Page 1

DURATECH CANADA (DTC)

5”, 6”, 7”, 8” & 10” dia.

SUMMARY

Factory-built CHIMNEY

TYPE HT

OUR PRODUCTS LIVE UP TO OUR NAME, WARNING. . . . . . . . . . . . . . . 2

KEEP YOUR CHIMNEY CLEAN, SIZING CHART . . . . . . . . . . . . . . . . . . . 3

GENERAL INSTALLATION NOTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTERIOR STRAIGHT INSTALLATION WITH MULTIPLE FLOORS . . . . . . . 5

INTERIOR INSTALLATION WITH CATHEDRAL CEILING . . . . . . . . . . . . . . 7

OFFSET INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

EXTERIOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

INTERIOR INSTALLATION ON A FURNACE & WATER HEATER . . . . . . . . 12

SPECIALIZED COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

INSTALLATION

AND

OPERATION

INSTRUCTIONS

Read these instructions and keep them for future reference

Listed: CAN/ULC-S629 (6’’,7’’,8’’ only)

CAN /ULC-S604

UL-103HT

Duravent

www.duravent.com

PIDURATECH REV. 3 21/2014

1

Page 2

OUR PRODUCTS LIVE UP TO OUR NAME

CONGRATULATIONS!

You have just purchased one of the safest chimneys

in North America. Designed with care, using the latest

technology, it has been manufactured in accordance

with ISO International Standards of Quality. The

chimney is easy to install and all parts of the system

are built to fit perfectly with each other. If you’re

handy, know how to use a few simple tools and have

some basic carpentry skills, you can install your

DURATECH CANADA (DTC) chimney yourself over one

weekend. Or you can hire a professional to do the job.

BURNING SMART

How you burn wood in your stove or fireplace directly affects the

formation of creosote. Smaller, hotter fires are better than large,

smouldering ones. Fast, effective start ups are important, as is the

moisture content of the wood. Ideally, you should use seasoned

wood with a moisture content of 20 25%. A surface thermometer is

an excellent investment. Properly seasoned wood can produce 8,600

BTUs per pound.

APPLICATIONS

WOOD AND COAL STOVES

DURATECH CANADA (DTC) chimney has been designed for use with wood,

gas, oil and coal in residential, commercial and industrial applications.

WARNING

A MAJOR CAUSE OF CHIMNEY-RELATED FIRES IS FAILURE TO MAINTAIN

REQUIRED CLEARANCES (AIR SPACES) TO COMBUSTIBLE MATERIALS.

IT IS OF UTMOST IMPORTANCE THAT THIS CHIMNEY BE INSTALLED

ONLY IN ACCORDANCE WITH THESE INSTRUCTIONS.

RECOMMENDATIONS

Clearance

The clearances stated in this guide are minimum requirements: if more

space is available, use it. Minimum clearances mean leaving unobstructed

air space. Do not fill these spaces with any material whatsoever, especially

not insulating material. If you insulate your attic later, be sure to maintain

the necessary clearance.

Inspection

Contact local building or fire officials about restrictions, installation

inspection and permit that may be required in your area.

Replacement Parts

If a component of your chimney system is damaged it must be replaced

by an identical one from Duravent.

NOT ALL WOOD IS CREATED EQUAL

Some types of wood have greater energy potential than others. Some

logs will give you a hot, crackling fire, others will burn longer and more

evenly. Choose the type of flame you prefer. The following table shows

how different types of wood burn.

Wood

Type

Black Locust Excellent Very Few Slight Excellent

Maple Excellent Few Good Excellent

Oak Excellent Few Fair Excellent

Hickory Excellent Moderate Slight Excellent

Beech Good Few Slight Excellent

Cherry Excellent Few Excellent Good

Apple Excellent Few Excellent Good

Elm Good Very Few Fair Good

Ash Good Few Slight Good

Birch Good Moderate Slight Good

Hemlock Low Many Good Fair

Pine Poor Moderate Good Fair

Cedar Poor Many Good Fair

Ability To Create

Long Lasting Coals

Sparks Fragrance Heating

Qualities

Table 1

2

DURATECH CANADA (DTC) has been listed to ULC-S629 , 2100 F in

diameter 6,7 and 8 inches for wood/coal application . Note that for

interior enclosed installation, premium shield are required around

the chimney. Refer to specific Canadian installation section for proper

installation.

DURATECH CANADA (DTC) is also designed for use with gas or oil

fired heating appliances such as furnace, hot water heaters and other

appliances, as per ULC-S604 standards in diameter 5 to 10 inches.

In these types of installations, no premium shields are required even

where the chimney is enclosed.

If you are planning to install a wood stove, we recommend that you:

1. Choose a stove that bears the label of a testing laboratory (such as

UL, CSA, WH, ULC or ICBO).

2. Choose the right size stove. Do not buy one larger than you need.

3. Connect only one appliance to a chimney.

4. Never overfire your stove. If any part of the stove or stove pipe is

glowing red, then you are overfiring. Immediately close the stove’s

dampers until the system cools. The high temperature caused by

overfiring can permanently damage the stove and stove pipe and may

overheat nearby combustible walls and furniture.

5. Install the stove and stove pipe as described in the installation

instructions accompanying the stove. Be certain to maintain the

required clearances to combustible construction.

6. Keep your flue gases between 300°F and 500°F. This will maximize

efficiency while minimizing condensation and creosote formation. Do

not fill your stove with wood and allow it to smoulder for 8 to 10 hours.

This condition produces large amounts of creosote in the chimney.

7. Do not burn sea driftwood or treated wood. These combustibles are

highly corrosive to all types of stainless steel.

FACTORY BUILT FIREPLACE

DURATECH CANADA (DTC) in Canada is also suitable for use with closed

or opened certified fireplaces.

Note that the premium shields are normally not required for factorybuilt fireplace installation, including interior chase.

When doing so please refer to the fireplace installation instructions to

install the chimney.

Page 3

KEEP YOUR CHIMNEY CLEAN SIZING CHART

CHIMNEY OPERATION AND MAINTENANCE

Wood stoves can quickly create large deposits of creosote in the chimney.

Some wood stoves can create enough creosote in two weeks to cause

a chimney fire. When using a wood stove, we recommend that you:

1. Initially inspect the chimney system weekly. From this, you will learn

how often it will be necessary to clean your chimney.

2. The chimney should be inspected at least once every 2 months during

the heating season to determine if a creosote or soot build-up has

occurred: if creosote or soot has accumulated, it should be removed

to reduce the risk of chimney fire.

3. Have your chimney cleaned by a qualified chimney sweep. If you want

to clean your chimney yourself: clean your chimney using plastic,

wood or stainless steel brushes. Do not use a brush that will scratch

the stainless steel interior of your chimney.

4. Do not expect chemical chimney cleaners to keep your chimney clean.

Their use does not negate the necessity of periodically inspecting and

cleaning your chimney.

CHIMNEY FIRES

If you are having a chimney fire, follow these steps:

1. Close all heater doors and combustion air controls. For fireplaces,

block the fireplace opening with a non-combustible material (such as

a steel sheet).

2. Alert your family to the possible danger.

3. If you require assistance, alert your fire department.

4. If possible, use a dry chemical fire extinguisher, baking soda or sand

to control the fire. Do not use water as it may cause a dangerous

steam explosion.

5. Watch for smouldering or fire on combustibles next to the stove,

stove pipe and chimney. Check outside to ensure that sparks and

hot embers coming out of the chimney are not igniting the roof.

6. Do not use the stove again until your chimney and stove pipe have been

inspected by a qualified chimney sweep or Fire Department Inspector.

DURATECH DTC chimney has been designed to withstand the intense

heat of a chimney fire. Nevertheless chimney fires are dangerous

and should be prevented.

BEFORE HIRING A CHIMNEY SWEEP

1. Does the company or individual have adequate liability insurance

in case of damage?

2. How long has the company been in business?

3. Does the company offer current references?

4. Is the company involved in any unresolved disputes?

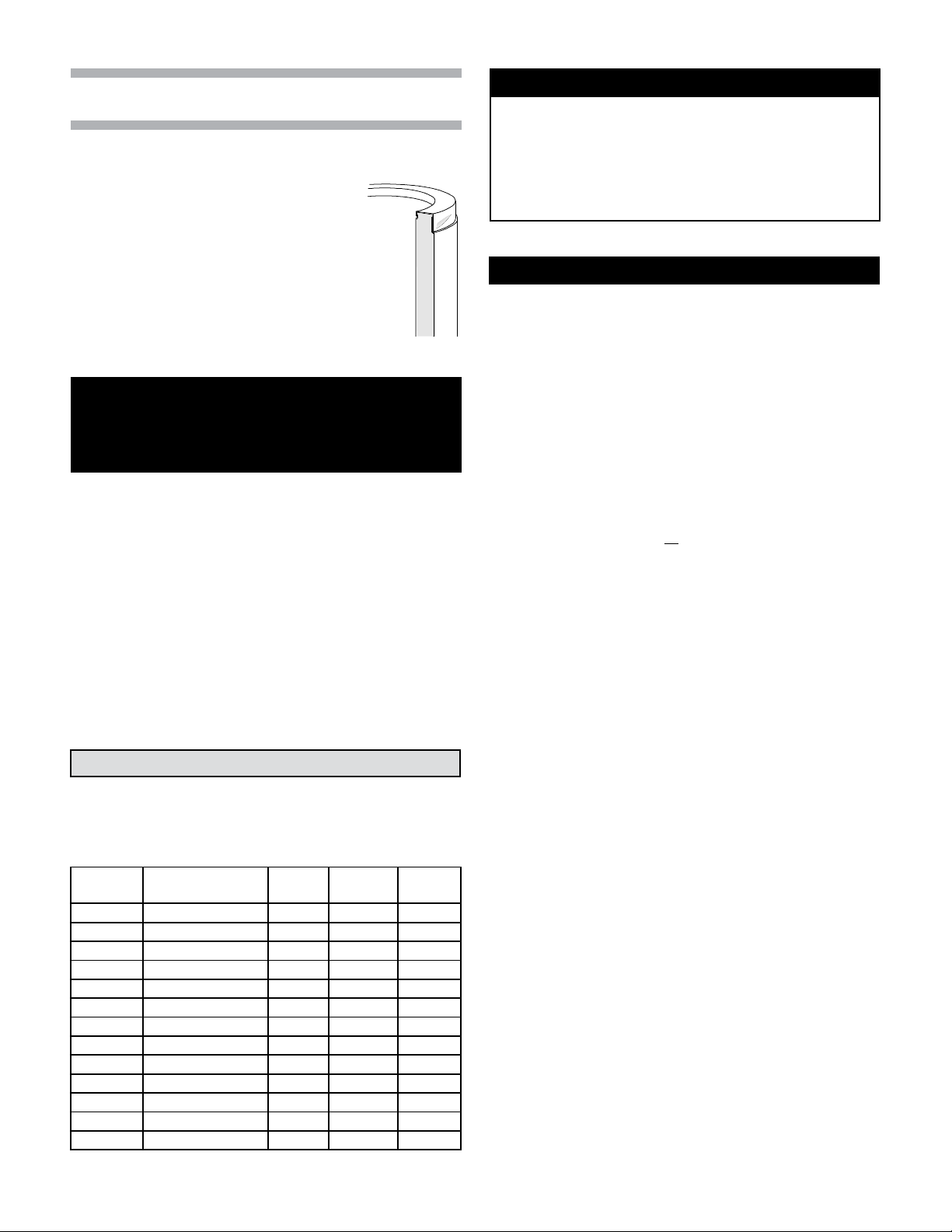

CHIMNEY-SIZE

OUTSIDE-DIAMETER

HOLE-DIMENSION-REQUIRED

Base-support (DTC-BS)

Cathedral support (DTC-RCSC)

Square support (DTC-CS)

Finish support (DTC-FSC)

Firestop (DTC-FS)

MAX. LENGTH HEIGHT SUPPORTED **

Base support (DTC-BS)

Tee support (DTC-TS)

Roof support (DTC-RS)

Radiation Shield Connector

Support (DTC-FRSCS)

Cathedral support (DTC-RCSC)

Square support (DTC-CS)

Adj. square support

(DTC-CSAS)

Finish support (DTC-FSC)

Offset support (DTC-RESU)

Insulated tee (DTC-TSS) *

CLEARANCE TO

COMBUSTIBLES

5” 6” 7” 8” 10”

7” 8” 9” 10” 12”

12-1/8” 12-1/8” 14-3/8” 14-3/8” --

-- 12-1/8” 14-3/8” 14-3/8” --

-- 12-1/8” 14-3/8” 14-3/8” 14-3/8”

-- 12-1/8” 14-3/8” 14-3/8” --

11-3/8” 12-3/8” 13-3/8” 14-3/8” 16-3/8”

-- 32’ 32’ 32’ 32’

63’ 63’ 55’ 48’ 39’

42’ 34’ 27’ 24’ 20’

-- 30' 24’ 21’ --

-- 75’ 65’ 59’ --

-- 60’ 50’ 45’ 35’

27’ 22’ -- -- --

-- 75’ 65’ 59’ --

-- 28’ 24’ 20’ 14’

63’ 63’ 55’ 50’ 50’

2” 2” 2” 2” 2”

Table 2

* When installed on a concrete footing.

** NOTE: If greater height is required, use additional roof supports at

intervals not exceeding 30’

SIDES OF HOLE MUST

BE VERTICAL

HOLE SIZE

DOWN

B

ACROSS

SLOPE

A

12 IN

ROOF SLOPE

INCHES

X

Figure 1

CHIMNEY

SIZE

ROOF

SLOPE

x/12 A B A B A B A B A B

0 11-3/8 11-3/8 12-3/8 12-3/8 13-3/8 13-3/8 14-3/8 14-3/8 16-3/8 16-3/8

2/12 11-3/8 11-1/2 12-3/8 12-1/2 13-3/8 13-1/2 14-3/8 14-9/16 16-3/8 16-19/32

4/12 11-3/8 12 12-3/8 13 13-3/8 14-3/32 14-3/8 15-5/32 16-3/8 17-1/4

6/12 11-3/8 12-11/16 12-3/8 13-13/16 13-3/8 14-15/16 14-3/8 16-3/32 16-3/8 18-5/16

8/12 11-3/8 13-11/16 12-3/8 14-7/8 13-3/8 16-1/16 14-3/8 17-1/4 16-3/8 19-11/16

10/12 11-3/8 14-13/16 12-3/8 16-1/8 13-3/8 17-7/16 14-3/8 18-23/32 16-3/8 21-5/16

12/12 11-3/8 16-1/16 12-3/8 17-1/2 13-3/8 18-29/32 14-3/8 20-11/32 16-3/8 23-5/32

5” 6” 7” 8” 10”

HOLE SIZE

Table 3 - Refer to Figure 1

3

Page 4

1

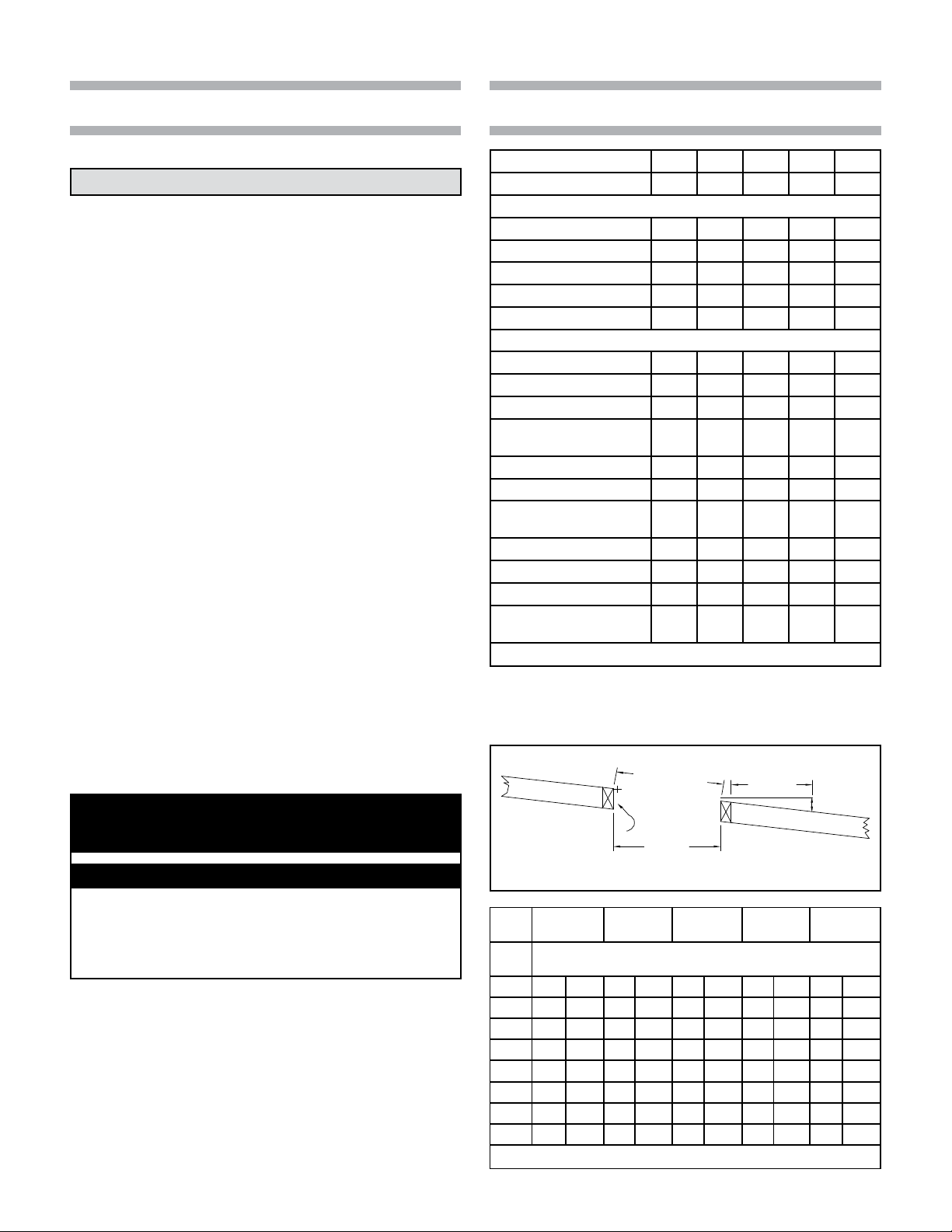

GENERAL INSTALLATION NOTES

INSTALLATION NOTES

1. The chimney is intended for use with solid (6’’,7’’,8’’ dia. only) or

liquid and gaseous fuel burning appliances.(all diameters)

Allowable flue gas temperature:

Maximum continuous 540°C (1000°F)

Brief forced firing 760°C (1400°F)

Tested to 1150°C (2100°F) - 30 minutes

2. On wood or coal stove application and in area where the chimney

is completely enclosed, it is required to install Premium shields

(telescopic of flexible) around the chimney and a Radiation shield

connector at the ceiling level.

For venting of gas or oil burning appliances Premium shields are

not required even where the chimney is enclosed.

For factory-built wood burning fireplaces, Premium shields

are usually not required, please follow fireplace installation

instruction.

3. The maximum height of chimney supported by the various supports

are outlined on page 3.

4. The supports described in this booklet should only be used with

Duravent model DURATECH CANADA (DTC), 5", 6", 7", 8" and 10"

factory built chimneys.

5. Size the chimney in accordance with the appliance manufacturer's

instructions.

6. When a firestop (DTC-FS , DTC-ISI or DTC-RSCI) needs to be

installed, it is important to follow the opening dimensions for the

floor openings prescribed in this manual. This way, the holes left

by the folded positioning tab of the firestop will be blocked by the

ceiling.

7. A chimney servicing a fireplace or an incinerator shall not serve any

other appliance.

8. The chimney shall extend at least 3 ft above its point of contact

with the roof and at least 2 ft higher than any wall, roof or adjacent

building within 10 ft of it.

9. The maximum height of unguided chimney above the roof is 5 ft.

10. The clearance between single wall pipe and unprotected combustible

material must not be less than 18" (see national building code and

NFPA 211) except: The distance between the vertical stove pipe and

the ceiling may be less than 18" and will be established by the finish

support.

11. Portions of the chimney which may extend through accessible

spaces shall be enclosed in all cases to avoid personal contact

with the chimney and damage to the chimney. When doing so on

woodstove or coal application, a telescopic or flexible Premium

shield must be installed (see Figure 2). Except for installation in

single and two-story family dwellings, the enclosure must have a

fire resistance rating equal to or greater than that of the floor or

roof assemblies through which they pass.

12. Do not fill the 2" space around the chimney with insulation or any

other material. Insulation placed in this area could cause adjacent

combustibles to overheat.

13. Self tapping screws are not required, but may be used to reinforce

the connection and avoid accidental unlocking of chimney lengths.

WARNING

2 ft

MIN.

10 ft

2" MIN.

RADIATION

SHIELD

CONNECTOR

(DTC-RSCI)

RADIATION

SHIELD

FIRESTOP

(DTC-FRSC)

SWIVEL

ADAPTOR

OPTIONAL

(DTC-SA)

PREMIUM SHIELD

(DTC-TRS or DTC-FLXS)

BASE TEE

* 18"

MINIMUM

* THE DISTANCE CAN BE REDUCED IF A

LISTED STOVE PIPE IS USED.

Figure 2

3 ft

MIN.

STORM

COLLAR

(DTC-SC)

ENCLOSURE

2" MIN.

SUPPORT

(DTC-FSC

OR DTC-BS)

7 1/2"

MIN.

* 18"

MINIMUM

The clearance between the chimney and combustible

material must not be less than 2", except where

established by the support. Do not fill this area with

insulation.

4

Page 5

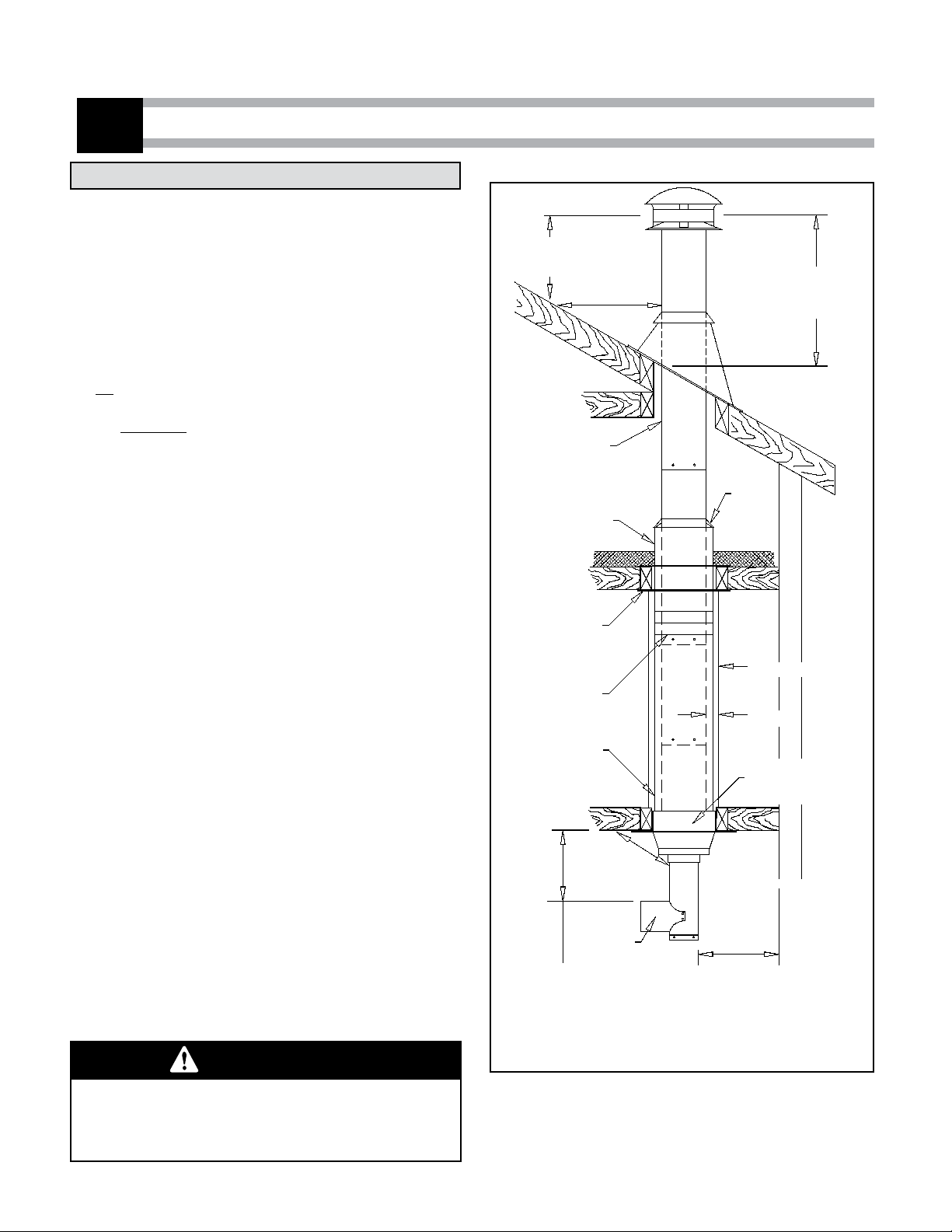

INTERIOR STRAIGHT INSTALLATION WITH MULTIPLE FLOOR

Locate the chimney in a convenient place as near as possible to the

appliance outlet.

Cut and frame the holes in the floor, ceiling and roof where the chimney

will pass.

Note: It is important to follow the opening dimensions for the floor

openings prescribed in this manual. This way, the holes left by the

folded positioning tab of the firestop (DTC-FS or DTC-ISI) will be

blocked by the ceiling.

HOLE SIZE

CHIMNEY

SIZE

5" 12-1/8" x 12-1/8" 11-3/8" x 11-3/8"

6" 12-1/8" x 12-1/8" 12-3/8’’ x 12-3/8’’

7" 14-3/8" x 14-3/8" 13-3/8’’ x 13-3/8’’

8" 14-3/8" x 14-3/8" 14-3/8’’ x 14-3/8’’

10" --- 16-3/8’’ x 16-3/8’’

FINISH SUPPORT

(DTC-FSC) or (DTC-BS)

RADIATION SHIELD*

& ROOF

Table 7 * For sloping roofs see size table 3 on page 3

From below push the finish support into the framed hole. Nail the support

to the framed box using (12) - 3" spiral nails (see figure 3).

If you are venting a Factory built fireplace or an oil or gas burning

appliance please refer to installation notes #2 (on page 4) for guidelines

on the use of the shields.

Shield through the roof opening down onto the Radiation Shield

Connector.Adjust the height of the shield`s tube so it terminates just

above the roof opening but under the flashing.Once satisfied with

positioning, secure both ends of the shield using self-tapping screws.

ROOF FLASHING INSTALLATION

Put the roof flashing in place. Seal the joint between the roof and the

flashing with roofing pitch.

For sloping roofs, place the flashing under the upper shingles and on

top of the lower shingles.

Nail the flashing to the roof using roofing nails.

Place the storm collar over the chimney and the flashing. Tighten it with

the bolt supplied making sure the joint is properly caulked (see figure 6).

Fit the rain cap to the top of the chimney. Turn it clockwise to lock it in place.

FINISH SUPPORT (DTC-FSC) or (DTC-BS)

NAILS

Figure 3

FOR UNENCLOSED INSTALLATION OR VENTING OF OIL

OR GAS APPLIANCES:

Refer to interior installation on a furnace and water heater guideline

(page 12).

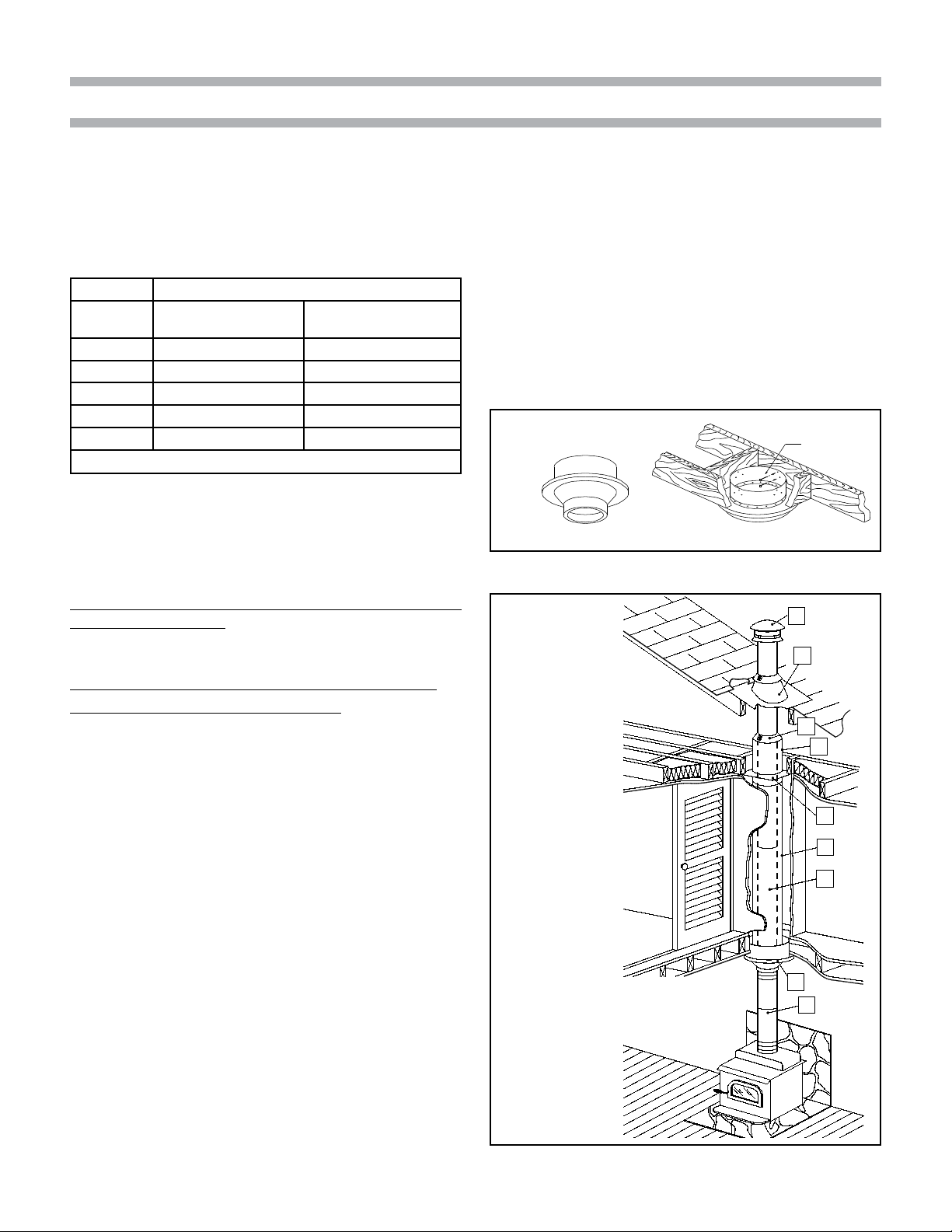

FOR ENCLOSED INSTALLATION (6’’,7’’,8’’ dia. only)

(woodstove or coal burning appliance):

- Lock the first chimney length into the support with the male coupling

on top.

- Slide a Telescopic Rigid shield (DTC-TRS) on top of that length all the

way to the bottom.

Stack the next chimney length on the first length. Be sure that the male

and female threads are not in line when putting the lengths together. Turn

the chimney clockwise to lock it in place. You may add a 1/2 in stainless

steel self tapping screw to prevent accidental unlocking.

Continue installing until the required chimney reached the attic level.

- At the ceiling level, install a Radiation Shield Connector (DTC-RSCI)

and a Radiation Shield Firestop (DTC-FRSC) (Figure 5)to the chimney.

Slide the Radiation Shield Connector down until the bottom of the insulated

tube passes just through the Radiation Shield Firestop as shown in Figure 4.

Adjust the height until a minimum of (1”) of the Radiation Shield Connector

passes throught the firestop below.

Once you are satisfied with positioning of the Radiation Shield Connector,

passes throught the firestop below. Fix it to the chimney from the attic

side using 3 self-tapping screws.

The Telescopic Shield is then slid upwards to the ceiling and attached to

the bottom of the Radiation Shield Connector using 3 self-tapping screws.

In the attic:

• If the chimney is not enclosed in the attic, a storm collar (DTC-SC) must

be installed on top of radiation Shield to prevent any loose insulation

from falling in the area between the chimney and the support.

• If the chimney is to be enclosed within the attic, continue installed

chimney sections up through the roof opening.Lower another Telescopic

1. BLACK STOVE PIPE

2. FINISHING SUPPORT

3. INSULATED LENGTH

4. PREMIUM SHIELD (TRS OR FS)

5. RADIATION SHIELD FIRESTOP

6. RADIATION SHIELD CONNECTOR

7. STORM COLLAR

8. ADJUSTABLE ROOM FLASHING

9. DELUXE RAIN CAP

Figure 4

9

8

7

6

5

4

3

2

1

5

Page 6

Figure 5

SCREWS

INSULATION PAD

RADIATION SHIELD

CONNECTOR

(DTC-RSCI)

RADIATION SHIELD

CONNECTOR FIRESTOP

(DTC-FRSC)

SILICONE

CAULKING

Figure 6

6

Page 7

2

INTERIOR INSTALLATION WITH CATHEDRAL CEILING

A - CATHEDRAL SUPPORT (DTC-RCSC)

This support is designed to be used in rooms

with cathedral ceilings (no attic space between

the ceiling and the roof). If the support is used as

a regular floor support, follow the instructions for

the finish support DTC-FSC on page 5.

Step 1. Situate the chimney in a convenient location as near as possible

to the appliance outlet. Cut and frame a hole in the roof for the

support. The sides of this hole must be vertical (figure 7) (see

table 3 on page 3).

Step 2. From above, place the support in the opening. Lower it to a

convenient height.

Note: The cone portion of the support must extend below the

ceiling. The minimum horizontal distance between the single

wall stove pipe and the ceiling is 18".

Using a level, make sure the support is vertical. If the support

extends above the roof, cut it flush with the top of the roof. Nail

the support to the framed opening using (12)-3" spiral nails

(figure 8).

SIDES OF HOLE MUST

BE VERTICAL

Figure 7

CHIMNEY (DTC-_SS)

FLASHING (DTC-F7)

MIN. HORIZONTAL

Figure 8

CLEARANCE 18" *

HOLE SIZE

DOWN

B

ACROSS

SLOPE

A

12 IN

ROOF SLOPE

INCHES

RAIN CAP (DTC-VC)

SILICONE

CAULKING

STORM COLLAR (DTC-SC)

(12) - 3" SPIRAL

NAILS

CATHEDRAL

SUPPORT (DTC-RCSC)

RAIN CAP (DTC-VC)

TO CONTINUE INSTALLATION SEE PREVIOUS STEP 3ON PAGE 5 .

B - SQUARE SUPPORT (DTC-CS) AND ADJUSTABLE

SQUARE SUPPORT (DTC-CSAS)

This support is similar in application and installation

as the cathedral support (DTC-CS). Install it using

the instructions above (refer to figure 9 for visual

references).

The adjustable square support requires an opening of 12"

x 12" up to 12" x 22-1/2" in the ceiling (see figure 10).

DTC-CS

SUPPORT EXTENSION (DTC-PS) (For square support only)

Steep pitched cathedral ceilings may require the use of a

square support extension (DTC-PS). This piece fits down

inside the square support and can be adjusted to increase

the support's length by up to 16".

The extension is attached to the support using the eight

metal screws provided. Be sure there is at least a 2" overlap

where the extension joins the support.

DTC-PS

FLASHING

(12) 3" lg. SPIRAL NAILS

Figure 9

(4) x 3" lg SPIRAL NAIL

OR SCREW

3-1/2"

(MIN.)

MIN. HORIZONTAL

CLEARANCE 18" *

SILICONE

CAULKING

STORM COLLAR (DTC-SC)

ROOF JOIST

3-1/2" MIN.

SQUARE CATHEDRAL

SUPPORT (DTC-SS)

12" TO 22-1/2"

(4) x 3" lg SPIRAL

NAIL OR SCREW

ADJUSTABLE ARM

PIPE CONNECTOR

(SINGLE WALL OR

DOUBLE WALL)

* THAT DISTANCE CAN BE REDUCED IF A LISTED STOVE PIPE IS USED.

Figure 10

7

Page 8

3

OFFSET DEVIATION

OFFSET CHIMNEY

RADIANT

SHIELD

CONNECTOR

(DTC-RSCI)

RADIANT

SHIELD

CONNECTOR

FIRESTOP

(DTC-FRSC)

SWIVEL

ADAPTORS

OPTIONAL

(DTC-SA)

FLEXIBLE

SHIELD

(DTC-FLXS)

Figure 11

If it is necessary to offset the chimney in order for it to pass through

an upstairs cupboard or to clear a joist, do this by using 15°, 30° or 45

insulated elbows. A maximum of two offsets (4 elbows in all) is allowed

in a chimney.

The minimum chimney height when using 15° offsets is 10’.

The minimum chimney height when using 30° offsets is 15’.

The maximum length of unsupported offset chimney is 6’. If the offset

chimney is longer than 6’, then it must be supported at 6’ intervals

using an offset support (DTC-RESU) or wall band (DTC-WSU). Or if a

Premium Shield is used then a Radiation Shield Connector (DTC-RSCI)

must be installed in the offset portion and attach to trusses with (2) two

plumbers straps.

FLASHING COLLAR (DTC-SC)

RADIANT SHIELD

CONNECTOR SUPPORT

(DTC-RSSR)

1” MIN

SPRING

SPACERS

INSTALLATION INSTRUCTIONS

Stack the next chimney length on the first length. Be sure that the male

and female threads are not in line when putting the lengths together. Turn

the chimney clockwise to lock it in place. You may add a 1/2in stainless

steel self tapping screw to prevent accidental unlocking. When you reach

the height at which the elbow will be installed:

Step 1. Install the insulated offset elbow on the vertical chimney length.

Turn it in the required direction and fasten it to the chimney with

the (4)-1/2" metal screws provided.

Step 2. Place the required offset chimney length (see chart below) on

the elbow. Turn it clockwise to lock it in place.

Step 3. Use another elbow to turn the chimney vertically. Again secure

the elbow to the chimney length using the (4)-1/2’’ metal screws.

For Enclosed installation (6", 7", and 8" dia. only)

(woodstove or coal burning appliance)

- Place the first chimney length on a flat surface with the male coupling

on top.

- Slide a flexible shield (DTC-FLXS) on top of that length all the way to

the bottom.

- Attach the flexible shield to the section using 3 x 1/2" stainless steel

self tapping screws.

- Slide this assembly in the support and turn clockwise to lock it in

place.

- At the ceiling level from the top, install a Radiation Shield Connector

(DTC-RSCI) and a Radiation Shield Support (DTC-FRSCS). Attach but

not tighten together yet (see Figure 13).

-

Slide the Radiation Shield Connector down until the bottom of the

insulated tube exceed the bottom of ceiling.

Adjust the height until a minimum of (1”) of the Radiation Shield

Connector exceed the bottom of ceiling ( see Figure 11)

Stack the next chimney length on the first length. Be sure that the male

and female threads are not in line when putting the lengths together. Turn

the chimney clockwise to lock it in place. You may add a 1/2 in stainless

steel self tapping screw to prevent accidental unlocking.

When you reach the height at which the elbow will be installed:

Step 1. Install the insulated offset elbow on the vertical chimney length.

Turn it in the required direction and fasten it to the chimney with

the (4)-1/2’ metal screws provided.

Step 2. Place the required offset chimney length (see table 8) on the

elbow. Turn it clockwise to lock it in place.

Step 3. Use another elbow to turn the chimney vertically. Again secure

the elbow to the chimney length using the (4)-1/2" metal screws.

Attach a spacer spring around the chimney at each elbow to help keep

the flexible shield centered. (See figure 11) Slide the flexible shield up

the chimney and attach it below the ceiling to the Support Radiation Shield

using 3 self tapping metal screws. If you are limited in space to screw,

install a Swivel Adaptor (DTC-SA) (figure 11) below the Shield Connector

(DTC-RSCI) and one on the top end of the flexible shield.

:

.

If you are venting a Factory built fireplace or an oil or gas burning

appliance please refer to installation notes #2 (on page 5) for guidelines

on the use of the Premium shields.

For Unenclosed installation or venting of oil or gas appliances:

Put the first chimney length in the support. Turn it clockwise to lock it

in place.

Note: the male coupling must be on top.

8

In the attic:

• Fix the radiation shield to the chimney and tight the support collar.

• If the chimney is not enclosed in the attic, a storm collar (DTC-SC) must

be installed on top of Radiation Shield to prevent any loose insulation

from falling in the area between the chimney and the support.

• If the chimney is to be enclosed within the attic, continue installed

chimney sections up through the roof opening. Lower another

Telescopic Shield through the roof opening down onto the Radiation

Shield Connector.Adjust the height of the shield`s tube so it terminates

just above the roof opening but under the flashing.Once satisfied with

positioning, secure both ends of the shield using self-tapping screws.

Page 9

3

OFFSET DEVIATION (CONT’D)

WARNING

A support must always be installed right above each

offset (two elbows) to support the chimney above the

offset.

RISE

OFFSET

Figure 12

SCREWS

RADIATION SHIELD

CONNECTOR SUPPORT

(DTC-FRSCS)

SCREWS

Figure 13

Install the remaining chimney as described in the instructions for the

Interior Straight installation.

RADIATION SHIELD

CONNECTOR

(DTC-RSCI)

SCREWS

ROOF SUPPORT (DTC-RS)

Figure 14

The roof support has three possible uses:

It may be used to support a chimney from the roof. It adjusts to any

roof pitch.

It may be used on a floor, ceiling or roof above an offset to support the

chimney above the offset.

It may be used on a floor, ceiling or roof as a supplementary support when

the chimney height exceeds that of the primary support. (See maximum

length height supported, page 3).

INSTALLATION INSTRUCTIONS

With the chimney extending through the hole in the roof, ceiling or floor

and the radiation shield in place, proceed as follows (Refer to figure 15

for visual references):

Step 1. Assemble the support collar to fit your chimney diameter, as

described on the instruction sheet supplied with the support.

Step 2. Slip the support down over the stainless steel chimney until its

brackets rest on the roof or floor. Tighten the collar around the

chimney, then secure it by screwing the four 1/2" metal screws

(supplied) through the holes located on each side of the collar

bolts and into the chimney (Figure 32).

Step 3. Center the chimney and nail or screw the support to the roof or

floor using (8) - 2-1/2" nails or (8) N°8 - 1-1/4" wood screws.

(figure 14).

INSTALLATION CALCULATIONS

Determine the offset required in view of the obstacles that must be avoided

(see figure 12). Refer to table 8 below to determine the elbows required

STORM COLLAR

(DTC-SC)

FLASHING

(DTC-FF)

RAIN CAP

(DTC-VC)

as well as the insulated length needed.

ROOF SUPPORT

OFFSET & RISE CHART MODEL DURATECH CANADA (DTC)

(5" @ 10")

ANGLE DIA. INCHES

15° 5" @ 10" Offset 3-5/16 4-5/16 5-7/8 7-7/16 10-1/2 13-5/8 15-3/8 16-7/16 18 19-1/2 22-5/8 25-3/4

Rise 15-11/16 19-9/16 25-3/8 31-3/16 42-3/4 54-3/8 60-15/16 64-13/16 70-9/16 76-3/8 87 99-9/16

30° 5" @ 10" Offset 7-7/16 9-7/16 12-7/16 15-7/16 21-7/16 27-7/16 30-13/16 32-13/16 35-13/16 38-13/16 44-13/16 50-13/16

Rise 20 23-1/2 28-11/16 33-7/8 44-1/4 54-11/16 60-9/16 64 69-1/4 74-7/16 84-13/16 95-1/4

45° 5" @ 10"

Offset

Rise

10-5/16 13-3/16 17-3/8 21-5/8 30-1/8 38-5/8 43-7/16 46-1/4 50-1/2 54-3/4 63-1/4 71-11/16

17-13/16 20-5/8 24-7/8 29-1/8 37-5/8 46-1/8 50-15/16 53-3/4 58 62-1/4 70-3/4 79-3/16

ONE LENGTH BETWEEN ELBOWS TWO LENGTHS BETWEEN ELBOWS

8 12 18 24 36 48 8 & 48 12 & 48 18 & 48 24 &48 36 & 48 48 & 48

Figure 15

(DTC-RS

2 in. MIN

6 in. MIN

Table 8

9

Page 10

4

EXTERIOR INSTALLATION

TEE & WALL SUPPORT

DTC-TS DTC-TSAC

ADJUSTABLE

Figure 16

Three supports are available, an adjustable with collar (DTC-TSA), an

adjustable with coupling (DTC-TSAC) and a non-adjustable with coupling

(DTC-TS).

ADJUSTABLE

DTC-TSA

INSTALLATION NOTES

If possible, install an interior chimney as it will provide better performance

than an exterior chimney. In areas with continuous temperatures below

-18°C (0°F), the use of an exterior chimney may result in operating

problems such as poor draft, excessive condensation of combustion

products and rapid accumulation of creosote when connected to a wood

burning appliance. If you do install an exterior chimney, we recommend

that you enclose it using an insulated enclosure.

1. The chimney may be enclosed or unenclosed. If enclosed at 2’’

clearance all around the chimney on a wood stove application, a

Premium shield must be installed around the chimney (Figure 19).

2. Maintain 2" clearance to combustible materials. Do not fill the 2" space

around the chimney with insulation or any other material.

3. A wall band must be used to secure the chimney to the wall. Maximum

distance between wall bands is 8 feet.

4. The minimum length of chimney extending past the inside wall is 5

inches.

5. The maximum length of chimney extending past the inside wall is 24

inches.

6. The distance between the stove pipe and a parallel combustible wall or

ceiling must not be less than 18". The distance between the horizontal

stove pipe and the unshielded vertical wall through which it passes

must not be less than 7 inches.

7. If an exterior installation is to be enclosed, allow for access to base

of tee to facilitate required cleaning.

8. The minimum distance between the bottom of the support and any

horizontal combustible (including the ground) is 6". This distance

can be reduced to 2 inches by using an insulated tee cap (DTC-TCI)

in conjunction with a (DTC-TSA) wall support.

9. The adjustable support (DTC-TSA) may only be installed with an

insulated tee cap (DTC-TCI) or a drain tee cap (DTC-TCD).

INSTALLATION INSTRUCTIONS STEPS

WALL FRAMED OPENING

WALL STUDS

FRAME OPENING WITH LUMBER

THE SAME DIMENSION AS

Figure 17

Determine where the chimney will pass through the wall.

• For concrete walls cut a hole slightly larger than the chimney.

• For combustible walls cut and frame a hole 4" larger than the chimney,

midway between the wall studs (see table below for sizing).

Normally wall studs are placed at 16" centers. With the hole midway

between them, the support will fasten to these studs and thus ensure a

strong attachment to the wall. (see Figure 17).

CHIMNEY SIZE COMBUSTIBLE CONCRETE

5" 11-3/8’’ x 11-3/8’’ 7-3/4’’

6" 12-3/8’’ x 12-3/8’’ 8-3/4’’

7" 13-3/8’’ x 13-3/8’’ 9-3/4’’

8" 14-3/8’’ x 14-3/8’’ 10-3/4’’

10" 16-3/8’’ x 16-3/8’’ 12-3/4’’

Table 9

Wood walls: from outside, put the square wall thimble (DTC-WTI) in the

hole. Nail in place using (4) 2’’ nails or 1’’ screws. This wall thimble is

adjustable from 7’’ to 12’’. From inside, wrap the insulation pad around

the tube of the square wall thimble previously installed. Place the metal

sheet around the insulation pad and close it by joining the staples at each

end of the metal sheet together. Make sure the gap is completely filled in

from inside to outside (cut insulation pad to proper length).

INSIDE

LEVEL

LARGE WALL SHIELD

1" SCREWS

Figure 18

Slide the large wall shield over the small wall shield. Using a level make

sure that the hole for the chimney to pass through is horizontal. Screw

the inner thimble in place with the provided screws (see Figure 18).

Note: The cavity surrounding the wall thimble must be filled with type

R-20 insulation (see Figure 18).

WALL STUD

WALL FRAMING

HOLE SIZE

OUTSIDE

TYPE R-20

INSULATION

SMALL WALL SHIELD

2" NAILS

10

Page 11

4

EXTERIOR INSTALLATION (CONT’D)

Attach the flue extension to the horizontal chimney length using the three

metal screws provided.

1. CAP

2. WALL THIMBLE

3. INSULATED TEE

4. INSULATED LENGTH

5. TEE SUPPORT

6. FLUE EXTENSION

7. PREMIUM SHIELD

8. RADIATION SHIELD FIRESTOP

9. RADIATION SHIELD CONNECTOR

10. STORM COLLAR

11. RAIN CAP

12. CENTERING SPRING

3

6

4

1

9

2

5

11

Stack a chimney length on top of the tee. Turn it clockwise to lock it in place.

FOR UNENCLOSED INSTALLATION OR VENTING OF OIL

10

8

OR GAS APPLIANCES:

Continue until the required chimney height is reached.

NOTE: At 8' intervals, attach the chimney to the wall using a wall band

(DTC-WSU).

If the chimney passes through the roof, cut a hole large enough to

provide 2" clearance between the chimney and the roof. For pitch roof,

see table 3 on page 3.

FOR ENCLOSED INSTALLATION AT 2" FROM COMBUSTIBLES

7

12

(Woodstove or coal burning appliance only):

Put a first chimney length on the Tee. Turn it clockwise to lock it in place

(see figure 4).

Note: the male coupling must be on top.

Slide a Radiation Shield Connector on that first chimney section and

fasten it using 3 self tapping metal screws.

Stack the next chimney length on the first length. Be sure that the male

and female threads are not in line when putting the lengths together. Turn

the chimney clockwise to lock it in place. You may add a 1/2in stainless

steel self tapping screw to prevent accidental unlocking.

Figure 19

Attach the clean-out cap to the support's flue extension using the

three metal screws provided. Make sure that the screws have pierced

through the flue extension. The cap is in the box with the insulated tee. If

an insulated tee cap is used, twist lock the tee cap to the tee (adjustable

support DTC-TSA only).

The minimum length of insulated chimney required to pass through the

wall will be thickness plus 7". The insulated chimney must extend at least

5" into the room beyond the finished wall. Insert this chimney length in

the side entry of the insulated tee. Turn it clockwise to lock it in place.

Seal this joint by wrapping it with the aluminium tape supplied with the

tee.Mount the insulated tee on the support so that the chimney length

which will go through the wall is perpendicular to the side of the support

that will fasten to the wall.

This step will require 2 people: (See figure 20)

Insert the chimney length of this tee-support assembly into the hole in

the wall. Using a level, ensure the tee is vertical, then attach the support

to the wall using (8) Nº. 10 x 1 - 1/4" wood screws or 4" spiral nails.

NOTE: To provide sufficient strength, the nails must be driven into the

wall studs. For concrete walls, the support should be attached using (8)

1/4" x 2" lag bolts.

Slide a telescopic rigid shield over that section and attach it to the radiation

shield connector.

Continue installing chimney sections up through the roof opening. Pull

the telescopic shield tube up to the roof opening Adjust the length of the

shield tube so that it terminates just above the roof opening but under the

flashing. Screw the sections of the shield together using 3 self tapping

screws per joint.

TO CONTINUE, SEE ROOF FLASHING INSTALLATION, ON PAGE 5.

5" Min.

WALL THIMBLE

(DTC-WTI)

INSULATED

CHIMNEY

(DTC-_SS)

FLUE EXTENSION

(DTC-AD)

WALL STUD

4 in. Nails or

#10 x 1-1/4 in. Screws

Figure 20

4 in. Nails or #10 x 1-1/4 in. Screws

LEVEL

TEE SUPPORT OR ADJUSTABLE TEE SUPPORT

(DTC-TS OR DTC-TSAC) AND INSULATED TEE CAP

(DTC-TCSS) OR ADJUSTABLE WALL SUPPORT

(DTC-TSA) AND INSULATED TWIST-LOCK CAP

(DTC-TCI) OR DRAIN TEE CAP (DTC-TCD)

11

Page 12

5

INTERIOR INSTALLATION ON A FURNACE AND WATER HEATER

Step 1. Locate the chimney in a convenient place as near as possible to

the appliance outlet. Cut and frame the holes in the floor, ceiling

and roof where the chimney will pass.

NOTE: It is important to follow the cutting dimensions for the

floor openings prescribed in this manual. This way, the holes left

by the folded positioning tab of the firestop (DTC-FS or DTC-ISI)

will be blocked by the ceiling.

Chimney Size Hole size

5’’ 12-1/8’’ x 12-1/8’’

6’’ 12-1/8’’ x 12-1/8’’

7’’ 14-3/8’’ x 14-3/8’’

8’’ 14-3/8’’ x 14-3/8’’

10’’ 14-3/8’’ x 14-3/8’’

Table 10

Step 2. From below push the support into the framed hole. Nail the

support to the framed box using (12) 3" spiral nails (see Figure

21).

Step 3. Put this first chimney length in the support. Turn it clockwise to

lock it in place.

NOTE: The male coupling must be on top.

Step 4. From below, install a firestop (DTC-FS) in each floor through

which the chimney passes (see Figure 22).

Step 5. Stack the next chimney length on the first length. Be sure that

the male and female threads are not in line when putting the

lengths together. Turn the chimney clockwise to lock it in place.

Continue until the required chimney height is reached.

Step 6. At the attic level, install a firestop (DTC-FS), from below and an

attic radiation shield (DTC-ISI) from above (see Figure 23).

Step 7. U.S. ONLY: Install the roof radiation shields in the roof joists.

These shields consist of four metal plates. Nail one plate to each

side of the joist using (2) 2-1/2’’ nails.

Step 8. Put the roof flashing in place. Seal the joint between the roof

and the flashing with roofing pitch.

For sloping roofs, place the flashing under the upper shingles

and on top of the lower shingles.

Nail the flashing to the roof using roofing nails.

Step 9. Place the storm collar over the chimney and the flashing. Tighten

it with the bolt supplied making sure the joint is properly caulked

(see Figure 24).

Fit the rain cap to the top of the chimney. Turn it clockwise to

lock it in place.

FINISH SUPPORT

(DTC-FSC) or (DTC-BS)

Figure 21

1. C0NNECTOR

2. BASE TEE FOR

TWIN CONNECTIONS

3. FINISH SUPPORT

4. FIRESTOP

5. INSULATED LENGTH

6. ROOF SUPPORT

7. ATTIC RADIATION

SHIELD

8. FLAT ROOF FLASHING

9. REGULAR RAIN CAP

Figure 22

NAILS

9

8

7

4

6

4

5

4

3

1

2

SILICONE

CAULKING

12

DTC-ISI

DTC-FSI

Figure 23

Figure 24

Page 13

SPECIALIZED COMPONENTS

ANCHOR PLATE (DTC-AP)

This support is used on a masonry fireplace

or on top of a furnace to provide a positive

connection to the chimney. It is not to

be used in contact with any combustible

material, such as on a wood floor.

INSTALLATION INSTRUCTIONS

Once the appliance is installed, bolt the anchor plate to it. Install the

chimney according to the installation instructions for the finish support

(DTC-FSC).

FACTORY-BUILT FIREPLACES

For chimneys installed on factory-built fireplaces, follow the installation

instructions accompanying the fireplace.

DTC-AP

Figure 25

INSULATED WALL RADIATION SHIELDS

INSULATED RADIATION SHIELD (DTC-FSI)

It must be used in combination with an attic radiation shield (DTC-ISI)

when passing through an attic. This component provides a 2"-safety

clearance to combustible materials surrounding the chimney.

ANGLED INSULATED RADIATION SHIELD

(DTC-WRSI30/DTC-WRSI45)

It has been designed for use when a chimney passes through a wall at

an angle. (See figure 27 for application).

Ø

INT.

Table 11

DTC-FSI DTC-WRSI30

7’’ 8’’ 10’’ 7’’ 8’’ 10’’ 7’’ 8’’ 10’’

A 16 16 18 37-3/4 39-3/4 45-5/16 26-5/8 28 30-1/2

B 3 3 3 16-5/8 17-5/8 19-3/8 16-5/8 17-5/8 19-3/8

C 13 13 5 12-5/8 13-5/8 15-3/8 12-1/8 13-1/2 14-7/8

D -- -- -- 33-3/4 35-3/4 39-1/4 22-1/8 23-1/2 26

E -- -- -- 3 3 3 3 3 3

FRAMING SIZE

DTC-WRSI45

A

Figure 26

B

B

C

DTC-FSI

D

A

C

E

DTC-WRSI30

DTC-WRSI45

13

Page 14

8

7

6

5

4

1. INSULATED ELBOW

2. INSULATED WALL RADIATION SHIELD

3. INSULATED LENGTH

4. OFFSEST SUPPORT

5. FIRESTOP

6. ATTIC RADIATION SHIELD

3

7. ADJUSTABLE ROOF SUPPORT

8. RAIN CAP

Figure 27

2

1

14

Page 15

M&G DuraVent Limited Lifetime Warranty

M&G DuraVent, Inc. (“DuraVent”) provides this limited

lifetime warranty for all of its products with the exception

of Ventinox® (lifetime), and PolyPro® (ten years). Subject

to the limitations set forth below, DuraVent warrants

that its products will be free from defects in material or

manufacturing, if properly installed, maintained and used.

DuraVent products are fully warranted if installed only by a

professional installer. This Warranty is transferable from the

original homeowner to the buyer of the home. This warranty

does not cover normal wear and tear, smoke damage or

damage caused by chimney res, acts of God, or any product

that was: (1) purchased other than from an authorized

DuraVent dealer, retailer or distributor; (2) modied or

altered; (3) improperly serviced, inspected or cleaned; or

(4) subject to negligence or any use not in accordance with

the installation instructions included with the product

as determined by DuraVent. Installation instructions are

available online at www.duravent.com under Support/

Literature and through our Customer Service Department

800-835-4429 or customerservice@duravent.com. This

limited lifetime warranty applies only to parts manufactured

by DuraVent.

DuraVent provides the following warranties for its products:

One Hundred Percent (100%) MSRP 15 years from the date of

purchase, and Fifty Percent (50%) thereafter, except for the

following limitations on: all Termination Caps and DuraBlack®

are warranted at One Hundred Percent (100%) for ve years.

All warranty obligations of DuraVent shall be limited to repair

or replacement of the defective product pursuant to the

terms and conditions applicable to each product line. These

remedies shall constitute DuraVent’s sole obligation and sole

remedy under this warranty. This warranty provides no cash

surrender value. The terms and conditions of this warranty

may not be modied, altered or waived by any action,

inaction or representation, whether oral or in writing, except

upon the express, written authority of an executive ocer of

DuraVent.

M&G DuraVent’s relining products including DuraLiner®,

DuraFlex® (SW, Pro, 316, 304), and Ventinox®. For purposes

of this warranty, a trained professional installer is dened as

one of the following: licensed contractors with prior chimney

installation experience, CSIA Certied Chimney Sweeps, NFI

Certied Specialists, or WETT Certied Professionals.

DuraVent must be notied and given the opportunity to

inspect defective product prior to replacement under the

terms of this limited lifetime warranty. All warranty claims

must be submitted with proof of purchase. Labor and

installation costs are not covered under this warranty. To

obtain warranty service contact: DuraVent Warranty Service,

877 Cotting Ct., Vacaville CA 95688, or call 800-835-4429.

WHERE LAWFUL, DURAVENT DISCLAIMS ALL OTHER

WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT WILL DURAVENT BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL, PUNITIVE OR

SPECIAL DAMAGES OR DIRECT OR INDIRECT LOSS OF ANY

KIND, INCLUDING BUT NOT LIMITED TO PROPERTY DAMAGE

AND PERSONAL INJURY. DURAVENT’S ENTIRE LIABILITY

IS LIMITED TO THE PURCHASE PRICE OF THIS PRODUCT.

SOME STATES DO NOT ALLOW LIMITATIONS ON IMPLIED

WARRANTIES, OR THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

AND YOU MAY ALSO HAVE OTHER RIGHTS THAT VARY FROM

STATE TO STATE.

For the most up-to-date installation instructions, see

www. duravent.com

REV 2.27.2013

Manufactured in Vacaville CA and Albany NY

Corn, bio-fuels, driftwood or other wood containing salt,

preservative-treated lumber, plastic and household trash or

garbage, or wood pellets containing such materials must not

be burned in the appliance or replace. In case of a chimney

re, the chimney must be inspected and approved by a

certied Chimney Sweep before reuse. After each annual

inspection, maintenance, and cleaning, the certied Chimney

Sweep must ll out and date the appropriate section of the

warranty card provided with the chimney liner.

LIMITATIONS ON INTERNET SALES: Notwithstanding any

other terms or conditions of this Limited Lifetime Warranty,

DuraVent provides no warranty for the following specic

products if such products are not installed by a qualied

professional installer: DuraTech®, DuraTech® DTC, DuraPlus

HTC®, DuraChimney® II, PelletVent Pro®, DirectVent Pro®,

FasNSeal®, FasNSeal® W2, FasNSeal® Flex, and PolyPro®, and

Member of M&G Group 800-835-4429 www.duravent.com L209 3/2012

®

15

Page 16

WARRANTY

When ordering repair parts, always give the following information:

This product has a limited lifetime warranty. Please read the warranty to

be familiar with its coverage.

Retain this manual. File it with your other documents for future reference.

PRODUCT REFERENCE INFORMATION

Please contact Duravent for the phone number of your nearest Duravent

dealer who will answer your questions or address your concerns.

Normally, all parts should be ordered through your Duravent distributor

or dealer. Parts will be shipped at prevailing prices at time of order.

1. The model number of the vent system.

2. The part number.

3. The description of the part.

4. The quantity required.

5. The installation date of the chimney system.

If you encounter any problems or have any questions concerning the

installation or application of this system, please contact your dealer.

DURAVENT

Visit us at www.duravent.com

Duravent reserves the right to make changes at any time, without notice, in design, materials,

specifications, prices. Consult your local distributor for chimney system code information.

Printed in Canada © 2013 DURAVENT

16

Duravent

www.duravent.com

Loading...

Loading...