Page 1

25AA256/25LC256

256K SPI™ Bus Serial EEPROM

Device Selection Table

Part Number VCC Range Page Size Temp. Ranges Packages

25LC256 2.5-5.5V 64 Byte I, E P, SN, ST, MF

25AA256 1.8-5.5V 64 Byte I P, SN, ST, MF

Features

• Max. clock 10 MHz

• Low-power CMOS technology

- Max. Write Current: 5 mA at 5.5V, 10 MHz

- Read Current: 5 mA at 5.5V, 10 MHz

- Standby Current: 1 µA at 5.5V

• 32,768 x 8-bit organization

• 64 byte page

• Self-timed ERASE and WRITE cycles (5 ms

max.)

• Block write protection

- Protect none, 1/4, 1/2 or all of array

• Built-in write protection

- Power-on/off data protection circuitry

- Write enable latch

- Write-protect pin

• Sequential read

• High reliability

- Endurance: 1,000,000 erase/write cycles

- Data retention: > 200 years

- ESD protection: > 4000V

• Temperature ranges supported;

- Industrial (I): -40°Cto +85°C

- Automotive (E): -40°C to +125°C

• Standard and Pb-free packages available

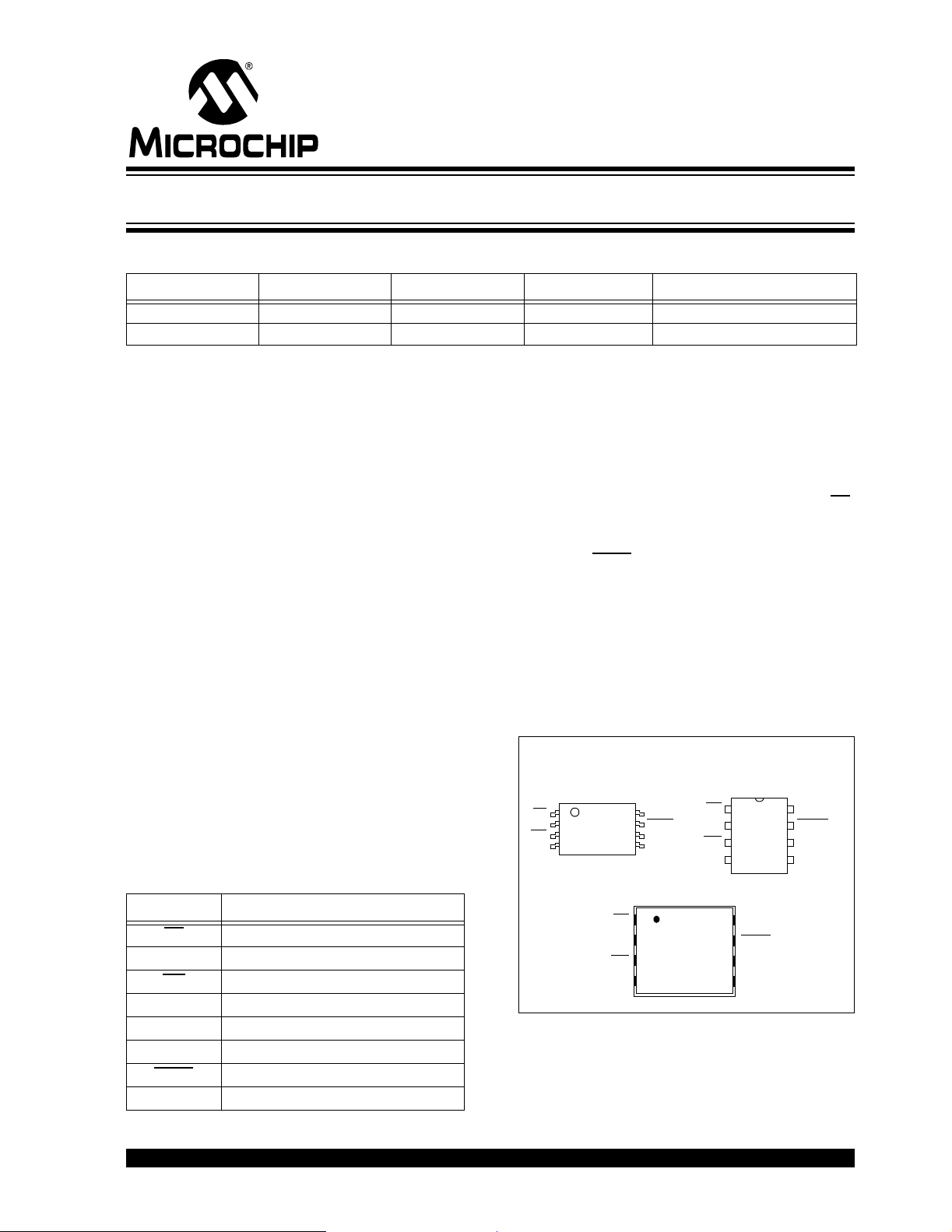

Pin Function Table

Name Function

CS Chip Select Input

SO Serial Data Output

WP

SS Ground

V

SI Serial Data Input

SCK Serial Clock Input

HOLD

CC Supply Voltage

V

* 25XX256

Write-Protect

Hold Input

is used in this document as a generic part number for the 25AA256, 25LC256 devices.

Description

The Microchip Technology Inc. 25AA256/25LC256

(25XX256

PROMs. The memory is accessed via a simple Serial

Peripheral Interface™ (SPI™) compatible serial bus.

The bus signals required are a clock input (SCK) plus

separate data in (SI) and data out (SO) lines. Access to

the device is controlled through a Chip Select (CS

input.

Communication to the device can be paused via the

hold pin (HOLD

transitions on its inputs will be ignored, with the

exception of Chip Select, allowing the host to service

higher priority interrupts.

The 25XX256 is available in standard packages

including 8-lead PDIP and SOIC, and advanced

packaging including 8-lead DFN and 8-lead TSSOP.

Pb-free (Pure Sn) finish is also available.

*

) are 256k-bit Serial Electrically Erasable

). While the device is paused,

Package Types (not to scale)

TSSOP

(ST)

1

CS

2

SO

3

WP

4

V

SS

SPI is a registered trademark of Motorola Corporation.

CS

SO

WP

VSS

8

CC

V

7

HOLD

6

SCK

5

SI

DFN

(MF)

1

2

3

4

V

25LC256

PDIP/SOIC

(P, SN)

CS

1

SO

2

3

WP

SS

4

8

VCC

7

HOLD

6

SCK

5

SI

25LC256

8

7

6

5

CC

V

HOLD

SCK

SI

)

2003 Microchip Technology Inc. Preliminary DS21822C-page 1

Page 2

25AA256/25LC256

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings

(†)

VCC.............................................................................................................................................................................6.5V

All inputs and outputs w.r.t. V

SS ......................................................................................................... -0.6V to VCC +1.0V

Storage temperature .................................................................................................................................-65°C to 150°C

Ambient temperature under bias...............................................................................................................-40°C to 125°C

ESD protection on all pins..........................................................................................................................................4 kV

† NOTICE: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the

device. This is a stres s ratin g only and func tional operati on of the devic e at thos e or any other co nditio ns abov e thos e

indicated in the operational listings of this specification is not implied. Exposure to maximum rating conditions for an

extended period of time may affect device reliability.

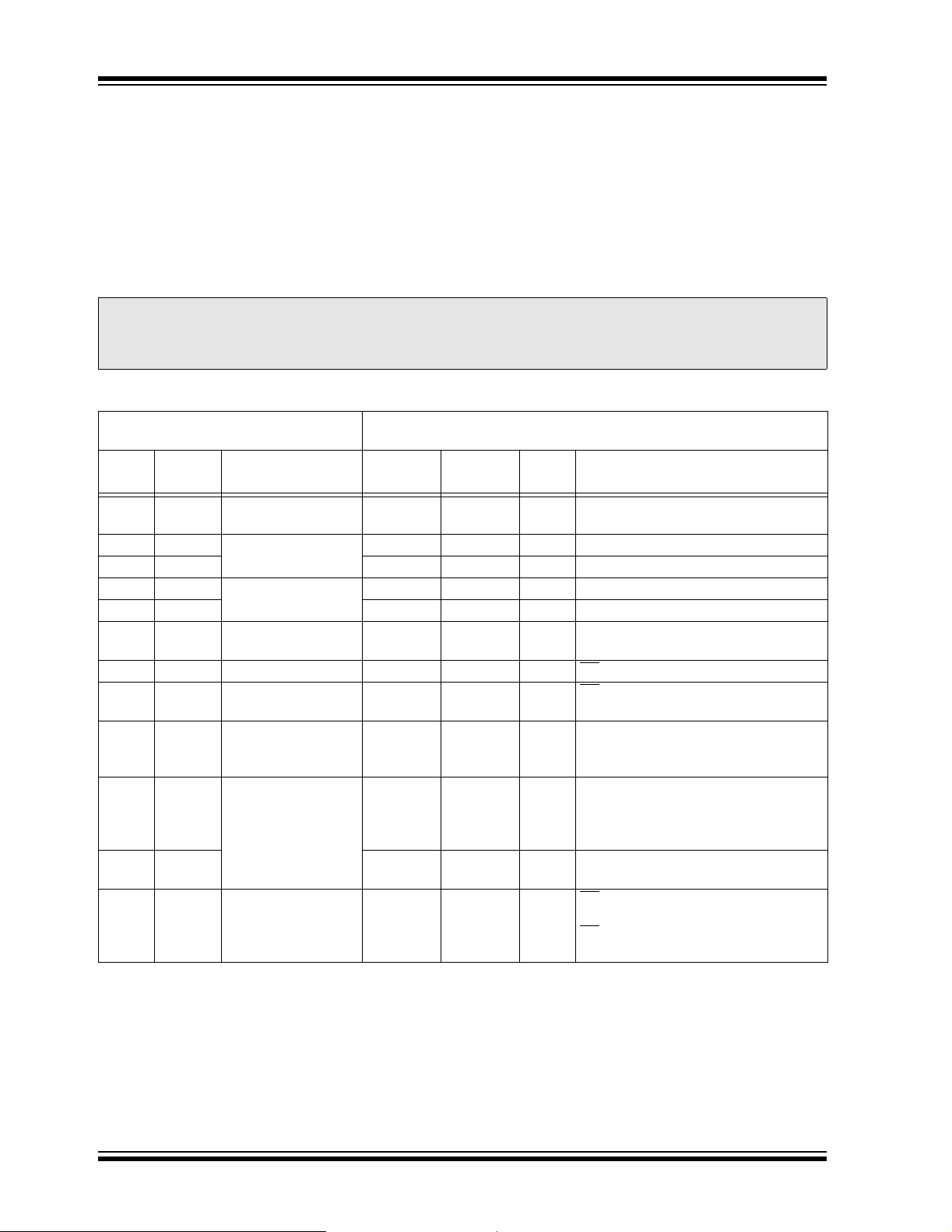

TABLE 1-1: DC CHARACTERISTICS

DC CHARACTERISTICS

Param.

No.

D001 V

Sym. Characteristic Min. Max. Units Test Conditions

IH1 High-level input

voltage

D002 V

D003 VIL2 -0.3 0.2VCC VVCC < 2.7V

D004 V

D005 VOL —0.2VIOL = 1.0 mA, VCC < 2.5V

IL1 Low-level input

voltage

OL Low-level output

voltage

D006 VOH High-level output

voltage

D007 I

LI Input leakage current — ±1 µACS = VCC, VIN = VSS TO VCC

D008 ILO Output leaka ge

current

D009 CINT Internal Capacitanc e

(all inputs and

outputs)

D010 I

CC Read

Operating Current

D011 I

CC Write —

D012 ICCS

Standby Current

Note: This parameter is periodically sampled and not 100% tested.

Industrial (I): TA = -40°C to +85°C VCC = 1.8V to 5.5V

Automotive (E): T

A = -40°C to +125°C VCC = 2.5V to 5.5V

.7 VCC VCC+1 V

-0.3 0.3VCC VVCC ≥ 2.7V

—0.4VIOL = 2.1 mA

VCC -0.5 — V IOH = -400 µA

—±1µACS = VCC, VOUT = VSS TO VCC

—7pFTA = 25°C, CLK = 1.0 MHz,

CC = 5.0V (Note)

V

—

—

5

2.5

mAmAVCC = 5.5V; FCLK = 10.0MHz;

SO = Open

VCC = 2.5V; FCLK = 5.0 MHz;

SO = Open

—

—

—

5

3

5

1

mAmAVCC = 5.5V

V

CC = 2.5V

µAµACS

= VCC = 5.5V, Inputs tied to VCC or

SS, 125°C

V

CS

= VCC = 5.5V, Inputs tied to VCC or

SS, 85°C

V

DS21822C-page 2 Preliminary 2003 Microchip Technology Inc.

Page 3

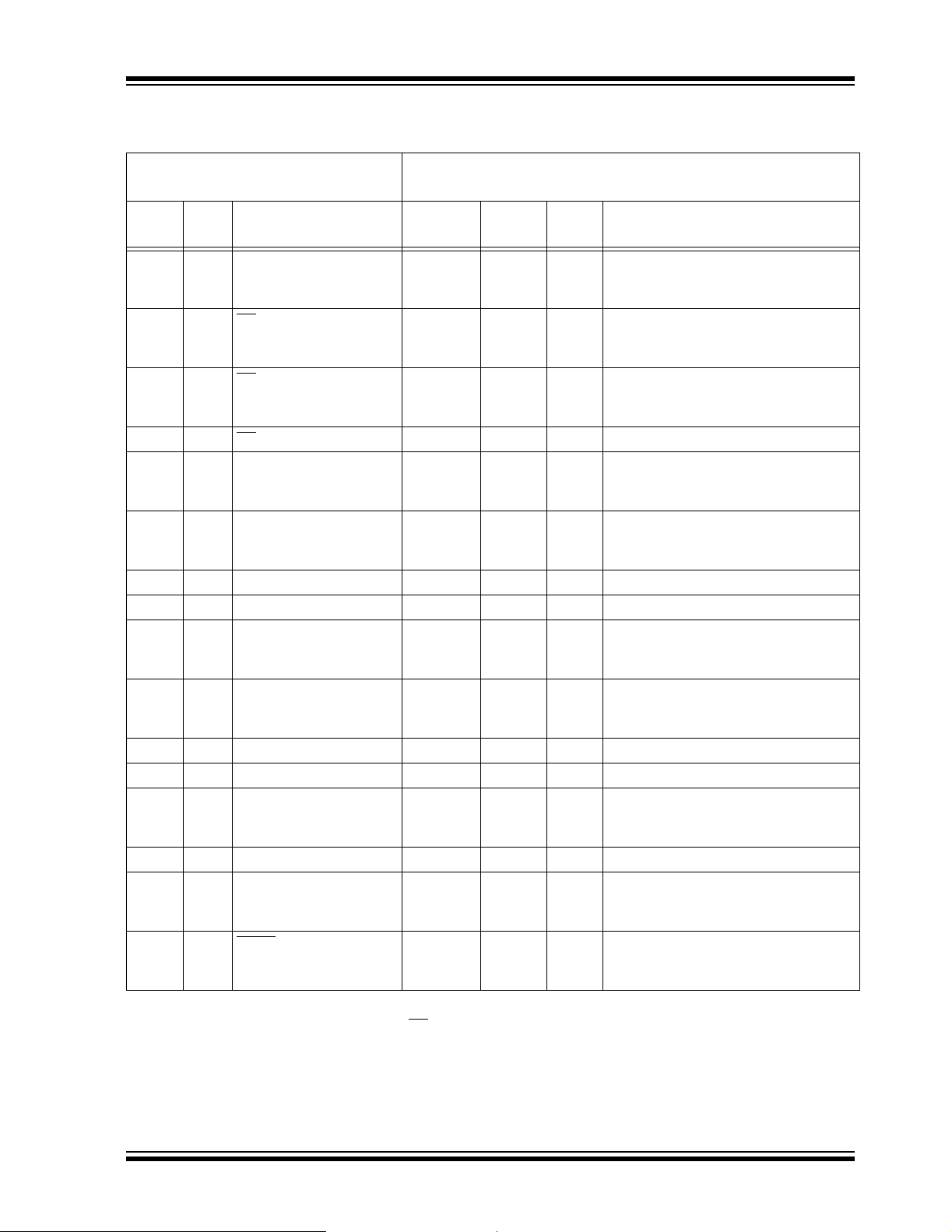

TABLE 1-2: AC CHARACTERISTICS

25AA256/25LC256

AC CHARACTERISTICS

Param.

No.

1F

2T

3T

4T

Sym. Characteristic Min. Max. Units Test Conditions

CLK Clock Frequency —

CSS CS Setup Time 50

CSH CS Hold Time 100

CSD CS Disable Time 50 — ns —

5 Tsu Data Setup Time 10

6THD Data Hold Time 20

7T

8T

9T

10 T

11 T

12 T

13 T

R CLK Rise Time — 2 µs (Note 1)

F CLK Fall Time — 2 µs (Note 1)

HI Clock High Time 50

LO Clock Low Time 50

CLD Clock Delay Time 50 — ns —

CLE Clock Enable Time 50 — ns —

V Output Valid from Clock

Low

14 T

15 T

16 T

HO Output Hold Time 0 — ns (Note 1)

DIS Output Disable Time —

HS HOLD Setup Time 20

Industrial (I): TA = -40°C to +85°C VCC = 1.8V to 5.5V

Automotive (E): T

A = -40°C to +125°C VCC = 2.5V to 5.5V

10

—

—

5

3

—

100

150

—

—

—

200

250

—

—

—

20

30

—

—

—

40

50

—

—

—

100

150

—

—

—

100

150

—

—

—

—

—

50

100

160

40

—

—

80

160

—

40

80

—

—

Note 1: This parameter is periodically sampled and not 100% tested.

2: TWC begins on the risi ng edg e o f C S after a valid write sequence a nd ends when the internal wri te c yc le is

complete.

3: This parameter is not tested but ensured by characterization. For endurance estimates in a specific

application, please consult the Total Endurance™ Model which can be obtained from our web site:

www.microchip.com.

MHz

MHz

MHz

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V(Note 1)

2.5V ≤ Vcc ≤ 4.5V(Note 1)

1.8V ≤ Vcc ≤ 2.5V(Note 1)

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

2003 Microchip Technology Inc. Preliminary DS 21822C-page 3

Page 4

25AA256/25LC256

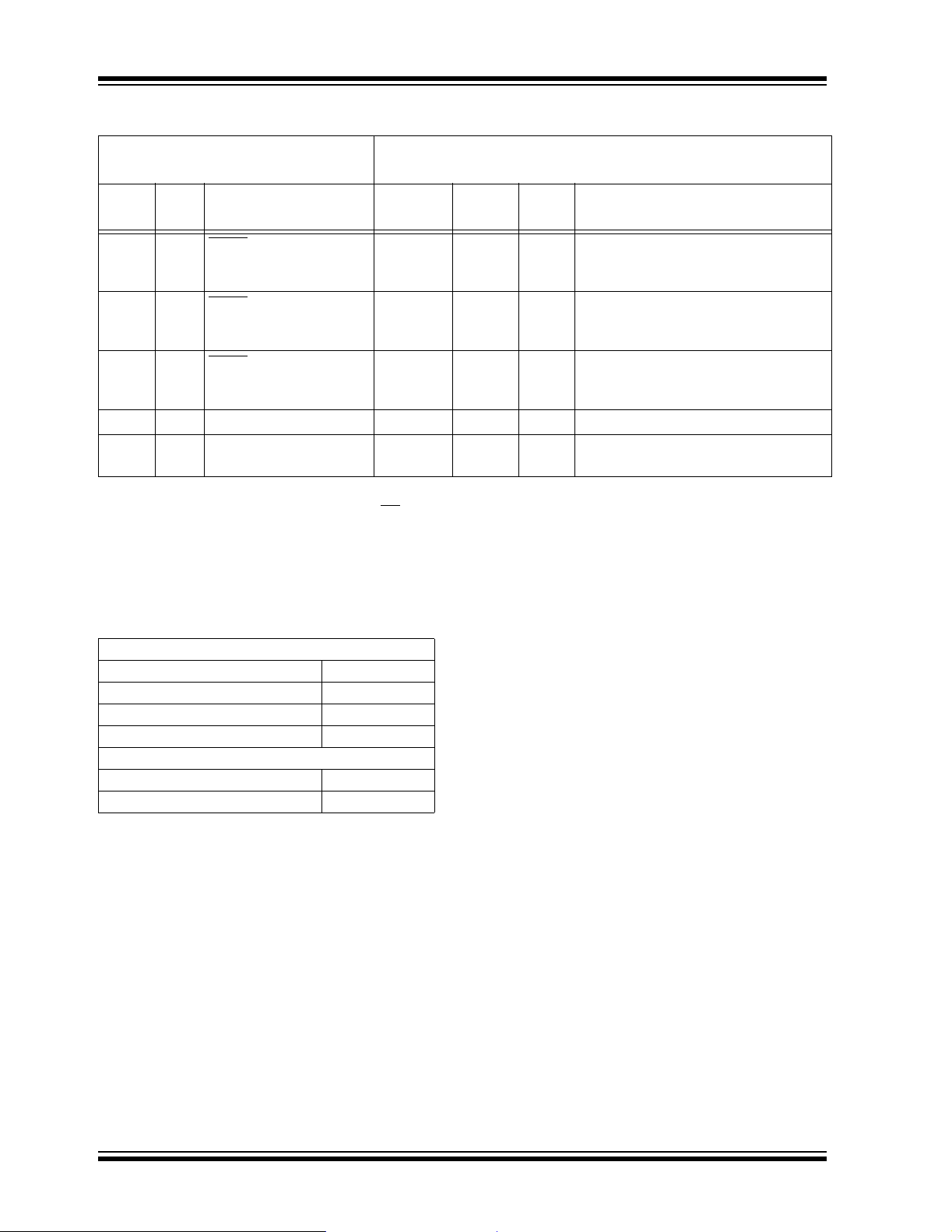

TABLE 1-2: AC CHARACTERISTICS (CONTINUED)

AC CHARACTERISTICS

Param.

No.

Sym. Characteristic Min. Max. Units Test Conditions

Industrial (I): T

Automotive (E): T

17 THH HOLD Hold Time 20

40

80

18 T

HZ HOLD Low to Output

High-Z

30

60

160

19 T

HV HOLD High to Output

Valid

30

60

160

20 T

WC Internal Write Cycle Time — 5 ms (NOTE 2)

A = -40°C to +85°C VCC = 1.8V to 5.5V

A = -40°C to +125°C VCC = 2.5V to 5.5V

—

—

—

—

—

—

—

—

—

ns

ns

ns

ns

ns

ns

ns

ns

ns

21 — Endurance 1M — E/W

Cycles

Note 1: This parameter is periodically sampled and not 100% tested.

WC begins on the rising edg e of CS after a valid write sequence and ends when the int ernal write cycle is

2: T

complete.

3: This parameter is not tested but ensured by characterization. For endurance estimates in a specific

application, please consult the Total Endurance™ Model which can be obtained from our web site:

www.microchip.com.

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

4.5V ≤ Vcc ≤ 5.5V(Note 1)

2.5V ≤ Vcc < 4.5V(Note 1)

1.8V ≤ Vcc < 2.5V(Note 1)

4.5V ≤ Vcc ≤ 5.5V

2.5V ≤ Vcc < 4.5V

1.8V ≤ Vcc < 2.5V

(N

OTE 3)

TABLE 1-3: AC TEST CONDITIONS

AC Waveform:

VLO = 0.2V —

VHI = VCC - 0.2V (Note 1)

HI = 4.0V (Note 2)

V

CL = 100 pF —

Timing Measurement Reference Lev el

Input 0.5 V

Output 0.5 VCC

Note 1: For VCC ≤ 4.0V

2: For Vcc > 4.0V

CC

DS21822C-page 4 Preliminary 2003 Microchip Technology Inc.

Page 5

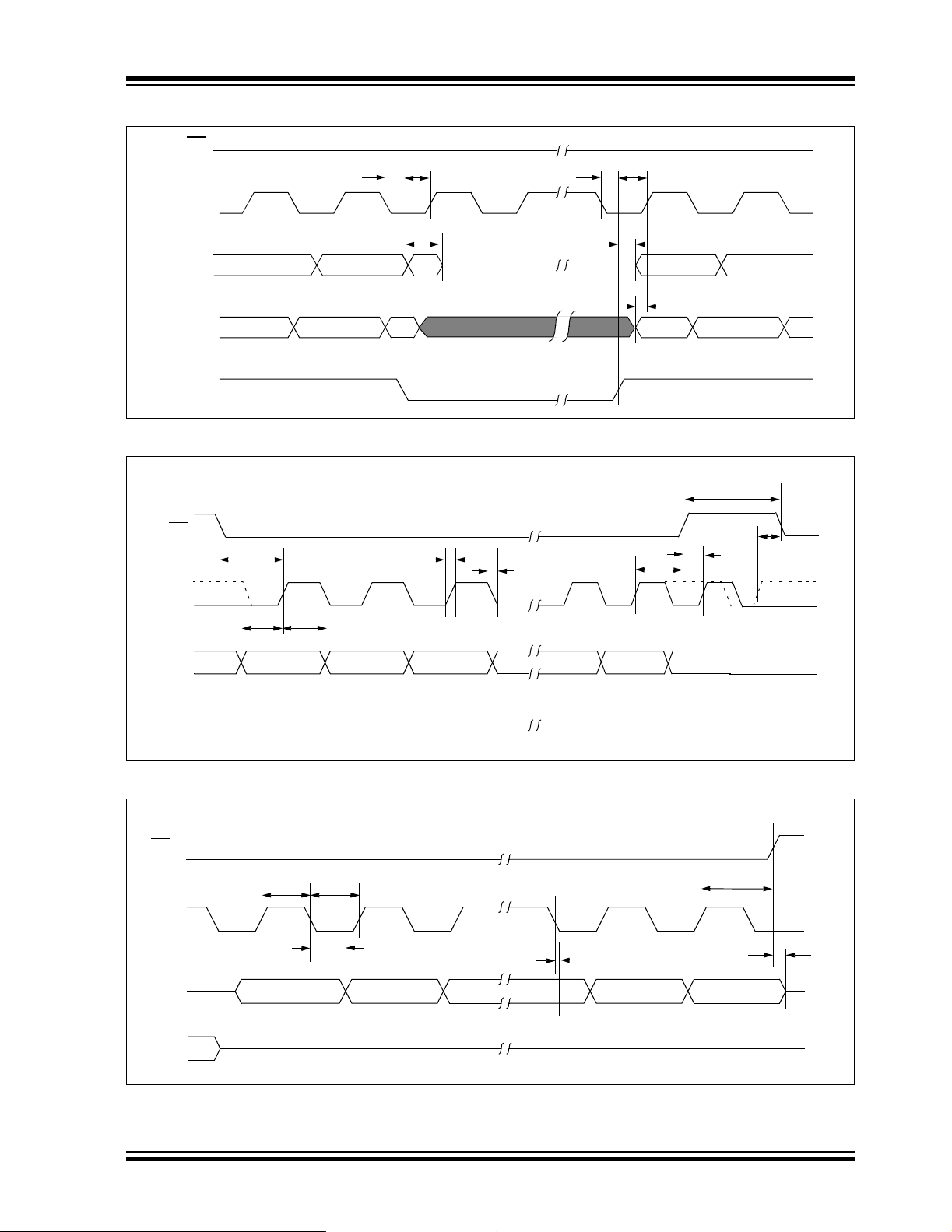

FIGURE 1-1: HOLD TIMING

CS

SCK

SO

n+2 n+1 n n-1

16

17

18

high-impedance

25AA256/25LC256

16

17

19

n

SI

HOLD

n+2 n+1 n

FIGURE 1-2: SERIAL INPUT TIMING

CS

2

Mode 1,1

Mode 0,0

SCK

65

SI

SO

MSB in

high-impedance

don’t care

7

8

LSB in

5

n

3

n-1

4

12

11

FIGURE 1-3: SERIAL OUTPUT TIMING

CS

9

10

SCK

13

SO

SI

2003 Microchip Technology Inc. Preliminary DS 21822C-page 5

MSB out

don’t care

14

3

Mode 1,1

Mode 0,0

15

ISB out

Page 6

25AA256/25LC256

2.0 FUNCTIONAL DESCRIPTION

2.1 Principles of Operation

The 25XX256 is a 32768 byte Serial EEPROM

designed to interf ace di rec tly with the Serial Peripheral

Interface (SPI) port of many of today’s popular

microcontroller families, including Microchip’s

PICmicro

microcontrollers that do not have a built-in SPI port by

using discrete I/O lines programmed properly in

firmware to match the SPI protocol.

The 25XX256 conta ins an 8-bit instr uction regi ster . The

device is accessed via the SI pin, with data being

clocked in on the rising edge of SCK. The CS

be low and the HOLD

operation.

Table 2-1 contains a list of the possible instruction

bytes and format for device operation. All instructions,

addresses, and data are transferred MSB first, LSB

last.

Data (SI) is sampled on the first rising edge of SCK

after CS

peripheral devices on the SPI bus, the user can assert

the HOLD input and place the 25XX256 in ‘HOLD’

mode. After releasing the HOLD

resume from the point when the HOLD

®

microcont rollers. It may also interfac e with

pin must

pin must be high fo r the entire

goes low. If the clock line is shared with other

pin, operation will

was asserted.

2.2 Read Sequence

The device is sele cted by p ulling CS low. The 8-bit read

instruction is transmitted to the 25XX256 followed by

the 16-bit address, with the first MSB of the address

being a don’t care bit. After the correct read instruction

and address are sent, the d ata st ored i n the memo ry at

the selected address is shifted out on the SO pin. The

data stored in the memory at the next address can be

read sequentially by continuing to provide c lock pulses .

The internal address pointer is automatically incremented to the next higher address after each byte of

data is shifted out. When the highest address is

reached (7FFFh), the address counter rolls over to

address 0000h allow in g th e rea d c yc le to b e co nti nue d

indefinitely. The read operation i s term inated by rai sing

pin (Figure 2 -1).

the CS

2.3 Write Sequence

Prior to any attempt to write data to the 25XX256, the

write enable latch must be set by issuing the WREN

instruction (Figure2-4). This is done by setting CS low

and then clocking out the proper instruction into the

25XX256. After all eight bits of the instruction are

transmitted, the CS

write enable latch. If the write operation is initiated

immediately after the WREN instruction without CS

being brought high, the data will not be written to the

array because the write enable latc h will not hav e been

properly set.

Once the write enable latch is set, the user may

proceed by setting the CS

instruction, followed by the 16-bit address, with the first

MSB of the address bein g a don’t c are bit, and then the

data to be writ ten. Up to 64 bytes of d ata ca n be sent to

the device before a write cycle is necessary. The only

restriction is that all of the bytes must reside in the

same page.

Note: Page write operations are limited t o writing

bytes within a single physical page,

regardless of the number of bytes

actually being written. Physical page

boundaries start at addresses that are

integer multiples of the page buf fer size (or

‘page size’) and, end at addresses that are

integer multiples of page size - 1. If a Page

Write comman d attem pt s to wri te a cross a

physical page boundary, the result is that

the data wraps around to the beginning of

the current page (overwriting data

previously stored there), instead of being

written to the next page as might be

expected. It is therefore necessary for the

application software to prevent page write

operations that would attempt to cross a

page boundary.

For the data to be actually written to the array, the CS

must be brought high after the Leas t Significant bit (D0)

of the n

brought high at any other time, the write operation will

not be completed. Refer to Figure 2-2 and Figure 2-3

for more detailed illustrations on the byte write

sequence and the page write sequence respectively.

While the write is in progress, the Status register may

be read to check the status of the WPEN, WIP, WEL,

BP1 and BP0 bits (Figure 2-6). A read attempt of a

memory array location will not be possible during a

write cycle. When the write cycle is completed, the

write enable latch is reset.

th

data byte has been clocked in. If CS is

must be brought high to set the

low, issuing a WRITE

DS21822C-page 6 Preliminary 2003 Microchip Technology Inc.

Page 7

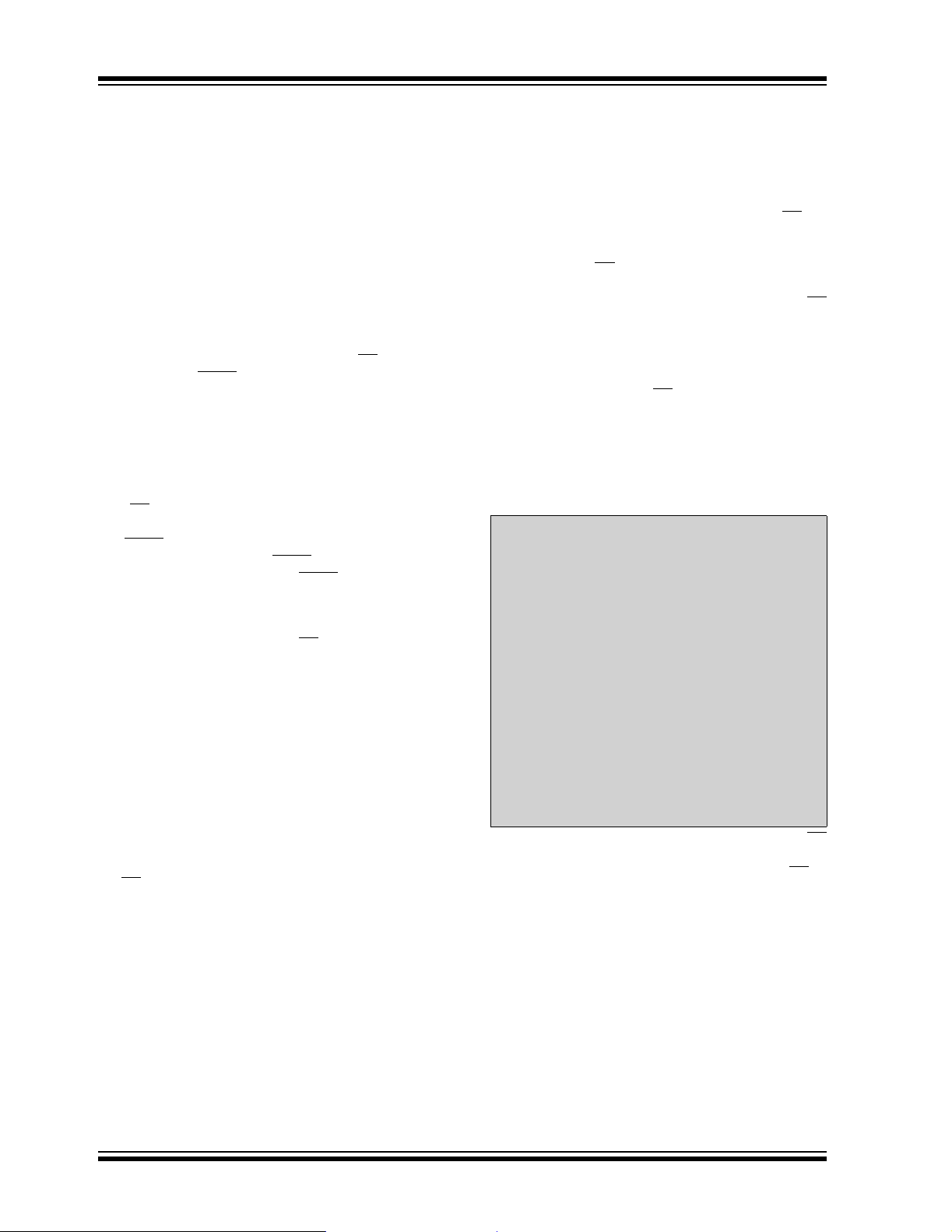

BLOCK DIAGRAM

25AA256/25LC256

SO

CS

SCK

HOLD

WP

I/O Control

SI

Status

Register

Logic

Memory

Control

Logic

VCC

VSS

X

Dec

HV Generato r

EEPROM

Array

Page Latches

Y Decoder

Sense Amp.

R/W Control

TABLE 2-1: INSTRUCTION SET

Instruction Name Instruction Format Description

READ

WRITE

WRDI

WREN

RDSR

WRSR

0000 0011

0000 0010

0000 0100

0000 0110

0000 0101

0000 0001

Read data from memory array beginning at selected address

Write data to memory array beginning at selected address

Reset the write enable latch (disable write operations)

Set the write enable latch (enable write operations)

Read Status register

Write Status register

FIGURE 2-1: READ SEQUENCE

CS

0 234567891011 21222324252627282930311

SCK

instruction 16-bit address

SI

SO

2003 Microchip Technology Inc. Preliminary DS 21822C-page 7

0100000 1 15 14 13 12 210

high-impedance

data out

76543210

Page 8

25AA256/25LC256

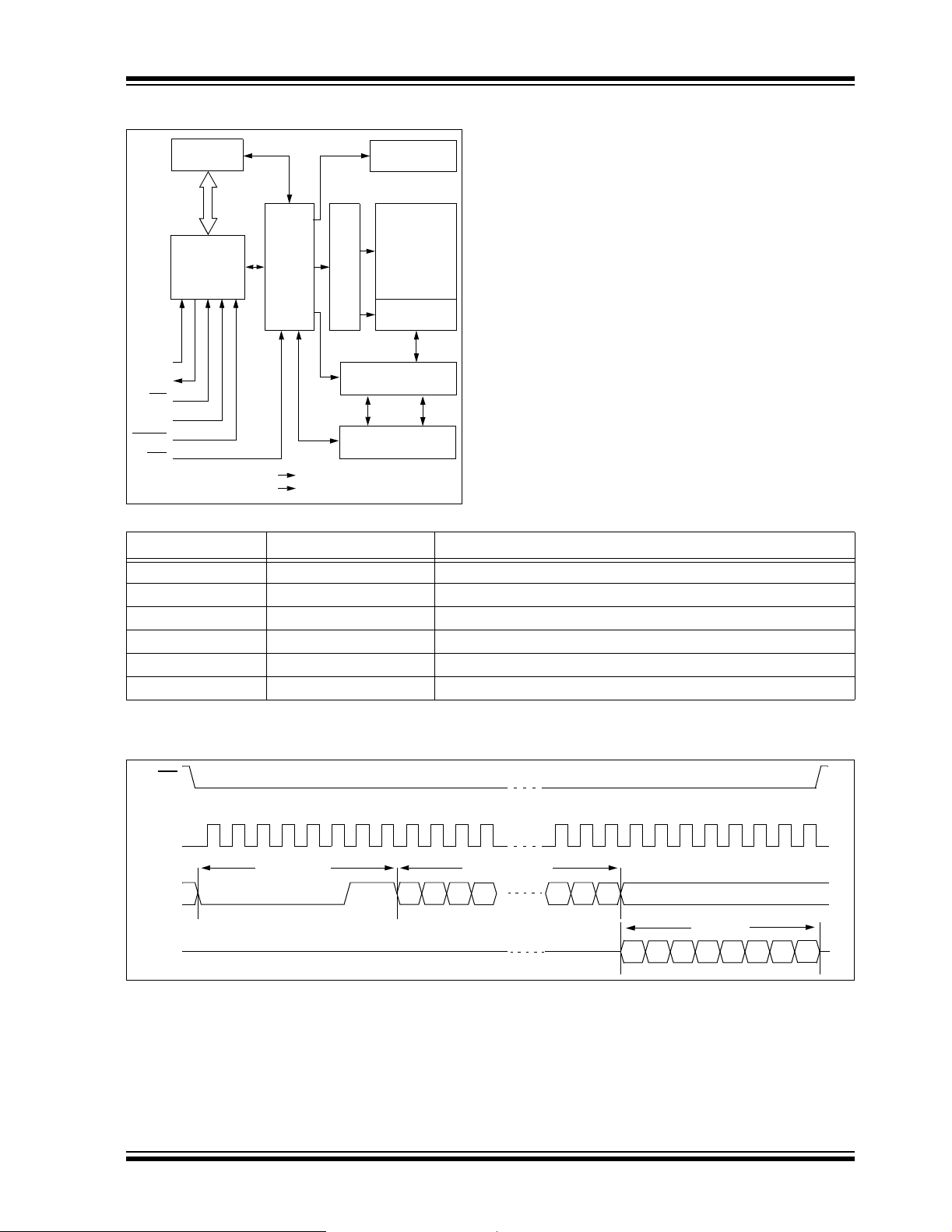

FIGURE 2-2: BYTE WRITE SEQUENCE

CS

91011 2122232425262728293031

SCK

SI

SO

0 23456718

instruction 16-bit address data byte

0000000 1 15 14 13 12

high-impedance

FIGURE 2-3: PAGE WRITE SEQUENCE

CS

8

SCK

SI

CS

0 2345671

instruction 16-bit address data byte 1

0000000 1 15 14 13 12

Twc

21076543210

9 1011 2122232425262728293031

21076543210

SCK

SI

32 34 35 36 37 38 3933

data byte 2

76543210

41 42 43 46 47

40

data byte 3

76543210

44 45

data byte n (64 max)

76543210

DS21822C-page 8 Preliminary 2003 Microchip Technology Inc.

Page 9

25AA256/25LC256

2.4 Write Enable (WREN) and Write

Disable (WRDI)

The 25XX256 contains a write enable latch. See

Table 2-4 for the Write-Protect Functionality Matrix.

This latch must be set before any write operation w ill be

completed internally. The WREN instruction will set the

latch, and the WRDI will reset the latch.

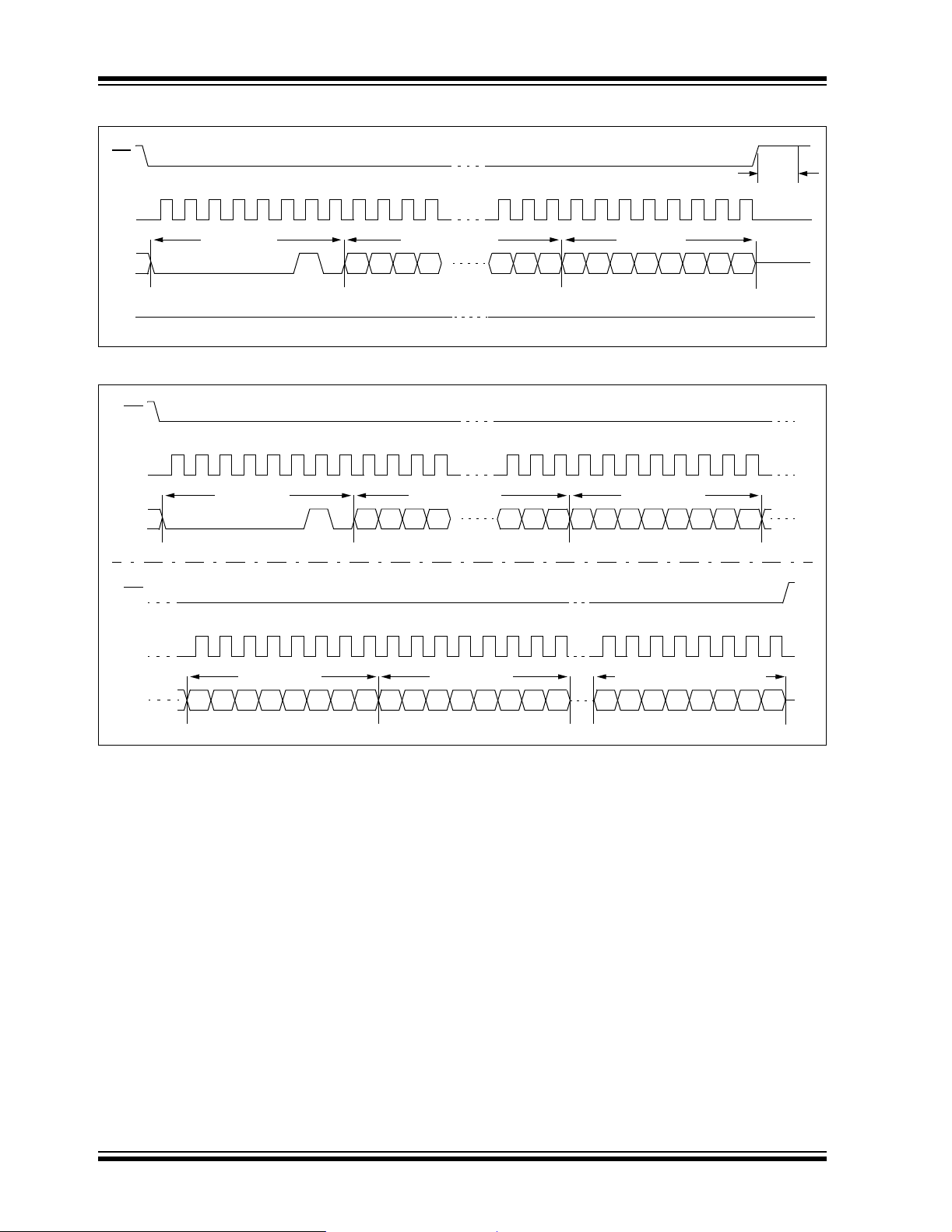

FIGURE 2-4: WRITE ENABLE SEQUENCE (WREN)

CS

0 2345671

SCK

SI

SO

010000 01

high-impedance

The following is a list of conditions under which the

write enable latch will be reset:

• Power-up

• WRDI instruction successfully executed

• WRSR instruction successfully executed

• WRITE instruction successfully executed

FIGURE 2-5: WRITE DISABLE SEQUENCE (WRDI)

CS

0 2345671

SCK

SI

SO

010000 01

high-impedance

0

2003 Microchip Technology Inc. Preliminary DS 21822C-page 9

Page 10

25AA256/25LC256

2.5 Read Status Register Instruction

(RDSR)

The Read Status Register instruction (RDSR) provides

access to the Status register. The Status register may

be read at any time, even during a write cycle. The

Status register is formatted as follows:

TABLE 2-2: STATUS REGISTER

7 654 3 2 1 0

W/R –––W/RW/R R R

WPEN X X X BP1 BP0 WEL WIP

W/R = writable/readable. R = read-only.

The Write-In-Process (WIP) bit indicates whether the

25XX256 is busy with a write operation. When set to a

1’, a write is in progress, when set to a ‘0’, no write is

‘

in progress. This bit is read-only.

The Wri te Enable Lat ch (WEL) bit indicat es the st atus

of the write enabl e la tch and i s read -o nly. When set to

a ‘

1’, the latch allows writes to the array, when set to a

0’, the latch prohibits writes to the array. The state of

‘

this bit can always be updated via the WREN or WRDI

commands regardless of the state of write protection

on the Status register. These commands are shown in

Figure 2-4 and Figure 2-5.

The Block Protection (BP0 and BP1) bits indicate

which blocks are currently write-protected. These bits

are set by the user issuing the WRSR instruction. These

bits are nonvolatile, and are shown in Table 2-3.

See Figure 2-6 for the RDSR timing sequence.

FIGURE 2-6: READ STATUS REGISTER TIMING SEQUENCE (RDSR)

CS

8

0 2345671

9101112131415

SCK

SO

SI

instruction

high-impedance

11000000

data from Status register

7654 2 10

3

DS21822C-page 10 Preliminary 2003 Microchip Technology Inc.

Page 11

25AA256/25LC256

2.6 Write Status Register Instruction

See Figure 2-7 for the WRSR timing sequence.

(WRSR)

The Write S t atus Regis ter inst ruction (WRSR) all ows the

user to write to the n onvolatile bit s in t he S t atus reg ister

as shown in Table 2-2. The user is able to select one of

four levels of protection for the array by writing to the

appropriate bits in the Status register. The array is

divided up into four segments. The user has the ability

to write-protect none, one, two, or all four of the

segments of the array. The partitioning is controlled as

shown in Table 2-3.

The Write-Protect Enable (WPEN) bit is a nonvolatile

bit that is available as an enable bi t for the WP

Write-Protect (WP

(WPEN) bit in the Status register control the

programmable hardware write-protect feature. Hardware write protection is enabled when WP

and the WPEN bit is high. Hardware write protection is

disabled when either the WP

bit is low. When the chip is hardware write-protected,

only writes to nonvolatile bits in the Status register are

disabled. See Table 2-4 for a matrix of functionality on

the WPEN bit.

) pin and the Write-Protect Enable

pin is high or the WPEN

pin. The

pin is low

FIGURE 2-7: WRITE STATUS REGISTER TIMING SEQUENCE (WRSR)

TABLE 2-3: ARRAY PROTECTION

BP1 BP0

00

01

10

11

Array Addresses

Write-Protected

none

upper 1/4

(6000h - 7FFFh)

upper 1/2

(4000h - 7FFFh)

all

(0000h - 7FFFh)

CS

8

0 2345671

SCK

instruction data to Status register

SI

SO

Note: An internal write cy cle (T WC) is initiat ed on the rising edge o f CS after a valid write S tatus Registe r sequence.

01000000

high-impedance

9101112131415

7654

210

3

2003 Microchip Technology Inc. Preliminary DS21822C-page 11

Page 12

25AA256/25LC256

2.7 Data Protection

The following protection has been implemented to

prevent in advertent writes to th e array:

• The write enable latch is reset on power-up

• A write enable instruction must be issued to set

the write enable latch

• After a byte write, page write or Status register

write, the write enable latch is reset

must be set high after the proper number of

•CS

clock cycles to start an internal write cycle

• Access to the array dur ing an internal write cycle

is ignored and programming is continued

2.8 Power-On State

The 25XX256 powers on in the following state:

• The device is in low-power Standby mode

=1)

(CS

• The write enable latch is reset

• SO is in high-impedance state

• A high-to-low-level transition on CS

enter active state

TABLE 2-4: WRITE-PROTECT FUNCTIONALITY MATRIX

WEL

(SR bit 1)

0xxProtected Protected Protected

10xProtected Writable Writable

110 (low) Protected Writable Protected

111 (high) Protected Writable Writable

x = don’t care

WPEN

(SR bit 7)

WP

(pin 3)

Protected Blocks Unprotected Blocks Status Register

is required to

DS21822C-page 12 Preliminary 2003 Microchip Technology Inc.

Page 13

25AA256/25LC256

3.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

Name Pin Number Function

CS

SO 2 Serial Data Output

WP

SS 4 Ground

V

SI 5 Serial Data Input

SCK 6 Serial Clock Input

HOLD

V

CC 8 Supply Voltage

3.1 Chip Select (CS)

A low level on this pin selects the device. A high level

deselects the device and forces it into Standby mode.

However, a programming cycle which is already

initiated or in progress will be completed, regardle ss of

input signal. If CS is brought high during a

the CS

program cycle, the de vice wil l go into S t andb y mode as

soon as the programming cycle is complete. When the

device is deselected, SO goes to the high-impedance

state, allowing multiple parts to share the same SPI

bus. A lo w-to-high transiti on on CS

sequence initiates an internal write cycle. After powerup, a low level on CS

being initiated.

3.2 Serial Output (SO)

The SO pin is used to transfer data out of the 25XX256.

During a read cycle, data is shifted out on this pin after

the falling edge of the serial clock.

1 Chip Select Input

3 Write-Protect Pin

7 Hold Input

after a valid write

is required p r ior to an y sequence

The WP

the St atus regi ster is low. This allo ws the use r to ins t al l

the 25XX256 in a system with WP pin grounded and

still be able to write to the Status register. The WP

functions will be enabled when the WPEN bit is set

high.

pin function is blocked when the WPEN bit in

pin

3.4 Serial Input (SI)

The SI pin is used to transfer data into the device. It

receives instructions, addresses and data. Data is

latched on the rising edge of the serial clock.

3.5 Serial Clock (SCK)

The SCK is used to synchronize the communication

between a master and the 25XX256. Instructions,

addresses or data pres en t on th e SI pin are latched on

the rising edge of t he c lo ck in put, while data on the SO

pin is updated after the falling edge of the clock input.

3.6 Hold (HOLD)

The HOLD pin is used to suspend transmission to the

25XX256 while in the mid dle of a seri al sequ ence w ithout having to retransmit the entire sequence again. It

must be held high any time this function is not being

used. Once the device is selected and a serial

sequence is underway, the HOLD

low to pause further serial communication without

resetting the serial sequence. The HOLD pin must be

brought low while SCK is low, otherwise the HOLD

function will not be invoked until the next SCK high-tolow transition. The 25XX256 must remain selected

during this sequence. The SI, SCK and SO pins are in

a high-impedance state during the time the device is

paused and transitions on these p ins will be ignored. To

resume serial communication, HOLD

high while the SCK pin is low, otherwise serial

communication will not resume. Lowering the HOLD

line at any time will tri-state the SO line.

pin may be pulled

must be brought

3.3 Write-Protect (WP)

This pin is used in conjunction with the WPEN bit in the

Status register to prohibit writes to the nonvolatile bits

in the Status register. When WP is low and WPEN is

high, writing to the no nvolatil e bits in the Status register

is disabled. All other operations function normally.

When WP

nonvolatile bit s i n t he Status register, operate normally .

If the WPEN bit is set, WP low during a Status register

write sequence will disable writing to the Status

register. If an internal write cycle has already begun,

WP

2003 Microchip Technology Inc. Preliminary DS21822C-page 13

is high, all functions, including writes to the

going low will have no effect on the write.

Page 14

25AA256/25LC256

4.0 PACKAGING INFORMATION

4.1 Package Marking Information

8-Lead DFN

XXXXXXX

T/XXXXX

YYWW

NNN

8-Lead PDIP

XXXXXXXX

T/XXXNNN

YYWW

8-Lead SOIC

XXXXXXXX

T/XXYYWW

NNN

Example

25LC256

I/MF

0328

Example:

25AA256

I/P 1L7

Example:

25LC256

I/SN 0328

:

1L7

0328

1L7

8-Lead TSSOP

XXXX

TYWW

NNN

Legend: XX...X Part number

T Temperature (I, E)

Blank Commercial

YY Year code (last 2 digits of calendar year) except TSSOP

which uses only the last 1 digit

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Note: Custom marking available.

Example:

5LE

I328

1L7

TSSOP 1st Line Marking Codes

Device

25AA256

25LC256 5LE

std mark

5AE

Pb-free

mark

NAE

NLE

DS21822C-page 14 Preliminary 2003 Microchip Technology Inc.

Page 15

25AA256/25LC256

8-Lead Plastic Dual Flat No Lead Package (MF) 6x5 mm Body (DFN-S)

A1

n

12

TOP VIEW

α

E1

E

B

R

D1 D

EXPOSED

METAL

PADS

BOTTOM VIEW

A2

A3

A

p

L

D2

PIN 1

ID

E2

Units

Dimension Limits

Number of Pins

Pitch

Overall Height

Molded Package Thickness

Standoff

Base Thickness

Overall Length

Molded Package Length

Exposed Pad Length

Molded Package Width

Exposed Pad Width D2 .085 .091 .097 2.16 2.31 2.46

Lead Width

Lead Length

Tie Bar Width

Mold Draft Angle Top

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010” (0.254mm) per side.

JEDEC equivalent: pending

Drawing No. C04-113

n

p

A

A2

A1

A3

E

E1

E2

DOverall Width

D1

B

L

R

α

MIN

INCHES

NOM

.050 BSC

.033

.026

.000

.152 .158 .163 3.85 4.00 4.15

.014

.020

.0004

.008 REF.

.194 BSC

.184 BSC

.236 BSC

.226 BSC

.016

.024

.014

MAX MIN

8

.039

.031

.002

.019

.030

12

MILLIMETERS*

1.27 BSC

0.00

0.20 REF.

4.92 BSC

4.67 BSC

5.99 BSC

5.74 BSC

0.35

0.50

0.85

0.65

0.01

0.40

0.60

.356

MAXNOM

8

1.00

0.80

0.05

0.47

0.75

12

2003 Microchip Technology Inc. Preliminary DS21822C-page 15

Page 16

25AA256/25LC256

8-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

D

2

n

E

β

eB

Number of Pins

Pitch

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

Dimension Limits MIN NOM MAX MIN NOM MAX

1

α

A

c

Units INCHES* MILLIMETERS

n

p

c

α

β

.008 .012 .015 0.20 0.29 0.38

A1

B1

B

88

.100 2.54

51015 51015

51015 51015

A2

L

p

DS21822C-page 16 Preliminary 2003 Microchip Technology Inc.

Page 17

8-Lead Plastic Small Outline (SN) – Narrow, 150 mil (SOIC)

E

E1

p

D

2

25AA256/25LC256

B

Number of Pins

Pitch

Standoff §

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-057

n

45°

c

β

n

p

A1

φ

c

α

β

1

h

A

φ

L

048048

A1

MILLIMETERSINCHES*Units

1.27.050

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004

6.206.025.79.244.237.228EOverall Width

3.993.913.71.157.154.146E1Molded Package Width

5.004.904.80.197.193.189DOverall Length

0.510.380.25.020.015.010hChamfer Distance

0.760.620.48.030.025.019LFoot Length

0.250.230.20.010.009.008

0.510.420.33.020.017.013BLead Width

1512015120

1512015120

2003 Microchip Technology Inc. Preliminary DS21822C-page 17

Page 18

25AA256/25LC256

8-Lead Plastic Thin Shrink Small Outline (ST) – 4.4 mm (TSSOP)

E

E1

p

D

2

n

B

1

A

c

A1

φ

β

A1

n

p

φ

c

α

β

048048

Number of Pins

Pitch

Standoff §

Foot Angle

Lead Thickne ss

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.005” (0.127mm) per side.

JEDEC Equivalent: MO-153

Drawing No. C04-086

L

MILLIMETERS*INCHESUnits

0.65.026

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.10.043AOverall Height

0.950.900.85.037.035.033A2Molded Package Thickness

0.150.100.05.006.004.002

6.506.386.25.256.251.246EOverall Width

4.504.404.30.177.173.169E1Molded Package Width

3.103.002.90.122.118.114DMolded Package Length

0.700.600.50.028.024.020LFoot Length

0.200.150.09.008.006.004

0.300.250.19.012.010.007BLead Width

10501050

10501050

DS21822C-page 18 Preliminary 2003 Microchip Technology Inc.

Page 19

APPENDIX A: REVISION HISTORY

Revision C

Corrections to Section 1.0, Electrical Characteristics.

25AA256/25LC256

2003 Microchip Technology Inc. Preliminary DS21822C-page 19

Page 20

25AA256/25LC256

NOTES:

DS21822C-page 20 Preliminary 2003 Microchip Technology Inc.

Page 21

25AA256/25LC256

ON-LINE SUPPORT

Microchip provides on-line support on the Microchip

World Wide Web site.

The web site is used b y Mic rochip as a me ans to m ake

files and information easily available to customers. To

view the site, the use r must have access to the Intern et

and a web browser, such as Netscape

Internet Explorer. Files are also available for FTP

download from our FTP site.

Connecting to the Microchip Internet

Web Site

The Microchip web site is available at the following

URL:

www.microchip.com

The file transfer site is available by using an FTP

service to connect to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of

services. Users may download files for the latest

Development Tools, Data Sheets, Application Notes,

User's Guides, Articles and Sample Programs. A

variety of Microchip specific business information is

also available, including listings of Microchip sales

offices, distr ibutors an d factory r epresentat ives. Other

data available for consideration is:

• Latest Microchip Press Releases

• Technical Support Section with Frequently Asked

Questions

• Design Tips

• Device Errata

• Job Postings

• Microchi p Consultant P rogram Member Listing

• Links to other useful web sites related to

Microchip Products

• Conferences for pr oducts, D evelopment Systems,

technical information and more

• Listing of seminars and events

®

or Microsoft

SYSTEMS INFORMATION AND UPGRADE HOT LINE

The Systems Information and Upgrade Line provides

system users a listing of the latest versions of all of

Microchip's development systems software products.

®

Plus, this line provides information on how customers

can receive the most c urrent upgra de kit s.The Hot Lin e

Numbers are:

1-800-755-2345 for U.S. and most of Canada, and

1-480-792-7302 for the rest of the world.

042003

2003 Microchip Technology Inc. Preliminary DS21822C-page 21

Page 22

25AA256/25LC256

READER RESPONSE

It is our intentio n to pro vi de you with the best documentation possible to ens ure suc c es sfu l u se of y ou r M ic roc hip product. If you wish to provid e your c omment s on org anizatio n, clarity, subject matter , and ways in w hich o ur document atio n

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this document.

To:

RE: Reader Response

From:

Application (optional):

Would you like a reply? Y N

Device: Literature Number:

Questions:

1. What are the best features of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this document easy to follow? If not, why?

Technical Publications Manager

Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________

Total Pages Sent ________

FAX: (______) _________ - _________

DS21822C25AA256/25LC256

4. What additions to the document do you think would enhance the structure and subject?

5. What deletions from the document could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

DS21822C-page 22 Preliminary 2003 Microchip Technology Inc.

Page 23

25AA256/25LC256

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. X /XX X

Device

Device 25AA256

Tape & Reel Blank =

Temperature Range I =

Package M F =

25LC256

T=

E=

P=

SN =

ST =

256k-bit, 1.8V, 64-Byte Page, SPI Serial EEPROM

256k-bit, 2.5V, 64-Byte Page, SPI Serial EEPROM

Standard packaging (tube)

Tape & Reel

-40°C to+85°C

-40°C to+125°C

Micro Lead Frame (6 x 5 mm body), 8-lead

Plastic DIP (300 mil body), 8-lead

Plastic SOIC (150 mil body), 8-lead

TSSOP, 8-lead

X

–

Te mp Range

Lead PackageTape & Reel

Finish

Examples:

a) 25AA256-I/STG = 256k-bit, 1.8V Serial

EEPROM, Industrial temp., TSSOP package,

Pb-free

b) 25AA256T-I/SN = 256k-bit, 1.8V Serial

EEPROM, Industrial temp., Tape & Reel, SOIC

package

c) 25AA256T-I/ST = 256k-bit, 1.8V Serial

EEPROM, Industrial temp., Tape & Reel,

TSSOP package

d) 25LC256-I/STG = 256k-bit, 2.5V Serial

EEPROM, Industrial temp., TSSOP package,

Pb-free

e) 25LC256-I/P = 256k-bit, 2.5V Serial EEPROM,

Industrial temp., P-DIP package

f) 25LC256T-E/ST = 256k-bit, 2.5V Serial

EEPROM, Extended temp., Tape & Reel,

TSSOP package

Lead Finish Blank =

G=

Standard 63% / 37% Sn/Pb

Matte Tin (Pure Sn)

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and

recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

2003 Microchip Technology Inc. Preliminary DS21822C-page 23

Page 24

25AA256/25LC256

NOTES:

DS21822C-page 24 Preliminary 2003 Microchip Technology Inc.

Page 25

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• Th ere are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the co de protection fea tures of our

products. Attempts to break microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, MPLAB, PIC, PICmic ro, PI C START,

PRO MATE and PowerSmart are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

AmpLab, FilterLab, microID, MXDEV, MXLAB, PI CMASTER,

SEEVAL and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Application Maestro, dsPICDEM, dsPICDEM.net, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, microPort,

Migratable Memory, MPASM, MPLIB, MPLINK, MPSIM,

PICkit, PICDEM, PICDEM.net, PowerCal, PowerInfo,

PowerMate, PowerTool, rfLAB, rfPIC, Select Mode,

SmartSensor, SmartShunt, SmartT el and Total Endurance are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2003, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systems is ISO 9001 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

2003 Microchip Technology Inc. Preliminary DS21822C-page 25

Page 26

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-72 00

Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Atlanta

3780 Mansell Road, Suite 130

Alpharetta, GA 30022

Tel: 770-640- 003 4

Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692- 384 8

Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285- 007 1

Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818- 742 3

Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538- 225 0

Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, IN 46902

Tel: 765-864- 836 0

Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263- 188 8

Fax: 949-263-1338

Phoenix

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-79 66

Fax: 480-792-4338

San Jose

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436- 795 0

Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Cana da

Tel: 905-673- 069 9

Fax: 905-673-6509

ASIA/PACIFIC

Australia

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-986 8-6 73 3

Fax: 61-2-9868-6755

China - Beijing

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85 282 10 0

Fax: 86-10-85282104

China - Chengdu

Rm. 2401-2402, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-86 766 20 0

Fax: 86-28-86766599

China - Fuzhou

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7 503 50 6

Fax: 86-591-7503521

China - Hong Kong SAR

Unit 901-6, Tower 2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401 -12 00

Fax: 852-2401-3431

China - Shanghai

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-62 75- 57 00

Fax: 86-21-6275-5060

China - Shenzhen

Rm. 1812, 18/F, Building A, United Plaza

No. 5022 Binhe Road, Futian District

Shenzhen 518033, China

Tel: 86-755-8 290 13 80

Fax: 86-755-8295-1393

China - Shunde

Room 401, Hongjian Building

No. 2 Fengxiangnan Road, Ronggui Town

Shunde City, Guangdong 528303, China

Tel: 86-765-8395507 Fax: 86-765-8395571

China - Qingdao

Rm. B505A, Fullhope Plaza,

No. 12 Hong Kong Central Rd.

Qingdao 266071, China

Tel: 86-532-5027355 Fax: 86-532-5027205

India

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-47 1- 616 6 Fax: 81-4 5-4 71 -6122

Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5932 or

82-2-558-5934

Singapore

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Kaohsiung Branch

30F - 1 No. 8

Min Chuan 2nd Road

Kaohsiung 806, Taiwan

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan

Taiwan Branch

11F-3, No. 207

Tung Hua North Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Austria

Durisolstrasse 2

A-4600 Wels

Austria

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45-4420-9895 Fax: 45-4420-9910

France

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany

Steinheilstrasse 10

D-85737 Ismaning, Germany

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy

Via Quasimodo, 12

20025 Legnano (MI)

Milan, Italy

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands

P. A. De Biesbosch 14

NL-5152 SC Drunen, Netherlands

Tel: 31-416-690399

Fax: 31-416-690340

United Kingdom

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshir e, England RG41 5T U

Tel: 44-118-921-5869

Fax: 44-118-921-5820

07/28/03

DS21822C-page 26 Preliminary 2003 Microchip Technology Inc.

Loading...

Loading...