Miami Tech Metal and Fire User Manual

2017-2018

Metal and Fire

Product Catalog

• ROOF JACK • SNAP LOCK PIPE • ROOF VENT • REGISTER BOXES •

ALUMINIUM Z-BAR • CAN STOCK • BOOT RAILS • FLAT S-LOCK •

HEAT SHIELDS • BOOT CLIPS • CONDENSING UNIT TIE DOWNS • DUCT GRILLE CLIPS • TEES

CONDENSING UNIT STANDS • SLEEVE DAMPER • DRAIN PANS • FITTINGS • RIGID VENT PIPES

• FIXED FILTER RACKS • AIR HANDLER STANDS • TAKE-OFF COLLARS • FLEX DUCT CONNECTOS • PIPE STANDS • REGISTER BOOT •

WWW.MIAMITECH.COM

OUR COMPANY

Miami Tech, Inc. was established in 1987 in a small warehouse with a handful of products to

offer. Today, Miami Tech spans over 135,000 square feet of manufacturing and warehousing space in

our three facilities located in Miami, Florida, with over 17,000 components in our product lines.

Miami Tech continuously designs, builds, and implements new methods of manufacturing, de-

livering quality, efciency and mass production to the industry. We continue to operate on the cutting

edge with fully automated production lines and CNC laser cutting technology ensuring consistent

quality of our products. Always striving to be ahead of the competition, we are constantly innovating

new designs and product lines as well as offering swift and versatile processing of custom requests

to cater to every last one of our customers’ needs. We work tirelessly to improve the products themselves, redesigning them based on you and your customers’ feedback.

Since we build to stock and ship from inventory at our highly efcient Miami Tech Distribution

Center, the moment we receive an order, it can be fullled and shipped within forty-eight hours and

in most cases the same day. You don’t have to wait two or three weeks for your order, which is the

industry standard. You can count on our friendly and knowledgeable customer representatives to get

it right, so you can receive it on time. As one of the leading manufacturers in the HVAC industry, we

strive to be the best, setting new standards in quality, service, and price.

Industry Leaders. Manufacturing Experts.

Setting the industry standard since 1987.

3611 NW 74th Street

Miami, Florida 33147

WWW.MIAMITECH.COM

Ph: (305) 693-7054

Fx: (305) 693-6152

OUR POLICIES

TERMS & CONDITIONS

Terms and Conditions of Sale

1. Terms 1%-10 days, Net 30 days. Add 1-1/2% per month service charge on all delinquent accounts.

2. All prices and/or designs are subject to chance without notice.

3. All claims for shortage, damage, etc., must be made within 24 hours from date of shipment. For LTL ship-

ments and truck loads, discrepancies must be noted on bill of lading.

Return Policy

1. No merchandise will be accepted for return without prior approval from Miami Tech, Inc.

2. No returns after 60 days.

3. No returns on special, custom, or non-stock products.

4. Returned merchandise will be subject to a 20% restocking fee.

Freight Policy

1. Freight is paid on a minimum order of $1,500.00 net for Florida (excluding Panhandle)

2. Freight is paid on a minimum order of $3,000.00 net for Florida Panhandle.

3. Freight is paid on a minimum order of $3,000.00 net for Alabama, Georgia, North/South Carolina.

4. For States not listed, orders freight will be addressed on a case by case basis.

Sales Policy

1. Minimum invoice charge is $50.00.

2. Minimum order of $100.00 net for local delivery.

3. Broken box charge is an additional 25%.

Special Sizes

If a particular size is not listed within this catalog, please do not hesitate to ask.

We are capable of manufacturing most sizes if given specications.

Warranty

Miami Tech, Inc., warrants that all the products and ttings it manufactures are produced in accordance with

the standards and specications shown within this catalog. No warranty of suitability for any particular purpose,

nor any other presentation of warranty, whether expressed or implied, is made respecting these products.

TABLE OF C ONTENTS

Air Conditioning Accessories

Aluminium Z-Bars ············································································································ 5

Can Stock ························································································································· 5

Boot Rails ························································································································· 5

Boot Clips ························································································································· 6

Heat Shields / Collar Start ······························································································· 6

Drive Cleat ························································································································ 6

Flat S-Lock ······················································································································· 7

Standing S-Lock ··············································································································· 7

Duct Grille Clip ················································································································· 7

Slotted Angle Iron ············································································································· 8

Air-Handler Bracket ·········································································································· 8

Hanging Strap ·················································································································· 8

Fiberglass Duct Support / Saddle ··················································································· 9

Mixing Box Bracket ·········································································································· 9

Nail Plate ·························································································································· 9

Sheet Metal Frame ········································································································ 10

Register Take-Off ··········································································································· 10

Refrigerant Line Cover ····································································································11

U-Channel ·······················································································································11

Filter Racks

Fixed Filter Racks ·········································································································· 12

Fixed Filter Racks w/ Door ···························································································· 12

Fixed Filter Racks w/ Door For Eco Temp ····································································· 12

Trane/American Standard Fixed Filter Rack ·································································· 13

Adjustable Filter Rack ···································································································· 13

Adjustable Air Handler Wall Bracket··············································································· 13

Condensing Unit Tie-Down Kits

Miami Tech Tie-Down Kits ····························································································· 14

Rheem/Ruud Tie-Down Kits ·························································································· 15

Trane/American Standard Tie-Down Kits ····································································· 15

Carrier/Bryant Tie-Down Kits ························································································· 16

Goodman Tie-Down Kits ······························································································· 16

Air Handler Bases

Trane/American Standard AIr-Handler Base ································································ 17

Trane/American Standard Air-Handler Base Sound Bafe Kit ····································· 17

Trane/American Standard Side Return Kit ··································································· 17

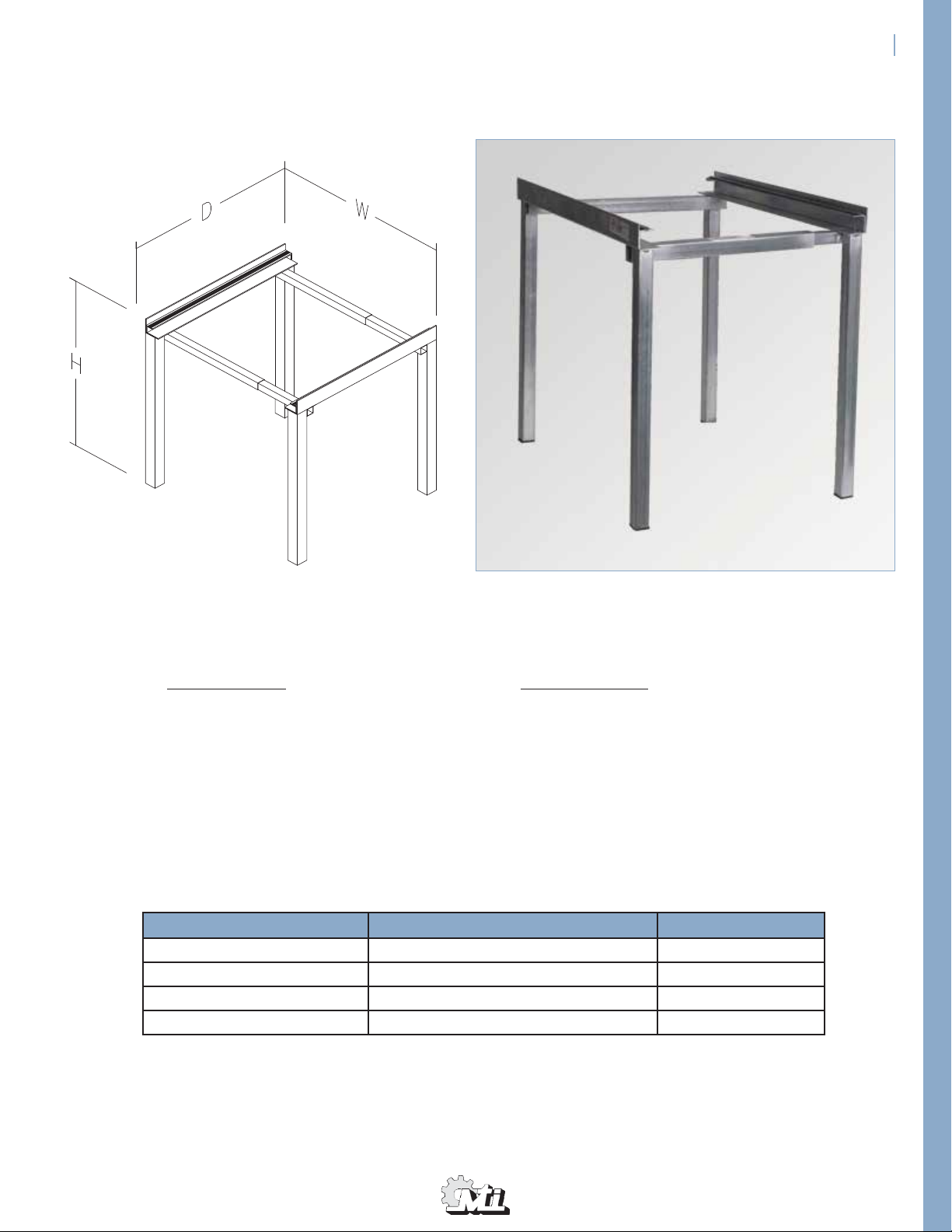

Model HAB ····················································································································· 18

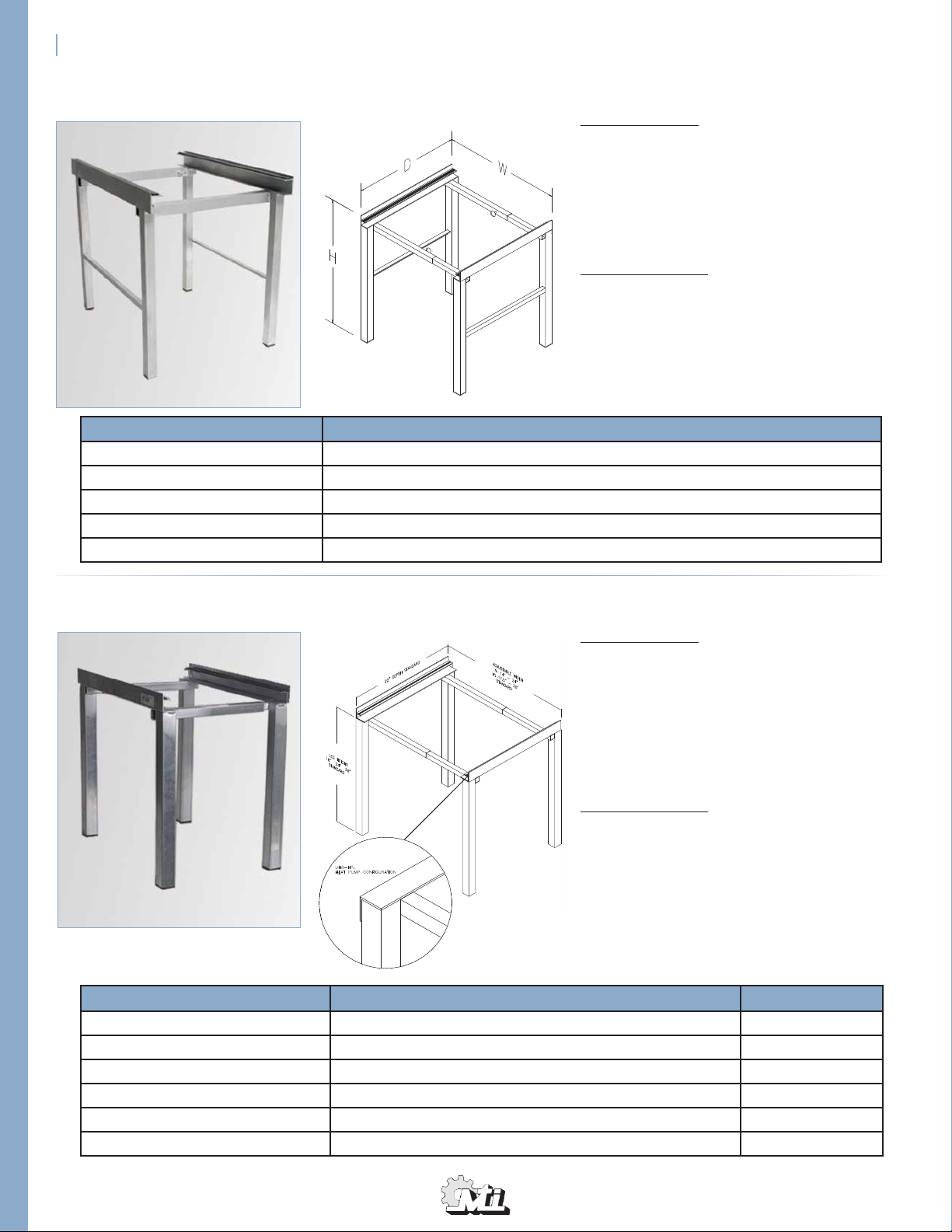

Model HEB ····················································································································· 19

Model AHEB ··················································································································· 20

Model UHB ····················································································································· 20

Condensing Unit Stands

Model AST (Non-HVHZ) Aluminum Condensing Unit Stand ······································· 21

Model AS14 Aluminum Condensing Unit Stand ······················································ 22-23

Aluminum Products & Condensing Unit Cage

Aluminum Condensing Unit Wall Mount Bracket (Wind Load Rated) ··························24

Aluminum Condensing Unit Heavy Duty Wall Mount Bracket ·····································24

Aluminum Pipe Stand ···································································································· 24

Single Leg Pipe Stand ··································································································· 25

Condensing Unit Cage ·································································································· 25

Collars & Accessories

Tab Collars For Fiberglass Duct (Regular / Nested) ····················································· 26

261 Collars ····················································································································· 27

Spin-in Collars for Fiberglass Duct (Standard / Tapered) ············································· 28

Spin-in Collars for Metal Duct (Standard / Tapered) ····················································· 29

Take-Off Collars ············································································································· 30

Ring-Seal Collars ··········································································································· 30

Sure-Seal Collars (Standard / Tapered) ········································································ 31

Flex Duct Connectors ···································································································· 32

Collar Rings ···················································································································· 32

Damper Assembly Kit ··································································································· 32

Collar Optional Accessories ·························································································· 33

Volume Dampers

Sleeve Dampers ············································································································ 34

Voume Dampers ············································································································ 34

Aluminum Opposed-Blade Volume Damper ································································· 35

Aluminum Parallel-Blade Volume Damper ··································································· 35

Motorized Opposed-Blade Volume Damper ································································· 36

Motorized Parallel-Blade Volume Damper ···································································· 36

Rectangular Motorized Zone Damper ···········································································37

Round Motorized Zone Damper ···················································································· 37

Drain Pans

Drain Pans ····················································································································· 38

Drain Pan w/ Rails ·········································································································38

Rheem/Ruud Horizontal Drain Pan ···············································································39

Auxiliary Drain Pan ········································································································ 39

Drain Pan Hanging Kit ··································································································· 39

Fiberglass Products

Fiberglass Reducers ······································································································ 40

Fiberglass Triangles ······································································································· 40

Fiberglass Plenum Boxes ······························································································ 40

Fiberglass Register Boxes ····························································································· 41

Fiberglass Return-Air Register Boxes ··········································································· 41

R-4/R-6 Register Boxes (Flanged / Unanged) ······························································· 42

Register Boxes

R-8 Register Boxes (Flanged/Unanged) ········································································ 43

R-6 Metal Top Box w/ Collar ····························································································· 43

R-8 Metal Top Box w/ Collar ····························································································· 44

Side-Outlet Register Box ·································································································· 44

Return Air Box ···················································································································45

Thru-Wall Box ···················································································································· 45

Mobile Home Return Box ·································································································· 46

Fiberglass Slanted Register Box ······················································································ 46

Adjustable Elbows & Metal Pipes

Adjustable Elbows ············································································································· 47

Snap Lock Pipes ··············································································································· 48

Rigid Vent Pipes ················································································································ 48

Metal Fittings

Metal Tees ························································································································· 49

End Cap ····························································································································· 49

Metal Reducer ··················································································································· 50

Rectangular Transition ······································································································ 50

Rectangular To Round Adapter ························································································ 51

Squate To Round Adapter ································································································· 51

In-Line Wye / Bull-Nose Wye / Adjustable Wye / Mobile Home Wye ······························ 52

Take-Off Collar for ICP Package-Units ············································································· 53

Take-Off Collar for Rheem/Ruud Package-Units ····························································· 54

Take-Off Collar for Nordyne Package-Units ····································································· 54

Take-Off Collar for Goodman Package-Units ··································································· 54

Register Boots

Plaster Ground Frame ······································································································ 55

Straight Register Boot ······································································································· 55

Center-End Register Boot ································································································· 56

Elbow Register Boot ·········································································································· 56

Wall Stack Products

Wall Stack Short-Way Elbows (Standard / 45º) and Long-Way Elbows ·························· 57

Wall Stack Straight and Elbow Transitions ······································································· 58

Wall Stack Centered Transitions ······················································································· 59

Wall Stack Pipe ················································································································· 59

Wall Stack Cap ·················································································································· 59

Side Wall Cap / Twin Side Wall Cap ·················································································· 60

Wall Stack Side Wall Cap ·································································································60

Roong Products

Galvanized Roof Vents ······································································································ 61

Aluminum Roof Vents ······································································································· 62

Roof Jack (Straight / Angled) ···························································································· 63

All Purpose Roof Jack (Straight / Angled) ········································································ 63

Line Jack ···························································································································· 64

Shanty Cap ························································································································ 64

Eave Vent ·························································································································· 64

Fire Product Line

Fire Damper Product Line Overview ················································································· 65

Fire Damper Selection Guide ······················································································66-68

Fire Damper and Ceiling Damper Ordering Guide ·························································· 69

Static System Fire Dampers

Model 150E Slimline ·········································································································· 70

Model 150F Slimline ·········································································································· 71

Dynamic System Fire Dampers

Model 151A ························································································································ 72

Model 151B ······················································································································· 73

Model 151C ······················································································································· 74

Model US-3 ························································································································ 75

Birdcage Fire Damper Assembly ······················································································ 75

Ceiling Dampers

Model 615 ·························································································································· 76

Model 616 ·························································································································· 77

Model FCB ························································································································· 77

Access Doors

Model FSA 100 and 101 ··································································································· 78

Model FSA 110 and 111 ···································································································· 79

Model FSA 115 and 116 ···································································································· 80

Model FSA 125SM and 126SM ························································································ 81

Model FSASMF ················································································································· 81

Ceiling Radiation Damper Boxes

Model CRPD ····················································································································· 82

Model CRD ························································································································ 83

Model CRDS ····················································································································· 84

Fire Damper Optional Accessories

Fixed Fire Damper Sleeve ································································································ 85

Adjustable Fire Damper Sleeve ························································································ 86

Picture Frame Angle ·········································································································· 86

Mounting Angles ················································································································ 87

ZB

AIR CONDITIONING ACCESSORIES

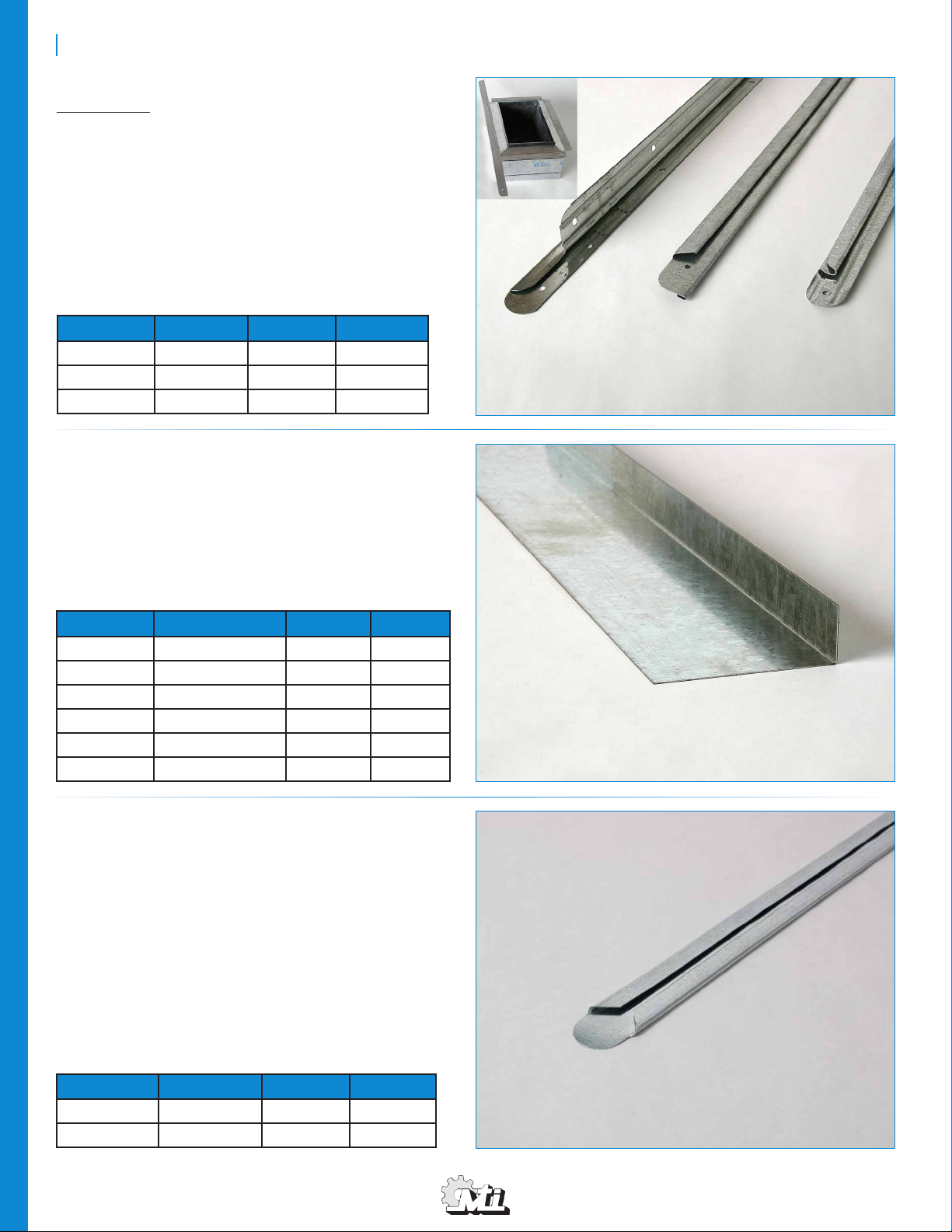

ALUMINUM Z-BAR

Part No. Size Gauge Qty.

ZB-2 1” .020 Mill Finish 100 ft

ZBR-2 1-1/2” .020 Mill Finish 100 ft

ZB-R8 2” .020 Mill Finish 80 ft

CAN STOCK / PLASTER ROUND

CS

BR

Part No. Size Gauge Qty.

CS-4 2” x 1-1/2” x 10’ 30ga 200 ft

CS-412 1.75” x 2.25” x 10’ 30ga 200 ft

CS-5 2” x 2-1/2” x 10’ 30ga 200 ft

BOOT RAIL

Part No. Size Gauge Qty.

BR-26 1” x 1” x 24” 26ga 50

BR-24 1” x 1” x 24” 24ga 50

BR-22 1” x 1” x 24” 22ga 50

5

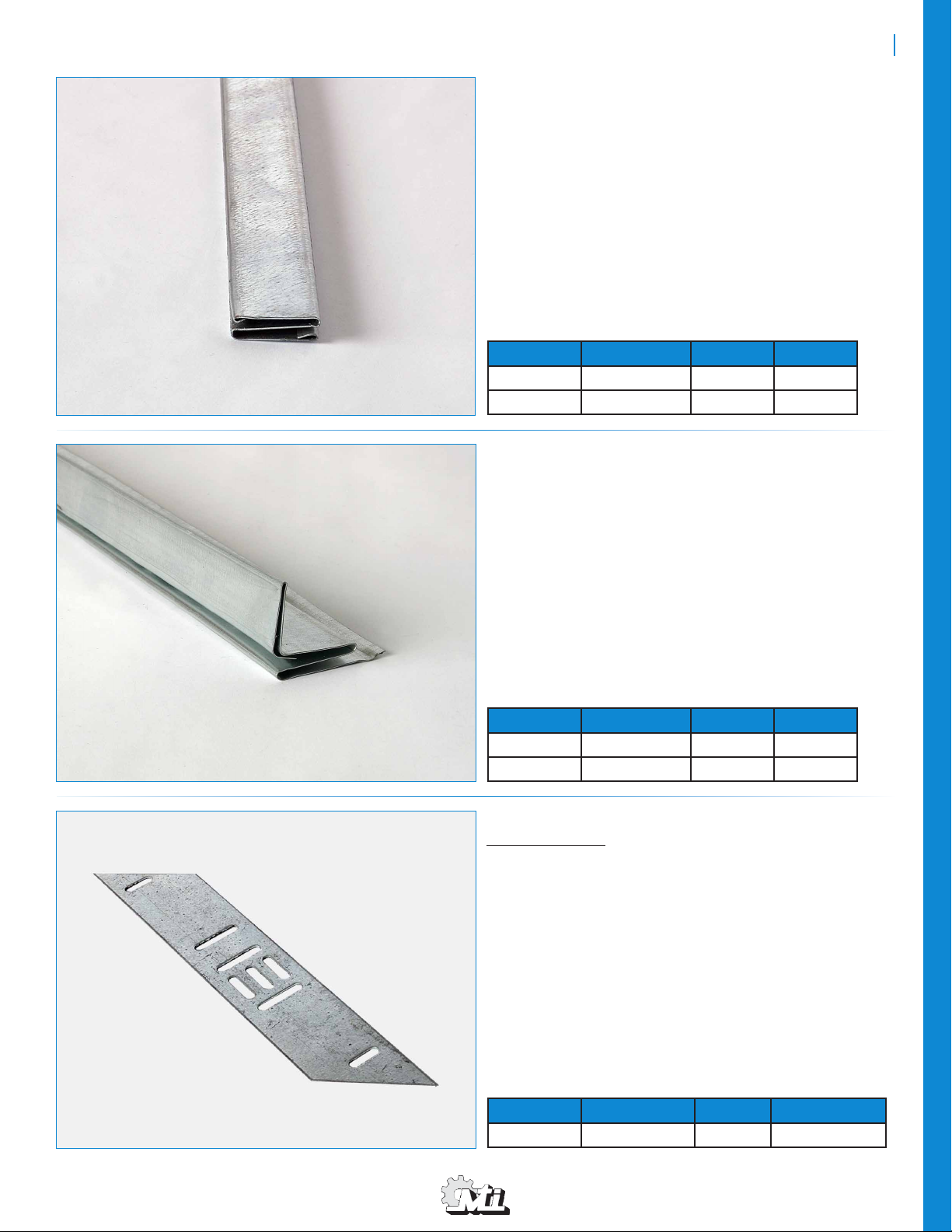

AIR CONDITIONING ACCESSORIES

BOOT CLIP

Product Models

• CBC: Combo Clip; for use with anged or unanged register box.

• BCE: Industry Standard Boot Clip.

• BCM: Miami Tech Design Boot Clip.

Part No. Length Gauge Qty.

BC-26M 26” 26ga 100

BC-26E 26” 26ga 100

CBC-26 26” 26ga 50

HEAT SHIELD / COLLAR START

Part No. Size Gauge Qty.

CS30-8 5-1/2” x 1/2” x 8’ 30ga 200 ft

CS26-8 6” x 1-1/2” x 8’ 26ga 200 ft

CS263-8 3” x 1” x 8’ 26ga 200 ft

CS263-10 3” x 1” x 10’ 26ga 200 ft

CS2675-8 6” x 3/4” x 8’ 26ga 200 ft

CS223-10 3” x 1” x 10’ 22ga 200 ft

CBC BCE BCM

CS-8/10

DRIVE CLEAT

Part No. Length Gauge Qty.

DRC26 1-1/8” x 10’ 26ga 100 ft

DRC24 1-1/8” x 10’ 24ga 100 ft

6

DRC

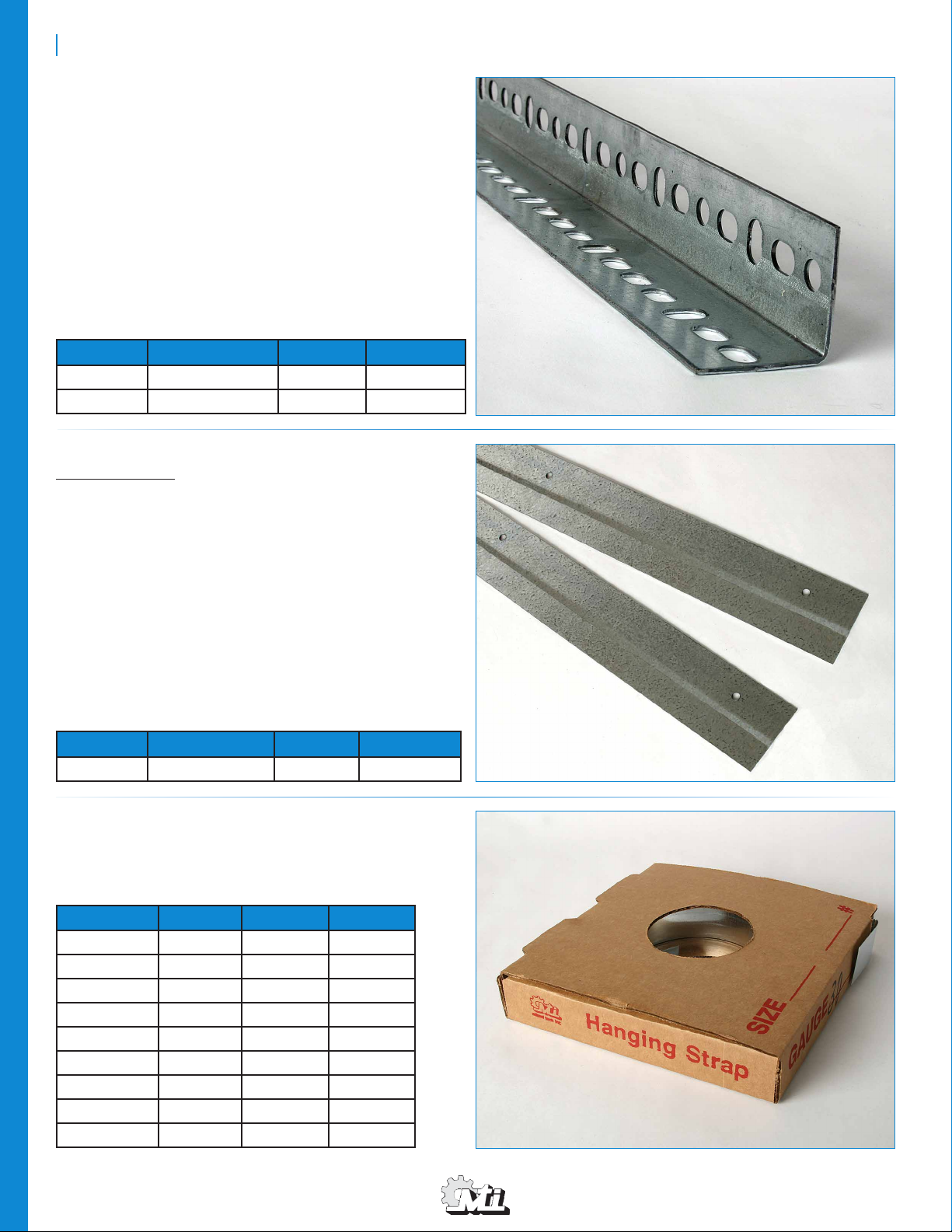

FSL

AIR CONDITIONING ACCESSORIES

FLAT S-LOCK

Part No. Size Gauge Qty.

FSL26 10 ft 26ga 100 ft

FSL24 10 ft 24ga 100 ft

STANDING S-LOCK

SSL

DC-150

Part No. Size Gauge Qty.

SSL26 10 ft 26ga 100 ft

SSL24 10 ft 24ga 100 ft

DUCT GRILLE CLIP

Product Information

• Designed for R-4 & R-6 ductboard.

• Sold & packaged per box.

Part No. Size Gauge Qty.

DC-150 1” x 5-7/8” 26ga 1 Box (100pcs)

7

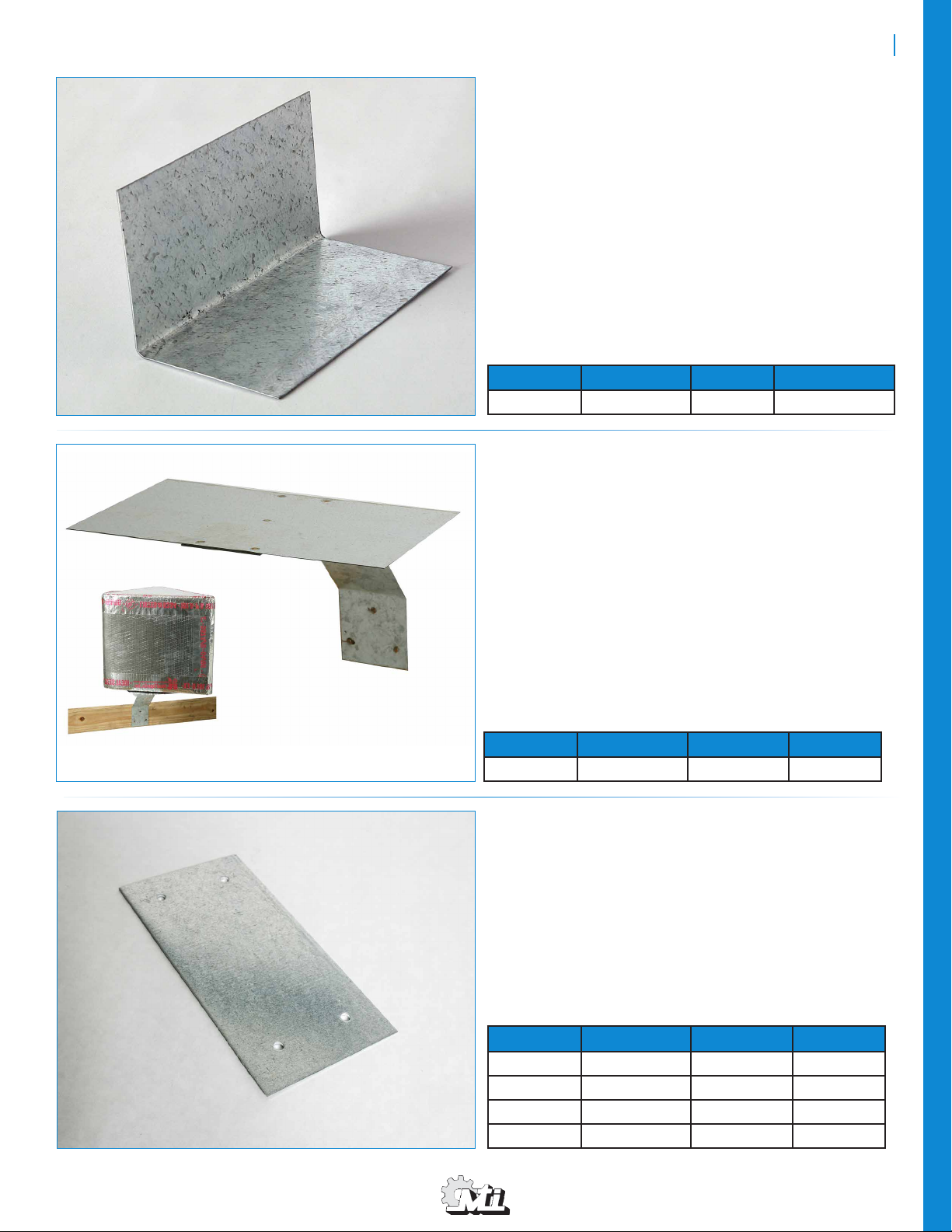

AIR CONDITIONING ACCESSORIES

SLOTTED ANGLE IRON

Part No. Size Gauge Qty.

SA10-16 1.5” x 1.5” x 10’ 16ga 50 ft

SA10-14 1.5” x 1.5” x 10’ 14ga 50 ft

AIR-HANDLER BRACKET

Product Information

• Sold in sets of 2pcs.

• Custom sizes available upon request.

SA

Part No. Size Gauge Quantity

AHB 2.25” x 20.75” 20ga 1 Set (2pcs)

HANGING STRAP

Part No. Size Gauge Qty.

HS1030 1” 30ga 1 Box

HS1026 1” 26ga 1 Box

HS1022 1” 22ga 1 Box

HS1530 1.5” 30ga 1 Box

HS1526 1.5” 26ga 1 Box

HS1522 1.5” 22ga 1 Box

HS2030 2” 30ga 1 Box

HS2026 2” 26ga 1 Box

HS2022 2” 22ga 1 Box

8

AHB

HS

AIR CONDITIONING ACCESSORIES

FIBERGLASS DUCT SUPPORT / SADDLE

DS

MBB

Part No. Size Gauge Qty.

DS1 2” x 2” x 4” 22ga 1 Set (10pcs)

MIXING BOX BRACKET

Part No. Size Gauge Qty.

MBB 8” x 12” 16ga/22ga 1

NAIL PLATE

NP

Part No. Size Gauge Qty.

NP36-16 3” x 6” 16ga 1

NP38-16 3” x 8” 16ga 1

NP36-22 3” x 6” 22ga 1

NP38-22 3” x 8” 22ga 1

9

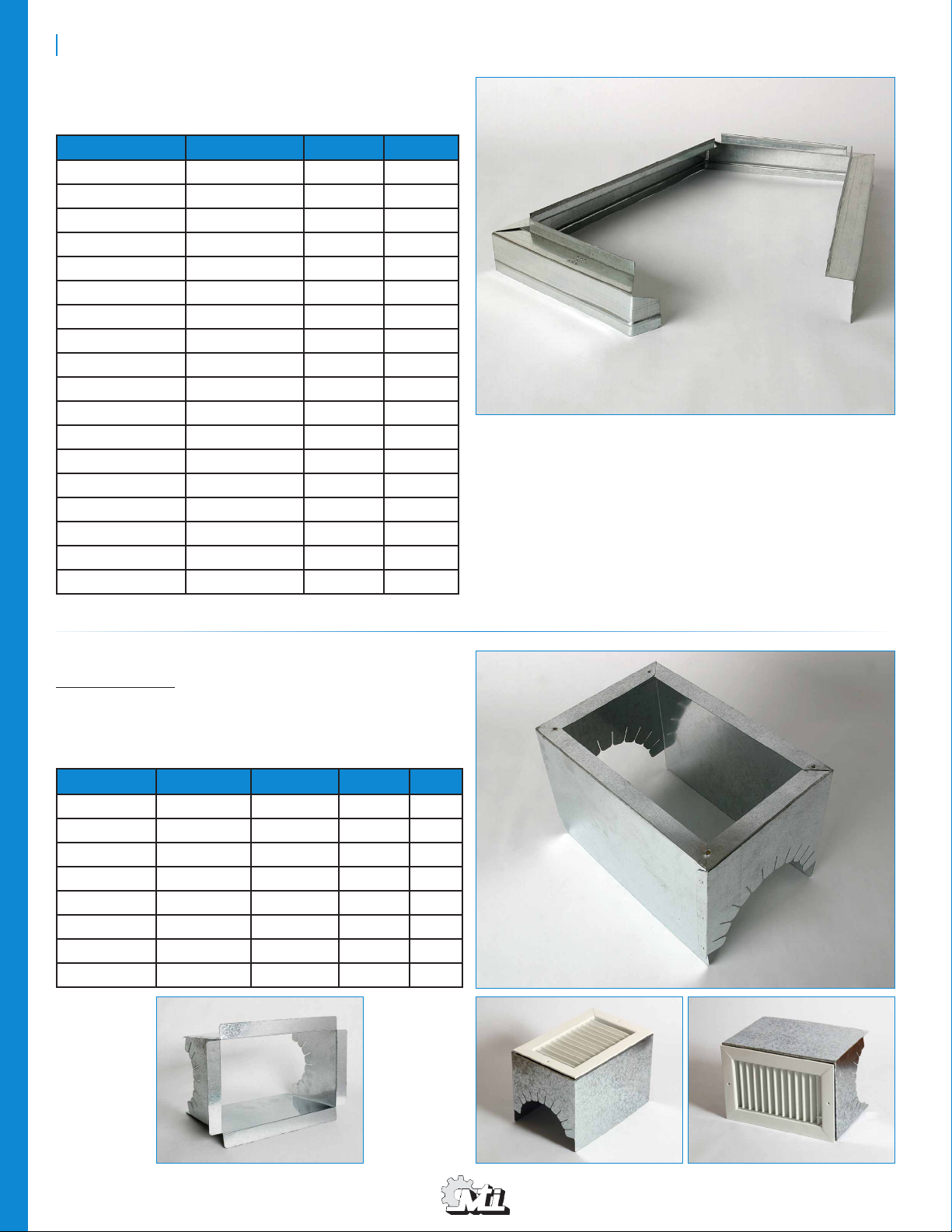

AIR CONDITIONING ACCESSORIES

SHEET METAL FRAME

Part No. Size Gauge Qty.

SMF0404 4” x 4” 28ga 1

SMF0604 6” x 4” 28ga 1

SMF0606 6” x 6” 28ga 1

SMF0804 8” x 4” 28ga 1

SMF0806 8” x 6” 28ga 1

SMF0808 8” x 8” 28ga 1

SMF1004 10” x 4” 28ga 1

SMF1006 10” x 6” 28ga 1

SMF1008 10” x 8” 28ga 1

SMF1010 10” x 10” 28ga 1

SMF1204 12” x 4” 28ga 1

SMF1206 12” x 6” 28ga 1

SMF1208 12” x 8” 28ga 1

SMF1210 12” x 10” 28ga 1

SMF1212 12” x 12” 28ga 1

SMF1406 14” x 6” 28ga 1

SMF1408 14” x 8” 28ga 1

SMF1414 14” x 14” 28ga 1

SMF

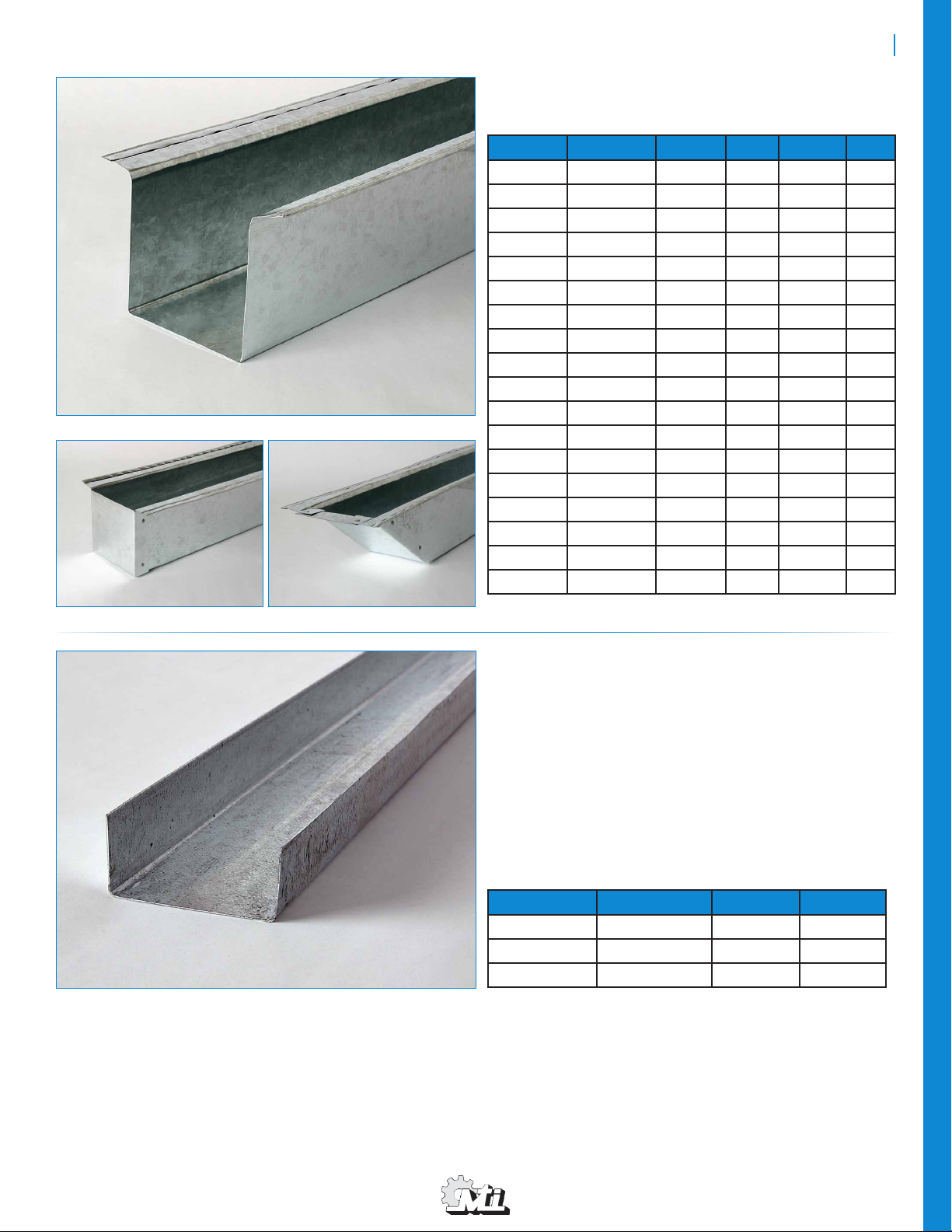

REGISTER TAKE-OFF

Product Information

• RTO Flange: If the pipe diameter is at least 2” larger than the RTO

height, ange will fold inward, otherwise ange will fold outward.

• Custom sizes available upon request.

Part No. Grille Size Duct Dia. Gauge Qty.

RTO848 8” x 4” 8” 26ga 1

RTO8410 8” x 4” 10” 26ga 1

RTO1068 10” x 6” 8” 26ga 1

RTO10610 10” x 6” 10” 26ga 1

RTO1268 12” x 6” 8” 26ga 1

RTO12610 12” x 6” 10” 26ga 1

RTO1288 12” x 8” 8” 26ga 1

RTO12810 12” x 8” 10” 26ga 1

RTO

10

RTO shown with grille for illustration purposes only.RTO shown with outward ange.

LC

LC-C LC-A

FLAT CAPPED ANGLE CAPPED

AIR CONDITIONING ACCESSORIES

REFRIGERANT LINE COVER

Part No. Size Length Cap Gauge Qty.

LC3-8 3” x 3” x 3” 8 ft - 26ga 5

LC4-8 4” x 4” x 4” 8 ft - 26ga 5

LC5-8 5” x 5” x 5” 8 ft - 26ga 5

LC6-8 6” x 6” x 6” 8 ft - 26ga 5

LC3-10 3” x 3” x 3” 10 ft - 26ga 5

LC4-10 4” x 4” x 4” 10 ft - 26ga 5

LC5-10 5” x 5” x 5” 10 ft - 26ga 5

LC6-10 6” x 6” x 6” 10 ft - 26ga 5

LC3-8C 3” x 3” x 3” 8 ft Flat 26ga 2

LC4-8C 4” x 4” x 4” 8 ft Flat 26ga 2

LC5-8C 5” x 5” x 5” 8 ft Flat 26ga 2

LC6-8C 6” x 6” x 6” 8 ft Flat 26ga 2

LC3-10C 3” x 3” x 3” 10 ft Flat 26ga 2

LC4-10C 4” x 4” x 4” 10 ft Flat 26ga 2

LC5-10C 5” x 5” x 5” 10 ft Flat 26ga 2

LC6-10C 6” x 6” x 6” 10 ft Flat 26ga 2

LC4A-8 4” x 4” x 4” 8 ft Angle 26ga 2

LC4A-10 4” x 4” x 4” 10 ft Angle 26ga 2

UC

U-CHANNEL

Part No. Size Gauge Qty.

UC-26 1” x 2” x 1” 26ga 100 ft

UC-22 1” x 2” x 1” 22ga 100 ft

UC-322 1” x 3” x 1” 22ga 100 ft

11

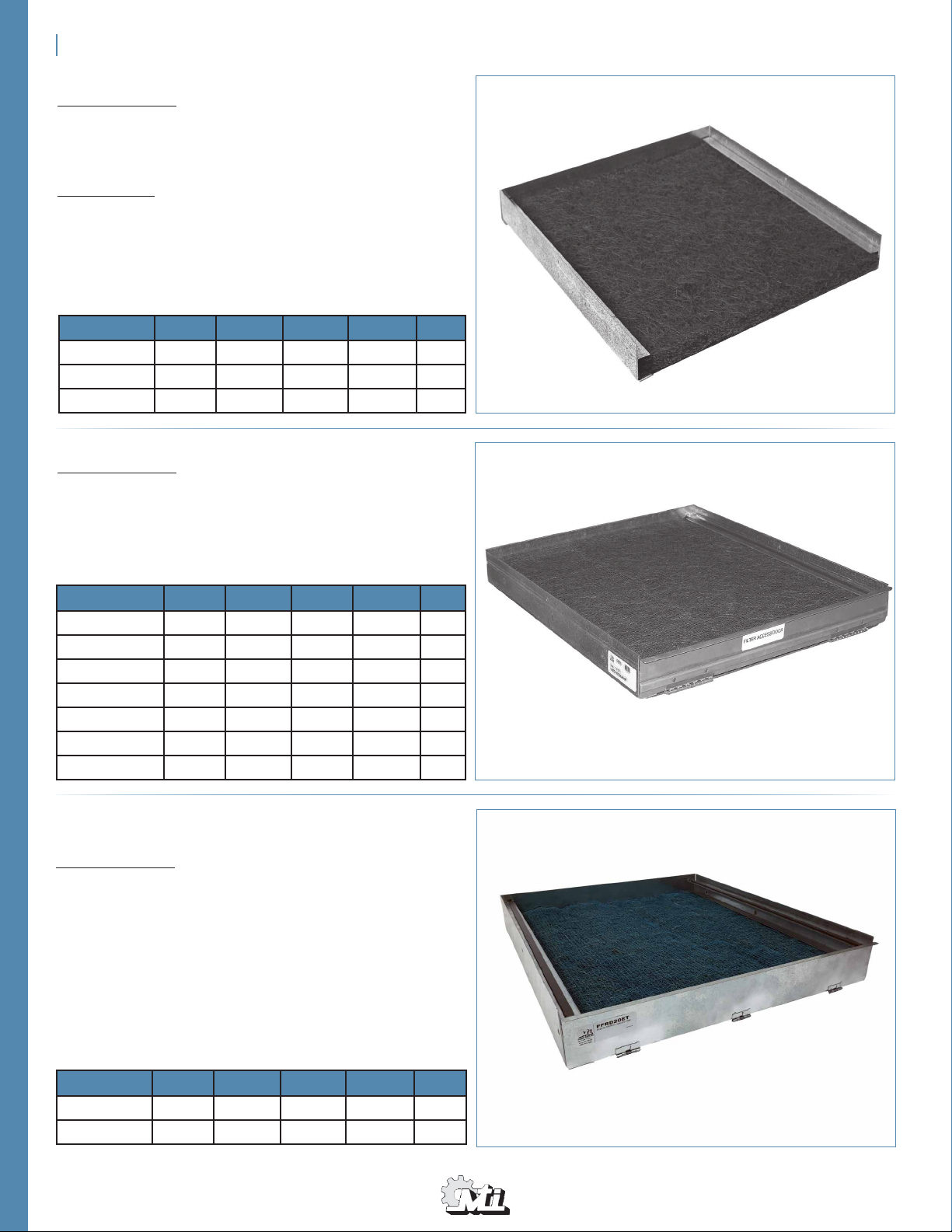

FILTER RACKS

FIXED FILTER RACK

Product Information

• Includes 1” hog hair lter with reinforced wires.

• 1/8” x 3/8” rubber strips included to minimize vibration.

• Pre-punched holes for easy fastening to air handler/base.

• All lter rack units are packaged in a box.

Product Options

• FFRI: Insulated xed lter rack for unconditioned space available

upon request.

Part No. Width Height Depth Gauge Qty.

FFR17.5RU 17-7/8” 2” 21.5” 16ga 1

FFR21RU 21-3/8” 2” 21.5” 16ga 1

FFR24RU 24-7/8” 2” 21.5” 16ga 1

FIXED FILTER RACK WITH DOOR

Product Information

• Features a hinged access door.

• Includes 1” hog hair lter with reinforced wires.

• 1/8” x 3/8” rubber strips included to minimize vibration.

• Pre-punched holes for easy fastening to air handler/base.

• All lter rack units are packaged in a box.

• RU: For Rheem/Ruud Units.

• Y: For York Units.

FFR

Part No. Width Height Depth Gauge Qty.

FFRD17.5RU 17-7/8” 2” 21.5” 16ga 1

FFRD21RU 21-3/8” 2” 21.5” 16ga 1

FFRD24RU 24-7/8” 2” 21.5” 16ga 1

FFRD17.5Y 17-7/8” 2” 21-7/8” 16ga 1

FFRD21Y 21-3/8” 2” 21-7/8” 16ga 1

FFRD24Y 24-7/8” 2” 21-7/8” 16ga 1

FFRD26Y 25-7/8” 2” 21-7/8” 16ga 1

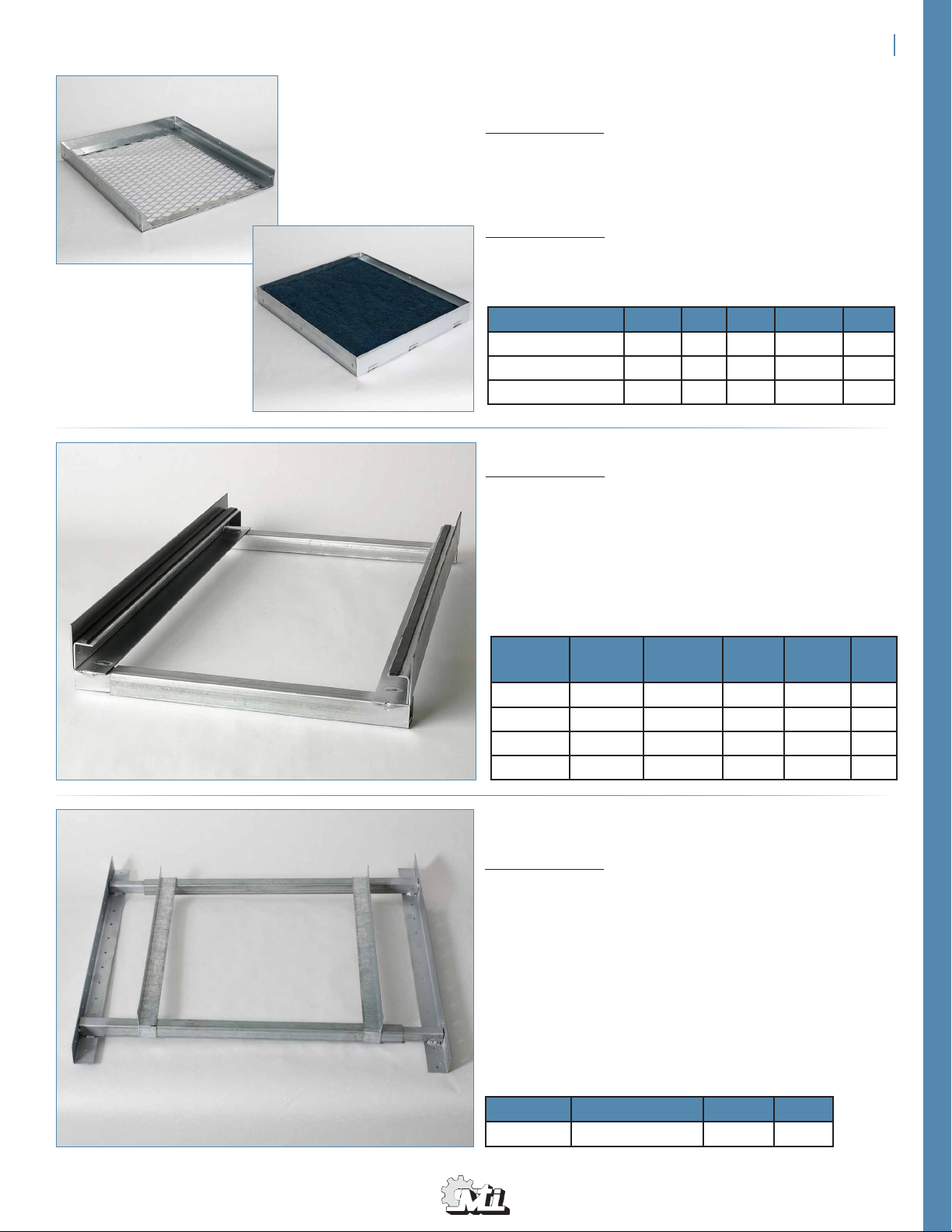

FIXED FILTER RACK WITH DOOR

FOR ECO TEMP

Product Information

• Includes 1” hog hair lter with reinforced wires.

• 1/8” x 3/8” rubber strips included to minimize vibration.

• Pre-punched holes for easy fastening to air handler/base.

• All lter rack units are packaged in a box.

FFRD

Part No. Width Height Depth Gauge Qty.

FFRD20ET 20” 3” 17” 16ga 1

FFRD22ET 22” 3” 17” 16ga 1

12

FFRDET

FFR-TAS

FFRD-TAS

FILTER RACKS

TRANE/AMERICAN STANDARD

FIXED FILTER RACK

Product Information

• Includes 1” hog hair lter with reinforced wires.

• Rubber strips included to minimize vibration.

• Pre-punched holes for easy fastening to air handler/base.

• FFRD model includes a spring-loaded hinged access door.

• All lter rack units are packaged in a box.

Ordering Guidelines

When ordering lter rack with door, add a “D” to the FFR part no.

Example: FFRD17.5TAS (includes spring-loaded hinged access door)

Part No. W H D Gauge Qty.

FFR17.5TAS-SM* 17.5” 2” 22” 16ga 1

FFR19.75TAS 19.75” 2” 22” 16ga 1

FFR23TAS 23” 2” 23” 16ga 1

* Includes safety mesh

ADJUSTABLE FILTER RACK

Product Information

• Rubber strips included to minimize vibration.

• Pre-punched holes for easy fastening to air handler/base.

FR

Part No.

Filter

Track

Width

Adjusts

Depth Gauge Qty.

FR1N 1” 14”-25” 22” 14ga 1

FR1W 1” 17”-27” 22” 14ga 1

FR2N 2” 14”-25” 22” 14ga 1

FR2W 2” 17”-27” 22” 14ga 1

ADJUSTABLE AIR HANDLER

WALL BRACKET

Product Information

• Wall bracket is MIG welded and maintains required 4” clearance

from rear wall.

• Accommodates units up to 30” wide and up to 350lbs in weight.

• Provides a space-saving solution for installations of air-handlers in a

shared space with a water heater.

• Main Angle: 1.5” x 1.5” 16 gauge galvanized steel.

• Cross Tube: 1” x 1” x 13/16” 16 gauge galvanized steel tube.

• Guide Angle: 1” x 1” 26 gauge galvanized steel angle.

AAWB

Part No. Width Adjusts Depth Qty.

AAWB26 14”-25” 26” 1

13

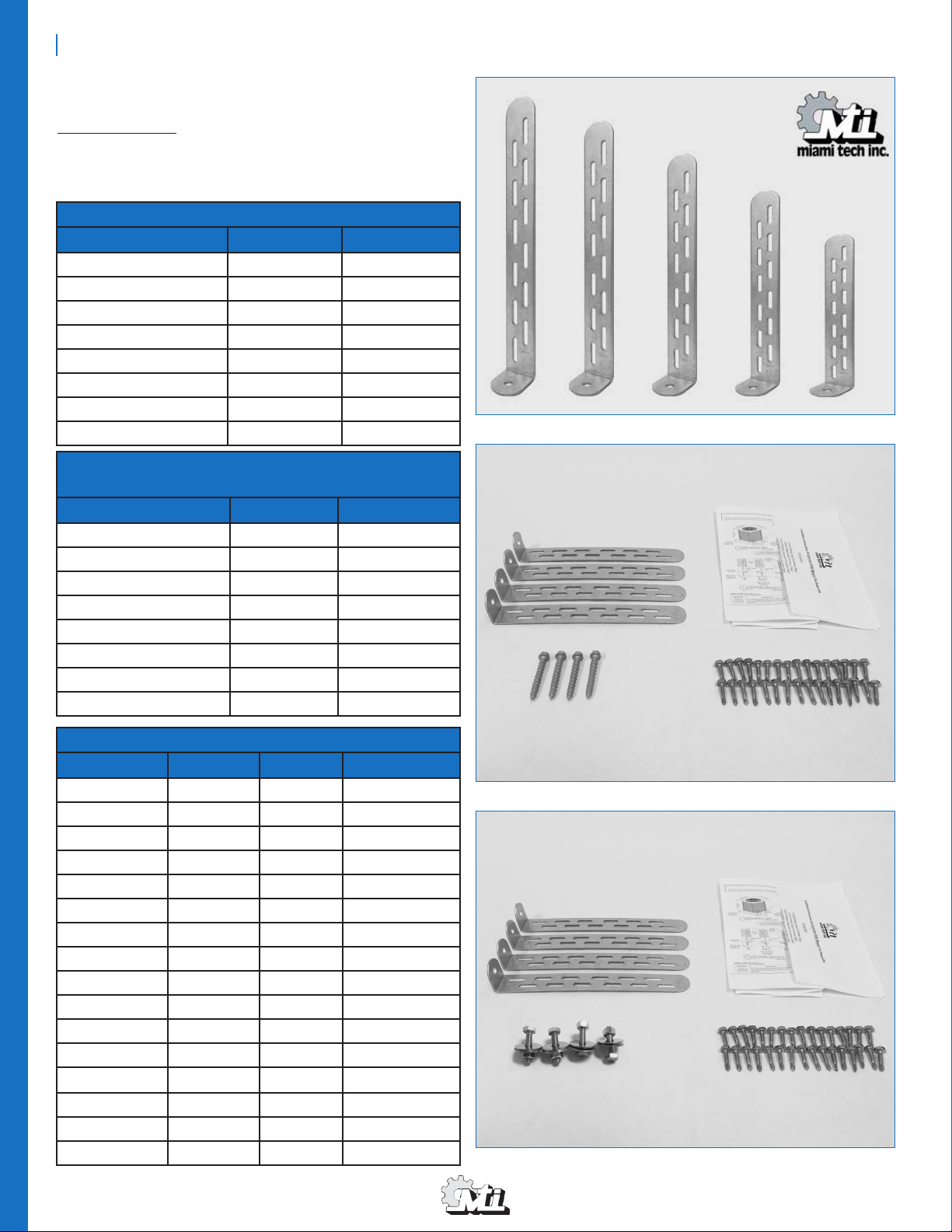

CONDENSING UNIT TIE-DOWN KITS

MIAMI TECH CONDENSING UNIT

TIE-DOWN KITS

Product Information

• Slotted design provides a universal mount.

• All certied tie-down kits are sold complete with stainless steel

hardware.

• Florida Product Approval #19731.

Ground/Slab Mount Certied Tie-Down Kits

Part No. CUTD Type Gauge

FL14CUTD6KG Galvanized 14ga

FL14CUTD8KG Galvanized 14ga

FL14CUTD10KG Galvanized 14ga

FL14CUTD12KG Galvanized 14ga

FL14CUTDA6KG Aluminum 14ga

FL14CUTDA8KG Aluminum 14ga

FL14CUTDA10KG Aluminum 14ga

FL14CUTDA12KG Aluminum 14ga

Roof-Top Rail Mount Wind Load Certied

Tie-Down Kits

Part No. CUTD Type Gauge

FL14CUTD6KR Galvanized 14ga

FL14CUTD8KR Galvanized 14ga

FL14CUTD10KR Galvanized 14ga

FL14CUTD12KR Galvanized 14ga

FL14CUTDA6KR Aluminum 14ga

FL14CUTDA8KR Aluminum 14ga

FL14CUTDA10KR Aluminum 14ga

FL14CUTDA12KR Aluminum 14ga

CUTD

Non-Certied Tie-Downs

Part No. Size Gauge Qty.

CUTD4 1” x 4” 14ga 50pk (4pcs)

CUTD6 1” x 6” 14ga 50pk (4pcs)

CUTD4-B 1” x 4” 14ga 200pcs

CUTD6-B 1” x 6” 14ga 200pcs

CUTD8-B 1” x 8” 14ga 200pcs

CUTD11-B 1” x 11” 14ga 100pcs

CUTD14-B 1” x 14” 14ga 100pcs

CUTD18-B 1” x 18” 14ga 100pcs

CUTDA4 1” x 4” Aluminum 50pk (4pcs)

CUTDA6 1” x 6” Aluminum 50pk (4pcs)

CUTDA4-B 1” x 4” Aluminum 200pcs

CUTDA6-B 1” x 6” Aluminum 200pcs

CUTDA8-B 1” x 8” Aluminum 200pcs

CUTDA11-B 1” x 11” Aluminum 100pcs

CUTDA14-B 1” x 14” Aluminum 100pcs

CUTDA18-B 1” x 18” Aluminum 100pcs

14

FL14CUTDKG

FL14CUTDKR

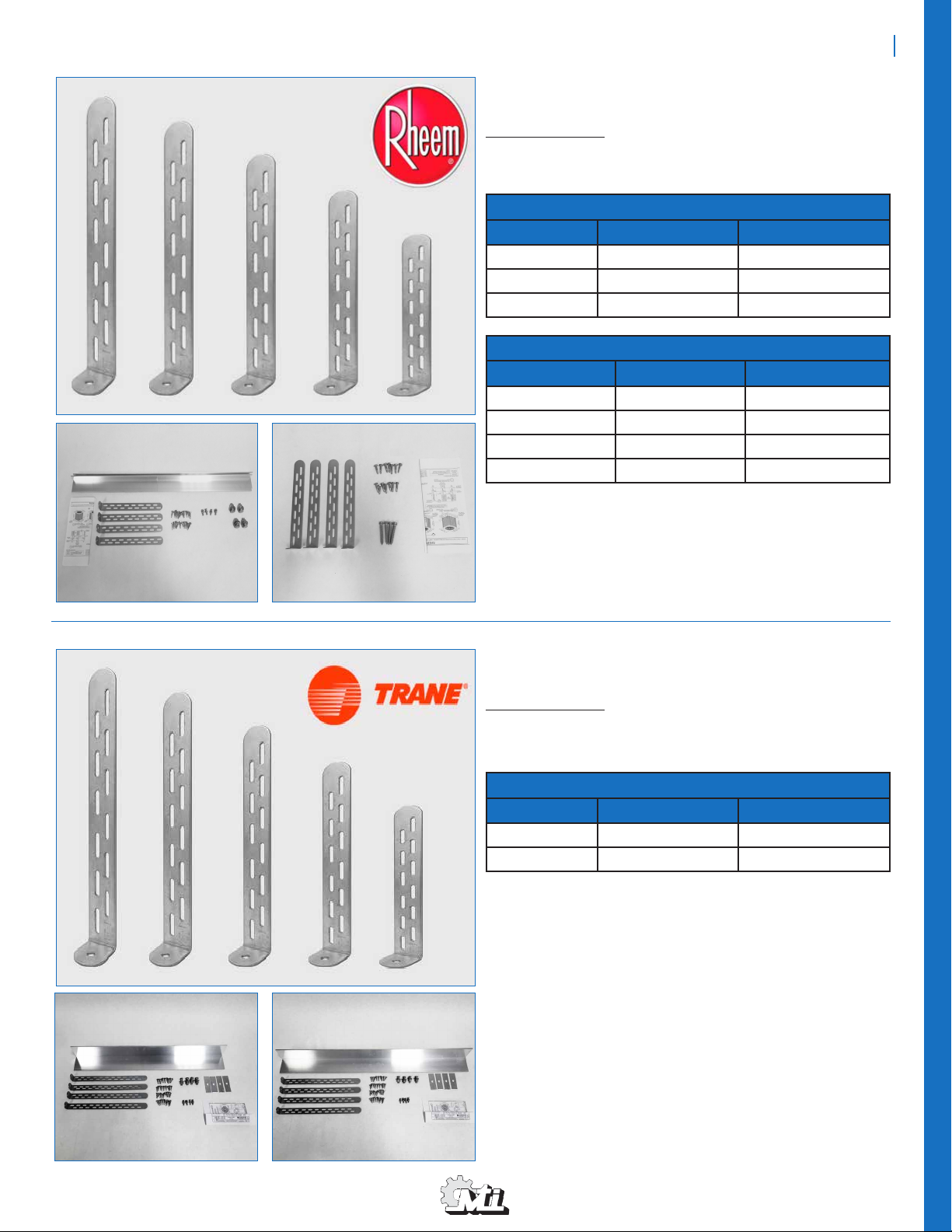

CONDENSING UNIT TIE-DOWN KITS

CONDENSING UNIT TIE-DOWN KITS FOR

RHEEM/RUUD

Product Information

• Miami Tech is proud to offer condensing unit tie-down kits engi-

neered specically for Rheem/Ruud units.

• Engineering data available at www.miamitech.com.

Roof Mount Wind Load Certied Tie-Down Kits

Part No. CUTD Type Mount Type

RRCUTD30K Galvanized Roof Mount

RRCUTD34K Galvanized Roof Mount

RRCUTD36K Galvanized Roof Mount

Ground Mount Certied Tie-Down Kits

Part No. CUTD Type Mount Type

RRCUTDSMK Galvanized Ground Mount

RRCUTDASMK Aluminum Ground Mount

RRCUTDLK Galvanized Ground Mount

RRCUTDALK Aluminum Ground Mount

RRCUTDK

RRCUTDSMK

CONDENSING UNIT TIE-DOWN KITS FOR

TRANE/AMERICAN STANDARD

Product Information

• Miami Tech is proud to offer condensing unit tie-down kits engineered

specically for Trane/American Standard units.

• Engineering data available at www.miamitech.com.

Roof Mount Wind Load Certied Tie-Down Kits

Part No. CUTD Type Mount Type

TASSB30K Galvanized Roof Mount

TASSB36K Galvanized Roof Mount

TASSB30K TASSB36K

15

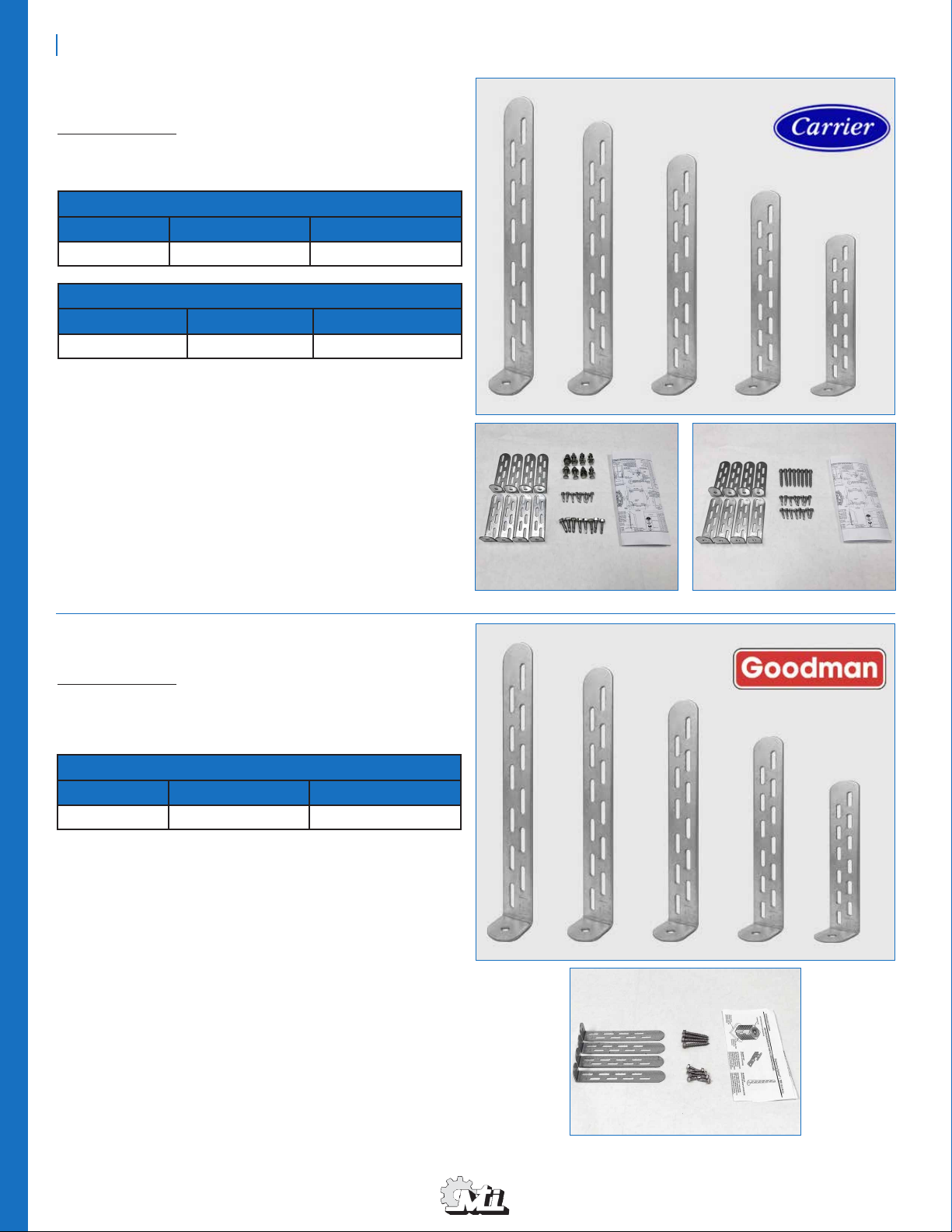

CONDENSING UNIT TIE-DOWN KITS

CONDENSING UNIT TIE-DOWN KITS

FOR CARRIER/BRYANT

Product Information

• Miami Tech is proud to offer condensing unit tie-down kits engi-

neered specically for Carrier/Bryant units.

Roof Mount Wind Load Certied Tie-Down Kits

Part No. CUTD Type Mount Type

CBCUTD4KR Galvanized Roof/Rail Mount

Ground Mount Certied Tie-Down Kits

Part No. CUTD Type Mount Type

CBCUTD4KG Galvanized Ground Mount

CONDENSING UNIT TIE-DOWN KITS

FOR GOODMAN

Product Information

• Miami Tech is proud to offer condensing unit tie-down kits engi-

neered specically for Goodman units.

Ground Mount Certied Tie-Down Kits

Part No. CUTD Type Mount Type

GACUTD6KG Galvanized Ground

CBCUTD4KR CBCUTD4KG

16

GACUTD6KG

TASB

TASB-SB

Shown with optional bafe kit factory installed.

AIR HANDLER BASE

TRANE/AMERICAN STANDARD

AIR-HANDLER BASE

Product Information

• Plastic capped feet to protect foundation surface.

• Pre-lter track accommodates a 1” thick air-lter (lter not included).

• Stands are individually boxed for easy inventory.

Product Construction

Frame:

- 16 gauge 1” x 1” square tube.

- 16 gauge 1” x 1” steel angle.

- 20 gauge 1/2” x 1/2” steel angle.

Mesh:

- 13 gauge 1.75” x .75” expanded steel.

Outside Casing:

- 16 gauge ASTM A-653 hot-dipped steel.

- 26 gauge ASTM A-653 hot-dipped steel.

Part No. Width Height Depth Qty.

TASB175 17-5/8” 17.25” 21” 1

TASB215 21-5/8” 17.25” 21” 1

TASB235 23-5/8” 17.25” 21” 1

TRANE/AMERICAN STANDARD

AIR-HANDLER BASE SOUND BAFFLE KIT

Product Information

• Fully powder coated to give a long lasting corrosion resistant nish.

• Installs in just minutes using the provided four #10 sheet metal

screws.

• Packaged in a 2” high box for easy transport and storage.

TASSBK

Product Construction

Body:

• 20 gauge powder-coated galvanized steel.

• 14 gauge powder-coated galvanized steel.

Part No. Width Qty.

TASSBK175 14.75” 1

TASSBK215 18.75” 1

TASSBK235 20.75” 1

TRANE/AMERICAN STANDARD

SIDE RETURN KIT

Product Information

• Designed to offer the end user exibility and convenience in the

• Installation of Trane and American Standard air handlers.

• Filter rack designed for widely available 16” x 20” x 1” lters.

• Individually boxed with installation instructions included.

MTISRKIT

Part No. Size Gauge Qty.

MTISRKIT1620 16” x 20” 26ga 1

17

AIR HANDLER BASE

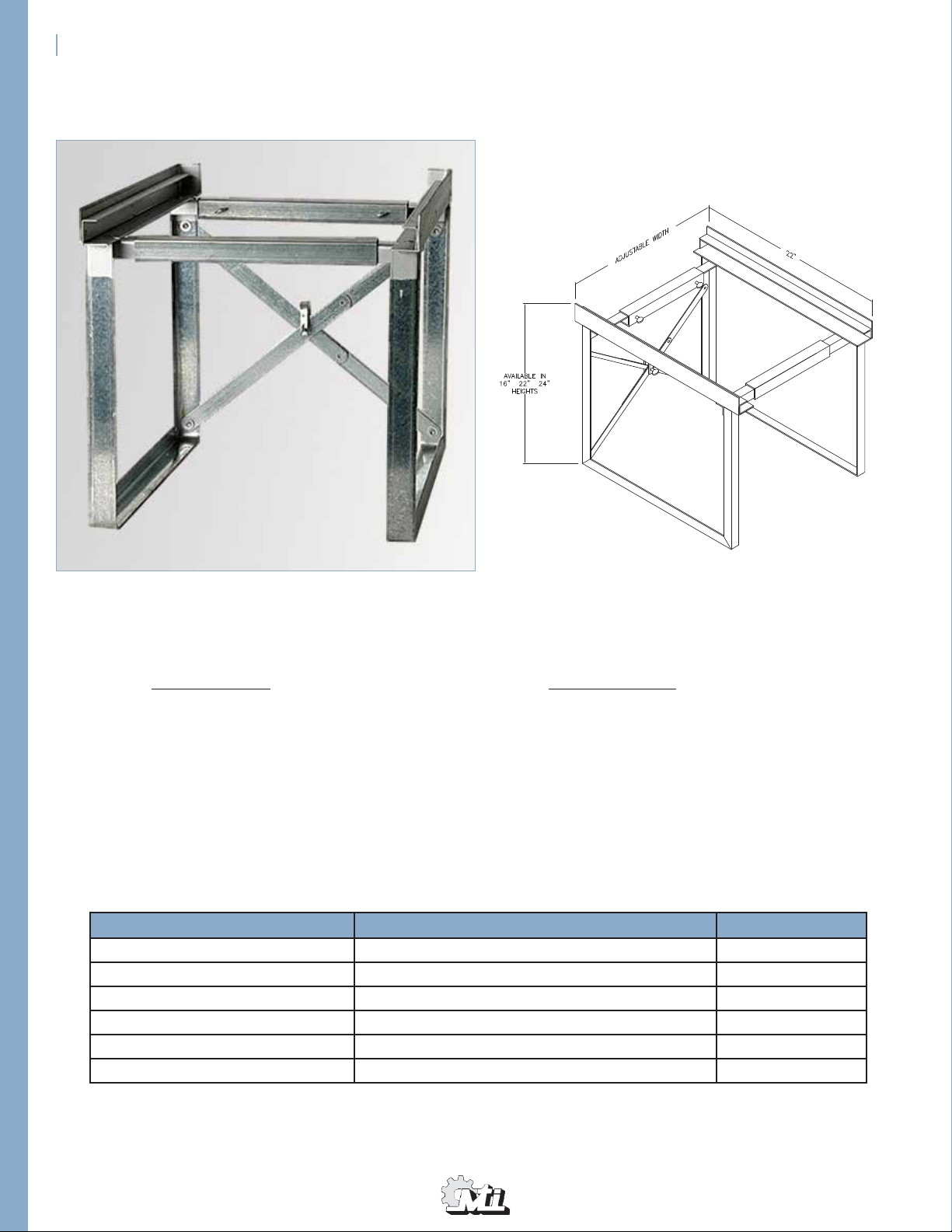

HEAVY DUTY ADJUSTABLE AIR HANDLER BASE

MODEL HAB

HAB

Product Information

• Standard 22” depth with lter rack.

• Air handler features adjustable width.

• Rated to support air handler units up to 200lbs.

• Rating tested by Construction Research Laboratory, Inc.

• All HAB stands are packaged in a 24” x 24” x 3” box.

• US Patent No. 5,308,037.

Part No. Height / Frame Type Qty.

HAB22/16N 16” / Narrow Frame 1

HAB22/16W 16” / Wide Frame 1

HAB22/22N 22” / Narrow Frame 1

HAB22/22W 22” / Wide Frame 1

HAB22/24N 24” / Narrow Frame 1

HAB22/24W 24” / Wide Frame 1

Product Construction

Legs:

• 16 gauge steel.

Height:

• Add 1.5” to leg height for total base height.

Adjustable Width Types:

• Narrow Frame (N): 14” to 25”.

• Wide Frame (W): 17” to 27”.

18

AIR HANDLER BASE

STEEL HEAVY DUTY ECONOMICAL ADJUSTABLE AIR HANDLER BASE

MODEL HEB

Product Information

• Standard 22” depth with lter rack.

• Filter rack is included.

• Plastic 1” caps in upper and lower leg openings.

• 1/8” x 3/8” rubber strips included to minimize vibration.

• Air handler features adjustable width.

Part No. Height / Frame Type Qty.

HEB18N 18” / Narrow Frame 1

HEB18W 18” / Wide Frame 1

HEB24N 24” / Narrow Frame 1

HEB24W 24” / Wide Frame 1

HEB

Product Construction

Legs:

• 16 gauge steel.

Frame:

• 14 gauge steel.

Adjustable Width Types:

• Narrow Frame (N): 14” to 24”.

• Wide Frame (W): 17” to 27”.

19

AIR HANDLER BASE

ALUMINUM HEAVY DUTY ECONOMICAL ADJUSTABLE AIR HANDLER BASE

Part No. Stand Size ( H x D x W )

AHEB1720W 17.5” x 20” x W (16” to 26”)

AHEB1722W 17.5” x 22” x W (16” to 26”)

AHEB1727W 17.5” x 27” x W (16” to 26”)

AHEB2422W 24” x 22” x W (16” to 26”)

AHEB2722W 27” x 22” x W (16” to 26”)

MODEL AHEB

Product Information

• Standard 22” depth with lter rack.

• Air handler features adjustable width.

• 1/8” x 3/8” rubber strips included to minimize vibration.

• No assembly required.

• Custom sizes are available upon request.

• 25 units per skid.

Product Construction

Material:

• 6003-T5 aluminum.

Adjustable Width:

• W: 16” to 26”.

AHEB

ULTRA HEAVY-DUTY ADJUSTABLE AIR HANDLER BASE

MODEL UHB

UHB

Part No. Height / Frame Type Qty.

UHB18N 18” / Narrow Frame 1

UHB18W 18” / Wide Frame 1

UHB24N 24” / Narrow Frame 1

UHB24W 24” / Wide Frame 1

UHB36N 36” / Narrow Frame 1

UHB36W 36” / Wide Frame 1

Product Information

• Standard 22” depth with lter rack.

• Filter rack is included.

• No assembly required.

• Plastic caps in lower leg openings.

• 1/8” x 3/8” rubber strips included to minimize vibration.

• Air handler features adjustable width.

• Custom sizes are available upon request.

• 20 stands per skid.

Product Construction

Legs:

• 1.5” x 1.5” x 16ga galvanized steel tubing.

Frame:

• 2” x 2” x 1/8” steel angles.

Adjustable Width Types:

• Narrow Frame (N): 14” to 24”.

• Wide Frame (W): 17.5” to 30”.

20

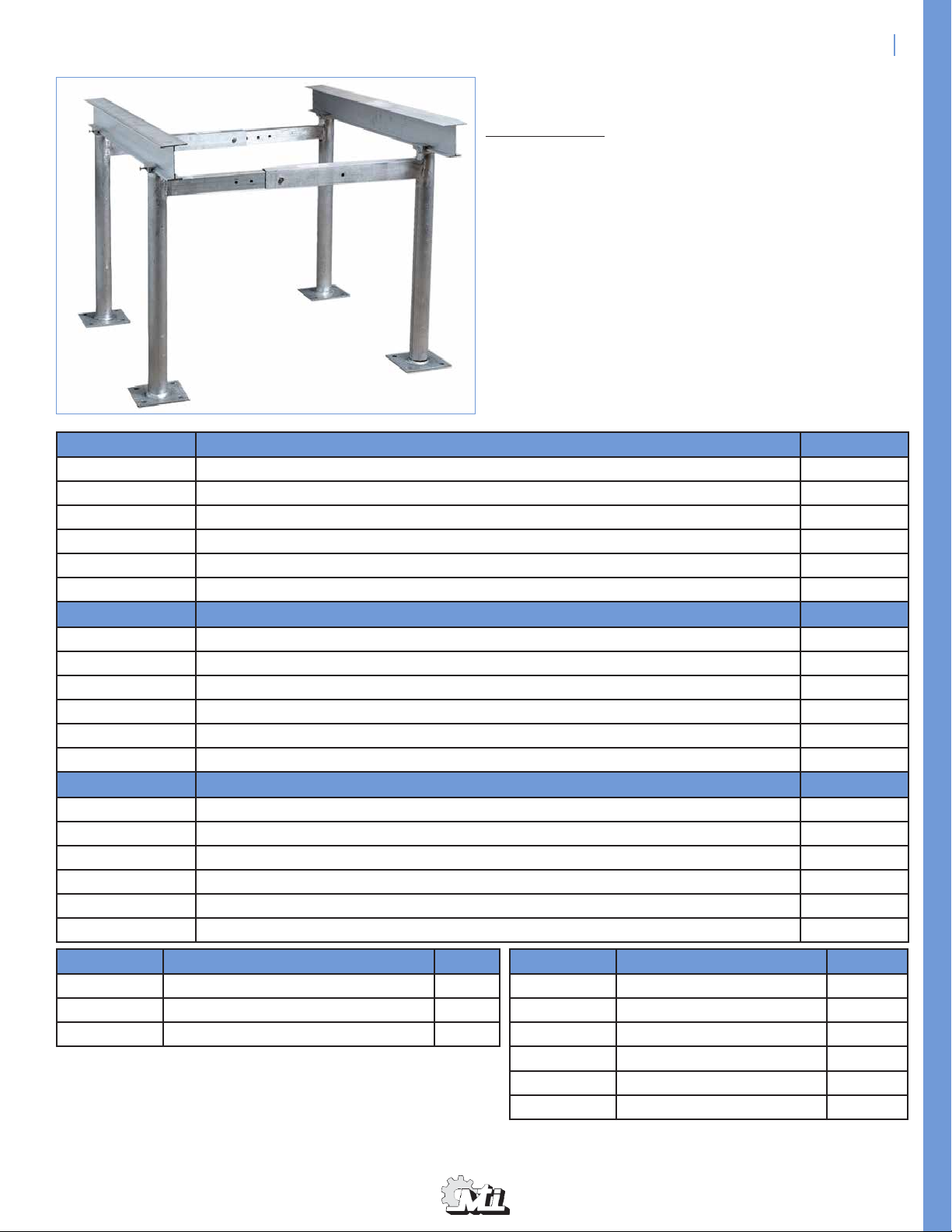

AST (NON-HVHZ) CONDENSING UNIT STAND

ALUMINUM CONDENSING UNIT STAND

FOR NON-HVHZ ZONE

Product Information

• Engineered specically for non-use in high velocity hurricane zones.

(HVHZ = Miami-Dade County & Broward County).

• Available with optional cross-mounting angle.

• Available with optional lead boots.

• Available with optional electrical box mounting bracket (EMB).

• Available with optional vibration pad to isolate vibration from condensing

unit.

• Engineer’s raised-seal drawings available.

• Florida State Approval #FL21464.

• Engineering backed calculator available at www.miamitech.com.

AST

Part No. AST 18.5” Stand Assembly Height

AST185Q-K3 Aluminum C/U Stand, 18.5” Legs (2 Frames), 1/4 Plate, 3’ I-Beam, For Non-HVHZ 18.5”

AST185Q-K6 Aluminum C/U Stand, 18.5” Legs (2 Frames), 1/4 Plate, 6’ I-Beam, For Non-HVHZ 18.5”

AST185Q-K9 Aluminum C/U Stand, 18.5” Legs (3 Frames), 1/4 Plate, 9’ I-Beam, For Non-HVHZ 18.5”

AST185Q-K12 Aluminum C/U Stand, 18.5” Legs (4 Frames), 1/4 Plate, 12’ I-Beam, For Non-HVHZ 18.5”

AST185Q-K15 Aluminum C/U Stand, 18.5” Legs (5 Frames), 1/4 Plate, 15’ I-Beam, For Non-HVHZ 18.5”

AST185Q-K18 Aluminum C/U Stand, 18.5” Legs (6 Frames), 1/4 Plate, 18’ I-Beam, For Non-HVHZ 18.5”

Part No. AST 24” Stand Assembly Height

AST240Q-K3 Aluminum C/U Stand, 24” Legs (2 Frames), 1/4 Plate, 3’ I-Beam, For Non-HVHZ 24”

AST240Q-K6 Aluminum C/U Stand, 24” Legs (2 Frames), 1/4 Plate, 6’ I-Beam, For Non-HVHZ 24”

AST240Q-K9 Aluminum C/U Stand, 24” Legs (3 Frames), 1/4 Plate, 9’ I-Beam, For Non-HVHZ 24”

AST240Q-K12 Aluminum C/U Stand, 24” Legs (4 Frames), 1/4 Plate, 12’ I-Beam, For Non-HVHZ 24”

AST240Q-K15 Aluminum C/U Stand, 24” Legs (5 Frames), 1/4 Plate, 15’ I-Beam, For Non-HVHZ 24”

AST240Q-K18 Aluminum C/U Stand, 24” Legs (6 Frames), 1/4 Plate, 18’ I-Beam, For Non-HVHZ 24”

Part No. AST 30” Stand Assembly Height

AST300Q-K3 Aluminum C/U Stand, 30” Legs (2 Frames), 1/4 Plate, 3’ I-Beam, For Non-HVHZ 30”

AST300Q-K6 Aluminum C/U Stand, 30” Legs (2 Frames), 1/4 Plate, 6’ I-Beam, For Non-HVHZ 30”

AST300Q-K9 Aluminum C/U Stand, 30” Legs (3 Frames), 1/4 Plate, 9’ I-Beam, For Non-HVHZ 30”

AST300Q-K12 Aluminum C/U Stand, 30” Legs (4 Frames), 1/4 Plate, 12’ I-Beam, For Non-HVHZ 30”

AST300Q-K15 Aluminum C/U Stand, 30” Legs (5 Frames), 1/4 Plate, 15’ I-Beam, For Non-HVHZ 30”

AST300Q-K18 Aluminum C/U Stand, 30” Legs (6 Frames), 1/4 Plate, 18’ I-Beam, For Non-HVHZ 30”

Part No. Post Pairs Size

AST185Q Aluminum C/U 18.5” Post Pairs 18.5”

AST240Q Aluminum C/U 24” Post Pairs 24”

AST300Q Aluminum C/U 30” Post Pairs 30”

Part No. I-Beams Size

ASTI-3 Aluminum I-Beam, 3’ 3’

ASTI-6 Aluminum I-Beam, 6’ 6’

ASTI-9 Aluminum I-Beam, 9’ 9’

ASTI-12 Aluminum I-Beam, 12’ 12’

ASTI-15 Aluminum I-Beam, 15’ 15’

ASTI-18 Aluminum I-Beam, 18’ 18’

21

AS14 CONDENSING UNIT STAND

ALUMINUM TELESCOPING CONDENSING UNIT STAND

MODEL AS14

Product Information

• 2014 Florida Building Code Compliant.

• Engineered to accommodate the larger SEER 13 units.

• Available with optional vibration pad to isolate vibration from

condensing unit.

• Available with optional cross-mounting angle (AS14CAB).

• Available with optional lead boots (LB).

• Available with optional electrical box mounting bracket

(EMB).

• Engineer’s raised-seal drawings available.

• Miami-Dade NOA #16-0601.01

• Protected under US Patent No. 9,052,120.

Product Construction

Body:

• All aluminum 6061-T6 alloy construction.

Legs:

• Patented webbed posts.

Part No. Standard AS14 Leg Assembly Size

AS14S18 Standard Aluminum Stand Leg Assembly, 2014 FBC 20-30” spread, 18” tall 18”

AS14S24 Standard Aluminum Stand Leg Assembly, 2014 FBC 20-30” spread, 24” tall 24”

AS14S30 Standard Aluminum Stand Leg Assembly, 2014 FBC 20-30” spread, 30” tall 30”

Part No. Heavy Duty AS14 Leg Assembly Size

AS14H18 Heavy Duty Aluminum Stand Leg Assembly, 2014 FBC 36-42” spread, 18” tall 18”

AS14H24 Heavy Duty Aluminum Stand Leg Assembly, 2014 FBC 36-42” spread, 24” tall 24”

AS14H30 Heavy Duty Aluminum Stand Leg Assembly, 2014 FBC 36-42” spread, 30” tall 30”

AS14

22

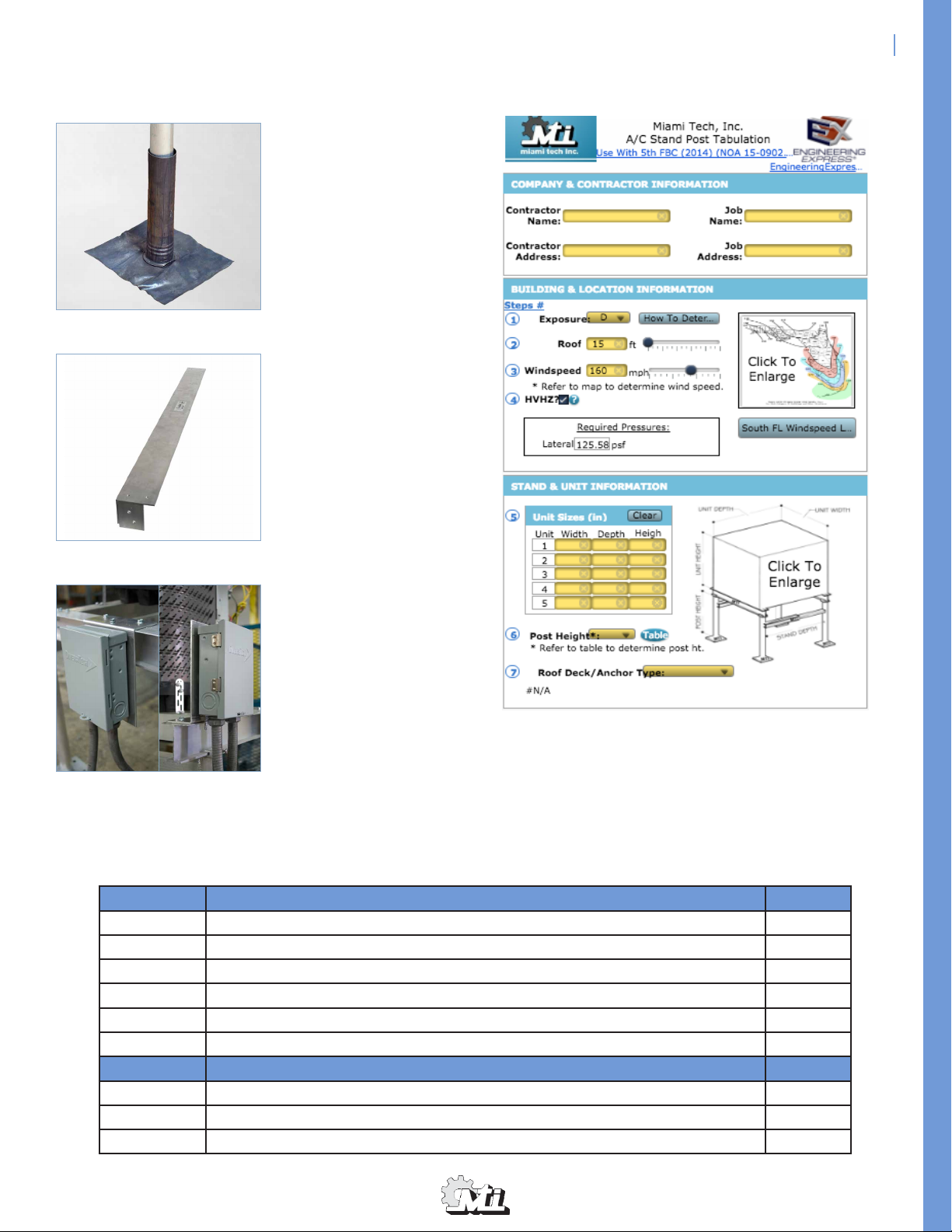

Lead Boot Option

The lead boot is a commonly used

item in the roong industry. When

the roof will have lightweight concrete poured over the base plates,

we recommend the usage of our

lead boots as it acts as an isolator

between the concrete and the aluminum to help prevent oxidation.

Cross Mounting Angle Option

Our aluminum cross mounting angle

allows us to extend the width of the

stand up to 42” (center to center of

beam). By widening the stance of

the stand, we can achieve much

higher PSF ratings for even the

most stringent requirements. When

a condensing unit is too narrow to

sit on the required stand, a set of

AS14CAB will allow for installation.

AS14 CONDENSING UNIT STAND

TOOLS TO GET THE JOB DONEAS14 OPTIONS

Electrical Mounting Bracket

(EMB) Option

Our optional electrical mounting

bracket allows the contractor to

mount the electrical box on our condenser stand in either a hanging or

standing position. Clean and easy.

In collaboration with the best team at Engineering Express, Miami

Tech is the rst HVAC manufacturer to introduce an interactive calculator to the industry, allowing both, contractors and wholesalers,

to plan out jobs in advance with engineer-backed accuracy. Not

only are we the rst in offering an interactive calculator, but also

the rst manufacturer with engineering data based-on real world

applications, giving contractors the added condence in knowing

their job is backed by the best engineering data available.

CALCULATOR AVAILABLE AT WWW.MIAMITECH.COM

Part No. I-Beams Size

AS14I-3 Aluminum Stand I-Beam, 2014 FBC, 3’ 3’

AS14I-6 Aluminum Stand I-Beam, 2014 FBC, 6’ 6’

AS14I-9 Aluminum Stand I-Beam, 2014 FBC, 9’ 9’

AS14I-12 Aluminum Stand I-Beam, 2014 FBC, 12’ 12’

AS14I-15 Aluminum Stand I-Beam, 2014 FBC, 15’ 15’

AS14I-18 Aluminum Stand I-Beam, 2014 FBC, 18’ 18’

Part No. Cross Mounting Angle Size

AS14CAB-30 3” x 3” x 1/8” In-Beam Cross Mounting Angle for 30” spread 30”

AS14CAB-36 3” x 3” x 1/8” In-Beam Cross Mounting Angle for 36” spread 36”

AS14CAB-42 3” x 3” x 1/8” In-Beam Cross Mounting Angle for 42” spread 42”

23

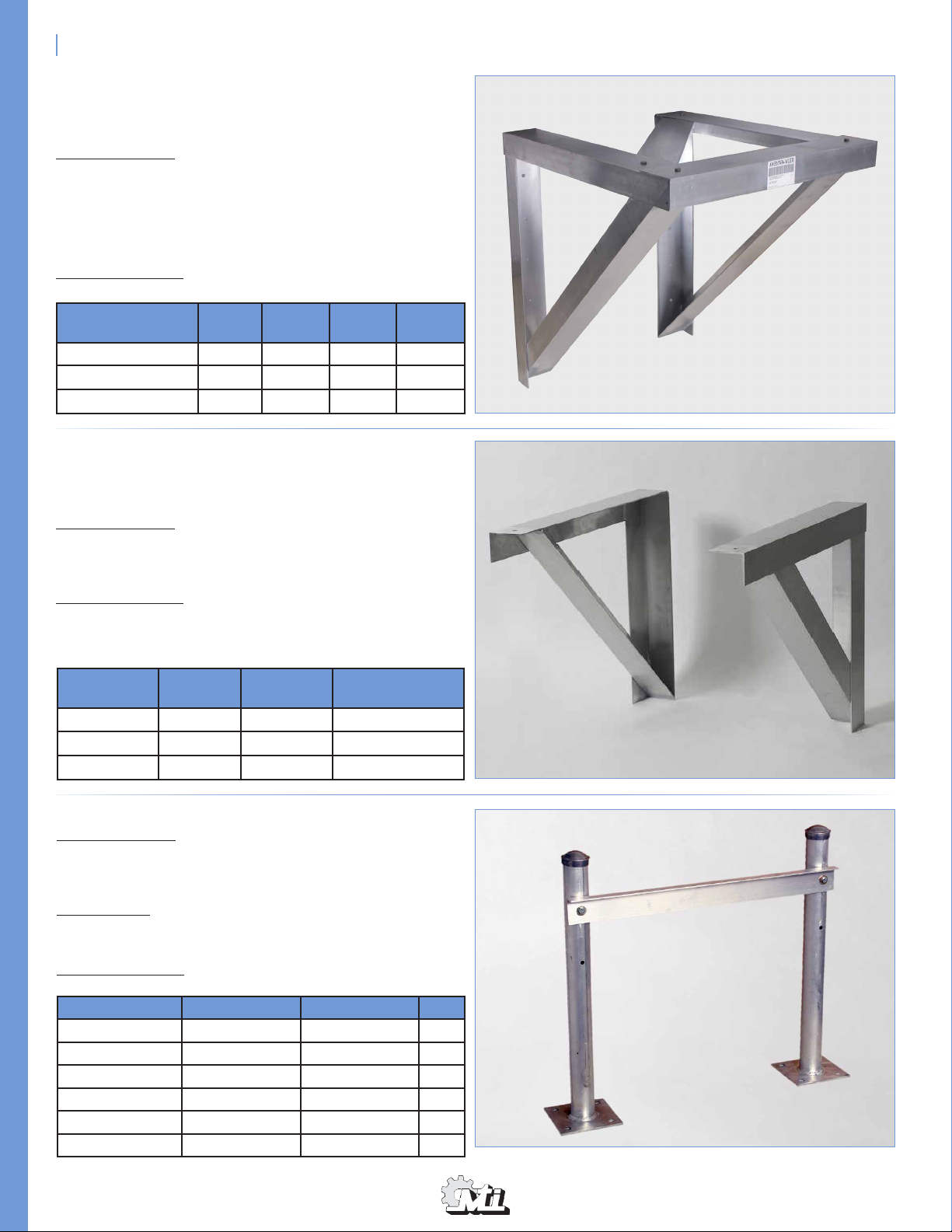

ALUMINUM PRODUCTS

MODEL AWB14 (WIND LOAD RATED)

ALUMINUM CONDENSING UNIT

WALL MOUNT BRACKET

Product Information

• FBC 2014 compliant.

• Rated for wind-loads up to 170 psf.

• Original raised-seal engineering drawings available at an additional

cost.

• Optional vibration pad made from recycled rubber to isolate vibration

from condensing unit available.

Product Construction

• 6061-T6 alloy temper aluminum.

Part No.

AWB143036-WLR24 30” 24” 14” 30” x 30”

AWB143636-WLR30 36” 30” 20” 38” x 36”

AWB144836-WLR36 48” 36” 26” 45” x 48”

Bracket

Length

Bracket

Spacing

Inner

Spacing

Max

Unit

MODEL AWB (WIND LOAD RATED)

ALUMINUM CONDENSING UNIT

HEAVY DUTY WALL MOUNT BRACKET

Product Information

• Rated for wind-loads up to 90 psf.

• Original raised-seal engineering drawings available at an additional

cost.

Product Construction

• 6061-T6 alloy temper aluminum.

Part No.

AWB2418 24” 18” 30” x 20” x 30”

AWB3630 36” 30” 30” x 30” x 35”

AWB4836 48” 36” 36” x 36” x 40”

Bracket

Length

Bracket

Height

Max Unit

(W x D x H)

AWB14

AWB

ALUMINUM PIPE STAND

Product Information

• Pipe stand features a 1/4” thick baseplate for solid support.

• Heavy duty welds at base provides superior strength.

• No eld welding required.

•

Product Models

• APSS: Standard Pipe Stand (Includes 1 Supporting Angle).

• APSH: Heavy-Duty Pipe Stand (Includes 2 Supporting Angles).

Product Construction

• 6061-T6 alloy temper aluminum.

Standard Heavy-Duty Size (W x H) Qty.

APSS20-18 APSH20-18 18” x 20” 1

APSS20-24 APSH20-24 24” x 20” 1

APSS20-36 APSH20-36 36” x 20” 1

APSS26-18 APSH26-18 18” x 26” 1

APSS26-24 APSH26-24 24” x 26” 1

APSS26-36 APSH26-36 36” x 26” 1

24

APS

APS1P

ALUMINUM PRODUCTS / CONDENSING UNIT CAGE

SINGLE LEG ALUMINUM PIPE STAND

Product Information

• Pipe stand features a 1/4” thick baseplate for solid support.

• Heavy duty welds at base provides superior strength.

• No eld welding required.

• Custom sizes available upon request.

Part No. Height Support Angle Width Qty.

APS1P18-12 18” 12” 1

APS1P18-18 18” 18” 1

APS1P18-20 18” 20” 1

APS1P24-12 24” 12” 1

APS1P24-18 24” 18” 1

APS1P24-20 24” 20” 1

APS1P30-12 30” 12” 1

APS1P30-18 30” 18” 1

APS1P30-20 30” 20” 1

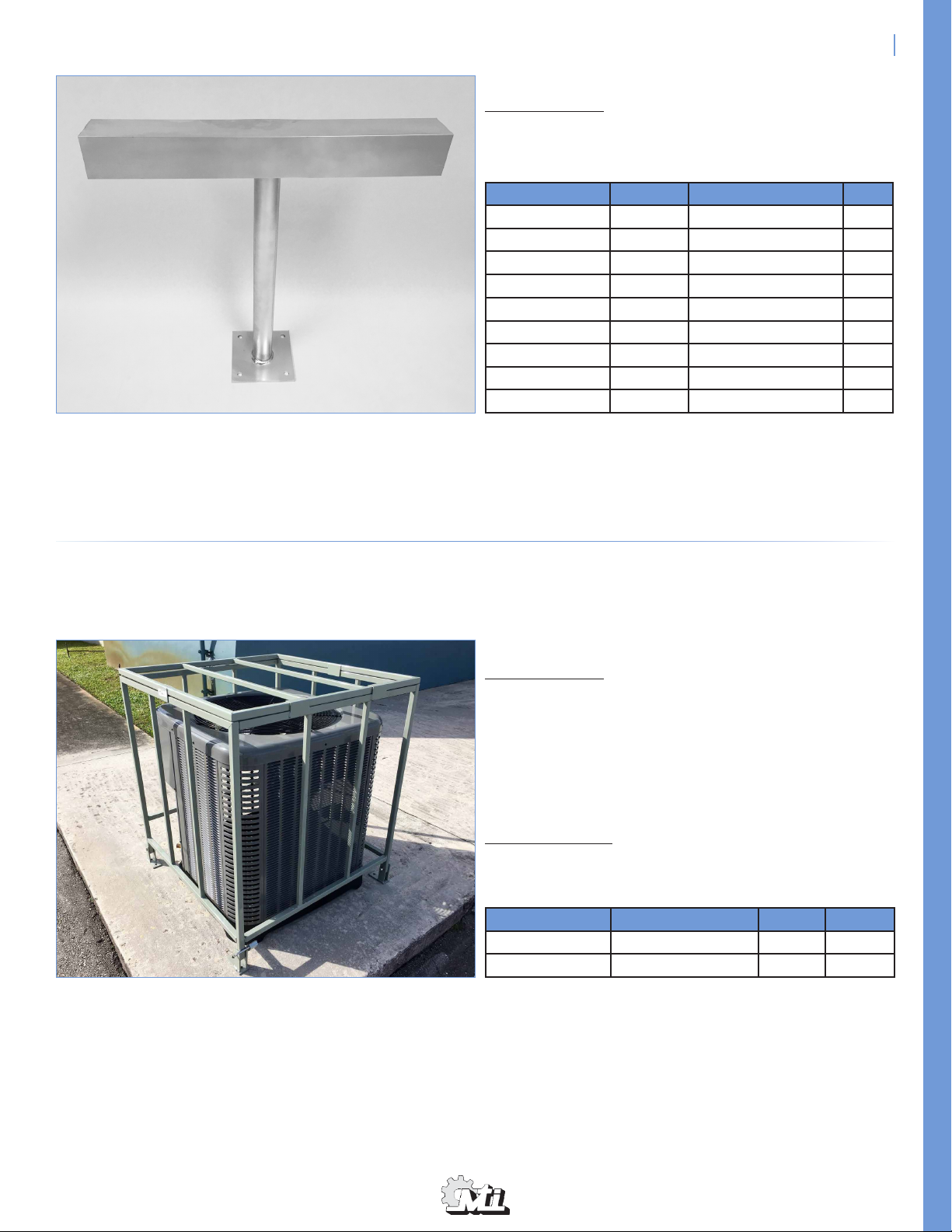

CUCRR

CONDENSING UNIT CAGE

Product Information

• Powder-coated galvanized steel for long-term resistance and MIG

welded.

• Ships knocked-down for easy storage and transportation.

• Removable top and side for easy service access.

• Pivot design allows for total access of condensing unit.

• 10” clearance between cage and slab for electrical and refrigerant

lines.

• 3” clearance between cage and slab on all other sides.

• Padlocks included. Anchoring hardware not included.

Product Construction

• 16ga galvanized steel tubes.

Part No. Size (H x D x W) Gauge Quantity

CUC403434RR 40” x 34” x 34” 16ga 1

CUC524040RR 52” x 40” x 40” 16ga 1

25

COLLARS

TAB COLLARS FOR FIBERGLASS

Product Information

• FCL designed to accommodate R-4 & R-6 ductboard.

• R8-FCL designed to accommodate R-8 ductboard.

• 180° hemmed circumference and no raw edges.

• FCL ange dimension (.700”) exceeds Florida Building code requirement of .625” (FL Building Code # 603.5.6).

Product Models

• FCL: One piece wide tab collar for R-4 or R-6 ductboard.

• R8-FCL: One piece wide tab collar for R-8 ductboard.

• FCZ: One piece wide tab collar with scoop.

• FCD: One piece wide tab collar with damper.

• FCZD: One piece wide tab collar with scoop and damper.

• FCLG: One piece wide tab collar with gasket.

• FCLN: Nested one piece wide tab collar.

• CG: Gasket only.

• FCD-SOE: FCD with Miami Tech’s 2” stand-off.

• FCZD-SOE: FCZD with Miami Tech’s 2” stand-off.

• Refer to page 33 for more details on collar options.

FCL

FCD

FCZD

FCLN

Case Quantities

Size FCL FCZ FCD FCZD FCLN CG R8-FCL R8-FCZ R8-FCD R8-FCZD Gauge

4” 100 80 100 80 40 80 100 80 100 80 30ga

5” 100 70 100 70 36 80 100 70 100 70 30ga

6” 75 60 75 60 36 80 75 60 75 60 30ga

7” 60 50 60 50 28 80 60 50 60 50 30ga

8” 50 40 50 40 22 80 50 40 50 40 30ga

9” 40 30 40 30 20 80 40 30 40 30 28ga

10” 40 30 40 30 16 80 40 30 40 30 28ga

12” 25 20 25 20 24 80 25 20 25 20 28ga

14” 20 15 20 15 20 80 20 15 20 15 28ga

16” 15 15 15 12 16 80 15 15 15 12 28ga

18” 15 10 15 8 14 80 15 10 15 8 28ga

20” 15 10 15 6 12 80 15 10 15 6 28ga

26

R8-FCL

261L

COLLARS

261 COLLAR

Product Information

• Body mechanically fastened together to ensure a rigid assembly.

Product Models

• 261L: 6” long starting collar plain.

• 261LZ: 6” long starting collar with scoop only.

• 261LD: 6” long starting collar with damper only.

• 261LZD: 6” long starting collar with scoop and damper.

• 261LD-SO: 261LD with standard 2” stand-off.

• 261LD-SOE: 261LD with Miami Tech’s 2” stand-off.

• 261LZD-SO: 261LZD with standard 2” stand-off.

• 261LZD-SOE: 261LZD with Miami Tech’s 2” stand-off.

• Refer to page 33 for more details on collar options.

261LZD 261LD

Size 261L 261LZ 261LD 261LZD Gauge Quantity

4” 261L04 261LZ04 261LD04 261LZD04 28ga 1

5” 261L05 261LZ05 261LD05 261LZD05 28ga 1

6” 261L06 261LZ06 261LD06 261LZD06 28ga 1

7” 261L07 261LZ07 261LD07 261LZD07 28ga 1

8” 261L08 261LZ08 261LD08 261LZD08 28ga 1

9” 261L09 261LZ09 261LD09 261LZD09 28ga 1

10” 261L10 261LZ10 261LD10 261LZD10 28ga 1

12” 261L12 261LZ12 261LD12 261LZD12 26ga 1

14” 261L14 261LZ14 261LD14 261LZD14 26ga 1

16” 261L16 261LZ16 261LD16 261LZD16 26ga 1

18” 261L18 261LZ18 261LD18 261LZD18 26ga 1

20” 261L20 261LZ20 261LD20 261LZD20 26ga 1

27

Loading...

Loading...