Page 1

The MG Car Company and Its Brethren

First off it's important to announce the meaning of the MG logo.

MG stands for Morris Garages. These being named after

William Morris, who was later created as Lord Nuffield. The

marque was first used in 1924 in a bull nosed sports car, now

affectionately name Old Number One. This formed the basis of

the MG Car Company, with Lord Nuffield at its head. In 1922

management of the MG Car Company was taken over by Cecil

Kimber. Kimber was an avid motor sports enthusiast and is also

credited for introducing the classic radiator style recognizable

on so many cars such as the T-Series MG's.

The Nuffield Organization not only owned the MG Car C

but a number of other marques as well, often competing

MG over the years. These included Morris and Riley. At times it

seemed that MG could never get the resources they ne

become world leaders in the marketplace. Not only were they competing with

the likes of Triumph and Austin, but the real battle seemed to go on internally

in the Nuffield Organization. This continued right through the merger of

Nuffield and Austin in 1952 which formed the British Motor Company (BMC)

MG's were produced in

production ceased in 1980. Other cars from the Nuffield organization were

also produced at Abingdon during the years and vied for precious resources.

Abingdon, England from the early 1930's until

ompan

with

eded to

y

.

The MG T-Series

Page 2

In 1936 the MG Car Company made a dramatic change in the design of their

sports cars. In this year they introduced the MGTA Midget. The MGTA

originated the familiar T-Series design element and to the casual observer, it

is hard to distinquish from the MGTC. The MGTA sported the famous radiator

design, the swept wings, running boards, folding windscreen, and large

accessible bonnet. It was a two seater sports car with a foldable hood and

side curtains. Just over 3,000 MGTA's were produced in three years of

production. The MGTA suffered from a poor performing engine and in 1939

the MGTB was introduced with the now famous XPAG engine. Only a few

were produced as in a few months World War II broke out.

During World War II production of MG's ceased as the MG Car Company was

put into service for the war effort making tanks and airplane parts, and other

military items. When the war end

get back to making sports cars. They revisited the MGTB and made a few

subtle changes. These were in the form of a wider body and shackles

replacing sliding trunnions for the spring mounts. The Nuffield Organization

also made another drastic change. They started taking an active interest in

selling their sports cars in North America. It appears that during the War a

number of American GI's had an opportunity to experience the T-Series MG's.

When the War ended a number of these cars were imported and then formally

sold into North America, especially the United States. The MGTC was

produced from 1945 to 1949 with a total production of about 10,000 cars.

ed the the MG Car Company was anxious to

Due to the fact that the United States had much more cash available to spend

on entertainment and sports than did war torn Britain, the Nuffield

Organization made a drastic change in their marketing, focusing on North

America. In 1949 the MGTC was fitted with many elements to make it more

North American such as front and rear bumpers, twin horns, and dual tail

lamps. Even by making these changes only a fraction of the MGTC's were

imported into North America. There were still too many issues with a car of

this type for different North America conditions. Amongst those were driving

on the right hand side of the road rather than the left, more high speed

maneuvers such as freeways, a softer ride, and some additional c

comforts. What was needed was a total redesign of the MGTC if the MG Car

Company was to capture a significant portion of the North American market.

What was missing was a total commitment from the Nuffield Organization to

do so.

reature

Page 3

The Legacy of the MGTD

In 1949 a small group of MG leaders, headed by John Thornley, got together

to try to create a car that was acceptable to the North American marketplace

while at the same time would limit the investment of the Nuffield Organization.

Clearly it would be impossible to completely create a new car, not only from a

financial point but from a timing standpoint as well. What was needed was a

little of the old, sprinkled with a little of the new. Another key factor was to

Page 4

borrow or incorporate features found in other Nuffield cars of the time that

were more up to date than the MGTC.

First it was decided to start with the MGTC. It was felt that the MGTC still

provided a favorable brand image to the North American marketplace. Many

elements of the MGTC were still believed to be important such as:

• The styling

• Safety Fast engineering

• The powertrain

• The familiarity of design

What was missing was:

• More futuristic styling

• Better turning and handling

• A smoother ride

• Left hand drive

• More creature comforts such as an optional heater and radio

Quickly a team of MG personnel took inventory of the components of the

Nuffield Organization that they had to work with. They discarded the TC's

frame because it was to light and not rigid enough. They found what they

wanted in the Y types. A small modification to the frame was to have it sweep

over the rear axle rather than under. This gave them more travel in the rear

springs so they could increase the damping. In addition they adopted rack and

pinion steering and front coil springs and wishbones. This and the change in

rear end suspension allowed for a smoother ride and better handling than the

MGTC. One of the major changes was to reduce the wheel size from 19

inches to 15 inches and increase the tire width to 5.50. All of these changes

made the MGTD a superior riding car over the MGTC.

Because of the use of the larger frame the body became 5 inches wider.

Although the body increased by 5 inches, only one inch actually found it's way

into the cockpit so there is an indiscernible difference in the seating width. The

biggest change that people notice about the MGTD from the MGTC is the lack

of wire wheels. As part of the Nuffield cost cutting challenge the more

expensiv

e wire wheels of former T-Series cars were replaced by solid steel

wheels. For the entire production run of the MGTD the factory took heat for

this decision. They constantly tried to create implausible technical reasons

why wire wheels would not work but their reasons were never accepted by the

marketplace. In fact wire wheels were one of the most popular aftermarket

accessories at the time. Nuffield itself had to offer an upgrade kit to wire

wheels during 1953 because the essentially identical 1954 MGTF chassis

sported wire wheels as an option.

Other changes between the MGTC and the MGTD were more styli

zed wings,

partially due to the smaller wheels. A dual production capable LHD or RHD

model, better brakes, adjustable steering column, and an interchangeable

dashboard for left or right hand driving were also incorporated. An optional

Page 5

radio and heater, as well as many accessories designed to improve the

performance of the car were made available.

The MGTD Models

The MGTD was produced from 1949 to August of 1953. During that period the

MGTD saw many subtle changes, but nothing drastic. See the pages on

production

was offered in three basic models although no more than two were ever

available at one time.

for details on the changes of the MGTD over the years. The MGTD

TD

The original MGTD was first produced in late 1949 and had it's formal

introduction in January of 1950. There were a total of four model years; 1950,

1951, 1952, and 1953. The first model set the stage for what the MGTD was.

Because of the short amount of time from the inception of the MGTD to the

delivery of the first cars, not everything was quite as the MG Car Company

would have liked it. In fact they were still making MGTC's on the production

line when the first MGTD's were produced. Other models were also being

made on the same assembly line at the same time. This says something of

the flexibility of the Abingdon work crews and factory.

Most changes to these early MGTD's were unnoticeable from the untrained

eye. One exception to this was the change from solid wheels to slotted

wheels. Still steal and not wire, but a change nothing else. Most of this seems

to be precipitated from the fact that the brakes were fading due to poor

cooling. Another change was to stiffen the body by adding an internal under

firewall tubular frame. It helped but the MGTD body bucket still seems to flex

quite a bit when pressed into corners.

TD II

The TD II (not to be confused with the MGTD Mark II) was essentially more

refinements done to the car by the factory. Minor changes to the engine

generated the need to create a new engine type, the XPAG/TD2. This in turn

caused them to designate these cars as TD2's, although even their marketing

Page 6

materials never really mentioned this change. There really weren't any model

years for the MGTD, as changes were introduced subtly. The biggest changes

occurred during the 1953 model year as sales of the MGTD started to fall in

favor of cars like the TR2 and Healey 100. In 1953 MG introduced round

taillamps (not sure what the feature of these were), turn signals, a three bow

top or hood, and moved the windscreen wiper motor central for safety

reasons.

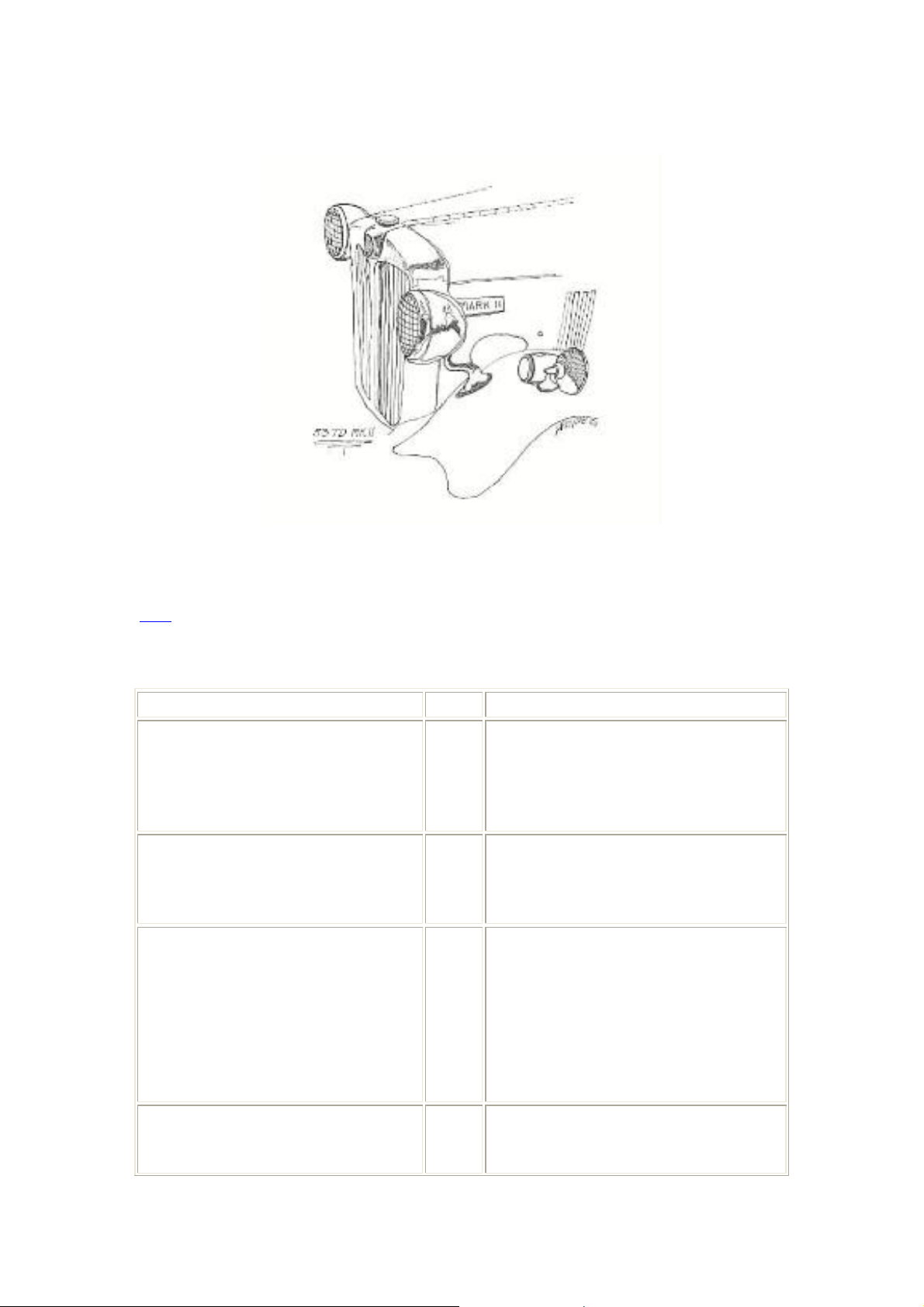

TD/C or TD Mark II

In the middle of 1950 model year the MG Car Company began factory

producing some special MGTD's known as the Mark II. These cars were

essentially regular MGTD's that had been given some extra factory

accessories and tuning. There was not an exact list of these features, and in

fact over the production of the MGTD the features of the Mark II would

change. It was also possible at the time to buy everything for a regular MGTD

that the Mark II model offered. Some of the changes were to increase the

base horsepower of the engine from 54 bhp to 57 bhp, larger tires, additional

Andrex friction shocks front and back, higher rear end ratios, dual fuel pumps,

and larger carburetors. Most of the features of the Mark II were a part of the

staged tuning that was described in various publications and offered as a

factory tuning manual.

From all these changes it appeared that little changed in how the car actually

handled. Many folks opted to buy a regular MGTD and go through a series of

Stage Tunings to increase the performance of the MGTD well above what the

Mark II achieved.

Page 7

The Follow-on of the MGTD

Production of the MGTD peaked in 1952 and 1953 found sales of the car

starting to fall. Again the MG Car Company found itself in need of a whole

new automobile but without the support of the parent BMC Organization.

The MG EX175

John Thornley's team at Abingdon had crafted a complete replacement for the

MGTD code named the EX175. Because of the organizational changes that

occurred when BMC took control of the MG Car Company, the EX175 was in

direct competition to it's new step cousin, the Austin-Healey 100. Since the

Healey was already committed, BMC did not want a new fangled MG to dilute

the possible sales so MG was left high and dry without a replacement for the

MGTD.

MGTF, MGTF 1500 and MGA

An effort to recapture the marketplace by doing what they had successfully

done before was attempted in 1953. Borrowing on the success of the MGTD

and Mark II as well as a little streamlining of the body, the MG Car Company

created the MGTF. The TF was immediately shunned by the public. It was

clear that all MG had done was to pound a bit on the body and fenders, add

some more comfortable bucket seats, and throw on some wire wheels. In fact

the car was worse in many ways because you could not easily get to the

engine to modify it or maintain it like you could on prior T types. The TF 1200

still performed poorly compared to other sports cars of the period. In 1955 MG

came out with a more powerful 1500 cc engine that replaced the tiring 1250

cc engine of past T Series cars.

Finish information on the MGTF can be found at this page

information on the MGTF please see these pages.

This larger capacity engine did improve the performance greatly and made

the MGTF 1500 a much better performing car on the freeways and tollways of

North America. Still the MGTF never captured the success of the MGTD and

was replaced by the MGA within two short years.

The MGA represented a significant change from the T-Series cars and

actually looked like it belonged to the era it w

much of the same chassis and drive train features as the MGTF but had an all

new streamlined body. Interestingly the car had a remarkable resemblance to

the EX175. Over time MG would make many changes to the MGA in both

styling, performance and handling. At one point they even offered a hard top,

called the MGA Coupe as well as a twin cam engine.

as produced in. It supported

. For more

Page 8

This section covers the finishes of the MGTD in type, material, and colors.

Note: It is generally not considered a deviation from the original if you

improve the finish of an item so long as you do not change the texture or

characteristic of that item.

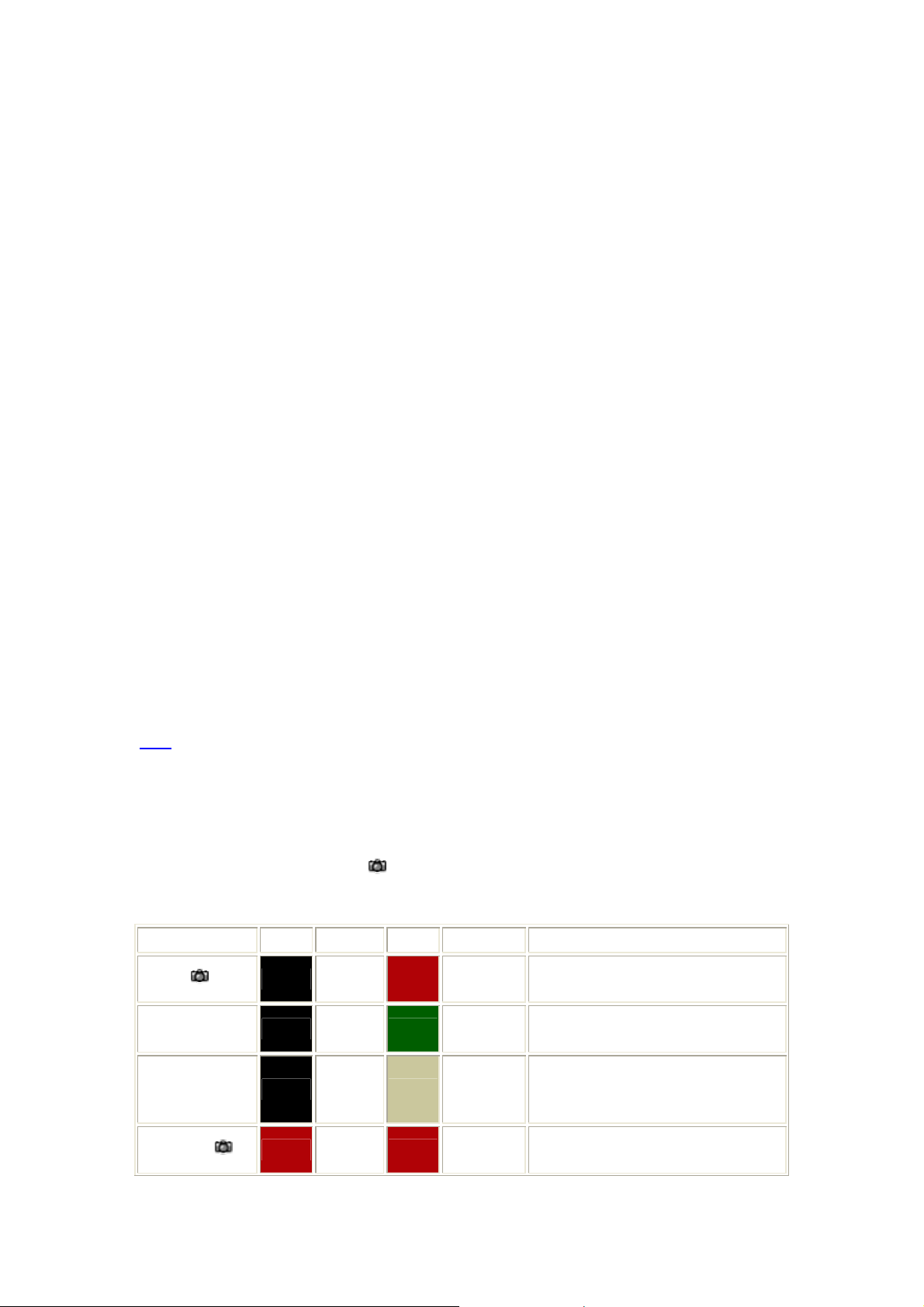

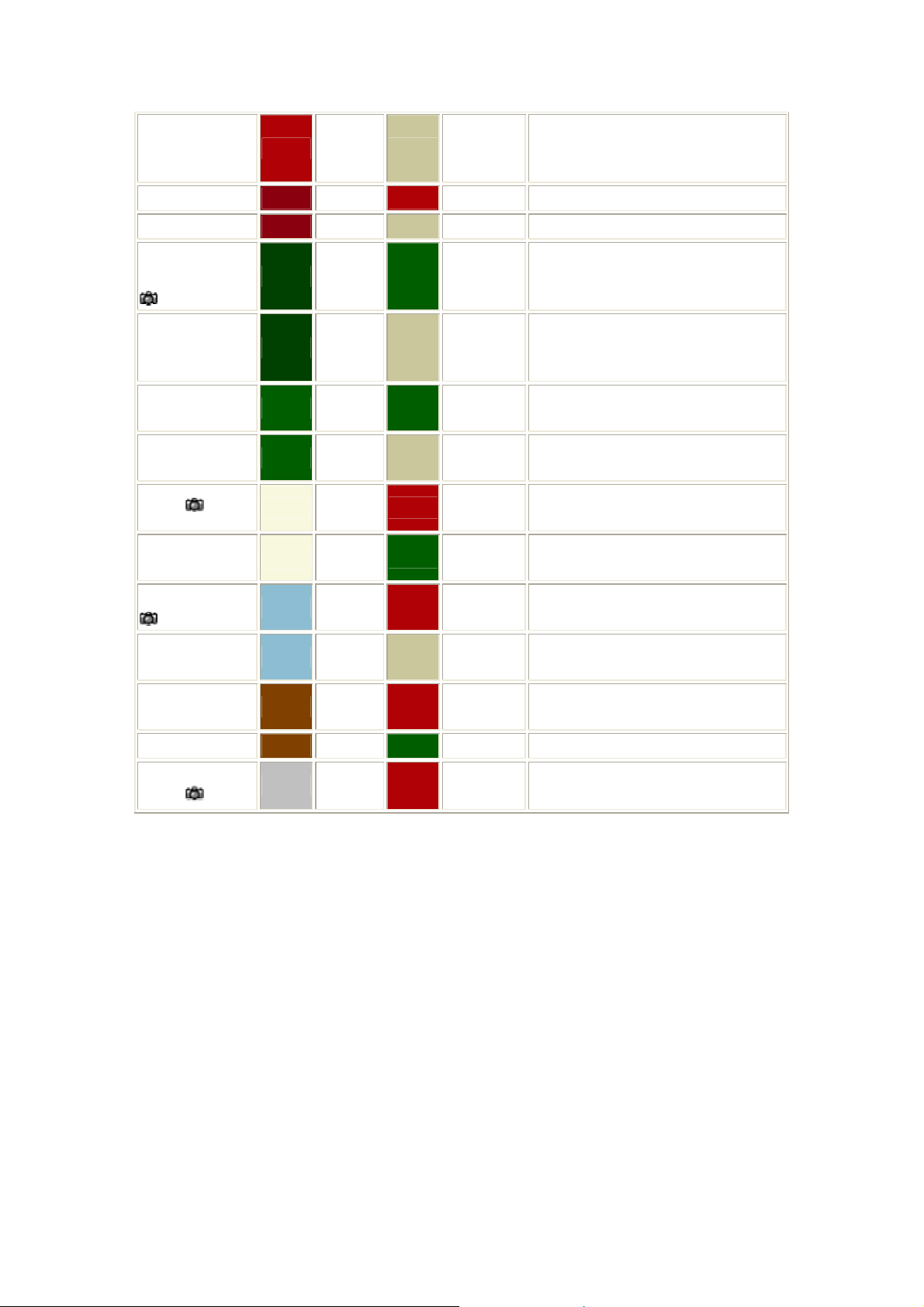

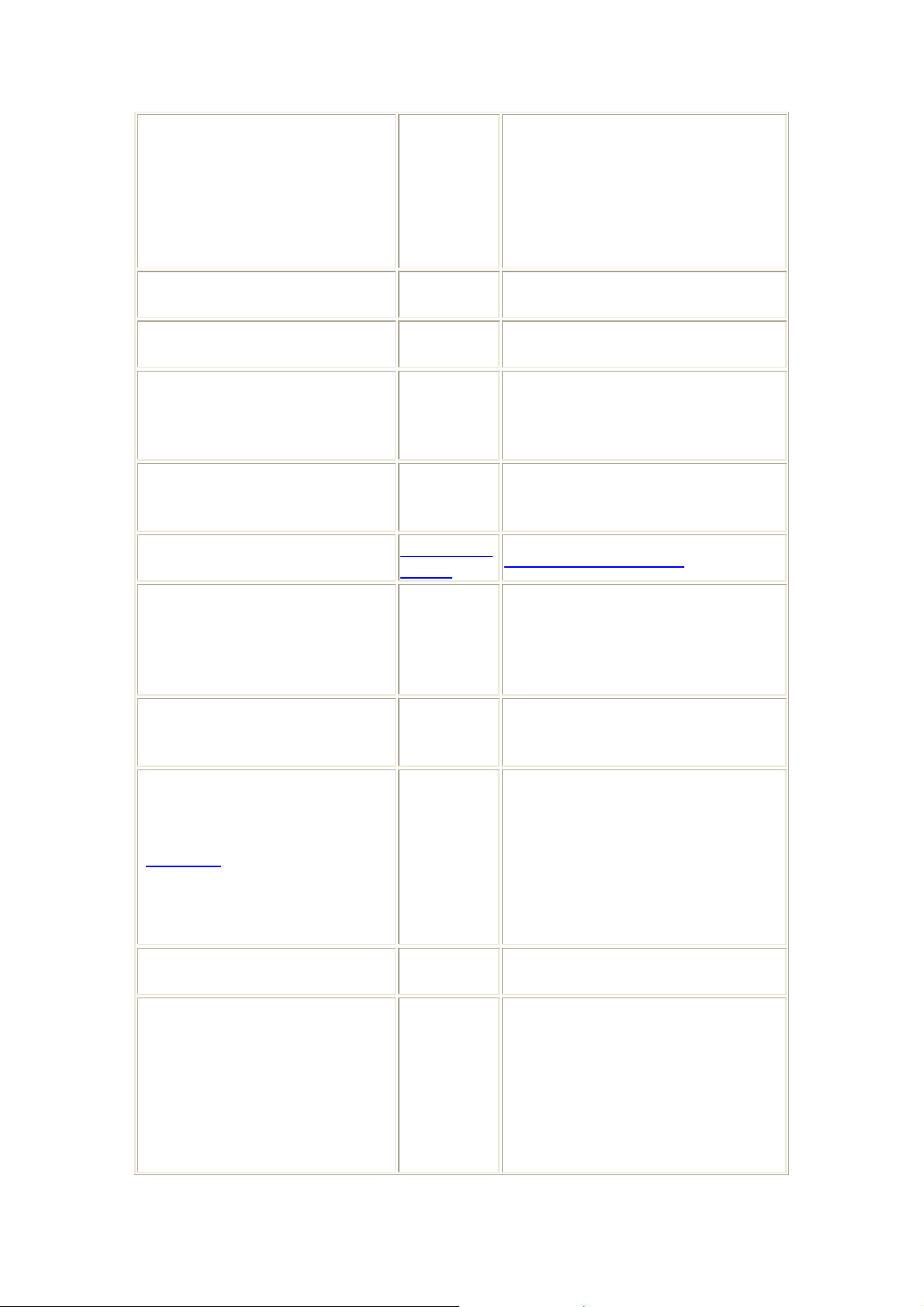

MGTD Color Schemes

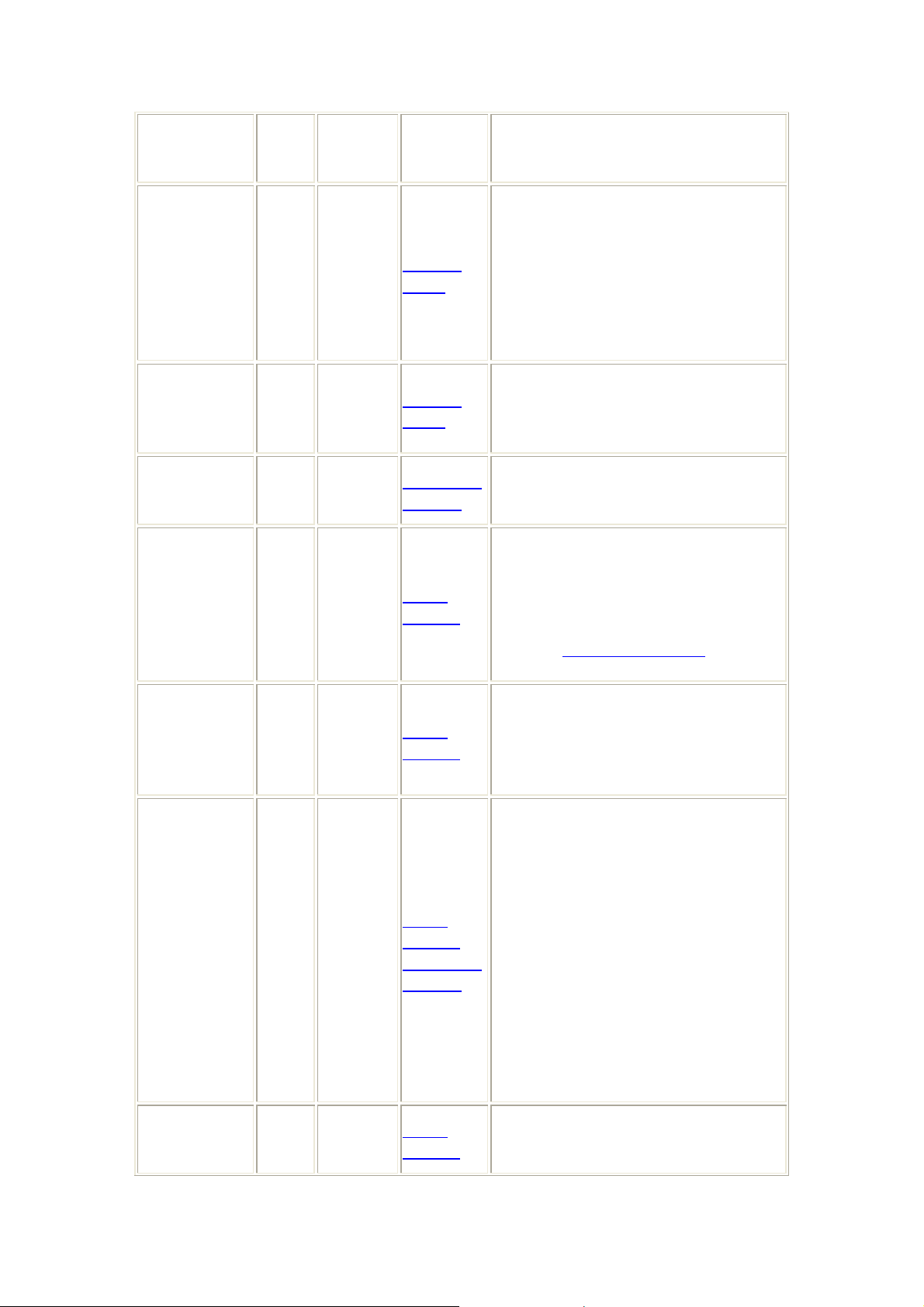

Top

The table below shows all the body and interior colors available during the

production of the MGTD. The radiator grill slats generally matched the interior

color.

Note: You may click on the

from an original brochure.

Body Color Interior Color Dates¹ Comments

Black

Green

Beige

MG Red

Red

Red

image to see a sample of this color scheme

19491953

19491953

19491951,

1953²

19491953

Page 9

1949-

Beige

Autumn Red Red 1951

Beige 1951

1951,

1953²

On red and green cars the grill

color for tan interiors could be

either tan or the body color.

Woodland

Green-BRG

Beige

Almond

Green

Beige

Ivory

Green

Clipper Blue

Beige

Sunburst

Bronze

Green

Green 1951

Red

Red ?

Red 1951 Metallic

19491953

19491951,

1953²

19491951

19491953

19491953

19491951

On red and green cars the grill

color for tan interiors could be

either tan or the body color.

Replaced by Silver Streak

Grey

Green 1951 Metallic

Silver Streak

Grey

¹ Date information used with permission from Original MG T Series by Anders

Clausager. Published by MBI Publishing Company 1-800-826-6600.

² Only on non exported cars.

Note: The colors in this table are approximate. Due to the nature of each

computer display and the limits of the color pallet of your system, there may

be a large difference between these colors and the actual production colors.

Note: Apparently MG did not have strict formulas or consistent suppliers for

their finishes, so even during the production of the T-Series there would be

large discrepancies between cars of the same color. The cars were also not

documented with their color on an ID plate. This practice did not start until the

MGTF model in late 1953.

Red

19521953

Metallic. Replaced Clipper

Blue

Page 10

Note: CKD cars were delivered with primer only. This was also available as

A

A

y

0

6

0

an orderable option so any paint color is original on one of these cars.

Note:The exterior piping (cord filled fabric material between sheet metal

parts) color matched the body paint color.

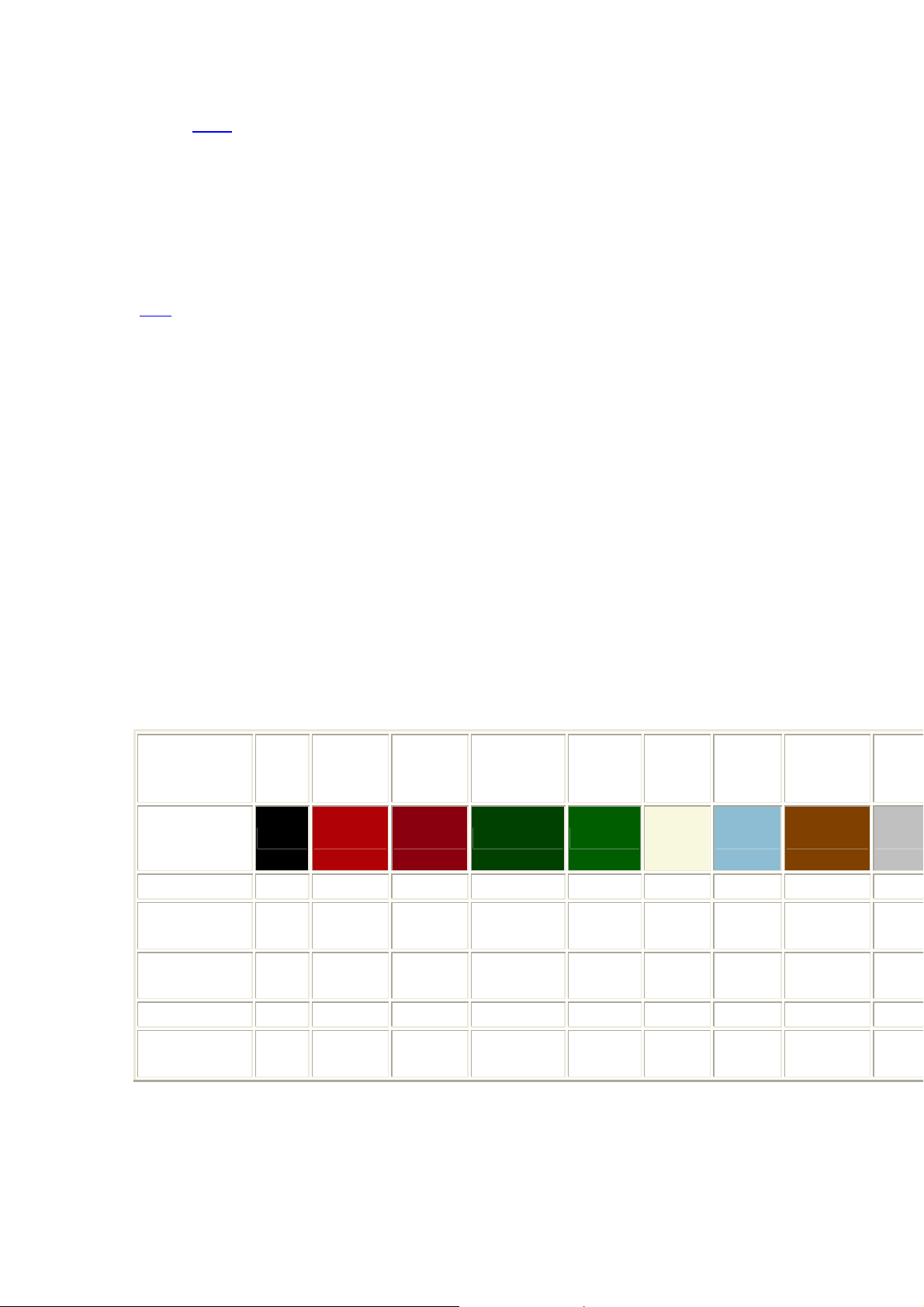

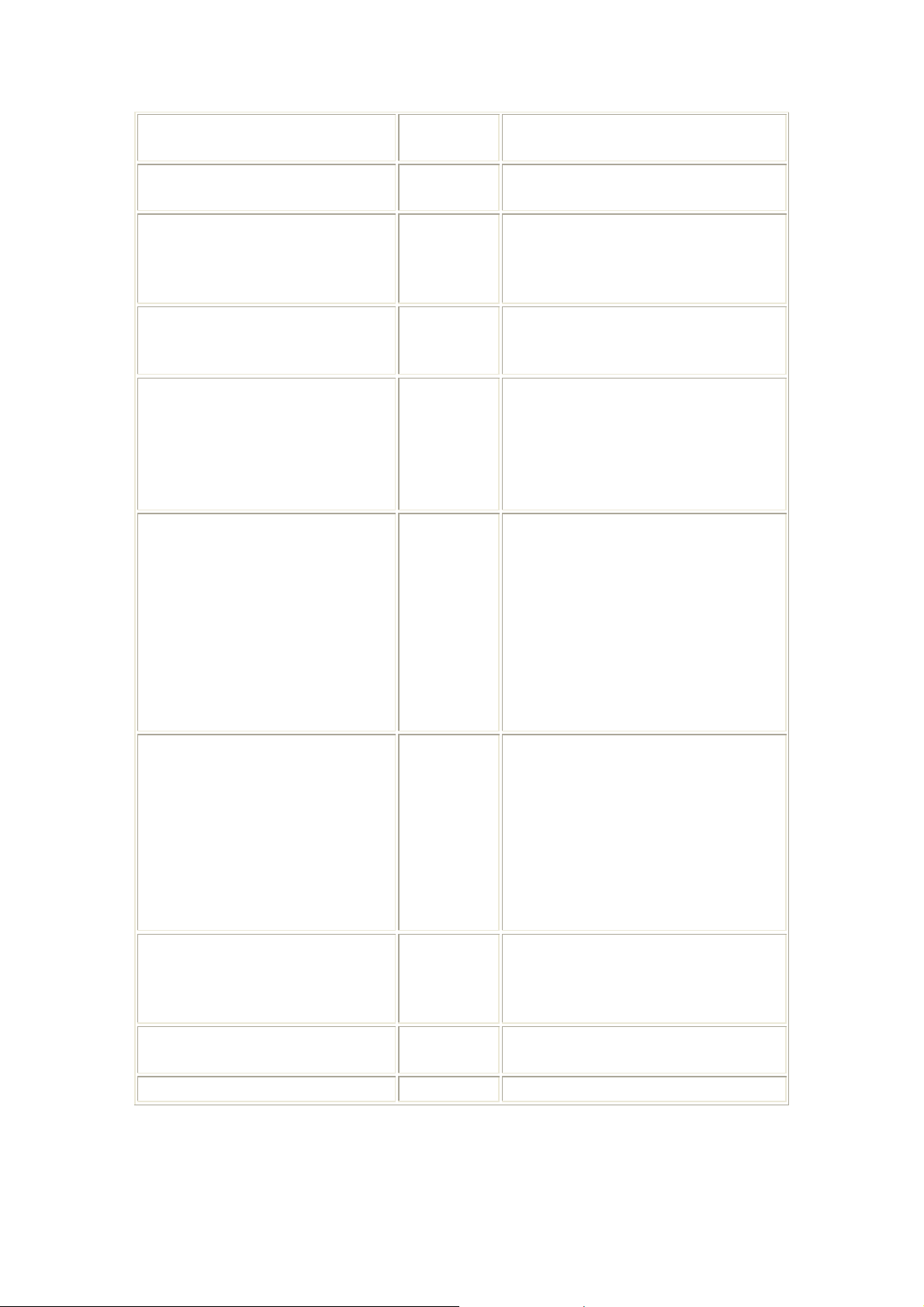

Paint Formulas

Top

Body Colors

This table provides a list of formulas or color equivalents to the original colors

used for the MGTD. As always you should have a quart (or gallon) of paint

mixed first and spray it on a large piece of sheet metal before you decide what

color you like. Even better is to get a few quarts of paint and give your car a

quick paint job before restoration to make sure you like the color. When you

are satisfied with the color choice then you can strip all the paint off and start

over. Sounds crazy, but at least you will like the results.

If you have a car that has never been stripped of its' paint you may be able to

tell what color it was originally by taking off a fender and looking at the area

that rested against the body bucket. I was not only able to do that but after the

use of a little rubbing c

areas that a color match was done after 25 years of service. The color was

compared to other cars painted the same color to insure that I had a

reasonable match.

ompound the paint was in good enough shape in those

Manufacture Black MG Red

Color

BMC Code

Dupont

Ditzler

(PPG)

R&M

Martin-

Senour

Note: The colors in this table are approximate. Due to the nature of each

computer display and the limits of the color pallet of your system, there may

be a large difference between these colors and the actual production colors.

BK1 RD14 RD6 GN29 GN37 YL5 BU14 N/A GR25

99

9000 71993 50930

A946 BM121R BM108R BM078 BM076 BM127 BM042 BM02

25011 20216 20561(?) 20214

utumn

Red

9383450H

Woodland

Green

93-98249

6606

2246

43342

lmond

Green

9396233H

44159 81271 12297 23662

Ivory

83449

25235

23235?

Clipper

Blue

9325888

25286 2528

Sunburst

Bronze

Silve

Strea

Gre

7203

3367

Page 11

Note: Match red or green grills with body color. When body is not red or green

o

e

then use MG Red or Almond Green as appropriate.

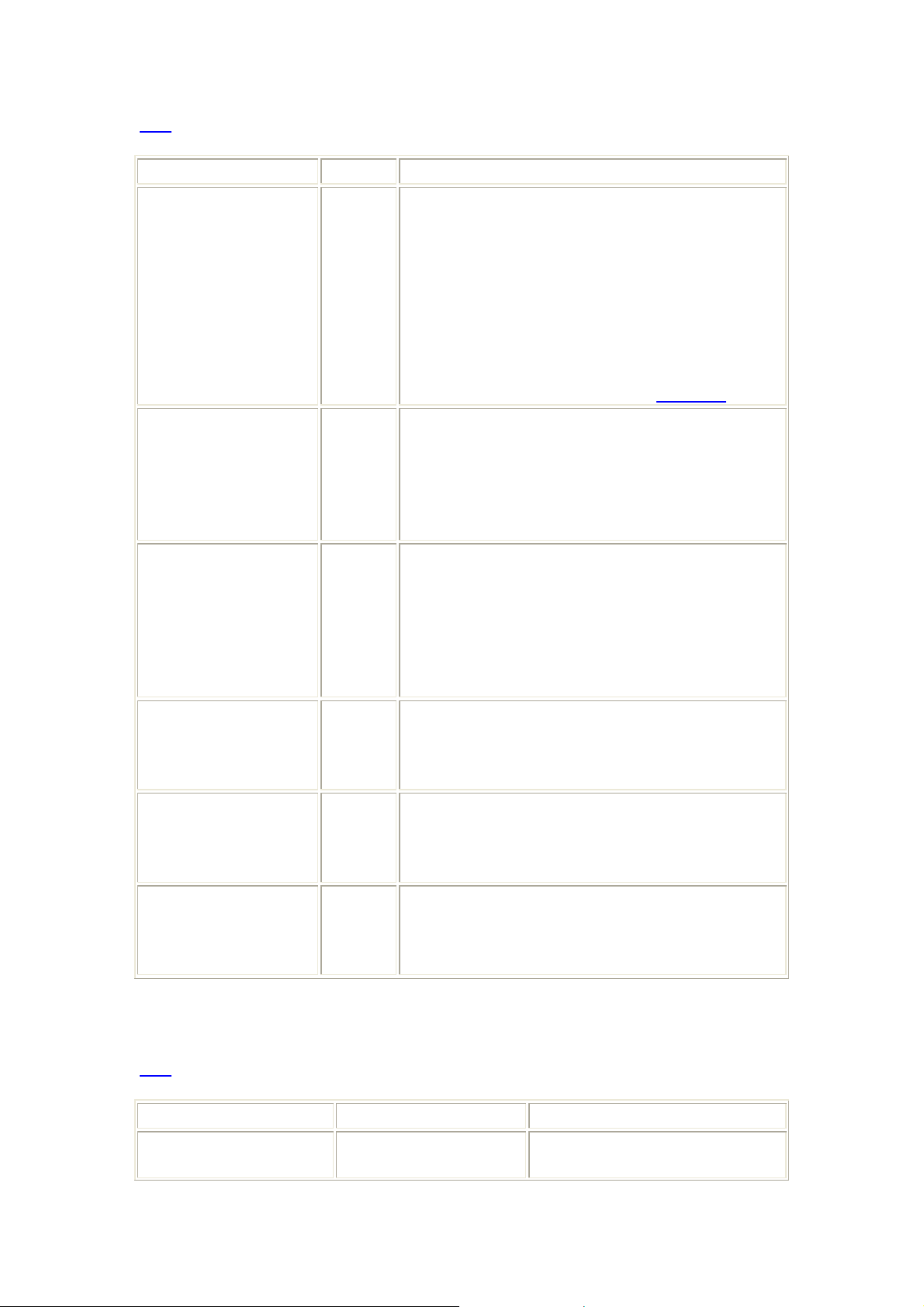

Miscellaneous Colors

This table provides colors for the non body components of the MGTD.

Note: Many of the colors in this table are approximate and not absolute. But

then again, even in the production of the MGTD non of the colors were

absolute either, so these are all reasonable choices.

Manufacture Chassis

Engine /

Transmission²

Hood

Sidecurtain

Frame

Instrument

Panel

(metallic)

2,3

Oil Filter

Early

Color

Dupont

Ditzler

R&M

99¹ 57597H 44371 43107LH 43094L

9000 50930

A946 AC402 BM145 M63-64 FM130

¹ I like to use Dupont Imron due to it's superior finish and longevity. The

original finish on the chassis parts was a semi gloss enamel.

² Close engine and instrument panel (220-530) paint colors can be obtained

from such suppliers as Moss Motors.

3

I believe that the TD instrument panel was the same darker color as the late

oil filter canister. The popular color is widely accepted to be the same as the

TF instrument panel. The paint supplied by Moss Motors is lighter than

original for the MGTD.

Tecalemit

Oil Filter

(metallic)

Purolat

Oil Filt

3

(metalli

4

The color of the valve cover is controversial. Generally it is most widely

accepted to be the same as the wheels, a metallic gray. Other evidence

suggests that it is a pale green/gray non metallic as shown. This is the same

color that early TC engines and firewalls were painted. I like to use a metallic

soft green/gray paint which is a good compromise and believed by some to be

correct also. This is also an acceptable color for the Purolator filter canister

although it was a bit darker in shade. There was a tendency to coat the valve

color with clear paint, after repainting it silver, that often turned greenish. For

this reason many feel that it was never greenish to begin with, but just silver.

Al Moss (who serviced TD's when new) reports that the valve cover and

wheels were originally painted with plain silver paint, non glossy. Similar to the

finish you would get out of a spray can today.

If you would like to see an unrestored TF valve cover then press here

. Care of

Don Harmer.

Page 12

5

This is an Imron color and the metallic effect is much stronger than original.

Sheet Metal Finishes

Top

The following table describes the finishes on the sheet metal of the MGTD.

Item Color Comment

Fenders, hood, front and rear

splash aprons, running boards,

firewall, fuel tank, fuel tank straps,

door hinges

Body

Color

Both sides of these items were

painted with the body color of the

car. The exception would be the

inside of the toolbox which was

black covered by an off-white felt.

Note that the fuel tank side panels

Fuel tank sides

Body

Color

had the edges chrome plated. Only

the interior of the outside finish was

painted the body color.

Body color on exterior finishes,

black on inside finishes. Note that

the black paint was not glossy but a

Body bucket, doors, tool box lid

(outside)

Body

Color

semigloss or satin finish. Used as a

protective coating more than a

shiny finish like the color coat. Note

that on some cars the inside of the

panels were painted the body color.

Scuttle, side curtain box, steering

wheel column and steering wheel

extruder plate, propeller shaft

Black

Page 13

tunnel, gearbox cover and plate,

hinge for seat back, sleeve for

seat hinge, rear cross brace

assembly (behind seat), crank

clips on seat back, inside of

toolbox.

Headlamp bodies, headlamp ring

retaining screw, King of the Road

medallion

Body

Color

Note that on early TD's (50 and 51)

the headlamp bodies were chrome

plated.

Engine and Transmission

Top

See the note on Gold Seal engines.

Item Color Comment

Engine block, head, tappet

inspection cover, water outlet

manifold, oil pan, timing chain

Engine

Red

This color was similar to MG red

but a little darker.

Page 14

cover, cradle, bearer plate,

transmission housing and

cover, oil pump housing, main

pulley, water pump, water

branch pipe, throttle return

spring clip, front motor mount

bracket

Breather pipe and clamp

Inlet manifold

Exhaust manifold, manifold

clamps

Engine stabilizer and bracket Black

Valve cover

Oil canister - old style Orange

Oil canister - newer style 1952

(Tecalemit) Part number

I62451

Engine

Red

Engine

Red

Aluminized

Light GrayGreen

Bronze

Some cars may have had this

painted black.

Some cars may have had this

painted black.

This is a spray of liquid aluminum

that gives the appearance of a

white, softly textured surface.

Very hard to keep clean.

Some like to cad plate the nuts

and expander but they were all

black.

See comments above

These were through away

elements. There is a decal that

went on these parts. Cast

element housings were an add

on.

A slightly darker color than the

instrument cluste

center color.

r/steering wheel

Oil canister - newer style 1952

(Purolator

I62429

Air cleaner, starter, generator

body, fan blades

Thermostat body, upper hose

elbow

) Part number

Used on some later cars. Noted

by the large attaching bolt and

Light

SilverGreen

Black

Black or

Engine

Red

capped plate at rear of the filter.

They had no identifying plate as

on the Tecalemit filters, but were

decorated with a decal naming

the company and listing the

maintenan

This is a controversial item. Many

believe that this was painted the

same color as the engine but

replaceme

Others believe that it was

assembled as a unit with the

radiator and therefore black. All

the pictures that I have are not

ce procedures.

nt parts were black.

Page 15

clear on this as they are in

shadow.

Generator fan/pulley, distance

piece

Engine block drain, oil drain,

engine ID plate

oil line - block to head

Carburetor parts: choke

coupler, jet links, springs,

couplings, anchor clips

Most carburetor parts (see

exceptions elsewhere), air

cleaner wing nut, transmission

dipstick cover wing nut,

carburetor overflow lines,

generator lubricator,

tachometer reduction gearbox,

crank handle, distributor body,

oil pressure gauge line and

brass coupling on firewall

Engine

Red

Natural

Brass

Engine

Red

Black

Natural

Most believe these to be red but

some claim they were black.

Some paint this the engine color.

The ID plate should be left natural

but on original cars the drains

were most likely painted red.

Many like to leave the brass ends

natural. Most likey all red from

factory.

Note that some of these parts

were blued and not painted black.

Bluing is a metal treatment that

has a black, transparent type of

look to it. It is very common on

firearms.

Many like to polish these

unfinished parts for an enriched

look.

Carburetors, fuel pump base

sections

Fuel pump and carburetor

fittings

Exhaust pipe bracket, clamp

and spacer on transmission

Gearbox remote linkage Natural

Natural

Aluminium

Natural

Black

Chassis

Polishing these items makes for a

very nice effect but was not

originally done. If you do polish

these parts it is recommend that

you spray the carburetor body

with a clear sealer because it will

be impossible to keep the polish

up after the carburetor is

assembled.

Brass parts left natural. Again

polishing and coating with a clear

paint will preserve the shine of

these parts.

Page 16

Top

Item Color Comment

It appears that the green and red were the

same as the red and green body colors. If you

do not have a red or green car, and your

interior is not tan, then choose the MG Red or

Radiator grill slats

Frame, suspension

parts, rear end,

brake drums, brake

lines, springs,

shocks and all

chassis parts.

Radiator

Interior

Color

Satin

(soft

mat)

Black

Satin

(soft

mat)

Black

Almond Green as the grill color appropriately.

The color that matched tan interior was a light

tan color. It is reported that on some red or

green cars with tan interiors, the grill slats

could be painted the body color.

Note See the comment on the Mark II's.

Note most people prefer to use a high gloss

paint for all the chassis parts in current

restorations because of its look and durability.

It is not recommended to finish the radiator

fins with a heavy based enamel. Optionally

you may first paint the fins with a heat based

(exhaust type) flat black finish and then paint

the rest of the radiator with a high gloss finish.

The original was paint

of satin gloss black paint.

ed with a very thin coat

Satin

Shock absorbers

Wheels Silver

Exhaust pipes,

exhaust pipe

brackets

(soft

mat)

Black

Black

Some late TD's with Armstrong shocks were

left unpainted for the body with the shock

arms painted black.

Al Moss reports that the valve cover and

wheels were originally painted with plain silver

paint, non glossy. Similar to the finish you

would get out of a spray can today.

Most today paint the exhaust system with

modern heat paint. Originally painted with

chassis paint which und

days.

oubtedly burnt off in

Woodwork

Top

Item Color Comment

Floorboards, shelf

behind seat

Black Made of mahogany plywood.

Page 17

Dash

Battery box underliner Black Made of mahogany plywood.

Covered in interior

cloth (Rexine)

Same material as seat backs

and door panels

Wooden panel behind

fuel tank

Note: All woodwork with the exception of the firewall mounting frame was

painted black. This was often oversprayed when the body was painted.

Black

Interior/Softgoods

Top

Item Color/Material Comment

Seat tops and

outside bottoms,

seat back face,

top of map pocket,

top of door piping

All door panels,

kick panels, seat

backs and rears,

boot area

Leather

vinyl cloth

(Rexine)

Died to match vinal cloth interior. Used

where wear and tear would be a factor.

Slightly textured precursor to vinyl. Note

that the wheel wells were padded with a

thin felt. Also on some cars the wooden

area that the spare tire bolts go through

received some light padding.

There was a small length of black vinal

that was tacked to the wood floor behind

the seats that covered the ends of the

wheel wells

over at both edges to form a ¾ inch wide

strip. It started in the back corner and

went forward over the edge. It then

turned the corner to the outside of the car

and terminated at the panel. It was

affixed to a small tack strip. The tack strip

is held to the wheel well by three small

rivets.

Also to note that the piping from the rear

at the hood tack strip, down under the

doors and along the dash top, was all

one piece. This material was similar to

the piping used on the fenders. At the

location of the door strikers the piping

was opened up and the spline was

removed to allow clearance for the door

striker. The striker underplates had holes

. This material was folded

Page 18

in them to allow for tacking the piping in

place. You will see a tacking hole in the

inner metal plate for the door latch to tack

the bead down.

On many cars the hidem that was used to

hide the tacks on the panels was in one

piece. This means that the panels were

put in place at one time as the hidem

continued from one panel to the next.

This is especially evident from the front

kick panel to the door sill panel.

The door panels, the panel under the

door, and the panel around the rear

wheel arch are a three ply plywood about

2-3 mm thick. The panel in front of the

doors is a about a 2 mm thick piece of

black cardboard so it will bend over the

"scuttle" hoop. Besides being tacked on

around the door, there are two small

chromed wood screws with finish

washers at the front to hold the front

panel on.

The hidem is one continuous piece from

the door latch to where the rear panel

and the panel below the door meet.

There is a short piece of hidem from the

door latch to the top of the front pannel.

The rear pannel's hidem is sewn on also,

but it is not contiuous with the hidem of

the two other panels. The trim panels are

long enough to go clear to bottom and

meet the main wood beam across the

bottom of the car.

The floor boards are cut slightly narrow

on the outside to allow room for the trim

panels.

Dash underpanel

Glovebox Interior

Tonneau cover,

top, side curtains

Black vinyl

(Rexine)

Brown flock like

coating

Tan canvas

There was a whole under the clock large

enough for a hand to fit through to allow

the clock to be reset. Panel was made of

hard fiberboard (similar to cardboard and

the same material as the glovebox).

Must have been sprayed on.

Similar to light tent material. Side curtain

ows were made of celluloid and

wind

Page 19

yellowed immediately. Side curtain nuts

were painted tan.

Toolbox

Side curtain box

Gear lever gaiter Leather Could either be black or interior color.

Steering column

excluder

Carpets

White woolen

felt

Black woolen

felt

Tan leather

Black short hair

wool

Carpets were untrimmed. The carpet

under the seats was separate from the

carpet in front of the seats. There was no

carpeting behind the seats, over the rear

end. Under the arch of the seat back,

covering the emergency brake cables,

was a piece of cardboard covered by

carpet with the front edge bound in black

leather (black Rexene is also

acceptable). Under the drivers feet was

stiched a rubber mat. The drivers side on

LHD cars starting in the 1951 model year

had a rubber footwell with the MG crest.

This was sewn into the carpet through a

recess about halfway from the edge. On

some cars a leather patch was sewn onto

the transmission tunnel to prevent wear

from the accelerator foot.

Page 20

Brightwork and Chrome

Top

Item Color Comment

Headlamp bodies, headlamp adjusting

nuts, headlamp rings, headlamp ring

retaining screw, King of the Road

medallion

Headlamp bracket to radiator Chrome

Radiator hose clamps, air cleaner

clamps, steering excluder clamp,

headlamp bracket to radiator bracket

bolts and nuts

Oil cap, body plate, MG Car Co. plate,

patent plate

Chrome

Cadmium

Nickel

Silver

Note that on later TD's

(late 51, 52 and 53) the

headlamp bodies were

painted the body color.

Some cars have this

body color or black

Zinc plating is often

used as a substitute for

Cadmium today. Some

headlamp bracket bolts

may have been chro

or painted body color.

Note that etched writing

or background on

nickeled items were

painted black. Plates

were made of brass.

Plates held in place with

brass round headed

slotted screws with

square nuts.

med

Air cleaner manifold

Transmission dipstick, engine dipstick Chrome

Hub caps Chrome

Hub cap medallions Polished Background painted red.

Radiator shell, nose Chrome

Radiator slats Chrome

Radiator medallion Chrome

Fuel tank filler cap, bonnet hinge strip Polished Polished stainless steel

Fuel tank filler cap lever, tail light and Chrome

Polished

Aluminium

Some like to paint the

background of the MG

Logo red or black.

Some like to paint the

background of the MG

Logo red or black.

See note on hub cap

medallions

Only on late model Mark

II's

Brown MG on cream

background. Late Mark

II's had black MG on

white background.

Page 21

marker light screws, windscreen screws

and nuts

Splash pan x-screws and washers front

and rear

Bumpers, overriders, door knobs, door

latches, side curtain clamps, side

curtain nuts in door tops, seat back

adjusters and brackets, fuel tank strap

nuts, side lamps, windscreen parts and

brackets, rear view mirror, tail lamp

rings and bodies, rear license plate

lamp cover, fuel tank side nuts and

washers, dashboard edging, glove box

hinges, bonnet handles, snaps and

studs, side curtain strips, emergency

brake handle and release button, gear

shift lever

Steering wheel medallion ring, horn

base, lamp bezels, gauge bezels, horn

push ring (early cars), starter and choke

knob bases, steering column

expandable cover

Fuel tank sides Chrome

Chrome

Chrome

Chrome

The inside of the fuel

tank sides were painted

the body color with

exposed edges in

chrome

Tach cable, speedo cable, choke cable,

starter cable, emergency brake cables,

clutch cable housings, water

temperature retainers on stabilizer rods,

bonnet latches (inside), seat runners,

fuel lines (braided), wire harness

retainer straps on rear frame tube, lug

nuts, front wheel grease cap, starter

switch

Door threshold plates, running board

strips

Cadmium

Many like to use the

"MG Car C

threshold plates which

were not original to TD's

but to MGTA's. TD's had

Polished

plain threshold plates.

The threshold plates

were held in place by

slotted flat headed

woodscrews. Some may

have been brass.

ompany"

Page 22

Miscellaneous

Top

Item Color Comment

While most of the car was painted in

pieces prior to assembly, there were

a few exceptions. In some cases

items were assembled and then

Firewall bolts, wood frame

and caulking

Crank, tonneau bar, crank

clips, front license plate

brackets, front license plate

and clips, starter cable

bracket on firewall, horns and

brackets, passenger foot

ramp, accelerator peddle

assembly, fuel pump body

Body

Color

Black Crank handle was brass

overpainted with a color coat while

others had bolts and fasteners hand

painted after assembly. The firewall

and body bucket were painted as an

assembly which meant that the

firewall bolts were painted the body

color.

Rear license plate brackets, Black Optionally can be color of body.

Page 23

rear license plate lamp base

Side curtain frames, top

frame, side curtain nuts on

frames

Tan

Spare tire carrier, head lamp

brackets, hood latch screw

heads

Fuel line Black

Steering wheel center,

steering wheel cap, and

instrument panel

Fuel tank strap bolt heads

and washers, side curtain

storage lid hinges

Rear splash pan bolts and

washers, instrument panel

carriage bolts

Door checks, bonnet latch

receivers on fenders, bonnet

bumpers

Water temperature tubing Black

Body

Color

Bronze

Interior

color

Black

Black

This was part of the chassis

assembly and got painted black.

Many today polish this with copper

polish for a nice effect.

Hand painted to match interior color.

Have also seen the side curtain

storage lid hinges cad plated

Many have these chrome or cad

plated as they scratch so easily

May have been treated to look black

rather than painted.

Windscreen wiper motor

cover

Windscreen "D" washer and

locknut (under Acorn nut)

Grease gun body Blueing

Tools Black

Wiring Harness Black Black with two thread yellow tracer.

Black

wrinkle

paint

Polished

Brass

Same type of finish found on

firearms

Nitty Details

The following items are the hardest to achieve for a person who is trying to

create an absolutely original car. In a Concours d'Elegance these would be

the items that could differentiate two winning cars. Some of these items will

most likely be impossible to achieve but they are interesting goals to pursue if

you want the ultimate in originality.

Page 24

It may well be that there never was an original TD once it left the dealer

showroom/lot, especially in the United States. It appears that modifying the

car was one of the major features of the model. This is attested by all the

accessories that were available at the time from dealers and parts suppliers

such as Arnolt and others.

Note: To see a picture of the detail item in a seperate window click on the

icon.

Item

Engine number that

matches body plate

Size of front splash apron

piping (smaller diameter

than rest of exterior piping)

Exhaust pipe diameter

Original engine oil pan bolts

Original soft metal tappet

cover bolts

Original flat gray

windscreen wiper wire

Rubber rear license plate

lamp wire cover

Correct battery (series,

Lucas, vented caps)

Cap style battery cable

connectors at battery

N/A

Make it yourself by taking the cord out of

a piece of the piping that you used on the

rest of the body and replace it with a 1/4

inch diameter cord

Hardware store or automotive supply

Abingdon Spares

Moss Motors, Abingdon Spares, Rhode

Island Wiring Services

Source

Black braided negative

battery and starter cables

Rubber starter switch (not

nylon) and rubber boots

Horn wire to battery cable

clip

Original spark plug wires

(plastic coated black cloth

braided wire)

Original spark plug caps

(black bakelite)

Spark plug wire retainer at

distributor (red fiberboard)

Black painted bolts on valve

Rhode Island Wiring Services, The InPoint

Check NOS at classic car parts shops

N/A

Page 25

cover

Original black coil

Correct dates (within a few

months prior to car date) on

starter, generator, and coil

Braided and cloth covered

wires and loom, black

sheath with dual yellow

tracer

Correct (small diameter)

braided fuel lines

Wooden battery box liner Moss Motors, 407-710

Rubber pads between

battery and battery clamp

Correct profile dashboard

attachment washers

Double slotted temperature

gauge conduit clips for

radiator stabilizer tubes

Moss Motors

British Auto Electric

Rhode Island Wiring Services, The InPoint

Local hardware store

Moss Motors

Radiator drain pipe

Appropriate front rebound

rubbers (short - late or tall early)

ID plates finished in nickel

silver

Oil cap finished in nickel

silver

Correct oil cap chain

covered in rubber tubing

Etched 'Auster' windscreen

emblem

Correct nuts (fat) on

windscreen frame

Brass finished flat 'D'

washer and lock nut on

windscreen sideframe

(under Acorn nut)

Moss Motors 408-730, 408-740

The rubber cover may not be original.

Most people from the period have no

memory of it.

Dunlop tires 5.50x15

Andrex shock absorbers on

TD Mk II

British Wire Wheel

Page 26

Glass tail and side lamp

lenses

Moss Motors 157-908

Lucas "Anchor" quartz

iodine headlamps

Wide topped bumpers

No rubber packing on

bumper overriders

Front license plate with

correct 'Z' brackets to

bumper

Original ignition switch with

correct labeling (not the

'window' variety)

Original tachometer and

speedometer cables

Original starter and choke

cables

N/A

While I do not know of a source for the

switch,Abingdon Spares, has a decal for

the labels. It is part number 39/2D. You

can also retain the original facia and knob

and marry it to a replacement body and

switch.

Under dash cover in black

Rexine

Original interior materials

(Rexine)

Leather on map pocket tops

and door piping, seat tops

Correct number of pleats on

seat cushions (6) with wider

borders

Correct holes on firewall

(there were some empties,

see manuals)

Original top/tonneau

materials

Original half tonneau cover

Correct radiator hoses

(large hose pebble finish)

Correct (thin and textured)

radiator webbing strip

Abingdon Spares, Moss Motors 451-795

Moss Motors, Abingdon Spares

Moss Motors, Abingdon Spares

Moss Motors, Abingdon Spares

Tapered rubber packing

under headlamp arms to

fenders. Not straight sided.

Abingdon Spares

Page 27

Correct routing and copper

carburetor overflow lines

with clip on front engine

plate

This arcticle from Just Brits will show you

how

Original hose clamps

(radiator hoses, air cleaner,

steering column)

'Mickey Mouse' air cleaner

wing nut

Original tan marbled

steering wheel

Original steering wheel

center piece

Moss Motors 326-388

I have not been happy with the

reproduction units as I feel the color is too

dark. If you have an old wheel you might

want to check with Kimble Engineering, in

the UK. They reportedly have the original

mold tooling for the steering wheel and

has them made in the original materials

(even in the original city).

Also note that I believe the centerpiece to

be darker than what is generally accepted

today. See finish details for more

information and the attached image.

Moss Motors 262-340

Plain door threshold plates

Original width running

board strips and rubber

Original Karvel unbound

carpeting

Original transmission

dipstick cover wing nut

Mahogany marine plywood

floorboards

Tan leather steering wheel

excluder at scuttle with

correct clamp

Sewn in rubber footwell

with MG logo

Painted interior color fuel

tank strap bolt heads and

washers

Painted instrument faces

rather than decals

Moss Motors, Abingdon Spares

Moss Motors 454-040

N/A

Vintage Restorations

Page 28

Original flocked lined glove

box

Original tools and tool case

Moss Motors 454-155

The In-Point and www.britishtool.com for

reproductions

Original hand crank with

brass handle, clips on rear

of seat back

Original operation manual,

workshop manual, parts

catalog

Original dealer brochures

Original Factory

Accessories

Direction of and correct

type of bolts and nuts (see

manuals for guidance on

positions)

Note that depending on the Concours d'Elegance that you are attending,

accessories that were available during the production run of the MGTD may

or may not be acceptable. This varies from event to event, judge to judge.

Moss Motors 386-150

N/A

Replacement Parts Reviews

We are greatly in debt to the many parts suppliers the world over who provide

replacement parts for the MG T-Series cars that we love. Sometimes new old

stock parts are still available but this is the exception. Many times an original

part can be repaired to function like new again. You might also find just the

part you need from a swapmeet, on-line auction, or a fellow enthusiast. When

Page 29

these options don't provide you with the original part that you need, you must

resort to replacement parts.

Many times the replacement parts are exactly as original. In this manner one

could not tell the replacement part from a new original part. Unfortunately this

is not always the case. Many times a substitution from an original part is all

that is available. While I understand the business economics that creating an

exact original replacement may not always justify the cost, I do support any

vendor that goes out of their way to create as an original part as is possible.

To that end I have created this list of replacement parts that I am aware of

and how they compare to the original part they are attempting to replace.

Grading:

This grade is assigned to a part that

A

is virtually identical to the original

part it is replacing.

This grade is for a part that looks

like a reasonable facsimile of the

original part but there are minor

B

differences that a reasonably

knowledgable enthusiast would

notice from the original

The assignment is for a part that

looks similar to the original part but

C

is clearly different upon immediate

inspection

This classification is assigned to a

part that functions in an equivalent

D

manner to the original but does not

look original at all.

This assignment is for a part that

does not function or look like the

F

original part that it is attempting to

replace.

Part Grade Number Vendor Comment

A good replacement for the original

coil. My part was marked 9-48 for

the date and the bottom end did

Ignition Coil B+ 143-210

Moss

Motors

Page 30

Tools and

A

Tool Roll

MGA Tool

Roll

A-

A

The InPoint

The InPoint

not match the rolled edge of the

original. It also did not sport the

Lucas name.

While I have not seen these parts

in person, the pictures do

represent a reasonable

replacement of the original tools.

The tool roll may not be completely

appropriate for the MGTD though. I

prefer their MGA tool rolls for later

TD's.

For later TD's (late 52 and 53), the

MGA tool roll may be a better

replacement than the Inpoints

standard TD/TC roll.

Battery A

Battery C 459-400

Hood Latch

Handles

Original style

luggage rack

A-

C

244-500

61 003A

Abingdon

Spares

Moss

Motors

Moss

Motors

Moss

Motors

Abingdon

Spares

great replacement for the original

battery even down to the ventilated

caps.

This battery had the same

dimensions and was made of

similar material but did not have

the correct top, lugs, and was

embossed with the Moss Logo.

Use the Abingdon Spares battery

instead.

A good imitation for the handle but

they came with American nuts and

threads. You will need to rethread

these for BSF and add your own

original nuts.

While similar to the original factory

rack there are three deviations.

One is the addition of a bar at the

top front that helps keep the

luggage from moving forward

during hard stops. This was not on

the original rack. A minor but

noticeable deviation is the

elimination of two small loops in

the rear bar that accommodated a

belt or strap for securing the

luggage. In addition the rack is

made from a much lighter material

than the original.

Steering

wheel center

and

A 262-340

Moss

Motors

This part is essentially

indistinguishable from the original.

The only question comes from the

Page 31

medallion color. It is finished in the widely

accepted lighter tan color.

A good replacement part that is

hard to tell from the original. May

Windscreen

wiper arms

Front and

Rear

Bumpers

A

B

735110

735111

Abingdon

Spares

Moss

Motors

Abingdon

Spares

want to have plated for a more

uniform look as some parts are

plated brass and others stainless

steel.

These bumpers are similar to the

original but not quite exact. Upon

closer inspection you would notice

that the profile on the original

bumper has a shelf on the top side

or more projection. These

replacement bumpers have the

same projection on the top as the

bottom. Since it is almost

impossible to find a original

bumper in existence today I would

probably expect that in a few years

no one, including an expert, would

be able to notice.

Bumper

Overrider

Rubber

Footwell

Toolbox Felt B 456-420

Toolbox Felt C ASL5798

Dash Light

Rheostat

A

B

C 145-900

Moss

Motors

Abingdon

Spares

Moss

Motors

Moss

Motors

Abingdon

Spares

Moss

Motors

These overriders generally appear

as original. I have noticed that they

are a bit wider at the top than

original overriders but that may be

in tolerance with the original parts.

While this part is close to the

original they forgot one important

aspect. The original footwell was

sewn into the carpet through a

recess in the outer edge. This

version does not have the recess.

While the correct color the texture

has a woven pattern to it rather

than the traditional smooth felt like

texture.

While the correct color the texture

has small waffle pattern to it rather

than the traditional smooth felt like

texture.

The original rheostat was replaced

by Lucas over 30 years ago with a

model that has an extended knob.

The original knob had a plain face

and was about ½ inch long. The

replacement is about 1 inch long

Page 32

and has an arrow on the face.

Socket Set A 142-800

Radiator

Webbing

Windshield

L/R Uprights

B 280-010

A

408-230

408-240

Moss

Motors

Moss

Motors

Moss

Motors

Looks like an exact replacement

for the original dash plugs.

Much thicker than original and

different texture. The original was

very thin (approx. 1/16 inch) and

had a pebbled texture to the

webbing.

Similar to the originals at first

inspection. One thing to look out

for is to make sure that the

castings you receive are

symetrical. Mine were not. Might

want to insist during the order that

they are the same or you will

charge them return shipping.

Plates, Etchings and Decals

If your TD, like most others, has been refinished a number of times some of

the little details may have been lost. In fact you may not even know they exist

unless you have compared your car to another. The details I refer to in this

section are found in the form of etchings and decals. These decals and

etchings were part of plates from the MG Car Company or their suppliers.

Some of these are available as replacement parts and offer good substitutes.

Many of these parts are not available or perhaps just need to be restored.

Within these pages I will describe these decals and etchings and provide a

digital image of the item so you can create your own or restore the etching on

your original part. I will also describe how you might go about the etching

process or where you could have this done. The items that I deal with in these

pages are:

• Original Air Cleaner Decal

• Auster windscreen builders plate

Page 33

• Desmo rear view mirror logo

• Chassis I.D. plate

• Body I.D. plate

• Patent number plate

• Sidescreen builders plate

• Tecalemit oil filter plate (late TD)

• Engine ID Plate

• Oil filler cap

• Gas filler cap lever

• Radiator builders plate

• Made in England plate

• MG Car Company threshold plates

Decals

Original Air Cleaner Decal

This decal was affixed to the top of the smooth topped air cleaners. Note the

image is not full size.

The Plate Details

Auster Windscreen Builders Plate

The Auster windscreen builders plate was attached to the bottom frame

member of the windscreen via two tiny round headed rivets. Make sure that

this plate is on the inside of the vehicle as many times you find it on the

outside of restored cars. This plate is unusual in that it is done in two colors.

Bright red for the Auster bracketed by black decorations to the sides.

This part is available from suppliers such as Moss Motors and Abingdon

Spares but they did not etch the part. Instead they just silk screened the

image onto a plate. If you want a more realistic copy then you will need to

etch the image into the plate.

Desmo Rear View Mirror Logo

The original over the dash review view mirror that was used on the MGTD

was supplied by Desmo. They included their logo on the back of the mirror

Page 34

(towards the front of the car) at the top. The metal parts of the mirror where

plated chrome.

Chassis I.D. Plate

The chassis ID plate designates your car and engine numbers. There are at

least two different versions of this plate. Reproductions of this plate only

support the early version and do not have the 2 on the TD/ that later cars had.

You may need to add this etching to a reproduction plate. These plates were

nickel and filled with black paint.

Body I.D. Plate

The body plate contained the body type and body number stamped into the

surface. The plate itself was plated in nickel with filled letters in black. These

can be obtained commercially.

Patent Number Plate

This plate was a little different in that it had a painted background (black) with

raised patent numbers. The plate was done in nickel. You can obtain these

commercially.

Sidescreen Builders Plate

This plate was attached to the right hand door's sidescreen at the top cross

member. It sported a black background with natural raised lettering.

Tecalemit Oil Filter Plate

This plate was affixed to all Tecalemit filters (late TD's) and was photo etched.

I do not have an easy way to restore this plate.

Engine ID Plate

Octagonal plate with inner circle ring. Raised letters riveted to the engine

block. Includes stamped engine number that is match on the chassis ID plate.

Page 35

Oil filler Cap

Etched around the oil cap filler were popular brands (recommended by the

factory?) of oil. This part was nickel plated with etched and black painted

letters.

Gas filler Cap Lever

This one may have been stamped on but an etching may be a good facsimile

just in case. Not painted to my knowledge but you could if you wanted more

contrast. Most have this chrome plated.

Radiator Builders Plate

Found on the upper right corner of the radiator core on the engine side.

Painted with the core but you could treat it in brass and paint for an enhanced

effect. Each plate carried a stamped serial number.

Another plate found on the tank top generally on the right hand side. These

plates were soldered to the tank and painted black overall.

Page 36

Note: These plates may be available in limited quantities. Please contact Jim

Threadgill for more information.

Made in England Plate

This plate was put on some export cars. It was found on the left end of the

tool box just below the band that the clasp is attached to. The plate was made

of brass and etched with the MG logo in front with the words MADE IN

ENGLAND along side it to the right. Not all export cars seem to posses this

plate. Certainly if you do not have two little holes on the left end of your

toolbox you probably are not a candidate. Finished in nickel and black paint.

MG Car Company Threshold Plates

OK. These are not original for TD's (MG TA's?) but everybody has them.

These were not plated but were natural aluminium that was polished and filled

with black paint.

Restoring Etchings

To restore or create a reproduction you have to go through a few steps. First

you must obtain an image of the original. This page should help you in that

regard. Secondly you will need to create a mask and then etch the item. After

this process you may need to have the item plated depending on it's original

finish. And finally you will have to fill in the etching with paint to make it stand

out (or conversely fill in the background). A few etchings were really a photo

chemical coloration and are not really painted on (ex: Tecalemit oil filter plate).

This article does not cover that process.

Etching

Etching is the process of removing a specified amount of material from an

object by using acid or some sort of abrasive. Etching is generally done via

some sort of mask either directly with an acid or using the mask to

photochemically treat the material first. In the case of the MGTD many of the

etchings were done over brass but other metals were used also. A very

popular use of etching is in the creation of printed circuit boards. In fact you

may find that process most useful to you. You can find a brief overview of the

etching process at this site.

Page 37

Warning: Anyone considering doing their own etching should realize that it is

a fairly difficult and dangerous process and your results will not be

guaranteed. I would suggest that you consider sending your part and mask

template (image) to a professional when etching is required. If you do decide

to try your own hand at etching you should experiment on like materials as the

part you will be ultimately using. Also I do not recommend trying to deepen or

re-etch existing parts, at least not by a layman.

To restore etched parts requires a few basic steps. First you must thoroughly

clean all of the parts to be treated. This includes removing any existing paint

and/or plating. Plating will generally have to be removed at a plating shop.

You will need some sort of mask that will indicate where the etching

should/sho

uld not take place. One these pages I will attempt to provide you

with images that you can use to generate your own etching masks from your

computer printer. Generally the best way to mask your part is to create the

mask with your computer. If you have a laser printer you can generate your

mask directly otherwise you will have to first print your mask and then transfer

the image to the mask material with a Xerographic copy machine. You can

find photo generated mask material and instructions to make the mask here

.

Once the parts have been stripped and cleaned you can begin the etching

process. Follow the instructions with your etching materials and mask. Be

sure to take all the environmental and personal protection precautions

because ac

id is very dangerous to you and the environment. See cautions

above.

Resources for Etching

• Photographic mask materials

• Etching process overview

• Etching Machinery & Supplies in the UK

• Etching resource for making plates etc.

• Brass name plate producer

• An example of etching brass from the model railroad hobby

• Nickel stripping and etching solutions

Plating

Most of the ID plates on the MGTD were nickel plated. Nickel differs from

chrome plating in that chrome plating is usually done in three layers. The first

being a layer of brass which provides a smooth uniform surface that can also

be lightly polished if needed between the first and second platting. The next

layer is nickel which gives it the silver look. Nickel has sort of a yellowish tinge

to it. Nickel can oxidize like any silver and can turn dark yellow and even gray

or black. It needs to be polished frequently to retain it's shine. Finally in

chrome plating the third layer is actually the chromium. This is applied in a

very thin, almost transparent layer. Its' main function is to protect the nickel

from abrasion and tarnishing. It also gives chrome plating that characteristic

bluish look.

Page 38

To properly plate your etched parts just have them nickel plated, straight over

the existing brass. Be careful that you do not have the plate overly polished

first otherwise you may remove some of the etching and/or your plate will look

to shiny and be confused with chrome plating, at least until it starts to tarnish.

Painting

Most of the etched parts were painted after the plating process. Some may

have been silk screened or photo etched as reported above. For those plates

that were painted here is how you can replace the paint.

First it is important to realiz

for the letters and was actually used as a filler. In other cases the paint

actually provided a dark background for the letters to rise above the

background and stand out. In either case the principal is the same. You will

need to put paint in the recessed or etched areas and leave the non etched

areas to rise above for contrast.

Start by making sure your plated etching is free from all grease and oil. Use a

good grade of commercial painting pre cleaner or alcohol to clean the surface.

Next obtain the correct color of paint, black in most cases, in a lacquer base.

Lacquer based paints work best because they are easier to work with after the

paint has cured. Do not use a primer! You will ne

the plate. A good tool for this would be an artist or hobby airbrush. Build up a

good deal of paint because the next process will remove most of it.

You will have to experiment a little from this point but the good news is that

you can do this over and over again without hurting any

having to redo much work. The object at this point is to remove all the paint on

the surface of the etching while still retaining the paint within the recesses.

This will be easy to do on those plates where the etchings make up the text

and figures. On the plates where the paint constitutes the body or

background, this may be a little tougher.

e that in some cases the paint provided a contrast

ed to spray the entire area of

thing or seriously

There are many techniques to remove the unwanted

Each has it's own benefits and detriments. You might find one useful for one

type of plate but totally inappropriate for another. Try them as you see fit.

paint from your etchings.

Removing Paint with Solvent

The easiest way to remove paint is through the use of a solvent. If you have

used a lacquer type of paint then lacquer thinner is what you will use. Other

types of paints may need another type of solvent. Use the solvent sparingly

and remove as much of the paint on the larger areas as you can. For tools I

like to use smooth cotton such as bed sheets wrapped in a mandrel or rod. I

soak the cloth and then wrap it tightly around the rod. Then I carefully wipe

this across the surface, removing a little paint each time. After each pass I

would recommend you use a new piece of cloth or an unused portion of you

cloth. Stop just sort of removing all the paint when you can see the raised

Page 39

portion coming through. At this point you will follow up with the polishing

technique described below.

You can also use cotton swabs to carefully remove paint in stubborn areas. If

you make a mistake and remove too much paint let the part dry for a while

and then recoat again. You can concentrate your touch-up in those difficult

areas and work it until you get the look you want.

Removing Paint with Polish

This technique is much slower than the solvent method but is less deliberate

in the removal of the paint. Start with a hard surface such as a 12 inch square

plate of glass or metal. It must be perfectly flat and smooth. Cover it with a

piece of smooth cotton. You can experiment with bed sheets or cotton Tshirts. Make sure there are no wrinkles or creases.

Using a fine hand polishing compound invert the plated piece and rub it over

the hard surface covered with cloth. You will need to inspect the part many

times during the operation to make sure you are only removing the paint that

you need to. Press down firmly but evenly while rubbing. You may need to

replace the cloth and/or add compound frequently as needed.

When you get to a point that you can just see the image coming through you

should switch to a car cleaner wax or a light

finer tools such as cotton swabs or your fingered covered in cloth to work

smaller areas. Once you have removed all the unwanted paint then buff with a

clean cloth. You may optionally coat your parts with clear to keep the nickel

from tarnishing and to protect your painted areas from wear.

er compound. You may also use

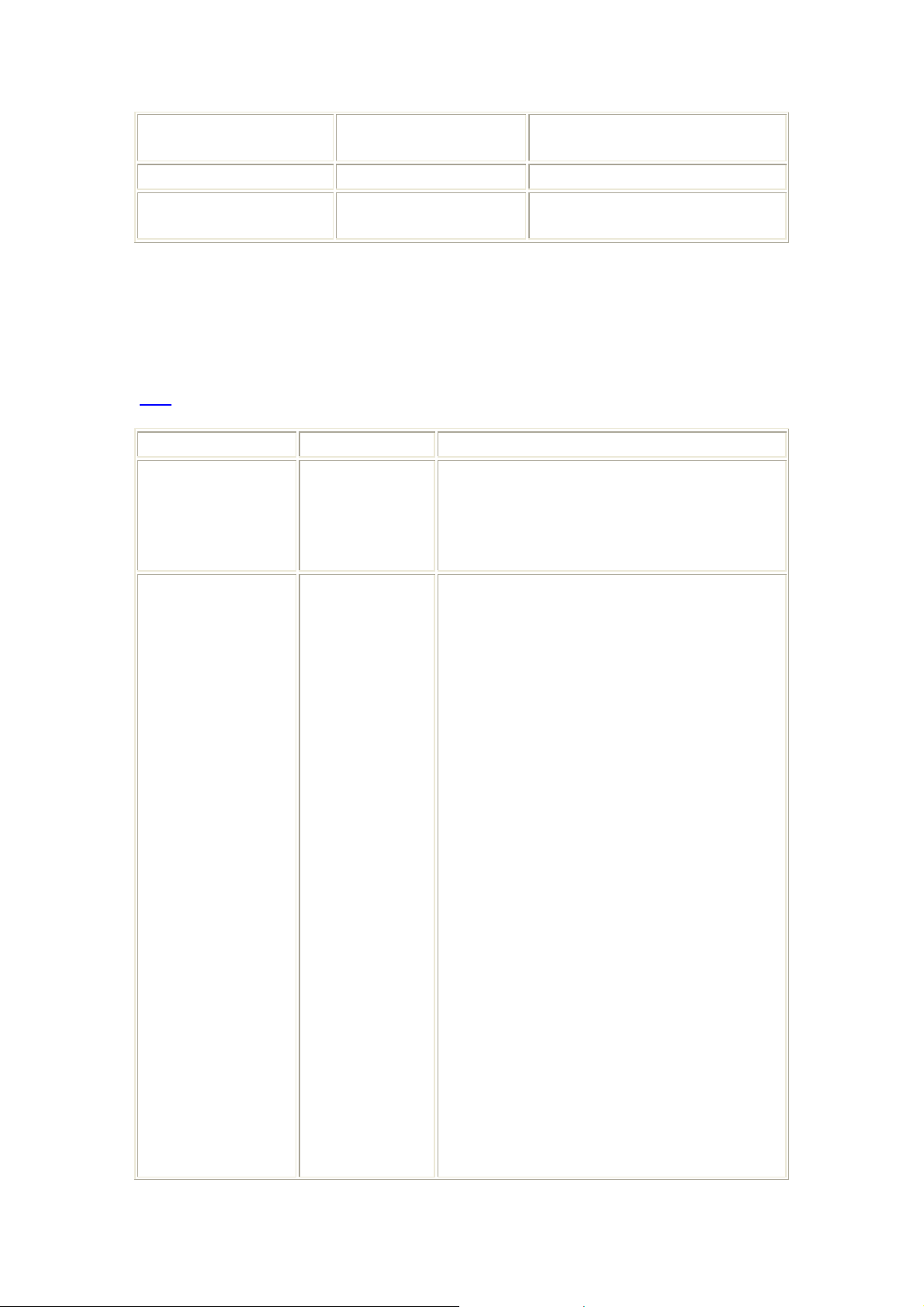

Engine Fasteners

Here is a list list of MGTD engine fasteners. The list includes original part

numbers and replacement part numbers from Abingdon Spares

Motors. Also included is a table of torque values for specified fasteners. This

list was compiled by Dave DuBois, Stuart Lock and TA Terry.

and Moss

Bolts

SIZE

5 -

0.80MM6

- 1MM

LENGTH

(INCH)

5/8 2BA3/16W

WRENCH

SIZE

DESCRIPTION/USE QTY

CAMSHAFT

THRUST

PLAT

THRUST PLATE

BOLT ACTUALLY

FOUND IN 2

ENGINES

ECAMSHAFT

2 AAA2356 5 - 84

ORIGINAL

P/N

ABINGDON

P/N

MOSS

P/N

320130

5 - 0.75 1 9/16 1/8 W FAN TO PULLEY 4 AAA5213 7 - 23 320-

Page 40

Mm 120

6 - 1MM ½ 3/16W

6 - 1MM ½ 3/16W

6 - 1MM 5/8 3/16W

6 - 1MM 5/8 3/16W BAFFLE TO SUMP 4 JA5117 3 - 173

6 - 1MM 5/8 3/16W

6 - 1MM 1 ½ 3/16W

6 - 1MM 1 ½ 3/16W

6 - 1MM 2 5/8 3/16W

UPPER REAR

MAIN SEAL

ROCKER COVER

SIDE BOSSES

OIL PICKUP TO

BAFFL

OIL PICKUP

COVER (L

OIL PICKUP TO

SUMP, DRILLED

FOR SAFETY WIRE

TIMING CHAIN

TENSIONER,

DRILLED FOR

SAFETY WIRE

OIL PUMP TO

BLOCK (EARLY

TD)

(LATE TD)

E

ATE TD)

3 AAA6142 3 - 12

3 AAA6142 3 - 12

2 JA5117 3 - 169

1 HP0405 3 - 167

2 ASL5853 3 - 161

2 AAA5792 5 - 8

4

AAA5586 3 - 99

2

320130

320130

320150

320150

320160

6 - 1MM 3 5/16 3/16W

6 - 1MM 3 ½ 3/16W

8 - 1MM ½ 3/16W

8 - 1MM 5/8 3/16W

8 - 1MM 5/8 3/16W

8 - 1MM 5/8 3/16W

8 - 1MM 3/4 1/4W

OIL PUMP TO

BLOCK, DRILLED

FOR SAFETY WIRE

(EARLY TD)

(LATE TD)

OIL PUMP TO

BLOCK, DRILLED

FOR SAFETY WIRE

OIL GALLERY

PLUGS

FRONT BEARING

PLAT

TIMING CHAIN

COVER TO FRONT

BEARING PLATE

CAM BEARING

DOWEL BOLTS (

DRILLED FOR

SAFETY WIRE)

CLUTCH TO

FLYWH

E TO BLOCK

EEL

2

AAA5586 3 - 99

4

2 AAA3093 3 - 97

5 X22968 3 - 8

2 AAA5343 3 - 40

2 X15012 3 - 39

2 AAA5621 5 - 44

6 AAA5609 13 - 47

320160

320170

328100

320260

320260

320900

321028

8 - 1MM 3/4 1/4W

ENGINE MOUNT

DLE TO

CRA

4 ASL5829 3 - 42

320260

Page 41

FRONT BEARING

PLATE

8 - 1MM 3/4 1/4W

8 - 1MM 3/4 1/4W

8 - 1MM 3/4 1/4W

8 - 1MM 3/4 1/4W

8 - 1MM 3/4 1/4W

8 - 1MM 7/8 1/4W

GENERATOR

ADJUSTING LINK

GENERATOR

MOUNTING

BRACKET TO

BLOCK

CLUTCH CABLE

BRACKET TO

SUMP (EARLY TD)

OIL FILTER

SUPPORT

BRACKET (EARLY

TD)

TIMING CHAIN

COVER TO FRONT

BEARER PLATE (2

BOLTS FROM

REA

R OF BEARER

PLATE)

WATER OUTLET

ELBOW TO HEAD

(TD)

1 X15012 3 - 149

2 CA1122 3 - 146

2 CA1122 13 - 31

3 CA1122 USE 3 - 39

2 CA1122 3 - 39

4 CA1258 3 - 132

320260

320260

320260

320260

320260

320270

8 - 1MM 7/8 1/4W

8 - 1MM 7/8 1/4W

8 - 1MM 7/8 3/16W

8 - 1MM 7/8 3/16W

8 - 1MM 1 1/4W

8 - 1MM 1 *

8 - 1MM 1 1/4W

8 - 1MM 1 1/4W

AIR CLEANER

ELBOW TO

CARBURE

WATER PUMP

(SHORT B

SUMP TO BLOCK

(CENTER BOLTS)

SUMP TO TIMING

CHAIN COVER

(DEEP HEAD)

WATER PUMP

(LONG BOLT)

REAR PLATE TO

HEAD (* SCREW

HEAD)

BELL HOUSING TO

ENGINE

BOTTOM

GENERATOR

MOUNTING

TOR

OLT)

4 CA1258 3 - 62A

1 CA1258 7 - 27

10 LA7431 3 - 74

2 AAA5340 3 - 73

1 JA5052 7 - 28

4 3 - 50

10 JA5052 3 - 58

2 X22853 3 - 153/157

320270

320270

320270

320265

320625

323180

321048

320625

8 - 1MM 1 1/8 3/16W SUMP TO BLOCK 2 AAA5341 3 - 75 320-

Page 42

8 - 1MM 1 1/4 13MM

(DEEP HEAD

SLOTTED - REAR 2

BOLTS)

GUDGEON PIN

CLAMP BOLTS

(ORIGINAL BOLTS

HAD 1/4W HEADS)

4 CA1009 5 - 17

615

320890

TIMING CHAIN

8 - 1MM 1 7/8 1/4W

8 - 1MM 2 1/4W

8 - 1MM 2 1/4 13MM1/4W

8 - 1MM 3 5/16 1/4W ROCKER TOWER 4 AAA5670 5 - 57

10 -

1.5MM

10 -

1.5MM

3/4 5/16W

7/8 3/8W

COVER TO

ENGINE

TIMING CHAIN

COVER TO

ENGINE (2 LOWER

BOLTS)

ROD BIG END

BOLTS (WITH

SELF LOCKING

NUTS) (DRILLED

FOR COTTER PIN)

CARBURETOR TO

MANIFOLD

FLYWHEEL TO

CRANKSHAFT,

DRILLED FOR

SAFETY WIRE

3 AAA5286 3 - 36

2 AAA5231 3 - 35

8 AEF123 5 - 15

4

4 AAA5609 13 - 61

320300

320310

320880

320330

320510

321108

10 -

1.5MM

10 -

1.5MM

12 -

1.5MM

12 -

1.5MM

1/4 - 26

BSF

1 5/16W

3 ½ 5/16W ROCKER TOWER 4 AAA5692 5 - 58

7/8 5/8W

1 3/8W19MM

1 1/4 3/16W

STARTER TO

BLOCK

CRANKSHAFT

PULLEY

BOLT/STARTING

DOG (CAN USE 1

1/8 SAE WRENCH)

TIMING GEAR TO

CAMSHAFT (SOME

BOLTS COME

WITH THIS

LARGER HEAD)

ENGINE

BREATHER PIPE

CLAMP BOLT

(SOME OF THESE

MAY BE 6 - 1MM)

2

1 AAA5279 5 - 30

1 AAA5788 5 - 35

1 CA1263

USE 23 125

320510

320530

433450

320670

320200

Page 43

1/4 - 20

W

1 3/8 1/4W

DISTRIBUTOR

CLAMP PINCH

BOLT (EARLY TD)

1

5/16 -22

BSF

5/16 -22

BSF

5/16 - 18

W

3/8 - 20

BSF

Studs

SIZE

6 1MM

LENGTH

1 7/8 N/A

3/4 1/4W

3/4 1/4W

5/8 1/4W

4 ½ 5/16W

(INCH)

WRENCHSIZE DESCRIPTION/USE QTY

CLUTCH RETURN

SPRING BRACKET

TO SUMP

AIR CLEANER TO

CARBURETOR (TD

MKII)

TOP GENERATOR

MOUNTING BOLT

(5/16 - 18 SAE

BOLT FITS)

OIL FILTER

HOUSING

TAPPET COVER

STUDS

1 AJG6255Z 13 - 22

4 23-185

1 3H2092 3 - 151

1 300852 3 - 197

ORIGINAL

P/N

3 AAA5595 3 - 16

ABINGDON

P/N

320360

320360

322510

MOSS

P/N

8 1MM

8 1MM

8 1MM

8 1MM

8 1MM

10 -

1.5MM

10 -

1.5MM

10 -

1.5MM

1 1/4 N/A

1 7/8 N/A

1 3/4 N/A

4 N/A

5 1/4 N/A

2 N/A

1 1/2 N/A

4 3/8 N/A

WATER OUTLET

ELBOW TO

THERMOSTAT

HOUSING STUD

LONG WATER

PUMP ST

SHORT WATER

PUMP ST

MANIFOLD TO

HEA

ROCKER COVER

STUDS

CARBURETOR TO

MANIFOLD STUDS

(TD MKII)

EXHAUST FLANGE

TO MANIFOLD

STUDS

HEAD TO BLOCK