Page 1

AN616

Digital Signal Processing with the PIC16C74

Author: Darius Mostowfi

Design Consultant

INTRODUCTION

This application note describes the basic issues that

need to be addressed in order to implement digital signal processing systems using the PIC16C74 and

provides application code modules and examples for

DTMF tone generation, a 60 Hz notch filter, and a

simple PID compensator for control systems. These

routines can also be used with other PIC16C6X and

PIC16C7XXX processors with minor modifications and

the addition of external analog I/O devices.

The use of general purpose microcontrollers for

low-end digital signal processing applications has

become more commonplace these days with the availability of higher speed processors. Since most signal

processing systems consist of a host processor and

dedicated DSP chip, the use of a single microcontroller

to perform both these functions provides a simpler and

lower cost solution. In addition, the single chip design

will consume less power which is ideal for battery

powered applications. The PIC16C74 with its on-chip

A/D, PWM module, and fast CPU is an ideal candidate

for use in these low-bandwidth signal processing

applications.

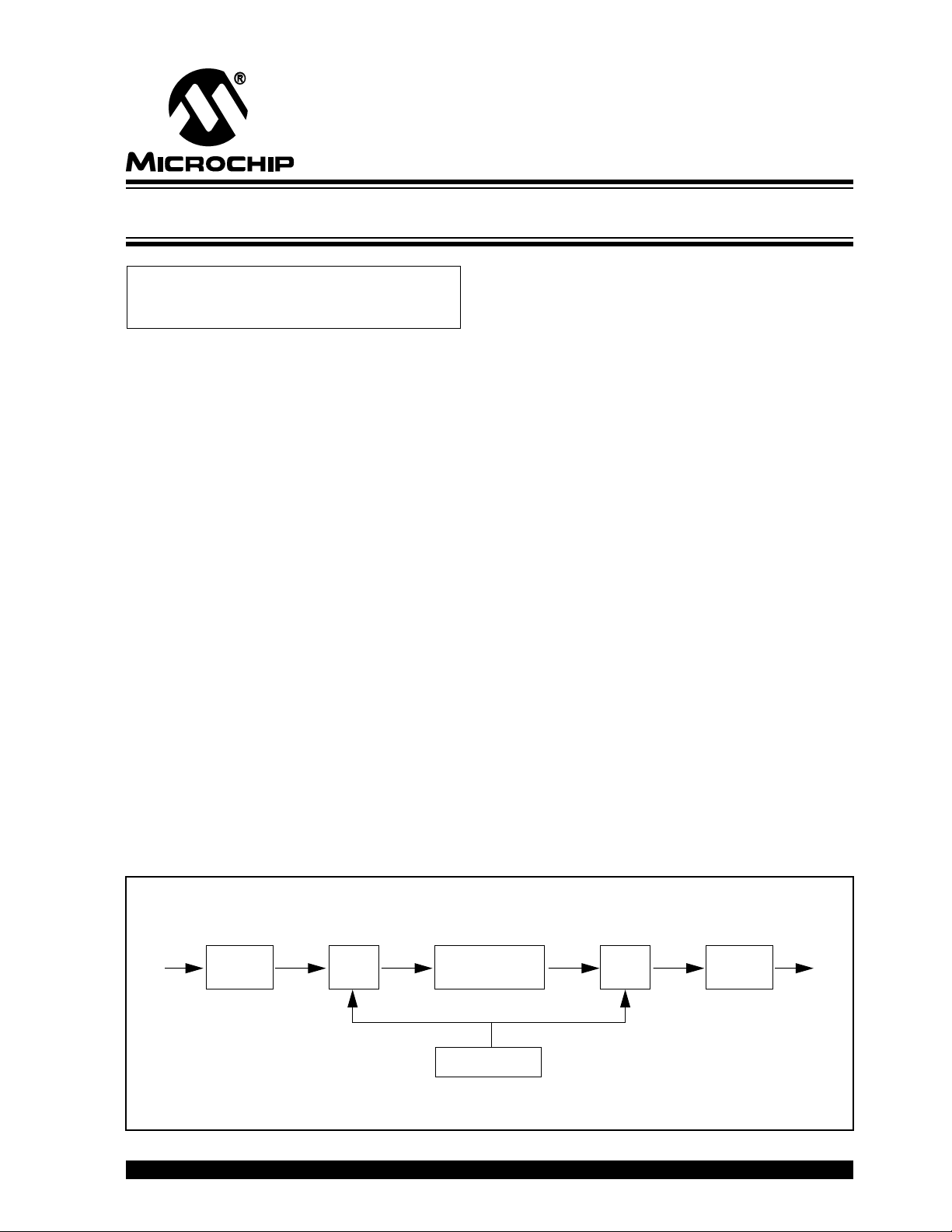

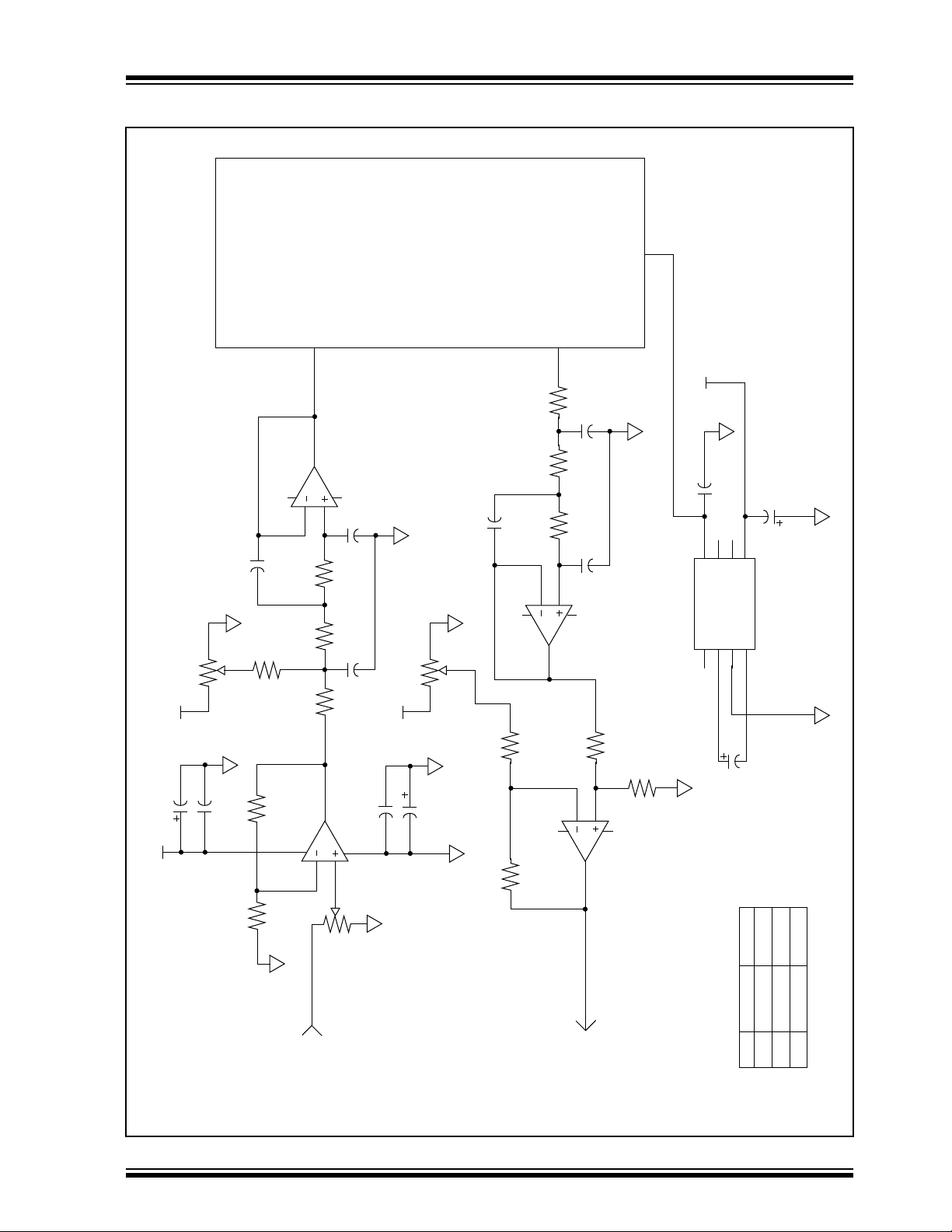

A typical signal processing system includes an A/D

converter, D/A converter, and CPU that performs the

signal processing algorithm as shown in Figure 1.

The input signal,

filter (commonly called the anti-aliasing filter) whose

function is to bandlimit the signal to below the Nyquist

rate (one half the sampling frequency) to prevent

aliasing. The signal is then digitized by the A/D

converter at a rate determined by the sample clock to

produce

system transfer function,

in the time-domain using a difference equation. The

output sample,

continuous-time signal,

output low-pass filter.

The calculation of the output signal using a difference

equation requires a multiply and accumulate (MAC)

operation. This is typically a single-cycle instruction on

DSP chips but can take many cycles to perform on a

standard microcontroller since it must be implemented

in code. Since the digitization of the signal, calculation

of the output, and output to the D/A converter all must

be completed within the sample clock period, the speed

at which this can be done determines the maximum

bandwidth that can be achieved with the system. The

relatively slow speed of most microcontrollers is the

major limitation when they are used in DSP applications but the PIC16C74’s fast instruction execution

speed (as fast as 200 ns/instruction) can provide the

performance required to implement relatively low bandwidth systems. In addition, the device’ s on-chip A/D and

PWM modules provide all the functions needed for a

single chip system. Only a few external components

are needed to use the PIC16C74 for tone generation,

filtering of transducer signals, or low bandwidth control.

x(n)

x(t)

, is first passed through an input

, the discrete-time input sequence. The

H(z)

, is typically implemented

y(n)

, is then converted back into the

y(t)

, by the D/A converter and

FIGURE 1: TYPICAL SIGNAL PROCESSING SYSTEM

X[t]

1997 Microchip Technology Inc. DS00616A-page 1

Low-pass

Filter

A/D

X[n]

H[z]

System Clock

Y[n]

D/A

Low-pass

Filter

Y[t]

Page 2

AN616

CODE DEVELOPMENT TOOLS

The code for these applications was written using

Byte Craft’s MPC C compiler . The MPC compiler provides

an Integrated Development Environment (IDE) and generates highly optimized code for the entire PICmicro™

family. For new PICmicro users that are familiar with C,

this is an ideal way to quickly develop code for these

processors. In addition, the listing files can be studied in

order to learn the details of PICmicro assembly language.

The modules and examples for this application note use

C for the main program body and in-line assembly language for the time-critical routines. MPC provides interrupt support so that interrupt service routines (ISRs) can

be easily written in either C or assembly. This f eature was

used to provide a timer ISR for one of the code modules.

The compiler proved to be a valuable tool that allowed

both high level and assemb ly language routines to be written and tested quickly.

In order to provide the double precision math functions

required for this application note, a couple of existing

math functions written for the PIC16C54 (AN525,

gramming PIC16C5X Devices on Logical Devices

converted for use with MPC. The double precision multiply

and addition routines were modified by first changing all

RAM declarations done in EQU statements to C

“

unsigned char

assembly language code was preceded by “ #asm ” and

ended by “ #endasm ” preprocessor directives which tell

the compiler where the in-line assembly code starts and

ends. Finally , an y macro sections and register names that

are defined differently in MPC were changed.

The assembly language routines for tone generation and

filtering were also written as C functions using the compiler. Assembly language routines written in this way can

be called directly from other assembly language modules

or called directly from C by using the label name as a C

function. Source listings for all the modules and example

programs can be found in the appendices at the end of

this application note. These modules can be directly compiled using the MPC compiler or, alternatively, the assembly language sections can be used with MPASM with

minor modifications.

” variable declarations. The main body of

Number Representation and Math Routines

One of the challenges of using any general purpose

microcontroller for signal processing algorithms is in

implementing the finite word-length arithmetic required to

perform the calculations. As mentioned before, the speed

at which the MAC operations can be performed limits the

maximum achievab le bandwidth of the system. Theref ore,

the routines that perform the multiplication and the main

signal processing algorithms need to be optimized for

speed in order to obtain the highest possible bandwidth

when using the PIC16C74.

The selection of word size and coefficient scaling are also

important factors in the successful implementation of signal processing systems. The effects of using a fixed word

length to represent the signal and do calculations fall into

Pro-

) were

three categories: signal quantization, round-off error, and

coefficient quantization. The signal quantization due to

the A/D converter and round-off error due to the finite precision arithmetic affect the overall signal-to-noise

performance of the system. Scaling of the input signal

should be done before the A/D converter to use the full

input range and maximize the input signal-to-noise ratio.

The use of double precision math for all calculations and

storing intermediate results, even if the input and output

signals are represented as 8-bit words, will help to reduce

the round-off error noise to acceptable levels. Coefficient

quantization occurs when the calculated coefficients are

truncated or rounded off to fit within the given word length.

This has the effect of moving the system transf er function

poles and zeros which can change the system gain, critical frequencies of filters, or stability of the system. The

successful implementation of these systems requires

careful design and modeling of these effects using one of

the many software programs that are available. The code

written for this application note was first modeled using

PC MA TLAB bef ore being implemented on the PIC16C74.

The algorithms in this application note are all

implemented using fixed point two’s compliment

arithmetic. Two math libraries were used for the

examples: one 8-bit signed multiply routine that was written specifically for the tone generation algorithm, and the

modified double precision routines for the PIC16C54 that

were used in the filtering routine. All numbers are stored

in fractional two’s compliment for mat where the MSB is

the sign bit and there is an implied decimal point right after

it. This is commonly referred to as Qx format where the

number after the Q represents the number of fractional

bits in the word. For instance, 16 bit words with the decimal point after the MSB would be referred to as Q15. This

format allows numbers over the range of -1 to 0.99 to be

represented and, because the magnitude of all numbers

is less than or equal to one, has the advantage that there

can be no overflow from a multiplication operation.

Since calculations are done using two’s compliment arithmetic, values read by the PIC16C74’ s A/D con verter need

to be converted to this format. This can be easily done if

the input is set up to read values in offset binary format.

In this representation, the most negative input voltage is

assigned to the number 0, zero volts is assigned the number 128, and the most positive voltage input is assigned

255. Since the PIC16C74 has a unipolar input A/D converter, a bipolar input signal must be scaled to be between

0 and 5V. One way to accomplish this is to use an op-amp

scaling and offset circuit. The signal should be centered

at 2.5V and have a peak to peak voltage swing of

4 to 4.5V. The offset binar y number can be converted to

two’s compliment format by simply complimenting the

MSB of the word. Once the signal processing calculations

are completed, the number can be converted back to offset binary by complimenting the MSB before it is written

to the PWM module. A similar level shifting circuit can be

used at the PWM output to restore the DC level of the signal. Using this technique allows a wide range of analog

input voltages to be handled by the PIC16C74.

DS00616A-page 2

1997 Microchip Technology Inc.

Page 3

AN616

A/D and D/A Conversion

The PIC16C74’s internal 8-bit A/D converter and PWM

modules can be used to implement analog I/O for the system. The A/D converter along with an external anti-aliasing filter provides the analog input for the system.

Depending on the input signal bandwidth and the sampling frequency, the filter can be a simple single pole RC

filter or a multiple pole active filter . The PWM output along

with an external output “smoothing” filter provides the D/A

output for the system. This can be a simple RC filter if the

PWM frequency is much higher (five to ten times) than the

analog signal that is being output. Alternatively, an active

filter can also be used at the PWM output . Since the use

of the A/D and PWM modules is covered in detail in the

data sheet for the part, they will not be covered here. In

addition, since the PIC16C74’s A/D conv erter is similar to

the PIC16C71 and the PWM module is the same as the

PIC16C74, the use of these is also covered in application

notes AN546, AN538, and AN539.

Appendix A contains the listing for the C module “

GIO.C

” that has the functions that read the A/D conv erter

input, initialize the PWM module, and write 8-bit values to

the PWM module. The number format (offset binary or

two’s compliment) f or the A/D and PWM v alues as well as

the PWM resolution and mode are set using “ #define ”

pragmas at the beginning of the module. The

get_sample() function takes the A/D input multiplexor

channel number as an argument and returns the measured input value. The init_PWM() function takes the

PWM period register PR2 value as an argument. The

write_PWM() function takes the output values for PWM

module1 and 2 and writes them to the appropriate registers using the specified resolution. If the second argument

to the function is 0, the registers for PWM module 2 are

unaffected. The PWM resolution is always 8-bits but the

mode used depends on the PWM frequency.

The A/D conversions need to be perf ormed at the system

sample rate which requires that some form of sample

clock be generated internally or input from an external

source. One way to generate this clock internally, in software with minimal effort, is to use the Timer2 interrupt.

Since Timer2 is used to generate the PWM period,

enabling the Timer2 interrupt and using the Timer2

postscaler can generate an interrupt at periods that are

integer divisors of the PWM period. The ISR can set a

software “sample flag” that is checked by the main routine .

Once the sample flag is asserted by the ISR, the main

routine can then clear it and perform the signal processing

operation, output the next sample, and then wait for the

sample flag to be asserted true again. Alternatively, a

separate timer/counter or external clock input can be

used for the system sample clock. The latter two methods

have the advantage that the PWM frequency can be set

independent of the sampling period. For best results, the

PWM frequency should be set for at least five times the

maximum frequency of the analog signal that is bring

reproduced. The example programs illustrate the use of

both of the methods for generating an internal sample

clock.

ANALO-

Tone Generation

For systems that need to provide audible feedback or to

provide DTMF signaling for telcom applications, the

PIC16C74’s PWM module can be used to generate these

signals. One wa y to do this is to output samples of a sin usoidal waveform to the PWM module at the system sampling rate. This method is relatively simple but is limited to

single tones and may require large amounts of memory

depending on the number of samples used per cycle of

the wavefor m and the number of tones that need to be

generated. A more efficient method of generating both

single and dual-tone signals is to use a difference equation method. This method uses a difference equation that

is derived from the z-transform of a sinusoid as follows:

The z-transform of a sinusoid is

1–

z

ω

--------------------------------------------------1 2z

where the period ω = 2 πƒ and T is the sampling period.

If this is interpreted as the transfer function

H(z) = Y(z)/X(z) then the difference equation can be found

taking the inverse z-transform and applying the associated shift theorem as follows:

rearranging:

-1

Y(z)(1 - 2z

Y(z) = z

taking the inverse z-transform:

-1

Z

[Y(z)] = Z-1[z-1X(z)sinωT + z-1Y(z)2cosωT - z-2Y(z)]

y(n) = sin

If we let

written as:

y(n) = a x(n - 1) + 2b y(n - 1) - y(n - 2)

thus we have a diff erence equation with coefficients

b

. Note that only two coefficients are needed to generate

a sinusoidal output sequence. These are calculated from

the relationship above and stored in memory for use by

the tone generation algorithm.

If we input an impulse to this system (x(n) = 1 at n = 0 and

is zero elsewhere) then the output of the system will be a

discrete-time sinusoidal sequence. Note that at n = 0, the

output will always be 0 and x(n) is only 1 at n = 1 so the

sequence becomes:

cosωT + z-2) = X(z)(z-1sinωT)

-1

X(z)sinωT + z-1Y(z)2cosωT - z-2Y(z)

ω

T x(n - 1) + 2cosωT y(n - 1) - y(n - 2)

a = sin ω T

and

y(0) = 0

y(1) = a

y(n) = 2b y(n - 1) - y(n - 2)

for n equal to or greater than 2

Tsin

1–

ω

Tcos– z2–+

b = cos ω T

, the equation can be

a

and

1997 Microchip Technology Inc. DS00616A-page 3

Page 4

AN616

In order to further simplify the implementation of the algorithm, we can omit the first sample period. Since the output is already at 0 before starting, this will make no

difference in the final output other than the fact that it will

be time shifted by one sample. To generate dual tones,

the algorithm is executed once for each tone and the two

output samples are summed together. Since the output

must be calculated and output to the D/A each sample

period, a limitation exists on the frequency of the tone that

can be produced for a given sample rate and processor

speed. The higher the ratio of the sample clock to the tone

frequency , the better , b ut a sample rate of at least three to

four times the highest tone output should produce a sine

wave with acceptable distortion.

Appendix B contains the listing for the “ PICTONE.C ” module which uses the difference equation method to produce

variable length tones from the PWM module. Timer2 is

used to generate the PWM period as well as the sample

clock and tone duration timer. To send a tone, the coefficients and duration are written to the appropriate variables and then the tone routine is called. If the a2 and b2

coefficients are cleared, the routine will only generate a

single tone sequence. The difference equation algorithm

uses 8-bit signed math routines for the multiply operations. Using 8-bit coefficients reduces the accuracy by

which the tones can be generated but greatly reduces the

number of processor cycles needed to perform the algorithm since only single precision arithmetic is used. The

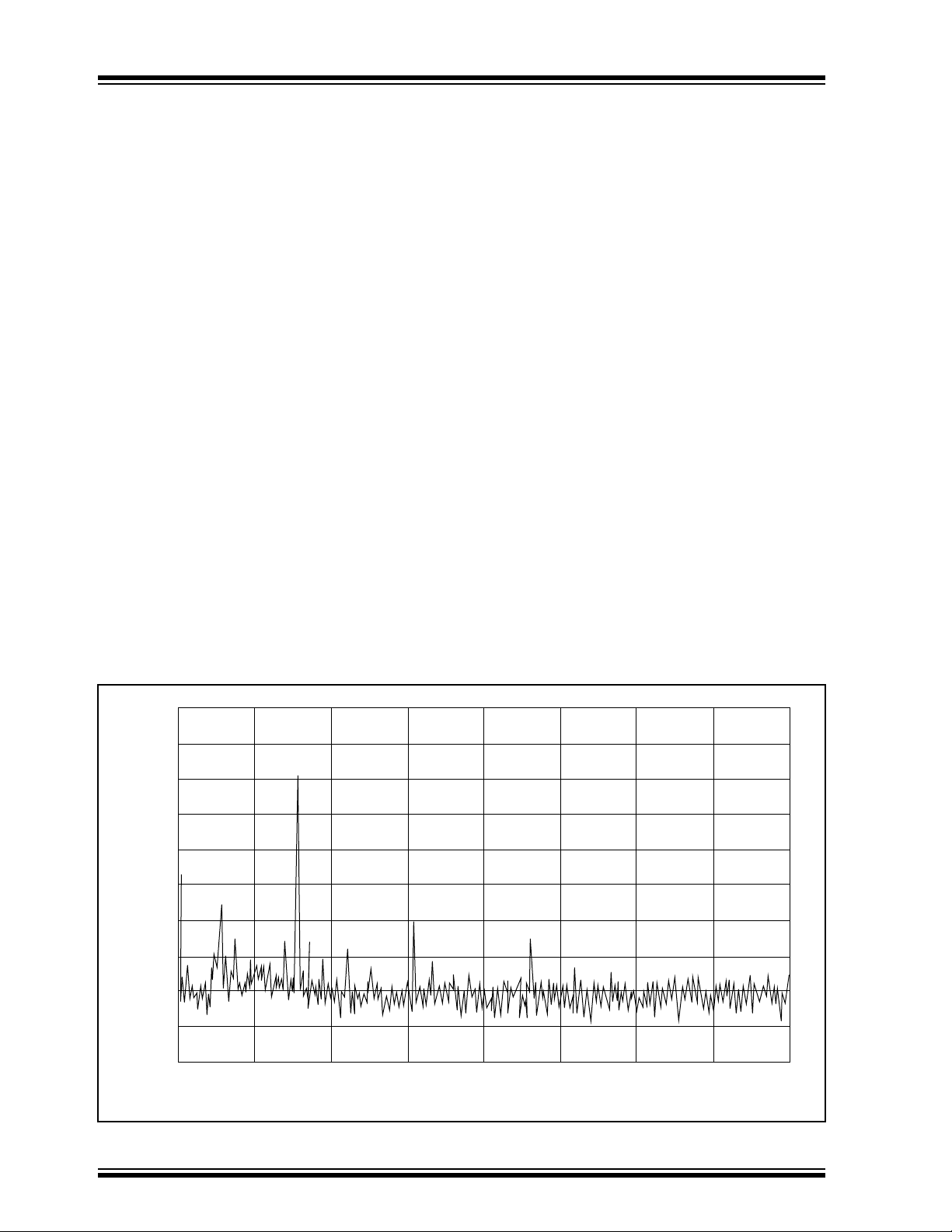

spectrum of a single tone signal generated using this routine is shown in Figure 2.

Note that the second harmonic is better than 40 dB below

the fundamental. Accuracy of this particular tone is better

than 0.5%.

An example program “ DTMFGEN.C ” illustrates the use of

the tone module to generate the 16 standard DTMF tones

used for dialing on the telephone system. A sampling rate

of 6.5 kHz was used which allows dual tones to be generated on a processor running at 10 MHz. Accuracy with

respect to the standard DTMF frequencies is better than

1% for all tones and all harmonics above the fundamental

frequency are greater than 30 dB down.

FIGURE 2: SINGLE TONE SIGNAL

0.0

-10

-20

-30

-40

-50

-60

-70

Relative Amplitude (dB)

-80

-90

-100

0.0 500 1.0k 1.5k 2.0k 2.5k 3.0k 3.5k

PIC16C74 Tone Generation Routine Output Spectrum - 770 Hz Fundamental

Frequency (Hz)

DS00616A-page 4

1997 Microchip Technology Inc.

Page 5

AN616

Digital Filters

Digital filters with critical frequencies up to a kilohertz or

so can be implemented on the PIC16C74. Digital filters

fall into two classes: Finite Impulse Response (FIR) and

Infinite Impulse Response (IIR) filters. FIR filters require

more coefficients and multiplication operations to implement practical filters and are not as well suited for implementation on the PIC16C74. IIR type filters are typically

designed starting with an analog filter prototype and then

performing an analog to digital transformation to produce

the digital filter coefficients. The subject of digital filter

design is not within the scope of this application note but

there are many excellent texts that cover the theory and

design of these filters.

The implementation of a second-order IIR filter is done by

using a second-order difference equation. A

second-order infinite impulse response (IIR) filter has a

transfer function of the form:

b

+ b1z-1 + b2z

H(z) =

Where a

polynomials of the system transfer function that, when

factored, yield the system poles and zeros. The difference

equation found by taking the inverse z-transform and

applying the shift theorem is:

y(n) =

b

Since the transfer function coefficients are used directly in

the difference equation, this is often called the “Direct

Form I” implementation of a digital filter. This form has its

limitations due to numerical accuracy issues but is effective for implementing second-order systems.

Appendix C contains the listing for the general-purpose

filter routine “ IIR_FILT.C ” that can be used to implement low-pass, high-pass, bandpass, and bandstop

(notch) filters. The filter() function takes an 8-bit input

value x(n) and calculates the output value y(n) . The filter

coefficients are stored as 16-bit two’s compliment

numbers and computation of the output is done using

double precision arithmetic. Since the coefficients

generated from the filter design program will be in decimal

form, they need to be scaled to be less than 1 and then

multiplied by 32,768 to put them in Q15 format. Additional

scaling by factors of two may be required to prevent overflow of the sum during calculations. If this is done, the output must be multiplied by this scale factor to account for

this. The “ IIR_FILT.C ” module contains two other subroutines required for the filtering program. One if these is

a decimal adjust subroutine to restore the decimal place

after two 16-bit Q15 numbers are multiplied. The subroutine shifts the 32-bit result left by one to get rid of the extra

, a

, b

1

x(n) + b1x(n - 1) + b2x(n - 2) - a1y(n - 1) - a2y(n - 2)

0

, b

2

0

0

1 + a1z-1 + a2z

, and b

1

are the coefficients of the

2

-2

-2

sign bit. The other routine scales the output by factors of

two and is used after the output of the filter has been

calculated to account for the scaling of the coefficients.

An example program “ NOTCH_60.C ” is provided that illustrates the implementation of a 60 Hz notch filter using the

“ IIR_FILT.C ” module. The filter was modeled and

designed using PC MATLAB before being implemented

on the PIC16C74. A sample rate of 1 kHz is used which

means that signals up to a few hundred hertz can be processed. The filter provides an attenuation of about 40 dB

at 60 Hz and can be used to remove interference from

sensor signals in a system.

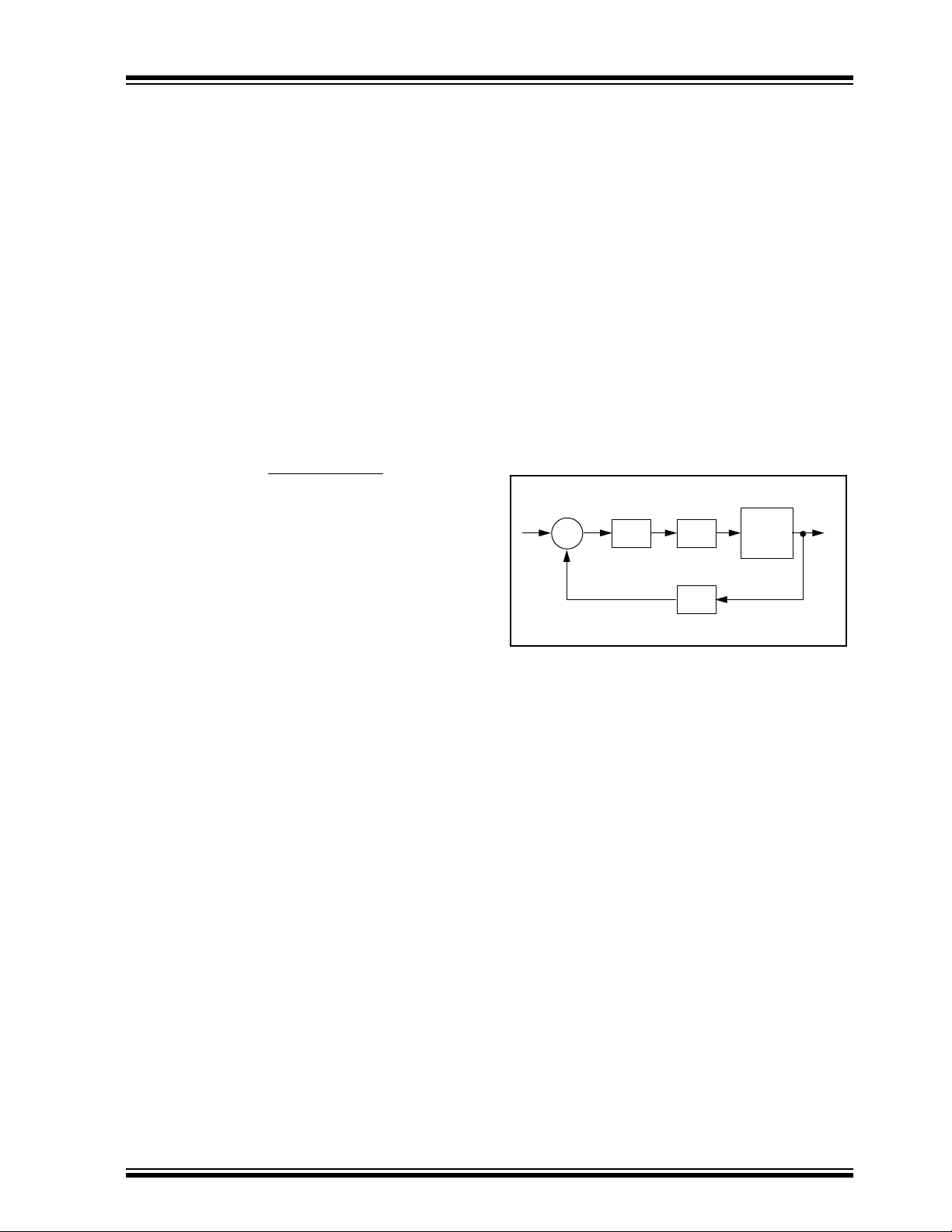

Digital Control

A low bandwidth digital control system can be

implemented on the PIC16C74 using the analog I/O and

IIR filter routines. A typical digital control system is shown

below:

FIGURE 3: TYPICAL DIGITAL CONTROL

SYSTEM

r

+

The input, r , is the reference input and

continuous-time output of the system.

transfer function of the plant (controlled system) and

is the digital compensator. The error signal is calculated

by subtracting the measured output signal,

reference. The controller transfer function is essentially a

filter that is implemented in the time-domain using a difference equation. Since digital control system design is a

complex subject and the design of a suitable compensator depends on the system being controlled and the performance specifications, only the implementation issues

will be discussed.

e[n]

∑

K[z]

-

D/A

y[n]

A/D

G[s]

Plant

y(t)

G(s)

is the analog

y[t]

is the

K(z)

y(n)

, from the

1997 Microchip Technology Inc. DS00616A-page 5

Page 6

AN616

One popular and well understood compensator is the Proportional-Integral-Derivative (PID) controller whose transfer function is of the form:

K

K(z) = KP +

Where

K

is the proportional gain,

,and

implemented directly or can be put in the form of a standard second-order difference equation from the modified

transfer function as shown below:

Since the numerator coefficients will be greater than one,

a gain factor

ing coefficients are less than one. In this way, the IIR filter

routine can be used to implement the controller. After the

filter routine, the output

before being output to the PWM module. Since the gain

can be high, this result needs to be checked for overflow

and limited to the maximum 8-bit value, if required. Saturating the final result prevents the system from going

unstable if overflo w in the math does occur . The gains can

also be applied externally at the D/A output. F or e xample ,

the PWM can drive a power op-amp driver that provides a

± 20 volt swing for a DC motor.

P

K

is the derivative gain. The transfer function can be

D

H(z) =

y(n) =

(KIT2 + KPT + KD) - (2KD + KPT)z-1 + KDz

(K

+ KIT +

P

2K

- (KP +

K

+

T

D

T

D

x(n - 2) - y(n - 1)

K

needs to be factored out so that the result-

I

+ KD(1 - z-1)

-1

1 - z

K

is the integral gain

I

T(1 - z-1)

K

D

)x(n)

T

)x(n - 1)

y

needs to be multiplied by

-2

RESULTS AND CONCLUSION

The results obtained using the PIC16C74 in these applications were impressive. The tone generation routines

produce very clean sinusoidal signals and DTMF tones

generated using this routine have been used to dial numbers over the telephone system with excellent results. In

addition, tones used for audible f eedback are more pleasing to the ear than those generated from a port pin as is

typically done on processors without PWM modules.

Using the PIC16C74 to generate these tones eliminates

the need for special DTMF generator IC’s thus reducing

the cost and simplifying the design. The tone routine

requires approximately 125 instruction cycles to calculate

an output sample for a single tone output and

230 instruction cycles to calculate an output sample for a

dual tone output.

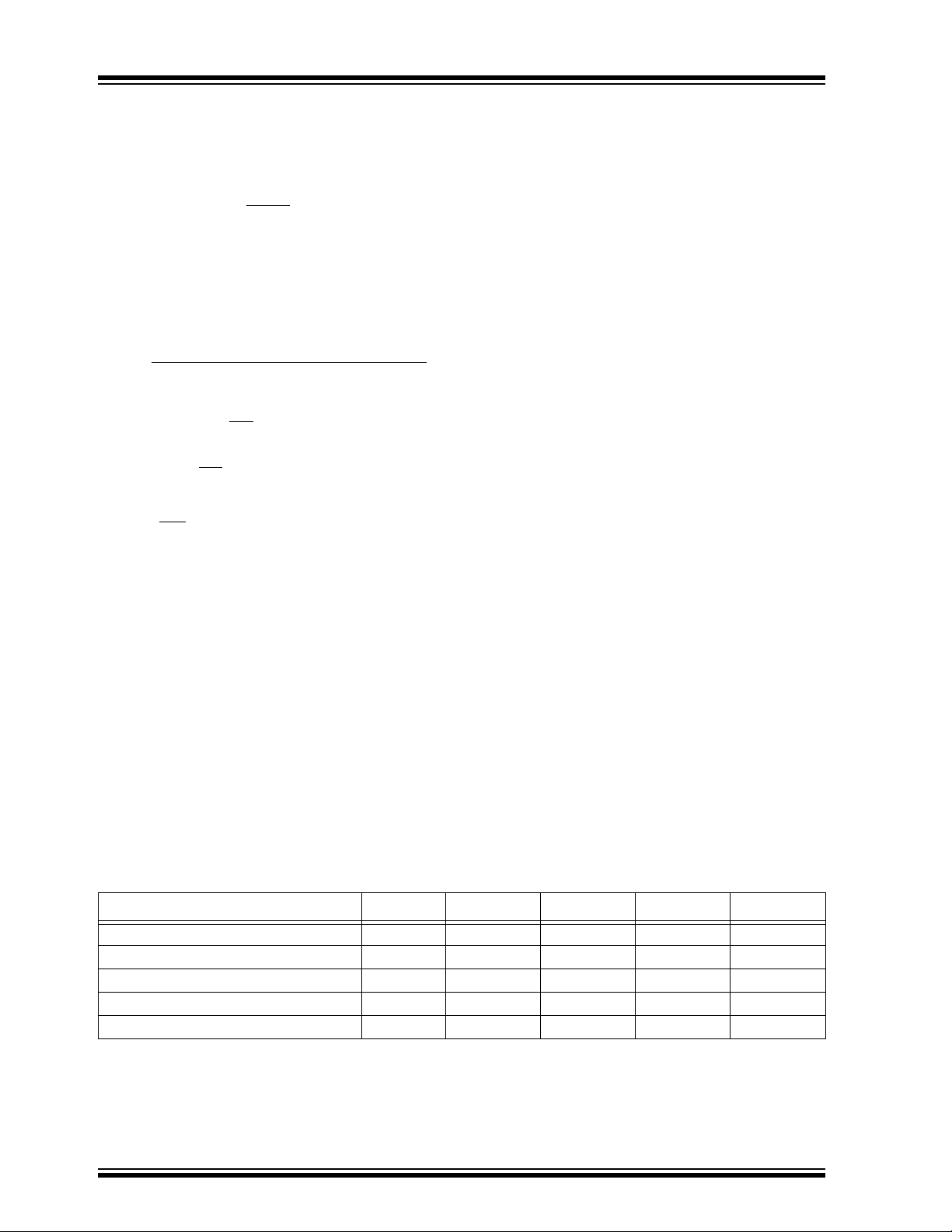

The IIR filtering routines produce good results and have

been used to filter 60 Hz signals on sensor lines and also

to implement a simple PID controller system with excellent

results. The IIR routine takes approximately 1670 instruction cycles to calculate the output. Table 1 shows the performance that can be expected with the PIC16C74 for

various processor speeds.

In conclusion, the PIC16C74 provides the necessary performance to provide these simple, low bandwidth signal

processing operations. This means that products using

this device can benefit from cost and power savings by

eliminating specialized components that normally perform these tasks.

K

References

Antoniou, A. Digital Filters: Analysis and Design. NY:

McGraw-Hill Book Co., 1979.

Openheim, A.V. and Schafer, R.W. Digital Signal

Processing. Englewood Cliffs, N.J.: Prentice-Hall, Inc.,

1975.

TABLE 1: PIC16C74 IIR FILTER PERFORMANCE

4 MHz 8 MHz 10 MHz 16 MHz 20 MHz

A/D Input (35 cycles + 15 µs) 50 µs 32.5 29 23.75 22

IIR Filter (1850 cycles) 1850 925 740 462.5 370

PWM Output (62 cycles) 62 31 24.8 15.5 12.4

Total 1962 988.5 793.8 501.75 368.4

Max. Sampling Frequency ~500 Hz ~1000 Hz ~1250 Hz ~2000 Hz ~2500 Hz

DS00616A-page 6

1997 Microchip Technology Inc.

Page 7

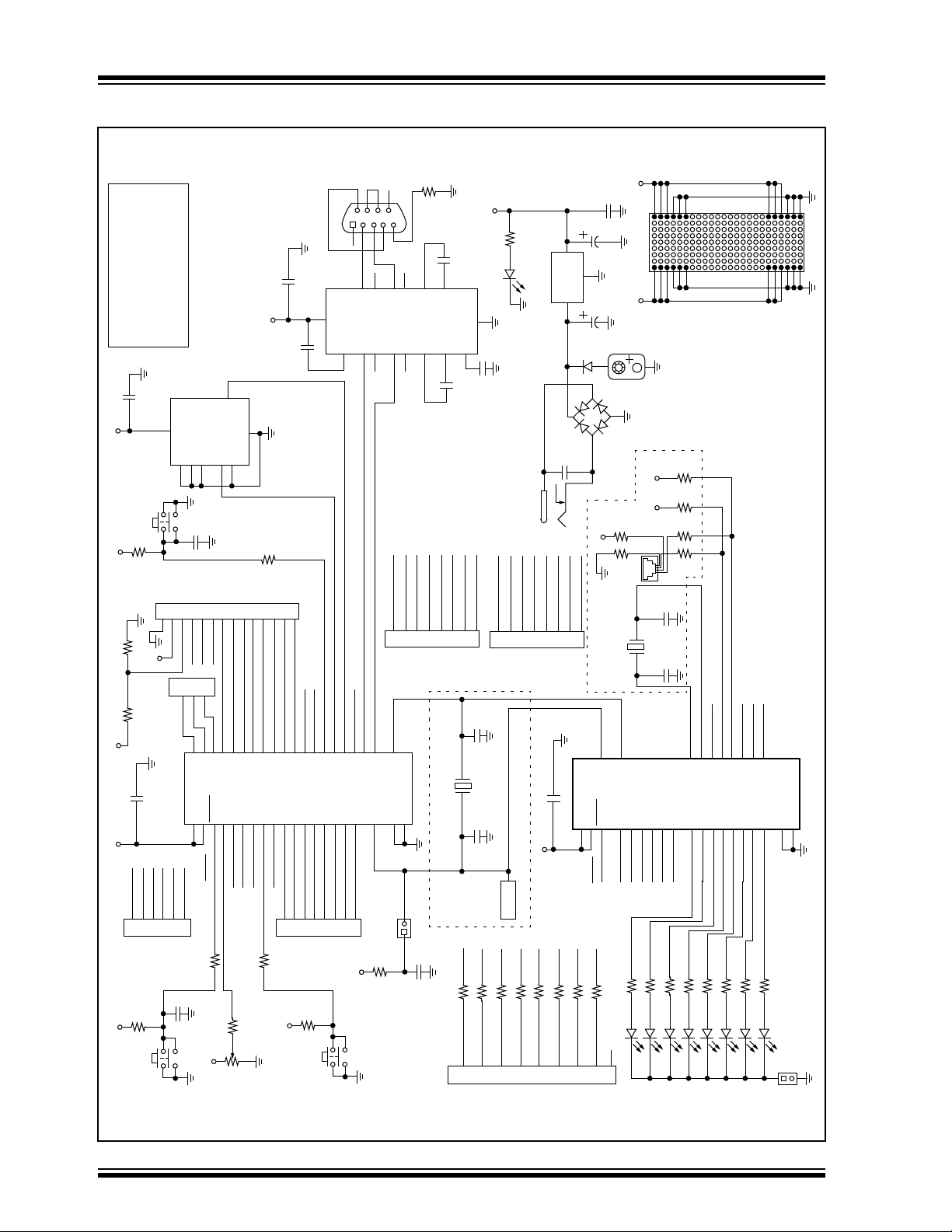

FIGURE 4: SCHEMATIC

Board

PICDEM2

(See Figure 5)

AN616

+V (12 VDC In)

100k

Input Offset Adjust

VR1

+5V

10 µF

C9

C12

+V (12 VDC In)

RA1

7

U1B

LM324

5

6

(see table)

Ca

20k

R10

0.1 µF

100k

R11

11

10k

R4

Cc

(see table)

10k 10k

Cb

(see table)

R2 R1

10k

Output Offset Adjust

C13

VR3

+5V

10 µF

C10

10k

1 R3

U1A

0.1 µF

LM324

3

VR2

4

47k

2

(see table)

Ca

470k

R13

470k

R12

RC1

-V

Cb

(see table)

0.1 µF

C11

10k 10k 10k

U2

876

V+

OSCLVVD

C+

NC

123

Cc

(see table)

R6 R5 R7

9

10

8

U1C

LM324

10k

R9

12

13

14

U1D

10k

R8

LM324

5

GND

4

10 µF

C8

10 µF

C7

C-

LMC7660IN

250 Hz 3.4 kHz

Ca 1 µF 0.082 µF

Cb 0.15 µF 0.012 µF

Cc 0.0039 µF 300 pF

Signal In

(DC Coupled)

Input Level Adjust

Signal Output

(DC Coupled)

Capacitor Values for 250 Hz and 3.4 kHz

3 Pole Chebyshev Filter - 1 dB Passband Ripple

1997 Microchip Technology Inc. DS00616A-page 7

Page 8

AN616

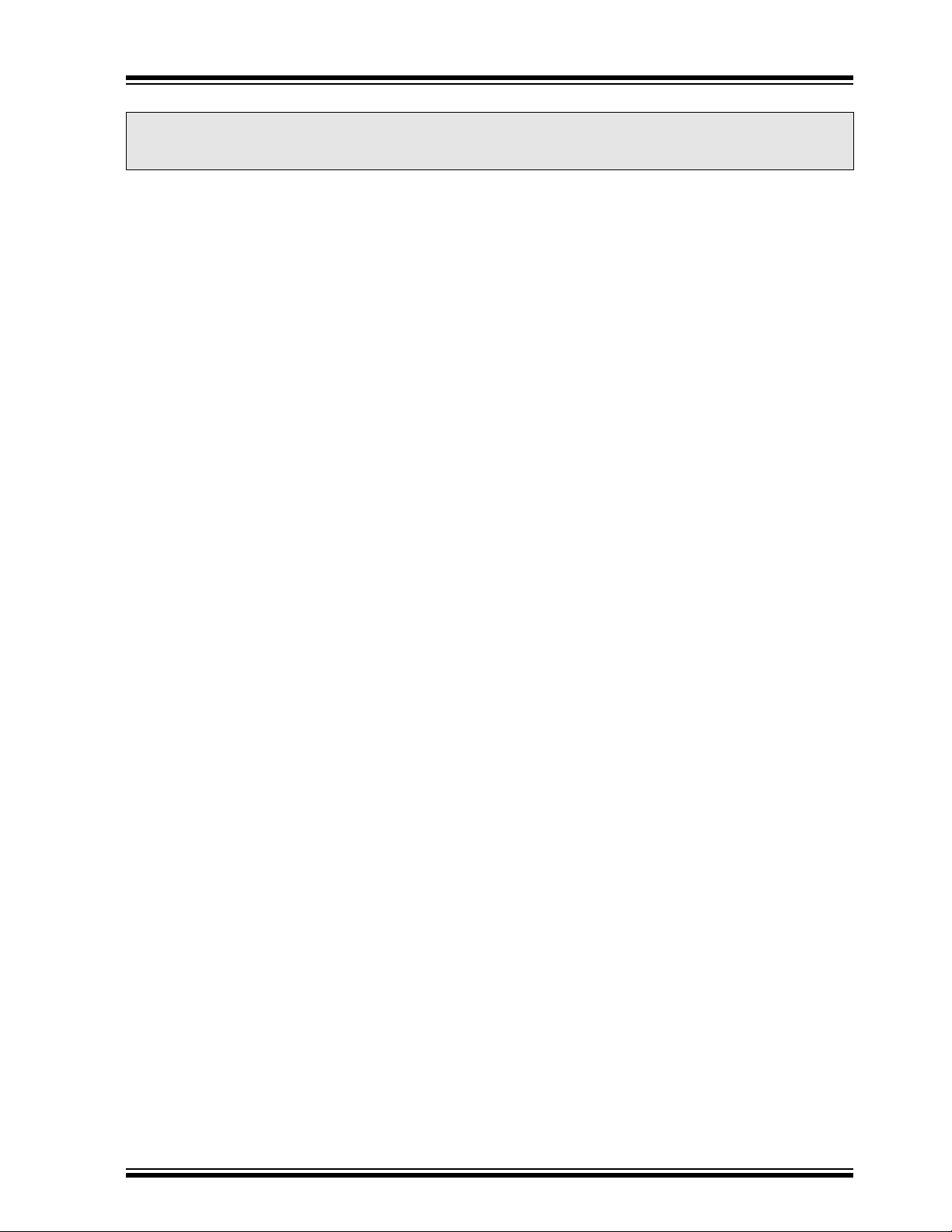

FIGURE 5: PICDEM2 SCHEMATIC TIE-IN

Notes:

C10

+5V

+5V

R6

R5

C2

+5V +5V

RA

+5V

Unless otherwise specified,

resistance values are in ohms,

5% 1/4W. Capacitance values

0.1

S3

R7

4.7k

1

330

+5V

10k

0.1

RA0

RA12RA23RA34RA45RA5

1

R1

4.7k

S1

8

RE

U4

are in microfarads.

2

1

C1

VDD

A0

3J34

RE0

U1

6

0.1

24LC01B

A1

A2

2

3

0.1

C9

RA15RA26RA3

RE1

RE2

9

10

8

RE0

RE1

VDD

VDD

11

32

MCLR 12RA0

470

R17

+5V

5

SDA

SCL

6

7

For

LCD

19 RD0 7

RE2

RD0

RA0

MCLR

R2

R16

WP

DSPLY

20 RD1 8

RD1

RA1

RA13RA2 4

SS

V

RD2 922RD3

21

RD2

RA2

R18

470

5k

10

RD3

RA3 5

11

RD4

27

RA3

RA46RA5 7

470

+5V

R19

RD4

RA4

470

28 RD51229 RD6 13

RD5

RA5

RB

C11

RD6

RB0 331

+5V

0.1

0.1

C12

30 RD71415 OSO

RD7

RB0

RB1

RB1 342

RB2 353

16 OSI

RC0

RB2

RB3 364

R3

RC1

RB3

4.7k

S2

U3

16

17 RC2

RC2

RB4

RB4 375

VCC

18 SCL

RB5 386RB6 397

J1

2

23 SDA

RC3

RB5

678

12345

7

14

T1OUT

MAX232A

V+

T1IN

10

11

TX

24 RC5

25 TX

26 RX

RC4

RC5

RC6

RB6

RB7

131231

RB7 40

8

+5V

9

13

T2OUT

T2IN

12

RX

1 (RC0) OSO

RC

OSC2

14

RC7

OSC1

R4

4.7k

8

R1IN

R2IN

R1OUT

R2OUT

9

2 (RC1) OSI

3 RC2

OSC2

Vss

Vss

OSC1

J7

10

R14

C15

4

C2+

C1+

1

C13

4 (RC3) SCL

5 (RC4) SDA

PIC16C64

Provision Only

C3

20 pF

J4

Keyboard

+5V+5V

0.1

C19

+5V

RB7

X1

PIC16C73

Vss

Vss

8

19

J6

470

R15

0.1

D1

GRN

15

0.1

1 RD0

RD

RN3

2 RD1

Not Populated

Y2

OUT

RB2

RN3

3

3

3 RD2

TXCO

RB3

4

4

Power

4 RD3

RN3

J2

RB4

3

5

LM78L05

1

3

5 RD4

6 RD5

C8

+5V

RB5

RN3

4

6

5

C2-

GND

V-

C1-

6

3

0.1

C14

6 RC5

7 (RC6) TX

8 (RC7) RX

C5

Y1

TBD

20 pF 20 pF

C4

RB1

RB0

RN3

RN3

4

1

2

C18

OUT

U5

COM

IN

220

C17

CR2

1N914

4

1

2

CR1

0.01

C16

2

DJ005A

+5V

7 RD6

8 RD7

Provision Only

OSC1

9

U2

0.1

MCLR

VDD

1

20

MCLR

RB7

RB6

RN3

RN3

4

4

789

9 Pin Header

220

J8

W02M

3

R9

R8

Not Populated

OSC2

10

OSC1

RA0 2

+9V

Battery

10

10

Y3

OSC2

RA0

RA1

RA1 3

RB0

RN1

D2

Breadboard

+5V +5V

J5

C7

TBD

C6

RA2

RA3

RA4

RA2 4

RA3 5

RA4 6

RB2

RB1

RN1

RN1

D4

D3

R13

R12

R11

R10

20 pF

20 pF

OSO12OSI13RC214SCL15SDA

11

RA5

RA5 7

RB021RB122RB223RB324RB4 25

RB3

RN1

D5

820

820

10

10

RC0

RB0

RC1

RB1

RB4

RN2

D6

RC2

RB2

RN2

RC3

RB3

RB5

D7

RC517TX18RX

16

RC4

RC5

RB4

RB5

RB5 26

RB6 27

RB6

RN2

D8

RC6

RB6

RN2

RC7

28

RB7

RB7

D9

DS00616A-page 8 1997 Microchip Technology Inc.

Page 9

AN616

Please check the Microchip BBS for the latest version of the source code. Microchip’s Worldwide Web Address:

www.microchip.com; Bulletin Board Support: MCHIPBBS using CompuServe

®

(CompuServe membership not

required).

APPENDIX A:ANALOG I/O MODULE

/****************************************************************************

* Analog I/O Module

*

* Written for “Digital Signal Processing with the PIC16C74” Application Note

*

* This module contains functions that read the A-D inputs, initialize the PWM

* ports, and write values to the PWM ports.

*

* D. Mostowfi 4/95

****************************************************************************/

#define active 1 /* define active as 1 */

#define LOW 0 /* define LOW as 0 */

#define HIGH 1 /* define HIGH as 1 */

#define OFFSET 0 /* define offset binary mode as 0 */

#define TWOS 1 /* define two’s compliment mode as 1 */

#define AD_FORMAT TWOS /* define A-D format as TWOS */

#define PWM_FORMAT TWOS /* define PWM format as TWOS */

#define PWM_RES HIGH /* define PWM resolution as HIGH */

bits FLAGS; /* general purpose flags */

#define sample_flag FLAGS.1 /* define sample_flag as FLAGS.1 */

/*****************************************************************************

* A-D Converter Routine - reads A-D converter inputs

*

* usage:

* - call get_sample(channel #)

* - returns 8 bit value

*****************************************************************************/

char get_sample(char channel)

{

char i;

ADRES=0; /* clear ADRES */

STATUS.C=0; /* clear carry */

RLCF(channel); /* and rotate channel 3 times */

RLCF(channel); /* to put in proper position */

RLCF(channel); /* for write to ADCON0 */

ADCON0=channel; /* write channel to ADCON0 */

ADCON0.0=1; /* turn on A-D */

i=0; /* set delay loop variable to 0 */

while(i++<=5){}; /* delay (to ensure min sampling time) */

ADCON0.2=1; /* start conversion */

while(ADCON0.2){} /* wait for eoc */

ADCON0.0=0; /* turn off a-d converter */

if(AD_FORMAT==TWOS){ /* if format is two’s compliment */

ADRES.7=!ADRES.7; /* compliment MSB */

}

return ADRES; /* return value in a-d result reg */

}

/******************************************************************************

* PWM Initialization Routine - sets up PR2, sets output to mid-point, and

* starts timer 2 with interrupts disabled.

*

* usage:

1997 Microchip Technology Inc. DS00616A-page 9

Page 10

AN616

* - call init_PWM(PR2 register value)

******************************************************************************/

void init_PWM(char _pr2)

{

PR2=_pr2; /* reload value for 40khz PWM period */

CCP1CON.5=0; /* set CCPxCON = 0 for 50% output */

CCP1CON.4=0;

CCP2CON.5=0;

CCP2CON.4=0;

if(PWM_RES==HIGH){ /* if resolution is high, set CCPRxH=0 and */

CCPR1H=0x00; /* CCPRxL=0x20 for 50% PWM duty cycle */

CCPR1L=0x20;

CCPR2H=0x00;

CCPR2L=0x20;

}

else{

CCPR1H=0x00; /* if resolution is low, set CCPRxH=0 and */

CCPR1L=0x80; /* CCPRxL=0x80 for 50% PWM duty cycle */

CCPR2H=0x00;

CCPR2L=0x80;

}

T2CON.TMR2ON=1; /* start timer 2 */

PIE1.TMR2IE=0; /* and disable timer 2 interrupt */

}

/*******************************************************************************

* PWM Output Routine - writes output values to PWM ports

*

* Both high resolution and low resolution modes write 8 bit values - use of

* high or low resolution depends on PWM output period.

*

* usage:

* - call write_PWM(channel 1 value, channel 2 value)

* if channel 2 value=0, PWM port 2 not written

*******************************************************************************/

void write_PWM(bits pwm_out1, bits pwm_out2)

{

if(PWM_FORMAT==TWOS){ /* if format is two’s compliment */

pwm_out1.7=!pwm_out1.7; /* compliment msb’s */

pwm_out2.7=!pwm_out1.7;

}

if(PWM_RES==HIGH){ /* if resolution is high */

STATUS.C=0; /* clear carry */

pwm_out1=RRCF(pwm_out1); /* rotate right and write two lsb’s */

CCP1CON.4=STATUS.C; /* to CCP1CON4 and CCP1CON5 */

STATUS.C=0;

pwm_out1=RRCF(pwm_out1);

CCP1CON.5=STATUS.C;

if(pwm_out2!=0){ /* if pwm_out2 not 0, do the same */

STATUS.C=0; /* for channel 2 */

pwm_out2=RRCF(pwm_out2);

CCP2CON.4=STATUS.C;

STATUS.C=0;

pwm_out2=RRCF(pwm_out2);

CCP2CON.5=STATUS.C;

}

}

CCPR1L=pwm_out1; /* write value to CCPR1L */

if(pwm_out2!=0){ /* if pwm_out2 not 0, do the same */

CCPR2L=pwm_out2; /* for CCPR2L */

}

} /* done */

DS00616A-page 10 1997 Microchip Technology Inc.

Page 11

AN616

Please check the Microchip BBS for the latest version of the source code. Microchip’s Worldwide Web Address:

www.microchip.com; Bulletin Board Support: MCHIPBBS using CompuServe

®

(CompuServe membership not

required).

APPENDIX B:TONE GENERATION MODULE

/*****************************************************************************

* Tone Generation Module

*

* Written for “Digital Signal Processing with the PIC16C74” Application Note.

*

* This module contains a C callable module that generates single or dual

* tones using a difference equation method:

*

* y1(n)=a1*x(n-1)+b1*y1(n-1)-y1(n-2)

* y2(n)=a2*x(n-1)+b2*y2(n-1)-y2(n-2)

*

* The routine is written in assembly language and uses the optimized signed

* 8x8 multiply routine and scaling routine in the file 8BITMATH.C.

*

* D. Mostowfi 2/95

*****************************************************************************/

#include “\mpc\apnotes\8bitmath.c” /* 8 bit signed math routines */

#define sample_flag FLAGS.1 /* sample flag */

#define no_tone2 FLAGS,2 /* no tone 2 flag */

extern char ms_cntr; /* millisecond counter for tone loop */

char a1; /* first tone (low-group) coeeficient 1 */

char a2; /* first tone (low-group) coefficient 2 */

char b1; /* second tone (high group) coefficient 1 */

char b2; /* second tone (high group) coefficient 2 */

char duration; /* tone duration */

char y1; /* output sample y1(n) for tone 1 */

char y2; /* output sample y2(n) for tone 2 */

/******************************************************************************

* Tone function - generates single or dual tone signals out PWM port 1.

*

* usage:

* - write coefficients for tone 1 to a1 and b1

* - write coefficents for tone 2 to a2 and b2 (0 if no tone 2)

* - write duration of tone in milliseconds to duration

* - call tone() function

*******************************************************************************/

void tone(void)

{

char y1_1; /* y1(n-1) */

char y1_2; /* y1(n-2) */

char y2_1; /* y2(n-1) */

char y2_2; /* y2(n-2) */

PIR1.TMR2IF=0; /* clear timer 2 interrupt flag */

PIE1.TMR2IE=1; /* and enable timer 2 interrupt */

ms_cntr=0; /* clear ms counter */

STATUS.RP0=0; /* set proper bank!!! */

#asm

clrf y1 ; clear output byte and taps

clrf y2 ;

clrf y1_1 ;

clrf y1_2 ;

1997 Microchip Technology Inc. DS00616A-page 11

Page 12

AN616

clrf y2_1 ;

clrf y2_2 ;

bcf no_tone2 ; clear no tone 2 flag

clrf ms_cntr ; clear millisecond counter

first_sample:

movf a1,W ; first iteration

movwf y1 ; y1(n)=a1

movwf y1_1 ;

movlw 0x00 ;

iorwf a2,W ;

btfsc STATUS,Z ; generate second tone (a2 !=0) ?

bsf no_tone2 ;

movf a2,W ; y2(n)=a2

movwf y2 ;

movwf y2_1 ;

movf y2,W ;

addwf y1,F ; y1(n)=y1(n)+y2(n) (sum two tone outputs)

tone_loop:

movf ms_cntr,W ; test to see if ms=duration (done?)

subwf duration,W ;

btfsc STATUS,Z ;

goto tone_done ;

wait_PWM:

btfss FLAGS,1 ; test sample flag (sample period elapsed?)

goto wait_PWM ; loop if not

bcf FLAGS,1 ; if set, clear sample flag

#endasm

write_PWM((char)y1,0); /* write y1 to PWM port */

#asm

next_sample:

movf b1,W ; y1(n)=b1*y1(n-1)-y1(n-2)

movwf multcnd ;

movf y1_1,W ;

movwf multplr ;

call _8x8smul ;

call scale_16 ;

movf y1_2,W ;

subwf result_l,W ;

movwf y1 ;

movf y1_1,W ; y1(n-2)=y1(n-1)

movwf y1_2 ;

movf y1,W ; y1(n-1)=y1(n)

movwf y1_1 ;

btfsc no_tone2 ;

goto tone_loop ;

movf b2,W ; y2(n)=b2*y2(n-1)-y2(n-2)

movwf multcnd ;

movf y2_1,W ;

movwf multplr ;

call _8x8smul ;

call scale_16 ;

movf y2_2,W ;

subwf result_l,W ;

movwf y2 ;

movf y2_1,W ; y2(n-2)=y2(n-1)

movwf y2_2 ;

movf y2,W ; y2(n-1)=y2(n)

movwf y2_1 ;

DS00616A-page 12 1997 Microchip Technology Inc.

Page 13

movf y2,W ;

addwf y1,F ; y1(n)=y1(n)+y2(n) (sum two tone outputs)

goto tone_loop ; go and calculate next sample

tone_done:

#endasm

CCP1CON.5=0; /* reset PWM outputs to mid value */

CCP1CON.4=0;

CCP2CON.5=0;

CCP2CON.4=0;

CCPR1H=0x00;

CCPR1L=0x20;

CCPR2H=0x00;

CCPR2L=0x20;

PIE1.TMR2IE=0; /* disable timer 2 interrupts */

PIR1.TMR2IF=0; /* and clear timer 2 interrupt flag */

}

AN616

1997 Microchip Technology Inc. DS00616A-page 13

Page 14

AN616

Please check the Microchip BBS for the latest version of the source code. Microchip’s Worldwide Web Address:

www.microchip.com; Bulletin Board Support: MCHIPBBS using CompuServe

®

(CompuServe membership not

required).

APPENDIX C:DTMF TONE GENERATION

/*****************************************************************************

* DTMF tone generation using PIC16C74

*

* Written for the “Digital Signal Processing Using the PIC16C74” Ap Note

*

* Generates 16 DTMF tones (1-9,0,*,#,A,B,C,D) out PWM port 1

*

* Uses PICTONE.C and ANALOGIO.C modules

*

* D. Mostowfi 4/95

******************************************************************************/

#include “\mpc\include\delay14.h”

#include “\mpc\include\16c74.h” /* c74 header file */

#include “\mpc\math.h”

#include “\mpc\apnotes\analogio.c” /* analog I/O module */

#include “\mpc\apnotes\pictone.c” /* tone generation module */

bits pwm1;

/* Function Prototypes */

void main_isr();

void timer2_isr();

/* 16C74 I/O port bit declarations */

/* global program variables */

char tmr2_cntr; /* timer 2 interrupt counter */

char delay_cntr; /* delay time counter (10ms ticks)*/

/* Tone Coefficients for DTMF Tones */

const DTMF_1[4]={30, 51, 48, 27};

const DTMF_2[4]={30, 51, 56, 19};

const DTMF_3[4]={30, 51, 64, 11};

const DTMF_4[4]={33, 48, 48, 27};

const DTMF_5[4]={33, 48, 56, 19};

const DTMF_6[4]={33, 48, 64, 11};

const DTMF_7[4]={36, 45, 48, 27};

const DTMF_8[4]={36, 45, 56, 19};

const DTMF_9[4]={36, 45, 64, 11};

const DTMF_0[4]={40, 41, 56, 19};

const DTMF_star[4]={40, 41, 48, 27};

const DTMF_pound[4]={40, 41, 64, 11};

const DTMF_A[4]={30, 51, 75, 2};

const DTMF_B[4]={33, 48, 75, 2};

const DTMF_C[4]={36, 45, 75, 2};

const DTMF_D[4]={40, 41, 75, 2};

/*****************************************************************************

* main isr - 16C74 vectors to 0004h (MPC __INT() function) on any interrupt *

* assembly language routine saves W and Status registers then tests flags in

* INTCON to determine source of interrupt. Routine then calls appropriate isr.

* Restores W and status registers when done.

DS00616A-page 14 1997 Microchip Technology Inc.

Page 15

*****************************************************************************/

void __INT(void)

{

if(PIR1.TMR2IF){ /* timer 2 interrupt ? */

PIR1.TMR2IF=0; /* clear interrupt flag */

timer2_isr(); /* and call timer 2 isr */

}

/* Restore W, WImage, and STATUS registers */

#asm

BCF STATUS,RP0 ;Bank 0

MOVF temp_PCLATH, W

MOVWF PCLATH ;PCLATH restored

MOVF temp_WImage, W

MOVWF __WImage ;__WImage restored

MOVF temp_FSR, W

MOVWF FSR ;FSR restored

SWAPF temp_STATUS,W

MOVWF STATUS ;STATUS restored

SWAPF temp_WREG,F

SWAPF temp_WREG,W ;W restored

#endasm

}

AN616

/****************************************************************************

* timer 2 isr - provides PWM sample clock generation and millisecond counter

* for tone routine

*****************************************************************************/

void timer2_isr(void)

{

sample_flag=active; /* set sample flag (150us clock) */

PORTB.7=!PORTB.7; /* toggle PORTB.7 at sample rate */

if(tmr2_cntr++==7){ /* check counter */

tmr2_cntr=0; /* reset if max */

ms_cntr++; /* and increment millisecond ticks */

}

}

void main()

{

/* initialize OPTION register */

OPTION=0b11001111;

/* initialize INTCON register (keep GIE inactive!) */

INTCON=0b00000000; /* disable all interrupts */

/* initialize PIE1 and PIE2 registers (peripheral interrupts) */

PIE1=0b00000000; /* disable all interrupts */

PIE2=0b00000000;

/* initialize T1CON and T2CON registers */

T1CON=0b00000000; /* T1 not used */

T2CON=0b00101000; /* T2 postscaler=5 */

/* initialize CCPxCON registers */

CCP1CON=0b00001100; /* set CCP1CON for PWM mode */

CCP2CON=0b00001100; /* set CCP2CON for PWM mode (not used in demo) */

/* initialize SSPCON register */

SSPCON=0b00000000; /* serial port - not used */

1997 Microchip Technology Inc. DS00616A-page 15

Page 16

AN616

/* initialize ADCONx registers */

ADCON0=0b00000000; /* A-D converter */

ADCON1=0b00000010;

/* initialize TRISx register (port pins as inputs or outputs) */

TRISA=0b00001111;

TRISB=0b00000000;

TRISC=0b10000000;

TRISD=0b00001111;

TRISE=0b00000000;

/* clear watchdog timer (not used) */

CLRWDT();

/* initialize program variables */

tmr2_cntr=0;

/* initialize program bit variables */

FLAGS=0b00000000;

/* intialize output port pins (display LED’s on demo board) */

PORTB=0;

/* enable interrupts... */

INTCON.ADIE=1; /* Peripheral interrupt enable */

INTCON.GIE=1; /* global interrupt enable */

init_PWM(0x3e); /* initialize PWM port */

PORTB=0x01; /* write a 1 to PORTB */

a1=DTMF_1[0]; /* and send a DTMF “1” */

b1=DTMF_1[1];

a2=DTMF_1[2];

b2=DTMF_1[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x02; /* write a 2 to PORT B */

a1=DTMF_2[0]; /* and send a DTMF “2” */

b1=DTMF_2[1];

a2=DTMF_2[2];

b2=DTMF_2[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x03; /* write a 3 to PORTB */

a1=DTMF_3[0]; /* and send a DTMF “3” */

b1=DTMF_3[1];

a2=DTMF_3[2];

b2=DTMF_3[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x04; /* write a 4 to PORTB */

a1=DTMF_4[0]; /* and send a DTMF “4” */

b1=DTMF_4[1];

DS00616A-page 16 1997 Microchip Technology Inc.

Page 17

a2=DTMF_4[2];

b2=DTMF_4[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x05; /* write a 5 to PORTB */

a1=DTMF_5[0]; /* and send a DTMF “5” */

b1=DTMF_5[1];

a2=DTMF_5[2];

b2=DTMF_5[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x06; /* write a 6 to PORTB */

a1=DTMF_6[0]; /* and send a DTMF “6” */

b1=DTMF_6[1];

a2=DTMF_6[2];

b2=DTMF_6[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x07; /* write a 7 to PORTB */

a1=DTMF_7[0]; /* and send a DTMF “7” */

b1=DTMF_7[1];

a2=DTMF_7[2];

b2=DTMF_7[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

AN616

PORTB=0x08; /* write a 8 to PORTB */

a1=DTMF_8[0]; /* and send a DTMF “8” */

b1=DTMF_8[1];

a2=DTMF_8[2];

b2=DTMF_8[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x09; /* write a 9 to PORTB */

a1=DTMF_9[0]; /* and send a DTMF “9” */

b1=DTMF_9[1];

a2=DTMF_9[2];

b2=DTMF_9[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x0; /* write a 0 to PORTB */

a1=DTMF_0[0]; /* and send a DTMF “0” */

b1=DTMF_0[1];

a2=DTMF_0[2];

b2=DTMF_0[3];

duration=150;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

1997 Microchip Technology Inc. DS00616A-page 17

Page 18

AN616

PORTB=0x0e; /* write a 0x0e to PORTB */

a1=DTMF_star[0]; /* and send a DTMF “*” */

b1=DTMF_star[1];

a2=DTMF_star[2];

b2=DTMF_star[3];

duration=250;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x0f; /* write a 0x0f to PORTB */

a1=DTMF_pound[0]; /* and send a DTMF “#” */

b1=DTMF_pound[1];

a2=DTMF_pound[2];

b2=DTMF_pound[3];

duration=250;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x0a; /* write a 0x0a to PORTB */

a1=DTMF_A[0]; /* and send a DTMF “A” */

b1=DTMF_A[1];

a2=DTMF_A[2];

b2=DTMF_A[3];

duration=250;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x0b; /* write a 0x0b to PORTB */

a1=DTMF_B[0]; /* and send a DTMF “B” */

b1=DTMF_B[1];

a2=DTMF_B[2];

b2=DTMF_B[3];

duration=250;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x0c; /* write a 0x0c to PORTB */

a1=DTMF_C[0]; /* and send a DTMF “C” */

b1=DTMF_C[1];

a2=DTMF_C[2];

b2=DTMF_C[3];

duration=250;

tone();

Delay_Ms_20MHz(200); /* delay 100ms (200/2 using MPC delays) */

PORTB=0x0d; /* write a 0x0d to PORTB */

a1=DTMF_D[0]; /* and send a DTMF “D” */

b1=DTMF_D[1];

a2=DTMF_D[2];

b2=DTMF_D[3];

duration=250;

tone();

PORTB=0; /* write a 0 to PORTB */

while(1){} /* done (loop) */

}

DS00616A-page 18 1997 Microchip Technology Inc.

Page 19

AN616

Please check the Microchip BBS for the latest version of the source code. Microchip’s Worldwide Web Address:

www.microchip.com; Bulletin Board Support: MCHIPBBS using CompuServe

®

(CompuServe membership not

required).

APPENDIX D:IIR FILTER MODULE

/*****************************************************************************

* Second-Order IIR Filter Module

*

* Written for “Digital Signal Processing with the PIC16C74” Application Note.

*

* This routine implements an IIR filter using a second order difference

* equation of the form:

*

* y(n) = b0*x(n)+b1*x(n-1)+b2*x(n-2)+a1*y(n-1)+a2*y(n-2)

*

* D. Mostowfi 3/95

*****************************************************************************/

#include “\mpc\apnotes\dbl_math.c”

bits x_n; /* input sample x(n) */

unsigned long y_n; /* output sample y(n) */

unsigned long x_n_1; /* x(n-1) */

unsigned long x_n_2; /* x(n-2) */

unsigned long y_n_1; /* y(n-1) */

unsigned long y_n_2; /* y(n-2) */

char rmndr_h; /* high byte of remainder from multiplies */

char rmndr_l; /* low byte of remainder from multiplies */

#define A1_H 0xd2 /* filter coefficients */

#define A1_L 0x08 /* for 60Hz notch filter */

#define A2_H 0x11 /* Fs= 1kHz */

#define A2_L 0x71

#define B0_H 0x18

#define B0_L 0xbb

#define B1_H 0xd2

#define B1_L 0x08

#define B2_H 0x18

#define B2_L 0xb9

/******************************************************************************

* Filter initialization - clears all taps in memory.

*

* usage:

* - call init_filter()

* use at program initialization

******************************************************************************/

void init_filter(){

#asm

clrf y_n ; clear output value

clrf y_n+1 ;

clrf y_n_1 ; and all filter “taps”

clrf y_n_1+1 ;

clrf y_n_2 ;

clrf y_n_2+1 ;

clrf x_n_1 ;

clrf x_n_1+1 ;

clrf x_n_2 ;

clrf x_n_2+1 ;

#endasm

1997 Microchip Technology Inc. DS00616A-page 19

Page 20

AN616

}

/******************************************************************************

* Assembly language subroutines for main filter() function

******************************************************************************/

#asm

;

; Add Remainder subroutine - adds remainder from multiplies to ACCc

;

add_rmndr:

btfss sign,7 ; check if number is negative

goto add_r_start ; go to add_r_start if not

comf ACCcLO ; if so, negate number in ACC

incf ACCcLO ;

btfsc STATUS,Z ;

decf ACCcHI ;

comf ACCcHI ;

btfsc STATUS,Z ;

comf ACCbLO ;

incf ACCbLO ;

btfsc STATUS,Z ;

decf ACCbHI ;

comf ACCbHI ;

add_r_start:

movf rmndr_l,W ; get low byte of remainder

addwf ACCcLO ; and add to ACCcLO

btfsc STATUS,C ; check for overflow

incf ACCcHI ; if overflow, increment ACCcHI

movf rmndr_h,W ; get high byte of remainder

addwf ACCcHI ; and add to ACCcHI

btfsc STATUS,C ; check for overflow

incf ACCbLO ; if overflow, increment ACCbLO

btfss sign,7 ; check if result negative

goto add_r_done ; if not, go to add_r_done

comf ACCcLO ; if so, negate result

incf ACCcLO ;

btfsc STATUS,Z ;

decf ACCcHI ;

comf ACCcHI ;

btfsc STATUS,Z ;

comf ACCbLO ;

incf ACCbLO ;

btfsc STATUS,Z ;

decf ACCbHI ;

comf ACCbHI ;

add_r_done:

retlw 0 ; done

;

; Decimal Adjust Subroutine - used after each Q15 multiply to convert Q30 result

; to Q15 number

dec_adjust:

bcf sign,7 ; clear sign

btfss ACCbHI,7 ; test if number is negative

goto adjust ; go to adjust if not

bsf sign,7 ; set sign if negative

comf ACCcLO ; and negate number

incf ACCcLO

DS00616A-page 20 1997 Microchip Technology Inc.

Page 21

btfsc STATUS,Z

decf ACCcHI

comf ACCcHI

btfsc STATUS,Z

comf ACCbLO

incf ACCbLO

btfsc STATUS,Z

decf ACCbHI

comf ACCbHI

adjust:

rlf ACCcHI ; rotate ACC left 1 bit

rlf ACCbLO ;

rlf ACCbHI ;

btfss sign,7 ; check if result should be negative

goto adj_done ; if not, done

comf ACCbLO ; if result negative, negate ACC

incf ACCbLO

btfsc STATUS,Z

decf ACCbHI

comf ACCbHI

adj_done:

retlw 0 ; done

AN616

;

; Output Scaling Routine - used to scale output samples by factors of

; 2, 4, or 8 at end of filter routine

;

scale_y_n:

bcf sign,7 ; clear sign,7

btfss y_n+1,7 ; test if y(n) negative

goto start_scale ; go to start_scale if not

bsf sign,7 ; set sign,7 if negative

comf y_n ; and compliment y(n)

incf y_n ;

btfsc STATUS,Z ;

decf y_n+1 ;

comf y_n+1 ;

start_scale:

bcf STATUS,C ; clear carry

rlf y_n+1 ; and rotate y(n) left

rlf y_n ;

bcf STATUS,C ;

rlf y_n+1 ;

rlf y_n ;

bcf STATUS,C ;

rlf y_n+1 ;

rlf y_n ;

btfss sign,7 ; test if result is negative

goto scale_y_done ; go to scale_y_done if not

comf y_n ; negate y(n) if result is negative

incf y_n ;

btfsc STATUS,Z ;

decf y_n+1 ;

comf y_n+1 ;

scale_y_done:

retlw 0 ; done

#endasm

1997 Microchip Technology Inc. DS00616A-page 21

Page 22

AN616

/******************************************************************************

* Filter function - filter takes current input sample, x(n), and outputs next

* output sample, y(n).

*

* usage:

* - write sample to be filtered to x_n

* - call filter()

* - output is in MSB of y_n (y_n=MSB, y_n+1=LSB)

*

******************************************************************************/

void filter(){

#asm

clrf y_n ; clear y(n) before starting

clrf y_n+1 ;

clrf ACCbLO ; move x(n) to ACCbHI

movf x_n,W ; (scale 8 bit - 16 bit input)

movwf ACCbHI ;

movlw B0_H ; get coefficient b0

movwf ACCaHI ; y(n)=b0*x(n)

movlw B0_L ;

movwf ACCaLO ;

call D_mpyF ;

movf ACCcHI,W ; save remainder from multiply

movwf rmndr_h ;

movf ACCcLO,W ;

movwf rmndr_l ;

call dec_adjust ;

movf ACCbHI,W ;

movwf y_n+1 ;

movf ACCbLO,W ;

movwf y_n ;

movlw B1_H ; get coefficient b1

movwf ACCaHI ; y(n)=y(n)+b1*x(n-1)

movlw B1_L ;

movwf ACCaLO ;

movf x_n_1+1,W ;

movwf ACCbHI ;

movf x_n_1,W ;

movwf ACCbLO ;

call D_mpyF ;

call add_rmndr ; add in remainder from previous multiply

movf ACCcHI,W ; and save new remainder

movwf rmndr_h ;

movf ACCcLO,W ;

movwf rmndr_l ;

call dec_adjust ;

movf y_n+1,W ;

movwf ACCaHI ;

movf y_n,W ;

movwf ACCaLO ;

call D_add ;

movf ACCbHI,W ;

movwf y_n+1 ;

movf ACCbLO,W ;

movwf y_n ;

movlw B2_H ; get coefficient b2

movwf ACCaHI ; y(n)=y(n)+b2*x(n-2)

movlw B2_L ;

movwf ACCaLO ;

movf x_n_2+1,W ;

DS00616A-page 22 1997 Microchip Technology Inc.

Page 23

movwf ACCbHI ;

movf x_n_2,W ;

movwf ACCbLO ;

call D_mpyF ;

call add_rmndr ; add in remainder from previous multiply

movf ACCcHI,W ; and save new remainder

movwf rmndr_h ;

movf ACCcLO,W ;

movwf rmndr_l ;

call dec_adjust ;

movf y_n+1,W ;

movwf ACCaHI ;

movf y_n,W ;

movwf ACCaLO ;

call D_add ;

movf ACCbHI,W ;

movwf y_n+1 ;

movf ACCbLO,W ;

movwf y_n ;

movlw A1_H ; get coefficient a1

movwf ACCaHI ; y(n)=y(n)+a1*y(n-1)

movlw A1_L ;

movwf ACCaLO ;

movf y_n_1+1,W ;

movwf ACCbHI ;

movf y_n_1,W ;

movwf ACCbLO ;

call D_mpyF ;

call add_rmndr ; add in remainder from previous multiply

movf ACCcHI,W ; and save new remainder

movwf rmndr_h ;

movf ACCcLO,W ;

movwf rmndr_l ;

call dec_adjust ;

movf y_n+1,W ;

movwf ACCaHI ;

movf y_n,W ;

movwf ACCaLO ;

call D_sub ;

movf ACCbHI,W ;

movwf y_n+1 ;

movf ACCbLO,W ;

movwf y_n ;

AN616

movlw A2_H ; get coefficient a2

movwf ACCaHI ; y(n)=y(n)+a2*y(n-2)

movlw A2_L ;

movwf ACCaLO ;

movf y_n_2+1,W ;

movwf ACCbHI ;

movf y_n_2,W ;

movwf ACCbLO ;

call D_mpyF ;

call add_rmndr ;

call dec_adjust ;

movf y_n+1,W ;

movwf ACCaHI ;

movf y_n,W ;

movwf ACCaLO ;

call D_sub ;

movf ACCbHI,W ;

movwf y_n+1 ;

movf ACCbLO,W ;

movwf y_n ;

1997 Microchip Technology Inc. DS00616A-page 23

Page 24

AN616

movf x_n_1,W ; x(n-2)=x(n-1)

movwf x_n_2 ;

movf x_n_1+1,W ;

movwf x_n_2+1 ;

movf x_n,W ; x(n-1)=x(n)

movwf x_n_1+1 ;

clrf x_n_1 ;

movf y_n_1,W ; y(n-2)=y(n-1)

movwf y_n_2 ;

movf y_n_1+1,W ;

movwf y_n_2+1 ;

movf y_n,W ; y(n-1)=y(n)

movwf y_n_1 ;

movf y_n+1,W ;

movwf y_n_1+1 ;

call scale_y_n ;

movf y_n+1,W ; shift lsb of y_n to msb

movwf y_n ;

#endasm

}

DS00616A-page 24 1997 Microchip Technology Inc.

Page 25

AN616

Please check the Microchip BBS for the latest version of the source code. Microchip’s Worldwide Web Address:

www.microchip.com; Bulletin Board Support: MCHIPBBS using CompuServe

®

(CompuServe membership not

required).

APPENDIX E: NOTCH FILTER

/*****************************************************************************

* 60 Hertz Notch Filter

*

* Written for “Digital Signal Processing with the PIC16C74” Application Note.

*

* This example program use the filter() function to implement a 60Hz notch

* filter. T0 is used to generate a 1kHz sample clock. The program samples the

* input signal x(n) on A-D channel 1, calls the filter routine signal, and

* outputs y(n) to PWM channel 1.

*

* If FILTER set to 0, performs straight talkthru from A-D to PWM output.

* T0 period can be changed to cary the sample rate.

*

* D. Mostowfi 4/95

******************************************************************************/

#include “\mpc\include\16c74.h” /* c74 header file */

#include “\mpc\apnotes\analogio.c” /* analog I/O module */

#include “\mpc\apnotes\iir_filt.c” /* iir filter module */

#define FILTER 1

/* Function Prototypes */

void main_isr();

void timer0_isr();

/*****************************************************************************

* main isr - 16C74 vectors to 0004h (MPC __INT() function) on any interrupt *

* assembly language routine saves W and Status registers then tests flags in

* INTCON to determine source of interrupt. Routine then calls appropriate isr.

* Restores W and status registers when done.

*****************************************************************************/

void __INT(void)

{

if(INTCON.T0IF){ /* timer 0 interrupt ? */

INTCON.T0IF=0; /* clear interrupt flag */

timer0_isr(); /* and call timer 0 isr */

}

/* Restore W, WImage, and STATUS registers */

#asm

BCF STATUS,RP0 ;Bank 0

MOVF temp_PCLATH, W

MOVWF PCLATH ;PCLATH restored

MOVF temp_WImage, W

MOVWF __WImage ;WImage restored

MOVF temp_FSR, W

MOVWF FSR ;FSR restored

SWAPF temp_STATUS,W

MOVWF STATUS ;RP0 restored

SWAPF temp_WREG,F

SWAPF temp_WREG,W ;W restored

#endasm

}

/*****************************************************************************

* timer 0 interrupt service routine

***************************************************************************/

void timer0_isr(void)

1997 Microchip Technology Inc. DS00616A-page 25

Page 26

AN616

{

TMR0=100; /* reload value for 1ms period */

PORTB.0=!PORTB.0; /* toggle PORTB.0 */

sample_flag=active; /* set sample flag */

}

void main()

{

/* initialize OPTION register */

OPTION=0b00000011; /* assign prescaler to T0 */

/* initialize INTCON register (keep GIE inactive!) */

INTCON=0b00000000; /* disable all interrupts */

/* initialize PIE1 and PIE2 registers (periphreal interrupts) */

PIE1=0b00000000; /* disable all peripheral interrupts */

PIE2=0b00000000;

/* initialize T1CON and T2CON registers */

T1CON=0b00000000; /* T1 not used */

T2CON=0b00000000; /* T2 not used */

/* initialize CCPxCON registers */

CCP1CON=0b00001100; /* set CCP1CON for PWM mode */

CCP2CON=0b00000000; /* CCP2CON=0 (PWM 2 not used) */

/* initialize SSPCON register */

SSPCON=0b00000000; /* serial port - not used */

/* initialize ADCONx registers */

ADCON0=0b00000000; /* a-d converter */

ADCON1=0b00000010;

/* initialize TRISx register (port pins as inputs or outputs) */

TRISA=0b00001111;

TRISB=0b00000000;

TRISC=0b11111011;

TRISD=0b11111111;

TRISE=0b11111111;

/* clear watchdog timer (not used) */

CLRWDT();

/* initialize program bit variables */

FLAGS=0b00000000;

/* intialize output port pins */

PORTB=0;

/* enable interrupts... */

INTCON.T0IE=1; /* peripheral interrupt enable */

INTCON.GIE=1; /* global interrupt enable */

init_PWM(0x40); /* init PWM port */

init_filter(); /* init filter */

while(1){

while(!sample_flag){} /* wait for sample clock flag to be set */

sample_flag=0; /* clear sample clock flag */

x_n=get_sample(1); /* read ADC channel 1 into x(n) */

if(FILTER==1){ /* if filter enabled */

filter(); /* call filter routine */

}

else{ /* or else write x(n) to y(n) (talkthru) */

y_n=x_n;

}

write_PWM((char)y_n,0); /* write y_n to PWM port 1 */

}

DS00616A-page 26 1997 Microchip Technology Inc.

Page 27

AN616

Please check the Microchip BBS for the latest version of the source code. Microchip’s Worldwide Web Address:

www.microchip.com; Bulletin Board Support: MCHIPBBS using CompuServe

®

(CompuServe membership not

required).

APPENDIX F: 8-BIT MULTIPLY AND SCALING ROUTINES

/******************************************************************************

* 8 bit Multiply and Scaling Routines

*

* Written for “Digital Signal Processing with the PIC16C74” Application Note.

*

*

* This module provides a 8 bit signed multiply and scaling routine for the

* PICTONE.C tone generation program. The routines are adapted from “Math

* Routines for the 16C5x” in Microchip’s Embedded Controller Handbook.

*

* All numbers are assumed to be signed 2’s compliment format.

*

* D. Mostowfi 11/94

*******************************************************************************/

char multcnd; /* 8 bit multiplicand */

char multplr; /* 8 bit multiplier */

char result_h; /* result - high byte */

char result_l; /* result - low byte */

char sign; /* result sign */

#asm

;

; 8x8 signed multiply routine

; called from PICTONE.C module (assembly language routine)

;

.MACRO mult_core bit

btfss multplr,bit

goto \no_add

movf multcnd,W

addwf result_h,F

\no_add:

rrf result_h

rrf result_l

.ENDM

_8x8smul:

movf multcnd,W ; get multiplicand

xorwf multplr,W ; and xor with multiplier

movwf sign ; and save sign of result

btfss multcnd,7 ; check sign bit of multiplicand

goto chk_multplr ; go and check multipier if positive

comf multcnd ; negate if negative

incf multcnd ;

chk_multplr:

btfss multplr,7 ; check sign bit of multiplier

goto multiply ; go to multiply if positive

comf multplr ; negate if negative

incf multplr ;

multiply:

movf multcnd,W ; set up multiply registers

bcf STATUS,C ;

clrf result_h ;

clrf result_l ;

mult_core 0 ; and do multiply core 8 times

mult_core 1 ;

1997 Microchip Technology Inc. DS00616A-page 27

Page 28

AN616

mult_core 2 ;

mult_core 3 ;

mult_core 4 ;

mult_core 5 ;

mult_core 6 ;

mult_core 7 ;

set_sign:

btfss sign,7 ; test sign to see if result negative

retlw 0 ; done if not! (clear W)

comf result_l ; negate result if sign set

incf result_l ;

btfsc STATUS,Z ;

decf result_h ;

comf result_h ;

retlw 0 ; done (clear W)

;

; Scaling Routine (used after a multiply to scale 16 bit result)

; Operates on result_h and result_l - final result is in result_l

; routine divides by 32 to restore Q7 result of 2*b*y(n-1) in tone

; generation algorithm

;

scale_16:

btfss sign,7 ; test if negative (sign set from mult)

goto start_shift ; go to start shift if pos.

comf result_l ; negate first if neg.

incf result_l ;

btfsc STATUS,Z ;

decf result_h ;

comf result_h ;

start_shift:

bcf STATUS,C ; clear status

rrf result_h ; and shift result left 5x (/32)

rrf result_l ;

rrf result_h ;

rrf result_l ;

rrf result_h ;

rrf result_l ;

rrf result_h ;

rrf result_l ;

rrf result_h ;

rrf result_l ;

btfss sign,7 ; test if result negative

goto scale_done ; done if not negative

comf result_l ; negate result if negative

incf result_l ;

btfsc STATUS,Z ;

decf result_h ;

comf result_h ;

scale_done: ;

retlw 0 ; done (clear W)

#endasm

DS00616A-page 28 1997 Microchip Technology Inc.

Page 29

AN616

Please check the Microchip BBS for the latest version of the source code. Microchip’s Worldwide Web Address:

www.microchip.com; Bulletin Board Support: MCHIPBBS using CompuServe

®

(CompuServe membership not

required).

APPENDIX G:DOUBLE PRECISION MATH ROUTINES

/******************************************************************************

* Double Precision Math Routines

*

* This module contains assembly language routines from “Math Routines for the

* 16C5x” from Microchip’s Embedded Controller Handbook that have been adapted

* for use with the Bytecraft MPC C Compiler.

*

* Routines are used IIR_FILT.C module written for “Digital Signal Processing

* with the PIC16C74” Application Note.

*

* D. Mostowfi 3/95

*****************************************************************************/

/*

Start of converted MPASM modules:

;*******************************************************************

; Double Precision Addition & Subtraction

;

;*******************************************************************;

; Addition : ACCb(16 bits) + ACCa(16 bits) -> ACCb(16 bits)

; (a) Load the 1st operand in location ACCaLO & ACCaHI ( 16 bits )

; (b) Load the 2nd operand in location ACCbLO & ACCbHI ( 16 bits )

; (c) CALL D_add

; (d) The result is in location ACCbLO & ACCbHI ( 16 bits )

;

; Performance :

; Program Memory : 07

; Clock Cycles : 08

;*******************************************************************;

; Subtraction : ACCb(16 bits) - ACCa(16 bits) -> ACCb(16 bits)

; (a) Load the 1st operand in location ACCaLO & ACCaHI ( 16 bits )

; (b) Load the 2nd operand in location ACCbLO & ACCbHI ( 16 bits )

; (c) CALL D_sub

; (d) The result is in location ACCbLO & ACCbHI ( 16 bits )

;

; Performance :

; Program Memory : 14

; Clock Cycles : 17

;*******************************************************************;

;

*/

char ACCaLO; //equ 10 changed equ statements to C char variables

char ACCaHI; //equ 11

char ACCbLO; //equ 12

char ACCbHI; //equ 13

;

#asm /* start of in-line assembly code */

; include “mpreg.h” commented out these

; org 0 two lines (MPASM specific)

;*******************************************************************

; Double Precision Subtraction ( ACCb - ACCa -> ACCb )

;

D_sub call neg_A2 ; At first negate ACCa; Then add

;

;*******************************************************************

1997 Microchip Technology Inc. DS00616A-page 29

Page 30

AN616

; Double Precision Addition ( ACCb + ACCa -> ACCb )

;

D_add movf ACCaLO,W

addwf ACCbLO ;add lsb

btfsc STATUS,C ;add in carry

incf ACCbHI

movf ACCaHI,C

addwf ACCbHI ;add msb

retlw 0

neg_A2 comf ACCaLO ; negate ACCa ( -ACCa -> ACCa )

incf ACCaLO

btfsc STATUS,Z

decf ACCaHI

comf ACCaHI

retlw 0

;*******************************************************************

; Double Precision Multiplication

;

; ( Optimized for Speed : straight Line Code )

;

;*******************************************************************;

; Multiplication : ACCb(16 bits) * ACCa(16 bits) -> ACCb,ACCc ( 32 bits )

; (a) Load the 1st operand in location ACCaLO & ACCaHI ( 16 bits )

; (b) Load the 2nd operand in location ACCbLO & ACCbHI ( 16 bits )

; (c) CALL D_mpy

; (d) The 32 bit result is in location ( ACCbHI,ACCbLO,ACCcHI,ACCcLO )

;

; Performance :

; Program Memory : 240

; Clock Cycles : 233

;

; Note : The above timing is the worst case timing, when the

; register ACCb = FFFF. The speed may be improved if

; the register ACCb contains a number ( out of the two

; numbers ) with less number of 1s.

;

; The performance specs are for Unsigned arithmetic ( i.e,

; with “SIGNED equ FALSE “).

;*******************************************************************;

;

#endasm

//char ACCaLO; equ 10 Commented out - already defined in Dbl_add

//char ACCaHI; equ 11

//char ACCbLO; equ 12

//char ACCbHI; equ 13

char ACCcLO; //equ 14 changed equ statements to C char variables

char ACCcHI; //equ 15

char ACCdLO; //equ 16

char ACCdHI; //equ 17

char temp; //equ 18

char sign; //equ 19

#asm

;

; include “mpreg.h” commented out these

; org 0 two lines (MPASM specific)

;*******************************************************************

SIGNED equ 1 ; Set This To ‘TRUE’ if the routines

; ; for Multiplication & Division needs

; ; to be assembled as Signed Integer

; ; Routines. If ‘FALSE’ the above two

DS00616A-page 30 1997 Microchip Technology Inc.

Page 31

; ; routines ( D_mpy & D_div ) use

; ; unsigned arithmetic.

;*******************************************************************

; multiplication macro

;

.MACRO mulMac ; changed macro to conform to MPC macro

; LOCAL NO_ADD ; language - declaration is different

; ; and macro labels are preceded by “/”

rrf ACCdHI ; rotate d right

rrf ACCdLO

btfss STATUS,C ; need to add?

goto \NO_ADD ; no addition necessary

movf ACCaLO,W ; Addition ( ACCb + ACCa -> ACCb )

addwf ACCbLO ; add lsb

btfsc STATUS,C ; add in carry

incf ACCbHI

movf ACCaHI,W

addwf ACCbHI ;add msb

\NO_ADD rrf ACCbHI

rrf ACCbLO

rrf ACCcHI

rrf ACCcLO

;

.ENDM ; end of modified macro

;