Page 1

24AA04/24LC04B

4K I2C™ Serial EEPROM

Device Selection Table

Part

Number

24AA04 1.8-5.5 400 kHz

24LC04B 2.5-5.5 400 kHz I, E

Note 1: 100 kHz for VCC <2.5V

Vcc

Range

Max. Clock

Frequency

(1)

Temp.

Ranges

I

Features:

• Single supply with operation down to 1.8V

• Low-power CMOS technology:

- 1 mA active current, typical

-1μA standby current, typical (I-temp)

• Organized as 2 blocks of 256 bytes (2 x 256 x 8)

• 2-wire serial interface bus, I

• Schmitt Trigger inputs for noise suppression

• Output slope control to eliminate ground bounce

• 100 kHz (24AA04) and 400 kHz (24LC04B)

compatibility

• Self-timed write cycle (including auto-erase)

• Page write buffer for up to 16 bytes

• Hardware write-protect for entire memory

• Can be operated as a serial ROM

• Factory programming (QTP) available

• ESD protection > 4,000V

• 1,000,000 erase/write cycles

• Data retention > 200 years

• 8-lead PDIP, SOIC, TSSOP, DFN and MSOP

packages

• 5-lead SOT-23 package

• Pb-free finish available

• Available for extended temperature ranges:

- Industrial (I): -40°C to +85°C

- Automotive (E): -40°C to +125°C

2

C™ compatible

Description:

The Microchip Technology Inc. 24AA04/24LC04B

(24XX04*) is a 4 Kbit Electric all y Era sable PROM. Th e

device is organized as two blocks of 256 x 8-bit

memory with a 2-wire serial interface. Low-voltage

design permits operation down to 1.8V, with standby

and active currents of only 1 μA and 1 mA,

respectively. The 24XX04 also has a page write

capability fo r up to 16 bytes of data. The 24X X04 is

available in the standard 8-pin PDIP, surface mount

SOIC, TSSOP, 2x3 DFN and MSOP packages and is

also available in the 5-lead SOT-23 package.

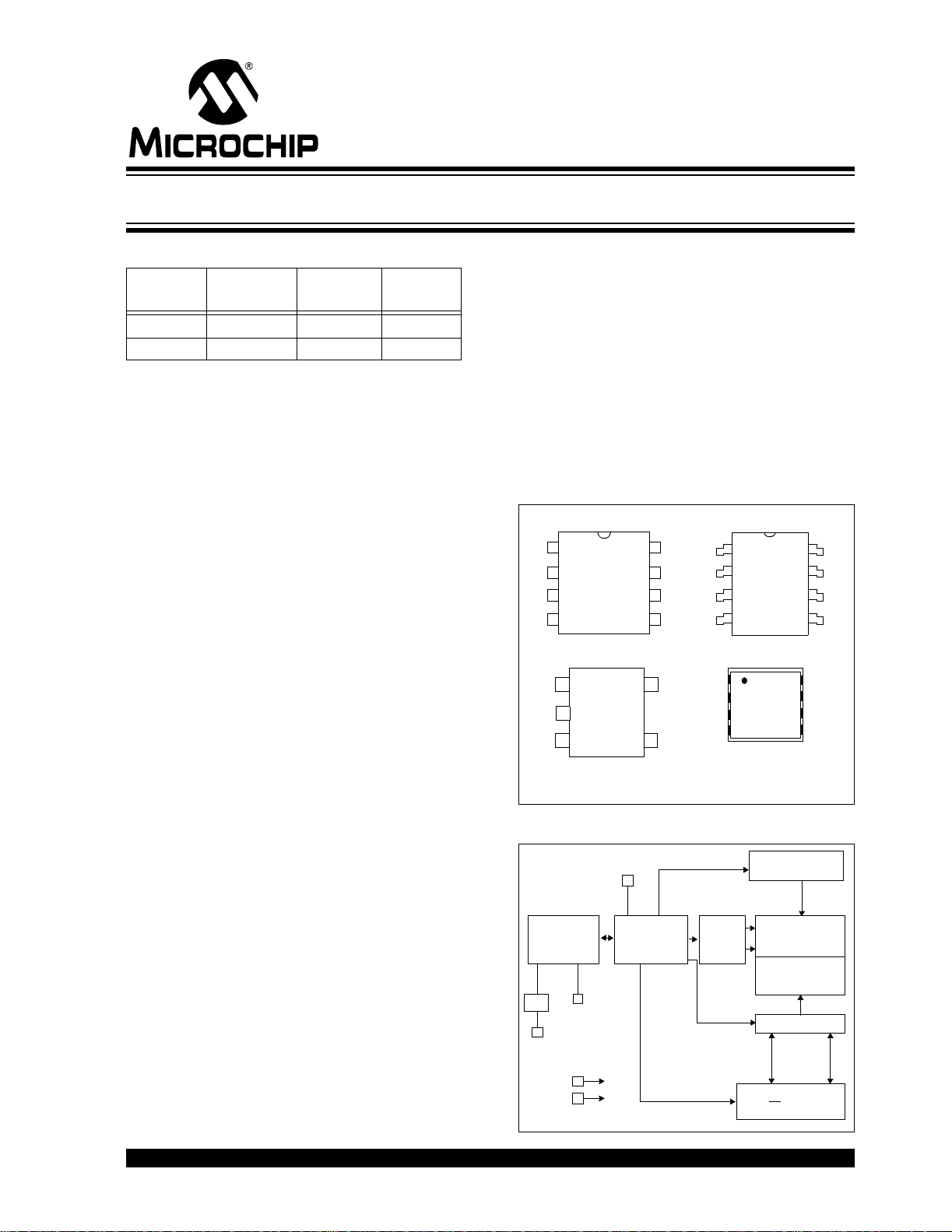

Package Types

A0

A1

A2

SS

V

V

SOIC, TSSOP

1

2

3

4

1

A0

2

A1

3

A2

SS

4

DFN

8

V

CC

7

WP

6

SCL

5

SDA

CC

V

8

WP

7

SCL

6

5

SDA

PDIP, MSOP

1

A0

2

A1

3

A2

4

V

SS

SOT-23-5

15

SCL

2

Vss

3

SDA

Note: Pins A0, A1 and A2 are not used by the 24XX04. (No

internal connections).

8

VCC

7

WP

6

SCL

5

SDA

WP

4

Vcc

Block Diagram

HV

Generator

EEPROM

Array

Page

Latches

YDEC

I/O

SDA

I/O

Control

Logic

SCL

WP

Memory

Control

Logic

XDEC

V

CC

VSS

© 2005 Microchip Technology Inc. DS21708E-page 1

Sense Amp.

R/W Control

Page 2

24AA04/24LC04B

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings

VCC.............................................................................................................................................................................6.5V

All inputs and outputs w.r.t. V

Storage temperature ...............................................................................................................................-65°C to +150°C

Ambient temperature with power applied................................................................................................-65°C to +125°C

ESD protection on all pins ......................................................................................................................................................≥ 4kV

† NOTICE: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to

the device. This is a stress rating only and functional operation of the device at those or any other conditions

above those indica ted in the opera tional li stings of this sp ecification is not i mplied. Ex posure to maximum rating

conditions for extended periods may affect device reliability.

SS ......................................................................................................... -0.3V to VCC +1.0V

(†)

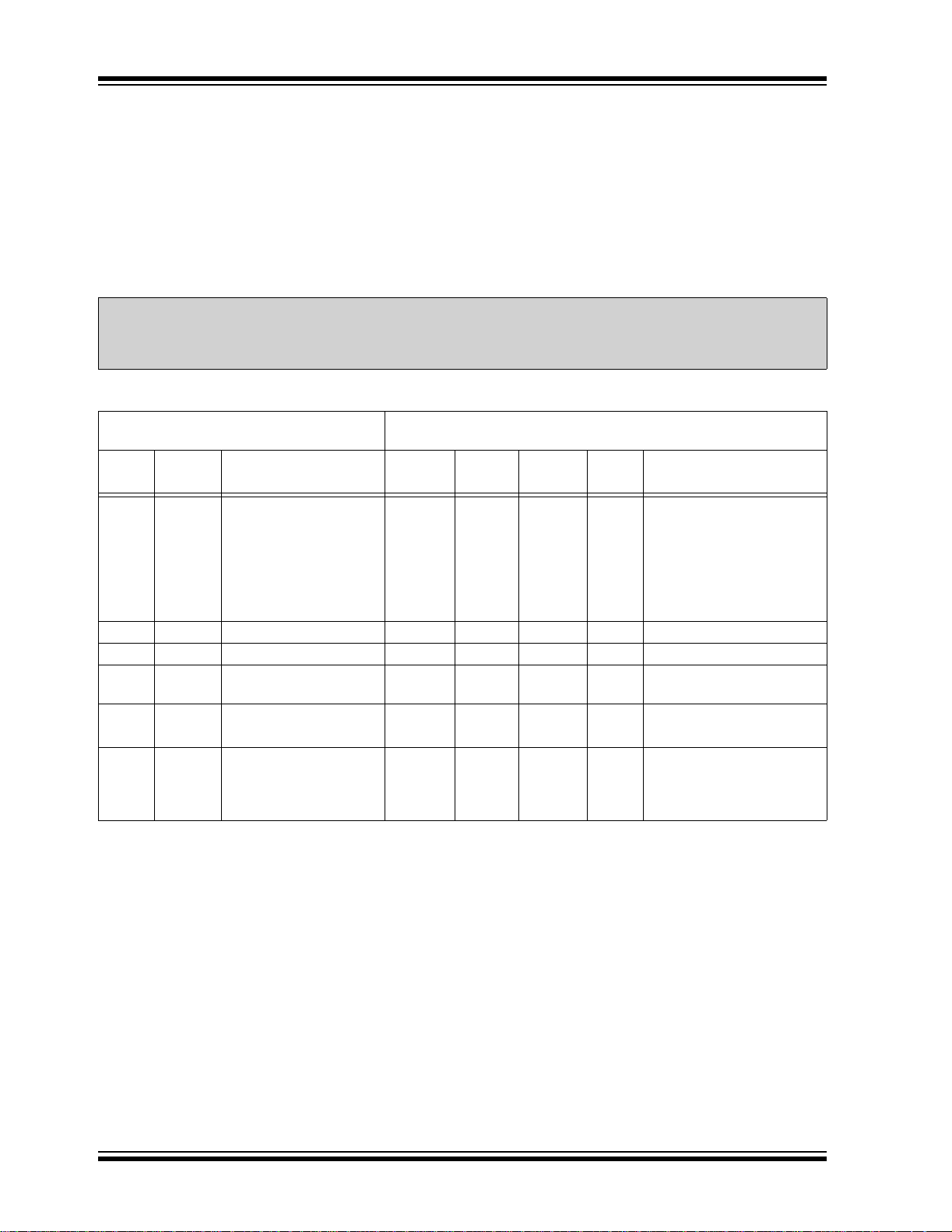

TABLE 1-1: DC CHARACTERISTICS

DC CHARACTERISTICS

Param.

No.

D1 V

D2 — High-level input voltage 0.7 V

D3 VIL Low-level input voltage — — 0.3 VCC V—

D4 VHYS Hysteresis of Schmitt

D5 V

D6 ILI Input leakage current ——±1μAVIN = VSS or VCC

D7 ILO Output leakage current ——±1μAVOUT = VSS or VCC

D8 CIN,

D9 I

D10 ICC read — 0.05 1 mA —

D11 ICCS Standby current —

Note: This parameter is periodically sampled and not 100% tested.

Sym. Characteristic Min. Typ. Max. Units Conditions

IH WP, SCL and SDA pins — ————

Trigger inputs

OL Low-level output voltage — — 0.40 V IOL = 3.0 mA, VCC = 2.5V

Pin capacitance

OUT

C

CC write Operating current —0.13mAVCC = 5.5V, SCL = 400 kHz

(all inputs/outpu t s)

Industrial (I): TA = -40°C to +85°C, VCC = +1.8V to +5.5V

Automotive (E): T

CC ——V—

0.05 VCC ——V(Note)

——10pFVCC = 5.0V (Note)

—

A = -40°C to +125°C, VCC = +2.5V to +5.5V

A = 25°C, FCLK = 1 MHz

T

0.01

—

1

5

μAμAIndustrial

Automotive

SDA = SCL = VCC

WP = VSS

DS21708E-page 2 © 2005 Microchip Technology Inc.

Page 3

24AA04/24LC04B

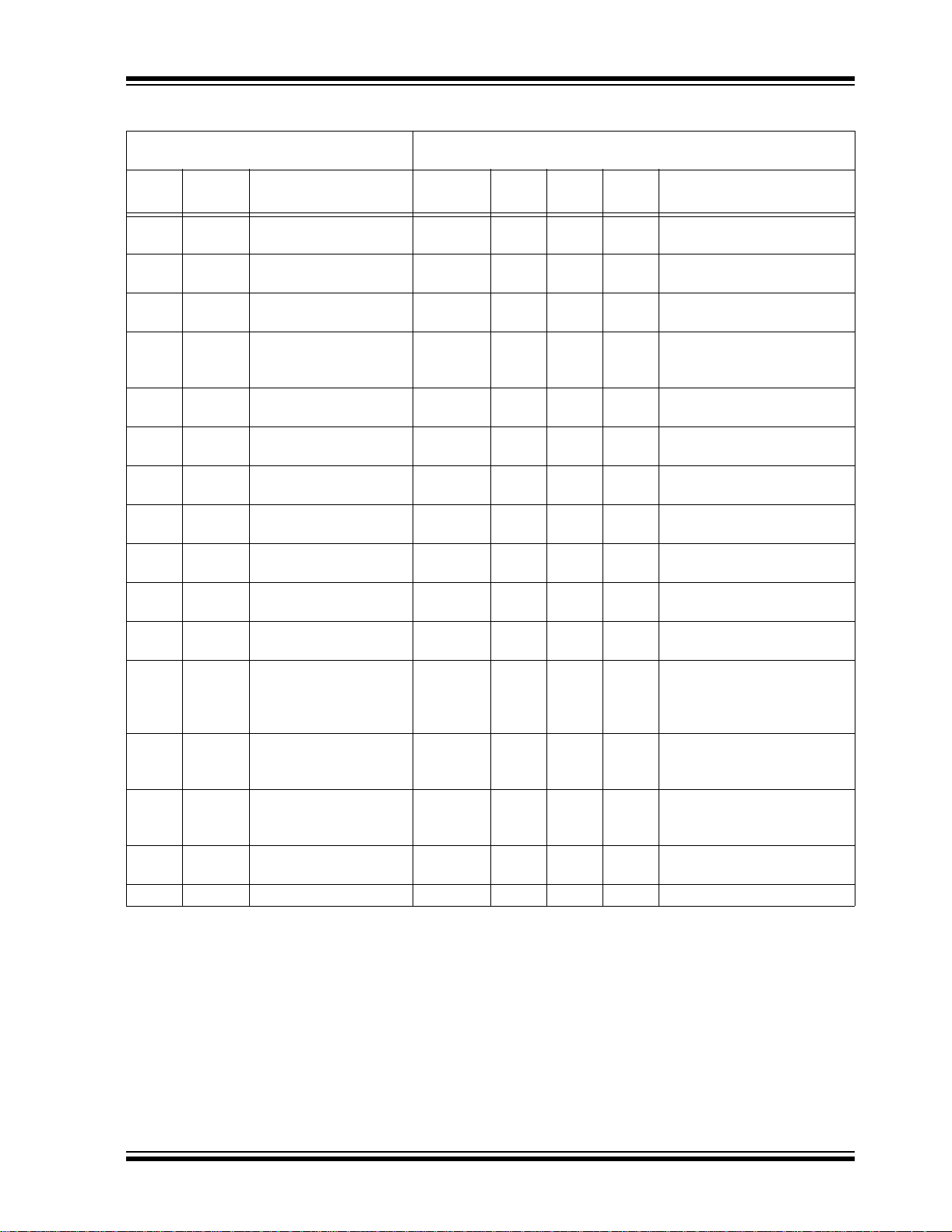

TABLE 1-2: AC CHARACTERISTICS

AC CHARACTERISTICS

Param.

No.

1F

Sym. Characteristic Min. Typ. Max. Units Conditions

CLK Clock frequency —

2 THIGH Clock high time 600

3T

LOW Clock low time 1300

4TR SDA and SCL rise time

(Note 1)

5T

6T

7T

F SDA and SCL fall time — —

HD:STA Start condition hold time 600

SU:STA Start condition setup

time

8THD:DAT Data input hold time 0 —

9T

10 T

SU:DAT Data input setup time 100

SU:STO Stop condition setup

time

11 TAA Output valid from clock

(Note 2)

12 TBUF Bus free time: Time the

bus must be free before

a new transmission can

start

13 TOF Output fall time from VIH

minimum to V

IL

maximum

14 T

SP Input filter spike

suppression

(SDA and SCL pins)

15 TWC Write cycle time

(byte or page)

16 — Endurance 1M — — cycles 25°C, (Note 4)

Note 1: Not 100% tested. C

B = total capacitance of one bus line in pF.

2: As a transmitter, the device must provide an internal minimum delay time to bridge the undefined region

(minimum 300 ns) of the falling edge of SCL to avoid unintended generation of Start or Stop conditions.

3: The co mbine d T

SP and VHYS specifications are due to new Schmit t Trigger inputs w h ic h p rov id e i mp rov ed

noise spike suppression. This eliminates the need for a

4: This parameter is not tested but ensured by characterization. For endurance esti mates in a specific

application, please co nsult the Tota l Enduran ce™ Model whic h can be obt ain ed from Mi crochi p’ s web site

at www.microchip.com.

Industrial (I): TA = -40°C to +85°C, VCC = +1.8V to +5.5V

Automotive (E): T

—

4000

4700

—

—

A = -40°C to +125°C, VCC = +2.5V to +5.5V

—

—

—

—

—

—

—

—

400

100

—

—

—

—

300

1000

kHz 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

CC < 2.5V (24AA04)

ns 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

CC < 2.5V (24AA04)

ns 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

CC < 2.5V (24AA04)

ns 2.5V ≤ VCC ≤ 5.5V (Note 1)

1.8V ≤ V

CC < 2.5V (24AA04)

(Note 1)

300 ns (Note 1)

—

4000

600

4700

—

—

—

—

—

—

—

—

ns 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

CC < 2.5V (24AA04)

ns 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

CC < 2.5V (24AA04)

—ns(Note 2)

—

250

600

4000

—

—

1300

4700

20+0.1C

—

—

—

—

—

—

—

—

—

B

—

—

—

—

—

—

900

3500

—

—

250

250

ns 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

CC < 2.5V (24AA04)

ns 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

CC < 2.5V (24AA04)

ns 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

CC < 2.5V (24AA04)

ns 2.5V ≤ VCC ≤ 5.5V

1.8V ≤ V

ns 2.5V ≤ V

1.8V ≤ V

CC < 2.5V (24AA04)

CC ≤ 5.5V

CC < 2.5V (24AA04)

— — 50 ns (Notes 1 and 3)

——5ms—

TI specification for standard operation.

© 2005 Microchip Technology Inc. DS21708E-page 3

Page 4

24AA04/24LC04B

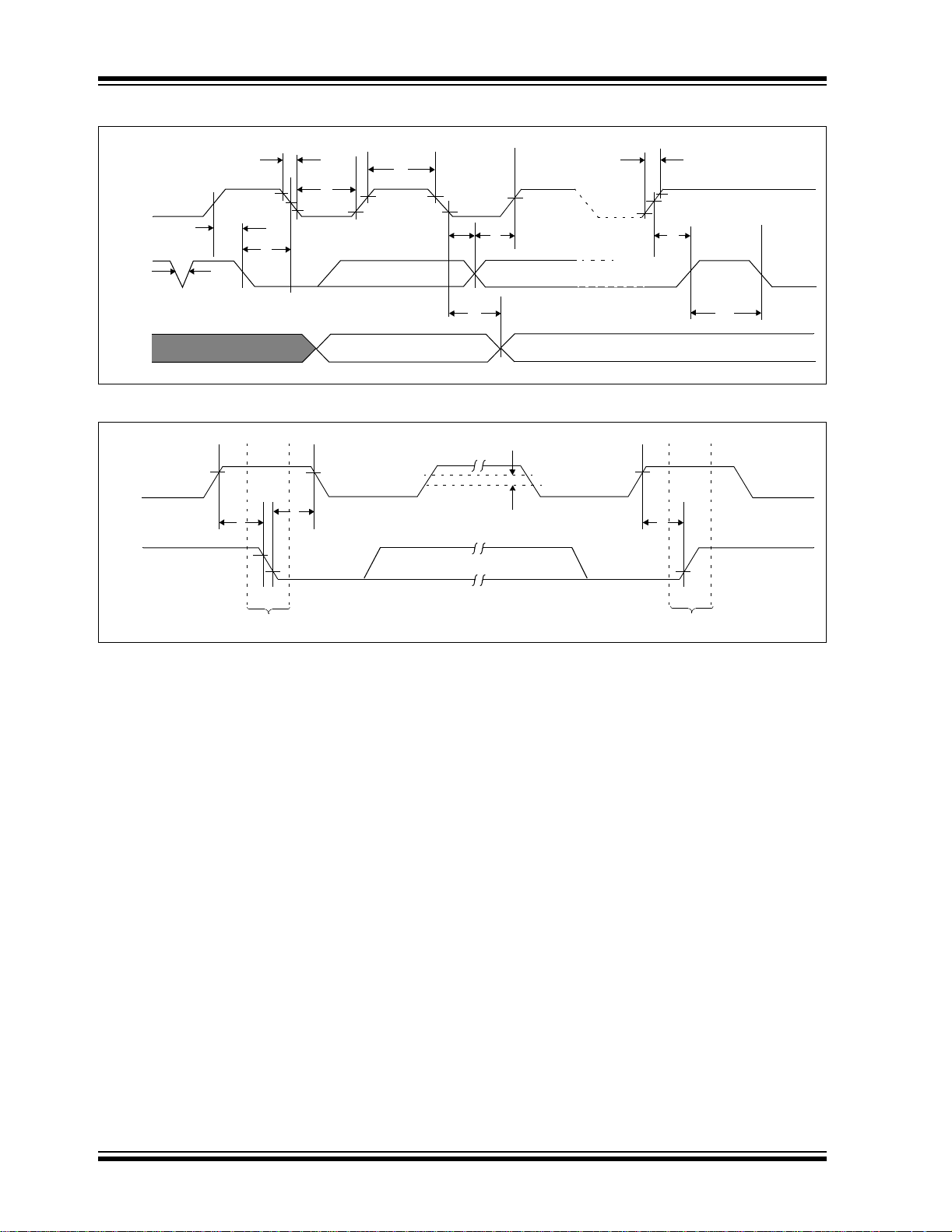

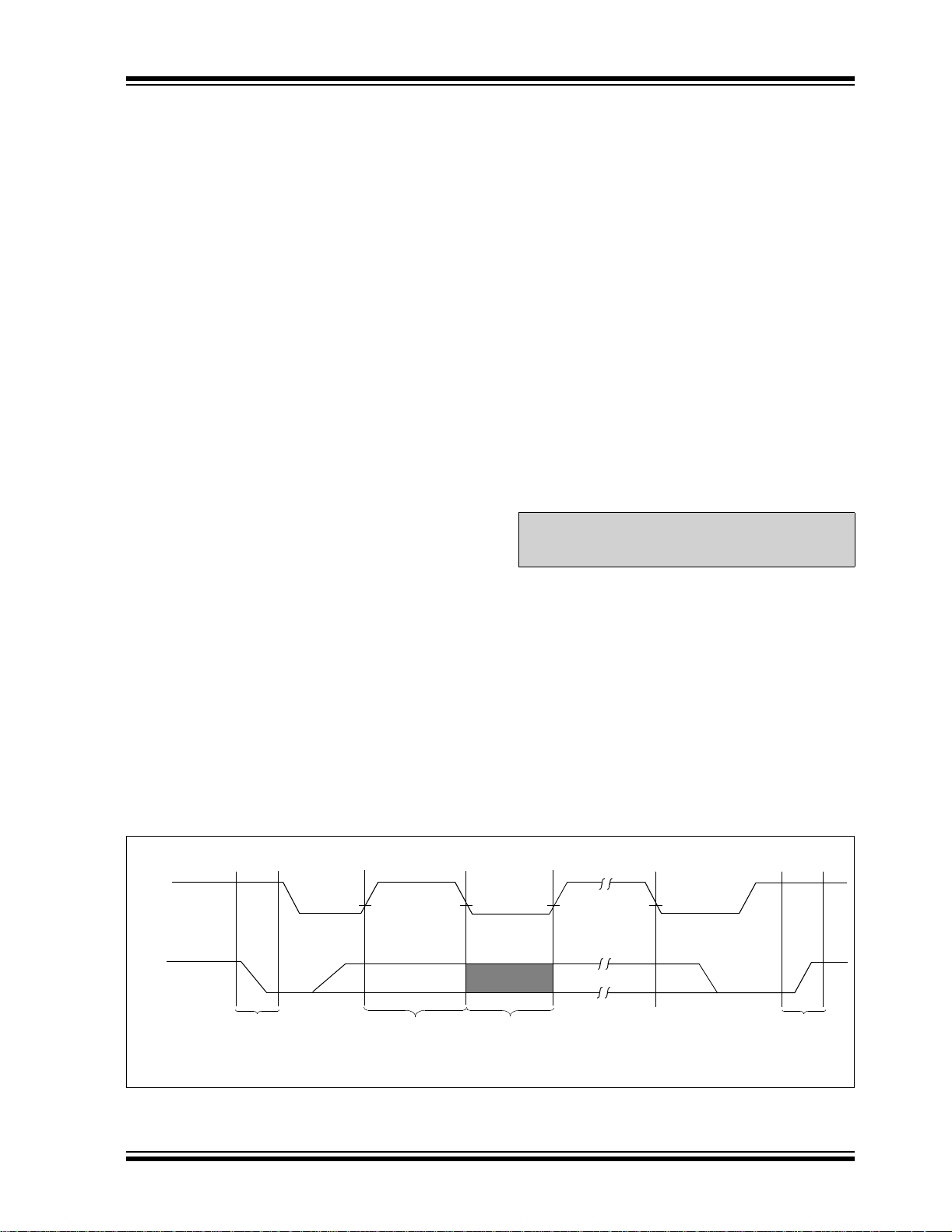

FIGURE 1-1: BUS TIMING DATA

SCL

SDA

IN

SDA

OUT

5

3

7

6

14

2

FIGURE 1-2: BUS TIMING START/STOP

SCL

7

SDA

6

4

8

9

11

D4

10

12

10

Start Stop

DS21708E-page 4 © 2005 Microchip Technology Inc.

Page 5

24AA04/24LC04B

2.0 FUNCTIONAL DESCRIPTION

The 24XX04 supports a bidirectional, 2-wire bus and

data transmission protocol. A device that sends data

onto the bus i s defined as t ransmitter, while a de vice

receiving data is defined as a receiver. The bus has to

be controlled by a master device which generates the

Serial Clock (SCL), controls the bus access and

generates the Start and Stop conditions, while the

24XX04 works as slave. Both master and slave can

operate as transmitter or receiver, but the master

device determines which mode is activated.

3.0 BUS CHARACTERISTICS

The following bus protocol has been defined:

• Data transfer may be initiated only when the bus

is not busy.

• During data transfer, the data line must remain

stable wheneve r the c lock lin e is high . Changes i n

the data line while the clock line is high will be

interpreted as a Start or Stop condition.

Accordingly, the following bus conditions have been

defined (Figure 3-1).

3.1 Bus Not Busy (A)

Both data and clock lines remain high.

3.2 Start Data Transfer (B)

A high-to-low transition of the SDA line while the clock

(SCL) is high determines a Start condition. All

commands must be preceded by a Start condition.

3.3 Stop Data Transfer (C)

A low-to-high transition of the SDA line while the clock

(SCL) is high determines a Stop condition. All

operations must be ended with a Stop condition.

3.4 Data Valid (D)

The state of the data line represents valid data when,

after a Start condition, the data line is stable for the

duration of the high period of the clock signal.

The data on the line must be changed during the low

period of the clock signal. There is one clock pulse per

bit of data.

Each data transfer is initiated with a S tart condition and

terminated with a Stop condition. The number of data

bytes transferred between Start and Stop conditions is

determined by the master device and is, theoretically,

unlimited (although only the last sixteen will be stored

when doing a write operation). When an overwrite does

occur, it will replace data in a first-in first-out (FIFO)

fashion.

3.5 Acknowledge

Each receiving device, when addressed, is obliged to

generate an acknowledge after the reception of each

byte. The ma ster devi ce m ust gener at e an ex tr a cloc k

pulse which is associated with this Acknowledge bit.

Note: The 24XX04 does not generate any

Acknowledge bits if an internal

programming cycle is in progress.

The device that acknowledges has to pull down the

SDA line during the ackn owledge clock pulse in such a

way that the SDA line is stable low during the high

period of the acknowledge related clock pulse. Of

course, setup and hold times must be taken into

account. During reads, a master must signal an end of

data to the sla ve by no t gene rating a n Ack nowl edge b it

on the last byte that has be en c loc ke d ou t of th e sl av e.

In this case, the sl ave (24 XX04) will leave the data lin e

high to enable the master to generate the Stop

condition.

FIGURE 3-1: DATA TRANSFER SEQUENCE ON THE SERIAL BUS

SCL

SDA

© 2005 Microchip Technology Inc. DS21708E-page 5

(A) (B) (D) (D) (A)(C)

Start

Condition

Address or

Acknowledge

Valid

Data

Allowed

to Change

Stop

Condition

Page 6

24AA04/24LC04B

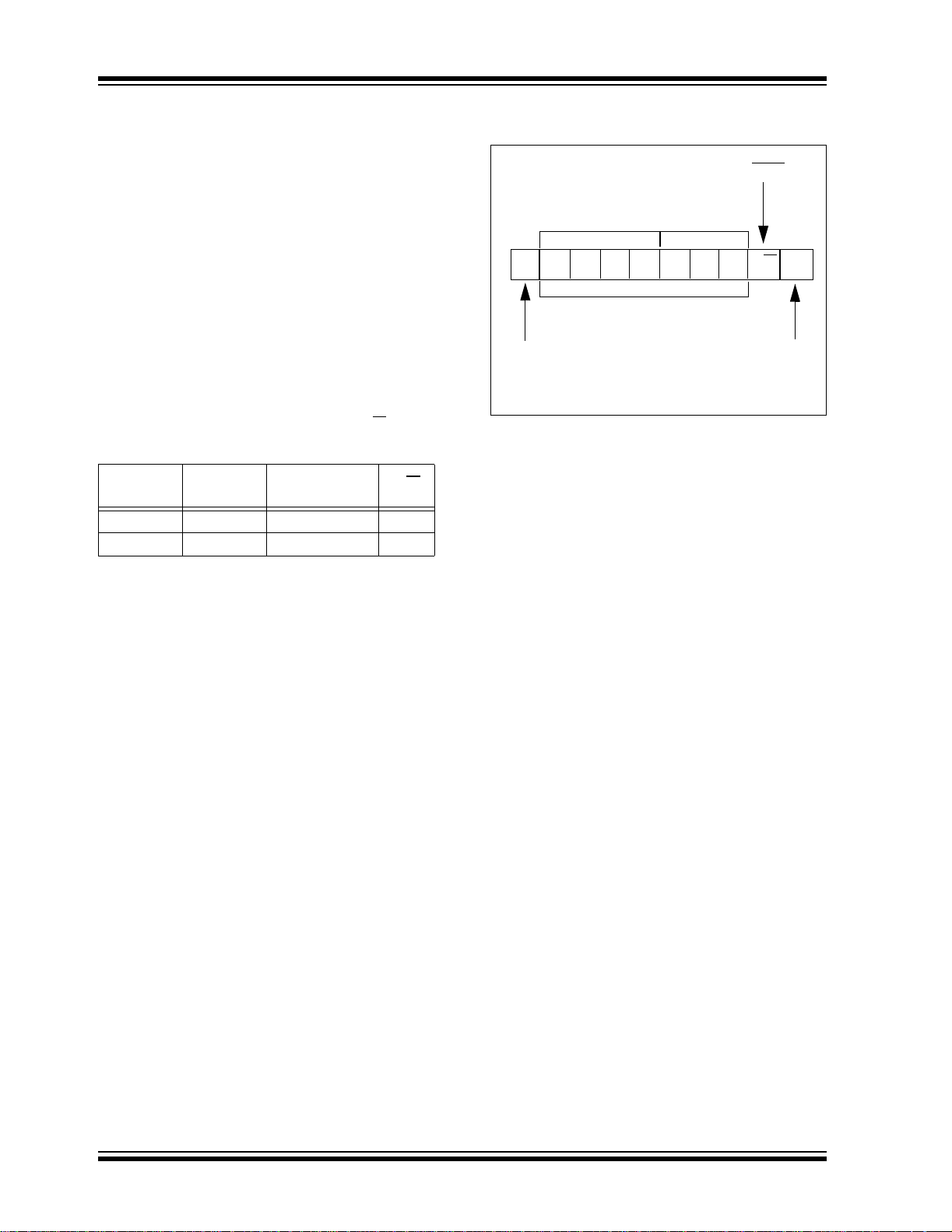

3.6 Device Addressi ng

A control byte is the first byte received following the

Star t condition from the m aster devi ce. The co ntrol byte

consists of a four-bit control code . For the 24XX04, thi s

is set as ‘

The next two bit s of the control by te are “don’t care s” for

the 24XX04. The last bit, B0, is used by the master

device to select which of the two 256-word blocks of

memory are to be accessed. This bit is, in effect, the

Most Significant bit of the word address.

The last bit of the control byte defines the operation to

be performed. When set to ‘

selected. When set to ‘

Following the Start condition, the 24XX04 monitors the

SDA bus checking the device type identifier being

transmitted and, upon receiving a ‘

slave device outputs an Acknowledge signal on the

SDA line. Depending on the state of the R/W bit, the

24XX04 will select a read or write operation.

Operation

1010’ binary for read and write operations.

1’, a read operation is

0’, a write operation is se lecte d.

1010’ code, the

Read

Write

Control

Code

1010

1010

Block Select R/W

Block Address

Block Address

1

0

FIGURE 3-2: CONTROL BYT E

ALLOCATION

Read/Write

Block

Control Code

10 10

S

Start Bit

x = “don’t care”

Slave Address

Select

Bits

xxB0

Acknowledge Bit

R/W

Bit

ACK

DS21708E-page 6 © 2005 Microchip Technology Inc.

Page 7

24AA04/24LC04B

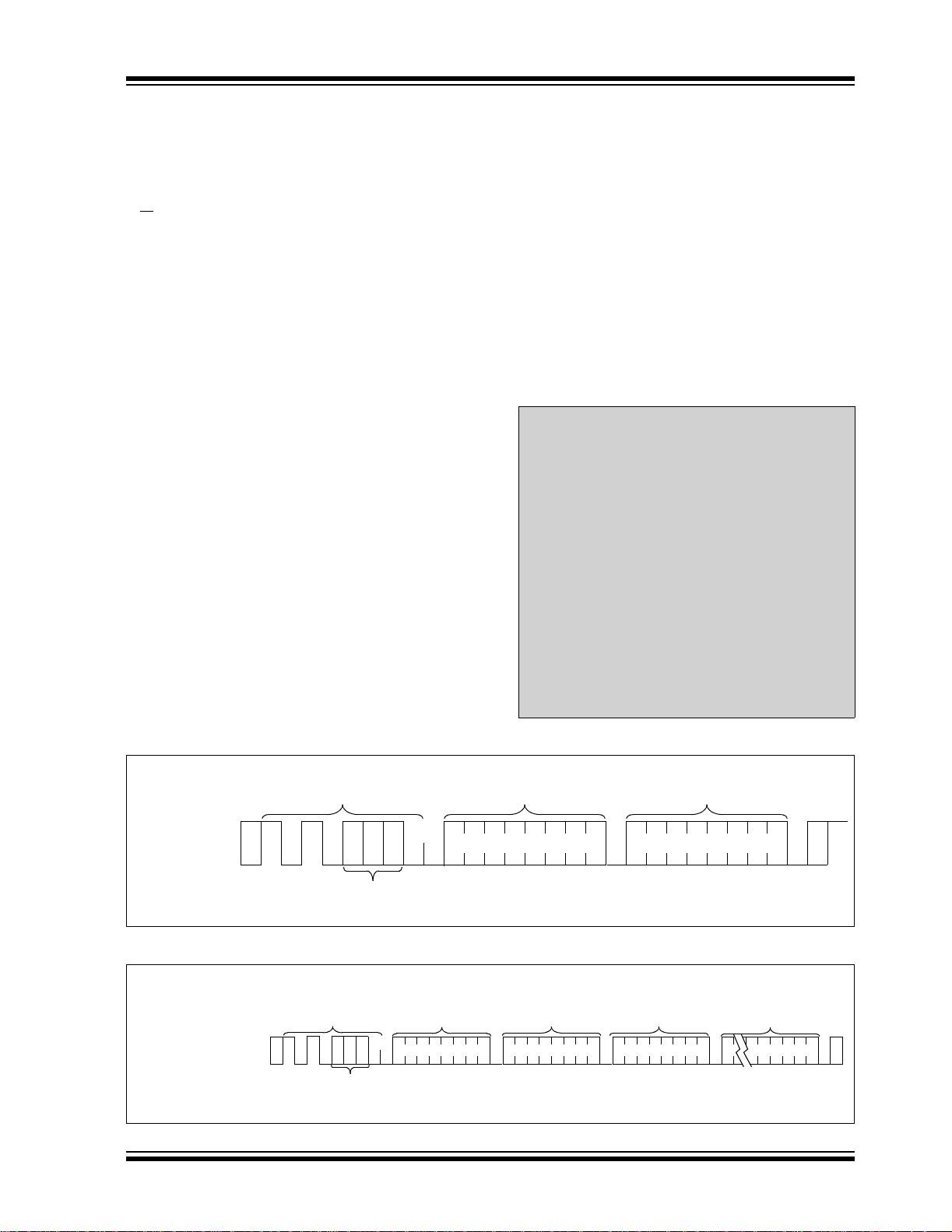

4.0 WRITE OPERATION

4.1 Byte Write

Following the Start condition from the master, the

device code (4 bits), the block address (3 bits) and the

R/W bit, which is a logic low, is placed onto the bus by

the master transmitter. This indicates to the addressed

slave receiver that a byte with a word address will

follow once it has generated an Acknowledge b it during

the ninth clock cycl e. Therefore, th e next byte trans mitted by the master is the word address and will be

written into the Address Pointer of the 24XX04. After

receiving another Acknowledge signal from the

24XX04, the master device will transmit the data word

to be written into the addressed memory location. The

24XX04 acknowledges again and the master

generates a Stop condition. This initiates the internal

write cycle and, during this time, the 24XX04 will not

generate Acknowledge signals (Figure 4-1).

4.2 Page Wri te

The write control byte, word address and the first data

byte are transmitted to the 24 XX04 in th e same w ay a s

in a byte write. But instead of generating a Stop condition the master transmits up to 16 data bytes to the

24XX04, which are temporarily stored in the on-chip

page buffer and will be written into memory once the

master has transmitted a Stop condition. Upon receipt

of each word, the four lowe r-order Add ress Poi nter bit s

are internally incremented by ‘

bits of the word addres s rem ai n con stant. If the master

should transmit m ore th an 16 words prior to ge neratin g

the Stop condition, the address counter will roll over

and the previously rec eived dat a will be overwritt en. As

with the byte wri te operatio n, once the S t op condi tion is

received an internal write cycle will begin (Figure 4-2).

Note: Page w rite operatio ns are limite d to writin g

bytes within a single physical page

regardless of the number of bytes

actually being written. Physical page

boundaries start at addresses that are

integer multiples of the page buf fer size (or

‘page size’) an d end at addresses that are

integer multiples of [page size – 1]. If a

Page Write command attempts to write

across a physical page boundary, the

result is that the data wraps around to the

beginning of the current page (overwriting

data previously stored there), instead of

being written to the next p age as might be

expected. It is therefore necessary for the

application software to prevent page write

operations that would attempt to cross a

page boundary.

1’. The higher-order 7

FIGURE 4-1: BYTE WRITE

Bus Activity

Master

SDA Line

Bus Activity

S

T

A

R

T

S P

x = “don’t care”

10

Control

Byte

10

x

Block

Select

Bits

Word

Address

x

0

B0

A

C

K

A

C

K

Data

S

T

O

P

A

C

K

FIGURE 4-2: PAGE WRITE

S

T

Bus Activity

Master

SDA Line

Bus Activity

x = “don’t care”

© 2005 Microchip Technology Inc. DS21708E-page 7

Control

A

R

T

S P

1

010

Byte

xx

Block

Select

Bits

B0

0

A

C

K

Word

Address (n)

Data (n) Data (n + 15)

A

C

K

Data (n + 1)

A

C

K

A

C

K

S

T

O

P

A

C

K

Page 8

24AA04/24LC04B

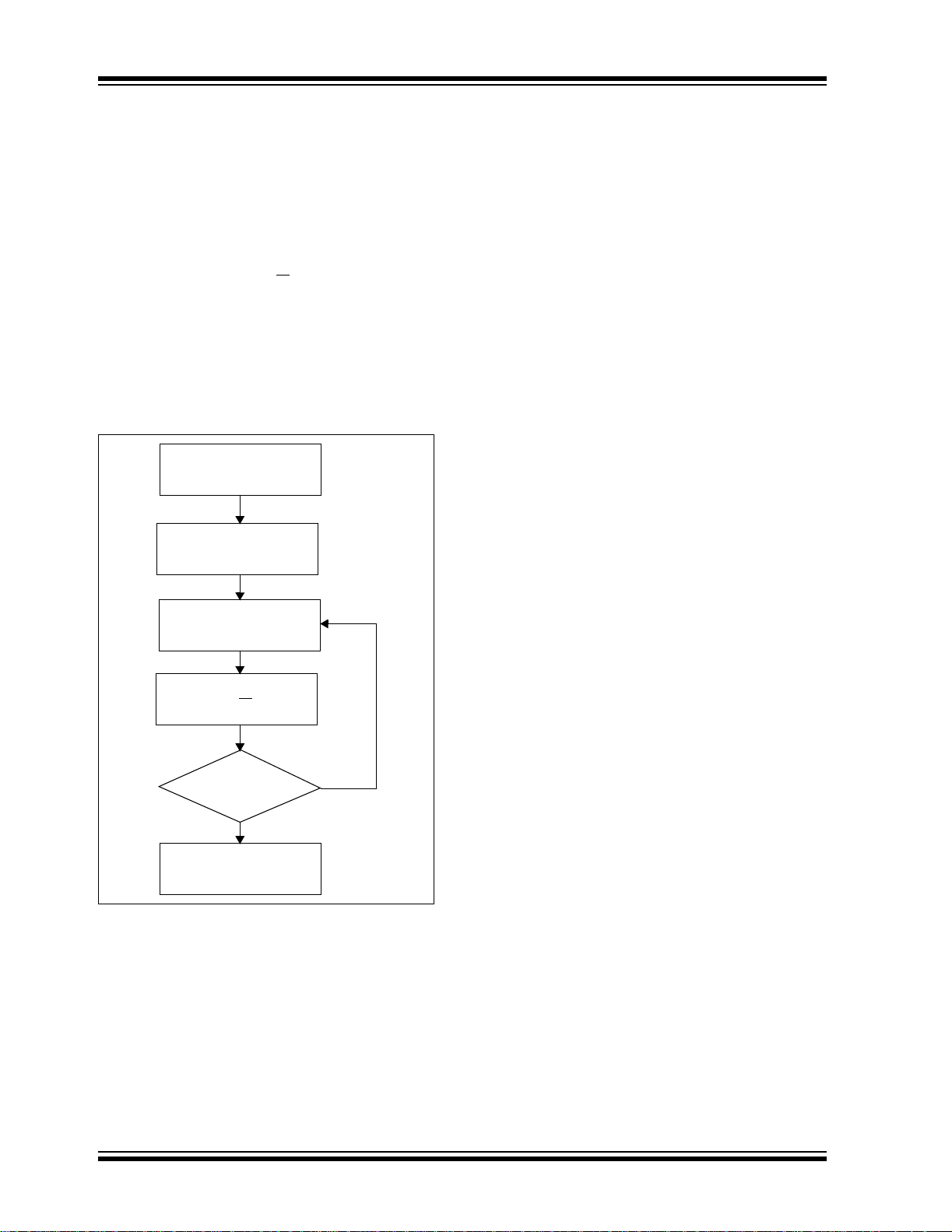

5.0 ACKNOWLEDGE POLLING

Since the device will not acknowledge during a write

cycle, this can be used to determine when the cycle is

complete (this feature can be used to maximize bus

throughput). Once the Stop condition for a Write

command has been issu ed from the mas ter , the device

initiates the int ernally-timed wri te cycle and ACK pol ling

can then be initiated immediately. This involves the

master sending a S tart c ondition fo llowed by the contro l

byte for a Write c ommand (R/W

busy with the write cycle, no ACK will be returned. If the

cycle is complete, the device will return the ACK and

the master can then proceed with the next Read or

Write command. See Figure 5-1 for a flow diagram of

this operation.

FIGURE 5-1: ACKNOWLEDGE POLLING

FLOW

Send

Write Command

Send Stop

Condition to

Initiate Write Cycle

= 0). If the device is still

6.0 WRITE PROTECTION

The WP pin a llows t he user to wri te-prot ect the entire

array (000-1FF) when the pin is tied to V

SS the write protection is disabled.

V

CC. If tied to

Send Start

Send Control Byte

with R/W

Acknowledge

(ACK = 0)?

= 0

Did Device

Yes

Next

Operation

No

DS21708E-page 8 © 2005 Microchip Technology Inc.

Page 9

24AA04/24LC04B

7.0 READ OPERATION

Read operations are initiated in the same way as write

operations, with the exception that the R/W

slave address is set to ‘

1’. There are three basic types

of read operations: current addr ess read , rand om rea d

and sequential read.

7.1 Current Address Read

The 24XX04 contains an address counter that maintains the address of the last word accessed, internally

incremented by ‘

1’. Therefore, if the previous access

(either a read or write opera tio n) w as to address

next current address read operati on would access da ta

from address

with R/W

n + 1. Upon receipt of the sl ave add res s

bit set to ‘1’, the 24XX04 issues an acknowledge and transmits the 8-b it data w ord. The master will

not acknowledge the tra nsfer , but does generate a Stop

condition and the 24XX04 discontinues transmission

(Figure 7-1).

7.2 Random Read

Random read operations allow the master to access

any memory location in a random manner. To perform

this type of read operatio n, th e w ord add ress m us t firs t

be set. This is accomplished by sending the word

address to the 24XX04 as part of a write operation.

Once the word address is sent , the master ge nerates a

Start condition following the acknowledge. This terminates the write operation, but not before the internal

Address Pointer is set. The master then issues the

control byte agai n, but wi th the R /W

24XX04 will then issue an acknowledge and transmit

the 8-bit data word. The master will not acknowledge

the transfer , but does generate a S top con dition and the

24XX04, will discontinue transmission (Figure 7-2).

bit set to a ‘1’. The

bit of the

n, the

7.3 Sequential Read

Sequential reads are initiated in the same way as a

random read, except that once the 24XX04 transmits

the first data byte, the master issues an acknowledge

as opposed to a Stop condition in a random read. This

directs the 24XX04 to transmit the next sequentiallyaddressed 8-bit word (Figure 7-3).

To provide se quential read s, the 24XX04 co ntains an

internal Address Pointer that is incremented by one

upon completion of each operation. This Address

Pointer allows the entire memory contents to be serially

read during one operation.

7.4 Noise Protection

The 24XX04 employs a VCC threshold detector circuit

which disables the internal erase/write logic if the V

is below 1.5V at nominal conditions.

The SCL and SDA inputs have Schmitt Trigger and

filter circuits which suppress noise spikes to assure

proper device operation, even on a noisy bus.

CC

FIGURE 7-1: CURRENT ADDRESS READ

S

Bus Activity

Master

SDA Line

Bus Activity

x = “don’t care”

© 2005 Microchip Technology Inc. DS21708E-page 9

T

A

R

T

1

SP

01

Control

Byte

0

xx

Block

Select

Bits

B0

S

Data (n)

1

A

C

K

T

O

P

N

o

A

C

K

Page 10

24AA04/24LC04B

FIGURE 7-2: RANDOM READ

S

Bus Activity

Master

SDA Line

Bus Activity

x = “don’t care”

T

Control

A

R

T

S P

1010

Byte

Select

xx

Block

Bits

B0

0

FIGURE 7-3 : SEQUENT I AL REA D

Bus Activity

Master

SDA Line

Bus Activity

Control

Byte

Data (n) Data (n + 1) Data (n + 2) Data (n + x)

1

A

C

K

A

C

K

A

C

K

Word

Address (n)

S

T

Control

A

R

T

S

A

C

K

A

C

K

1

01

Byte

0

xx

Block

Select

Bits

B0

Data (n)

1

A

C

K

A

C

K

S

T

O

P

N

o

A

C

K

S

T

O

P

P

N

o

A

C

K

DS21708E-page 10 © 2005 Microchip Technology Inc.

Page 11

24AA04/24LC04B

8.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 8-1.

TABLE 8-1: PIN FUNCTION TABLE

Name PDIP SOIC TSSOP DFN MSOP SOT23 Description

A0 1 1 1 1 1 — Not Connected

A1 2 2 2 2 2 — Not Connected

A2 3 3 3 3 3 — Not Connected

SS 444 4 4 2Ground

V

SDA 5 5 5 5 5 3 Serial Address/Data I/O

SCL666 6 6 1Serial Clock

WP 7 7 7 7 7 5 Write-Protect Input

CC 8 8 8 8 8 4 +1.8V to 5.5V Power Supply

V

8.1 Serial Address/Data Input/Output

(SDA)

SDA is a bidirectional pin used to transfer addresses

and data into and out of the de vice . Sinc e it i s an opendrain terminal, the SDA bus requires a pull-up resistor

CC (typical 10 kΩ for 100 k Hz, 2 kΩ for 400 kHz).

to V

For normal data transfer, SDA is allowed to change

only during SCL low. Changes during SCL high are

reserved for indicating Start and Stop conditions.

8.2 Serial Clock (SCL)

The SCL input is used to sync hro ni ze th e da t a tra ns fer

to and from the device.

8.3 Write-Protect (WP)

The WP pin must be connected to either VSS or VCC.

If tied to V

(read/write the entire memory 000-1FF).

If tied to V

memory will be write-protected. Read operations are

not affected.

This feature allows the user to use the 24XX04 as a

serial ROM when WP is enabled (tied to V

SS, normal memory operation is enabled

CC, write operations are inhibited. The entire

CC).

8.4 A0, A1, A2

The A0, A1 and A2 pins are not used by the 24XX04.

They may be left floating or tied to either V

SS or VCC.

© 2005 Microchip Technology Inc. DS21708E-page 11

Page 12

24AA04/24LC04B

9.0 PACKAGING INFORMATION

9.1 Package Marking Information

8-Lead PDIP (300 mil)

XXXXXXXX

T/XXXNNN

YYWW

8-Lead SOIC (150 mil)

XXXXXXXT

XXXXYYWW

NNN

8-Lead TSSOP

XXXX

TYWW

NNN

Example:

24LC04B

I/P 13F

Example:

SN 0527

Example:

3

e

0527

24LC04BI

3

e

13F

4L04

I527

13F

8-Lead MSOP

XXXXXT

YWWNNN

5-Lead SOT-23

XXNN

8-Lead 2x3 DFN

XXX

YWW

NN

Example:

Example:

M33F

Example:

234

527

13

4L4BI

52713

DS21708E-page 12 © 2005 Microchip Technology Inc.

Page 13

24AA04/24LC04B

l

1st Line Marking Codes

Part Number

24AA04 4A04 4A04T B3NN — 231 —

24LC04B 4L04 4L4BT M3NN N3NN 234 235

Note: T = Temperature grade (I, E)

NN = Alphanumeric traceability code

Legend: XX...X Part number or part number code

Note: For very small packages with no room for the Pb-free JEDEC designator

Note: In the event the full Microchip pa rt numbe r can not be ma rked on one line , it wil

TSSOP MSOP

T Temperature (I, E)

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code (2 characters for small packages)

Pb-free JEDEC designator for Matte Tin (Sn)

3

e

, the marking will only appear on the outer carton or reel label.

3

e

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

I Temp. E Temp. I Temp. E Temp.

SOT-23 DFN

Note: Please visit www.microchip.com/Pbfree for the latest information on Pb-free conversion.

*Standard OTP marking consists of Microchip part number, year code, week code, and traceability code.

© 2005 Microchip Technology Inc. DS21708E-page 13

Page 14

24AA04/24LC04B

8-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

D

2

n

E

β

eB

Number of Pins

Pitch

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

Dimension Limits MIN NOM MAX MIN NOM MAX

1

α

A

c

Units INCHES* MILLIMETERS

n

p

c

α

β

.008 .012 .015 0.20 0.29 0.38

A1

B1

B

88

.100 2.54

51015 51015

51015 51015

A2

L

p

DS21708E-page 14 © 2005 Microchip Technology Inc.

Page 15

8-Lead Plastic Small Outline (SN) – Narrow, 150 mil (SOIC)

E

E1

p

D

2

24AA04/24LC04B

B

Number of Pins

Pitch

Standoff §

Foot Angle

Lead Thickness

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-057

n

45°

c

β

n

p

A1

φ

c

α

β

1

h

A

φ

L

048048

A1

MILLIMETERSINCHES*Units

1.27.050

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.751.551.35.069.061.053AOverall Height

1.551.421.32.061.056.052A2Molded Package Thickness

0.250.180.10.010.007.004

6.206.025.79.244.237.228EOverall Width

3.993.913.71.157.154.146E1Molded Package Width

5.004.904.80.197.193.189DOverall Length

0.510.380.25.020.015.010hChamfer Distance

0.760.620.48.030.025.019LFoot Length

0.250.230.20.010.009.008

0.510.420.33.020.017.013BLead Width

1512015120

1512015120

© 2005 Microchip Technology Inc. DS21708E-page 15

Page 16

24AA04/24LC04B

8-Lead Plastic Thin Shrink Small Outline (ST) – 4.4 mm (TSSOP)

E

E1

p

D

2

n

B

1

A

c

A1

φ

β

Units

A1

n

p

φ

c

α

β

048048

Number of Pins

Pitch

Standoff §

Foot Angle

Lead Thickne ss

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.005” (0.127mm) per side.

JEDEC Equivalent: MO-153

Drawing No. C04-086

L

MILLIMETERS*INCHES

0.65.026

α

A2

MAXNOMMINMAXNOMMINDimension Limits

88

1.10.043AOverall Height

0.950.900.85.037.035.033A2Molded Package Thickness

0.150.100.05.006.004.002

6.506.386.25.256.251.246EOverall Width

4.504.404.30.177.173.169E1Molded Package Width

3.103.002.90.122.118.114DMolded Package Length

0.700.600.50.028.024.020LFoot Length

0.200.150.09.008.006.004

0.300.250.19.012.010.007BLead Width

10501050

10501050

DS21708E-page 16 © 2005 Microchip Technology Inc.

Page 17

8-Lead Plastic Micro Small Outline Package (MS) (MSOP)

E

E1

p

D

2

B

n 1

24AA04/24LC04B

α

A

c

(F)

β

Units

Dimension Limits

Number of Pins

Pitch

Overall Height

Molded Package Thickness

Standoff

Overall Width

Molded Package Width

Overall Length

Foot Length

Foot Angle

Lead Thickness

Lead Width

Mold Draft Angle Top

Mold Draft Angle Bottom

*Controlling Parameter

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not

exceed .010" (0.254mm) per side.

JEDEC Equivalent: MO-187

Drawing No. C04-111

A2

A1

E1

MIN

n

p

A

E

D

L

φ

c

B

α

β

.026 BSC

.030

.000

.193 TYP.

.118 BSC

.118 BSC

.016 .024

.037 REFFFootprint (Reference)

0° - 8°

.003

.009

5°

5° -

L

INCHES

NOM

.033

.006

.012

φ

A1

MAX NOM

8

.043

-.037

.006

-

.031

.009

.016

-

15°

15°

MIN

0.75

0.00

0.40

0.08

0.22

MILLIMETERS*

MAX

8

0.65 BSC

--

0.85

-

4.90 BSC

3.00 BSC

3.00 BSC

0.60

0.95 REF

0°

-

-

-

A2

1.10

0.95

0.15

0.80

8°

0.23

0.40

15°5° 15°5° -

© 2005 Microchip Technology Inc. DS21708E-page 17

Page 18

24AA04/24LC04B

5-Lead Plastic Small Outline Transistor (OT) (SOT-23)

E

E1

p

B

p1

D

n

c

β

Number of Pins

Pitch

Outside lead pitch (basic)

Foot Angle

Lead Thickne ss

Mold Draft Angle Top

Mold Draft Angle Bottom

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MO-178

Drawing No. C04-091

1

A

φ

L

n

p

p1

φ

c

α

β

.038

A1

MILLIMETERSINCHES*Units

0.95

1.90.075

α

A2

MAXNOMMINMAXNOMMINDimension Limits

55

1.451.180.90.057.046.035AOverall Height

1.301.100.90.051.043.035A2Molded Package Thickness

0.150.080.00.006.003.000A1Standoff §

3.002.802.60.118.110.102EOverall Width

1.751.631.50.069.064.059E1Molded Package Width

3.102.952.80.122.116.110DOverall Length

0.550.450.35.022.018.014LFoot Length

10501050

0.200.150.09.008.006.004

0.500.430.35.020.017.014BLead Width

10501050

10501050

DS21708E-page 18 © 2005 Microchip Technology Inc.

Page 19

24AA04/24LC04B

8-Lead Plastic Dual Flat No Lead Package (MC) 2x3x0.9 mm Body (DFN) – Saw Singulated

p

D

b

n

L

PIN 1

ID INDEX

AREA

(NOTE 2)

TOP VIEW

A3

Dimension Limits

Number of Pins

Pitch

Overall Height

Standoff

Contact Thickness

Overall Length

3)

(Note

(Note

3)

Exposed Pad Length

Overall Width

Exposed Pad Width

Contact Width

Contact Length

*Controlling Parameter

Notes:

Package may have one or more exposed tie bars at ends.1.

Pin 1 visual index feature may vary, but must be located within the hatched area.2.

3.

Exposed pad dimensions vary with paddle size.

4. JEDEC equivalent: MO-229

Drawing No. C04-123

E

Units

n

p

A

A1

A3

D

D2

E

E2

b

L

A1

EXPOSED

A

MIN

.031

.000 .001

.055

.047

.008

.012

METAL

PAD

21

D2

BOTTOM VIEW

EXPOSED

TIE BAR

(NOTE 1)

INCHES

NOM

8

.020 BSC

.039

.002

.008 REF.

.079 BSC

-- --

.118 BSC

-- -.010

.016

.064

.071

.012

.020

MINMAX NOM

0.80

0.00

1.39

1.20

0.20

0.30

E2

MILLIMETERS*

8

0.50 BSC

0.90.035

0.02

0.20 REF.

2.00 BSC

3.00 BSC

0.25

0.40

Revised 05/24/04

MAX

1.00

0.05

1.62

1.80

0.30

0.50

© 2005 Microchip Technology Inc. DS21708E-page 19

Page 20

24AA04/24LC04B

APPENDIX A: REVISION HISTORY

Revision C

Corrections to Section 1.0, Electrical Characteristics.

Revision D

Added DFN package.

Revision E

Revised Fig ur e 3 -2 C o nt ro l B yte Al l oc at io n; Fi g ure 4- 1

Byte Write; Figure 4-2 Page Write; Section 6.0 Write

Protection; Figure 7-1 C urrent Address Read ; Figure 72 Random Read; Figure 7-3 Sequential Read.

DS21708E-page 20 © 2005 Microchip Technology Inc.

Page 21

24AA04/24LC04B

THE MICROCHIP WEB SITE

Microchip provides onlin e support v ia our W WW site at

www.m ic roc hi p.c om . Thi s web si te i s us ed as a m ean s

to make files and information easily available to

customers. Accessible by using your favorite Internet

browser, the web site contains the following

information:

• Product Support – Data sheets and errata,

application notes and sample programs, design

resources, user’s guides and hardware support

documents, lat est softwa re releases and archived

software

• General Technical Support – Frequently Asked

Questions (FAQ), technical support requests,

online discussion groups, Microchip consultan t

program member listing

• Business of Microchip – Product selector and

ordering guides, latest Microchip press releases,

listing of s eminars and events, listin gs of

Microchip sales offices, distributors and factory

representatives

CUSTOMER CHANGE NOTIFICATION SERVICE

CUSTOMER SUPPORT

Users of Microchip products can receive assistance

through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor,

representative or field application engineer (FAE) for

support. Local sales offices are also available to help

customers. A listing of sales offices and locations is

included in the back of this document.

T echnic al support is avail able throug h the web si te

at: http://support.microchip.com

Microchip’s customer notification service helps keep

customers current on Microchip products. Subscribers

will receive e-mail notification whenever there are

changes, updates, revisions or errata related to a

specified produ ct family or develo pment tool of inte rest.

To register, access the Microchip web site at

www.microchip.com, click on Customer Change

Notification and follow the registration instructions.

© 2005 Microchip Technology Inc. DS21708E-page 21

Page 22

24AA04/24LC04B

READER RESPONSE

It is our intentio n to pro vi de you with the best documentation possible to ens ure suc c es sfu l u se of y ou r M ic roc hip product. If you wish to provid e your c omment s on org anizatio n, clarity, subject matter, and ways in w hich o ur docum entatio n

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this document.

To:

RE: Reader Response

From:

Application (optional):

Would you like a reply? Y N

Device: Literature Number:

Questions:

1. What are the be st features of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this document easy to follow? If not, why?

Technical Publications Manager

Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________

Total Pages Sent ________

FAX: (______) _________ - _________

DS21708E24AA04/24LC04B

4. What additions to the document do you think would enhance the structure and subject?

5. What deletions from the document could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

DS21708E-page 22 © 2005 Microchip Technology Inc.

Page 23

24AA04/24LC04B

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. X /XX

Device

PackageTemperature

Range

Device: 24AA04: = 1.8V, 4 Kbit I2C Serial EEPROM

Temperature

Range:

Package: MC = 2x3 DFN, 8-lead

Lead Finish: Blank = Pb-free – Matte Tin (see Note 1)

24AA04T: = 1.8V, 4 Kbit I

(Tape and Reel)

24LC04B: = 2.5V, 4 Kbit I

24LC04BT: = 2.5V, 4 Kbit I

(Tape and Reel)

I = -40°C to +85°C

E = -40°C to +125°C

P = Plastic DIP (300 mil body), 8-lead

SN = Plastic SOIC (150 mil body), 8-lead

ST = Plastic TSSOP (4.4 mm), 8-lead

MS = Plastic Micro Small Outline (MSOP), 8-lead

OT = S OT-23, 5-lead (Tape and Reel only)

G = Pb-free – Matte Tin only

2

C Serial EEPROM

2

C Serial EEPROM

2

C Serial EEPROM

X

Lead Finish

Examples:

a) 24AA04-I/P: Industrial Temperature,

1.8V, PDIP package

b) 24AA04-I/SN: Industrial Temperature,

1.8V, SOIC package

c) 24AA04T-I/OT: Industrial Temperature,

1.8V, SOT-23 package, tape and reel

d) 24LC04B-I/P: Industrial Temperature,

2.5V, PDIP package

e) 24LC04B-E/SN: Extended Temperature,

2.5V, SOIC package

f) 24LC04BT-I/OT: Industrial Temperature,

2.5V, SOT-23 package, tape and reel

Note 1: Most products manufactured after January 2005 will have a Matte Tin (Pb-free) finish. Most products manufactured

before January 2005 will have a finish of approximately 63% Sn and 37% Pb (Sn/Pb). Please visit ww w.microchip.com

for the latest information on Pb-free conversion, including conversion date codes.

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

© 2005 Microchip Technology Inc. DS21708E-page23

Page 24

24AA04/24LC04B

NOTES:

DS21708E-page 24 © 2005 Microchip Technology Inc.

Page 25

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are com mitted to continuously improving the code protect ion f eatures of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Mill ennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of M icrochip’s prod ucts as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor,

MPASM, MPLIB, MPLI NK, MPSIM, PICkit , PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, rfLAB, rfPICDEM, Select Mode,

Smart Serial, SmartTel, Total Endurance and WiperLock are

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2005, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

© 2005 Microchip Technology Inc. DS21708E-page 25

Page 26

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-2229-0061

Fax: 91-80-2229-0062

India - New Delhi

Tel: 91-11-5160-8631

Fax: 91-11-5160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 604-646-8870

Fax: 604-646-5086

Philippines - Manila

Tel: 632-634-9065

Fax: 632-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Weis

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-352-30-52

Fax: 34-91-352-11-47

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

08/24/05

DS21708E-page 26 © 2005 Microchip Technology Inc.

Loading...

Loading...