MicroCal, LLC

22 Industrial Drive East

Binding Stability Kinetics support@microcalorimetry.com

Northampton, MA 01060 USA

Phone: +413 586 7720

Fax: +413 586 0149

VP-ITC MicroCalorimeter

User’s Manual

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Table Of Contents

General ............................................................................................................................................................i

How To Use This Manual ............................................................................................................................i

How to Get Help from MicroCal................................................................................................................ ii

Symbols..................................................................................................................................................... iii

Operators Safety...........................................................................................................................................iv

Product Safety................................................................................................................................................v

Instrument Specifications .............................................................................................................................v

Safety Specifications.....................................................................................................................................vi

European Users: CE Mark........................................................................................................................ vii

Instrument Safety Compliance.................................................................................................................. vii

Section 1: VP-ITC System Introduction.....................................................................................................1

1.1 VP ITC – The Basics...........................................................................................................................2

1.2 Data Acquisition and Instrument Control............................................................................................3

1.3 Suitable Laboratory Environment.........................................................................................................4

1.4 VP-ITC Parts and Accessories .............................................................................................................5

1.5 Setting Up the VP-ITC Instrument.......................................................................................................7

1.6 Pipette Assembly..................................................................................................................................9

1.7 The ThermoVac..................................................................................................................................11

Section 2: VPViewer and Origin Software...............................................................................................14

2.1 VPViewer and Origin Software Overview .........................................................................................15

2.2 Powering Up the VP-ITC Instrument..................................................................................................15

2.3 VPViewer Main Window...................................................................................................................17

2.4 ITC Controls Window........................................................................................................................21

2.5 Thermostat/Calibration Window ........................................................................................................26

2.6 Setup/Maintenance Window...............................................................................................................27

2.7 Constants Window..............................................................................................................................30

2.8 Real Time Data Display in Origin......................................................................................................31

2.9 ITC Cell Status ...................................................................................................................................34

Section 3: Running an ITC Experiment ...................................................................................................36

3.1 Designing ITC Experiments...............................................................................................................37

3.2 Using the ThermoVac to Degas Samples...........................................................................................41

3.3 Cell Loading.......................................................................................................................................43

3.4 Loading the Auto-Pipette....................................................................................................................44

3.5 Choosing The Run Parameters ...........................................................................................................47

3.6 Carrying Out Experimental Runs .......................................................................................................48

3.7 The Single Injection Method (SIM) ..................................................................................................49

3.8 Using the ThermoVac for Cleaning the ITC Sample Cell..................................................................51

3.9 Cleaning Syringes...............................................................................................................................53

Section 4: Experimental Tutorials ............................................................................................................54

4.1 Water-Water Baselines.......................................................................................................................55

4.2 Methanol Tutorial...............................................................................................................................64

4.3 Rnase-2’CMP Experiment Tutorial....................................................................................................67

Section 5: Instrument Maintenance...........................................................................................................68

5.1 Cleaning The Cells and Pipette ..........................................................................................................69

5.2 Replacing Pipette Plunger Tips ..........................................................................................................73

5.3 Y-axis Calibration ..............................................................................................................................77

5.4 Replacing Injection Syringes & Height Adjustment ..........................................................................79

5.5 Temperature Calibration.....................................................................................................................81

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Section 6: Tips and Troubleshooting ........................................................................................................85

6.1 User Tips and FAQs...........................................................................................................................86

6.2 Troubleshooting..................................................................................................................................87

6.3 A Note About Buffers ........................................................................................................................89

6.4 Selecting the Proper Stirring Rate ......................................................................................................90

6.5 Estimation of Required Concentrations..............................................................................................91

Section 7: Additional Features ...................................................................................................................92

7.1 Extended Data Display.......................................................................................................................93

7.2 Customizing VPViewer......................................................................................................................94

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

General

How to Use This Manual

This manual describes the VP-ITC; its setup, operation and maintenance.

Once the instrument is setup (as described in Section 1), a new user may wish to go directly to

Section 4 and run through the experimental tutorials for a “hands on” approach to learning about

the instrument and software. The user should then refer back to sections 2 and 3 for detailed

descriptions toward a better understanding of the intricacies of the instrument. Section 5 contains

important information for maintaining the instrument performance. Section 6 provides tips for

optimizing the performance and troubleshooting techniques for commonly encountered problems.

Section 7 provides description of some more advanced features.

Much of this manual provides descriptions of the VP-ITC instrument and software. Bullets or step

numbers are typically used when the user is requested to perform an operation.

• Indicates a step to perform an operation

1. Steps are numbered when the sequence of operations is critical.

i

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

How to Get Help from MicroCal

The service department at MicroCal, LLC is available to help you during normal business hours, Monday

through Friday from 8:00 AM to 5:00 PM (EST). Service personnel may be contacted by e-mail, phone or

fax, with the preference being by phone or e-mail. When e-mailing MicroCal for technical assistance, if

possible, please attach a recent data file(s) (*.itc, raw ITC data files) that demonstrate the problem. Also,

please include with the correspondence, all details that may be relevant to the problem. In instances where

the problem or question relates to post run data analysis, it is best to attach the raw data file (*.ITC) and the

Origin document (*.opj) generated during data analysis.

There are 2 general categories of problems associated with the VP-ITC and its operation. The most extreme

category is when a system is simply not working, at all. Problems that prevent users from operating the

VP-ITC require immediate consultation with a MicroCal technician. Customers should not attempt to

repair the VP-ITC hardware or software unless instructed to do so by a MicroCal service

representative.

The second, and less extreme general category of problems is when a VP-ITC instrument is functioning, but

is not operating within its normal performance specifications. Large baseline drifting, non-repeatable control

peaks (Water/Water) and/or an increase in short term noise level are all examples of performance problems,

typically correctable by the operator. For performance issues such as these it is recommended that customers

carry out the following minimum diagnostic steps prior to contacting MicroCal for service:

1.) Thoroughly clean the cells. Do not assume they are clean. As a minimum, use the provided

Cell Cleaning Apparatus to pass 500 ml of a 10-25% ammoniated detergent in water solution,

followed by 500 ml of cold water rinse, through the sample cell. Discretion may call for a more

rigorous cleaning procedure as described herein.

2.) Refill both the reference and sample cells with filtered degassed water. Fill a thoroughly

cleaned syringe with water and/or use a different syringe.

3.) Go to the Setup/Maintenance window within VPViewer 2000 (as described, starting on page

27) and activate the extended data mode. (While in extended data mode, ITC data files will

contain all available information produced by the VP-ITC and often times is helpful in

diagnosis of problems).

4.) Carry out a minimum of 25, 10µL injections of water into water

5.) Consult the troubleshooting section of this manual.

If, after completion of the 5 steps listed above, the ITC performance is not corrected, contact the MicroCal

service department for help. The water run, in extended data mode, should be provided to the MicroCal

service technician for evaluation. The service department with comments and recommendations will then

contact customers.

MicroCal, LLC Contact Information:

Primary Contact Phone 413-586-7720

Toll Free Phone Number 800-633-3115

Facsimile 413-586-0149

Web Site: www.MicroCalorimetry.com

Please forward corrections or suggestions concerning this manual to info@MicroCalorimetry.com

MAU130030 Rev. E ii

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Symbols

Symbols used in this manual

! Warns the user of possible damage to the unit, draws attention to the risk of injury or

contains safety notes and warnings.

Symbols used on the VP-ITC instrument

Caution: Read the instruction manual before operating

Instrument (supply) ON

Instrument (supply) OFF

Protective Earth (Ground) Terminal

Origin® is a registered trademark of Origin Lab, Northampton, MA

VP is a registered trademark of MicroCal, LLC, Northampton, MA

MicroCal is a registered trademark of MicroCal, LLC, Northampton, MA

Windows™ is a registered trademark of Microsoft Corporation

iii

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Operators Safety

! The points below are intended to enhance your safety awareness and to draw your attention to risks

which only you, the operator, can prevent. MicroCal has set high standards for ourselves in developing

and constructing the VP-ITC. Each unit constructed is fully tested to operational and safety standards.

It should be noted that no amount of design or constructed safeguards can anticipate or prevent improper

handling. It is intended that only responsible people trained in basic laboratory protocol in procedures

and safety techniques operate this instrument. This product is intended to operate from a power

source that does not apply more than 260 V rms between the supply conductors or between either

supply conductor and ground. A protective ground connection, by way of the grounding

conductor in the power cord, is essential for safe operation

! To avoid any hazard, use only a fuse of the correct type, voltage rating and current rating as

specified on the back of the VP-ITC. This is a 1 Amp 250 Volt Time-lag (Time Delay) fuse.

! Repairs, alterations or modifications must only be carried out by specialist personnel. The

MicroCal Service Department will be happy to serve you for any repair work or operational

questions.

! To enhance safety always plug the instrument into a Ground Fault Circuit Interrupter (GFCI)

device.

! A solution can become an electrical conductor when in contact with electricity and can create a

hazard with the potential of burns or death. Use caution when using solutions near the instrument

and adhere to the following items:

! If any liquid is spilled on or around the instrument unplug the instrument immediately

and wipe it up, if there is any possibility that some of the liquid may have leaked into

the instrument case contact MicroCal immediately. DO NOT PLUG THE

INSTRUMENT INTO ANY POWER MAINS, until the problem is resolved.

! Do not over fill the cell and reservoir. There is a small reservoir located at the top of

the access tubes to catch a minimum amount of overflow, do not exceed the capacity of

the reservoir

and allow any fluid to leak into the instrument cabinet.

! This device is not designed to the Medical Devices Directive 93/42/EEC and should not be used for

medical purposes and/or in the diagnosis of patients.

! When using volatile or hazardous solutions in the cells, the operator should always follow proper

laboratory procedures in handling (e.g. wear safety glasses and protective clothing) and disposing

of such materials and allow the internal cells to cool down to room temperature before removing

any solutions from the cells.

! All solutions in the cells must be cooled down below 50 ºC before removing from the cells to

prevent the glass syringes from breaking due to the hot liquids.

MAU130030 Rev. E iv

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Product Safety

We have used all means to design and produce the VP-ITC to prevent any damage to the instrument during

normal usage. The instrument is solidly built using the latest in micro-technology in its components and

design, but of course, this cannot prevent damage due to physical mistreatment. The attentiveness of the

operator to the identification of materials which could corrode the Hastelloy® Alloy C-276 cells, the

prevention of freezing solutions in the cells and the responsible handling and usage of the instrument should

ensure a long service life for the VP-ITC.

! The VP-ITC cells are constructed out of Hastelloy

corrosion by strong bases, but strong acids should be avoided. Please refer to the accompanying

booklet “Hastelloy

®

Alloy C-276” for further information.

®

C-276. Hastelloy is extremely resistant to

! The freezing of solutions in filled cells will cause irreparable damage to the cells due to the

expansion of the solution in the cells.

! When moving the VP-ITC the instrument should always be in its normal operating or its vertical

position. The instrument should never be moved in a sideways position, due to the nature of the

crystal detectors used for the instruments thermal sensing, which are strong in a compression

mode but weak when subjected to shear stresses.

Instrument Specifications

Model or Type : VP-ITC

Performance Specifications

Short Term Noise (RMS Average) : 0.5 nanocal/sec (2 nanowatts)A

Control Peak Repeatability : Mean ≤ 1.5µCal., s.d. ≤150 nCal B

Minimum Response Time (high gain) : 20 seconds

Operating Temperature Range : 2° to 80° C

Physical Specifications

Cell Material : Hastelloy® Alloy C-276

Dimensions (L x W x H in inches)

Cell : 17 x 8 x 15

Controller : 15½ x 16½ x 7½

Monitor : 9 x 15 x 15½

Weight (lbs)

Cell : 20

Controller : 25

Monitor : 12

A

For passive mode, using 3-min time intervals and 2 second filter for data points. This noise specification depends on AC power

fluctuations, and is stated here for stable AC voltage, which would be obtained using an isolated line or voltage regulator.

B

Mean energy for a series of thirty, 10 µl injections of water into water or buffer into buffer run isothermally at 30ºC, high gain

mode, stirring at 300 rpm

v

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Safety Specifications

Instrument Specifications (excluding Controller)

Electrical Specifications

Electrical Ratings:

Voltage : 110 - 240 Volts

Frequency : 50 / 60 Hz

Power : 70 watts

Fuses (2) : Primary=1.0 A, 250 V, Time Delay

Output : Secondary/Data Connection only

Protective Earth Terminals : Internal/external marked

Mode of Operation : Continuous

Classification : Class I

Atmospheric Specifications

Operating:

Temperature : 10° to 40° C

Humidity : 0 to 75% RH noncondensing

Atmospheric Pressure : 700 HPa to 1060 HPa

Storage: (in original shipping containers with no liquid in cells)

Temperature : -40° to +70° C (no liquid in cells)

Humidity : 10% to 90%

Atmospheric Pressure : 500 HPa to 1060 HPa

Cleaning the VP-ITC Instrument Case

Always shut down the computer controller and VP-ITC instrument and disconnect the mains power supply

cord before cleaning the case. To clean the instrument case, use a damp, lint-free cloth. Avoid abrasives or

solvents that can permanently damage the finish. With the damp cloth, gently wipe the external surfaces of

the instrument.

MAU130030 Rev. E vi

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

European Users: CE Mark

MicroCal VP-ITC calorimeters carry the CE marking which confirms that they meet the applicable European

Community Technical Directives.

Following the provisions of the applicable European council directives:

89/336/EEC, 93/68/EEC Electromagnetic Compatibility

73/23/EEC, 93/68/EEC Low Voltage

Is in conformity with the following harmonized standards:

EN 61326-1:1997, A1:1998, A2:2001 Electrical equipment for measurement, control and laboratory use –

EN 61000-3-2:2000, A1:2001 Limits for harmonic currents emissions

EN 61000-3-3:1995 Limitation of voltage changes, fluctuations and flicker in low-

EN 61010-1:2001, IEC 61010-1:2001 Safety requirements for electrical equipment for measurement,

EN 61010-2-010:2003,

IEC 61010-2-010:2003

EMC requirements

voltage systems

control and laboratory use

Particular requirements for laboratory equipment for the heating of

materials

Instrument Safety Compliance

MicroCal VP-ITC calorimeters carry the CUE Safety Certification Mark,

authorized by TÜV America, a division of TÜV Süddeutschland, to signify that:

1) the instrument has been tested by an accredited Certification Body and meets

applicable Canadian electrical safety standards/requirements (CSA/SCC).

2) the instrument has been tested by an NRTL (Nationally Recognized Testing

Laboratory) and meets applicable United States electrical safety

standards/requirements (ANSI/UL).

3) the instrument has been tested by a Competent and Notified Body for applicable EU Directives

and meets applicable safety standards/requirements (EN/IEC).

vii

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Section 1: VP-ITC System Introduction

This section starts by providing some basic information about the VP-ITC and the computer

controller. Then it provides instructions for setting up the VP-ITC instrument and accessories. It

ends by providing information about the ThermoVac instrument.

1

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

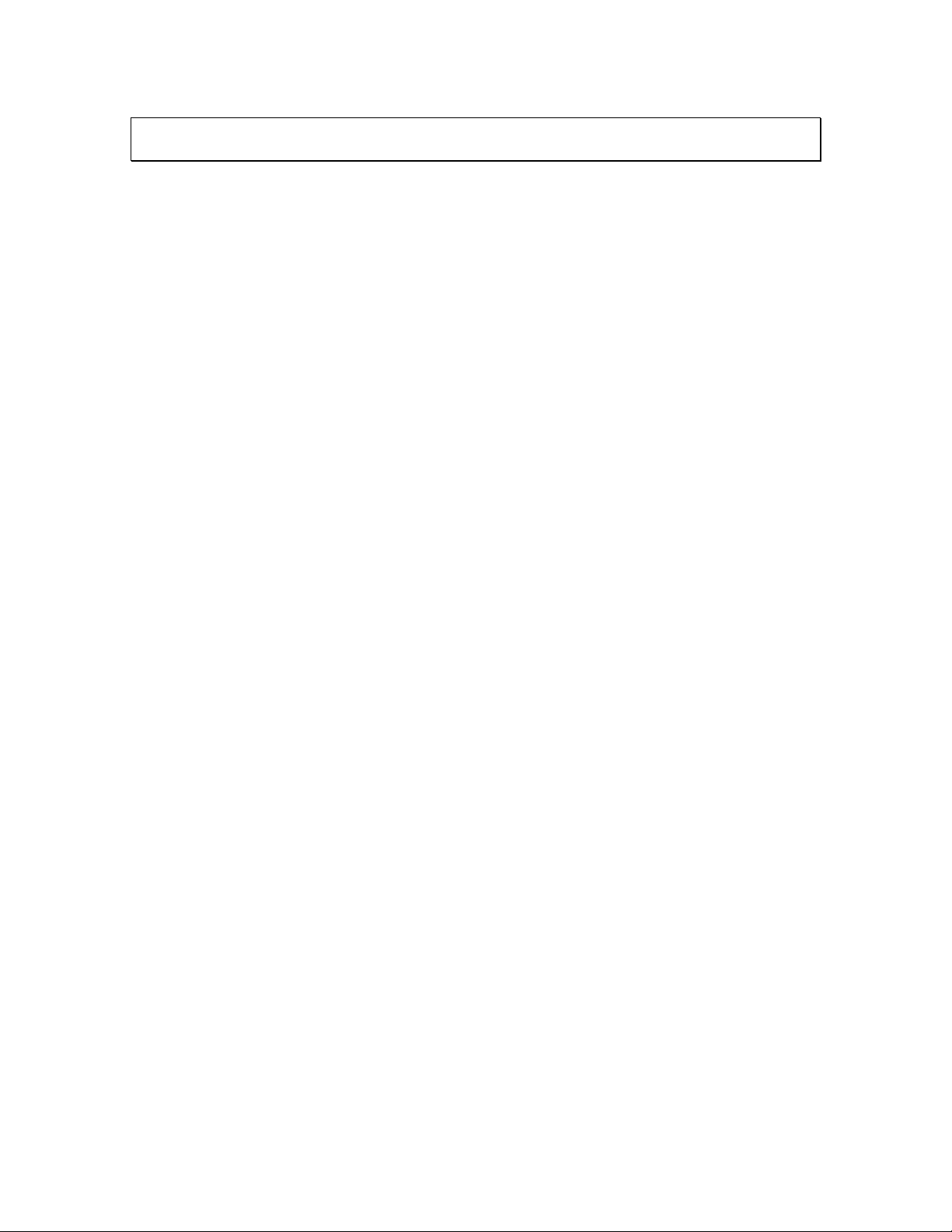

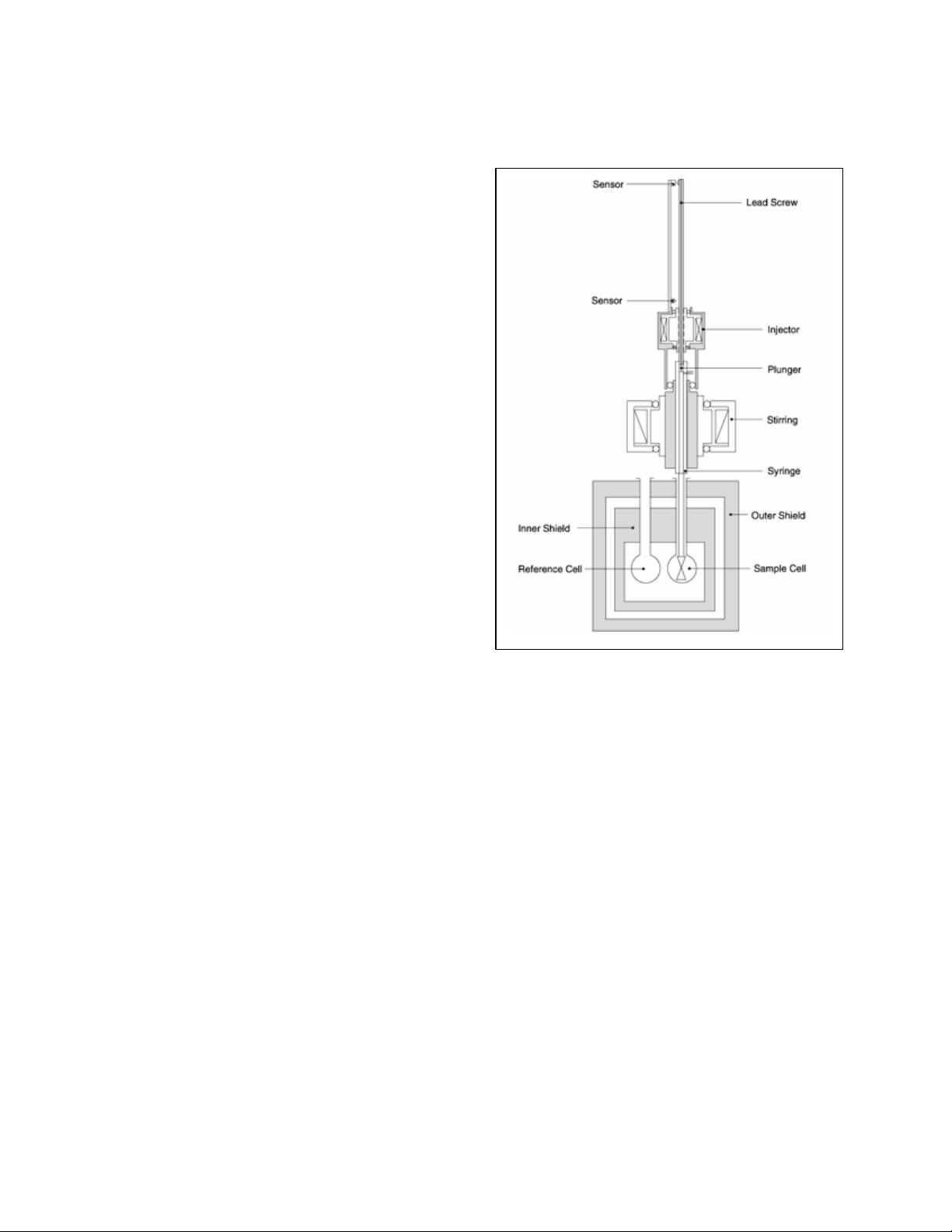

1.1 VP ITC – The Basics

The VP-ITC (Isothermal Titration Calorimeter)

Unit directly measures heat evolved or absorbed

in liquid samples as a result of mixing precise

amounts of reactants. A spinning syringe is

utilized for injecting and subsequent mixing of

reactants. Spin rates are user selectable.

The normal operating range is 2°C to 80°C.

Wetted cell surfaces are Hastelloy® Alloy C 276.

Sample and reference cells are accessible for

filling and cleaning through the top of the unit.

The sample cell is on the right as one faces the

front of the unit.

A pair of identical coin shaped cells is enclosed

in an adiabatic Outer Shield (Jacket). Access

stems travel from the top exterior of the

instrument to the cells. Both the coin shaped

cells and the access stems are totally filled with

liquid during operation. This requires

approximately 1.8 ml. per cell even though the

working volume of the cell is only 1.4 ml

Temperature differences between the reference

cell and the sample cell are measured, calibrated

to power units and displayed to the user as well

as saved to disk. The data channel is referred to as the DP signal, or the differential power

between the reference cell and the sample cell. This signal is sometimes referred to as the

“feedback” power used to maintain temperature equilibrium. Calibration of this signal is obtained

electrically by administering a known quantity of power through a resistive heater element

located on the cell.

The syringe containing a “ligand” is titrated (injected) into the cell containing a solution of the

“macromolecule”. An injection which results in the evolution of heat (exothermic) within the

sample cell causes a negative change in the DP power since the heat evolved chemically provides

heat that the DP feedback is no longer required to provide. The opposite is true for endothermic

reactions. Since the DP has units of power, the time integral of the peak yields a measurement of

thermal energy, ∆H. This heat is released or absorbed in direct proportion to the amount of

binding that occurs. When the macromolecule in the cell becomes saturated with added ligand,

the heat signal diminishes until only the background heat of dilution is observed.

With the VP-ITC system the entire experiment takes place under computer control. The user

inputs the experimental parameters (temperature, number of injections, injection volumes) and

the computer carries out the experiment. Origin software is then used to analyze the ITC data

using fitting models to calculate reaction stoichiometry (n), binding constant (K

), enthalpy (∆H)

b

and entropy (∆S).

MAU130030 Rev. E 2

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

1.2 Data Acquisition and Instrument Control

Two computer interface boards and a serial interface that reside inside the Computer Controller

operate the VP-ITC. The boards are pre-configured and calibrated at MicroCal, and need no

adjustments by the user.

Data acquisition is accomplished through a 16-bit A/D (analog to digital) converter board. There

are five differential inputs to the A/D, consisting of the DP or differential power between the

reference and sample cells, the Jacket Temperature, the DeltaT (temperature difference between

the cells and the adiabatic jacket), Shield Temperature (the outer shield temperature), and the

ATP channel (heat sink information). The default A/D inputs range from –1.25 volts to +1.25

volts for all input channels but can be changed through VPViewer. Additional available input

ranges are +/- 2.5 and +/- 5 volts.

ITC instrument control is accomplished through the second interface board, a 16-bit D/A (digital

to analog) converter board. Programmed by the VPViewer software, this board will regulate the

temperature of the VP-ITC, equilibrate the ITC in preparation for a titration run, and carry out the

ITC experiment.

The VP ITC injection system mounts on top of the cell unit and is controlled by VPViewer

through a standard RS-232 serial interface in the Computer Controller

Although other Windows’ programs can be used while the VP-ITC is running without affecting

the data acquisition or calorimeter control, it should be realized that there are real time operations

taking place during an experiment, and that performing CPU intensive tasks while an experiment

is in progress can ‘glitch’ the ITC baseline. Users are encouraged to avoid large file copying to

disk drives, large print jobs and recursive control loops while the VP-ITC is in the midst of an

injection run. Users can carry out routine data analysis while the VP-ITC is running.

3

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

1.3 Suitable Laboratory Environment

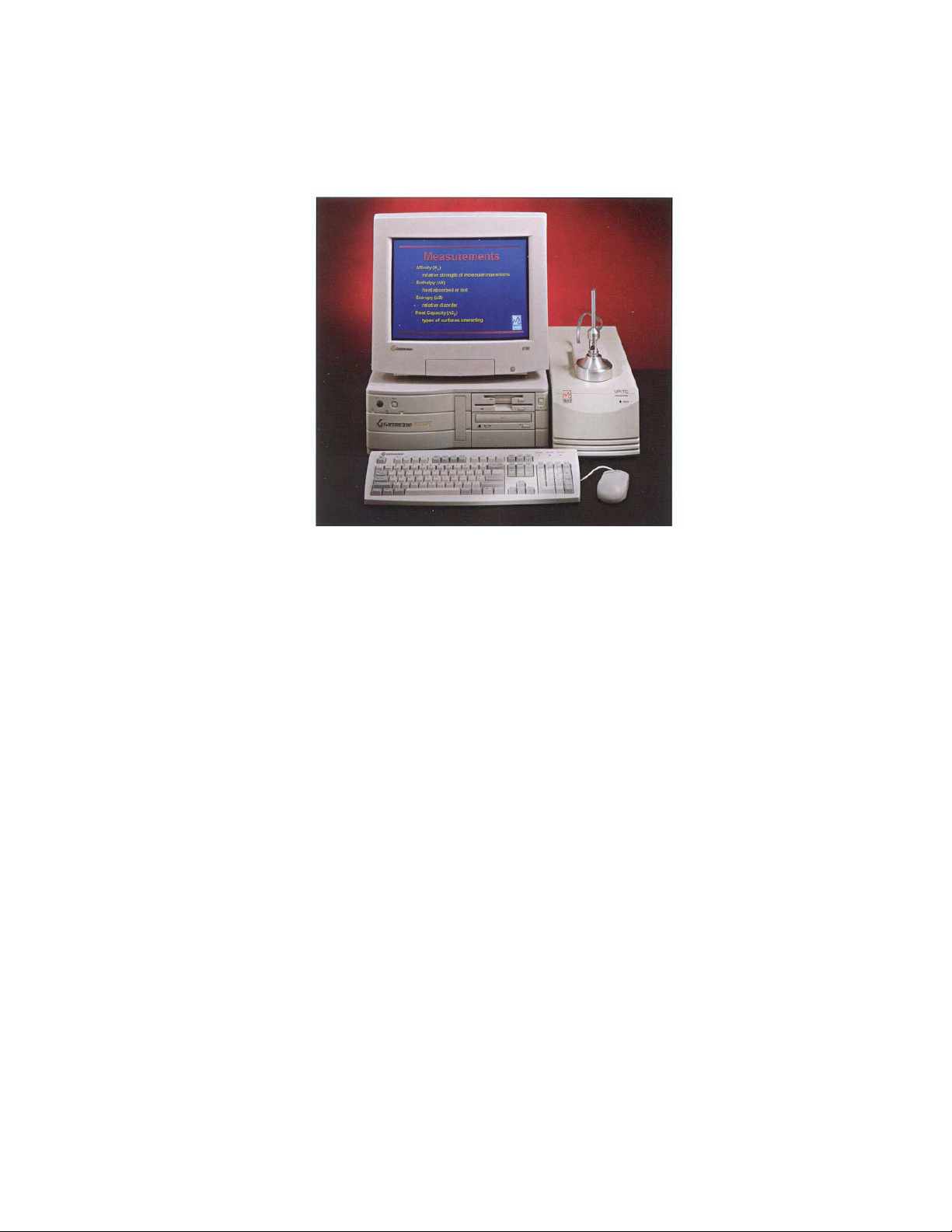

The VP-ITC with Computer Controller requires about 1 meter of normal bench space (ca. 70 cm

wide). The ThermoVac degassing station will require another 25 cm length of bench space. This

location should be away from strong drafts, room temperature fluctuations, intense sunlight,

vibrations and strong electrical or magnetic fields (as may be produced by an NMR, microwave

oven, large motors or refrigeration units). In addition the mains power source (115 to 240 VAC)

should be properly grounded and free from voltage fluctuations, harmonic distortions, power dips

and spikes. The AC power line should be dedicated to the MicroCal system and should not share

that power with additional equipment.

Although, the power filtering in the VP-ITC instrument is adequate for most laboratory

environments, some disturbances may affect the performance of the instrument and it may be

necessary to have the AC Mains power source evaluated (see table below) or install a power

conditioner. Since power source problems can be manifested in many different ways, it is not

possible to recommend a power conditioner for all situations. It is recommended that you test a

power conditioner, at your location, before you purchase it. If you believe you are experiencing

power source related problems, please contact a MicroCal engineer.

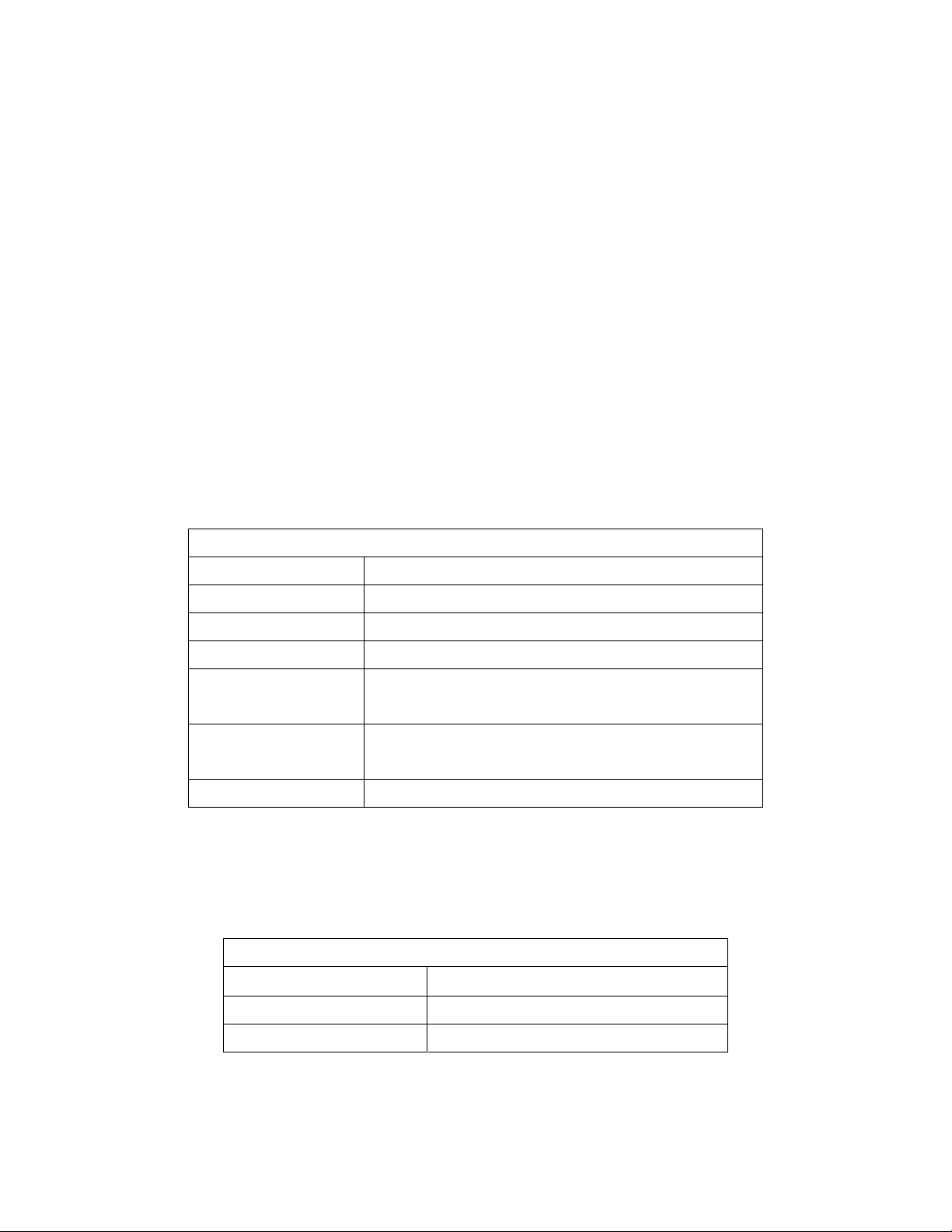

VP-ITC AC Mains Requirements

Specification Requirement

Voltage Regulation

Frequency Stability

Power Line Noise

Harmonic Content

Ground Noise

Ground Quality

< 3% Common Mode or Differential Mode at any Frequency

< 2 VAC Ground to Neutral Peak-To-Peak at any Frequency

115 to 240 VAC, stable to ± 3%

0.5% Maximum Deviation

< 5% Total Harmonic Distortion to 1500 Hz

< 3% For any Single Frequency

< 1 VAC Peak-To-Peak

< 25 Ohm

It is emphasized that room temperature fluctuations (i.e. maximum 2.5° C) due to the cycling

on/off of heating and cooling systems, strong air currents, sunlight directly on the instrument and

through space electromagnetic waves may cause subtle performance problems.

VP-ITC Environmental (Operating) Requirements

Temperature

10° to 28° C, constant to 2.5° C

Humidity

Atmospheric Pressure

MAU130030 Rev. E 4

0 to 75% Relative Humidity, non-condensing

70 HPa to 1060 HPa

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

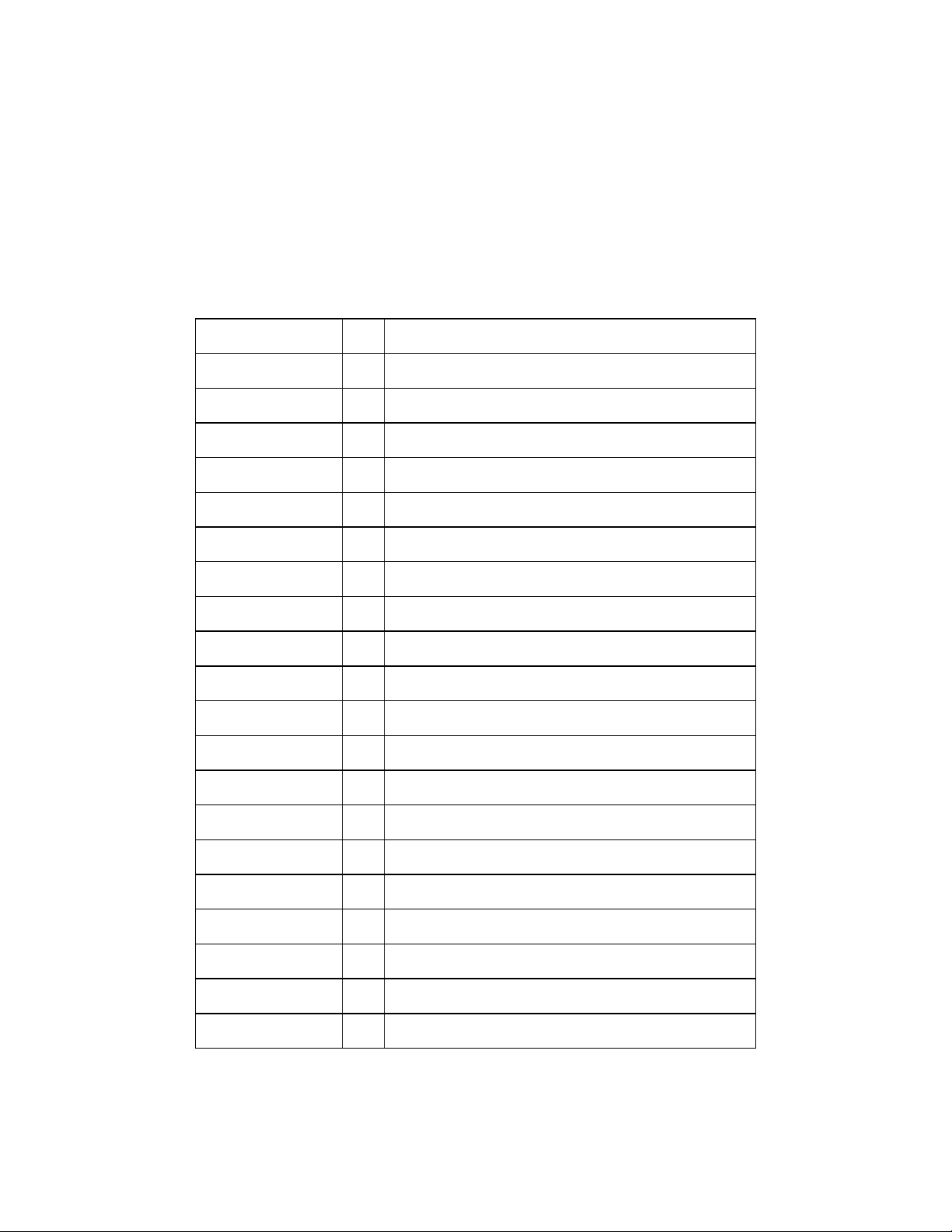

1.4 VP-ITC Parts and Accessories

In addition to the VP-ITC instrument, Computer Controller and connecting cables, there are

various accessories shipped with the VP-ITC for its normal operation. The parts and accessories

may include, but are not limited to the items listed below and on the next page. A list of the

actual parts and accessories shipped with your order will be listed in the documentation included

with your shipment.

Part Number QTY Description

ASS130010 1

ASS130140 1

ASS130150 1

INT100010 1

(call for part number) 1

SOF100040 1

SOF100025 1

ASS100030 1

ASS130070 1

(call for part number) 1

SYN161714 2

NDL130020 1

ASS130090 1

VP-ITC Cell

Pipette Stand

Injector/Stirrer Base (mounted on top of ITC cell unit)

Computer Controller

Printer (optional)

VPViewer software

Origin software

Main cable

Serial Cable with two 9 pin (RS232) adapters

A.C. Mains Power Cord

Hamilton 2.5ml filling syringes

18 guage, 8.5” long needle with Plastic syringe

Cleaning Device

ASS130120 1

ASS130330 1

ASS130370 1

TRY100010 1

MAU130010 1

MAU130020 1

MAU130030 1

Adapter (for Cleaning Device)

Shipping Cap

Temperature Standard (TC-2)

Accessory Tray

ITC Data Analysis in Origin Manual

Hastelloy Information Booklet

VP-ITC User’s Manual (this manual)

5

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

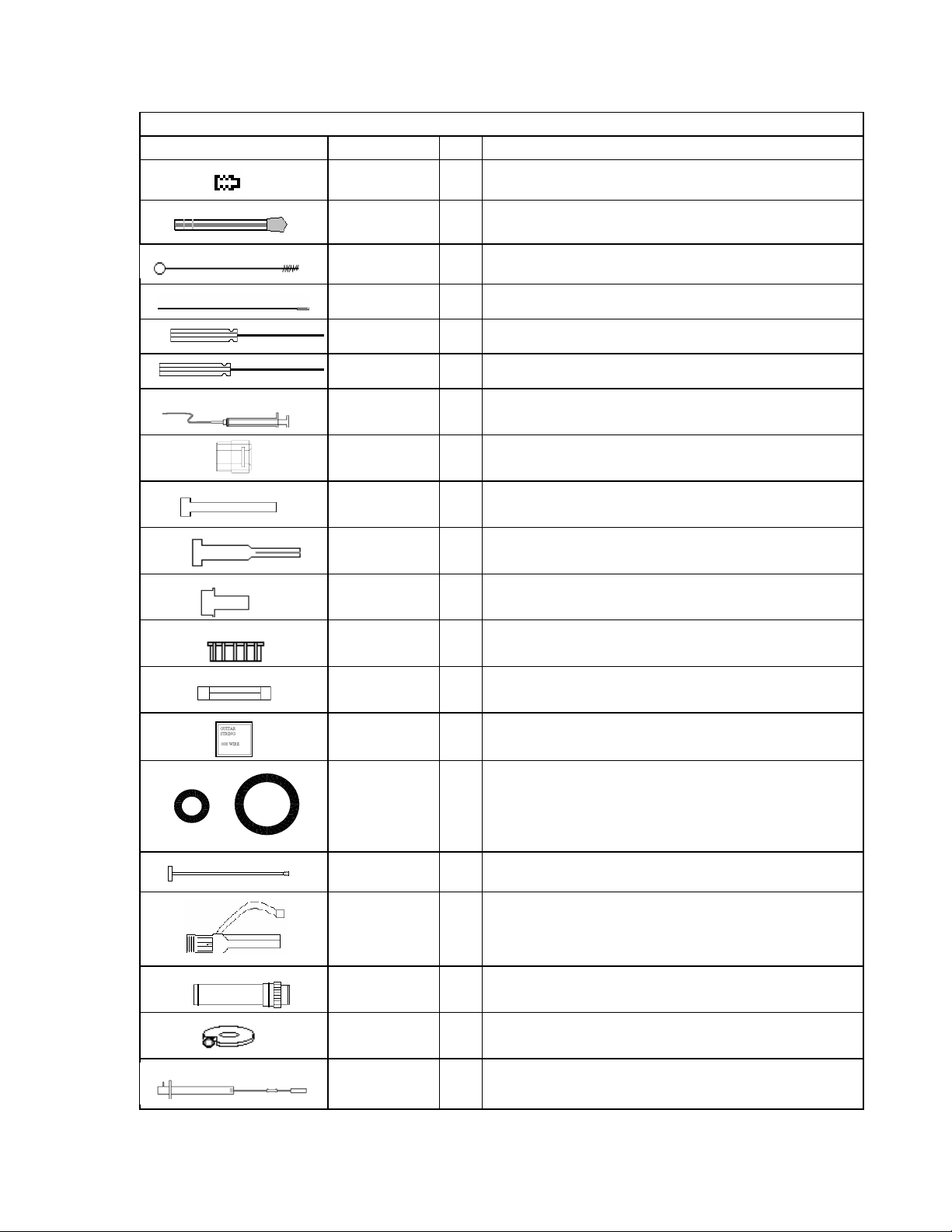

VP-ITC Accessories in Wooden Box (KIT130010)

Icon Part Number QTY Description

TIP130020 9

ASS130360 1

Plunger Tips for Injection Syringe

250 µL Tip Sizer (Glass Bore with Green Cap)

BRU130010 1

ASS130170 1

DRI130010 1

DRI130020 1

ASS130210 1

ASS130230 1

Large Tube brush

Reference Plug Assembly

Hex driver (050”) for syringe clamps

Hex driver (7/64") for injector stand

Plastic Syringe Assembly (3cc) with tubing

Tube holder (white) for pipette stand

MSP13057 1

MSP13056 1

MSP13058 1

MSP13043 1

FUS100010 2

Plunger Tip Pusher tool

Plunger Tip Puller tool

Guide sleeve

Threaded Cap

Fuses (1A/250V, 5x20mm Slo-Blo Fuse)

WIR90006 1

.013 Cleaning wire injection syringe

ORG00005V

ORG00011V

MAU130030 Rev. E 6

ORG00016V

PGR130010 1

ASS130160 1

ASS130200 1

MSP13028 1

SYA13022 3

Jar WITH 10 OF EACH OF:

1

005 O-Ring for Cleaning Device

011 O-Ring for Adapter & Syringe Holder

016 O-Ring for Syringe Holder

250 µl Plunger (for Cleaning Injection Syringe)

Pipette Injector

Syringe Holder (metal - pipette base)

Syringe clamp for bottom of injection syringe

Injection syringes

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

1.5 Setting Up the VP-ITC Instrument

All VP-ITC and Computer Controller connections and setup must be done with the units

turned off and unplugged to avoid damage.

Components Required for Assembly

Computer Controller with CPU, Monitor, Keyboard, Mouse, Power Cord, (Printer is optional)

VP-ITC Instrument with flat Main Cable, Serial Cable with Adapters, Power Cord

(Please Note: The Pipette Assembly is described is section 1.6).

Setup the Computer Controller

• Set up the Computer Controller following the instructions that came with the computer. It is

advisable to ensure the computer is working properly before proceeding.

Connect the Flat Main Cable

One end of the Flat Main Cable has a 37 pin male connector (labeled ‘Cell’) that attaches to the

rear of the VP-ITC cell. The other end of the cable has two 37-pin male that attach to the rear of

the computer. The connector labeled ‘J1’ is for the D/A (digital to analog) I/O (input-output)

computer board. The connector labeled ‘J2’ is for the A/D (analog to digital) I/O board.

(Note: The J2 connector cable will be slightly shorter than the J1 connector cable. Also, the 37

pin plugs are wider on one side than the other to allow the cable to fit in one direction only. If a

contortion of the cable appears necessary to accommodate the appropriate connections contact

MicroCal for assistance.)

• Connect each of the two Flat Main Cable connectors (labeled J1 & J2) to their appropriate 37

pin female connector at the rear of the host Computer Controller. (The connectors at the rear

of the Computer Controller will also be labeled J1 and J2.)

• Connect the main cable end labeled ‘CELL’ to the cell connector, located at the back of the

VP-ITC instrument (labeled 4, on the next page).

Connect the Serial Cable

The serial cable has two 9 pin serial connectors; one connector is female and the other is male.

The female end is to be attached to the serial port (Com 1 or Com A) of the Computer Controller.

The male end is to be attached to the serial plug on the back of the pipette controller/stirring base

on the VP-ITC. (Note: Failure to connect the sserial connectors correctly will prevent the VP-

ITC injection system from operating properly.)

• Connect the female end of the serial cable to the Computer Controller at the serial port.

• Connect the male end of the serial cable to the serial connector on the back of the pipette

controller/stirring base on the VP-ITC (connector labeled 6, on page 8).

(Note: Earlier versions of the VP-ITC require a slightly different serial cable and connection

sequence. Contact MicroCal for further information.)

7

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Connect the Mains Power Cord

• Connect the power cord to the inlet power receptacle located on the back of the VP-ITC.

Connect the power plug only to a mains power supply receptacle with a 3 wire, protective

earth ground, plug and Ground Fault Circuit Interrupter (GFCI). Please Note: It is strongly

recommended that the VP-ITC be provided a dedicated AC power line with no other

equipment being powered on that line. (see page 4 for more information about selecting a

location for the instrument)

*

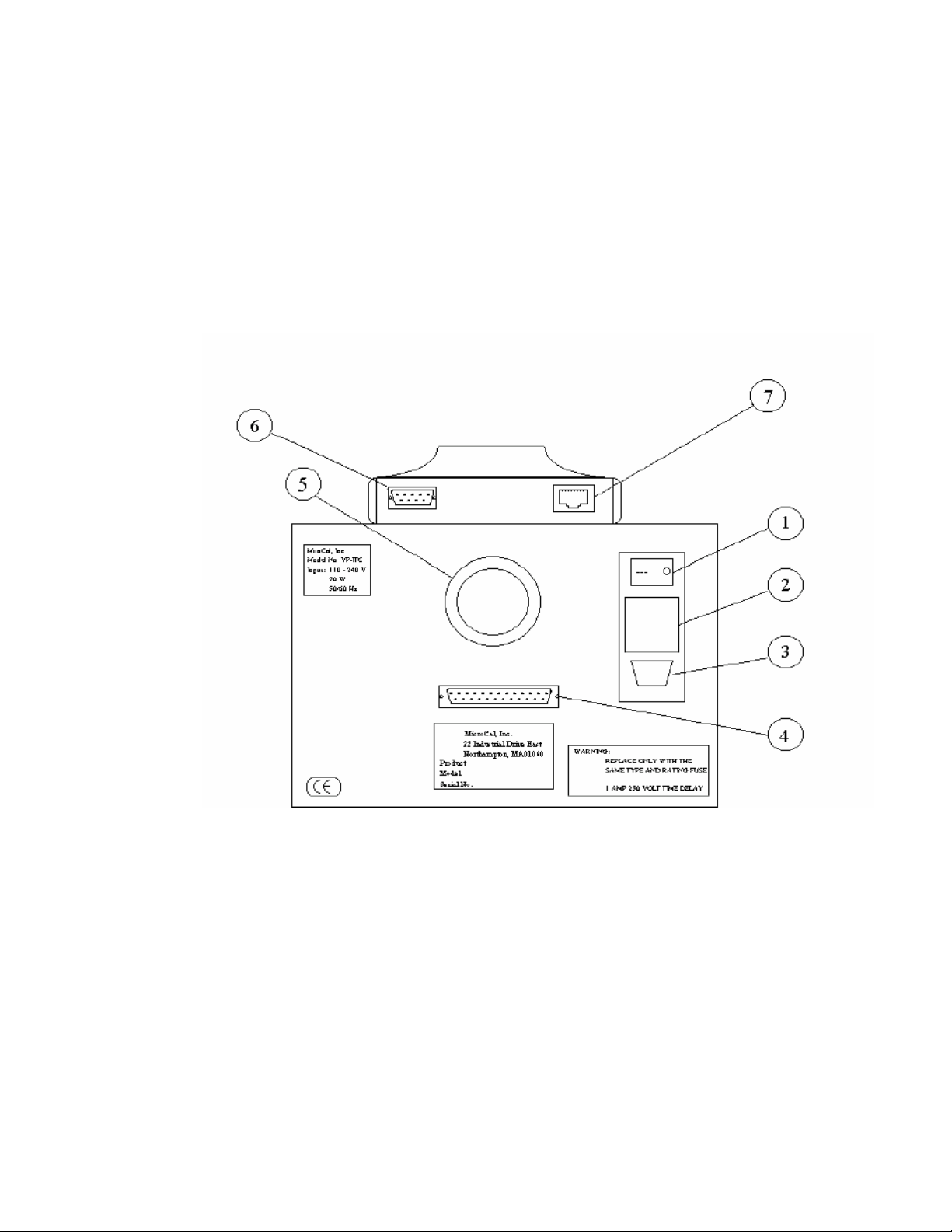

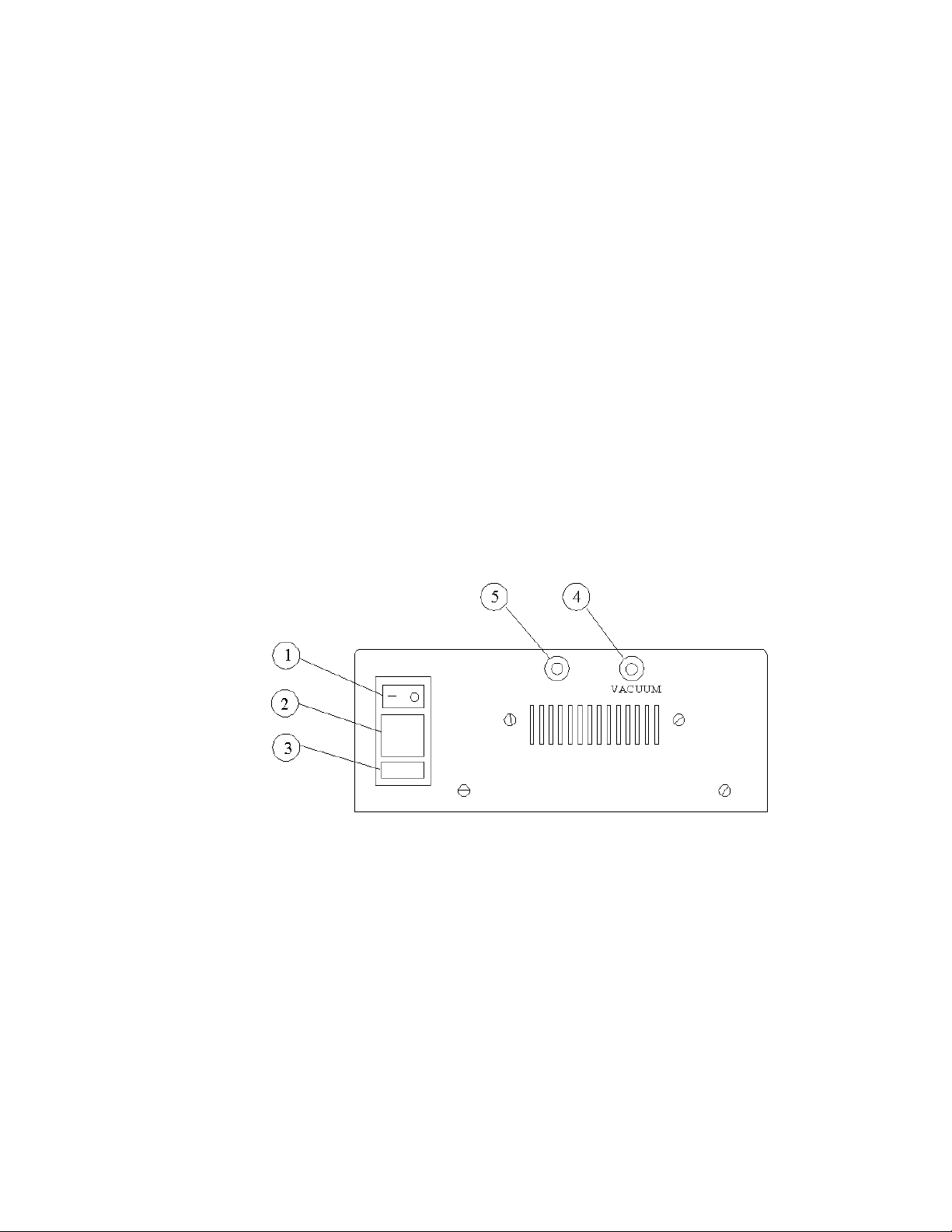

VP-ITC Cell - Back View

1) Main power switch

2) 2 Power fuses

3) IEC 320 inlet power receptacle

4) Cell connector

5) Fan

6) Pipette controller/stirring base serial port

7) Pipette controller connector

* Earlier versions of the VP-ITC Cell have a different connection configuration

MAU130030 Rev. E 8

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

1.6 Pipette Assembly

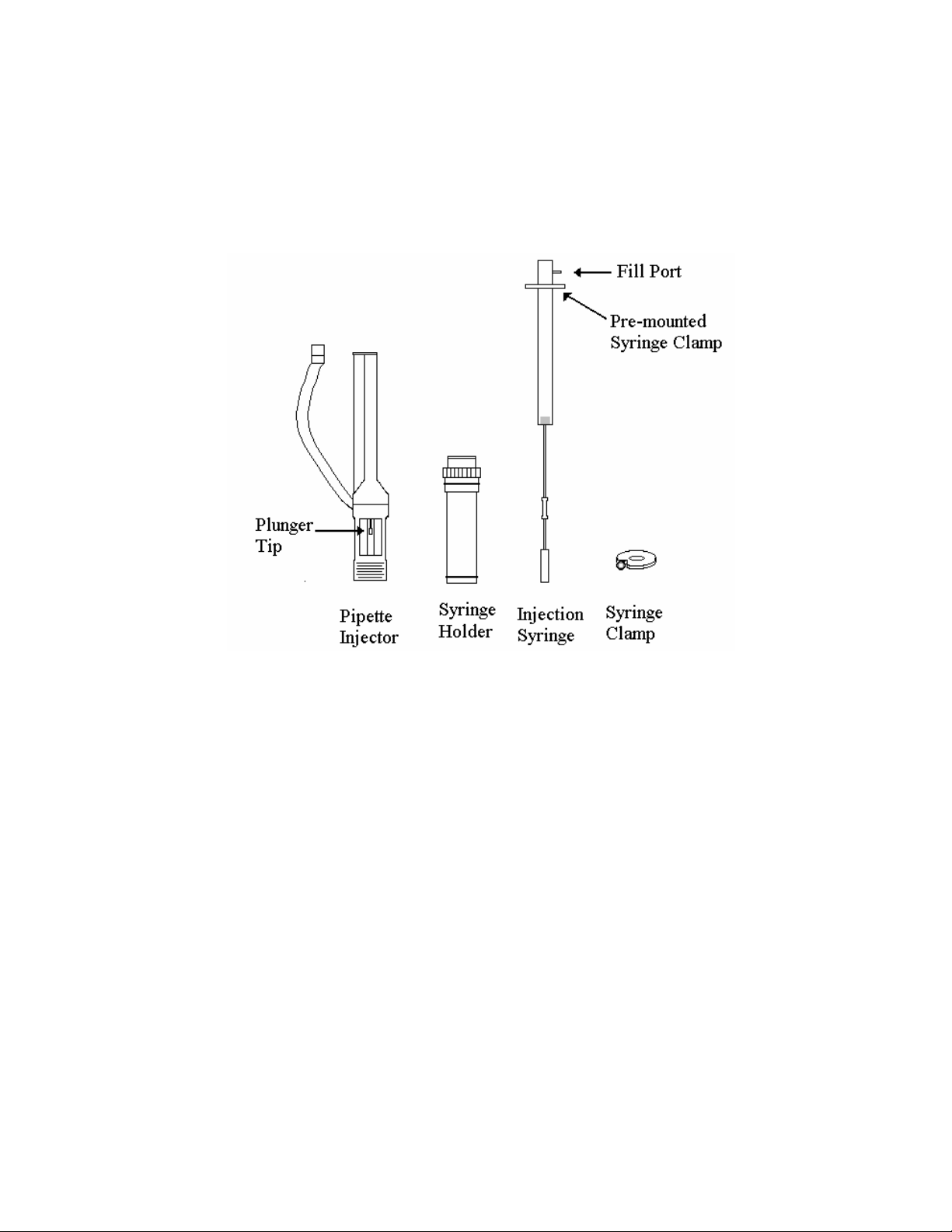

The pipette assembly consists of the injection syringe with pre-mounted top syringe clamp, a

bottom syringe clamp, the syringe holder and the pipette injector.

! Caution: At all times when handling the injection syringe you want to use care to

prevent the long needle from any action that may cause it to bend. If the long needle is

bent far enough it will become a permanent bend that will make the syringe unusable

for any experiments.

! Caution: Never attempt to couple/decouple the pipette from the syringe assembly unless

the pipette plunger is in the open port position (all the way up). Failure to follow this

recommendation may result in a bend in the pipette screw. Even a slight bend will

result in improper operation of the pipette.

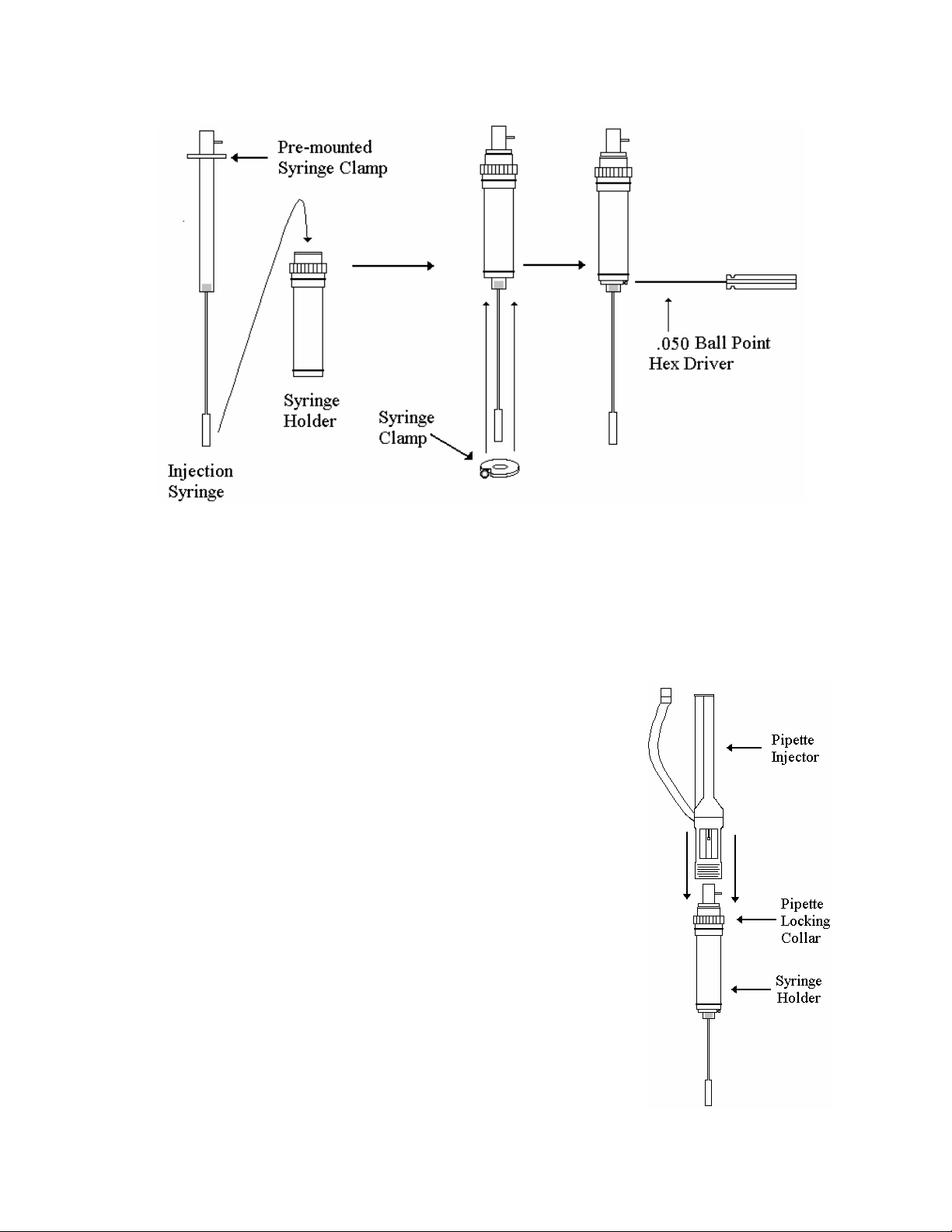

To assemble the pipette, please do the following (please refer to diagrams on next page):

The height must be adjusted for any syringe that was not part of the original shipment of your

VP-ITC instrument. Please refer to Section 5.4 Replacing Injection Syringes & Height

Adjustment (page 79) for instruction on adjusting the height of the syringe.

• Insert an injection syringe into the syringe holder until the top syringe clamp is firmly seated

against the top of the syringe holder. (see diagram next page)

• Insert the bottom syringe clamp over the syringe needle onto the glass part of the syringe.

9

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

• Make sure the top syringe clamp is still seated against the top of the syringe holder, hold the

bottom syringe clamp tightly against the bottom of the syringe holder and gently tighten the

set screw using the accessory 0.050” Ball Point Hex Driver.

! Use care not to over tighten the set screw, as too much pressure will cause the glass to

break. You want to tighten the screw just enough to prevent the bottom syringe clamp

from moving freely.

• Insert the syringe holder into the pipette holder (attached to the

side of the VP-ITC).

• Bring the pipette injector directly above the syringe holder, start

bringing the injector down while observing the plunger tip of the

pipette injector to insure that it is being inserted into the hole in

the glass barrel of the injector syringe, then mate the screws of the

pipette injector to the locking collar of the syringe holder

• With your fingers, turn the locking collar until it is fully tightened

on the pipette injector.

When the locking collar is fully tightened there should be only a

couple threads of the pipette injector viewable.

• Plug the connector of the pipette into the back of the pipette

controller/stirring base (connector labeled 7, on page 8) to

complete the pipette assembly.

MAU130030 Rev. E 10

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

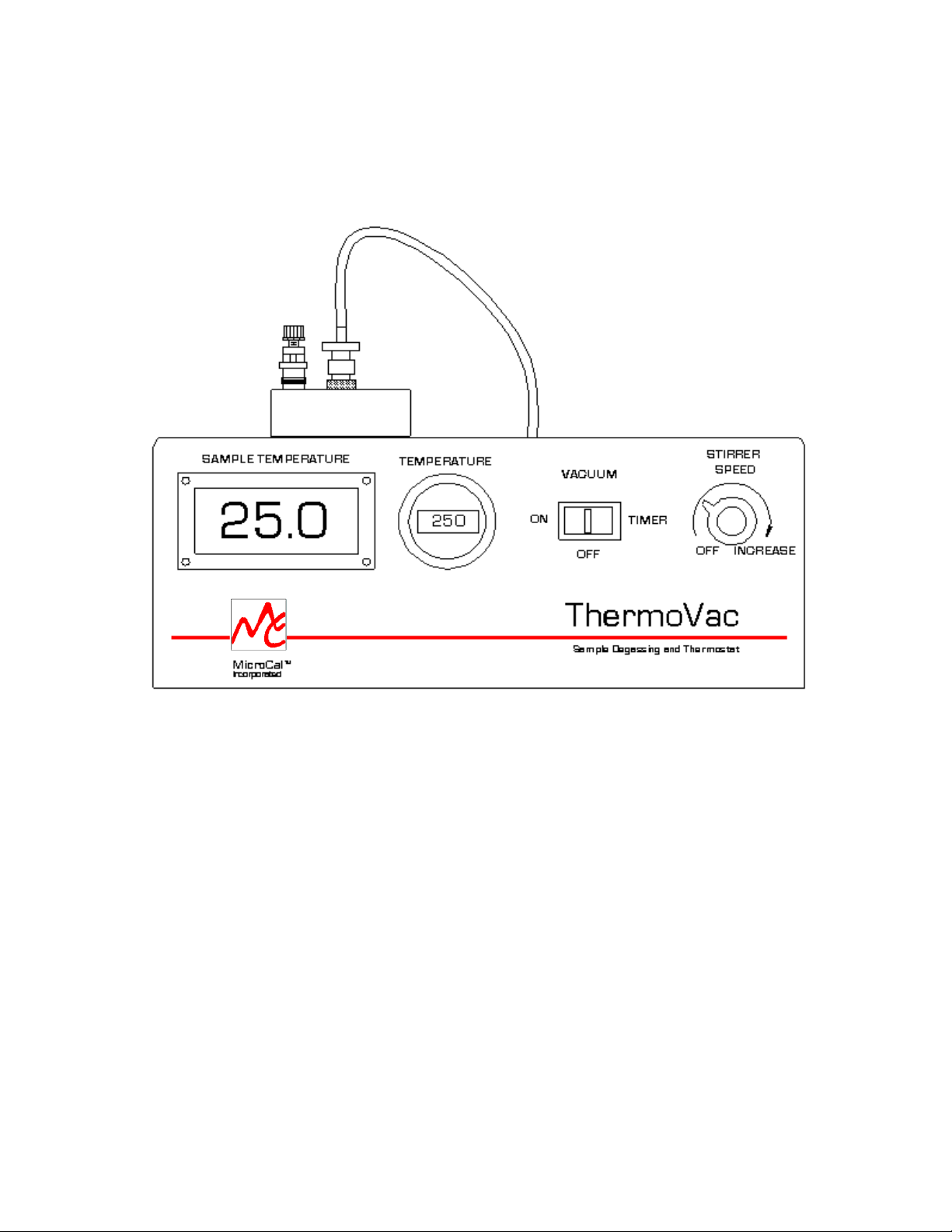

1.7 The ThermoVac

ThermoVac Description

To facilitate degassing samples and cleaning the cells, you have been provided with the

ThermoVac accessory, a device for thermostatting and degassing samples. The unit is capable of

thermostatting a sample at any temperature from 0 to 80 °C, pulling a vacuum of 28.4 inches of

mercury and stirring the sample using small magnetic stir bars.

11

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

ThermoVac Accessories

The ThermoVac and accessories may include, but are not limited to the items listed below. A list

of the actual items shipped with your order will be included in the documentation included with

your shipment.

Quantity Description

1 ThermoVac

3 Stir Bars (Small)

3 Stir Bars (Medium)

2 In-line filters

5 Test Tubes (Small) – for conserving sample volume

5 Test Tubes with Cap (Medium)

1 Test Tube Holder

1 Flask with Hose & Luer Lock Connector

2 Fuses (1A/250V) 5x20mm Slo-Blo

1 A.C. Mains Power Cord

Front Panel Controls

VACUUM

The ThermoVac is capable of pulling a maximum vacuum of 28.4 inches of

mercury. If the VACUUM switch is pushed to the right the vacuum pump

will turn on and remain on for approximately 5 minutes (recommended time

for degassing samples), then the pump will shut off. If you desire to remove

the vacuum before the preset time you must turn off the main power switch (located at the rear of

the instrument). When the switch is pushed to the left the vacuum pump will remain on until it is

manually turned off (either by pushing the VACUUM switch to its middle, OFF, position or by

turning off the main power switch).

TEMPERATURE

Use this dial to set the temperature, in °C, for thermostatting the sample chamber. The rightmost

digit sets the temperature value in tenths of a degree. Typically, ITC samples are thermostatted to

a temperature that is below the desired run temperature for the sample. This should also allow for

any temperature increase that may occur during the transfer of solution from the ThermoVac to

the ITC cells or syringe.

SAMPLE TEMPERATURE

Displays the current temperature of the sample chamber.

MAU130030 Rev. E 12

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

STIRRER

This switch will activate a rotating magnetic field that will stir your sample when a small

magnetic stir bar is placed in the tube containing your sample. You may adjust the speed of the

Stirrer motor from 0 RPM (OFF) to the maximum speed of 800 RPM (full turn clockwise).

ADJUSTABLE VACUUM BLEEDER

Allows manual adjustment of the vacuum strength within the degassing chamber of the

ThermoVac.

There is no vacuum gauge on the ThermoVac, but the strength of the vacuum may need to be

adjusted based on the behavior of your samples under vacuum. Depending on the specific sample

being degassed, and on the temperature of the sample, the vacuum strength might be enough to

boil the sample and subsequently change the concentration and/or spill the sample. This may be

avoided by adjusting the strength of the vacuum with the bleeder screw. By turning the top of the

bleeder screw in the counter-clockwise direction you will lower the strength of the vacuum within

the ThermoVac and avoid boiling your sample. Similarly, the vacuum strength can be increased,

by turning the top of the bleeder screw in the clockwise direction. The bleeder screw (and

vacuum strength) can be fixed in a desirable position by tightening the lower nut, located at the

base of the bleeder screw assembly, all the way in the clockwise direction.

REAR PANEL

1. Power Main Switch

2. 2 Power Fuses

3. IEC Inlet Power Receptacle

4. Vacuum Port

5. Pressure Port

13

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Section 2: VPViewer and Origin Software

This section details the features of the VPViewer and Origin software. VPViewer provides the

user interface to control the VP-ITC instrument and conduct the experiment. Origin (in this

project window) is used only for plotting the data received from the VP-ITC instrument. A

separate project window for Origin (Origin for ITC) is used for analyzing data.

New users may find this section too detailed for their immediate needs and for that reason skip

this section and proceed to the Section 4 tutorials for a ‘hands on’ approach to learning the

software though simple experiments. While performing the tutorials, the user should refer to this

section when further detail is desired about a specific software function. After performing the

tutorials, it is advised to read through this entire section for a thorough understanding of the

software.

MAU130030 Rev. E 14

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

2.1 VPViewer and Origin Software Overview

The VPViewer 2000 software controls the operation of the VP-ITC calorimeter. It is within

VPViewer 2000 that all ITC experimental parameters are entered, runs are controlled and data is

saved to the hard disk of the Computer Controller. By default, all data that is generated in the run

state of an ITC experiment will be saved to disk, with no user interaction.

When VPViewer 2000 is started it opens a linked copy of a project window in Origin, named

VPITCPlot.opj. This project window of Origin is strictly for real time display of data from

VPViewer and is not intended for data analysis or saving data; VPViewer automatically saves all

relevant experimental data.

Please note: If Origin is closed by accident, an error message will appear and the data display

will be lost until Origin is again reopened by utilizing the VPViewer 2000 menu, System|Open

Origin. VPViewer 2000 must be used to open up Origin for real-time display or the real-time

plotting will not work. As long as VPViewer remains open, the experiment will continue and all

data will still be automatically saved to disk independent of the real-time plotting.

Operation Within a Windows™ Environment

Only one copy of VPViewer will be permitted to run at any given time. If a second instance of

the application is detected, VPViewer will immediately terminate itself. Users should feel free to

run Origin

applications. In general, VPViewer is a multi-tasking application with some subtle limitations. If

VPViewer detects a conflict that may jeopardize its ability to acquire data, it will inform you of

this conflict. In such instances you should contact MicroCal.

for data analysis simultaneously with VPViewer, as well as most other Windows’

Although, other Windows’ programs can be used while the VP-ITC is running without affecting

the data acquisition or calorimetric control it should be realized that there are real time operations

taking place during a run, and that performing CPU intensive tasks while a run is in progress can

‘glitch’ the ITC baseline. Users should avoid large file copying to disk drives, large print jobs

and recursive control loops while the VP-ITC is in the midst of a run.

2.2 Powering Up the VP-ITC Instrument

The VP-ITC main power switch and the VPViewer software application can be left on

indefinitely. There may be occasions when the instrument is turned off and then turned back on.

Problems can arise if the recommended power up sequence is not followed. Whenever powering

up the VP-ITC, please follow the steps below in order:

1. Turn on the computer controller. The VP-ITC power switch must be off.

2. Once the computer controller is on and Windows is running, turn on the power

switch at the rear of the VP-ITC.

3. Launch the VPViewer application by double clicking its icon on

the Windows desktop or from the Windows taskbar by selecting

Start : P

Please note: Failure to adhere to this sequence when powering up the VP-ITC

may result in the injection system not responding.

rograms : MicroCal’s VPITC : VPViewer ITC.

15

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

A Note About ITC Power Control

The main power for the VP-ITC cell unit is controlled by the VPViewer software application.

The presence or absence of power to the cell unit is indicated by the Power LED located on the

front panel of ITC cell. When the power to the cell unit is on, the LED will shine bright orange

and when the power to the cell unit is off, then the LED will also be off. In order for the cell unit

power to turn on, the cell must be plugged in, the power switch at the rear of the cell must be in

the on position, and VPViewer must be opened and running. Upon opening the VPViewer

application, it may take several seconds for the ITC cell power and the Power LED to come on.

Likewise, after closing VPViewer it will require a minute or so for the cell power and Power LED

to turn off.

When the VPViewer application is first opened it will go into an ‘Initialization’ state for less than

one minute, as will be indicated in the cell status. During the ‘Initialization’ state the VPVIewer

application is disabled and will not fully respond to mouse/keyboard events. As soon as the

‘Initialization’ state is over with, then the VPViewer application will become fully enabled and

the ITC injection system will be initialized as well.

The VP-ITC was designed to have its power on for extended periods of time. This will keep the

electronics at the normal operating temperature for better repeatability. It is recommended that

the power to the ITC cell unit be turned off during extended periods of down time, such as

holidays and vacations.

MAU130030 Rev. E 16

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

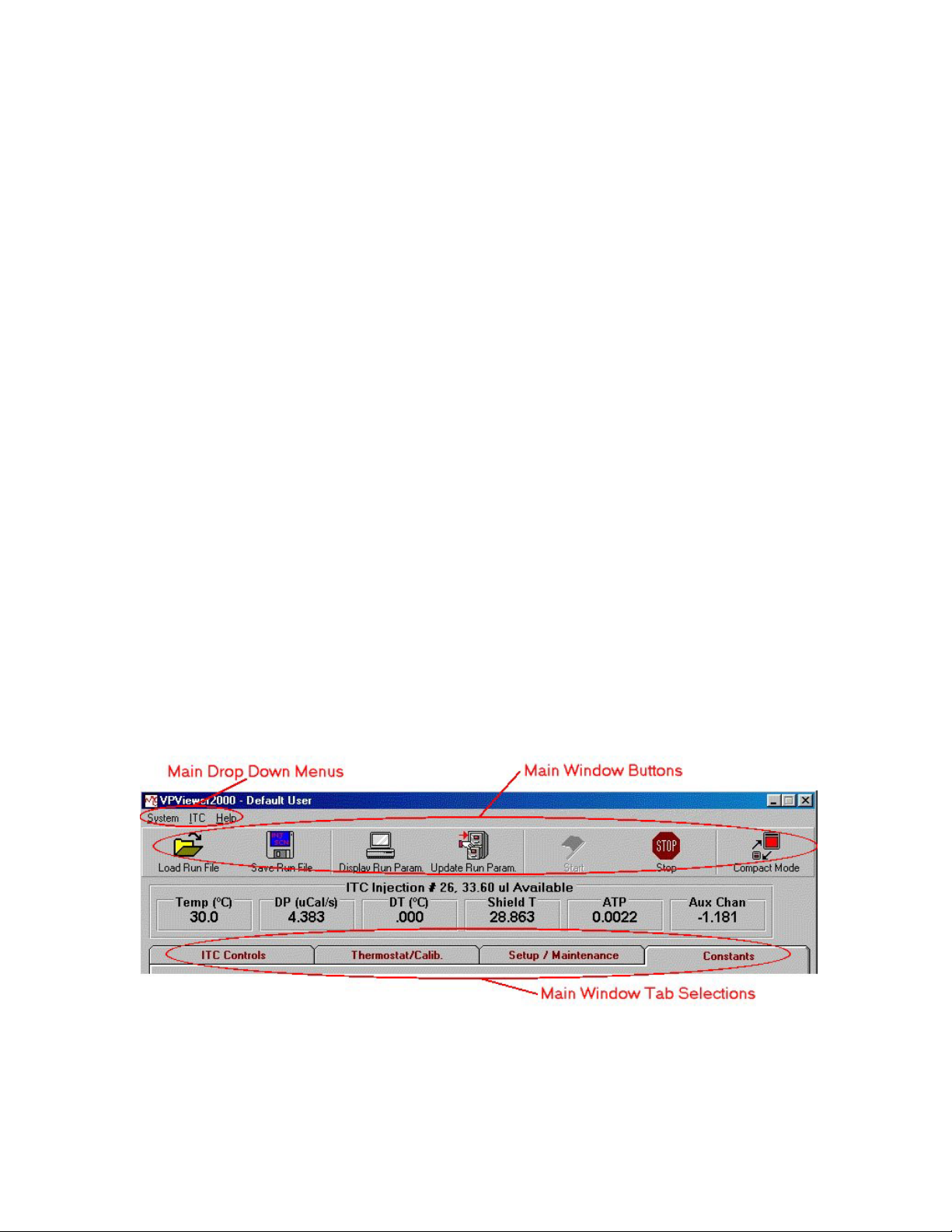

2.3 VPViewer Main Window

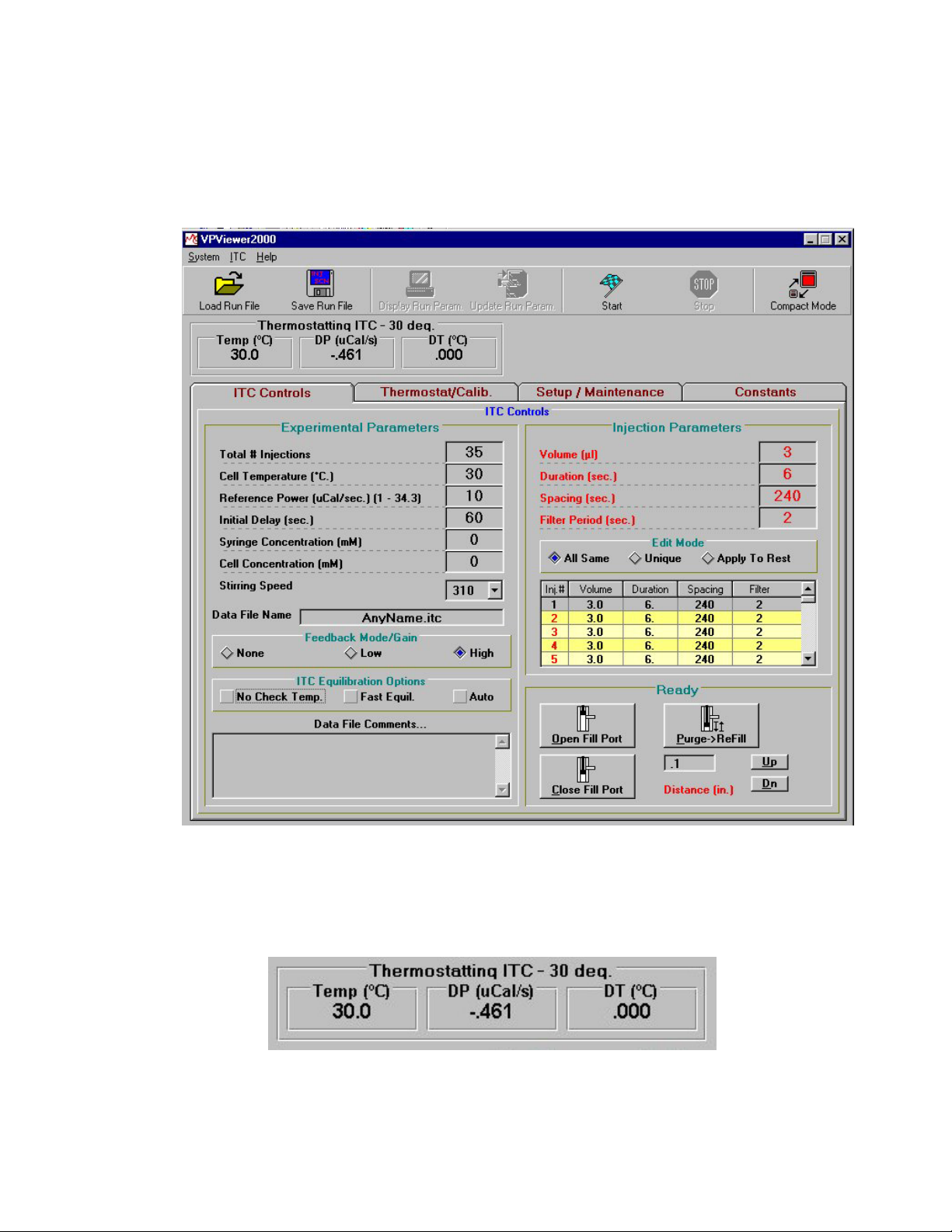

When you launch VPViewer, the Main Window of VPViewer is displayed (as shown below).

VPViewer Data Channel Display

By default, VPViewer displays three data channels and the status of the instrument.

Instrument Status

In the above illustration, the instrument is Thermostatting (ITC) at 30 °C.

17

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Temp(Celsius)

This text box displays the current temperature, in degrees Celsius, of the adiabatic jacket.

DP (uCal/sec)

This text box displays the Differential Power, in µCal/sec., between the reference cell and the

sample cell. Positive DP values means that the reference cell is hotter than the sample cell, while

negative DP values means that the sample cell is hotter than the reference cell. In terms of

reactions (assuming they take place in the sample cell) exothermic reactions will cause the DP to

deflect in the negative direction while endothermic reactions will cause the DP to deflect in the

positive direction. The power units for the DP data channel may be displayed in mCal/min.,

µCal/sec. or µWatts. Experimental data will always be saved in units of µCal/sec.

Whenever the VP-ITC is equilibrated the DP value should be positive and stable. The power

level of the equilibrated DP signal should be close (+/- 1 µCal/sec.) to the ‘Reference Power’

setting, as set prior to starting the run.

DT (deg. C)

This text box displays the Differential Temperature, in degrees Celsius, between the adiabatic

jacket and the calorimeter cells (i.e. the average temperature of both cells).

Whenever the VP-ITC is equilibrated the DT signal should be close to zero degrees Celsius (+/-

0.05) and stable.

Menus and Buttons

The VPViewer Main Window contains drop down menus, buttons and Window Tabs. The Main

Drop Down Menu selections generally control global system functions The Main Window Buttons

allow easy access to features that are frequently used. The Main Window Tab Selections provide

detailed windows for specific functions. The details of these controls can be found in the

following sections.

VPViewer Main Drop Down Menus

The Main Drop Down Menus at the top of VPViewer will provide access to some of the less

frequently used functions of the application.

MAU130030 Rev. E 18

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

System: Quit Program. Selecting Quit Program prompts the user to see if they

want to terminate the VPViewer application. Responding with yes will

terminate the program and any run in progress. All ITC run, or partial

run data will be saved to disk. Approximately a minute or so after

program termination, the power to the VP-ITC will also be shut down.

Power to the VP-ITC will not be restored until the VPViewer

application is run again.

ITC: Print/Save As Text Run Parameters. This

function allows users to print or save to a file

the run parameters that are being used for an

ITC run. While run parameters are always

included as part of the ITC data file header, the

Print/Save As Text Run Parameters menu

option provides the user with a nicely formatted listing of run parameters, ideal for data

presentation or general record keeping.

Start ITC Calibration Run. This option is used to check the accuracy of the ITC yaxis measurements (DP signal). Please refer to Section 5.3 Y-axis Calibration starting

on page 75 for details on y-axis calibration.

Help: Help. Allows access to the help menus. At the time of release of this User’s

Manual the on-line help was still under development.

About. Provides specific details about this version of software and contact

information for MicroCal, LLC.

VPViewer Main Window Buttons

The Main Window buttons allow access to VPViewer’s frequently used functions. The figure

below shows all the buttons available for use. Depending on the current state of the instrument,

some of the buttons would be grayed out and not available. (Specifically, the Start button is

only available when the ITC is in its idle state. The Stop, Update Run Param. and Display Run

Param. buttons are available when the VP-ITC is active, in a prerun, run or postrun state.)

Load Run File: Clicking on this button will display the file open dialog box to load previously

saved run parameters into the ITC Controls Window. Run parameters may be loaded from one

of two types of files; run parameters may be loaded from a previous experiment’s data file

(*.itc), (the run parameters being extracted from the data file header) or they may be loaded from

a setup file (*.inj) which was previously saved in the Save Run File option (as described below).

19

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Save Run File. Displays the file save dialog box which allows saving of the currently displayed

run parameters. By saving the run parameters to a setup file (*.inj) they may be reloaded and

reused in the future by selecting Load Run File as described above

Display Run Parameters. Displays the current run parameters for the run in progress. This

button is available only when the VP-ITC is in a non-idle state.

Update Run Parameters. Updates the current run parameters for the run in progress. When the

ITC is in a non-idle state, this button must be clicked to realize the change of any run

parameters. This button is available only when the VP-ITC is in a non-idle state.

Note: Only run parameters that have not yet been applied on the run in progress may be

updated, all others will be ignored (e.g. after the stirring has commenced for an experiment,

changes to the experimental stir speed will be ignored.

Start. Click this button to start an ITC experiment, using the parameters entered into the ITC

Controls Window.

Stop. This button terminates the current run. Available only when the VP-ITC is in a non-idle

state.

Compact/Standard Mode Button

Clicking this button will shrink VPViewer’s Main Window and change

the icon to the Compact Mode (as shown below). VPViewer’s Main

Window size cannot be manually adjusted. It has only 2 sizes, the

compact mode size and the standard size. Clicking on the Standard Mode button will restore the

window to its original size.

MAU130030 Rev. E 20

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

2.4 ITC Controls Window

The ITC Controls window (shown below) is the main access point for operating the VP-ITC

instrument.

Below is a description for each of the run parameters displayed in the ITC Controls window.

Experimental Parameters

Total # Injections

Enter the total number of injections (500 is the maximum) for the titration (ITC) experiment.

Cell Temperature (° C)

Enter the desired temperature for the experiment.

If there is a check mark next to the No Check Temp. option in the ITC Equilibration Options

group (see below), the entered temperature will be ignored and the experimental temperature will

take place at the current cell temperature. If there is no check mark, then the cell will scan to the

entered temperature and equilibrate before the experiment will start. Please Note: When the

instrument is programmed to scan to a new temperature (i.e. there is not a check mark next to the

No Check Temp. option), the sample should be cooled (before loading into the cell) below the

experimental temperature, so that after loading, the temperature of the sample in the cell will be

21

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

at or below the experimental temperature. If the loaded sample is at a higher temperature, there

will be a long equilibration period before the experiment will begin. (See page 87 more

information).

Reference Power (µCal/sec.)

Throughout an ITC experiment, a small constant amount of power (equal to the value entered

here) is continuously supplied to the offset heater of the reference cell. This causes the DP

feedback system to become positive to supply compensating power to the sample cell that will

equilibrate the temperatures. During an experiment the DP baseline will equilibrate near the value

entered in this box. The reference power setting is often referred to as the baseline setting.

The best choice for the reference power setting will be determined by the anticipated size and

direction of the titration peaks. Large exotherms will require a large reference power setting (ca.

30 µCal/sec.) and large endotherms will require a very small reference power setting (ca. 2

µCal/sec.).

Initial Delay (sec.)

Enter the time, in seconds, from the start of the experimental data collection until the time of the

first injection. The minimum time allowed by VPViewer for this parameter is 60 seconds; this is

necessary to establish a baseline prior to the first injection.

Syringe Concentration (mM)

Enter the mM concentration of the solution in the syringe.

This value is stored in the data file header and used in Origin for ITC data analysis. This value is

used only during data analysis and an entry is not required to perform an experiment. If the value

is not entered or entered incorrectly the user will be warned, but it can also be entered/edited in

data analysis.

Cell Concentration (mM)

Enter the mM concentration of the solution in the cell.

This value is stored in the data file header and used in Origin for ITC data analysis. This value is

used only during data analysis and an entry is not required to perform an experiment. If the value

is not entered or entered incorrectly the user will be warned, but it can also be entered/edited in

data analysis.

Stirring Speed

Select the desired stirring rate from the drop down list (310 is recommended for most ITC

experiments).

There are 5 stirring rates available, they are ca. 0, 270, 310, 500 and 580 RPM (revolutions per

minute). The exact stir rate for your instrument is measured and the value is entered into the

software. The default rate of ca. 310 RPM has been found to be desirable for most experiments.

If the solution in the sample cell contains suspended particles (e.g. agarose beads), faster stirring

will be necessary. Please refer to the section Selecting the Proper Stirring Rate starting on page

90, for more information.

MAU130030 Rev. E 22

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Data File Name

Following Windows filename requirements enter up to 16 characters for the filename. The

program will automatically add .ITC for an extension name, so that the raw data file will be

recognized by Origin as a VP-ITC data file. Do not start the filename with a number nor include

any hyphens, periods or spaces in the filename, as Origin will not accept the file. Please note:

Origin for ITC data analysis can only distinguish a difference in file names for the first 10

characters, therefore if you will be analyzing more than one data file in a single session of Origin

make sure that each file name has a unique combination of characters within the first 10.

Feedback Mode/Gain

Select one of the three available modes, None, Low or High (High is recommended for most ITC

experiments).

The feedback modes can be described as active (Low or High) or passive (None). High gain will

provide the fastest response time, while passive mode (None) will provide the highest sensitivity

(slowest response time). Most ITC reactions will require using the High gain feedback mode,

which yields the fastest response time. Monitoring of long, slow thermal process in the VP-ITC

(i.e. kinetics, metabolic rates) might benefit from using the passive or low gain feedback modes.

ITC Equilibration Options

This group of check boxes determines how VP-ITC will equilibrate before collecting data for the

experiment. To start an experiment in the shortest possible time put a check mark in each box.

No Check Temp. – When this check box is selected the Cell Temperature (°C) text box entry

will be ignored and the experiment will start at the current cell temperature. Otherwise the cell

will equilibrate at the temperature entered into the Cell Temperature (°C) text box before the

experiment can start. Please Note: When there is not a check mark next to the No Check Temp.

option, the cell sample should be cooled (before loading) far enough below the experimental

temperature, so that after loading, the temperature of the sample will be at or below the

experimental temperature. If the loaded cell sample is at a higher temperature, there will be a

long equilibration period before the experiment will begin. (See page 87 for more information).

Fast Equil. – When this check box is selected, VPViewer will not establish a non-stirring

equilibration period. This will allow for slightly faster equilibrations and in general is the best

way to run the ITC. There may be instances where the operator would like to view a non-stirring

baseline and can do so by removing the check mark next to this option.

Auto – When this check box is selected the ITC experiment will proceed through the

equilibration states (Pre-stirring and Final Baseline) and complete the experiment without any

further interaction from the user. Users can still force an equilibration state to the next

equilibration state by double clicking on the DP data box (just as is done with the auto-start

option inactive).

Data File Comments

You may type into this text box comments about your experiment to be saved in the header of the

data file for future reference.

23

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Injection Parameters

The Injection Parameters group allows you to define the volume, duration, spacing between

injections, and the filter period for each injection. At the bottom of this group is a summary table

that lists, by row number, these parameters. You may select an injection to edit by clicking on a

row to highlight it; the parameters for this injection will be entered into the text boxes. Then,

depending on the Edit Mode selected, you may edit the text boxes to effect all injections (All

Same), only the currently highlighted injection (Unique) or the currently highlighted injection

and all the following injections (Apply To Rest).

Volume (µl)

Enter the volume of titrant (in micro liters), to be injected from the pipette into the sample cell for

the selected injection(s).

Duration (sec.)

Enter the time, in seconds, for the titrant to be injected into the sample cell for the selected

injection(s).

Note: VPViewer will default this value to be twice the number entered in the Volume text box.

Spacing (sec.)

Enter the time, in seconds, between the beginning of the selected injection(s) and the beginning of

the next injection.

The user is responsible for specifying enough time between the injections to allow the DT signal

to return to the baseline after an injection peak deflection. Typical values for this parameter

range from 180-300 seconds, depending on the size of the peak and the kinetics of the reaction.

Filter Period (sec.)

This is the time period (in seconds) in which the data channel conversions are averaged to

produce a single data point for plotting and saving.

For fast reactions, a filter period of 2 seconds is sufficient to obtain enough data points for

representation of the peak for accurate integration of the area. For monitoring of very long, slow

thermal processes, the filter period may be increased accordingly to avoid accumulation of excess

data points. Please note: Although there may be a practical limit for a data set size, only

available disk space would limit the number of data points that VPViewer is able to collect and

save.

Edit Mode

All Same – Selecting this option causes all injections to be assigned the same parameter values

as entered into the Injection Parameter text boxes.

Unique – This option allows you to set up injections using different parameters. You may

customize each injection to have different volumes, duration, spacing or filter periods. Editing

the Injection Parameter text boxes when this option is selected effects only the injection that is

currently highlighted in the summary table. Likewise the values displayed in the individual

parameter boxes apply only to the injection that is currently highlighted in the summary table.

MAU130030 Rev. E 24

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Apply To Rest – Selecting this option, you will be assigning the injection parameters for the

currently highlighted injection (in the summary table), to all ensuing injections. Likewise, editing

an injection parameter while this option is selected affects the currently highlighted injection (in

the summary table), as well as all ensuing injections.

Pipette Controls

This group of buttons control the injector movements

of the pipette. The group box is labeled Ready when

pipette controls are enabled or Busy when a movement

is currently being made. The end of a movement is

signaled by a beep and the group label, switching from

Busy to Ready

Open Fill Port

This button is used for positioning the plunger tip for loading the pipette with your sample. When

you click on this button the injector screw of the pipette plunger will retract until the plunger tip

is positioned just above the fill port of the injection syringe. This will allow you to attach the

hose of the plastic syringe to the fill port for filling the pipette injection syringe with your sample.

Close Fill Port

This button is for positioning the plunger below the fill port after filling the pipette with your

sample. When you click on the button the injector screw will extend so the plunger tip is just

below the filling port of the injection syringe. This should be done immediately after filling the

pipette syringe and before removing the hose of the filling syringe.

Purge->Refill

This button will completely extend the plunger tip of the pipette injector to inject the sample

back into the filling test tube, and then raise the plunger to refill the injection syringe. When the

movement is complete the plunger tip of the injection syringe will be positioned to its original

position, just below the filling port. A beep will indicate the start of the movement a second beep

will indicate completion of the movement.

The purpose of the purge/refill procedures is to dislodge any air bubbles from inside walls of the

injection syringe (which may have occurred during the first filling) and expel them back into the

titrant solution. It is recommended to perform this procedure twice, after loading the pipette

before an experiment.

Distance (in.)

You may move the injector a set distance, either up or down, by entering the distance to be

moved (in inches) in the text box and clicking either the Up or Dn (Down) button.

25

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

2.5 Thermostat/Calibration Window

The Thermostat/Calibration Window allows access to the thermostat control and DP calibration

pulse function.

Thermostat Control

Thermostat Control allows for setting of the thermostat temperature, which will be maintained

during the VP-ITC Thermostatting state. Pre-thermostatting the VP-ITC and samples will result

in shorter equilibration times. Additionally, high temperature thermostatting during cell cleaning

can improve the effects of the cleaning.

Pulse Control

The Pulse Control allows for manually administering a DP calibration pulse. While this is not

the most thorough method of checking the y-axis calibration, it is the quickest and most

convenient method. Pulses may be applied any time the DP signal is equilibrated and the

resulting deflection used as a crude calibration assessment. Using a pulse which is relatively

large ( > +/- 5 mCal/min.) will expose DP calibration errors that are greater than 1%. Any users

who feel that the y-axis calibration requires adjustment should contact MicroCal prior to

attempting any changes to the VP-ITC calibration constants.

MAU130030 Rev. E 26

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

2.6 Setup/Maintenance Window

The Setup/Maintenance window allows access to change user preferences for the default settings

of run parameters. Systems having multiple users may benefit from having customized settings.

User Setup

Data File Path: Indicates the path (excluding file name) where VP-ITC data files will be saved.

The path should be located on a local hard drive and not on any floppy or CD-ROM

drive. This setting may only be changed while the VP-ITC is in the idle state,

Thermostatting. To change the current data file path, double click on the existing path

text and a dialog box will open allowing you to change the path. The desired data

directory must already exist in order to select it from the dialog box. Note: In order to be

read into Origin for data analysis the path cannot contain any spaces.

Setup File Path: Indicates the path (excluding file name) where VP-ITC setup files will be saved

and loaded. The specified path should be located on a local hard drive and not on any

floppy or CD-ROM drives. To change the current setup file path, double click on the

existing path text and a dialog box will open allowing you to change the path. The

desired setup directory must already exist in order to select it from the dialog box.

27

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Init. Setup File: Specifies the initial setup file, which will be loaded into the experimental control

window, the first time it is opened. Specifying the initial setup file as LastRun1.inj will

result in the last run parameters that were executed to be loaded at startup.

Cells Boot Temperature: Upon launching VPViewer, the ITC will scan to, and then thermostat

at, the temperature entered into this text box.

Default Shield DT: The default temperature difference between the ITC adiabatic jacket and the

outer shield of the VP-ITC. The default setting of a 1 degree difference has been found

to be ideal for all ITC applications and should not be changed without consultation with a

MicroCal engineer.

Analog Input Range: Determines the maximum range of measurable DC voltages for all VP-

ITC data channels. The default range of +/- 1.25 volts is adequate for almost all ITC

applications and provides for the greatest sensitivity. In instances where heats are too

large to be measured using the default setting, increasing the Analog Input Range can

increase the range of DP measurement. Please consult a MicroCal engineer prior to

making this change.

Save/Add/Erase User: These buttons provide a convenient way of maintaining unique startup

parameters and placing data files in different folders for multiple users. (See section 7.2

Customizing VPViewer, starting on page 89, for more information)

Y-Axis Scale

The Y-axis group allows for changing of the current y-axis (DP) units. Available y-axis units are

mCal/min., µCal/sec. and µWatts. By default, y-axis units will be displayed in µCal/sec.

Changing y-axis units will only change the power units for ‘local’ data displayed in real-time,

within VPViewer and Origin. All data files will be saved with the default units of µCal/sec

Diagnostics

This group is used for diagnostics and troubleshooting and

would normally not be utilized unless instructed by a MicroCal

engineer.

Export Current Data: Users may be instructed by a MicroCal

engineer to click the Export Current Data button. This provides service personnel with a

convenient means of capturing ITC data, which otherwise is not saved to disk.

Plot Idle Data: Users may be instructed by a MicroCal engineer to checkmark the Plot Idle

Data, for use in troubleshooting. This provides service personnel with a convenient

means of capturing ITC data, which otherwise is not saved to disk.

Extended Data Mode: This mode of operation will save all data the VP

instrument produces to the data file. This provides MicroCal

engineers with extra data for troubleshooting.

Show Noise: When this box is checked the Real-Time Noise group box

will be displayed. From this group you may elect to numerically

display the RMS (Root-Mean-Squared) or PTP (Peak-To-Peak)

noise.

MAU130030 Rev. E 28

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

Pipette Maintenance

This group of buttons provides controls for replacing plunger tips.

It is recommended to replace tips once a month when using the VPITC daily. (For more information refer to the section on Replacing

Pipette Plunger Tips starting on page 73).

Remove Old Tip – Click this button to position the injector plunger

screw in a retracted position, so that the accessory tools may be

used to remove the old plunger tip.

Install New Tip – Click this button to position the injector plunger

(in a retracted position) so that the Tip Pusher Tool may be used to

insert a new plunger tip on to the end of the plunger screw.

Polish New Tip – After installing a new tip, clicking this button will position the injector plunger

tip (in an extended position) so that the glass polishing tool may be used to polish the plunger for

first time use.

New Tip Polished – After polishing a new tip click this button to the plunger screw, this will

position the screw properly for putting the pipette back together.

29

MAU130030 Rev. E

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

2.7 Constants Window

This window provides viewing access to the calibration constants for your particular VP-ITC

instrument. Shown below are calibration constants that are typical of the VP-ITC. This window

is password protected and should not be changed without instructions by a MicroCal Engineer.

MAU130030 Rev. E 30

MicroCal, LLC VP-ITC MicroCalorimeter User’s Manual

2.8 Real Time Data Display in Origin

Data Display Project Window Overview (VPITCPLOT.OPJ)

When VPViewer is opened, it will open the OriginTM project window VPITCPLOT.OPJ.

VPITCPLOT.OPJ has been customized for real time data display. This project of Origin is

dedicated for data display only, and should not be used for data analysis. Users should open a

separate copy of Origin for ITC, to perform data analysis.

This section is intended to detail those features that are contained in the VPITCPLOT.OPJ data