MFZ

CS 300 Gate Controls / rev. 04.06 - 1

2006

Operating Instructions for Control CS 300

GB

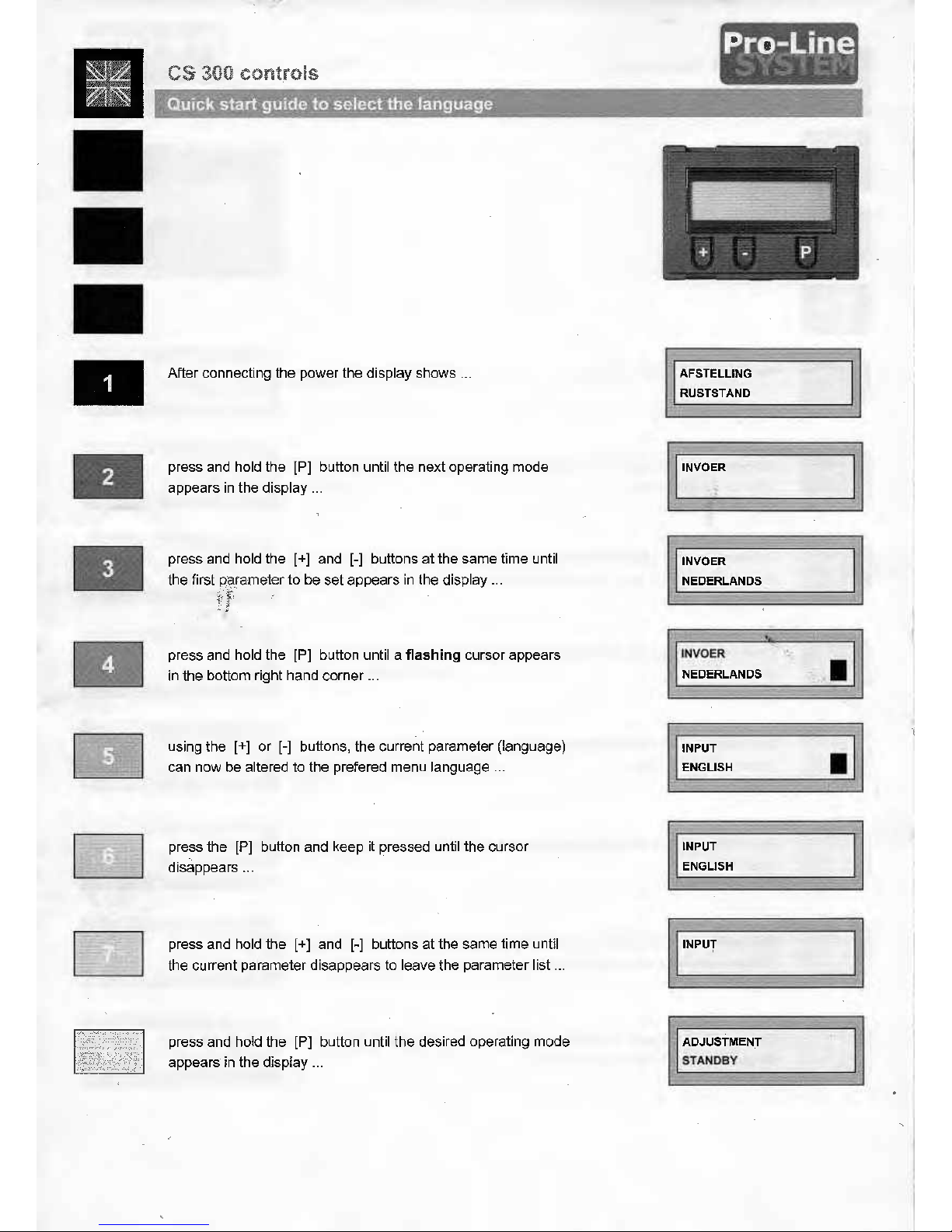

After connecting the power the display shows ...

press and hold the [P] button until the next operating mode

appears

in

the display

...

press and hold the [+] and [-] buttons at the same tirne until

the first parameter to be set appears

in

the display

...

press and hold the [P] button until a flashing cursor appears

in

the bottom right hand corner

...

using the [+] or [-] buttons, the current parameter (language)

can now be alte red to the prefered menu language

...

press the [P] button and keep it pressed until the cursor

, .

disappears

...

press and hold the [+] and [-] buttons at the same tirne until

the current parameter disappears to leave the parameter list

...

press and hold the [P] button until the desired operating mode

appears

in

the display

...

AFSTELLING

RUSTSTAND

INVOER

NEDERLANDS

INVOER

NEDERLANDS

INPUT

ENGLISH

INPUT

ENGLISH

INPUT

ADJUSTMENT

STANDBY

·

;<·

[

セセIN[⦅@

•

MFZ

2 – CS 300 Gate Controls / rev. 04.06

1. Contents 3. General safety instructions

MFZ

2. Key to symbols

Guarantee

The function and safety of the equipment is only

guaranteed if the warning and safety instructions

included in these operating instructions are adhered

to.

MFZ Antriebe GmbH + Co.KG is not liable for any

personal injury or damage to property that occurs as

a result of the warning and safety instructions being

disregarded.

Using the equipment for its intended purpose

The CS 300 controls are designed only for controlling

gates and doors with digital end position systems.

It is only permitted to operate the equipment in dry

rooms.

Target group

Only qualifi ed and trained electricians may connect,

programme and service the controls.

Qualifi ed and trained electricians meet the following

requirements:

- knowledge of the general and specifi c safety and

accident prevention regulations,

- knowledge of the relevant electrical regulations,

- trained in the use and care of appropriate safety

equipment,

- capable of recognising the dangers associated with

electricity.

Instructions for installation and connection

- The controls must be disconnected from the

electricity supply before carrying out electrical

works. It must be ensured that the electricity supply

remains disconnected during the works.

- Local protective regulations must be complied with.

- Mains cables and control cables must be laid

separately.

Danger of personal injury!Danger of personal injury!

The safety instructions must be

observed!

Warning! Danger to property! Warning! Danger to property!

The safety instructions must be

observed!

InformationInformation

Reference to other sources of

information.

1. Contents 2

2. Key to symbols 2

3. General safety instructions 2

4. Overview of products 3

5. Initial Operation 5

6. Programming with the LED module 8

7. Programming with the LCD monitor 10

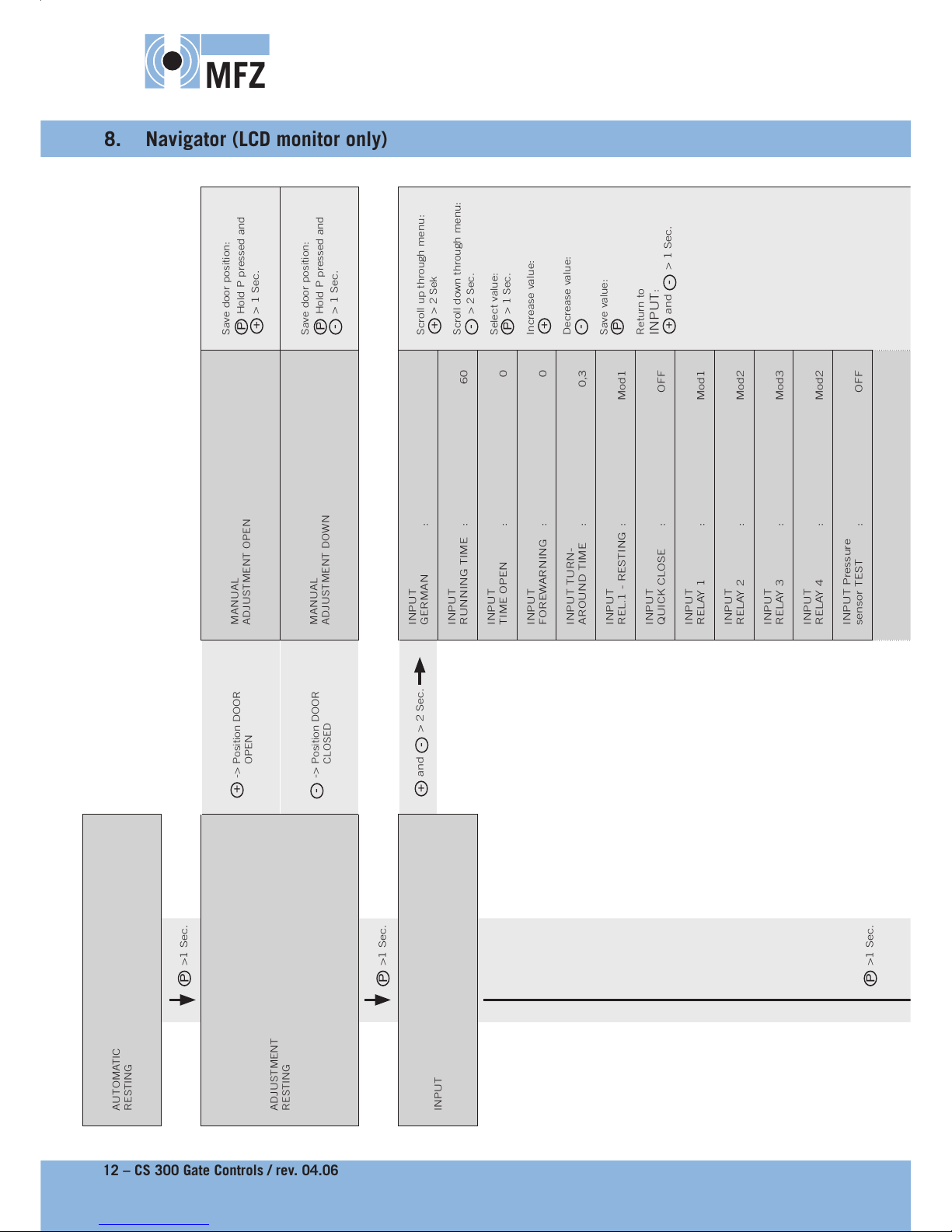

8. Navigator (LCD monitor only) 12

9. Overview of functions 14

10. Error messages and rectifi cation 18

11. Technical data 19

12. EU Declaration of Conformity 19

MFZ

GB

CS 300 Gate Controls / rev. 04.06 – 3

Regulations and bases for testing

For connecting, programming and servicing, the

following regulations must be observed (the list is not

exhaustive).

Construction product standards

- EN 13241-1 (Products without fi re resistance or

smoke control characteristics)

- EN 12445 (Safety in use of power operated doors

- Test methods)

- EN 12453 (Safety in use of power operated doors

- Requirements)

- EN 12978 (Safety devices for power operated doors

and gates - Requirements and test methods)

Electromagnetic compatibility

- EN 50081-1 (Radio disturbance, household

appliances)

- EN 50082-1 (Immunity, household appliances)

- EN 50014-1 (Emission, household appliances)

- EN 61000-3-2 (Disturbances in supply systems

- harmonic currents)

- EN 61000-3-3 (Disturbances in supply systems

- voltage fl uctuations)

Machinery guidelines

- EN 60204-1 (Safety of machinery, electrical

equipment of machines)

- EN 292-1 (Safety of machinery - Basic concepts,

general principles for design - Basic terminology,

methodology)

Low voltage

- EN 60335-1 (Household and similar electrical

appliances - Safety)

- EN 60335-2-103 (Particular requirements for

drives for gates, doors and windows)

Professional association (D)

- BGR 232 (Directive for Power-driven Windows,

Doors and Gates)

4.1 Various options4.1 Various options

The following package options are available for the

CS 300 controls:

- CS 300 control with LCD monitor

- CS 300 control with LCD monitor in housing

- CS 300 control with LED module for setting

the OPEN and CLOSED door positions (further

adjustment settings are not possible)

- CS 300 control without LED module and without

LCD monitor (module or monitor are required for

adjusting the settings)

All the above options can be fi tted with a plug-in

weekly timer and a plug-in radio receiver.

The following options are available for the housing.

- housing with 3-button input unit

- housing with membrane keypad

- housing with key switch ON/OFF

- housing with main switch

- housing with emergency off switch

The operating instructions describe the connection

possibilities and programming procedures for the

different models:

- CS 300 control with LED board

- CS 300 control with attached LCD display board

4. Overview of products GB

MFZ

4 – CS 300 Gate Controls / rev. 04.06

4. Overview of products

4.3 CS 300 basic board 4.3 CS 300 basic board

(with attached LCD display monitor)(with attached LCD display monitor)

1

2

3

4

5

6

7

8

B2

B1

W

V

U

1

2

3

4

5

6

7

8

9

10

N

L3

L2

L1

X5

X4

X3

X2

X11

X7

X6

X12

PEPEPE

X1

X10

1

2

3

4

5

6

7

8

9

10

X8

X9

H4

Key:

X1: terminal block

mains connection

X2 : terminal block

motor

X3: terminal block

command devices

X4: terminal block

safety elements

X5: terminal block

relay

X6: sockets for internal

ON-OFF switch

X7: sockets for internal

3-button input unit

X8: socket for monitor

(under monitor)

X9: sockets for

radio receiver

X10: sockets for

weekly timer

X11: sockets for digital

end-position system

X12: socket for external

radio receiver

H4: status display for

safety edge protection

(SEP) – illuminated when

SEP is working

MFZ

GB

CS 300 Gate Controls / rev. 04.06 – 5

5. Initial Operation

5.1 General5.1 General

Warning! Warning!

To guarantee that the equipment

functions properly, the following points

must be ensured:

- The gate or door is installed and ope

rational.

- The MFZ drive motor is installed and

ready for operation.

- The command and safety devices are

installed and ready for operation.

- The control housing with the CS 300

control is installed.

Information:Information:

For the installation of the gate/door,

the MFZ drive motor and the command

and safety devices, the relevant

manufacturer’s instructions are to

be adhered to.

5.2 Mains connection5.2 Mains connection

Danger! Danger!

To guarantee that the controls function

properly, the following points must be

ensured:

- The mains voltage must correspond

to the voltage stated on the type

plate.

- For a three-phase current, a

clockwise rotating fi eld is required.

- For a permanent connection, an

all-pole main switch must be used.

- For a three-phase connection, only

3-way automatic circuit breakers

(10A) may be used.

Detailed circuit diagram for mains connection and

motor

UVWB1B2

L1 L2 L3 N

PEPEPE

13 5 13 5

24 6 24 6

X2

X1

X11

T1

K2

K1

M

M1

Key:

K1: protection, CLOSE

K2: protection, OPEN

M1: motor

T1: transformer

X1: terminal block for mains connection

X2: terminal block for motor

X11: sockets for digital end position system with

safety circuit (STOP CIRCUIT)

Connection:

Connect the digital end-position system to the Connect the digital end-position system to the

control.control.

Connect the control to the mains.Connect the control to the mains.

Connect the control to the motor.Connect the control to the motor.

☞

☞

☞

GB

MFZ

6 – CS 300 Gate Controls / rev. 04.06

5. Initial Operation

5.3 Allocation of connections for command

and safety devices

Command and safety devices can be connected to

terminals X3, X4 and X5.

Terminal block X3

- CLOSE switch

- impulse switch

1

- OPEN switch

- STOP switch

- Emergency off, slack rope

switch, wicket door contact,

draw-in protection

Terminal block X4

(for optoelectronic safety edge protection)

- PART – OPEN

2

- safety edge

protection OPTO

- photoelectric

drive-through

barrier

3

- 24 V DC / 500 mA

4

1

sequence control

2

button or selector switch

3

effective in down direction

4

for external switching devices

(connection to terminals 1 and 2)

wt: white

gr: green

br: brown

Terminal block X4

(for 8.2 kOhm safety edge protection)

- PART - OPEN

2

- safety edge protection

- photoelectric drive-through

barrier

3

- 24 V DC / 500 mA

4

Terminal block X4

(for pneumatic safety edge protection – pressure

sensor test:

- A 8.2 kOhm resistor must be connected in series

- The input point pressure sensor TEST must be

switched on)

- PART - OPEN

2

- safety edge protection

- photoelectric drive-through

barrier

3

- 24 V DC / 500 mA

4

Terminal block X5

(potential free switch contact)

- relay 1

- relay 2

- relay 3

- relay 4

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

+

-

wt

gr

br

0 V

Signal

+12 V

1

2

3

4

5

6

7

8

9

10

+

-

8,2 KOhm

1

2

3

4

5

6

7

8

9

10

+

-

8,2 KOhm

MFZ

GB

CS 300 Gate Controls / rev. 04.06 – 7

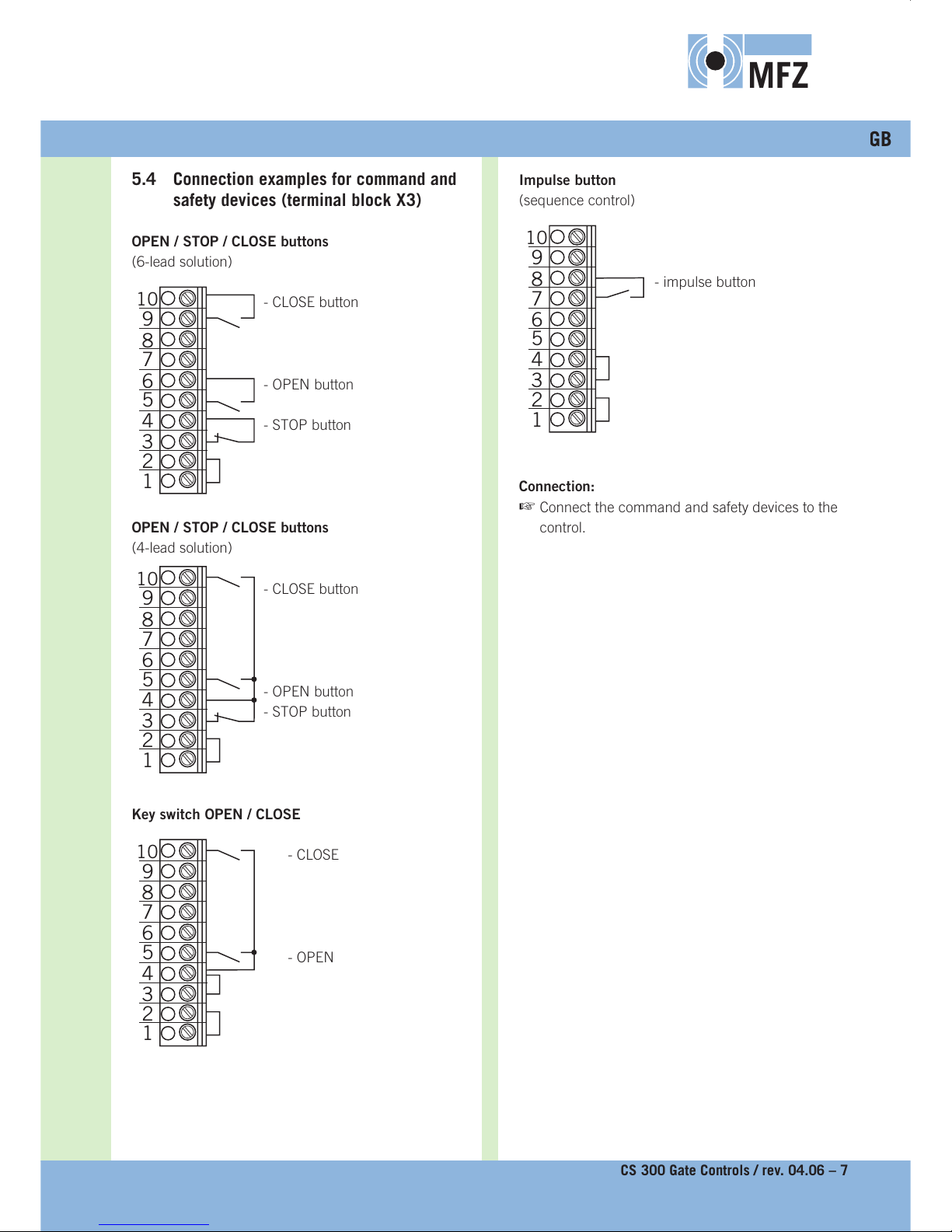

Impulse button

(sequence control)

- impulse button

Connection:

Connect the command and safety devices to the Connect the command and safety devices to the

control.control.

☞

5.4 Connection examples for command and

safety devices (terminal block X3)

OPEN / STOP / CLOSE buttons

(6-lead solution)

- CLOSE button

- OPEN button

- STOP button

OPEN / STOP / CLOSE buttons

(4-lead solution)

- CLOSE button

- OPEN button

- STOP button

Key switch OPEN / CLOSE

- CLOSE

- OPEN

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

MFZ

8 – CS 300 Gate Controls / rev. 04.06

6.1 Overview of LED module6.1 Overview of LED module

Key:

LED off

LED illuminated

LED fl ashing

6. Programming with the LED module

6.2 LED module, modes of operation6.2 LED module, modes of operation

With the LED module, the controls have two modes of operation:

1. AUTOMATIC

2. ADJUSTMENT

Information:Information:

The current mode of operation of the control is shown via the LEDs.

- In the AUTOMATIC mode, no LEDs fl ash.

- In the ADJUSTMENT mode, at least one LED fl ashes.

Pressing the P button toggles between the modes of operation.

Operating mode 1: AUTOMATIC

In the AUTOMATIC operating mode the door system is operated.

LED displays:

H1 H2 Status

The door is open. The programmed OPEN end position has been reached.

The door is closed. The programmed CLOSED end position has been reached.

The door is between end positions. No end position has been reached.

The door has been moved beyond the CLOSED/OPEN end position.

MFZ

GB

CS 300 Gate Controls / rev. 04.06 - 9

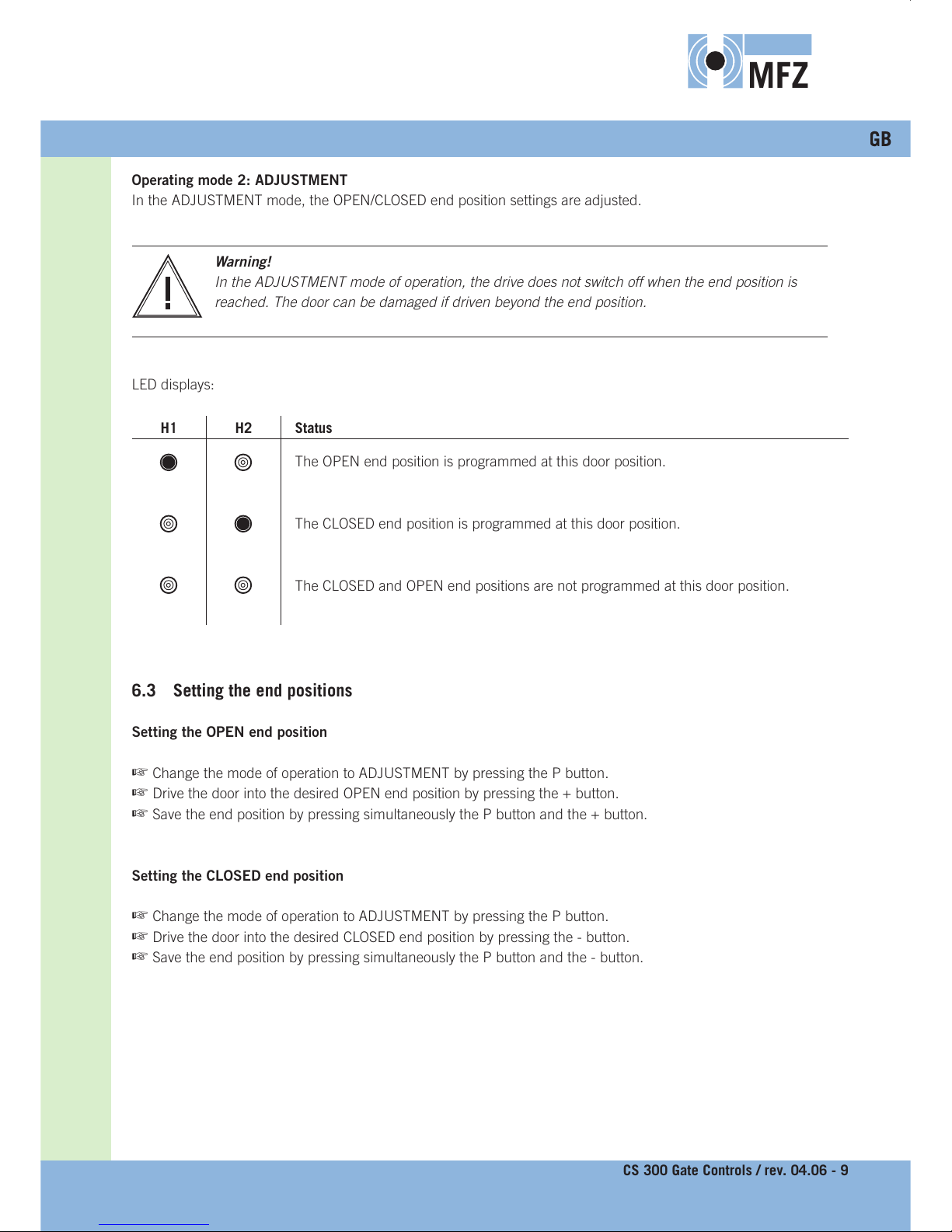

Operating mode 2: ADJUSTMENT

In the ADJUSTMENT mode, the OPEN/CLOSED end position settings are adjusted.

Warning!Warning!

In the ADJUSTMENT mode of operation, the drive does not switch off when the end position is

reached. The door can be damaged if driven beyond the end position.

LED displays:

H1 H2 Status

The OPEN end position is programmed at this door position.

The CLOSED end position is programmed at this door position.

The CLOSED and OPEN end positions are not programmed at this door position.

6.3 Setting the end positions6.3 Setting the end positions

Setting the OPEN end position

Change the mode of operation to ADJUSTMENT by pressing the P button.Change the mode of operation to ADJUSTMENT by pressing the P button.

Drive the door into the desired OPEN end position by pressing the + button.Drive the door into the desired OPEN end position by pressing the + button.

Save the end position by pressing simultaneously the P button and the + button.Save the end position by pressing simultaneously the P button and the + button.

Setting the CLOSED end position

Change the mode of operation to ADJUSTMENT by pressing the P button.Change the mode of operation to ADJUSTMENT by pressing the P button.

Drive the door into the desired CLOSED end position by pressing the - button.Drive the door into the desired CLOSED end position by pressing the - button.

Save the end position by pressing simultaneously the P button and the - button.

☞

☞

☞

☞

☞

☞

MFZ

10 – CS 300 Gate Controls / rev. 04.06

7.1 Overview of the LCD monitor7.1 Overview of the LCD monitor

7. Programming with the LCD monitor

A

B

CD E

F

G

AUTOMATIC O

RESTING

Key:

A: mode of operation /

diagnostic info

B: parameter /

diagnostic info

C: + button

D: - button

E: P button

F: value / status

G: value / status

H: jumper

H

MFZ

GB

CS 300 Gate Controls / rev. 04.06 – 11

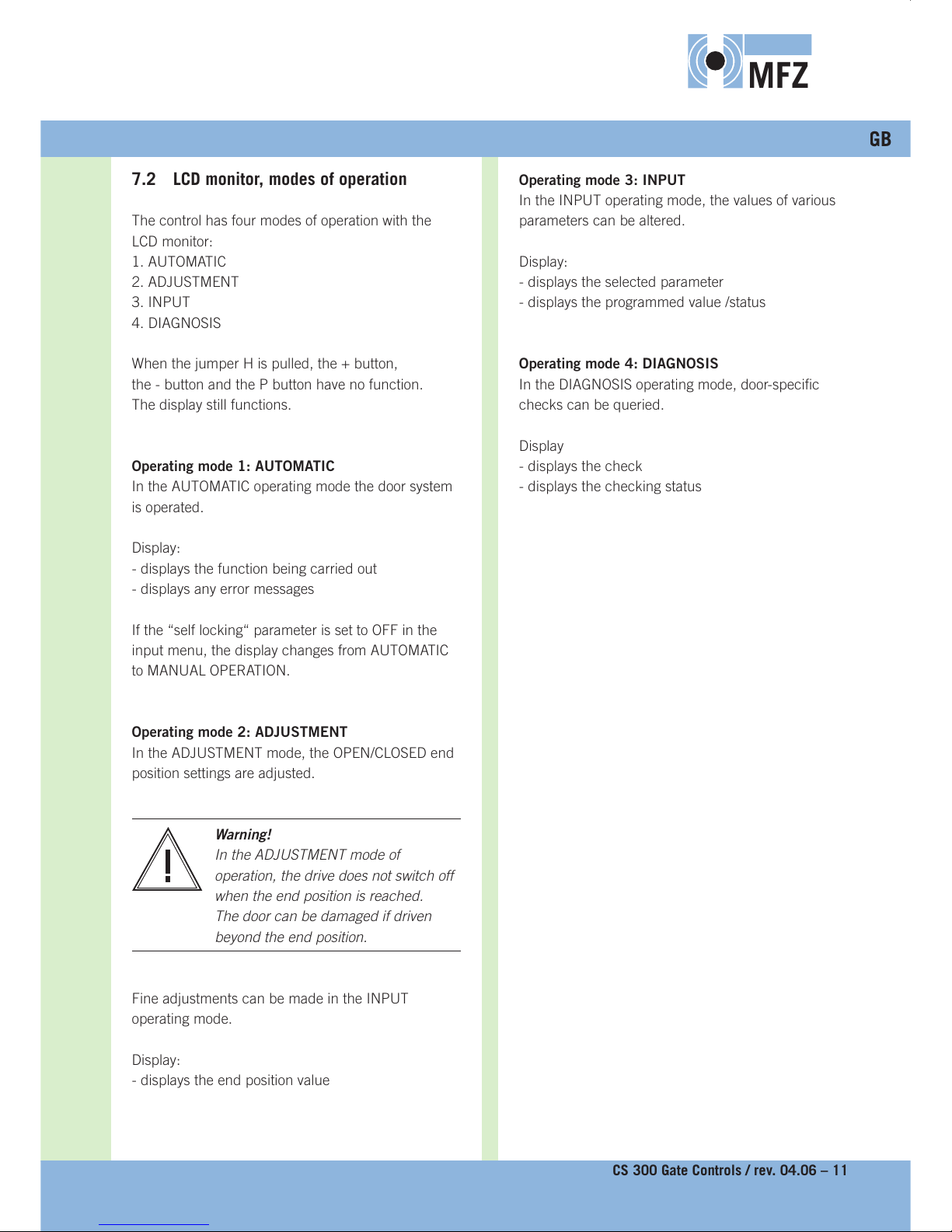

7.2 LCD monitor, modes of operation7.2 LCD monitor, modes of operation

The control has four modes of operation with the

LCD monitor:

1. AUTOMATIC

2. ADJUSTMENT

3. INPUT

4. DIAGNOSIS

When the jumper H is pulled, the + button,

the - button and the P button have no function.

The display still functions.

Operating mode 1: AUTOMATIC

In the AUTOMATIC operating mode the door system

is operated.

Display:

- displays the function being carried out

- displays any error messages

If the “self locking“ parameter is set to OFF in the

input menu, the display changes from AUTOMATIC

to MANUAL OPERATION.

Operating mode 2: ADJUSTMENT

In the ADJUSTMENT mode, the OPEN/CLOSED end

position settings are adjusted.

Warning! Warning!

In the ADJUSTMENT mode of

operation, the drive does not switch off

when the end position is reached.

The door can be damaged if driven

beyond the end position.

Fine adjustments can be made in the INPUT

operating mode.

Display:

- displays the end position value

Operating mode 3: INPUT

In the INPUT operating mode, the values of various

parameters can be altered.

Display:

- displays the selected parameter

- displays the programmed value /status

Operating mode 4: DIAGNOSIS

In the DIAGNOSIS operating mode, door-specifi c

checks can be queried.

Display

- displays the check

- displays the checking status

MFZ

12 – CS 300 Gate Controls / rev. 04.06

AUTOMATIC

RESTING

>1 Sec.

ADJUSTMENT

RESTING

+

-> Position DOOR

OPEN

MANUAL

ADJUSTMENT OPEN

Save door position:

Hold P pressed and

> 1 Sec.

-> Position DOOR

CLOSED

MANUAL

ADJUSTMENT DOWN

Save door position:

Hold P pressed and

> 1 Sec.

>1 Sec.

INPUT

and

> 2 Sec.

INPUT

GERMAN :

Scroll up through menu:

> 2 Sek

Scroll down through menu:

> 2 Sec.

Select value:

> 1 Sec.

Increase value:

Decrease value:

Save value: Return to

INPUT:

and

> 1 Sec.

INPUT

RUNNING TIME : 60

>1 Sec.

INPUT

TIME OPEN : 0

INPUT

FOREWARNING : 0

INPUT TURN-

AROUND TIME : 0,3

INPUT

REL.1 - RESTING : Mod1

INPUT

QUICK CLOSE : OFF

INPUT

RELAY 1 : Mod1

INPUT

RELAY 2 : Mod2

INPUT

RELAY 3 : Mod3

INPUT

RELAY 4 : Mod2

INPUT Pressure

sensor TEST : OFF

8. Navigator (LCD monitor only)

MFZ

GB

CS 300 Gate Controls / rev. 04.06 - 13

INPUT

DELAY-OPEN : OFF

INPUT

FINE-OPEN : 4050

INPUT

FINE-CLOSE : 3950

INPUT

BES-OPEN : 4000

INPUT

BES-CLOSE : 4000

INPUT

ROT. FIELD : RE

INPUT

REVERSE OFF : 50

INPUT

POWER : 0

INPUT

AUTO LEVEL : OFF

INPUT

SELF LOCK : ON

INPUT

SU/WI : MOD1

DIAGNOSIS

Scroll up through menu:

> 2 Sek

Scroll down through menu:

> 2 Sec.

Return to AUTOMATIC

operating mode:

Only query is possible

ES UP : ON

ES DOWN : ON

OPEN BUTTON : OFF

PART OPEN : OFF

CLOSE BUTTON : OFF

SEP : ON

IMPULS : OFF

TIMER : OFF

P/E BARRIER : ON

STOP CIRCUIT : ON

CYCLE : 4

AVE : 2599

MFZ

14 – CS 300 Gate Controls / rev. 04.06

9. Overview of functions

9.1 Automatic operating mode

Display Description

AUTOMATIC

OPEN

The door is driven to the OPEN* end position

AUTOMATIC

CLOSE

The door is driven to the CLOSED* end position

AUTOMATIC

RESTING

The door stands between the end positions

AUTOMATIC O

RESTING

The door stands at the OPEN end position

AUTOMATIC o

RESTING

The door stands at the position PART OPEN („before-end position“ up)

AUTOMATIC U

RESTING

The door stands at the CLOSED end position

AUTOMATIC u

RESTING

The door stands at the position PART CLOSE („before-end position“ down)

AUTOMATIC r

RESTING

The door stands in the position where the reversing switches off

*When the gate is being driven OPEN, the power currently being used is displayed

MFZ

GB

CS 300 Gate Controls / rev. 04.06 - 15

9.2 Input operating mode9.2 Input operating mode

Function Description Setting options Factory setting

DEUTSCH Select the menu language DEUTSCH

ENGLISH

FRANCAIS

ESPANOL

NEDERLANDS

POLSKI

CESKY

DEUTSCH

RUNNING

TIME

Monitoring the max. running time for an open and close movement 1 – 250 Seconds 60 Seconds

OPEN

TIME

After the door has opened, it runs in the CLOSE direction again after the

set time has elapsed.

Open time > 0 = impulse functions only work in OPEN direction

0 – 600 Seconds 0 =

Auto-close off

ADVANCE

WARNING

TIME

The traffi c light fl ashes before the door starts to move downwards.

The programmed forewarning time is only active if the open time > 0 or if

in radio-impulse operating mode

0 - 120 Seconds 0 = Off

TURNA-

ROUND

TIME

Standing time at every change of direction 0,1 - 2,0 Seconds

(in 1/10 Sec)

0,3 Seconds

REL.1

RESTING

MOD1: Relay 1 resting OFF

MOD2: Relay 1 resting ON

MOD1

MOD2

MOD1

QUICK

CLOSE

ON: The open time is cut short after the photoelectric barrier has

been passed (door closes immediately)

OFF: The open time continues as usual

ON

OFF

OFF

RELAY 1 MOD1: Relay 1 is permanently ON when the door is moving and

fl ashes for forewarning

MOD2: Relay 1 fl ashes when the door is moving and as a forewarning

MOD3: Relay 1 is permanently ON when the door is moving and as a

forewarning

MOD1

MOD2

MOD3

MOD1

RELAY 2 MOD1: Relay 2 gives impulse on OPEN command

MOD2: OPEN end position

MOD3: CLOSE end position

MOD4: Before-end position OPEN

MOD5: Before-end position CLOSE

MOD1

MOD2

MOD3

MOD4

MOD5

MOD2

RELAY 3 MOD1: Error message

MOD2: OPEN end position

MOD3: CLOSE end position

MOD4: Before-end position OPEN

MOD5: Before-end position CLOSE

MOD6: From before CLOSE position to CLOSE position

MOD1

MOD2

MOD3

MOD4

MOD5

MOD6

MOD3

RELAY 4 MOD1: Magnetic locking function

MOD2: Brake

MOD3: Brake negated

MOD4: Brake remains ON during open time

MOD5: Brake remains ON during open time and direction turnaround

(relay switches OFF when turnaround initiated by SEP)

MOD1

MOD2

MOD3

MOD4

MOD5

MOD2

MFZ

16 – CS 300 Gate Controls / rev. 04.06

Function Description Setting options Factory setting

Pressure

sensor

TEST

ON: PS testing is active

OFF: PS testing is inactive

The testing of the PS switch takes place in the CLOSE end position. For

this, the PS contact must be temporarily broken when the gate lowers to

rest on the ground.

ON

OFF

OFF

DELAY-

OPEN

ON: Forewarning before opening

OFF: Immediate opening

ON

OFF

OFF

FINE-

OPEN

Fine adjustment of OPEN end position 0 – 8190 4050

FINE-

CLOSE

Fine adjustment of CLOSE end position 0 – 8190 3950

BES-OPEN Setting the before-end position switch point for the OPEN direction

(PART-OPEN)

0 – 8190 4000

BES-

CLOSE

Setting the before-end position switch point for the CLOSE direction 0 – 8190 4000

ROT.

FIELD

C: clockwise rotating fi eld

A: anti-clockwise rotating fi eld

This setting may only be altered in the case of a special customised drive

installation!

RE

LI

RE

REVERSE

OFF

The point where the reversing switch is activated before the CLOSE end

position is reached.

10 – 250 50

POWER The power is displayed during the opening movement.

If the power monitoring facility is activated, a value must be set, which

is lower than the lowest value displayed during opening. The larger the

difference, in comparison to the lowest value displayed, the less sensitive

the reaction of the power monitoring.

The power monitoring facility is only activated if the value is set to be > 0.

0 – 999 0

AUTO-

LEVEL

ON: Align with ground, ON

OFF: Align with ground, OFF

ON

OFF

OFF

SELF

LOCK.

ON: Automatic operation

OFF: Manual operation

ON

OFF

ON

SU/WI MOD1: PART-OPEN button at terminal X4 (9 + 10)

MOD2: PART-OPEN selector switch at terminal X4 (9 + 10)

When the selector switch is closed, all OPEN commands go to

the before-end switch OPEN

MOD1

MOD2

MOD1

MFZ

GB

CS 300 Gate Controls / rev. 04.06 - 17

9.3 Diagnostic operating mode

Display Meaning Status

ES-OPEN OPEN end position OFF: confi rmed

ON: not confi rmed

ES-CLOSE CLOSE end position OFF: confi rmed

ON: not confi rmed

OPEN BUTTON OPEN button OFF: confi rmed

ON: not confi rmed

PART OPEN PART OPEN button (X4 / 9 + 10) OFF: confi rmed

ON: not confi rmed

CLOSE BUTTON CLOSE button OFF: confi rmed

ON: not confi rmed

SEP Safety edge protection ON: system circuit is closed

OFF: system is interrupted (fault)

IMPULSE Impulse button OFF: confi rmed

ON: not confi rmed

TIMER Weekly timer OFF: confi rmed

ON: not confi rmed

P/E BARRIER Photoelectric drive-through barrier ON: circuit closed

OFF: interrupted (fault)

STOP CIRCUIT - Stop button of controls

- Stop systems of drive

ON: circuit closed

OFF: interrupted (fault)

CYCLE Gate-cycle counter Displays the gate cycles

AVE Absolute value encoder Shows the gate position value

MFZ

18 – CS 300 Gate Controls / rev. 04.06

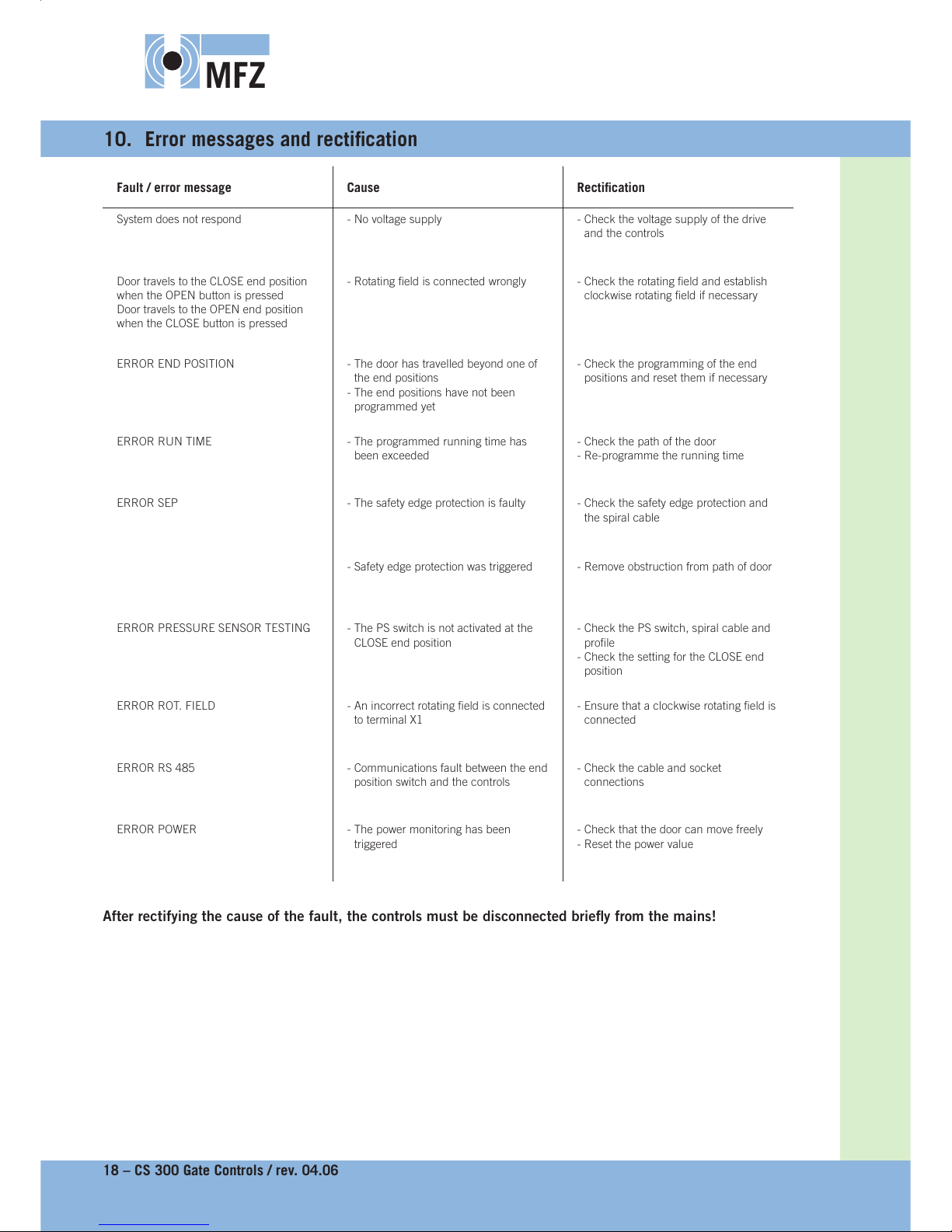

10. Error messages and rectifi cation

Fault / error message Cause Rectifi cation

System does not respond - No voltage supply - Check the voltage supply of the drive

and the controls

Door travels to the CLOSE end position

when the OPEN button is pressed

Door travels to the OPEN end position

when the CLOSE button is pressed

- Rotating fi eld is connected wrongly - Check the rotating fi eld and establish

clockwise rotating fi eld if necessary

ERROR END POSITION - The door has travelled beyond one of

the end positions

- The end positions have not been

programmed yet

- Check the programming of the end

positions and reset them if necessary

ERROR RUN TIME - The programmed running time has

been exceeded

- Check the path of the door

- Re-programme the running time

ERROR SEP - The safety edge protection is faulty - Check the safety edge protection and

the spiral cable

- Safety edge protection was triggered - Remove obstruction from path of door

ERROR PRESSURE SENSOR TESTING - The PS switch is not activated at the

CLOSE end position

- Check the PS switch, spiral cable and

profi le

- Check the setting for the CLOSE end

position

ERROR ROT. FIELD - An incorrect rotating fi eld is connected

to terminal X1

- Ensure that a clockwise rotating fi eld is

connected

ERROR RS 485 - Communications fault between the end

position switch and the controls

- Check the cable and socket

connections

ERROR POWER - The power monitoring has been

triggered

- Check that the door can move freely

- Reset the power value

After rectifying the cause of the fault, the controls must be disconnected briefl y from the mains!

MFZ

GB

CS 300 Gate Controls / rev. 04.06 – 19

Model CS 300

Voltage 400 / 230 V

Frequency 50 Hz

Current 10 A max.

Protection grade IP 65

Operating

temperature

-10˚ C to +60˚ C

Protection class I

Control voltage 24 V DC

Dimensions 215 mm x 275 mm x 190 mm

Weight 1,8 kg

Manufacturer:

MFZ Antriebe GmbH & Co. Kg, Neue Muehle 4,

48739 Legden, Germany

We hereby declare that, by virtue of their conceptual

development and design, as well as their

manufacture as we have brought them onto the

market, the products cited below:

CS300 Door Controls

conform to the relevant basic health and safety

regulations of the following EU guidelines and

standards:

EU Construction Products Directive 89/106/EU

DIN EN 13241-1

DIN EN 12453

DIN EN 12445

DIN EN 12978

EU Electromagnetic Compatibility Directive

89/336/EU

EN 50081-1

EN 50082-1

EN 55014-1

EN 61000-3-2

EN 61000-3-3

EU Machinery Directive 98/37/EU

EN 60204-1

EN 292-1

EU Low Voltage Directive 73/23/EU

EN 60335-1

EN 60335-2-103

BGR 232 - Directive for Power-driven Windows,

Doors and Gates Directive for Power-driven

Windows, Doors and Gates

Legden, 1 February 2006

Manufacturer‘s signature:

Hans-Joachim Molterer

Position of signatory:

Manager

11. Technical data 12. EU Declaration of Conformity

MFZ

Loading...

Loading...