Page 1

Epsilon STS

TM

200A and 400A/600A

Static Transfer Switch

Installation and User Manual

86-504004-00 B03

www.mgeups.com

Standard Features

◗ Epsilon 200A System

◗ Epsilon 400A/600A

System

Page 2

Page 3

Installation and User Manual

Chaptername i86-504004-00 B03

Epsilon STS

TM

200A and 400A/600A

Static Transfer Switch

Installation and User manual

Revision History

Epsilon STS 200A and 400A/600A STS,

Installation and User Manual

86-12345-00 B02

Revision: A00 Initial Release 06/2002

B00 ECN: 002866 09/2002

B01 ECN:#003777 03/2004

B02 ECN:#004471 07/2005

B03 ECN:#004991 10/2006

Copyright © 2005 MGE UPS SYSTEMS, INC.

All rights reserved. Printed in U.S.A.

MGE UPS SYSTEMS, INC.

1660 Scenic Avenue

Costa Mesa, CA 92626

(714) 557-1636

Technical Support:

1-800-

523-0142 (during business hours)

Customer Care Center:

1-800-438-7373

(Hours: 24/7)

Page 4

Epilson STS

TM

ii 86-504004-00 B03

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS – This manual contains important instructions for the Epsilon STSTMthat must be

followed during operation of the equipment.

WARNING Opening enclosures expose hazardous voltages. Always refer service to

qualified personnel only.

ATTENTION L'ouverture des cabinets expose des tensions dangereuses. Assurez-vous

toujours que le service ne soit fait que par des personnes qualifiees.

WARNUNG! Das öffnen der Gehäuse legen gefährliche Spannungen bloss. Service

sollte immer nur von qualifizierten Personal durchgeführt werden.

WARNING As standards, specifications, and designs are subject to change, please

ask for confirmation of the information given in this publication.

ATTENTION Comme les normes, spécifications et produits peuvent changer, veuillez

demander confirmation des informations contenues dans cette publication.

WARNUNG! Normen, Spezifizierungen und Pläne unterliegen Anderungen. Bitte verlan-

gen Sie eine Bestätigung über alle Informationen, die in dieser Ausgabe

gemacht wurden.

NOTE This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct the interference at user's

own expense.

Certification Standards

◗ IEEE 587-1980/ANSI C62.41 for Cat. B3, 1980 Standards for Surge Withstand Ability

◗ FCC rules and regulations of Part 15, Subpart J, Class A , EN50081-2 (use shielded cables)

◗ UL listed under 1008, Standards for Transfer Switch Equipment.

◗ NEMA PE 1 (National Electrical Manufacturers Association) - Uninterruptible Power Systems

◗ NEMA 250 (National Electrical Manufacturers Association)

– Enclosures for Electrical Equipment (1000 Volts Maximum)

◗ NFPA 70 – National Electrical Code

◗ ISO 9001 Quality Assurance, NEC, ANSI, NEMA, NFPA, IEEE.

◗ Occupational Safety & Health Administration (OSHA)

Important Safety Information and Standards

Page 5

Installation and User Manual

iii86-504004-00 B03 How To Use This Manual and Symbol Usage

WARNING To reduce the risk of fire or electric shock, install in a temperature and

humidity controlled indoor area free of conductive contaminant’s.

This equipment is intended only for installations in a RESTRICTED

ACCESS LOCATION.

ATTENTION Pour réduire le riske d'inccendie ou d'électrocution, installer dans une

enciente intérieure contrôlée en température et humidité et sans

contaminant’s conducteurs.

Ce matériel est destiné seulement pour des installations dans un

EMPLACEMENT RESTREINT d'accès.

WARNUNG! Um die Gefahr von Feuer und elektrischem Schock zu reduzieren, muss

das Gerät in einem temperatur - und feuchtigkeitskontrollierten Raum, frei

von leitungsfähigen Verunreinigungen, installiert werden. Dieses Gerät ist

nur für die Installation an einem Ort mit eingeschränkter Zugangserlaubnis

vorgesehen.

Diese Ausrüstung ist nur für Anlagen in einem EINGESCHRäNKTEN

ZUGRIFF STANDORT bestimmti.

WARNING HIGH LEAKAGE CURRENT. Earth connection essential before

connecting supply.

ATTENTION COURANT DE FUITE ELEVE. Raccordement a la terre indispensable

avant le raccordement au reseau.

WARNUNG! Hoher Ableitstrom Vor Inbetriebnahme Schutzleiterverbindung

herstellen.

How to use this manual and Symbol Usage

This manual is designed for ease of use and easy location of information.

This manual uses four icon symbols with text to convey important information and tips.

WARNING Indicates information provided to protect the user and service personnel against safety

hazards and/or possible equipment damage.

CAUTION Indicates information provided to protect the user and service personnel against possible

equipment damage.

IMPORTANT Indicates information provided as an operating instruction, or as an operating tip.

NOTE Indicates information provided as an operating tip or an equipment feature.

Page 6

Epilson STS

TM

iv 86-504004-00 B03CAUTION: Record All Serial Numbers

CAUTION: Record All Serial Numbers!

RECORD ALL SERIAL NUMBERS FOR THE Epilson STSTMAND COMPONENTS.

THESE SERIAL NUMBERS WILL BE REQUIRED IF YOUR SYSTEM NEEDS SERVICE.

KEEP THIS MANUAL IN A PLACE WHERE YOU CAN REFERENCE THE SERIAL

NUMBERS IF SERVICE IS REQUIRED!

UPS SERIAL NUMBER: _______________________________________________________

MODULE SERIAL NUMBER: ____________________________________________________

BATTERY SERIAL NUMBER: ___________________________________________________

ADDITIONAL MODULES SERIAL NUMBERS:

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

Page 7

Contents

Contents

c i86-504004-00 B03

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . .ii

Certification Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

How to use this manual and Symbol Usage . . . . . . . . . . . . . . . . . . . .iii

CAUTION: Record All Serial Numbers! . . . . . . . . . . . . . . . . . . . . . . .iv

Quick Start

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

First steps by an on-site qualified Technical Engineer . . . . . . . . . . . . .QS —1

Required Equipment and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .QS —1

Step 1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .QS —2

Step 2 Connection of Utility Power Inputs . . . . . . . . . . . . . . . . . . . . .QS —4

Connect Input Power from Two Sources . . . . . . . . . . . . . . . .QS —4

Step 3 Connection of the Load Outputs . . . . . . . . . . . . . . . . . . . . . .QS —4

Step 4 Call MGE UPS Systems for Field Engineer Service . . . . . .QS —5

Step 5 Arrival of MGE Field Engineer . . . . . . . . . . . . . . . . . . . . . . . .QS —5

Optional Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .QS —6

Section 1 Introduction

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1.1 Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1.2 Section Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1.3 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2

1.4 Epsilon STSTM System Characteristics . . . . . . . . . . . . . . . . . . .1 — 3

1.4.1 PMM2 Plus and PMM2 Ultra . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1.5 System Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 5

1.6 Single Line Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 7

1.7 System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 8

1.7.1 Electrical Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . .1 — 8

1.7.2 Electrical Cable Access and Connections . . . . . . . . . . . . . . . . . .1 — 9

1.7.3 Connecting Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 9

1.7.4 Accessing Electrical Connections . . . . . . . . . . . . . . . . . . . . . . .1 — 10

Page 8

Epilson STS

TM

Contentsc ii 86-504004-00 B03

Section 2 Setup and Installation

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

2.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

First steps by an on-site qualified Technical Engineer . . . . . . . .2 — 1

Final steps by MGE Field Service Engineer . . . . . . . . . . . . . . . .2 — 1

Required Equipment and Tools . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

2.1 Cabinet Placement and Environment . . . . . . . . . . . . . . . . . . . . .2 — 2

2.2 Clearances and FootPrint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 2

2.2.1 Conduit Plate Location (bottom entry) . . . . . . . . . . . . . . . . . . . . .2 — 3

2.3 Source #1 AC Input Connections . . . . . . . . . . . . . . . . . . . . . . . .2 — 3

2.3.1. Source #2 AC Input Connections . . . . . . . . . . . . . . . . . . . . . . . .2 — 3

2.3.2 AC Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 3

2.3.3 Remote Emergency Power Off (REPO) Cable Connections . . .2 — 4

2.3.4 Remote Source Loss Test Cable Connections . . . . . . . . . . . . . .2 — 4

2.3.5 Connection of the Relay Communication Card . . . . . . . . . . . . . .2 — 5

2.3.6 Characteristics of the Output Contacts . . . . . . . . . . . . . . . . . . . .2 — 6

2.3.7 Characteristics of the Input Contacts . . . . . . . . . . . . . . . . . . . . .2 — 6

2.3.8 Removing the Communications Card Cover . . . . . . . . . . . . . . . .2 — 7

2.3.9 Replacing the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 7

2.4 Setting Operation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 8

2.5 Setting the Output Relay Contacts and Inputs Switching States 2 — 9

2.5.1 Connection of the JBUS Communication Card . . . . . . . . . . . . .2 — 10

2.6 Check Points Before and After Start Up . . . . . . . . . . . . . . . . . .2 — 10

2.6.1 Pre-Start Up Safety Check List . . . . . . . . . . . . . . . . . . . . . . . .2 — 10

2.6.2 Post-Start Up Safety Check List . . . . . . . . . . . . . . . . . . . . . . . .2 — 10

Section 3 Operation

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

3.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —1

3.1 Preparation for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —1

3.2 Pre-Start Up Safety Check List . . . . . . . . . . . . . . . . . . . . . . . . . .3 —1

3.2.1 Normal Start Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —2

3.2.2 Post Start Up Safety Check List . . . . . . . . . . . . . . . . . . . . . . . . . .3 —3

3.2.3 Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —3

3.3 Transfer Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —4

3.3.1 Automatic Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —4

3.3.2 Manual Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —4

3.3.3 Automatic Retransfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —4

3.3.4 Transfer Authorization/Prohibition . . . . . . . . . . . . . . . . . . . . . . . . .3 —5

3.4 Maintenance Bypass/Molded Case Switches/Live System Test .3 —5

3.4.1 Switch Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —5

3.4.2 Electrical Bypass Switch Interlock . . . . . . . . . . . . . . . . . . . . . . . .3 —5

3.4.3 Electric Input-Bypass Switch Interlock . . . . . . . . . . . . . . . . . . . . .3 —5

3.4.4 Mechanical Key Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —5

3.4.5 Live System Test (Except with 4-Interlock System) . . . . . . . . . . .3 —6

Page 9

Installation and User Manual

Section 3 Operation (continued)

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

3.4.6 EPO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —6

3.5 Preferred Source Selection (Symmetrical Operation) . . . . . . . . .3 —6

3.6 Sensing and Transfer Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —6

3.7 Overload Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —6

3.8 Shorted SCR Protection (including Backfeed Protection) . . . . . .3 —6

3.9 Open SCR Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —7

3.10 Source Cross-Connection Protection . . . . . . . . . . . . . . . . . . . . . .3 —7

3.11 Bypass Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —7

3.12 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —9

3.13 Front Display Interface Panel . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —10

3.14 Operator Interface Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —14

3.15 Epsilon STS™ Customization . . . . . . . . . . . . . . . . . . . . . . . . . .3 —15

Glossary

Reorder Form

MGE Warranty & Proprietary Rights for Three Phase Products

MGE Standard Three Phase Warranty

Proprietary Rights Statement

Warranty and Product Registration

User Information

Product information

Warranty Extension (Warranty+)

Customer Care Center - Single Phase Products

Technical Support and Product Services

Who to Contact

Scheduling Field Service Engineer Support

Return Policy for Repair of ThreePhase Products (RGA)

Contents c iii86-504004-00 B03

Page 10

Figures

figure description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

QS-1 Positioning of 200A Epsilon STS™. . . . . . . . . . . . . . . . . . . . . .QS —2

QS-2 Positioning of 400/600A Epsilon STS™ . . . . . . . . . . . . . . . . . .QS —3

QS-3 200A STS Input/Output Power Connections. . . . . . . . . . . . . . .QS —4

QS-4 400/600A STS Input/Output Power Connections. . . . . . . . . . . .QS —5

QS-5a 200A STS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .QS —6

QS-5b 400/600A STS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .QS —6

1-1a: Epsilon STS™ - 200A Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2

1-1b: Epsilon STS™ - 400/600A Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2

1-2: PMM2 and PMM2 Ultra Cabinets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1-3: Operator Input Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 6

1-4: Single Line Diagram, Epsilon STSTM with Options. . . . . . . . . . . . . . . . .1 — 7

1-5: 200A STS Power and Control Wire Connections. . . . . . . . . . . . . . . . .1 — 10

1-6: 400/600 STS Power and Control Wire Connections. . . . . . . . . . . . . . .1 — 11

2-1: 200STS and 400/600A STS Cabinet Clearances. . . . . . . . . . . . . . . . . .2 — 2

2-2: 200A /400/600A STS Cabinet Footprint and Top View. . . . . . . . . . . . . .2 — 3

2-3: Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 4

2-4: Output Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 6

2-5: Removing the Communications Card Cover. . . . . . . . . . . . . . . . . . . . . .2 — 7

2-6: Removing the Communications Card Cover. . . . . . . . . . . . . . . . . . . . . .2 — 7

2-7: SA2 and Dip switch location on communication card. . . . . . . . . . . . . . .2 — 8

2-8: JBUS Communication Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 10

3-1: Front Display Interface Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —10

3-2: LCD Normal Operation Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —11

3-3: Manual Operation Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —12

3-4: LED Mimic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —13

3-5: LCD Display Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —14

3-6: Customization Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —15

Tables

table description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

1-1: Input/Output Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 10

1-2: Input/Output Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 11

2-1: Heat Rejection Data and Rated Current. . . . . . . . . . . . . . . . . . . . . . . . .2 — 2

2-2: Relay Contacts (communications card) . . . . . . . . . . . . . . . . . . . . . . . . .2 — 5

3-1: Customization Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 —15

Epilson STS

TM

Contentsc iv 86-504004-00 B03

Page 11

Quick Start QS —186-504004-00 B03

On-Site Quick Start

CAUTION Scheduling of the MGE Field Service Engineers typically should be

done 7 to 10 days before they are required on-site. If the startup of

the UPS is critical to maintaining your schedule, please call the

MGE toll free telephone number at

1-800-438-7373 for assistance.

Final installation and start-up should be completed by a qualified MGE Field Service Engineer.

This On-site Quick Start will guide qualified engineers through unpacking and positioning the unit, the equipment,

tools, and steps required to perform power input/output connections to prepare the unit for MGE Field Service

Engineers to perform on-site final installation and startup.

To insure a successful installation, each of these (4) steps should be followed in their correct sequence.

Note that any unauthorized installation may cause damage to the UPS(s) and void the MGE warranty.

First steps by an on-site qualified Technical Engineer

Step 1. Unpack and position the unit

Step 2. Connect the main (utility) power

Step 3. Connect the output to the power distribution panel

Step 4. The MGE Field Service Engineer finalizes installation and the startup process.

Optional : Procedure for temporary power prior to the final startup.

Required Equipment and Tools

The following equipment and tools are recommended for on-site installation:

◗ Digital volt meter (DVM)

◗ 1/8 inch slotted screwdriver

◗ Pallet jack/forklift

◗ Conduit installation tools

◗ Nut driver set

Page 12

Step 1 Unpacking

Once the Epsilon STSTMUPS System has been inspected and received from the shipping courier, the unit should

be moved with the use of a fork lift or pallet jack to a position as close to the final installation location as possible.

Prior to any installation, the following items should be observed upon receipt of the Epsilon STSTM 10-30 kVA UPS.

1. Inspect shipment for any damage prior to receipt. Damage claims should be filed directly with the courier.

Replacements for damaged components should be ordered through MGE Customer Support Services at 1-800438-7373.

2. Remove wrapping and foam corners to verify that the equipment nameplate (located on the inside door of the

cabinet) details a system that corresponds with the equipment ordered. See Figure QS-1.

3. The casters on the unit will allow it to be positioned into the final installation location. At this point, the

leveling legs can be adjusted to provide a level and stable footing for the Epsilon STS™ system.

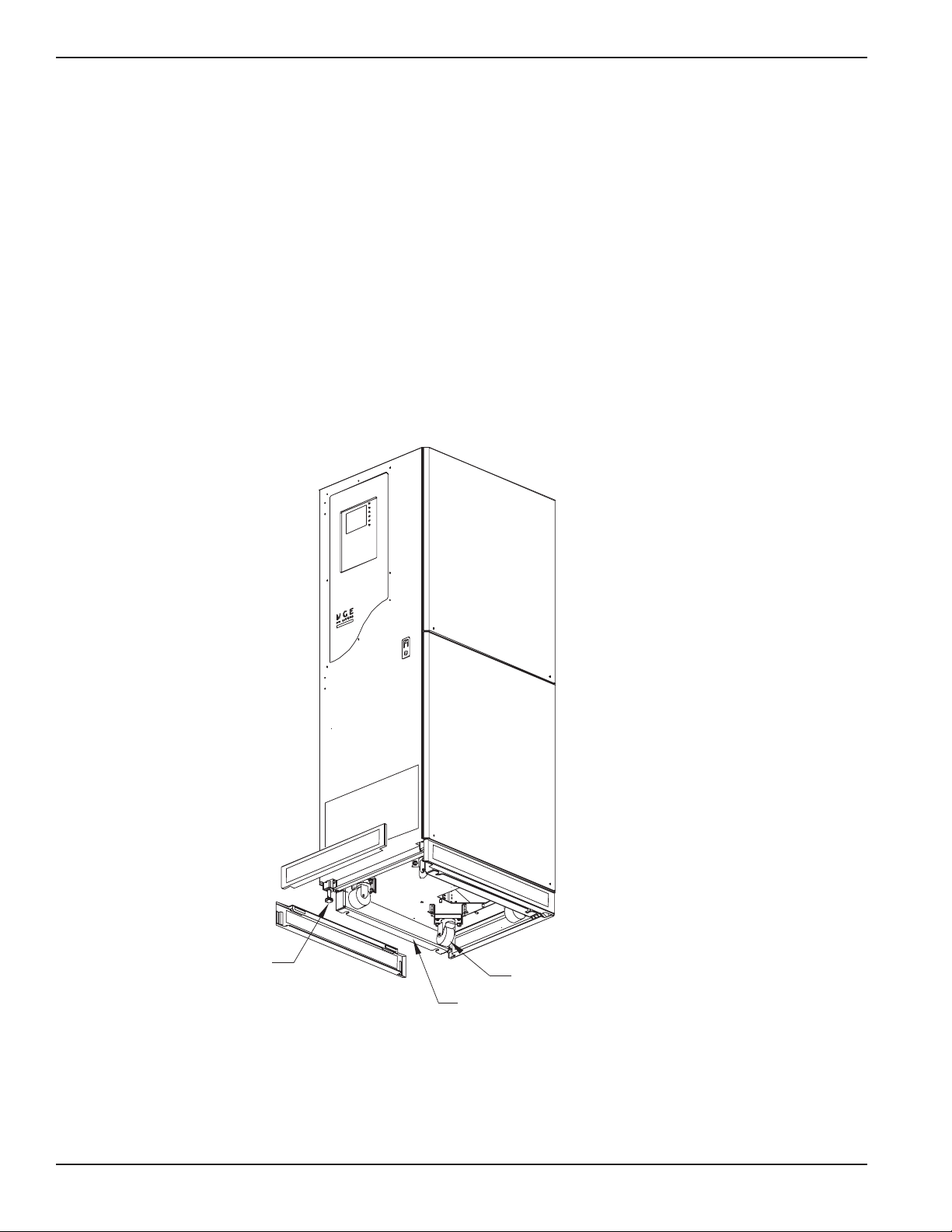

Figure QS-1 Positioning of 200A Epsilon STS™.

Epilson STS

TM

Quick StartQS —2 86-504004-00 B03

CASTERS

LEVELING

JACKS

OPTIONAL SEISMIC

BRACKETS

SECURED USING 3/8 BOLT

Page 13

Installation and User Manual

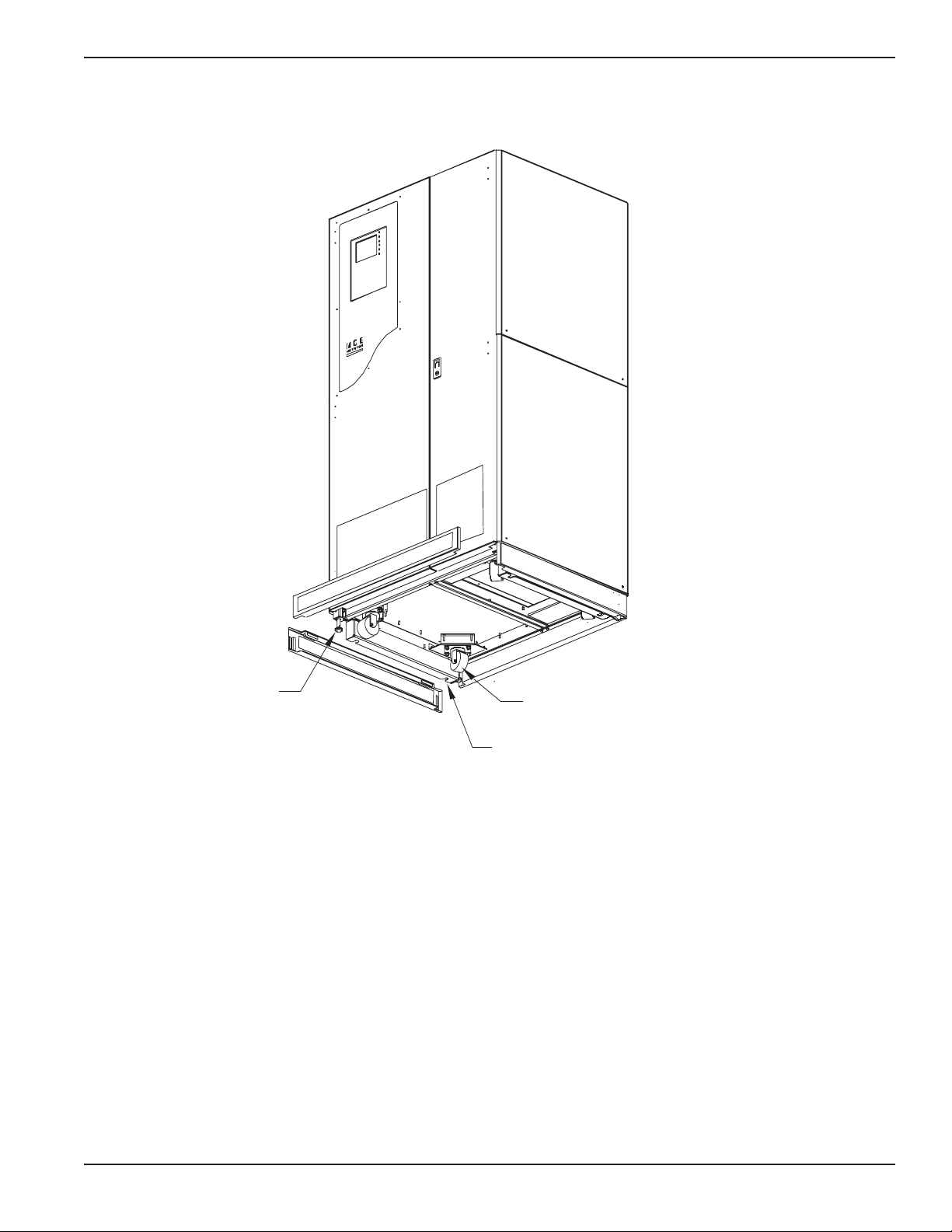

Figure QS-2 Positioning of 400/600A Epsilon STS™

Quick Start QS —386-504004-00 B03

CASTERS

LEVELING

JACKS

OPTIONAL SEISMIC

BRACKETS

SECURED USING 3/8 BOLT

Page 14

Step 2 Connection of Utility Power Inputs

Connect Input Power from Two Sources

The Epsilon STS™ systems provides for either top or bottom cable entry. Connections are to be made with 75°C

copper wire cables and using the lugs supplied with the STS unit. Refer to section 2.0 Installation and/or the system

installation drawing(s) for more details (such as cable size and number of conductors).

NOTE:

Three phase input power supplied as a Wye must have a

separate, solidly

grounded neutral that will be connected to the STS

neutral busbar. If neutral is not supplied or not required for the load,

connect only three phases and ground.

It is recommended to use isolation transformers so that the neutral of

both AC sources can be grounded to the same potential.

Step 3 Connection of the Load Outputs

The Epsilon STS™ system provides for either top or bottom cable entry. Connections are to be made with 75°C

copper wire cables and using the lugs supplied with the STS unit. Refer to section 2.0 Installation and/or the system

installation drawing(s) for more details (such as cable size and number of conductors).

NOTE:

Input and output cables inside the STS cabinet must be braced at 12”

intervals

as shown in Figures QS-3 and QS-4.

For Control Wiring connections refer to section 2.0 Installation.

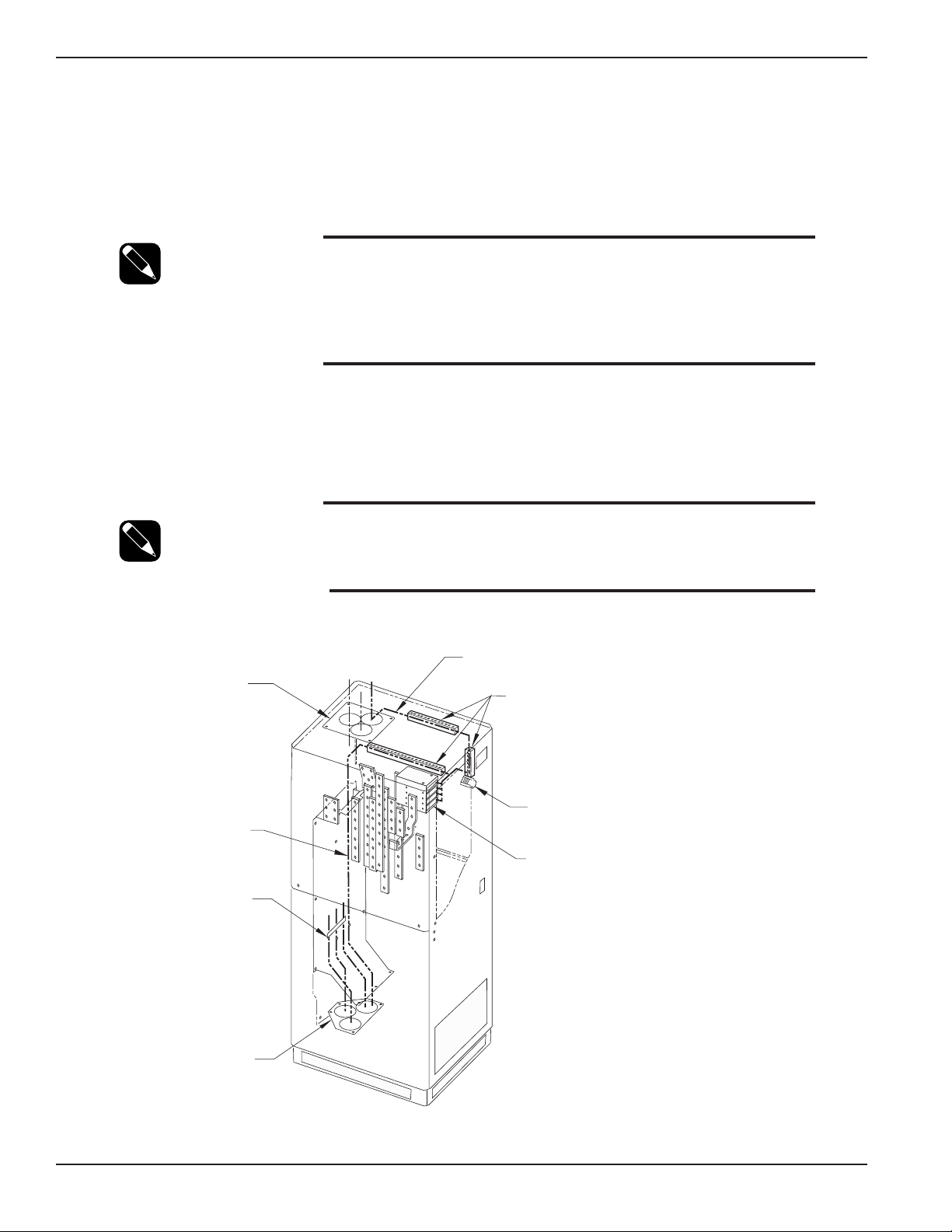

Figure QS-3 200A STS Input/Output Power Connections.

Epilson STS

TM

Quick startQS —4 86-504004-00 B03

COMMUNICATION

CARDS

TB1

TERMINAL

CONTROL WIRES

THREADED THROUGH

PANDUIT/WIRE-WAYS

TOP ENTRY

CONDUIT PLATE

CONTROL

WIRES

BRACE AT

12" INTERVALS

BOTTOM ENTRY

CONDUIT PLATE

CONTROL WIRE

PANDUIT/WIRE-WAYS

Page 15

Installation and User Manual

Figure QS-4 400/600A STS Input/Output Power Connections.

Step 4 Arrival of MGE Field Engineer

The MGE Field Engineer will finalize

the initial Epsilon STS™ start-up. To insure a successful installation

and

reliable STS service, the MGE Field Engineer will verify all of the installation connections, fusing, and then will

examine the extensive set of

Epsilon STS™

personalization parameters to insure that the operation of the STS

exactly matches your installation requirements.

Quick start QS —586-504004-00 B03

CONTROL WIRES

THREADED THROUGH

UNIT

CONTROL WIRE

PANDUIT/WIRE-WAYS

TOP ENTRY

CONDUIT PLATE

BRACE AT

12" INTERVALS

BOTTOM ENTRY

CONDUIT PAN

COMMUNICATION

CARDS

TB1

TERMINAL

CONTROL WIRES

CONTROL WIRE

PANDUIT/WIRE-WAYS

Page 16

Optional Steps

Should you require AC power on site prior to the arrival of the MGE Field Engineer, the following procedure will

provide the AC power in the bypass mode. Should you have any questions about this procedure, do not hesitate

to contact MGE Customer Support.

A. Ensure that all switches, CB1-5 in the STS are open (off).

B. Apply input power to the source S1 input of the STS by closing the upstream circuit breaker for source S1. The

STS controls will power up and issues alarm(s). Silence the alarm buzzer by pressing the “Alarm Silence”

pushbutton on the front display panel.

C. Lock CB5 (S2 bypass switch) and remove the lock key (for 4-interlock system, also lock CB2 and remove key).

Using key(s), unlock and close CB4 (S1 bypass switch).

D.

At this point, power will be available for site usage until the STS is properly

commissioned.

E. Upon arrival of the MGE Field Service Engineer, the main power must be disconnected so that a safe and

proper commissioning of the unit may be accomplished.

WARNING Do not, under any circumstance, close CB1, CB2, CB3A and

CB3B (if installed) until the unit has been commissioned by an

MGE Field Engineer.

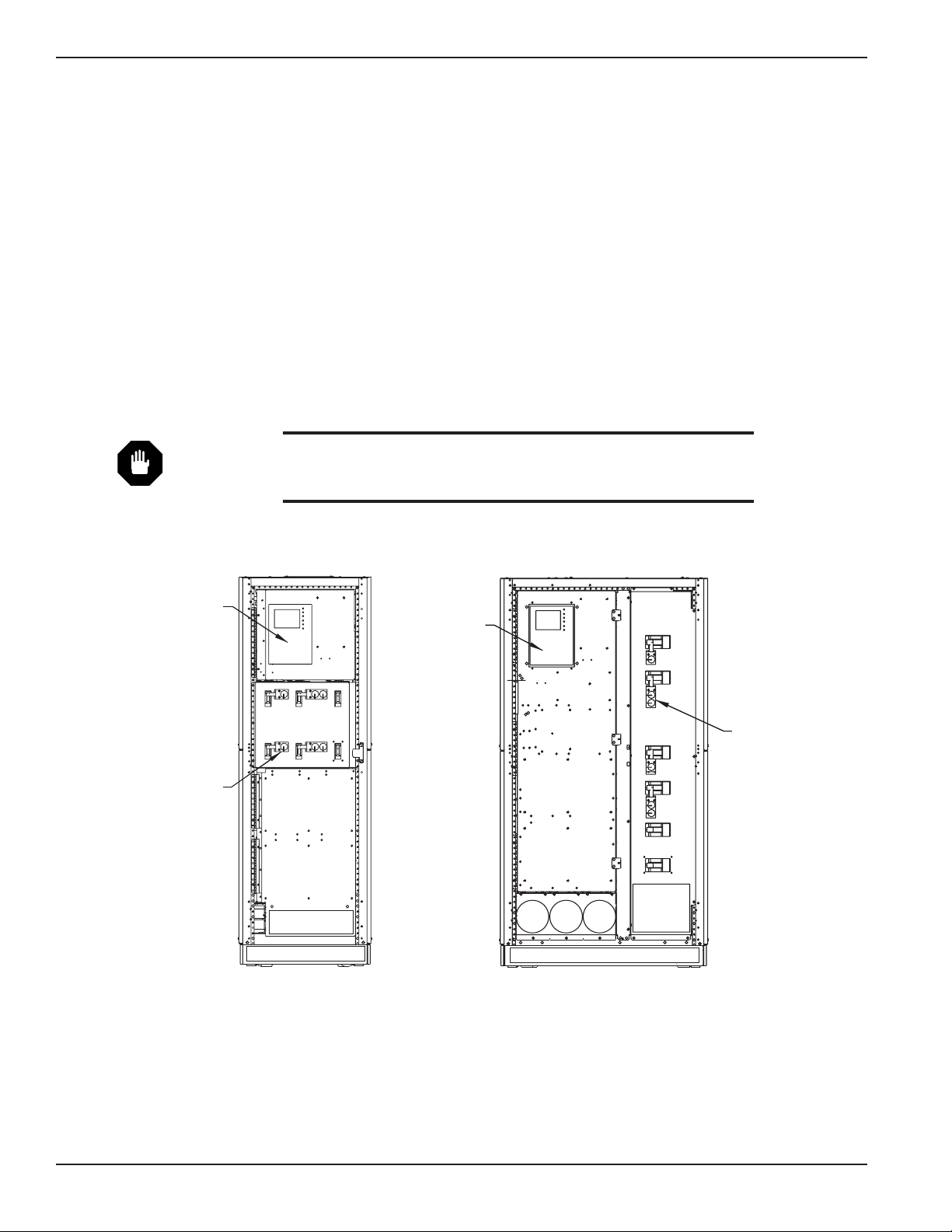

Figure QS-5a 200A STS Figure QS-5b 400/600A STS

Epilson STS

TM

Quick startQS —6 86-504004-00 B03

KEY INTERLOCKS

(2 - STANDARD

4 - OPTIONAL)

STS MONITOR

CB1

CB2

CB4

CB5

CB3A

CB3B

STS MONITOR

KEY INTERLOCKS

(2 - STANDARD

4 - OPTIONAL)

CB2

CB5

CB3A

CB3B

CB1

CB4

Page 17

Introduction

1.0 Scope

Introduction is a general description of system characteristics of Epsilon STSTM, its intended use and applicable

electrical, mechanical and environmental specifications.

1.1 Reference Manuals

160304-00 C00 JBUS/RS232, Installation and User manual.

1.2 Section Descriptions

Quick Start

This Quick Start will guide qualified engineers through unpacking and positioning the unit, the equipment, tools, and

steps required to perform power input/output connections to prepare the unit for MGE Field Service Engineers to

perform on-site final installation and startup.

1 Introduction

Introduction is a general description of system characteristics of Epsilon STS

TM,

its intended use and applicable

electrical, mechanical and environmental specifications.

2 Setup and Installation

Setup and Installation guides the User through tools and equipment required for making hardwire connections.

Included are power cable connections with wire diagrams for configuring the product to specifications, and

obtaining MGE field service assistance for final installation and startup.

3 Operation

Operation describes Epsilon STS

TM

system characteristics of indicators and controls, startup and shutdown proce-

dures, safety checklists, modes and specifications and theory of operating the Epsilon STS

TM

system.

1 — 186-504004-00 B03 Introduction

Page 18

1.3 General Description

The Epsilon STS™ system is available in two different cabinet sizes

. Dimensions for the cabinets

are:

◗ 200A cabinet: 72”H x 24”W x 30”D

◗ 400A/600A cabinet: 72”H x 38”W x 30”D

Both cabinets are designed to provide for top and/or bottom entry of input and output power feeds.

The Epsilon STS™ system can be purchased to accept 208 VAC, 220 VAC, 240 VAC, 440 VAC, 480 VAC, 575 VAC

or 600 VAC utility feed.

Figure 1-1a: Epsilon STS™ - 200A Cabinet. Figure 1-1b: Epsilon STS™ - 400/600A Cabinet.

Physical Characteristics

Enclosure Type NEMA 1, Free-standing, modular configured with hinged dead front construction

protecting high voltage areas.

Enclosure Dimensions Depth:

30” (System will pass through standard

36” wide door).

Height: 72”.

Width: 24” for 200A STS; 38” for 400A and 600A STS.

Accessibility Front access for operation and maintenance. Front or side access for customer power

connection points.

Power Connections/

All power connections and terminations to be solid copper braced rated for

Busbars

100KAIC.

(400/600A models may be a combination of copper busbars and cables).

Cable Entry Top and Bottom.

Mounting 360° Casters and Leveling Jacks with 1” minimum adjustment.

Epilson STS

TM

Introduction1 — 2 86-504004-00 B03

Page 19

Installation and User Manual

1.4 Epsilon STSTMSystem Characteristics

The Epsilon digital Static Transfer Switch (STS) is a solid state, three-phase, break-before-make, dual position

switch designed to connect a critical three-phase load to one of two separate, independent, synchronized sources

of three-phase power. The STS consists of six pairs of SCR's connected in an AC switch configuration. Each 3phase input is fed through a molded case automatic switch which provides short circuit protection by means of a

magnetic trip only. The switch then feeds three pairs of “hockey-puck” SCR's, each pair consisting of two SCR's in

an anti-parallel arrangement. The SCR outputs for each corresponding phase from both inputs are then connected

and fed through an output isolation molded case switch to the output terminals. These SCR's are rated to carry the

full 100% load (continuous rated) while operated as stipulated herein and at the maximum ambient temperature

specified. The source to which the load is normally connected to is designated

as the “Preferred” source, and the

other redundant, standby source is the “Alternate” source. Selection of which input source is preferred is user selectable from the operator control panel, by control contact inputs, or through the communications port(s).

In normal operation, the load is connected to the preferred source as long as

all phases of the preferred source are

within the acceptable limits. Upon failure

of the preferred source (more degraded than the alternate source), the

load will be transferred to the alternate source until such time as the preferred source returns to within acceptable

limits. The switching action itself is practically instantaneous and the time involved in the operation is mainly the

sensing time required to determine that a transfer is necessary, normally a small fraction of a cycle.

The STS is controlled by a number of system operating variables which define the operation and performance of

the system. Many of these variables may be adjusted for site-specific criteria.

The determination to transfer from one source to the other involves the evaluation of Source Qualities and System

Operating parameters:

Source Quality Concerns the evaluation of a sources ability to support the critical load by evaluating

the voltage, phase, current and frequency of a source on a real time basis.

System Operating Parameters control transfers between the two sources, given the state of both

sources and the load together with the specified site-specific operating criteria.

During a transfer (or re-transfer), the SCR's of the loaded source are turned off and the SCR's of the previously

unloaded source are turned on in such a way as to prevent any cross-current between sources, even if the sources

have large phase displacement. Normally, transfer between sources with large phase difference is not allowed.

The molded case switches with magnetic trips will provide short circuit protection

only – overcurrent protection must be

provided by upstream and/or downstream devices.

Triple-redundant control power supplies, independent gate drive circuits for each sources SCR switch and other

design features provide the optimal level of reliability and immunity to single point failures. The Epsilon STS™ is

also built to withstand up to 100KA of available short circuit current.

A Bypassing scheme is provided. This can be used to manually bypass the AC load directly to either of the two

power sources and isolate the static switching for servicing.

The Epsilon STS™ is available in three current ratings – 200A, 400A and 600A (208-600V range). The 200A model

is natural convection cooled. The 400A and 600A models use forced air cooling by fans (with one redundant fan).

The STS is designed for installation in a room where humidity and temperature can be controlled. The recommended and maximum environmental parameters are listed in Appendix B, of this document.

The Epsilon STS™ is listed for safety by Underwriters Laboratories, Inc. (UL) under UL Standard 1008.

Introduction 1 — 386-504004-00 B03

Page 20

1.4.1 PMM2Plus and PMM2Ultra

In the PMM2Plus configuration, the input of the PMM2cabinet is supplied by the output of the STS. The dual input

distribution system accepts two independent AC input sources feeding to the STS. If the preferred input source

power is not available, the STS will transfer to the alternate input source, avoiding interruption to the critical load.

The output power is conditioned and stepped down to distribution voltage via an isolation transformer, feeding

panelboards or main frame circuit beakers.

In the PMM

2

Ultra configuration, an isolation transformer feeds each STS input

source upstream of the STS. The

transformer secondary output of the PMM

2

-1

(left cabinet) supplies the Source-1 input and PMM2-2 (right cabinet)

supplies Source-2 input of the STS cabinet. If the preferred source input power is not available, the STS will transfer

to the alternate input source, avoiding interruption to the critical load. The output of the STS connects to the output

busbars of the PMM

2

-1 and PMM2-2 cabinets, feeding panelboards or main frame

Figure 1-2: PMM2 and PMM2Ultra Cabinets.

Epilson STS

TM

Introduction1 — 4 86-504004-00 B03

Page 21

Installation and User Manual

1.5 System Major Components

Source #1 CB1 Input isolation molded case switch with magnetic trip for

isolating SCR static switch

#1 and associated components from source S1.

Source #2 CB2 Input isolation molded case switch with magnetic trip for

isolating SCR static switch

#2 and associated components from source S2.

Output CB3A Output isolation molded case switch with magnetic trip for isolating both static switch

sections from the load.

Output CB3B Optional, redundant output isolation molded case switch with magnetic trip (paral-

leled with CB3A) for isolating both static switch sections from the load.

Source #1 Bypass CB4 Maintenance bypass molded case switch with magnetic trip for bypassing the static

switch section and connecting the load directly to source S1.

Source #2 Bypass CB5 Maintenance bypass molded case switch with magnetic trip for bypassing the static

switch section and connecting the load directly to source S2.

Keyed Interlocks Provided on the two bypass switches to prevent closure of both at the same time.

An optional interlocking scheme is available for additional keyed interlocks on the

source isolation switches to ensure that, prior to bypassing to a particular source,

the STS transfers the load to that source if the load is not already being powered by

that source. On closure of a bypass switch, the control logic will also shunt trip

opposite bypass and input isolation switches if necessary to prevent cross-connection of the two sources.

SCR Static Switch Assy. Three heatsink assemblies containing six pairs of “hockey-puck” SCR's. Switch #1

and #2 (each having 3 pairs of SCR's) automatically switch the load to either source

S1 or S2.

Control Electronics The microprocessor-based core control uses FPGA’s for input and output signal

processing and control sequencing to optimize sensing time.

Front Display Panel The LCD screen, pushbuttons and LED mimic diagram make up the display.

Gate Drive & Acq. PCA Independent gate drive and acquisition circuits for each sources SCR switch.

Backfeed Protection Assy A separate redundant circuit for each source provides backfeed protection to ensure

that there is no cross-connection between the two sources in the event of a shorted

SCR on the inactive source with the upstream circuit breaker open.

TVSS Assemblies Optional Transient Voltage Surge Suppressor on each source input.

Triple-Redundant

Control Power Supplies Three, independent DC control power supply assemblies (fed from each of the two

sources and the STS output) provide redundant DC control power.

CB Control Assembly A separate circuit supplies DC control power (fed directly from the output terminals)

for shunt-tripping the power switches CB1-5 and for supplying EPO power even in

maintenance bypass mode.

Output Snubber Assembly Provides preload under no-load conditions.

Communications Card Cage Relay card providing programmable contacts (6 outputs/2 inputs) and JBUS card for

RS232 or RS485 connections. Two slots available for options.

Customer Terminal Block Terminals for connection of remote Emergency Power Off (EPO) and Source Loss

Test switch.

Fans (400/600A Models only) Ventilation fans provide forced-air cooling

in the 400/600A models. 200A models are

convection cooled.

Introduction 1 — 586-504004-00 B03

Page 22

Front Display Panel Comprised of a 4.7” x 3.6” LCD with associated “soft” keys for monitoring status,

alarms, changing certain settings and performing

certain operations; an LED “mimic”

diagram display for indicating switch status and power flow; and manual control

pushbuttons for manual transfer functions.

Hard Keys Manual, dedicated keys (pushbuttons) that have a single function.

Input Power The Epsilon STS™ is normally connected to two separate, independent sources,

Source S1 and Source S2. Power from each source can be provided by the

electrical utility company, a generator or a UPS.

SCR Switch A set of three pairs of SCR's that function as a three-phase, AC switch for each

source.

Soft Keys Programmable keys (pushbuttons) associated with the LCD, that can be used for

several different functions depending on the displayed screen

Static Transfer Switch (STS) All components within the Epsilon STS™ cabinet that function as a system to

transfer the critical load between two independent sources of power using solidstate SCR switches or bypass to either source using manual bypass switches

PMM

2

Plus A configuration with the Epsilon STS™ and PMM2cabinet. The input of the PMM

2

cabinet is supplied by the output of the STS. Refer to the PMM2manual 86-50500400 for more details.

PMM

2

Ultra A configuration with the Epsilon STS™ and PMM2cabinet. PMM2isolation trans-

formers feed each STS input source upstream of the STS. The transformer

secondary output of the PMM

2

-1 (left cabinet) supplies the Source-1 input and

PMM

2

-2 (right cabinet) supplies Source-2 input of the STS cabinet. The output of

the STS connects to the output busbars of the PMM

2

-1 and PMM2-2 cabinets,

feeding panelboards or main frame circuit beakers. Refer to the PMM

2

manual 86-

505004-00 for more details.

Figure 1-3: Operator Input Display.

Epilson STS

TM

Introduction1 — 6 86-504004-00 B03

RETURN TO

PREFERRED

SOURCE

LIMITS

Synchro

= 0º

A 2A B 1A C 3A

0 KW 1 KVA

NORMAL OPERATION

PF 0.0

Preferred

UPS 1

60.0 HZ

A-B 503 V

B-C 501 V

C-A 507 V

UPS 2

60.0 HZ

A-B 504 V

B-C 503 V

C-A 508 V

!

volt

HELP KEY

LCD GRAPHIC

DISPLAY

LED STATUS &

MIMIC DIAGRAM

"SOFT" FUNCTION

KEYS

MAIN MENU KEY

ALARM SILENCE KEY

LAMP TEST KEY

MANUAL OPERATIONS

KEY

MANUAL CONTROL

KEYED SWITCH

Page 23

Installation and User Manual

1.6 Single Line Diagram

During normal operation, CB1, 2, 3A and 3B (if installed) are closed and the load receives power from the

designated preferred source through either SW1 or SW2 SCR switch. In the event of a preferred source failure, the

STS will transfer the load to the alternate source in a fraction of a cycle. If bypassed by closing either CB4 or CB5

bypass switch, CB1, 2, 3A and 3B (if installed) are opened, isolating the static switch section for maintenance.

Figure 1-4: Single Line Diagram, Epsilon STSTMwith Options.

Introduction 1 — 786-504004-00 B03

CB1

A

SOURCE

#1

SW1

B

C

A

B

C

N

G

CB4

CB2

A

SOURCE

#2

SW2

B

C

A

B

C

N

G

CB5

N

G

AC-DC PS 1

AC-DC PS 2

AC-DC PS 3

TVSS 1

(OPTION)

FUSE

CONTROLS

TVSS 2

(OPTION)

FUSE

CB3A

CB3B

(OPTION)

A

TO

CRITICAL

LOAD

B

C

A

B

C

N

G

OUTPUT

SOURCE

S1

INPUT

SOURCE

S2

INPUT

STS CABINET

CB CONTROL

EPO PS

EPO

SHUNT TRIPS

BYPASS LEDs

1

TB1

2 3 4

EPO

(SEE SECTION 2.5.2.1)

SOURCE LOSS TEST

(SEE SECTION 2.5.2.2)

COMMUNICATIONS

RELAY

CARD

(SEE SECT. 2.5.3)

JBUS/MODBUS

CARD

(SEE SECT. 2.5.4)

OPTION

CARD

OPTION

CARD

Page 24

1.7 System Specifications

Recommended environment 20° to 25°C (68° to 77°F); 50% relative humidity; computer room or other

temperature and humidity-controlled environment.

Operating temperature 10° to 40°C (50° to 104°F).

Storage -10° to 60°C (-14° to 140°F).

Humidity up to 95% non-condensing (operating).

Altitude sea level to 8,500 feet without derating.

Acoustic noise 65 dBA typical at rated load as measured 5 feet from the front of the STS module.

1.7.1 Electrical Electrical Characteristics

Nominal Input Voltage

208, 220, 240, 440, 480, 575, 600 VAC ± 15%, three(3) phase, 3 or 4-wire plus

ground.

Nominal Output

208, 220, 240, 440, 480, 575,600 VAC ± 15%, three(3) phase, 3 or 4-wire plus

Voltage

ground to correspond with input voltage. .

Maximum Continuous 200, 400, 600 Amps.

Current

Molded Case Switch 250, 400, 600 Amps.

Rating

Input/Output 50/60 Hz ± 5 Hz.

Frequency

Load Power Factor Unity to 0.60 lagging or

leading.

Non-Linear Loads 100% of its rating up to

Capability maximum crest factor of 3.5.

Overload Rating 150% for 15 minutes;

1000% for three(3) cycles.

Source Voltage

Up to 10% THD with notching

Distortion and ringing transients.

Output Voltage Less than 1% added.

Distortion

Voltage Transient Up to 6 KV (6000 volt spike)

per IEEE C62.41 for Cat. B3.

Meets EN 50082-1

Withstand (with optional TVSS installed). Such transient levels shall not effect the

operation of the STS. The STS may transfer on over-voltage conditions.

Short Circuit Withstand Up to 100KA.

Harmonic Current Unlimited.

(Feedback from the

Load)

Emission Limits Meets FCC Part 15 Class A, EN 50081-2.

Epilson STS

TM

Introduction1 — 8 86-504004-00 B03

Page 25

Installation and User Manual

1.72 Electrical Cable Access and Connections

Electrical connections and other cabinet interconnection will vary depending upon the configuration and options

selected with your Epsilon STS™ system. Refer to the installation drawings supplied with your equipment.

CAUTION: Before making any electrical connections, verify that all circuit beakers

are in the "off" position. Customer-supplied upstream protective devices

and distribution circuits should be OFF.

Risk of Electric Shock. For Plus and Ultra configurations, the PMM

2

equipment receives power from more than one source. Disconnect all

sources to this equipment before servicing.

1.7.3 Connecting Power Cables

To access the connection terminal busbars, open the front door of the Epsilon STS™. Remove the screws securing

the swing-out control panel (upper panel in the 200A STS) and open it. Remove the safety panel located in the

upper left hand section of the unit.

a) Connect the 3-phase, ground and neutral (if used) conductors of input AC

Source #1 to the Source #1 busbars.

b) Connect the 3-phase, ground and neutral (if used) conductors of input AC

Source #2 to the Source #2 busbars.

c) Connect the 3-phase, ground and neutral (if used) conductors supplying the load to the Output busbars.

d) Securely brace all cables at 12” intervals with cable ties.

e) Replace and secure all panels and covers back in place.rated voltage and tolerances

Introduction 1 — 986-504004-00 B03

Page 26

1.7.4 Accessing Electrical Connections

CAUTION:

Only an authorized electrical professional should access electrical

con-

nections. A severe shock hazard exists.

The ONLY user serviceable items in the Epsilon STS™ unit are:

A. The input power connections

B. The load connection

C. Any wire connections to the customer control terminal block.

D. The communication card options

The access method for connections made to the communication cards is clearly seen when the front door to the

Epsilon STS™ unit is opened. Figure 1-5 and 1-6 show the panduit wire-ways used to thread wire through the

conduit plates (top or bottom entry).

However

, access to the input and load power connections is made through

the removal of the safety panel located in the upper left of the Epsilon STS™ front (with the door open). This safety

panel is removed by first removing the screws securing the panel. It can then be removed by lifting the safety panel

away from the unit.

Figure 1-5: 200A STS Power and Control Wire Connections.

Table 1-1: Input/Output Power Connections.

# OF CABLES PER MINIMUM CABLE LUG CONDUIT

CABLE SIZE (SUPPLIED) HOLE

PHASE N GND (75°C, CU) DIA. (QTY.)

1 2 1 # 4/0 AWG # 4/0, 3/8” STUD 2-1/2” (3)

(T&B L973 OR EQUIV.)

Epilson STS

TM

Introduction1 — 10 86-504004-00 B03

COMMUNICATION

CARDS

TB1

TERMINAL

CONTROL WIRES

THREADED THROUGH

PANDUIT/WIRE-WAYS

TOP ENTRY

CONDUIT PLATE

CONTROL

WIRES

BRACE AT

12" INTERVALS

BOTTOM ENTRY

CONDUIT PLATE

CONTROL WIRE

PANDUIT/WIRE-WAYS

Page 27

Installation and User Manual

Figure 1-6: 400/600 STS Power and Control Wire Connections.

Table 1-2: Input/Output Power Connections.

STS # OF CABLES PER MINIMUM CABLE LUG CONDUIT

RATING PHASE N GND CABLE SIZE (SUPPLIED) HOLE

(AMPS) (75°C, CU) DIA. (QTY.)

400 2 4 1 # 250 MCM # 250 MCM, 3/8” STUD 4” (3)

(T&B M973 OR EQUIV.)

600 3 5 1 # 250 MCM # 250 MCM, 3/8” STUD 4-1/2” (3)

(T&B M973 OR EQUIV.)

Introduction 1 — 1186-504004-00 B03

CONTROL WIRES

THREADED THROUGH

UNIT.

CONTROL WIRE

PANDUIT/WIRE-WAYS

TOP ENTRY

CONDUIT PLATE

BRACE AT

12" INTERVALS

BOTTOM ENTRY

CONDUIT PAN

COMMUNICATION

CARDS

TB1

TERMINAL

CONTROL WIRES

CONTROL WIRE

PANDUIT/WIRE-WAYS

Page 28

(This page left blank intentionally)

Epilson STS

TM

1 — 12 86-504004-00 B02

Page 29

Setup and Installation

2.0 Scope

Setup and Installation guides the User through tools and equipment required for making hardwire connections.

Included are power cable connections with wire diagrams for configuring the product to specifications, and

obtaining MGE field service assistance for final installation and startup.

Final installation and start-up should be completed and performed by a qualified MGE Field Service

Engineer.

CAUTION Scheduling of the MGE Field Service Engineers typically should be

done 7 to 10 days before they are required on-site. If the startup of

the UPS is critical to maintaining your schedule, please call the

MGE toll free telephone number at

1-800-438-7373 for assistance.

To insure a successful installation, each of these (5) steps should be followed in their correct sequence.

Note that any unauthorized installation may cause damage to the UPS(s) and void the MGE warranty.

First steps by an on-site qualified Technical Engineer

Step 1. Unpack and position the unit

Step 2. Connect the main (utility) power

Step 3. Connect the output to the power distribution panel

Step 4. The MGE Field Service Engineer finalizes installation and the startup process.

Optional: Procedure for temporary power prior to the final startup.

Required Equipment and Tools

The following equipment and tools are recommended for on-site installation:

◗ Digital volt meter (DVM)

◗ 1/8 inch slotted screwdriver

◗ Pallet jack/forklift

◗ Conduit installation tools

◗ Nut driver set

2 — 186-504004-00 B03 Installation

Page 30

2.1 Cabinet Placement and Environment

The complete STS system may consist of more than one cabinet depending on whether the STS is a stand-alone

unit or it is used in conjunction with input isolation or output distribution cabinets such as the Power Management

Module

2

(PMM2) cabinets. Cabinets must be arranged in the required positions to ensure proper connections.

When facing the Epsilon STS™ from the front, the standard arrangement provides for any PMM

2

Plus auxiliary

cabinets to be located on the right hand side. The PMM

2

Ultra has cabinets located on both

sides of the STS. The

interconnect cables and side barrier(s) are supplied with the PMM2cabinet. The interconnect brackets are

supplied with the Epsilon STS™.

The Epsilon STS™ is intended for use in an environment where control of temperature and humidity is provided.

The maximum operating and recommended environmental parameters are listed in Appendix B.

The Epsilon STS™ cabinets generate heat and exhaust air through the top portion of its enclosures. Air intake is

through the lower front or bottom of the cabinet. All other auxiliary cabinets are convection cooled. To assist you

in planning for your HVAC needs, heat rejection data is provided in Table 2.1 for a worst case scenario (i.e.,

maximum rated power output).

Table 2-1: Heat Rejection Data and Rated Current.

Data Rate

STS Module BTU/Hr

200A 5,600

400A 11,400

600A 16,700

2.2 Clearances and FootPrint

As can be seen in the following illustration, the footprint for each cabinet is nominally 30" deep. Additionally,

adequate space must be included in the front of each cabinet (approx. 36") to allow the door of the cabinet to be

opened for service and maintenance procedures.

Figure 2-1: 200STS and 400/600A STS Cabinet Clearances.

Epilson STS

TM

Installation2 — 2 86-504004-00 B03

12" MIN.

RECOMMENDED FOR

AIR EXHAUST

CEILING

FLOOR

AIR INLET

(DO NOT BLOCK)

12" MIN.

RECOMMENDED FOR

AIR EXHAUST

CEILING

FLOOR

AIR INTAKE

FILTER WINDOW

(DO NOT BLOCK)

AIR INLET

(DO NOT BLOCK)

Page 31

Installation and User Manual

2.2.1 Conduit Plate Location (bottom entry)

Cable entry through the bottom is the standard preferred design for the Epsilon STS™ cabinet. Please see the

following figure for the location of the bottom entry conduit plate.

Figure 2-2: 200A /400/600A STS Cabinet Footprint and Top View.

2.3 Source #1 AC Input Connections

The connections to be made are the three phases, neutral (if used) and ground cables of input AC Source #1 to the

STS. The main 3-phase cables of input Source #1 are terminated at the Source #1 input busbars. Neutral (if

supplied) and Ground cables are terminated at the Neutral (N) and Ground (GND) busbars respectively. All cables

from Source #1 should be run in a single conduit separately from all other cables (power supply or computer-system

interconnection cables). They should not pass near interference-emitting

equipment or sensitive loads. Complete

wiring instructions for your installation

are provided on the installation drawings supplied with the equipment. See

Figure 1-5 and 1-6, refer to table 1-1 and 1-2 for details.

2.3.1. Source #2 AC Input Connections

The connections to be made are the three phases, neutral (if used) and ground cables of input AC Source #2 to the

STS. The main 3-phase cables of input Source #2 are terminated at the Source #2 input busbars. Neutral (if

supplied) and Ground cables are terminated at the Neutral (N) and Ground (GND) busbars respectively. All cables

from Source #2 should be run in a single conduit separately from all other cables (power supply or computer-system

interconnection cables). They should not pass near interference-emitting

equipment or sensitive loads. Complete

wiring instructions for your installation

are provided on the installation drawings supplied with the equipment. See

Figure 1-5 and 1-6, refer to table 1-1 and 1-2 for details.

2.3.2 AC Output Connections

The connections to be made are the three phases, neutral(if used) and ground cables from the load to the STS.

The main 3-phase cables from the load are terminated at the Output busbars. Neutral(if supplied) and Ground

cables are terminated at the Neutral(N) and Ground(GND) busbars respectively. All cables from the load should be

run in a single conduit separately from all other cables(power supply or computer-system interconnection cables).

Installation 2 — 386-504004-00 B03

REMOVABLE

CONDUIT PLATE

8.3 X 8.3 OPENING

LEVELING JACKS

(4 PLACES)

CASTERS

(4 PLACES)

REMOVABLE

CONDUIT PAN

10.0 X 7.0 OPENING

TOP VIEWFOOTPRINT

REMOVABLE

CONDUIT PLATE

20.6 X 7.3 OPENING

LEVELING JACKS CASTERS REMOVABLE

CONDUIT PAN

12.4 X 16.5 OPENING

TOP VIEWFOOTPRINT

200A STS

400/600A STS

Page 32

They should not pass near interference-emitting equipment or sensitive loads.

Complete wiring instructions for your

installation are provided on the installation

drawings supplied with the equipment.

2.3.3 Remote Emergency Power Off (REPO) Cable Connections

Control connections are available for “Remote Emergency Power Off” (REPO) through a customer-supplied

normally open dry contact or pushbutton.

a) Connect the emergency power off N.O. contact or pushbutton to terminals 1 and 2 of the customer terminal

block TB1. Run control wires in the wireway provided in the front portion of the STS cabinet. See Figures 1-5

and 1-6, they show the panduit wire-ways used to thread wire through the conduit plates ( top or bottom entry).

b) If two or more STS’s are connected in parallel to a single REPO contact or pushbutton, ensure that each side

of the contact or pushbutton is connected to the same terminal on all the STS’s.

2.3.4 Remote Source Loss Test Cable Connections

Control connections are available for “Remote Source Loss Test” through a customer-supplied normally open dry

contact or pushbutton.

a) Connect the source loss test N.O. contact or pushbutton to terminals 3 and 4 of the customer terminal block

TB1. Run control wires in the wireway provided in the front portion of the STS cabinet. See Figures 1-5 and

1-6, they show the panduit wire-ways used to thread wire through the conduit plates ( top or bottom entry).

b) If two or more STS’s are connected in parallel to a single Source Loss Test contact or pushbutton, ensure that

each side of the contact or pushbutton is connected to the same terminal on all the STS’s.

Figure 2-3: Control Connections

Epilson STS

TM

Installation2 — 4 86-504004-00 B03

TB1

REMOTE EPO

N.O. CONTACT

OR PUSHBUTTON

REMOTE

SOURCE LOSS TEST

N.O. CONTACT

OR PUSHBUTTON

4

3

2

1

Page 33

Installation and User Manual

2.3.5 Connection of the Relay Communication Card

The relay communications card contains six programmable dry contact outputs and two programmable dry contact

inputs, and is standard on the Epsilon STS™. The inputs and outputs are factory programmed according to

functions listed in Table 2-2.

Table 2-2: Relay Contacts (communications card)

Inputs Factory Setting Options (available on both contacts)

- Reset Memorized Faults.

1.A - Select Source S1 as Preferred. - Sele ct Source S1as Preferred.

- Select Source S2 as Preferred.

- Enable Automatic Retransfer.

1.B - Select Source S2 as Preferred. - Disable Automatic Retransfer.

- Enable Transfers.

- Disable Transfers.

Note: 1. Power sources connected to card must be equipped with protection devices with a maximum breaking capacity of 2A.

2. Connections must be form “C” Dry Contacts.

Outputs Factory Setting Options (available on all contacts)

1.1 - Power supplied to Load. - Power supplied to Load.

- Summary Alarm (source or STS fault).

1.2 - Summary Alarm - STS Fault.

(source or STS fault). - Source S1 Out-of-Tolerance.

1.3 - STS Fault. - Source S2 Out-of-Tolerance.

- Sources Out-of-Phase.

1.4 - Overload Condition. - Source S1 Active.

- Source S2 Active.

1.5 - Source S1 - Source S1 is Preferred Source.

Out-of-Tolerance. - Automatic Transfer Disabled.

1.6 - Source S2 - Overload Condition.

Out-of-Tolerance.

The indications 1.X become 2.X for a second optional card of the same type.

Installation 2 — 586-504004-00 B03

Page 34

2.3.6 Characteristics of the Output Contacts

Relay type Normally Open.

Max. voltage 250VAC, 30VDC.

Max. current 2A.

Cable 4 x 18 AWG, cover plate hole diameter 0.26 inch ± 0.01 inch

Figure 2-4: Output Contacts.

2.3.7 Characteristics of the Input Contacts

Switched voltage 5 VDC.

Consumption 10 mA.

Cable 4 x 22 AWG, hole diameter 0.2 inch ± 0.02 inch

Output alarms are always activated on the conditions stated unless requested

by the customer to operate on other

conditions.

Input contacts are designed for remote STS operation. Use extreme caution when using these contacts so as not to

endanger persons or compromise the STS load.

CAUTION: Isolate and lock-out all power sources for this card before

making connections. Never connect ELSV (governed by UL1778)

and non-ELSV circuits to the different outputs of the same card.

Epilson STS

TM

Installation2 — 6 86-504004-00 B03

6

5

4

3

2

1

BA

Page 35

Installation and User Manual

2.3.8 Removing the Communications Card Cover

a) Remove the cover “3” secured by the screws “1”.

b) Run the communications cables through the cable entry holes “4”.

c) Connect the conductors to the input “6” and output “5” terminal blocks (see connection example in diagram

below).

Figure 2-5: Removing the Communications Card Cover.

2.3.9 Replacing the Cover

d) Put the cover back in place and secure it with the screws “1”.

e) Tighten the screws “7” to clamp the cables.

f) Indicate the locations of the power sources on the labels.

g) Insert the card in its slot.

h) Secure the card with two screws “2”.

Figure 2-6: Replacing the Communications Card Cover.

Installation 2 — 786-504004-00 B03

1

2

3

4

5

6

A

B

1

2

3

2

5

7

6

4

1

2

3

4

5

6

A

B

4

3

5

6

1

2

2

7

Page 36

2.4 Setting Operation Mode

Set DIP switch SA1 for one of the following configuration modes:

First Card

Second Card (optional)

Standard Mode (default) Standard Mode (default)

All switches OFF SA1 switch 1 ON

First Card

Second Card (optional)

Programmable Mode Programmable Mode

SA1 switch 3 ON SA1 switches 1 & 3 ON

Figure 2-7: SA2 and Dip switch location on communication card.

SA1

ON OFF

8

1

SA1

ON OFF

8

1

SA1

ON OFF

8

1

SA1

ON OFF

8

1

Epilson STS

TM

Installation2 — 8 86-504004-00 B03

SA1 SA2

SA1 DIP Switch

SA2 DIP Switch

Page 37

2.5 Setting the Output Relay Contacts and Input Switching States

Set DIP switch SA2 for one of the following configuration modes:

N.O. Setting (default)

All switches OFF

N.C. Setting

All switches ON

It is possible to individually set each relay and input to N.O. or N.C. mode by setting each switch on SA2 individually. The parameters for relays 1 to 6 are set using SA2 DIP switches 1 to 6 respectively. The parameters for inputs

A and B are set using SA2 DIP switches 7 and 8 respectively.

When the SA2 DIP switch is set to OFF, the relay/input is set to N.O.

When the SA2 DIP switch is set to ON, the relay/input is set to N.C.

SA2

ON OFF

8

N.O.N.C.

1

Installation and User Manual

Installation 2 — 986-504004-00 B03

SA1

ON OFF

8

1

NOTE:

By default, all the relay contacts are

Normally Open (NO) (see section 1.4):

◗ Contact open = relay not controlled.

◗ Contact closed = relay controlled.

By default, the inputs are activated when the

external contact is closed (NO):

◗ External contact open = input not activated.

◗ External contact closed = input activated.

Page 38

2.5.1 Connection of the JBUS Communication Card

The JBUS communications card provides two DB-9 ports (RS232 and RS485 communications). Only one communication port may be used at a time.

For information on using the communication card, see the JBUS communication card manual.

Figure 2-8: JBUS Communication Card.

2.6 Check Points Before and After Start Up

Before starting the Epsilon STS™, be certain that you fully understand the operation of the indicators, controls, and

operational sequences. MGE UPS SYSTEMS,INC. offers professional start up services in most countries. It is

suggested that before applying power to your Epsilon STS™, your contract with MGE for a professional start up with

an MGE Field Engineer.

2.6.1 Pre-Start Up Safety Check List

◗ All power and control wires have been properly connected and securely tightened.

◗ The upstream and downstream protective devices are not tripped, and have been sized properly for the

STS and load requirements.

◗ The input voltage is the same as indicated on the STS nameplate, located inside the door of the Epsilon

STS™ module.

◗ The air filters located inside the STS module door (400/600A units only) are properly installed and free of

dust, dirt, and debris. Make certain that no objects block the air intake underneath and around the front

bottom of the STS module and the air exhaust on the top of the STS module is free of obstructions.

◗ All switches in the STS, CB1-5, are in the OFF (open) position.

◗ All panels and covers are replaced and secured back in place.

2.6.2 Post-Start Up Safety Check List

After initial start-up of the system, normal operation should be tested. At the minimum, the following tests should

be performed as applicable to your installation.

◗ Emergency power off (EPO) test.

◗ Remote emergency power off (REPO) test (if applicable).

◗ STS start up on preferred source.

◗ Transfer test on preferred source loss.

◗ Maintenance bypass procedure.

Epilson STS

TM

Installation2 — 10 86-504004-00 B03

JBUS/MODBUS

54321

9876

RS232:

Pin 2: Rxd (or Txd)

Pin 3: Txd (or Rxd)

Pin 5: Com (shield)

RS485:

JBUS

Pin 4: RxPin 5: Tx-

MODBUS

Pin 8: Rx+

Pin 9: Tx+

Page 39

Operation

3.0 Scope

Operation describes Epsilon STSTMsystem characteristics of indicators and controls, startup and shutdown procedures, safety checklists, modes and specifications and theory of operating the Epsilon STS

TM

system.

3.1 Preparation for Operation

Several items must be considered when preparing the Epsilon STS™ system for operation.

Configuration The STS cabinet and any auxiliary cabinets (such as PMM cabinets containing power

distribution panels, transformers, etc.) must be arranged in the required configuration

to insure that the interconnection cables are located in the correct adjacent cabinets.

Location The cabinets must be situated in a location that provides for proper

air flow and heat

rejection.

Environment The room in which the Epsilon STS™ system is located must maintain environmental

conditions within recommended tolerances.

Electrical Connections All electrical connections must utilize the top or bottom conduit entries provided. See

section 2 for details for connections.

The following sections discuss in more detail these items.

3.2

Pre-Start Up Safety Check List

◗ Ensure all power and control wires have been properly connected and securely tightened. Recheck phase

rotation for both sources and proper grounding of the equipment.

◗ Check to see that the upstream and downstream protective devices are not tripped, and have been sized

properly for the STS and load requirements.

◗ Check that the input voltage is the same as indicated on the STS nameplate, located inside the door of the

Epsilon STS™ module.

◗ Verify that the air filters located inside the STS module door (400/600A units only) are properly installed and

free of dust, dirt, and debris. Make certain that nothing is blocking the air intake underneath and around the

front bottom of the STS module and that the air exhaust on the top of the STS module is free of all obstructions.

◗

Verify that all switches, CB1-5 in the STS are in the “off” (open) position.

◗ All panels and covers are replaced and secured back in place.

◗ Check to see that the cabinet is resting on its the lifting leveler and not on the 4 casters.

◗ Check that the load-circuit beakers (where applicable) are in the "OFF" position.

3 —186-504004-00 B03 Operation

Page 40

3.2.1 Normal Start Up Procedure

With all of the initial safety check points verified, the Epsilon STS™ system can now be powered. The following

procedure should be used after the Epsilon STS™ system has been commissioned (typically by an MGE Field

Service Engineer).

1. Ensure that all switches, CB1, 2, 3A, 3B(if installed), 4 and 5 in the STS are OFF (open).

2. Energize both input sources and check for correct voltage, phase rotation and source synchronization. The

STS controls will be powered up and the display LCD should turn on. The LED indicators and mimic diagram

should also be functioning. The display and buzzer may indicate an alarm since the source isolation switches,

CB1 and CB2 are open.

3. If external load circuit breaker(s) are not installed between the STS output and the load, check that the load is

ready for power application.

4. Check that Source #1 is the preferred source (factory default setting) – as indicated on the LCD display and the

“Preferred Source S1” LED located in the mimic diagram.

5. Close the Source #1 bypass switch, CB4, which connects the output to Source #1, bypassing the static switch

section. Output is now energized by Source #1. The bypass switches are interlocked – see note.

NOTE CB4 and CB5 bypass switches are key-interlocked.

The standard 2-interlock system, lock the opposite bypass

switch and remove the key (for the optional 4-interlock system,

it is also necessary to open the opposite source isolation

switch (CB1 or CB2), lock it, remove the key). Using the

removed key(s), unlock and close the selected bypass switch.

6. Apply power to the load by closing the load-circuit beakers (if installed), including PMM power distribution circuit

beakers (where applicable).

7. Close the Source #1 (preferred) isolation switch, CB1. The STS will turn on the preferred source SCR Switch

1. Verify on the LED mimic diagram

on the front display panel. Also check the operating status on the LCD screen.

8. Close the Source #2 (alternate) isolation switch, CB2. Verify on the LED mimic diagram on the front display

panel. Also check the operating status on the LCD screen – no alarms should be displayed.

9. Static switch operation may now be checked by opening the preferred source isolation switch, CB1. The STS

will transfer to the alternate source. Verify on the LED mimic diagram on the front display panel. Also check

the operating status on the LCD screen.

10. Re-close the preferred source isolation switch, CB1. After the preset retransfer time delay, the STS will retransfer

back to the preferred Source #1.

11. Close the STS output isolation switch(es), CB3A (and CB3B if installed). Source #1 power is now supplied

through the static switch to the output of the STS.

12. Open (and lock) the Source #1 bypass switch, CB4. The load is now supplied through the static switch. Verify

on the LED mimic diagram on the front display panel. Also check the operating status on the LCD screen.

13. The STS is now in the normal operating mode:

CB1, CB2, CB3A and CB3B(if installed) - CLOSED.

CB4 AND CB5 - OPEN

LCD screen - Normal Operation

LED Mimic diagram - “Source S1 Available”, “Source S2 Available”, “CB1”, “CB2”, “Switch 1”, “CB3”, “Load”

and “In Sync” LED's on.

Epilson STS

TM

Operation3 —2 86-504004-00 B03

Page 41

Installation and User Manual

3.2.2 Post Start Up Safety Check List

After initial start up of the system, normal operation of the STS should be verified. At the minimum, the following should

be checked as applicable to your installation:

◗ Remote emergency power off (REPO) operation (all switches in the STS should trip off). After this test, reset

all switches in the OFF position and repeat the start up procedure.

◗ Maintenance bypass procedure.

◗ Proper readings on the LCD display for Voltages, Current, Frequency and Power.

◗

Operation of the Manual Control pushbuttons (“hard keys”) on the front panel.

CAUTION

EXPOSURE TO HAZARDOUS VOLTAGES.

Dangerous voltage levels are still present inside the

STS cabinet. When bypassed/isolated, control power

supply circuits are still live and power is

provided for indicator lights and emergency power off

circuits. Disconnect all sources of power before

servicing. Refer servicing to qualified service

personnel.

3.2.3 Shutdown Procedure

To isolate and shutdown the static switch section of the STS:

1. Check that the desired bypass source is available and that the LCD and mimic diagram display indicate that the

static switch is on the desired bypass source.

2. Follow the Bypass Procedure to bypass the static switch and connect the load through the bypass switch to the

desired bypass source. Isolation switches CB1, CB2, CB3A and CB3B (if installed) will be in the OFF (or

Tripped) position.

Operation 3 —386-504004-00 B03

Page 42

3.3 Transfer Operations

3.3.1 Automatic Transfers

Automatic transfer of the load from one source to the other is accomplished by turning off the active source SCR's

and turning on the inactive source SCR's in a sequence and timing that allows a combined sense and on transfer

time of less than one quarter cycle (4.17ms). Automatic transfer is initiated under any of the following conditions,

provided transfer is authorized and the “inactive” source is not more degraded than the “active” source:

a) Under-voltage on any phase of the active source.

b) Over-voltage on any phase of the active source.

c) Under-frequency of the active source.

d) Over-frequency of the active source.

e) Open SCR on the active source (transfer to inactive source, then shunt trip the active C.B. and inhibit

retransfer until repair is made and the system is reset).

f) Shorted SCR on the inactive source (transfer to shorted inactive source, then shunt trip the previously active

C.B. to prevent retransfer. Inhibit transfers and retransfers until repair is made and the system is reset).

g) SCR Over-temperature on the active source (if there are no current overload faults, transfer to inactive source

and inhibit re-transfer until repair is made and the system is reset. If inactive source subsequently fails, transfer

back to the active side if it is within acceptable limits, including over-temperature limits).

h) SCR Gate Drive power supply failure on the active source (transfer to inactive source and inhibit re-transfer

until repair is made and the system is reset).

i) TVSS failure on the active source (if optional TVSS is installed).

3.3.2 Manual Transfers

The STS can be operated as a manual switch when the Manual Control keyed switch on the front panel is in the

ON position, enabling the manual control pushbuttons and some setpoint changes, for the following manual operations:

a) Manual Change Preferred Source Pushbutton – Selects other source as Preferred, causing a transfer (without

break) to the selected source if it is available and within acceptable limits and is not the active source. If the

two sources are outside the preset in sync phase window, a transfer (with break) can be made by pressing the

manual Override Limits pushbutton simultaneously.

b) Manual Return to Preferred Source Pushbutton - If auto-retransfer is disabled, pressing this pushbutton will

initiate a retransfer back to the preferred source, overriding owner selected

auto retransfer time delay.

To prevent normal automatic transfers, the operator can use the Change Preferred Source pushbutton to transfer

to the desired source, and then shut down the feeder to the other inactive source.

3.3.3 Automatic Retransfers

Automatic retransfer of the load from the alternate source back to the preferred is accomplished by turning off the

active alternate source SCR's and turning on the inactive preferred source SCR's in a sequence and

timing that

allows a combined sense and transfer time of less than one quarter

cycle (4.17ms). Providing the inactive preferred

source is not more degraded

than the active alternate source, retransfer will occur under the following conditions:

a) If retransfer is not prohibited, retransfer will occur after an owner selected

time delay after the preferred source

becomes available and within acceptable limits.

b) If retransfer is prohibited, retransfer can be manually initiated by pressing

the manual Return to Preferred