2.5Gbps GPON/BPON ONU SERDES

SY87725L Evaluation Board

Micrel Inc. • 2180 Fortune Drive • San Jose, CA 95131 • USA • tel +1 (408) 944-0800 • fax + 1 (408) 474-1000 • http://www.micrel.com

July 2008

M9999-071108-B

General Description

The SY87725L evaluation board is designed for

convenient setup and quick evaluation of the SY87725L

using a single power source. The evaluation board is

optimized to interface directly to 50Ω test equipment since

the evaluation board is configured with AC-coupled inputs

and AC-coupled outputs.

All datasheets and support documentation can be found

on Micrel’s web site at: www.micrel.com.

Features

∑ Single +3.3V power supply

∑ AC-coupled configuration for direct interface with 50Ω

test equipment

∑ 2.5G/1.25G/625M down stream

∑ 1.25G/625M/156M up stream

Related Documentation

∑ SY87725L, 2.5Gbps GPON/BPON ONU Serdes

Datasheet

__________________________________________________________________________________________

Evaluation Board

Micrel, Inc.

SY87725L Evaluation Board

July 2008

2

M9999-071108-B

Evaluation Board Description

AC-Coupled Evaluation Board

The SY87725L is 64-pin EPAD-TQFP package. The

evaluation board is designed to operate with a single 3.3V

±10% power supply and is configured with AC-coupled

inputs and outputs. The high-speed input and output

channels are brought out to SMA connectors through

matched-length AC-coupled differential strip-line traces.

AC-Coupled Input

For ease of use, the AC-coupled inputs are biased onboard. The user need only supply the appropriate input

swing to the board.

AC-Coupled Output

The SY87725L is configured with AC-coupled outputs

allowing the board to interface directly with 50Ω

equipment. AC-coupling allows the board to use a single

power supply.

Unused Output

Single-Ended to Scope

Unused complimentary outputs should be terminated into

50Ω-to-ground to prevent unwanted reflections.

AC-Coupled Evaluation Board Setup

Setting up the SY87725L AC-Coupled Evaluation

Board

1. Set the voltage on a DC supply to +3.3V and

turn off the supply. Connect the GND terminal to

the negative side of a DC power supply.

Connect the VCC terminal to the positive side of

a DC power supply.

2. For a LVPECL input signal, set VT to VCC–2.0V.

3. Signal Generator: Using a differential signal

source, set the amplitude of each side of the

differential pair to 400mV (800mV measured

differentially). Set the offset to a positive value,

the value of the offset is not critical, since the

AC-coupled inputs will be automatically biased.

Turn off the outputs of the signal source.

4. I/O Cable Interface: Using equal length 50Ω

impedance coaxial cables connect the signal

source to the inputs on the evaluation board.

Using equal length 50Ω impedance coaxial

cables connect the outputs of the evaluation

board to the oscilloscope of another

measurement device that has an internal 50Ω

termination. Unequal length cables are not

recommended since they introduce duty cycle

distortion and unwanted signal delays.

5. Connect the trigger input of the scope to the

trigger output of the signal generator.

6. Set the evaluation board dipswitch to the

appropriate input selection.

7. Enable the signal source, turn on the DC source,

and monitor the outputs.

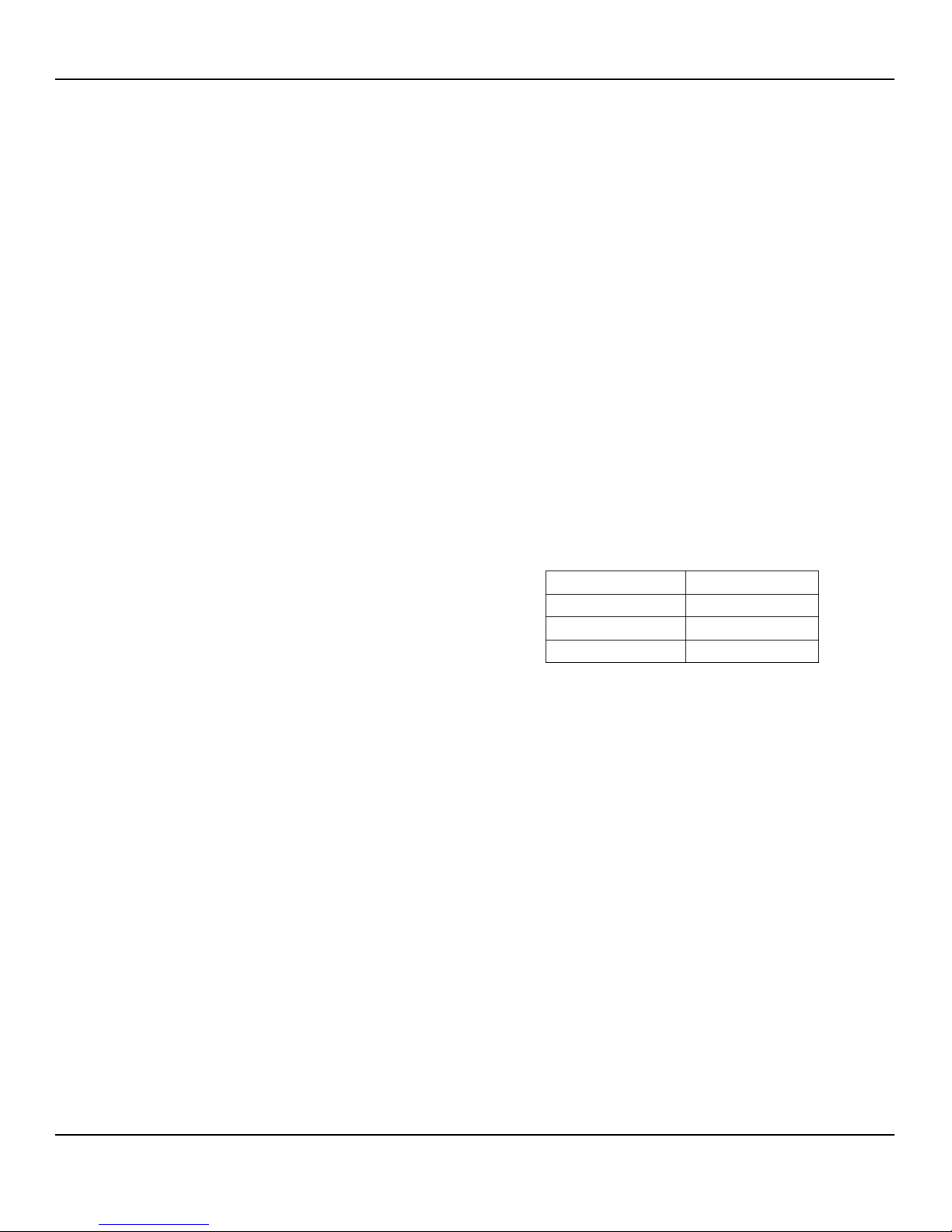

Evaluation Board Layout

PC Board Layout

The evaluation boards are constructed with Rogers 4003

material and are coplanar in design fabricated to minimize

noise, achieve high bandwidth and minimize crosstalk.

L1

GND and Signal

L2

GND

L3

VCC

L4

GND

Table 1. Layer Stack

Micrel, Inc.

SY87725L Evaluation Board

July 2008

3

M9999-071108-B

Evaluation Board Schematic

Micrel, Inc.

SY87725L Evaluation Board

July 2008

4

M9999-071108-B

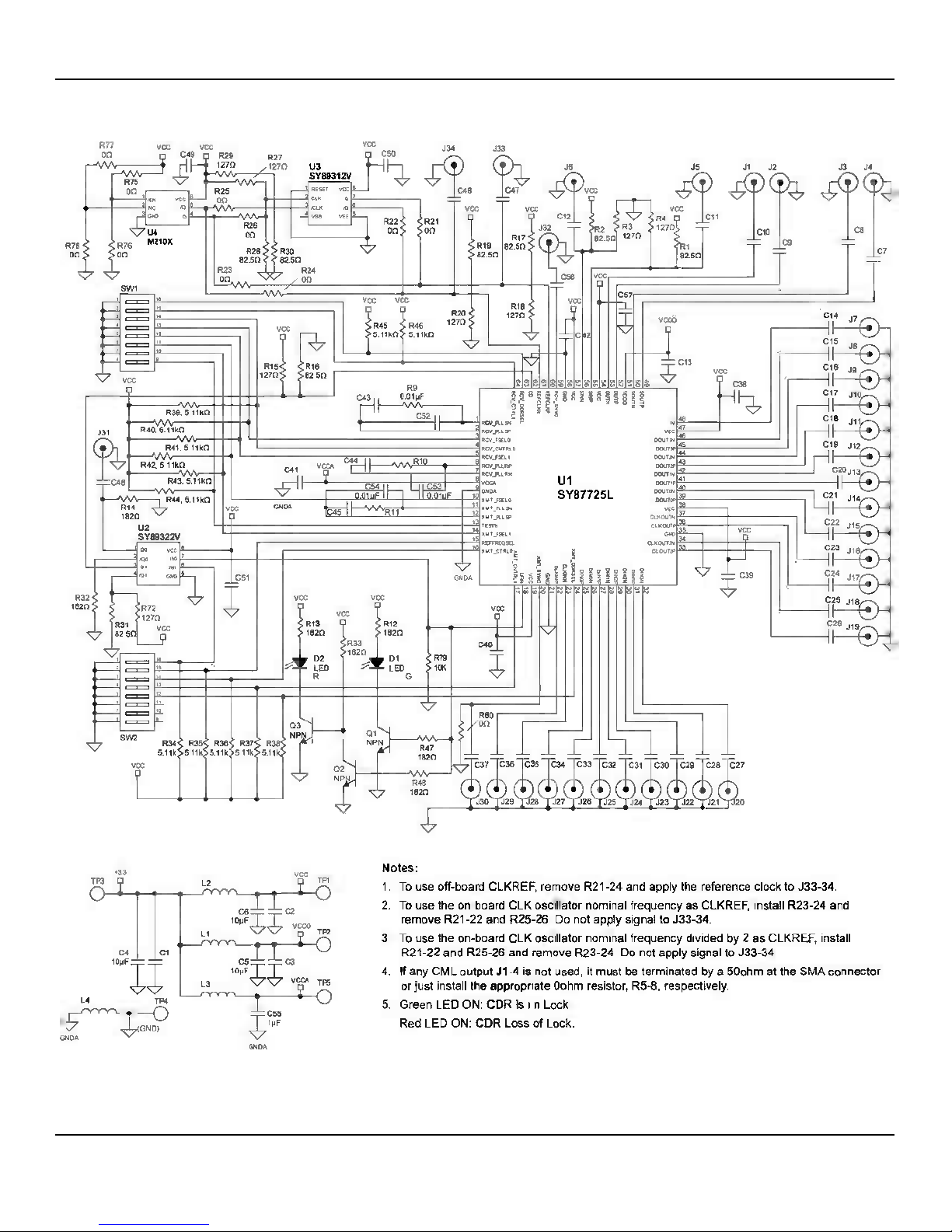

How to Use this Document

The following pages show the individual test modes built

into the SY87725L. The diagram for each mode shows

the main data flow for that mode. The table of required

switch settings lists the switch settings for that mode;

unlisted switch settings are not used in that mode. The

diagram to the left of the table shows the actual dip switch

settings as they would appear on the evaluation board.

The dip switches are configured with a pull-up resistor on

the output so when the switch is in the “OFF” position the

output is HIGH and when the switch is in the “ON”

position the output is pulled to ground, LOW.

The test flow diagram in the Appendix lists the modes in

order from the minimum functionality to the full

configuration. This allows the user to start with the

simplest configuration and progress to the full

configuration.

Micrel, Inc.

SY87725L Evaluation Board

July 2008

5

M9999-071108-B

Remote Loopback Data

This is the most basic test mode. It loops back the data

from SIN to SOUT and is used to verify the connections to

SIN and SOUT as well as the power supply connections

to the evaluation board. The SOUT output can be

monitored with a scope or a serial BERT.

Figure 1. Switch Settings for Remote Loopback Data

Switch Settings

Function

TESTb = 1

Disables factory test mode

(enables normal operation)

XMT_CTRL0/1 = 00

Selects the remote loopback

mode so SDOUT = SDIN

Table 2. Required Switch Settings for

Remote Loopback Data Flow

Micrel, Inc.

SY87725L Evaluation Board

July 2008

6

M9999-071108-B

Remote Loopback Recovered Clock

Verifies correct operation of the receive CDR. A RefClk of

155.52MHz or 77.76MHz (selected by REFFREQSEL)

must be supplied for the CDR to function. When CD is

HIGH, the recovered clock coming out of SOUT will be

synchronous and at the same data rate as the data

coming into SIN. When CD is LOW, the clock coming out

of SOUT will be synchronous with the RefClk source.

Figure 2. Switch Settings for Remote Loopback

Recovered Clock

Switch Settings

Function

RCV_FSEL0/1 = 11

Sets receive CDR frequency to

2.48832Gbps (For other

frequencies, refer to Receive

Frequency Selection Table on

page 7 of SY87725L

Datasheet.)

TESTb = 1

Disables factory test mode

(enables normal operation)

CD = 1

Enables clock and data

recovery

REFFREQSEL = 1

Selects RefClk of 155.52MHz

(Set to “0” for 77.76MHz

RefClk)

XMT_CTRL0/1 = 10

Selects the remote loopback

mode so SDOUT = recovered

clock

Table 3. Required Switch Settings for

Remote Loopback Recovered Clock Flow

Micrel, Inc.

SY87725L Evaluation Board

July 2008

7

M9999-071108-B

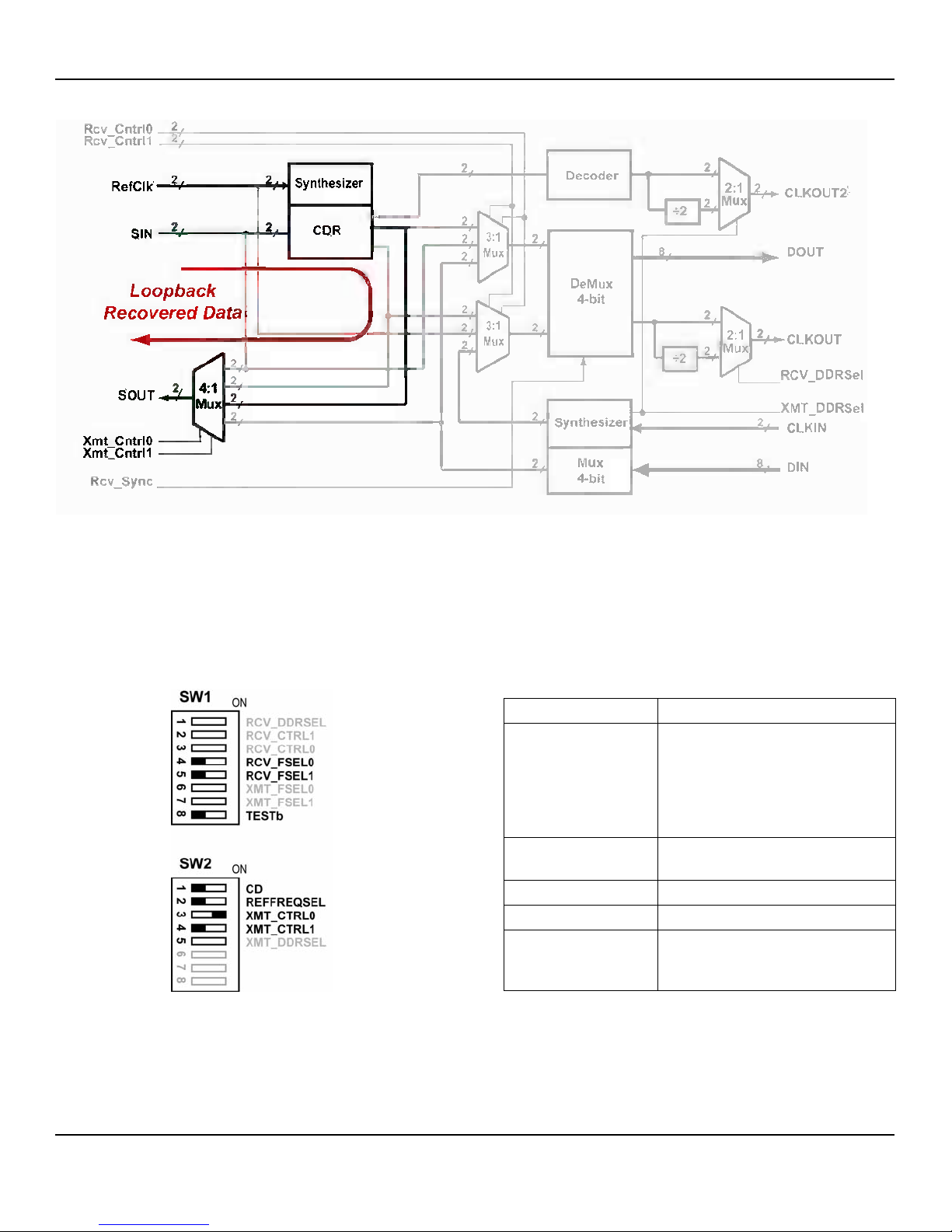

Remote Loopback Recovered Data

Verifies correct operation of the receive CDR. A RefClk of

155.52MHz or 77.76MHz (selected by REFFREQSEL)

must be supplied for the CDR to function. When CD is

HIGH, the recovered data coming out of SOUT will be the

same data coming into SIN (retimed). CDR operation can

be verified with a serial BERT.

Figure 3. Switch Settings for Remote Loopback

Recovered Data

Switch Settings

Function

RCV_FSEL0/1 = 11

Sets receive CDR frequency to

2.48832Gbps (For other

frequencies, refer to Receive

Frequency Selection Table on

page 7 of SY87725L Data

sheet.)

TESTb = 1

Disables factory test mode

(enables normal operation)

CD = 1

Enables clock and data recovery

REFFREQSEL = 1

Selects RefClk of 155.52MHz

XMT_CTRL0/1 - 01

Selects the remote loopback

mode so SDOUT = recovered

data

Table 4. Required Switch Settings for

Remote Loopback Recovered Data Flow

Micrel, Inc.

SY87725L Evaluation Board

July 2008

8

M9999-071108-B

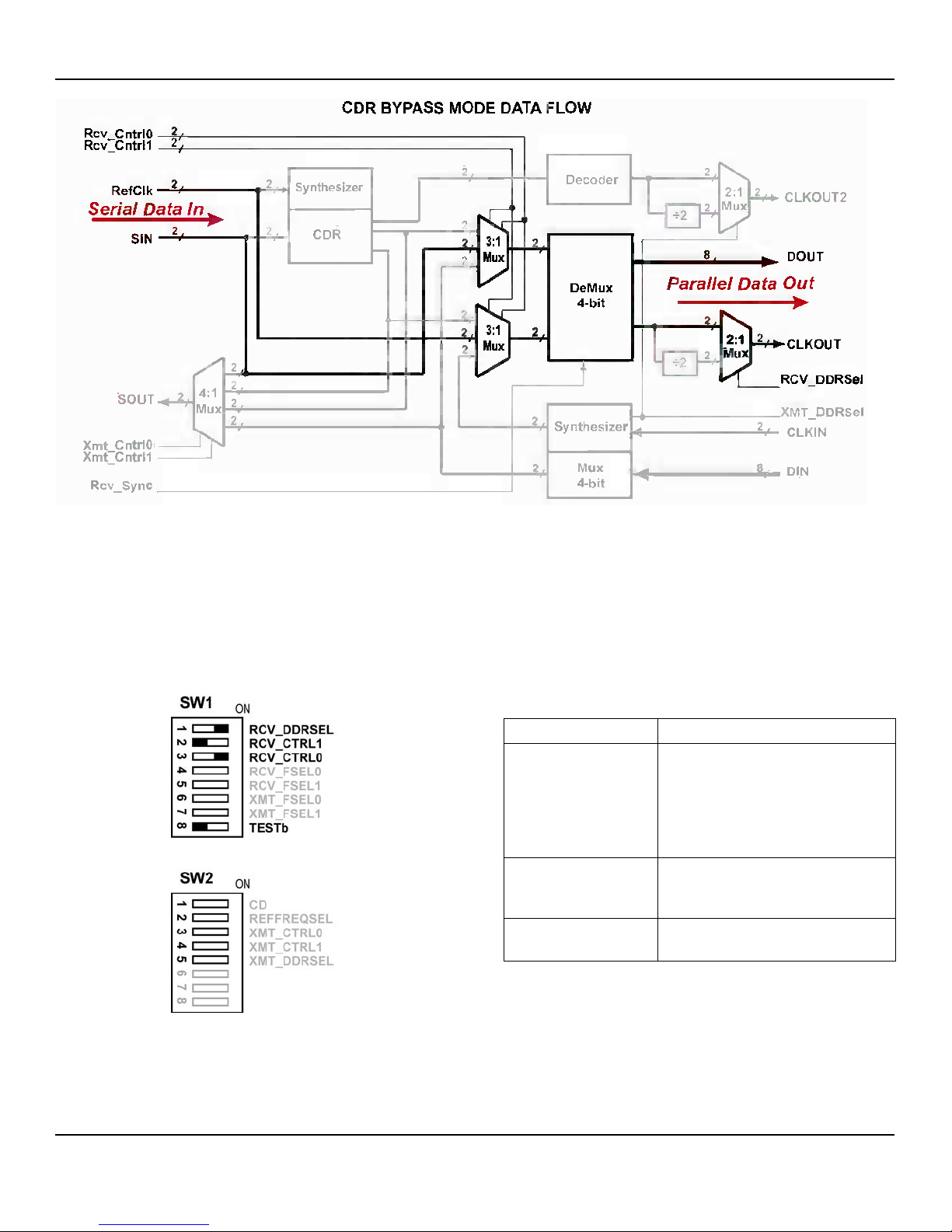

CDR Bypass Mode

Verifies correct operation of the receive DeMux. In this

mode the CDR is bypassed so the serial data coming into

SIN must be clocked in by the serial clock coming into the

RefClk input. In this mode only, the RefCLK will be

155.52MHz or 77.76MHz and must be at the same

rate as the Serial Data In (SIN). For example, if REFCLK

is 155.52MHz, then SIN must be at 155.52Mbps. The 4bit parallel data at the output of DOUT0-3 can be verified

with a parallel BERT.

Figure 4. Switch Settings for CDR Bypass Mode

Switch Settings

Function

RCV_DDRSEL = 0

Sets receive CLKOUT frequency

to be the RefClk frequency

divided-by 4. (If RCV_DDRSEL =

1, the CLKOUT frequency will be

the RefClk frequency divided-by

8.)

RCV_CTRL0/1 = 01

RefClk & SIN bypass CDR

(RefClk must be at the clock rate

of SIN data.)

TESTb = 1

Disables factory test mode

(enables normal operation)

Table 5. Required Switch Settings for

CDR Bypass Mode Data Flow

Micrel, Inc.

SY87725L Evaluation Board

July 2008

9

M9999-071108-B

Local Loopback Data Flow

Verifies correct operation of the transmit 4-bit Mux and

the receive 4-bit DeMux through the parallel interface. In

this mode parallel clock and data are applied to the

CLKIN and DIN0-3 transmit inputs and is then serialized

and fed into the receive 4-bit DeMux where it is output at

the CLKOUT and 4-bit parallel DOUT0-3 outputs. The

CLKIN is multiplied by 4 up to the serial rate by the

synthesizer (clock multiplier). This allows a parallel BERT

to be used to verify the Mux and DeMux operation

independent of the CDR.

Figure 5. Switch Settings for Local Loopback Data

Switch Settings

Function

RCV_DDRSEL = 0

Sets Clkout to be at parallel data

rate

RCV_CTRL0/1 = 10

Sets up local loopback

XMT_FSEL0/1 = 01

Sets parallel data rate to be

1.24416Gbps/4

TESTb = 1

Disables factory test mode

(enables normal operation)

XMT_DDRSEL = 0

Selects CLKIN to be at parallel

data rate. CLKIN must correspond

to the DIN0-3 data rate.

Table 6. Required Switch Settings for

Local Loopback Data Flow

Micrel, Inc.

SY87725L Evaluation Board

July 2008

10

M9999-071108-B

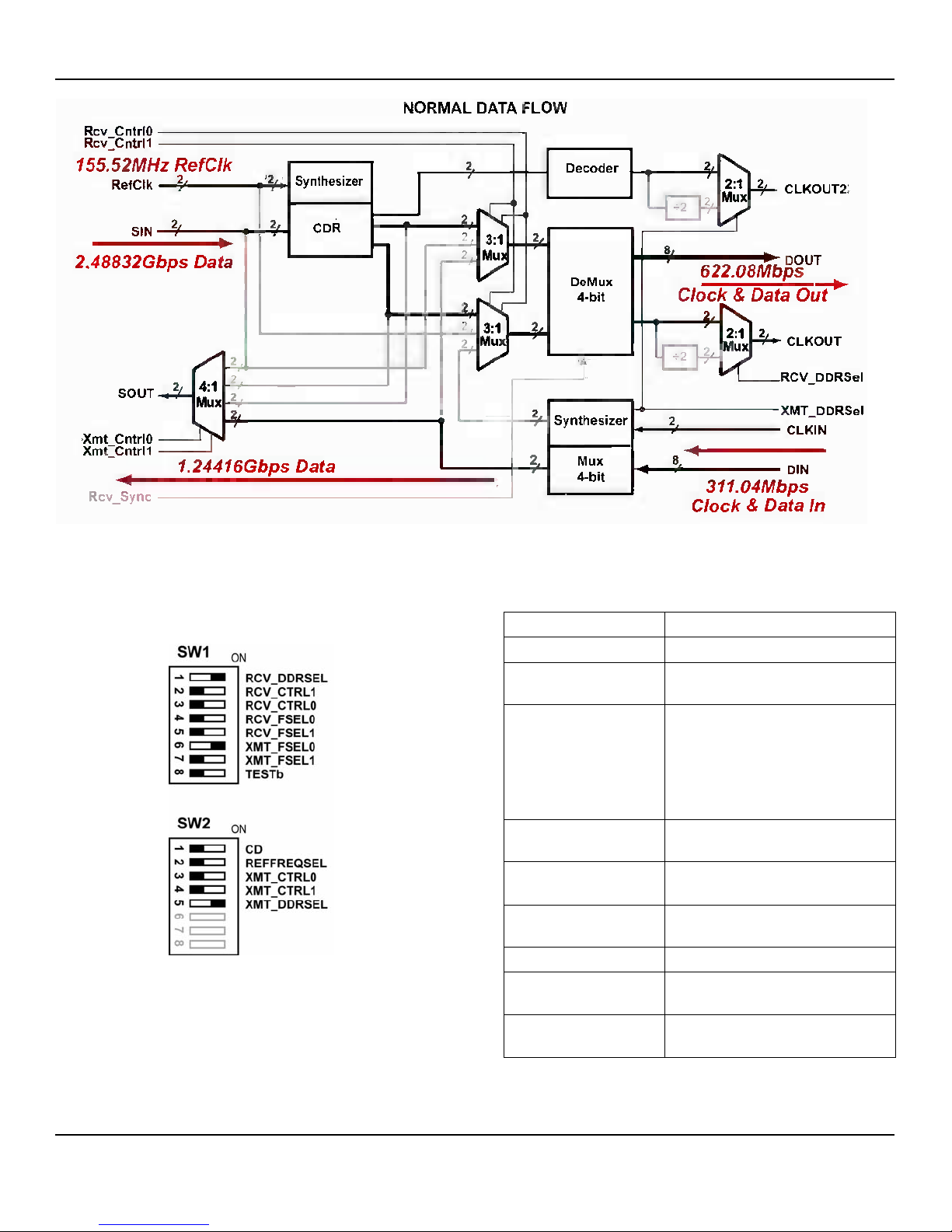

Normal Data Flow

This is the normal operating mode and verifies the receive

and transmit sections independently, which means any

combination of the allowed receive and transmit data

rates can be used. The switch settings below select the

frequencies and data rates specified in the block diagram.

Figure 6. Switch Settings for Normal Data Flow

Switch Settings

Function

RCV_DDRSEL = 0

Sets Clkout at parallel data rate

RCV_CTRL0/1 = 11

Selects the normal receive data

path

RCV_FSEL0/1 = 11

Sets receive CDR frequency to

2.48832Gbps (For other

frequencies, refer to Receive

Frequency Selection Table on

page 7 of SY87725L Data

sheet.)

XMT_FSEL0/1 = 01

Sets parallel data rate to be

1.24416Gbps/4

TESTb = 1

Disables factory test mode

(enables normal operation)

CD = 1

Enables clock and data

recovery

REFFREQSEL = 1

Selects RefClk of 155.52MHz

XMT_CTRL0/1 = 11

Selects the normal transmit

data path

XMT_DDRSEL = 1

Selects Clkin to be at parallel

data rate

Table 7. Required Switch Settings for

Normal Data Flow

Micrel, Inc.

SY87725L Evaluation Board

July 2008

11

M9999-071108-B

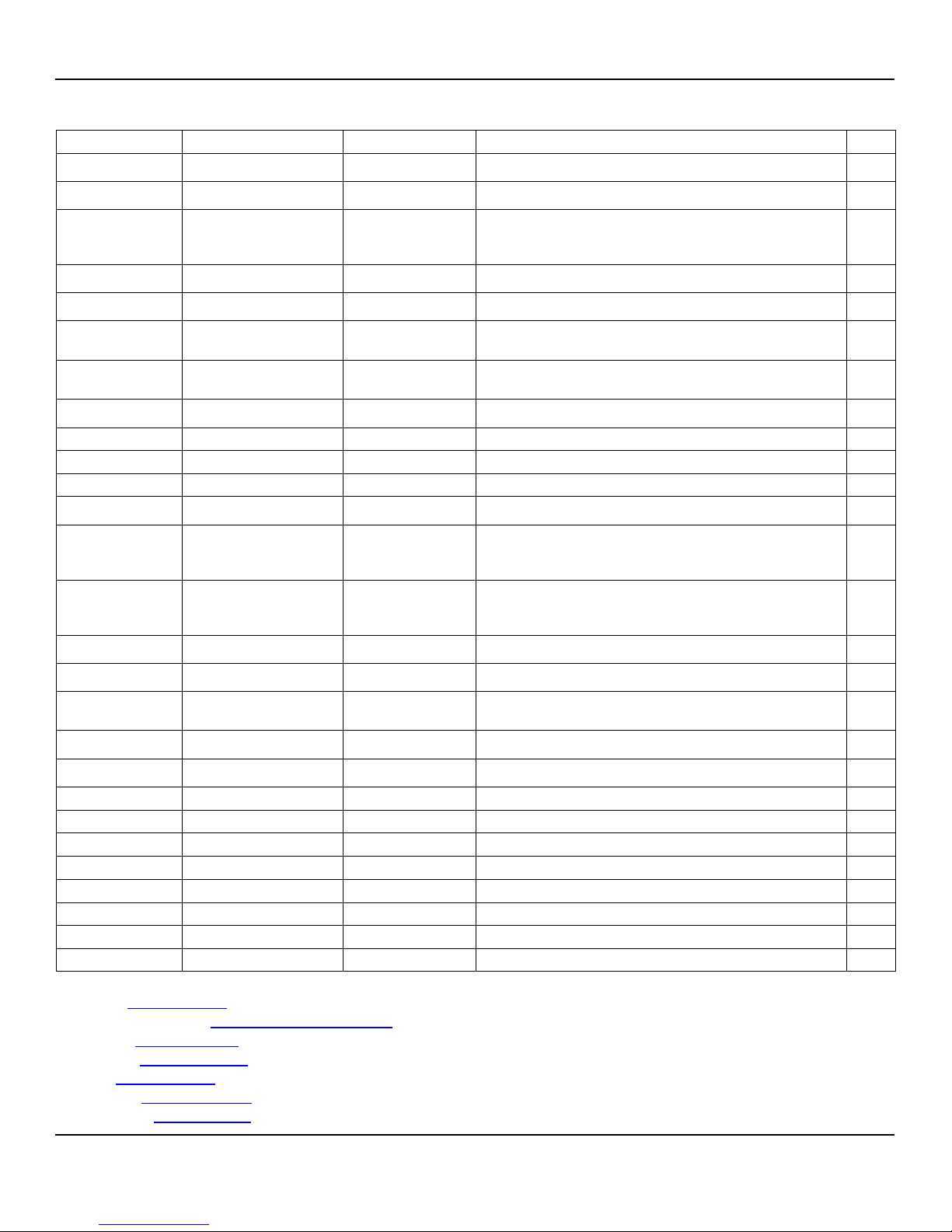

BiIl of Materials

Item

Part Number

Manufacturer

Description

Qty

C1-C3

VJ0603Y104JXJAT

Vishay

(1)

0.1mF, ceramic capacitor, size 0603

3

C4-C6

VJ1206Y106JXJAT

Vishay

(1)

10 mF, ceramic capacitor, size 1206

3

C7-C36, C38C42, C45-C51,

C56-C57

VJ0402Y104JXJAT

Vishay

(1)

0.1mF, ceramic capacitor, size 0402

43

C43-C45, C55

VJ0603Y105JXJAT

Vishay

(1)

1.0mF, ceramic capacitor, size 0603

4

C52-C54

VJ0402Y103JXJAT

Vishay

(1)

0.01mF, ceramic capacitor, size 0402

3

J3-J6, J32-J34

142-0711-821

Johnson

Components

(2)

SMA End Launch Receptacle connector

8

J7-J34

142-0711-201

Johnson

Components

(2

SMA Connector. Strait Jack Receptacle. Surface Mount.

28

L1-L4

IMC0805RK122J01

Vishay

(1)

1.2mH Ferrite bead inductor

4

D1

67-1640-1-ND

Digikey

(3)

Green LED

1

D2

67-1636-1-ND

Digikey

(3)

Red LED

1

Q1-Q3

MMBT3904WT1

ON Semi

(4)

General purpose NPN transistor

3

C37

CRCW040200R0F

Vishay

(1)

0W resistor, size 0402

1

R1-R2, R15,

R17, R19, R27,

R29, R72

CRCW04021270F

Vishay

(1)

127W, 1% resistor, size 0402

8

R3-R4, R16,

R18, R20, R28,

R30-R31

CRCW040282R5F

Vishay

(1)

82.5W resistor, size 0402

8

R9, R11

CRCW04021002F

Vishay

(1)

1.2kW, 5% resistor, size 0402

2

R10

CRCW04021002F

Vishay

(1)

390W, 5% resistor, size 0402

5

R12-R14, R32,

R47-R48

CRCW04021820F

Vishay

(1)

182W, 1% resistor, size 0402

6

R33-R46

CRCW04025111F

Vishay

(1)

5.11kW, 5% resistor, size 0402

14

R49-R53

CRCW04021002F

Vishay

(1)

10kW, 5% resistor, size 0402

5

SW1-SW2

TDA08H0SB1

C&K

(5)

DIP Switch, SMT

2

TP3

5010K-ND

Digikey

(3)

PC Test point Multi-purpose, Red

1

TP4

5011K-ND

Digikey

(3)

PC Test point Multi-purpose, Black

1

U1

SY87725L

Micrel

(7)

2.5Gbps GPON/APON ONU SERDES

1

U2

SY89322V

Micrel

(7)

Dual LVTTL-to-Differential LVPECL Translator

1

U3

SY89312V

Micrel

(7)

LVPECL ÷ 2 Clock Divider

1

U4

M210024BPN

MtronPTI

(6)

155.52MHz Clock Oscillator

1

PCB

SY87725_EB_R0

Micrel

(7)

Bare PCB

1

Notes:

1. Vishay: www.vishay.com

2. Johnson Components: www.johnsoncomponents.com.

3. Digi-key: www.digikey.com

4. On-Semi: www.on-semi.com

5. C&K: www.vishay.com

6. MtronPTI: www.mtronpti.com

7. Micrel, Inc.: www.micrel.com.

Micrel, Inc.

SY87725L Evaluation Board

July 2008

12

M9999-071108-B

APPENDIX

TEST FLOW DIAGRAM FOR SY87725L EVALUATION BOARD

Micrel, Inc.

SY87725L Evaluation Board

July 2008

13

M9999-071108-B

APPENDIX

TEST FLOW DIAGRAM FOR SY87725L CONTINUED

Micrel, Inc.

SY87725L Evaluation Board

July 2008

14

M9999-071108-B

HBW Support

Hotline: 408-955-1690

Email Support: HBWHelp@micrel.com

Application Hints and Notes

For application notes on high speed termination on

PECL and LVPECL products, clock synthesizer

products, SONET jitter measurement, and other High

Bandwidth products go to Micrel’s website at:

http://www.micrel.com/. Once in Micrel’s website, follow

the steps below:

1. Click on “Product Info”.

2. In the Applications Information Box, choose

“Application Hints and Application Notes.”

MICREL, INC. 2180 FORTUNE DRIVE SAN JOSE, CA 95131 USA

TEL +1 (408) 944-0800 FAX +1 (408) 474-1000 WEB http://www.micrel.com

The information furnished by Micrel in this data sheet is believed to be accurate and reliable. However, no responsibility is assumed

by Micrel for its use. Micrel reserves the right to change circuitry and specifications at any time without notification to the customer.

Micrel Products are not designed or authorized for use as components in life support appliances, devices or systems where

malfunction of a product can reasonably be expected to result in personal injury. Life support devices or systems are devices or

systems that (a) are intended for surgical implant into the body or (b) support or sustain life, and whose failure to perform can be

reasonably expected to result in a significant injury to the user. A Purchaser’s use or sale of Micrel Products for use in life support

appliances, devices or systems is a Purchaser’s own risk and Purchaser agrees to fully indemnify Micrel for any damages

resulting from such use or sale.

© 2007 Micrel, Incorporated.

Loading...

Loading...