Page 1

USER GUIDE

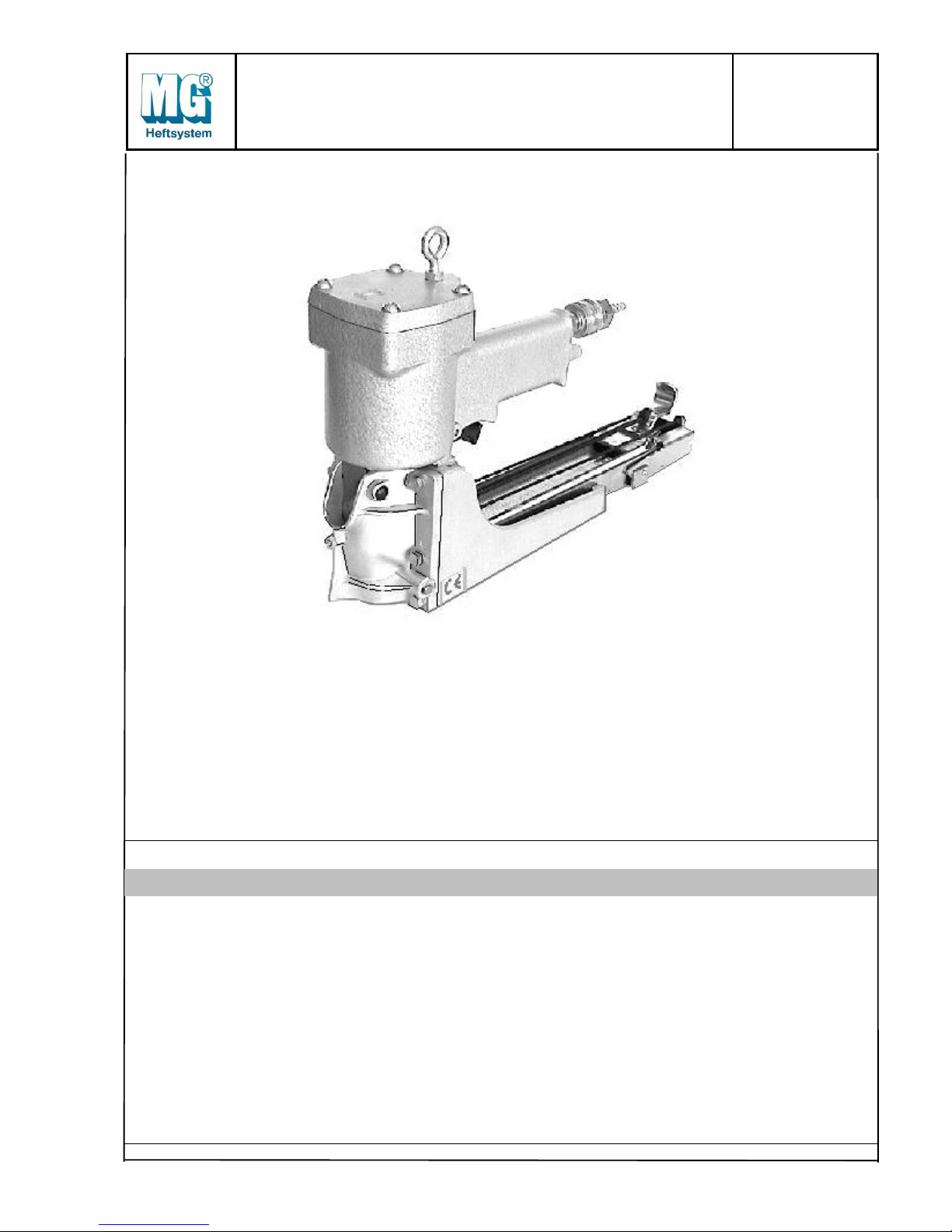

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 1

Version: 0711

ET 572

Page 1 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

Operating Instructions

Pneumatic Blind Stapler

Type TOP SP P, TOP B P

Series V04/ 1096

Light - easy to handle - compact - balanced

Pneumatic carton stapler for the fast and stable blind stapling of filled folding boxes made of

corrugated cardboard. Loading capacity 120 TOP-staples

IMPORTANT

Before the first commissioning read this manual thoroughly and completely and keep it in a safe place.

Observe and follow the safety instructions and only use the machine if you are sure that you have

completely understood all the instructions.

Failure to comply can lead to injuries!

If you have any questions, contact the manufacturer

MEZGER Heftsysteme GmbH

Saganer Straße 24

90475 Nürnberg

Germany

Page 2

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 2

Version: 0711

ET 572

Page 2 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

Pneumatic Blind Stapler

Type/description:

Serial number:

Year of construction:

Preface

It is necessary to acquire the knowledge conveyed by this ORIGINAL OPERATING INSTRUCTION for

a safe operation. The information is presented in brief and clear form. The chapters are sorted by

numbers

Copyright

The copyright of this operation manual remains with MEZGER Heftsysteme GmbH

Contents overview

Contents overview ................................................................................................................. 2

1 Conformity ...................................................................................................................... 2

2 Safety instructions .......................................................................................................... 3

3 Intended use ................................................................................................................... 4

4 Transport and initial commissioning ................................................................................ 5

5 Function description ........................................................................................................ 6

6 Fundamental notes on the work technique and handling ................................................ 6

7 Decommissioning ........................................................................................................... 7

8 Maintenance and care .................................................................................................... 7

9 Error detection ................................................................................................................ 9

10 Technical data ................................................................................................................ 9

11 Service .......................................................................................................................... 10

1 Conformity

This machine was built in conformity with the following EU guidelines:

Machinery directive 2006/42/ EG

See the labeling on the machine

Page 3

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 3

Version: 0711

ET 572

Page 3 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

2 Safety instructions

Safety instructions and important explanations, are labeled with the following pictograms.

The symbols used in the operating instructions have the following meaning:

Symbol Signal word Meaning

Warning notice

Warning of possible injuries to persons or

possible damage to property

Warning of possible defects or destruction

of the machine

Prohibition

Indicates

general

Prohibitions!

Warning notice

Risk of fingers being crushed!

Prohibition

Protect from moisture!

Read all these instructions before using the stapler and keep the safety instructions in a safe place.

Safety on the well.

The operating personnel must be trained in the handling of the stapler and they must have fully read

and understood the operating instruction.

To avoid injury or damage, the operator must additionally observe the company's internal safety

guidelines!

In addition, we would like to refer to further national rules and safety provisions which are not

contained in this manual.

Keep persons who are not instructed, especially children, away from the machine

and from your work area!

If damage to the stapler is determined by the operator during production, the machine may no longer

be used and must be repaired by a professional!

Only original parts may be used as spare parts!

Page 4

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 4

Version: 0711

ET 572

Page 4 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

3 Intended use

The machine is only to be used as intended. It may only be used, operated and maintained according

to the information contained in this operating manual.

Only materials and staples defined for this machine may be used, as this could otherwise lead

to malfunctions. The stapling machine may only be used as specifically described in this

operating manual. Any other application is only permitted after a prior written approval from the

manufacturer.

Any other usage is not regarded as intended use and can lead to damage to persons or property. The

operator of the machine is solely liable for damages deriving from any non-intended use.

The operator must ensure that the stapling machine is only operated as intended and that all types of

hazards to life and health for the user or third parties are avoided. In addition, a compliance with the

accident prevention regulations and other safety regulations and laws must be observed.

If the stapler is abused for purposes other than the specified usage scenarios, this

can lead to accidents

3.1 Application area/designated use

Pneumatic blind stapler TOP SP P and TOP B P are used for stapling filled folding boxes made of

single and double corrugated cardboard. The TOP blind staplers are also available as manually

operated machines (single and two-handed). The TOP staple to be used is selected for the respective

cardboard quality. The staple should be bent within and the lowest cardboard layer without puncturing

it. This prevents a damaging of the packaged goods. If there is no danger of damaging the packaged

goods it is also possible to perform a stapling through all layers, meaning that the staple is bent over

outside of the lowest cardboard layer.

TOP SP P

(TOP SPECIAL - labeled on the machine with TOP SP) is primarily used for applications

involving double corrugated cardboard. The correct staple for this is the TOP SP 18. But to be able

to also staple single corrugated cardboard, TOP SP 11 staples can be used without making

changes to the machine.

TOP B P

(labeled on the machine with TOP B) is primarily used for applications involving single

corrugated cardboard. For this, the following staples varieties with different leg lengths are available:

TOP B 10, TOP B 12.

But to be able to also staple double corrugated cardboard, TOP SP 15 staples can be used without

making changes to the machine.

Page 5

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 5

Version: 0711

ET 572

Page 5 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

With the TOP blind stapler a bottom stapling of empty boxes is also possible. The machine is hereby

introduced into the empty box and stapled from the inside outwards, or the empty carton is placed over

a buck and stapled from the outside inwards. After the empty carton is filled and the top stapled, the

bottom side can also be stapled just like the top after turning it over.

3.2 Ambient conditions

The machine should be operated at room temperature, protected against environmental influences.

Use within an explosive atmosphere is permitted only with prior consent and written permission of the

manufacturer.

3.3 Operating personnel

Only trained and knowledgeable staff is permitted to operate the machine.

Note: Competent, is someone who based on his training and experience has sufficient knowledge in

the field of stapling machines and is familiar with the relevant government industrial safety regulations,

accident prevention regulations and the generally accepted rules of technology (e.g. DIN standards,

VDE regulations) to the extent that he can assess the secure state of machines and in particular the

state of stapling machines.

4 Transport and initial commissioning

The stapling machine is delivered completely assembled and can be transported as a whole.

Transportation equipment can also be used for transporting the machine.

Before the stapler is put into operation, please read all instructions in this manual. This stapling

machine may only be put into operation by trained personnel.

To make the stapler ready for operation after delivery, the following tasks must be carried out:

- Check the equipment for completeness

- Insert the staples.

-

Connect the pressurized air and set it to 4 (min.) – 6 bar (max.)

The stapler is delivered ready for operation.

When the stapling machine is ready for operation, it is prohibited to touch the

stapling ejection opening or the running stapler! DANGER OFINJURY!

Oxygen or combustible gases may not be used as a propulsion source for pressure

driven machines.

Page 6

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 6

Version: 0711

ET 572

Page 6 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

The machine should only be operated with an

interstaged maintenance unit (filter, water extractor, oil

vaporizer, manometer; not contained within the scope

of delivery) since dirt and water in the pressurized air

can lead to damages. We recommend suspending the

stapling machine on a balancer (weight equalization),

for example, the B 2/4. A spiral compressed air hose

DS 75 is used to supply the compressed air.

5 Functionality description

The machine is placed on the cardboard box to be stapled and then triggered. The

trigger time should not be less than 0.5 seconds, since this could otherwise lead to

malfunctions. The staple is hereby ejected from the staple opening and penetrates the

box, where it is bent and anchored.

The machine may only be lifted from the cardboard box after the

staple has been bent in the box meaning that the staple has

completely been ejected from the machine, since this could

otherwise lead to malfunctions.

The stapling will be more rigid if the machine is pressed onto

the cardboard box harder. The nose and the two markings on

the head piece to serve as a guide and mark the ejection point

of the staple. The machine should be pressed onto the

cardboard box in a slightly top-heavy way.

The penetration depth of the staples is determined by the

respective staple type. It is not intended for adjustments to be

made on the machine.

6 Fundamental notes on the work technique and handling

Before the operator starts to use the machine he must acquire information about the application

scenario and check if the machine is suitable for it.

Carefully follow all safety instructions!

Check to make sure that the stapling machines are not damaged and that they can

be operated in a safe way.

The operating safety of the stapling machine must be checked before starting the work and constantly

rechecked!

Safety devices may not be bypassed or rendered ineffective!

Keep your work area in order.

Disorder in the work area can cause accidents.

• Use only ORIGINAL TOP staples that are made specifically for this quality equipment. Third-party

staples can cause considerable damage and malfunctions.

B 2/4

DS 75

Nose trigger

Page 7

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 7

Version: 0711

ET 572

Page 7 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

• Never perform a stapling without cardboard. Only lift the machine from the cardboard box after the

stapling process has been completed.

• Do not staple on a hard underlay.

• Should a staple failure arise, correct it immediately and do not trigger any further stapling.

• Shut down the machine after use. If possible, the TOP blind stapler should be suspended over the

packaging center. Available accessories:

B 2/4 Balancer (weight equalization) with a swivelling load hook

DS DS 75 spiral compressed air hose with an extended length of 7.5 m

W/EINH maintenance unit consisting of a pressure regulator, water separator and an oil vaporizer

• Periodically clean the cardboard dust from the TOP blind stapler - preferably with a blowgun.

7 Decommissioning

If the unit is not used for a prolonged period of time, disconnect the air supply and extract the staples.

Notice of residual risks

Protect the machine from moisture!

Do not operate the machine in a humid environment!

Only operate the machine within buildings!

Compressed air connections should be checked regularly.

When working on pressurized air connections and hoses the stapler must be

depressurized.

8 Maintenance and care

The stapling machine does not require a great deal of care, but should be cleaned and maintained on a

regular basis. Soiling should be removed directly by the operator after the machining processes.

Any alterations to the stapling machine especially to the safety equipment - are

prohibited!

Page 8

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 8

Version: 0711

ET 572

Page 8 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

Before the start of all major maintenance and cleaning, all safety precautions must be taken and the

pressurized air supply must be switched off and disconnected.

The following work processes/inspections should be performed by knowledgeable personnel on a

regular basis:

• Regular cleaning of the stapling machine

• Regular oiling of the movable parts (no graphite oil!) - on a weekly basis

• Check the maintenance unit for condensation. If necessary remove the condensation.

• The maintenance unit should be set to 1 drop of oil per 30 stapling cycles. (1/8 turn)

• In case of sluggishness or blockage of the driver, loosen the screws (57 and 58) on the head piece

(51) thus releasing any possibly present stress in head-piece and then tighten these screws firmly

again.

• Cleaning of cardboard dust

Only ORIGINAL spare parts may be used. (see “spare parts list”)

Failure to comply will void any guarantee claim and exclude any liability!

Only original spare parts are subjected to our quality control. To ensure a safe and reliable operation,

only spare parts from the manufacturer may be used.

All technical equipment, especially the safety equipment, must be inspected by professional staff after

a modification or repair.

8.1 Reloading of TOP staples

Pull the transport puck (9) back and upwards until it snaps in. After

inserting the 3 staple strips (120 staples) gently press down the

transport puck (excessive force will cause a rupture of the transport

bands and a breaking of the staple strips) and bring it into a tensioned

position.

09

57 51

58

Page 9

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 9

Version: 0711

ET 572

Page 9 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

9 Error detection

During any kind of defect, the machine is to be shut down and separated from the

pressurized air supply until the flawless operation is ensured again. Please do not

try to dismantle or repair the machine.

9.1 Removing jammed staples

If there is a malfunction or staples are jammed proceed as described in the following.

In the event of a malfunction, which is more extensive than just some jammed

staples, please contact us. The machine will be examined by our specialists

and the malfunction will be remedied.

• Interrupt the air supply.

• Remove any staples still present in the staple repository.

• Remove the two screws (12) and extract the

staple repository (03)

• Remove all the staples from the unit and clean

the machine from dirt and debris.

• After the staples have been removed, the repository is to be

inserted again.

• Reconnect the air supply.

10 Technical Data

Machine: TOP SP P, TOP B P

Air pressure during the stapling process: 4 to 6 bar, cylinder max. 7 bar

Air consumption during the stapling: 0.48-0.72 NL/stapling

Stapling speed approx. 0.2 s/stapling

Weight without the staples approx. 2.9 kg

Length x Width x Height 350mm x 85 mm x 188 mm

Air supply connection: 6mm = ¼”

Staple for TOP SP P TOP SP 11, TOP SP 18

Staple for TOP B P TOP B 10, 12 und TOP B 15

Capacity: 120 staples

Noise emission: < 70 dB(A)

12

03

Page 10

USER GUIDE

Pneumatic Blind Stapler

TOP SP P, TOP B P

Page: 10

Version: 0711

ET 572

Page 10 of 10 18.10.11 P:\Technik\TOP\Bedienungsanleitung\Englisch\Operation Instructions TOP P 0711.DOC

10.1

Versions

Blind stapler TOP SP P

for staples TOP SP 11 and TOP SP 18

Blind stapler TOP B P

for staples TOP B 10, 12 and 15

11 Service

Repairs performed by:

MEZGER Heftsysteme GmbH

Saganer Straße 24

90475 Nürnberg

Germany

or

authorized professional companies

Damages which are caused in particular by natural wear and tear, overloading, misuse or damage

caused by the user or other use contrary to the operating instructions will be excluded from the

warranty.

Keep the operating instructions, safety instructions, parts list and proof of purchase in a safe place.

TOP SPECIAL TOP B

Loading...

Loading...