Page 1

PIC18F16Q41 Curiosity Nano

PIC18F16Q41 Curiosity Nano Hardware User Guide

Preface

The PIC18F16Q41 Curiosity Nano Evaluation Kit is a hardware platform to evaluate microcontrollers in the

PIC18‑Q41 Family. This board has the PIC18F16Q41 microcontroller (MCU) mounted.

Supported by MPLAB® X IDE, the board provides easy access to the features of the PIC18F16Q41 to explore how to

integrate the device into a custom design.

The Curiosity Nano series of evaluation boards include an on-board debugger. No external tools are necessary to

program and debug the PIC18F16Q41.

• MPLAB® X IDE - Software to discover, configure, develop, program, and debug Microchip microcontrollers.

• Code examples on GitHub - Get started with code examples.

• PIC18F16Q41 website - Find documentation, data sheets, sample, and purchase microcontrollers.

• PIC18F16Q41 Curiosity Nano website - Kit information, latest user guide, and design documentation.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 1

Page 2

PIC18F16Q41 Curiosity Nano

Table of Contents

Preface........................................................................................................................................................... 1

1. Introduction............................................................................................................................................. 4

1.1. Features....................................................................................................................................... 4

1.2. Board Overview............................................................................................................................4

2. Getting Started........................................................................................................................................ 5

2.1. Quick Start....................................................................................................................................5

2.1.1. Driver Installation...........................................................................................................5

2.1.2. Kit Window.....................................................................................................................5

2.1.3. MPLAB® X IDE Device Family Packs............................................................................5

2.2. Design Documentation and Relevant Links................................................................................. 5

3. Preprogrammed Application....................................................................................................................7

4. Curiosity Nano.........................................................................................................................................8

4.1. On-Board Debugger Overview..................................................................................................... 8

4.1.1. Debugger.......................................................................................................................8

4.1.2. Virtual Serial Port (CDC)................................................................................................9

4.1.2.1. Overview..................................................................................................... 9

4.1.2.2. Operating System Support.......................................................................... 9

4.1.2.3. Limitations................................................................................................. 10

4.1.2.4. Signaling....................................................................................................10

4.1.2.5. Advanced Use........................................................................................... 11

4.1.3. Mass Storage Device...................................................................................................11

4.1.3.1. Mass Storage Device Implementation.......................................................12

4.1.3.2. Configuration Words..................................................................................12

4.1.3.3. Special Commands................................................................................... 12

4.1.4. Data Gateway Interface (DGI)..................................................................................... 13

4.1.4.1. Debug GPIO..............................................................................................13

4.1.4.2. Timestamping............................................................................................14

4.2. Curiosity Nano Standard Pinout................................................................................................. 14

4.3. Power Supply............................................................................................................................. 15

4.3.1. Target Regulator.......................................................................................................... 15

4.3.2. External Supply............................................................................................................17

4.3.3. VBUS Output Pin.........................................................................................................17

4.3.4. Power Supply Exceptions............................................................................................18

4.4. Low-Power Measurement.......................................................................................................... 19

4.5. Programming External Microcontrollers..................................................................................... 20

4.5.1. Supported Devices...................................................................................................... 20

4.5.2. Software Configuration................................................................................................ 20

4.5.3. Hardware Modifications............................................................................................... 21

4.5.4. Connecting to External Microcontrollers...................................................................... 22

4.6. Connecting External Debuggers................................................................................................ 23

5. Hardware User Guide........................................................................................................................... 25

5.1. Connectors.................................................................................................................................25

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 2

Page 3

PIC18F16Q41 Curiosity Nano

5.1.1. PIC18F16Q41 Curiosity Nano Pinout..........................................................................25

5.1.2. Using Pin Headers.......................................................................................................25

5.1.3. Operational Amplifier................................................................................................... 26

5.2. Peripherals................................................................................................................................. 26

5.2.1. LED..............................................................................................................................27

5.2.2. Mechanical Switch.......................................................................................................27

5.2.3. Crystal..........................................................................................................................27

5.2.4. On-Board Debugger Implementation...........................................................................28

5.2.4.1. On-Board Debugger Connections............................................................. 28

6. Hardware Revision History and Known Issues..................................................................................... 29

6.1. Identifying Product ID and Revision........................................................................................... 29

6.2. Revision 3...................................................................................................................................29

6.3. Revision 2...................................................................................................................................29

7. Document Revision History...................................................................................................................30

8. Appendix............................................................................................................................................... 31

8.1. Schematic...................................................................................................................................31

8.2. Assembly Drawing......................................................................................................................33

8.3. Curiosity Nano Base for Click boards™...................................................................................... 34

8.4. Disconnecting the On-Board Debugger..................................................................................... 35

The Microchip Website.................................................................................................................................37

Product Change Notification Service............................................................................................................37

Customer Support........................................................................................................................................ 37

Microchip Devices Code Protection Feature................................................................................................ 37

Legal Notice................................................................................................................................................. 38

Trademarks.................................................................................................................................................. 38

Quality Management System....................................................................................................................... 39

Worldwide Sales and Service.......................................................................................................................40

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 3

Page 4

1. Introduction

User Switch

(SW0)

User LED

(LED0)

PIC18F16Q41

MCU

32.768 kHz

Crystal Footprint

Debugger

Power/Status

LED

Micro-USB

Connector

1.1 Features

• PIC18F16Q41 Microcontroller

• One Yellow User LED

• One Mechanical User Switch

• Footprint for 32.768 kHz Crystal

• On-Board Debugger:

– Board identification in Microchip MPLAB® X IDE

– One green power and status LED

– Programming and debugging

– Virtual serial port (CDC)

– One debug GPIO channel (DGI GPIO)

• USB Powered

• Adjustable Target Voltage:

– MIC5353 LDO regulator controlled by the on-board debugger

– 1.8–5.1V output voltage (limited by USB input voltage)

– 500 mA maximum output current (limited by ambient temperature and output voltage)

PIC18F16Q41 Curiosity Nano

Introduction

1.2 Board Overview

The Microchip PIC18F16Q41 Curiosity Nano Evaluation Kit is a hardware platform to evaluate the PIC18F16Q41

microcontroller.

Figure 1-1. PIC18F16Q41 Curiosity Nano Board Overview

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 4

Page 5

2. Getting Started

2.1 Quick Start

Steps to start exploring the PIC18F16Q41 Curiosity Nano board:

1. Download Microchip MPLAB® X IDE.

2. Download MPLAB® XC C Compiler.

3. Launch MPLAB® X IDE.

4. Optional: Use MPLAB® Code Configurator to generate drivers and examples.

5. Write your application code.

6. Connect a USB cable (Standard-A to Micro-B or Micro-AB) between the PC and the debug USB port on the

board.

2.1.1 Driver Installation

When the board is connected to your computer for the first time, the operating system will perform a driver software

installation. The driver file supports both 32- and 64-bit versions of Microsoft® Windows® XP, Windows Vista®,

Windows 7, Windows 8, and Windows 10. The drivers for the board are included with MPLAB® X IDE.

PIC18F16Q41 Curiosity Nano

Getting Started

2.1.2 Kit Window

Once the board is powered, the green status LED will be lit, MPLAB® X IDE will auto-detect which boards are

connected. The Kit Window in MPLAB® X IDE will present relevant information like data sheets and board

documentation. The PIC18F16Q41 device on the PIC18F16Q41 Curiosity Nano board is programmed and debugged

by the on-board debugger and, therefore, no external programmer or debugger tool is required.

Tip: The Kit Window can be opened in MPLAB® X IDE through the menu bar Window > Kit Window.

2.1.3 MPLAB® X IDE Device Family Packs

Microchip MPLAB® X IDE requires specific information to support devices and tools. This information is contained in

versioned packs. For the PIC18F16Q41 Curiosity Nano, board MPLAB® X version 5.40 with device family pack

“PIC18F-Q_DP” version 1.8 and tool pack “nEDBG_TP” version 1.4 or newer are required. For more information on

packs and how to upgrade them, refer to the MPLAB® X IDE User’s guide - Work with Device Packs.

Tip: The latest device family packs are available through Tools > Packs in MPLAB® X IDE or online at

Microchip MPLAB® X Packs Repository.

2.2 Design Documentation and Relevant Links

The following list contains links to the most relevant documents and software for the PIC18F16Q41 Curiosity Nano

board:

• MPLAB® X IDE - MPLAB X IDE is a software program that runs on a PC (Windows®, Mac OS®, Linux®) to

develop applications for Microchip microcontrollers and digital signal controllers. It is called an Integrated

Development Environment (IDE) because it provides a single integrated “environment” to develop code for

embedded microcontrollers.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 5

Page 6

PIC18F16Q41 Curiosity Nano

Getting Started

• MPLAB® XC Compilers - MPLAB® XC8 C Compiler is available as a free, unrestricted-use download.

Microchips MPLAB® XC8 C Compiler is a comprehensive solution for your project’s software development on

Windows®, macOS® or Linux®. MPLAB® XC8 supports all 8-bit PIC® and AVR® microcontrollers (MCUs).

• MPLAB® Code Configurator - MPLAB Code Configurator (MCC) is a free software plug-in that provides a

graphical interface to configure peripherals and functions specific to your application.

• Microchip Sample Store - Microchip sample store where you can order samples of devices.

• MPLAB Data Visualizer - MPLAB Data Visualizer is a program used for processing and visualizing data. The

Data Visualizer can receive data from various sources such as serial ports and on-board debugger’s Data

Gateway Interface, as found on Curiosity Nano and Xplained Pro boards.

• Microchip PIC® and AVR® Examples - Microchip PIC and AVR Device Examples is a collection of examples

and labs that use Microchip development boards to showcase the use of PIC and AVR device peripherals.

• Microchip PIC® and AVR® Solutions - Microchip PIC and AVR Device Solutions contains complete

applications for use with Microchip development boards, ready to be adapted and extended.

• PIC18F16Q41 Curiosity Nano website - Kit information, latest user guide, and design documentation.

• PIC18F16Q41 Curiosity Nano on Microchip Direct - Purchase this kit on Microchip Direct.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 6

Page 7

3. Preprogrammed Application

The PIC18F16Q41 mounted on the Curiosity Nano Evaluation Kit is preprogrammed with an application ready to

utilize the integrated operational amplifier.

To get started with the application, find the user guide, code, and hex files for this application available online on

GitHub.

PIC18F16Q41 Curiosity Nano

Preprogrammed Application

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 7

Page 8

4. Curiosity Nano

Curiosity Nano is an evaluation platform of small boards with access to most of the microcontrollers I/Os. The

platform consists of a series of low pin count microcontroller (MCU) boards with on-board debuggers, which are

integrated with MPLAB® X IDE. Each board is identified in the IDE. When plugged in, a Kit Window is displayed with

links to key documentation, including relevant user guides, application notes, data sheets, and example code.

Everything is easy to find. The on-board debugger features a virtual serial port (CDC) for serial communication to a

host PC and a Data Gateway Interface (DGI) with debug GPIO pin(s).

4.1 On-Board Debugger Overview

PIC18F16Q41 Curiosity Nano contains an on-board debugger for programming and debugging. The on-board

debugger is a composite USB device consisting of several interfaces:

• A debugger that can program and debug the PIC18F16Q41 in MPLAB® X IDE

• A mass storage device that allows drag-and-drop programming of the PIC18F16Q41

• A virtual serial port (CDC) that is connected to a Universal Asynchronous Receiver/Transmitter (UART) on the

PIC18F16Q41, and provides an easy way to communicate with the target application through terminal software

• A Data Gateway Interface (DGI) for code instrumentation with logic analyzer channels (debug GPIO) to visualize

program flow

The on-board debugger controls a Power and Status LED (marked PS) on the PIC18F16Q41 Curiosity Nano board.

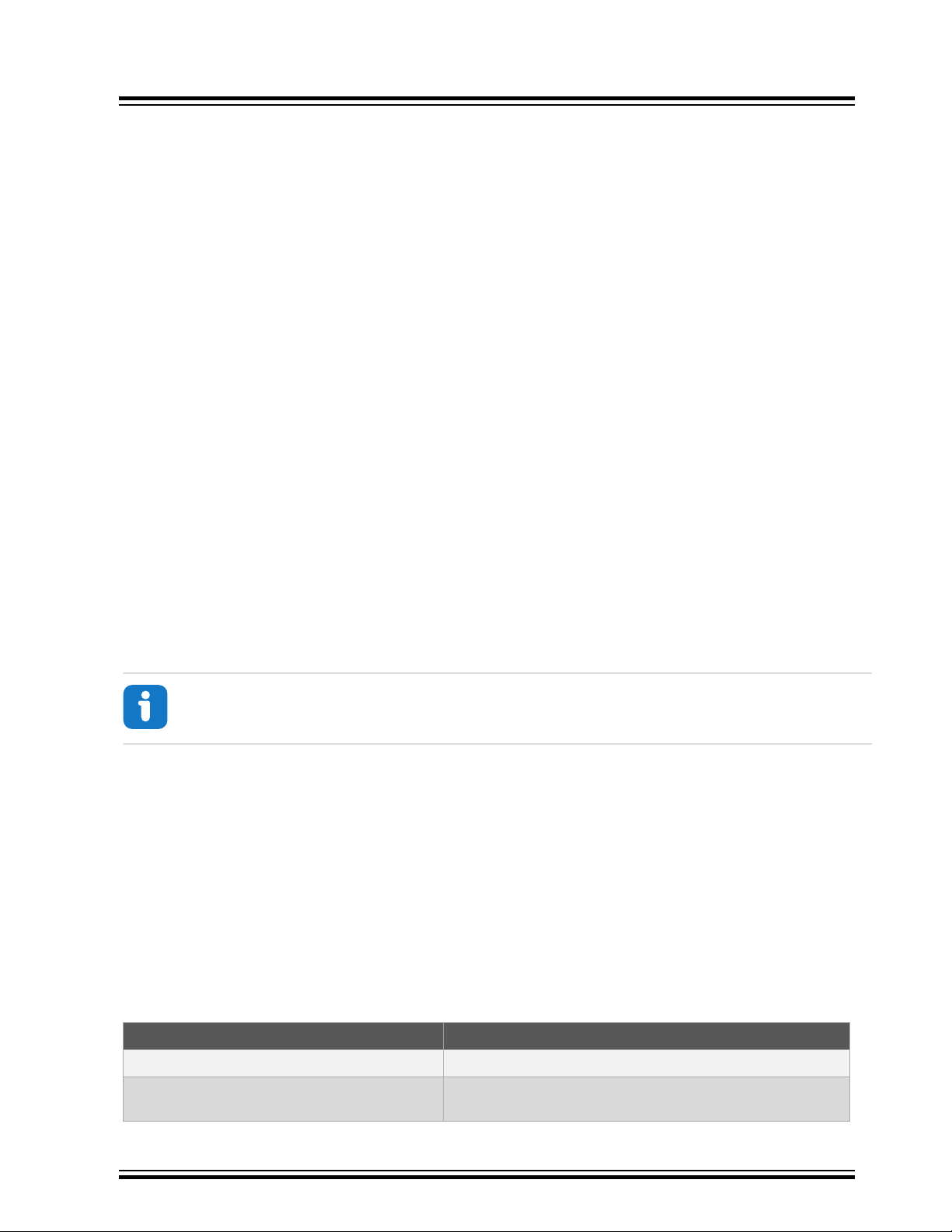

The table below shows how the LED is controlled in different operation modes.

Table 4-1. On-Board Debugger LED Control

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Operation Mode Power and Status LED

Boot Loader mode The LED blinks slowly during power-up

Power-up The LED is ON

Normal operation The LED is ON

Programming Activity indicator: The LED blinks slowly during programming/debugging

Drag-and-drop

programming

Fault The LED blinks rapidly if a power fault is detected

Sleep/Off The LED is OFF. The on-board debugger is either in a sleep mode or powered down.

4.1.1 Debugger

The on-board debugger on the PIC18F16Q41 Curiosity Nano board appears as a Human Interface Device (HID) on

the host computer’s USB subsystem. The debugger supports full-featured programming and debugging of the

PIC18F16Q41 using MPLAB® X IDE.

Success: The LED blinks slowly for 2 sec

Failure: The LED blinks rapidly for 2 sec

This can occur if the board is externally powered.

Info: Slow blinking is approximately 1 Hz, and rapid blinking is approximately 5 Hz.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 8

Page 9

Remember: Keep the debugger’s firmware up-to-date. Firmware upgrades are automatically done when

Target MCU

UART TX

UART RX

Debugger

USB

CDC RX

CDC TX

PC

Terminal

Software

Target

Receive

Target

Send

Terminal

Receive

Terminal

Send

using MPLAB® X IDE.

4.1.2 Virtual Serial Port (CDC)

The virtual serial port (CDC) is a general purpose serial bridge between a host PC and a target device.

4.1.2.1 Overview

The on-board debugger implements a composite USB device that includes a standard Communications Device Class

(CDC) interface, which appears on the host as a virtual serial port. The CDC can be used to stream arbitrary data in

both directions between the host computer and the target: All characters sent through the virtual serial port on the

host computer will be transmitted as UART on the debugger’s CDC TX pin, and UART characters captured on the

debugger’s CDC RX pin will be returned to the host computer through the virtual serial port.

Figure 4-1. CDC Connection

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Info: As shown in Figure 4-1, the debugger’s CDC TX pin is connected to a UART RX pin on the target

for receiving characters from the host computer. Similarly, the debugger’s CDC RX pin is connected to a

UART TX pin on the target for transmitting characters to the host computer.

4.1.2.2 Operating System Support

On Windows machines, the CDC will enumerate as Curiosity Virtual COM Port and appear in the Ports section of the

Windows Device Manager. The COM port number can also be found there.

Info: On older Windows systems, a USB driver is required for CDC. This driver is included in installations

of MPLAB® X IDE.

On Linux machines, the CDC will enumerate and appear as /dev/ttyACM#.

Info: tty* devices belong to the “dialout” group in Linux, so it may be necessary to become a member of

that group to have permissions to access the CDC.

On MAC machines, the CDC will enumerate and appear as /dev/tty.usbmodem#. Depending on which terminal

program is used, it will appear in the available list of modems as usbmodem#.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 9

Page 10

4.1.2.3 Limitations

Not all UART features are implemented in the on-board debugger CDC. The constraints are outlined here:

• Baud rate: Must be in the range of 1200 bps to 500 kbps. Any baud rate outside this range will be set to the

closest limit, without warning. Baud rate can be changed on-the-fly.

• Character format: Only 8-bit characters are supported.

• Parity: Can be odd, even, or none.

• Hardware flow control: Not supported.

• Stop bits: One or two bits are supported.

4.1.2.4 Signaling

During USB enumeration, the host OS will start both communication and data pipes of the CDC interface. At this

point, it is possible to set and read back the baud rate and other UART parameters of the CDC, but data sending and

receiving will not be enabled.

When a terminal connects on the host, it must assert the DTR signal. As this is a virtual control signal implemented

on the USB interface, it is not physically present on the board. Asserting the DTR signal from the host will indicate to

the on-board debugger that a CDC session is active. The debugger will then enable its level shifters (if available) and

start the CDC data send and receive mechanisms.

Deasserting DTR in debugger firmware version 1.20 or earlier has the following behavior:

• Debugger UART receiver is disabled, so no further data will be transferred to the host computer

• Debugger UART transmitter will continue to send data that is queued for sending, but no new data is accepted

from the host computer

• Level shifters (if available) are not disabled, so the debugger CDC TX line remains driven

Deasserting DTR in debugger firmware version 1.21 or later has the following behavior:

• Debugger UART receiver is disabled, so no further data will be transferred to the host computer

• Debugger UART transmitter will continue to send data that is queued for sending, but no new data is accepted

from the host computer

• Once the ongoing transmission is complete, level shifters (if available) are disabled, so the debugger CDC TX

line will become high-impedance

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Info: For all operating systems: Be sure to use a terminal emulator that supports DTR signaling. See

4.1.2.4 Signaling.

Remember: Set up the terminal emulator to assert the DTR signal. Without the signal, the on-board

debugger will not send or receive any data through its UART.

Tip: The on-board debugger’s CDC TX pin will not be driven until the CDC interface is enabled by the

host computer. Also, there are no external pull-up resistors on the CDC lines connecting the debugger and

the target, which means that during power-up, these lines are floating. To avoid any glitches resulting in

unpredictable behavior like framing errors, the target device should enable the internal pull-up resistor on

the pin connected to the debugger’s CDC TX pin.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 10

Page 11

4.1.2.5 Advanced Use

CDC Override Mode

In normal operation, the on-board debugger is a true UART bridge between the host and the device. However, in

certain use cases, the on-board debugger can override the basic operating mode and use the CDC TX and RX pins

for other purposes.

Dropping a text file into the on-board debugger’s mass storage drive can be used to send characters out of the

debugger’s CDC TX pin. The filename and extension are trivial, but the text file must start with the characters:

CMD:SEND_UART=

Debugger firmware version 1.20 or earlier has the following limitations:

• The maximum message length is 50 characters – all remaining data in the frame are ignored

• The default baud rate used in this mode is 9600 bps, but if the CDC is already active or has been configured,

the previously used baud rate still applies

Debugger firmware version 1.21 and later has the following limitations/features:

• The maximum message length may vary depending on the MSC/SCSI layer timeouts on the host computer

and/or operating system. A single SCSI frame of 512 bytes (498 characters of payload) is ensured, and files of

up to 4 KB will work on most systems. The transfer will complete on the first NULL character encountered in the

file.

• The baud rate used is always 9600 bps for the default command:

CMD:SEND_UART=

PIC18F16Q41 Curiosity Nano

Curiosity Nano

The CDC Override Mode should not be used simultaneously with data transfer over the CDC/terminal. If a CDC

terminal session is active at the time a file is received via CDC Override Mode, it will be suspended for the

duration of the operation and resumed once complete.

• Additional commands are supported with explicit baud rates:

CMD:SEND_9600=

CMD:SEND_115200=

CMD:SEND_460800=

USB-Level Framing Considerations

Sending data from the host to the CDC can be done byte-wise or in blocks, which will be chunked into 64-byte USB

frames. Each such frame will be queued up for sending to the debugger’s CDC TX pin. Transferring a small amount

of data per frame can be inefficient, particularly at low baud rates, as the on-board debugger buffers frames and not

bytes. A maximum of four 64-byte frames can be active at any time. The on-board debugger will throttle the incoming

frames accordingly. Sending full 64-byte frames containing data is the most efficient method.

When receiving data on the debugger’s CDC RX pin, the on-board debugger will queue up the incoming bytes into

64-byte frames, which are sent to the USB queue for transmission to the host when they are full. Incomplete frames

are also pushed to the USB queue at approximately 100 ms intervals, triggered by USB start-of-frame tokens. Up to

eight 64-byte frames can be active at any time.

If the host (or the software running on it) fails to receive data fast enough, an overrun will occur. When this happens,

the last-filled buffer frame will be recycled instead of being sent to the USB queue, and a full data frame will be lost.

To prevent this occurrence, the user must ensure that the CDC data pipe is being read continuously, or the incoming

data rate must be reduced.

4.1.3 Mass Storage Device

The on-board debugger includes a simple Mass Storage Device implementation, which is accessible for read/write

operations via the host operating system to which it is connected.

It provides:

• Read access to basic text and HTML files for detailed kit information and support

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 11

Page 12

• Write access for programming Intel® HEX formatted files into the target device’s memory

• Write access for simple text files for utility purposes

4.1.3.1 Mass Storage Device Implementation

The on-board debugger implements a highly optimized variant of the FAT12 file system that has several limitations,

partly due to the nature of FAT12 itself and optimizations made to fulfill its purpose for its embedded application.

The Curiosity Nano USB device is USB Chapter 9-compliant as a mass storage device but does not, in any way, fulfill

the expectations of a general purpose mass storage device. This behavior is intentional.

When using the Windows operating system, the on-board debugger enumerates as a Curiosity Nano USB Device

that can be found in the disk drives section of the device manager. The CURIOSITY drive appears in the file manager

and claims the next available drive letter in the system.

The CURIOSITY drive contains approximately one MB of free space. This does not reflect the size of the target

device’s Flash in any way. When programming an Intel® HEX file, the binary data are encoded in ASCII with

metadata providing a large overhead, so one MB is a trivially chosen value for disk size.

It is not possible to format the CURIOSITY drive. When programming a file to the target, the filename may appear in

the disk directory listing. This is merely the operating system’s view of the directory, which, in reality, has not been

updated. It is not possible to read out the file contents. Removing and replugging the board will return the file system

to its original state, but the target will still contain the application that has been previously programmed.

To erase the target device, copy a text file starting with “CMD:ERASE” onto the disk.

By default, the CURIOSITY drive contains several read-only files for generating icons as well as reporting status and

linking to further information:

• AUTORUN.ICO – icon file for the Microchip logo

• AUTORUN.INF – system file required for Windows Explorer to show the icon file

• KIT-INFO.HTM – redirect to the development board website

• KIT-INFO.TXT – a text file containing details about the board’s debugger firmware version, board name, USB

serial number, device, and drag-and-drop support

• STATUS.TXT – a text file containing the programming status of the board

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Info: STATUS.TXT is dynamically updated by the on-board debugger. The contents may be cached by

the OS and, therefore, do not reflect the correct status.

4.1.3.2 Configuration Words

Configuration Words (PIC® MCU Targets)

Configuration Word settings included in the project being programmed after program Flash is programmed. The

debugger will not mask out any bits in the Configuration Words when writing them, but since it uses Low-Voltage

Programming mode, it is unable to clear the LVP Configuration bit. If the incorrect clock source is selected, for

example, and the board does not boot, it is always possible to perform a bulk erase (always done before

programming) and restore the device to its default settings.

4.1.3.3 Special Commands

Several utility commands are supported by copying text files to the mass storage disk. The filename or extension is

irrelevant – the command handler reacts to content only.

Table 4-2. Special File Commands

Command Content Description

CMD:ERASE

CMD:SEND_UART=

Executes a chip erase of the target

Sends a string of characters to the CDC UART. See “CDC

Override Mode.”

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 12

Page 13

...........continued

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Command Content Description

CMD:SEND_9600=

CMD:SEND_115200=

CMD:SEND_460800=

CMD:RESET

CMD:POWERTOGGLE

CMD:0V

CMD:1V8

CMD:3V3

CMD:5V0

Sends a string of characters to the CDC UART at the baud rate

specified. Note that only the baud rates explicitly specified here

are supported! See “CDC Override Mode” (Debugger firmware

v1.21 or newer.)

Resets the target device by entering Programming mode and

then exiting Programming mode immediately thereafter. Exact

timing can vary according to the programming interface of the

target device. (Debugger firmware v1.16 or newer.)

Powers down the target and restores power after a 100 ms

delay. If external power is provided, this has no effect.

(Debugger firmware v1.16 or newer.)

Powers down the target device by disabling the target supply

regulator. If external power is provided, this has no effect.

(Debugger firmware v1.16 or newer.)

Sets the target voltage to 1.8V. If external power is provided,

this has no effect. (Debugger firmware v1.21 or newer.)

Sets the target voltage to 3.3V. If external power is provided,

this has no effect. (Debugger firmware v1.16 or newer.)

Sets the target voltage to 5.0V. If external power is provided,

this has no effect. (Debugger firmware v1.16 or newer.)

Info: The commands listed here are triggered by the content being sent to the mass storage emulated

disk, and no feedback is provided in the case of either success or failure.

4.1.4 Data Gateway Interface (DGI)

Data Gateway Interface (DGI) is a USB interface for transporting raw and timestamped data between on-board

debuggers and host computer-based visualization tools. MPLAB Data Visualizer is used on the host computer to

display debug GPIO data. It is available as a plug-in for MPLAB® X IDE or a stand-alone application that can be used

in parallel with MPLAB® X IDE.

Although DGI encompasses several physical data interfaces, the PIC18F16Q41 Curiosity Nano implementation

includes logic analyzer channels:

• One debug GPIO channel (also known as DGI GPIO)

4.1.4.1 Debug GPIO

Debug GPIO channels are timestamped digital signal lines connecting the target application to a host computer

visualization application. They are typically used to plot the occurrence of low-frequency events on a time-axis – for

example, when certain application state transitions occur.

The figure below shows the monitoring of the digital state of a mechanical switch connected to a debug GPIO in

MPLAB Data Visualizer.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 13

Page 14

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Figure 4-2. Monitoring Debug GPIO with MPLAB® Data Visualizer

Debug GPIO channels are timestamped, so the resolution of DGI GPIO events is determined by the resolution of the

DGI timestamp module.

Important: Although bursts of higher-frequency signals can be captured, the useful frequency range of

signals for which debug GPIO can be used is up to about 2 kHz. Attempting to capture signals above this

frequency will result in data saturation and overflow, which may cause the DGI session to be aborted.

4.1.4.2 Timestamping

DGI sources are timestamped as they are captured by the debugger. The timestamp counter implemented in the

Curiosity Nano debugger increments at 2 MHz frequency, providing a timestamp resolution of a half microsecond.

4.2 Curiosity Nano Standard Pinout

The 12 edge connections closest to the USB connector on Curiosity Nano boards have a standardized pinout. The

program/debug pins have different functions depending on the target programming interface, as shown in the table

and figure below.

Table 4-3. Curiosity Nano Standard Pinout

Debugger Signal Target MCU Description

ID — ID line for extensions

CDC TX UART RX USB CDC TX line

CDC RX UART TX USB CDC RX line

DBG0 ICSPDAT Debug data line

DBG1 ICSPCLK Debug clock line

DBG2 GPIO0 debug GPIO0

DBG3 MCLR Reset line

NC — No connect

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 14

Page 15

USB

DEBUGGER

PS LED

NC

ID

CDC RX

CDC TX

DBG1

DBG2

VBUS

VOFF

DBG3

DBG0

GND

VTG

CURIOSITY NANO

USB

Target

MCU

Power source

Cut strap

Power consumer

P3V3

DEBUGGER

Power converter

DEBUGGER

Regulator

VUSB

Target

Regulator

Power Supply

strap

Adjust

Level

shifter

VLVL

VREG

I/O

I/O

GPIO

straps

I/O

On/Off

Measure

On/Off

ID system

#VOFF

PTC

Fuse

Power protection

VBUS

Target

Power

strap

VTG

PIC18F16Q41 Curiosity Nano

Curiosity Nano

...........continued

Debugger Signal Target MCU Description

VBUS — VBUS voltage for external use

VOFF — Voltage Off input. Disables the target regulator and

target voltage when pulled low.

VTG — Target voltage

GND — Common ground

Figure 4-3. Curiosity Nano Standard Pinout

4.3 Power Supply

The board is powered through the USB port and contains two LDO regulators, one to generate 3.3V for the on-board

debugger, and an adjustable LDO regulator for the target PIC18F16Q41 microcontroller and its peripherals. The

voltage from a USB connector can vary between 4.4V to 5.25V (according to the USB specification) and will limit the

maximum voltage to the target. The figure below shows the entire power supply system on PIC18F16Q41 Curiosity

Nano.

Figure 4-4. Power Supply Block Diagram

4.3.1 Target Regulator

The target voltage regulator is a MIC5353 variable output LDO. The on-board debugger can adjust the voltage output

supplied to the board target section by manipulating the MIC5353’s feedback voltage. The hardware implementation

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 15

Page 16

PIC18F16Q41 Curiosity Nano

Curiosity Nano

is limited to an approximate voltage range from 1.7V to 5.1V. Additional output voltage limits are configured in the

debugger firmware to ensure that the output voltage never exceeds the hardware limits of the PIC18F16Q41

microcontroller. The voltage limits configured in the on-board debugger on PIC18F16Q41 Curiosity Nano are 1.8–

5.5V.

Info: The target voltage is set to 3.3V when the board is manufactured. It can be changed through the

MPLAB® X IDE project properties. Any change to the target voltage is persistent, even after a power

toggle. The resolution is less than 5 mV but may be limited to 10 mV by the adjustment program.

Info: Voltage settings that are set up in MPLAB® X IDE are not immediately applied to the board. The

new voltage setting is applied to the board when the debugger is accessed in any way, like pushing the

Refresh Debug Tool Status button in the project dashboard tab, or programming/reading program memory.

Info: There is a simple option to adjust the target voltage with a drag-and-drop command text file to the

board. This supports a set of common target voltages. See section 4.1.3.3 Special Commands for further

details.

The MIC5353 supports a maximum current load of 500 mA. It is an LDO regulator in a small package, placed on a

small printed circuit board (PCB), and the thermal shutdown condition can be reached at lower loads than 500 mA.

The maximum current load depends on the input voltage, the selected output voltage, and the ambient temperature.

The figure below shows the safe operating area for the regulator, with an input voltage of 5.1V and an ambient

temperature of 23°C.

Figure 4-5. Target Regulator Safe Operation Area

The voltage output of the target regulator is continuously monitored (measured) by the on-board debugger. If it is

more than 100 mV over/under the set device voltage, an error condition will be flagged, and the target voltage

regulator will be turned off. This will detect and handle any short-circuit conditions. It will also detect and handle if an

external voltage, which causes VCC_TARGET to move outside of the voltage setting monitoring window of ±100 mV,

is suddenly applied to the VTG pin, without setting the VOFF pin low.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 16

Page 17

Info: The on-board debugger has a monitoring window of VCC_TARGET±100 mV. If the external voltage

WARNING

WARNING

WARNING

is measured under this limit, the on-board debugger status LED will blink rapidly. If the external voltage is

measured above this limit, the on-board debugger status LED will continue to shine. If the external voltage

is removed, the status LED will start to blink rapidly until the on-board debugger detects the new situation

and turns the target voltage regulator back on.

4.3.2 External Supply

PIC18F16Q41 Curiosity Nano can be powered by an external voltage instead of the on-board target regulator. When

the Voltage Off (VOFF) pin is shorted to ground (GND), the on-board debugger firmware disables the target regulator,

and it is safe to apply an external voltage to the VTG pin.

It is also safe to apply an external voltage to the VTG pin when no USB cable is plugged into the DEBUG connector

on the board.

The VOFF pin can be tied low/let go at any time. This will be detected by a pin-change interrupt to the on-board

debugger, which controls the target voltage regulator accordingly.

Applying an external voltage to the VTG pin without shorting VOFF to GND may cause permanent damage

to the board.

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Do not apply any voltage to the VOFF pin. Let the pin float to enable the power supply.

The absolute maximum external voltage is 5.5V for the on-board level shifters, and the standard operating

condition of the PIC18F16Q41 is 1.8–5.5V. Applying a higher voltage may cause permanent damage to

the board.

Info: If an external voltage is applied without pulling the VOFF pin low and an external supply pulls the

voltage lower than the monitoring window’s lower limit (target voltage setting – 100 mV), the on-board

debugger status LED will blink rapidly and shut the on-board regulator off. If an external voltage is

suddenly removed when the VOFF pin is not pulled low, the status LED will start to blink rapidly, until the

on-board debugger detects the new situation and switches the target voltage regulator back on.

Programming, debugging, and data streaming is still possible with an external power supply – the debugger and

signal level shifters will be powered from the USB cable. Both regulators, the debugger, and the level shifters are

powered down when the USB cable is removed.

Info: In addition to the power consumed by the PIC18F16Q41 and its peripherals, approximately 100 µA

will be drawn from any external power source to power the on-board level shifters and voltage monitor

circuitry when a USB cable is plugged in the DEBUG connector on the board. When a USB cable is not

plugged in, some current is used to supply the level shifters voltage pins, which have a worst-case current

consumption of approximately 5 µA. Typical values may be as low as 100 nA.

4.3.3 VBUS Output Pin

PIC18F16Q41 Curiosity Nano has a VBUS output pin that can be used to power external components that need a 5V

supply. The VBUS output pin has a PTC fuse to protect the USB against short circuits. A side effect of the PTC fuse

is a voltage drop on the VBUS output with higher current loads. The chart below shows the voltage versus the current

load of the VBUS output.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 17

Page 18

Figure 4-6. VBUS Output Voltage vs. Current

PIC18F16Q41 Curiosity Nano

Curiosity Nano

4.3.4 Power Supply Exceptions

This is a summary of most exceptions that can occur with the power supply.

Target Voltage Shuts Down

This can happen if the target section draws too much current at a given voltage. This will cause the thermal shutdown

safety feature of the MIC5353 regulator to kick in. To avoid this, reduce the current load of the target section.

Target Voltage Setting is Not Reached

The maximum output voltage is limited by the USB input voltage (specified to be 4.4-5.25V), and the voltage drop

over the MIC5353 regulator at a given voltage setting and current consumption. If a higher output voltage is needed,

use a USB power source that can provide a higher input voltage or use an external voltage supply on the VTG pin.

Target Voltage is Different From Setting

This can be caused by an externally applied voltage to the VTG pin, without setting the VOFF pin low. If the target

voltage differs more than 100 mV over/under the voltage setting, it will be detected by the on-board debugger, and

the internal voltage regulator will be shut down. To fix this issue, remove the applied voltage from the VTG pin, and

the on-board debugger will enable the on-board voltage regulator when the new condition is detected. Note that the

PS LED will be blinking rapidly if the target voltage is below 100 mV of the setting, but will be lit normally when it is

higher than 100 mV above the setting.

No, Or Very Low Target Voltage, and PS LED is Blinking Rapidly

This can be caused by a full or partial short-circuit and is a special case of the issue mentioned above. Remove the

short-circuit, and the on-board debugger will re-enable the on-board target voltage regulator.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 18

Page 19

No Target Voltage and PS LED is Lit 1

Target Power strap (top side)

This occurs if the target voltage is set to 0.0V. To fix this, set the target voltage to a value within the specified voltage

range for the target device.

No Target Voltage and PS LED is Lit 2

This can be the issue if power jumper J100 and/or J101 is cut, and the target voltage regulator is set to a value within

the specified voltage range for the target device. To fix this, solder a wire/bridge between the pads for J100/J101, or

add a jumper on J101 if a pin header is mounted.

VBUS Output Voltage is Low or Not Present

This is most likely caused by a high-current drain on VBUS, and the protection fuse (PTC) will reduce the current or

cut off completely. Reduce the current consumption on the VBUS pin to fix this issue.

4.4 Low-Power Measurement

Power to the PIC18F16Q41 is connected from the on-board power supply and VTG pin through a 100 mil pin header

marked with “POWER” in silkscreen (J101). To measure the power consumption of the PIC18F16Q41 and other

peripherals connected to the board, cut the Target Power strap and connect an ammeter over the strap.

To measure the lowest possible power consumption, follow these steps:

1. Cut the POWER strap with a sharp tool.

2. Solder a 1x2 100 mil pin header in the footprint.

3. Connect an ammeter to the pin header.

4. Write firmware that:

4.1. Tri-states any I/O connected to the on-board debugger.

4.2. Sets the microcontroller in its lowest power sleep mode.

5. Program the firmware into the PIC18F16Q41.

Figure 4-7. Target Power Strap

PIC18F16Q41 Curiosity Nano

Curiosity Nano

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 19

Page 20

Tip: A 100-mil pin header can be soldered into the Target Power strap (J101) footprint for easy

connection of an ammeter. Once the ammeter is no longer needed, place a jumper cap on the pin header.

Info: The on-board level shifters will draw a small amount of current even when they are not in use. A

maximum of 2 µA can be drawn from each I/O pin connected to a level shifter for a total of 10 µA. Keep

any I/O pin connected to a level shifter in tri-state to prevent leakage. All I/Os connected to the on-board

debugger are listed in 5.2.4.1 On-Board Debugger Connections. To prevent any leakage to the on-board

level shifters, they can be disconnected completely, as described in 8.4 Disconnecting the On-Board

Debugger.

4.5 Programming External Microcontrollers

The on-board debugger on PIC18F16Q41 Curiosity Nano can be used to program and debug microcontrollers on

external hardware.

4.5.1 Supported Devices

All external AVR microcontrollers with the UPDI interface can be programmed and debugged with the on-board

debugger with Atmel Studio.

External SAM microcontrollers that have a Curiosity Nano Board can be programmed and debugged with the onboard debugger with Atmel Studio.

PIC18F16Q41 Curiosity Nano can program and debug external PIC18F16Q41 microcontrollers with MPLAB X IDE.

PIC18F16Q41 Curiosity Nano

Curiosity Nano

4.5.2 Software Configuration

No software configuration is required to program and debug the same device that is mounted on the board.

To program and debug a different microcontroller than what is mounted on the board, Atmel Studio must be

configured to allow free selection of devices and programming interfaces.

1. Navigate to

2. Select the Tools > Tool settings category in the options window.

3. Set the Hide unsupported devices option to False.

Tools > Options through the menu system at the top of the application.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 20

Page 21

Figure 4-8. Hide Unsupported Devices

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Info: Atmel Studio allows any microcontroller and interface to be selected when the Hide unsupported

devices setting is set to False, also microcontrollers and interfaces which are not supported by the on-

board debugger.

4.5.3 Hardware Modifications

The on-board debugger is connected to the PIC18F16Q41 by default. These connections must be removed before

any external microcontroller can be programmed or debugged. Cut the GPIO straps shown in the figure below with a

sharp tool to disconnect the PIC18F16Q41 from the on-board debugger.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 21

Page 22

GPIO straps (bottom side)

PIC18F16Q41 Curiosity Nano

Figure 4-9. Programming and Debugging Connections to Debugger

Curiosity Nano

Info: Cutting the connections to the debugger will disable programming, debugging, and data streaming

from the PIC18F16Q41 mounted on the board.

Tip: Solder in 0Ω resistors across the footprints or short-circuit them with solder to reconnect the signals

between the on-board debugger and the PIC18F16Q41.

4.5.4 Connecting to External Microcontrollers

The figure and table below show where the programming and debugging signals must be connected to program and

debug external microcontrollers. The on-board debugger can supply power to the external hardware or use an

external voltage as a reference for its level shifters. Read more about the power supply in 4.3 Power Supply.

The on-board debugger and level shifters actively drive data and clock signals (DBG0, DBG1, and DBG2) used for

programming and debugging, and in most cases, the external resistor on these signals can be ignored. Pull-down

resistors are required on the ICSP™ data and clock signals to debug PIC® microcontrollers.

DBG3 is an open-drain connection and requires a pull-up resistor to function.

PIC18F16Q41 Curiosity Nano has pull-down resistors R204 and R205 connected to the ICSP data and clock signal

(DBG0 and DBG1). There is also a pull-up resistor R200 connected to the #MCLR signal (DBG3). The location of pull

resistors is shown in the 8.2 Assembly Drawing in the appendix.

Remember:

• Connect GND and VTG to the external microcontroller

• Tie the VOFF pin to GND if the external hardware has a power supply

• Make sure there are pull-down resistors on the ICSP data and clock signals (DBG0 and DBG1) to

support the debugging of PIC microcontrollers

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 22

Page 23

Figure 4-10. Curiosity Nano Standard Pinout

USB

DEBUGGER

PS LED

NC

ID

CDC RX

CDC TX

DBG1

DBG2

VBUS

VOFF

DBG3

DBG0

GND

VTG

CURIOSITY NANO

Table 4-4. Programming and Debugging Interfaces

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Curiosity Nano Pin UPDI ICSP

DBG0 UPDI DATA SWDIO

DBG1 — CLK SWCLK

DBG2 — — —

DBG3 — #MCLR #RESET

4.6 Connecting External Debuggers

Even though there is an on-board debugger, external debuggers can be connected directly to the PIC18F16Q41

Curiosity Nano to program/debug the PIC18F16Q41. The on-board debugger keeps all the pins connected to the

PIC18F16Q41 and board edge in tri-state when not actively used. Therefore, the on-board debugger will not interfere

with any external debug tools.

™

SWD

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 23

Page 24

2

3

4

5

678

1

MCLR

VDD

Ground

DATA

CLOCK

3 = Ground

4 = PGD

5 = PGC

6 = Unused

7 = Unused

8 = Unused

2 = VDD

1 = MCLR

MPLAB® PICkit™ 4

USB

DEBUGGER

PS LED

NC

ID

CDC RX

CDC TX

DBG1

DBG2

VBUS

VOFF

DBG3

DBG0

GND

VTG

CURIOSITY NANO

CAUTION

CAUTION

PIC18F16Q41 Curiosity Nano

Curiosity Nano

Figure 4-11. Connecting the MPLAB® PICkit™ 4 In-Circuit Debugger/Programmer to PIC18F16Q41 Curiosity

Nano

The MPLAB PICkit 4 In-circuit Debugger/Programmer is capable of delivering high voltage on the MCLR

pin. R110 can be permanently damaged by the high voltage. If R110 is broken, the on-board debugger can

not enter Programming mode of the PIC18F16Q41, and will typically fail at reading the device ID.

To avoid contention between the external debugger and the on-board debugger, do not start any

programming/debug operation with the on-board debugger through MPLAB® X IDE or mass storage

programming while the external tool is active.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 24

Page 25

5. Hardware User Guide

USB

DEBUGGER

PIC18F16Q41

SW0

LED0

PS LED

NC

NC

ID

ID

CDC RX

CDCRX

UART[n] TXRB7

CDC TX

CDCTX

UART[n] RXRB5

DBG1

DBG1

RA1ICSPCLK

DBG2

DBG2

RC0SW0

RB7

RB7

UART[n] TXCDC RX

RB5

RB5

UART[n] RXCDC TX

RB4

RB4

I2C1 SDA

RB6

RB6

I2C1 SCL

RC5

RC5

SPI[n] MOSI

RC4

RC4

SPI[n] MISO

RC6

RC6

SPI[n] SCK

RC7

RC7

SPI[n] SS

GND

GND

VBUS

VBUS

VOFF

VOFF

DBG3

DBG3

RA3 MCLR

DBG0

DBG0

RA0 ICSPDAT

GND

GND

VTG

VTG

RA5

RA5

ANA5 (SOSCI)

RA4

RA4

ANA4 (SOSCO)

RC0

RC0

ANC0 PWM[n] SW0

RA0

RA0

ANA0 PWM[n]

RC1

RC1

ANC1 PWM[n] LED0

RC2

RC2

ANC2 OPA1 OUT

RA2

RA2

ANA2 OPA1 IN2 DAC1

RC3

RC3

ANC3 OPA1 IN1

GND

GND

DEBUGGER

PIC18F16Q41

Analog

Debug

I2C

SPI

UART

Peripheral

Port

PWM

Power

Ground

OPAMP

Shared pin

PIC18F16Q41

Curiosity Nano

5.1 Connectors

5.1.1 PIC18F16Q41 Curiosity Nano Pinout

All the PIC18F16Q41 I/O pins are accessible at the edge connectors on the board. The image below shows the

board pinout.

Figure 5-1. PIC18F16Q41 Curiosity Nano Pinout

PIC18F16Q41 Curiosity Nano

Hardware User Guide

Info: Peripheral signals shown in the image above, such as UART, I2C, SPI, ADC, PWM, and others, are

shown at specific pins to comply with the Curiosity Nano Board standard. These signals can usually be

routed to alternate pins using the Peripheral Pin Select (PPS) feature in the PIC18F16Q41.

5.1.2 Using Pin Headers

The edge connector footprint on PIC18F16Q41 Curiosity Nano has a staggered design where each hole is shifted 8

mil (~0.2 mm) off-center. The hole shift allows the use of regular 100 mil pin headers on the board without soldering.

Once the pin headers are firmly in place, they can be used in normal applications like pin sockets and prototyping

boards without any issues.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 25

Page 26

PIC18F16Q41 Curiosity Nano

Figure 5-2. Attaching Pin-Headers to the Curiostiy Nano Board

Hardware User Guide

Figure 5-3. Connecting to Curiosity Nano Base for Click boards

Tip: Start at one end of the pin header and gradually insert the header along the length of the board.

Once all the pins are in place, use a flat surface to push them in.

Tip: For applications where the pin headers will be used permanently, it is still recommended to solder

them in place.

Important: Once the pin headers are in place, they are hard to remove by hand. Use a set of pliers and

carefully remove the pin headers to avoid damage to the pin headers and PCB.

™

5.1.3 Operational Amplifier

PIC18F16Q41 features an internal operational amplifier (OPA) with a flexible connection scheme using multiple

inputs, inverting and non-inverting. This allows a large number of analog signal conditioning configurations, many

requiring no external components.

For information about operational amplifier on the edge connector and any shared functionality see 5.1.1

PIC18F16Q41 Curiosity Nano Pinout.

5.2 Peripherals

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 26

Page 27

5.2.1 LED

There is one yellow user LED available on the PIC18F16Q41 Curiosity Nano board that can be controlled by either

GPIO or PWM. The LED can be activated by driving the connected I/O line to GND.

Table 5-1. LED Connection

PIC18F16Q41 Pin Function Shared Functionality

RC1 Yellow LED0 Edge connector

5.2.2 Mechanical Switch

The PIC18F16Q41 Curiosity Nano board has one mechanical switch. This is a generic user-configurable switch.

When the switch is pressed, it will drive the I/O line to ground (GND).

Tip: There is no externally connected pull-up resistor on the switch. To use the switch, make sure that an

internal pull-up resistor is enabled on pin RC0.

Table 5-2. Mechanical Switch

PIC18F16Q41 Pin Description Shared Functionality

PIC18F16Q41 Curiosity Nano

Hardware User Guide

RC0 User switch (SW0) Edge connector, On-board debugger

5.2.3 Crystal

The PIC18F16Q41 Curiosity Nano Board has a 32.768 kHz crystal footprint made for standard 3.2 mm by 1.5 mm

surface mount crystals with two terminals.

The crystal footprint is not connected to the PIC18F16Q41 by default, as the GPIOs are routed out to the edge

connector. To use the crystal, some hardware modifications are required.

• The two I/O lines routed to the edge connector must be disconnected to reduce the chance of contention to the

crystal, and to remove excessive capacitance on the lines.

• Disconnect the edge connector by cutting the two cut-straps on the bottom side of the board, marked RA4 and

RA5.

• Connect the crystal by soldering on a solder blob on each of the circular solder points next to the crystal on the

top side of the board, J210 and J211.

The crystal has a cut-strap next (J209) to it, which can be used to measure the oscillator safety factor. This is done by

cutting the strap and adding a 0402 SMD resistor across the strap. More information about oscillator allowance and

safety factor can be found in the AN2648 application note from Microchip.

The cut straps and solder points can be seen in Figure 5-4.

Table 5-3. Crystal Connections

RA4 SOSCO (Crystal output) Edge connector

RA5 SOSCI (Crystal input) Edge connector

PIC18F16Q41 Pin Function Shared Functionality

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 27

Page 28

Figure 5-4. Crystal Connection and Cut Straps

Top side

Bo�om side

J208

J207

J211

J210

32.768 kHz

Crystal footprint

J209

5.2.4 On-Board Debugger Implementation

PIC18F16Q41 Curiosity Nano features an on-board debugger that can be used to program and debug the

PIC18F16Q41 using ICSP. The on-board debugger also includes a virtual serial port (CDC) interface over UART and

debug GPIO. MPLAB® X IDE can be used as a front-end for the on-board debugger for programming and debugging.

MPLAB Data Visualizer can be used as a front-end for the CDC and debug GPIO.

PIC18F16Q41 Curiosity Nano

Hardware User Guide

5.2.4.1 On-Board Debugger Connections

The table below shows the connections between the target and the debugger section. All connections between the

target and the debugger are tri-stated as long as the debugger is not actively using the interface. Hence, since there

are little contaminations of the signals, the pins can be configured to anything the user wants.

For further information on how to use the capabilities of the on-board debugger, see 4.1 On-Board Debugger

Overview.

Table 5-4. On-Board Debugger Connections

PIC18F16Q41

Pin

RB5 CDC TX UART RX (PIC18F16Q41 RX line) Edge connector

RB7 CDC RX UART TX (PIC18F16Q41 TX line) Edge connector

RA0 DBG0 ICSPDAT Edge connector

RA1 DBG1 ICSPCLK Edge connector

RC0 DBG2 SW0/GPIO Edge connector

RA3 DBG3 MCLR Edge connector

Debugger Pin Function Shared Functionality

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 28

Page 29

PIC18F16Q41 Curiosity Nano

Hardware Revision History and Known Issues

6. Hardware Revision History and Known Issues

This user guide is written to provide information about the latest available revision of the board. The following

sections contain information about known issues, a revision history of older revisions, and how older revisions differ

from the latest revision.

6.1 Identifying Product ID and Revision

The revision and product identifier of the PIC18F16Q41 Curiosity Nano board can be found in two ways: Either by

utilizing the MPLAB® X IDE Kit Window or by looking at the sticker on the bottom side of the PCB.

By connecting PIC18F16Q41 Curiosity Nano to a computer with MPLAB® X IDE running, the Kit Window will pop up.

The first six digits of the serial number, which is listed under kit information, contain the product identifier and revision.

Tip: The Kit Window can be opened in MPLAB® X IDE through the menu bar Window > Kit Window.

The same information can be found on the sticker on the bottom side of the PCB. Most boards will have the identifier

and revision printed in plain text as A09-nnnn\rr, where “nnnn” is the identifier, and “rr” is the revision. Boards with

limited space have a sticker with only a data matrix code, containing the product identifier, revision, and serial

number.

The serial number string has the following format:

"nnnnrrssssssssss"

n = product identifier

r = revision

s = serial number

The product identifier for PIC18F16Q41 Curiosity Nano is A09‑3378.

6.2 Revision 3

PIC18F16Q41 silicon revision A5 or later is mounted on this revision of the board.

6.3 Revision 2

Revision 2 is the initially released board revision.

PIC18F16Q41 silicon revision A4 is mounted on this revision of the board.

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 29

Page 30

7. Document Revision History

Revision Date Description

A 09/2020 Initial document release

PIC18F16Q41 Curiosity Nano

Document Revision History

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 30

Page 31

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

D D

C C

B B

A A

2 of 4

PIC18F 16Q40 Curiosity Nan o

8/13/2020

PIC18F16Q40_Curiosity_Nano_Target_MCU.SchDoc

Project Title

PCB Assembly Number: PCBA Revision:

File:

PCB Number: PCB Revision:

Designed with

Drawn By:

ML

Sheet Title

Target MCU

Engineer:

PB

A08-3084 2

Size

A3

A09-3373 2

Page:

Date:

Altium.com

3.9p

C203

N.M

3.9p

C204

N.M

GND

100n

C200

GND

32KHz C rystal

DBG0

1k

R203

USER LE D

VCC_TARGET

GND

USER BUTT ON

1k

R202

YELLOW LED

SML-D12Y1WT86

21

D200

TS604VM1-035CR

1 3

42

SW200

CDC_TX

CDC_RX

DBG2

GND VCC_EDGE

GNDGND

DBG1

DBG3

DBG2

DEBUGG ER CONNE CTIO NS

DBG1

DBG3

J209

DBG0

PIC18F 16Q40

ICSPDAT

ICSPCLK

GPIO0

MCLR

DBG0

DBG1

DBG2

DBG3

Debugger

CDC TX

CDC RX

UART[n] RX

UART[n] TX

PIC18F16Q40

RA3_MCLR

RA1_ANA1_ICSPCLK

J210

J211XOUT

XIN

GND

2.2uF

C205

VCC_EDGE

GND

RA0_ANA0_ICSPDAT

RC0_ANC0_SW0

RC1_ANC1_LED0

RC2_ANC2RC3_ANC3

RC4_SPI_MISO

RC5_SPI_MOSI

RC6_SPI_SCK

RC7_SPI_SS

RA2_ANA2

RA4_ANA4_SOSCO

RA5_ANA5_SOSCI

RB4_I2C1_SDA

RB5_UART_RX

RB6_I2C1_SCLRB7_UART_TX

RA4_ANA4_SOSCO

RA5_ANA5_SOSCI

RB7_UART_TX

RB5_UART_RX

RB4_I2C1_SDA

RB6_I2C1_SCL

RC4_SPI_MISO

RC5_SPI_MOSI

RC6_SPI_SCK

RC7_SPI_SS RC3_ANC3

RA2_ANA2

RC2_ANC2

RC1_ANC1_LED0

RA0_ANA0_ICSPDAT

RC0_ANC0_SW0

RA4_ANA4_SOSCO

RA5_ANA5_SOSCI

RA1_ANA1_ICSPCLK

RA0_ANA0_ICSPDAT

RA3_MCLR

RC0_ANC0_SW0

RB7_UART_TX

RB5_UART_RX

TARGET BULK

PRO G/DEBUG Pu ll

47k

R204

47k

R205

GND

VTG 1.8V - 5.5V

VOFF

ID_SYS

ID_SYS

VOFF

DBG0

DBG1

CDC RX3CDC TX4DBG15DBG260 TX71 RX82 SDA93 SCL104 MOSI115 MISO126 SCK137 SS14GND

15

DBG3

28

DBG0

27

GND

26

VCC

25

PWM 3

20

ADC 2

19

ADC 1

18

ADC 0

17

GND

16

ADC 724ADC 6

23

ADC 5

22

PWM 4

21

DEBUGGER

TARGET

ID

2

VOFF

29

RESERVED

1

VBUS

30

CNANO30-pin edge connector

J200

VBUS

J201

J203

J205

J206

J202

J204

NC

RA1

RC0

RA3

RA0

RB7

RB5

Name Pin

RC0_ANC0_SW0

RC1_ANC1_LED0

RA4

RA5

32.768kHz

VMK3-9001-32K7680000TR

XC200

N.M

J207

J208

47k

R200

CDC_TX

CDC_RX

CDC_TX

CDC_RX

DBG2

DBG1

DBG3

DBG0

VOFF

ID_SYS

VCC_TARGET

VCC_TARGET

RA3/MCLR/VPP4RC55RC46RC37RC68RC79RB7

10

RB611RB5

12

RB413RC214RC115RC016RA2

17

ICSPCLK/RA118ICSPDAT/RA0

19

VSS

20

VDD1SOSCI/RA52SOSCO/RA4

3

PIC18F16Q40-I/SS

U200

Crystal datasheet:

Ccrystal = 7pF

max ESR = 70kOhm

Accuracy ±20ppm

Estimated parameters

Cxin = 5pF

Cxout = 5pF

Cpcb = 2.5pF

Estimated load

C = 2 (Ccrystal- Cpara - Cpcb)

C = 2 (7pF - 2.5pF - 2.5pF)

C = 4pF

Selected in design

C = 3.9pF

RX/TX on the header denotes the

input/output direction of the signal

respective to it's source.

CDC TX is output from the DEBUGGER.

CDC RX is input to the DEBUGGER.

TX is output from the TARGET device.

RX is input to the TARGET device.

mounted close to slave device(s).

PIC18F16Q41 Curiosity Nano

Appendix

8. Appendix

8.1 Schematic

Figure 8-1. PIC18F16Q41 Curiosity Nano Schematic

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 31

Page 32

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

D D

C C

B B

A A

3 of 4

PIC18F 16Q41 Curiosity Nan o

4/6/2020

PIC18F16Q41_Curiosity_Nano_Debugger.SchDoc

Project Title

PCB Assembly Number: PCBA Revision:

File:

PCB Number: PCB Revision:

Designed with

Drawn By:

ML

Sheet Title

Debugger

Engineer:

PB

A08-3086 2

Size

A3

A09-3378 2

Page:

Date:

Altium.com

DEBUGG ER USB MIC RO-B CONNE CTOR

GND

USBD_P

USBD_N

100n

C107

100n

C108

1k

R107

VCC_P3V3

SRST

STATUS_LED

SHIELD

VBUS

VCC_P3V3

GND

TP100

Testpoint Array

1 2

3 4

5 6

7 8

9 10

TCK

TDO

TMS

Vsup

TDI GND

TRST

SRST

VTref

GND

J102

GND

4.7uF

C100

DBG0

DBG0

21

GREEN LED

SML-P12MTT86R

D100

VBUS1D-2D+3GND5SHIELD16SHIELD27ID4SHIELD38SHIELD4

9

MU-MB0142AB2-269

J105

PAD

33

PA001PA012PA023PA03

4

GND

10

VDDANA

9

PA045PA056PA067PA07

8

PA08

11

PA09

12

PA10

13

PA11

14

PA14

15

PA15

16

PA16

17

PA17

18

PA18

19

PA19

20

PA22

21

USB_SOF/PA23

22

USB_DM/PA24

23

USB_DP/PA25

24

PA27

25

RESETN

26

PA28

27

GND

28

VDDCORE

29

VDDIN

30

SWDCLK/PA30

31

SWDIO/PA31

32

SAMD21E18A-MUT

U100

VOUT1VOUT

2

GND

3

EN4VIN

6

NC

5

EP

7

MIC5528-3.3YMTU101 VCC_P3V3

GND

USBD_P

USBD_N

GND

1u

C106

VCC_MCU_CORE

VCC_P3V3

VCC_P3V3

2.2uF

C101

GND

74LVC1T45FW4-7

VCCA

1

VCCB

6

A

3

GND

2

DIR5B

4

U103

VCC_P3V3

GND

74LVC1T45FW4-7

VCCA

1

VCCB

6

A

3

GND

2

DIR5B

4

U104

VCC_P3V3

GND

74LVC1T45FW4-7

VCCA

1

VCCB

6

A

3

GND

2

DIR5B

4

U105

VCC_P3V3

GND

GND

GND

GND

VCC_EDGE

GND

74LVC1T45FW4-7

VCCA

1

VCCB

6

A

3

GND

2

DIR5B

4

U107

VCC_P3V3

GND

DBG2

DBG3_CTRL

S1_0_TX

S1_1_RX

S0_2_TX

DAC

VTG_ADC

RESERVED

S0_3_CLK

DBG0_CTRL

CDC_TX_CTRL

BOOT

DEBUGGE R POWE R/STATUS LED

EN1BYP

6

VOUT

4

GND

2

VIN

3

NC/ADJ

5

GND

7

MIC5353U102

100n

C102

GND

GND

47k

R101

27k

R104

GND

33k

R106

2.2uF

C103

GND

1k

R108

J100

VCC_LEVELVCC_REGULATOR

74LVC1T45FW4-7

VCCA

1

VCCB

6

A

3

GND

2

DIR5B

4

U106

VCC_P3V3

GND

DBG1

CDC_RX

CDC_TX

DBG3

DBG1_CTRL

DEBUGG ER REGUL ATOR

REG_ENABLE

REG_ENABLE

47k

R103

VCC_LEVEL

VCC_LEVEL

VCC_LEVEL

VCC_LEVEL

VCC_LEVEL

47k

R102

47k

R105

SWCLK

GND

47k

R100

GND

DBG2

S0_0_RX

DBG1_CTRL

DBG0_CTRL

DBG3 OP EN DRAIN

TARGET ADJUST ABLE REGUL ATOR

SRST

DEBUGG ER TEST POINT

DBG2_CTRL

VOFF

CDC_RX_CTRL

47k

R109

DBG1

CDC_TX_CTRL

CDC_RX_CTRL

SWCLK

REG_ADJUST

DBG2_GPIO

DBG3_CTRL

DBG2_CTRL

DBG3

1k

R110

VBUS_ADC

1

2 3

DMN65D8LFB

Q101

ID_SYS

VOFF

1k

R112

VCC_P3V3

VTG_ADC

DAC

MIC94163

VIN

B2

VOUT

A1

VINA2EN

C2

GND

C1

VOUT

B1

U108

GND

ID_SYS

VTG_EN

VTG_EN

VBUS_ADC

SWDIO

ID_SYS

TP101

GND

SWDIO

VOFF

47k

R111

GND

ID PI N

VCC_VBUS

MC36213

F100

VCC_VBUS

VCC_VBUS

J101

VCC_TARGET

47k

R113

DEBUGGER

UPDI

UPDI

GPIO

GPIO

RESET

Signal

DBG0

DBG1

DBG2

DBG3

ICSP

Interface

DAT

CLK

GPIO

MCLR

CDC TX

CDC RX

UART RX

UART TX

UART RX

UART TX

TARGET TARGET

VCC - -

SWD

SWDAT

SWCLK

SWO/GPIO

RESET

UART RX

UART TX

TARGET

-

CDC_TX

CDC_RX

AVR programming

connector for factory

programming of

DEBUGGER.

MIC5528:

Vin: 2.5V to 5.5V

Vout: Fixed 3.3V

Imax: 500mA

MIC5353:

Vin: 2.6V to 6V

Vout: 1.25V to 5.1V

Imax: 500mA

Dropout (typical): 50mV@150mA, 160mV @ 500mA

Accuracy: 2% initial

Thermal shutdown and current limit

Maximum output voltage is limited by the input voltage and the dropout voltage in the regulator.

(Vmax = Vin - dropout)

J100:

Cut-strap used for full separation of target power from the level shifters and on-board regulators.

- For current measurements using an external power supply, this strap could be cut for more

accurate measurements. Leakage back through the switch is in the micro ampere range.

J101:

This is footprint for a 1x2 100mil pitch pin-header that can be used for easy current measurement

to the target microcontroller and the LED / Button. To use the footprint:

- Cut the track between the holes, and mount a pin-header

Adjustable output and limitations:

- The DEBUGGER can adjust the output voltage of the regulator between 1.25V and 5.1V to the target.

- The voltage output is limited by the input (USB), which can vary between 4.40V to 5.25V

- The level shifters have a minimal voltage level of 1.65V and will limit the minimum operating voltage allowed for the

target to still allow communication.

- The MIC94163 has a minimal volatege level of 1.70V and will limit the minimum voltage delivered to the target.

- Firmware configuration will limit the voltage range to be within the the target specification.

PTC Resettable fuse:

Hold current: 500mA

Trip current: 1000mA

R113:

Pull down to prevent

DBG3_CTRL from

floating when debugger is

not powered.

PIC18F16Q41 Curiosity Nano

Appendix

© 2020 Microchip Technology Inc.

User Guide

DS50003048A-page 32

Page 33

8.2 Assembly Drawing

b

PAC10002

PAC10001

COC100

PAC10102

PAC10101

COC101

PAC10201

PAC10202

COC102

PAC10301

PAC10302

COC103

PAC10602