MFJ-1835

10,12,15,17,20 Meter

Cobweb Antenna

Instruction Manual

Caution: Read All Instructions Before Assembling and

Using This Product!

MFJ

300 Industrial Park Road

Starkville, MS, 39759 USA

Tel: 662-323-5869 Fax: 662-323-6551

Introduction: The MFJ-1835 is a compact five-band loop array especially

designed for limited-space installations. Using horizontal polarization, it packs a

3-4 dB gain advantage over ground-independent verticals plus superior immunity

to local noise and RFI. In addition, MFJ’s highly efficient Spider-Match® network

and adjustable tuning tabs guarantee low minimum-SWR on every band. The

MFJ-1835 only measures 9-feet on a side, yet it features a full half-wave element

on every band for no-compromise DX performance -- even when running QRP!

The MFJ-1835 is solidly constructed to take on extreme weather. With sky-gray

fiberglass spreaders and stranded-wire elements, it blends in with any backdrop.

Best of all, it’s omni-directional, so you can omit the rotor and mount it high in the

air using standard low-cost TV-antenna hardware.

Parts List: Before starting assembly, please check the package contents against

the parts list below to ensure all items have been included.

[ ] 2 8" x 8" Aluminum Mounting Plate (737-1835)

[ ] 4 72" Fiberglass Element Support Tube (811-1835-1)

[ ] 1 43" Fiberglass Feed Tube (811-1835-2)

[ ] 1 50-Ohm to 12.5 Ohm Match Box (10-1835-1)

[ ] 1 Mast-Mounting Bracket (735-1835)

[ ] 5 Element End-insulators, 12" x .5" (737-0115)

[ ] 2 Rolls, 10-Meter Element Wire (13-1835-10)

[ ] 2 Rolls, 12-Meter Element Wire (13-1835-12)

[ ] 2 Rolls, 15-Meter Element Wire (13-1835-15)

[ ] 2 Rolls, 17-Meter Element Wire (13-1835-17)

[ ] 2 Rolls, 20-Meter Element Wire (13-1835-20)

[ ] 1 Parts Pack (17-1835-1)

Parts Pack Contents:

[ ] 31 6-32 x 1" screw (656-1000S)

[ ] 14 6-32 x 3/8" screw (656-0375S)

[ ] 47 6-32 Kep Nut (705-0632S-K)

[ ] 21 #6 Flat Washer (561116)

[ ] 2 U-Bolt Assembly (758-9199)

[ ] 5 Cable Tie (745-2158B)

[ ] 10 Tuning adjustment strips (737-1615)

If any components are missing or damaged, refer to the warrantee for

replacement instructions.

Preparation and Site Safety: The MFJ-1835 is lightweight, but a second pair of

hands will always ensure greater safety during assembly and installation. Install

fiberglass spreaders on a flat level surface (driveway, garage floor, etc.) and

complete the assembly using a 5-6 foot temporary mast or pole. The mast will

allow you to string and tension wire element at eye level. Always wear safety

glasses when working with spreaders, and keep the assembly area clear of

people, pets, clutter and debris. Never assemble or install any antenna near

power lines or residential entrance cables!

Important Warning: This antenna is an electrical conductor and, if it comes

into contact with power lines, you can be KILLED. Never assemble or

install any antenna near power lines!

Tools: 7/16" and 5/16" nut drivers, #2 phillips-head screwdriver, diagonal cutters.

Assembly Instructions:

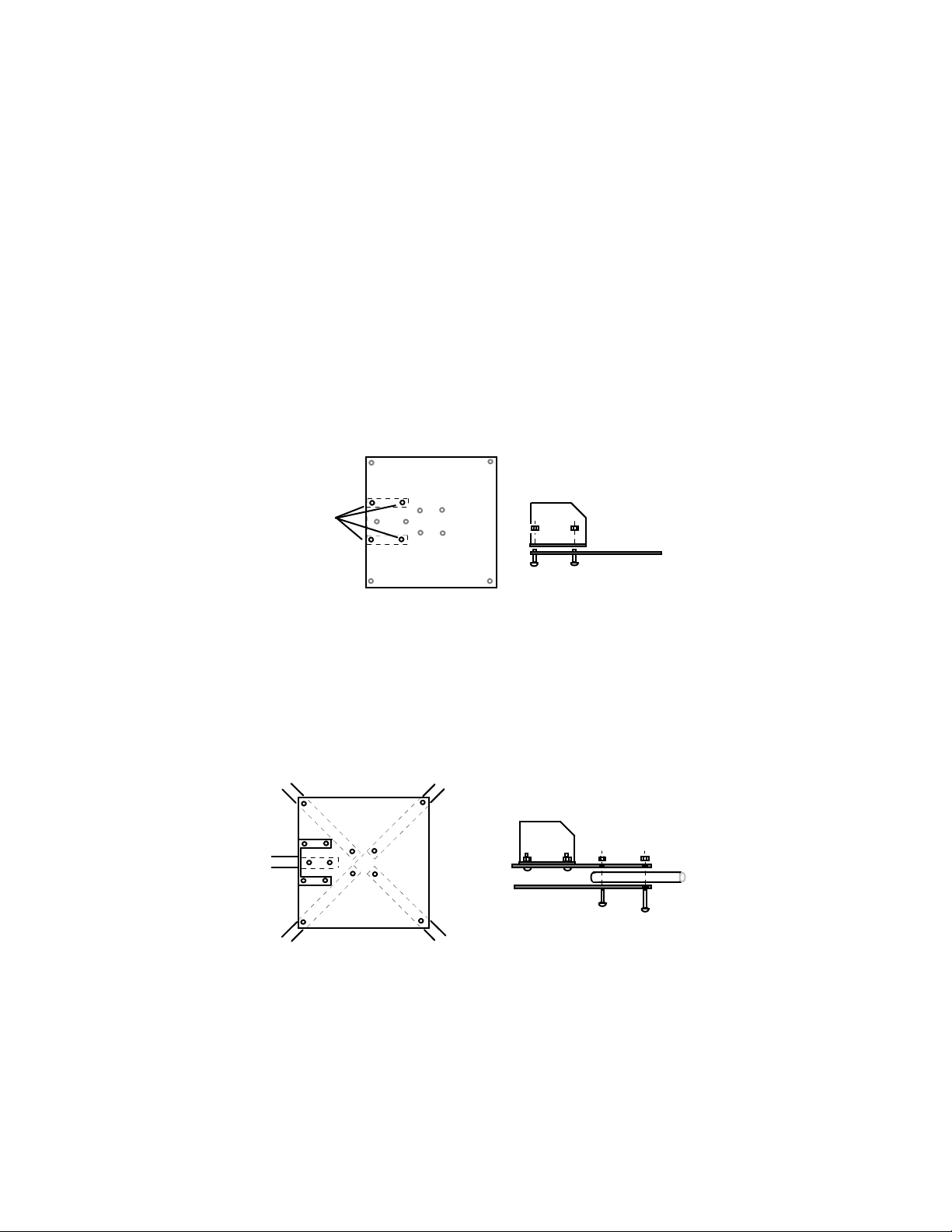

[ ] Locate one of the 8" x 8" aluminum mounting plates and install the mastmount bracket using four (4) 3/8" screws and nuts. Insert screws so the nuts

install on the mast-mount side of the plate. This is the side that will be oriented

toward the ground during final assembly and installation.

Mounting Plate

Mounting

Bracket

Holes

[ ] Locate the second mounting plate and position it so all mounting holes align

with the first plate.

[ ] Install one of the fiberglass support arms as shown, inserting it between the

two plates and securing it with two (2) 1" screws and nuts. Insert screws so the

nuts install on the mounting bracket side of the plate. Finger-tighten for now –

they will be tightened later.

Mounting Plate

Install Tubes Between

the Two Mounting Plates

[ ] Install the remaining three spreader arms in the same manner.

[ ] Locate the matching-network support arm. Before installing, observe the

tube's mounting hole pattern closely. One set of holes will be closer to the end of

the tube than the set at the opposite end. Install using the pair of holes closest to

the end using two (2) 1" screws and nuts.

[ ] Tighten down all of the 6-32 arm-mounting hardware at this time. Also, check

the mounting bracket screws.

[ ] Before continuing with assembly, flip the spreader frame over and mount it on

a temporary mast (5-6 feet). Install the two U-bolt assemblies in the mast mount

and secure the temporary mast. The U-bolts accept tube diameters up to 1-3/4".

[ ] Locate the match box and install it as shown, using the mounting hole closest

to the tip of the feed tube arm (the other hole isn’t used). Secure with a 6-32 nut.

Female UHF

In-Line Connector

Mounting Plates

Mast Mount

Bracket

U-Bolts

Mast

Match Box

Mounting Stud

Hole

Not Used

Balun

Ferrites

Feed Tube

Tie-Wraps

[ ] Use three nylon tie-wraps to secure the coax pigtail to the support tube. The

two remaining tie-wraps may be used later to secure your coax to the feed tube.

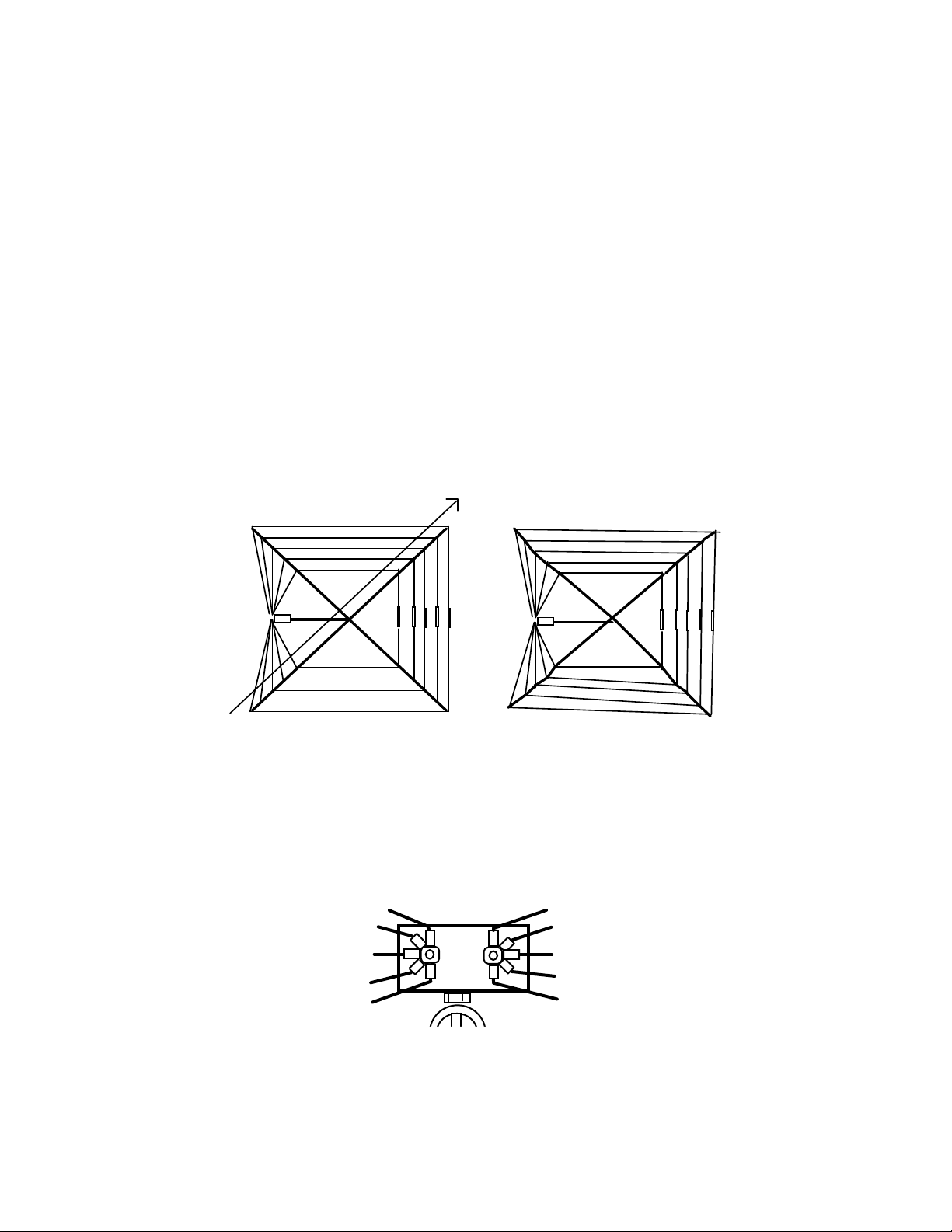

[ ] Install flat washers on four (4) 1-inch screws and insert them at the four 10meter spreader locations (holes nearest the center of the antenna). Insert screws

from the top down and thread a nut onto each one (do not tighten).

[ ] Connect a 10-meter element wire to one of the matchbox feed screws and

temporarily start a nut over the ring lug to prevent it from slipping off.

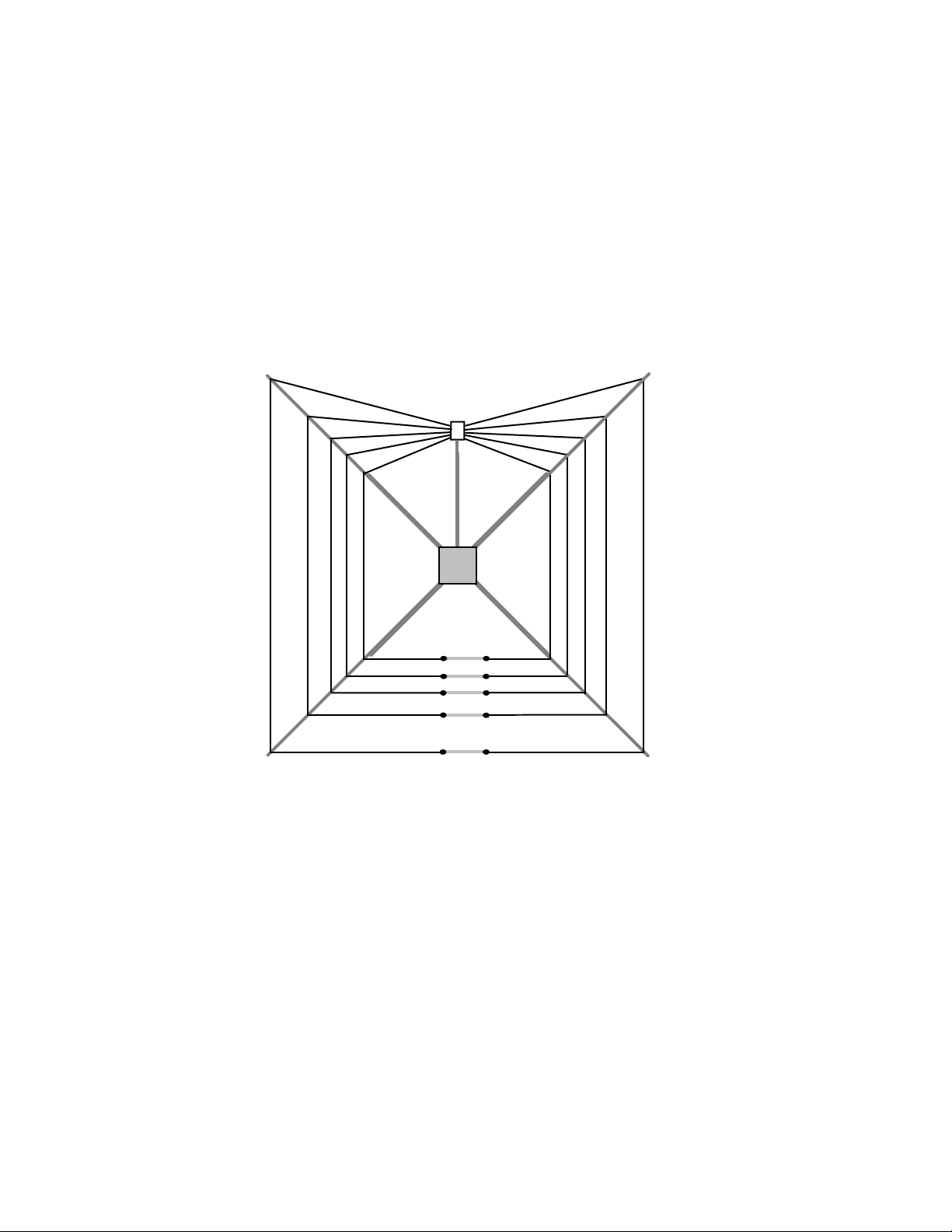

String wire from feedpoint

to insulator

>

Pass wire

Feedpoint

under washer

Insulator

Do not tighten nut

Secure to end hole

Insulator

>

[ ] Route the element wire around two adjacent spreaders, catching it under the

flat washers. Do not tighten the screws -- the wire should remain free to slide

back and forth.

[ ] Connect a plastic insulator to the opposite end of the 10-meter wire using a

3/8" screw. Install it in the mounting hole at the end and allow it to hang down.

[ ] In similar fashion, install the other 10-meter wire, connecting the ring lug to

to confirm that each leg is straight

the match box and routing the wire around to the opposite side of the frame.

[ ] At the far end, connect the second wire to the opposite end of the insulator

using the end-hole. Don’t be concerned if the element wire sags. You'll adjust it

later after all of the wires are installed.

[ ] Install the 12-meter loop using the same procedure outlined above.

[ ] Install the 15-meter loop.

[ ] Install the 17-meter loop.

[ ] Install the 20-meter loop.

[ ] With all five element wires installed, reduce wire sag by relocating the rig lugs

(as needed) to other mounting holes in the insulators. Do not tension the wires so

tightly that they distort the spreaders or pull the frame out of square. The

objective is to equalize tension and minimize (but not eliminate) sag. Sight down

each support tube to ensure it is straight and 90-degree from the adjacent tubes.

Good

Not Good

Sight down the length of the frame

[ ] Once satisfied with wire tensioning, tighten all spreader screws to secure

each wire in place. Also, tighten the element nuts on the matchbox, fanning out

the ring lugs as needed to ensure flat metal-to-metal contact between each

eyelet. Check all other hardware to confirm everything is secure.

Fan leads so lugs make

full surface-to-surface

contact

Initial Setup: The antenna should be mounted at least 6 feet above ground for

the initial tune-up (higher if practical). If available, use a handheld antenna

analyzer -- it will make tuning a lot faster and safer. Also, when checking SWR,

back away from the elements -- especially in the area surrounding the end

insulators. If you get too close, you could detune them with your body. When

using a transmitter and SWR bridge to check SWR, apply the minimum amount

of power needed to calibrate the bridge and do not make physical contact with

energized elements!

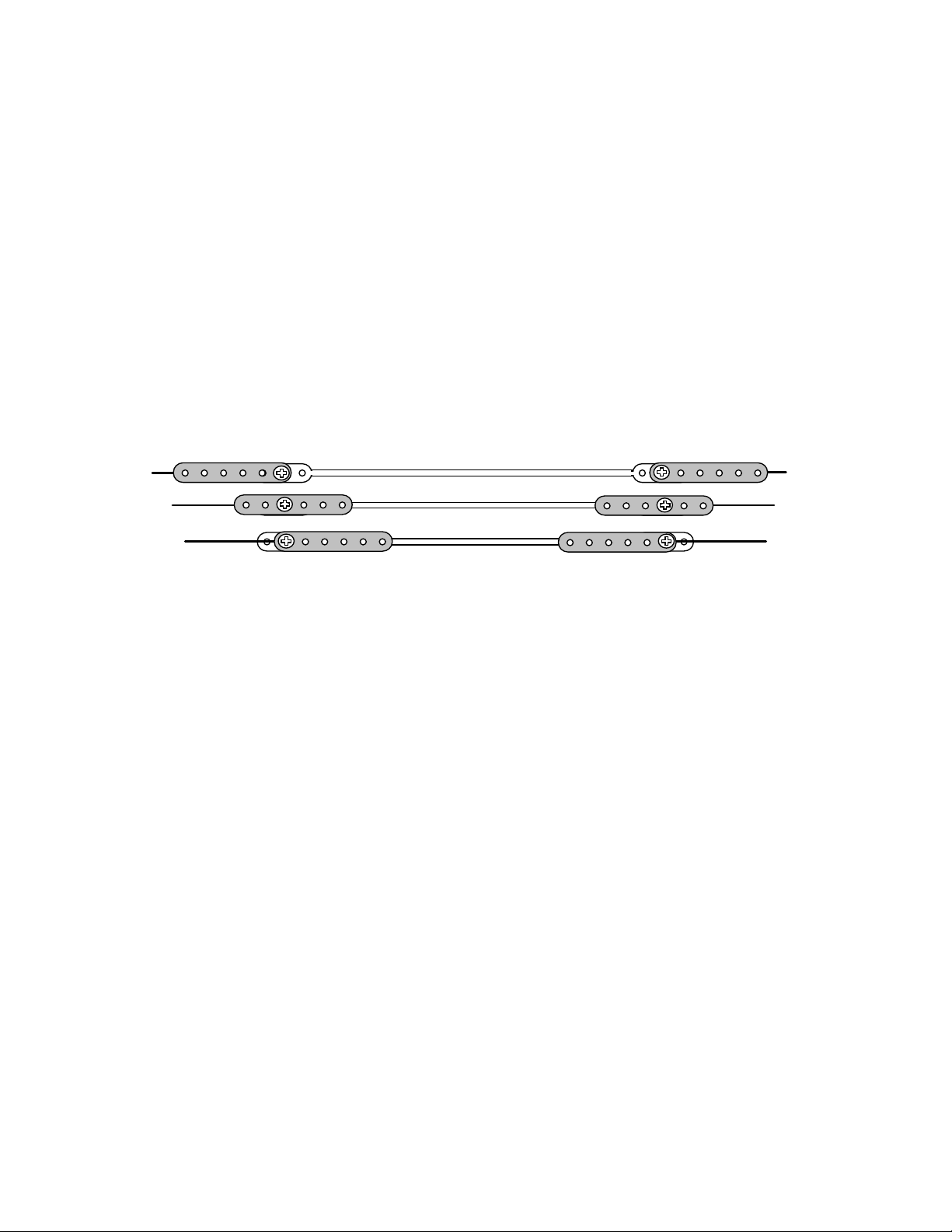

Tuning Procedure: The element wires are pre-cut to resonate at or slightly

above the high-frequency edge of each band. The trim-tab tuning strips are

installed on the insulators to move the minimum-SWR frequency down toward

your favorite band segments without disrupting wire tensioning on the frame. To

lower frequency, position the tabs to electrically extend the element length. Start

with the 20-meter element and work your way in toward the 10-meter element.

Highest in Frequency

Middle Range

Lowest in Frequency

If minimum SWR occurs where you want to it without installing tabs, omit them. If

the tabs fail to pull the frequency low enough, swing one tab down so the end

hole is clear of the insulator and add a short length of wire using a 6-32 screw.

Bandwidth: The 2:1 bandwidth for a half-wave loop is normally much narrower

than it is for a straight-line half-wave dipole, so tune carefully. Also, when

adjusting the antenna close to ground, you may fail to get a deep SWR dip on

one or more of the bands. In this event, tune for the best dip you can get at your

target frequency. The minimum SWR will drop substantially once the antenna is

repositioned at a higher location. After you've installed the antenna at its final

location, always double-check to ensure the lowest SWR points remain where

you want them. New surroundings may cause one or more points to shift. Take

the time to re-adjust -- it’s time well invested.

Antenna Tuners: You may use the MFJ-1835 in conjunction with a tuner to

achieve full-band low-SWR coverage on the wider bands (20, 15, and 10

meters). A tuner will also prove helpful if the elements accumulate ice, snow, or

heavy rain (precipitation loading normally lower resonant frequency). However,

don't use your tuner to compensate for mistuned elements! Perform a careful

tune-up under dry conditions at the time of installation to ensure the best overall

performance.

Antenna Mounting: The MFJ-1835 performs best when raised 20-feet or more

above ground and positioned well away from nearby wiring, metal surfaces, and

large conductive objects. Use any mast diameter between 1-1/4" and 1-3/4" OD,

but the larger diameter is recommended for taller masts. Also, avoid installing

guy wires in close proximity to the elements. Finally, never install where humans

or animals can come in contact with the elements. Be especially attentive to

safety when conducting portable operations in public areas!

Important Warning: Contact with energized element wires can (and will)

cause severe RF burns or even death! Never install the MFJ-1835 where

humans or pets could make accidental contact.

Coaxial Feedline: For best results, use new uncontaminated 50-ohm coax and

avoid making splices that could take on water and cause contamination. The

MFJ-1835 is light in weight and not designed for high power operation, so any

premium grade RG-8X (or Mini-8) should work well (RG-58 okay for short runs).

Larger cables such as RG-8 or 9914 have lower loss, but will add extra weight to

your installation. With lighter cable, you can safely mount the antenna higher in

the air which is normally more beneficial.

Antenna Grounding: Always install a Safety Ground to protect your property

and your equipment from near-by lightning strikes. Connect the base of the

support mast to a suitable ground rod installation using one or more runs of #10

solid aluminum ground wire. Also, always install a barrel connector or junction

box where the cable enters your building and unhook it at the first sign of

threatening weather. Lightning arrestors may provide some protection from

nearby strikes, but a complete disconnect is your only real protection against a

very close or direct hit!

Theory of Operation: The MFJ-1835 consists of five concentrically arranged

1/2-wave horizontal loops mounted on a fiberglass X-frame. The footprint is

square, with all five elements fed in parallel through a reactance-compensated

broadband autotransformer. The radiation pattern is virtually omni-directional (±

1.5 dB). A sleeve-style ferrite balun is installed at the feedpont to choke off

unwanted common-mode radiation. The balun also reduces receiver-noise

pickup and spurious RFI signals generated by consumer devices. Weighing just

over eight pounds, the MFJ-1835 installs easily on virtually any portable or

permanent mast from 1-1/4” to 1-3/4” OD.

Specifications:

Minimum SWR: 1.1:1 or lower all bands, measured at 20' AGL

Modeled Gain: 4.7 dBi at 20-feet AGL on 14.2 MHz with 37º TOA.

Modeled Pattern: Omni-directional, ±1.5 dB, max. gain on axis with feedpoint.

Power Handling: 300-W pep SSB/CW recommended, never exceed 600-W

Dimensions: 9’ x 9’ per side, 12' diagonally

Weight: 8.2 pounds

Mast Size 1-3/4" OD maximum

Warrantee

If manufactured by MFJ Enterprises, Inc. and purchased from an authorized dealer or directly

from MFJ, we warrant to the original owner that this product shall be free from defects in material

and workmanship for a period of 12 months from date-of-purchase provided the following terms

and conditions are satisfied:

1. The purchaser must retain a dated proof-of-purchase (bill of sale, cancelled check, credit card

or money order receipt, etc.) describing the product so as to establish the validity of the warranty

claim. In addition, the original copy or machine reproduction of such proof shall be provided to

MFJ at the time of warranty service. MFJ shall have the discretion to deny warranty service

without dated proof-of-purchase. Any evidence of alteration, erasure, or forgery shall be

cause to void any and all warranty terms immediately.

2. MFJ agrees to repair or replace, at its option and without charge to the original

owner, any defective product under warranty, provided the product is returned postage prepaid to

MFJ Enterprises, Inc. with a personal check, cashiers check, or money order in the amount of

$7.00 to cover postage and handling.

3. MFJ Enterprises, Inc. will supply any replacement parts free of charge for any MFJ product

under warranty upon request. A dated proof-of-purchase and a $5.00 personal check, cashiers

check, or money order must be provided to cover postage and handling for parts and materials.

4. This warranty shall not be voided for owners who attempt to repair defective units. Technical

consultation is available by calling (662) 323-5869.

5. This warranty does not apply to kits sold by or manufactured by MFJ Enterprises, Inc. (once

assembly begins, the owner becomes the manufacturer).

6. Wired and tested PC board products are covered by this warranty provided only the wired and

tested PC board product is returned. Wired and tested PC boards installed in the owner’s own

cabinet or connected to switches, jacks, or cables, etc. and sent to MFJ Enterprises, Inc. will be

returned at the owner’s expense un-repaired.

7. Under no circumstances shall MFJ Enterprises, Inc. be liable for consequential damages to

persons or property by the use of any MFJ products.

8. Out-of-warranty Service: MFJ Enterprises, Inc. will repair any out-of-warranty product provided

the unit is shipped prepaid. All repaired units will be shipped COD to the owner. Repair charges

will be added to the COD fee unless other arrangements are made.

9. This warranty is given in lieu of any other warranty expressed or implied.

10. MFJ Enterprises, Inc. reserves the right to make changes or improvements in the design or

manufacture of its products without incurring any obligation to install such changes upon products

previously manufactured.

11. All MFJ products to be serviced in-warranty or out-of-warranty should be addressed to MFJ

Enterprises, Inc., 300 Industrial Park Road, Starkville, Mississippi 39759, USA and must be

accompanied by a letter describing the problem in detail along with a copy of a dated proof-ofpurchase.

12. This warranty conveys specific rights, and you may also be entitled to other rights which may

vary from state to state.

Loading...

Loading...