Page 1

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 1

MAGNETIC LINEAR

SLIDING DOOR OPERATOR

INSTALLATION INSTRUCTIONS

_________________________________

MODEL:

EDM MM50 & MM80

Auto & Assist Version

(Japanese Type)

ORIGINAL INSTRUCTIONS

DATE: 2011

MICOM Autodoor | Osaka – Japan

No. MM0004

Page 2

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 2

WARNING: Avoidance of Injury, Electric shock and Fire

Installation and adjustment must be performed by approved personnel only.

Repair and/or alteration to the control box and motor are prohibited.

Power should be switched off during installation and service.

Switch power off when not in use.

Power supply 100V AC (Control Box Power Input AC 100V).

Keep away from any item which creates steam, heat or a humidifier.

Do not touch when a lightning storm occurs.

Should a burning smell be detected, switch power off at fuse.

Contact your MICOM representative immediately.

Do not put hands, flammable liquids, gases or items affected by high temperatures onto operator during

operation.

Do not spray pesticides or detergents onto operator directly.

CAUTION: Avoidance of Injury and Malfunctions

Ensure sliding door travel area is clear before switching power switch ON.

Do not hit or restrict door whilst moving.

Keep fingers, clothing and hair clear of belt and all moving parts.

Protective gloves should be worn when handling metal parts.

Page 3

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 3

CAUTION: Avoidance of Injury during Maintenance & Disposal

Risk of electrocution or personal injury can be avoided by switching mains power off for routine maintenance.

Risk of crushing or impact by a falling door panel or other solid object onto a person can be avoided by laying

any heavy object horizontally onto the floor at one the side of the working area. Risk of tripping or falling can

be avoided, by placing any removed objects to one side of the working area. A safe working area should be

maintained by cordon or other temporary boundary.

IMPORTANT NOTICE: Avoidance of Injury during Cleaning

To be performed by authorised personnel only:

With power OFF - Using neutral detergent, wet and twist a soft cloth to wipe clean the operator.

If power is not switched off before cleaning, there is risk of electrocution or personal injury due to door

movement.

IMPORTANT: NOTICE TO USER

Do not hang any items on the rail or door as this will cause improper operation of sensors and function of door

operator.

Teaching Stoke – Teaching will be operated after power on or a power cut. Please note that teaching is slower than

normal operation. Please refer to Section 2 for Teaching Operation.

Door frame may alter after original installation due to the condition of the building. Further adjustment may be needed

later after installation.

IF YOU HAVE ANY PROBLEMS – PLEASE SWITCH OFF THE PRODUCT AND CONTACT A MICOM

REPRESENTATIVE IMMEDIATLEY OR E-MAIL: info@micomautodoor.com

Page 4

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 4

AUTO Type

ASSIST Type

Push & Go Function

Vi-Part Synchronisation

Open Speed Adjuster

Closer Speed Adjuster

Open Timer

Ratchet Switch (Flip Flop) Function

Obstruction Protection

E-Lock LK1 - Fail Safe (Option)

Push & Go Function

Open Speed Adjuster

Partial Open Adjuster

Open Timer

Ratchet Switch (Flip Flop) Function

Hold Open Function – Setting By Hand

Free Stop Function – Setting By Hand

Obstruction Protection

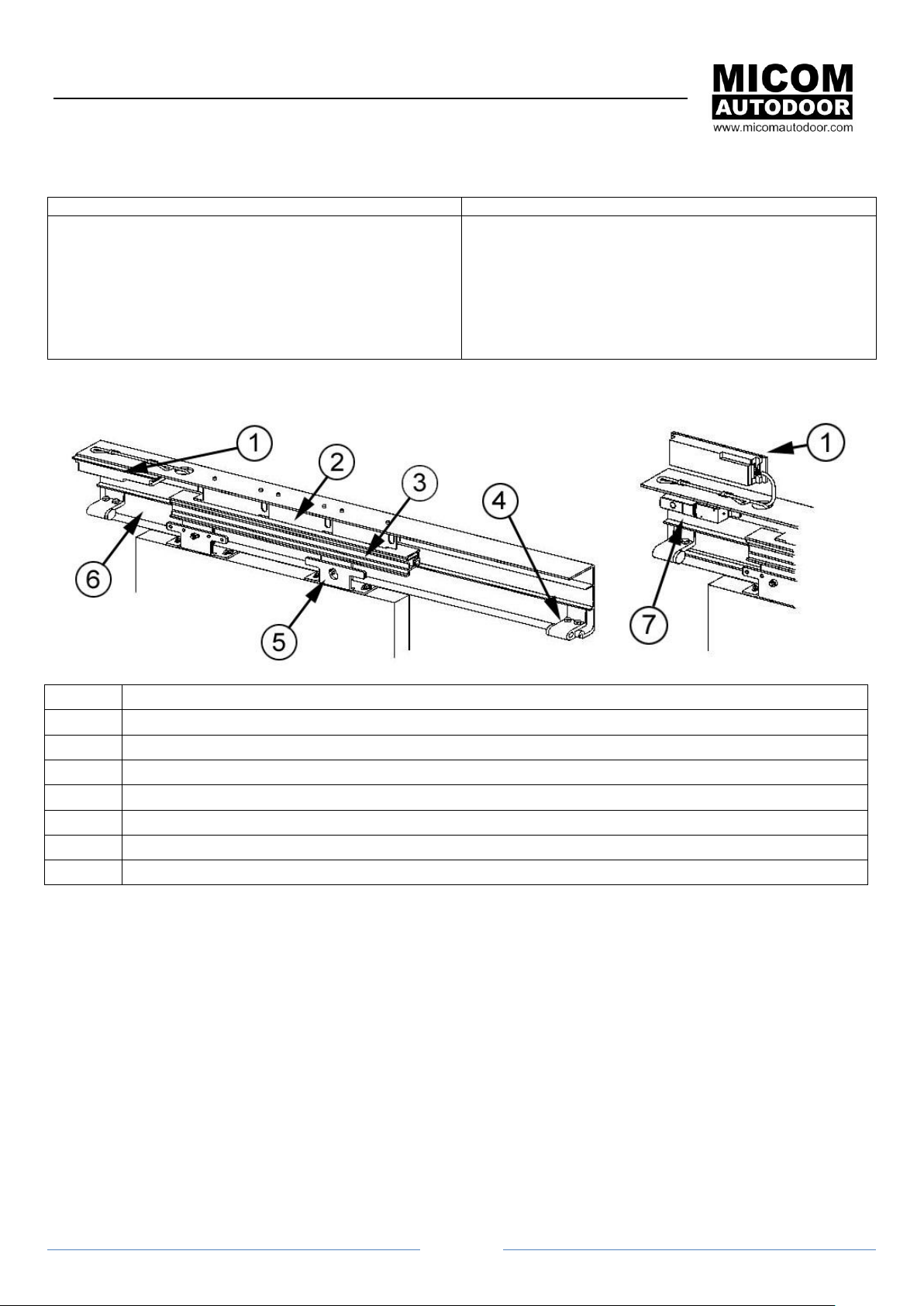

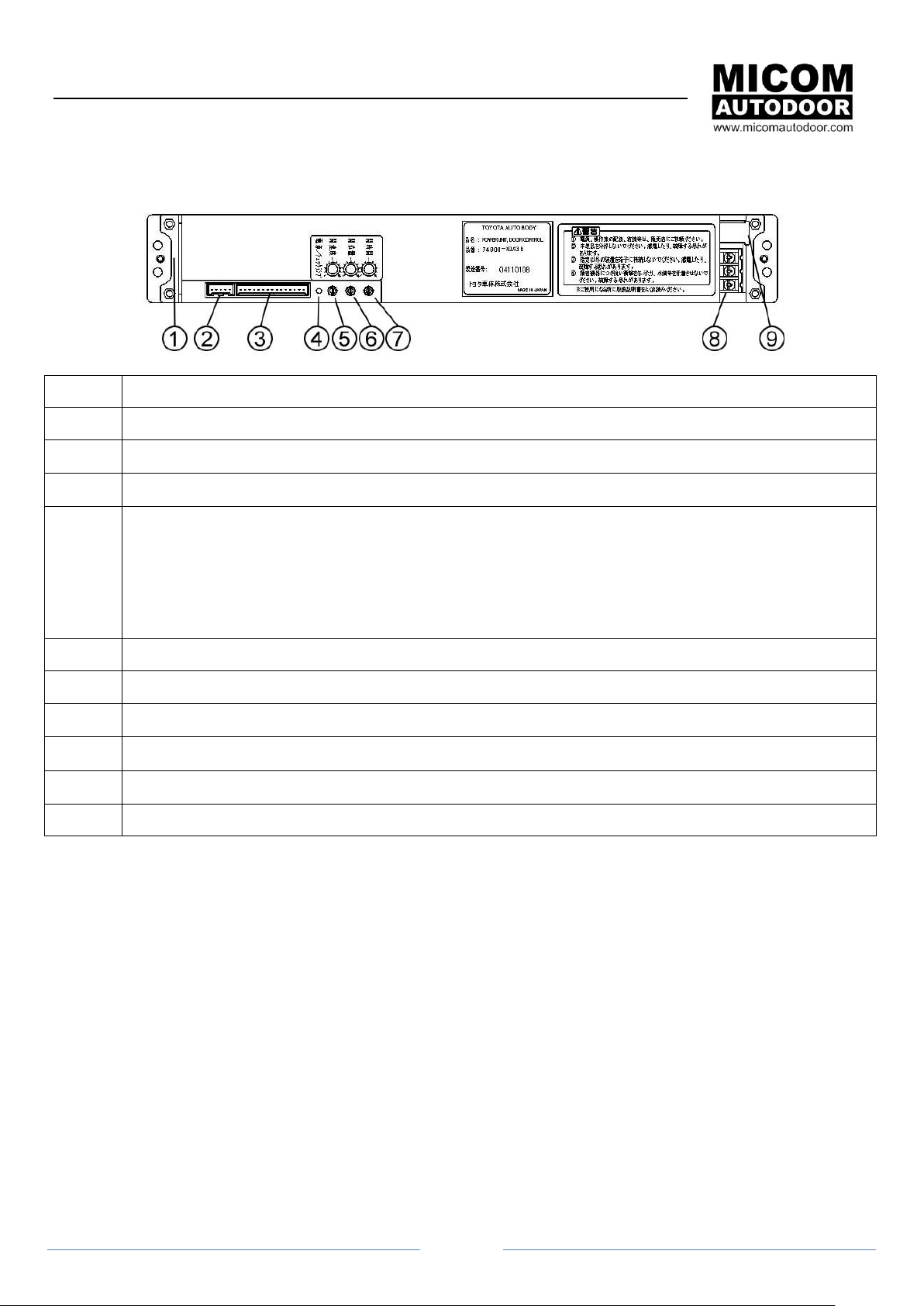

No.

Part Description

1

Control Box Assembly - MM50 & MM80 Assist Type

2

Magnetic Linear Motor MM50 & MM80

3

Moving Magnet

4

Stopper

5

Hanger Roller Assembly

6

Aluminium Rail

7

Electronic Lock (Option)

1. Operator Description (MM50 & MM80 from Japan)

1.1 Parts

Page 5

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 5

No.

Description

1

Motor Connection – Already Connected

2

E-Lock Connection (option)

3

Harness Connector – Signal Input / Output Data

4

LED -

Power On – Green LED will Flash 5sec. Then Green LED ON

Activation Signal / Safety Signal Input – Green LED OFF

LED RED ON – Over Heating Protection – Automatically Stop / Open

LED RED FLASHING SLOWLY – Obstruction Stop

LED RED FLASHING QUICKLY (with Beep) - Problem with E-Lock.

5

Open Speed Adjuster - 200~500mm/s (Default 400mm/s)

6

Model AUTO Type: Close Speed Adjuster - 200~500mm/s (Default 300mm/s)

6

Model ASSIST type: Partial Open Adjuster (0=50% ~ 10=100%).

7

Open Timer Adjuster - 1~10 sec. (Default 3sec.) & Ratchet.

8

Power Input – AC100V +/- & Earth

9

Power Switch – ON/OFF Input

1.2 Control Box MM50 & MM80 (Auto & Assist Type)

Page 6

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 6

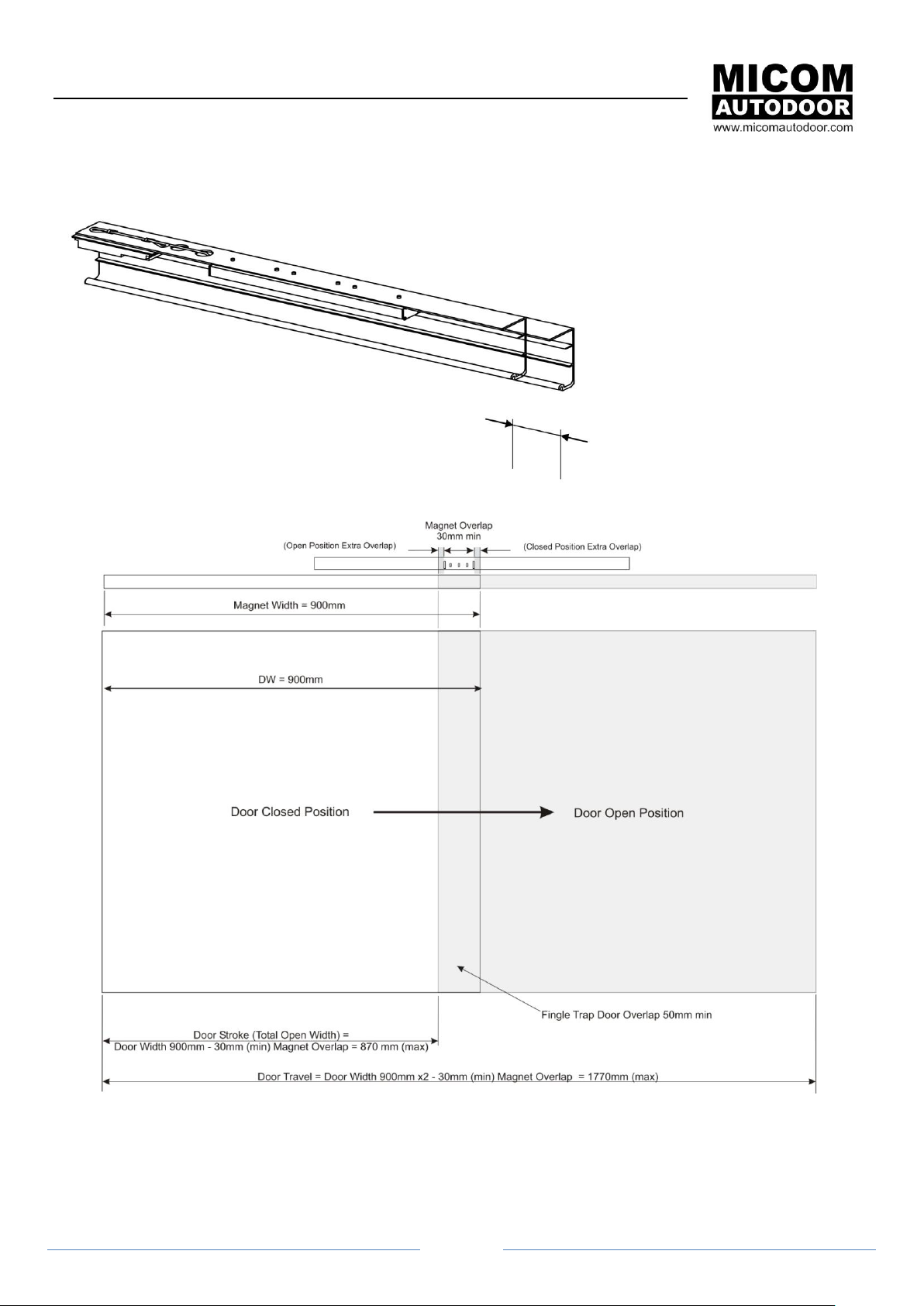

Cut to size for required installation.

Control and Linear Motor must be

protected from metal particles.

Applicable Door Width +/- 100mm (50mm Each Side) of Magnet Length.

Applicable Door:

Magnet Length 800mm = Door Width Min 700mm to Max 900mm

Magnet Length 900mm = Door Width Min 800mm to Max 1000mm

Magnet Length 1100mm = Door Width Min 1000mm to Max 1200mm

Note: Door position and alignment to

magnet can be left side, right side or

central depending on requirement.

2. Installation

2.1 Cutting Rail

2.2 Applicable Door

Page 7

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 7

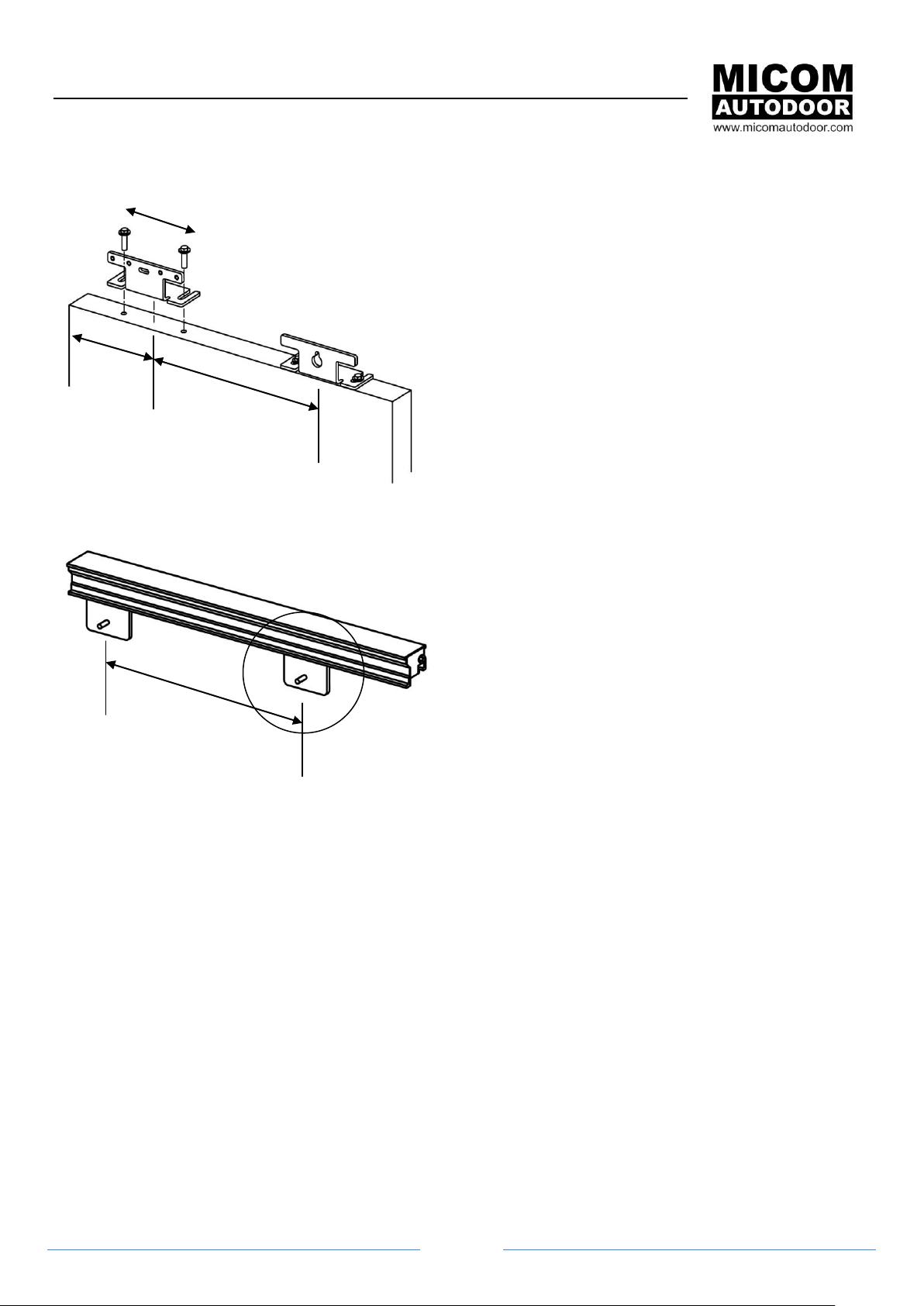

Position of hangers – Hangers should not be closer than

shown. If the pitch is too close, the door will not move

smoothly. Fix with M8 Bolts supplied.

Fixing Plate Pitch Adjustment – Loosen x2 M4 screws

and adjust the position of the fixing plate to same

distance as Hanger on door. (do not forget to re-tighten).

Note: Adjust Fixing Plate of Closing side only.

185mm

Hanger Pitch

Fixing Plate Pitch

2.3 Hanger Assemblies

2.3.1 Moving Magnet

Page 8

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 8

X3 Plastic Protection Plates – Do not remove

- To protect Linear Motor and Magnet

during installation

- Retain to future maintenance

2.4 Installation of Operator

Using appropriate fixing, attach operator to horizontal surface.

2.4 Installation of Door

Step1. Position door without fixing.

Step2. Hanging Door – Use 1

st

Page 9

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 9

Door mounted without tightening

hangers

Once bolts are tightened,

door and hangers will be

aligned.

Secure door leaf with M8 Nut

X3 Plastic Protection Plates

Step3. Hanging Door – Use 2

Step4. Tightening hangers with M8 nut.

nd

Page 10

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 10

2.5 Plastic Protection Plates

It is important to have x3 plastic protection plates in place when installation is being carried out. These plates protect

the Linear Magnetic Motor and the Moving Magnet from being in contacting with each other and causing damage. As

well as maintaining the correct 2mm distance between the Linear motor and moving magnet before the hanger

assemblies are tightened.

Note: Please keep protection plates for future maintenance requirement.

With door hung on Hanger bracket

but not tightened, ensure plastic

protection plates are in place.

Tighten M8 nut with flat washer

Maintain exact Horizontal and

Vertical alignment.

IMPORTANT: Confirm linear motor and moving

magnet are EXACTLY 2mm horizontally and

vertically aligned along length of motor. (use

plastic protection plate to check). Motor and

magnet should not be in contact with each other

at any point.

Remove plastic protection plate

2.6 Stopper Installation

Page 11

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 11

See Linear Motor –

There you will find

white markings.

These indicate the

overlap allowance

between the Linear

Motor and Moving

Magnet. As explained

below.

Note: If there is not enough overlap, this will be cause of defective operation.

Full Closed

X

Full Open

X

Correction

Position of Moving

Magnet

30mm Min.

Magnet Overlap

Distance

(White Mark)

Incorrect

Position of

Moving Magnet

Correction Position

of Moving Magnet

30mm Min

Magnet Overlap

Distance

(White Mark)

Incorrect

Position of

Moving Magnet

30mm

30mm

Motor

Motor

Moving Magnet

Moving Magnet

Motor

Motor

Moving Magnet

Moving Magnet

2.7 Moving Magnet – Set up & Correct Positioning

Page 12

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 12

1. Power Switch On/Off Plug In.

2. AC100V

3. AC100V

4. EARTH

Activation Input (SS)

Cable

Red

Activation Signal Input

Green

Common

Black

AC100V output (Japan use only)

White

AC100V output (Japan use only)

Threshold Safety Input (SB)

Cable

Red

Safety Signal Input

Green

Common

Black

AC100V output (Japan use only)

White

AC100V output (Japan use only)

Vi-Part & Function Input/Output - AUTO Type Only

Cable

Yellow

Closed End Signal Output

Blue

Common (Closed End Output)

Purple

Bi-Parting Signal Input

Orange

Bi-Parting Signal Output

Green

Ground

Notes:

- Model MM50 & MM80 is a NC (Normally Closed) circuit.

0 Voltage output of SS, SB, Vi-Part & Function Cables.

100V AC 1A output of Black and White cables to be

isolated (Japan use only).

SB =

Safety

SS =

Activation

Vi-Part & Function

(AUTO Type)

2.8 Wiring

2.8.1 Power Input & Mains Switch

2.8.2 Harness Wiring

Page 13

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 13

Learning CycleWith the Power ON/OFF Switch provided, power can be switched ON to begin

the Teaching Stoke process.

Teaching will begin once the power is turned ON. A full open and close cycle

stroke will be performed at SLOW speed.

CAUTION: When learning, allow the Door to Fully Open / Close. If sensors are

fitted, step back from the activation area. Do not obstruct the door when

teaching.

(a) Closed –

Activate to start the teaching process. The door will start to move SLOWLY in

the open direction. Once the door has reached its FULL open position, it will

return SLOWLY in the closing direction, until FULLY CLOSED.

Do not stand in the detection area when the door is teaching, as it will not

close.

(b) Not Closed –

The door will start to automatically close to the fully closed end. Once reaching

FULLY closed position, teaching can be performed as above.

(c) Closed with E-Lock -

If the operator is fitted with E-Lock, the teaching will always being with the door in FULLY closed and LOCKED

position.

(d) Teaching Complete Once the door has opened fully and then returned to the fully closed position and stopped – teaching is complete.

3. Operation

3.1 Teaching or Learning Operation

Each time the power is switched OFF (by switch or power cut), a teaching stroke must be carried out at the next

power ON.

3.1.1 Learning Operation - Door Starting Position:

3.2 Normal Operation

After the teaching process is successfully completed, the operator will be ready to accept all customary activations.

With door in closed position, it can be activated to open. After pre-set open time, the door will close. It will re-open if

any activation signal or safety signal is turned on. If there is no such activation, the door will close fully.

With an E-Lock fitted, the door will lock after it is fully closed.

CAUTION: If the door does not stop at the closed end position and re-opens automatically. The operator is not

installed correctly. Please contact your MICOM Representative or email: info@micomautodoor.com

Page 14

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 14

Push to Open

Push to Close

3.3 Activation & Functions

Not only can the operator be activated by all customary sensors and activation devices, but also by hand activation.

Please see supporting Wiring Diagrams for accessory options.

MM50 & MM80 incorporates an assist activation function as standard. Moving the door by hand in the direction of

open for 2cm will activate the door. After pre-set open time it will close automatically.

a. Activation by Hand (Push & Go) (Auto & Assist Type) - By simply pushing the door in the open direction for

2cm, the operator will be activated and carry out automatic open and close cycle.

b. Hold Open by Hand (Assist Type) – By holding the door in the full open position, an audible signal will be

heard. The door is now in Hold Open. To close, again simply pull the door, no more than 2cm and the door

will automatically close.

c. Free Stop (Assist Type) – Once door is in motion, hold the door (by handle if fitted) at any position before it

reaches the full open position. The door will stop and be free to move by hand as a manual sliding door. To

re-activate, return the door to full closed position.

d. Partial Open (Assist Type) - Partial Open is adjustable by the Partial Open adjuster. Adjustable range 0 = 50%

to 10=100% Open. Factory Setting at 100% Full Open. Partial open is a fixed setting by control. The use of a

Partial Open Switch Selection is not applicable. Partial Open % setting is effective after activation through SS

input. When activation by hand (Push & Go), Partial Open % setting is ignored and door opens to 100% Full

open.

e. Ratchet Function (Auto & Assist Type) – By use of the Open Timer Setting Adjustment – Turning the timer to

max, the Ratchet Function will be enabled. Ratchet operation enables the door to be opened and closed with

a switch.

Caution: It is not recommended to use an activation sensor for Ratchet Function. See Section 3.3

Ratchet Function with E-Lock – it is not possible to use Assist Activation (Push & Go) feature as the door

cannot be opened by hand. The door must only be activated by a switch.

3.4 Obstruction Detection

EDM MM Controller is always calculating door position and door speed. If the door hits an obstruction during closing,

the door will stop immediately with light force and reverses to the open position.

The door will then close after the preset open time at slow speed. Should the door find the obstruction again, the door

will stop. Door will return to operation upon the next activation signal. With the obstructing cleared, normal operation

will continue.

Page 15

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 15

4.1 OPEN SPEED – ADJUSTER 1.

Open / Close Speed is adjustable by the speed adjuster. Turning Right = Faster (F).

Adjustable range is 200~500mm/s. Factory Setting Speed: Open Speed at 400mm/s /

Close Speed at 300mm/s.

4.2.1 AUTO TYPE: CLOSE SPEED – ADJUSTER 2.

Close Speed is adjustable by the speed adjuster. Turning Right = Faster (F). Adjustable

range is 200~500mm/s. Factory Setting Close Speed at 300mm/s

CAUTION: It is recommended not to set the Close Speed to max for safety or pedestrians.

4.2.2 ASSIST TYPE: PARTIAL OPEN ADJUSTER 2.

Partial Open is adjustable by the Partial Open adjuster. Adjustable range 0 = 50% to

10=100% Open. Factory Setting at 100% Full Open.

Note: Partial open is a fixed setting by control. The use of a Partial Open Switch Selection

is not applicable.

4.3 OPEN TIMER & RATCHET – ADJUSTER 3.

Open time will begin when the door has reached its full open position. (Turning Right =

Longer (L)). Adjustable range is 1~10sec. (Factory Setting Open Time: 2~3sec)

4.3.1 Ratchet Function

Turning the adjuster to max, open time will become infinite (no limit). The door will stop at

the open position which is known as Ratchet Function (or Flip Flop). See Section 2.5

CAUTION: Please take care to turn the adjusters gently with a thin screwdriver. Do not turn the adjuster

strongly with force as the adjuster will be broken.

4. Operation Adjustment

Page 16

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 16

Plug No.3 – Close Pressure

Close Pressure

Connected

On = ACTIVE (Factory Setting)

Disconnected

Off = NOT ACTIVE

Breaking

Level

Plug No.1

White

Plug No.2

White

Applicable Door

MM50 Single

MM80 Single

Heavy

1

Connected

Disconnected

40-50kg

40-80kg

2 (Factory Setting)

Connected

Connected

30-40kg

30-40kg

3

Disconnected

Connected

20-30kg

20-30kg

Light

4

Disconnected

Disconnected

20-25kg

20-25kg

Plug No.1 Adjustment

2 pin / White

Plug No.2 Adjustment

3 pin / Black

Plug No.3 – Close Pressure

2 pin / Black

4.4 AUTO Type - Open / Close Breaking & Sensing Function (with Bi-Part)

4.4.1 Close Pressure Adjustment

4.4.2 Open / Close Breaking Force Adjustment

NOTE: Above door size and weight should be used as a guide only. Please check breaking force setting by sight.

For Example: Door Open / Close Force Level ‘2’ = Factory setting Plug no.1 & Plug no.2 – Connected.

If the braking is too weak (door hits a little hard) - Set to level ‘1’ = Plug no.2 – Disconnect & Plug no1 - Connected.

If the breaking is too hard (door jumps) – Set to level ‘3’ = Plug no.1 – Disconnect & Plug no. 1 – Connected.

Page 17

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 17

Plug No.3 – Close Pressure

Close Pressure

Connected

On = ACTIVE (Factory Setting)

Disconnected

Off = NOT ACTIVE

Breaking

Level

Plug No.1

White

Plug No.2

White

Applicable Door

MM50 Single

MM80 Single

Heavy

1

Connected

Disconnected

40-50kg

40-80kg

2 (Factory Setting)

Connected

Connected

30-40kg

30-40kg

3

Disconnected

Connected

20-30kg

20-30kg

Light

4

Disconnected

Disconnected

20-25kg

20-25kg

Plug No.1 Adjustment

2 pin / White

Plug No.2 Adjustment

3 pin / Black

Plug No.3 – Close Pressure

2 pin / Black

4.5 ASSIST Type - Open / Close Breaking & Sensing Function

4.5.1 Close Pressure Adjustment

4.5.2 Open / Close Breaking Force Adjustment

NOTE: Above door size and weight should be used as a guide only. Please check breaking force setting by sight.

For Example: Door Open / Close Force Level ‘2’ = Factory setting Plug no.1 & Plug no.2 – Connected.

If the braking is too weak (door hits a little hard) - Set to level ‘1’ = Plug no.2 – Disconnect & Plug no1 - Connected.

If the breaking is too hard (door jumps) – Set to level ‘3’ = Plug no.1 – Disconnect & Plug no. 1 - Connected

Page 18

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 18

Problem

Possible Solution

Does not power on. LED does not light.

Check wiring or power source. Wire to controller is

disconnected?

Keeps Beeping (RED LED blinking quickly)

E-Lock Error. Wire to E-Lock is disconnected?

Dead Bolt is not located into hole for Lock?

Does not open after sensor (SS) is activated

Sensor wire is not connected?

Sensor is connected to Safety Wire (SB)?

Does not open even if Safety (SB) is connected

Sensor (SS) is disconnected?

Door is closed?

Door Opens (from fully closed) when Safety (SB) is

activated

Safety Sensor is connected to Activation wire (SS)?

Does not open with wireless touch switch or button

Wire from receiver of touch switch is disconnected?

There is an obstruction stopping signal?

Battery and direction are ok?

Channel of switch and received is same?

Model

EDM MM-50

EDM MM-80

Application

ASSIT=Single | AUTO=Single or Vi-Part

ASSIT=Single | AUTO=Single or Vi-Part

Door Weight (max)

20-50 Kg per Leaf

20-80kg per Leaf

Power Supply

100V AC ( Control 100V AC +/- 10%) 50/60Hz Max 4A

Open Speed

Adjustable 200 ~ 500mm/s (Factory Default 400mm/s)

Closing Speed

Adjustable 200 ~ 500mm/s (Factory Default 300mm/s)

Open Timer

1~10sec Max – (Factor Default 3sec) & Ratchet (Flip Flop)

Motor

Brushless Magnet Movable Linear DC Motor

Environment (Temp)

Ambient temperature -10C ~ +40C

(no (condensation or icing)

Ambient humidity 30% ~ 85% RH (no hazardous materials must be present in the

atmosphere)

5. Trouble Shooting

6. Specification

6.1 Technical

Page 19

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 19

A. ACTIVATION SIGNAL INPUT

RED = ACTIVATION (SS)

GREEN = COM

WHITE – 100VDC (Japan Only)

BLACK – 100VDC (Japan Only)

B. THRESHOLD SAFETY SIGNAL INPUT

RED – ACTIVATION (SB)

GREEN – COM

WHITE – 100VDC (Japan Only)

BLACK – 100VDC (Japan Only)

C. VI-PART & FUNCTION SIGNAL

INPUT/OUTPUT

BLUE – COM (CLOSE END OUTPUT)

YELLOW – CLOSED END OUTPUT

GREEN – COM

ORANGE – VI-PARTING OUTPUT

PURPLE – VI-PARTING OUTPUT

Note:

Model MM50 & MM80 is a NC (Normally

Closed) circuit.

0 Voltage output of SS, SB, Vi-Part &

Function Cables.

100V AC 1A output of Black and White

cables to be isolated (Japan use only).

MM50 & MM80 – Harness Wiring & Connections

Page 20

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 20

Basic Wiring – Single & Bi-Part - Activation & Safety

Vi-Parting Synchronization (Bi-Part)

Page 21

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 21

Notes: When door is synchronized using Vi-Parting connection, it is possible to include a switch to change operation

for Single Door use. SWITCH ON = Synchronization | SWITCH OFF = Individual

Notes: Door 1 will not open if door 2 is open. Door 2 will not open is door 1 is open.

Vi-Parting Synchronization (Bi-Part) or Individual Operation by Switch

Interlock

Page 22

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 22

Wiring: Yellow – Closed End Signal / Blue – Com (Closed End Signal)

Load Capacity: 0.3A AC125V / 1A / DC24V

Notes: Door will open and close when access is authorized from card reader, keypad or other security system.

Closed End Output Signal – Digital Counter (Option)

Security Wiring (Option) – Access Control

Page 23

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 23

Notes: Door will open and close by activation only during pre-set time.

Notes: Entering room is restricted with timer device. Exit from room is allowed.

Security Wiring (Option) – Timer

Security Wiring (Option) – Timer Access

Page 24

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 24

MM50 & MM80

Rail Length (mm)

Entrance Width (mm)

Standard Size Option

Single - Left /

Right

1666 / 1925 /

2232 / 2512 /

2710

833 / 962.5 / 1116 / 1256 / 1355

Cut to Size (Made to Order)

Single

1500 - 1800

750 - 900

1801 - 2200

900 - 1100

2201 - 2710

1100 - 1350

2711 - 3200

1355 - 1600

NOTE: E-Lock is available with AUTO type only. Assist type

does not support E-Lock. E-Lock offers LK1 FAILSAFE

(UNLOCK without power) function only.

If an E-lock is fitted, it is not possible to open the door by hand. The

door will be unlocked upon an activation signal to the controller and

open automatically. Once a full open and close cycle has been

performed, the door will lock with E-lock once fully closed.

If there is a problem with the E-Lock, the controller will show this

when either in teaching mode or during normal operation.

7.1 Teaching with E-Lock

LED will flash RED with Buzzer.

Lock output Signal

(Option – With Counter)

Wiring:

Red – Lock output

signal

Black – Com

Load Capacity: 0.3A /

AC125V / 1A / DC24V

E-Lock Harness

E-Lock Body

6.2 Applicable Door Size

7. Electronic Lock (Option)

Page 25

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 25

8. Health & Safety

It is recommended that the following installation guide lines be followed in compliance with safety standards.

8.1 Safety During the Open Cycle

Provision should be made to deter person from occupying the area through which the door travels during the open

cycle. A ‘keep clear’ sign is recommended to be fixed to the screen or wall across which the door travels. Where

practical, the following is recommended to be fitted: Barrier or Pocket Screen installed along the line of the opening

leaf. (Pocket Screen: H=1500mm min from finished floor level)

8.2 Safety During the Close Cycle

Provision should be made using one of the following, to prevent a door shutting on traffic during the closing cycle. A

Safety Beam is recommended to be positioned between the jambs at a height of 300mm – 600mm above the finished

floor level. Alternately we recommend the use of an appropriate presence sensing safety device covering the

threshold area, in relation to where a risk assessment shows there is a significant proportion of traffic using the

entrance /exit doors, who are potentially vulnerable (e.g. elderly, infirm, disabled or very young).

8.3 End User - Occupier Safety Tests - Recommended

To ensure safe daily use of our automatic door system, we recommend the follow be applied in compliance with safety

standards.

The occupier is responsible for the undertaking of the following test procedure, which should be carried out at least

weakly, unless a different schedule of tests is identified in the risk assessment priory to installation.

1. There should be no notice boards, literature racks, merchandise displays or other distractions or obstructions in the

vicinity of the door which may congest or inhibit traffic flow.

Automatic Activation Device Test:

2. Test sensors by walking towards the door opening. The door should start to open when a person is approx 1400mm

(5ft) from the door. The door should slide smoothly to the open position and stop without impact

3. Step out of the activation zone. After a time delay (normal 1s ~ 5s) the door should close smoothly.

4. Repeat steps 2 and 3 on the other side of the opening, if the door has two way operation.

Safety Devices

5. Safety Beams. If safety beams are fitted, place a test object on the threshold at the full open position, step out of

the diction area and confirm the door remains open.

General Test

6. Check that the door area has no tripping or slipping hazards

7. Check all door panels for cracked or broken glass.

8. Check doors have signs correctly displayed at recommended viewing heights if fitted

9. Check the position and security of associated screens and barriers if fitted.

10. Check the operation of manual activation, remote activation or other stop devices if fitted.

11. Check and remove any distractions / obstructions in the vicinity of the doors.

Page 26

MODEL: EDM MM50 & MM80

MAGNETIC LINEAR SLIDING DOOR OPERATOR

Page 26

Authorised Technician Check List

Applicable to Sliding, Telescopic, Curved, Prismatic and Folding Door

Site:

Serial No:

Door Type:

Opening Width:

Time

Open Time: sec

Closing Time: sec

Hold Open Time: sec

Closing Energies (Commissioning Only)

At Low Speed: J

At Max Speed: J

Static Entrapment Force: N

Activation Distances

Straight Approach: m

Side Approach: m

Safety Device/s

Hold Open Beams

Number Fitted:

Height/s above Floor Level: m

Presence Sensors

Field Width: m

Field Depth: m

Hold Open time: sec

Drawing in protection

Leading Stile to Jamb: mm

Outer Stile to mullion: mm

Barrier Rail / Safety Side Screen: Fitted / Not Fitted

Escape System

Fail Open: Active / Not Active

Breakout: Fitted / Not fitted

Break out force: N

Signage Fitted: Y/N

General Comments:

Name:

Time:

Signed:

Date:

8.4 Installation Check List

It is recommended that the following is carried out by the authorised technician and that the following information is

provided during installation commissioning and at each annual safety inspection. We therefore provide the basis for

such checks to be carried out in compliance with safety standards.

(Example)

Loading...

Loading...