Micom SWING SW, SWING SWSP Installation Manual

MICOM SWING SW & SWSP

Installation Manual

Page 1

MICOM AUTODOOR

Automatic Swing Door Operator

Model: MICOM SWING

Model SW & SWSP

Original Instructions

INSTALLATION MANUAL

The installation instruction detailed within are soley for profesional installers and not intended to be

handed over to the end user.

OSAKA – JAPAN

www.micomautodoor.com

vers.0001

MICOM SWING SW & SWSP

Installation Manual

Page 2

Contents:

No.

Section

1

INTRODUCTION

2

TECHNICAL SPECIFICATIONS

3

COMPONENTS

4

PARTS

4.1

ID COMPONANT

4.2

ID OPERATOR

5

INSTALLATION OF THE OPERATOR

5.1

PREPARATION - Tools required

5.2

PREPERATION

6

FIXING

6.1

INTRODUCTION

6.2

SET AND ADJUST ARTICULATED ARM (PUSH)

6.3

SET SLIDING ARM (PULL)

6.4

SET UP TENSION STRING

6.5

ADJUST OPENING LIMIT LEVER

7

OPERATION OF THE MICOM SWING-SW & SP SYSTEM

7.1

START UP. SELF-LEARNING

7.2

NORMAL OPERATION

7.3

ELECTRICAL FAULT

7.4

ERRORS

8

CONNECTIONS

8.1

CONNECTION TO THE ELECTRICAL NETWORK

8.2

BASIC INTERNAL CONNECTIONS

9

CONNECTION FROM OTHER COMPONENTS

9.1

P1 connector. Connection from control card for ST-500 access control

9.2

P2 connector. 24V output

9.3

P3 connector. Supervision output(Security Sensor Monitor)

9.4

P4 connector. Emergency stop (Emergency Stop)

9.5

P13 connector. (Emergency Open/Close)

9.6

P5 connector. NIGHT BANK (Forced opening)

9.7

P6 connector. Feed in order to block or automatic 24Vdc latch (Lock)

9.8

P12 connector. lock or automatic Feed in order to block or automatic 12Vdc latch (Lock)

9.9

P9 connector. Internal movement sensor (Internal Sensor)

9.10

P8 connector. External movement sensor(External Sensor)

9.11

P10 connector: Security sensor 1 (Security 1)

9.12

P14 connector: Security sensor 2 (Security 2)

9.13

P7 connector: Selector switch A ( 3 point switch)

9.14

P11 connector: Selector switch B (Digital)

10

DOUBLE DOOR (DUAL) CONNECTION

11

PROBLEMS

11.1

INTERFERENCE

12

PROGRAMMING OF THE CONTROL UNIT

12.1

INTRODUCTION

MICOM SWING SW & SWSP

Installation Manual

Page 3

12.2

PROGRAMMING MENU

12.2.1

Enter into the programming menu

12.2.2

Modify the programming parameter

12.2.3

Exit the programming menu and save the modifications

12.2.4

Programming example

12.2.5

Programming RESET

13

PROGRAMMING PARAMETRES

14

PROBLEM SOLVING. ERROR TABLE

15

MAINTENANCE

16

DECLARATION OF COMPLIANCE

MICOM SWING SW & SWSP

Installation Manual

Page 4

IMPORTANT NOTICE

Please carefully read the instructions before installing the door operator. We hold no

responsibility for loss or damages caused if the following precautions are not

observed.

NOTCIE: It is important for security reasons that all persons follow these instructions.

Please keep these instructions.

When performing Maintenance and Installation tasks, the machine must be disconnected

from the standard electricity supply.

Use the correct electrical feed (See section “2.-Technical Specifications”)

Ensure that the operator is earthed! The operator covering is made of a metal material

which conducts electricity and it is easy for conduction to appear, so please ensure that

the earth cable is connected.

The operator covering is not totally sealed and therefore dampness can destroy the

electronic components within.

Do not remove screws and bolts from the internal structure of the Control Unit. Do not

open, repair or alter any part of the Control Unit. Failure to comply will result in loss of

warranty.

Installation and maintenance of this product can be performed by MICOM authorized

personnel only.

Before plugging in the 3-way connector (power on), make sure that no objects obstruct

the travel of the automatic door.

Follow all the indicated instructions, bearing in mind that an incorrect installation could

provoke serious damage.

It is important to separate Sensor and Selector cables from mains power (230Vac)

cables. As it could provoke the micro-processor to function incorrectly - in the short term

or long term - or even cause irreversible damage.

In the event that all the cables require to be passed through one pipe, those pertaining to

the automatic door must be shielded and must be earthed at both ends. The installation

technicians must not mix the cables within the operator. Always attempt to separate

signals cables (photocell, selector, radar, motor, etc.) from power cables (230V or 110V).

Follow all indicated instructions, as improper installation could cause severe damage.

Please keep these instructions.

Note: Installation instructions detailed here within meet the requirements of BSEN 16005 and if

necessary can be verified.

MICOM SWING SW & SWSP

Installation Manual

Page 5

Notes: For more information, please read the “Section 3.1” of the Installation Manual.

In certain installations of automatic doors, some installers may sometimes place

operation selector cables and power supply cables (230Vac) within the same tube.

This must never be done as it may cause, in the short or long term, the

microprocessor to work incorrectly or to break down irreversibly.

It is advised to avoid placing cables within the same tube. Those belonging to the

automatic door must be shielded and properly grounded at both ends.

It is always necessary to try to separate signal cables (photocell, selector, radars,

engine, etc.) from voltage cables (230V or 110V).

IMPORTANT SAFETY NOTICE!!!

When the door starts for the first time, it will automatically perform a series

of opening and closing cycles (normally between 3 to 5 times) – Known as

teaching or self-learning mode.

Please note these learning cycles are performed at high speed without

safety features enabled.

Keep clear of the entrance and doors. Ensure that no pedestrians pass

through the doors during the initial learning, installation or maintenance.

Keep clear of doors when opening or closing during learning. It is advisable

to identify and restrict the area with warning signs.

MICOM SWING SW & SWSP

Installation Manual

Page 6

1. INTRODUCTION

This instruction manual contains all the information to carry out the installation, maintenance and service

of the MICOM SWING SW and SWING SWSP operators.

These operators are used for to automate swing doors of either one or two panels, both for inside

and outside, opening inwards or outwards.

The mechanism incorporates an opening limiter inside, it is not necessary to have any stopper on the

floor or wall.

The difference between the operators MICOM SWING-SW and MICOM SWING-SP is:

SW: Power Close

SWSP: Spring Close

The MICOM SWING is a non handed swing door operator system is to be utilized for automatic

swinging pedestrian doors. It is suitable for Single and Double applications. Its small size and

attractive housing design will compliment the aesthetics of any door. MICOM SWING SW & SWSP is

very compact, durable and high-quality automatic swing door operator system.

MICOM SWING operator is totally reversible and therefore it can be adapted without needing to

change the mechanics or the programming. It can accommodate Left and Right Push as well as Left

and Right Pull applications.

INSTALLATIONS – TO FOLLOW

MICOM SWING SW & SWSP

Installation Manual

Page 7

2. TECHINCAL SPECIFICATION

MICOM SWING SW

MICOM SWING SWSP

Closure with spring

NO

YES

Arm system

Push (Articulate) and Pull (Slide)

Push & Go

Yes (Adjustable)

Power

230/110VAC 50,60Mhz 2Amp

Opening speed

15-75deg/sec. (Adjustable)

Weight of operator

9kg

Control system

Micro-processor

Braking regulator

Automatic

Opening time

0-60 sec. (10 positions)

Close Pressure

Elimination of door to frame gap.

Electric pressure in 5 steps (adjustable)

Safety Function

Obstruction during opening, door will stop and an alarm will sound.

Obstruction during closing, door will reverse and slowly close.

Obstruction remains, door will stop and an alarm will sound.

Failure Detection

Alarm on failure detection (acoustic and on LED display)

Operation

Continuous opening and closing

Emergency Battery

The door will continue to function in the event of an

electrical outage (optional)

Locking

Electrical Lock of 12/24 VDC (optional)

Operating Environment

Ambient temperature from -20C ~ +50C (no condensation or icing).

Ambient humidity 30% ~ 85%.

(no hazardous materials in the atmosphere)

Max open angle

110 degrees (adjustable).

Max leaf

250 kg

Operator dimensions

120 x 130 x 570 mm (height, depth, length).

MICOM SWING SW & SWSP

Installation Manual

Page 8

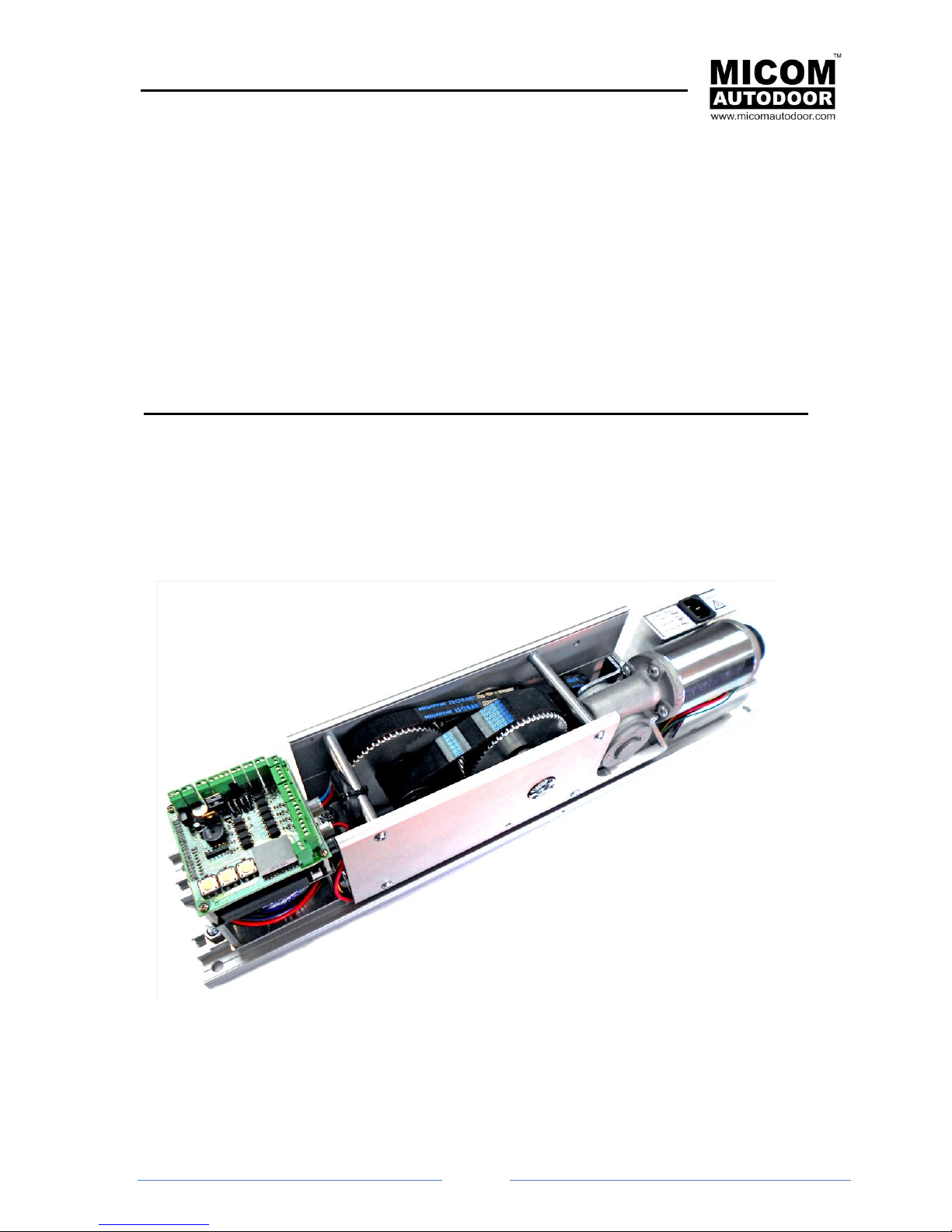

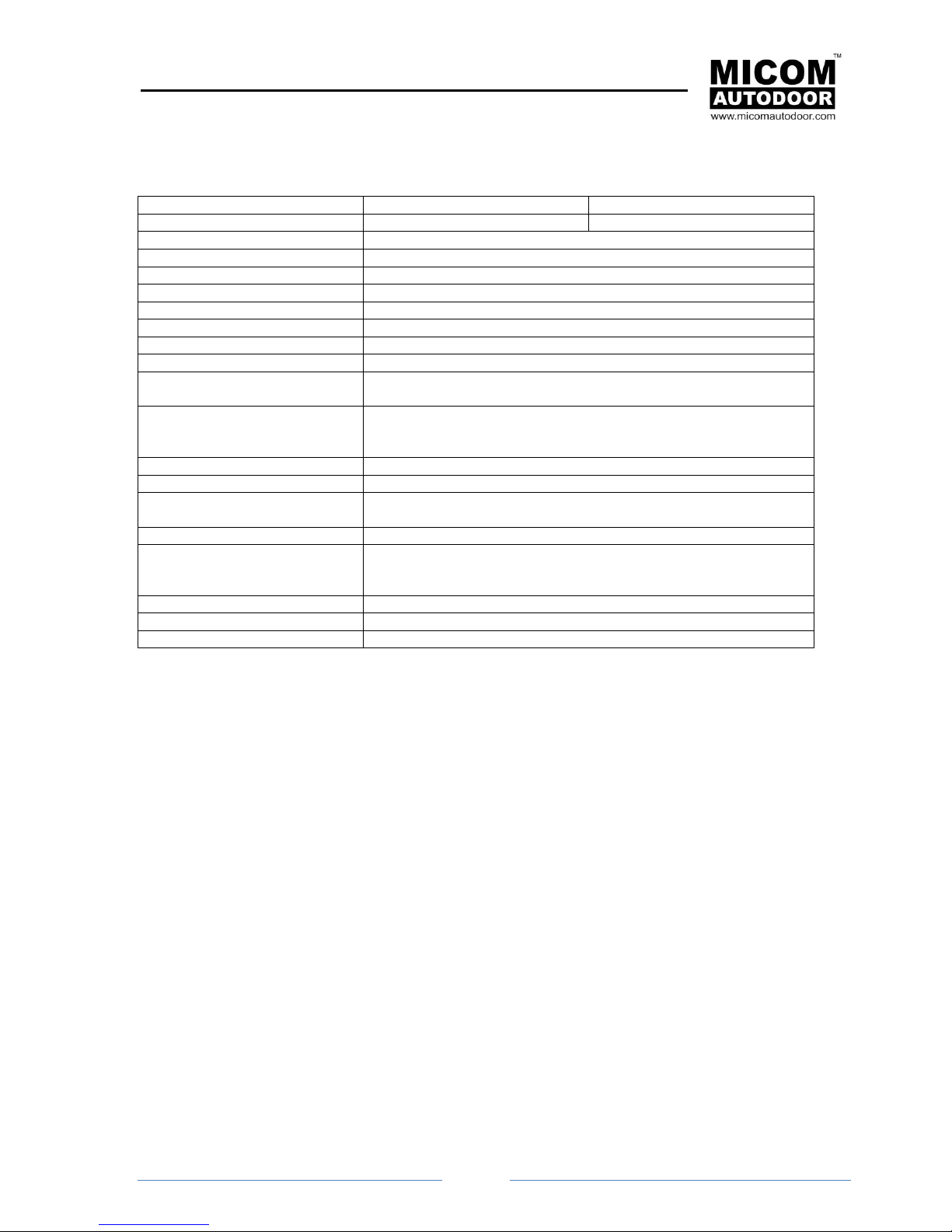

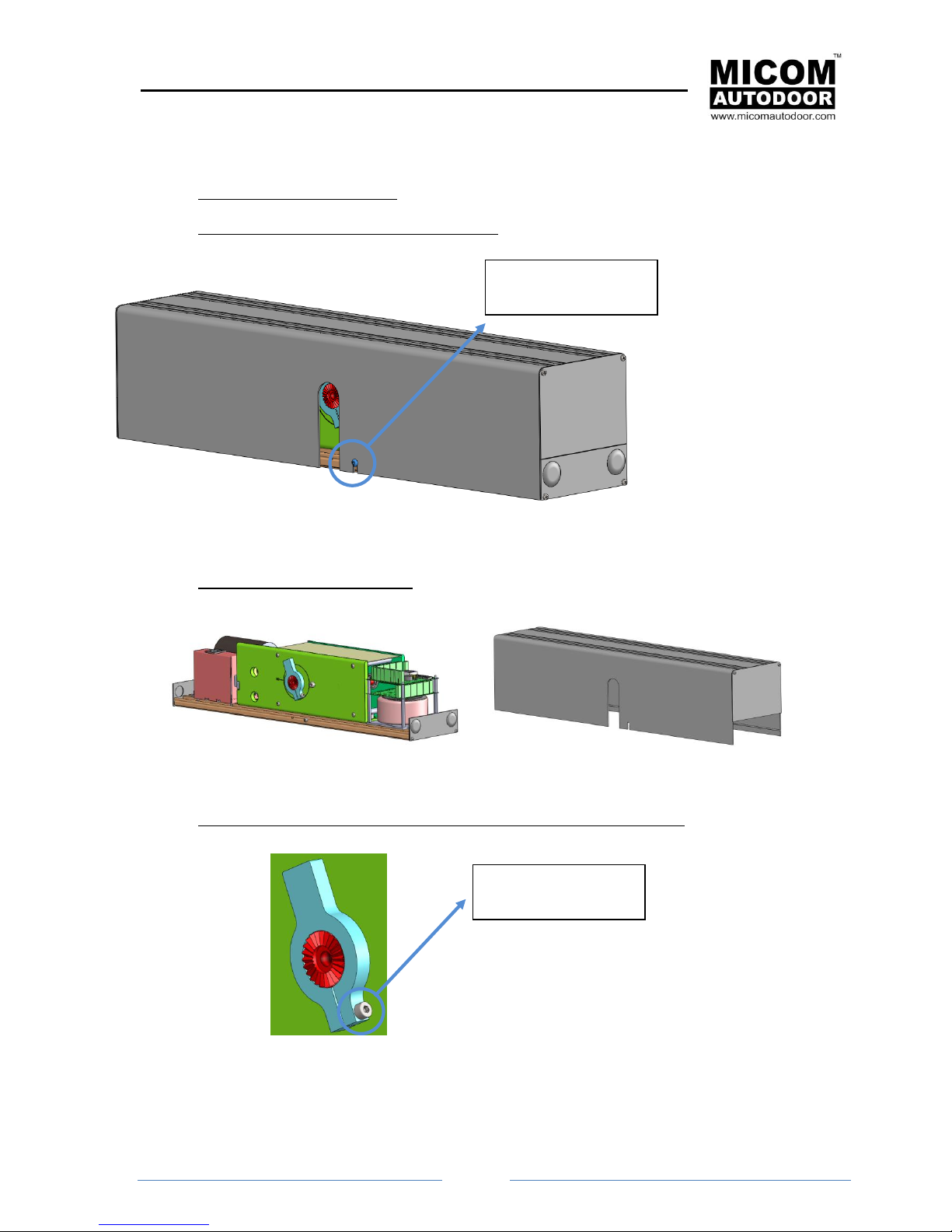

3. COMPONANT PARTS

Exterior views of the operator

Interior view of the operator

2 1 9

7

6

8

10

11 4 5

12

3

MICOM SWING SW & SWSP

Installation Manual

Page 9

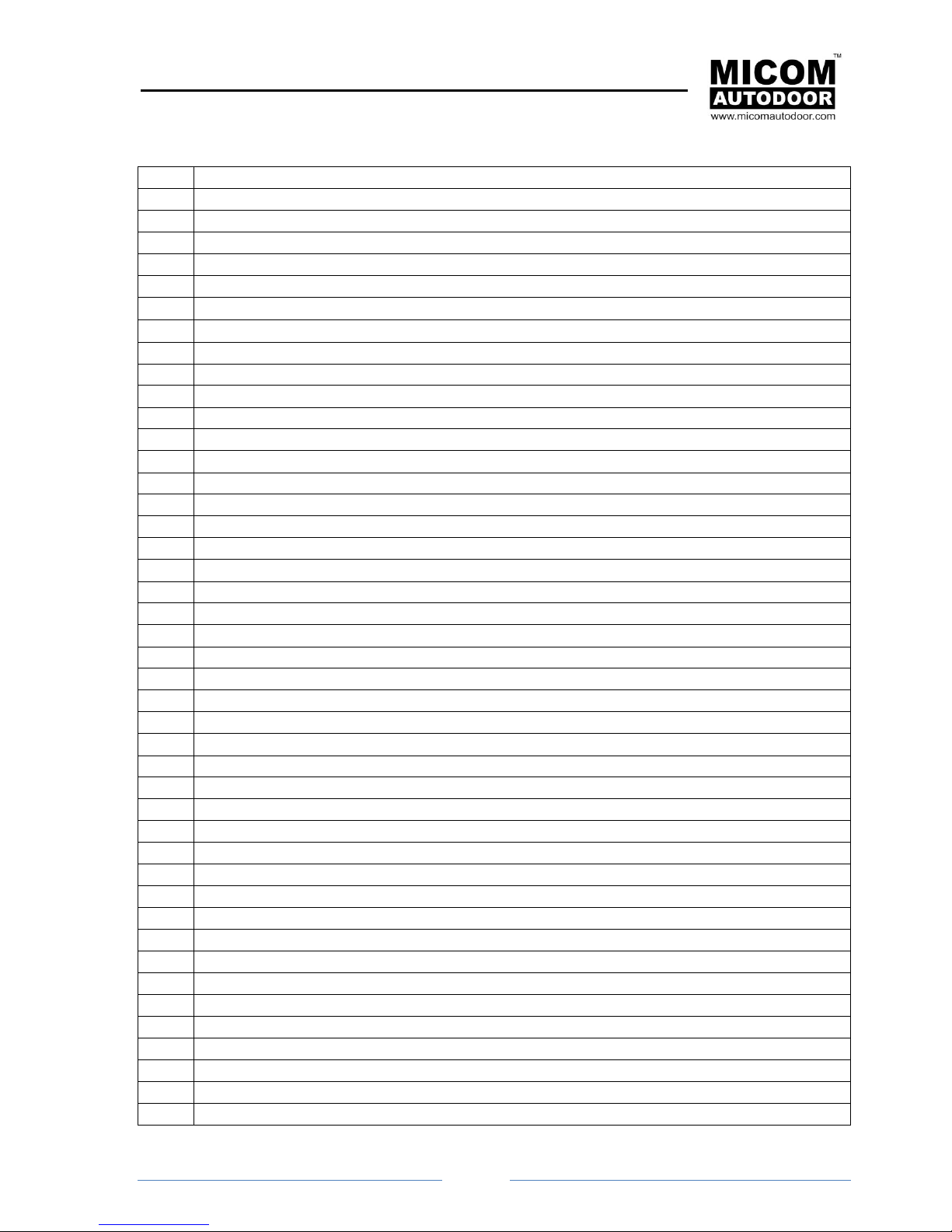

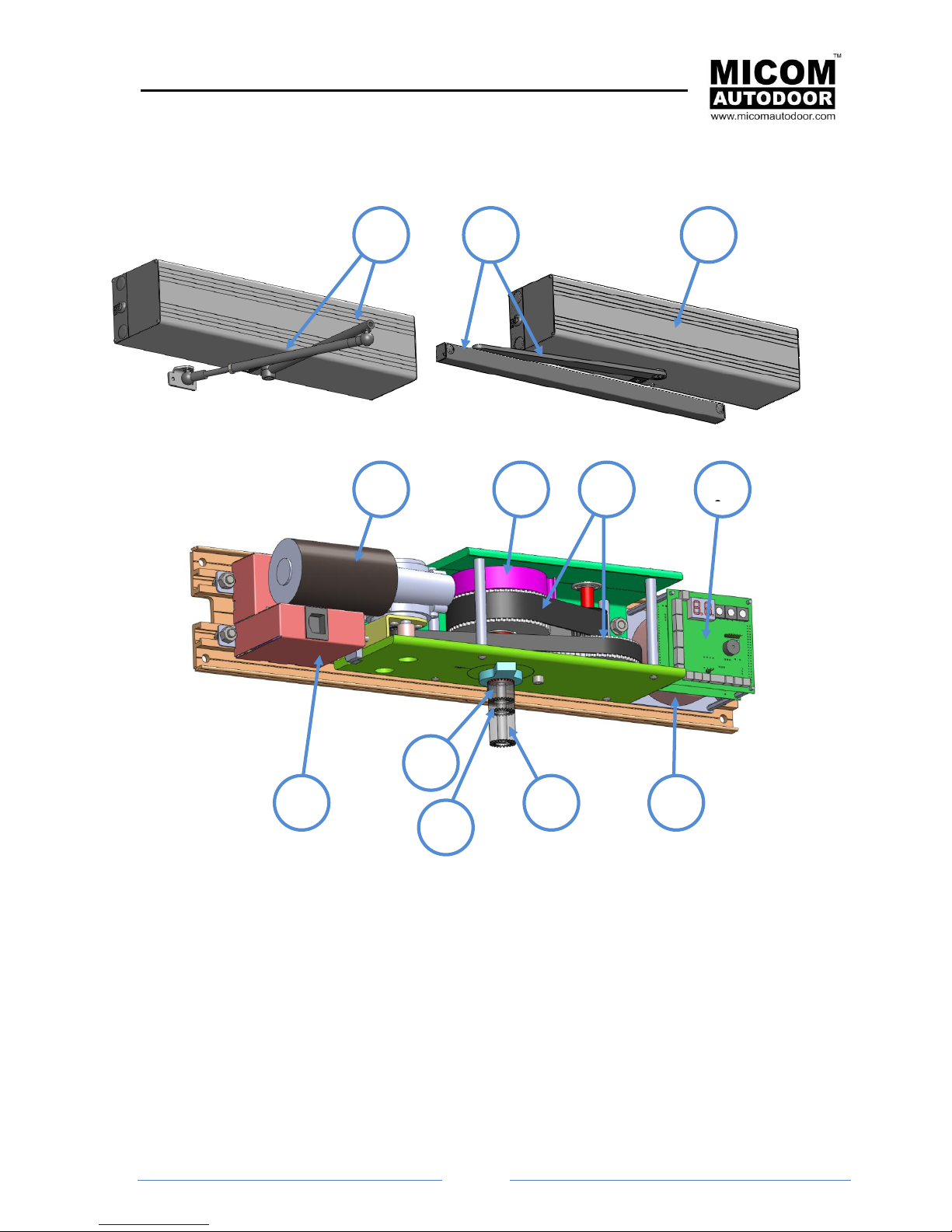

4. PARTS LIST

4.1 List of components and operators

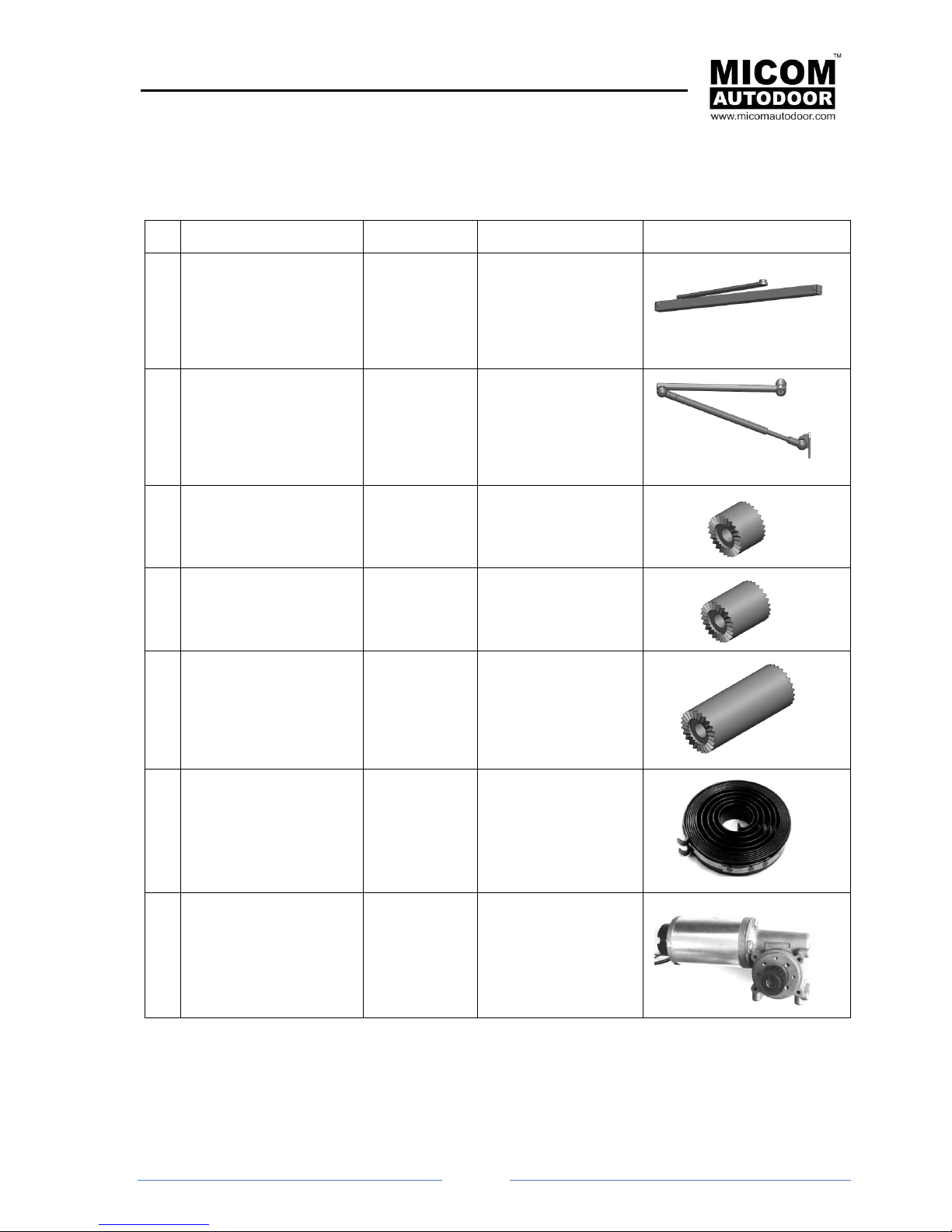

Nº

Components

Reference

Description

Image

01

Sliding arm (pull)

For MI-SW-Pull

2002277

Transmits the force of

the mechanism to the

door. Normally this is

used when the door

panel must open

inwards.

02

Articulated arm(push)

For MI-SW-Push

2002278

Transmits the force of

the mechanism to the

door. Normally this is

used when the door

panel must open

outwards.

03

Separator for MICOM

SWING-SW of 20mm

(optional)

2030001

This allows an increase

the height of the

mechanism by 20 mm

04

Separator for MICOM

SWING -SW of 30mm

(optional)

2030002

This allows an increase

the height of the

mechanism by 30 mm

05

Separator for MICOM

SWING -SW of 60mm

(optional)

2030003

This allows an increase

the height of the

mechanism by 60 mm

06

MICOM SWING-SP

SPRING

Only available for MICOM

SWING-SP operators

2002273

Allows door to close

when there is a power

cut

07

Motor-reducer for

MICOM SWING-SW

2002270

Continuous current

motor

MICOM SWING SW & SWSP

Installation Manual

Page

10

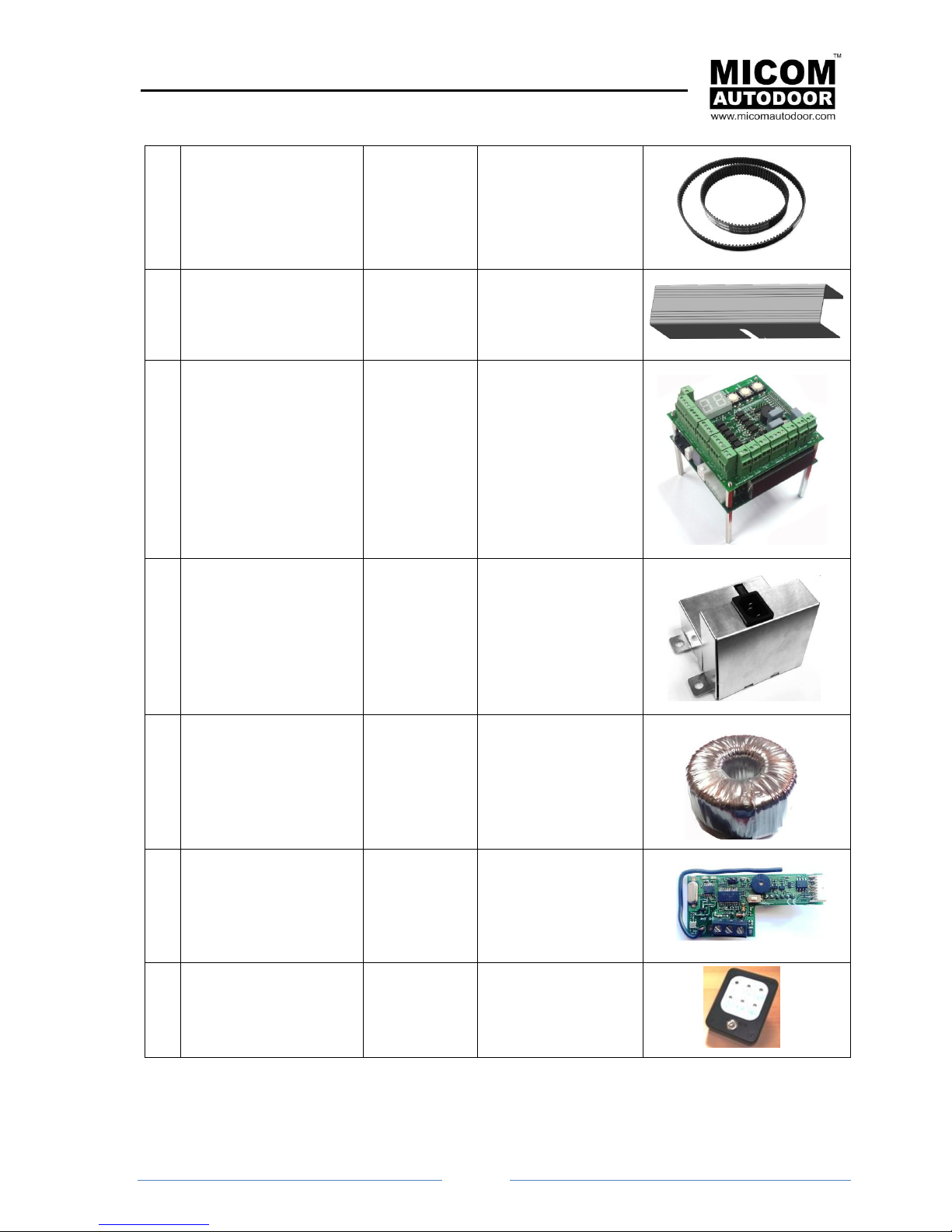

08

25mm BELT for MICOM

SWING -SW

2002271

Belt Reduction Gear

09

Front cover for MICOM

SWING -SW

2002274

Extruded Aluminum

10

Control unit for MICOM

SWING -SW

2002269

Microprocessor Control

11

Feed source for MICOM

SWING -SW

2002276

12

Transformer for MICOM

SWING -SW

2002275

13

Access control card ST500 (option)

5001097

To open the door by

means a radio

transmitter, proximity

key, tag, etc...

14

Digital selector SLD-5

(option)

2002109

Digital selector

MICOM SWING SW & SWSP

Installation Manual

Page

11

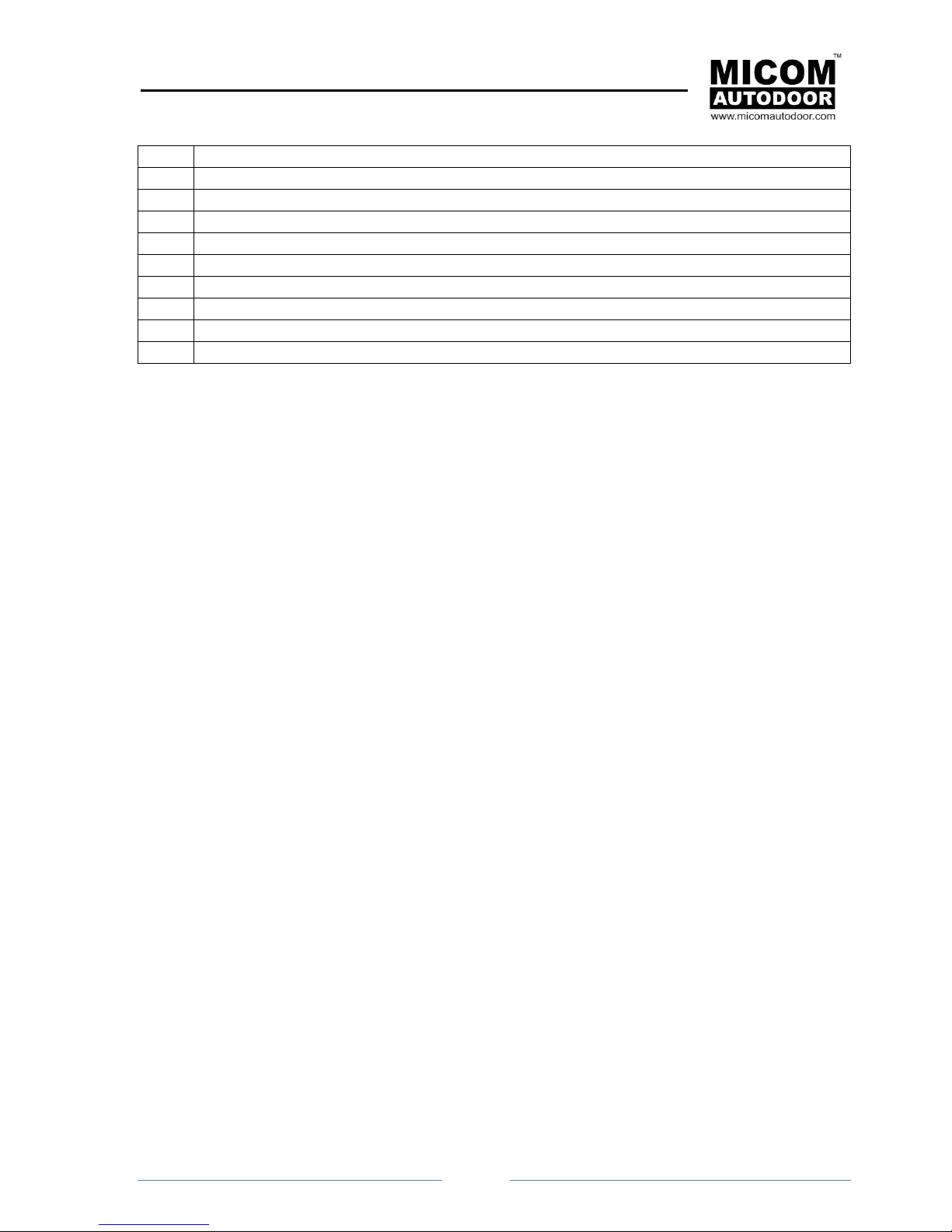

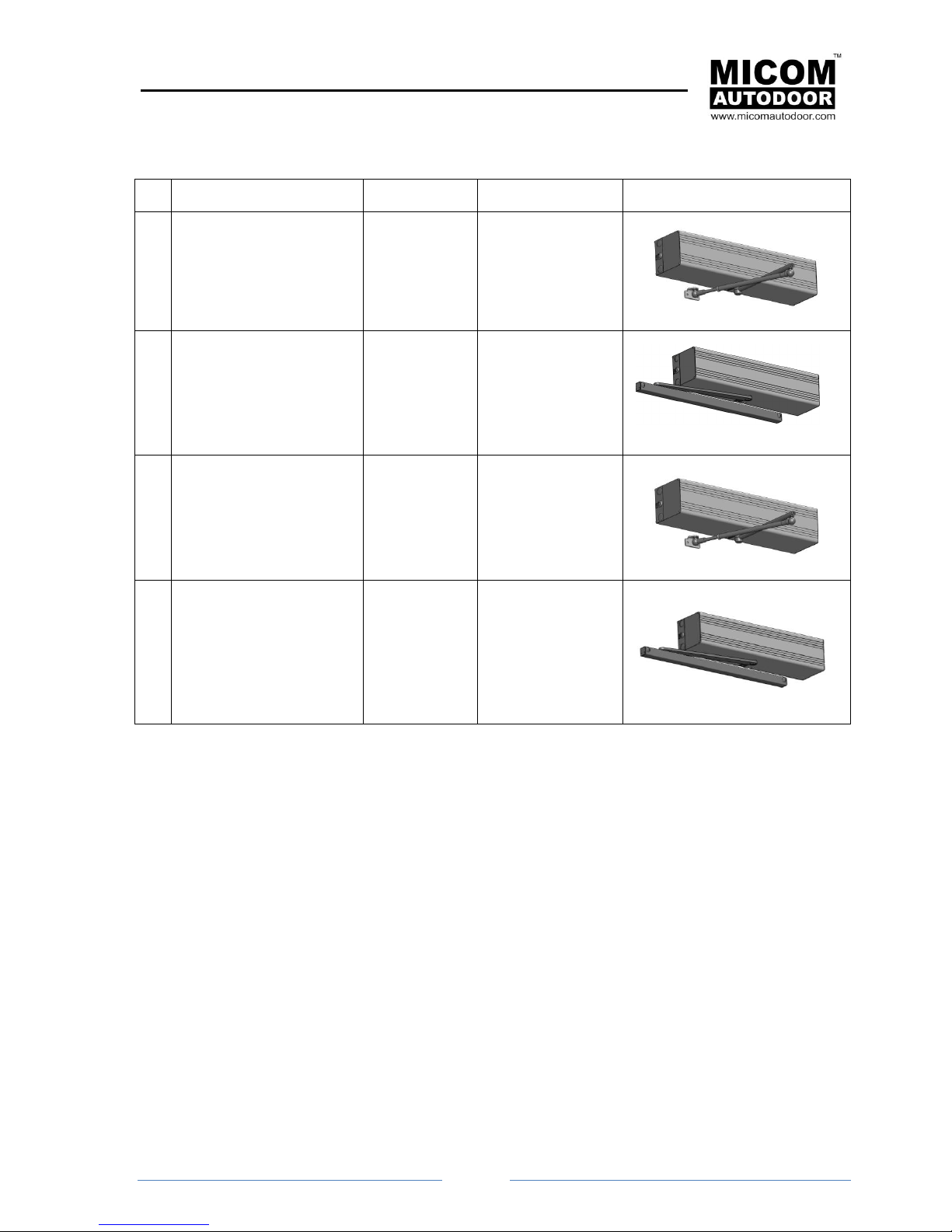

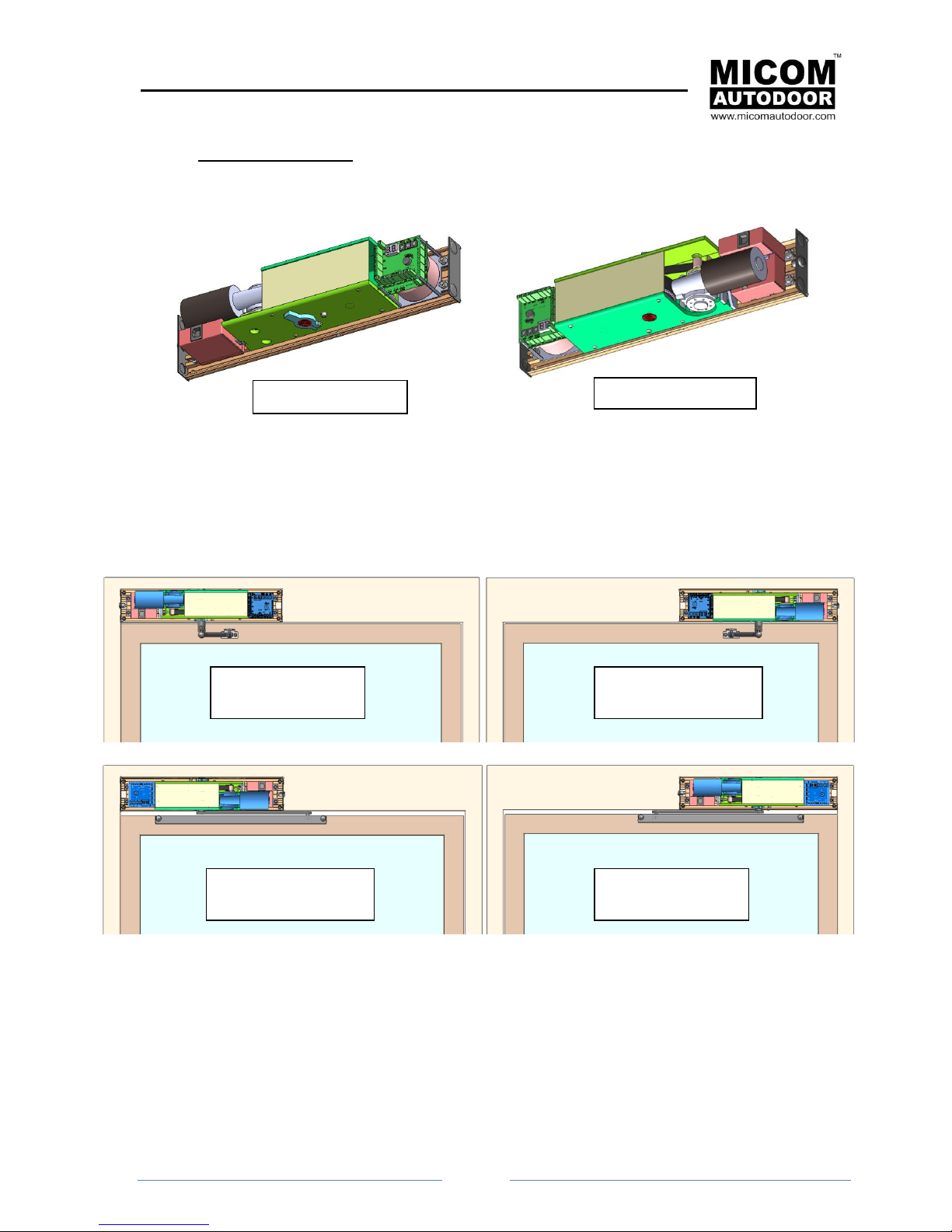

4.2 Identification of Operators

Nº

Operators

Reference

Description

Image

A1

MICOM SWING

SW-Push

2002279

Operator for swing

doors with

articulated arm

A2

MICOM SWING

SW-Pull

2002280

Operator for swing

doors with sliding

arm

A3

MICOM SWING

SWSP-Push

2002281

Operator for swing

doors with

articulated arm and

incorporated closing

spring

A4

MICOM SWING

SWSP-Pull

2002282

Operator for swing

doors with sliding

arm and

incorporated closing

spring

MICOM SWING SW & SWSP

Installation Manual

Page

12

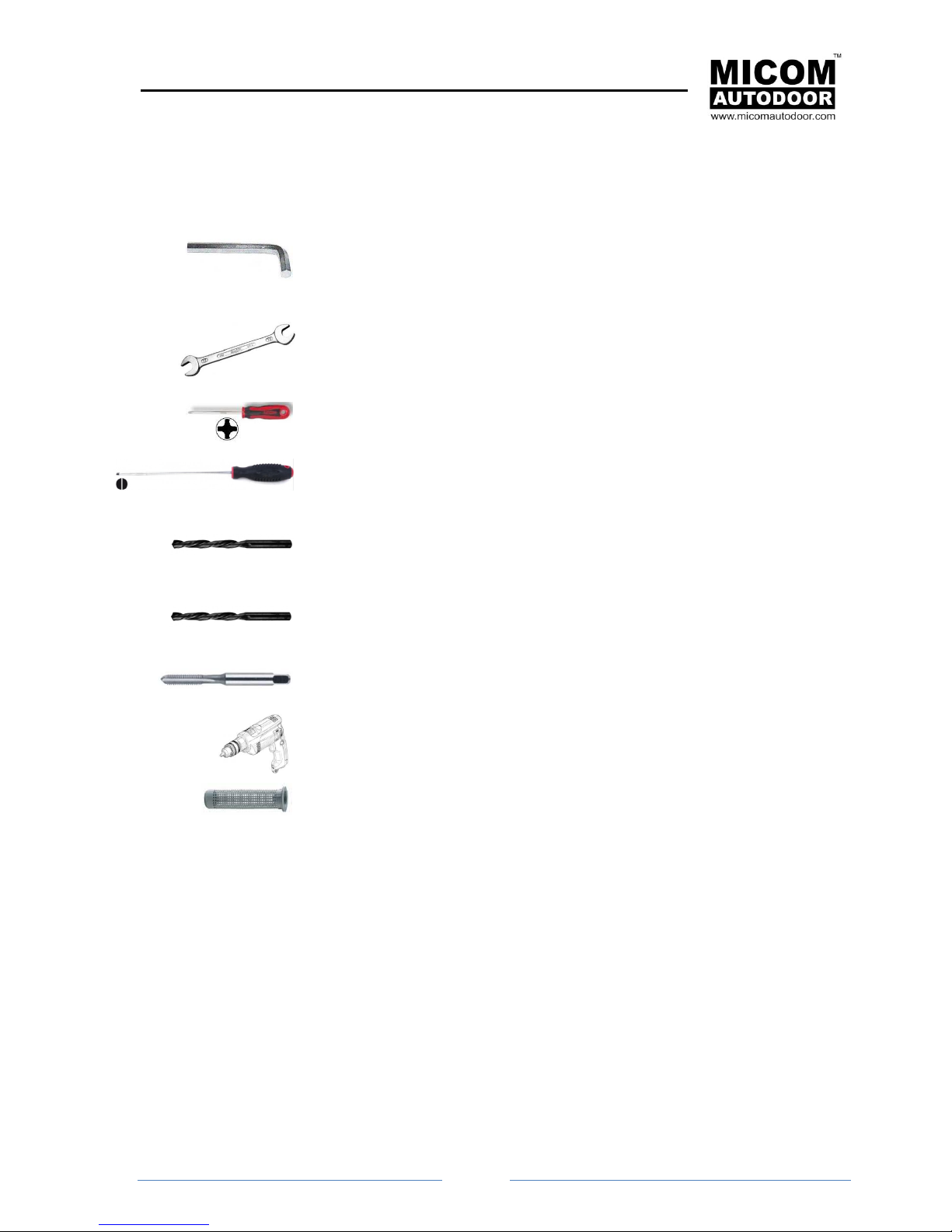

5. INSTALLATION OF THE OPERATOR

5.1 Preperation - Required tools

Allen key. Sizes:

● 2’5

● 3

● 5

Spanner. Sizes:

● 13

● 14

Phillips screwdriver. Sizes:

● #0

● #1

Flat Screwdriver. Sizes:

● 2

Drill bit for wall/concrete. Sizes:

● 8

● 6

Drill bit for metal. Sizes:

● 5

● 4

Plug for metric thread:

● M6

Drill

Wall plug

MICOM SWING SW & SWSP

Installation Manual

Page

13

5.2 Prepare Operator

● Unpack the operator with care.

● Remove the central screw from the front cover

1. Remove the front cover with care

2. Loosen the screw at the end of the reel so that this can move or turn easily.

Remove screw with

2’5 Allen key

Loosening with Allen

key 3

MICOM SWING SW & SWSP

Installation Manual

Page

14

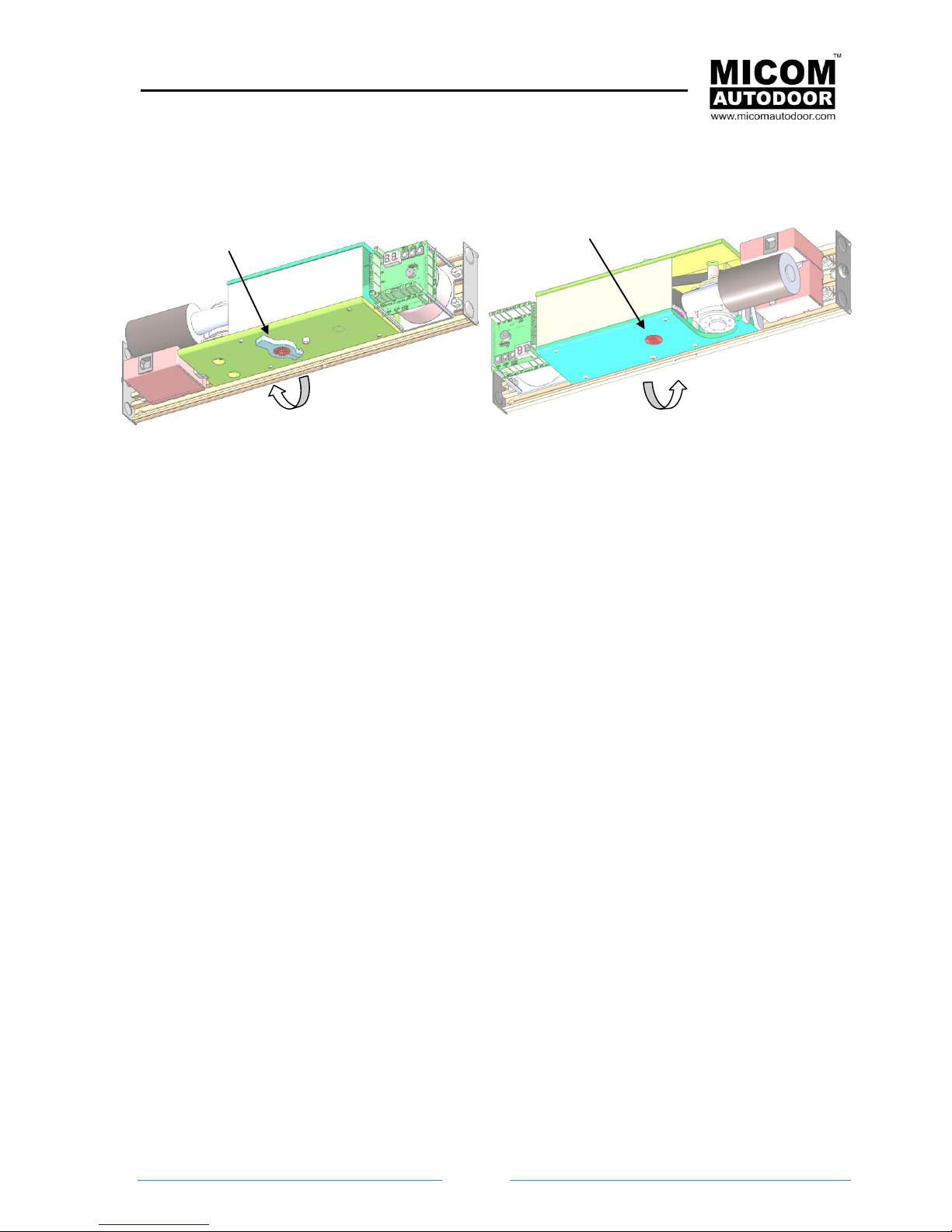

3. Orientate the operator. Before fixing the operator to the door frame or wall, we should study

the orientation of the same, which can be: Normal or Reversed.

The orientation of the operator depends on the following factors:

opening direction

placement (this can be on the framework or on the door panel)

situation of the door (right or left)

Installation Examples

The operator is totally reversible and therefore it can be adapted to any of the previous factors without

needing to change the mechanics or the programming. It is sufficient to turn it around to orientate it in

one direction or the other.

Therefore, if by mistake the operator was installed upside down. Upon giving the order to open it

actually closes, by simply changing the orientation we can solve the problem.

Normal Position

Reverse Position

Normal Position

(Left Push)

Reverse Position

(Right Push)

Normal Position

(Right Pull)

Reverse Position

(Left Pull)

MICOM SWING SW & SWSP

Installation Manual

Page

15

There are two ways to know how to orientate the operator:

A. By Motor Pivot Direction:

A. One method consists of turning the motor’s pivot manually. We can use the operator arm

B.

B. Turning the motor’s pivot manually, we can use the operator arm to assist us. By turning

motor pivot in both directions, using the operator arm to assist in this moment by hand, we

can see that the motor turns with no resistance in one direction; while on the other hand,

turning the motor in the other direction needs greater force. In summary:

Low resistance when turning corresponds to the opening direction of the door.

High resistance when turning corresponds to the closing direction of the door.

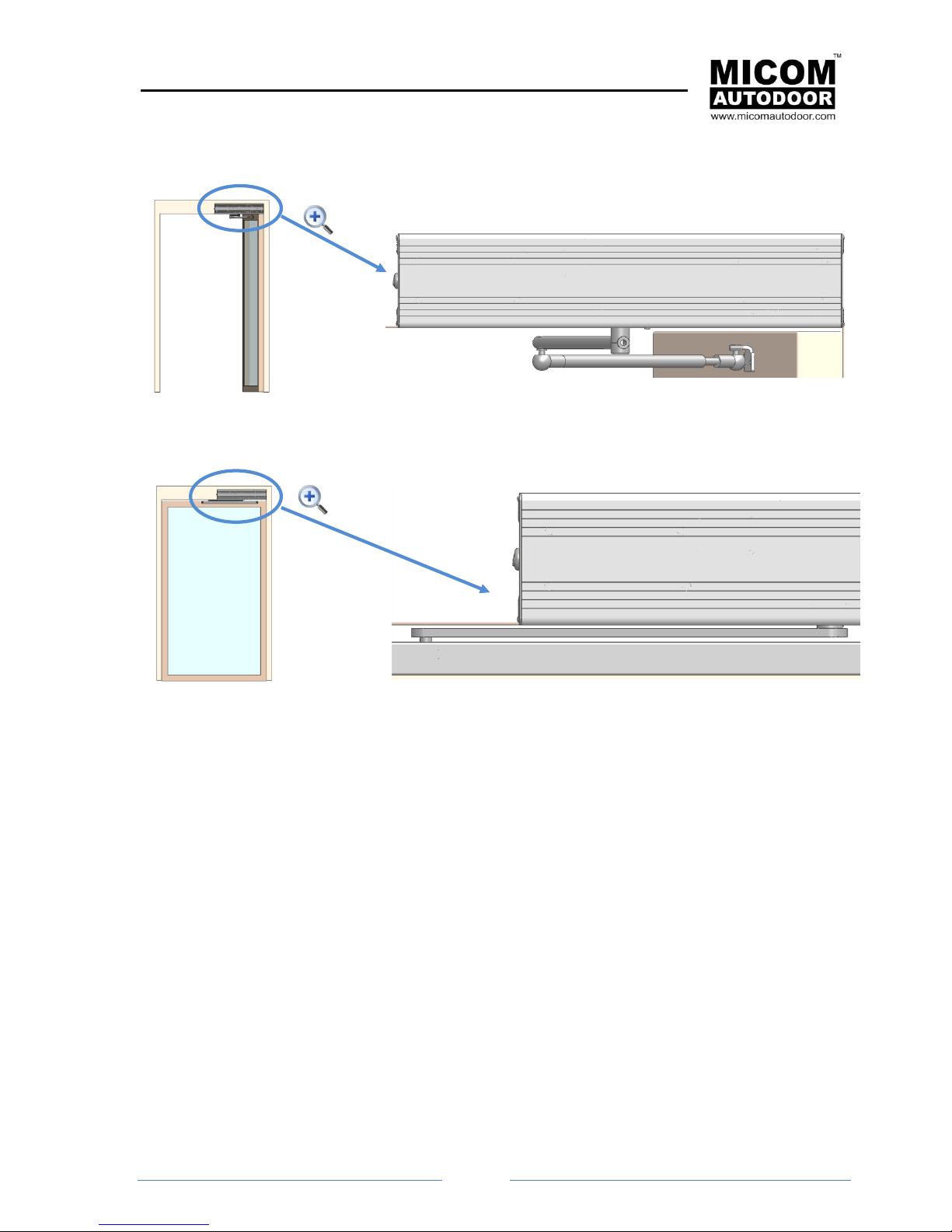

6. FIXING OPERATOR

6.1 Introduction

In order to fix the operator to the door frame, a template is provided with indication as to where the

fixture holes should be. There are 6 holes represented (4 fix the operator to the frame and 2 fix the

operator arm to the door).

These 6 holes are the minimum required that must be used to fix the mechanism correctly.

Before proceeding to fix the operator we recommend keeping the following advice in consideration:

● If the operator is fixed to a thin metal surface (less than 10mm thickness) it is strongly advised

to use threaded screws metric size M6 instead of self-tapping screws.

● If the operator is fixed onto a hollow brick it is strongly advised to use a plastic wall plug and a

threaded rod metric size M6.

Motor Pivot Direction

Motor Pivot Direction

MICOM SWING SW & SWSP

Installation Manual

Page

16

● When the operator with an articulated arm (push) is fixed, a security distance should be used

so that the arm does not hit against the door frame.

● When installing and operator with a sliding arm (pull), leave a safe distance so that the arm

does not knock against the door panel.

Important notice: In the event of using less fixture points than those required, or not following the

previous advice, there is a risk of the mechanism coming unfixed or falling. This would put the people

using the automatic door in danger.

Clearance or security distance

with respect to the door frame.

Security distance = 11mm

Clearance or

security

distance with

respect to the

door panel

(max. 9mm)

MICOM SWING SW & SWSP

Installation Manual

Page

17

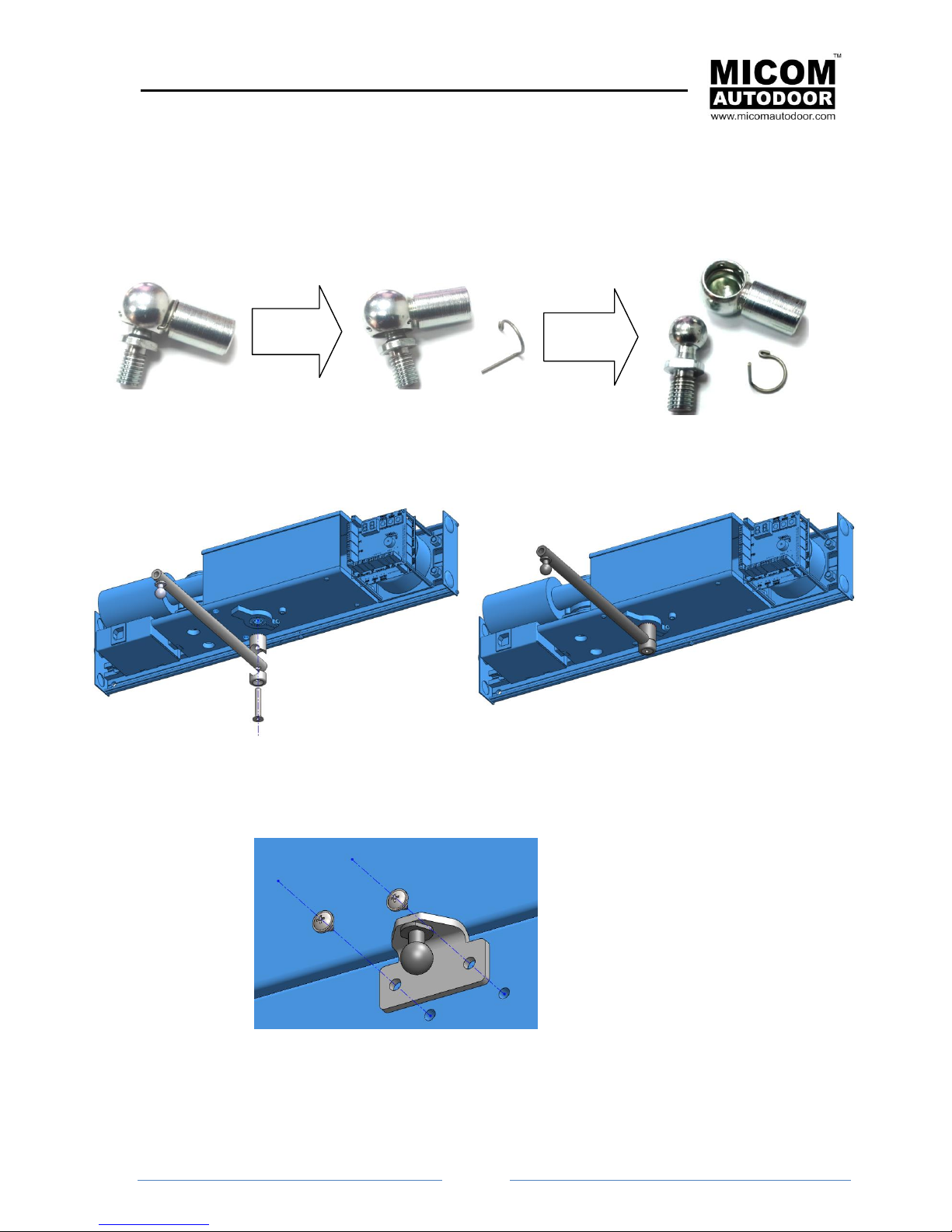

6.2 Fix and Adjust to Articulated (Push) Arm

In order to fix and adjust the articulated arm:

1. Separate the two parts of the arm joints. In order to separate them, you will have to remove

the security ring.

2. Screw in the upper part of the arm.

3. Make two holes in the door by following the indications as shown in drawings.

Remove

circlip

Separate

parts

MICOM SWING SW & SWSP

Installation Manual

Page

18

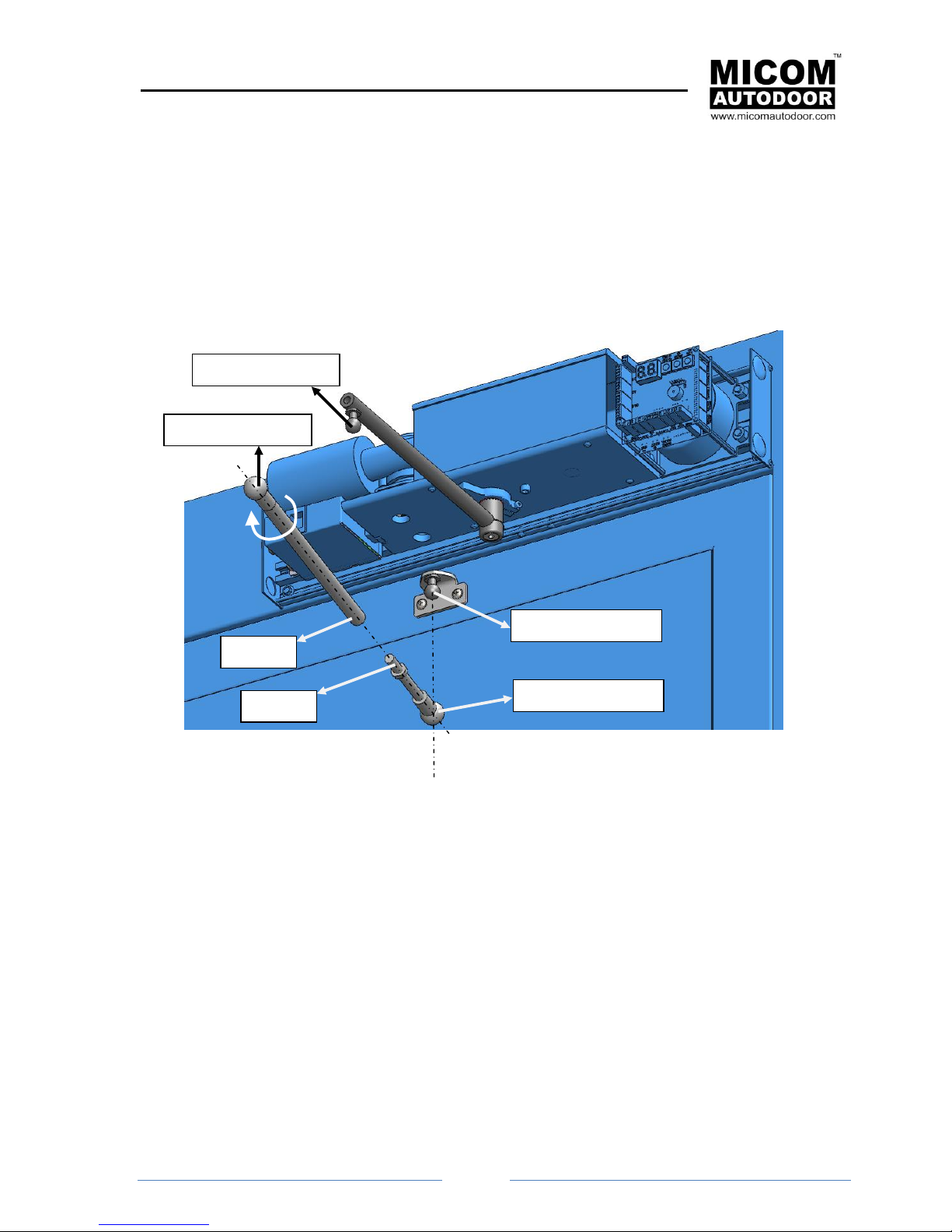

4. Introduce joint 1 (socket) into joint 2 (plug) (see the following figure).

5. Join “Part A” with “Part B” (see following figure).This will be achieved by screwing it in.

6. Close the door and keep it closed until the arm has been installed.

7. By turning “Part A” we can lengthen or shorten the arm if we turn it in one direction or the

other. Turn “Part A” so that joint 4 (socket) meets up with joint 3 (plug) (see the following

figure).

8. Then place each joint into its security ring.

9. Open and close the door and check that it is working correctly.

Note: Adjust the end of the rod (for more details see section “6.5.-ADJUST OPENING LIMIT”).

Label 2 (plug)

Label 1 (socket)

Part B

Part A

Label 4 (plug)

Joint 3 (socket)

Loading...

Loading...