MIC2199 Micrel

85.0

90.0

95.0

100.0

02468

EFFICIENCY (%)

I

LOAD

(A)

V

OUT

= 3.3V

查询MIC2199供应商

MIC2199

General Description

The MIC2199 is a high-power 300kHz synchronous buck

DC-to-DC controller housed in a small 4mm × 4mm MLF™

12-lead package. The MIC2199 operates from a wide 4.5V to

32V input and can be programmed for output voltages from

0.8V to 6V. The wide input voltage capability makes the

MIC2199 an ideal solution for point-of-load DC-to-DC conversion in 5V, 12V, 24V, and 28V systems.

The 300kHz switching frequency allows the use of a small

inductor and small output capacitors. The current mode PWM

control along with the external COMP pin allows for ease of

stability compensation and fast transient response across a

wide range of applications.

An all N-Channel synchronous architecture and powerful

output drivers allow up to 20A of output current capability.

For smaller external components, refer to the 500kHz

MIC2198.

The MIC2199 is available in a 12-pin 4mm × 4mm MLF™

package with a junction temperature range from –40°C to

125°C.

300kHz 4mm

××

× 4mm Synchronous Buck Converter

××

Features

• 4.5V to 32V input range

• 4mm × 4mm MLF™ package

• 300kHz PWM operation

• 95% efficiency

• Output voltage adjustable down to 0.8V

• 20A output current capability

• Drives all N-Channel MOSFETs

• Logic controlled micropower shutdown

• Cycle-by-cycle current limiting

• Adjustable undervoltage lockout

• Frequency foldback overcurrent protection

Applications

• Point-of-load DC-to-DC conversion from 5V, 12V,

24V, 28V supplies

• Telecom equipment

• Wireless modems

• Servers

• Base stations

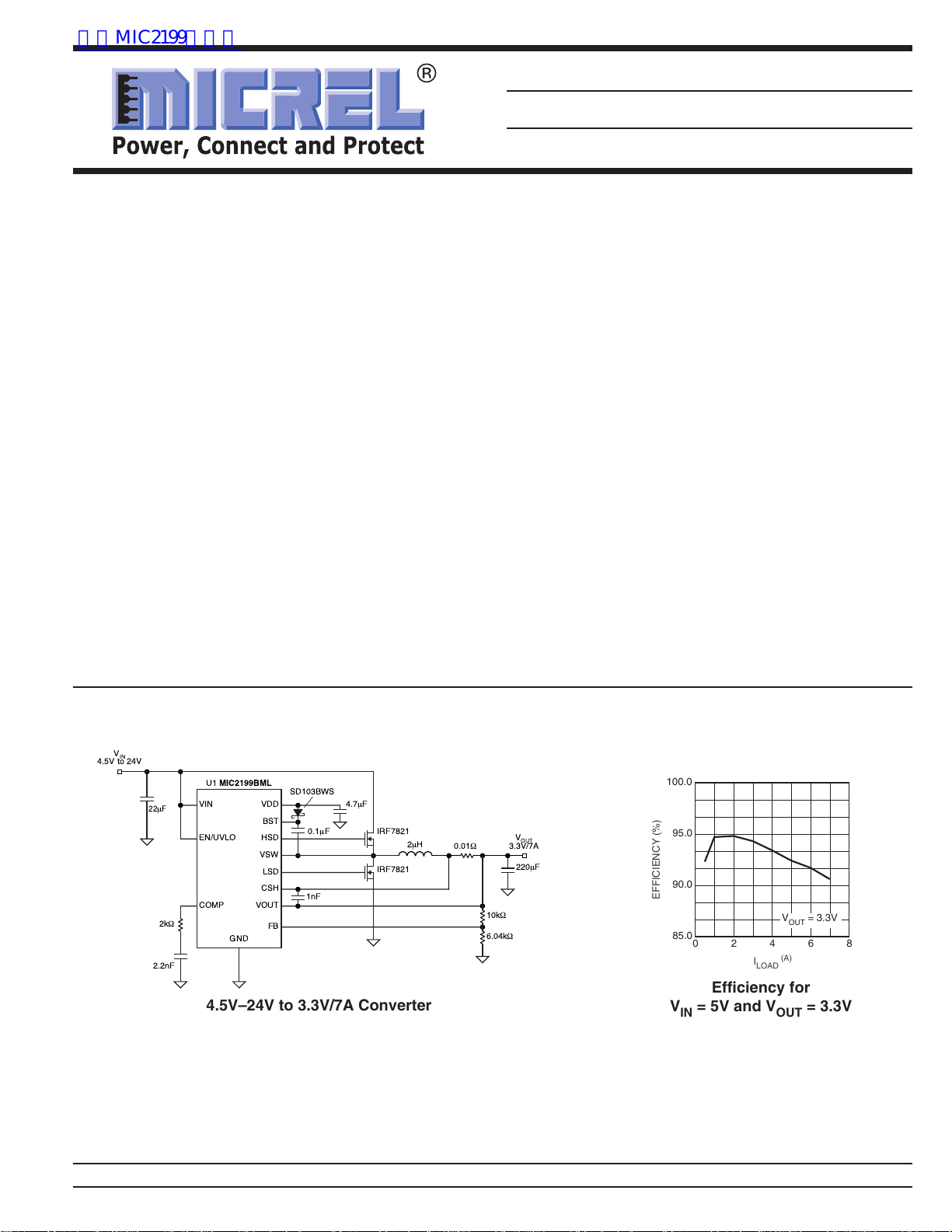

Typical Application

MLF and

November 2004 1 MIC2199

Micro

Micrel, Inc. • 2180 Fortune Drive • San Jose, CA 95131 • USA • tel + 1 (408) 944-0800 • fax + 1 (408) 474-1000 • http://www.micrel.com

m

MIC2199BML

W

#

"

!

"

"!

m

m

m

4.5V–24V to 3.3V/7A Converter

LeadFrame are trademarks of Amkor Technology, Inc.

W

W

m

W

Efficiency for

VIN = 5V and V

OUT

= 3.3V

MIC2199 Micrel

Ordering Information

Part Number Voltage Temperature Range Package

MIC2199BML Adj –40°C to +125°C 12-lead 4×4 MLF™

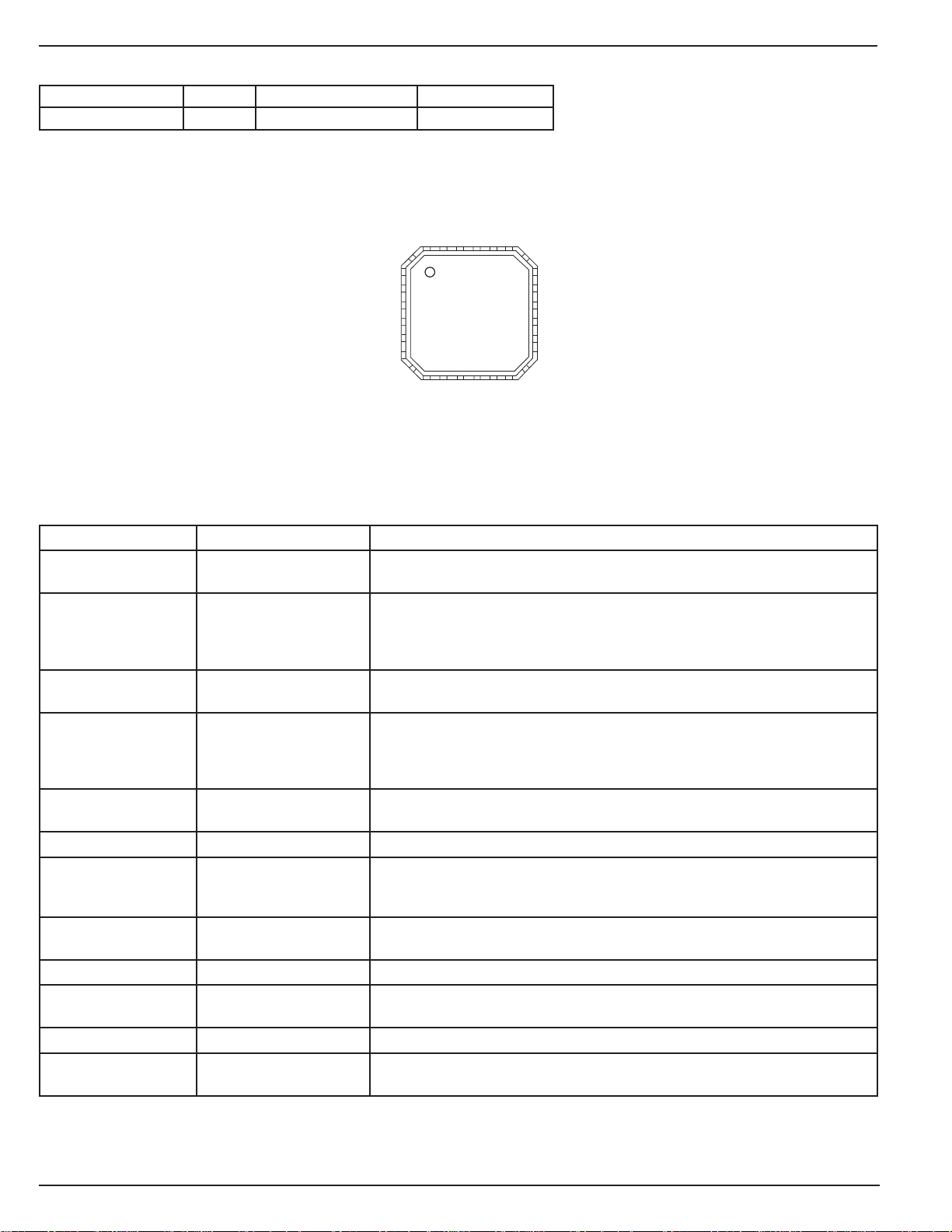

Pin Configuration

COMP

EN/UVLO

CSH

VOUT

VIN56

Pin Description

Pin Number Pin Name Pin Function

1 COMP Compensation (Output): Internal error amplifier output. Connect to capacitor

2 EN/UVLO Enable/Undervoltage Lockout (Input): Low-level signal powers down the

3 FB Feedback (Input): Regulates FB pin to 0.8V. See

4 CSH Current-Sense High (Input): Current limit comparator non-inverting input. A

5 VOUT Current-Sense Low (Input): Output voltage feedback input and inverting

6 VIN Unregulated Input (Input): +4.5V to +32V supply input.

7 VDD 5V Internal Linear-Regulator (Output): V

8 LSD Low-Side Drive (Output): High-current driver output for low-side N-Channel

9 GND Ground (Return).

10 BST Boost (Input): Provides drive voltage for the high-side MOSFET driver. The

11 VSW Switch (Return): High-side MOSFET driver return.

12 HSD High-Side Drive (Output): High-current driver output for high-side MOSFET.

1

2

3

FB

4

××

4

×4 MLF-12L (ML)

××

12

11

10

9

87LSD

HSD

VSW

BST

GND

VDD

or series RC network to compensate the regulator control loop.

controller. Input below the 2.5V threshold disables switching and functions

as an accurate undervoltage lockout (UVLO). Input below the threshold

forces complete micropower (<0.1µA) shutdown.

“Applications Information”

for resistor divider calculations.

built-in offset of 100mV between CSH and V

current-sense resistor set the current limit threshold level. This is also the

non-inverting input to the current sense amplifier.

input for the current limit comparator and the current sense amplifier.

drive supply voltage and internal supply bus for the IC. Bypass to GND with

4.7µF.

MOSFET. Voltage swing is between ground and VDD.

drive voltage is higher than the input voltage by VDD minus a diode drop.

This node voltage swing is between ground and VIN +5V minus a diode drop.

pins in conjunction with the

OUT

is the external MOSFET gate

DD

MIC2199 2 November 2004

MIC2199 Micrel

Absolute Maximum Ratings (Note 1)

Analog Supply Voltage (V

Digital Supply Voltage (V

Driver Supply Voltage (B

Sense Voltage (V

OUT

Enable Pin Voltage (V

) .......................................+34V

IN

) .........................................+7V

DD

) .................................. VIN + 7V

ST

, CSH) ............................. 7V to –0.3V

EN/UVLO

) ...................................... V

Operating Ratings (Note 2)

Analog Supply Voltage (V

Output Voltage Range (V

Junction Temperature (T

Package Thermal Resistance

IN

4×4 MLF-12L (θJA) .............................................. 60°C/W

) ........................ +4.5V to +32V

IN

) ........................ +0.8V to +6V

OUT

) ....................... –40°C to +125°C

J

Power Dissipation (PD)

4×4 MLF™ ................................. 665mW @ TA = 85°C

Ambient Storage Temperature (TS) ......... –65°C to +150°C

ESD, Note 3

Electrical Characteristics (Note 4)

VIN = VEN = 12V; TJ = 25°C, unless noted, bold values indicate –40°C ≤ TJ ≤ +125°C

Parameter Condition Min Typ Max Units

Feedback Voltage Reference (±1%) 0.792 0.8 0.808 V

Feedback Voltage Reference (±2%) 0.784 0.816 V

Feedback Voltage Reference 4.5V < VIN < 32V, 0 < (V

Feedback Bias Current 10 nA

Output Voltage Range 0.8 6 V

Output Voltage Line Regulation VIN = 4.5V to 32V, V

Output Voltage Load Regulation 25mV < (V

Input and VDD Supply

Quiescent Current excluding external MOSFET gate drive current 1.6 2.5 mA

Shutdown Quiescent Current V

Digital Supply Voltage (VDD)I

Undervoltage Lockout VIN upper threshold (turn-on threshold) 4.25 4.4 V

Enable/UVLO

Enable Input Threshold 0.6 1.1 1.6 V

UVLO Threshold 2.2 2.5 2.8 V

Enable Input Current V

Current Limit

Current Limit Threshold Voltage (V

Error Amplifier

Transconductance Error Amplifier GM

Oscillator Section

Oscillator Frequency 270 300 330 kHz

Maximum Duty Cycle 80 85 %

Minimum On-Time 170 200 ns

EN/UVLO

= 0mA to 5mA 4.7 5.0 5.3 V

L

VIN lower threshold (turn-off threshold) 3.95 4.1 V

EN/UVLO

CSH

CSH

= 0V 0.1 5 µA

= 5V 0.1 5 µA

– V

OUT

CSH

– V

OUT

) 55 75 95 mV

– V

CSH

– V

OUT

) < 60mV 0.5 %

) < 60mV (±3%) 0.776 0.824 V

OUT

= 60mV 0.03 %/V

0.2 mS

November 2004 3 MIC2199

MIC2199 Micrel

Parameter Condition Min Typ Max Units

Frequency Foldback Threshold measured at V

Foldback Frequency 75 kHz

Gate Drivers

Rise/Fall Time CL = 3000pF 60 ns

Output Driver Impedance source 5 8.5 Ω

sink 3.5 6 Ω

Driver Non-Overlap Time 80 ns

Note 1. Exceeding the absolute maximum rating may damage the device.

Note 2. The device is not guaranteed to function outside its operating rating.

Note 3. Devices are ESD protected; however, handling precautions are recommended. Human body model, 1.5k in series with 100pF.

Note 4. Specification for packaged product only.

pin 0.25 0.40 0.55 V

OUT

MIC2199 4 November 2004

MIC2199 Micrel

0.808

0.810

0.812

0.814

0.816

0.818

0.820

0 5 10 15 20 25 30 35

REFERENCE VOLTAGE (V)

SUPPLY VOLTAGE (V)

V

FB

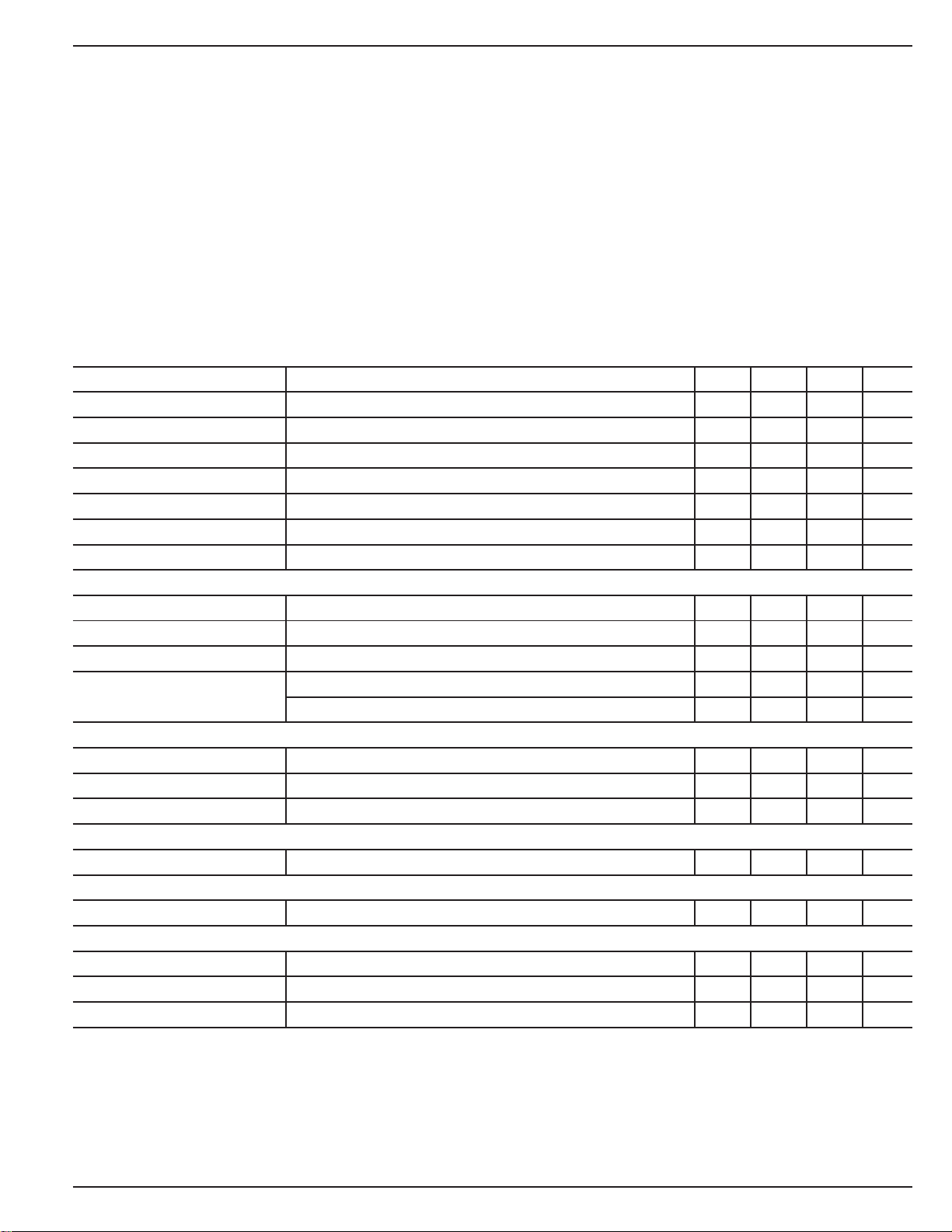

Line Regulation

4.94

4.95

4.96

4.97

4.98

4.99

5.00

5.01

5.02

0 5 10 15 20 25 30

V

DD

REGULATOR VOLTAGE (V)

LOAD CURRENT (mA)

V

DD

Load Regulation

-0.15

-0.10

-0.05

0.00

0.05

0.10

0.15

0.20

0.25

0 5 10 15 20 25 30 35

FREQUENCY VARIATION (%)

SUPPLY VOLTAGE (V)

Oscillator Frequency

vs. Supply Voltage

Typical Characteristics

Quiescent Current

4.0

3.5

3.0

2.5

2.0

1.5

CURRENT (mA)

1.0

0.5

0.82

0.818

0.816

0.814

0.812

0.810

0.808

0.806

FB VOLTAGE (V)

0.804

0.802

0.8

vs. Temperature

V

FB

Shutdown

0

-40 -20 0 20 40 60 80 100120140

TEMPERATURE (°C)

vs. Temperature

-40 -20 0 20 40 60 80 100120140

TEMPERATURE (°C)

PWM

UVLO

Quiescent Current

vs. Supply Voltage

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

QUIESCENT CURRENT (mA)

0

4 9 14 19 24 29 34

SUPPLY VOLTAGE (V)

6.0

5.0

4.0

3.0

2.0

1.0

REGULATOR VOLTAGE (V)

DD

V

0.0

Line Regulation

0 4 8 121620242832

SUPPLY VOLTAGE (V)

Shutdown

V

DD

PWM

UVLO

5.20

5.15

5.10

5.05

5.00

4.95

4.90

REGULATOR VOLTAGE (V)

DD

4.85

V

4.80

88

86

84

82

80

November 2004 5 MIC2199

78

76

74

72

70

OVERCURRENT THRESHOLD (V)

V

DD

vs. Temperature

-40 -20 0 20 40 60 80 100120140

TEMPERATURE (°C)

Overcurrent Threshold

vs. Temperature

-40 -20 0 20 40 60 80 100120140

TEMPERATURE (°C)

Oscillator Frequency

vs. Temperature

10

8

6

4

2

0

-2

-4

-6

-8

FREQUENCY VARIATION (%)

-10

-40 -20 0 20 40 60 80 100120140

TEMPERATURE (°C)

Current Limit

3.5

3

2.5

2

1.5

1

OUTPUT VOLTAGE (V)

0.5

0

012345

Foldback

VIN = 5V

V

= 3.3V

OUT

R

= 20mV

CS

OUTPUT CURRENT (A)

MIC2199 Micrel

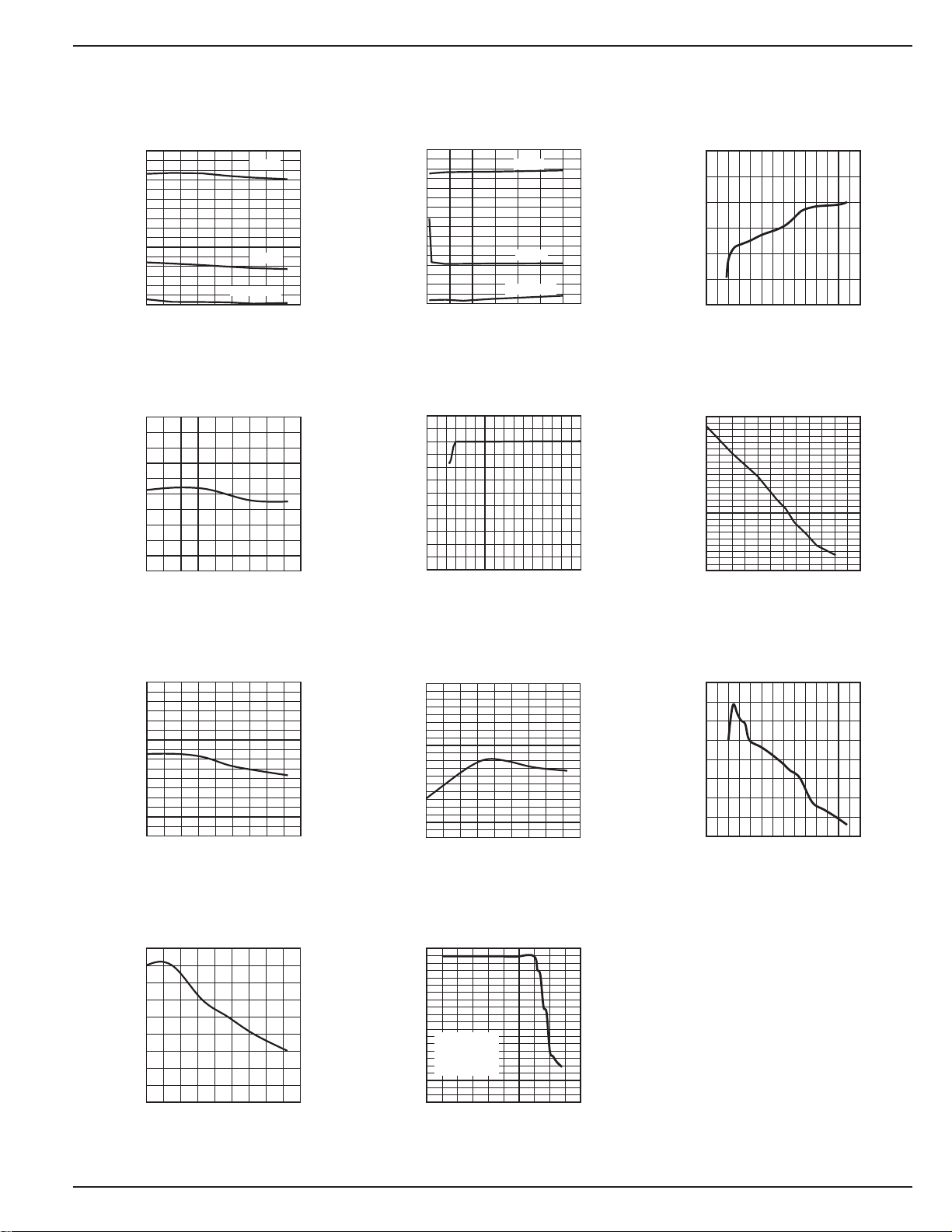

Block Diagram

V

IN

C

IN

V

EN/UVLO

DD

2

Control

Logic

Current

Limit

Reference

BG

0.8V

V

V

IN

VDD

7

VIN

6

BST

10

HSD

12

VSW

11

LSD

8

PGND

9

Q2

Q1

D2

C

D1

BST

L1

4.7µF

R

CS

V

OUT

C

OUT

PWM OUTPUT

PWM

CORRECTIVE

RAMP

Error

Amp

100k

BG

V

Gm = 0.2×10

C

COMP

R

COMP

RESET

Oscillator

COMP

1

MIC2199

Figure 1. Internal Block Diagram

Functional Description

The MIC2199 is a BiCMOS, switched-mode, synchronous

step-down (buck) converter controller. Current-mode control

is used to achieve superior transient line and load regulation.

An internal corrective ramp provides slope compensation for

stable operation above a 50% duty cycle. The controller is

optimized for high-efficiency, high-performance DC-DC converter applications.

The MIC2199 block diagram is shown above.

The MIC2199 controller is divided into 5 functions.

• Control loop

• Current limit

• Reference, enable and UVLO

• MOSFET gate drive

• Oscillator

Current

Sense

Amp

AV = 2

-3

CSH

4

VOUT

5

FB

3

⎞

⎛

V 0.8V

=+1

OUT

V6V

OUT(max)

⎝

= .0

R1

R2

⎠

R1

R2

Control Loop

The MIC2199 operates in PWM (pulse-width-modulation)

mode. In PWM mode, the synchronous buck converter forces

continuous current to flow in the inductor which also improves

cross regulation of transformer coupled, multiple output configurations.

PWM Control Loop

The MIC2199 uses current-mode control to regulate the

output voltage. This method senses the output voltage (outer

loop) and the inductor current (inner loop). It uses inductor

current and output voltage to determine the duty cycle of the

buck converter. Sampling the inductor current removes the

inductor from the control loop, which simplifies compensation.

A block diagram of the MIC2199 PWM current-mode control

loop is shown in Figure 2 and the PWM mode voltage and

current waveform is shown in Figure 3. The inductor current

is sensed by measuring the voltage across the resistor, RCS.

MIC2199 6 November 2004

MIC2199 Micrel

Current

Sense

Amp

V

BG

0.8V

V

BG

Error

Amp

V

IN

V

DD

CORRECTIVE

RAMP

PWM

COMPARATOR

RESET

Oscillator

7

10

6

12

11

8

9

4

5

3

1

COMP

100k

MIC2199

FB

R2

R1

VOUT

CSH

VDD

BST

C

IN

VIN

HSD

Q2

Q1

D1

D2

C

BST

C

OUT

V

IN

V

OUT

L1

VSW

LSD

PGND

C

COMP

R

COMP

4.7µF

SR

Q

CONTROL LOGIC AND

PULSE-WIDTH MODULATOR

R

CS

Gm = 0.2×10

-3

AV = 2

Reference

⎞

⎠

⎛

⎝

A ramp is added to the amplified current-sense signal to

provide slope compensation, which is required to prevent

unstable operation at duty cycles greater than 50%.

A transconductance amplifier is used for the error amplifier,

which compares an attenuated sample of the output voltage

with a reference voltage. The output of the error amplifier is

the COMP (compensation) pin, which is compared to the

current-sense waveform in the PWM block. When the current

signal becomes greater than the error signal, the comparator

turns off the high-side drive. The COMP pin (pin 1) provides

access to the output of the error amplifier and allows the use

of external components to stabilize the voltage loop.

V 0.8V

=+1

OUT

R1

R2

Figure 2. PWM Operation

V

IN

V

SW

I

Reset

Pulse

V

HSD

V

LSD

L1

VIN + V

November 2004 7 MIC2199

0V

I

LOAD

0A

V

DD

0V

DD

0V

0V

DD

V

Figure 3. PWM-Mode Timing

MIC2199 Micrel

Current Limit

The MIC2199 output current is detected by the voltage drop

across the external current-sense resistor (RCS in Figure 2.).

The current limit threshold is 75mV±20mV. The currentsense resistor must be sized using the minimum current limit

threshold. The external components must be designed to

withstand the maximum current limit. The current-sense

resistor value is calculated by the equation below:

CS

55mV

=

I

OUT(max)

R

The maximum output current is:

I

OUT(max)

The current-sense pins CSH (pin 4) and V

=

95mV

R

CS

(pin 5) are

OUT

noise sensitive due to the low signal level and high input

impedance. The PCB traces should be short and routed close

to each other. A small (1nF to 0.1µF) capacitor across the

pins will attenuate high frequency switching noise.

When the peak inductor current exceeds the current limit

threshold, the current limit comparator, in Figure 2, turns off

the high-side MOSFET for the remainder of the cycle. The

output voltage drops as additional load current is pulled from

the converter. When the output voltage reaches approximately 0.4V, the circuit enters frequency-foldback mode and

the oscillator frequency will drop to 75kHz while maintaining

the peak inductor current equal to the nominal 75mV across

the external current-sense resistor. This limits the maximum

output power delivered to the load under a short circuit

condition.

Reference, Enable and UVLO Circuits

The output drivers are enabled when the following conditions

are satisfied:

• The V

voltage (pin 7) is greater than its under-

DD

voltage threshold (typically 4.25V).

• The voltage on the enable pin is greater than the

enable UVLO threshold (typically 2.5V).

The internal bias circuit generates a 0.8V bandgap reference

voltage for the voltage error amplifier and a 5V VDD voltage

for the gate drive circuit. The MIC2199 uses FB (pin 3) for

output voltage sensing.

The enable pin (pin 2) has two threshold levels, allowing the

MIC2199 to shut down in a low current mode, or turn off output

switching in UVLO mode. An enable pin voltage lower than

the shutdown threshold turns off all the internal circuitry and

reduces the input current to typically 0.1µA.

If the enable pin voltage is between the shutdown and UVLO

thresholds, the internal bias, VDD, and reference voltages are

turned on. The output drivers are inhibited from switching and

remain in a low state. Raising the enable voltage above the

UVLO threshold of 2.5V enables the output drivers.

Either of two UVLO conditions will disable the MIC2199 from

switching.

• When the VDD drops below 4.1V

• When the enable pin drops below the 2.5V threshold

MOSFET Gate Drive

The MIC2199 high-side drive circuit is designed to switch an

N-Channel MOSFET. Referring to the block diagram in

Figure 2, a bootstrap circuit, consisting of D2 and C

supplies energy to the high-side drive circuit. Capacitor C

BST

BST

is charged while the low-side MOSFET is on and the voltage

on the VSW pin (pin 11) is approximately 0V. When the highside MOSFET driver is turned on, energy from C

BST

is used

to turn the MOSFET on. As the MOSFET turns on, the voltage

on the VSW pin increases to approximately VIN. Diode D2 is

reversed biased and C

floats high while continuing to

BST

keep the high-side MOSFET on. When the low-side switch is

turned back on, C

is recharged through D2.

BST

The drive voltage is derived from the internal 5V VDD bias

supply. The nominal low-side gate drive voltage is 5V and the

nominal high-side gate drive voltage is approximately 4.5V

due the voltage drop across D2. A fixed 80ns delay between

the high- and low-side driver transitions is used to prevent

current from simultaneously flowing unimpeded through both

MOSFETs.

Oscillator

The internal oscillator is free running and requires no external

components. The nominal oscillator frequency is 500kHz. If

the output voltage is below approximately 0.4V, the oscillator

operates in a frequency-foldback mode and the switching

frequency is reduced to 75kHz.

Figure 4. Startup Waveform

Above 0.4V, the switching frequency increases to 500kHz

causing the output voltage to rise a greater rate. The rise time

of the output is dependent on the output capacitance, output

voltage, and load current. The oscilloscope photo in Figure 4

show the output voltage at startup.

,

MIC2199 8 November 2004

MIC2199 Micrel

Minimum Pulsewidth

The MIC2199 has a specified minimum pulsewidth. This

minimum pulsewidth places a lower limit on the minimum duty

cycle of the buck converter.

Figure 5 shows the minimum output voltage versus input

supply voltage for the MIC2199. For example, for VIN = 15V,

V

= 1V would be the lowest achievable voltage that

OUT

conforms to the minimum-on-time.

2.5

2.0

1.5

1.0

0.5

OUTPUT VOLTAGE (V)

0.0

4.5 9.5 14.5 19.5 24.5 29.5

INPUT VOLTAGE (V)

Figure 5. Minimum Output Voltage

vs. Input Supply Voltage

November 2004 9 MIC2199

MIC2199 Micrel

I

95mV

R

OVERCURRENT(max)

CS

=

Applications Information

Following applications information includes component selection and design guidelines.

Inductor Selection

Values for inductance, peak, and RMS currents are required

to select the output inductor. The input and output voltages

and the inductance value determine the peak-to-peak inductor ripple current. Generally, higher inductance values are

used with higher input voltages. Larger peak-to-peak ripple

currents will increase the power dissipation in the inductor

and MOSFETs. Larger output ripple currents will also require

more output capacitance to smooth out the larger ripple

current. Smaller peak-to-peak ripple currents require a larger

inductance value and therefore a larger and more expensive

inductor. A good compromise between size, loss and cost is

to set the inductor ripple current to be equal to 20% of the

maximum output current.

The inductance value is calculated by the equation below.

V(V V)

× −

L

where:

fS = switching frequency

0.2 = ratio of AC ripple current to DC output current

V

The peak-to-peak inductor current (AC ripple current) is:

I

The peak inductor current is equal to the average output

current plus one half of the peak-to-peak inductor ripple

current.

I I 0.5 I

The RMS inductor current is used to calculate the I2×R losses

in the inductor.

II1

Maximizing efficiency requires the proper selection of core

material and minimizing the winding resistance. The high

frequency operation of the MIC2199 requires the use of ferrite

materials for all but the most cost sensitive applications.

Lower cost iron powder cores may be used but the increase

in core loss will reduce the efficiency of the power supply. This

is especially noticeable at low output power. The winding

resistance decreases efficiency at the higher output current

levels. The winding resistance must be minimized although

this usually comes at the expense of a larger inductor.

The power dissipated in the inductor is equal to the sum of the

core and copper losses. At higher output loads, the core

losses are usually insignificant and can be ignored. At lower

output currents, the core losses can be a significant contribu-

OUT IN(max) OUT

=

V f 0.2 I

IN(max) S OUT(max)

IN(max)

=

PP

=+×

PK

INDUCTOR(rms) OUT(max)

×× ×

= maximum input voltage

V(V V)

× −

OUT IN(max) OUT

VfL

IN(max) S

OUT(max)

××

PP

=×+

⎛

1

⎜

3II

⎝

OUT(max)

2

⎞

P

⎟

⎠

tor. Core loss information is usually available from the magnetics vendor.

Copper loss in the inductor is calculated by the equation

below:

PI R

INDUCTORCu

The resistance of the copper wire, R

=×

INDUCTOR(rms)

2

WINDING

WINDING

, increases with

temperature. The value of the winding resistance used should

be at the operating temperature.

R R 1 0.0042 (T T )

WINDING(hot) WINDING(20 C) HOT 20 C

=×+×−

()

°°

where:

T

= temperature of the wire under operating load

HOT

T

= ambient temperature

20°C

R

WINDING(20°C)

is room temperature winding resistance

(usually specified by the manufacturer)

Current-Sense Resistor Selection

Low inductance power resistors, such as metal film resistors

should be used. Most resistor manufacturers make low

inductance resistors with low temperature coefficients, designed specifically for current-sense applications. Both resistance and power dissipation must be calculated before the

resistor is selected. The value of R

is chosen based on

SENSE

the maximum output current and the maximum threshold

level. The power dissipated is based on the maximum peak

output current at the minimum overcurrent threshold limit.

R

SENSE

55mV

=

I

OUT(max)

The maximum overcurrent threshold is:

The maximum power dissipated in the sense resistor is:

PI R

D(R ) OVERCURRENT(max)

=×

SENSE

2

CS

MOSFET Selection

External N-Channel logic-level power MOSFETs must be

used for the high- and low-side switches. The MOSFET gateto-source drive voltage of the MIC2199 is regulated by an

internal 5V VDD regulator. Logic-level MOSFETs, whose

operation is specified at VGS = 4.5V must be used.

It is important to note the on-resistance of a MOSFET

increases with increasing temperature. A 75°C rise in junction temperature will increase the channel resistance of the

MOSFET by 50% to 75% of the resistance specified at 25°C.

This change in resistance must be accounted for when

calculating MOSFET power dissipation.

Total gate charge is the charge required to turn the MOSFET

on and off under specified operating conditions (VDS and

VGS). The gate charge is supplied by the MIC2199 gate drive

circuit. At 500kHz switching frequency, the gate charge can

be a significant source of power dissipation in the MIC2199.

At low output load this power dissipation is noticeable as a

MIC2199 10 November 2004

MIC2199 Micrel

D

V

V

OUT

IN

=

×η

reduction in efficiency. The average current required to drive

the high-side MOSFET is:

IQf

G[high-side](avg) G S

=×

where:

I

G[high-side](avg)

=

average high-side MOSFET gate current

QG = total gate charge for the high-side MOSFET

taken from manufacturer’s data sheet

with VGS = 5V.

fs = 300kHz

The low-side MOSFET is turned on and off at VDS = 0

because the freewheeling diode is conducting during this

time. The switching losses for the low-side MOSFET is

usually negligible. Also, the gate drive current for the low-side

MOSFET is more accurately calculated using C

at VDS =

ISS

0 instead of gate charge.

For the low-side MOSFET:

ICVf

G[low-side](avg) ISS GS S

=××

Since the current from the gate drive comes from the input

voltage, the power dissipated in the MIC2199 due to gate

drive is:

PVI I

GATEDRIVE IN G[high- side](avg) G[low-side](avg)

=+

()

A convenient figure of merit for switching MOSFETs is the onresistance times the total gate charge (R

× QG). Lower

DS(on)

numbers translate into higher efficiency. Low gate-charge

logic-level MOSFETs are a good choice for use with the

MIC2199. Power dissipation in the MIC2199 package limits

the maximum gate drive current.

Parameters that are important to MOSFET switch selection

are:

• Voltage rating

• On-resistance

• Total gate charge

The voltage rating of the MOSFETs are essentially equal to

the input voltage. A safety factor of 20% should be added to

the V

DS(max)

of the MOSFETs to account for voltage spikes

due to circuit parasitics.

The power dissipated in the switching transistor is the sum of

the conduction losses during the on-time (P

CONDUCTION

) and

the switching losses that occur during the period of time when

the MOSFETs turn on and off (PAC).

PP P

=+

SW CONDUCTION AC

where:

PIR

CONDUCTION

PP P

=+

AC AC(off) AC(on)

=×

SW(rms)

2

SW

RSW = on-resistance of the MOSFET switch.

Making the assumption the turn-on and turnoff transition

times are equal, the transition time can be approximated by:

CVC V

×+ ×

ISS GS OSS IN

t

=

T

I

G

where:

C

ISS

and C

are measured at VDS = 0.

OSS

IG = gate drive current (1A for the MIC2199)

The total high-side MOSFET switching loss is:

P(VV)Itf

=+×××

AC IN D PK T S

where:

tT = switching transition time (typically 20ns to 50ns)

VD = freewheeling diode drop, typically 0.5V.

fS it the switching frequency, nominally 300kHz

The low-side MOSFET switching losses are negligible and

can be ignored for these calculations.

RMS Current and MOSFET Power Dissipation

Calculation

Under normal operation, the high-side MOSFETs RMS current is greatest when VIN is low (maximum duty cycle). The

low-side MOSFETs RMS current is greatest when VIN is high

(minimum duty cycle). However, the maximum stress the

MOSFETs see occurs during short circuit conditions, where

the output current is equal to I

“Sense Resistor”

section). The calculations below are for

OVERCURRENT(max)

. (See the

normal operation. To calculate the stress under short circuit

conditions, substitute I

OVERCURRENT(max)

for I

OUT(max)

. Use

the formula below to calculate D under short circuit conditions.

−

D 0.063 1.8 10 V

SHORTCIRCUIT

= − ××

3

IN

The RMS value of the high-side switch current is:

IDI

SW(high side)(rms) OUT(max)

−

=× +

⎜

⎝

⎛

⎛

I1DI

SW(low side)(rms) OUT(max)

−

= −

()

⎜

⎝

2

⎞

I

2

PP

⎟

12

⎠

2

⎞

I

2

PP

+

⎟

12

⎠

where:

D = duty cycle of the converter

η = efficiency of the converter.

Converter efficiency depends on component parameters,

which have not yet been selected. For design purposes, an

efficiency of 90% can be used for VIN less than 10V and 85%

can be used for VIN greater than 10V. The efficiency can be

more accurately calculated once the design is complete. If the

assumed efficiency is grossly inaccurate, a second iteration

through the design procedure can be made.

November 2004 11 MIC2199

MIC2199 Micrel

For the high-side switch, the maximum DC power dissipation

is:

PRI

SWITCH1(dc) DS(on)1

=×

SW1(rms)

2

For the low-side switch (N-Channel MOSFET), the DC power

dissipation is:

PRI

SWITCH2(dc) DS(on) 2

=×

SW 2(rms)

2

Since the AC switching losses for the low side MOSFET is

near zero, the total power dissipation is:

PP

low-side MOSFET(max) SWITCH2(dc)

=

The total power dissipation for the high side MOSFET is:

PPP

high sideMOSFET(max) SWITCH 1(dc) AC−

=+

External Schottky Diode

An external freewheeling diode is used to keep the inductor

current flow continuous while both MOSFETs are turned off.

This dead time prevents current from flowing unimpeded

through both MOSFETs and is typically 80ns The diode

conducts twice during each switching cycle. Although the

average current through this diode is small, the diode must be

able to handle the peak current.

I I 2 80ns f

=×× ×

D(avg) OUT S

The reverse voltage requirement of the diode is:

VV

DIODE(rrm)

=

IN

The power dissipated by the Schottky diode is:

PIV

=×

DIODE D(avg) F

where:

VF = forward voltage at the peak diode current

The external Schottky diode, D2, is not necessary for circuit

operation since the low-side MOSFET contains a parasitic

body diode. The external diode will improve efficiency and

decrease high frequency noise. If the MOSFET body diode is

used, it must be rated to handle the peak and average current.

The body diode has a relatively slow reverse recovery time

and a relatively high forward voltage drop. The power lost in

the diode is proportional to the forward voltage drop of the

diode. As the high-side MOSFET starts to turn on, the body

diode becomes a short circuit for the reverse recovery period,

dissipating additional power. The diode recovery and the

circuit inductance will cause ringing during the high-side

MOSFET turn-on.

An external Schottky diode conducts at a lower forward

voltage preventing the body diode in the MOSFET from

turning on. The lower forward voltage drop dissipates less

power than the body diode. The lack of a reverse recovery

mechanism in a Schottky diode causes less ringing and less

power loss. Depending on the circuit components and operating conditions, an external Schottky diode will give a 1/2%

to 1% improvement in efficiency.

Output Capacitor Selection

The output capacitor values are usually determined by the

capacitors ESR (equivalent series resistance). Voltage rating

and RMS current capability are two other important factors in

selecting the output capacitor. Recommended capacitors are

tantalum, low-ESR aluminum electrolytics, and OS-CON.

The output capacitor’s ESR is usually the main cause of

output ripple. The maximum value of ESR is calculated by:

V

∆

R

ESR

OUT

≤

I

PP

where:

V

= peak-to-peak output voltage ripple

OUT

IPP = peak-to-peak inductor ripple current

The total output ripple is a combination of the ESR and the

output capacitance. The total ripple is calculated below:

∆V

OUT

⎛

I(1D)

× −

PP

=

⎜

Cf

⎝

OUT S

×

2

⎞

IR

+×

()

⎟

PP ESR

⎠

2

where:

D = duty cycle

C

= output capacitance value

OUT

fS = switching frequency

The voltage rating of capacitor should be twice the output

voltage for a tantalum and 20% greater for an aluminum

electrolytic or OS-CON.

The output capacitor RMS current is calculated below:

I

I

C

OUT(rms)

PP

=

12

The power dissipated in the output capacitor is:

PIR

DISS(C C ESR(C )

=×

OUT

)

OUT(rms)

2

OUT

Input Capacitor Selection

The input capacitor should be selected for ripple current

rating and voltage rating. Tantalum input capacitors may fail

when subjected to high inrush currents, caused by turning the

input supply on. Tantalum input capacitor voltage rating

should be at least 2 times the maximum input voltage to

maximize reliability. Aluminum electrolytic, OS-CON, and

multilayer polymer film capacitors can handle the higher

inrush currents without voltage derating.

The input voltage ripple will primarily depend on the input

capacitors ESR. The peak input current is equal to the peak

inductor current, so:

∆VI R

=×

IN INDUCTOR(peak) ESR(C )

IN

MIC2199 12 November 2004

MIC2199 Micrel

The input capacitor must be rated for the input current ripple.

The RMS value of input capacitor current is determined at the

maximum output current. Assuming the peak-to-peak inductor ripple current is low:

II D(1D)

C (rms) OUT(max)

≈ ××−

IN

The power dissipated in the input capacitor is:

PIR

DISS(C )

=×

C (rms)

IN

2

IN

ESR(C )

IN

Voltage Setting Components

The MIC2199 requires two resistors to set the output voltage

as shown in Figure 6.

FB

3

R1

R2

MIC2199

Error

Amp

V

REF

0.8V

Figure 6. Voltage-Divider Configuration

The output voltage is determined by the equation:

Where: V

VV 1

⎛

=×+

O REF

for the MIC2199 is typically 0.8V.

REF

⎜

⎝

R1

R2

⎞

⎟

⎠

A typical value of R1 can be between 3k and 10k. If R1 is too

large it may allow noise to be introduced into the voltage

feedback loop. If R1 is too small in value it will decrease the

efficiency of the power supply, especially at low output loads.

Once R1 is selected, R2 can be calculated using:

VR1

×

R2

REF

=

VV

−

O REF

Voltage Divider Power Dissipation

The reference voltage and R2 set the current through the

voltage divider.

V

I

DIVIDER

REF

=

R2

The power dissipated by the divider resistors is:

P (R1 R2) I

DIVIDER DIVIDER

=+×

2

Efficiency Calculation and Considerations

Efficiency is the ratio of output power to input power. The

difference is dissipated as heat in the buck converter. Under

light output load, the significant contributors are:

• Supply current to the MIC2199

• MOSFET gate-charge power (included in the IC

supply current)

• Core losses in the output inductor

To maximize efficiency at light loads:

• Use a low gate-charge MOSFET or use the smallest MOSFET, which is still adequate for maximum

output current.

• Use a ferrite material for the inductor core, which

has less core loss than an MPP or iron power core.

Under heavy output loads the significant contributors to

power loss are (in approximate order of magnitude):

• Resistive on-time losses in the MOSFETs

• Switching transition losses in the MOSFETs

• Inductor resistive losses

• Current-sense resistor losses

• Input capacitor resistive losses (due to the capacitors ESR)

To minimize power loss under heavy loads:

• Use logic-level, low on-resistance MOSFETs. Multiplying the gate charge by the on-resistance gives

a figure of merit, providing a good balance between low and high load efficiency.

• Slow transition times and oscillations on the voltage and current waveforms dissipate more power

during turn-on and turnoff of the MOSFETs. A

clean layout will minimize parasitic inductance and

capacitance in the gate drive and high current

paths. This will allow the fastest transition times

and waveforms without oscillations. Low gatecharge MOSFETs will transition faster than those

with higher gate-charge requirements.

• For the same size inductor, a lower value will have

fewer turns and therefore, lower winding resistance. However, using too small of a value will

require more output capacitors to filter the output

ripple, which will force a smaller bandwidth, slower

transient response and possible instability under

certain conditions.

• Lowering the current-sense resistor value will decrease the power dissipated in the resistor. However, it will also increase the overcurrent limit and

will require larger MOSFETs and inductor components.

• Use low-ESR input capacitors to minimize the

power dissipated in the capacitors ESR.

November 2004 13 MIC2199

MIC2199 Micrel

Decoupling Capacitor Selection

The 4.7µF decoupling capacitor is used to minimize noise on

the VDD pin. The placement of this capacitor is critical to the

proper operation of the IC. It must be placed right next to the

pins and routed with a wide trace. The capacitor should be a

good quality tantalum. An additional 1µF ceramic capacitor

may be necessary when driving large MOSFETs with high

gate capacitance. Incorrect placement of the VDD decoupling

capacitor will cause jitter or oscillations in the switching

waveform and large variations in the overcurrent limit.

A 0.1µF ceramic capacitor is required to decouple the VIN.

The capacitor should be placed near the IC and connected

directly to between pin 6 (VIN) and pin 9 (GND).

PCB Layout and Checklist

PCB layout is critical to achieve reliable, stable and efficient

performance. A ground plane is required to control EMI and

minimize the inductance in power, signal and return paths.

The following guidelines should be followed to insure proper

operation of the circuit.

• Signal and power grounds should be kept separate

and connected at only one location. Large currents

or high di/dt signals that occur when the MOSFETs

turn on and off must be kept away from the small

signal connections.

• The connection between the current-sense resistor and the MIC2199 current-sense inputs (pin 4

and 5) should have separate traces, through a 10Ω

resistor on each pin. The traces should be routed

as closely as possible to each other and their

length should be minimized. Avoid running the

traces under the inductor and other switching

components. The 10Ω resistor should be placed

close as possible to pins 4 and 5 on the MIC2199

and a 1nF to 0.1µF capacitor placed between pins

4 and 5 will help attenuate switching noise on the

current sense traces. This capacitor should be

placed close to pins 4 and 5.

• When the high-side MOSFET is switched on, the

critical flow of current is from the input capacitor

through the MOSFET, inductor, sense resistor,

output capacitor, and back to the input capacitor.

These paths must be made with short, wide pieces

of trace. It is good practice to locate the ground

terminals of the input and output capacitors close

to each.

• When the low-side MOSFET is switched on, current flows through the inductor, sense resistor,

output capacitor, and MOSFET. The source of the

low-side MOSFET should be located close to the

output capacitor.

• The freewheeling diode, D1 in Figure 2, conducts

current during the dead time, when both MOSFETs

are off. The anode of the diode should be located

close to the output capacitor ground terminal and

the cathode should be located close to the input

side of the inductor.

• The 4.7µF capacitor, which connects to the V

DD

terminal (pin 7) must be located right at the IC. The

VDD terminal is very noise sensitive and placement

of this capacitor is very critical. Connections must

be made with wide trace. The capacitor may be

located on the bottom layer of the board and

connected to the IC with multiple vias.

• The VIN bypass capacitor should be located close

to the IC and connected between pins 6 and 9.

Connections should be made with a ground and

power plane or with short, wide trace.

MIC2199 14 November 2004

MIC2199 Micrel

Package Information

××

4

×4 12-Lead MLF™ (ML)

××

MICREL, INC. 2180 FORTUNE DRIVE SAN JOSE, CA 95131 USA

The information furnished by Micrel in this datasheet is believed to be accurate and reliable. However, no responsibility is assumed by Micrel for its use.

Micrel reserves the right to change circuitry and specifications at any time without notification to the customer.

TEL + 1 (408) 944-0800 FAX + 1 (408) 474-1000 WEB http://www.micrel.com

Micrel Products are not designed or authorized for use as components in life support appliances, devices or systems where malfunction of a product can

reasonably be expected to result in personal injury. Life support devices or systems are devices or systems that (a) are intended for surgical implant into

the body or (b) support or sustain life, and whose failure to perform can be reasonably expected to result in a significant injury to the user. A Purchaser’s

use or sale of Micrel Products for use in life support appliances, devices or systems is at Purchaser’s own risk and Purchaser agrees to fully indemnify

Micrel for any damages resulting from such use or sale.

© 2004 Micrel, Incorporated.

November 2004 15 MIC2199

Loading...

Loading...