Page 1

Page 2

means

*

A

*

Highest quality cost-controlled work

*

Competent operators following

predetermined servicing schedule

It

involves the use of efficient, modern methods

and equipment, eliminates guesswork and cuts

down servicing time. We don't plan to make

servicing more expensive, just more efficient.

Leycare follows a predetermined servicing se-

quence which must be rigidly followed by our

trained operators. There's no room for corner

cutting in Leycare.

. . .

new standard in car maintenance

. . .

a

Page 3

TOURER

and

GT

(GHN5

(GHD5

and

and

GHN4)

GHD4)

Handbook

Publication Part

N3.

AKD

7598 (8th Edition)

Includes a Supplement for Cars with Impact Absorbing Bumpers

Leyland Cars-Sales

Longbridge, Birmingham B31

2TB.

England

Leyland Cars-Service

Cowley, Oxford

1

BRITISH LEYLAND

OX4

2PG.

UK

England

LIMITED

1976

Page 4

FOREWORD

This Handbook introduces you to your British Leyland car. Your car is built

to a high standard of quality and reliability and with good driving, correct car

care and regular maintenance should give you carefree and economical motoring.

The introductory pages cover the operation and function of the controls, switches

and general equipment fitted.

The main part of the Handbook gives detailed information on jacking, wheel

changing, bulb renewal, lubrication and the servicing procedure of components.

Regular maintenance at the recommended intervals is essential to maintain your

car at the original standard of efficiency and you will find our detailed recommendations under 'MAINTENANCE SUMMARY'. Those items which require

specialized equipment should be carried out by a Distributor or Dealer. Refer to

the 'GENERAL DATA' for information required during servicing and the dayto-day running of the vehicle such as tyre pressures, oil capacities, etc.

Our Distributors and Dealers are trained and available to service your car for

you, and details of our maintenance scheme are included in your Passport

Service. Look for the Leycare Service sign.

References to right- or left-hand are made as if the car is being viewed from the

rear.

to

Page 5

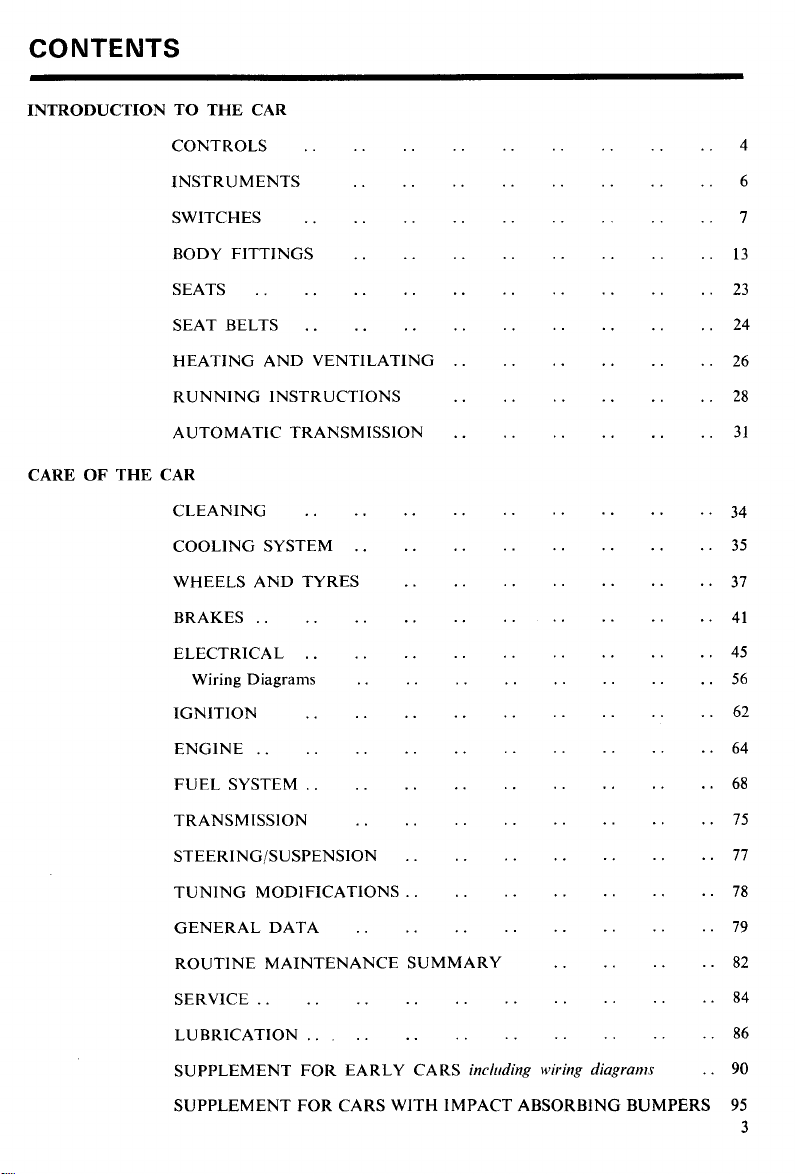

CONTENTS

INTRODUCTION TO THE CAR

CONTROLS

INSTRUMENTS

SWITCHES

BODY FITTINGS

SEATS

SEAT BELTS

HEATING AND VENTlLATlNG

RUNNING INSTRUCTIONS

AUTOMATIC TRANSMISSION

CARE OF THE CAR

CLEANING

COOLING SYSTEM

WHEELS AND TYRES

BRAKES

ELECTRICAL

IGNITION

..

. . . .

. . . .

....

.

..

....

......

.

. . .

.

....

Wiring Diagrams . .

.

. . .

. . .

.

.

.

.

. .

.

.

.

.

.

ENGINE

FUELSYSTEM

TRANSMISSION

STEERING/SUSPENSION

TUNING MODIFICATIONS

GENERAL DATA

ROUTINE MAINTENANCE SUMMARY

SERVICE

LUBRICATION

SUPPLEMENT FOR EARLY CARS

SUPPLEMENT FOR CARS WITH IMPACT ABSORBING BUMPERS

.

. . . .

....

....

....

.

. .

....

. . . . .

....

.

. . . . . . . . . . .

.

.

.

.

. . .

.

....

. .

. .

. .

. . . . .

.

.

....

. .

. . . . . . . . . . . .

inchrding wiring diagrann

. .

78

79

82

84

86

90

95

3

Page 6

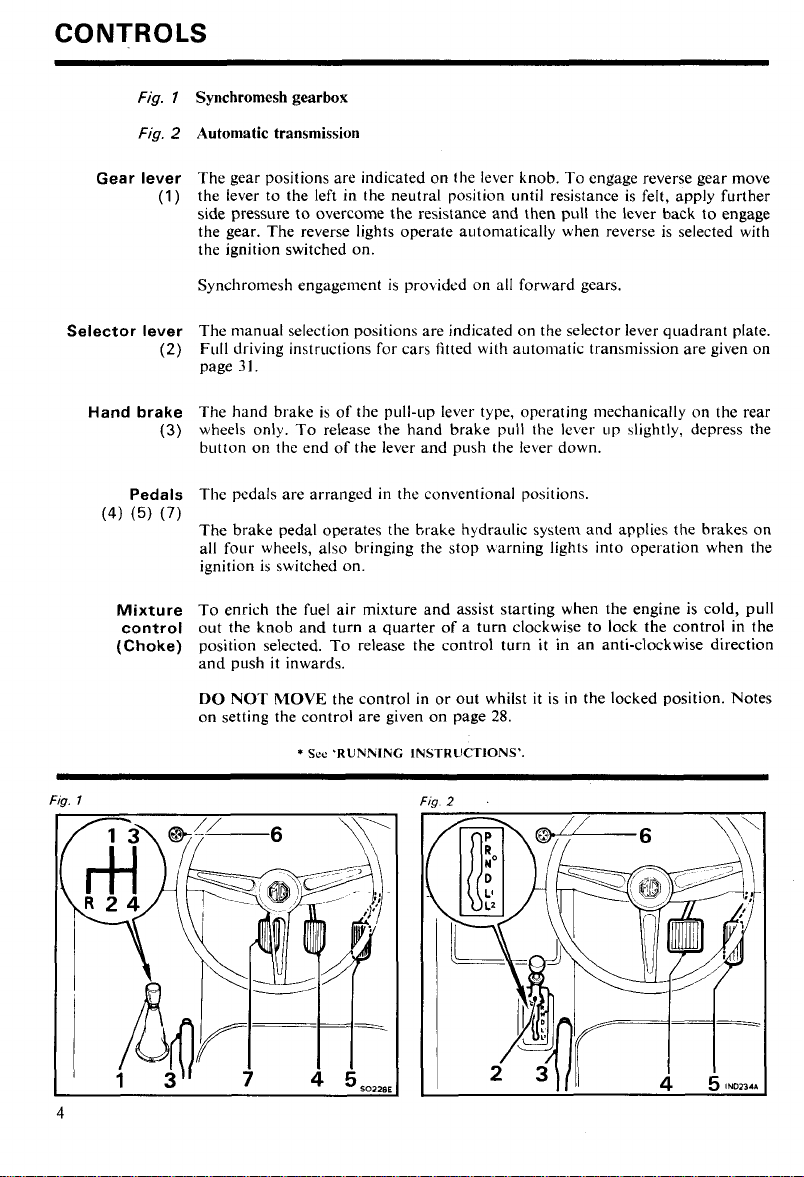

CONTROLS

Fig.

I

Synchromesh gearbox

Fig.

2

Automatic transmission

Gear lever

(1)

Selector lever

(2)

Hand brake

(3)

Pedals

(4)

(5)

(7)

Mixture

control

(Choke)

The gear positions are indicated on the lever knob. To engage reverse gear move

the lever to the left in the neutral position until resistance is felt, apply further

side pressure to overcome the resistance and then pull the lever back to engage

the gear. The reverse lights operate autoniatically when reverse is selected with

the ignition switched on.

Synchromesh engagement is

prokidcd on all forward gears.

The manual selection positions are indicated on the selector lever quadrant plate.

Full driving instructions for cars fitted with a~~toniatic transmission are given on

page

3

1.

The hand brake is of the pull-LIP lever type, operating mechanically on the rear

wheels only. To release the hand brake pull the lever up 4ightly, depress the

button on the end of the lever and push the lever down.

The pedals are arranged in the conventional positions.

The brake pedal operates the brake hydraulic system and applies

the

brakes on

all four wheels, also bringing the stop uarning lights into operation when the

ignition is switched on.

To enrich the fuel air mixture and assist starting when the engine is cold, pull

out the knob and turn a quarter of a turn clockwise to lock the control in the

position selected. To release the control turn it in an anti-clockwise direction

and push it inwards.

DO NOT MOVE the control in or out whilst it is in the locked position. Notes

on setting the control are given on page

*

Sce

'RUNlrlING INSTRUCTIONS'.

28.

Page 7

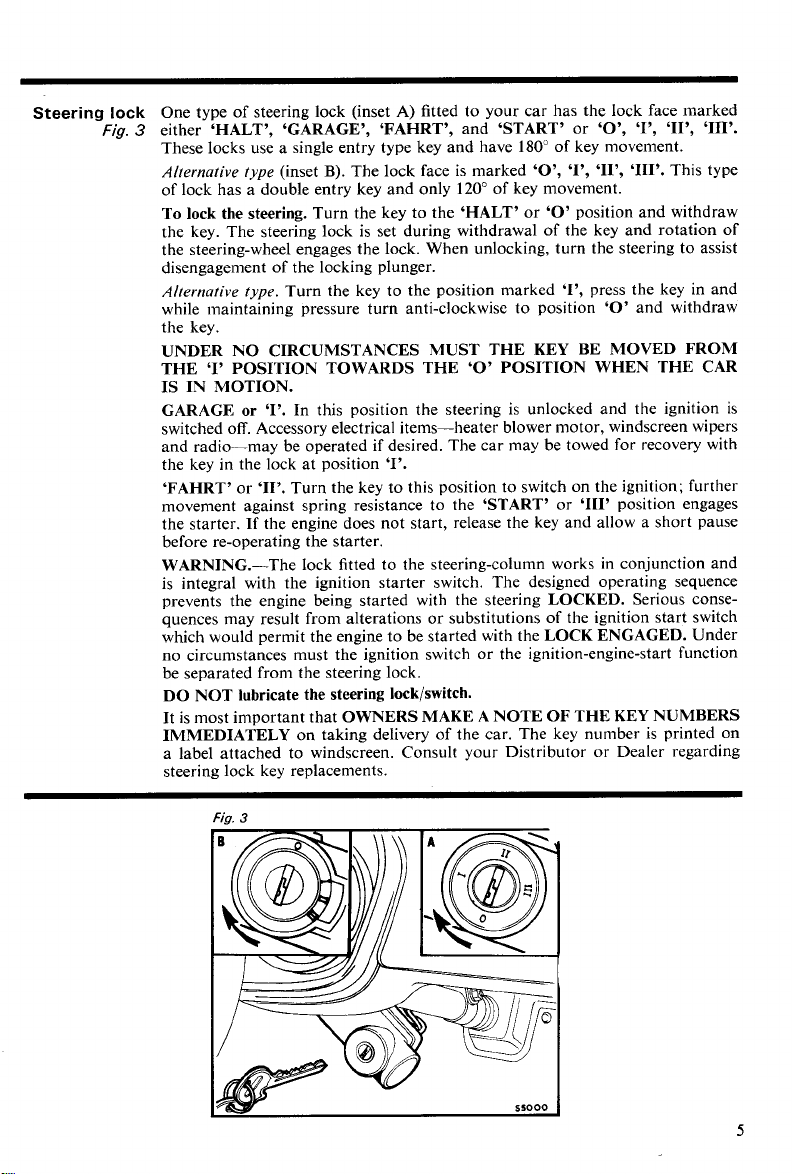

Steering

lock

One type of steering lock (inset

Fig.

3

either 'HALT', 'GARAGE', 'FAHRT', and 'START' or 'O', 'l', 'II', '111'.

These locks use a single entry type key and have 180" of key movement.

Alternative type

of lock has a double entry key and only 120" of key movement.

(inset

B).

To lock the steering. Turn the key to the 'HALT' or

the key. The steering lock is set during withdrawal of the key and rotation of

the steering-wheel engages the lock. When unlocking, turn the steering to assist

disengagement of the locking plunger.

Alternative type.

while maintaining pressure turn anti-clockwise to position

the key.

Turn the key to the position marked 'I', press the key in and

A)

fitted to your car has the lock face marked

The lock face is marked 'O', '1'' 'II', '111'. This type

'0'

position and withdraw

'0'

UNDER NO CIRCUMSTANCES MUST THE KEY BE MOVED FROM

THE 'I' POSITION TOWARDS THE

'0'

POSITION WHEN THE CAR

IS IN MOTION.

GARAGE

switched off. Accessory electrical items-heater blower motor, windscreen wipers

and radio-may be operated if desired. The car may be towed for recovery with

the key in the lock at position

'FAHRT'

movement against spring resistance to the

the starter.

before re-operating the starter.

or

'1'.

In this position the steering is unlocked and the ignition is

'1'.

or '11'. Turn the key to this position to switch on the ignition; further

'START' or '111' position engages

If the engine does not start, release the key and allow a short pause

WARNING.-The lock fitted to the steering-column works in conjunction and

is integral with the ignition starter switch. The designed operating sequence

prevents the engine being started with the steering

quences may result from alterations or substitutions of the ignition start switch

which would permit the engine to be started with the

no circumstances must the ignition switch or the ignition-engine-start function

be separated from the steering lock.

LOCKED. Serious conse-

LOCK ENGAGED. Under

DO NOT lubricate the steering lock/switch.

It

is most important that OWNERS MAKE A NOTE OF THE KEY NUMBERS

IMMEDIATELY

a label attached to windscreen. Consult your Distributor or Dealer regarding

steering lock key replacements.

on taking delivery of the car. The key number is printed on

and withdraw

Page 8

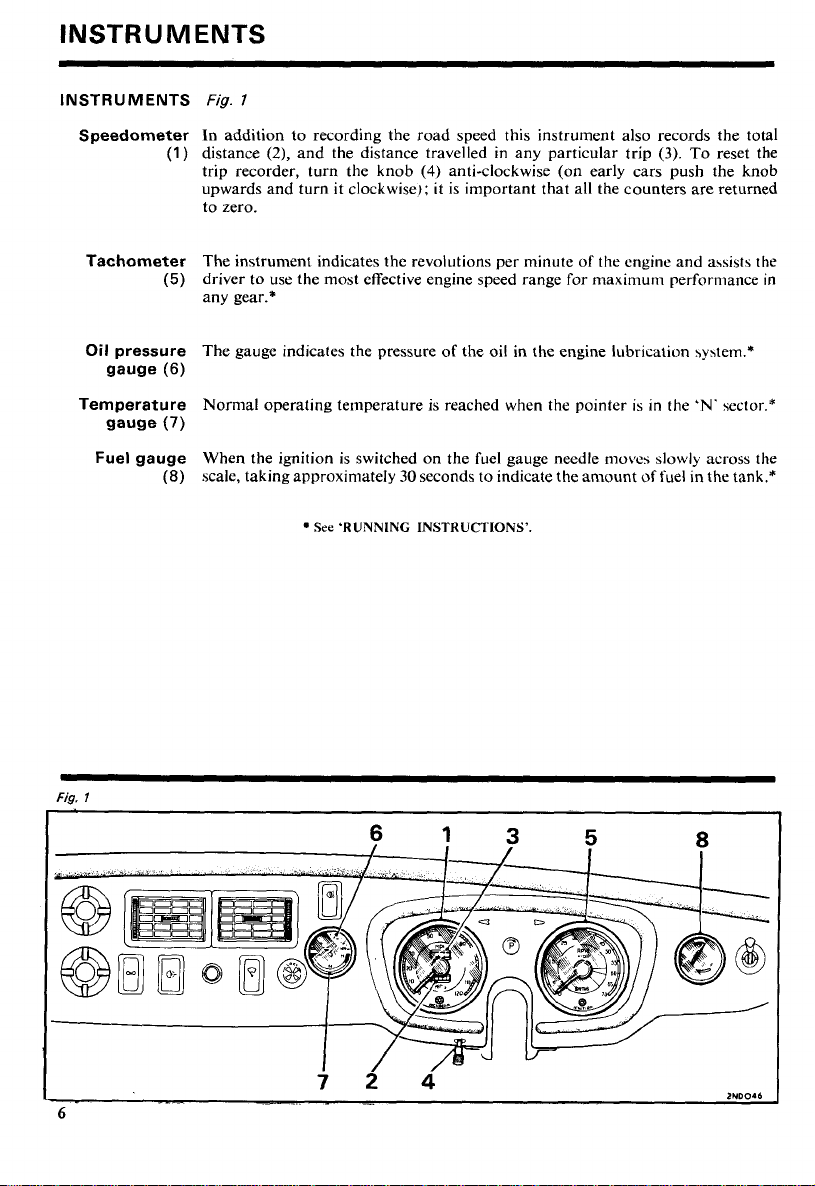

INSTRUMENTS

INSTRUMENTS

Speedometer

(1)

Tachometer

(5)

Oil

pressure

gauge

(6)

Temperature

gauge

(7)

Fuel gauge

(8)

Fig.

l

In addition to recording the road speed this instrument also records the total

distance

trip recorder, turn the knob

upwards and turn it clockwise); it is important that all the counters are returned

to zero.

The instrument indicates the revolutions per minute of the engine and assists the

driver to use the most effective engine speed range for maximum performance in

any gear.*

The gauge indicates the pressure of the oil in the engine lubrtcation \y\tem.*

Nornlal operating temperature is reached when the pointer is in the

When the ignition is switched on the fuel gauge needle moves slowly across the

scale, taking approximately

(2),

and the distance travelled in any particular trip

(4) anti-clockwise (on early cars push the knob

30

seconds to indicate the amount

See

'RUNNING INSTRUCTIONS'.

(3).

To reset the

'N.

sector.*

of

fuel in the tank.*

Page 9

SWITCHES

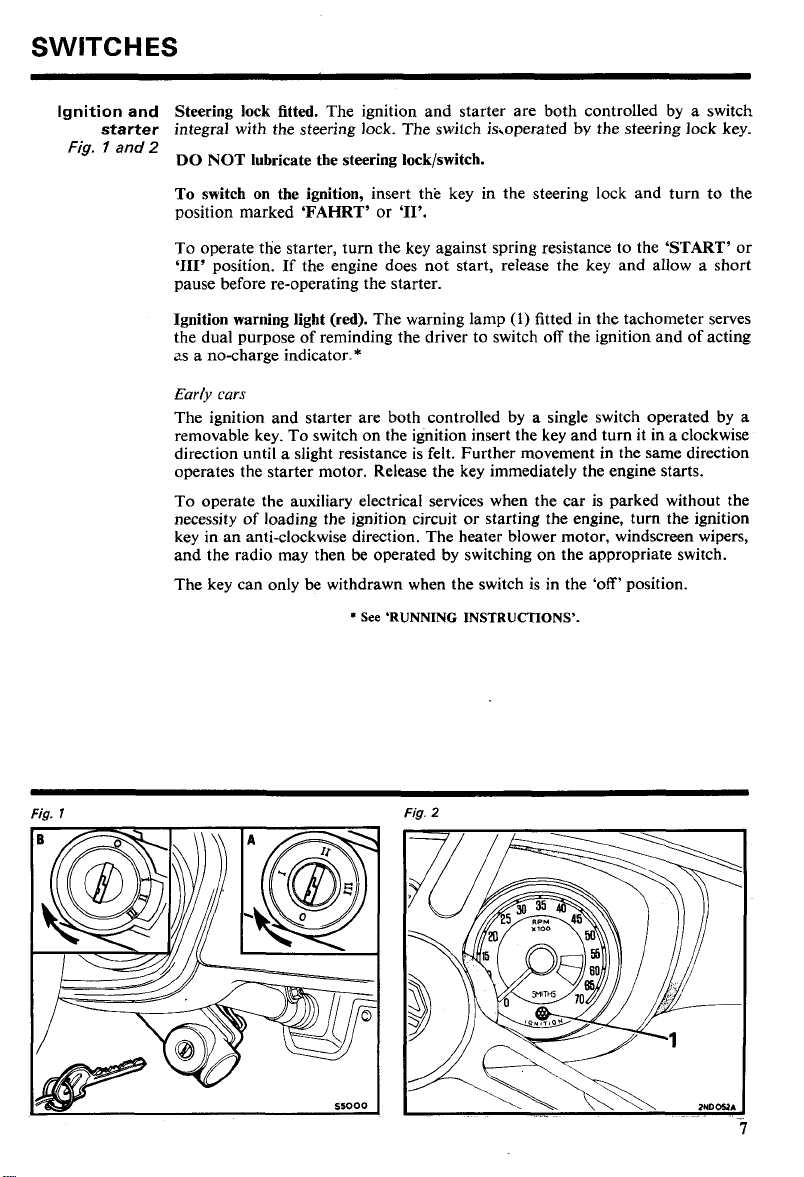

Ignition

starter

Fig. 7 and

and

Steering lock fitted. The ignition and starter are both controlled by a switch

integral with the steering lock. The switch is,operated by the steering lock key.

2

DO NOT lubricate the steering lock/switch.

To switch on the ignition, insert the key in the steering lock and turn to the

position marked 'FAHRT' or

'11'.

To operate the starter, turn the key against spring resistance to the 'START' or

'111'

position.

If

the engine does not start, release the key and allow a short

pause before re-operating the starter.

(1)

Ignition warning light (red). The warning lamp

fitted in the tachometer serves

the dual purpose of reminding the driver to switch off the ignition and of acting

as a no-charge indicator.*

Early cars

The ignition and starter are both controlled by a single switch operated by a

removable key. To switch on the ignition insert the key and turn it in a clockwise

direction until a slight resistance is felt. Further movement in the same direction

operates the starter motor. Release the key immediately the engine starts.

To operate the auxiliary electrical services when the car is parked without the

necessity of loading the ignition circuit or starting the engine, turn the ignition

key in an anti-clockwise direction. The heater blower motor, windscreen wipers,

and the radio may then be operated by switching on the appropriate switch.

The key can only be withdrawn when the switch is in the 'off' position.

*

See 'RUNNING INSTRUCTIONS'.

Fig.

l

Fig.

2

Page 10

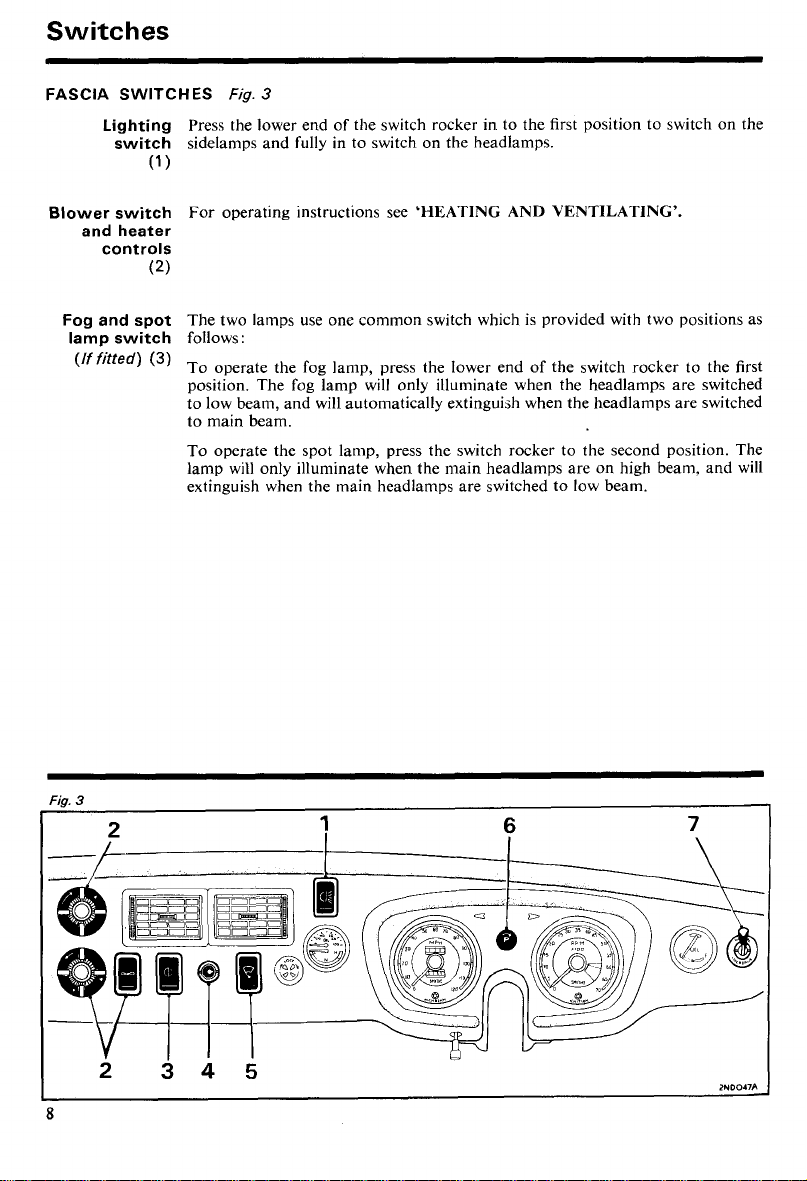

Switches

FASCIA

Blower switch

SWITCHES

Lighting

switch

(1

and heater

controls

(2)

Fog and spot

lamp switch

(If

fitted)

(3)

Fig.

3

Press the lower end of the switch rocker in to the first position to switch on the

sidelamps and fully in to switch on the headlamps.

)

For operating instructions see

'HEATING AND VENTILATING'.

The two lamps use one common switch which is provided with two positions as

follows:

To operate the fog lamp, press the lower end of the switch rocker to the first

position. The fog lamp will only illuminate when the headlamps are switched

to low beam, and will automatically extinguish when the headlamps are switched

to main beam.

To operate the spot lamp, press the switch rocker to the second position. The

lamp will only illuminate when the main headlamps are on high beam, and will

extinguish when the main headlamps are switched to low beam.

Page 11

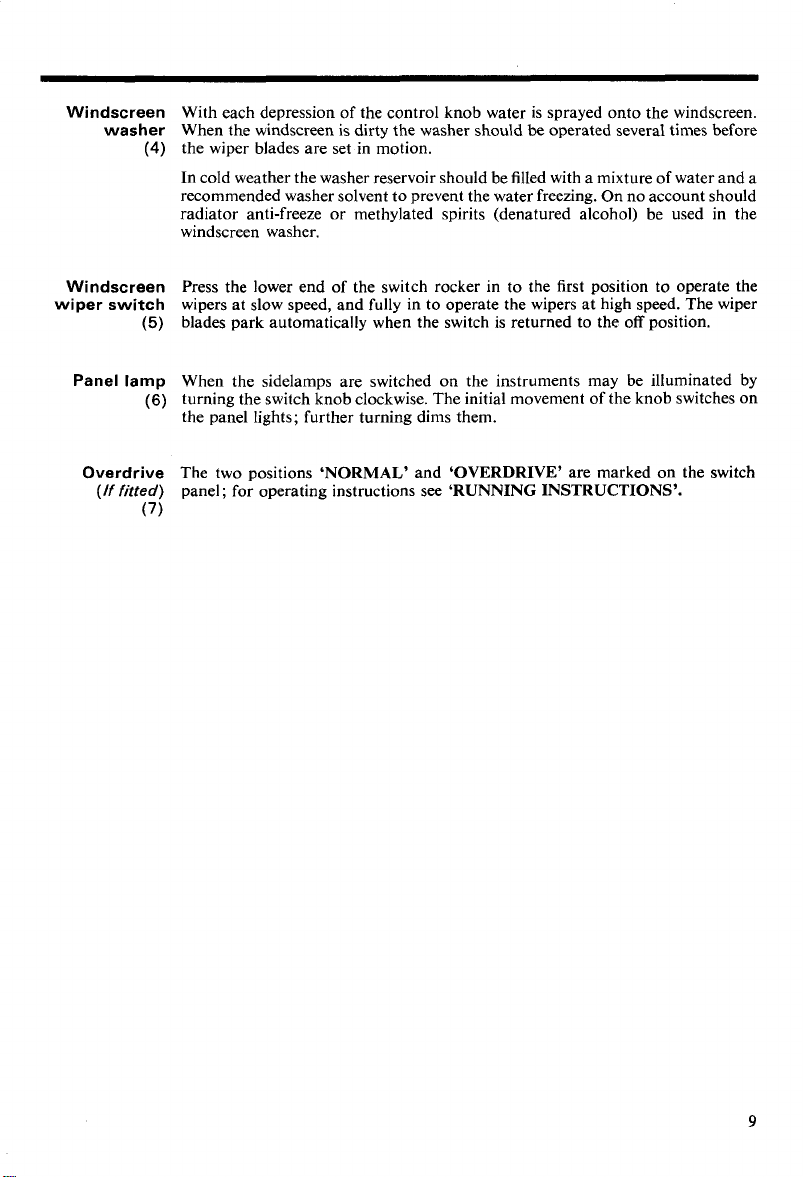

Windscreen

washer

(4)

With each depression of the control knob water is sprayed onto the windscreen.

When the windscreen is dirty the washer should be operated several times before

the wiper blades are set in motion.

In cold weather the washer reservoir should be filled with a mixture of water and a

recommended washer solvent to prevent the water freezing. On no account should

radiator anti-freeze or methylated spirits (denatured alcohol) be used in the

windscreen washer.

Windscreen

wiper switch

(5)

Panel lamp

(6)

Overdrive

(If fitted)

(7)

Press the lower end

of

the switch rocker in to the first position to operate the

wipers at slow speed, and fully in to operate the wipers at high speed. The wiper

blades park automatically when the switch is returned to the off position.

When the sidelamps are switched on the instruments may be illuminated by

turning the switch knob clockwise. The initial movement of the knob switches on

the panel lights; further turning dims them.

The two positions

panel; for operating instructions see

'NORMAL'

and

'OVERDRIVE'

are marked on the switch

'RUNNING INSTRUCTIONS'.

Page 12

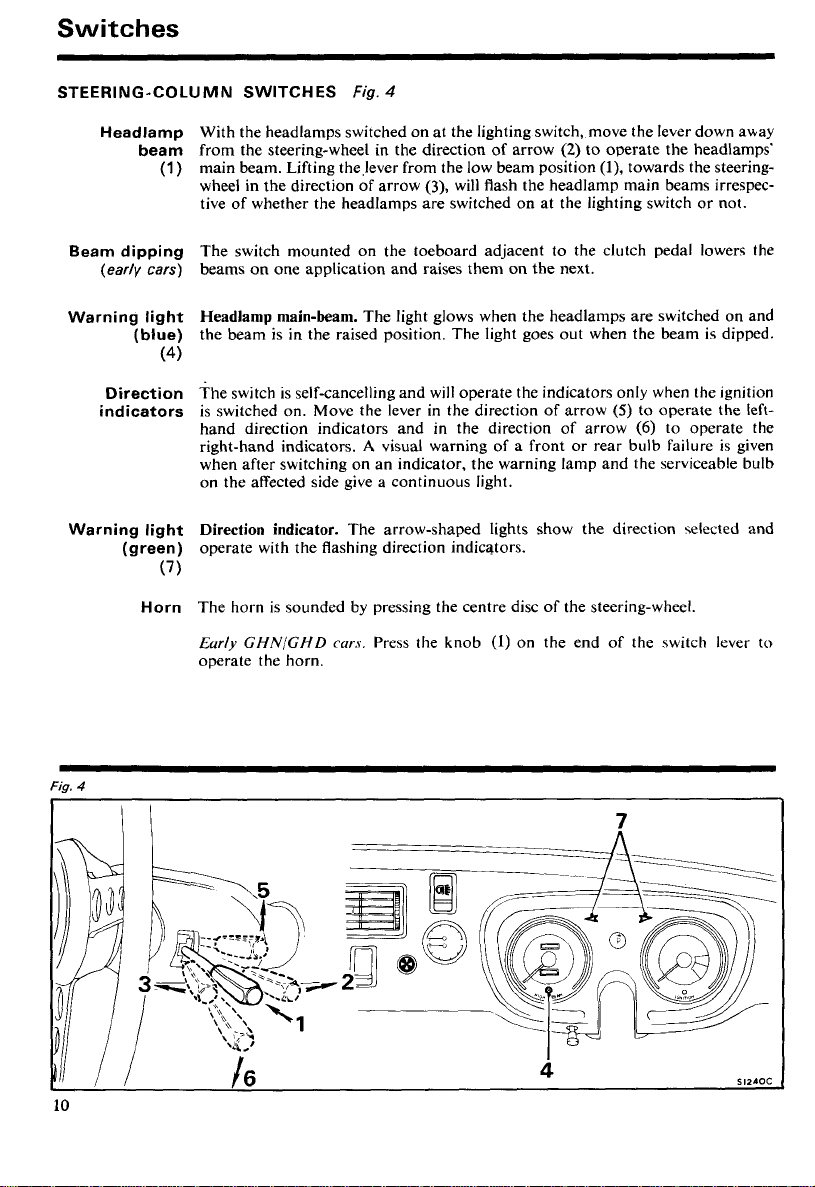

Switches

STEERING-COLUMN

Headlamp

beam

(1

)

SWITCHES

With the headlamps switched on at the lighting switch, move the lever down ahay

from the steering-wheel in the direction of arrow

main beam. Lifting thelever from the low beam position

wheel in the direction of arrow

tive of whether the headlamps are switched on at the lighting switch or not.

Beam dipping

(early cars)

Warning light Headlamp main-beam.

(blue)

Direction

indicators

The switch mounted on the toeboard adjacent to the clutch pedal lowers the

beams on one application and raises them on the next.

the beam is in the raised position. The light goes out when the beam is dipped.

(4)

The switch is self-cancelling and will operate the indicators only when the ignition

is switched on. Move the lever in the direction of arrow

hand direction indicators and in the direction of arrow

right-hand indicators.

when after switching on an indicator, the warning lamp and the serviceable bulb

on the affected side give a continuous light.

Warning light Direction indicator.

(green)

operate with the flashing direction indicators.

(7)

Horn

The horn is sounded by pressing the centre disc of the steering-wheel.

Eurly

GHNIGHD

operate the horn.

Fig.

4

(2)

to overate the headlamps'

(l),

(3),

will flash the headlamp main beams irrespec-

towards the steering-

The light glows when the headlamps are switched on and

(5)

to operate the left-

(6)

A

visual warning of a front or rear bulb failure is given

to operate the

The arrow-shaped lights show the direction selected and

curs.

Press the knob

(1)

on the end of the switch lever to

Fig.

4

Page 13

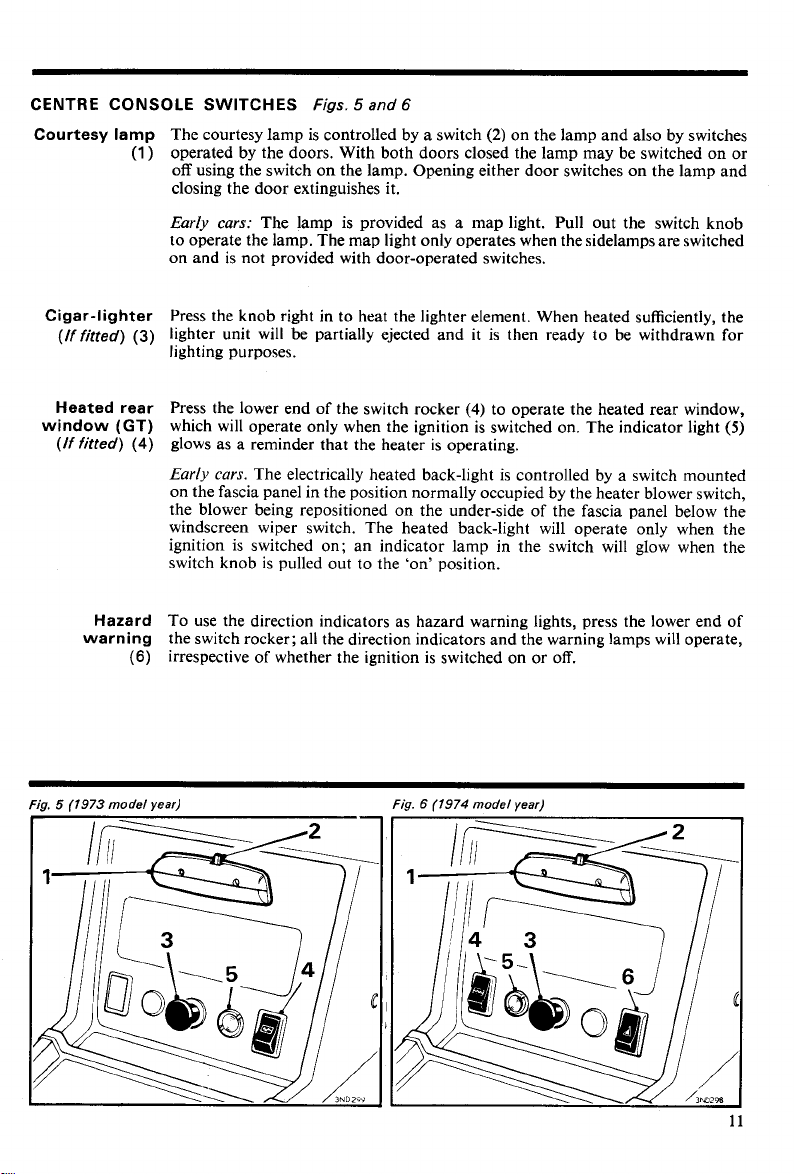

CENTRE CONSOLE SWITCHES

Courtesy lamp

The courtesy lamp is controlled by a switch

operated by the doors. With both doors closed the lamp may be switched on or

(1

)

off using the switch on the lamp. Opening either door switches on the lamp and

closing the door extinguishes it.

Early

cars:

The lamp is provided as a map light. Pull out the switch knob

to operate the lamp. The map light only operates when thesidelampsare switched

on and is not provided with door-operated switches.

Figs. 5 and

6

(2)

on the lamp and also by switches

Cigar-lighter

(If fitted)

(3)

Heated rear

window (GT)

(If fitted)

(4)

Hazard

warning

(6)

Fig. 5 (7973 model

Press the knob right in to heat the lighter element. When heated sufficiently, the

be

lighter unit will

partially ejected and it is then ready to be withdrawn for

lighting purposes.

Press the lower end of the switch rocker

(4)

to operate the heated rear window,

which will operate only when the ignition is switched on. The indicator light

glows as a reminder that the heater is operating.

Early cars.

The electrically heated back-light is controlled by a switch mounted

on the fascia panel in the position normally occupied by the heater blower switch,

the blower being repositioned on the under-side of the fascia panel below the

windscreen wiper switch. The heated back-light will operate only when the

ignition is switched on; an indicator lamp in the switch will glow when the

switch knob is pulled out to the 'on' position.

To use the direction indicators as hazard warning lights, press the lower end of

the switch rocker; all the direction indicators and the warning lamps will operate,

irrespective of whether the ignition is switched on or off.

year)

Fig. 6 (7974 model

year)

(5)

Page 14

Switches

INTERIOR OR TAILGATE LAMP SWITCH

The lamp mounted above the seats is controlled by a switch on the lamp and

GT

also by a switch operated by the tailgate. The lamp lights as the tailgate is raised

and switches off as the tailgate is lowered.

GT

On early

switch on each door hinge post which operates as the doors are opened or closed.

A

switch is also provided on the lamp for use when both doors are closed.

cars an interior lamp mounted above the seats is controlled by

a

Page 15

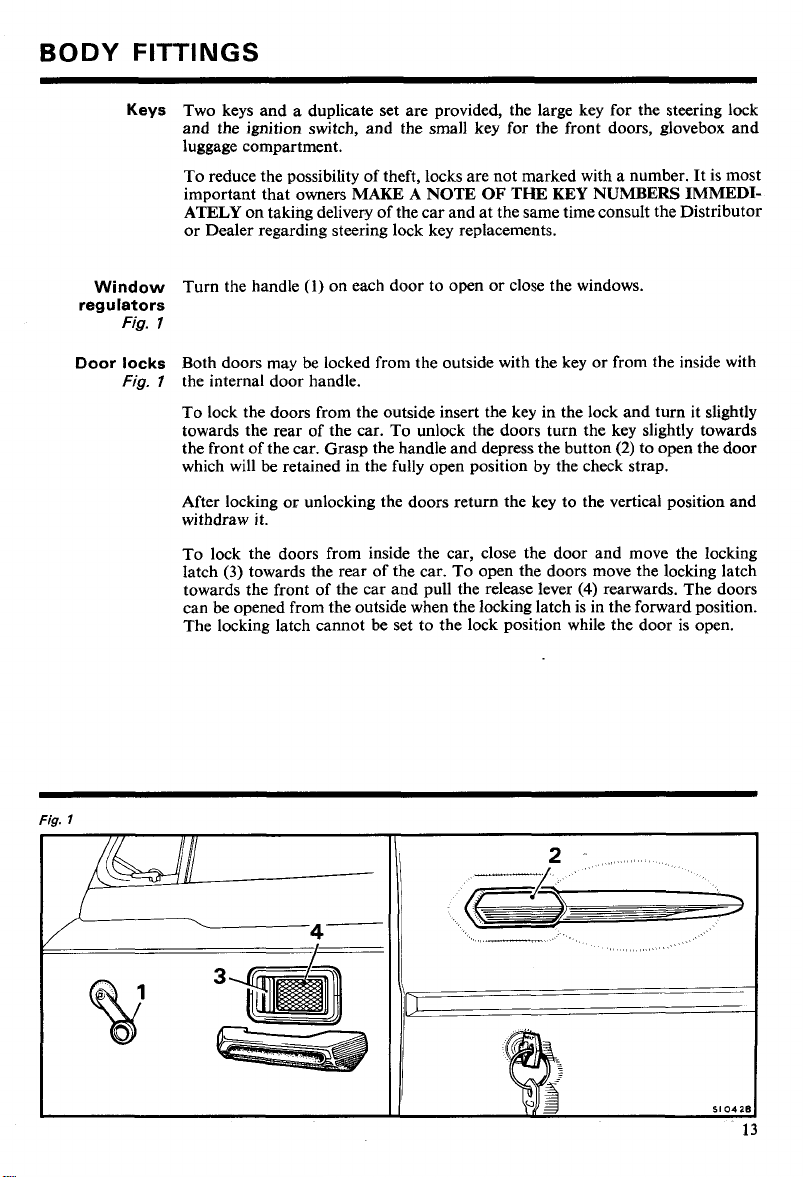

BODY

FITTINGS

Keys

Two keys and a duplicate set are provided, the large key for the steering lock

and the ignition switch, and the small key for the front doors, glovebox and

luggage compartment.

To reduce the possibility of theft, locks are not marked with a number. It is most

important that owners

ATELY

or Dealer regard& steering lock key replacements.

on taking deliverv of the car and at the same time consult the Distributor

MAKE A NOTE OF

THE

KEY

NUMBERS IMMEDI-

Door locks

Fig.

l

Window

regulators

Fig.

Fig. 7 the internal door handle.

Turn the handle

7

Both doors may be locked from the outside with the key or from the inside with

To lock the doors from the outside insert the key in the lock and turn it slightly

towards the rear of the car. To unlock the doors turn the key slightly towards

the front of the car. Grasp the handle and depress the button

which will be retained in the fully open position by the check strap.

After locking or unlocking the doors return the key to the vertical position and

withdraw it.

To lock the doors from inside the car, close the door and move the locking

(3)

latch

towards the front of the car and pull the release lever

can be opened from the outside when the locking latch is in the forward position.

The locking latch cannot be set to the lock position while the door is open.

towards the rear of the car. To open the doors move the locking latch

(1)

on each door to open or close the windows.

(4)

(2)

to open the door

rearwards. The doors

Page 16

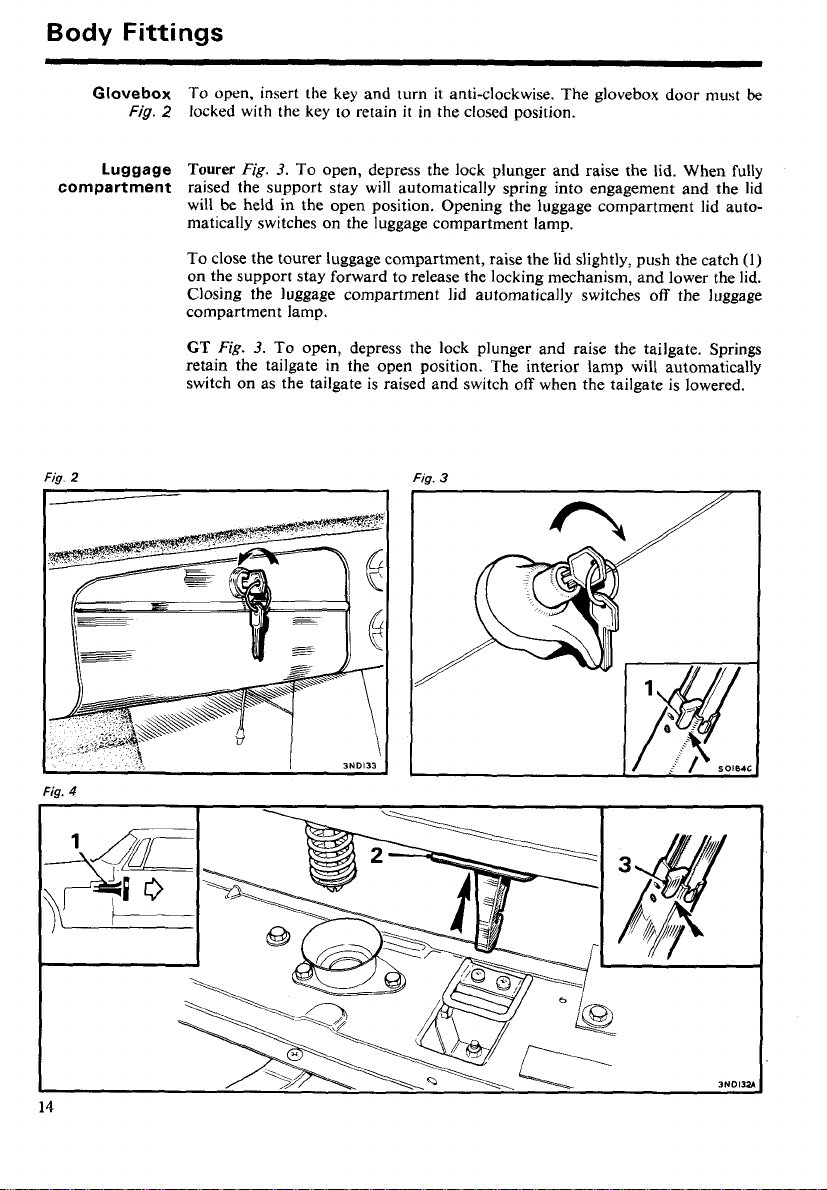

Body

Fittings

Glovebox

Luggage

compartment

Fig.

2

Fig.

2

locked with the key to retain

Tourer

Fig.

3.

To open, depress the lock plunger and raise the lid. When fully

it

in the closed position.

raised the support stay will automatically spring into engagement and the lid

will be held in the open position. Opening the luggage compartment lid automatically switches on the luggage compartment lamp.

To close the tourer luggage compartment, raise the lid slightly, push the catch

on the support stay forward to release the locking mechanism, and lower the lid.

Closing the luggage compartment lid automatically switches off the luggage

compartment lamp.

To open, insert the key and turn it anti-clockwise. The glovebox door must

GT

Fig.

3.

To open, depress the lock plunger and raise the tailgate. Springs

retain the tailgate in the open position. The interior lamp will automatically

switch on as the tailgate is raised and switch off when the tailgate is lowered.

Fig.

3

be

(1)

Fig.

4

Page 17

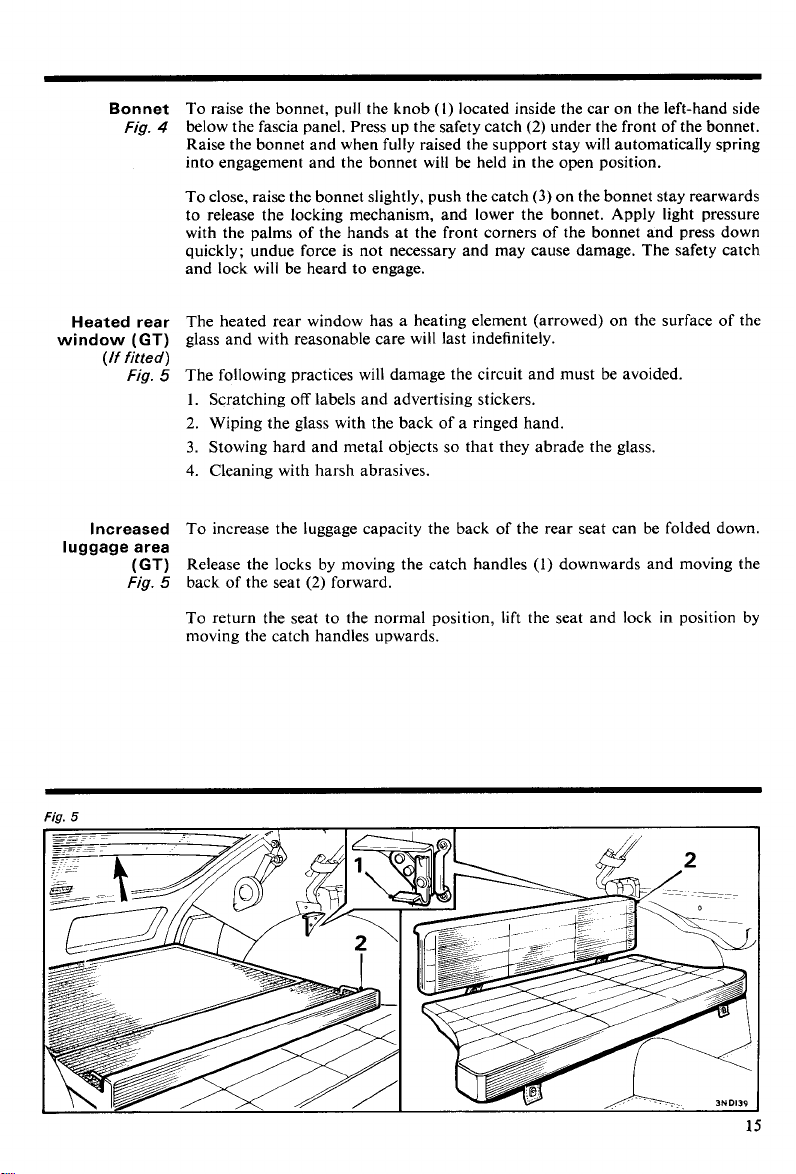

Bonnet

Fig.

To raise the bonnet, pull the knob (l) located inside the car on the left-hand side

4

below the fascia panel. Press up the safety catch

(2)

under the front of the bonnet.

Raise the bonnet and when fully raised the support stay will automatically spring

into engagement and the bonnet

wiH be held in the open position.

Heated rear

window

luggage area

(GT)

(If fitted)

Fig.

Increased

(GT)

Fig.

To close, raise the bonnet slightly, push the catch

(3)

on the bonnet stay rearwards

to release the locking mechanism, and lower the bonnet. Apply light pressure

with the palms of the hands at the front corners of the bonnet and press down

quickly; undue force is not necessary and may cause damage. The safety catch

and lock will be heard to engage.

The heated rear window has a heating element (arrowed) on the surface of the

glass and with reasonable care will last indefinitely.

5

The following practices will damage the circuit and must be avoided.

1.

Scratching off labels and advertising stickers.

2.

Wiping the glass with the back of a ringed hand.

3.

Stowing hard and metal objects so that they abrade the glass.

4. Cleaning with harsh abrasives.

To increase the luggage capacity the back of the rear seat can be folded down.

Release the locks by moving the catch handles

5

back of the seat

(2)

forward.

(1)

downwards and moving the

To return the seat to the normal position, lift the seat and lock in position by

moving the catch handles upwards.

Page 18

Body

Fittings

Mirrors

Arm-rest and

ashtray

Fig.

6

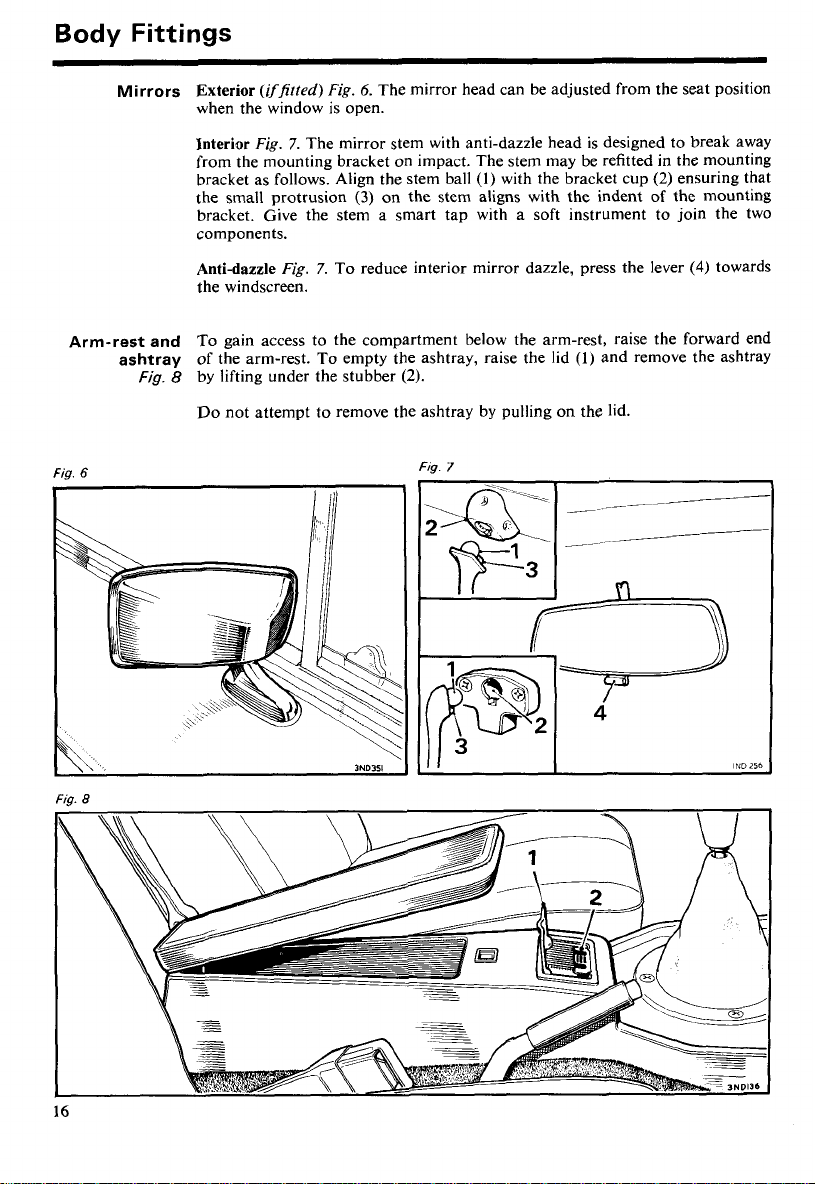

Exterior

(iffirted)

Fig.

6.

The mirror head can be adjusted from the seat position

when the window is open.

Interior

Fig.

7.

The mirror stem with anti-dazzle head is designed to break away

from the mounting bracket on impact. The stem may be refitted in the mounting

(l)

bracket as follows. Align the stem ball

the small protrusion

(3)

on the stem aligns with the indent of the mounting

with the bracket cup

bracket. Give the stem a smart tap with a soft instrument to join the two

components.

Anti-dazzle

Fig.

7.

To reduce interior mirror dazzle, press the lever

the windscreen.

To gain access to the compartment below the arm-rest, raise the forward end

of the arm-rest. To empty the ashtray, raise the lid

Fig. 8 by lifting under the stubber

(2).

(1)

and remove the ashtray

Do not attempt to remove the ashtray by pulling on the lid.

FI~.

7

(2)

ensuring that

(4)

towards

Fig.

8

Page 19

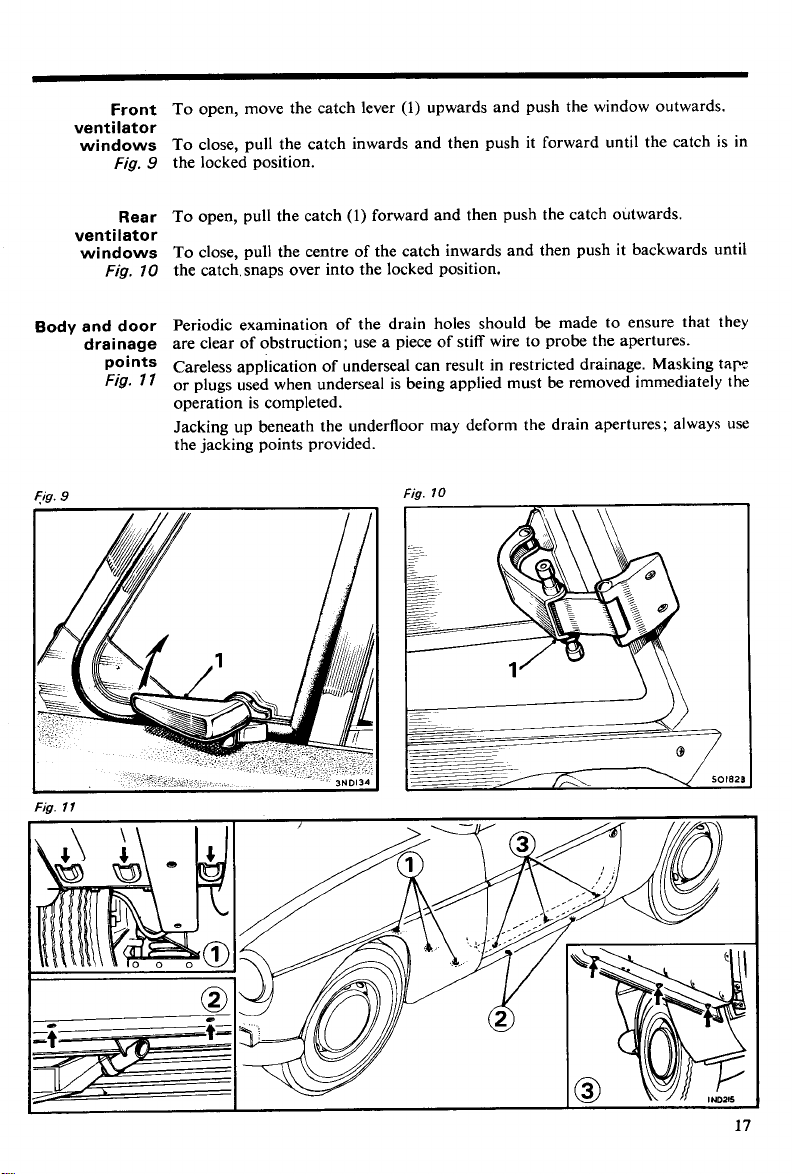

Front

ventilator

windows

Fig.

To open, move the catch lever

(1)

upwards and push the window outwards.

To close, pull the catch inwards and then push it forward until the catch is in

the locked position.

9

Rear

ventilator

windows

Fig.

70

Body and door

drainage

points

Fig.

7

Fig.

9

To open, pull the catch

(1)

forward and then push the catch outwards.

To close, pull the centre of the catch inwards and then push it backwards until

the catch, snaps over into the locked position.

Periodic examination of the drain holes should be made to ensure that they

are clear of obstruction; use a piece of stiff wire to probe the apertures.

Careless application of underseal can result in restricted drainage. Masking

I

or plugs used when underseal is being applied must be removed immediately the

operation is completed.

Jacking up beneath the underfloor may deform the drain apertures; always use

the jacking points provided.

Fig.

10

tap

Fig.

l

l

Page 20

Body

Fittings

Lowering the

hood

Fig.

Fig.

Fig.

12

73

14

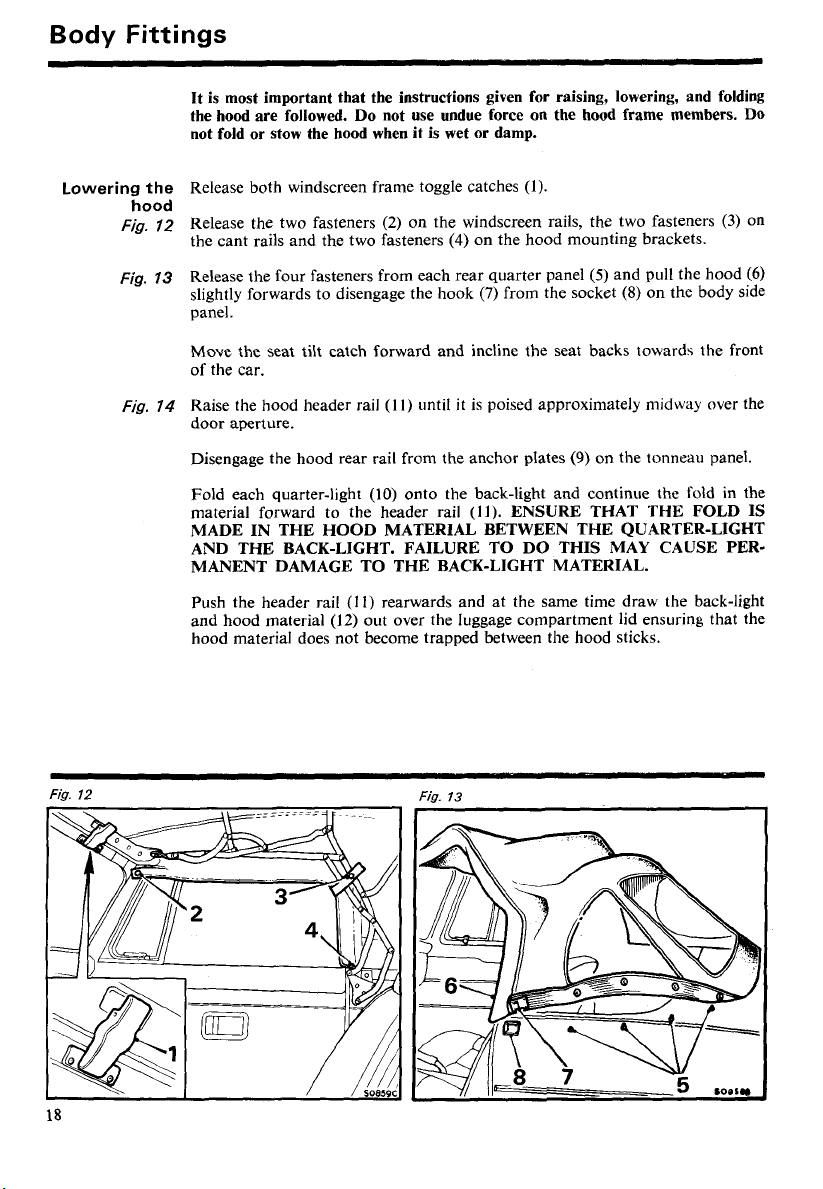

It is most important that the instructions given for raising, lowering, and folding

the hood are followed.

not fold or stow the hood when it is wet or damp.

Release both windscreen frame toggle catches

Release the two fasteners

the cant rails and the two fasteners

Release the four fasteners from each rear quarter panel

slightly forwards to disengage the hook

Do

not use undue force on the hood frame members.

(1).

(2)

on the windscreen rails, the two fasteners

(4)

on the hood mounting brackets.

(5)

(7)

from the socket

and pull the hood

(8)

on the body side

(3)

DO

on

(6)

panel.

Move the seat tilt catch forward and incline the seat backs towards the front

of the car.

(11)

until

it

Raise the hood header rail

is poised approximately midway over the

door aperture.

(9)

Disengage the hood rear rail from the anchor plates

(10)

Fold each quarter-light

material forward to the header rail

onto the back-light and continue the fold in the

(11).

ENSURE THAT THE FOLD IS

on the tonneau panel.

MADE IN THE HOOD MATERIAL BETWEEN THE QUARTER-LIGHT

AND THE BACK-LIGHT. FAILURE TO DO THIS MAY CAUSE PERMANENT DAMAGE TO THE BACK-LIGHT MATERIAL.

Push the header rail

and hood material

(I I)

rearwards and at the same time draw the back-light

(12)

out over the luggage compartment lid ensuring that the

hood material does not become trapped between the hood sticks.

Fia.

12

Fig.

73

Page 21

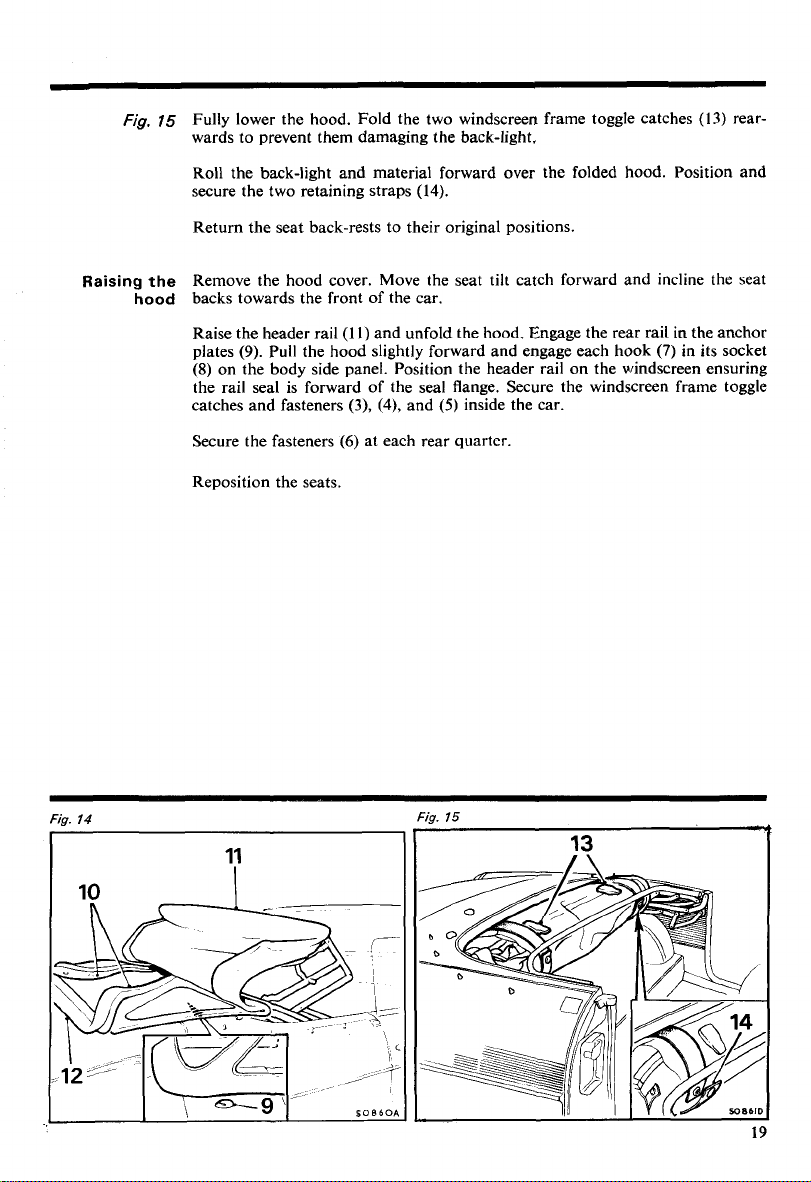

Fig.

75

Fully lower the hood. Fold the two windscreen frame toggle catches

wards to prevent them damaging the back-light.

(13)

rear-

Raising

Roll the back-light and material forward over the folded hood. Position and

secure the two retaining straps

(14).

Return the seat back-rests to their original positions.

Remove the hood cover. Move the seat tilt catch forward and incline the seat

the

hood

backs towards the front of the car.

Raise the header rail

(9).

plates

(8)

Pull the hood slightly forward and engage each hook

on the body side panel. Position the header rail on the windscreen ensuring

(l

l)

and unfold the hood. Engage the rear rail in the anchor

the rail seal is forward of the seal flange. Secure the windscreen frame toggle

(3),

(4),

and

(5)

catches and fasteners

Secure the fasteners

(6)

at each rear quarter.

inside the car.

Reposition the seats.

(7)

in its socket

Fig.

Fig.

14

15

13

Page 22

Body

Fittings

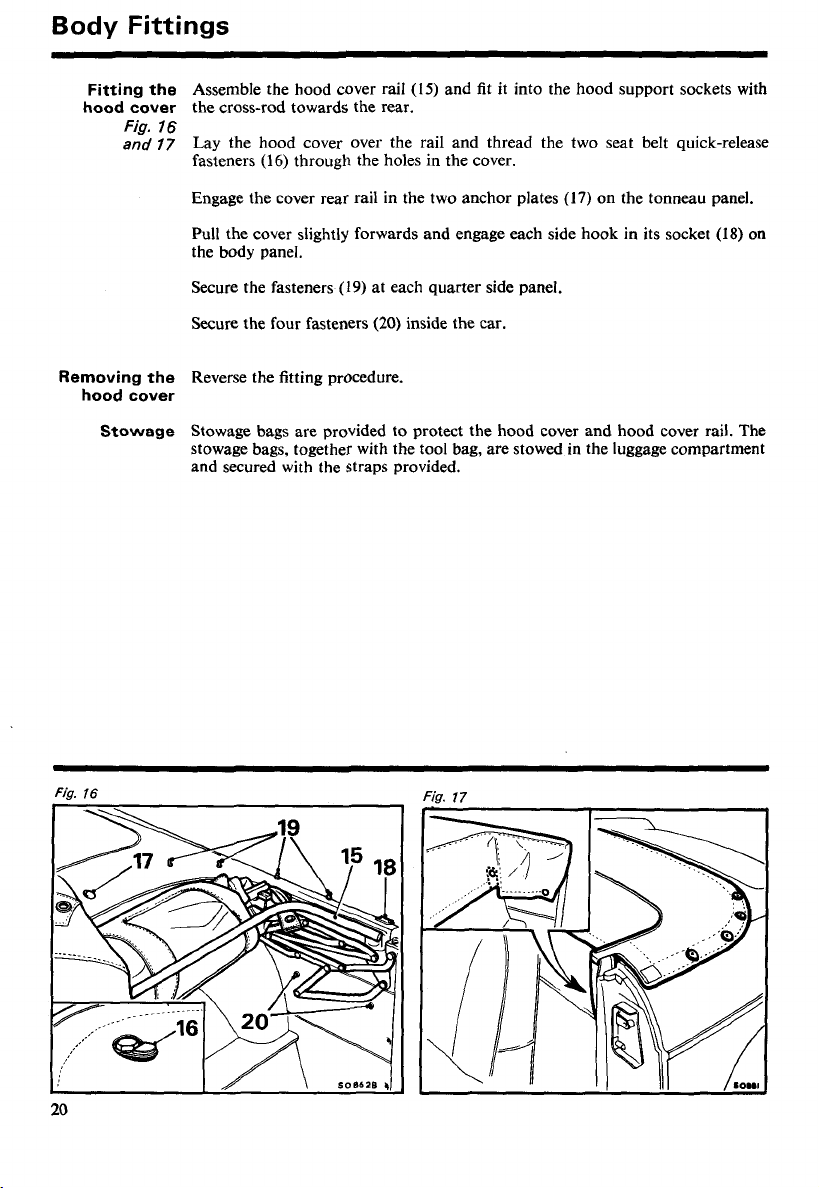

Fitting the

hood cover

Fig.

76

and

77

Removing the

hood cover

Stowage

Assemble the hood cover rail (IS) and fit it into the hood support sockets with

the cross-rod towards the rear.

Lay the hood cover over the rail and thread the two seat belt quick-release

fasteners

Engage the cover rear rail in the two anchor plates (17) on the tonneau panel.

Pull the cover slightly forwards and engage each side hook in its socket

the body panel.

Secure the fasteners

Secure the four fasteners

Reverse the fitting procedure.

Stowage bags are provided to protect the hood cover and hood cover rail. The

stowage bags, together with the tool bag, are stowed in the luggage compartment

and secured with the straps provided.

(16)

through the holes in the cover.

(19)

at each quarter side panel.

(20)

inside the car.

(18)

on

Fig.

16

l

Page 23

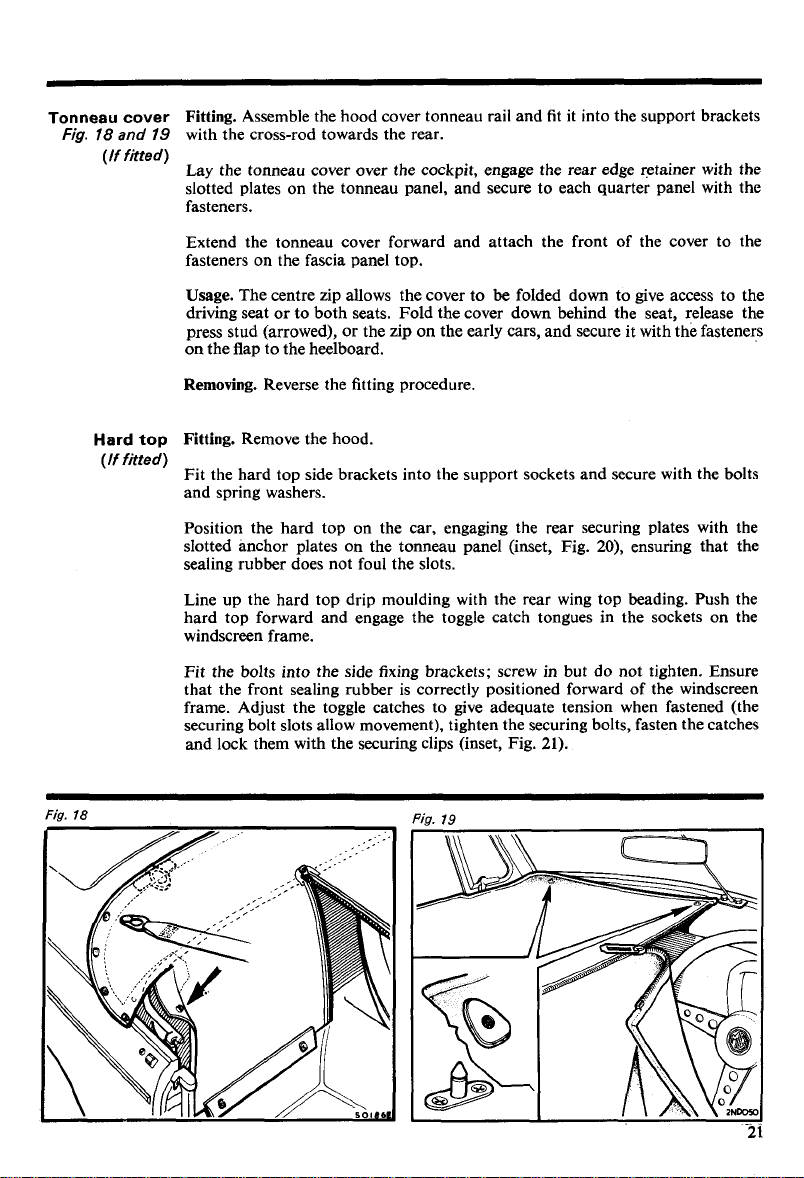

Tonneau cover

Fig.

78

and

19

(If fitted)

Fitting.

Assemble the hood cover tonneau rail and fit it into the support brackets

with the cross-rod towards the rear.

Lay the tonneau cover over the cockpit, engage the rear edge retainer with the

slotted plates on the tonneau panel, and secure to each quarter panel with the

fasteners.

Extend the tonneau cover forward and attach the front of the cover to the

fasteners on the fascia panel top.

Usage.

The centre zip allows the cover to be folded down to give access to the

driving seat or to both seats. Fold the cover down behind the seat, release the

press stud (arrowed), or the zip on the early cars, and secure it with the fasteners

on the flap to the heelboard.

Fig.

Hard

(If fitted)

18

top

Removing.

Fitting.

Reverse the fitting procedure.

Remove the hood.

Fit the hard top side brackets into the support sockets and secure with the bolts

and spring washers.

Position the hard top on the car, engaging the rear securing plates with the

20),

slotted anchor plates on the tonneau panel (inset, Fig.

ensuring that the

sealing rubber does not foul the slots.

Line up the hard top drip moulding with the rear wing top beading. Push the

hard top forward and engage the toggle catch tongues in the sockets on the

windscreen frame.

Fit the bolts into the side fixing brackets; screw in but do not tighten. Ensure

that the front sealing rubber is correctly positioned forward of the windscreen

frame. Adjust the toggle catches to give adequate tension when fastened (the

securing bolt slots allow movement), tighten the securing bolts, fasten the catches

and lock them with the securing clips (inset, Fig.

21).

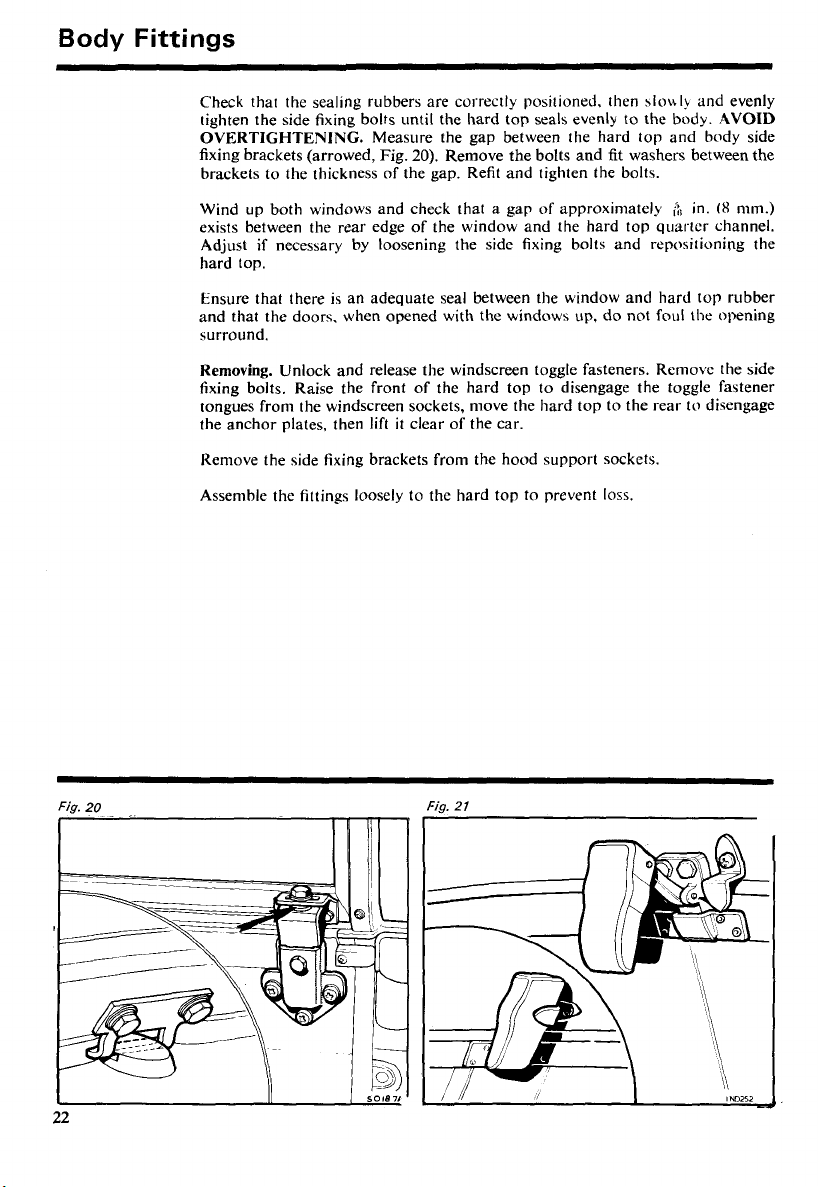

Page 24

Body

Fittings

Check that the sealing rubbers are correctly positioned, then

tighten the side fixing bolts until the hard top seals evenly to the body.

OVERTIGHTENING.

fixing brackets (arrowed, Fig.

brackets to the thickness of the gap. Refit and tighten the bolts.

Wind up both windows and check that a gap of approximately

exists between the rear edge of the window and the hard top quarter channel.

Adjust

if

hard top.

Ensure that there is an adequate seal between the window and hard top rubber

and that the doors. when opened with the windows up, do not foul the opening

surround.

Removing.

fixing bolts. Raise the front of the hard top to disengage the toggle fastener

tongues from the windscreen sockets, move the hard top to the rear to disengage

the anchor plates, then lift

Reniove the side fixing brackets from the hood support sockets.

Assemble the fittings loosely to

necessary by loosening the side fixing bolts and repositioning the

Unlock and release the windscreen toggle fasteners. Rernovc the side

Measure the gap between the hard top and body side

20).

Remove the bolts and

it

clear of the car.

thc hard top to prevent loss.

~10\\1y

and evenly

AVOID

fit

washers between the

&

in.

(8

mm.)

Fig.

22

20

Fig.

21

Page 25

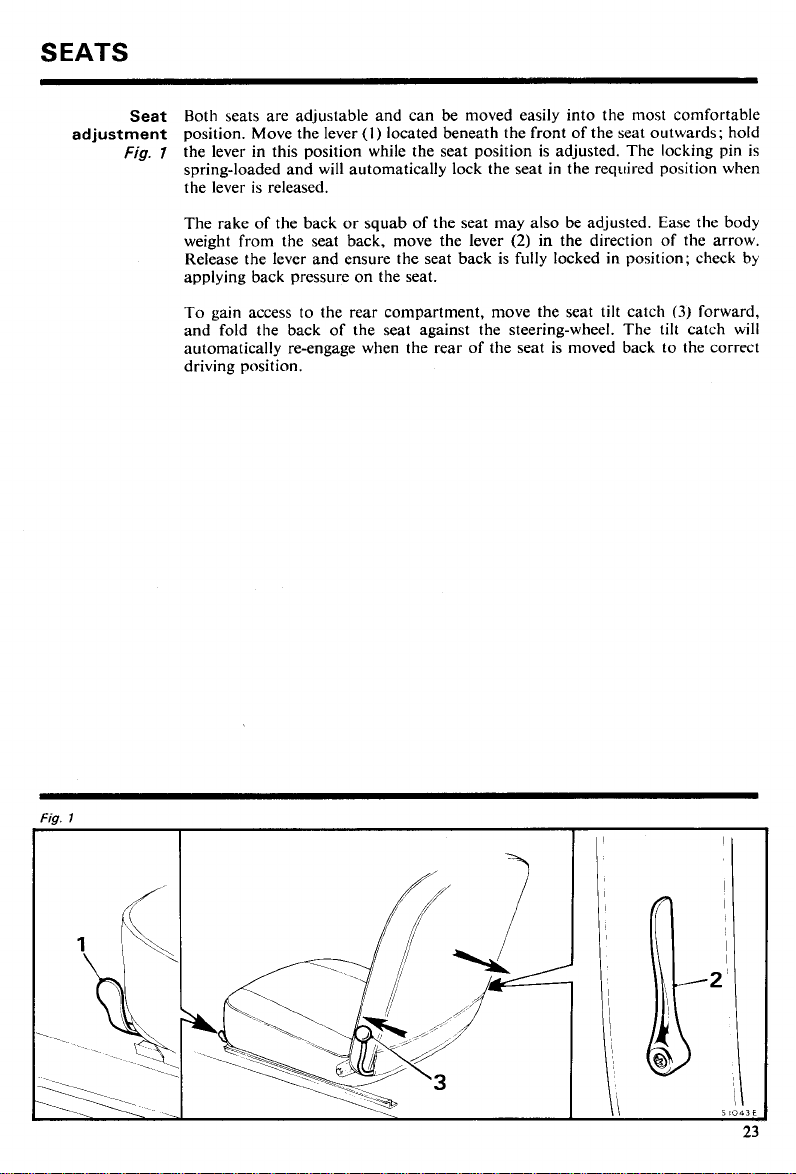

SEATS

adjustment

Both seats are adjustable and can be moved easily into the most comfortable

Seat

position. Move the lever

the lever in this position while the seat position is adjusted. The locking pin is

Fig.

7

spring-loaded and will automatically lock the seat in the required position when

the lever is released.

The rake of the back or squab of the seat may also be adjusted. Ease the body

weight from the seat back, move the lever

Release the lever and ensure the seat back is fully locked in position; check by

applying back pressure on the seat.

(I)

located beneath the front of the seat outwards; hold

(2)

in the direction of the arrow.

To gain access to the rear compartment,

and fold the back of the seat against the steering-wheel. The tilt catch will

automatically re-engage when the rear of the seat is moved back to the correct

driving position.

move the seat tilt catch

(3)

forward,

Page 26

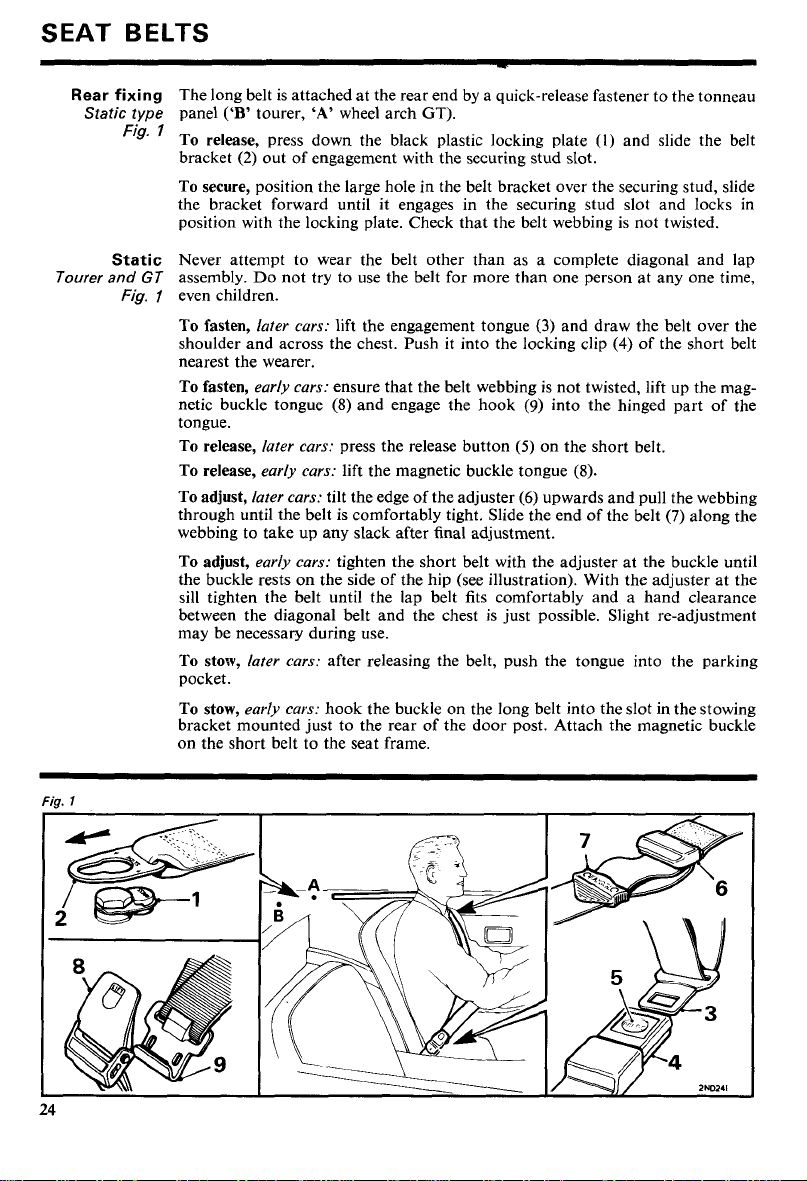

SEAT

Rear

Static type

BELTS

fixing

The long belt is attached at the rear end by a quick-release fastener to the tonneau

panel

Fig.

To release, press down the black plastic locking plate

bracket

To secure, position the large hole in the belt bracket over the securing stud, slide

the bracket forward until it engages in the securing stud slot and locks in

position with the locking plate. Check that the belt webbing is not twisted.

('B'

tourer,

'A'

wheel arch

(2)

out of engagement with the securing stud slot.

GT).

(I)

and slide the belt

Static

Tourer and

Fig.

Never attempt to wear the belt other than as a complete diagonal and lap

GT

assembly. Do not try to use the belt for more than one person at any one time,

1

even children.

To fasten,

later cars:

shoulder and across the chest. Push it into the locking clip

lift the engagement tongue

(3)

and draw the belt over the

(4)

of the short belt

nearest the wearer.

To fasten,

early cars:

netic buckle tongue

ensure that the belt webbing is not twisted, lift up the mag-

(8)

and engage the hook

(9)

into the hinged part of the

tongue.

To release,

To release,

To adjust,

later cars:

early cars:

later cars:

through until the belt is comfortably tight. Slide the end of the belt

press the release button

(5)

lift the magnetic buckle tongue

tilt the edge of the adjuster

(6)

on the short belt.

(8).

upwards and pull the webbing

(7)

webbing to take up any slack after final adjustment.

To adjust,

early cars:

tighten the short belt with the adjuster at the buckle until

the buckle rests on the side of the hip (see illustration). With the adjuster at the

sill tighten the belt until the lap belt fits comfortably and a hand clearance

between the diagonal belt and the chest is just possible. Slight re-adjustment

may be necessary during use.

To stow,

later cars:

after releasing the belt, push the tongue into the parking

pocket.

To stow,

early cars:

hook the buckle on the long belt into the slot in the stowing

bracket mounted just to the rear of the door post. Attach the magnetic buckle

on the short belt to the seat frame.

along the

Page 27

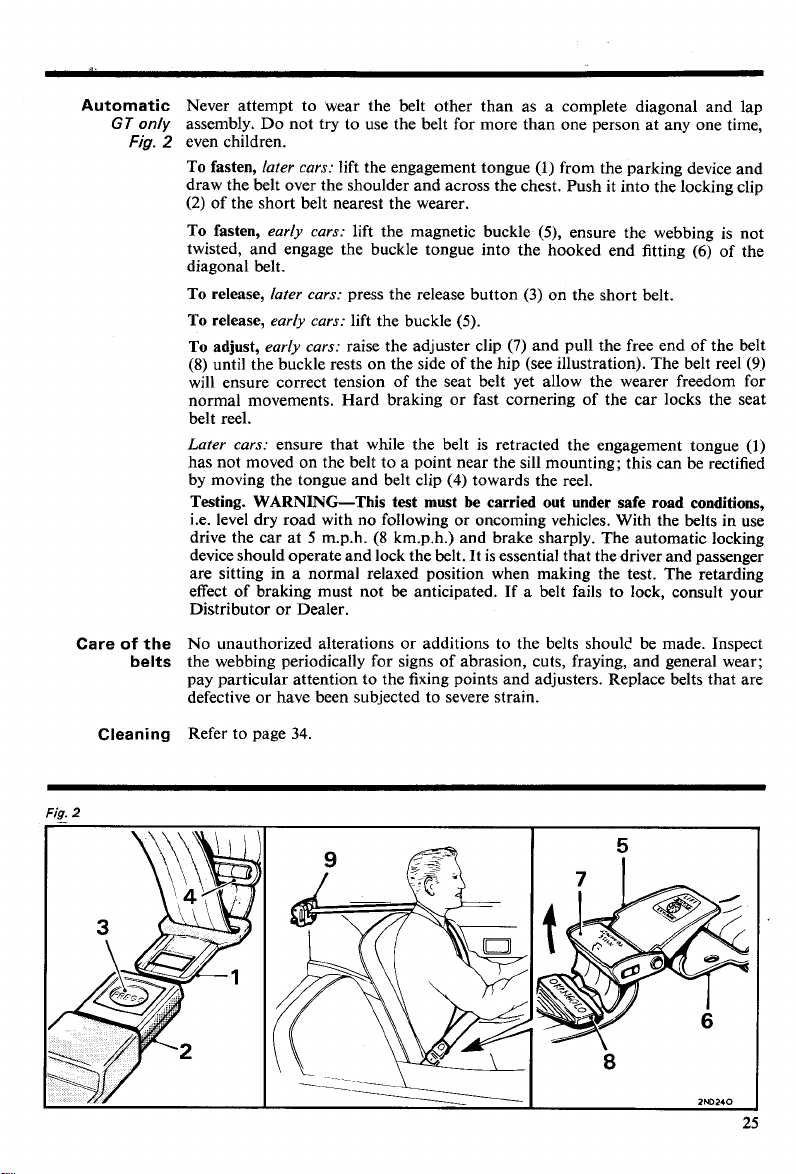

Automatic

GT

only

Fig.

Care

of

the

belts

Never attempt to wear the belt other than as a complete diagonal and lap

assembly. Do not try to use the belt for more than one person at any one time,

2

even children.

To fasten,

later cars:

lift the engagement tongue (1) from the parking device and

draw the belt over the shoulder and across the chest. Push it into the locking clip

(2)

of the short belt nearest the wearer.

To fasten,

twisted, and engage the buckle tongue into the hooked end fitting

early cars:

lift the magnetic buckle (5), ensure the webbing is not

(6)

diagonal belt.

To release,

To release,

To adjust,

(8)

later cars:

early cars:

early cars:

press the release button

lift the buckle (5).

raise the adjuster clip

(3)

on the short belt.

(7)

and pull the free end

of

until the buckle rests on the side of the hip (see illustration). The belt reel

will ensure correct tension of the seat belt yet allow the wearer freedom for

normal movements. Hard braking or fast cornering of the car locks the seat

belt reel.

Later cars:

ensure that while the belt is retracted the engagement tongue

has not moved on the belt to a point near the sill mounting; this can be rectified

(4)

by moving the tongue and belt clip

towards the reel.

Testing. WARNING-This test must be carried out under safe road conditions,

i.e. level dry road with no following or oncoming vehicles. With the belts in use

(8

drive the car at 5 m.p.h.

krn.p.h.) and brake sharply. The automatic locking

device should operate and lock the belt. It is essential that the driver and passenger

are sitting in a normal relaxed position when making the test. The retarding

effect of braking must not be anticipated. If a belt fails to lock, consult your

Distributor or Dealer.

No unauthorized alterations or additions to the belts shoulc' be made. Inspect

the webbing periodically for signs of abrasion, cuts, fraying, and general wear;

pay particular attention to the fixing points and adjusters. Replace belts that are

defective or have been subjected to severe strain.

of the

the belt

(9)

(l)

Fia.

Cleaning

2

Refer to page

34.

Page 28

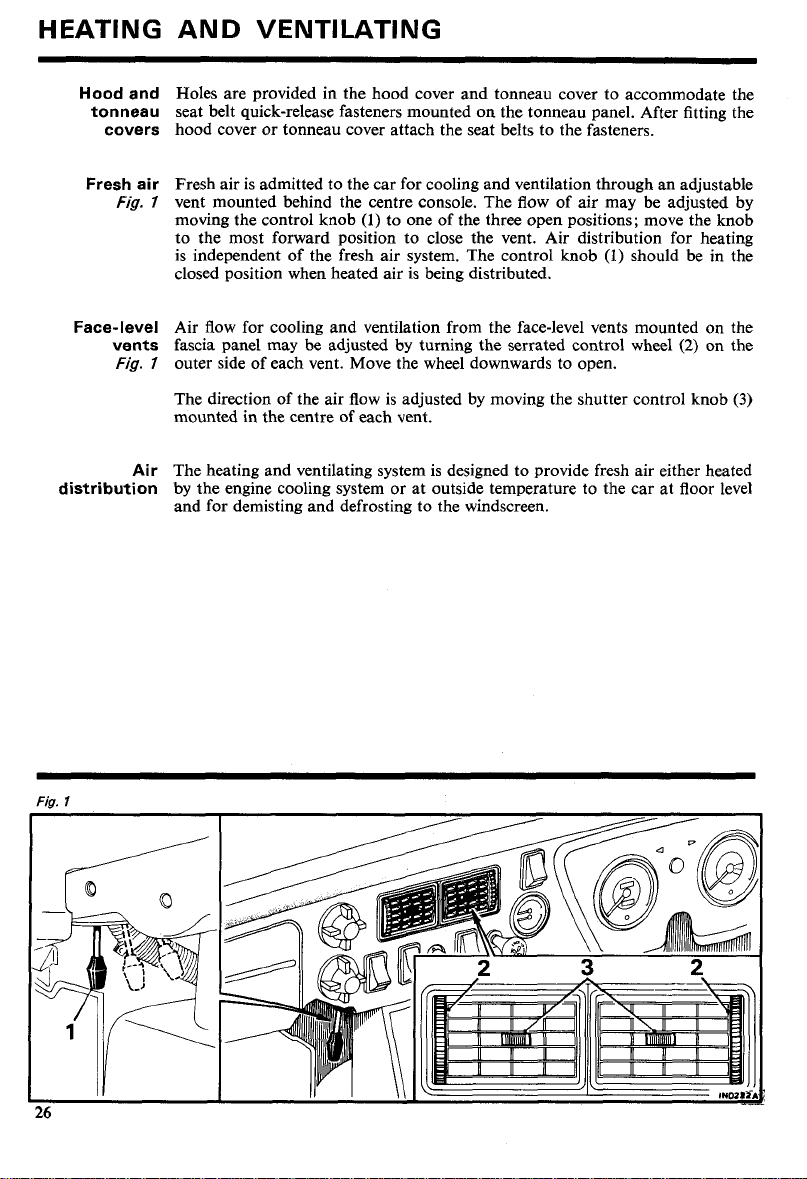

HEATING AND VENTILATING

Hood and

tonneau

covers

Fresh air

Fig.

Face-level

vents

Fig.

Air

distribution

Holes are provided in the hood cover and tonneau cover to accommodate the

seat belt quick-release fasteners mounted on the tonneau panel. After fitting the

hood cover or tonneau cover attach the seat belts to the fasteners.

Fresh air is admitted to the car for cooling and ventilation through an adjustable

7

vent mounted behind the centre console. The flow of air may be adjusted by

moving the control knob

(1)

to one of the three open positions; move the knob

to the most forward position to close the vent. Air distribution for heating

(1)

should

is independent of the fresh air system. The control knob

be

closed position when heated air is being distributed.

Air flow for cooling and ventilation from the face-level vents mounted on the

fascia panel may be adjusted by turning the serrated control wheel

7

outer side of each vent. Move the wheel downwards to open.

(2)

The direction of the air flow is adjusted by moving the shutter control knob

mounted in the centre of each vent.

The heating and ventilating system is designed to provide fresh air either heated

by the engine cooling system or at outside temperature to the car at floor level

and for demisting and defrosting to the windscreen.

in the

on the

(3)

Page 29

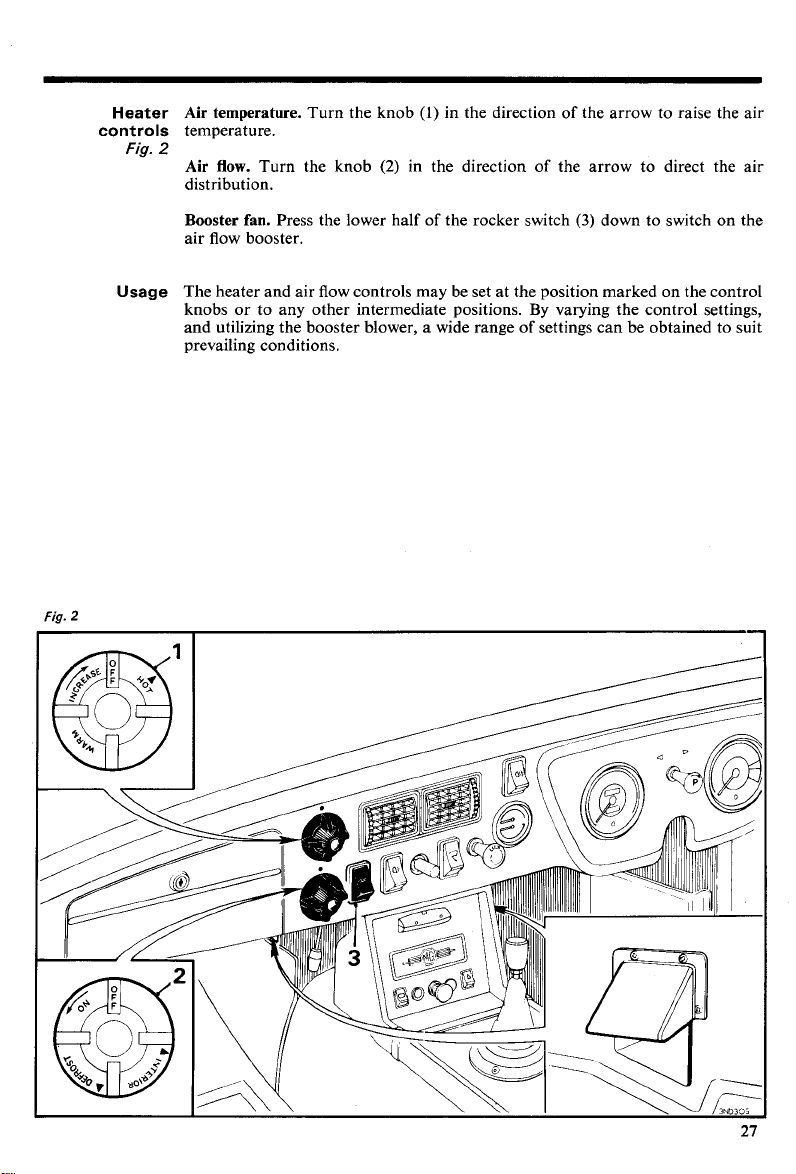

Heater Air temperature.

controls

Fig.

temperature.

2

Air flow.

Turn the knob

distribution.

Booster

fan.

air flow booster.

Turn the knob

(l)

in the direction of the arrow to raise the air

(2)

in the direction of the arrow to direct the air

Press the lower half of the rocker switch

(3)

down to switch on the

Fig.

Usage

The heater and air flow controls may be set at the position marked on the control

By

knobs or to any other intermediate positions.

varying the control settings,

and utilizing the booster blower, a wide range of settings can be obtained to suit

prevailing conditions.

2

Page 30

RUNNING INSTRUCTIONS

WARNING. Exhaust fumes will be drawn into the car if it is driven with the boot

lidltailgate open, causing a health hazard to passengers and driver.

If it is imperative that the car

effects can

(l)

(2)

(3)

(4)

(5)

be

minimised by adopting the following procedure:

Close all windows.

Open the face vents fully.

Set the heater controls to circulate the maximum amount of cold or hot air.

Switch on the blower motor to maximum speed.

Do not travel at high speed.

be

driven with the boot lidltailgate open, adverse

Choice

Filling up

with fuel

of

fuel

Starting

The octane number of a motor fuel is an indication given by the fuel technicians

of its knock resistance (pinking). High-octane fuels have been produced to

improve the efficiency of engines by allowing them to operate on high compression ratios, resulting in better fuel economy and greater power. Fuels with

an octane rating of below

not suitable. Should it be necessary to use a fuel with a lower octane number,

the car must be used very carefully until the correct fuel can be obtained.

When filling up with fuel avoid filling the tank until fuel is visible in the filler

intake tube. Should this be done and the car left in the sun, there will be a considerable risk of fuel leakage due to expansion, and consequent danger from

exposed fuel. If inadvertently overfilled and the car is to be parked, take care

to park it in the shade with the filler intake as high as possible.

The fuel tank is vented through the filler cap.

filler cap to fit this model.

Check that the gear lever is in the neutral position.

If the engine is cold, pull out the mixture control (choke) and lock it in the desired

position by turning the control knob a quarter of a turn clockwise. In extremely

cold conditions it may be necessary to pull the control out to its fullest extent.

Switch on the ignition, check that the ignition warning light glows and that the

fuel gauge registers, then operate the starter.

As soon as the engine starts, release the ignition key and warm up the engine at

a fairly fast speed (see 'Warming up'). Check that the oil pressure gauge is

registering and that the ignition warning light has gone out. Unlock the mixture

control (choke) and push it in completely as soon as the engine will run evenly

without its use.

32

See page

when automatic transmission is

97

(high compression) or

fitted.

93

(low compression) are

UNIPART

market a lockable

Starter

Do not operate the starter for longer than five to six seconds.

To prevent damage the starter cannot be operated while the engine is running.

If the engine fails to start, the ignition key must be returned to the 'off' position

before the starter can be operated again.

If after a reasonable number of attempts the engine should fail to start, switch

off the ignition and investigate the cause. Continued use of the starter when the

engine will not start not only discharges the battery but may also damage the

starter.

Page 31

Mixture contro

(choke)

Always use the minimum setting for the shortest possible time.

As soon as possible after the engine has started, push the control completely

home.

+

To obtain a fast engine idling speed, set the control to within the first

(12

mm.) approx. of its initial movement.

The control may be locked in the required position by turning the knob a quarter

of a turn clockwise.

in.

Ignition

warning light

Oil pressure

gauge

Warming up

Temperature

gauge

The light should glow when the ignition is switched on, and go out and stay out

at all times while the engine is running above normal idling speed. Failure to do

so indicates

correctly tensioned before consulting your Distributor or Dealer.

The gauge should register a pressure as soon as the engine is started up. The

pressure may rise above

from cold and as the oil is circulated and warmed the pressure should then drop

to between

and to approximately

Should the gauge fail to register any pressure, stop the engine immediately and

investigate the cause. Start by checking the oil level.

Research has proved that the practice of warming up an engine by allowing it to

idle slowly is definitely harmful. The correct procedure is to let the engine run

fairly fast, approximately

temperature as quickly as possible. Allowing the engine to work slowly in a cold

state leads to excessive cylinder wear, and far less damage is done by driving the

car straight onto the road from cold than by letting the engine idle slowly in

the garage.

For automatic transmission see page

Normal operating temperature is reached when the pointer is in the

Overheating may cause serious damage. Investigate immediately any upward

change in the temperature gauge reading. Check coolant level and fan belt tension.

a

fault in the battery charging system. Check that the fan belt is

80

50

and

80

lb./sq. in.

10

lb./sq. in.

to

25

1,000

(5.6

kg./an2) when the engine is started

(33

to

5.6

Ib./sq. in.

r.p.m., so that it attains its correct working

kg./~m.~) at normal running speeds

(.7

to

1.7

kg./cm.=) at idling speed.

32.

'N'

sector.

Running in

The treatment given to a new car will have an important bearing on its subsequent

life, and engine speeds during this early period must be limited. The following

instructions should be strictly adhered to.

500

miles

(800

(72

km.):

km.p.h.).

During the first

DO NOT

DO NOT

DO NOT

exceed

operate at full throttle in any gear.

allow the engine to labour in any gear.

45

m.p,h.

Page 32

Running Instructions

Tachometer For normal road work, and to obtain the most satisfactory service from your

Wet brakes If the car has been washed, driven through water, or over wet roads for pro-

Towing Should it become necessary to tow the car, use the towing eyes provided (see

Vehicle loading Due consideration

Towing

engine, select the appropriate gear to maintain engine speeds of between

and 4,500 r.p.m.

When maximum acceleration is required upward gear selections should be made

when the needle reaches the yellow sector (5,500-6,000

excessive use of the highest engine speeds will tend to shorten the life of the

engine. Allowing the engine to pull hard at low engine speeds must

as this also has a detrimental effect on the engine.

(6,000

The beginning of the red sector

for the engine. Never allow the needle to enter the red sector.

longed periods full braking power may not be available. Dry the brakes by

applying the foot brake lightly several times while the car is in motion. Keep

the hand brake applied while using high-pressure washing equipment.

'AUTOMATIC TRANSMISSION').

must

be

the car. Any loads carried on a luggage rack (Tourer), or roof rack (GT), or

downward load from a towing hitch must also be included in the maximum

loading-see 'GENERAL DATA'.

The towing weight of

using bottom gear a gradient of up to 1 in

weight not exceeding this figure. It may be necessary to adjust the maximum

towing weight to comply with local conditions and regulations. The recom-

mended downward load of a trailer or caravan on the towing hitch is

(34 to 45 kg.), but this may be reduced or exceeded at the discretion of the driver.

Any load carried on the roof or downward load from a towing hitch must also

be included in the maximum loading of the vehicle.

given to the overall weight carried when fully loading

1,680

lb.

(762

r.p.m.) indicates the maximum safe speed

kg.) is the maximum that is permissible. When

8

can be ascended while towing a

r.p.m.). Prolonged or

be

75

2,000

avoided

to 100 lb.

Overdrive The overdrive unit, controlled by a switch on the fascia, provides a higher

(When

fitted)

driving ratio for use with third or fourth gear. To engage overdrive move the

switch down to the 'OVERDRIVE' position; to disengage, move the lever

to 'NORMAL'. Accelerator pedal pressure should

necessary to depress the clutch pedal during engagement or disengagement.

The overdrive can be engaged at any throttle opening when in third or top gear.

If increased acceleration is required the overdrive can

alteration to the throttle setting. Do not 'switch out' the overdrive when travelling

at speeds exceeding normal third or top gear road speeds.

In certain driving conditions while travelling in third gear, the overdrive can

switched in to provide a top gear ratio or out to provide third gear acceleration

without the necessity of changing gear.

If for any reason the overdrive does not disengage, do not reverse the car otherwise

extensive damage may result.

be

maintained and it is not

be

'switched out' without

be

Page 33

AUTOMATIC TRANSMISSION

(If

fitted)

Description The usual flywheel and clutch are replaced by a fluid torque converter which is

Driving

features box, which will soon become apparent in time saved, safer driving, and less

Selector The positions for manual selection are marked

positions the selector lever quadrant plate.

coupled to a hydraulically operated planetary gearbox providing three forward

ratios and reverse. All forward ratios are automatically engaged in accordance

with accelerator position, speed of the car, and road load.

Automatic selection may be over-ridden by manual selection of first or second

ratio using the selector lever when engine braking or increased acceleration is

desired.

The automatic transmission has many advantages over a manually selected geardriving fatigue.

The technique of driving a car fitted with automatic transmission to its fullest

advantage is very soon mastered. The following points, however, must always be

observed.

'P'

or

'R'

DO NOT select

before selecting

DO NOT select

with the car stationary.

DO NOT select

Fig.

I

The stop (1) provided between

'P'

or

of

To select

raising the spring-loaded slide

also be raised when selecting the other positions with the lever at

DO NOT raise the slide when the car is in motion.

Park. In this position the transmission is mechanically locked. Use this position

P

when parked, starting, or when the car is stationary with the engine running for

tuning or adjustment.

DO NOT select

before selecting

R

Reverse. DO NOT select

operate automatically when

Neutral. The hand brake must be applied at all times when the lever is in

N

Use this position for starting.

D

Drive. This position is used when driving in normal traffic and road conditions.

Changes of all forward ratios are automatic.

Lock-up second ratio. Automatic changes are confined to first and second ratios

L2

only. This position is used when rapid acceleration or engine braking is required.

DO NOT select

Lock-up first ratio. In this position the transmission is locked to provide first

L1

ratio only.

'P'.

'D',

'L2'

'R'

while the car is moving.

'P'

or

'R'

'P'

'P'.

'L2'

while the car is moving; always apply the hand brake

'LT, 'Ll',

at speeds above

from any of the other positions, move the lever forward,

when the car is moving, and always apply the hand brake

at speeds above

or

'R'

when the engine is running at high speed

68

m.p.h.

(l

l0 km.p.h.).

'P',

'R',

'N',

'D',

'N'

and

'R'

is to minimize inadvertent selection

(2)

sufficiently to clear the stop. The slide must

'R'

when the car is moving forward. The reverse lights

'R'

is selected with the ignition switched on.

68

m.p.h.

(l

l0

km.p.h.).

'LT,

'P'

'Ll',

or

on

'R'.

'N'.

Page 34

Automatic

Transmission

(If fitted)

Starting the

engine

Driving

The procedure given in 'RUNNING INSTRUCTIONS' for starting the engine

also applies to cars fitted with automatic transmission. The following points,

however, should

The starter will only operate when the selector lever is in the

Driving with a cold engine may result in stalling. Before driving the car, warm

a cold engine by setting the mixture control (choke) to the fast idle position

page

28),

drive with the mixture control in the fast idle position as this may cause sudden

acceleration when the brakes are released.

Selecting a driving position. Always release the accelerator pedal and apply the

foot brake before moving the selector lever to the required position. This will

prevent the car from 'creeping' (i.; a tendency for the car to move very slowly

forward if

This creeping feature can

space.

Moving

off. The selector can

'Ll',

or

stances. After releasing the brakes, moving off will

much the accelerator pedal is depressed. Discretion in the use of the accelerator

must be exercised when in slippery road conditions or if optimum fuel economy

is to be achieved.

Selector in

gressively up or down in accordance with changes in road speed, accelerator

position, and road load.

The effect of the engine acting as a partial brake (engine braking) when the

accelerator is released, as with a manual gearbox, is not present when driving

with the selector in

be

noted.

'P'

or

'N'

positions.

until the engine warms and will run without its use. Take care not to

'D',

'Ll',

or

'L2'

is selected or backwards when

be

used to advantage when manoeuvring in a confined

be

'LT,

selection of the position being dependent on prevailing circum-

'D'.

The automatic selection of all forward ratios takes place pro-

in any one of the forward driving positions

be

smooth regardless of how

'R'

(see

is selected).

'D',

'D'.

Fig.

2

Page 35

Selector in

'L2'.

Selection of first and second ratios only will occur automatically

in accordance with changing conditions. Appropriate engine braking is available

'LT

when the accelerator pedal is released. Manual selection of

when driving in

a smooth down-change to second ratio. Use

'D'

at any speed below 68 m.p.h.

(1

10 km.p.h.) and will provide

'LT

when road conditions demand

can be made

rapid acceleration or full engine braking; for example, when overtaking, ap-

'LT

proaching or negotiating bends or gradients. It is recommended that

is used

when towing a caravan or other vehicles at speeds up to 40 m.p.h. (64 km.p.h.).

'Ll'.

Selector in

The transmission will remain in first ratio irrespective of changes

in road or driving conditions. This position provides full engine braking and full

engine power for example, when starting off on, or ascending, very steep gradients.

Avoid overspeeding the engine.

Stopping. Release the accelerator and apply the brakes.

Soft surfaces. When the rear wheels fail to grip on muddy or snow-covered

roads, the car may be rocked backwards and forwards by alternately selecting

'D'

'Ryand

while using light accelerator pressure.

Increased

When lower gear acceleration is required for overtaking or hill-climbing, etc.,

acceleration down-changes of gear can be made by depressing the accelerator pedal. The

Fig.

2

maximum down-change speeds are preset to give optimum performance without

overspeeding the engine.

At speeds up to 30 m.p,h. (48 km.p.h.) in top gear, depression of the accelerator

pedakwithin the limits of its normal travel (1) will produce a down-change to

second gear. Fully depressing the pedal beyond its normal travel (2) (termed

'kick-down') will produce a down-change to first gear.

At speeds above 30 m.p.h. (48 km.p.h.) within the 'kick-down' speed range,

downchanges may be made by depressing the pedal to the 'kick-down' position.

be

The speeds below which 'kick-down' changes can

made are:

From third to second gear, 52 to 56 m.p.h. (82 to 90 km.p.h.).

From second to first gear, 28 to 32 m.p.h. (45 to 52 km.p.h.).

Towing

For recovery the car may be towed with the selector lever at

3

extra

pints (34

US.

pints, 1.7 litres) of fluid are added to the transmission

'N',

provided an

and, even then, the car should be towed at speed no faster than 30 m.p.h.

km.p.h.) and for a distance not exceeding 40 miles (64 km.).

(48

If the transmission is inoperativg, remove the propeller shaft or lift the rear

wheels.

be

NOTE.-The car cannot

tow-started.

Selector The lamp for illuminating the selector lever and quadrant is controlled by the

illumination lever-type switch adjacent to it and will only operate when the panel lights are

(inset Fig.

early cars)

I

switched on. The brilliance of the light may be varied by the panel light switch

(see page 9), and the area of illumination may be altered by moving the sliding

hood (3) up or down the lamp body.

Page 36

CLEANING

Interior Carpets: Clean with a semi-stiff brush or a vacuum cleaner, preferably before

washing the outside of the car. Occasionally give the carpets a thorough cleaning;

dilute one part UNIPART Upholstery Cleaner with eight parts warm water,

apply vigorously with a semi-stiff brush and wipe over with a damp sponge or

cloth. Carpets must not be 'dry-cleaned'.

Plastic faced upholstery: Clean with diluted upholstery cleaner. Spot clean with

UNIPART Upholstery Cleaner spread thinly over the surface with a brush or

cloth, leave for five minutes, then wipe over with a damp sponge or cloth.

Nylon faced upholstery: Remove loose dirt with a brush or vacuum cleaner.

The nylon pile has been chemically treated to resist soiling and care must be

taken when cleaning. Use UNIPART Nylon Cleaner. To remove a stain, apply

the cleaner, then pat and wipe with a clean cloth in the direction of the pile

until the stain is removed. DO NOT RUB. When dry, gently brush against the

pile, then with the pile.

Body Regular care of the body finish is necessary if the new appearance of the car

exterior is to be maintained against the effects of air pollution, rain, and mud.

Wash the bodywork frequently, using a soft sponge and plenty of water containing UNIPART Car Shampoo. Large deposits of mud must

water before using the sponge. Smears should be removed by a second wash in

clean water, and with the sponge if necessary. When dry, clean the surface of the

car with a damp chamois-leather. In addition to the regular maintenance, special

attention is required if the car is driven in extreme conditions such as sea spray

or on salted roads. In these conditions and with other forms of severe

tion an additional washing overation is necessarv which should include underbody hosing. Any damage; aieas should be irnmddiate~~ covered with paint and

a complete repair effected as soon as possible. Before touching-in light scratches

and abrasions with paint, thoroughly clean the surface. Use petrollwhite spirit

(gasoline/hydrocarbon solvent) to remove spots of grease or tar.

The application of UNIPART Hi-shine Car Polish is all that is required to remove

traffic film and to ensure the retention of the new appearance.

be

softened with

contan&-

Bright trim Never use an abrasive on stainless, chromium, aluminium, or plastic bright parts

Windscreen

Seat belts Do not attempt to bleach the belt webbing or re-dye it. If the belts become soiled,

and on no account clean them with metal polish. Remove spots of grease or tar

with petrol/white spirit (gasoline/hydrocarbon solvent) and wash frequently with

water containing UNIPART Car Shampoo. When the dirt has been removed

polish with a clean dry cloth or chamois-leather until bright. Any slight tarnish

found on stainless or plated components which have not received regular attention may be removed with UNIPART Chrome Cleaner. An occasional application of light mineral oil or grease will help to preserve the finish, particularly

during winter when salt may be used on the roads, but these protectives must

not be applied to plastic finishes.

If windscreen smearing has occurred it can be removed with UNIPART Glass

Cleaner.

sponge with warm water using a non-detergent soap and allow to dry naturally.

Do not use caustic soap, chemical cleaners or detergents for cleaning: do not dry

with artificial heat or by direct exposure to the sun.

UNIPART products mentioned above are obtainable from your Distributor or

Dealer.

Page 37

COOLING SYSTEM

Radiator

filler cap

(1

Draining the

cooling

system

Filling the

cooling

system

The system is pressurized to

10

Ib./sq. in.

(.7

kg./cm." when hot, and the pressure

must be released gradually when the filler cap is removed. It is advisable to

)

protect the hands against escaping steam and turn the cap slowly anti-clockwise

until the resistance of the safety stops is felt. Leave the cap in this position until

all pressure is released. Press the cap downwards against the spring to clear the

safety stops, and continue turning until it can be lifted off.

To drain the cooling system on cars not fitted with drain taps or plugs, slacken

the hose clip and remove the bottom hose at its connection to the radiator.

drain plug is provided on the engine cylinder block.

(2)

On early cars the radiator is provided with a drain tap

(3)

or tap

(4)

a drain plug

on the right-hand side of the cylinder block.

and the engine with

When draining in freezing weather, do so when the engine is hot. Run the engine

slowly for one minute when the water has ceased flowing to clear any water

from the pump and other places where it might collect. Finally, leave a reminder

on the vehicle to the effect that the cooling system has been drained.

Collect the coolant in a clean container if it is to be used again, as cars are filled

333

with a

per cent solution of anti-freeze before they leave the factory.

'To avoid wastage by overflow add just sufficient coolant to cover the bottom

of the header tank. Run the enrvnc

bring the surface to the level ot

uqtil

it is hot and add sufficient coolant to

~dicator positioned inside the header tank

thi

below the filler neck.

NOTE.-If

draining or filling the system.

a heater

is

fitted ensure that the heater control

is

set to

'HOT'

A

when

Page 38

Cooling

Frost

precautions

System

Water expands when it freezes, and if precautions are not taken there is considerable risk of bursting the radiator, cylinder block, or heater. The heater unit

cannot be drained with the cooling system; it is therefore essential to use anti-

freeze in the cooling system in freezing conditions.

We recommend the use of

Bluecol U universal

anti-freeze to protect the cooling

system.

U

Bluecol

If

B.S.

compatible with Bluecol

universal is not available any anti-freeze conforming to specification

3151

or B.S.

3152

may be used. Anti-freezes to these specifications are

U

universal and can be used with it. Bluecol U universal

should not be mixed with other universal anti-freezes.

After filling with anti-freeze solution, attach a warning label to a prominent

position on the car stating the type of anti-freeze contained in the cooling system

to ensure that the correct type is used for topping-up.

Anti-freeze can remain in the cooling system for two years provided that the

specific gravity of the coolant is checked periodically and anti-freeze added as

necessary. The specific gravity check should be carried out by an authorized

Distributor or Dealer. After the second year the system should be drained and

flushed by inserting a hose in the filling orifice and allowing water to flow through

until clean. Make sure that the cooling system is water-tight, examine all joints

and replace any defective hose with a new one. Refill with the appropriate

anti-freeze solution.

The recommended quantities of anti-freeze solution are given below.

Do not use radiator anti-freeze solution in the windscreen-washing equipment.

Use the correct washer solvent, which will not damage the paintwork.

Anti-

freeze

%

25

33$

50

Commences

to freeze

"C.

13

-19

-36

"F.

-2

-33

Frozen solid

"C.

9

26

-36

-48

"F.

--l5

-33

-53

Amount of anti-fleeze

Pfs.

US.

--

24

3f

5

Pfs.

3

4

6

Litres

1.5

2

3

Page 39

WHEELS

AND

TYRES

Jacking up

Fig.

maintenance

maintenance

Pressed type

Removing and

wheel hub

Jack

WHEELS

Preventive

fefitting the

cap

Fig.

The jack is designed to lift one side of the car at a time. Apply the hand brake

7

and block the wheels on the opposite side to that being jacked; use a wood block

jammed tight against the tyre tread,

Insert the lifting arm of the jack into the socket located in the door sill panel.

Make certain that the jack lifting arm is pushed fully into the socket and that the

base of the jack is on firm ground.

The jack should lean slightly outwards at the

top to allow for the radial movement of the car as it is raised.

WARNING.-Do

means of support.

not work beneath the vehicle

with

the lifting jack as the sole

Place suitable supports under the front side-members or rear

axle to give adequate support and safety while working.

If the jack is neglected it may be difficult to use in a roadside emergency. Examine

it occasionally, clean off accumulated dust, and lightly oil the thread to prevent

the formation of rust.

Owners are recommended to check the wheel nuts for tightness each week in

addition to checking the other items listed. Take care not to overtighten. Torque

wrench setting

60

to

65

lb. ft.

(8.3

to 9 kg. m.).

lnsert the wheel hub cap lever into the recess formed in the wheel. Lever the hub

cap from its retaining button using a sideways motion.

To refit the hub cap, place the hub cap over two of the retaining buttons and

2

resting on the third. Give the face of the hub cap a sharp blow with the hand

in the vicinity of the third button. Check that the rim is fully engaging all retaining buttons.

Fig.

l

Page 40

Wheels

and

Tyres

Removing and

refitting

and Fig.

Removing and

Fig.

4

(1)

Wire

type

refitting

4

(2)

Fig.

Maintenance

Slacken the four nuts securing the road wheel to the hub; turn anti-clockwise to

loosen and clockwise to tighten. Raise the car with the jack to lift the wheel

3

clear of the ground and remove the nuts. Withdraw the road wheel from the hub.

When refitting the road wheel locate the wheel on the hub, lightly tighten the

(1)

nuts

side

with the wheel nyt spanner (securing nuts must be fitted with the taper

towards the wheel), and lower the jack. Fully tighten the wheel nuts, tighten-

ing them diagonally and progressively, at the same time avoid over-tightening.

(2)

The wheel centre trim

must be removed and fitted to the wheel in use.

Use the mallet to slacken the winged hub nut or the spanner to slacken the

octagonal hub nut used.

Always jack up a wheel before using the hammer, and always hammer the nuts

tight.

'LEFT'

or

Locknuts are marked

'RIGHT'

must be fitted, and also with the word

to show to which side of the car they

'UNDO'

and an arrow.

Before replacing a wheel wipe all serrations, threads, and cones of the wheel and

hub and then lightly coat them with grease. If a forced change is made on the

road, remove, clean, and grease as soon as convenient.

When the car is new, after the first long run or after

50

miles

(80

km.) of short

runs, jack up the wheels and hammer the nuts to make sure that they are tight.

a

year remove the wheels for examination and regreasing.

Once

Fin

.?

Fig.

4

Page 41

Spare wheel

The spare wheel is secured to the floor of the luggage compartment on tourer

cars and below the luggage compartment floorboard on GT cars. To gain access

5)

to the spare wheel on GT cars (Fig.

turn back the luggage compartment floor

covering, unscrew the two quick-release screws and lift the floorboard.

The spare wheel supplied with new cars is inflated above the recommended

running pressure. The pressure must be checked and adjusted before use.

Wheel and

tyre balancing

Radial-ply

tyres

FIO

5

Unbalanced wheel and tyre assemblies may be responsible for abnormal wear

of the tyres and vibration in the steering. Consult your

Distributor/Dealer.

Radial-ply tyres should only be fitted in sets of four, although in certain circum-

a

stances it is permissible to fit

struction must not be used on the same axle.

pair on the rear wheels; tyres of different con-

A

pair must never be fitted to the

front wheels with conventional tyres at the rear. Consult your Distributor or

Dealer before changing to radial-ply tyres.

be

The positional changing of wheels must not

undertaken if radial-ply tyres

have been fitted to the rear wheels only.

Fia.

6

Page 42

Wheels

maintenance

and

Tyres

Tyre

To obtain the best tyre mileage and to suppress the development of uneven

wear on the tyres the wheels can be interchanged diagonally bringing the spare

Fig.

6

wheel into use (see

Excessive local distortion as a result of striking a kerb, a large stone, a deep

pot-hole, etc., may cause the casing cords to fracture.

Tyres, including the spare, must be maintained at the pressures recommended

'GENERAL DATA');

(see

week, and regulate as necessary. Pressures should

cold; do not reduce the pressure in warm tyres where the increase above the

normal pressure is die to temperature.

See that the valve caps are screwed down firmly by hand. The cap prevents the

entry of dirt into the valve mechanism and forms an additional seal on the valve.

preventing any leakage if the valve core is damaged.

Flints and other sharp objects should be removed with a penknife or similar tool.

If neglected, they may work through the cover.

Any oil or grease which may get onto the tyres should be cleaned off by using fuel

sparingly. Do not use paraffin (kerosene), which has a detrimental effect on

rubber.

When repairing tubes have punctures or injuries vulcanized. Ordinary patches

should only be used for emergencies.

Vulcanizing is absolutely essential in the case of tubes manufactured from

synthetic rubber.

Radial-ply tyres).

check with an accurate tyre gauge at least once a

be

checked when the tyres are

Page 43

BRAKES

Brake and

clutch master

cylinder

Fig.

Front brakes

Fig.

To check the level of the fluid in the brake

reservoirs, remove the plastic filler caps.

,

The fluid level must be maintained at 4 in. (13 mm.) below the bottom of the

filler cap. Top up if necessary with UNIPART

high-boiling-point brake fluid conforming to specification S.A.E. J1703c with

a minimum boiling point of 260"

type of fluid. Frequent topping-up is indicative of a leak in the system whch

must be checked and the leak rectified immediately.

Before refitting the filler caps, separate the dome (3) from the filler cap and check

that the breather holes indicated by the arrows are clear. Snap-fit the dome onto

the filler cap.

NOTE.-Brake fluid can have a detrimental effect on paintwork. Ensure that

brake fluid is not allowed to contact paint-finished surfaces.

Wear on the disc brake friction pads (arrowed) is automatically compensated

2

for and manual adjustment is therefore not required. Before the lining material

has worn down to the minimum thickness of in. (1.6 mm.) the brake pads

should be renewed. Special equipment is required to renew brake pads; this work

should be entrusted to your Distributor or Dealer.

C.

(500" F.) may be used. Do not use any other

(l)

and clutch

550

Brake

(2)

master cylinder

Fluid;

alternatively

a

Page 44

Brakes

Rear brakes

Adjusting

Fig.

Inspecting rear

brake linings

Fig.

Excessive brake pedal travel is an indication that the rear brake-shoes require

be

adjusting. The brakes on both rear wheels must

adjusted to regain even and

efficient braking.

Block the front wheels, fully release the hand brake and jack up each rear wheel

3

in turn. Turn the adjuster (arrowed) in a clockwise direction (viewed from the

centre of the car) until the wheel is locked, then turn the adjuster back until the

wheel is free to rotate without the shoes rubbing. Repeat the adjustment on the

other rear brake.

Chock the front wheels and release the hand brake. Jack up each wheel in turn,

placing suitable supports beneath the vehicle-see

4

'WARNING'

on page 37.

Remove the road wheel and slacken the brake-shoe adjuster.

(1)

Remove the two countersunk screws

wheels) and withdraw the brake-drum

(pressed wheels) or the four nuts (wire

(2).

Inspect the linings (3) for wear, and clean the dust from the backplate assembly

and drum, preferably using methylated spirit (denatured alcohol). Brake lining

dust is dangerous to health if inhaled and therefore should not be blown from

the drums. Make certain that sufficient lining material remains to allow the car

to run until the next regular inspection is due without the thickness falling below

the safe limit.

Refit the brake-drums and road wheel, and adjust the brake-shoes.

Fig.

4

Page 45