Page 1

dsPIC33CK Low-Voltage

Motor Control Board

User’s Guide

2020 Microchip Technology Inc. DS50002927A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Trademarks

The Microchip name and logo, the Microchip logo, Adaptec,

AnyRate, AVR, AVR logo, AVR Freaks, BesTime, BitCloud, chipKIT,

chipKIT logo, CryptoMemory, CryptoRF, dsPIC, FlashFlex,

flexPWR, HELDO, IGLOO, JukeBlox, KeeLoq, Kleer, LANCheck,

LinkMD, maXStylus, maXTouch, MediaLB, megaAVR, Microsemi,

Microsemi logo, MOST, MOST logo, MPLAB, OptoLyzer,

PackeTime, PIC, picoPower, PICSTART, PIC32 logo, PolarFire,

Prochip Designer, QTouch, SAM-BA, SenGenuity, SpyNIC, SST,

SST Logo, SuperFlash, Symmetricom, SyncServer, Tachyon,

TempTrackr, TimeSource, tinyAVR, UNI/O, Vectron, and XMEGA

are registered trademarks of Microchip Technology Incorporated in

the U.S.A. and other countries.

APT, ClockWorks, The Embedded Control Solutions Company,

EtherSynch, FlashTec, Hyper Speed Control, HyperLight Load,

IntelliMOS, Libero, motorBench, mTouch, Powermite 3, Precision

Edge, ProASIC, ProASIC Plus, ProASIC Plus logo, Quiet-Wire,

SmartFusion, SyncWorld, Temux, TimeCesium, TimeHub,

TimePictra, TimeProvider, Vite, WinPath, and ZL are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BlueSky, BodyCom, CodeGuard,

CryptoAuthentication, CryptoAutomotive, CryptoCompanion,

CryptoController, dsPICDEM, dsPICDEM.net, Dynamic Average

Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial

Programming, ICSP, INICnet, Inter-Chip Connectivity, JitterBlocker,

KleerNet, KleerNet logo, memBrain, Mindi, MiWi, MPASM, MPF,

MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach,

Omniscient Code Generation, PICDEM, PICDEM.net, PICkit,

PICtail, PowerSmart, PureSilicon, QMatrix, REAL ICE, Ripple

Blocker, SAM-ICE, Serial Quad I/O, SMART-I.S., SQI,

SuperSwitcher, SuperSwitcher II, Total Endurance, TSHARC,

USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and

ZENA are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

The Adaptec logo, Frequency on Demand, Silicon Storage

Technology, and Symmcom are registered trademarks of Microchip

Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology Germany

II GmbH & Co. KG, a subsidiary of Microchip Technology Inc., in

other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2020, Microchip Technology Incorporated, All Rights Reserved.

For information regarding Microchip’s Quality Management Systems,

please visit www.microchip.com/quality.

ISBN: 978-1-5224-5762-6

DS50002927A-page 2 2020 Microchip Technology Inc.

Page 3

dsPIC33CK LOW-VOLTAGE

MOTOR CONTROL BOARD

USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 5

Chapter 1. Introduction.................................................................................................. 9

1.1 Overview ........................................................................................................ 9

1.2 Features ....................................................................................................... 10

1.3 Block Diagram .............................................................................................. 11

Chapter 2. Board Interface Description ..................................................................... 13

2.1 Introduction ................................................................................................... 13

2.2 Board Connectors ........................................................................................ 13

2.3 User Interface Hardware .............................................................................. 19

2.4 Pin Functions of the dsPIC DSC .................................................................. 25

Chapter 3. Hardware Description ............................................................................... 29

3.1 Introduction ................................................................................................... 29

3.2 Hardware Sections ....................................................................................... 29

Appendix A. Schematics and Layout......................................................................... 43

A.1 Board Schematics and Layout ..................................................................... 43

Appendix B. Electrical Specifications........................................................................ 55

B.1 Introduction .................................................................................................. 55

Appendix C. Design Details ........................................................................................ 57

C.1 Introduction .................................................................................................. 57

C.2 Current Amplifier Circuits ............................................................................. 57

C.3 Auxiliary Power Supply ................................................................................ 61

Worldwide Sales and Service .................................................................................... 66

2020 Microchip Technology Inc. DS50002927A-page 3

Page 4

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

NOTES:

DS50002927A-page 4 2020 Microchip Technology Inc.

Page 5

dsPIC33CK LOW-VOLTAGE

MOTOR CONTROL BOARD

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs and/

or tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This preface contains general information that will be useful to know before using the

dsPIC33CK Low-Voltage Motor Control Board. Topics discussed in this preface

include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Website

• Product Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

The user’s guide describes the dsPIC33CK Low-Voltage Motor Control Board. The

document is organized as follows:

• Chapter 1. “Introduction” – This chapter introduces the board and provides a

brief overview of its features.

• Chapter 2. “Board Interface Description” – This chapter provides information

about the board input and output interfaces.

• Chapter 3. “Hardware Description” – This chapter describes the hardware

sections of the board.

• Appendix A. “Schematics and Layout” – This appendix provides board

schematics and layout.

• Appendix B. “Electrical Specifications” – This appendix summarizes the

electrical specifications.

• Appendix C. “Design Details” – This appendix provides design calculations for

certain hardware sections.

2020 Microchip Technology Inc. DS50002927A-page 5

Page 6

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly braces and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS50002927A-page 6 2020 Microchip Technology Inc.

Page 7

RECOMMENDED READING

This user’s guide describes how to use the dsPIC33CK Low-Voltage Motor Control

Board. The device-specific data sheets contain additional information on programming the

specific microcontroller or Digital Signal Controller (DSC) devices. Other useful

documents are listed below. The following Microchip documents are available and

recommended as supplemental reference resources:

dsPIC33CK256MP508 Family Data Sheet (DS70005349)

This document provides device-specific information for the dsPIC33CK256MP508

16-bit Digital Signal Controller with High-Resolution PWM and CAN Flexible Data

(CAN FD).

MCP2200 Data Sheet (DS50002106)

This document provides device-specific information for the MCP2200 USB 2.0 to

UART Protocol Converter with GPIO.

MPLAB® X IDE User’s Guide (DS50002027)

This document describes how to set up the MPLAB X IDE software and use it to

create projects and program devices.

Preface

AN1299, Single-Shunt Three-Phase Current Reconstruction Algorithm for

Sensorless FOC of a PMSM (DS01299)

AN1160, Sensorless BLDC Control with Back-EMF Filtering Using a

Majority Function (DS01160)

AN1078, Sensorless Field Oriented Control of a PMSM (DS01078)

AN1292, Sensorless Field Oriented Control (FOC) for a Permanent

Magnet Synchronous Motor (PMSM) Using a PLL Estimator and Field

Weakening (FW) (DS01292)

AN1017, Sinusoidal Control of PMSM Motors with dsPIC30F DSC

(DS01017)

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readme subdirectory of the MPLAB X IDE installation directory. The Readme files

contain updated information and known issues that may not be included in this

user’s guide.

For step-by-step instructions to set up and run a motor control application using the

dsPIC33CK Low-Voltage Motor Control Board, refer to the Readme file provided along

with the motor control application code.

dsPIC33 Family Reference Manuals

Specific Family Reference Manuals (FRMs) are available for each module, which

explains the operation of the dsPIC

modules. The specifics of each device family are discussed in their data sheet.

To obtain any of these documents, visit the Microchip website at: www.microchip.com.

2020 Microchip Technology Inc. DS50002927A-page 7

®

DSC MCU family architecture and peripheral

Page 8

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

THE MICROCHIP WEBSITE

Microchip provides online support via our website at www.microchip.com. This website

is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the website contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

PRODUCT CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip website at www.microchip.com, click on Product

Change Notification and follow the registration instructions.

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or FAE for support. Local

sales offices are also available to help customers. A listing of sales offices and locations is included in the back of this document.

Technical support is available through the website at: http://support.microchip.com.

DOCUMENT REVISION HISTORY

Revision A (March 2020)

This is the initial released version of this document.

DS50002927A-page 8 2020 Microchip Technology Inc.

Page 9

dsPIC33CK LOW-VOLTAGE

MOTOR CONTROL BOARD

Chapter 1. Introduction

1.1 OVERVIEW

The dsPIC33CK Low-Voltage Motor Control Board is targeted to drive a low-voltage,

three-phase Permanent Magnet Synchronous Motor (PMSM) or Brushless DC (BLDC)

motor using the dsPIC33CK256MP508. This dsPIC

single-core 16-bit DSC with enhanced on-chip peripherals, such as

High-Resolution PWM (HRPWM),12-bit high-speed ADC cores, analog comparators with

DAC, op amps, QEI, CAN-FD, SENT, UART, SPI, I

In some instances of the document text, the dsPIC33CK Low-Voltage Motor Control Board

is also referred to as the ‘Motor Control Board’ to enhance readability. The Motor Control

Board is shown in Figure 1-1.

FIGURE 1-1: dsPIC33CK LOW-VOLTAGE MOTOR CONTROL BOARD

®

DSC features a 100 MIPS,

2

C, DMA, timers, etc.

USER’S GUIDE

2020 Microchip Technology Inc. DS50002927A-page 9

Page 10

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

1.2 FEATURES

Key features of the Motor Control Board are as follows:

• Three-Phase Motor Control Power Stage with the Following Electrical Specifications:

- Input DC voltage: 12V to 48V

- Nominal phase RMS current: 10A at +25°C ambient temperature

• Motor Phase Current Feedbacks to Implement Field-Oriented Control (FOC) of a

PMSM/BLDC Motor

• DC Bus Current Feedback for Overcurrent Protection and to Implement Single

Shunt Current Reconstruction Algorithm

• DC Bus Voltage Feedback for Overvoltage Protection

• Phase Voltage Feedbacks to Implement Sensorless Trapezoidal Control

• Hall Sensor Interface

• Quadrature Encoder Interface (QEI)

• On-Board Temperature Sensor for Monitoring the MOSFET Temperature

• Optional External Temperature Sensor (thermistor) Interface

• Debug Serial Interface (USB to UART)

• PICkit™ On-Board (PKOB4) for Programming and Debugging

• Two mikroBUS™ Sockets to Support Connectivity, Sensors and Communication

Interfaces by Plugging in mikroBUS Add-On Boards

• User Interface Elements:

- Two debug LEDs

- One potentiometer

- Three push buttons

- PWM indication LEDs

- Power-on status indication LED

• Auxiliary Power Supply to Power External Interfaces and On-Board Circuitry

DS50002927A-page 10 2020 Microchip Technology Inc.

Page 11

1.3 BLOCK DIAGRAM

`

Debug

Interface

Push Buttons

LEDs

Potentiometer

DC-DC

Converter

(MIC28511)

DC-DC

Converter

(MCP16301)

+3.3V Output

LDO

(MCP1826)

Motor Terminal

Input Terminal

12-48 VDC, 24A

Input Jack

PKOB V4

MCLR

Push Button

ICSP Header

MIC4605 x 3

Half-Bridge MOSFET Drivers

Current

Sensing

Temp Sensor

for Thermal

Protection

Current

Sensing

Shunt

Position

Feedbacks

Quadrature

Encoder

Interface

Hall Sensor

Interface

Reset

Control

I/O Control – Analog, Digital, Pull-up, Pull -Down, Remappable, Change Notification

Program/

HR PWM

SCCP

DAC/

Comparators

QEI

Timer1

ADC – 2 x Dedicated Core and Shared Core

Op Amps

Clock

CLC

PTG

Interrupt

Control

Temperature

_

Current Shunt Feedbacks

Op Amps for

Phase

Currents

Amplification

I

A_EXT,

I

B_EXT,

I

C_EXT

Op Amp for

Bus Current

Amplification

I

BUS_EXT

Voltages

Scaling

Circuit

g

_A

,

_B

,

_C

I

BUS_FILT_EXT

p

g

DC Voltage

Scaling

Circuit

BUS

mikroBUS Socket-B

mikroBUS™ Socket-A

IA,

IB,

I

BUS

The block diagram of the dsPIC33CK Low-Voltage Motor Control Board is shown in

Figure 1-2. For more information on electrical specifications, refer to

Appendix B. “Electrical Specifications”.

FIGURE 1-2: THE MOTOR CONTROL BOARD BLOCK DIAGRAM

Introduction

Quadrature Encoder

Feedbacks

Speed/

EXT

TEMP

External

Interface

Hall Sensor Feedbacks

Three-Phase Inverter Bridge

J14

Connector

dsPIC33CK256MP508

V

V

V

es

Phase

Volta

MCP6024

Phase

PWMs

MCP651S

V

MOSFET Temperature

Three-Phase Inverter

Phase

Shunts

Bus

J2

Connector

MCP9700

CAN FD

PMP

WDT

SENT

DMT

UART

DMA

CRC

e

ut DC Volta

In

SPI

I2C

Other Interfaces

MCP2200

USB to UART Converter

+12V +5V

+12V Output

ICSP™

Debug

Auxiliary Power Supply

+5V Output

J1

Connector

12-24 VDC, 2.5A

User Interface

+3.3 VA

Program/

+3.3V

2020 Microchip Technology Inc. DS50002927A-page 11

Page 12

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

NOTES:

DS50002927A-page 12 2020 Microchip Technology Inc.

Page 13

Chapter 2. Board Interface Description

2.1 INTRODUCTION

This chapter provides a more detailed description of the input and output interfaces of the

dsPIC33CK Low-Voltage Motor Control Board. This chapter covers the following topics:

• Board Connectors

• User Interface Hardware

• Pin Functions of the dsPIC DSC

2.2 BOARD CONNECTORS

This section summarizes the connectors on the Motor Control Board. The connectors

are intended for:

• Supplying input power to the Motor Control Board

• Delivering inverter outputs to the motor

• Interfacing motor position sensors, such as Hall sensors or the Quadrature

Encoder

• Enabling the user to program/debug the dsPIC33CK256MP508 device

• Interfacing the Click Boards™

• Establishing communication with the host PC

• Interfacing the external temperature sensor (thermistor)

The connectors on the Motor Control Board are shown in Figure 2-1 and summarized

in Ta b le 2 -1 .

dsPIC33CK LOW-VOLTAGE

MOTOR CONTROL BOARD

USER’S GUIDE

2020 Microchip Technology Inc. DS50002927A-page 13

Page 14

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

J13

J10

J6

J3

J4

J11

J12

J9

J7

J8

J14

J16

J1

J2

FIGURE 2-1: CONNECTORS – dsPIC33CK LOW-VOLTAGE MOTOR CONTROL BOARD

TABLE 2-1: MOTOR CONTROL BOARD CONNECTORS

Connector

Designator

J1 3 Populated Input DC power supply jack

J2 2 Populated Input DC power supply – two-pin terminal connector (5 mm pitch,12-30 AWG wire insert)

J3 6 Not Populated UART interface connections

J4 2 Not Populated Erase jumper – used to switch PICkit™ On-Board (PKOB)

J6 5 Populated USB Micro-B connector for establishing the serial interface with the host PC

J7 6 Populated Hall sensor interface terminal connector (2.54 mm pitch, 20-30 AWG wire insert)

J8 6 Populated Quadrature Encoder Interface terminal connector (2.54 mm pitch,

J9 2 Not Populated External temperature sensor (thermistor) interface connector (2.5 mm pitch)

J10 6 Not Populated ICSP™ header – interfacing programming/debugging the dsPIC® DSC

J11 16 Populated mikroBUS™ socket for interfacing a Click Board™ with the Motor Control Board,

J12 16 Populated mikroBUS socket for interfacing a Click Board with the Motor Control Board, labeled

J13 5 Populated PICkit On-Board (PKOB) programmer/debugger interface connector (standard

J14 3 Populated Three-phase inverter output for connecting motor (5 mm pitch,

J16 2 Not Populated Jumper (2.54 mm pitch) which may be optionally used to connect the positive supply

No. of

Pins

Status Description

programmer/debugger to Boot Recovery mode through MPLAB

20-30 AWG wire insert)

labeled as ‘A’ on the board

as ‘B’ on the board

female USB Micro-B connector)

12-30 AWG wire insert)

DC

) input of connectors, J1 and J2; shorted by default on the board using PCB trace

(V

®

X IDE

DS50002927A-page 14 2020 Microchip Technology Inc.

Page 15

Board Interface Description

Auxiliary Power Supply

Three-Phase Inverter

VDC

NT1

Net Tie

J16

Jumper

Populated by Default

J2

J1

PGND

24A

2.5A

PGND

dsPIC33CK Low-Voltage Motor Control Board

Note 1: The Motor Control Board is designed to operate at a DC voltage range of 12V to 48V. When

powering the board through J1, limit the voltage to 24V Max. When the applied voltage is greater

than 24V, always use connector J2 to power the board.

2: When J1 and J2 are shorted through either J16 or NT1, always power the Motor Control Board

using only one connector, either J1 or J2.

2.2.1 Power Supply Connectors (J1, J2, J16)

The board is designed to operate in the DC voltage range of 12-48V. As shown in

Figure 2-2, the Motor Control Board can be powered through either coaxial plug J1 or

through terminal connector J2.

FIGURE 2-2: INPUT DC POWER SUPPLY CONNECTORS

(1,2)

If required, the power to the inverter can be disconnected by cutting the trace of the net

tie, NT1, and the rest of the circuitry can be powered through the supply connected to

the coaxial plug J1. The connection between the net tie can be bridged back by populating jumper J16, restoring the connection between J1 and J2, such that either input

connector, J1 or J2, can be used for powering the Motor Control Board. Connector J1

can carry current up to 2.5A and connector J2 can handle up to 24A. Ta bl e 2 -2 and

Ta bl e 2 -3 summarize the pin assignments of connectors, J1 and J2, respectively.

TABLE 2-2: PIN DESCRIPTION – CONNECTOR J1

Pin # Signal Name Pin Description

1VDC DC Input Supply Positive

2 PGND DC Input Supply Negative or PGND

3 PGND DC Input Supply Negative or PGND

Pin # Signal Name Pin Description

1 PGND DC Input Supply Negative or PGND

2VDC DC Input Supply Positive

TABLE 2-3: PIN DESCRIPTION – CONNECTOR J2

2020 Microchip Technology Inc. DS50002927A-page 15

Page 16

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

2.2.2 UART Interface Header (J3)

A 5-pin header, J3, is a UART interface provided to connect an external UART-USB

converter or for accessing UART signals by disabling the MCP2200 device (see U13

in Figure A-5). Ta bl e 2 -4 summarizes the pin functions of connector J3.

TABLE 2-4: PIN DESCRIPTION – CONNECTOR J3

Pin # Signal Name Pin Description

1 +3.3V +3.3V Supply

2 DEBUG_TX UART Transmit Pin of dsPIC® DSC

3 DEBUG_RX UART Receive Pin of dsPIC DSC

4 DGND Digital Ground

5 MCP2200_RST Setting this Pin Low (connecting to Ground) will

Disable the MCP2200 (U13)

2.2.3 USB Serial Interface (J6)

The Motor Control Board uses an on-board MCP2200 device (see U13 in Figure A-5)

as a bridge between the UART and USB (see Table 2-5) for providing the host PC

interface.

TABLE 2-5: PIN DESCRIPTION – CONNECTOR J6

Pin # Signal Name Pin Description

0 No Connection Body is Connected to Digital Ground

1 5V_USB USB +5 V

2 UART_USB_N USB Data-

3 UART_USB_P USB Data+

4 No Connection —

5 GND Digital Ground

DC

2.2.4 Hall Sensor Interface Connector (J7)

Hall sensors are used to detect the rotor position and speed of the motor. Connector

J7 can be used to interface the Hall sensor outputs with the Motor Control Board,

enabling sensor-based BLDC motor control applications. Table 2-6 shows the pin

descriptions of connector J7. The connector provides two supply outputs, +5V and

+3.3V, which can be used as input supplies of the Hall sensors based on the sensor

specification.

TABLE 2-6: PIN DESCRIPTION – CONNECTOR J7

Pin # Signal Name Pin Description

1 +5V +5V Supply to Hall Sensors

2 +3.3V +3.3V Supply to Hall Sensors

3 DGND Digital Ground

4 HA Hall Sensor A Feedback from the Motor

5 HB Hall Sensor B Feedback from the Motor

6 HC Hall Sensor C Feedback from the Motor

DS50002927A-page 16 2020 Microchip Technology Inc.

Page 17

Board Interface Description

2.2.5 Quadrature Encoder Interface Connector (J8)

Quadrature Encoders are used to detect the rotor position and speed of the motor.

Connector J8 can be used to interface the encoder outputs with the Motor Control

Board, enabling sensor-based BLDC/PMSM motor control applications. Ta b le 2 -7

shows the pin description of connector J8. The connector provides two supply outputs,

+5V and +3.3V, which can be used as input supplies to the Quadrature Encoder based

on the encoder specification.

TABLE 2-7: PIN DESCRIPTION – CONNECTOR J8

Pin # Signal Name Pin Description

1 +5V +5V Supply to Quadrature Encoder

2 +3.3V +3.3V Supply to Quadrature Encoder

3 DGND Digital Ground

4 QEA Quadrature Encoder Phase A Feedback of the Motor

5 QEB Quadrature Encoder Phase B Feedback of the Motor

6 INDX Quadrature Encoder INDEX Feedback of the Motor

2.2.6 External Temperature Sensor Interface Connector (J9)

The 2-pin connector (2.5 mm pitch) J9 can be used for interfacing a thermistor to the

board. This is not populated by default. When needed, populate the connector with

Part Number B2B-EH-A(LF)(SN) or similar.

2.2.7 ICSP™ Header for Programmer/Debugger Interface (J10)

The 6-pin header J10 can be used for connecting the programmer/debugger, for

example, PICkit™ 3, for programming and debugging the dsPIC33CK256MP508.

This is not populated by default. When needed, populate the connector with

Part Number 68016-106HLF or similar. The pin details are provided in Table 2-8.

TABLE 2-8: PIN DESCRIPTION – CONNECTOR J10

Pin # Signal Name Pin Description

1MCLR

2DVDD Digital Supply Voltage

3 DGND Digital Ground

4 PGD Device Programming Data Line (PGD)

5 PGC Device Programming Clock Line (PGC)

6 No Connection —

Device Master Clear (MCLR)

2020 Microchip Technology Inc. DS50002927A-page 17

Page 18

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

2.2.8 mikroBUS™ Sockets for Interfacing a Click Board™ (J11, J12)

Two mikroBUS sockets are provided on the Motor Control Board which can be used to

expand the functionality by attaching an add-on board, called a ‘Click Board’. The

mikroBUS sockets, J11 and J12, are labeled as ‘A’ and ‘B’, respectively. The

Motor Control Board implements the mikroBUS socket pinouts, as specified in the

“mikroBUS™ Standard Specifications v2.0” (refer to www.mikroe.com/mikrobus).

The pinout consists of three groups of communication pins (SPI, UART and I

additional pins (PWM, interrupt, analog input, Reset and chip select) and two power

groups (+3.3V-GND and 5V-GND).

For pin mapping information between the dsPIC DSC and the mikroBUS sockets, refer

to the schematics in Section A.1 “Board Schematics and Layout” or

Section 2.4 “Pin Functions of the dsPIC DSC”.

2.2.9 USB Connector for PKOB Interface (J13)

This is a standard female USB Micro-B connector that provides USB communication

when interfacing with the PICkit On-Board (PKOB) programming/debugging tool. Pin

assignments for connector J13 are shown in Ta bl e 2 -9 .

TABLE 2-9: PIN DESCRIPTION – CONNECTOR J13

Pin # Signal Name Pin Description

2

C), six

0 No Connection Body is Connected to GND

1VBUS USB 5V

2 D_N USB Data-

3 D_P USB Data+

4 No Connection —

5 GND PKOB Ground (GND)

2.2.10 Inverter Output Connector (J14)

The Motor Control Board can drive a three-phase PMSM/BLDC motor. Motor control

inverter outputs are available on connector J14. Pin assignments for connector J14 are

shown in Ta b le 2 - 10 .

TABLE 2-10: PIN DESCRIPTION – CONNECTOR J14

Pin # Signal Name Pin Description

1 PHASE C Phase 3 Output of Inverter

2 PHASE B Phase 2 Output of Inverter

3 PHASE A Phase 1 Output of Inverter

DS50002927A-page 18 2020 Microchip Technology Inc.

Page 19

Board Interface Description

LD1

LD2

LD3

LD11

LD10

LD4

LD5

LD7

LD6

LD9

LD8

2.3 USER INTERFACE HARDWARE

This section describes the LEDs, push buttons, potentiometer and test points available

on the Motor Control Board.

2.3.1 LEDs

The LEDs provided on the Motor Control Board are shown in Figure 2-3 and

summarized in Tab le 2- 11.

FIGURE 2-3: LEDs – dsPIC33CK LOW-VOLTAGE MOTOR CONTROL BOARD

TABLE 2-11: LEDs

LED

Designator

LD1 Yellow USB receive LED activity output. Refer to the “MCP2200 Data Sheet” for more details.

LD2 Green USB transmit LED activity output. Refer to the “MCP2200 Data Sheet” for more details.

LD3 Red Power-on status indication, connected to auxiliary supply output: +3.3V.

LD4 Green Indicates PWM1H (PWM_AH), used for controlling top MOSFET of the inverter Half-Bridge A.

LD5 Green Indicates PWM1L (PWM_AL), used for controlling bottom MOSFET of the inverter Half-Bridge A.

LD6 Green Indicates PWM2H (PWM_BH), used for controlling top MOSFET of the inverter Half-Bridge B.

LD7 Green Indicates PWM2L (PWM_BL), used for controlling bottom MOSFET of the inverter Half-Bridge B.

LD8 Green Indicates PWM4H (PWM_CH), used for controlling top MOSFET of the inverter Half-Bridge C.

LD9 Green Indicates PWM4L (PWM_CL), used for controlling bottom MOSFET of the inverter Half-Bridge C.

LD10 Yellow User-defined LED provided for debugging purposes (LED1).

LD11 Yellow User-defined LED provided for debugging purposes (LED2).

2020 Microchip Technology Inc. DS50002927A-page 19

LED

Color

LED Indication

Page 20

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

SW1 SW2 SW3

SW4

MCLR

2.3.2 Push Buttons

The push buttons provided on the Motor Control Board are shown in Figure 2-4 and

summarized in Tab le 2- 12.

The push buttons, SW1, SW2 and SW3, are provided to control motor operations; for

example, starting or stopping the motor. The functions of these push buttons are

defined by the motor control application firmware.

FIGURE 2-4: PUSH BUTTONS – dsPIC33CK LOW-VOLTAGE MOTOR CONTROL BOARD

TABLE 2-12: PUSH BUTTONS

SI #

1 SW1 Push button provided for general purpose (BUTTON1).

2 SW2 Push button provided for general purpose (BUTTON2).

3 SW3 Push button provided for general purpose (BUTTON3).

4 SW4 This push button is tied to the MCLR

DS50002927A-page 20 2020 Microchip Technology Inc.

Push Button

Designator

will reset the dsPIC

®

DSC.

LED Indication

pin of the dsPIC33CK256MP508. Pressing this button

Page 21

Board Interface Description

POT1

2.3.3 Potentiometer

The potentiometer on the Motor Control Board (shown in Figure 2-5) is connected to

one of the analog inputs of the device and can be used for setting the speed reference.

FIGURE 2-5: POTENTIOMETER – dsPIC33CK LOW-VOLTAGE MOTOR CONTROL BOARD

2020 Microchip Technology Inc. DS50002927A-page 21

Page 22

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

DGND

+12V

+5V

PGND

VDC

PGND

+3.3 VA

+3.3V

DGND

IBUS_EXT

IBUS_FILT_EXT

AGND

VBUS

IBUS

TP12

TP11

VB

VA

VC

IB_EXT

IA_EXT

IA

TP14

AGND

AL

AH

BH

BL

CH

CL

DGND

TP21

HALL_A

HALL_B

HALL_C

QEI_A

QEI_B

QEI_INDEX

QEI_HOME

HOME

DGND

LED1

LED2

IC_EXT

VREF

TP13

IB

2.3.4 Test Points

There are several test points on the Motor Control Board to monitor various signals,

such as motor feedback voltages, motor currents, auxiliary supply outputs, etc. These

test points are marked in Figure 2-6 and summarized in Table 2-13.

FIGURE 2-6: TEST POINTS – dsPIC33CK LOW-VOLTAGE MOTOR CONTROL BOARD

DS50002927A-page 22 2020 Microchip Technology Inc.

Page 23

Board Interface Description

TABLE 2-13: BOARD TEST POINTS

Test Point # Signal Description

Power Supply Inputs and Outputs

TP1 VDC Input DC Power Supply

TP3 +12V +12V Supply – output of on-board MIC28511 device-based

buck converter

TP7 PGND Power Ground

TP22 PGND Power Ground

TP4 +5V +5V Supply – output of on-board MCP16301 device-based buck converter

TP5 +3.3V +3.3V Digital Supply – output of on-board +3.3V LDO (MCP1826)

TP8 DGND Digital Ground

TP18 DGND Digital Ground

TP19 DGND Digital Ground

TP6 +3.3VA +3.3V Analog Supply

TP9 AGND Analog Ground

TP20 AGND Analog Ground

Analog Signals

TP17 V

IA IA Internal Amplifier (dsPIC33CK256MP508 Op Amp 1) output of Phase A leg

IA_EXT IA_EXT External Amplifier (MCP6024 U5A) output of Phase A leg current feedback of

IB IB Internal Amplifier (dsPIC33CK256MP508 Op Amp 2) output of Phase B leg

IB_EXT IB_EXT External Amplifier (MCP6024 U5B) output of Phase A leg current feedback of

IC_EXT IC_EXT External Amplifier (MCP6024 U5C) output of Phase A leg current feedback of

BUS IBUS Internal Amplifier (dsPIC33CK256MP508 Op Amp 3) output of bus current

I

IBUS_EXT IBUS_EXT External Amplifier (U15 MCP651S) output of bus current feedback of inverter

IBUS_FILT_EXT IBUS_FILT_EXT Filtered Bus Current Feedback of Inverter, which is amplified by MCP651S

VA VA Phase A Voltage Feedback

VB VB Phase B Voltage Feedback

VC VC Phase C Voltage Feedback

BUS VBUS DC Bus Voltage Feedback

V

TP14 TEMP_LOCAL MOSFET Temperature – output of on-board temperature sensor, MCP9700 (U14)

TP21 TEMP_EXT Output of External Temperature Sensor interfaced through connector J9

REF +1.65V Voltage Reference to bias op amp outputs

current feedback of inverter

inverter

current feedback of inverter

inverter

inverter

feedback of inverter

(U15); this output is connected to the negative input of one of the internal

comparators of dsPIC33CK256MP508 (U9) for overcurrent protection

2020 Microchip Technology Inc. DS50002927A-page 23

Page 24

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

TABLE 2-13: BOARD TEST POINTS (CONTINUED)

Test Point # Signal Description

PWM Outputs

J15-1 AL PWM1L Output from dsPIC® DSC, which controls bottom MOSFET of the

Inverter Half-Bridge A

J15-2 AH PWM1H Output from dsPIC

Half-Bridge A

J15-3 BL PWM2L Output from dsPIC DSC, which controls bottom MOSFET of the

Inverter Half-Bridge B

J15-4 BH PWM2H Output from dsPIC DSC, which controls top MOSFET of the Inverter

Half-Bridge B

J15-5 CL PWM4L Output from dsPIC DSC, which controls bottom MOSFET of the

Inverter Half-Bridge C

J15-6 CH PWM4L Output from dsPIC DSC, which controls top MOSFET of the Inverter

Half-Bridge C

Hall Sensor Feedbacks

HALL_A HALL_A Hall Sensor A Feedback connected to dsPIC DSC input

HALL_B HALL_B Hall Sensor B Feedback connected to dsPIC DSC input

HALL_C HALL_C Hall Sensor C Feedback connected to dsPIC DSC input

Quadrature Encoder Feedbacks

QEI_A QEI_A Quadrature Encoder A Feedback connected to dsPIC DSC input

QEI_B QEI_B Quadrature Encoder B Feedback connected to dsPIC DSC input

QEI_INDEX QEI_INDEX Quadrature Encoder INDEX Feedback connected to dsPIC DSC input

QEI_HOME QEI_HOME Quadrature Encoder HOME Feedback connected to dsPIC DSC input

HOME HOME This test point can be optionally used to interface the HOME signal feedback

with the Motor Control Board

LEDs and General Purpose I/Os

LED1 LED1 LED1 Output from dsPIC

LED2 LED2 LED2 Output from dsPIC DSC

TP11 TP11 Connected to the port pin RE4 of the dsPIC DSC; this test point can be

optionally used as a general purpose input or output

TP12 TP12 Connected to the port pin RE5 of the dsPIC DSC; this test point can be

optionally used as a general purpose input or output

TP13 TP13 Connected to the port pin RE15 of the dsPIC DSC; this test point can be

optionally used as a general purpose input or output

DSC, which controls top MOSFET of the Inverter

®

DSC

DS50002927A-page 24 2020 Microchip Technology Inc.

Page 25

2.4 PIN FUNCTIONS OF THE dsPIC DSC

The on-board dsPIC33CK256MP508 device (see U9 in Figure A-2) enables the control

of various features of the Motor Control Board through its peripherals and CPU

capability. Pin functions of the dsPIC DSC are grouped according to their functionality

and presented in Ta bl e 2- 14 .

Board Interface Description

TABLE 2-14: dsPIC

Signal

dsPIC DSC Configuration – Supply, Reset, Clock and Programming

+3.3V 12, 31, 51, 71 V

DGND 11, 32, 50, 70 V

+3 .3VA 25 AV

AGND 26 AV

OSCI 34 OSCI/CLKI/AN5/RP32/

OSCO 35 OSCO/CLKO/AN6/RP33/

MCLR

PGD 55 PGD3/RP37/SDA2/PMA14/

PGC 56 PGC3/RP38/SCL2/RB6

dsPIC DSC Internal Amplifier Connections for Current Amplification

SHUNT_IA_P 20 OA1IN+/AN9/PMA6/RA2 Operational

SHUNT_IA_N 18 OA1IN-/ANA1/RA1

IA 16 OA1OUT/AN0/CMP1A/

SHUNT_IB_P 45 PGC2/OA2IN+/RP36/RB4 Operational

SHUNT_IB_N 43 PGD2/OA2IN-/AN8/RP35/

IB 41 OA2OUT/AN1/AN7/ANA0/

SHUNT_IBUS_P 29 OA3IN+/AN14/CMP2B/

SHUNT_IBUS_N 28 OA3IN-/AN13/CMP1B/

I

BUS

dsPIC® DSC

9MCLR Reset Connects to a push button (SW4), ICSP™

23 OA3OUT/AN4/CMP3B/

®

DSC PIN FUNCTIONS

Pin #

dsPIC DSC Pin Function

DD

SS

DD

SS

PMD10/PMA10/RB0

PMA1/PMALH/PSA1/RB1

PMCS1/PSCS/RB5

IBIAS0/RA0

RB3

CMP1D/CMP2D/CMP3D/

RP34/SCL3/INT0/RB2

ISRC1/RP50/PMD13/

PMA13/RC2

ISRC0/RP49/PMA7/RC1

IBIAS3/RA4

dsPIC DSC

Peripheral

Supply +3.3V digital supply to dsPIC DSC

Oscillator with PLL Connects to crystal (X2) on the board

In-Circuit Serial

Programming™

(ICSP™) or

In-Circuit Debugger

Amplifier 1

(Op Amp #1) and

Dedicated ADC

Core #0

Amplifier 2

(Op Amp #2) and

Dedicated ADC

Core #1

Operational

Amplifier 3

(Op Amp #3) and

Shared ADC Core

Remarks

Digital ground

+3.3V analog supply to dsPIC DSC

Analog Ground

header (J10) and PKOB circuit

Connects to ICSP header (J10) and

PKOB programming/debugging tool

Differential current feedback from shunt

resistor Rsh1 connects to noninverting and

inverting inputs of Op Amp #1 through input

resistors

Op Amp #1 output, which is amplified Phase A

current. For the output to be available, configure and enable Op Amp #1, populate the

resistor R125 (0R) in the amplifier feedback

and remove R121 if populated

Differential current feedback from shunt

resistor Rsh2 connects to noninverting and

inverting inputs of Op Amp #2 through input

resistors

Op Amp #2 output, which is amplified Phase B

current. For the output to be available, configure and enable Op Amp #2, populate the

resistor R133 (0R) in the amplifier feedback

and remove R129 if populated

Differential current feedback from shunt

resistor Rsh4 connects to noninverting and

inverting inputs of Op Amp #3 through input

resistors

Op Amp #3 output, which is amplified bus

current. For the output to be available, configure and enable Op Amp #3, populate the

resistor R141 (0R) in the amplifier feedback

and remove R137 if populated

2020 Microchip Technology Inc. DS50002927A-page 25

Page 26

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

TABLE 2-14: dsPIC® DSC PIN FUNCTIONS (CONTINUED)

Signal

Amplified Currents from External Amplifiers: U5 and U15

IA_EXT 16 OA1OUT/AN0/CMP1A/

IB_EXT 41 OA2OUT/AN1/AN7/ANA0/

IBUS_EXT 23 OA3OUT/AN4/CMP3B/

Overcurrent Detection and Fault Output

IBUS_FILT_EXT 21 DACOUT1/AN3/CMP1C/RA3 High-Speed Analog

Voltage Feedbacks

V_BUS 33 AN15/CMP2A/IBIAS2/RP51/

V_A 30 AN17/ANN1/IBIAS1/RP54/

V_B 19 AN23/RE3 Shared ADC Core Phase B voltage feedback

V_C 17 AN22/RE2 Shared ADC Core Phase C voltage feedback

Temperature Feedbacks and Potentiometer (POT #1 – Speed Reference)

TEMP_LOCAL 15 AN12/ANN0/RP48/RC0 Shared ADC Core MOSFET die temperature sensed by

TEMP_EXT 58 TDO/AN2/CMP3A/RP39/

SPEED_

REFERENCE

Hall Sensor Feedbacks (Interfaced via Connector J7)

HALL_A 42 RE8 I/O Ports and

HALL_B 44 RE9

HALL_C 57 RE10

Quadrature Encoder Feedbacks (Interfaced via Connector J8)

QEI_A 5 RP60/PWM8H/PMD7/RC12 Remappable

QEI_B 6 RP61/PWM8L/PMA5/RC13

QEI_INDEX 7 RP62/PWM6H/PMA4/RC14

QEI_HOME 8 RP63/PWM6L/PMA3/RC15

Debug Interface (J6, J5 or PKOB)

DEBUG_RX 13 RP78/PCI21/RD14 Remappable

DEBUG_TX 14 ANN2/RP77/RD13

dsPIC® DSC

Pin #

61 PGC1/AN11/RP41/SDA1/RB9 Shared ADC Core Potentiometer (POT1) can be used for setting

dsPIC DSC Pin Function

IBIAS0/RA0

CMP1D/CMP2D/CMP3D/

RP34/SCL3/INT0/RB2

IBIAS3/RA4

PMD11/PMA11/RC3

PMD12/PMA12/RC6

SDA3/RB7

dsPIC DSC

Peripheral

Dedicated ADC

Core #0

Dedicated ADC

Core #1

Shared ADC Core Bus current amplified by the amplifier U15;

Comparator #1

(CMP #1) and

DAC #1

Shared ADC Core DC bus voltage feedback

Shared ADC Core Phase A voltage feedback

Shared ADC Core Feedback from external temperature sensor

Change

Notification (CN)

feature of I/O and

QEI

function of I/O and

UART

Phase Current A amplified by the amplifier

U5-A; when using this output, populate the

resistor R121 (0R), remove the resistor R125 if

populated and disable dsPIC DSC Operational

Amplifier #1

Phase Current B amplified by the amplifier

U5-B; when using this output, populate the

resistor R129 (0R), remove the resistor R133,

if populated and disable dsPIC DSC

Operational Amplifier #2

when using this output, populate the resistor

R137 (0R), remove the resistor R141, if populated and disable dsPIC DSC Operational

Amplifier #3

Amplified bus current is further filtered prior to

connecting to the positive input of the CMP #1

used for overcurrent detection. Overcurrent

threshold can be set through DAC. Comparator

output is internally available as Fault input of the

PWM Generators so that it can be used for

shutting down PWMs without CPU intervention.

MCP9700 (U14) can be used for thermal

protection

interfaced via connector J9

the speed reference in motor control application

Change Notification interrupt can be enabled

to identify the transitions of any of the Hall

sensor inputs

QEI module can be configured to read position

or speed information based on the encoder

signals as required by the motor control

application

These signals are connected to MCP2200

(U13), header J5 and PKOB; connect and

disconnect appropriate jumper resistors to

establish serial communication via any of

these channels

Remarks

DS50002927A-page 26 2020 Microchip Technology Inc.

Page 27

Board Interface Description

TABLE 2-14: dsPIC® DSC PIN FUNCTIONS (CONTINUED)

Signal

PWMs for Controlling Three-Phase Inverter (Q1 to Q6)

PWM_AH 1 RP46/PWM1H/PMD5/RB14 PWM Generator #1 Controls top MOSFET Q1 of the Inverter

PWM_AL 3 RP47/PWM1L/PMD6/RB15 Controls bottom MOSFET Q2 of the Inverter

PWM_BH 78 TDI/RP44/PWM2H/PMD3/

PWM_BL 80 RP45/PWM2L/PMD4/RB13 Controls bottom MOSFET Q4 of the Inverter

PWM_CH 73 RP65/PWM4H/RD1 PWM Generator #4 Controls top MOSFET Q5 of the Inverter

PWM_CL 74 RP64/PWM4L/PMD0/RD0 Controls bottom MOSFET Q6 of the Inverter

User Interface (LEDs, Push Buttons, General Purpose I/Os)

LED1 37 RE6 I/O Ports Connected to general purpose LED LD10

LED2 39 RE7 Connected to general purpose LED LD11

BUTTON1 59 RE11 Connected to push button SW1

BUTTON2 62 RE12 Connected to push button SW2

BUTTON3 64 RE13 Connected to push button SW3

TP11 22 RE4 Test point TP11 can be optionally used as a

TP12 24 RE5 Test point TP12 can be optionally used as a

TP13 79 RE15 Test point TP13 can be optionally used as a

Click Board™ Socket A Signals (J11)

CLICK_AN_A 4 AN21/RE1 Analog Channel or

CLICK_RST_A 77 RE14 GPIO

CLICK_CS_A 75 TMS/RP42/PWM3H/PMD1/

CLICK_SCK_A 27 RP76/RD12 Can be configured

CLICK_MISO_A 38 AN18/CMP3C/ISRC3/RP74/

CLICK_MOSI_A 36 AN19/CMP2C/RP75/PMA0/

CLICK_SDA_A 68 RP68/ASDA3/RD4 Alternate I

CLICK_SCL_A 69 RP67/ASCL3/RD3

CLICK_TX_A 40 AN16/ISRC2/RP55/PMD8/

CLICK_RX_A 52 RP71/PMD15/RD7

CLICK_INT_A 10 RP79/PCI22/PMA2/RD15 Can be configured

CLICK_PWM_A 76 TCK/RP43/PWM3L/PMD2/

dsPIC® DSC

Pin #

dsPIC DSC Pin Function

RB12

RB10

PMD9/PMA9/RD10

PMALL/PSA0/RD11

PMA8/RC7

RB11

dsPIC DSC

Peripheral

Phase A

Phase A

PWM Generator #2 Controls top MOSFET Q3 of the Inverter

GPIO

Remappable Pin or

PWM or GPIO

as SPI Input/

Output or Clock

through

Remappable

Feature

and Clock Pins of

2

I

C #3

Can be configured

as UART RX and

TX through

Remappable

Feature

as Interrupt Pin

through

Remappable

Feature

Can be configured

as SCCP Input or

Output or use PWM

Generator Output

2

C Data

Phase B

Phase B

Phase C

Phase C

general purpose input or output

general purpose input or output

general purpose input or output

Click Board socket is provided to extend the

feature by interfacing appropriated Click

Boards.

Pin feature requirement changes are based on

the Click Board inserted in the socket; the

signals are allocated as per the general

requirements.

Remarks

2020 Microchip Technology Inc. DS50002927A-page 27

Page 28

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

TABLE 2-14: dsPIC® DSC PIN FUNCTIONS (CONTINUED)

Signal

Click Board™ Socket B Signals (J12)

CLICK_AN_B 2 AN20/RE0 Analog Input or

CLICK_RST_B 72 RP66/RD2 Remappable Pin or

CLICK_CS_B 48 RP73/PCI20/RD9 Remappable Pin or

CLICK_SCK_B 46 RP56/ASDA1/SCK2/RC8 Dedicated SPI #2

CLICK_MISO_B 49 RP72/SDO2/PCI19/RD8

CLICK_MOSI_B 47 RP57/ASCL1/SDI2/RC9

CLICK_SDA_B 63 RP52/PWM5H/ASDA2/RC4 Alternate I

CLICK_SCL_B 65 RP53/PWM5L/ASCL2/

CLICK_TX_B 54 RP69/PMA15/PMCS2/RD5 Can be configured

CLICK_RX_B 53 RP70/PMD14/RD6

CLICK_INT_B 67 RP59/PWM7L/RC11 Can be configured

CLICK_PWM_B 66 RP58/PWM7H/PMRD/

dsPIC® DSC

Pin #

dsPIC DSC Pin Function

PMWR/PMENB/PSWR/RC5

PMWR/PSRD/RC10

dsPIC DSC

Peripheral

GPIO

GPIO

PWM or GPIO

Pins

2

and Clock Pins of

2

I

C #2

as UART RX and

TX through

Remappable

Feature

as Interrupt Pin

through

Remappable

Feature

Can be configured

as SCCP Input or

Output or use as

PWM Generator

Output

C Data

Remarks

Click Board socket is provided to extend the

feature by interfacing appropriated Click

Boards.

Pin feature requirement changes based on the

Click Board inserted in the socket; the signals

are allocated as per the Click Board signal

generic requirements.

DS50002927A-page 28 2020 Microchip Technology Inc.

Page 29

Chapter 3. Hardware Description

3.1 INTRODUCTION

This chapter provides a detailed description of the hardware features of the

dsPIC33CK Low-Voltage Motor Control Board. The Motor Control Board is intended to

demonstrate the capability of the dsPIC33CK family of single core Digital Signal

Controllers (DSCs) for motor control applications.

The motor control inverter on the Motor Control Board is controlled by the highest pin

count variant dsPIC33CK256MP508 device from the dsPIC33CK family. The Motor

Control Board incorporates a Hall sensor/Quadrature Encoder Interface (QEI), and

sensing circuits to measure DC voltage, phase voltages, bus current and phase

currents, etc. In addition, a USB-UART interface, mikroBUS™ sockets and a PICkit™

On-Board (PKOB) programmer/debugger circuit are provided.

The motor control inverter can be operated by using an input voltage in the range of

12V to 48V and can deliver a continuous output phase current of 10A (RMS) in the

specified operating range. For more information on electrical specifications, see

Appendix B. “Electrical Specifications”.

dsPIC33CK LOW-VOLTAGE

MOTOR CONTROL BOARD

USER’S GUIDE

3.2 HARDWARE SECTIONS

This chapter covers the following hardware sections of the dsPIC33CK Low-Voltage

Motor Control Board:

• dsPIC33CK256MP508 and Auxiliary Circuits

• Power Supply

• Three-Phase Inverter Bridge

• Current Sensing Circuits

• Voltage Sensing Circuit

• Hall Sensor/Quadrature Encoder Interface

• External Temperature Sensor Interface

• User Interface

• Debug Serial UART Interface

• mikroBUS™ Sockets

• Programmer/Debugger Interface

Figure 3-1 and Ta b le 3 -1 describe the hardware sections of the Motor Control Board.

2020 Microchip Technology Inc. DS50002927A-page 29

Page 30

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

1

11

9

8

10

4

4

1

8

4

4

3

6

7

2

5

FIGURE 3-1: HARDWARE SECTIONS

TABLE 3-1: HARDWARE SECTIONS

Section No. Hardware Sections

1 dsPIC33CK256MP508 and Auxiliary Circuits

2 Power Supply

3 Three-Phase Inverter Bridge

4 Current Sensing Circuits

5 Voltage Sensing Circuit

6 Hall Sensor/Quadrature Encoder Interface

7 External Temperature Sensor Interface

8 User Interface

9 Debug Serial UART Interface

10 mikroBUS™ Sockets

11 Programmer/Debugger Interface

DS50002927A-page 30 2020 Microchip Technology Inc.

Page 31

Hardware Description

3.2.1 dsPIC33CK256MP508 and Auxiliary Circuits

The dsPIC33CK Low-Voltage Motor Control Board features the dsPIC33CK256MP508

from Microchip’s dsPIC

®

DSC portfolio. dsPIC33C family devices implement a

100 MIPS high-performance dsPIC DSC core, and also integrate analog peripherals,

such as high-speed ADCs, op amps and analog comparators. The device also implements up to 16-channel, high-resolution Pulse-Width Modulators (PWMs) with built-in

Fault protection, triggering and synchronization features, which makes this dsPIC

device an ideal platform for the development of time-critical PMSM/BLDC motor control

applications.

The high-resolution PWM module in the dsPIC33C can generate, at specific instances,

multiple ADC triggers for measuring motor currents, phase voltages, inverter input voltage, total bus inverter current, etc. These feedbacks are required for implementing

motor control algorithms, such as sensor or sensorless Field-Oriented Control (FOC),

torque control, trapezoidal control, initial position detection, wind milling, flux

weakening and single-shunt current reconstruction. The PWM Control Input (PCI) of

the PWM module can be used for shutting down PWM outputs immediately when a

Fault is detected and synchronizing multiple PWM Generators (PGs) used for

controlling the three-phase inverter bridge.

The comparator module, along with the Digital-to-Analog Converter (DAC), can be

used for detecting overcurrent or overtemperature Faults to protect the inverter or

motor in case of malfunction. The dsPIC DSC has three operational amplifiers. These

can be configured by connecting an external input and feedback resistors for amplifying

currents sensed by shunt resistors.

The Change Notification (CN) feature of the I/O ports, along with the timer, can be used

for detection of Hall sensor state changes to obtain position and speed of the motor in

sensor-based BLDC motor control applications. Similarly, the Quadrature Encoder

Interface (QEI) in the dsPIC DSC can be configured to obtain the position/speed

information from the Quadrature Encoder feedbacks of the motor, which are required

for sensor-based Field-Oriented Control of PMSMs.

The dsPIC DSC also integrates several communication peripherals, such as CAN FD,

SENT, SPI, I

2

C and UART for communicating with the host PC, central controller or

master controller. Additionally, it features a Watchdog Timer, Deadman Timer, ECC

engine and BIST module required for safety-critical applications.

In the Motor Control Board, a provision is provided to mount an external crystal

oscillator to use its output as the dsPIC DSC clock input. Push button SW4 is tied to

the MCLR

pin of the device and is provided to reset the dsPIC DSC. One of the

program/debug pin pairs, PGC3/PGD3, of the dsPIC device is connected to the

programmer/debugger interfaces provided on the Motor Control Board, along with

MCLR

, to allow programming/debugging of the dsPIC33CK256MP508. Decoupling

capacitors are provided on all the power supply pins of the dsPIC DSC, including the

V

DD/GND and AVDD/AGND pairs.

2020 Microchip Technology Inc. DS50002927A-page 31

Page 32

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

DC-DC

Converter

(MIC28511)

DC-DC

Converter

(MCP16301)

+3.3V Output

LDO

(MCP1826)

+5V

Input Terminal

Input Jack

MIC4605 x 3

Half-Bridge MOSFET Drivers

VDC

J16

Jumper

NT1

Net Tie

AGND

3.2.2 Power Supply

The Motor Control Board can be powered through coaxial plug J1 or terminal connector

J2. Connector J1 can carry current up to 2.5A and connector J2 can handle up to 24A.

The board is designed to operate in the DC voltage range of 12-48V. DC link capacitors

are placed in parallel with the input to minimize the effects of voltage variation, depending on the load, and to reduce ripple currents generated by the motor control inverter

during switching. The power supply block diagram is shown in Figure 3-2.

The input DC supply connects to the motor control inverter and auxiliary power supply.

The auxiliary power supply section consists of two DC-DC converters and an LDO voltage regulator. The MIC28511 synchronous buck converter generates +12V output,

which powers the three half-bridge gate drivers used for driving the MOSFETs of the

three-phase inverter. The MCP16301 buck converter generates a +5V output, which is

provided to power the speed/position sensors interfaced via connectors, J7 and J8, and

the Click Boards™ interfaced via the mikroBUS™ sockets, J11 and J12. The fixed 3.3V

LDO MCP1826 generates +3.3V, which powers all logical circuits, including the

dsPIC33CK256MP508, operational amplifiers, mikroBUS sockets, USB to UART

converter, user interface elements, temperature sensors, speed/position sensors and

programmer/debugger Interfaces.

FIGURE 3-2: POWER SUPPLY BLOCK DIAGRAM

Three-Phase Inverter

Three-Phase Inverter Bridge

J2

Connector

+12V

+3.3 VA

+3.3V

Auxiliary Power Supply

PGND

+12V Output

+5V Output

J1

Connector

DGND

The 3.3V digital and analog supply, and ground connections are logically separated

using jumper resistors. In the Motor Control Board design documents, the digital

supply, digital ground, analog supply and analog ground are labeled as +3.3V, DGND,

+3.3 VA and AGND, respectively.

When required, the power to the inverter can be separated by cutting the trace between

net tie NT1. Then, the rest of the circuitry can be powered through the coaxial plug J1

and only the three-phase inverter powered through connector J2. The connection

between the net tie can be bridged back by populating jumper J16, restoring

connections between J1 and J2.

For additional details, refer to C.3 “Auxiliary Power Supply”, Section 2.2.1 “Power

Supply Connectors (J1, J2, J16)” and Figure A-1.

DS50002927A-page 32 2020 Microchip Technology Inc.

Page 33

Hardware Description

+3.3 VA

R117

10k

R119

2.49k

U10

DNP

R120

7.5k

C74

DNP

C75

0.1 µF

AGND AGND AGND

R114

1k

C70

1000 pF

U5D

-D

+D

OUTD

MCP6024

R118

20R

V

REF

TP17

C72

0.1 µF

V

REF

13

12

14

1

32

3.2.3 Three-Phase Inverter Bridge

The three-phase motor power stage is implemented using six N-channel MOSFETs,

configured as three half-bridges. A resistor is connected across the gate and source of

each MOSFET to ensure a soft turn-off of the MOSFET when the gate signal is

disconnected. Low-ESR ceramic capacitors are provided across each half-bridge for

filtering high-frequency noise. The output of the three-phase inverter bridge is available

on connector J14.

Three half-bridge gate drivers (3 x MIC4605) are used for driving the low-side and

high-side MOSFETs of the motor control inverter. The high-side driver is powered by the

bootstrap circuit. The bootstrap circuit consists of an internal diode and an external

capacitor connected across to the gate driver HS and HB pins. The input pull-down resistors are internal to the gate driver. The gate drivers are powered by a +12V supply. Even

though the HS pin is rated for negative voltage, a diode resistor clamp is provided to

clamp the negative voltage on the HS pin to prevent excessive negative voltage from

damaging the driver. Depending upon the application and amount of negative voltage on

the switch node, a different resistor and diode can be selected. For more information,

refer to the “MIC4605 Data Sheet” (DS20005853) at: www.microchip.com.

3.2.4 Current Sensing Circuits

3.2.4.1 VOLTAGE REFERENCE CIRCUIT

The Reference Voltage (V

REF) is generated on the Motor Control Board; it is half the

analog supply voltage (+3.3 VA), that is, approximately +1.65V. This is used for providing a DC voltage shift on the op amp output, allowing measurement of positive and

negative current swings as a single supply amplifier is used for current amplification.

The reference circuit (see Figure 3-3) is built around one of the MCP6024 op amps

(labeled as ‘D’). The resistors, R117, R119 and R120, form the voltage divider circuit

and generate a voltage equal to half of the analog voltage (+3.3 VA). The op amp, U5D

(MCP6024-D), is used as a buffer. The resistors, R114, R118 and C70, form a compensation circuit to drive capacitive loads, where C70 acts as a high-frequency feedback

path and R114 is used as a feedback path for low-frequency signals. The reference

voltage is connected to the inputs of the current sensing amplifiers providing DC bias

to amplifier outputs.

FIGURE 3-3: VOLTAGE REFERENCE CIRCUIT

2020 Microchip Technology Inc. DS50002927A-page 33

Page 34

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

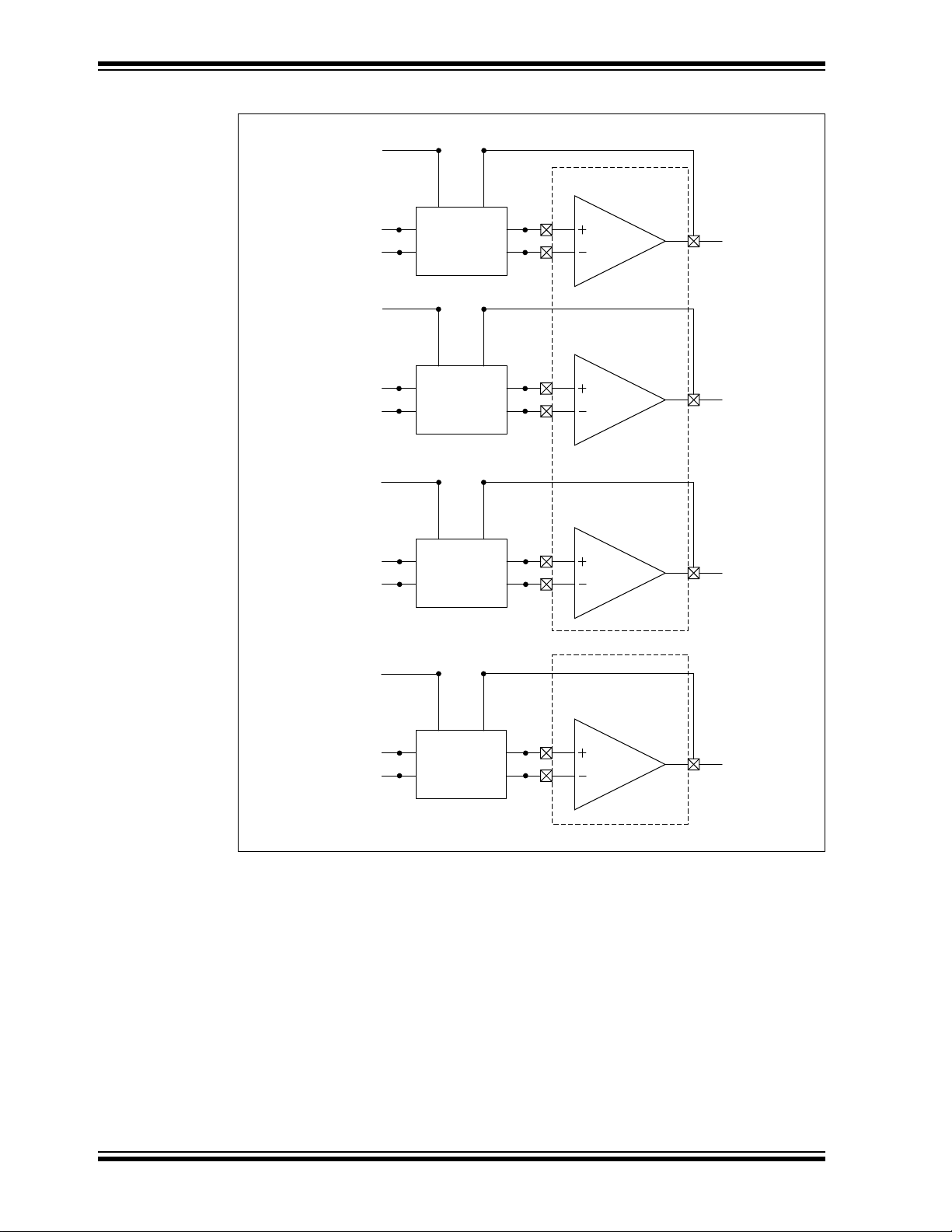

3.2.4.2 CURRENT AMPLIFIERS

Field-Oriented Control (FOC) of the PMSM/BLDC motor requires the motor phase

current information for implementation. In the Motor Control Board, shunt resistors,

Rsh1, Rsh2 and Rsh3, are provided in each inverter leg to measure the amount of

current flowing through the motor phases. An additional shunt resistor, Rsh4, is

provided for sensing the total bus current as this information is necessary for overcurrent protection and current control of BLDC motors. The DC bus current information

can also be used for reconstruction of motor phase currents by appropriately sampling

currents during the PWM switching period, which is called a single-shunt reconstruction

algorithm.

Noninverting differential amplifier configuration is used for amplifying the voltage drop

across the shunt resistors proportional to the currents flowing through three-phase

Inverter Phases A, B and C, and bus current, respectively. The output voltage of the

amplifiers is shifted by Voltage Reference (V

current swings. The Common-mode and Differential-mode filters are added between

the input pins of all the amplifiers for noise filtering. It is also possible to add filters at

the output of the external amplifiers, U5-A, U5-B, U5-C

and U15.

The block diagram in Figure 3-4 illustrates the interconnections between the external

amplifiers and the dsPIC DSC analog peripherals, including internal amplifiers,

comparator, ADC, etc. The Motor Control Board enables phase and bus current amplification through external amplifiers, U5 and U15, and dsPIC DSC internal amplifiers,

Op Amp 1 (OA1), Op Amp 2 (OA2) and Op Amp 3 (OA3). The op amps, OA1, OA2 and

OA3, that are internal to dsPIC33CK256MP508, are used for Phase A, Phase B and

bus current amplification. Three out of four amplifiers (U5-A, U5-B and U5-C) in the

quad amplifier, MCP6024, are configured to amplify current flowing through Inverter

Phases A, B and C. Amplified Phase C current (IC_EXT) is connected directly to an

analog input of the dsPIC DSC. The selection between internal and external amplifier

outputs is done via resistor jumpers (see Table 3-2) for Phase A, Phase B and the bus

currents when they are used as current feedbacks.

The op amp, MCP651S (U15), is added for DC bus current amplification. This amplifier

is configured to sense bus current. The U15 amplifier output is further filtered

(IBUS_FILT_EXT) and is connected to the internal Comparator 1 positive input

(CMP1C). The Comparator 1 negative input is configured to use the internal DAC output to set the overcurrent threshold. The Comparator 1 output (CMP1) generates an

active-high output when overcurrent is detected. This comparator output is available to

the PWM Generators of the high-resolution PWM module as a Fault input. If the Fault

is enabled in the PWM Generators, and CMP1 is selected as an active-high Fault

source during an overcurrent Fault condition, the motor control PWMs will be disabled,

thus protecting the MOSFETs.

REF) +1.65V to allow positive and negative

DS50002927A-page 34 2020 Microchip Technology Inc.

Page 35

Hardware Description

TABLE 3-2: SELECTION BETWEEN EXTERNAL AND INTERNAL AMPLIFIER OUTPUTS

Jumper Resistor Settings

Current

Signal

Amplified Phase A

Currents

IA or IA_EXT

Amplified Phase B

Currents

IB or IB_EXT

Amplified Phase C

Currents

IC_EXT

Amplified Bus

Currents

IBUS or

IBUS_EXT

Populate Remove Populate Remove

R125 R121 R121 R125 In internal amplifier configuration,

configure and enable Op Amp 1 (OA1).

In external amplifier configuration,

ensure internal amplifier Op Amp 1

(OA1) is disabled.

R133 R129 R129 R133 In internal amplifier configuration,

configure and enable Op Amp 2 (OA2).

In external amplifier configuration,

ensure internal amplifier Op Amp 2

(OA2) is disabled.

Not Applicable Phase C current is amplified only by

external amplifier U5-C and its output

(IC_EXT) is connected directly to an

analog input of the dsPIC

R141 R137 R137 R141 In internal amplifier configuration,

configure and enable Op Amp 3 (OA3).

In external amplifier configuration,

ensure internal amplifier Op Amp 3

(OA3) is disabled.

RemarksInternal Amplifier Output External Amplifier Output

®

DSC.

The gain of the amplifier used for phase current and bus current sensing is set for

sensing 22A peak current by default. The gain of the amplifier can be changed, as

required by the application, by modifying the amplifier input and feedback resistors.

For more information, refer to C.2 “Current Amplifier Circuits”.

2020 Microchip Technology Inc. DS50002927A-page 35

Page 36

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

PGND

Three-Phase Inverter Bridge

)

)

)

REF

REF

REF

REF

REF

REF

REF

DAC

REF

AGND

T

IB

0R

R125

IA

0R

R133

0R

R141

R137

I

BUS

Note 1: This is a representational diagram only; for detailed schematics, refer to Appendix A. “Schematics

and Layout”.

FIGURE 3-4: CURRENT SENSE CONFIGURATION

Phase A Current (-)

Phase A Current (+)

Phase B Current (-)

Phase B Current (+)

Phase C Current (-)

Phase C Current (+)

+1.65V (+3.3VA/2)

Phase A Current (+)

Phase A Current (-

V

(+1.65V)

V

(+1.65V)

V

(+1.65V)

V

(+1.65V)

Rsh1 (0.010ȍ)

Phase B Current (+)

Rsh1 (0.010ȍ)

Phase B Current (-

Bus Current (+)

Rsh1 (0.010ȍ)

Bus Current (-)

MCP6024

-

U5A

+

-

U5B

+

-

U5C

+

IA_EX

Phase A Current (-)

Phase A Current (+)

V

IB_EXT

Phase B Current (-)

Phase B Current (+)

V

IC_EXT

IBUS_EXT

Bus Current (-)

Bus Current (+)

V

-

U5D

+

(1)

VDC

Phase C Current (+)

Phase C Current (-)

(+1.65V)

(+1.65V)

(+1.65V)

Rsh1 (0.010ȍ

R121

DNP

R129

DNP

DNP

dsPIC33CK256MP508

-

OA1

+

-

OA2

+

ADC

-

OA3

+

HRPWM

PG1

PG2

PG4

Fault PCI I/P

Bus Current (-)

Bus Current (+)

V

(+1.65V)

DS50002927A-page 36 2020 Microchip Technology Inc.

MCP651S

-

U15

+

R108

IBUS_FILT_EXT

C66

-

CMP1

+

Page 37

3.2.5 Voltage Sensing Circuit

VBUS

301R

R83

V_BUS

DC Bus Voltage

VDC

3.3k

R87

0.1 μF

C52

V_A

V_B

PHASE_A

PHASE_B

V_C

PHASE_C

3.3k

R86

VB

301R

R82

3.3k

R84

VC

301R

R80

VA

301R

R81

3.3k

R85

1

2

3

BAS40-04

D6

1

2

3

BAS40-04

D5

1

2

3

BAS40-04

D4

1

2

3

BAS40-04

D7

AGND AGND AGND AGND

AGND

AGND

AGNDAGND

34k

R76

34k

R73

34k

R74

34k

R77

34k

R69

34k

R68

34k

R67

34k

R70

+3.3VA +3.3 VA

+3.3 VA

+3.3 VA

1000 pF

C51

1000 pF

C49

1000 pF

C50

A voltage sensing network is provided to scale down the DC supply voltage powering

the inverter to connect it to an analog channel of the dsPIC DSC for voltage measurement. The voltage divider network, formed by resistors, R69, R77 and R87, divides the

DC input voltage (V

DC input voltage (V_BUS) is connected to the analog input pin of the dsPIC DSC for

measurement.

FIGURE 3-5: VOLTAGE SENSING CIRCUIT

The Motor Control Board can also be to used to run BLDC motors with a trapezoidal

commutation scheme by monitoring back-EMF signals. For such an application, the

motor back-EMF is scaled down by voltage dividers before they are applied to the

analog channels of the dsPIC DSC. The filter capacitors are provided to filter the noise.

The voltage divider network divides phase voltages (PHASE_A, PHASE_B and

PHASE_C) at a voltage scaling ratio of 1:21.6 (see Figure 3-5). The scaled back-EMF

signals (V_A, V_B and V_C) are connected to analog input pins of the dsPIC DSC.

In case of any voltage transients, kickbacks or resistor failures, the clamping diodes are

provided at the scaled voltage outputs to ensure the voltages at the analog inputs do

not exceed the voltage limits of the dsPIC DSC inputs.

DC) at a voltage scaling ratio of 1:21.6 (see Figure 3-5). The scaled

Hardware Description

3.2.6 Hall Sensor/Quadrature Encoder Interface

The Motor Control Board can also be used to run PMSM/BLDC motor control

applications using the Hall sensor/Quadrature Encoder to determine rotor position and

speed. The connectors, J7and J8, are provided to interface Hall sensor feedback and

encoder feedback, respectively, with the Motor Control Board. The Hall sensor and

Quadrature Encoder Interface circuit supports either open-collector or push-pull

output sensors.

The Hall sensors and Quadrature Encoder can be powered by the +5V supply or +3.3V

supply available through the interface connector terminals. A capacitor is added to

each signal output to reduce the noise. The voltage divider can be configured to scale

down the sensor signal, from a +5V level to a +3.3V level, when push-pull output

sensors are powered by a +5V supply. For circuit details, refer to Figure A-6 in

Appendix A. “Schematics and Layout”.

The connector J7 and J8 pinouts are summarized in Section 2.2.4 “Hall Sensor

Interface Connector (J7)” and Section 2.2.5 “Quadrature Encoder Interface

Connector (J8)”.

2020 Microchip Technology Inc. DS50002927A-page 37

Page 38

dsPIC33CK Low-Voltage Motor Control Board User’s Guide

AGND

DNP

R98

AGND

TEMP_EXT

DNP

R93

DNP

C57

1

2

DNP

J9

+3.3 VA

TEMP_EXT

TP21

3.2.7 External Temperature Sensor Interface

The Motor Control Board provides an optional external temperature sensor interface

circuit. This circuit can be used to interface a thermistor for measuring motor winding

temperature, etc. As shown in Figure 3-6, the temperature sensor and resistor R98

form a +3.3V analog supply voltage divider, setting the voltage proportional to the

temperature at the analog input of the dsPIC DSC. To reduce the noise, temperature

feedback can be further filtered by the RC filter, R93 and C57. This circuit is not

populated by default. When used, populate the connector J9 with

Part Number B2B-EH-A(LF)(SN) or similar, and components, R98, R93 and C57,

appropriately.

FIGURE 3-6: EXTERNAL TEMPERATURE INTERFACE CIRCUIT

3.2.8 User Interface