MICRO-AIR SC 150 Owner's Manual

AIR CLEANERS

OWNER’S MANUAL

READ COMPLETE INSTRUCTIONS BEFORE OPERATING.

PLEASE FILE FOR FUTURE REFERENCE.

MODEL SC 150

CAUTION

MODEL SC 150 SPECIFICATIONS

Input Volts: 120 Volts, 60Hz

220 Volts, 50 Hz

Maximum Current:

Draw- 120V. 2.4 amps

220V. 1.2 amps

CFM: 200 for Dual Arm Unit

150 for Single Arm Unit

dBA*: Exhaust- 63 for Dual Arm Unit

62 for Single Arm Unit

Inlet- 58 for Dual Arm Unit

57 for Single Arm Unit

*measured at 6’ distance

Dimensions: 11 1/4”h. x 14 3/8”w x 27” l.

with 3’ long arm assembly

Shipping Wt.: 53 1/2 lbs. Single Arm

55 lbs Dual Arm

Actual Wt. 45 1/2 lbs. Single Arm

47 lbs. Dual Arm

FEATURES:

• Compact size - high CFM

• Attractive paint finish

• Self supporting arm assy.

• Lighted switch

• Thermally protected, fan-cooled motor.

• Flexible design for bench top, under table or wall

mount applications.

• Easy access to all parts for service and maintenance.

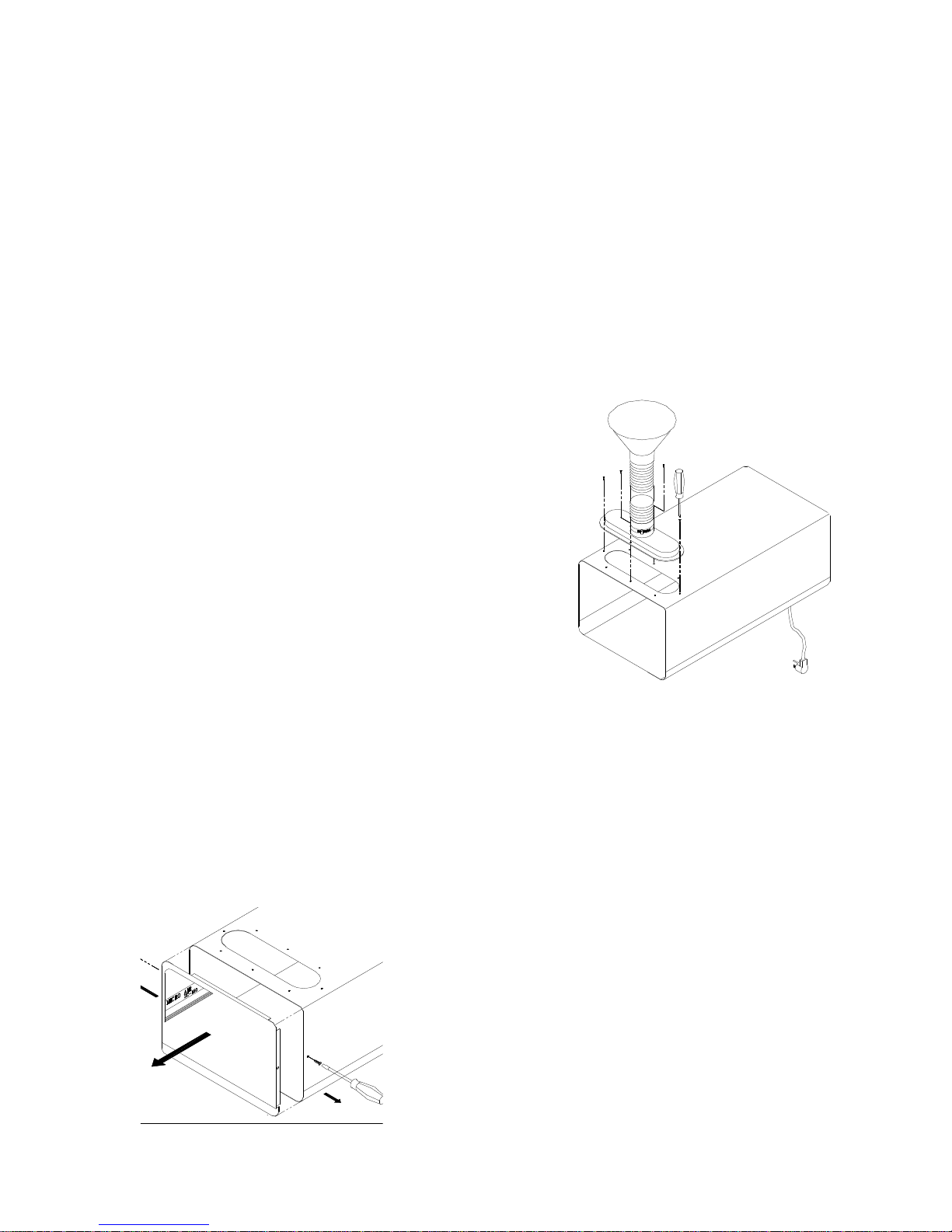

3. Looking inside the unit, remove the two (2) filter spring

retainers and pull out the foam prefilter, HEPA filter and

charcoal/ purasorb filter. REMOVE THE PLASTIC WRAP

THAT PROTECTS THE CHARCOAL/ PURASORB FILTER

DURING STORAGE.

4. Remove the arm assembly from the second carton consisting

of one or two flexible hoses and a black formed plastic

manifold. Taped to the underside of the manifold is a clear

bag containing four (4) black screws. Remove screws and

disgard bag.

5. Place the plastic manifold upon the large oval hole on the

SC150 cabinet, align the four pre-drilled holes on the

manifold to those on the cabinet.

6. Using a slot head screw driver, secure the plastic manifold

and hose assembly to the cabinet with the four (4) self

tapping black screws obtained from step 4. (FIG. 2)

PRE-OPERATING INSTRUCTIONS

NOTE: The SC150 is shipped in two cartons. Carton 1 contains the

main unit w/ instructions. Carton 2 contains the arm (or arms)

assembly.

1. Upon receipt, remove the units from cartons. Inspect for any

freight damage that may have occured during shipping.

Report any damage to the freight company.

2. Remove filter access door by removing the two phillips head

screws as shown. Grasp the underside of the door offset

and lift slightly to remove. (FIG. 1)

FIG. 1

FIG. 2

7. Re-install filters removed in step 2 and secure with filter

spring retainer. NOTE: Filters should be pressed firmly into

unit for positive seal resulting in no filter bypass. Replace

the filter access door.

NOTE: INSTALL CHARCOAL FILTER BEFORE HEPA

FILTER.

OPERATION

1. Before operating, simply plug the SC150 power cord into

any grounded electrical outlet rated at nameplate voltage.

2. Once the SC150 has been plugged in, turn the unit on.

Position inlet nozzle(s) approximately 6” from point of

containment to be captured.

IMPORTANT: TAKE CARE TO SEE THAT THE INLET

NOZZLE(S) DO NOT TOUCH HOT SURFACES SUCH

AS SOLDERING IRONS, WHICH WOULD BE RESULT

IN THE DEFORMATION OF THE PLASTIC NOZZLE.

3. The SC150 has a fan-cooled, thermally protected motor,

and is designed to operate for continuous duty if required.

NOTE: After some time,the flexible hose may not hold in a horizontal

PART NO. 33085-01

position. This can be fixed by simply twisting the hose

counterclockwise thereby slightly reducing the hose diameter and

tightening the segmented joints.

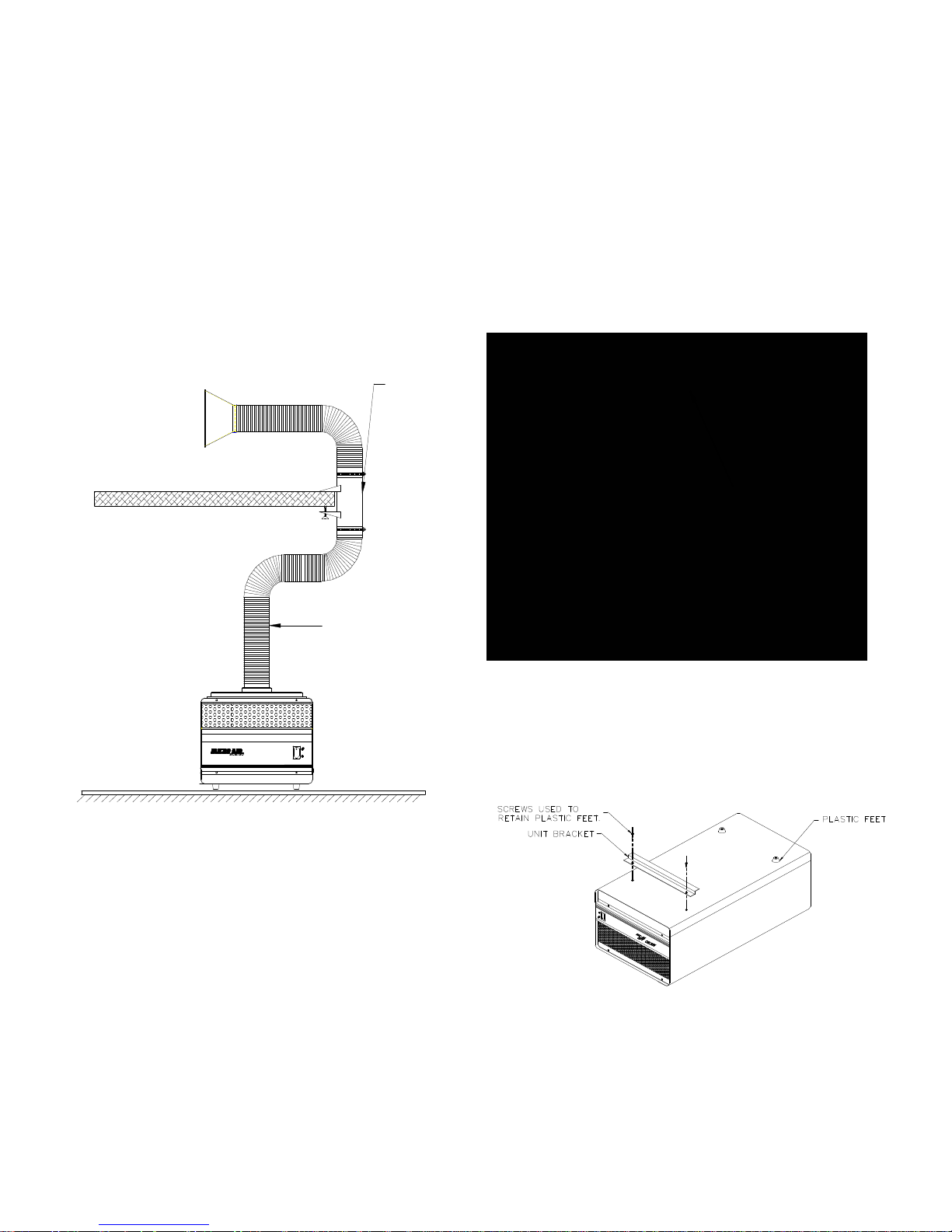

OPTIONAL INSTALLATION APPLICATIONS

This section displays options available to the SC150 for specific

applications:

A. Table Bracket Mounting (See FIG. 3.)

1. This option is designed when the customer wishes to place

the unit on the floor and clamp the hose to a bracket on the

table. This clears space for the worker.

TABLE CLAMP

BRACKET

SC150 INSTALLATION INSTRUCTIONS FOR VERTICAL

WALL MOUNT APPLICATIONS

This kit (Part No. 33076-01) contains:

1 33078-01 Wall Bracket

1 33080-01 Unit Bracket

3 P103 #10 x 1 1/4” Long Hex Screw

1. Remove the two plastic feet near the air exhaust end of

the SC150 using a phillips head screw driver. Retain the

screws.

2. Attach the unit bracket to the bottom of the SC150 using

screws that originally secured plastic feet. (See FIG 5.)

OPTIONAL WALL

BRACKET NOT

FOR VERTICAL

INSTALLATION

PART NO. 33076-01

EXTENSION HOSE OR PVC

SUPPLIED BY OTHERS. 3"

INSIDE DIAMETER REQUIRED.

FIG. 3

B. Optional Wall Mount Assembly for Vertical

Installation. (See Fig. 4)

1. This installation allows the SC150 to be mounted on a

wall in a vertical position. The exhaust is then pointed

upward, and the arm (or arms) is at the bottom end,

close to the work area.

FIG. 4

FIG. 5

Loading...

Loading...