Page 1

MiCOM P721 & P723

High Impedance Differential Protection

P72x/EN T/C21

Software Version 11.D

Technical Guide

Page 2

Page 3

Technical Guide P72x/EN T/C21

Contents

MiCOM P721/723

Page 1/2

MiCOM P721 & P723

HIGH IMPEDANCE DIFFERENTIAL PROTECTION

TECHNICAL GUIDE

CONTENTS

Safety Section

Introduction

Handling, Installation and Case Dimensions

User Guide

Menu Content Tables

Technical Data

Getting Started

Pxxxx/EN SS/G11

P72x/EN IT/C21

P72x/EN IN/C21

P72x/EN FT/C21

P72x/EN HI/C21

P72x/EN TD/A11

P72x/EN GS/C21

Application

Communication Database

Commissioning and Maintenance Guide

Connection Diagrams

Commissioning Test & Records Sheets

Hardware/Software Version History and Compatibility

P72x/EN AP/C21

P72x/EN CT/A11

P72x/EN CM/C21

P72x/EN CO/A11

P72x/EN RS/A11

P72x/EN VC/C21

Page 4

P72x/EN T/C21 Technical Guide

Contents

Page 2/2

MiCOM P721/P723

BLANK PAGE

Page 5

Pxxx/EN SS/G11

SAFETY SECTION

Page 6

Page 7

Pxxx/EN SS/G11

Safety Section Page 1/8

STANDARD SAFETY STATEMENTS AND EXTERNAL

LABEL INFORMATION FOR SCHNEIDER ELECTRIC

EQUIPMENT

1. INTRODUCTION 3

2. HEALTH AND SAFETY 3

3. SYMBOLS AND EXTERNAL LABELS ON THE EQUIPMENT 4

3.1 Symbols 4

3.2 Labels 4

4. INSTALLING, COMMISSIONING AND SERVICING 4

5. DECOMMISSIONING AND DISPOSAL 7

6. TECHNICAL SPECIFICATIONS FOR SAFETY 8

6.1 Protective fuse rating 8

6.2 Protective Class 8

6.3 Installation Category 8

6.4 Environment 8

Page 8

Pxxx/EN SS/G11

Page 2/8 Safety Section

BLANK PAGE

Page 9

Pxxx/EN SS/G11

Safety Section Page 3/8

1. INTRODUCTION

This guide and the relevant equipment documentation provide full information on safe

handling, commissioning and testing of this equipment. This Safety Guide also includes

descriptions of equipment label markings.

Documentation for equipment ordered from Schneider Electric is despatched separately from

manufactured goods and may not be received at the same time. Therefore this guide is

provided to ensure that printed information which may be present on the equipment is fully

understood by the recipient.

The technical data in this safety guide is typical only, see the technical data section of the

relevant product publication(s) for data specific to a particular equipment.

Before carrying out any work on the equipment the user should be familiar with the

contents of this Safety Guide and the ratings on the equipment’s rating label.

Reference should be made to the external connection diagram before the equipment is

installed, commissioned or serviced.

Language specific, self-adhesive User Interface labels are provided in a bag for some

equipment.

2. HEALTH AND SAFETY

The information in the Safety Section of the equipment documentation is intended to ensure

that equipment is properly installed and handled in order to maintain it in a safe condition.

It is assumed that everyone who will be associated with the equipment will be familiar with

the contents of that Safety Section, or this Safety Guide.

When electrical equipment is in operation, dangerou s voltages will be present in certain parts

of the equipment. Failure to observe warning notices, incorrect use, or improper use may

endanger personnel and equipment and also cause personal injury or physical damage.

Before working in the terminal strip area, the equipment must be isolated.

Proper and safe operation of the equipment depends on appropriate shipping and handling,

proper storage, installation and commissioning, and on careful operation, maintenance and

servicing. For this reason only qualified personnel may work on or operate the equipment.

Qualified personnel are individuals who:

• Are familiar with the installation, commissioning, and operation of the equipment and

of the system to which it is being connected;

• Are able to safely perform switching operations in accordance with accepted safety

engineering practices and are authorised to energize and de-energize equipment and

to isolate, ground, and label it;

• Are trained in the care and use of safety apparatus in accordance with safety

engineering practices;

• Are trained in emergency procedures (first aid).

The equipment documentation gives instructions for its installation, commissioning, and

operation. However, the manual cannot cover all conceivable circumstances or include

detailed information on all topics. In the event of questions or specific problems, do not take

any action without proper authorization. Contact the appropriate Schneider Electric technical

sales office and request the necessary information.

Page 10

Pxxx/EN SS/G11

Page 4/8 Safety Section

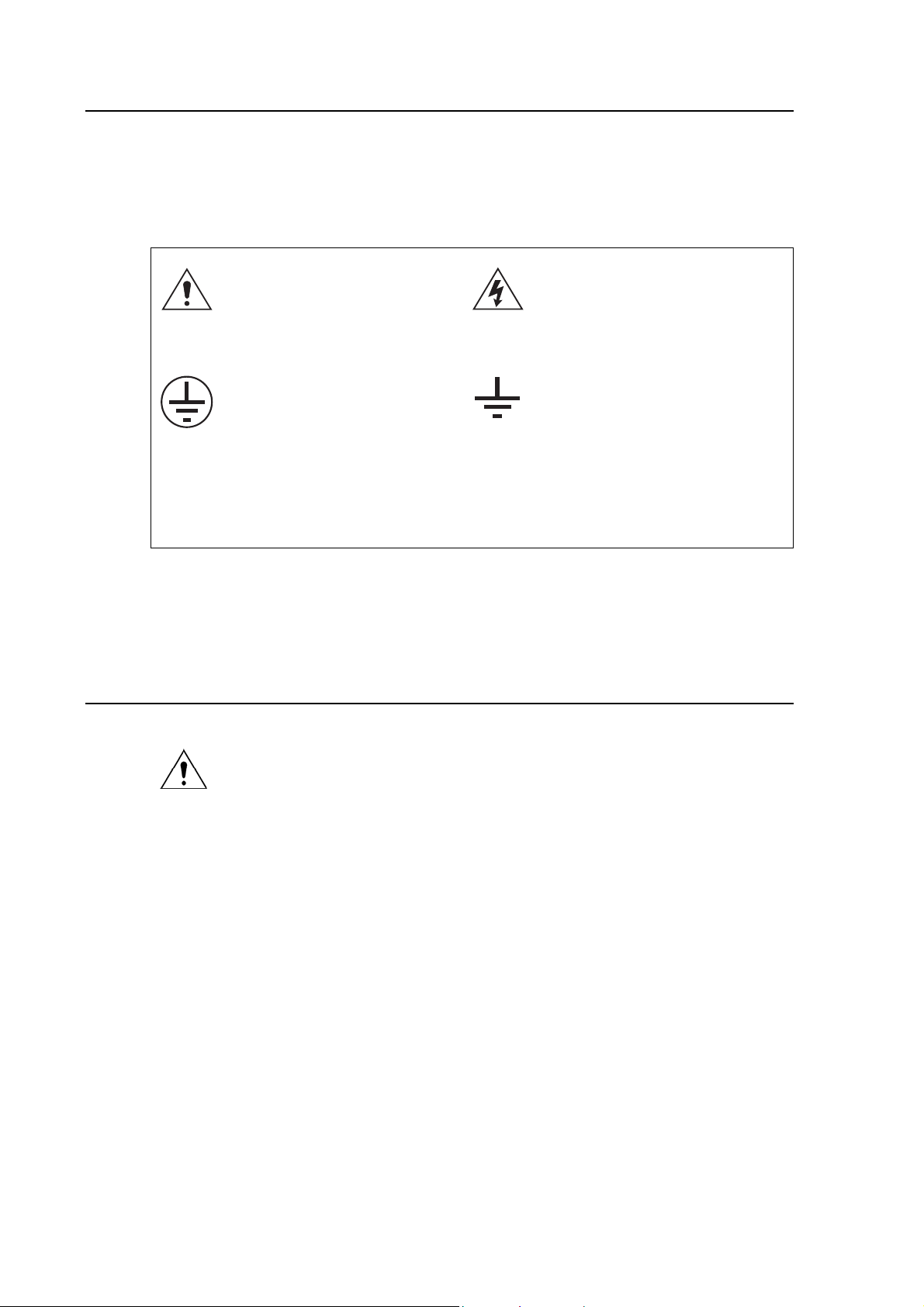

3. SYMBOLS AND EXTERNAL LABELS ON THE EQUIPMENT

For safety reasons the following symbols and external labels, which may be used on the

equipment or referred to in the equipment documentation, should be understood before the

equipment is installed or commissioned.

3.1 Symbols

Caution: refer to equipment documentation Caution: risk of electric shock

Protective Conductor (*Earth) terminal

*NOTE: THE TERM EARTH USED THROUGHOUT THIS GUIDE IS THE

3.2 Labels

See Safety Guide (SFTY/4L M/G11) for equipment labelling information.

Functional/Protective Conductor (*Earth)

terminal.

Note: This symbol may also be used for a

Protective Conductor (Earth) Terminal if that

terminal is part of a terminal block or subassembly e.g. power supply.

DIRECT EQUIVALENT OF THE NORTH AMERICAN TERM

GROUND.

4. INSTALLING, COMMISSIONING AND SERVICING

Equipment connections

Personnel undertaking installation, commissioning or servicing work for this

equipment should be aware of the correct working procedures to ensure safety.

The equipment documentation should be consulted before installing,

commissioning, or servicing the equipment.

Terminals exposed during installation, commissioning and maintenance may

present a hazardous voltage unless the equipment is electrically isolated.

The clamping screws of all terminal block connectors, for field wiring, using M4

screws shall be tightened to a nominal torque of 1.3 Nm.

Equipment intended for rack or panel mounting is for use on a flat surface of a

Type 1 enclosure, as defined by Underwriters Laboratories (UL).

Any disassembly of the equipment may expose parts at hazardous voltage, also

electronic parts may be damaged if suitable electrostatic voltage discharge (ESD)

precautions are not taken.

If there is unlocked access to the rear of the equipment, care should be taken by

all personnel to avoid electric shock or energy hazards.

Voltage and current connections shall be made using insulated crimp terminations

to ensure that terminal block insulation requirements are maintained for safety.

Watchdog (self-monitoring) contacts are provided in numerical relays to indicate

the health of the device. Schneider Electric strongly recommends that these

contacts are hardwired into the substation's automation system, for alarm

purposes.

Page 11

Pxxx/EN SS/G11

Safety Section Page 5/8

To ensure that wires are correctly terminated the correct crimp terminal and tool

for the wire size should be used.

The equipment must be connected in accordance with the appropriate connection

diagram.

Protection Class I Equipment

- Before energizing the equipment it must be earthed using the protective

conductor terminal, if provided, or the appropriate termination of the

supply plug in the case of plug connected equipment.

- The protective conductor (earth) connection must not be removed since

the protection against electric shock provided by the equipment would be

lost.

- When the protective (earth) conductor terminal (PCT) is also used to

terminate cable screens, etc., it is essential that the integrity of the

protective (earth) conductor is checked after the addition or removal of

such functional earth connections. For M4 stud PCTs the integrity of the

protective (earth) connections should be ensured by use of a locknut or

similar.

The recommended minimum protective conductor (earth) wire size is 2.5 mm²

(3.3 mm² for North America) unless otherwise stated in the technical data section

of the equipment documentation, or otherwise required by local or country wiring

regulations.

The protective conductor (earth) connection must be low-inductance and as short

as possible.

All connections to the equipment must have a defined potential. Connections that

are pre-wired, but not used, should preferably be grounded when binary inputs

and output relays are isolated. When binary inputs and output relays are

connected to common potential, the pre-wired but unused connections should be

connected to the common potential of the grouped connections.

Before energizing the equipment, the following should be checked:

- Voltage rating/polarity (rating label/equipment documentation),

- CT circuit rating (rating label) and integrity of connections,

- Protective fuse rating,

- Integrity of the protective conductor (earth) connection (where

applicable),

- Voltage and current rating of external wiring, applicable to the application.

Accidental touching of exposed terminals

If working in an area of restricted space, such as a cubicle, where there is a risk of

electric shock due to accidental touching of terminals which do not comply with

IP20 rating, then a suitable protective barrier should be provided.

Equipment use

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Removal of the equipment front panel/cover

Removal of the equipment front panel/cover may expose hazardous live parts,

which must not be touched until the electrical power is removed.

Page 12

Pxxx/EN SS/G11

Page 6/8 Safety Section

UL and CSA/CUL Listed or Recognized equipment

To maintain UL and CSA/CUL Listing/Recognized status for North America the

equipment should be installed using UL or CSA Listed or Recognized parts for

the following items: connection cables, protective fuses/fuseholders or circuit

breakers, insulation crimp terminals and replacement internal battery, as

specified in the equipment documentation.

For external protective fuses a UL or CSA Listed fuse shall be used. The Listed

type shall be a Class J time delay fuse, with a maximum current rating of 15 A

and a minimum d.c. rating of 250 Vd.c., for example type AJT15.

Where UL or CSA Listing of the equipment is not required, a high rupture

capacity (HRC) fuse type with a maximum current rating of 16 Amps and a

minimum d.c. rating of 250 Vd.c. may be used, for example Red Spot type NIT or

TIA.

Equipment operating conditions

The equipment should be operated within the specified electrical and

environmental limits.

Current transformer circuits

Do not open the secondary circuit of a live CT since the high voltage produced

may be lethal to personnel and could damage insulation. Generally, for safety,

the secondary of the line CT must be shorted before opening any connections to

it.

For most equipment with ring-terminal connections, the threaded terminal block

for current transformer termination has automatic CT shorting on removal of the

module. Therefore external shorting of the CTs may not be required, the

equipment documentation should be checked to see if this applies.

For equipment with pin-terminal connections, the threaded terminal block for

current transformer termination does NOT have automatic CT shorting on removal

of the module.

External resistors, including voltage dependent resistors (VDRs)

Where external resistors, including voltage dependent resistors (VDRs), are fitted

to the equipment, these may present a risk of electric shock or burns, if touched.

Battery replacement

Where internal batteries are fitted they should be replaced with the recommended

type and be installed with the correct polarity to avoid possible damage to the

equipment, buildings and persons.

Insulation and dielectric strength testing

Insulation testing may leave capacitors charged up to a hazardous voltage. At the

end of each part of the test, the voltage should be gradually reduced to zero, to

discharge capacitors, before the test leads are disconnected.

Insertion of modules and pcb cards

Modules and PCB cards must not be inserted into or withdrawn from the

equipment whilst it is energized, since this may result in damage.

Insertion and withdrawal of extender cards

Extender cards are available for some equipment. If an extender card is used,

this should not be inserted or withdrawn from the equipment whilst it is energized.

This is to avoid possible shock or damage hazards. Hazardous live voltages may

be accessible on the extender card.

Page 13

Pxxx/EN SS/G11

Safety Section Page 7/8

External test blocks and test plugs

Great care should be taken when using external test blocks and test plugs such

as the MMLG, MMLB and MiCOM P990 types, hazardous voltages may be

accessible when using these. *CT shorting links must be in place before the

insertion or removal of MMLB test plugs, to avoid potentially lethal voltages.

*Note: When a MiCOM P992 Test Plug is inserted into the MiCOM P991 Test

Block, the secondaries of the line CTs are automatically shorted, making

them safe.

Fiber optic communication

Where fiber optic communication devices are fitted, these should not be viewed

directly. Optical power meters should be used to determine the operation or

signal level of the device.

Cleaning

The equipment may be cleaned using a lint free cloth dampened with clean water,

when no connections are energized. Contact fingers of test plugs are normally

protected by petroleum jelly, which should not be removed.

5. DECOMMISSIONING AND DISPOSAL

De-commissioning

The supply input (auxiliary) for the equipment may include capacitors across the

supply or to earth. To avoid electric shock or energy hazards, after completely

isolating the supplies to the equipment (both poles of any dc supply), the

capacitors should be safely discharged via the external terminals prior to

de-commissioning.

Disposal

It is recommended that incineration and disposal to water courses is avoided.

The equipment should be disposed of in a safe manner. Any equipment

containing batteries should have them removed before disposal, taking

precautions to avoid short circuits. Particular regulations within the country of

operation, may apply to the disposal of the equipment.

Page 14

Pxxx/EN SS/G11

Page 8/8 Safety Section

6. TECHNICAL SPECIFICATIONS FOR SAFETY

Unless otherwise stated in the equipment technical manual, the following data is applicable.

6.1 Protective fuse rating

The recommended maximum rating of the external protective fuse for equipments is 16A,

high rupture capacity (HRC) Red Spot type NIT, or TIA, or equivalent. Unless otherwise

stated in equipment technical manual, the following data is applicable. The protective fuse

should be located as close to the unit as possible.

CAUTION - CTs must NOT be fused since open circuiting them may

produce lethal hazardous voltages.

6.2 Protective Class

IEC 60255-27: 2005

EN 60255-27: 2006

6.3 Installation Category

IEC 60255-27: 2005

EN 60255-27: 2006

6.4 Environment

The equipment is intended for indoor installation and use only. If it is required for use in an

outdoor environment then it must be mounted in a specific cabinet or housing which will

enable it to meet the requirements of IEC 60529 with the classification of degree of

protection IP54 (dust and splashing water protected).

Pollution Degree - Pollution Degree 2 Compliance is demonstrated by reference

Altitude - Operation up to 2000m to safety standards.

IEC 60255-27:2005

Class I (unless otherwise specified in the equipment

documentation). This equipment requires a protective

conductor (earth) connection to ensure user safety.

Installation Category III (Overvoltage Category III):

Distribution level, fixed installation.

Equipment in this category is qualification tested at

5 kV peak, 1.2/50 µs, 500 Ω, 0.5 J, between all

supply circuits and earth and also between

independent circuits.

EN 60255-27: 2006

Page 15

Introduction P72x/EN IT/C21

MiCOM P721/P723

INTRODUCTION

Page 16

Page 17

Introduction P72x/EN IT/C21

MiCOM P721/P723 Page 1/10

CONTENTS

1. INTRODUCTION 3

2. HOW TO USE THIS MANUAL 4

3. INTRODUCTION TO THE MiCOM RANGE 5

4. INTRODUCTION TO THE MiCOM P721 & P723 PROTECTIONS 6

5. MAIN FUNCTIONS 7

5.1 Main functions 7

5.2 General functions 7

5.3 Ordering options 9

Page 18

P72x/EN IT/C21 Introduction

Page 2/10 MiCOM P721/P723

BLANK PAGE

Page 19

Introduction P72x/EN IT/C21

MiCOM P721/P723 Page 3/10

1. INTRODUCTION

The differential protections of the MiCOM P72x range are Schneider Electric numerical high

impedance differential protection. MiCOM P721 and P723 have been designed to provide

differential protection and a high impedance differential protection

The differential protection consists to measure the summation of n Current Transformers

(CTs) secondary currents. Without internal fault, this sum is null. If an internal fault occurs,

the protection measures the leak current. If an external fault occurs (with non-saturated CT),

the Kirchhoff's law is conserved and no current is measured.

The high impedance differential protection main application is a CT saturation in a busbar

(when a serious and external fault occurs).

Page 20

P72x/EN IT/C21 Introduction

Page 4/10 MiCOM P721/P723

2. HOW TO USE THIS MANUAL

This manual provides a description of MiCOM P721 and P723 functions and settings. The

goal of this manual is to allow the user to become familiar with the application, installation,

setting and commissioning of these relays.

This manual has the following format:

P72x/EN IT Introduction

The introduction presents the documentation structure and a

brief presentation of the relay, including functions.

P72x/EN IN Handling, installation and case dimensions

This section provides logistics general instructions for handling,

installing and stocking..

P72x/EN FT User Guide

This section provides relay settings with a brief explanation of

each setting and detailed description. It also provides recording

and measurements functions including the configuration of the

event and disturbance recorder and measurement functions.

P72x/EN HI Menu content tables

This section shows the menu structure of the relays, with a

complete list of all of the menu settings.

P72x/EN AP Application Notes

This section includes a description of common power system

applications of the relay, calculation of suitable settings, some

typical worked examples, and how to apply the settings to the

relay.

P72x/EN TD Technical data and curve characteristics

This section provides technical data including setting ranges,

accuracy limits, recommended operating conditions, ratings and

performance data. Compliance with norms and international

standards is quoted where appropriate.

P72x/EN CT Communication database

This section provides an overview regarding the communication

interfaces of the relay. Detailed protocol mappings, semantics,

profiles and interoperability tables are not provided within this

manual. Separate documents are available per protocol,

available for download from our website.

P72x/EN CM Commissioning and Maintenance Guide

Instructions on how to commission the relay, comprising checks

on the calibration and functionality of the relay.

P72x/EN CO Connection diagrams

This section provides the mechanical and electrical description.

External wiring connections to the relay are indicated.

P72x/EN RS Commissioni ng test and records sheets

This section contains checks on the calibration and functionality

of the relay.

P72x/EN VC Hardware/Software version history and compatibility

History of all hardware and software releases for the product.

Page 21

Introduction P72x/EN IT/C21

MiCOM P721/P723 Page 5/10

3. INTRODUCTION TO THE MiCOM RANGE

MiCOM is a comprehensive solution capable of meeting all electricity supply requirements. It

comprises of a range of components, systems and services from Schneider Electric.

Flexibility is central to the MiCOM concept.

MiCOM provides the ability to define an application solution and, through extensive

communication capabilities, to integrate this solution with your power supply control system.

The components within MiCOM are:

• P range protection relays

• C range control products

• M range measurement products for accurate metering and monitoring

• S range versatile PC support and substation control packages

MiCOM products include extensive facilities for recording information on the state and

behaviour of a power system, using disturbance and fault records.

They can also provide measurements of the power system at regular intervals to a control

centre enabling remote monitoring and control to take place.

For up-to-date information on any MiCOM product, refer to the technical publications, which

can be obtained from: Schneider Electric or your local sales office; alternatively visit our web

site.

www.schneider-electric.com

Page 22

P72x/EN IT/C21 Introduction

Page 6/10 MiCOM P721/P723

4. INTRODUCTION TO THE MiCOM P721 & P723 PROTECTIONS

The range of MiCOM protection relays is built on the success of the MIDOS, K and MODN

ranges by incorporating the last changes in digital technology. Relays from the MiCOM P72x

range are fully compatible and use the same modular box concept.

MiCOM P721 and P723 high impedance differential protections provide differential protection

and high impedance differential protection (with P79x high impedance accessory) for

machines, power transformers and busbar installations as well as for other applications

where differential protection is required.

The P721 relay provides simple restricted earth current fault protection. Furthermore, P723

relay is used for 3-phases fault protection.

In addition to its protective functions, each relay offers control and recording features. They

can be fully integrated to a control system so protection, control, data acquisition and

recording of faults, events and disturbances can be made available.

The relays are equipped on the front panel with a liquid crystal display (LCD) with 2 x 16

back-lit alphanumerical characters, a tactile 7 button keypad (to access all settings, clear

alarms and read measurements) and 8 LEDs that indicate the status of MiCOM P721 and

P723 protections.

In addition, the use of the RS485 communication port makes it possible to read, reinitialise

and change the settings of the relays, if required, from a local or remote PC computer loaded

with MiCOM S1 software.

Its flexibility of use, reduced maintenance requirements and ease of integration allow the

MiCOM P72x range to provide an adaptable solution for the problems of the protection of

electric networks.

Page 23

Introduction P72x/EN IT/C21

MiCOM P721/P723 Page 7/10

5. MAIN FUNCTIONS

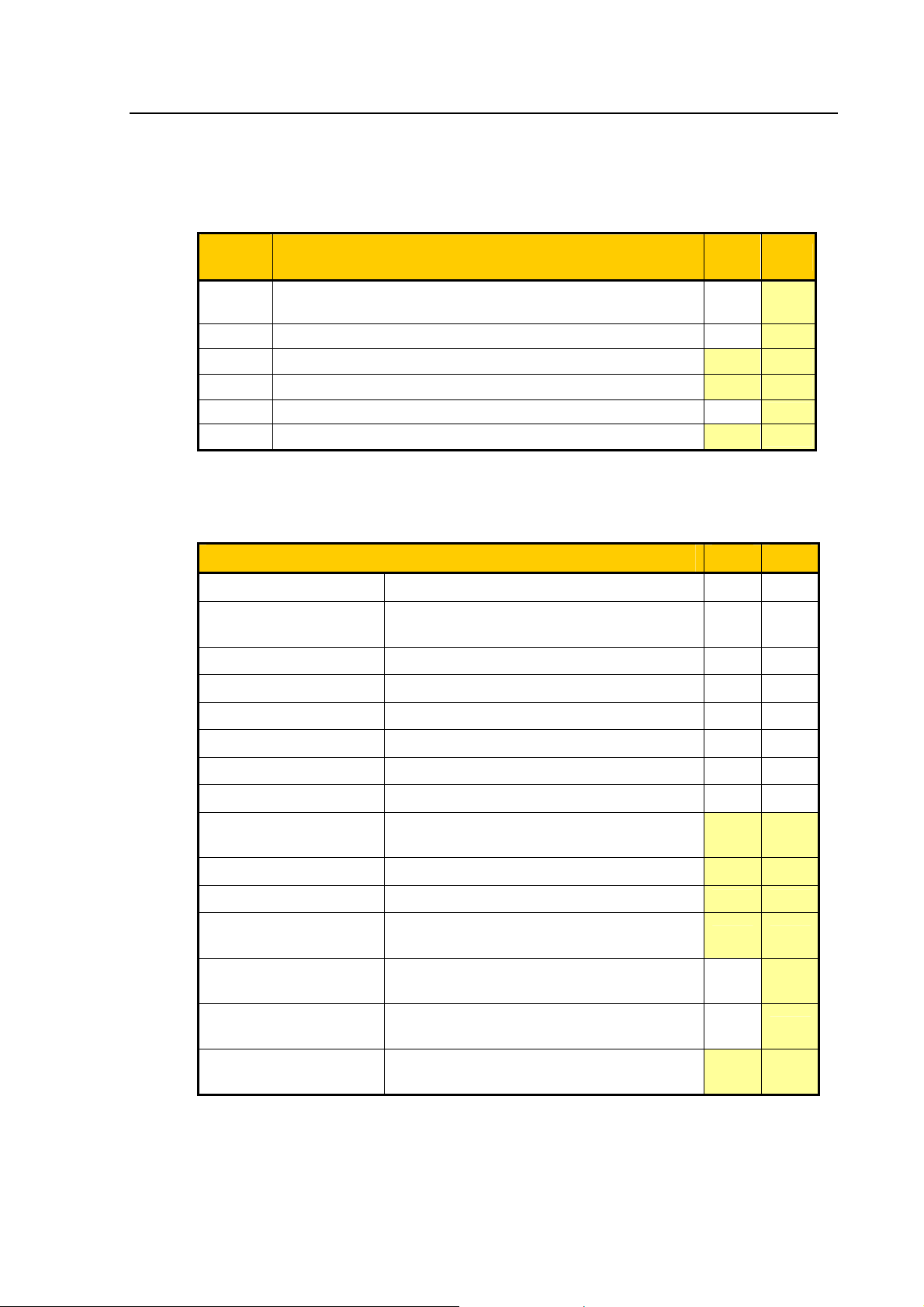

5.1 Main functions

The following table shows the functions available for the different models of the MiCOM

P72x range of relays.

ANSI

CODES

87

95 Phase bus-wire supervision

87N Restricted earth fault protection

95N Earth bus-wire supervision

87CZ Check zone input

50BF Breaker failure detection

5.2 General functions

The following table shows the general features available.

GENERAL FEATURES P721 P723

Number of digital inputs 2 5

Total number of outputs

relays

Events recording 250 250

Fault recording 25 25

FEATURES P721 P723

Phase segregated high impedance current differential

protection

• •

• •

• •

4 8

•

•

•

Disturbance recording 5 5

Instantaneous records 5 5

Setting group 2 2

Auxiliary timers 2 4

Communication IEC60870-5-103, DNP 3.0 & Modbus RTU

(rear and front port)

Settings software MiCOM S1

Logic equation AND, OR and NOT gates (8 equations)

Measurements Neutral supervision / differential currents

(INdiff)

Phase supervision / differential currents

(IAdiff, IBdiff and ICdiff)

Maximum differential currents (ImaxAdiff,

ImaxBdiff, and ImaxCdiff)

Maximum differential neutral currents

(ImaxNdiff

• •

• •

• •

• •

• •

•

•

Page 24

P72x/EN IT/C21 Introduction

Page 8/10 MiCOM P721/P723

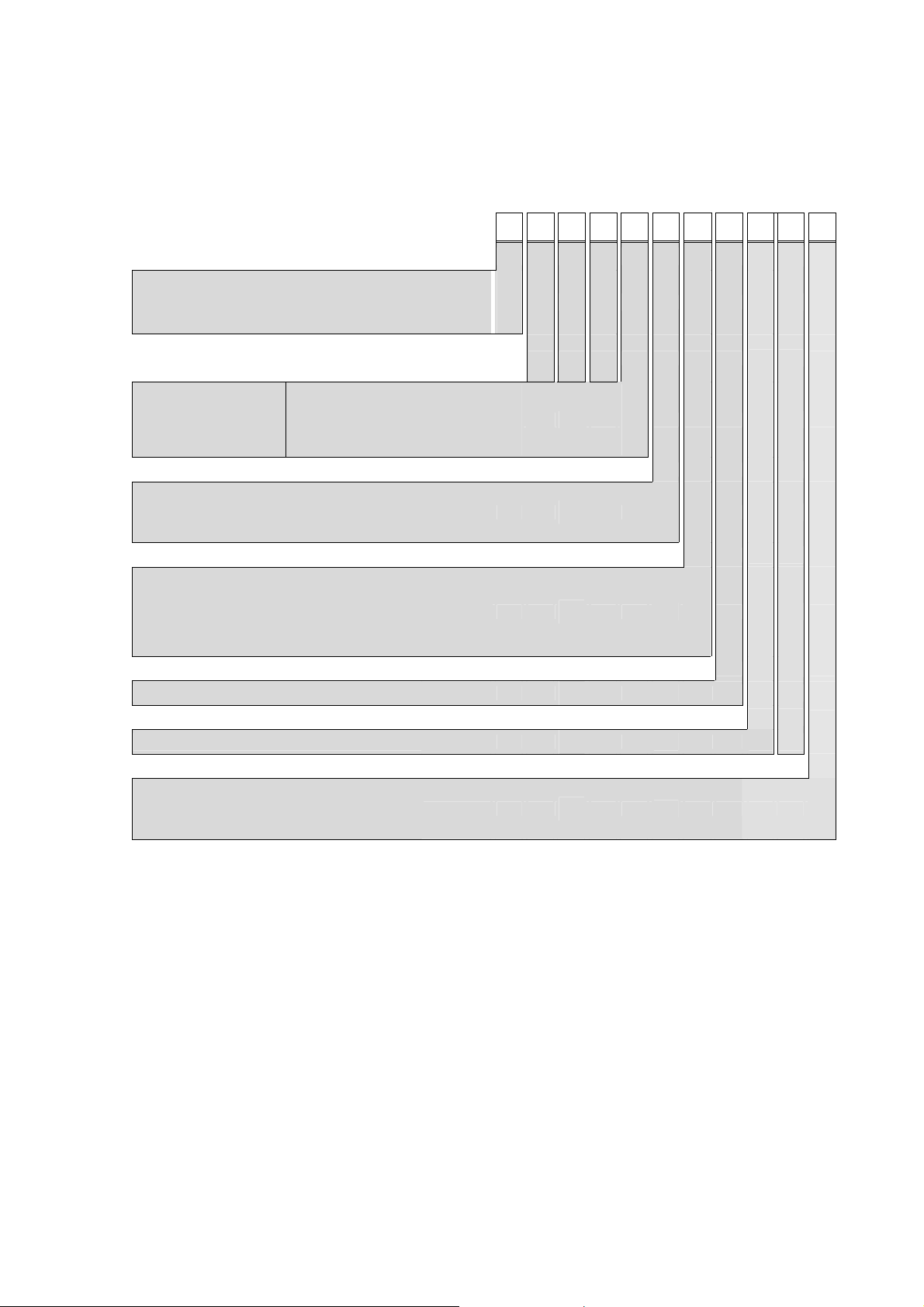

Application overview

FIGURE 1: FUNCTIONAL DIAGRAM

Page 25

Introduction P72x/EN IT/C21

MiCOM P721/P723 Page 9/10

5.3 Ordering options Information Required with Order

Relay Type (differential protection)

Variant

Simple phase high impedance differential

protection

Simple phase or three phase high impedance

protection with binary I/O extension

Auxiliary and digital input voltage

Auxiliary voltage digital input voltage

48-250 Vdc / 48-240 Vac

48-250 Vdc / 48-240 Vac

48-250 Vdc / 48-240 Vac

48-250 Vdc / 48-240 Vac

24-250Vdc / 48-240Vac

Rear port communication interface

Modbus

K-Bus/Courier

IEC 60870-5-103

DNP 3.0

Default HMI language

French

English / American

Spanish

German

Italian

Portuguese

Platform

phase 2 with standard software

Software

Unless specified the latest version will be delivered

Mounting option

None (default)

Pre-fixed HMI (no withdrawability)

Sealed cover

Pre-fixed HMI + Sealed cover

(2)

(2)

(1)

: special application

(2) :

: not available

105-145 Vdc

48-250 Vdc (ENA UK)

110 Vdc –30% / +20%

220 Vdc –30% / +20%

24-250 Vdc / 24 / 240 Vdc

(1)

P72 0 0 0

(1)

(1)

1

3

H

T

V

W

Z

1

2

3

4

0

1

2

3

4

7

2

0

1

2

3

Page 26

P72x/EN IT/C21 Introduction

Page 10/10 MiCOM P721/P723

BLANK PAGE

Page 27

Handling, Installation and Case Dimensions P72x/EN IN/C21 MiCOM P721/P723

HANDLING, INSTALLATION

AND CASE DIMENSIONS

Page 28

Page 29

Handling, Installation and Case Dimensions P72x/EN IN/C21

MiCOM P721/P723 Page 1/10

CONTENTS

1. GENERAL CONSIDERATIONS 3

1.1 Receipt of relays 3

1.2 Electrostatic discharge (ESD) 3

2. HANDLING OF ELECTRONIC EQUIPMENT 4

3. RELAY MOUNTING 5

4. UNPACKING 6

5. STORAGE 7

6. DIMENSIONS 8

6.1 Connection of power terminals, and Signals terminals 8

6.2 Communication port RS485 9

6.3 Earthing 9

7. CASE DIMENSIONS 10

Page 30

P72x/EN IN/C21 Handling, Installation and Case Dimensions

Page 2/10 MiCOM P721/P723

BLANK PAGE

Page 31

Handling, Installation and Case Dimensions P72x/EN IN/C21

MiCOM P721/P723 Page 3/10

1. GENERAL CONSIDERATIONS

BEFORE CARRYING OUT ANY WORK ON THE EQUIPMENT, THE

USER SHOULD BE FAMILIAR WITH THE CONTENTS OF THE SAFETY

GUIDE SFTY/4LM/E11 OR LATER ISSUE, OR THE SAFETY AND

TECHNICAL DATA SECTIONS OF THE TECHNICAL MANUAL AND

ALSO THE RATINGS ON THE EQUIPMENT RATING LABEL.

1.1 Receipt of relays

Protective relays, although generally of robust construction, require careful treatment prior to

installation on site. Upon receipt, relays should be examined immediately to ensure no

damage has been sustained in transit. If damage has been sustained during transit a claim

should be made to the transport contractor and Schneider Electric should be promptly

notified.

Relays that are supplied unmounted and not intended to be installed immediately should be

returned with their protective polythene bags.

1.2 Electrostatic discharge (ESD)

The relays use components that are sensitive to electrostatic discharges.

The electronic circuits are well protected by the metal case and the internal module should

not be withdrawn unnecessarily. When handling the module outside its case, care should be

taken to avoid contact with components and electrical connections. If removed from the case

for storage, the module should be placed in an electrically conducting antistatic bag.

There are no setting adjustments within the module and it is advised that it is not

unnecessarily disassembled. Although the printed circuit boards are plugged together, the

connectors are a manufacturing aid and not intended for frequent dismantling; in fact

considerable effort may be required to separate them. Touching the printed circuit board

should be avoided, since complementary metal oxide semiconductors (CMOS) are used,

which can be damaged by static electricity discharged from the body.

Page 32

P72x/EN IN/C21 Handling, Installation and Case Dimensions

Page 4/10 MiCOM P721/P723

2. HANDLING OF ELECTRONIC EQUIPMENT

A person’s normal movements can easily generate electrostatic potentials of several

thousand volts. Discharge of these voltages into semiconductor devices when handling

electronic circuits can cause serious damage, which often may not be immediately apparent

but the reliability of the circuit will have been reduced.

The electronic circuits are completely safe from electrostatic discharge when housed in the

case. Do not expose them to risk of damage by withdrawing modules unnecessarily.

Each module incorporates the highest practicable protection for its semiconductor devices.

However, if it becomes necessary to withdraw a module, the following precautions should be

taken to preserve the high reliability and long life for which the equipment has been designed

and manufactured.

1. Before removing a module, ensure that you are at the same electrostatic potential as

the equipment by touching the case.

2. Handle the module by its frontplate, frame or edges of the printed circuit board. Avoid

touching the electronic components, printed circuit track or connectors.

3. Do not pass the module to another person without first ensuring you are both at the

same electrostatic potential. Shaking hands achieves equipotential.

4. Place the module on an antistatic surface, or on a conducting surface which is at the

same potential as yourself.

5. Store or transport the module in a conductive bag.

If you are making measurements on the internal electronic circuitry of an equipment in

service, it is preferable that you are earthed to the case with a conductive wrist strap. Wrist

straps should have a resistance to ground between 500kΩ – 10MΩ.

If a wrist strap is not available you should maintain regular contact with the case to prevent a

build-up of static. Instrumentation which may be used for making measurements should be

earthed to the case whenever possible.

More information on safe working procedures for all electronic equipment can be found in

BS5783 and IEC 147-OF. It is strongly recommended that detailed investigations on

electronic circuitry or modification work should be carried out in a special handling area such

as described in the above-mentioned BS and IEC documents.

Page 33

Handling, Installation and Case Dimensions P72x/EN IN/C21

MiCOM P721/P723 Page 5/10

3. RELAY MOUNTING

Relays are dispatched either individually or as part of a panel/rack assembly.

If an MMLG test block is to be included it should be positioned at the right-hand side of the

assembly (viewed from the front). Modules should remain protected by their metal case

during assembly into a panel or rack.

For individually mounted relays an outline diagram is supplied in section 6 of this chapter

showing the panel cut-outs and hole centres.

Page 34

P72x/EN IN/C21 Handling, Installation and Case Dimensions

Page 6/10 MiCOM P721/P723

4. UNPACKING

Care must be taken when unpacking and installing the relays so that none of the parts is

damaged or the settings altered. Relays must only be handled by skilled personnel. The

installation should be clean, dry and reasonably free from dust and excessive vibration. The

site should be well lit to facilitate inspection. Relays that have been removed from their cases

should not be left in situations where they are exposed to dust or damp. This particularly

applies to installations which are being carried out at the same time as construction work.

Page 35

Handling, Installation and Case Dimensions P72x/EN IN/C21

MiCOM P721/P723 Page 7/10

5. STORAGE

If relays are not to be installed immediately upon receipt they should be stored in a place

free from dust and moisture in their original cartons. Where de-humidifier bags have been

included in the packing they should be retained. The action of the de-humidifier crystals will

be impaired if the bag has been exposed to ambient conditions and may be restored by

gently heating the bag for about an hour, prior to replacing it in the carton.

Dust which collects on a carton may, on subsequent unpacking, find its way into the relay; in

damp conditions the carton and packing may become impregnated with moisture and the dehumifier will lose its efficiency.

Storage temperature: –25°C to +70°C.

Page 36

P72x/EN IN/C21 Handling, Installation and Case Dimensions

Page 8/10 MiCOM P721/P723

6. DIMENSIONS

6.1 Connection of power terminals, and Signals terminals

The individual equipment are delivered with sufficient M4 screws to connect the relay via

annular terminals, with a maximum recommended of two annular terminals per contact.

If necessary, Schneider Electric can provide annular terminals to crimp. 5 references exist

according to the section of the wire (see below). Each reference corresponds to a sachet of

100 terminals.

Page 37

Handling, Installation and Case Dimensions P72x/EN IN/C21

MiCOM P721/P723 Page 9/10

To insure the insulation of the terminals and to respect the security and safety instructions,

an isolated sleeve can be used.

We recommend the following cable cross-sections:

− Auxiliary sources Vaux: 1.5 mm²

− Communication Port see paragraph 6.2

− Other circuits 1.0 mm²

Because of the limitations of the annular terminals, the maximum wire cross-section which

can be used for the connector blocks (for current inputs and signals) is of 6mm² by using non

-insulated annular terminals. When only pre- insulated terminals can be used, the maximum

wire cross-section is reduced to 2, 63 mm² per annular terminal. If a more significant wire

cross-section is necessary, two wires can be put in parallel, each one finished by a separate

annular terminal.

All the terminal blocks used for connections, except of the port RS485, must be able to

withstand a nominal voltage of minimum 300V peak value.

We recommend to protect the auxiliary source connection by using a fuse of type NIT or TIA

with a breaking capacity of 16A. For security reasons, do never install fuses in current

transformers circuits. The other circuits must be protected by fuses.

6.2 Communication port RS485

Connections to RS485 is made using annular terminals. It is recommended that a two core

screened cable, is used with a maximum total length of 1000 m or a200nF total cable

capacitance.

Typical specification:

− Each core: 16/0.2 mm copper conductor, PVC insulated.

− Nominal conductor area: 0.5 mm² per core

− Screen: Overall braid, PVC sheathed

− Linear capacitance between conductor and earth: 100pF/m

6.3 Earthing

Each equipment must be connected to a local earth terminal by the intermediary of a M4

earth terminals. We recommend a wire of minimal section of 2.5 mm², with annular terminals

on the side of the equipment. Because of the limitations of the annular terminals, the

possible maximum section is of 6mm² by wire. If a larger section is necessary, one can use

cables connected in parallel, each one ending with an annular terminal separated on the side

of the equipment. One can also use a metal bar.

NOTE: To prevent any electrolytic risk between copper conductor or brass

conductor and the back plate of the equipment, it is necessary to take

precautions to isolate them one from the other. This can be done in

several ways, for example by inserting between the conductor and the

case a plated nickel or insulated ring washer or by using a tin

terminals.

Page 38

P72x/EN IN/C21 Handling, Installation and Case Dimensions

Page 10/10 MiCOM P721/P723

7. CASE DIMENSIONS

MiCOM P721 and P723 relays are available in a 4U metal case for panel or flush mounting.

Weight: 1.7 to 2.1 Kg

External size: Height case 152 mm

front panel 177 mm

Width case 97 mm

front panel 103 mm

Depth case 226 mm

front panel + case 252 mm

P0078ENb

MiCOM P721 AND P723 RELAYS CASE DIMENSIONS

NOTE: The chassis is normally secured in the case by four screws (Self tap

screws 6x1.4), to ensure good seating. The fixing screws should be

fitted in normal service (do not add washers). Do not discard these

screws.

Page 39

User Guide P72x/EN FT/C21

MiCOM P721/P723

USER GUIDE

Page 40

Page 41

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 1/38

CONTENTS

1. PRESENTATION OF MiCOM P721 AND P723 PROTECTIONS 3

1.1 USER INTERFACE 4

1.1.1 Relay Overview 4

1.1.2 Front panel description 5

1.1.3 LCD display and keypad description 6

1.1.4 LEDs 7

1.1.5 Description of the two areas under the top and bottom flaps 8

1.1.6 The USB/RS232 cable (to power and set the relay) 8

1.2 Menu structure 9

1.3 Password 9

1.3.1 Password protection 9

1.3.2 Password entry 9

1.3.3 Changing the password 10

1.3.4 Change of setting invalidation 10

1.4 Displays of Alarm & Warning Messages 10

1.4.1 Electrical Network Alarms 10

2. MENUS 13

2.1 Default display 13

2.2 Menu contents description 13

2.3 OP PARAMETERS Menu 14

2.4 CONFIGURATION menu 15

2.4.1 Submenu CONFIGURATION 15

2.4.2 Submenus LED 5 to 8 16

2.4.3 Submenu GROUP SELECT 18

2.4.4 Submenu ALARMS 18

2.4.5 Submenu INPUTS 19

2.4.6 Submenu OUTPUT RELAYS 19

2.5 MEASUREMENTS Menu 20

2.5.1 If Earth protection is selected 20

2.5.2 If Phase protection is selected (P723 only) 20

2.6 COMMUNICATION Menu 21

2.7 PROTECTION Menu 22

2.7.1 Earth protection configuration 22

2.7.2 Phase protection configuration 24

2.8 AUTOMAT. CTRL Menu 25

2.8.1 Submenu Trip Commands 25

2.8.2 Submenu Latch of trip output relay by Function 26

2.8.3 Submenu Blocking Logic 1 / 2 27

2.8.4 Outputs Relays submenu 27

Page 42

P72x/EN FT/C21 User Guide

Page 2/38 MiCOM P721/P723

2.8.5 Latch of the auxiliary output relays (RL2 to RL8) 29

2.8.6 Inputs submenu 29

2.8.7 CIRCUIT BREAKER FAILURE submenu 31

2.8.8 Submenu Logic Equations 31

2.9 RECORDS Menu 34

2.9.1 Fault Record submenu 34

2.9.2 INSTANTANEOUS RECORDS submenu 35

2.9.3 DISTURBANCE RECORD submenu 35

3. WIRING 36

3.1 Auxiliary supply 36

3.2 Current measurement inputs 36

3.3 Logic inputs 36

3.4 Output relays 36

3.5 Communication 37

3.5.1 RS485 rear communication port 37

3.5.2 RS232 front communication port 37

Page 43

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 3/38

1. PRESENTATION OF MiCOM P721 AND P723 PROTECTIONS

MiCOM P721 and P723 are fully numerical relays designed to perform electrical protection

and control functions.

The following section describes the MiCOM P72x range and the main differences between

the different models.

MiCOM relays are powered either from a DC (2 voltage ranges) or an AC auxiliary power

supply.

Using the front panel, the user can easily navigate through the menu and access data,

change settings, read measurements, etc.

Eight LEDs situated in the front panel help the user to quickly know the status of the relay

and the presence of alarms. Alarms that have been detected are stored and can be

displayed on the back-lit LCD.

Any short time voltage interruption (<50ms) is filtered and regulated through the auxiliary

power supply.

Regarding current inputs, MiCOM P721 has one earth current input available for 1A and 5A

rated CTs.

MiCOM P723 has 3 phase and 1 earth current inputs available for 1 and 5 Amps rated CTs.

On each one of these relays, it is possible to combine 1 and 5 Amp curre nt inputs together (ie a mix between 1A for earth fault and 5A for phase connections).

MiCOM P721 and P723 relays continuously measure phase and earth currents and take into

account the true RMS current value up to 10th harmonic (at 50 Hz).

Output relays are freely configurable and can be activated by any of the control or protection

functions available in the relay. Logic inputs can also be assigned to various control

functions.

On their rear terminals MiCOM P721 and P723 have a standard RS485 port available. When

ordering, the user can choose between the following communication protocols: ModBus

RTU, IEC 60870-5-103 or DNP3.0.

Using RS485 communication channel, all stored information (measurements, alarms, and

parameters) can be read and settings can be modified when the chosen protocol allows it.

Reading and modification of this data can be carried out on site with a standard PC loaded

with Schneider Electric setting software.

Thanks to its RS485 based communication, MiCOM P721 and P723 relays can be

connected directly to a digital control system. All the available data can then be gathered by

a substation control system and be processed either locally or remotely.

Page 44

P72x/EN FT/C21 User Guide

Page 4/38 MiCOM P721/P723

1.1 USER INTERFACE

1.1.1 Relay Overview The next figures show the P721 and P723 protections.

The table shows the case size.

Height Depth Width

4U (177mm) 226mm 20 TE

The hinged covers at the top and bottom of the relay are shown closed. Extra physical

protection for the front panel can be provided by an optional transparent front cover; this

allows read only access to the relays settings and data but does not affect the relays IP

rating. When full access to the relay keypad is required to edit the settings, the transparent

cover can be unclipped and removed when the top and bottom hinged covers are open.

Page 45

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 5/38

1.1.2 Front panel description MiCOM P721 and P723 relay front panel allows the user to easily enter relay settings,

display measured values and alarms and to clearly display the status of the relay.

Top cover

Top cover

Fixed

Fixed

function

function

LED

LED

User

User

programmable

programmable

function LEDs

function LEDs

Keypad

Keypad

Cover (not used)

Cover (not used)

Front comms port

Front comms port

P3602ENg

P3602ENg

FIGURE 1: MiCOM P721 AND P723 FRONT PANEL DESCRIPTION

The front panel of the relay has three separate sections:

1. The LCD display and the keypad,

2. The LEDs

3. The two zones under the upper and lower flaps.

Page 46

P72x/EN FT/C21 User Guide

A

A

Page 6/38 MiCOM P721/P723

1.1.3 LCD display and keypad description The front panel components are shown below. The front panel functionality is identical for

the P721 and P723 relays.

1.1.3.1

1.1.3.2

LCD display

In the front panel, a liquid crystal display (LCD) displays settings, measured values and

alarms. Data is accessed through a menu structure.

The LCD has two lines, with sixteen characters each. A back-light is activated when a key is

pressed and will remain lit for five minutes after the last key press. This allows the user to be

able to read the display in most lighting conditions.

Keypad

The keypad has seven keys divided into two groups:

• Two keys located just under the screen (keys and c).

Keys and c are used to read and acknowledge alarms. To display successive alarms,

press key c. Alarms are displayed in reverse order of their detection (the most recent alarm

first, the oldest alarm last). To acknowledge the alarms, the user can either acknowledge

each alarm using or go to the end of the ALARM menu and acknowledge all the alarms

at the same time.

When navigating through submenus, key is also used to come back to the head line of

the corresponding menu.

NOTE: To acknowledge a relay latched refer to the corresponding submenu

section.

• Four main keys , , , located in the middle of the front panel.

They are used to navigate through the different menus and submenus and to do the setting

of the relay.

The key is used to validate a choice or a value (modification of settings).

Read key

Read key

Arrow keys

Arrow keys

Enter key

Enter key

P3950ENc

P3950ENc

Clear key

Clear key

rrow keys

rrow keys

Page 47

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 7/38

1.1.4 LEDs The LED labels on the front panel are by default written in English, however the user has

self-adhesive labels available with MiCOM relays on which it is possible to write using a ball

point pen.

The top four LEDs indicate the status of the relay (Trip condition, alarm LED, equipment

failure, auxiliary supply).

The four lower LEDs are freely programmable by the user and can be assigned to display a

threshold crossing for example (available for all models) or to show the status of the logic

inputs.The description of each one of these eight LEDs located in the left side of the front

view is given hereafter (numbered from the top to bottom from 1 to 8):

LED 1

LED 8

LED 1 Colour: RED Label: Trip

LED 1 indicates that the relay has issued a trip order to the cut-off element. This LED

recopies the trip order issued to the Trip logic output. Its normal state is unlit. As soon as a

triggering order is issued, the LED lights up. It is cleared when the associated alarm is

acknowledged either through the front panel, or by a remote command, a digital input, or by

a new fault (CONFIGURATION/Alarms menu).

LED 2 Colour: ORANGE Label: ALARM

LED 2 indicates that the relay has detected an alarm. This alarm can either be a threshold

crossing (instantaneous), or a trip order (time delayed). As soon as an alarm is detected, the

LED starts blinking. After all the alarms have been read, the LED lights up continuously.

After acknowledgement of all the alarms, the LED is extinguished.

NOTE: It is possible to configure the instantaneous alarms to be self reset or

not by choosing Yes or No in the CONFIGURATION/Alarms Menu.

The alarm LED can be reset either through the front panel, or by remote command, by a

digital input, or by a new fault (CONFIGURATION/Alarms menu).

LED 3 Colour: ORANGE Label: Warning

P3951ENa

LED 3 indicates internal alarms of the relay. When the relay detects a « non critical » internal

alarm (typically a communication failure), the LED starts blinking continuously. When the

relay detects a fault that is considered as « critical », the LED lights up continuously. Only

the disappearance of the cause of the fault can clear this LED (repair of the module,

clearance of the Fault).

LED 4 Colour: GREEN Label: Healthy

LED 4 indicates that the relay is powered by an auxiliary source at the nominal range.

LED 5 to 8 Colour: RED Label: Aux.1 to 4.

Page 48

P72x/EN FT/C21 User Guide

Page 8/38 MiCOM P721/P723

These LEDs are user programmable and can be set to display information about

instantaneous and time-delayed thresholds as well as the status of the logic inputs. Under

the CONFIGURATION/LED menu of the relay, the user can select the information he wishes

to associate with each LED. He can affect more than one function to one LED. The LED will

then light up when at least one of the associated information is valid (OR gate). The LED is

cleared when all the associated alarms are acknowledged.

1.1.5 Description of the two areas under the top and bottom flaps

1.1.5.1

Relay Identification

Under the upper flap, a label identifies the relay according to its model number (order

number) and its serial number. This information defines the product in a way that is unique.

In all your requests, please make reference to these two numbers.

Under the model and serial number, you will find information about the level of voltage of the

auxiliary supply and the nominal earth current value.

1.1.5.2

Lower flap

Under the lower flap, a RS232 port is available in all MiCOM relays. It can be used either to

download a new version of the application software version into the relay flash memory or to

download/retrieve settings plugging a laptop loaded with MiCOM S1 setting software.

To withdraw more easily the active part of the MiCOM relay (i-e the chassis) from its case,

open and remove the two flaps, then with a 3mm screwdriver, turn the extractor located

under the upper flap, and pull it out of its case pulling the flaps towards you.

1.1.6 The USB/RS232 cable (to power and set the relay) The USB/RS232 cable is able to perform the following functions:

1. It is able to power the relay from its front port. This allows the user to view or modify

data on the relay even when the auxiliary power supply of the relay has failed or when

the relay is not connected to any power supply. The USB port of the PC supplies the

power necessary to energize the relay. This lasts as long as the battery of the PC can

last.

2. It provides an USB / RS 232 interface between the MiCOM relay and the PC. This

allows the user to be able to change the setting of the relay using a PC with its USB

port.

It eases the use of the relay allowing the retrieval of records and disturbance files for

example when the auxiliary supply has failed or is not available.

The associated driver (supplied with the relay) needs to be installed in the PC. For more

information, refer to MiCOM E2 User Guide.

Page 49

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 9/38

1.2 Menu structure

The relay’s menu is arranged in a tabular structure. Each setting in the menu is referred to

as a cell, and each cell in the menu may be accessed by reference to a row and column

address. The settings are arranged so that each column contains related settings, for

example all of the disturbance recorder settings are contained within the same column. As

shown in the figure, the top row of each column contains the heading that describes the

settings contained within that column. Movement between the columns of the menu can only

be made at the column heading level. A complete list of all of the menu settings is given in

the Menu Content tables (P72x/EH HI section).

Column header

1.3 Password

Column

data

settings

OP

param

Config.

Measur.

MENU STRUCTURE

Comm.

Protections

Autom. Ctrl

Records

P0106ENb

1.3.1 Password protection A password is required for relay settings, especially when changing the various thresholds,

time delays, communication parameters, allocation of inputs and outputs relays.

The password consists of four capital characters. When leaving factory, the password is set

to AAAA. The user can define his own combination of four characters.

Should the password be lost or forgotten, the modification of the stored parameters is

blocked. It is then necessary to contact the manufacturer or his representative and a standby password specific to the relay may be obtained.

The programming mode is indicated with the letter "P" on the right hand side of the display

on each menu heading. The letter "P" remains present as long as the password is active

(5 minutes if there is no action on the keypad).

1.3.2 Password entry The input of the password is requested as soon as a modification of a parameter is made for

any one of the six/eight menus and the submenus. The user enters each one of the 4

characters and then validates the entire password with .

After 5 seconds, the display returns to the point of the preceding menu.

If no key is pressed inside of 5 minutes, the password is deactivated. A new password

request is associated with any subsequent parameter modification.

Page 50

P72x/EN FT/C21 User Guide

Page 10/38 MiCOM P721/P723

1.3.3 Changing the password To change an active password, go to the OP. PARAMETERS menu and then to the

Password submenu. Enter the current password and validate it. Then press and enter the

new password character by character and validate the new password using .

The message NEW PASSWORD OK is displayed to indicate that the new password has

been accepted.

1.3.4 Change of setting invalidation The procedure to modify a setting is described in the following sections of this manual. If there is a need to get back to the old setting push key before validating the setting

change. The following message will then appear on the LCD for a few seconds and the old

setting will remain unchanged.

UPGRADE

CANCEL

1.4 Displays of Alarm & Warning Messages

Alarm messages are displayed directly on the front panel LCD. They have priority over the

default display presenting measured current values. As soon as the relay detects an alarm

condition (crossing of a threshold for example), the associated message is displayed on the

front panel LCD and the LED Alarm (LED 2) lights up.

We distinguish two types of alarm and warning messages:

- Alarm messages generated by the electrical power network.

- Warning messages caused by hardware or software faults from the relay.

1.4.1 Electrical Network Alarms Any crossing of a threshold (instantaneous or time delay) generates an "electrical network

alarm". The involved threshold is indicated. Regarding the phase thresholds, the phase

designation (A, B or C) is also displayed.

If several alarms are triggered, they are all stored in their order of appearance and presented

on the LCD in reverse order of their detection (the most recent alarm first, the oldest alarm

last). Each alarm message is numbered and the total number of alarm messages is

displayed.

The user can read all the alarm messages pressing c.

The user acknowledges and clears the alarm messages from the LCD pressing .

The user can acknowledge each alarm message one by one or all by going to the end of the

list to acknowledge, and clear, all the alarm messages pressing .

The control of the ALARM LED (LED 2) is directly assigned to the status of the alarm

messages stored in the memory.

If one or several messages are NOT READ and NOT ACKNOWLEDGED, the ALARM LED

(LED 2) flashes.

If all the messages have been READ but NOT ACKNOWLEDGED, the ALARM LED (LED 2)

lights up continuously.

If all the messages have been ACKNOWLEDGED, and cleared, if the cause that generated

the alarm disappears, the ALARM LED (LED 2) is extinguished.

Page 51

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 11/38

The different electrical system alarms are listed below:

Alarm Signification

[95] SUP + phase fault

Phase bus-wire supervision alarm (phase A, B or C).

indication

[95] tSUP + phase fault

indication

[87] DIFF + phase fault

indication

[87] tDIFF + phase fault

indication

Time delayed phase bus-wire supervision alarm (phase A, B

or C). This alarm acknowledges [95] SUP alarm.

Phase segregated high impedance current differential

protection alarm (phase A, B or C).

Phase segregated high impedance current differential

protection alarm (phase A, B or C). This alarm

acknowledges [87] DIFF alarm.

[95N] SUP Earth bus-wire supervision alarm.

[95N] tSUP Time delayed earth bus-wire supervision alarm. This alarm

acknowledges [95N] SUP alarm.

[87N] DIFF Earth high impedance current differential protection alarm

[87N] tDIFF Time delayed earth high impedance current differential

protection alarm. This alarm acknowledges [87N] DIFF

alarm.

[87CZ] check zone Check zone input. This alarm appears after [95] tSUP.

Buswire shorting Buswire shorting information.

tAux 1 / tAux2 / tAux3 /

tAux4

t AUX1, t AUX2, t AUX 3 and t AUX 4 time-out. These alarms

can be inhibited using CONFIGURATION/ALA RMS menu

tEquation A to H t Equation A, B, C, D, E F,G and H

CB Failure (50BF) Circuit breaker failure indication (the CB does not trip on tBF

time. tBF can be set under the AUTOMAT. CTRL/CIRCUIT

BREAKER Fail menu.

Logical output relays

At least one output relay is latched.

latched

Maintenance Mode

The relay is in maintenance mode.

Relay Hardware or Software Warning Messages

Any software or hardware fault internal to MiCOM relay generates a "hardware/software

alarm" that is stored in memory as a "Hardware Alarm". If several hardware alarms are

detected they are all stored in their order of appearance. The warning messages are

presented on the LCD in reverse order of their detection (the most recent first and the oldest

last). Each warning message is numbered and the total stored is shown.

The user can read all warning messages pressing c, without entering the password.

It is not possible to acknowledge and clear warning messages caused by internal relay

hardware or software failure. This message can only be cleared once the cause of the

hardware or software failure has been removed.

The control of the WARNING LED (LED 3) is directly assigned to the status of the warning

messages stored in the memory.

If the internal hardware or software failure is major (i.e. the relay cannot perform protection

functions), the WARNING LED (LED 3) lights up continuously.

− major fault: Protection and automation functions of the equipment are blocked. In this

condition, the protection relay detects the corresponding fault and activates RL0 Watch

Dog relay (35-36 terminals contact is closed).

For instance: the “DEF. ANA” fault (fault in the analog circuit channel) is considered as a

major fault because the protection functions will not operate correctly.

Page 52

P72x/EN FT/C21 User Guide

Page 12/38 MiCOM P721/P723

− minor fault: Protection and automation functions of the relay operate. A minor fault will not

activate RL0 Watch Dog relay (35-36 terminals contact is closed, 36-37 terminals is

open). This fault causes a LED alarm and is displayed on the LCD panel.

The Watch Dog relay controls the correct operation of the protection and automation

function. This relay fault “RL0 relay” is activated if the following functions or checks are

faulty:

− microprocessor operation,

− power supply check,

− reconstituted internal power supply check,

− heating of a circuit board component monitoring,

− analog channel monitoring (acquisition sampling),

− program execution monitoring,

− communication ports monitoring.

If the internal hardware or software failure is minor (like a communication failure that has no

influence on the protection and automation functions), the WARNING LED (LED 3) will flash.

Possible Hardware or Software alarm messages are:

Major fault:

The protection and automation functions are stopped.

The RL0 watchdog relay is de-energised (35-36 contact clo sed).

<< CALIBRATION ERROR.>>: Calibration zone failure

<< CT ERROR >>: Analog channel failure

<< DEFAULT SETTINGS (*) >>

<< SETTING ERROR (**) >>

(*) DEFAULT SETTINGS: Each time the relay is powered ON it will check its memory

contents to determine whether the settings are set to the factory defaults. If the relay detects

that the default settings are loaded an alarm is raised. The ALARM LED (YELLOW) will light

up and the Watch Dog contact will be activated.

Only one parameter in the relay's menu needs to be changed to suppress these messages

and to reset the watch dog. This alarm is only an indication to the user that the relay has its

default settings applied.

(**) SETTING ERROR: Each time the relay is powered ON it will check the coherence of the

setting data. If the relay detects a problem with the settings, a "HARDWARE" ALARM will

appear on the LCD display followed by "SETTING ERROR" message (when pushing on the

button).. The ALARM LED (YELLOW) will light up and the Watch Dog contact will be

activated. To reset this alarm it is necessary to power ON and OFF the relay. Following this,

the last unsuccessful setting change will then need to be re-applied. If the alarm persists, i.e.

the "SETTING ERROR" alarm is still displayed, please contact Schneider Electric Customer

Care Services for advice and assistance.

Minor fault:

The MiCOM relay is fully operational.

The RL0 watchdog relay is energised (35-36 contact open, 36-37 contact closed).

<< COMM.ERROR >>: Communication failure

<< CLOCK ERROR >>: Time tag failure

<< STATS RESET >>: Statistical data recorded (like CB supervision statistics (Number of CB

opening, etc) have been reset.

Page 53

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 13/38

2. MENUS

The menu of MiCOM P721 and P723 relays is divided into main menus and submenus. The

available content depends on the model of the relay.

2.1 Default display

By default, the LCD displays the current value measured (selected phase or earth). As soon

as an alarm is detected by the relay, that information is considered as more important and

the alarm message is then displayed instead of the default value.

2.2 Menu contents description

The menu of MiCOM P72x relays is divided into eight main sections. To access these menus

from the default display press . To return to the default display from these menus or sub-

menus press .

DEFAULT

DISPLAY

OP PARAMETERS

CONFIGURATION

MEASUREMENTS

COMMUNICATION

PROTECTION G1

PROTECTION G2

AUTOMAT. CTRL

RECORDS

FIGURE 2: ORGANIZATION OF MiCOM P72X MAIN MENU

NOTE: The content of the menu is presented in the document P72x/EN HI.

This table helps the user to navigate through the different menus and

submenus.

For MiCOM P72x range, while navigating between submenu points,

the user can press the key to go back to the corresponding head

menu.

Using MiCOM S1 Studio, the menu is displayed with a tree structure. A click on the “+” sign

(or a double click on the menu title) opens the corresponding submenu.

The second column displays the corresponding value for each parameter.

Page 54

P72x/EN FT/C21 User Guide

Page 14/38 MiCOM P721/P723

2.3 OP PARAMETERS Menu

On the P72x front panel, press to access the menu OP PARAMETERS from the default

display.

OP PARAMETERS

Password

* * * *

Password

AAAA

Heading of the OP PARAMETERS menu

Press to access the menu content.

Password entry. This password is required when

modifying relay settings and parameters (see §

1.3).

To enter a password, enter it letter by letter using

to go up or down in the alphabet.

After each letter, press to enter the following letter. At

the end, press to validate the password. If the

password is correct, the message « PASSWORD OK »

is displayed on the screen.

NOTE: The password is initially set in factory to AAAA.

WARNING: NO SETTING CHANGES DONE EITHER LOCALLY (THROUGH RS232)

OR REMOTELY (THROUGH RS485) WILL BE ALLOWED DURING THE 5

FIRST MINUTES FOLLOWING A CHANGE OF PASSWORD.

Language

ENGLISH

Indicates the default language used by the device.

Possible choices are English, French, German, Spanish,

Italian and Portuguese languages.

Description

Indicates the type of relay.

Pxxx

Reference

MiCOM

Displays the reference that lists the equipment

associated with the relay.

Software version

Displays the version of the software

XX

Frequency

50 Hz

Active Group

1

Input 54321

Status 10110

Nominal value of the network frequency. Select either 50

or 60Hz.

Displays the active protection and automation group.

This value can be either 1 or 2.

Displays the status of the logic Inputs

Logic Inputs are numbered from 1 to 5 for P723, 1 to 2

for P721.

When the status of one input is:

- state 0: it means that the input is de-energised,

- state 1: it means that the input is energised.

Relay 87654321

Status 01011101

Displays the status of the logic outputs.

Logic Outputs are numbered from 1 to 8 for P723 and 1

to 4 for P721.

When The state of each output is:

- state 0: it means that the output relay is activated,

- state 1: it means that the output relay is not activated.

To activate an unlatching operation, the password is

requested.

NOTE: The Watch-dog output (RL0) is not displayed in

the output status menu.

Date

Displays the date (12/08/09 = 12 August 2009).

12/08/09

Time

Displays the time (13:57:44 = 1:57:44 pm).

13:57:44

Page 55

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 15/38

Product code

Displays the product code.

P723xxxxxxxxx

Serial number

XXXXXXXX

2.4 CONFIGURATION menu

Under this menu, the different submenus are:

CONFIGUR-

ATION

Connection

Led 8

Output

relays

led 5

Group select

Press to access the CONFIGURATION menu from the default display, then until the

desired submenu header is displayed.

2.4.1 Submenu CONFIGURATION

Displays the serial number

Led 6

Alarms

Led 7

Inputs

2.4.1.1

CONFIGURATION

Heading of the CONFIGURATION menu.

Connection

Protection line select.

EARTH

Heading of the Connection submenu. This submenu is

used to select and configure earth or phase protection,

P723 only.

This menu is used to select the configuration of the

protection (phase or earth supervision).

Protection choices: Earth or Phase.

Input selection

Current

The input selection menu is used to select Voltage unit

instead of Current.

Possible choices: Voltage or Current.

Submenu Configuration with Earth protection selected

E/Gnd Text

N

Choose a label (displayed with the associated values) for

E/Gnd.

Possible choices are N, E, or G.

Stabiliz Resist. N

30 Ω

This stabilizing resistor N (E or G) value is displayed only

if the analogue input mode is the Voltage mode.

It is used to set the resistor value of the P79x resistor

inserted in the outside input circuit of the protection.

Setting choice: 30Ω to 4000Ω, accuracy 0.1Ω.

The value is settable digit by digit, using or keys

to change the value, and or key to modify an other

digit.

E/Gnd CT Primary

1000 A

Choose the rated primary current of the earth CT.

Setting range: from 1 to 9999 – step 1.0000

Page 56

P72x/EN FT/C21 User Guide

Page 16/38 MiCOM P721/P723

E/Gnd CT sec

1 A

Choose the rated secondary current of the earth CT.

Setting value: 1 or 5.

2.4.1.2

Submenu Configuration with Phase selected (P723 only)

Phases Text

L1, L2, L3

Choose a label (displayed with the associated

measurement value) for the 3 phases.

Possible choices are “L1, L2, L3”, “A, B, C” or “R, S, T”.

The values are modified after entering the password.

Stabiliz Resist. L1

30 Ω

This stabilizing resistor L1 (A or R) value is displayed

only if the analogue input mode is the Voltage mode.

It is used to set the resistor value of the P79x resistor

inserted in the outside input circuit of the protection

(phase L1).

Setting choice: 30Ω to 4000Ω, accuracy 0.1Ω.

The value is settable digit by digit, using or keys

to change the value, and or key to modify an other

digit.

Stabiliz Resist. L2

As above for phase L2 (or B or S).

30 Ω

Stabiliz Resist. L3

As above for phase L2 (or C or T).

30 Ω

Line CT Primary

1000 A

Choose the rated primary current of the CT.

Setting range: from 1 to 9999 – step 1.0000

Line CT sec

1 A

2.4.2 Submenus LED 5 to 8 The LED 5 to LED 8 configuration submenu is used to assignate to a LED a protection

function (the LED lights up when the protection function is active).

The following table lists the protection functions that can be assigned to the LEDs (5 to 8) for

each model of relay.

Function P721 P723 Information

[87] Diff

[87N] Diff

[87] tDiff

[87N] tDiff

[87CZ] Check zone

[95] Sup

Choose the rated secondary current of the CT.

Setting value: 1 or 5.

X Phase differential protection threshold

X X Earth differential protection threshold

X Time delayed phase differential protection

threshold

X X Time delayed earth differential protection

threshold

X Check Zone status

X Phase high impedance differential threshold

(buswire supervision)

[95N] Sup

[95] tSup

[95N] tSup

X Earth high impedance differential threshold

(buswire supervision)

X Time delayed phase high impedance differential

threshold (buswire supervision)

X X Time delayed earth high impedance differential

threshold (buswire supervision)

Page 57

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 17/38

Function P721 P723 Information

[95A] tSupA

[95B] tSupB

[95C] tSupC

Input 1

Input 2

Input 3

Input 4

Input 5

tAux 1

tAux 2

tAux 3

tAux 4

tEqu.A

tEqu.B

tEqu.C

tEqu.D

tEqu.E

tEqu.F

tEqu.G

tEqu.H

X Time delayed phase A (or L1, or R) high

impedance differential threshold (buswire

supervision)

X As above for phase B (or L2 or S)

X As above for phase C (or L3 or T)

X X Copy of the status of the Logic Input n°1

(“automat ctrl/inputs” menu)

X X Copy of the status of the Logic Input n°2

X Copy of the status of the Logic Input n°3

X Copy of the status of the Logic Input n°4

X Copy of the status of the Logic Input n°5

X X Copy of Aux1 Logic Input delayed by Aux1 time

time (Aux1 logic input and aux1 time are set with

“automat ctrl/inputs” menu)

X X Copy of Aux2 Logic Input delayed by Aux2 time

X Copy of Aux3 Logic Input delayed by Aux3 time

X Copy of Aux4 Logic Input delayed by Aux4 time

X X Time delayed logical output of Equation A.

X X Time delayed logical output of Equation B.

X X Time delayed logical output of Equation C.

X X Time delayed logical output of Equation D.

X X Time delayed logical output of Equation E.

X X Time delayed logical output of Equation F.

X X Time delayed logical output of Equation G.

X X Time delayed logical output of Equation H.

NOTES: ⇒ Each parameter can be assigned to one or more LED's.

⇒ One or more parameters (OR logic) can provocate each LED to

light up.

MiCOM S1 Studio setting:

The LED 5 (6, 7 or 8) submenu contains up to 3 lines parameter settings. In the value

column, each line represents a setting value. State “1” means that the corresponding

parameter is associated to the LED.

The corresponding parameters are displayed in the setting panel: from 00 (last digit) up to

1E (first digit).

Page 58

P72x/EN FT/C21 User Guide

Page 18/38 MiCOM P721/P723

P72x Front panel setting:

Press to access the LED 5 CONFIGURATION submenu, then twice (press to access

to others LEDs CONFIGURATION submenus).

Select “Yes” to assignate a LED to a function.

CONFIGURATION

Led 5

Led 5

Function No

2.4.3 Submenu GROUP SELECT The submenu “GROUP SELECT” is used to select the active protection group

CONFIGURATION

Group Select

Change Group

Input = INPUT

Heading LED 5 submenu.

Activate (select choice “Yes” or inhibit (“No”) LED 5

operation when:

- an alarm is exceeded,

- a threshold time delay has elapsed.

Refer to previous tables for protection functions list.

Heading of the “GROUP SELECT” sub-menu.

Setting choice : MENU or INPUT

MENU is used to change settings group via HMI and/or

RS485 port.

If MENU is selected, the following menu is displayed:

Setting Group

1

2.4.4 Submenu ALARMS

CONFIGURATION

Alarms

Inst. Self-reset ?

No

Reset led on

fault ? No

Alarm tAux1

inhib No

Select active setting protection group 1 or 2.

Heading of the Alarms submenu.

Setting choices: Yes or No.

Setting choice Yes: the alarms that are instantaneous

will be self reset when they come back to a normal value

(below the threshold).

Setting choice No: the alarms that are instantaneous will

be need to be acknowledged by the user to be reset.

Yes: the LED associated with an old alarm will be

automatically reset when a new fault occurs. This is

done to avoid a display of numerous alarms that are not

active any more.

No: the appearance of a new fault will not automatically

reset LEDs associated with an old fault.

Yes: auxiliary timer 1 output will not raise an alarm.

Alarm LED stays OFF, no message will be displayed on

the HMI.

No: auxiliary timer 1 will raise an alarm.

Alarm tAux2

As above with timer 2.

inhib No

Page 59

User Guide P72x/EN FT/C21

MiCOM P721/P723 Page 19/38

Alarm tAux3

As above with timer 3 (P723 only)

inhib No

Alarm tAux4

inhib No

Alarm tAux5

inhib No

2.4.5 Submenu INPUTS A digital input can be configured to be activated either on low level or on high level. Low level

(or high level) depends of the application of the digital inputs.

The user has to set under the Menu CONFIGURATION the auxiliary voltage (AC or DC) for