Page 1

ATWINC/ATWILC/ATSAMB/

ATBTLC

MCHPRT2 User Guide

Introduction

This document provides detailed information about the MCHPRT2 tool, which allows the user to easily

configure, evaluate and test an RF system. This tool simplifies the effort during the early stage of

development, regulatory certification and production testing. The MCHPRT2 tool with v1.0 is used for this

demonstration. MCHPRT2 is a Windows®-based software program.

Note: The ATWINC, ATWILC, ATBTLC, and ATSAMB denotes the following:

• ATWINC15x0

• ATWINC3400

• ATWILC1000

• ATWILC3000

• ATBTLC1000

• ATSAMB11

Features

The MCHPRT2 tool includes the following functions for the ATWINC/ATWILC and ATBTLC/ATSAMB

devices:

• Flexible Graphical User Interface (GUI) configuration Options

• Inbuilt Command Line Interpreter (CLI)

• Wi-Fi® RF Performance Evaluation

• Bluetooth® Low Energy (BLE) RF Performance Evaluation

• Continuous Wave (CW) Transmitter

• RF Frequency Offset Calibration

• e-Fuse Programming

• Register Read/Write

• Register Range Dump

• Received Signal Strength Indicator (RSSI) Reading

• Firmware (FW) Upgrade

• Gain Table Update

• Webpage Upgrade

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 1

Page 2

ATWINC/ATWILC/ATSAMB/ATBTLC

Table of Contents

Introduction......................................................................................................................1

Features.......................................................................................................................... 1

1. Prerequisite............................................................................................................... 4

1.1. Hardware Prerequisites................................................................................................................4

1.2. Software Prerequisite................................................................................................................... 5

1.3. UART/I2C Pin Details .................................................................................................................. 7

1.4. Power-Up/Down Sequence.......................................................................................................... 7

1.5. Hardware Setup......................................................................................................................... 10

2. Graphical User Interface..........................................................................................13

2.1. Wi-Fi........................................................................................................................................... 13

2.2. Bluetooth Low Energy (ATWILC3000/ATWINC3400).................................................................22

2.3. Temperature Calibration Calculator............................................................................................27

2.4. Bluetooth Low Energy (ATBTLC/ATSAMB)................................................................................27

2.5. Register......................................................................................................................................32

2.6. eFuse......................................................................................................................................... 34

2.7. Firmware Upgrade......................................................................................................................36

3. Command Line........................................................................................................ 39

3.1. Wi-Fi........................................................................................................................................... 39

3.2. Bluetooth (ATWILC3000/ATWINC3400).....................................................................................54

3.3. BLE (ATBTLC1000/ATSAMB11)................................................................................................ 65

3.4. HCI Command............................................................................................................................73

3.5. Register......................................................................................................................................76

3.6. eFuse (ATWINC/ATWILC)..........................................................................................................81

3.7. efuse ATBTLC/ATSAMB.............................................................................................................87

3.8. Firmware Upgrade......................................................................................................................89

4. Appendix A - Python® Example...............................................................................96

4.1. Example..................................................................................................................................... 96

5. Appendix B - HCI Command Tools..........................................................................98

5.1. HCI Initialization......................................................................................................................... 98

5.2. HCI Command............................................................................................................................99

5.3. UART Initialization....................................................................................................................102

5.4. Serial Port.................................................................................................................................103

6. Appendix C - Firmware Update............................................................................. 108

6.1. Firmware Update......................................................................................................................108

7. Appendix D - Erase and Program ATSAMB11.......................................................113

8. Appendix E - eFuse and MAC Address ................................................................114

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 2

Page 3

ATWINC/ATWILC/ATSAMB/ATBTLC

9. Revision History.....................................................................................................116

The Microchip Website................................................................................................ 117

Product Change Notification Service........................................................................... 117

Customer Support........................................................................................................117

Microchip Devices Code Protection Feature............................................................... 117

Legal Notice.................................................................................................................118

Trademarks..................................................................................................................118

Quality Management System.......................................................................................119

Worldwide Sales and Service......................................................................................120

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 3

Page 4

1. Prerequisite

This chapter provides the hardware and software prerequisites for using MCHPRT2 tool with the

ATWINC/ATWILC series and ATBTLC/ATSAMB series.

1.1 Hardware Prerequisites

This section provides the hardware tools that are required to test the RF system. ATWINC/ATWILC is

connected to the GUI using Aardvark™ or serial bridge. SAM-ICE™ is used to connect ATBTLC/ATSAMB

to GUI.

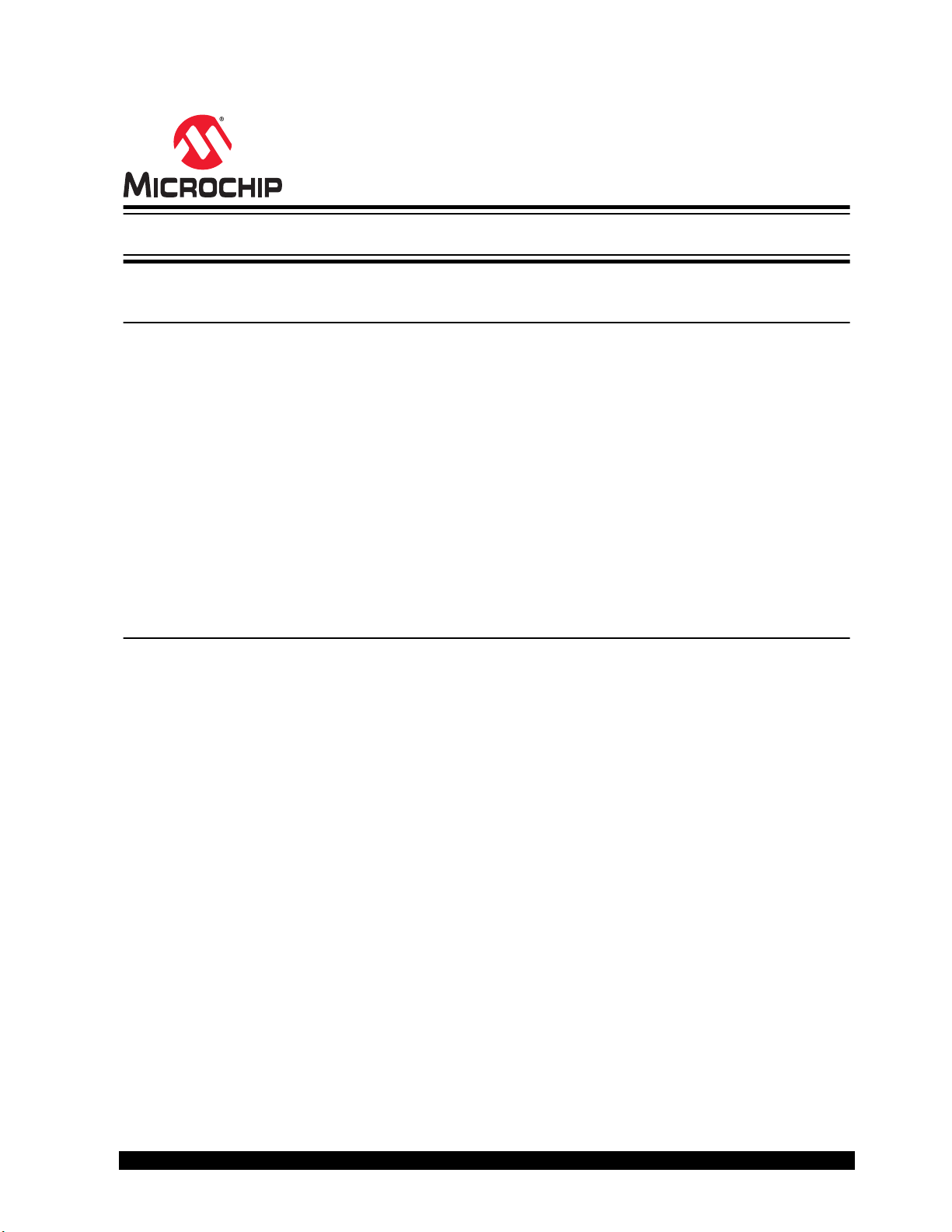

1.1.1 Aadvark I2C Host Adapter

Aardvark I2C/HCI Host adapter is used to interface PC via USB to I2C pins of ATWINC/ATWILC. The

same is shown in the following figure. For more information, refer to http://www.totalphase.com/products/

aardvark-i2cspi/.

Figure 1-1. Aardvark I2C/HCI Host Adapter

ATWINC/ATWILC/ATSAMB/ATBTLC

Prerequisite

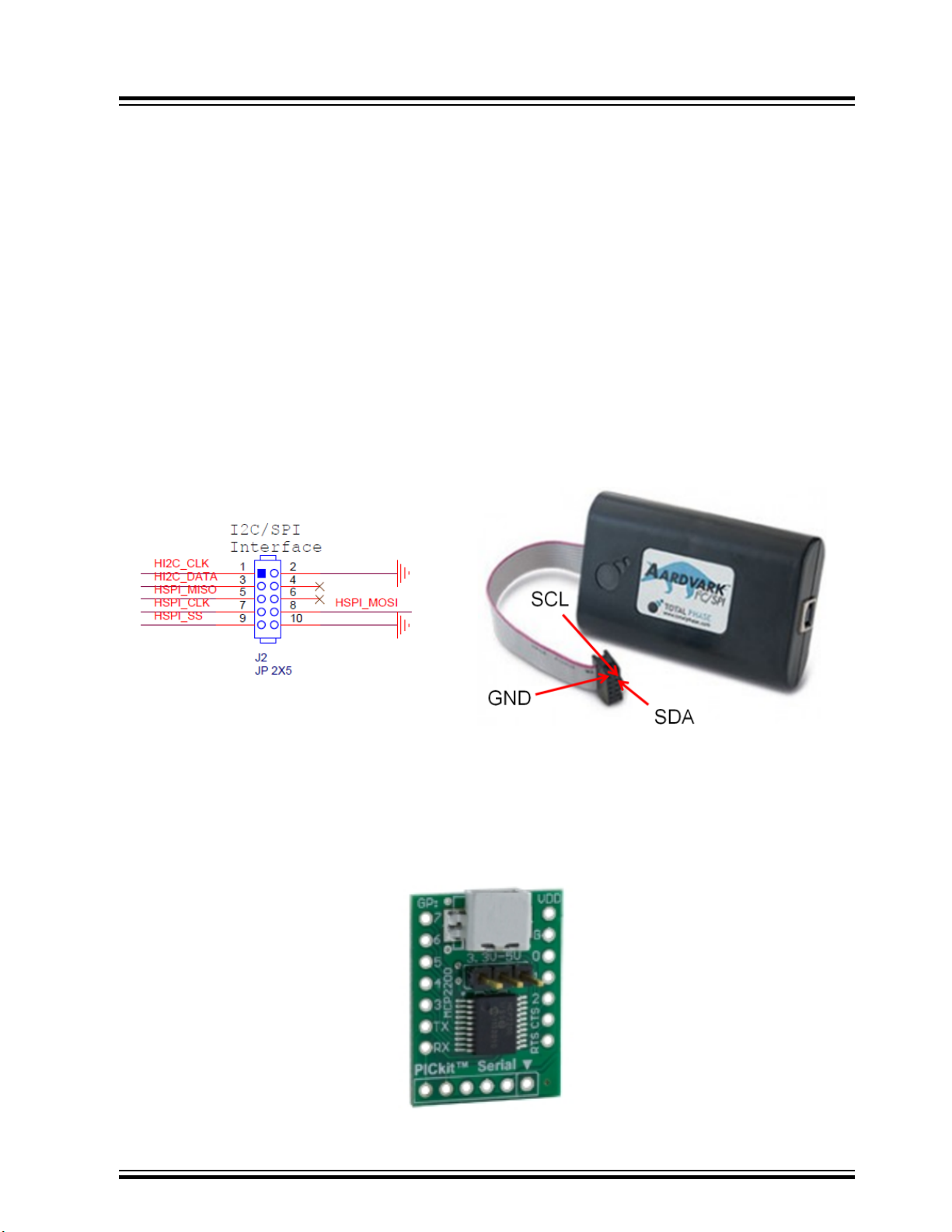

1.1.2 USB - UART Converter

This USB-UART converter (MCP2200) Breakout Module) will be used to interface PC to the UART DTM

interface of ATWINC3XXX, ATBTLC1000 and ATSAMB11 devices. Any generic USB-UART converter can

also be used.

Figure 1-2. USB - UART Converter

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 4

Page 5

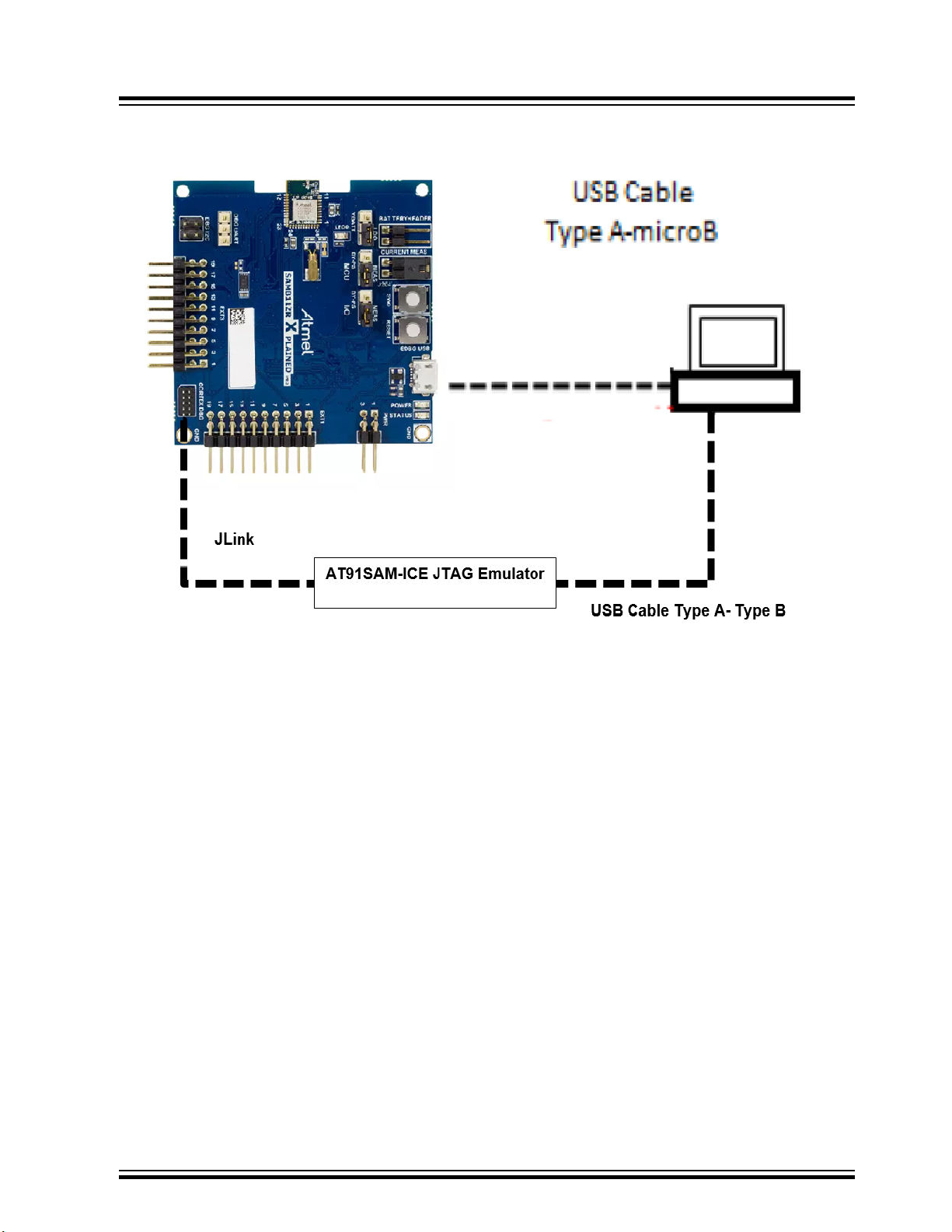

1.1.3 JTAG Emulator

The AT91SAM-ICE is a JTAG emulator designed for ARM® core based MCUs and MPUs. It is used to

program test firmware. For more information, refer to http://www.microchip.com/DevelopmentTools/

ProductDetails.aspx?PartNO=at91sam-ice

Figure 1-3. AT91SAM-ICE JTAG Emulator

ATWINC/ATWILC/ATSAMB/ATBTLC

Prerequisite

1.2 Software Prerequisite

1.2.1 Serial Bridge Connection (ATWILC/ATWINC)

MCHPRT2 GUI can be operated without the Aadvark tool with the help of serial bridge application from

Atmel Studio. In the GUI, instead of I2C select UART. Enter the valid Com port, baud rate and click Init to

start evaluating the RF test system. For more information, see the Serial Bridge Application Note.

1.2.2 MCHPRT2 GUI Tool

The MCHPRT2 tool allows the user to easily configure, evaluate and test an RF system. It simplifies the

effort during the early stage of development. The later sections have a detailed explanation on how the

tool is used to test the RF system.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 5

Page 6

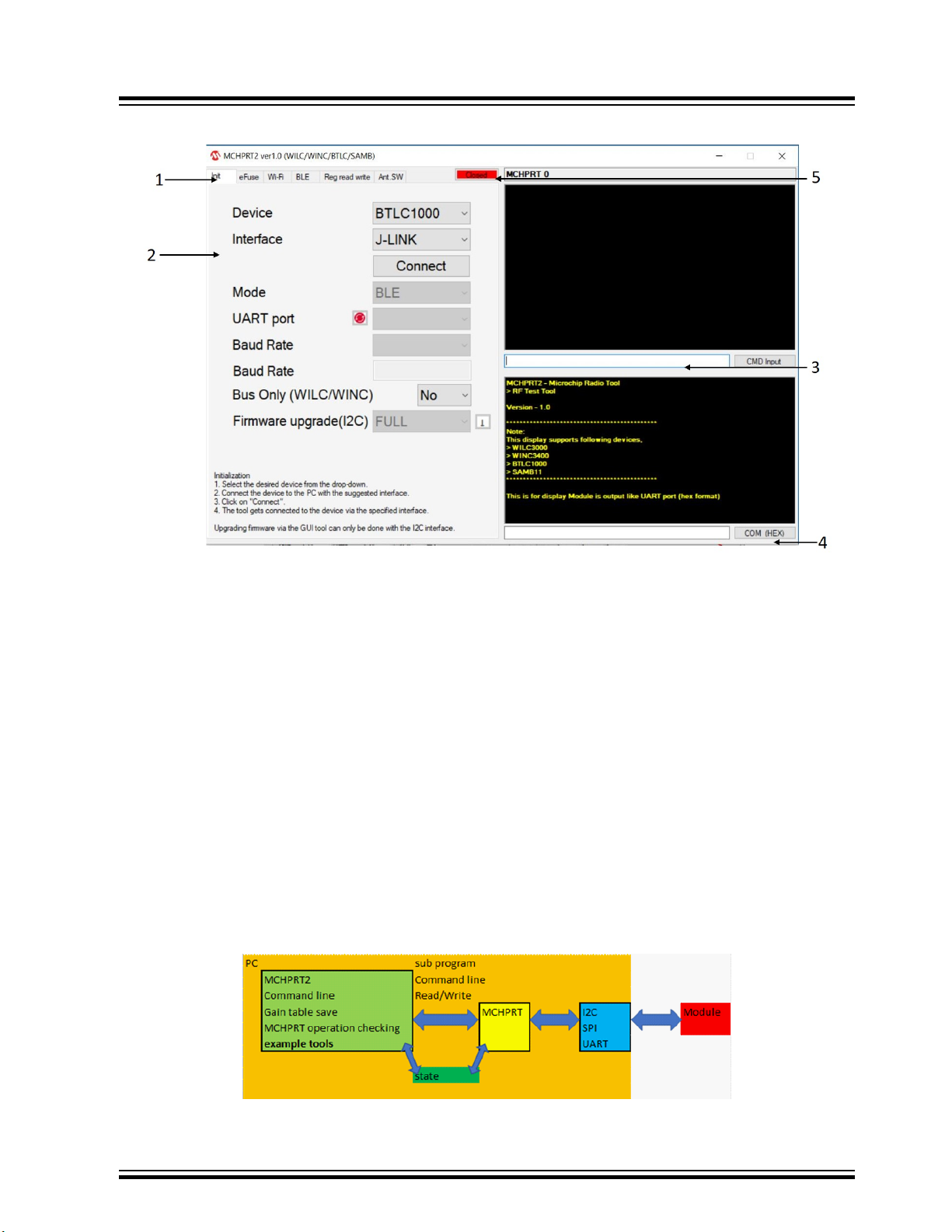

Figure 1-4. MCHPRT2 GUI Tool

ATWINC/ATWILC/ATSAMB/ATBTLC

Prerequisite

1. Click the tab for Initialization, eFuse, Wi-Fi, BLE or Register read and write option.

2. It is a function block for the selected tab.

3. CMD command line block.

4. Com port block.

5. Device connectivity status:

– Close: Sub process "MCHPRT" is close.

– Ready: "MCHPRT" is waiting for the command.

– Processing: "MCHPRT" is running.

1.2.2.1 MCHPRT2 Software Architecture

MCHPRT2 is a C# program using MCHPRT command line function for RF test or automation test

example. The following link has an example of process function to open, send and receive the command.

https://docs.microsoft.com/en-us/dotnet/api/system.diagnostics.process?

redirectedfrom=MSDN&view=netframework-4.7.2.

The following is the architecture of MCHPRT2.

Figure 1-5. MCHPRT2

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 6

Page 7

For MCHPRT2 source code contact Microchip sales.

1.3 UART/I2C Pin Details

Connect the UART or I2C to PC, and power on the ATWINC/ATWILC/ATBTLC/ATSAMB. Ensure that

ATWINC/ATWILC/ATBTLC/ATSAMB is in the right test mode with the correct pins.

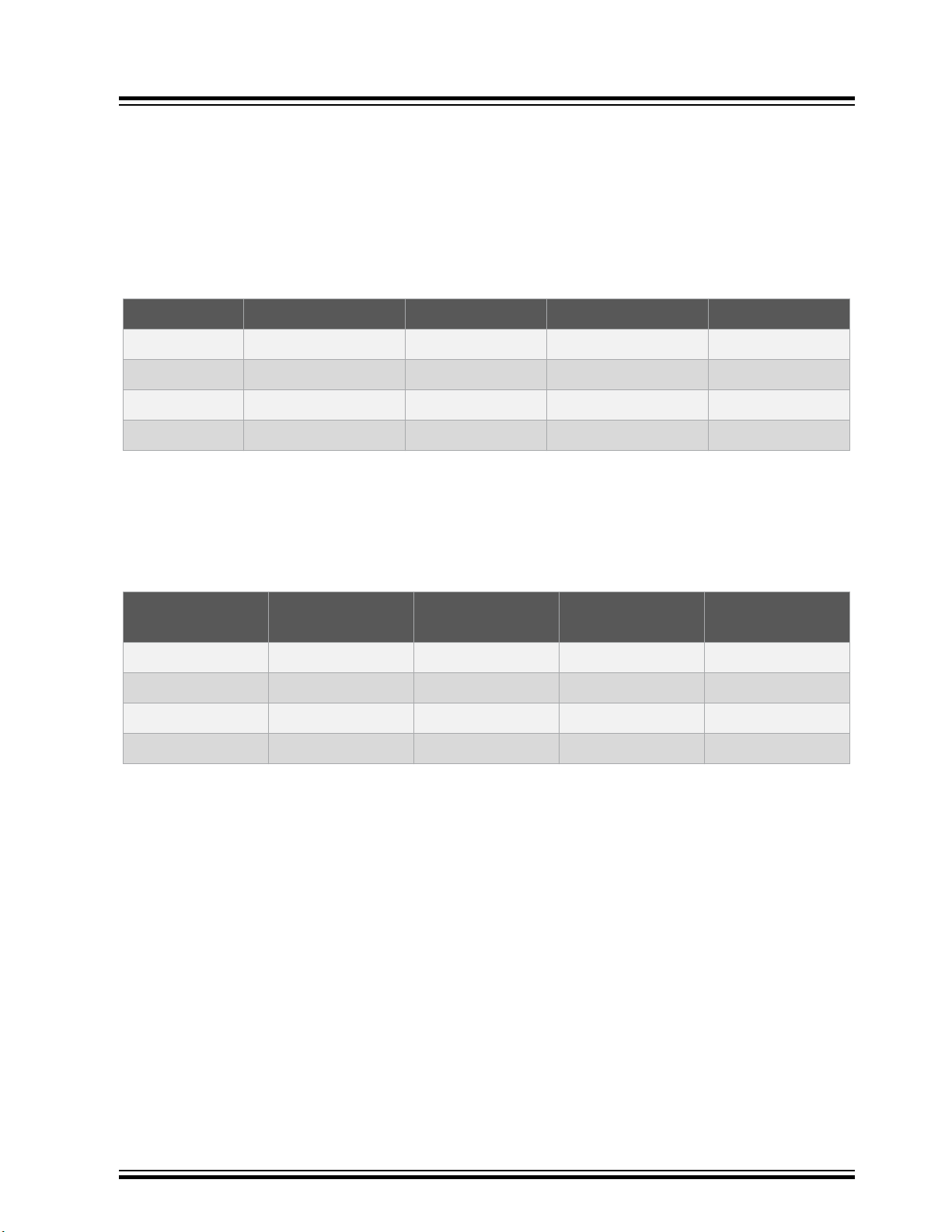

The following table provides the I2C connection for ATWINC/ATWILC 1XXX and 3XXX series.

Table 1-1. I2C Connection

Connections 1XXX Module series 1XXX Chip series 3XXX Module series 3XXX Chip series

I2C Slave Data Pin 3 Pin 33 Pin 10 Pin 16

I2C Slave clock Pin 2 Pin 32 Pin 11 Pin 17

BT_TXD NA NA Pin 8 Pin 14

BT_RXD NA NA Pin 9 Pin 15

Connect the J-Link and power on the ATBTLC/ATSAMB-ZR series. Connect the BT_TXD and BT_RXD

lines to the UART input pins of an USB-UART converter.

ATWINC/ATWILC/ATSAMB/ATBTLC

Prerequisite

The following table provides the J-Link connection for ATBTLC/ATSAMB series. Pin 41-49 is ground

exposed paddle; it must be soldered to system ground.

Table 1-2. J-Link Connection

Connections ATBTLC ZR

Module series

SWCLK Pin 12 Pin 35 Pin 12 Pin 35

SWDIO Pin 13 Pin 36 Pin 13 Pin 36

BT_TXD Pin 15 Pin 38 Pin 15 Pin 38

BT_RXD Pin 14 Pin 37 Pin 14 Pin 37

Note: MCHPRT/MCHPRT2/HCI_Command tools have DTR enable or disable function on UART.

For example:

SAMB11 Xpro board serial port setting is different, which only supports the following conditions:

serialport.DtrEnable = true;

serialport.Handshake = Handshake.RequestToSend;

serialport.RtsEnable = true;

In MCHPRT/MCHPRT2/hci_command tools DTR must be enabled.

ATBTLC ZR Chip

series

ATSAMB ZR

Module series

ATSAMB ZR Chip

series

1.4 Power-Up/Down Sequence

This section provides the power-up/down sequence for ATWINC/ATWILC/ATSAMB/ATBTLC.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 7

Page 8

ATWINC/ATWILC/ATSAMB/ATBTLC

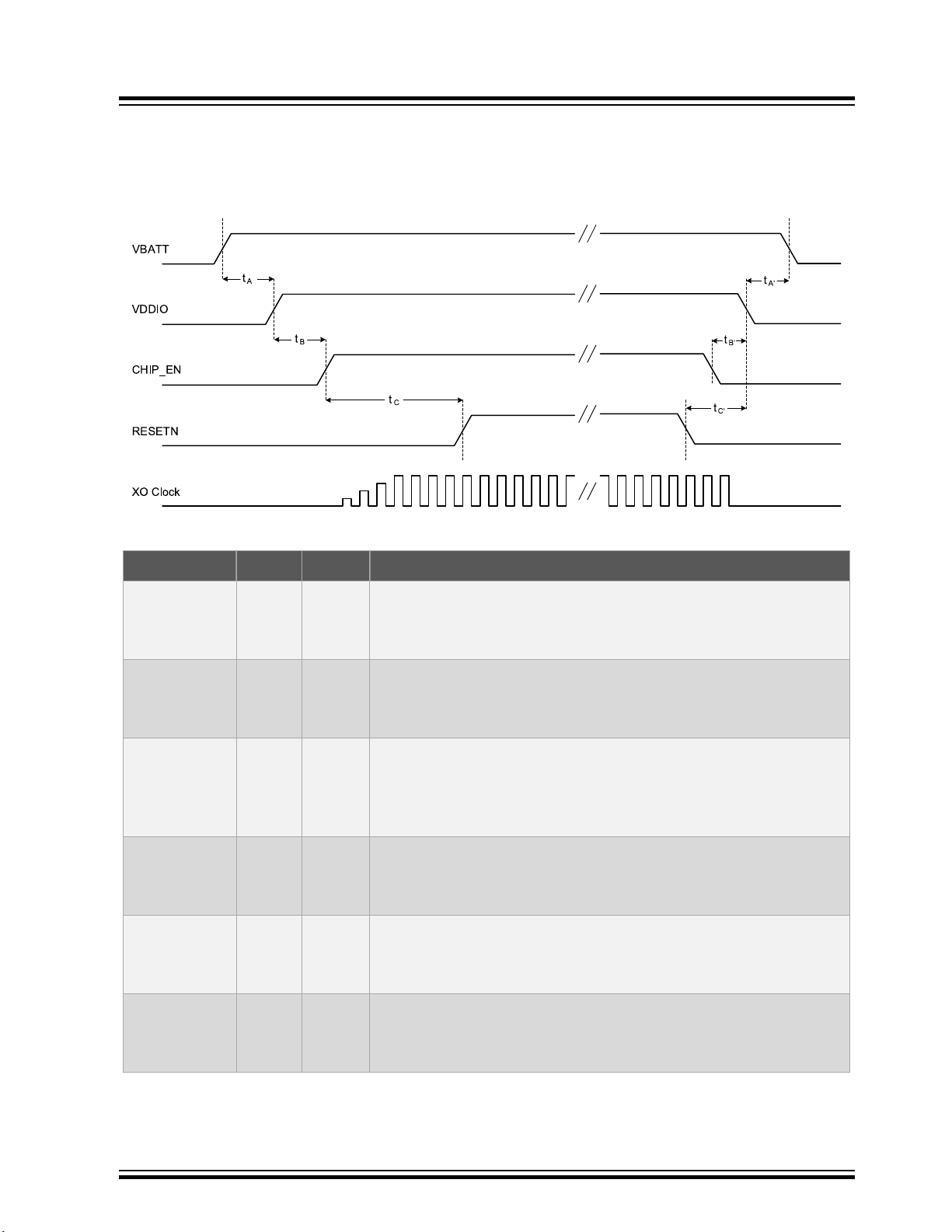

1.4.1 Power-up/down Sequence (ATWINC/ATWILC)

The power-up/down sequence for ATWINC/ATWILC is shown in the following figure. The timing

parameters are provided in following the table.

Figure 1-6. Power-up/down Sequence (ATWINC/ATWILC)

Prerequisite

Table 1-3. Power-up/down Sequence Timing Parameters

Parameter Min. Units Description

• VBATT rise to VDDIO rise

t

A

0 ms

• VBATT and VDDIO can rise simultaneously or can be tied

together. VDDIO must not rise before VBATT.

• VDDIO rise to CHIP_EN rise

t

B

0 ms

• CHIP_EN must not rise before VDDIO. CHIP_EN must be

driven high or low, not left floating.

• CHIP_EN rise to RESETN rise

t

C

5 ms

• This delay is needed because the XO clock must stabilize

before RESETN removal. RESETN must be driven high or low,

not left floating.

• VDDIO fall to VBATT fall

t

A’

0 ms

• VBATT and VDDIO can fall simultaneously or can be tied

together. VBATT must not fall before VDDIO.

• CHIP_EN fall to VDDIO fall

t

B’

0 ms

• VDDIO must not fall before CHIP_EN. CHIP_EN and RESETN

can fall simultaneously.

t

C’

© 2019 Microchip Technology Inc.

0 ms

• RESETN fall to VDDIO fall

• VDDIO must not fall before RESETN. RESETN and CHIP_EN

can fall simultaneously.

User Guide

DS50002893A-page 8

Page 9

ATWINC/ATWILC/ATSAMB/ATBTLC

It is mandatory that the ATWINC/ATWILC chip is in the right bootloader state for establishing connection

from GUI through I2C. To do that, the host MCU must power-up the ATWINC/ATWILC chip and then

perform the reset sequence as defined in the figure Power-up/down Sequence (ATWINC/ATWILC). This

is done very easily from the host MCU by calling the nm_bsp_init() and nm_bsp_reset() function. The

code snippet for the same is as shown below,

int main(void)

{/* Initialize the board. */

system_init();

/* Initialize the BSP. */

nm_bsp_init();

nm_bsp_reset();

while(1) {

}

}

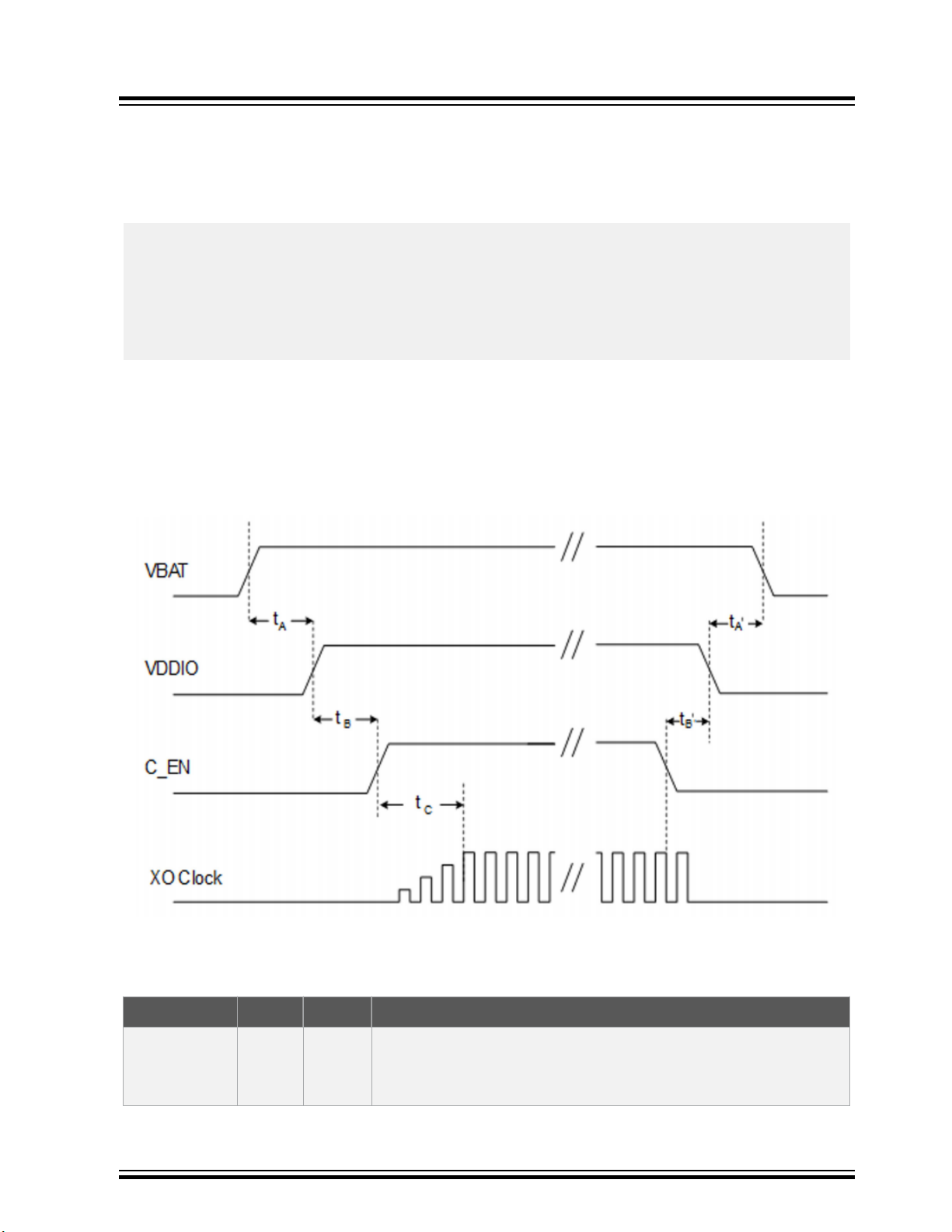

1.4.2 Power-up/down Sequence (ATBTLC/ATSAMB)

The power-up/down sequence for ATBTLC/ATSAMB is shown in the following figure. The timing

parameters are provided in following the table. For SAMB11, ensure that the steps referred in Appendix

A5 Erase and Program SAMB11 are followed before establishing connection with MCHPRT2 GUI.

Figure 1-7. Power-up/down Sequence (ATBTLC/ATSAMB)

Prerequisite

Note: Pull the A0_GPIO_0 (Wake Up pin) High during the test.

Table 1-4. Power-up/down Sequence Timing Parameters

Parameter Min. Units Description

• VBAT rise to VDDIO rise

t

A

0 ms

• VBAT and VDDIO can rise simultaneously or can be tied

together.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 9

Page 10

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Parameter Min. Units Description

• VDDIO rise to C_EN rise

t

B

0 ms

• C_EN must not rise before VDDIO. C_EN must be driven high

or low, not left floating.

Prerequisite

t

C

t

A’

t

B’

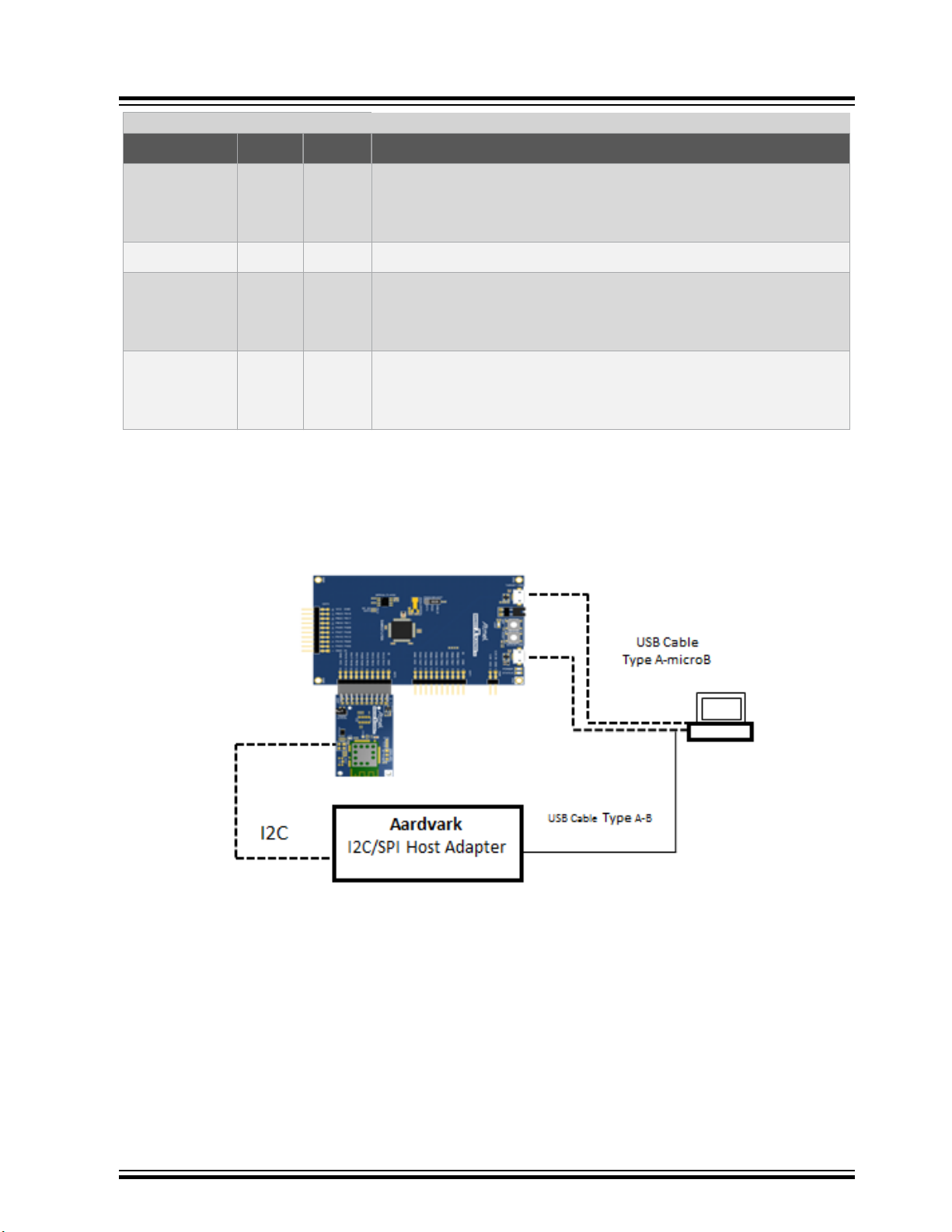

1.5 Hardware Setup

The following figures illustrate the block diagram of the test setup using ATWINC.

Figure 1-8. ATWINC1500 Hardware Setup

10 ms C_EN rise to 31.25 kHz (2 MHz/64) oscillator stabilizing

• VDDIO fall to VBAT fall

0 ms

• VBAT and VDDIO can fall simultaneously or can be tied

together.

• C_EN fall to VDDIO fall

0 ms

• C_EN must fall before VDDIO. C_EN must be driven high or

low, not left floating.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 10

Page 11

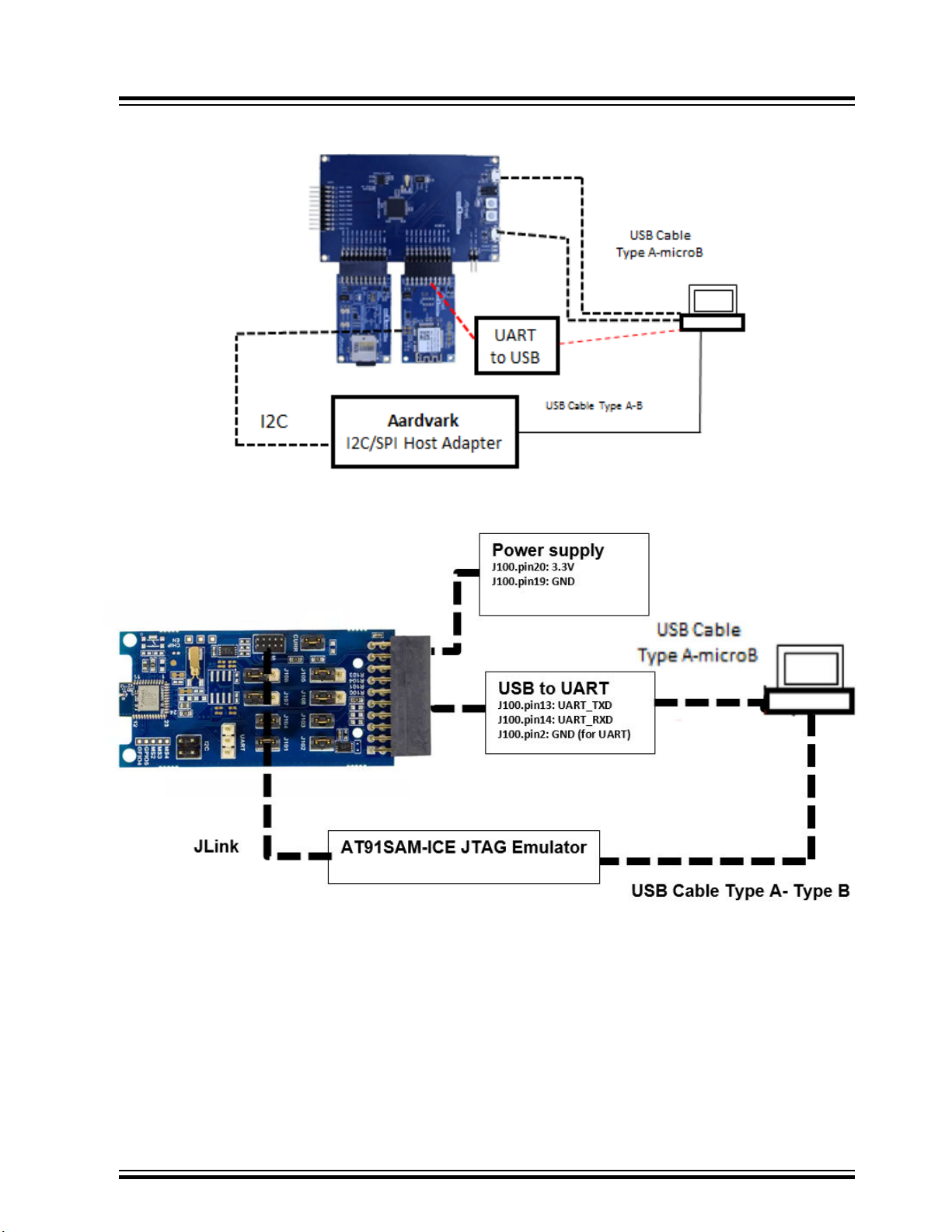

Figure 1-9. ATWINC3400 Hardware Setup

ATWINC/ATWILC/ATSAMB/ATBTLC

Prerequisite

Figure 1-10. ATBTLC Hardware Setup

Note: AO_GPIO_0 and CHIP_EN pins to be pulled to logic HIGH as per the Power-up/down Sequence.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 11

Page 12

Figure 1-11. ATSAMB Hardware Setup

ATWINC/ATWILC/ATSAMB/ATBTLC

Prerequisite

Note: AO_GPIO_0 and CHIP_EN pins to be pulled to logic HIGH as per the Power-up/down Sequence.

Prior to connecting to the GUI, follow the steps mentioned in 7. Appendix D - Erase and Program

ATSAMB11.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 12

Page 13

2. Graphical User Interface

This chapter provides the steps to follow to put the device in Wi-Fi and Bluetooth test mode, and set

registers, eFuse bits and perform firmware upgrade using the MCHPRT2 tool.

2.1 Wi-Fi

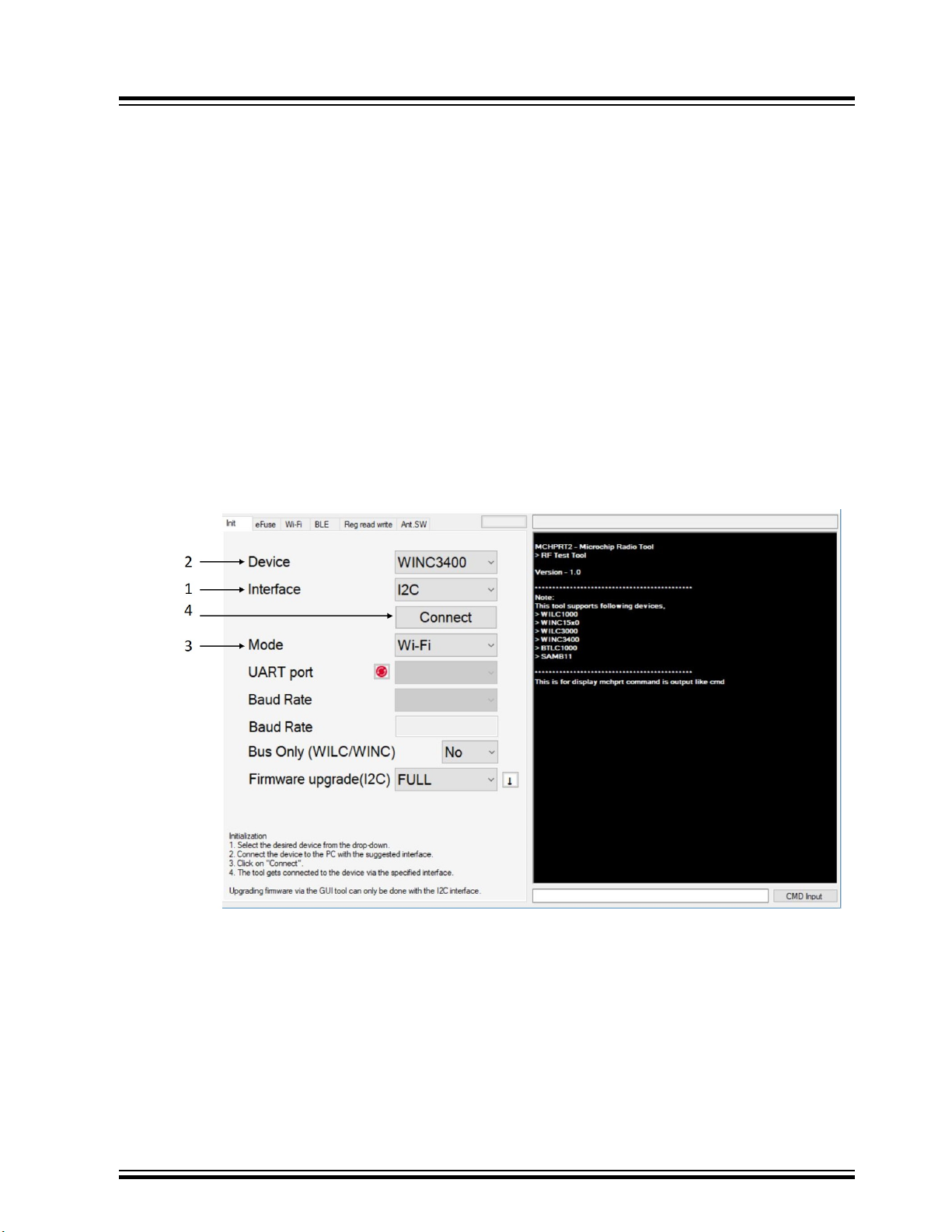

2.1.1 Initialization

Perform the following steps for Wi-Fi initialization.

1. Double-click to open the MCHPRT2.exe executable file and, select the interface as “I2C” when

using “I2C” connection. Select the interface as ‘UART’ when using serial bridge UART connection.

2. Select the device from the Device series drop down box.

3. Choose Wi-Fi as the mode from the drop down box.

4. Click Connect to initialize the device.

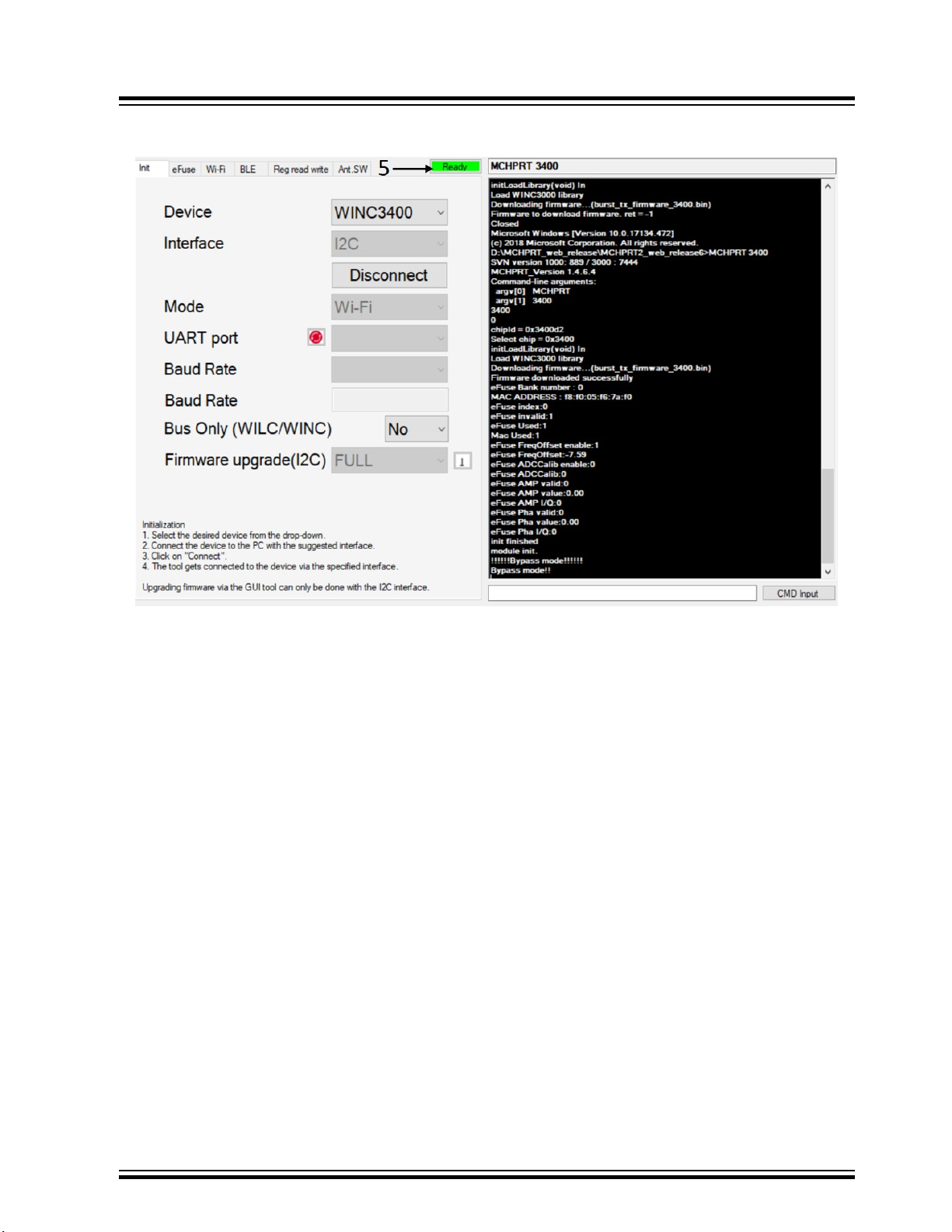

5. After initialization is complete, the status of the process bar displays Ready.

Figure 2-1. Wi-Fi Initialization

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

Note: The CLI information is displayed on the right hand side.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 13

Page 14

Figure 2-2. Wi-Fi Initialization

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

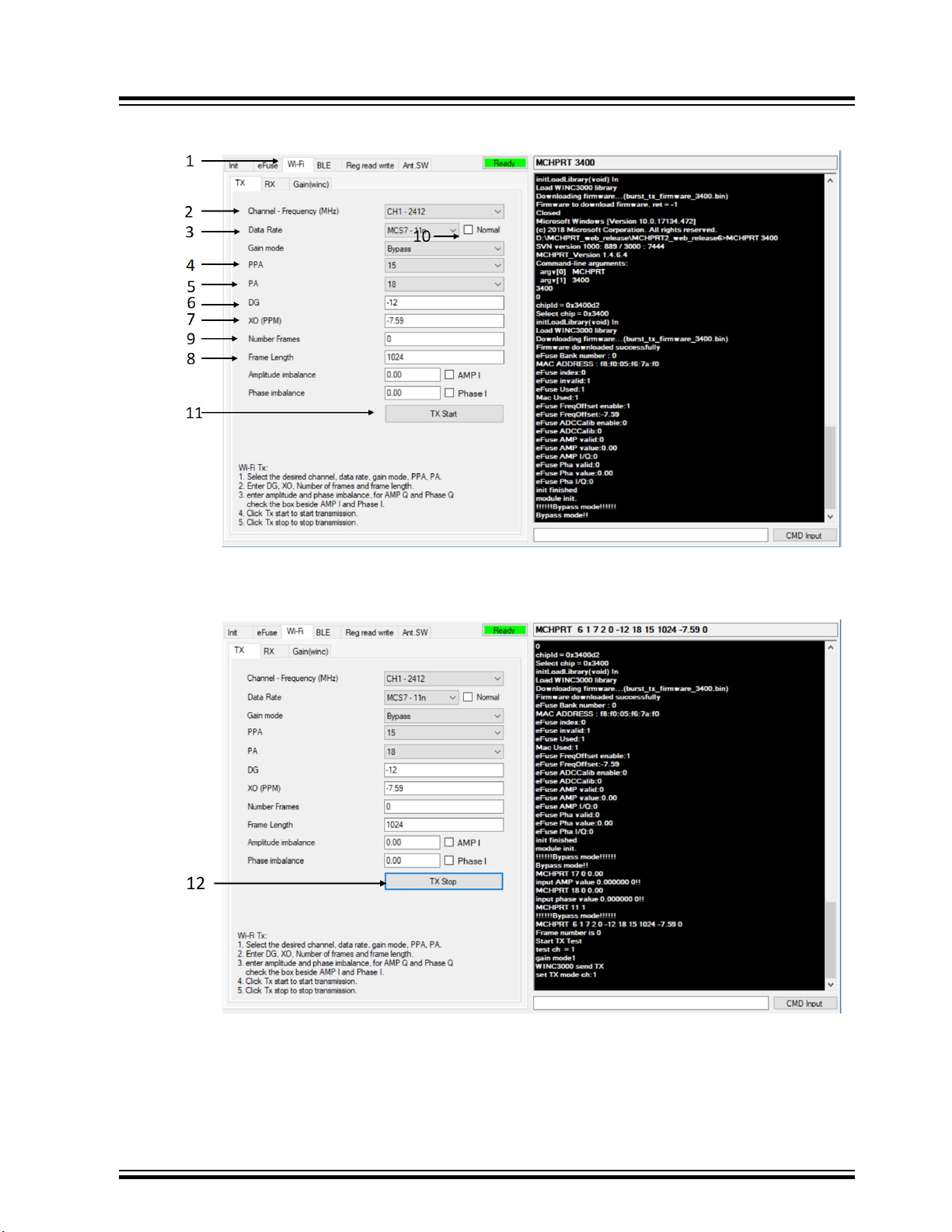

2.1.2 Transmission (TX)

2.1.2.1 Start TX - Gain, Channel, Data Rate

Set the following parameters to Start TX:

1. Navigate to the Wi-Fi tab.

2. Select the desired channel CH for testing.

3. Select the desired data rate from the drop down box and choose the Gain mode (Dynamic/Bypass/

FLASH(WINC1500/WINC3400 only).

Note: In Bypass mode, PPA, PA, and Digital Gain are enabled. The value is set within the

specified value besides PPA, PA, and Digital Gain. In Dynamic and Flash gain mode, PPA, PA, and

Digital Gain are disabled.

4. Enter PPA.

5. Enter PA.

6. Enter Digital Gain (-7 ~ -15).

7. XO offset.

8. Length (0~1024).

9. Frames ( 0 for con’t TX mode).

10. For CW mode of transmission select the check box before Normal, to enter CW mode.

11. Click TX start to Start TX.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 14

Page 15

Figure 2-3. Start Tx

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

12. Click TX stop to Stop TX.

Figure 2-4. Stop Tx

Note: The value that is written to amplitude and phase imbalance in the Wi-Fi tab is used for testing. It is

not written into the eFuse.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 15

Page 16

Note:

• Bypass mode: Gain values are used from the value entered in the GUI.

• Dynamic mode: Gain Values are used from the loaded test firmware (.bin gain table).

• Flash mode (For WINC devices): Gain values are used from Flash memory.

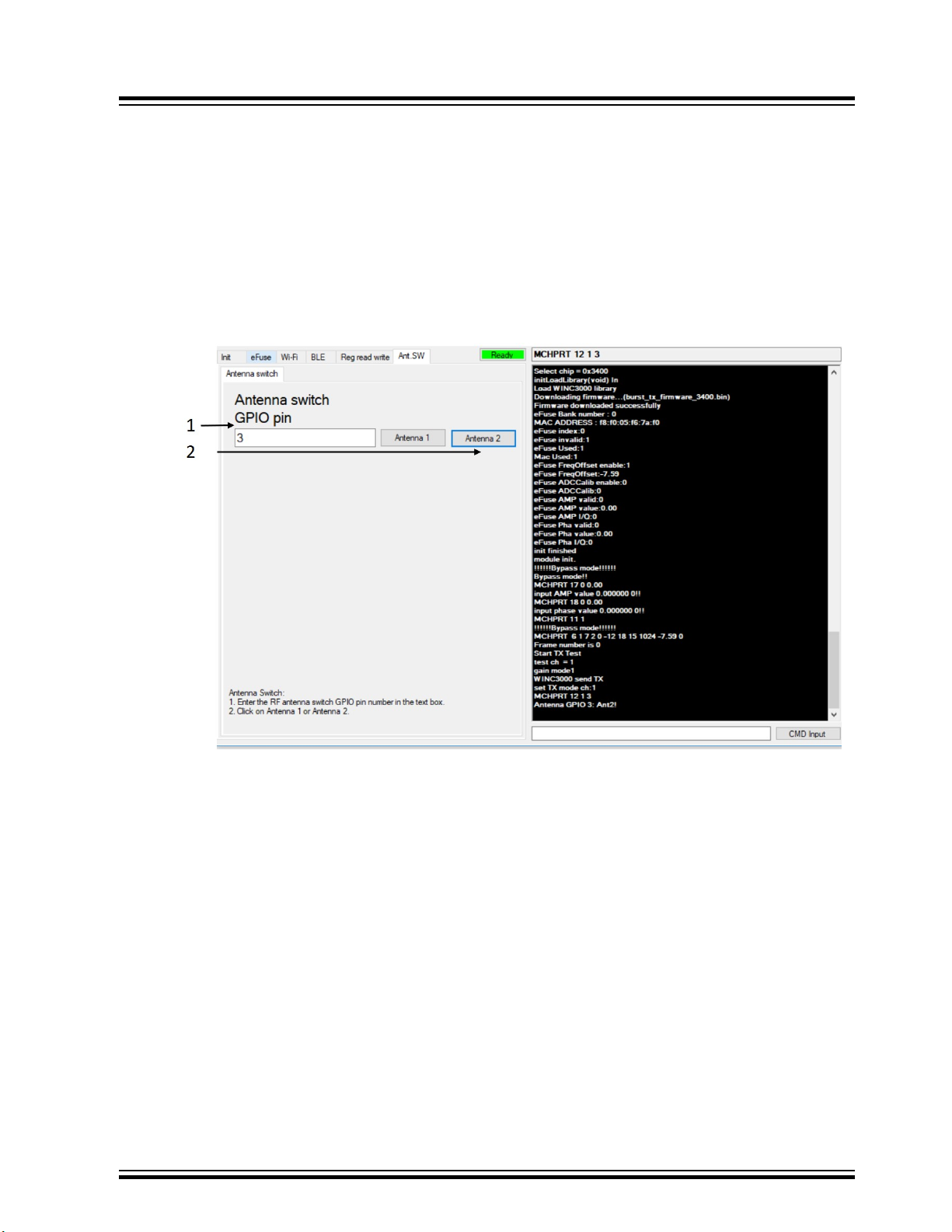

2.1.2.2 Antenna Switch

Set the following parameters for Antenna switch (ATWILC1000/ATWINC15x0).

1. Enter the GPIO number for switching the antenna.

2. Click on the Antenna 2 button for switching.

Figure 2-5. Enable Antenna Switch

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

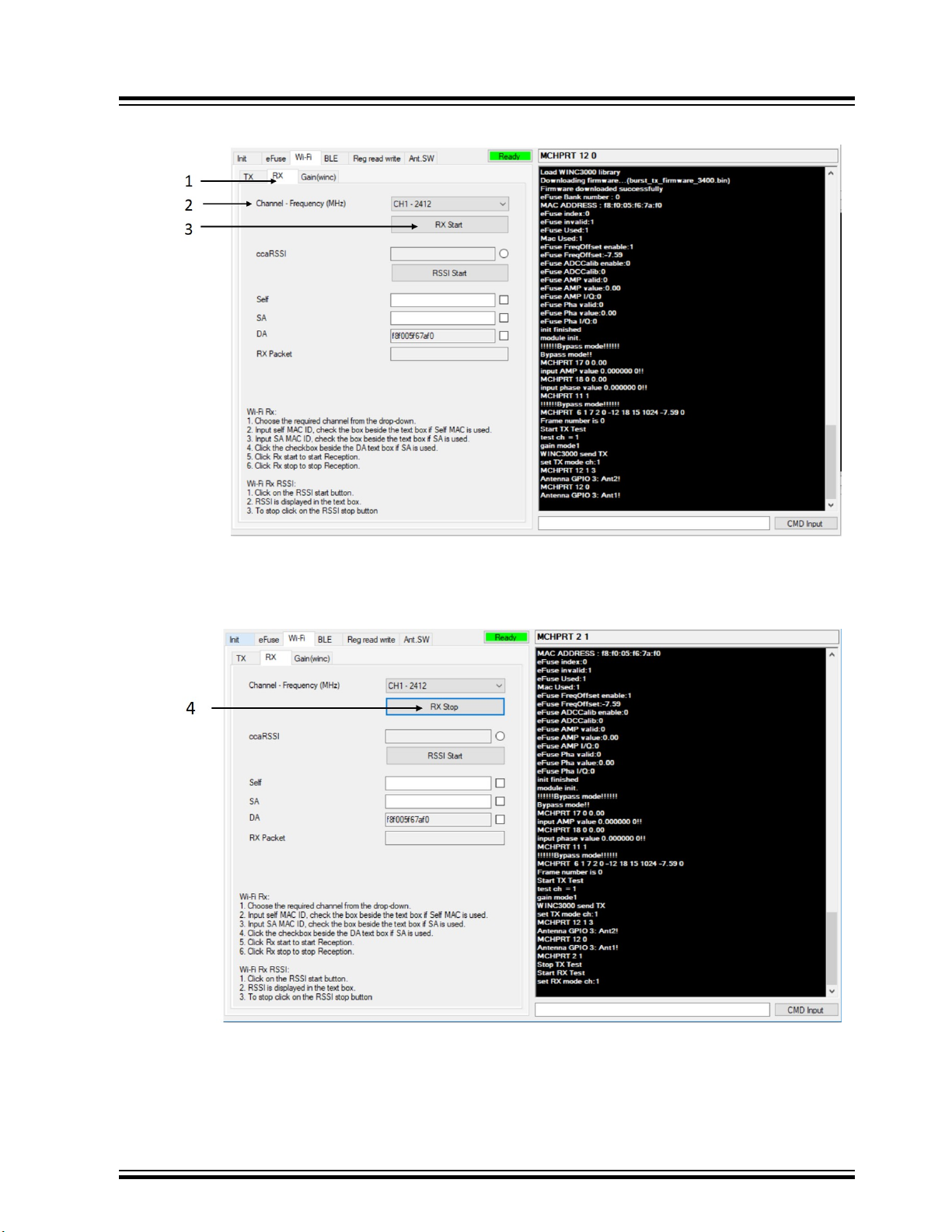

2.1.3 Receive (RX)

2.1.3.1 Start RX

Perform the following steps to Start RX:

1. Navigate to the RX tab, under the Wi-Fi tab.

2. Select the required channel from the Channel - Frequency (MHz) drop down box.

3. Click RX start to start the receive test.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 16

Page 17

Figure 2-6. Start RX Test

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

4. Click RX stop to stop receiving and the number of received packets is shown in RX packet text

box.

Figure 2-7. Stop RX

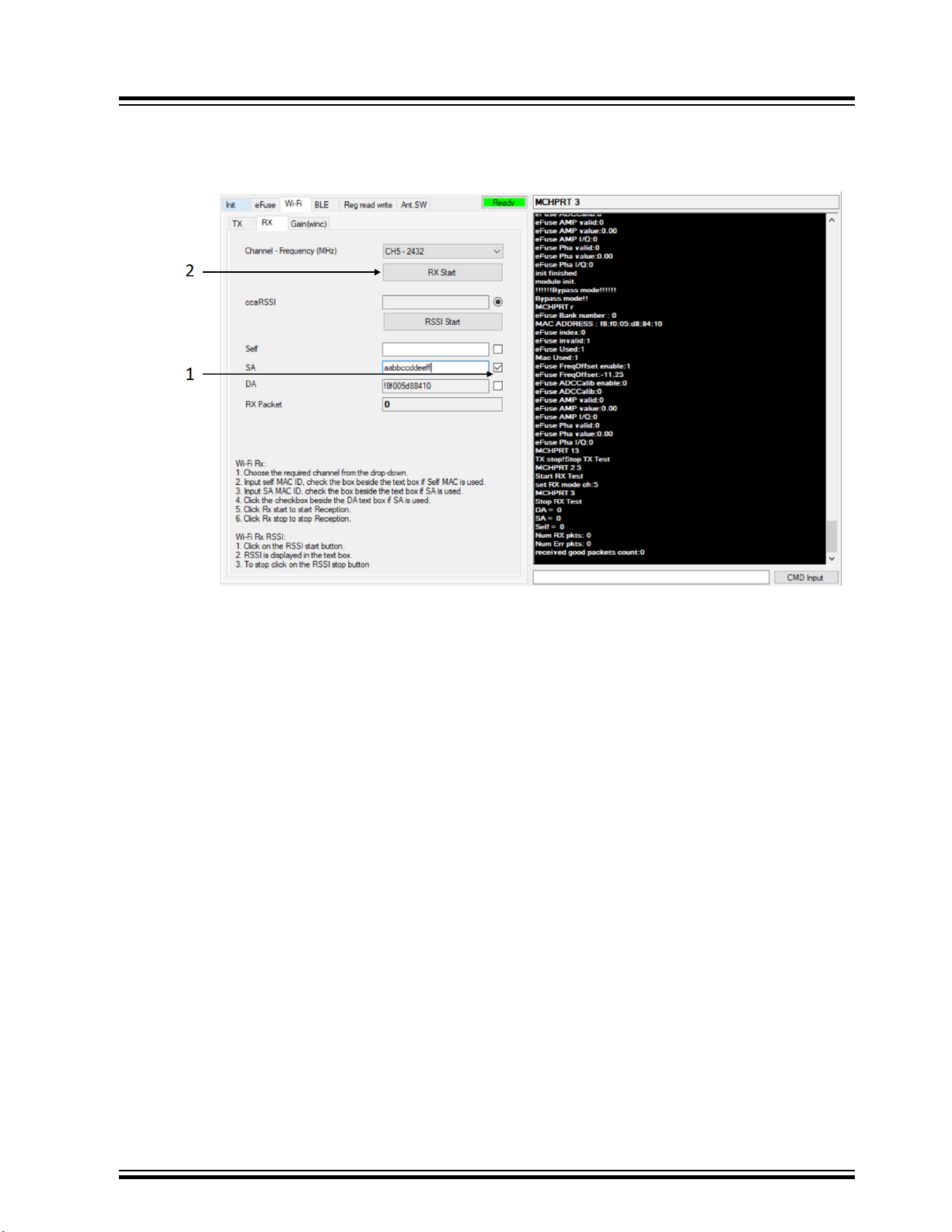

2.1.3.2 RX MAC Filter Control

2.1.3.2.1 Enable RX MAC Filter SA (Source)

Perform the following steps to enable RX MAC filter for SA.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 17

Page 18

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

1. Click on the SA check box and input Source MAC address in the text box.

2. Click RX start to start the RX test.

Figure 2-8. Enable RX MAC Filter SA

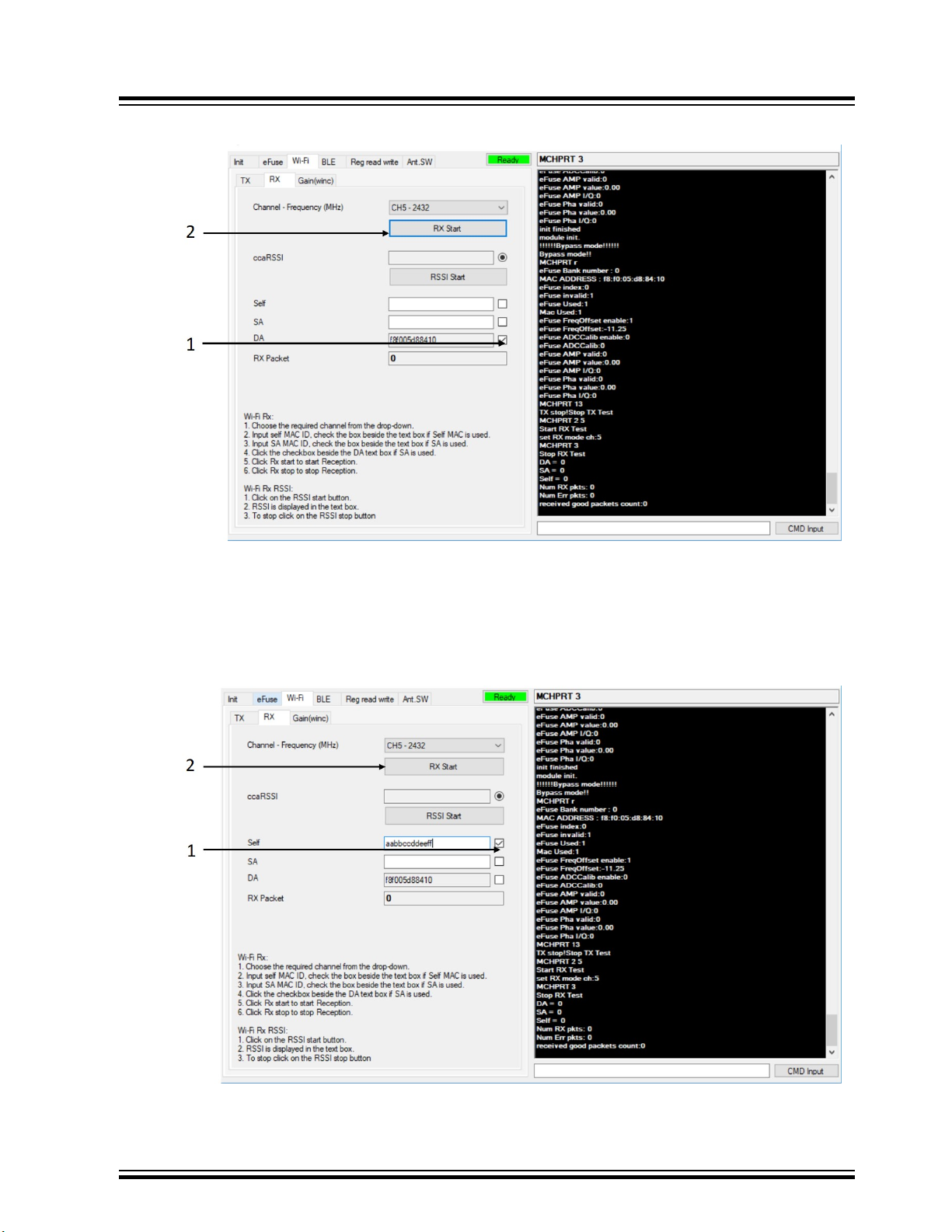

2.1.3.2.2 Enable RX MAC Filter DA (Destination)

Perform the following steps to enable RX MAC filter for DA.

1. Click the DA check box to enable RX MAC filter for DA.

2. Click on RX start to start the RX test.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 18

Page 19

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 2-9. Enable RX MAC Filter DA

Graphical User Interface

2.1.3.2.3 Enable Override Self MAC Address

Perform the following steps to enable override self MAC address.

1. Click on Self check box and input Self MAC address in the text box.

2. Click RX start to start the RX test.

Figure 2-10. Enable Override Self MAC Address

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 19

Page 20

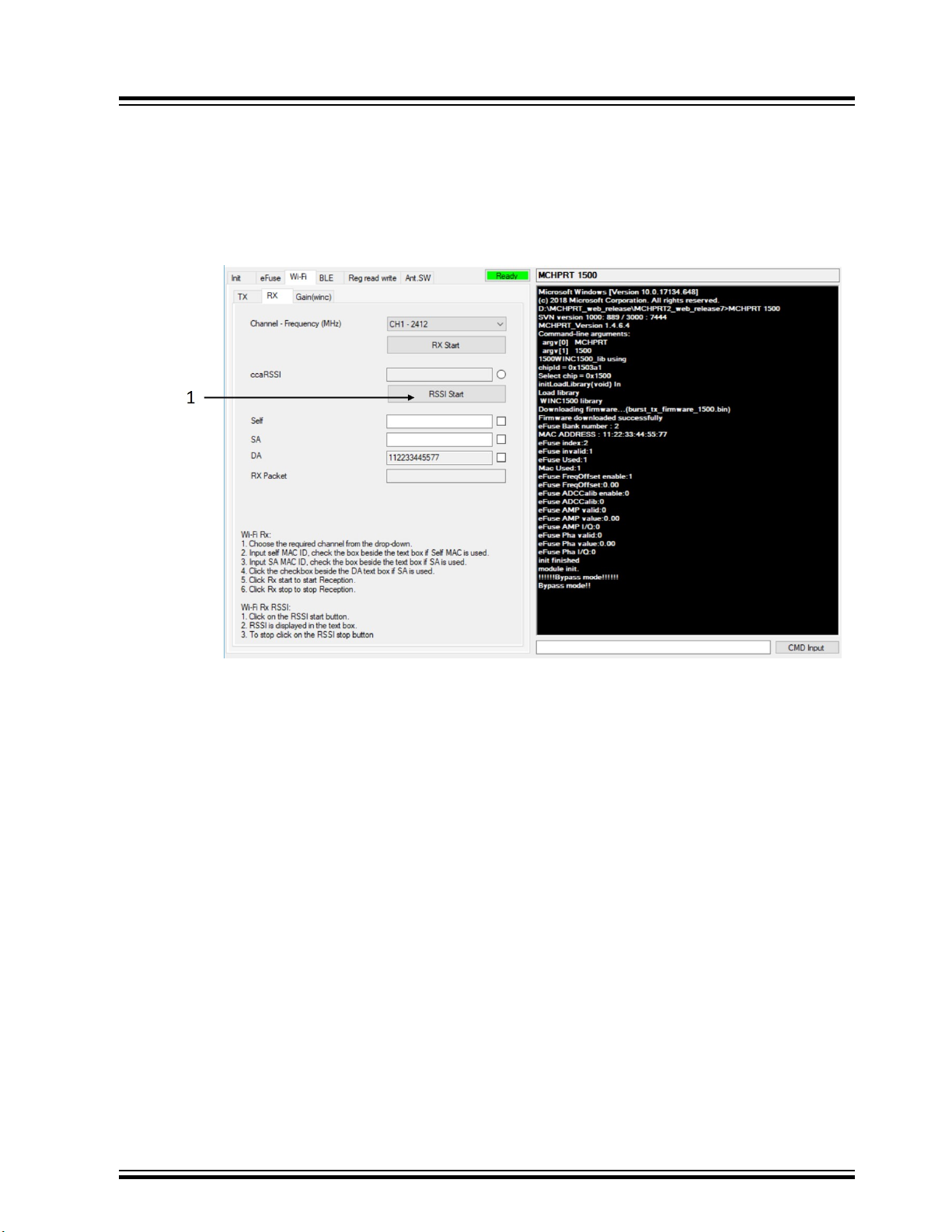

2.1.3.3 ccaRSSI

Perform the following steps to start RSSI test:

1. Click RSSI start to start receiving the signal strength displayed in the tab next to ccaRSSI.

Note: If a valid Wi-Fi packet is received, the indicator next to the ccaRSSI text box displays as

selected.

Figure 2-11. Start RSSI

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

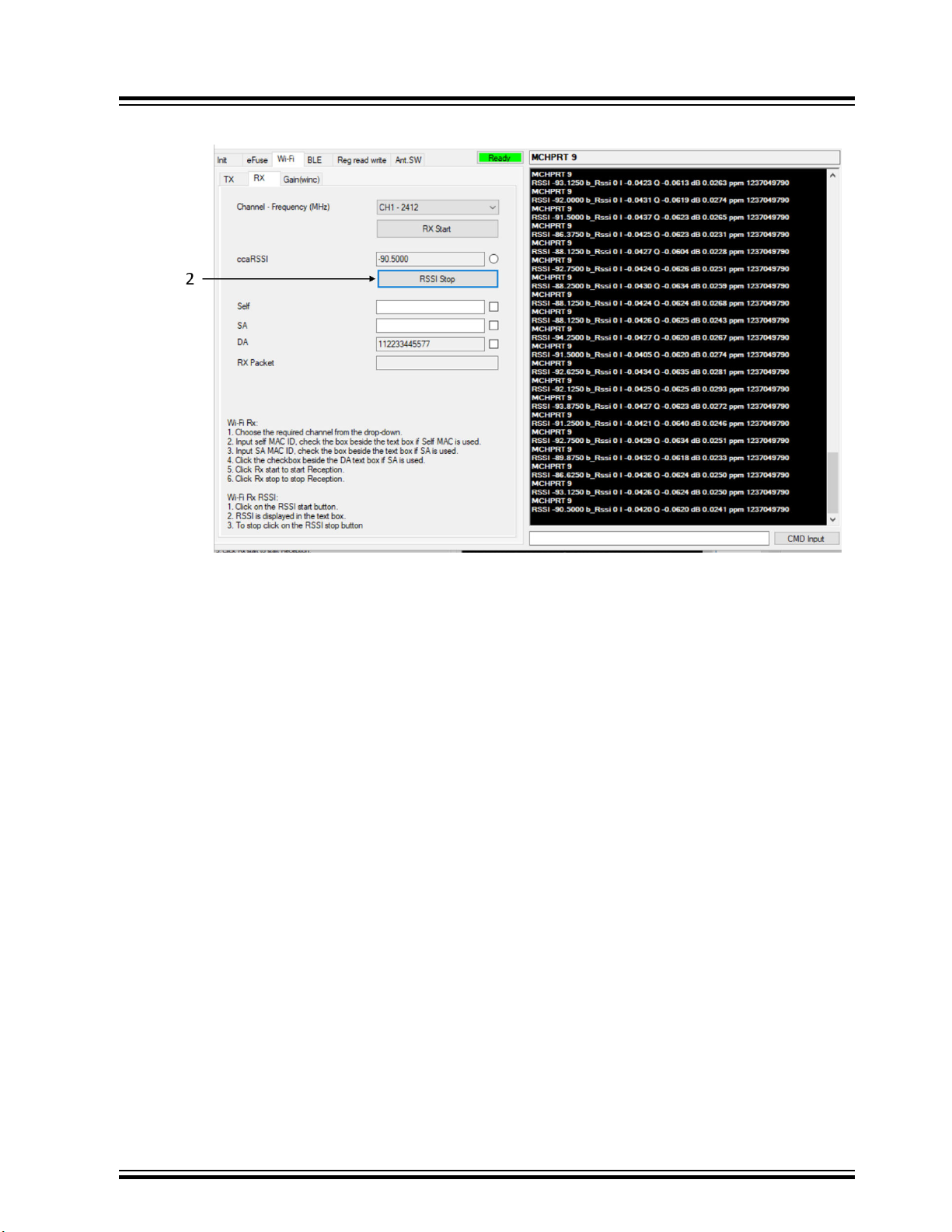

2. Click RSSI stop to stop measuring RSSI.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 20

Page 21

Figure 2-12. Stop RSSI

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

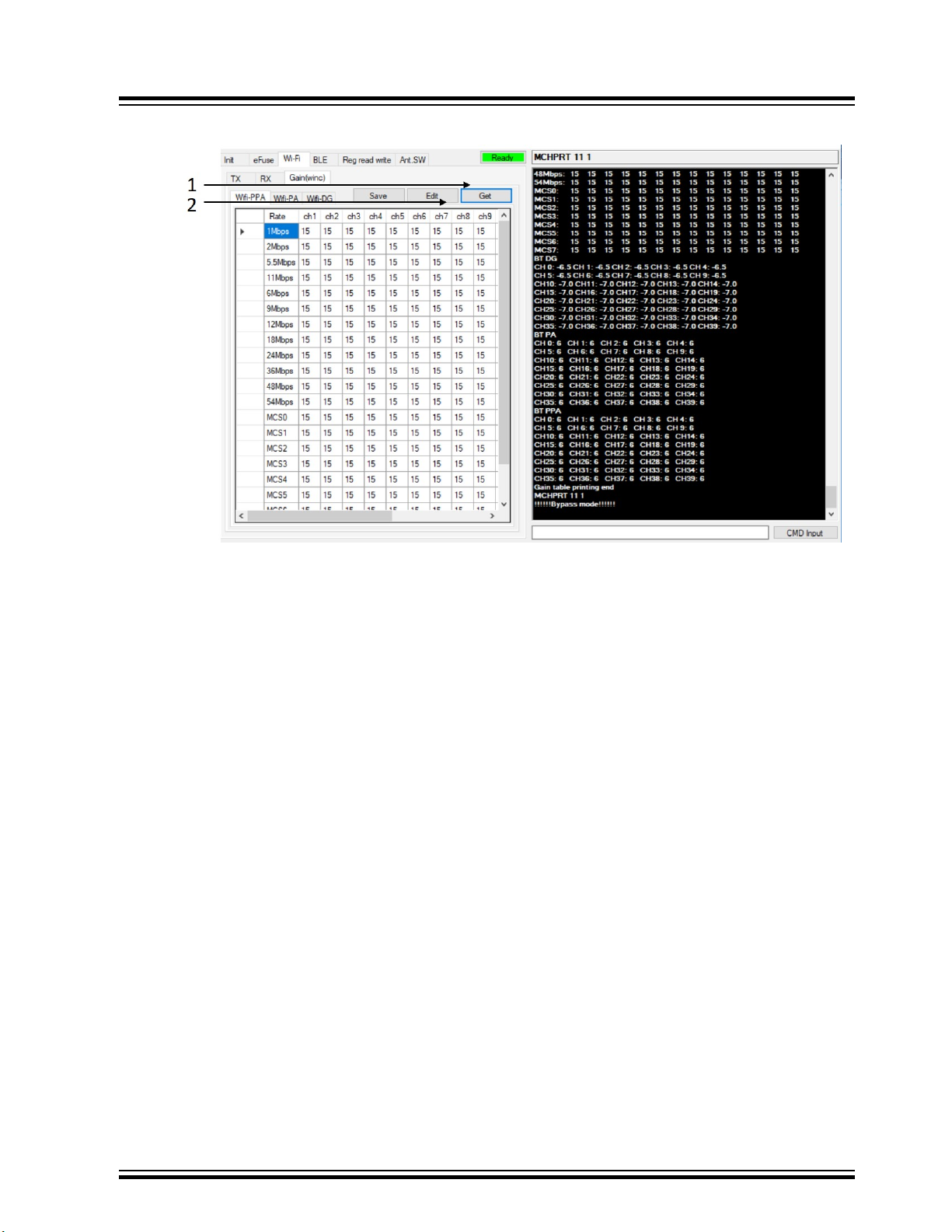

2.1.4 Gain Table

Perform the following steps for Gain table settings:

1. Navigate to Gain(winc) under Wi-Fi tab and, click Get to get the Wifi-PPA, Wifi-PA and Wifi-DG.

2. Click Edit to change the values of PPA, PA and DG. Click Save to apply the changes.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 21

Page 22

Figure 2-13. Gain Table Update

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

2.2 Bluetooth Low Energy (ATWILC3000/ATWINC3400)

2.2.1 Initialization

Perform the following steps for Bluetooth initialization.

1. Double-click on MCHPRT2.exe to open the GUI tool and select the device from the drop down box.

2. Select the interface as “I2C” when using “I2C” connection, and as “UART” when using serial bridge

UART connection.

3. Select the Mode as BLE from the drop down box, next to Mode.

4. Click Connect.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 22

Page 23

Figure 2-14. Bluetooth Initialization

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

5. The process bar status displays Ready, after the initialization completes.

6. Navigate to BLE comport tab under BLE.

7. Select the COM port number and, select Baud rate as 115200.

8. Click Open to connect to the selected COM port.

Figure 2-15. Selecting COM Port

To check if DTR is enabled, see 1.3 UART/I2C Pin Details .

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 23

Page 24

2.2.2 TX

Set the following parameters for Bluetooth TX.

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

1. Navigate to TX tab under BLE and choose the desired channel from Channel-Frequency dropdown.

2. Select the payload.

3. Select gain mode.

4. Select PPA and PA values from the drop down box.

5. Enter Digital gain.

6. Enter XO offset.

7. Select Frame Length.

8. Select the check box next to payload drop down box, to enable CW mode.

9. Click TX Start to start transmission.

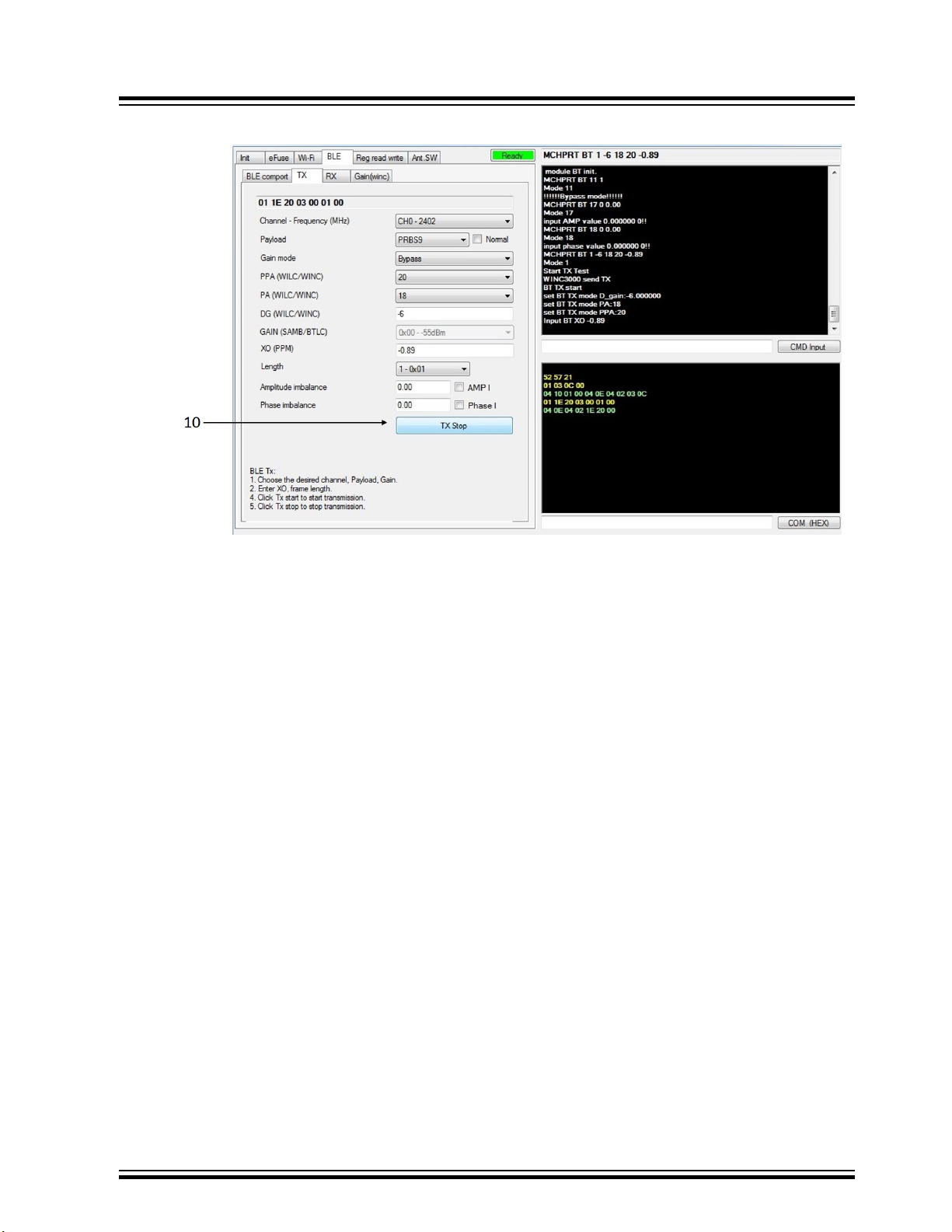

Figure 2-16. Start TX for Bluetooth

10. Click TX Stop to stop transmission.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 24

Page 25

Figure 2-17. Stop TX for Bluetooth

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

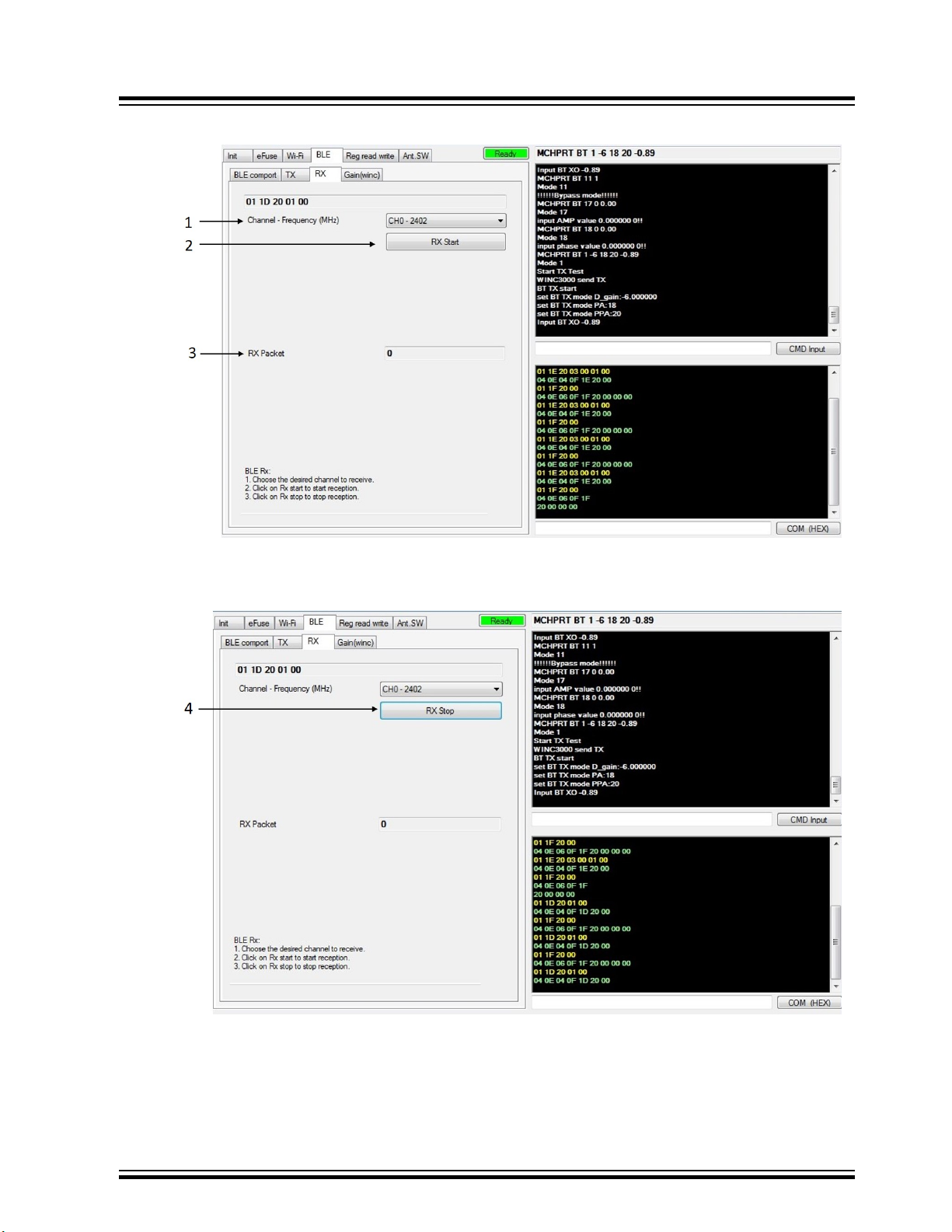

2.2.3 RX

Set the following parameters for RX test:

1. Navigate to RX tab under BLE and choose the required channel from the Channel-Frequency drop

down box.

2. Click RX start to start the reception.

3. Rx packet shows the number of successful packets received.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 25

Page 26

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 2-18. Start Bluetooth RX Test

Graphical User Interface

4. Click RX stop to stop the reception.

Figure 2-19. Stop Bluetooth RX Test

2.2.4 Direct Test Mode

1. Stop all the Tx or Rx tests before starting DTM mode.

2. After the BLE initialization, reconnect the COM port to the testing equipment.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 26

Page 27

ATWINC/ATWILC/ATSAMB/ATBTLC

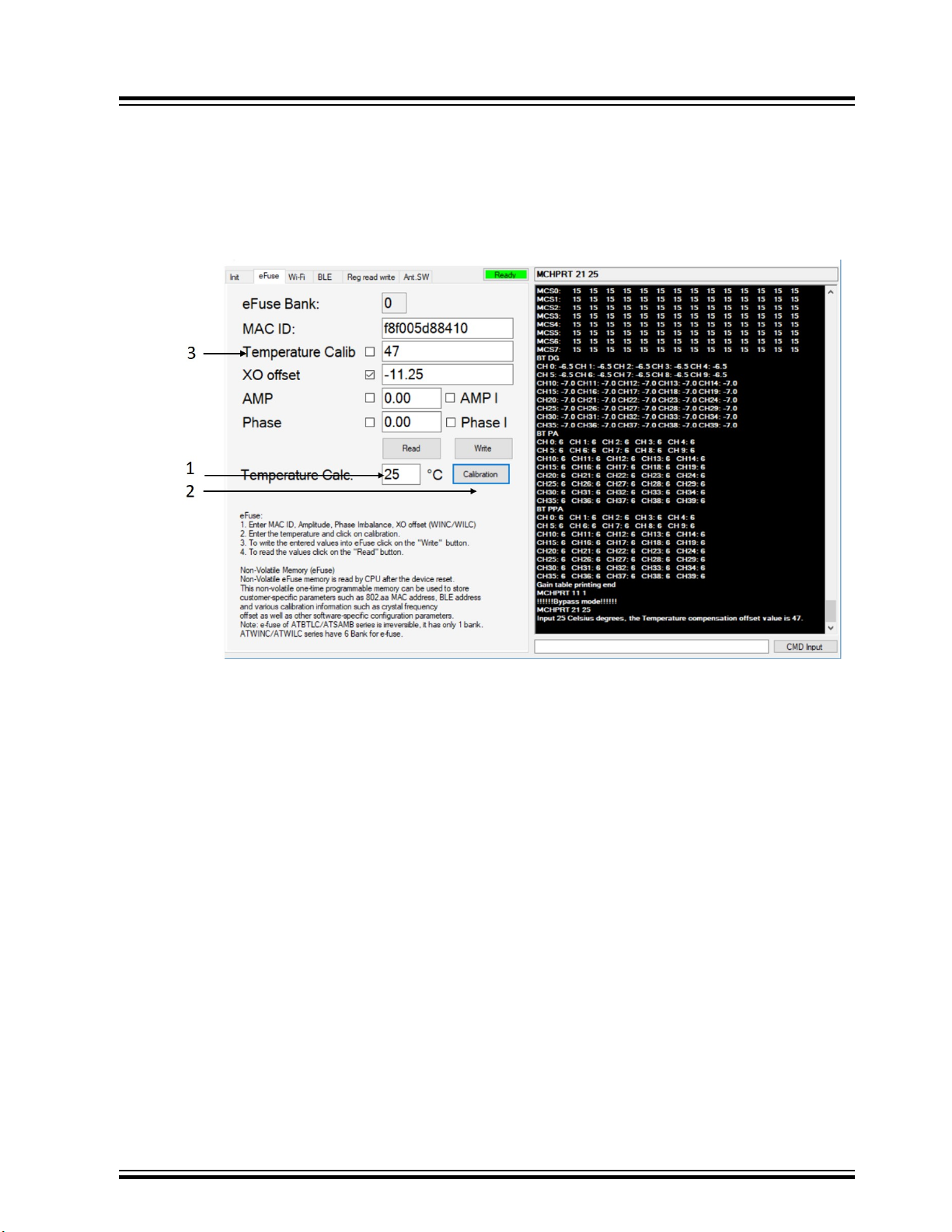

2.3 Temperature Calibration Calculator

1. Navigate to eFuse and type the current temperature value in the text box.

2. Click Calibration.

3. The calibrated temperature value is displayed in the text box beside Temperature Calib.

Figure 2-20. Temperature calibration procedure

Graphical User Interface

Note: Temperature calibration only works in Dynamic mode. The current WILC/WINC firmware

doesn’t support this feature. It is for future reference.

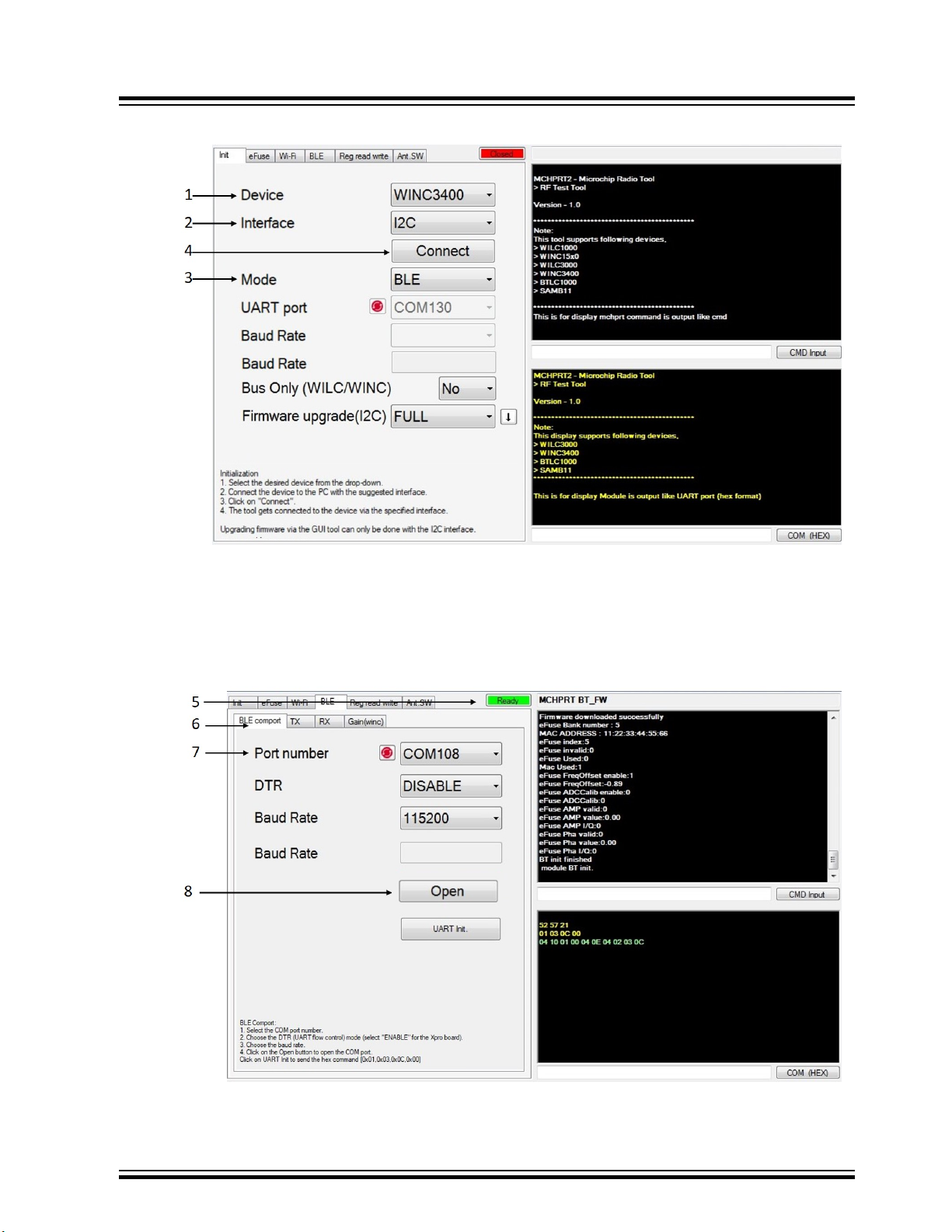

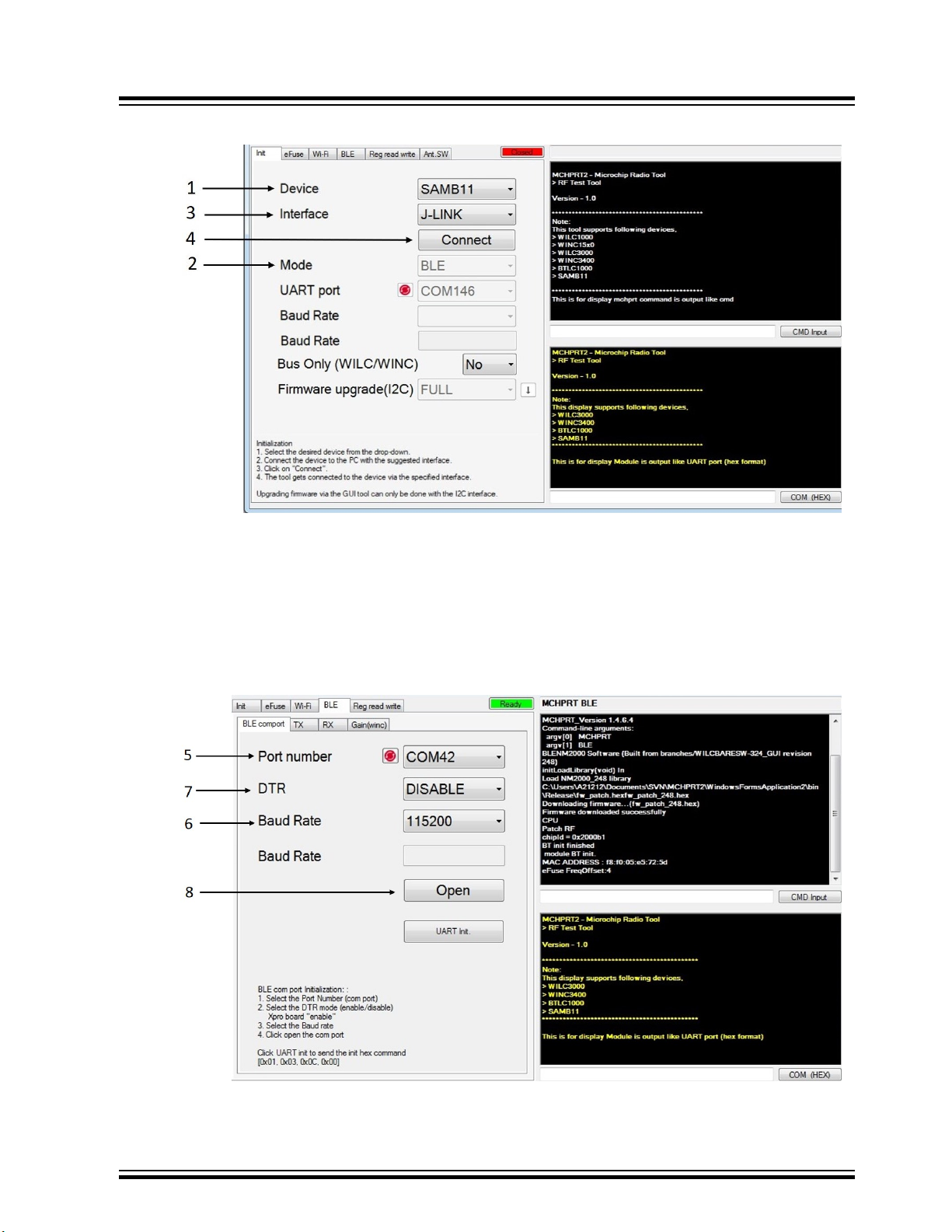

2.4 Bluetooth Low Energy (ATBTLC/ATSAMB)

2.4.1 Initialization

Perform the following steps for BLE initialization. For SAMB11, ensure that the steps referred in Appendix

A5 Erase and Program SAMB11 are followed before establishing connection with MCHPRT2 GUI.

1. Double click on MCHPRT2.exe to open the GUI and select the device from the drop-down.

2. Select the mode as BLE.

3. Select interface as J-link.

4. Click Connect to initialize. When the initialization is complete, the process bar status displays

Ready.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 27

Page 28

Figure 2-21. BLE Initialization

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

Note: Select J-Link for ATBTLC/ATSAMB series and I2C or UART for ATWILC3000/ATWINC3400.

5. Navigate to BLE comport tab below BLE and choose COM port number.

6. Type ‘115200’ as baud rate.

7. Select DTR as disable for Microchip boards. Refer 1.3 UART/I2C Pin Details to check if DTR is

enabled.

8. Click Open to connect to COM port.

Figure 2-22. Selecting COM Port

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 28

Page 29

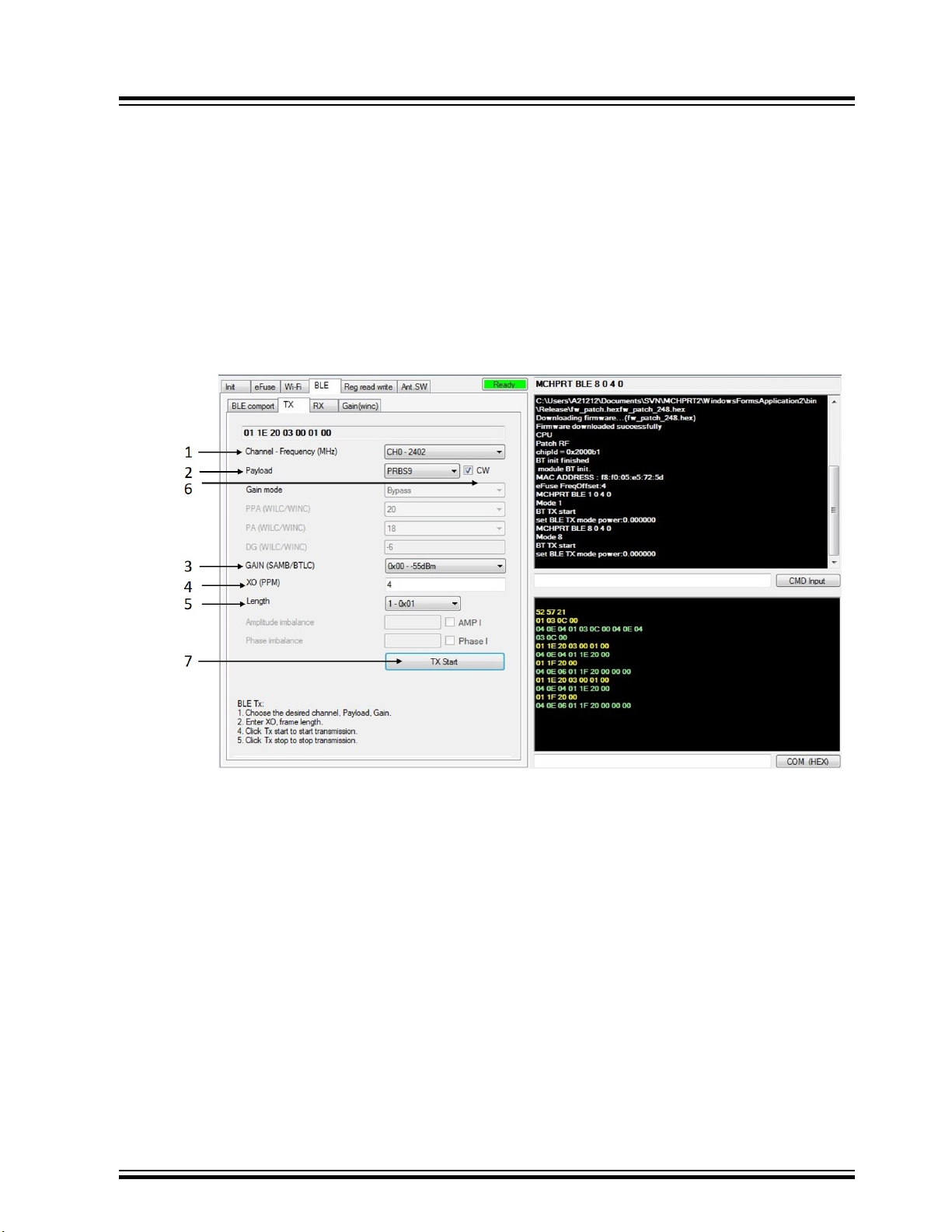

2.4.2 TX

Set the following parameters for transmitting in BLE Test mode.

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

1. Navigate to TX tab under BLE and choose the desired channel from Channel-Frequency drop down

box.

2. Select payload.

3. Select Gain.

4. Enter XO offset value in the text tab.

5. Select the frame length.

6. Select the check box before payload for CW mode.

7. Click TX Start to start the transmission.

Figure 2-23. Start TX for BLE

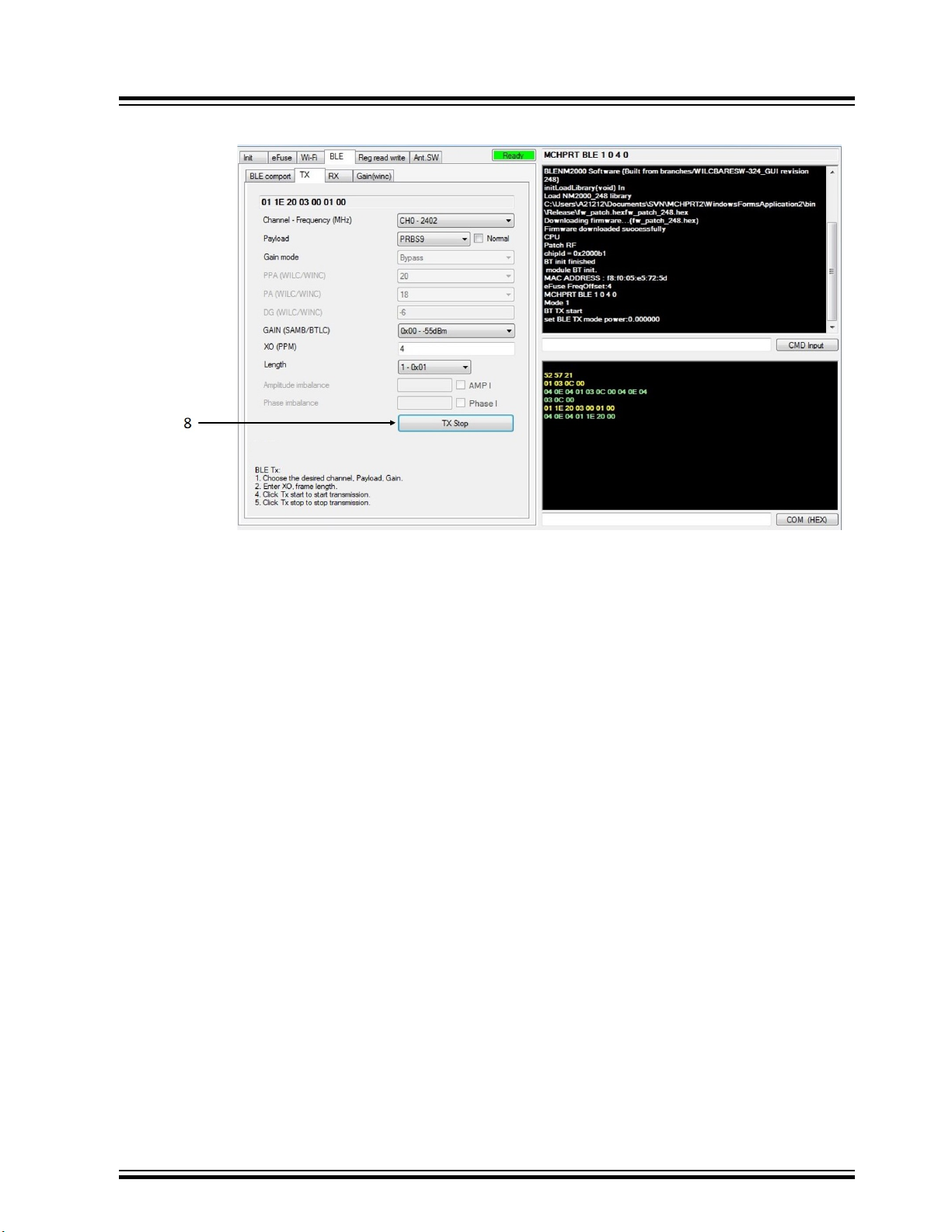

8. Click TX Stop to stop the transmission.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 29

Page 30

Figure 2-24. Stop TX for BLE

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

2.4.3 RX

Set the following parameters for RX test.

1. Navigate to RX tab under BLE and choose the desired channel from the Channel-Frequency dropdown box.

2. Click RX Start to start the reception.

3. RX packet shows the number of successful packets received.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 30

Page 31

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 2-25. Start Bluetooth RX Test

Graphical User Interface

4. Click RX Stop to stop the reception.

Figure 2-26. Stop Bluetooth RX Test

2.4.4 Direct Test Mode

After initialization, connect the COM port to testing equipment.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 31

Page 32

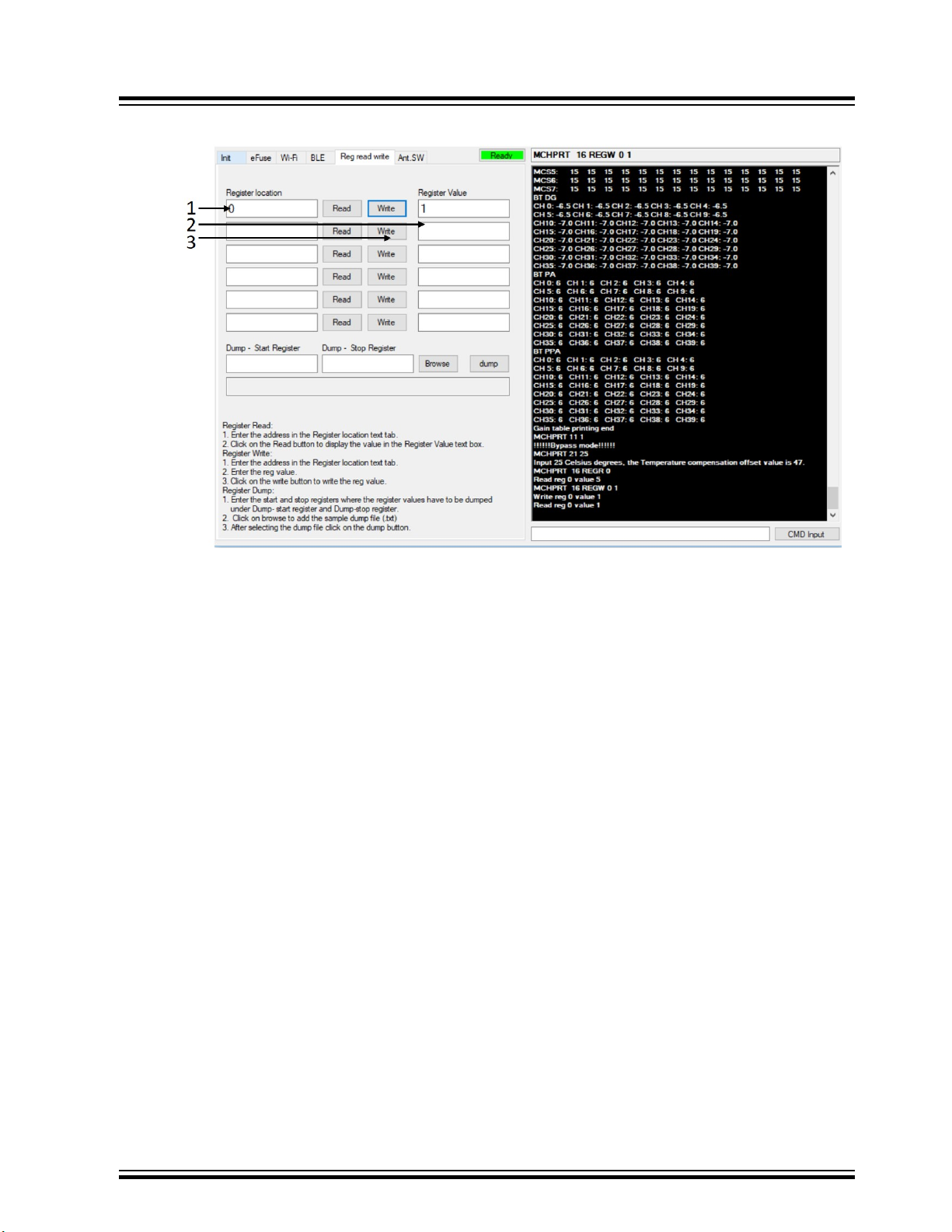

2.5 Register

Navigate to Reg read and write tab.

2.5.1 Read

Perform the following steps to read the register values.

1. Enter the address in the Register location text tab, as shown in the following figure.

2. Click Read button to display value in the Register Value text box.

Figure 2-27. Read Reg Value

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

2.5.2 Write

Perform the following steps to write the register values.

1. Type the register location.

2. Type the register value in the Register value text box.

3. Click Write to write into the specified location.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 32

Page 33

Figure 2-28. Write Reg Value

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

2.5.3 Register Dump

Perform the following steps to dump the registers.

1. Enter the start and stop registers where the register values has to be dumped under Dump- start

register and Dump-stop register.

2. Click Browse to add the sample dump file (.txt).

3. After selecting the dump file click Dump.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 33

Page 34

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 2-29. Adding the Sample Dump File

Graphical User Interface

4. After dumping the registers, the process bar indicates blue color.

2.6 eFuse

2.6.1 Read

Perform the following steps to read eFuse.

1. Open MCHPRT2 GUI tool.

2. After initialization, navigate to eFuse tab.

3. Click Read to see the written parameters.

Note: The format for dump file is .txt.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 34

Page 35

Figure 2-30. Read eFuse

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

2.6.2 Write

Perform the following steps to write eFuse:

1. Navigate to eFuse tab. To update gain correction, XO offset , AMP and Phase imbalance enter the

2. Click Write to write efuse.

3. If only a few parameters are required to be written to eFuse, then the other parameter follows the

4. The eFuse bank number automatically updates by +1. If the module is new, the bank will be Null.

respective values.

previous eFuse information. To confirm this enter letter "Y" in the CMD Input text box and click on

CMD Input. After the eFuse is written, "eFuse write finish" displays in the command window.

On first write, the bank number gets incremented by +1 until it reaches 5. (0-5 banks).

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 35

Page 36

Figure 2-31. Enable eFuse Write

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

Figure 2-32. Enter Y

2.7 Firmware Upgrade

Perform the following steps to upgrade the firmware using the MCHPRT2 Tool. It is the same firmware

upgrade example that is available in Atmel Studio. See 6. Appendix C - Firmware Update for details.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 36

Page 37

ATWINC/ATWILC/ATSAMB/ATBTLC

Important: Before the FW upgrade, update the firmware files in following folder:

• ..\MCHPRT\upgrade_1500\firmware\firmware (for ATWINC1500)

• ..\MCHPRT\upgrade_3400\firmware\firmware (for ATWINC3400)

1. Select the chip from the drop down menu.

2. Select the upgrade items from the list.

3. Click

to start the firmware upgrade.

Figure 2-33. FW Upgrade

Graphical User Interface

4. After the upgrade is successful, the log displays as “PASS”, see the following figure.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 37

Page 38

ATWINC/ATWILC/ATSAMB/ATBTLC

Graphical User Interface

Figure 2-34. Successful Upgrade

Note: ASF has the latest firmware. For information on how to add the upgrade file into MCHPRT2 tool

folder, see the Firmware upgrade folder in MCHPRT2 package.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 38

Page 39

3. Command Line

The commands that are sent using command line can also be sent from the GUI by entering the

command in the CMD Input text box.

3.1 Wi-Fi

3.1.1 Initialization

The following table provides the command syntax for Wi-Fi initialization.

Table 3-1. Wi-Fi Initialization

Command Syntax MCHPRT X

X X refers to Chip selection:

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Auto Chip Selection

• 0 – Autodetect Chip with I2C

• 0_UART – Autodetect Chip with UART

Fast Connection

• 1000 – ATWILC1000 series with I2C

• 1000_UART – ATWILC1000 series with UART

• 1500 – ATWINC15X0 series with I2C

• 1500_UART – ATWINC15X0 series with UART

• 3000 – ATWILC3000 series with I2C

• 3000_UART – ATWILC3000 series with UART

• 3400 – ATWINC3400 series with I2C

• 3400_UART – ATWINC3400 series with UART

Example MCHPRT 0

Autodetect Chip with I2C connector

MCHPRT 0_UART

Autodetect Chip with UART connector

The following figure illustrates the Wi-Fi initialization.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 39

Page 40

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-1. Console Log of Wi-Fi Initialization (MCHPRT 0)

Command Line

3.1.2 TX

3.1.2.1 Start TX - Gain, Channel, Data Rate

The following table provides the command syntax for gain, channel and data rate of the TX test.

Table 3-2. Start TX: After Initialization

Command Syntax MCHPRT 6 X Y Z A B C D L F

X X refers to TX channel: 1 to 14

• 1 – Channel 1 (2412 MHz)

• 6 – Channel 6 (2437 MHz)

• 14 – Channel 14 (2484 MHz)

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 40

Page 41

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT 6 X Y Z A B C D L F

Y Z Y refer to Rate, Z refers to Preamble:

Rate = 0 Preamble = 0 11b 1 Mbps -

Rate = 1 Preamble = 0 11b 2 Mbps -

Rate = 2 Preamble = 0 11b 5.5 Mbps -

Rate = 3 Preamble = 0 11b 11 Mbps -

Rate = 0 Preamble = 1 11g 6 Mbps -

Rate = 1 Preamble = 1 11g 9 Mbps -

Rate = 2 Preamble = 1 11g 12 Mbps -

Command Line

Rate = 3 Preamble = 1 11g 18 Mbps

Rate = 4 Preamble = 1 11g 24 Mbps -

Rate = 5 Preamble = 1 11g 36 Mbps -

Rate = 6 Preamble = 1 11g 48 Mbps -

Rate = 7 Preamble = 1 11g 54 Mbps -

Rate = 0 Preamble = 2 11n MCS - 0 0x80

Rate = 1 Preamble = 2 11n MCS - 1 0x81

Rate = 2 Preamble = 2 11n MCS - 2 0x82

Rate = 3 Preamble = 2 11n MCS - 3 0x83

Rate = 4 Preamble = 2 11n MCS - 4 0x84

Rate = 5 Preamble = 2 11n MCS - 5 0x85

Rate = 6 Preamble = 2 11n MCS - 6 0x86

Rate = 7 Preamble = 2 11n MCS - 7 0x87

A A refers to bandwidth:

0/1 – 20 MHz

-

B B refers to Digital Gain (Bypass mode):

Range: -20 to 0

DG: Dynamic Gain

C C refers to PA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 9, 6, 3, 0

• ATWILC3000/ATWINC3400 – 18, 15, 12, 9, 6, 3

DG: Dynamic Gain

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 41

Page 42

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT 6 X Y Z A B C D L F

D D refers to PPA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 18, 15, 12, 9, 6, 3

• ATWILC3000/ATWINC3400 – 20, 18, 15, 12, 6, 0

DG: Dynamic Gain

L L refers to length:

0 – 1500

Maximum limit is 1500

F F refers Frequency offset :

-50 to +50 base on Crystal

XO : eFuse XO value

Example MCHPRT 6 1 7 2 0 -10 18 6 1500 0

Channel 1. MCS 7 – 20 MHz, length 1500, 0 ppm, offset DG – 10, PPA 6 , PA

18

Command Line

The following figure shows the example start TX test.

Figure 3-2. Console Log of TX Test Mode

The Wi-Fi TX mode starts as shown in the following figure.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 42

Page 43

Figure 3-3. TX Mode Start

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

3.1.2.2 CW

The following table provides the command syntax for CW TX mode.

Table 3-3. Start TX CW: After Initialization

Command Syntax MCHPRT 8 X Y Z A B C D L F

X X refers to TX channel: 1 to 14

• 1 – Channel 1 (2412 MHz)

• 6 – Channel 6 (2437 MHz)

• 14 – Channel 14 (2484 MHz)

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 43

Page 44

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT 8 X Y Z A B C D L F

Y Z Y refer to Rate, Z refers to Preamble:

Rate = 0 Preamble = 0 11b 1 Mbps -

Rate = 1 Preamble = 0 11b 2 Mbps -

Rate = 2 Preamble = 0 11b 5.5 Mbps -

Rate = 3 Preamble = 0 11b 11 Mbps -

Rate = 0 Preamble = 1 11g 6 Mbps -

Rate = 1 Preamble = 1 11g 9 Mbps -

Rate = 2 Preamble = 1 11g 12 Mbps -

Command Line

Rate = 3 Preamble = 1 11g 18 Mbps

Rate = 4 Preamble = 1 11g 24 Mbps -

Rate = 5 Preamble = 1 11g 36 Mbps -

Rate = 6 Preamble = 1 11g 48 Mbps -

Rate = 7 Preamble = 1 11g 54 Mbps -

Rate = 0 Preamble = 2 11n MCS - 0 0x80

Rate = 1 Preamble = 2 11n MCS - 1 0x81

Rate = 2 Preamble = 2 11n MCS - 2 0x82

Rate = 3 Preamble = 2 11n MCS - 3 0x83

Rate = 4 Preamble = 2 11n MCS - 4 0x84

Rate = 5 Preamble = 2 11n MCS - 5 0x85

Rate = 6 Preamble = 2 11n MCS - 6 0x86

Rate = 7 Preamble = 2 11n MCS - 7 0x87

A A refers to bandwidth:

0/1 – 20 MHz

-

B B refers to Digital Gain (Bypass mode):

Range: -20 to 0

DG: Dynamic Gain

C C refers to PA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 9, 6, 3, 0

• ATWILC3000/ATWINC3400 – 18, 15, 12, 9, 6, 3

DG: Dynamic Gain

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 44

Page 45

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT 8 X Y Z A B C D L F

D D refers to PPA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 18, 15, 12, 9, 6, 3

• ATWILC3000/ATWINC3400 – 20, 18, 15, 12, 6, 0

DG: Dynamic Gain

L L refers to length:

0 – 1500

Maximum limit is 1500

F F mean Frequency offset : -50 to +50 base on Crystal

XO : eFuse XO value

Example MCHPRT 8 1 7 2 0 -10 18 6 1500 0

Channel 1. MCS 7 – 20 MHz, length 1500, 0 ppm offset DG – 10, PPA 6 ,

PA 18 CW mode

Command Line

The following figure shows the example of start CW TX mode.

Figure 3-4. Console Log of CW TX Mode

The CW TX mode starts as shown in the following figure.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 45

Page 46

Figure 3-5. CW TX Mode Start

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

3.1.2.3 Gain Mode

The following table provides the command syntax for Gain mode settings.

Table 3-4. Gain Mode setting: After Initialization, Before TX Start

Command Syntax MCHPRT 11 X

X X refers to Gain mode:

Example MCHPRT 11 1

The following figure shows the example of Gain mode.

• 0 – Dynamic gain mode

• 1 – Bypass gain mode (default)

• 2 – Flash gain mode

Bypass mode

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 46

Page 47

Figure 3-6. Console Log of Gain Mode

3.1.2.4 Antenna Switch

The following table provides the command syntax for Antenna switch (ATWILC1000/ATWINC15X0).

Table 3-5. Antenna Switching: After Initialization

Command Syntax MCHPRT 12 X Y

X X refers to Antenna:

Y Y refers to GPIO pin:

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

• 0 – antenna 1 (default)

• 1 – antenna 2

• 3 – GPIO3

Example MCHPRT 12 0 3

The following figure shows the example of Antenna switch.

Figure 3-7. Console Log of Antenna Switch

3.1.2.5 Stop TX

The following table provides the command syntax for Stop TX test.

Table 3-6. Stop TX: After Initialization and TX Start

Command Syntax MCHPRT 13

Example MCHPRT 13

The following figure shows the example of Stop TX test.

Antenna switching A

Stop TX

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 47

Page 48

Figure 3-8. Console Log of Stop TX Test Mode

3.1.3 RX

3.1.3.1 Start RX

The following table provides the command syntax for RX test.

Table 3-7. Start RX: After Initialization

Command Syntax MCHPRT 2 X

X X refers to TX channel: 1 to 14

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

• 1 – Channel 1 (2412 MHz)

• 6 – Channel 6 (2437 MHz)

• 14 – Channel 14 (2484 MHz)

Example MCHPRT 2 1

The following figure shows the example of start RX test.

Figure 3-9. Console Log of RX Test Mode

3.1.3.2 Start RX with MAC Filter Selection

The following table provides the command syntax for RX test with MAC filter selection.

Table 3-8. Start RX with MAC Filter selection: After Initialization

Command Syntax MCHPRT X Y Z A

X X refers to RX mode:

RX mode in Channel 1 Start with reset the count

• 2_DA – Destination Filter

• 2_SA – Source Filter

• 2_Self – Override self MAC address

• 2_SA_DA – SA with DA

• 2_Self_DA – Self with DA

• 2_SA_Self – SA with Self

• 2_SA_Self_DA – All MAC filter apply

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 48

Page 49

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

...........continued

Command Syntax MCHPRT X Y Z A

Y Y refers to TX channel: 1 to 14

• 1 – Channel 1 (2412 MHz)

• 6 – Channel 6 (2437 MHz)

• 14 – Channel 14 (2484 MHz)

Z In “2_SA”, “2_SA_DA”, “2_SA_Self”, “2_SA_Self_DA”

Source MAC address

In “2_Self”, “2_Self_DA”

Self MAC address

A In “2_SA_Self_DA”

Self MAC address

Example MCHPRT 2_SA_Self_DA 1 112233445566 665544332211

RX with Source MAC filter: 112233445566 and DA MAC filter and Self

MAC address: 665544332211 in Channel 1 Start with reset the count

MCHPRT 2_SA_DA 12 112233445566

RX with Source MAC filter: 112233445566 in Channel 12 Start with

reset the count

MCHPRT 2_Self_DA 13 665544332211

RX with DA MAC filter and Self MAC address: 665544332211 in

Channel 13 Start with reset the count

The following figure shows the example of RX with Source MAC filter: 112233445566 and DA MAC filter

and Self MAC address: 665544332211 in Channel 1 Start with reset the count.

Figure 3-10. Console Log of RX with Source MAC Filter (Channel 1)

The following figure shows the example of RX with Source MAC filter: 112233445566 in Channel 12 Start

with reset the count.

Figure 3-11. Console Log of RX with Source MAC Filter (Channel 12)

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 49

Page 50

The following figure shows the example of RX with DA MAC filter and Self MAC address: 665544332211

in Channel 13 Start with reset the count.

Figure 3-12. Console Log of RX with Source MAC Filter (Channel 13)

3.1.3.3 RX Package Report

The following table provides the command syntax for RX package report.

Table 3-9. RX Package Report: After Initialization and Start RX

Command Syntax MCHPRT 3

Example MCHPRT 3

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Report the package number (package count will not reset)

The following figure shows the example of RX package report.

Figure 3-13. Console Log of RX Package Report

3.1.3.4 RSSI Reading

The following table provides the command syntax for RSSI reading once.

Table 3-10. RX Package Report Once: After Initialization and Start RX

Command Syntax MCHPRT 9

Example MCHPRT 9

The following figure shows the example of RSSI reading once.

Figure 3-14. Console Log of RSSI Reading Once

Report the RSSI reading once

3.1.3.5 RSSI Reading in Seconds

The following table provides the command syntax for RSSI reading in seconds.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 50

Page 51

ATWINC/ATWILC/ATSAMB/ATBTLC

Table 3-11. RX Package Report: After Initialization and Start RX

Command Syntax MCHPRT 10 X

X X refers to the number of sec report the RSSI reading

Example MCHPRT 10 2

Report the RX RSSI reading in 10 sec

The following figure shows the example of RSSI reading.

Figure 3-15. Console Log of RSSI Reading

Command Line

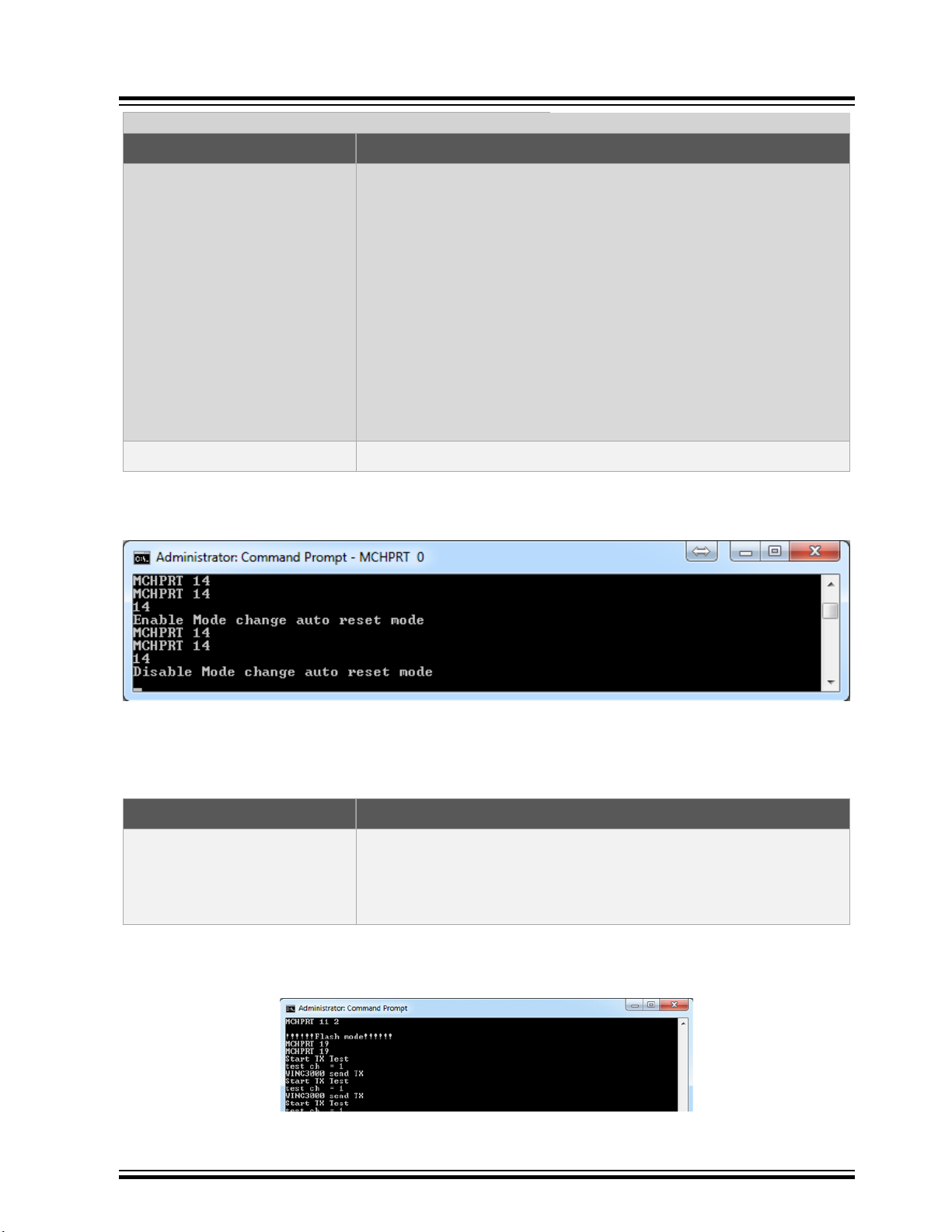

3.1.3.6 Auto Reset Mode

The following table provides the command syntax for Auto Reset mode.

Table 3-12. Auto Reset Mode

Command Syntax MCHPRT 14

Enable Enable refers to that the MCHPRT will auto reset with the mode

change

For example:

MCHPRT 8 1 7 7 0 -10 18 6 1500 0

(Module auto reset)

MCHPRT 6 1 7 7 0 -10 18 6 1500 0

(Module auto reset)

MCHPRT 2 1

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 51

Page 52

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

...........continued

Command Syntax MCHPRT 14

Disable (default) Disable refers that the MCHPRT will not auto reset with the mode

change. Command flow must follow the correct step.

For example:

MCHPRT 8 1 7 7 0 -10 18 6 1500 0

MCHPRT 13

MCHPRT 6 1 7 7 0 -10 18 6 1500 0

MCHPRT 13

MCHPRT 2 1

Each TX information change or change to RX mode, requires to send

stop TX command.

Example MCHPRT 14

The following figure shows the example of Auto Reset mode.

Figure 3-16. Console Log of Auto Reset Mode

3.1.3.7 Digital Gain Table Printing

The following table provides the command syntax for Digital Gain Table Printing.

Table 3-13. Digital Gain Table Printing: After Initialization and Before TX and RX

Command Syntax MCHPRT 19

Example MCHPRT 19

The following figure shows the example of Digital Gain Table Printing.

Module will start TX from Channel 1 to Channel 14 for checking gain

table and then printing the gain table in current Gain mode. This is not

applicable for Bypass mode.

Figure 3-17. Console Log of Digital Gain Table Printing

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 52

Page 53

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Figure 3-18. Console Log of Display Gain Table Printing WINC3400

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 53

Page 54

3.1.3.8 Deinitialization

The following table provides the command syntax for deinitialization.

Table 3-14. Deinitialization: After Initialization

Command Syntax MCHPRT 4

Example MCHPRT 4

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Deinitialization

The following figure shows the example of deinitialization.

Figure 3-19. Console Log of Deinitialization

3.2 Bluetooth (ATWILC3000/ATWINC3400)

3.2.1 Bluetooth Initialization

The following table provides the command syntax for Bluetooth initialization. Refer to 1.3 UART/I2C Pin

Details to check if DTR is enabled or not.

Table 3-15. Initialization

Command Syntax MCHPRT BT X

BT • BT refers to I2C

• BT_UART refers to UART connect

• BT_DTR refers to I2C and DTR enable

• BT_UART_DTR refers to UART connect and DTR enable

• BT_FW refers to firmware upload

X X refers to the port number for Bluetooth UART

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 54

Page 55

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT BT X

Example MCHPRT BT 90

The following figure shows the example of Bluetooth initialization.

Figure 3-20. Console Log of Bluetooth Initialization

Command Line

Table 3-16. Bluetooth initialization without serial port

Command Syntax MCHPRT BT

BT • BT refers to I2C

• BT_UART refers to UART connect

• BT_DTR refers to I2C and DTR enable

• BT_UART_DTR refers to UART connect and DTR enable

• BT_FW refers to firmware upload

Example MCHPRT BT

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 55

Page 56

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-21. Console Log of Bluetooth Initialization without Serial Port

Command Line

3.2.2 Bluetooth DTM

The following table provides the command syntax for Bluetooth DTM mode initialization.

Table 3-17. Initialization of DTM Mode

Command Syntax MCHPRT DTM init

Example MCHPRT DTM init

The following figure shows the example of DTM initialization.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 56

Page 57

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-22. Console Log of DTM Initialization

Command Line

The following table provides the command syntax for DTM mode exit.

Table 3-18. Exit DTM Mode

Command Syntax MCHPRT 9 5

Example MCHPRT 9 5

The following figure shows the example of DTM mode exit.

Figure 3-23. Console Log of DTM Mode Exit

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 57

Page 58

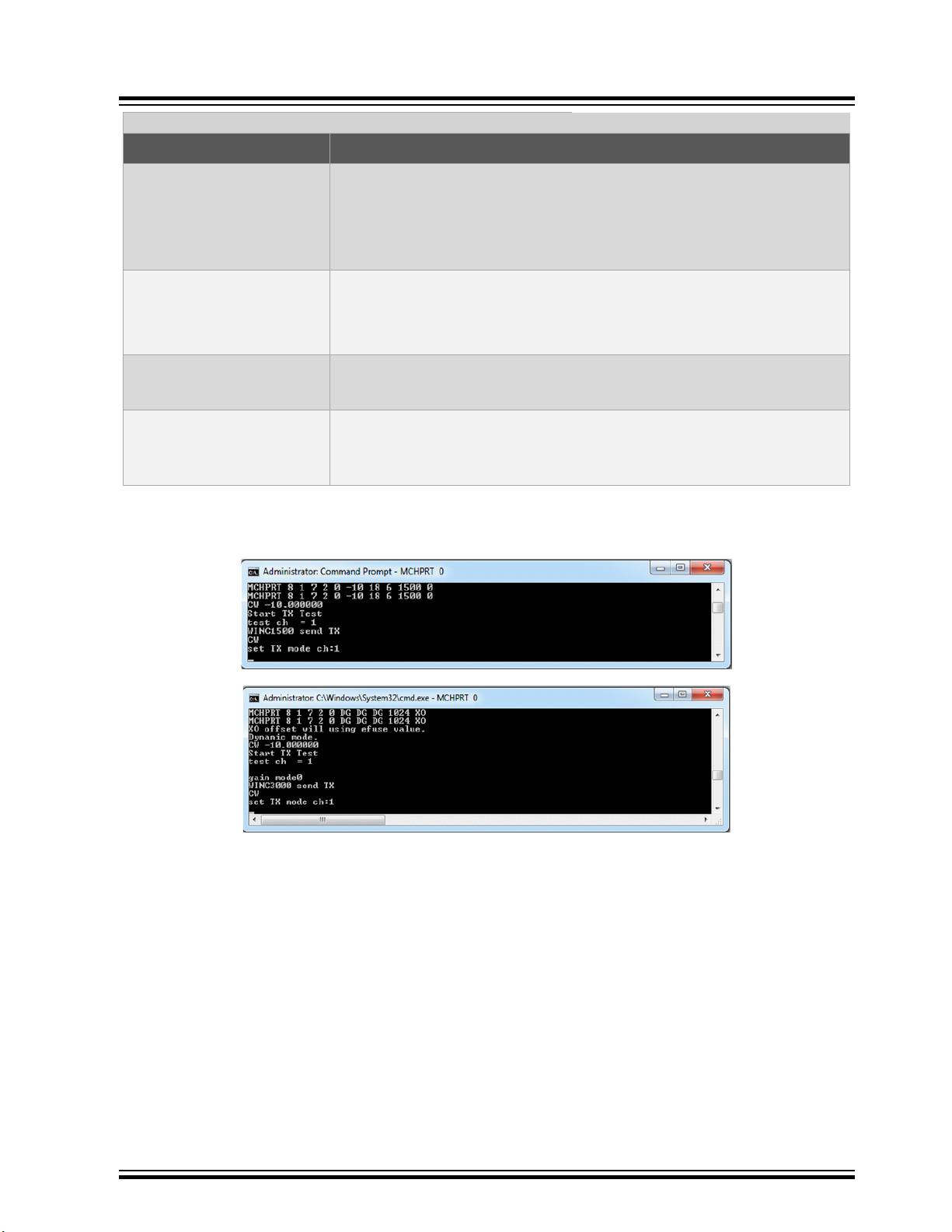

3.2.3 Bluetooth TX

The following table provides the command syntax for the Bluetooth TX test.

Table 3-19. Start Bluetooth TX: After Bluetooth Initialization

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Command

Syntax

X X refer to TX channel: 0 to 39

Y Y refers to Length: 0 – 37

Z Z refers to Payload: 1 – 8

A A refers to Digital Gain (Bypass mode):

MCHPRT BT 1 X Y Z A B C F

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

• 1 - 0x1

• 37 – 0x25

• 1 – PRBS9

• 2 – 11110000

• 3 – 10101010

• 4 – PRBS15

• 5 – 11111111

• 6 – 00000000

• 7 – 00001111

• 8 – 01010101

Range : -20 to 0

DG: Dynamic Gain

B B refers PA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 9, 6, 3, 0

• ATWILC3000/ATWINC3400 – 18, 15, 12, 9, 6, 3

DG: Dynamic Gain

C C refers to PPA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 18, 15, 12, 9, 6, 3

• ATWILC3000/ATWINC3400 – 20, 18, 15, 12, 6, 0

Dynamic Gain

F F refers to Frequency offset :

-50 to +50 base on Crystal

XO : eFuse XO value

Example MCHPRT BT 1 0 37 0 -6 6 6 XO

Channel 0. 0x25 length, PRBS9 DG – 10, PPA 6 , PA 6

The following figure shows the example of Bluetooth TX test mode.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 58

Page 59

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-24. Console Log of Bluetooth TX Test Mode

Command Line

The Bluetooth TX mode starts as shown in the following figure.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 59

Page 60

Figure 3-25. BT TX Mode Start

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Table 3-20. Start Bluetooth TX: After Bluetooth Initialization without Serial Port Connection

Command Syntax MCHPRT BT 1 X Y Z A B C F

A A refers to Digital Gain (Bypass mode):

Range : -20 to 0

DG: Dynamic Gain

B B refers PA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 9, 6, 3, 0

• ATWILC3000/ATWINC3400 – 18, 15, 12, 9, 6, 3

Dynamic Gain

C C refers to PPA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 18, 15, 12, 9, 6, 3

• ATWILC3000/ATWINC3400 – 20, 18, 15, 12, 6, 0

Dynamic Gain

F F refers to Frequency offset :

-50 to +50 base on Crystal

XO : eFuse XO value

Example MCHPRT BT 1 -6 6 6 XO

DG – 10, PPA 6 , PA 6

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 60

Page 61

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-26. Bluetooth Tx Log without Serial Port Connection

Command Line

3.2.3.1 CW

The following table provides the command syntax for the Bluetooth TX CW mode.

Table 3-21. Start Bluetooth TX CW: After Bluetooth Initialization with serial port

Command Syntax MCHPRT BT 2 X Y Z A B C F

X X refer to TX channel: 0 to 39

Y Y refers to Length: 0 – 37

© 2019 Microchip Technology Inc.

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

• 1 – 0x1

• 37 – 0x25

User Guide

DS50002893A-page 61

Page 62

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT BT 2 X Y Z A B C F

Z Z refers to Payload: 1 – 8

• 1 – PRBS9

• 2 – 11110000

• 3 – 10101010

• 4 – PRBS15

• 5 – 11111111

• 6 – 00000000

• 7 – 00001111

• 8 – 01010101

A A refers to Digital Gain (Bypass mode):

Range : -20 to 0

DG: Dynamic Gain

B B refers PA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 9, 6, 3, 0

• ATWILC3000/ATWINC3400 – 18, 15, 12, 9, 6, 3

Command Line

DG: Dynamic Gain

C C refers to PPA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 18, 15, 12, 9, 6, 3

• ATWILC3000/ATWINC3400 – 20, 18, 15, 12, 6, 0

DG: Dynamic Gain

Example MCHPRT BT 2 0 37 0 -6 6 6 18 20

Channel 0. 0x25 length, PRBS9 DG – 6, PPA 6 , PA 6 CW mode

The following figure shows the example of Bluetooth CW mode.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 62

Page 63

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-27. Console Log of Bluetooth CW Mode

The Bluetooth CW mode starts as shown in the following figure.

Figure 3-28. BT CW Mode Start

Command Line

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 63

Page 64

ATWINC/ATWILC/ATSAMB/ATBTLC

Table 3-22. Start Bluetooth TX CW: After Bluetooth Initialization without serial port

Command Syntax MCHPRT BT 8 A B C F

A A refers to Digital Gain (Bypass mode):

Range : -20 to 0

DG: Dynamic Gain

B B refers PA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 9, 6, 3, 0

• ATWILC3000/ATWINC3400 – 18, 15, 12, 9, 6, 3

Dynamic Gain

C C refers to PPA gain (Bypass mode):

• ATWILC1000/ATWINC15X0 – 18, 15, 12, 9, 6, 3

• ATWILC3000/ATWINC3400 – 20, 18, 15, 12, 6, 0

Dynamic Gain

F F refers to Frequency offset :

-50 to +50 base on Crystal

Command Line

Example MCHPRT BT 8 -6 6 6 XO

Figure 3-29. Console Log of Bluetooth CW Mode without Serial Port

3.2.4 Bluetooth Start RX

The following table provides the command syntax for Bluetooth RX test.

Table 3-23. Start Bluetooth RX: After Bluetooth Initialization with Serial Port

Command Syntax MCHPRT BT 3 X

X X refers to TX channel: 0 to 39

XO : eFuse XO value

DG – 6, PPA 6 , PA 6 CW mode

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

Example MCHPRT BT 3 0

RX mode in Channel 1 Start with reset the count

The following figure shows the example of start Bluetooth RX test.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 64

Page 65

Figure 3-30. Console Log of Bluetooth RX Mode

3.2.5 Bluetooth RX Package Count

The following table provides the command syntax for Bluetooth RX package count.

Table 3-24. Start Bluetooth RX Package Count: After Bluetooth Initialization with Serial Port

Command Syntax MCHPRT BT 4

Example MCHPRT BT 4

The following figure shows the example of Bluetooth RX package count.

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Print out good package number

Figure 3-31. Console Log of Bluetooth RX Package Count

3.2.6 BLE Deinitialization

The following table provides the command syntax for BLE deinitialization.

Table 3-25. BLE Deinitialization: After Initialization

Command Syntax MCHPRT BT 5

Example MCHPRT BT 5

The following figure shows the example of BLE deinitialization.

Figure 3-32. Console Log of BLE Deinitialization

BT Deinitialization

3.3 BLE (ATBTLC1000/ATSAMB11)

3.3.1 BLE Initialization

The following table provides the command syntax for BLE initialization. Refer 1.3 UART/I2C Pin Details

to check if DTR is enabled or not.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 65

Page 66

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Table 3-26. Initialization with Serial Port

Command Syntax MCHPRT BLE X

BLE BLE_DTR refers to enable Bluetooth UART

X X refers to the port number for Bluetooth UART

Example MCHPRT BLE 146

The following figure shows the example of BLE initialization. Refer to 1.3 UART/I2C Pin Details to check

if DTR is enabled or not.

Figure 3-33. Console Log of BLE Initialization

Table 3-27. Initialization without Serial Port

Command Syntax MCHPRT BLE

BLE BLE_DTR refers to enable Bluetooth UART

X X refers to the port number for Bluetooth UART

Example MCHPRT BLE

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 66

Page 67

Figure 3-34. Console Log of BLE Initialization without Serial Port

3.3.2 BLE TX (Transmit)

The following table provides the command syntax for the BLE TX test.

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Table 3-28. Start BLE TX: After BLE Initialization with Serial Port

Command Syntax MCHPRT BLE 1 X Y Z A B

X X refer to TX channel: 0 to 39

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

Y Y refers to Length: 0 – 37

• 1 – 0x1

• 37 – 0x25

Z Z refers to Payload: 0 – 7

• 0 – PRBS9

• 1 – 11110000

• 2 – 10101010

• 3 – PRBS15

• 4 – 11111111

• 5 – 00000000

• 6 – 00001111

• 7 – 01010101

A A refers to Gain:

0: 0x00 1: 0x01 2: 0x02 3: 0x03 4: 0x04 5: 0x05 6: 0x06 7: 0x07 8:

0x08 9: 0x09 10: 0x0A 11: 0x0B.….….56: 0x29 57: 0x30 58: 0x3A 59:

0x3B60: 0x3C 61: 0x3D 62: 0x3E 63: 0x3F

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 67

Page 68

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT BLE 1 X Y Z A B

B B mean XO offset value (optional): 0-15

0thbit adds 1.25pf

st

1

bit adds 2.5pf

2nd bit adds 5pf

3rd bit adds 5pf

Example: 11 mean 1011 adds a 8.75pf load cap to circuit. Default

value 7 will apply when no input XO offset value.

Example MCHPRT BLE 1 0 37 1 14

or

MCHPRT BLE 1 0 37 1 14 11

Channel 0. 0x25 length, PRBS9 Gain setting – 0x20

In MCHPRT BLE 1 X Y Z A B command, A B are optional settings.

Command Line

The following figure shows the example of BLE TX test mode.

Figure 3-35. Console Log of BLE TX Test Mode

Table 3-29. Start BLE TX: After BLE Initialization without Serial Port

Command Syntax MCHPRT BLE 1 A B X

X X refer to TX channel: 0 to 39

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

A A refers to Gain:

0: 0x00 1: 0x01 2: 0x02 3: 0x03 4: 0x04 5: 0x05 6: 0x06 7: 0x07 8:

0x08 9: 0x09 10: 0x0A 11: 0x0B.….….56: 0x29 57: 0x30 58: 0x3A 59:

0x3B60: 0x3C 61: 0x3D 62: 0x3E 63: 0x3F

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 68

Page 69

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT BLE 1 A B X

B B mean XO offset value (optional): 0-15

0thbit adds 1.25pf

st

1

bit adds 2.5pf

2nd bit adds 5pf

3rd bit adds 5pf

Example: 11 mean 1011 adds a 8.75pf load cap to circuit. Default

value 7 will apply when no input XO offset value.

Example MCHPRT BLE 1 14 7 0

Channel 0. Gain setting – 0x20

Figure 3-36. Console Log of BLE Tx Test Mode without Serial Port

Command Line

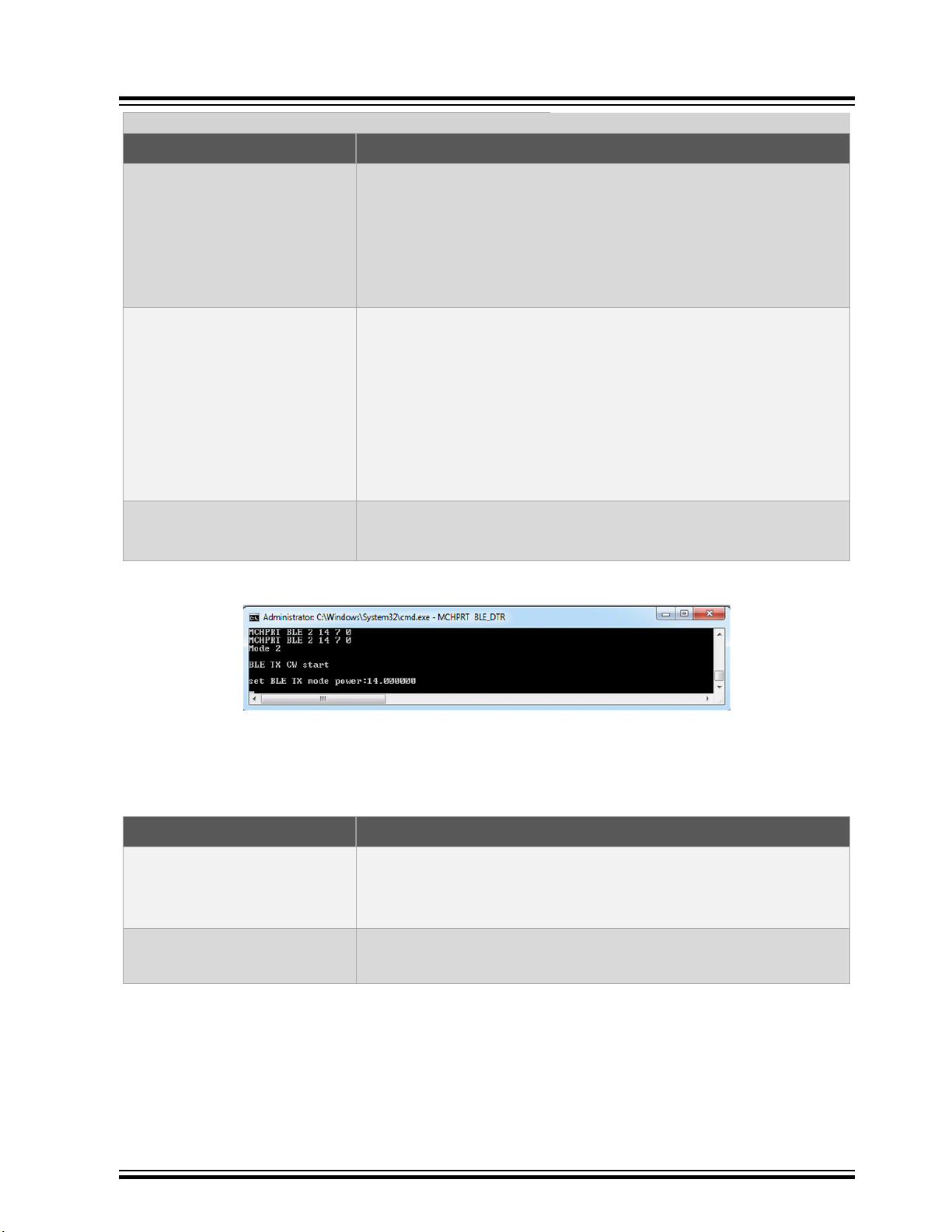

3.3.2.1 CW

The following table provides the command syntax for the BLE TX CW mode.

Table 3-30. Start BLE TX CW: After BLE Initialization with Serial Port

Command Syntax MCHPRT BLE 2 X Y Z A B

X X refer to TX channel: 0 to 39

Y Y refers to Length: 0 – 37

Z Z refers to Payload: 0 – 7

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

• 1 – 0x1

• 37 – 0x25

• 0 – PRBS9

• 1 – 11110000

• 2 – 10101010

• 3 – PRBS15

• 4 – 11111111

• 5 – 00000000

• 6 – 00001111

• 7 – 01010101

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 69

Page 70

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT BLE 2 X Y Z A B

A A refers to Gain:

0: 0x00 1: 0x01 2: 0x02 3: 0x03

4: 0x04 5: 0x05 6: 0x06 7: 0x07

8: 0x08 9: 0x09 10: 0x0B 11: 0x0D

12: 0x11 13: 0x15 14: 0x20 15: 0x3B

B B mean XO offset value (optional): 0-15

0th bit adds 1.25pf

st

1

bit adds 2.5pf

2nd bit adds 5pf

3rd bit adds 5pf

Example: 11 mean 1011 adds a 8.75pf load cap to circuit. Default

value 7 will apply when no input XO offset value

Command Line

Example MCHPRT BLE 2 0 37 1 14

or

MCHPRT BLE 2 0 37 1 14 11

Channel 0. 0x25 length, PRBS9 Gain setting – 0x20 CW mode

The following figure shows the example of BLE CW mode.

Figure 3-37. Console Log of BLE CW Mode

Table 3-31. Start BLE TX CW: After BLE Initialization without Serial Port

Command Syntax MCHPRT BLE 2 X Y Z A B

X X refer to TX channel: 0 to 39

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 70

Page 71

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT BLE 2 X Y Z A B

A A refers to Gain:

0: 0x00 1: 0x01 2: 0x02 3: 0x03

4: 0x04 5: 0x05 6: 0x06 7: 0x07

8: 0x08 9: 0x09 10: 0x0B 11: 0x0D

12: 0x11 13: 0x15 14: 0x20 15: 0x3B

B B mean XO offset value (optional): 0-15

0th bit adds 1.25pf

st

1

bit adds 2.5pf

2nd bit adds 5pf

3rd bit adds 5pf

Example: 11 mean 1011 adds a 8.75pf load cap to circuit. Default

value 7 will apply when no input XO offset value

Command Line

Example MCHPRT BLE 2 14 7 0

Figure 3-38. Console Log of BLE CW Mode without Serial Port

3.3.3 BLE RX

The following table provides the command syntax for BLE RX test.

Table 3-32. Start BLE RX: After BLE Initialization with Serial Port

Command Syntax MCHPRT BLE 3 X

X X refers to TX channel: 0 to 39

Example MCHPRT BLE 3 0

Channel 0. 0x25 length, PRBS9 Gain setting – 0x20 CW mode

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

Channel 0. RX mode start

The following figure shows the example of start BLE RX test.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 71

Page 72

Figure 3-39. Console Log of BLE RX Mode

3.3.4 BLE RX Packet Count

The following table provides the command syntax for BLE RX packet count.

Table 3-33. Start BLE RX Packet Report: After BLE Initialization with Serial Port

Command Syntax MCHPRT BLE 4

Example MCHPRT BLE 4

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Print out good packet number

The following figure shows the example of BLE RX packet count.

Figure 3-40. Console Log of BLE RX Packet Count

3.3.5 BLE Deinitialization

The following table provides the command syntax for BLE deinitialization.

Table 3-34. BLE Deinitialization: After Initialization

Command Syntax MCHPRT BT 5

Example MCHPRT BT 5

The following figure shows the example of BLE deinitialization.

Figure 3-41. Console Log of BLE Deinitialization

BT Deinitialization

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 72

Page 73

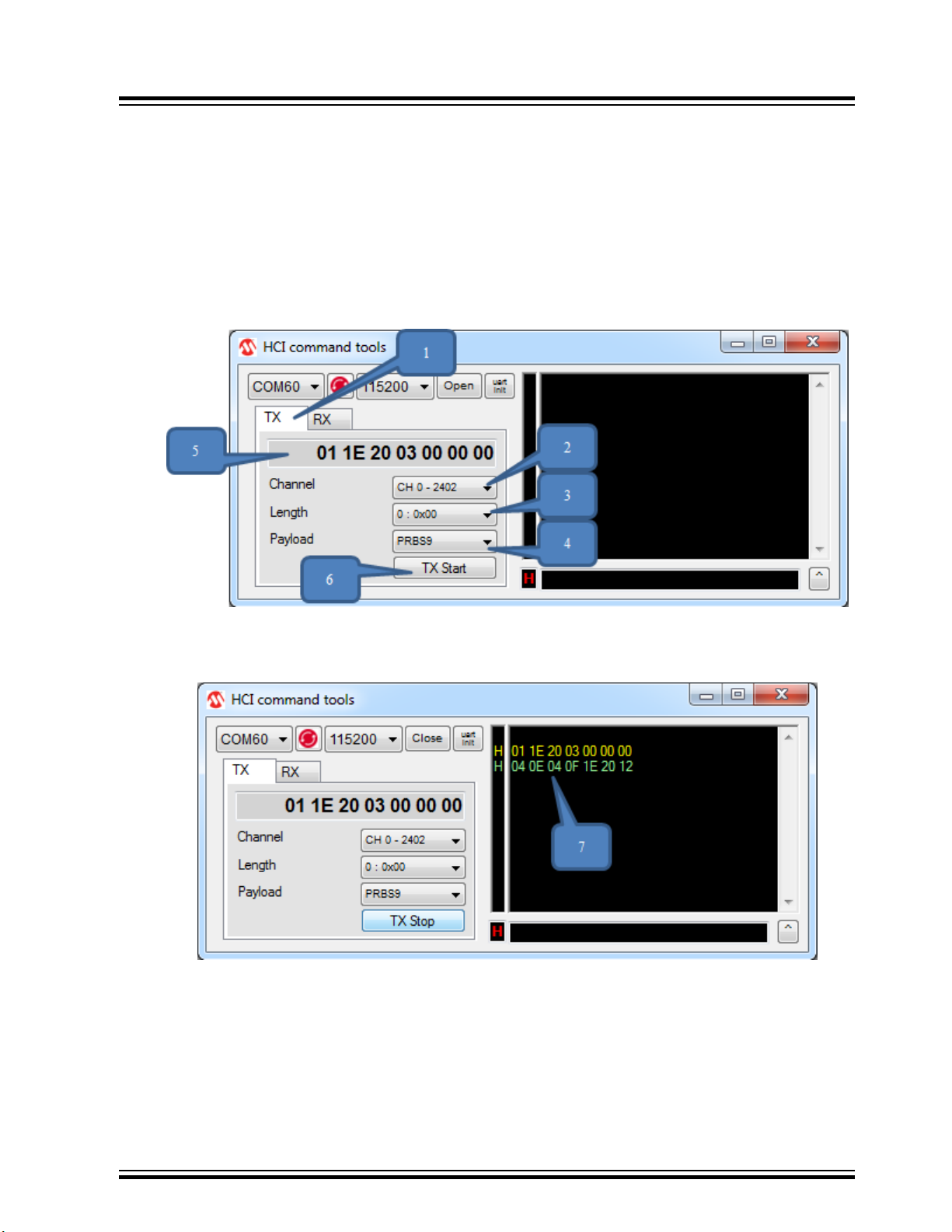

3.4 HCI Command

3.4.1 Initialization of COM Port

The following table provides the command syntax for initialization of COM port. Refer to 1.3 UART/I2C

Pin Details to check if DTR is enabled or not.

Table 3-35. Initialization

Command Syntax MCHPRT HCI X

HCI HCI_DTR refers to DTR enable

X X refers to the port number for Bluetooth UART

Example MCHPRT HCI 94

The following figure shows the example of initialization of COM port.

Figure 3-42. Console Log of Initialization of COM Port

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

3.4.2 HCI TX

The following table provides the command syntax for the HCI TX test.

Table 3-36. Start HCI TX: HCI command only

Command Syntax MCHPRT HCI 1 X Y Z

X X refer to TX channel: 0 to 39

Y Y refers to Length: 0 – 37

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

• 1 – 0x1

• 37 – 0x25

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 73

Page 74

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT HCI 1 X Y Z

Z Z refers to Payload: 0 – 7

• 0 – PRBS9

• 1 – 11110000

• 2 – 10101010

• 3 – PRBS15

• 4 – 11111111

• 5 – 00000000

• 6 – 00001111

• 7 – 01010101

Example MCHPRT HCI 1 0 37 1

Channel 0. 0x25 length, PRBS9

The following figure shows the example of HCI TX test mode.

Figure 3-43. Console Log of HCI TX Test Mode

Command Line

3.4.3 HCI RX

The following table provides the command syntax for HCI RX test.

Table 3-37. Start HCI RX: HCI command only

Command Syntax MCHPRT HCI 3 X

X X refers to TX channel: 0 to 39

Example MCHPRT HCI 3 0

The following figure shows the example of start HCI RX test.

• 0 – Channel 0 (2402 MHz)

• 39 – Channel 39 (2480 MHz)

Channel 0. RX mode start

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 74

Page 75

Figure 3-44. Console Log of HCI RX Mode

3.4.4 HCI RX Package Count

The following table provides the command syntax for HCI RX package count.

Table 3-38. Start HCI RX Package Count: HCI command only

Command Syntax MCHPRT HCI 4

Example MCHPRT HCI 4

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

Print out good package number

The following figure shows the example of HCI RX package count.

Figure 3-45. Console Log of HCI RX Package Count

3.4.5 HCI UART Initialization Command

The following table provides the command syntax for HCI UART initialization command.

Table 3-39. Send UART Init Command and Print out Reply

Command Syntax MCHPRT HCI 6

Example MCHPRT HCI 6

The following figure shows the example of HCI UART initialization command.

Figure 3-46. Console Log of HCI UART Init Command

Print out the reply

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 75

Page 76

3.4.6 HCI Deinitialization

The following table provides the command syntax for HCI deinitialization.

Table 3-40. HCI Deinitialization: HCI command only

Command Syntax MCHPRT HCI 5

Example MCHPRT HCI 5

The following figure shows the example of HCI deinitialization.

Figure 3-47. Console Log of HCI Deinitialization

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

COM port Deinitialization

3.5 Register

3.5.1 Read

The following table provides the command syntax for Reg value read before initialization.

Table 3-41. Reg Value Read: Before Initialization ATWINC/ATWILC

Command Syntax MCHPRT REGR X

REGR • REGR refers to using I2C

X X refers to register number which reads and print value

Example MCHPRT REGR 0

The following figure shows the example of reg value read before initialization.

• REGR_UART refers to using UART

Reg 0 value will be printed

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 76

Page 77

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-48. Console Log of Reg Value Read Before Initialization

The following table provides the command syntax for Reg value read after initialization.

Table 3-42. Reg Value Read: After Initialization ATWINC/ATWILC/ATBTLC/ATSAMB

Command Line

Command Syntax MCHPRT 16 REGR X

X X refers to register number which reads and print the value

Example MCHPRT 16 REGR 0

Reg 0 value will be printed

The following figure shows the example of reg value read after initialization.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 77

Page 78

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-49. Console Log of Reg Value Read After Initialization

Command Line

3.5.2 Write

The following table provides the command syntax for Reg value write before initialization.

Table 3-43. Reg Value Write: Before Initialization ATWINC/ATWILC

Command Syntax MCHPRT REGW X Y

REGW • REGW refers to using I2C

X X refers to register number which writes the register location

Y Y refers to write register value which writes the register value

Example MCHPRT REGW 0 8

The following figure shows the example of reg value write before initialization.

© 2019 Microchip Technology Inc.

• REGW_UART refers to using UART

Reg 0 value will change to 8

User Guide

DS50002893A-page 78

Page 79

ATWINC/ATWILC/ATSAMB/ATBTLC

Figure 3-50. Console Log of Reg Value Write Before Initialization

The following table provides the command syntax for Reg value write after initialization.

Command Line

Table 3-44. Reg Value Write: After Initialization ATWINC/ATWILC/ATBTLC/ATSAMB

Command Syntax MCHPRT 16 REGW X Y

X X refers to register number which writes the register location

Y Y refers to write register value which writes the register value

Example MCHPRT 16 REGW 0 8

Figure 3-51. Console Log of Reg Value Write After Initialization

3.5.3 Dump

The following table provides the command syntax for Reg value dump before initialization.

Table 3-45. Reg Value Dump: Before Initialization ATWINC/ATWILC

Command Syntax MCHPRT REGD X Y F

Reg 0 value will change to 8

REGD • REGD refers to using I2C

• REGD_UART refers to using UART

X X refers to register number which reads the register value

Y Y refers to stop register number which reads the register value

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 79

Page 80

ATWINC/ATWILC/ATSAMB/ATBTLC

...........continued

Command Syntax MCHPRT REGD X Y F

F F refers to register information file name

Example: test.txt

Example MCHPRT REGD 0 10 test.txt

Report the RX RSSI reading in 10 sec

The following figure shows the example of reg value dump before initialization.

Figure 3-52. Console Log of Reg Value Dump Before Initialization

Command Line

The following table provides the command syntax for Reg value dump after initialization.

Table 3-46. Reg Value Dump: After Initialization ATWINC/ATWILC/ATBTLC/ATSAMB

Command Syntax MCHPRT 16 REGD X Y F

X X refers to register number which reads the register value

Y Y refers to stop register number which reads the register value

F F refers to register information file name

Example: test.txt

Example MCHPRT 16 REGD 0 10 test.txt

Report the RX RSSI reading in 10 sec

The following figure shows the example of reg value dump after initialization.

Figure 3-53. Console Log of Reg Value Dump After Initialization

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 80

Page 81

Figure 3-54. Sample test.txt

3.6 eFuse (ATWINC/ATWILC)

For efuse structure refer 8. Appendix E - eFuse and MAC Address

3.6.1 Read

The following table provides the command syntax for read eFuse before initialization.

Table 3-47. Read eFuse: Before Initialization

Command Syntax MCHPRT r

r • r refers to I2C

ATWINC/ATWILC/ATSAMB/ATBTLC

Command Line

• r_UART refers to UART

Example MCHPRT r

eFuse information display

The following figure shows the example of read eFuse before initialization.

Figure 3-55. Console Log of Read eFuse Before Initialization

The following table provides the command syntax for read eFuse after initialization.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 81

Page 82

ATWINC/ATWILC/ATSAMB/ATBTLC

Table 3-48. Read eFuse: After Initialization

Command Syntax MCHPRT 16 r

Example MCHPRT 16 r

eFuse information display

The following figure shows the example of read eFuse after initialization.

Figure 3-56. Console Log of Read eFuse After Initialization

Command Line

3.6.2 Write

3.6.2.1 Write MAC ID Only

The following table provides the command syntax for write MAC ID only.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 82

Page 83

ATWINC/ATWILC/ATSAMB/ATBTLC

Table 3-49. Write MAC ID in eFuse: Before Initialization

Command Syntax MCHPRT XXXXXXXXXXXX or

MCHPRT MAC_UART XXXXXXXXXXXX

MAC_UART • MAC_UART refers to UART

• Without MAC_UART refers to I2C

XXXXXXXXXXXX XXXXXXXXXXXX refers to MAC ID

Example MCHPRT 1234567890AB

eFuse updates the MAC ID: 1234567890AB

eFuse only writes the MAC, remaining information will be copied from

the previous bank.

Example:

Before: BANK 0 MAC 0123456789AB XO offset 1.1

After: Bank 1 MAC 1234567890AB XO offset 1.1

The following figure shows the example of write MAC ID in eFuse.

Command Line

Figure 3-57. Console Log of Write MAC ID for eFuse

3.6.2.2 Write MAC ID Information

The following table provides the command syntax for write MAC ID and frequency offset only before

initialization.

© 2019 Microchip Technology Inc.

User Guide

DS50002893A-page 83

Page 84

ATWINC/ATWILC/ATSAMB/ATBTLC

Table 3-50. Write MAC ID in eFuse: Before Initialization

Command Syntax MCHPRT XXXXXXXXXXXX Y IQ A AE P PE T TEor

MCHPRT MAC_UART XXXXXXXXXXXX Y IQ A AE P PE T TE

MAC_UART • MAC_UART refers to UART

• Without MAC_UART refers to I2C

XXXXXXXXXXXX refers to MAC ID

XXXXXXXXXXXX XXXXXXXXXXXX refers to MAC ID

Y Y refers to frequency offset value

If "XO" is given as input then it disables the XO in eFuse.

A A refers to IQ imbalance amplitude correction value.

Give the value as "0". The current WILC/WINC firmware doesn’t

support this feature, it is for future reservation

If "AMP" is given as input then it disable amplitude imbalance in efuse.

AE AE refers to correction value real or imaginary

0: Real

Command Line

1: Imaginary

If "AMP" is given as input then it disable amplitude imbalance in efuse.

P P refers to phase correction value in IQ imbalance.

Give the value as "0". The current WILC/WINC firmware doesn’t

support this feature, it is for future reservation

If "Phase" is given as input then it disable phase imbalance in efuse.

PE PE refers to correction value real or imaginary

0: Real

1: Imaginary