93AA46/56/66

1K/2K/4K 1.8V Microwire

FEATURES

• Single supply with programming operation down

to 1.8V

• Low power CMOS technology

- 70

µ

A typical active READ current at 1.8V

-2

µ

A typical standby current at 1.8V

• ORG pin selectable memory configuration

- 128 x 8- or 64 x 16-bit organization (93AA46)

- 256 x 8- or 128 x 16-bit organization

(93AA56)

- 512 x 8 or 256 x 16 bit organization (93AA66)

• Self-timed ERASE and WRITE cycles

(including auto-erase)

• Automatic ERAL before WRAL

• Power on/off data protection circuitry

• Industry standard 3-wire serial I/O

• Device status signal during ERASE/WRITE cycles

• Sequential READ function

• 10,000,000 ERASE/WRITE cycles guaranteed on

93AA56 and 93AA66

• 1,000,000 E/W cycles guaranteed on 93AA46

• Data retention > 200 years

• 8-pin PDIP/SOIC

(SOIC in JEDEC and EIAJ standards)

• Temperature ranges supported

- Commercial (C): 0 ° C to +70 ° C

Serial EEPROM

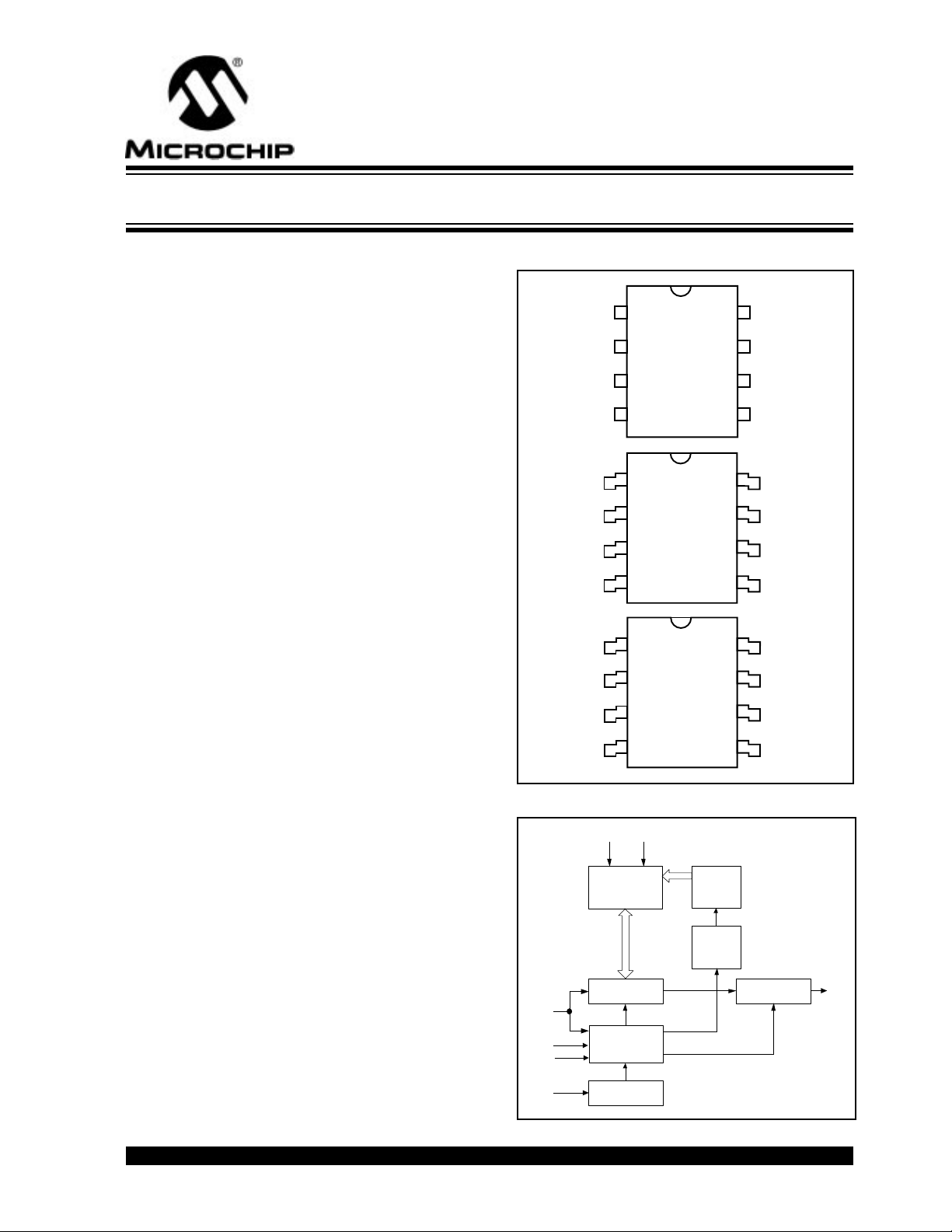

PACKA GE TYPES

DIP

1

CS

CLK

DI

DO

SOIC

CS

CLK

DI

DO

SOIC

NU

Vcc

CS

CLK

2

3

4

1

2

3

4

1

2

3

4

93AA66

93AA66

93AA66X

8

93AA46

93AA56

7

6

5

8

93AA46

93AA56

7

6

5

8

93AA46X

93AA56X

7

6

5

V

CC

NU

ORG

V

SS

V

NU

ORG

V

ORG

Vss

DO

DI

CC

SS

DESCRIPTION

The Microchip Technology Inc. 93AA46/56/66 are 1K,

2K and 4K low voltage serial Electrically Erasable

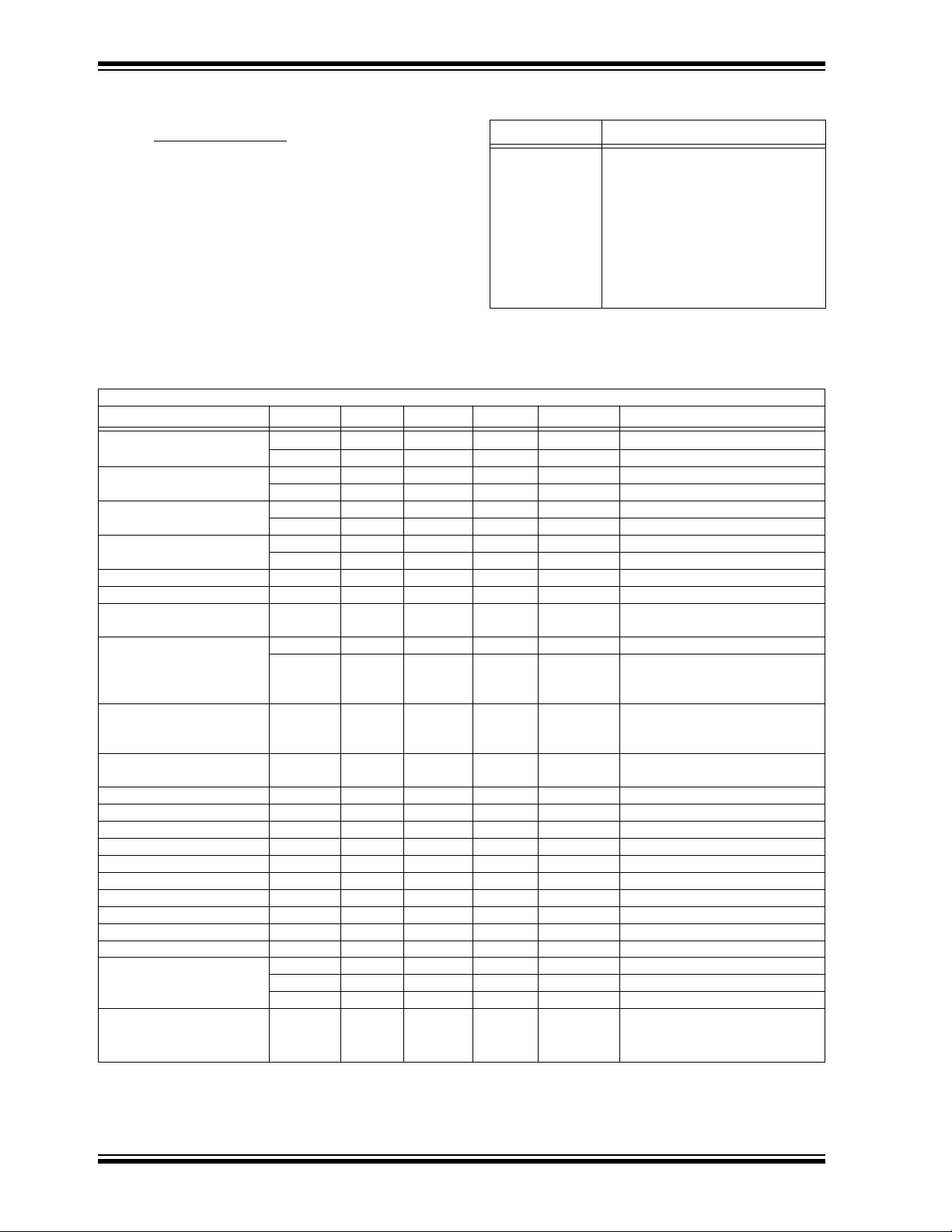

BLOCK DIAGRAM

V

CC VSS

PROMs. The device memory is configured as x8 or x16

bits depending on the ORG pin setup. Advanced

CMOS technology makes these devices ideal for low

power non-volatile memory applications. The 93AA

MEMORY

ARRAY

ADDRESS

DECODER

Series is available in standard 8-pin DIP and surface

mount SOIC packages. The rotated pin-out 93AA46X/

56X/66X are offered in the “SN” package only.

DATA REGISTER

DI

MODE

ORG

CS

CLK

Microwire is a registered trademark of National Semiconductor Incorporated.

1996 Microchip Technology Inc. DS20067G-page 1

DECODE

LOGIC

CLOCK

GENERATOR

ADDRESS

COUNTER

OUTPUT

BUFFER

DO

≥

93AA46/56/66

≥

µ

µ

µ A µ

µ A µ A µ

≥

1.0 ELECTRICAL CHARACTERISTICS

1.1 Maxim

V

CC

............................................................................7.0V

All inputs and outputs w.r.t. V

Storage temperature................................-65˚C to +150˚C

Ambient temp. with power applied...........-65˚C to +125˚C

Soldering temperature of leads (10 seconds)........+300˚C

ESD protection on all pins ......................................... 4 kV

*Notice: Stresses above those listed under “Maximum ratings”

may cause permanent damage to the device. This is a stress rating only and functional operation of the device at those or any

other conditions above those indicated in the operational listings

of this specification is not implied. Exposure to maximum rating

conditions for extended periods may affect device reliability.

um Ratings

SS

..........-0.6V to V

CC

+1.0V

TABLE 1-1: PIN FUNCTION TABLE

Name Function

CS Chip Select

CLK Serial Data Clock

DI Serial Data Input

DO Serial Data Output

V

SS

ORG Memory Configuration

NU Not Utilized

V

CC

Ground

Power Supply

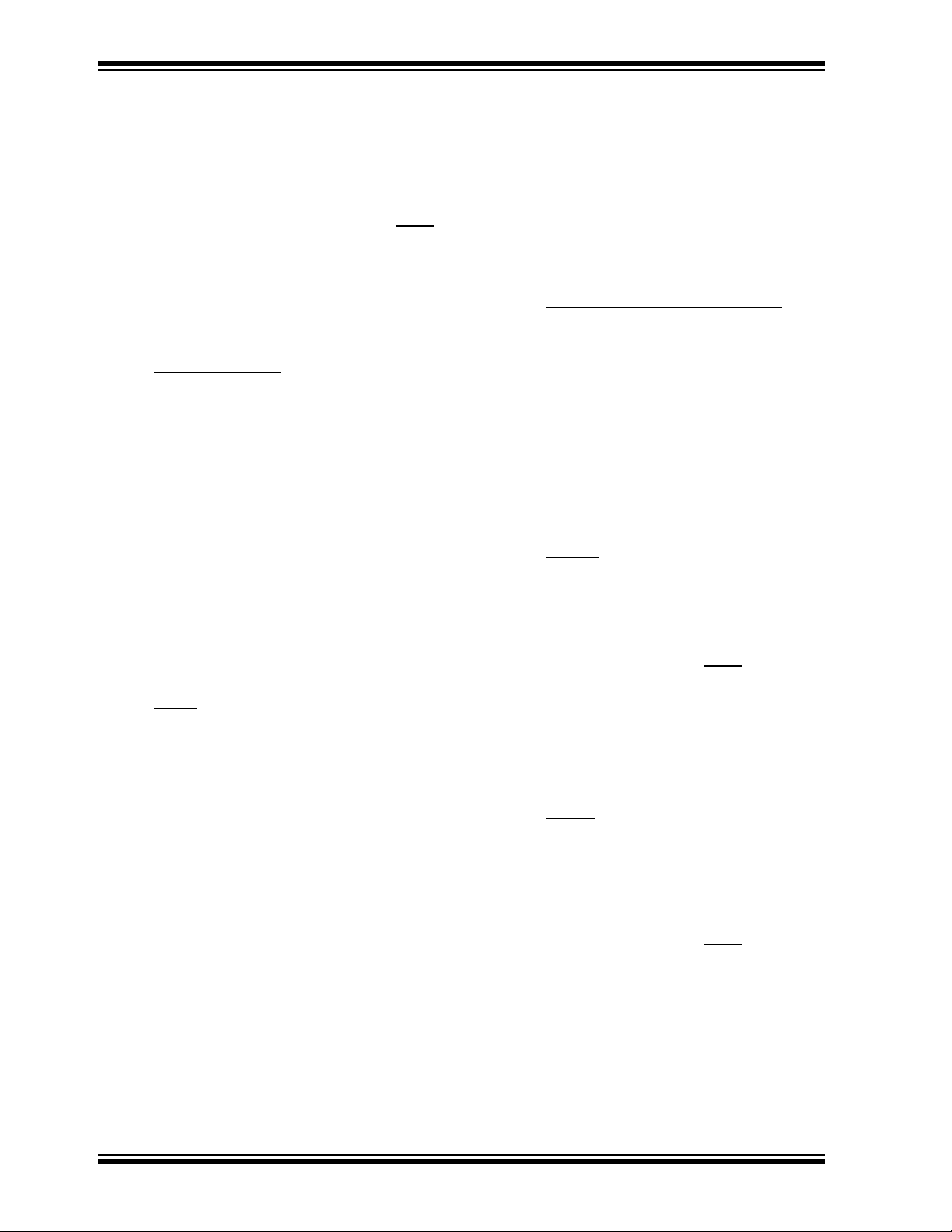

TABLE 1-2: DC AND AC ELECTRICAL CHARACTERISTICS

V

CC

= +1.8V to +5.5V Commercial (C): Tamb = 0˚C to +70˚C

Parameter Symbol Min Typ Max Units Conditions

High level input voltage V

Low level input voltage V

Low level output voltage V

High level output voltage V

Input leakage current I

Output leakage current I

Pin capacitance

(all inputs/outputs)

Operating current I

Standby current I

Clock frequency F

Clock high time T

Clock low time T

Chip select setup time T

Chip select hold time T

Chip select low time T

Data input setup time T

Data input hold time T

Data output delay time T

Data output disable time T

Status valid time T

Program cycle time T

Endurance

93AA46

93AA56/66

Note 1: This parameter is tested at Tamb = 25 ° C and F

2: This parameter is periodically sampled and not 100% tested.

3: This parameter is not tested but guaranteed by characterization. For endurance estimates in a specific appli-

cation, please consult the Total Endurance Model which can be obtained on our BBS or website.

IH

1 2.0 — V

IH

2 0.7 V

V

IL

1 -0.3 — 0.8 V V

IL

2 -0.3 — 0.2 V

V

OL

1 — — 0.4 V I

OL

2 — — 0.2 V I

V

OH

1 2.4 — — V I

OH

2V

V

LI

LO

C

IN

, C

OUT

CC

write — — 3 mA F

CC

read — —

I

CC

CC

-0.2 — — V I

—V

-10 — 10

-10 — 10

—— 7 pFV

CC

+1 V V

CC

+1 V V

CC

1

mA

500

70

CCS

100

30

2

CLK

CKH

CKL

CSS

CSH

CSL

T

T

—

—

DIS

DIH

PD

CZ

SV

WC

EC

WL

250 ns

250 ns

50 ns Relative to CLK

0 ns Relative to CLK

250 ns

100 ns Relative to CLK

100 ns Relative to CLK

4 10 ms ERASE/WRITE mode

8 15 ms ERAL mode (Vcc = 5V ± 10%)

16 30 ms WRAL mode (Vcc = 5V ± 10%)

1M

10M

—

—

CLK

2

1

MHz

MHz

400 ns CL = 100 pF

100 ns CL = 100 pF (Note 2)

500 ns CL = 100 pF

1M

10M

—

—

= 1 MHz.

CC

2.7V

CC

< 2.7V

CC

2.7V

VV

AV

AV

CC

< 2.7V

OL

= 2.1 mA; V

OL

= 100 µ A; V

OH

= -400 µ A; V

OH

= -100 µ A; V

IN

= 0.1V to V

OUT

= 0.1V to V

IN

/V

OUT

Tamb = +25˚C, F

CLK

=2 MHz; V

F

CLK

= 2 MHz; V

CLK

= 1 MHz; V

F

A

CLK

= 1 MHz; V

F

CLK = CS = 0V; V

CLK = CS = 0V; V

A

CLK = CS = 0V; V

V

CC

4.5V

CC

< 4.5V

V

25 ° C, Vcc = 5.0V, Block Mode

(Note 3)

CC

= 4.5V

CC

= 1.8V

CC

CC

CC

CC

= 0V (Note 1 & 2)

CLK

CC

=5.5V (Note 2)

CC

CC

CC

CC

CC

CC

= 4.5V

= 1.8V

= 1 MHz

= 5.5V

= 3.0V

= 1.8V

= 5.5V

= 3.0V

= 1.8V

DS20067G-page 2

1996 Microchip Technology Inc.

93AA46/56/66

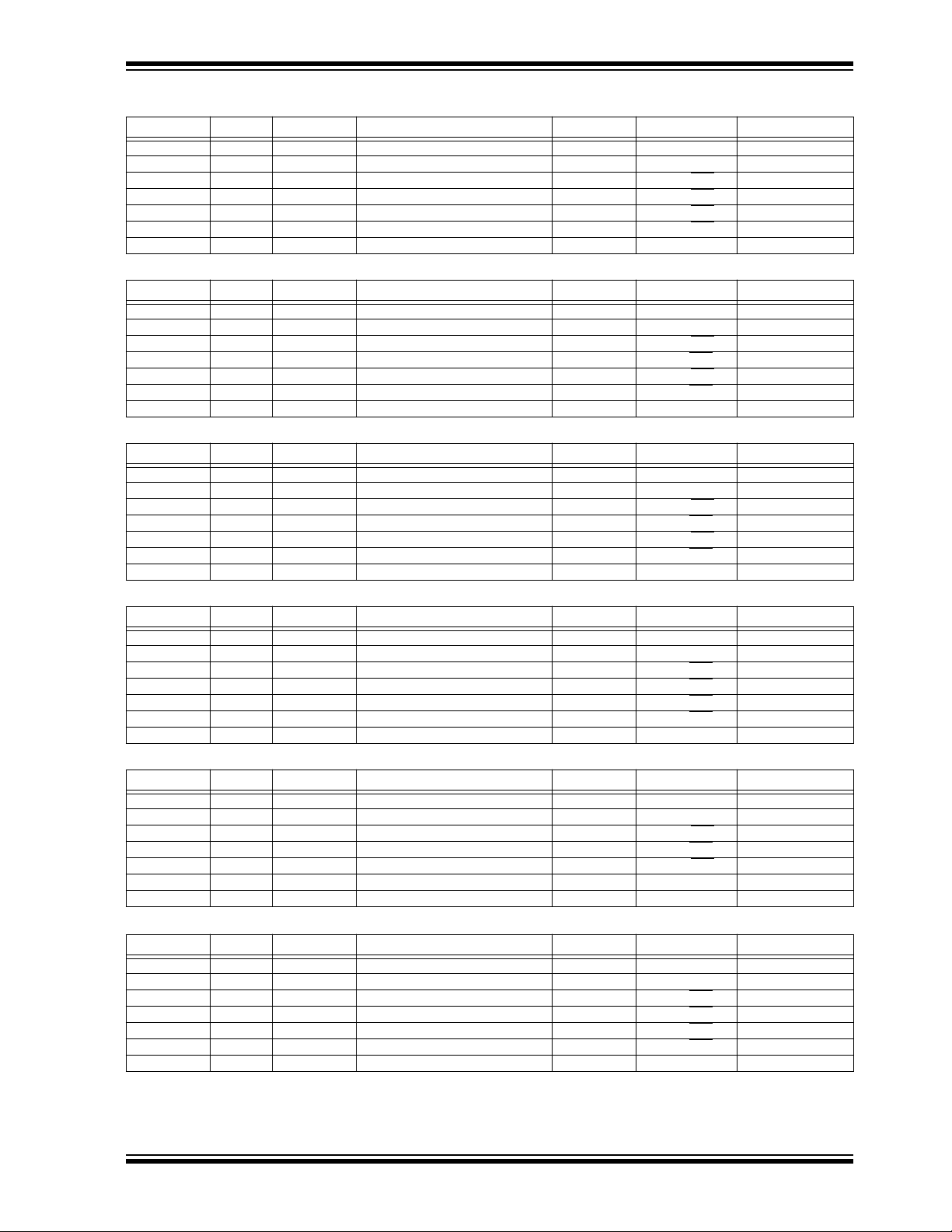

TABLE 1-3: INSTRUCTION SET FOR 93AA46: ORG = 1 (X 16 ORGANIZATION)

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

READ 1 10 A5 A4 A3 A2 A1 A0 — D15 - D0 25

EWEN 1 00 1 1 X X X X — High-Z 9

ERASE 1 11 A5 A4 A3 A2 A1 A0 — (RDY/BSY

ERAL 1 00 1 0 X X X X — (RDY/BSY

WRITE 1 01 A5 A4 A3 A2 A1 A0 D15 - D0 (RDY/BSY

WRAL 1 00 0 1 X X X X D15 - D0 (RDY/BSY

EWDS 1 00 0 0 X X X X — High-Z 9

TABLE 1-4: INSTRUCTION SET FOR 93AA46: ORG = 0 (X 8 ORGANIZATION)

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

READ 1 10 A6 A5 A4 A3 A2 A1 A0 — D7 - D0 18

EWEN 1 00 1 1 X X X X X — High-Z 10

ERASE 1 11 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY

ERAL 1 00 1 0 X X X X X — (RDY/BSY

WRITE 1 01 A6 A5 A4 A3 A2 A1 A0 D7 - D0 (RDY/BSY

WRAL 1 00 0 1 X X X X X D7 - D0 (RDY/BSY

EWDS 1 00 0 0 X X X X X — High-Z 10

TABLE 1-5: INSTRUCTION SET FOR 93AA56: ORG = 1 (X 16 ORGANIZATION)

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

READ 1 10 X A6 A5 A4 A3 A2 A1 A0 — D15 - D0 27

EWEN 1 00 1 1 X X X X X X — High-Z 11

ERASE 1 11 X A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY

ERAL 1 00 1 0 X X X X X X — (RDY/BSY

WRITE 1 01 X A6 A5 A4 A3 A2 A1 A0 D15 - D0 (RDY/BSY

WRAL 1 00 0 1 X X X X X X D15 - D0 (RDY/BSY

EWDS 1 00 0 0 X X X X X X — High-Z 11

TABLE 1-6: INSTRUCTION SET FOR 93AA56: ORG = 0 (X 8 ORGANIZATION)

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

READ 1 10 X A7 A6 A5 A4 A3 A2 A1 A0 — D7 - D0 20

EWEN 1 00 1 1 X X X X X X X — High-Z 12

ERASE 1 11 X A7 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY

ERAL 1 00 1 0 X X X X X X X — (RDY/BSY

WRITE 1 01 X A7 A6 A5 A4 A3 A2 A1 A0 D7 - D0 (RDY/BSY

WRAL 1 00 0 1 X X X X X X X D7 - D0 (RDY/BSY

EWDS 1 00 0 0 X X X X X X X — High-Z 12

TABLE 1-7: INSTRUCTION SET FOR 93AA66: ORG = 1 (X 16 ORGANIZATION)

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

READ 1 10 A7 A6 A5 A4 A3 A2 A1 A0 — D15 - D0 27

EWEN 1 00 1 1 X X X X X X — High-Z 11

ERASE 1 11 A7 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY

ERAL 1 00 1 0 X X X X X X — (RDY/BSY

WRITE 1 01 A7 A6 A5 A4 A3 A2 A1 A0 D15 - D0 (RDY/BSY

WRAL 1 00 0 1 X X X X X X D15 - D0 (RDY/BSY) 27

EWDS 1 00 0 0 X X X X X X — High-Z 11

TABLE 1-8: INSTRUCTION SET FOR 93AA66: ORG = 0 (X 8 ORGANIZATION)

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

READ 1 10 A8 A7 A6 A5 A4 A3 A2 A1 A0 — D7 - D0 20

EWEN 1 00 1 1 X X X X X X X — High-Z 12

ERASE 1 11 A8 A7 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY

ERAL 1 00 1 0 X X X X X X X — (RDY/BSY

WRITE 1 01 A8 A7 A6 A5 A4 A3 A2 A1 A0 D7 - D0 (RDY/BSY

WRAL 1 00 0 1 X X X X X X X D7 - D0 (RDY/BSY

EWDS 1 00 0 0 X X X X X X X — High-Z 12

)9

)9

)25

)25

)10

)10

)18

)18

)11

)11

)27

)27

)12

)12

)20

)20

)11

)11

)27

)12

)12

)20

)20

1996 Microchip Technology Inc. DS20067G-page 3

93AA46/56/66

2.0 FUNCTIONAL DESCRIPTION

When the ORG pin is connected to V

nization is selected. When it is connected to ground,

the (x8) organization is selected. Instructions,

addresses and write data are clocked into the DI pin on

the rising edge of the clock (CLK). The DO pin is normally held in a high-Z state except when reading data

from the device, or when checking the READY/BUSY

status during a programming operation. The ready/

busy status can be verified during an Erase/Write operation by polling the DO pin; DO low indicates that programming is still in progress, while DO high indicates

the device is ready. The DO will enter the high-Z state

on the falling edge of the CS.

2.1 ST

The START bit is detected by the device if CS and DI

are both HIGH with respect to the positive edge of CLK

for the first time.

Before a STAR T condition is detected, CS, CLK, and DI

may change in any combination (except to that of a

STAR T condition), without resulting in any device operation (READ, WRITE, ERASE, EWEN, EWDS, ERAL,

and WRAL). As soon as CS is HIGH, the device is no

longer in the standby mode.

An instruction following a START condition will only be

executed if the required amount of opcode, address

and data bits for any particular instruction is clocked in.

After execution of an instruction (i.e., clock in or out of

the last required address or data bit) CLK and DI

become don't care bits until a new start condition is

detected.

ART Condition

2.2 DI/DO

It is possible to connect the Data In and Data Out pins

together. However, with this configuration it is possible

for a “bus conflict” to occur during the “dummy zero” that

precedes the READ operation, if A0 is a logic HIGH

level. Under such a condition the voltage level seen at

Data Out is undefined and will depend upon the relative

impedances of Data Out and the signal source driving

A0. The higher the current sourcing capability of A0,

the higher the voltage at the Data Out pin.

2.3 Data Protection

During power-up, all programming modes of operation

are inhibited until V

1.4V. During power-down, the source data protection

circuitry acts to inhibit all programming modes when

V

CC has fallen below 1.4V at nominal conditions.

The EWEN and EWDS commands give additional protection against accidentally programming during normal operation.

After power-up, the device is automatically in the

EWDS mode. Therefore, an EWEN instruction must be

performed before any ERASE or WRITE instruction can

be executed.

CC has reached a level greater than

, the (x16) orga-

CC

2.4 READ

The READ instruction outputs the serial data of the

addressed memory location on the DO pin. A dummy

zero bit precedes the 16 bit (x16 organization) or 8 bit

(x8 organization) output string. The output data bits will

toggle on the rising edge of the CLK and are stable after

the specified time delay (T

sible when CS is held high. The memory data will automatically cycle to the next register and output

sequentially.

PD). Sequential read is pos-

2.5 Erase/Write Enable and Disable (EWEN,EWDS)

The 93AA46/56/66 power up in the Erase/Write Disable

(EWDS) state. All programming modes must be preceded by an Erase/Write Enable (EWEN) instruction.

Once the EWEN instruction is executed, programming

remains enabled until an EWDS instruction is executed

or V

CC is removed from the device. To protect against

accidental data disturb, the EWDS instruction can be

used to disable all Erase/Write functions and should follow all programming operations. Execution of a READ

instruction is independent of both the EWEN and

EWDS instructions.

2.6 ERASE

The ERASE instruction forces all data bits of the specified address to the logical “1” state. CS is brought low

following the loading of the last address bit. This falling

edge of the CS pin initiates the self-timed programming

cycle.

The DO pin indicates the READY/BUSY

device if CS is brought high after a minimum of 250 ns

low (T

CSL). DO at logical “0” indicates that program-

ming is still in progress. DO at logical “1” indicates that

the register at the specified address has been erased

and the device is ready for another instruction.

The ERASE cycle takes 4 ms per word typical.

status of the

2.7 WRITE

The WRITE instruction is followed by 16 bits (or by 8

bits) of data which are written into the specified

address. After the last data bit is put on the DI pin, CS

must be brought low before the next rising edge of the

CLK clock. This falling edge of CS initiates the selftimed auto-erase and programming cycle.

The DO pin indicates the READY/BUSY

device if CS is brought high after a minimum of 250 ns

low (T

CSL) and before the entire write cycle is complete.

DO at logical “0” indicates that programming is still in

progress. DO at logical “1” indicates that the register at

the specified address has been written with the data

specified and the device is ready for another instruction.

The WRITE cycle takes 4 ms per word typical.

status of the

DS20067G-page 4

1996 Microchip Technology Inc.

93AA46/56/66

2.8 Erase All (ERAL)

The ERAL instruction will erase the entire memory

array to the logical “1” state. The ERAL cycle is identical

to the ERASE cycle except for the different opcode. The

ERAL cycle is completely self-timed and commences at

the falling edge of the CS. Clocking of the CLK pin is not

necessary after the device has entered the self clocking

mode. The ERAL instruction is guaranteed at 5V ±

10%.

The DO pin indicates the READY/BUSY

status of the

device if CS is brought high after a minimum of 250 ns

low (T

CSL) and before the entire write cycle is complete.

The ERAL cycle takes (8 ms typical).

FIGURE 2-1: SYNCHRONOUS DATA TIMING

VIH

CS

CLK

DO

(READ)

DO

(PROGRAM)

VIL

VIH

VIL

VIH

DI

VIL

VOH

VOL

VOH

VOL

TDIS

TSV

TCSS

TCKH TCKL

TDIH

TPD

2.9 Write All (WRAL)

The WRAL instruction will write the entire memory array

with the data specified in the command. The WRAL

cycle is completely self-timed and commences at the

falling edge of the CS. Clocking of the CLK pin is not

necessary after the device has entered the self clocking

mode. The WRAL command does include an automatic ERAL cycle for the device. Therefore, the WRAL

instruction does not require an ERAL instruction but the

chip must be in the EWEN status. The WRAL instruction is guaranteed at 5V ± 10%.

The DO pin indicates the READY/BUSY

device if CS is brought high after a minimum of 250 ns

low (T

CSL).

The WRAL cycle takes 16 ms typical.

TPD

STATUS VALID

status of the

TCSH

TCZ

TCZ

FIGURE 2-2: READ TIMING

CSL

CS

CLK

DI

TRI-STATE

DO

Tri-State is a registered trademark of National Semiconductor Incorporated.

1996 Microchip Technology Inc. DS20067G-page 5

TRI-STATE™

• A • • • A001 1

n

Dx • • • D00 Dx* • • • D0 Dx*

• • •

T

D0

93AA46/56/66

FIGURE 2-3: EWEN TIMING

CS

CLK

T

CSL

DI

0 01

FIGURE 2-4: EWDS TIMING

CS

CLK

DI

0 01

FIGURE 2-5: WRITE TIMING

CS

CLK

1 1

0 0

XX

XX

• • •

• • •

CSL

T

TCSL

DI

DO

01

TRI-STATE

• • •

•A1 A0

n

Dx

• • •

D0

BUSY

READY

TWC

DS20067G-page 6 1996 Microchip Technology Inc.

FIGURE 2-6: WRAL TIMING

V

CS

CLK

93AA46/56/66

T

CSL

STANDBY

DI

DO

01

TRI-STATE

Guaranteed at Vcc = +4.5V to +6.0V.

FIGURE 2-7: ERASE TIMING

CS

CLK

1

DI

TRI-STATE

DO

11

01

An

An-1 An-2

• • •

D0X0 X • • •Dx

BUSY

READY

TWL

TRI-STATE

TCSL

CHECK STATUS

STANDBY

A0• • •

TSV

BUSY

TCZ

READY

TRI-STATE

FIGURE 2-8: ERAL TIMING

CS

CLK

0

0

DI

DO

TRI-STATE

• Guaranteed at VCC = 5.0V ±10%.

11

TWC

CSL

T

CHECK STATUS

0

TS

BUSY

EC

T

READY

STANDBY

TCZ

TRI-STATE

1996 Microchip Technology Inc. DS20067G-page 7

93AA46/56/66

3.0 PIN DESCRIPTION

3.1 Chip Select (CS)

A HIGH level selects the device. A LOW level deselects

the device and forces it into standby mode. However, a

programming cycle which is already initiated and/or in

progress will be completed, regardless of the CS input

signal. If CS is brought LOW during a program cycle,

the device will go into standby mode as soon as the programming cycle is completed.

CS must be LOW for 250 ns minimum (T

consecutive instructions. If CS is LOW, the internal control logic is held in a RESET status.

3.2 Serial Clock (CLK)

The Serial Clock is used to synchronize the communication between a master device and the 93AAXX.

Opcode, address, and data bits are clocked in on the

positive edge of CLK. Data bits are also clocked out on

the positive edge of CLK.

CLK can be stopped anywhere in the transmission

sequence (at HIGH or LOW level) and can be continued

anytime with respect to clock HIGH time (T

clock LOW time (T

ter freedom in preparing opcode, address, and data.

CLK is a “Don't Care” if CS is LOW (device deselected).

If CS is HIGH, but START condition has not been

detected, any number of clock cycles can be received

by the device without changing its status (i.e., waiting

for START condition).

CLK cycles are not required during the self-timed

WRITE (i.e., auto ERASE/WRITE) cycle.

After detection of a start condition the specified number

of clock cycles (respectively LOW to HIGH transitions of

CLK) must be provided. These clock cycles are

required to clock in all required opcode, address, and

data bits before an instruction is executed (see instruction set truth table). CLK and DI then become don't care

inputs waiting for a new start condition to be detected.

CKL). This gives the controlling mas-

CSL) between

CKH) and

3.4 Data Out (DO)

Data Out is used in the READ mode to output data synchronously with the CLK input (T

edge of CLK).

This pin also provides READY/BUSY

during ERASE and WRITE cycles. READY/BUSY

tus information is available on the DO pin if CS is

brought HIGH after being LOW for minimum chip select

LOW time (T

has been initiated.

The status signal is not available on DO, if CS is held

LOW or HIGH during the entire WRITE or ERASE

cycle. In all other cases DO is in the HIGH-Z mode. If

status is checked after the WRITE/ERASE cycle, a pullup resistor on DO is required to read the READY signal.

CSL) and an ERASE or WRITE operation

PD after the positive

status information

sta-

3.5 Organization (ORG)

When ORG is connected to VCC, the (x16) memory

organization is selected. When ORG is tied to V

(x8) memory organization is selected. ORG can only be

floated for clock speeds of 1MHz or less for the (x16)

memory organization. For clock speeds greater than 1

MHz, ORG must be tied to V

CC or VSS.

SS, the

Note: CS must go LOW between consecutive

instructions.

3.3 Data In (DI)

Data In is used to clock in a START bit, opcode,

address, and data synchronously with the CLK input.

DS20067G-page 8 1996 Microchip Technology Inc.

NOTES:

93AA46/56/66

1996 Microchip Technology Inc. DS20067G-page 9

93AA46/56/66

NOTES:

DS20067G-page 10 1996 Microchip Technology Inc.

93AA46/56/66

93AA46/56/66 Product Identification System

To order or to obtain information, e.g., on pricing or delivery, please use the listed part numbers, and refer to the factory or the listed

sales offices.

93AA46/56/66 -/P

Package: P = Plastic DIP (300 mil Body), 8-lead

SN = Plastic SOIC (150 mil Body), 8-lead

SM = Plastic SOIC (207 mil Body), 8-lead

(93AA46/56/66)

Temperature Blank = 0°C to +70°C

Range:

Device:

93AA46/56/66

93AA46/56/66X

93AA46T/56T/66T Microwire Serial EEPROM (Tape and Reel)

93AA46XT/56XT/66XT Microwire Serial EEPROM (Tape and Reel)

Microwire Serial EEPROM

Microwire Serial EEPROM in alternate

pinouts (SN package only)

1996 Microchip Technology Inc. DS20067G-page 11

WORLDWIDE SALES & SERVICE

AMERICAS

Corporate Office

Microchip Technology Inc.

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 602 786-7200 Fax: 602 786-7277

Technical Support:

Web:

http://www.microchip.com

Atlanta

Microchip Technology Inc.

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770 640-0034 Fax: 770 640-0307

Boston

Microchip Technology Inc.

5 Mount Royal Avenue

Marlborough, MA 01752

Tel: 508 480-9990 Fax: 508 480-8575

Chicago

Microchip Technology Inc.

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 708 285-0071 Fax: 708 285-0075

Dallas

Microchip Technology Inc.

14651 Dallas Parkway, Suite 816

Dallas, TX 75240-8809

Tel: 972 991-7177 Fax: 972 991-8588

Dayton

Microchip Technology Inc.

Suite 150

Two Prestige Place

Miamisburg, OH 45342

Tel: 513 291-1654 Fax: 513 291-9175

Los Angeles

Microchip Technology Inc.

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 714 263-1888 Fax: 714 263-1338

New Y ork

Microchip Technmgy Inc.

150 Motor Parkway, Suite 416

Hauppauge, NY 11788

Tel: 516 273-5305 Fax: 516 273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408 436-7950 Fax: 408 436-7955

Toronto

Microchip Technology Inc.

5925 Airport Road, Suite 200

Mississauga, Ontario L4V 1W1, Canada

Tel: 905 405-6279 Fax: 905 405-6253

602 786-7627

ASIA/PACIFIC

China

Microchip Technology

Unit 406 of Shanghai Golden Bridge Bldg.

2077 Yan’an Road West, Hongiao District

Shanghai, Peoples Republic of China

Tel: 86 21 6275 5700

Fax: 011 86 21 6275 5060

Hong Kong

Microchip Technology

RM 3801B, Tower Two

Metroplaza

223 Hing Fong Road

Kwai Fong, N.T. Hong Kong

Tel: 852 2 401 1200 Fax: 852 2 401 3431

India

Microchip Technology

No. 6, Legacy, Convent Road

Bangalore 560 025 India

Tel: 91 80 526 3148 Fax: 91 80 559 9840

Korea

Microchip Technology

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku,

Seoul, Korea

Tel: 82 2 554 7200 Fax: 82 2 558 5934

Singapore

Microchip Technology

200 Middle Road

#10-03 Prime Centre

Singapore 188980

Tel: 65 334 8870 Fax: 65 334 8850

Taiwan, R.O.C

Microchip Technology

10F-1C 207

Tung Hua North Road

Taipei, Taiwan, ROC

Tel: 886 2 717 7175 Fax: 886 2 545 0139

EUROPE

United Kingdom

Arizona Microchip Technology Ltd.

Unit 6, The Courtyard

Meadow Bank, Furlong Road

Bourne End, Buckinghamshire SL8 5AJ

Tel: 44 1628 850303 Fax: 44 1628 850178

France

Arizona Microchip Technology SARL

Zone Industrielle de la Bonde

2 Rue du Buisson aux Fraises

91300 Massy - France

Tel: 33 1 69 53 63 20 Fax: 33 1 69 30 90 79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann-Ring 125

D-81739 Muenchen, Germany

Tel: 49 89 627 144 0 Fax: 49 89 627 144 44

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleone Pas Taurus 1

Viale Colleoni 1

20041 Agrate Brianza

Milan Italy

Tel: 39 39 6899939 Fax: 39 39 689 9883

JAPAN

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shin Yokohama

Kohoku-Ku, Y okohama

Kanagawa 222 Japan

Tel: 81 45 471 6166 Fax: 81 45 471 6122

9/3/96

All rights reserved. 1996, Microchip Technology Incorporated, USA. 9/96

Printed on recycled paper.

Information contained in this publication regarding device applications and the like is intended through suggestion only and may be superseded by updates. No representation or warranty is given and no liability is assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement

of patents or other intellectual property rights arising from such use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property rights. The Microchip logo and

name are registered trademarks of Microchip Technology Inc. All rights reserved. All other trademarks mentioned herein are the property of their respective companies.

DS20067G-page 12 1996 Microchip Technology Inc.

Loading...

Loading...