Page 1

AP-1301 Operator’s Guide

Page 2

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Copyright Notice

Copyright ©2002 by MediaFORM, Inc. USA. All rights reserved.

This manual and the accompanying illustrations may not be copied, reproduced,

electronically transmitted, or tra nslated into another language, in whole, or in par t,

without the written consent of MediaFORM, Inc. USA

MediaFORM, Inc. USA, CD2CD, CD2CD PRO, CD-5400L, CD-5908, CD-5916,

CD-3702, CD-3703, CD-3704, CD-3706P, cdDIRECTOR, AP-1001, AP-1301,

Easi-DAT and Easi-AUDIO are trademarks of MediaFORM, Inc. USA

Other trademarks referred to are the property of their respective trademark or

registered trademark holders.

Warranty

MediaFORM, Inc. USA warrants to the original purchaser that the equipment that you have purchased is free

from defects in materials and workmanship, for a period of time as follows:

Autoloader Electronics & Mechanical Parts 1 year

Thermal Transfer CD Printer 6 months limited warranty

This warranty is applicable when the warranty registration has been completed and returned to MediaFORM,

Inc. USA within a reasonable period of time following the purchase and the warranty is NOT transferable. This

warranty does not apply to malfunctions caused by misuse, negligence, accident, or alteration, nor is

MediaFORM, Inc. USA responsible for consequential damages related to the use of this equipment.

This warranty is made in lieu of any other warranty expressed or implied.

Printer Warranty Policy

Individual printer manufacturers are responsible for the products they provide. As a convenience, MediaFORM,

Inc. USA will honor any service issue related to a defective printer while under its respective manufacturer’s

warranty providing that the printer has been purchased from MediaFORM, Inc. USA either directly or

indirectly. MediaFORM, Inc. USA assumes no responsibility for printers NOT purchased through

MediaFORM, Inc. USA

Piracy

The copying of audio, video, or software without the permission of the copyright holder is illegal. MediaFORM,

Inc. USA accepts no responsibility for the copyright use or misuse of this equipment. It is the sole responsibility

of the user to ensure that the legal rights of copyright in duplicating and printing are respected.

MediaFORM, Inc. USA

122 Oscar Way

Chester Springs, PA 19425

Tel.: (610) 458-9200

Fax.: (610) 458-9554

Email: documentation@mediaform.com

www: http://www.mediaform.com

Page 1

Page 3

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Table of Contents

COPYRIGHT NOTICE............................................................................................................................................. 1

ABOUT MEDIAFORM DUPLICATION SYSTEMS.............................................................................................4

W

HAT TO EXPECT FROM YOUR MEDIAFORM PRINTING SYSTEM.............................................................................. 4

ABOUT THIS MANUAL........................................................................................................................................... 4

A

WORD ABOU T WINDOWS NT 4.0............................................................................................................................ 4

GETTING STARTED................................................................................................................................................ 5

W

HAT’S IN THE BOX ................................................................................................................................................. 5

Options:................................................................................................................................................................ 5

ACKING MATERIALS ................................................................................................................................................ 5

P

S

ETUP ........................................................................................................................................................................ 6

What you will need................................................................................................................................................ 6

Attaching a Monitor.............................................................................................................................................. 7

Attaching the Mouse.............................................................................................................................................. 7

Attaching the Keyboard ........................................................................................................................................ 8

Attaching the Network Cable................................................................................................................................ 8

Attaching the Printer Cable.................................................................................................................................. 9

T

HE BEST PLACE TO PUT YOUR SYSTEM................................................................................................................. 10

AFETY PRECAUTIONS............................................................................................................................................. 10

S

O

RIENTATION TO THE DIFFERENT PARTS - AP-1301I .............................................................................................. 11

Front View .......................................................................................................................................................... 11

Rear View............................................................................................................................................................ 11

O

RIENTATION TO THE DIFFERENT PARTS – AP-1301T............................................................................................. 12

Front View .......................................................................................................................................................... 12

Rear View............................................................................................................................................................ 12

R

EMOVING PACKING RESTRAINTS........................................................................................................................... 13

I

NPUT AND OUTPUT SPINDLES................................................................................................................................. 13

Assembling The Spindles............................................................................................................................... .13

Installing The Spindles .................................................................................................................................... 13

Spindle Designations ....................................................................................................................................... 14

SYSTEM STARTUP ................................................................................................................................................ 15

A

LIGNING THE PRINTER........................................................................................................................................... 16

S

TARTUP THE AP-1301 SOFTWARE ......................................................................................................................... 19

OPERATION............................................................................................................................................................ 20

THE LABEL DESIGNER TAB............................................................................................................................... 21

T

HE LABEL DESIGNER MENU BAR .......................................................................................................................... 22

HE TOOL BAR ........................................................................................................................................................ 22

T

THE JOB TAB.......................................................................................................................................................... 25

T

HE JOB MENU BAR ................................................................................................................................................ 25

C

REATING A PRIN T JOB ............................................................................................................................................ 26

JOB ID................................................................................................................................................................ 26

GENERAL OPTIONS.......................................................................................................................................... 26

LABEL FILE ....................................................................................................................................................... 27

QUANTITY.......................................................................................................................................................... 28

Page 2

Page 4

AP-1301 i/t Operator’s Guide

Document Revision: 100102

COMMENTS....................................................................................................................................................... 28

OPEN, SAVE AND SUBMIT JOB .................................................................................................................................. 28

STATUS SCREEN.................................................................................................................................................... 30

J

OB QUEUE .............................................................................................................................................................. 30

J

OB QUEUE SCREEN................................................................................................................................................. 31

UNNING JOBS......................................................................................................................................................... 32

R

C

OMPLETED JOBS .................................................................................................................................................... 32

Page 3

Page 5

AP-1301 i/t Operator’s Guide

About MediaFORM Duplication Systems

Thank you for purchasing MediaFORM’s AP-1301 i/t automated CD

Printing system. MediaFORM manufactures a wide variety of CD

duplication equipment, including a variety of manual and fully automatic

CD duplicators and printers. We hope you will consider us for all of your

duplication needs.

What to expect from your MediaFORM printing System

This printing system was professionally designed and manufactured to give

you years of trouble free operation. To avoid accidental damage, please be

sure to read this manual thoroughly before operating your unit.

Note: It is also important to note that this unit, while it is essentially

a PC equipped with Windows NT 4.0 Workstation, is a

dedicated duplication appliance. The removal or addition of

any software components may compromise this unit’s

operation. Please make every attempt to leave this unit “as is”

and dedicated to the task of printing CDs.

Document Revision: 100102

About This Manual

Please read through this manual thoroughly before starting the unit. Once

you have finished reading, follow along chapter by chapter with the unit in

front of you. This will give you the firmest understanding of how to operate

this system

A word about Windows NT 4.0

It is this manual’s focus to cover the application software at the heart of the

AP-1301. This system is built on Microsoft’s Windows NT 4.0 Workstation

Operating System. Windows NT is a very complex and powerful operating

system, which for our purposes, is touched only briefly. For the fullest

understanding, consider purchasing a Windows NT 4.0 Workstation guide.

There have been many such books published on this topic, and you will

find them readily available at a local bookstore.

Page 4

Page 6

Getting Started

Carefully remove your new CD printing system from the shipping

container. Please inspect the contents and verify it against your packing

slip. Be sure to report any errors in shipping as soon as possible.

What’s In The Box

Your new AP-1301i or t includes the following:

• AP-1301 base unit

• Power cord

• Three spindles. These serve as the containers to hold both printed and

unprinted CD-Rs

• This manual

• Printer: The AP-1301t includes the MediaFORM Spectrum2 CD Printer

(Thermal Printing), while the AP-1301i includes the Primera Signature

III and IV CD-R Printer (Ink jet)

• AP-1301t PDS Printer docking station (AP-1301t Only).

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Options:

• If the AP-1301i is purchased, the AP-1301t PDS docking station may be

purchased as an option so that the unit can be used with both ink jet and

thermal printing solutions.

• Signature III or IV CD-R Printer

• MediaFORM Spectrum CD printer (Thermal transfer based technology

requires AP-1301t PDS docking station)

• Additional ink (AP-1301i) or printer ribbons (AP-1301t)

• SVGA Monitor

• Keyboard and mouse

Packing Materials

It is always a good idea to save the original packaging in case the unit

requires service in the future. This will prevent further damage from

occurring in transit, as the result of a poorly packed system.

Page 5

Page 7

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Setup

Before the unit can be operated, you will need to setup the different

components.

What you will need

You will need the following

• MediaFORM AP-1301 base unit

• MediaFORM Spectrum2 CD Printer (Requires the MediaFORM AP-

1301t PDS docking station) or Primera Signature III or IV printer (AP1301i).

• Parallel printer cable (included with printer)

• Various included cables

• Quality blank CD-R’s. Thermal white printable is recommended for the

AP-1301t and Ink Jet White Printable for the Ap-1301i. While the use

of media with adhesive labels may work, it is not recommended nor

supported.

• SVGA monitor (Sold Separately) capable of a minimum 800 x 600

resolution at 75Hz.

• Keyboard with DIN style connector (Sold Separately)

Page 6

Page 8

AP-1301 i/t Operator’s Guide

Document Revision: 100102

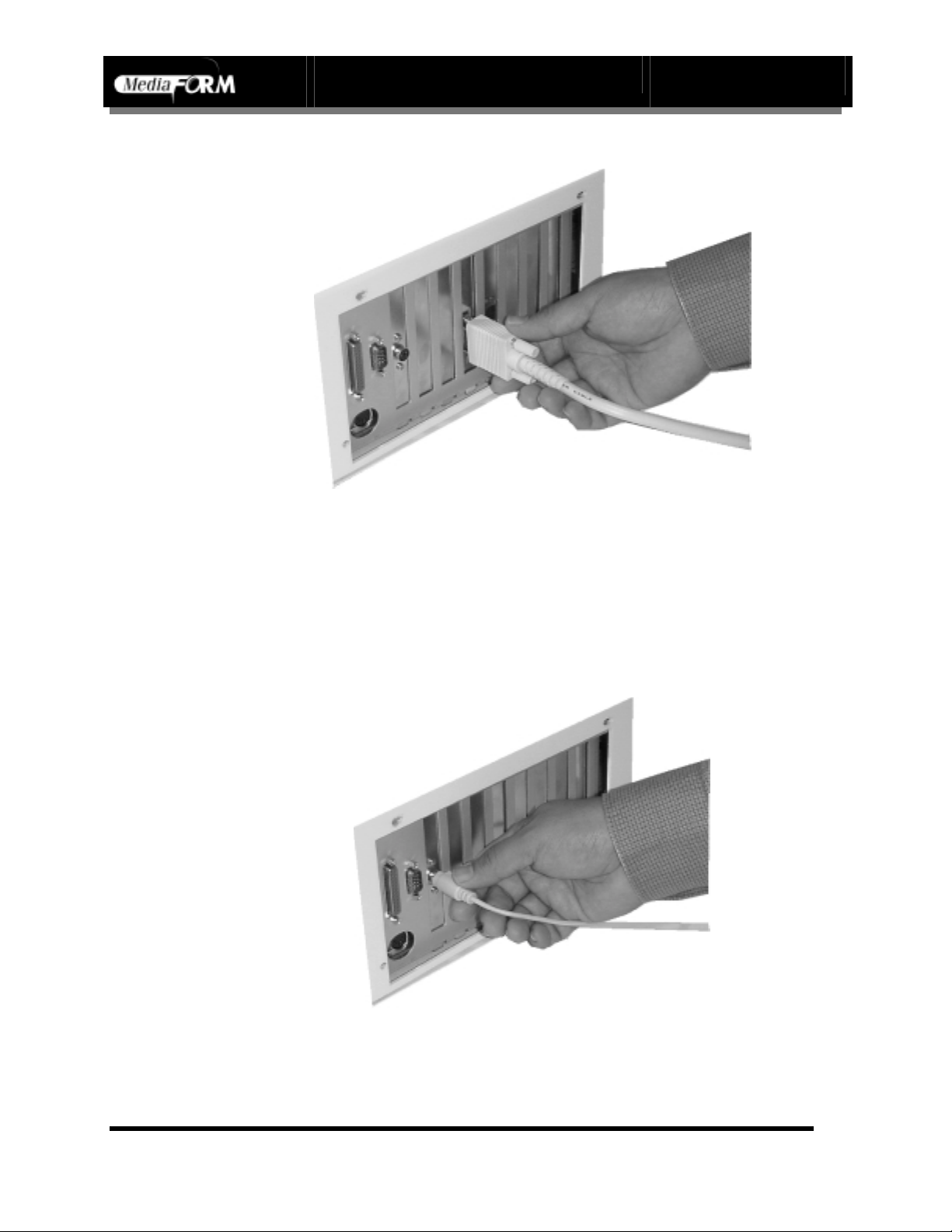

Attaching a Monitor

Place the monitor on either side of the AP-1301. Connect the male DB-15

(15-pin) connector of the monitor cable to the female DB15 connector on

the AP-1301 base unit. Connect the monitor’s power cable to the AC wall

jack. Reference the documentation that accompanied the monitor if you

need help

Attaching the Mouse

Either a Microsoft compatible serial or P/S2 mouse may be used. For a

serial mouse, use the DB-9 male connector located on the back of the AP1301 base unit. For a P/S2 mouse, use the mini DIN connector located on

the back of the AP-1301 base unit.

Page 7

Page 9

AP-1301 i/t Operator’s Guide

Document Revision: 100102

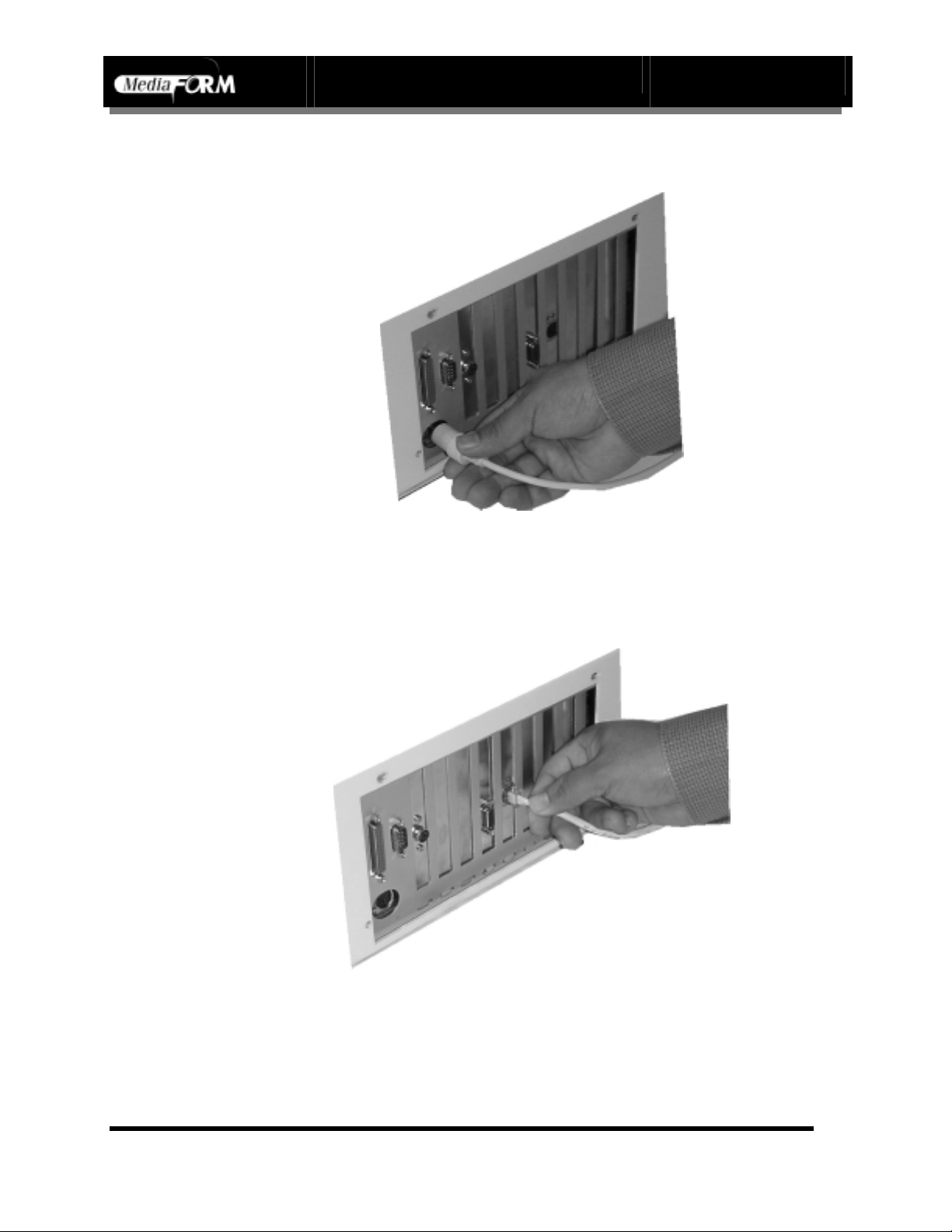

Attaching the Keyboard

Connect the keyboard to the large DIN located on the back of the AP-1301

base unit.

Attaching the Network Cable

If you wish to connect the AP-1301 to your network, connect a suitable

patch cord to the RJ-45 network port on the back of the AP-1301 base unit.

Use a category 3 or better patch cable for 10Base-T and category 5 for

100Base-TX.

Page 8

Page 10

AP-1301 i/t Operator’s Guide

Document Revision: 100102

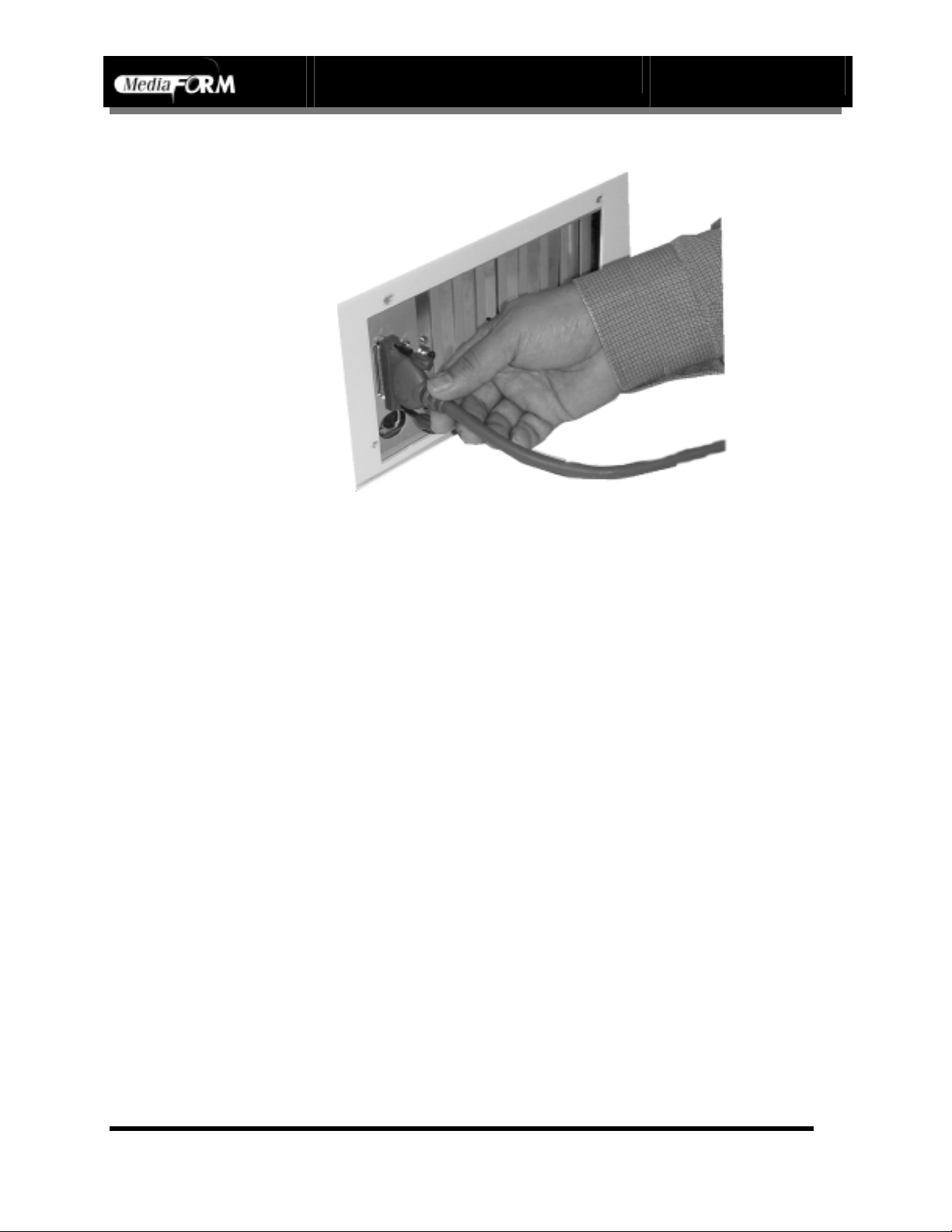

Attaching the Printer Cable

Connect the printer cable included with your printer to the female DB-25

connector on the back of the AP-1301 base unit. Connect the other end to

the port on the back of the printer. Use only IEEE-1284 compatible printer

cables.

With you printer placed on the deck of the Ap-1301, attach the printer and

power cables.

Page 9

Page 11

AP-1301 i/t Operator’s Guide

The Best Place To Put Your System

The best place for your unit is in a climate-controlled area, free of dirt, dust,

humidity, excessive heat, and electronic or electromagnetic interference. As

your AP-1301 is network ready, you may want to locate it near a network

jack. Place the AP-1301 i/t on a firm and steady work surface, allowing

sufficient room for all of your work materials. Also, allow at least six

inches of clearance around the unit for ventilation.

Safety Precautions

Your system shipped with a three-prong power connector, and is intended

for use with properly grounded AC receptacles only. Do NOT try to defeat

the third “ground” prong. All computer peripherals should be properly

grounded, and the AP-1301 is no different. The use of a power conditioner,

such as a UPS (Uninterruptable Power Supply) or a surge protector, is

always recommended with sensitive computer equipment. If you are

considering using such a device, the minimum system recommended is

400VA.

Document Revision: 100102

Repairs should only be attempted by authorized, factory-trained

technicians. MediaFORM reserves the right to void the warranty if

unauthorized service is performed.

Page 10

Page 12

AP-1301 i/t Operator’s Guide

Orientation to the Different Parts - AP-1301i

Front View

Document Revision: 100102

Rear View

Page 11

Page 13

(front bracket)

AP-1301 i/t Operator’s Guide

Orientation to the Different Parts – AP-1301t

Front View

Document Revision: 100102

Rear View

(rear bracket)

Page 12

Page 14

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Removing Packing Restraints

The AP-1301 ships with a picker mechanism restraint, to ensure that the unit is not

damaged in transit. This restraint must be removed before operation or power-on. If you

have not already done so, remove the restraint before turning the unit on. Save the styrene

restraint, in the event that you need to transport the unit.

Input and Output Spindles

The spindles serve as the containers to store the blank and

printed CD-R’s. They must be installed before operation of

the unit. Let’s do so now.

First, locate the three spindles provided with your system.

Inside the original shipping carton was a smaller carton,

called the accessory box. It is in this box that you will find

the input and out spindles, along with the power cord

needed to operate the unit.

Assembling The Spindles

Assemble each spindle by screwing the metal spindle spike into the top of the plastic

spindle base. Turn the spindle clockwise until snug. Be sure you thread properly to

ensure that each spindle is fully upright.

Installing The Spindles

Position the AP-1301 unit so that the front

panel is facing you. Locate the metal

spindle guide pins marked “Spindle 1”,

“Spindle 2”, and “Spindle 3”. These pins

are found on the top deck of the unit,

behind the picker arm column, to the left

and right side.

In the bottom center of each spindle base

is a hole. Align the hole with the three

guide pins found on the deck of the AP1301 unit. Place the spindle on top of the

guide pin, so that the spindle stands

vertically. Repeat the procedure until all

three spindles are installed.

Page 13

Page 15

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Spindle Designations

The AP-1301 uses three spindles. Spindle 1 is dual purpose, and is used for both input

and output. Spindle 2 is for output only. Spindle 3, like spindle 1, is also dual purpose

and is used for both input and output.

To start, place the desired number of discs to be printed on spindle 1. If you wish to

do a quantity greater than one spindle allows, place the remainder on spindle 3. The

processing of discs begins with the blanks being drawn from spindle 1, and the

printed out being placed on spindle 2. Once spindle 1 runs empty, discs will then be

drawn from spindle 3. The outputted product will then be placed on spindle 1. In the

end, all completed discs will be on the front most spindles.

Page 14

Page 16

System Startup

Locate the switch on your SVGA monitor and turn it to the on position.

Next, locate the printer power switch (refer to separate printer

documentation if you need help).

Next, we must verify that the voltage selector switch is set correctly on

each module; it is located between the two power receptacles. The AP-1301

supports both 115 VAC and 230 VAC at 50 ~ 60 Hz. Please confirm that

the appropriate voltage (115 VAC for North America) has been selected.

AP-1301 i/t Operator’s Guide

Document Revision: 100102

CAUTION

CAUTION

CAUTIONCAUTION

Always use properly grounded receptacles, or severe damage

to your system may occur. The use of a surge protector or UPS

(Uninterruptable Power Supply) is always recommended with

sensitive computer products.

Page 15

Page 17

AP-1301 i/t Operator’s Guide

Document Revision: 100102

• Now that you have confirmed the proper voltage setting, it is time to

turn the unit on.

• Make sure you power on the unit using the switch seen below, which is

located on the back of the AP 1301.

• The AP-1301 is Windows NT based and may take a couple of minutes

to start up. Upon a successful startup, you will be greeted by the

Windows NT Logon screen. When prompted, press CTRL-ALTDELETE and enter:

U

ser Name: mediaform

Password: mediaform

When logging on to Windows NT, the password is case sensitive.

• Once you logon, you will be greeted by the Windows NT desktop. For

those of you familiar with Windows 95 or Windows 98, you will find it

to be virtually the same user interface.

Note: You may want to consider supplementing this

manual with a Windows NT 4.0 Workstation

guide, many of which are readily available at

local book stores

Aligning the Printer

Before you can begin automated printing, you may need to align the printer.

Printer alignment consists of running an alignment program, and adjusting

the printer’s position by moving the brackets, which hold it in place.

Alignment is complete when the discs are placed perfectly centered in the

printer’s tray.

The brackets have been preset at the factory. Due to slight variations in

printers, and the surface on which the AP-1301 is ultimately set, the

brackets may need adjustment to “fine- tune” the printers position. Before

making any changes, the Printer Alignment Utility appearing on the

Windows NT desktop should be run.

Page 16

Page 18

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Be sure to close all applications, especially the CD-3703

application itself, as it will conflict with the Printer

Alignment Utility. Locate the “Printer Alignment” ICON

Printer

Alignmen

t Utility

depicted to the left, on the desktop. Double-click on it to

launch the Printer Alignment Utility. The splash screen

below will be displayed.

• Place a disc on the input spindle. This is the spindle at the right front

side of the unit. Click on P

erform Test. You will be prompted:

Page 17

Page 19

AP-1301 i/t Operator’s Guide

Document Revision: 100102

• Follow the on-screen instruction and then click on Yes. If you click on

N

o, the process will be aborted. You will be asked:

• Once the printer’s tray is fully extended, click on Y

es to continue or No

to abort the process.

• Check the positioning of the disc in the tray. If not perfectly centered,

adjust the printer’s position by loosening the screws that hold the

brackets in place, and then adjust the printer in the appropriate direction.

Click on OK and run this test again until the disc is placed centered in

the tray. When you are happy with the results, push the brackets up

against the printer to hold it in place, and then tighten them down.

You should not have to perform this procedure again unless you relocate

the system.

• Click on Ex

it to quit the program. You will be prompted to restart the

system. To do so, click the START button on the taskbar. You will then

click SHUTDOWN. When asked, select RESTART.

Page 18

Page 20

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Startup the AP-1301 Software

When the system restarts, logon as you did before. After logging on, click

the AP-1301 ICON to bring up the main AP-1301 application. The Job tab

will be displayed:

Page 19

Page 21

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Operation

If you have not already done so, be sure that you have read the section entitled “Getting

Started”. This section walks you through the preliminary setup of the unit, which must be

accomplished prior to operation.

The AP-1301 is broken up into three tabs. The Status Tab, the Job Tab, and the Label

Designer Tab. The Status Tab shows what print job is running, what is queued to run, and

what has been completed.

Before a print job can be submitted, the CD design must be produced. This can be done

in two basic ways. The primary way is to use the Label Designer tab of the AP-1301

application itself. We will detail this process in a moment. The other way is through a

graphic design software package that enables you to design your own template. From

there, rather than print to the printer itself, you simply change the print driver setting to

“Print to File”. This will generate a file with a .PRN extension, which can then be used as

the “Label File” when submitting a job.

Page 20

Page 22

AP-1301 i/t Operator’s Guide

Document Revision: 100102

The Label Designer Tab

To start designing your CD, click on the Label Designer tab. Here is where we have the

ability to customize your CD’s appearance with text and graphic images. The Label

Designer tab supports a variety of graphic image formats, as well as any installed

Windows True Type font.

The Label Designer tab is dominated by two concentric circles, which graphically

represent the appearance of the CD you are designing. Horizontally along the top left side

of the tab is the menu bar. Vertically at the bottom left, is the toolbar.

Page 21

Page 23

AP-1301 i/t Operator’s Guide

The Label Designer Menu Bar

As we look at the AP-1301’s Label Designer, we see the top horizontal

toolbar, containing New, Open, Save, Delete, and Help (Please take note

that HELP was not implemented for this revision)

The menu button functions are as follows:

Clicking on the new button will clear the screen, and allow you to

start on a new label design.

Allows you to open an existing label file (*.LBL).

Allows you to save the label currently displayed

Allows you to delete an object currently selected with the pick

tool, described in the “toolbar” section.

Not currently implemented

Document Revision: 100102

.

The Tool Bar

At the bottom left of your screen, you will find a vertical

toolbar. The toolbar consists of five buttons or tools. These are

the: Point / Select Tool, Type Text Tool, Im port Bitmap Tool,

Select Font Tool, and the Add Date Tool.

The menu buttons functions are as follows:

Select this tool by clicking on it. Once selected, it can be used to

reposition text or graphic images. You may also use it to select

items to be deleted, by using the DELETE button on the Menu

Bar

Page 22

Page 24

AP-1301 i/t Operator’s Guide

Used to add text to the label being designed. Select this tool, and

click on the location where the text should appear. Use the

“Point” tool to reposition it, or double click on the text created to

Document Revision: 100102

modify it. To change fonts or colors, you must first use the

“Select Font” tool, and then the “Type Text” tool.

Allows you to import a graphic image file. It is best to use

images optimized for the current printer. With the MediaFORM

Spectrum, 300 DPI pictures of no more than 4.5” work best. For

the Primera, 600 DPI (or 1200, but little improvement will be

seen) pictures of no more than 4.5” square.

Select this tool to choose the desired font or color, before

selecting the “Type Text” tool

Allows you to add a dynamic date field that will reflect the

current date when printed

Using “Type Text” Tool

The text tool allows you to create a text element for your CD. It can be

repositioned, or it’s font attribute changed, by using the Point tool below.

To use this tool:

• Select Type Text tool by clicking

on that button

• Move the cursor (mouse) to the

image of the CD, and click once

• Enter the text you wish to display.

For our example, we will type

“Label Designer”

Using “Point” Tool

The point tool is used to select the different elements that make up your

CD’s design. This tool is the one used when you wish to reposition an

element or change its attributes such as size, font, or location.

To change fonts in a text element:

• Select Point by clicking on that button

• Click on the text or graphic, and hold down the mouse. You will then

maneuver the object to it’s appropriate location. You may resize graphic

Page 23

Page 25

AP-1301 i/t Operator’s Guide

Document Revision: 100102

images by clicking on one of the corner handles of the graphic, and

dragging it to increase or decrease its size.

• To change the attributes of a text element, simply double-click on it. To

change the text fill in the box, or to change the font, click on the Select

Font button displayed.

Note: To change FONT color, you must first select the font, type

size, and color, using the Select Font option

Using “Import Bitmap” Tool

The Import Bitmap tool allows you to import a graphic image from a file.

To use the Import Bitmap tool:

• Select Import Bitmap by clicking on that button

• Choose the graphics file you desire from any available BMP, JPG, TIF,

or any of the other various supported formats.

• Click Open to display your selection

• Click on Point to place it in position

• Click on the border (see image) and you may enlarge or shrink the

image

• Select Save, and you will save the file as an “LBL”(Label”) f ile. If you

wanted to name it Test, the file will be called Test.lbl

Congratulations, you have just designed your first CD!

Page 24

Page 26

AP-1301 i/t Operator’s Guide

Document Revision: 100102

The Job Tab

Once you have designed your CD, the Job Tab is your next stop. It is through this tab of

the AP-1301 application that all print jobs are submitted. A print job can be thought of

simply as a work order. This work order defines how many discs are to be produced, and

which artwork is to be used. New jobs are created here. In addition, you may recall and

use previously saved jobs. In this way, job files of frequently produced discs can be

created once, and then reused many times.

The Job Menu Bar

Looking at the AP-1301’s Job tab, you will see the top horizontal toolbar

containing: New, Open, Save, About, and Help (Please take note that

HELP was not implemented for this revision)

.

Page 25

Page 27

AP-1301 i/t Operator’s Guide

Document Revision: 100102

The Job Tab menu button functions are as follows:

Clicking on the new button will clear the screen and allow you to

create a new job.

Allows you to open an existing job file (*.job).

Allows you to save the job currently displayed for future use.

Displays the version information of the AP-1301 application

currently running.

Not currently implemented

Creating a print Job

In order to start printing, you must first create a print job. Fill in the fields as described

below:

JOB ID

• This field can contain up to 20 user-defined characters. While the

contents of this field are up to you, it is a mandatory field and cannot be

left blank. You may want to consider a date code, product number,

invoice number, or work order number. The number entered here will be

displayed while the job is running and may prove to be a useful

reference.

GENERAL OPTIONS

PRINT

• Print should always be left selected. If disabled,

the unit will not print. This checkbox is for

service use only.

ALIGN

• “Align” may be used with units that have the

MediaFORM USA’s SmartAlign optical disc

alignment option installed. This option allows

Page 26

Page 28

LABEL FILE

AP-1301 i/t Operator’s Guide

Document Revision: 100102

you to print relative to the artwork on a pre-silk screened disc. In other

words, you can have your CD-Rs silk screened with generic artwork,

and then customize them by printing in an area left for the title. The

SmartAlign feature will rotate the disc before printing, so that the

overprint is in the area left for the title or unique information.

The “Label File” field displays the desired label file to be used for printing.

Only “.LBL” and “.PRN” are used.

Note: PRN files are created when the printer properties port setting is set to

PRINT-TO-FILE. This allows other applications to create printable files.

These files must be created with the appropriate printer, either the

Primera or the MediaFORM Spectrum, set as the default printer. These

files are essentially captured printer dump files. PRN files, once created,

are not editable. It is also important to note that they contain all printer

settings. In the event of a problem when using a PRN file as the source,

check your printer’s settings in START-SETTINGS-PRITNERS, and then

regenerate the PRN file. These setting will be saved within the PRN file

and will over-ride any current printer settings.

To select the desired label file, the steps are as follows:

• Click on Browse Print Files. The following dialog box will be

displayed:

Page 27

Page 29

AP-1301 i/t Operator’s Guide

Document Revision: 100102

• By default, the LABELS folder will open. Click on and highlight the

desired file you are selecting.

• Click on the “open” button, and the highlighted label file will be

selected.

QUANTITY

• Enter the desired number of discs to print, of the selected label file.

COMMENTS

• This is an optional field. Any comments, such as job description, may

be entered here.

Open, save and submit job

Page 28

Page 30

AP-1301 i/t Operator’s Guide

Document Revision: 100102

The above three buttons will also be found on the Job Tab. “Open” and

“Save” have the same functionality as the buttons on the horizontal tool

bar, appearing at the top left of the Job Tab. The buttons function as

follows:

Open Job

• Performs the same task as Open does in the top horizontal toolbar.

• Allows you to open an existing job file.

Save As

• Saves the JOB file as it appears on your screen.

• Performs the same task as Save does in the top horizontal toolbar

Submit

• Starts the displayed JOB.

Page 29

Page 31

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Status Screen

The Status Tab allows you to monitor the progress of jobs. As you view the Status tab,

you will notice 3 panes. Each of these panes shows the different “states” of a job. The top

pane shows you which jobs are pending, the second pane shows which job is running,

and the third and bottom most pane shows which jobs have been completed or have

failed.

Job Queue

Within Job Queue, there are 3 fields and 2 buttons:

Job ID

• The Job ID is the name that was given to the job when it was created.

Note: It can be a good idea to give each job a unique ID. We recommend

using something such as work order number, an invoice number, or a

date code.

Page 30

Page 32

Total

• This field shows the total number of CDs that are requested, per job.

Requested

• This field displays the time the job was submitted to the CD-3703

Eclipse

Job Queue Screen

Here you see how a job appears when it is in the Job Queue pane:

Note: In this example, you see a job waiting to be processed. For the Job

In addition to the 3 features mentioned, you see the Start New Job and

Remove Job buttons.

Start New Job:

• Allows you to start a new job. Upon clicking here, you will be returned

to the Job Tab. Any jobs currently being processed will continue to run.

Remove Job

• This allows you to remove a job from the queue. This has no effect on

the job file itself. It simply deletes it is as a pending job. The job file

may be opened, or submitted at a later time.

AP-1301 i/t Operator’s Guide

Document Revision: 100102

ID, we named it, “This next job is yours”! To reiterate what was

mentioned earlier in the Job Screen; we recommend that you give

each job a set of unique identifying numbers, letters, or a

combination of both.

Page 31

Page 33

Running Jobs

Within the

JobID

• This is the JOBID of the active job.

Total

• Represents the desired number of discs to print.

Good

• Represents the number of discs successfully completed.

Bad

• Represents the number of discs that have failed to print correctly. If this

Started

• Represents the time your job was submitted.

Status

• The Status field shows you what is happening to your job as it is being

AP-1301 i/t Operator’s Guide

Document Revision: 100102

Running Jobs pane, there are 6 fields:

number is high, you may need to readjust the alignment of the printer on

the deck of the AP-1301.

processed. This will typically read printing, or loading.

Completed Jobs

Within Completed Jobs there are many of the same fields discussed earlier

in this section. The Completed field is the only new field. This field

displays the time at which the job was completed.

Page 32

Loading...

Loading...