WORKSHOP TECHNICAL MANUAL

MICROCAR

2

INTRODUCTION

This manual has been made to help you in the repairing and maintenance

operations. It contains all the details about the car and the indications for the fitting

and unfitting.

We advice you to read very carefully the paragraphes linked to your interventions.

Our After Sales department stays at your disposal for any further information.

With the aim of improving its models, MICROCAR specifies this whole brochure is not contractual

and keeps the right to change (without warning) its car specifications.

Concept / ATTRAITSGRAPHIC 05 49 71 20 62

3

SUMMARY

Pages

SUPPLYING .................................................... 4

IDENTIFICATION ............................................ 5

LIFTING ........................................................... 5

TECHNICAL CHARACTERISTICS ........... ......6

D...OOR REMOVAL..............................................8

INTERIOR DOOR MAINTENANCE ................... 9

REAR DOOR ......................................... ..........14

FRONT BUMPERS REMOVAL.................. ......19

FRONT WINGS REMOVAL..............................20

DOOR HINGES REMOVAL............................. 22

BONNET REMOVAL ...................................... 22

OPTI .C LIGHTS REMOVAL............................ 22

BACK BUMPERS REMOVAL ........................ 23

HATCHBACK OPENING SWITCH REMOVAL.24

INTERIOR TRIM REMOVAL........................... 25

SAFETY BELT RETRACTOR REMOVAL..... 27

TR .IM ROOF CHANGING............................... 27

D . ASHBOARD REMOVAL............................... 29

R EVERSER LEVER REMOVAL.................... .35

R . EAR QUARTER PANEL REMOVAL........... 36

B ACK WING REMOVAL ................................ 37

WINDSCREEN REMOVAL...............................42

ROOF REMOVAL ........................................... 44

B ..ODY SIDE REMOVAL................................. 46

SOU ..NDPROOFING FLOOR KIT GLUING.... 50

SOUNDPROOFING KIT APRON GLUING..... 51

ABS REPAIRING............................................. 52

ALUMINIUM REPAIRING ............................. 53

FLOOR REPAIRING ...................................... 54

CARPET REPAIRING .................................... 55

Pages

P . AINTING COMPONENTS AND REPAIRING...... ..56

SO UNDPROOFING ENGINE PANEL REMOVAL... 58

TR ANSMISSION REMOVAL.................................... 60

TRANSMISSSION GAITER CHANGING................................ 61

VARIATO R REMOVAL ............................................ 62

RECEPTOR PULLEY REMOVAL............................. 66

RE. VERSER DRIVE AXLE REMOVAL....................... 68

RE ..VERSER DRIVE AXLE BOX REMOVAL............... 71

S TARTER REMOVAL .............................................. 74

ENGINE REMOVAL ................................................. 75

ENGINE CRADLE REMOVAL................................. 76

ENGINE . CRADLE EQUIPEMEMENT...................... 78

BR .AKE PAD REPLACING....................................... 88

FR ONT HUB BEARING REPLACING ..... .............................90

FRON T HUB BEARING REPLACING .................................94

STEERING............................................................... 96

B RAKING SYSTEM BLEEDING ....................... ......99

P ARKING BRAKE REGULATING ....................... 100

BACK EXHAUST ................................................... 101

E LECTRIC SYSTEM ............................................ 102

FUSES ................................................................... 103

LO AD VOLTAGE CONTROL ................................ 104

F RONT WINDSCREEN ......................................... 105

INSTRUMENT ADJUSTMENT .........................107

VENTILATION CONNECTING .............................. 108

ENCLOSED ........................................................... 109

ELECTRIC PLANS

TECHNICAL INFORMATION N° 247

TECHNICAL INFORMATION N° 249

4

SUPPLYING

Engine oil

Box oil

Brake liquid

Coolant

liquid

Windscreen washer

QUANTITIES

1,50 liter

0,50 liter

3 liters

The level in the

radiator must be 1cm

above the radiator fins

1 liter

SUPPLYING TYPE

CERAMIC SYMBOL 5W40

TRANS EPA 80W90

DOT 4 blue ribbon

TRANSFLUID

Windscreen washer IGOL

5

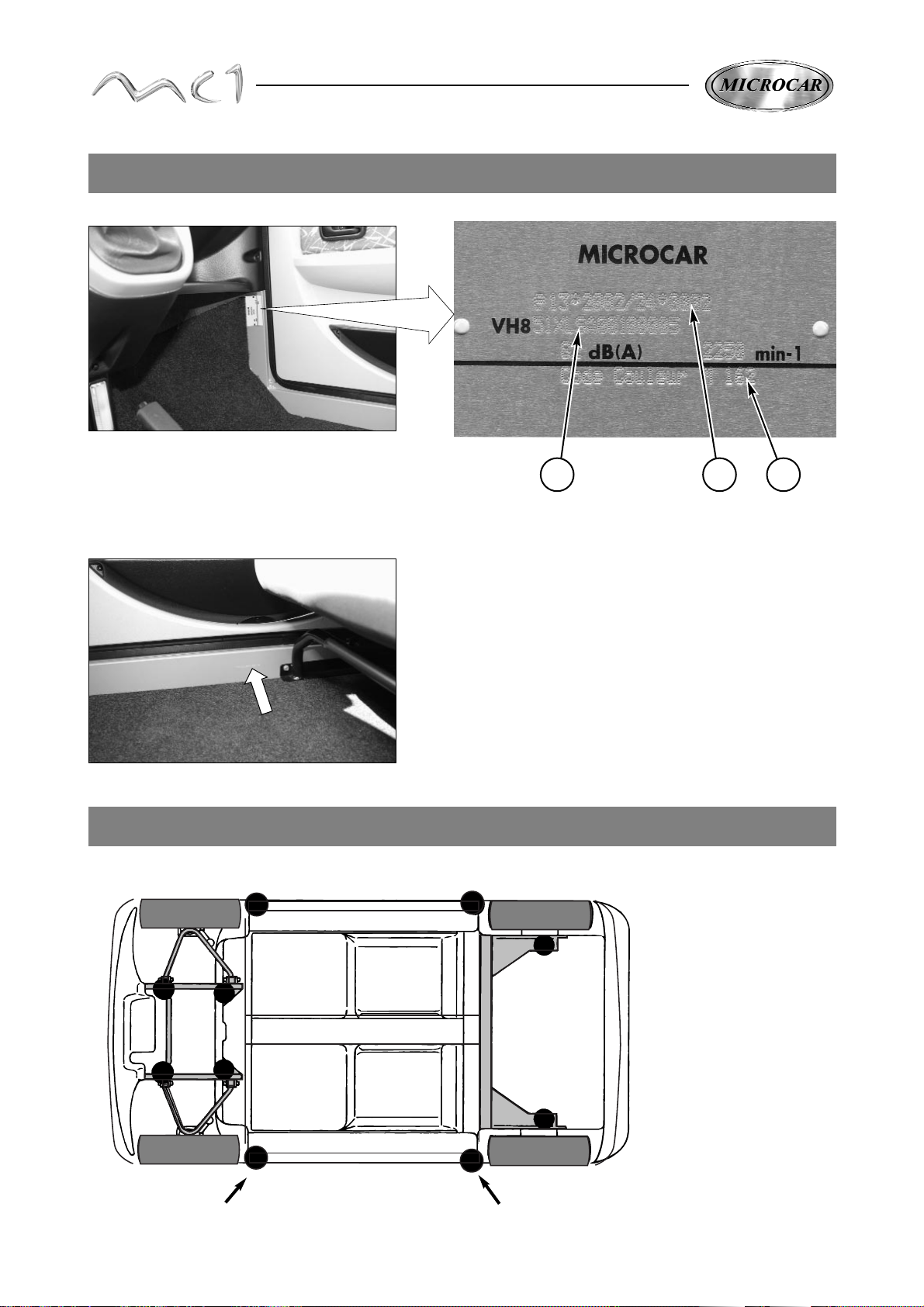

LIFTING

CAR IDENTIFICATION

With a workshop jack, use only the lifting points as shown below.

NOTA : Take care to insert

a wood block between the

jack and the car.

FRONT :

Under the carcase of the body

BACK

Under the carcase of the body

Constructor plate

The constructor plate is situated inside the car

on the front right pillar (under the instrument

panel below the passenger seat).

1-Vin number

2-Homologation number

3-Painting reference number

vin number

The vin number is put on the right side member

near the passenger seat.

1 2 3

6

Engine

Brand ............................................................................ LOMBARDINI

Type ................................................................................ LDW 502/M3

Cycle ............................................................................... Diesel (4 times)

Cubic capacity......................................................................... 505 cm

3

Cylinders ............................................................................. 2 in lines

Coolant ........................................................................... Liquid

Used fuel ......................................................................... Diesel

Feed type ........................................................................ Injection (electric pump)

Fuel tank capacity ........................................................... 16 liters

Electric feed ................................................................... Alternator

Movement transmission

Gearbox with continual variation automatic transmission with reverse and forward gear.

Automatic centrifugal clutch.

Maximum speed authorized.

Suspension

Double action, hydraulic shock absorbers with front and back helical springs

Direction

Direction type : rack (without maintenance)

Steering diameter :8.20m

Braking

Service brake : hydraulic double circuit which acts on front and back wheels

Parking brake : mechanical, it acts on the 2 back wheels

Wheels

Sizes : 145/60R13 65S

Wheels pressure: Front = 1,6 bar.

Back = 1,8 bar.

Body

Carcase in aluminium mechanical soldered profiles

Floor and apron in SANDWIFORM cellular composite panels

ABS trim

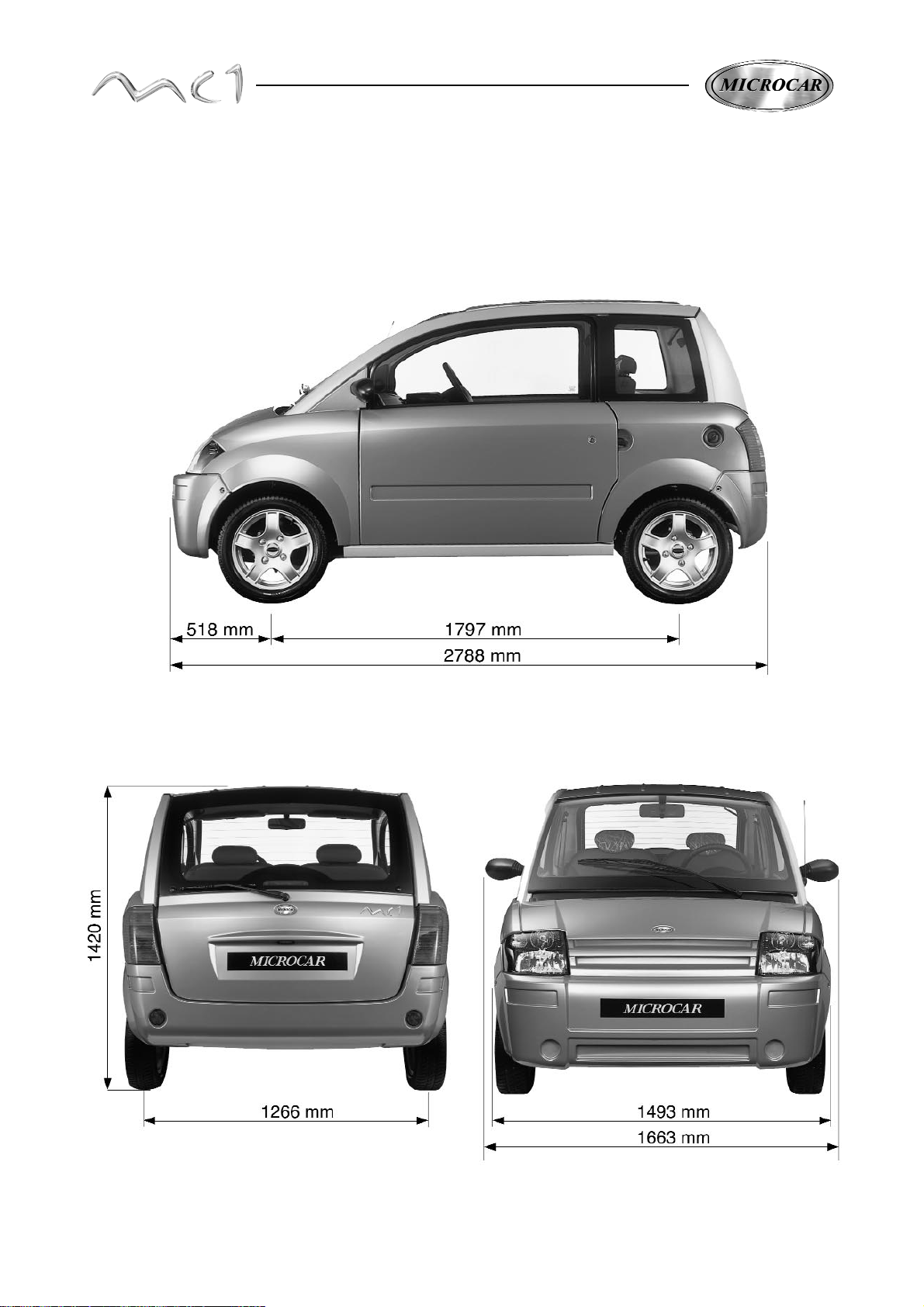

Weight and size

Discharged weight : 348 kg.

Running weight : 400 kg.

Total athorized loaded weight : 620 kg.

TECHNICAL CHARACTERISTICS

7

SIZES : (in mm)

8

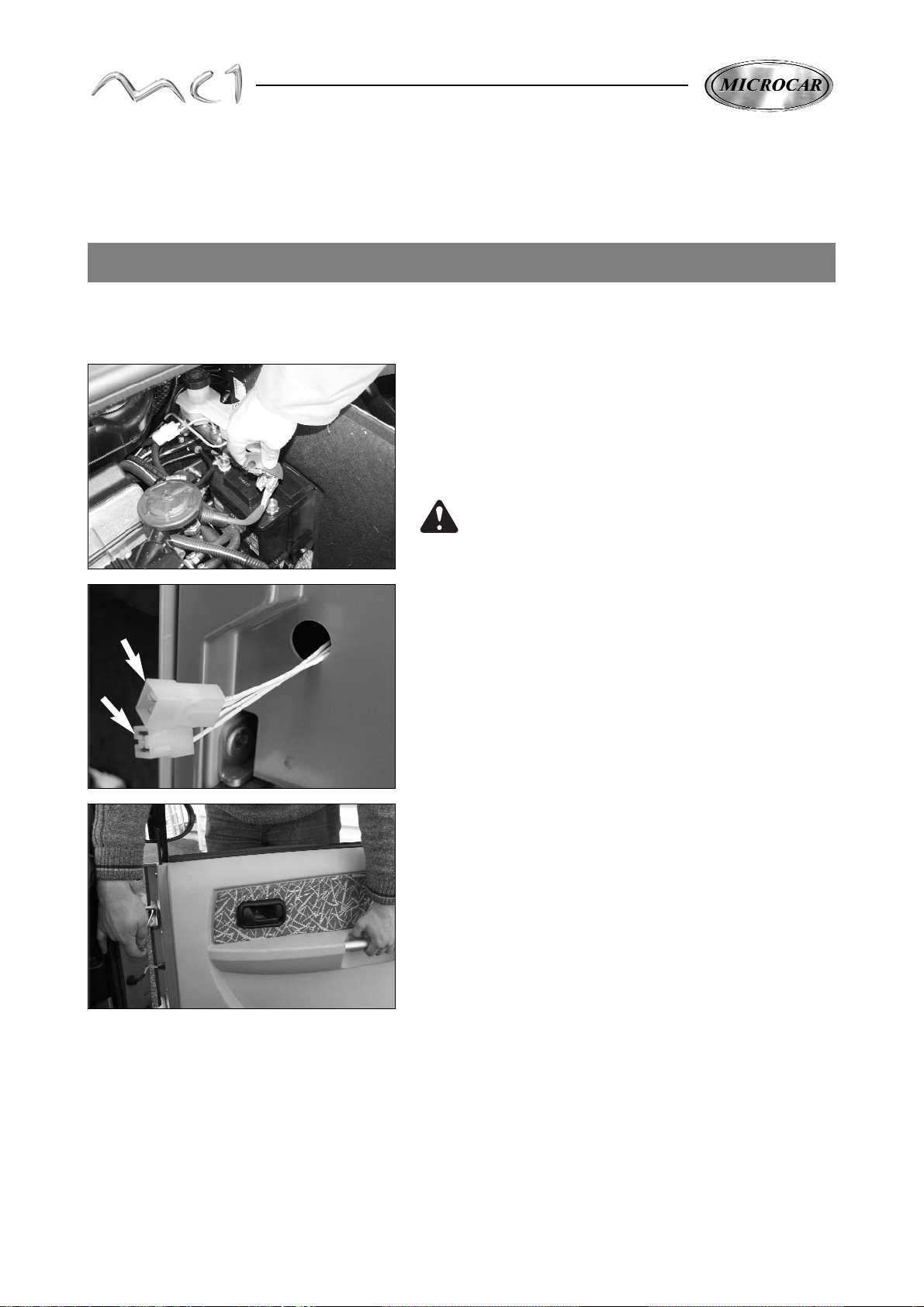

To take out the door, open the bonnet and unplug

the battery using the red speed disconnecting cable terminal

(+).

Take off the ducts of the body pillar, take out and unplug

the 2 connectors of the window winder beam and central locking

✱ .

✱ It depends on the version

DOOR REMOVAL

Hold the door with the handle and put the 2 fixing screws

of the hinges.

(Set screw 7 N/m)

The fitting of the door is made at the reverse from the

removal operations.

Before intervening on any components of the

electric setting, unplug the positive cable (red)

of the battery.

9

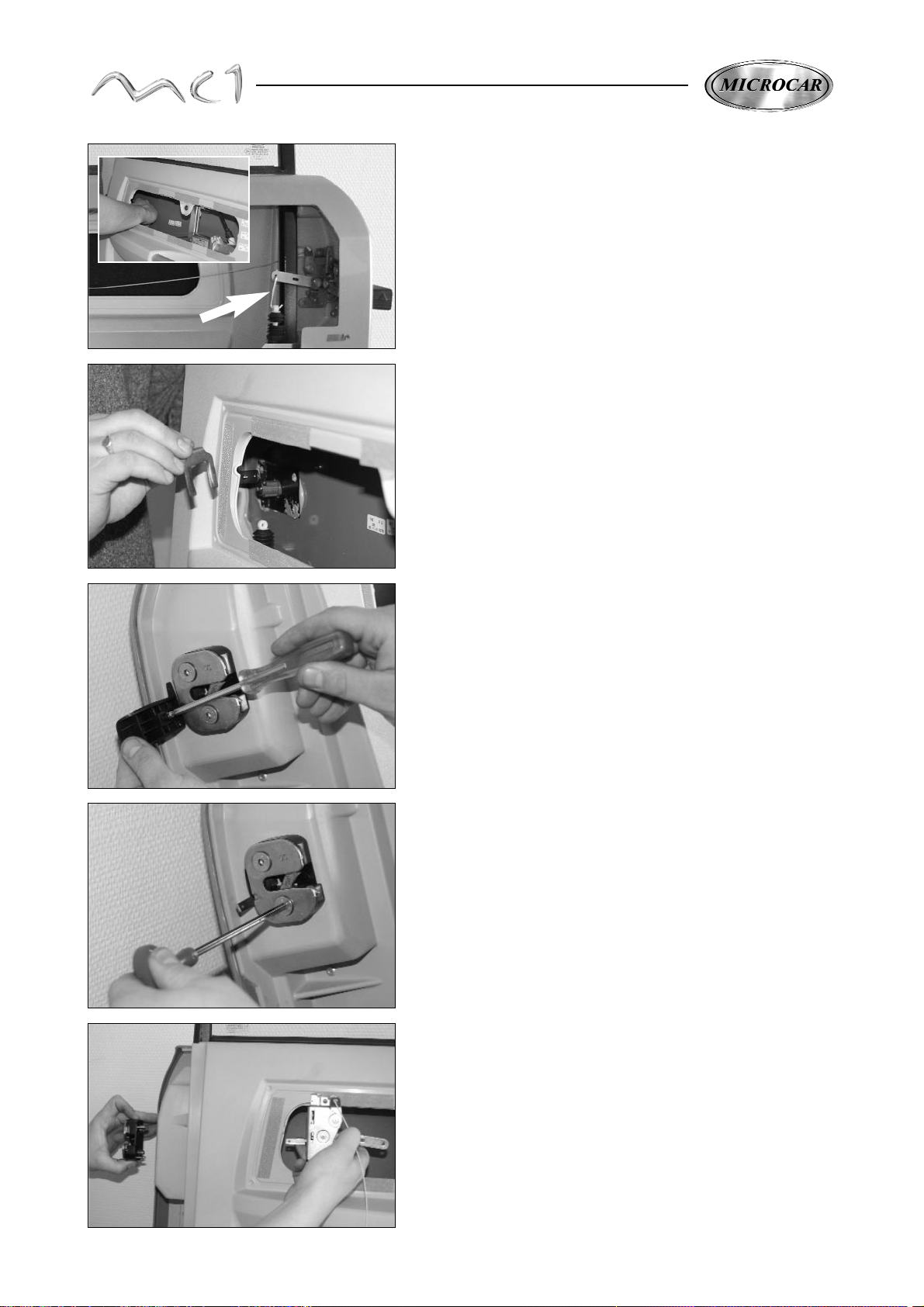

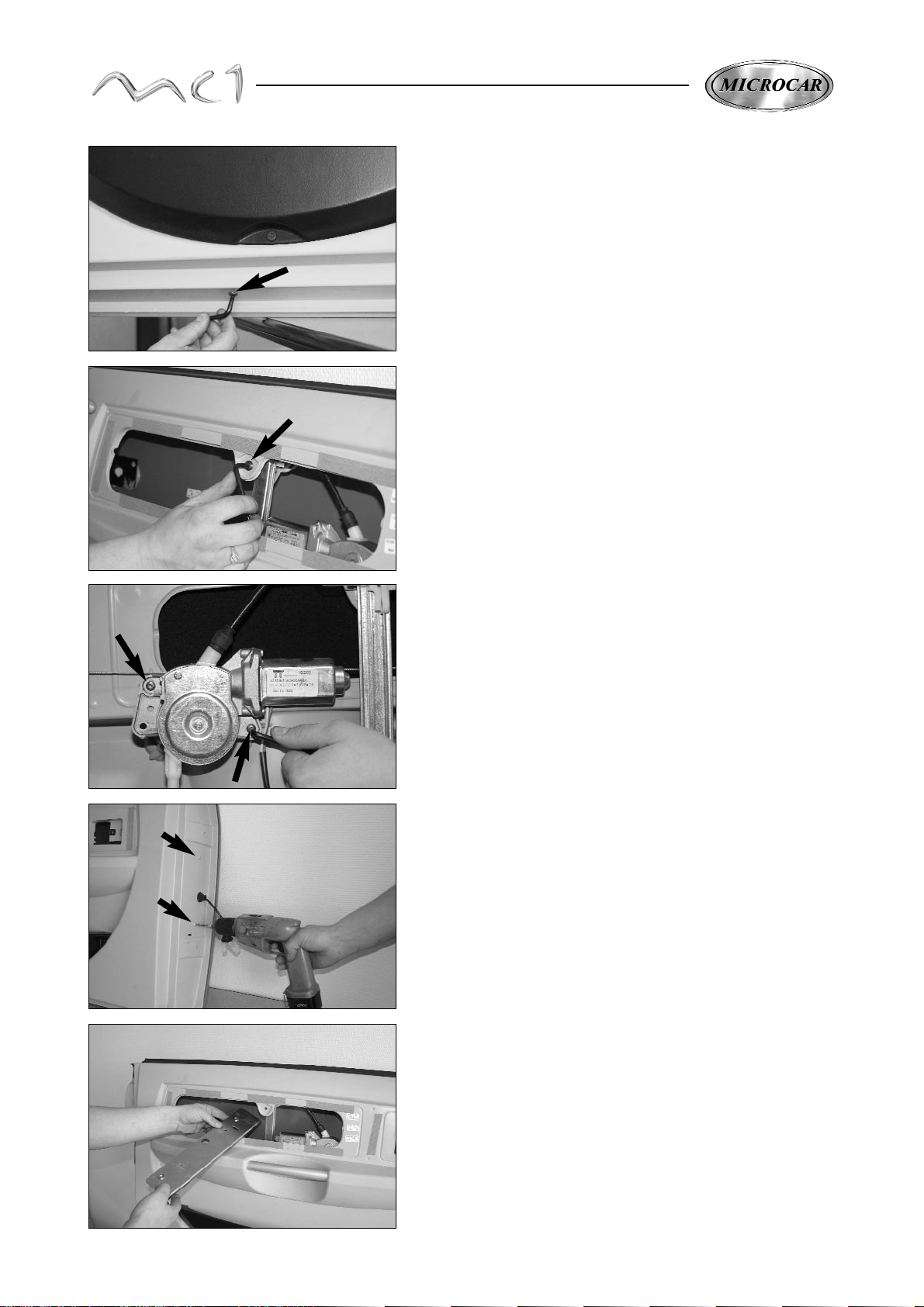

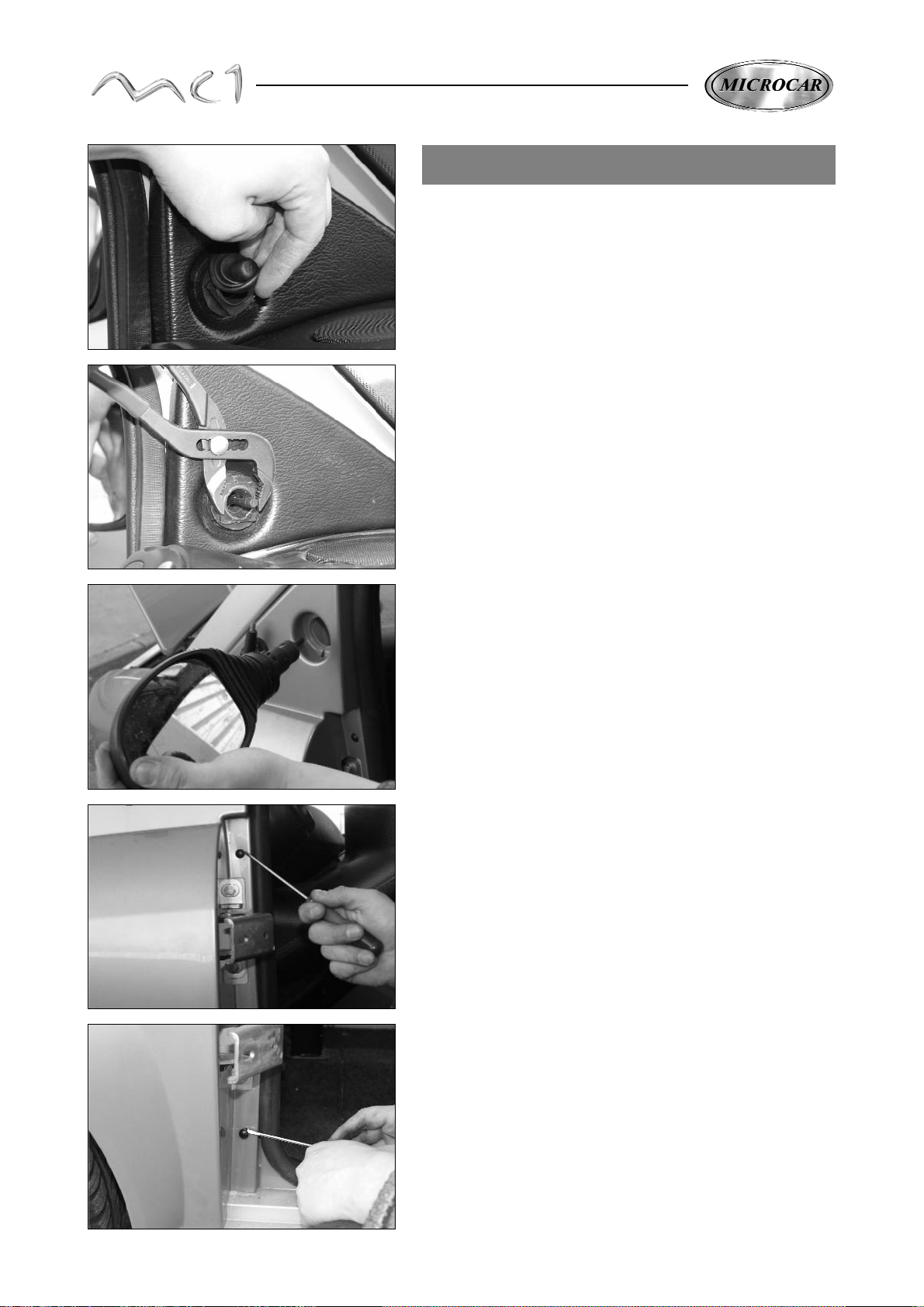

Take the fixing screw out of the interior door opening

switch.

INTERVENTIONS

ON THE INTERIOR DOOR

EQUIPEMENTS

Take out the cap of the handle.

With a screwdriver, unclip the opening tip on the

handle.

Take out the command.

Take off the trim starting in a conner

(fixed with a VELCRO strip)

We advice you to hold the sticker VELCRO

to avoid that it comes undone.

10

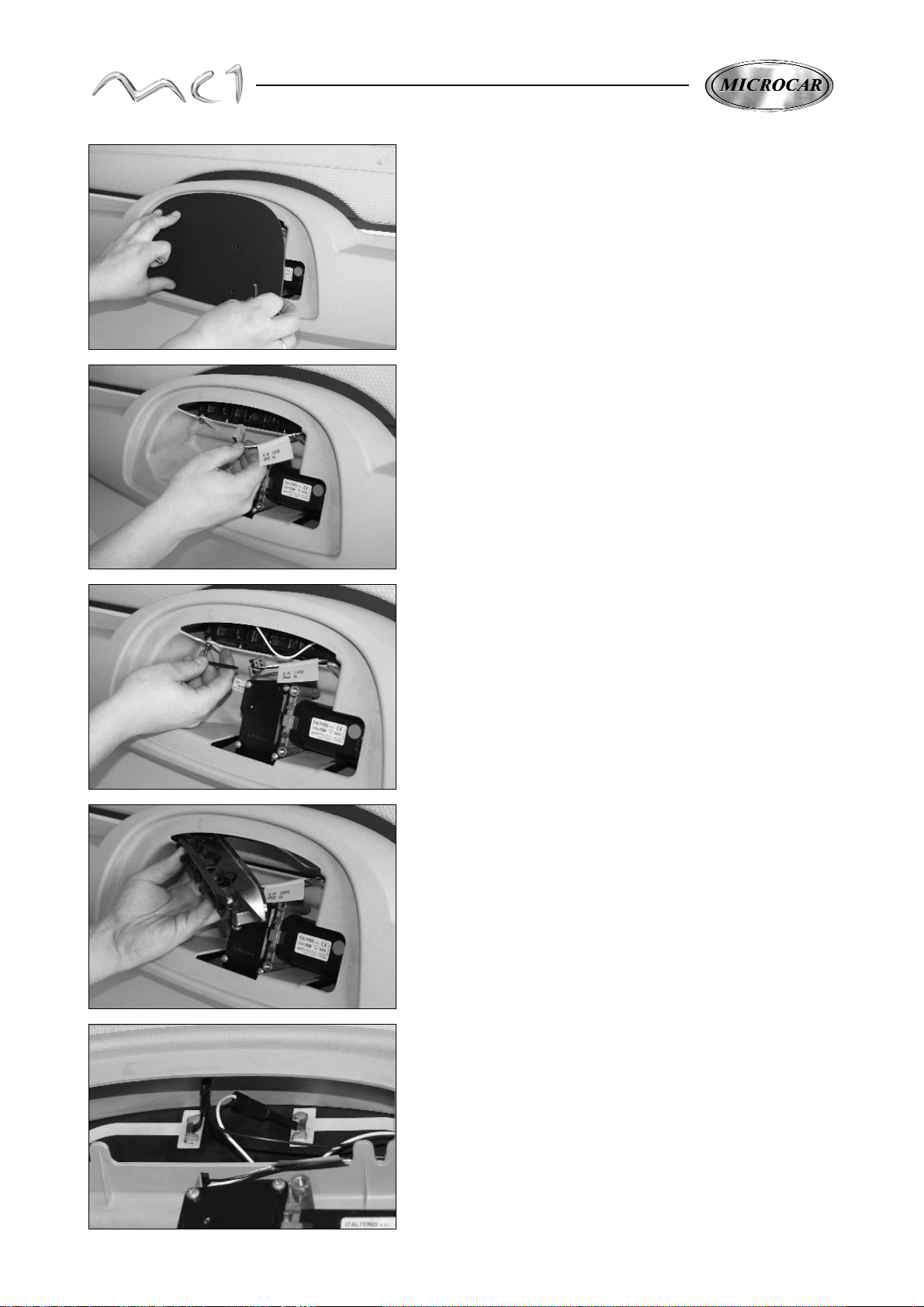

Take out the interior and exterior lock.

With a cuciform screwdriver, unscrew the fixing screw and take off

the plastic handle.

Take out the 2 fixing screws of the exterior lock

(key 6 sections).

LOCK AND CYLINDER LOCK DOORS

NOTA :to make the following operations easier, we advice

you to take the door out.

(see chapter "door removal" page 8)

Take out the central locking rod inside the door.

Take out the cylinder lock, pulling up its fixing fork and taking

off the cylinder lock from its place.

11

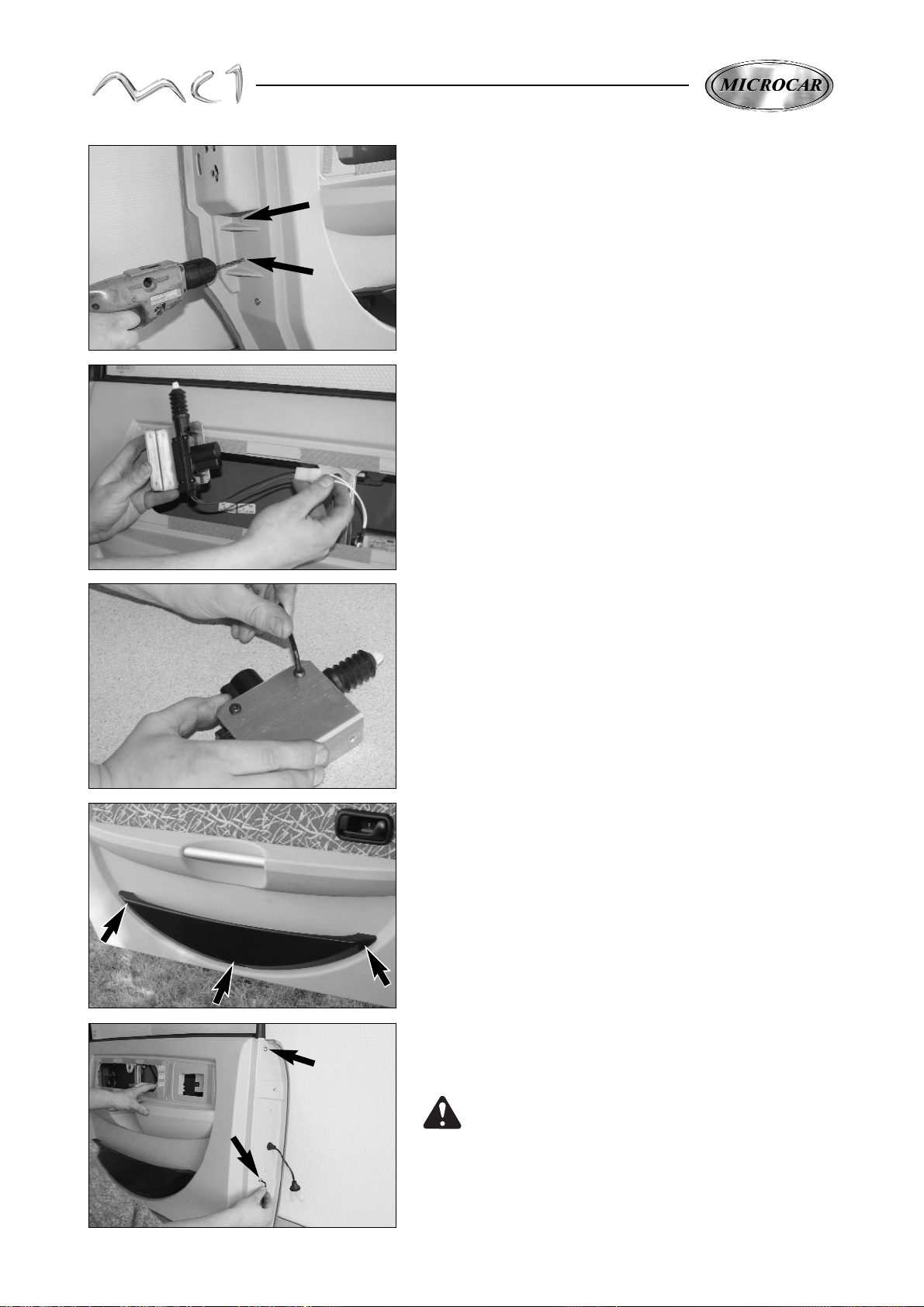

CENTRAL LOCKING ENGINE

Tha nks to a drilling machine (drill Ø 5) take out the 2 rivets of

the fixing of the central locking engine mounting plate.

Take out the plate and engine and unplug the electric

beam.

Take off the 2 engine fixing screws.

DOOR POCKET

Withe a screwdriver, take off the 3 black plastic rivets

and take out the door pocket.

DOOR WINDOW

Take out the 4 fixing screws of the door frame, 2 screws at the front

and 2 at the back.

To take out the door window, it is better that it goes up

at the maximum.

12

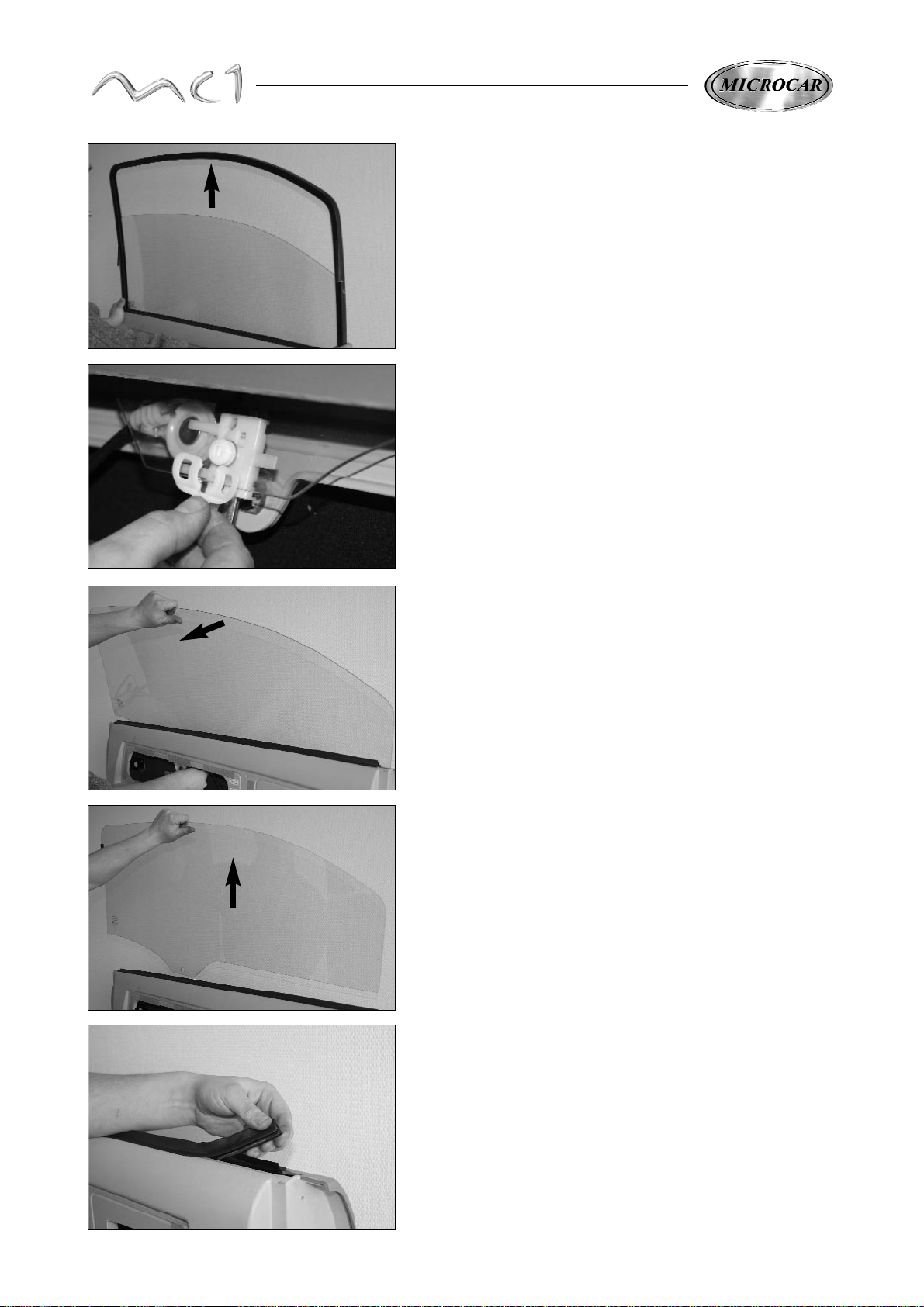

Lean slightly the window of the interior of the door

to take it out of the fixing axle.

Take out the window pulling it up.

Take off the joints.

Take out the door frame pulling it up.

Undo the fixing axle of the window.

13

ELECTRIC WINDOW WINDER

Take out the inferior fixing screw of the

window winder runner.

Take out the superior fixing screw of the window winder runner.

Take off the 2 screws of the window winder engine.

Unplug the electric beam and take out the window winder

of the interior door.

HINGE REINFORCEMENT PLATE

With a drilling machine (drill Ø 5) take out the 2 fixing rivets

of the hinge reinforcement plate.

Take off the beam and take out the plate.

All the reassembly operations of the interior door elements are made at the

reverse from the removal operations.

14

REAR DOOR

REAR DOOR REMOVAL

Unplug the battery using the red speed disconnecting cable

terminal (+).

Remove the ball joints of the 2 gas compass.

Take off the hatchback.

The fitting of the hatchback has to be made at the reverse from

the removal operations.

3rd PARKING LIGHT

After having unplugged the battery, take out the 2 fixing screws

of the hatch of the rear window.

Open the hatchback.

Unplug the hatchback electric beam, behind the right side

trim and take it out of the trim.

Hold the hatchback and take off the 2 fixing screws of the

hinges on the body.

Nota: When fitting again, for a perfect waterproofness, put some

silicone joint in the places of the hinges fixing screws.

15

Take off the hatch.

Unplug the beam of the 3d parking light.

Take out the 2 fixing screws of 3d parking light.

Take off the 3d parking light.

After having taken out the 3d parking light, you will be able to

reach the defrosting back window beam.

NOTA : The electric beam inside the hatchback can't be dismantled,

it is assembled first in the factory.

16

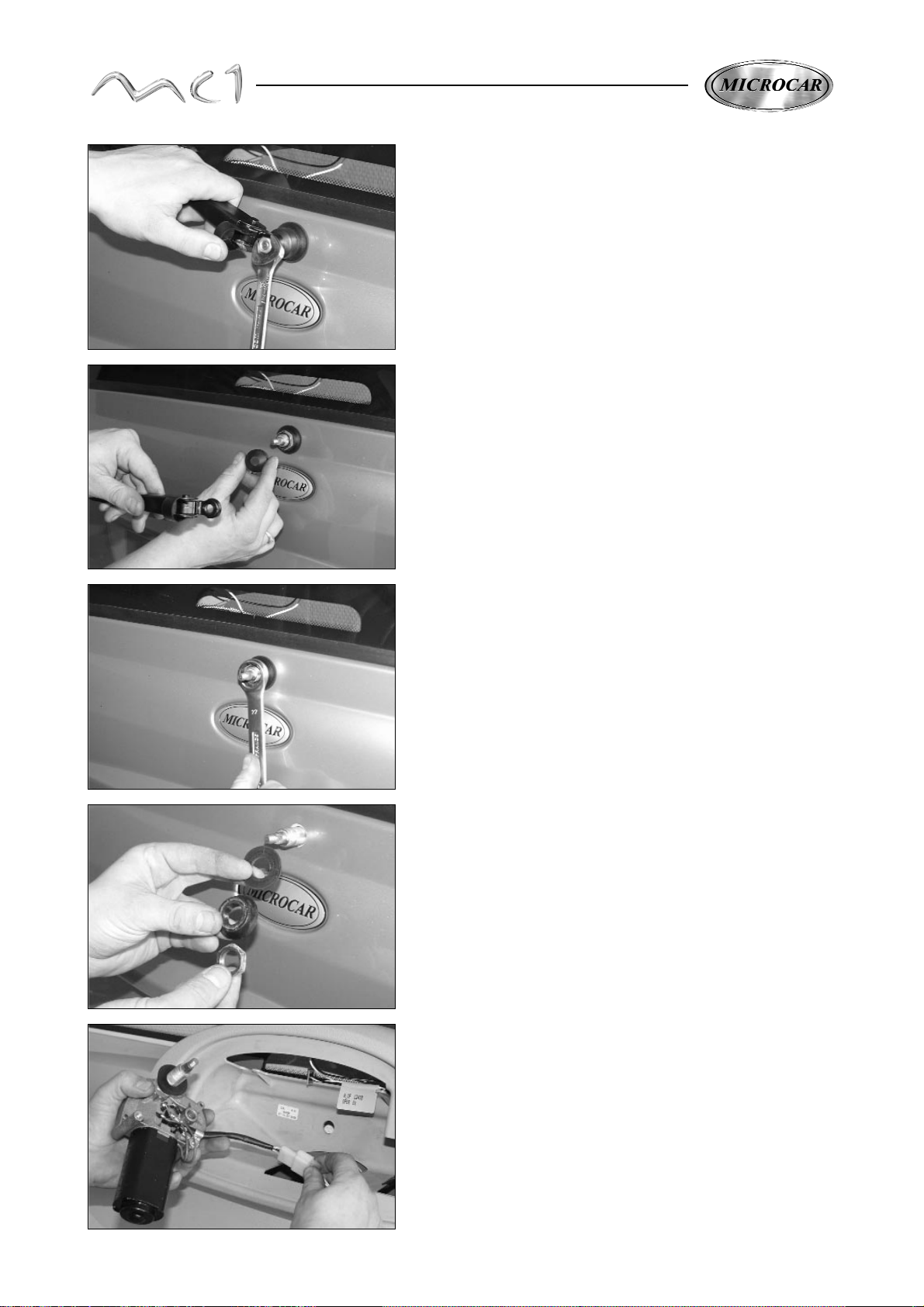

BACK WINDSCREEN WIPER

After having unplugged the battery and taken out the hatch of

the back window (see paragraph "3d parking light" page 14)

take out the fixing nut of the wiper arm under the nut cover.

Take out the wiper arm and the nut cap.

Take out the M16 fixing nut of the windscreen wiper engine.

Take out the spacer and washer.

Take out the windscreen wiper engine from inside the

hatchback and unplug its beam.

The fitting is made at the reverse from the removal operations

17

PLATE LIGHT

After having unplugged the battery, thanks to a screwdriver,

undo the plate light and take it out from its place.

Unplug the beam from the light plate.

HATCHBACK HINGE

After having taken out the hatchback (see paragraph hatchback

removal), take off the fixing nut and take out the hinge.

(set screw 6N/m)

REAR DOOR BOX STABLE

Take out the 2 fixing screws from the box stable.

REAR DOOR

After having made all these operations, take out the glass section.

.

18

Loosen the 2 compass ball joints.

(Set screw when fitting again 4,2 N/m).

Take out the 2 ball joints with nuts and washers.

Unglue the window from the hatchback.

Use the piano rope given in the gluing window kit

(réf. 0 700 200).

Make the cable slided between the window and the hatchback

on all length.

Use the gluing kit (ref 0700200) taking care of cleaning the

surfaces which must be glued.

Apply the primary of the kit on all the length of the window

Apply the primary (réf. 1 002 818) on the ABS of the hatchback.

Take out all the wastes of the

previous gluing.

Be carefull not to damage the ABS of the hatchback.

The reassembly of the rear door is made at the reverse

from the removal operations.

It is necessary to put the primary on all the parts

which must be glued (windows and body).

Put a line of glue on the primary.

Fit again the window on the hatchback and fix it with

2 ball joints + washers + nuts (set screw 4,2 N/m)

Let dry during 6 hours before doing new manipulations

Some primaries can damage the ABS.

It is necessary to apply the primary 5 minutes

before gluing. This one keeps its efficiency during

72 hours at the maximum.

19

FRONT BUMPER REMOVAL

Open the bonnet and take out the superior soundproofing.

Thanks to a screwdriver, take out the 2 black plastic rivets

inferior fixing.

Take out the 2 black plastic rivets from the wings

Fall over the bumper to the front and make it turn around its

superior fixing pegs on the sealed beam units.

Take the bumper out of the superior fixing pegs.

Use the flexibility of the ABS bumper to make this operation.

Do not force or break the centring pegs of the

sealed beam units.

The fitting of the bumper is made at the reverse from

the removal operations.

20

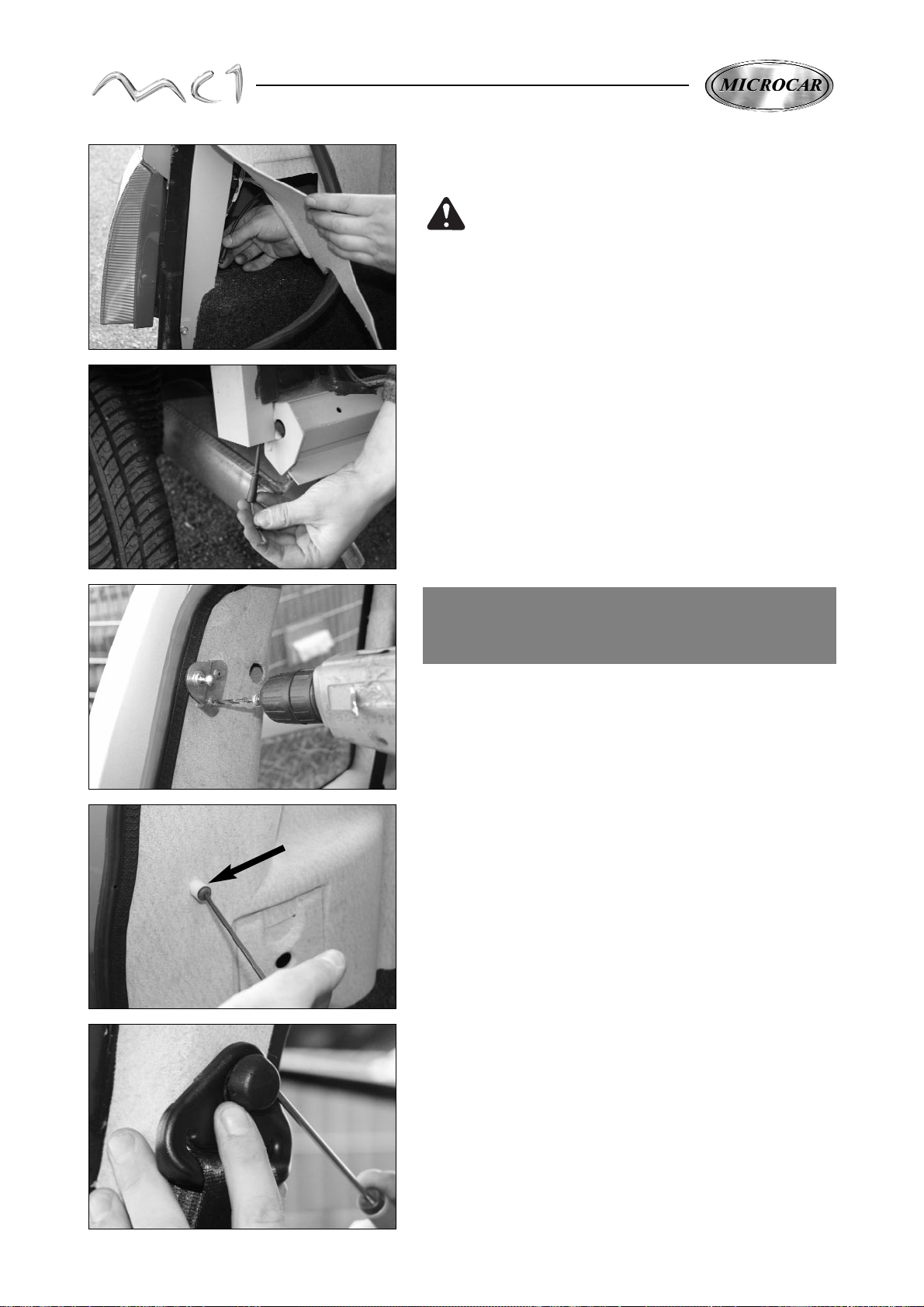

FRONT WINGS REMOVAL

Take out the door.

Take out the front bumper (voir page 19).

Take off the gaiter nut cover which fixes the door mirror.

With a combination pliers, take out the plastic nut from the

door mirror fixing.

Take out the door mirror.

With a screwdriver, take out the black plastic rivet of the superior

fixing from the pillar wing.

Take out the black plastic inferior fixing rivet.

21

Take out the black plastic superior front fixing rivet.

Take out the black plastic inferior front fixing rivet.

Take out the door joint.

Take out the aerial of the left wing (1 fixing screw)

Remove the outside temperature sensor of the right wing

(Cyanocrylate glue)

Take out the wing.

The fitting of the wing is made at the reverse from the

removal operations.

When reassembly the wing, after having cleaned the residues of

silicone, put 2 waterproof lines of silicone (ref 0022509)

(see picture), up and down the pillar of the door to avoid the

water infiltration.

22

DOOR HINGES

REMOVAL

Take out the door (see page 8).

Take out the front bumper (see page 19).

Take out the front wing (see page 20).

Take out the door hinges, 3 fixing screws per hinge

(set screw when fitting again 7 N/m).

BONNET REMOVAL

Unlock the bonnet without opening and take out the

2 fixing bolts of the hinges from the front pillar.

(set screw when reassembling 3,5 N/m).

Take out the bonnet.

When reassembling the bonnet, adjust this one with the 2 regulating

screws to obtain a correct position with the body.

SEALED BEAM

REMOVAL

Open the bonnet.

Unplug the battery.

Remove the front bumper (see page 19)

Take out the superior fixing nut (see picture)

Unplug the 4 electric connections.

23

BACK BUMPER

REMOVAL

Take off the 3 inferior fixing nuts of the sealed beam

unit.

Take out the sealed beam unit.

The fitting is made at the reverse from the removal operations.

Open the rear window.

With a screwdriver, take out the black plastic inferior fixing

rivet of the back bumper.

Take out the 2 black plastic fixing rivets which fix the

bumper on the back wings.

Hold the bumpe rand take out the 2 last black plastic rivets

fix it on the the inferior cross beam.

Take out the bumper.

24

OPENING HATCHBACK

SWITCH REMOVAL

Bumper removal (see page 23).

Take out the 2 fixing screws of the hatchback lock with its 2

spacer rings.

(set screw when fitting 5 N/m).

Take the cable out of the lock.

WIth a drilling machine (drill Ø 5) take the 2 fixing rivets out of

bumper support, undo the duct from the switch cable

and take the support out.

Take out the 2 fixing screws of the hatchback opening

switch.

Take the switch out of its place.

25

When assembling, to make the passage of

the cable easier, take locally the hatchback

joint out and rise up the interior trim to put

the cable in the back pillar hole.

Make the cable come out of the profile tube of the back pillar

and assemble at the reverse from the removal operations.

Take out the rear door (see page 14).

Take out the shelf which hides the luggage with a drilling

machine (drill Ø 5) take out the 2 fixing gaz strut support

rivets. Take out the rear plate.

INTERIOR TRIM REAR

QUARTER PANEL

With a screwdriver, take off the superior plastic inking cover of the belt.

26

Take out the superior fixing screw, inking belt.

(set screw when reassembly 35 N/m).

Take the 2 fixing screws out of the bench seat support.

(set screw when reassembly 10 N/m).

With a screwdriver, take out the plastic cover of the inferior catch

of the belt.

Rise up lightly the bench seat and take out the screw of the inferior

catch of the belt.

(set screw when fitting back 35 N/m).

Take the joint out of the rear door.

27

Take out partly the joint of the door.

Take out the trim and take out the belt and the beam.

The fitting is made at the reverse from the removal operations

SAFETY BELT RETRACTOR

REMOVAL

Take out the interior trim (see page 25).

Take out the fixing screw of the safety belt retractor

(set screw when fitting back 35 N/m).

CHANGING OF THE

INTERIOR ROOF TRIM

With a Stanley knife, make 2 cuts on the front part

of the roof trim.

Use the 2 cuts to take the roof in an easy way and to remove

the front trim.

Take totally out the roof trim taking it up to the front.

Remove a maximum of glue in the corners of the roof

to position easier the new trim.

28

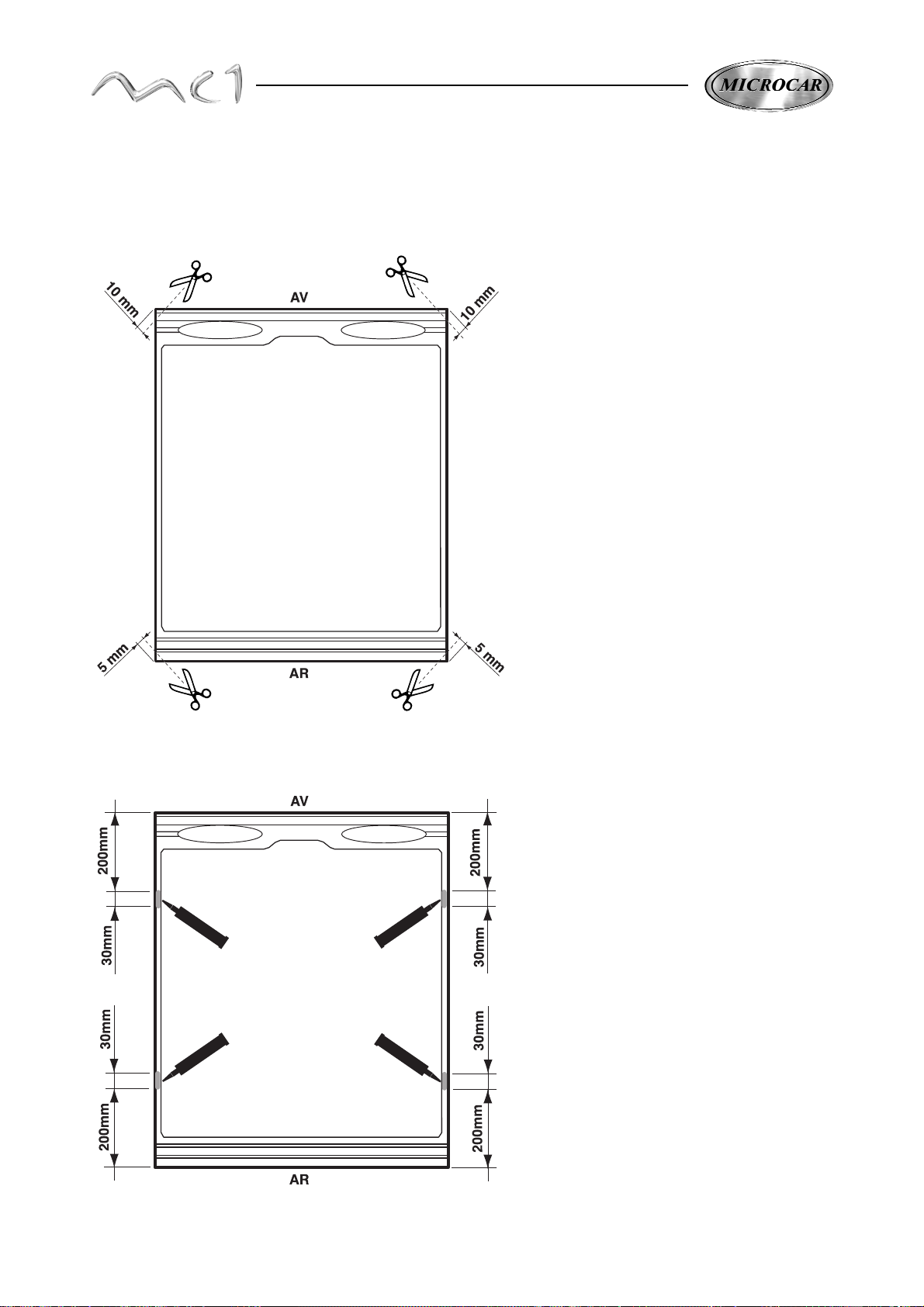

PREPARATION OF THE NEW ROOF TRIM

Cut the 4 corners of the roof trim at 45°.

10mm in front and 5mm in back following the

drawing.

Put 4 lines of glue (ref 0700200)

following the drawing.

Fit the trim and hold it with strips.

Stop the car a half day

(the necessary time to dry the glue)

29

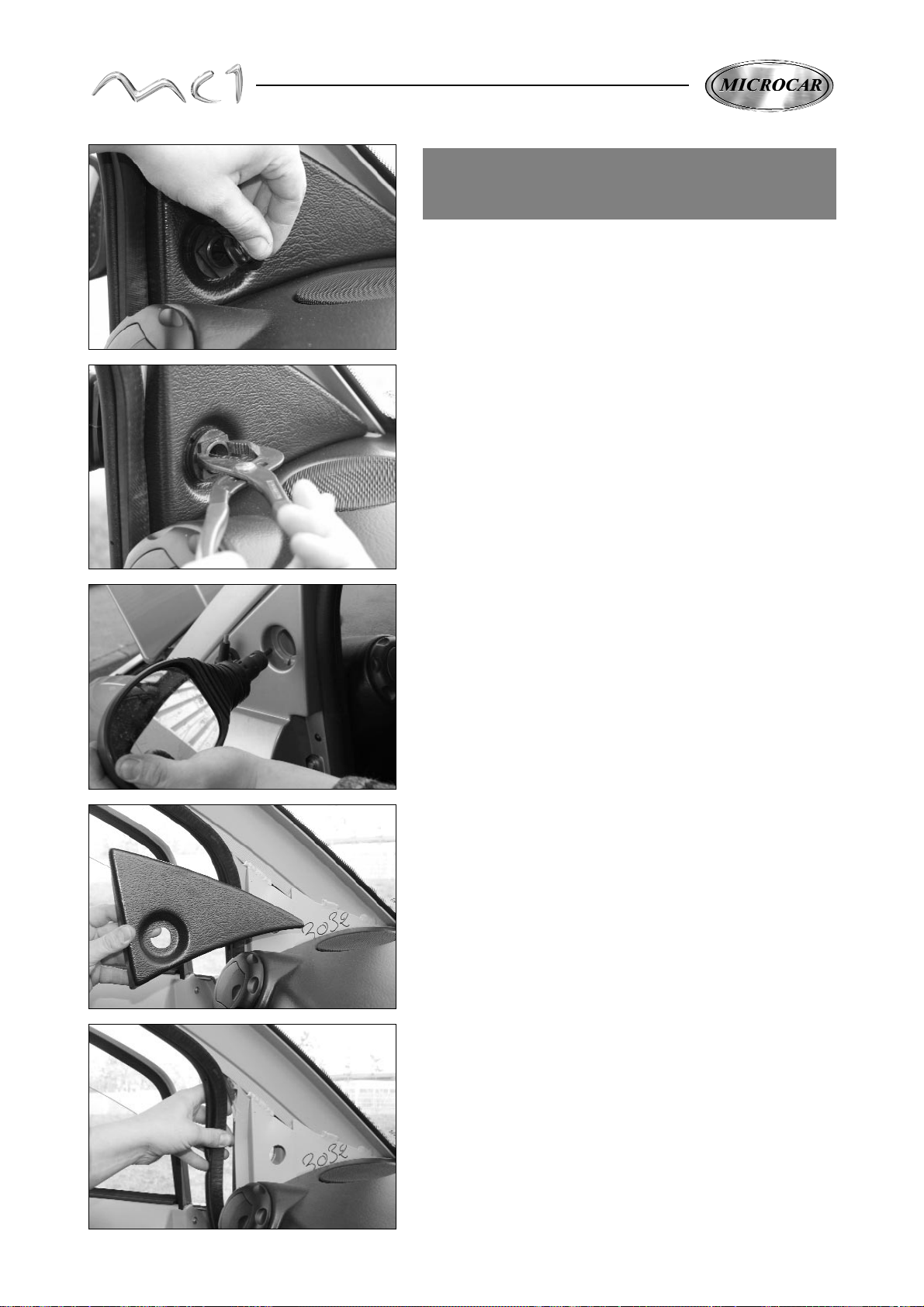

Open the bonnet.

Unplug the battery.

Take out the gaiter which hides the nut of the left door mirror.

INSTRUMENT PANEL

REMOVAL

With a combination pliers, take out the fixing palstic

nut of the left door mirror.

Remove the left side door mirror.

Take out the left side interior cover.

Take out the 2 joints of the front part of the right and left doors.

30

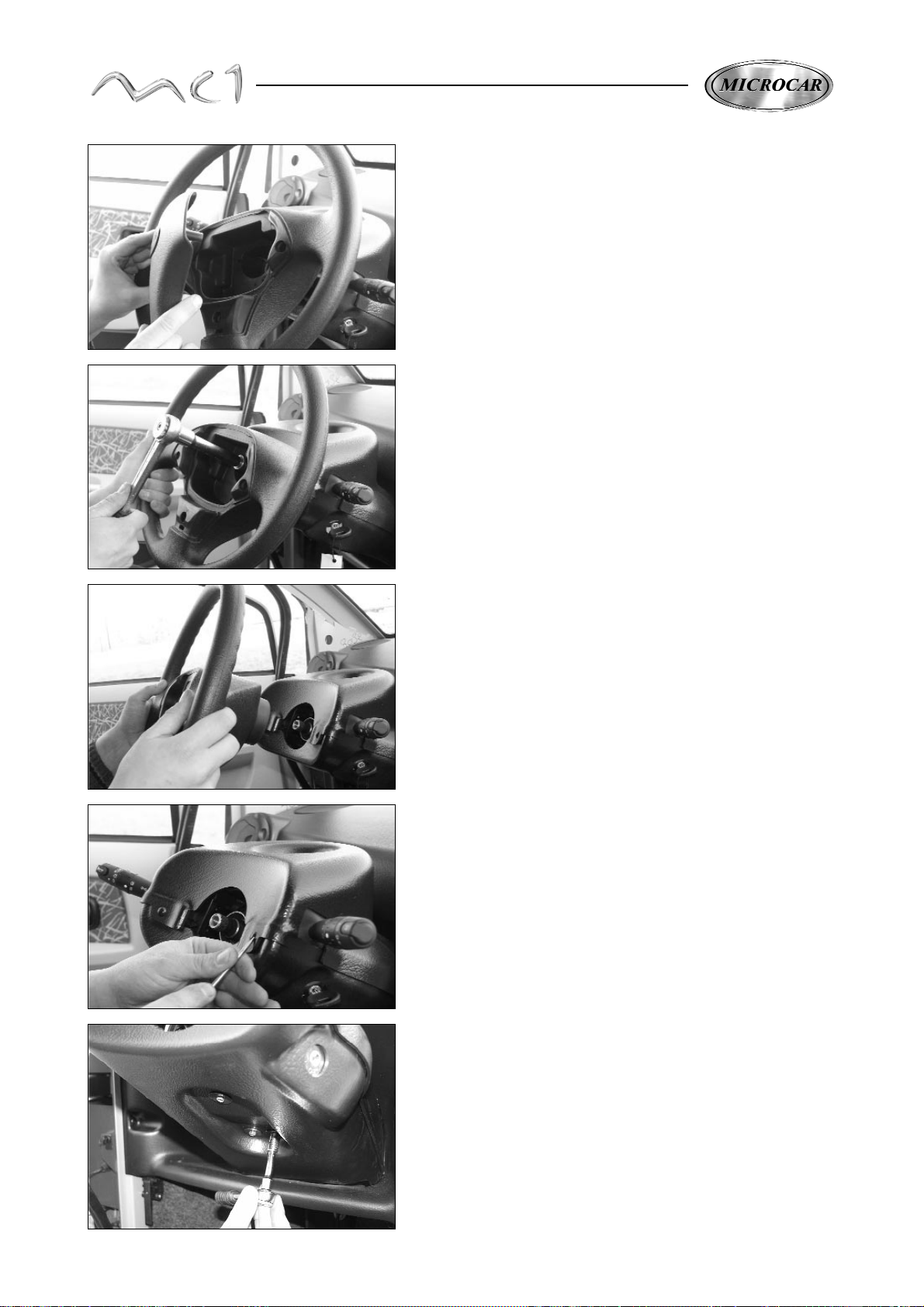

Remove the central cover of the steering wheel.

Take out the central fixing screw of the steering wheel.

(set screw when fitting 30 N/m).

Take out the steering wheel of the steering column.

With a screwdriver, take out the 3 black fixing plastic rivets

of the column covers.

Take out the 2 fixing screws of the inferior column cover.

31

Take out the inferior column cover.

Take out the superior column cover.

Unplug the connectors of the electric beam from the

lever.

Take out the 3 cruciform fixing screws of the lever.

Take out the lever.

32

EVENTUAL STARTER SWITCH

REMOVAL

Position the ignition key between the mark M and A and

with 2 screwdrivers, retract the 2 holding lugs of the stater switch.

Take out the fixing screw of the starter switch.

Take out the starter of its sleeve.

Take out the radio.

Check the form of the radio and unplug it.

Unplug and take out the 2 electric controlled

windows.

33

Unplug the connectors on the distress signal switch

and the 2 connectors of the cigar lighter.

Take out the bulb of heating switch support.

Take out the button of the distress signal.

Take out the ventilation switch cover.

Take out the central fixing nut of the ventilation switch

Take out the reverser lever gaiter

34

Take out and unplug the 2 loud speakers of the instrument

panel.

With a screwdriver, take out the black plastic inferior fixing rivet

of the instrument panel.

Take out the 2 left and right black fixing plastic rivets of the

instrument panel.

Undo the heating throttle switch on the housing diffuser.

Undo the heating fan switch cable, engine compartment side.

35

Take out lightly the instrument panel and unplug the

instruments from the back.

Disconnect the 2 ducts of the fans.

Take out the instrument panel.

The reassembly is made at the reverse from the

removal operations.

REVERSER LEVER

REMOVAL

Take out the instrument panel (see page 29).

Take out the 3 fixing screws of the reverser lever

unit.

To take out only the lever, take the 2 side screws

and the screw down the lever and take out the Yoke axle

of the switch cable.

36

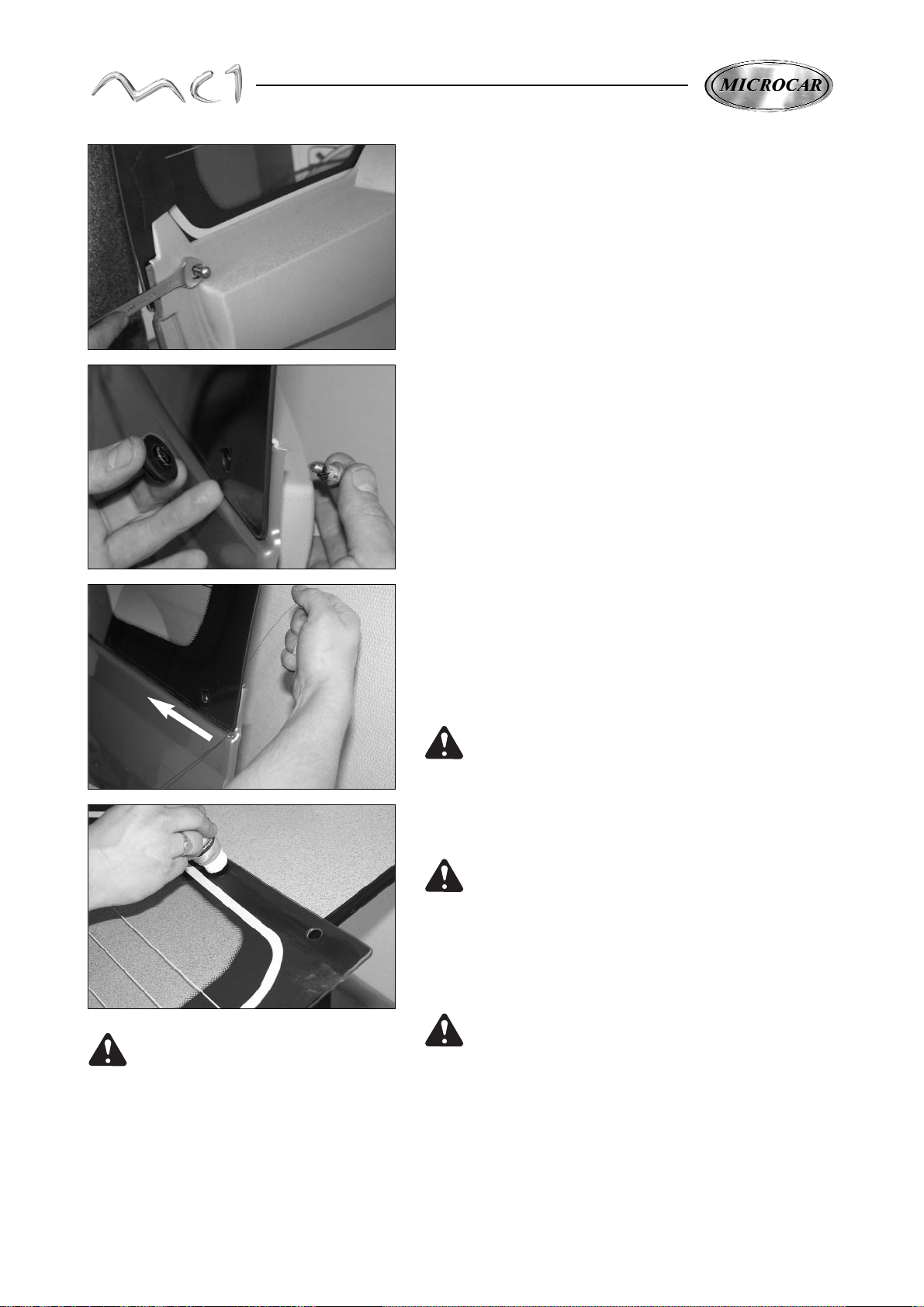

REAR QUARTER PANELWINDOW REMOVAL

2

1

Insert a piano rope between the door pillar and the rear quarter panel.

The piano rope is inside the window glue kit ref 0700200

Cut the glue joint on the side of the window and take it out.

Take care not to cut the inside trim.

For the assembly of the rear quarter panel window, clean all the

residues of the glue which stay on the body.

To glue the rear quarter panel window, use the kit glue (ref 0700200)

and the primary ABS (ref 1002818).

• Degrease (Adhekit ref. 1002659) or alcool.

• Apply the primary of the glue kit (ref 0700200) on the alu surfaces

(1) and on the side of the quarter light gluing surface.

• Apply the primary (réf. 1 002 818) on the ABS (2).

Some primaries make the ABS reacted

use only the primary (réf. 1 002 818).

To have a perfect window, you must primarise

the 2 parts to glue.

The primaries must be applied at least 5 minutes

before the gluing of the windows.

The primaries keep their efficiency during 72

hours.

Apply a line of the glue which is in the kit on the primary and

lift up the window, check its well centring on the body and hold

it in position with strips.

Stop the car during the 6 following hours.

37

BACK WHEEL TRIM REMOVAL

With damaged wood scissors and a thermal scrapper

unglue the wheel trim rear quarte panel from the back wing.

Unglue the wheel trim from the pillaracting from low to high.

With a Stanley knife, cut the upper joint next to the ABS of the wheel

trim.

Heat and unglue the covering of the roof.

BACK WING REMOVAL

Remove the hatchback (see page 14)

Remove the back bumpers (see page 23)

Remove the inside trim (see page 25)

Remove the back lights.

Remove the quarter light (see page 36)

Unglue and take off the rear side panel groove.

Do not warm up the ABS more than 60°

It is better to use an adjustable thermal scrapper.

Do not warm up the ABS of the roof more than 60°

38

Take out the striker plate.

With a screwdriver, take out the filler neck.

Disconnect the chute of the body.

With wood scissors and thermal scrapper, unglue the upper part

of the back wing.

Warm up the last points where the glue catches respecting the

maximum temperature not to damage the other ABS pieces

and take out the back wheel trim.

NOTA : When reassembly, the wheel trim must imperatively be

replaced by a new piece.

Do not warm up the ABS more than 60°

39

From the inside of the car, remove the wing from the floor.

Unglue the wing from the waterproof chute piece.

Remove the wing from the back door pillar starting from the top.

Take out the back wing.

Unglue the lower part.

Do not burn the carpet.

40

Remove the piece from the back carcase pillar.

Remove the low part on the back cross beam.

Take out the back waterproof pieces.

Use the glue kit TWINTEX -ABS-ALU ref 1002657

The fitting is done at the reverse from the removal operations.

With wood scissors, remove the back waterproof pieces.

NOTA: Those operations do not necessarily require

the use of a thermal scrapper.

BACK WATERPROOF PIECE REMOVAL

Degrease the parts which must be glued with the

product in the kit (ref 1002659)

Clean all pieces which must be fitted again.

Clean all the glue residues which stay on the pieces which must be

assembled.

41

Act step by step.

Glue and position each piece holding in position

with a clamp during 4 hours.

The fire must be made with a gun. Flame the side which must be glued.

(the smoother)

All the Sandwiform surfaces will have to be fired before

being glued.

All the ABS and Alu surfaces which must be glued

will have to be degreased with the cleanerdegreaser (ref 1002659)

42

Take out all the frame joints of the windscreen. Take out the inside

door mirror.

With a pliers, insert a piano rope delivered in the kit (ref 0700200)

between the pillar and the windscreen and cut the glue fixing

joint of the windscreen all around it.

On the lower part, take care no to cut the instrument

panel with the piano rope.

Take out the windscreen.

WINDSCREEN REMOVAL

FRONT WINDSCREEN PREPARING

Fit 2 new joints (ref 0664097) on the upper and lower

part of the windscreen and cut them in the right length.

NEW WINDCREEN FITTING

Fit 2 new joints (ref 0664097) on the upper and lower part of

the windscreen and cut them in the right length.

Put a point of cyanocrilate glue in the corners.

43

Fit the inside door mirror on its support.

Clean all the glue residues which stay on the body.

Apply the ABS primary (ref 1002818) on the upper part of the

apron cover.

Alll the alu surfaces which must be glued will have to be degreased with the

product in the kit (ref 1002659).

Use the glue kit (ref 0700200)

Apply the primary all around the windcreen level with the joints.

Apply a line of glue on the primary and fit back the windscreen.

Check its well centring on the body, hold it in pressure in its definitive

position and stop the car during the 6 following hours.

44

ROOF REMOVAL

Remove the hatchback (see page 14).

Remove the windscreen (see page 42).

Remove the 2 finishing joints of the roof.

With damaged wood scissors and regulated thermal

scrapper, warm up the back part of the hatchback

(maximum temperature 60°) and remove the roof from the

back cross beam.

Do the same to remove the roof from the sides of the body.

Always start the removal of the back roof to the front

on the both sides, then remove it from the front cross beam.

Remove the roof.

Clean all the residues of the glue which stay on the body

frame. Degrease all the alu surfaces which must be glued with

the product Adekit (ref 1002659).

Put a line of glue in the corners on the front part of the frame

(glue kit TWINTEX-ABS-ALU ref 1002657)

NEW ROOF FITTING

Put a line of glue in the corners on the back parts of the frame.

45

Apply the ABS primary (ref 1002818) all around the parts

of the roof which must be glued.

Put a line of glue (ref 0700200) all around the support surface

of the roof.

Put the roof.

Check its well position on the body, hold it in pressure

in its definitive and let it dry 6 hours.

Clean with a spatula to take off the glue left in the corners.

Put back the 2 finishing joints of the roof.

46

SIDE BODY REMOVAL

Place the car on an elevator or on a classic stand.

Support on the front under the engine cradle.

• Remove the door (see page 8).

• Remove the hatchback (see page 14).

• Remove the front bumper (see page 19).

• Remove the back bumper (see page 23).

• Remove the bonnet (see page 22).

• Remove the front wing (see page 20).

• Remove the door hinges (see page 22).

• Remove windscreen (see page 42).

• Remove the roof (see page 44).

• Remove the inside trim (see page 25).

• Remove the quarter light (see page 36).

• Remove the back wing (seepage 37).

• Remove the back light and its waterproof piece (see page 37).

• Remove the safety belt kit and the striker plate (see pages 27 et 38).

• Remove the instrument panel (see page 29).

• Remove the opening switch of the hatchback (see page 24).

Support on the back under the cross beam and the axle.

47

Take out the upper fixing screw of the back shock absorber

(set screw when assembling 40N/m)

With damaged wood scissors and an adjustable thermal scrapper

(maximum heating temperature 60°), unglue the floor from the side

frame).

Unglue very carefully the apron cover from the frame

Take care not to damage the dash panel cover

because this one is weaker than the floor.

Remove the 2 upper fixing screws of the engine cable.

(set screw when assembling 22N/m)

Remove the 2 low fixing screws of the engine craddle

(set screw when fitting again 22N/m)

48

Remove the 2 fixing screws of the instrument panel cross beam

(set screw when fitting again 7N/m)

Remove the 2 fixing screws of the low back cross beam

(set screw when reassembly 9,5N/m)

Remove the 4 fixing screws of the rear axle support

(set screw when fitting again 9,5N/m)

Hold the body of the side and remove the fixing screw of the upper

cross beam of the windscreen (set screw when reassembly 9,5N/m)

Remove the 3 fixing screws of the upper back cross beam

(set screw when fitting again 9,5N/m)

49

Remove the side of the body

The reassembly of the side of the body is made at the reverse from the removal operations.

When reassembling, check very carefully the geometric dimensions of the body.

50

FLOOR SOUNDPROOF KIT GLUING

The soundproof floor kit is fixed with glue (Neoprene, Sicaflex...)

Put some glue on the soundproof kit components

Position the components and plaster them down well on the floor

to spread the glue.

51

SOUNDPROOF APRON KIT GLUING

The soundproof apron kit is available under the reference 1002454.

The gluing of the soundproof apron kit is made with glue (Neoprene, Sicaflex...) as for the

soundproof kit floor.

Soundproof greneral view after gluing.

52

ABS REPAIRING

When the ABS is broken or deeply scratched, with a drilling

machine, make a hole at the 2 ends to stop the break.

Do a milling on a deep scratch

(see drawing)

Make a milling on the both sides on a break

(see drawing)

Always use an appropriate cut speed

to avoid making the ABS melted down.

faire fondre l’ABS.

Use the following products to repair the ABS

A - ABS degreasing (réf. 1 003 036)

B - Kalico fiber (réf. 1 003 037)

C - Waterproof sticky strip (réf. 1 003 038)

D - ABS repairing kit + 2 mixers (réf. 1 002 656)

E - Mixers 50 cc (réf. 0 700 249)

In case of scratch :

• Wet lightly a rag with the degreasing (A) and degrease the

surface which is to glue.

In case of break :

• Wet lightly a rag with the degreasing (A) and degrease the

surface which is to glue.

Break

Scratch

A

C

D

B

E

• Fill in again the break using te reparing ABS kit (D).

Drying time : 3 hours

Do not make the degreasing poured too much

on the ABS

Do not make the degreasing poured too much

on the ABS

• Apply a sticky strip (C)on the break, outside to avoid

excess glue.

53

Inside,fill in again the break using the ABS repairing kit (D)

apply the Kalico fiber (B) on the glue to reinforce the repairing.

Drying time : 3 hours

After drying :

Take off the sticky strip outside and sand the repairing

to obtain the original form of the part.

Apply a body finishing mastic, to fill in the scratches cased by

the sanding.

Make a finishing sanding.

ALU REPAIRING

Clean and degrease the aluminium parts to repair.

Apply a specific alu mastic for the repairing.

54

FLOOR REPAIRING

The floor material(Sandwiform) is made with a cellular

plate (A) (smocking) recovered with 2 Twintex sheets

(B) and 1 of it is recovered with a finishing carpet inside.

In case of shock or break, it is necessary to make the

repairing as said above.

Pre cut the Twintex sheet outside (without

carpet) ~ 4 cm around the damaged part.

Avoid cutting the smocking.

Take off and cut the damaged Twintex sheet.

Charge the smocking with the Sandwiform with the glue kit

réf. 1 002 657.

The rigidity of the part won't be ensured with

the repairing glue kit.

Cut a piece of Twintex sheet (ref 1002806)

Flame the side which is to glue (the smoother)

For any gluing on the sandwiform, it is necessary to

flame the parts which are to glue.

Without flaming, the gluing won't work on the twintex.

B

B

B

55

Put the black twintex part on the roof part which is to repair

and apply the repairing kit glue (ref 1002657)

Hold the parts in contact, plastered down.

Drying time : 6 hours.

Use the carpet kit repairing (réf. 1 003 030).

The carpet can be glued with a neoprene glue or with teh repairing kit

(réf. 1 002 657).

Be carefull to the gluing way.

The glued sid emust be the flamed side.

The flaming ensures the glues, mastic and paint

to stay. You can obtain it with a speed passe of a

flame on the surfaces without burning the material

(transformation of surface molecules)

CARPET REPAIRING

For a good waterproofness of the sandwiform

use the product 3M ref 08868 indicated in the

technical information 247.

56

PAIINTING FORMULA AND COMPOSITION : MC1 water formula

Blue

OXYGEN

M 162

2003

Red

SPORT

N 327

2003

Grey

Métropolitain

N 501

2003

Grey

Body

Frame

2003

SIKKENS

AKZO NOBEL

334WB 874,6

955 894,7

099 922,8

744 964,4

379 1056,3

ot os beeing

made

It is beeing

made

It is beeing

made

GLASURIT

M4 731,6

M010 876,7

M176 953,4

M011 994,8

A997 1011,4

A503 1023,8

A031 1035,8

A550 1044,1

M4 603,6

M99/03 610,6

A359 811,6

A323 928,1

A329 1008,5

A926 1018,5

M4 700,6

M99/07 739,4

M99/04 762,7

A926 853,7

A550 886,6

A031 907,9

A097 915,7

M1 1008,7

Step 1

M4 731,2

M99/03 819,6

M011 897,6

M506 923,6

A031 1006,8

A926 1034,1

A149 1054,9

Step 2

923-155 545,5

522-322 974,1

ICI AUTOCOLOR

Sous couche

P565-888 1626

Couche principale

P967-9957 309,3

P967-9933 523,8

P967-9938 573,8

P978-9951 618,5

P967-9954 784,8

P968-9988 1017,2

P275-366/372A 1035,1

P935-2018 1138,6

Sous couche

P565-889 1624

Couche principale

P967-9971 553,2

P967-9921 627,5

P967-9907 664,6

P968-9989 681,1

P978-9951 695,1

P968-9988 728,1

P967-9935 783,4

P967-9926 1022,8

P275-366/372 1031

P935-2018 1134,1

Sous couche

P565-888 1626

Couche principale

P967-9938 565,5

P967-9948 716,2

P967-9957 750,1

P967-9920 767,1

P978-9951 787,8

P968-9986 863,2

P968-9988 1017,8

P275-366/372 1036,7

P935-2018 1140,4

Sous couche

P565-888 324,9

P565-889 1624,4

Couche principale

P968-9987 765

P967-9948 833,8

P967-9905 847,2

P978-9951 1038,4

P275-366/372 1057,5

P935-2018 1163,2

DU PONT

Sous couche

1401W 504,5

1421W 565

1406W 592,3

1428W 615,8

1430W 621,5

1620WB 915,1

1630WB 1110,9

Teinte de fond

1511W 90

1470W 101,1

1420W 102,7

1405W 103,6

1640WB 921,7

1650WB 1012,6

1464W 80,2

1453W 147,9

1539W 183,8

1468W 215,5

1450W 239,4

1506W 260,8

1405W 266,8

1402W 270,6

1640WB 645,1

1650WB 1019,7

1535W 168,6

1405W 211,5

1463W 242,1

1418W 270,2

1401W 297,5

1421W 318,2

1505W 337,5

1640WB 676

1650WB 1015

It is beeing

made

STANDOX

Sous couche

WB372 223,6

WB370 790,6

WB369 891,3

WB357 1006,1

WB373 1105,8

Teinte de fond

WB399 935,2

WB329 996,9

WB336 1027,8

WB386 376,8

WB398 645,7

WB361 899,5

WB311 1006,4

WB372 1024,9

WB393 192,1

WB398 698,1

WB009 760,7

WB372 948,2

WB357 983,5

WB370 1025,6

WB376 1030,1

394 789,5

370 986,8

363 1016,3

374 1045,8

369 1049,7

367 1051,7

PPG

412 361,7

417 567

405 681,1

483 756,1

485 824,5

408 889,7

491 954,9

413 987,5

400 1013,6

446 447,4

439 682,9

437 879,1

487 957,6

464 996,8

406 1008,6

413 1013,3

491 312

408 554,1

483 773,7

481 857,3

443 927,2

413 968,4

451 998,4

487 1010,9

4002 1015,3

main coat

483 778,4

400 914,6

408 992,4

423 1023,5

440 1029,3

Mat varnish

800 546,8

759 984,2

SPIES HECKER

Under coat

WB801 564,8

WB803 787,5

WB837 901,9

WB820 1002,2

WB822 1101,5

Back tint

WB888 931,5

WB870 993

WB886 1023,7

WB815 270

WB882 648,4

WB858 755,7

WB843 1010,5

WB803 1029

WB815 504

WB813 695,4

WB803 882,2

WB800 944,5

WB801 986,5

WB837 1021,7

WB829 1026,1

WB818 789,5

WB801 986,8

WB827 1016,3

WB805 1045,8

WB820 1049,7

WB807 1051,7

57

PAIINTING FORMULA AND COMPOSITION : MC1 Solvant formula

Blue

OXYGEN

M 162

2003

Red

SPORT

N 327

2003

Grey

Métropolitain

N 501

2003

Grey

Body

Frame

2003

SIKKENS

AKZO NOBEL

AUTOBASE +

Q914F 714,9

Q065 942

Q110 958,6

Q160 972,6

Q652 983,4

Q726 987,3

Q436 527,3

Q811U 542,3

Q271 568,6

Q190 618,5

Q726 673,5

Q279 769,1

Q065 998,9

Q811R 352,8

Q673 363,9

Q110 393,2

Q195 435,8

Q160 515,7

Q065 742,9

Q190 987,8

Q811E 356,8

Q671 366,7

Q328 378,6

Q235 395,1

Q914F 566,7

Q110 783,4

Q065 1017,4

GLASURIT

352-91 172,5

M010 677,7

M179 872

A531 908,6

A929 934,9

M25 954,3

A555 960,8

352-91 174

M99/20 195,5

A353 575,1

A324 756,3

A335 876,8

A125 901,1

A929 911

352-91 174

M99/20 517,8

M99/19 552,5

A929 690,7

M1 808,4

A531 885

M25 925,9

A353 929,9

First step

352-91 174

M011 732,4

M99/20 776,8

M99/12 802,1

M506 816,8

M25 899,8

A929 933,8

A307 959,1

M105 960,8

Snd step

923-144 535,9

522-322 974,3

ICI AUTOCOLOR

P425-988 194

P420-933 334,3

P425-900 371,4

P425-948 379,6

P425-954 441,5

P425-957 581,8

P192-5600 969,7

Sous couche

P565-889 1624

Couche principale

P425-971 481,1

P425-921 553,3

P425-900 589,3

P425-984 619,3

P425-989 643,4

P420-907 679,4

P429-976 733,5

P420-926 950

P192-5600 1010,1

Sous couche

P565-888 1626

Couche principale

P425-986 351,7

P425-948 519,1

P425-900 591,9

P420-960RT 616,2

P425-988 635,6

P425-957 667,2

P420-920 740

P420-938 1025

Sous couche

P565-888 1626

Couche principale

P425-987 461,9

P425-948 496,5

P420-905 503,4

P425-900 757,5

P192-5600 1034,7

Vernis mat

P565-554 501,6

P100-2020 668,9

P190-XXXX 1003,2

DU PONT

Under coat

AM1 114,7

AM6 170,3

AM21 203,6

AM28 222,6

AM31 237,9

XB155 468,8

XB165 977,8

Back tint

AM732 97,4

AM70 135,4

AM2 173,2

AM5 176,3

AM20 177,3

XB155 401,4

XB165 949

AM64 207,3

AM63 317,7

AM50 357,1

AM66 394,7

AM2 422,1

AM77 449,5

AM94 459,2

AM5 464,4

XB155 957,6

AM94 107,6

AM21 207,1

AM5 292,7

AM14 367,5

4530S 422

AM1 451,3

AM31 476

AM64 482,3

AM46 485,1

XB155 982,6

AM1 117,5

AM95 175,7

AM17 220

AM5 245,4

AM70 247,4

XB155 462

XB165 989,7

STANDOX

Under coat

MB563 233

MB570 841,8

MB855 892,1

MB589 974,1

MB859 1018,1

Back tint

MB299 769,6

MB591 844,1

MB586 911,1

MB572 926,9

MB561 445,4

MB883 776,3

MB811 846,1

MB810 903,3

MB598 929,5

MB571 937,6

MB593 206,6

MB598 637,5

MB008 703,1

MB571 824,4

MB885 889,1

MB570 948,6

590 718,5

570 880,1

563 924,9

574 942,8

569 948,2

585 950

PPG

954 880,7

756 933,5

776 957

753 971,7

755 980,5

791 330,4

773 519,2

759 672,6

953 761,1

779 843,7

792 914,5

752 938,1

772 955,8

768 328,4

759 574,7

767 684,7

740 793,1

755 852,2

741 894,9

954 935,9

953 952,3

Main coat

768 725

753 886,1

759 939,8

740 969,3

778 981,7

779 984,4

Mat varnish

800 546,8

759 984,2

SPIES HECKER

Under coat

MB501 606,4

MB527 838,5

MB538 920,2

MB556 970,3

MB554 1014,1

Back tint

MB299 769,6

MB591 844,1

MB586 911,1

MB572 926,9

MB582 332,3

MB543 779,5

MB542 837

MB558 907

MB510 933,3

MB502 941,5

MB510 429,2

MB513 635

MB502 755,8

MB799 821,1

MB547 885,5

MB501 944,8

MB514 718,5

MB501 880,1

MB527 924,9

MB505 942,8

MB520 948,2

MB552 950

58

SOUNDPROOF ENGINE

PANEL REMOVAL

Remove the front bumper (see page 19).

Remove the 2 lower flaps of the bumper support

Take off the 2 lower fixing screws of the front soundproof

panel.

Take out the 2 upper fixing screws of the panel.

Take out the fixing screw on the right side.

Undo the soundproof panel taking it to the front.

Take out the 3 fixing screws of the right lower

soundproof panel.

59

Take out the 3 fixing screws of the lower left soundproof

panel.

Take out the 3 fixing screws of the lower lright soundproof panel.

Take out the waterproof radiator sheet metal and

take off the soundproof right panel taking it out to the front.

Take out the 3 fixing screws of the upper left soundproof

panel.

Take out the fixing screw of the left soundproof panel

and take out to the front the panel.

The fitting of the panels is made at the reverse from the

removal operations.

60

TRANSMISSION

REMOVAL

Place the car on an elevator or on a chassis stand.

Remove the front wheel.

(set screw when fitting again 120N/m)

Take out the suspension arm fixing screw.

(set screw when reassembling 40N/m)

With a hub puller (FACOM ref U16B), uncouple the suspension

arm from the hub.

Take out the transmission end screw on the hub

(set screw when reassembling 120N/m)

Uncouple the hub of the transmission

With a screwdriver, act as a lever to disconnect the

reverser drive axle and take off the transmission.

61

TRANSMISSION GAITER CHANGE

Remove the fixing gaiter collars.

Drag the gaiter on the shaft to free the joint.

Separate the fixing circlips from the transmission shaft.

Take out the gaiter.

After having greased the joint and fitted a new gaiter, fit all back

at the reverse from the removal operations.

The 2 transmission gaiters are not identical, respect the

fitting way (see drawing below)

Wheel Side

Reverser axle side

62

VARIATOR REMOVAL

The complete variator is adjusted in the factory and in case of repairing, it is necessary to use the MICROCAR

original pieces.

It doesn't require a lot of maintenance but to obtain a maximum performance, it is important that the mobile flanges

slide freely. So it can be necessary to clean it well.

POWER PULLEY REMOVAL

NOTA : The first MC1 models can be equiped with the same

variators as the VIRGO.

The adjustments are different, see specific paragraph

(page 64 et 65).

Take out the screw and its fixing washer and take out the pulley

(set screw when reassembling 60N/m)

Take out the nut and its washer bell lock.

(set screw when reassembling 100N/m)

Take out the bell.

63

Take out the 3 blocks with their flyweights and sounproof springs

Replace the springs in case of wear.

Be carefull to the fitting way of the blocks, they must run freely

in their place.

Take out the half pulley of its axle.

NOTA : For a cleaning, it is not necessary to dismantle the

inside spring of the mobile half pulley.

In case of change of the spring or the bearing :

- Compress the upper bearing and take out the inside circlips.

- Take out the upper bearing

- Find and take out the adjustment spacer of the spring.

Clean the parts with compressed air. Dry well and degrease

the pulleys (lubricate with fine oil the axle of the fixed half pulley)

The fitting operations of the power pulley are made at the

reverse from the removal operations.

64

• Position the belt setting washers (A)

(Réf. 0 782 373 et 0 782 374) on the shaft of the fixed half pulley.

• Position 4 adjustment spring spacers (B) thickness 1,2mm (Réf. 0 780 352) in the lower bearing (D)

• fit the spring (Réf. 1 000 660).

• Position 2 adjustment spacers (B) thickness 1,2mm (Réf. 0 780 352) in the upper bearing (E)

• Position 1 adjustment spacer (C) thickness 0,6mm (Réf. 0 780 357) in the upper bearing (E)

NOTA : Always share the number of adjustment spacers on each side of the spring.

POWER PULLEY SPRING SETTING

ADJUSTMENT IN THE FACTORY

1ST VERSION MODEL

D

65

• Position 5 adjustment spring spacers (B) thickness 1,2mm (Réf. 0 780 352) in the lower bearing (D)

• fit the spring (Réf. 1 000 660).

• Position 5 other adjustment spacers (B) thickness 1,2mm (Réf. 0 780 352) in the upper bearing (E)

• Position the adjustment spacer (B) thickness 0.6 mm (Réf. 0 780 352) in the upper bearing (E)

• Position the belt setting washers (A) thickness 1mm (Réf. 1 002 568) inside the spring

NOTA : Always share the number of adjustment spacers on each side of the spring.

POWER PULLEY SPRING SETTING

(ADJUSTMENT IN THE FACTORY)

2nd VERSION MODEL

66

RECEIVER PULLEY

DISMANTLING

Take off the fixing nut of the receiver pulley

(set screw when fitting back 60N/m)

Take out the receiver pulley of the axle box and take out the key.

Find the spring position.

Take off the inside circlips compressing the fixed came.

Take out the fixed came and the spring.

Take out the half mobile pulley.

Clean the pieces with diesel and compressed air

Dry well and degrease the pulleys (lubricate with fine oil the

axle of the half fixed pulley).

1ST VERSION RECEIVER PULLEY FITTING

For the fitting, put the mobile half pulley

on its axle, position the spring on the mobile

pulley in the hole (C) and position the

other spring end in the hole (2) of the fixed

came.

C

2

67

2ND VERSION RECEIVER PULLEY FITTING

For the fitting, put the mobile half pulley

on its axle, position the spring on the mobile

pulley in the hole (A) and position the

other spring end in the hole (4

) of the fixed

came.

A

4

Position the key of the shaft on the same line as the came.

Compress the spring and turn the mobile half pulley

at the reverse from a watch needles , to change a came step.

Fit back the outside circlips.

NOTA : For the usual maintenance of the receiver pulley,

it is not necessary to take it out, a diesel cleaning on the sliding

(behind the spring) is sufficient.

68

CHANGER BRIDGE REMOVAL

Unplug the battery using the red speed (+) disconnecting cable

cable terminal.

Take off the lower soundproof panel.

(see page 58).

Take off the fixing screws of the suspension arms of the

hub.

(set screw when fitting back 40N/m).

With a hub puller (FACOM ref U16B) uncouple the suspension

arms from the hub.

With a screwdriver, act as a lever to disconnect the changer

bridge and take off the transmission.

69

Before untightening all the fixing of the changer bridge

wedge the underneath of the engine sump to prevent

it from tipping.

Take out the 2 fixing bolts of the changer bridge on the back rubber

mounting.

(set screw when fitting back 12N/m)

• Untighten the 2 fixing screws of the changer bridge support

(set screw when fitting back 30N/m).

•Hold the changer bridge and take out the 2 fixing screws (A)

(see drawing)

• Take out the changer bridge from below the car.

• Make the fitting at the reverse from the removal operations.

Take out the receiver pulley of the variator (see page 66).

Uncouple the changer bridge switch command

Unplug the speed sensor.

A

70

1

6

2

4

5

3

8

9

10

11

4

14

7

13

12

15

16

17

18

19

20

17

21

28

10

11

32

31

30

29

27

26

25

22

23

24

41

40

39

38

37

36

35

34

33

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Left housing bridge

Right housing bridge

Housing bridge joint

10 x 10 x 0,9 socket

Ball bearing

Waterproof ring

Entry shaft

2nd reduction shaft bearing

Spring ring

Waterproof ring

Ball bearing

Reverse gear shaft

Mobile reverse gearing

2nd reduction shaft

Spring ring

1st reduction shaft

Ball bearing

Fixed reverse gearing

Coupling sleeve

Spacer

Breather cap

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Transmitter joint

Digital meter transmeter

M4 x 12 screw

12 x 1,5 level screw

12 x 18 x 1,5 washer

Drain plug

Ball

Spring

screw

TH 10 x 1,5 screw

Lever spring

washer support

Differential

Gear lever group

O ring seal

Spring ring

Selector guide

Selector lever

Selector washer

Selector nut

71

REVERSER TRANSAXLE

REMOVAL

Before opening the door , we advice you to clean it with petroleum or

diesel and to dry it with compressed air.

Drain the gearbox oil by its oil change hole (27)

Take out the holding screw (31), the spring (29) and the ball (28).

Take out the 8 screws that gather the 2 half housing

Separate the 2 half housing (1) and (2) lightly hiting

with a rubber hammer in the axle of the entry shaft (7).

Never introduce a screwdriver between the 2 half haousing

as lever , not to damage the joints.

Throw the old paper joint (3) between the 2 half housing

and take a new one for the fitting.

Take out the return spring.

Take out reverse gear axle (12).

Take out the entry shaft(7).

72

1

6

2

4

5

3

8

9

10

11

4

14

7

13

12

15

16

17

18

19

20

17

21

28

10

11

32

31

30

29

27

26

25

22

23

24

41

40

39

38

37

36

35

34

33

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Left housing bridge

Right housing bridge

Housing bridge joint

10 x 10 x 0,9 socket

Ball bearing

Waterproof ring

Entry shaft

2nd reduction shaft bearing

Spring ring

Waterproof ring

Ball bearing

Reverse gear shaft

Mobile reverse gearing

2nd reduction shaft

Spring ring

1st reduction shaft

Ball bearing

Fixed reverse gearing

Coupling sleeve

Spacer

Breather cap

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Transmitter joint

Digital meter transmeter

M4 x 12 screw

12 x 1,5 level screw

12 x 18 x 1,5 washer

Drain plug

Ball

Spring

screw

Vis TH 10 x 1,5

Lever spring

washer support

Differential

Gear lever group

O ring seal

Spring ring

Selector guide

Selector lever

Selector washer

Selector nut

73

Take out the intermediate gearing and the differential

(34).

Take out the different bearings with a universal hub puller

We advice you not to do anything on the differential (34)

In case of anomaly, replace the differential.

You must change the waterproof joint (3)

of the half housing when fitting back.

Maxi oil capacity : 0,5 liter.

Checking by the level screw (25).

For the fitting, follow the reverse operations of removal

Be carefull to the well position of the selector peg in the dog clutch sleeve.

74

STARTER REMOVAL

Unplug the battery using the disconnecting speed red cable

terminal (+).

Take out the air filter.

Take out the electric feed of the starter

Take out the variator (see page 62).

Take out the flywheel.

Take out the fixing starter support : 3 fixing screws on the engine

and 2 fixing screwson the bridge.

Do not completely take off the fixing axles

of the changer bridge box.

Take out the support and the starter.

75

ENGINE REMOVAL

Unplug the battery using the speed red (+)disconnecting cable

terminal.

Take out the front bumper (see page 19).

Take out the soundproof engine panel

(see page 58).

Take out the front cross beam (2 fixing screws) and the engine

hold cable.

Take out the power pulley and the belt (see page 62).

Take out the throttle cable.

Find and take out the 2 fuel feed hoses

Fix the engine with a hoist or a workshop crane.

Uncouple the engine from the changer bridge.

(2 fixing screws).

Take out the fixing screws of the engine on the front

front rubber mounting.

Take out the engine of its place.

Drain the cooling system at the level of the

radiator inside hose.

Take out the 2 heating tubes

Take out the 3 cooling hoses

Unplug all the electric feeds

Uncouple the tube from the exhaust

manifold.

Take out the fixing screw of the exhaust

tube on the engine housing.

76

ENGINE CRADLE REMOVAL

Unplug the battery using the red speed disconnecting (+)

cable terminal.

• Remove the front bumper (see page 19).

• Remove the soundproof engine (see page 58).

• Remove the 2 doors (see page 8)

• Remove the 2 front wings (see page 20).

• Remove the 2 light optics (see page 22).

• Unplug the 2 heating hoses.

• Find and take out the 2 fuel feed hoses.

• Unplug the accelerator cables.

• Unplug the the changer bridge.

• Uncouple the tube of the exhaust manifold

• Take off the air induction duct

• Take off the exhaust fixing tube on the engine housing.

• Unplug the opening bonnet cable

• Uncouple the rack of the steering column (see page 96).

• Unplug the rigid tubes at the joint of front brakes fuses.

• Take out the windscreen washer tube.

• Unplug all the electric feed cables betwen the body and the engine cradle.

• Place the car on an elevator ar on a chassis stand.

• Take out the front wheels.

• Put a trolley under the engine cradle and chock the cradle.

77

Take out the fixing screws of the cradle on the engine, right side

(set screw when fitting back 22N/m)

Take out the fixing screws of the cradle on the engine, left side

(set screw when fitting back 22N/m)

With the trolley, take out the cradle of the body.

78

ENGINE CRADLE

EQUIPMENT

Fit the waterproof joint between the manifold and the exhaust tube

Be carefull to the fitting way, (boss up)

Fix the tubulure on the exhaust manifold with 2 M8 screws

without blocking them.

Fix the M12 lower fixing screw of the exhaust tube

on the engine, without blocking it.

Tighten the 2 M8 fixing nuts of the exhaust tube on

the manifold.

Tighten the M12 lower fixing screw of the exhaust tube

on the engine (set screw 45N/m).

79

Fit the interference eliminator wire on the engine housing.

Fit the holding belt clamp on the changer bridge with its washer

and its fixing screw.

Block the fixing screw of the holding belt clamp

(set screw 8N/m)

Put a circlip on the 2 exit changer bridge axles.

Settle, without driving them in, the 2 fixing screws of the changer

bridge with their washers.

80

Fit the changer bridge on their support and introduce the 2 fixing

screws.

Tighten the fixing screws of the changer bridge.

(set screws 60N/m)

Grease the 2 axles of the exit transmission and the

entry shaft of the changer bridge.

On the front of the engine cradle, fit a spacer washer

on the 4 fixing inserts of the elastic plots.

Fit the 2 elastic plots and fix them on the cradle with 4 screws

and washers (set screws 12N/m).

81

At the back of the engine cradle, fix 4 spacer

washers on the fixing axles of the elastic plots.

Fit the inside screws of the elastic plots and fix them on the

cradle with 4 screws and washers.

(set screw 12N/m)

Fit the fixed battery clamp.

Fix the electric fuel pump on the engine cradle with 2 rubber

washers, 2 bolts and 2 washers.

(set screw 12N/m)

Fix the steering rack on the cradle, 2 fixing screws + 2

washers (set screw 120N/m)

82

Fit the 2 suspension triangles on the engine cradle

(set not 70N/m)

With a hoist or a workshop crane, fit the engine on the

cradle.

Fit the anti-couple stop support clamp

Fit the conical stop on the anti-couple stop support

clamp.

Fix the changer bridge on the back elastic plots with a

washer nut. (set screw 30N/m)

83

Fix the engine on the front elastic plots with screws and

washers. (set screw 30 N/m).

Fit the receiver pulley on the changer bridge axle with its

key.

Fix the pulley with a washer and a nut.

(set screw 60N/m)

Fit the power pulley with the belt on the axle of the flywheel.

Fit its fixing screw with glue.

(set screw 60N/m)

84

Fit the exhaust tube rubber mounting.

Position the radiator on the engine cradle and fix it to the front

lwith a screw and a fixing washer.

Fix the radiator to the back with 2 screws and fixing washers.

Fix the upper hose between the radiator and the engine

with 2 serflex collars.

Fit the lower hose between the radiator and the engine with 2

serflex collars.

85

Fit the shock absorbers in the 2 hubs, fix them with a nut and washers

(set screw 25N/m)

Fit together the 2 transmissions on the axles of the

changer bridge.

Fit the lengther on the variator side.

Fit the hose Ø 10 with 2 collar clips.

Fit the banjo of the brake hose with a copper joint

on each side and fit it with its screw on the brake caliper.

Fit the lower ball joint on the hub and fix it with 3 screws and

3 washers (screw fitted on the brake)

(set screw 10N/m).

86

Fit the hub and the right shock absorbers on the

transmission (steering lever to the back).

Fix it on the suspension triangle with a screw

(set screw 40N/m)

Put the mudflap on the shock absorbers.

Fit the washers (1) and(2) on the shock absorber heads.

Fit the rubber mountings.

Position the shock absorber heads on the engine cradle

supports(4).

Fit the rubber mountings.

Fit the washers (6) and the nuts (7).

Block the fixing shock absorbers cap nut

(set screw 20N/m)

Fit the hub and the left shock absorbers on the

transmission (steering lever to the back).

Fix it on the suspension triangle with a screw

(set screw 40N/m)

6

7

5

3

4

2

1

87

Fix the 2 mudflaps on the engine craddle withe 4 black

plastic rivets.

Fix the 2 steering ball joints on the levers.

(set screw 22N/m)

Fit the screws + the hub axle wahers

(set screw 120N/m)

Fix the 2 brake fuses on the engine craddle

Fit the steering transmission on the rack, a fixing bolt +

washers

(set screw 22N/m)

88

BRAKE PADS

CHANGING

Always replace the brake pad complet train.

Lift up the car and take off the wheels

(set screw 60N/m)

On the front, unplug the wear light wire.

Take out if necessary, a bit of braking liquid of the tank thanks to

a syringue.

Put the 2 fixing axles to the outside.

Take off the fixing axles with holding pad springs.

With a combination pliers, compress the piston caliper

and push it in its place.

89

Take off the 2 brake pads

• Control the waterproofness of the piston and the good condition of the brake caliper

and the weak of the discs (the thickness of the discs must be between 4 to 5mm on the front

and 3 to 4mm at the back). Below these sizes, the discs must be replaced immediately.

• Set some new pads

• Fit back at the reverse from the removal operations

• Press several times on the brake pedal

• Control and complete the level of the necessary brake liquid, do the bleed of the brake.

90

FRONT HUB

BEARING CHANGING

Lift up the car on an elevator

Take off the wheel

Take off the brake pads (see page 88)

With a 6 sides key, take off the 2 fixing screws of the brake caliper

Take off the fixing nut of the steering joint.

(set screw when fitting back 22N/m)

Take out the steering joint, use a hub puller

FACOM Réf. U16B.

Take out the fixing nut hub of the lower pivot

(set screw when fitting back 40N/m)

With a hub puller FACOM Réf. U16B, uncouple

the hub from the suspension triangle.

91

Take out the fixing nut of the transmission on the hub.

(set screw when fitting back 120N/m)

Take out the transmission of hub

Take out the fixing screw of the shock absorbers on the hub

(set screw when fitting back 25N/m)

Take out the half train.

Take out the 4 screws of the wheels support

set screw when fitting back 60N/m)

Take out the wheel support end the brake disc.

92

FRONT BRAKE

H UB

93

With a circlips pliers, take off the circlips which hold the

bearing.

With a press, take out the bearing from its place

Replace the bearing and make the fitting at the reverse from

the removal operations.

94

BACK HUB

BEARING CHANGE

Put the car on an elevator

Take off the back wheel

(set screw 60N/m)

Take out the brake pads (see page 88)

WIth a 6 sides key, take out the 2 fixing screw of the

back caliper.

Take out the caliper of the disc.

Take out the central fixing of the hub

Set screw when fitting back 120N/m)

With a hub puller, take out the back hub

Replace the bearings

The fitting back is made at the reverse from the removal

operations.

95

BCKHU

96

STEERING

Place the car on an elevator

Take out the 2 front wheels

(set screw when fitting back 60N/m)

STEERING RACK

REMOVAL

Take out the 2 front wheels

(set screw when fitting back 22N/m)

Take out the 2 hub with a hub puller FACOM

réf. U16B.

Take out the fixing bolt and uncouple the steering column

of the rack

(set screw whenfitting back 22N/m)

Take out the 2 fixing screws of the rack.

(set screw when fitting back 120N/m)

97

Take out the rack

The fitting back is made at the reverse from the removal

operations

GAITER CHANGE

ON THE RACK

REPAIR RACK KIT

After having taken down the hubs.

Cut the fixing plastic collar gaiters and make the gaiters

slided to the exterior.

Fit back the new gaiters taking care to grease the rack

Use a standard grease.

Hardness regulating of the steering control. A regulating screw on

the rack allows the hardness of the steering to incresa or to

decrease.

For each regulating of the hardness of the rack

you must punch the nut to avoid it to

get out of control.

A repair steering rack kit which contains a bush + bearing +

joints is available under the reference :

1 002 788

Take out the waterproof bush.

Take out the inside circlip to take out the rack axle

Connecting rod

After having taken out the gaiter, with a screwdriver, take out the fins

of the brake washer of the notches of the ball joints.

With a vice pliers, untighten the connecting rod and take out

the connecting .

Crimp again the lock washer after the fitting of

the new connecting rod.

98

Make the alignment controlwith a specific machine. The regulating is made at the level of the steering hubs

The repartition of the steering must be equal on the right and on the left and the steering wheels in straight

position.

If you do not have any specific machine for the regulating of the adjustment, fix some rules on the back

wheels and regulate as before at the level of steering hubs.

The back train is regulated when building, so it is not possible to make any regulating.

ALIGNMENT

FRONT AND BACK GEOMETRIC TRAIN

SIZES CONDITIONS : discharged car filled up.

FRONT TRAIN

BACK TRAIN

ADJUSTMENT

L

0° ± 5’

R

0° ± 5’

BODY

L

0° ± 30’

R

0° ± 30’

PIVOT

L

16° ± 1°

R

16° ± 1°

CATER

L

4° ± 1°

R

4° ± 1°

ALIGNMENT

L

+ 25’ ± 25’

R

+ 25° ± 25’

BODY

L

- 25’ ± 25’

R

- 25’ ± 25’

99

Fill in the tank with braking liquid

Nota : make the bleeding after : every repairing

during which one the braking circuit has been

opened, and when it is necessary to push several

times on the pedal to obtain the braking or if

you feel an elasticity in the pedal.

BRAKING WITH A SPECIAL

MACHINE

• Follow the form of the constructor of the

used machine

• Start the bleeding by the wheel the faster of

the master cylinder and do as follow : back

right wheel, back left wheel, front right wheel

front left wheel

•Do not use again the drained brake liquid.

• Seal the air braking screws with the dust

covers after having made the braking.

• Press several times on the braking pedal

• Fill the liquid in the tank, at the end of the

circuit bleeding

• Make a try.

BRAKING HYDRAULIC CIRCUIT BLEEDING

BLEEDING WITHOUT SPECIAL MACHINE

Nota - During the bleeding operations, check if the level of the

liquid in the tank stays at the minimum.

•Control and if need be complete the level of the liquid

in the compensation tank. The bleeding must be made as

follow : back right wheel, back left wheel, front right wheel

front left wheel

• Take off the dust cover of the bleeding screw, connect the

tuyau de purge en laissant plbleeding tube letting plunge

the other end in a transparent container.

• With a apropriated key, open the bleeding screw with a half turn

and press on the brake pedal several times and in its total run

till the liquid which goes out don't have any air bubble

anymore

• Close the bleeding screw when the brake pedal is pressed

2 persons are necessary to make the bleeding in these

conditions. It is also necessary to always complete the level

of brake liquid which has gone out.

• Do the same on the other wheels in the indicated way

• Put back all the caps on every bleeding screw.

• Control the new level of the brake liquid in the tank and fill in

if need be.

• Press several times on the brake pedal.

100

• After having settled the 2 cables in the compensator

and be sured that the main circuit is correctly drained

• Press several times on the pedal.

• Control the untightened parking brake, the rotation

of the back wheels.

First adjustment:

Make a lever on the compensator and adjust the tension of

the cables with the regulating nuts of the compensator.

It is necessary to have 4 notches at the maximum

on the handbrake lever.

Ragulating :

The regulating of the handbrake must be checked

for each maintenance. The regulating must be only made

on the calipers.

1) Untighten the 2nd nut of the screw which provides

the lost.

2) Tighten the screw to put the pads in contact with the disc

(without forcing, tightening by hand)

PARKING BRAKE ADJUSTMENT

3) Tighten again the screw between 1/3 and 1/2

turn at the maximum (120 to 180°). The pads

must lap the disc without blocking the wheel in

in rotation.

4) Tighten again the 2nd screw on the washer with

a couple of 10 N/m without making the screw turned

5)The same for the 2nd calliper.

6) Check the deflection of the handbrake level

(4steps at the maximum).

• Grease the compensator.

• Be sure that the 2 cables slide correctly-

and the light of parking brake works

Loading...

Loading...