C

查询24AA32供应商

24AA32

2

32K 1.8V I

C

Smart Serial EEPROM

FEATURES

• Voltage operating range: 1.8V to 6.0V

- Peak write current 3 mA at 6.0V

- Maximum read current 150 µ A at 6.0V

- Standby current 1 µ A typical

• Industry standard two-wire bus protocol, I

compatible

- Including 100 kHz (1.8V) and 400 kHz (5V)

modes

• Self-timed ERASE and WRITE cycles

• Power on/off data protection circuitry

• Endurance:

- 10,000,000 Erase/Write (E/W) cycles guaran-

teed for High Endurance Block

- 1,000,000 E/W cycles guaranteed for Stan-

dard Endurance Block

• 8 byte page, or byte modes available

• 1 page x 8 line input cache (64 bytes) for fast write

loads

• Schmitt trigger, filtered inputs for noise suppression

• Output slope control to eliminate ground bounce

• 2 ms typical write cycle time, byte or page

• Factory programming (QTP) available

• Up to 8 devices may be connected to the same

bus for up to 256K bits total memory

• Electrostatic discharge protection > 4000V

• Data retention > 200 years

• 8-pin PDIP/SOIC packages

• Temperature ranges

- Commercial (C): 0 ° C to +70 ° C

2

DESCRIPTION

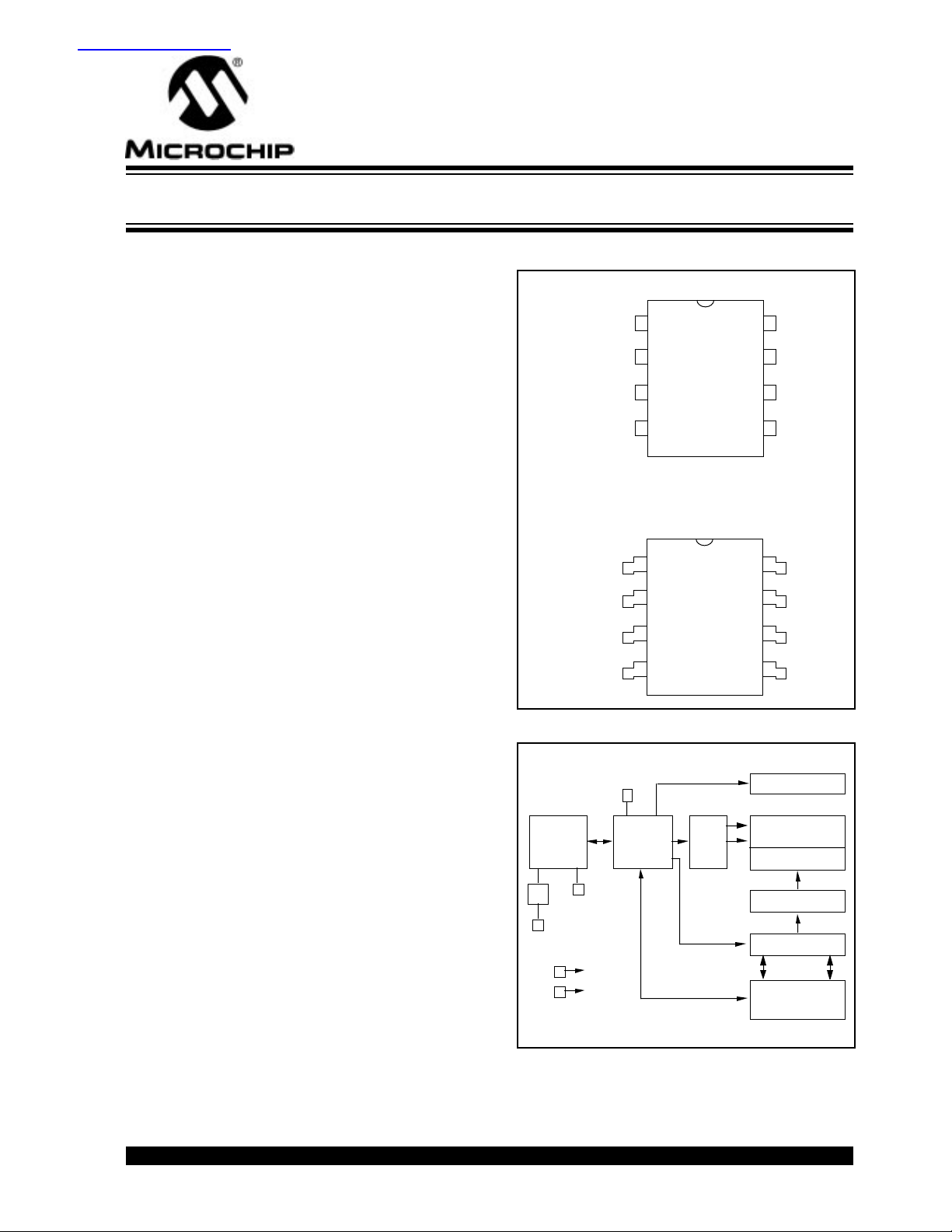

P ACKA GE TYPES

PDIP

A0

1

A1

2

A2

3

V

4

SS

SOIC

A0

A1

A2

V

SS

1

2

3

4

BLOCK DIAGRAM

A0..A2

24AA32

24AA32

8

VCC

7

NC

6

SCL

5

SDA

8

V

CC

7

NC

6

SCL

5

SDA

HV GENERATOR

The Microchip T echnology Inc. 24AA32 is a 4K x 8 (32K

bit) Serial Electrically Erasable PROM capable of operation across a broad voltage range (1.8V to 6.0V). This

device has been developed for advanced, low power

applications such as personal communications or data

acquisition. The 24AA32 features an input cache for

fast write loads with a capacity of eight 8-byte pages, or

64 bytes. It also features a fixed 4K-bit block of ultrahigh endurance memory for data that changes frequently. The 24AA32 is capable of both random and

sequential reads up to the 32K boundary. Functional

address lines allow up to 8 - 24AA32 devices on the

same bus, for up to 256K bits address space. Advanced

CMOS technology and broad voltage range make this

device ideal for low-power/low voltage, nonvolatile code

2

I

C is a trademark of Philips Corporation.

1996 Microchip Technology Inc. DS21124C-page 1

I/O

CONTROL

LOGIC

I/O

SCL

SDA

CC

V

VSS

and data applications. The 24AA32 is available in the

standard 8-pin plastic DIP and 8-pin surface mount

SOIC package.

MEMORY

CONTROL

LOGIC

XDEC

EEPROM ARRAY

PAGE LATCHES

Cache

YDEC

SENSE AMP

R/W CONTROL

24AA32

µ

µ

µ

1.0 ELECTRICAL CHARACTERISTICS

1.1 Maxim

V

CC

..................................................................................7.0V

All inputs and outputs w.r.t. V

Storage temperature..................................... -65˚C to +150˚C

Ambient temp. with power applied................ -65˚C to +125˚C

Soldering temperature of leads (10 seconds)............. +300˚C

ESD protection on all pins ..................................................≥ 4 kV

*Notice: Stresses above those listed under “Maximum Ratings”

may cause permanent damage to the device. This is a stress rating only and functional operation of the device at those or any

other conditions above those indicated in the operational listings

of this specification is not implied. Exposure to maximum rating

conditions for extended periods may affect device reliability.

TABLE 1-2: DC CHARACTERISTICS

A0, A1, A2, SCL and SDA pins:

um Ratings*

SS

...............-0.6V to V

Parameter Symbol Min Max Units Conditions

CC

+1.0V

TABLE 1-1: PIN FUNCTION TABLE

Name Function

A0..A2 User Configurable Chip Selects

V

SS

SDA Serial Address/Data I/O

SCL Serial Clock

V

CC

NC

CC

V

= +1.8V to 6.0V

Commercial (C): Tamb = 0˚C to +70˚C

Industrial (I): Tamb = -40˚C to +85˚C

Ground

+1.8V to 6.0V Power Supply

No Internal Connection

High level input voltage V

Low level input voltage V

Hysteresis of Schmitt Trigger inputs V

Low level output voltage V

Input leakage current I

Output leakage current I

Pin capacitance

(all inputs/outputs)

Operating current I

Standby current I

Note: This parameter is periodically sampled and not 100% tested.

I

CC

CC

IH

IL

HYS

OL

LI

LO

C

IN

C

OUT

Write

Read

CCS

.7 V

CC

— .3 Vcc V

CC

.05 V

— .40 V I

-10 10

-10 10

,

—10pFV

—

—

—5

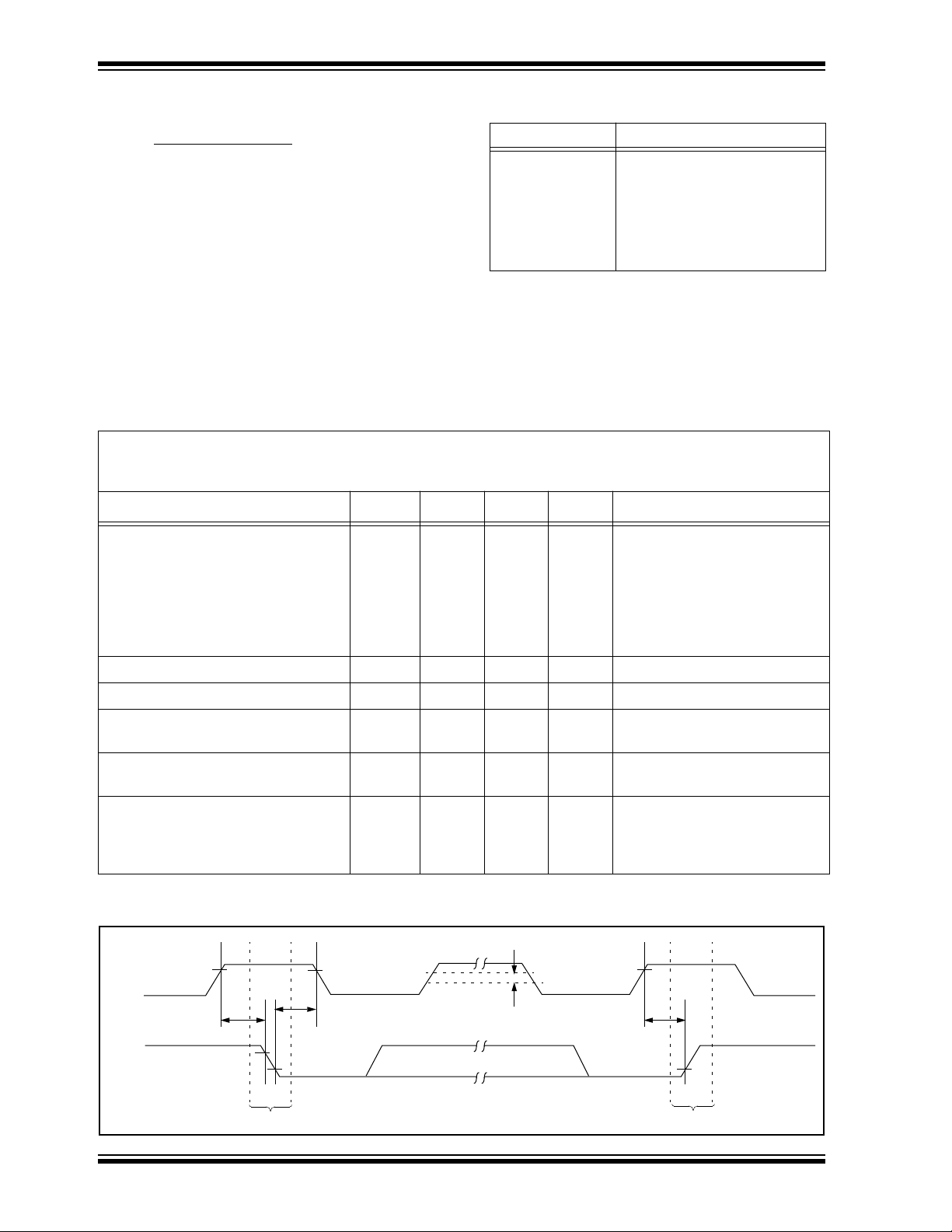

FIGURE 1-1: BUS TIMING START/STOP

SCL

TSU:STA

THD:STA

—V

— V (Note)

OL

IN

AV

OUT

AV

CC

Tamb = 25˚C, Fclk = 1 MHz

3

150

mA

µ

CC

V

CC

A

V

CC

A

V

(Note)

2

µ

A

V

CC

(Note)

VHYS

TSU:STO

= 3.0 mA

= .1V to V

= .1V to V

CC

CC

= 5.0V Note 1

= 6.0V, SCL = 400 kHz

= 6.0V, SCL = 400 kHz

= 5.0V, SCL = SDA = V

= 1.8V, SCL = SDA = V

CC

CC

SDA

DS21124C-page 2

START STOP

1996 Microchip Technology Inc.

24AA32

TABLE 1-3: AC CHARACTERISTICS

V

CC

= 1.8V-6.0V

Parameter Symbol

STD. MODE

Min Max Min Max

Clock frequency F

Clock high time T

Clock low time T

SDA and SCL rise time T

SDA and SCL fall time T

START condition hold time T

START condition setup time T

Data input hold time T

Data input setup time T

STOP condition setup time T

Output valid from clock T

Bus free time T

Output fall time from V

IL

max

V

IH

min to

Input filter spike suppression

HIGH

HD

SU

HD

SU

SU

T

T

CLK

LOW

R

F

:

STA

:

STA

:

DAT

:

DAT

:

STO

AA

BUF

OF

SP

— 100 — 400 kHz

4000 — 600 — ns

4700 — 1300 — ns

— 1000 — 300 ns (Note 1)

— 300 — 300 ns (Note1)

4000 — 600 — ns After this period the first

4700 — 600 — ns Only relevant for repeated

0—0—ns

250 — 100 — ns

4000 — 600 — ns

— 3500 — 900 ns (Note 2)

4700 — 1300 — ns Time the bus must be free

— 250 20 +0.1

— 50 — 50 ns (Note 3)

(SDA and SCL pins)

Write cycle time T

WR

— 5 — 5 ms/page (Note 4)

Endurance

High Endurance Block

Rest of Array

Note 1: Not 100% tested. C

—

—

B

= total capacitance of one bus line in pF.

10M

1M

—

—

2: As a transmitter, the device must provide an internal minimum delay time to bridge the undefined region

(minimum 300 ns) of the falling edge of SCL to avoid unintended generation of START or STOP conditions.

3: The combined T

and V

SP

specifications are due to new Schmitt trigger inputs which provide improved

HYS

noise and spike suppression. This eliminates the need for a Ti specification for standard operation.

4: The times shown are for a single page of 8 bytes. Multiply by the number of pages loaded into the write

cache for total time.

5: This parameter is not tested but guaranteed by characterization. For endurance estimates in a specific appli-

cation, please consult the Total Endurance Model which can be obtained on our BBS or website.

CC

V

= 4.5 - 6.0V

FAST MODE

B

C

10M

1M

Units Remarks

clock pulse is generated

START condition

before a new transmission

can start

250 ns (Note 1), C

—

cycles 25

—

C, Vcc = 5.0V, Block

Cycle Mode (Note 5)

B

≤

100 pF

°

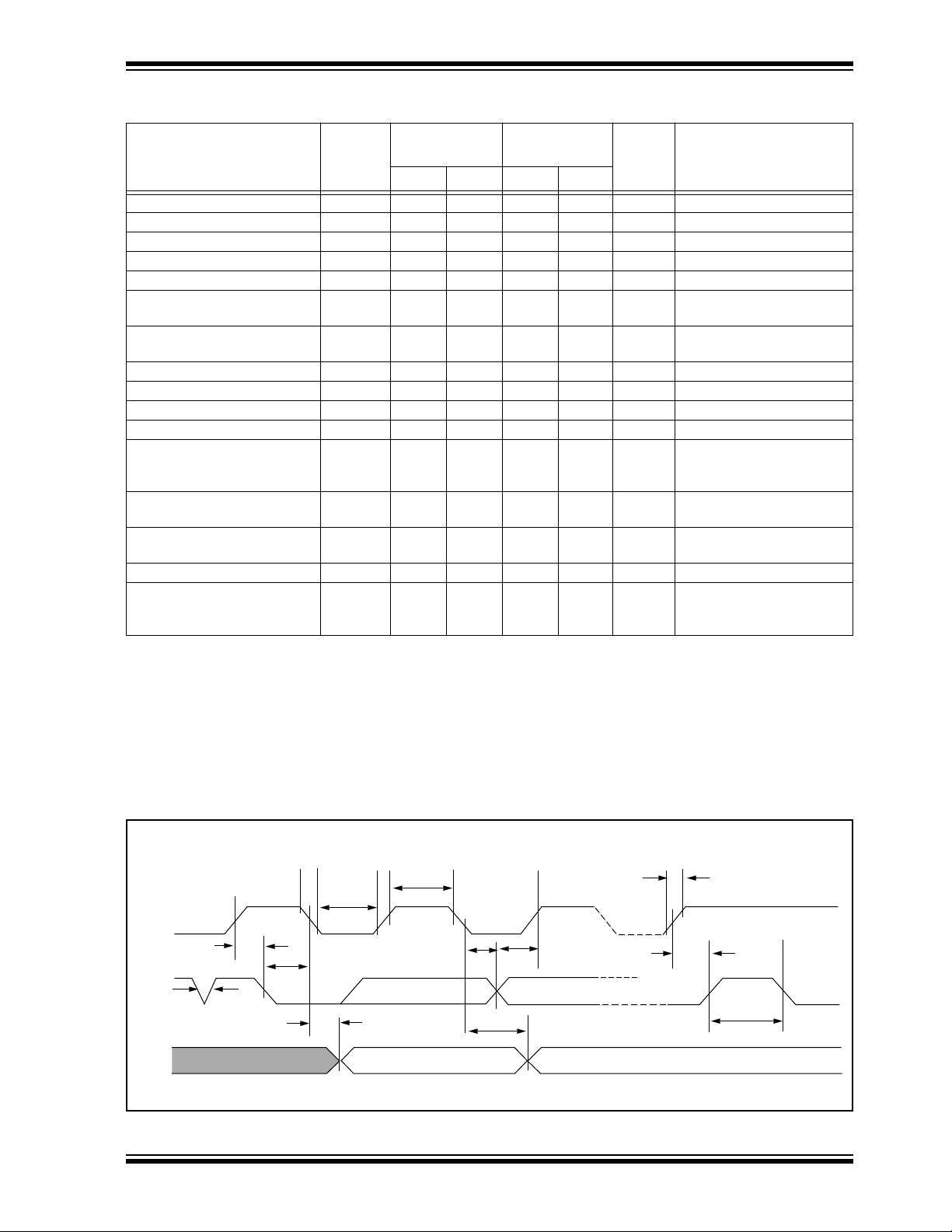

FIGURE 1-2: BUS TIMING DATA

TF

TLOW

SCL

TSU:STA

THD:STA

SDA

IN

SDA

OUT

1996 Microchip Technology Inc. DS21124C-page 3

TSP

TAA

THIGH

THD:DAT

TAA

TSU:DAT

TSU:STO

TR

TBUF

24AA32

2.0 FUNCTIONAL DESCRIPTION

The 24AA32 supports a bidirectional two-wire bus and

data transmission protocol. A device that sends data

onto the bus is defined as transmitter, and a device

receiving data as receiver. The bus must be controlled

by a master device which generates the serial clock

(SCL), controls the bus access, and generates the

START and STOP conditions, while the 24AA32 works

as slave. Both master and slave can operate as transmitter or receiver but the master device determines

which mode is activated.

3.0 BUS CHARACTERISTICS

The following bus protocol has been defined:

• Data transfer may be initiated only when the bus is

not busy.

• During data transfer, the data line must remain

stable whenever the clock line is HIGH. Changes

in the data line while the clock line is HIGH will be

interpreted as a START or STOP condition.

Accordingly, the following bus conditions have been

defined (Figure 3-1).

3.1 Bus not Busy (A)

Both data and clock lines remain HIGH.

3.2 Start Data Transfer (B)

A HIGH to LOW transition of the SDA line while the

clock (SCL) is HIGH determines a STAR T condition. All

commands must be preceded by a START condition.

3.3 Stop Data Transfer (C)

3.4 Data Valid (D)

The state of the data line represents valid data when,

after a START condition, the data line is stable for the

duration of the HIGH period of the clock signal.

The data on the line must be changed during the LOW

period of the clock signal. There is one clock pulse per

bit of data.

Each data transfer is initiated with a START condition

and terminated with a STOP condition. The number of

the data bytes transferred between the START and

STOP conditions is determined by the master device.

3.5 Acknowledge

Each receiving device, when addressed, is obliged to

generate an acknowledge signal after the reception of

each byte. The master device must generate an extra

clock pulse which is associated with this acknowledge

bit.

Note: The 24AA32 does not generate any

acknowledge bits if an internal programming cycle is in progress.

A device that acknowledges must pull down the SDA

line during the acknowledge clock pulse in such a way

that the SDA line is stable LOW during the HIGH period

of the acknowledge related clock pulse. Of course,

setup and hold times must be taken into account. During reads, a master must signal an end of data to the

slave by NOT generating an acknowledge bit on the last

byte that has been clocked out of the slave. In this

case, the slave (24AA32) will leave the data line HIGH

to enable the master to generate the STOP condition.

A LOW to HIGH transition of the SDA line while the

clock (SCL) is HIGH determines a STOP condition. All

operations must be ended with a STOP condition.

FIGURE 3-1: DATA TRANSFER SEQUENCE ON THE SERIAL BUS

(A) (B) (D) (D) (A)(C)

SCL

SDA

START

CONDITION

ADDRESS OR

ACKNOWLEDGE

VALID

DATA

ALLOWED

TO CHANGE

STOP

CONDITION

DS21124C-page 4

1996 Microchip Technology Inc.

24AA32

3.6 De

A control byte is the first byte received following the

start condition from the master device. The control byte

consists of a four bit control code; for the 24AA32 this

is set as 1010 binary for read and write operations. The

next three bits of the control byte are the device select

bits (A2, A1, A0). They are used by the master device

to select which of the eight devices are to be accessed.

These bits are in effect the three most significant bits of

the word address. The last bit of the control byte defines

the operation to be performed. When set to a one a

read operation is selected, and when set to a zero a

write operation is selected. The next two bytes received

define the address of the first data byte (Figure 3-3).

Because only A11...A0 are used, the upper four

address bits must be zeros. The most significant bit of

the most significant byte of the address is transferred

first.

Following the start condition, the 24AA32 monitors the

SDA bus checking the device type identifier being

transmitted. Upon receiving a 1010 code and appropriate device select bits, the slave device outputs an

acknowledge signal on the SDA line. Depending on the

state of the R/W

write operation.

vice Addressing

bit, the 24AA32 will select a read or

FIGURE 3-2: CONTROL BYTE

ALLOCATION

STAR T READ/WRITE

SLAVE ADDRESS

1010A2A1A0

Operation

Read 1010 Device Address 1

Write 1010 Device Address 0

Control

Code

Device Select R/W

R/W A

FIGURE 3-3: ADDRESS SEQUENCE BIT ASSIGNMENTS

CONTROL BYTE

1010

SLAVE

ADDRESS

A2A1A

0

DEVICE

SELECT

BUS

R/W

ADDRESS BYTE 1

0000

A11A10A

ADDRESS BYTE 0

A

9

8

A

•• ••••

7

A

0

1996 Microchip Technology Inc. DS21124C-page 5

24AA32

4.0 WRITE OPERATION

4.1 Split Endurance

The 24AA32 is organized as a continuous 32K block of

memory. However, the first 4K, starting at address 000,

is rated at 10,000,000 E/W cycles guaranteed. The

remainder of the array, 28K bits, is rated at 100,000 E/

W cycles guaranteed. This feature is helpful in applications in which some data change frequently, while a

majority of the data change infrequently. One example

would be a cellular telephone in which last-number

redial and microcontroller scratch pad require a highendurance block, while speed dials and lookup tables

change infrequently and so require only a standard

endurance rating.

4.2 Byte Write

Following the start condition from the master, the control code (four bits), the device select (three bits), and

the R/W

by the master transmitter. This indicates to the

addressed slave receiver that a byte with a word

address will follow after it has generated an acknowledge bit during the ninth clock cycle. Therefore the next

byte transmitted by the master is the high-order byte of

the word address and will be written into the address

pointer of the 24AA32. The next byte is the least significant address byte. After receiving another acknowledge signal from the 24AA32 the master device will

transmit the data word to be written into the addressed

memory location.

bit which is a logic low are clocked onto the bus

The 24AA32 acknowledges again and the master generates a stop condition. This initiates the internal write

cycle, and during this time the 24AA32 will not generate

acknowledge signals (Figure 4-1).

4.3 Page Write

The write control byte, word address and the first data

byte are transmitted to the 24AA32 in the same way as

in a byte write. But instead of generating a stop condition, the master transmits up to eight pages of eight

data bytes each (64 bytes total) which are temporarily

stored in the on-chip page cache of the 24AA32. They

will be written from cache into the EEPROM array after

the master has transmitted a stop condition. After the

receipt of each word, the six lower order address

pointer bits are internally incremented by one. The

higher order seven bits of the word address remain constant. If the master should transmit more than eight

bytes prior to generating the stop condition (writing

across a page boundary), the address counter (lower

three bits) will roll over and the pointer will be incremented to point to the next line in the cache. This can

continue to occur up to eight times or until the cache is

full, at which time a stop condition should be generated

by the master. If a stop condition is not received, the

cache pointer will roll over to the first line (byte 0) of the

cache, and any further data received will overwrite previously captured data. The stop condition can be sent

at any time during the transfer. As with the byte write

operation, once a stop condition is received, an internal

write cycle will begin. The 64-byte cache will continue

to capture data until a stop condition occurs or the operation is aborted (Figure 4-2).

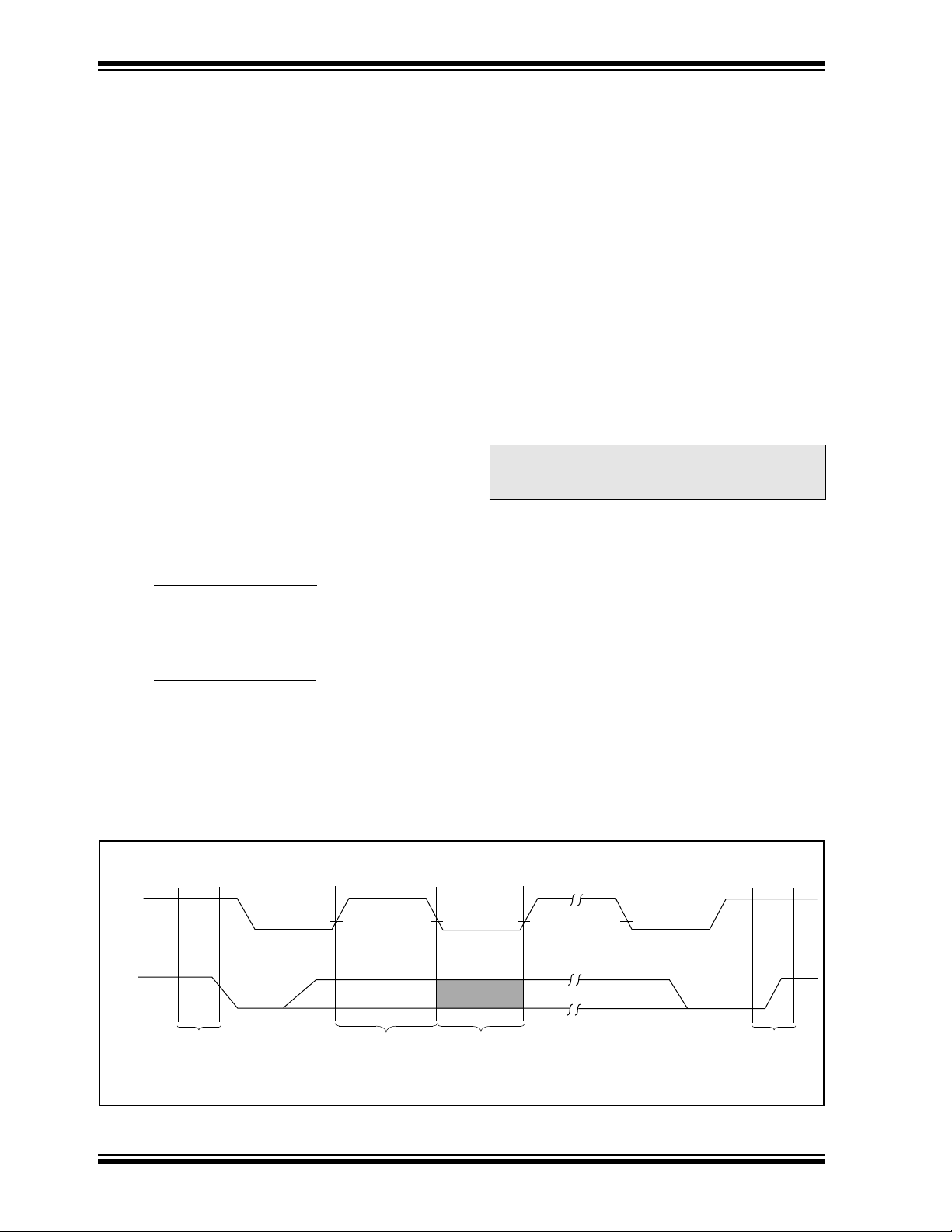

FIGURE 4-1: BYTE WRITE

Bus Activity:

Master

SDA Line

Bus Activity

S

t

a

Control

r

Byte

t

0000

A

C

K

Word

Address (1)

A

C

K

Word

Address (0)

Data

A

C

K

S

t

o

p

A

C

K

FIGURE 4-2: PAGE WRITE (FOR CACHE WRITE, SEE FIGURE 7-1)

S

t

a

Bus Activity:

Master

SDA Line

Bus Activity

DS21124C-page 6 1996 Microchip Technology Inc.

rtControl

Byte

0000

A

C

K

Word

Address (1)

A

C

K

Word

Address (0)

Data n Data n + 15

A

C

K

A

C

K

7

S

t

o

p

A

C

K

24AA32

5.0 ACKNOWLEDGE POLLING

Since the device will not acknowledge during a write

cycle, this can be used to determine when the cycle is

complete (this feature can be used to maximize bus

throughput). Once the stop condition for a write command has been issued from the master, the device initiates the internally timed write cycle. ACK polling can

be initiated immediately. This involves the master sending a start condition followed by the control byte for a

write command (R/W

the write cycle, then no ACK will be returned. If the

cycle is complete, then the device will return the ACK

and the master can then proceed with the next read or

write command. See Figure 5-1 for flow diagram.

FIGURE 5-1: ACKNOWLEDGE POLLING

= 0). If the device is still busy with

FLOW

Send

Write Command

Send Stop

Condition to

Initiate Write Cycle

Send Start

Send Control Byte

with R/W = 0

Did Device

Acknowledge

(ACK = 0)?

No

6.0 READ OPERATION

Read operations are initiated in the same way as write

operations with the exception that the R/W

slave address is set to one. There are three basic types

of read operations: current address read, random read,

and sequential read.

6.1 Current Address Read

The 24AA32 contains an address counter that maintains the address of the last word accessed, internally

incremented by one. Therefore, if the previous access

(either a read or write operation) was to address n (n is

any legal address), the next current address read operation would access data from address n + 1. Upon

receipt of the slave address with R/W

24AA32 issues an acknowledge and transmits the eight

bit data word. The master will not acknowledge the

transfer but does generate a stop condition and the

24AA32 discontinues transmission (Figure 6-1).

6.2 Random Read

Random read operations allow the master to access

any memory location in a random manner. To perform

this type of read operation, first the word address must

be set. This is done by sending the word address to the

24AA32 as part of a write operation (R/W

After the word address is sent, the master generates a

start condition following the acknowledge. This terminates the write operation, but not before the internal

address pointer is set. Then the master issues the control byte again but with the R/W

24AA32 will then issue an acknowledge and transmit

the eight bit data word. The master will not acknowledge the transfer but does generate a stop condition

which causes the 24AA32 to discontinue transmission

(Figure 6-2).

bit set to a one. The

bit of the

bit set to one, the

bit set to 0).

Yes

Next

Operation

FIGURE 6-1: CURRENT ADDRESS READ

S

t

a

Bus Activity:

Master

SDA Line

Bus Activity

1996 Microchip Technology Inc. DS21124C-page 7

Control

r

Byte

t

Data n

A

C

K

S

t

o

p

N

O

A

C

K

24AA32

6.3 Contiguous Addressing Across

Multiple Devices

The device select bits A2, A1, A0 can be used to

expand the contiguous address space for up to 256K

bits by adding up to eight 24AA32's on the same bus.

In this case, software can use A0 of the control byte

as

address bit A12, A1 as address bit A13, and A2 as

address bit A14.

6.4 Sequential Read

Sequential reads are initiated in the same way as a random read except that after the 24AA32 transmits the

first data byte, the master issues an acknowledge as

opposed to the stop condition used in a random read.

This acknowledge directs the 24AA32 to transmit the

next sequentially addressed 8 bit word (Figure 6-3).

Following the final byte transmitted to the master, the

master will NOT generate an acknowledge but will generate a stop condition.

FIGURE 6-2: RANDOM READ

S

T

A

R

T

CONTROL

BYTE

WORD

ADDRESS (1)

To provide sequential reads the 24AA32 contains an

internal address pointer which is incremented by one at

the completion of each operation. This address pointer

allows the entire memory contents to be serially read

during one operation. The address pointer, however,

will not roll over from address 07FF to address 0000. It

will roll from 07FF to unused memory space.

6.5 Noise Protection

The SCL and SDA inputs have filter circuits which suppress noise spikes to ensure proper device operation

even on a noisy bus. All I/O lines incorporate Schmitt

triggers for 400 kHz (Fast Mode) compatibility.

WORD

ADDRESS (0)

S

T

A

R

T

CONTROL

BYTE

DATA n

S

T

O

P

000

SDA LINE

BUS

ACTIVITY:

A

C

K

0

FIGURE 6-3: SEQUENTIAL READ

Bus Activity:

Master

SDA Line

Bus Activity

Control

Byte

A

C

K

A

C

K

A

C

K

A

C

K

N

O

A

C

K

S

t

Data n + 2

A

C

K

A

C

K

A

C

K

Data n + XData n + 1Data n

o

p

N

O

A

C

K

DS21124C-page 8 1996 Microchip Technology Inc.

24AA32

6.6 PAGE CACHE AND ARRAY MAPPING

The cache is a 64 byte (8 pages x 8 bytes) FIFO buffer.

The cache allows the loading of up to 64 bytes of data

before the write cycle is actually begun, effectively providing a 64-byte burst write at the maximum bus rate.

Whenever a write command is initiated, the cache

starts loading and will continue to load until a stop bit is

received to start the internal write cycle. The total length

of the write cycle will depend on how many pages are

loaded into the cache before the stop bit is given. Maximum cycle time for each page is 5 ms. Even if a page

is only partially loaded, it will still require the same cycle

time as a full page. If more than 64 bytes of data are

loaded before the stop bit is given, the address pointer

will 'wrap around' to the beginning of cache page 0 and

existing bytes in the cache will be overwritten. The

device will not respond to any commands while the

write cycle is in progress.

6.7 Cache Write Starting at a Page

Boundary

If a write command begins at a page boundary

(address bits A2, A1 and A0 are zero), then all data

loaded into the cache will be written to the array in

sequential addresses. This includes writing across a 4K

block boundary. In the example shown below,

(Figure 4-2) a write command is initiated starting at

byte 0 of page 3 with a fully loaded cache (64 bytes).

The first byte in the cache is written to byte 0 of page 3

(of the array), with the remaining pages in the cache

written to sequential pages in the array. A write cycle is

executed after each page is written. Since the write

begins at page 3 and 8 pages are loaded into the

cache, the last 3 pages of the cache are written to the

next row in the array.

6.8 Cache Write Starting at a Non-Page

Boundary

When a write command is initiated that does not begin

at a page boundary (i.e., address bits A2, A1 and A0

are not all zero), it is important to note how the data is

loaded into the cache, and how the data in the cache is

written to the array. When a write command begins, the

first byte loaded into the cache is always loaded into

page 0. The byte within page 0 of the cache where the

load begins is determined by the three least significant

address bits (A2, A1, A0) that were sent as part of the

write command. If the write command does not start at

byte 0 of a page and the cache is fully loaded, then the

last byte(s) loaded into the cache will roll around to

page 0 of the cache and fill the remaining empty bytes.

If more than 64 bytes of data are loaded into the cache,

data already loaded will be overwritten. In the example

shown in Figure 7-2, a write command has been initiated starting at byte 2 of page 3 in the array with a fully

loaded cache of 64 bytes. Since the cache started loading at byte 2, the last two bytes loaded into the cache

will'roll over' and be loaded into the first two bytes of

page 0 (of the cache). When the stop bit is sent, page

0 of the cache is written to page 3 of the array. The

remaining pages in the cache are then loaded sequentially to the array. A write cycle is executed after each

page is written. If a partially loaded page in the cache

remains when the STOP bit is sent, only the bytes that

have been loaded will be written to the array.

6.9 Power Management

This design incorporates a power standby mode when

the device is not in use and automatically powers off

after the normal termination of any operation when a

stop bit is received and all internal functions are complete. This includes any error conditions, ie. not receiving an acknowledge or stop condition per the two-wire

bus specification. The device also incorporates V

monitor circuitry to prevent inadvertent writes (data corruption) during low-voltage conditions. The V

tor circuitry is powered off when the device is in standby

mode in order to further reduce power consumption.

DD

DD moni-

7.0 PIN DESCRIPTIONS

7.1 A0, A1, A2 Chip Address Inputs

The A0..A2 inputs are used by the 24AA32 for multiple

device operation and conform to the two-wire bus standard. The levels applied to these pins define the

address block occupied by the device in the address

map. A particular device is selected by transmitting the

corresponding bits (A2, A1, A0) in the control byte

(Figure 3-3).

7.2 SDA Serial Address/Data Input/Output

This is a bidirectional pin used to transfer addresses

and data into and data out of the device. It is an open

drain terminal, therefore the SDA bus requires a pullup

resistor to V

kHz)

For normal data transfer SDA is allowed to change only

during SCL low. Changes during SCL high are

reserved for indicating the START and STOP conditions.

7.3 SCL Serial Clock

This input is used to synchronize the data transfer from

and to the device.

CC (typical 10KΩ for 100 kHz, 1KΩ for 400

1996 Microchip Technology Inc. DS21124C-page 9

24AA32

FIGURE 7-1: CACHE WRITE TO THE ARRAY STARTING AT A PAGE BOUNDARY

1

Write command initiated at byte 0 of page 3 in the array;

First data byte is loaded into the cache byte 0.

cache page 0

2 64 bytes of data are loaded into cache.

cache

byte 0

3

Write from cache into array initiated by STOP bit.

Page 0 of cache written to page 3 of array.

Write cycle is executed after every page is written.

page 0

page 0 page 1 page 2

cache

byte 1

• • •

cache

byte 7

cache page 1

bytes 8-15

cache page 2

bytes 16-23

4 Remaining pages in cache are written

to sequential pages in array.

page 1 page 2 • • • byte 7 • • •

byte 0 byte 1 page 4 page 7

page 4 • • • page 7page 3

5

Last page in cache written to page 2 in next row.

• • •

cache page 7

bytes 56-63

array row n

array row n + 1

FIGURE 7-2: CACHE WRITE TO THE ARRAY STARTING AT A NON-PAGE BOUNDARY

Last 2 bytes

loaded into

page 0 of cache.

3

cache

byte 0

1 Write command initiated; 64 bytes of data

loaded into cache starting at byte 2 of page 0.

cache

byte 1

cache

byte 2

4 Write from cache into array initiated by STOP bit.

Page 0 of cache written to page 3 of array.

Write cycle is executed after every page is written.

• • •

cache

byte 7

cache page 1

bytes 8-15

2 Last 2 bytes loaded 'roll over'

to beginning.

cache page 2

bytes 16-23

• • •

5

Remaining bytes in cache are

written sequentially to array.

cache page 7

bytes 56-63

page 0

page 0

6

page 1 page 2 • • • • • •

page 1 page 2

Last 3 pages in cache written to next row in array.

byte 0 byte 2byte 1

page 4 page 7

byte 7byte 3 byte 4

page 4 • • • page 7page 3

array

row n

array

row

n + 1

DS21124C-page 10 1996 Microchip Technology Inc.

24AA32

24AA32 Product Identification System

To order or to obtain information, e.g., on pricing or delivery, please use the listed part numbers, and refer to the factory or the listed

sales offices.

24AA32 -/P

Package: P = Plastic DIP (300 mil Body), 8-lead

Temperature Blank = 0˚C to +70˚C

Range:

Device: 24AA32 16K I

SN = Plastic SOIC (150 mil Body), 8-lead

2

C Serial EEPROM

2

24AA32T 16K I

C Serial EEPROM (Tape and Reel)

1996 Microchip Technology Inc. DS21124C-page 11

WORLDWIDE SALES & SERVICE

AMERICAS

Corporate Office

Microchip Technology Inc.

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 602 786-7200 Fax: 602 786-7277

Technical Support:

Web:

http://www.microchip.com

Atlanta

Microchip Technology Inc.

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770 640-0034 Fax: 770 640-0307

Boston

Microchip Technology Inc.

5 Mount Royal Avenue

Marlborough, MA 01752

Tel: 508 480-9990 Fax: 508 480-8575

Chicago

Microchip Technology Inc.

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 708 285-0071 Fax: 708 285-0075

Dallas

Microchip Technology Inc.

14651 Dallas Parkway, Suite 816

Dallas, TX 75240-8809

Tel: 972 991-7177 Fax: 972 991-8588

Dayton

Microchip Technology Inc.

Suite 150

Two Prestige Place

Miamisburg, OH 45342

Tel: 513 291-1654 Fax: 513 291-9175

Los Angeles

Microchip Technology Inc.

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 714 263-1888 Fax: 714 263-1338

New Y ork

Microchip Technmgy Inc.

150 Motor Parkway, Suite 416

Hauppauge, NY 11788

Tel: 516 273-5305 Fax: 516 273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408 436-7950 Fax: 408 436-7955

Toronto

Microchip Technology Inc.

5925 Airport Road, Suite 200

Mississauga, Ontario L4V 1W1, Canada

Tel: 905 405-6279 Fax: 905 405-6253

602 786-7627

ASIA/PACIFIC

China

Microchip Technology

Unit 406 of Shanghai Golden Bridge Bldg.

2077 Yan’an Road West, Hongiao District

Shanghai, Peoples Republic of China

Tel: 86 21 6275 5700

Fax: 011 86 21 6275 5060

Hong Kong

Microchip Technology

RM 3801B, Tower Two

Metroplaza

223 Hing Fong Road

Kwai Fong, N.T. Hong Kong

Tel: 852 2 401 1200 Fax: 852 2 401 3431

India

Microchip Technology

No. 6, Legacy, Convent Road

Bangalore 560 025 India

Tel: 91 80 526 3148 Fax: 91 80 559 9840

Korea

Microchip Technology

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku,

Seoul, Korea

Tel: 82 2 554 7200 Fax: 82 2 558 5934

Singapore

Microchip Technology

200 Middle Road

#10-03 Prime Centre

Singapore 188980

Tel: 65 334 8870 Fax: 65 334 8850

Taiwan, R.O.C

Microchip Technology

10F-1C 207

Tung Hua North Road

Taipei, Taiwan, ROC

Tel: 886 2 717 7175 Fax: 886 2 545 0139

EUROPE

United Kingdom

Arizona Microchip Technology Ltd.

Unit 6, The Courtyard

Meadow Bank, Furlong Road

Bourne End, Buckinghamshire SL8 5AJ

Tel: 44 1628 850303 Fax: 44 1628 850178

France

Arizona Microchip Technology SARL

Zone Industrielle de la Bonde

2 Rue du Buisson aux Fraises

91300 Massy - France

Tel: 33 1 69 53 63 20 Fax: 33 1 69 30 90 79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann-Ring 125

D-81739 Muenchen, Germany

Tel: 49 89 627 144 0 Fax: 49 89 627 144 44

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleone Pas Taurus 1

Viale Colleoni 1

20041 Agrate Brianza

Milan Italy

Tel: 39 39 6899939 Fax: 39 39 689 9883

JAPAN

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shin Yokohama

Kohoku-Ku, Y okohama

Kanagawa 222 Japan

Tel: 81 45 471 6166 Fax: 81 45 471 6122

9/3/96

All rights reserved. 1996, Microchip Technology Incorporated, USA. 9/96

Printed on recycled paper.

Information contained in this publication regarding device applications and the like is intended through suggestion only and may be superseded by updates. No representation or warranty is given and no liability is assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement

of patents or other intellectual property rights arising from such use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property rights. The Microchip logo and

name are registered trademarks of Microchip Technology Inc. All rights reserved. All other trademarks mentioned herein are the property of their respective companies.

DS21124C-page 12 1996 Microchip Technology Inc.

Loading...

Loading...