Page 1

93AA46A/B/C, 93LC46A/B/C,

93C46A/B/C

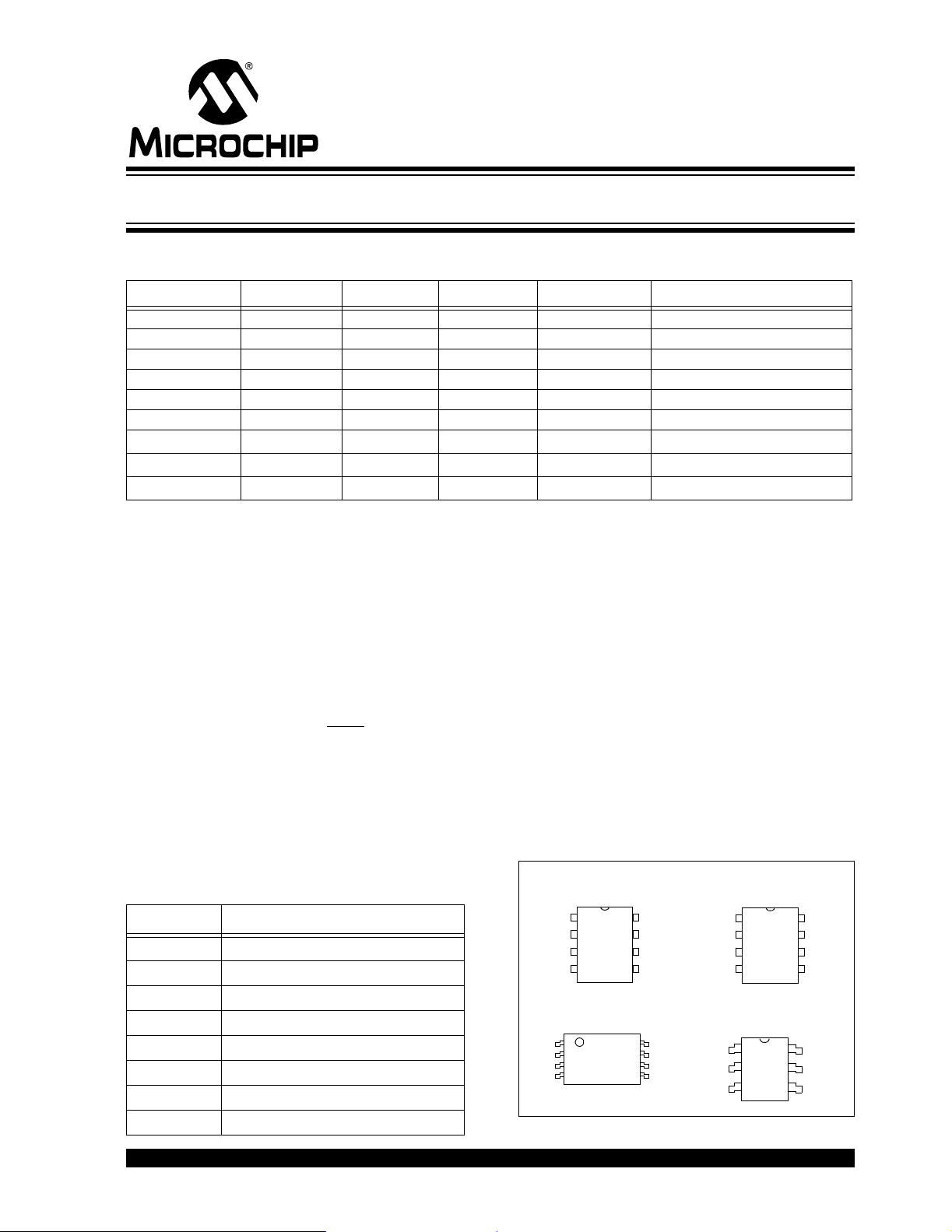

1K Microwire Compatible Serial EEPROM

Device Selection Table

Part Number VCC Range ORG Pin Word Size Temp Ranges Packages

93AA46A 1.8-5.5 No 8-bit I P, SN, ST, MS, OT

93AA46B 1.8-5-5 No 16-bit I P, SN, ST, MS, OT

93LC46A 2.5-5.5 No 8-bit I, E P, SN, ST, MS, OT

93LC46B 2.5-5.5 No 16-bit I, E P, SN, ST , MS, OT

93C46A 4.5-5.5 No 8-bit I, E P, SN, ST, MS, OT

93C46B 4.5-5.5 No 16-bit I, E P, SN, ST, MS, OT

93AA46C 1.8-5.5

93LC46C 2.5-5.5 Yes 8 or 16-bit I, E

93C46C 4.5-5.5 Yes 8 or 16-bit I, E

Yes

8 or 16-bit I P, SN, ST , MS

P, SN, ST, MS

P, SN, ST, MS

Features

• Low-power CMOS technology

• ORG pin to select word size for ‘46C version

• 128 x 8-bit organization ‘A’ ver. devices (no ORG)

• 64 x 16-bit organization ‘B’ ver. devices (no ORG)

• Self-timed ERASE/WRITE cycles (including

auto-erase)

• Automatic ERAL before WRAL

• Power-on/off data protection circuitry

• Industry standard 3-wire serial I/O

• Device St a tus signal (READ Y/BUSY

)

• Sequential READ function

• 1,000,000 E/W cycles

• Data retention > 200 years

• Temperature ranges supported

- Industrial (I) -40°C to +85°C

- Automotive (E) -40°C to +125°C

Pin Function Table

Name Function

CS Chip Select

CLK Serial Data Clock

DI Serial Data Input

DO Serial Data Output

V

SS Ground

NC No internal connection

ORG Memory Configuration

V

CC Power S upply

Description

The Microchip Technology Inc. 93XX46A/B/C devices

are 1K bit low voltage serial Electrically Erasable

PROMs (EEPROM). Word-selectable devices such as

the 93AA46C, 93LC46C or 93C46C are dependent

upon external logic levels driving the ORG pin to set

word size. For dedicated 8-bit communication, the

93AA46A, 93LC46A or 93C46A devices are available,

while the 93AA46B, 93LC46B and 93C46B devices

provide dedicated 16-bit communication. Advanced

CMOS technology makes these devices ideal for low

power, nonvolatile memory applications. The entire

93XX Series is available in standard packages including 8-lead PDIP and SOIC, and advanced packaging

including 8-lead MSOP, 6-lead SOT-23, and 8-lead

TSSOP. Pb-free (Pure Matte Sn) finish is also

available.

Package Types (not to scale)

ROTATED SOIC

(ex: 93LC46BX)

NC

1

8

V

CS

CLK

CC

2

3

4

ORG*

7

SS

V

6

DO

DI

5

TSSOP/MSOP

(ST, MS)

1

CS

2

CLK

3

DI

4

DO

* ORG pin is NC on A/B devices

8

V

CC

7

NC

6

ORG*

5

V

SS

CS

CLK

DO

DO

V

SS

DI

DI

PDIP/SOIC

(P, SN)

1

2

3

4

SOT-23

(OT)

1

6

2

5

3

4

V

CC

8

7

NC

6

ORG*

SS

V

5

V

CC

CS

CLK

2003 Microchip Technology Inc. DS21749D-page 1

Page 2

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings

(†)

VCC.............................................................................................................................................................................7.0V

All inputs and outputs w.r.t. V

SS ......................................................................................................... -0.6V to VCC +1.0V

Storage temperature ...............................................................................................................................-65°C to +150°C

Ambient temperature with power applied................................................................................................-40°C to +125°C

ESD protection on all pins ......................................................................................................................................................≥ 4kV

† NOTICE: Stres ses above those listed under “Absolute Max imum Rat ing s” m ay cause pe rmanent damage to

the device. This is a stress rating only and functional operation of the device at those or any other conditions

above those indicated in the opera tional lis tings of thi s specifica tion is not implied. Expo sure to max imum rating

conditions for extended periods may affect device reliability.

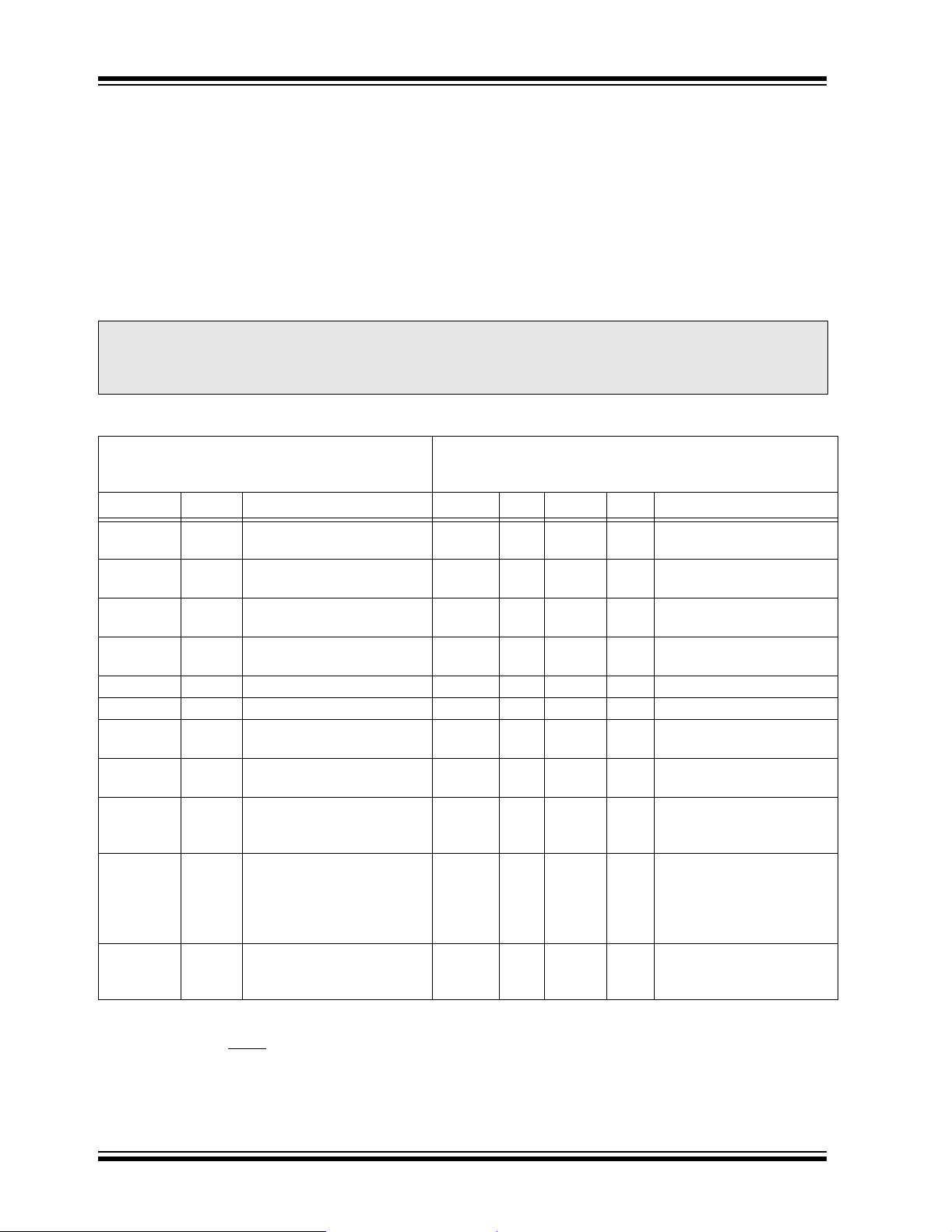

TABLE 1-1: DC CHARACTERISTICS

V

All parameter s apply over the specified ranges

unless otherwise noted.

Param. No. Symbol Parameter Min Typ Max Units Conditions

D1 VIH1

IH2

V

D2 V

IL1

IL2

V

D3 VOL1

V

OL2

D4 VOH1

OH2

V

D5 I

LI Input leakage current — — ±1 µAVIN = VSS to VCC

High-level input voltage 2.0

Low-level input voltage -0.3

Low-level output voltage —

High-level output voltage 2.4

D6 ILO Output leakage current — — ±1 µAVOUT = VSS to VCC

D7 CIN,

C

OUT

D8 ICC

Pin capacitanc e

(all inputs/outputs)

Write current —

write

D9 I

D10 I

CC read Read current —

CCS Standby current —

D11 VPOR VCC voltage detect

93AA46A/B/C, 93LC46A/B/C

93C46A/B/C

Note 1: This parameter is periodically sampled and not 100% tested.

2: ORG pin not available on ‘A’ or ‘B’ versions.

3: READY/BUSY

status must be cleared from DO, see Section3.4 "Data Out (DO)".

CC = range by device (see Table on Page 1)

Industrial (I): T

Automotive (E): T

0.7 VCC

-0.3

—

VCC - 0.2——

A = -40°C to +85°C

A = -40°C to +125°C

——VCC +1

CC +1

V

—

—

—

—

0.8

0.2 VCC

0.4

0.2

—

—

VVV

CC ≥ 2.7V

CC < 2.7V

V

VVVCC ≥ 2.7V

CC < 2.7V

V

OL = 2.1 mA, VCC = 4.5V

VVI

I

OL = 100 µA, VCC = 2.5V

VVI

OH = -400 µA, VCC = 4.5V

OH = -100 µA, VCC = 2.5V

I

——7pFVIN/VOUT = 0V (Note 1)

T

A = 25°C, FCLK = 1 MHz

—

—

—

—

—

500

—

—

100

—

—

2

—

1

500

—

1

5

mAµAFCLK = 3 MHz, VCC = 5.5V

CLK = 2 MHz, VCC = 2.5V

F

mA

CLK = 3 MHz, VCC = 5.5V

F

CLK = 2 MHz, VCC = 3.0V

F

µA

CLK = 2 MHz, VCC = 2.5V

F

µA

I-Temp

µA

µA

E-Temp

CLK = CS = 0V

ORG = DI = VSS or VCC

OTE 3)

—

—

1.5V

3.8V

—

—

(Note 2) (N

VV(Note 1)

DS21749D-page 2 2003 Microchip Technology Inc.

Page 3

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

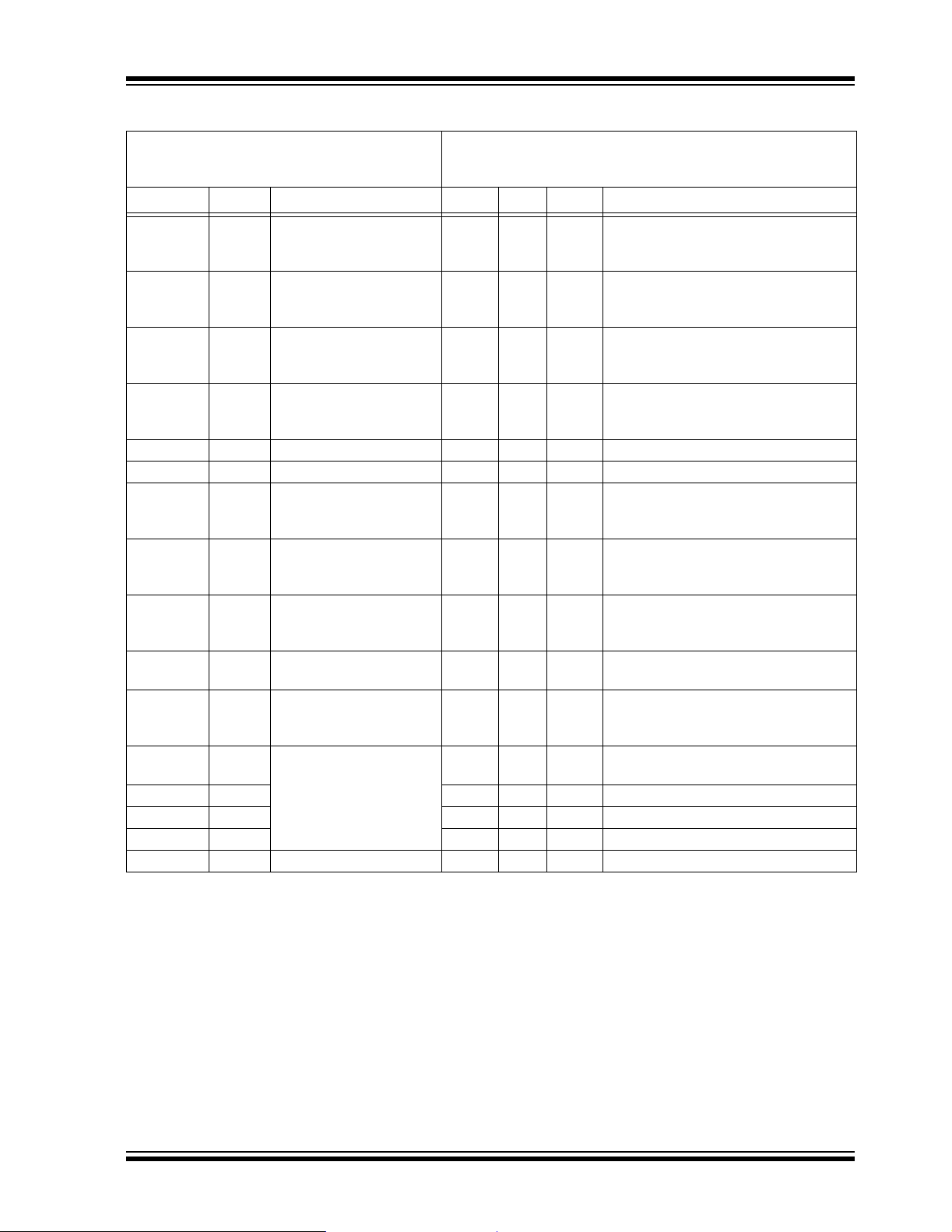

TABLE 1-2: AC CHARACTERISTICS

All parameters apply over the specified

ranges unless otherwise noted.

Param. No. Symbol Parameter Min Max Units Conditions

A1 FCLK Clock frequency — 3

A2 TCKH Clock high time 200

A3 TCKL Clock low time 100

A4 TCSS Chip Select setup time 50

A5 TCSH Chip Select hold time 0 — ns 1.8V ≤ VCC < 5.5V

A6 T

CSL Chip Select low time 250 — ns 1.8V ≤ VCC < 5.5V

A7 TDIS Data input setup time 50

A8 TDIH Data input hold time 50

A9 TPD Data output delay time —

A10 TCZ Data output disable time —

A11 T

A12 T

A13 T

A14 T

SV Status valid time — 200

WC Program cycle time — 6 ms Erase/Write mode (AA and LC

WC — 2 ms Erase/Write mode (93C versions)

EC — 6 ms ERAL mode, 4.5V ≤ VCC ≤ 5.5V

A15 TWL — 15 m s WRAL mode, 4.5V ≤ VCC ≤ 5.5V

A16 — Endurance 1M — cycles 25°C, VCC = 5.0V, (Note 2)

Note 1: This parameter is periodically sampled and not 100% tested.

2: This application is not tested but ensured by characterization. For endurance estimates in a specific

application, please co nsult the Total Endurance™ Model which may be obtained from w ww .microchip.com.

VCC = range by device (see Table on Page 1)

Industrial (I): T

Automotive (E): T

250

450

200

450

100

250

A = -40°C to +85°C

A = -40°C to +125°C

MHz

2

MHz

1

MHz

—ns

ns

ns

—ns

ns

ns

—ns

ns

ns

4.5V ≤ VCC < 5.5V, 93XX46C only

2.5V ≤ V

1.8V ≤ V

CC < 5.5V

CC < 2.5V

4.5V ≤ VCC < 5.5V, 93XX46C only

2.5V ≤ V

1.8V ≤ V

CC < 5.5V

CC < 2.5V

4.5V ≤ VCC < 5.5V, 93XX46C only

2.5V ≤ V

1.8V ≤ V

CC < 5.5V

CC < 2.5V

4.5V ≤ VCC < 5.5V

2.5V ≤ V

1.8V ≤ V

CC < 4.5V

CC < 2.5V

—ns4.5V ≤ VCC < 5.5V, 93XX46C only

100

250

2.5V ≤ V

1.8V ≤ V

CC < 5.5V

CC < 2.5V

—ns4.5V ≤ VCC < 5.5V, 93XX46C only

100

250

—

—

—

200

250

400

100

200

300

500

2.5V ≤ V

1.8V ≤ V

ns 4.5V ≤ VCC < 5.5V, CL = 100 pF

2.5V ≤ V

1.8V ≤ V

ns 4.5V ≤ VCC < 5.5V, (Note 1)

1.8V ≤ V

ns 4.5V ≤ V

2.5V ≤ V

1.8V ≤ V

CC < 5.5V

CC < 2.5V

CC < 4.5V, CL = 100 pF

CC < 2.5V, CL = 100 pF

CC < 4.5V, (Note 1)

CC < 5.5V, CL = 100 pF

CC < 4.5V, CL = 100 pF

CC < 2.5V, CL = 100 pF

versions)

2003 Microchip Technology Inc. DS21749D-page 3

Page 4

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

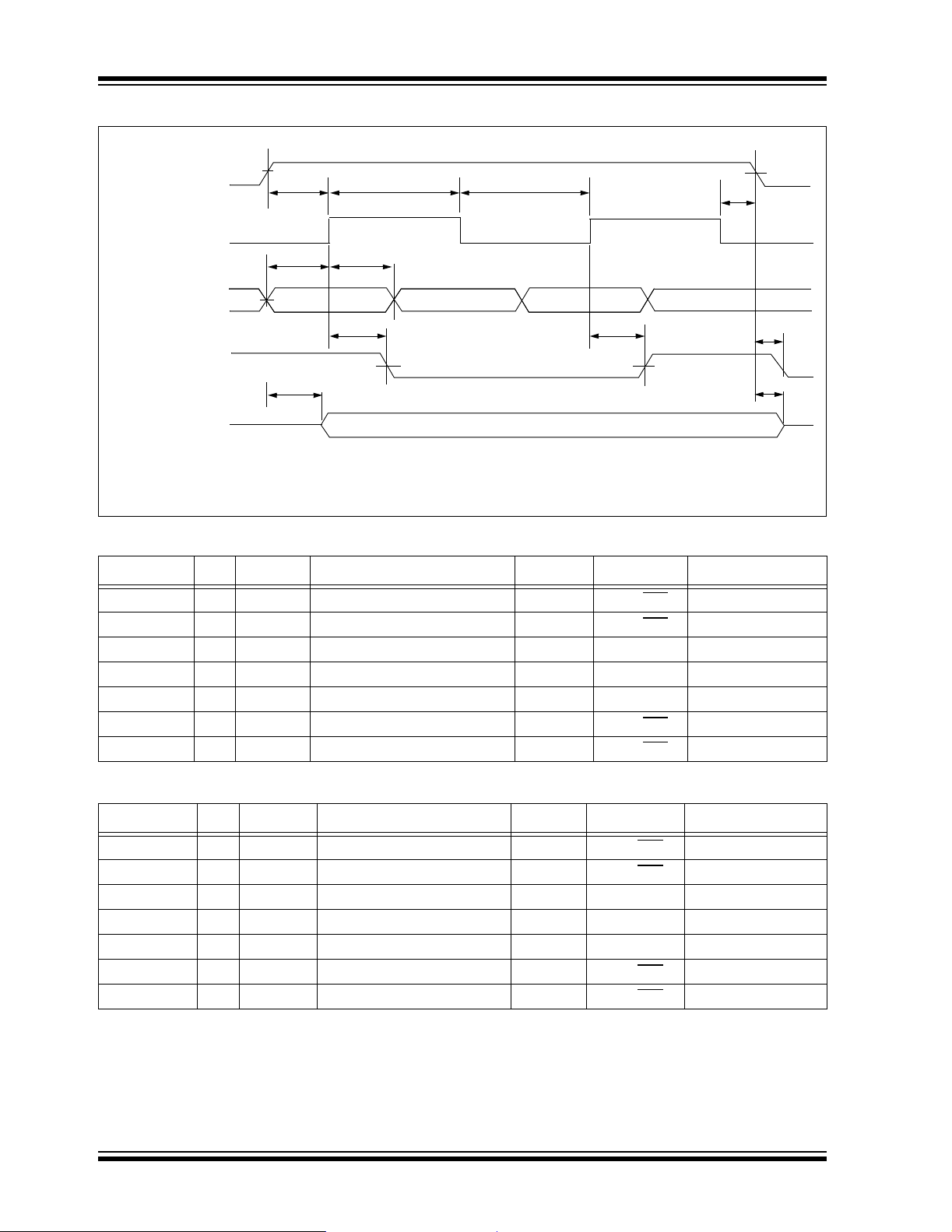

FIGURE 1-1 : SYNCHRONOUS DA TA TIMING

IH

V

CS

CSS

VIL

VIH

CLK

VIL

TDIS

VIH

DI

VIL

VOH

DO

(READ)

(PROGRAM)

DO

VOL

VOH

VOL

TSV

Note: TSV is relative to CS.

T

TCKH

TDIH

TPD

TCKL

TPD

STATUS VALID

TCSH

TCZ

TCZ

TABLE 1-3: INSTRUCTION SET FOR X 16 ORGANIZATION (93XX46B OR 93XX46C WITH ORG = 1)

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

ERASE

ERAL

EWDS

EWEN

READ

WRITE

WRAL

1 11 A5A4A3A2A1A0 — (RDY/BSY)9

1 00 1 0 X X X X — (RDY/BSY)9

1 00 0 0 X X X X — HIGH-Z 9

1 00 1 1 X X X X — HIGH-Z 9

1 10 A5A4A3A2A1A0 — D15 - D0 25

1 01 A5A4A3A2A1A0 D15 - D0 (RDY/BSY)25

1 00 0 1 X X X X D15 - D0 (RDY/BSY)25

TABLE 1-4: INSTRUCTION SET FOR X 8 ORGANIZATION (93XX46A OR 93XX46C WITH ORG = 0)

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

ERASE

ERAL

EWDS

EWEN

READ

WRITE

WRAL

1 11 A6A5A4A3A2A1A0 — (RDY/BSY)10

1 00 10XXXXX — (RDY/BSY)10

1 00 00XXXXX — HIGH-Z 10

1 00 11XXXXX — HIGH-Z 10

1 10 A6A5A4A3A2A1A0 — D7 - D0 18

1 01 A6A5A4A3A2A1A0 D7 - D0 (RDY/BSY)18

1 00 0 1 X X X X X D7 - D0 (RDY/BSY)18

DS21749D-page 4 2003 Microchip Technology Inc.

Page 5

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

2.0 FUNCTIONAL DESCRIPTION

When the ORG* pin is connected to VCC, the (x16)

organization is selected. When it is connected to

ground, the (x8) organization is selected. Instructions,

addresses and write d ata a re clocke d into the D I pin on

the rising edge of the clock (CLK). The DO pin is

normally held in a HIGH-Z state except when reading

data from the device, or when checking the READY/

status during a programming operation. The

BUSY

READY/BUSY

Write operation by polli ng the DO pi n; DO low indicate s

that programming is still in progress, while DO high

indicates the de vi ce is rea dy. DO will ente r th e HI GH -Z

state on the falling edge of CS.

2.1 Start Condition

The Start bit is detected by the device if CS and DI are

both high with respect to the positive edge of CLK for

the first time.

Before a Start conditi on is detect ed, CS, CL K, and DI

may change in any combination (except to that of a

Start condition), without resulting in any device

operation (READ, WRITE, ERASE, EWEN, EWDS,

ERAL, or WRAL). As soon as CS is high, the device is

no longer in Standby mode.

An instruction following a Start condition will only be

executed if the requi red opcode, address and data bits

for any particular instruction are clocked in.

2.2 Data In/Data Out (DI/DO)

It is possible to connect the Data In and Data Out pins

together. However, with this configuration it is possible

for a “bus conflict” to occur during the “dummy zero”

that precedes the READ ope r atio n, i f A0 is a lo gic hig h

level. Under such a condition the voltage level seen at

Data Out is undefine d and will depend upon the rela tive

impedances of Data Out and the signal source driving

A0. The higher the current sourcing capability of A0,

the higher the voltage at the Data Out pin. In order to

limit this current, a resistor should be connected

between DI and DO.

status can be verified during an Erase/

2.3 Data Protection

All modes of operation ar e inhibited when VCC is below

a typical voltage of 1.5V for '93AA' and '93LC' devices

or 3.8V for '93C' devices.

The EWEN and EWDS commands give additional

protection against accidentally programming during

normal operation.

Note: For added protection, an EWDS command

should be performed after every write

operation.

After power-up, the device is automatically in the

EWDS mode. Therefore, an EWEN instruction must be

performed before the initial ERASE or WRITE instruction

can be executed.

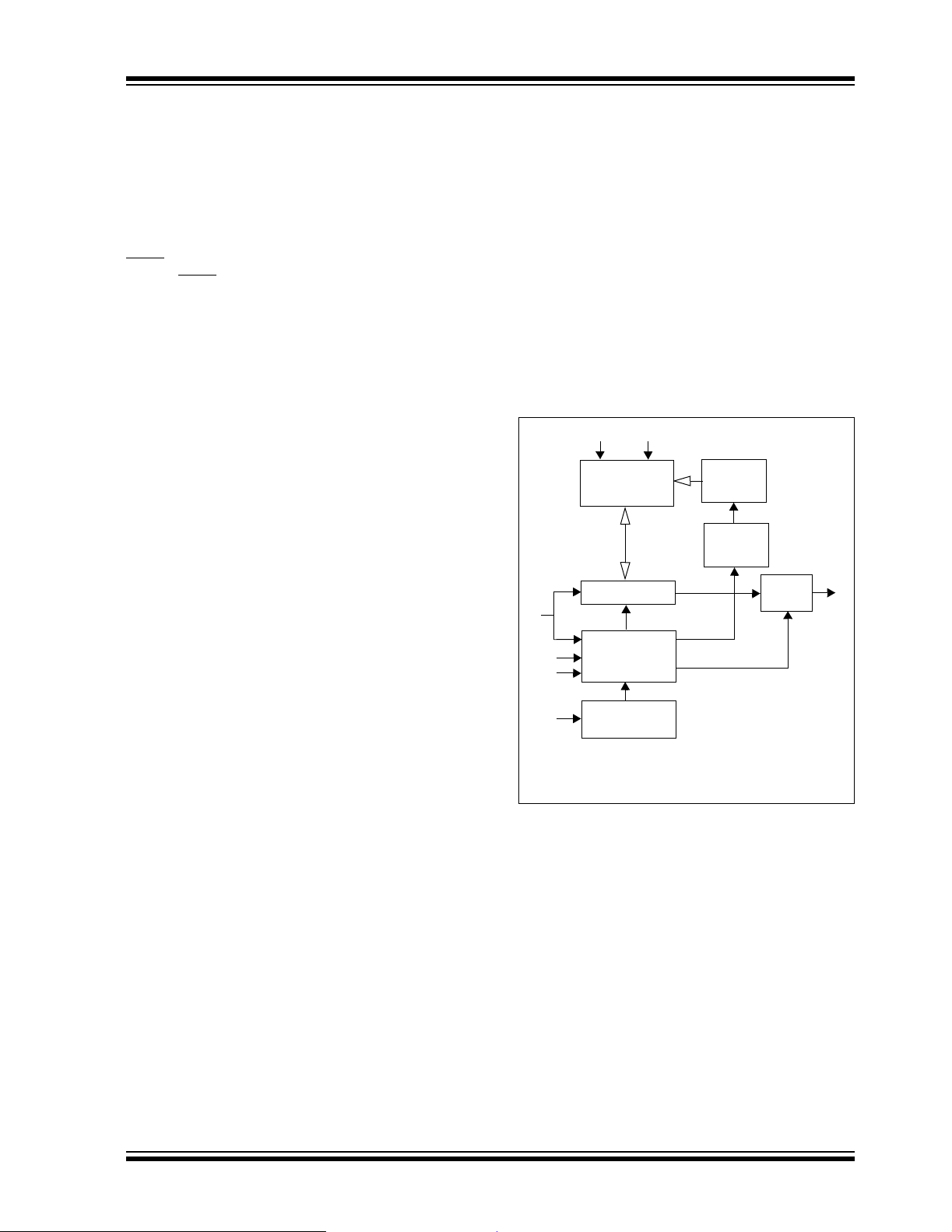

Block Diagram

V

CC VSS

Memory

Array

Data Register

DI

Mode

ORG*

CS

CLK

*ORG input is not avai lable on A/B devices

Decode

Logic

Clock

Register

Address

Decoder

Address

Counter

Output

Buffer

DO

2003 Microchip Technology Inc. DS21749D-page 5

Page 6

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

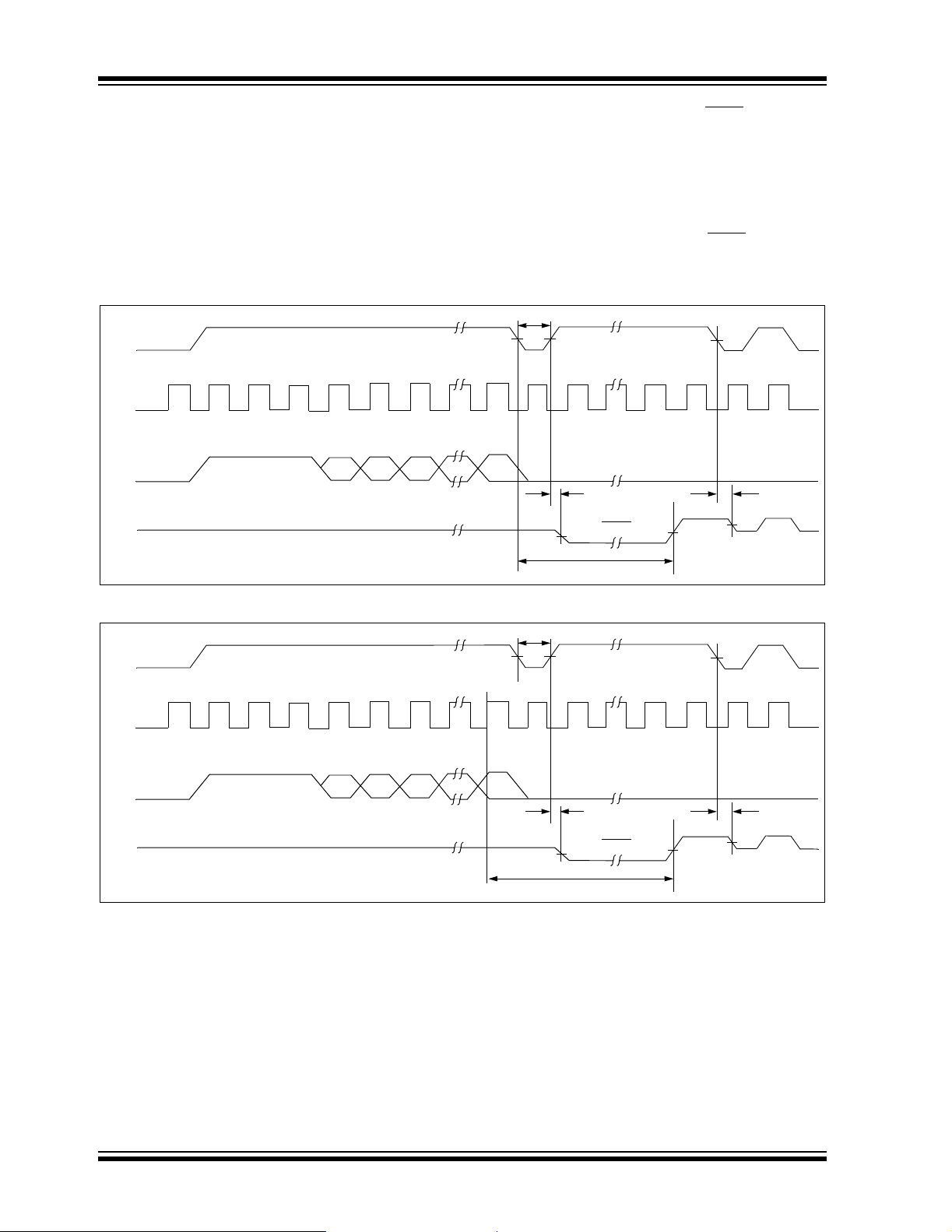

2.4 ERASE

The ERASE instruction forces all data bits of the

specified address to the logical ‘1’ state. CS is brought

low following the loading of the last address bit. This

falling edge of the CS pin initiates the self-timed

programming cycle , exc ept on ‘93C ’ dev ices w here th e

rising edge of CLK before the last address bit initiates

The DO pin indicates the READY/BUSY

device if CS is brought high after a minimum of 250 ns

low (T CSL). DO at logical ‘0’ indicates that programming

is still in progress. DO at logical ‘1’ indicates that the

register at the specified address has been erased and

the device is ready for another instruction.

Note: Issuing a Start bit and then taking CS low

the write cycle.

FIGURE 2-1 : ERASE TI MI NG FOR 9 3A A AN D 93L C D EVIC E S

CSL

T

CS

CLK

DO

DI

HIGH-Z

1

1

1A

N

AN-1 AN-2

•••

A0

will clear the READY/BUSY

DO.

CHECK STATUS

T

SV TCZ

BUSY READY

status of the

status from

HIGH-Z

FIGURE 2-2: ERASE TIMING FOR 93C DEVICES

CS

CLK

DO

DI

HIGH-Z

1

1

1A

N

AN-1 AN-2

•••

A0

WC

T

CSL

T

CHECK STATUS

T

SV TCZ

BUSY READY

WC

T

HIGH-Z

DS21749D-page 6 2003 Microchip Technology Inc.

Page 7

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

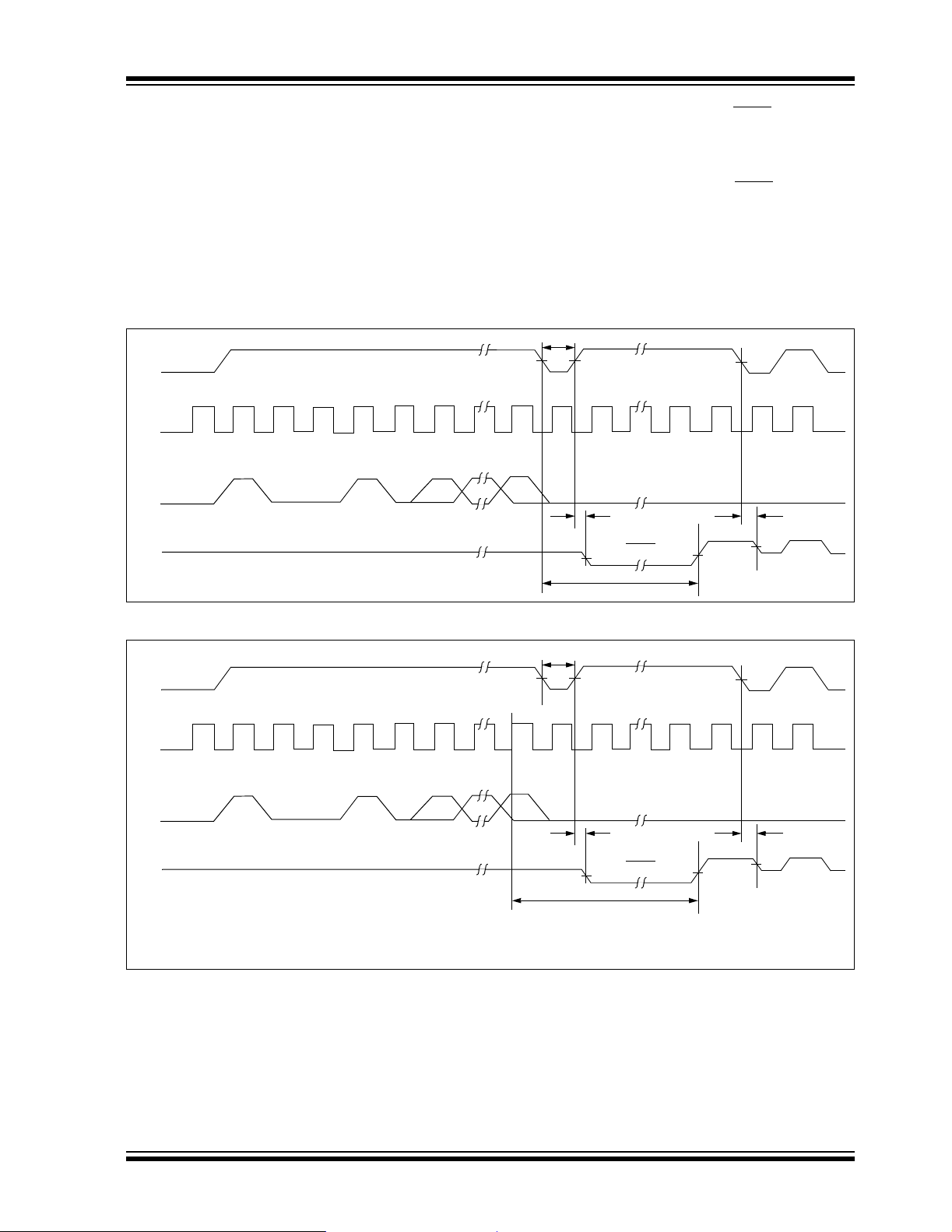

2.5 ERASE ALL (ERAL)

The Erase Al l (ERAL) instruction will erase the entire

memory array to the logical ‘1’ state. The ERAL cycle is

identical to the ERASE cycle, except for the different

The DO pin indicates the READY/BUSY

device, if CS is brough t high a fter a minimum of 250 n s

low (TCSL).

Note: Issuing a Start bit and then taking CS low

opcode. The ERAL cycle is completely self-timed and

commences at the falling edge of the CS, except on

CC must be ≥ 4.5V for proper operation of ERAL.

‘93C’ devices where the rising edge of CLK before the

V

last data bit initiates the write cycle. Clocking of the

CLK pin is not necessary after the device has entered

the ERAL cycle.

FIGURE 2-3 : ERAL TIM IN G FO R 93 AA A ND 9 3L C DE VI C ES

CSL

T

CS

CLK

DI

DO

HIGH-Z

VCC must be ≥ 4.5V for proper operation of ERAL.

10010X

•••

X

will clear the READY/BUSY

DO.

CHECK STATUS

T

SV TCZ

BUSY READY

EC

T

status of the

status from

HIGH-Z

FIGURE 2-4: ERAL TIMIN G FOR 93 C DEVI CES

CS

CLK

DO

DI

HIGH-Z

10010X

•••

CSL

T

CHECK STATUS

X

T

SV TCZ

BUSY READY

T

EC

HIGH-Z

2003 Microchip Technology Inc. DS21749D-page 7

Page 8

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

2.6 ERASE/WRITE DISABLE And ENABLE (EWDS/EWEN)

The 93XX46A/B/C powers up in the ERASE/WRITE

Disable (EWDS) state. All Programming modes must be

preceded by an ERASE/WRITE Enable (EWEN)

instruction. Once the EWEN instruction is executed,

programming remains enabled until an EWDS instruction is

executed or Vcc is removed from the device.

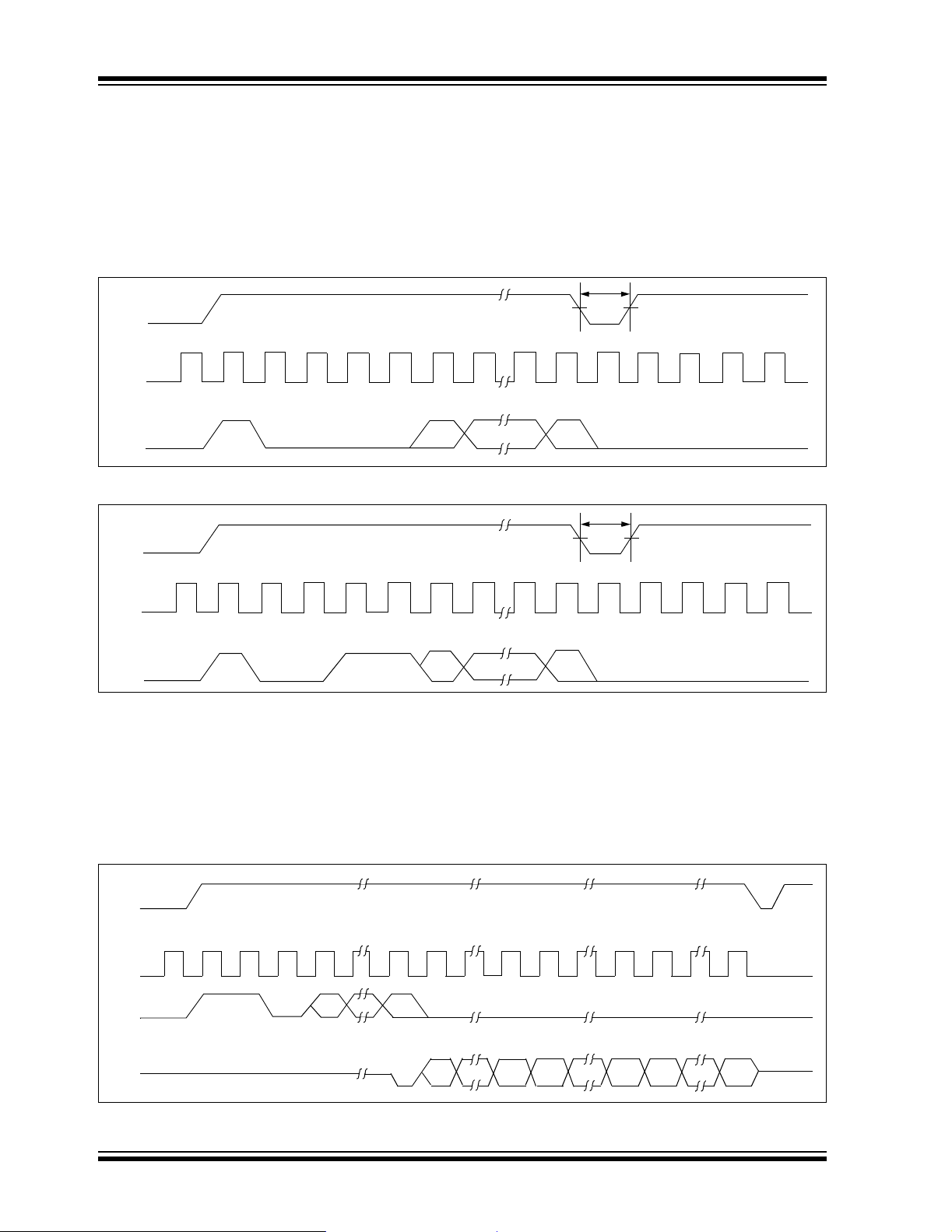

FIGURE 2-5: EWDS TIMING

CS

CLK

DI

10

000X

FIGURE 2-6: EWEN TIMING

CS

To protect against accidental data disturbance, the EWDS

instruction can be used to disable all ERASE/WRITE

functions and should follow all programming operatio ns.

Execution of a READ instruction is independent of both the

EWEN and EWDS instructions.

T

CSL

•••

X

TCSL

CLK

1X

DI

00 1 1X

2.7 READ

The READ instruction outputs the serial data of the

addressed memory lo cation on the DO pin. A dummy

zero bit precedes the 8-bit (If O RG pin is low or A-V e rsion

devices) or 16-bit (If ORG pin is high or B-version

devices) output st ring. The ou tput da ta bi ts will togg le on

FIGURE 2-7 : READ TIMI N G

CS

CLK

DI

110

An

••• A0

•••

the rising edge of the CLK and are stable after the

specified ti me delay (T

PD). Sequential read is possible

when CS is held high. The memory data will

automatically cycle to the next register and output

sequentially.

DO

DS21749D-page 8 2003 Microchip Technology Inc.

HIGH-Z

0Dx

•••

D0 Dx

•••

D0

Dx D0

•••

Page 9

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

2.8 WRITE

The WRITE instruction is followed by 8 bits (If ORG is

low or A-version devices) or 16 bits (If ORG pin is high

or B-version devices) of data which are written into the

specified address. For 93AA46A/B/C and 93LC46A/B/

C devices, after the last data bit is clocked into DI, the

falling edge of CS initiates the self-timed auto-erase

and programming cycle. For 93C46A/B/C devices, the

The DO pin indicates the READY/BUSY

device, if CS is brough t high a fter a minimum of 250 n s

low (T CSL). DO at logical ‘0’ indicates that programming

is still in progress. DO at logical ‘1’ indicates that the

register at the specified address has been written with

the data specified and the device is ready for another

instruction.

Note: Issuing a Start bit and then taking CS low

self-timed auto-erase and programming cycle is

initiated by the rising edge of CLK on the last data bit.

FIGURE 2-8 : WRITE T I MI NG FOR 93AA AND 93LC DEV I CES

T

CSL

CS

CLK

0

DI

DO

1

HIGH-Z

1An

•••

A0 Dx

•••

D0

will clear the READY/BUSY

DO.

TSV

BUSY

READY

status of the

status from

TCZ

HIGH-Z

FIGURE 2-9: WRITE TIMING FOR 93C DEVICES

CS

CLK

0

DI

DO

1

HIGH-Z

1An

•••

A0 Dx

•••

D0

Twc

T

CSL

Twc

TSV

BUSY

READY

TCZ

HIGH-Z

2003 Microchip Technology Inc. DS21749D-page 9

Page 10

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

2.9 WRITE ALL (WRAL)

The Write All (WRAL) instruction will write the entire

memory array with the data specified in the command.

For 93AA46A/B/C and 93LC 46A/B/C de vices , after th e

The DO pin indicates the READY/BUSY

device if CS is brought high after a minimum of 250 ns

low (TCSL).

Note: Issuing a Start bit and then taking CS low

last data bit is clocked into DI, the falling edge of CS

initiates the self-timed auto-erase and programming

CC must be ≥ 4.5V for proper operation of WRAL.

cycle. For 93C46A/B/C devices, the self-timed auto-

V

erase and programming cycle is initiated by the rising

edge of CLK on the last data bit. Clocking of the CLK

pin is not necessary after the device has entered the

WRAL cycle. The WRAL command does include an

automatic ERAL cycle for the device. Therefore, the

WRAL instruction does not require an ERAL instruction

but the chip must be in the EWEN status.

FIGURE 2-10: WRAL TIMING FOR 93AA AND 93LC DEVICES

CS

CLK

0

DI

1

01X

0

•••

Dx

X

•••

will clear the READY/BUSY

DO.

TCSL

D0

TSV

status of the

status from

TCZ

DO

VCC must be ≥ 4.5V for proper operation of WRAL.

HIGH-Z

FIGURE 2-11: WRAL TIMIN G FOR 93C DEVI CES

CS

CLK

DO

0

DI

1

HIGH-Z

01X

0

•••

X

Dx

•••

D0

TCSL

READY

BUSY

T

WL

TSV

BUSY

WL

T

HIGH-Z

TCZ

READY

HIGH-Z

DS21749D-page 10 2003 Microchip Technology Inc.

Page 11

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

3.0 PIN DESCRIPTIONS

TABLE 3-1: PIN DESCRIPTIONS

SOIC/PDIP/

Name

CS 1 5 3 Chip Select

CLK 2 4 4 Serial Clock

DI 3 3 5 Data In

DO 4 1 6 Data Out

Vss 5 2 7 Ground

ORG/NC 6 N/A 8 Organization / 93XX46C

NC 7 N/A 1 No Internal Connection

V

CC 8 6 2 Power Supply

MSOP/

TSSOP

SOT-23 Rotated SOIC Function

No internal connection / 93XX46A/B

3.1 Chip Select (CS)

A high level sel ects the device; a low lev el deselects

the device and fo rces it into S t andby mo de. Howev er , a

programming cycle wh ic h is al ready in progress will be

completed, regardless of the Chip Select (CS) input

signal. If CS is brou gh t l ow duri ng a p rogram cycle, the

device will go into Standby mode as soon as the

programming cycle is com pleted.

CS must be low for 250 ns minimum (T

consecutive instructions. If CS is low, the internal

control logic is held in a Reset status.

CSL) between

3.2 Serial Clock (CLK)

The Serial Clock is used to synchronize the communication between a master device and the 93XX series

device. Opcodes, address and data bits are clocked in

on the positive edge of C LK. Dat a bit s are also c locke d

out on the positive edge of CLK.

CLK can be stopped anywhere in the transmission

sequence (at high or low level) and can be continued

anytime with respect to clock high time (T

clock low time (T

freedom in preparing opcode, address and data.

CLK is a “Don't Care” if CS is low (device deselected).

If CS is high, but the Start condition has not been

detected (DI = 0), any number of clock cycle s can be

received by the device without changing its status (i.e.,

waiting for a Start condition).

CLK cycles are not required during the self-timed

WRITE (i.e., auto ERASE/WRITE) cycle.

After detection of a S ta rt condition t he specified numb er

of clock cycle s (respectively low-to-high tr ansitions of

CLK) must be provided. These clock cycles are

required to clock in all required opcode, address and

CKL). This gives the controlling master

CKH) and

data bits b efor e an instruction is executed. CL K and DI

then become don't care inputs waiting for a new Start

condition to be detected.

3.3 Data In (DI)

Data In (DI) is used to clock in a Start bit, opcode,

address and data synchronously with the CLK input.

3.4 Data Out (DO)

Data Out (DO) is used in the READ mode to output

data synchronously with the CLK input (T

positive edge of CLK).

This pin also provides READY/BUSY

tion during ERASE and WRITE cycles. READY/BUSY

status information is available on the DO pin if CS is

brought high after being low for minimum Chip Select

low time (TCSL) and an ERASE or WRITE operation

has been initiated.

The Status signal is not available on DO, if CS is held

low during th e entire ERASE or W RITE cycle. In this

case, DO is in the HIGH-Z mode. If status is checked

after the ERASE/WRITE cycle, the d ata line will be hig h

to indicate the device is ready.

Note: Issuing a Start bit and then taking CS low

will clear the READY/BUSY

DO.

PD after the

status informa-

status from

3.5 Organization (ORG)

When the ORG pin i s connected to VCC or Logic HI, th e

(x16) memory organiza tion is sel ected. Whe n the ORG

pin is tied to VSS or Logic LO, the (x8) memory

organization is selected. For proper operation, ORG

must be tied to a valid logic level.

93XX46A devices are always x8 organization and

93XX46B devices are always x16 organization.

2003 Microchip Technology Inc. DS21749D-page 11

Page 12

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

4.0 PACKAGING INFORMATION

4.1 Package Marking Information

8-Lead MSOP (150 mil)

XXXXXXT

YWWNNN

6-Lead SOT-23

XXNN

8-Lead PDIP

XXXXXXXX

XXXXXNNN

YYWW

8-Lead SOIC

Example:

3L46BI

2281L7

Example:

1EL7

Example:

93LC46B

I/SN 1L7

0228

Example:

MSOP 1st Line Marking Codes

Device

93AA46A

93AA46B

93AA46C

93LC46A

93LC46B

93LC46C

93C46A

93C46B

93C46C

T = blank for commercial, “I” for Industrial,

“E” for Extended.

SOT23 Marking Codes

Device

93AA46A

93AA46B

93LC46A

93LC46B

93C46A

93C46B

Pb-free topside mark is same; Pb-free

noted only on carton label.

std mark

3A46AT

3A46BT

3A46CT

3L46AT

3L46BT

3L46CT

3C46AT

3C46BT

3C46CT

I-temp

1BNN

1LNN

1ENN

1PNN

1HNN

1TNN

Pb-free

mark

GA46AT

GA46BT

GA46CT

GL46AT

GL46BT

GL46CT

GC46AT

GC46BT

GC46CT

E-temp

–

–

1FNN

1RNN

1JNN

1UNN

XXXXXXXX

XXXXYYWW

NNN

8-Lead TSSOP

XXXX

TYWW

NNN

Legend: XX...X Part number

T Temperature

Blank Commercial

I Industrial

E Extended

YY Year code (last 2 digits of calendar year) except TSSOP

and MSOP which use only the last 1 digit

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric trac ea bil ity code

Note: Custom marking available.

93LC46B

I/SN 0228

1L7

Example:

L46B

I228

1L7

TSSOP 1st Line Marking Codes

Device

93AA46A

93AA46B

93AA46C

93LC46A

93LC46B

93LC46C

93C46A

93C46B

93C46C

Temperature grade is marked on line 2.

std mark

A46A

A46B

A46C

L46A

L46B

L46C

C46A

C46B

C46C

Pb-free

mark

GAAA

GAAB

GAAC

GLAA

GLAB

GLAC

GCAA

GCAB

GCAC

DS21749D-page 12 2003 Microchip Technology Inc.

Page 13

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

8-Lead Plastic Micro Small Outline Package (MS) (MSOP)

E

E1

p

D

2

B

n 1

α

A

c

(F)

β

Units

Dimension Limits

Number of Pins

Pitch

Overall Height

Molded Package Thickness

Standoff

Overall Width

Molded Package Width

Overall Length

Foot Length

Foot Angle

Lead Thickness

Lead Width

Mold Draft Angle Top

Mold Draft Angle Bottom

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not

exceed .010" (0.254mm) per side.

JEDEC Equivalent: MO-187

Drawing No. C04-111

A2

A1

E1

MIN

n

p

A

E

D

L

φ

c

B

α

β

.026 BSC

.030

.000

.193 TYP.

.118 BSC

.118 BSC

.016 .024

.037 REFFFootprint (Reference)

0° - 8°

.003

.009

5°

5° -

L

INCHES

NOM

.033

.006

.012

φ

A1

MAX NOM

8

--

-

-

.043

.037

.006

.031

.009

.016

15°

15°

MIN

0.75

0.00

0.40

0.08

0.22

MILLIMETERS*

MAX

8

0.65 BSC

--

0.85

-

4.90 BSC

3.00 BSC

3.00 BSC

0.60

0.95 REF

0°

-

-

-

A2

1.10

0.95

0.15

0.80

8°

0.23

0.40

15°5° 15°5° -

2003 Microchip Technology Inc. DS21749D-page 13

Page 14

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

6-Lead Plastic Small Outline Transistor (OT) (SOT-23)

E

E1

B

n

c

β

Number of Pins

Pitch

Outside lead pitch (basic)

Molded Package Thickness

Standoff

Molded Package Width

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not

exceed .005" (0.127mm) per side.

n

p

p1

A2

A1

E1

φ

c

α

β

p1

D

1

A

φ

NOM

A1

MINMAX

L

MINDimension Limits

α

A2

MILLIMETERSINCHES*Units

NOM

0.95.038

1.90.075

MAX

66

1.451.180.90.057.046.035AOverall Height

1.301.100.90.051.043.035

0.150.080.00.006.003.000

3.002.802.60.118.110.102EOverall Width

1.751.631.50.069.064.059

3.102.952.80.122.116.110DOverall Length

0.550.450.35.022.018.014LFoot Length

10501050

0.200.150.09.008.006.004

0.500.430.35.020.017.014BLead Width

10501050

10501050

JEITA (formerly EIAJ) equivalent: SC-74A

Drawing No. C04-120

DS21749D-page 14 2003 Microchip Technology Inc.

Page 15

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

8-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

D

2

n

E

β

eB

Number of Pins

Pitch

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

Dimension Limits MIN NOM MAX MIN NOM MAX

1

α

A

c

Units INCHES* MILLIMETERS

n

p

c

α

β

.008 .012 .015 0.20 0.29 0.38

A1

B1

B

88

.100 2.54

51015 51015

51015 51015

A2

L

p

2003 Microchip Technology Inc. DS21749D-page 15

Page 16

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

8-Lead Plastic Small Outline (SN) – Narrow, 150 mil (SOIC)

E

E1

p

D

2

B

Number of Pins

Pitch

Standoff §

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-057

n

45°

c

β

n

p

A1

φ

c

α

β

1

h

A

φ

L

048048

A1

MILLIMETERSINCHES*Units

1.27.050

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004

6.206.025.79.244.237.228EOverall Width

3.993.913.71.157.154.146E1Molded Package Width

5.004.904.80.197.193.189DOverall Length

0.510.380.25.020.015.010hChamfer Distance

0.760.620.48.030.025.019LFoot Length

0.250.230.20.010.009.008

0.510.420.33.020.017.013BLead Width

1512015120

1512015120

DS21749D-page 16 2003 Microchip Technology Inc.

Page 17

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

8-Lead Plastic Thin Shrink Small Outline (ST) – 4.4 mm (TSSOP)

E

E1

p

D

2

n

B

1

A

c

A1

φ

β

A1

n

p

φ

c

α

β

048048

Number of Pins

Pitch

Standoff §

Foot Angle

Lead Thickne ss

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.005” (0.127mm) per side.

JEDEC Equivalent: MO-153

Drawing No. C04-086

L

MILLIMETERS*INCHESUnits

0.65.026

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.10.043AOverall Height

0.950.900.85.037.035.033A2Mold ed Packag e Thickness

0.150.100.05.006.004.002

6.506.386.25.256.251.246EOverall Width

4.504.404.30.177.173.169E1Mold ed Packag e Width

3.103.002.90.122.118.114DMolded Package Length

0.700.600.50.028.024.020LFoot Length

0.200.150.09.008.006.004

0.300.250.19.012.010.007BLead Width

10501050

10501050

2003 Microchip Technology Inc. DS21749D-page 17

Page 18

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

APPENDIX A: REVISION HISTORY

Revision D

Corrections to Section 1.0, Electrical Characteristics.

Section 4.1, 6-Lead SOT-23 package to OT.

DS21749D-page 18 2003 Microchip Technology Inc.

Page 19

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

ON-LINE SUPPORT

Microchip provides on-line support on the Microchip

World Wide Web site.

The web site is used b y Mic rochip as a me ans to m ake

files and information easily available to customers. To

view the site, the use r must have access to the Intern et

and a web browser, such as Netscape

Internet Explorer. Files are also available for FTP

download from our FTP site.

Connecting to the Microchip Internet

Web Site

The Microchip web site is available at the following

URL:

www.microchip.com

The file transfer site is available by using an FTP

service to connect to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of

services. Users may download files for the latest

Development Tools, Data Sheets, Application Notes,

User's Guides, Articles and Sample Programs. A variety of Micr ochip specific bu siness informatio n is also

available, including listings of Microchip sales offices,

distributors and factory representatives. Other data

available for consideration is:

• Latest Microchip Press Releases

• Technical Support Section with Frequently Asked

Questions

• Design Tips

• Device Errata

• Job Postings

• Microchip Consultant Program Member Listing

• Links to other useful web sites related to

Microchip Products

• Conferences for p roducts, D evelopment Systems,

technical information and more

• Listing of seminars and events

®

or Microsoft

SYSTEMS INFORMATION AND UPGRADE HOT LINE

The Systems Information and Upgrade Line provides

system users a listing of the latest versions of all of

Microchip's development systems software products.

®

Plus, this line provides information on how customers

can receive the most c urrent upgra de kit s.The Hot Lin e

Numbers are:

1-800-755-2345 for U.S. and most of Canada, and

1-480-792-7302 for the rest of the world.

042003

2003 Microchip Technology Inc. DS21749D-page 19

Page 20

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

READER RESPONSE

It is our intentio n to pro vi de you with the best documentation possible to ens ure suc c es sfu l u se of y ou r M ic roc hip product. If you wish to provid e your c omment s on org anizatio n, clarity, subject matter, and ways in w hich o ur docum entatio n

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this document.

To:

RE: Reader Response

From:

Application (optional):

Would you like a reply? Y N

Device: Literature Number:

Questions:

1. What are the best featur es of this doc ument?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this document easy to follow? If not, why?

Technical Publications Manager

Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________

Total Pages Sent ________

FAX: (______) _________ - _________

DS21749D93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

4. What additions to the document do you think would enhance the structure and subject?

5. What deletions from the document could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

DS21749D-page 20 2003 Microchip Technology Inc.

Page 21

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. X

Device

X

Pinout

X

Tape & Reel

Temperature

/XX

Package

Range

Device 93AA46A: 1K 1.8V Microwire Serial EEPROM

Pinout: Blank = Standard pinout

Tape & Reel: Blank = Standard packaging

Temperature Range I = -40°C to +85°C

Package MS = Plastic MSOP (Micro Small outline, 8-lead)

93AA46B: 1K 1.8V Microwire Serial EEPROM

93AA46C: 1K 1.8V Microwire Serial EEPROM w/ORG

93LC46A: 1K 2.5V Microwire Serial EEPROM

93LC46B: 1K 2.5V Microwire Serial EEPROM

93LC46C: 1K 2.5V Microwire Serial EEPROM w/ORG

93C46A: 1K 5.0V Microwire Serial EEPROM

93C46B: 1K 5.0V Microwire Serial EEPROM

93C46C: 1K 5.0V Microwire Serial EEPROM w/ORG

X = Rotated pinout

T = Tape & Reel

E = -40°C to +125°C

OT = SOT-23, 6-lead (Tape & Reel only)

P = Plastic DIP (300 mil body), 8-lead

SN = Plastic SOIC (150 mil body), 8-lead

ST = TSSOP, 8-lead

X

Lead Finish

Examples:

a) 93AA46C-I/MS: 1K, 128x8 or 64x16 Serial

EEPROM, MSOP package, 1.8V

b) 93AA46B-I/MS: 1K, 64x16 Serial EEPROM,

MSOP package, 1.8V

c) 93AA46AT-I/OT: 1K, 128x8 Serial EEPROM,

SOT-23 package, tape and reel, 1.8V

d) 93AA46CT-I/MS: 1K, 128x8 or 16x16 Serial

EEPROM, MSOP package, tape and reel, 1.8V

a) 93LC46A-I/MS: 1K, 128x8 Serial EEPROM,

MSOP package, 2.5V

b) 93LC46BT-I/OT: 1K, 64x16 Serial EEPROM,

SOT-23 package, tape and reel, 2.5V

c) 93LC46B-I/MS: 1K, 64x16 Serial EEPROM,

MSOP package, 2.5V

d) 93LC46BXT-I/SNG: 1K, 64x16 Serial

EEPROM, SOIC package, rotated pinout,

Industrial temperature, Pb-free finish, 2.5V

a) 93C46B-I/MS: 1K, 64x16 Serial EEPROM,

MSOP package, 5.0V

b) 93C46C-I/MS: 1K, 128x8 or 16x16 Serial

EEPROM, MSOP package, 5.0V

c) 93C46AT-I/OT: 1K, 128x8 Serial EEPROM,

SOT-23 package, tape and reel, 5.0V

Lead Finish: Blank = Standard 63% / 37% SnPb

G = Pure Matte Sn

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences

and recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of

the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

2003 Microchip Technology Inc. DS21749D-page 21

Page 22

93AA46A/B/C, 93LC46A/B/C, 93C46A/B/C

NOTES:

DS21749D-page 22 2003 Microchip Technology Inc.

Page 23

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the co de protection fea tures of our

products. Attempts to break microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, MPLAB, PIC, PICmic ro, PI C START,

PRO MATE and PowerSmart are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

AmpLab, FilterLab, microID, MXDEV, MXLAB, PICMASTER,

SEEVAL and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Application Maestro, dsPICDEM, dsPICDEM.net, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, microPort,

Migratable Memory, MPASM, MPLIB, MPLINK, MPSIM,

PICkit, PICDEM, PICDEM.net, PowerCal, PowerInfo,

PowerMate, PowerTool, rfLAB, rfPIC, Select Mode,

SmartSensor, SmartShunt, SmartT el and Total Endurance are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2003, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

2003 Microchip Technology Inc. DS21749D-page 23

Page 24

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-72 00

Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Atlanta

3780 Mansell Road, Suite 130

Alpharetta, GA 30022

Tel: 770-640- 003 4

Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692- 384 8

Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285- 007 1

Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818- 742 3

Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538- 225 0

Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, IN 46902

Tel: 765-864- 836 0

Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263- 188 8

Fax: 949-263-1338

Phoenix

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-79 66

Fax: 480-792-4338

San Jose

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436- 795 0

Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Cana da

Tel: 905-673- 069 9

Fax: 905-673-6509

ASIA/PACIFIC

Australia

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-986 8-6 73 3

Fax: 61-2-9868-6755

China - Beijing

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85 282 10 0

Fax: 86-10-85282104

China - Chengdu

Rm. 2401-2402, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-86 766 20 0

Fax: 86-28-86766599

China - Fuzhou

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7 503 50 6

Fax: 86-591-7503521

China - Hong Kong SAR

Unit 901-6, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401 -12 00

Fax: 852-2401-3431

China - Shanghai

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-62 75- 57 00

Fax: 86-21-6275-5060

China - Shenzhen

Rm. 1812, 18/F, Building A, United Plaza

No. 5022 Binhe Road, Futian District

Shenzhen 518033, China

Tel: 86-755-8 290 13 80

Fax: 86-755-8295-1393

China - Shunde

Room 401, Hongjian Building

No. 2 Fengxiangnan Road, Ronggui Town

Shunde City, Guangdong 528303, China

Tel: 86-765-8395507 Fax: 86-765-8395571

China - Qingdao

Rm. B505A, Fullhope Plaza,

No. 12 Hong Kong Central Rd.

Qingdao 266071, China

Tel: 86-532-5027355 Fax: 86-532-5027205

India

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-47 1- 616 6 Fax: 81-4 5-4 71 -6122

Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5932 or

82-2-558-5934

Singapore

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Kaohsiung Branch

30F - 1 No. 8

Min Chuan 2nd Road

Kaohsiung 806, Taiwan

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan

Taiwan Branch

11F-3, No. 207

Tung Hua North Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Austria

Durisolstrasse 2

A-4600 Wels

Austria

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45-4420-9895 Fax: 45-4420-9910

France

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany

Steinheilstrasse 10

D-85737 Ismaning, Germany

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy

Via Quasimodo, 12

20025 Legnano (MI)

Milan, Italy

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands

P. A. De Biesbosch 14

NL-5152 SC Drunen, Netherlands

Tel: 31-416-690399

Fax: 31-416-690340

United Kingdom

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshir e, England RG41 5T U

Tel: 44-118-921-5869

Fax: 44-118-921-5820

07/28/03

DS21749D-page 24 2003 Microchip Technology Inc.

Loading...

Loading...