MG Midget J1 1933, Midget J2 1933 Instruction Manual

The

Instruction

Manual

Midget

(J

Series]

Price

f0l-

net

The

Instruction Manual

for

the

Midget

The

M.G.

Midget

model

J2

Two-Seater

TELEGRAMS

EMGEE

The

M.G.

Cm Company, Ltd.

zP,V:R,N,',N:

ABINGDON SIR WlLLlAM

TELEPHONE

R. MORRIS.

BT.

251

(3

LINES)

MANAGING

ABINGDON-

D1 RECTOR

ON-THAM ES

Abingdon-on-Thrrmes

cEclL K~MBER

M

I.*

E.

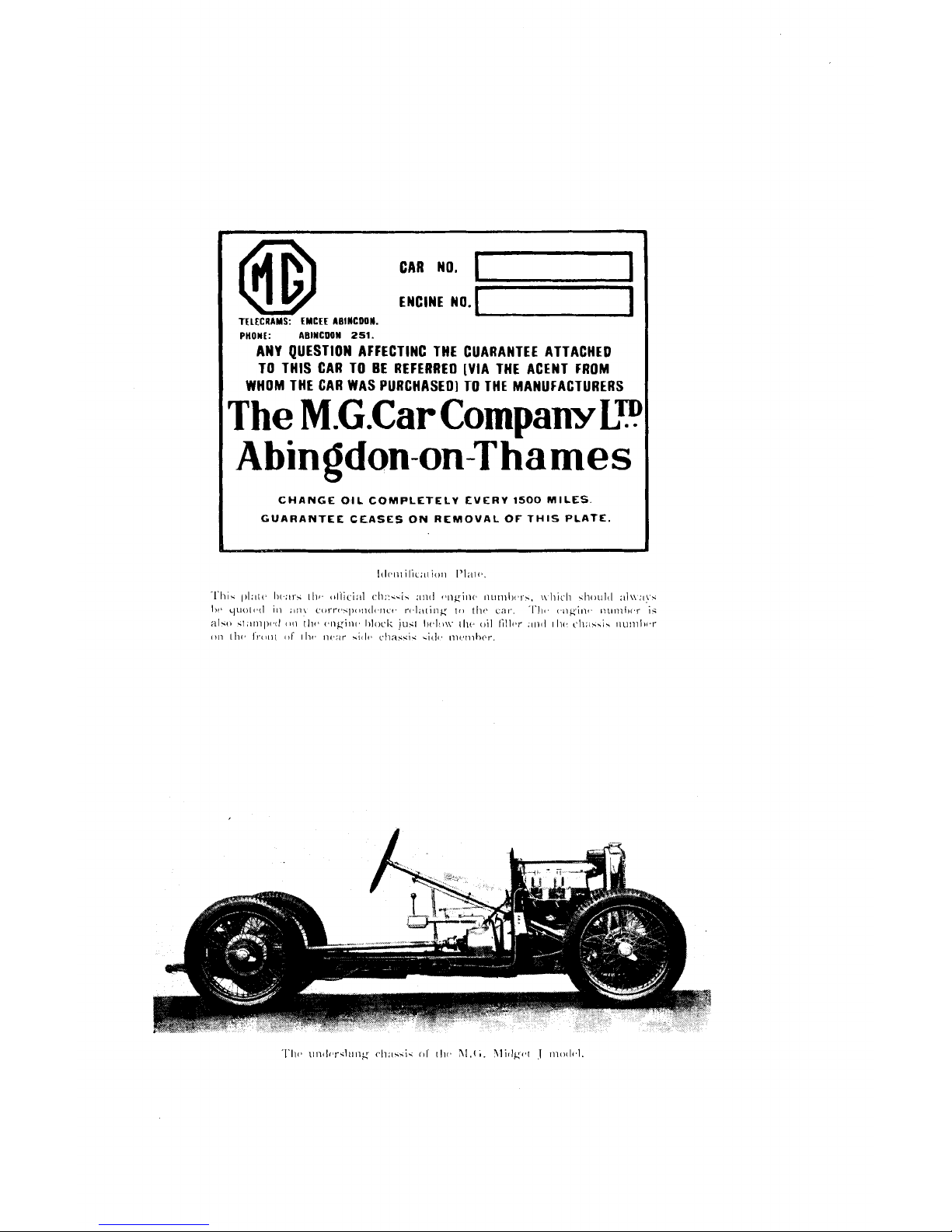

CAR NO.

I-1

TELECRAMS:

EMCEE

ABINCDON.

PHOllt: lBlYCDOW

251.

ANY QUESTION

AFFECTING

THE CUARANTEE ATTACHED

TO THIS CAR TO BE REFERRED [VIA THE ACENT FROM

1

WHOM THE CAR WAS PURCHASED] TO THE MANUFACTURERS

The

M.G.Car

Company

L?

Abingdon-on-Thames

CHANGE OIL COMPLETELV EVERV

1500

MILES.

GUARANTEE

CEASES

ON

REMOVAL

OF

THIS

PLATE.

Chassis

No

.............................................................................

Must be quoted

1

in

a11

Engine

No.

!

oorrsspondenoe

...........................

Owner

:

IMPORTANT

HE

attention of owners of new

..G.

Midget Sports cars is

drawn to the following.

The importance of carefully

running-in a new engine cannot

be over-estimated, and care and

restraint during the first 2,000

miles will be handsomely repaid.

Change the engine oil after the

first 500 miles, and every

1,OOr-

1,500 miles thereafter.

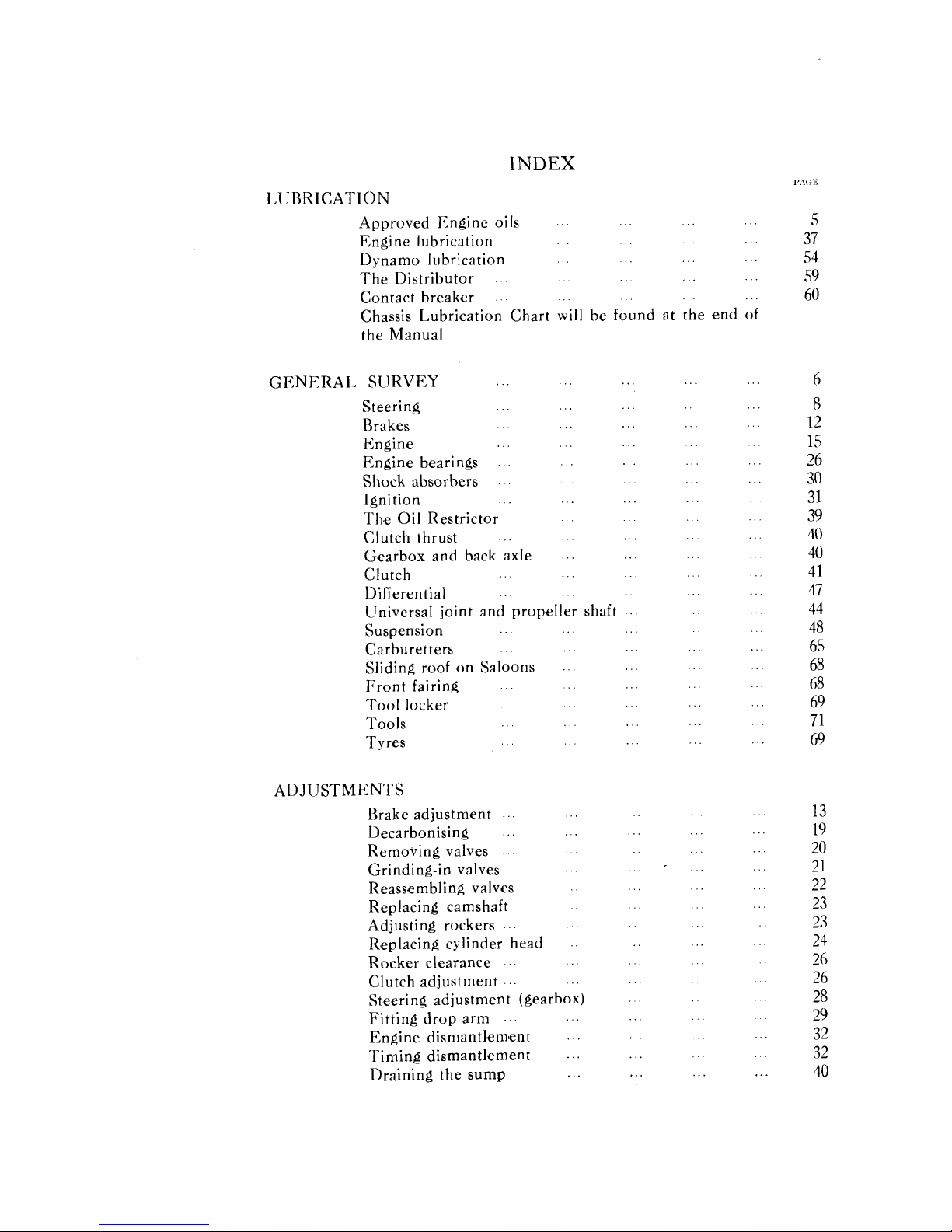

INDEX

I.

URRICATION

...

... ...

Approv'ed Engine oils

...

...

...

...

...

Engine lubrication

...

...

...

...

Dynamo lubrication

...

...

...

...

The Distributor

...

...

...

...

Contact break'er

...

.

.

Chassis Lubrication Chart will be found at the end of

the Manual

...

...

...

...

GENERAL SURVEY

...

...

...

...

Steering

...

...

...

...

Brakes

...

...

...

...

Engine

... ...

...

Engine bearings

...

...

...

...

Shock absorbers

...

...

...

...

...

Ignition

...

...

...

Th. e

Oil

Restrictor

...

...

...

...

Clutch thrust

...

...

Gmearbox and back axle

...

...

...

...

...

Clutch

...

...

...

...

Differ'ential

...

Universal joint and propeller shaft

...

...

Suspension

...

Carburetters

Sliding roof on Saloons

...

Front fairing

Tool locker

...

Tools

Tyres

.

.

ADJUSTMENTS

...

Brake adjustment

...

Decarbonising

...

Removing valves

Grinding-in valv. es

Reassembling valv'es

Replacing camshaft

...

Adjusting rockers

Replacing cylinder head

...

Rocker clearance

Clutch adjustment

...

Steering adjustment (gearbox)

...

Fitting drop arm

...

...

Engine dismantl. em'ent

...

Timing dismantlement

...

Draining the sump

Axle disnl:~ntlen~ent

.

.

...

...

Removing the dynamo

...

'I'he detection and remedy of ignition f;rults

.

... ...

l'ngine will not fire

...

...

...

Misfiring :~nd had starting

...

...

Iicpl:~cenlcnt of lamp bulbs

...

...

...

Carburetters

...

...

Carburetter synchronising

...

Tyre pressure

... ...

...

...

...

...

Removing tyres

.

.

...

I)yn:~mo

...

13rushes

...

Conlmutator

Dynamo field fuse

'Third brush regulator

...

Starter motor

...

Battery

...

Ammeter

F

11

ses

...

The

Cut-out

...

Distributor

Coil

CVarinng lamp

..

...

Headlamps

Side lamps and tail I:~nlp

...

Horn

...

Petrol pump

...

Wiring diagrams

...

52

...

53

...

54

...

54

...

56

...

56

...

57

...

S8

...

58

...

58

59

...

60

...

60

...

61

...

62

...

62

...

63

facing page

49

'I'he lista of

M.G.

Agents. Radi:ltor Repair Service Ilepots. 13ucas Agents.

:Ire to he found at the end of the Manual

.

FOREWORD.

PAGE

ONE

IJAGE

TWO

The

Manual

of

the

M.G.

Midget

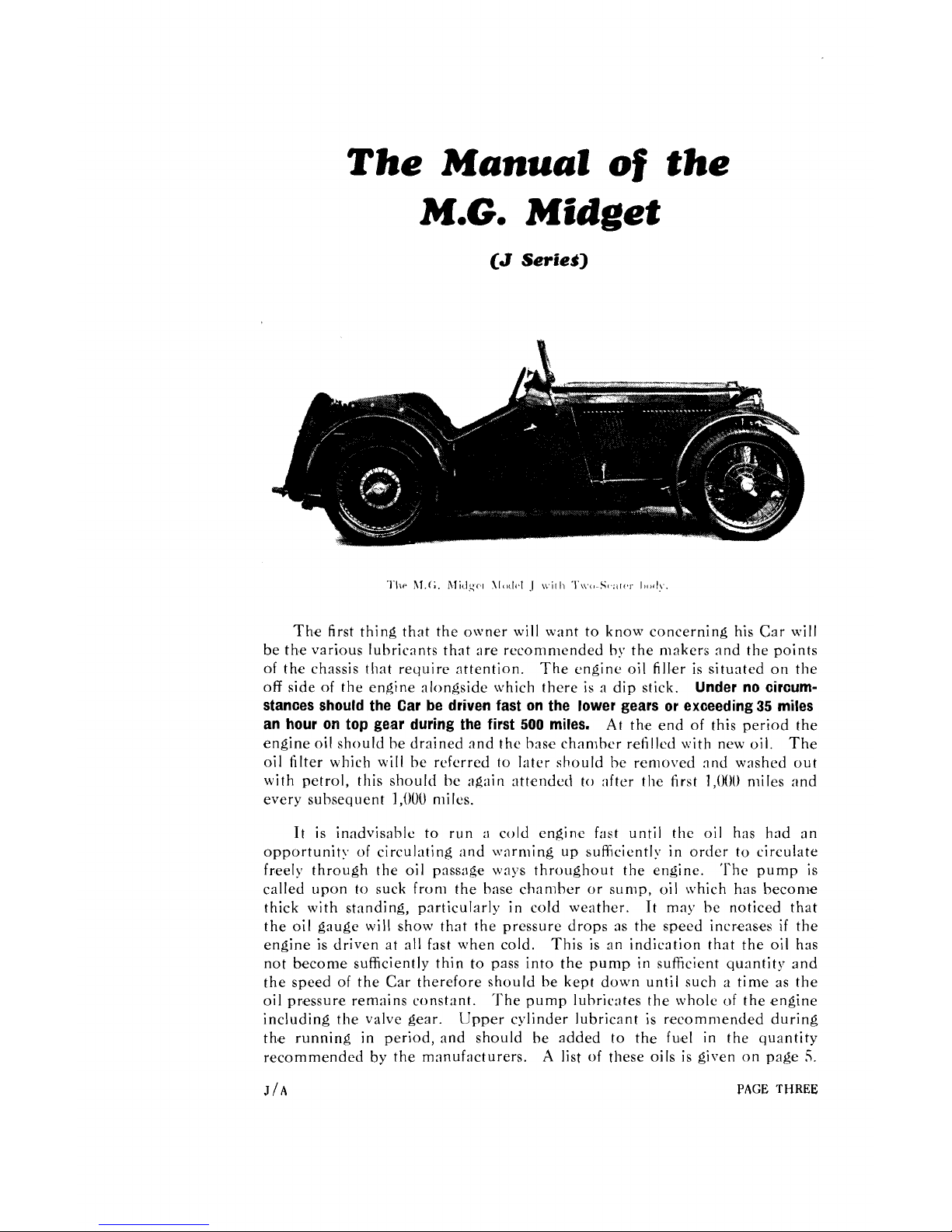

The first thing that the owner will want to know concerning his Car will

be the various lubricants that are recommended by the makers and the points

of

the chassis that require attention. The engine

oil

filler is situated on the

off

side

of

the engine alongside which there is a dip stick.

Under no circumstances should the Car be driven fast on the lower gears or exceeding 35 miles

an hour on top gear during the first 500 miles.

At

the end

of

this period the

engine

oil

should be drained and the base chamber refilled with new

oil.

The

oil

filter which will be refcrred to later should be removed and washed out

with petrol, this should be again attended to after the first

1,000

miles and

every subseq~~ent

1,000

miles.

It is inadvisable to run

:I

cold engine fast until the

oil

has had an

opportunity

of

circulriting and warming up aufficientl!. in order to circulate

freely through the

oil

passage ways throughout the engine. The pump is

called upon to suck from the base chamber or sump,

oil

which has become

thick with standing, particularly in cold weather. It may be noticed that

the

oil

gauge will show that the pressure drops as the speed increases if the

engine is driven at all fast when cold. This is an indication that the

oil

has

not become sufficiently thin to pass into the pump in suficient quantity and

the speed

of

the Car therefore should be kept down until such a time as the

r

>

oil

pressure remains constant. I he pump lubric:~tes the wholc

of

the engine

including the valve gear. Upper cylinder lubricant is recommended during

th'e running in period, and should be added to the fuel in the quantity

recommended by the manufacturers.

A

list

of

these oils is given on page

5.

J/A

PAGE THREE

It is just

:1b

in~portant nhen warnling up the cncinc not to allo\\~ it to tick

o\Ter too slo\\'ly (:ipprosini:~tely,

1,000

r.p.m. is the hest w:~rniing up engine

speed), as this will pre\ ent the qlinder \\:ills being properly luhricnted owing

to thickness of the oil, :ilso do not use the choke :Iny IonQcr than necessary.

,

.

I

he gearhos and rear :~xle are provided n it11 hes:iQon shape ups situated

in such a manner that they :~utonintic:~Il) indicate the height level to which

oil

should he filled, :~nd prevent the possibility of over filling. It should he

renicmhercd that the Car should not he n~ovcd in :In!. \\.:~y \vhen the gear

box and hack axle :Ire being filled, otherwise additional luhric:~nt may be

carried round

by

the teeth

of

the gears thus causing the housing to contain

more

oil

than they need and above the proper level.

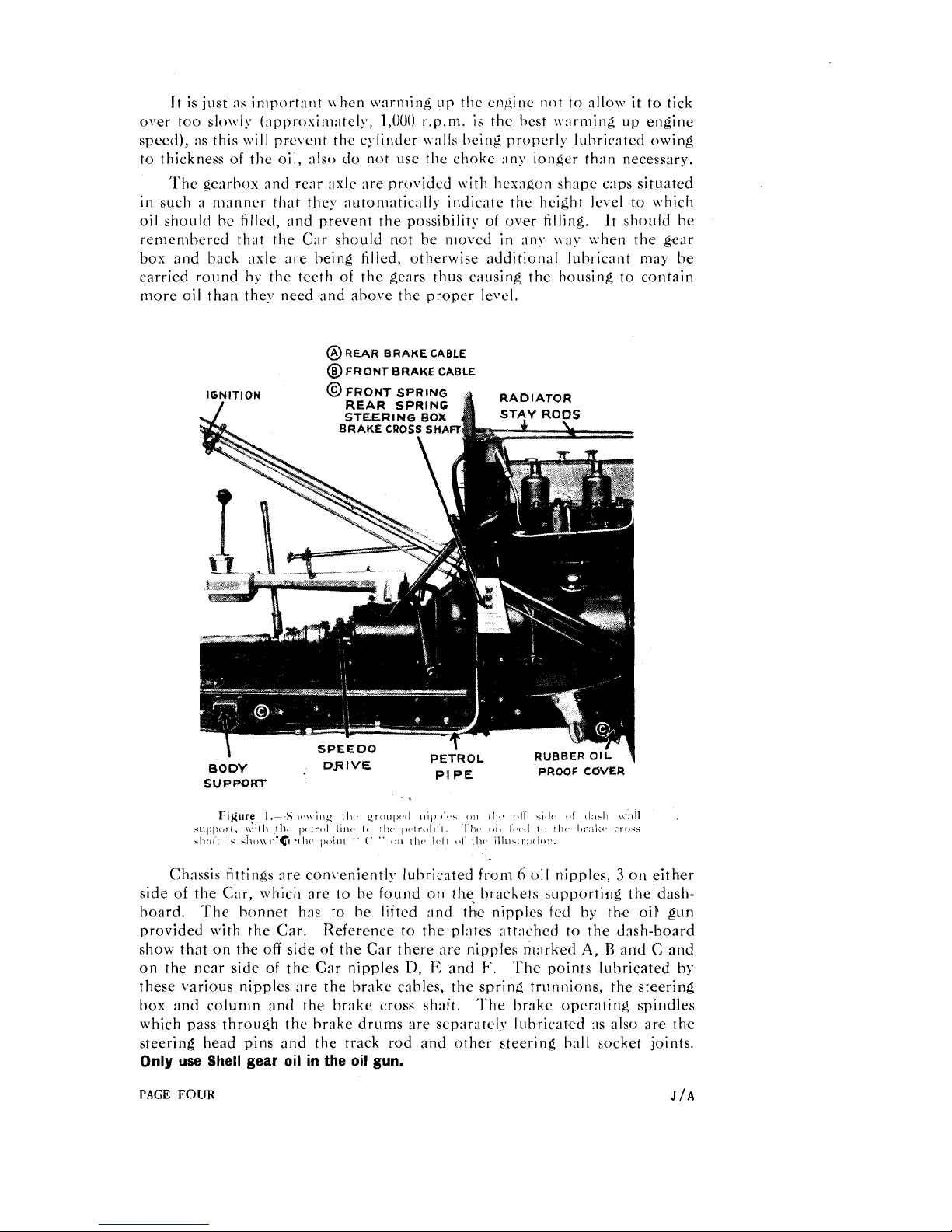

@

REAR

BRAKE

CABLE

@FRONT

BRAKE

CABLE

v

a.

-

SUPPORT

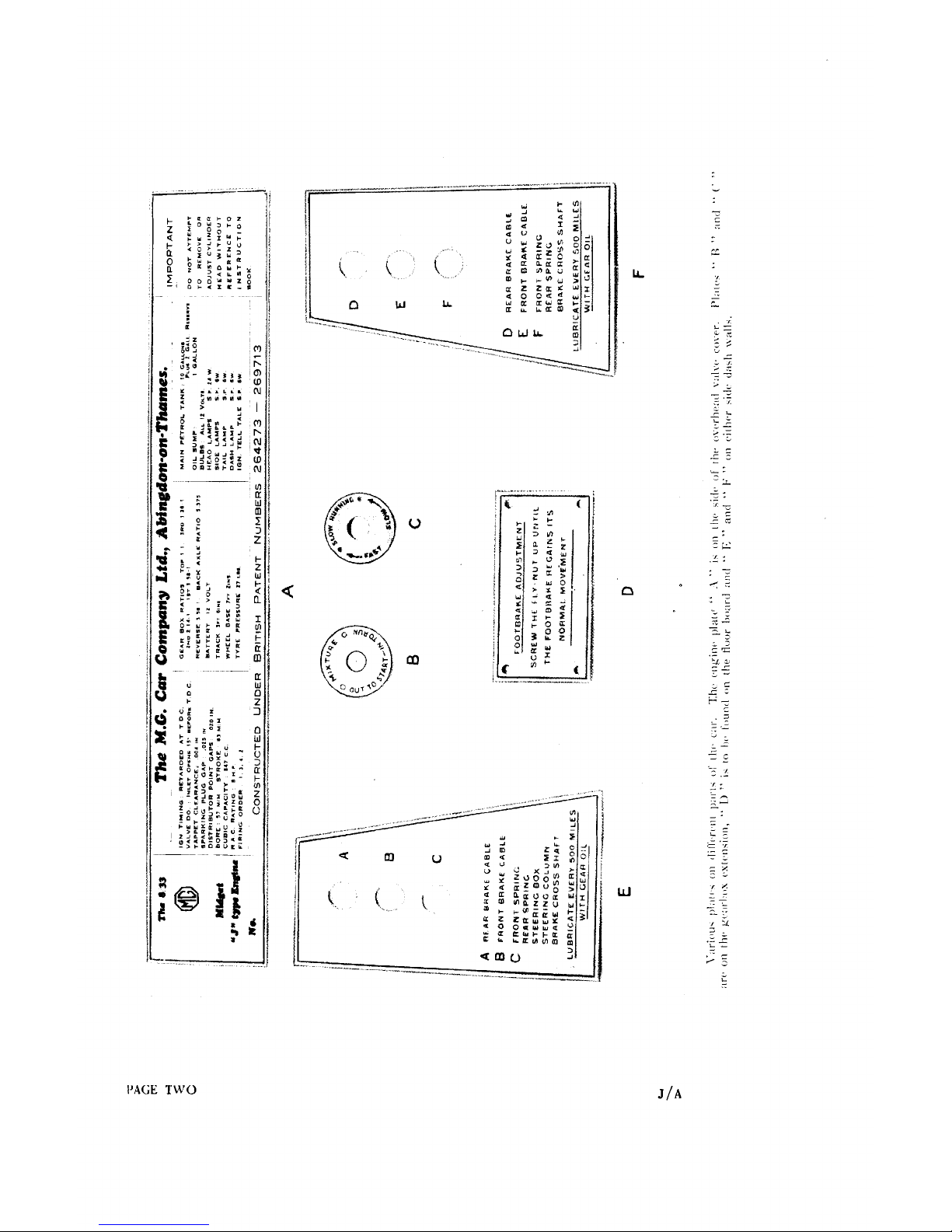

Chassis fittings :Ire conveniently lubricated from

A

oil

nipples, 3 on either

side

of

the Car, which are to he found

on

the brackets supportiiig the dash-

hoard. The bonnet has to be lifted and the nipples fed

by

the

oiP

gun

provided with the Car. Reference to the pl:~tes :~tt:~ched to the dash-board

show that on the

off

side

of

the C:lr there are nipples n~:~rked

A,

H

and C and

on the near side

of

the C:lr nipples

D,

1'

and

F.

'l'he points luhricated by

these various nipples are the hr;tke cables, the spring trunnions, the steering

box and colunln and the bnke cross shaft. 'l'he hrake opcr:~ting spindles

which pass through the hrake drums are separately lubricated

:IS

also are the

steering head pins and the track rod and other steering hall socket joints.

Only use Shell gear oil in the oil gun.

PAGE

FOUR

J

/A

A

lubricating chart is provided at the end of the book indicating the

lubrication that is carried out from the central dash-board nipples and is

shown in black and the other points on the Chassis that have to he individually

lubricated are shown

with a red circle surrounding them, and

if

there is any

doubt in any owner's mind as to the exact location of the nipples, they can

be seen in one or more of the illustrations of the parts contained in this

manual.

'The following lubricants are recommended by the Company

:

Approved Engine Oils.

Everv M.G. Midget is tested on AeroShell and

the sump and spare tin are filled with the same brand when the car is issued

new.

W,e very strongly recommend the use of this oil, as we have found it

most satisfactory under the most arduous racing conditions.

On the rare occasions when AeroShell cannot be obtained the following

is the list of Oils approved for use

:-

Shell Triple (summer and winter).

Castrol

XI,

(winter), XXI, (summer).

Uuckham's Adcol

NP2

(winter), NI'3 (summer).

Sports

"

Filtrate " (regd.) (summer and winter).

Mobiloil

"

AF

"

(\\inter),

" D "

(summer).

Morrisol (summer and winter).

I'r;~tts' He:~vy (summer and winter).

I'rice's Motorine

"

C " de 1,uxe (summer :~nd \\inter).

Speedolene

"

13

"

(summer and winter).

Sternol

WW

Heavy (summer and winter).

Gearbox and Back Axle.-As

in the case of engine oils, we ;llso append

the following list as approved for use in the gearbox and back axle

:

-

Gcarhov

ant1

Back

Aslc.

Shell Gear Oil.

Castrol Gear Oil.

I)uckham1s Ge:lr

Oil

"

N."

Filtrate Gear

Oil

(regd.).

Mobiloil

"

C."

(Mobiloil " Cif'

"

for gearbox in \\inter).

t'ratts' Gear Oil.

Price's Motorine

Amber

"

R."

SpeedoIene

"

H."

Stern01 Liquid Ambroleum.

Upper Cylinder and Supercharger Vane Lubricants.

Shell Ilpper Cylinder 1,ubric:lnt.

Castrollo.

Gargoyle Ilpper Cylinder I>ubricant.

Mixtrol.

and under no circumstances must a mineral and vegetable base oil be mixed

in the engine.

Great care should b,e exercised in mixing oils at all, and

it

is far prcferable

if

anybody wishes to run on a particular oil or is sop forced by circumstances,

that the old oil should be drained out first :~nd a completc

replenishment

made.

[Tnder no circumstances should paraffin be used to wash out the lubric-

ating system unless the engine is being dismantled.

More detailed instruction

of the lubricating system of the engine will be found on

p:~ges 37-40 which

J/A

PAGE

FIVE

deals with the complete travel of the oil from the sump to the pump, thence

through the various pipes and passnges in the engine to

the

main 2nd big

end benrings and to the overhead valve gear. The oil pump is provided with

a relief valve of very simple construction consisting of a spring and dash-pot

enclosed in a cover plug.

The details of this will also be found on page

38.

We will now leave the general lubrication summary with the advice to

only use recommended oils whenever obtainable.

Five gallon drums can

always he supplied by :~ccrcdited Agents, and this is by far the cheapest

way of buying oil. Keep the receptacle that is used for filling clean

and covered, :~nd also wash around back axle and gear box filler

caps before these

:Ire unscrewed.

The Engine, gearbox, and back axle should

preferably be drained prior to refilling after the Car has been running some

time, so that the lubricant has had a chance to become fluid.

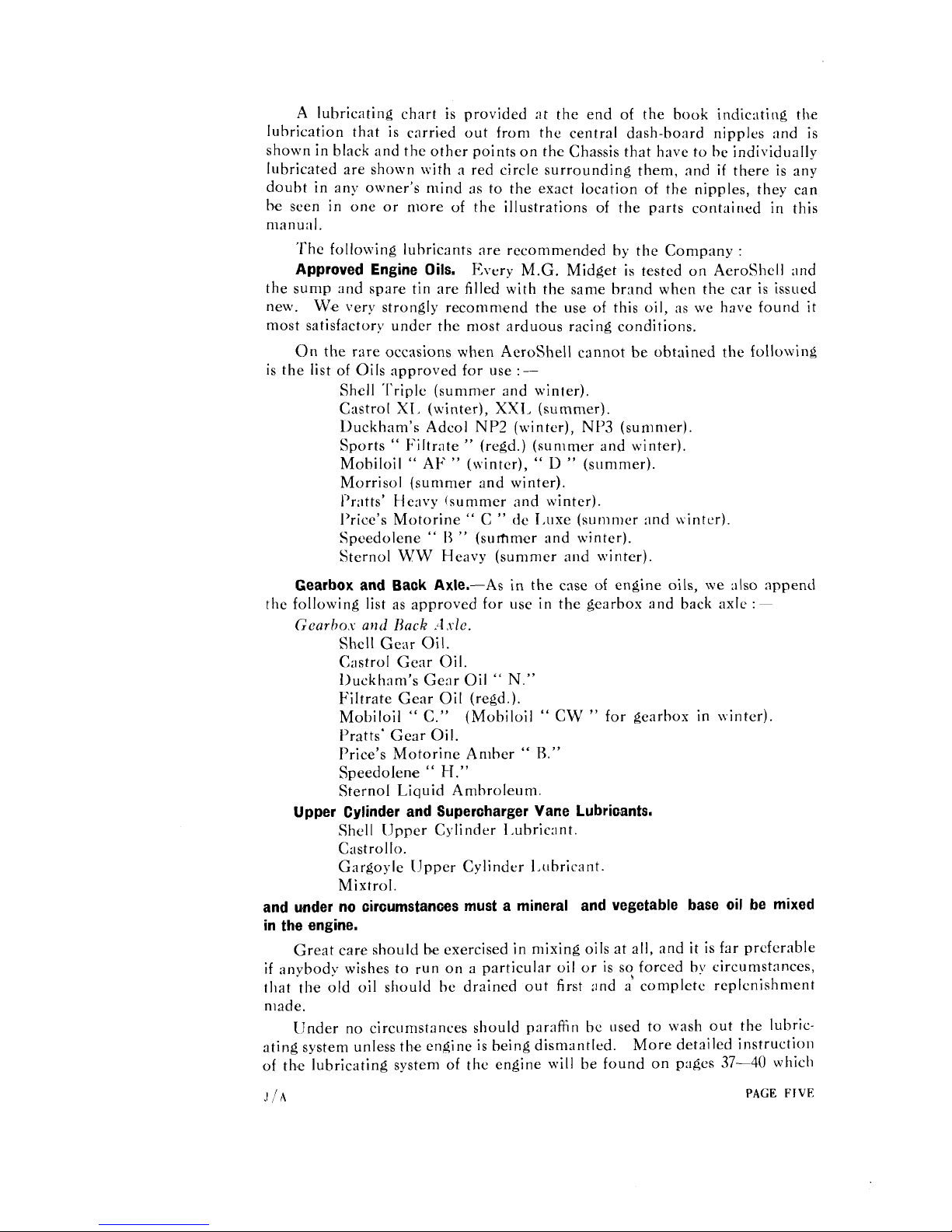

General Survey.

Immediately after taking delivery of the car

it

is

advisable to become familiar with its general mechanical details and in order

to assist as mucli

;IS

possible

it

has been thought advisable to give a brief

pictorial survey.

Figure

2.-LJndcrnc;1tli \it,\\.

of

[hc

3l.t;.

Midget chassis, sho\\.ing

rhc

Burgess silencer and

the

ribbed Elclctron

sump.

The view shown in Illustration No. 3 is perhaps

:I

little unconventional

to sonle people, but

it

is the view obtained by looking

nt

a chassis from under-

r.

nenth. I he batteries and petrol tank are not in position, but the under

shield bene:~th the ge:ir box and front passenger's compartment can be seen.

Certain views taken from below will be described later, more particularly

the front nnd rear axles.

The engine suspension is three point, the single or front point being

mounted in the centre of the front cross member of the chassis.

The nose

piece of the engine is fitted into the cross member by means of

:I

split bearing

into which is fitted

a

rubher bush. This nose piece hns two brackets, one on

either side, on to which the radiator is fixed by means of two studs.

The underslung chassis frame is of unusual design having an extremely

low centre of gravity,

the main principles of which having already been tested

and brought to perfection in competition work and racing.

PAGE

SIX

J/A

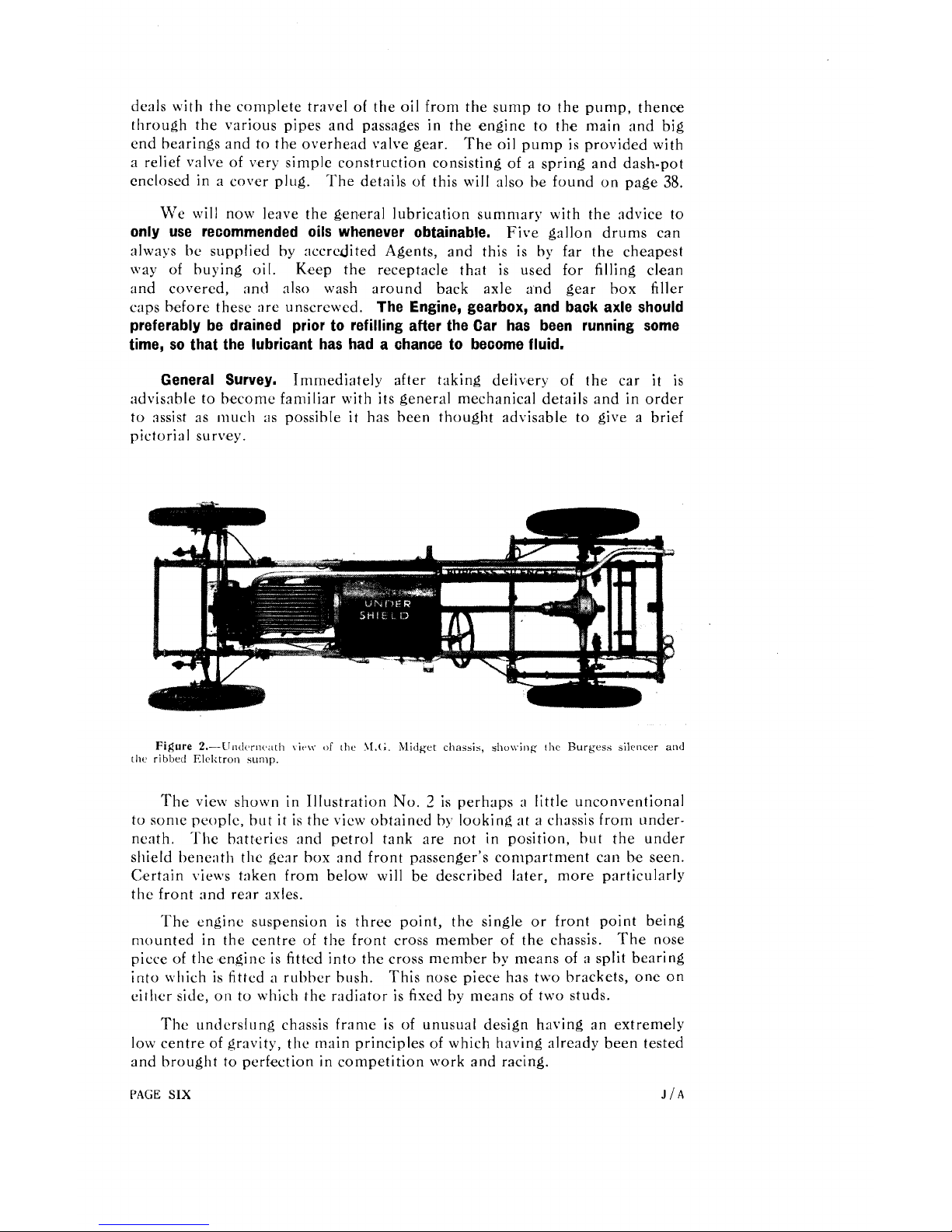

Figure 3 is a rear end view of the chassis and shows the back axle attached

to the springs

by

long

"

U

"

bolts and a spacer, the mounting of the shock

absorbers, the rear cover to the back axle with its filler cap, antl the cradle for

the battery. The

rear cross member has extensions on either side in which

the rear end of the rear springs are located.

9

PETROL

PIPES

Figure

3.-R(.:rr

vie*\\,

(IT

chasqis with Ixlltrari(,s rrmovc.~l from cradl~, b\~owing position

of

shock :~l)sc~rhr.rs antl prlrol fwd pipr~.; cm

~hr

J

I

ch;~ssis (+-s(.;~lr'r :rnd Snlonrttv).

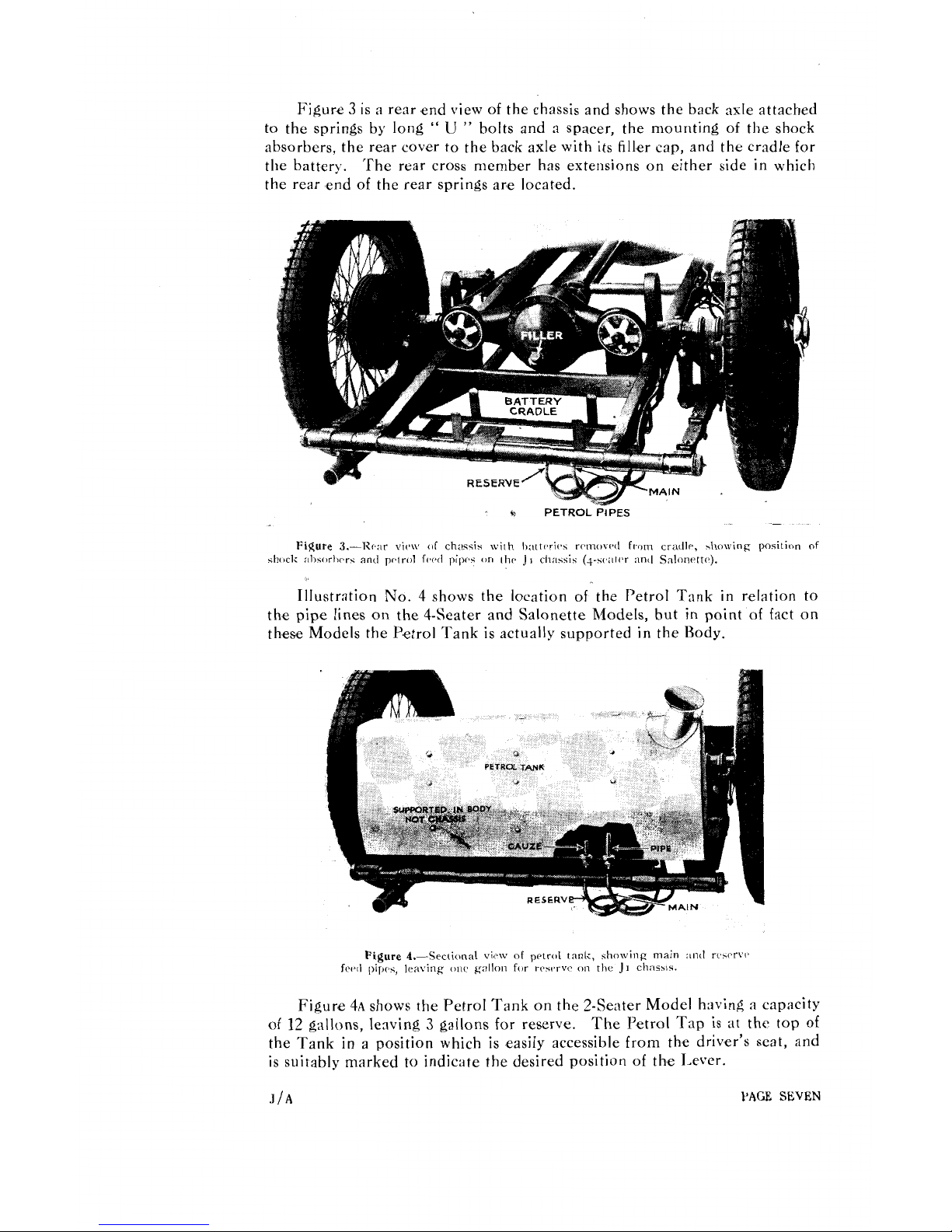

Illustration

No.

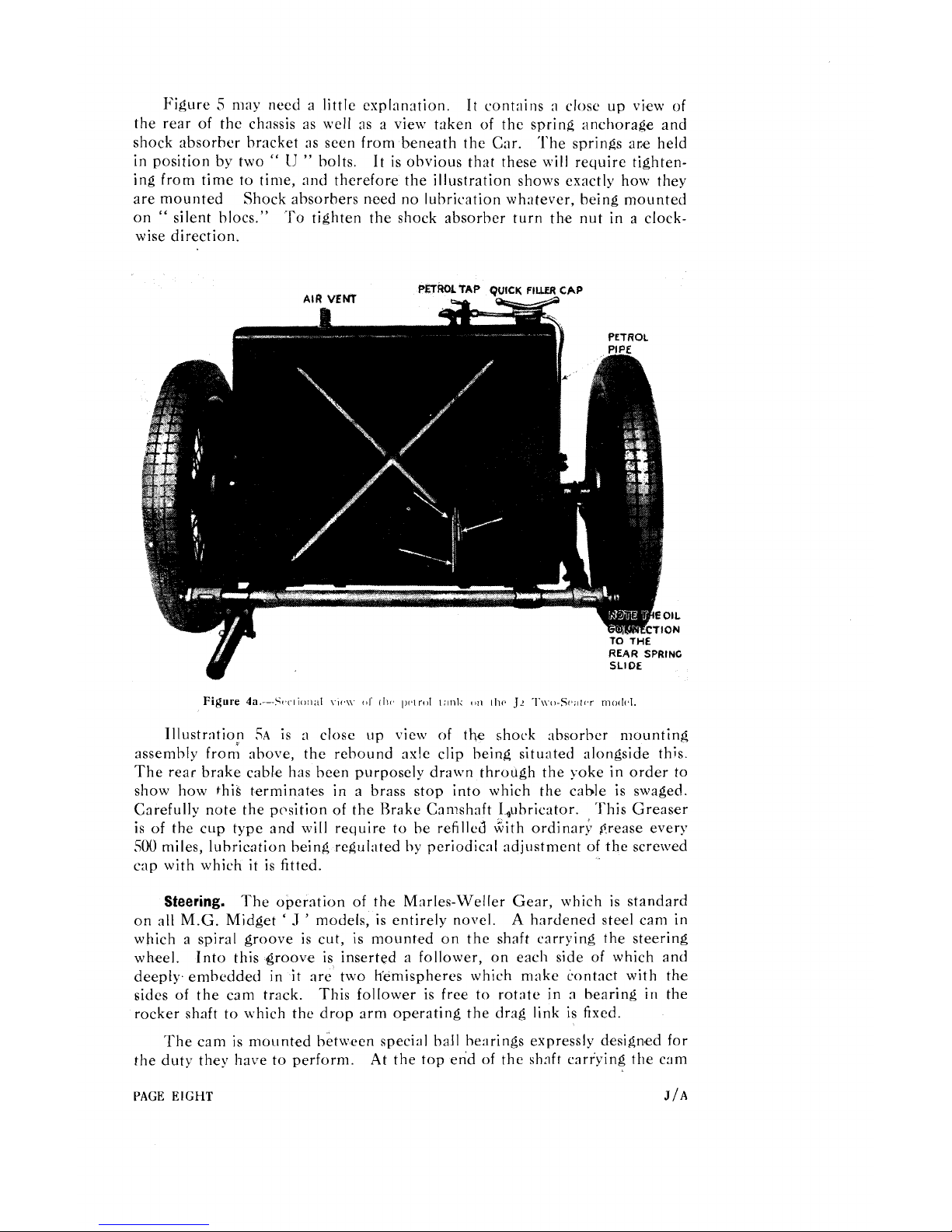

4 shows the location of the Petrol Tank in relation to

the pipe lines on the 4-Seater and Salonette Models, hut in point of fact on

these Models the P,etrol Tank is actually supported in the Body.

Figure

4.-Sectitrn:~l view of petrc~l tank, showing main :~nd rc.crvl,

fw~l pip(,.;, leaving on(. gallon for rcst2rvc

on

the

J

I

ch:~ssis.

Figure 4.A shows the Petrol Tank on the 2-Seater Model having a capacity

of 12 gallons, lenving

3

gallons for reserve.

The Petrol Tap is at the top of

the Tank in

a

position which is easily accessible from the driver's seat, and

is suitably marked

to

indicate the desired position of the Lever.

JIG

PAGE

SEVEN

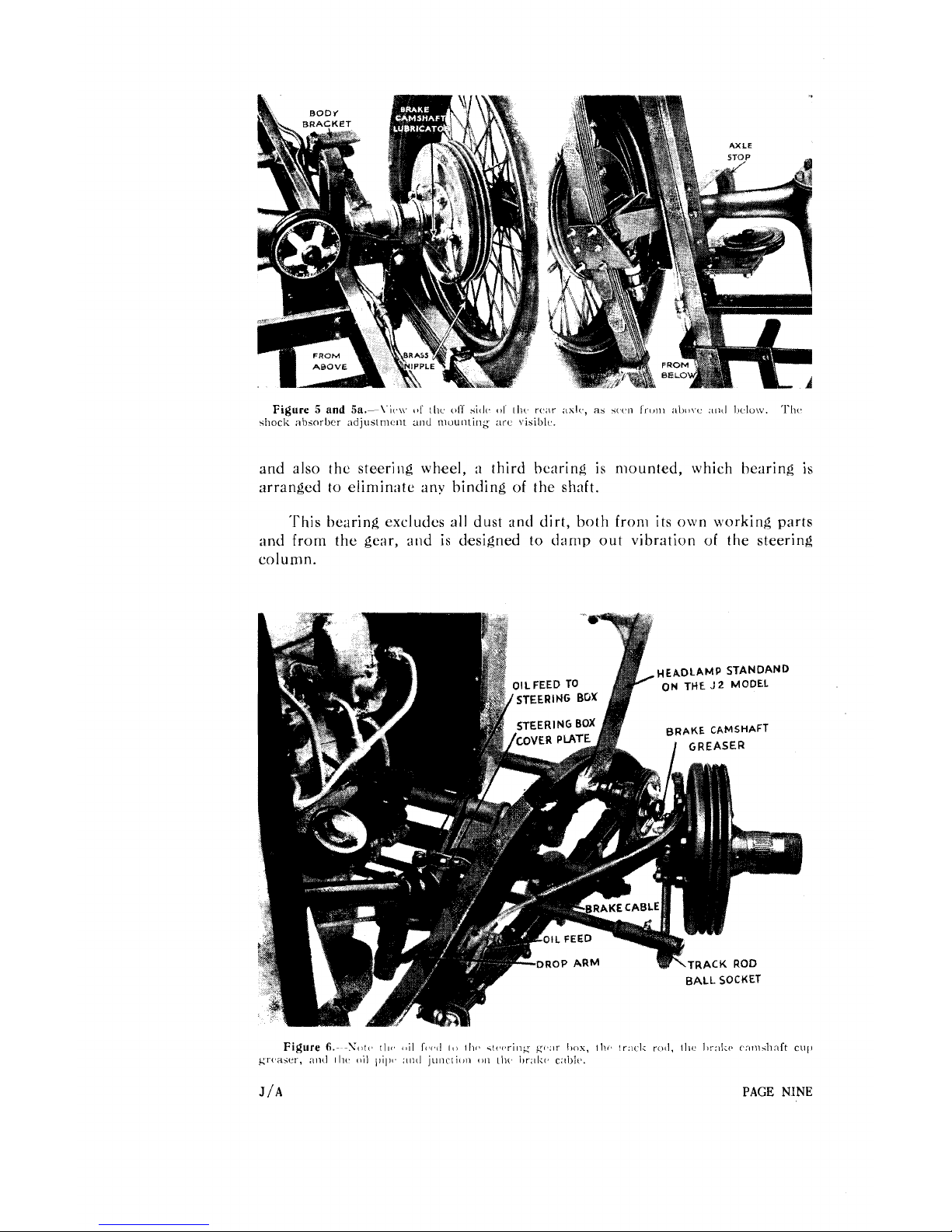

Figure 5 may need a little exp1:lnation.

It

cont;lins

:I

close up view of

the rear of the chnssis as well as a view taken of the spring anchorage and

shock absorber bracket as seen from beneath the Car. The springs ane held

in position by two

"

IJ

"

bolts.

It

is obvious that these will require tightening from time to time, and therefore the illustration shows exactly how they

are mounted Shock absorbers need no luhrication wh:itever, being mounted

on

"

silent blocs." To tighten the shock absorber turn the nut in a clock-

wise direction.

Illustration

,:A

is n close up view of the shock absorber mounting

assembly fron; above, the rebound axle clip being situated alongside this

The rear brake cable has been purposely drawn through the yoke in order to

show how

this

terminat,es in a brass stop into which the cable is swaged.

Carefully note the pcsition of the Brake Camshaft I~lhricator. This Greaser

is of the cup type and will require to be refilled iiiith ordinar$ Prease every

500

miles, lubrication being regulated hy periodical adjustment of the screwed

cap with which

it

is fitted.

Steering.

The operation of the Marles-Weller Gear, which is standard

on aii M.G. Midget

'

.l

'

models, is entirely novel.

A

hardened steel cam in

which a spiral groove is cut, is mounted on the shaft carrying the steering

wheel. Into this groove is inserted a follower, on each side of which and

deeply embedded in it are two h'ernispheres which make contact with the

sides of the cam track. This follower is free to rotate in a bearing in the

rocker shaft to which the drop arm operating the

drag link is fixed.

The cam is mounted between special ball hearings expressly designed for

the duty they have to perform.

At the top end of the shnft carrying the cam

PAGE

EIGHT

J/A

and also the steering wheel,

;I

third bearing is mounted, which hearing is

arranged

to

eliminate any binding of the shaft.

'This hearing excludes all dust and dirt, both from its own working parts

and from the gear, and is designed to damp out vibration

of

the steering

column.

r

.

I

he rocker shnft is carri,ed in nmsive phosphor bronze hearings providing

adequately ;lg;linst the shocks to which this part is subjected in use.

The oper:~tion of the gear is very simple. As the steering wheel and cam

are

rot:lted, the hemispheres and follower engaging the cam are moved backwards and forwards in the groove, thus imparting the required motion to the

drop arm :~nd drag link. At the snmc time each hemisphere aligns itself in

its seating to the side of the track engaging with it, and the follower, complete

with its four hemispheres, also adjusts itself in the bearing in the rocker shaft.

It will he seen from this

that a consider:~ble area is always evenly

presented to the csm track by the hemispheres, and this area and the selfalignment of the contacting faces is the fundamental difference between the

Marles-Weller and other types of steering gears.

The area and the self-alignment explained above

are responsible for the

sweet perfornunce and long life of the Marles-Weller gear, the same action

being available throughout the whole of its movement.

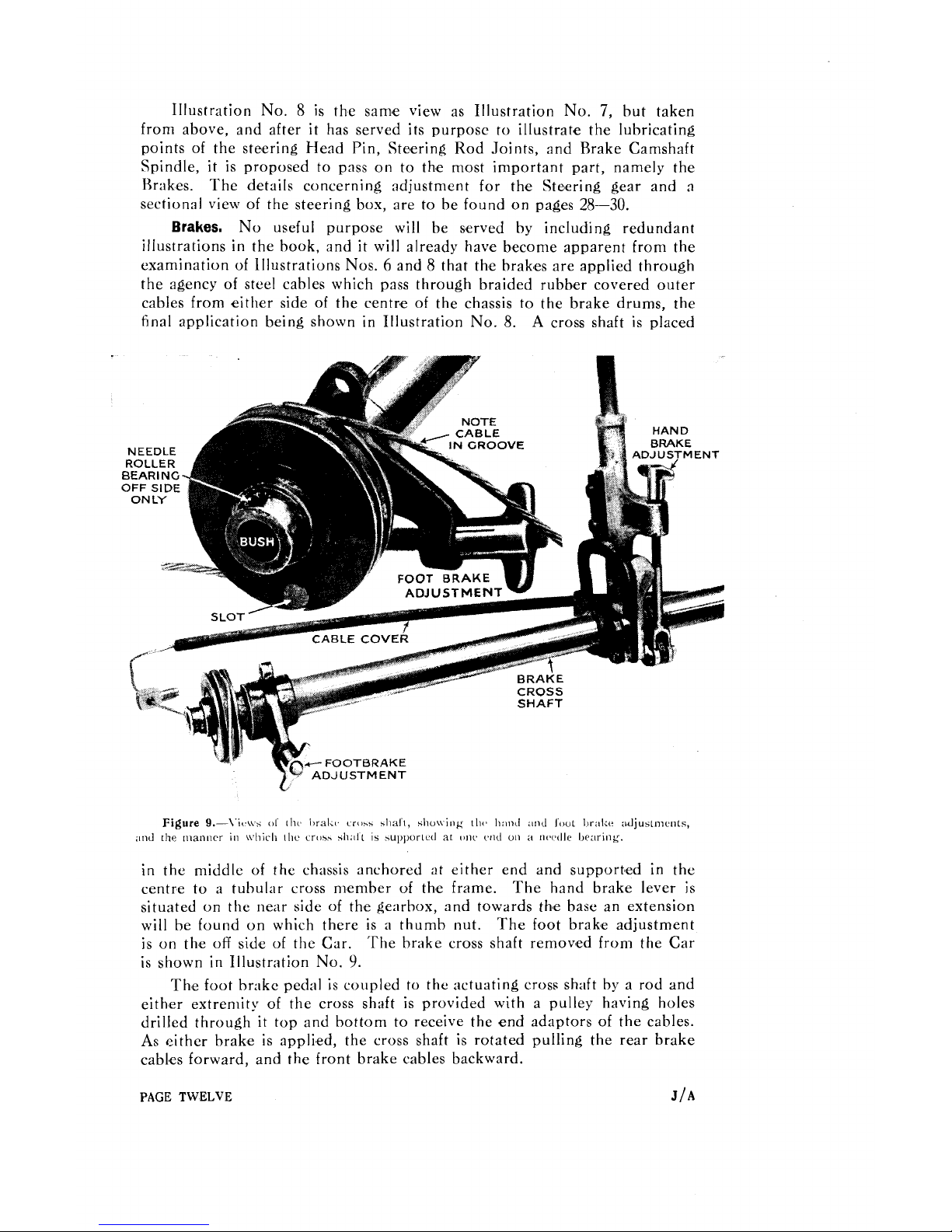

The view of the Steering Gear Rox in Illustration No.

6

hesides showing

the oil feed to the steering gear box and track rod also shows the drop arm

and the track rod ball socket. Every articulating joint of the Steering is

PAGE

TEN

J/A

fitted with an oil nipple.

The track rod is thread'ed at either end. In fact,

all the Steering Rods, or, to he more exact, Tubes,

ar,e threaded. This per-

mits of accurate adjustment, and to take care of any irr'egularities in the

tracking of the wheels.

Illustration No.

7

is an underneath view of th7e front end of the

frame showing the near side steering arm to which are attached two ball

sockets of the Steering Rods. This illustration shows clearly the shock

absorber mounting, the rubber buffer between the frame and the spring and

the various lubricators on the near side front axle assembly.

J

/A

PAGE ELEVEN

Illustration No. 8 is the sam~e view as Illustration No.

7,

but taken

from above, and after it has served its purpose to illustrate the lubricating

points of the steering Head Pin, Ste,ering Rod Joints, and Brake Camshaft

Spindle,

it

is proposed to pass on to the most important part, namely the

Brakes.

The details concerning adjustment for the Steering gear and a

section31 view of the steering box, are to be found on pages

28-30.

Brakes.

No useful purpose will be served by including redundant

illustrations in the book, and it will already have become apparent from the

examination of

illustrations

Nos. 6 and 8 that the brak'es are applied through

the agency of steel cables which pass through braided rubbmer covered outer

cables from either side of the centr,e of the chassis to the brake drums, the

tinal application being shown in Illustration No.

8.

A

cross shaft is placed

ADJUSTMENT

Figure

9.-\.it.\\-s

oI

hi

i~ralil. cross shal~, shu\ving 1111.

11:11111

;~nd IouL I)r;~l<e ;I~~USLIIICIILS,

;~nd the manncr in \\.hiclr the croz.5 sh;111

is

iupporlal at onc cncl un a 11lwllr Ilraring.

in the middle of the chassis anchored at either end and support'ed in the

centre to

a

tubular cross member of thme frame. The hand brake lever is

situated on the near side of the gearbox, and towards th'e base an extension

will be found on which there is

a

thumb nut. The foot brakme adjustment

is on the off side of the Car. 'The brake cross shaft remov'ed from the Car

is shown in Illustration No.

9.

The foot br:~kc pedal is coupled to the actuating cross shaft by a rod and

either extremity of the cross shaft is provided with a pulley having holes

drilled through it top and bottom to receive the end adaptors of the cables.

As either brake is applied, the cross shaft is rotated pulling the rear brake

cabks forward, and the front brake cables backward.

PAGE

TWELVE

J/

A

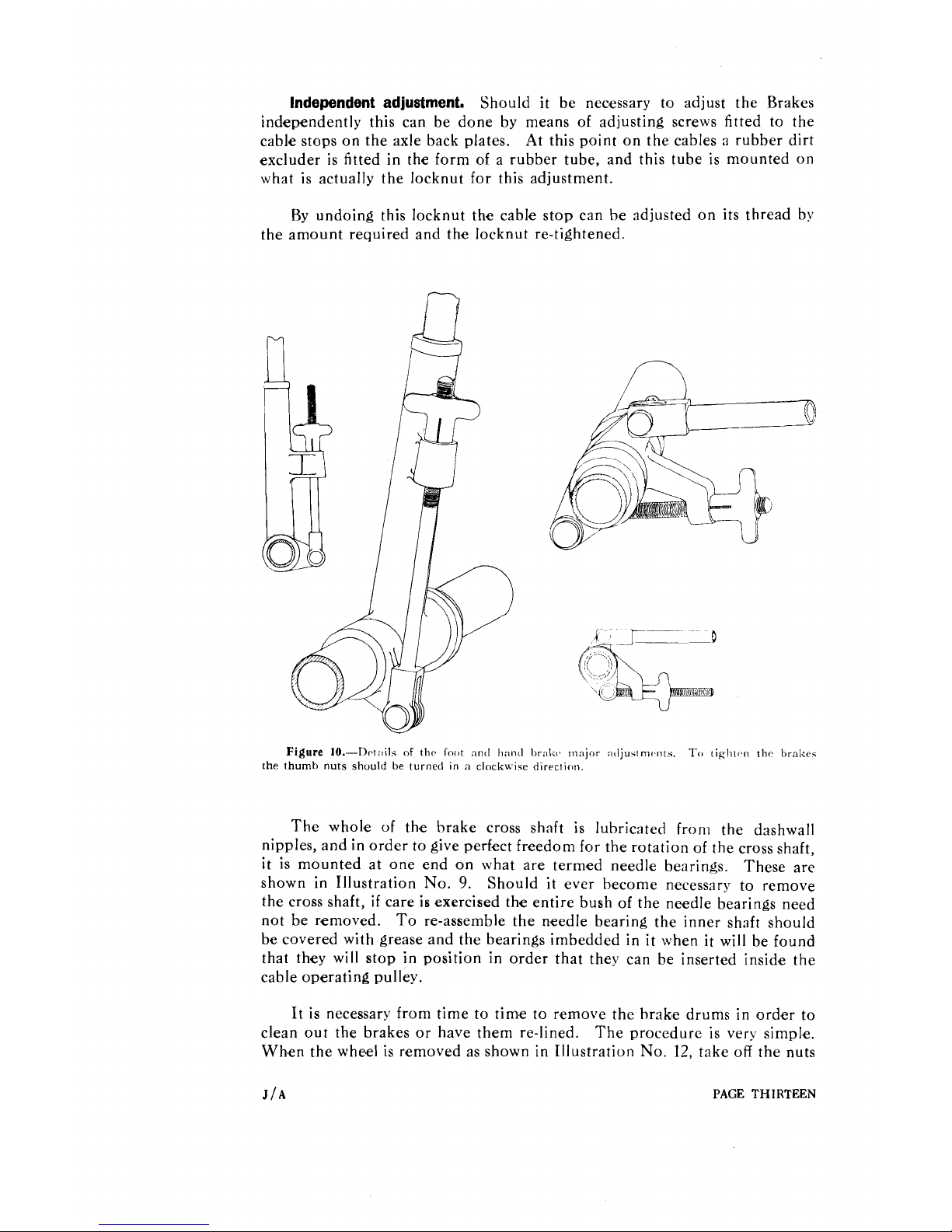

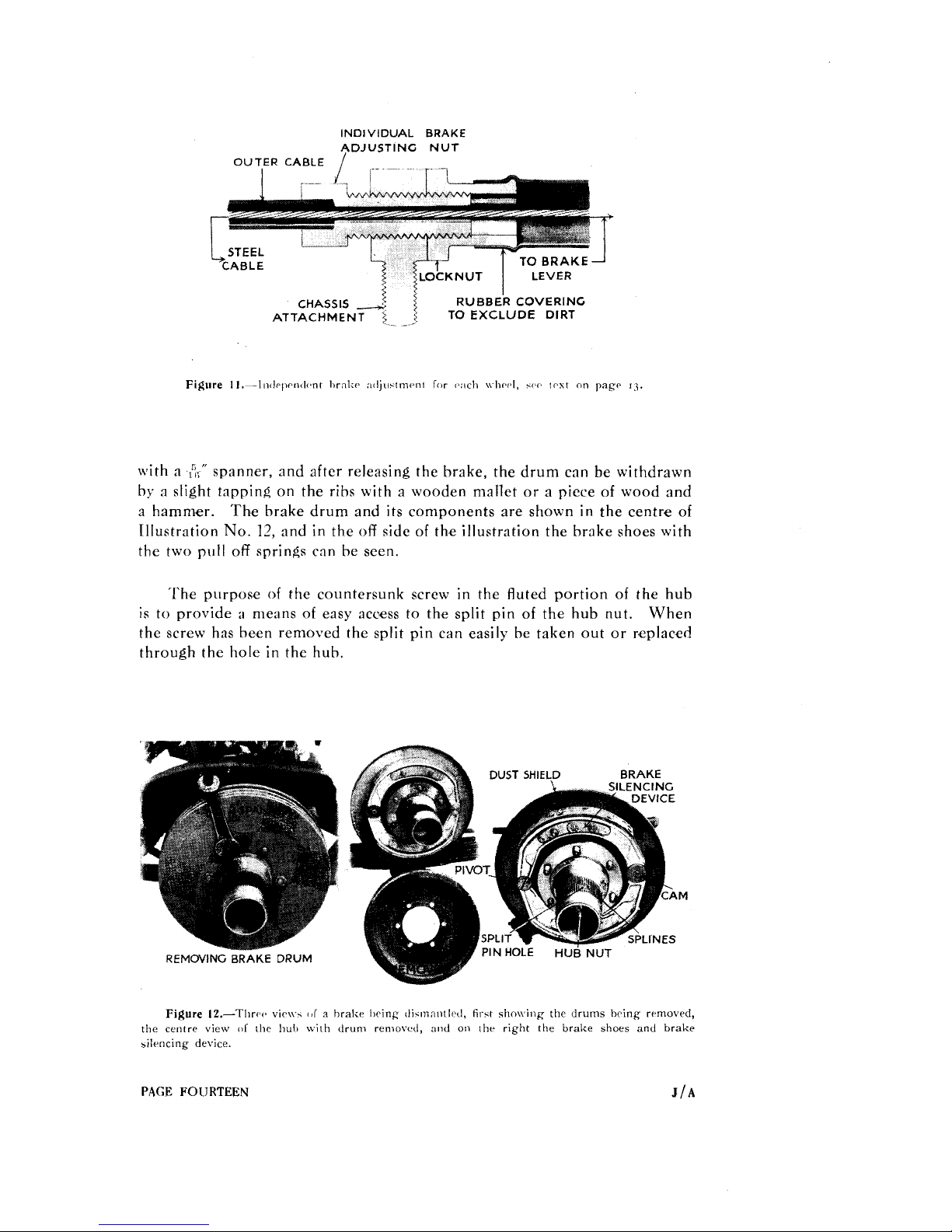

Independent adjustment.

Should it be nec'essary to adjust the Brakes

independently this can be done by means of adjusting screws fitted to the

cable stops on the axle back plates. At this point on the cables a rubber dirt

excluder is fitted in the form of a rubber tube, and this tube is mounted on

what is actually the

locknut for this adjustment.

By undoing this locknut the cable stop can be adjusted on its thread by

the amount required and the locknut re-tightened.

Figure

10.-Dct:~ils

of

the

Toot

and hand Ixal.;~, ~n;~jor

:~djustm~wts.

TCI

riglilr~ thc brakes

[he thumb nuts should be turned in

;l

clockwise direction.

The whol,e of th,e brake cross shaft is lubricated from the dashwall

nipples, and in order to give perfect freedom for the rotation of the cross shaft,

it

is mounted at one end on what are term'ed needle bearings. These are

shown in Illustration No.

9.

Should it ever become necessary to remove

the cross shaft,

if

care is exercised the entire bush of the needle bearings need

not be removed.

To re-assemble the n,eedle bearing the inner shaft should

be covered with grease and the bearings imbedded in it when it will be found

that they will stop in position in order that they can be inserted inside the

cable operating pulley.

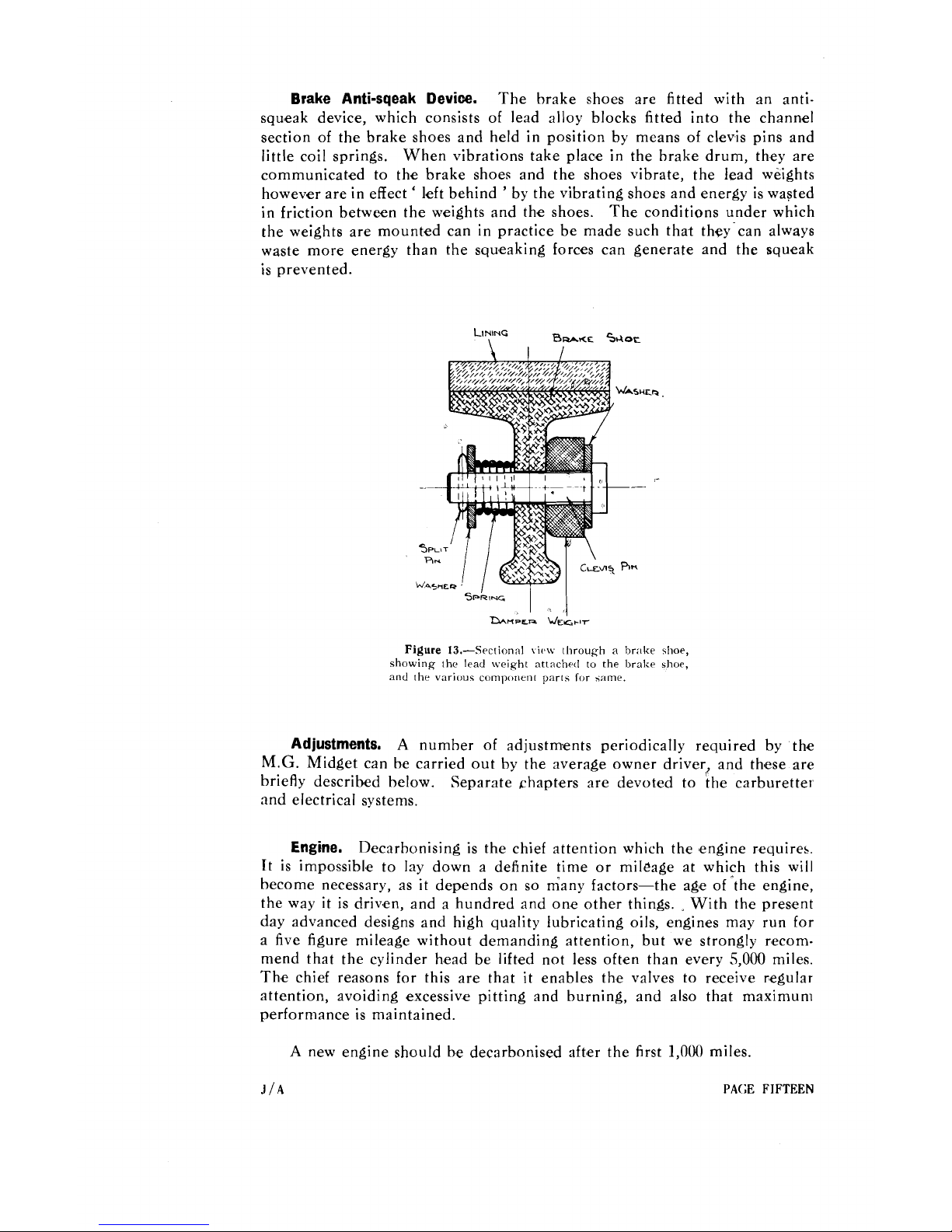

It is necessary from time to time to remove the hrak'e drums in order to

clean out the brakes or have them re-lined. The procedure is very simple.

Wh,en the wheel is r'emoved as shown in Illustration No.

12,

take

off

the nuts

J/A

PAGE

THIRTEEN

INDIVIDUAL

BRAKE

ADJUSTING NUT

OUTFR

CABLE

/

with a

6;''

spanner, and after releasing the brake, the drum can be withdrawn

by a slight tapping on the ribs with a wooden mallet or a piece

of

wood and

a hammer. The brake drum and its components are shown in the centre

of

Illustration

No.

12,

and in the

off

side

of

the illustration the brake shoes with

the two pull

off

springs can be seen.

'The purpose

of

the countersunk screw in the fluted portion

of

the hub

is to provide

a

means

of

easy acoess to the split pin

of

the hub nut.

When

the screw has been removed the split pin can easily be taken out or r,eplaced

through the hole in the hub.

REMOVING

BRAKE

DRUM

DUST

SHIELD

BRAKE

Figure

12.-l'llrw

vie\\

..

I!T

a

hrakr Iwing dicmnnrltd,

firct

*h\\

ing the drums hcing rrmowd,

the centre view

111

the

1x111

with drum reniovcd, and on khr right the brake shoes and brake

silrncing device.

PAGE

FOlJRTEGN

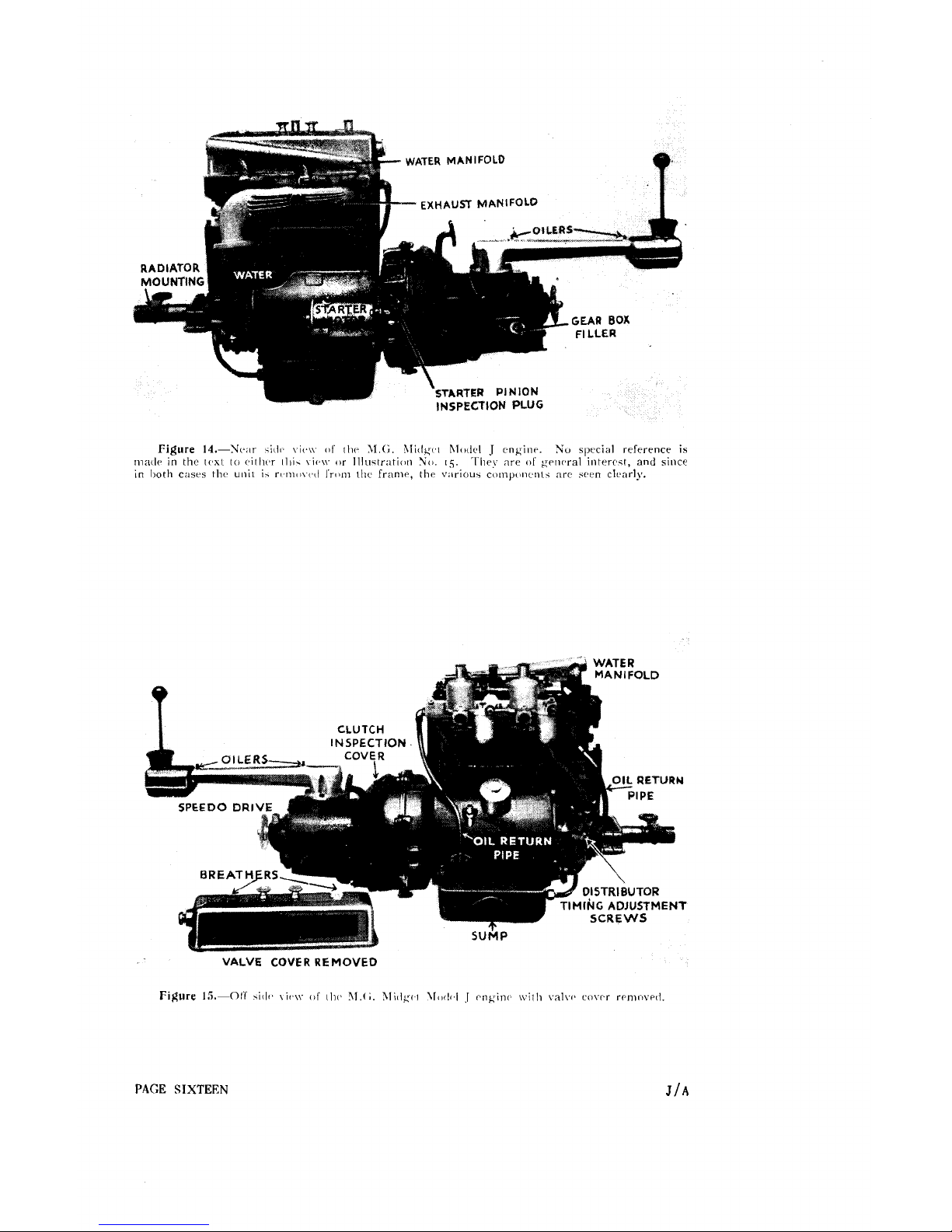

Brake

Anti-sqeak

Device.

The brake shoes are fitted with an antisqu'eak device, which consists of lead alloy blocks fitted into the channel

section of the brake shoes and held in position by means of clevis pins and

little coil springs. When vibrations take plac'e in the brake drum, they are

communicated to the brake shoes and the shoes vibrate, the lead weights

however are in effect

'

left behind ' by the vibrating shoes and energy is wasted

in friction between the weights and the shoes. The conditions under which

the weights are mounted can in practice be made such that they can always

waste more energy than the squeaking forces can generate and the squeak

is prevented.

Figure

13.-Sectional

\I(,\\

through a hr,~lw 41oe,

showing the lead \\eight attached to the bralw shoe,

and the various component parts Ior 5.lme.

Adjustments.

A

number of adjustmlents periodically required by the

M.G.

Midget can be carried out by the average owner driver? and thmese are

briefly described below. Separate chapters are devoted to the carburetter

and electrical systems.

Engine.

D'ecarbonising is the chief attention which the 'engine requires.

It is impossibl,e to lay down a definite time or mileage at which this will

become necessary, as

it

depends on so Gany factors-the ag~e of 'the engine,

the way

it

is driv,en, and a hundred and on,e other things. With the present

day advanced designs and high quality lubricating oils, enginses may run for

a five figure mileage without demanding attention, but we strongly recom-

mend that the cylinder h.ead be lift'ed not less oft'en than every

5,000

miles.

Th,e chief reasons for this are that

it

enables the valves to receive r,egular

attention, avoiding excessiv.e pitting and burning, and also that maximum

performance is maintained.

A

new engine should be decarbonised &er the first

l,O(M)

miles.

J

/A

PAGE

FIFTEEN

WATER

MANIFOLD

EXHAUSl

MANlFOLQ

STARTER

PINION

INSPECTION

PLUG

VALVE

COVER

REMOVED

Figure

15.-01.1'

5iil1~

\it,\\.

of

tl11>

1l.c;. 3li~lg1.1

\l<xI<,I

I

rngin~,

\vi:li valvv covc.r reninv~11.

PAGE

SIXTEEN

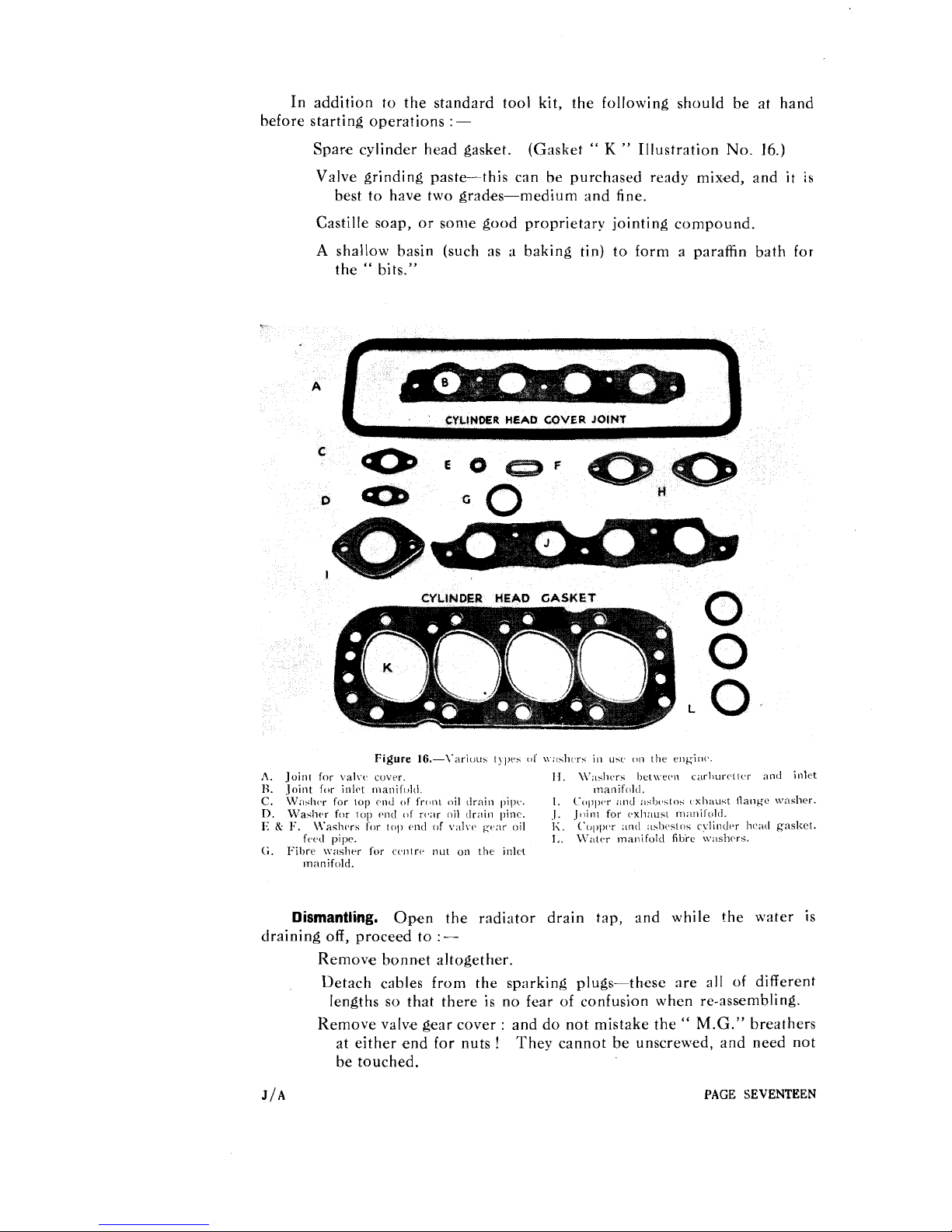

In addition to the standard tool kit, the following should be at hand

before starting operations

:

-

Spar,e cylinder head gasket.

(Gasket

"

K

"

Illustration No.

16.)

Valve grinding paste-this can be purchased ready mix,ed, and

it

is

best to have two grad,es-medium and fine.

Castille soap, or some good proprietary

jointing compound.

A

shallow basin (such as a baking tin) to form a paraffin bath for

the

"

bits."

CYLlNDER

HEAD

GASKET

L

A.

Join1 for \:alv<z covrr.

lJ.

\V:dirrs het\ver>n c;~rl)urctt(~r an11 inlet

1:.

Joint for inlct manifold. manifold.

C.

W;rsIwr for top end

OF

front oil drain pil~v.

1.

('oI>~x.r

;L"']

;~st),.s~os vxhau~t Hangc \vasher.

D.

Waslirr for top rwtl

01'

r(.;lr oil clrain ~>inc.

J.

Jclint for c.xli:lust rn;lnilolrl.

1

K.

I;.

\Vaslir,rs for

11111

end

[IF

v;11\.r Kt,:rr oil

1.

C'c,~,~x.r

;11i<1

;~slrc~str~s c\lindr.r li~%;~tl gasltct.

frrd pipr.

I,.

\V:llrr ~naiiifold

fihie

\v:lslicrs.

G.

Fibre \vasIirr

for

cvntrv nut on the inlct

manifold.

Dismantling.

Open the radiator drain tap, and while the water is

draining off, proceed to

:

-

Remove bonn'et altogether.

Detach cables from the sparking plugs-these are all of different

lengths so that there is no fear of confusion when re-assembling.

Remove valv,e gear cover

:

and do not mistake the " M.G." breathers

at either end for nuts

!

They cannot be unscrew,ed, and need not

be touched.

J/A

PAGE SEVENTEEN

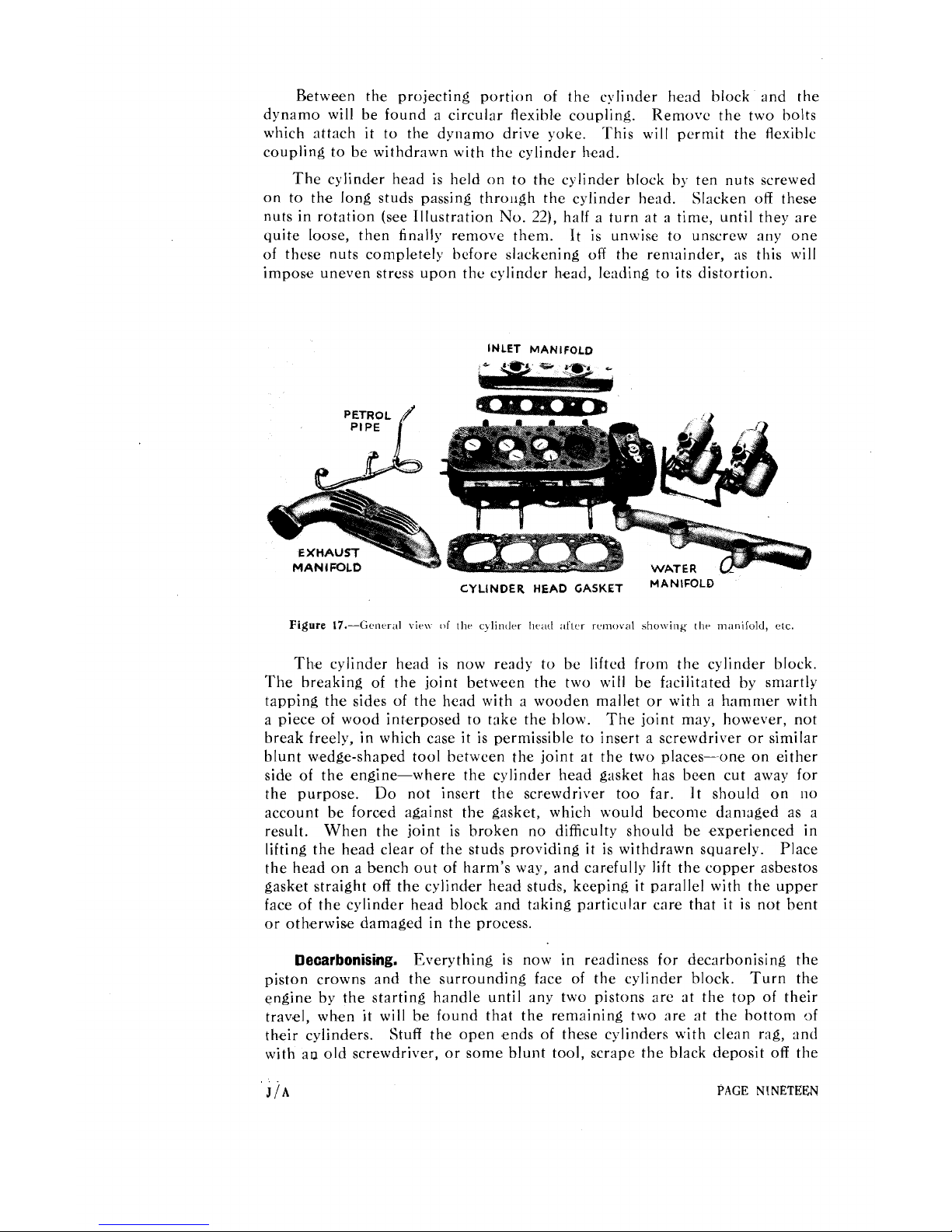

Attention may now be turn,ed to the Carburetters, which must be

removed after uncoupling the Petrol pipe, throttle and mixture controls, but

it is not necessary to dismantle the Inlet Manifold.

R,elease the Water Manifold by undoing the three attachm,ent clips

shown in Illustration No.

18

and then proceed to detach the Front Exhaust

Pipe befo~e removing the Water and Exhaust Manifolds in turn.

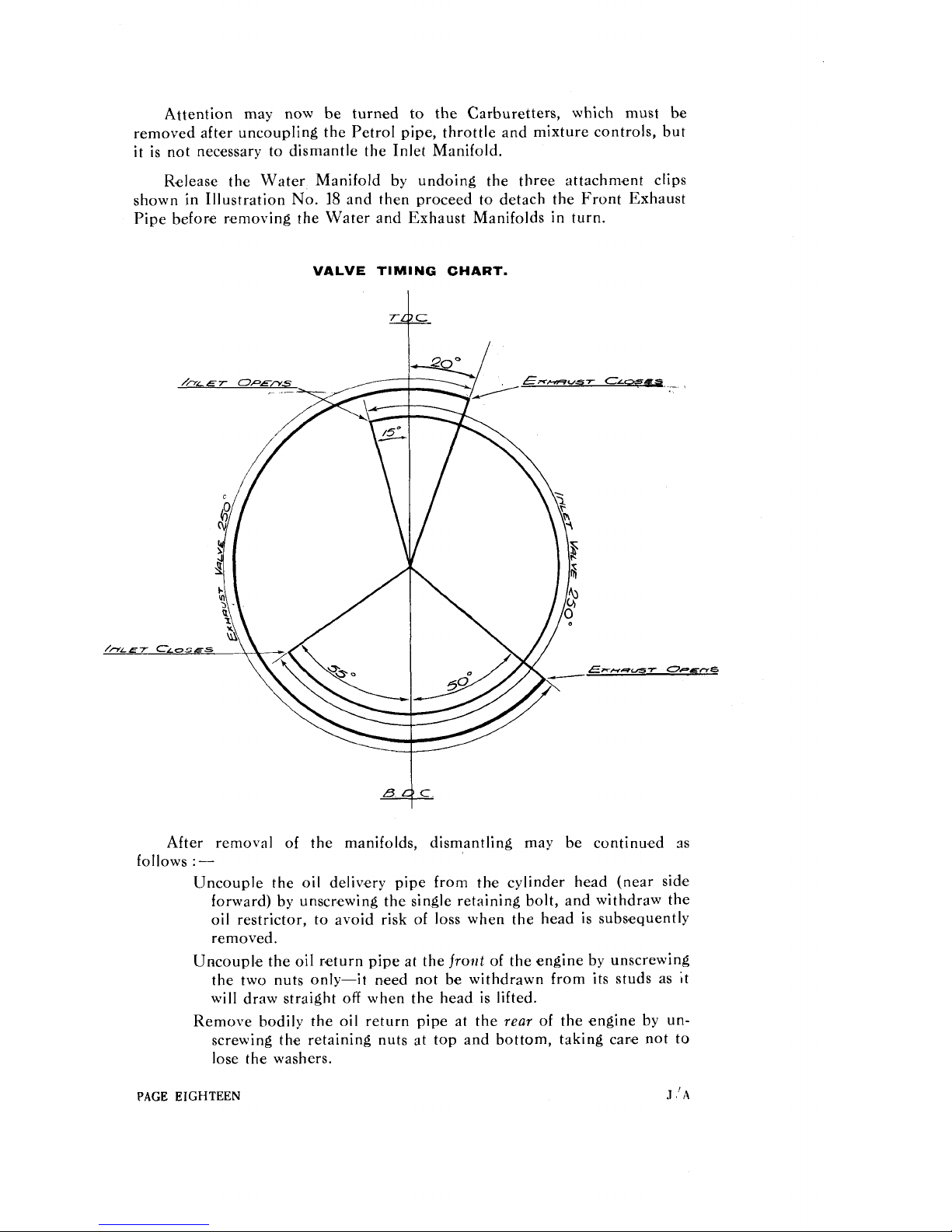

VALVE TIMING CHART.

4

After removal of the manifolds, dismantling may be continu,ed as

follows

:-

Uncouple the oil deliv,ery pipe from th.e cylinder head (near sidse

forward) by unscnewing the single retaining bolt, and withdraw the

oil restrictor, to avoid risk of loss when the head is

subs,equently

removed.

Uncoupl,e the oil rmeturn pipe at the frotzt

of

the engine by unscrewing

the two nuts only-it n'eed not be withdrawn from its studs as it

will draw straight off when the head is lifted.

Remove bodily the oil return pipe at the rear

of

the engine by unscrewing th'e retaining nuts at top and bottom, taking cane not to

lose the washers.

PAGE

EIGHTEEN

.l

A

Between the projecting portion of the cylinder head block and the

dynamo will be found a circular flexible coupling.

Removc the two bolts

which attach it to the dynamo drive yoke.

This will permit the flexiblc

coupling to be withdrawn with the cylinder head.

The cylind,er head is held on to the cylinder block by ten nuts screwed

on to the long studs passing

throllgh the cylinder head.

Slacken off these

nuts in rotation (see Illustration

No.

23,

half a turn at a time, until they are

quite loose, then finally remove them. It is unwise to unscrew any one

of these nuts completely before slackening off the remainder, as this will

impose uneven stress upon the cylinder hsead, leading to its distortion.

INLET MANIFOLD

CYLINDER HEAD

GASKET

MAN'F0LD

Figure

17.-Genrral viw

of

the cjlindrr lie,lrl aller rc~noval

shelving

thr

man~fold,

etc.

The cylinder head is now ready to be lifted from the cylinder block.

The breaking of the joint between the two will be facilitated by smartly

tapping the sides of the head with a wooden mallet or with

a

hammer with

a piece of wood interposed to take the hlow. The joint may, however, not

break freely, in which case it is permissible to insert a screwdriver or similar

blunt wedge-shaped tool bet-cen the joint at the two places-one on either

side of the engine-where the cylinder head gasket has been cut away for

the purpose. Do not insert the screwdriver too far. It should on no

account be forc'ed against the gasket, which would become damaged as a

result. When the joint is broken no difficulty should be experienced in

lifting the head clear of the studs providing it is withdrawn squarely. Place

the head on a bench out of harm's way, and carefully lift the copper asbestos

gasket straight off the cylinder head studs, keeping it parallel with the upper

face of the cylinder head block and taking particular care that it is not bent

or otherwise damaged in the process.

Decarbonising.

Everything is now in readiness for decarbonising the

piston crowns and the surrounding face of the cylinder block.

Turn the

engine by the starting handle until any two pistons are at the top of their

travel,

whmen

it

will be found that the remaining two are at the bottom of

their cylinders. Stuff the open ends of these cylinders with clean rag, and

with au old screwdriver, or some blunt tool, scrape the black deposit off the

pistons and the face

of

the cylinder block adjacent to the cylinder bores.

With a clean rag damped with paraffin clean

off

every trace

of

foreign matter

remaining, hut

do

rlot

attempt to polish things up with emery cloth or other

abrasive, or you will do far more harm than good. When these two pistons

have been properly clc:~ned give the starting handle half a turn and clean

the other two in the same way.

Attention should now he given to the cylinder head. Remove the

sparking plugs with the special Spanner

and turn the head upside

down, thus exposing the combustion chambers, in each of which will be

observed the circular heads

of

two valves-one inlet and one exhaust (see

Illustration

No.

17).

With a hlunt screwdriver carefully scrape away the carbon

deposit

adhering to the surface

of

the combustion spaces, taking particular care to

go

round each valve with a small screwdriver in order to remove all trace

of

carbon. Clean the combustion chambers and valve h,eads carefully with rag

moistened with paraffin.

Removing the Valves.

Having thoroughly cleaned the combustion

spaces and valve heads, place the cylinder head on the bench the right way

up.

To

obtain access to the valve springs, it is necessary to remove the

camshaft. This is easil! xhieved

hy

unscrewing the four nuts holding the

camshaft bearing caps in position. These should he given half a turn in

rotation, in a similar manner to the cylinder head retaining nuts, until they

are 8eventually removed. The camshaft can then be lifted from its bearings

PAGE

TWENTY

.

J/A

Loading...

Loading...