MIC2085/2086 Micrel

查询MIC2085供应商

MIC2085/MIC2086

Single Channel Hot Swap Controllers

General Description

The MIC2085 and MIC2086 are single channel positive

voltage hot swap controllers designed to allow the safe

insertion of boards into live system backplanes. The MIC2085

and MIC2086 are available in 16-pin and 20-pin QSOP

packages, respectively. Using a few external components

and by controlling the gate drive of an external N-Channel

MOSFET device, the MIC2085/86 provide inrush current

limiting and output voltage slew rate control in harsh, critical

power supply environments. Additionally, a circuit breaker

function will latch the output MOSFET off if the current limit

threshold is exceeded for a programmed period of time. The

devices’ array of features provide a simplified yet robust

solution for many network applications in meeting the power

supply regulation requirements and affords protection of

critical downstream devices and components.

All support documentation can be found on Micrel’s web

site at www.micrel.com.

Features

• MIC2085: Pin for pin functional equivalent to the

LTC1642

• 2.3V to 16.5V supply voltage operation

• Surge voltage protection to 33V

• Operating temperature range –40°C to 85°C

• Active current regulation limits inrush current

independent of load capacitance

• Programmable inrush current limiting

• Analog foldback current limiting

• Electronic circuit breaker

• Dual-level overcurrent fault sensing

• Fast response to short circuit conditions (< 1µs)

• Programmable output undervoltage detection

• Undervoltage lockout protection

• Power-on reset (MIC2085/86) and

power-good (MIC2086) status outputs

• /FAULT status output

• Driver for SCR crowbar on overvoltage

Applications

• RAID systems

• Cellular base stations

• LAN servers

• WAN servers

• InfiniBand™ Systems

• Industrial high side switching

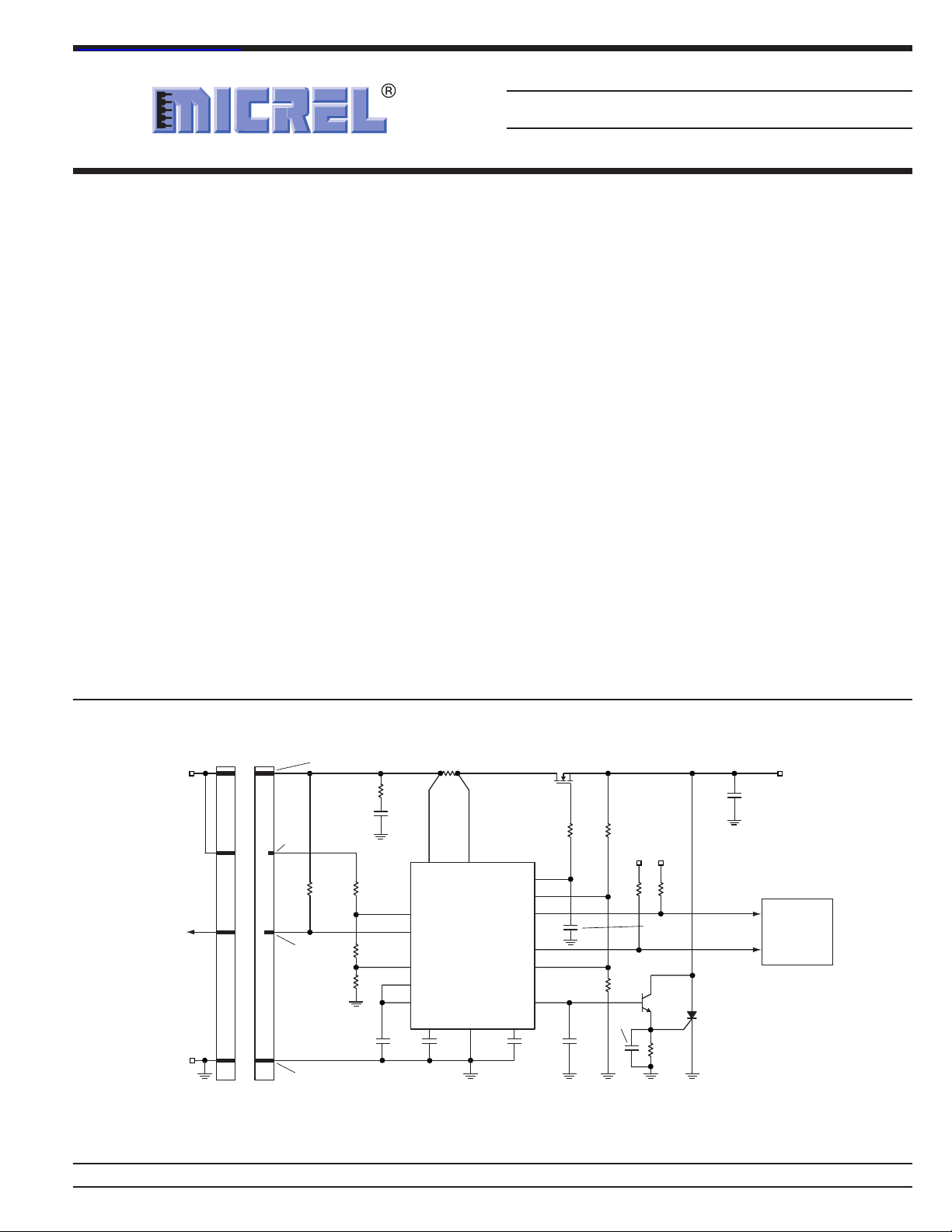

T ypical Application

(PowerPAK

/POR

FB

283

Q1

Si7884DP

14

11

10

5

7

1

C6

0.01µF

TM

SO-8)

*R6

10Ω

R7

127kΩ

1%

R10

47kΩ

R8

16.2kΩ

1%

C7

0.033µF

µ

s

V

LOGIC

C2

0.022µF

R11

47kΩ

Q2

2N4401

**R9

180Ω

C

LOAD

220µF

Output Signal

(Power Good)

Power-On Reset

Output

Q3

TCR22-4

V

OUT

12V@5A

PWRGD

LOGIC

CONTROLLER

/RESET

34

C1

µ

F

1

16 15

4

ON

6

/FAULT

9

OV

12

COMP—

13

REF

CPOR

C4

µ

F

0.1

R

SENSE

0.007Ω

2%

12

SENSEVCC

MIC2085

GATE

COMP+

COMPOUT

CRWBR

GND

CFILTER

C5

8200pF

POR/START-UP DELAY = 60ms

Circuit-Breaker Response Time = 500

*R6 is an optional component used for noise filtering

**R9 needed when using a sensitive gate SCR

V

12V

/FAULT

GND

IN

Backplane

Connector

PCB Edge

Connector

(or Short)

Long

Pin

Short

Pin

R5

47kΩ

Medium

Pin

Long

Pin

R2

100kΩ

1%

R3

1.82kΩ

1%

R4

10kΩ

1%

Overvoltage (Input) = 13.3V

Undervoltage Lockout = 10.8V

Undervoltage (Output) &

Power-Good (Output) = 11.4V

R1

3.3Ω

C3

µ

F

0.1

InfiniBand is a trademark of InfiniBand Trade Association

PowerPAK is a trademark of Vishay Intertechnology Inc.

Micrel, Inc. • 1849 Fortune Drive • San Jose, CA 95131 • USA • tel + 1 (408) 944-0800 • fax + 1 (408) 944-0970 • http://www.micrel.com

January 2004 1 M0235-121903

MIC2085/2086 Micrel

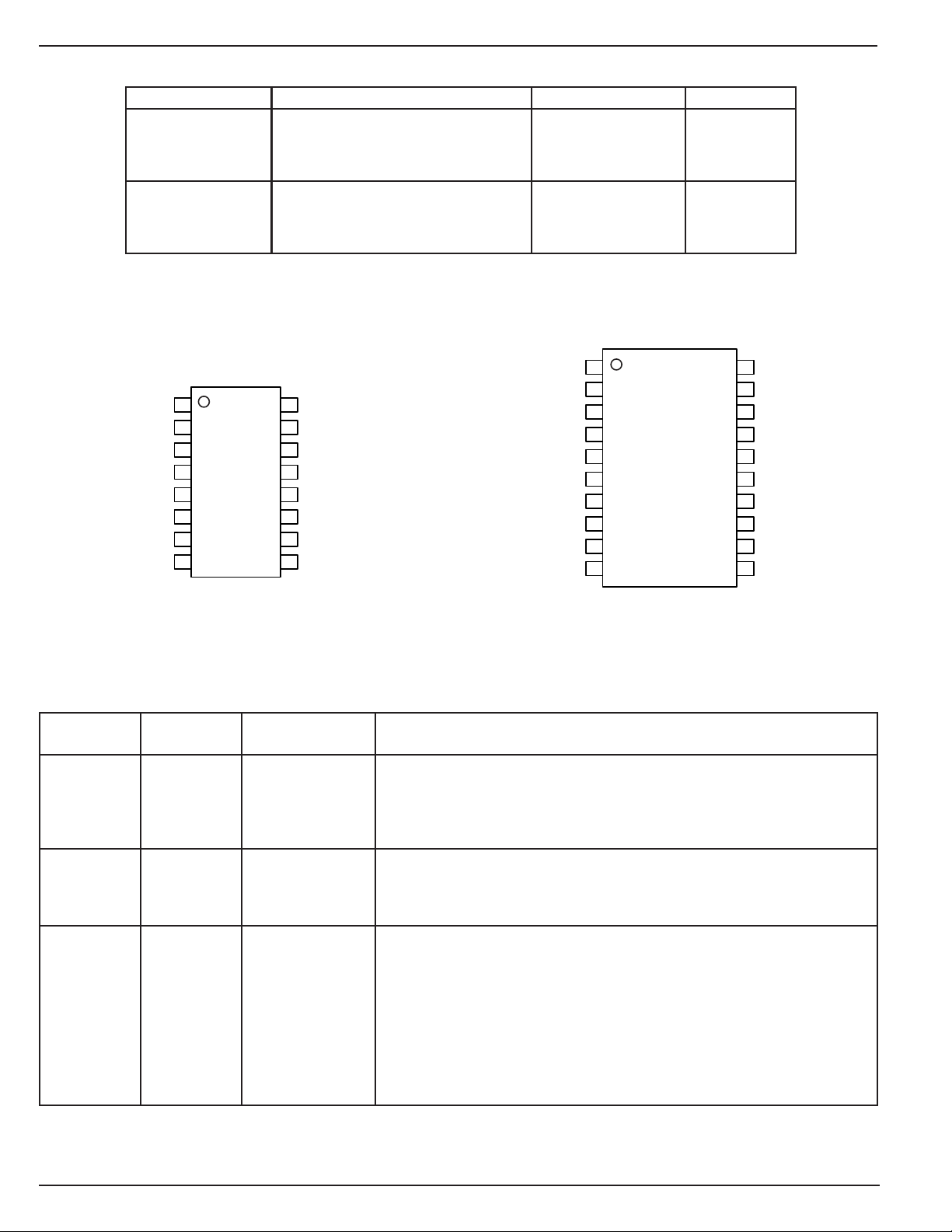

Ordering Information

Part Number Fast Circuit Breaker Threshold Discharge Output Package

MIC2085-xBQS x = J, 95mV NA 16-pin QSOP

x = K, 150mV*

x = L, 200mV*

x = M, Off

MIC2086-xBQS x = J, 95mV Yes 20-pin QSOP

x = K, 150mV*

x = L, 200mV*

x = M, Off

*Contact factory for availability.

Pin Configuration

CFILTER

CPOR

ON

/POR

/FAULT

FB

GND

1CRWBR

1CRWBR

2

3

4

5

6

7

8

16 VCC

SENSE

15

GATE

14

REF

13

COMP–

12

COMP+

11

COMPOUT

10

OV

9

CFILTER

PWRGD

CPOR

ON

/POR

/FAULT

FB

GND

GND

2

3

4

5

6

7

8

9

10

20 VCC

VCC

19

SENSE

18

GATE

17

REF

16

DIS

15

COMP–

14

COMP+

13

COMPOUT

12

OV

11

MIC2085

16-Pin QSOP (QS)

MIC2086

20-Pin QSOP (QS)

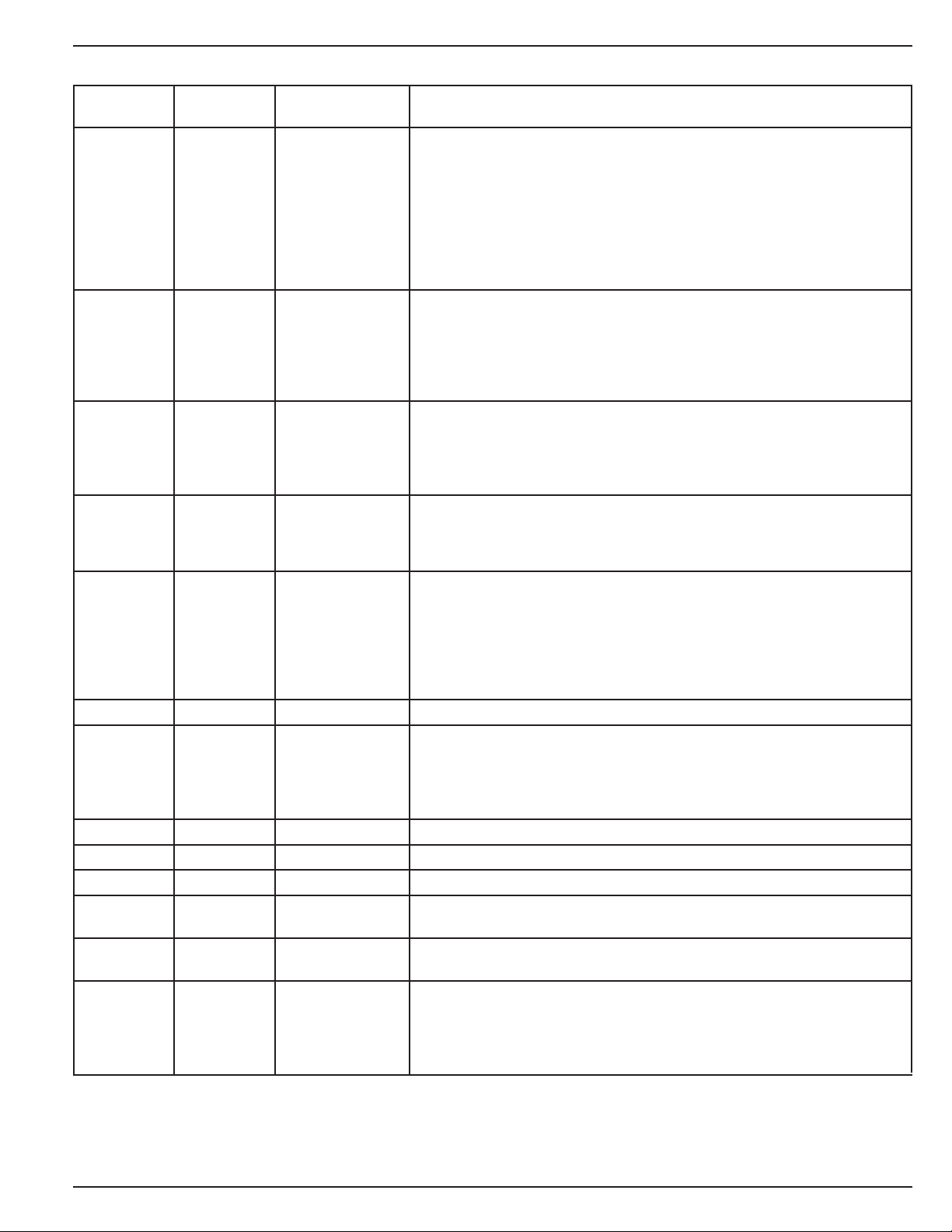

Pin Description

Pin Number Pin Number Pin Name Pin Function

MIC2086 MIC2085

1 1 CRWBR Overvoltage Timer and Crowbar Circuit Trigger: A capacitor connected to

this pin sets the timer duration for which an overvoltage condition will trigger

an external crowbar circuit. This timer begins when the OV input rises above

its threshold as an internal 45µA current source charges the capacitor. Once

the voltage reaches 470mV, the current increases to 1.5mA.

2 2 CFILTER Current Limit Response Timer: A capacitor connected to this pin defines the

period of time (t

fault condition and trip the circuit breaker. If no capacitor is connected, then

t

OCSLOW

OCSLOW

defaults to 5µs.

3 3 CPOR Power-On Reset Timer: A capacitor connected between this pin and ground

sets the start-up delay (t

VCC rises above the UVLO threshold, the capacitor connected to CPOR

begins to charge. When the voltage at CPOR crosses 1.24V, the start-up

threshold (V

C

POR

above V

CPOR rises above the power-on reset delay threshold (VTH), the timer

START

is immediately discharged to ground. When the voltage at FB rises

, capacitor C

FB

resets by pulling CPOR to ground, and /POR is deasserted.

If C

= 0, then t

POR

) in which an overcurrent event must last to signal a

) and the power-on reset interval (t

START

), a start cycle is initiated if ON is asserted while capacitor

begins to charge again. When the voltage at

POR

defaults to 20µs.

START

POR

). When

M0235-121903 2 January 2004

MIC2085/2086 Micrel

Pin Description (Cont.)

Pin Number Pin Number Pin Name Pin Function

MIC2086 MIC2085

4 4 ON ON Input: Active high. The ON pin, an input to a Schmitt-triggered compara-

tor used to enable/disable the controller, is compared to a VTH reference

with 100mV of hysteresis. Once a logic high is applied to the ON pin

> 1.24V), a start-up sequence is initiated as the GATE pin starts

(V

ON

ramping up towards its final operating voltage. When the ON pin receives a

low logic signal (V

high if VCC is above the UVLO threshold. ON must be low for at least 20µs

in order to initiate a start-up sequence. Additionally, toggling the ON pin

LOW to HIGH resets the circuit breaker.

5 5 /POR Power-On Reset Output: Open drain N-Channel device, active low. This pin

remains asserted during start-up until a time period t

voltage rises above the power-good threshold (V

C

determines t

POR

at the FB pin, /POR is asserted for a minimum of one timing cycle, t

/POR pin has a weak pull-up to VCC.

6 N/A PWRGD Power-Good Output: Open drain N-Channel device, active high. When the

voltage at the FB pin is lower than 1.24V, the PWRGD output is held low.

When the voltage at the FB pin is higher than 1.24V, then PWRGD is

asserted. A pull-up resistor connected to this pin and to VCC will pull the

output up to VCC. The PWRGD pin has a weak pull-up to VCC.

7 6 /FAULT Circuit Breaker Fault Status Output: Open drain N-Channel device, active

low. The /FAULT pin is asserted when the circuit breaker trips due to an

overcurrent condition. Also, this pin indicates undervoltage lockout and

overvoltage fault conditions. The /FAULT pin has a weak pull-up to VCC.

8 7 FB Power-Good Threshold Input: This input is internally compared to a 1.24V

reference with 3mV of hysteresis. An external resistive divider may be used

to set the voltage at this pin. If this input momentarily goes below 1.24V,

then /POR is activated for one timing cycle, t

undervoltage condition. The /POR signal de-asserts one timing cycle after

the FB pin exceeds the power-good threshold by 3mV. A 5µs filter on this pin

prevents glitches from inadvertently activating this signal.

9,10 8 GND Ground Connection: Tie to analog ground.

11 9 OV OV Input: When the voltage on OV exceeds its trip threshold, the GATE pin

is pulled low and the CRWBR timer starts. If OV remains above its threshold

long enough for CRWBR to reach its trip threshold, the circuit breaker is

tripped. Otherwise, the GATE pin begins to ramp up one POR timing cycle

after OV drops below its trip threshold.

12 10 COMPOUT Uncommitted Comparator’s Open Drain Output.

13 11 COMP+ Comparator’s Non-Inverting Input.

14 12 COMP- Comparator’s Inverting Input.

15 NA DIS Discharge Output: When the MIC2086 is turned off, a 550Ω internal resistor

at this output allows the discharging of any load capacitance to ground.

16 13 REF Reference Output: 1.24V nominal. Tie a 0.1µF capacitor to ground to ensure

stability.

17 14 GATE Gate Drive Output: Connects to the gate of an external N-Channel

MOSFET. An internal clamp ensures that no more than 13V is applied

between the GATE pin and the source of the external MOSFET. The GATE

pin is immediately brought low when either the circuit breaker trips or an

undervoltage lockout condition occurs.

< 1.14V), the GATE pin is grounded and /FAULT is

ON

after the FB pin

POR

). The timing capacitor

. When an output undervoltage condition is detected

POR

FB

, indicating an output

POR

POR

. The

January 2004 3 M0235-121903

MIC2085/2086 Micrel

Pin Description (Cont.)

Pin Number Pin Number Pin Name Pin Function

MIC2086 MIC2085

18 15 SENSE Circuit Breaker Sense Input: A resistor between this pin and VCC sets the

current limit threshold. Whenever the voltage across the sense resistor

exceeds the slow trip current limit threshold (V

is adjusted to ensure a constant load current. If V

exceeded for longer than time period t

OCSLOW

TRIPSLOW

, then the circuit breaker is

tripped and the GATE pin is immediately pulled low. If the voltage across the

sense resistor exceeds the fast trip circuit breaker threshold, V

any point due to fast, high amplitude power supply faults, then the GATE pin

is immediately brought low without delay. To disable the circuit breaker, the

SENSE and VCC pins can be tied together.

The default V

TRIPFAST

are available: 150mV, 200mV, or OFF(V

factory for availability of other options.

for either device is 95mV. Other fast trip thresholds

TRIPFAST

19,20 16 VCC Positive Supply Input: 2.3V to 16.5V. The GATE pin is held low by an

internal undervoltage lockout circuit until VCC exceeds a threshold of 2.18V.

If VCC exceeds 16.5V, an internal shunt regulator protects the chip from

VCC and SENSE pin voltages up to 33V.

), the GATE voltage

TRIPSLOW

(48mV) is

TRIPFAST

, at

disabled). Please contact

M0235-121903 4 January 2004

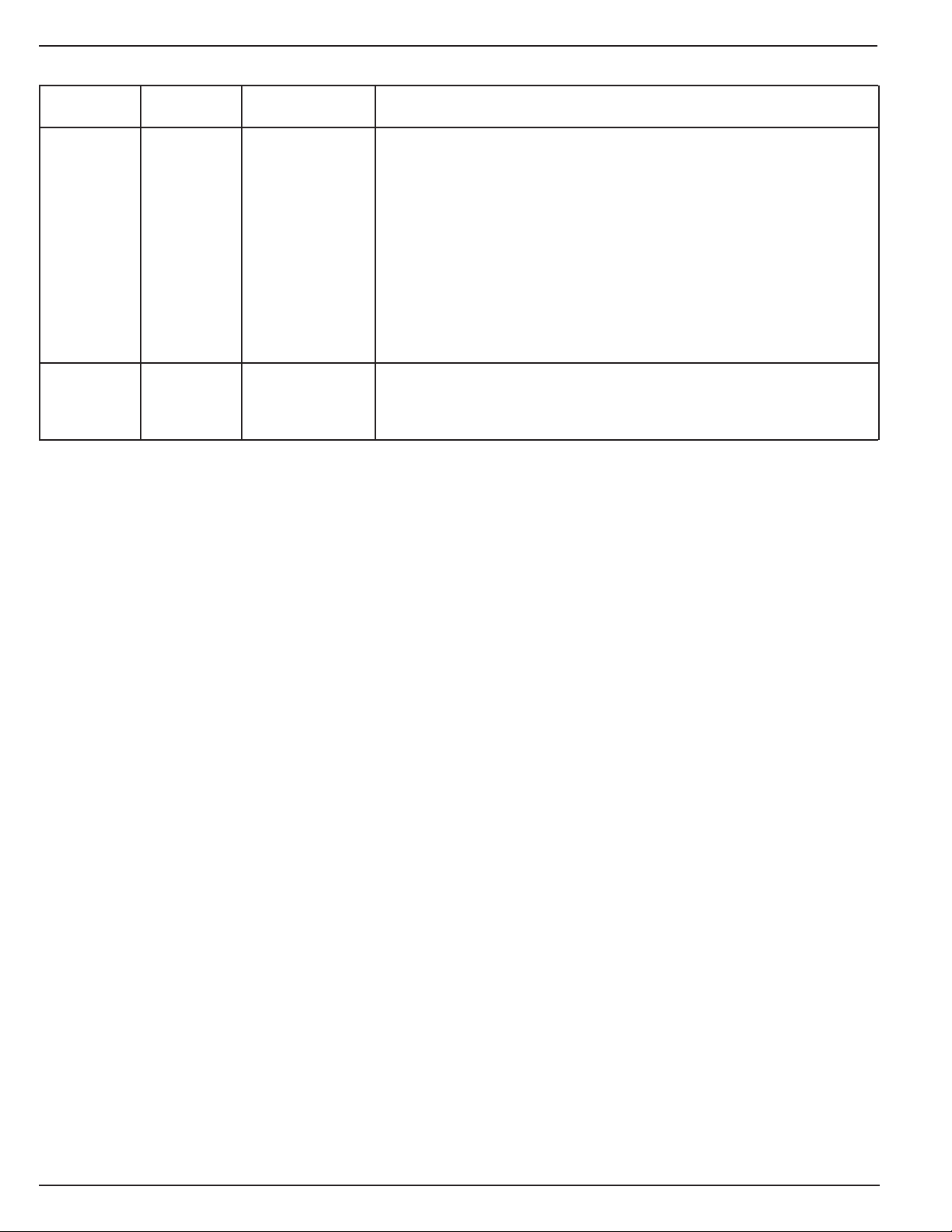

MIC2085/2086 Micrel

Absolute Maximum Ratings

(1)

(All voltages are referred to GND)

Supply Voltage (VCC) ..................................... –0.3V to 33V

SENSE Pin..........................................–0.3V to VCC + 0.3V

GATE Pin ....................................................... –0.3V to 22V

ON, DIS, /POR, PWRGD, /FAULT,

COMP+, COMP–, COMPOUT ....................... –0.3V to 20V

CRWBR, FB, OV, REF..................................... –0.3V to 6V

Maximum Currents

Digital Output Pins .....................................................10mA

(/POR, /FAULT, PWRGD, COMPOUT)

DIS Pin .......................................................................30mA

ESD Rating:

Human Body Model...................................................2kV

Machine Model........................................................200V

Operating Ratings

Supply Voltage (VCC) .................................... 2.3V to 16.5V

Operating Temperature Range .................. –40°C to +85°C

Junction Temperature (TJ) ........................................ 125°C

Package Thermal Resistance R

16-pin QSOP.....................................................112°C/W

20-pin QSOP.......................................................91°C/W

(2)

θ(J-A)

Electrical Characteristics

(3)

VCC = 5.0V, TA = 25°C unless otherwise noted. Bold indicates specifications over the full operating temperature range of –40°C to +85°C.

Symbol Parameter Condition Min Typ Max Units

V

CC

I

CC

V

UV

V

UVHYST

V

FB

V

FBHYST

V

OV

∆V

OV

V

OVHYST

I

OV

V

TH

I

CPOR

Supply Voltage 2.3 16.5 V

Supply Current 1.6 2.5 mA

Undervoltage Lockout Threshold VCC rising 2.05 2.18 2.28 V

VCC falling 1.85 2.0 2.10 V

UV Lockout Hysteresis 180 mV

FB (Power-Good) Threshold Voltage FB rising 1.19 1.24 1.29 V

FB Hysteresis 3mV

OV Pin Threshold Voltage OV pin rising 1.19 1.24 1.29 mV

OV Pin Threshold Voltage 2.3V < VCC < 16.5V 5 15 mV

Line Regulation

OV Pin Hysteresis 3mV

OV Pin Current 0.2 µA

POR Delay and Overcurrent (CFILTER) V

Timer Threshold

CPOR

, V

CFILTER

rising 1.19 1.24 1.29 V

Power-On Reset Timer Current Timer on –2.5 –2.0 –1.5 µA

Timer off 5 mA

I

TIMER

Current Limit /Overcurrent Timer on –30 –20 –15 µA

Timer Current (CFILTER) Timer off 2.5 mA

V

∆V

I

CR

V

CR

CR

TRIP

CRWBR Pin Threshold Voltage 2.3V < VCC < 16.5V 445 470 495 mV

CRWBR Pin Threshold Voltage 2.3V < VCC < 16.5V 4 15 mV

Line Regulation

CRWBR Pin Current CRWBR On, V

CRWBR On, V

CRWBR Off, V

Circuit Breaker Trip Voltage V

(Current Limit Threshold) 2.3V ≤ V

TRIP

= VCC –V

≤ 16.5V V

CC

= 0V –60 –45 –30 µA

CRWBR

= 2.1V –1.5 –1.0 mA

CRWBR

= 1.5V 3.3 mA

CRWBR

SENSE

V

TRIPSLOW

TRIPFAST

x = K 150 mV

x = J 80 95 110 mV

40 48 55 mV

x = L 200 mV

V

GS

External Gate Drive V

GATE

– V

CC

VCC < 3V 4 8 9 V

5V < VCC < 9V 11 12 13 V

9V < VCC < 15.0V 4.5 21–V

CC

13 V

January 2004 5 M0235-121903

MIC2085/2086 Micrel

Electrical Characteristics (Cont.)

Symbol Parameter Condition Min Typ Max Units

I

GATE

I

GATEOFF

V

ON

V

ONHYST

I

ON

V

START

V

OL

I

PULLUP

V

REF

∆V

LNR

∆V

LDR

I

RSC

V

COS

V

CHYST

R

DIS

GATE Pin Pull-up Current Start cycle, V

=16.5V –22 –16 –8 µA

V

CC

GATE

= 0V

VCC = 2.3V –20 –14 –8 µA

GATE Pin Sink Current /FAULT = 0, V

V

= 16.5V 25 50 mA

CC

GATE

>1V

VCC = 2.3V 12 20 mA

ON Pin Threshold Voltage ON rising 1.19 1.24 1.29 V

ON falling 1.09 1.14 1.19 V

ON Pin Hysteresis 100 mV

ON Pin Input Current VON = V

Undervoltage Start-up V

Timer Threshold

/FAULT, /POR, PWRGD Output I

Voltage (PWRGD for MIC2086 only)

OUT

CC

rising 1.19 1.24 1.29 V

CPOR

= 1.6mA 0.4 V

0.5 µA

Output Signal Pull-up Current /FAULT, /POR, PWRGD = GND –20 µA

/FAULT, /POR, PWRGD, COMPOUT (PWRGD for MIC2086 only)

Reference Output Voltage I

LOAD

= 0mA; C

= 0.1µF 1.21 1.24 1.27 V

REF

Reference Line Regulation 2.3V < VCC < 16.5V 5 10 mV

Reference Load Regulation I

Reference Short-Circuit Current V

Comparator Offset Voltage VCM = V

Comparator Hysteresis VCM = V

= 1mA 2.5 7.5 mV

OUT

= 0V 3.5 mA

REF

REF

REF

–5 5 mV

3mV

Discharge Pin Resistance ON pin toggles from HI to LOW 100 550 1000 Ω

AC Electrical Characteristics

(4)

Symbol Parameter Condition Min Typ Max Units

t

OCFAST

t

OCSLOW

t

ONDLY

t

FBDLY

Notes:

1. Exceeding the absolute maximum rating may damage the device.

2. The device is not guaranteed to function outside its operating rating.

3. Specification for packaged product only.

4. Specification for packaged product only.

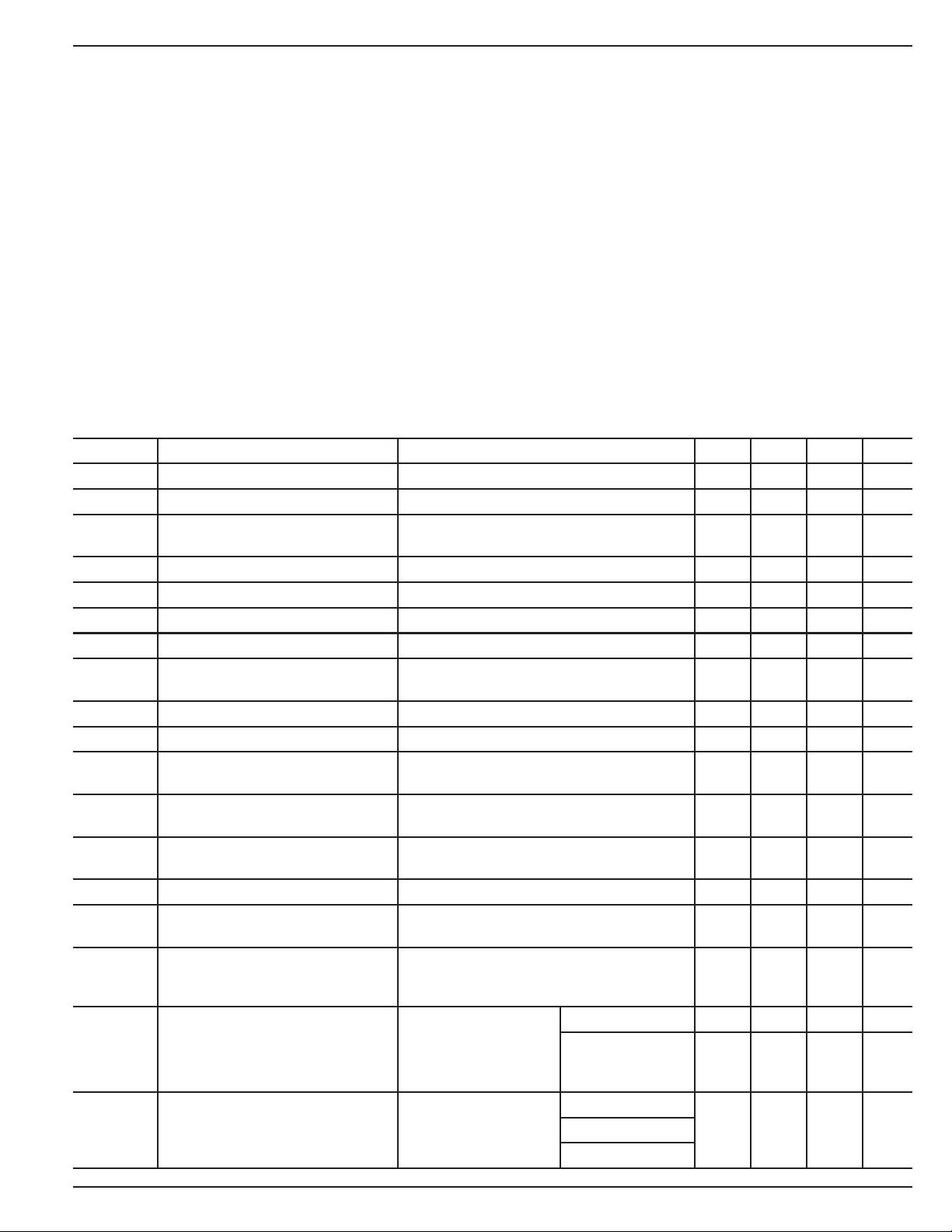

Fast Overcurrent Sense to GATE VCC = 5V 1 µs

Low Trip Time V

C

–V

CC

GATE

= 100mV

SENSE

= 10nF, See Figure 1

Slow Overcurrent Sense to Gate VCC = 5V 5 µs

Low Trip Time V

CC

C

FILTER

–V

= 50mV

SENSE

= 0, See Figure 1

ON Delay Filter 20 µs

FB Delay Filter 20 µs

M0235-121903 6 January 2004

MIC2085/2086 Micrel

1V

48mV

V

GATE

t

OCSLOW

V

TRIPFAST

(VCCÐV

SENSE

)

t

OCFAST

1V

0

CFILTER

0

0

1.24V

Timing Diagrams

Figure 1. Current Limit Response

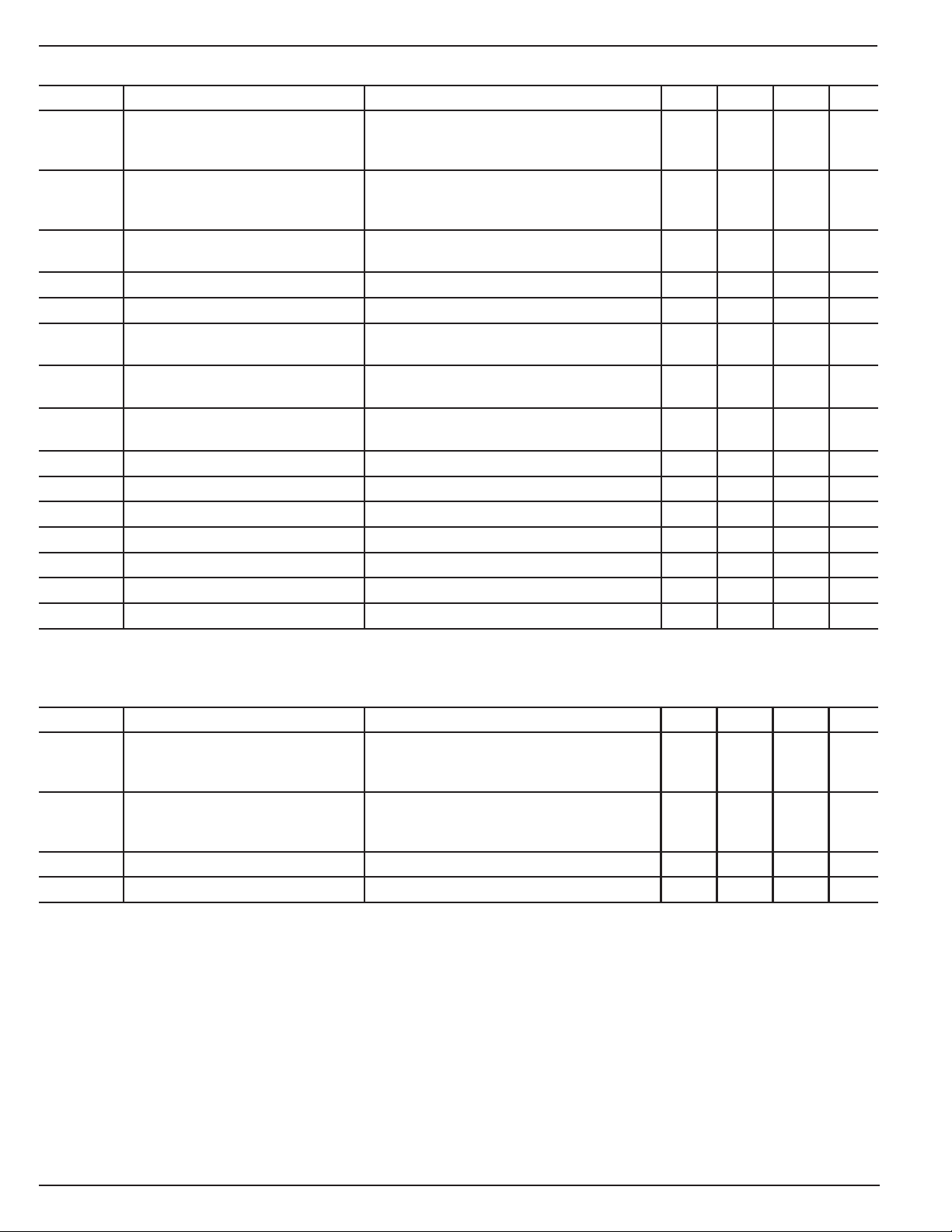

ON

CPOR

GATE

FB

FB

CPOR

/POR

0

0

0

1.24V

t

POR

Figure 2. Power-On Reset Response

t

ONDLY

1.24V

0

1.24V

0

0

0

Arm Fast Comparator

t

START

1.24V

Arm Slow Comparator

t

POR

1.24V

/POR

0

Figure 3. Power-On Start-Up Delay Timing

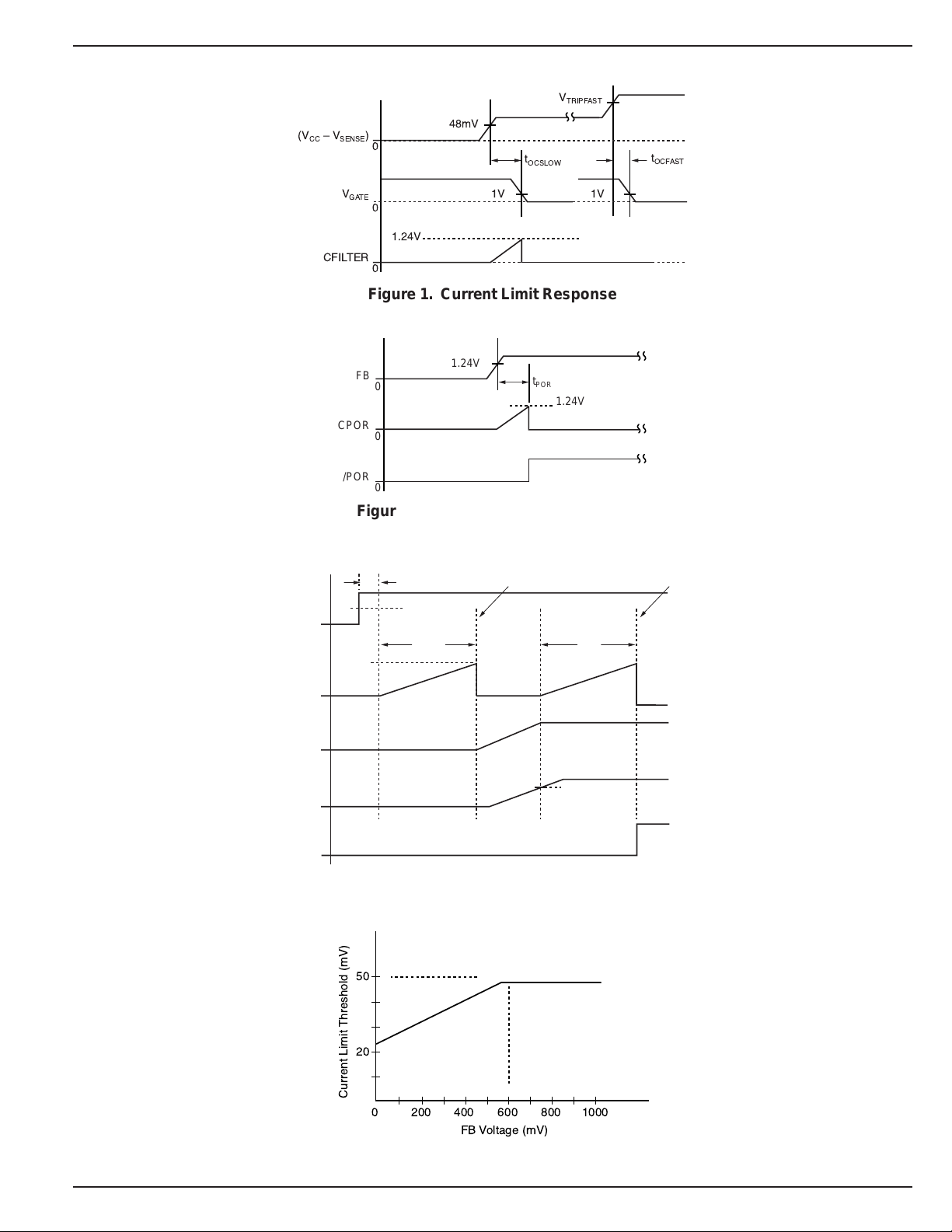

50

January 2004 7 M0235-121903

20

Current Limit Threshold (mV)

0

600 800 1000

400200

FB Voltage (mV)

Figure 4. Foldback Current Limit Response

MIC2085/2086 Micrel

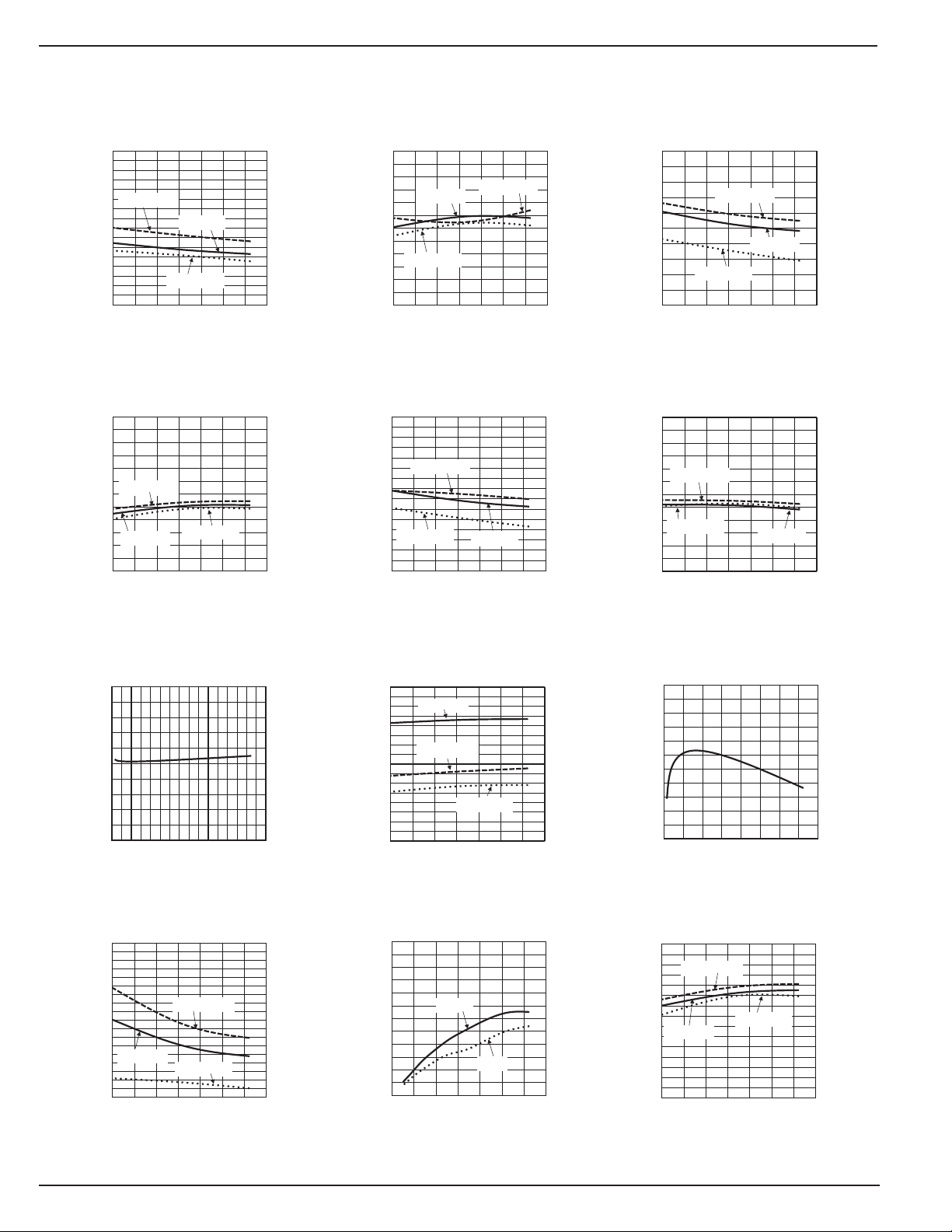

g

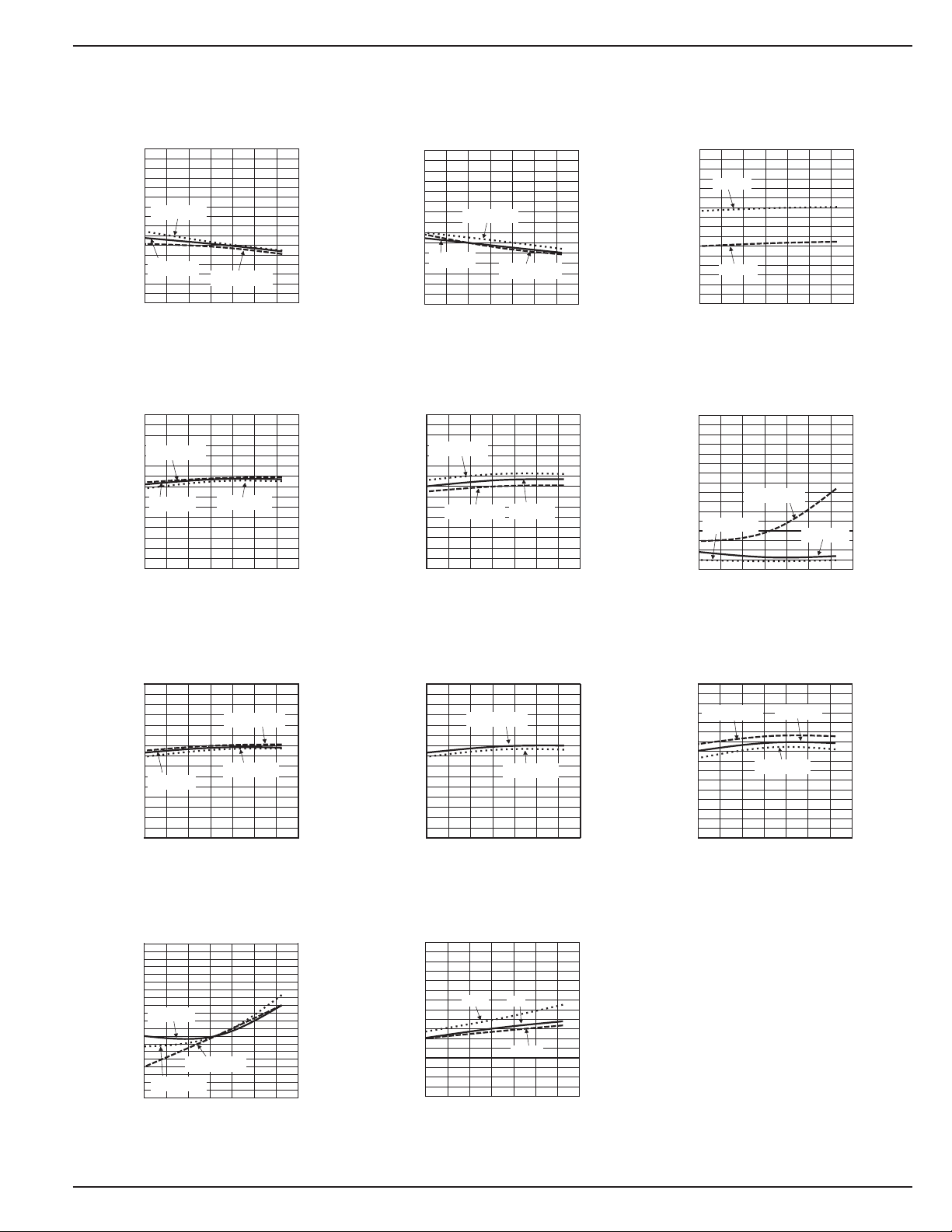

Typical Characteristics

Supply Current

4.0

vs. Temperature

3.5

3.0

V

= 16.5V

CC

2.5

2.0

VCC= 5V

1.5

1.0

SUPPLY CURRENT (mA)

0.5

0.0

-40 -20 0 20 40 60 80 100

Overcurrent Timer Current

34

VCC= 2.3V

TEMPERATURE (°C)

vs. Temperature

30

26

(µA)

VCC= 16.5V

22

TIMER

I

18

VCC= 5V

14

10

-40 -20 0 20 40 60 80 100

VCC= 2.3V

TEMPERATURE (°C)

Power-On Reset Timer Current

vs. Temperature

2.6

(µA)

CPOR

I

2.4

2.2

2.0

1.8

VCC= 5V

VCC= 2.3V

VCC= 16.5V

1.6

1.4

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

Overcurrent Timer (Off) Current

vs. Temperature

5

4

VCC= 16.5V

3

(mA)

2

TIMER

I

VCC= 2.3V

1

0

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

VCC= 5V

Power-On Reset Timer (Off) Current

10

vs. Temperature

9

(mA)

I

CPOR

8

7

6

5

4

3

2

VCC= 16.5V

VCC= 5V

VCC= 2.3V

1

0

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

Gate Pull-Up Current

vs. Temperature

30

25

20

VCC= 16.5V

(µA)

15

GATE

I

10

VCC= 2.3V

5

0

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

VCC= 5V

Gate Pull-Up Current

vs. V

25

20

15

(A)

10

GATE

I

5

0

2 4 6 8 10 12 14 16 18

Gate Sink Current

100

vs. Temperature

CC

(V)

V

CC

90

80

(mA)

70

60

VCC= 16.5V

50

GATEOFF

40

I

VCC= 5V

30

VCC= 2.3V

20

10

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

External Gate Drive

vs. Temperature

16

VCC= 5V

14

12

10

8

6

4

VCC= 16.5V

VCC= 2.3V

(V)

GS

V

2

0

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

Gate Sink Current

600

vs. Gate Volta

500

400

(mA)

300

GATEOFF

200

I

100

0

02468101214

12V

V

CC

GATE

5V

CC

(V)

External Gate Drive

vs. V

22

20

18

16

14

(V)

12

GS

10

V

8

6

4

2

0

2 4 6 8 10 12 14 16 18

POR Delay/Overcurrent

e

(mV)

V

TH

1.25

1.24

1.23

1.22

1.21

1.20

Timer Threshold

vs. Temperature

VCC= 16.5V

VCC= 5V

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

CC

(V)

V

CC

VCC= 2.3V

M0235-121903 8 January 2004

MIC2085/2086 Micrel

1.7

1.8

1.9

2.0

2.1

2.2

2.3

2.4

2.5

-40 -20 0 20 40 60 80 100

UVLO THRESHOLD (V)

TEMPERATURE (°C)

10

14

18

22

26

-40 -20 0 20 40 60 80 100

I

PULLUP

(µA)

TEMPERATURE (°C)

Output Signal Pull-Up Current

vs. Temperature

VCC= 16.5V

VCC= 2.3V

VCC= 5V

Typical Characteristics

Current Limit Threshold

(Fast Trip)

120

115

110

105

(mV)

100

TRIPFAST

V

1.30

1.25

1.20

ON THRESHOLD (V)

1.15

vs. Temperature

VCC= 2.3V

95

90

VCC= 5V

85

80

-40 -20 0 20 40 60 80 100

ON Pin Threshold (Rising)

VCC= 16.5V

VCC= 5V

-40 -20 0 20 40 60 80 100

VCC= 16.5V

TEMPERATURE (°C)

vs. Temperature

VCC= 2.3V

TEMPERATURE (°C)

Current Limit Threshold

(Slow Trip)

vs. Temperature

55

53

(mV)

51

49

TRIPSLOW

V

47

45

-40 -20 0 20 40 60 80 100

1.20

1.15

1.10

ON THRESHOLD (V)

1.05

VCC= 2.3V

VCC= 5V

TEMPERATURE (°C)

ON Pin Threshold (Falling)

vs. Temperature

VCC= 2.3V

VCC= 16.5V

-40 -20 0 20 40 60 80 100

VCC= 16.5V

VCC= 5V

TEMPERATURE (°C)

UVLO Threshold

vs. Temperature

UVLO+

UVLO–

ON Pin Input Current

vs. Temperature

40

35

30

25

20

15

10

5

ON PIN INPUT CURRENT (nA)

0

-40 -20 0 20 40 60 80 100

VCC= 16.5V

VCC= 2.3V

TEMPERATURE (°C)

VCC= 5V

FB (Power-Good) Threshold

1.30

1.25

1.20

FB THRESHOLD (V)

1.15

-40 -20 0 20 40 60 80 100

Comparator Offset Voltage

0.5

0.4

0.3

January 2004 9 M0235-121903

0.2

0.1

0.0

-40 -20 0 20 40 60 80 100

COMPARATOR OFFSET VOLTAGE (V)

vs. Temperature

VCC= 5V

TEMPERATURE (°C)

vs. Temperature

VCC= 5V

VCC= 16.5V

VCC= 2.3V

TEMPERATURE (°C)

VCC= 16.5V

VCC= 2.3V

Overvoltage Pin Threshold

1.30

1.25

1.20

1.15

OVERVOLTAGE PIN THRESHOLD (V)

1000

900

800

700

(Ω)

600

DIS

500

R

400

300

200

vs. Temperature

VCC= 16.5V

VCC= 2.3V

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

Discharge Pin Resistance

vs. Temperature

2.3V

5V

16.5V

-40 -20 0 20 40 60 80 100

TEMPERATURE (°C)

MIC2085/2086 Micrel

Test Circuit

V

12V

R

I

IN

IN

C1

0.47mF

R2

154k

W

1%

R3

20k

1%

4

ON

W

SW1

ON/OFF

SENSE

0.01

W

5%

12

34

19,20 18

VCC

SENSE

MIC2086

Si7892DP

(PowerPAK

17

GATE

8

FB

5

/POR

Q1

TM

SO-8)

R1

10

W

C2

0.022mF

Downstream

Signal

R4

97.6k

1%

R5

12.4k

1%

I

OUT

V

OUT

R

LOAD

C

LOAD

W

W

Not all pins shown for clarity.

C3

0.047mF

GNDCPOR CFILTER

9,10 23

DIS

C4

0.047mF

15

SW2

DIS

R6

4.4k

W

C5

0.033mF

R7

1.5k

W

Q2

ZTX788A

R8

330

W

Q3

TCR22-4

M0235-121903 10 January 2004

MIC2085/2086 Micrel

Functional Characteristics

CC

V

ON

C

OUT

I

IN =

I

CC

V

/FAULT

V

POR

OUT

5V/div

1V/div

1V/div

1A/div

5V/div

10V/div

10V/div

12V Hot Insert Response

C

TIME (20ms/div.)

Inrush Current Response

C

R

LOAD =

LOAD =

R

LOAD =

LOAD =

V

IN =

1000µF

V

IN =

5700µF

12V

4.8Ω

12V

3.4Ω

ON

POR

C

OUT

V

/POR

ON

OUT

V

FB

1V/div

1V/div

5V/div

10V/div

1V/div

5V/div

1V/div

12V Turn On Response

TIME (20ms/div.)

Power-Good Response

C

LOAD =

C

R

LOAD =

R

LOAD =

LOAD =

V

IN =

1000µF

V

IN =

1000µF

12V

4.8Ω

12V

4.8Ω

IN

I

ON

GATE

= I

I

V

OUT

IN

OUT

1A/div

1V/div

20V/div

2A/div

5V/div

TIME (10ms/div.)

Turn Off — Normal Discharge

V

(External) = 0

R

DIS

R

LOAD =

C

LOAD =

SW2 = HIGH

TIME (2.5ms/div.)

12V

IN =

4.8Ω

1000µF

PG

ON

GATE

= I

I

V

OUT

IN

OUT

10V/div

1V/div

20V/div

2A/div

5V/div

TIME (10ms/div.)

Turn Off — Crowbar Discharge

V

R

LOAD =

C

LOAD =

SW2 = LOW

TIME (2.5ms/div.)

12V

IN =

4.8Ω

1000µF

January 2004 11 M0235-121903

MIC2085/2086 Micrel

Functional Characteristics (continued)

Turn On Into Short Circuit

ON

1V/div

1V/div

CFILTER

/FAULT

V

OUT

10V/div

5V/div

C

LOAD =

V

IN =

R

LOAD =

1000µF

12V

0

TIME (10ms/div.)

M0235-121903 12 January 2004

MIC2085/2086 Micrel

Functional Block Diagram

MIC2086

SENSE

VCC

CFILTER

GND

FB

CPOR

18 (15)

19,20 (16)

2 (2)

9,10 (8)

8 (7)

3 (3)

20mA

20mA

20mA

17 (14)

16 (13)

12 (10)

13 (11)

14 (12)

7 (6)

5 (5)

15

6

GATE

REF

COMPOUT

COMP+

COMPÐ

DIS*

/FAULT

/POR

PWRGD*

Charge

Pump

48mV

+

Ð

13V

1.24V

+

Ð

95mV

V

REG1

V

CC1

20mA

CC1

UVLO

2.2V

Circuit Breaker

Response

or

UVLO

REG2

+

Ð

21V

550

W

V

CC1

V

CC1

+

1.24V

1.24V

Ð

+

Glitch

Ð

Filter

Logic

V

CC1

1.5mA

V

CC1

V

CC1

45mA

V

CC1

2.5mA

1.24V

+

Ð

+

Ð

0.45V

1 (1)

CRWBR

ON

4 (4)

1.24V

*DIS and PWRGD are not available on MIC2085.

Pin numbers for MIC2085 are in parenthesis ( ) where applicable.

+

Glitch

Ð

Filter

Glitch

Filter

+

Ð

1.24V

11 (9)

OV

MIC2086 Block Diagram

January 2004 13 M0235-121903

MIC2085/2086 Micrel

Functional Description

Hot Swap Insertion

When circuit boards are inserted into live system backplanes

and supply voltages, high inrush currents can result due to

the charging of bulk capacitance that resides across the

supply pins of the circuit board. This inrush current, although

transient in nature, may be high enough to cause permanent

damage to on-board components or may cause the system’s

supply voltages to go out of regulation during the transient

period which may result in system failures. The MIC2085/86

acts as a controller for external N-Channel MOSFET devices

in which the gate drive is controlled to provide inrush current

limiting and output voltage slew rate control during hot plug

insertions.

Power Supply

VCC is the supply input to the MIC2085/86 controller with a

voltage range of 2.3V to 16.5V. The VCC input can withstand

transient spikes up to 33V. In order to help suppress transients and ensure stability of the supply voltage, a capacitor

of 1.0µF to 10µF from VCC to ground is recommended.

Alternatively, a low pass filter, shown in the typical application

circuit, can be used to eliminate high frequency oscillations as

well as help suppress transient spikes.

Start-Up Cycle

When the voltage on the ON pin rises above its threshold of

1.24V, the MIC2085/86 first checks that its supply (VCC) is

above the UVLO threshold. If so, the device is enabled and

an internal 2µA current source begins charging capacitor

C

to 1.24V to initiate a start-up sequence (i.e., start-up

POR

delay times out). Once the start-up delay (t

CPOR is pulled immediately to ground and a 15µA current

source begins charging the GATE output to drive the external

MOSFET that switches VIN to V

. The programmed start-

OUT

up delay is calculated using the following equation:

V

tC

START POR

=× ≅× µ

TH

I

CPOR

0.62 C ( F)

POR

where VTH, the POR delay threshold, is 1.24V, and I

the POR timer current, is 2µA. As the GATE voltage continues ramping toward its final value (VCC + VGS) at a defined

slew rate (See

nated Start-Up”

“Load Capacitance”/“Gate Capacitance Domi-

sections), a second CPOR timing cycle

begins if: 1)/FAULT is high and 2)CFILTER is low (i.e., not

an overvoltage, undervoltage lockout, or overcurrent state).

This second timing cycle, t

, starts when the voltage at the

POR

FB pin exceeds its threshold (VFB) indicating that the output

voltage is valid. The time period t

is equivalent to t

POR

and sets the interval for the /POR to go Low-to-High after

“power is good” (See Figure 2 of

“Timing Diagrams”

current regulation is employed to limit the inrush current

transient response during start-up by regulating the load

current at the programmed current limit value (See

Limiting and Dual-Level Circuit Breaker”

section). The following equation is used to determine the nominal current

limit value:

V

I

LIM

TRIPSLOW

==

R

SENSE SENSE

48mV

R

START

) elapses,

(1)

CPOR

START

). Active

“Current

(2)

where V

TRIPSLOW

in the electrical table and R

is the current limit slow trip threshold found

is the selected value that

SENSE

will set the desired current limit. There are two basic start-up

modes for the MIC2085/86: 1)Start-up dominated by load

capacitance and 2)start-up dominated by total gate capacitance. The magnitude of the inrush current delivered to the

load will determine the dominant mode. If the inrush current

is greater than the programmed current limit (I

LIM

capacitance is dominant. Otherwise, gate capacitance is

dominant. The expected inrush current may be calculated

using the following equation:

C

LOAD

C

GATE

GATE

15 A

is the total GATE capacitance

where I

INRUSH I

GATE

≅× ≅µ×

GATE

is the GATE pin pull-up current, C

load capacitance, and C

(C

of the external MOSFET and any external capacitor

ISS

C

C

LOAD

GATE

connected from the MIC2085/86 GATE pin to ground).

Load Capacitance Dominated Start-Up

In this case, the load capacitance, C

, is large enough to

LOAD

cause the inrush current to exceed the programmed current

limit but is less than the fast-trip threshold (or the fast-trip

threshold is disabled, ‘M’ option). During start-up under this

condition, the load current is regulated at the programmed

current limit value (I

) and held constant until the output

LIM

voltage rises to its final value. The output slew rate and

equivalent GATE voltage slew rate is computed by the

following equation:

I

Output Voltage Slew Rate, dV /dt

where I

quently, the value of C

is the programmed current limit value. Conse-

LIM

must be selected to ensure that

FILTER

the overcurrent response time, t

OUT

OCSLOW

LIM

=

C

LOAD

, exceeds the time

needed for the output to reach its final value. For example,

given a MOSFET with an input capacitance C

4700pF, C

is 2200µF, and I

LOAD

is set to 6A with a 12V

LIMIT

ISS

input, then the load capacitance dominates as determined by

the calculated INRUSH > I

,

. Therefore, the output voltage

LIM

slew rate determined from Equation 4 is:

Output Voltage Slew Rate, dV /dt

and the resulting t

OCSLOW

approximately 4.5ms. (See

Overcurrent Timer Delays”

GATE Capacitance Dominated Start-Up

OUT

needed to achieve a 12V output is

“Power-On Reset, Start-Up, and

section to calculate t

=

2200 F

6A

µ

In this case, the value of the load capacitance relative to the

GATE capacitance is small enough such that the load current

during start-up never exceeds the current limit threshold as

determined by Equation 3. The minimum value of C

will ensure that the current limit is never exceeded is given by

the equation below:

I

C (min)

GATE

GATE

=×

I

LIM

C

LOAD

), then load

(3)

is the

LOAD

(4)

= C

GATE

V

2.73

=

ms

GATE

.)

that

OCSLOW

(5)

=

M0235-121903 14 January 2004

MIC2085/2086 Micrel

where C

capacitance (C

connected to the GATE pin of the MOSFET. Once C

is the summation of the MOSFET input

GATE

) and the value of the external capacitor

ISS

GATE

is

determined, use the following equation to determine

the output slew rate for gate capacitance dominated start-up.

I

dV /dt (output)

OUT

Table 1 depicts the output slew rate for various values of C

I

GATE

C

GATE

0.001µF 15V/ms

0.01µF 1.5V/ms

0.1µF 0.150V/ms

1µF 0.015V/ms

GATE

=

C

GATE

= 15µA

dV

OUT

(6)

GATE

/dt

Table 1. Output Slew Rate Selection for GATE

Capacitance Dominated Start-Up

Current Limiting and Dual-Level Circuit Breaker

Many applications will require that the inrush and steady state

supply current be limited at a specific value in order to protect

critical components within the system. Connecting a sense

resistor between the VCC and SENSE pins sets the nominal

current limit value of the MIC2085/86 and the current limit is

calculated using Equation 2. However, the MIC2085/86 exhibits foldback current limit response. The foldback feature

allows the nominal current limit threshold to vary from 24mV

up to 48mV as the FB pin voltage increases or decreases.

When FB is at 0V, the current limit threshold is 24mV and for

FB ≥ 0.6V, the current limit threshold is the nominal 48mV.

(See Figure 4 for Foldback Current Limit Response characteristic).

The MIC2085/86 also features a dual-level circuit breaker

triggered via 48mV and 95mV current limit thresholds sensed

across the VCC and SENSE pins. The first level of the circuit

breaker functions as follows. Once the voltage sensed across

these two pins exceeds 48mV, the overcurrent timer, its

duration set by capacitor C

, starts to ramp the voltage

FILTER

at CFILTER using a 2µA constant current source. If the

voltage at CFILTER reaches the overcurrent timer threshold

(VTH) of 1.24V, then CFILTER immediately returns to ground

as the circuit breaker trips and the GATE output is immediately shut down. For the second level, if the voltage sensed

across VCC and SENSE exceeds 95mV at any time, the

circuit breaker trips and the GATE shuts down immediately,

bypassing the overcurrent timer period. To disable current

limit and circuit breaker operation, tie the SENSE and VCC

pins together and the CFILTER pin to ground.

Output Undervoltage Detection

The MIC2085/86 employ output undervoltage detection by

monitoring the output voltage through a resistive divider

connected at the FB pin. During turn on, while the voltage at

the FB pin is below the threshold (VFB), the /POR pin is

asserted low. Once the FB pin voltage crosses VFB, a 2µA

current source charges capacitor C

voltage reaches 1.24V, the time period t

CPOR pin is pulled to ground and the /POR pin goes HIGH.

.

If the voltage at FB drops below VFB for more than 10µs, the

. Once the CPOR pin

POR

elapses as the

POR

/POR pin resets for at least one timing cycle defined by t

(see Applications Information for an example).

Input Overvoltage Protection

The MIC2085/86 monitors and detects overvoltage conditions in the event of excessive supply transients at the input.

Whenever the overvoltage threshold (VOV) is exceeded at

the OV pin, the GATE is pulled low and the output is shut off.

The GATE will begin ramping one POR timing cycle after the

OV pin voltage drops below its threshold. An external CRWBR

circuit, as shown in the typical application diagram, provides

a time period that an overvoltage condition must exceed in

order to trip the circuit breaker. When the OV pin exceeds the

overvoltage threshold (VOV), the CRWBR timer begins charging the CRWBR capacitor initially with a 45µA current source.

Once the voltage at CRWBR exceeds its threshold (VCR) of

0.47V, the CRWBR current immediately increases to 1.5mA

and the circuit breaker is tripped, necessitating a device reset

by toggling the ON pin LOW to HIGH.

Power-On Reset, Start-Up, and Overcurrent Timer

Delays

The Power-On Reset delay, t

, is the time period for the

POR

/POR pin to go HIGH once the voltage at the FB pin exceeds

the power-good threshold (VTH). A capacitor connected to

CPOR sets the interval, t

start-up delay, t

(see Equation 1).

START

POR

, and t

is equivalent to the

POR

A capacitor connected to CFILTER is used to set the timer

which activates the circuit breaker during overcurrent conditions. When the voltage across the sense resistor exceeds

the slow trip current limit threshold of 48mV, the overcurrent

timer begins to charge for a period, t

C

defaults to 5µs. If t

. If no capacitor is used at CFILTER, then t

FILTER

OCSLOW

elapses, then the circuit breaker

OCSLOW

, determined by

is activated and the GATE output is immediately pulled to

ground. The following equation is used to determine the

overcurrent timer period, t

tC

OCSLOW

=×≅×µ

FILTER

OCSLOW

V

I

TIMER

.

TH

0.062 C ( F)

FILTER

where VTH, the CFILTER timer threshold, is 1.24V and

I

, the overcurrent timer current, is 20µA. Tables 2 and

TIMER

3 provide a quick reference for several timer calculations

using select standard value capacitors.

POR

OCSLOW

(7)

January 2004 15 M0235-121903

MIC2085/2086 Micrel

C

POR

t

POR

= t

START

0.01µF 6ms

0.02µF 12ms

0.033µF 18.5ms

0.05µF 30ms

0.1µF 60ms

0.33µF 200ms

Table 2. Selected Power-On Reset and

Start-Up Delays

C

FILTER

t

OCSLOW

1800pF 100µs

4700pF 290µs

8200pF 500µs

0.010µF 620µs

0.020µF 1.2ms

0.033µF 2.0ms

0.050µF 3.0ms

0.1µF 6.2ms

0.33µF 20.75ms

Table 3. Selected Overcurrent Timer Delays

Applications Information

Output Undervoltage Detection

For output undervoltage detection, the first consideration is to

establish the output voltage level that indicates “power is

good.” For this example, the output value for which a 12V

supply will signal “good” is 11V. Next, consider the tolerances

of the input supply and FB threshold (VFB). For this example,

the 12V supply varies ±5%, thus the resulting output voltage

may be as low as 11.4V and as high as 12.6V. Additionally,

the FB threshold has ±50mV tolerance and may be as low as

1.19V and as high as 1.29V. Thus, to determine the values of

the resistive divider network (R5 and R6) at the FB pin, shown

in Figure 5, use the following iterative design procedure.

1) Choose R6 so as to limit the current through the

divider to approximately 100µA or less.

V

FB(MAX)

R6

≥

100 A

µ

R6 is chosen as 13.3kΩ ± 1%.

2) Next, determine R5 using the output “good”

voltage of 11V and the following equation:

VV

OUT(Good)

1.29V

≥

100 A

=

FB

≥Ω

µ

R5 R6

+

()

R6

12.9k

.

(8)

Using some basic algebra and simplifying Equation 8 to

isolate R5, yields:

–1

OUT(Good)

(8.1)

= 11V, and R6 is

R5 R6

where V

=

FB(MAX)

V

OUT(Good)

V

FB(MAX)

= 1.29V, V

13.3kΩ. Substituting these values into Equation 8.1 now

yields R5 = 100.11kΩ. A standard 100kΩ ± 1% is selected.

Now, consider the 11.4V minimum output voltage, the lower

tolerance for R6 and higher tolerance for R5, 13.17kΩ and

101kΩ, respectively. With only 11.4V available, the voltage

sensed at the FB pin exceeds V

FB(MAX)

, thus the /POR and

PWRGD (MIC2086) signals will transition from LOW to

HIGH, indicating “power is good” given the worse case

tolerances of this example.

Input Overvoltage Protection

The external CRWBR circuit shown in Figure 5 consists of

capacitor C4, resistor R7, NPN transistor Q2, and SCR Q3.

The capacitor establishes a time duration for an overvoltage

condition to last before the circuit breaker trips. The CRWBR

timer duration is approximated by the following equation:

t

OVCR

()

≅

I

CR

CR

≅×µ0

.01 C4( F)

(9)

C4 V

×

where VCR, the CRWBR pin threshold, is 0.47V and ICR, the

CRWBR pin current, is 45µA during the timer period (see the

CRWBR timer pin description for further description). A

similar design approach as the previous undervoltage detection example is recommended for the overvoltage protection

circuitry, resistors R2 and R3 in Figure 5. For input overvoltage protection, the first consideration is to establish the input

voltage level that indicates an overvoltage triggering a system (output voltage) shut down. For this example, the input

value for which a 12V supply will signal an “output shut down”

is 13.2V (+10%). Similarly, from the previous example:

1) Choose R3 to satisfy 100µA condition.

R3

≥

V

OV(MIN)

100 A

µ

1.19V

≥

100 A

≥Ω

11.9k

µ

.

R3 is chosen as 13.7kΩ ±1%.

2) Thus, following the previous example and

substituting R2 and R3 for R5 and R6, respectively, and 13.2V overvoltage for 11V output

“good”, the same formula yields R2 of 138.3kΩ.

The next highest standard 1% value is 140kΩ.

Now, consider the 12.6V maximum input voltage (V

CC

+5%),

the higher tolerance for R3 and lower tolerance for R2, 13.84k

and 138.60kΩ, respectively. With a 12.6V input, the voltage

sensed at the OV pin is below V

OV(MIN)

, and the MIC2085/86

will not indicate an overvoltage condition until VCC exceeds

at least 13.2V.

M0235-121903 16 January 2004

MIC2085/2086 Micrel

V

IN

12V

C1

1µF

4

9

C3

0.05µF

ON

OV

R2

140kΩ

1%

R3

13.7kΩ

1%

R1

100kΩ

Overvoltage (Input) = 13.3V

Undervoltage (Output) = 11.0V

POR/START-UP Delay = 30ms

*R7 needed when using a sensitive gate SCR.

Additional pins omitted for clarity.

R

SENSE

0.012Ω

2%

12

34

16 15

SENSEVCC

MIC2085

CPOR

GND

83

GATE

FB

/POR

/FAULT

CRWBR

IRF7822

14

7

5

6

1

C4

0.01µF

Q1

(SO-8)

0.033µF

R4

10Ω

C2

0.022µF

Downstream

Signals

C5

R5

100kΩ

1%

R6

13.3kΩ

1%

Q2

2N4401

*R7

180Ω

Q3

TCR22-4

C

LOAD

220µF

V

OUT

12V@3A

Figure 5. Undervoltage/Overvoltage Circuit

January 2004 17 M0235-121903

MIC2085/2086 Micrel

/

PCB Connection Sense

There are several configuration options for the MIC2085/86’s

ON pin to detect if the PCB has been fully seated in the

backplane before initiating a start-up cycle. In the typical

applications circuit, the MIC2085/86 is mounted on the PCB

with a resistive divider network connected to the ON pin. R2

is connected to a short pin on the PCB edge connector. Until

the connectors mate, the ON pin is held low which keeps the

GATE output charge pump off. Once the connectors mate,

the resistor network is pulled up to the input supply, 12V in this

example, and the ON pin voltage exceeds its threshold (VON)

of 1.24V and the MIC2085/86 initiates a start-up cycle. In

Figure 6, the connection sense consisting of a logic-level

discrete MOSFET and a few resistors allows for interrupt

control from the processor or other signal controller to shut off

the output of the MIC2085/86. R4 keeps the GATE of Q2 at

VIN until the connectors are fully mated. A logic LOW at the

/ON_OFF signal turns Q2 off and allows the ON pin to pull up

above its threshold and initiate a start-up cycle. Applying a

logic HIGH at the /ON_OFF signal will turn Q2 on and short

the ON pin of the MIC2085/86 to ground which turns off the

GATE output charge pump.

V

IN

12V

ON_OFF

GND

Backplane

Connector

PCB Edge

Connector

Short

Long

Pin

Pin

R4

10kΩ

R1

20kΩ

R3

100Ω

PCB Connection Sense

Long

Pin

Undervoltage (Output) = 11.4V

POR/START-UP DELAY = 30ms

*Q2 is TN0201T (SOT-23)

Additional pins omitted for clarity.

*Q2

R2

20kΩ

C1

1µF

R

SENSE

0.008Ω

2%

12

34

16 15

4

ON

CPOR

C2

0.05µF

SENSEVCC

MIC2085

GND

83

GATE

FB

/POR

/FAULT

Q1

Si7860DP

(PowerPAK

14

7

5

1

TM

SO-8)

R5

10Ω

C2

0.01µF

R6

127kΩ

1%

R7

16.2kΩ

1%

Downstream

Signals

C

LOAD

220µF

V

OUT

12V@5A

Figure 6. PCB Connection Sense with ON/OFF Control

M0235-121903 18 January 2004

MIC2085/2086 Micrel

Higher UVLO Setting

Once a PCB is inserted into a backplane (power supply), the

internal UVLO circuit of the MIC2085/86 holds the GATE

output charge pump off until VCC exceeds 2.18V. If VCC falls

below 2V, the UVLO circuit pulls the GATE output to ground

and clears the overvoltage and/or current limit faults. For a

higher UVLO threshold, the circuit in Figure 7 can be used to

delay the output MOSFET from switching on until the desired

input voltage is achieved. The circuit allows the charge pump

R1

to remain off until VIN exceeds

R2

×

1.24V+

. The GATE

1

drive output will be shut down when VIN falls below

R1

R2

×

1.14V+

. In the example circuit (Figure 7), the rising

1

UVLO threshold is set at approximately 11V and the falling

UVLO threshold is established as 10.1V. The circuit consists

of an external resistor divider at the ON pin that keeps the

GATE output charge pump off until the voltage at the ON pin

exceeds its threshold (VON) and after the start-up timer

elapses.

V

IN

12V

C1

1µF

R1

392kΩ

1%

4

R2

49.9kΩ

1%

C3

0.1µF

Undervoltage Lockout (Rising) = 11.0V

Undervoltage Lockout (Falling) = 10.1V

Undervoltage (Output) = 11.4V

POR/START-UP Delay = 60ms

Additional pins omitted for clarity.

R

SENSE

0.010Ω

2%

12

34

16 15

SENSEVCC

ON

MIC2085

CPOR

GND

83

GATE

/POR

FB

IRF7822

(SO-8)

14

7

5

Q1

R3

10Ω

Downstream

Signal

Figure 7. Higher UVLO Setting

C2

0.01µF

R4

127kΩ

1%

R5

16.2kΩ

1%

C

LOAD

220µF

V

OUT

12V@4A

January 2004 19 M0235-121903

MIC2085/2086 Micrel

Fast Output Discharge for Capacitive Loads

In many applications where a switch controller is turned off by

either removing the PCB from the backplane or the ON pin is

reset, capacitive loading will cause the output to retain

voltage unless a ‘bleed’ (low impedance) path is in place in

order to discharge the capacitance. The MIC2086 is equipped

with an internal MOSFET that allows the discharging of any

load capacitance to ground through a 550Ω path. The discharge feature is configured by wiring the DIS pin to the

output (source) of the external MOSFET and becomes active

R

SENSE

0.007

W

V

IN

12V

ON Signal

R1

47k

C1

1mF

W

4

ON

5%

12

34

19,20 18

SENSE

VCC

MIC2086

(DIS pin output is low) once the ON pin is deasserted. Figure

8(a) illustrates the use of the discharge feature with an

optional resistor (R5) that can be used to provide added

resistance in the output discharge path. For an even faster

discharge response of capacitive loads, the configuration of

Figure 8(b) can be utilized to apply a crowbar to ground

through an external SCR (Q3) that is triggered when the DIS

pin goes low which turns on the PNP transistor (Q2). See the

different

“Functional Characteristic”

curves for a comparison

of the discharge response configurations.

Q1

Si7892DP

(PowerPAK

17

GATE

8

FB

15

DIS

TM

SO-8)

R2

10

W

C2

0.022mF

*R5

R3

110k

1%

R4

14.7k

1%

W

W

C

LOAD

1500mF

V

OUT

12V@5A

V

IN

12V

ON Signal

R1

47k

5

C3

0.01mF

PWRGD

GNDCPOR CFILTER

9,10 23

/POR

C4

0.01mF

6

Downstream

Signals

(a)

R

SENSE

0.007

W

5%

12

C1

1mF

W

4

ON

34

19,20 18

SENSE

VCC

MIC2086

Si7892DP

(PowerPAK

17

GATE

8

FB

5

/POR

Q1

TM

SO-8)

R2

10

W

C2

0.022mF

Downstream

Signal

R6

4.4k

W

R3

110k

1%

R4

14.7k

1%

V

OUT

12V@5A

C

LOAD

1500mF

W

W

Q2

ZTX788A

R7

220

W

Q3

TCR22-4

C3

0.01mF

Undervoltage (Output) = 11V

POR/START-UP Delay = 6ms

Circuit Breaker Response Time = 620ms

*R5 of Figure 8(a) is optional to combine in series

with internal 550

Additional pins omitted for clarity.

W.

GNDCPOR CFILTER

9,10 23

(b)

DIS

C4

0.01mF

15

R5

1.5k

W

C5

0.022mF

Figure 8. MIC2086 Fast Discharge of Capacitive Load

M0235-121903 20 January 2004

MIC2085/2086 Micrel

Auto-Retry Upon Overcurrent Faults

The MIC2085/86 can be configured for automatic restart after

a fault condition. Placing a diode between the ON and

/FAULT pins, as shown in Figure 9, will enable the autorestart capability of the controller. When an application is

configured for auto-retry, the overcurrent timer should be set

to minimize the duty cycle of the overcurrent response to

prevent thermal runaway of the power MOSFET. See

“MOSFET Transient Thermal Issues”

section for further

detail. A limited duty cycle is achieved when the overcurrent

timer duration (t

timer duration (t

OCSLOW

START

) is much less than the start-up delay

) and is calculated using the following

equation:

t

Auto Retry Duty Cycle

−=×

OCSLOW

t

START

100%

(10)

An InfiniBand™ Application Circuit

The circuit in Figure 10 depicts a single 50W InfiniBand™

module using the MIC2085 controller. An InfiniBand™

backplane distributes bulk power to multiple plug-in modules

that employ DC/DC converters for local supply requirements.

The circuit in Figure 10 distributes 12V from the backplane to

the MIC2182 DC/DC converter that steps down +12V to

+3.3V for local bias. The pass transistor, Q1, isolates the

MIC2182’s input capacitance during module plug-in and

allows the backplane to accommodate additional plug-in

modules without affecting the other modules on the backplane.

The two control input signals are VBxEn_L (active LOW) and

a Local Power Enable (active HIGH). The MIC2085 in the

circuit of Figure 10 performs a number of functions. The gate

output of Q1 is enabled by the two bit input signal VBxEn_L,

Local Power Enable = [0,1]. Also, the MIC2085 limits the drain

current of Q1 to 7A, monitors VB_In for an overvoltage

condition greater than 16V, and enables the MIC2182 DC/DC

converter downstream to supply a local voltage rail. The

uncommitted comparator is used to monitor VB_In for an

undervoltage condition of less than 10V, indicated by a logic

LOW at the comparator output (COMPOUT). COMPOUT

may be used to control a downstream device such as another

DC/DC converter. Additionally, the MIC2085 is configured for

auto-retry upon an overcurrent fault condition by placing a

diode (D1) between the /FAULT and ON pins of the controller.

V

IN

5V

R1

47kΩ

R2

ON SIGNAL

/FAULT

OUTPUT

Undervoltage (Output) = 4.27V

POR/START-UP Delay = 12ms

Circuit Breaker Response Time = 290µs

Auto-Retry Duty Cycle = 2.5%

Additional pins omitted for clarity.

33kΩ

D1

1N914

0.02µF

Figure 9. Auto-Retry Configuration

R

SENSE

0.012Ω

5%

12

34

C1

1µF

16 15

4

ON

6

/FAULT

CPOR

C3

SENSEVCC

MIC2085

GND

83

GATE

/POR

CFILTER

2

14

7

FB

5

C4

4700pF

Q1

IRF7822

(SO-8)

R3

10Ω

C2

0.022µF

Downstream

Signal

R4

34kΩ

1%

R5

14.7kΩ

1%

C

LOAD

220µF

V

OUT

5V@2.5A

January 2004 21 M0235-121903

MIC2085/2086 Micrel

InfiniBand™ Application

VB_In

(12V)

VBxEn_L

VB_Ret

InfiniBandª

Backplane

Long

Short

Long

165k

R3

13.3k

W

1%

C1

0.01mF

Local Power

Enable

1%

InfiniBandª

MODULE

R

SENSE

0.007

W

5%

12

34

R2

W

C3

0.1mF

0.022mF

R1

10k

9

11

3

12

13

OV

COMP+

CPOR

COMPÐ

REF

CFILTER

C4

W

16 15

SENSEVCC

MIC2085

GNDONCRWBR

28

GATE

COMPOUT

/POR

/FAULT

78.7k

11k

R4

W

1%

R5

W

1%

C5

0.033mF

Q1

IRF7822

(SO-8)

R7

R6

174k

10

W

14

10

5

7

FB

6

D1

1N914

4

1

Overvoltage (Input) = 16.0V

Undervoltage (Input) = 10.0V

Undervoltage (Output) &

Power-Good (Output) = 10.0V

Circuit Breaker Response Time = 1.2ms

POR/START-UP Delay = 18.5ms

Auto-Retry Duty Cycle = 6.5%

W

1%

C2

0.022mF

Power-On Reset

Output

R8

25.5k

W

1%

MIC2182

DC/DC Converter

V

IN

/UV

RUN/SS

GND

3.3V @ 4A

Figure 10. A 50W InfiniBand™ Application

Sense Resistor Selection

The MIC2085 and MIC2086 use a low-value sense resistor to

measure the current flowing through the MOSFET switch

(and therefore the load). This sense resistor is nominally

valued at 48mV/I

LOAD(CONT)

. To accommodate worst-case

tolerances for both the sense resistor (allow ±3% over time

and temperature for a resistor with ±1% initial tolerance) and

still supply the maximum required steady-state load current,

a slightly more detailed calculation must be used.

The current limit threshold voltage (the “trip point”) for the

MIC2085/86 may be as low as 40mV, which would equate to

a sense resistor value of 40mV/I

LOAD(CONT)

. Carrying the

numbers through for the case where the value of the sense

resistor is 3% high yields:

R

SENSE(MAX)

=

Once the value of R

40mV

1.03 I

()

()

LOAD(CONT)

has been chosen in this manner,

SENSE

it is good practice to check the maximum I

38.8mV

=

I

LOAD(CONT)

LOAD(CONT)

(11)

which

the circuit may let through in the case of tolerance build-up in

the opposite direction. Here, the worst-case maximum current is found using a 55mV trip voltage and a sense resistor

that is 3% low in value. The resulting equation is:

I

LOAD(CONT,MAX)

=

55mV

0.97 R

()

()

SENSE(NOM)

56.7mV

=

R

SENSE(NOM)

(12)

As an example, if an output must carry a continuous 6A

without nuisance trips occurring, Equation 11 yields:

R

SENSE(MAX)

38.8mV

==Ω

6A

6.5m

.

The next lowest standard value is 6.0mW. At the other set

of tolerance extremes for the output in question:

I

LOAD(CONT,MAX)

56.7mV

=

6.0m

9.45A

=

Ω

,

almost 10A. Knowing this final datum, we can determine

the necessary wattage of the sense resistor, using P = I2R,

where

(0.97)(R

I will be I

SENSE(NOM)

LOAD(CONT, MAX)

).

These numbers yield the following:

P

MAX

, and R will be

= (10A)2 (5.82mΩ)

= 0.582W.

In this example, a 1W sense resistor is sufficient.

MOSFET Selection

Selecting the proper external MOSFET for use with the

MIC2085/86 involves three straightforward tasks:

• Choice of a MOSFET which meets minimum

voltage requirements.

• Selection of a device to handle the maximum

continuous current (steady-state thermal

issues).

• Verify the selected part’s ability to withstand any

peak currents (transient thermal issues).

MOSFET Voltage Requirements

The first voltage requirement for the MOSFET is that the drainsource breakdown voltage of the MOSFET must be greater

than V

. For instance, a 16V input may reasonably be

IN(MAX)

expected to see high-frequency transients as high as 24V.

Therefore, the drain-source breakdown voltage of the MOSFET

must be at least 25V. For ample safety margin and standard

availability, the closest minimum value should be 30V.

M0235-121903 22 January 2004

MIC2085/2086 Micrel

The second breakdown voltage criterion that must be met is

a bit subtler than simple drain-source breakdown voltage. In

MIC2085/86 applications, the gate of the external MOSFET

is driven up to a maximum of 21V by the internal output

MOSFET. At the same time, if the output of the external

MOSFET (its source) is suddenly subjected to a short, the

gate-source voltage will go to (21V – 0V) = 21V. Since most

power MOSFETs generally have a maximum gate-source

breakdown of 20V or less, the use of a Zener clamp is

recommended in applications with VCC ≥ 8V. A Zener diode

with 10V to 12V rating is recommended as shown in Figure

11. At the present time, most power MOSFETs with a 20V

gate-source voltage rating have a 30V drain-source breakdown rating or higher. As a general tip, choose surface-mount

devices with a drain-source rating of 30V or more as a starting

point.

Finally, the external gate drive of the MIC2085/86 requires a

low-voltage logic level MOSFET when operating at voltages

lower than 3V. There are 2.5V logic level MOSFETs available. Please see Table 4,

Vendors”

for suggested manufacturers.

“MOSFET and Sense Resistor

MOSFET Steady-State Thermal Issues

The selection of a MOSFET to meet the maximum continuous

current is a fairly straightforward exercise. First, arm yourself

with the following data:

• The value of I

question (see

LOAD(CONT, MAX.)

“Sense Resistor Selection”

for the output in

).

• The manufacturer’s data sheet for the candidate

MOSFET.

• The maximum ambient temperature in which the

device will be required to operate.

• Any knowledge you can get about the heat

sinking available to the device (e.g., can heat be

dissipated into the ground plane or power plane,

if using a surface-mount part? Is any airflow

available?).

The data sheet will almost always give a value of on resistance given for the MOSFET at a gate-source voltage of 4.5V,

and another value at a gate-source voltage of 10V. As a first

approximation, add the two values together and divide by two

to get the on-resistance of the part with 8V of enhancement.

Call this value RON. Since a heavily enhanced MOSFET acts

as an ohmic (resistive) device, almost all that’s required to

determine steady-state power dissipation is to calculate I2R.

The one addendum to this is that MOSFETs have a slight

increase in RON with increasing die temperature. A good

approximation for this value is 0.5% increase in RON per °C

rise in junction temperature above the point at which RON was

initially specified by the manufacturer. For instance, if the

selected MOSFET has a calculated RON of 10mΩ at a

TJ = 25°C, and the actual junction temperature ends up

at 110°C, a good first cut at the operating value for R

ON

would be:

RON ≅ 10mΩ[1 + (110 - 25)(0.005)] ≅ 14.3mΩ

The final step is to make sure that the heat sinking available

to the MOSFET is capable of dissipating at least as much

power (rated in °C/W) as that with which the MOSFET’s

performance was specified by the manufacturer. Here are a

few practical tips:

1. The heat from a surface-mount device such as

an SO-8 MOSFET flows almost entirely out of

the drain leads. If the drain leads can be soldered down to one square inch or more, the

copper will act as the heat sink for the part. This

copper must be on the same layer of the board

as the MOSFET drain.

Q1

IRF7822

(SO-8)

R3

10Ω

14

C2

0.01µF

7

FB

6

Downstream

5

Signals

Undervoltage (Output) = 11.0V

POR/START-UP Delay = 60ms

*Recommended for MOSFETs with gate-source

breakdown of 20V or less (IRF7822 VGS(MAX) = 12V)

for catastrophic output short circuit protection.

Additional pins omitted for clarity.

*D1

1N5240B

10V

R4

100kΩ

1%

R5

13.3kΩ

1%

C

LOAD

220µF

12V@5A

V

OUT

V

12V

R

SENSE

0.007Ω

IN

C1

1µF

R1

47kΩ

4

R2

33kΩ

0.1µF

2%

12

34

16 15

SENSEVCC

ON

MIC2085

CPOR

C3

GND

GATE

/FAULT

/POR

83

Figure 11. Zener Clamped MOSFET GATE

January 2004 23 M0235-121903

MIC2085/2086 Micrel

2. Airflow works. Even a few LFM (linear feet per

minute) of air will cool a MOSFET down substantially. If you can, position the MOSFET(s)

near the inlet of a power supply’s fan, or the

outlet of a processor’s cooling fan.

3. The best test of a surface-mount MOSFET for

an application (assuming the above tips show it

to be a likely fit) is an empirical one. Check the

MOSFET's temperature in the actual layout of

the expected final circuit, at full operating

current. The use of a thermocouple on the drain

leads, or infrared pyrometer on the package, will

then give a reasonable idea of the device’s

junction temperature.

MOSFET Transient Thermal Issues

Having chosen a MOSFET that will withstand the imposed

voltage stresses, and the worse case continuous I2R power

dissipation which it will see, it remains only to verify the

MOSFET’s ability to handle short-term overload power dissipation without overheating. A MOSFET can handle a much

higher pulsed power without damage than its continuous

dissipation ratings would imply. The reason for this is that, like

everything else, thermal devices (silicon die, lead frames,

etc.) have thermal inertia.

In terms related directly to the specification and use of power

MOSFETs, this is known as “transient thermal impedance,”

or Z

. Almost all power MOSFET data sheets give a

θ(J-A)

Transient Thermal Impedance Curve. For example, take the

following case: VIN = 12V, t

I

LOAD(CONT. MAX)

is 2.5A, the slow-trip threshold is 48mV

OCSLOW

has been set to 100msec,

nominal, and the fast-trip threshold is 95mV. If the output is

accidentally connected to a 3Ω load, the output current from

the MOSFET will be regulated to 2.5A for 100ms (t

OCSLOW

before the part trips. During that time, the dissipation in the

MOSFET is given by:

P = E x I E

P

MOSFET

= (4.5V x 2.5A) = 11.25W for 100msec.

MOSFET

= [12V-(2.5A)(3Ω)] = 4.5V

At first glance, it would appear that a really hefty MOSFET is

required to withstand this sort of fault condition. This is where

the transient thermal impedance curves become very useful.

Figure 12 shows the curve for the Vishay (Siliconix) Si4410DY,

a commonly used SO-8 power MOSFET.

Taking the simplest case first, we’ll assume that once a fault

event such as the one in question occurs, it will be a long time

– 10 minutes or more – before the fault is isolated and the

channel is reset. In such a case, we can approximate this as

a “single pulse” event, that is to say, there’s no significant duty

cycle. Then, reading up from the X-axis at the point where

“Square Wave Pulse Duration” is equal to 0.1sec (=100msec),

we see that the Z

of this MOSFET to a highly infrequent

θ(J-A)

event of this duration is only 8% of its continuous R

This particular part is specified as having an R

50°C/W for intervals of 10 seconds or less. Thus:

Assume TA = 55°C maximum, 1 square inch of copper at the

drain leads, no airflow.

Recalling from our previous approximation hint, the part has

an R

of (0.0335/2) = 17mΩ at 25°C.

ON

Assume it has been carrying just about 2.5A for some time.

When performing this calculation, be sure to use the highest

anticipated ambient temperature (T

) in which the

A(MAX)

MOSFET will be operating as the starting temperature, and

find the operating junction temperature increase (∆TJ) from

that point. Then, as shown next, the final junction temperature

is found by adding T

and ∆TJ. Since this is not a closed-

A(MAX)

form equation, getting a close approximation may take one or

two iterations, but it’s not a hard calculation to perform, and

tends to converge quickly.

Then the starting (steady-state)TJ is:

TJ≅ T

≅ T

A(MAX)

A(MAX)

x I2 x R

+ ∆T

J

+ [RON + (T

θ(J-A)

– TA)(0.005/°C)(RON)]

A(MAX)

TJ≅ 55°C + [17mΩ + (55°C-25°C)(0.005)(17mΩ)]

)

x (2.5A)2 x (50°C/W)

TJ≅ (55°C + (0.122W)(50°C/W)

≅ 61.1°C

Iterate the calculation once to see if this value is within a few

percent of the expected final value. For this iteration we will

start with TJ equal to the already calculated value of 61.1°C:

TJ≅ TA + [17mΩ + (61.1°C-25°C)(0.005)(17mΩ)]

x (2.5A)2 x (50°C/W)

TJ ≅ ( 55°C + (0.125W)(50°C/W) ≅ 61.27°C

θ(J-A)

θ(J-A)

.

of

Normalized Thermal Transient Impedance, Junction-to-Ambient

Single Pulse

–3

10

–2

10

Square Wave Pulse Duration (sec)

10

–1

Notes:

P

DM

t

1

t

2

t

– TA = PDMZ

1

t

2

thJA

thJA

= 50°C/W

(t)

30

1. Duty Cycle, D =

2. Per Unit Base = R

3. T

JM

4. Surface Mounted

110

0.1

Thermal Impedance

Normalized Effective Transient

0.01

2

1

Duty Cycle = 0.5

0.2

0.1

0.05

0.02

–4

10

Figure 12. Transient Thermal Impedance

M0235-121903 24 January 2004

MIC2085/2086 Micrel

So our original approximation of 61.1°C was very close to the

correct value. We will use TJ = 61°C.

Finally, add (11.25W)(50°C/W)(0.08) = 45°C to the steadystate TJ to get T

J(TRANSIENT MAX.)

= 106°C. This is an accept-

able maximum junction temperature for this part.

PCB Layout Considerations

Because of the low values of the sense resistors used with the

MIC2085/86 controllers, special attention to the layout must

be used in order for the device’s circuit breaker function to

operate properly. Specifically, the use of a 4-wire Kelvin

connection to measure the voltage across R

SENSE

is highly

recommended. Kelvin sensing is simply a means of making

sure that any voltage drops in the power traces connecting to

the resistors does not get picked up by the traces themselves.

Additionally, these Kelvin connections should be isolated

from all other signal traces to avoid introducing noise onto

these sensitive nodes. Figure 13 illustrates a recommended,

Current Flow

to the Load

W W

*SENSE RESISTOR

(2512)

multi-layer layout for the R

, Power MOSFET, timer(s),

SENSE

overvoltage and feedback network connections. The feedback and overvoltage resistive networks are selected for a

12V application (from Figure 5). Many hot swap applications

will require load currents of several amperes. Therefore, the

power (VCC and Return) trace widths (W) need to be wide

enough to allow the current to flow while the rise in temperature for a given copper plate (e.g., 1 oz. or 2 oz.) is kept to a

maximum of 10°C ~ 25°C. Also, these traces should be as

short as possible in order to minimize the IR drops between

the input and the load. For a starting point, there are many

trace width calculation tools available on the web such as the

following link:

http://www.aracnet.com/cgi-usr/gpatrick/trace.pl

Finally, plated-through vias are utilized to make circuit con-

nections to the power and ground planes. The trace connections with indicated vias should follow the example shown for

the GND pin connection in Figure 13.

Current Flow

*POWER MOSFET

(SO-8)

D

D

D

D

to the Load

G

S

S

S

**R4

10

W

Via to GND Plane

Via to POWER (VCC)

Plane

16

VCC

15

SENSE

14

GATE

13

REF

**C

12

COMP-

GATE

R3

13.7k

1%

10

11

COMP+

COMPOUT

W

R2

140k

W

1%

9

MIC2085

CRWBR

CFILTER

CPORON/POR

4

3

2

1

**C

FILTER

Current Flow

from the Load

W

**C

POR

Via to GND Plane

/FAULT

FB

5

6

GND OV

7

8

R5

100k

W

1%

R6

13.3k

W

1%

DRAWING IS NOT TO SCALE

*See Table 4 for part numbers and vendors