Page 1

Galaxy PW™

100 to 225kVA

Uninterruptible Power Systems

Installation and User Manual

86-133060-00 A00

www.mgeups.com

Features

◗ Single and Parallel UPSs

◗ Battery Cabinet

◗ Maintenance Bypass

◗ Optional Up-link to an

IBM AS4000

Page 2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS – This manual contains important instructions for the Galaxy PW™ that must be

followed during operation of the equipment.

WARNING Opening enclosures expose hazardous voltages. Always refer service to

qualified personnel only.

ATTENTION L'ouverture des cabinets expose des tensions dangereuses. Assurez-vous tou-

jours que le service ne soit fait que par des personnes qualifiees.

WARNUNG! Das öffnen der Gehäuse legen gefährliche Spannungen bloss. Service sollte

immer nur von qualifizierten Personal durchgeführt werden.

WARNING As standards, specifications, and designs are subject to change, please ask for

confirmation of the information given in this publication.

ATTENTION Comme les normes, spécifications et produits peuvent changer, veuillez

demander confirmation des informations contenues dans cette publication.

WARNUNG! Normen, Spezifizierungen und Pläne unterliegen Anderungen. Bitte verlangen

Sie eine Bestätigung über alle Informationen, die in dieser Ausgabe gemacht

wurden.

NOTE This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at user's own expense.

Certification Standards

◗ IEEE 587-1980/ANSI C62.41 1980 Standards for Surge Withstand Ability

◗ FCC rules and regulations of Part 15, Subpart J, Class A

◗ UL listed under 1778-ULC, Standards for Uninterruptible Power Supply Equipment

◗ NEMA PE 1 (National Electrical Manufacturers Association) - Uninterruptible Power Systems

◗ NEMA 250 (National Electrical Manufacturers Association)

– Enclosures for Electrical Equipment (1000 Volts Maximum)

◗ NFPA 70 – National Electrical Code

◗ ISO 9001

◗ Occupational Safety & Health Administration (OSHA)

Galaxy PW™ UPS 100 to 225kVA

Important Safety Information and Standardsii 86-133060-00 A00

Page 3

How To Use This Manual and Symbol Usage iii86-133060-00 A00

WARNING To reduce the risk of fire or electric shock, install in a temperature and humidity

controlled indoor area free of conductive contaminants.

This equipment is intended only for installations in a RESTRICTED ACCESS

LOCATION.

ATTENTION Pour réduire le riske d'inccendie ou d'électrocution, installer dans une enciente

intérieure contrôlée en température et humidité et sans contaminants conducteurs.

Ce matériel est destiné seulement pour des installations dans un EMPLACEMENT RESTREINT d'cAccès.

WARNUNG! Um die Gefahr von Feuer und elektrischem Schock zu reduzieren, muss das

Gerät in einem temperatur - und feuchtigkeitskontrollierten Raum, frei von

leitungsfähigen Verunreinigungen, installiert werden. Dieses Gerät ist nur für

die Installation an einem Ort mit eingeschränkter Zugangserlaubnis vorgesehen.

Diese Ausrüstung ist nur für Anlagen in einem EINGESCHRäNKTEN ZUGRIFF

STANDORT bestimmti.

WARNING HIGH LEAKAGE CURRENT. Earth connection essential before connecting

supply.

ATTENTION COURANT DE FUITE ELEVE. Raccordement a la terre indispensable avant

le raccordement au reseau.

WARNUNG! Hoher Ableitstrom Vor Inbetriebnahme Schutzleiterverbindung herstellen.

How to Use This Manual and Symbol Usage

This manual is designed for ease of use and easy location of information.

Locate specific topics in the Table of Contents.

For terms used in the text refer to the Glossary.

Typographical conventions use single quote marks in procedures to denote a prompt for User action:

For example:

1. After the selections are complete, click on the “Save” button.

This manual uses four icon symbols with text to convey important information and tips.

WARNING indicates information provided to protect the user and service personnel against

safety hazards and/or possible equipment damage.

CAUTION indicates information provided to protect the user and service personnel against

possible equipment damage.

IMPORTANT indicates information provided as an operating instruction, or as an operating tip.

NOTE indicates information provided as an operating tip or an equipment feature.

Installation and User Manual

Page 4

iv 86-133060-00 A00

Galaxy PW™ UPS 100 to 225kVA

CAUTION: Record All Serial Numbers!

RECORD ALL SERIAL NUMBERS FOR THE GALAXY PW™ AND COMPONENTS.

THESE SERIAL NUMBERS WILL BE REQUIRED IF YOUR SYSTEM NEEDS SERVICE.

KEEP THIS MANUAL IN A PLACE WHERE YOU CAN REFERENCE THE SERIAL

NUMBERS IF SERVICE IS REQUIRED!

UPS SINGLE SERIAL NUMBER: ___________________________________________________

UPS PARALLEL SERIAL NUMBER: _________________________________________________

BATTERY CABINET SERIAL NUMBER: ______________________________________________

MBP SERIAL NUMBER: ___________________________________________________________

ADDITIONAL MODULE SERIAL NUMBERS:

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

____________________________ ______________________________

CAUTION: Record All Serial Numbers

Page 5

Installation and User Manual

Galaxy PW™

100 to 225kVA

Installation and User Manual

Revision History

Galaxy PW™ 100 to 225kVA Installation and User Manual 86-133060-00 A00

Revision: X1 Initial Release 06/2003

A00 ECN#: 003469 02/2006

Copyright © 2006 MGE UPS SYSTEMS, INC.

All rights reserved. Printed in U.S.A.

MGE UPS SYSTEMS, INC.

1660 Scenic Avenue

Costa Mesa, CA 92626

(714) 557-1636

Technical Support:

1-800-

523-0142 (during business hours)

Customer Care Center:

1-800-438-7373

(Hours: 24/7)

v86-133060-00 A00

Page 6

(This page left blank intentionally)

Galaxy PW™ UPS 100 to 225kVA

vi 86-133060-00 A00

Page 7

Contents

Contents

c i86-133060-00 A00

description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Certification Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

How to Use This Manual and Symbol Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

CAUTION: Record All Serial Numbers! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Section 1 Introduction

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1.1 Section Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 1

1.2 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2

1.3 System Major Power Components . . . . . . . . . . . . . . . . . . . . . . . .1 — 3

1.4 Different Types of Galaxy PW™ Systems . . . . . . . . . . . . . . . . . .1 — 4

1.4.1 Single UPS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1.4.2 Parallel UPS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1.5 System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 5

1.5.1 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 5

1.6 Electrical Parameters for Selecting Protective Devices . . . . . . . .1 — 6

1.6.1 Normal AC Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 6

1.6.2 Bypass AC Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 7

1.7 Recommended Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 8

1.7.1 Protection Upstream of Galaxy PW™ . . . . . . . . . . . . . . . . . . . . .1 — 8

1.7.2 Protection Downstream of Galaxy PW™ . . . . . . . . . . . . . . . . . . .1 — 8

1.8 Parallel Connected UPS Units . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 9

Section 2 System Setup

2.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

2.0.1 First steps by an on-site qualified Technical Engineer . . . . . . . .2 — 1

2.0.2 Final steps by MGE Field Service Engineer . . . . . . . . . . . . . . . . .2 — 1

2.0.3 Required Equipment and Tools . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 1

2.1 Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 2

2.1.1 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 2

2.1.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 3

2.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 4

Page 8

Galaxy PW™ UPS 100 to 225kVA

Contentsc ii 86-133060-00 A00

Section 2 System Setup (continued)

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

2.3 Galaxy PW™ Cabinet Major Components . . . . . . . . . . . . . . . . . .2 — 5

2.4 Battery Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 6

2.5 Remote External Maintenance Bypass Cabinet . . . . . . . . . . . . . .2 — 7

2.6 General Instructions for Screens . . . . . . . . . . . . . . . . . . . . . . . . .2 — 8

2.6.1 Control Panel Indicators and Definitions . . . . . . . . . . . . . . . . . . .2 — 8

2.7 System Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 10

2.7.1 Single UPS unit or Redundant Parallel UPS . . . . . . . . . . . . . . .2 — 10

2.8 Parallel UPS Unit for Increased Output . . . . . . . . . . . . . . . . . . .2 — 11

Section 3 Installation

3.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 1

3.1 Optional Communications Card Installation . . . . . . . . . . . . . . . . .3 — 1

3.2 Notes on Connection of Power Circuits . . . . . . . . . . . . . . . . . . . .3 — 1

3.3 Power-Circuit Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 2

3.4 Hot Swap Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 2

3.5 Connections Between Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 4

3.5.1 Connections Between UPOZ Boards . . . . . . . . . . . . . . . . . . . . . .3 — 4

3.5.2 Connections Between UPS Cabinets and the

Remote External Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 4

3.5.3 Connections Between MUSI Boards . . . . . . . . . . . . . . . . . . . . . .3 — 5

3.6 Environmental Signal of the Media Contacts 11 Board . . . . . . . .3 — 7

3.6.1 Signal Reception . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 7

3.6.2 Signal Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 7

3.7 "Media Contacts 11" Standard Auxiliary Circuits Connection . . . .3 — 9

3.7.1 Battery Circuit Breaker "QF1" Connection . . . . . . . . . . . . . . . . .3 — 10

3.8 Installation of the "Temperature Monitor" in the

Battery Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 10

3.8.1 "Temperature Monitor" installation in a Battery Room . . . . . . . .3 — 11

3.8.2 Connection of the Battery "Temperature Monitor" . . . . . . . . . . .3 — 12

3.9 About Final Installation Steps . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 14

Section 4 Operation

4.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.1 Start-up of a Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.1.1 Start-up of an Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.1.2 Emergency Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 1

4.1.3 Single UPS Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 2

4.1.4 Parallel UPS Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 2

4.2 Operation in On-line Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 3

4.2.1 Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 3

4.2.2 Operation with the Normal AC Source Down . . . . . . . . . . . . . . . .4 — 4

4.3 Operation with the Normal AC Source Restored . . . . . . . . . . . . .4 — 5

Page 9

Installation and User Manual

Section 4 Operation (continued)

section description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

4.4 Operation with Engine Generator Set . . . . . . . . . . . . . . . . . . . . .4 — 6

4.5 Battery Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 7

4.6 Inverter Shutdown or Overload . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 7

4.6.1 Single UPS Unit (On-line mode) . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 8

4.6.2 Parallel UPS Without Redundancy . . . . . . . . . . . . . . . . . . . . . . . .4 — 8

4.6.3 Parallel UPS With Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 9

4.7 Output Voltage Quality and Continuity . . . . . . . . . . . . . . . . . . . .4 — 9

4.7.1 Steady State Voltage Regulation . . . . . . . . . . . . . . . . . . . . . . . .4 — 10

4.7.2 Transient Voltage Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 10

4.8 Measurement System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 11

4.8.1 Voltage Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 12

4.8.2 Current Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 12

4.8.3 Power and Frequency Measurements . . . . . . . . . . . . . . . . . . . .4 — 12

4.8.4 Battery Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 12

4.9 Selections and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 13

4.10 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 16

4.11 Maintenance Bypass Option . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 16

4.12 Logging and Time-Stamping . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 17

4.12.1 Event Time-Stamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 17

4.12.2 Consulting Logged (time-stamped) Events . . . . . . . . . . . . . . . .4 — 17

4.13 Setting the Date and Time for the UPS - Utilization

Via the Galaxy PW™ Display . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 18

4.14 Consulting Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 19

4.14.1 Consulting Recorded Measurements . . . . . . . . . . . . . . . . . . . . .4 — 21

Section 5 Maintenance

5.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 1

5.1 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 1

5.2 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 2

5.2 Maintenance Isolation Procedures . . . . . . . . . . . . . . . . . . . . . . . .5 — 2

5.2.1 Single UPS Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 2

5.3 Steps for Parallel UPS Redundancy to Increase Output . . . . . . .5 — 4

5.4 Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 6

5.5 Visual Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 6

5.6 Functional System Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 6

5.7 Testing Parallel Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 7

5.7.1 Galvanic Isolation and Voltage Matching Transformers . . . . . . . .5 — 7

5.8 Management of Computer Networks . . . . . . . . . . . . . . . . . . . . . .5 — 7

5.8.1 Integrated SNMP Agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 7

5.8.2 Two-channel Network Board . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 7

Contents c iii86-133060-00 A00

Page 10

Appendices

description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

Appendix A

Front Control Panel Display Definitions . . . . . . . . . . . . . . . . . . . . . . . . . .A — 1

Display of Primary and Secondary Messages . . . . . . . . . . . . . . . . . . . . .A — 4

Primary Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 5

Secondary Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 6

Appendix B

Monitoring - Electrical Supervision Options . . . . . . . . . . . . . . . . . . . . . .A — 11

"Teleservice" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 11

Utilization Via Teleservice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 11

GTC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 11

GTC + Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 11

Appendix C

Link to an IBM AS/400® Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . .A — 13

Connect and Configure the AS400 Link . . . . . . . . . . . . . . . . . . . . . . . . .A — 13

MGE Warranty & Proprietary Rights for Three Phase Products

MGE Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W—1

Proprietary Rights Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W—1

MGE Customer Care Center

Technical Support and Product Services . . . . . . . . . . . . . . . . . . . . . . . . .W—3

Who To Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W—3

Scheduling Field Service Engineer Support . . . . . . . . . . . . . . . . . . . . . . .W—3

Return Policy for Repair (RMA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .W—3

Glossary

Term and Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G — 1

Reorder Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RO—1

Galaxy PW™ UPS 100 to 225kVA

Contentsc iv 86-133060-00 A00

Page 11

Installation and User Manual

Figures

figure description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

1-1: Galaxy PW™ System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 2

1-2: Galaxy PW™ Single UPS System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 4

1-3: Fuse Curve Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 7

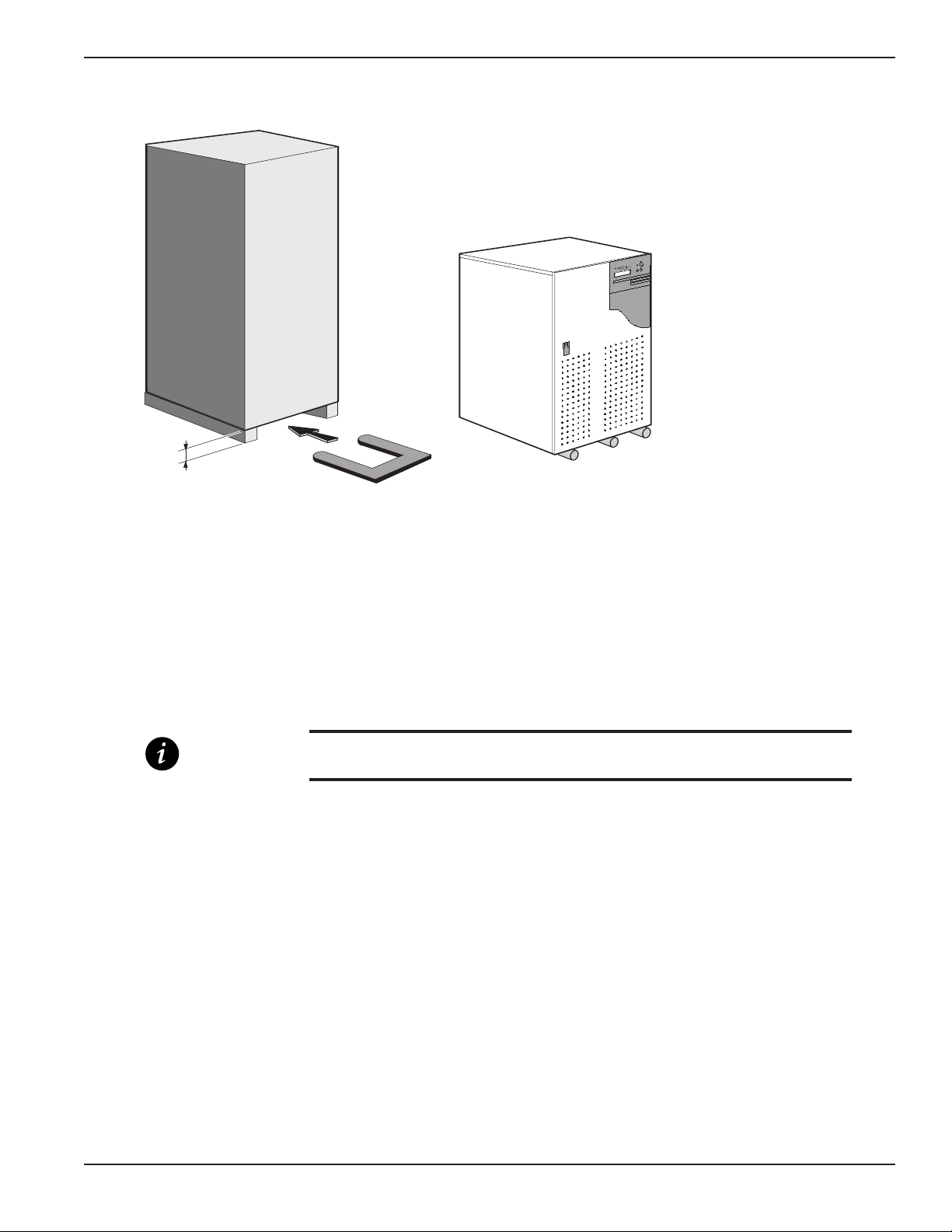

2-1: Handling Cabinet From the Bottom or Rolling on Bars. . . . . . . . . . . . . . .2 — 3

2-2: Dismantling Leg Supports and Attaching Spacers to Cabinet. . . . . . . . .2 — 4

2-3: Layout of the Major Cabinet Components. . . . . . . . . . . . . . . . . . . . . . . .2 — 5

2-4: Component Layout in a Battery Cabinet or a

Battery Circuit-breaker Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 6

2-5: 350A and 1200A Maintenance Bypass Cabinet. . . . . . . . . . . . . . . . . . . .2 — 7

2-6: Control Panel Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 8

2-7: Single UPS Unit Start-up Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 — 10

2-9: Parallel UPS Unit for Increased Output. . . . . . . . . . . . . . . . . . . . . . . . . .2 — 11

3-1: Galaxy PW™ Single UPS Unit Wire Diagram. . . . . . . . . . . . . . . . . . . . . .3 — 2

3-2: Single UPS Unit Power Circuit Connections. . . . . . . . . . . . . . . . . . . . . . .3 — 2

3-3: Parallel UPS Unit Power Circuit Diagram. . . . . . . . . . . . . . . . . . . . . . . . .3 — 3

3-4: Connections Between UPOZ Boards. . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 4

3-5: Two Parallel UPS Units Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 5

3-6: Three Parallel UPS Units Connections. . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 6

3-7: Four Parallel UPS Units Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 6

3-8: Standard Auxiliary Circuits Connections. . . . . . . . . . . . . . . . . . . . . . . . . .3 — 9

3-9: Installing the "Temperature Monitor" in a Battery Cabinet. . . . . . . . . . .3 — 10

3-10: Temperature Monitor" Base. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 — 11

3-11: Single UPS Unit Connection of the Battery "Temperature Monitor". . . .3 — 12

3-12: Connection of the Battery "Temperature Monitor."

(In Parallel UPS Units with Batteries in Same Room.) . . . . . . . . . . . . .3 — 13

3-13: Connection to the "Media Contacts 11" Board. . . . . . . . . . . . . . . . . . . .3 — 14

4-1: Control Panel and Circuit Breaker Diagram. . . . . . . . . . . . . . . . . . . . . . .4 — 1

4-2: Single UPS Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 2

4-3: Parallel UPS Two Parallel Connected UPS Units. . . . . . . . . . . . . . . . . . .4 — 2

4-4: Parallel UPS Two to Four Parallel Connected UPS Units. . . . . . . . . . . .4 — 2

4-5: Normal Operation Indicator Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 3

4-6: Normal AC Source Indicator Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 4

4-7: Normal Operation Mode Indicator Diagram. . . . . . . . . . . . . . . . . . . . . . .4 — 5

4-8: Battery Charge Cycle Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 6

4-9: Installation with an Engine Generator Set. . . . . . . . . . . . . . . . . . . . . . . . .4 — 6

4-10: Operating in On-line Mode Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 7

4-11: Overload Curve Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 9

4-12: Measurement System Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 11

4-13: Display of Alarm Messages.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 — 16

5-1: UPS Isolation Diagram for Normal AC Bypass Source. . . . . . . . . . . . . . .5 — 3

5-2: Panel Procedures for UPS Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 3

5-3: Start-up After Isolation Procedure is Completed. . . . . . . . . . . . . . . . . . . .5 — 3

5-4: Isolate All UPS’s Procedures Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 4

Contents c v86-133060-00 A00

Page 12

Figures (continued)

figure description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

5-5: Start-up Procedure After Isolation Diagram. . . . . . . . . . . . . . . . . . . . . . .5 — 5

5-6: Redundancy for Increased Output Diagram. . . . . . . . . . . . . . . . . . . . . . .5 — 5

5-7: MAC Address Sticker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 — 7

Tables

table description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page

1-1: Electrical Parameters for Normal AC Source. . . . . . . . . . . . . . . . . . . . . .1 — 6

1-2: Electrical Parameters for Bypass AC Source. . . . . . . . . . . . . . . . . . . . . .1 — 7

1-2A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 7

1-3: Rating Recommended for Devices Upstream of Single UPS. . . . . . . . . .1 — 8

1-4: Rating Recommended for Devices Downstream of Single UPS. . . . . . .1 — 8

1-5: Parameters for Bypass AC Source and

Load Cables for a Parallel UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 — 9

Galaxy PW™ UPS 100 to 225kVA

Contentsc vi 86-133060-00 A00

Page 13

Introduction

1.0 Scope

Introduction is a general description and overview of Galaxy PW™ 100 to 225kVA components, its intended use,

environment, and applicable specifications, power input/output requirements, and system characteristics for

different system configurations.

1.1 Section Descriptions

1 Introduction

Introduction is a general description and overview of the Galaxy PW™ 100 to 225kVAcomponents, its intended use,

environment, and applicable specifications, power input/output requirements, and system characteristics for

different system configurations.

2 System Setup

System Setup describes receiving and handling of the Galaxy PW™ 100 to 225kVA, a description of major components, the battery cabinet, and definition of the control panel indicators. Includes electrical, mechanical and

environmental specifications.

3 Installation

Installation guides the User through single and parallel UPS unit power cable connections, hot swap options,

connections between cabinets, communication card connections, battery temperature monitoring. Wire diagrams

are included for configuring the unit to specifications.

4 Operation

Operation describes the theory of operation, start-up for single and parallel units, modes of operation, normal specifications for operating the Galaxy PW™ 100 to 225kVA. The User procedures include display messages,

measurement systems, alarms, battery cabinet, and log time-stamping procedures.

5 Maintenance

Maintenance procedures for isolation for maintenance, startup for single and parallel units, functional and visual

checks, software configurations, and testing scenarios.

Appendices

A List of primary and secondary display messages.

B Electrical supervision options. (Teleservice and GTC Cards)

C Instructions of the optional IBM AS400 up link process.

1 — 186-133060-00 A00 Introduction

Page 14

1.2 General Description

The cabinets are cooled by forced ventilation. The air enters via the doors and grids at the bottom and is discharged

through the roof, which means the cabinets can be positioned against the back wall.

Connections are made through the bottom. (Connections through the top are an available option.)

The connection cables may be run in three ways:

◗ In a trench running under the cabinets.

◗ Under a false floor.

◗ On the floor under the cabinets, in the free space equal to the height of the feet; in this case the cables

should be run side by side to avoid blocking the flow of air for ventilation.

The cables for connections are between:

◗ The battery and UPS cabinets (power and control cables).

◗ The bypass AC-source transformer in an auxiliary cabinet and the UPS cabinet.

Only the wires for the inter cabinet control connections between parallel-connected UPS units are supplied.

The other power cables for connections between cabinets are not supplied.

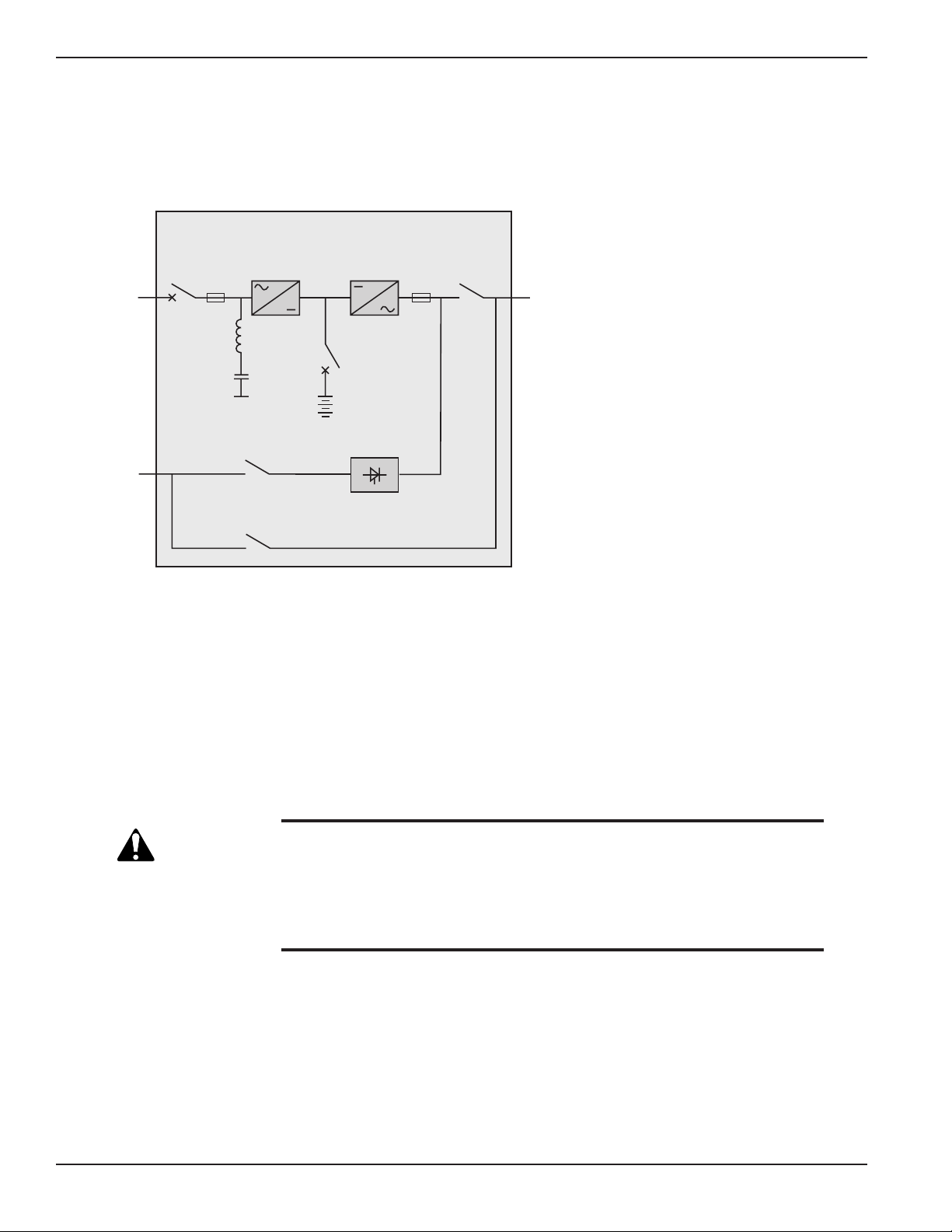

Figure 1-1: Galaxy PW™ System.

Galaxy PW™ UPS 100 to 225kVA

Introduction1 — 2 86-133060-00 A00

Page 15

Installation and User Manual

1.3 System Major Power Components

Rectifier/charger module (A) Converts 3-phase AC power from the normal AC source supply (1) into DC power

for the normal inverter input and float charges or recharges the battery.

Battery unit (D) Provides backup power for the inverter in the event of a voltage drop or a normal AC

source failure.

Inverter module (B) Converts the DC power supplied by the rectifier/charger module or the battery unit

into 3-phase AC power for the load.

Static bypass module (C) Ensures the instantaneous transfer of the load to the bypass AC source input in the

event of an inverter shutdown (initiated by the user or by a protective device) or a

sudden overload.

Maintenance Bypass Isolates the UPS for maintenance and transfers the load to bypass AC source input

without interrupting the supply of power. The maintenance bypass is made up of

three manual switches (Q3BP, Q4S and Q5N).

External Bypass Option for parallel UPSs and Hot-Swapping.

Q5N: Isolation of the inverters of all the parallel UPS systems from the load.

Q3BP: Bypass for maintenance.

The normal AC input and the bypass AC input have different functions and, depending on the installation, may be

protected differently upstream and/or come from different sources.

When increased power is required, several Galaxy PW™ units may be connected in parallel (up to four, refer to

section 4.0). In this configuration, an "isolation" function is added for the UPS system as a whole for maintenance

purposes, without interrupting the supply of power to the load.

Introduction 1 — 386-133060-00 A00

Page 16

1.4 Different Types of Galaxy PW™ Systems

1.4.1 Single UPS System

Figure 1-2: Galaxy PW™ Single UPS System.

Note: *The Fuse is to protect against catastrophic rectifier/inverter semiconductor failure.

1.4.2 Parallel UPS System

Parallel UPSs can be utilized when increased power is required (two to four parallel units), or an external bypass

must be added.

CAUTION PARALLEL UPS WITH EXTERNAL MAINTENANCE BYPASS During mainte-

nance operation, when CB1 (MBP) is closed and CB2 (UPS ISOLATION) is

open, each UPS control panel display will show a message “LOAD

PROTECTED” when the UPS is placed in ON-LINE MODE. In this mode the

critical load is not protected because it is supplied by the maintenance

bypass power.

Legend:

Q1 (Molded CB NA): Isolation of

the rectifier/charger (A) from

the normal AC source (1);

rectifier/charger (A) start-up.

QF1 (circuit breaker): Battery (D)

protection and isolation.

Q5N (switch): Isolation of the UPS

(B) from the load.

Q4S (switch): Isolation of the static

bypass (C) from the bypass

AC source (2).

Q3BP (switch): Bypass switch for

maintenance.

FUE (fuses): Protection of the

rectifier/charger (A) from the

normal AC source.

FUS (fuses): Protection of the

inverter (B) from the load.

Switch Q3BP is lock on open

position on parallel UPS

systems constituted to

increase available power.

maintenance bypass:

Q3BP

inverter (B):

DC to AC

power

isolation:

Q4S

isolation and

protection:

Q5N

rectifier/

charger (A):

AC to DC

power

QF1: isolation

and protection

normal

AC input

load

battery (D):

backup power

static bypass (C):

bypass

AC input

Q1

isolation

and

protection

(1)

(2)

harmonic

fliter

*FUSE

*FUSE

Galaxy PW™ UPS 100 to 225kVA

Introduction1 — 4 86-133060-00 A00

Page 17

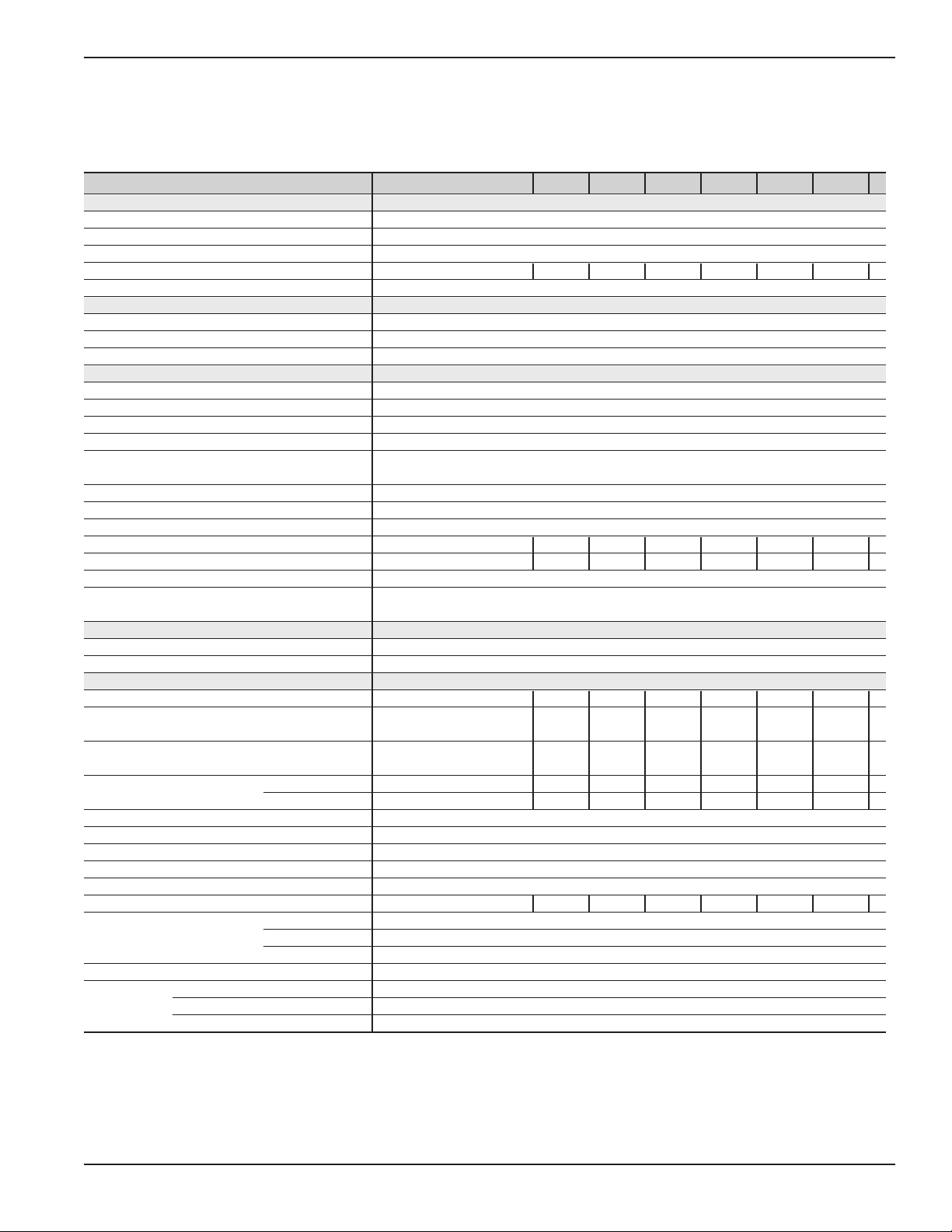

1.5 System Specifications

1.5.1 Electrical Characteristics

Installation and User Manual

Introduction 1 — 586-133060-00 A00

UPS power rating in kVA 100 130 150 180 200 225

Normal AC input

number of conductors 3 phases

rated voltage and tolerances 480 V ± 10% (adjustable to ± 15%)

rated frequency and tolerances 60 Hz / ± 10%

THDI < 14% < 11% < 10% < 8% < 7.6% < 7.5%

power factor up to 0.9

Bypass AC input

number of conductors 3 phases 3 phases + neutral

rated voltage and tolerances 480 V / ± 10%

rated frequency and tolerances 60 Hz / ± 10%

Load

number of conductors 3 phases 3 phases + neutral

Ph/Ph voltages 480 V

Ph/N voltages 277 V

voltage fluctuations (Ph/Ph,Ph/N) ± 1%

adjustable frequency and tolerances

(on battery power) 60 Hz ± 0.05 Hz

synchronization with bypass ± 0.5 Hz (adjustable from ± 0.25 Hz to ± 2 Hz)

transient voltage variation for 0 to 100% load step change

± 2% (with battery), +2%/-6% (without battery)

permissible overloads 150% for 1 minute, 125% for 10 minutes

Isc Ph/Ph (% of I rated) 4.7 3.6 3.2 2.6 2.4 2.1

Isc Ph/N (% of I rated) 7.4 5.7 5 4.1 3.7 3.3

THDU Ph/Ph and Ph/N for linear load < 1.5% Ph/Ph, < 2% Ph/N

THDU Ph/Ph and Ph/N for non-linear load < 2% Ph/Ph, < 3% Ph/N

(at 80% of Pn)

Battery

voltage floating 512V to 561V

standard battery type gas-recombination sealed lead-acid battery

UPS characteristics

active power (kW) 100 130 150 180 200 202.5*

efficiency at 50% load (%) 90.5 91 92 92.5 92.5 93

(values ± 1%)

efficiency at 100% load (%) 92.5 93 93 93 93.5 93.5

(values ± 1%)

heat losses (1) in KW 8.1 9.8 11.3 13.5 13.9 14.1

in cal./s 1940 2350 2700 3240 3340 3380

storage temperature range ºF (ºC) -13 to 158 (-25 to 70) dry heat — unit without battery

-4 to 113 (-20 to 45) — unit with battery

operating temperature range ºF (ºC) 32 to 95, 104 for 8 hours (0 to 35, 40 for 8 hours)

relative humidity 95% maximum non condensing at ambient temperature

maximum operating altitude without derating, FT(m)

< 3280 (< 1000)

noise level (dBA) 62 63 64 65 67 68

dimensions, in. (mm) width 47.8 (1215)

depth 33 (840)

height 74.8 ± .39 (1900 ± 10)

weight lbs (kg) 3050 (1388)

standards design NFPA / NEC / NEMA / OSMA

product and safety UL 1778 - ULC

electromagnetic compatibility FCC Part 15, Subport J, Class A - IEEE587 / ANSI 62.41

(1): The losses indicated are those produced at full rated load with the battery float charging. They must be taken into account when sizing the ventilation system.

* pf of 225kVA unit has 0.9 and remaining units have 1.0.

Page 18

1.6 Electrical Parameters for Selecting Protective Devices

1.6.1 Normal AC Source

The parameters given in Table 1-1 can be used to determine the required rating of the upstream protective circuit

breaker on the normal AC input for one single-UPS or parallel-UPS unit.

Normal and Bypass AC Input:

number of conductors 3 phases

rated voltage and tolerances 480 V ± 10% (adjustable to ± 15%)

rated frequency and tolerances 60 Hz / ± 10%

IMPORTANT It is essential to choose the type of circuit breaker according to its breaking

capacity and the prospective short-circuit current at its place of installation.

This choice must also be made so as to protect the static-switch semiconductors with respect to the maximum permissible currents and ensure

discrimination between the UPS output fuses and the downstream

protection devices.

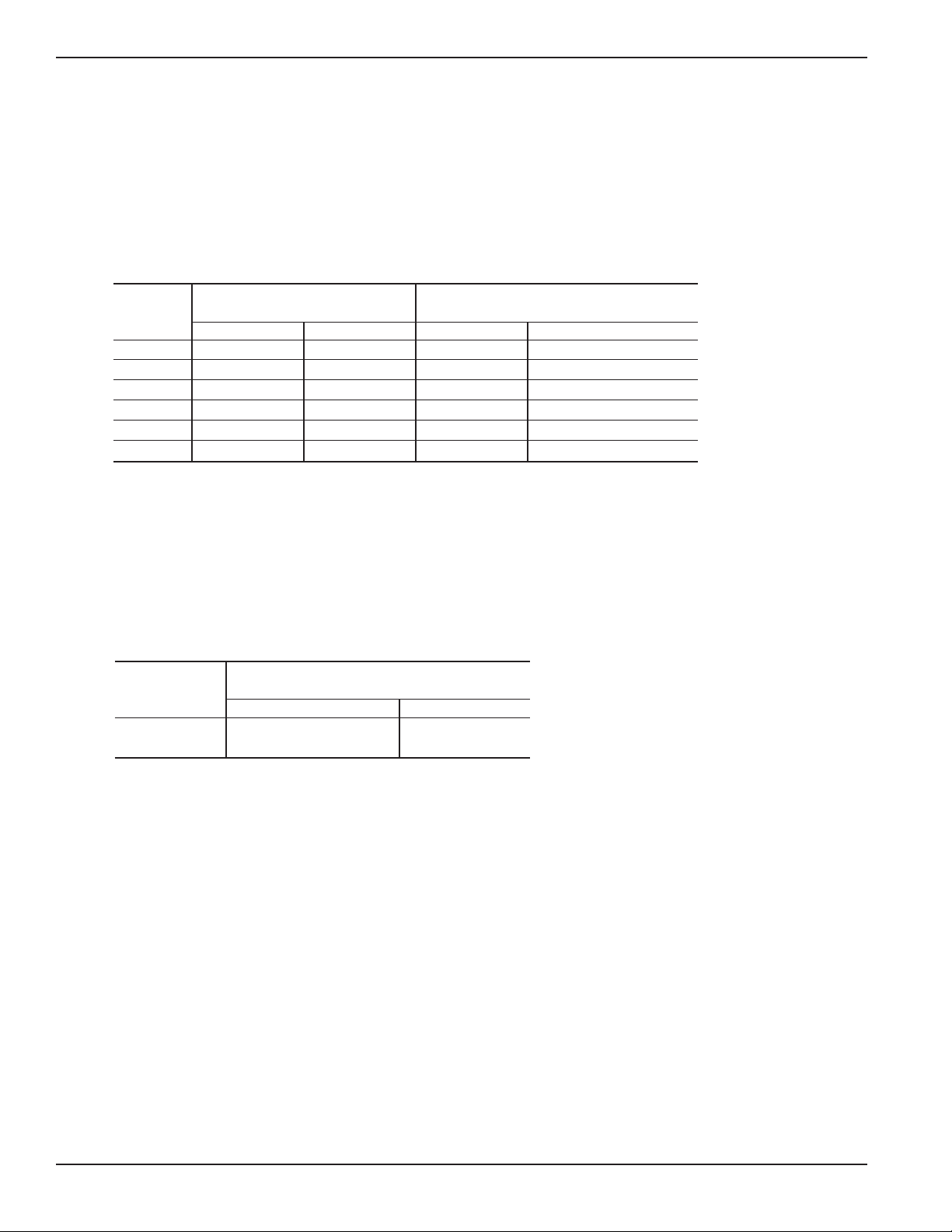

Table 1-1: Electrical Parameters for Normal AC Source.

Electrical parameters for the normal AC source

rated current normal AC source

UPS rated current In for unit: for 25% for 50%

output with battery at start without battery (2) overload (3) overload (3)

in kVA of charge cycle (1)

100 166 159 199 239

130 214 205 256 308

150 245 236 295 354

180 295 283 354 425

200 328 316 395 474

225 332 320 400 480

(1) The rated normal AC source currents (In) have been determined for a rated phase-to-phase voltage of 480 V,

a battery with a 10 minute backup time at the beginning of its charge (412 x 1, 2 = 494 Volts) and full rated load

with a power factor of 0.9.

(2) The rated normal AC source currents (In) have been determined for float charging voltage and full rated load

with a power factor of 0.9

(3) The normal AC source currents given for an overload of 25% or 50% are maximum values. They have been

determined for a battery with float charging voltage and a load power factor of 0.9. When choosing the circuit

breaker rating, use the "rated current" column and check that the circuit breaker tripping curves are compatible

with the values in the overload columns.

Galaxy PW™ UPS 100 to 225kVA

Introduction1 — 6 86-133060-00 A00

Page 19

Installation and User Manual

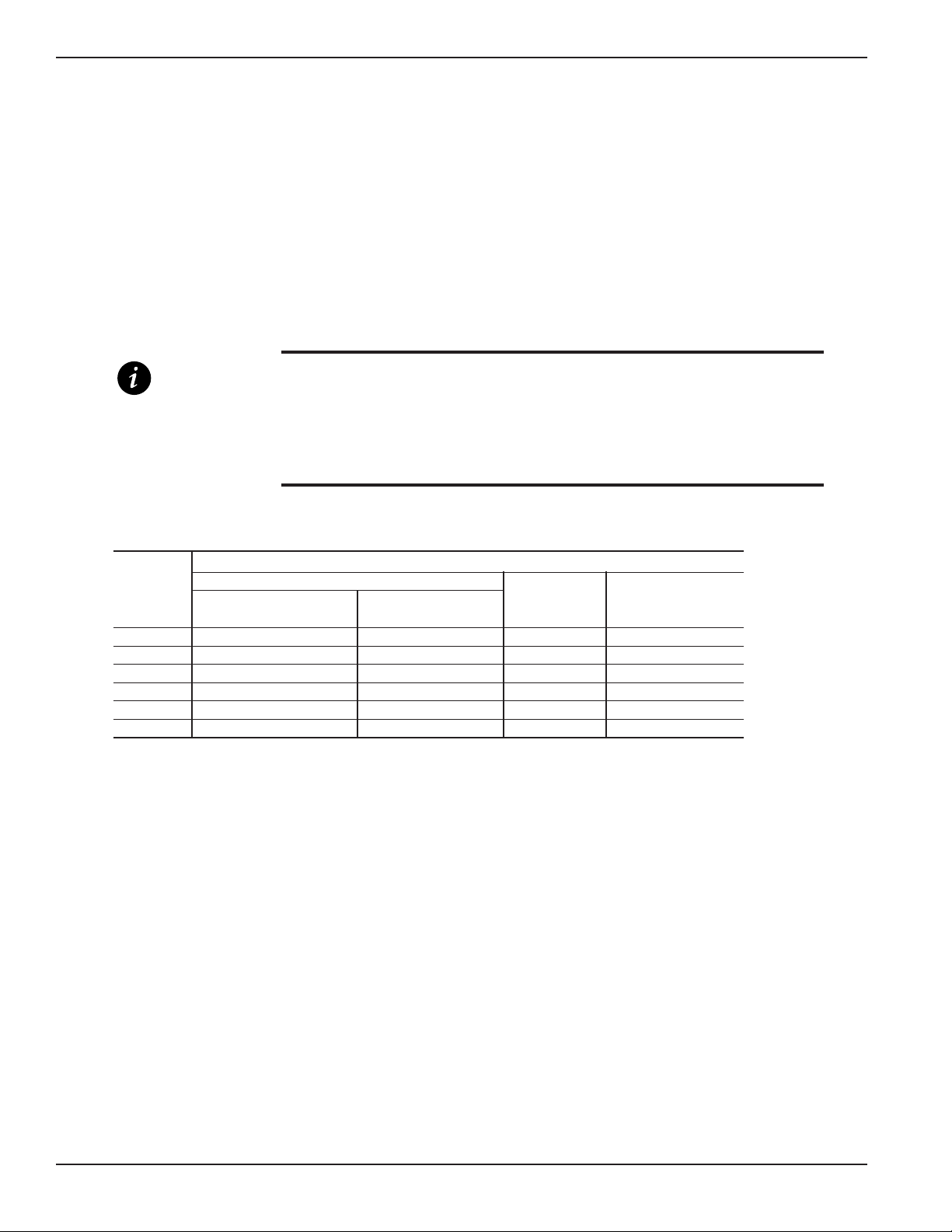

1.6.2 Bypass AC Source

The parameters given in Table 1-2 and 1-2A can be used to determine the required rating of the upstream protective circuit breaker on bypass AC input.

NOTE If the installation includes a transformer on the bypass AC input, allow for the

inrush current caused by magnetization of the transformer windings.

Table 1-2: Electrical Parameters for Bypass AC Source.

Electrical parameters for bypass AC source (480 V)

rated UPS current bypass AC source (1)

output rated current In for unit: for 25% for 50%

in kVA overload overload (3)

100 120 150 180

130 156 205 234

150 180 236 270

180 217 283 325

200 241 316 362

225 271 320 407

(1) The bypass AC source currents have been determined for a rated phase-to-phase voltage of 480 V, a load

power factor of 0.9 and for full rated load as well as overloads of 25% or 50%. When choosing the circuit breaker

rating, use the "rated current" column and check that the circuit breaker tripping curves are compatible with the

data in the overload columns. See table and chart below.

Table 1-2A:

UPS output maximum permissible current

in kVA

100 50 In for 20 ms

130 38 In for 20 ms

150 33 In for 20 ms

180 27 In for 20 ms

200 25 In for 20 ms

225 22 In for 20 ms

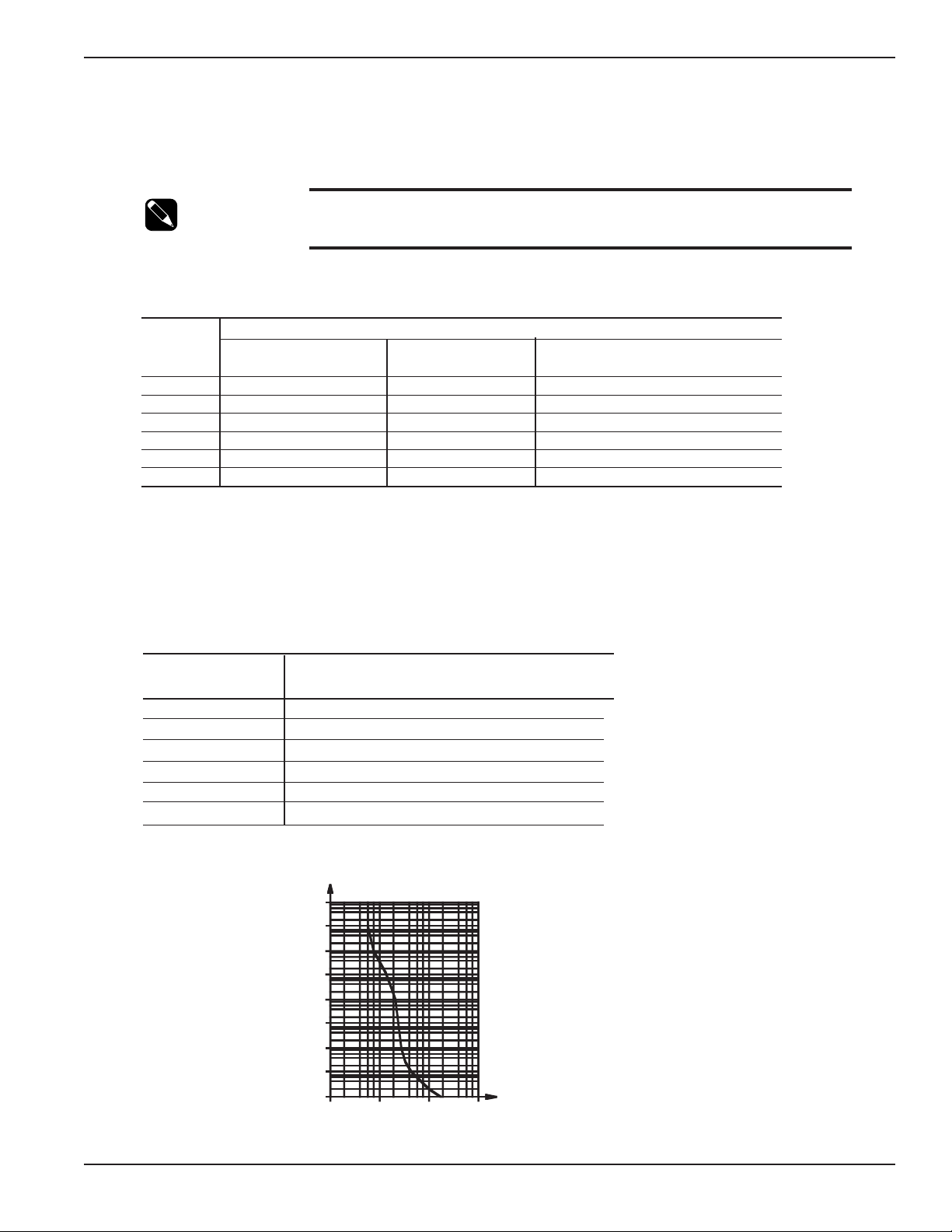

Figure 1-3: Fuse Curve Chart.

10

4

t(s)

I(A)

10

3

10

2

10

1

1

10-

1

10-

4

10-

3

10-

2

10

2

10

3

10

4

Introduction 1 — 786-133060-00 A00

Page 20

1.7 Recommended Protection

1.7.1 Protection Upstream of Galaxy PW™

The information provided here is purely indicative, for a single UPS unit. Check that all the criteria mentioned in the

previous section are taken into account (short-circuit current and protection of the static switch semiconductors on

the bypass AC input).

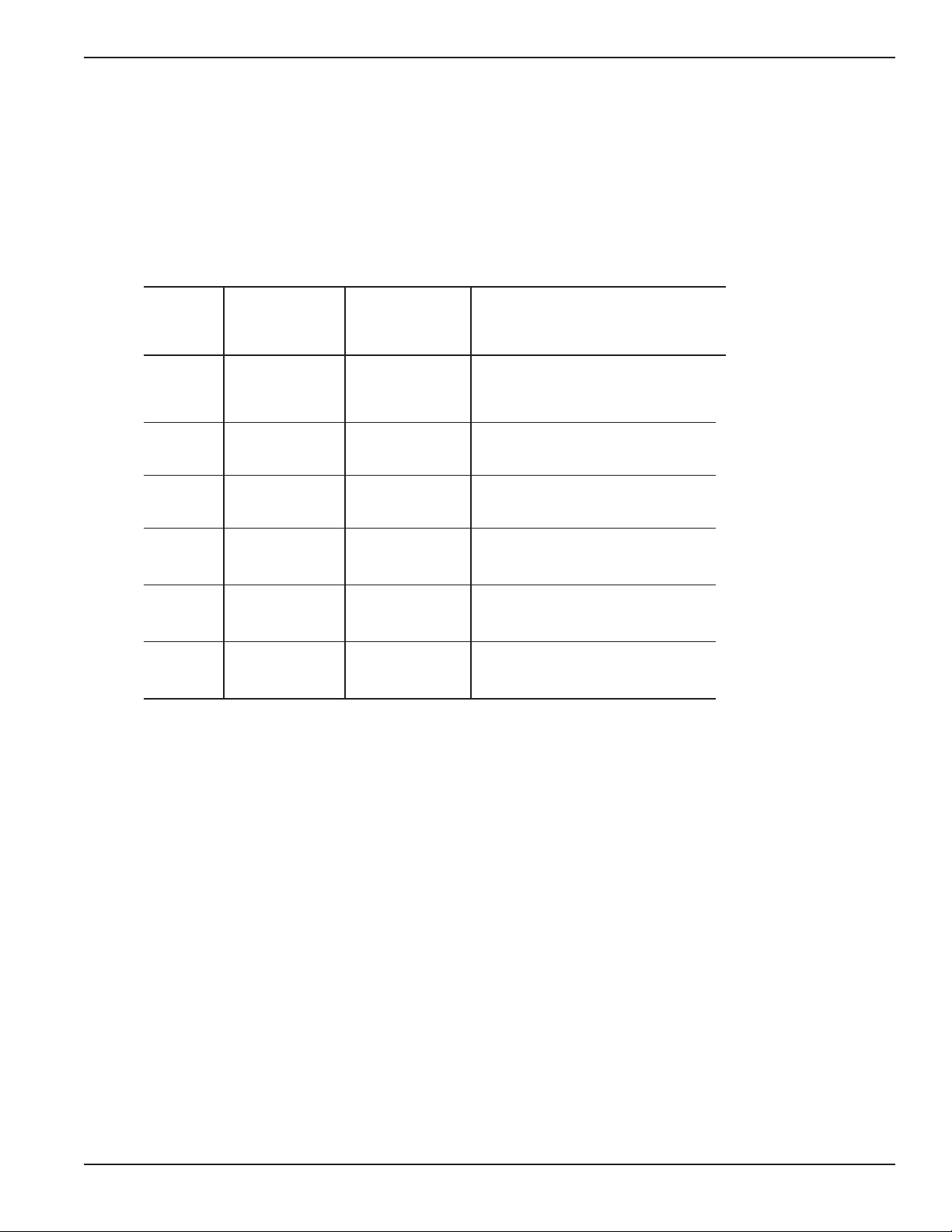

Table 1-3: Rating Recommended for Devices Upstream of Single UPS.

Ratings

rated UPS CB on normal CB on bypass

output AC input AC input

in kVA circuit breaker control unit circuit breaker control unit

100 125A 125A 125A 125A

130 160A 160A 160A 160A

150 250A 200A 250A 200A

180 250A 250A 250A 250A

200 400A 400A 400A 400A

225 400A 400A 400A 400A

1.7.2 Protection Downstream of Galaxy PW™

These protection devices ensure discrimination for each of the Galaxy PW™ output circuits. If the recommended

downstream protection is not installed and a short-circuit occurs, the result may be a break longer than 20-min on

all the other output circuits.

Table 1-4: Rating Recommended for Devices Downstream of Single UPS.

Ratings

rated UPS downstream circuit

output breaker(s)

in kVA circuit breaker control unit

100 to 225kVA 100A 63A curve C

100A curve B

Galaxy PW™ UPS 100 to 225kVA

Introduction1 — 8 86-133060-00 A00

Page 21

Installation and User Manual

1.8 Parallel Connected UPS Units

For installations with redundant units, take into account only the units required to supply the load power (e.g. for an

installation made up of 3 parallel-connected UPS units, one being redundant, only 2 UPS units are used to

determine bypass AC source and load currents and cable cross-sections).

Table 1-5 serves as an example for a parallel connected installation comprising up to four UPS units.

Table 1-5: Parameters for Bypass AC Source and Load Cables for a Parallel UPS.

Parameters

rated unit number of total UPS bypass AC

output parallel- rated output source or load

in kVA connected in kVA line current

units in Amps

100 2 200 240

3 300 360

4 400 480

130 2 260 312

3 390 468

4 520 624

150 2 300 360

3 450 540

4 600 720

180 2 360 434

3 540 651

4 720 868

200 2 400 482

3 600 723

4 800 964

225 2 450 542

3 675 813

4 900 1084

Introduction 1 — 986-133060-00 A00

Page 22

(This page left blank intentionally)

Galaxy PW™ UPS 100 to 225kVA

Introduction1 — 10 86-133060-00 A00

Page 23

System Setup

2.0 Scope

System Setup describes receiving and handling of the Galaxy PW™ 100 to 225kVA, a description of major components, the battery cabinet, and definition of the control panel indicators, which includes electrical, mechanical and

environmental specifications.

MGE also recommends obtaining an MGE field service engineer for final installation and basic startup for single and

parallel units.

CAUTION Scheduling of the MGE Field Service Engineers typically should be done 7 to

10 days before they are required on-site. If the startup of the UPS is critical

to maintaining your schedule, please call the MGE toll free telephone number

at

1-800-438-7373 for assistance.

The MGE Field Service Engineers will

insure a

quick installation for the initial safe startup and configuration of your Galaxy PW™.

Final installation and start-up should be completed by a qualified MGE Field Service Engineer.

2.0.1 First steps by an on-site qualified Technical Engineer

Step 1. Unpack and position the unit.

Step 2. Connect the main (utility) power.

Step 3. Connect the power circuits.

2.0.2 Final steps by MGE Field Service Engineer

Step 4. Call MGE and wait for the MGE Field Service Engineer to complete the installation.

Step 5. The MGE Field Service Engineer finalizes installation and the startup process.

Optional: Procedure for temporary power prior to the final startup.

2.0.3 Required Equipment and Tools

The following equipment and tools are recommended for on-site installation:

◗ Digital volt meter (DVM)

◗ 1/8 inch slotted screwdriver

◗ Pallet jack/forklift

◗ Conduit installation tools

◗ Nut driver set

2 — 186-133060-00 A00 System Setup

Page 24

2.1 Receiving

On delivery, check that the equipment has not been damaged in transport (declare any damage to the carrier in

accordance with customary claim procedures).

Also check that the characteristics noted in the test report for the equipment correspond to those specified on the

order form. In the event of a non-conforming item, quote the delivery note reference number when making your

claim.

2.1.1 Handling

The cabinets are delivered on pallets, equipped with a shock absorbing system. Ideally, the equipment should be

unpacked just before installation (see "unpacking" section below). Cabinet weights and dimensions are specified on

the packaging. Cabinets may be handled in one of the following ways (see Figure 2-1):

Rolling on Bars (B)

Do not mount the foot pads, but place the cabinet on the rollers (at least three). The cabinet may be pulled on rollers

using a sling positioned horizontally. This technique should only be used when absolutely necessary (narrow

doorway or corridor, preventing the use of a fork-lift or pallet-mover).

From the Bottom (A)

The cabinets can be moved from the front or the rear (715 mm wide cabinets) using a pallet truck or fork-lift truck,

or on the 4 surfaces (1015 mm and 1215 mm wide cabinets) using a fork-lift truck.

Fork tunnel height: 140 ±10 mm.

Fork opening: 560, 650 or 700 mm according to cabinets width.

The 715 mm wide cabinets are designed to pass through 715 mm wide openings, and the other cabinets are

designed to pass through 825 mm wide openings. For narrow openings, (follow the instructions below) cabinets are

normally 825 mm deep.

This depth can be reduced to:

◗ 817 mm by removing rear panels.

◗ 805 mm by removing doors.

◗ 800 mm by removing doors and door hinges.

unpack the cabinet, refer to section 2.2 ‘Unpacking’, page 4. The cabinet can then be handled by lifting machines

on all surfaces after the pallets have been dismantled by removing the rear panels, and remove the fixing screws

using a "torx" screwdriver.

Removing the doors:

1. Open the door(s).

2. Disconnect the door earth connection from the frame.

3. For cabinets fitted with a control panel, carefully disconnect the ribbon cables from the panel circuit boards

located on the inside of the door.

4. Knock out the hinge pins from below.

5. Remove the door(s).

Removing the door hinges:

1. Remove the screws holding the side panels to the hinges.

2. Remove the central screw holding the hinge.

Galaxy PW™ UPS 100 to 225kVA

System Setup2 — 2 86-133060-00 A00

Page 25

Installation and User Manual

Figure 2-1: Handling Cabinet From the Bottom or Rolling on Bars.

2.1.2 Storage

The equipment must be stored in a dry and well-aired location, sheltered from rain, water sprays or splashes and

all chemical agents. Storage in original packing is recommended, since this packaging is designed to provide

maximum protection during storage and handling. If the unit must be unpacked prior to final installation, cover the

equipment with a shroud providing protection against dust, debris, or paint.

Please dispose of the packaging in accordance with the applicable legislation.

IMPORTANT Transport: the temperatures must remain within the -30° to +50°C range and the

duration should not exceed 30 days.

Storage: the battery is of the sealed lead-acid or vented lead-acid type and should not be stored for more than six

months at 20°C without recharging for batteries that are initially fully charged (for partially charged batteries, the

storage time should be reduced). After the recommended maximum storage time, the battery must be charged,

requiring partial start-up of the equipment (rectifier-charger).

The battery cells can be stored at a temperature between -20°C and +45°C if delivered in their initial packing.

The ideal battery storage temperature is between 15° and 25°C (higher temperatures result in reduced storage life

or downgraded technical characteristics). If higher temperatures cannot be avoided during transport or storage,

please consult us.

System Setup 2 — 386-133060-00 A00

A

From Bottom

B

On Rollers

Page 26

2.2 Unpacking

1. Remove the packing box and the document holder on the top of the cabinet; raise the cabinet.

2. Dismantle the blocks fixed beneath the cabinet by M12 screws, see Figure 2-2 (A or B), according to the width

of the cabinet);

3. Dismantle the 4 M12 screws screwed on the 4 leg supports (C).

4. Withdraw the "hexagonal spacer + leg" assemblies delivered inside the document holder.

5. Screw the spacers onto the cabinet frame (C).

6. Lock these spacers in position using a 24 mm flat wrench, and fit the cabinet on its legs.

7. Adjust cabinet height and verticality by screwing or unscrewing the legs using a 13 mm flat wrench.

Figure 2-2: Dismantling Leg Supports and Attaching Spacers to Cabinet.

Galaxy PW™ UPS 100 to 225kVA

System Setup2 — 4 86-133060-00 A00

A B C

Page 27

Installation and User Manual

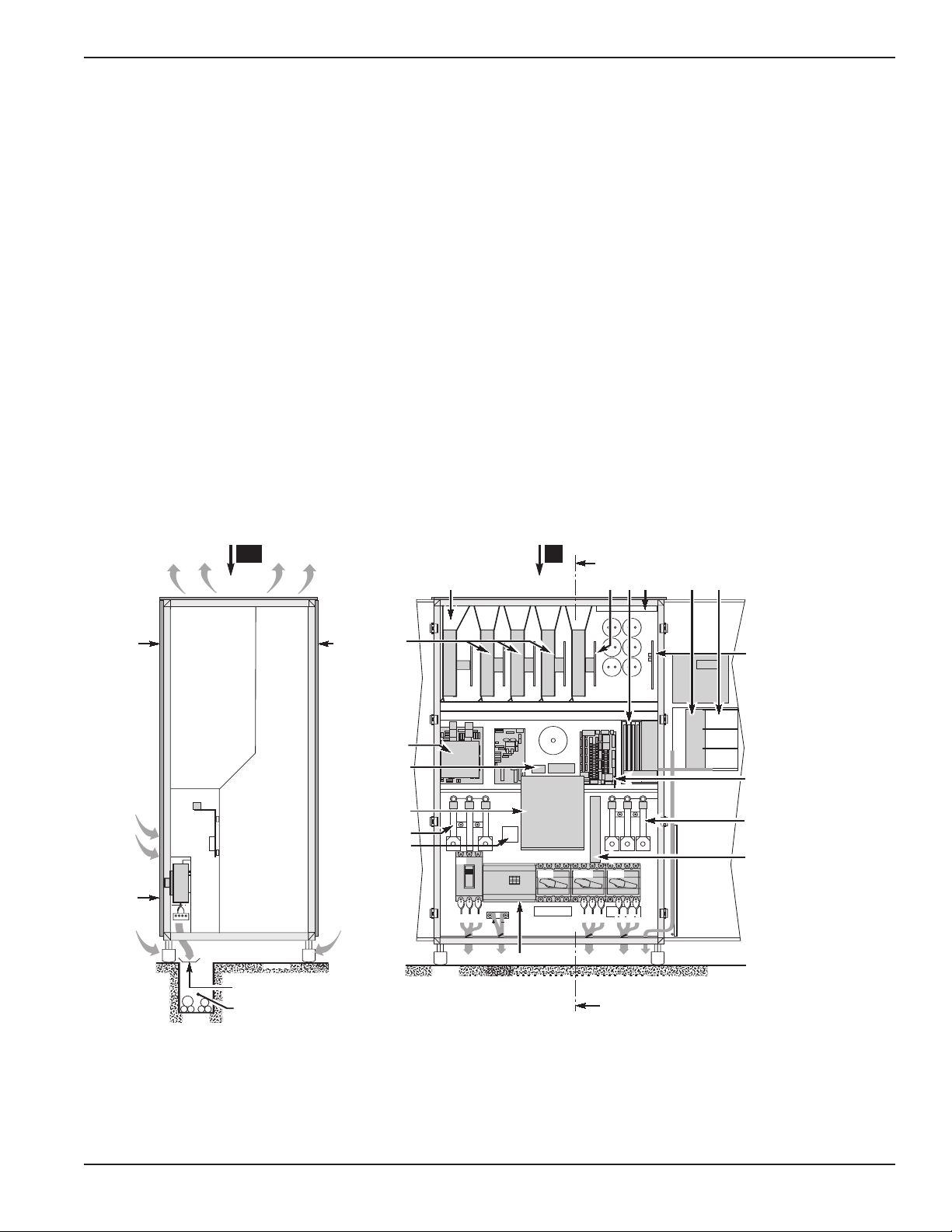

2.3 Galaxy PW™ Cabinet Major Components

Legend:

AA: cross-sectional view of the cabinet,

B: front view of the cabinet,

C: front panel,

D: rear panel,

1: normal AC input connection,

2: bypass AC input connection,

E: load connection,

F: battery connection,

G: air inlets,

H: air outlets,

I: cable exit through the bottom,

J: trough, if applicable,

K: rectifier/charger module,

L: inverter module,

M: static-bypass module,

Figure 2-3: Layout of the Major Cabinet Components.

System Setup 2 — 586-133060-00 A00

H

G

G

H

F

E

1

P

2

G

Y

Q1

Q4S

Q5NQ3BP

L1

L2

L3

L1L2L3

L1

L2

L3

GND

N

M

Q

Z

S

L

A

B

M

N 3

T

W

U

R

A

X

J

I

1, 2, E,F

D

C

AA

K

O

V

N: rack containing electronic boards,

O: Media Contacts 11 board,

P: slot for communications boards,

Q: FUE input fuses,

R: FUS output fuses,

S: RALI board,

T: UPOZ /UCOZ board,

U: MUSI board,

V: backfeed protection (contactor),

W: control wire routing,

X: fuses for overvoltage protection RC circuit on bypass,

Y: control-wire connection (auxiliary "Media Contacts 11" circuits and

communications options).

z: EP0I Board

3: VETI Board

Page 28

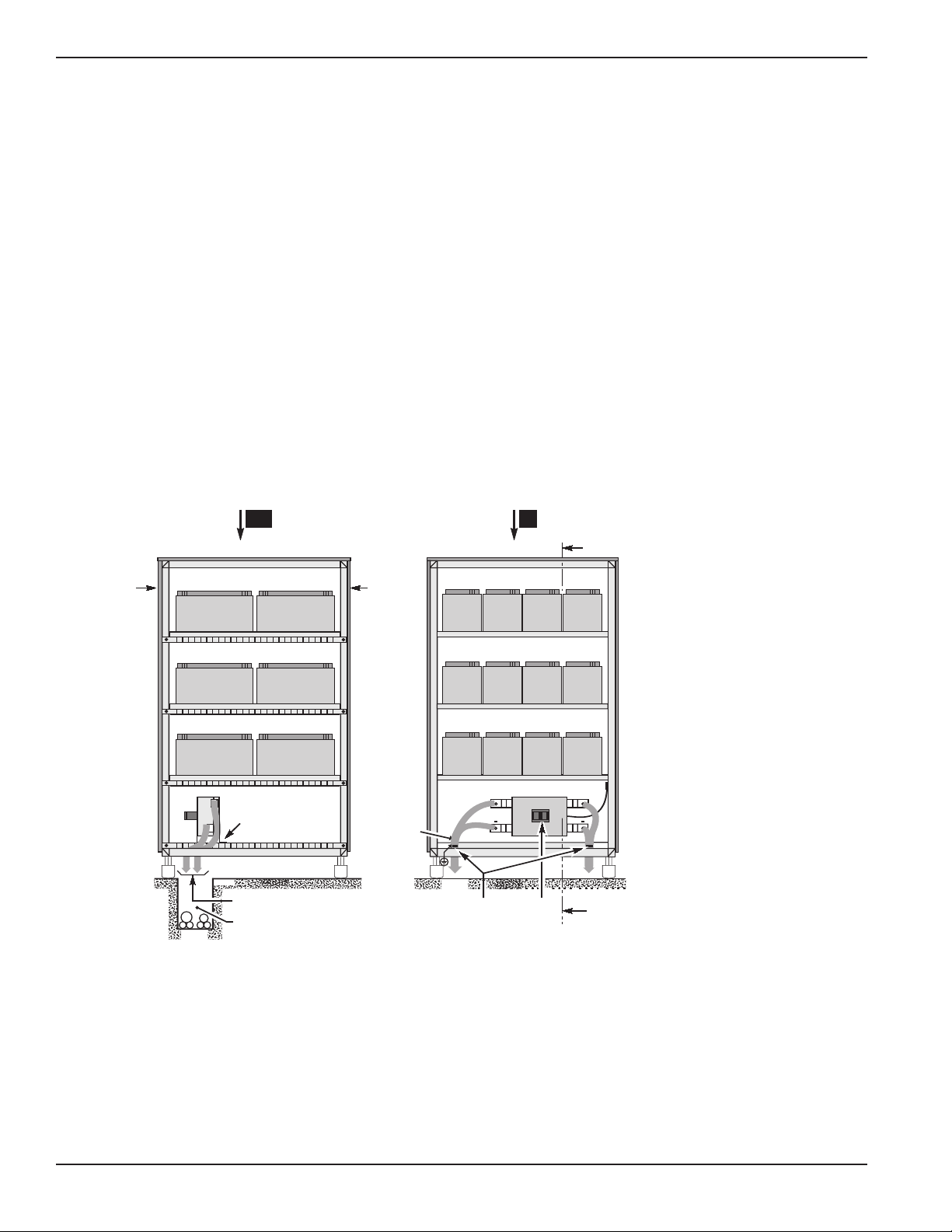

2.4 Battery Cabinet

Legend:

AA: cross-sectional view of the cabinet,

B: front view of the cabinet,

C: front panel,

D: rear panel,

E: cable ties to duckboard shelf,

F: cable exit through the bottom,

G: trough, if applicable,

H: connection of exposed conductive parts to duckboard shelf,

I: cable exit to battery connection point in UPS cabinet,

J: cable exit to an additional battery cabinet, if applicable,

K: cable ties to duckboard shelf,

L: fixture locking circuit breaker "QF1" in the open position.

Figure 2-4: Component Layout in a Battery Cabinet or a Battery Circuit-breaker Enclosure.

Galaxy PW™ UPS 100 to 225kVA

System Setup2 — 6 86-133060-00 A00

XR1

QF1

+

+

D

C

A

A

LK

I

J

F

G

E

H

BAA

Page 29

Installation and User Manual

2 — 786-133060-00 A00

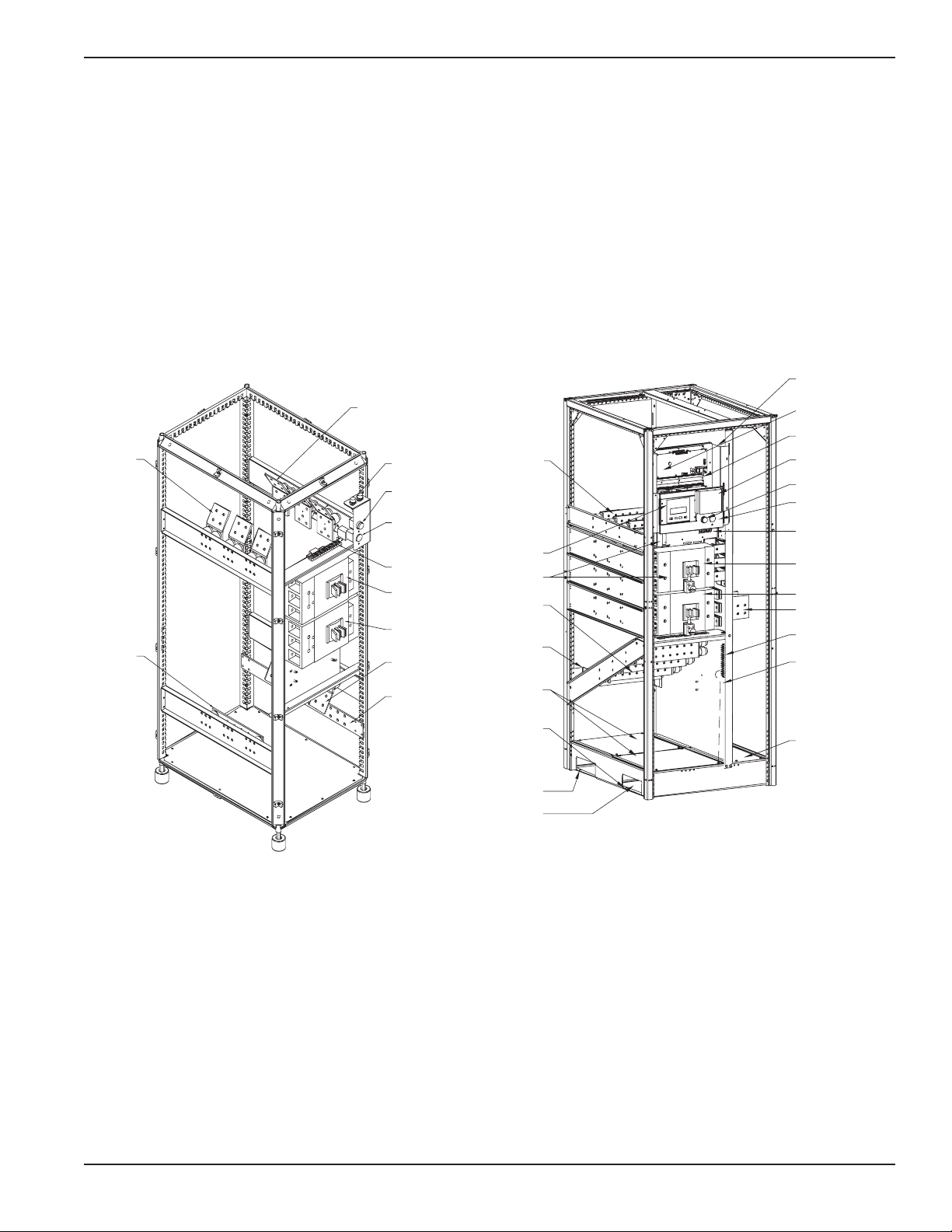

2.5 Remote External Maintenance Bypass Cabinet

350A and 1200A (See Figure 2-5)

Refer to “Installation Instructions” 90-133056-01 for detailed information about 350A cabinet.

Refer to Installation drawing 90-133077-00 for detailed information about 1200A cabinet.

If your installation is custom designed, a separate installation drawing may apply to your system.

All external wiring are provided and installed by the user.

Transfer instructions can be found in front of the cabinet including the proper operation of the kick key interlock.

Figure 2-5: 350A and 1200A Maintenance Bypass Cabinet.

1200A

NEURTRAL

(NOT SHOWN)

CRITICAL LOAD

DISPLAY METER

T1

MAINTENANCE

BYPASS

GROUND

REMOVABLE

PANELS

FOR POWER

CONDUIT ENTRY

SEISMIC

MOUNTING

CUTOUTS

SEISMIC HOLE

LOCATION

FORKLIFT OPENINGS

(LEFT & RIGHT

SIDE TYPICAL)

MULTI CIRCUIT

MONITOR BOARD

MULTI CIRCUIT

MONITOR BOARD

F1, F2

F3 TO F8

TRANSFER INITIATE (SI)

ELECTRIC INTERLOCK

(KA)

TB2

CB2

CB1

UPS OUTPUT

TB1

CONTROL WIRE

ROUTING

REMOVABLE PANEL

FOR CONTROL AND

POWER

CONDUIT ENTRY

F1, F2

TRANSFER

INITIATE (SI)

ELECTRIC

INTERLOCK

(KA)

350A

CRITICAL LOAD

TB1

MBP

TERMINALS

NEUTRAL

CB2

UPS ISOLATION

CB1

MAINTENANCE

BYPASS

UPS

TERMINALS

GROUND

System Setup

Page 30

2.6 General Instructions for Screens

To display the desired information and enter commands using the ▲, ▼ and ø keys:

1. Press the key to exit the time-stamping consultation mode and return to the main menu. If no commands

are entered for five minutes, the system automatically returns to the normal display mode.

To scroll through the screens displaying information:

1. Press the

▲ and ▼ keys to scroll up and down through the screens.

For time-stamped events, the display begins with the last event logged. To access older events, press the

▼ key.

If during consultation, you wish to review more recent events, press the

▲ key.

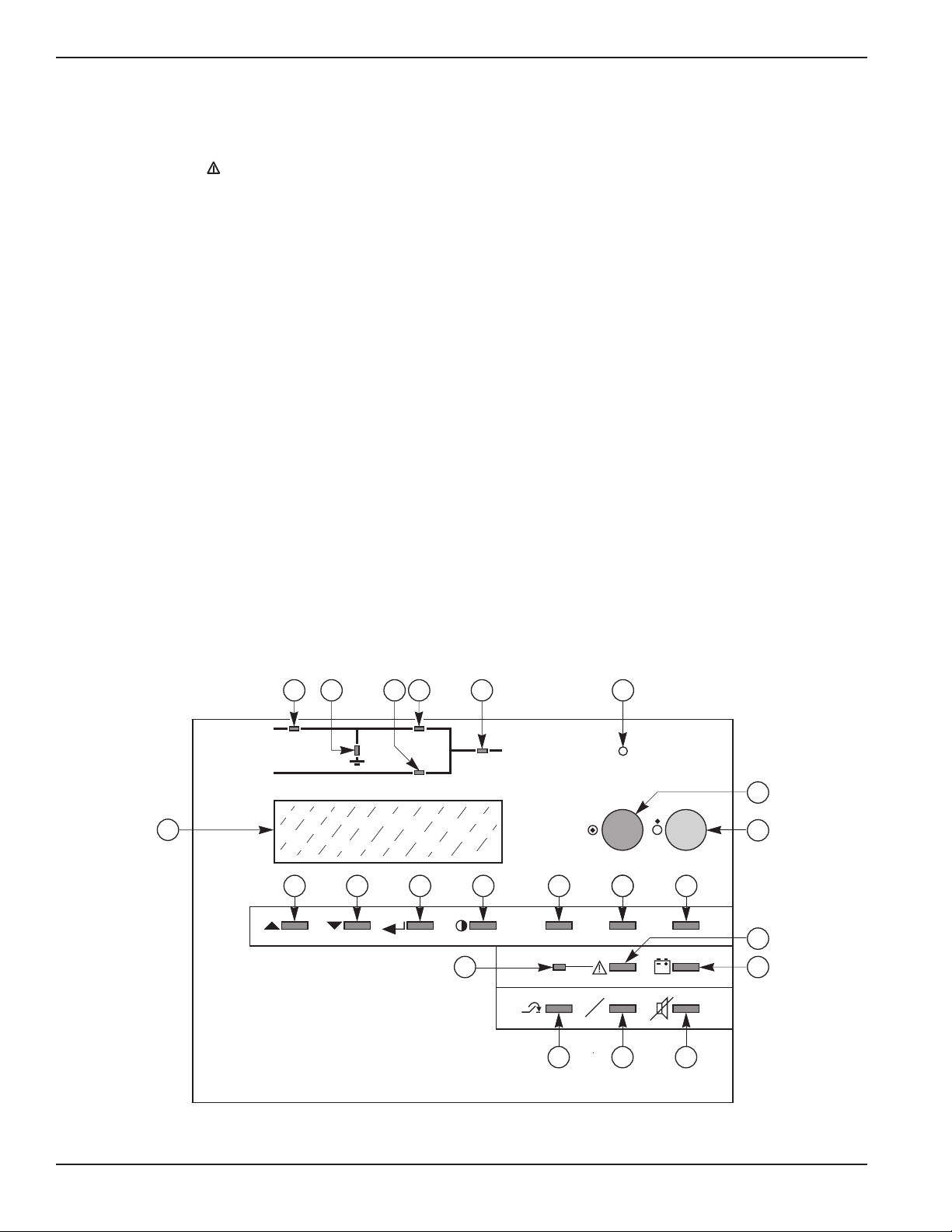

2.6.1 Control Panel Indicators and Definitions

The control panel on the Galaxy PW™UPS comprises the basic controls and indications required to check the

general status of the system. See Figure 2-6.

Located in the upper right part of the cabinet front, the control panel is designed to provide an easy and rapid

overview of system status. See Figure 2-6.

Interpretation of symbols is very simple and requires no particular training. The information concerns only the

cabinet on which the panel is located. Refer to Appendix A for a complete List of Primary and Secondary display

messages.

The panel indicates:

◗ Normal operation (load protected).

◗ Operation with load on battery power.

◗ Abnormal situations (operating problem).

◗ Dangerous situations (load not protected).

Figure 2-6: Control Panel Indicators.

1

2

VAW.Hz

fault

18

17

8

7

643 521

22

2119 20

16

9 10 11 12 13 1514 15

Galaxy PW™ UPS 100 to 225kVA

System Setup2 — 8 86-133060-00 A00

Page 31

Installation and User Manual

Control Panel Alphanumeric Legend:

1 "Rectifier/charger" light Indicates on/off and charging activity.

2 "Battery light" Indicates battery status.

3 "Static-bypass" light Indicates static bypass tolerance status.

4 "Inverter" light Indicates inverter on/off status.

5 "Load" light Indicates Load supplied and not supplied.

6 Buzzer The buzzer sounds in load operating situations.

7 "Inverter ON" button This button is used to start the inverter locally.

8 "Inverter OFF" button This button turns the inverter off locally.

9 -10 Keys These keys are used to select commands in the main menu and access the secondary

messages.

11 Key This key is used to validate the user’s choice.

12

øø

Key This key is used to access the main menu: display language, display-contrast setting,

sound level of the buzzer, lamp test, date and time settings, inverse-video and event log.

13 "V" Key This key is used to access voltage measurements.

14 "A" Key This key is used to access current measurements.

15 "W.Hz" Key This key is used to access other measurements:

16 "Anomaly" light This indicator light indicates the presence of anomalies.

17

⁄⁄

Key This key is used to access the primary messages.

18

ıı

"Battery" Key This key is used to access battery measurements:

19 "Forced-transfer" This key is used to voluntarily transfer the load to the inverter or from the inverter to the

static bypass (return transfer).

20 "Alarm reset" This key is used to reset stored alarms. The system accepts resetting only when alarms

have been cleared.

21 "Buzzer reset" This key is used to stop the buzzer. However, new alarms set the buzzer off again.

22 Display The display continuously indicates the system operating status.

System Setup 2 — 986-133060-00 A00

Page 32

2.7 System Start-up

2.7.1 Single UPS unit or Redundant Parallel UPS

Proceed in the following order: See Figure 2-7.

1. Close the upstream switches supplying normal and bypass AC source power (on the LV switchboard).

2. Close normal AC input switch Q1. The system powers up:

- the rectifier/charger automatically starts.

- green light 1 on the control panel goes on.

- light 2 turns red.

3. Close bypass AC input switch Q4S:

- green lights 3 and 5 on the control panel go on.

4. Close inverter output switch Q5N.

5. Close battery circuit breaker QF1:

- light 2 goes off.

6. Open maintenance bypass switch Q3BP.

7. Press the "inverter on" button 7 on the control panel:

- the green "inverter" light 4 flashes.

- the inverter starts, then, if the bypass AC source transfer conditions are satisfied, the load is transferred

to the inverter if the on-line mode is selected.

- the green "static-bypass" light 3 goes off.

- the green "inverter" light 4 shines for on-line mode.

Figure 2-7: Single UPS Unit Start-up Diagram.

Q5NQ1 Q4S

QF1

0

I

3

1

2

1

0

1

0

1

0

1

0

1

0

Q3BP

1

0

1

0

1

0

1

0

1

0

1

0

1

0

5

4

6

1

0

1

0

1

0

1

0

7

8

1

2

8

7

643 521

22

Galaxy PW™ UPS 100 to 225kVA

System Setup2 — 10 86-133060-00 A00

Page 33

Installation and User Manual

2.8 Parallel UPS Unit for Increased Output

Proceed in the following order: See Figure 2-8.

1. Check that all load devices are off or that the load is disconnected.

2. Close the upstream switch supplying normal AC source power (on the LV switchboard).

3. Close the normal AC input circuit breakers Q1 on the UPS units. The system powers up:

- the rectifier/chargers automatically start,

- the green "rectifier/charger" lights 1 in the control panels go on,

- lights 2 turn red.

4. Close the battery circuit breakers QF1.

- lights 2 go off.

- green lights 3 and 5 on the control panels go on.

5. Close Main 2 input switch Q4S for the units.

6. Close output switches Q5N for the inverters and in the external bypass unit.

7. Open maintenance bypass switch Q3BP in the external bypass unit.

8. Press the "inverter on" button 7 on each control panel:

- the green "inverter" lights 4 flash.

9. When a sufficient number of inverters are ready, the inverter-output contactors close:

- the green "inverter" lights 4 shine permanently green.

- the "static-bypass" lights 3 go off.

Figure 2-8: Parallel UPS Unit for Increased Output.

3

1

2

1

0

1

0

7

Q5N

1

0

Q4S

Q1

Q5N

1

0

Q4S

Q1

QF1

0

I

1

0

1

0

Q1

1

0

1

0

1

0

7

8

1

2

8

7

643 521

22

5 6 7

4

Q5N

Q3BP

external bypass

1

0

1

0

1

0

1

0

System Setup 2 — 1186-133060-00 A00

Page 34

(This page left blank intentionally)

Galaxy PW™ UPS 100 to 225kVA

2 — 12 86-133060-00 A00

Page 35

3 — 186-133060-00 A00

Installation

3.0 Scope

Installation guides the User through single and parallel UPS unit power cable connections, hot swap options,

connections between cabinets, communication card connections, battery ‘temperature monitoring’ installation. Wire

diagrams are included for configuring the unit to specifications.

MGE recommends obtaining an MGE field service engineer for final installation and basic startup for single and

parallel units. Final installation and start-up should be completed and performed by a qualified MGE Field

Service Engineer.

3.1 Optional Communications Card Installation

Three slots are available on the "Media Contacts 11" board for optional communications. See the position of these

slots marked "P" in Figure 2-3, page 2—5.

Installation of Boards setup notes:

◗ Boards may be installed with the UPS on, without removing the protective covers.

◗ Boards must be pushed to the end of the slots to ensure correct installation.

◗ Board front plates must be screwed to the protective "Media Contacts 11" board cover.

◗ Wire routing holes are provided in the support for the "Media Contacts 11" board for tying down the wires;

◗ The control wires must then be routed through the cableway marked "W" in figure 2-3, page 2—5.

3.2 Notes on Connection of Power Circuits

◗ Open the doors and remove the lower terminal shields (secured by screws to the cabinet chassis) of the

UPS cabinets, connect the power cables, each cabinet must be grounded.

◗ All the cabinets must be interconnected for equipotential bonding, forming a mesh which is itself connect-

ed to the building structure and earthing electrode.

The connection drawings hereafter show the cabinets with doors open and terminal shields removed.

CAUTION Before making connections, check that switches Q1, Q4S, Q3BP, Q5N and QF1 are

in the "open" position.

IMPORTANT For parallel UPS with an external bypass unit, the power connections between

each UPS cabinet and the external bypass unit must imperatively be of the same

length. Outside the cabinets, separate the auxiliary wiring from the power cables.

Installation

Page 36

3.3 Power-Circuit Wiring Diagrams

The single UPS wire diagram is for typical UPS installations shown in Figure 3-1. The heavy lines represent the

cables that must be connected (F), refer to section 3.5 ‘Connections Between Cabinets’ for more detail on cables.

Figure 3-1: Galaxy PW™ Single UPS Unit Wire Diagram.

Legend:

1: Normal AC source,

2: Bypass AC source,

A: Rectifier/charger module,

B: Inverter module,

C: Static-bypass module,

D: Battery cabinet next to the

Galaxy PW™ UPS cabinet,

E: Additional battery cabinets,

F: The equipotential-bonding

connection between cabinets.

3.4 Hot Swap Options

The external bypass may be used to construct a bypass outside the UPS, thus making it possible to shutdown the

UPS for maintenance purposes.

The option may be used for single UPS units and redundant parallel UPS. For the power-circuit connections of a

single UPS unit see Figure 3-2, for the power-circuit connections of parallel UPS see Figure 3-3.

Power cables for UPS-to-bypass connections are not supplied.

Figure 3-2: Single UPS Unit Power Circuit Connections.

Legend:

1: Normal AC source.

2: Bypass AC source.

A: Rectifier/charger module.

B: Inverter module.

C: Static-bypass module.

D: Battery cabinet next to the

Galaxy PW™ UPS cabinet.

E: Additional battery cabinets.

F: The equipotential-bonding

connection between cabinets.

Galaxy PW™ UPS 100 to 225kVA

Installation3 — 2 86-133060-00 A00

C

B

A

Q4S

Q1 Q5N

Galaxy PW

Q3BP

2

1

D

+

–

+

–

E

F

QF1

F

Q4S

2

Q3BP

Q5N

( )

( )

( )

( )

2

1

C

B

A

Q4S

D

+

–

+

–

E

F

QF1

Q1 Q5N

Galaxy PW

F

Q3BP

( )

( )

Page 37

Installation and User Manual

Figure 3-3: Parallel UPS Unit Power Circuit Diagram.

Legend:

1: Normal AC source,

2: Bypass AC source,

A: Rectifier/charger module,

B: Inverter module,

C: Static-bypass module,

D: Battery cabinet next to the

Galaxy PW™ UPS cabinet,

E: Additional battery cabinets,

F: The equipotential-bonding

connection between cabinets.

Installation 3 — 386-133060-00 A00

Galaxy PW

2

1

D

+

–

+

–

E

F

QF1

F

2

1

D

+

–

+

–

E

F

QF1

F

Galaxy PW

2

Q3BP

Q5N

2

C

B

A

Q4S

Q1 Q5N

( )

( )

C

B

A

Q4S

Q1 Q5N

( )

( )

( )

Page 38

3.5 Connections Between Cabinets

These connections are made on the UPOZ board (marked T) and MUSI board (marked U). See Figure 2-3, page 2—5.

3.5.1 Connections Between UPOZ Boards

These connections are made using the cables (A) supplied, see Figure 3-4.

The purpose of the connection is to make a loop. Connector XM137 on the UPOZ board of one UPS unit must be

connected to connector XM136 on the UPOZ board of the next UPS unit and so on until the first board is returned

to origin.

Figure 3-4: Connections Between UPOZ Boards.

3.5.2 Connections Between UPS Cabinets and the Remote External Bypass

Refer to the installation drawing included with the Maintenance Bypass Cabinet for control and power connections.

These connections are provided and installed by the user.

'UPOZ'

Galaxy PWTM 1

'UPOZ'

Galaxy PWTM 2

'UPOZ'

Galaxy PWTM 3

XM137

XM138

XM137

XM138

XM137

XM138

A

Galaxy PW™ UPS 100 to 225kVA

Installation3 — 4 86-133060-00 A00

Page 39

Installation and User Manual

3.5.3 Connections Between MUSI Boards

These connections are made using the special cables (A) supplied, see Figures 3-5.

1. Connectors XM5, XM6 and XM7 on the MUSI board are used to transmit signals.

2. Connectors XM10, XM11 and XM12 on the MUSI board are used to receive signals.

3. Connector XM5 is associated with connector XM10 for communication with one UPS unit; similarly, XM6 is

associated with connector XM11 for communication with a second UPS unit and XM7 is associated with

connector XM12 for communication with a third UPS unit.

◗ For connection with two parallel UPS units, see Figure 3-5.

◗ For connection with three parallel UPS units, see Figure 3-6, page 3—6.

◗ For connection with four parallel UPS units, see Figure 3-7, page 3—6.

IMPORTANT Outside the cabinets, group the "UPOZ" inter-board and "MUSI" inter-board

connections with the inter-cabinet auxiliary connections, and separate this

assembly using power cables.

Figure 3-5: Two Parallel UPS Units Connections.

'MUSI'

Galaxy PW

TM 1

'MUSI'

Galaxy PW

TM 2

A

XM10

XM11

XM12

XM5

XM6

XM7

XM10

XM11

XM12

XM5

XM6

XM7

Installation 3 — 586-133060-00 A00

Page 40

Figure 3-6: Three Parallel UPS Units Connections.

Figure 3-7: Four Parallel UPS Units Connections.

'MUSI'

Galaxy PW

TM 1

'MUSI'

Galaxy PW

TM 2

A

XM5

XM6

XM7

XM5

XM6

XM7

'MUSI'

Galaxy PW

TM 3

XM5

XM6

XM7

'MUSI'

Galaxy PW

TM 4

XM5

XM6

XM7

XM10

XM11

XM12

XM10

XM11

XM12

XM10

XM11

XM12

XM10

XM11

XM12

'MUSI'

Galaxy PW

TM 1

'MUSI'

Galaxy PW

TM 2

A

XM5

XM6

XM7

XM5

XM6

XM7

'MUSI'

Galaxy PWTM 3

XM5

XM6

XM7

XM10

XM11

XM12

XM10

XM11

XM12

XM10

XM11

XM12

Galaxy PW™ UPS 100 to 225kVA

Installation3 — 6 86-133060-00 A00

Page 41

Installation and User Manual

3.6 Environmental Signal of the Media Contacts 11 Board

Terminals XR2, XR3, XR4 and XR5 on the "Media Contacts 11" board of each type of unit can be used to receive

signals from the operating environment and to transmit signals concerning the operating status of the UPS, see

Figure 2-3, page 2—5 for the position of the board, item 1 and 2).

3.6.1 Signal Reception

The signals should be provided by volt-free contacts.

Emergency off: An NC contact causes shutdown of the inverter and the rectifier/charger, opening of

the battery circuit breaker, blocking of the static bypass and activation of a relay

contact on the "Media Contacts 11" board.

Battery room

ventilation fault: A ‘NO’ contact causes shutdown of the rectifier/charger.

Battery circuit

breaker QF1 closed: A ‘NO’ contact prevents inverter start-up if the circuit breaker is open.

Battery temperature: A PC-board, placed near the battery, supplies information on the battery tempera-

ture, thus enabling the rectifier/charger to regulate the battery voltage.

"Auxiliary" signals: Depending on the selected settings, these signals may be used to provoke:

- forced shutdown of the inverter (whatever the status of the bypass AC source),

- protected shutdown of the inverter (load transfer to the bypass AC source).

- limiting of the current drawn by the rectifier/charger (programmable value) when

supplied by an engine generator set with an insufficient power rating. The additional

power required by the inverter is supplied by the battery which discharges,

- limiting of the battery charge current (programmable value) if the normal AC source

is replaced by an engine generator set with an insufficient power rating.

3.6.2 Signal Transmission

An auxiliary 24 V

power supply: Isolated and backed up, is used to supply:

- the undervoltage release of the battery circuit breaker(s) QF1.

- the board that measures the temperature in the battery room.

"low battery"

warning signal: (Volt-free changeover contact) indicating that battery time is about to run out.

The warning threshold may be personalized.

"load on UPS" signal: (Volt-free changeover contact) indicating that the load is supplied by the

inverter. For a single-UPS unit, one volt-free changeover contact may be used

to indicate that the load is supplied by the bypass AC source.

Installation 3 — 786-133060-00 A00

Page 42

"load on battery power" signal: (Volt-free changeover contact) indicating that the inverter is supplied

by the battery in the following cases:

- normal AC source outage or voltage drop.

- rectifier/charger shutdown.

- rectifier/charger current limiting.

This signal, which may be used to initiate process saving and shutdown

procedures, is time-delayed 30 seconds to avoid unnecessary operations

following micro-breaks.

"Maintenance position" signal: (Volt-free changeover contact) indicating that:

- maintenance bypass switch Q3BP is closed,

- bypass AC source input switch Q4S is open,

- inverter output switch Q5N is open,

- battery circuit breaker QF1 is open.

Signal to open battery

circuit breaker(s) QF1: In the event the "emergency off" button is pressed or to avoid an excessive

battery discharge (lasting more than three times the rated backup time plus two

hours).

Repo Contact: (Volt-free changeover contact) used to trip switching devices in the event of an

emergency shutdown.

"General Alarm" information: (Volt-free changeover contact) which includes:

- internal faults.

- information on temperatures outside tolerances in the battery room (optional).

- overload information (> In).

- static-switch ventilation and power-supply faults.

NOTE The maximum breaking capacity of the changeover contacts is 5A at 250V.

Galaxy PW™ UPS 100 to 225kVA

Installation3 — 8 86-133060-00 A00

Page 43

Installation and User Manual

3.7 "Media Contacts 11" Standard Auxiliary Circuits Connection

Connecting the auxiliary circuits to the three connectors on the "Media Contacts 11" board in the Galaxy PW™ UPS

cabinet, see the position of this board, marked "O", see Figure 2-3, page 2—5.

Recommended cable cross-section: 1 mm

2

. The male connectors that fit the female connectors on the board (XR2

to XR5) are supplied. The contacts are volt-free and are shown in the diagram under the following conditions: UPS

on, contact at rest. Contact breaking capacity: 250 V, 5 A.

Figure 3-8: Standard Auxiliary Circuits Connections.

Installation 3 — 986-133060-00 A00

Media Contacts 11 Board

12

11

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

-12V

-12V

24V CC

-12V

XR3 connector

AC

AC

AC

power supply

input or output signals:

input or output signals:

emergency shutdown breaker circuit REPO

(jumper Y

XR2 connector

harmonic filter

battery cubicle

XA13 terminal block

correction with optional electric boad for

measuring battery temperature

temperature

signal

OF1 battery circuit-breaker opening command

harmoni

cs over-temperature fault

battery-room ventilation fault

-12V

+12V

QF1 battery

circuit breaker

closed

QF1 battery

circuit breaker

opening command

XA1 terminal block

output signals:

EPO

XR2 XR3 XR4 XR5

12 - - - - - - - - - -1 10 - - - - - - - -1 10 - - - - - - - -1 10 - - - - - - - -1

circuit

thermal measuring

of the

harmoinc-filter

circulator

10

9

8

7

6

5

4

3

2

1

XR4 connector

output signals:

load or battery

10

9

8

7

6

5

4

3

2

1

XR4 connector

low-battery shutdown warning

load or inverter

AC

AC

2

1

2

1

2

1

AC

Optional alarm

free auxilary contact

XR2

XR3

XR4

XR5

XR1

12 - - - - - - - - - -110- - - - - - - - - 1 10- - - - - - - - - 1 10- - - - - - - - - 1

Page 44

3.7.1 Battery Circuit Breaker "QF1" Connection

Connect the cable from connector XR3 (pins 2 to 8) on the "Media Contacts 11" board in the UPS cabinet to

connector XR1 in the battery cabinet containing battery circuit breaker QF1.

IMPORTANT

In the case of a complex installation with parallel units, there should be only one

emergency shutdown pushbutton and this pushbutton must interrupt all the units.

This pushbutton must therefore have as many contacts as there are units in the

installation. The emergency shutdown pushbutton turns off the rectifier/ chargers

and inverters, opens the battery circuit breakers (QF1), the input circuit breaker (Q1)

on the normal source, the backfeed protection contactor (K4S) on the bypass AC

source, blocks the static switches and activates a contact on the "Media Contacts 11"

board (terminals 1 to 3 on connector XR4).

3.8 Installation of the "Temperature Monitor" in the Battery Cabinet

The "Temperature Monitor" unit is placed inside the battery cabinet housing circuit-breaker QF1. See Figure 3-9.

1. Open the unit cover, and before fixing, break the self-cleaving seal on the base of the unit for insertion of the

connecting cable.