General Description

MIC2172/3172

100kHz 1.25A Switching Regulators

Features

The MIC2172 and MIC317 2 are complete 100kHz SMPS

current-mode controllers with internal 65V 1.25A power

switches. The MIC2172 features external frequency

synchronization or frequency adjustment, while the

MIC3172 features an enable/shutdown control input.

Although primarily intended for voltage step-up

applications, the floating switch architecture of the

MIC2172/3172 mak es it practical for step-do wn, inverting,

and Cuk configurations as well as isolated topologies.

Operating from 3V to 40V, the MIC2 172/3172 draws only

7mA of quiescent current making it attractive for battery

operated supplies.

The MIC3172 is for appl ications that require on/of f control

of the regulator. The MIC3172 is externally shutdown by

applying a TTL low s ignal to EN (enable) . When disable d,

the MIC3172 draws only leakage current (typically less

than 1µA). EN must be high for normal operation. For

applications not requ ir in g c ontrol , EN must be tied to V

TTL high.

The MIC2172 is for applications requiring two or more

SMPS regulators that op erate from the same input su pply.

The MIC2172 features a S YNC input which allows loc king

of its internal oscillator to an external reference. This

makes it possible to avoid the audible beat frequencies

that result from the unequal oscillator frequencies of

independent SMPS regu lat or s .

A reference signal can be supplied by one MIC2172

designated as a master. To insure locking of the slave’s

oscillators, the reference oscillator frequency must be

higher than the slave’s. The master MIC2172’s oscillator

frequency is increased up to 135kHz by connecting a

resistor from SYNC to ground (see applications

information).

The MIC2172/3172 is ava ilable in an 8-pin plastic DIP or

SOIC for –40°C to +85°C operation.

IN or

• 1.25A, 65V internal switch rating

• 3V to 40V input voltage range

• Current-mode operation

• Internal cycle-by-cycle current limit

• Thermal shutdown

• Low external parts count

• Operates in most switching topologies

• 7mA quiescent current (operating)

• <1µA quiescent current, shutdown mode (MIC3172)

• TTL shutdown compatibility (MIC3172)

• External frequency synchronization (MIC2172)

• External frequency trim (MIC2172)

• Fits most LT1172 sockets (see applications info)

Applications

• Laptop/palmtop computers

• Toys

• Hand-held instruments

• Off-line converter up to 50W (requires external power

switch)

• Predriver for higher power capability

• Master/slave configurations (MIC2172)

___________________________________________________________________________________________________________

Micrel Inc. • 2180 Fortune Drive • San Jose, CA 95131 • USA • tel +1 (408) 944-0800 • fax + 1 (408) 474-1000 • http://www.micrel.com

April 2006

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

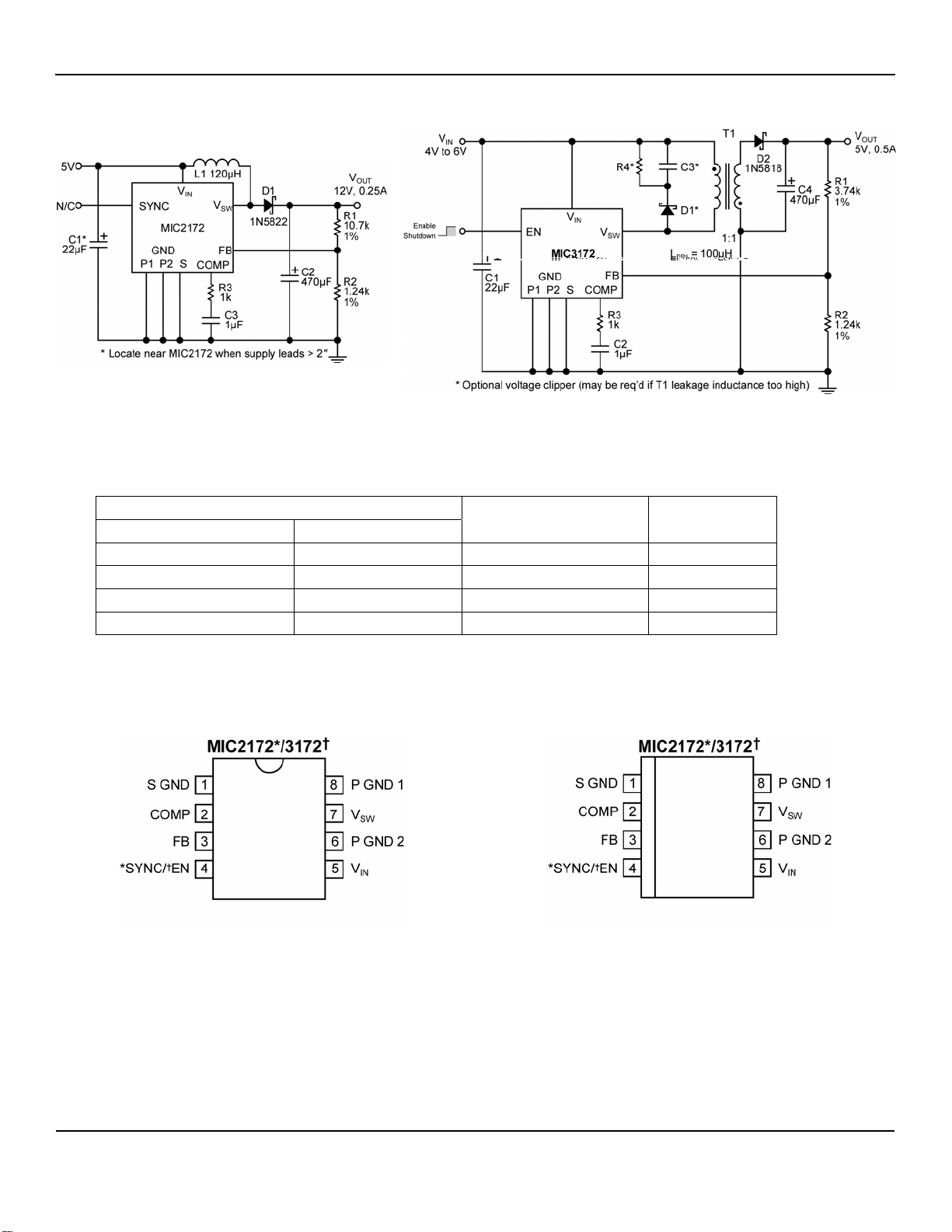

Typical Applications

Figure 1. MIC2172 5V to 12V Boost Converter

Ordering Information

Part Number

Standard Pb-Free

MIC2172BN MIC2172YN –40°C to +85°C 8-pin plastic DIP

MIC2172BM MIC2172YM –40°C to +85°C 8-pin SOIC

MIC3172BN MIC3172YN –40°C to +85°C 8-pin plastic DIP

MIC3172BM MIC3172YM –40°C to +85°C 8-pin SOIC

Note:

1. Other Voltage available. Contact Micrel for details.

Pin Configuration

Figure 2. MIC3172 Flyback Converter

Junction Temp. Range Package

8-pin DIP (N) 8-pin SOIC (M)

April 2006 2

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

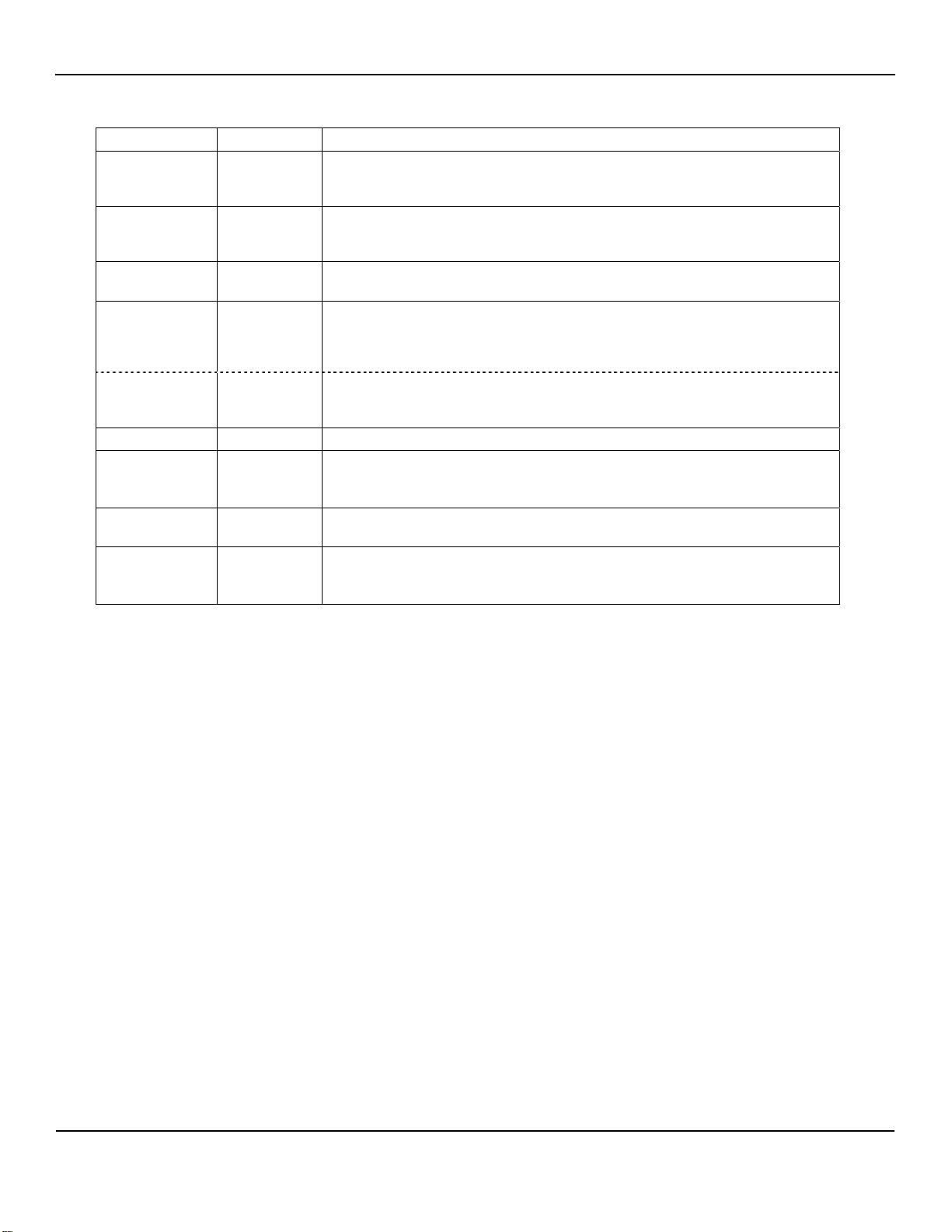

Pin Description

Pin Number Pin Name Pin Function

1 S GND Signal Ground: Internal analog circuit ground. Connect directly to the input filter

capacitor for proper operation (see applications info). Keep separate from power

grounds.

2 COMP Frequency Compensation: Output of transconductance type error amplifier.

Primary function is for loop stabilization. Can also be used for output voltage

soft-start and current limit tailoring.

3 FB Feedback: Inverting input of error amplifier. Connect to external resistive divider

to set power supply output voltage.

4 (MIC2172) SYNC Synchronization/Frequency Adjust: Capacitively coupled input signal greater

than device’s free running frequency (up to 135kHz) will lock device’s oscillator

on falling edge. Oscillator frequency can be trimmed up to 135kHz by adding a

resistor to ground. If unused, pin must float (no connection).

4 (MIC3172) EN Enable: Apply TTL high or connect to VIN to enable the regulator. Apply TTL low

or connect to ground to disable the regulator. Device draws only leakage current

(<1µA) when disabled.

5 VIN Supply Voltage: 3.0V to 40V

6 P GND 2

7 VSW Power Switch Collector: Collector of NPN switch. Connect to external inductor or

8 P GND 1

Power Ground #2: One of two NPN power switch emitters with 0.3

sense resistor in series. Required. Connect to external inductor or input voltage

ground depending on circuit topology.

input voltage depending on circuit topology.

Power Ground #1: One of two NPN power switch emitters with 0.3

sense resistor in series. Optional. For maximum power capability connect to P

GND 2. Floating pin reduces current limit by a factor of two.

Ω current

Ω current

April 2006 3

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

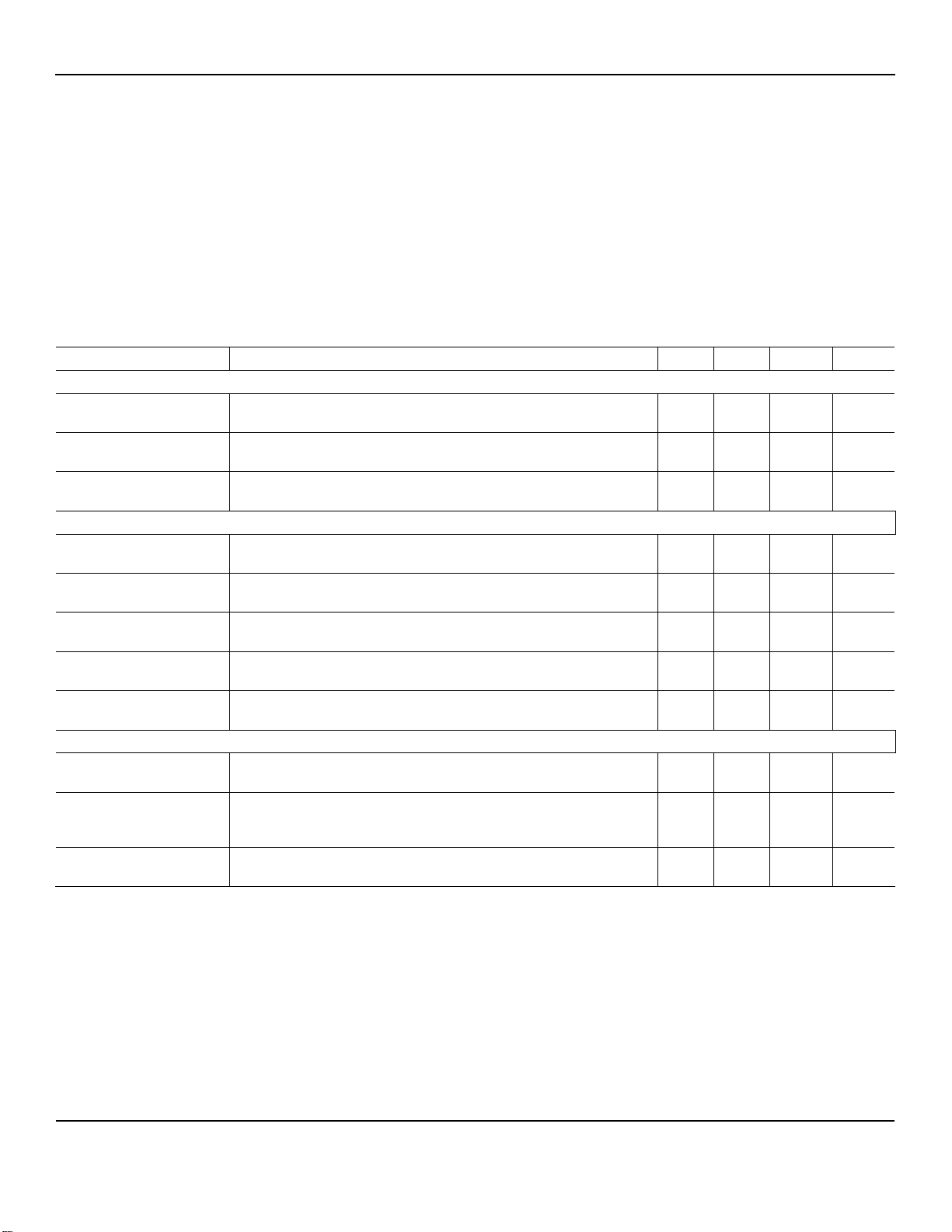

Absolute Maximum Ratings MIC2172

Input Voltage.................................................................. 40V

Switch Voltage............................................................... 65V

Sync Current............................................................... 50mA

Feedback Voltage (Transient, 1ms) ............................ ±15V

Operating Temperature Range

8-pin PDIP.................................................–40 to +85 °C

8-pin SOIC ................................................–40 to +85°C

Junction Temperature................................–55°C to +150°C

Thermal Resistance

θ

θ

8-pin PDIP................................................. 130°C/W

JA

8-pin SOIC................................................. 120°C/W

JA

Storage Temperature ................................–65°C to +150°C

Soldering (10 sec.) ...................................................+300°C

Electrical Characteristics MIC2172

Note 1, 3. Unless otherwise specified, V

Parameter Condition Min Typ Max Units

Reference Section

Feedback Voltage (VFB) 1.220

Feedback Voltage Line

Regulation

Feedback Bias Current

)

(I

FB

Error Amplifier Section

Transconductance

/∆VFB)

(∆I

COMP

Voltage Gain

COMP

/∆VFB)

(∆V

Output Current V

Output Swing High Clamp, VFB = 1V

Compensation Pin

Threshold

ON Resistance ISW = 1A, VFB = 0.8V 0.76 1

Current Limit Duty Cycle = 50%, TJ ≥ 25°C

Breakdown Voltage (BV) 3V ≤ VIN ≤ 40V

Notes:

1. Exceeding the absolute maximum rating may damage the device.

2. The device is not guaranteed to function outside its operating rating.

3. Devices are ESD sensitive. Handling precautions recommended. Human body model, 1.5k in series with 100pF.

4. Specification for packaged product only.

Pin 2 tied to pin 3

3V ≤ VIN ≤ 40V

310 750

∆I

= ±25µA 3.0

COMP

0.9V ≤ V

= 1.5V 125

COMP

Low Clamp, V

Duty Cycle = 0 0.8

Duty Cycle = 50%, TJ < 25°C

Duty Cycle = 80%, Note 2

= 5mA

I

SW

IN = 5V.

1.240 1.264

1.214

1.274

0.03

1100

3.9 6.0

2.4

≤ 1.4V 500 800 2000 V/V

COMP

7.0

175 350

= 1.5V

FB

100

1.8

0.25

2.1

0.35

400

2.3

0.52

0.9 1.08

0.6

1.25

Output Switch Section

1.1

1.25

1.25

1

65

75 V

3

3.5

2.5

V

V

%/V

nA

nA

µA/mV

µA/mV

µA

µA

V

V

V

V

Ω

Ω

A

A

A

April 2006 4

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Typical Characteristics MIC2172 (cont)

Parameter Condition Min Typ Max Units

Oscillator Section

Frequency (fO) 88

Duty Cycle [δ(max)]

100 112

85

80 89

115

95

kHz

kHz

%

Sync Coupling Capacitor

Required for Frequency

VPP = 3.0V

= 40V

V

PP

22

2.2

51

4.7

120

10

pF

pF

Lock

Input Supply Voltage Section

Minimum Operating

2.7

3.0

V

Voltage

Quiescent Current (IQ) 3V ≤ VIN ≤ 40V, V

Supply Current Increase

)

(∆I

IN

∆I

= 1A, V

SW

COMP

= 0.6V, ISW = 0 7

COMP

= 1.5V 9 20 mA

9

mA

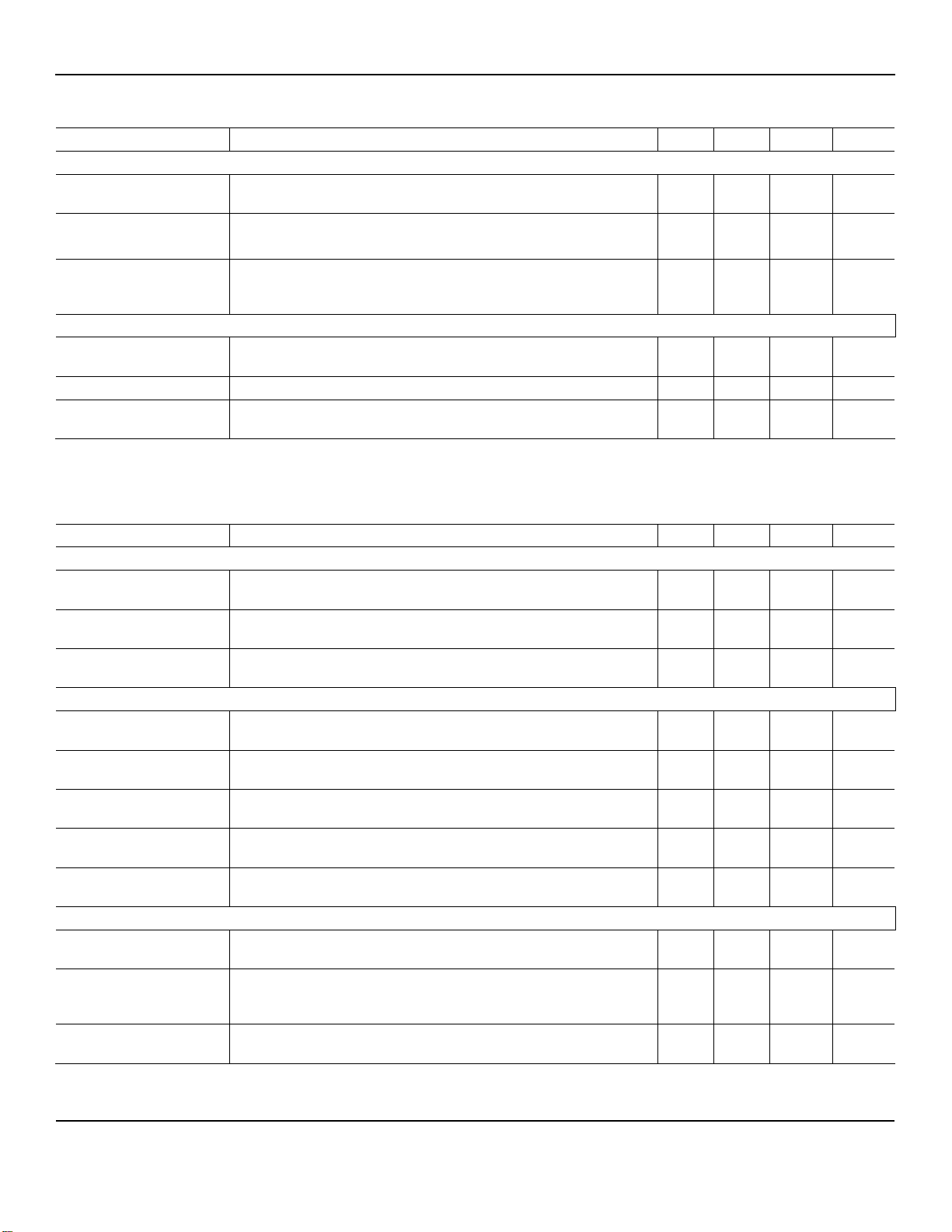

Electrical Characteristics MIC3172

Note 1, 3. Unless otherwise specified, V

IN = 5V.

Parameter Condition Min Typ Max Units

Reference Section

Feedback Voltage (VFB) 1.224

Feedback Voltage Line

Pin 2 tied to pin 3

1.240 1.264

1.214

3V ≤ VIN ≤ 40V 0.07

1.274

%/V

V

V

Regulation

Feedback Bias Current

)

(I

FB

310 750

1100

nA

nA

Error Amplifier Section

Transconductance

/∆VFB)

(∆I

COMP

Voltage Gain

COMP

/∆VFB)

(∆V

Output Current V

Output Swing High Clamp, VFB = 1V

Compensation Pin

Threshold

∆I

= ±25µA 3.0

COMP

2.4

0.9V ≤ V

COMP

≤ 1.4V 500 800 2000 V/V

COMP

= 1.5V 125

100

1.8

Low Clamp, V

= 1.5V

FB

0.25

Duty Cycle = 0 0.8

0.6

3.9 6.0

7.0

175 350

400

2.1

0.35

2.3

0.52

0.9 1.08

1.25

µA/mV

µA/mV

µA

µA

V

V

V

V

Output Switch Section

ON Resistance ISW = 1A, VFB = 0.8V 0.76 1

1.1

Current Limit Duty Cycle = 50%, TJ ≥ 25°C

Duty Cycle = 50%, TJ < 25°C

Duty Cycle = 80%, Note 2

Breakdown Voltage (BV) 3V ≤ VIN ≤ 40V

= 5mA

I

SW

1.25

1.25

1

65

3.5

2.5

75 V

3

Ω

Ω

A

A

A

April 2006 5

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Typical Characteristics MIC3172 (cont)

Parameter Condition Min Typ Max Units

Oscillator Section

Frequency (fO) 88

Duty Cycle [δ(max)]

100 112

85

80 89

115

95

kHz

kHz

%

Sync Coupling Capacitor

Required for Frequency

VPP = 3.0V

= 40V

V

PP

22

2.2

51

4.7

120

10

pF

pF

Lock

Input Supply Voltage Section and Enable Section

Minimum Operating

2.7

3.0

V

Voltage

Quiescent Current (IQ) 3V ≤ VIN ≤ 40V, V

Supply Current Increase

)

(∆I

IN

∆I

= 1A, V

SW

COMP

= 0.6V, ISW = 0 7

COMP

= 1.5V 9 20 mA

Enable Input Threshold

Enable Input Current VEN = 0V

= 2.4V

V

EN

Bold type denotes specifications applicable to the full operating temperature range.

Note 1. Devices are ESD sensitive. Handling precautions required.

Note 2. For duty cycles (δ) between 50% and 95%, minimum guaranteed switch current is given by I

Note 3. Specification for packaged product only.

0.4

1.2

–1 0

2

= 0.833 (2- δ) for the MIC3172.

CL

9

2.4

1

10

mA

V

µA

µA

April 2006 6

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Typical Characteristics

April 2006 7

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Typical Characteristics (cont.)

April 2006 8

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Functional Characteristics

MIC2172 Block Diagram

MIC3172 Block Diagram

April 2006 9

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Functional Description

Refer to “Block Diagram MIC2172” and “Block Diagram

MIC3172.”

Internal Power

The MIC2172/3172 operates when V

EN ≥ 2.0V for the MIC317 2). An internal 2.3V regulator

V

supplies biasing to all internal circuitry including a

precision 1.24V band gap reference.

The enable control (MIC 3172 only) enables or disables

the internal regulator which supplies power to all other

internal circuitry.

PWM Operation

The 100kHz oscillator generates a signal with a duty

cycle of approximately 90%. The current-mode

comparator output is us ed t o r ed uc e th e d uty cycle when

the current amplifier output voltage exceeds the error

amplifier output voltage. The resulting PWM signal

controls a driver which supplies base current to output

transistor Q1.

Current Mode Advantages

The MIC2172/3172 operate s in cur rent mode r ather than

voltage mode. There are three distinct advantages to

this technique. Feedback loop compensation is greatly

IN is ≥ 2.6V (and

simplified because inductor current sensing removes a

pole from the closed loop response. Inherent cycle-bycycle current limiting gre atly improves the power switch

reliability and pr ovides automatic output current limiting.

Finally, current-m ode operatio n provides a utomatic i nput

voltage feed for ward whic h prevents inst antaneous input

voltage changes from disturbing the output voltage

setting.

Anti-Saturation

The anti-saturation dio de (D1) increases the usable d uty

cycle range of the MIC2172/3172 by eliminating the

base to collector stored charge which would delay Q1’s

turnoff.

Compensation

Loop stability compensation of the MIC2172/3172 can

be accomplished b y connecting an appropriate network

from either COMP to circuit ground (Typical

Applications) or COMP to FB.

The error amplif ier output (COMP) is also useful for s oft

start and current limiting. Because the error amplifier

output is a transconduc tance type, the output impedance

is relatively high which m eans the outp ut volta ge can be

easily clamped or adjusted externally.

April 2006 10

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Application Information

Using the MIC3172 Enable Control (New Designs)

For new designs requiring enable/shutdown control,

connect EN to a T TL or CMOS control signal (figure 3).

The very low driver current requirement ensures

compatibility regardless of the driver or gate used.

Figure 3. MIC3172 TTL Enable/Shutdown

Using the MIC3172 in LT1172 Applications

The MIC3172 can be used in most original LT1172

applications by adapting the MIC3172’s

enable/shutdown feature to the existing LT1172 circuit.

Unlike the LT1172 wh ich can be shutdown by reducing

the voltage on pin 2 (V

) below 0.15V, the MIC 3172 has

C

a dedicated enable/shutdown pin. To replace the

LT1172 with the MIC3172, determine if the LT1172’s

shutdown feature is used.

By using the MIC3172, U1 and Q1 shown in figure 5 can

be eliminated, reducing the total components count.

Synchronizing the MIC2172

Using several unsynchronized switching regulators in the

same circuit will cause beat frequencies to appear on the

inputs and outputs. T hese beat frequencies can be very

low making them difficult to filter.

Micrel’s MIC2172 can be synchronized to a single

master frequenc y avoiding the possibility of undes irable

beat frequencies in multiple regulator circuits. The

master frequency can be an external oscillator or a

designated master MIC2172. The master frequency

should be 1.05 to 1.20 tim es the s lave’s 1 00k Hz nominal

frequency to guarantee synchronization.

Circuits without Shutdown

If the shutdown featur e is not being used, c onnect EN to

V

IN to continuously enable the MIC3172 or use an

MIC2172 with

SYNC open (figure 4).

Figure 4. MIC2172/3172 Always Enabled

Circuits with Shutdown

If shutdown was used in th e original LT 1172 applicat ion,

connect EN to a logic gate that produces a TTL logiclevel output signal that matches the shutdown signal.

The MIC3172 will be enabled b y a logic-high input and

shutdown with a logic-low input (figure 5). The actual

components perform ing the functions of U1 and Q1 ma y

vary according to the original application.

Figure 6. Master/Slave Synchronization

Figure 6 shows a typical application where several

MIC2172s operate from the same supply voltage. U1’s

oscillator frequenc y is incre ased abo ve U2’s and U3’s by

connecting a resistor from SYNC to ground. U2-SYNC

and U3-SYNC are capacitively coupled to the master’s

output (V

). The slaves lock to the negative (falling

SW

edge) of U1’s output waveform.

Figure 5. Adapting to the LT1172 Socket

April 2006 11

Figure 7. External Synchronization

Care must be exercised to insure that the master

MIC2172 is always operating in continuous mode.

Figure 7 shows how one or more MIC2172s can be

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

locked to an external reference frequency. The slaves

lock to the negative (falling edge) of the external

reference waveform.

Soft Start

A diode-coupled c apacitor from COMP to circu it ground

slows the output voltage rise at turn on (figure 8).

Figure 8. Soft Start

The additional time it takes for the error amplifier to

charge the capacitor cor responds to the tim e it takes the

output to reach regulation. Diode D1 discharges C1

when V

IN is removed.

Another soft start circuit is shown in figure 8A. The

circuit uses capacitor C1 to c ontrol th e output risetime b y

providing feedback from the output to the FB pin. The

output voltage starts to rise when the MIC31 72 regu lator

starts switching. T his is the dv/dt of the outpu t will for ce

a current through ca pacitor C1, which flo ws through the

lower feedback resistor, R2, increasing the voltage on

the FB pin. This increased voltage on the FB pin

reduces the duty cycle at th e V

pin, limiting the turn- on

SW

time of the output. Increasing the value of C1 causes

the output voltage to rise more slowly. Diode D1 is

reverse biased in normal operation and prevents C1

from appearing in parall el with the upper voltage d ivider

resistor, which would affect stability and transient

response. Zener diode D 2 clamps the voltage s een by

the feedback pin and pr ovides a discharge path for C1

when the power supply is turned off.

Current Limit

For designs demanding less output current than the

MIC2172/3172 is c apable of deliver ing, P GN D 1 c an be

left open reducing the current capability of Q1 by onehalf.

Figure 8b. Without Soft Start

Figure 8c. With Soft Start

Figure 8a. Additional Soft Start Circuit

This circuit onl y limits the dv/dt of the output when the

boost converter is runn ing. It will not decreas e the dv/dt

or the initial inrush ca used by appl ying the input v oltage.

Figure 8B shows the turn-on without a soft start circuit

and Figure 8C shows how the s oft start circuit reduces

inrush and prevents output voltage overshoot.

April 2006 12

Figure 9. Current Limit

Alternatively, the maximum current limit of the

MIC2172/3172 can be reduced by adding a voltage

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

clamp to the COMP output (figure 9). This feature can be

useful in applications requiring either a complete

shutdown of Q1’s switching action or a form of current

fold-back lim iting. T his use of the COMP o utput do es n ot

disable the oscillator, amplifiers or other circuitry,

therefore the supply current is never less than

approximately 5mA.

Thermal Management

Although the MIC2172/3172 family contains thermal

protection circuitry, for best reliability, avoid prolonged

operation with junction temperatures near the rated

maximum.

The junction temperature is determined by first

calculating the power dissipation of the device. For the

MIC2172/3172, the tota l power dissipation is the sum of

the device operating losses and power switch losses.

The device operating losses are the dc losses

associated with biasing all of the internal functions plus

the losses of the power switch driver circuitry. The dc

losses are calculat ed from the supply voltage (V

device supply current (I

). The MIC2172/3172 supply

Q

) and

IN

current is almost constant regardless of the supply

voltage (see “Electrical Characteristics”). The driver

section losses (not inc ludin g the s witch) are a f unction of

supply voltage, power switch current, and duty cycle.

()

+

()

⎡

+=

⎢

⎣

⎛

IVI VP

⎜

SWINQINdriverbias

50

⎝

⎤

+

δ0.004

⎞

⎟

⎥

⎠

⎦

where:

P

(bias+driver)

V

IN

I

= quiescent supply current

Q

I

SW

= device operating losses

= supply voltage

= power switch current

(see “Design Hints: Switch Current Calculations”)

δ = duty cycle

VVV

±+

V

V

δ

=

= output voltage

OUT

= D1 forward voltage drop

F

INFOUT

VV

+

FOUT

As a practical example refer to figure 1.

V

= 5.0V

IN

I

= 0.006A

Q

I

= 0.625A

SW

δ = 60% (0.6)

Then:

driverbias

+

()

()

driverbias

+

()

0.068WP

=

Power switch dissipation calculations are greatly

simplified by mak ing two assumptions which are usu ally

fairly accurate. First, the majority of loss es in the power

switch are due to on-loss es. To find thes e los ses, as si gn

a resistance value to the collector/emitter terminals of

the device using the satur ation voltage versus collector

current curves (see Typical Performance

Characteristics). Power switch losses are calculated by

modeling the switch as a resistor with the switch duty

cycle modifying the average power dissipation.

= (ISW)2 RSW δ

P

SW

From the Typical performance Characteristics:

R

= 1Ω

SW

Then:

P

= (0.625)2 × 1 × 0.6

SW

= 0.234W

P

SW

= 0.068 + 0.234

P

(total)

= 0.302W

P

(total)

The junction temperature for any semiconductor is

calculated using the following:

T

= TA + P

J

(total) θJA

Where:

T

= junction temperature

J

= ambient temperature (maximum)

T

A

= total power dissipation

P

(total)

θ

= junction to ambient thermal resistance

JA

For the practical example:

T

= 70°C

A

θ

= 130°C/W (for plastic DIP)

JA

Then:

T

= 70 + 0.30 ⋅ 130

J

T

= 109°C

J

This junction temperature is below the rated maximum of

150°C.

Grounding

Refer to figure 10. Heavy lines indicate high current

paths.

⎡

⎛

0.62550.0065P

+×=

⎜

⎢

⎝

⎣

50

0.60.004

+

⎞

⎟

⎠

⎤

⎥

⎦

April 2006 13

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

L1 is operating in continuous mode if it does not

discharge completely before the MIC2172/3172 power

switch is turned on again.

Discontinuous Mode Design

Given the maximum output current, solve equation ( 1) to

determine whether the device can operate in

discontinuous m ode without initiat ing the internal de vice

current limit.

I

⎞

⎛

Figure 10. Single Point Ground

A single point ground is strongly recommended for

proper operation.

The signal ground, compensation network ground, and

feedback network connections are sensitive to minor

voltage variations. The input and output capacitor

grounds and power ground conductors will exhibit

voltage drop when carrying large currents. Keep the

sensitive circuit gro und traces separate from the power

ground traces. Small voltage variations applied to the

sensitive circuits c an prevent the MIC2172/3172 or any

switching regulator from functioning properly.

Applications and Design Hints

Access to both the collector and emitter(s) of the NPN

power switch makes the MIC2172/3172 extremely

versatile and suita ble f or us e in most PWM power supply

topologies.

Boost Conversion

Refer to figure 11 for a typical boost conversion

application where a +5V logic supply is available but

+12V at 0.14A is required.

Figure 11. 5V to 12V Boost Converter

The first step in designing a boost converter is

determining whether induc tor L1 will caus e the con verter

to operate in either continuous or discontinuous mode.

Discontinuous m ode is preferred because the f eedback

control of the converter is simpler.

When L1 discharges its current completely during the

MIC2172/3172’s off -time, it is opera ting in disconti nuous

mode.

April 2006 14

CL

⎜

2

I

δ

⎝

≤ (1)

OUT

V

= (1a)

Where:

I

= internal switch current limit

CL

= 1.25A when δ < 50%

I

CL

I

= 0.833 (2 – δ) when δ ≥ 50%

CL

(Refer to Electrical Characteristics.)

= maximum output current

I

OUT

= minimum input voltage

V

IN

δ = duty cycle

= required output volta ge

V

OUT

= D1 forward voltage drop

V

F

For the example in figure 11.

I

= 0.14A

OUT

= 1.147A

I

CL

= 4.75V (minimum)

V

IN

δ = 0.623

V

= 12.0V

OUT

= 0.6V

V

F

Then:

1.147

⎛

⎜

⎝

≤

I

OUT

0.141AI

≤

OUT

This value is greater than the 0.14A output current

requirement so we can proceed to find the inductance

value of L1.

()

L1≤ (2)

IN

Where:

P

= 12 ⋅ 0.14 = 1.68W

OUT

f

SW

= 1⋅10

5

For our practical example:

δ V

⎟

IN

⎠

OUT

VVV

±+

INFOUT

VV

+

FOUT

⎞

⎟

2

⎠

××

12

2

δ V

f P 2

SWOUT

kHz (100kHz)

0.6234.75

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

()

L1

≤

≤ 26.062µH (use 27µH)

I

L1

×

2

0.6234.75

5

1011.682

×××

Equation (3) solves for L1’s maximum current value.

T V

I

L1(peak)

= (3)

ONIN

L1

Where:

= δ / fSW = 6.23×10-6 sec

T

ON

6

−

106.234.75

I

L1(peak)

I

L1(peak)

=

= 1.096A

××

6

−

1027

×

Use a 27µH inductor with a peak current rating of at

least 1.4A.

Flyback Conversion

Flyback converter topology may be used in low power

applications where voltage isolation is required or

whenever the input vo ltage can be less than or greater

than the output voltage. As with the step-up converter

the inductor (transformer primary) current can be

continuous or disconti nuous. Discontinuous operat ion is

recommended.

Figure 12 shows a practical flyback converter design

using the MIC3172.

Switch Operation

During Q1’s on time ( Q1 is the intern al NPN transis tor—

see block diagrams), energy is stored in T1’s primary

inductance. During Q1’s off time, stored energy is

partially discharged into C4 (output filter capacitor).

Careful selection of a low ESR capacitor for C4 may

provide satisfactory output ripple voltage making

additional filter stages unnecessary.

C1 (input capacitor) may be red uced or elim inated if t he

MIC3172 is located near a low impedance voltage

source.

Output Diode

The output diode allows T 1 to store ener gy in its prim ary

inductance (D2 nonco nducting) and release energ y into

C4 (D2 conducting). T he low forward voltage drop of a

Schottky diode minimizes power loss in D2.

Frequency Compensation

A simple frequenc y compensation network consisting of

R3 and C2 prevents output oscillations.

High impedance output stages (transconductance type)

in the MIC2172/3172 often perm it sim plified lo op-s tabil ity

solutions to be connected to circuit ground, although a

more conventional technique of connecting the

components from the error amplifier output to its

April 2006 15

inverting input is also poss i ble.

Voltage Clipper

Care must be taken to minimize T1’s leakage

inductance, otherwise it may be necessary to

incorporate the volta ge clipper c onsisting of D1, R4, a nd

C3 to avoid second breakdown (failure) of the

MIC3172’s power NPN Q1.

Enable/Shutdown

The MIC3172 includes the enable/shutdown feature.

When the device is s h utdo wn, total suppl y curren t is l ess

than 1µA. This is ideal for battery applications where

portions of a system ar e powered only when needed. If

this feature is not r equired, simpl y connect EN to V

to a TTL high voltage.

Discontinuous Mode Design

When designing a discontinuous flyback converter , first

determine whether the device can safely handle the

peak primary current dem and placed on it by the output

power. Equation (8) finds the maximum duty cycle

required for a given input voltage and output power. If

the duty cycle is greater than 0.8, discontinuous

operation cannot be used.

δ ≥

VI

OUT

IN(min)CL

(8)

P 2

For a practical example let:

= 5.0V × 0.25A = 1.25W

P

OUT

= 4.0V to 6.0V

V

IN

I

= 1.25A when δ < 50%

CL

Then:

1.252

×

δ

≥

≥ 0.5 (50%) Use 0.55.

δ

41.25

×

The slightly hig her dut y cycle valu e is used to overco me

circuit ineffic iencies. A f ew iterat ions of equati on (8) m ay

be required if the dut y cycle is found to be greater than

50%.

Calculate the maximum transformer turns ratio

N

PRI/NSEC

, that will guarantee safe operation of the

a, or

MIC2172/3172 power switch.

VF V

a±≤ (9)

V

IN(max)CECE

SEC

Where:

a = transformer maximum turns ratio

= power switch collector to emitter maximum

V

CE

voltage

M9999-041806

(408) 955-1690

IN or

Micrel MIC2172/3172

F

= safety derating factor (0.8 for most

CE

commercial and industrial applications)

= maximum input voltage

V

IN(max)

= transformer secondary voltage (V

V

SEC

OUT

+ V

)

F

For the practical example:

V

= 65V max. for the MIC2172/3172

CE

= 0.8

F

CE

= 5.6V

V

SEC

Then:

a±×≤

a

≤ 8.2143

6.00.865

5.6

Next, calculate the maximum primary inductance

required to store th e neede d output energ y with a po wer

switch duty cycle of 55%.

2

2

T Vf 0.5

ON

L ≤ (10)

PRI

P

IN(min)SW

OUT

Where:

L

= maximum primary inductance

PRI

= device switching frequency (100kHz)

f

SW

= minimum input voltage

V

IN(min)

= power switch on time

T

ON

Then:

2

−

≤

L

PRI

L

PRI ≤ 19.23µH

()

1.25

625

105.54.01010.5

××××

Use an 18µH primary inductance to overcome circuit

inefficiencies.

To complete the design the inductance value of the

secondary is found which will guar antee that the energy

stored in the transformer during the power switch on

time will be completed disc harged into the output dur ing

the off-time. This is necessary when operating in

discontinuous-mode.

2

2

T Vf 0.5

OFF

L ≤ (11)

SEC

P

SECSW

OUT

Where:

L

= maximum secondary inductance

SEC

= power switch off time

T

OFF

Then:

2

−

625

104.55.61010.5

×××××

L

≤

L

SEC

SEC

≤ 25.4µH

1.25

()

Figure 12. MIC3172 5V 0.25A Flyback Converter

April 2006 16

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Finally, recalculate the transform er turns ratio to insure

that it is less than the value earlier found in equation (9).

L

L

PRI

SEC

a ≤ (12)

Then:

5

−

101.8

a

≤

×

5

−

102.54

×

a ≤ 0.84 Use 0.8 (same as 1:1.25).

This ratio is less than th e ratio ca lcula ted in equat ion ( 9).

When specifying the tra nsform er it is necessar y to know

the primary peak current which must be withstood

without saturating the transformer core.

T V

I =

PEAK(pri)

ONIN(min)

L

PRI

So:

6

−

××

I

PEAK(pri)

I

PEAK(pri)

= (13)

= 1.22A

105.54.0

18µ8

Now find the minimum reverse voltage requirement for

the output rectifier. This rectifier must have an avera ge

current rating greater th an the maximum output current

of 0.25A.

a

VV

()

V+≥ (14)

BR

OUTIN(max)

a

F

BR

Where:

V

= output rectifier maximum peak reverse

BR

voltage rating

a = transformer turns ratio (0.8)

F

= reverse voltage safety derating factor (0.8)

BR

Then:

()

0.85.06.0

V

≥

BR

15.625VV

≥

BR

×+

0.80.8

×

A 1N5817 will safely handle voltage and current

requirements in this example.

Forward Converters

Micrel’s MIC2172/3172 can be used in several circuit

configurations to generate an output voltage which is

less than the input voltage ( buck or step-down to polog y).

Figure 13 shows the MIC3172 in a voltage step-down

application. Beca use of the internal ar chitecture of these

devices, more external components are required to

implement a step-down r egulat or than with other dev ices

offered by Micrel (r efer to the LM257x or LM457x family

of buck switchers). However, for step-down conversion

April 2006 17

requiring a transf orm er (f orward), th e MIC2 172/31 72 i s a

good choice.

A 12V to 5V step-down converter using transformer

isolation (forward) is shown in figure 14. Unlike the

isolated flyback converter which stores energy in the

primary inductance during the controller’s on-time and

releases it to the load during the off-time, the forward

converter transfers energy to the output during the ontime, using the off-tim e to reset the transformer core. In

the application shown, the transformer core is reset by

the tertiary winding discharging T1’s peak magnetizing

current through D2.

For most forward converte rs the duty cycle is limited to

50%, allowing the transf ormer flux to reset with only two

times the input voltage appearing across the power

switch. Although during normal operation this circuit’s

duty cycle is well below 50%, the MIC2172 (and

MIC3172) has a maximum dut y cycle capability of 90 %.

If 90% was required dur ing operation (start-up and hi gh

load currents), a complete reset of the transformer

during the off -time would require the voltage across t he

power switch to be ten times the input voltage. This

would limit the input voltage to 6V or less for forward

converter applications.

To prevent core saturation, the application given here

uses a duty cycle limiter consisting of Q1, C4 and R3.

Whenever the MIC3172 exceeds a duty cycle of 50%,

T1’s reset winding current turns Q1 on. This action

reduces the dut y cycle of the MIC3172 unti l T1 is abl e to

reset during each cycle.

Fluorescent Lamp Supply

An extremely useful application of the MIC3172 is

generating an ac voltage f or fluorescent lamps used as

liquid crystal display back lighting in portable computers.

Figure 15 shows a complete po wer supply for lighting a

fluorescent lamp. Transistors Q1 and Q2 together with

capacitor C2 form a Royer oscillator. The Royer

oscillator generates a sine wave whose frequency is

determined by the ser i es L/ C c irc uit c omprised of T1 and

C2. Assuming that the MIC3172 and L1 ar e absent, and

the transistors’ emitters are grounded, circuit operation is

described in “Oscillator Operation.”

Oscillator Operation

Resistor R2 provides initial base current that turns

transistor Q1 on and im presses the inp ut voltage acro ss

one half of T1’s primary winding (Pri 1). T1’s feedba ck

winding provides additional base drive (positive

feedback) to Q1 f or c ing it well in to s at ur ation for a peri od

determined by the Pri 1/C2 time constant. Once the

voltage across C2 has reached its maximum circuit

value, Q1’s collector current will no longer increase.

Since T1 is in s er ies with Q1, this drop in pr imary current

causes the flux in T1 to change and because of the

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Figure 13. Step-Down or Buck Regulator

mutual coupling to t he feedback windin g further reduc es

primary current eventually turning Q1 off. The primary

windings now change state with the feedback winding

forcing Q2 on re peating the alternate half cycle ex actly

as with Q1. This action produces a sinusoidal voltage

wave form; whose amplit ude is proportional to the i nput

voltage, across T1’s primary winding which is stepped

up and capacitively coupled to the lamp.

Lamp Current Regulation

Initial ionization (lighting) of the fluorescent lamp

requires several times the ac voltage across it than is

required to sustain current through the device. The

current through the lamp is sampled and regulated by

the MIC3172 to achie ve a given intensit y. The MIC3172

uses L1 to maintain a constant average curr ent through

the transistor em itters. This current controls the voltage

amplitude of the Ro yer osci llator and m ainta ins the lam p

current. During the negative half cycle, lamp current is

rectified by D3. During the positive half cycle, lamp

current is rectified b y D2 thr ough R4 and R5. R3 a nd C5

filter the voltage dropped across R4 and R5 to the

MIC3172’s feedback pin. The MIC3172 maintains a

constant lamp curr ent by adjusting its duty cycle to k eep

the feedback voltag e at 1.24V. The intens ity of the lam p

is adjusted using potentiometer R5. The MIC3172

adjusts its duty cycle accordingly to bring the average

voltage across R4 and R5 back to 1.24V.

On/Off Control

Especially important for battery powered applications,

the lamp can be remotely or automatically turned off

using the MIC3172’s EN pin. The entire circuit draws

less than 1µA while shutdown.

Efficiency

To obtain maximum circuit efficiency careful s election of

Q1 and Q2 for lo w collecto r to em itter saturation voltage

is a must. Inductor L1 should be chosen f o r minimal core

and copper losses at the switching frequency of the

MIC3172, and T1 should be carefully constructed from

magnetic materials optimized for the output power

required at the Royer oscillator frequency. Suitable

inductors may be obtained from Coiltronics, Inc., tel:

(407) 241-7876.

April 2006 18

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

Figure 14. 12V to 5V Forward Converter

Figure 15. LCD Backlight Fluorescent Lamp Supply

April 2006 19

M9999-041806

(408) 955-1690

Micrel MIC2172/3172

t

Package Information

8-Pin Plastic DIP (N)

8-Pin SOIC (M)

MICREL, INC. 2180 FORTUNE DRIVE SAN JOSE, CA 95131 USA

TEL +1 (408) 944-0800 FAX +1 (408) 474-1000 WEB http:/www.micrel.com

The information furnished by Micrel in this data sheet is believed to be accurate and reliable. However, no responsi b ility is assumed by Micrel for its

Micrel Products are not designed or authorized for use as components in life support appliances, devices or syst ems where malfu nction of a product

can reasonably be expected to result in personal injury. Life support devices or systems are devices or systems that (a) are intended for surgical implan

into the body or (b) support or sustain life, and whose failure to perform can be reasonably expected to result in a significant injury to the user. A

Purchaser’s use or sale of Micrel Products for use in life support appliances, devices or syst ems is a Purchaser’s own risk and Pu rchaser agrees to fully

April 2006 20

use. Micrel reserves the right to change circuitry and specifications at any time without notification to the customer.

indemnify Micrel for any damages resulting from such use or sale.

© 2004 Micrel, Incorporated.

M9999-041806

(408) 955-1690

Loading...

Loading...