Page 1

MICOM SWING SW & SWSP

Installation Manual

Page 1

MICOM AUTODOOR

Automatic Swing Door Operator

Model: MICOM SWING

Model SW & SWSP

Original Instructions

INSTALLATION MANUAL

The installation instruction detailed within are soley for profesional installers and not intended to be

handed over to the end user.

OSAKA – JAPAN

www.micomautodoor.com

vers.0001

Page 2

MICOM SWING SW & SWSP

Installation Manual

Page 2

Contents:

No.

Section

1

INTRODUCTION

2

TECHNICAL SPECIFICATIONS

3

COMPONENTS

4

PARTS

4.1

ID COMPONANT

4.2

ID OPERATOR

5

INSTALLATION OF THE OPERATOR

5.1

PREPARATION - Tools required

5.2

PREPERATION

6

FIXING

6.1

INTRODUCTION

6.2

SET AND ADJUST ARTICULATED ARM (PUSH)

6.3

SET SLIDING ARM (PULL)

6.4

SET UP TENSION STRING

6.5

ADJUST OPENING LIMIT LEVER

7

OPERATION OF THE MICOM SWING-SW & SP SYSTEM

7.1

START UP. SELF-LEARNING

7.2

NORMAL OPERATION

7.3

ELECTRICAL FAULT

7.4

ERRORS

8

CONNECTIONS

8.1

CONNECTION TO THE ELECTRICAL NETWORK

8.2

BASIC INTERNAL CONNECTIONS

9

CONNECTION FROM OTHER COMPONENTS

9.1

P1 connector. Connection from control card for ST-500 access control

9.2

P2 connector. 24V output

9.3

P3 connector. Supervision output(Security Sensor Monitor)

9.4

P4 connector. Emergency stop (Emergency Stop)

9.5

P13 connector. (Emergency Open/Close)

9.6

P5 connector. NIGHT BANK (Forced opening)

9.7

P6 connector. Feed in order to block or automatic 24Vdc latch (Lock)

9.8

P12 connector. lock or automatic Feed in order to block or automatic 12Vdc latch (Lock)

9.9

P9 connector. Internal movement sensor (Internal Sensor)

9.10

P8 connector. External movement sensor(External Sensor)

9.11

P10 connector: Security sensor 1 (Security 1)

9.12

P14 connector: Security sensor 2 (Security 2)

9.13

P7 connector: Selector switch A ( 3 point switch)

9.14

P11 connector: Selector switch B (Digital)

10

DOUBLE DOOR (DUAL) CONNECTION

11

PROBLEMS

11.1

INTERFERENCE

12

PROGRAMMING OF THE CONTROL UNIT

12.1

INTRODUCTION

Page 3

MICOM SWING SW & SWSP

Installation Manual

Page 3

12.2

PROGRAMMING MENU

12.2.1

Enter into the programming menu

12.2.2

Modify the programming parameter

12.2.3

Exit the programming menu and save the modifications

12.2.4

Programming example

12.2.5

Programming RESET

13

PROGRAMMING PARAMETRES

14

PROBLEM SOLVING. ERROR TABLE

15

MAINTENANCE

16

DECLARATION OF COMPLIANCE

Page 4

MICOM SWING SW & SWSP

Installation Manual

Page 4

IMPORTANT NOTICE

Please carefully read the instructions before installing the door operator. We hold no

responsibility for loss or damages caused if the following precautions are not

observed.

NOTCIE: It is important for security reasons that all persons follow these instructions.

Please keep these instructions.

When performing Maintenance and Installation tasks, the machine must be disconnected

from the standard electricity supply.

Use the correct electrical feed (See section “2.-Technical Specifications”)

Ensure that the operator is earthed! The operator covering is made of a metal material

which conducts electricity and it is easy for conduction to appear, so please ensure that

the earth cable is connected.

The operator covering is not totally sealed and therefore dampness can destroy the

electronic components within.

Do not remove screws and bolts from the internal structure of the Control Unit. Do not

open, repair or alter any part of the Control Unit. Failure to comply will result in loss of

warranty.

Installation and maintenance of this product can be performed by MICOM authorized

personnel only.

Before plugging in the 3-way connector (power on), make sure that no objects obstruct

the travel of the automatic door.

Follow all the indicated instructions, bearing in mind that an incorrect installation could

provoke serious damage.

It is important to separate Sensor and Selector cables from mains power (230Vac)

cables. As it could provoke the micro-processor to function incorrectly - in the short term

or long term - or even cause irreversible damage.

In the event that all the cables require to be passed through one pipe, those pertaining to

the automatic door must be shielded and must be earthed at both ends. The installation

technicians must not mix the cables within the operator. Always attempt to separate

signals cables (photocell, selector, radar, motor, etc.) from power cables (230V or 110V).

Follow all indicated instructions, as improper installation could cause severe damage.

Please keep these instructions.

Note: Installation instructions detailed here within meet the requirements of BSEN 16005 and if

necessary can be verified.

Page 5

MICOM SWING SW & SWSP

Installation Manual

Page 5

Notes: For more information, please read the “Section 3.1” of the Installation Manual.

In certain installations of automatic doors, some installers may sometimes place

operation selector cables and power supply cables (230Vac) within the same tube.

This must never be done as it may cause, in the short or long term, the

microprocessor to work incorrectly or to break down irreversibly.

It is advised to avoid placing cables within the same tube. Those belonging to the

automatic door must be shielded and properly grounded at both ends.

It is always necessary to try to separate signal cables (photocell, selector, radars,

engine, etc.) from voltage cables (230V or 110V).

IMPORTANT SAFETY NOTICE!!!

When the door starts for the first time, it will automatically perform a series

of opening and closing cycles (normally between 3 to 5 times) – Known as

teaching or self-learning mode.

Please note these learning cycles are performed at high speed without

safety features enabled.

Keep clear of the entrance and doors. Ensure that no pedestrians pass

through the doors during the initial learning, installation or maintenance.

Keep clear of doors when opening or closing during learning. It is advisable

to identify and restrict the area with warning signs.

Page 6

MICOM SWING SW & SWSP

Installation Manual

Page 6

1. INTRODUCTION

This instruction manual contains all the information to carry out the installation, maintenance and service

of the MICOM SWING SW and SWING SWSP operators.

These operators are used for to automate swing doors of either one or two panels, both for inside

and outside, opening inwards or outwards.

The mechanism incorporates an opening limiter inside, it is not necessary to have any stopper on the

floor or wall.

The difference between the operators MICOM SWING-SW and MICOM SWING-SP is:

SW: Power Close

SWSP: Spring Close

The MICOM SWING is a non handed swing door operator system is to be utilized for automatic

swinging pedestrian doors. It is suitable for Single and Double applications. Its small size and

attractive housing design will compliment the aesthetics of any door. MICOM SWING SW & SWSP is

very compact, durable and high-quality automatic swing door operator system.

MICOM SWING operator is totally reversible and therefore it can be adapted without needing to

change the mechanics or the programming. It can accommodate Left and Right Push as well as Left

and Right Pull applications.

INSTALLATIONS – TO FOLLOW

Page 7

MICOM SWING SW & SWSP

Installation Manual

Page 7

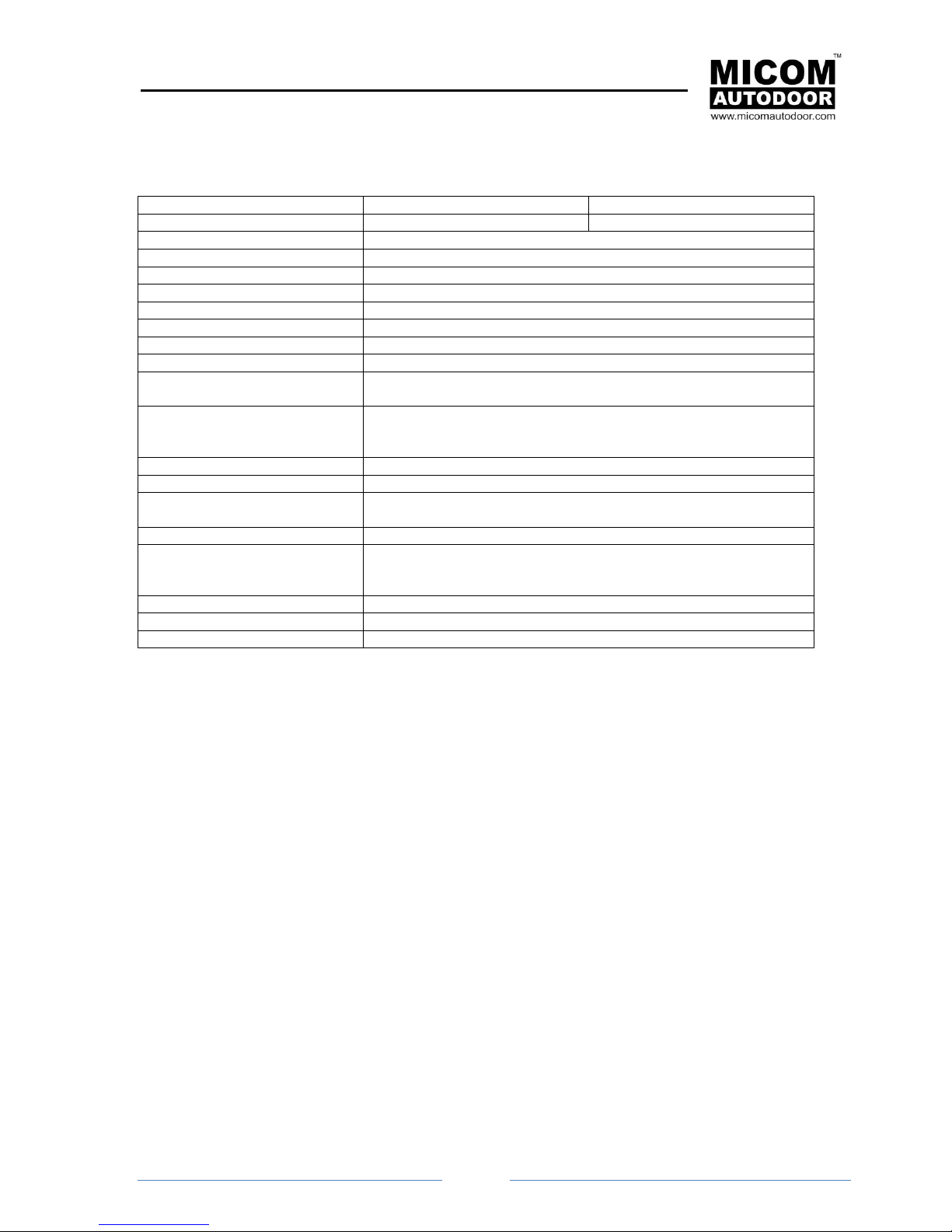

2. TECHINCAL SPECIFICATION

MICOM SWING SW

MICOM SWING SWSP

Closure with spring

NO

YES

Arm system

Push (Articulate) and Pull (Slide)

Push & Go

Yes (Adjustable)

Power

230/110VAC 50,60Mhz 2Amp

Opening speed

15-75deg/sec. (Adjustable)

Weight of operator

9kg

Control system

Micro-processor

Braking regulator

Automatic

Opening time

0-60 sec. (10 positions)

Close Pressure

Elimination of door to frame gap.

Electric pressure in 5 steps (adjustable)

Safety Function

Obstruction during opening, door will stop and an alarm will sound.

Obstruction during closing, door will reverse and slowly close.

Obstruction remains, door will stop and an alarm will sound.

Failure Detection

Alarm on failure detection (acoustic and on LED display)

Operation

Continuous opening and closing

Emergency Battery

The door will continue to function in the event of an

electrical outage (optional)

Locking

Electrical Lock of 12/24 VDC (optional)

Operating Environment

Ambient temperature from -20C ~ +50C (no condensation or icing).

Ambient humidity 30% ~ 85%.

(no hazardous materials in the atmosphere)

Max open angle

110 degrees (adjustable).

Max leaf

250 kg

Operator dimensions

120 x 130 x 570 mm (height, depth, length).

Page 8

MICOM SWING SW & SWSP

Installation Manual

Page 8

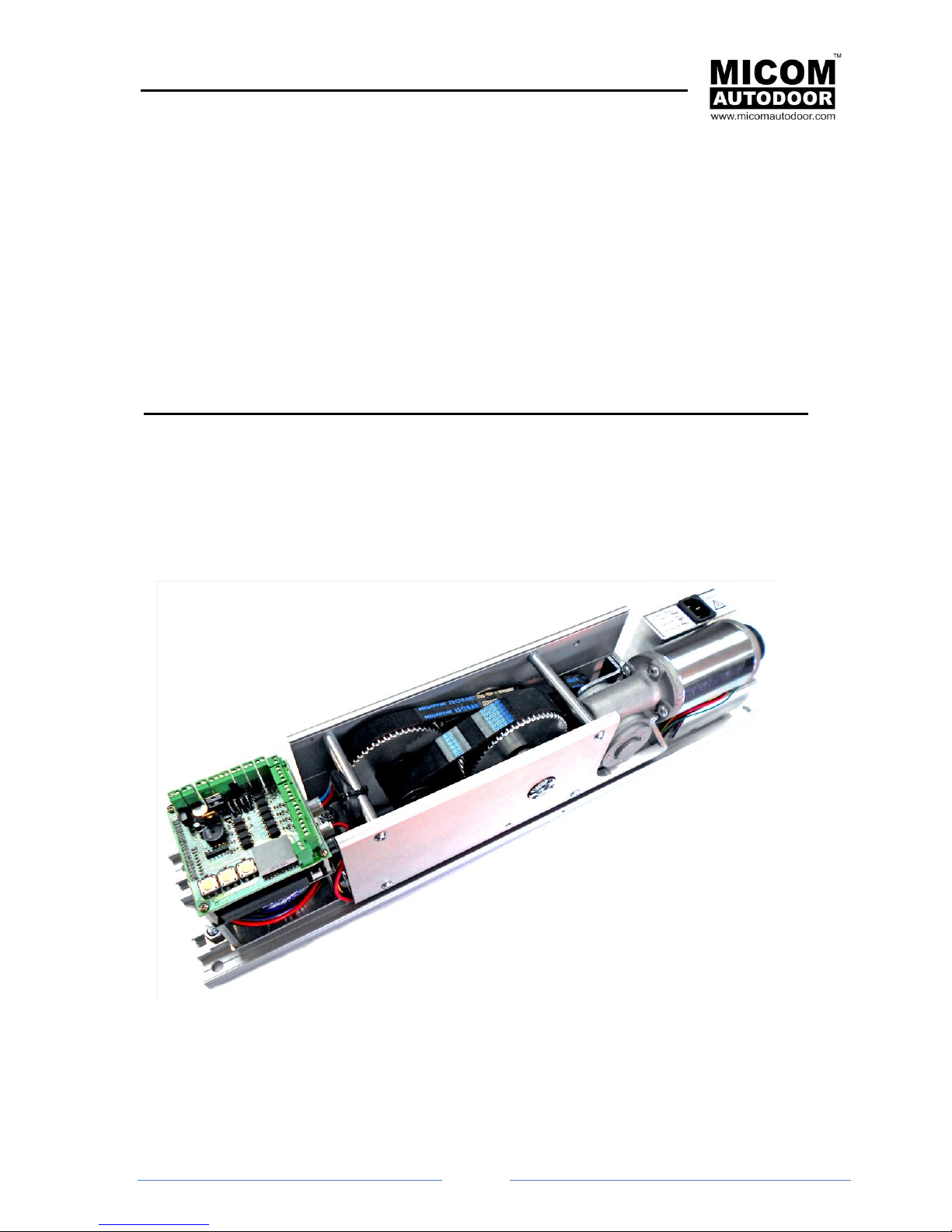

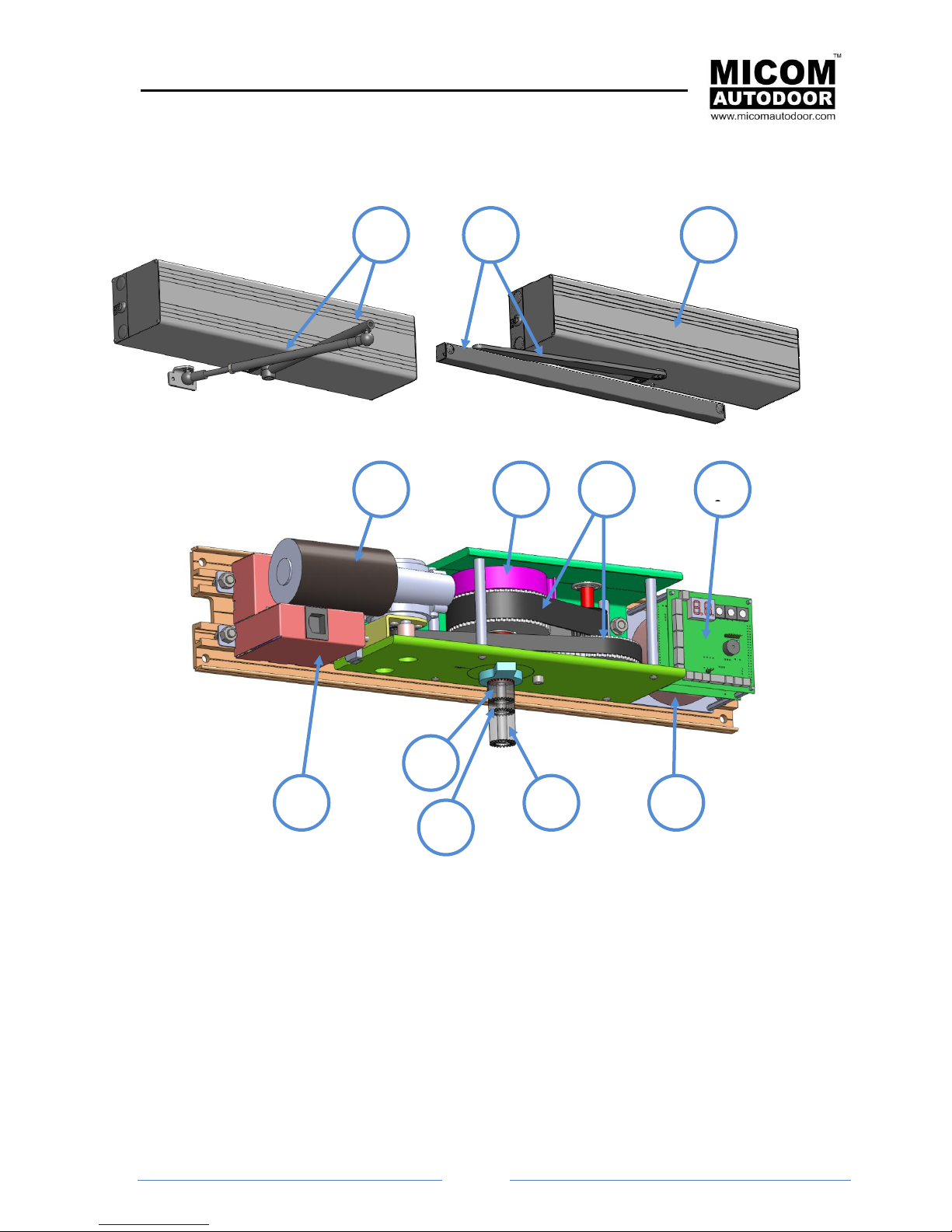

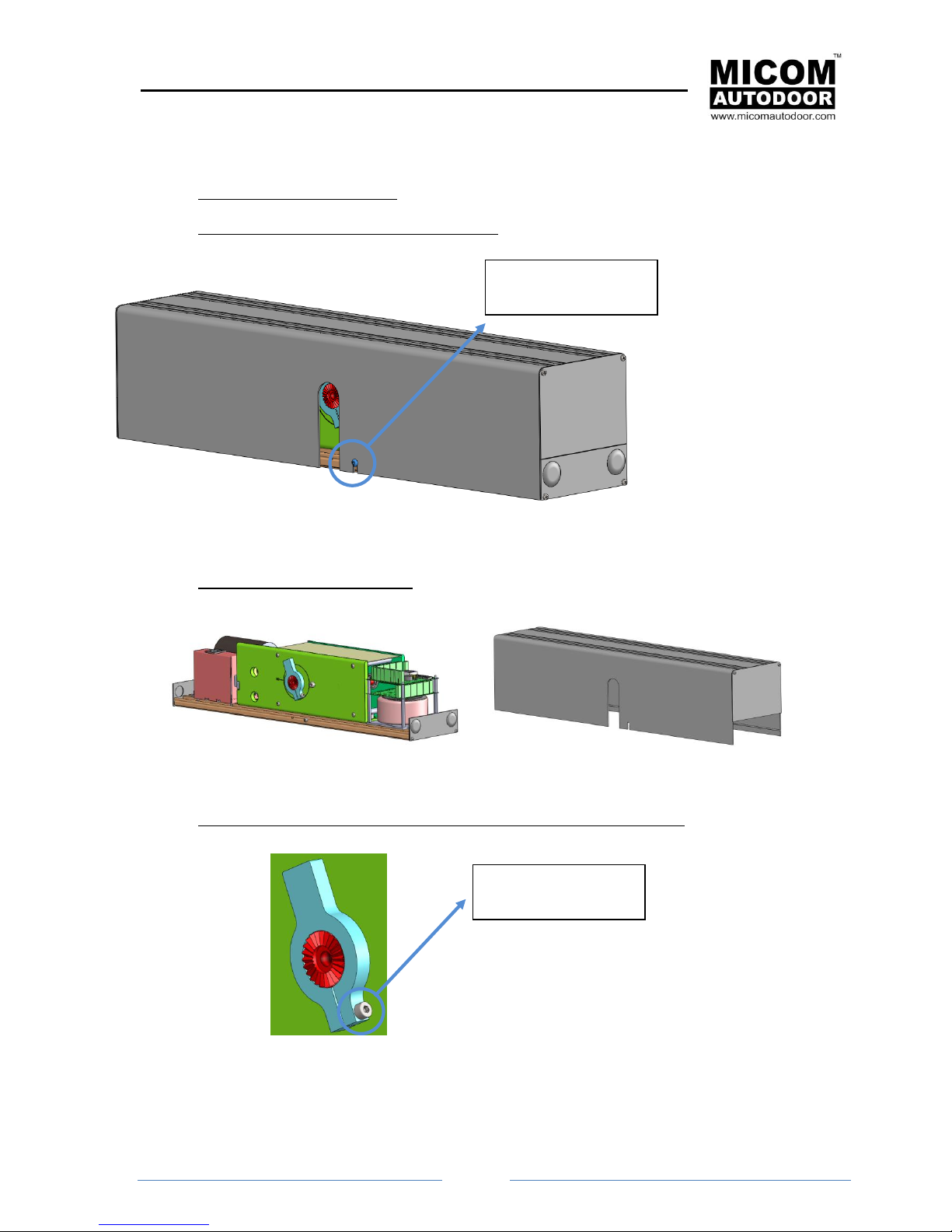

3. COMPONANT PARTS

Exterior views of the operator

Interior view of the operator

2 1 9

7

6

8

10

11 4 5

12

3

Page 9

MICOM SWING SW & SWSP

Installation Manual

Page 9

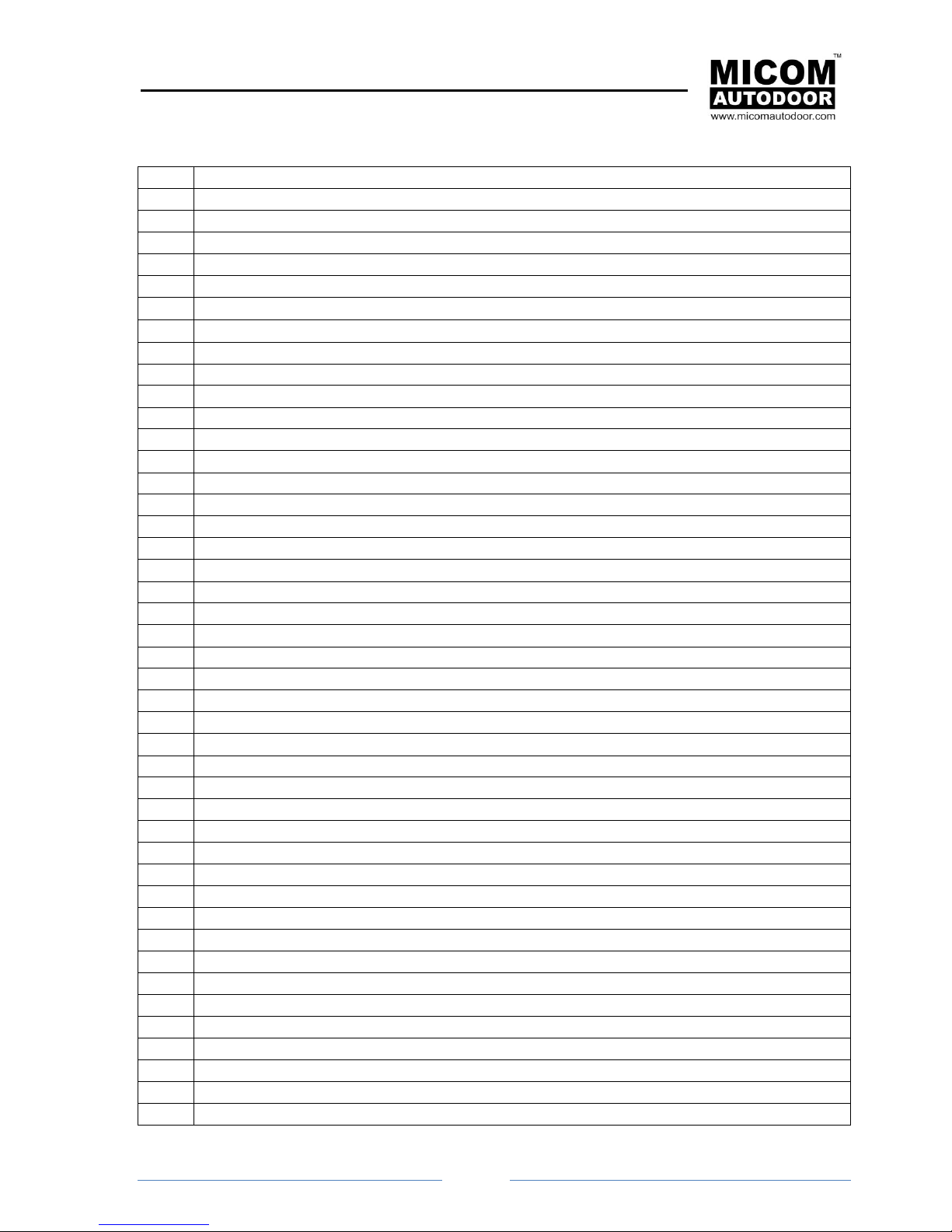

4. PARTS LIST

4.1 List of components and operators

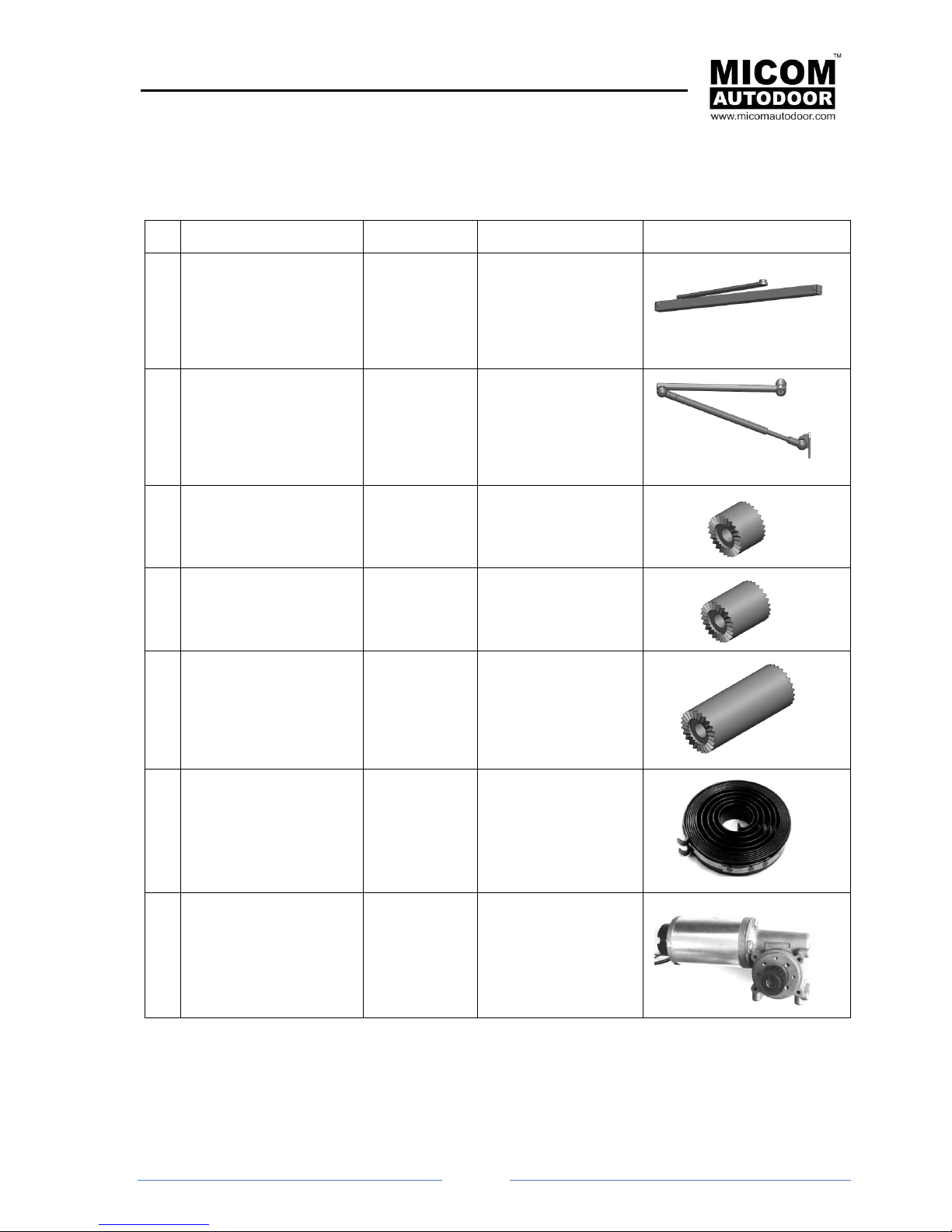

Nº

Components

Reference

Description

Image

01

Sliding arm (pull)

For MI-SW-Pull

2002277

Transmits the force of

the mechanism to the

door. Normally this is

used when the door

panel must open

inwards.

02

Articulated arm(push)

For MI-SW-Push

2002278

Transmits the force of

the mechanism to the

door. Normally this is

used when the door

panel must open

outwards.

03

Separator for MICOM

SWING-SW of 20mm

(optional)

2030001

This allows an increase

the height of the

mechanism by 20 mm

04

Separator for MICOM

SWING -SW of 30mm

(optional)

2030002

This allows an increase

the height of the

mechanism by 30 mm

05

Separator for MICOM

SWING -SW of 60mm

(optional)

2030003

This allows an increase

the height of the

mechanism by 60 mm

06

MICOM SWING-SP

SPRING

Only available for MICOM

SWING-SP operators

2002273

Allows door to close

when there is a power

cut

07

Motor-reducer for

MICOM SWING-SW

2002270

Continuous current

motor

Page 10

MICOM SWING SW & SWSP

Installation Manual

Page

10

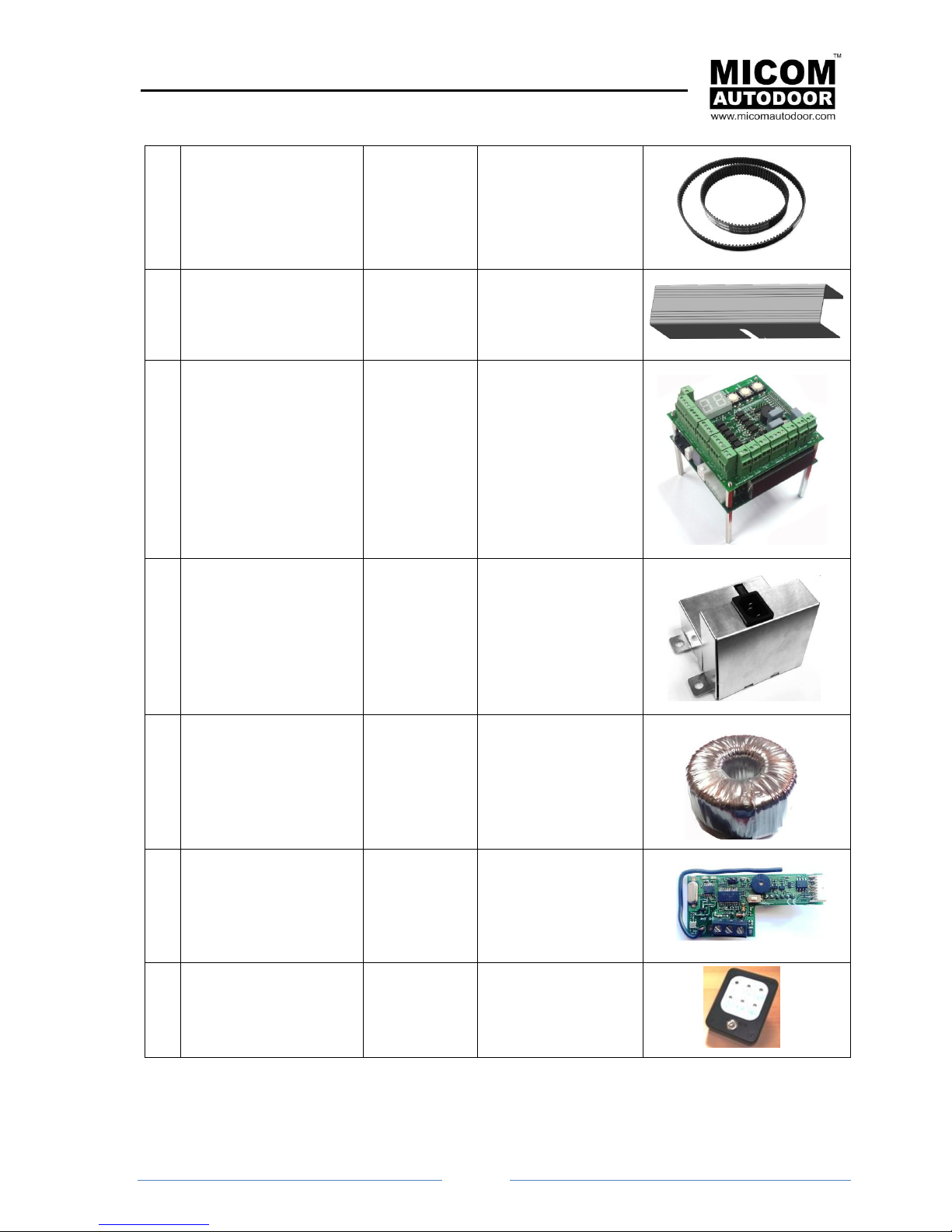

08

25mm BELT for MICOM

SWING -SW

2002271

Belt Reduction Gear

09

Front cover for MICOM

SWING -SW

2002274

Extruded Aluminum

10

Control unit for MICOM

SWING -SW

2002269

Microprocessor Control

11

Feed source for MICOM

SWING -SW

2002276

12

Transformer for MICOM

SWING -SW

2002275

13

Access control card ST500 (option)

5001097

To open the door by

means a radio

transmitter, proximity

key, tag, etc...

14

Digital selector SLD-5

(option)

2002109

Digital selector

Page 11

MICOM SWING SW & SWSP

Installation Manual

Page

11

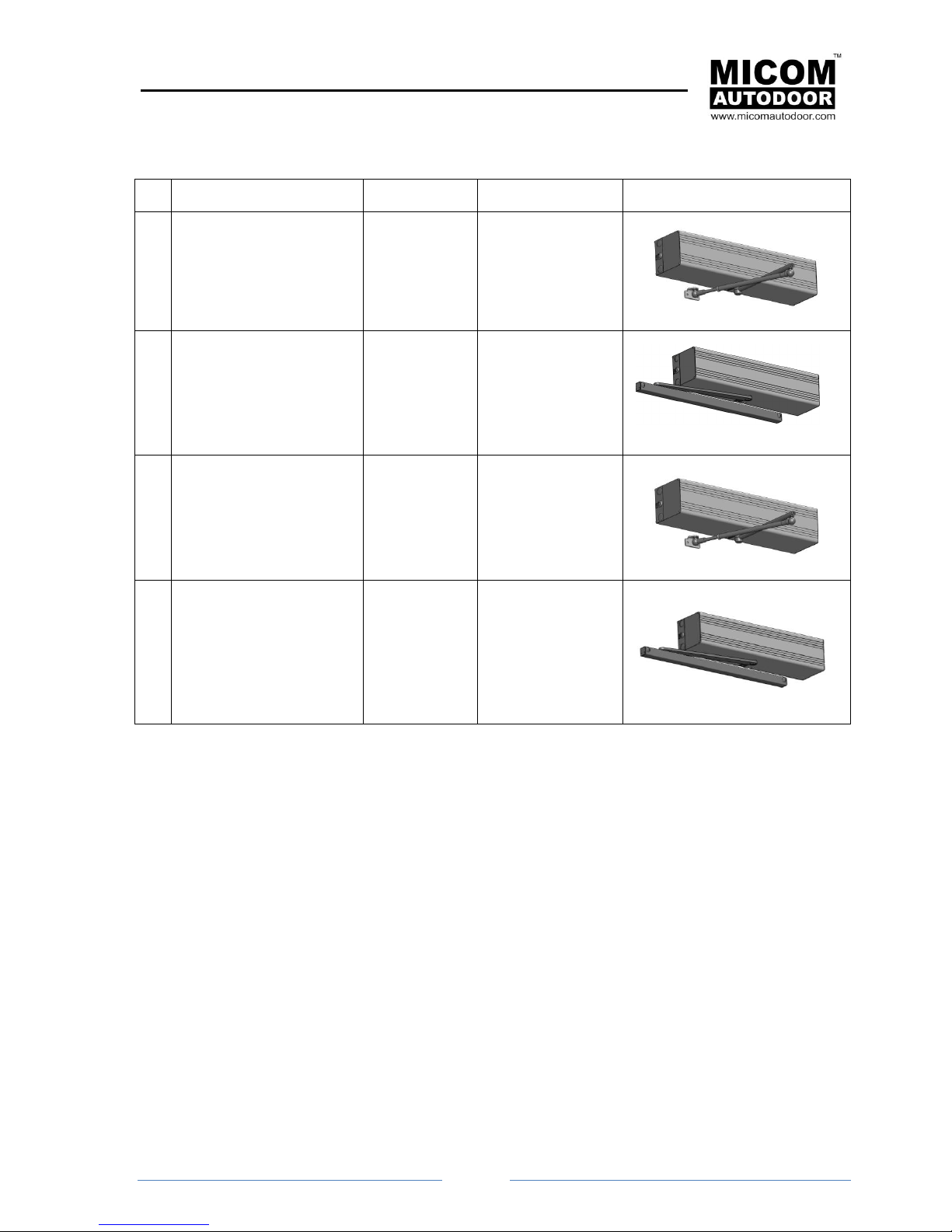

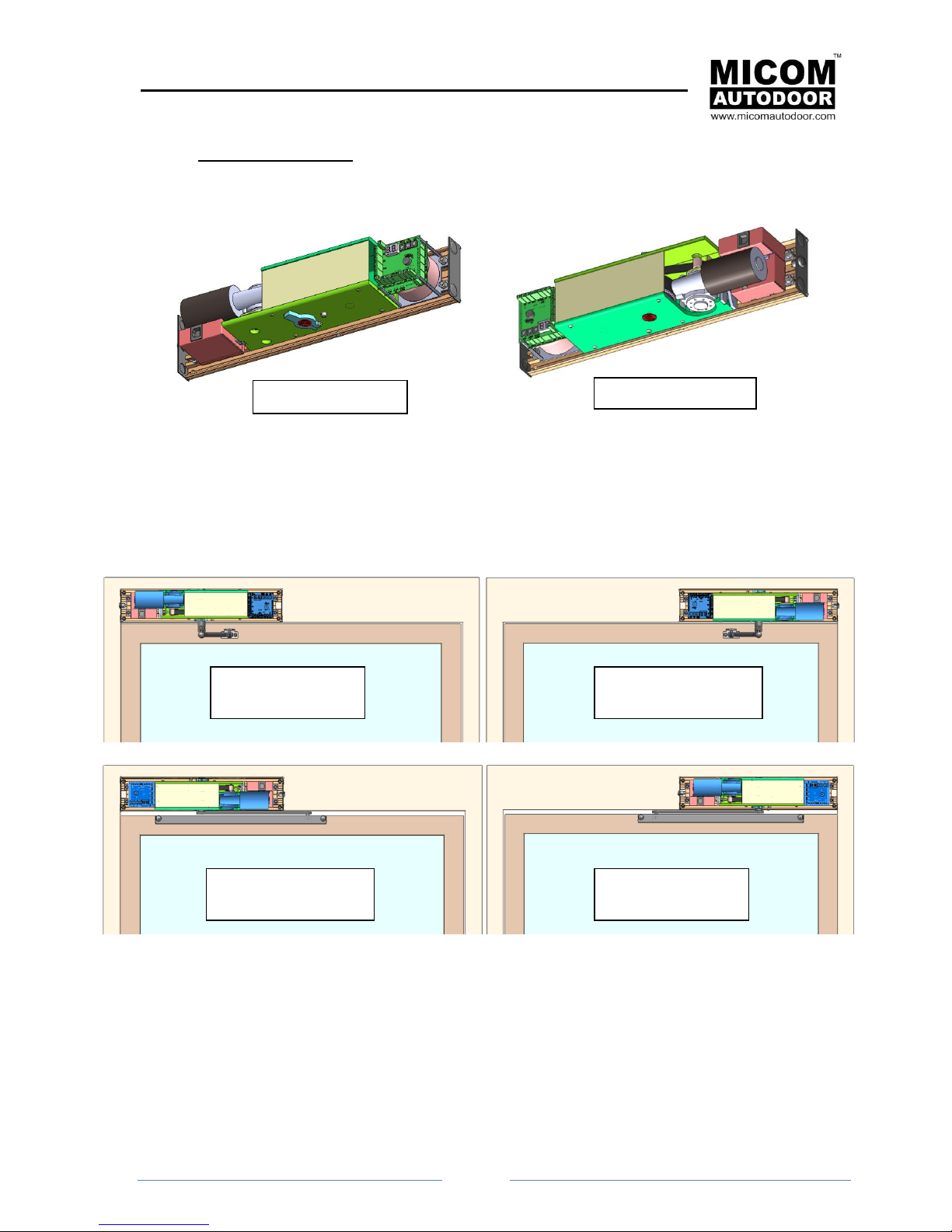

4.2 Identification of Operators

Nº

Operators

Reference

Description

Image

A1

MICOM SWING

SW-Push

2002279

Operator for swing

doors with

articulated arm

A2

MICOM SWING

SW-Pull

2002280

Operator for swing

doors with sliding

arm

A3

MICOM SWING

SWSP-Push

2002281

Operator for swing

doors with

articulated arm and

incorporated closing

spring

A4

MICOM SWING

SWSP-Pull

2002282

Operator for swing

doors with sliding

arm and

incorporated closing

spring

Page 12

MICOM SWING SW & SWSP

Installation Manual

Page

12

5. INSTALLATION OF THE OPERATOR

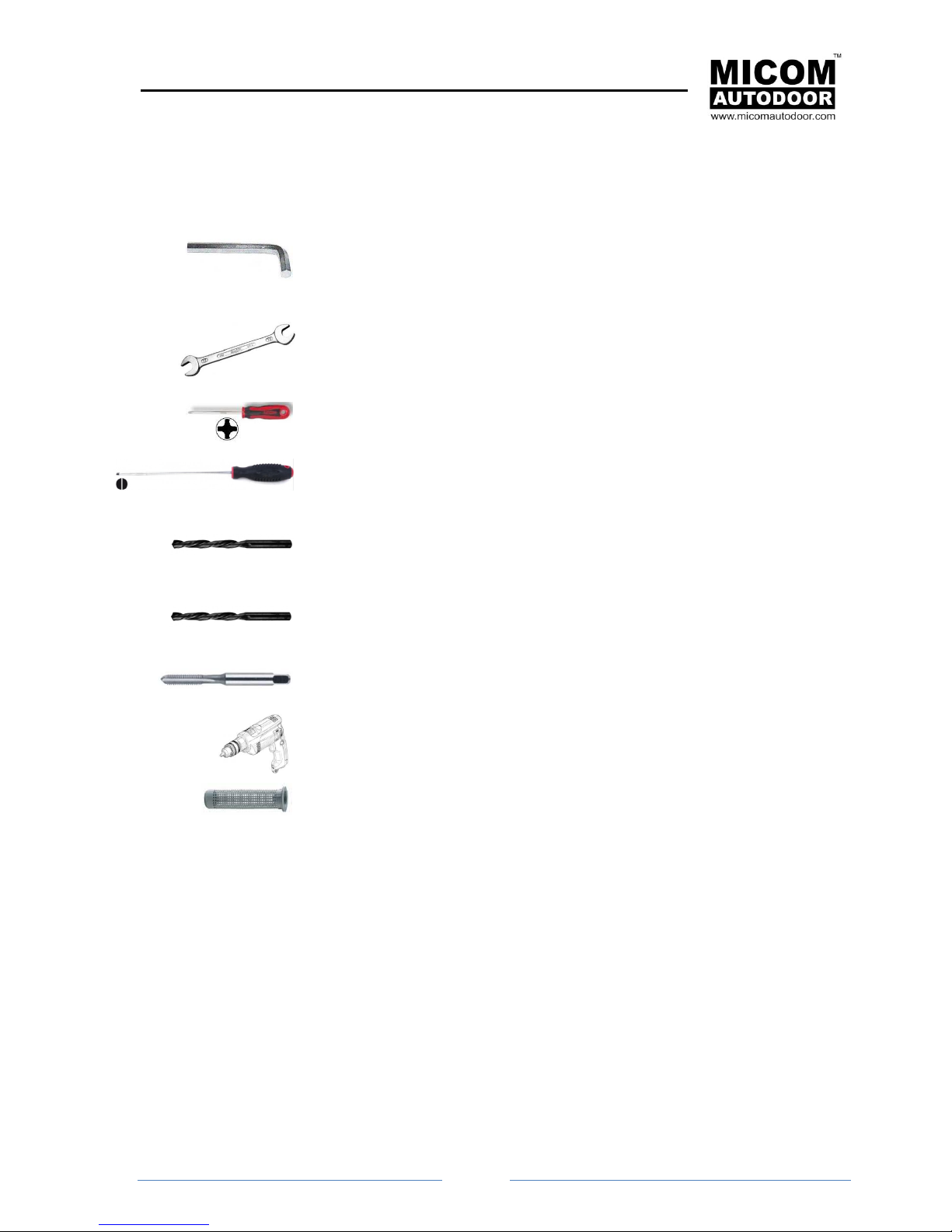

5.1 Preperation - Required tools

Allen key. Sizes:

● 2’5

● 3

● 5

Spanner. Sizes:

● 13

● 14

Phillips screwdriver. Sizes:

● #0

● #1

Flat Screwdriver. Sizes:

● 2

Drill bit for wall/concrete. Sizes:

● 8

● 6

Drill bit for metal. Sizes:

● 5

● 4

Plug for metric thread:

● M6

Drill

Wall plug

Page 13

MICOM SWING SW & SWSP

Installation Manual

Page

13

5.2 Prepare Operator

● Unpack the operator with care.

● Remove the central screw from the front cover

1. Remove the front cover with care

2. Loosen the screw at the end of the reel so that this can move or turn easily.

Remove screw with

2’5 Allen key

Loosening with Allen

key 3

Page 14

MICOM SWING SW & SWSP

Installation Manual

Page

14

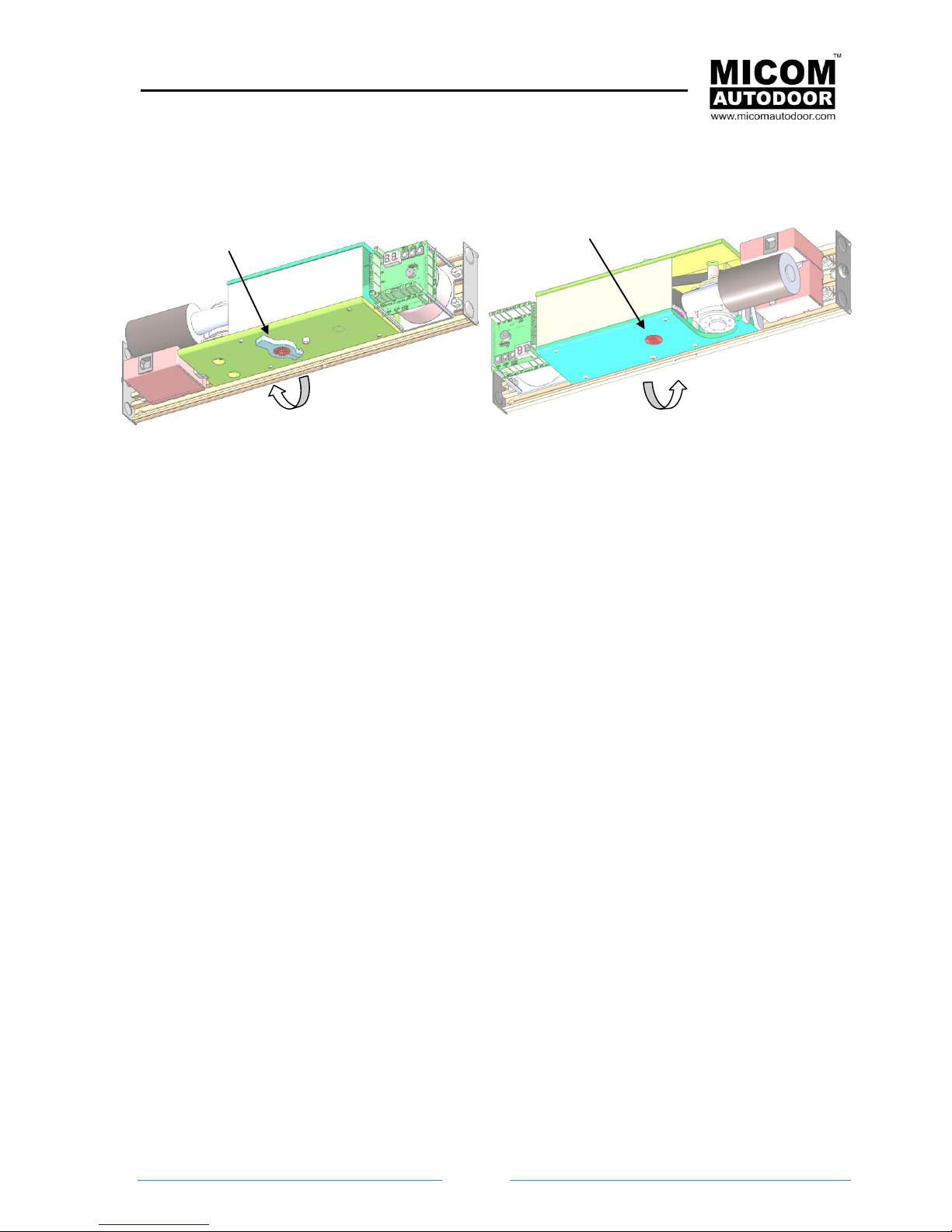

3. Orientate the operator. Before fixing the operator to the door frame or wall, we should study

the orientation of the same, which can be: Normal or Reversed.

The orientation of the operator depends on the following factors:

opening direction

placement (this can be on the framework or on the door panel)

situation of the door (right or left)

Installation Examples

The operator is totally reversible and therefore it can be adapted to any of the previous factors without

needing to change the mechanics or the programming. It is sufficient to turn it around to orientate it in

one direction or the other.

Therefore, if by mistake the operator was installed upside down. Upon giving the order to open it

actually closes, by simply changing the orientation we can solve the problem.

Normal Position

Reverse Position

Normal Position

(Left Push)

Reverse Position

(Right Push)

Normal Position

(Right Pull)

Reverse Position

(Left Pull)

Page 15

MICOM SWING SW & SWSP

Installation Manual

Page

15

There are two ways to know how to orientate the operator:

A. By Motor Pivot Direction:

A. One method consists of turning the motor’s pivot manually. We can use the operator arm

B.

B. Turning the motor’s pivot manually, we can use the operator arm to assist us. By turning

motor pivot in both directions, using the operator arm to assist in this moment by hand, we

can see that the motor turns with no resistance in one direction; while on the other hand,

turning the motor in the other direction needs greater force. In summary:

Low resistance when turning corresponds to the opening direction of the door.

High resistance when turning corresponds to the closing direction of the door.

6. FIXING OPERATOR

6.1 Introduction

In order to fix the operator to the door frame, a template is provided with indication as to where the

fixture holes should be. There are 6 holes represented (4 fix the operator to the frame and 2 fix the

operator arm to the door).

These 6 holes are the minimum required that must be used to fix the mechanism correctly.

Before proceeding to fix the operator we recommend keeping the following advice in consideration:

● If the operator is fixed to a thin metal surface (less than 10mm thickness) it is strongly advised

to use threaded screws metric size M6 instead of self-tapping screws.

● If the operator is fixed onto a hollow brick it is strongly advised to use a plastic wall plug and a

threaded rod metric size M6.

Motor Pivot Direction

Motor Pivot Direction

Page 16

MICOM SWING SW & SWSP

Installation Manual

Page

16

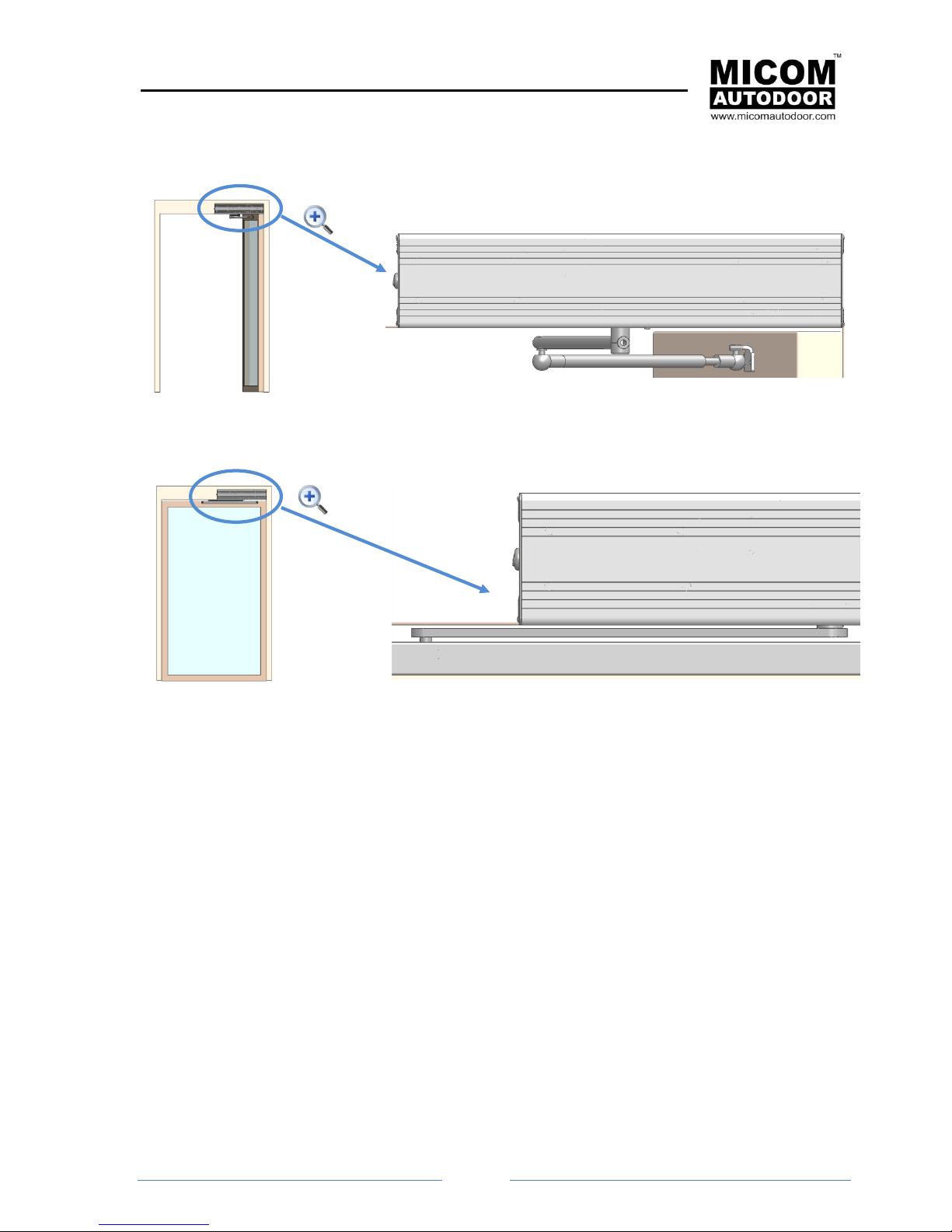

● When the operator with an articulated arm (push) is fixed, a security distance should be used

so that the arm does not hit against the door frame.

● When installing and operator with a sliding arm (pull), leave a safe distance so that the arm

does not knock against the door panel.

Important notice: In the event of using less fixture points than those required, or not following the

previous advice, there is a risk of the mechanism coming unfixed or falling. This would put the people

using the automatic door in danger.

Clearance or security distance

with respect to the door frame.

Security distance = 11mm

Clearance or

security

distance with

respect to the

door panel

(max. 9mm)

Page 17

MICOM SWING SW & SWSP

Installation Manual

Page

17

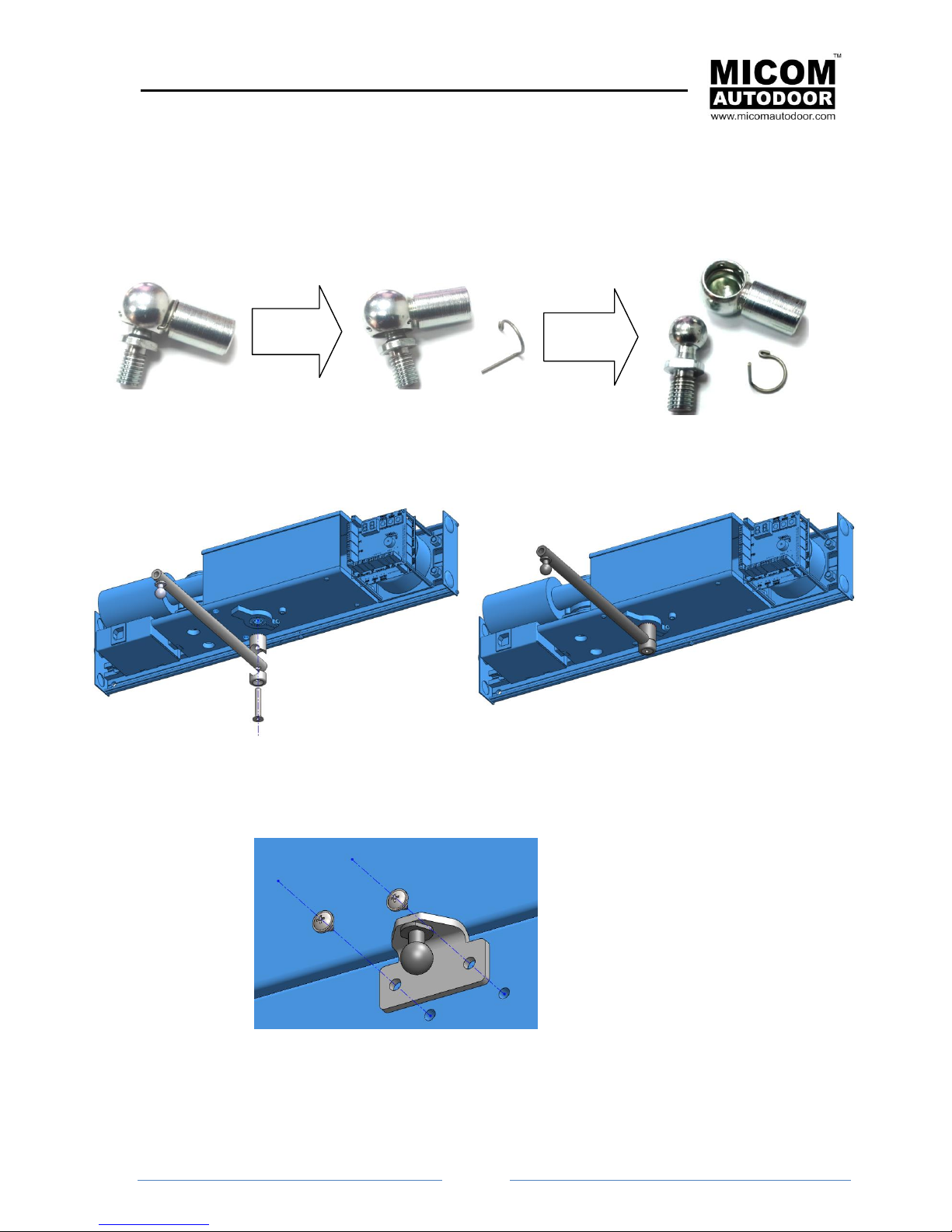

6.2 Fix and Adjust to Articulated (Push) Arm

In order to fix and adjust the articulated arm:

1. Separate the two parts of the arm joints. In order to separate them, you will have to remove

the security ring.

2. Screw in the upper part of the arm.

3. Make two holes in the door by following the indications as shown in drawings.

Remove

circlip

Separate

parts

Page 18

MICOM SWING SW & SWSP

Installation Manual

Page

18

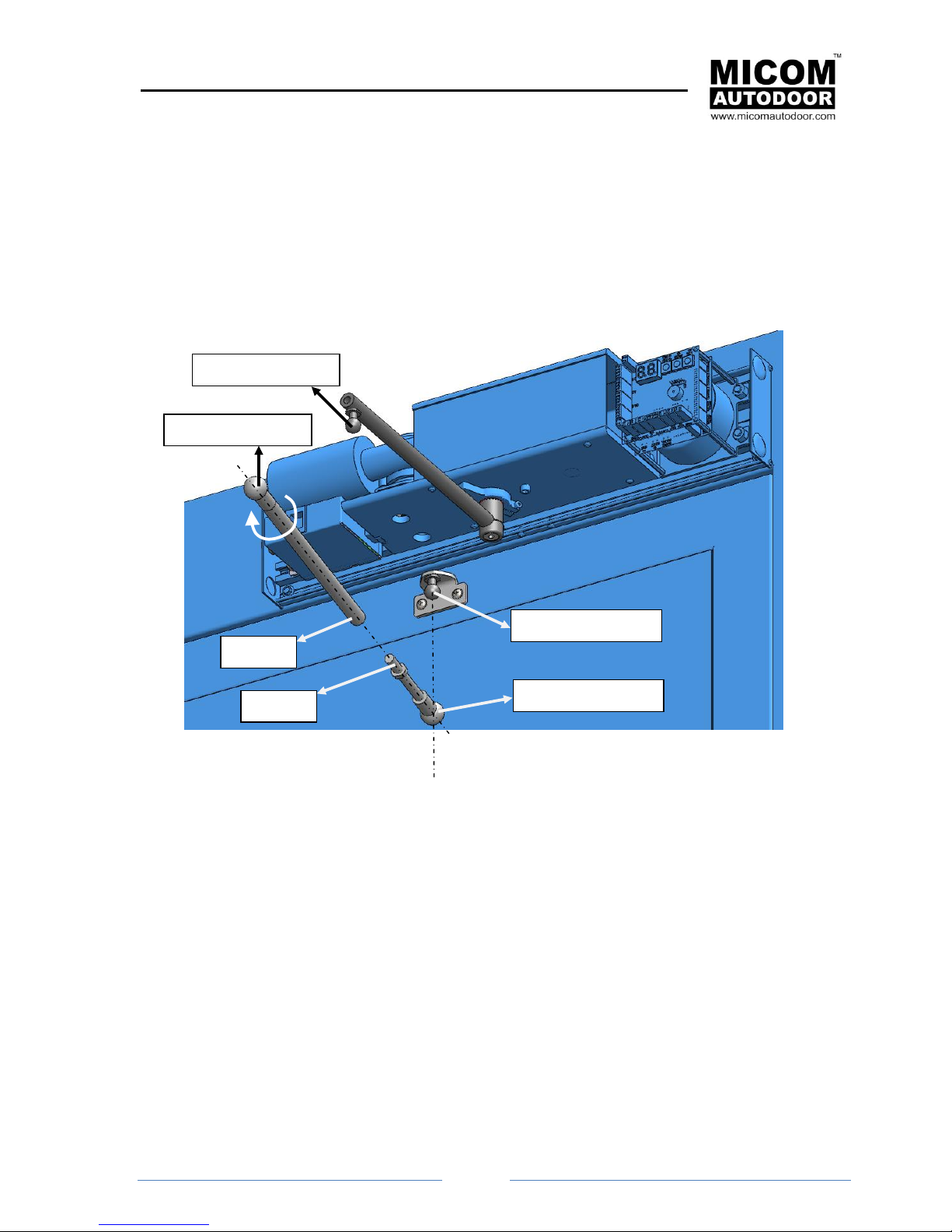

4. Introduce joint 1 (socket) into joint 2 (plug) (see the following figure).

5. Join “Part A” with “Part B” (see following figure).This will be achieved by screwing it in.

6. Close the door and keep it closed until the arm has been installed.

7. By turning “Part A” we can lengthen or shorten the arm if we turn it in one direction or the

other. Turn “Part A” so that joint 4 (socket) meets up with joint 3 (plug) (see the following

figure).

8. Then place each joint into its security ring.

9. Open and close the door and check that it is working correctly.

Note: Adjust the end of the rod (for more details see section “6.5.-ADJUST OPENING LIMIT”).

Label 2 (plug)

Label 1 (socket)

Part B

Part A

Label 4 (plug)

Joint 3 (socket)

Page 19

MICOM SWING SW & SWSP

Installation Manual

Page

19

6.3 Fixing Slide Arm (Pull)

In order to fix and adjust the sliding arm:

1. Remove the end covers to be able to work freely.

2. Introduce Part_B into Part_A, for one of its extremes.

3. Following the drawing instructions Make 2 holes in the door and fix the arm to the door panel.

4. With the door in the closed position. Fix Part_B of the arm to the motor pivot. Put the covers

back on.

Part_A

Part_B

Part_A

Part_B

Page 20

MICOM SWING SW & SWSP

Installation Manual

Page

20

6.4 Set up of the Tension Spring

MICOM SWING SPSW has a door-closing system. In order for this to function perfectly, the tension

spring must be pre-loaded. This load can be higher or lower depending upon the size/weight of the

door panel or the clients’ requirements. To load the spring:

1. Make sure the operator is not connected to the electricity supply. If it is, take the plug out from

the feed source.

2. Remove the operator arm; it will be sufficient to remove the screw that links the arm to the

motor pivot.

3. Loosen the lever screw so that this can move and turn easily.

4. Press the ‘-TEST’ button and without letting it go, connect the electricity supply to the operator

using the 3pin plug. If it has been done correctly the letter F will appear, followed by the

number 0 on the screen.

5. On the screen the letter F appears followed by the number 0, which represents the force

loaded on the spring; value 0 is the lowest. If we press +RESET, the number will increase and

the motor will start to turn. As the motor turns the spring will be charged. The higher we

increase the value, the more the spring will be charge. Please see the following table how

value F relates to the spring force.

“F” Value

Force loaded on the spring

Recommendation

0

0

Invalid

1

9Nm

Doors up to 50Kg

2

13Nm

Doors up to 100Kg

3

18Nm

Doors up to 150Kg

4

22Nm

Doors up to 180Kg

Loosen with Allen

key 3

Keep pressing before

and after connecting

the operator to the

electrical supply

Page 21

MICOM SWING SW & SWSP

Installation Manual

Page

21

6. After assigning a value to F, wait for the motor to stop turning (normally no more than a

minute). When the motor stops, close the door and fix the arm to the motor pivot.

7. Then press “-TEST” once more to save the changes and to check that the letter “F”

disappears from the screen.

8. Disconnect the operator from the electricity supply

9. Open the door manually and check that it closes by itself.

10. Adjust the end of the run.

6.5 Adjusting Opening Limit

Steps to follow:

1. Loosen the screw for the limit lever so that it can move and turn freely.

2. Open the door to the desired opening point. If the operator is spring closing, it is necessary to apply

either a door stopper or something similar so that the door stays open, until finished adjusting the

limit.

3. Turn the lever until the final limit is obtained.

Loosen with Allen

key 3

Page 22

MICOM SWING SW & SWSP

Installation Manual

Page

22

4. Tighten the lever screw so that it is fixed firmly to the motor pivot.

7. OPERATION OF MICOM SWING SW & SWSP UNIT

7.1 Start Up and Self Learning

IMPORTANT NOTICE: When the MICOM SWING SW & SWSP system starts up for the first time, the

self-adjustment process will start for the system. This process will carry out an opening and closing

cycle to find the actual length of the door stroke.

It is very important to allow the door to carry out these cycles freely, i.e. with no obstacles. It is

therefore recommended that no-one goes near the door. If the panel has any obstruction during the

learning cycle, the whole process should be re-started via the RESET on the control unit (see section

12.2.5 - for more information).

During the Self-learning process, the automatic door will automatically carry out the following actions:

1. Prior to starting, ensure that the operator selector has been connected, as well as the electricity

supply, transformer, motor and the control unit.

2.Plug in connector to the supply situated to the right of the Control Unit and place the operator

selector on any function, except that of closing or manual.

3.The door opens slowly until it reaches its opening position.

4.The door closes slowly until it reaches its closing position.

5.From here on the door will work normally, although the first movements will often brake early. As the

operator continues with the closing and opening cycles, the door will gradually find the most efficient

braking point.

This process is only carried out on the first occasion when the automatic door is activated and

every time the RESET is used. (see section“12.2.5.-”).

If for any reason you are unable to carry out the Self-learning process correctly, you must go

through the process again through “RESET” on the Control Unit.

Tighten with Allen

key 3

Page 23

MICOM SWING SW & SWSP

Installation Manual

Page

23

Every time that important changes take place on the automatic door, such as: change of

position of the stoppers, change to the size of the panels or change to the weight of the

panels, in these cases you always have to do a “RESET” in order for the Control Unit to adapt

to the changes.

After carrying out a “RESET” on the Control Unit, as well as re-starting the Self-learning, the

parameters will be cancelled off and will return to the factory settings. There are certain

parameters that will not cancel off after a “RESET”, such as: the number of cycles and the

function time.

7.2 Normal Function

In order to ensure that the System is working correctly, check the “POWER ON”, located on the

Control Unit is always switched ON.

When the Control Unit receives an impulse to open (for example, a movement sensor, an emergency

command or switch/sensor) the “INPUT ON” on the display screen will activate. The motor will then

start to turn and provide movement to the automatic door panels to open.

When there is no signal to open, the motor will turn in reverse direction until the door is fully closed.

When it receives the signal to stop (by means of pressing the emergency stop button) the door will

brake and will remain still while the signal to stop is in place.

POWER ON

INPUT ON

Page 24

MICOM SWING SW & SWSP

Installation Manual

Page

24

7.3 Electrical Fault

If the operator is equipped with a battery system (optional) and there is a cut in the electricity supply,

the door will continue to function normally until the battery is dead.

Once the battery is almost empty, the automatic door will cease to function until the general electricity

supply returns or until the “Night Bank” or Night Switch is activated.

If the “Night Bank” (switch) comes into action, it will activate the battery system and the motor will

open/close the door.

When the electricity supply fails and if the operator is not equipped with a battery system:

- with the MICOM SWING-SW model will stop working.

- with the MICOM SWING-SWSP model the door will only close.

7.4 Errors

A case could occur where the system has suffered a problem and therefore would cease to function

correctly, e.g. in the event of a power cut or when the automatic door hits a pedestrian.

In these cases, the automatic door will give both a visual and acoustic signal to indicate what error

has taken place (for more information see section”14. PROBLEM SOLVING. ERROR TABLE”).

Page 25

MICOM SWING SW & SWSP

Installation Manual

Page

25

8. CONNECTIONS

8.1 Connection to the Electrical supply

The control unit can work at 230V or 110V, depending on client requirements. The feed power is 230V

when it leaves the factory but the system can be configured to work at 110V; only a small modification

has to be carried out inside of the feed supply (contact us for more details).

The control unit is compatible with frequencies 50Hz and 60Hz.

Power connection is by way of 3 pin connector plug located in the upper part of the operator (see the

following image). It is compulsory to earth the power supply in order to avoid problems when the

product is working and also to protect users from dangerous situations.

ATTENTION!!

Be extremely careful

with this

connection. An error

can damage the

Control Unit and

cause serious injury

or death.

Live

Earth

Neutral

Page 26

MICOM SWING SW & SWSP

Installation Manual

Page

26

8.2 Internal Basic Connections

Connection from the transformer to the feed supply.

The connection from the transformer to the supply should be done with an 8-wire cable. This

connection takes place in the factory and the technician should only have to do it in the event of a

breakdown or when having to replace components (see the following figure for more details).

Connection from the supply to the control unit.

The connection from the supply source to the control unit will be done with a 4-wire cable. This

connection will be done in the factory and the technician should only have to do it in the event of a

breakdown or when having to replace components (see the following figure for more details).

Connection from the motor to the Control Unit

The connection from the motor is done with two cables: one of 2 wires (feed) and the other 4 wires

(position coder). This connection is done in the factory and the technician should only have to do it in

the event of a breakdown or when having to replace components (see the following figure for more

details).

Connection:

Motor / Control Unit

Connection:

Transformer / Power Supply

Connection:

Power Supply / Control Unit

Page 27

MICOM SWING SW & SWSP

Installation Manual

Page

27

9. Connection of other Components

The EMICON card provides the function of inter-connecting the Control Unit to the various

components: emergency battery, sensors, emergency button, control system, selectors, etc.

The following are the connections:

P2: 24Vdc Output. 0,3A max

P3: Security sensor monitor (TEST)

P4: Emergency Stop

P13: Emergency Open/Close

P11: Selector B

P7: Selector A

(It is located

on the side of the

operator)

P6:

24Vdc bolt

(Lock)

P9: Internal Sensor

P10: Closing safety

Sensor (Security 1)

P8: External Sensor

P5:

Night

Bank/

Switch

P14: Opening safety

Sensor (Security 2)

P12:

12Vdc bolt

(Lock)

P1: Access control card ST-500

Page 28

MICOM SWING SW & SWSP

Installation Manual

Page

28

9.1 P1 Connector. Access control card ST-500 connection

The P1 connector links to the access control card, which allows control of the opening and closing of

the door by means of remote controls, proximity key, tag, etc.

9.2 P2 Connector. 24V output

The P2 connector has a power supply output of 24V. This output can be used when additional

components are required to be connected to the automatic door, e.g. access control systems via

password, etc.

Consider the consumption required by the component being connected as the maximum current is

300mA.

Access control

card ST-500

Page 29

MICOM SWING SW & SWSP

Installation Manual

Page

29

9.3 P3 Connector. Monitoring output (Security Sensor Monitor)

The P3 connector is a communication output used by some presence detectors. It will check if the

sensor is working correctly with this communication and therefore increasing the level of security for

the automatic door (EN16005).

This connection takes place between the P3 connector and the sensor input, which is usually called

“MONITORING”, or supervision input”.

The P3 connector output is 24V and its polarity must be taken into consideration as shown in the

following image:

Page 30

MICOM SWING SW & SWSP

Installation Manual

Page

30

NOTE: The Control Unit does not have the Monitoring function activated when it leaves the factory.

In order to activate it, parameters 18, 19 or 35 need to be programmed - depending upon which

sensor we want to Monitor in the Control Unit (see section “12.-PROMGRAMMING OF THE

CONTROL UNIT”).

Parameter 18 activates the Monitoring of the sensors connected to P10 (Closing Safety), Parameter

19 P9 (internal sensor).

Parameter 35 activates the Monitoring of the sensors connected to P14 (Opening Safety).

P3 is connection of the Monitoring signal of multiple sensors. i.e : safety when closing, movement or

safety when opening.

9.4 P4 Connector. Emergency Stop

The P4 connector is an input used for connection to the emergency stop device. This input is

programmed when leaving the factory to work with Normally Open contacts (NO), but can be

programmed to work with Normally Closed contacts (NC), (please see section “13 PROGRAMMING PARAMETRES” - Parameter Nº22”).

When this input is activated the door will immediately stop.

9.5 P13 Connector. Emergency Open/Close

This input is connected mainly to the fire alarm and anti-panic systems and its function is to Open or

Close the door in any situation, except when the function selector is in the position of CLOSED or

MANUAL.

This input is programmed at the factory so that it works with Normally Open (NO) contacts. The door

can open but it can be programmed to function with Normally Closed (NC) contacts, or for the door to

close (see section “13.-PROGRAMMING PARAMETRES” - Parameter Nº32”).

9.6 P5 Connector. Night Bank / Switch

Its function is to Open the door in whatever situation, including a power cut (battery optional).

In the event of a fault in the general electricity supply, this signal can open the door by making use of

an emergency battery (this battery is optional and is not included in the operator).

This input has priority over the function selector.

This input only works with Normally Open (NO) contacts.

9.7. P6 Connector. E-Lock or Automatic Bolt (Lock) 24Vdc

The P6 connector is a 24Vdc output.

NOTICE! Never go over the maximum consumption. If so the control unit will be damaged. The

maximum consumption is 7W (300mA).

Automatic alternating current bolts are not allowed; their use provokes severe damage to the control

unit. Only automatic bolts that work with direct current can be connected. Special attention should be

paid to the voltage value; in the event of placing an automatic bolt that is different from 24V, the

control unit will be damaged.

Page 31

MICOM SWING SW & SWSP

Installation Manual

Page

31

This input has 5 working modes:

Value 0 = No Lock Fitted (recommended when using Push&Go)

Value 1 = Automatic Bolt unlocked with 12/24Vdc; and locked with 0V. *

Value 2 = Automatic Bolt unlocked with 0V; and locked with 12/24Vdc. *

Value 3 = Automatic Bolt unlocked with 12/24Vdc; and locked with 0V. **

Value 4 = Automatic Bolt unlocked with 0V; and locked with 12/24Vdc. **

* It unlocks just prior to the door opening and during the first 0º~20ºof opening.

** It unlocks just prior to the door opening and during the entire process of opening/closing.

These functions are programmable in the Unit Control (see section “13.-PROGRAMMING PARAMETRES” -

Parameter Nº15).

Page 32

MICOM SWING SW & SWSP

Installation Manual

Page

32

In the event that the E-lock used should have polarity, the connection has to be carried out as follows:

Note: If the E-Lock product has no polarity, then connections are free

9.8 P12 Connector. Supply for E-Lock or automatic bolt 12Vdc (Lock)

The P12 connector has the same qualities as the P6. The only difference is that the P12 connector

works with 12Vdc voltage and therefore the automatic bolts connected in the P12 must be 12V DC.

Note: Special attention must be given to the working voltage value; in the event of placing an

automatic bolt that is different from 12 V, the control unit will be damaged.

Page 33

MICOM SWING SW & SWSP

Installation Manual

Page

33

9.9 P9 Connector. Internal movement sensor (Internal Sensor)

The P9 connector is used to connect a motion sensor.

The connector consists of 4 poles:

● Two poles are used to supply the sensor. The output is 24V DC.

● The other two poles are the input of the sensor signal, which can be: free of voltage (relay

output, no polarity) or by transistor (with polarity).

The signal input is programmed at the factory to act as a Normally Open contact. It can also be

configured as Normally Closed contact (see section “13.-PROGRAMMING PARAMETRES” Parameter Nº19).

9.10 P8 Connector. External movement sensor (External Sensor)

The P8 connector is used to connect a movement sensor.

The connector consists of 4 poles:

● Two poles are used to supply the sensor. The output is 24V DC.

● The other two poles are the input of the sensor signal, which can be: free of voltage (relay

output, no polarity) or transistor (with polarity).

The input signal is programmed from the factory to act as a Normally Open contact, although it can be

configured as a Normally Closed contact as well (see section “13.-PROGRAMMING PARAMETRES”

- Parameter Nº20”).

Page 34

MICOM SWING SW & SWSP

Installation Manual

Page

34

Its connection is identical to that of the P9 connector, except that it can be carried out in the P8

connector.

9.11 P10 Connector: Closing Safety Sensor 1 (Security 1)

The P10 connector is used to connect the security sensor (or presence sensor) which protects from

possible obstruction in the door closing movement.

The connector consists of 4 poles:

● Two poles are used to supply the sensor. The output is 24V DC.

● The other two poles are the input to the sensor signal, which can be: free from voltage (relay

output, no polarity) or by transistor (with polarity).

The signal input comes programmed from the factory to act as a Normally Closed contact, although it

can be configured as a Normally Open contact as well (see section “13.-PROGRAMMING

PARAMETRES” - Parameter Nº21”).

Page 35

MICOM SWING SW & SWSP

Installation Manual

Page

35

In the event of needing more than one security sensor with NC (Normally Closed) contacts there

needs to be a connection in series with the signal sensors, just as can be seen in the following figure:

9.12 P14 Connector: Opening Safety Sensor 2 (Security 2)

The P14 connector is used to connect the security sensor. This sensor protects from possible

collisions of door opening movement.

The connector consists of 4 poles:

● Two poles are used to feed the sensor. The output feed is 24V DC.

● The other two poles are the input of the sensor signal, which can be: free of voltage (relay

output, no polarity) or transistor (with polarity).

The signal input comes programmed from the factory to act as Normally Open contact, although it can

be configured as a Normally Closed contact as well (see section “5.3.-PROGRAMMING

PARAMETRES” - Parameter Nº33”).

Its connection is identical to that of the P10 connector except that it is carried out in the P14

connector.

Page 36

MICOM SWING SW & SWSP

Installation Manual

Page

36

9.13 P7 Connector: Selector A (Switch in three positions)

The P7 connector connects the selector on the side of the operator.

This selector has three positions, which are:

I - HOLD OPEN - This mode allows the door to stay open.

0 - MANUAL – The door will only open or close manually.

II - AUTOMATIC - This mode allows entering and exiting automatically.

The connection is carried out by a two-wire cable without polarity.

This connection is carried out in the factory and is very simple to replace if needed.

Note: If Selector B (Digital) is connected the action of this selector will be cancelled. Selector B will

have priority over Selector A.

2 Cables

Page 37

MICOM SWING SW & SWSP

Installation Manual

Page

37

9.14 P11 connector: Selector B (Digital)

The P11 connector connects a Digital Selector. In order to change the function mode of the automatic

door and keep it in its memory.

The connection is by a 4- wire cable. Please be careful in the connection because these cable hasve

polarity.

Note: Bridge P7 of the control unit must be connected (it already comes connected from the factory).

Digital Selector B

The voltage used is 5V.

Multiple selectors B (Digital) can be connected to the same Control Unit.

When this selector is connected to the Control Unit, Selector A (three position selector) becomes

deactivated and stops working.

If multiple Selector B (Digital) are required, the following configuration of Selector B is necessary:

1.- Open the cover to access to the electronic board. For this you will have to remove 4

internal screws.

2.- Once the screws have been removed, remove a “Bridge” called P5.

3.- This procedure should be carried out on all the selectors connected to the operator

EXCEPT in one of them. This should be the one furthest away from the operator. If, for

example, we have an operator with three connected selectors, we should remove the “bridge”

to the two selectors nearest to the operator; the selector which is the furthest away, will not be

modified.

NOTICE! Selector B (Digital) must be connected to the correct Connector. If connected to

wrong connector (for example, sensor or security sensor), it will be irreversibly damaged and

could also damage the Control Unit.

Page 38

MICOM SWING SW & SWSP

Installation Manual

Page

38

Operating Modes

The Selector B (Digital) has 6 buttons, giving various working modes. It also has 6 LED indicators that

show the current working mode. All of the working modes available are as follows:

“Close” mode. This mode allows us to close the door (locked if it has an electro-

magnetic lock). In this mode the emergency opening system (battery) will remain

disconnected.

“Exit only” mode. This mode only allows to exit.

“Entre only” mode. This mode only allows Entry only.

“Automatic” mode. This mode allows to enter and exit.

“Permanently open” mode.

“Manual” mode. In this mode, the operator does not act on the door and allows it to

open or close manually.

Memory Retension

Another function that Selector B (Digital) offers is to save the setting in the memory even after a

power cut. There are 2 possible working modes.

“NO MEMORY” mode. In this programming mode the state of the selector is NOT saved in the

memory in the event of a power cut. When the power resumes the automatic door will always be reestablished in the “close” working mode.

In order to activate the NO MEMORY mode, keep the ‘close’ button pressed down for 5 seconds.

“WITH MEMORY” mode. In this programming mode, the state of the selector is saved in the

memory when there is a power cut and therefore when the electric supply returns, the operator will

Page 39

MICOM SWING SW & SWSP

Installation Manual

Page

39

resume the same state as to prior to the power cut.

In order to activate the WITH MEMORY mode, the ‘Automatic’ button must be pressed down for 5

seconds.

Note: This programming mode has been implemented by the factory.

10. DOULE DOOR OPERATION (DUAL)

Installation of Double Swing operation:

● Two operators are used in double doors - one for each door. Install both operators (for more

information see section 5.-OPERATOR INSTALLATION).

● Place a bridge P17 in each of the control units (this comes installed from the factory).

● Connect the TX signal from the P11 connector from operator 1 with the TX signal connector

P11 of operator 2. Connect the RX signal of the P11 connector of operator 1 with the RX

signal of the P11 connector of operator 2.

● Check the resistance value with a polimetre (Ω) between TX and RX. If everything is correct,

you should obtain a value between 55 and 65 Ω. If this is not the case, check that a bridge

has been done on P17. If you continue to receive an incorrect value, remove the bridge

situated in the B selectors (digital).

● Go into programming and assign the following values to the Master door:

● Parameter 37 = 1

● Go into programming and assign the following values to the Slave door:

● Parameter 37 = 2

● It may be required to alter the following parameters relating to the double doors:

● Parameter 38, Parameter 41, Parameter 42.

Page 40

MICOM SWING SW & SWSP

Installation Manual

Page

40

11. PROBLEMS

11.1 Interference

NOTICE: In certain automatic doors installations it could require to wire cables together. This should

never be done. It is important to keep sensor and function selector cables apart from mains power

cables. If wired together, it could make the microprocessor function incorrectly in either the long term

or short term, resulting in irreversible damage and break down.

If it is necessary to pass all cables through the same pipe, the cables belonging to the automatic door

must be shielded and earthed at both ends. Always try to keep the power cables (230V or 110V) away

from the signal cables (photocell, selector, radar, motor, etc.).

The function selector cable and the power supply cables (230V or 110V) should never be bound

together and must always where ever possible be separated.

Page 41

MICOM SWING SW & SWSP

Installation Manual

Page

41

12. PROGRAMMING THE CONTROL UNIT

12.1 Introduction

The Control Unit has an area dedicated to programming of distinctive parameters of the automatic

door, such as: speed, opening time, brake power, etc.

The programming is carried out via a LED display and 3 buttons, as shown in the following image.

12.2 Programming Menu

12.2.1 Enter into the programming menu

To get into the programming menu press the “ENTER PROG.” for approximately 5 seconds.

While pressing “ENTER PROG.”, the Control Unit will make a sound and the display screen will show

the letter “P”, once every second.

Once 5 seconds have passed, a “00” message will show on the screen and this will indicate that the

programming menu is now active. Stop pressing “ENTER PROG.”.

This operation should only be carried out after the automatic door has stopped.

12.2.2 Modify the programming parameter

When in the programming menu, modify the programming parameters as follows:

- Initially the display will show two digits that go from “00” to “50”, this represents the parameter

we wish to modify (see section “5.3.-Programming parameters”).

Pressing “ENTER”, it will show the value of the parameter which is represented by “=”,

followed by the number representing this value, e.g. “=0”.

Every time press “ENTER” it will go between the change parameter mode and change

parameter value mode.

- When the buttons “+” and “-” are in the change parameter mode, select the parameter

required. When in the change of parameter value mode, these buttons will increase or

decrease this particular value.

DISPLAY

Buttons

Page 42

MICOM SWING SW & SWSP

Installation Manual

Page

42

12.2.3 Exit Programming Menu & Saving Modifications

In order to exit the programming menu and save all the changes carried out, you must do the

following:

● Go into the “00”parametre

● Press “ENTER”

● Press “+”

12.2.4 Programming Example

We wish to change the option how the emergency stop works and we want this function to act as

normally closed contact. In order to do this we need to follow the following steps:

● If the door is working, we have to wait until it finishes opening or closing. In order to avoid

possible accidents while we reprogrammed, we recommend putting the function selector at

“door closed” or “door open”.

● Hold the “ENTER” button for 5 seconds until the display screen shows the “00” message.

● Now press 22 times on the “+”, that is until the number 22 appears on the display (if we look

at the table from section “5.3.- Programming parameters”, we will see that 22 represents the

emergency stop parameter).

● Press “ENTER”. The display screen will show the “=0” value which indicates that the

emergency stop is configured to work as a normally open contact.

● Press “+”. The display screen will show the “=1” value which indicates that the emergency

stop is configured to work as a normally closed contact.

● Press “ENTER”. The display screen will show the value “22”.

● At this moment, the emergency stop has been programmed as a normally closed contact.

Now we are need to Exit the programming and save the data:

● Press “-“ 22 times, i.e. until the value of “00” appears on the display screen.

● Press “ENTER”.

● Press “+”.

Page 43

MICOM SWING SW & SWSP

Installation Manual

Page

43

2. Press and hold “ENTER PROG.”

1. Press and hold “+ RESET”

3. If done correctly, 3 red lines will blink on the

display. Press and hold both buttons until sound

signal disappear (5 seconds approx.).

12.2.5 RESET of the programming

The control unit retains programming parameters in its memory and also other important details such

as door operation setting from the learning process as well as braking adjustments etc…

This data can be reset to factory default setting.

The RESET of the Control Unit can be done in two ways:

First (recommended)

● Remove the power supply from the Control Unit (if so, also the battery).

● Press the “RESET” button and keep it pressed, then re-insert the power supply to the Control

Unit.

● Wait 5 seconds until the Control Unit stops beeping.

● Stop pressing the “RESET” button.

Second

● Press the “+ RESET” button and then “ENTER PROG.” and maintain them both pressed for

5 seconds.

Page 44

MICOM SWING SW & SWSP

Installation Manual

Page

44

13. PROGRAM PARAMETERS

Parameter

Description

Adjust

Value

Factory

Setting

00

Exit programming

01

Display screen rotation

From 0 to 2

0

Value 0 = Automatic

Value 1 = Normal

Value 2 = Reserve

02

Automatic Closing Timer

From 1 to 9

2

Value 1 = 1 second

Value 2 = 2 seconds

Value 3 = 3 seconds

Value 4 = 4 seconds

Value 5 = 5 seconds

Value 6 = 10 seconds

Value 7 = 20 seconds

Value 8 = 30 seconds

Value 9 = 60 seconds

03

Opening Speed

From 0 to 9

6

Value 1 = 15º/s

Value 2 = 25º/s

Value 3 = 35º/s

Value 4 = 45º/s

Value 5 = 50º/s

Value 6 = 55º/s

Value 7 = 60º/s

Value 8 = 65º/s

Value 9 = 75º/s

04

Closing Speed

From 0 to 5

2

Value 1 = 15º/s

Value 2 = 25º/s

Value 3 = 35º/s

Value 4 = 45º/s

Value 5 = 50º/s

05

Dynamic Opening Force

From 1 to 9

9

Value 1 = Even Minimum Strength

Value 9 = Even Maximum Strength

06

Dynamic Closing Force

From 1 to 9

9

Value 1 = Even Minimum Strength

Value 9 = Even Maximum Strength

Page 45

MICOM SWING SW & SWSP

Installation Manual

Page

45

07

Opening Deceleration

From 0 to 9

5

Value 0 =Gradual Deceleration

Value 9 = Rapid Deceleration

08

Closing Deceleration

From 0 to 9

0

Value 0 = Gradual Deceleration

Value 9 = Rapid Deceleration

09

Static Opening Force

From 0 to 4

0

Value 0 = 0 N

Value 1 = 10 N

Value 2 = 20 N

Value 3 = 30 N (recommended in areas of high winds)

Value 4 = 40 N ((recommended in areas of high winds)

10

Static Closing Force

From 0 to 4

1

Value 0 =0 N (recommended when using the Push&Go)

Value 1 = 10 N

Value 2 = 20 N

Value 3 = 30 N (recommended in areas of high winds)

Value 4 = 40 N (recommended in areas of high winds)

11

Push & Go

0 or 5

0

Value 0 = Deactivated

Value 1 = Activated in 2º

Value 2 = Activated in 3º

Value 3 = Activated in 5º

Value 4 = Activated in 9º

Value 5 = Activated in 15º

12

Acoustic Warning

0 or 1

1

Value 0 = Deactivated

Value 1 = Activated

13

Brake Point on Opening

From 0 to 6

2

Value 0 = At 0º of the total opening

Value 1 = At 5º of the total opening

Value 2 = At 10º of the total opening

Value 3 = At 15º of the total opening

Value 4 = At 20º of the total opening

Value 5 = At 25º of the total opening

Value 6 = At 30º of the total opening

14

Brake Point on Closing

From 0 to 6

2

Value 0 = At 0º of closing (this value is only available if there is

no automatic bolt)

Value 1 = At 5ºof closing (this value is only available if there is no

automatic bolt)

Page 46

MICOM SWING SW & SWSP

Installation Manual

Page

46

Value 2 = At 10º of closing

Value 3 = At 15ºof closing

Value 4 = At 20ºof closing

Value 5 = At 25º of closing

Value 6 = At 30º of closing

15

Electromagnetic Lock

From 0 to 4

1

Value 0 = No Lock Fitted (recommended when using Push&Go)

Value 1 = Automatic Bolt unlocked with 12/24Vdc;

and locked with 0V. *

Value 2 = Automatic Bolt unlocked with 0V;

and locked with 12/24Vdc. *

Value 3 = Automatic Bolt unlocked with 12/24Vdc;

and locked with 0V. **

Value 4 = Automatic Bolt unlocked with 0V;

and locked with 12/24Vdc. **

* It unlocks just prior to the door opening and during the first

0º~20ºof opening.

** It unlocks just prior to the door opening and during the entire

process of opening/closing.

16

Electromagnetic Lock Release Force

From 0 to 4

1

Value 0 = 10N

Value 1 = 15N

Value 2 = 20N

Value 3 = 25N (recommended in areas of high winds)

Value 4 = 30N (recommended in areas of high winds)

17

Acoustic Warning prior to Closing

0 or 1

0

Value 0 =Deactivated warning

Value 1 = Activated warning

18

Safety Sensor in Monitoring Mode (Closing side)

0 or 1

0

Value 0 =Monitoring Mode deactivated

Value 1 =Monitoring Mode activated

19

Internal Activation Sensor / Device Input

From 0 to 2

0

Value 0 = NO (Normally Open).

Value 1 = NC (Normally Closed).

Value 2 = Bi-stable.

20

External Activation Sensor / Device Input

0 or 1

0

Value 0 = NO (Normally Open).

Value 1 = NC (Normally Closed).

Page 47

MICOM SWING SW & SWSP

Installation Manual

Page

47

21

Safety Sensor Input (Closing Side)

0 or 1

1

Value 0 = NO (Normally Open)

Value 1 = NC (Normally Closed)

22

Emergency Stop Input

0 or 1

0

Value 0 = NO (Normally Open)

Value 1 = NC (Normally Closed)

23

NIGHT BANK / Switch

0

Value 0 = Emergency Opening Mode NO (Normally Open)

24

Low Energy System (Low Kinetic Energy)

From 0 to 6

0

Value 0 = System deactivated.

Value 1 = Activated. Weight of the lower panel or equal to 50Kg.

Value 2 = Activated. Weight of the lower panel or equal to 60Kg.

Value 3 = Activated. Weight of the lower panel or equal to 70Kg.

Value 4 =Activated. Weight of the lower panel or equal to 80Kg.

Value 5 = Activated. Weight of the lower panel or equal to 90Kg.

Value 6 =Activated. Weight of the lower panel or greater than

90Kg.

25

Acoustic warning at the entrance

From 0 to 3

0

Value 0 =Deactivated warning.

Value 1 =Warning lasting 1 second.

Value 2 =Warning lasting 2 seconds.

Value 3 =Warning lasting 3 seconds.

26

Battery Monitoring

From 0 to 2

0

Value 0 = No Battery.

Value 1 =Monitoring Activated

Value 2 = Monitoring Deactivated

27

Reserved

Not available

28

Closing Force after Deceleration

From 0 to 5

1

Value 0 = Low

Value 1 =Medium-Low

Value 2 = Medium

Value 3 = Medium-High

Value 4 = High (recommended in areas of high winds)

Value 5 = Very High (recommended in areas of high winds)

29

Opening Force after Deceleration (motor damping effect)

From 0 to 5

2

Value 0 = Low (recommended when using Push&Go system)

Value 1 = Medium-Low

Value 2 = Medium

Value 3 = Medium-High

Page 48

MICOM SWING SW & SWSP

Installation Manual

Page

48

Value 4 = High (recommended in areas with high winds)

Value 5 = Very High (recommended in areas with high winds)

30

Lock Delay

From 0 to 1

0

Value 0 = 0,5 second

Value 1 = 1 second

Value 2 = 2 second

Value 3 = 3 second

Value 4 = 4 second

31

Interlock Mode

From 0 to 1

0

Value 0 = Deactivated

Value 1 = Activated

32

Emergency Open/Close Input

From 0 to 3

0

Value 0 = Emergency Opening Mode NO

Value 1 = Emergency Opening Mode. NC

Value 2 =Emergency Closing Mode. NO

Value 3 =Emergency Closing Mode. NC

33

Safety Sensor Input (Opening Side)

From 0 to 1

0

Value 0 = NO Door stops on detection

Value 1 = NC Door stops on detection

Value 2 = NO Door opens slowly on detection

Value 3 = NC Door opens slowly on detection

34

Open Limit Prior to Physical Stop

From 0 to 1

0

Value 0 = Deactivated

Value 1 = Activated

35

Safety Sensor Monitoring Mode (Opening Side)

0 or 1

0

Value 0 = Monitoring deactivated

Value 1 = Monitoring activated

36

Selector B (Digital) SLD-5 Monitoring Mode

0 or 1

0

Value 0 = Monitoring deactivated

Value 1 = Monitoring activated

37

Double Door (Dual) Function

From 0 to 2

0

Value 0 = Not defined (Single door)

Value 1 = Master

Value 2 = Slave

38

Double Door Closing Sequence

From 0 to 2

0

Value 0 =Both doors open at the same time.

Value 1 = The master door opens first and closes after the slave

door.

Page 49

MICOM SWING SW & SWSP

Installation Manual

Page

49

Value 2 = The master door will open before the slave door and

they close at the same time

39

Function of the Channel 2 receptor

From 0 to 2

0

Value 0 =Close the door immediately

Value 1 = Activates and deactivates the Push & Go (one beep

confirms the activation; two beeps the deactivation)

Value 2 = Activates and Deactivates the function of door opening

40

Lock Out (Opening Against a Wall or Fixed Structure)

From 0 to 2

0

Value 0 = No Wall or Fixed Structure

Value 1 = Opening Safety sensor (safety 2) is deactivated last 10º

of opening

Value 2 = Opening Safety sensor (safety 2)is deactivated last 20º

of opening

41

Master & Slave Door Offset

From 0 to 4

0

Value 0 = 5º

Value 1 = 10º

Value 2 = 15º

Value 3 = 20º

Value 4 = 25º

42

Master & Slave Door Closing Offset

From 0 to 5

0

Value 0 = No security distance

Value 1 = 5º

Value 2 = 10º

Value3 = 20º

Value 4 = 30º

Value 5 = 40º

43

Internet System (Optional)

From 0 to 2

0

44

Internet System (Optional)

From 0 to 9

0

45

Obstruction Sensitivity

From 0 to 4

0

Value 0 = very low (it takes 4sec. to detect an obstruction)

Value 1 = low (it takes 3sec. to detect an obstruction)

Value 2 = medium (it takes 4sec. to detect an obstruction)

Value 3 = high (it takes 1sec. to detect an obstruction)

Value 4 = very high (it takes 0.5sec. to detect an obstruction)

46

Automatic bolt unlocked on ‘manual function mode’

From 0 to 1

0

Value 0 = Deactivated

Value 1 = Activated

50

Technical Diagnostics

From 0 to 7

Value 1 = Number of cycles completed.

Display will show the number of cycles via digits, scrolling from left

hand digit.

Page 50

MICOM SWING SW & SWSP

Installation Manual

Page

50

For example, to show the number 2500, it will appear as follows:

● “2”

● …..

● ”5”

● …..

● ”0”

● …..

● ”0”

● …..

Value 2 = Shows the charge level of the battery.

I I I I = Level Maximum

I I I I

I I I I = Level High

I I I I

I I = Level Medium

I I

= Level Low

I

Value 3= Number of days functioning.

To show the number of days working on the display the numeral

digits will appear, one after the other, starting with the digit

situated to the left.

For example, to show the number of 2500, the following will

appear:

● “2”

● …..

● ”5”

● …..

● ”0”

● …..

Page 51

MICOM SWING SW & SWSP

Installation Manual

Page

51

● ”0”

● …..

Value 4= Software Version.

Value 5= Test Monitoring Output (activates for 4 seconds).

Value 6= Indicates the strength charged on the spring.

Value 7= Indicates, approximately, the weight of the door panels.

Value 8= Indicates the type of operator installed: 1=SW; 2=SWSP

Value 9= Indicates the value of the motor.

Value 10=Shows error counter 0

Value 11= Shows error counter 1

Value 12= Shows error counter 2

Value 13= Shows error counter 3

Value 14= Shows error counter 4

Value 15= Shows error counter 5

Value 16= Shows error counter 6

Value 17= Shows error counter 7

Value 18= Shows error counter 8

Value 19= Shows error counter 9

Value 20= Shows error counter 10

Value 21=Shows error counter 11

Value 22= Shows error counter 12

Page 52

MICOM SWING SW & SWSP

Installation Manual

Page

52

14. TROUBLE SHOOTING – ERROR TABLE

When the automatic door finds itself in a state of error, a message will appear on the Control Unit

display screen which indicates the type of error that has occurred. An acoustic signal will be heard.

In order to recognize the type of error that has occurred from the signal as long and short sounds are

employed:

__ Long sound

_ Short sound

Error

Acoustic

Sound

Description

Solution

E0

__ __ __

Error in

calculation

of the door

run.

- The door movement should be no less than 20º.

- Remove any obstacle that stops the door panels from carrying

out its movement.

- If the weight of the door goes over the maximum allowed, the

load must be lightened.

- The mechanical components in the door are not functioning

correctly, whether because of abnormal rubbing, imbalance or

breakage.

- The motor connector is in bad condition or disconnected.

E1

_ __ _ __ _ __

Knocks

when

opening

- The door has been knocked during the opening movement.

Remove any obstacle that could obstruct its movement.

- If the problem persists, remove the supply and check that the

door panels are working correctly throughout their run. When the

door receives its supply again, the error should disappear.

- If the problem occurs now and again without there having been

an obstacle or impediment, carry out a RESET or reduce the even

opening motor.

- Decrease the impact sensitivity value (parameter 45)

E2

__ _ _ __ _ _

__

Knocks

when

closing

-- The door has been knocked during the closing movement.

Remove any obstacle that could obstruct its movement.

- If the problem persists, remove the supply and check that the

door panels are working correctly throughout their run. When the

door receives its power supply again, the error should disappear.

- If the problem occurs now and again without there having been

an obstacle or blockage, carry out a RESET or reduce the even

closing motor.

- Decrease the impact sensitivity value (parameter 45)

E4

_ _ _ _ __

Error in the

supervision

of the

opening

security

- Check that the opening security sensor connected has the

supervision is activated. (Monitoring).

- Check that the security sensor is correctly connected.

Page 53

MICOM SWING SW & SWSP

Installation Manual

Page

53

sensor

(monitoring

the opening)

- If the problem persists, replace the security sensor with a new

one.

E5

_ _ _ _ _ __

Broken belt

or reducer of

the broken

motor

- Check the good working state of the motor belts. If the belt is

damaged, replace it with a new one.

- Test the motor to turn manually. In the event that it does not turn

easily (a small force applied to the end of the arm should make it

turn), replace the motor with a new one of identical characteristics.

E6

_ _ _ _ _ _ __

Error in the

supervision

of the

closing

security

sensor(moni

toring)

- Check that the security sensor connected has the supervision

option activated (Monitoring).

- Check that the security sensor is correctly connected.

- If the problem persists, replace the security sensor with a new

one.

E7

_ _ _ _ _ _ _

__

Emergency

open in the

case of an

electrical

fault

- If there has been an electrical fault, then it is normal that this

error appears.

- If there has been no electrical fault, check that the supply

connection on the Control Unit has a voltage of between 100V and

230V AC.

- If the problem persists, change the Control Unit with a new one.

E8

_ _ _ _ _ _ _ _

__

Error in the

automatic

bolt

- The automatic door is closed and will not open. Check that the

automatic lock is connected and is working correctly.

- Check that the automatic lock parameter has been programmed

correctly (see section “5.3.-PROGRAMMING PARAMETRES”

parameters nº15).

- Lightly lubricate the movement zone of the lock (Caution: the

electrical area should not be lubricated).

- If the problem persists replace the electrical lock with a new one.

- Decrease the impact sensitivity value (parameter 45)

E9

A short sound

every 30

seconds

Battery in

poor

condition

- Check the battery is connected to the unit control.

- If the problem persists the battery is discharged and should be

left to charge for at least 15 minutes. For this it will only be

necessary to plug the Control Unit into the electricity supply.

- If the problem persists then replace the battery by a new one.

E10

_ _ _ _ _ _ _ _

_ _ __

Error in the

motor

- The motor is in bad condition or the operator is too inclined or

uneven.

E11

_ _ _ _ _ _ _ _

_ _ _ __

Erroneous

position

- Check that the cabling of the motor coder is correctly connected

and in good condition along the length of its run.

- Check that the arm of the mechanism is correctly fixed and

Page 54

MICOM SWING SW & SWSP

Installation Manual

Page

54

doesn’t have any space.

E12

_ _ _ _ _ _ _ _

_ _ _ _ __

Error in the

supervision

of the

internal

sensor

movement

(internal

sensor)

- Check that the internal movement sensor connected has the

supervision option activated (Monitoring).

- Check that the movement sensor is correctly connected.

-If the problem persists, replace the movement sensor with a new

one.

14.1 Trouble Shooting

Problem

Solution

The POWER symbol on the

LED display does not light

up.

- There is a fault in the supply or the Control Unit to the electricity

supply (110-230Vac).

- Turn off the Control Unit. After some seconds have gone past,

connect the Control Unit up again.

- If the problem persists, replace the Control Unit by a new one.

The INPUT ON signal does

not light up on the display

when the sensor is

activated.

- Check that the function selector is correctly connected and is

working correctly.

- Check that the function selector is not in the position of “Door

closed” or “Manual Door”.

- Check that the sensors are correctly connected. It could be that

one of the components connected to the control unit is creating a

short circuit due to a bad connection. Check the 24Vdc in

connector P2.

- If the problem persists, replace the Control Unit by a new one.

The door doesn’t close or

open completely and there

are some centimeters

required to complete the

operation.

- Check that there is no friction in the movement.

- Check that the arm is working correctly to the end.

- If the problem persists, increase the even closing and opening

motor after the brake (Parameter 28 and 29) until the problem is

resolved.

-If the problem persists, adjust parameters 13 and 14.

Page 55

MICOM SWING SW & SWSP

Installation Manual

Page

55

The door doesn’t open and

always remains closed

- Check that the opening security sensor is not activated or

defective.

-Check that the function selector is not on “close” or “manual”

mode.

- If the function selector has a lock and key, place the key on the

ON position.

- If the problem persists, disconnect the function selector and

check with a Vdc voltage meter that the P7 connector has a

voltage of 5V (for more information consult sector 4.2.).

● If the voltage is “0V”, it is possible that the Control Unit

could be broken and we therefore recommend you to

disconnect and then re-connect again.

● If the voltage is “5V”, replace the function selector with a

new one.

The door doesn’t close.

- Check that the closing security sensor is not activated or is

defective.

The B Selector (Digital) is

not working correctly

- Check that the connections have been done correctly (for more

information consult section 4.3.14.-).

- Check that between the TX and RX Control Unit terminals there is

a resistance value of 60 ohms (measure this with a digital

multicentre). If the resistance value shows 1200 ohms or higher,

then more bridges than necessary have been removed. If the

resistance value in 30 ohms or less, then more than one selector

has been connected and not enough bridges have been removed

(for more information consult section “4.3.14.- P11 Connector:

Selector B (Digital)”).

The door takes a while to

react upon opening

If parameter 15 is different from 0, then the control unit will wait 0,5

seconds prior to commence opening in order for the automatic bolt

not to get stuck. If the door doesn’t have an automatic bolt, then

change the parameter value 15 to 0.

The mechanism starts to

brake too soon

If more than 10 complete opening cycles have not taken place, this

is normal. One has to wait for at least 15 opening/closing cycles

have taken place.

If the problem is not resolved, carry out a RESET.

If the problem is not resolved, increase the value in parameters: 7,

8, 13, and 14.

Page 56

MICOM SWING SW & SWSP

Installation Manual

Page

56

If considerable force is

required to push the door

when the Push&Go option is

in use

Assign value 0 to the following parameters: 10, 15, 29

Assign value 1 to parameter 11

Page 57

MICOM SWING SW & SWSP

Installation Manual

Page

57

15. MAINTENANCE

The automatic doors require servicing and maintenance. It is essential to be aware of the importance

in carrying out maintenance in order to enjoy a secure and trustworthy product.

The adjustments and service will ensure a safe and correct function of the automatic doors.

Regular inspections should be carried out as indicated under the national regulations and the times

deemed necessary. It is especially important when dealing with approved fire doors or doors operating

as emergency opening doors.

In the event that there are no specific scheduled inspection regulations, we recommend these are

carried out maximum every 6 months.

For the correct function of the automatic door, we recommend replacement of the parts that have a

limited life span. In the following table we indicate the parts which have to be periodically checked.

Part

Reference

MICOM-SWING-SP SPRING

2002273

25mm BELT for MICOM SWING-SW

2002271

15mm BELT for MICOM SWING-SW

2002272

Loading...

Loading...