MHP JNR4, TRG2, THRG2, WNK4, WRG4 Owner's Manual

...

MODERN HOME PRODUCTS GAS GRILLS

Owners Manual

Assembly and Maintenance Instructions

For Models JNR4, WNK4, WRG4, WHRG4, TJK2, TRG2,

and THRG2 Series

THIS GAS APPLIANCE IS DESIGNED FOR OUTDOOR USE ONLY.

If you smell gas:

1. Shut off gas to appliance.

2. Extinguish any open flame.

3. Open Lid.

4. If odor continues, immediately call

1. Do not store or use gasoline or

2. An LP cylinder not connected for

Follow all leak-test procedures carefully in this manual before using. Do

this even if the grill was dealer assembled. Do not try to light this appliance

without reading the “Lighting” in-

structions in this manual.

FOR YOUR SAFETY

your gas supplier or your fire department.

FOR YOUR SAFETY

other flammable vapors and liquids in the vicinity of this or any

other appliance.

use shall not be stored in the vicinity of this or any other appliance.

FOR YOUR SAFETY

YOU MUST READ THIS OWNERS

MANUAL BEFORE OPERATING

YOUR GAS GRILL.

Rev (7-16)

THESE INSTRUCTIONS SHOULD BE LEFT WITH

THE CUSTOMER. KEEP THESES INSTRUCTIONS

FOR FUTURE REFERENCE.

Safety

DANGER

Failure to follow the Dangers, Warnings and Cautions contained in this Owner’s Manual may result in serious

bodily injury or death, or in a fire or an explosion causing damage to property.

WARNINGS

CALIFORNIA PROPOSITION 65 WARNING: Chemicals known to the Sate of California to cause cancer, and birth defects or other

reproductive harm are created by the combustion of propane, charcoal, wood products, or natural gas used with this grill, and in the

preparation of grilled foods.

Do not store a spare or disconnected liquid propane cylinder under or near the barbecue.

Improper assembly may be dangerous. Please carefully follow the assembly instructions in this manual.

After a period of storage, and/or nonuse, the MHP Gas Barbecue Grill should be checked for gas leaks and burner obstructions

before use. See instructions in this manual for correct procedures.

Do not operate the MHP Gas Barbecue Grill if there is a gas leak present.

Do not use a flame to check for gas leaks.

Combustible materials should never be within 18 inches of the bottom, back or sides of your MHP Gas

Barbecue Grill.

Do not put a barbecue cover or anything flammable on, or in the storage area under the barbecue.

Children should never use your MHP Gas Barbecue Grill. Accessible parts of the barbecue may be very hot. Keep young children

away while it is in use.

You should exercise reasonable care when operating your MHP Gas Barbecue Grill. It will be hot during

cooking or cleaning and should never be left unattended, or moved while in operation.

Should the burners go out while in operation, turn all gas valves off. Open lid and wait five minutes before

attempting to relight, using the lighting instructions.

Do not use charcoal or lava rock in your MHP Gas Barbecue Grill.

Never lean over open grill or place hands or fingers on the front edge of cooking box.

Do not enlarge the valve orifices or burner ports when cleaning the valves or burners.

The MHP Gas Barbecue Grill should be thoroughly cleaned on a regular basis.

Liquid propane gas is not natural gas. The conversion or attempted use of natural gas in a liquid propane

unit or liquid propane gas in a natural gas unit is dangerous and will void your warranty.

Do not attempt to disconnect any gas fitting while your barbecue is in operation.

Use heat-resistant barbecue mitts or gloves when operating barbecue.

LIQUID PROPANE GAS UNITS ONLY

Use the regulator that is supplied with your MHP Gas Barbecue Grill.

Do not attempt to disconnect the gas regulator or any gas fitting while your barbecue is in operation.

A dented or rusty propane cylinder may be hazardous and should be checked by your local liquid propane

supplier. Do not use a liquid propane cylinder with a damaged valve.

Although your liquid propane cylinder may appear to be empty, gas may still be present, and the propane

cylinder should be transported and stored accordingly.

If you see, smell or hear the hiss of escaping gas from the liquid propane cylinder:

1. Move away from the liquid propane cylinder.

2. Do not attempt to correct the problem yourself.

3. Call your fire department.

2

TABLE OF CONTENTS

Safety (Dangers & Warnings)……………. 2

Warranty……………………………………... 4

General Instructions………………………. 5

Mountings……………………………………. 6 -13

Cart……………………………………………….. 6 -7

Deck/Patio……………………………………….. 7-9

In-Ground………………………………………… 9

Optimum Console………………………………. 10 -11

Built-In……………………………………………. 12 -13

JNR/WNK Grill Assembly…………………. 14 -18

TJK Grill Assembly…………………………. 19 - 20

WRG4 & TRG2 Assembly…………………. 21-22

WHRG4 & THRG2 Assembly…………………. 23-24

Contents

Gas & LP Tank Connections……………… 25 - 26

Leak Testing & Lighting The Grill……….. 27

Maintenance…………………………………. 28 - 29

Annual Maintenance………………………….

General Maintenance………………………...

28

28 - 29

30 Tube Bending………………………………..

Troubleshooting……………………………. 31

Parts Information…………………………… 28 - 31

MHP Grill upgrade options for added

versatility, convenience and cooking enjoyment.

Exclusive, rust-free anodized aluminum cooking

grids. This unique cooking system heats up faster, re-

duces flare ups and cooks all foods at a higher temperature, thereby searing in the delicious barbeque juices.

Wide-ribbed side for grilling steaks, chops, burgers and

ribs, branding them with sear lines. The flip side, with its

smooth surface is ideal for grilling delicate foods such as

fish, seafood and vegetables.

Stainless Steel Side Burner.

The premium commercial grade

stainless steel side burner is

12,000 BTU rated, has its own

electronic ignition, and is factory

assembled for simple drop-in

installation.

Infra-Roast™ Rotisserie Burner

System. Infra-red rear burner heats

up fast to quickly put a seal around

meats for juicier and more moist

results. Constructed of commercial

grade stainless steel and is easy to

install or remove for normal grilling.

3

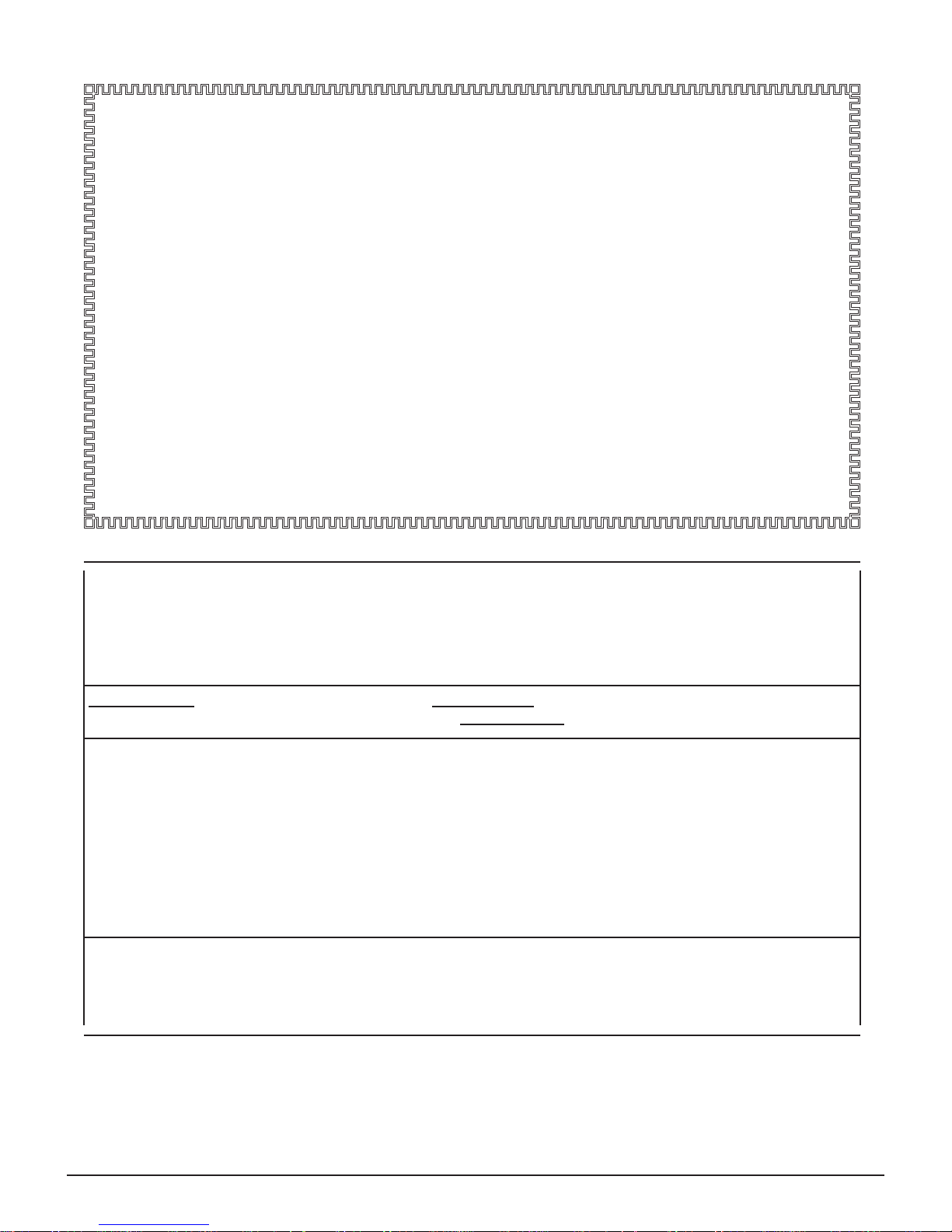

LIMITED WARRANTY

Modern Home Products Corp. Offers to the original purchaser a Limited Warranty on all grill components as described below.

These components will be free from defects in material and workmanship (excluding paint) when subject to normal domestic use

and service. The highest quality paint is used where applicable, but due to various atmosphere conditions, chemicals, fertilizers,

care, cleaning and actual use, no extended warranty can be made on paint. Also, for these reasons the limited warranty does not

cover rust or aluminum oxidation, unless there is a loss of structural integrity on the grill components.

Warranty coverage begins on the original date of purchase, confirmed by return registration card and bill of sale. Proof of purchase is required to validate warranty.

Any component that proves defective within the warranty period will, if returned to the factory freight prepaid, be repaired or

replaced free of charge. Warranties shall not apply, nor will MHP assume responsibility for damages that might result from failure to

follow MHP’s instructions, local codes, or when the grill has been tampered with, or altered in any way MHP shall not be liable for

any transportation charges, labor costs, or export duties.

Repair or replacement of a MHP gas grill part does not extend the limited warranty beyond its original term from date of purchase, or begin a new limited warranty period.

This warranty does not include the cost of any inconvenience or property damage due to the failure of the product and does not

cover damage due to misuse, abuse, accident, damage arising out of transportation of the product, or damage incurred through

commercial use of the products. This express warranty is the sole warranty given by the manufacturer and is in lieu of all other

warranties, expressed or implied, including implied warranty of merchantability or fitness for a particular purpose.

GRILLS IN A COMMERCIAL, COMMUNITY OR MULTI-TENANT APPLICATION WILL HAVE A 1 YEAR WARRANTY ON

ALL PARTS.

MODERN HOME PRODUCTS CORP., 150 S. Ram Road, Antioch, IL 60002

Gas Grill Warranty Terms effective after 10/1/2003

***Lifetime***

Against Rust Through

Top Casting • Bottom Casting • Control Panel • Side Shelf Brackets • Bottom Shelf Frame • Tank Ring • Cast Legs

• Stainless Steel Fasteners • In-Ground & Patio Base Post • Stainless Steel Column • Stainless Steel Shelves

• Stainless Steel Burner • Venturi Tube • Stainless Steel & SearMagic® Cooking Grids • Stainless Steel & SearMagic® Warming Racks

5-Year Warranty: Infrared Burners and Porcelain Briquettes 1-Year Warranty: All other Components Including; Ignitor System • Gas

Valve • NuStone Side Shelves • Patio Base • Knobs • Rock Grate 30 Day Warranty: Paint

WHAT IS NOT COVERED

Transportation and shipping costs.

Labor for replacement or repairs.

Removal and reinstallation cost.

The costs of a service call to diagnose a problem.

Damage from accident, misuse, alteration, abuse, improper

installation or storage.

Inoperable due to improper installation or storage.

This warranty does not imply or assume any responsibility for consequential damages that might result from use, misuse, or improper installation of this

cooking appliance.

This warranty does not cover claims which do not involve defective workmanship or materials.

A bill of sale, cancelled check, or payment record should be kept to verify purchase date and establish warranty period.

Finishes on surface that are damaged by improper installation,

improper storage, accident, misuse, abuse or alteration.

All warranties are non-transferable and apply only to the original

purchaser.

Warranties are null & void if grills are put into commercial or

community use.

Burners, clogged due to rust or food residue.

Your MHP Gas Barbecue Grill is identified by a model number and a serial number located on the left side of the control panel. Always use both the

model and serial numbers when contacting Modern Home Products about your grill. For future reference, take the time now to record the model and

serial numbers below:

MODEL NUMBER: ________________ SERIAL NUMBER: ________________ DATE PURCHASED: ________________

How to contact us: phone: 1-888-647-4745, fax: 1-800-637-2918, E-mail: customerservice@mhpgrills.com or write: Customer Service, Modern Home

Products, 150 S. Ram Road, Antioch, IL 60002.

MODEL IDENTFICATION

4

General Instructions

GENERAL INSTRUCTIONS

This installation guide provides you with easy to follow illustrations and instructions to assemble your MHP Gas Barbecue

Grill.

Before you start assembling and using your MHP Gas Barbecue Grill we recommend that you read through all precautions, safe guards and instructions to avoid any personal injury or property damage.

Check Local Codes. Contact your local LP dealer or Natural

Gas company for recommended installation procedures and

regulations. If there are no local codes, installation must conform to the latest National Fuel Gas Code: ANSI Z 223.1. For

Canada, installation must comply with local codes and/or

Standard CAN/CGA-B-149-1 for natural gas installation and

CAN/CGA- B-149-2 for propane installation.

For LP Gas Models the supplied Type 698 (HR4B) Regulator

must be used. Any replacement pressure regulator or hose

assembly must meet or exceed the specifications of the HR4B

Regulator.

Only Worthington, Manchester, or Wolfdale brand cylinders

should be used with this appliance.

For Natural Gas Models the grill is designed to operate at a

pressure of 7” water column (W.C.) (1.75 kPa). Check your gas

utility for local pressure. Pressures other than approximately 7”

W.C. could affect the performance of your grill.

ASSEMBLY INSTRUCTIONS

There are 9 steps to assembling your MHP Gas Barbecue Grill:

The mounting, LP tank mounting, control panel, gas supply

connection, grill lid, lid handle, side shelves, and rock grate,

cooking grid and warming rack.

The grill itself is partially assembled with the Burner, Venturis,

Ignitor Collector Box and the Gaslow Regulator installed.

The JNR, WNK and TJK grills are specifically designed to fit

the five mounting methods: Cart, In-Ground Post, Deck/Patio

Base, Column and Built-in.

You will need the following tools to assemble your grill:

A Phillips head screwdriver

A standard flat head screwdriver

Two 7/16” wrenches or sockets

STORAGE

Turn gas OFF at the LP cylinder (or at the shut OFF valve in

the case of Natural Gas) when the MHP Gas Barbecue Grill is

not in use.

Do not store spare LP cylinders under the MHP Gas Barbecue

OPERATING SAFEGUARDS

Do not install your MHP Gas Barbecue Grill in or on

recreational vehicles and/or boats.

Never use your MHP Gas Barbecue Grill near combus-

tible surfaces, including roof overhangs, roofs, vinyl

siding and window shutters.

Use this barbecue outdoors in a well-ventilated area.

Do not use your MHP Gas Barbecue Grill in a shed, gar-

age, building, breezeway or any other confined area.

Do not use any kind of combustible material on or near

the top, bottom, back or sides of the grill. Maintain at

least an 18 inch clearance.

Leak test all gas supply line connections.

Do not let children operate a gas grill.

Keep the area around the grill clear of combustible va-

pors or liquids such as gasoline.

When operating the grill do not leave unattended. Keep

children and pets away.

Keep fuel supply hose and electrical supply cord away

from any heated surface.

YOUR GRILL IS DESIGNED FOR OUTDOOR USE ONLY.

It should also not be used in an enclosed area such as a shed or garage

because combustion uses available oxygen and discharges carbon monoxide.

The grill must be located no closer than 18" from any combustible surface

behind or to the sides. Grill should not be located under overhead unprotected combustible surfaces.

Keep the area around the grill clear of combustible materials, flammable

vapors or liquids such as gasoline.

Do not obstruct the flow of combustion and ventilation air.

SAFETY

5

Carton contains the following components for the cart mounting:

Please check to be sure that all parts are included before proceeding.

Contact your dealer or the factory if any parts are missing.

CART HARDWARE WCP4 WCN4 JCP4 JCN4

Grill Heads (WNK4,WRG4,WHRG4, (JNR4)

TJK2,TRG2,THRG2)

Long Legs 2 2 2 2

Short Legs 2 2 2 2

Lower Shelf Frame 1 1 1 1

Stainless Grease Cup 1 1 1 1

8" Rubber Wheels 2 2 2 2

Axle 22 1/2" 1 1 1 1

Axle Hitch Pins 2 2 2 2

Axle Washers 2 2 2 2

Hub Caps 2 2 2 2

Hose Retaining Ring 1 1 1 1

1/4-20x1-1/2 Slotted Bolt 10 10 8 8

1/4-20x3/4 Slotted Bolt 2 2 4 4

1/4-20 Kep Nut 10 10 8 8

10-24x1/2" Rd.Hd. Slot 1 1 1 1

10-x24 Kep Nut 1 1 1 1

12' Nat. Gas Hose Kit N/A 1 N/A 1

Mountings

Duro-Cast Cart

Step 1: Leg Assembly (Fig 2)

1. Tip the grill head bottom on end as shown in Fig. 2

(TIP: work on protected area such as: carpet, tarp

or one of the boxes to protect cart finish.

2. Attach the two short legs to the left end of the grill

head bottom with the “Hose Ring Hole” leg facing

grill front. Note: The short legs are stamped on

the inside (Front or Back). Use two 1/4-20x1-1/2"

slotted bolts for each leg. Insert bolts from inside

grill box, attach leg and fasten with 1/4-20 Kep nuts.

3. Attach the two long legs to the right end of the grill

head bottom. Use two 1/4-20x1-1/2" slotted bolts

for each leg, insert bolts from inside grill box, attach

leg and fasten with 1/4-20 Kep nuts.

4. Attach the hose clamp ring to the front left short leg

with the 10x24x1/2" Rd. Hd. slotted bolt.

FINGER TIGHTEN ALL BOLTS UNTIL

LOWER SHELF IS ATTACHED.

Tank Ring Kit

Tank Ring 1 N/A 1 N/A

1/4-20x1-1/2" Slotted Bolt 1 N/A 1 N/A

1/4-20x 3/4" Hex Bolt 1 N/A 1 N/A

1/4-20 Thumb Screw 1 N/A 1 N/A

1/4-20 Kep Nut 3 N/A 3 N/A

Complete View of Cart Assembly

FIG. 1

FIG. 2

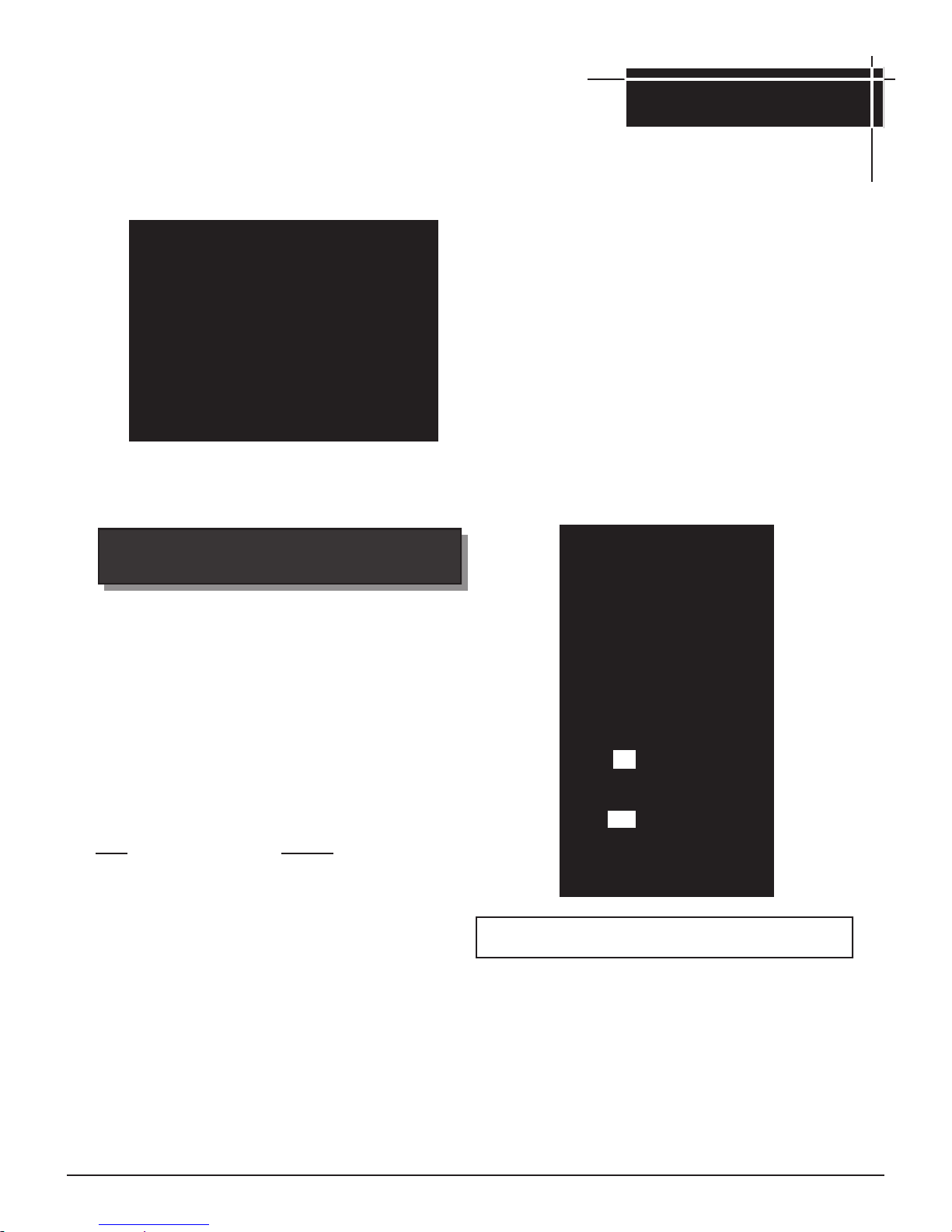

Step 2: Lower Shelf and Axle Assembly

1. Bolt shelf to the (4) legs as follow:

(A) WCP and WCN (Fig. 3) carts uses (2) 1/4-20x

1-1/2" slotted bolts and Kep nuts to fasten the

frame to the long legs and (2) 1/4-20x3/4" slotted

head bolts to fasten the frame to the short legs.

(B) JCP and JCN (Fig. 4) carts use (4) 1/4-20x

3/4" slotted head bolts to fasten the frame at all 4

corners.

Note: Do Not Completely Tighten At This Point

2. Install (1) axle hitch pin into the small end hole

and install washer. Slide (1) wheel onto axle, hub cap side out.

3. Slide open axle end through the short leg holes

and install remaining wheel, washer and hitch pin.

Install hubcaps after the cart bolts are completely

tightened.

Stand grill upright to seat legs and tighten all bolts

and nuts making legs and frame rigid. Recheck fasteners for tightness.

6

Continue Assembly Instructions

Step 3: WCP3/WCN3 Lower Shelf Assembly (Fig.

Fig. 5

Mountings

Fig. 3

Step 3: JCP3/JCN3 Lower Shelf Assembly (Fig. 4)

Fig. 4

Step 3: Tank Holder Ring Assembly For LP

Gas Models (Fig. 5)

1. The LP Tank Holder Ring Connects to the lower

shelf cross frame with the ring notches resting on

the axle frame.

2. Align the rear tank ring-fitting hole over the lower

cross frame hole. Insert a 1/4-20x5/8" slotted bolt

through the top and fasten with a 1/4-20 Kep nut

from below.

3. Fasten the thumb screw (1/4-20x3/4") to the tank

ring fitting with the 1/4-20 Hex nuts. The Hex nut

slips into the captive slot on the tank ring fitting.

4. Use a 1/4-20x1-1/2" slotted bolt and a 1/4-20 Kep

nut to connect the tank holder flanges together.

For Natural Gas Models

(Note: Tank Holder Ring is not Included With Natural Gas

Models).

Natural Gas Models

Fig. 6

If the grill is to use Natural Gas from the supplied 12foot hose (Fig. 6): the hose must pass through the hose ring

(See Fig. 1). The hose will have a quick-disconnect

fitting at the source and the source will have a gas shut off

valve with easy access.

When you have completed the mounting assembly go to

the appropriate Grill Assembly Section and

Assemble the grill head.

Deck/Patio Mounting

Assembly Instructions (MPB)

• All grill head models may be mounted on the Deck/Patio base.

• The gas supply may be either LP or Natural.

• The grill head bottom should not be attached to the post until

the mount is fastened to a deck/patio.

7

Continue on Following page

•Deck/Patio base fits all MHP Grill Heads

•The gas supply may be either LP or Natural.

•The grill head should not be attached to the post until the base

has been mounted to the deck or patio.

Please check to be sure that all parts are included before proceeding.

Contact your dealer if any parts are missing.

Parts Quantity

2' Post 1

Patio Base 1

Post Access Door 1

Grease Cup Holder 1

28” Stainless Steel Tubing 1

Stainless Steel Grease Cup 1

Hardware Kit

¼ - 20 x ¾" Hex Head Bolts 7

¼ - 20 Kep Nuts 7

¼" Flat Washers 7

8 - 32 x ½" Self Tapping Screw 1

Tube Clip 1

Mountings

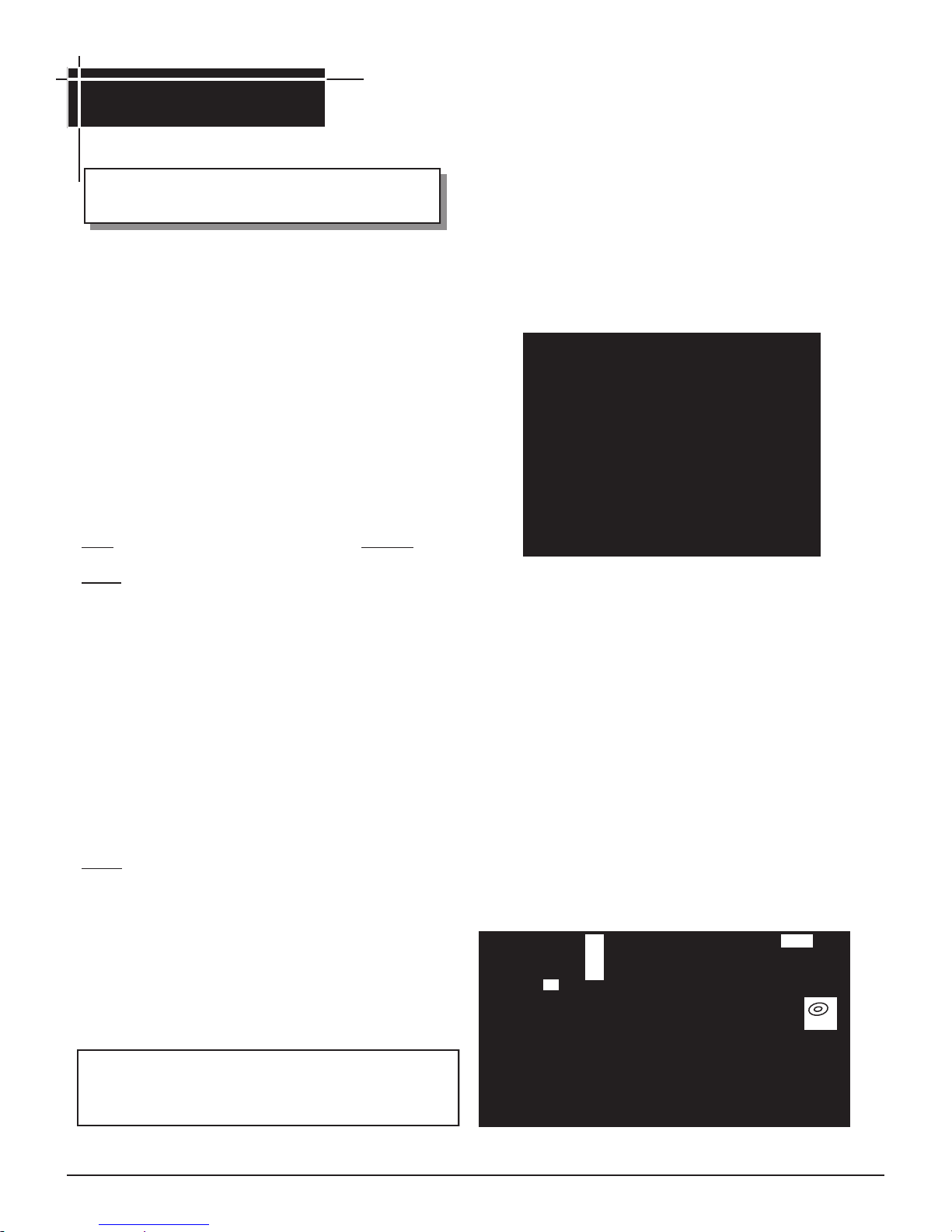

Deck/Patio Base

1. Mark the location of the four holes at the outside corners of the

patio base and drill four holes. The base will be fastened down

with lag bolts (not supplied by MHP) after you have connected

the gas supply line. The top post notch is the front and the rear

access door will be in the back of the grill.

2. Run the gas supply line into the post from the bottom to reach

the access door and bend it 90° to exit the base at either notch.

The patio base is notched on two sides to allow the gas line to

exit either right or left.

3. Secure the gas line with the tube clip. (Option: On a raised deck

if the gas supply line is to be run straight up into the post from

below use the tube clip to attach the gas line to the deck for

support.

4. At the access door connect a 3/8" flare coupling (not supplied by

MHP) to the gas supply line and Stainless Steel tubing. Position

the tubing in the top notch of the post. Bend the tubing at the top

end to match the Feed Line of the grill valve. Do not kink the

tubing.

TUBE BENDING: For proper bending of the stainless steel tubing, see

page 26 for bending instructions.

Step 1: Deck/Patio Base Mounting Assembly (Fig. 5)

1. Turn base on edge and insert the 2’ post. Align the notches in

the post with the notches in the base. IMPORTANT: Close

tolerances may require you to tap the top of the post to seat it

completely in the base socket which will then align the bolt

slots.

2. Fasten post to base with four ¼ - 20 x ¾" Hex bolts, washers

and Kep nuts. Follow exact placement of washers as indicated. Tighten securely.

3. Attach the tube clip with the 8 - 32 self-tapping screw either on

the right or left side of the base depending on the direction of

your gas supply line.

Step 3: Attaching The Grill Head Bottom To The Deck/

Patio Post (Fig. 7 & Fig. 8)

1. To make the post-to-flange connection easier, remove the grill

burner by taking out the small clip located under the bottom grill

head. This will allow access to hold the Kep nuts inside the

post.

2. Set the grill head bottom carefully in place, align holes and use

the ¼ - 20 x ¾" bolts and ¼-20 Kep nuts to attach the grill

flange to the post.

Step 2: Deck/Patio Mounting Installation

(Fig. 6)

Position the patio base at the desired location on a deck or

patio. CAUTION: Be certain there are no combustible mate-

rials above, behind, left or right closer than 18" away.

8

Mountings

3. Mount the grease cup holder to the rear flange hole with a ¼ 20 x ¾" bolt and ¼-20 Kep nut. The grease cup holder is sup-

plied with the grill head.

When you complete the mount assembly go to the appropriate Grill Assembly Section and assemble the grill

head.

In-Ground Mounting

Assembly Instructions (MPP)

•All MHP Grill Heads may be mounted on the 4 foot post

for in-ground installation.

•The gas supply may be either LP or Natural.

•The grill head should not be attached to the post until the

post is permanently cemented in ground.

Please check to be sure that all parts are included before proceeding. Contact your dealer if any parts are missing.

Parts Quantity

4' Post 1

Post access door 1

28” Stainless Steel Tubing 1

Stainless Steel Grease Cup 1

Stainless Grease Cup Holder 1

¼ - 20 x ¾" Hex Head Bolts 3

¼ - 20 Kep Nuts 3

Step 1: In-Ground Mounting Installation (Fig. 9)

1. Dig a posthole about 8 inches wide by 2 feet deep. Cau-

tion: Locate the hole so that the mounted grill head has

a clearance of 18 inches away from any combustible

object or surface; back, left or right.

Center the post in the hole and plumb it. Pour in cement

(gravel) up to the gas line access hole.

Keep in mind that the gas line access hole is on

the back of the post and the notch at the top if facing front.

Recheck plumb and allow cement to set.

2. Run the gas supply line into the post access hole (just above

the cement). Make a 90° bend to reach the access door

opening.

The gas supply line should be trenched at least 18

inches below the surface of the ground to prevent damage

from digging. CAUTION: The gas supply line must be reg-

ulated (in the case of natural gas that means connected

after your gas meter and regulator) and that you have an

easily accessible shut-off valve.

3. At the access door connect a 3/8" flare coupling (not supplied

by MHP) to the gas supply line and Stainless Steel tubing.

Position the tubing in the top notch of the post. Bend the

tubing at the top end to match the Feed Line of the grill valve.

Do not kink the tubing.

TUBE BENDING: For proper bending of the stainless steel tubing, see

page 26 (Fig. 47) for bending instructions.

6”

18”

Step 2: Attaching The Grill Head Bottom To The In-

Ground Post (Fig. 7 & 8)

To attach the grill head to the post please refer to Step 3 of the

Deck/Patio installation procedures on page 8 and follow instructions.

When you complete the mount assembly Go to the appropriate Grill head section and assemble the Grill Head.

9

Mountings

Stainless Steel and Aluminum Column

Assembly Instructions

Step 1: Connect the Tank Locking Bar (Fig. 10)

1. From box “A” locate and attach the Tank Lock Bar across the

back of the pedestal column. Use the ¾" S.S. Hex bolt, Nylon

All MHP Grill Heads may be mounted on the

Column.

The gas supply may be either LP or Natural.

Lock Bar Spacer and a Kep nut on each side to fasten the

Tank Lock Bar in place. This spreads and holds the correct

spacing at the back of the column.

The grill head should not be attached to the Col-

umn until the console is completely assembled.

The Column comes in two cartons—Box A con-

tains the console and all associated hardware. Box

B contains either the pedestal or cart base and all

base hardware.

Please check to be sure that all parts are included before proceeding. Contact your dealer if any parts are missing.

Parts Quantity

BOX A

Stainless Steel Front Panel 1

Stainless Steel or Aluminum Column 1

Stainless Grease Cup 1

Tank Lock Bar 1

Hardware Kit

Nylon Lock Bar Spacers 2

¼ - 20x1¼" S.S. Hex Head Bolts 4

¼ - 20 S.S. KEP Nuts 12

¼ S. S. Washers 10

¼ - 20 x ¾" S.S. Hex Bolts 8

Rectangular Washers (Aluminum Column Only) 4

2-piece Gasket (Stainless Steel Column Only) 1

Aluminum Reinforcing Bar (Aluminum Column Only) 2

BOX B

Cast Aluminum Base 1

Stainless Steel Flexible Tubing, 28” (OPN Only) 1

Step 2: Attach the Base to the Pedestal (Fig. 11)

1. Before bolting the pedestal column to the base, the 2-piece

gasket (stainless steel column only) must be installed to create a

barrier between the two metals. Remove the backing strips

from the gasket to expose the adhesive and stick the gasket

to the bottom lip of the pedestal column. Make sure to align

the holes.

2. Attaching the pedestal column to the base will be easier to

handle by laying the pedestal column face down and matching the holes on the pedestal column lip to the holes on the

base. Use six ¾” bolts, six stainless steel washers (stainless

column) or four large rectangular washers (aluminum column), and on the underside six round washers and KEP nuts.

3. IMPORTANT: the large rectangular washers are used at the

sides on top of the pedestal column lip. The round washers

and KEP nuts are used under the base. Tighten securely and

stand unit upright.

12’ Nat. Gas Hose/Quick Discount (OCN Only) 1

Axle (OCN or OCP Only) 1

Axle Clips (OCN or OCP Only) 2

6 " Wheels (OCN or OCP Only) 2

Hub Caps (OCN or OCP Only) 2

(Rect. for Aluminum Only)

(Round washers for stainless)

Note: While assembling, peel the thin white protective film covering from

the stainless steel surfaces, especially in areas which will be partially

hidden after assembled. Do Not Scrape off.

(Gasket for Stainless Only)

10

OPTION: For Portable Base Only: (Fig. 12)

1. Attach the wheels by slipping the axle through the base, slide

the wheels on and secure with the axle clips. Finish by snapping the hub caps on before standing unit upright. For units

with casters, place caster stem into stem opening of the portable base, press and snap into place. (Fig. 12A)

Fig. 12A

Step 3: Connect the Grill Head Bottom to Stainless Steel

Column (Fig. 13)

1. Attach the grill head bottom to the pedestal column top with four

¼ - 20 x1 ½" Hex bolts, washers under the bolt head and Kep nuts.

Peel the remaining protective coating off the pedestal column.

Stainless Steel Column

Mountings

Step 4: Attaching the Access Panel (Fig. 14)

Note: Do not attach the front access panel until the control

panel has been attached to the grill head bottom and

the gas supply line has been properly connected and

leak tested.

1. The front access panel attaches directly under the control

panel and hides the access opening. Lift the access panel

up behind the lip of the control panel, then slip the bottom

double edge of the access panel (upward pressure may be

needed) over the edge of the access opening.

Step 3: Connect the Grill Head Bottom to Aluminum

Column (Fig. 13A)

1. Attach the grill head bottom to the pedestal column top with four

¼ - 20 x1 ½" Hex bolts, washers under the bolt head, reinforcing

bar and Kep nuts.

Aluminum Column

Bolt

Washer

Grill Bottom

Reinforcing

Bar

Column

Nut

Aluminum Reinforcing

Bar (2)

Fig. 13A

When you complete the mount assembly go to the appropriate Grill Assembly Section and assemble the grill head.

Caution: Combustible material should never be within 18

inches of the bottom, back or sides of your MHP Gas Barbecue Grill.

11

Mountings

Built-in Mounting

Assembly Instructions (NMS-GS, NMS2-GS

Enclosure Sleeve and NMS-DS Door Set)

The WNK or TJK model grills may be mounted as a built

-in with the NMS-GS enclosure sleeve.

The WRG4, WHRG4, TRG2 and THRG2 requires the

NMS2-GS enclosure sleeve.

For use with natural or hard–plumbed propane gas.

Do not place or store a spare LP gas cylinder under or

near the grill.

Enclosure must be constructed from non combustible

materials and with adequate ventilation.

The Built-In kit and grill head connection will be assem-

bled upside down.

Refer to appropriate section for grill head assembly.

Please check to be sure that all parts are included before proceeding. Contact your dealer if any parts are missing.

Parts Quantity

GRILL HEAD ENCLOSURE SLEEVE

Front Face Plate for NMS (26" W x 11" H x 1½" D) 1

Right Side “L” Bracket 19" x 11" 1

Left Side “L” Bracket 19" x 11" 1

Rear Support Bracket 26 1/8" long 1

Grease Tray 1

Heat Shield 1

Hardware Kit

¼ - 20 x ¾" Hex Head Bolts 12

20 x 1 ¼" Hex Head Bolts 4

¼" Nuts 4

¼" Flat Washers 4

¼" Lock Washers 16

NMS-DS DOOR SET

Frame for Door Set 1

Left Hand Door 1

Right Hand Door 1

Magnetic Catches 2

Door Handles 2

Important Notes:

Your structure should have a 3" to 4" concrete base on a sand

footing.

The panel doors must have a 4" to 6" minimum elevation from the

ground.

If your structure includes a back splash, allow 11" to the back edge

of grill opening to allow the lid to open completely.

Combustible material should never be within 18 inches of the

bottom, back or sides of your Grill.

Complete View Of Built-In

Step 1: Required Dimensions For Built-In

(Fig. 16)

1. The grill head fits into an opening of 27½" wide by 11" high

by 18" deep.

2. The Panel doors fit into an opening of 27¼" wide by 16¾" tall.

3. The side burner fits a surface opening of 10¼" wide by 11¾"

front to back. It should be at least 5" away from the grill opening.

(The front face flanges on the mounting and the panel doors

overlap the required opening surfaces by 1 5/8" and provide a

clean look.)

The NMS and NMS2 Kits have not been submitted to CSA for approval as of this printing.

12

Loading...

Loading...