MHP WNK, TJK, WRG, TRG, THRG Installation Instructions Manual

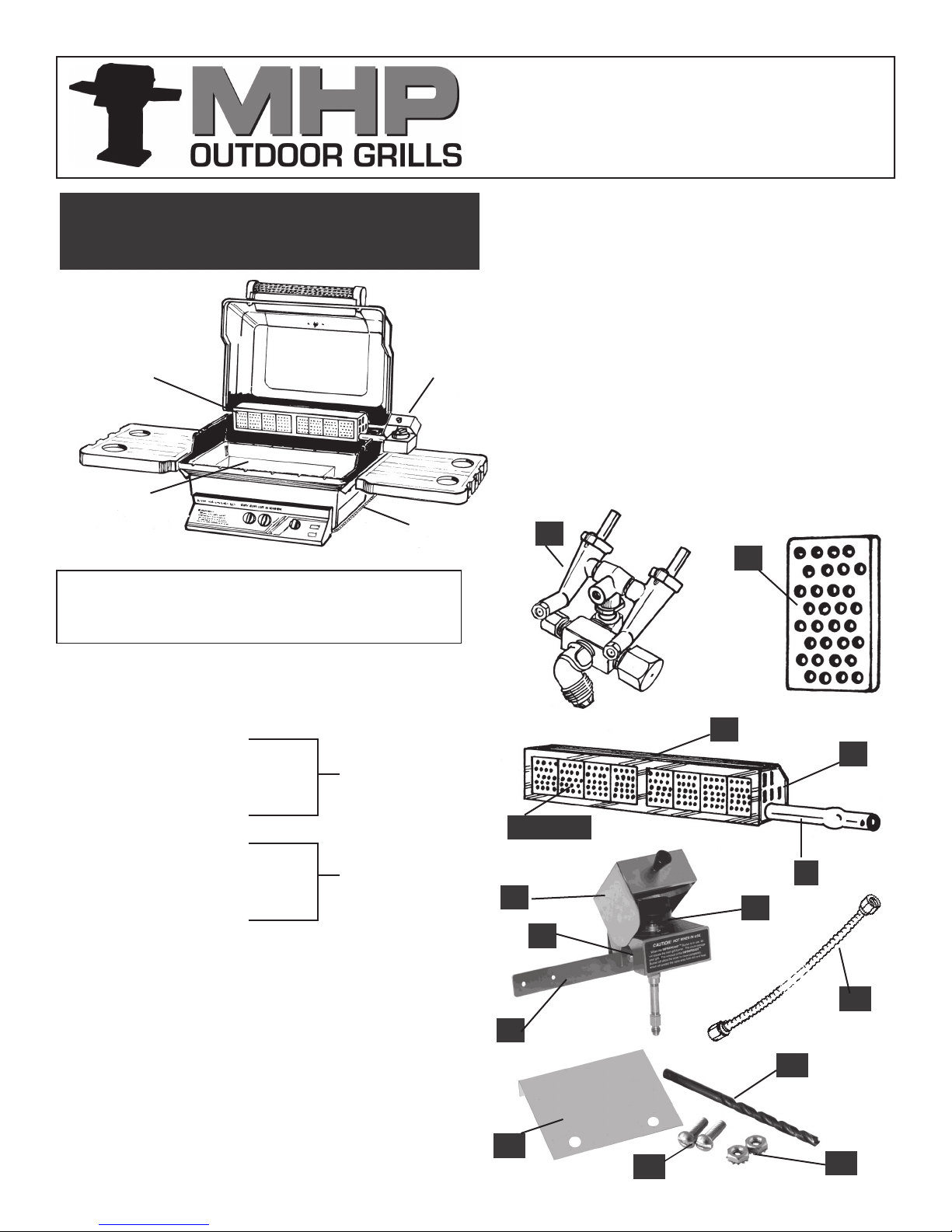

Infra-Roast Rotisserie

Burner

Installation Instructions

(Grill Models: WNK, WRG, TJK, TRG, and THRG Series)

Congratulations on your new purchase. We

wish you many enjoyable and memorable

cookouts.

Rear Burner

Installed

Drip Pan

Cooking

Grids Removed

UNPACK ALL COMPONENTS AND MATCH THEM WITH

THE PARTS DESCRIPTIONS ON RIGHT. CONTACT YOUR

DEALER IF ANY THING IS MISSING.

Control

Box

Gas Supply

S.S Tube

NOTE: The Infra-Roast Burner System RRB II is available for

both free standing and built-in grills (models above). The correct

part number for free standing grills is GGRRB2 and fits both NuStone and Fold Down Stainless Steel Shelf Models. GGBIRRB is

the correct part number for Built-In Models. You must specify

Natural or Propane as there is a difference in Orifice size.

It is very important that you have the correct burner to match

the gas being used.

When the rotisserie back burner is being used, DO NOT USE

THE INTERIOR BURNERS AT THE SAME TIME. It would create

too much heat and spoil the food on the rotisserie, and it could

damage the grill.

Before starting the installation, turn the gas off at its source; tank

or hose or pipe valve, not just at the front control panel valve.

Please read these instructions completely. The MHP Dealer or

the factory can answer any questions you may have.

1.

3.

1. Main Grill Replacement Control Valve and Manifold (Factory

Assembled)

2. Stainless Steel Burner Box

3. 8 Ceramic Tiles (not assembled)

4. Burner Tube (Venturi)

5. End Cap

6. Control Valve– Infra-Roast Burner

7. Control Valve Box

8. Valve/Box Mounting Bracket

9. Control Valve Knob

10. 1/4" Flare Flexible Stainless Steel Tubing

11. Drill Hole Template

12. Drill Bit

13. Two—10-24 x 1 3/4" Bolts

14. Two—10-24 Kep Nuts

Tools Required: Two wrenches capable of adjustment to cover a

range from 1/2" to 11/16"; a flat blade screwdriver, a pair of pliers and

an electric drill. No pipe sealant is necessary on flare fittings.

Factory Assembled

Factory Assembled

3. Installed

7.

6.

8.

11.

13.

2.

5.

4.

9.

10.

12.

14.

The first step in the installation is to remove the grill’s front con-

trol panel so you can gain easy access to the main grill control

valve and replace it with the new valve/manifold combination.

Make sure the gas is “OFF” at the main source. Using two

wrenches, as illustrated, disconnect the gas supply line from

the Main Control Valve under the center of the Control Panel. It

is easier to do it now while the valve is sturdily mounted.

Remove the Cooking Grids, rocks and rock grate from the grill

to get at the two 1/4-20 nuts that hold the Control Panel to the

grill casting. Remove these nuts using a 7/16" wrench. Pull the

panel carefully away from the grill and if you haven’t already,

disconnect the Ignitor wire from the Ignitor.

The Main Control Valve is held on a bracket with a single 1/-20

bolt with a 7/16" hex head nut. Remove the bolt and replace

this “OLD” valve with the new one. Tighten securely. Recycle

the old brass valve.

After reattaching the control panel with the two nuts previously

removed, reinstall the main fuel hose, as shown, using two

wrenches. Replace the Ignitor sire.

DO NOT TURN ON THE FUEL SUPPLY YET.

VERY IMPORTANT NOTE:

As illustrated at right. The main fuel supply from the tank, hose or

pipe connects to the 3/8" flare fitting that has no cap on it (No. 1).

The capped 3/8" flare fitting (No. 2) is for a future connection to a

side burner. Do not loosen or remove this cap unless it will be used

for the side burner.

The capped 1/4" flare fitting (No. 3) will be used to supply gas to the

Infra-Roast burner which you are installing now. Two wrenches

should be used to remove the cap so that the fitting will not be loosened from the manifold.

Next, drill the two control box mounting holes on the back side of the

bottom grill casting using the supplied drill bit and ;metal template. The

grill lid may be removed for easier access during this operation.

Standing behind the grill, position the template to rest on top of the bottom casting lip and slip it to the right until it contacts the hinge. Hold it

firmly in this position and using the supplied drill bit spot the holes enough

to break the paint surface to use as drill spot and indicator.

Remove the metal template and finish drilling the holes completely

through the casting.

Now you cant bolt the control bracket to the casting using the supplied

bolts and kep nuts.

NOTE: Built-In Grill Models Do Not need the casting drilled. The control

box and bracket simply bolt down to the two through mounting holes on

the stainless steel sleeve behind the right corner of the grill.

DISCONNECT GAS

SUPPLY LINE

Always Use Two Wrenches

One To Hold The Fixture

One To Loosen Or Tighten

This Is To Assure

Proper Tightening

REMOVE CONTRO PANEL

MOUNTING

IGNITOR

MOUNTING

DISCONNECT

IGNITOR WIRE

NEW VALVE ASSEMBLY

FACTORY INSTALLED 1/4"

FLARE CAP TOBE REMOVED

TO ATTACH 1/4" S.S. FLEXIBLE

GAS LINE TO BURNER

VALVE MANIFOLD

DIVIDES GAS TO

MAIN FUEL INLET TO

VALVE 3/8" FLARE

MOUNTING CONTROL BOX

3

CONTROL VALVE

3 OUTLETS

1

DRILL HOLES

Mounting

Bolt

NUT

BOLT

GAS SUPPLY

HOSE

1/4-20 X 3/4"

HEX HEAD BOLT

MAIN FUEL

INLET VALVE

FACTORY INSTALLED

3/8" FLARE CAP FOR

FUTURE SIDE BURNER

DO NOT REMOVE

1/4" FLARE CONNECTION

FOR S. S. GAS LINE

1/4-20

KEP NUT

2

CONNECTION

METAL TEMPLATE

FLUSH AGAINST

HINGE

MOUNT TO

BOTTOM

CASTING US-

ING BOLTS

AND KEP NUTS

SUPPLIED

Loading...

Loading...