Page 1

Installation Instructions

All-Fuel Chimney System

5” to 8” diameter

DuraTech

Page 2

A MAJOR CAUSE OF VENT RELATED FIRES IS FAILURE

TO MAINTAIN REQUIRED CLEARANCES (AIR SPACES) TO

COMBUSTIBLE MATERIALS. IT IS OF THE UTMOST IMPORTANCE

THAT DOUBLE WALL DURATECH BE INSTALLED ONLY IN

ACCORDANCE WITH THESE INSTRUCTIONS.

NOTE:

Read through all of these instructions before

beginning your installation. Failure to install

as described in this instruction will void the

manufacturer’s warranty, and may have an

effect on your homeowner’s insurance and

UL listing status. Keep these instructions for

future reference. This booklet also contains

instructions for installing a venting system

within an existing masonry chimney, and

for installations passing through a cathedral

ceiling.

Dear Customer, Installer, or End User:

We welcome any comments regarding matters

pertaining to our DuraVent products.

We welcome any ideas, input or complaints

and I’ll make sure that someone responds

directly back to you.

Send your emails to:

president@duravent.com

If you are searching for tech support or product

information, please phone us at 800-835-4429.

Or email us at:

techsupport@duravent.com

LISTED

MH7399

Page 3

ALLFUEL CHIMNEY SYSTEM, 5” TO 8” DIAMETER

For the most up-to-date installation instructions, see www.duravent.com

CONTENTS

CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PERMITS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DURATECH CHIMNEY APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

EQUIPMENT & MATERIALS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHIMNEY DIAMETER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CHIMNEY HEIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CHIMNEY PLACEMENT. . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CHIMNEY ENCLOSURE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

STOVE RECOMMENDATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

STEP-BY-STEP DIRECTIONS . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . 6

CEILING SUPPORTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

OFFSET ELBOW INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EXTENDED ROOF BRACKET INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .13

ROOF SUPPORTED INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TEE-SUPPORTED INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MASONRY FIREPLACE INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ZERO-CLEARANCE FIREPLACE INSTALLATIONS . . . . . . . . . . . . . . . . . . . 22

CONNECTION FROM APPLIANCE TO CHIMNEY SYSTEM . . . . . . . . . . . . . 22

CHIMNEY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

DuraTech

3

Page 4

CLEARANCES

Always allow at least a 2-inch clearance

between DuraTech Chimney Pipe and any

combustible materials. Never ll any required

clearance space with insulation or any other

materials. Combustible materials include

lumber, plywood, sheetrock, plaster and lath,

furniture, curtains, electrical wiring and building

insulation. Keep single wall stovepipe at least

18 inches away from combustible materials,

unless a clearance reduction system that is

acceptable to the authority having jurisdiction

is used, or the appliance to be installed is

listed and the instructions specify a different

clearance.

PERMITS

Contact your local Building Ofcial or Fire

Ofcial regarding permits, restrictions, and

installation inspections in your area.

DURATECH CHIMNEY

APPLICATIONS

DuraTech Chimney is a complete chimney

system tested and listed to UL 103 HT for the

United States, and ULC S604 in Canada. In

the U.S., DuraTech Chimney can be used with

wood stoves, replaces, reboxes, furnaces,

boilers, water heaters, stoves, ranges, or

other residential-type appliances fueled by oil,

gas, coal, or wood, that require a UL103 HT

chimney system. In Canada, DuraTech can

be used with oil & gas red appliances listed

for use with a Type A Chimney, in accordance

with ULC S604 . DuraTech is also listed for use

in Canada with some factory-built replaces;

check with your replace manufacturer.

Otherwise, DuraTech has not been approved

for use with solid fuel appliances in Canada.

DuraTech Chimney is available in 5”, 6”, 7” &

8” diameters (UL 103 HT Rated), as well as

10”, 12”, 14” & 16” diameters (UL 103 Rated).

Do not use with forced draft, positive-pressure

appliances. The DuraTech Chimney system

may have a maximum of two (2) offsets (four

elbows total) of 30° from vertical. DuraTech

Chimney is listed under UL Re-examination

Service Number MH7399.

EQUIPMENT & MATERIALS

Hammer Drill

Caulking Gun Plumb Bob

Screwdrivers Tin Snips

(Phillips & Standard)

Saber or Keyhole Saw Level

Dependable Ladder Tape Measure

Proper Gloves and Shoes Eye Protection

Materials You May Need:

500ºF RTV Silicone Sealant

8 Penny Nails

#8, 2-1/2” & 1-1/2” Wood Screws

Roong Nails

INSTALLATION NOTES

Proper planning for your DuraTech Chimney

installation will result in greater safety,

efciency, and convenience, as well as

saving time and money. You must use

only authorized DuraTech Chimney parts

to maintain a listed Chimney system (not

including the connector pipe). Do not mix

parts or try to match with other products,

or use improvised solutions. Do not install

damaged or modied parts. Table 1 lists the

authorized DuraTech Chimney components.

Practice good workmanship. Sloppy work

could jeopardize your chimney’s safety. Keep

electrical wiring and insulation away from all

chimneys and stovepipes. If you have any

questions, be sure to contact either your dealer

or DuraVent directly.

4

Page 5

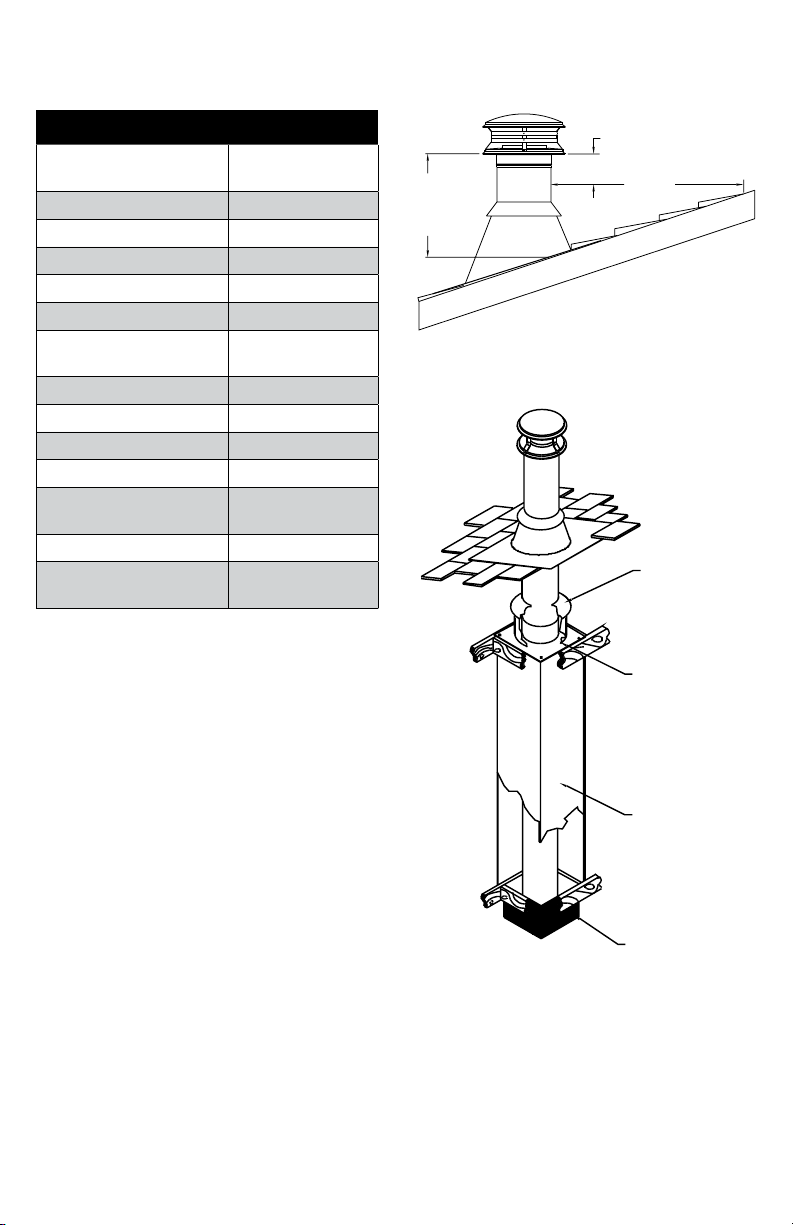

DuraTech Chimney Components

6”, 12”, 18”, 24”, 36”, 48” pipe

sections

Elbow with swivel Attic Insulation Shield

Tee with Tee Cap Elbow Strap

Adjustable Tee Support Bracket Adjustable Wall Strap

Chimney Cap Anchor Plate

Round Ceiling Support Box Extended Roof Bracket

Trim collars for Round

Support Boxes

Square Ceiling Support Box Chase Top Flashing

Flat Ceiling Support Box Flat Roof Flashing

Roof Support Storm Collar

Trim collar for Roof Support

Wall Thimble Base Tee and Double

Finishing Collar Firestop

Reduced Clearance

Support Box

Firestop Radiation

Shield

Adjustable Roof

Flashing

Transistion Anchor Plate

Base Tee

CAS Ceiling Support

Table 1

CHIMNEY DIAMETER

Follow the appliance manufacturer’s

instructions to determine chimney diameter

and clearances between combustible materials

and your heating appliance. Never choose

a chimney with an inside diameter smaller

than your appliance’s outlet. To calculate the

chimney’s outside diameter, add 2 inches to

the inside diameter.

3 FT MIN

ABOVE

ROOF

ATTIC

SPACE

OCCUPIED

SECOND

FLOOR

2 FT MIN ABOVE HIGHEST

POINT OF ROOF WITHIN

10 FT

10 FT

Figure 1

ATTIC

INSULATION

SHIELD

FIRESTOP

RADIATION

SHIELD

(INSIDE)

ENCLOSURE

MUST HAVE 2

INCHES OF

CLEARANCE

BETWEEN

CHIMNEY AND

WALL

CHIMNEY HEIGHT

The National Fire Protection Association

Standard #211 states: “Chimneys shall extend

at least three feet above the highest point

where it passes through the roof of a building,

and at least two feet higher than any portion

of a building within ten feet.” (Fig 1) DuraTech

Chimney may be installed up to 60 feet high. If

the chimney extends more than 5 feet above

FIRST

FLOOR

SUPPORT

BOX

Figure 2

the roof, an Extended Roof Bracket must be

used (see page 12). Due to the overlap of the

joints, subtract 1-1/4 inches from each Chimney

Section’s height to calculate installed height.

5

Page 6

CHIMNEY PLACEMENT

When deciding the location of your chimney,

try to avoid modications to roof beams and

other structural components of the building.

CHIMNEY ENCLOSURE REQUIREMENTS

Through Rooms: Interior chimneys shall be

enclosed where they extend through closets,

storage areas, occupied spaces, or anyplace

where the surface of the chimney could be

contacted by persons or combustible materials.

Maintain at least a 2-inch air space between

the outer wall of the chimney and the enclosure

(Fig 2).

Multi-Story: Consult local building codes for

requirements in your area. In the U.S., the

National Fire Protection Association Standard

#211 states: “Factory-built chimneys that

pass through oors of buildings requiring the

protection of vertical openings shall be enclosed

with approved walls having a re resistance

rating of not less than one hour when such

chimneys are located in a building less than

4 stories in height, and not less than 2 hours

when such chimneys are located in a building

more than 4 stories in height.” In Canada,

except in single-family and two-family dwellings,

chimneys which extend through another story

must have an enclosure with a re resistance

rating equal to or greater than that of the oor or

roof assembly through which they pass.

Cold Climates: In cold climates, chimneys

mounted on an outside wall should be

enclosed in a chase. Exterior chases reduce

condensation and creosote formation, and

enhance draft. Include an access door by the

Tee Cap for chimney cleaning (Refer to Fig 23).

6

STOVE RECOMMENDATIONS

Follow the stove manufacturer’s instructions.

The requirements stated below pertain to

all stoves or other appliances installed with

DuraTech Chimney systems.

Choice: Choose an appliance that is listed by

a recognized testing laboratory, is appropriate

for your needs, and is not larger than required.

Installation: Once the chimney system is in

place, install the stovepipe to connect the

appliance to the chimney as described in the

appliance manufacturer’s instructions. Be sure

to maintain all required clearances.

Flues: Connect only one solid fuel appliance

per chimney.

Operation: Follow the appliance

manufacturer’s instructions for maximum

efciency and safety. Overring can damage

the appliance, stovepipe and chimney.

Fuels: Do not burn driftwood, plastic, or

chemically treated wood such as railroad

ties. They are corrosive to your appliance,

stovepipe and chimney. Follow the appliance

manufacturer’s instructions and safety manual

in regards to fuels. Not all appliances are

equipped to burn coal. Coal with a low sulfur

content will reduce the possibility of corrosion.

Mobile Homes: Please read the appliance

manufacturer’s instructions and safety manual

carefully. Not all appliances are listed for use

in mobile homes.

STEP-BY-STEP DIRECTIONS

There are ve general types of DuraTech

Chimney installations:

1.Ceiling-supported

2.Roof-supported

3.Tee-supported (through-the-wall)

4.Masonry Fireplace

5.Zero-Clearance Fireplace

Review the step-by-step directions before

beginning your installation.

Page 7

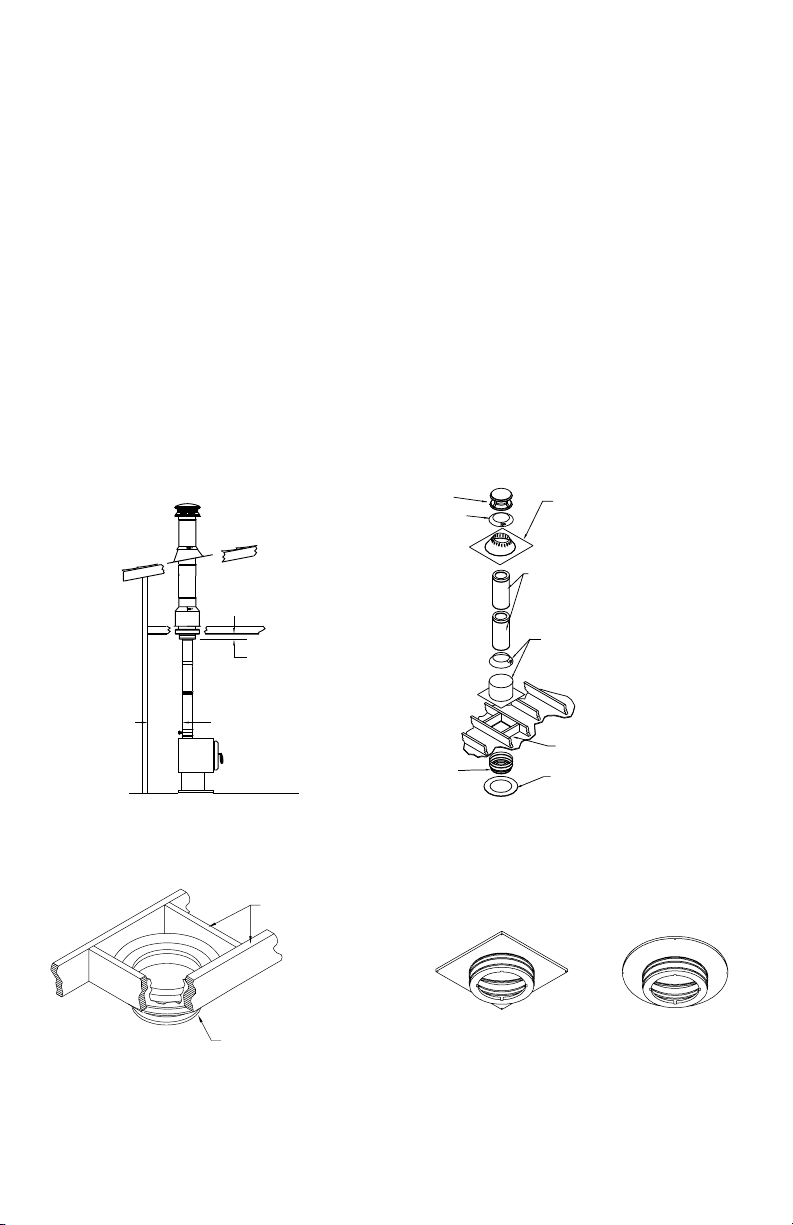

CEILING SUPPORTED

1. Place Appliance: Position the appliance

according to the manufacturer’s instructions.

The ue outlet collar should be placed

between the rafters or joists above, if possible.

2. Frame Support Opening: Drop a plumb

bob to the center of the appliance’s ue outlet

and mark this center point on the ceiling. Refer

to Table 2 for specic framing and clearance

dimensions. Mark appropriate cutting lines

around the center point. Cut a square hole in

the ceiling for the Support Box. Frame a level,

square opening centered over the hole which

you have cut. (Figures 3 and 4).

3. Install Support Box: For installation into

a at ceiling, there is the option of the Round

Support Box, the Flat Ceiling Support Box,

the Square Ceiling Support Box , Reduced

Clearance Support Box , or the CAS Ceiling

Support. The CAS Ceiling Support is only

used when installing the CAS system. Refer

to the DuraTech CAS Installation Instructions

for directions on how to install the remainder

of the Combustion Air System.. The Flat

Ceiling Support Box is primarily used for

Oil Appliances and comes unpainted. For

the Square Ceiling Support Box, Reduced

Clearance Support Box, and the CAS Ceiling

MINIMUM OF 3

INCHES BELOW

FINISHED CEILING

18 INCHES

MINIMUM FOR

SINGLE WALL

STOVEPIPE

ROUND SUPPORT

BOX

JOISTS & FRAMING

3 INCH MIN REQUIRED

BELOW FINISHED CEILING

CHIMNEY CAP

Figure 3

STORM

COLLAR

ROUND SUPPORT BOX WITH

SQUARE TRIM COLLAR

ADJUSTABLE FLASHING

CHIMNEY SECTIONS

ATTIC INSULATION SHIELD

FRAMED OPENING

ROUND TRIM COLLAR

3 INCH MIN BELOW

FINISHED CEILING

ROUND SUPPORT BOX WITH

ROUND TRIM COLLAR

Figure 4 Figure 5

7

Page 8

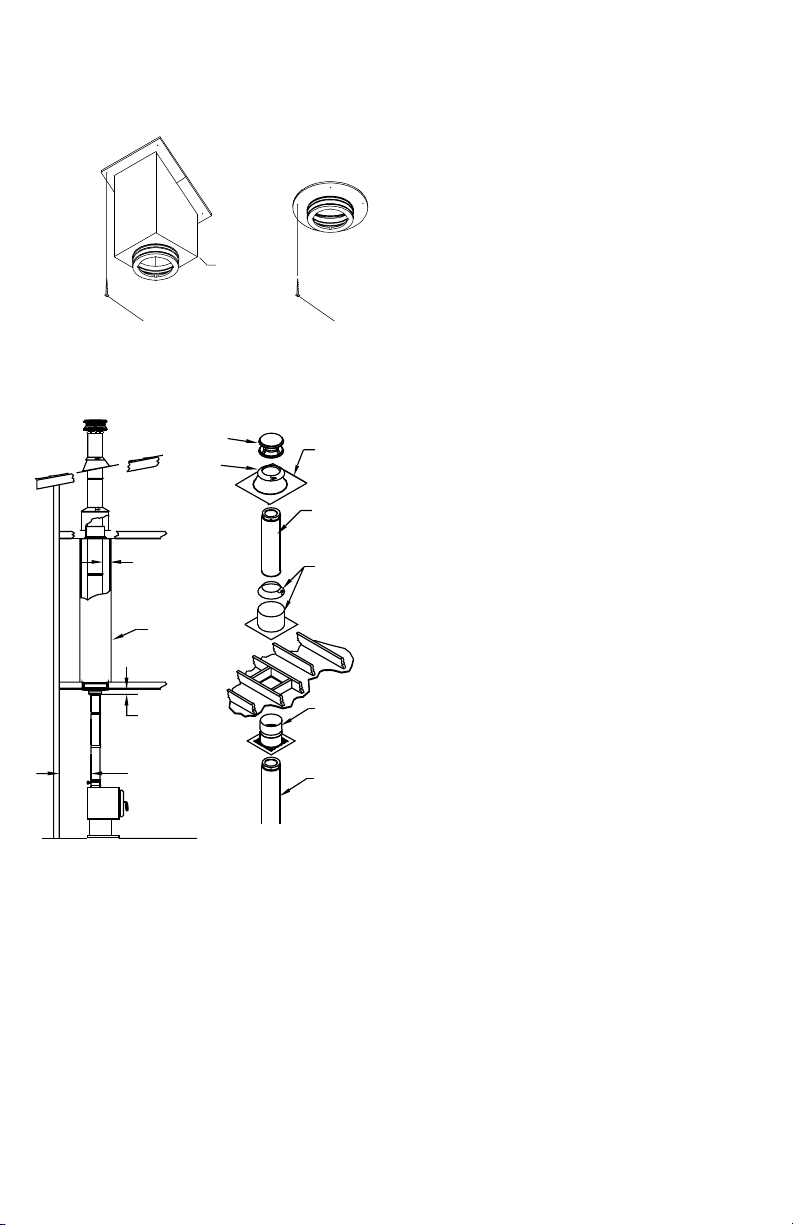

SQUARE CEILING

SUPPORT BOX WITH

TRIM FRAME

IN PLACE

WOOD SCREWS ARE

REQUIRED

ROUND CEILING

SUPPORT WITH TRIM

IN PLACE

MIN OF 2

INCHES

BELOW

FINISHED

CEILING

WOOD SCREWS ARE

REQUIRED

Figure 6

CAP

STORM

COLLAR

2 INCH MIN

CLEARANCE

TO INSIDE OF

ENCLOSURE

FRAMED

ENCLOSURE

MIN OF 3

INCHES BELOW

FINISHEDCEILING

18 INCH MIN FOR

SINGLE WALL

STOVEPIPE

ADJUSTABLE

FLASHING

CHIMNEY

SECTION

ATTIC

INSULATION

SHIELD

FIRESTOP

RADIATION

SHIELD

CHIMNEY

SECTION

Figure 7

Support, refer to the Square ceiling installation

below. The Round Ceiling Support Box has

the option of a square or round Trim Collar

available (Fig 5). The bottom of the Round

Support Box must extend at least 3 inches

below the nished ceiling. Level the Support

Box and secure it to the framing using at least

three 8-penny nails per side (min. of 12 total).

Alternatively, you may use 1-1/2” #8 wood

screws (min. of 12 total), instead of nails.

Next, secure the Trim Collar (round or square)

to the framing members using the (4) 1” long,

round-head wood screws provided (Fig 6).

For installation into a cathedral ceiling, you

must use the Square Ceiling Support Box or

Reduced Clearance Support Box (or the CAS

Ceiling Support if installing the CAS system)

and the two-piece Trim. The bottom of the

square portion of the Support Box must be a

minimum of 2-inches lower (round portion is

an additional 3 inches lower) than the nished

ceiling at the lowest side of the penetration

(Fig 5 & 6). Level the Support Box and

secure it to the framing using at least three (3)

8-penny nails per side (minimum of 12 nails

total), or a minimum of (3) #8, 1-1/2” wood

screws. Adjust the overlapping “U-shaped”

Trim pieces so they cover the Support Box,

and secure them to the framing members

using the (6) 1-1/4” long, round head wood

screws provided (see Fig 6).

4. Frame Openings: Frame openings in

each ceiling or oor above the Support Box

(Fig 7). These openings are to hold the

Firestop Radiation Shield and Attic Insulation

Shield. Locate each opening by dropping a

plumb bob to the four corners of the opening

below. Maintain the framing dimensions as

specied in Table 2.

Warning: other than the framing for the

Reduced Clearance Support Box, any

combustible materials around the chimney

must still meet the minimum 2” clearance

requirement. If Elbows must be used to

avoid an obstruction, refer to the Offset Elbow

Installation section.

5. Cut Roof Opening: Cut an opening in the

roof directly above the opening below, and

at least 4 inches larger than the chimney’s

outside diameter to provide at least a

2-inch clearance all around the chimney.

The chimney must be centered within this

8

Page 9

Framing Dimensions

Chimney Diameter

5” 6” 7” 8”

CATHEDR AL CEILIN G

SUPPO RT BOX

FLAT CEIL ING

SUPPO RT BOX

ROUND CEILING

SUPPO RT BOX

FIRES TOP RADIATION

SHIEL D

WALL THIMB LE 111/4” 121/4” 131/4” 141/4”

CAS C EILING

SUPPO RT

CAS WALL THI MBLE NA 121/4” NA 141/4”

REDUC ED

CLEAR ANCE

SUPPO RT BOX

111/4” 121/4” 131/4” 141/2”

111/4” 121/4” 131/4” 141/2”

111/4” 121/4” 131/4” 141/4”

111/4” 121/4” 131/4” 141/4”

NA 121/4” NA 141/2”

NA 101/4” NA NA

Table 2

FRAMING

FIRESTOP

RADIATION SHIELD

Figure 8

opening and maintain the 2-inch clearance to

combustibles.

6. Install Firestop Radiation Shield: A

Firestop Radiation Shield is required in

multistory installations at each oor penetration

TWIST CLOCKWISE

TO TIGHTEN

Figure 9

ATTIC INSULATION

SHIELD

Figure 10

above that where the Support Box is located.

Example: in a multistory home where the

appliance is on the ground oor (Support

Box is in the 1st oor ceiling), you would

need a Firestop Radiation Shield at the 2nd

oor ceiling, and at the 3rd oor ceiling, etc.,

including where the chimney penetrates into

the attic. Figure 7 shows a typical 2-story

installation with an attic.

Note: a Firestop Radiation Shield is not

installed where the chimney penetrates

through the roof. The Firestop Radiation

Shield is installed on the underside of the

ceiling/oor framing, with the cylindrical

“tube” portion of the shield pointing

upward. (Fig 8). Use a minimum of either

(1) 8 penny nail or (1) #8, 1-1/2” wood screws

per corner. Refer to Table 2 for framing

requirements.

9

Page 10

Figure 11

ROOFING

FASTENERS

ADJUSTABLE

FLASHING

Figure 12

PUSH COLLAR

DOWN TO

FLASHING AND

SEAL WITH NONHARDENING HIGHTEMP SILICONE

SEALANT

Figure 13

7. Assemble Chimney Sections: Lower

the female end of the rst Chimney Section

in the Support Box (Fig 9). It will twist-lock

clockwise onto the male end of the Support

Box. Turn Pipe Sections rmly clockwise to

lock them together. Sheet metal screws are

not required, but they may be used to reinforce

the connection, if desired. Use only 1/2” (or

shorter) sheet metal screws. Do not penetrate

the inner liner of the chimney.

8. Install Attic Insulation Shield: The

Attic Insulation Shield is required where the

chimney passes into an attic. Its purpose is

to prevent debris and insulation from getting

too close to the chimney (Fig 10). An installed

Attic Insulation Shield is 15 inches high. In

attic areas where this shield cannot t, you

must enclose the attic portion of the chimney

in a framed enclosure. If the chimney is fully

enclosed through the attic, an Attic Insulation

Shield is not required. If the chimney passes

into the attic, install the Attic Insulation Shield

as follows:

a. If the Firestop Radiation Shield extends

above the attic oor, no modications are

necessary. The Firestop Radiation Shield will

t inside the Attic Insulation Shield.

b. Assemble Chimney Sections until at least

18 inches of chimney extends above the

Firestop Radiation Shield.

c. Extend the Firestop Radiation Shield tube

extension (keep at least 1” overlap), and

secure in place using sheet metal screws.

d. Slip the Attic Insulation Shield over the

Chimney and Firestop Radiation Shield until

the base sits squarely on the framed opening

(Fig 7 & 10).

e. Secure the Attic Insulation Shield to the

top of the framed opening using at least (3)

8-penny nails or (3) #8, 1-1/2” wood screws

per side (Fig 10).

f. Wrap the Collar of the Attic Insulation Shield

around the chimney and fasten it loosely. Slide

the Collar down to meet the Attic Insulation

Shield. Slip the tab through the adjacent slot

and fold it back to tighten and secure the

Collar (Fig 11).

9. Attach Flashing: In new construction,

assemble the Chimney Sections to a point

above the roof, then slip the Flashing over

the chimney. On an existing roof, center

and install the Flashing before extending the

10

Page 11

chimney above the roof. Allow space to permit

sliding the next Chimney Section up through

the Flashing. Always insure the chimney

remains vertical (use a level), and that at least

a 2-inch clearance to combustible materials is

maintained all around. Install the upper edge

of the Flashing under the roong. Nail to the

roof along the upper edge and down each side

with 1-inch roong nails. Do not nail the lower

edge of the Flashing (Fig 12). Seal top and

upper sides of ashing with roong compound

or sealant. Be sure to follow local building

practices, as needed. Seal all nail heads with

a non-hardening waterproof sealant. On at

or tarred and graveled roofs, nail and seal the

Flat Roof Flashing to the roof on all sides with

roong compound. Do not put screws through

the Flashing into the Chimney Pipe.

10. Finish Top: Apply a high-temperature

(500ºF), non-hardening waterproof sealant

around the chimney at the point where the

Storm Collar will meet the chimney just above

the Flashing. (Figures 12 and 13). Slide the

Storm Collar down over the chimney to the top

of the Flashing. Tighten and seal the Storm

Collar against the sealant. After installing

sufcient Chimney Sections to meet the height

requirement (Fig 1), attach the Chimney Cap

onto the top of the chimney by holding the

collar of the cap and twist locking it clockwise

onto the chimney. Do not hold upper portion

of the cap and twist, as this may damage the

cap. The Chimney Cap can be removed for

chimney cleaning as described in the Chimney

Maintenance section of the instructions. Use

an Extended Roof Bracket if the chimney

extends more than 5 feet above the roof.

(Figures 16 & 17 in the Extended Roof

Bracket section). If you are located in heavy

snow country, it is recommended that a Snow

Splitter be installed. The Snow Splitter can be

purchased from DuraVent or fabricated locally

SPLITTER

SPLITTER

TOP VIEW

Figure 14

from heavy gauge sheet metal (Fig 14). This

will protect the chimney by routing the snow

around it.

11. Enclosures: Enclose chimneys where

they pass through occupied spaces, including

closets. Always maintain at least a 2 inch

clearance between the chimney and any

combustible materials. Interior enclosures

may be constructed with standard framing and

sheathed with sheetrock or plywood. Use Wall

Straps as needed to maintain a minimum of 2

inches of air space between the chimney and

combustible materials.

OFFSET ELBOW INSTALLATION

Elbows are manufactured in 15° and 30°

angles measured from the vertical. A 30°

Elbow is the largest that can be used in an

offset. A 30° Elbow may not be combined

with a 15° Elbow to make a 45° offset. Avoid

Elbows if possible, since a totally vertical

chimney is more efcient. When Elbows

are necessary to avoid obstructions such as

rafters, ridgepoles, or joists, use no more than

11

Page 12

ELBOW STRAP

CHIMNEY

SECTION

ELBOW

RISE

(INCHES)

Strap, Tee Support, or similar support method

to support the weight of the pipe and to relieve

stress on the Elbows. Attach the second Elbow

above the Chimney Section to complete the

offset (Fig 15).

2. Secure Offset: Place the Elbow Strap’s

band around the angled portion of the top

Elbow, then tighten the nut and bolt until the

clamp is rm. Wrap the Elbow Strap end over

an adjacent joist or rafter and secure it with at

OFFSET

(INCHES)

ADDITIONAL ELBOW

ELBOW STRAP

STRAPS REQUIRED

FOR EACH CHIMNEY

SECTION USED IN

OFFSET

ELBOW STRAPS

OR TEE SUPPORTS

ARE REQUIRED TO

SUPPORT WEIGHT

OF OFFSET AND

TO RELIEVE

STRESS ON

ELBOWS

ELBOW

TWO OR MORE

CHIMNEY

SECTIONS

Figure 15

2 pairs of Elbows in any one chimney system.

1. Attach Elbows: Attach Elbow to Chimney

Section or other Elbow by twisting clockwise

until they lock rmly. Attach one Elbow to the

Chimney Section below, and align it for the

offset. Elbows for DuraTech have a swivel

feature that allow for 360º rotation at their base

for ease of installation. Refer to Table 3 to

determine the required offset length and attach

an appropriate length (or lengths) of Chimney

Section(s) above the Elbow. Important:

For each chimney pipe section in the offset

(between the elbows), there must be an Elbow

Elbow

Angle

from

Vertical

15” 0” 2” 16 ½”

15” 6” 3 ¼” 21 ¼”

15” 12” 4 ¾” 27

15” 18” 6 ¼” 32 ¾”

15” 24” 8” 38 ½”

15” 36” 11” 50 ¼”

15” 48” 14 ¼” 61 ¾”

15” 48” + 6” 15 ½” 66 ½”

15” 48” + 12” 17” 72 ¼”

15” 48” + 18” 18 ½” 78:

15” 48” + 24” 20” 83 ¾”

30” 0” 4” 15 ¾”

30” 6” 6 ¼”

30” 12” 9 ¼” 25 ¼”

30” 18” 12 ¼” 30 ¼”

30” 24” 15 ¼” 35 ½”

30” 36” 21 ¼” 46”

30” 48” 27 ¼” 56 ¼”

30” 48” + 6” 29 ¾” 60 ½”

30” 48” + 12” 32 ¾” 65 ¾”

30” 48” + 18” 35 ¾” 71”

30” 48” + 24” 38 ¾” 76”

Chimney

Length

Between

Elbows

Offset

Inches

Table 3

Rise

Inches

12

Page 13

least (2) 8-penny nails or (2) #8, 1-1/2 screws.

Do not add more Chimney Sections until

the Elbows are supported. Be sure that the

chimney remains vertical. If there is more than

one Chimney Section between the Elbows,

install a second Elbow Strap around the joint of

the two Chimney Sections (Fig 15).

EXTENDED ROOF BRACKET

INSTALLATION

If the chimney extends more than 5 feet

above the rooine, an Extended Roof Bracket

must be installed at every 5-foot increment

of chimney height above the rooine, leaving

no more than 5 feet of chimney extending

above the last pipe bracket. The Extended

Roof Bracket consists of the Pipe Band, the

Adjustable Legs, and the Roof Brackets.

1. Mount Pipe Band: Slip the Pipe Band

around the chimney and secure by tightening

the nut and bolt.

2. Attach the Legs: The Adjustable Legs

of the assembly will adjust from 67” to 114”.

Secure one end of each Leg to the Pipe Band

using the nuts and bolts included (2 per Leg).

Position the Adjustable legs so they form

approximately a 60° angle with the chimney,

and with each other (Figures 16 and 17). Be

sure that there is at least 3” of overlap between

the top and bottom halves of the Adjustable

Leg. In order to secure Legs in proper

position, there is a hole provided in the outer

leg where the outer and inner halves overlap.

Use a 1/4” drill bit to drill through the inner leg

at that location. Use the nut & bolt provided to

pin the Adjustable Legs in position.

3. Install Roof Brackets: Mount the two

Roof Brackets where each of the Adjustable

Legs meets the roof, using (4) 1” roong nails

or screws per bracket. Seal the nail heads

carefully with a non-hardening, waterproof

sealant. Attach the bottom end of the

EXTENDED ROOF

PIPE BAND

AROUND

CHIMNEY

SECTION

BRACKET ASSEMBLY

ADJUSTABLE

LEGS ADJUST

FROM 67 TO

114 INCHES

Figure 16

CHIMNEY CAP

EXTENDED ROOF

MUST USE EXT.

ROOF BRACKET IF

OVER 5 FT

BRACKET

ADJUSTABLE LEGS

Figure 17

Adjustable Legs to the Roof Brackets using the

nuts & bolts provided.

ROOF SUPPORTED

INSTALLATIONS

There are two types of Roof Supported

Installations: (1) Using a Square Ceiling

Support Box, Reduced Clearance Support

Box, or CAS Ceiling Support; and (2) Using a

Roof Support.

(1) For a Square Ceiling Support Box,

Reduced Clearance Support Box, or CAS

Ceiling Support installation, make sure that

the square box portion of the Support Box can

extend at least 2” below the low side of the

nished ceiling (Fig 19). If the CAS Ceiling

Support is used, refer to the DuraTech CAS

13

Page 14

SQUARE PORTION

OF SUPPORT BOX

NEEDS A MIN OF 2

INCHES CLEARANCE TO

FINISHED CEILING

CAP ADJUSTABLE

STORM

COLLAR

FLASHING

CHIMNEY

SECTION

18 INCH MIN CLEARANCE

FOR SINGLE-WALL

STOVEPIPE

Figure 18

CHIMNEY

SECTION

CHIMNEY

SECTION

Figure 19

SQUARE

CEILING

SUPPORT BOX

OR REDUCED

CLEARANCE

SUPPORT BOX

CAP

STORM

COLLAR

CHIMNEY

SECTION

FRAMED

OPENING

ADJUSTABLE

FLASHING

CHIMNEY

SECTION

CHIMNEY

SECTION

SQUARE

CEILING

SUPPORT BOX

OR REDUCED

CLEARANCE

SUPPORT BOX

Installation Instructions for directions on how

to install the remainder of the Combustible Air

System. The Support Box must remain level,

and the top edge of the box must cover the

edge of the roof’s decking material. Square

Ceiling Support Boxes are available in 11-inch,

24-inch, and 36-inch heights. The Reduced

Clearance Support Box is available in 24”

length for 6” diameter chimney only. Mobile

14

home chimney installations are roof supported.

Do not seal openings in ashing.

1. Place Appliance: Place the appliance in its

proper location, referring to the manufacturer’s

instructions as to allowable distances from

combustibles, etc.

2. Cut Openings: Cut a roof opening in your

desired location, just as in a Ceiling-Supported

Installation (Steps 1 through 5). If a separate

Page 15

ceiling and roof exists, as shown in Figure

18 (Low Attic), rst cut and frame a ceiling

opening as described in Ceiling-Supported

Installations (Step 2). Refer to Table 2 for

clearance and framing specications. If it is

desired to install through a cathedral ceiling

(Fig 19), then the hole is cut in the roof.

3. Install Support Box: Slip the Square

Support Box, Reduced Clearance Support

Box, or the CAS Ceiling Support into the

framed opening so the square portion projects

at least 2 inches below the nished ceiling and

rafters (bottom of round portion is 5” below),

and extends above the ceiling to framing or

decking materials to which it can be nailed.

Level the Support Box, and slit the corners

to the rooine where they extend beyond it.

Bend the aps (created by the slitting) ush

with the roof, and nail the Support Box to the

roof or framing with at least three (3) 8-penny

nails, or (3) 1-1/2”, #8 screws, per side (Fig

20). Be sure to keep the Support Box level.

Screw the trim sections into the ceiling (Fig 6).

4. Complete Installation: Refer to Steps 7,

9 & 10 in the Ceiling Supported Installation

section to complete the Roof Supported

installation.

Figure 20

(2) A Roof Support is also used in installations

where there is a cathedral ceiling, and a

Square Ceiling Support is not desired. The

Roof Support allows the DuraTech chimney

to come down into the room below the level

of the ceiling (Fig 21). The Roof Support can

support a maximum of 45 feet of DuraTech

Chimney total, and maximum of 20 feet below

the support. If a taller stack of DuraTech

Chimney is required, you must use a Square

Ceiling Support Box instead.

1. Cut and frame opening to provide a

minimum 2” clearance on all sides of the

chimney pipe. Note: Opening in nished

ceiling should be circular/oval in order for it to

be covered by Trim Collar.

2. Bolt on the Roof Support Brackets to

the Roof Support Band using the supplied

DURABLACK

SLIP CONNECTOR

ROOF SUPPORT

TRIM COLLAR

FINISHING COLLAR

ROOF SUPPORT

(SUPPORT

BRACKETS AND

BAND)

SECURE ROOF

SUPPORT BAND TO

CHIMNEY USING

4 SHEET METAL

SCREWS

Figure 21

USE 4 NAILS (OR

SCREWS) ON

EACH SIDE OF

SUPPORT

TIGHTEN BOLT

ON ROOF

SUPPORT BAND.

15

Page 16

DURATECH CHIMNEY

PIPE

FLOORING

MIN OF 3” BELOW

CEILING OR

EXPOSED FRAMING

ROOF SUPPORT

FRAMING

MEMBERS

(ALL SIDES)

FIRESTOP

RADIATION SHIELD

(TRIM RADIATION

SHIELD IF NEEDED

TO AVOID ROOF

SUPPORT)

Figure 22

hardware. Attach the Roof Support Brackets

to roof using (4) 8 penny nails or (4) #8, 1-1/2”

screws per side (Fig 21).

3. Determine how much DuraTech Chimney

will be extending into the room (minimum of

3” below the ceiling). Be sure to maintain the

proper clearance to combustibles (walls and

ceilings) for the connector pipe. Once you have

identied the proper height for your installation,

attach the of the Roof Support Band to the

Chimney Section by tightening the Bolt, and

secure it by using (4) supplied sheet metal

screws.

4. Attach desired length of Chimney Sections

above and below the roof level (max. of 45’

total, 20’ below the support). To transition to the

Connector Pipe, attach the Finishing Collar by

twist locking it to the bottom section of DuraTech

Chimney.

5. Slide Trim Collar over the DuraTech Chimney

and attach the Trim Collar to the ceiling using

(4) 1-1/4” screws provided (Fig 21).

6. Refer to Steps 10 & 11 in the Ceiling

Supported Installation section to complete the

Roof Supported installation.

Alternative Installation Location for Roof

Support: The Roof Support may be used at the

bottom of a Chimney installation (Fig 22). This

may be useful for some basement installations.

Maintain a minimum of 2” clearance to

combustibles at all times. The DuraTech

Chimney needs to extend a minimum of 3”

below the nished ceiling or exposed framing

members. Please note that you cannot extend

the chimney all the way to the appliance - you

must have some connector pipe.

1. Cut and frame opening to provide a minimum

of 2” clearance on all sides of the chimney.

Be sure to maintain the proper clearance to

combustibles for the connector pipe.

2. Bolt on the Roof Support Brackets to

the Roof Support Band using the supplied

hardware. Attach the Roof Support Brackets

to oor using (4) 8 penny nails or (4) #8, 1-1/2”

screws per side (Fig 22).

3. Determine how much DuraTech Chimney

will be extending into the room (minimum of

3” below the framing), and attach the of the

Roof Support Band to the Chimney Section by

tightening the Bolt, and secure it by using (4)

supplied sheet metal screws (Fig 21 & 22).

4. Install a Firestop Radiation Shield below the

nished ceiling or framing members. Trim the

‘tube’ portion of the Firestop Radiation Shield

as needed if it interferes with the Roof Support

Installation.

5. Follow steps 4, 5 & 6 for the Roof Support.

TEE-SUPPORTED INSTALLATIONS

Tee-Supported installations are used when

passing through a wall to an outside chimney.

The Tee Support can hold a maximum of

50-feet of DuraTech Chimney without the Tee

Support Straps, or70-feet with use of Tee

Support Straps. The Tee Support and Wall

Straps are adjustable, allowing from 2” - 6” of

clearance between the chimney and the wall,

16

Page 17

as needed to t your installation. There are

two options when installing a Tee-Supported

installation: the Tee Support above the Tee, or

the Tee Support below the Tee. The required

parts and general conguration are as shown

in Figures 23, 24, 25 and 26.

1. Place Appliance: Position the appliance

according to the manufacturer’s instructions. It

is a good idea to try to position the appliance

so it will allow the chimney to line up centered

between studs.

2. Locate, Cut & Frame Opening:

Determine

the location where the chimney will pass through

the wall. The chimney should pass through

the wall, centered between two studs. The

height of the penetration can be determined

by positioning sections of stove pipe until you

have the desired conguration (refer to the

appliance manufacturer’s installation instructions

for restrictions on stove pipe). Cut and frame

an opening in the inner and outer walls at this

location. Refer to Table 2 for the appropriate

framing dimensions.

3. Install Wall Thimble: The Wall Thimble

is two-piece component which includes the

Interior half and the Exterior half. On the

outside wall, install the back portion of the Wall

Thimble. Center the back portion of the Wall

Thimble (with shield inside wall) in the framed

opening of the outside wall. Be sure to seal

the ange of the Wall Thimble around the wall

by using a non-hardening waterproof sealant.

Attach the back portion of the Wall Thimble to

the outside wall using at least (4) 8-penny nails

or (4) #8, 1-1/2” wood screws. There must be

MIN 6 INCHES

CLEARANCE

BETWEEN CAP AND

CHASE TOP

CHASE TOP

FLASHING

FRAMED EXTERIOR

ENCLOSURE

TYPICAL THRUTHE-WALL TEE

SUPPORTED

INSTALLATION

ACCESS DOOR

FOR CLEANING

Figure 23

CHIMNEY SECTION

OF 6 INCHES INTO ROOM)

WALL THIMBLE

ASSEMBLY

TEE BRANCH (MUST

PENETRATE A MINIMUM

FINISHING COLLAR

CHIMNEY TEE

USE 8 PENNY NAILS OR #8, 2 1/2” WOOD

SCREWS. USE 4 FOR EACH SUPPORT

LEG.

TEE SUPPORT IS ADJUSTABLE TO

ALLOW FROM 2” - 6” CLEARANCE FROM

CHIMNEY TO WALL.

TEE CAP

Figure 24

17

Page 18

WALL THIMBLE

COVER PLATE

FINISHING

COLLAR

TEE BRANCH

(MUST EXTEND AT

LEAST 6 INCHES

INTO ROOM)

Figure 25

CHIMNEY TEE

BACK OF WALL THIMBLE

(SECURE WITH 4 NAILS

OR 4 SCREWS)

TEE SUPPORT MAY BE

INSTALLATION WITH TEE

BELOW TEE SUPPORT

(SHOWN WITH LEG

BRACKETS MOUNTED

ABOVE SUPPORT

PLATE)

TEE SUPPORT WITH

LEG BRACKETS

MOUNTED ABOVE

SUPPORT PLATE CAN

SUPPORT A MAXIMUM

OF 50-FEET OF

CHIMNEY.

INSTALLED WITH LEG BRACKETS

ABOVE OR BELOW SUPPORT

PLATE AS SHOWN

8-PENNY NAILS OR #8, 2 1/2”

WOOD SCREWS, 4 PER SIDE

a continuous shield within the wall. If the two

halves of the Wall Thimble do not overlap, a eldfabricated extension constructed out of 26-gauge

galvanized or stainless steel is needed.

4. Install Tee Support: Install the Tee Support

on the outside wall. Position Tee Support so

that the chimney Tee will be centered inside

the Wall Thimble (Figs 24, 25, & 26). The Tee

Support may be installed either above the Tee or

below the Tee (within one pipe section), as seen

ADJUSTABLE WALL STRAP,

ALLOWS 2”-6” CLEARANCE

TO WALL

8-PENNY NAILS OR #8,

2 1/2” WOOD SCREWS,

2 PER SIDE

ADJUSTABLE TEE

SUPPORT ALLOWS 2”-6”

CLEARANCE TO WALL

CLEANOUT CAP

Figure 26

in Figure 26. The Tee Support can support up

to 50-feet of chimney by itself, or up to 70-feet

of chimney if the Tee Support Straps are used

(Fig 24, 26). Important: Verify that Tee Support

is level, and secure the leg brackets of the Tee

Support to the wall using (4) #8, 2-1/2” screws for

each side. Slide support base over leg brackets

to adjust for desired clearance to wall, and secure

by tightening bolts. (Figs 26 & 27).

5. Install Tee and Cleanout Chimney

INSTALLATION

WITH TEE BELOW

TEE SUPPORT

(SHOWN WITH

LEG BRACKETS

MOUNTED BELOW

SUPPORT PLATE)

USE (4) 1/2”

SHEET METAL

SCREWS TO

SECURE BAND

AROUND

CHIMNEY

USE 1/2”

SHEET METAL

SCREWS TO

SECURE BAND

TO SUPPORT

BASE

18

Page 19

Section: Twist lock the Tee onto a desired

length of Chimney to be used as the cleanout

section. Use only one chimney section (any

length) to attach to bottom of the Tee. Tighten

support band around chimney section at

proper height to insure that Tee is centered

through Wall Thimble (Fig 25 & 26). Use the

1/2” sheet metal screws provided to insure

a tight connection between support band

and chimney section. Connect support band

to support base using the 1/2” sheet metal

screws provided (Fig 26). Twist lock Tee Cap

into bottom of Chimney Cleanout section.

6. Install Branch onto Tee: From inside

the house, attach the Chimney Branch up

to 24” chimney section, depending on wall

thickness, positioned horizontally used to pass

through the wall) to the Tee by twist locking it

clockwise. Important: The Chimney section

used to penetrate through the wall must extend

at least 6” into the room (Fig 25 & 27). Use

high-temperature sealant (500ºF) to seal

between the Wall Thimble and the Chimney on

the outer wall.

7. Install Cover Plate and Finishing Collar:

After the Chimney Branch is secured in place

(penetrating at least 6” into the room), slide

the Cover Plate over the Branch and attach

it to the framing using (4) 1-1/4” long, round

head wood screws. Be sure that the Branch

is centered in the opening of the Cover Plate.

Twist lock the Finishing Collar on to the

female end of the Chimney Branch by twisting

clockwise.

8. Complete Chimney: Attach the Chimney

Sections as in Step 7 in the Ceiling Supported

Installation section. Secure the chimney to

the wall with Wall Straps at a minimum of

8-foot intervals and maintain at least 2 inches

of clearance to combustible materials. The

Wall Straps are adjustable to allow from 2”- 6”

EXTENDED ROOF

SUPPORT BRACKET

ADJUSTABLE WALL

STRAP

2 INCHES MIN

6 INCHES MIN

INTO ROOM

ADJUSTABLE

FLASHING

2 INCHES MIN

FRAMED CHASE

ADJUSTABLE TEE

SUPPORT

ACCESS DOOR

FOR CLEANING

Figure 27

clearance to combustibles. Slip the Wall Straps

around the chimney, tighten the bolts, adjust

the clearance, and fasten the Wall Straps to

the wall with (4) #8, 1-1/2” long wood screws.

Once the chimney is at the minimum height

specied in Figure 1, attach the Chimney Cap

onto the top of the chimney by holding it by

the collar and twist locking it clockwise onto

the Chimney Pipe. If the chimney penetrates

an overhang, frame for at least 2 inches of

clearance, and install Flashing and Storm

Collar as described in Steps 9 & 10 for Ceiling

Supported Installations. Another option is to

cut away the overhang for a 2-inch clearance

(Fig 28). If the chimney extends more than 5

feet above the top Wall Strap or Flashing, use an

Extended Roof Support Bracket.

9. Install Chase Top Flashing: It is

recommended that a Tee Supported Chimney be

enclosed in a chase. If a chase enclosure has

been constructed, you can either use a standard

at-roof ashing, or you can use a Chase Top

19

Page 20

2 INCHES MIN

ALLOW MIN OF 2 INCHES

AIR SPACE ON ALL SIDES

2 INCHES MIN

Figure 28

ALLOW 1 INCH AIR

GAP BETWEEN STORM

COLLAR AND CHASE TOP

FLASHING

1/2 INCH AIR SPACE

ESTABLISHED BY

SPACERS

Flashing. Using a Chase Top Flashing allows

for a lower prole for the chimney. The Chase

Top Flashing has an opening that is 3” larger

in diameter than the DuraTech Chimney. If the

Chase Top Flashing can t over your chase

enclosure as required (Fig 29) then install as

directed, or trim as needed. However, if the

Chase Top Flashing is smaller than your chase

enclosure, you will need to provide a galvanized

sheet capable of covering your chase and

overhanging the sides by 1/2 - 3/4 inch. Attach

the Chase Top Flashing to the galvanized sheet

using appropriate sheet metal screws and nonhardening waterproof sealant. Use the Chase

Top Flashing Spacers to allow the proper air-gap

clearances on the galvanized sheet. The Chase

Top Flashing Spacers are available to insure

that the proper air-gap is maintained. Figure 29

displays in some detail, how these air gaps are

established using the Spacers and Chase Top

Flashing. Secure the Chase Top Flashing to the

chase using a sufcient number of #8, 1-1/2”

wood screws, being careful to insure the air

CHIMNEY CAP

STORM COLLAR

6 INCH MIN CLEARANCE

BETWEEN BOTTOM OF

CAP AND CHASE TOP

FLASHING

20

1/4 INCH

AIR

SPACE

CHIMNEY

SECTIONS

FRAMED CHASE

ENCLOSURE

Figure 29

CHASE TOP

FLASHING

SPACER

1/2 INCH

1/4 INCH

Page 21

gap is maintained between the ashing and the

T

W

H

and 30” high, and the chimney height as 20’.

12” diameter pipe.

Dotted line represents sample problem.

CHIMNEY SIZING CHART

FOR FIREPLACE INSTALLATIONS

T

W

H

T

8

7

6

30

16

14

20

8

10

15

12

10

50

40

30

24

48

60

36

42

72

HEIGHT

36

30

42

24

48

18

WIDTH

18

20

22

24

20

18

60

72

84

84

HEIGHT

(FEET)

CHIMNEY

FIREPLACE

OPENING (INCHES)

CHIMNEY

PIPE

DIAMETER

(INCHES)

chase. Seal the screw heads with non-hardening

sealant. When installing the Storm Collar, allow

a 1” air space between the bottom of the Storm

Collar and the Chase Top Flashing .

MASONRY FIREPLACE

INSTALLATIONS

1. Determine Chimney Size: Use Table 4 to

determine the correct diameter chimney for your

replace.

2. Mount Anchor Plate: Chimneys for masonry

replaces begin with an Anchor Plate. Make

sure the surface of the masonry chimney has

a level surface on which to attach the Anchor

Plate. If the top of the masonry does not have

a level surface, then you will need to modify the

masonry accordingly. Follow the requirements

of your local building department for connecting

factory-built chimneys to masonry reboxes or

masonry chimneys. Center the Anchor Plate

over the masonry ue opening, and seal the

Anchor Plate with a high-temperature (1000ºF)

sealant. Secure Anchor Plate with at least (4)

1/4” x 4” masonry anchors (Fig 30). It is very

important that the Anchor Plate is level. Be sure

to maintain a 1” min. clearance to combustibles

from the Anchor Plate.

3. Attach Chimney: Twist lock the rst

Chimney Section clockwise onto the Anchor

Plate.

4. Finish Chimney: Install the rest of the

chimney as directed in the Ceiling Supported

Installation section, Steps 4 through 10

Refer to Figure 1 and Table 4 for chimney

height requirements. Always maintain at least

2 inches of clearance to combustible materials,

and enclose the chimney where it passes

through occupied areas. Use a Wall Strap for

every eight (8) feet of chimney height.

Table 4

21

Page 22

MAINTAIN 1 INCH MIN

CLEARANCE FROM ANCHOR

ANCHOR

PLATE

NOTE:

Follow local

building code

requirements

for connecting

factory-built

chimney to

masonry

replaces.

HIGH TEMP

SEALANT

PLATE TO COMBUSTIBLES

MASONRY

ANCHOR BOLTS (4)

REQUIRED

(NOT FURNISHED)

EXISTING

MASONRY

CHIMNEY

WITH LEVELED

SURFACE

Figure 30

CHIMNEY

SECTION

SHEET METAL

SCREWS

(4 REQUIRED)

ANCHOR

PLATE

Figure 31

ZERO-CLEARANCE FIREPLACE

INSTALLATIONS

1. Manufacturer’s Instructions: Carefully

read and comply with the manufacturer’s

installation instructions for your replace. Be

sure that DuraTech is approved for use with

your appliance.

2. Anchor Plate: Attach an Anchor Plate

to the replace top with (4) 5/8” sheet metal

screws (Fig 31). Check with the appliance

manufacture about the use of high temperature

sealants.

3. Chimney Sections: Attach a Chimney

Section to the Anchor Plate by twist-locking

clockwise.

4. Completion: Install the remainder of the

chimney as instructed for a standard CeilingSupported installation, (using a Firestop

Radiation Shield in the 1st oor ceiling instead

of the Support Box). Always maintain at least

2 inches of clearance to combustibles, and

enclose the chimney where it passes through

occupied areas.

CONNECTION FROM APPLIANCE

TO CHIMNEY SYSTEM

1. Single Wall Stovepipe: If single wall stovepipe

is desired, DuraVent’s “DuraBlack” single-wall

stovepipe is recommended. The connection

to the Ceiling Support Box, or Finishing Collar

is made with a DuraBlack Slip Connector or a

Snap-Lock Adapter. The beaded end of the Slip

Connector or Snap Lock Adapter slips into the

opening in the Ceiling Support or Finishing Collar.

Align the tabs on the Slip Connector or Snap

Lock Adapter with the notches in the face of the

Support Box or Finishing Collar, push it in and

rotate to lock it in place. Further instructions for

assembling DuraBlack Stovepipe are contained in

their shipping cartons. Remember, the minimum

clearance to combustibles for single wall stovepipe

is 18 inches.

2. Close Clearance Connector Pipe (DVL):

DuraVent manufactures a close clearance

connector pipe, also referred to as “DVL”. DVL

may be positioned as close as 6 inches to a

combustible wall, and as close as 8 inches to

a combustible ceiling, provided the appliance

installation instructions permit this distance. In

order to join this type of connector to the Support

Box or Finishing Collar, a DVL/DuraBlack Chimney

Adapter is required. The DVL/DuraBlack Chimney

Adapter slips into the opening in the Support Box

22

Page 23

or Finishing Collar. Align the tabs on the DVL/

DuraBlack Chimney Adapter with the slots cut into

the face of the Support Box or Finishing Collar, and

push it in, and rotate to lock it in place. Detailed

instructions for assembling the remainder of the

close clearance system are included in the DVL

shipping cartons.

3. Connection to Oil-Burning Appliance: DVL

is especially recommended for oil appliances

because of the corrosive nature of oil-burning

exhaust. When connecting to an oil burning

appliance, refer to National Fire Protection

Association Standard #211. Table 6-5.1.1 in NFPA

211 states that you must allow for 18” clearance

to combustibles if you are using single wall vent

connector. If , however, your appliance is Type-L

Vent listed and you are using a listed Type-L Vent

connector, then you are permitted to use the

clearances as specied by the vent listing.

CHIMNEY MAINTENANCE

1. Creosote and Soot: When wood is burned

slowly, it produces tar and other organic vapors,

which combine with expelled moisture to produce

creosote. The creosote vapors condense in the

relatively cool chimney ue of a slow-burning re.

As a result, creosote residue accumulates on the

ue lining. When ignited, this creosote makes an

extremely hot re.

2. Access: Chimneys must be installed so that

access is provided for inspection and cleaning.

3. When to Clean: The chimney should be

inspected at least once every month during the

heating season to determine if creosote or soot has

built up. Check spark arrestor screens at least every

2 to 4 weeks. If creosote or soot has accumulated,

it should be cleaned or replaced to reduce the risk of

chimney re.

4. How to Clean: Have your chimney cleaned

by a Certied Chimney Sweep if you have doubts

about your ability to clean it. Use a plastic, wood, or

steel brush. Do not use a brush that will scratch the

stainless steel liner of your chimney. Scrub the spark

arrestor with a wire brush. To remove the Chimney

Cap for cleaning unscrew the four (4) screws that

attach the cap’s support legs to the cap base. The

Tee Cleanout Cap can be removed by turning

counter-clockwise. Be sure to replace Tee Cleanout

Cap when you are nished cleaning the chimney.

5. Coal: Warning: Coal with a high sulfur content can

lead to premature failure of the chimney. To reduce

corrosion in chimneys where coal is burned, clean

the chimney thoroughly within 48 hours of shutting

down the stove for the season. An annual inspection is

required due to the corrosive nature of the fuel.

6. Chemical Cleaners: Use chemical cleaners

only as a last resort, and use only those which

the manufacturer specically warrants as being

noncorrosive to the chimney liner. DuraVent will

assume no liability for damage resulting from the use

of chemical cleaners.

7. In Case of Fire: If a ue re occurs, close all

appliance air inlets, and call your Fire Department.

Do not use the chimney again, until it has been

inspected for possible damage.

8. Painting: As an option, you can coat all exterior

metal parts, with the exception of the Chimney

Cap, with high temperature, rust proof paint. Wash

the metal with a vinegar and water solution before

painting. Painting the chimney will help to increase

chimney life.

9. Creosote Formation: DuraVent assumes

no liability for any structural damage or roof

contamination as the result of creosote formation. It

is the owner’s responsibility to comply with inspection

and cleaning requirements as described in these

instructions, and those of the appliance manufacturer.

23

Page 24

M&G DURAVENT LIMITED LIFETIME WARRANTY

M&G DuraVent, Inc. (“DuraVent”) provides this limited lifetime warranty for all of its products with the exception of Ventinox® (lifetime), and

PolyPro® (ten years). Subject to the limitations set for th below, DuraVent warrants that its products will be free from defects in material or

manufacturing, if properly installed, maintained and used. DuraVent products are fully warranted if installed only by a professional installer.

This Warranty is transferable from the original homeowner to the buyer of the home. This warranty does not cover normal wear and tear, smoke

damage or damage caused by chimney res, acts of God, or any product that was: (1) purchased other than from an authorized DuraVent

dealer, retailer or distributor; (2) modied or altered; (3) improperly serviced, inspected or cleaned; or (4) subject to negligence or any use not

in accordance with the installation instructions included with the product as determined by DuraVent. Installation instructions are available

online at www.duravent.com under Support/Literature and through our Customer Service Department 800-835-4429 or customerservice@

duravent.com. This limited lifetime warranty applies only to parts manufactured by DuraVent.

DuraVent provides the following warranties for its products: One Hundred Percent (100%) MSRP 15 years from the date of purchase, and Fifty

Percent (50%) thereafter, except for the following limitations on: all Termination Caps and DuraBlack® are warranted at One Hundred Percent

(100%) for ve years.

All warranty obligations of DuraVent shall be limited to repair or replacement of the defective product pursuant to the terms and conditions

applicable to each product line. These remedies shall constitute DuraVent’s sole obligation and sole remedy under this warranty. This warranty

provides no cash surrender value. The terms and conditions of this warranty may not be modied, altered or waived by any action, inaction or

representation, whether oral or in writing, except upon the express, written authority of an executive ocer of DuraVent.

Corn, bio-fuels, driftwood or other wood containing salt, preservative-treated lumber, plastic and household trash or garbage, or wood pellets

containing such materials must not be burned in the appliance or replace. In case of a chimney re, the chimney must be inspected and

approved by a certied Chimney Sweep before reuse. After each annual inspection, maintenance, and cleaning, the certied Chimney Sweep

must ll out and date the appropriate section of the warrant y card provided with the chimney liner.

LIMITATIONS ON INTERNET SALES: Notwithstanding any other terms or conditions of this Limited Lifetime Warranty, DuraVent provides no

warranty for the following specic products if such products are not installed by a qualied professional installer: DuraTech®, DuraPlus HTC®,

DuraChimney® II, PelletVent Pro®, DirectVent Pro®, FasNSeal®, FasNSeal® W2, FasNSeal® Flex, and PolyPro®, and M&G DuraVent’s relining

products including DuraLiner®, DuraFlex® (SW, Pro, 316, 304), and Ventinox®. For purposes of this warranty, a trained professional installer is

dened as one of the following: licensed contractors with prior chimney installation experience, CSIA Certied Chimney Sweeps, NFI Certied

Specialists, or WETT Cer tied Professionals.

DuraVent must be notied and given the opportunity to inspect defective product prior to replacement under the terms of this limited lifetime

warranty. All warranty claims must be submitted with proof of purchase. Labor and installation costs are not covered under this warranty. To

obtain warranty service contact: DuraVent Warranty Service, 877 Cotting Ct., Vacaville CA 95688, or call 800-835-4429.

WHERE LAWFUL, DURAVENT DISCLAIMS ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT WILL DURAVENT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL,

PUNITIVE OR SPECIAL DAMAGES OR DIRECT OR INDIRECT LOSS OF ANY KIND, INCLUDING BUT NOT LIMITED TO PROPERTY DAMAGE AND

PERSONAL INJURY. DURAVENT’S ENTIRE LIABILITY IS LIMITED TO THE PURCHASE PRICE OF THIS PRODUCT. SOME STATES DO NOT ALLOW

LIMITATIONS ON IMPLIED WARRANTIES, OR THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO YOU. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS THAT VARY FROM STATE TO STATE.

For the most up-to-date installation instructions, see

www. duravent.com

REV 3.22.2012

Manufactured in Vacaville CA and Albany NY

Customer Service Support 800-835-4429 707-446-4740 FAX www.duravent.com

DuraTech is a registered trademark of the M&G DuraVent, Inc.

All rights reserved. Made in the USA. M&G DuraVent is a member of M&G Group. ©2012

L150 5/2012

Loading...

Loading...