Page 1

L338 11/2011

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

ADI LT

LOW TEMPERATURE

BOILER

Page 2

L338 11/2011

2

IINNDDEEXX

1. INTRODUCTION _________________________________________________________________________________ 4

2. REGULATIONS _________________________________________________________________________________ 5

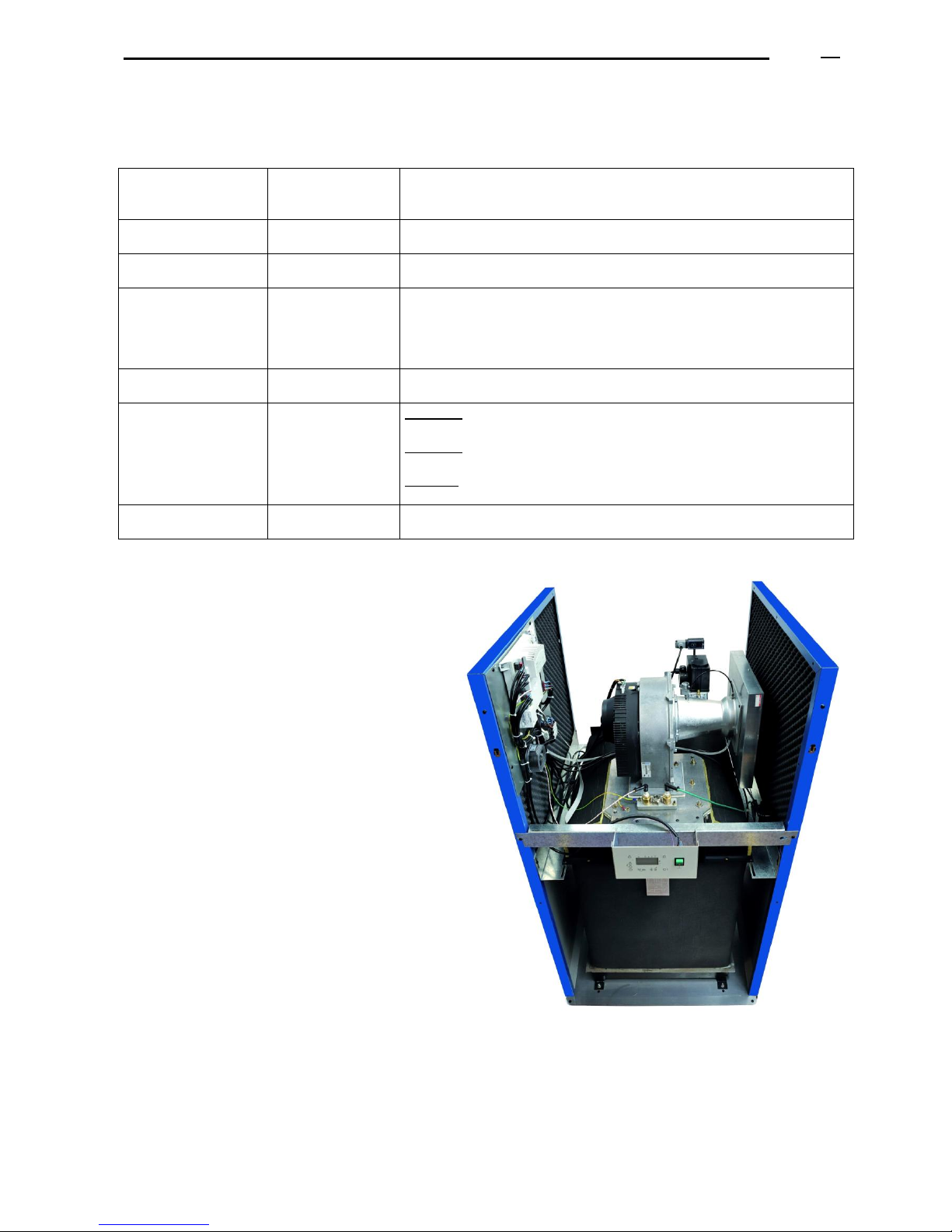

3. EEC APPROVALS AND CERTIFICATIONS ___________________________________________________________ 5

4. BOILER GENERAL VIEW: DESCRIPTION OF THE COMPONENTS ________________________________________ 6

5. DIMENSIONS ___________________________________________________________________________________ 8

6. TECHNICAL DATA RANGE ADI LT ________________________________________________________________ 10

6.1 Models ADI LT 105 to ADI LT 400_________________________________________________________________ 10

ADI LT 105 to ADI LT 475: modulating power from 30% ________________________________ _________________ 10

6.2 Models ADI LT 475 to ADI LT 950_________________________________________________________________ 11

ADI LT 475: modulating power from 30% _____________________________________________________________ 11

ADI LT 550 to ADI LT 950: modulating power from 40% ________________________________ _________________ 11

7. BOILER HEAT EXCHANGER ________________________________________________________________ _____ 12

8. POWER MODULATION AND COMBUSTION SYSTEM _________________________________________________ 13

8.1 ASSEMBLY OF GAS CONNECTION – AIR-GAS INLET _______________________________________________ 14

8.2 AIR INLET FILTER _____________________________________________________________________________ 16

9. BURNER ______________________________________________________________________________________ 16

9.1 IGNITION AND IONISATION KIT __________________________________________________________________ 16

10. CONTROL PANEL - SIEMENS __________________________________________________________________ 17

10.1 DISPLAY ____________________________________________________________________________________ 18

10.2 STANDARD OR INITIAL DISPLAY _______________________________________________________________ 18

10.3 ADJUSTMENT OF THE SET-UP BOILER FLOW TEMPERATURE ______________________________________ 18

10.4 BOILER LOCKOUT CODE ______________________________________________________________________ 19

10.5 FUNCTION BOILER MAINTENANCE _____________________________________________________________ 19

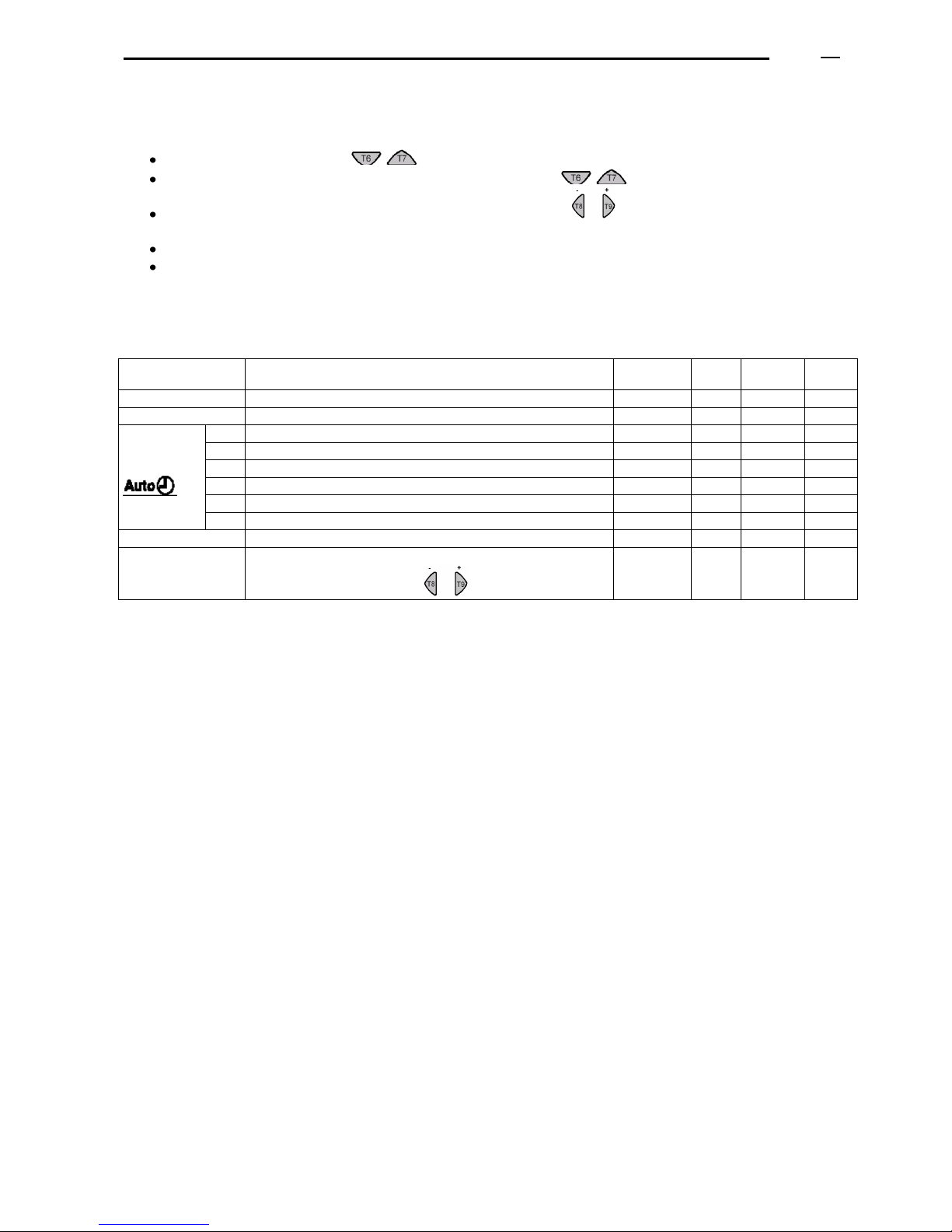

10.6 AVAILABLE PARAMETERS THAT CAN BE ADJUSTED BY THE FINAL USER ___________________________ 20

11. DATA AND INFORMATION VISUALIZED ON THE DISPLAY - SIEMENS __________________________________ 21

11.1 AVAILABLE INFORMATION ____________________________________________________________________ 21

11.1.2 Available readings at Maintenance level 1 _______________________________________________________ 21

11.1.3 Available readings at Maintenance Level 2 ______________________________________________________ 22

11.1.4 Available readings at Maintenance Level 3 ______________________________________________________ 22

11.2 CODES OF THE BOILER OPERATION PHASES ____________________________________________________ 22

11.3 ERROR CODES VISUALIZED ON THE DISPLAY ___________________________________________________ 23

11.4 OPTIONAL: FLOW TEMPERATURE FUNCTION OF OUTSIDE TEMPERATURE __________________________ 23

11.5 VIEW OF THE BOILER CONTROL UNIT _________________________________________________________ 23

11.6 REGULATION OF SEVERAL BOILERS ___________________________________________________________ 24

11.6.1 Boilers simple sequence _____________________________________________________________________ 24

11.6.2 External control unit with signals 0…10 V to regulate the start-up and modulation of each boiler. ________ 24

11.6.3 External control unit regulating and optimizing all the boilers’combined operation. ____________________ 25

11.6.4. Remote Control or telecomputing ________________________________________ Error! Bookmark not defined.

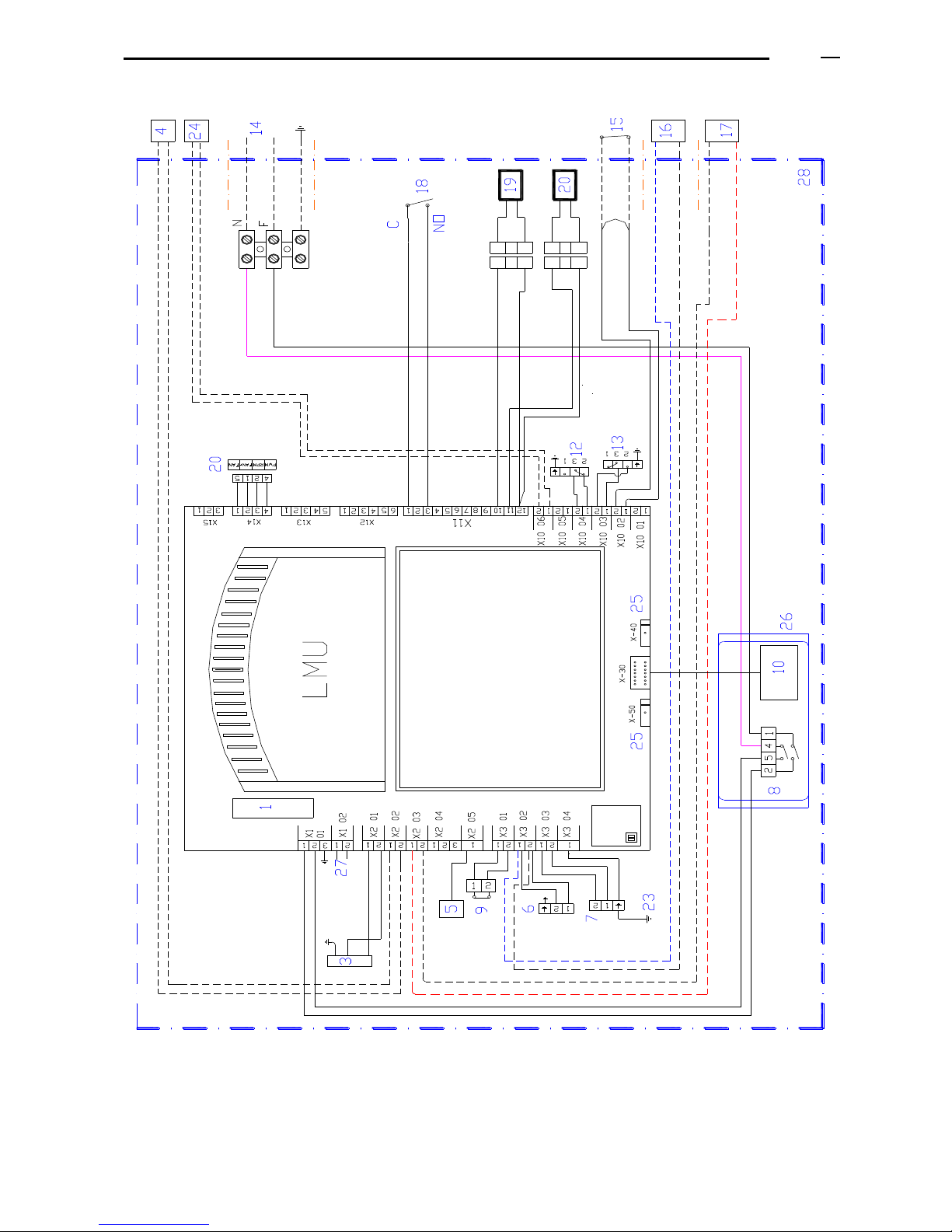

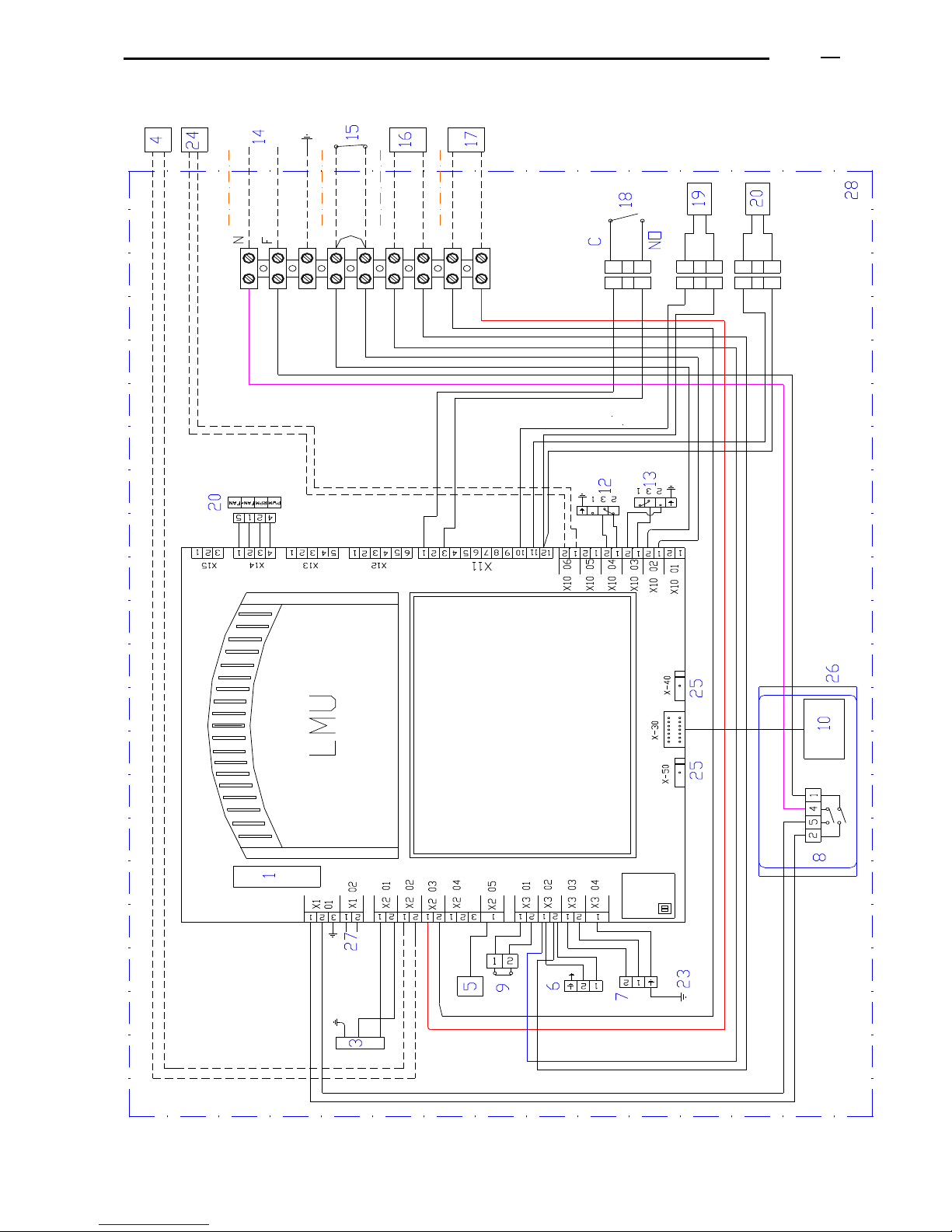

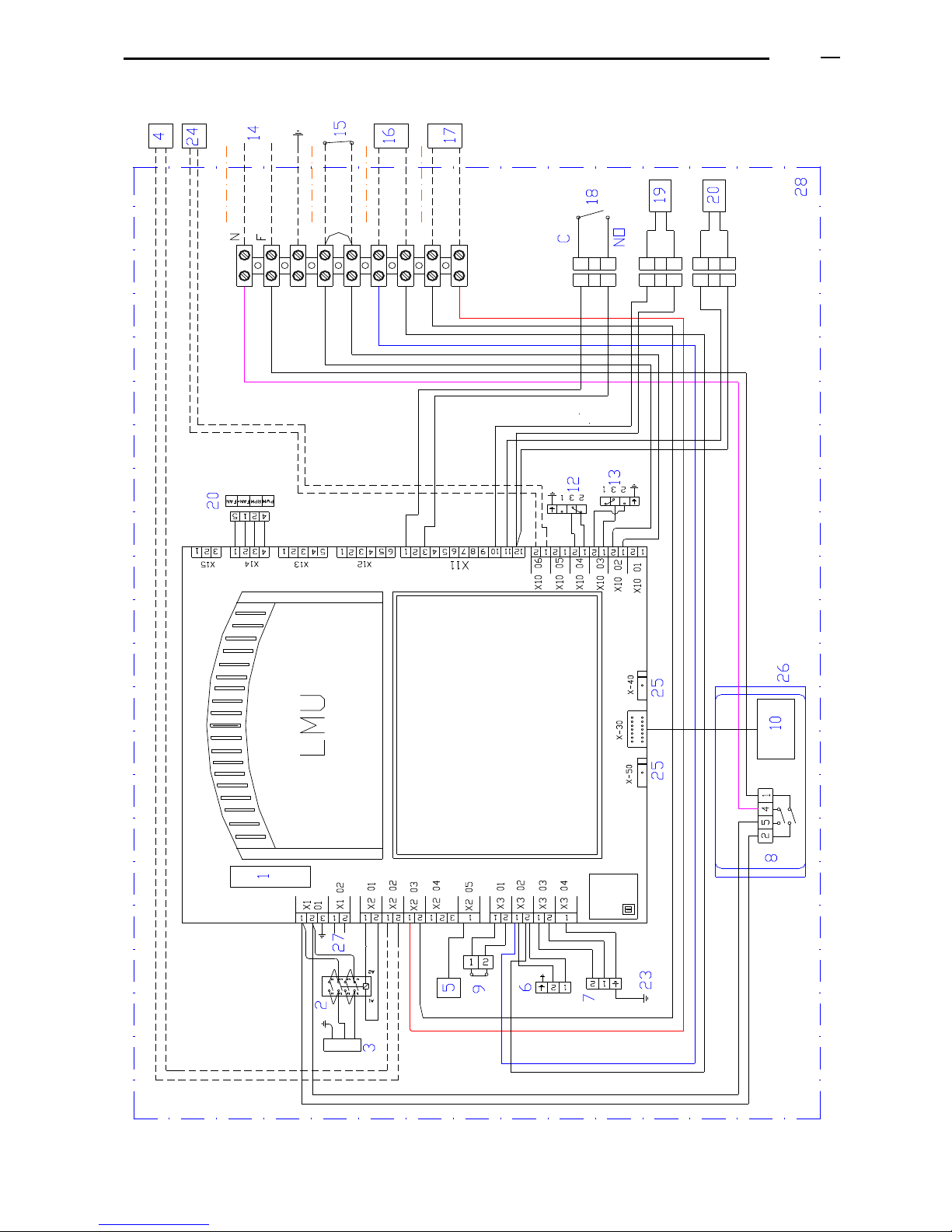

12. ELECTRIC DRAWINGS _________________________________________________________________________ 28

12.1 ELECTRIC DRAWING ADI LT 105 - ADI LT 200 __________________________________________________ 29

12.2 ELECTRIC DRAWING ADI LT 250 - ADI LT 325 ___________________________________________________ 30

12.3 ELECTRIC DRAWING ADI LT 400 - ADI LT 750 __________________________________________________ 31

Page 3

L338 11/2011

3

13. SAFETIES ____________________________________________________________________________________ 32

14. BOILERS IDENTIFICATION LABEL _______________________________________________________________ 32

15. INSTALLATION _______________________________________________________________________________ 33

15.1 BOILERS HEAT OUTPUT ______________________________________________________________________ 33

15.2 LIFTING AND TRANSPORTING THE BOILERS BY A CRANE _________________________________________ 33

15.3 BOILERS ROOM _____________________________________________________________________________ 33

15.4 GAS SUPPLY ________________________________________________________________________________ 34

15.4.1. Gas pressure higher than 45 mbar. ____________________________________________________________ 34

15.5 DRAINING OF THE BOILER CONDENSED PRODUCTS ______________________________________________ 35

15.5.1. Water condensing __________________________________________________________________________ 35

15.5.2. Neutralization treatment of the condensed products. _____________________________________________ 35

15.5.3. Evacuation piping of condensed products. _____________________________________________________ 35

15.5.4. Boiler chimney_____________________________________________________________________________ 35

15.6 CHIMNEYS __________________________________________________________________________________ 36

15.6.1. Chimney sizing ____________________________________________________________________________ 36

15.6.2. Flue draught stabilizer ______________________________________________________________________ 37

15.6.3. Old installation ________________________________________________________________ ____________ 37

15.7 HYDRAULIC INSTALLATION ___________________________________________________________________ 38

15.7.1 Data to be considered _______________________________________________________________________ 38

15.7.2 Overpressure safety valve ____________________________________________________________________ 38

15.7.3 Hydraulic pressure drop _____________________________________________________________________ 39

15.7.4 Water manifold _____________________________________________________________________________ 40

15.7.5 Water quality of the installation _______________________________________________________________ 41

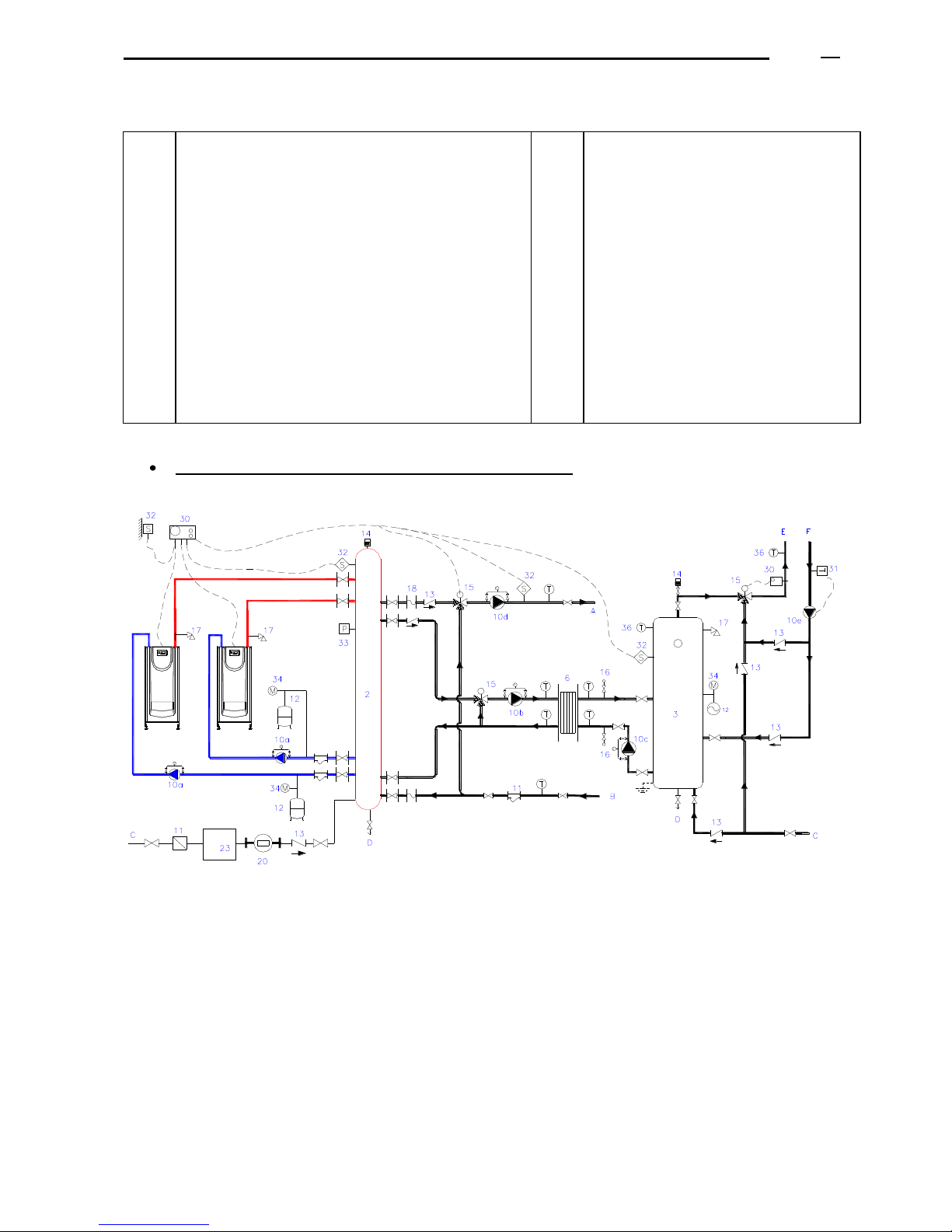

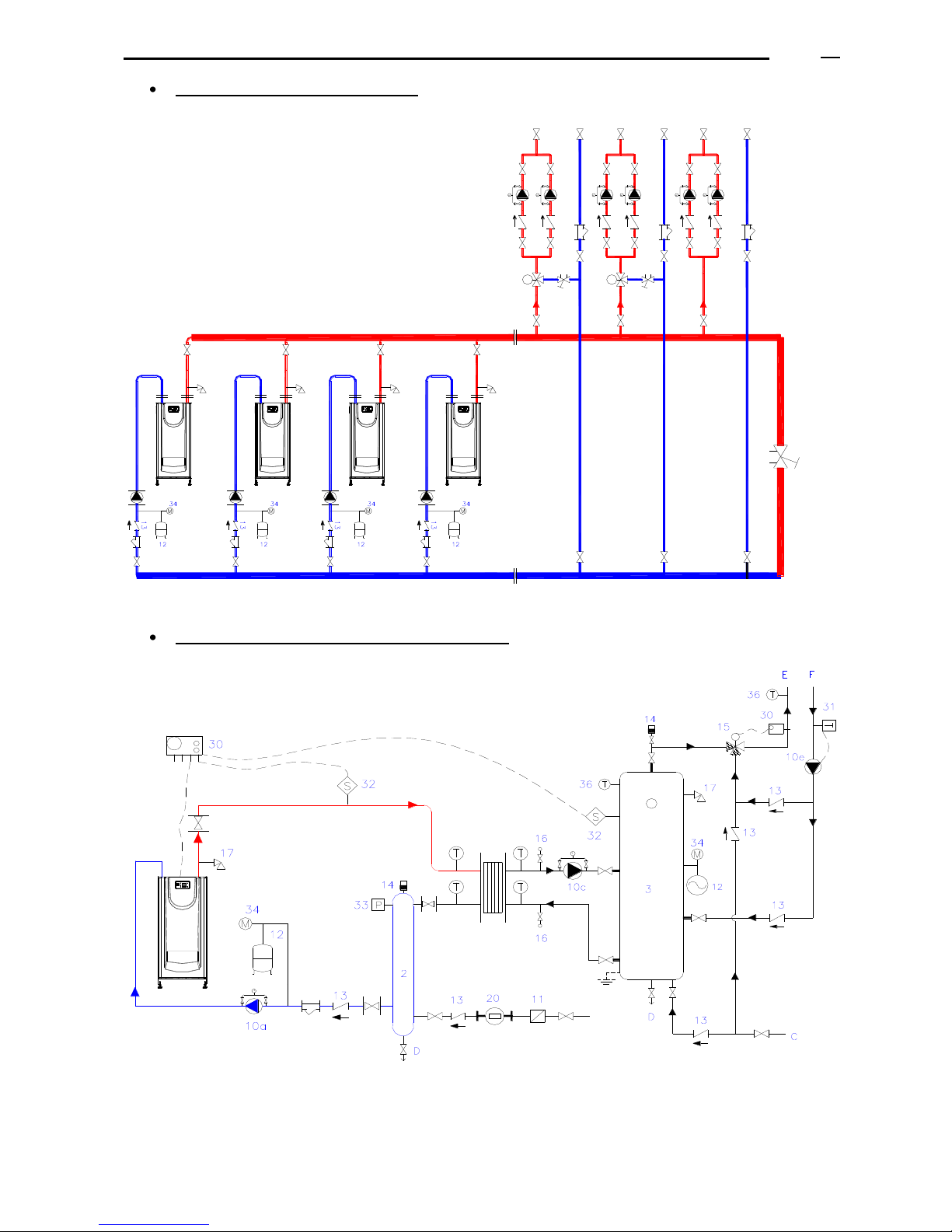

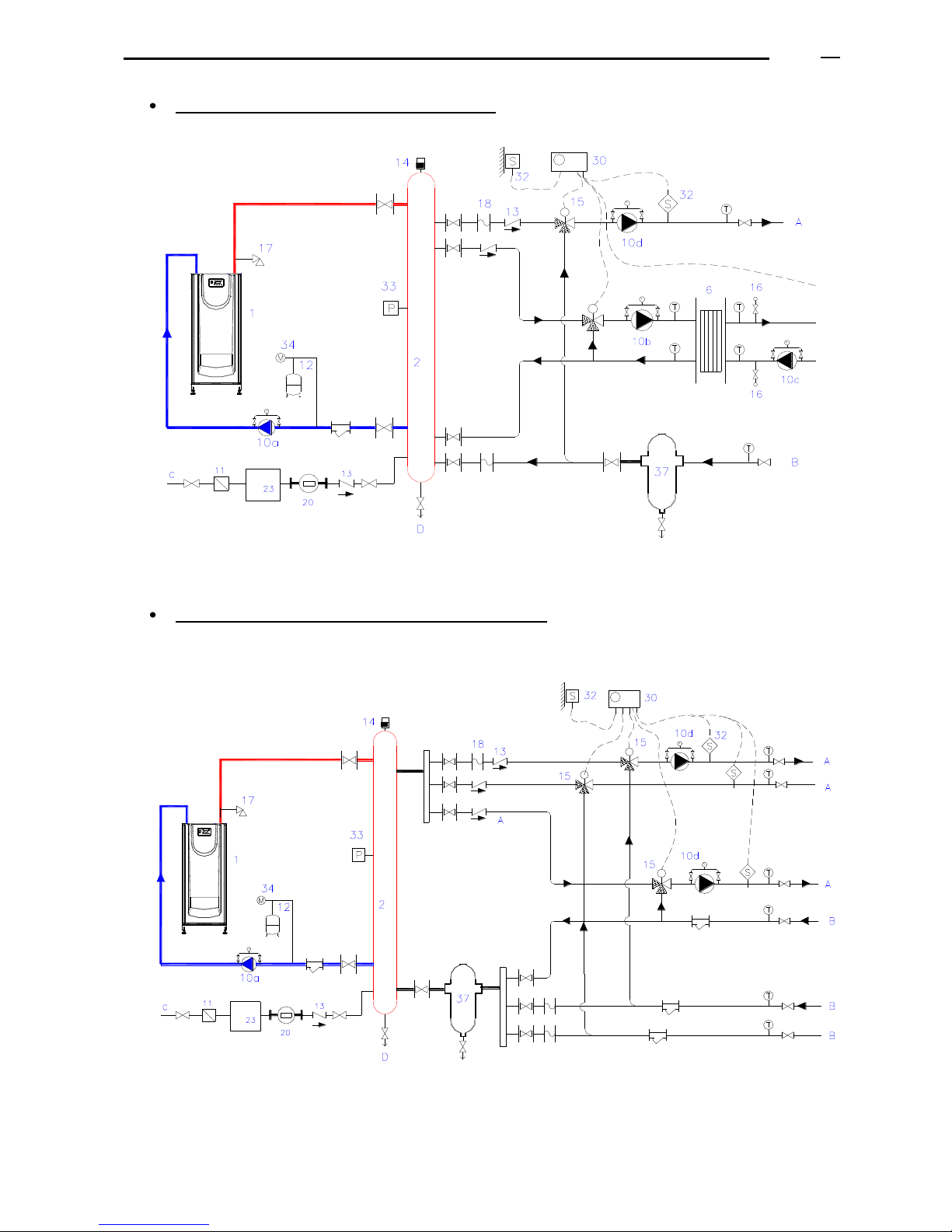

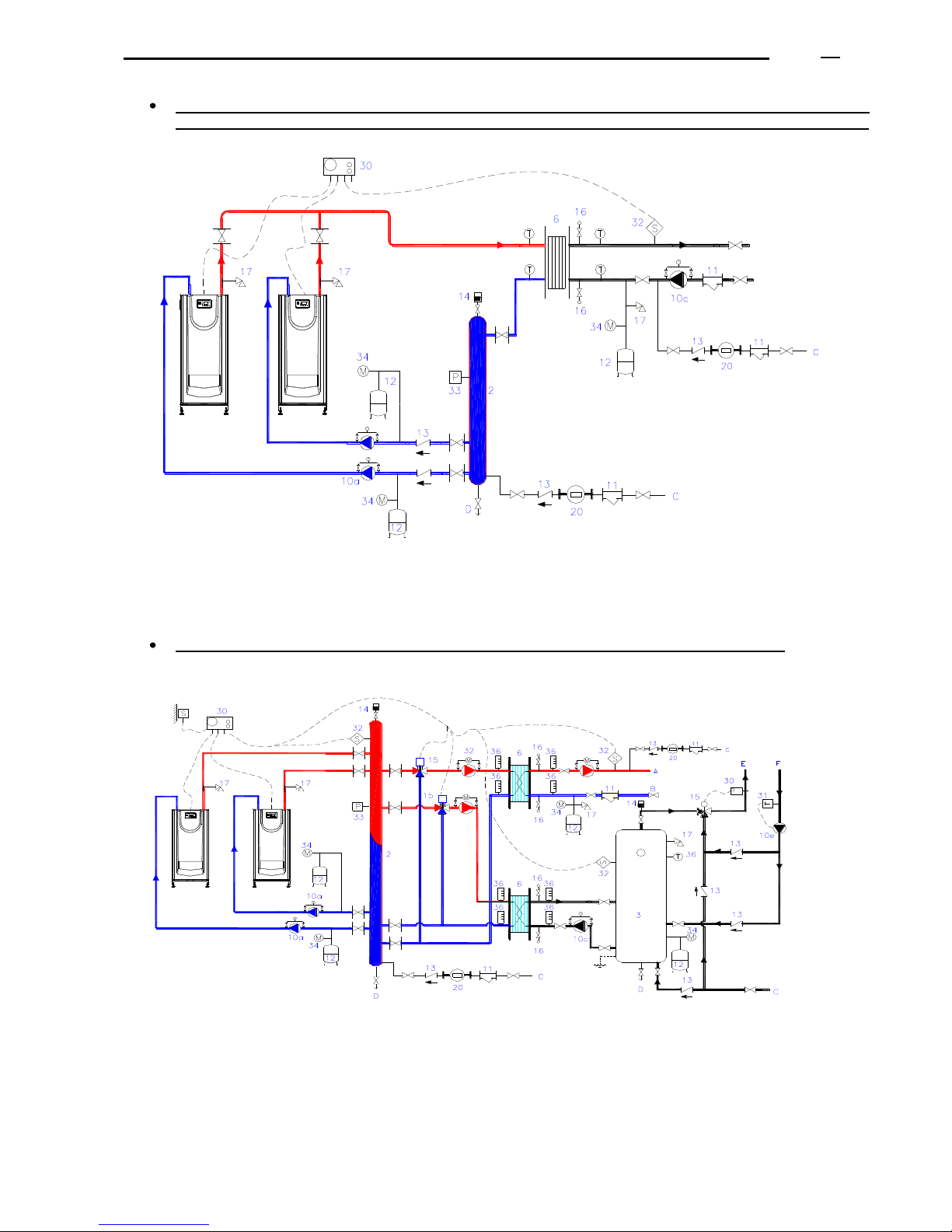

15.7.6 System drawings ___________________________________________________________________________ 42

16.1 BEFORE THE START-UP ______________________________________________________________________ 46

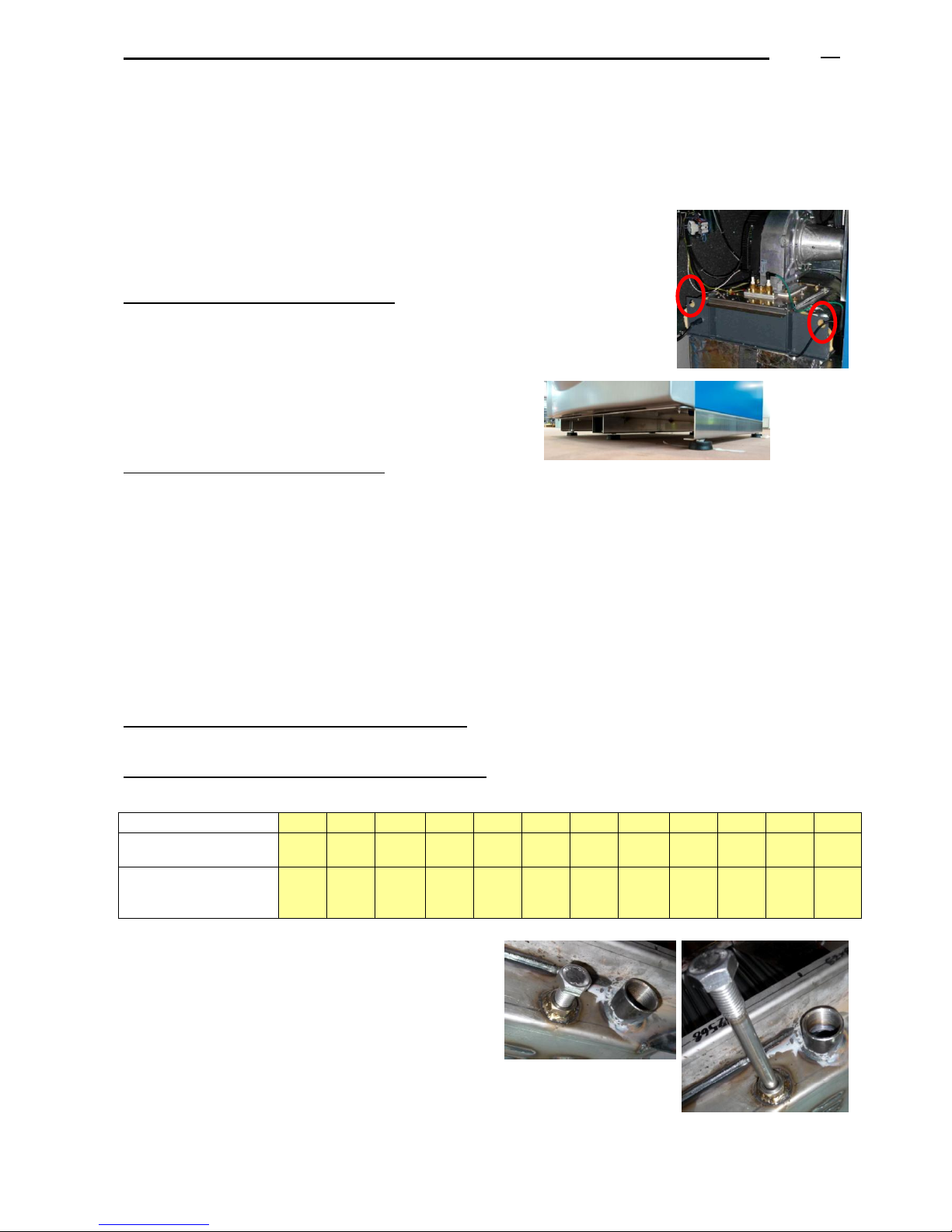

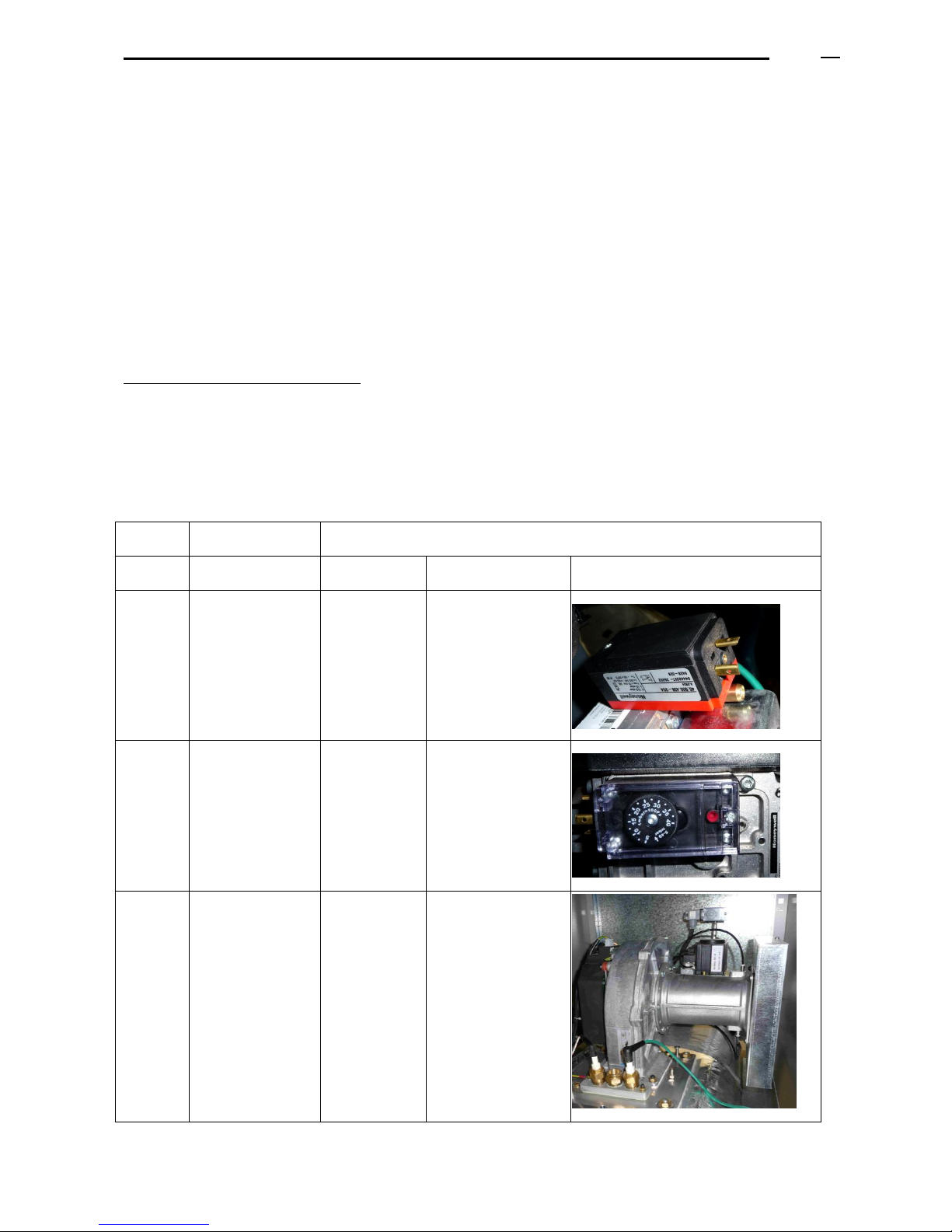

AIR AND GAS PRESSURE SWITCH: _________________________________________________________________ 46

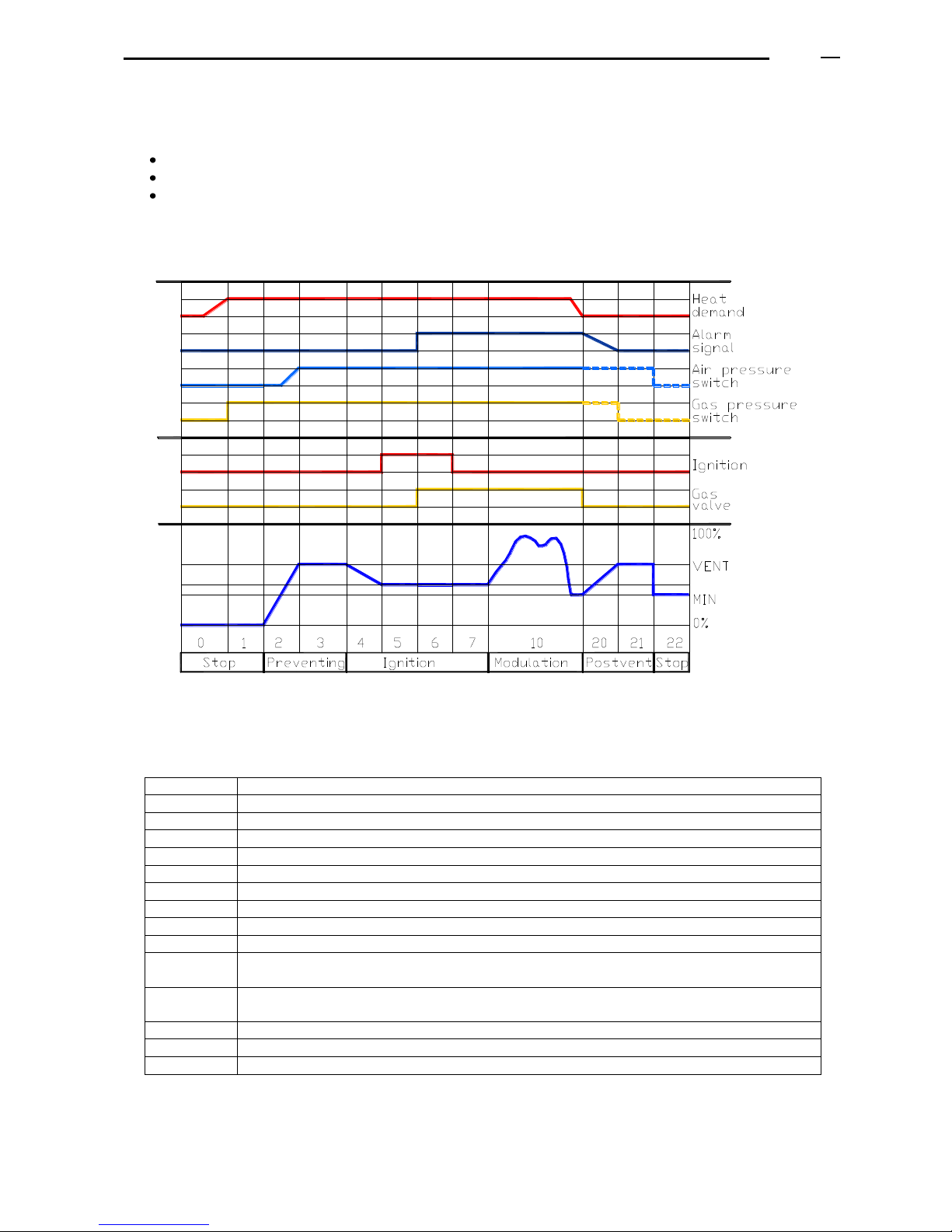

16.2 THE BOILER CONTROL UNIT AND OPERATING CYCLE ____________________________________________ 47

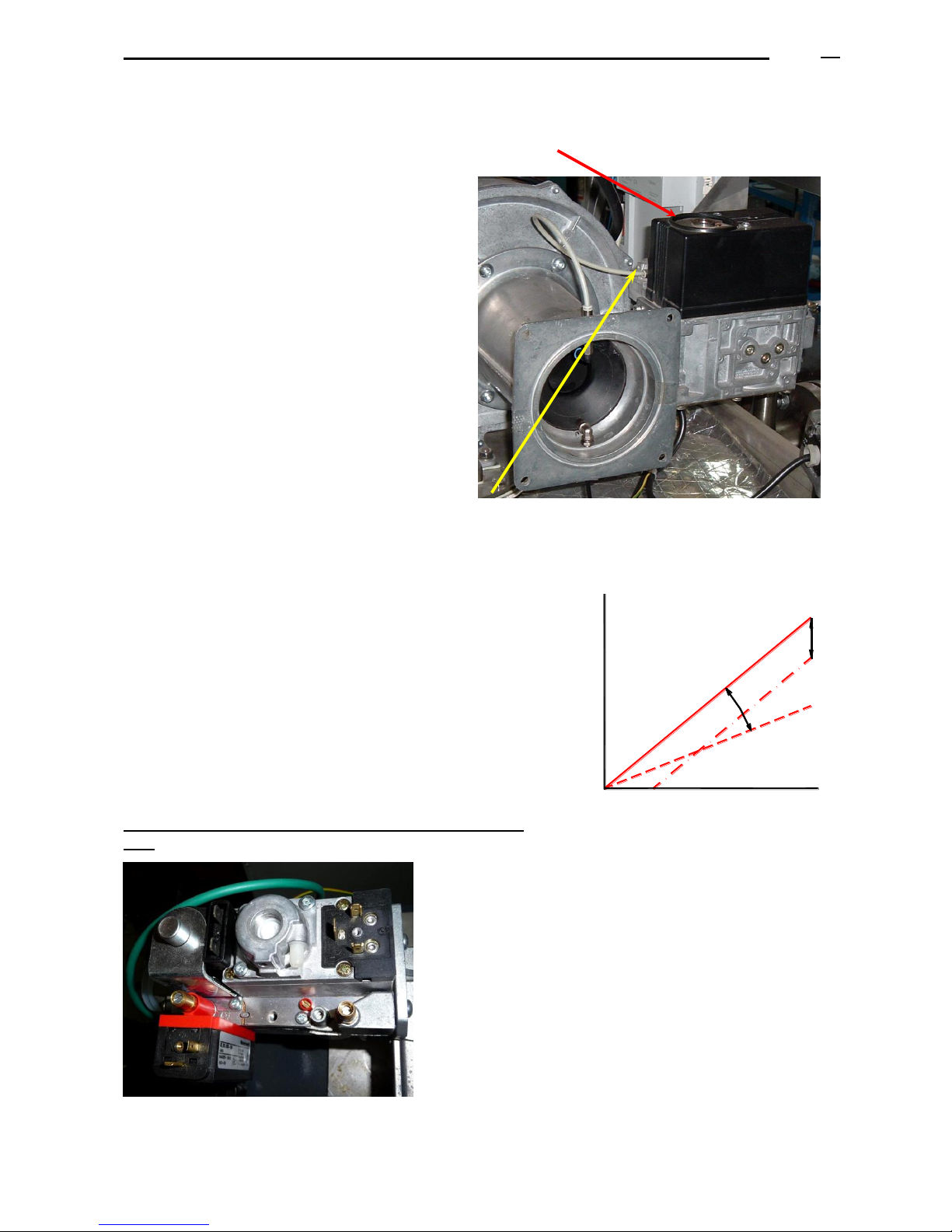

16.3 GAS - AIR ADJUSTMENTS _____________________________________________________________________ 48

16.3.1 Combustion adjustment _____________________________________________________________________ 48

16.3.2 Change of fuel: from Propane gas to Natural gas _________________________________________________ 50

17. MAINTENANCE _______________________________________________________________________________ 50

17.1 PROCEDURE TO DISMANTLE THE BURNER ______________________________________________________ 50

17.2 POSITION OF PROBES AND SENSORS _________________________________________________________ 52

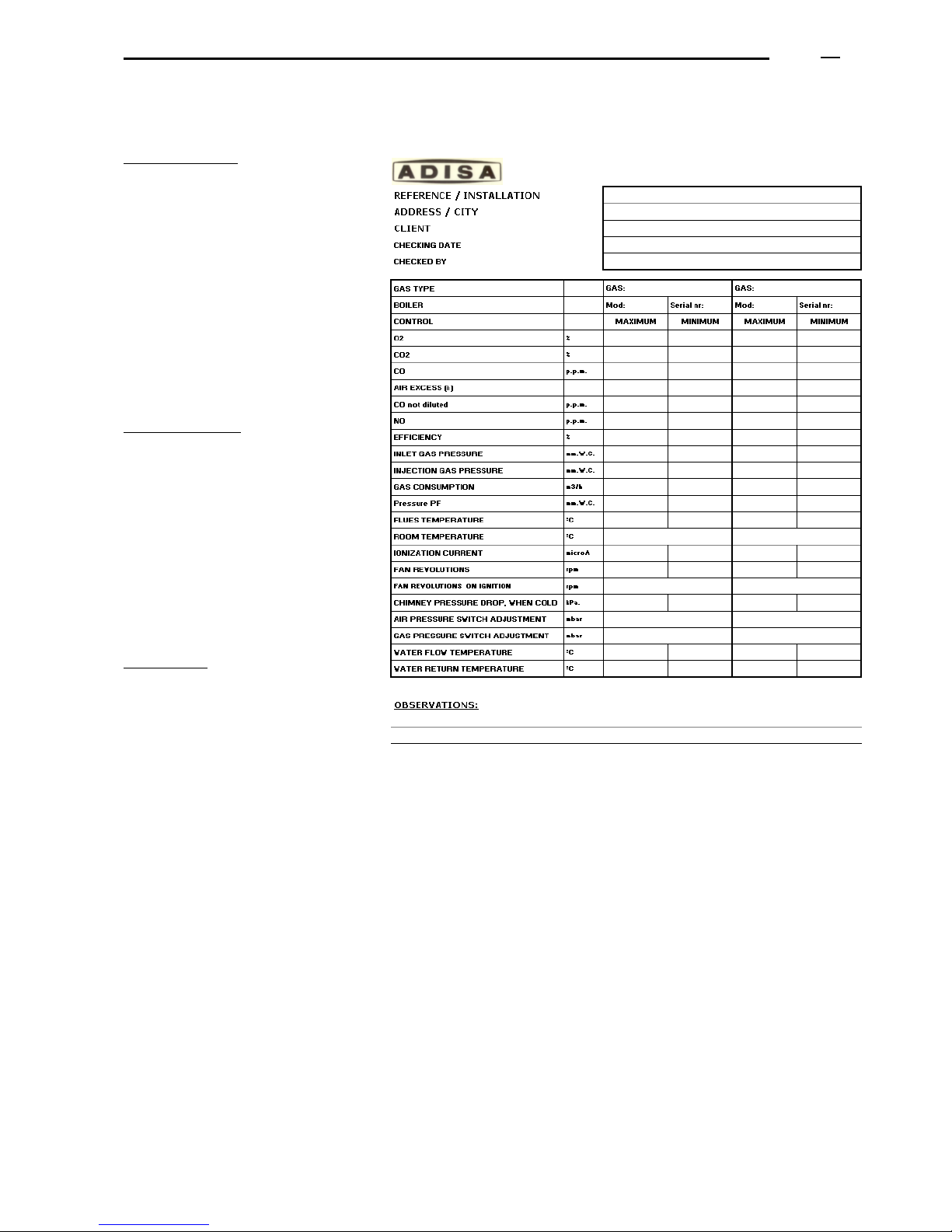

17.2 COMBUSTION DATA __________________________________________________________________________ 53

18. BOILER GUARANTEE __________________________________________________________________________ 54

19. APPENDIX I: LIST OF ERROR CODES ____________________________________________________________ 56

Data indicated in the present manual are liable to changes.

MHS Boilers has the right to make modifications without notice of any product of its range.

No company, person or entity external to MHS Boilers can modify this document.

Page 4

ADI LT boiler - Technical Manual Page

L338 11/2011

4

1. INTRODUCTION

The global trend, European and international, aims at improving energetic efficiency both in buildings and

generators, in order to reduce pollutant emissions in the atmosphere (directive SAVE, KYOTO agreement)

Carbon dioxide (CO2) is one of the greenhouse gases that remain the longest in the atmosphere. In accordance

with IEO2007, predicted CO2 emissions will be 33.9 billon tons in 2015 and 42.9 in 2030.

This is why the European campaign known as “20-20-20 in 2020” has been created, with the aim, among others, of

cutting carbon dioxide emissions by 20% by 2020.

MHS Boilers specialise in the manufacturing of gas boilers with high efficiency performances and reduced pollutant

emissions (“clean combustion”), has developed an innovating and revolutionary product contributing to a

technological evolution in the field of water boilers for centralized installations: the ADI LT boiler.

The main characteristics of the ADI LT boiler are:

- Maximum efficiency in every kind of installations at any working temperatures.

Renovation of installations with traditional heat radiators

New installations of very Low Temperature (heating floor, fan-coils, A.H.U., etc.).

Domestic Hot Water (D.H.W.S.), in accordance with anti-legionella regulations.

- EEC Approval by CERTIGAZ, with 3 performance stars for its high energetic efficiency (according to the

European directive 92/42/EEC).

- Efficiency up to 105%.

- Boiler certified as “Low temperature”: flow temperature up to 90ºC, no limit of return temperature.

- Boiler heat exchanger in stainless steel.

- Power outputs from 104 to 905 kW.

- Maximum efficiency per year :

Variable temperature on boiler.

Boiler power modulation according to the demands of the installation.

High reduction of stop/start cycles.

Minimum heat losses due to convection/radiation through the boiler.

Inconsiderable heat losses through the chimney when the boiler is not operating.

- Gas boilers with modulating burner starting from 30% of power (depending on the installation conditions and

models).

- Burner power modulation by varying the premix air-gas flow by means of a motor fan of variable speed.

- Reduced electric consumptions per year thanks to the motor fan of variable speed for the air-gas inlet.

- Ecological combustion (“PREMIX” burner of innovative design).

NOx: about 10 ppm, CO: about 50 ppm (both referred to 3% O2).

- Boiler regulation and control adaptable to all systems available on the market:

The boiler can operate by means of its own regulation.

It can be connected to a sequence control unit in an installation with several boilers.

It can be connected to Building Manage System (B.M.S.).

It can be connected to telecomputing.

- Reduced dimensions and weight:

Boiler heat exchanger ADI LT 475 (440 kW of output) Large: 81 cm, Long: 94 cm, Weight: 490 kg

Easy installation in boiler rooms of difficult access.

Installation in terraces (reinforcement of the structure is not required).

Space saving in boiler room (464 kW in less than 0,76 m2).

Page 5

ADI LT boiler - Technical Manual Page

L338 11/2011

5

2. REGULATIONS

The installation must be designed and realized by qualified professionals in accordance with the current regulations

referring to gas, air venting, flues evacuation, electricity, safeties, fire prevention, etc.

The boiler maintenance must be realized following the instructions of the manufacturer’s technical manual and with

a minimum regularity as indicated by the current regulations.

3. EEC APPROVALS AND CERTIFICATIONS

ADISA boilers, model ADI LT, are certified as follows:

MODEL

ADI LT

105 to 400

475 to 750

850 to 950

GAS BOILERS

DIR. 90/396/EEC

1312CL5485

(AND EFFICIENCY DIR.

92/42/EEC)

1312CL5488

-----

The European Directive of Boilers Efficiency, dir. 92/42/EEC, only applied to boilers from 4 to 400 kW.

Page 6

ADI LT boiler - Technical Manual Page

L338 11/2011

6

4. BOILER GENERAL VIEW: DESCRIPTION OF THE COMPONENTS

A

Boiler heat exchanger (higher collector)

B

Flanges (boiler heat exchanger – burner – air/gas fan)

C

Ignition-ionization kit

D

Flame indicator

E

Motor fan (variable speed)

F

Fan G Venturi for air inlet and mix with gas

H

Multiblock gas valve

J

Boiler control unit and power modulation

L

Hot water flow

M

Hot water return

N

Flues outlet

P

Gas connection

Q

Air pressure switch

R

Air filter

S

Ignition transformer

T

Gas pressure switch

U

Pressure sensor

V

Air purgers (manual)

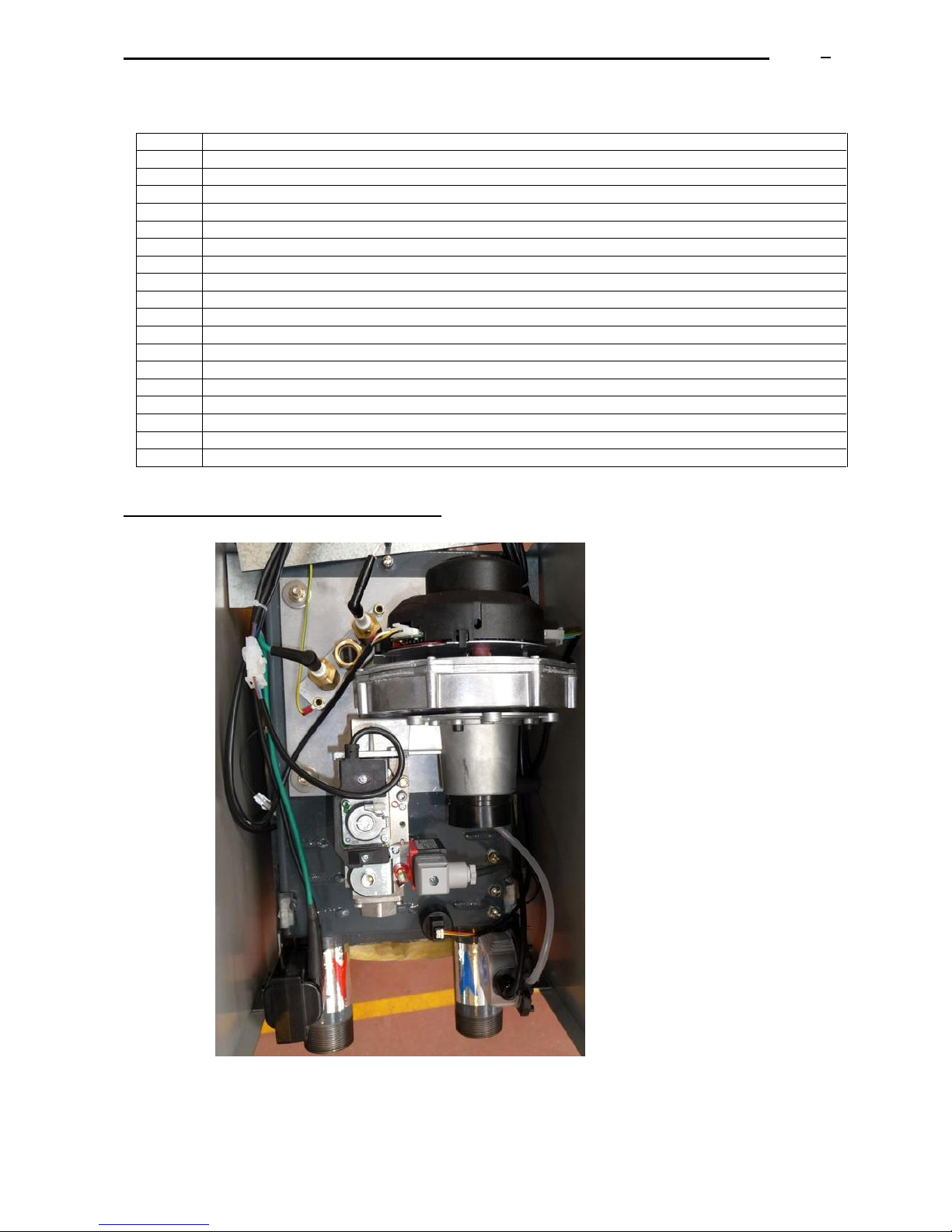

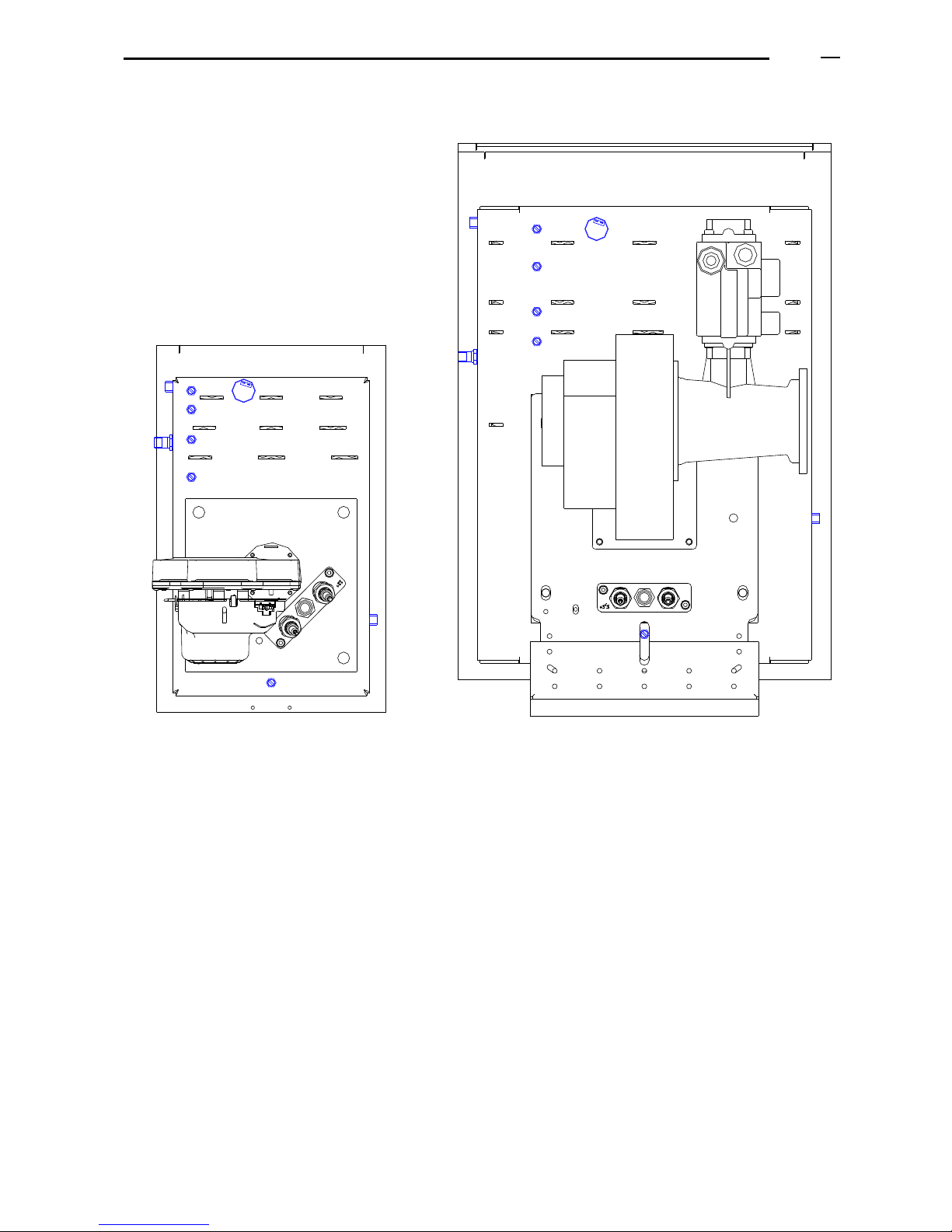

Models ADI LT 105 to 200 (view from above):

(B)

(D)

(F)

(E)

(C)

(S)

(Q)

(H)

(P)

(T)

(U)

(L)

(M)

(V)

(V)

Page 7

ADI LT boiler - Technical Manual Page

L338 11/2011

7

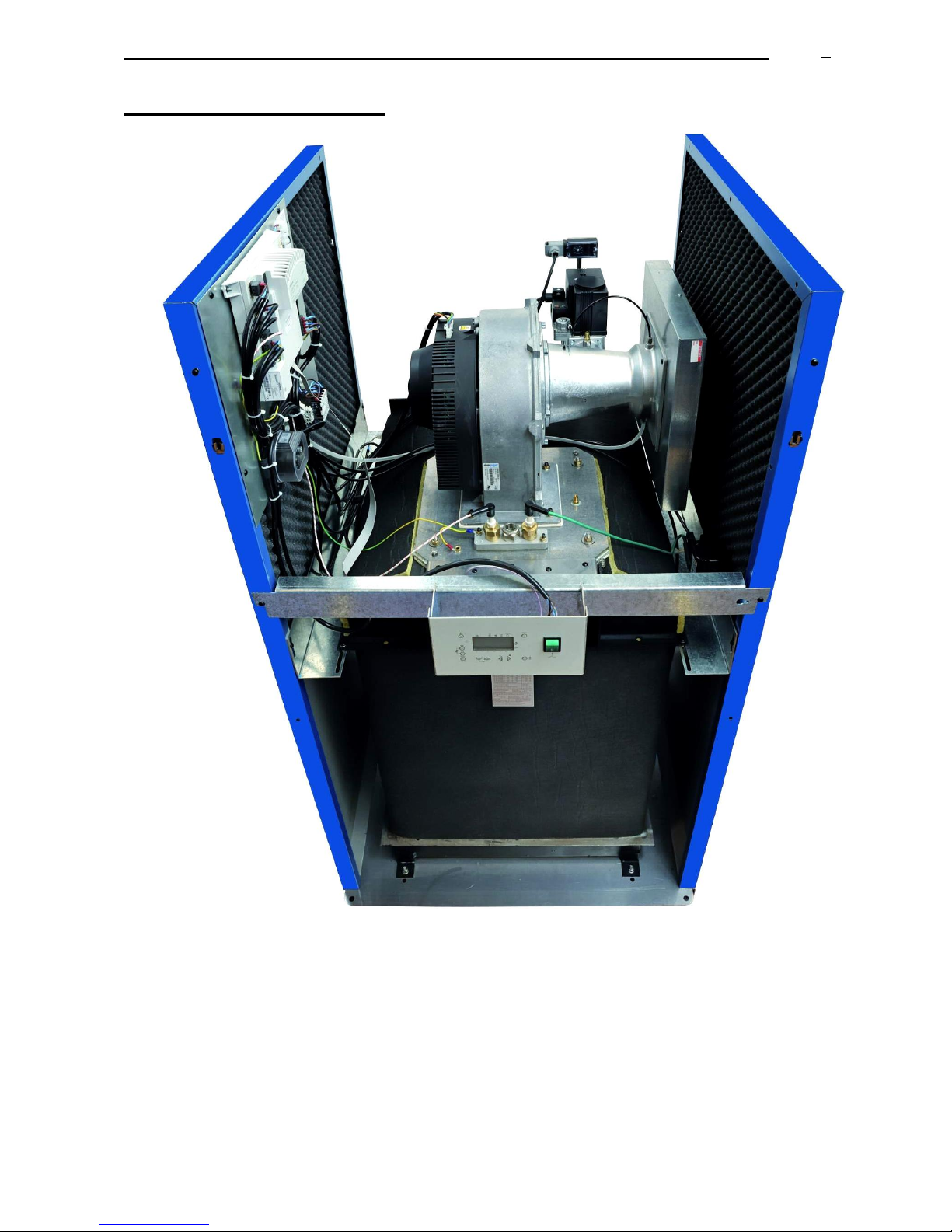

Models ADI LT 250 and higher:

(A)

(C)

(D)

(B)

(J)

(Q)

(H)

(G)

(F)

(E)

(R)

(S)

Page 8

ADI LT boiler - Technical Manual Page

L338 11/2011

8

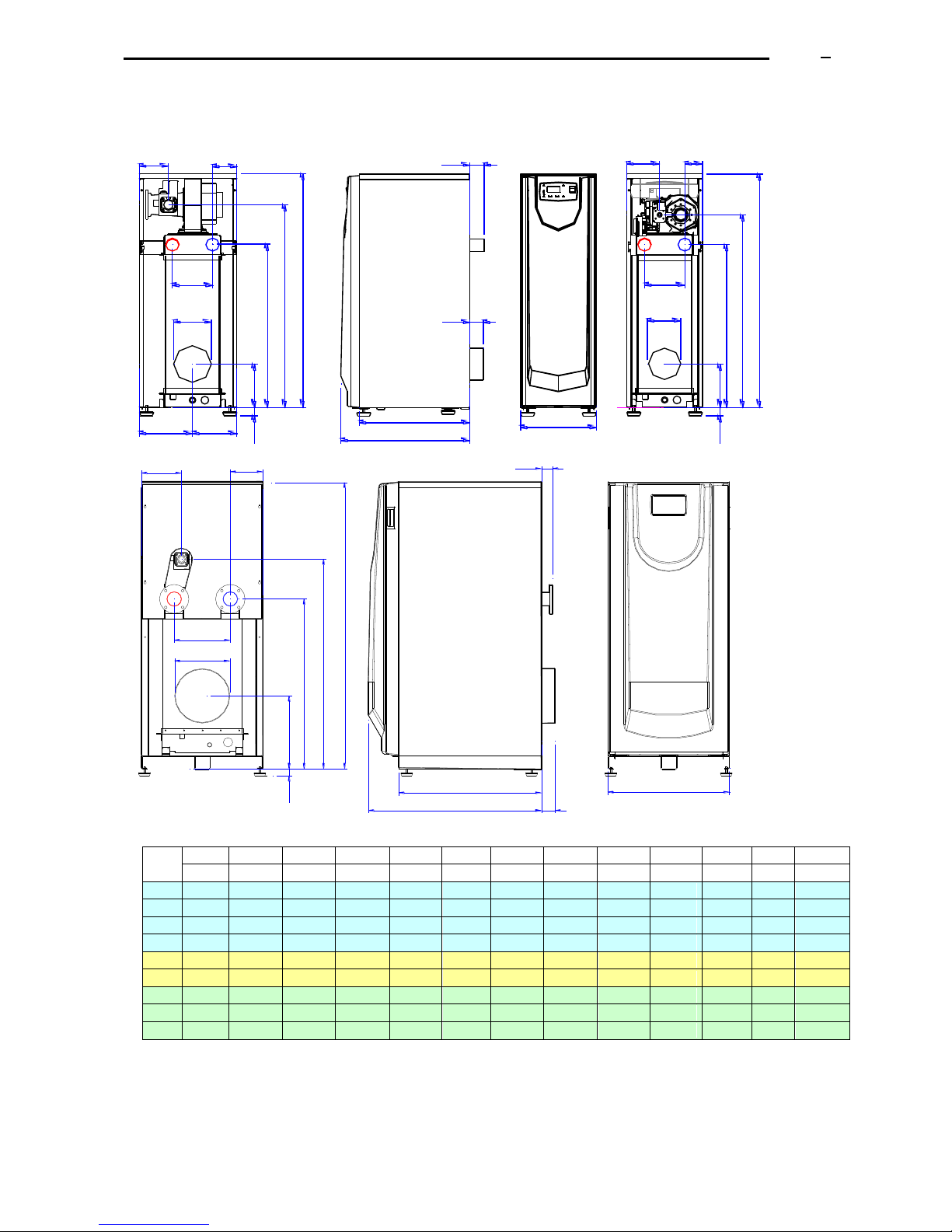

5. DIMENSIONS

12

9b

9a

8

7

12

9b

9a

8

7

AA

4

6

5

AA

4

5

6

LA

F

F

AL

LF

L2

L1

AL

GL

GL

245 205

HF

HA

HG

SB

H

HF

HA

HG

H

SB

A

Model

CD

A

AA

AL

F (7)

H

HA

HF

HG

L1

L2

LA

LF

GL

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

105

350

185

82,5

150

1110

774

198

915

595

510

66

62

151,5

130

450

185

112,5

150

1110

774

198

963

595

510

66

62

134,3

150

450

185

112,5

150

1110

774

198

963

615

530

66

62

134,3

200

450

185

112,5

150

1110

774

198

963

635

546

66

62

134,3

250

660

305

177,5

175

1583

937

403

1156

940

775

61

75

217,3

275

660

305

177,5

175

1583

937

403

1156

940

775

61

75

217,3

325

810

360

225

250

1583

936

445

1156

940

775

61

75

292

400

810

360

225

250

1583

936

445

1190

940

775

61

75

249,3

475

810

360

225

250

1583

936

445

1190

940

775

61

75

249,3

(*) Attention: Heights H, HG, HA, HF, without taking into consideration the increase due to the silent-block feet

supplied with the boiler (dimension “SB”).

Note: data in the present document are liable to changes without prior warning.

L1

L2

12

9b

9a

AL

AA

F

7

4

6

5

A

LF

LA

GL

HF

HA

HG

H

SB

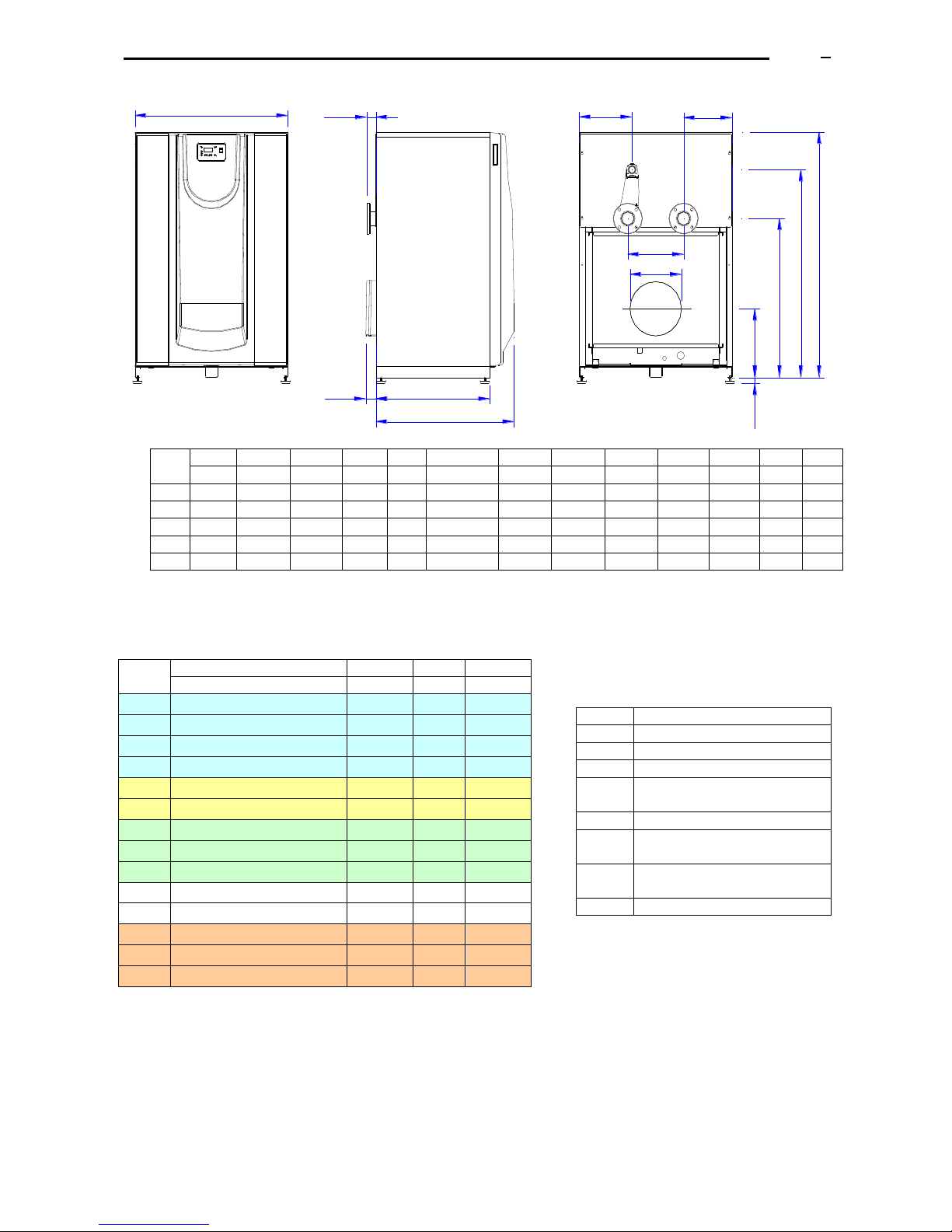

ADI LT

250 - 475

ADI LT 105

ADI LT 130- 150-200

Page 9

ADI LT boiler - Technical Manual Page

L338 11/2011

9

Gas connection: the installation company must install a female 3-pieces coupling, for an easier dismantling

and maintenance of the boiler.

Add gas filter.

A

H

HG

HA

F

9b

L1

L2LF

12

HF

SB

8

9a

AA

LA

GL

4

6

AL

5

Model

CD

A

AA

AL

F (7) H HA

HF

HG

L1

L2

LA

LF

GL

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

550

1040

380

320

350

1583

1026

443

1341

940

775

63

69

359

650

1040

380

320

350

1583

1026

443

1341

940

775

63

69

359

750

1040

400

320

350

1583

1022

443

1365

940

775

63

69

360

850

1040

400

330

350

1583

1022

443

1365

1160

995

93

---

360

950

1040

400

330

350

1583

1022

443

1365

1160

995

93

---

360

(*) Attention: Heights H, HG, HA, HF, without taking into consideration the increase due to the silent-block feet

supplied with the boiler (dimension “SB”).

Note: data in the present document are liable to changes without prior warning.

ADI LT

4-5

6 9 12

Diam.

Diam.

Diam.

Diam.

105

2", threaded

3/4"

¾”

½” H

130

2", threaded

1"

¾”

½” H

150

2", threaded

1"

¾”

½” H

200

2", threaded

1"

¾”

½” H

250

2 ½", to be flanged (PN 6)

1"1/4

1”1/2

½” M

275

2 ½", to be flanged (PN 6)

1"1/4

1”1/2

½” M

325

2 ½", to be flanged (PN 6)

1"1/4

1”1/2

½” M

400

2 ½", to be flanged (PN 6)

1"1/4

1”1/2

½” M

475

2 ½", to be flanged (PN 6)

1"1/4

1”1/2

½” M

550

3", to be flanged (PN 6)

1"1/4

1”1/2

½” M

650

3", to be flanged (PN 6)

1"1/4

1”1/2

½” M

750

4", to be flanged (PN 10)

1"1/4

1”1/2

½” M

850

4", to be flanged (PN 10)

1"1/4

1”1/2

½” M

950

4", to be flanged (PN 10)

1"1/4

1”1/2

½” M

ADI LT 550 - 950

Legend

Concept

4

Hot water flow

5

Hot water return

6

Gas connection (female)

7

F

Flues outlet (connection to

chimney)

8

Anti-vibration supports

9

Boiler water draining (female-

threaded sleeve)

12

Draining of condensed products

(female or male-threaded sleeve)

13

Control panel

Page 10

ADI LT boiler - Technical Manual Page

L338 11/2011

10

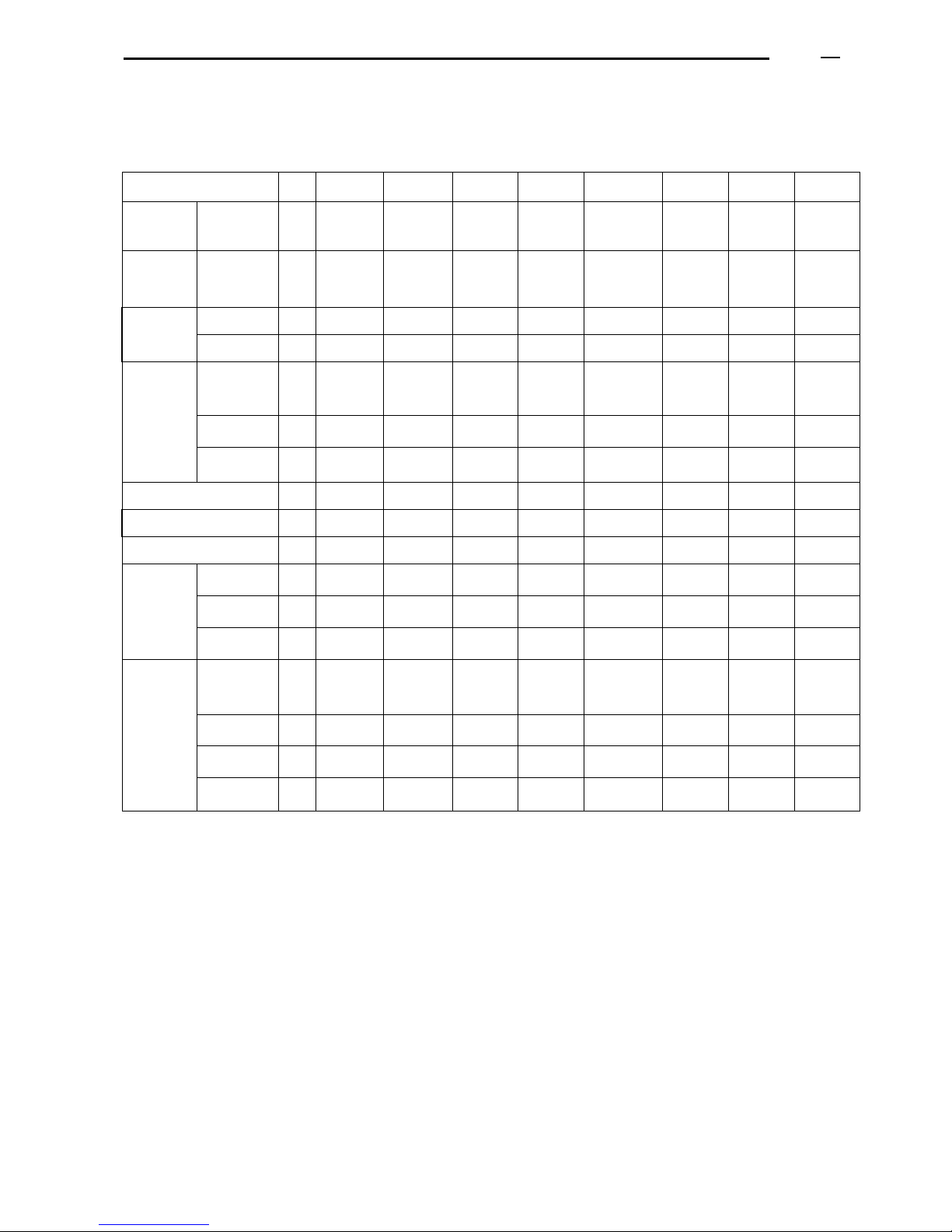

6. TECHNICAL DATA RANGE ADI LT

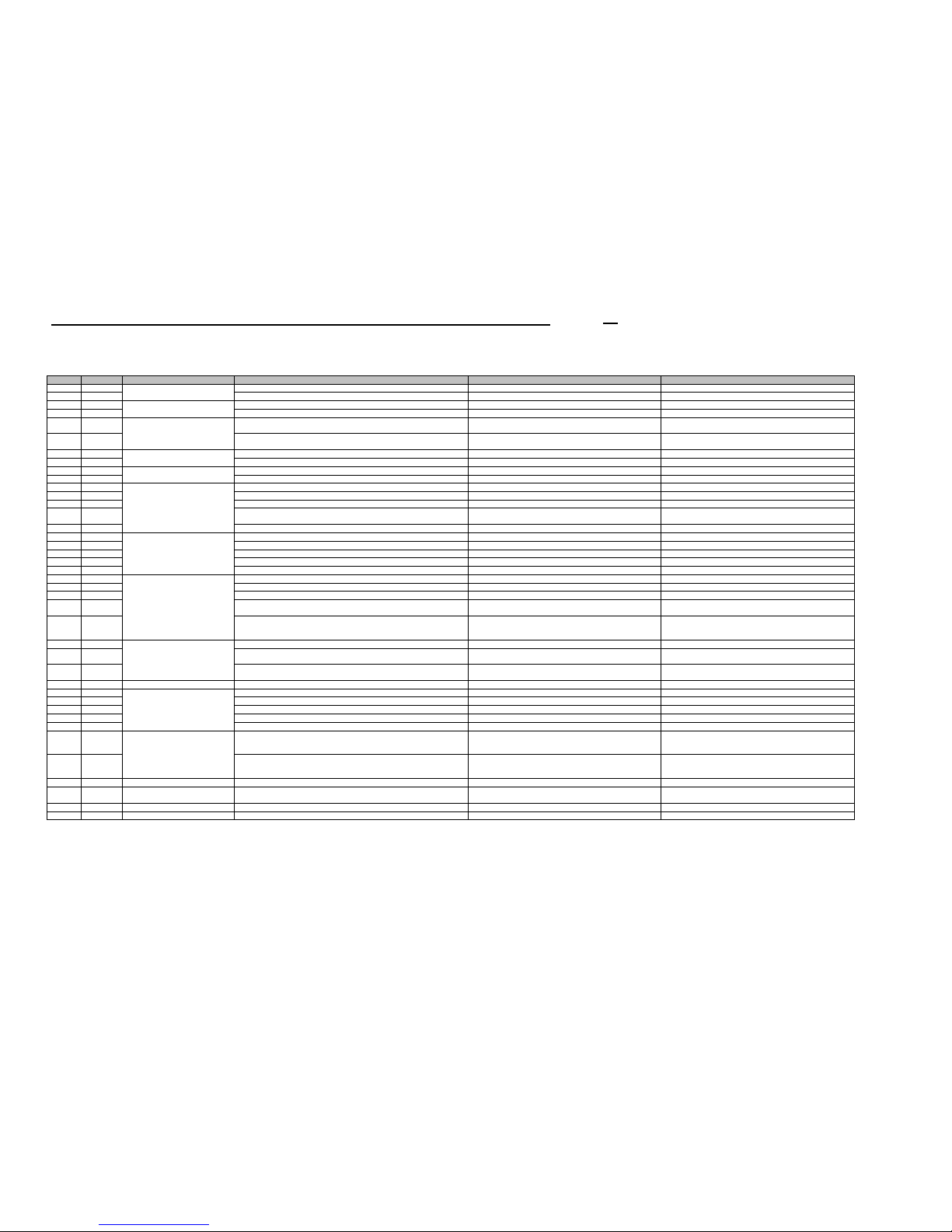

6.1 Models ADI LT 105 to ADI LT 400

CONCEPT

Units

105

130

150

200

250

275

325

400

Power output

Maximum power

(average water

temp: 70ºC)

kW

104

130

149,3

190

230

262

322

380

Power output

Minimum power

(average water

temp: 40ºC)

kW

34,4

43,3

49,3

62,8

76,0

84,8

104,9

124,4

Power input

Maximum

kW

109,6

138,0

157,2

200,0

242,3

270,0

334,0

396,0

Minimum

kW

32,9

41,4

47,2

60,0

72,7

81,0

100,2

118,8

Natural Gas

Gas flow Max.

m3/h

10,2

12,8

14,6

18,6

22,5

25,1

31,0

36,8

(G20)

Flues flow

m3/h

238

300

341

434

550

614

759

899

Flues Residual

Press.

Pa

18,9

64,8

90

67,5

54

70,8

90

90

Boiler weight without water

kg

110

110

112

123

139

330

350

440

Water capacity

litros

30

30

30

33

36

76

85

99

Max. water pressure

bar

5

5 5 5 5 5 5 5

Water

ΔT = 10ºC

m3/h

8,9

11,2

12,8

16,3

19,8

22,5

27,7

32,7

flow

ΔT = 12ºC

m3/h

7,5

9,3

10,7

13,6

16,5

18,8

23,1

27,2

rate

ΔT = 15ºC

m3/h

6,0

7,5

8,6

10,9

13,2

15,0

18,5

21,8

Electric

Consumption

at max. output

W

134

182

222

129

201

177

342

445

at min. Output

W

24

31

41

26

36

22

60

79

Maximum

consumption

W

255

268

282

256

314

259

342

445

Supply

V

1x230 V

1x230 V

1x230 V

1x230 V

1x230 V

1x230 V

1x230 V

1x230 V

Natural gas L.C.V. = 10,757 kW/m3 (38,728 MJ/m3 )

Propane gas = CONSULT

Electric supply to the boiler: 230 V, 50 Hz, single-phase and Earth.

The electric protection of each boiler must be prepared considering the maximum value between the

electric consumption at the start-up and the electric consumption at the maximum power output.

ADI LT 105 to ADI LT 475: modulating power from 30%

Note: data in the present document are liable to changes without prior warning.

Page 11

ADI LT boiler - Technical Manual Page

L338 11/2011

11

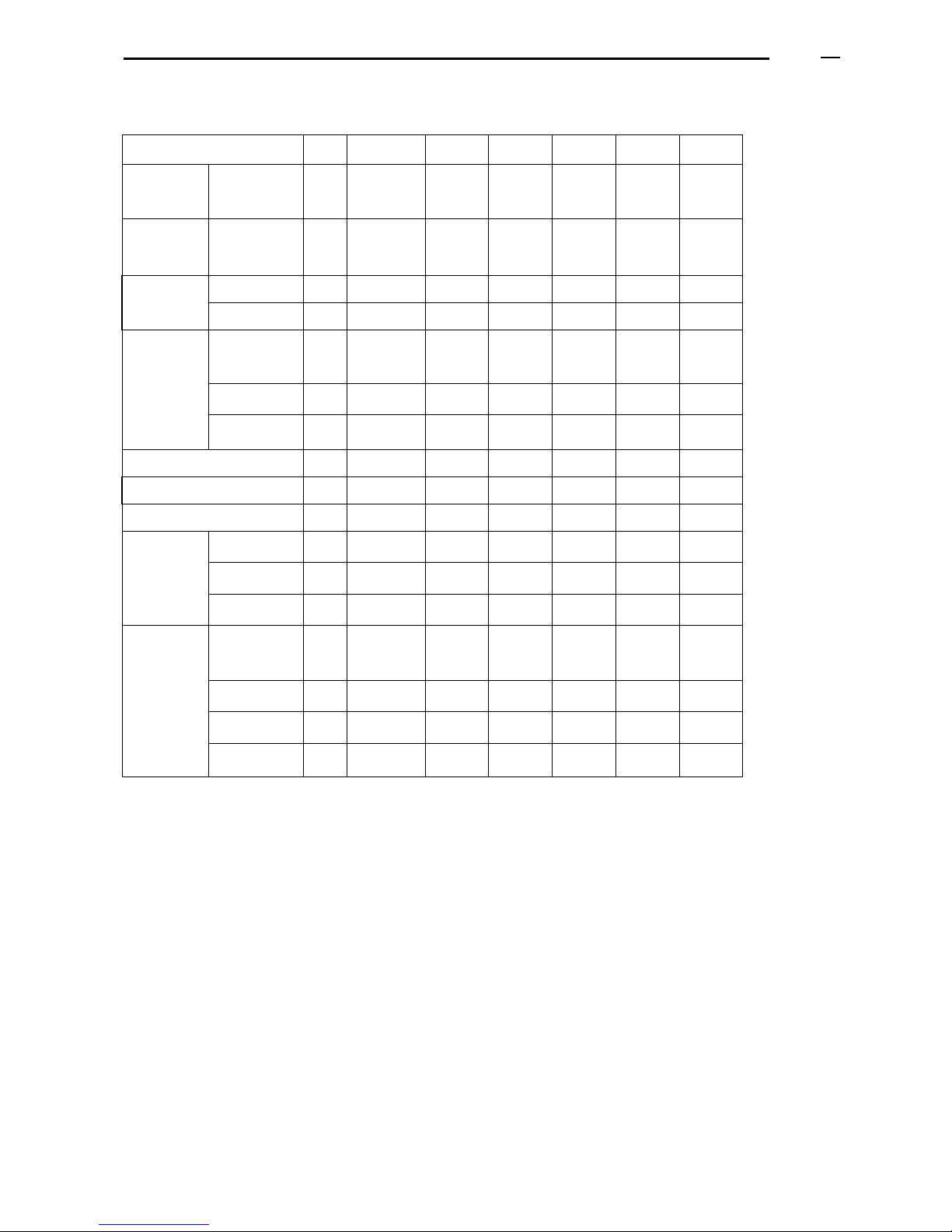

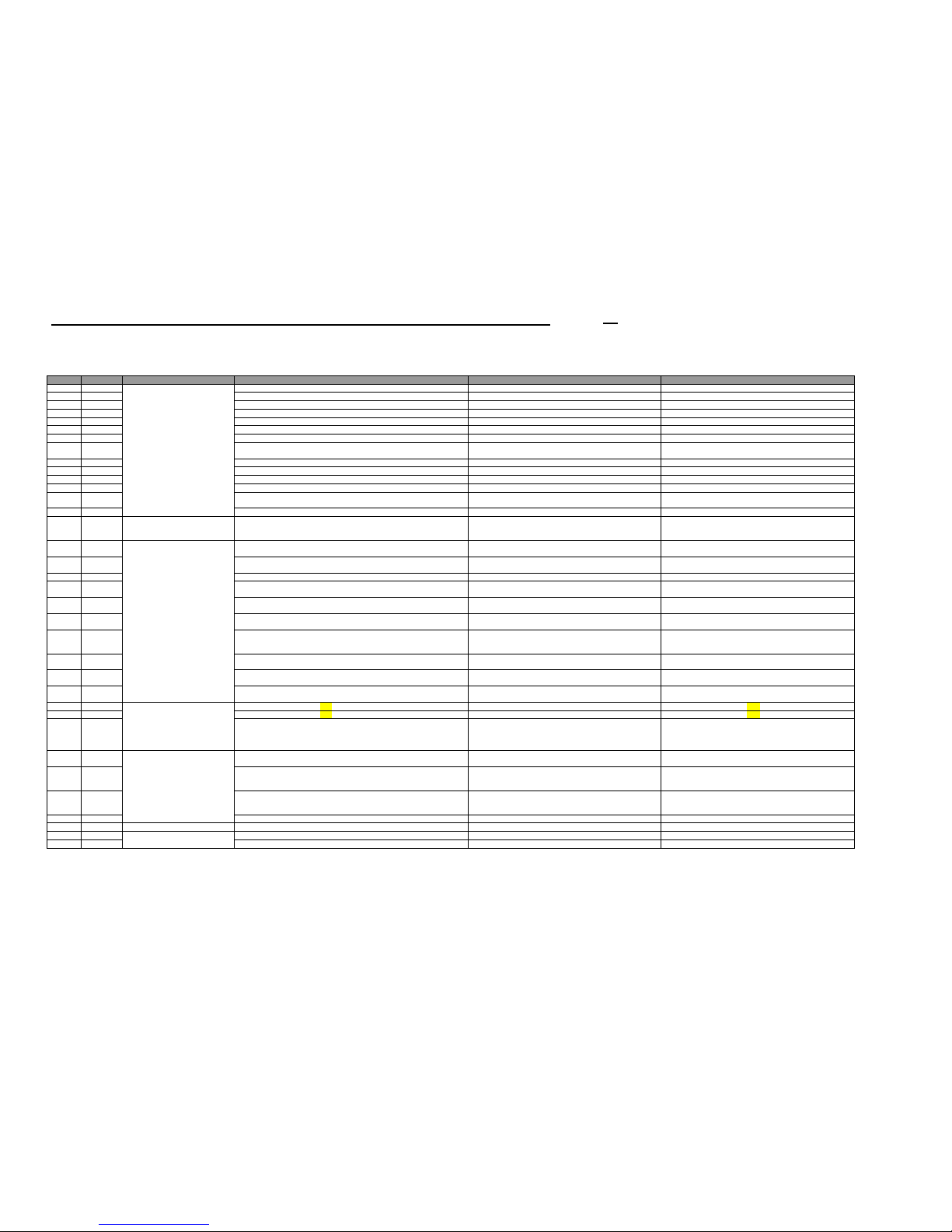

6.2 Models ADI LT 475 to ADI LT 950

CONCEPT

Units

475

550

650

750

850

950

Power output

Maximum power

(average water

temp: 70ºC)

kW

464

545

616

695

800

905

Power output

Minimum power

(average water

temp: 40ºC)

kW

151,8

236,7

266,8

299,3

346,9

392,9

Power input

Maximum

kW

483,3

563,6

638,3

720,2

829,0

942,7

Minimum

kW

145,0

225,4

255,3

288,1

331,6

377,1

Natural Gas

Gas flow Max.

m3/h

44,9

52,4

59,3

67,0

77,1

87,6

(G20)

Flues flow

m3/h

1098

1170

1321

1491

1771

2014

Flues Residual

Press.

Pa

90

180

132

108

Boiler weight without water

kg

490

490

500

500

500

585

Water capacity

litros

118

112

160

160

160

188

Max. water pressure

bar

5 5 5 5 5

5

Water

ΔT = 10ºC

m3/h

39,9

46,9

53,0

59,8

68,8

77,8

flow

ΔT = 12ºC

m3/h

33,3

39,1

44,1

49,8

57,3

64,9

rate

ΔT = 15ºC

m3/h

26,6

31,2

35,3

39,8

45,9

51,9

Electric

Consumption at

max. output

W

727

668

859

1165

at min. Output

W

81

86

115

124

Maximum

consumption

W

727

668

859

1165

Supply

V

1x230 V

1x230 V

1x230 V

1x230 V

3x380 V

3x380 V

Natural gas L.C.V. = 10,757 kW/m3 (38,728 MJ/m3 )

Propane gas = CONSULT

Electric supply to the boiler:

ADI LT 475 – 750: 230 V, 50 Hz, single-phase and Earth.

ADI LT 1300 – 950: 380 V, 50 Hz, tri-phasal, and Earth.

The electric protection of each boiler must be prepared considering the maximum value between the

electric consumption at the start-up and the electric consumption at the maximum power output.

ADI LT 475: modulating power from 30%

ADI LT 550 to ADI LT 950: modulating power from 40%

Note: data in the present document are liable to changes without prior warning.

Page 12

ADI LT boiler - Technical Manual Page

L338 11/2011

12

7. BOILER HEAT EXCHANGER

The boiler heat exchanger (flues-water) is made of

stainless steel: is a stainless steel enriched with a special

alloy (for a better resistance to corrosion and to high

temperatures).

The boiler heat exchanger consists of 2 water collectors,

an upper one and a lower one, connected by means of

multiple vertical tubes forming the combustion chamber.

The vertical tubes generate a big heat transfer surface that

uses the sensible heat of the flues.

During the manufacturing process, the boiler is subjected

to a strict quality control, realized through a process of

three leak tests: one with penetrant liquids, another one

with air pressure and the last one with water pressure.

The boiler heat exchanger is insulated.

Several manual purgers are installed in the higher part of

the boiler for the air venting of the boiler.

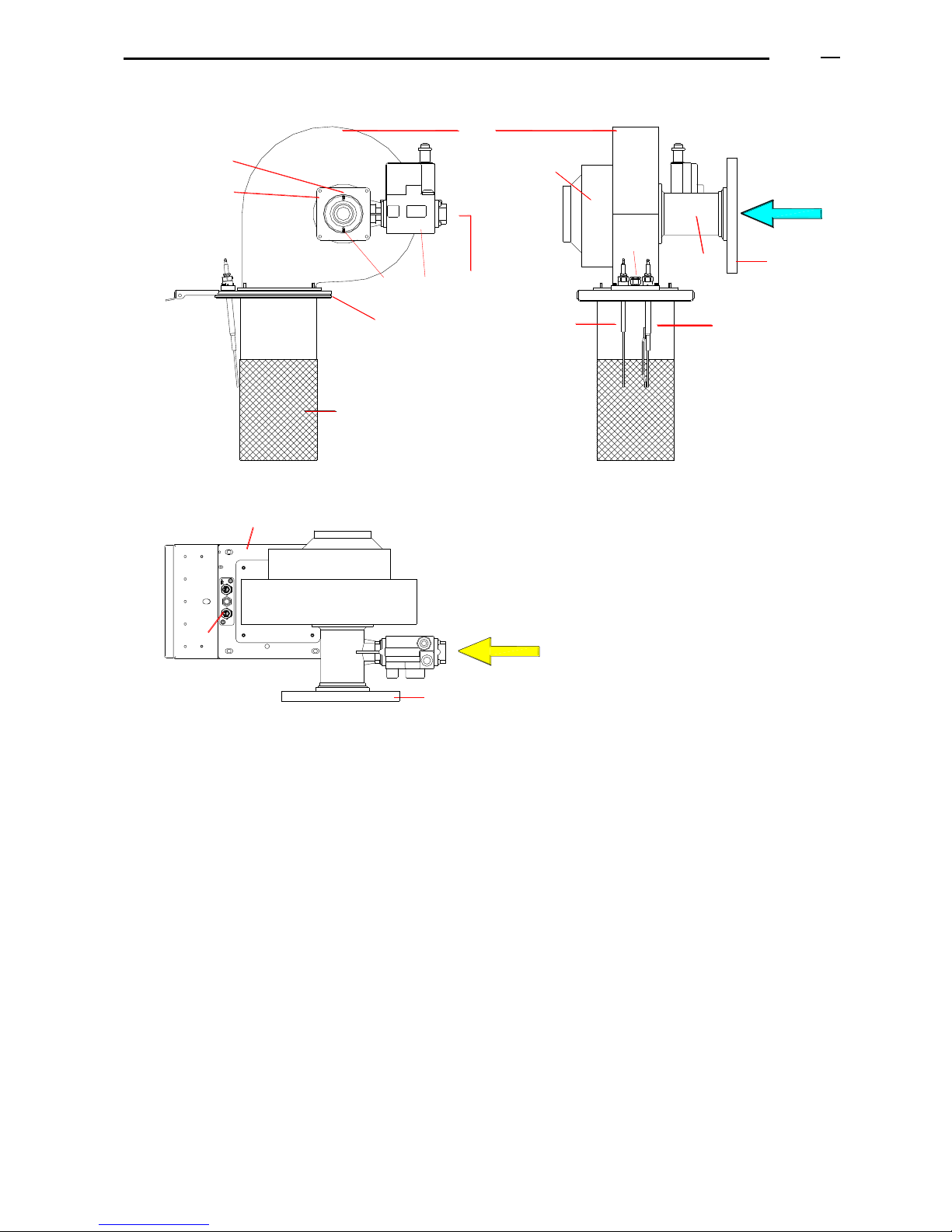

Front and rear view: models ADI LT 200 and lower

Front and rear view ADI LT 250 and higher

Page 13

ADI LT boiler - Technical Manual Page

L338 11/2011

13

8. POWER MODULATION AND COMBUSTION SYSTEM

12

11

7

15

1

5

13

15

5

11

14

6

7

3

2

8

9

4

10

(1) Burner of fire resisting alloy mesh

(2) Ionization electrode (checking the flame presence)

(3) Ignition electrode

(4) Pilot flame

(5) Venturi for the air-gas mix

(6) Double multi-block gas valve

(7) Gas inlet (boiler gas connection to the installation)

(8) Fan for the air-gas mix

(9) Motor fan, of variable speed

(10) Air inlet

(11) Flange of the group motor-fan, to be coupled to the flange of the boiler heat exchanger

(12) Ignition-ionization kit

(13) Pressure connection for the gas valve (just models LT 250 and higher).

(14) Pressure connection for the safety air pressure switch

(15) Air filter (just models LT 250 and higher).

(16) Electrodes support

(17) Gasket for electrodes support.

NOTE: this is a guide diagram; according to the model, the position of the electrodes, the pilot flame, the

motor fan and of the double multi-block gas valve can vary.

Page 14

ADI LT boiler - Technical Manual Page

L338 11/2011

14

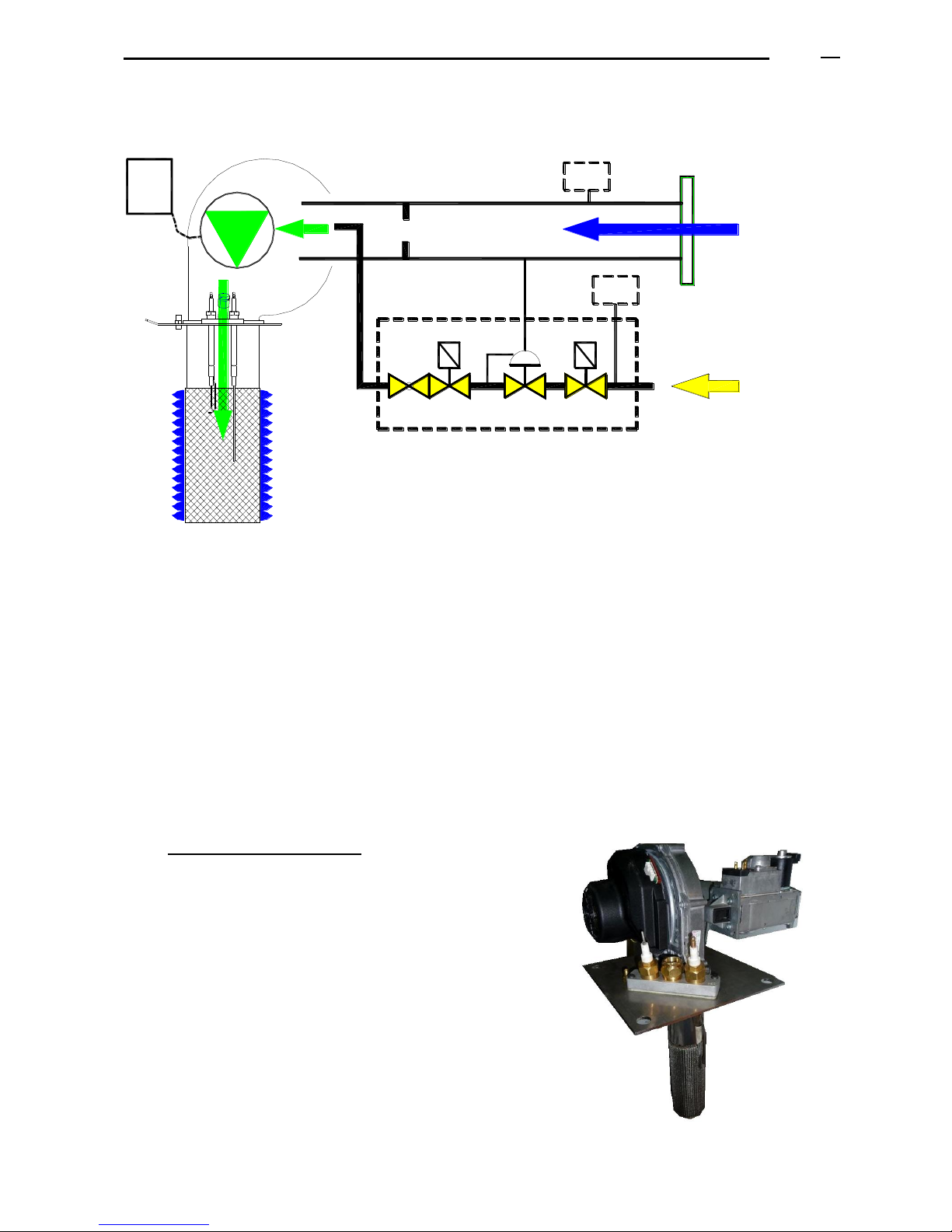

8.1 ASSEMBLY OF GAS CONNECTION – AIR-GAS INLET

The ADI LT boiler includes an air-gas premix system of modulating combustion, composed of:

1

B

8-9

2

6

6b

6a

7

15

Pa

5

13

Pg

10

V. Venturi operating as an air-gas mixer, ensuring combustion with a constant proportion of air/gas to the

premix burner, throughout its power modulation range.

The venturi produces a depression and drives the gas (G) towards the gas valve outlet (VV).

It operates as an additional safety: if there is no air inlet, there will be no gas admission.

VV. The multiblock gas valve regulates the gas outlet pressure according to the pressure value in the

venturi.

Note: (13) in models LT 250 and higher: a coupling pipe between the multi-block gas valve and the venturi

measures the pressure drop before the mix. For lower models there is no pipe, the connection between the

multi-block gas valve and the venturi is internal.

M. The power modulation is realized by varying the fan speed, which also produces a variation of the

air-gas mix flow entering into the burner (B).

Pg. Minimum inlet pressure switch: adjusted at 15 mbar.

Pa. Air pressure switch: safety of operation, in case of obstruction of the air inlet,

the motor-fan stops.

In Models ADI LT 105 to 200: these pieces form one only

global group: burner, burner-holder plate, motor-fan, venturi

and multi-block gas valve.

Page 15

ADI LT boiler - Technical Manual Page

L338 11/2011

15

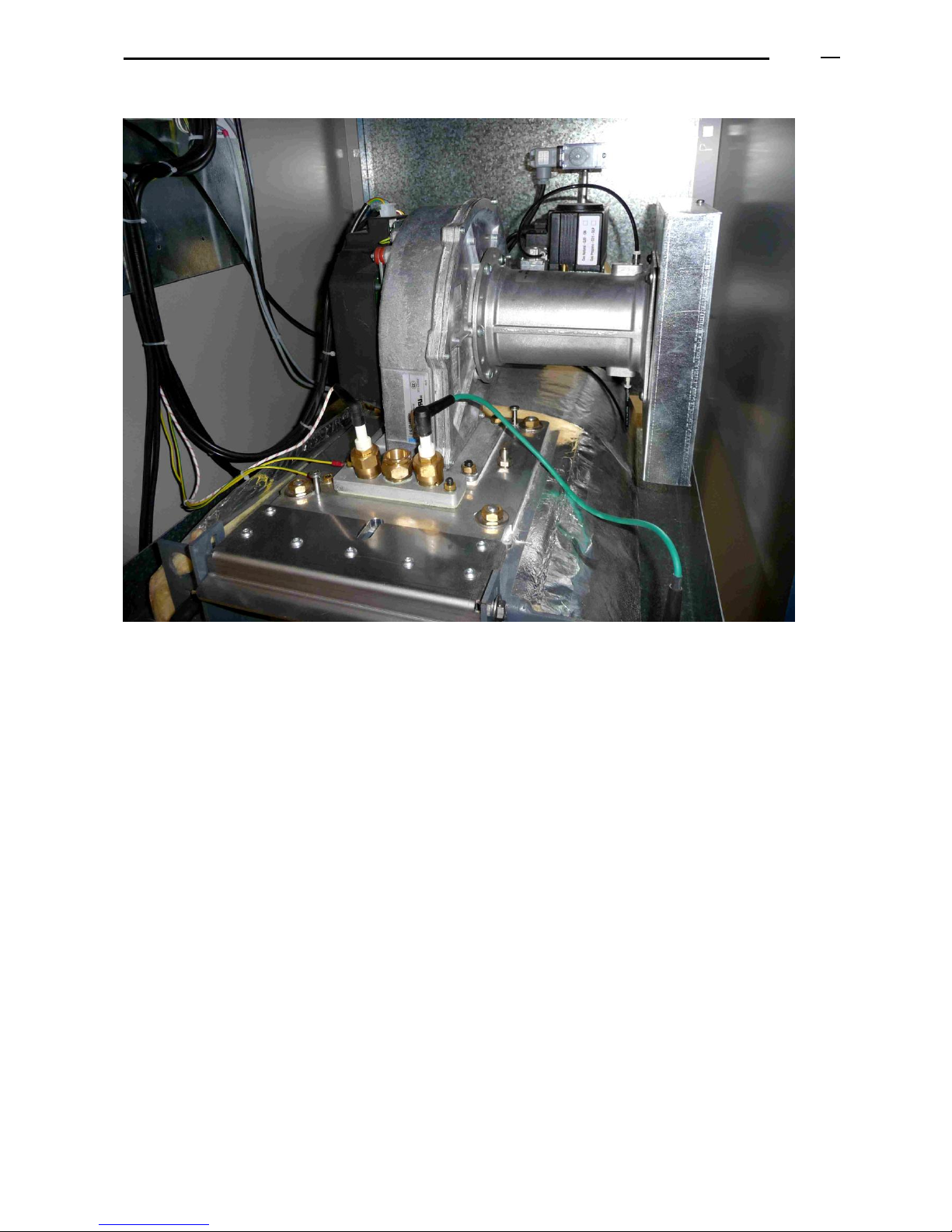

Exploded view of the assembly burner – fan – gas valve for models LT 250 and higher:

Motor-Fan basculating attached

to the body of the boiler.

Page 16

ADI LT boiler - Technical Manual Page

L338 11/2011

16

8.2 AIR INLET FILTER

The air inlet to the venturi is protected by a filter retaining the dust that is

usually in the atmosphere.

Attention: it is important to avoid excessively dusty or dirty environments (for

ex. in case of building work in the same room or in places next to the

ventilation ducts of the boiler room) or environments with aggressive

steams (evacuation or air outlet of industrial laundries...).

See an example of the filter in the attached photo.

Only included in models LT 250 and higher.

9. BURNER

The boiler includes an air-gas premix burner of innovative design and material:

Fire resisting alloy mesh.

Homogeneous and stable combustion in case of any change in the power demand.

High mechanic resistance and high resistance to high temperatures.

Very low thermal inertia fast cooling (for an easier maintenance).

Fast answer to the changes of the power demand.

Thanks to its structure and design, noise produced by the combustion is very low and without resonance.

The cylindrical shape of the burner allows the flame to be homogeneously distributed. It is vertically introduced in

the boiler.

The boiler incorporates an ionization flame control. The minimum ionization value must always be superior to 5

microamperes.

9.1 IGNITION AND IONISATION

KIT

The ignition is electronic by means of an

electric transformer that produces a

train of sparks on the ignition electrode

(3), with the special feature that the

sparks fly from the electrode to the

mass included in this electrode, and not

on the burner.

The safety of flame presence is realized

by means of an ionization electrode (2).

The minimum ionization value must be

always higher than 5 microamperes.

(16) Electrodes holder plate

(17) Joint for the set.

ADI LT

Inclination (X)

105

13º

130 – 200

16º

250- 750

5,5º

850 - 950

17

16

3

4

2

.

.

X

Page 17

ADI LT boiler - Technical Manual Page

L338 11/2011

17

10. CONTROL PANEL - SIEMENS

The boiler control panel is placed in the upper part of the boiler front.

ITEM

Concept

1

Button for boiler reset (T1)

2

Not operational: Select D.H.W.S. circuit (T2). D.H.W.S. on/off

3

Select heating circuit 1 (T3). Change the operation mode:

Automatic mode: Circuit 1 works according to time program 1

Permanent nominal mode according to the circuit setpoint , adjustment by default.

Permanent mode according to reduced setpoint

Standby: circuit 1 disconnected, anti-freezing function activated .

4

Adjust boiler set-up flow temperature (T4)

5

Not operational: Adjust D.H.W .S. set-up temperature

6

Button to change the line of the display that you want to select

(T6) to go down, (T7) to go up.

7

8

To modify the values of adjustment of the parameters on the display,

To decrease (T8), and to increase (T9)

9

10

Access to the available information

11

Display of data and operation modes

12

Function maintenance, stop controller (press simultaneously switches 4 and 5)

To go to the initial display, press T2

(A)

(11)

(A) Boiler on/off switch (11) Display: readings, messages, errors...

Page 18

ADI LT boiler - Technical Manual Page

L338 11/2011

18

10.1 DISPLAY

10.2 STANDARD OR INITIAL DISPLAY

10.3 ADJUSTMENT OF THE SET-UP BOILER FLOW TEMPERATURE

The boiler flow temperature wiil be changed according to the configuration (with or without external temperature

sensor).

1

Not available (water pressure)

2

Values

3

Maintenance, manual operation

To take measurements of the boiler flues.

Stop of the active controller

4

Not available: D.H.W.S.: temperature or D.H.W.S. actived.

Heating activated or reading of boiler set-up temperature

: reading of the outside temperature

: level of operation at a nominal set-up temperature

: level of operation at a reduced set-up temperature

: flame

: failure

5

Time of day, adjustments of parameters or error code

6

Heating circuit operation mode:

Automatic, according to the time program at a nominal

set-up temperature or at a reduced set-up temperature.

: operation at a nominal set-up temperature all the time.

: operation at a reduced set-up temperature all the time.

: boiler in standby / waiting.

7

Not available: D.H.W.S. operation mode

8

Time programming of use of the heating circuit

1

Operation mode for heating

2

Not available (D.H.W.S. mode)

3

Level of operation of the heating circuit

4

Time of day

5

Real value of the boiler flow temperature

6

Not available

7

State of the flame

8

Time bar

9

Boiler operation mode

Meaning

Press the button T4 of flow temperature to adjust the set-up

temperature of the heating circuit

Increase the set-up value by pressing T9, or decrease it by

pressing T8

Press the button T2 to save the changes and go back to the

initial display.

Page 19

ADI LT boiler - Technical Manual Page

L338 11/2011

19

10.4 BOILER LOCKOUT CODE

To detect the type of error, see the list of “Error codes visualized on the display” described in the paragraph 11.3 of

the present document.

Once solved the cause of the lockout, reset the boiler by pressing the button T1 during more than half a second,

.

To go back to the initial display, press the button T2 .

10.5 FUNCTION BOILER MAINTENANCE

If you are on the main display (if not, press the button T3), press T10, “info”

Press simultaneously the buttons T4 and T5 during more than 6 seconds,

and then press both again,

On the right of the display a pointer will flicker pointing to

The display will show the percentage (%) of power at which the boiler is working.

In order to realize the maintenance operations, the action PID of the controller on the boiler will be deactivated. The

boiler power can be increased or decreased, by pressing one of the buttons T8 or T9

If you wish to go directly to the maximum power (on the display: 100%) or to the minimum power (on the display:

0%), you can press T7 or T6

To get out of the mode maintenance, press T2 .

Meaning

In case of boiler lockout, a glittering error code appears on the

display (see example: E 151)

Press key T2 and then press key info, T10, to get access to the

error subcode (see example: 238)

Page 20

ADI LT boiler - Technical Manual Page

L338 11/2011

20

10.6 AVAILABLE PARAMETERS THAT CAN BE ADJUSTED BY THE FINAL USER

Press the button T6 or T7 , to accede directly to the programming level “final user”.

Select the required line by pressing the buttons T6 and T7, , the display will show “Pxxx”

Adjust the required value by pressing the buttons T8 and T9, .

The adjusted value will be saved when changing line.

Press the button T2 to get out of the programming level. Changes won’t be saved.

Press the button T10 to get out of the programming level. Changes will be saved.

If nothing changes after 8 minutes or any other button has been pressed, you will come back to the initial display

and changes won’t be saved.

If you go to another level or line, changes will be automatically saved.

Line

Function

Adjustment

range

Unit

Resolution

Value by

default

1

Current time

0 ... 23:59

h / min

1 min

--- 5 Boiler reduced set-up temperature

TRN

ºC

0.5

69.0

Time

programming

11

Time program Heating circuit 1: phase 1, start-up time

00:00... 24:00

hh:mm

10 min

06:00

12

Time program Heating circuit 1: phase 1, stop time

00:00... 24:00

hh:mm

10 min

22:00

13

Time program Heating circuit 1: phase 2, start-up time

00:00... 24:00

hh:mm

10 min

24:00

14

Time program Heating circuit 1: phase 2, stop time

00:00... 24:00

hh:mm

10 min

24:00

15

Time program Heating circuit 1: phase 3, start-up time

00:00... 24:00

hh:mm

10 min

24:00

16

Time program Heating circuit 1: phase 3, stop time

00:00... 24:00

hh:mm

10 min

24:00

31-36

Not available: Time programs of D.H.W.S. circuit

00:00... 24:00

hh:mm

10 min

06:00

45

Standard time programs for heating

(press simultaneously T8 and T9, , during 3 seconds)

No / Yes

----

-----

No

Page 21

ADI LT boiler - Technical Manual Page

L338 11/2011

21

11. DATA AND INFORMATION VISUALIZED ON THE DISPLAY - SIEMENS

11.1 AVAILABLE INFORMATION

11.1.1 Available readings at the User level

When you are on the main display (if not, press the button T2), press T10, “info”

Every time you press T10, a different message appears on the display.

To go back to the initial or normal display, press the button T2

(if you do not vary anything after 8 minutes, you will automatically go back to the initial display).

General information (user level)

Step

Value shown on the display

1 Not available: D.H.W.S. temperature

2

Not available: boiler circuit water pressure

3 Phase of the boiler operation (see paragraph 11.2)

4 Available only if an outside temperature probe is connected: reading of the outside

temperature.

5 Error code (see paragraph 11.3)

In case of no error, a 0 will appear on the display, in the opposite case, the corresponding

error code will be visualized.

6 Reading of the boiler flow temperature.

11.1.2 Available readings at Maintenance level 1

When you are on the main display (if not, press the button T2), press T10, “info”

Press simultaneously, during 3 seconds at least, the buttons T6 and T7 .

The first reading will be visualized on the display, corresponding to the letter “b0”.

Choose the required parameter by pressing the buttons T8 and T9

To go back to the initial or normal display, press T2

(if you do not vary anything after 8 minutes, you will automatically go back to the initial display)

Information of temperatures (maintenance level 1)

Code

Description

b0

Internal diagnosis code (software) for the LMU control unit

b1

Boiler return temperature

b2

Value not available: D.H.W.S. temperature (probe 2)

b3

Not available (only available for the condensing range ADI LT: combustion flues temperature)

b4

Outside temperature (if the external probe is connected and the control unit is programmed)

b5

Composite outside temperature (average of hours) (if the external probe is connected and the control unit is

programmed).

In the last hour.

b6

Attenuated outside temperature (average of summer/winter) (if the external probe is connected and the control unit

is programmed). Yearly average.

b7

Value not available: flow temperature of the mixing circuit (according to programming and installation)

b8

Value not available: flow temperature in the common collector, by means of an additional probe.

b9

Value not available: temperature in the primary circuit collector, by means of an additional probe.

Page 22

ADI LT boiler - Technical Manual Page

L338 11/2011

22

11.1.3 Available readings at Maintenance Level 2

When you are on the main display (if not, press switch T2), press button T10, “info”

Press simultaneously, during 3 seconds at least, the buttons T6 and T7 .

Press once switch T7,

Choose the required parameter by pressing the buttons T8 and T9

To go back to the initial display, press the button T2 (if you do not vary anything after 8 minutes you will

automatically go back to the initial display).

Operation values (maintenance level 2)

Code

Description

c0, c7-c9

Not used

c1

Value of the ionization current (must be higher than 5 microamperes)

c2

Fan revolutions per minute (Rpm) at that moment (multiplay the obtained reading by 100 to have “rpm”)

c3

Operation value between “maximum value defined” and “minimum value defined” (% PWM)

c4

Percentage of the boiler input/charge at that moment (%):

Value “0” minimum output; value “100” maximum output.

c5

Not available: percentage of operation or of setting of the modulating pump (signal PWM)

c6

Difference between the boiler set-up flow temperature and the real temperature

11.1.4 Available readings at Maintenance Level 3

When you are on the main display (if not, press switch T2), press the button T10, “info”

Press simultaneously, during 3 seconds at least, the buttons T6 and T7 .

Press trice the button T7,

Choose the required parameter by pressing the buttons T8 and T9

To go back to the initial or normal display, press switch T2 (if you do not vary anything after 8 minutes you go

automatically back to the initial display).

Set-up temperatures (maintenance level 3)

Code

Description

d0, d7-d9

Not used.

d1

Consigna del regulador modulante (controller PID)

d2

Consigna de temperatura de impulsión de caldera (ºC)

d3

Not available: Set-up room temperature (according to programming and installation)

d4

Not available: set-up D.H.W.S. temperature (according to programming and installation)

d5

Maximum percentage of the fan modulation for the boiler model, referred to the maximum referido al

máximo propio del ventilador

d6

Maximum speed of the fan at maximum output (multiply the read value by 100 to obtain r.p.m.)

11.2 CODES OF THE BOILER OPERATION PHASES

Display

Meaning

00

Boiler in stand-by (the installation does not have any request of heat)

01

Signal of boiler start-up

02

Motor fan is activated (revolutions increase)

03

Phase of pre-venting

04

Time of stand-by (control of the fan speed)

05

Time of pre-ignition

06

Safety time of ignition and ionization control (constant). The image of a flame appears.

07

Safety time of ignition and ionization control (variable)

10

Operation in heating mode

11

Phase not available: Operation of D.H.W.S.

12

Phase not available: Operation of heating and D.H.W.S. in parallel.

20 / 21

Post air venting starts and fan stops

22

Self-test and return to the initial position

99

Alarm / lockout (the alarm code is visualized on the display)

If the phases finish off in a short time, its code is not shown on the display.

Page 23

ADI LT boiler - Technical Manual Page

L338 11/2011

23

11.3 ERROR CODES VISUALIZED ON THE DISPLAY

See the errors list in the appendix at the end of the present document.

To show the error subcode, follow the procedure indicated in the paragraph 10.4 of this document.

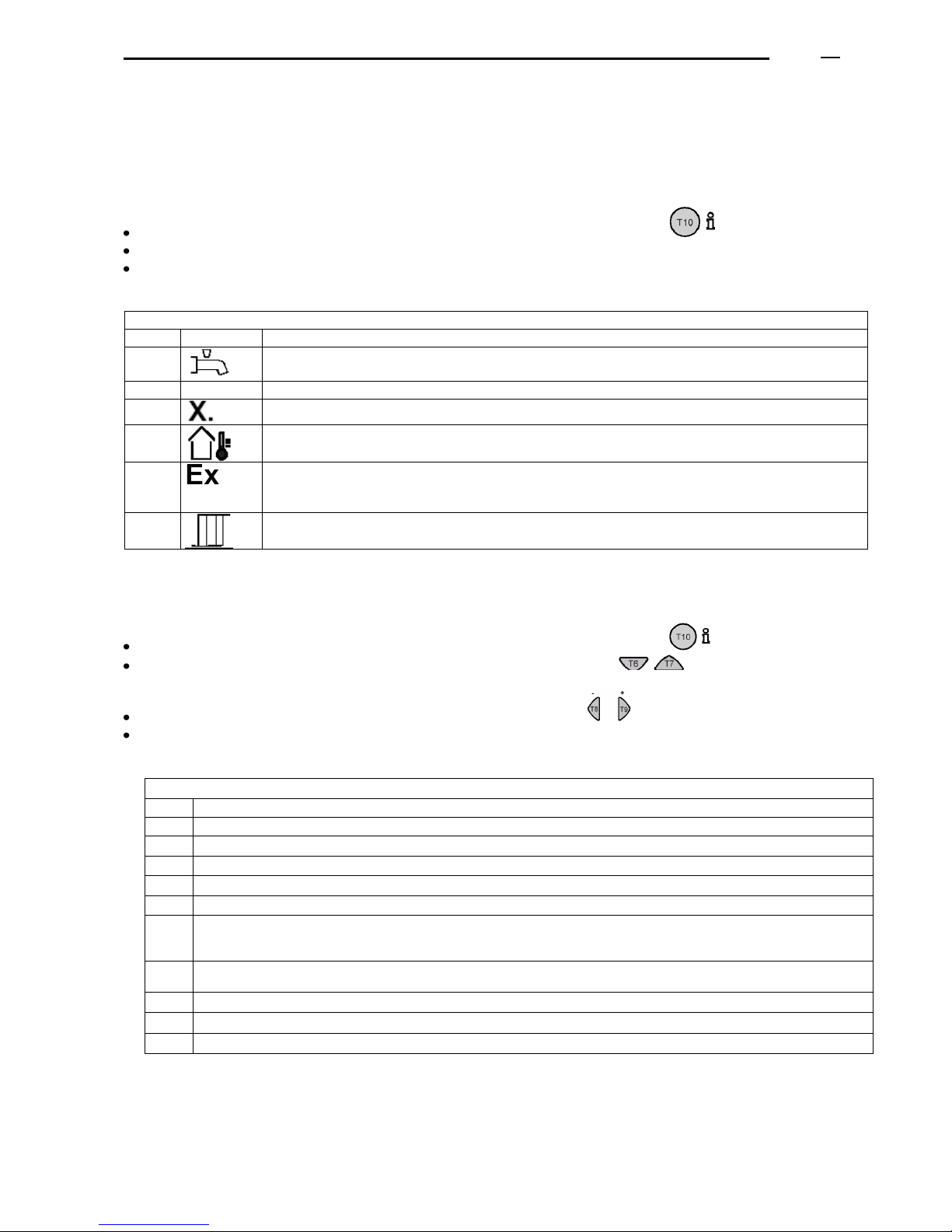

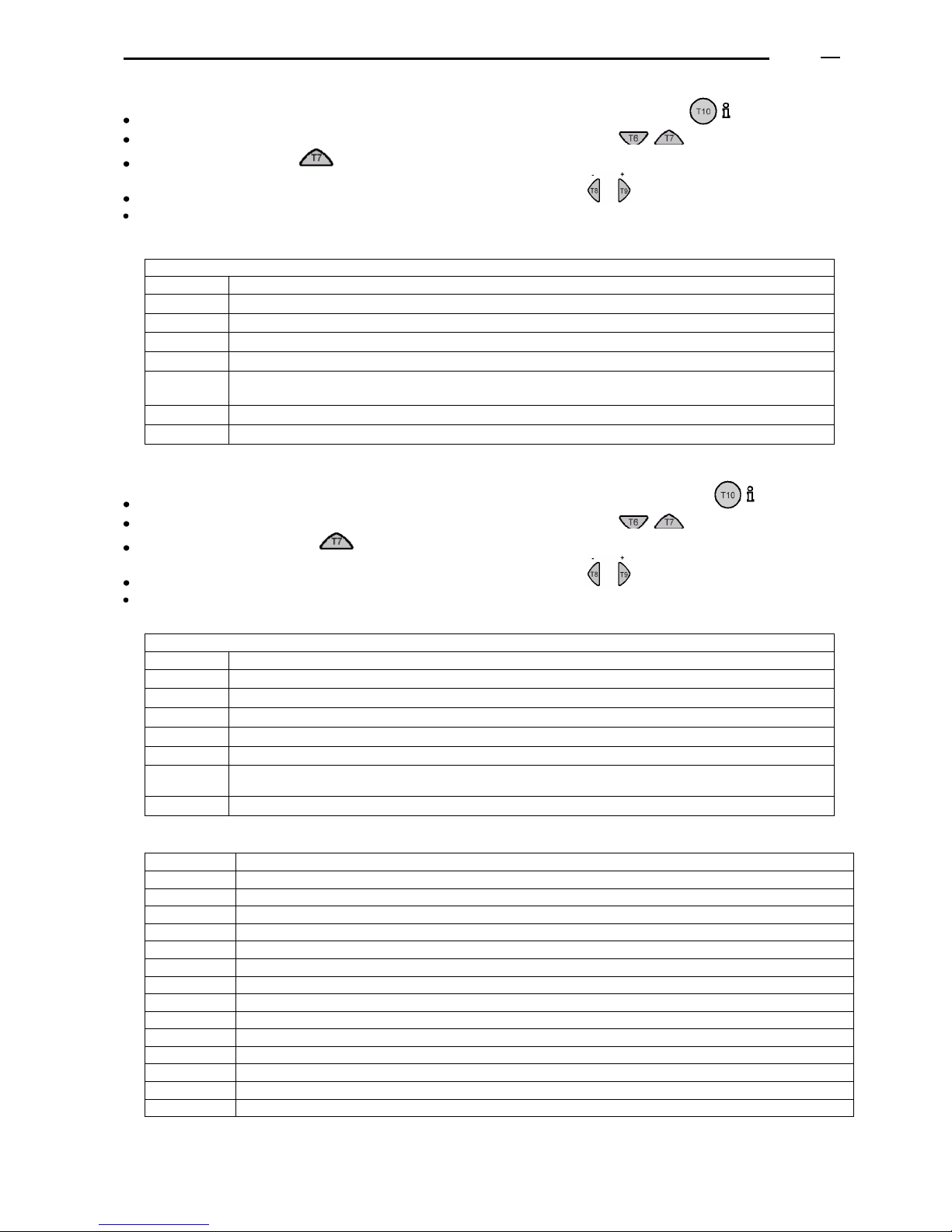

11.4 OPTIONAL: FLOW TEMPERATURE FUNCTION OF OUTSIDE TEMPERATURE

Attention: this function is optional and must be notified to the Official Technical Service in order to activate it.

An outside temperature probe should be added (supplied separately from the boiler and not included in the price)

and connected to terminals 1 and 2 of the strip X10-06 positioned in the LMU control unit of the ADI LT boiler.

These are the possible curves of operation:

Boiler flow

temperature (ºC)

External temperature (ºC)

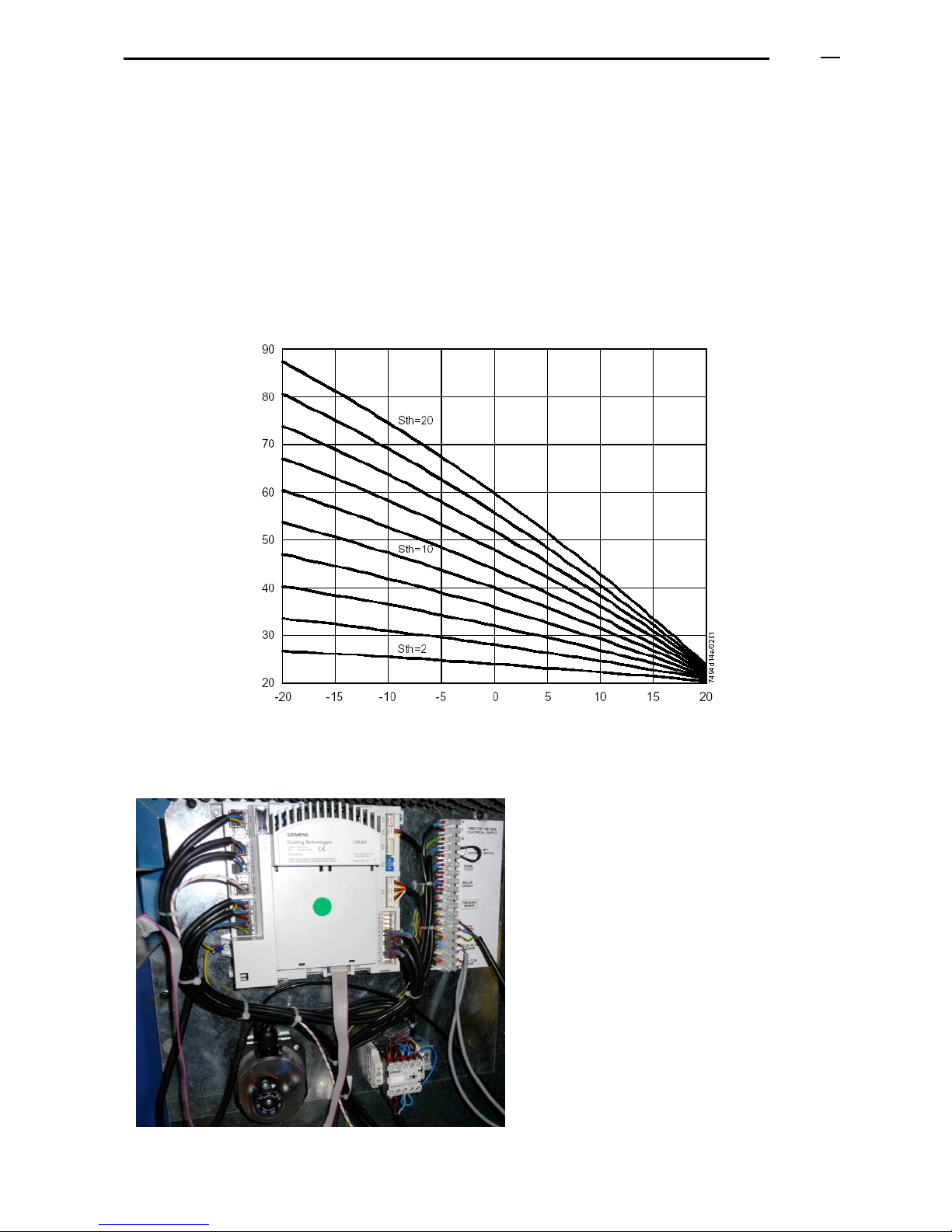

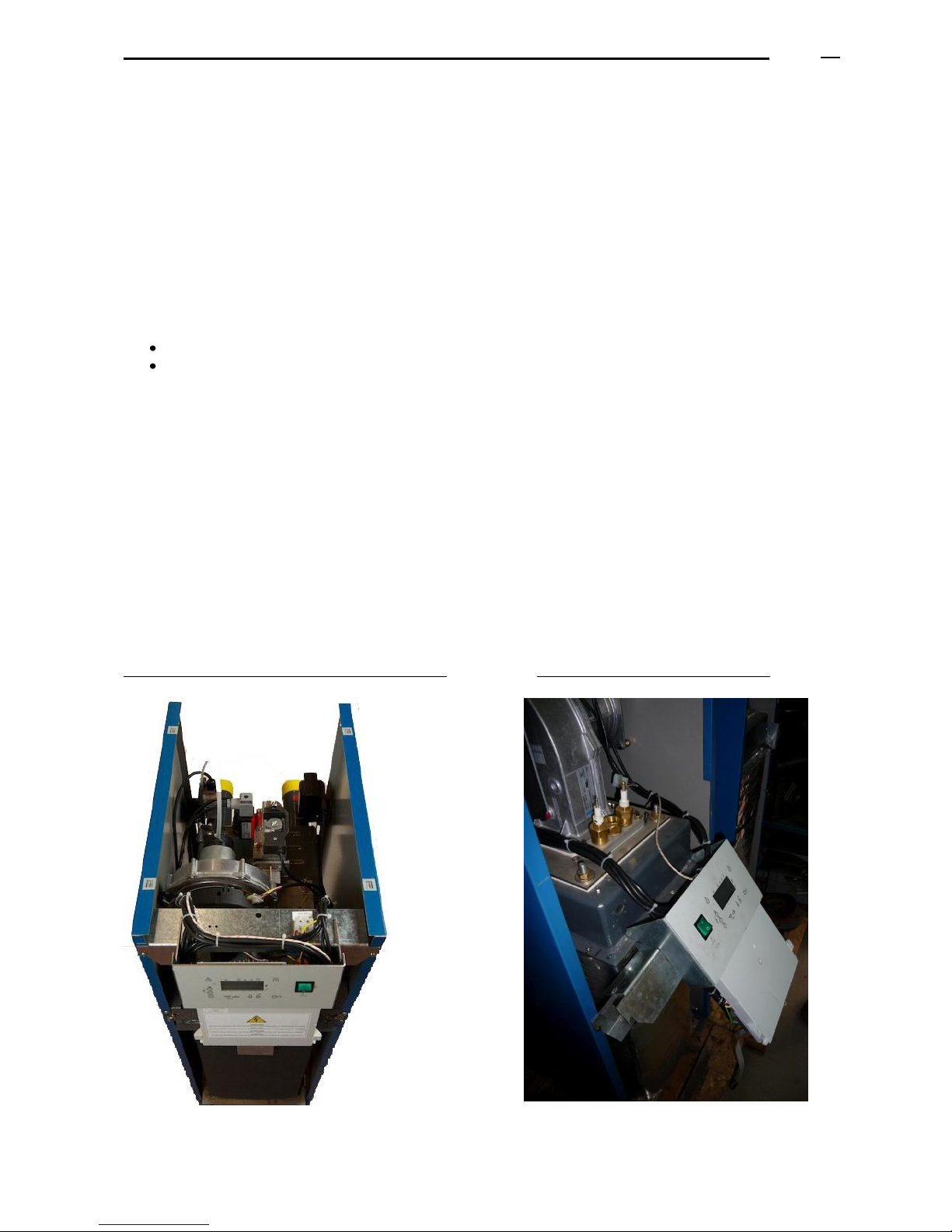

11.5 VIEW OF THE BOILER CONTROL UNIT

According to the boiler model, the position of

the control unit varies:

The position of the strip and of the contactor vary

(just in models of big power output). See electric

diagrams.

Page 24

ADI LT boiler - Technical Manual Page

L338 11/2011

24

11.6 REGULATION OF SEVERAL BOILERS

In an installation with several boilers it is important that the power generated by the boilers adapts at any moment

to the demand of the installation, always optimizing the generators’ efficiency.

11.6.1 Boilers simple sequence

The control unit must regulate the stop/start sequence of each boiler according to the demand of the installation (by

means of the flow temperature probe, which is common to all boilers, and at a constant flow temperature).

Then, each boiler will regulate its own power modulation according to the set-up temperature programmed for each

one.

The set-up temperature value of the control unit must be a bit higher than the value adjusted in each boiler.

We recommend realizing the boilers’ sequence and regulation according to the instructions indicated in the

following paragraphs.

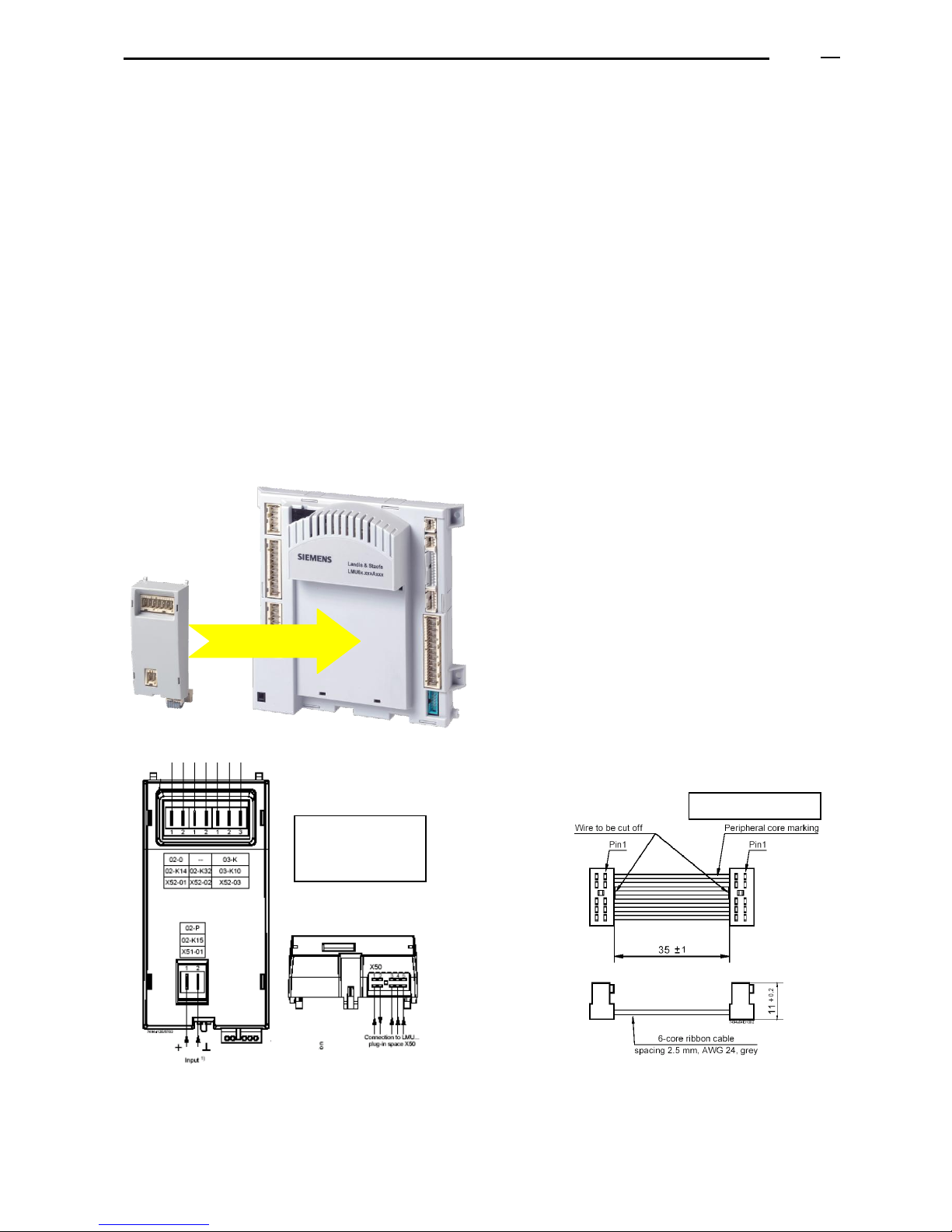

11.6.2 External control unit with signals 0…10 V to regulate the start-up and modulation of each boiler.

So that each boiler can receive and process an external signal type 0…10 V, it must be provided with (consult

prices):

- An additional module, or clip-in, model AGU 2.51

- A cable for connecting the additional module to the boiler control unit, mod. AGU2.104A109

Clipin

AGU2.510A109

LMU

This module enables an analog entry, that can be of two types:

- Probe (NTC, 10 KΏ)

- Voltage signal: 0…10 V

The signal 0…10 V will transmit to the boiler or a set-up temperature

value or a percentage of power output, so that it can operate (as it

will be set up in our factory).

The signal 0…10 V must be connected to the terminal + (1) of the

strip X51-01 of the “clipin”; to terminal 2 is connected neutral + earth.

Just one module type AGU2.510 can be connected to the boiler

control unit LMU, even though a total of 2 modules of different type

can be connected.

The connection between the module clip-in AGU2.510 and the boiler

control unit LMU must be realized by connecting the cable to the

terminal X50 of the LMU (see electric diagrams).

Do not connect the cable to terminals X52.

Front and lower

view of the

“clipin”

Connecting cable

Page 25

ADI LT boiler - Technical Manual Page

L338 11/2011

25

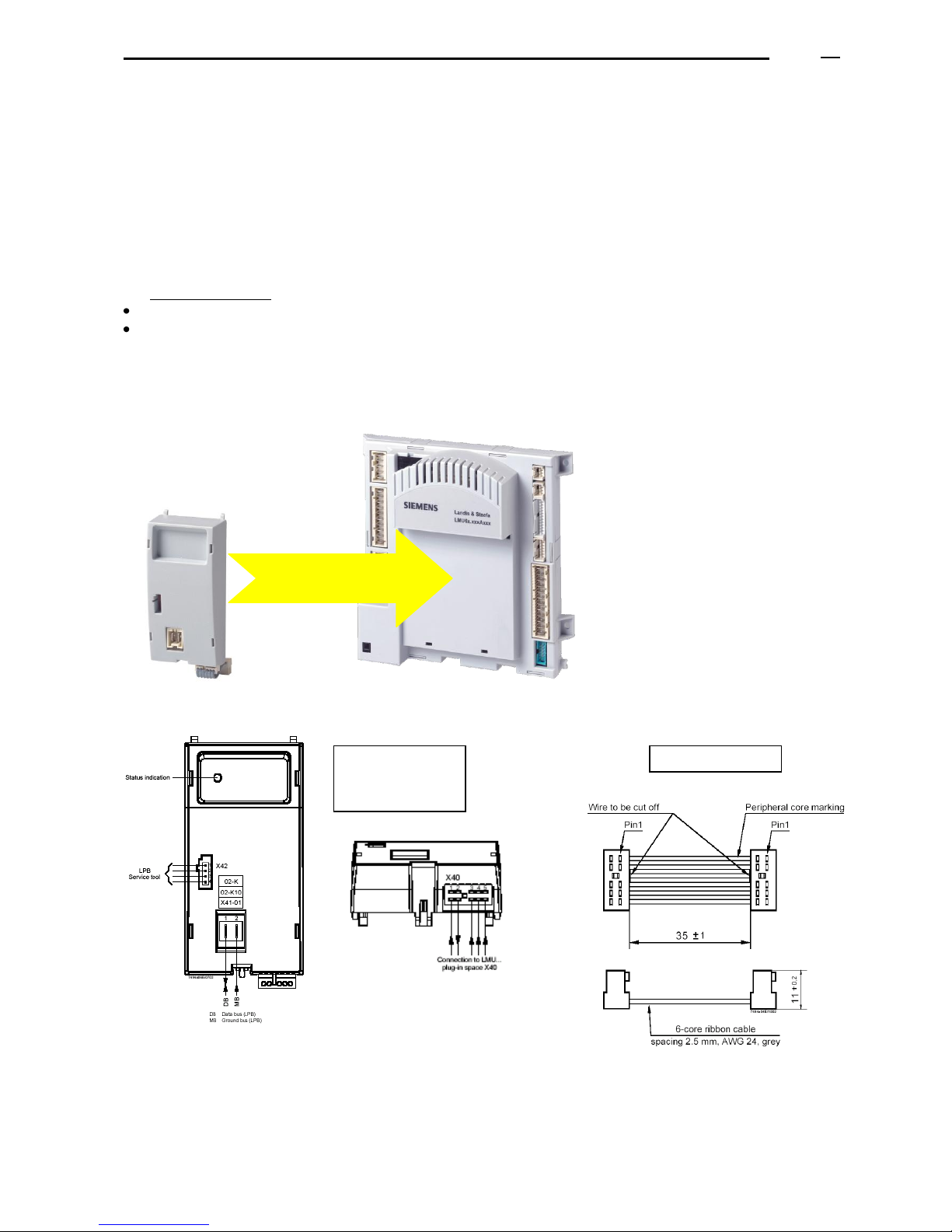

11.6.3 External control unit regulating and optimizing all the boilers’combined operation.

When there are several boilers supplying the same installation, the control units type RVS 63,…, enable to realize a

sequence up to 15 boilers equipped with the LMU control unit.

The sequence control unit allows evaluating the demand of the installation and regulating the boilers according to a

strategy of selection.

The communication bus LPB allows visualizing on the display of the sequence control unit RVS any error or

message coming from one of the boilers connected.

a) Add to each boiler:

An additional module “Clip-in” (consult the current pricelist) of communication bus type LPB, module OCI 420

A cable for connecting the additional module to the boiler control unit, mod. AGU2.104A109.

The Official Technical Service must realize a change in the internal parameters, in order to use this regulation on

the boiler.

The additional module OCI 420 must be connected to the LMU control unit of each boiler.

Clipin OCI420

LMU

Just one module type OCI420 can be

connected to the boiler control unit LMU,

but there can be a total of 2 different

modules.

The module OCI420 must be connected to

the boiler control unit LMU by connecting

the cable (ref. AGU2.104) to the terminal

X40 (see electric diagrams)

Connect the cables (normal electric cable)

to the terminals 1 and 2 of the strip X41-01

of the module OCI420, in order to connect

the sequence control unit RVS 63 (or

another control unit) and so realize the

connection by bus LPB.

Connecting cable

Front and lower

view of the

“clipin”

Page 26

ADI LT boiler - Technical Manual Page

L338 11/2011

26

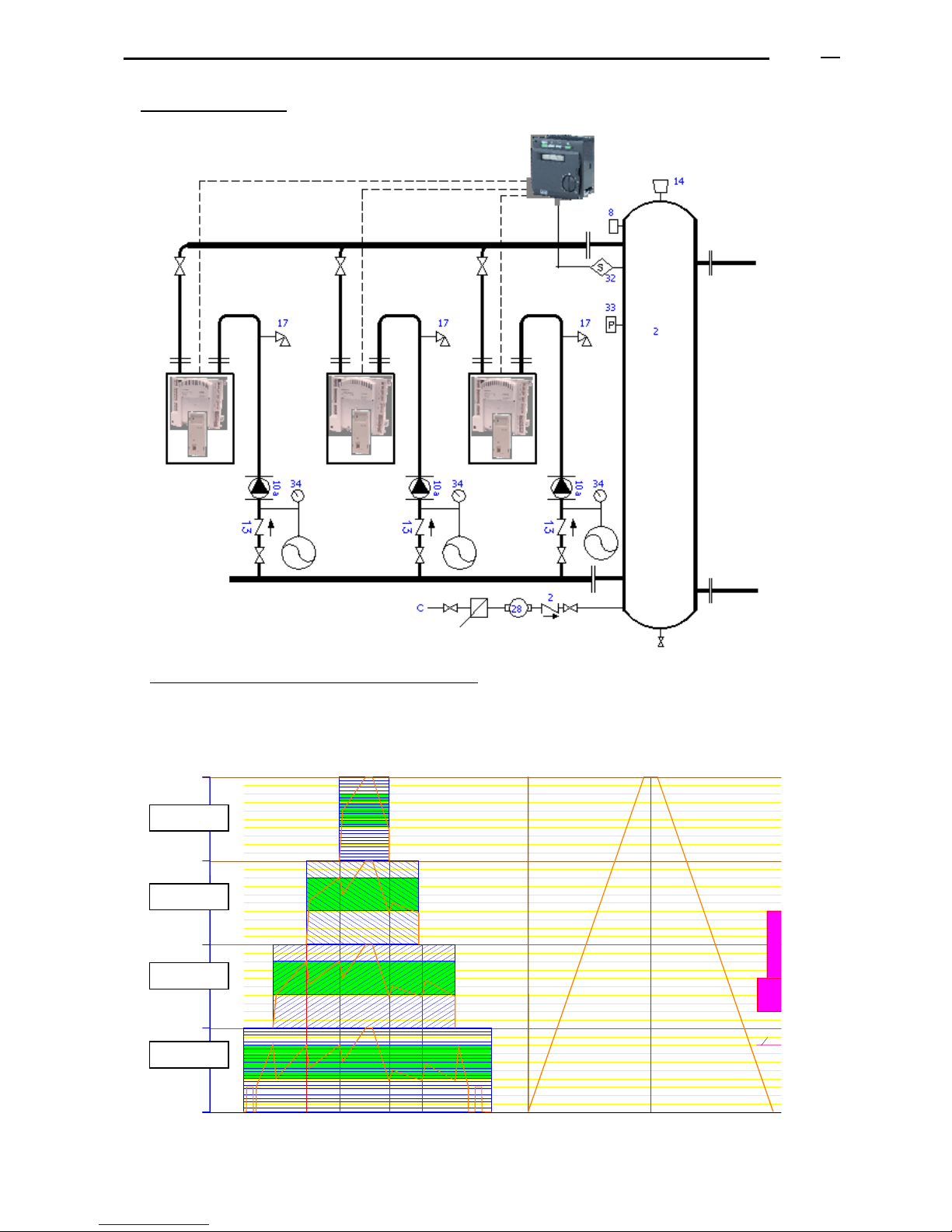

b) Boilers and installation

c) Example of boilers sequence and power regulation

Example of a possible sequence that can be realized (multiple options can be chosen).

Sequence control unit RVS 63,…

K e s s e l 4

K e s s e l 1 K e s s e l 2 K e s s e l 3

L e i s t B a n d M a x = 8 0 %

L e i s t B a n d M in = 4 0 %

O n / O f f

K e s s e l 2

O n / O f f

K e s s e l 3

O n / O f f

K e s s e l 4

300

200

100

400

Boiler 1

Boiler 2

Boiler 3

Boiler 4

LMU

LMU

LMU

OCI 420

OCI 420

OCI 420

Boiler 1

Boiler 2

Boiler 3

Page 27

ADI LT boiler - Technical Manual Page

L338 11/2011

27

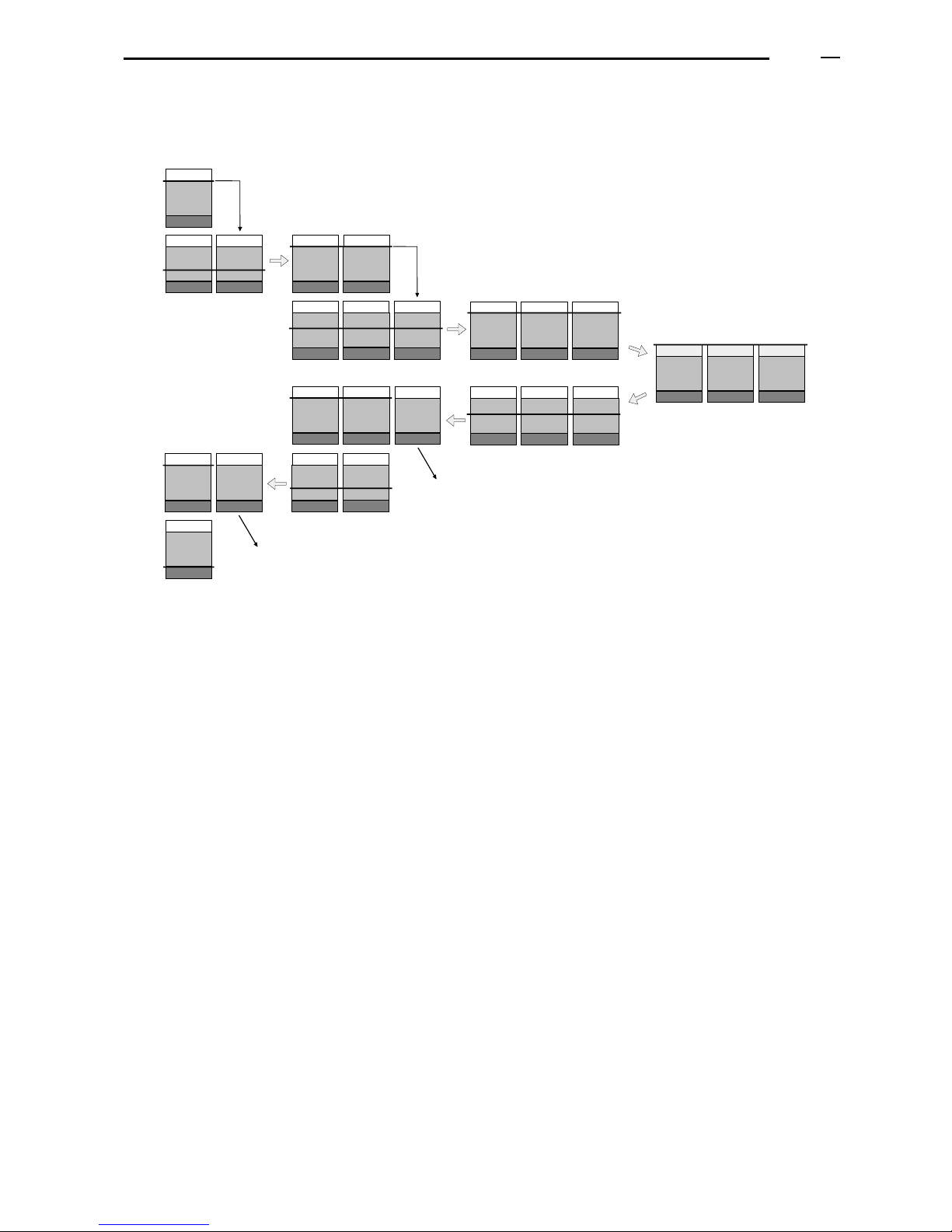

2379Z05

ON

ON

53%

53%53%

80%

40%

40%

80% 80%

80%

80% 80%

100%

100%

100%

OFF

OFF

53%

53%53%

80% 80%

40%

40%

80%

20%

In this example, the boilers activation and their power regulation would be realized as shown below:

Page 28

ADI LT boiler - Technical Manual Page

L338 11/2011

28

12. ELECTRIC DRAWINGS

The electric installation must comply with the current rules. The electric power consumed by each boiler is indicated

in the table of technical characteristics.

ADI LT 105 to ADI LT 750: The electric supply must be 220/230 V, 50 Hz, single phase, earth connection.

(Remember: in case of 220/230 V, two phases, it is necessary to install an electric insulating transformer with one

of the phases of the secondary connected to earth acting as neutral).

ADI LT 1300 to ADI LT 950 : The electric supply must be tri-phasal 380 V, 50 Hz, earth connection.

Legend of the electric drawing:

1. Fuse

2. Contactor

3. Electric supply of the motor fan

4. Option: Boiler pump stop/start

(Consult: the use of separation relays depends on the programming of the control unit)

5. Probe / ionization electrode

6. Electric supply (220/230 V) of the multi-block gas valve

7. Ignition transformer (220/230 V)

8. General switch: ON/OFF

9. Safety overheating thermostat

10. Display of reading

11. Signal of control of the modulation of the variable speed fan (PWM)

12. Air pressure switch

13. Minimum gas pressure switch

14. Main Electric supply to the boiler:

ADI LT 105 to 750: 220/230 V, 50 Hz, single phase with earth connection.

ADI LT 1300 to 950: Tri-phasal, 380 V, 50 Hz, with earth connection.

15. Stop/start switch external to the boiler: Stop/start external contact (open/close).

16. Signal of the boiler status: terminals with tension of 220/230 V, to be separated by means of a

relay.

17. Alarm indicator of boiler lockout: these are terminals with live tension of 220/230 V, to be

separated by means of a relay.

18. Water pressure sensor.

19. Return water temperature probe/sensor.

20. Flow water temperature probe/sensor.

23. Earth connection for burner

24. Option: Outside temperature probe (Consult: according to programming and installation)

25. Communication bus with additional modules “clip-in”. See the corresponding paragraphs.

26. Boiler control panel

27. Optional: electric supply of 220/230 V for additional modules “clip-in”

28. Boiler.

Page 29

ADI LT boiler - Technical Manual Page

L338 11/2011

29

12.1 ELECTRIC DRAWING ADI LT 105 - ADI LT 200

Page 30

ADI LT boiler - Technical Manual Page

L338 11/2011

30

12.2 ELECTRIC DRAWING ADI LT 250 - ADI LT 325

Page 31

ADI LT boiler - Technical Manual Page

L338 11/2011

31

12.3 ELECTRIC DRAWING ADI LT 400 - ADI LT 750

Page 32

ADI LT boiler - Technical Manual Page

L338 11/2011

32

13. SAFETIES

These are the safeties included in the boiler:

Cause for safety

activation

Safety

component of

the boiler

Boiler restart

No flame

Ionization

electrode

Manual reset

Fan failure/air

passage obstruction

Air pressure

switch

Manual reset

Overheating

Safety

overheating

thermostat

> 90ºC+- hysteresis: the regulation stops the boiler.

> 95ºC: boiler lockout, error on the display. Manual reset.

> 100ºC: fan at the maximum power to cool down the boiler.

> around 103ºC: lockout, other error on the display, manual reset.

No gas

Minimum gas

pressure switch

Automatic reset

Low water flow

through the boiler

Boiler control unit

Safety 1: if the DeltaT in the boiler is higher than the maximum Delta

T, the power drops by 20%.

Safety 2: if it overcomes “the maximum Delta T” + 8ºC, the boiler

operates at the minimum power.

Safety 3: if it overcomes a higher value, the boiler stops and an error

message appears on the display E 154/434 or E 154/433.

Lack of water

pressure in the circuit

Pressure sensor

The boiler stops for safety if pressure in the circuit is around 0,8 bar.

14. BOILERS IDENTIFICATION LABEL

The identification label of each boiler is placed:

a) In the front of the boiler, attached to the

higher water collector of the boiler heat

exchanger.

In order to visualize it, you have to lift up the

top casing of the boiler and remove the front

casing. You will see the serial number and the

boiler model.

b) In an adhesive label in the external part of

the boiler, where you will see the rest of data.

BOILER FRONT VIEW

Page 33

ADI LT boiler - Technical Manual Page

L338 11/2011

33

15. INSTALLATION

15.1 BOILERS HEAT OUTPUT

The boilers total power output to be installed must be the proper one to respond to the demands of the installation.

In order to generate heating with the maximum efficiency at every moment, it is important to consider the number of

the boilers to be installed, so that the total power should be appropriate for the different demands of the installation

in the different periods of the year.

15.2 LIFTING AND TRANSPORTING THE BOILERS BY A CRANE

15.2.1 Models ADI LT 250 and higher:

a) In order to lift the boilers by a crane, attach the straps to the boiler hooks: there

are 2 in the front and 1 in the back of the boiler heat exchanger. Before realizing

this operation, you have to dismantle / take out all the casing panels of the boiler.

b) They are provided with some sections on the base to ease

their transport by transpallet.

c) Anti-vibrating supports (silent-blocks) are supplied with

each boiler.

15.2.2 Models ADI LT 200 and lower

Supplied on pallet. Anti-vibrating supports (silent-blocks) are supplied with each boiler.

15.3 BOILERS ROOM

The boilers room must be clean, well vented and lightened, and must comply with the current regulations for gas

equipments. It is important to avoid environments with excess of humidity, dust and aggressive steams. If the

boilers room needs to have some building works, the boilers should be switched off and protected in order to avoid

dust.

For an easier maintenance it is important to respect the minimum distances indicated by the regulations and the

manufacturer’s instructions, both for one boiler and for several boilers. Every part of the boiler must be easily

accessible.

Installation of several boilers (modular assembly): being the boilers maintenance realized from the front and the

back, several boilers can be installed leaving a minimum distance of 10 cm between them.

MINIMUM FREE HEIGHT TO REMOVE THE BURNER:

In order to remove the burner, leave a free space between the top of the boiler and the ceiling.

Model

LT 105

LT 130

LT 150

LT 200

LT 250

LT 275

LT 325

LT 400

LT 475

LT 550

LT 650

LT 750

Minimum nett free space

from the top of the boiler

350

600

600

197

197

97

97

167

167

282

282

282

Free height from the leaing

point of the boiler on the

floor

1475

1725

1725

1725

1805

1705

1705

1775

1775

1975

1975

1975

Boiler draining: Connect the boiler draining to the

boilers room drainage.

In order to drain water from the boiler, turn off the boiler,

close the cut-off valves and open the boiler draining.

Beside the boiler draining, there is a connection with a

threaded bar that has to be unscrewed and taken out in

order to allow the draining of the water from the boiler.

Page 34

ADI LT boiler - Technical Manual Page

L338 11/2011

34

15.4 GAS SUPPLY

The gas supply pressure, the gas flow and the dimensions of the gas connection, they all depend on the type of

gas used, according to the boiler installed and the current regulations.

Gas connection: the installing company has to install a three-pieces coupling per boiler in order to facilitate the

dismantling and the maintenance of every boiler.

The boiler incorporates a small mesh. If the connecting pipe is not clean or has particles, the mesh will immediately

block, so the installing company will have to install a gas filter before the boiler gas connection.

If the boilers gas pressure is higher than the maximum value indicated in this manual, it is necessary to install a gas

pressure governor so that the inlet working pressure can be in accordance with the values required.

It is advisable to install a flue gas header previous to the boilers that will operate as a gas inertial tank when the

boilers start working.

When different consumptions are simultaneously required, the dimensions of the gas pipes and of the gas

connections must be calculated so that, when all the consumptions are demanded simultaneously, the inlet working

gas pressure to each boiler will correspond to the values indicated in this manual (see table TECHNICAL DATA).

15.4.1. Gas pressure higher than 45 mbar.

Units Boiler model

Inertial

volume

m3

1

ADI LT 105

0,0102

1

ADI LT 130

0,0128

1

ADI LT 150

0,0146

1

ADI LT 200

0,0186

1

ADI LT 250

0,0225

1

ADI LT 275

0,0251

1

ADI LT 325

0,0310

1

ADI LT 400

0,0368

1

ADI LT 475

0,0449

1

ADI LT 550

0,0529

1

ADI LT 650

0,0598

1

ADI LT 750

0,0672

2

ADI LT 325

0,0621

2

ADI LT 400

0,0736

2

ADI LT 475

0,0899

2

ADI LT 550

0,1058

2

ADI LT 650

0,1196

2

ADI LT 750

0,1344

3

ADI LT 325

0,0931

3

ADI LT 400

0,1104

3

ADI LT 475

0,1348

3

ADI LT 550

0,1587

3

ADI LT 650

0,1794

2

ESQUEMA VARIAS CALDERAS

4

5

3

1

ESQUEMA UNA CALDERA

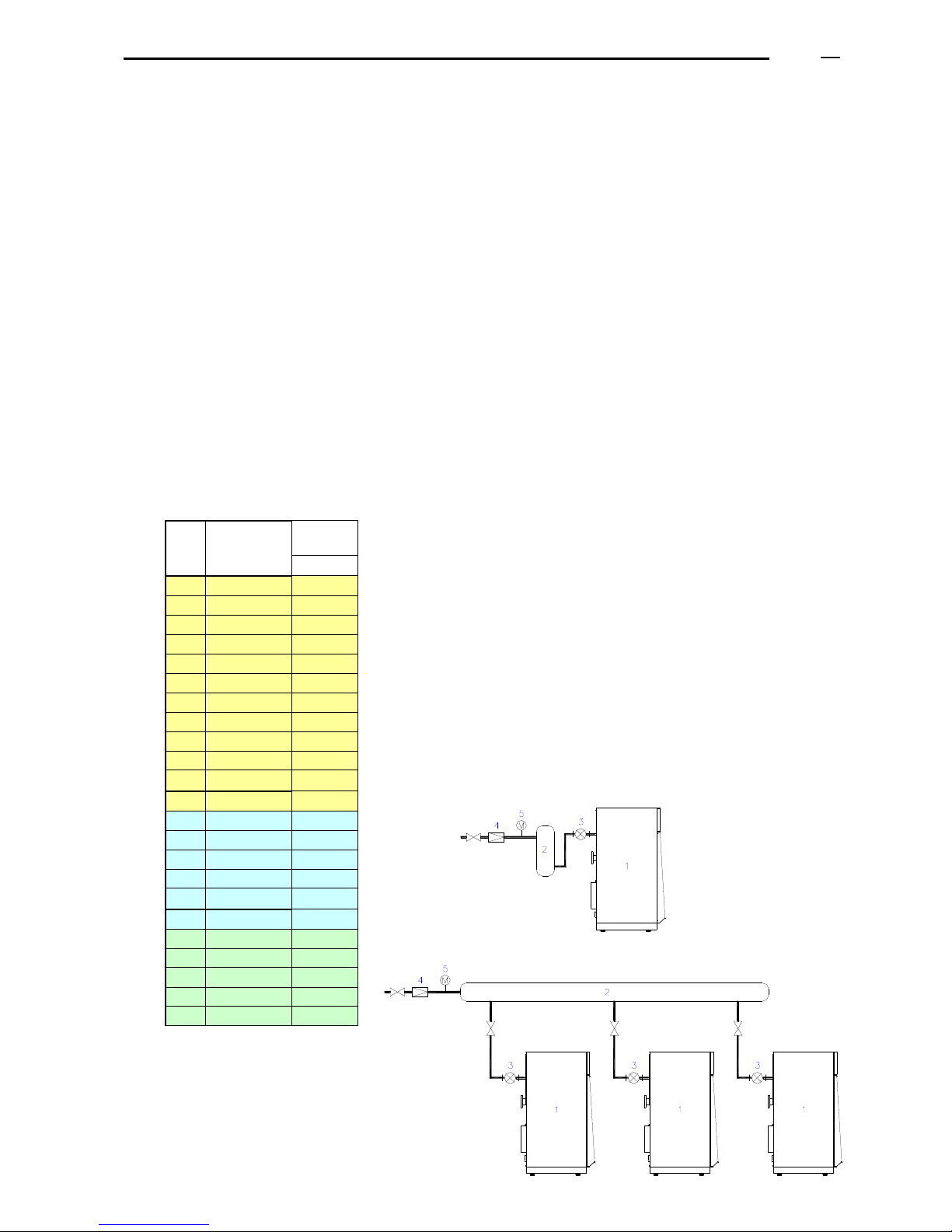

A gas pressure governor must be installed to reduce

pressure to a value in accordance with the table of

paragraph “Technical data”.

An inertial tank must be installed between the gas

pressure governor and the boiler, acting as a gas

inertial volume when the boiler starts up and as an

absorber/compensating of the pressure rise produced

by the closing of the gas pressure governor when the

boiler stops (see diagrams below).

Its volume will be at least equal to 1/1000 of the boilers

maximum flow per hour.

This inertial tank must be placed as close as possible

to the boiler.

2

ESQUEMA VARIAS CALDERAS

4

5

3

1

ESQUEMA UNA CALDERA

DIAGRAM OF 1 BOILER

DIAGRAM OF SEVERAL BOILERS

1. BOILER

2. GAS INERTIAL TANK

3. GAS FILTRE

4. GAS GOVERNOR

5. MANOMETER

Page 35

ADI LT boiler - Technical Manual Page

L338 11/2011

35

15.5 DRAINING OF THE BOILER CONDENSED PRODUCTS

15.5.1. Water condensing

Having the heat exchanger in stainless steel, the ADI LT boiler has no limit of the minimum return temperature.

This allows obtaining a higher profit of the heat generated by the combustion products:

- Sensible heat: the heat transferred due to the cooling of burnt gases.

- Latent heat: the heat transferred due to the energy issuing from the water steam when it condenses and

turns into liquid.

The energetic efficiency added thanks to the use of the latent heat of the condensed products can be up to 11% in

case of natural gas, which is the relation between the High Calorific Value (HCV) and the Low Calorific Value

(LCV).

The theoretical volume of the condensed products can be:

- 1,63 kg / m3

- up to 0,14 kg / kWh

15.5.2. Neutralization treatment of the condensed products.

For natural gas, the condensed water has a pH value that can be between 3,5 and 5,5.

It is recommended to realize a neutralization treatment of the condensed products before throwing them to the

general drainage of the building, or similar.

Generally, you have to make the condensed products circulate mixed with a sort of powder, which can be calcium

carbonate, hydrolyte of magnesium (salt formed by calcium hydride, CaH2, and magnesium) or similar, in order to

neutralize them, which means to increase the value of its pH so that it will be between 6,5 and 9.

It is recommended to realize periodical measurements of the water pH after the neutralization treatment: when the

value measured is lower than 6,5 it is recommended to replenish with the powder.

In any case, the neutralization treatment must be realized in conformity with the local, autonomic and national laws.

The neutralization system should be placed at a level of height lower than the boiler draining/outlet of the

condensed products. If this is not possible, consider the installation of a pump of condensed products.

15.5.3. Evacuation piping of condensed products.

- The boiler outlet of the condensed products should be connected to a siphon.

(Fill the siphon with clean water before starting the boiler).

- Some boiler models should be placed on a base with sufficient height to allow the installation of the draining of the

condensed products, of the siphon and of the connection to the neutralization piping of the condensed products.

- The evacuation of the condensed products to the general drainage should be realized in a visible way, through a

visible connection, open funnel or similar.

- Due to the characteristics of the condensed water, the material of the piping must be resistant to the action of the

acid water, for example: plastics (P.V.C).

- The evacuation pipe must have a minimum slope of 30 mm / metre

- Drainage by means of an external piping is not recommended, due to the risks of condensation and corrosion.

15.5.4. Boiler chimney

The chimney must be realized with materials that are resistant to condensed water, which is acid.

The gaskets joining the components of the chimney must be watertight.

The chimney must comply with the national and European regulations.

Page 36

ADI LT boiler - Technical Manual Page

L338 11/2011

36

15.6 CHIMNEYS

The flues outlet, according to the current rules, must ensure a correct evacuation of the burnt gases, without

backward flows and without producing condensed products. The natural draught of the chimney must evacuate the

burnt gases from the boiler flues outlet.

15.6.1. Chimney sizing

The internal diameter depends on:

- Heat input of the boilers, type, number of boilers installed and water working temperatures.

- Type of gas.

- Chimney: vertical height, horizontal length (minimum slope: of 3 to 5%),

- Number of elbows and their angles (they should be reduced to the minimum).

- The chimney material and if it is insulated or not.

If several boilers are connected to the same chimney, it is important to consider the distance between them and the

dimensions of the flue header.

The base of the vertical chimney must include a drainage pipe to evacuate the condensed products.

With regard to boilers, these are the data to be considered for calculation:

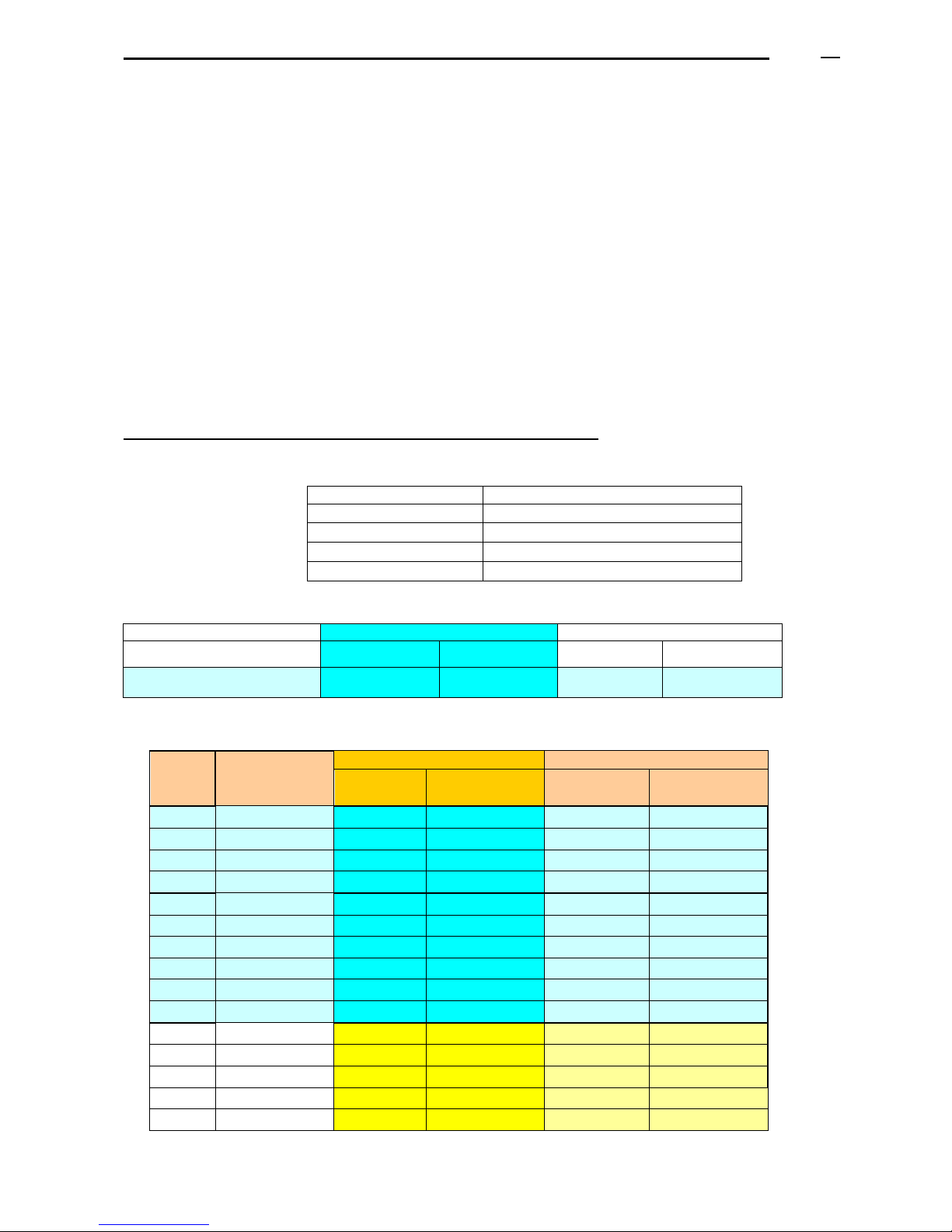

- Values of CO2, for Natural Gas: for all the boilers is recommended to adjust at 8,1% of CO2

Models

Range CO2 (%) for Natural Gas

ADI LT 105 to 200

7,3 - 9,1%

ADI LT 250 to 325

7,3 - 8,5%

ADI LT 400 to 750

7,3 - 8,8%

ADI LT 850 to 950

-----

- Flues temperature:

Flues temp.

MAXIMUM POWER

MINIMUM POWER

Average Water temperature

High ( 70ºC)

Low ( 40ºC)

High ( 70ºC)

Low ( 40ºC)

Flues Temp.

90 - 100ºC

65 - 75ºC

75ºC

40ºC

- Residual pressure at the flues output of the boiler:

Model

ADI LT

Ø flues output of the

boiler; External

diam. (mm)

MAXIMUM POWER

MINIMUM POWER

Power Input

kW

Residual Pressure

(Pa)

Power Input

kW

Residual Pressure

(Pa)

70

150

68

18,9

22,0

2,5

85

150

85

64,8

27,5

5,0

105

150

104

90,0

33,7

35,0

120

150

120

67,5

38,9

5,0

175

150

161,8

54,0

52,3

5,0

200

175

197,5

70,8

63,1

15,0

250

175

241

90,0

77,4

20,5

325

250

294

90,0

94,4

9,0

375

250

354

90,0

113,6

45,5

450

250

440

180,0

140,9

23,0

550

350

530

132,0

229,9

27,0

650

350

598

108,0

258,8

44,5

750

350

675

18,9

292,0

2,5

850

350

800

180

346,9

950

350

905

270

392,9

Page 37

ADI LT boiler - Technical Manual Page

L338 11/2011

37

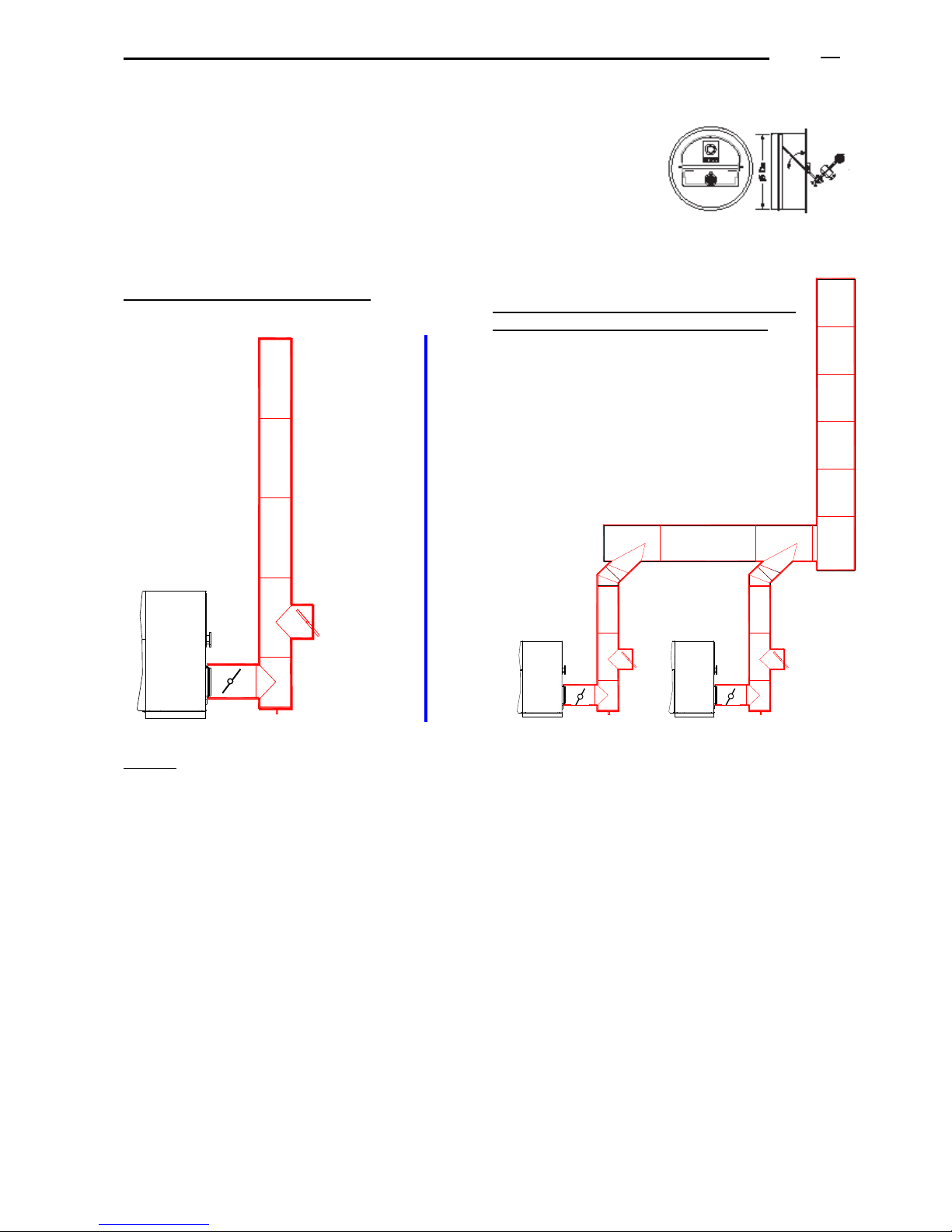

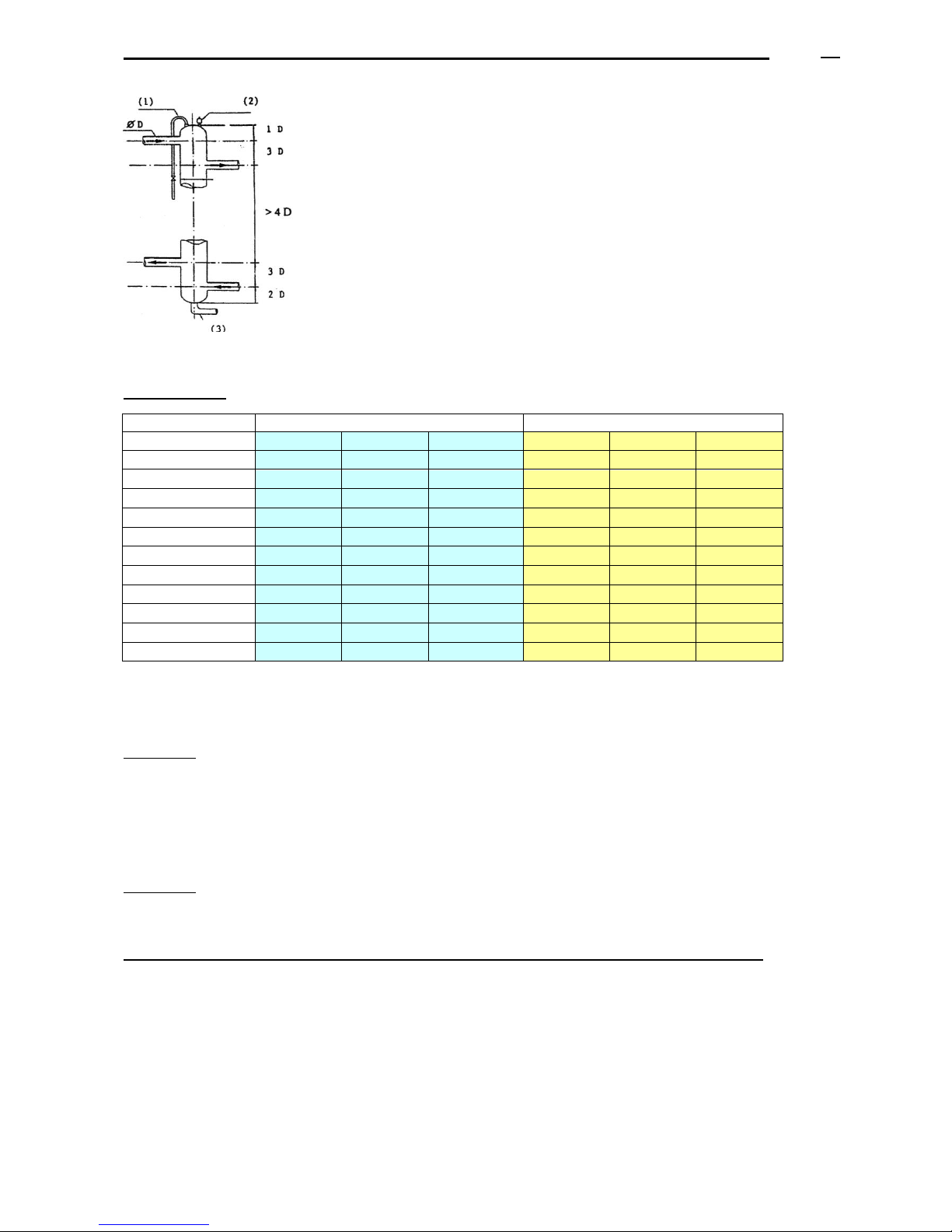

15.6.2. Flue draught stabilizer and volume control damper

It is strongly advised to install volume control dampers in all flue systems

and where excessive draught is likely to be encountered, then draught

stabilisers also should included.

In this case, you have to install a stabilizer for each boiler to guarantee

the correct draught of the chimney in all the boiler operating modes: at

the minimum power, at the maximum power and at intermediate points.

Example of a flue draught stabilizer:

Example 1: installation with 1 boiler

5

1

4

2

3

6

7

Legend:

1. Boiler

2. Adjustable/lockable volume control damper in initial flue section which should be as short as possible

3. “T” chimney

4. Draining: outlet of the condensed products and of rain water

5. Flue draught stabilizer

6. Vertical section of the chimney

7. Chimney outlet

8. Connection between boilers and flues collector

9. “T” to connect the flues collector to each boiler

10. Flues collector (we recommend that it has an upward slope up to the vertical section of the chimney, min. 3%)

CAUTION: Check that no flues gases are escaping through the damper (5). Damage may be caused to persons.

It is a responsibility of the installer company to check and ensure the proper operation of this matter. The

manufacturer of the boilers declines any responsibility for these matters.

15.6.3. Old installation

- If using a metallic and insulated chimney already existing, before installing the boiler it is advisable to verify that

the chimney has the right dimensions to allow a correct evacuation of the burnt gases and an easy cleaning of

its interior.

1

7

55

4

2

3

1

4

2

3

6

10

9

8 8

9

Example 2: installation with two boilers and

one common chimney (see regulations)

2

2

2

Page 38

ADI LT boiler - Technical Manual Page

L338 11/2011

38

- In case of using a brick chimney already existing, it is necessary to fit it with an internal metal casing in order to

avoid water condensing in all its length. If it is not possible to do it, it is advisable to install a new insulated

chimney, preferably made of stainless steel and in accordance with the current regulations.

15.7 HYDRAULIC INSTALLATION

15.7.1 Data to be considered

Concept

Value

Minimum water working pressure

1 bar

Maximum water working pressure

5 bar

Maximum flow temperature

90ºC

Minimum water pressure safety device

The boiler includes a water pressure switch, than stops the boiler once the water pressure achieves a minimum

value. Stop: at 0,8 + 0,1 bar, Reactivates at 1 + 0,2 bar

It is important to consider the following instructions (see hydraulic diagrams):

- Cut-off/closing valves in the flow and return pipes of each boiler.

- Do not weld the boiler to the installation piping.

- Models ADI LT 105 to ADI LT 200: male threaded flow-return connections of 2”.

- Higher models: flanged connections, up to 3” (PN 6), 4” (PN 10)

- Closed expansion vessel, calculated and installed according to the regulations.

- Overpressure safety valves and boiler draining in accordance with the current regulations.

- A pressure switch whose function is to stop the boiler if the hydraulic pressure is lower than the minimum

value.

- An air venting, or automatic purger of big capacity, installed in the flow pipe or in the higher part of the flow

circuit of the installation.

- A filter with a stainless-steel mesh of 0.3 mm in the heating return of every boiler.

- A water meter in the refilling of the primary circuit.

- A draining pipe for the evacuation of condensed products: it must be connected to the drainage of the boilers

room and it is important that the outlet is visible to verify if it condenses.

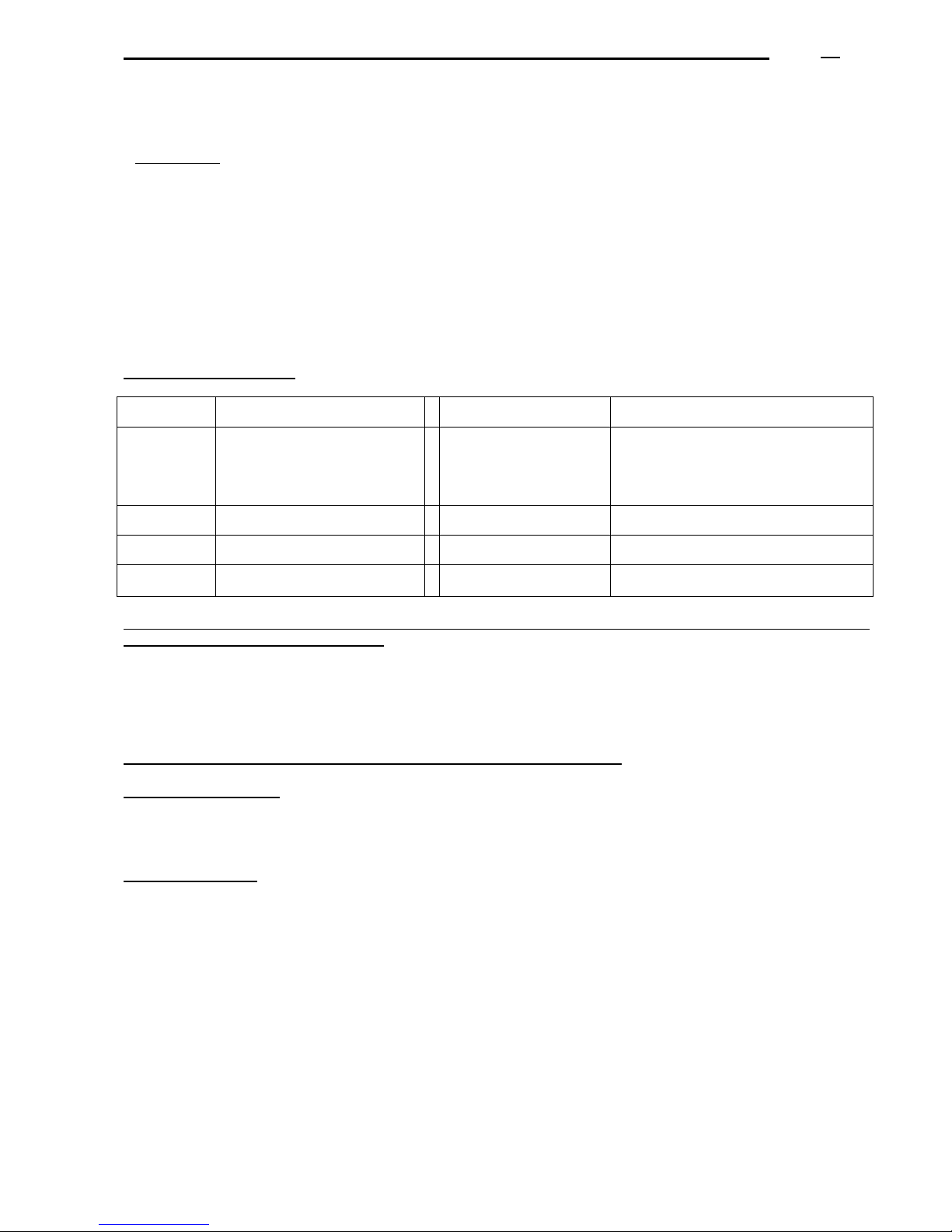

15.7.2 Overpressure safety valve

The boilers maximum operating pressure is 5 bar. This value must never be exceeded and precautions must be

taken to avoid this could happen, even accidentally.

It is important to install overpressure safety valves in each boiler, according to the current regulations and to the

equipments installed. Minimum dimensions of the safety valve:

ADI LT

105

130

150

200

250

275

325

400

475

550

650

750

850

950

105

INCHES

1"

1"

1"

1"1/4

1"1/4

1"1/4

1"1/2

1"1/2

2"

2"

2"

2"

Page 39

ADI LT boiler - Technical Manual Page

L338 11/2011

39

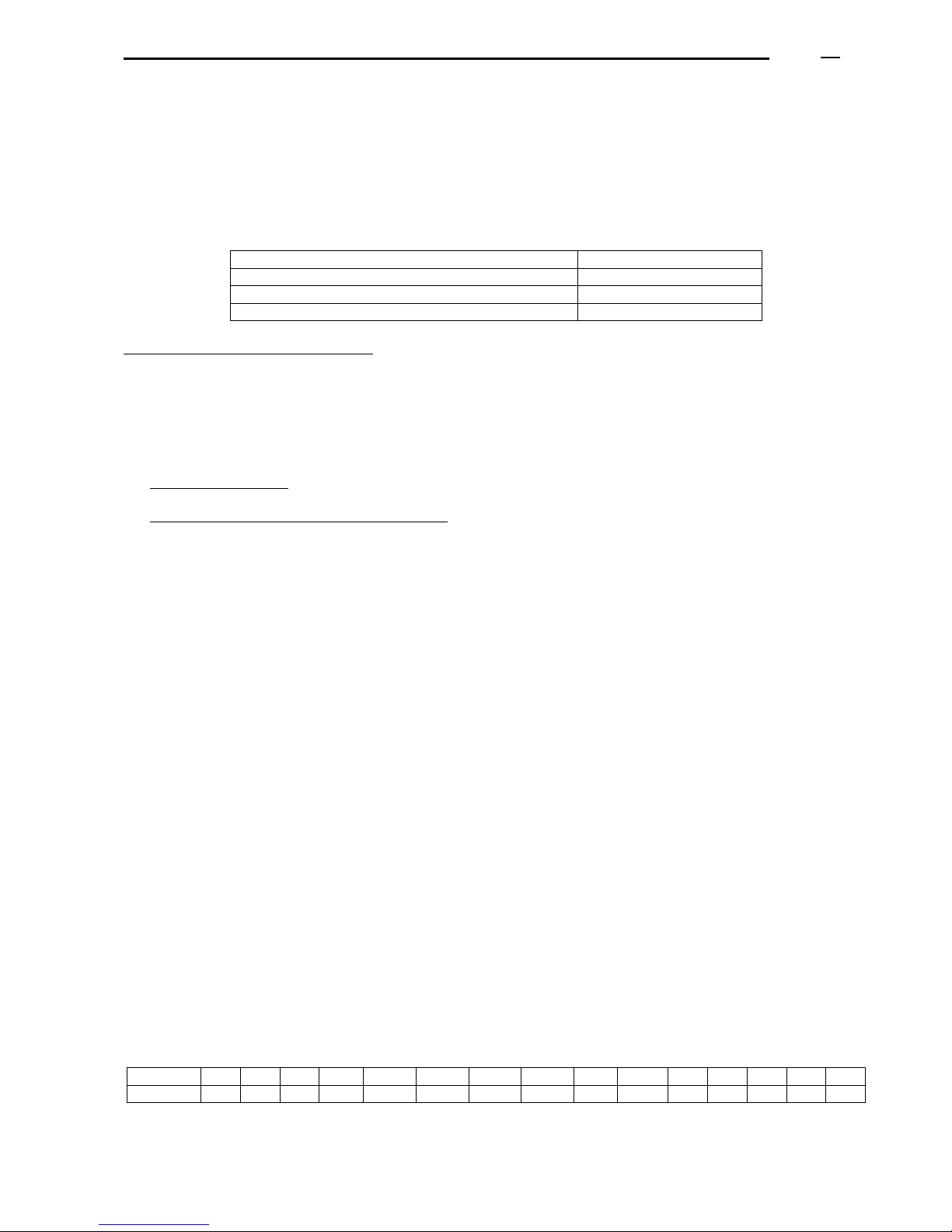

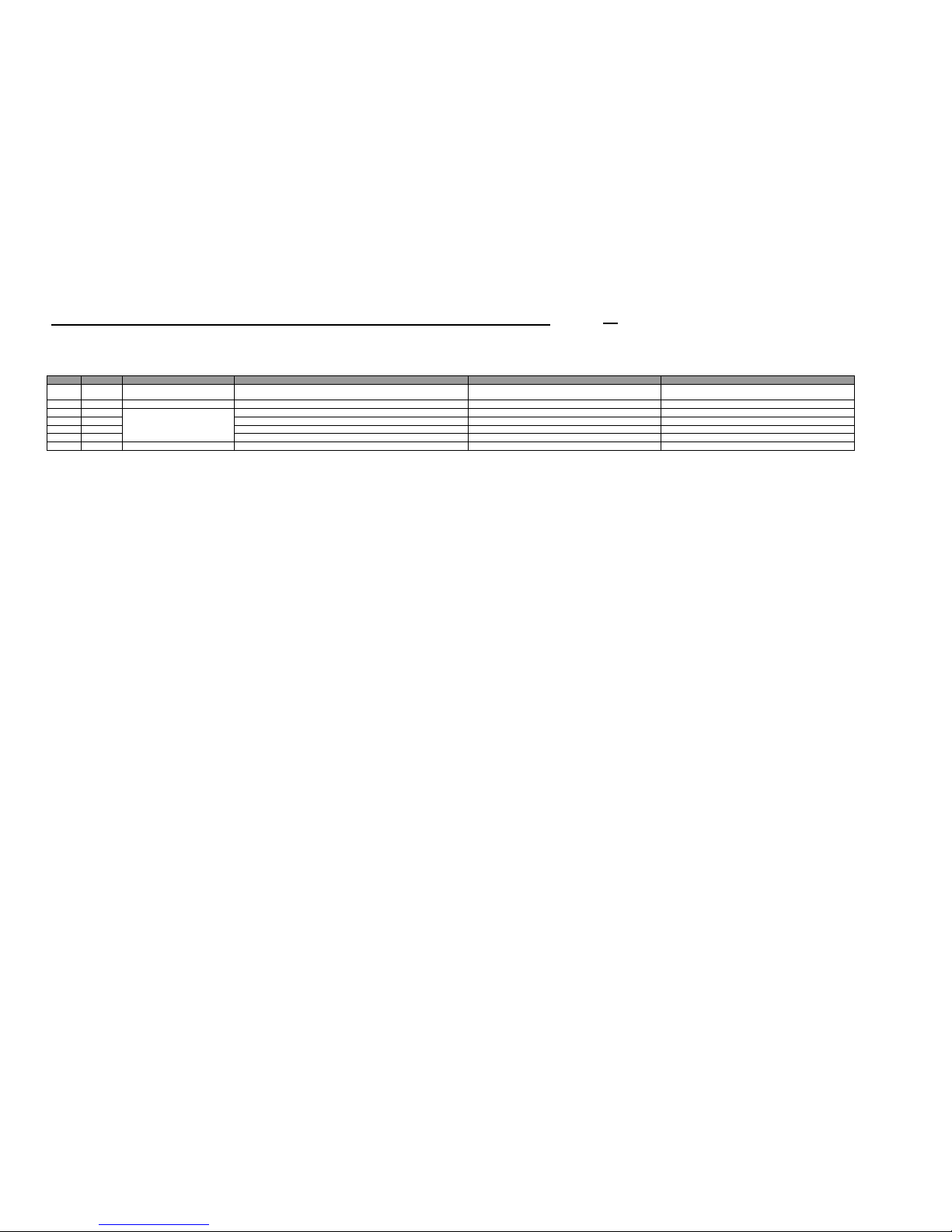

15.7.3 Hydraulic pressure drop

The boiler pressure drop depends on the water flow; the maximum ∆T must be 15 ºC:

Units

105

130

150

200

250

275

325

400

475

550

650

750

850

950

ΔT = 10ºC

m3/h

8,9

11,2

12,8

16,3

19,8

22,5

27,7

32,7

39,9

46,9

53,0

59,8

68,8

77,8

ΔT = 12ºC

m3/h

7,5

9,3

10,7

13,6

16,5

18,8

23,1

27,2

33,3

39,1

44,1

49,8

57,3

64,9

ΔT = 15ºC

m3/h

6,0

7,5

8,6

10,9

13,2

15,0

18,5

21,8

26,6

31,2

35,3

39,8

45,9

51,9

If you have to stop the boiler pump, it is required that you stop it with a time delay (3 to 5 minutes) once the boiler

has stopped. This can be obtained by installing a timer-disconnect electrical relay.

ADI LT

250 - 450

ADI LT

105 - 200

Page 40

ADI LT boiler - Technical Manual Page

L338 11/2011

40

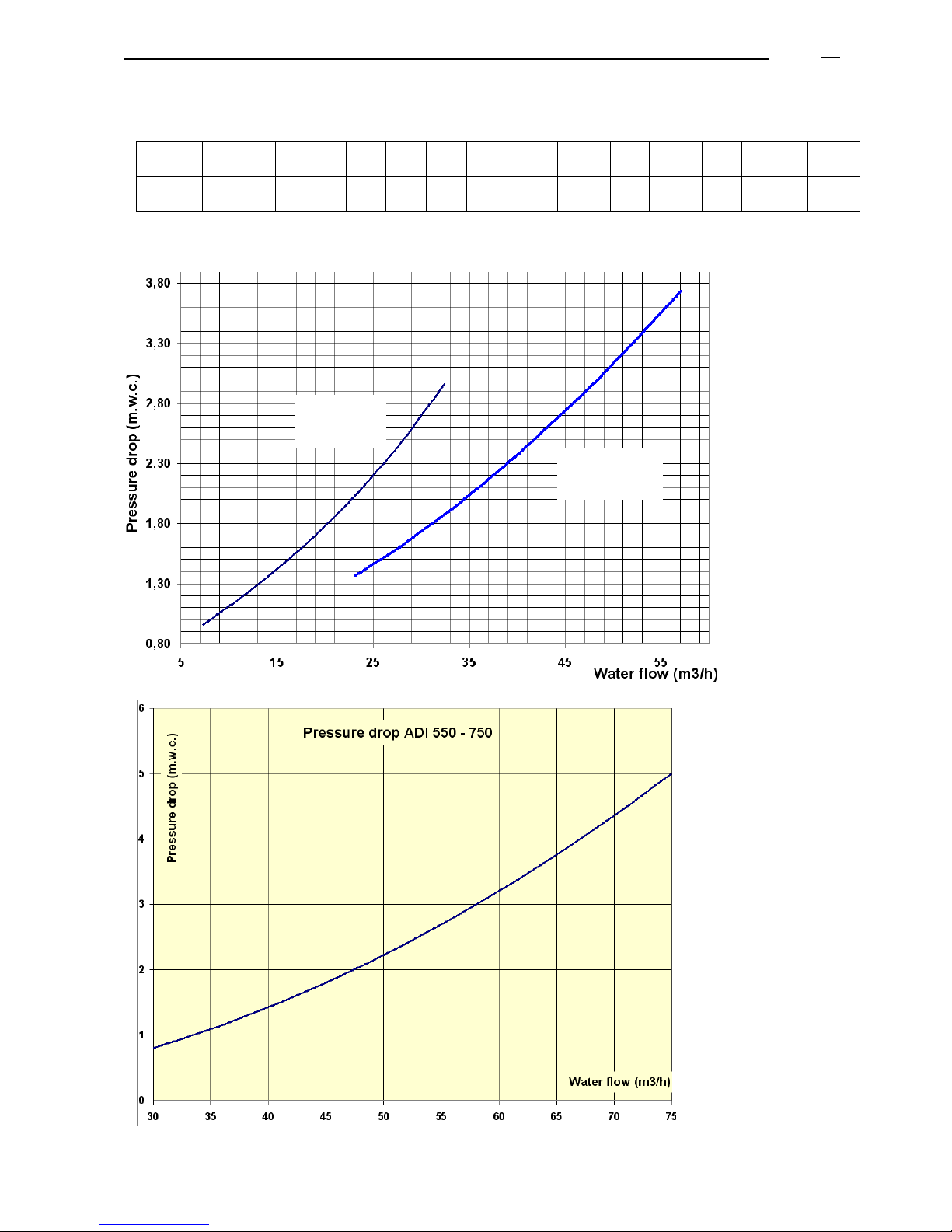

15.7.4 Water manifold

- It avoids hydraulic unbalances between the circuits and the boilers.

- It ensures a constant water flow to the boiler, independently from the

consumptions required. In accordance with current regulations.

- In case of heavy sludge in the water, it drives it to the bottom of the tank. It can

not avoid lighter sludge.

It is necessary to install (2) an automatic purger of big capacity in the higher part of

the tank, (3) an appropriate drainage with a diameter of 50/60, and optionally, (1) a

manual purger with a diameter of 15/21.

According to the total power installed (the sum of the heating output of all the boilers installed), may be calculated

the dimensions of the water manifold, as shown in this chart: diameter (inches) and minimum height.

Inertial volume

ADI LT

OPTION 1 (see text)

OPTION 2 (see text)

Nr. Boilers

1 boiler

2 boilers

3-4 boilers

1 boiler

2 boiler

3-4 boilers

ADI LT 105

20 litre

30 lit.

40 lit.

40 lit.

65 lit.

75 lit.

ADI LT 120

32 lit.

45 lit.

65 lit.

50 lit.

100 lit.

125 lit.

ADI LT 200

35

55

80

60

115

175

ADI LT 200

55

85

120

80

155

200

ADI LT 250

35

40

55

65

125

175

ADI LT 325

55

65

100

100

190

250

ADI LT 375

75

100

150

125

245

300

ADI LT 475

105

155

220

175

335

375

ADI LT 550

70

100

150

150

175

225

ADI LT 650

105

165

200

175

250

310

ADI LT 750

135 lit.

210 lit.

300 lit.

200 lit.

300 lit.

385 lit.

This inertial volume may be distributed between (see system drawings in this document) :

o Water header / collectors linked by a by-pass (not closed) or one common water header / manifold.