MICRO-AIR RP4, RP8, RP6 Installation And Operation Manual

MICRO-AIR DUST COLLECTOR

Installation and Operation Manual

MODEL RP4, RP6, RP8

This manual contains specifi c cautionary statements relative to worker safety. Read this manual thoroughly

and follow as directed. It is impossible to list all the hazards of dust control equipment. It is important that

use of the equipment be discussed with a Micro Air Representative. Persons involved with the equipment or

systems should be instructed to operate in a safe manner.

Important:

1

TABLE OF CONTENTS

CAUTIONS 3

SPECIFICATIONS 4

INSTALLATION

INSPECTION 5

EQUIPMENT / TOOLS REQUIRED 5

ASSEMBLY OF UNIT 5

COMPRESSED AIR INTALLATION 6

ELECTRICAL INSTALLATION 6

UNITS INSTALLED OUTDOORS 7

UNIT OPERATION 7

CARTRIDGE CLEANING OPERATION 7

ROTO-PULSE CLEANING TIMER ADJUSTMENTS 8

AFTER-PULSE CLEANING TIMER ADJUSTMENTS 8

OPTIONAL COMPONENT INSTALLATION

DUST COLLECTION TRAY INSTALLATION PROCEDURE 9

DUST COLLECTION HOPPER INSTALLATION PROCEDURE 10

DUST COLLECTOR LEF BRACING INSTALLATION PROCEDURE 11

SILENCER INSTALLATION PROCEDURE (64” LEGS ONLY) 12

MAGNEHELIC KIT INSTALLATION PROCEDURE 13

PHOTOHELIC KIT INSTALLATION PROCEDURE 14

INLET PLENUM INSTALLATION PROCEDURE 15

BARREL LID KIT INSTALLATION PROCEDURE 16

MOTOR SHROUD INSTALLATION 17

AFTER FILTER KIT INSTALLATION 18

WIRING DIAGRAMS

RP4 WIRING DIAGRAM 19

RP6 WIRING DIAGRAM 20

RP8 WIRING DIAGRAM 21

RPO4 WIRING DIAGRAM 22

RPO6 WIRING DIAGRAM 23

RPO8 WIRIING DIAGRAM 24

RP PARTS LIST 25

2

Cautions:

Avoid mixing combustible materials, such

as buffi ng lint, paper, wood, aluminum, and

magnesium dust, and with dust generated from

grinding ferrous metals due to the potential fi re

hazard caused by sparks in the dust collector.

Under no conditions should the persons operating

the dust collector be allowed to put cigarettes or

any burning object into the hood or ducting of any

dust collector system.

All users of Micro-Air Dust Collector Equipment

should comply with all National and Local Fire

Codes and/or other appropriate codes when

determinimg the location and operation of dust

control equipment.

Many of the processes outlined in this manual

will expose the installer to circuits powered by

high voltage. This installation is recommended

for professional electricians or MicroAir trained

personnel.

All wiring must be done in accordance with

applicable National, State, and local electrical

code. MicroAir does not determine what is

acceptable in any local jurisdiction and cannot

be held responsible for wiring that does not

meet local codes.

Improper installation or operation of this

equipment can cause damage to equipment

and / or injury to personell. The installation/

operation manual must be read and followed in

its entirety.

When dust collectors are used to collect fl ammable

or explosive dusts, the dust collector should be

located outside the building. Also, an installer

of fi re extinguisher equipment, familiar with this

type of fi re hazard and local fi re codes, should be

consulted for recommendations and installation

of the proper fi re extinguishing equipment. Dust

collectors do not contain fi re extinguishing

equipment.

Explosion relief vents are required on some

applications. Consult with an insurance

underwriter or a NFPA manual to determine proper

vent size ratio. Vents installed on dust control

equipment within a building, must be vented to

the outside to minimize changes of secondary

explosion. Consult the proper authority having

jurisdiction to determine proper method of venting.

Dust collectors do not contain Explosion Relief

Vents, except on special order.

3

MICRO-AIR DUST COLLECTOR SPECIFICATIONS

Input Voltage:

208-230/460VAC 60 Hz 3-Phase

Maximum Current:

5HP: 208-230V 13.2 - 12.0 amps

460V 6.0 amps

7-1/2HP: 208-230V 21.0-18.8 amps

460V 9.4 amps

10HP: 208-230V 26.4-24.0 amps

460V 12.0 amps

Motor:

5HP, 3-Phase TEFC Motor, 3450 RPM

7-1/2HP, 3-Phase TEFC Motor, 3450 RPM

10HP, 3-Phase TEFC Motor, 3450 RPM

Cabinet Dimensions:

RP4, RPO4 129” H x 42” W x 62” D

RP6, RPO6 151” H x 42” W x 62” D

RP8, RPO8 171” H x 42” W x 62” D

Weight:

RP4, RPO4 1315 lb.

RP6, RPO6 1460 lb.

RP8, RPO8 1850 lb.

Filter Area:

RP4, RPO4 936 square feet

RP4, RPO4 1404 square feet

RP4, RPO4 1872 square feet

Dust Trap Capacity (Optional):

2.8 cubic feet total

Air Recuirements:

1.1 SCFM at 80 psi per second of cleaning pulse: 2.7 scfm total.

•

Minimum air line 3/4 inch at 80 psi maximum.

•

3/4” NPT Female fi tting is standard for shp air attachment.

•

Clean, dry, compressed air at the correct pressure is required for the cleaning system to operate correctly

•

It is recommended that a pressure regulator and coalescing fi lter be installed between the copressed air

•

source and the inlet to the dust collector.

4

Installation:

Inspection:

The Micro-Air Dust Collector is shipped on one

skid. The skid should be inspected for any visible

damage that may have occurred during shipment.

One skid is the blower motor, collector cabinet,

Dust collection Tray/Hopper, Mounting Legs.

Additional equipment that may be shipped

includes:

Leg Cross Bracing Kit

55 Gallon Barrel Lid Kit

Inlet Plenum with (4) 14” x 14” Inlets

Discharge Silencer

Hepa After-Filter Kit

Photohelic Kit

Remote Start/Stop Station

Equipment/Tools Required:

Equipment and tools needed for proper installation

will include the following:

Crane or Lift Truck

Lift Straps or Chain

1/2” Scocket Wrench

Pipe Wrench

Assembly of Unit:

1. Determine the location where the unit is to be

installed. Be sure to allow suffi cient room to

access the unit for servicing and maintenance

on all sides.

CAUTION: THE UNIT SHOULD BE LIFTED

OFF THE SKID AND SET INTO POSITION BY

UTILIZING THE LIFTING LUGS PROVIDED.

SEVERE DAMAGE MAY RESULT FROM ANY

OTHER LIFTING METHOD.

FIGURE 1

3. Bolt on the four legs. The two lower bolts at each

corner will be removed and used to attach each

leg (see Figure 2).

CAUTION: THE UNIT SHOULD BE LIFTED

OFF THE SKID AND SET INTO POSITION BY

UTILIZING THE LIFTING LUGS PROVIDED.

SEVERE DAMAGE MAY RESULT FROM ANY

OTHER LIFTING METHOD.

2. Lift the unit with a lift truck or overhead

crane using the four lifting lugs located at the

corners of the unit (see Figure 1).

NOTE: Each lifting strap or chain should be rated

for 2000 lb. The chains located on the motor

side should be 10 inches shorter that the chains

on the fi lter side to properly balance the unit

while lifting. Recommended chain lengths are as

follows.

Front side 48 inches

Motor side 38 inches

FIGURE 2

5

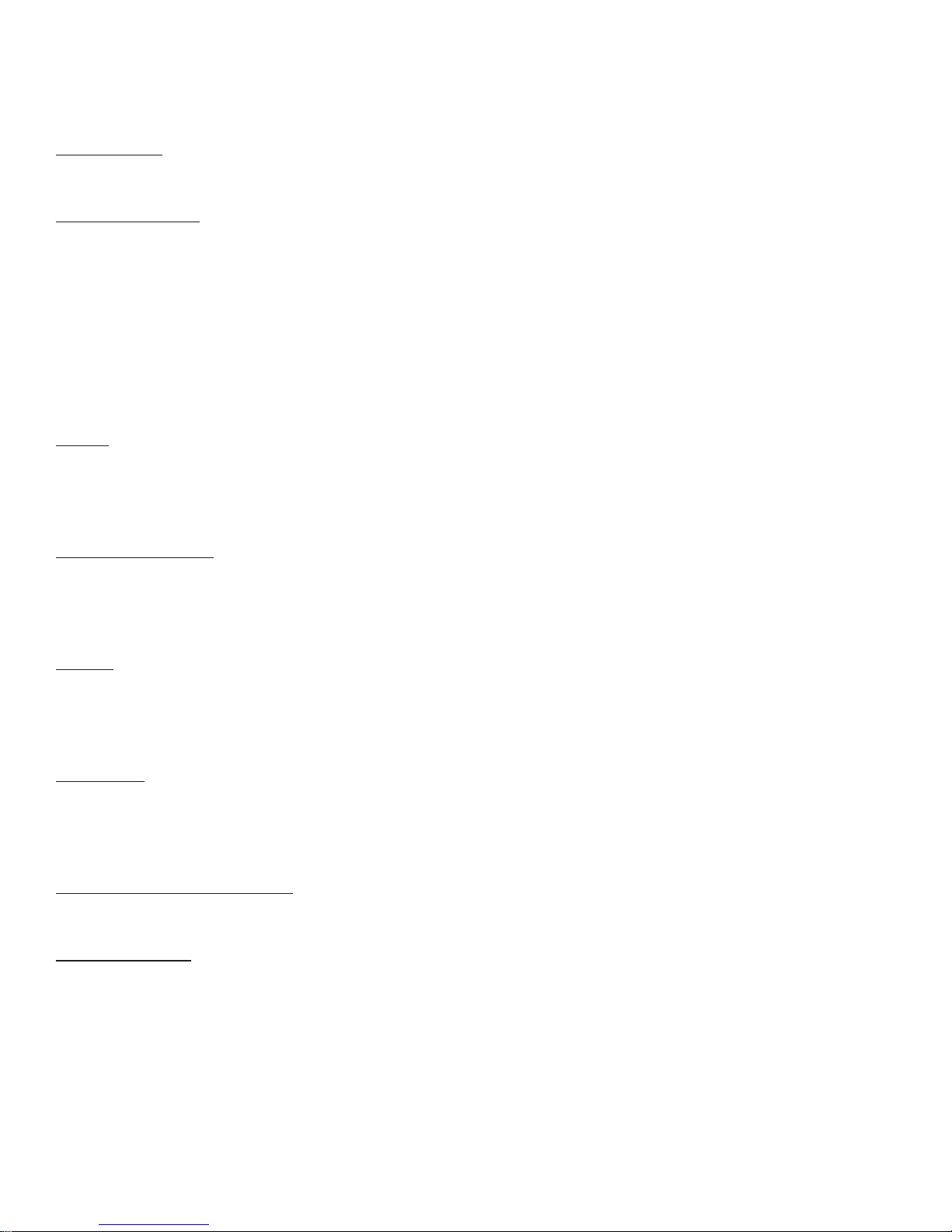

3. When the legs have been completely installed

each leg should be bolted to the ground using the

hole provided in the base plate of the leg 9see

Figure 2A).

4. After the legs have been properly anchored, the

dust containment system can be installed. (refer to

pages 9-10).

LEG

BASE PLATE

1/2” DIA. HOLE

FIGURE 2A

Compressed Air Installation

The compressed air inlet for the Roto-Pulse cleaning

system is at the top of the piping assembly located on

the backside of the unit near the blower motor (see

Figure 3). Aminimum of a 3/4 inch line and plant air

at a pressure at 80 psi is required for proper operation

of the Roto-Pulse cleaning system.

Electrical Installation

1. Remove the electrical box cover located on the

backside of the unit near the blower motor.

2. Make connections from your supply power to

terminal L1, L2, and L3. Wire size should be

rated for motor horsepower load needed for

your application (see Figure 4).

NOTE: A 7/8” diameter hole is provided for

conduit connection of supply power.

1. Connect the power. Momentarily turn the

unit on and off with the start/stop switches. Note

the rotation of the motor. Proper rotation can

be viewed at the open end of the blower motor

(remove the motor access plate if your unit has

been supplied with a motor/silencer shroud). The

proper rotation is in the clockwise direction.

NOTE: All electrical work must be done by

a qualifi ed electrician according to local and

national codes.

CAUTION: Installation can cause exposure to

live components. Disconnect electrical power

before proceeding with installation. Proper

lock out / tag out procedures should be used.

NOTE: Clean, dry, compressed air at the correct

pressure is required for the cleaning system to

operate correctly. It is recommended that a

pressure regulator and coalescing fi lter be installed

between the compressed air source and the inlet to

the dust collector.

FIGURE 3

FIGURE 4

6

4. If motor rotation is in the proper direction then

AMP draw of the motor should be checked.

Correct motor AMP draw information is

located on the inside of the Electrical Box

Cover. If motor current is higher than rated

for the motor supplied, do not continue

operation. Re-check your wiring (refer to

the inside of the electrical box cover) and if

problems continue contact your Micro-Air

Dust Collector representative for instructions.

5. Reassemble the electrical box cover onto the

enclosure.

Units Installed Outdoors

1. The remote Start/Stop Control Enclosure

supplied with the unit is not rated for outdor

use. The Control enclosure must be mounted

indoors.

2. When the enclosure is mounted, make

connection from your supply power to

terminals L1, L2, and L3. Wire size should be

rated for motor horsepower load needed for

your application (see Figure 4).

3. When power connections have been made

refer to wiring diagrams on pages 23-25 for

wiring required between the remote Start/Stop

enclosure and the Nema 4 J-box located on the

unit.

4. When supply power hase been terminated,

reconnect the power. Momentarily turn the

unit on and off with the Start/Stop switches.

Note the rotation of the motor. Proper rotation

can be viewed at the open end of the blower

motor (Remove the motor access plate if

your unit has been supplied with a motor/

silencer shroud). The proper rotation is in the

clockwise direction.

5. If the motor rotation is in the proper

direction then AMP draw of the motor

should be checked. correct motor AMP

draw information is located on the inside of

the Electrical Box Cover. If motor current

is higher than rated for the motor supplied,

do not continue operation. Re-check your

wiring (refer to the inside of the electrical box

cover) and if problems continue contact your

Micro Air Dust Collector representative for

instructions.

6. Reassemble the electrical box cover onto the

enclosure.

Unit Operation

1. Turn the unit on via the start switch located on the

side of the electrical box.

NOTE: Some particulate may pass through the

cartridge fi lters and blower upon initial start-up. This

will end once the fi lters have been seasoned and a

power cake has formed on the fi lter. If this condition

continues to occure refer to the section “Roto-Pulse

Cleaning Timer Adjustments” to increase the period

of time between pulses.

2. once the unit is running the Roto-Pulse cleaning

system will be operational. Operation is detected

by hearing a .07-second air pulse approximately

every 5 seconds. If adjustment to timing of

pulses is desired refer to the secion “Roto-Pulse

Cleaning Timer Adjustments”.

3. Check the After-Pulse Cleaning cycle by turning

off the unit via the stop switch located on the

side of the electrical box. The unit should

continue to pulse every 5 seconds for a period of

approximately 17 minutes. If adjustment to the

after-pulse time is desired, refer to the section

labeled “After-Pulse Cleaning”.

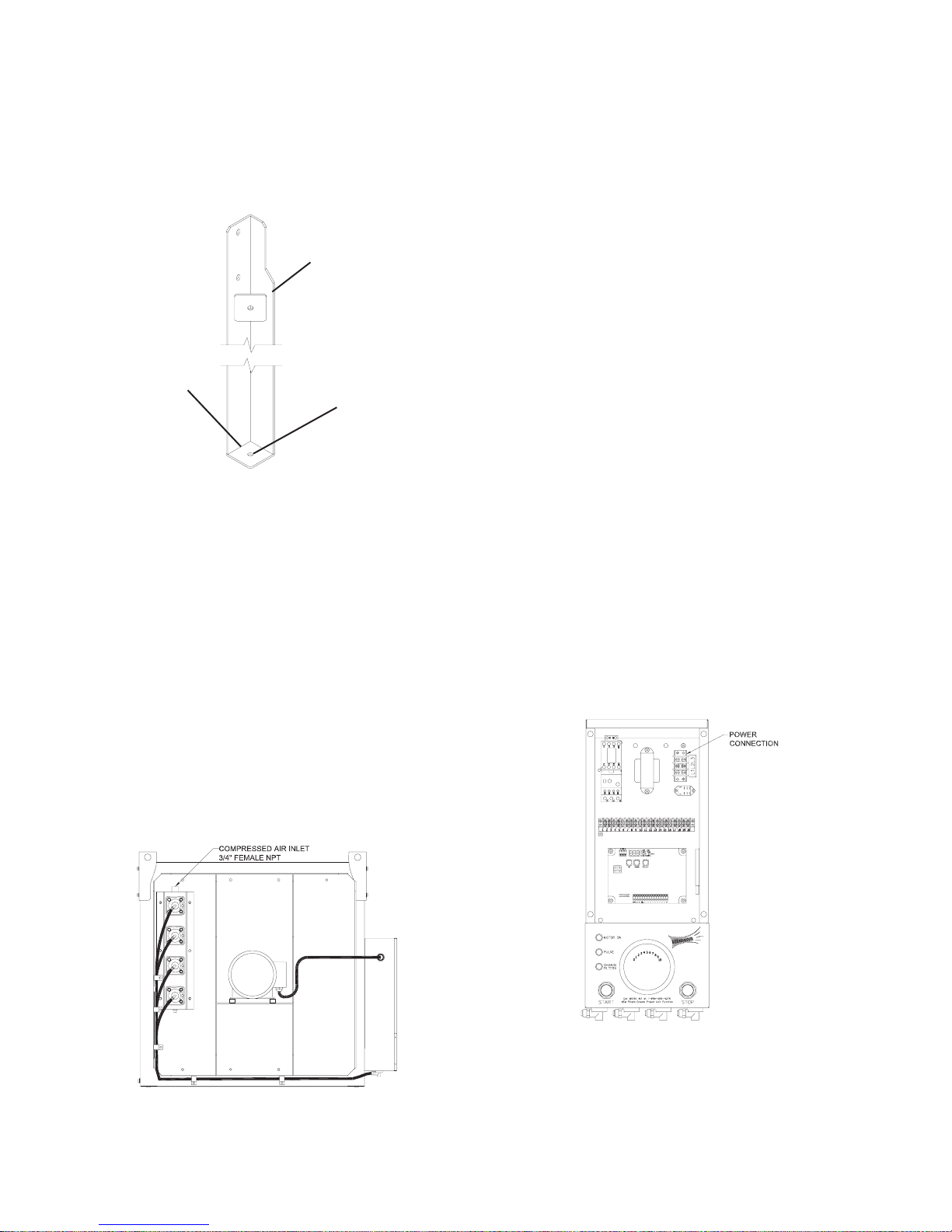

Cartridge Cleaning Operation

The Micro Air Dust Collector is designed with the

Roto-Pulse Cleaning System to clean the cartridge

fi lters.

This system provides superior cleaning performance

using a rotating tube with pre-drilled holes (see

Figure 5). As the diaphragm valve opens, the RotoPulse tube rotates while air exits the holes, thus

providing the cleaning of the cartridge.

FIGURE 5

7

1. For proper cleaning, the compressed air pressure

should be regulated at 80 psi maximum.

2. During normal operation the Roto-Pulse cleaning

system is factory set to clean two (2) cartridge

fi lters for a period of .07 seconds every 5 seconds.

3. Once the unit is turned off, the cleaning cycle

will continue for a period of 17 minutes. Do not

service the fi lters until cleaning is completed.

CAUTION: Allow 20 minutes of downtime before

opening fi lter access doors. After-Pulse system is

momentarily operational After unit is turned off.

4. The Roto-Pulse cleaning operation dislodges

particles from the cartridges. Particles then fall

down into the dust collector hopper/tray.

NOTE: When servicing the collection system, be

sure to turn the unit off.

Roto-Pulse Cleaning Timer

Adjustments

This can be adjusted from .05 seconds to 600

seconds. To adjust this time press the select

button on the timer board untill the on time

LED is lit. Press the up/down buttons untill

the desired value is displayed. Press select to

set the new value.

NOTE: While this time can be adjusted we

recommend that you leave the “ON TIME” at

the factory setting. If less cleaning is needed

you should increase the time between pulses as

means of reducing the amount of cleaning. If

more cleaning is needed you should decrease the

amount of time between pulses. Beware, as the

time between pulses is decreased for additional

cleaning, this will increase your compressed air

consumption and create an additional load on your

compressed air system.

5. once adjustments have been made replace the

electrical box cover and reconnect the power.

6. Start the unit and observe the new pulse

settings and determine if additional

adjustments are necessary. If more adjusting

is needed, repeat the previous steps.

CAUTION: Installation can cause exposure to live

components. Disconnect electrical power before

proceeding with timer adjustments. Proper lock

out / tag out procedures should be used.

1. Turn unit off via the stop switch and disconnect

power.

2. Remove the electrical box cover.

3. The timer control board is pre-set at the factory

to clean two (2) cartridge fi lters every 5 seconds.

This time can be adjusted from 1 second to 999

seconds. To adjust this time press the select button

on the timer board untill the off time LED is lit.

Press the up/down buttons untill the desired value

is displayed. Press select to set the new value.

NOTE: Cleaning of the fi lters too often will decrease

your level of performance. A certain level of dust

cake on the fi lters will improve the effi ciency of

the fi lter cartridges. You should try to maintain a

minimum of 1 in w.c. of pressure differential across

the fi lters. If you can not maintain this minimum

level of differential across the fi lters the time between

cleaning pulses should be increased until this can be

achieved.

4. The timer control board is preset at the factory

to have a cleaning pulse duration of .07 seconds.

After-Pulse Cleaning Timer

Adjustments

1. The unit is equipped with an After-Pulse

Cleaning Cycle. This cycle will continue to

clean the cartridge fi lters for a period of time

after the unit is turned off.

2. The length of the After-Pulse operation is

preset at the factory for 999 seconds (17

minutes). This time can be adjusted from 0

seconds to 999 seconds. To adjust this time

press the select button untill the off time LED

is lit. Press and hold the select button for 3

seconds. Press the up/down buttons untill the

desired value is displayed. Press select to set

the new value. The After-Pulse operation can

be disabled by setting the time value to zero

(0) seconds.

Explosion Vent Maintenance

Refer to explosion vent instructions supplied

by the vent manufacturer for information

regarding use and maintenance of the

explosion vent.

8

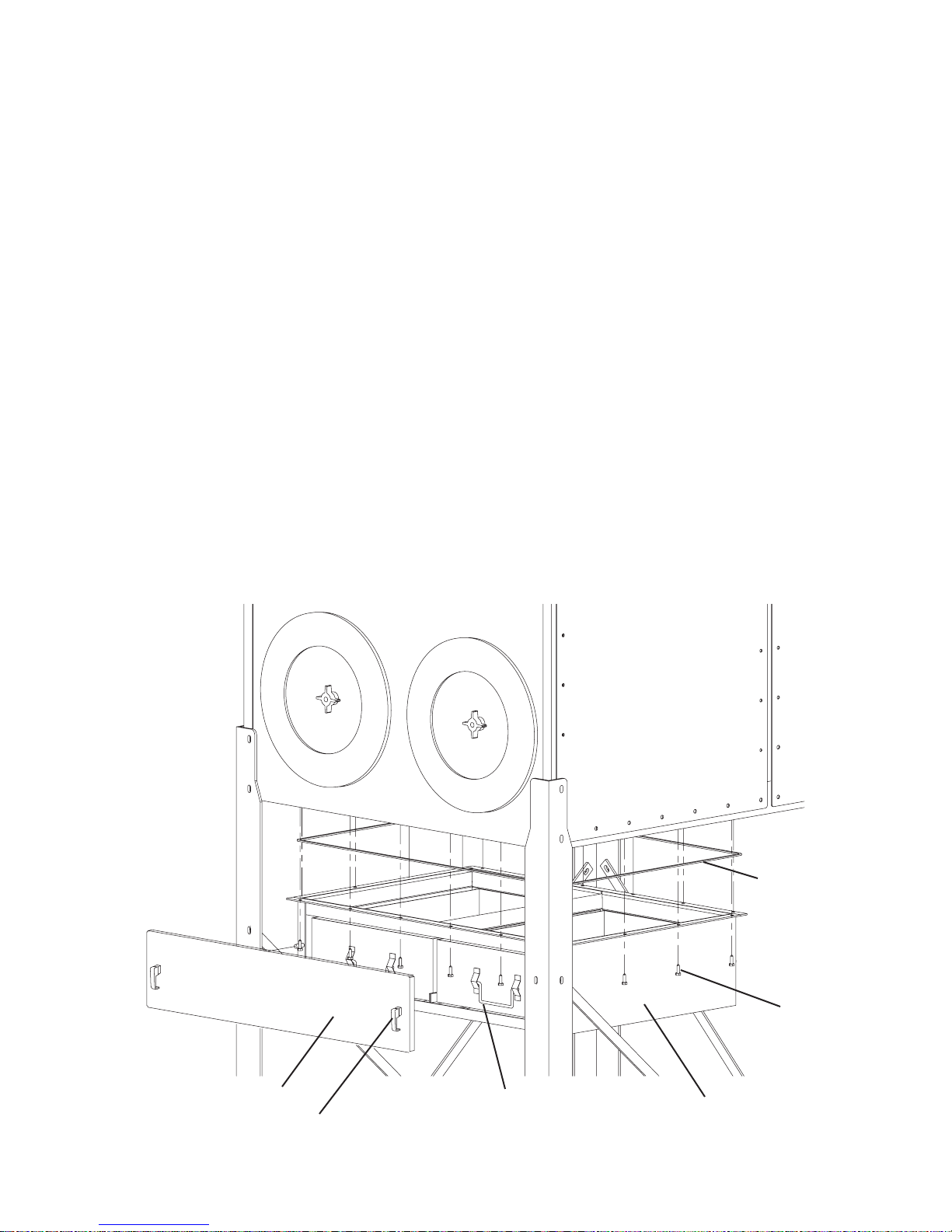

RP DUST COLLECTOR

DUST COLLECTION TRAY INSTALLATION PROCEDURE

This Kit Includes:

20 ea. P3543 Self-Tapping Screws

12 ft. P3686 3/16” x 1” Self-Adhesive Foam

86 in. P1367 1” x 3/4” Foam (Placed at inside of Access Door)

1 ea. 38379-01 Dust Tray Weldment

2 ea. 38380-01 Dust Tray

1 ea. 38378-01 Dust Tray Access Door

2 ea. P1372 Door Latch

NOTE: Dust tray access door must be removed prior to assembly

INSTALLATION:

1. Apply self-adhesive foam to the bolt hole fl ange on the dust tray.

2. Align the hole pattern on the dust tray fl anges with the hole pattern on the underside ot the unit.

3. Attach the dust tray (38379-01), usting twenty (20) self-tapping screws, to the unit.

DUST TRAY ACCESS DOOR

DOOR LATCH

HANDLE

FIGURE 6

9

SELF-ADHEASIVE

FOAM

SELF-TAPPING

SCREWS

DUST TRAY WELDMENT

Loading...

Loading...