 discrimination bits and the 16-bit sync

value. The encrypted portion alone provides up to four

billion changing code combinations.

The 34 bits of Fixed Code Data are made up of 2 status bits, 4 button bits and the 28-bit serial number. The

fixed and encrypted sections combined increase the

number of code combinations to 7.38x 10

THOP

Fixed Portion of

Transmission

TFIX

Guard

Time

TG

19

.

FIGURE 4-2: CODE WORD ORGANIZATION

34 bits of Fixe d Portion 32 bits of Encrypted Por tion

Button

Status

S2 S1 S0 S3

Button

Status

1 1 1 1

Serial Number

(28 bits)

Serial Number

(28 bits)

MSb

MSb

Repeat

(1 bit)

Repeat

(1 bit)

VLOW

(1 bit)

LOW

V

(1 bit)

Note: SEED replaces Encrypted Portion when all button inputs are activated at the same time.

Button

Status

S2 S1 S0 S3

OVR

(2 bits)

DISC

(10 bits)

SEED

(32 bits)

Sync Counter

(16 bits)

66 Data bits

Transmitted

LSb first.

LSb

LSb

2001 Microchip Technology Inc. DS21143B-page 9

Page 10

HCS301

4.3 Synchronous T ransmi ssion Mode

Synchronous T ran smis sion mode can b e used t o cl ock

the code word out using an external clock.

To enter Synchronous Transmission mode, the Programming mode start-up sequence must be executed

as shown in Figure 4-3. If either S1 or S0 is set on the

falling edge of S2 (or S3), the device enters Synchronous Transmissio n mo de. In th is mo de, it fu ncti ons as

a normal transmitter, with the exception that the timing

of the PWM data string is cont rol led ext ernal ly and 16

extra bits are transm itted at the end with the code word.

The button code will be the S0, S1 value at the falling

edge of S2 or S3. The timing of th e PWM da ta string is

controlled by sup plyin g a cl ock o n S2 or S3 and sh ould

not exceed 20 kHz. The code word is the same as in

PWM mode with 16 reserved bits at the end of the

word. The reserved bits can be ignored. When in Synchronous Transmission mode S2 or S3 should not be

toggled until all internal processing has been completed as shown in Figure 4-4.

FIGURE 4-3: SYNCHRONOUS TRANSMISSION MODE

TPS

PWM

S2

S[1:0]

TPH1

TPH2

“01,10,11”

t = 50ms

Preamble

Header

Data

FIGURE 4-4: CODE WORD ORGANIZATION (SYNCHRONOUS TRANSMISSION MODE)

Fixed Portion Encrypted Portion

MSb

Reserved

(16 bits)

Padding

(2 bits)

Button

Status

S2 S1 S0 S3

Serial Number

(28 bits)

Button

Status

S2 S1 S0 S3

DISC+ OVR

(12 bits)

82 Data bits

Transmitted

LSb first.

Sync Counter

(16 bits)

LSb

DS21143B-page 10 2001 Microchip Technology Inc.

Page 11

HCS301

5.0 SPECIAL FEATURES

5.1 Code Word Completion

The code word completion feature ensures that entire

code words are transmitted, even if the button is

released before the code word is complete. If the button is held down beyond the time for one code word,

multiple code words will result. If another button is activated during a transmission, the active transmission

will be aborted an d a ne w tran smis sion will be gin u sing

the new button information.

5.2 LED Output Operation

During normal transmission the LED output is LO W. If

the supply voltage drops below the low voltage trip

point, the LED output will be toggl ed at appr oximate ly

5Hz during the transmission (Section 3.6.4).

5.3 RPT: Repeat Indicator

This bit will be low for the first transmitted word. If a

button is held down for more than one transmitted cod e

word, this bit will be set to indicate a repeated code

word and remain set until the button is released.

5.4 VLOW: Voltage LOW Indicator

5.6 Seed Trans mission

In order to i nc rea se t h e l e vel o f se c ur it y i n a s ys t em , i t

is possible for the receiver to implement what is known

as a secure l earn functio n. This c an be done by utiliz ing

the seed value stored in EEPROM, transmitted only

when all three button inputs are pressed at the same

time (Table5-1). Instead of the normal key generation

inputs being used to create the crypt key, this seed

value is used.

TABLE 5-1: PIN ACTIVATION TABLE

Function S3 S2 S1 S0

Standby 0

Hopping Code

Seed Code 15

1

2

13

14

000 0

000 1

001 0

--- 110 1

111 0

111 1

The VLOW signal is transmitted so the receiver can giv e

an indication to the user that the transmitter battery is

low. The VLOW bit is included in every transmission

(Figure 4-2 and Figure 8-5) and will be transmitted as a

zero if the operating voltage is above the low voltage

trip point. Refer to Figure4-2. The trip point is selectable based on the b attery voltage being used. See Se ction 3.6.3 for a description of how the low voltage trip

point is configured.

5.5 Auto-shutoff

The Auto-shutoff function automatically stops the

device from transmitting if a button inadvertently gets

pressed fo r a lo ng p eri od of tim e. Th is w ill prev ent the

device from draining the battery if a button gets

pressed whil e the transmitte r is in a pocket or purse .

This function can be enabled or disabled and is

selected by setting or clearing the Auto-shutoff bit (see

Section 3.4.1). Setting this bit hi gh will enable the function (turn Auto-shutoff function on) and setting the bit

low will disable th e func tion. Time-out pe riod is appro ximately 25 seconds.

2001 Microchip Technology Inc. DS21143B-page 11

Page 12

HCS301

5.7 Blank Alternate Code Word

Federal Communications Commission (FCC) part 15

rules specify the limits on worst case av erage fundamental power and harmonics that can be transmitted in

a 100 ms window. For FCC a ppro val pur pos es, it may

therefore be advantageous to minimize the transmission duty cycle. This ca n be achieved by minim izing the

duty cycle of the individual bits as well as by blanking

out consecutive code words. Blank Alternate Code

Word (BACW) may be used to reduce the average

power of a transmi ssion by tra nsmittin g only ev ery sec-

ond code word (Figure 5-1). This is a selectable feature

that is determined in conjunction with the baud rate

selection bit BSL0.

Enabling the BACW optio n may lik ewise a llow the user

to transmit a higher am plitud e transmis sion as the tim e

averaged power is reduced. BACW effectively halves

the RF on time for a given transmission so the RF output power could theoretically be doubled while maintaining the same time averaged output power.

FIGURE 5-1: BLANK ALTERNATE CODE WORD (BACW)

Amplitude

BACW Disabled

(All words transmitted)

BACW Enabled

(1 out of 2 transmitted)

BACW Enabled

(1 out of 4 transmitted)

A

2A

4A

Code Word

Code Word Code Word Code Word

Time

DS21143B-page 12 2001 Microchip Technology Inc.

Page 13

HCS301

6.0 PROGRAMMING THE HCS301

When using the HCS301 in a s ystem, the user will have

to program some parameters into the device including

the serial number and the secret key before it can be

used. The programming cycle allows the user to input

all 192 bits in a serial data stream, which are then

stored internally in EEPROM. Programming will be

initiated by forcing the PWM line high, after the S2 (or

S3) line has been held high for the appropriate length

of time line (Table 6-1 and Figure 6-1). After the Program mode is entered, a d elay mu st be prov ided to the

device for t he automatic bulk write cyc le to compl ete.

This will set all locations in th e EEPROM to zeros. Th e

device can then be programmed by clocking in 16 bits

at a time, using S2 (or S3) as the clock line and PWM

as the data in line. After each 16-bit word is loaded, a

FIGURE 6-1: PROGRAMMING WAVEFORMS

S2 (S3)

(Clock)

PWM

(Data)

Enter Program

Mode

TPS

TPH1

TPBW

TCLKH

TCLKL

Bit 0 Bit 1 Bit 2 Bit 3 Bit 14 Bit 15 Bit 16 Bit 17

TDS

TDH

programming delay is requir ed for the internal pro gram

cycle to complet e. This delay can t ake up to T

end of the programming cycle, the device can be verified (Figure 6-2) by reading back the EEPROM. Reading is done by clocking the S2 (or S3) line and reading

the data bits on PWM . For security reaso ns, it is not

possible to execute a verify function without first programming the EEPROM. A Verify operation c an on ly

be done once, immediately following the Program

cycle.

Note: To ensure that the device does not acci-

dentally enter Programming mode, PWM

should never be pulled high by the circuit

connected to it. Special care should be

taken when driving PNP RF transistors.

TWC

WC. At the

TPH2

Note 1: Unused button inputs to be held to ground during the entire programming sequence.

2: The VDD pin must be taken to ground after a Program/Verify cycle.

Data for Word 0 (KEY_0)

Repeat for each word (12 times)

FIGURE 6-2: VERIFY WAVEFORMS

End of Programming Cycle Beginning of Verify Cycle

PWM

(Data)

S2 (S3)

(Clock)

Note: If a Verify operation is to be done, then it must immediately follow the Program cycle.

Data from Word 0

Bit 0Bit191Bit190

TWC

Bit 1 Bit 2 Bit 3 Bit 15Bit 14 Bit 16 Bit 17 Bit190 Bit191

TDV

Data for Word 1

2001 Microchip Technology Inc. DS21143B-page 13

Page 14

HCS301

TABLE 6-1: PROGRAMMING/VERIFY TIMING REQUIREMENTS

VDD = 5.0V ± 10%, 25 °C ± 5 °C

Parameter Symbol Min. Max. Units

Program mode setup time

Hold time 1

Hold time 2

Bulk Write time

Program delay time

Program cycle time

Clock low time

Clock high time

Data setup time

Data hold time

Data out valid time

Note 1: Typical values - not tested in production.

TPS 3.5 4.5 ms

PH1 3.5 —ms

T

PH2 50 — µs

T

PBW 4.0 — ms

T

T

PROG 4.0 — ms

T

WC 50 — ms

TCLKL 50 — µs

CLKH 50 — µs

T

DS 0—

T

DH 30 —

T

TDV —30

µs

µs

µs

(1)

(1)

(1)

DS21143B-page 14 2001 Microchip Technology Inc.

Page 15

HCS301

7.0 INTEGRATING THE HCS301 INTO A SYSTEM

Use of the HCS301 in a system requires a compatible

decoder . This decoder is typically a microco ntroller with

compatible firmware. Microchip will provide (via a

license agreement) firmware routines that accept

transmissions from the HCS301 and decrypt the

hopping code portion of the data stream. These

routines provide system designers the means to

develop their own decoding system.

7.1 Learning a Transmitter to a

Receiver

A transmitter must first be ’ learned’ by a decoder before

its use is allowed in the system. Several learning strategies are possible, Figure 7-1 details a typical learn

sequence. Core to each, the decoder must minimally

store each learned trans mitter’ s seri al nu mber and c urrent synchronization counter value in EEPROM. Additionally, the decoder typically stores each transmitter’s

unique crypt key. The maximum number of learned

transmitters will therefore be relative to the available

EEPROM.

A transmitter’s serial number is transmitted in the clear

but the synchronization counter only exists in the code

word’s encrypted portion. The decoder obtains the

counter value by decrypting using the same key used

to encrypt the information. The K

symmetrical block cipher so the e ncryption and decryption keys are identical and referred to generally as the

crypt key. The encoder receives its crypt key during

manufacturing. The decoder is programmed with the

ability to generate a crypt key as well as all but one

required input to the key generation routine; typically

the transmitter’s serial number.

Figure 7-1 summarizes a typical learn sequence. The

decoder receives and authenticates a first transmission; first button press. Authentication involves generating the ap propriate crypt ke y, decrypting, v alidating

the correct key usage via the discrimination bits and

buffering th e counter v alue. A seco nd transmi ssion is

received and authenticated. A final check verifies the

counter values were sequential; consecutive button

presses. If the learn sequence is successfully complete, the decoder stores the learned transmitter’s

serial number, current synchronization counter value

and appropriate crypt key. From now on the crypt key

will be retrieved from EEPROM during normal operation instead of recalculating it for each transmission

received.

Certain learning strategies have been patented and

care must be taken not to infringe.

EELOQ algorithm is a

FIGURE 7-1: TYPICAL LEARN

SEQUENCE

Enter Learn

Mode

Wait for Reception

of a Valid Code

Generate Key

from Serial Number

Use Generated Key

to Decrypt

Compare Discrimination

2001 Microchip Technology Inc. DS21143B-page 15

Page 16

HCS301

Page 17

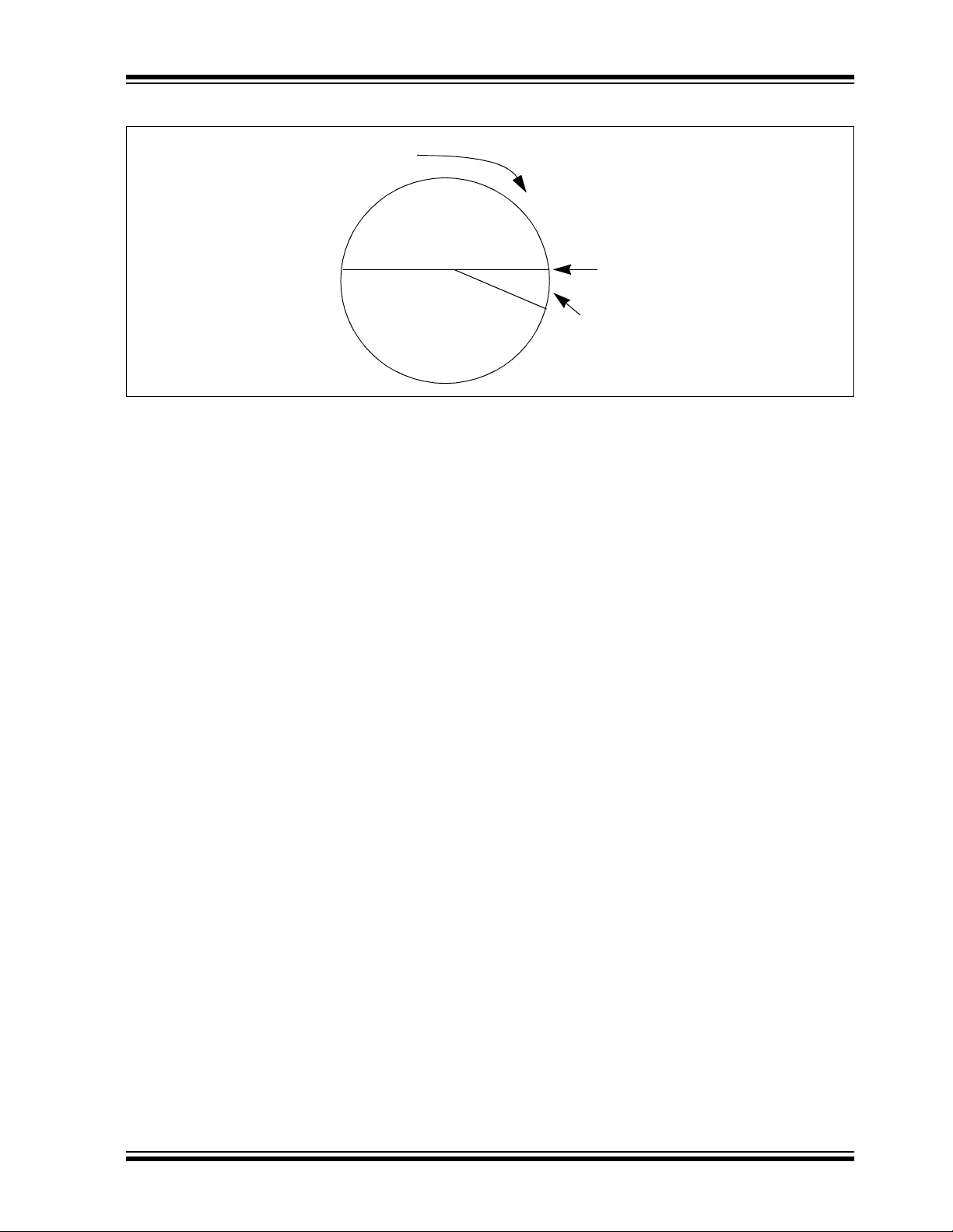

FIGURE 7-3: SYNCHRONIZATION WINDOW

Entire Window

rotates to eliminate

use of previously

used codes

Blocked

Window

(32K Codes)

Double Operation

(resynchronization )

Window

(32K Codes)

HCS301

Stored

Synchronization

Counter Value

Single Operation

Window

(16 Codes)

2001 Microchip Technology Inc. DS21143B-page 17

Page 18

HCS301

8.0 ELECTRICAL CHARACTERISTICS

TABLE 8-1: ABSOLUTE MAXIMUM RATINGS

Symbol Item Rating Units

VDD Supply voltage -0.3 to 13.3 V

V

IN Input voltage -0.3 to 13.3 V

VOUT Output voltage -0.3 to VDD + 0.3 V

I

OUT Max output current 25 mA

T

STG Storage temperature -55 to +125 °C (Note)

TLSOL Lead soldering temp 300 °C (Note)

V

ESD ESD rating 4000 V

Note: Stresses above those listed under “ABSOLUTE MAXIMUM RATINGS” may cause permanent damage to

the device.

TABLE 8-2: DC CHARACTERISTICS

Commercial(C): Tamb = 0 °C to +70 °C

Industrial (I): Tamb = -40 °C to +85 °C

3.5V < VDD < 13.0V

Parameter Sym. Min Typ* Max Unit Conditions

Operating current (avg) I

Standby current I

High level Input voltage V

CC 0.6

1.5

8.0

CCS 110µA

IH 0.4 VDD VDD+

1.0

3.0

12.0

mA

V

0.3

Low level input voltage VIL -0.3 0.15 VDD V

High level output voltage V

Low level output voltage V

sink current ILED 3.5

LED

Pull-down Resist anc e;

OH 0.5 VDD VIOH = -2 mA

OL 0.08 VDD VIOL = 2 mA

4.7

2.7

S0-3 40 60 80

R

3.7

5.9

4.6

mA VDD = 6.6V, VLOW source = 0

kΩ

S0-S3

Pull-down Resist anc e;

R

PWM 80 120 160

kΩ

PWM

Note: Typical values are at 25 °C.

VDD = 3.5V

V

DD = 6.6V

DD = 13.0V

V

(Figure 8-1)

DD = 13.0V, VLOW source = 1

V

VIN = 4.0V

VIN = 4.0V

DS21143B-page 18 2001 Microchip Technology Inc.

Page 19

FIGURE 8-1: TYPICAL ICC CURVE OF HCS301 WITH EXTERNAL RESISTORS

50Ω External

12.0

10.0

8.0

6.0

mA

4.0

2.0

0.0

23456789 1112

VBAT [V]

1 κΩ External

12.0

10

HCS301

13

mA

mA

10.0

8.0

6.0

4.0

2.0

0.0

23456789 11121310

VBAT [V]

2 κΩ External

12.0

10.0

8.0

6.0

4.0

2.0

0.0

23456789 11121310

VBAT [V]

LEGEND

Typical

Maximum

Minimum

2001 Microchip Technology Inc. DS21143B-page 19

Page 20

HCS301

FIGURE 8-2: POWER-UP AND TRANSMIT TIMING

Button Press

PWM

Output

Button

Input

Sn

Detect

BP

T

TTD

T

DB

Code

Word

1

Multiple Code Word Transmission

TTO

Code

Word

2

Code

Word

3

Code

Word

4

Code

Word

n

TABLE 8-3: POWER-UP AND TRANSMIT TIMING

VDD = +3.5 to 13.0V

Commercial(C): Tamb = 0°C to +70°C

Industrial(I): Tamb = -40°C to +85°C

Symbol Parameter Min Max Unit Remarks

TBP Time to second button press 10 + Code

TD Transmit delay from button det ect 10 26 ms

T

TDB Debounce Delay 6 15 ms

T

TO Auto-shutoff time-out period 20 120 s

Note 1: TBP is the time in w hich a sec ond b utton c an b e pr esse d witho ut co mpleti on of th e first code word a nd the

intention was to press the combination of buttons.

2: Typical values - not tested in production.

(2)

Word

26 + Code

Word

ms (Note 1)

FIGURE 8-3: CODE WORD FORMAT

TE

TE

TE

Bit Period

T

BP

LOGIC ‘0’

LOGIC ‘1’

50% Duty Cycle

Preamble

TP

DS21143B-page 20 2001 Microchip Technology Inc.

Header

TH

Encrypted Portion

of Transmission

THOP

Fixed Portion of

Trans mission

TFIX

Guard

Time

TG

Page 21

FIGURE 8-4: CODE WORD FORMAT: PREAMBLE/HEADER PORTION

HCS301

P1

50% Duty Cycle Preamble Header

23 TE 10 TE Data Bits

P12

FIGURE 8-5: CODE WORD FORMAT: DATA PORTION

Serial Number Button Code Status

LSB

MSB MSB S3 S0 S1 S2 VLOW RPT

Bit 30

Bit 31

Bit 32 Bit 33 Bit 58 Bit 59

Bit 60

Bit 61

Fixed Portion

Bit 62 Bit 63Bit 64 Bit 65

Header

LSB

Bit 0 Bit 1

Encrypted Portion

TABLE 8-4: CODE WORD TRANSMISSION TIMING REQUIREMENTS

VDD = +2.0 to 6.0V

Commercial(C):Tamb = 0 °C to +70 °C

Industrial(I):Tamb = -40 °C to +85 °C

Symbol Characteristic

Number

E

of T

All 1 out of 2 1 out of 4

Min. Typ. Max. Min. Typ. Max. Min. Typ. Max. Units

Code Words Transmitted

Bit 0 Bit 1

Guard

Time

T

TBP

TP

TH

THOP

TFIX

TG

—

—

Note: The timing parameters are not tested but derived from the oscillator clock.

Basic pulse element

E

PWM bit pulse width

Preamble duration

Header duration

Hopping code duration

Fixed code duration

Guard Time

Total Transmit Time

PWM data rate

1 260 400 660 130 200 330 65 100 165 µs

3 780 1200 1980 390 600 990 195 300 495 µs

23 6.0 9.2 15.2 3.0 4.6 7.6 1.5 2.3 3.8 ms

10 2.6 4.0 6.6 1.3 2.0 3.3 0.7 1.0 1.7 ms

96 25.0 38.4 63.4 12.5 19.2 31.7 6.2 9.6 15.8 ms

102 26.5 40.8 67.3 13.3 20.4 33.7 6.6 10.2 16.8 ms

39 10.1 15.6 25.7 5.1 7.8 12.9 2.5 3.9 6.4 ms

270 70.2 108.0 178.2 35.1 54.0 89.1 17.6 27.0 44.6 ms

— 1282 833 505 2564 1667 1010 5128 3333 2020 bps

2001 Microchip Technology Inc. DS21143B-page 21

Page 22

HCS301

FIGURE 8-6: HCS301 TE VS. TEMP (BY CHARACTERIZATION ONLY)

1.7

1.6

1.5

1.4

1.3

1.2

E

T

1.1

1.0

0.9

0.8

0.7

0.6

-50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

TE MAX.

VDD = 3.5V

VDD = 5.0V

TE MAX.

VDD = 5.0V

Typical

VDD = 5.0V

TE Min.

TEMPERATURE

DS21143B-page 22 2001 Microchip Technology Inc.

Page 23

9.0 PACKAGING INFORMATION

9.1 Package Marking Information

8-Lead PDIP (300 mil) Example

HCS301

XXXXXXXX

XXXXXNNN

HCS301

XXXXXNNN

YYWW

8-Lead SOIC (150 mil) Example

XXXXXXX

XXXYYWW

HCS301

XXX0025

NNN

Legend: XX...X Customer specific information*

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

0025

NNN

Note: In the event the full Micro chip p art num ber can not be ma rked on one line, it will

be carried over to the next l ine thus lim it ing t he nu mb er of av ai lab le cha r ac ters

for customer specific information.

* Standard PICmicro device marking consists of Microchip part number, year code, week code, and

traceability code. For PICmicro device marking beyond this, certain price adders apply. Please check

with your Microchip Sales Office. For QTP devices, any special marking adders are included in QTP

price.

2001 Microchip Technology Inc. DS21143B-page 23

Page 24

HCS301

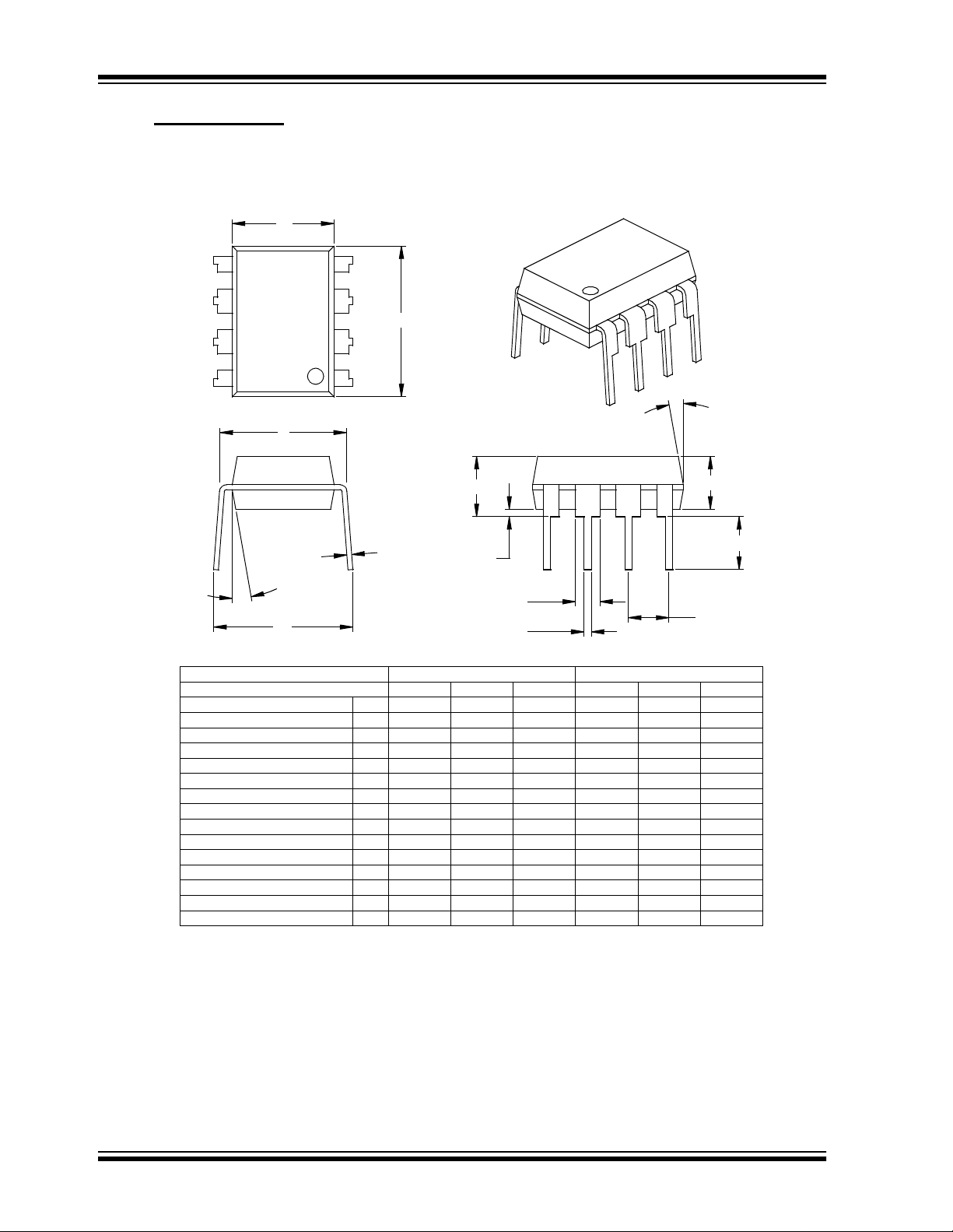

9.2 Package Details

8-Lead Plastic Dual In-line (P) - 300 mil (PDIP)

E1

2

D

n

E

β

eB

Number of Pins

Pitch

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

Dimension L imits MIN NOM MAX MIN NOM MAX

1

α

A

c

Units INCHES* MILLIMETERS

n

p

c

α

β

.008 .012 .015 0.20 0.29 0.38

A1

B1

B

88

.100 2.54

51015 51015

51015 51015

A2

L

p

DS21143B-page 24 2001 Microchip Technology Inc.

Page 25

8-Lead Plastic Small Outline (SN) - Narrow, 150 mil (SOIC)

E

E1

p

D

2

HCS301

B

Number of Pins

Pitch

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

n

°

45

c

β

1

h

φ

L

MILLIMETERSINCHES*Units

n

p

φ

c

α

β

048048

MAXNOMMINMAXNOMMINDimension Limits

88

1.27.050

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004A1Standoff §

6.206.025.79.244.237.228EOverall Width

3.993.913.71.157.154.146E1Molded Package Width

5.004.904.80.197.193.189DOverall Length

0.510.380.25.020.015.010hChamfer Distance

0.760.620.48.030.025.019LFoot Length

0.250.230.20.010.009.008

0.510.420.33.020.017.013BLead Width

1512015120

1512015120

2001 Microchip Technology Inc. DS21143B-page 25

Page 26

HCS301

ON-LINE SUPPORT

Microchip provides on-line support on the Microchip

World Wide Web (WWW) site.

The web site is used b y Micr ochip as a means to mak e

files and information easily available to customers. To

view the site, the use r must hav e access to the Intern et

and a web browser, such as Netscape or Microsoft

Explorer. Files are also available for FTP download

from our FTP site.

Connecting to the Microchip Internet Web Site

The Microchip web site is available by using your

favorite Internet browser to attach to:

www.microchip.com

The file transfer site is available by using an FTP service to connect to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of

services. Users may download files for the latest

Development Tools, Data Sheets, Application Notes,

User’s Guides, Articles and Sample Programs. A variety of Micr ochip specific bu siness informati on is also

available, including listings of Microchip sales offices,

distributors and factory representatives. Other data

available for consideration is:

• Latest Microchip Press Releases

• Technical Support Section with Frequently Asked

Questions

• Design Tips

• Device Errata

• Job Postings

• Microchip Consultant Pr ogram Member Listing

• Links to other useful web sites related to

Microchip Products

• Conferences for p roducts, D evelopment Systems,

technical information and more

• Listing of seminars and events

Systems Information and Upgrade Hot Line

The Systems Information and Upgrade Line provides

system users a listing of the latest versions of all of

Microchip's development systems software products.

Plus, this line provides information on how customers

can receive any currently available upgrade kits.The

Hot Line Numbers are:

1-800-755-2345 for U.S. and most of Canada, and

1-480-792-7302 for the rest of the world.

DS21143B-page 26 2001 Microchip Technology Inc.

Page 27

HCS301

READER RESPONSE

It is our intentio n to pro vi de you with the best do cu me nt ation possible to e ns ure suc c ess ful use of your Mic roc hip pro duct. If you wish to prov ide y our co mmen ts on org aniza tion, c larity, subject matter, and ways in which our doc ument atio n

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this Data Sheet.

To:

RE: Reader Response

From:

Application (optional):

Would you like a reply? Y N

Device:

Questions:

1. What are the best features of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this data sheet easy to follow? If not, why?

Technical Publications Manager

Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________

HCS301

Literature Number:

Total Pages Se nt

FAX: (______) _________ - _________

DS21143B

4. What additions to the data sheet do you think would enhance the structure and subject?

5. What deletions from the data sheet could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

8. How would you improve our software, systems, and silicon products?

2001 Microchip Technology Inc. DS21143B-page 27

Page 28

HCS301

HCS

/P

HCS301 PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

301 -

Package: P = Plastic DIP (300 mil Body), 8-lead

Temperature Blank = 0°C to +70°C

Range: I = –40°C to +85°C

Device: HCS301

SN = Plastic SOIC (150 mil Body), 8-lead

Code Hopping Encoder

=

HCS301T

Code Hopping Encoder (Tape and Reel)

=

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences

and recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of

the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

DS21143B-page 28 2001 Microchip Technology Inc.

Page 29

Microchip’s Secure Data Products are covered by some or all of the following patents:

Code hopping encoder patents issued in Europe, U.S.A., and R.S.A. — U.S.A.: 5,517,187; Europe: 0459781; R.S.A.: ZA93/4726

Secure learning patents issued in the U.S.A. and R.S.A. — U.S.A.: 5,686,904; R.S.A.: 95/5429

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, FilterLab,

K

EELOQ, MPLAB, PIC, PICmicro, PICMASTER, PICSTART,

PRO MATE, SEEVAL and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

dsPIC, ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, microID,

microPort, Migratable Memory, MPASM, MPLIB, MPLINK,

MPSIM, MXDEV, PICC, PICDEM, PICDEM.net, rfPIC, Select

Mode and Total Endurance are trademarks of Microchip

Technology Incorporated in the U.S . A .

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2001, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwid e head qu art ers,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999. The

Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs and microperipheral

products. In addition, Microchip’s quality

system for the design and manufacture of

development systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hoppin g

2001 Microchip Technology Inc. DS21143B - page 29

DS21143B-page 30 2001 Microchip Technology Inc.

Page 30

Loading...

Loading...