Page 1

AN247

A CAN Bootloader for PIC18F CAN Microcontrollers

Author: Ross M. Fosler

Microchip Technology Inc.

INTRODUCTION

Among the many features built into Microchip’s

Enhanced FLASH Microcontroller devices is the capability of the program memory to self-program. This very

useful feature has been deliberately included to give

the user the ability to perform bootloading operations.

Devices like the PIC18F458 are designed with a designated “boot block”, a small section of protectable program memory allocated specifically for bootload

firmware.

This application note demonstrates a simple bootloader implementation for the PIC18F families of microcontrollers with a CAN module. The goals of this

implementation are to stress maximum performance

and functionality, while requiring a minimum of code

space. For users developing CAN enabled systems, it

provides a low level framework that can be used with

higher level network protocols to develop more

complex and custom-tailored systems.

CONSIDERATIONS FOR FIELD PROGRAMMING OVER THE CAN BUS

The combination of FLASH technology and robust network communication capability in a single device

makes over-the-network programmability a very desirable option. However, this makes bootloading on a

CAN bus network a very different challenge from more

typical uses, such as using a bootloader to program a

single FLASH device in isolation. Let’s consider some

of the key issues in over-the-network programming.

Single or Group Programming

Providing bootloading capability over a CAN bus network takes some forethought. For example, a system

with a number of nodes may have identical firmware in

several nodes. Since every node on a CAN bus can

see all passing data, it may be more efficient to

program these identical nodes in a single pass.

However, in other cases where a node or many nodes

are unique, it may only be necessary to open

peer-to-peer communications to program the device.

This can be the simplest programming system,

because the programming source could contain all the

intelligence and freely manipulate the target memory.

The drawback to this is a lack of efficiency, as directly

manipulating the target memory and manually verifying

data takes significant time on the CAN bus.

To make the operation more efficient, the programming

target could be given some intelligence, like selfverification. This would make communications

unidirectional, essentially cutting the time on the CAN

bus in half.

Overall, the best savings is to design all the nodes in

the system with similar, modular firmware. Each node

could then use only those modules required for its task,

but the entire group of nodes could be updated simultaneously. The sacrifice here is program memory overhead, since some nodes may have resident firmware

that is not used.

Programming a Running System

An interesting situation is bootloading in an active and

functioning system. In this instance, one or more of the

nodes are taken off-line to update their firmware, yet

the functionality of the entire system is not completely

disabled. This, of course, requires that the target node

or nodes have some functional independence from

other parts of the networked system.

There are priority issues to contend with when programming in an active system. For example, what priority can be given to the bootloader without affecting

the critical communications in the system? If higher priority is given to nodes running the bootloader than

other nodes running their normal application, then it

may take time for data to be received when data is

being streamed to the programming target. Thus, critical systems that require relatively low latency for data

transmission or reception may fail to function as

expected. In the opposite situation, assigning the programming target with a priority that is too low could lead

to extremely long programming times, simply because

the programming source and target are continually

waiting for an IDLE bus to pass data.

In an active network, planning is necessary to provide

sufficient bus time for programming. One solution is

simply to give relatively high priority to bootloader programming operations, then design the programming

source to “inject” time for other applications while

streaming data on the CAN bus. Thus, bus time is

always available and controlled by the programming

source.

2003 Microchip Technology Inc. DS00247A-page 1

Page 2

AN247

Even with careful planning, there may be situations

where safety is actually compromised as a result of bus

contention. In these cases, the best option may be to

put all nodes in the network into a “Configuration” mode

and shut down all system functions.

Boot Mode Entry

Boot mode entry is determined by an event. This could

be a hardware event, such as pressing one or more

buttons after a device RESET. It could also be a network event, such as a special set of data that tells a

device to enter Boot mode. One example is a network

boot ID that is mapped directly into the CAN ID. Then

the key, along with specific target information, could be

embedded in the data field of a CAN frame. The key

information could put one or more nodes into Boot

mode.

BOOTLOADER FIRMWARE

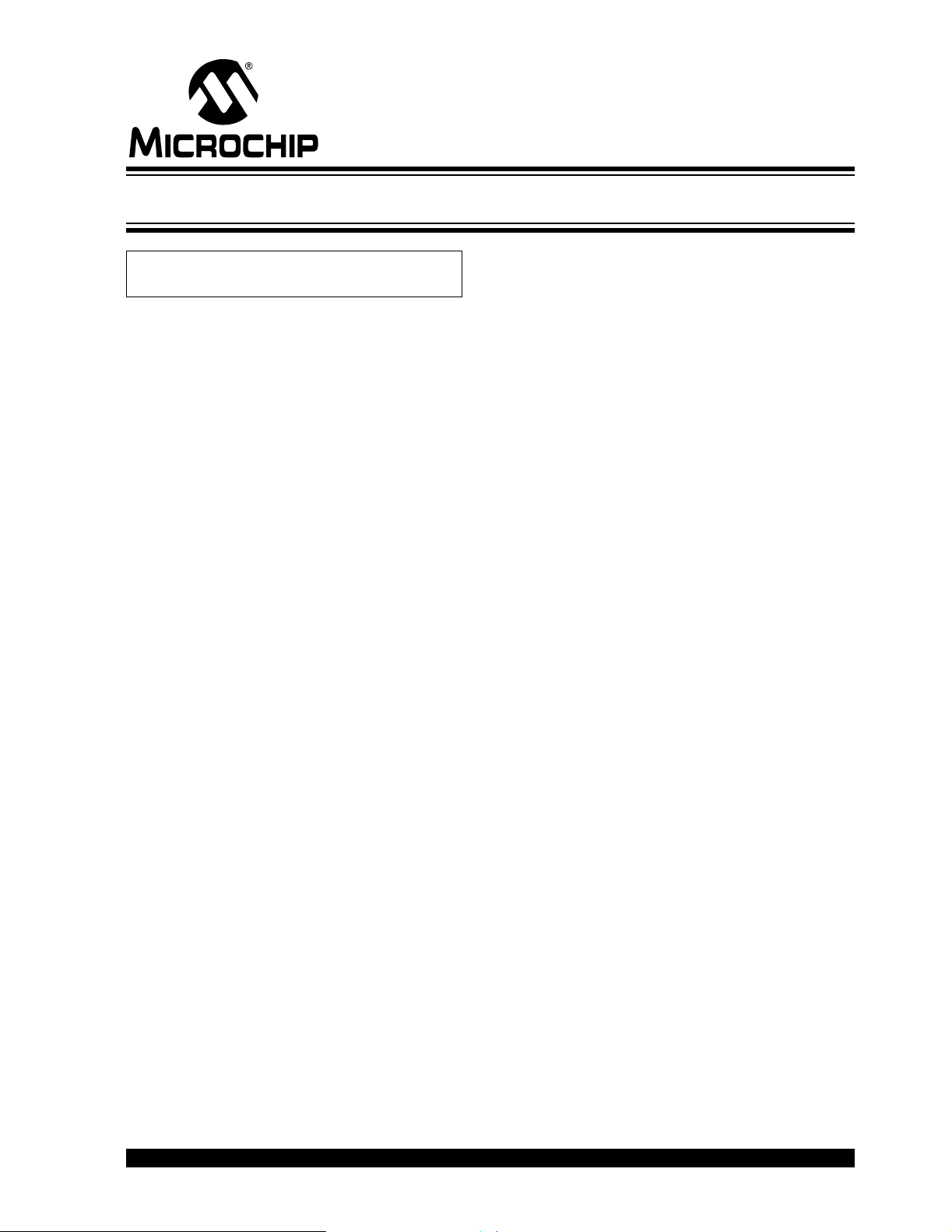

Basic Operation Overview

An overview of the CAN bootloader’s operation is

shown in Figure 1. A CAN Message Identifier and data

is received through the CAN module. One bit in the

identifier is used to indicate whether to PUT or GET

data. Another is used to determine if the message is to

be interpreted as data to be programmed or bootloader

control information. Writing data automatically invokes

the appropriate function to write to memory (FLASH,

Data EEPROM, or Configuration Memory). Writing to

the Control registers sets the operation of the

bootloader.

The bootloader can be configured at build time to support one of two mutually exclusive modes of operation.

In P Mode (or Put-only) mode, the microcontroller only

accepts PUT commands, and never “talks back” to the

source. In PG Mode, both PUT and GET commands

are accepted, allowing the source to both read from

and write to the target’s memory.

A more detailed explanation is provided in subsequent

sections.

FIGURE 1: BOOTLOADER FUNCTIONAL

BLOCK DIAGRAM

TXRX

Bootloader Firmware

CAN

Module

(Msg Identifier)

Configuration

Data

CONTROL/DATA

PUT/GET

FLASH

Program

Memory

EE

Data

Memory

Memory

Control/Data Buffer

Bootloader

Control

Registers

D8

D0

Memory I/O

Logic

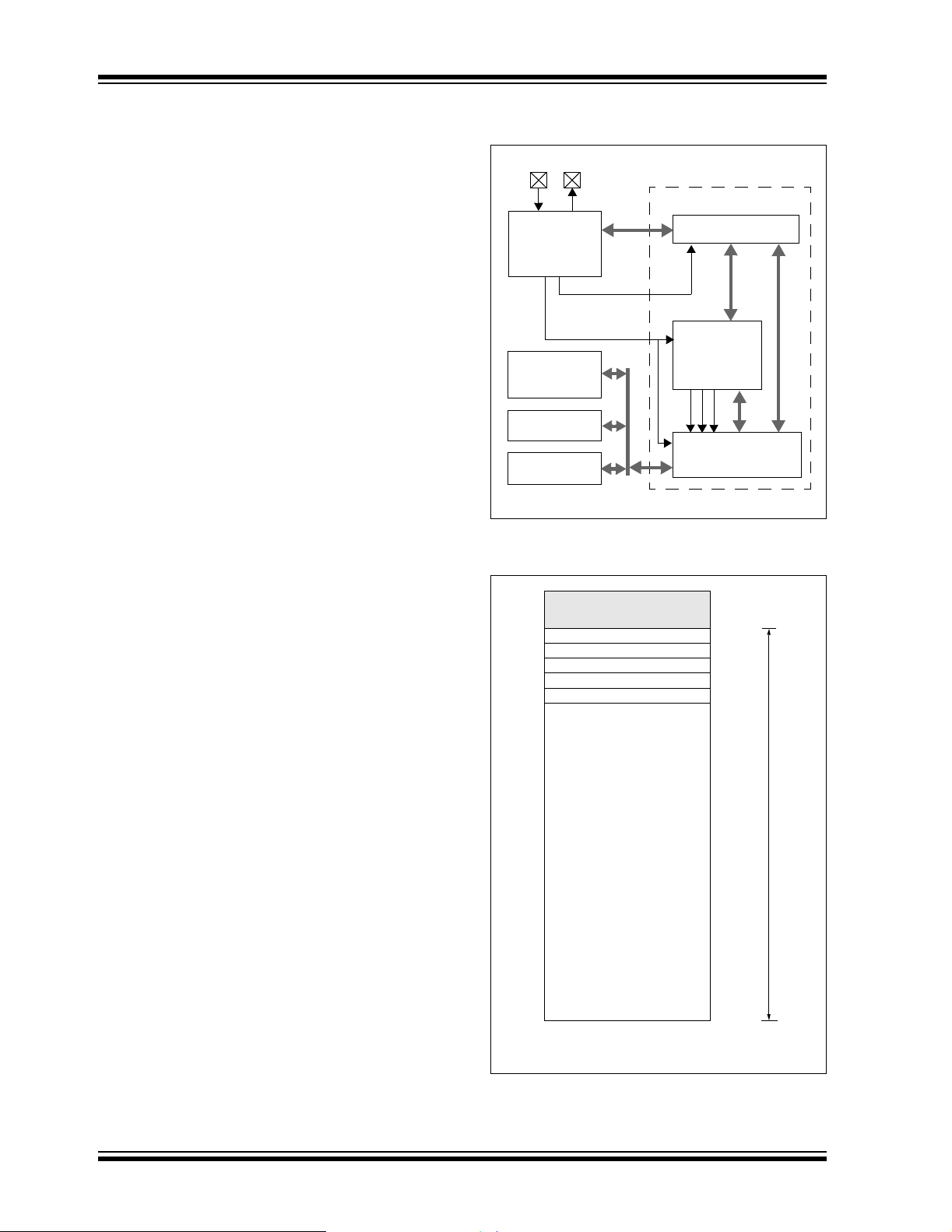

FIGURE 2: PROGRAM MEMORY MAP OF

THE PIC18F458

Boot Program

RESET Vector

High Priority Interrupt Vector

Low Priority Interrupt Vector

0000h

0200h

0208h

0218h

Memory Organization

Program Memory

User Memory Space

PROGRAM MEMORY USAGE

Currently, PIC18F devices reserve the first 512 bytes of

Program Memory as the boot block. Future devices

may expand this, depending on application requirements for these devices. This bootloader is designed to

occupy the current designated boot block of 512 bytes

(or 256 words) of memory using the recommended

options. Note, however, some compile time options can

grow the bootloader beyond the boot block. Figure 2

Note: Memory areas not shown to scale.

shows a memory map of the PIC18F458. The boot

area can be code protected to prevent accidental

overwriting of the boot program.

DS00247A-page 2 2003 Microchip Technology Inc.

7FFFh

Page 3

AN247

REMAPPED MEMORY AND VECTORS

Since the hardware RESET and interrupt vectors lie

within the boot area and cannot be edited if the block is

protected, they are remapped through software to the

nearest parallel locations outside the boot block.

Remapping is simply a branch for interrupts, so PIC18F

users should note an additional latency of 2 instruction

cycles to handle interrupts. Upon RESET, there are

some boot condition checks, so the RESET latency is

an additional 10 instruction cycles (as seen in the

example source code).

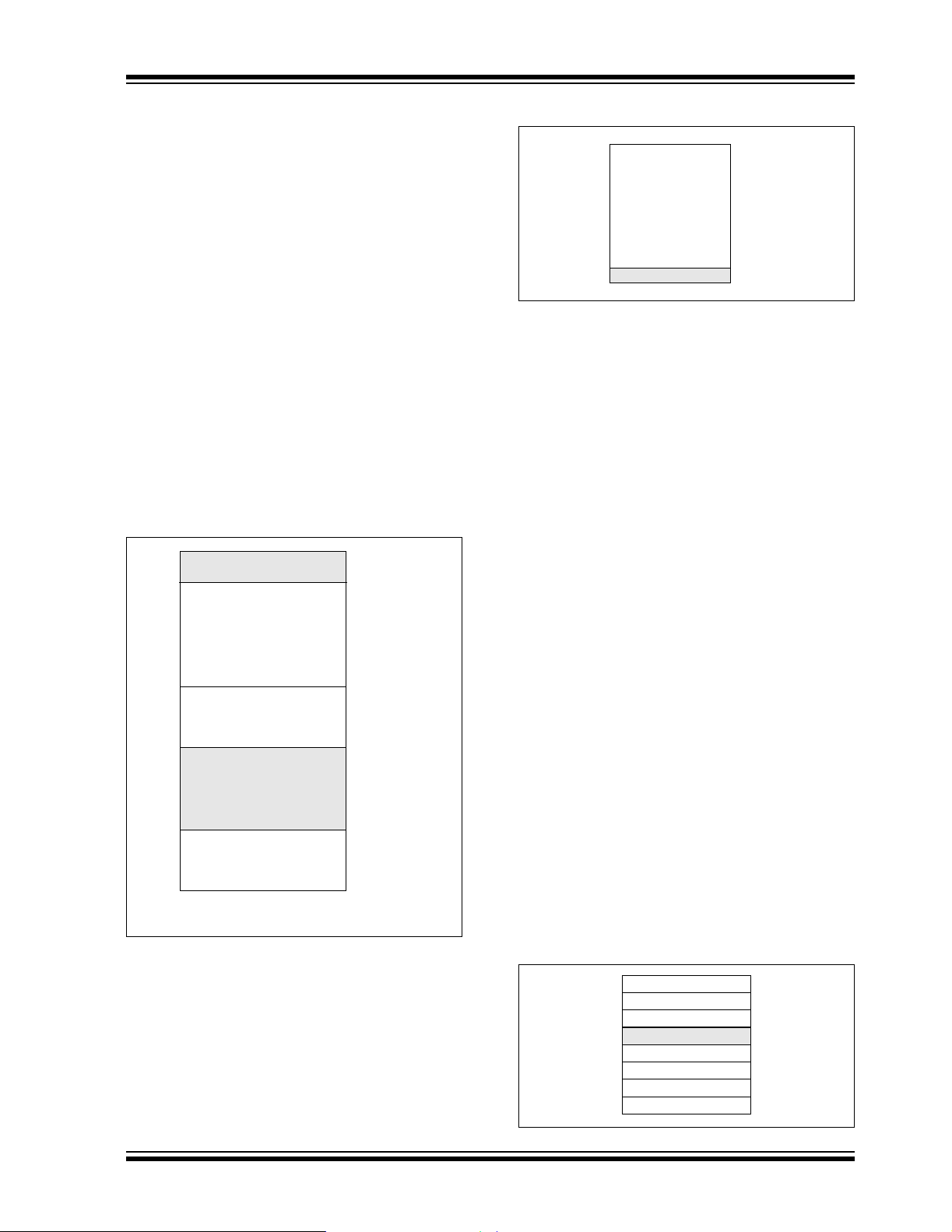

Notice the memory regions do not necessarily correlate

to the physical addresses in the device (see Figure 3).

For example, EEDATA is located at F00000h; however,

in the PIC18 device, EEDATA operates as a separate

module and is not located in the device memory map.

In addition, the regions only define where the bootloader operates and the type of memory that it operates

on. This should not be interpreted as meaning that

writable memory is available over the entire defined

memory areas.

FIGURE 3: BOOTLOADER MEMORY

REGIONS

Boot Program

(000h - 1FFh)

Program Memory

Config Memory

Unused

000000h

2FFFFFh

300000h

3FFFFFh

FIGURE 4: DATA MEMORY MAP

000h

EE Data

Memory

Boot Control Byte

XXXh

COMMUNICATION AND CONTROL PROTOCOL

From the functional view in Figure 1, the bootloader

looks and behaves like a hardware module. This is

mostly because the bootloader’s operation is dictated

by two “commands” derived from single bit values, as

well as a set of defined Control registers.

Basic Bootloader Commands

There are essentially two data control commands: PUT

and GET. These commands are implemented through

a single bit passed via the CAN Message Identifier field

(in this version, bit 1 of the 18-bit Extended Identifier

field); the command is PUT when the bit is ‘0’, and GET

when it is ‘1’. PUT or GET can operate on either a type

of memory or the Control register set. GET commands

are ignored if P-Mode is specified.

The CONTROL/DATA bit, also defined in the Identifier

field (in this version, bit 0 of the Extended Identifier),

indicates the destination of the frame data. When the

bit is ‘0’, the data is interpreted as Control register

content; when it is ‘1’, the data is programming data.

The bit assignments for PUT/GET and CONTROL/DATA

are arbitrary, and are defined by compile time definitions.

The user may change the locations of these bits in the

identifier as the application requires.

F00000h

EEPROM Data

FFFFFFh

Note: Memory areas not shown to scale.

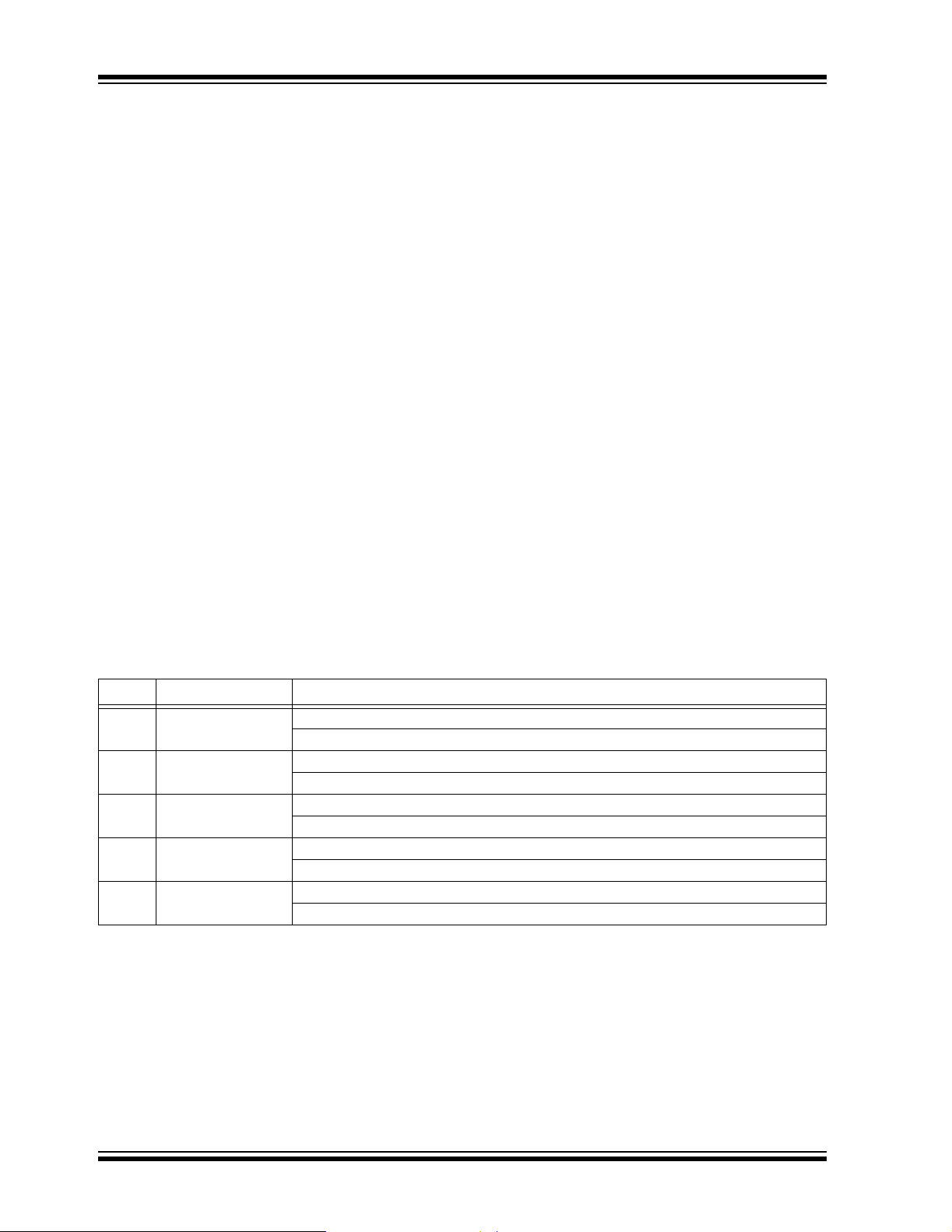

Control Registers

There are eight Control registers, which represent the

maximum number of bytes that can be contained in the

data field of a single CAN frame. The registers are

shown in order in Figure 5.

FIGURE 5: CONTROL REGISTERS

DATA MEMORY USAGE

The last location in Data Memory of the device

(Figure 4) is reserved as a non-volatile Boot mode flag.

This location contains FFh by default, which indicates

Boot mode. Any other value in this location indicates

normal Execution mode.

2003 Microchip Technology Inc. DS00247A-page 3

Address Low

Address High

Address Upper

(Reserved)

Control Bits

Command

Data A

Data B

D0

D1

D2

D3

D4

D5

D6

D7

Page 4

AN247

The Control registers are:

• Address Low (D0): This contains the low order

byte of the address pointer.

• Address High (D1): This register contains the

middle byte of the address pointer.

• Address Upper (D2): This register contains the

high order byte of the address pointer.

• Reserved (D3): This register is reserved for

expanded addressing.

• Control Bits (D4): This register contains bits that

define the basic operation of the bootloader.

• Command (D5): This location contains the immediate bootloader command. This is available to

allow special functions.

• Data A and Data B (D6 and D7): These Data

registers are reserved for expansions of the

bootloader command set.

Address Information

Control registers, D0 through D2, contain a 24-bit

address which can point to anywhere in the device’s

address space. Figure 3 shows the defined regions.

Control Bits

The five control bits in register D4 define how the

bootloader functions at run time. They are:

• WRITE_UNLOCK: Set this bit to unlock write

operations. This bit is provided to insure any write

operations to memory are intentional. This bit is

automatically cleared after a RESET.

• ERASE_ONLY: Set this bit to allow erase opera-

tions on Program Memory, but not write operations. This is useful when it is only necessary to

erase a section of memory. The address must be

on a 64-byte boundary to erase.

• AUTO_ERASE: Set this bit to automatically erase

while writing to memory. On every 64-byte boundary, the bootloader will automatically erase before

writing. This is useful when writing large sequential blocks of data over old data in Program

Memory.

• AUTO_INC: Set this to automatically increment

the address after each write or read operation.

This is useful when writing large sequential blocks

of data.

• ACK: In PG mode, set this bit to force the bootloader to send Acknowledgement of every PUT

command received. An Acknowledgement is

simply an empty CAN frame. This is useful in systems that require fully synchronized flow between

the source and the target.

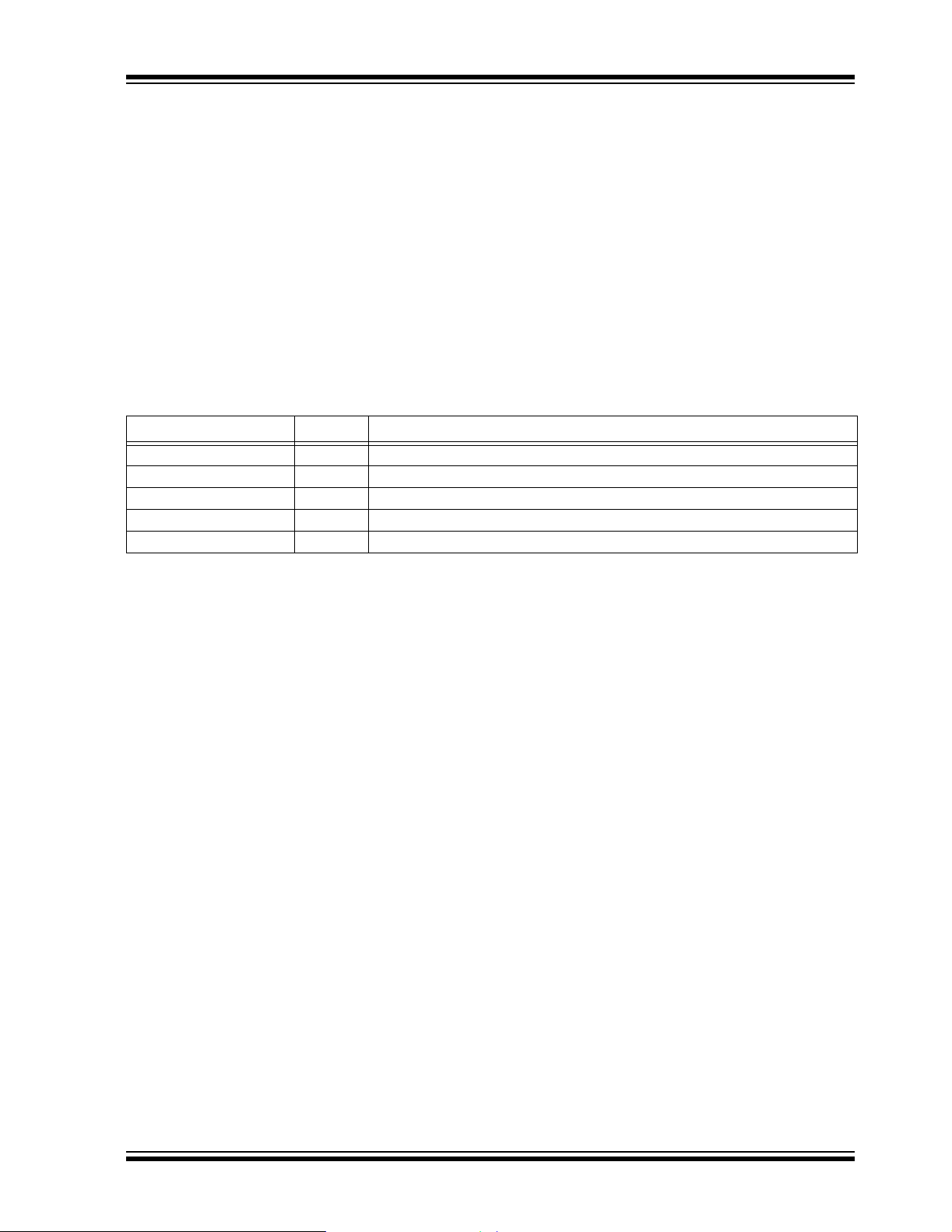

TABLE 1: SUMMARY OF CONTROL BITS (REGISTER D4)

Bit # Bit Name Description

0 WRITE_UNLOCK 0 = Prevent writing (default).

1 = Allow write to any memory.

1 ERASE_ONLY 0 = Allow write after erase (default).

1 = Don’t write after erase.

2 AUTO_ERASE 0 = Don’t automatically erase before writing.

1 = Erase if on 64-byte border, then write (default).

3AUTO_INC 0 = Update pointer manually.

1 = Increment pointer automatically after operation (default).

4ACK 0 = Don’t send Acknowledgement.

1 = Send an empty CAN frame after every PUT command (PG mode only)(default).

DS00247A-page 4 2003 Microchip Technology Inc.

Page 5

AN247

Command and Data

There are four commands defined to add functionality

and reliability to the bootloader. These are summarized

in Table 2. They are:

• NOP: No operation. This is supplied to allow

writing Control registers without issuing a

command.

• RESET: Reset the device via the RESET

instruction.

• INIT_CHK: Initialize the checksum and verify registers. This clears the internal 16-bit checksum

and clears the verify flags.

• CHK_RUN: Test the checksum and verify registers;

if valid, then clear the last location of EEPROM.

Data is passed through the Data registers in the

Control register set and added to the checksum;

the program checks for zero. The internal

self-verify flag is also tested for zero.

Note that these are not the only commands that may be

implemented. Users may expand on this basic set by

using the high order bits of register D4, or using combinations of bits to define an expanded command set.

Registers D5 through D7 may also be used to define

additional parameters in combination with commands.

The basic 8-register structure for control allows users

to expand the command sets to their own needs.

TABLE 2: SUMMARY OF SPECIAL COMMANDS (COMMAND REGISTER D5)

Command Code Description

NOP 00h No operation.

RESET 01h Issue a Software Reset to the device.

INIT_CHK 02h Initialize internal checksum and verify registers.

CHK_RUN 03h Test the checksum and verify, then clear the last location of EEPROM if valid.

All other commands 04h - FFh Undefined - operate as NOP.

BOOTLOADER DETAILS

Reading/Writing/Erasing Program Memory

For writing to FLASH Program Memory, the Control

register address must point to memory region 000000h

to 2FFFFFh. Read operations occur at the byte level.

Write operations are performed on multiples of 8 bytes

(one block), while erase operations are performed on

64 bytes (one row).

Writing is an immediate operation. When the PUT

“DATA” command is received, the address already

stored in the Control registers is decoded and the data

is written to the target’s Program Memory. Data is only

written if the write operation has been unlocked.

When writing Program Memory, the memory should be

erased first. Either the auto erase or erase only options

can be used to erase memory on every 64-byte border.

The default operation is that bits can only be cleared

when written to. An erase operation is the only action

that can be used to set bits in Program Memory. Thus,

if the bootloader protection bits are not set up in the

Configuration registers, operations on memory from

000h to 1FFh could partially or completely disable the

bootloader firmware.

User IDs (starting at address 200000h) are considered

to be part of Program Memory and are written and

erased like normal FLASH Program Memory.

Reading/Writing EEPROM Data Memory

For writing to EEPROM Data Memory, the Control register address must point to memory region F00000h to

FFFFFFh. Read and write operations occur at the byte

level. Write operations must be unlocked before any

write operation can take place.

Note that the last location of the Data Memory is used

as a boot flag. Writing anything other than FFh to the

last location indicates normal code execution.

Configuration Bits

PIC18F devices allow access to the device configuration bits (addresses starting at 300000h) during normal

operation. In the bootloader, the Control register

address must point to memory region 300000h to

3FFFFFh to provide Configuration Memory access.

Data is read one byte at a time and, unlike Program

Memory, is written one byte at a time. Since configuration bits are automatically erased before being written,

the erase control bit will have no affect on Configuration

Memory.

Having access to configuration settings is very powerful; it is also potentially very dangerous. For example,

assume that the system is designed to run in HS mode

with a 20 MHz crystal. If the bootloader changes the

oscillator setting to LP mode, the system will cease to

function - including the bootloader! Basically, the

system has been killed by improperly changing one bit.

2003 Microchip Technology Inc. DS00247A-page 5

Page 6

AN247

It is also important to note some configuration bits are

single direction bits in Normal mode; they can only be

changed to one state, and cannot be changed back.

The code protection bits in Configuration registers 5L

and 5H are a good example. If any type of code protection is enabled for a block, it cannot be disabled without

a device programmer. Essentially, the bootloader

cannot reverse code protection.

The Device ID (addresses 3FFFFEh and 3FFFFFh) is

also considered Program Memory. While they can be

accessed, however, they are read only and cannot be

altered.

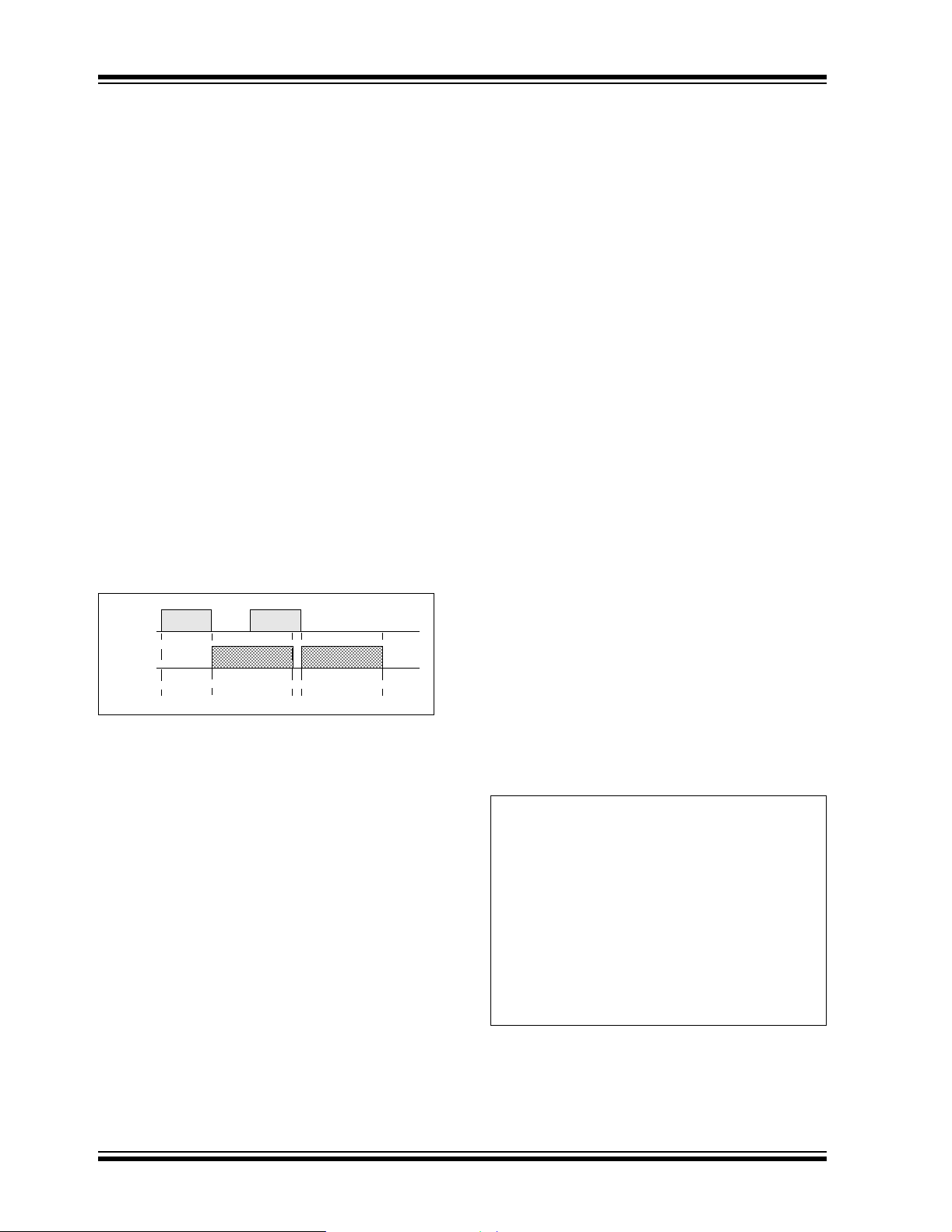

Write Latency

When writing data, there is a specific time that the programming source must wait for to complete the programming operation. Fortunately, the CAN module

actually buffers received data; therefore, receiving can

actually overlap memory write operations (Figure 6). In

general, it takes about 2 ms for Program Memory write

operations, while EEDATA takes about 4 ms. Not all

PIC18F devices have the same time specifications, so

it is important to verify the write times for the specific

device to be used.

FIGURE 6: CAN RECEIVE VS.

MEMORY WRITE

CAN

Message

Receive

Memory

Write

CAN

Msg

Writing in Assembly

When writing in assembly, the boot block and new vectors must be considered. For modular code, this is generally just a matter of changing the linker script file for

the project. An example is given in Appendix C. If an

absolute address is assigned to a code section, the

address must point somewhere above the boot block.

For those who write absolute assembly, all that is necessary to remember is that the new RESET vector is at

200h, and the interrupt vectors are at 208h and 218h.

No code except the bootloader should reside in the

boot block.

Writing in C

When using the MPLAB® C18 C compiler to develop

PIC18F firmware for an application, the standard

start-up object (c018.o or c018i.o) must be rebuilt

with the new RESET vector. Like modular assembly,

the linker file must be changed to incorporate the protected boot block and new vectors. Appendix C shows

an example linker file.

Users of other compilers should check with the compiler’s software user guide to determine how to change

the start-up code and vectors.

Bootloader Re-Entry

If the need exists to re-enter Boot mode from the application (and it usually does), the last location of the data

EEPROM must be set to FFh. The code in Example 1

demonstrates how this might be done in an application.

Since the bootloader assumes RESET conditions, a

RESET instruction should be initiated after setting the

last location.

WRITING CODE

The bootloader operates as a separate entity, which

means that an application can be developed with very

little concern about what the bootloader is doing. This

is as it should be; the bootloader should be dormant

code until an event initiates a boot operation. Under

ideal circumstances, bootloader code should never be

running during an application’s intended normal

operation.

When developing an application with a resident

bootloader, some basic principles must be kept in mind.

DS00247A-page 6 2003 Microchip Technology Inc.

EXAMPLE 1: SETTING THE LAST

LOCATION OF THE

DATA MEMORY

SETF EEADR ; Point to the last byte

SETF EEADRH

SETF EEDATA ; Bootmode control byte

MOVLW b'00000100 ; Setup for EEData

MOVWF EECON1

MOVLW 0x55 ; Unlock

MOVWF EECON2

MOVLW 0xAA

MOVWF EECON2

BSF EECON1, WR ; Start the write

NOP

BTFSC EECON1, WR ; Wait

BRA $ - 2

RESET

Page 7

AN247

Debugging

For most situations, it is not necessary to have the

bootloader firmware in memory to do debugging of an

application with either the MPLAB ICD 2 or ICE

devices. However, branch statements must be inserted

at the hardware vectors to get to the new designated

vectors. It may also be useful to have the start-up timing match exactly to the bootloader entry. When development of the application is finished, either remove the

branches and rebuild the project, or export only the

memory above the boot block. This code can then be

distributed to those who are updating their firmware.

COMPILE TIME OPTIONS

Compile time options are available to provide initial settings as well as features. Some features require more

memory than others. Compiling certain combinations of

options can actually generate code that is larger than

the designated boot block.

Modes of Operation (Compile Time)

The bootloader can be built to support either one of two

mutually exclusive modes of operation:

• P Mode - Only PUT commands are accepted. The

device will never ‘talk back’ to the source.

• PG Mode - Both PUT and GET are allowed. The

source can actually read out of the target’s

memory as well as write to the target’s memory.

The compile time definition, ALLOW_GET_CMD, selects

the mode.

Self-Verification

The definition, MODE_SELF_VERIFY, enables a

self-verification feature. With this feature, the firmware

reads back the data written to any type of memory (not

Control registers), and it compares the read data with

the source (received) data. A flag is set in a register if

verification failed.

Vectors

The RESET and interrupt vectors can be set to any

location using the following definitions:

• RESET_VECT

• HIGH_INT_VECT

• LOW_INT_VECT

The default values reside at addresses 200h, 208h,

and 218h, outside of the boot block; they parallel the

default PIC18F458 interrupt vectors. If compiling some

features causes the bootloader to be larger than the

boot block, then these vectors must be adjusted to

addresses above the used memory area. If the jump is

farther than a relative branch, then the definition,

NEAR_JUMP, must be removed.

Other Basic Settings

There are several other definitions that set CAN

specific settings. These determine which bits of the

message identifier are used for the PUT/GET and

CONTROL/DATA commands, the CONTROL/DATA bit

used for GET responses, as well as the filters and

masks for the programming node. Refer to Table 3 for

specific details.

2003 Microchip Technology Inc. DS00247A-page 7

Page 8

AN247

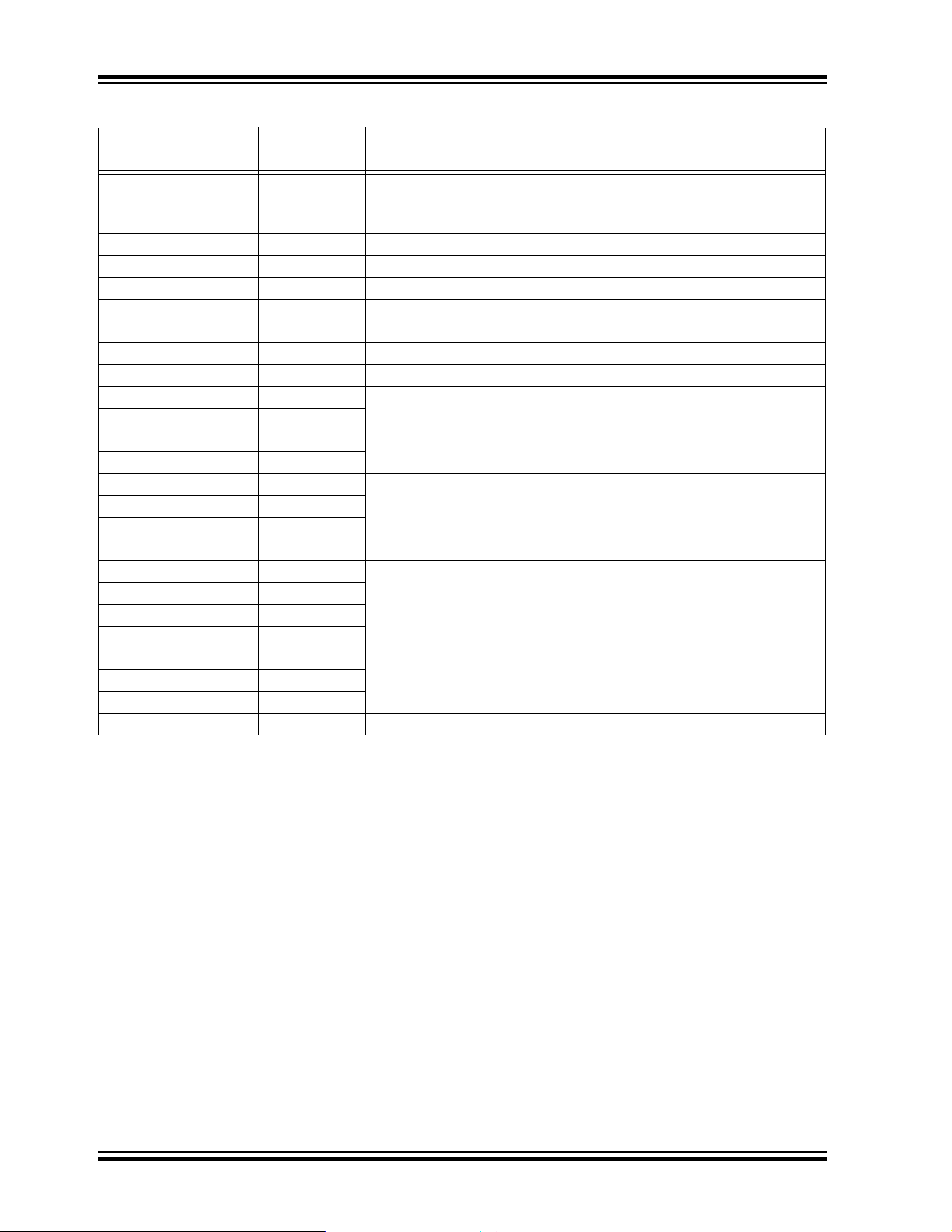

TABLE 3: SUMMARY OF COMPILE TIME DEFINITIONS

Definition

ALLOW_GET_CMD N/A Allows GET commands. If not present, then the bootloader will only

MODE_SELF_VERIFY N/A Enables self-verification of data written to memory.

NEAR_JUMP N/A Uses BRA to jump to vectors. If not defined, then it uses GOTO.

HIGH_INT_VECT 208h Remapped high priority interrupt vector.

LOW_INT_VECT 218h Remapped low priority interrupt vector.

RESET_VECT 200h Remapped RESET vector.

CAN_CD_BIT RXB0EIDL<0> Received CONTROL/DATA select bit.

CAN_PG_BIT RXB0EIDL<1> Received PUT/GET select bit.

CANTX_CD_BIT TXB0EIDL<0> Transmitted CONTROL/DATA select bit.

CAN_TXB0SIDH 10000000 Transmitted identifier for target node.

CAN_TXB0SIDL 00001000

CAN_TXB0EIDH 00000000

CAN_TXB0EIDL 00000100

CAN_RXF0SIDH 00000000 Receive filter for target node.

CAN_RXF0SIDL 00001000

CAN_RXF0EIDH 00000000

CAN_RXF0EIDL 00000111

CAN_RXM0SIDH 11111111 Receive mask for target node.

CAN_RXM0SIDL 11100011

CAN_RXM0EIDH 11111111

CAN_RXM0EIDL 11111100

CAN_BRGCON1 11000001 CAN bit rate control.

CAN_BRGCON2 10111010

CAN_BRGCON3 00000111

CAN_CIOCON 00100000 CAN I/O control.

Value

(Default)

Description

receive CAN messages.

DS00247A-page 8 2003 Microchip Technology Inc.

Page 9

AN247

TIPS FOR SUCCESSFUL FIELD PROGRAMMING

Successful programming can take several forms,

depending on which compile time options are selected.

In P-Mode with self-verification enabled, the programmed target keeps a running 16-bit sum of all the

data written to memory. In addition, every write operation is verified by reading back and comparing the data,

providing some assurance that all data was received

and that all data was correctly written.

In PG mode without self-verification, the programming

source can read as well as write data. Thus, verification

is provided directly by the source.

EXAMPLE PROGRAMMING SEQUENCE (P MODE)

1. Put the programming target in Boot mode.

2. Send a control packet. Load the address with

the beginning memory. Unlock write operations.

Enable auto erase. Disable erase only. Issue a

Self-Verify Reset.

3. Send Program Memory data. The data must be

8 bytes and aligned on an even 8-byte address.

4. Wait an appropriate amount of time.

5. Repeat steps 3 and 4 until all Program Memory

is written.

6. Send EEPROM Data Memory data.

7. Wait an appropriate amount of time.

8. Repeat steps 6 and 7 until all EEPROM Data

Memory is written except for the last location.

9. Send one byte of Configuration Memory data.

10. Wait an appropriate amount of time.

11. Repeat steps 9 and 10 until all the desired con-

figuration settings are written. If setting memory

protection, write these last.

12. Send a control packet. Send a check and run

command. Also, send the two’s compliment of

the sum of all data written in the Data registers

in the same packet.

13. Send a RESET command. If self-verification suc-

ceeded, then the node should be running the new

application. This could be verified at the application level by the programming source, or any

other node in the network that communicates

with the target.

EXAMPLE PROGRAMMING SEQUENCE (PG MODE)

1. Put the programming target in Boot mode.

2. Send a control packet. Load the address with

the beginning memory. Unlock write operations.

Enable auto erase. Disable erase only.

3. Send Program Memory data. The data must be

8 bytes and aligned on an even 8-byte address.

4. Wait an appropriate amount of time.

5. Read back the data written and compare. If fail,

then reset the pointer and try again, steps 3

and 4.

6. Repeat steps 3, 4, and 5 until all Program

Memory is written.

7. Send EEPROM Data Memory data.

8. Wait an appropriate amount of time.

9. Read back the data written and compare. If fail,

then reset the pointer and try again, steps 7

and 8.

10. Repeat steps 7, 8, and 9 until all EEPROM Data

Memory is written except for the last location.

11. Send one byte of Configuration Memory data.

12. Wait an appropriate amount of time.

13. Read back the data written and compare. If fail,

then reset the pointer and try again, steps 11

and 12.

14. Repeat steps 11, 12, and 13 until all the desired

configuration settings are written. If setting

memory protection, write these last.

15. Write 00h to the last location of EEPROM Data

Memory.

16. Send a RESET command. Functionality should

be verified at the application level by the

programming source, or any other node in the

network that communicates with the target.

2003 Microchip Technology Inc. DS00247A-page 9

Page 10

AN247

RESOURCES

For most builds, the PIC18F CAN bootloader resides

within the device’s Boot Block (000h to 1FFh), and

does not impact the normal Program Memory space

beyond the relocation of the interrupt vectors.

As noted, some combinations of compile time options

(for example, selecting both PG mode and self-verify)

will result in a bootloader that exceeds the Boot Block

size. In these cases, it will be necessary to relocate any

user application code and the interrupt vectors above

the boundary of the bootloader, being careful to avoid

code overlap. If Program Memory space is not critical,

the optimal solution may be to locate all application

code and the interrupt vectors above the upper boundary of Block 0 (1FFFh). Write protecting Block 0 to

protect the bootloader is desirable, but not essential.

The bootloader uses 12 bytes of data SRAM during

operation. It also uses 1 byte of data EEPROM at all

times, as the normal operation/bootloader flag.

REFERENCES

W. L awren z, CAN System Engineering From Theory to

Practical Applications. New York: Springer-Verlag

New York Inc., 1997.

MPLAB-CXX Compiler User’s Guide, Microchip

Technology Inc., 2000 (Document number DS51217).

Microchip Technology Inc., Application Note AN851, “A

FLASH Bootloader for PIC16 and PIC18 Devices”

(Document number DS00851).

DS00247A-page 10 2003 Microchip Technology Inc.

Page 11

AN247

APPENDIX A: A SIMPLE

PROGRAMMING

INTERFACE

To demonstrate the functionality of the CAN bootloader,

a simple serial-to-CAN interface is discussed briefly

here. The hardware, controller firmware and software

are designed to work as a package. Users are encouraged to use this design example as a starting point for

developing their own programming systems.

The Hardware

An underlying assumption of the bootloader is that

some method exists to introduce the new program data

to the target CAN network. There may be cases, however, where no provision has been made for a network

to communicate with an outside data source. In these

cases, it is necessary to introduce a CAN node whose

sole function is to provide an external data interface.

A schematic outline for the interface’s hardware is presented in Figure A-1 and Figure A-2 (following pages).

The heart of the design is a PIC18F458 microcontroller,

which runs the programming firmware and provides

both CAN and RS-232 communications. Interfaces to

the CAN bus and programming data source are provided by an external CAN transceiver and RS-232

interface.

Optional status LEDs, headers for accessing the controller’s I/O ports and power regulation are provided in

the design. These may be modified, removed or

expanded upon as the system design requires.

The Firmware

The firmware is an extension of the PIC18F serial bootloader discussed in Microchip Application Note AN851,

“A FLASH Bootloader for PIC16 and PIC18 Devices”.

Two new commands (RD_SRAM and WT_SRAM) have

been added to provide access to SRAM, thus allowing

complete control of all the peripherals (including the

CAN module) through the serial bootloader.

A summary of the commands and syntax for the PIC18

FLASH Bootloader is provided in Appendix A of

Application Note AN851.

The Host Software

The software portion of the interface is designed to run

on IBM

Windows®. It provides a simple graphic-based tool to

translate program files in Intel

data for the programmer firmware.

THE CANCOMM CONTROL

The software interface uses an ActiveX® control to provide simple communications with the CAN module

through the serial port. For those who wish to experiment with the interface, a total of 4 properties and 13

methods are available to the user. These are listed in

Table A-1.

THE USER INTERFACE

A simple graphic and text interface allows the user to

keep track of the bootloading operations in real-time.

Examples of the interface’s dialogs are shown in

Figure A-3.

®

compatible computers running Microsoft

®

HEX format into serial

®

TABLE A-1: ActiveX METHODS USED BY THE HOST SOFTWARE

Method Type Purpose

BitRate Property Sets the bit rate of the comm port.

CommPort Property Specifies the comm port.

MaxTimeOut Property Specifies the maximum wait (in milliseconds) for data to be received in

the computer’s serial buffer.

MaxRetrys Property Specifies the maximum number of times to resend a serial packet.

SetFilter Method Sets a CAN filter on the interface.

SetMask Method Sets a CAN mask on the interface.

GetMsg Method Gets the message from the CAN receive buffer.

PutMsg Method Puts the message in the CAN transmit buffer.

SetBitRate Method Sets the CAN bit rate.

Init Method Initializes the CAN module on the interface.

IsGetMsgRdy Method Determines if the receive buffer has data.

IsPutMsgRdy Method Determines if the transmit buffer is open.

GoOnBus Method Puts the interface on the CAN bus.

GoOffBus Method Takes the interface off the CAN bus.

GetStat Method Gets the current status of the interface CAN module.

OpenComm Method Opens serial communications to the interface

CloseComm Method Closes communications to the CAN interface.

2003 Microchip Technology Inc. DS00247A-page 11

Page 12

AN247

FIGURE A-1: BOOTLOADER HARDWARE INTERFACE FOR CAN NETWORKS

(MCU AND SERIAL INTERFACES)

PIC18F458/PT

DS00247A-page 12 2003 Microchip Technology Inc.

Page 13

FIGURE A-2: BOOTLOADER HARDWARE INTERFACE FOR CAN NETWORKS

(POWER SUPPLY, DISPLAYS AND CONNECTION HEADERS)

AN247

2003 Microchip Technology Inc. DS00247A-page 13

Page 14

AN247

FIGURE A-3: EXAMPLE DIALOGS FOR THE CANCOMM HOST SOFTWARE:

OUTPUT STATUS MESSAGES (TOP) AND PROGRESS BAR (BOTTOM)

DS00247A-page 14 2003 Microchip Technology Inc.

Page 15

AN247

Software License Agreement

The software supplied herewith by Microchip Technology Incorporated (the “Company”) is intended and supplied to you, the

Company’s customer, for use solely and exclusively with products manufactured by the Company.

The software is owned by the Company and/or its supplier, and is protected under applicable copyright laws. All rights are reserved.

Any use in violation of the foregoing restrictions may subject the user to criminal sanctions under applicable laws, as well as to civil

liability for the breach of the terms and conditions of this license.

THIS SOFTWARE IS PROVIDED IN AN “AS IS” CONDITION. NO WARRANTIES, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE APPLY TO THIS SOFTWARE. THE COMPANY SHALL NOT, IN ANY CIRCUMSTANCES, BE LIABLE FOR

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, FOR ANY REASON WHATSOEVER.

APPENDIX B: CAN BOOTLOADER FIRMWARE

;*****************************************************************************

;*

;* Microchip CAN Bootloader

;*

;*****************************************************************************

;* FileName: CANIO.asm

;* Dependencies:

;* Processor: PIC18F with CAN

;* Assembler: MPASMWIN 03.10.04 or higher

;* Linker: MPLINK 03.10.04 or higher

;* Company: Microchip Technology Incorporated

;*

;* Basic Operation:

;* The following is a CAN bootloader designed for PIC18F microcontrollers

;* with built-in CAN such as the PIC18F458. The bootloader is designed to

;* be simple, small, flexible, and portable.

;*

;* The bootloader can be compiled for one of two major modes of operation:

;*

;* PG Mode: In this mode the bootloader allows bi-directional communication

;* with the source. Thus the bootloading source can query the

;* target and verify the data being written.

;*

;* P Mode: In this mode the bootloader allows only single direction

;* communication, i.e. source -> target. In this mode programming

;* verification is provided by performing self verification and

;* checksum of all written data (except for control data).

;*

;* The bootloader is essentially a register-controlled system. The control

;* registers hold information that dictates how the bootloader functions.

;* Such information includes a generic pointer to memory, control bits to

;* assist special write and erase operations, and special command registers

;* to allow verification and release of control to the main application.

;*

;* After setting up the control registers, data can be sent to be written

;* to or a request can be sent to read from the selected memory defined by

;* the address. Depending on control settings the address may or may not

;* automatically increment to the next address.

;*

;* Commands:

;* Put commands received from source (Master --> Slave)

;* The count (DLC) can vary.

;* XXXXXXXXXXX 0 0 8 XXXXXXXX XXXXXX00 ADDRL ADDRH ADDRU RESVD CTLBT SPCMD CPDTL CPDTH

;* XXXXXXXXXXX 0 0 8 XXXXXXXX XXXXXX01 DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

;*

;* The following response commands are only used for PG mode.

;* Get commands received from source (Master --> Slave)

;* Uses control registers to get data. Eight bytes are always assumed.

;* XXXXXXXXXXX 0 0 0 XXXXXXXX XXXXXX10 _NA__ _NA__ _NA__ _NA__ _NA__ _NA__ _NA__ _NA__

;* XXXXXXXXXXX 0 0 0 XXXXXXXX XXXXXX11 _NA__ _NA__ _NA__ _NA__ _NA__ _NA__ _NA__ _NA__

2003 Microchip Technology Inc. DS00247A-page 15

Page 16

AN247

;*

;* Put commands sent upon receiving Get command (Slave --> Master)

;* YYYYYYYYYYY 0 0 8 YYYYYYYY YYYYYY00 ADDRL ADDRH ADDRU RESVD STATS RESVD RESVD RESVD

;* YYYYYYYYYYY 0 0 8 YYYYYYYY YYYYYY01 DATA0 DATA1 DATA2 DATA3 DATA4 DATA5 DATA6 DATA7

;*

;* Put commands sent upon receiving Put command (if enabled) (Slave --> Master)

;* This is the acknowledge after a put.

;* YYYYYYYYYYY 0 0 0 YYYYYYYY YYYYYY00 _NA__ _NA__ _NA__ _NA__ _NA__ _NA__ _NA__ _NA__

;* YYYYYYYYYYY 0 0 0 YYYYYYYY YYYYYY01 _NA__ _NA__ _NA__ _NA__ _NA__ _NA__ _NA__ _NA__

;*

;* ADDRL - Bits 0 to 7 of the memory pointer.

;* ADDRH - Bits 8 - 15 of the memory pointer.

;* ADDRU - Bits 16 - 23 of the memory pointer.

;* RESVD - Reserved for future use.

;* CTLBT - Control bits.

;* SPCMD - Special command.

;* CPDTL - Bits 0 - 7 of special command data.

;* CPDTH - Bits 8 - 15 of special command data.

;* DATAX - General data.

;*

;* Control bits:

;* MODE_WRT_UNLCK-Set this to allow write and erase operations to memory.

;* MODE_ERASE_ONLY-Set this to only erase Program Memory on a put command. Must be on 64-byte

;* boundary.

;* MODE_AUTO_ERASE-Set this to automatically erase Program Memory while writing data.

;* MODE_AUTO_INC-Set this to automatically increment the pointer after writing.

;* MODE_ACK-Set this to generate an acknowledge after a 'put' (PG Mode only)

;*

;* Special Commands:

;* CMD_NOP 0x00 Do nothing

;* CMD_RESET 0x01 Issue a soft reset

;* CMD_RST_CHKSM 0x02 Reset the checksum counter and verify

;* CMD_CHK_RUN 0x03 Add checksum to special data, if verify and zero checksum

;* then clear the last location of EEDATA.

;* Memory Organization (regions not shown to scale):

;* |-------------------------------|0x000000 (Do not write here!)

;* | Boot Area |

;* |-------------------------------|0x000200

;* | |

;* | Prog Mem |

;* | |

;* |-------------------------------|0x1FFFFF

;* | User ID |0x200000

;* |-------------------------------|

;* |:::::::::::::::::::::::::::::::|

;* |:::::::::::::::::::::::::::::::|

;* |-------------------------------|

;* | Config |0x300000

;* |-------------------------------|

;* |:::::::::::::::::::::::::::::::|

;* |:::::::::::::::::::::::::::::::|

;* |-------------------------------|

;* | Device ID |0x3FFFFE - 0x3FFFFF

;* |-------------------------------|

;* |:::::::::::::::::::::::::::::::|

;* |:::::::::::::::::::::::::::::::|

;* |-------------------------------|0xF00000

;* | EEDATA |

;* | (remapped) |(Last byte used as boot flag)

;* |-------------------------------|0xFFFFFF

;

DS00247A-page 16 2003 Microchip Technology Inc.

Page 17

;* Author Date Comment

;*~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

;* Ross Fosler 11/26/02 First full revision

;*

;*****************************************************************************/

; *****************************************************************************

#include p18cxxx.inc

#include canio.def

; *****************************************************************************

; *****************************************************************************

#ifndef EEADRH

#define EEADRH EEADR+1

#endif

#define TRUE 1

#define FALSE 0

#define WREG1 PRODH ; Alternate working register

#define WREG2 PRODL

#define MODE_WRT_UNLCK _bootCtlBits,0 ; Unlock write and erase

#define MODE_ERASE_ONLY_bootCtlBits,1 ; Erase without write

#define MODE_AUTO_ERASE_bootCtlBits,2 ; Enable auto erase before write

#define MODE_AUTO_INC _bootCtlBits,3 ; Enable auto inc the address

#define MODE_ACK _bootCtlBits,4 ; Acknowledge mode

#define ERR_VERIFY _bootErrStat,0 ; Failed to verify

#define CMD_NOP 0x00

#define CMD_RESET 0x01

#define CMD_RST_CHKSM 0x02

#define CMD_CHK_RUN 0x03

; *****************************************************************************

AN247

; *****************************************************************************

_MEM_IO_DATA UDATA_ACS 0x00

; *****************************************************************************

_bootCtlMem

_bootAddrL RES 1 ; Address info

_bootAddrH RES 1

_bootAddrU RES 1

_unused0 RES 1 ; (Reserved)

_bootCtlBits RES 1 ; Boot Mode Control bits

_bootSpcCmd RES 1 ; Special boot commands

_bootChkL RES 1 ; Special boot command data

_bootChkH RES 1

_bootCount RES 1

_bootChksmL RES 1 ; 16 bit checksum

_bootChksmH RES 1

_bootErrStat RES 1 ; Error Status flags

; *****************************************************************************

2003 Microchip Technology Inc. DS00247A-page 17

Page 18

AN247

; *****************************************************************************

_STARTUPCODE 0x00

; *****************************************************************************

bra _CANInit

bra _StartWrite

; *****************************************************************************

_INTV_H CODE 0x08

; *****************************************************************************

#ifdef NEAR_JUMP

bra HIGH_INT_VECT

#else

goto HIGH_INT_VECT

#endif

; *****************************************************************************

_INTV_L CODE 0x18

; *****************************************************************************

#ifdef NEAR_JUMP

bra LOW_INT_VECT

#else

goto LOW_INT_VECT

#endif

; *****************************************************************************

; *****************************************************************************

_CAN_IO_MODULE CODE

; *****************************************************************************

; Function: VOID _StartWrite(WREG _eecon_data)

;

; PreCondition: Nothing

; Input: _eecon_data

; Output: Nothing. Self write timing started.

; Side Effects: EECON1 is corrupted; WREG is corrupted.

; Stack Requirements: 1 level.

; Overview: Unlock and start the write or erase sequence to protected

; memory. Function will wait until write is finished.

;

; *****************************************************************************

_StartWrite:

movwf EECON1

btfss MODE_WRT_UNLCK ; Stop if write locked

return

movlw 0x55 ; Unlock

movwf EECON2

movlw 0xAA

movwf EECON2

bsf EECON1, WR ; Start the write

nop

btfsc EECON1, WR ; Wait (depends on mem type)

bra $ - 2

return

; *****************************************************************************

DS00247A-page 18 2003 Microchip Technology Inc.

Page 19

; *****************************************************************************

; Function: _bootChksm _UpdateChksum(WREG _bootChksmL)

;

; PreCondition: Nothing

; Input: _bootChksmL

; Output: _bootChksm. This is a static 16 bit value stored in the Access Bank.

; Side Effects: STATUS register is corrupted.

; Stack Requirements: 1 level.

; Overview: This function adds a byte to the current 16 bit checksum

; count. WREG should contain the byte before being called.

;

; The _bootChksm value is considered a part of the special

; register set for bootloading. Thus it is not visible.

;

;***************************************************************************

_UpdateChksum:

addwf _bootChksmL, F ; Keep a checksum

btfsc STATUS, C

incf _bootChksmH, F

return

; *****************************************************************************

; *****************************************************************************

; Function: VOID _CANInit(CAN, BOOT)

;

; PreCondition: Enter only after a reset has occurred.

; Input: CAN control information, bootloader control information

; Output: None.

; Side Effects: N/A. Only run immediately after reset.

; Stack Requirements: N/A

; Overview: This routine is technically not a function since it will not

; return when called. It has been written in a linear form to

; save space.Thus 'call' and 'return' instructions are not

; included, but rather they are implied.

;

; This routine tests the boot flags to determine if boot mode is

; desired or normal operation is desired. If boot mode then the

; routine initializes the CAN module defined by user input. It

; also resets some registers associated to bootloading.

;

; *****************************************************************************

_CANInit:

clrf EECON1

setf EEADR ; Point to last location of EEDATA

setf EEADRH

bsf EECON1, RD ; Read the control code

incfsz EEDATA, W

AN247

#ifdef NEAR_JUMP

bra RESET_VECT ; If not 0xFF then normal reset

#else

goto RESET_VECT

#endif

clrf _bootSpcCmd ; Reset the special command register

movlw 0x1C ; Reset the boot control bits

movwf _bootCtlBits

movlb d'15' ; Set Bank 15

bcf TRISB, CANTX ; Set the TX pin to output

movlw CAN_RXF0SIDH ; Set filter 0

movwf RXF0SIDH

movlw CAN_RXF0SIDL

movwf RXF0SIDL

comf WREG ; Prevent filter 1 from causing a

2003 Microchip Technology Inc. DS00247A-page 19

Page 20

AN247

movwf RXF1SIDL ; receive event

movlw CAN_RXF0EIDH

movwf RXF0EIDH

movlw CAN_RXF0EIDL

movwf RXF0EIDL

movlw CAN_RXM0SIDH ; Set mask

movwf RXM0SIDH

movlw CAN_RXM0SIDL

movwf RXM0SIDL

movlw CAN_RXM0EIDH

movwf RXM0EIDH

movlw CAN_RXM0EIDL

movwf RXM0EIDL

movlw CAN_BRGCON1 ; Set bit rate

movwf BRGCON1

movlw CAN_BRGCON2

movwf BRGCON2

movlw CAN_BRGCON3

movwf BRGCON3

movlw CAN_CIOCON ; Set IO

movwf CIOCON

clrf CANCON ; Enter Normal mode

; *****************************************************************************

; *****************************************************************************

; This routine is essentially a polling loop that waits for a

; receive event from RXB0 of the CAN module. When data is

; received, FSR0 is set to point to the TX or RX buffer depending

; upon whether the request was a 'put' or a 'get'.

; *****************************************************************************

_CANMain:

bcf RXB0CON, RXFUL ; Clear the receive flag

btfss RXB0CON, RXFUL ; Wait for a message

bra $ - 2

clrwdt

#ifdef ALLOW_GET_CMD

btfss CAN_PG_BIT ; Put or get data?

bra _CANMainJp1

lfsr 0, TXB0D0 ; Set pointer to the transmit buffer

movlw 0x08

movwf _bootCount ; Setup the count to eight

movwf WREG1

bra _CANMainJp2

#endif

_CANMainJp1

lfsr 0, RXB0D0 ; Set pointer to the receive buffer

movf RXB0DLC, W

andlw 0x0F

movwf _bootCount ; Store the count

movwf WREG1

bz _CANMain ; Go back if no data specified for a put

_CANMainJp2

; *****************************************************************************

DS00247A-page 20 2003 Microchip Technology Inc.

Page 21

; *****************************************************************************

; Function: VOID _ReadWriteMemory()

;

; PreCondition:Enter only after _CANMain().

; Input: None.

; Output: None.

; Side Effects: N/A.

; Stack Requirements: N/A

; Overview: This routine is technically not a function since it will not

; return when called. It has been written in a linear form to

; save space.Thus 'call' and 'return' instructions are not

; included, but rather they are implied.

;

; This is the memory I/O engine. A total of eight data

; bytes are received and decoded. In addition two control

; bits are received, put/get and control/data.

;

; A pointer to the buffer is passed via FSR0 for reading or writing.

;

; The control register set contains a pointer, some control bits

; and special command registers.

;

; Control

; <PG><CD><ADDRL><ADDRH><ADDRU><_RES_><CTLBT><SPCMD><CPDTL><CPDTH>

;

; Data

; <PG><CD><DATA0><DATA1><DATA2><DATA3><DATA4><DATA5><DATA6><DATA7>

;

; PG bit: Put = 0, Get = 1

; CD bit: Control = 0, Data = 1

;

; *****************************************************************************

_ReadWriteMemory:

btfscCAN_CD_BIT ; Write/read data or control registers

bra _DataReg

AN247

; *****************************************************************************

; This routine reads or writes the bootloader control registers,

; then executes any immediate command received.

_ControlReg

lfsr 1, _bootCtlMem

_ControlRegLp1

#ifdef ALLOW_GET_CMD

btfsc CAN_PG_BIT ; or copy control registers to buffer

movff POSTINC1, POSTINC0

btfss CAN_PG_BIT ; Copy the buffer to the control registers

#endif

movff POSTINC0, POSTINC1

decfsz WREG1, F

bra _ControlRegLp1

#ifdef ALLOW_GET_CMD

btfsc CAN_PG_BIT

bra _CANSendResponce; Send response if get

#endif

; *********************************************************

; This is a no operation command.

movf _bootSpcCmd, W; NOP Command

bz _SpecialCmdJp2; or send an acknowledge

; *********************************************************

2003 Microchip Technology Inc. DS00247A-page 21

Page 22

AN247

; *********************************************************

; This is the reset command.

xorlw CMD_RESET ; RESET Command

btfsc STATUS, Z

reset

; *********************************************************

; This is the Selfcheck reset command. This routine

; resets the internal check registers, i.e. checksum and

; self verify.

movf _bootSpcCmd, W ; RESET_CHKSM Command

xorlw CMD_RST_CHKSM

bnz _SpecialCmdJp1

clrf _bootChksmH ; Reset chksum

clrf _bootChksmL

bcf ERR_VERIFY ; Clear the error verify flag

; *********************************************************

; This is the Test and Run command. The checksum is

; verified, and the self-write verification bit is checked.

; If both pass, then the boot flag is cleared.

_SpecialCmdJp1

movf _bootSpcCmd, W ; RUN_CHKSM Command

xorlw CMD_CHK_RUN

bnz _SpecialCmdJp2

movf _bootChkL, W ; Add the control byte

addwf _bootChksmL, F

bnz _SpecialCmdJp2

movf _bootChkH, W

addwfc _bootChksmH, F

bnz _SpecialCmdJp2

btfsc ERR_VERIFY ; Look for verify errors

bra _SpecialCmdJp2

setf EEADR ; Point to last location of EEDATA

setf EEADRH

clrf EEDATA ; and clear the data

movlw b'00000100' ; Setup for EEData

rcall _StartWrite

_SpecialCmdJp2

#ifdef ALLOW_GET_CMD

bra _CANSendAck ; or send an acknowledge

#else

bra _CANMain

#endif

; *****************************************************************************

DS00247A-page 22 2003 Microchip Technology Inc.

Page 23

; *****************************************************************************

; This is a jump routine to branch to the appropriate memory access function.

; The high byte of the 24-bit pointer is used to determine which memory to access.

; All program memories (including Config and User IDs) are directly mapped.

; EEDATA is remapped.

_DataReg

; *********************************************************

_SetPointers

movf _bootAddrU, W ; Copy upper pointer

movwf TBLPTRU

andlw 0xF0 ; Filter

movwf WREG2

movf _bootAddrH, W ; Copy the high pointer

movwf TBLPTRH

movwf EEADRH

movf _bootAddrL, W ; Copy the low pointer

movwf TBLPTRL

movwf EEADR

btfss MODE_AUTO_INC ; Adjust the pointer if auto inc is enabled

bra _SetPointersJp1

movf _bootCount, W ; add the count to the pointer

addwf _bootAddrL, F

clrf WREG

addwfc _bootAddrH, F

addwfc _bootAddrU, F

_SetPointersJp1

AN247

_Decode

movlw 0x30 ; Program memory < 0x300000

cpfslt WREG2

bra _DecodeJp1

#ifdef ALLOW_GET_CMD

btfsc CAN_PG_BIT

bra _PMRead

#endif

bra _PMEraseWrite

_DecodeJp1

movf WREG2,W ; Config memory = 0x300000

xorlw 0x30

bnz _DecodeJp2

#ifdef ALLOW_GET_CMD

btfsc CAN_PG_BIT

bra _PMRead

#endif

bra _CFGWrite

_DecodeJp2

movf WREG2,W ; EEPROM data = 0xF00000

xorlw 0xF0

bnz _CANMain

#ifdef ALLOW_GET_CMD

btfsc CAN_PG_BIT

bra _EERead

#endif

bra _EEWrite

; *****************************************************************************

2003 Microchip Technology Inc. DS00247A-page 23

Page 24

AN247

; *****************************************************************************

; Function: VOID _PMRead()

; VOID _PMEraseWrite()

;

; PreCondition:WREG1 and FSR0 must be loaded with the count and address of

; the source data.

; Input: None.

; Output: None.

; Side Effects: N/A.

; Stack Requirements: N/A

; Overview: These routines are technically not functions since they will not

; return when called. They have been written in a linear form to

; save space.Thus 'call' and 'return' instructions are not

; included, but rather they are implied.

;

; These are the program memory read/write functions. Erase is

; available through control flags. An automatic erase option

; is also available. A write lock indicator is in place to

; ensure intentional write operations.

;

; Note: write operations must be on 8-byte boundaries and

; must be 8 bytes long. Also erase operations can only

; occur on 64-byte boundaries.

;

; *****************************************************************************

#ifdef ALLOW_GET_CMD

_PMRead:

tblrd*+ ; Fill the buffer

movff TABLAT, POSTINC0

decfsz WREG1, F

bra _PMRead ; Not finished then repeat

bra _CANSendResponce

#endif

_PMEraseWrite:

btfss MODE_AUTO_ERASE ; Erase if auto erase is requested

bra _PMWrite

_PMErase:

movf TBLPTRL, W ; Check for a valid 64 byte border

andlw b'00111111'

bnz _PMWrite

_PMEraseJp1

movlw b'10010100' ; Setup erase

rcall _StartWrite ; Erase the row

_PMWrite:

btfsc MODE_ERASE_ONLY ; Don't write if erase only is requested

#ifdef ALLOW_GET_CMD

bra _CANSendAck

#else

bra _CANMain

#endif

movf TBLPTRL, W ; Check for a valid 8 byte border

andlw b'00000111'

bnz _CANMain

movlw 0x08

movwf WREG1

DS00247A-page 24 2003 Microchip Technology Inc.

Page 25

_PMWriteLp1

movf POSTINC0, W ; Load the holding registers

movwf TABLAT

rcall _UpdateChksum ; Adjust the checksum

tblwt*+

decfsz WREG1, F

bra _PMWriteLp1

#ifdef MODE_SELF_VERIFY

movlw 0x08

movwf WREG1

_PMWriteLp2

tblrd*- ; Point back into the block

movf POSTDEC0, W

decfsz WREG1, F

bra _PMWriteLp2

movlw b'10000100' ; Setup writes

rcall _StartWrite ; Write the data

movlw 0x08

movwf WREG1

_PMReadBackLp1

tblrd*+ ; Test the data

movf TABLAT, W

xorwf POSTINC0, W

btfss STATUS, Z

bsf ERR_VERIFY

decfsz WREG1, F

bra _PMReadBackLp1 ; Not finished then repeat

#else

tblrd*- ; Point back into the block

movlw b'10000100' ; Setup writes

rcall _StartWrite ; Write the data

tblrd*+ ; Return the pointer position

#endif

AN247

#ifdef ALLOW_GET_CMD

bra _CANSendAck

#else

bra _CANMain

#endif

; *****************************************************************************

2003 Microchip Technology Inc. DS00247A-page 25

Page 26

AN247

; *****************************************************************************

; Function: VOID _CFGWrite()

; VOID _CFGRead()

;

; PreCondition:WREG1 and FSR0 must be loaded with the count and address of the source data.

; Input: None.

; Output: None.

; Side Effects: N/A.

; Stack Requirements: N/A

; Overview: These routines are technically not functions since they will not

; return when called. They have been written in a linear form to

; save space. Thus 'call' and 'return' instructions are not

; included, but rather they are implied.

;

; These are the Config memory read/write functions. Read is

; actually the same for standard program memory, so any read

; request is passed directly to _PMRead.

;

; *****************************************************************************

_CFGWrite:

#ifdef MODE_SELF_VERIFY ; Write to config area

movf INDF0, W ; Load data

#else

movf POSTINC0, W

#endif

movwf TABLAT

rcall _UpdateChksum ; Adjust the checksum

tblwt* ; Write the data

movlw b'11000100'

rcall _StartWrite

tblrd*+ ; Move the pointers and verify

#ifdef MODE_SELF_VERIFY

movf TABLAT, W

xorwf POSTINC0, W

btfss STATUS, Z

bsf ERR_VERIFY

#endif

decfsz WREG1, F

bra _CFGWrite ; Not finished then repeat

#ifdef ALLOW_GET_CMD

bra _CANSendAck

#else

bra _CANMain

#endif

; *****************************************************************************

DS00247A-page 26 2003 Microchip Technology Inc.

Page 27

; *****************************************************************************

; Function: VOID _EERead()

; VOID _EEWrite()

;

; PreCondition:WREG1 and FSR0 must be loaded with the count and address of

; the source data.

; Input: None.

; Output: None.

; Side Effects: N/A.

; Stack Requirements: N/A

; Overview: These routines are technically not functions since they will not

; return when called. They have been written in a linear form to

; save space. Thus 'call' and 'return' instructions are not

; included, but rather they are implied.

;

; This is the EEDATA memory read/write functions.

;

; *****************************************************************************

#ifdef ALLOW_GET_CMD

_EERead:

clrf EECON1

bsf EECON1, RD ; Read the data

movff EEDATA, POSTINC0

infsnz EEADR, F ; Adjust EEDATA pointer

incf EEADRH, F

decfsz WREG1, F

bra _EERead ; Not finished then repeat

bra _CANSendResponce

#endif

AN247

_EEWrite:

#ifdef MODE_SELF_VERIFY

movf INDF0, W ; Load data

#else

movf POSTINC0, W

#endif

movwf EEDATA

rcall _UpdateChksum ; Adjust the checksum

movlw b'00000100' ; Setup for EEData

rcall _StartWrite ; and write

#ifdef MODE_SELF_VERIFY

clrf EECON1 ; Read back the data

bsf EECON1, RD ; verify the data

movf EEDATA, W ; and adjust pointer

xorwf POSTINC0, W

btfss STATUS, Z

bsf ERR_VERIFY

#endif

infsnz EEADR, F ; Adjust EEDATA pointer

incf EEADRH, F

decfsz WREG1, F

bra _EEWrite ; Not finished then repeat

#ifdef ALLOW_GET_CMD

#else

bra _CANMain

#endif

; *****************************************************************************

2003 Microchip Technology Inc. DS00247A-page 27

Page 28

AN247

; *****************************************************************************

; Function: VOID _CANSendAck()

; VOID _CANSendResponce()

;

; PreCondition:TXB0 must be preloaded with the data.

; Input: None.

; Output: None.

; Side Effects: N/A.

; Stack Requirements: N/A

; Overview: These routines are technically not functions since they will not

; return when called. They have been written in a linear form to

; save space. Thus 'call' and 'return' instructions are not

; included, but rather they are implied.

;

; These routines are used for 'talking back' to the source. The

; _CANSendAck routine sends an empty message to indicate

; acknowledgement of a memory write operation. The

; _CANSendResponce is used to send data back to the source.

;

; *****************************************************************************

#ifdef ALLOW_GET_CMD

_CANSendAck:

btfss MODE_ACK

bra _CANMain

clrf TXB0DLC ; Setup for a 0 byte transmission

bra _CANSendMessage

#endif

#ifdef ALLOW_GET_CMD

_CANSendResponce:

movlw 0x08 ; Setup for 8 byte transmission

movwf TXB0DLC

_CANSendMessage

btfsc TXB0CON,TXREQ ; Wait for the buffer to empty

bra $ - 2

movlw CAN_TXB0SIDH ; Set ID

movwf TXB0SIDH

movlw CAN_TXB0SIDL

movwf TXB0SIDL

movlw CAN_TXB0EIDH

movwf TXB0EIDH

movlw CAN_TXB0EIDL

movwf TXB0EIDL

bsf CANTX_CD_BIT ; Setup the command bit

btfss CAN_CD_BIT

bcf CANTX_CD_BIT

bsf TXB0CON, TXREQ ; Start the transmission

bra _CANMain

#endif

; *****************************************************************************

END

DS00247A-page 28 2003 Microchip Technology Inc.

Page 29

APPENDIX C: LINKER SCRIPT EXAMPLES

Assembly Linker Script for PIC18F452

// Linker command file for 18F452 with bootloader

// By R. Fosler

LIBPATH .

CODEPAGE NAME=boot START=0x0 END=0x1FF PROTECTED

CODEPAGE NAME=prog START=0x200 END=0x7FFF

CODEPAGE NAME=idlocs START=0x200000 END=0x200007 PROTECTED

CODEPAGE NAME=config START=0x300000 END=0x30000D PROTECTED

CODEPAGE NAME=devid START=0x3FFFFE END=0x3FFFFF PROTECTED

CODEPAGE NAME=eedata START=0xF00000 END=0xF000FF PROTECTED

ACCESSBANK NAME=accessram START=0x0 END=0x7F

DATABANK NAME=gpr0 START=0x80 END=0xFF

DATABANK NAME=gpr1 START=0x100 END=0x1FF

DATABANK NAME=gpr2 START=0x200 END=0x2FF

DATABANK NAME=gpr3 START=0x300 END=0x3FF

DATABANK NAME=gpr4 START=0x400 END=0x4FF

DATABANK NAME=gpr5 START=0x500 END=0x5FF

ACCESSBANK NAME=accesssfr START=0xF80 END=0xFFF PROTECTED

AN247

C18 Linker Script

// Sample linker command file for 18F452 with Bootloader

// Ross M. Fosler, 03/27/2002

LIBPATH .

FILES c018i.o

FILES clib.lib

FILES p18f452.lib

CODEPAGE NAME=boot START=0x0 END=0x1FF PROTECTED

CODEPAGE NAME=vectors START=0x200 END=0x229 PROTECTED

CODEPAGE NAME=page START=0x22A END=0x7FFF

CODEPAGE NAME=idlocs START=0x200000 END=0x200007 PROTECTED

CODEPAGE NAME=config START=0x300000 END=0x30000D PROTECTED

CODEPAGE NAME=devid START=0x3FFFFE END=0x3FFFFF PROTECTED

CODEPAGE NAME=eedata START=0xF00000 END=0xF000FF PROTECTED

ACCESSBANK NAME=accessram START=0x0 END=0x7F

DATABANK NAME=gpr0 START=0x80 END=0xFF

DATABANK NAME=gpr1 START=0x100 END=0x1FF

DATABANK NAME=gpr2 START=0x200 END=0x2FF

DATABANK NAME=gpr3 START=0x300 END=0x3FF

DATABANK NAME=gpr4 START=0x400 END=0x4FF

DATABANK NAME=gpr5 START=0x500 END=0x5FF

ACCESSBANK NAME=accesssfr START=0xF80 END=0xFFF PROTECTED

STACK SIZE=0x100 RAM=gpr5

2003 Microchip Technology Inc. DS00247A-page 29

Page 30

AN247

APPENDIX D: SOFTWARE

DISCUSSED IN THIS

APPLICATION NOTE

All of the software covered in this application note is

available as a single WinZip archive file. The archive

may be downloaded from the Microchip corporate

web site at:

www.microchip.com

DS00247A-page 30 2003 Microchip Technology Inc.

Page 31

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications. No

representation or warranty is given and no liability is assumed by

Microchip Technology Incorporated with respect to the accuracy

or use of such information, or infringement of patents or other

intellectual property rights arising from such use or otherwise.

Use of Microchip’s products as critical components in life

support systems is not authorized except with express written

approval by Microchip. No licenses are conveyed, implicitly or

otherwise, under any intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, K

EELOQ,

MPLAB, PIC, PICmicro, PICSTART, PRO MATE and

PowerSmart are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

FilterLab, microID, MXDEV, MXLAB, PICMASTER, SEEVAL

and The Embedded Control Solutions Company are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Accuron, dsPIC, dsPICDEM.net, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial Programming,

ICSP, ICEPIC, microPort, Migratable Memory, MPASM, MPLIB,

MPLINK, MPSIM, PICC, PICkit, PICDEM, PICDEM.net,

PowerCal, PowerInfo, PowerTool, rfPIC, Select Mode,

SmartSensor, SmartShunt, SmartTel and Total Endurance are

trademarks of Microchip Technology Incorporated in the U.S.A.

and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark of

Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2003, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

2003 Microchip Technology Inc. DS00247A - page 31

Page 32

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-4338

Atlanta

3780 Mansell Road, Suite 130

Alpharetta, GA 30022

Tel: 770-640-0034 Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Marketing Support Division

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401-2402, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-86766200 Fax: 86-28-86766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Hong Kong SAR

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1812, 18/F, Building A, United Plaza

No. 5022 Binhe Road, Futian District

Shenzhen 518033, China

Tel: 86-755-82901380 Fax: 86-755-82966626

China - Qingdao

Rm. B505A, Fullhope Plaza,

No. 12 Hong Kong Central Rd.

Qingdao 266071, China

Tel: 86-532-5027355 Fax: 86-532-5027205

India

Microchip Technology Inc.

India Liaison Office

Marketing Support Division

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Microchip Technology (Barbados) Inc.,