MG midget mark 3, midget mark III User Manual

MIDGET

(GAN

5UC)

STEE RING-COLU

MN

LOCK

Note

the key number and

remove the label from the

car

immedia tely. Refer to

page 6.

MARK

III

HANDBOOK

Publication Part No. AKD 7937

I

BRITISH

I

British

Leyland

(Austin-Morris)

Limited

MIDGET

(GAN

5UC)

MARK

III

FOREWORD

This

Handbook

provides an introduction to your car, together with information on the care

and

periodic maintenance required to combine trouble-free motoring with minimal running costs.

Claims for the replacementofparts under warranty

must

be submitted to the supplying Distributor

or Dealer, or when this is

not

possible, to the nearest Distributor or Dealer, informing

them

of the

vendor's

name

and

address. Except in emergency, warranty work should always be carried

out

by

an appointed Distributor or Dealer.

By keeping the Passport to Service, signed by the Distributor, Dealer, or vendor in the vehicle, you

can quickly establish the date of purchase

and

provide the necessary details if adjustments are

required to be carried

out

under warranty.

Regular use of the Passport to Service Maintenance Scheme is the best safeguard against the

possibility of abnormal repair bills at a later date. Failure 'to have your

car

correctly maintained

could invalidate the terms of the

Warranty

and may result in unsatisfactory operation of the emission

control systems .

Safety features embodied in the car may be impaired if

other'than

genuine parts are fitted . In certain

territories, legislation prohibits the fitting of parts

not

to the vehicle manufacturer's specification.

Owners purchasing accessories while travelling

abroad

should ensure

that

the accessory

and

its

fitted location on the car conform to mandatory requirements existing in their country of origin.

Your

Distributor or Dealer is provided with the latest information concerning special service tools

and

workshop techniques. This enables him to undertake

your

service

and

repairs in the most efficient

and

economic manner.

Further

' details on Service Parts will be found under

'SERVICE'

on page 60. Please note

that

references to right- or left-hand in this Handbook are made when viewing the car from the rear.

Specification details set

out

in this

Handbook

apply to a range of vehicles

and

not

to any particular

vehicle.

For

the specification of any particular vehicle owners should consult their Distributor or

Dealer.

The Manufacturers reserve the right to vary their specifications with or without notice,

and

at such

times

and

in such manner as they think fit.

Major

as well as minor changes may be involved in

accordance with the Manufacturer's policy of constant product improvement.

Whilst every effort is made to ensure the accuracy of the particulars contained in this

Handbook,

neither the Manufacturer

nor

the Distributor or Dealer, by whom this

Handbook

is supplied, shall

in any circumstances be held liable for any inaccuracy or the consequences thereof.

Emission Controls

Your

car is fitted with emission controls

and

devices required by the United States Clean Air

Act and regulations issued by the Environmental Protection Agency.

1

Please read carefully the Emission Control Systems section of this

Handbook

which contains

information on the emission systems fitted to your

car

and the recognition of symptoms .of

possible malfunctions which could affect emissions . .

an appointed

Distnbutor

or Dealer.

By keeping the Passport to Service, signed by the Distributor, Dealer, or vendor in the vehicle, you

can quickly establish the date of purchase

and

provide the necessary details if adjustments are

required to be carried

out

under warranty.

Regular use of the Passport to Service Maintenance Scheme is the best safeguard against the

possibility of abnormal repair bills at a later date. Failure ' to have your

car

correctly maintained

could invalidate the terms of the

Warranty

and may result in unsatisfactory operation of the emission

control systems .

Safety features embodied in the

car

may be impaired if

other

than

genuine parts are fitted. In certain

territories, legislation prohibits the fitting of parts

not

to the vehicle manufacturer's specification.

CONTENTS

INTRODUCTIO

N TO

THE

CAR

CONT ROLS

WARNING

SYSTEMS

LOCK S

IN STRUME NTS

AND

SWITCHES

..

BODY

FITTINGS

SEATS

AND

SEAT BELTS

H ATING

AND

VENTILATING

RU N NING

INSTRUCTIONS

CARE O F

THE

CAR

L

ANING

OO

LING

SYSTEM

WHEELS

AND

TYRES

BRAKE S

..

LECTRICAL

WIR

ING

DIAGRAM

IGNITION

ENGIN E

..

EMISSION

CONTROL

SYSTEMS

FUEL SYSTEM . .

GEARBOX

AND

REAR

AXLE

STEERING

AND

SUSPENSION

GE NE R AL

DATA

t\Jf A

TNTPNANrp';:T

Tt\Jft\Jf A

DV

LOCK S

IN STRUME NTS

AND

SWITCHES

..

BODY

FITTINGS

SEATS

AND

SEAT BELTS

HEATIN G

AND

VENTILATING

R

UNNING

INSTRUCTIONS

Page

4

5

6

8

11

16

18

19

22

23

25

28

31

38

40

42

44

50

53

54

55

8

11

16

18

19

CONTROLS

WARNING

SYSTE

MS

.

Fig. 1

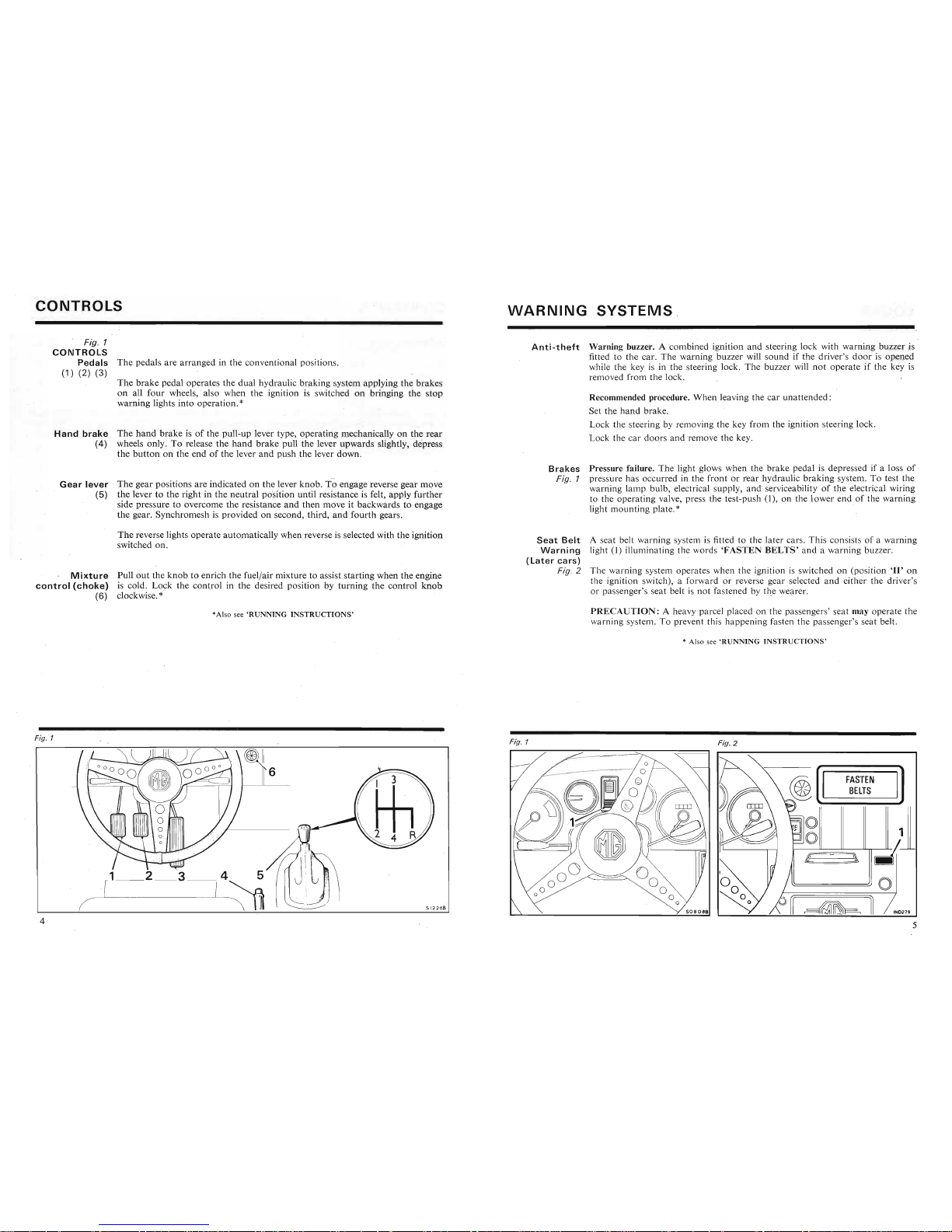

CONTROLS

Pedals

The pedals are arranged in the conventional positions.

(1) (2) (3)

The brake pedal operates the dual hydraulic braking system applying the brakes

on all four wheels, also when the ignition is switched on bringing the stop

warning lights into operation.

*

Ha n d b r

ake

The

hand

brake is of the pull-up lever type, operating mechanically on the

rear

(4) wheels only. To release the

hand

brake pull the lever upwards slightly, depress

the

button

on the end of the lever

and

push the lever down.

Anti

-theft

Warning buzzer. A combined ignition and steering lock with warning buzzer is

fitted to the car. The warning buzzer

will sound if the driver's

door

is opened

while the key is in the steering lock. The buzzer will not operate if the key is

removed from the lock.

Recommended procedure. When leaving the car unattended:

Set the hand brake.

Lock the steering by removing the key from the ignition steering lock .

Lock the car doors and remove the key.

Gearlever

(5)

The gear positions are indicated on the lever knob. ioengage reverse gear move

the lever to the right in the neutral position until resistance is felt, app ly further

side pressure to overcome the resistance and then move it backwards to engage

the gear. Synchromesh is provided on second, third,

and

.fourth gears.

Brakes

Fig. 1

Pressure failure. The light glows when the brake pedal is depressed if a loss of

pressure has occurred in the front or rear hydraulic braking system. To test the

warning lamp bulb, electrical supply, andserviceability of the electrical wiring

to the operating valve, press the test-push

(1), on the

lower

end of the warmng

light mounting plate .

*

The reverse lights operate automatically when reverse is selected with the ignition

switched on.

Mi

xture

Pull

out

the knob to enrich the fuel/air mixture to assist starting when the engine

control(choke)

is cold. Lock the control in the desired position by turning the control

knob

(6) clockwise. *'

Seat

Belt

A seat belt warning system is fitted to the later cars. This consists of a warning

Warning

light

(I)

illuminating the words 'FASTEN

BELTS'

and a warning buzzer.

(Later

cars)

Fig. 2 The warning system operates when the ignition is switched on (position .'11' on

the ignition switch) ; a forward or reverse gear selected and either the driver's

or passenger's seat belt is not fastened by the wearer.

*Also see 'R UNNI NG

INSTRUCTIONS'

PRECAUTION:

A heavy parcel placed on the passengers' seat may operate the

warn ing system . To prevent this happening fasten the passenger's seat belt.

* Also see

'RUNNING

INSTRUCTIONS

'

Fig. 2

Set the hand brake.

Lock the steering by removing the key from the ignition steering lock .

Lock the car doors and remove the key.

I

11

11

FASTEN

BELTS

11

11

Fig. 1

6

HandbrakeThe

hand

brake is of the pull-up lever type, operating mechanically on the

rear

(4) wheels only. To release the

hand

brake pull the lever upwards slightly, depress

the

button

on the end of the lever

and

push the lever down.

Fig. 1

Gearlever

(5)

The gear positions are indicated on the lever knob. ioengage reverse gear move

the lever to the right in the neutral position until resistance is felt, app ly further

side pressure to overcome the resistance and then move it backwards to engage

the gear. Synchromesh is provided on second, third,

and

.fourth gears.

Brakes

Fig. 1

Pressure failure. The light glows when the brake pedal is depressed if a loss of

pressure has occurred in the front or rear hydraulic braking system. To test the

warning lamp bulb, electrical supply, andserviceability of the electrical wiring

to the operating valve, press the test-push

(1), on the

lower

end of the warmng

light mounting plate .

*

~OCKS

.

It

is most impor tan t that owners MAKE A

NOTEOFTHE

KEY

NUMBERS

IMMEDIATELY

on taking delivery of the car

and

at the same time consult

their Distributor or Dealer regarding steering lock key replacements.

Ignition

and

Insert the key in the lock, and turn to positi onT.In this position the ignition

starter

is off but electrical items not wired through the ignition switch may be operated,

viz. ra dio. Turn the key to position '

ll'

to switch on the ignition; further move-

ment to

'Ill'

operates the starter. .

Keys

Identification. To reduce the possibility of theft, locks are

not

marked with a

number. Owners are advised to make a note of the numbers stamped on the

keys, on the numbered tag supplied, or on a label stuck to

the

windscreen.

The

driver and pa ssenger doo r locks use a common key. The luggage compartment

and steer ing locks are operated by separate keys.

The fuel gauge or direction indicators will not operate unless the ignition switch

is at position

'll'.

To remove the key from the lock, turn the key to position

'I'

, press the key in,

and while maintaining pressure turn an ti-clockwise to position '0 ' and withdraw

the key.

Steering

The lock face is marked

'0'

(off),

'I'

(auxiliary), 'II' (ignition),

'Ill

' (start). To

Fig. 1 lock the car steering the key must be removed f

rom

the lock (4).

To remove the key from the lock, turn the key to position 'I', press the key in,

and

while maintaining pressure turn anti-clockwise to position

'0'

and withdraw

the key . The steering lock is set during withd ra wal of the key and

rota

tion of

the steering-wheel engages the lock.

Under no circumstances must the key be moved from the

'I'

position towards

the

'0

' position

WHEN

THE

CAR IS IN

MOTION.

The car may be towed

for recovery with the key in the lock at position

'I'

.

(5) Ignition warning light (red). The ignition warning light serves the dual purpose

of reminding the driver to switch off the. ignition and of acting as a no-charge

indicato r. The light should glow when the ignition is switched on, and go out

and

stay out at all times while the engine is running above no rmal idling speed.

Doors

The door key can only be inserted or withdrawn when the key and key slot (1)

Fig. 2 are vertica l. For ward key movement locks, opposite unlocks. To lock the doors

from inside the car, turn the locking lever

(2), downwards.

WARNING.- The lock fitted to the steering-column works in conjunction

and

is integral with the ignition starter switch. The designed operating sequence

prevents the engine being started with the steering

LOCKED

. Serious

consequences may result f

rom

alterations or substitution of the ignition

start

switch which would permit the engine to be started with the

LOCK

ENGAGED.

Under no circumstances must the ignition switch or the ignition engine

start

function be separated from the steering lock.

Lugga

ge The luggage compartment lid is locked by turning the key (3) clockwise one

half

compartme

nt turn.

Fig. 3

4

Fig. 3

To remove the key from the lock, turn the key to position

'I'

, press the key in,

and while maintaining pressure turn an ti-clockwise to position '0 ' and withd raw

the key.

Fig. 2

~o

...

~

~

Wller'.

'

.ll

~'

~

u,

ll«

Humu""m'V_uu,ll«

keys, on the numbered tag supplied, or on a label stuck to

the

windscreen.

The

driver and pa ssenger doo r locks use a common key. The luggage compartment

and steer ing locks are operated by separate keys.

Fig. 1

Steering

The lock face is marked

'0'

(off),

'I'

(auxiliary), 'II' (ignition),

'Ill

' (start) . To

Fig. 1 lock the car steering the key must be removed f

rom

the lock (4).

To remove the key from the lock, turn the key to position 'I', press the key in,

and

while maintaining pressure turn anti-clockwise to position

'0'

and withdraw

the key . The steering lock is set during withd ra wal of the key and

rota

tion of

the steering-wheel engages the lock.

(5) Ignition warning light (red). The ignition warning light serves the dual purpose

of reminding the driver to switch off the. ignitio n and of acting as a no-charge

indicato r. The light should glow when the ignition is switched on, and go out

and

stay out at all times while the engine is running above no rmal idling speed.

INSTRUMENTS

AND

SWITCHES

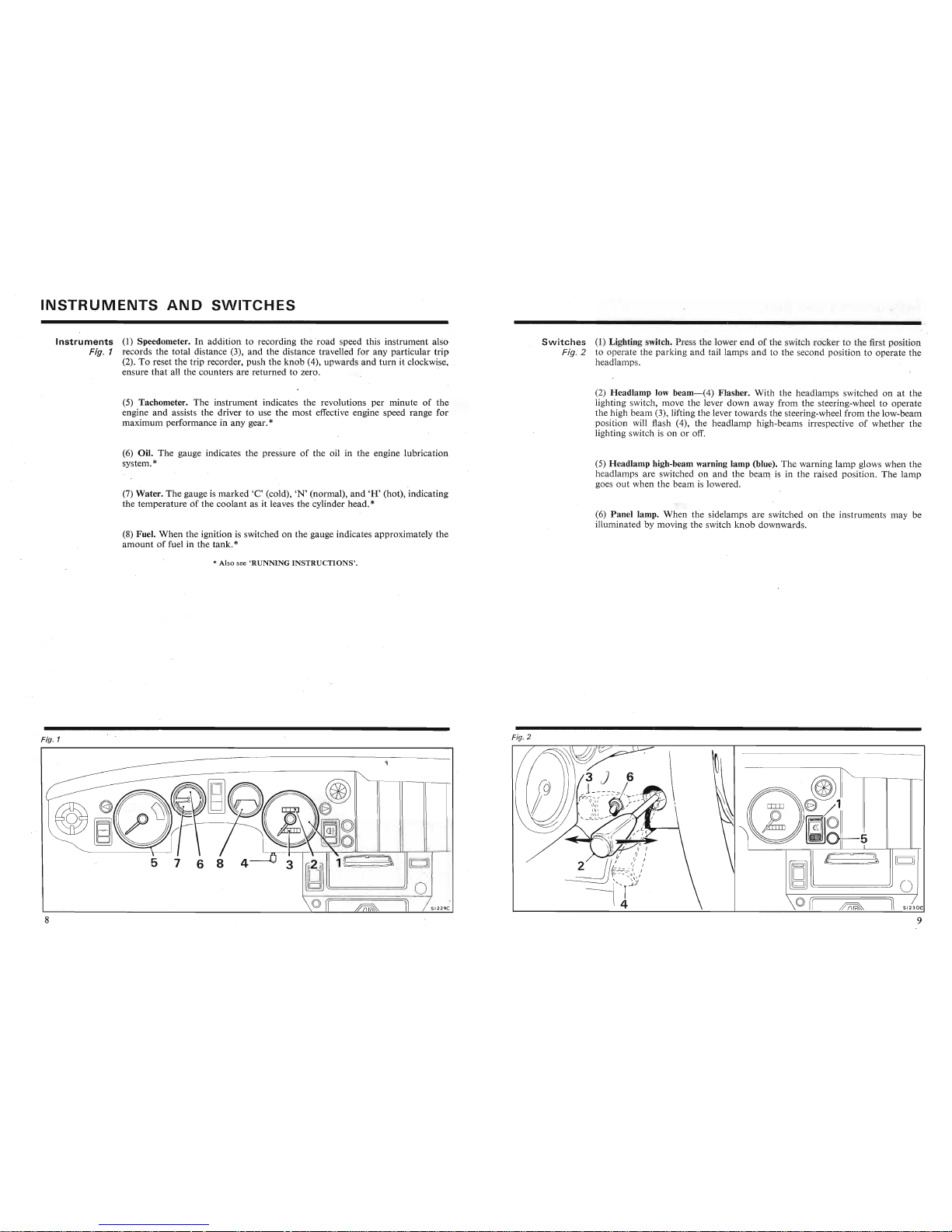

Inst

ruments

(1) Speedometer. In addition to recording the

road

speed this instrument also

Fig. 1 records the total distance (3),

and

the distance travelled for any particular

trip

(2). To reset the trip recorder, push the

knob

(4), upwards

and

turn

it clockwise ,

ensure

that

all the counters are returned to zero.

Switche

s (1) Lighting switch. Press the lower end of the switch rock er to the first po sition

Fig. 2 to operate the

par

king

and

tail lamps

and

to the second position to operate the

headlamps.

(5) Tachometer. The instrument indicates the revolutions per minute of the

engine

and

assists the driver to use the most effective engine speed range for

maximum performance in any gear.

*

(2)

Hea

dlamp low beam

-(4)

Flasher.

With

the headlamps switched on at the

lighting switch, move the lever down away from the steering-wheel to operate

the high beam (3), lifting the lever towards the steering-wheel

from

the low-beam

position will flash (4), the headlamp high-beams irre spective of whether the

lighting switch is on or off.

(6) Oil . The gauge indicates the pressure of the oil in the engine lubrication

system.

*

(7) Water. The gauge is marked

'C'

(cold),

'N'

(normal),

and'H' (hot), indicating

the temperature

Ofthe coolant as it leaves the cylinder head. *

(8) Fuel. When the ignition is switched on the gauge indicates approximately the

amount

of fuel in the tank. *

(5)

Hea

dlamp high-beam warning lamp (blue). The warning lamp glows when the

headlamps are switched on

and

the beam is in the rai sed position. The lamp

goes out when the beam is lowered.

(6)

Pan

el lamp. When the sidelamps are switched on the instruments may be

illuminated by moving the switch

knob

downwards.

*Also see

'RUN

NING

INSTRUCTIONS'

.

~

-

3 J 6 \

~l

~

L_la

-

::

::::

:

'

--- ,

(iJ

(J)

V

:'

~

'"

I

-d

;,._---

,

~

~

.

n@

,

""

f)l:'

(((

If

)))eJ

'·j

J~

:

: :

...

d:

...

::,

...

1

nu

M"

~"U

n~n,

,~Ln.

'"

vpv.

' V

the high beam (3), lifting the lever towards the steering-wheel

from

the low-beam

position will flash (4), the head lamp high-beams irrespective of whether the

lighting switch is on or off.

Fig. 2

~

:~~~{i)~

no".nn

l_u

engine

and

assists the driver to use the most effective engine speed range for

maximum performance in any gear.

*

Fig. 1

(6) Oil . The gauge indicates the pressure of the oil in the engine lubrication

system.

*

(7) Water. The gauge is marked

'C'

(cold),

'N'

(normal),

and'H' (hot), indicating

the temperature

Ofthe coolant as it leaves the cylinder head. *

(5)

Hea

dlamp high-beam warning lamp (blue). The warning lamp glows when the

headlamps are switched on

and

the beam is in the raised position. The lamp

goes out when the beam is lowered.

(6)

Pan

el lamp. When the sidelamps are switched on the instruments may be

illuminated by moving the switch

knob

downwards.

Instruments

and

Switches

Switches

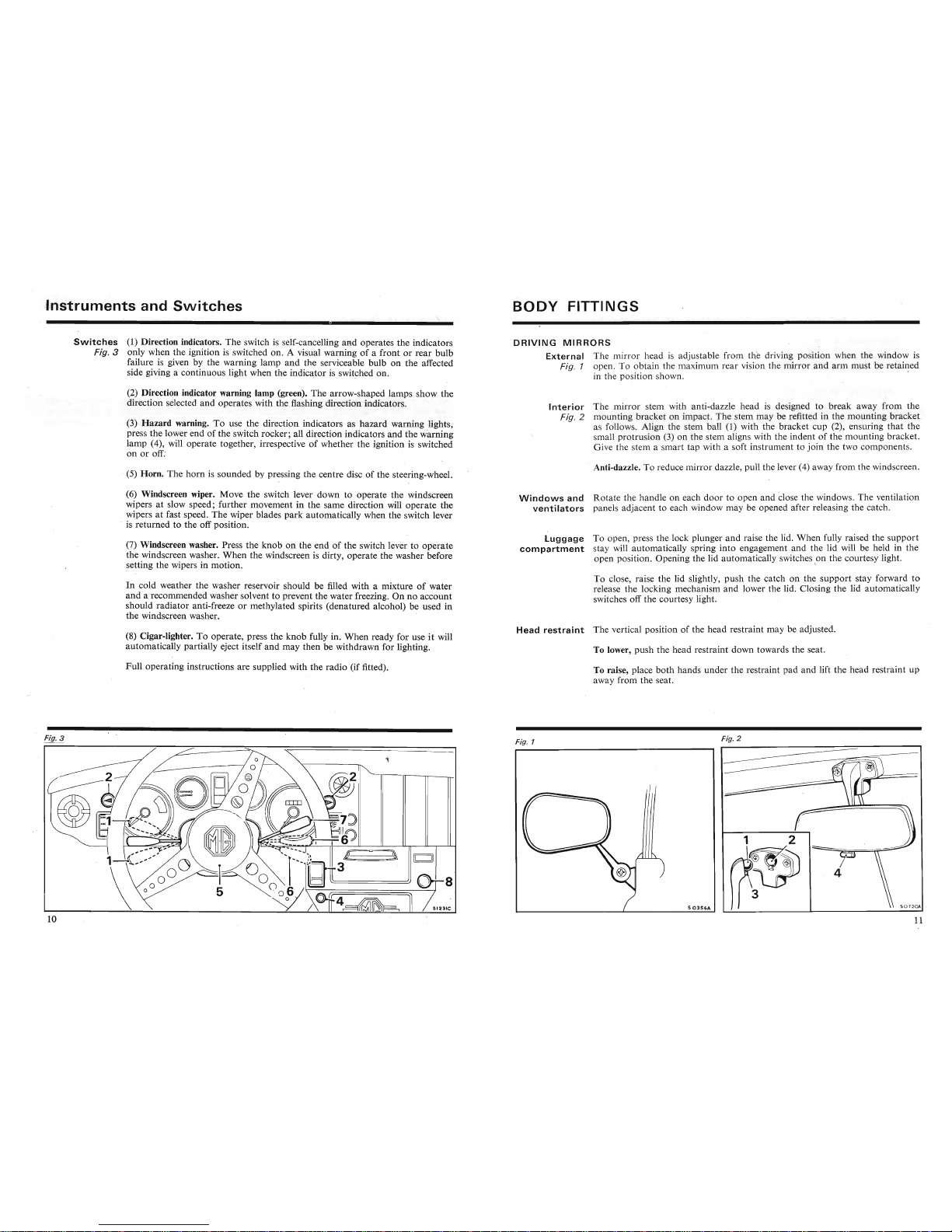

(1) Direction indicators. The switch is self-cancelling and operates the indicators

Fig. 3 only when the ignition is switched on. A visual warning of a front or rear bulb

failure is given by the warning lamp and the serviceable bulb on the affected

side giving a continuous light when the indicator is switched on.

BODY

FITTINGS

DRIVING

MIRRORS

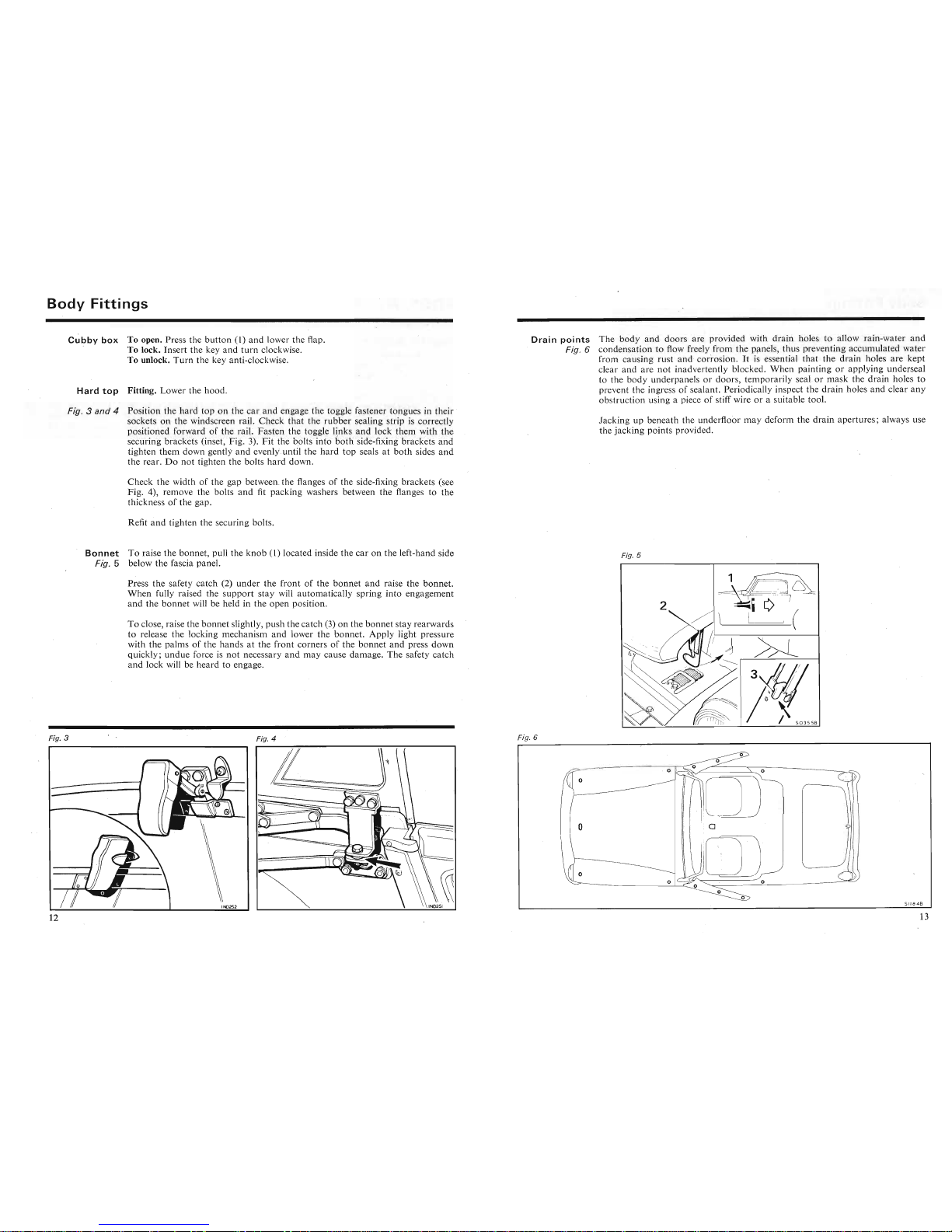

External

The mirror head is adjustable from the driving position when the window is

Fig. 1 open. To obtain the maximum rear vision the mirror and

arm

must be

retai~ed

in the position shown.

(2) Direction indicator warning lamp (green). The arrow-shaped lamps show the

direction selected and operates with the.flashing direction indicators.

(3)

Hazard

warning. To use the direction indicators as hazard warning lights,

press the lower end of the switch rocker; all direction indicators and the warning

lamp (4), will operate together, irrespective of whether the ignition is switched

on or off:

.(5) Horn. The

horn

is sounded by pressing the centre disc of the steering-wheel.

Interior

Fig. 2

The mirror stem with anti-dazzle head is designed to break away from the

mounting bracket on impact. The stem may be refitted in the mounting bracket

as follows. Align the stem ball

(1) with the bracket cup (2), ensuring

that

the

small prot rusion

(3) on the stem aligns with the indent of the mounting bracket.

Give the stem a smart tap with a soft instrument to join the two components .

Anti-dazzle. To reduce mirror dazzle, pull the lever (4) away from the windscreen .

(6) Windscreen wiper. Move the switch lever down to operate the windscreen

wipers at slow speed; further movement in the same direction will operate the

wipers at fast speed. The wiper blades

park

automatically when the switch lever

, is returned to the off position.

(7) Windscreen washer. Press the knob on the end of the switch lever to operate

the windscreen washer. When the windscreen is dirty, operate the washer before

setting the wipers in motion.

In

cold weather the washer reservoir should be filled with a mixture of water

and a recommended washer solvent to prevent the water freezing. On no account

should radiator anti-freeze or methylated spirits (denatured alcohol) be used in

the windscreen washer. .

(8) Cigar-lighter. To operate, press the knob fully in. When ready for use it will

automatically partially eject itself

and

may then be withdrawn for lighting.

Full operating instructions are supplied with the radio (if fitted).

Windows

and

Rot

ate the handle on each door to open and close the windows. The ventilation

ventilators

panels adjacent to each window may be opened after releasing the catch .

Luggage

To open, press the lock plunger

and

raise the lid. When fully raised the

support

compartment

stay will automatically spring into engagement and the lid will be held

III

the

open posit ion . Opening the lid automatically switches ,on the courtesy light.

To close, raise the lid slightly,

push

the catch on the support stay forward to

release the locking mechanism and lower the lid. Closing the lid automatically

switches off the courtesy light.

Head

restraint

The vertical position of the head restraint may be adjusted.

To lower, push the head restraint down towards the seat.

To raise, place

both

hands under the restraint pad and lift the head restraint up

away from the seat.

(3)

Hazard

warning. To use the direction indicators as hazard warning lights,

press the lower end of the switch rocker; all direction indicators and the warning

lamp (4), will operate together, irrespective of whether the ignition is switched

on or off:

.(5) Horn. The

horn

is sounded by pressing the centre disc of the steering-wheel.

Fig. 1

(

Interior

Fig. 2

Fig. 2

)

mirror

If/lm

With

anti- azzie neaa

IS

aeSlgn::oreaK

away

rrom~

e

mounting bracket on impact. The stem may be refitted in the mounting bracket

as follows. Align the stem ball (1) with the bracket cup (2), ensuring

that

the

small prot rusion

(3) on the stem aligns with the indent of the mounting bracket.

Give the stem a smart tap with a soft instrument to join the two components .

Anti-dazzle. To reduce mirror dazzle, pull the lever (4) away from the windscreen .

(6) Windscreen wiper. Move the switch lever down to operate the windscreen

wipers at slow speed; further movement in the same direction will operate the

wipers at fast speed. The wiper blades

park

automatically when the switch lever

, is returned to the off position.

Windows

and

Rot

ate the handle on each door to open and close the windows. The ventilation

ventilators

panels adjacent to each window may be opened after releasing the catch .

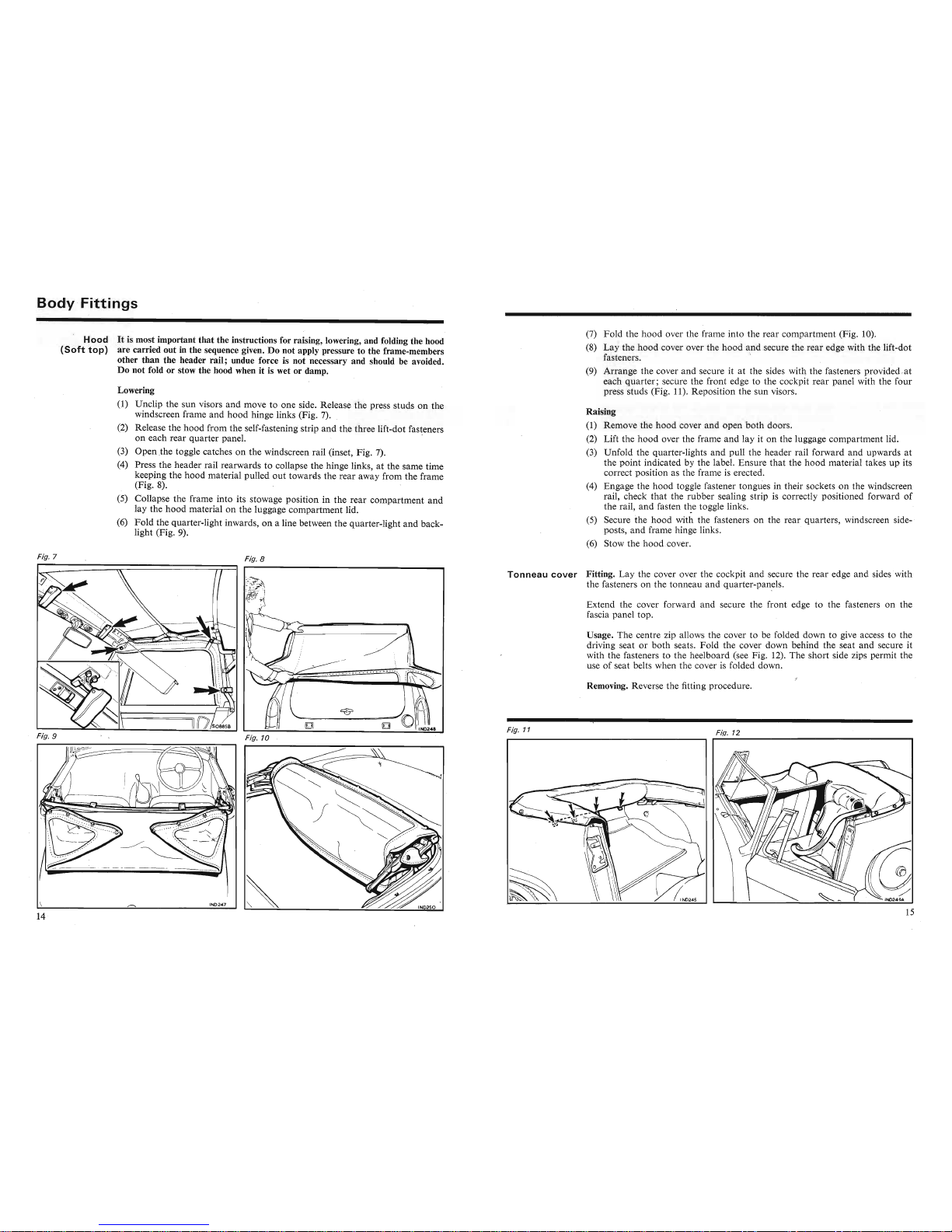

Body

Fittings

Cubby

box

To open. Press the b

utto

n (I )

and

lower the flap.

To lock. Insert the key a nd t

urn

clockwise.

To unlock.

Turn

the key anti-clockwise.

Hard

top

Fitting. Lo we r the h

ood.

Fig. 3 and 4

Position

the

hard

toponthe

car

and enga ge

the

toggle faste ner

tongu

es in their

sockets

on

the

windscreen rail.

Checkthat

the

rubb

er sealing strip is correctly

positioned for

ward

of the rail. Fasten th e toggle link s and lock them with th e

secur ing

bra

ckets (inset,

Fig

. 3).

Fit

the bolts

into

both

side-fixing

brackets

and

tighten

them

down gentl y and evenly .until the

hard

top

seals at

both

sides

and

the

rear.Donot

tighten the

bolts

hard

down

.

Dra i n point s

The

body and doors

are

prov

ided wit h drain hol es to

allo

w ra in-water and

Fig. 6 conde nsation to flow freely fro m the pan els,

thu

s prev

enting

accu mulated water

from

causing r ust and c

orros

ion. It is esse ntial that

thedrain

holes a re ke pt

clear a nd

are

not inad vertentl y blocked .When p

ainting

or applying

unde

rsea I

to the bo dy

und

erpan els or doors, te

mporar

ily

sealorma

sk th edrain hol es to

prevent th e

ingr

essofsealant. Period icall y inspect the

drain

holes a nd clea r an y

o

bstr

uction usin g a piece of stiff wire or a suitable tool.

Jac king up bene

ath

the

underfloor

ma y d

eform

the

drain

aperture

s; a lways use

the jacking

pointspro

vided.

Che

ck the

widthofthe

gap between. the flanges of

the

side-fixing

bracket

s (see

Fig. 4),

remove

the

bolts

and

fit

packing

washers between

the

flanges to

the

thicknessof

the gap .

Refit

and

tighten the securing bolts.

Bonnet

To

raise the

bonnet,

pull th e

knob

(1) located inside

the

caronthe

left-hand side

Fig. 5 below the fascia panel.

Fig. 5

Pre ssthe safety

catch

(2)

underthefrontofthe

bonnet

and raise

the

bonn

et.

When

fully ra ised the

supportstay

will

autom

atically spring

into

engagement

and

the

bonn

et will be held in

theopen po sition.

To

close, raise the

bonnet

slightly, pu sh

the

catch

(3)onthe

bonnet

stay rea rwards

to release

the

locking mech

anismand

lower

the

bonn

et.

Appl

y light pres

sure

with

the

palmsofthe

hand

s at

the

front

cornersofthe

bonnet

and press do wn

quickly ;

und

ue force is

not

necessary

andmay

cause

damage.

The

safety

catch

and

lock

will be

heard

to engage.

n

Jac

king up ben e

ath

the

underfloor

ma y d

eform

the

drain

aperture

s; always use

the jacking

point

s provided.

Fig

. 6

Fig.4

.

\,

-=

Fig. 3 and 4

Position

the

hard

toponthe

car

and enga ge

the

toggle fasten e r

tongu

es in their

so

cketsonthe

windscreen rail.

Check

that

the rub

ber

sealing str ip is

cor

rectl y

positioned

for

ward

of the rai l. Fasten th e toggle link s

and

lock th em with th e

secur ing

bra

ckets (inset ,

Fig

. 3).

Fit

the bolts

into

both

side-fixing

brackets

and

tighten

them

down gentl y and evenly .until the

hard

top

seals at

both

sides

and

the

rear.Donot

tighten the

bolts

hard

down

.

Fig. 3

Che

ck the

widthofthe

gap between. the flanges of

the

side-fixing

bracket

s (see

Fig. 4) ,

remove

the

bolts

and

fit

packing

washers between

the

flanges to

the

thicknessofthe gap.

Refit

and

tighten the securing bolts.

Body

Fitti

ngs

Hood

It

is most important

that

the instructions for raising, lowering, and folding the hood

(Soft

top)

are carried out in the sequence given. Do not apply pressure to the frame-members

other than the header rail; undue force is not necessary and should be avoided.

Do not fold or stow the hood when it is wet or damp.

Lowering

(1) Unclip the sun visors and move to one side. Release the press studs on the

windscreen frame and hood hinge links (Fig. 7). .

(2) Release the hood from the self-fastening strip and the three lift-dot fasteners

on each rear quarter panel. '

(3) Open

.the toggle catches on the windscreen rail (inset, Fig. 7).

(4) Press the header rail rearwards to collapse the hinge links at the same time

keeping the

hood

material pulled out towards the rear away from the frame

(Fig. 8).

(5) Collapse the frame into its stowage position in the rear compartment

and

lay the

hood

material on the luggage compartment lid.

(6)

Fold

the quarter-light inwards, on a line between the quarter-light and back-

light (Fig. 9).

(7)

Fold

the hood over the frame into the rear compartment (Fig. 10).

(8) Lay the hood cover over the hood and secure the rear edge with the lift-dot

fasteners. '

(9) Arrange the cover and secure it at the sides with.the fasteners provided

.at

each

quarter;

secure the front edge to the cockpit rear panel with the four

press studs (Fig. 11). Reposition the sun visors.

Raising

(1) Remove the hood cover and open

both

doors.

(2) Lift the

hood

over the frame and lay it on the luggage compartment lid.

(3) Unfold the quarter-lights and pull the header rail forward and upwards at

the point indicated by the label. Ensure that the

hood

material takes up its

correct position as the frame is erected.

(4) Engage the hood toggle fastener tongues in their sockets on the windscreen

rail, check that the rubber sealing strip is correctly positioned forward of

the rail, and fasten

t~e

toggle links.

(5) Secure the hood with the fasteners on the rear quarters, windscreen side-

posts,

and

frame hinge links.

(6) Stow the

hood

cover.

Usage. The centre zip allows the cover to be folded down to give access to the

driving seat or

both

seats.

Fold

the cover down behind the seat and secure it

with the fasteners to the heel

board

(see Fig. 12). The short side zips permit the

use of seat belts when the cover is folded down .

Fi.q.12

Removing. Reverse the fitting procedure.

-f<~~

-r~

I~:

"';

~JI

~~~,~-_

.

7

<.

. \

~."~:.

~::''-'';

-':;'-.,

~

\

Raising

(1) Remove the hood cover and open

both

doors.

(2) Lift the

hood

over the frame and lay it on the luggage compartment lid.

(3) Unfold the quarter-lights and pull the header rail forward and upwards at

the point indicated by the label. Ensure that the

hood

material takes up its

correct position as the frame is erected.

(4) Engage the hood toggle fastener tongues in their sockets on the windscreen

rail, check that the rubber sealing strip is correctly positioned forward of

the rail, and fasten

t~e

toggle links.

(5) Secure the hood with the fasteners on the rear quarters, windscreen side-

_~~.~~_

A

.._

~~~l..:_~~

1 :_1,

~

Tonneau

cover

Fitting. Lay the cover over the cockpit and secure the rear edge and sides with

the fasteners on the tonneau and qua rter-panels,

Extend the cover forward and secure the front edge to the fasteners on the

fascia panel top.

Fig. 11

Fig.

8

~',.""

,

~

"e,~

,:::::,'

J

~

~

vu",iV

L!~c"~

'(;~'c:111

llVV\;LVVI

MU\;.

l'..l:ll:(1SI:

lilt:

press

STUQ

windscreen frame and hood hinge links (Fig. 7).

(2) Release the hood from the self-fastening strip and the three lift-dot fasteners

on each rear quarter panel. '

(3) Open

.the toggle catches on the windscreen rail (inset, Fig. 7).

(4)

Pres~

the header rail rearwards to collapse the hinge links, at the same time

keeping the

hood

material pulled out towards the rear away from the frame

(Fig. 8).

(5) Collapse the frame into its stowage position in the rear compartment

and

lay the

hood

material on the luggage compartment lid.

(6)

~0.td

~~~

quarter-light inwards, on a line between the quarter-light and back-

Fig. 7

SEATS

AND

SEAT BELTS

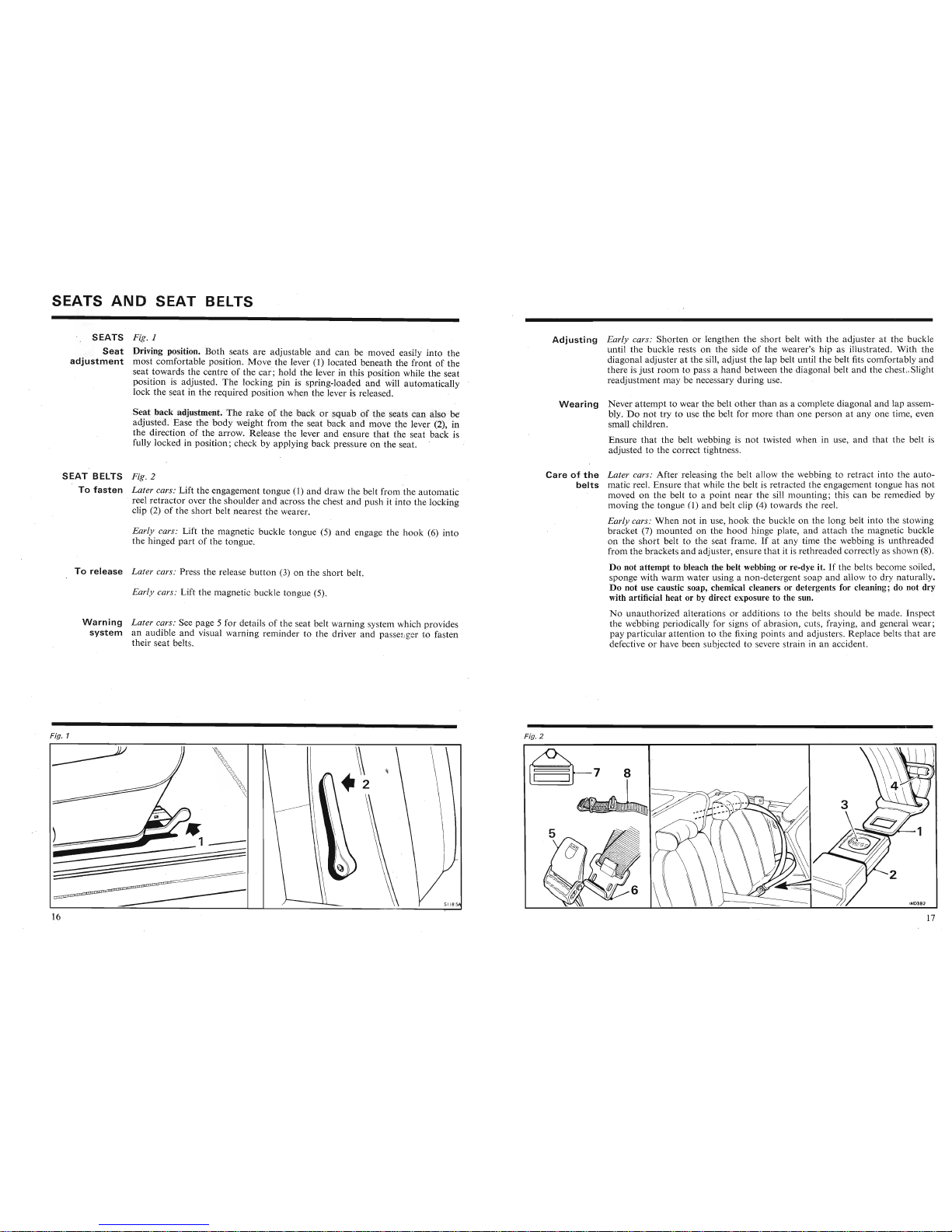

SEATS

Fig. 1

Seat

Driving position. Both seats are adjustable and

can

be moved easily

into

the

adjustment

most comfortable position.

Move

the lever (1) located beneath the front of the

seat towards the centre of the

car;

hold the lever in this position while the seat

position is adjusted. The locking pin is spring-loaded

and

will automatically

lock the seat in the required position when the lever is released. '

Adjusting

Early cars: Shorten or lengthen the short belt with the adjuster at the buckle

until the buckle rests on the side

of the wearer's hip as illustrated. With the

diagonal adjuster at the sill, adjust the lap belt until

the

belt fits comfortably

and

there is

just

room

to pass a

hand

between the diagonal belt

and

the chest..Slight

readjustment may be necessary during use.

Seat

back adjustment. The rake of the back or

squab

of the seats

can

also be

adjus~ed.~ase

the body weight from the seat back

and

move the lever (2), in

the direction of the arrow. Release the lever

and

ensure

that

the seat back is

fully locked in position; check by applying back pressure on the seat.

Wearing

Never

attempt

to wear the belt

other

than as a complete diagonal and lap assem-

bly.

Do

not

try to use the belt for more

than

one person at

anyone

time, even

small children.

Ensure

that

the belt webbing is

not

twisted when in use, and

that

the belt is

adjusted to the correct tightness.

SEAT

BELTS

Fig. 2

To

fasten

Later

cars: Lift the engagement tongue (1) and draw the belt from

the

automatic

, reel retractor over the shoulder

and

across the chest and push it into the locking

clip (2) of the short belt nearest the wearer.

Early cars: Lift the magnetic buckle tongue (5)

and

engage the

hook

(6)

into

the hinged

part

of the tongue.

To

release

Later

cars: Press the release

button

(3) on the short belt.

Early cars: Lift the magnetic buckle tongue (5).

Warning

Later

cars: See page 5 for details of the seat belt warning system which provides

system

an audible

and

visual warning reminder to the driver

and

passenger to fasten

their seat belts.

Careofthe

Later cars: After releasing the belt allow the webbing to retract into the auto-

belts

matic reel. Ensure

that

while the belt is 'retracted the engagement tongue has

not

moved on the belt to a point near the sill mounting; this can be remedied by

moving the tongue

0)

and belt clip (4) towards the reel. '

Early cars:

When

not

in use,

hook

the buckle on the long belt into the stowing

bracket

(7) mounted on the

hood

hinge plate,

and

attach

the magnetic buckle

on the short belt to the seat frame. If at any time the webbing is unthreaded

from the brackets

and

adjuster, ensure

that

it is rethreaded correctly as shown (8).

Do not attempt to bleach the belt webbing or re-dye it.

If

the belts become soiled,

sponge with warm water using a non-detergent soap and allow to dry naturally.

Do not use caustic soap, chemical cleaners or detergents for cleaning; do not dry

with artificial heat or by direct exposure to the sun.

No unauthorized alterations or additions to the belts should be made . Inspect

the webbing periodically for signs of abrasion, cuts, fraying, and general wear ;

pay particular attention to the fixing points and adjusters. Replace belts

that

are

defective or have been subjected to severe strain in an accident.

Fig. 1

8

Ensure

that

the belt webbing is

not

twisted when in use, and

that

the belt is

adjusted to the correct tightness.

vvcallll~

~7

Fig. 2

\

Seat

back adjustment. The rake of the back or

squab

of the seats

can

also be

adjus~ed.~ase

the body weight from the seat back

and

move the lever (2), in

the direction of the arrow. Release the lever

and

ensure

that

the seat back is

fully locked in position; check by applying back pressure on the seat.

SEAT

BELTS

Fig. 2

To

fasten

Later

cars: Lift the engagement tongue (1) and draw the belt from

the

automatic

, reel retractor over the shoulder

and

across the chest and push it into the locking

clip (2) of the short belt nearest the wearer.

Careofthe

Later cars: After releasing the belt allow the webbing to retract into the auto-

belts

matic reel. Ensure

that

while the belt is 'retracted the engagement tongue has

not

moved on the belt to a point near the sill mounting; this can be remedied by

moving the tongue

0)

and belt clip (4) towards the reel. '

Early cars:

When

not

in use,

hook

the buckle on the long belt into the stowing

1 _~1_ _ •

/,..,

'\.~__

._.L

_.J

_ __ L L '-- L

__

...J L

~

a _ _

__

1

_.L

_ _ __ ...J~LL

_

~

L .L L

~~_~~~~.L':

~L~

,..-1_1

~

Loading...

Loading...