Page 1

Topaz S3

Inverters

0.5 kVA, 1 kVA,

and 2 kVA

Owner's Manual

Page 2

86-153061-00ii

IMPORTANT SAFETY INSTRUCTION

SA VE THESE INSTRUCTIONS — This manual contains important instructions for all inverters that must be

followed during installation, operation and maintenance of the equipment.

WARNING

Opening enclosures expose hazardous voltages. Always refer service

to qualified personnel only.

ATTENTION

L'ouverture des cabinets expose des tensions dangereuses. Assurezvous toujours que le service ne soit fait que par des personnes qualifiees.

WARNUNG!

Offene Raeume entladen gefaehrliche Stromspannungen. Bitte

wenden sie sich an qualifiziertes Dienstpersonal.

WARNING

To reduce the risk of fire or electric shock, install in a temperature and

humidity controlled indoor area free of conductive contaminants.

ATTENTION

Pour réduire le riske d'inccendie ou d'électrocution, installer dans une

enciente intérieure contrôlée en température et humidité et sans

contaminants conducteurs.

WARNUNG!

Um die Gefahr von Feuer und elektrischem Schock zu reduzieren,

muss das Geraet in einem temperatur - und feuchtigkeitskontrolliertem Raum, frei von leitungsfaehigen Verunreinigungen, installiert

werden..

Page 3

NOTE

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to

correct the interference at his own expense.

WARNING

As standards, specifications, and designs are subject to change,

please ask for confirmation of the information given in this publication.

ATTENTION

Comme les normes, spécifications et produits peuvent changer,

veuillez demander confirmation des informations contenues dans

cette publication.

WARNUNG!

Normen, Spezifizierung en und Plaene unterliegen Aenderungen. Bitte

beantragen Sie schriftliche Bestaetigung ueber Informationen die in

dieser Herausgabe gemacht wurden.

86-153061-00 iii

Owner’s Manual

Page 4

iv 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 5

86-153061-00 v

For service call

1-800-523-0142

86-153061-00 B03 3/99

Copyright © 1997 MGE UPS Systems, Inc.

All rights reserved. Printed in U.S.A.

MGE UPS Systems, Inc.

1660 Scenic Avenue

Costa Mesa, CA 92626

(714) 557-1636

Topaz S3 Inverters

0.5KVA, 1 kVA, AND 2kVA

Owner’s Manual

This manual covers these models:

PRODUCTS MODEL RATING

Topaz S3 Inverters 63054 500 VA

63104 1000 V A

63204 2000 V A

Page 6

vi 86-153061-00

Warranty

MGE UPS Systems warranty: warranties to distributors and other commercial customers: MGE UPS Systems warrants

equipment manufactured by MGE UPS Systems to be free from defects in materials and workmanship for a period of one

year from date of installation, but no longer than eighteen months from purchase by end user. No warranty shall extend

more than three years beyond date of manufacture, except for Ultra-Isolator® Noise Suppressors which carry a five-year

warranty. If within such period purchaser discovers such item was not as warranted above and promptly notifies the

company in writing, MGE UPS Systems shall repair or replace the item at the Company's option.

This warranty shall not apply:

(a) to equipment repaired or altered by others than MGE UPS Systems,

(b) to equipment subjected to negligence, accident, or damage by circumstances beyond MGE UPS Systems' control, or

to improper operation, maintenance, or storage, or to other than normal use or service.

With respect to equipment not manufactured by MGE UPS Systems, the warranty obligations of MGE UPS Systems shall

in all respects conform and warranties do not cover reimbursement for labor, transportation, removal, installation, or other

expenses which may be incurred in connection with repair or replacement. Except as may be expressly provided in an

authorized writing by MGE UPS Systems, MGE UPS Systems shall not be subject to any other obligations or liabilities

whatsoever with respect to equipment manufactured by MGE UPS Systems or services rendered by MGE UPS Systems.

Service and Factory Repair - Call 1 - 800 - 523 - 0142

Direct questions about the operation, repair, or servicing of this equipment to MGE UPS Systems Customer Support

Services. Include the part number, assembly number, and serial number of the unit in any correspondence. Should you

require factory service for your equipment, contact MGE UPS Systems Customer Support Services and obtain a Return

Goods Authorization (RGA) prior to shipping your unit. Never ship equipment to MGE UPS Systems without first obtaining

an RGA.

Proprietary Rights Statement

The information in this manual is the property of MGE UPS Systems, and represents a proprietary article in which MGE

UPS Systems, retains any and all patent rights, including exclusive rights of use and/or manufacture and/or sale.

Possession of this information does not convey any permission to reproduce, print, or manufacture the article or articles

shown herein. Such permission may be granted only by specific written authorization, signed by an officer of MGE UPS

Systems.

IBM, ES/9000, and AS/400 are trademarks of International Business Machines Corporation. MGE UPS Systems are

trademarks of MGE UPS Systems. Other trademarks that may be used herein are owned by their respective companies

and are referred to in an editorial fashion only.

Revision History

Topaz S3 Inverters 0.5 kVA, 1 kVA, and 2 kVA Owner's Manual

86-153061-00

Copyright © 1995 MGE UPS Systems. All rights reserved. Printed in U.S.A.

Revision: A02 New Release 5/96

A03 ECN# S3-051 7/98

B03 ECN# ---------- 3/99

Topaz S3 Inverters

0.5 kVA,1 kVA, & 2kVA

Owner’s Manual

Page 7

Section . . . . . . . . . . . . Description Page

Safety Information inside front cover

Service and Factory Repair vi

Warranty vi

Table of Contents vii

How to Use This Manual xi

Section I — Introduction

1.0 . . . . . . . . . . . . . . . Scope 1-1

1.1 . . . . . . . . . . . . . . . General Description 1-2

1.2 . . . . . . . . . . . . . . . Options 1-2

1.3 . . . . . . . . . . . . . . . Specifications 1-2

1.4 . . . . . . . . . . . . . . . Characteristics of Model 1-3

1.5 . . . . . . . . . . . . . . . Electrical Specifications 1-3

1.5.1 Surge Withstand Capability 1-3

1.5.2 DC Input Conducted Emission 1-3

1.5.3 Efficiency 1-3

1.5.4 Harmonic Distor tion 1-4

1.5.5 Line Regulation 1-4

1.5.6 Load Regulation 1-4

1.5.7 Power Factor 1-4

1.5.8 Output Frequency 1-4

1.5.9 Frequency Stability 1-4

1.5.10 Short Circuit Current 1-4

1.5.11 Overload Capability 1-4

1.5.12 Transient Deviation and Recovery 1-4

1.6 . . . . . . . . . . . . . . . Indicators and Controls 1-5

1.6.1 Digital LCD 1-5

1.6.2 Status Indicators (LEDs) 1-8

1.6.2.1 Bypass LED color 1-8

1.6.2.2 Inverter LED color 1-8

1.6.2.3 Lamp Test 1-8

1.6.3 Remote Alarm Indication 1-9

1.6.3.1 Utility Failure 1-10

1.6.3.2 Minor Alarm 1-10

1.6.3.3 Major Alarm 1-10

1.6.4 Front Panel Controls 1-10

1.6.4.1 Input DC Circuit Breaker 1-11

1.6.4.2 Scroll Switch 1-11

1.6.5 Inverter Module Switches

And Controls 1-11

1.6.5.1 Output Voltage Selection 1-14

1.6.5.2 Micro-Processor "DIP"

Switch Settings 1-14

1.7 . . . . . . . . . . . . . . . Mechanical Specifications 1-14

vii

Contents

Page 8

Section Description Page

1.7.1 Dimensions 1-15

1.7.2 Weight 1-15

1.8 . . . . . . . . . . . . . . . Environmental Specifications 1-15

1.8.1 Operating Temperature 1-15

1.8.2 Non-Operating Temperature 1-15

1.8.3 Operating Humidity 1-15

1.8.4 Operating Altitude 1-15

1.8.5 Audible Noise 1-15

1.8.6 Cooling 1-15

Section II — Installation and Operation

2.0 . . . . . . . . . . . . . . . Scope 2-1

2.1 . . . . . . . . . . . . . . . Receiving 2-1

2.2 . . . . . . . . . . . . . . . Handling 2-1

2.3 . . . . . . . . . . . . . . . Storage 2-1

2.4 . . . . . . . . . . . . . . . Prerequisites to Installation 2-1

2.5 . . . . . . . . . . . . . . . Installation 2-1

2.5.1 Location 2-2

2.5.2 Mounting And Wiring Access 2-3

2.5.3 Grounding 2-5

2.5.4 Inverter Connection 2-5

2.5.4.1 Hard Wire Access 2-8

2.5.4.2 Knockout Access 2-8

2.5.4.3 DC Hard Wire Connection 2-8

2.5.4.4 Alarm Hard Wire Connection 2-8

2.5.4.5 AC Hard Wire Connection 2-8

2.5.5 Cooling 2-9

2.6 . . . . . . . . . . . . . . . Inverter Set Up 2-9

2.6.1 Voltage Selection 2-10

2.6.2 Frequency Selection 2-10

2.6.3 Bypass 2-8

2.6.4 On-Line, Off-Line Operation 2-10

2.6.5 Automatic Restart 2-10

2.7 . . . . . . . . . . . . . . . Operation 2-11

Section III — Theory of Operation

3.0 . . . . . . . . . . . . . . . Scope 3-1

3.1 . . . . . . . . . . . . . . . General Description of the Inverter 3-1

3.1.1 Battery Booster 3-3

3.1.1.1 Hysteretic Booster Operation 3-3

3.1.2 Dual Inverters 3-5

3.1.2.1 Average Current Mode 3-6

3.1.2.2 Reference Sine Wave and Control 3-6

3.1.3 Static Transfer Switch and

Maintenance Bypass Relay 3-7

3.1.3.1 On-Line, Off-Line Mode, and

Static Transfer Switch 3-7

viii 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 9

Section Description Page

3.1.3.1.1 Static Transfer Switch 3-7

3.1.3.1.2 Start Up Sequence 3-8

3.1.3.2 Off-Line Mode 3-8

3.1.4 Digital LCD 3-8

3.1.5 Status Indicators (LEDs) 3-8

3.1.5.1 "Bypass" 3-9

3.1.5.2 "Inverter" 3-9

3.1.6 Power Supply 3-9

3.1.6.1 Supply Description 3-9

3.1.6.2 Supply Operation 3-10

Section IV— Maintenance and Service

4.0 . . . . . . . . . . . . . . . Scope 4-1

4.1 . . . . . . . . . . . . . . . Safety Instructions 4-1

4.2 . . . . . . . . . . . . . . . Preventive Maintenance 4-1

4.3 . . . . . . . . . . . . . . . Replacement Parts 4-2

4.4 . . . . . . . . . . . . . . . Troubleshooting and MGE Ser vicing 4-2

4.4.1 Installation Checks 4-3

4.4.2 Basic Inverter System (-92 Models) 4-4

4.4.3 Inverter With static Transfer Switch

(-94 Models) 4-5

4.4.4 ON-LINE Mode 4-6

4.4.5 OFF-LINE Mode 4-6

4.4.6 Troubleshooting Guide 4-6

Glossary g-1

Illustrations

figure description page

1-1 System Status Readout 1-5

1-1A Line 1 Measurement Readout 1-7

1-1B Line 2 Measurement Readout 1-7

1-1C Line 1 and 2 Measurement Readout 1-8

1-2 Remote Alar m Connection Diagram 1-9

1-3A Inverter Module Configuration

for .5 kVA & 1 kVA 1-12

1-3B Inverter Module Configuration

for 2 kVA 1-13

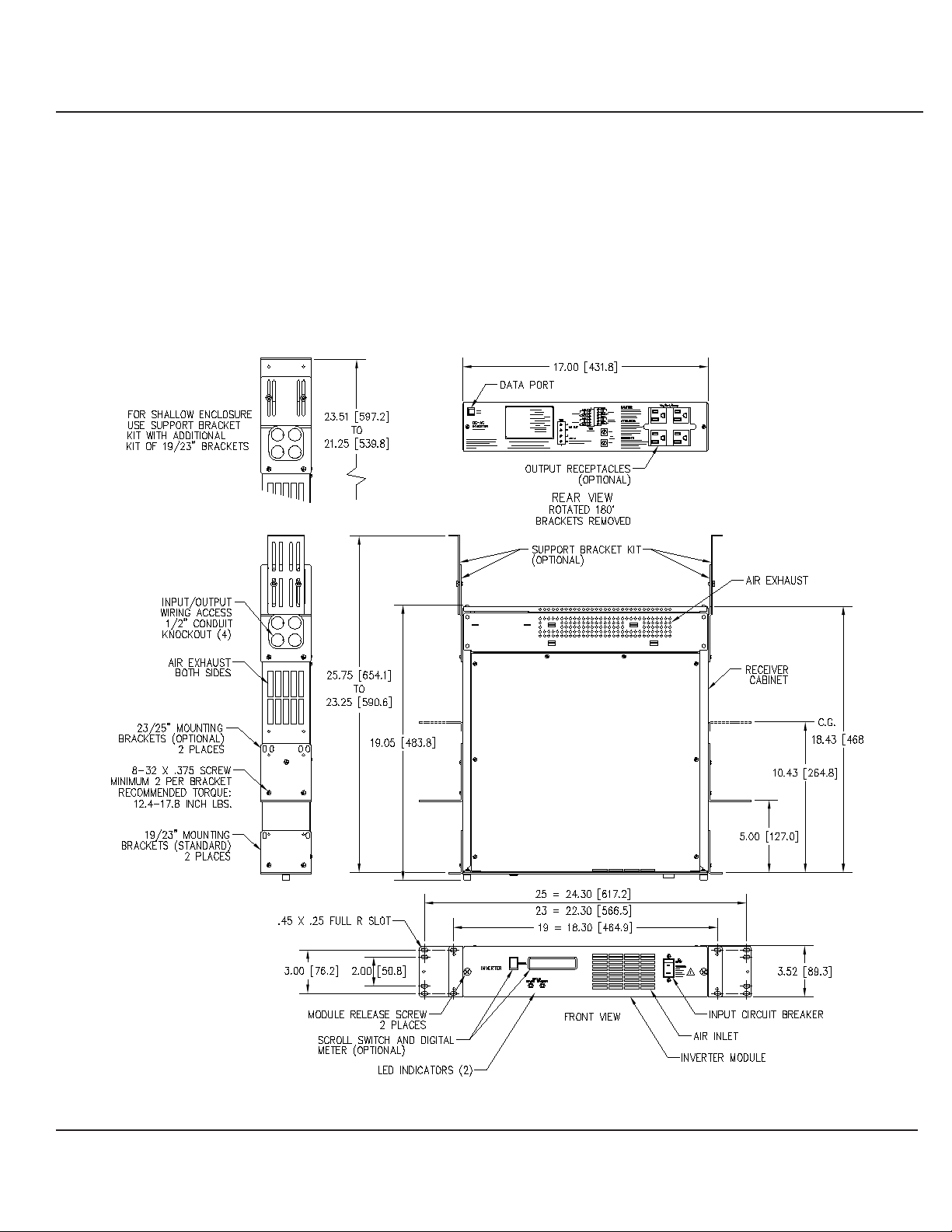

2-1A Outline and Mounting

for .5 kVA & 1 kVA 2-2

2-1B Outline and Mounting

for .2 kVA 2-3

2-2A Wiring Access and Connection

for .5 kVA & 1 kVA 2-6

2-2B Wiring Access and Connection

for .5 kVA & 1 kVA 2-7

86-153061-00 ix

Owner’s Manual

Page 10

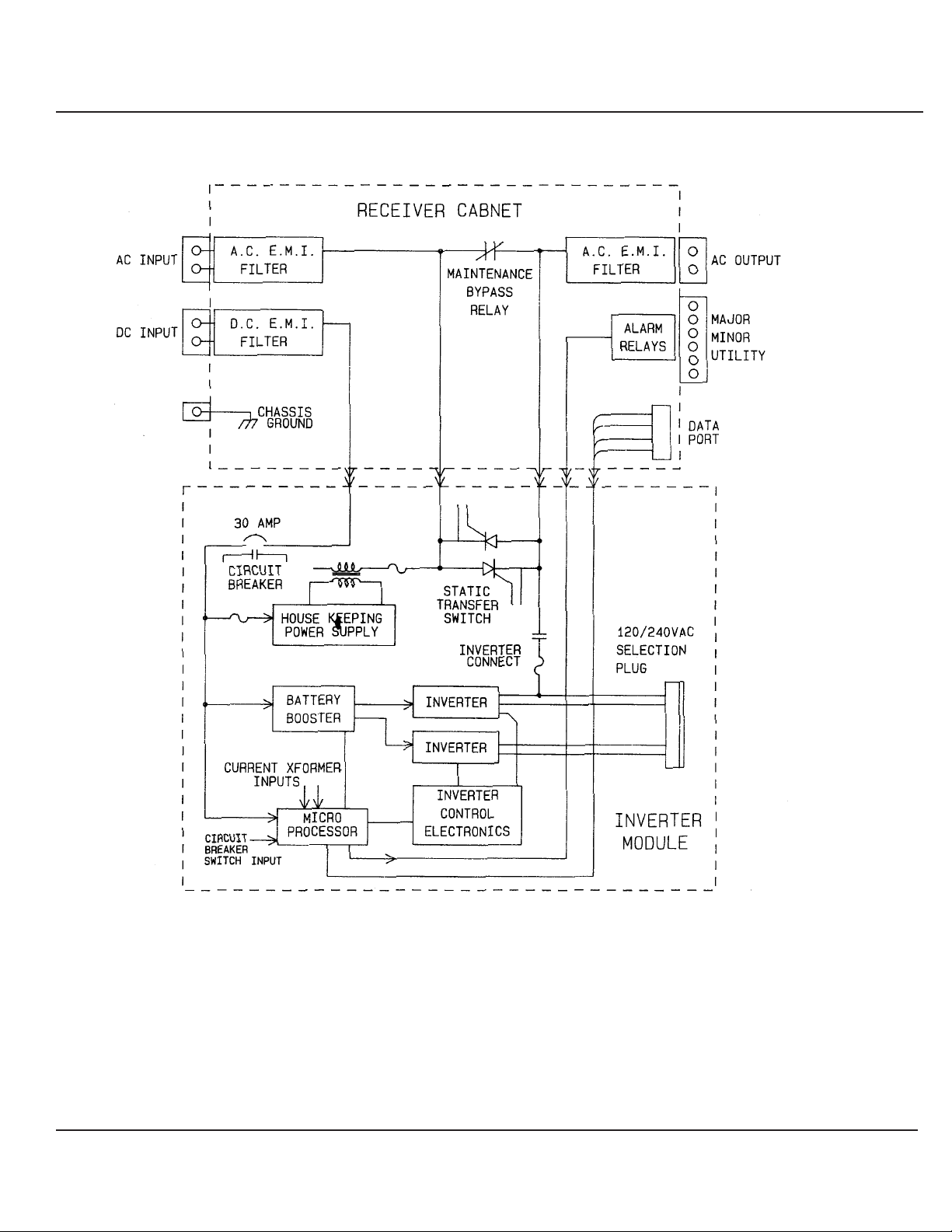

3-1 Inverter Block Diagram 3-2

3-2 Hysteretic Booster Diagram 3-4

3-3 Dual Inverter and Waveform

Diagram 3-5

Tables

Table Description Page

1-1 Characteristics of Inverter 1-3

1-2 LCD Readout Definitions 1-6

2-1 Recommended Input/Output Wiring 2-4

4-1 Installation Checklist 4-3

4-2 Troubleshooting Checklist 4-7

x 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 11

How T o Use This Manual:

This manual is designed for ease of use and easy location of

information.

To quickly find the meaning of terms used within the text, look

to the Glossary.

The paragraph symbol (¶) indicates numbered paragraphs

that can be quickly found in the Contents on page iii.

This manual uses Noteboxes to convey important

information.

Noteboxes come in four varieties:

NOTE

A NOTE notebox indicates information provided as an operating tip or

an equipment feature.

IMPORTANT

An IMPORTANT notebox

indicates information

provided as an operating

instruction, or as an operating tip.

CAUTION

A CAUTION notebox indicates information provided to protect the user

and service personnel

against possible equipment damage.

WARNING

A WARNING notebox indicates information provided to protect the user

and service personnel

against safety hazards

and/or possible equipment damage.

86-153061-00 xi

Owner’s Manual

Page 12

xii 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 13

This manual provides technical information required for

installation, operation and maintenance of the Topaz S3

inverters with power ratings of 0.5 kVA, 1.0 kVA, and 2kVA.

Please read this manual before operating the Topaz S3

equipment. Please retain this manual for future reference.

The manual is divided into four sections:

Section I — Introduction

This section introduces the Topaz S3 family of single phase

inverters, including a general description of the system and

its internal components, a description of available options,

and system specifications.

Section II — Installation and Operation

This section presents installation and operating information

for Topaz S3 inverters, including an overview of the system,

its components, and their function; a description of the

indicators and controls and their function; and operational

sequences to be followed for all conditions of normal,

emergency, and maintenance operation.

Section III — Theory of Operation

This section contains the elementary block diagram of the

Inverter Module and Receiver Cabinet and a brief

description of the operation of the electronics of each block.

1.0 Scope

WARNING

An AC output will be present at the output terminals immediately when

AC input is energized even without the inverter module installed in the

receiver cabinet.

ATTENTION

La tension alternative de sortie appara ît dès la mise sous tension de

le'entrée, même si le module onduleur n'est pas installé.

WARNUNG

Die Netzausgangsspannung ist unmittelbar an den

Ausgangsklemmen,sowie der Netzeingang angeschlossen wird-slebst

wenn der Einschub nicht im Gestell ist.

1 — 1Introduction

Introduction

Page 14

Section IV — Maintenance and Service

This section describes maintenance of the Topaz S3 inverter,

including safety instructions, preventive maintenance, and

information about replacement parts, and customer service.

A Glossary in the rear of this manual provides definitions of

terms used within the text.

The sine wave inverter provides stable, distortion-free AC

power from a DC input source, at a selectable output voltage

and frequency, for sensitive equipment which must be

operated in locations where commercial AC power is not

available. With a static switch option, the inverter also forms

a reliable and economical part of uninterruptible power

systems in either on-line or off-line mode. See Section III,

Theory of Operation, for detailed information on inverter

characteristics.

This model is designed for rack mounting in 19 inch, 23 inch,

or 25 inch racks and either flush front panel or center

mountable, depending on the position and location of the

mounting flanges.

Check the model dash number of your unit to make sure it is

the type you need. Standard options are as follows:

Description Product Numbers

500VA & 1kVA 2kVA

Topaz S3 Inverter with Status indicators. 63054-92, 63104-92 63204-92

Topaz S3 Inverter with Status indicators,

Digital LCD, and Static Transfer Switch. 63054-94, 63104-94 63204-94

Receptacles:

(4) NEMA 5-15R 6310-R91 6320-R91

(4) IEC-320 6310-R92 6320-R92

Support Bracket Kit (Recommended when using forward mounted brackets) for 19” Rack unit:

Bracket for 23”/25” rack mount: 6310B-N4 6320B-N4

LCD display meter with static switch

Communication interface

Spare kit (63204-94-SK1)

Specifications subject to revision without notice.

1.3 Specifications

1.2 Options

1.1 General Description

1 — 2 86-153061-00Introduction

S3 Static Inverters 1kVA

Page 15

Table : Characteristics of Inverter

1- 1

Model Output Nominal Input Max. Nominal Output AC Amperes at

Number Power Input Voltage Input DC Selectable Output Voltage of:

Rating Voltage Range Current

(VA/Watts) (Vdc)** (Vdc) Amperes 120V 220V 230V 240V

63204* 2000/1680 -48 42 to 57 60 16.6 8.4 8.4 8.4

63104* 1000/840 -48 40 to 60 30 8.3 4.2 4.2 4.2

63054* 500/420 -48 40 to 60 16 4.2 2.1 2.1 2.1

*Model number is followed by a two-digit dash number :

-92 = Inverter with Status indicators.

-94 = Inverter with Status indicators, Digital LCD, and Static Transfer Switch.

**DC voltage rating is given with respect to earth or chassis ground.

0.5 microsecond, 100 kHz ringing wave with 6000V peak,

with no resulting damage per IEEE587.

Less than 30 dBrnC.

80% minimum (on-line mode).

97% typical (off-line mode).

1.5.3 Efficiency

1.5.2 DC Input

Conducted

Emission

1.5.1 Surge Withstand

Capability

1.5 Electrical

Specifications

1.4 Characteristics

of Model

86-153061-00 1 — 3Introduction

Owner’s Manual

Page 16

Introduction

Does not exceed 3% for all linear and non-linear (computer)

load conditions within the VA/Watt rating.

Inverter output RMS voltage will vary 1% maximum for line

variations between low line and high line at any load between

no load to rated load.

Inverter output RMS voltage will vary 1% maximum for load

variations between no load and full load at nominal line.

2 kVA/1680 Watts, 1 kVA/840 Watts, and .5 kVA/420 Watts

maximum rating available over power factor range of 0.6

leading to 0.6 lagging over rated DC input voltage range.

Crest factor up to 3:1 for non-linear loads within rated

VA/Watt ratings.

50 or 60 Hz, user selectable (see Figure 1-3). When option

-94, Static Transfer Switch is installed and utility AC is

present, the output frequency will be phase locked to within

+/- 6 degrees of the utility frequency. Frequency slew rate

shall be less than one Hz per second. When 60 Hz is

selected, the input frequency must be between 57 to 63 Hz

or when 50 Hz is selected, the input frequency must be

between 47 to 53 Hz or a BYPASS error will be displayed.

Free run frequency stability shall be within +/- 0.02% of the

selected frequency (50Hz or 60Hz).

300% minimum of rated load current for four to five cycles.

Short circuit defined as loads greater than 220% of rated

current.

Continuous overload up to 125% of rated VA/watts at 40º

celsius maximum (120% of rated VA/watts for 2 kVA).

Moderate overload of 125% (120% for 2 kVA) to 150%, 1800

cycles (30 seconds at 60Hz). Severe overload of 150% to

220%, 24 cycles (0.4 seconds at 60Hz).

For a 0 to 100% linear load step change, inverter output

voltage will deviate no more than 20% of rated value, and

shall recover within 1ms.

1.5.12 Transient Deviation

and Recovery

1.5.11 Overload Capability

1.5.10 Short Circuit

Current

1.5.9 Frequency Stability

1.5.8 Output Frequency

1.5.7 Power Factor

1.5.6 Load Regulation

1.5.5 Line Regulation

1.5.4 Harmonic

Distortion

1 — 4 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 17

See Figure 2-1 on page 2-2 for the location of indicators and

controls.

The LCD displays two lines of twenty characters. Two types

of messages are displayed:system status or measurement.

A system status message is the default at turn-on, after a

system failure or stop sequence.

Each line consists of three columns that identify: 1) power

source, 2) source mode, 3) source status. Power source

definitions are as follows:"INV ." ref ers to the in verter module.

"BYP" refers to the bypass mechanism, either maintenance

bypass relay or static transfer switch.

For definitions of source mode and source status messages,

as well as corresponding LED status indicator colors, refer to

Table 1-2 .

Figure : System Status Readout

1- 1

1.6.1 Digital LCD (Liquid

Crystal Display)

1.6 Indicators and

Controls

86-153061-00 1 — 5Introduction

Owner’s Manual

Upper Scroll Switch

LCD

INV: on normal

BYP: ready normal

Lower Scroll Switch

Column 1

Power

Source

Column 2

Source

Mode

Line 1

Line 2

Column 3

Source

Status

Page 18

Table : LCD Readout Definitions

1- 2

Column 1 Column 2 Column 3 Power Source Mode / Status Definition LED status

Power Source Source

Source Mode Status

SYSTEM SET TO THE ON-LINE Inverter

(INVERTER) MODE. LED

LINE 1 INV: on normal System is on the inverter delivers power to the load. Green

LINE 1 INV: on dc low Input DC voltage is less than 42 volts. Yellow

LINE 1 INV: on dc high Input DC voltage greater than 57 volts. Yellow

LINE 1 INV: on overload Load greater than 125% of rated VA or Watts.** Yellow

120% for 2 kVA

LINE 1 INV: off DC LOW On Bypass. Input DC voltage less than 39.5 volts. Red

LINE 1 INV: off DC HIGH On Bypass. Input DC voltage greater than 60 volts. Red

LINE 1 INV: off DC FAIL On Bypass. Input circuit breaker turned OFF. Red.

LINE 1 INV: off overload On Bypass. Load >125%, see specification. Red

120% for 2 kVA

LINE 1 INV: off software On Bypass. Shut down, micro-processor problem. Red

LINE 2 BYP: ready normal Input AC voltage in tolerance, ready to go to bypass. Blink Green

LINE 2 BYP: ready ac low Input AC voltage less than 85% of nominal. Blink Yellow

LINE 2 BYP: ready AC LOW Input AC voltage less than 71% of nominal. Blink Red

LINE 2 BYP: ready ac high Input AC voltage greater than 110% of nominal. Blink Yellow

LINE 2 BYP: ready AC HIGH Input AC voltage greater than 112% of nominal. Blink Red

LINE 2 BYP: ready AC FAIL Input AC returned, inverter NOT phase locked. Blink Red

LINE 2 BYP: ready ac warn Input AC less than 85%, inverter phase locked. Blink Red

SYSTEM SET TO THE OFF-LINE Bypass LED

(BYPASS) MODE.

LINE 1 INV: ready normal Inverter in stand-by, ready to operate Blink Green

LINE 1 INV: ready dc low Input DC less than 42 volts. Blink Yellow

LINE 1 INV: ready dc high Input DC greater than 57 volts. Blink Yellow

LINE 1 INV: off DC LOW Input DC less than 39.5 volts. Blink Red

LINE 1 INV: off DC HIGH Input DC greater than 60 volts. Blink Red

LINE 2 BYP: static normal Exter nal AC input powering load. Voltage in

tolerance. Green

LINE 2 BYP: ready ac low Input AC voltage less than 85% of nom. On

inverter Yellow

LINE 2 BYP: ready AC LOW Input AC voltage less than 71% of nom.On inverter. Red

LINE 2 BYP: ready ac high Input AC voltage greater than 110% nom. On

inverter. Yellow

LINE 2 BYP: ready AC HIGH Input AC voltage greater than 112% nom.

On inverter.* Red

LINE 2 BYP: maint nor mal Input DC breaker Off, input AC in tolerance. Green

LINE 2 BYP: maint ac low Input DC breaker Off, input AC less than 85% nom. Yellow

LINE 2 BYP: maint AC LOW Input DC breaker Off, input AC less than 72% nom. Red

LINE 2 BYP: maint ac high Input DC breaker Off, input AC greater than

110% nom. Yellow

LINE 2 BYP: maint AC HIGH Input DC breaker Off, input AC greater than

112% nom. Red

LINE 2 BYP: maint ac warn Input DC breaker Off, system recovering from

AC hi/low Yellow

NOTE: In the maintenance bypass mode, the load will be powered from the input AC source,

independent of its voltage level.

* If inverter failure or DC input loss occurs, and AC input voltage is greater than 112% of nominal, the system will shut down

to protect users equipment.

** If overload is not removed, unit will transfer to Bypass, Inverter Ready will be displayed (see specification).

1 — 6 Introduction 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 19

The LCD can display a total of 10 different measurements, with two measurement values per

line.The following is a list of measurements displayed:

Load Volts (Vrms) %Load (higher of watts/VA)

Utility Volts (Vrms) Frequency (Hz)

DC Input Volts (VDC) DC Input current (Amps)

Load Watts Load Current (Arms)

Inverter internal temperature (deg. C) Inverter frequency (Hz)

To display a measurement, press and hold the UPPER or LOWER scroll switch until the LCD

read-out changes to the desired measurement.

Figure : Line 1 Measurement Readout

1- 1A

Figure : Line 2 Measurement Readout

1- 1B

The same measurements can be displayed on both Line 1

and Line 2 of the LCD, so it is possible to display up to four

different measurements simultaneously.

86-153061-00 1 — 7Introduction

Owner’s Manual

Column 1

Measurement

PRESS

AND HOLD

LOWER

SCROLL

SWITCH

LOAD: 120V 121 %

BYP: ready normal

Column 2

Value

Column 3

Value

INV: on normal

PRESS

AND HOLD

LOWER

SCROLL

SWITCH

DC IN: 51.5V 22.8A

Column 1

Measurement

Column 2

Value

Column 3

Value

Page 20

Figure : Line 1 and 2 Measurement Readout, Status Indicators

1- 1C

Two indicators are provided and identified as "STATUS". One

indicator is labeled "BYPASS", the other "INVERTER". In

normal condition, if the OFF-LINE (bypass) mode has been

selected, the "BYPASS" LED will glow continuously and the

"INVERTER" LED will blink ON and OFF. If the ON-LINE

(inverter) mode has been selected, the "INVERTER" LED will

glow continuously, the "BYPASS" LED will blink. Blink rate is

one second on, one second off.

GREEN -- Utility voltage and frequency within tolerance.

YELLOW -- Warning! Utility voltage or frequency not in

tolerance.

RED -- Alert! Bypass abnormal. Utility voltage or frequency

either too low or too high, can not transfer to bypass.

NOT ILLUMINATED -- Bypass not available.

GREEN -- Inverter ON, no warnings or faults.

YELLOW -- Warning! -- Inverter overload or overload

recovery cycle, thermal warning, or DC warning.

-- Bypass abnormal.

RED -- Alert! Inverter not operating. Stopped for abnormal

Inverter, overload, short circuit, thermal warning, DC

warning, or DC circuit breaker OFF.

At power up or software recovery, an automatic lamp test

sequence will be automatically initiated. Both indicators will

simultaneously go through a RED-YELLOW-GREEN lamp

test sequence.

1.6.2.3 Lamp T est

1.6.2.2 Inverter LED Color

1.6.2.1 Bypass LED Color

1.6.2 Status Indicators

(LEDs)

1 — 8 Introduction 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

PRESS

AND HOLD

LOWER

SCROLL

SWITCH

LOAD: 120V 121%

DC IN: 51.5V 22.8A

STATUS

BYPASS INVERTER

Page 21

Three alarm relays are provided. 1) UTILITY FAILURE, 2)

MINOR alarm, 3) MAJOR alarm. All relays are identical,

however the UTILITY and MINOR relays are wired as a

SPDT units, whereas the MAJOR alarm relay is a DPDT unit.

Relays are energized under normal operating condition. Deenergizing of the relays results in an ALARM signal as shown

in figure 1-2. Relay contact rating is 2 amperes maximum for

120/240V A C, 25 to 125VDC with a s witched load of 50 Watts.

Connection diagram is clearly labeled on the rear panel for

these alarm relays. See Figure 1-2.

Figure : Remote Alarm Connection Diagram

1- 2

1.6.3 Remote Alarm

Indication

86-153061-00 1 — 9Introduction

Owner’s Manual

Page 22

Alarm if Utility voltage is not within proper limits. Contacts

are:

TB2-1 = NC, TB2-2 - Common, TB2-3 = NO.

A minor alarm will occur for any of the following:

1) inverter output or static transfer switch ov erload or short

circuit.

2) thermal warning or fault.

3) Input DC loss.

4) Static transfer switch failure.

5) 4 transfers to bypass within 4 minutes (on-line mode).

Contacts are: TB2-4 = NC, TB2-5 = Common, TB2-6 = NO.

A major alarm will occur when the load is not powered by the

Inverter or the Utility AC (static transfer switch or

maintenance bypass relay). Two sets of contacts are

provided. Contact set 1 for utility failure alarm: TB2-7 = NC,

TB2-8 = Common, TB2-9 = NO. Contact set 2 for inverter

failure alarm: TB2-10 = NC, TB2-11 = Common, TB2-12 =

N0.

1.6.4 Front Panel

Controls

1.6.3.3 Major Alarm

1.6.3.2 Minor Alarm (Only

Available on Model

With Static Transfer

Switch)

1.6.3.1 Utility Failure (Only

Available on Model

With Static Transfer

Switch)

1 — 10 Introduction 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 23

A circuit breaker is located on the front panel and identified

as "DC INPUT". Tur ning the breaker to the ON position will

apply the input D.C. voltage to a capacitor bank through a

resistor network to limit the inrush current. After a few

seconds of delay, the DC capacitor bank voltage will be

within a few volts of the input. Then a relay will close and

apply the full battery voltage to the capacitor bank. After

energizing of the relay, the Inverter will be allowed to operate.

Placing the circuit breaker to the OFF position will disable the

Inverter. If the BYPASS option is available, the unit will

transfer to BYPASS, thus the load will be powered from the

Utility power source through the BYPASS switches. The

receiver cabinet contains a maintenance bypass relay to

allow the inverter module to be removed without removing

power from the load provided the BYPASS option is

available.

This is a three position rocker switch and is associated with

the digital LCD. The center position is OFF. Pushing the

UPPER switch will allow scrolling through the various LINE 1

read-outs. Pushing the LOWER switch allows scrolling

through various LINE 2 read-outs in the reverse direction.

When looking at the left hand side of the inverter module,

openings are provided to select the output voltage (120 or

240 VAC) and switches to set up various commands to the

microprocessor. See Figure 1-3A and Figure 1-3B.

1.6.5 Inverter Module

Switches and

Controls

1.6.4.2 Scroll Switch

1.6.4.1 Input DC Circuit

Breaker

86-153061-00 1 — 11Introduction

Owner’s Manual

Page 24

Figure : Inverter Module Configuration for .5kVA and 1kVA

1- 3A

1 — 12 Introduction 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 25

Figure : Inverter Module Configuration for 2kVA

1- 3B

86-153061-00 1 — 13Introduction

Owner’s Manual

Page 26

Selection of the AC output voltage is accomplished by

moving a connector plug. The printed circuit board has a 10

pin connector (J3) and its mate is a 9 pin plug (P3). Moving

this plug to the left (rear) position selects the 120VAC

position (100, 110, 115, 120 VAC). Moving of the plug to the

right (toward the front panel) connects the inverter to produce

240VAC (200, 220, 230, or 240VAC).

An eight position DIP switch can be seen through the access

hole in the left side of the inverter module. The switches are

labeled "MICRO CONTROL SELECT". The switch functions

are clearly labeled. Switch positions 1 and 2 are reserved

and should be set to the OFF position. Switch position 3 is

ON when no BYPASS option is installed, OFF when the

BYPASS option is installed. Switch position 4 is OFF if AUT O

RESTART is desired, ON if manual restart is desired. Switch

position 5 & 6 select the output voltage of the inverter.

Switches 5 & 6 OFF = 120 or 240 VAC output, 5 ON & 6

OFF = 115 or 230 VAC output, 5 OFF & 6 ON = 110 or 220

VAC output, 5 ON & 6 ON = 100 or 200 VAC. See Figure 1-3.

The inverter assembly consists of an inverter module which

slides into the receiver cabinet. The receiver cabinet consists

of a left and right side "U" channel and a rear housing which

contains EMI filters, Maintenance bypass relay, Alarm relays,

and wire termination points. The inverter module is an easily

removable module which is secured into the receiver cabinet

via two thumb screws. All input and output power and signal

wires go through a single multi-pin connector located on the

rear of the inverter module. See Figures 2-1 and 2-2.

1.7 Mechanical

Specifications

1.6.5.2 Micro-Processor

“DIP” Switch

Settings

WARNING

Modules with "BYPASS" option installed may be damaged when utility

voltage and inver ter output voltage settings are not the same.

ATTENTION

Un module avec l'option "BYPASS" risque d'être endommagé si les

réglages de tension du réseau et de sortie onduleur ne sont pas les

mêmes.

WARNUNG!

Nach Installation des "BYPASS" muss die Spannung dieselbe sein wie

die Inverter Ausgangsspannung, ansonsten Beschaedigung des

Inverter Module.

1.6.5.1 Output Voltage

Selection

1 — 14 Introduction 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 27

These dimensions include both the receiver cabinet and the

inverter module. Depth is inclusive of the inver ter module

thumb screws.

0.5 kVA, 1 kVA 2 kVA

HEIGHT: 3.50 in (8.9 cm) 5.3 in (13.4 cm)

WIDTH: 17.0 in (43.2 cm) 17.0 in (43.2 cm)

DEPTH: 19.0 in (48.3 cm) 19.0 in (48.3 cm)

0.5 kVA & 1 kVA 2 kVA

Receiver cabinet 8.0 lbs (3.63 Kg) 11 lbs (5 Kg.)

Inverter module 23.0 lbs (10.44 Kg) 31 lbs. (14 Kg.)

Total weight with

mounting brackets 39.0 lbs (17.7 Kg). 51 lbs.(23.18 Kg.)

Continuous overload to 125% of rated VA/Watts @ 50

degrees celsius maximum for 0.5 kVA & 1 kVA, and 120% of

rated VA/Watts @ 40 degrees celsius for 2 kVA. Full output

power/VA and short term (30 seconds) overload to 125%

between -10 to +50 degrees celsius. Derate power/VA

linearly to zero between +50 and +70 degrees celsius.

-40 to +75 degrees celsius. for shipping, but not

recommended for storage. See Section 2.3 for storage

recommendations.

0 to 90% relative, without condensation.

To 10,000 feet above sea level. Derate maximum ambient of

50 degrees celsius by 3 degrees celsius per 1000 ft. at

altitude above 3300 feet (30 degrees celsius maximum at

10,000 feet).

Less than 60 dBA per Type 2, IEC and ANSI SI.4, 1981 when

measured in a 55 dBA environment at a distance of 4 feet

from any surface.

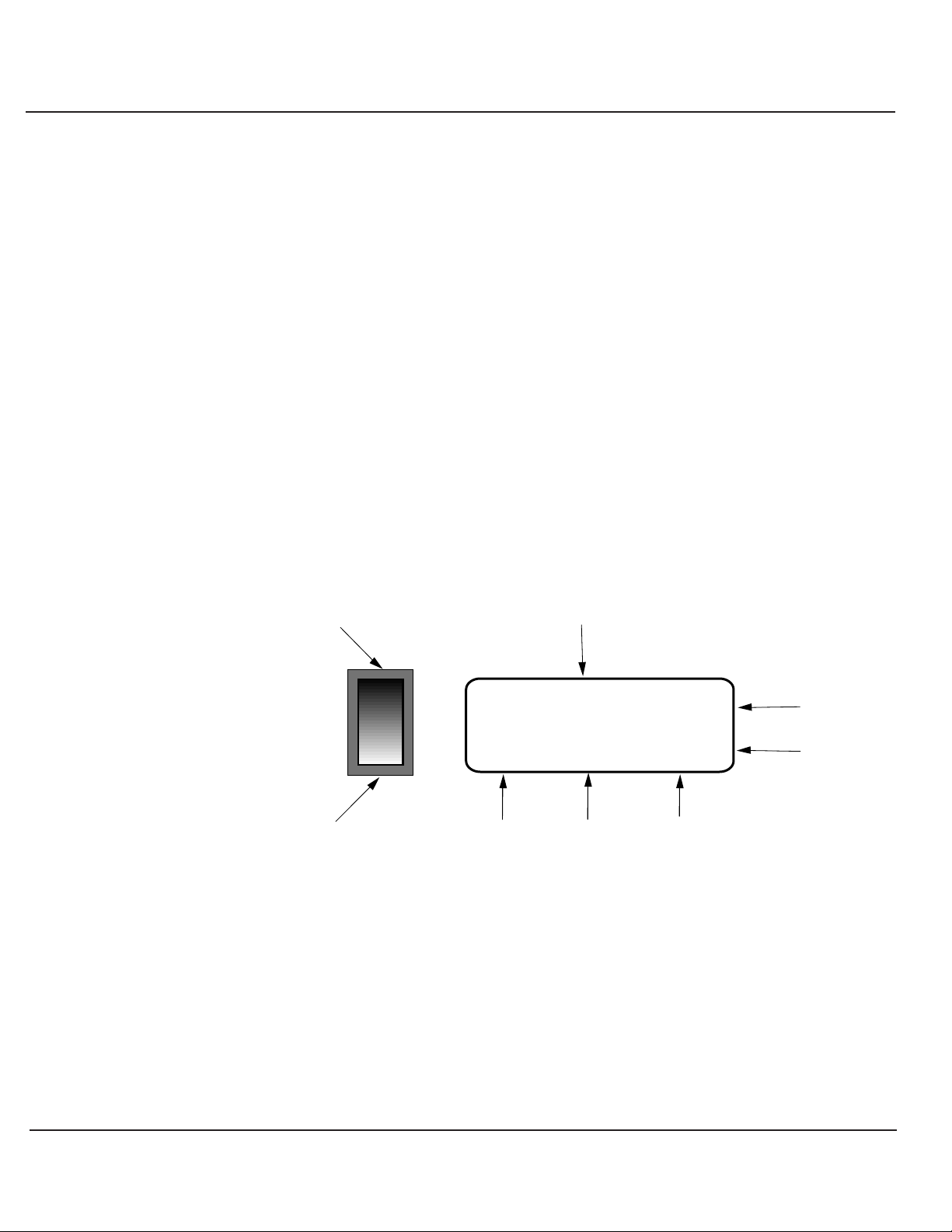

Forced air. Air inlet is located on the front panel. Exhaust is

out the sides of the receiver cabinet. See Figure 2-1.

1.8.6 Cooling

1.8.5 Audible Noise

1.8.4 Operating Altitude

1.8.3 Operating Humidity

1.8.2 Non-Operating

Temperature

1.8.1 Operating

Temperature

1.8 Environmental

Specifications

1.7.2 Weight

1.7.1 Dimensions

86-153061-00 1 — 15Introduction

Owner’s Manual

Page 28

1 — 16 Introduction 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 29

This section describes the installation of the Topaz S3 0.5

kVA, 1 kVA, & 2 kVA including receiving, handling, storage,

and installation procedures.

Before accepting the shipment from the freight carrier,

inspect the exterior surfaces of all shipping containers or

packaging used, and the equipment, for damage that may

have occurred during transit. If the shipping containers or

equipment show evidence of damage, note the damage on

the receiving document (bill of lading) prior to signing for

receipt of equipment.

Damage claims should be filed directly with the carrier.

Replacements for damaged components should be ordered

through MGE Customer Support Services, @ 1-800-5230142 ext. 476.

No special handling required.

If the equipment is to be stored prior to installation, it should

be stored in a cool, dry, well-ventilated location that is

protected against rain, splashing water , chemical agents, etc.

The equipment should be covered with a tarpaulin or plastic

wrapper to protect it against dust, dirt, paint, or other foreign

materials.

An efficient Topaz S3 installation depends on careful

planning and site preparation. Installation of static inverter

equipment must be handled by skilled technicians and

electricians familiar with the special requirements of highenergy electrical equipment. The installation must comply

with the requirements of the National Electrical Code (NEC,

ANSI/NFPA 70, latest issue) and with local codes and requirements as applicable.

We strongly recommend contacting MGE Customer Support

Services @ 1-800-523-0142 ext. 476 for system start-up.Do

not allow unqualified personnel to handle, install, or operate

the Topaz S3 inverter.

2.5 Installation

2.4 Prerequisites to

Installation

2.3 Storage

2.2 Handling

2.1 Receiving

2.0 Scope

2 — 1Installation and Operation

Installation and Operation

Page 30

The equipment is designed for installation in a protected

environment. Factors to be considered in selecting a

location include ventilation, environmental conditions, and

accessibility. Optimum operation of the unit will be obtained

by careful consideration of its location. Install the unit in a

clean, dry location with an unrestricted air flow surrounding

the equipment. See Figure 2-1A and Figure 2-1B.

Figure : Outline and Mounting for .5kVA & 1kVA

2- 1A

2.5.1 Location

2 — 2 Installation and Operation 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 31

Figure : Outline and Mounting for 2kVA

2- 1B

The side mounting brackets can be positioned f or either a 19

inch, 23 inch, or 25 inch rack. The Inverter can also be

mounted either flush with the front panel or at the chassis

midpoint. Prior to mounting the Inverter in the rack,

determine the position of all input and output wiring.

NOTE

Input and output conductors must be sized for the maxim um current

as shown in Table 2-1 and otherwise be in compliance with applicable electrical codes. Be sure all connections are fully tightened.

D.C.input terminals can accommodate wire size up to one "0" gauge

wire.

2.5.2 Mounting And

Wiring Access

86-153061-00 2 — 3Installation and Operation

Owner’s Manual

Page 32

Table : Recommended Input/Output Wiring

2- 1

Model DC Input AC Output AC Input

Current Current Current

Max.

Current 63054 16 AMPS 5 AMPS 5 AMPS

Min.Wire

Size (500VA) 12 AWG 14 AWG 14 AWG

Max.

Current 63104 30 AMPS 10 AMPS 10 AMPS

Min.Wire

Size (1kVA) 10 AWG 14 AWG 14 AWG

Max.

Current 63204 60 AMPS 17 AMPS 17 AMPS

Min.Wire

Size (2kVA) 8 AWG 12 AWG 12 AWG

NOTE: Maximum circuit breaker rating for AC input shall be

20 Amperes, Maximum DC input current should be limited

to 50 Amperes. Wire gauge for both AC and DC wiring shall

be selected according to the national electrical code.

WARNING

This product is considered permanently connected equipment and

must have a readily accessible disconnect device incorporated in the

fixed wiring.

ATTENTION

Ce produit est considere comme equipement connecte en permanence

et doit avoir un appareil de deconnexion facilement accessible incorpore dans le cablage fixe.

WARNUNG!

Dieses Produkt ist ein fest zusammengefuegtes Geraet und muss eine

leicht erreichbare Abschaltungsvorrichtung im Leitungsnetz enthalten.

2 — 4 Installation and Operation 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 33

For safety and proper operation of the unit, including

maximum attenuation of electrical noise, suitable grounding

is required. A separate grounding electrode conductor

should be connected from the ground (GND) terminal to a

nearby grounding electrode, and should be sized per

National Electrical Code Article 250-94. The grounding

electrode should be grounded structural metal, a metal water

pipe, or a suitable ground rod (National Electrical Code,

Article 250-26). The grounding electrode should be as near

as possible to the unit.

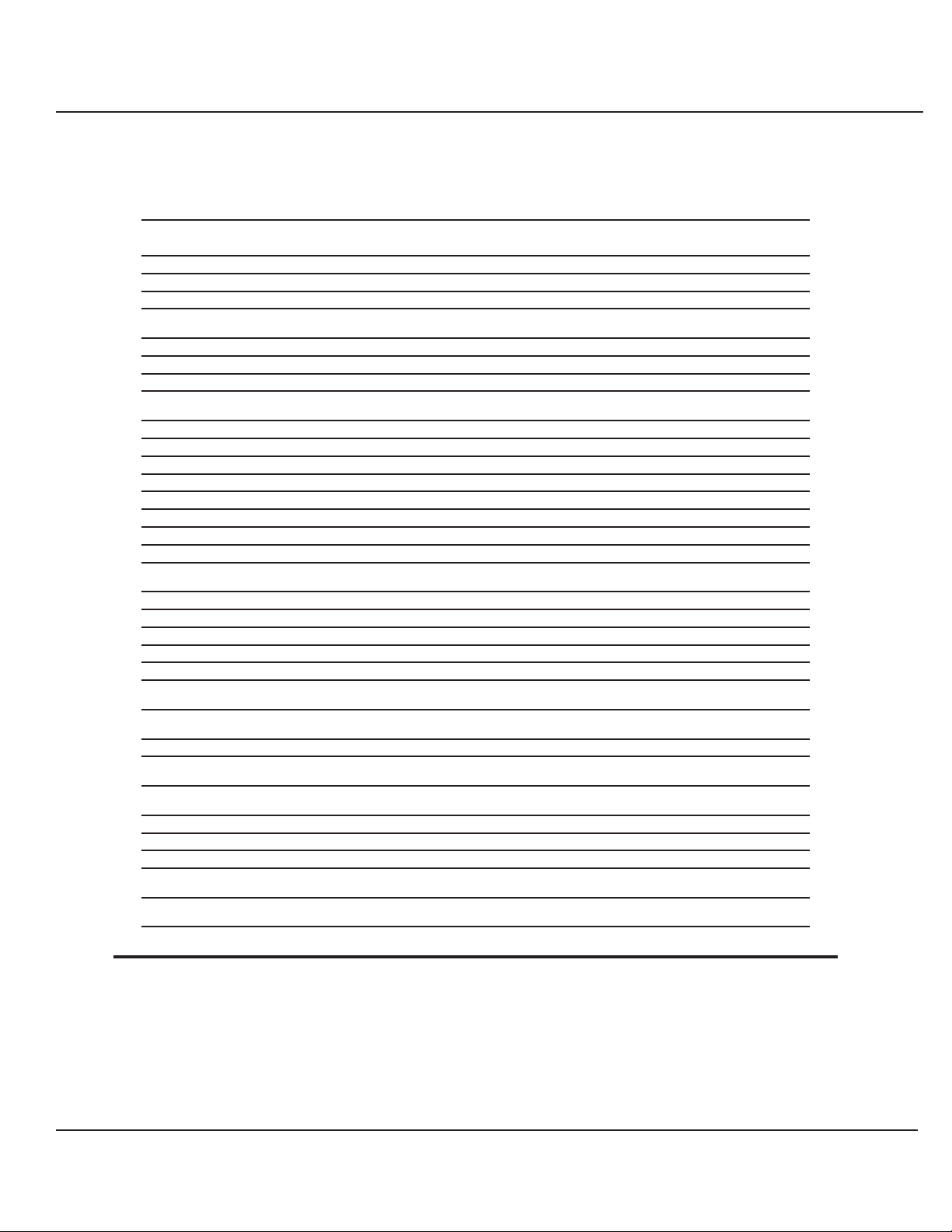

After the inverter assembly has been attached to the rack,

remove the Inver ter module from its receiver cabinet using

the two thumb screws and perform the following steps See

Figure 2-2A and Figure 2-2B.

2.5.4 Inverter Connection

2.5.3 Grounding

86-153061-00 2 — 5Installation and Operation

Owner’s Manual

Page 34

Figure : Wiring Access and Connection for .5 kVA & 1 kVA

2- 2A

2 — 6 Installation and Operation 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 35

Figure : Wiring Access and Connection for 2 kVA

2- 2B

86-153061-00 2 — 7Installation and Operation

Owner’s Manual

Page 36

Remove the cover plate on the rear of the inverter receiver

cabinet to gain access to the wiring compartment.

Route the DC input, AC output, AC input (Static Transfer

Switch option), and alarm signal wires through the selected

knockout holes, using the appropriate conduit bushings . Use

knockout cutters to obtain the proper conduit/bushing sizes.

Be sure that the DC input conductors are connected

POSITIVE to the +DC terminal (40) and the NEGATIVE to

the -DC terminal (41).

Before connecting the AC output wires or AC input wires

(optional), the ALARM wires should be connected to TB2.

Refer to Figure 1-2 for proper wiring. Alarm relays are shown

in their "ALARM", de-energized position. MAJOR alarm (no

power to the load) terminals are TB2-7 to TB2-12. MINOR

alarm (Inverter Stopped) terminals are TB2-4 to TB2-6.

Utility failure (if Static Transfer Switch option is installed)

terminals are TB2-1 to TB2-3.

AC output is on terminal block TB3, marked "AC OUT".

Make sure the white NEUTRAL wire is connected to AC OUT

"N" and the LINE or HOT wire is connected to AC OUT "L".

If a Static Transfer Switch option is installed, connect the

Utility AC input to terminal block TB3, marked "AC IN".

Again make sure the white NEUTRAL wire is connected to

AC IN "N" and the LINE or HOT wire is connected to AC IN

"L" terminal.

2.5.4.5 AC Hard Wire

Connection

2.5.4.4 Alarm Hard Wire

Connection

NOTE

This inverter was designed with the intent that the user will terminate

the positive polarity terminal of the DC source to earth or chassis

ground. For a positive or floating DC input consult MGE

Customer Support Services.

2.5.4.3 DC Hard Wire

Connection

2.5.4.2 Knockout Access

2.5.4.1 Hard Wire Access

2 — 8 Installation and Operation 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 37

For optimum inverter performance, provide ventilation

clearance from exterior surfaces as follows:

Top and bottom: 0.25 inches [6.3 mm]

Front and sides: 1.50 inches [38.1 mm]

• Verify the inverter module is NOT installed into its

receiver cabinet.

• After the receiver cabinet has been wired, verify that a

separate grounding electrode has been connected to

the chassis "GROUND" lug.

• Turn on the Utility AC and verify the proper AC voltage

exists at ACIN "L" with respect ACIN "N" and chassis

"GROUND".

• Turn on the DC supply to the unit.

• Verify polarity of the DC voltage, positive on "+DC" and

negative on "-DC".

• Turn OFF all AC and DC power to the receiver cabinet.

• The Inver ter module is delivered from the factory set for

120 VAC, 60 Hz , auto-restart, ON LINE (Inverter) mode

operation.

• See Figure 1-3 and perfor m the following steps for a

personalized inverter set up.

2.6 Inverter Set UP

2.5.5 Cooling

WARNING

AC output will be present at the output terminals immediately when AC

input is energized even without the inverter module installed in the

receiver cabinet.

ATTENTION

La tension alternative de sortie appara ît dès la mise sous tension de

le'entrée, même si le module onduleur n'est pas installé.

WARNUNG!

Die Netzausgangsspannung ist unmittelbar an den Ausgangsklemmen,

sowie der Netzeingang angeschlossen wird-slebst wenn der Einschub

nicht im Gestell ist.

86-153061-00 2 — 9Installation and Operation

Owner’s Manual

Page 38

Viewed from the left side of the Inverter module, access

holes can be seen for selecting the AC output voltage via a

120VAC/240VAC hard wired connector plug, and setting of

the MICRO CONTROL "DIP" switches. If low output voltage

is desired (100 to 120VAC) the jumper plug must be in the

120VAC position, toward the rear of the unit. If high voltage

output is desired (200 to 240V AC) then the jumper plug must

be removed and placed in the 240VAC position, side toward

the front panel. Also make sure the MICRO CONTROL

SELECT "DIP" switches 5 and 6 are set to the desired

voltage position. For 120VAC or 240VAC output, switch 5

must be OFF, switch 6 OFF. For 115VAC or 230VAC, switch

5 must be ON, 6 OFF. For 110VAC or 220VAC, s witch 5 must

be OFF, 6 ON. For 100VAC or 200VAC, switch 5 must be

ON, 6 ON.

With the Static Transfer Switch option installed, the

frequency selected must be the same as the utility AC

frequency. If the Utility frequency is 60 Hz and the Inverter is

set for 50 Hz, the microprocessor can not phase lock to the

input, and consequently transfer from Inver ter to Utility for

overload or Inverter shut down can not be accomplished

without causing transients on the output. During star t up of

the Inverter, the load is always powered from the Utility and

upon transfer to the Inver ter, the output voltage will transfer

at some unknown phase. So if 60 Hz operation is desired,

set the MICRO CONTROL SELECT "DIP" switch 7 to OFF

for 60 Hz, ON for 50 Hz.

If the Static Transfer Switch is installed, the MICRO

CONTROL SELECT "DIP" switch 3 must be set to the OFF

position. If the Static Transfer Switch option is not installed,

set this switch to the ON position.

If the Static Transfer Switch option is installed , either the ON

line (output from the Inverter) or OFF line (output from the

Utility power source) mode of operation may be selected. To

select the ON line (Inverter) mode, set MICRO CONTROL

SELECT "DIP" switch 8 to OFF. For OFF line (Utility)

operation, set switch 8 to ON.

Some users do not want the Inverter to automatically restart

upon application of DC power to the unit. Under this

condition, set the MICRO CONTROL SELECT "DIP" switch

4 to ON (manual restart required by turning the DC circuit

breaker OFF and then back to ON). If it is desired that the

Inverter automatically start up upon application of DC, the

MICRO CONTROL SELECT "DIP" switch 4 must be set to

the OFF position.

2.6.5 Automatic Restart

2.6.4 On-Line, Off-Line

Operation

2.6.3 Bypass

2.6.2 Frequency

Selection

2.6.1 Voltage Selection

2 — 10 Installation and Operation 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 39

When all selections have been made, perfor m the following

steps to operate the inverter:

A) Be sure that all loads are disconnected or turned OFF

and AC input power to models with a Static Transfer

Switch is OFF.

B) Refer to the installation checklist in Table 2-1 (page

4-3)and be sure that all control settings and terminal

block screws are tight.

C) Check again to see that the DC voltage on the inver ter

identification label matches the voltage of your power

source.

D) Set the DC input breaker located on the front panel of

the Inverter module to the OFF position.

E) Install the inverter module into its receiver cabinet and

tighten the two thumb screws.

F) Apply a DC voltage to the DC input terminals.

G) Again, using a voltmeter or polarity tester, verify the

voltage at the DC input terminals, positive on +DC (40)

and negative on -DC (41).

H) Turn ON the DC circuit breaker. Within less than a

second, a relay will energize which should be audible.

Then the "STATUS" indicators will sequence through

their RED, YELLOW, GREEN lamp test sequence. The

alarm relays will also be cycling through various states

as the lamp test is progressing. As the battery booster

starts, a "chirp" sound may emanate from the unit. The

Inverter will start, producing the appropriate

voltage/frequency on the ACOUT terminal block, TB3.

The "STATUS" indicator for the "INVERTER" should be

illuminated Green. Verify the proper output voltage with

a voltmeter at TB3. The "STATUS" indicator "BYPASS"

should be RED, blinking ON and OFF at a 1 second

rate.

I) Turn On the Utility AC and verify the "STATUS" indicator

identified as "BYPASS" turns GREEN and continues to

blink ON and OFF at a 1 second rate, indicating the

Inverter is powering the AC output. If BYPASS indicator

is a steady GREEN color, the "INVERTER" LED should

be GREEN, blinking ON and OFF, indicating that the

Utility is powering the AC output. The mode was

selected in paragraph 2.6.4.

J) Units with the DIGITAL LCD option. Scroll through the

readout menu using the SCROLL push-button and

verify the DC input, AC input if applicable, and AC

output voltages agree with the voltmeter readings

previously taken.

2.7 Operation

86-153061-00 2 — 11

Owner’s Manual

Page 40

K) Tur n the DC circuit breaker on the front panel to the

OFF position. Verify that AC voltage is still on the AC

OUT terminal block TB3.

L) Loosen the thumb screws securing the Inverter module

into its receiver cabinet and remove the module. Verify

Utility voltage is still on the output terminal block, TB3.

M) Turn OFF all the AC and DC input voltages.

N) Reinstall the Inverter module. Inverter is ready for

operation. Connect loads and tur n ON the unit.

WARNING

Module may be damaged if removed with the DC breaker closed.

ATTENTION

Le module risque d'être endommagé s'il est retiré avec le disjoncteur

DC fermé.

WARNUNG!

Entfernung des Moduls mit geschlossenem Gleichstromunterbrecher

koennte zu Schaden fuehren.

2 — 12 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 41

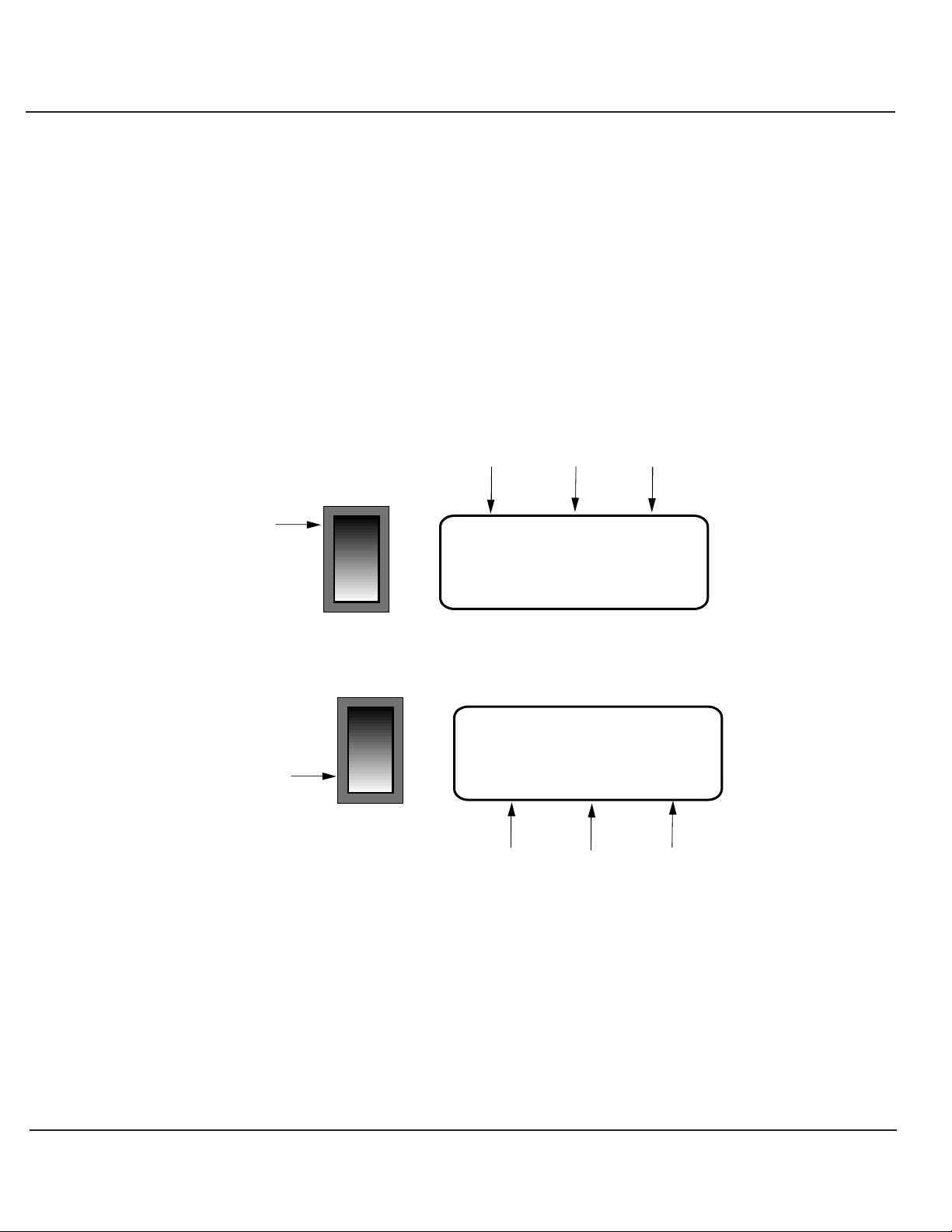

This section describes the theory of operation of the Topaz

S3 Inverter systems.

The inverter utilizes a "Fly-back" conv erter to boost the input

voltage to two regulated +/- 200 volt outputs. Two identical

inverters are contained in the unit, both inverters controlled

by a single PWM to generate sinusoidal AC outputs . The two

inverters can be connected in parallel to produce 120 VAC

output or connected in series for 240VAC output. This

approach minimizes the size and weight of the magnetics

since both the battery booster and inverter operate at

relatively high frequency, greater than 20 kHz. A modular

approach was taken which allows easy field replacement of

the inverter module without removing power from the load.

Figure 3-1 is a block diagram of the inverter.

3.1 General Description

of the Inverter

3.0 Scope

3 — 1Theory of Operation

Theory of Operation

Page 42

Figure : Inverter Block Diagram

3- 1

3 — 2 Theory of Operation 86-153061-00

S3 Static Inverters 1kVA

Page 43

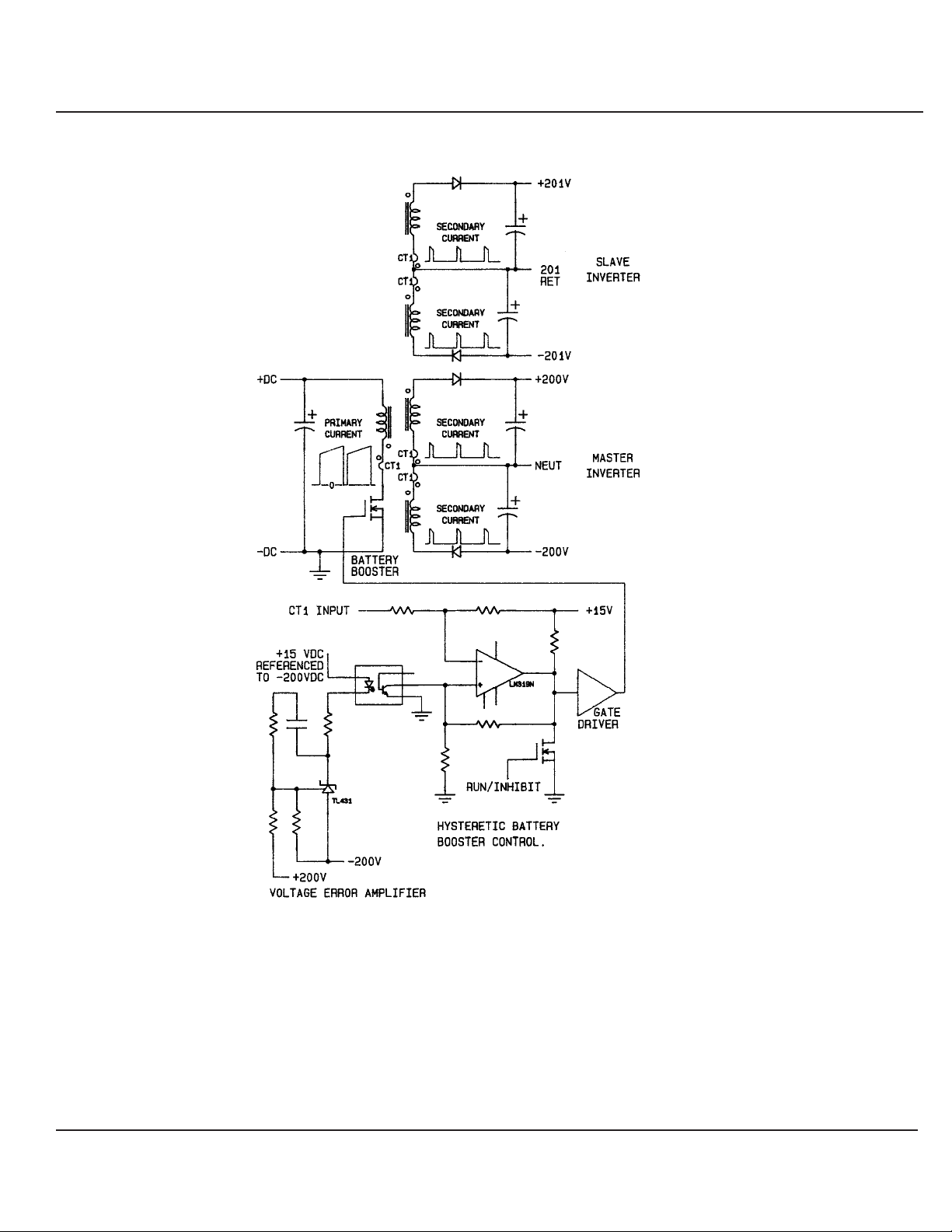

The battery booster is a "continuous" mode Fly-back

converter which takes the DC input voltage and boost it to

four separate outputs of 200 volts. Two of these outputs are

connected in series to produce -200 VDC and +200 VDC and

used by one of the Inverters. The other two outputs are also

connected in series to produce a second -200 and +200 VDC

to be used by the second Inverter. The booster transformer,

which is actually a coupled inductor, is used to isolate the

primary DC input from the two +/-200 VDC outputs used to

generate the two AC outputs. The total DC bus voltage (+/200 volts) of one inverter is regulated. Feedback is provided

through an analogue optical coupler to control a hysteretic

current mode switch.

Figure 3-2 shows the basic concept of the booster. The

voltage error amplifier (TL431) measures the +/-200 VDC

bus (400 volts total) of one of the Inver ters and provides an

error signal (via an optical coupler) to a comparator. If the +/200 volt bus is lower than normal, the voltage applied to the

positive input of the comparator will become higher, a

demand for more current. A "DC" current transformer

measures the current in the primary and secondaries of the

"coupled inductor". The output of the DC current transformer

is applied to the negative input of the comparator. When the

inductors current has reached the required level, as

measured by the DC current transformer, the comparator

turns OFF, thus turning the Boost switch OFF. Now the

energy stored in the coupled inductor is transferred to the

output energy storage capacitors of the four 200 volt outputs .

Since the turns ratio of the coupled inductor (transformer) is

1:1:1:1:1, all four DC outputs will be at the same voltage. A

resistor placed between the positive input and output of the

comparator controls the hysteresis level. The hysteresis

current is set at 7.5 A. When the measured current falls

below the hysteresis level applied to the positive input of the

comparator, the comparator turns back ON, which turns ON

the boost switch. Now the cycle starts all over again. The

operating frequency of the battery booster is a function of

input and output voltage, ranging between 20 kHz to 35 kHz.

Since the booster switch (parallel FET) turns ON before the

current in the output secondaries of the transformer goes to

zero, the primary current starts at some level set by the

hysteresis level. This is called a "CONTINUOUS" mode

Flyback converter.

3.1.1.1 Hysteretic Booster

Operation

3.1.1 Battery Booster

86-153061-00 3 — 3Theory of Operation

Owner’s Manual

Page 44

Figure : Hystertic Booster Diagram

3- 2

3 — 4 Theory of Operation 86-153061-00

S3 Static Inverters 1kVA

Page 45

As indicated, two identical inverters are used to produce

either 120 or 240VAC depending on parallel or series

connection of their outputs. Each inverter is a conventional

half bridge, that is, only two FET switches are used in each

inverter. See Figure 3-3. The output of each inverter is

applied to a coupled choke. Since the choke acts as a

transformer, the two windings of the choke must have the

same voltage at any given time. Therefore if all four of the

200 VDC capacitors are at the same voltage, the output of

the two inverters must be identical (within 2% of one

another). Note that the FET switches are driven in

synchronization. Control of the inverter is unique in that the

inverter uses what is called "Aver age Current Mode Control".

This is actually a control of the choke current and results in

excellent dynamic response to step loads, overloads, and

short circuits.

Figure : Dual Inverter and Waveform Diagram

3- 3

3.1.2 Dual Inverters

86-153061-00 3 — 5Theory of Operation

Owner’s ManualS3 Static Inverters 1kVA

Page 46

A microprocessor is used in the Inverter system to generate

a reference sine wav e via one of its three PWM outputs . The

PWM signal is filtered to make a clean sine wave. This sine

wave is applied to a voltage error amplifier. The other input

to the voltage error amplifier is the output of one of the

inverters, called the master inverter. The voltage error

amplifier controls the amount of current the inverter supplies

to its output filter capacitor and output load. A second

amplifier (current error amplifier) compares the current

command (voltage error amplifier output) to the choke

current (voltage from another DC current transformer) and

produces an error signal which is applied to a motor control

PWM chip which completes the loop. Operating frequency of

the Inverter is 33kHz, generated by the motor control chips

oscillator.

The microprocessor is used to enable and disable the

battery booster, generate the sine wave reference signal,

enable and disable the Inverter, measure battery

current/voltage, Utility current/voltage/frequency, Output

current/voltage/frequency, provide LCD metering data, and

communicate with other equipment. Selection of the

Inverter’s output voltage and frequency (as set by the DIP

switch) is accessible through the side of the inverter module.

Isolation between DC input electronics and AC output (Line

side) electronics is via high speed optical couplers. If Utility

voltage is present and its frequency is close to the setting on

the DIP switch, then the sine wave reference signal will

become phase locked to the Utility. Frequency slew rate is

less than 1 Hz per second, phase error will be less than 6

degrees. The microprocessor is supplied by power from the

DC input side and the sine wave reference must be provided

to the Inverter, located on the secondary (AC output) side. A

high speed optical coupler is used to get the PWM signal to

the Inverter electronics. This PWM signal is filtered by a two

stage R-C filter and then buffered before it is applied to the

voltage error amplifier. Enable/disable of the Inverter by the

microprocessor is also via this same optical coupler.

Feedback of the input and output AC voltage is

accomplished by using the motor control PWM oscillator

(triangle wave shape, ramping linearly between +4 and -4

volts at 33 kHz rate) to make a PWM signal. This signal is

applied to an optical coupler, buffered, and filtered to

produce an isolated replica of the AC voltages. The

microprocessor has eight analogue inputs, two of which are

used to measure the AC signals. Other inputs to the micro

are: Inverter output current, Utility current (for back feed

protection), battery voltage, battery current, and two heat

sink temperatures.

3.1.2.2 Reference Sine

Wave and Control

3.1.2.1 Average Current

Mode

3 — 6 Theory of Operation 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 47

This is an optional feature that is described below.

The ON LINE mode is defined as allowing the load to

operate from the Inverter instead of the Utility power. If the

Inverter should fault for some reason (overload, short circuit,

over temperature, DC voltage not within specification, or

Inverter failure) the system will transfer to the "BYPASS"

mode (through the Static Transfer Switch) if the Utility v oltage

is within proper limits. For severe overloads, the

Maintenance Bypass relay located in the receiver cabinet will

be de-energized, shorting out the Static Transfer Switch, thus

preventing damage to the Static Transfer Switch. The

advantage of ON LINE operation is that the AC output is at a

fixed voltage level and frequency and is free of all of the

transients, sags, and brown out conditions that occur on the

Utility power grid.

The Static Transfer Switch is a pair of back to back SCRs

located in the inverter module. The SCRs are tur ned on as

soon as the Utility voltage is present. It is commanded OFF

by the microprocessor. The receiver cabinet also contains a

maintenance bypass relay which is connected in parallel with

the SCRs. The relay needs to be energized to open the

contacts that parallel the SCRs. Energizing of this relay is

also under the control of the microprocessor. Power to the

microprocessor is from the utility and the DC input.

3.1.3.1.1Static Transfer

Switch

3.1.3.1 On-Line, Off-Line

Mode, and Static

Transfer Switch

3.1.3 Static T ransfer

Switch and

Maintenance

Bypass Relay

86-153061-00 3 — 7Theory of Operation

Owner’s Manual

Page 48

When the inverter is enabled (by turning ON the front panel

DC circuit breaker) the microprocessor goes through its start

up sequence, including phase locking the reference sine

wave to the Utility AC input. Then the maintenance bypass

relay is energized, opening its contacts. The inverter is

turned ON to check its functional operation, then turned back

OFF. The Inverter output relay is closed , Inver ter enabled

and the Static Transfer Switch (SCRs) are turned OFF. This

sequence is accomplished without any break (less than 1

millisecond) in output voltage to the load. If a severe

overload should occur, the static transfer switch (SCRs) will

be turned back ON and the Inverter disabled until the

overload is removed. For overloads greater than 150%, the

maintenance bypass relay will be de-energized, effectively

shorting out the SCRs. Other overloads and failure of the

Inverter will also cause transfer to the bypass mode . The DIP

switch accessible through a opening in the side of the

Inverter module must be set to the proper position to achieve

this mode of operation.

This mode allows the load to be powered at all times from the

Utility power source through the Static Transfer Switch.The

maintenance Bypass relay will be energized (contacts open).

When the DC circuit breaker (on the front panel) is turned

ON, the inverter will go through a sequence similar to that

defined above, except the Inverter will not be powering the

load. Transfer to the Inverter will occur only if the Utility

voltage fails to be within specified limits (-20% to +10%). The

STA TUS indicator will b link indicating the inv erter status. The

DIP switch located on the side of the Inverter module must

be set to the proper position to obtain this mode of operation.

Advantage of OFF LINE mode is that the system is more

efficient. Only a small amount of power is required by the

Inverters electronics (less than 30 watts).

The digital LCD has two lines of 20 characters. A "SCROLL"

switch allows scrolling through the display messages which

include as a minimum: Utility voltage and utility frequency

(only with static transfer switch), output voltage , output

current, output frequency, input DC voltage, input DC

current, percent load. All of this data is supplied to the LCD

from the microprocessor.

Two LEDs are on the front panel identified as "ST ATUS". The

left most LED is for "BYPASS" status and the right LED is for

"INVERTER" status.

3.1.5 Status Indicators

(LEDs)

3.1.4 Digital LCD Display

3.1.3.2 Off-Line Mode

3.1.3.1.2 Start Up Sequence

3 — 8 Theory of Operation 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 49

A blinking LED indicates that the load is powered by the

Inverter, not from the Utility. The "BYPASS" LED will be

illuminated Green if the Utility is within acceptable voltage

and frequency limits as specified by the 50/60 Hz DIP switch

setting. Yellow indicates the Utility is not within proper limits.

Red indicates the utility is out of tolerance, do not transfer to

bypass. Not illuminated indicates that bypass is not

available.

A blinking LED indicates that the load is being powered by

the Utility source and not from the Inverter. Green indicates

the Inverter is ready to power the load. Yellow indicates

Inverter warnings for overload or overload recovery cycle,

thermal DC, and bypass abnormal conditions. Red indicates

the Inverter can not operate properly. LED not illuminated

indicates the inverter is not ON.

An internal power supply is used within the inverter module

which makes several 15 VDC outputs from the -48 VDC

battery input and/or utility AC power through a transformer

and bridge rectifier. The 15 volt outputs are used to power

the AC side electronics ( + & - 15VDC for the control circuits ,

one +15 VDC output to operate the "master" inverters half

bridge driver), and a second +15 VDC output to operate the

"slave" inver ters half bridge driver. Battery side electronics

(hysteretic battery booster and microprocessor) also

requires + & - 15 VDC.

The power supply is a discontinuous mode "Flyback" supply,

that is, the current in the "Flyback" transformer is zero at the

beginning of every switching cycle. The supply was

designed to produce an output power of 20 watts from D.C.

input voltages ranging from 35 VDC to 80 VDC. Control of

this supply is by an industry standard UC3842AN current

mode control PWM chip operating at 100 kHz. The +15 VDC

output on the Battery side (D.C.) is the regulated voltage.

Tight coupling of the transformer ensures that all other

outputs are reasonably close to 15 volts. Within the

UC3842AN integrated circuit, the voltage error amplifier

positive input terminal is set at one half of the chip's

reference (+5.00 volts). So the negative input terminal (VFB)

must also be at +2.50 volts. A 2490 ohm resistor is

connected from the VFB terminal to ground (1.00 mA.) To

obtain +15 VDC, we need 12.5 volts across a resistor at 1.0

mA, or 12,500ohms. A 12400 ohm resistor was used and the

+15 VDC is actually 14.95 volts.

3.1.6.1 Supply Description

3.1.6 Power Supply

3.1.5.2 “Inverter”

3.1.5.1 “Bypass”

86-153061-00 3 — 9Theory of Operation

Owner’s Manual

Page 50

The duty cycle of the UC3842ANs oscillator is set up to be

about 45%. The output of the chip drives the gate of an

IRF840 FET. The "Drain" of the FET is connected to a

"Flyback" transformer (actually a coupled inductor of 50 uHy

primary inductance). At the beginning of the switching cycle,

the FET is turned ON. Current starts to build up linearly in

the primary of this inductor. A resistor located in the

"Source" lead of the FET is used to measure the current in

the primary of the transformer. This signal is applied to the

UC3842ANs current sense port. When this voltage (current

in the transformer's primary) reaches the correct level as

determined by the chip’s voltage error amplifier output, the

FET is turned OFF. Now the energy stored in the "Flyback"

transformer is transferred into the output capacitors.

Remember! Energy (Watt -seconds) times the number of

energy bundles per second is equal to Watts. If the

transformer windings are tightly coupled, all windings should

receive the needed energy to keep all of the outputs at the

same voltage. If the +15 VDC output should become higher

than desired, the voltage error amplifier will start to decrease

its output and thus reduce the amount of energy being

supplied to the output capacitors. If the error amplifier's

output should become less than one volt, no energy will be

stored in the transformers and thus no energy will be

transferred to the output capacitors.

3.1.6.2 Supply Operation

3 — 10 Theory of Operation 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 51

This section describes maintenance and service of the

Topaz S3 Inverters Systems, including safety instructions,

preventive maintenance, descriptions of replacement parts

kits, and service.

IMPORTANT SAFETY INSTRUCTIONS FOR SERVICING

INVERTER SERVICING SHOULD BE PERFORMED OR

SUPERVISED BY QUALIFIED PERSONNEL ONLY.

The following preventive maintenance routines should be

considered the minimum requirements; your installation and

site may require additional prev entiv e maintenance to assure

optimal performance from your installed Topaz S3 series

Inverter System and associated equipment. We strongly

recommend contracting MGE Customer Support Services

for preventive and remedial maintenance.

The technician or electrician performing preventive

maintenance on the inverter must be familiar with the

indicators, controls, and operation of the inverter, as

described in this manual.

4.2 Preventive

Maintenance

WARNING

DC input power to the inverter is normally from a batter y bank with a

very high short-circuit capacity. Accidental welding and severe burns

can be caused by mistakes while connecting or disconnecting these

conductors.

ATTENTION

L'entrée DC de l'onduleur est normalement alimentée par une batterie

avee un courant de court-circuit élevé. Une erreur lors de la connexion ou deconnexion de ces conducteurs peut causer des soudures

accidentelles et des brûlures sérieuses.

WARNUNG!

Gleichstrom zum Wechselrichter kommt gewoehnlich von der

Batteriebank mit einer sehr hohen Kurzschluss Leistungsfaehigkeit.

Unbeabsichtigtes Schweissen und schwere Verbrennungen koennen

die Folgevon fehlerhafter Verbindung und Trennung sein.

4.1 Safety Instructions

4.0 Scope

4 — 1Maintenance and Ser vice

Maintenance and Service

Page 52

a. Ensure that all equipment is clean and free of loose

dust, dirt, and debris. The exterior of all enclosures

may be cleaned with a mild solution of soap and water,

lightly applied with a lint-free cloth.

b. Inspect the air intake and exhaust openings and clean

as required. Verify that air flows freely through the

equipment. Clean the air intake and exhaust openings

with compressed air or with a soft brush.

c. No further maintenance is required.

Two levels of replacement parts are available for the Topaz

S3 Inverter Systems. The two levels are designated B and

C. The level that you should keep on hand for your

installation will vary depending on the type of maintenance

planned on site, and the configuration of your Topaz S3

Inverter Systems. Having the replacement parts on hand will

prevent any unacceptable delays (due to time involved

obtaining spare parts) during critical periods, such as system

start-up. Any items used during start-up will be replaced by

MGE at no charge. Contact MGE Customer Support

Services for specific recommendations. A description of

each level is provided below:

Level Description

B This level of replacement parts is recommended when

the user can tolerate short-duration UPS downtime to

obtain replacement parts in the event of a major inverter

failure.

C This level of replacement parts is recommended when

the user can tolerate only a minimum of downtime in the

event of a major inverter failure.

Should you encounter a problem in the operation of a Topaz

S3 Inverter Systems and need MGE UPS Systems to

service your product, please take into account the following

recommendations.

To the extent that you feel comfortable with the unit, leave it

in its current state, make a record of the display lights and

messages and call either your local MGE Field Engineer or

MGE's Customer Support Services at 1-800-523-0142 for

assistance. Leaving the unit in its current state will enable

MGE's field engineers to troubleshoot your product and bring

it back on line more easily.

If you are not comfortable with the current status of the unit,

you may want to take the following actions:

4.4 Troubleshooting

and MGE Servicing

4.3 Replacement Parts

4 — 2 Maintenance and Ser vice 86-153061-00

Topaz S3 Inverters 0.5 kVA, 1 kVA, & 2 kVA

Page 53

Many operation problems are due to incorrect installation or

setup. Before turning the unit on, review Section 2 for

instructions pertaining to your particular system. Use the

checklist in Table 4-1 in this review. If the system fails to

operate properly after being turned on, the Table 4-1

checklist should be reverified.

Table: Installation Checklist

4- 1

Installation Item To Be Basic Inver ter System Inverter With Static Transfer

Verified Switch

DC Input Terminals

Voltage

Polarity

AC Input Terminals

Voltage

Connections

AC Output Terminals

Connections

Input Conductor Size

Output Conductor Size

Output V oltage Select

Frequency Select

Bypass Select

On/Off Line

Auto/Manual Start

4.4.1 Installation Checks

86-153061-00 4 — 3Maintenance and Ser vice

Owner’s Manual

Page 54

Before the inverter system can be turned on with the DC

circuit breaker on the front panel, the DC power source must

be energized. Upon turning the DC circuit breaker ON, a

relay will energize and the cooling fan will start to operate

after a short delay of less than one second. The Inverter

STATUS indicator will go through a RED, YELLOW, GREEN

lamp test sequence. The Bypass STATUS indicator will not

be illuminated. After another short delay (less than 2

seconds) a "chirp" sound should be heard from the Inverter

as the Battery Booster circuit starts up. The Inverter status

indicator should turn GREEN indicating power is being

supplied to the output. Using a voltmeter, verify the proper

output voltage at the Receiver Cabinet terminal board,

between ACOUT "L" and "N" terminals. If the Inverter

STATUS indicator is YELLOW, an overload condition exists.

If it is RED, the Inver ter has shut down, either from a severe

overload or Inverter malfunction. If the Inverter STATUS

indicator should be YELLOW or RED, turn the DC circuit

breaker OFF and disconnect the load wires from the ACOUT

terminal block. Turn the DC circuit breaker back ON and

verify the Inverter goes through its normal start-up sequence

(lamp test, battery booster start-up). The Inverter STATUS

indicator should be GREEN. If it is GREEN, a problem

probably exists in the output load. First verify the Inverter's

output voltage by using a voltmeter to check the AC output

voltage on the ACOUT terminal board. Verify that a short

does not exist between the Line and Neutral wires and that