Page 1

OPERATORS AND PARTS MANUAL NO. 05-01-TRAILER

TANDEM TRAILER

MODELS

XT2200

XT2200L

XT2200XL

07/05

MODELS

XT1600

XT1600L

DO NOT OPERATE EQUIPMENT UNTIL THIS MANUAL HAS BEEN READ AND UNDERSTOOD.

MANUFACTURED BY

County Hwy. A West

P.O. Box 405

Dorchester, Wisconsin 54425-0405

Phone 715-654-5132 • FAX 715-654-5513

1-800-325-9103

www.meyermfg.com

E-mail: sales@meyermfg.com

Page 2

Tandem Trailer Page 2

Page 3

TABLE OF CONTENTS

Table of Contents ....................................3

Introduction .......................................4

Warranty .........................................5

Safety ..........................................6

Safety Precautions....................................7

Transporting .......................................8

Use Safety Chain ..................................8

Attaching Trailer with brakes To Tow Vehicle ....................9

Farm implement tires.................................9

Safety precautions ................................9

Maintenance Instructions................................10

Lubrication -

Inspection ......................................10

Pack Wheel Bearings ................................11

Adjust Wheel Bearing Preload ...........................11

Farm Implement Tires ...............................11

Service & Maintenance Tips ..........................11

Meyer Equipment Wheel Torque ..........................12

Brake Maintenance .................................13

Bleeding Of Brakes ...............................13

Tire inflation.....................................13

Repair parts ......................................14

Models XT1600 & XT1600L Frame & O-Beam ...................14

Model XT2200, XT2200L & XT2200XL Frame ...................16

Model XT2200, XT2200L & XT2200XL Frame ...................17

Model XT2200, XT2200L & XT2000XL O-Beam ..................18

Model XT2200, XT2200L & XT2000XL Axle & Wheels...............19

Hub For Models XT1600 & XT1600L .......................20

Hub For Models XT2200, XT2200L & XT2000XL .................21

XT2200 Optional Brake Package ..........................22

Trailer And Box Mounting Specification Sheet ...................26

Specifications ....................................27

Figure 2. .......................................10

Tandem Trailer Page 3

Page 4

INTRODUCTION

Congratulations on your purchase of a new Meyer

farm equipment product. Undoubtedly you have given

much consideration to your purchase and we’re proud

that you have selected Meyer. Pride in craftsmanship,

engineering and customer service have made Meyer

products the finest in the farm equipment industry

today.

There is no substitute for quality. That is why

thousands of people like you have purchased Meyer

farm equipment. They felt it was the best equipment to

serve their farming needs, now and in years to come.

We ask that you follow our policy of “safety first,” and

we strongly suggest that you read through the owner’s

manual before operating your Meyer farm equipment.

Meyer Manufacturing Corporation wants to thank you

for not compromising quality. We are determined to

offer excellence in customer service as well as

provide you with the very best value for your dollar.

REMEMBER:

FARM EQUIPMENT BUYERS

TRUST THE NAME MEYER!

IMPORTANT:

Complete Meyer Mfg. Corp. invoice and promptly

forward a copy to Meyer Mfg. Corp. to validate the

manufacturer’s warranty. The product model and

serial number are recorded on this certificate and

below for proper identification of your Meyer Farm

Trailer.

Model No. ______________________________

Serial No. ______________________________

Date of Purchase________________________

At the back of this manual is the repair parts section.

All replacement parts are to be obtained from or

ordered through your Meyer dealership. When

ordering repair parts, refer to the parts section and

give complete information including quantity, correct

part number, detailed description and even Model No.

and Serial No. of the Meyer Farm Trailer which needs

repair parts.

Sincerely,

All Employees of

MEYER MANUFACTURING CORPORATION

Meyer Mfg. Corp. reserves the right to make

improvements in design, or changes in specifications

at any time, without incurring any obligation to owners

of units previously sold.

This supersedes all previous published instructions.

NOTE: All references to right hand (RH), left hand

(LH), front and rear apply to the product as viewed

from the rear of the trailer.

Tandem Trailer Page 4

Page 5

WARRANTY

Meyer Mfg. Corp. warrants new Meyer’s trailers to be free from defects in material and workmanship under

normal recommended use and service, as stated in the operator’s manual, as follows:

1.

Meyer Mfg. will repair or replace F.O.B. Dorchester, WI, as Meyer Mfg. elects, any part of a new Meyer’s

trailer which is defective in material or workmanship.

a. Without charge for either parts or labor during the first year following delivery to the original retail cus

tomer, and;

b. Without charge for parts (not labor) during the second year following delivery to the original retail cus

tomer.

2.

Warranty forms must be completed and returned to Meyer Mfg. Corp. for this warranty to be valid.

3.

This warranty is the sole and exclusive warranty which is applicable in connection with manufacture and

sale of this product and Meyer Mfg. Corp. responsibility is limited accordingly.

-

-

Tandem Trailer Page 5

Page 6

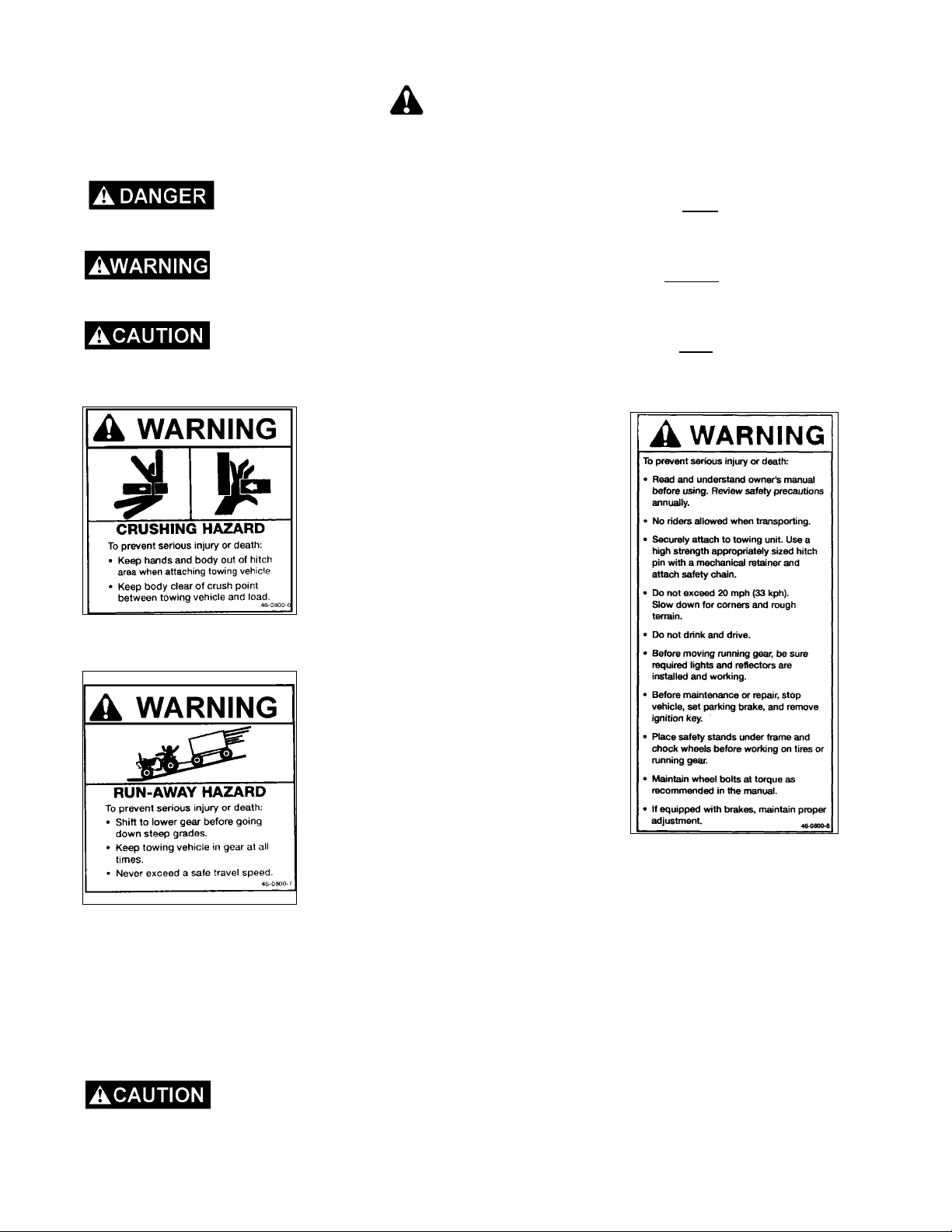

SAFETY

A brief definition of signal words that are used in this manual is as follows.

indicates an imminently hazardous situation which, if not avoided, WILL

serious injury.

indicates a potentially hazardous situation which, if not avoided, COULD

serious injury, and includes hazards that are exposed when guards are removed.

indicates a potentially hazardous situation which, if not avoided, MAY

moderate injury. It is also used to alert against unsafe practices.

Part No. 46-0800-6

result in death or

result in death or

result in minor or

Part No. 46-0800-8

Part No. 46-0800-7

NOTE: THESE DECALS ARE APPLIED TO MEYER’S

TRAILERS AND ARE INCLUDED IN THIS MANUAL FOR

REFERENCE.

READ ALL DECALS ON THE TRAILER AND IN THIS MANUAL. KEEP THESE

DECALS CLEAN AND REPLACE ANY LOST OR DAMAGED DECALS. BECOME FAMILIAR WITH ALL

TRACTOR CONTROLS.

Tandem Trailer Page 6

Page 7

SAFETY PRECAUTIONS

This symbol is used to call your attention to instructions concerning your personal safety. Be sure

to observe and follow these instructions. Take time to be careful!

BEFORE YOU ATTEMPT TO OPERATE THIS EQUIPMENT, READ AND STUDY THE

FOLLOWING SAFETY INFORMATION. IN ADDITION, MAKE SURE THAT EVERY INDIVIDUAL WHO

OPERATES OR WORKS WITH THE EQUIPMENT, WHETHER FAMILY MEMBER OR EMPLOYEE, IS

FAMILIAR WITH THESE SAFETY PRECAUTIONS.

Require anyone who will operate this machine to read and understand this manual. Give necessary instructions.

DO NOT operate, service, inspect or otherwise handle this equipment until you have read this Owner’s Manual

and have been properly trained in its intended usage.

Do not allow minors (children) or inexperienced persons to operate this machine.

Do not allow riders on this machine at any time.

Inspect when first delivered and regularly thereafter; that all connections and bolts are tight and secure before

operating.

Do not operate until all shields, covers and guards are in place.

Make certain area is clear of people, tools, and other objects before moving trailer.

Keep hands, feet and clothing away from moving parts. Loose or floppy clothing should not be worn by the

operator.

Do not step on the trailer at any time.

Keep away from power lines. Contact with electric lines may result in serious injury or death by electrocution!

Use only properly rated running gear and tires.

Do not tow at speeds in excess of 20 MPH when transporting.

You must observe all applicable traffic laws when transporting on public roadways (where legal to do so). Check

local laws for all highway lighting and marking requirements.

Always install a SMV emblem for transporting on roadways and keep this emblem clean and bright.

MEYER MFG. CORP. PROVIDES GUARDS FOR EXPOSED MOVING PARTS FOR THE OPERATOR’S

PROTECTION; HOWEVER, SOME AREAS CANNOT BE GUARDED OR SHIELDED IN ORDER TO ASSURE

PROPER OPERATION. THE OPERATOR’S MANUAL AND DECALS ON THE MACHINE ITSELF WARN

YOU OF DANGERS AND MUST BE READ AND OBSERVED CLOSELY!

Study the Above Safety Rules

FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY

Tandem Trailer Page 7

Page 8

TRANSPORTING

DO NOT OPERATE WHILE

UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS.

Be certain your forage box is properly mounted to the

trailer. Consult your dealer if you have any questions

about the tie down kit from the manufacturer.

INSPECT REGULARLY THAT

ALL CONNECTIONS AND BOLTS ARE TIGHT

AND SECURE BEFORE OPERATING. FAILURE

TO HEED MAY RESULT IN SERIOUS PERSONAL

INJURY OR DEATH.

DO NOT TOW AT SPEEDS

GREATER THAN 20 MPH. FAILURE TO HEED

MAY RESULT IN SERIOUS PERSONAL INJURY

OR DEATH.

Operating speed is dictated by the terrain over which

you are traveling. Always use caution. Avoid

traveling on slopes or hills that are unsafe.

Always disconnect the PTO drive shaft from the

tractor and return it to its storage bracket on the

unloading unit for transporting. Failure to do this may

result in equipment damage.

ALWAYS USE A SAFETY

HITCH PIN WITH A LOCKING DEVICE.

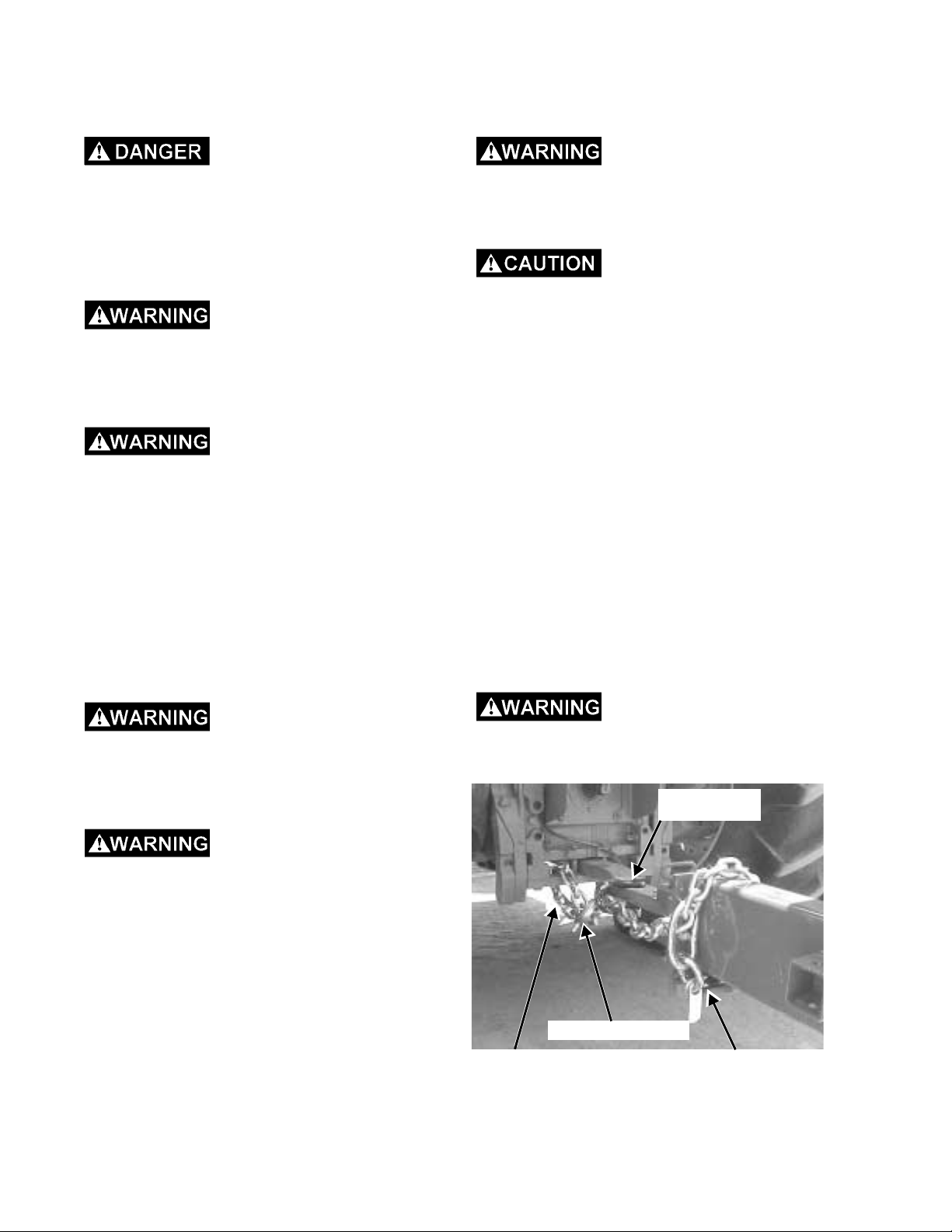

USE SAFETY CHAIN

A SAFETY CHAIN MUST BE

INSTALLED TO RETAIN THE CONNECTION

BETWEEN TRACTOR (OR OTHER TOWING

VEHICLE) AND SPREADER WHENEVER

TRAVELING ON PUBLIC ROADS IN CASE THE

HITCH CONNECTION WOULD SEPARATE. A

SUGGESTED ATTACHMENT IS ILLUSTRATED

ON FIGURE 1.

The chain must be strong enough to hold the weight of

the loaded trailer. If using a grab hook at the end(s) of

the chain to secure the chain to itself, a hook latch

must be installed.

The length of the safety chain is not to be any longer

than necessary to turn without interference. If any

chain links or attachment hardware are broken or

stretched, repair before using. Store chain so it does

not corrode or become damaged. Do not use this

chain for other implements because the strength and

length of chain may not be adequate. Identify this

chain for use on this particular trailer.

OBSERVE ALL APPLICABLE

TRAFFIC LAWS WHEN TRANSPORTING ON

PUBLIC ROADWAYS. CHECK LOCAL LAWS

FOR ALL HIGHWAY LIGHTING AND MARKING

REQUIREMENTS.

INSTALL A SMV EMBLEM ON

REAR OF FORAGE BOX FOR TRANSPORTING

ON ROADWAYS AND KEEP THIS EMBLEM

CLEAN AND BRIGHT. FAILURE TO HEED MAY

RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

If you will travel on public roads and it is legal to do so,

you must know all rules governing such operation.

This will include lighting and brake requirements in

addition to traffic rules. You may also be required to

install a safety chain device on the running gear.

Check for traffic constantly. Be sure that no one is

attempting to pass and that all traffic is sufficiently

clear before making any turns.

ALWAYS TRAVEL UPHILL OR

DOWNHILL ON INCLINES AND SLOPES TO

PREVENT ROLLOVER

INTERMEDIATE

SUPPORT

HOOK W/HOOK LATCH

TOWING MACHINE

ATTACHING POINT

ROUTE CHAIN THRU

LOOP UNDER TONGUE

(Use hook latch)

Figure 1. Safety Chain Installation

Tandem Trailer Page 8

Page 9

BE SURE YOU HAVE

ADEQUATE CLEARANCE FOR YOUR LOADED

TRAILER TO AVOID CONTACT WHEN

TRAVELING UNDER ELECTRICAL POWER

LINES. CONTACT CAN RESULT IN SEVERE

ELECTRICAL SHOCK OR ELECTROCUTION.

ATTACHING TRAILER WITH

BRAKES TO TOW VEHICLE

PLEASE NOTE THAT THE

SURGE BRAKES ARE TO BE USED FOR

ASSISTING IN STOPPING ONLY AND ARE NOT

TO BE RELIED ON AS THE ONLY MEANS FOR

STOPPING THE TOWED PIECE OF EQUIPMENT.

USE CAUTION AS SERIOUS INJURY OR DEATH

COULD RESULT.

Attach the towing vehicle to the trailer using a proper

sized hitch pin to handle the load being towed. Check

that safety pins are inserted properly to prevent

accidental uncoupling. Do not pull trailer if the hitch

plates are damaged. Use a safety chain as instructed

on page 8. Connect the breakaway chain from the

actuator to the tow vehicle fastening to the bumper or

hitch assembly. Allow extra slack for turning corners

but not too much slack for the chain to be dragging on

the pavement. Maintain as straight a connection to

the tow vehicle as possible. The safety breakaway

chain will only function after the hitch pin and safety

chains have failed.

DO inspect the tube and tire for cord or side

•

damage, cuts or wear. Unrepairable damaged

items must be discarded.

DO check for mismatched components or tire and

•

wheel sizes.

DO lubricate tire with a non-flammable tire

•

lubricant approved for that purpose.

DO place tire and wheel in inflation cage or

•

restraining device before inflating beyond 5 PSI.

DO use an extension hose with a PSI gauge and

•

clip on chuck when inflating the tire so you can

stand to one side.

Don’ts

DON’T work on a tire/wheel assembly before

•

removing the valve core and completely deflating.

DON’T re-inflate a tire that has been run flat or in

•

an under inflated condition before removing and

inspection.

DON’T reuse damaged, defective worn or

•

mismatched parts.

DON’T rework, weld, heat or braze any rim /wheel

•

parts for any reason.

DON’T inflate any tire beyond 40 PSI to seat the

•

beads. If beads are not seated at 40 PSI. STOP!

Deflate and determine problem.

DON’T hammer, strike or pry on a rim/wheel

•

assembly that contains any inflation pressure.

•

DON’T inflate a tire without using an inflation

cage or restraining device.

•

DON’T inflate beyond the maximum PSI specified

for the tire or rim.

NOTE: The safety breakaway chain is not to act as a

parking brake. Trailers with free backing brakes will

not hold in reverse direction. To release the

breakaway lever pry up on the spring clip to release

lever

FARM IMPLEMENT TIRES

SAFETY PRECAUTIONS

Do’s

•

DO remove the valve core and deflate the tire

before any work is performed.

•

DO use the proper and approved tools to

demount and mount the tire.

•

DO inspect all rim/wheel parts for wear, damage,

cracks, rust or mismatched components.

Destroy damaged or unserviceable parts.

Study the Above Safety Rules

FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

Tandem Trailer Page 9

Page 10

MAINTENANCE INSTRUCTIONS

BEFORE SERVICING OR INSPECTING THIS TRAILER, HAVE IT HITCHED TO A

TRACTOR WITH ENGINE OFF, KEYS REMOVED AND PARKING BRAKE SET OR CHOCK ALL FOUR

WHEELS OF TRAILER.

FAILURE TO COMPLY WITH OPERATING AND MAINTENANCE INSTRUCTIONS

MAY CAUSE SERIOUS PERSONAL INJURY.

L1

Both Sides

L2

Both Sides

L1

Both Sides

L2

L1

Both Sides

XT2200, XT2200L & XT2200XL

XT1600 &XT1600L TRAILERS

TOP VIEW

TRAILERS

SIDE VIEW

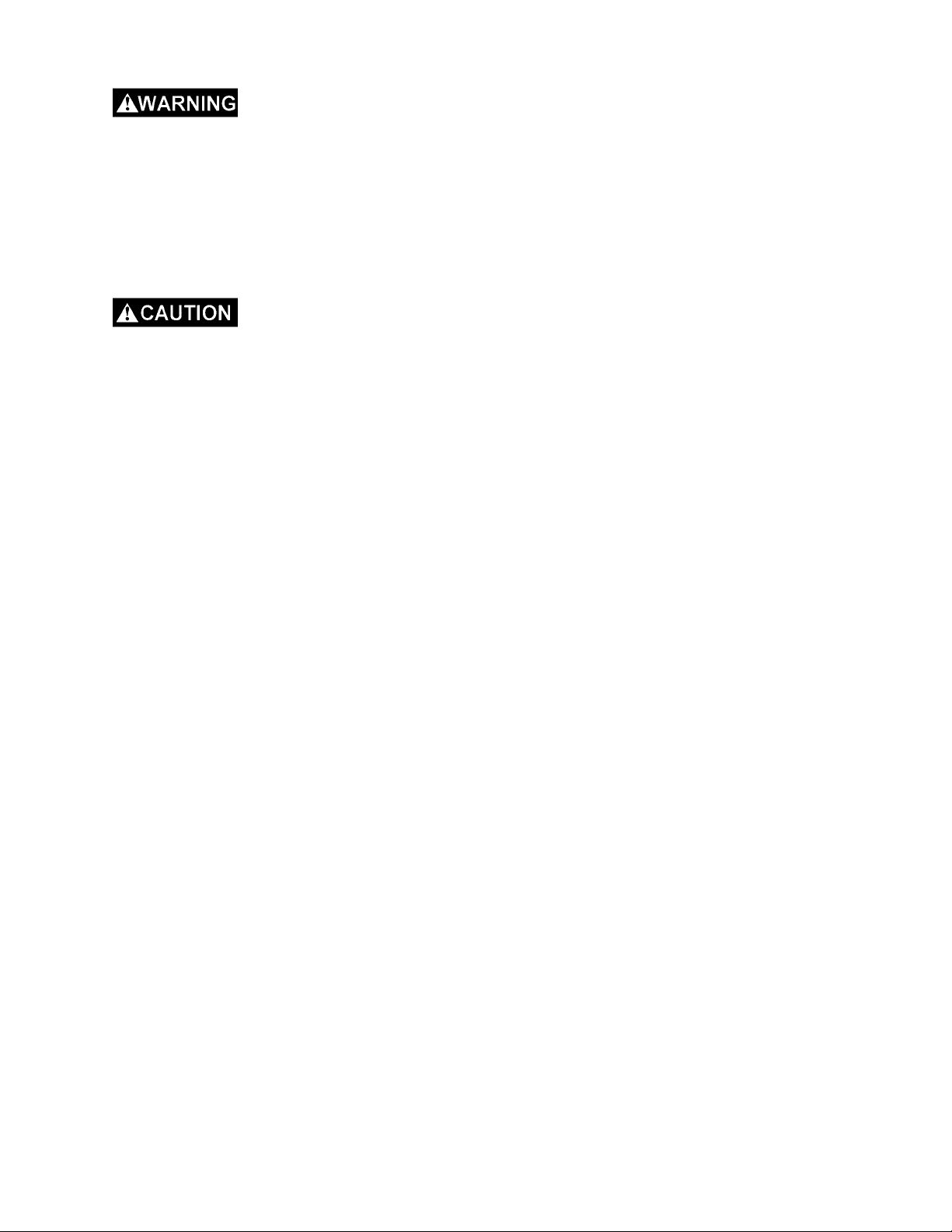

Figure 2. Lubrication Diagram

LUBRICATION - FIGURE 2.

FREQUENCY ITEM LOCATION PROCEDURE

Every 2 Work

Days Or 20

Loads

Annually Wheel Bearings L1 Clean and pack hub bearings. Use quality grade

Tandem Wings L2 Jack up empty trailer off ground and support

on adequate jack stands to relieve pressure

and grease until it purges.

of wheel bearing grease. See page 11.

INSPECTION

FREQUENCY ITEM PROCEDURE

Daily Wheel Hub Lug Bolts Check for proper torque as listed on page 12.

Wheel Hub Bearings Check bearing play and adjust bearing preload if required.

Tire Inflation Check inflation as listed on page 13.

Every 30 Days All Fasteners And

Connections

Annually Tires Check tires for wear and replace when necessary.

All Pivots And Bushings Check for wear and repair as required.

Check complete trailer for loose and fatigued fasteners. Check

all pivots for play. Tighten or replace as required.

Tandem Trailer Page 10

Page 11

DO NOT TOW AT SPEEDS IN

EXCESS OF 20 MPH.

PACK WHEEL BEARINGS

1.

Chock all four wheels or hitch to tractor with en

gine off, key removed and parking brake set.

Jack empty trailer off ground and support with ad

equate jack stands.

2.

Disassemble hub and remove all old grease.

Clean bearings in non flammable solvent and

dry.

3.

Reassemble hub and pack with quality wheel

bearing grease.

4.

Adjust wheel bearing preload as described in the

following instructions

ADJUST WHEEL BEARING

PRELOAD

1.

Chock all four wheels or hitch to tractor with engine off, key removed and parking brake set.

Jack empty trailer off ground and support with adequate jack stands.

2.

Push back and forth on each wheel assembly. If

play is detected, bearings need adjusting.

3.

If adjusting bearings, it is suggested the bearings

be repacked as described previously.

4.

Remove hub cap and remove cotter pin from

spindle nut.

5.

Tighten spindle nut to remove all play. It should

be snug and slight drag can be felt while rotating

the wheel

6.

If the cotter pin hole in the spindle does not line

up with the notch in spindle nut, back off the spin

dle nut only enough to line up. Reinstall cotter

pin. If cotter pin is damaged, replace it.

7.

Replace hub cap and lower wheel to the ground.

altered for any reason, tire performance will be

reduced.

CHECKING INFLATION

Inflation pressures should be checked at least every

week. Recommended inflation Pressures based on

total load on tires should be used. For accurate

inflation use a special low-pressure gauge with

one-pound gradations. Gauges should be checked

occasionally for accuracy. Always use sealing valve

caps to prevent loss of air.

TIRE OVERLOAD OR UNDER INFLATION

Tire overload or under inflation have the same effect

of over-deflecting the tire. Under such conditions the

tread on the tire will wear rapidly and unevenly,

particularly in the shoulder area. Radial cracking in the

upper sidewall area will be a problem. With under

inflated drive tires in high torque applications sidewall

buckles will develop leading to carcass breaks in the

sidewall. While an under inflated drive tire may pull

better in some soil conditions, this is not generally true

and not worth the high risk of tire damage that such an

operation invites.

OVER INFLATION

Over inflation results in an under-deflected tire

carcass. The tread is more rounded, concentrates

tread wear at the centerline area. Traction is reduced

in high torque service because ground contact of the

tread shoulder area is reduced and the harder

carcass—with reduced flexing characteristics—does

not work as efficiently. The tightly stretched

over-inflated carcass is more subject to weather

checking and impact break damage.

PRESSURE ADJUSTMENTS REQUIRED-SLOW

SPEED OPERATION

Higher tire loads are approved for intermittent service

-

operations at reduced speed. Under such conditions

inflation pressure must be increased to reduce tire

deflection and assure full tire service life. See Page

13 for proper inflation.

FARM IMPLEMENT TIRES

SERVICE & MAINTENANCE TIPS

Agricultural tires are designed to carry a specified load

at a specified inflation pressure when mounted on a

specified width rim. When these conditions are met,

the deflection of the tire carcass is in the optimum

range and maximum tire performance can be

expected. If this combination of design factors is

Tandem Trailer Page 11

USE OF PROPER WIDTH RIMS

Mention has been made of the importance of

mounting tires on rims of the specified width. When

this recommendation is not followed the following

conditions can result:

USE OF A RIM WIDER THAN RECOMMENDED

Use of a wider rim results in flattening of the tread

face. This feature may improve traction in some looser

soil conditions. In hard soils, however, the flatter tread

penetrates less effectively and tractive effort is

reduced. Additional stresses concentrated in the

shoulder area tend to increase the rate of shoulder

Page 12

tread wear. By spacing the tire beads farther apart the

sidewalls are forced to flex in an area lower than

normal and this can result in circumferential carcass

breaks and/or separation.

USE OF A RIM NARROWER THAN

RECOMMENDED

This condition brings potential mounting problems

because the rim shield or flange cover molded into

most drive tire designs tends to interfere with the

seating of the tire beads on a narrow rim. Once

mounted on a narrow rim, the tire shield applies undue

pressure on the rim flange, with possible tire sidewall

separation or premature rim failure at the heel radius.

On a narrow rim the tread of the tire is rounded. As

with the over-inflated tire tread wear will be

concentrated in the center area of the tread and

traction in the field will be reduced.

ROADING OF FARM TIRES

Tractor tires operate most of the time in field

conditions where the lugs can penetrate the soil, and

where all portions of the tread make contact with the

ground. In operating on hard roads with low inflation

pressure there is an undesirable distortion of the tire

during which the tread bars squirm excessively while

going under and coming out from under the load. On

highly abrasive or hard surfaces, this action wipes off

the rubber of the tread bars or lugs and wears them

down prematurely and irregularly.

material and cord fabric. There may be no visible

evidence of damage at the time. Later a premature

failure occurs which experience shows was started by

the overheated condition that developed when the

unit was towed at a high speed.

CARE AND STORAGE OF TRACTOR AND

IMPLEMENT TIRES

All tires should be stored indoors in a cool, dark, dry

area free from drafts. Both heat and light are sources

of oxidation on the tire surfaces—a result of which is

crazing and weather checking. Tires should never be

stored on oily floors or otherwise in contact with

solvents, oil or grease. Further, tires should not be

stored in the same area with volatile solvents. Such

solvents are readily absorbed by rubber and will

damage and weaken it.

Tires should be stored away from electric motors,

generators, arc welders, etc.. since these are active

sources of ozone. Ozone attacks rubber—to cause

crazing and weather checking.

Unmounted tires should be stored vertically on tread.

If stored for an extended period, tires should be

rotated periodically to reduce stress concentrations in

the area of ground contact. Tires should not be stored

flat and “stove piped” as they will become squashed

and distorted, making mounting on the rim

difficult—particularly for tubeless tires.

If tires are to operate for any length of time on roads or

other hard surfaces and the draft load is not great, it is

advisable to increase the pressure in the tire to the

maximum recommendation in order to reduce the

movement of the tread bars that causes excessive

wiping action.

Farm tractor and implement tires are designed for

low-speed operations not exceeding 25 miles per

hour. If tractors or implements are towed at high

speeds on the highway high temperatures may

develop under the tread bars and weaken the rubber

MEYER EQUIPMENT WHEEL TORQUE

BOLT/STUD

SIZE

½ ¾ 80 ft lbs Lug Bolt 85 ft lbs

9/16 7/8 80 ft lbs Lug Bolt 120 ft lbs

5/8 15/16/1-1/16 100 ft lbs Bevel or Flange

¾ 1-1/8 / 1-1/2 Flange Nut 378 ft lbs

SOCKET

SIZE

PRESS FORMED

WHEEL CENTER

Inflated tires mounted on rims should be stored under

conditions noted above, with inflation pressure

reduced to 10 PSI.

BOLT

TYPE

Nut

HEAVY DUTY

WHEEL CENTER

160 ft lbs

Tandem Trailer Page 12

Page 13

TIRE INFLATION

TIRE SIZE PLY PSI

11L-15 8 36

12.5L-15 8 36

12.5L-15 12 52

14L-16 12 44

16.5L-16 10 36

19LX16.1 10 32

21.5L-16.1 18 44

11R/22.5 used truck 75

425/65X22.5 used truck 75

28L-26 16 28

ANY CORROSIVE

MATERIALS (SALTWATER, FERTILIZERS) ARE

DESTRUCTIVE TO METALS. TO PROPERLY

MAINTAIN THE LIFE OF THE BRAKE SYSTEM

FLUSHING WITH A HIGH-PRESSURE WATER

HOSE IS RECOMMENDED. AFTER WASHING BE

SURE TO GREASE ACTUATOR BEARINGS

(SLIDES) AND OIL ALL MOVING PARTS. AT THE

END OF THE SEASON IT IS RECOMMENDED

THAT THE BRAKE DRUMS BE REMOVED AND

CLEANED INSIDE. REPACK WHEEL BEARINGS

BEING CAREFUL NOT TO CONTAMINATE THE

BRAKE SYSTEM WITH GREASE. THIS WOULD

BE A GOOD TIME TO READJUST THE BRAKES

PER PREVIOUS INSTRUCTIONS.

BLEEDING OF BRAKES

Before bleeding brakes fill the system with DOT 3

hydraulic brake fluid. Using a vacuum type brake

bleeder (this type of brake bleeder is available at your

local automotive store) follow manufacturers

directions for bleeding.

Install bleeder hose on first wheel cylinder to be bled,

if tandem bleed rear axles first. Have loose end of

hose submerged in a glass container of brake fluid to

observe bubbling. By working the manual hand pump

you will draw the air out of the brake lines filling it with

fluid.

BRAKE MAINTENANCE

Before towing, check that the brake fluid reservoir is

maintained to at least half full. If not refill with DOT 3

brake fluid. Check complete system for any leaks and

repair as needed. Examine actuator for bent parts or

excessive wear. Straighten or replace any worn parts

as needed. Check to see that all mounting bolts and

fasteners are tight.

Excessive actuator travel (over one inch) is a sign that

the brakes need to be adjusted. Jack wheel/tire off of

the ground and rotate tire in the forward direction.

Remove access hole cover plate on the lower back

side of the backing plate and adjust the brakes until

drag is felt on the wheel when spinning in the forward

direction. Back off adjuster twenty clicks (notches) for

two-wheel brake systems and fifteen clicks (notches)

for four wheel brake systems. Adjust all wheels being

sure to rotate in the forward direction only when

adjusting to ensure proper adjustment.

By loosening the bleeder screw located in the wheel

cylinder one turn the system is open to the

atmosphere through the passage drilled in the screw.

When the bubbling stops in the glass container close

the bleeder screw securely. Follow the same

procedure at each wheel cylinder being sure to

maintain the master cylinder fluid level at least one

half full of brake fluid. After all wheels are bled fill the

master cylinder to 3/8” below the full level.

Before using any equipment equipped with brakes the

operation of the brakes should be checked. During

travel attention should be paid to how the brakes are

functioning and any necessary adjustments should be

made. It will be necessary to check the brake lines

and brake linings for wear. Brake linings should be

replaced before the rivets or support plates come in

contact with the wheel drum. Make all necessary

maintenance before using equipment.

Tandem Trailer Page 13

Page 14

REPAIR PARTS

MODELS XT1600 & XT1600L FRAME & O-BEAM

Tandem Trailer Page 14

Page 15

MODELS XT1600 & XT1600L FRAME & O-BEAM

KEY PART NO. DESCRIPTION QTY.

1 75-1600 Trailer Frame Assembly-XT1600 1

75-1600-L Trailer Frame Assembly-XT1600L 1

2 75-0074 Bolt On Hitch 1

75-2005 Optional Swivel Hitch 1

3 956-3803 Jack 1

4 75-1601 Right O-Beam Assembly Less Hubs 1

75-1603 Right O-Beam Assembly W/Hubs 1

5 75-1602 Left O-Beam Assembly Less Hubs 1

75-1604 Left O-Beam Assembly W/Hubs 1

6 851-6311-2Z 5/8-11x2" Machine Bolt Grade 5 (Standard Hitch Only) 6

881-6314-2Z 5/8-14x2" Machine Bolt Grade 8 (Swivel Hitch Only) 6

7 881-5013-5Z 1/2-13x5" Machine Bolt Grade 8 (Prior to Serial #0816206) 2

881-6311-5.5Z 5/8-11x5-1/2" Machine Bolt Grade 8 (Serial #0816206 & Later) 2

8 30-0007 1/8" NPTx45 Degree Zerk 2

9 815-5013-Z 1/2-13 Nylon Insert Locknut (Prior to Serial #0816206) 2

815-6311-Z 5/8-11 Nylon Insert Locknut (Serial #0816206 & Later) 2

10 75-0107 3x18-1/2" Straight Spindle 4

11 75-3005-1 Pivot Shaft Weldment 2

12 75-0207 Hub (See Page 20) 4

13 75-0255 15x10" Wheel AR

75-0253-HD 16.1x11" Wheel AR

75-0262-HD 16.1x14" Wheel AR

75-0268-HD 22.5x8.25" Wheel AR

75-0260 22.5x13.5" Wheel AR

14 815-6311-Z 5/8-11 Nylon Insert Locknut 6

884-6318 5/8-18 Top Locknut Grade 8 6

Tandem Trailer Page 15

Page 16

MODEL XT2200, XT2200L & XT2200XL FRAME

PRIOR TO SERIAL #0822201

See Page 18 for O-Beam.

KEY PART NO. DESCRIPTION QTY.

1 75-2000 Trailer Frame Assembly - XT2200 1

75-2000-L Trailer Frame Assembly - XT2200L 1

75-2000-XL Trailer Frame Assembly - XT2200XL 1

2 75-2020 Plate, Brake Actuator Mount, Opt 1

3 956-3803 Jack 1

4 75-0074 Hitch Plate Assembly 1

5 851-6311-2Z 5/8-11 x 2” Machine Bolt Grade 5 6

6 815-6311-Z 5/8-11 Nylon Insert Locknut 6

Tandem Trailer Page 16

Page 17

MODEL XT2200, XT2200L & XT2200XL FRAME

SERIAL #0822201 AND LATER

PRIOR TO

SN# 0822225

KEY PART NO. DESCRIPTION QTY.

1 75-2200 Trailer Frame Assembly-XT2200 1

75-2200-L Trailer Frame Assembly-XT2200L 1

75-2200-XL Trailer Frame Assembly-XT2200XL 1

2 75-2020 Plate, Brake Actuator Mount (Optional) 1

3 956-3803 Jack 1

4 75-0074 Hitch Plate Assy, (Prior to Serial #0822225) 1

75-0076 Hitch Plate Assy. (Serial #0822225 & Later) 1

5 851-6311-2Z 5/8-11x2" Machine Bolt Grade 5 (Prior to Serial #0822225) 6

881-1014-2.5Z 1x2-1/2" Machine Bolt Grade 8 (Serial #0822225 & Later) 4

6 815-6311-Z 5/8-11 Nylon Insert Locknut (Prior to Serial #0822225) 6

884-1014-Z 1-14 Top Locknut (Serial #0822225 & Later) 4

7 75-2005 Optional Swivel Hitch (Prior to Serial #0822225) 1

901-3757 Swivel Hitch Assy. (Serial #0822225 & Later) 1

Tandem Trailer Page 17

Page 18

MODEL XT2200, XT2200L & XT2000XL O-BEAM

PRIOR TO SERIAL #0822201

KEY PART NO. DESCRIPTION QTY

1 75-0111 3-1/2" Spindle Assembly 4

2 75-2000-20 XT2200 O-Beam Center Pivot Shaft Welded Assembly 2

3 901-3867-2 Tandem Locking Collar 2

4 901-3864-2 Pivot Shaft Nylon Bushing 2

5 30-0006 Zerk 1/8" NPT x 90 Degrees 2

6 30-0006 Zerk 1/8" NPT x 90 Degrees 2

7 30-0009 1/8" NPT Coupler 2

8 30-0008 1/8" NPT Nipple 2

9 933-3626 Copper Tube Grease Line 31" (Includes zerks, fittings) 2

10 30-0002 1/8" NPT Straight Zerk 2

11 75-2010 Right O-Beam w/o Hubs 1

75-2010-B Brake Right O-Beam w/o Hubs 1

75-2012 Right O-Beam Complete w/Hubs 1

75-2012-B Brake Right O-Beam Complete w/Hubs 1

12 75-2013 Left O-Beam Complete w/Hubs 1

75-0213-B Brake Left O-Beam Complete w/Hubs 1

75-2011 Left O-Beam w/o Hubs 1

75-0211-B Brake Left O-Beam w/o Hubs 1

13 881-5013-6.5 HHCS, ½-13 x 6-1/2" Gr. 8 2

14 814-5013-Z ½-13 Center Locknut 2

15 75-0211 Hub (See Page 21) 4

16 75-0270 Wheel Rim SW18C x 16.1 x 10 Hole For 21.5 x 16.1 Tire 4

75-0269 Wheel Rim 12.25 x 22.5 x 10 Hole For Used 425/65/R22.5 Tire 4

Tandem Trailer Page 18

Page 19

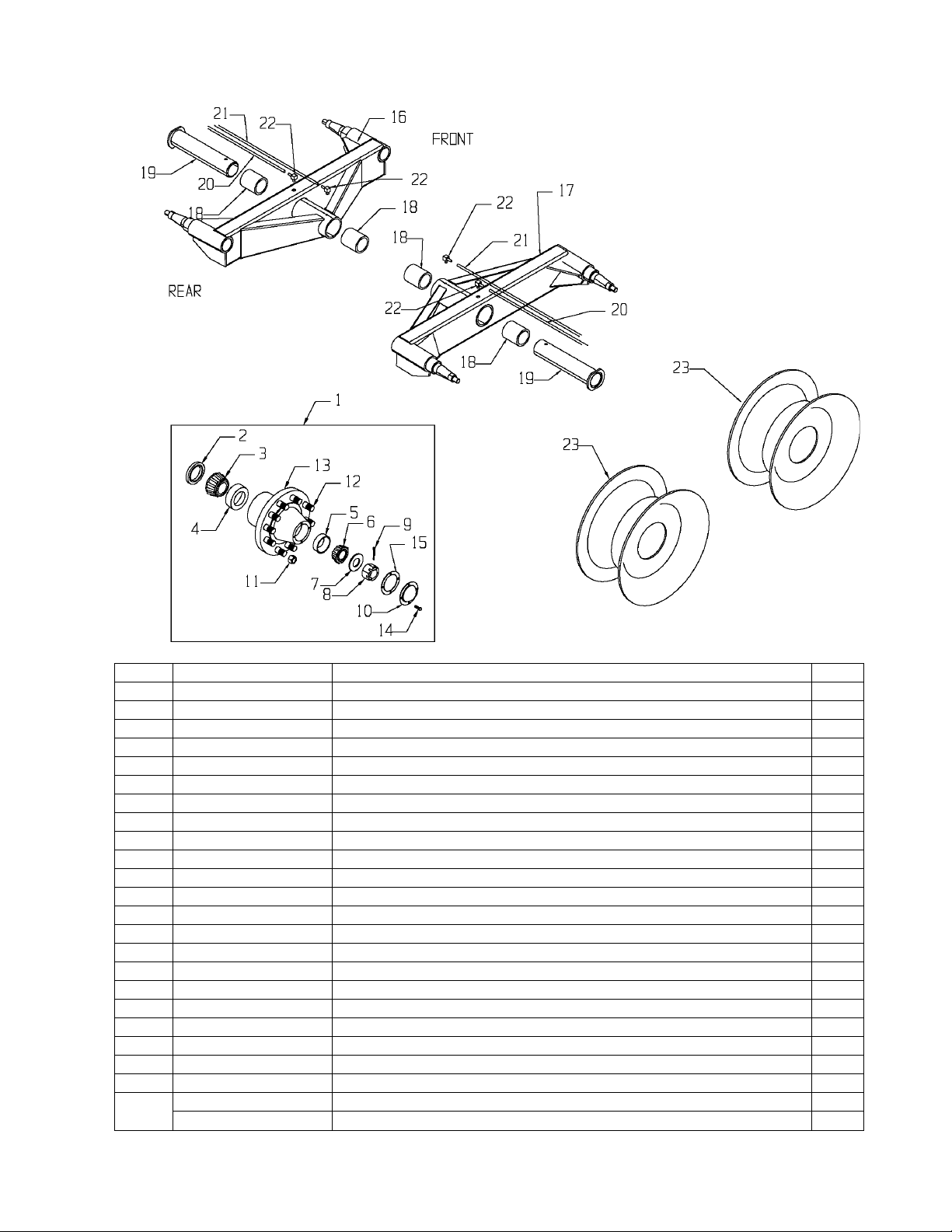

MODEL XT2200, XT2200L & XT2000XL AXLE & WHEELS

(SHORT OFFSET)

(LONG OFFSET)

SERIAL #0822201 AND LATER

KEY PART NO. DESCRIPTION QTY

1 75-0211 Hub Assembly Complete 15,000# 4

2 75-0211-2 Seal 1

3 75-0211-3 Bearing Cone 1

4 75-0211-4 Bearing Cup 1

5 75-0208-5 Bearing Cup 1

6 75-0208-6 Bearing Cone 1

7 75-0208-7 Washer 1

8 75-0208-8 Nut 1

9 75-0208-9 Cotter Pin 1

10 75-0208-10 Hub Cap 1

11 75-0208-11 Lug Nut - Flanged 10

12 75-0208-12 Stud Bolt 10

13 75-0211-1 Hub Only w/Races & Studs 1

14 75-0208-13 Hub Cap Bolt 4

15 75-0208-14 Hub Cap Gasket 1

16 901-8720-11-1 LH Tandem Wing Assembly, Less Hubs 1

17 901-8720-10-1 RH Tandem Wing Assembly, Less Hubs 1

18 901-8720-10-1-4 Nylon Pivot Sleeve 4

19 901-8720-15 O-Beam Pivot Assembly 2

20 955-3761 3/16x10" Grease Hose 2

21 955-3762 3/16X16" Grease Hose 2

22 30-0020 1/8" NPT Street L 4

23 75-0273 22.5x13 Wheel 0" Offset 425 Used Truck Tire 4

75-0270 18X16.1 Wheel 21.5L Implement Tire 4

Tandem Trailer Page 19

Page 20

HUB FOR MODELS XT1600 & XT1600L

KEY PART NO. DESCRIPTION QTY

0 75-0207 Hub , Complete Assembly 4

1 75-0207-1 Hub w/Races 1

2 75-0207-2 Grease Seal 1

3 75-0207-3 Inner Wheel Bearing 1

4 75-0207-4 Inner Wheel Race 1

5 75-0202-4 Outer Wheel Race 1

6 75-0202-3 Outer Wheel Bearing 1

7 75-0205-7 Washer 1

8 75-0205-8 Nut 1

9 75-0205-9 Cotter Pin 1

10 75-0205-10 Cap 1

11 75-0205-11 Lug Nut 8

12 75-0207-12 Stud Bolt 8

Tandem Trailer Page 20

Page 21

HUB FOR MODELS XT2200, XT2200L & XT2000XL

KEY PART NO. DESCRIPTION QTY

1 75-0211 Hub Assembly Complete 15,000# 4

2 75-0211-2 Seal 1

3 75-0211-3 Bearing Cone 1

4 75-0211-4 Bearing Cup 1

5 75-0208-5 Bearing Cup 1

6 75-0208-6 Bearing Cone 1

7 75-0208-7 Washer 1

8 75-0208-8 Nut 1

9 75-0208-9 Cotter Pin 1

10 75-0208-10 Hub Cap 1

11 75-0208-11 Lug Nut - Flanged 1

12 75-0208-12 Stud Bolt 1

13 75-0211-1 Hub Only w/Races & Studs 1

14 75-0208-13 Hub Cap Bolt 1

15 75-0208-14 Hub Cap Gasket 1

Tandem Trailer Page 21

Page 22

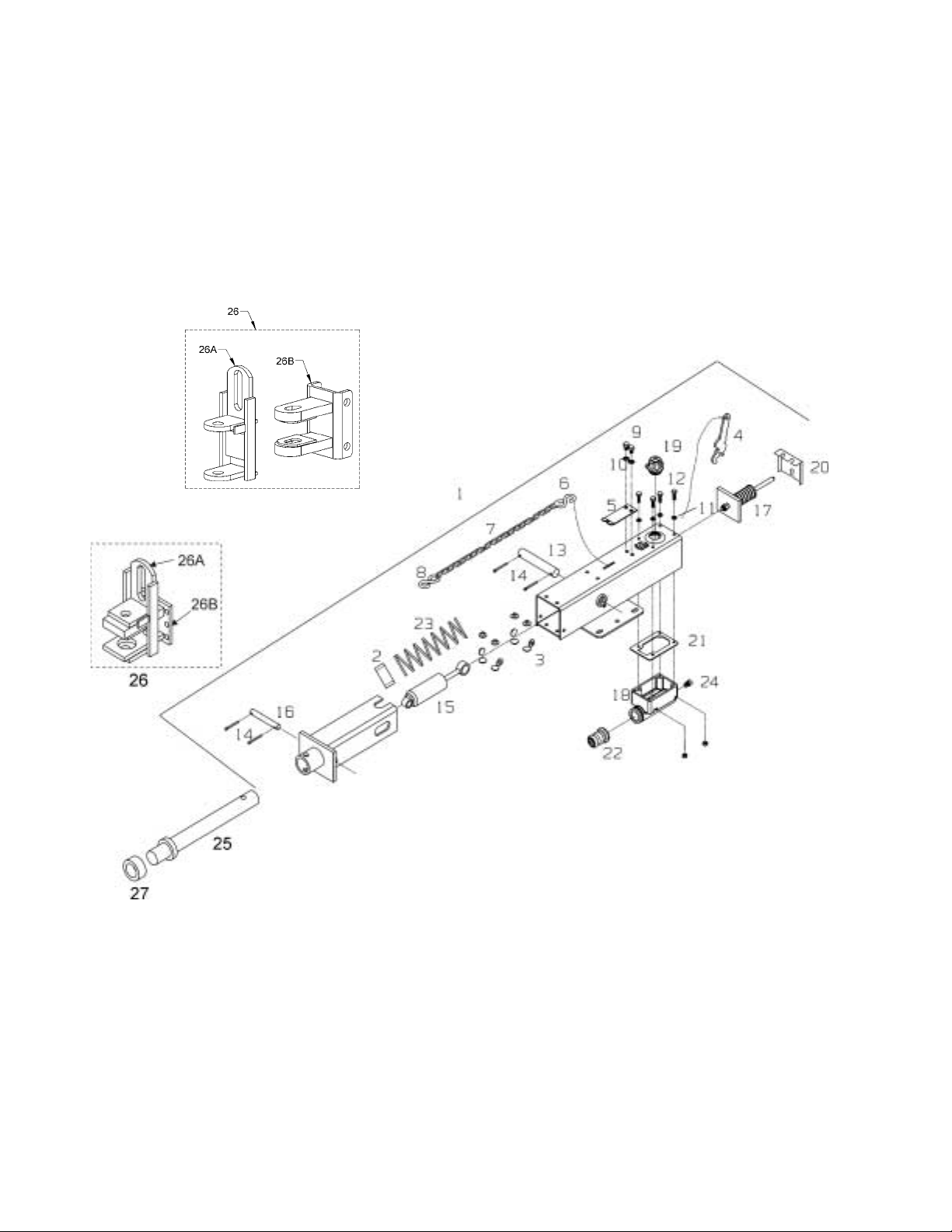

Serial # 0822225 & Later

Prior to Serial # 0822225

XT2200 OPTIONAL BRAKE PACKAGE

(1 OF 2)

Tandem Trailer Page 22

Page 23

XT2200 SERIES OPTIONAL BRAKE PACKAGE (1 OF 2)

KEY PART # DESCRIPTION QTY.

1 57-0032 XT2200 Trailer Optional Brake Actuator 1

2 57-0029-1 Spring Spacer 1

3 57-0029-2 Nylon Slide Bearing Button 12

4 *57-0029-3 Safety Break-Away Lever 1

5 *57-0029-4 Safety Break-Away Lock 1

6 57-0009-2 S-Hook (Heavy Stationary) 1

7 57-0030 Safety Break-Away Chain 96" 1

8 33-0032-1 S-Hook (Break-Away) 1

9 57-0029-5 5/16-18 x 5/8" Machine Bolt Grade 5 2

10 57-0029-6 5/16" External Tooth Lock-Washer 2

11 822-0025-Z ¼" Split Lock-Washer 4

12 851-2520-.75Z ¼-20 x ¾" Machine Bolt Grade 5 4

13 57-0029-7 Damper Pin 7/8 x 4-15/16" 1

14 57-0029-8 5/32 x 1-1/4" Cotter Pin 4

15 57-0029-9 Damper Shock 1

16 57-0029-10 Damper Pin 5/8 x 3-3/4" 1

17 57-0029-11 Push Rod Assembly 1

18 57-0029-12 Master Cylinder Assembly 1

19 57-0029-13 Actuator Filler Cap W/Diaphragm & O-Ring 1

20 57-0029-14 Actuator Rear Cover 1

21 57-0029-15 Master Cylinder Gasket 1

22 57-0029-16 Master Cylinder Protective Boot 1

23 29-0009 Spring 1

24 57-0029-17 Inverted Flare Fitting - Full Flow 1

25 75-2021 XT2200 Actuator Push Shaft Assembly (Prior to Serial # 0822225) 1

75-2021-L XT2200 Actuator Push Shaft Assembly (Serial # 0822225 & Later) 1

26 75-2022 XT2200 Brake Hitch Plate Weldment (Prior to Serial # 0822225) 1

75-0077 XT2200 Brake Hitch Plate Weldment (Serial # 0822225 & Later) 1

26A 75-2022-9 Outer Brake Hitch Plate (Prior to Serial #0822225) 1

75-0077-2 Outer Brake Hitch Plate (Serial #0822225 & Later) 1

26B 75-2022-8 Brake Hitch Plate (Prior to Serial #0822225) 1

75-0077-1 Brake Hitch Plate (Serial #0822225 & Later) 1

27 921-0005 1-1/2" Set Collar 1

THE FOLLOWING PARTS ARE NOT ILLUSTRATED

57-0029-18 1-1/4" Master Cylinder Repair Kit (Not Shown) 1

57-0029-19 Lever Replacement Kit (Includes Items W/*) 1

32-0024 9/32" Brake line Loom Clamp AR

57-0010 18"Hydraulic Brake Hose AR

57-0013 Frame Tee W/Clip AR

57-0014-2 Brake Line Union AR

57-0020 90" Brake Line AR

65-0006-5 Nylon Tie Straps AR

57-0017 Frame Tee Plug AR

75-0211-B XT2200 10 Bolt Brake Hub AR

813-5020-Z ½-20 Nut Fine Thread Zinc AR

822-0050-Z ½" Split Lock-Washer AR

825-25-1Z ¼ x 1" Self Tapping Screw AR

851-5020-1Z ½-20 x 1" UNF Grade 5 Machine Bolt Zinc AR

806-0050-Z ½" Internal Tooth Lock-Washer Zinc AR

33-1003 Rubber Grommet AR

57-0027 48" Brake Line Assembly AR

57-0033 1/8" NPT Plug AR

57-0041 Cluster Mount Bracket AR

57-0036 224” Brake Line AR

Tandem Trailer Page 23

Page 24

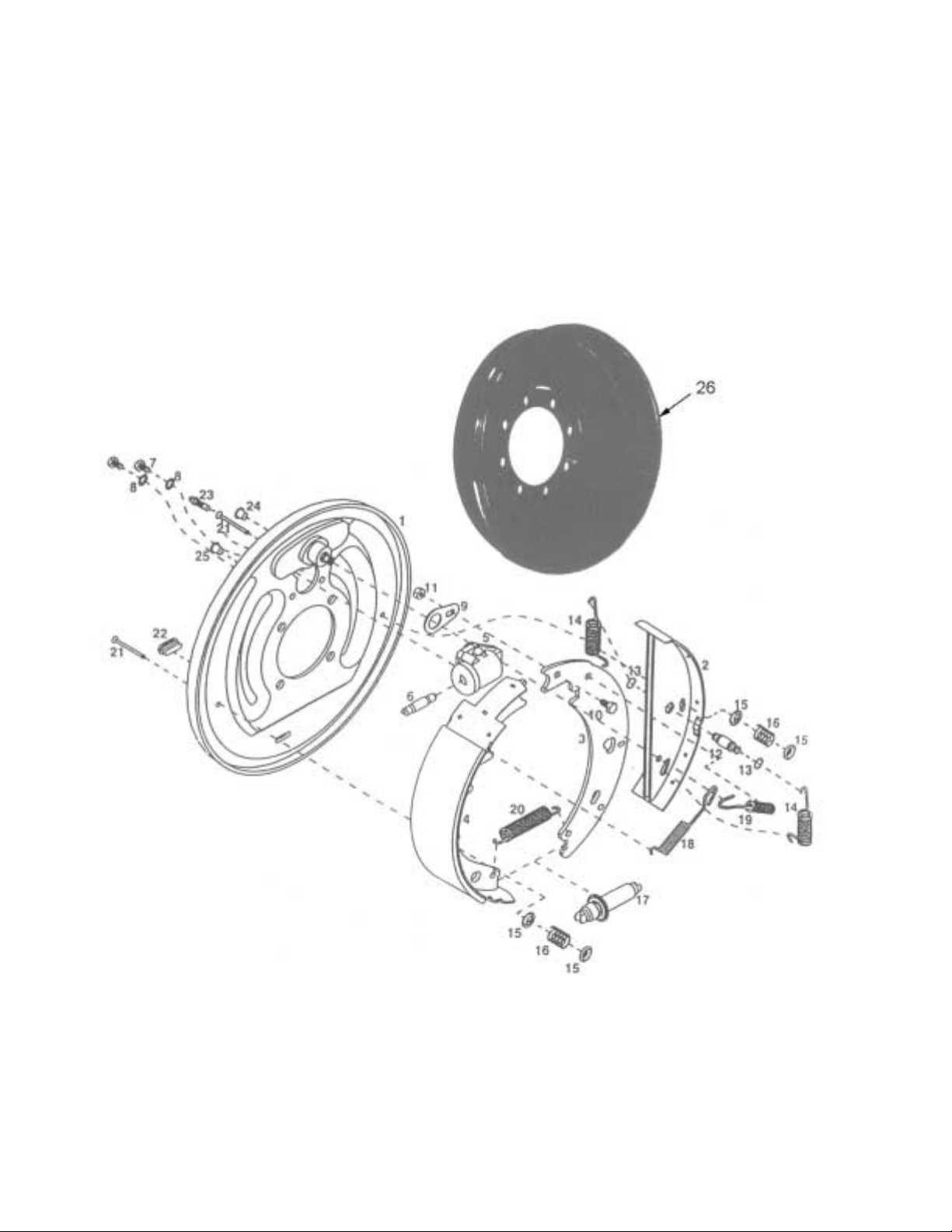

XT2200 OPTIONAL BRAKE PACKAGE (2 0F 2)

Tandem Trailer Page 24

Page 25

XT2200 SERIES OPTIONAL BRAKE PACKAGE (2 0F 2)

KEY PART # DESCRIPTION QTY.

57-0002 13" R.H. Free Backing Brake Assembly 1

57-0003 13" L.H. Free Backing Brake Assembly 1

1 57-0002-2 Back Plate Assembly 1

2 57-0002-3 Brake Shoe Assembly 1

3 57-0002-4 Shoe Lever 1

4 57-0002-5 Shoe Assembly 1

5 57-0003-1 Wheel Cylinder assembly Left 1

57-0002-1 Wheel Cylinder assembly Right (Not Shown) 1

6 57-0002-6 Push Rod 1

7 57-0002-7 5/16-18 UNC X ½" H.H.M.B. 2

8 57-0002-8 5/16" External Tooth Lockwasher 2

9 57-0002-9 Travel Link 1

10 57-0002-10 5/16-18 UNC X 5/8" H.H.M.B. 1

11 57-0002-11 5/16-18 UNC Bi-Way Locknut 1

12 57-0002-12 Double Pin shoe 1

13 57-0002-13 Retaining Ring 1

14 57-0002-14 Spring Shoe 2

15 57-0002-15 Cup Shoe Hold Down 4

16 57-0002-16 Spring-Shoe Hold Down 2

17 57-0002-17 Adjusting Screw Assembly 1

18 57-0002-18 Spring-Shoe 1

19 57-0002-19 Spring Lever 1

20 57-0002-20 Spring-Adjusting screw 1

21 57-0002-21 #1 Shoe Hold Down Pin 2

22 57-0002-22 Cover Plate-Adjusting Hole 1

23 57-0002-23 Replacement Bleeder 1

24 57-0002-24 Plastic Plug 1

25 57-0002-25 Plastic Plug 1

57-0002-26 Wheel Cylinder Repair Kit (Not Shown) Includes Spring, Cup & Boot 1

26 57-0040 13" Brake Drum AR

27 57-0007 Brake Mount Donut (Not Shown) AR

Tandem Trailer Page 25

Page 26

TRAILER AND BOX MOUNTING SPECIFICATION SHEET

TRAILERS XT1600 XT1600L XT2200 XT2200L XT2200XL

BOXES

4516 OK NA NA NA NA

4518 NA OK NA NA NA

4616 OK NA NA NA NA

4618 NA OK NA NA NA

4620 NA OK OK NA NA

4622 NA NA OK OK NA

4116 OK NA NA NA NA

4118 OK NA NA NA NA

4120 NA OK OK NA NA

4122 NA NA OK NA NA

4216 OK NA NA NA NA

4218 NA OK NA NA NA

4220 NA OK OK NA NA

4222 NA NA OK OK NA

6218 NA OK NA NA NA

6220 NA NA OK NA NA

6222 NA NA NA OK NA

6224 NA NA NA NA OK

3514 OK NA NA NA NA

3516 OK NA NA NA NA

3518 NA OK NA NA NA

3516-FB OK NA NA NA NA

3518-FB NA OK NA NA NA

3116 OK NA NA NA NA

3118 OK NA NA NA NA

3120 NA OK OK NA NA

3216 OK NA NA NA NA

3218 NA OK NA NA NA

3220 NA OK OK NA NA

8118 NA NA OK NA NA

8120 NA NA OK NA NA

8122 NA NA OK OK NA

8124 NA NA NA OK OK

8126 NA NA NA NA NA

9122 NA NA OK OK NA

9124 NA NA NA OK OK

9126 NA NA NA NA NA

9128 NA NA NA NA NA

9130 NA NA NA NA NA

NA-Not Available

LOADED BOXES MUST NOT EXCEED CARRYING CAPACITY OF TRAILERS

PTO UNLOAD BOXES- 50" - 64" HITCH PIN TO IMPLEMENT PTO KNUCKLE

HYDRAULIC UNLOAD BOXES- 50" - 64" HITCH PIN TO FRONT OF BOX/UNIT

81/9100 BOXES ON XT2000 SERIES TRAILERS- 12" OVER HANG OF BOX ON THE FRONT OF THE

TRAILER

Tandem Trailer Page 26

Page 27

SPECIFICATIONS

Model M1100 XT1600 XT1600L XT2200 XT2200L XT2200XL

Style Tandem Tandem Tandem

Capacity 22,000 lbs. 32,000 lbs. 32,000 lbs. 40,000 lbs. 40,000 lbs. 40,000 lbs.

Tread Width 76" 82" 82" 80" 80" 80"

Spindle Size 2" 3" 3" 3.5" 3.5" 3.5"

Heavy Duty

Hubs

Frame

Design

Weight 1,500#

Overall

Length

Bed Length 13' 8-1/2" 13' 7" 16' 10-1/2" 18' 20' 22'

Overall

Width

Bed Width 42" 42" 42" 42" 42" 42"

Stake

Spacing

Bed Height 30"

Adj. Clevis

Hitch

Options

Surge

Brakes

Swivel Clevis

Hitch

Riser

Package 4"

Various Tires

Sizes

6-Bolt 4570#

at 10 MPH

8" Channel 3x6x1/4"

w/12.5Lx15

20' 9-1/2" 20' 8-1/2" 24' 25' 2-1/2" 27' 2-1/2" 29' 2-1/2"

89"

w/12.5Lx15

42" 42" 42" 42" or

w/12.5Lx15

Standard Standard Standard Standard Standard Standard

N/A N/A N/A Optional Optional Optional

N/A N/A N/A Optional Optional Optional

N/A Optional

See Dealer See Dealer See Dealer See Dealer See Dealer See Dealer

8-Bolt

8000# at

10 MPH

Tubing

3,145#

w/riser

425/65x22.5

100-1/2"

w/16.5Lx16.

1 98-1/4"

w/425/65x22

.5

32"

w/14Lx16.1

w/o riser

38-1/2"

w/425/65x22

.5 w/riser

Req. for

19Lx16.1 or

425/65x22.5

Long

8-Bolt

8000# at

10 MPH

3x6x1/4"

Tubing

3,240#

w/riser

425/65x22.5

100-1/2"

w/16.5Lx16.

1 98-1/4"

w/425/65x22

.5

32"

w/14Lx16.1

w/o riser

38-1/2"

w/425/65x22

.5 w/riser

Optional

Req. for

19Lx16.1 or

425/65x22.5

Tandem Tandem

10-Bolt

15,000# at

10 MPH

4x8x1/4"

Tubing

3,680#

w/riser

w/21.5x16.1

102-1/2"

w/21.5x16.1

98-1/2"

w/425/65x22

.5

33-1/2" (Opt

or std)

44"

w/21.5x16.1

43-1/4"

w/425/65x22

.5

N/A N/A N/A

Long

10-Bolt

15,000# at

10 MPH

4x8x1/4"

Tubing

3,810#

w/riser

w/21.5x16.1

102-1/2"

w/21.5x16.1

98-1/2"

w/425/65x22

.5

42" or

33-1/2" (Opt

or std)

44"

w/21.5x16.1

43-1/4"

w/425/65x22

.5

Tandem

Long

10-Bolt

15,000# at

10 MPH

4x8x1/4"

Tubing

3,950#

w/riser

w/21.5x16.1

102-1/2"

w/21.5x16.1

98-1/2"

w/425/65x22

.5

42" or

33-1/2" (Opt

or std)

44"

w/21.5x16.1

43-1/4"

w/425/65x22

.5

Tandem Trailer Page 27

Page 28

B

Loading...

Loading...