Page 1

Easergy MiCOM P634

Transformer Differential Protection Device

P634/EN M/R-42-A

Version P634 -311 -410/411 -653

Technical Manual

Page 2

Page 3

IMPORTANT INFORMATION

NOTICE: Read these instructions carefully, and look at the equipment to become familiar

with the device before trying to install, operate, or maintain it. The following

special messages may appear throughout this documentation or on the equipment

to warn of potential hazards or to call attention to information that clarifies or

simplifies a procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an

electrical hazard exists, which will result in death or serious injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to a potential personal injury

hazard. Obey all safety messages that follow this symbol to avoid possible injury or

death.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided,

can result in death or serious injury.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided,

can result in minor or moderate injury.

NOTICE

NOTICE, used without safety alert symbol, indicates a potentially hazardous

situation which, if not avoided, can result in equipment damage.

Page 4

WARNING

When electrical equipment is in operation dangerous voltage will be present in certain parts of the

equipment. Failure to observe warning notices, incorrect use or improper use may endanger personnel

and equipment and cause personal injury or physical damage.

Before working in the terminal strip area, the P634 must be isolated. Where stranded conductors are

used, insulated crimped wire end ferrules must be employed.

The signals MAIN: Blocked/faulty and SFMON: Warning (LED) (permanently assigned to the

LEDs labeled OUT OF SERVICE and ALARM) can be assigned to output relays to indicate the health of

the P634. Schneider Electric strongly recommends that these output relays are hardwired into the

substation's automation system, for alarm purposes.

Any modifications to this P634 must be in accordance with the manual. If any other modification is

made without the express permission of Schneider Electric, it will invalidate the warranty, and may

render the product unsafe.

Proper and safe operation of this P634 depends on appropriate shipping and handling, proper storage,

installation and commissioning, and on careful operation, maintenance and servicing.

For this reason only qualified personnel may work on or operate this P634.

The User should be familiar with the warnings in the Safety Guide (SFTY/4LM/J11 or later version), with

the warnings in Chapter 5, (p. 5-1), Chapter 10, (p. 10-1), Chapter 11, (p. 11-1) and

Chapter 12, (p. 12-1) and with the content of Chapter 14, (p. 14-1), before working on the

equipment. If the warnings are disregarded, it will invalidate the warranty, and may render the

product unsafe.

Installation of the DHMI:

A protective conductor (ground/earth) of at least 1.5 mm² (US: AWG14 or thicker) must be connected

to the DHMI protective conductor terminal to link the DHMI and the main relay case; these must be

located within the same substation.

To avoid the risk of electric shock the DHMI communication cable must not be in contact with

hazardous live parts.

The DHMI communication cable must not be routed or placed alongside high-voltage cables or

connections. Currents can be induced in the cable which may result in electromagnetic interference.

PLEASE NOTE:

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of the

use of this material. A qualified person is one who has skills and knowledge related to the construction

and operation of electrical equipment and the installation, and has received safety training to

recognize and avoid the hazards involved.

Page 5

Qualified Personnel

are individuals who

are familiar with the installation, commissioning and operation of the P634 and of the system to

●

which it is being connected;

are able to perform switching operations in accordance with safety engineering standards and

●

are authorized to energize and de-energize equipment and to isolate, ground and label it;

are trained in the care and use of safety apparatus in accordance with safety engineering

●

standards;

are trained in emergency procedures (first aid).

●

Note

This operating manual gives instructions for installation, commissioning and operation of the P634.

However, the manual cannot cover all conceivable circumstances or include detailed information on all

topics. In the event of questions or specific problems, do not take any action without proper

authorization. Contact the appropriate technical sales office of Schneider Electric and request the

necessary information.

Any agreements, commitments, and legal relationships and any obligations on the part of Schneider

Electric, including settlement of warranties, result solely from the applicable purchase contract, which

is not affected by the contents of the operating manual.

Page 6

Page 7

Changes after going to press

Page 8

Page 9

P634

Table of Contents

1 Application and Scope ........................................................................................ 1-1

1.1 Overview - P634 ..........................................................................................................1-1

1.1.1 Design ........................................................................................................................................................... 1-2

1.2 Including Function Groups in the Configuration ..........................................................1-3

1.3 Overview of Function Groups - Part 1 ......................................................................... 1-4

1.4 Overview of Function Groups - Part 2 ......................................................................... 1-6

1.5 Configurable Function Keys ........................................................................................ 1-8

1.6 Inputs and Outputs ..................................................................................................... 1-9

1.7 Control and Display ...................................................................................................1-10

1.8 Information Interfaces ...............................................................................................1-11

2 Technical Data ....................................................................................................2-1

2.1 Conformity ..................................................................................................................2-1

2.2 General Data ...............................................................................................................2-2

2.2.1 General Device Data ..................................................................................................................................... 2-2

2.3 Tests ...........................................................................................................................2-4

2.3.1 Type Tests .....................................................................................................................................................2-4

2.3.2 Routine Tests .................................................................................................................................................2-7

2.4 Environmental Conditions ...........................................................................................2-9

2.5 Inputs and Outputs ................................................................................................... 2-10

2.5.1 Measuring Inputs .........................................................................................................................................2-10

2.5.2 Binary Signal Inputs .....................................................................................................................................2-11

2.5.3 IRIG‑B Interface ........................................................................................................................................... 2-12

2.5.4 Direct Current Input .....................................................................................................................................2-12

2.5.5 Resistance Thermometer ............................................................................................................................ 2-12

2.5.6 Direct Current Output ..................................................................................................................................2-12

2.5.7 Output Relays ..............................................................................................................................................2-13

2.5.8 BCD Measured Data Output ........................................................................................................................ 2-13

2.6 Interfaces ..................................................................................................................2-14

2.6.1 Local Control Panel ......................................................................................................................................2-14

2.6.2 PC Interface .................................................................................................................................................2-14

2.6.3 Serial Communication Interface .................................................................................................................. 2-14

2.6.4 IEC Communication Interface ......................................................................................................................2-15

2.6.5 IRIG‑B Interface ........................................................................................................................................... 2-15

2.7 Information Output ................................................................................................... 2-16

2.8 Settings – Typical Characteristic Data .......................................................................2-17

2.8.1 Main Function ..............................................................................................................................................2-17

2.8.2 Differential Protection ..................................................................................................................................2-17

2.8.3 Definite-Time and Inverse-Time Overcurrent Protection ............................................................................. 2-17

2.8.4 Time-Voltage Protection ..............................................................................................................................2-17

2.8.5 Overfluxing Protection .................................................................................................................................2-17

2.9 Deviations .................................................................................................................2-18

2.9.1 Deviations of the Operate Values ................................................................................................................2-18

2.9.2 Deviations of the Timer Stages ................................................................................................................... 2-20

2.9.3 Deviations of Measured Data Acquisition ....................................................................................................2-20

2.10 Resolution of the Fault Data Acquisition ...................................................................2-21

2.10.1 Time Resolution ...........................................................................................................................................2-21

2.10.2 Currents .......................................................................................................................................................2-21

2.10.3 Voltage ........................................................................................................................................................2-21

P634/EN M/R-42-A // P634‑311‑653 1

Page 10

P634

Table of Contents

2.11 Recording Functions ................................................................................................. 2-22

2.11.1 Organization of the Recording Memories .................................................................................................... 2-22

2.12 Power Supply ............................................................................................................ 2-24

2.13 Current Transformer Specifications .......................................................................... 2-25

2.13.1 Symbols .......................................................................................................................................................2-25

2.13.2 General Equations .......................................................................................................................................2-26

2.13.3 Transformer Differential Protection .............................................................................................................2-27

3 Operation ............................................................................................................3-1

3.1 Modular Structure .......................................................................................................3-1

3.2 Operator-Machine Communication ............................................................................. 3-3

3.3 Configuration of the Measured Value Panels (Function Group LOC) ........................... 3-4

3.3.1 Operation Panel .............................................................................................................................................3-5

3.3.2 Fault Panel .....................................................................................................................................................3-6

3.3.3 Overload Panel ..............................................................................................................................................3-7

3.3.4 Configurable Clear Key ..................................................................................................................................3-7

3.4 Communication Interfaces ..........................................................................................3-8

3.4.1 PC Interface (Function Group PC) .................................................................................................................. 3-9

3.4.2 Communication Interface 1 (Function Group COMM1) ................................................................................ 3-10

3.4.3 Communication Interface 2 (Function Group COMM2) ................................................................................ 3-19

3.4.4 Communication Interface IEC 61850 (Function Groups IEC and GOOSE) .................................................... 3-21

3.4.5 Redundant Ethernet Board ..........................................................................................................................3-31

3.5 IRIG-B Clock Synchronization (Function Group IRIGB) ...............................................3-34

3.6 Configurable Function Keys (Function Group F_KEY) ................................................ 3-35

3.7 Configuration and Operating Mode of the Binary Inputs (Function Group INP) .........3-37

3.8 Measured Data Input (Function Group MEASI) ..........................................................3-39

3.8.1 Direct Current Input on the Analog (I/O) Module Y ...................................................................................... 3-40

3.8.2 Input for Connection of a Resistance Thermometer .................................................................................... 3-43

3.9 Configuration, Operating Mode, and Blocking of the Output Relays (Function Group

OUTP) ........................................................................................................................3-45

3.9.1 Configuration of the Output Relays ............................................................................................................. 3-45

3.9.2 Operating Mode of the Output Relays ......................................................................................................... 3-45

3.9.3 Blocking the Output Relays ......................................................................................................................... 3-46

3.9.4 Testing the Output Relays ...........................................................................................................................3-47

3.10 Measured Data Output (Function Group MEASO) ......................................................3-48

3.10.1 General Settings ..........................................................................................................................................3-48

3.10.2 BCD Measured Data Output ........................................................................................................................ 3-50

3.10.3 Analog Measured Data Output .................................................................................................................... 3-53

3.10.4 Output of “External” Measured Data ...........................................................................................................3-59

3.11 Configuration and Operating Mode of the LED Indicators (Function Group LED) ...... 3-60

3.11.1 Configuring the LED Indicators ....................................................................................................................3-60

3.11.2 Layout of the LED Indicators ........................................................................................................................3-60

3.11.3 Operating Mode of the LED Indicators .........................................................................................................3-61

3.12 Main Functions of the P634 (Function Group MAIN) ..................................................3-63

3.12.1 Conditioning of the Measured Values ..........................................................................................................3-63

3.12.2 Phase Reversal Function ..............................................................................................................................3-67

3.12.3 Disconnecting Transformer Ends .................................................................................................................3-68

3.12.4 Selection of the Residual Current to be Monitored ......................................................................................3-72

3.12.5 Forming a Virtual Transformer End ..............................................................................................................3-72

3.12.6 Operating Data Measurement ..................................................................................................................... 3-75

3.12.7 Configuring and Enabling the Device Functions .......................................................................................... 3-86

3.12.8 Activation of “Dynamic Parameters” ...........................................................................................................3-88

2 P634/EN M/R-42-A // P634‑311‑653

Page 11

Table of Contents

3.12.9 Multiple Blocking ......................................................................................................................................... 3-89

3.12.10 Multiple Signaling of the Measuring Circuit Monitoring Function .................................................................3-90

3.12.11 Multiple Signaling ........................................................................................................................................3-90

3.12.12 Blocked/Faulty .............................................................................................................................................3-91

3.12.13 Starting Signals and Tripping Logic .............................................................................................................3-91

3.12.14 Time Tagging and Clock Synchronization ....................................................................................................3-95

3.12.15 Resetting Actions .........................................................................................................................................3-96

3.12.16 Assigning Communications Interfaces to Physical Communications Channels ............................................3-98

3.12.17 Test Mode ....................................................................................................................................................3-99

3.13 Parameter Subset Selection (Function Group PSS) ................................................. 3-100

3.14 Self-Monitoring (Function Group SFMON) ................................................................3-102

3.14.1 Tests During Start-up ................................................................................................................................ 3-102

3.14.2 Cyclic Tests ................................................................................................................................................3-102

3.14.3 Signals .......................................................................................................................................................3-102

3.14.4 Device Response .......................................................................................................................................3-103

3.14.5 Monitoring Signal Memory .........................................................................................................................3-104

3.14.6 Monitoring Signal Memory Time Tag .........................................................................................................3-104

3.15 Operating Data Recording (Function Group OP_RC) ............................................... 3-105

3.16 Monitoring Signal Recording (Function Group MT_RC) ............................................3-106

3.17 Overload Data Acquisition (Function Group OL_DA) ............................................... 3-107

3.17.1 Overload Duration .....................................................................................................................................3-107

3.17.2 Acquiring Measured Overload Data from the Thermal Overload Protection ..............................................3-108

3.18 Overload Recording (Function Group OL_RC) ..........................................................3-109

3.18.1 Start of Overload Recording ......................................................................................................................3-109

3.18.2 Counting Overload Events .........................................................................................................................3-109

3.18.3 Time Tagging .............................................................................................................................................3-109

3.18.4 Overload Logging ...................................................................................................................................... 3-110

3.19 Fault Data Acquisition (Function Group FT_DA) ...................................................... 3-111

3.19.1 Running Time and Fault Duration ..............................................................................................................3-112

3.19.2 Fault Data Acquisition Time .......................................................................................................................3-113

3.19.3 Acquisition of the Fault Currents ............................................................................................................... 3-114

3.19.4 Acquisition of the Differential and Restraining Currents ............................................................................3-115

3.19.5 Fault Data Reset ........................................................................................................................................3-117

3.20 Fault Recording (Function Group FT_RC) ................................................................ 3-118

3.20.1 Start of Fault Recording .............................................................................................................................3-118

3.20.2 Fault Counting ...........................................................................................................................................3-119

3.20.3 Time Tagging .............................................................................................................................................3-119

3.20.4 Fault Recordings ........................................................................................................................................3-120

3.20.5 Fault Value Recording ............................................................................................................................... 3-121

3.21 Differential Protection (Function Group DIFF) ......................................................... 3-123

3.21.1 Enabling or Disabling Differential Protection .............................................................................................3-123

3.21.2 Amplitude Matching ...................................................................................................................................3-124

3.21.3 Vector Group Matching ..............................................................................................................................3-128

3.21.4 Zero-sequence Current Filtering ................................................................................................................3-128

3.21.5 Tripping Characteristics .............................................................................................................................3-132

3.21.6 Rapid (high-set) Differential Protection ..................................................................................................... 3-134

3.21.7 Inrush Stabilization (2nd Harmonic Restraint) ...........................................................................................3-136

3.21.8 Overfluxing Stabilization (5th Harmonic Restraint) ................................................................................... 3-138

3.21.9 Saturation Discriminator ............................................................................................................................3-139

3.21.10 Measured Operating Data of Differential Protection ..................................................................................3-139

3.22 Ground Differential Protection (Function Groups REF_1 to REF_3) ..........................3-141

3.22.1 Enabling or Disabling Ground Differential Protection ................................................................................ 3-141

3.22.2 Blocking ground differential protection ..................................................................................................... 3-141

3.22.3 Amplitude Matching ...................................................................................................................................3-142

P634

P634/EN M/R-42-A // P634‑311‑653 3

Page 12

P634

3.22.4 Operating Modes .......................................................................................................................................3-144

3.22.5 Idiff>>> Threshold ....................................................................................................................................3-148

3.22.6 Applying Current Transformer Supervision ................................................................................................3-148

3.22.7 Measured Operating Data of Ground Differential Protection .....................................................................3-148

3.22.8 Protection of Autotransformers ................................................................................................................. 3-149

Table of Contents

3.23 Definite-Time Overcurrent Protection (Function Groups DTOC1 to DTOC4) ............3-152

3.23.1 Enabling or Disabling DTOC Protection ......................................................................................................3-152

3.23.2 Phase Current Stages ................................................................................................................................3-154

3.23.3 Negative-Sequence Current Stages ...........................................................................................................3-156

3.23.4 Residual Current Stages ............................................................................................................................3-157

3.23.5 General Starting ........................................................................................................................................3-159

3.23.6 General Trip Signal ....................................................................................................................................3-159

3.23.7 Counters of the DTOC Protection Function ................................................................................................3-160

3.24 Inverse-time Overcurrent Protection (Function Groups IDMT1 to IDMT3) ............... 3-161

3.24.1 Enabling or Disabling IDMT Protection .......................................................................................................3-161

3.24.2 Time-Dependent Characteristics ............................................................................................................... 3-163

3.24.3 Phase Current Stage ..................................................................................................................................3-167

3.24.4 Negative-Sequence Current Stage ............................................................................................................ 3-168

3.24.5 Residual Current Stage ..............................................................................................................................3-170

3.24.6 Hold Time ..................................................................................................................................................3-171

3.24.7 General Starting ........................................................................................................................................3-172

3.24.8 Counters of the IDMT Protection Function .................................................................................................3-173

3.25 Thermal Overload Protection (Function Groups THRM1 and THRM2) ......................3-174

3.25.1 Enabling or Disabling Thermal Overload Protection .................................................................................. 3-174

3.25.2 Readiness of Thermal Overload Protection ................................................................................................3-174

3.25.3 Selection of Current ...................................................................................................................................3-176

3.25.4 Tripping Characteristics .............................................................................................................................3-177

3.25.5 Coolant Temperature Acquisition .............................................................................................................. 3-178

3.25.6 Warning Signal .......................................................................................................................................... 3-180

3.26 Time-Voltage Protection (Function Group V<>) ..................................................... 3-182

3.26.1 Disabling and Enabling V<> Protection .....................................................................................................3-182

3.26.2 V<> Protection Readiness .........................................................................................................................3-182

3.26.3 Voltage Monitoring .................................................................................................................................... 3-182

3.27 Over-/Underfrequency Protection (Function Group f<>) ........................................ 3-185

3.27.1 Disabling or Enabling Over‑/Underfrequency Protection ............................................................................3-185

3.27.2 Undervoltage Blocking and Evaluation Time .............................................................................................3-186

3.27.3 Operating Modes of Over-/Underfrequency Protection ..............................................................................3-186

3.27.4 Frequency Monitoring ................................................................................................................................3-186

3.27.5 Frequency Monitoring Combined with Differential Frequency Gradient Monitoring (df/dt) ........................3-186

3.27.6 Frequency Monitoring Combined with Mean Frequency Gradient Monitoring (Δf/Δt) ................................ 3-187

3.27.7 f

Measurement ...............................................................................................................................3-189

min/fmax

3.28 Overfluxing Protection (Function Group V/f) ........................................................... 3-190

3.28.1 Enabling or Disabling Overfluxing Protection ............................................................................................ 3-190

3.28.2 Conditioning the Measured Value ..............................................................................................................3-190

3.28.3 Fixed-time Warning Stage .........................................................................................................................3-191

3.28.4 Fixed-time Tripping Stage ......................................................................................................................... 3-191

3.28.5 Variable-time Tripping Stage .....................................................................................................................3-191

3.29 Current Transformer Supervision (Function Group CTS) .........................................3-196

3.29.1 Enabling or Disabling the CTS Function .....................................................................................................3-196

3.29.2 Blocking CTS ..............................................................................................................................................3-196

3.29.3 Monitoring Condition ................................................................................................................................. 3-197

3.29.4 Signaling and Indication ............................................................................................................................3-199

3.29.5 Reset .........................................................................................................................................................3-200

3.29.6 Multiple Signaling from the CTS Function ..................................................................................................3-200

4 P634/EN M/R-42-A // P634‑311‑653

Page 13

Table of Contents

3.30 Measuring-Circuit Monitoring (Function Groups MCM_1 to MCM_4) ........................ 3-202

3.30.1 Enabling or Disabling Measuring-Circuit Monitoring ..................................................................................3-202

3.30.2 Measuring-Circuit Monitoring .....................................................................................................................3-202

3.30.3 Multiple Signaling from the Measuring-Circuit Monitoring Function .......................................................... 3-203

3.31 Circuit Breaker Failure Protection (Function Groups CBF_1 to CBF_4) .................... 3-204

3.31.1 Assigning Transformer Ends ......................................................................................................................3-204

3.31.2 Assigning Circuit Breakers .........................................................................................................................3-204

3.31.3 Assigning the Trip Command .....................................................................................................................3-204

3.31.4 Enabling or Disabling the CBF Function .....................................................................................................3-204

3.31.5 Readiness of Circuit Breaker Protection .................................................................................................... 3-205

3.31.6 Detecting a CB Tripping .............................................................................................................................3-206

3.31.7 Current flow monitoring .............................................................................................................................3-206

3.31.8 Evaluation of CB Status Signals .................................................................................................................3-207

3.31.9 Startup Criteria ..........................................................................................................................................3-208

3.31.10 Trip Commands ......................................................................................................................................... 3-210

3.31.11 Starting Trigger ......................................................................................................................................... 3-211

3.31.12 Fault Behind CB Protection ........................................................................................................................3-211

3.31.13 CB Synchronization Supervision ................................................................................................................3-212

3.32 Limit Value Monitoring (Function Group LIMIT) .......................................................3-213

3.32.1 Enabling or Disabling the Limit Value Monitoring Function ....................................................................... 3-213

3.32.2 Monitoring the Linearized Measured DC Values ........................................................................................ 3-213

3.32.3 Monitoring the Measured Temperature Value ........................................................................................... 3-214

3.33 Limit Value Monitoring (Function Groups LIM_1 to LIM_3) .......................................3-216

3.33.1 Monitoring Minimum and Maximum Phase Currents ................................................................................. 3-216

3.34 Transformer Monitoring (Function Group TRMON) ..................................................3-218

3.35 Programmable Logic (Function Groups LOGIC and LOG_2) .....................................3-219

3.36 Binary Counts (Function Group COUNT) ..................................................................3-227

3.36.1 Enable/Disable the Counting Function .......................................................................................................3-227

3.36.2 Debouncing ............................................................................................................................................... 3-227

3.36.3 Counting Function ..................................................................................................................................... 3-227

3.36.4 Transmitting the Counter Values via Communications Interface ...............................................................3-227

3.36.5 Counter Values Reset ................................................................................................................................3-228

P634

4 Design .................................................................................................................4-1

4.1 Designs .......................................................................................................................4-2

4.2 Dimensional Drawings ................................................................................................ 4-4

4.2.1 Dimensional Drawings for the 84 TE Case .....................................................................................................4-4

4.2.2 Detachable HMI .............................................................................................................................................4-5

4.3 Hardware Modules ......................................................................................................4-7

5 Installation and Connection ................................................................................ 5-1

5.1 Unpacking and Packing ...............................................................................................5-3

5.2 Checking Nominal Data and Design Type ...................................................................5-4

5.3 Location Requirements ...............................................................................................5-5

5.3.1 Environmental Conditions ..............................................................................................................................5-5

5.3.2 Mechanical Conditions ...................................................................................................................................5-5

5.3.3 Electrical Conditions for Auxiliary Voltage of the Power Supply .................................................................... 5-5

5.3.4 Electromagnetic Conditions ...........................................................................................................................5-5

5.4 Installation ..................................................................................................................5-6

5.5 Protective and Operational Grounding ......................................................................5-12

5.6 Connection ................................................................................................................5-13

5.6.1 Connecting Measuring and Auxiliary Circuits .............................................................................................. 5-13

P634/EN M/R-42-A // P634‑311‑653 5

Page 14

P634

5.6.2 Connecting the IRIG‑B Interface .................................................................................................................. 5-17

5.6.3 Connecting the Serial Interfaces ................................................................................................................. 5-17

Table of Contents

5.7 Location and Connection Diagrams .......................................................................... 5-22

5.7.1 Location Diagrams P634‑410/411 ................................................................................................................5-22

5.7.2 Terminal Connection Diagrams P634‑410/411 ............................................................................................ 5-22

6 Local Control (HMI) ............................................................................................. 6-1

6.1 Local Control Panel (HMI) ............................................................................................6-1

6.2 Display and Keypad .................................................................................................... 6-2

6.2.1 Text Display ...................................................................................................................................................6-2

6.2.2 Display Illumination .......................................................................................................................................6-2

6.2.3 Contrast of the Display ..................................................................................................................................6-2

6.2.4 Short Description of Keys .............................................................................................................................. 6-3

6.3 Display Levels .............................................................................................................6-5

6.4 Display Panels .............................................................................................................6-6

6.5 Menu Tree and Data Points .........................................................................................6-7

6.6 List Data Points ...........................................................................................................6-8

6.7 Note Concerning the Step-by-Step Descriptions .........................................................6-9

6.8 Configurable Function Keys ...................................................................................... 6-10

6.8.1 Configuration of the Function Keys F1 to Fx ................................................................................................6-11

6.9 Changing Between Display Levels ............................................................................ 6-14

6.10 Control at Panel Level ...............................................................................................6-15

6.11 Control at the Menu Tree Level .................................................................................6-16

6.11.1 Navigation in the Menu Tree ....................................................................................................................... 6-16

6.11.2 Switching Between Address Mode and Plain Text Mode ..............................................................................6-17

6.11.3 Change-Enabling Function ...........................................................................................................................6-18

6.11.4 Changing Parameters ..................................................................................................................................6-21

6.11.5 List Parameters ........................................................................................................................................... 6-22

6.11.6 Memory Readout .........................................................................................................................................6-25

6.11.7 Resetting .....................................................................................................................................................6-28

6.11.8 Password-Protected Control Actions ............................................................................................................6-29

6.11.9 Changing the Password ...............................................................................................................................6-31

7 Settings ...............................................................................................................7-1

7.1 Parameters .............................................................................................................. 7-1

7.1.1 Device Identification ............................................................................................................................. 7-3

7.1.2 Configuration Parameters .................................................................................................................. 7-12

7.1.3 Function Parameters ............................................................................................................................7-74

8 Information and Control Functions ......................................................................8-1

8.1 Operation ................................................................................................................. 8-1

8.1.1 Cyclic Values ............................................................................................................................................ 8-2

8.1.2 Control and Testing ............................................................................................................................8-151

8.1.3 Operating Data Recording ................................................................................................................8-160

8.2 Events ...................................................................................................................8-161

8.2.1 Event Counters .................................................................................................................................... 8-161

8.2.2 Measured Event Data .........................................................................................................................8-163

8.2.3 Event Recording .................................................................................................................................. 8-169

9 IEC 61850 Settings via IED Configurator .............................................................9-1

9.1 Manage IED .................................................................................................................9-2

9.2 IED Details .................................................................................................................. 9-3

6 P634/EN M/R-42-A // P634‑311‑653

Page 15

Table of Contents

9.3 Communications .........................................................................................................9-4

9.4 SNTP ........................................................................................................................... 9-5

9.4.1 General Config ...............................................................................................................................................9-5

9.4.2 External Server 1 ...........................................................................................................................................9-5

9.4.3 External Server 2 ...........................................................................................................................................9-5

9.5 Dataset Definitions ..................................................................................................... 9-6

9.6 GOOSE Publishing .......................................................................................................9-7

9.6.1 System/LLN0 ................................................................................................................................................. 9-7

9.7 GOOSE Subscribing .....................................................................................................9-9

9.7.1 Mapped Inputs ...............................................................................................................................................9-9

9.8 Report Control Blocks ............................................................................................... 9-12

9.8.1 System/LLN0 ............................................................................................................................................... 9-12

9.9 Controls .....................................................................................................................9-13

9.9.1 Control Objects ............................................................................................................................................9-13

9.9.2 Uniqueness of Control ................................................................................................................................. 9-13

9.10 Measurements .......................................................................................................... 9-15

9.11 Configurable Data Attributes .................................................................................... 9-16

9.11.1 System/LLN0 ............................................................................................................................................... 9-16

P634

10 Commissioning ................................................................................................. 10-1

10.1 Safety Instructions ....................................................................................................10-1

10.2 Commissioning Tests ................................................................................................10-4

10.2.1 Preparation ..................................................................................................................................................10-4

10.2.2 Testing .........................................................................................................................................................10-6

10.2.3 Checking the Binary Signal Inputs ...............................................................................................................10-6

10.2.4 Checking the Output Relays ........................................................................................................................10-6

10.2.5 Checking the Protection Function ................................................................................................................10-7

10.2.6 Completing Commissioning .......................................................................................................................10-10

11 Troubleshooting ................................................................................................11-1

12 Maintenance .....................................................................................................12-1

12.1 Maintenance Procedures in the Power Supply Area ..................................................12-2

12.2 Routine Functional Testing ....................................................................................... 12-4

12.3 Analog Input Circuits .................................................................................................12-5

12.4 Binary Opto Inputs ....................................................................................................12-6

12.5 Binary Outputs ..........................................................................................................12-7

12.6 Serial Interfaces ........................................................................................................12-8

13 Storage .............................................................................................................13-1

14 Accessories and Spare Parts .............................................................................14-1

15 Order Information .............................................................................................15-1

A1 Function Groups ............................................................................................... A1-1

A2 Internal Signals .................................................................................................A2-1

A3 Glossary ............................................................................................................A3-1

Modules ......................................................................................................................................A3-1

P634/EN M/R-42-A // P634‑311‑653 7

Page 16

P634 Table of Contents

Symbols ......................................................................................................................................A3-1

Examples of Signal Names ......................................................................................................... A3-7

Symbols Used .............................................................................................................................A3-8

A4 Telecontrol Interfaces .......................................................................................A4-1

A4.1 Telecontrol Interface per EN 60870-5-101 or IEC 870-5-101 (Companion Standard)

.................................................................................................................................. A4-1

A4.1.1 Interoperability ............................................................................................................................................A4-1

A4.2 Communication Interface per IEC 60870-5-103 ........................................................A4-9

A4.2.1 Interoperability ............................................................................................................................................A4-9

A5 P634 Version History ........................................................................................A5-1

8 P634/EN M/R-42-A // P634‑311‑653

Page 17

1 Application and Scope

1.1 Overview - P634

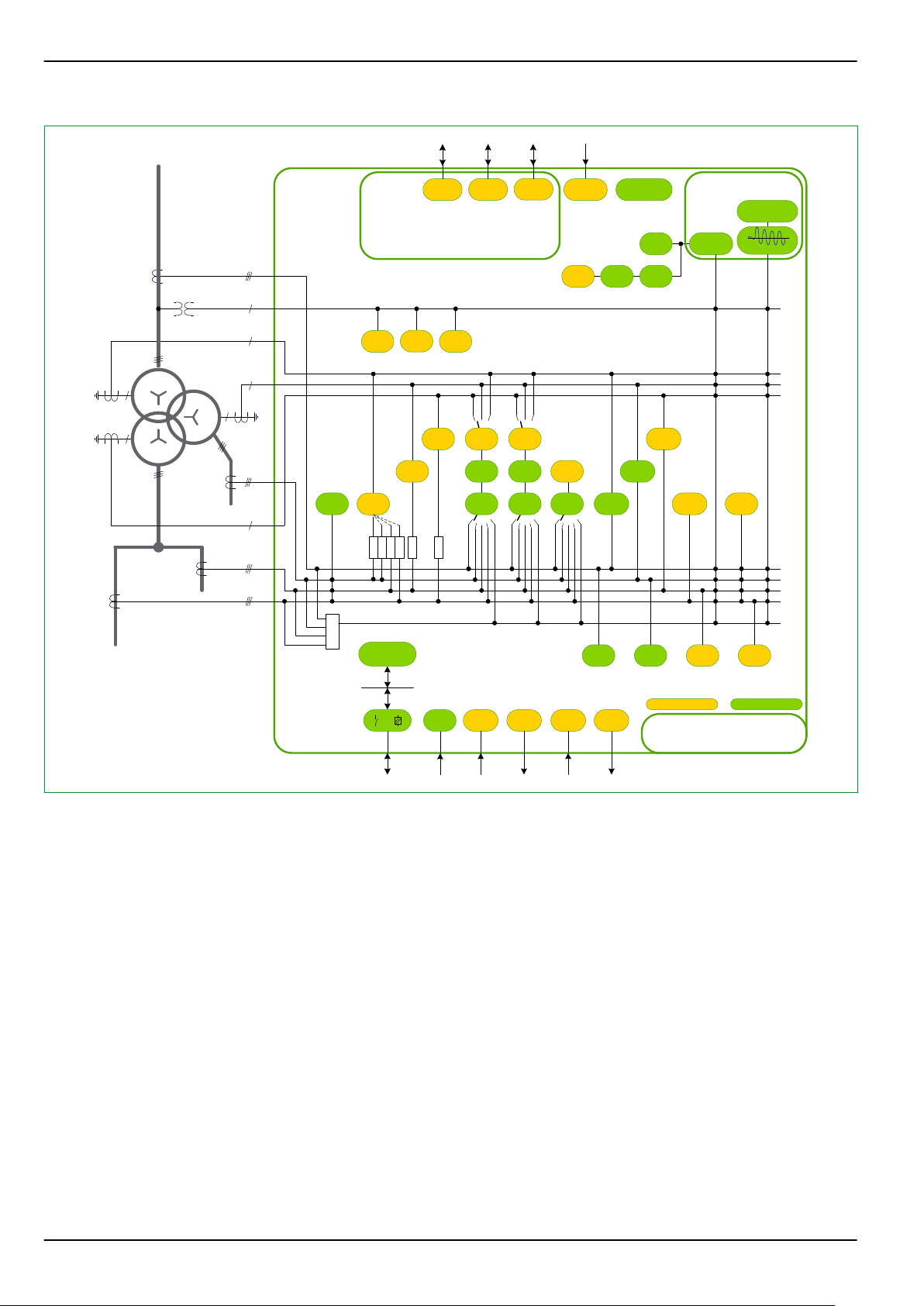

The P634 differential protection device is intended for the fast and selective

short-circuit protection of transformers, motors, generators and other

installations with 4 windings.

P634

Fig. 1-1: P634 in 84 TE case.

The P634 provides high-speed three-system differential protection using a tripleslope characteristic and two high-set differential elements in combination with

transformer inrush restraint, overfluxing restraint and through-stabilization.

Amplitude and vector group matching is done just by entering the nominal values

of transformer windings and associated current transformers. An (optional)

overreaching current measuring circuit monitoring function will prevent

unwanted tripping by differential protection for faults in the CT's secondary

circuit.

For ring bus and breaker-and-a-half applications a virtual winding can be defined

for which the current measuring inputs are based on the vector sum of currents

from two or three freely selectable windings.

Phase swapping allows motor / generator protection applications with enlarged

protection zones.

In addition many supplementary protective functions are incorporated in the

devices. These can be individually configured and cancelled.

The relevant protection parameters can be stored in four independent parameter

subsets in order to adapt the protection device to different operating and power

system management conditions.

The powerful programmable logic provided by the protection device also makes

it possible to accommodate special applications.

For a list of all available function groups see the Appendix.

P634/EN M/R-42-A // P634‑311‑653 1-1

Page 18

24

V/f

27/59

V<>

81

f<>

I

Y,b

I

Y,a

I

Y,c

V

I

P,a

I

P,b

I

P,c

I

P,d

I

virtual

87

DIFF

49

THRM1

49

THRM2

51

IDMT1

51

IDMT2

51

IDMT3

50

DTOC2

50

DTOC3

87G

REF_1

87G

REF_3

Metering

LIM_1

Overload rec.

Self Monitoring

LIM_2LIM_3

Fault rec.

Communication

to SCADA / substation control / RTU / modem ...

via RS485 or Fiber optics

using IEC 60870-5-101, -103, Modbus, DNP3, Courier

resp.

via RJ45 or Fiber optics using IEC 61850

16S

COMM1

16S

COMM2

16E

IEC

CLK

IRIGB

CMD_1SIG_1

26

MEASI MEASO

Transformer Differential Protection

P634

Always availableOptional

LIMIT

50

DTOC1

87G

REF_2

50/62BF

CBF_2

50/62BF

CBF_1

50/62BF

CBF_3

50/62BF

CBF_4

MCM_4MCM_3MCM_2MCM_1

CTS

Recording and

Data Acquisition

∑ ∑ ∑ ∑ ∑Φ ∑

LGC

LOGIC / LOG2

TRMON

P634

1 Application and Scope

Fig. 1-2: Function diagram.

1.1.1 Design

The P634 is modular in design. The plug-in modules are housed in a robust

aluminum case and electrically interconnected via one analog p/c board and one

digital p/c board.

1-2 P634/EN M/R-42-A // P634‑311‑653

Page 19

1 Application and Scope P634

1.2 Including Function Groups in the Configuration

Functions listed in the tables in Section 1.3, (p. 1-4) are self-contained

function groups and can be individually configured or de-configured according to

the specific application requirements by using the MiCOM S1 operating program.

Unused or cancelled function groups are hidden to the user, thus simplifying the

menu of the MiCOM S1.

This concept provides a large choice of functions and makes wide-ranging

application of the protection device possible, with just one model version. On the

other hand, simple and clear parameter settings can be made.

In this way the protection and control functions can be included in or excluded

from the configuration.

Example

For example, the current transformer supervision (function group CTS)

can be included in the configuration by setting

●

CTS: Function group CTS to With

can be excluded from the configuration by setting

●

CTS: Function group CTS to Without

P634/EN M/R-42-A // P634‑311‑653 1-3

Page 20

P634 1 Application and Scope

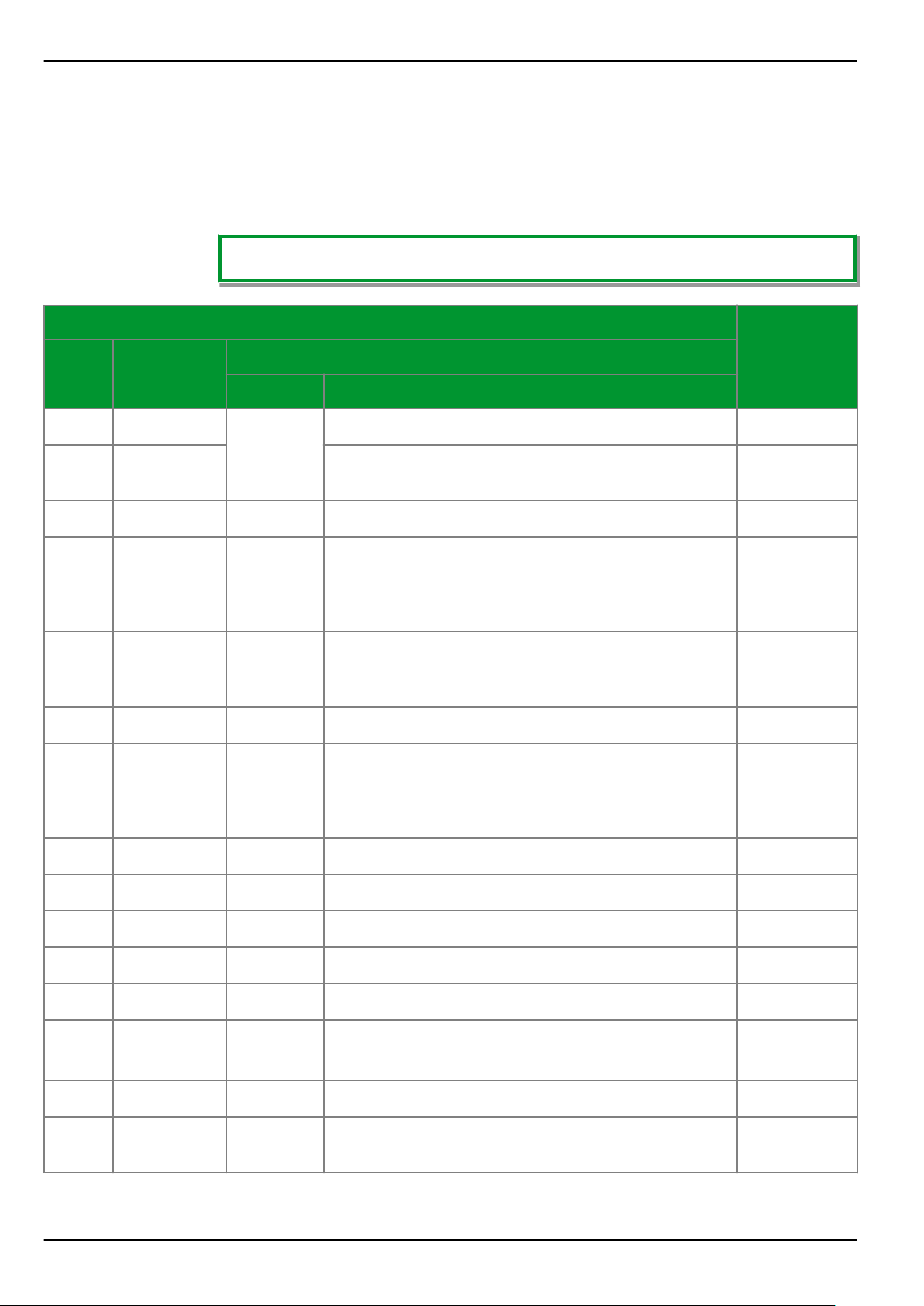

1.3 Overview of Function Groups - Part 1

The following tables list the function groups that can be included in or excluded

from the configuration of the P634.

✓ = Standard; (✓) = Ordering option.

Protection functions

P634ANSI IEC 61850 Function group

Abbrev. Description

87T PhsPDIF1 DIFF Differential protection, phase selective 4 wind.

PHAR1 Inrush stabilization (functionality that is part of the

DIFF function group)

87N

50TD

P/ Q/ N

DtpPhs- /

DtpEft- /

DtpNgsPTCO

REF_x Restricted earth-fault protection 3

DTOCx Definite-time overcurrent protection, 3 stages,

phase-, negative-sequence-, residual/starpoint-

overcurrent

x

51 P/

Q/ N

ItpPhs- /

ItpEft- /

ItpNgsPTCOx

IDMTx Inverse-time overcurrent protection, one stage,

phase-, negative-sequence-, residual/starpoint-

overcurrent

49 ThmPTTR1 THRMx Thermal overload protection 2

27/ 59

P/ Q/ N

VtpPhs- /

VtpNgs- /

V<> Time-voltage Protection 1

VtpPss- /

VtpRefPTyVx

81 FrqPTyFx f<> Over / Underfrequency protection 1

24

V/f Overfluxing protection 1

✓

3

3

50 BF RBRFx CBF_x Circuit breaker failure protection 4

CTS Current transformer supervision 1

30/ 74 AlmGGIO1 MCM_x Measuring-circuit monitoring 4

LIMIT

Limit value monitoring 3

LIM_x

LGC PloGGIOx LOGIC /

TRMON Transformer monitoring ✓

Programmable logic ✓

LOG_2

1-4 P634/EN M/R-42-A // P634‑311‑653

Page 21

1 Application and Scope P634

Communication functions

P634ANSI IEC 61850 Function group

Abbrev. Description

16S

CLK

16E

COMM1,

COMM2

2 communication interfaces serial, RS 422 / 485 or

fiber optic

(✓)

IRIGB Time synchronization IRIG-B (✓)

IEC Communication interface Ethernet (✓)

16E GosGGIOx GOOSE IEC 61850 (✓)

Measured value functions

P634ANSI IEC 61850 Function group

Abbrev. Description

26 RtdGGIO1

IdcGGIO1

MEASI

MEASO

Analog inputs and outputs

RTD input

●

1× Measuring data input 20 mA

●

2× Measuring data output 20 mA

●

(✓)

(✓)

(✓)

(✓)

P634/EN M/R-42-A // P634‑311‑653 1-5

Page 22

P634 1 Application and Scope

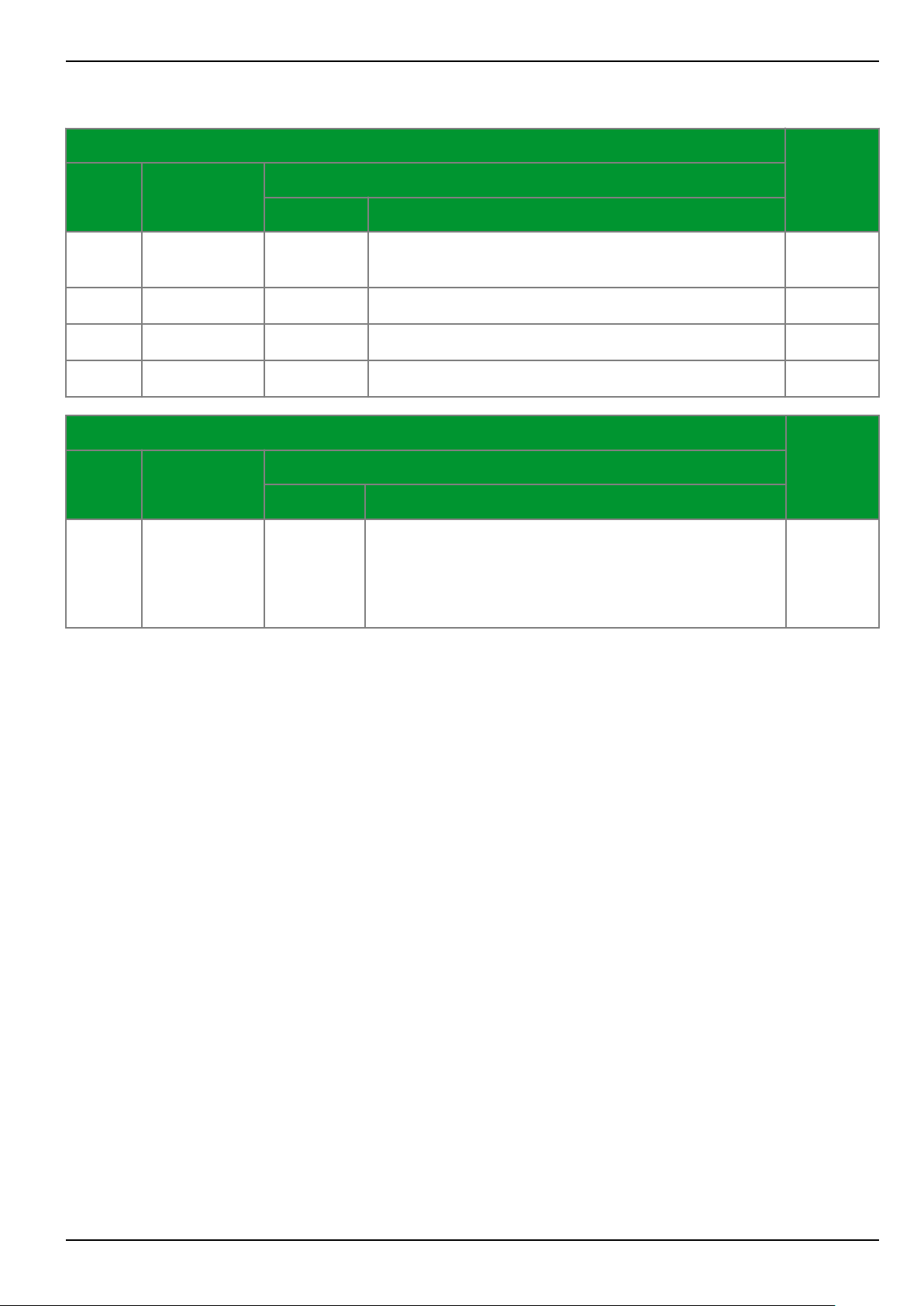

1.4 Overview of Function Groups - Part 2

The following tables list the function groups that are generally available for the

P634, and which cannot be excluded from the configuration.

✓ = Standard; (✓) = Ordering option.

Inputs and outputs

P634ANSI IEC 61850 Function group

Abbrev. Description

Measuring inputs

Phase currents

●

Residual current or star-point current

●

Voltage

●

INP

●

INP

●

OUTP

●

Binary inputs and outputs

Optical coupler inputs

●

Add. optical coupler inputs

●

Output relays

●

4×3

●

3

●

1

●

4 (… 10)

●

24

●

8 (… 22)

●

1-6 P634/EN M/R-42-A // P634‑311‑653

Page 23

1 Application and Scope P634

General functions

P634ANSI IEC 61850 Function group

Abbrev. Description

DVICE Device ✓

LOC Local control panel ✓

PC PC link ✓

F_KEY 6 configurable function keys ✓

LED LED indicators ✓

MAIN Main function ✓

LLN0.SGCB PSS Parameter subset selection ✓

SFMON Comprehensive self-monitoring ✓

OP_RC Operating data recording (time-tagged event

logging)

MT_RC Monitoring Signal Recording ✓

OL_DA Overload Data Acquisition ✓

OL_RC Overload recording (time-tagged event logging) ✓

✓

PTRCx /

RDRE1

FT_DA Fault data acquisition for a particular, settable point

in time during a fault

FT_RC Fault recording (time-tagged event logging together

with fault value recording of the phase and residual

currents as well as the voltage)

✓

✓

P634/EN M/R-42-A // P634‑311‑653 1-7

Page 24

P634 1 Application and Scope

1.5 Configurable Function Keys

To the right of the text display, there are six freely configurable function keys

available. These may be used for easy control operation access.

1-8 P634/EN M/R-42-A // P634‑311‑653

Page 25

1 Application and Scope P634

1.6 Inputs and Outputs

The nominal current and voltage values of the measuring inputs on the P634 can

be set with the function parameters.

The nominal voltage range of the optical coupler inputs is 24 to 250 V DC. As an

option binary signal input modules with a higher operate threshold are available.

The auxiliary voltage input for the power supply is also designed for an extended

range. The nominal voltage ranges are 60 to 250 V DC and 100 to 230 V AC. A 24

to 60 V DC version is also available.

All output relays can be utilized for signaling and command purposes.

The optional PT 100 input is lead-compensated, balanced and linearized for

PT 100 resistance thermometers as per IEC 751 / DIN EN 60751.

The optional 0 to 20 mA input provides open-circuit and overload monitoring,

zero suppression defined by a setting, plus the option of linearizing the input

variable via 20 adjustable interpolation points.

Two selectable measured values (cyclically updated measured operating data

and stored measured fault data) can be output as a burden-independent direct

current via the two optional 0 to 20 mA outputs. The characteristics are defined

via 3 adjustable interpolation points allowing a minimum output current (4 mA,

for example) for slave-side open-circuit monitoring, knee-point definition for fine

scaling, and a limitation to lower nominal currents (10 mA, for example). Where

sufficient output relays are available, a selectable measured value can be output

in BCD-coded form by contacts.

P634/EN M/R-42-A // P634‑311‑653 1-9

Page 26

P634 1 Application and Scope

1.7 Control and Display

Local control panel with an LC display containing 4 × 20 alphanumeric

●

characters.

23 LED indicators, 18 of which allow freely configurable function

●

assignment for the colors red and green. Furthermore there are various

operating modes and flashing functions available.

PC interface.

●

One or two communication interface(s) for connection to a substation

●

control system (optional).

1-10 P634/EN M/R-42-A // P634‑311‑653

Page 27

1 Application and Scope P634

1.8 Information Interfaces

Information is exchanged through the local control panel, the PC interface, or two

optional communication interfaces (channel 1 and channel 2).

Using the first channel of the communication interfaces (COMM1), the P634 can

be wired either to the substation control system or to a telecontrol system. This

channel is optionally available with a switchable protocol (per IEC 60870‑5‑103,

IEC 870‑5‑101, DNP 3.0, MODBUS or Courier).

The second communication interface (COMM2, communication protocol per

IEC 60870‑5‑103 only) is designed for remote control.

As an order option, there is an Ethernet interface for communication per

IEC 61850 available instead of channel 1.

External clock synchronization can be accomplished via one of the

communication protocols or by using the optional IRIG‑B input.

P634/EN M/R-42-A // P634‑311‑653 1-11

Page 28

P634 1 Application and Scope

1-12 P634/EN M/R-42-A // P634‑311‑653

Page 29

2 Technical Data

2.1 Conformity

Notice

Applicable to P634, version -311 -410/411 -653.

Declaration of Conformity

The product designated “P634 Transformer Differential Protection Device” has

been designed and manufactured in conformance with the European standards

EN 60255‑26 and EN 60255‑27 and with the “EMC Directive” and the “Low

Voltage Directive” issued by the Council of the European Community.

P634

P634/EN M/R-42-A // P634‑311‑653 2-1

Page 30

P634

2.2 General Data

2.2.1 General Device Data

Design

Surface-mounted case suitable for wall installation, or

●

Flush-mounted case for 19″ cabinets and for control panels.

●

Installation Position

Vertical ± 30°.

●

Degree of Protection

Per DIN VDE 0470 and EN 60529 or IEC 529.

IP 52 for the front panel.

●

Flush-mounted case:

●

o

IP 50 for the case (excluding the rear connection area)

o

IP 20 for the rear connection area, pin-terminal connection

o

IP 10 for the rear connection area, ring-terminal connection

Surface-mounted case:

●

o

IP 50 for the case

o

IP 50 for the fully enclosed connection area with the supplied rubber

grommets fitted

2 Technical Data

Weight

●

●

Dimensions and Connections

See dimensional drawings (Section 4.2, (p. 4-4)), and the location and

terminal connection diagrams (Section 5.7, (p. 5-22)).

Terminals

PC interface (X6)

●

Communication interfaces COMM1, COMM2

●

●

●

40 TE case: Approx. 7 kg

84 TE case: Approx. 11 kg

EIA RS232 (DIN 41652) connector, type D-Sub, 9-pin

Fiber (X7, X8)

o

F-SMA optical fiber connection per IEC 60874‑2 (for plastic fibers), or

o

optical fiber connection BFOC-ST® connector 2.5 per IEC 60874‑10‑1 (for

glass fibers).

(ST® is a registered trademark of AT&T Lightguide Cable Connectors.)

Wire leads (X9, X10)

o

M2 threaded terminal ends for wire cross-sections up to 1.5 mm² (US:

AWG16).

IRIG-B Interface (X11)

o

BNC plug

2-2 P634/EN M/R-42-A // P634‑311‑653

Page 31

2 Technical Data P634

Communication interface IEC 61850

Fiber (X7, X8)

●

o

optical fiber connection BFOC-ST® connector 2.5 per IEC 60874‑10 (for

glass fibers).

(ST® is a registered trademark of AT&T Lightguide Cable Connectors.)

Fiber (X13)

●

o

SC connector per IEC 60874‑14‑4 (for glass fibers)

Wire leads (X12)

●

o

RJ45 connector per ISO/IEC 8877.

Current measuring inputs (conventional inputs)

Threaded terminal ends, pin-type cable lugs: M5, self-centering with cage

●

clamp to protect conductor cross-sections ≤ 4 mm² (US: AWG12), or

Threaded terminal, ring-terminal connection: M4.

●

Other inputs and outputs

Threaded terminal ends, pin-type cable lugs: M3, self-centering with cage

●

clamp to protect conductor cross-sections 0.2 to 2.5 mm² (US: AWG25 to

AWG14), or

Threaded terminal ends, ring-type cable lugs: M4.

●

Creepage Distances and Clearances

Per EN 60255-27.

●

Pollution degree 3, working voltage 250 V,

●

overvoltage category III, impulse test voltage 5 kV.

●

P634/EN M/R-42-A // P634‑311‑653 2-3

Page 32

P634

2.3 Tests

2.3.1 Type Tests

Type Tests

All tests per EN 60255-26.

2.3.1.1 Electromagnetic Compatibility (EMC)

Interference Suppression

Per EN 55022 or IEC CISPR 22, Class A.

1 MHz Burst Disturbance Test

Per EN 60255-22-1, Class III.

Common-mode test voltage: 2.5 kV.

●

Differential test voltage: 1.0 kV.

●

Test duration: > 2 s.

●

Source impedance: 200 Ω.

●

2 Technical Data

Immunity to Electrostatic Discharge

Per EN 60255-22-2 and IEC 60255-22-2, severity level 4.

Contact discharge

Single discharges: > 10.

●

Holding time: > 5 s.

●

Test voltage: 8 kV.

●

Test generator: 50 to 100 MΩ, 150 pF / 330 Ω.

●

Immunity to Radiated Electromagnetic Energy

Per EN 61000‑4‑3 and ENV 50204, severity level 3.

Antenna distance to tested device: > 1 m on all sides.

●

Test field strength, frequency band 80 to 1000 MHz: 10 V / m.

●

Test using AM: 1 kHz / 80 %.

●

Single test at 900 MHz: AM 200 Hz / 100%.

●

Electrical Fast Transient or Burst Requirements

Per EN 61000-4‑4 and IEC 60255‑22‑4, severity levels 3 and 4.

Rise time of one pulse: 5 ns.

●

Impulse duration (50% value): 50 ns.

●

Amplitude: 2 kV / 1 kV or 4 kV / 2 kV.

●

Burst duration:15 ms.

●

Burst period: 300 ms.

●

Burst frequency: 5 kHz.

●

Source impedance: 50 Ω.

●

Power Frequency Immunity

Per IEC 60255‑22‑7, Class A:

2-4 P634/EN M/R-42-A // P634‑311‑653

Page 33

2 Technical Data

Phase-to-phase

RMS value 150 V.

●

Coupling resistance 100 Ω.

●

Coupling capacitor 0.1 μF, for 10 s.

●

Phase-to-ground

RMS value 300 V.

●

Coupling resistance 220 Ω.

●

Coupling capacitor 0.47 μF, for 10 s.

●

To comply with this standard, it is suggested to set the parameter (010 220)

INP: Filter to 6 [steps].

Current/Voltage Surge Immunity Test

Per EN 61000-4‑5 and EN 60255-22‑5, insulation class 4.

Testing of circuits for power supply and asymmetrical or symmetrical

lines.

Open-circuit voltage, front time / time to half-value: 1.2 / 50 µs.

●

Short-circuit current, front time / time to half-value: 8 / 20 µs.

●

Amplitude: 4 / 2 kV.

●

Pulse frequency: > 5 / min.

●

Source impedance: 12 / 42 Ω.

●

P634

Immunity to Conducted Disturbances Induced by Radio Frequency Fields

Per EN 61000-4-6 and EN 60255-22‑6, severity level 3.

Test voltage: 10 V.

●

Power Frequency Magnetic Field Immunity

Per EN 61000-4-8 or IEC 61000-4-8, severity level 4.

Test frequency: 50 Hz

●

Test field strength: 30 A / m.

●

Alternating Component (Ripple) in DC Auxiliary Energizing Quantity

Per EN 60255-11.

12 %.

●

2.3.1.2 Insulation

Voltage Test

Per EN 60255-27.

2 kV AC, 60 s

●

Only direct voltage (2.8 kV DC) must be used for the voltage test on the power

supply inputs. The PC interface must not be subjected to the voltage test.

Impulse Voltage Withstand Test

Per EN 60255-27.