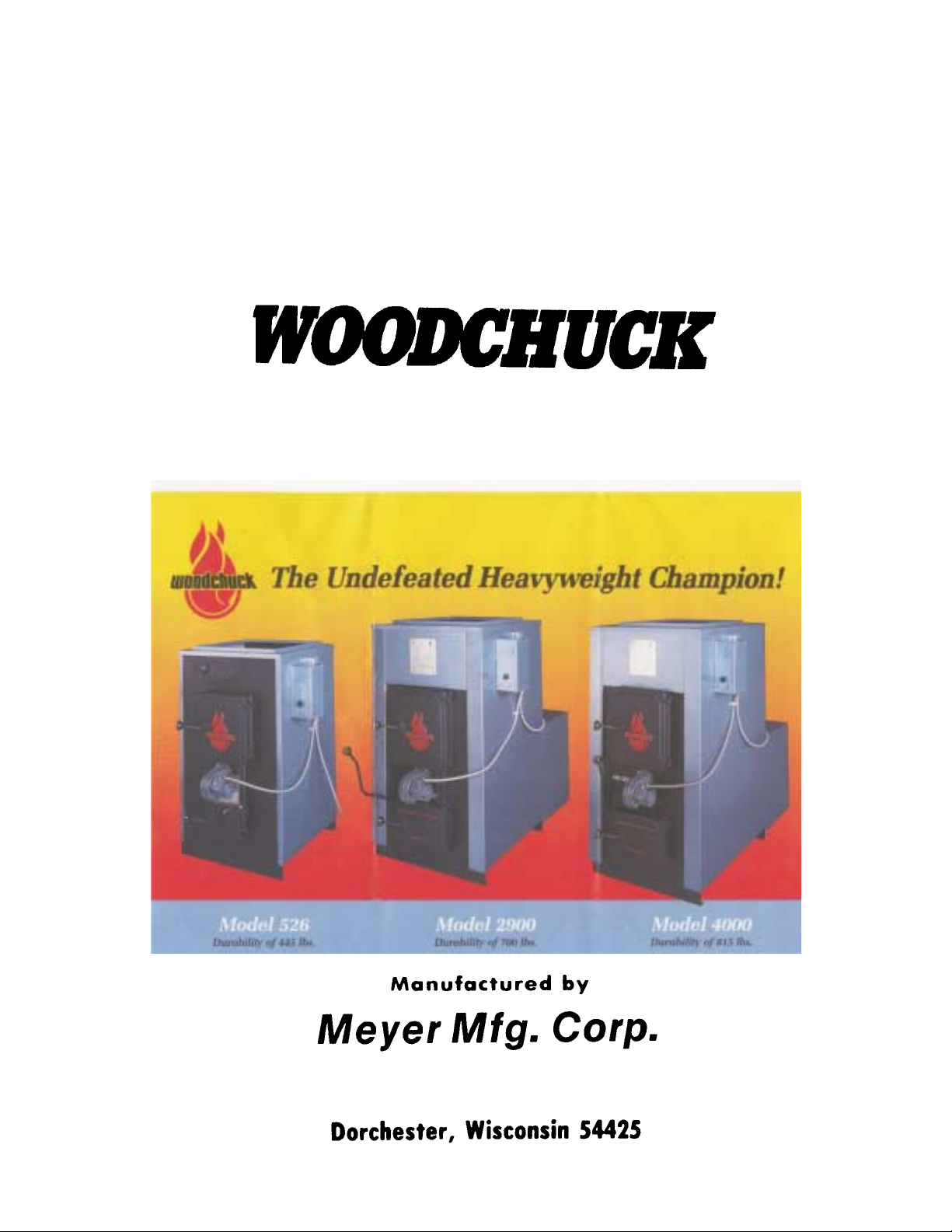

Page 1

INSTRUCTION AND PARTS BOOK

FOR

MODELS 526, 2900, & 4000

Installation must be made in accordance with local and state codes which

may differ from manual. Save these instructions.

WOOD/COAL FURNACES

07/97

Phone 715/654-5132

Fax 715/654-5513

Page 2

INTRODUCTION

Dear Woodchuck Owner,

Congratulations on your purchase of a Woodchuck heating appliance. Un

doubtedly you have given much consideration to your purchase and we’re

proud that you have selected a Woodchuck. Pride in craftsmanship and engi

neering have made your Woodchuck the finest heating appliance available to

day.

Solid fuels are abundant and inexpensive. Wood is our only renewable

source of fuel and conservative estimates put our coal reserves at 800 years.

Our dual fuel units provide the savings and comfort of solid fuels and the con

venience of electric heat in one attractive package.

There is no substitute for quality. That is why thousands of people like you

have purchased a Woodchuck. They also felt it was the best equipment to

serve their heating needs, now and in years to come. We ask that you follow

our policy of “safety first” and we strongly suggest that you read through the

owner’s manual before installing and operating your furnace.

For a lifetime of satisfaction, thank you for not compromising with quality.

Sincerely,

Donald A. Meyer

President

MEYER MANUFACTURING CORP.

-

-

-

-

We are constantly improving and updating our product in order to provide the

highest quality and value possible. Consequently pictures might sometimes dif

fer slightly from the actual product.

-

TRANSPORTATION DAMAGES

Before reading this manual and proceeding with the installation, inspect your new Woodchuck to make sure there

were no shipping damages. If you find there have been damages incurred, call your dealer immediately. He will

then take a course of action to correct the problem.

2

Page 3

TABLE OF CONTENTS

Page

Introduction..........................................................................................................................................................2

Table of Contents ................................................................................................................................................3

Furnace Safety ....................................................................................................................................................4

Specifications ......................................................................................................................................................5

General Information.............................................................................................................................................6

High Quality Construction ................................................................................................................................6

Efficiency .........................................................................................................................................................6

Comfort ............................................................................................................................................................6

Additional Comfort And Saving........................................................................................................................7

Operation.............................................................................................................................................................8

Common Sense ...............................................................................................................................................8

! If You Have Chimney Fire !............................................................................................................................8

! Important ! Operation Procedure In The Event of Power Failure ..................................................................8

Operating Your Woodchuck Furnace ..............................................................................................................9

Startup..........................................................................................................................................................9

Burning Wood In Your Woodchuck..................................................................................................................9

Helpful Hints...............................................................................................................................................10

Ash Removal..............................................................................................................................................10

Burning Coal In Your Woodchuck..................................................................................................................11

Starting A Coal Fire....................................................................................................................................11

Recharging.................................................................................................................................................11

Banking ......................................................................................................................................................11

Bituminous Recharging ..............................................................................................................................11

Helpful Hints...............................................................................................................................................11

Ash Removal..............................................................................................................................................12

Maintenance......................................................................................................................................................12

Trouble Shooting ...............................................................................................................................................13

Installation .........................................................................................................................................................15

General Requirements...................................................................................................................................15

Placement And Minimum Clearances............................................................................................................15

Chimney Installation ......................................................................................................................................17

Installing Your Woodchuck ............................................................................................................................18

Stove Pipe Installation ...................................................................................................................................18

Installation Of A Barometric Draft ..................................................................................................................18

Air Duct Installation........................................................................................................................................19

Woodchuck Final Assembly...........................................................................................................................20

Optional Shaker Grate Installation-Model 526 ...........................................................................................20

Install Shaker Grate Handle, Model 2900 Only..........................................................................................21

Install Firebrick ...........................................................................................................................................22

Install Optional Catalytic Combustor ..........................................................................................................22

Assemble Manual Draft-Model 526 Only ...................................................................................................23

Install Comfort Control Center And Forced Draft Blower ...........................................................................23

Install Circulating Blower............................................................................................................................24

Assemble Filter Box ...................................................................................................................................24

Electrical Hookup .......................................................................................................................................25

Repair Parts ......................................................................................................................................................27

3

Page 4

FURNACE SAFETY

THERE ARE INHERENT HAZARDS ASSOCIATED WITH THE OPERATION OF WOOD/COAL FURNACES. FOR

YOUR SAFETY READ, UNDERSTAND, AND HEED THE FOLLOWING:

DANGER:

RISK OF FIRE OR EXPLOSION. DO NOT BURN GARBAGE, GASOLINE, DRAIN OIL, OR OTHER FLAMMABLE

LIQUIDS. FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

DANGER:

NEVER USE CHEMICALS OR FLUIDS SUCH AS GASOLINE, CHARCOAL LIGHTER FLUID, DRAIN OIL, FUEL

OIL OR KEROSENE TO LIGHT A FIRE IN YOUR WOODCHUCK. FAILURE TO HEED MAY RESULT IN SERIOUS

PERSONAL INJURY OR DEATH.

DANGER:

DURING OPERATION, LOADING AND ASH DOORS, AND EXPOSED FIREBOX ARE EXTREMELY HOT. NEVER

TOUCH THESE PARTS WHEN HOT. FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY.

CAUTION:

· Risk Of Fire

· Do Not Operate With Fuel Loading Or Ash Removal Doors Open.

· Do Not Store Fuel Or Other Combustible Material Within Marked Installation Clearances.

· Under Certain Conditions Of Use, Creosote Buildup May Occur Rapidly. Inspect And Clean Flues And Chimney

Regularly.

· Wait 10 Seconds On First Latch Before Refueling. Opening Loading Door Rapidly Can Cause A Flame To Flash

Out The Door. Use Caution When Opening Loading Door.

· Unsafe To Load Coal Above Top Of Brick.

· Keep Ash Pan Out Of Unit During Operation. Ash Pan Can Get Very Hot.

· Ash Can Must Be Placed On A Noncombustible Surface.

· Never Use Anything But An Air Tight Metal Container To Dump Your Ashes In. Every Year Many Fires Are

Caused By Emptying Ashes Into Cardboard Boxes Or Paper Bags.

·

Proven Fact - Small Red Embers Buried In Ash Cans Stay Red Hot For Days. Ashes Are A Good Thermal Insu

lator And Keep Enough Oxygen Away So Embers Do Not Burn Out.

-

THERE ARE ADDITIONAL HAZARDS ASSOCIATED WITH IMPROPER INSTALLATION OF WOOD/COAL FUR

NACES AND WITH SERVICE AND MAINTENANCE OF WOOD/COAL FURNACES. FOR YOUR SAFETY READ,

UNDERSTAND, AND HEED THE FOLLOWING:

WARNING:

DISCONNECT APPLIANCE FROM ELECTRICAL SUPPLY BEFORE SERVICING UNIT. FAILURE TO HEED MAY

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

CAUTION:

·

Equipment Must Be Installed By A Qualified Heating Person.

·

Only “class A” All-fuel Or Solid Fuel Chimneys Intended Foe Use With Your Woodchuck Should Be Used.

·

Furnace Must Be Installed On A Noncombustible Floor Or 3/8" Thick Fireproof Millboard Or Equivalent.

FAILURE TO HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

4

-

Page 5

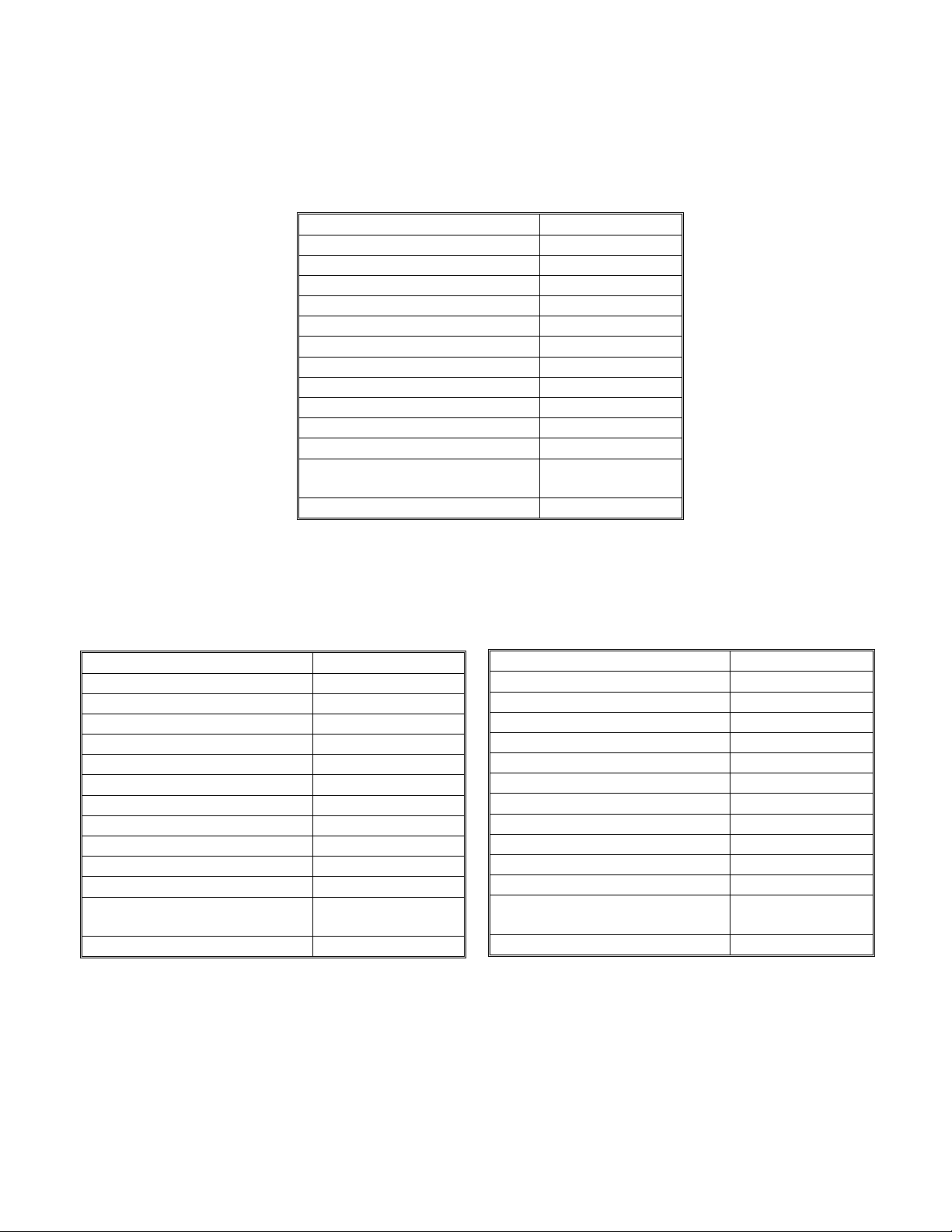

SPECIFICATIONS

MODEL 526

Height 42.5"

Width 24"

Depth 26"

Blower 850 to 1850 CFM

Max. BTU Capacity 120,000

Log Size 22"

Loading Door Size 14"x12"

Weight, Approx. 445 lbs.

Warm Air Plenum 20"x23"

Flue Outlet 6" Dia.

Flue Collar Height 41" Overall Height

Secondary Heat Exchange YES

Listings UL391, CSA B366,

1-M ETLM

Firebox Chamber 6.10 cu. ft.

MODEL 2900

Height 48.5"

Width 26"

Depth 28"

Blower 850 to 1850 CFM

Max. BTU Capacity 150,000

Log Size 22"

Loading Door Size 15"x13"

Weight, Approx. 700 lbs.

Warm Air Plenum 20"x23"

Flue Outlet 8" Dia.

Flue Collar Height 47" Overall Height

Secondary Heat Exchange YES

Listings UL391, CSA B366,

1-M ETLM

Firebox Chamber 7.70 cu. ft.

Height 51.5"

Width 26"

Depth 33"

Blower 850 to 1850 CFM

Max. BTU Capacity 180,000

Log Size 24"

Loading Door Size 15"x13"

Weight, Approx. 815 lbs.

Warm Air Plenum 20"x23"

Flue Outlet 8" Dia.

Flue Collar Height 50" Overall Height

Secondary Heat Exchange YES

Listings UL391, CSA B366,

Firebox Chamber 9.10 cu. ft.

MODEL 4000

1-M ETLM

DISCLAIMER NOTICE

The heating capacity specifications are provided as guidelines only and in no way guarantee the output or capacity

of the units. The actual BTU output depends on the type of fuel being burned and its condition, the thermostat set

ting, the draft adjustments and the chimney that the unit is installed into.

-

5

Page 6

GENERAL INFORMATION

Woodchuck furnaces represent the ultimate in solid fuel

and dual fuel heating appliances. From the massive

model 4000 to the economy model 526, each unit is de

signed to be attractive, durable and efficient while pro

viding the safety and comfort you and your family

deserve.

HIGH QUALITY CONSTRUCTION

Constructed of high grade, heavy gauge, hot rolled

steel plate, the firebox is continuously welded for an air

tight seal and structural strength. The heavy duty cast

iron doors are equipped with a positive latching device

for your safety. The loading door has a two-step safety

latch. The large cast iron grates provide for durability

and help promote efficient combustion of the fuel. The

firebox is lined with heavy duty firebrick and is done so

without any retainers to warp or burn out. These fea

tures together with high quality electrical components

provide the safety, efficiency and total control possible

only in a Woodchuck. Total control means that you can

better avoid overheating the unit and developing excessive and unsafe temperatures.

Woodchuck furnaces are subjected to the most stringent test criteria applicable by an independent third

party testing laboratory and listed/labeled as having

met or exceeded those standards. Finally, any machine, even this Woodchuck, is only as safe as the person operating it. This is why we have compiled this

comprehensive manual to assist you in operating your

Woodchuck properly and safely. Please read and follow

all instructions.

EFFICIENCY

channel." Here it comes into contact with the hot fire

box front and is warmed before entering the firebox.

The draft channel is equipped with adjustable orifices

which provide for the 80/20 distribution of the com

bustion air. A lever on the front of Models 2900/4000

allows for quick and easy adjustment of these orifices

to correspond to the fuel being used. As the air enters

the firebox it strikes a deflector which creates a turbu

lence and causes the oxygen to mix thoroughly with

the gases for complete combustion.

Finally, Woodchuck Model 2900/4000 furnaces are

designed to accept a catalytic combustor. This device

will cause the small amount of unburned fuel to ignite

before entering the secondary heat exchanger. The

benefits of all this are threefold:

A.) You obtain very high combustion efficiencies,

meaning you use less fuel.

B.) You reduce the amount of unburned fuel that can

collect in your chimney as creosote and hence reduce

the hazard of a chimney fire.

C.) You virtually eliminate pollution of the air we all

breathe.

Transfer efficiency refers to how effectively we transfer the heat generated inside the firebox to the rooms

we want to heat. Insufficient blower capacity will result

in poor transfer allowing the unused heat to escape

up the chimney. This is why we utilize a blower with

such large air handling capacity. The large surface

area of the firebox and secondary heat exchanger

provide for efficient transfer.

-

-

-

The total efficiency of a unit is broken down into com

bustion efficiency and transfer efficiency. We know that

when woodburning, 20% of it burns as fixed carbon.

The other 80% is in the gaseous state as it burns.

Therefore, to obtain efficient combustion of the wood it

is necessary to introduce 20% of the oxygen “under”

the fire to promote combustion of the solid material and

80% “over” the fire where it can readily react with the

gaseous material. Coal burns just the opposite of wood.

80% of it burns as fixed carbon and 20% burns in the

gaseous state. Therefore, before a furnace can burn

coal or wood efficiently, it must provide the 80/20 ratio

of combustion air and allow the operator to reverse the

ratio depending on the fuel being used. Combustion air

must be warm when it enters the firebox to further pro

mote complete combustion. Your Woodchuck furnace

provides all these features and more. Here is how:

when combustion air enters a Woodchuck furnace it en

ters into a “draft

COMFORT

-

Comfort and efficiency are closely related. The more

efficient the heating system is, the more comfortable

you and your family are. Not only are the Woodchuck

furnaces efficient, they can actually increase the effi

ciency of your home.

On a furnace with a conventional single speed

blower, the speed of the blower is a compromise

between comfort and efficiency. If the blower has a

large enough capacity to heat the home in the cold

est weather it will cycle rapidly in milder weather so

the system air is not as warm. If this air is moved

too rapidly it can actually feel cool. Air that is mov

ing at 3 ft. per second will feel 4° cooler than sta

tionary air at the same temperature. If the blower

capacity is enough to operate properly in mild

-

6

-

-

-

-

Page 7

weather, it will not be large enough to keep the

house

warm in cold weather. This could cause the furnace to

overheat and a loss of heat up the chimney. The result

then is a compromise which is neither efficient or com

fortable. Woodchuck furnaces, however, have a three

speed circulation blower which can be adjusted via a

three position rotary switch on the Comfort Control

Center. This allows the user to select the blower speed

to meet the air movement requirements of the installa

tion. In addition, when the weather is mild and the fur

nace is operating at a lower output, the blower can be

set on low to gently move the air. Similarly, when it is

cold and the furnace is operated at higher levels of

heat, output can be switched to higher speeds.

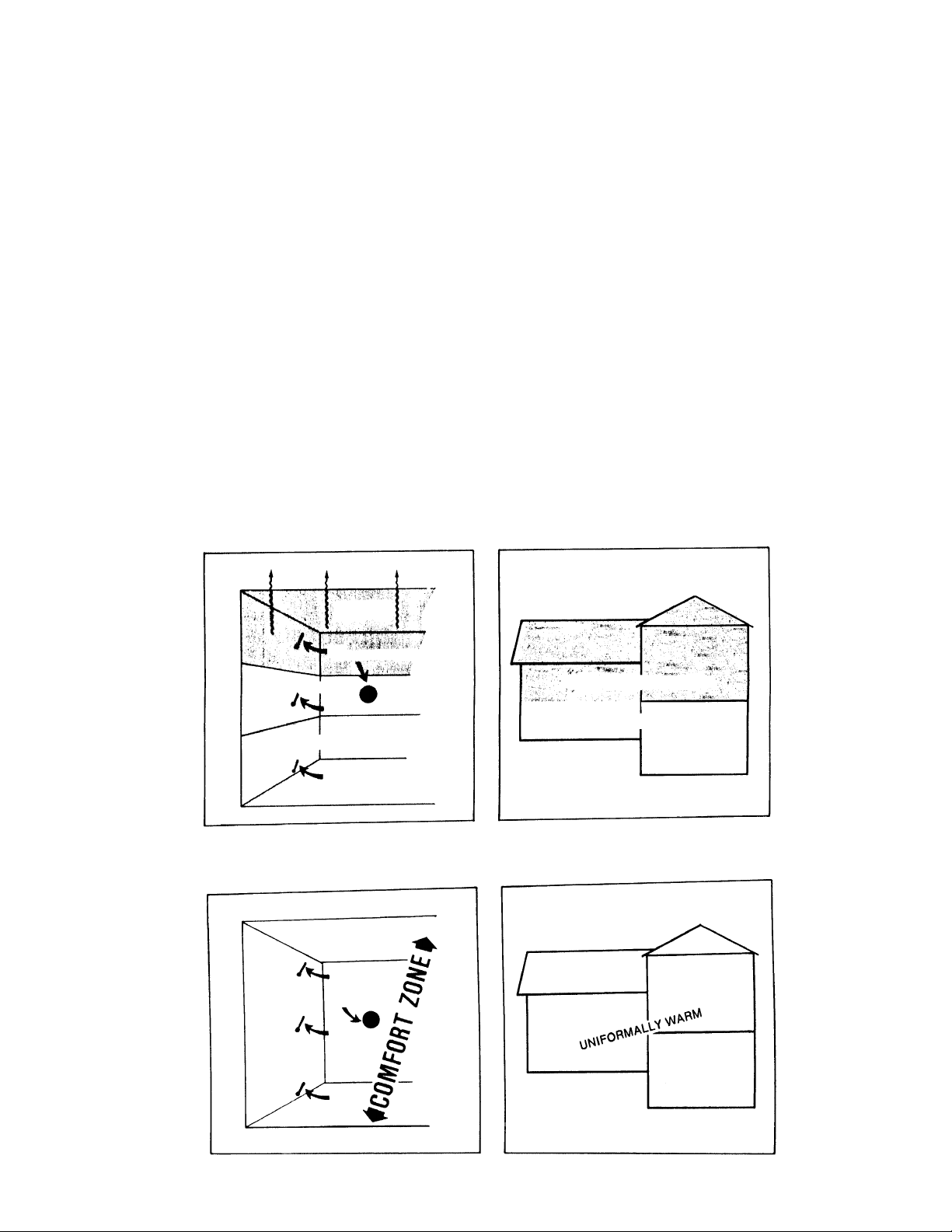

more comfortable and lose less heat through your ceil

ings as illustrated in figure 2.

This situation can be especially troublesome in

multi-level homes as illustrated in figure 3. As soon as

the blower shuts off, the air in the home begins to strat

ify; warm air rising to the upper levels and cool air col

lecting in the lower levels. The lower levels become

increasingly uncomfortable until the blower turns on

again. Unfortunately, the upper levels are still warm so

they become uncomfortably warm before the blower

turns off. By allowing for a steadier, more continuous

operation of the blower the entire house stays at a

more constant and comfortable level, figure 4.

ADDITION COMFORT AND SAVING

-

-

-

But how can all this improve the efficiency of your

home? As figure 1 illustrates, heated air rises away

from the living area and stratifies. This causes large

temperature differentials between the ceiling where

heat is lost rapidly through conduction and the floor

where children often play. By allowing for continuous

air movement, even during periods of low heat output,

this stratification is not allowed to take place. You are

WASTED HEAT

ZONE

82°

THERMOSTAT

COMFORT ZONE

74°

DISCOMFORT ZONE

60°

FIGURE 1

Options are available for your Woodchuck furnace, and

one of these deserve special mention. The Aqua-Si

phon is capable of pre-heating your domestic water

free of charge during the heating season for additional

saving to you.

UNCOMFORTABLY HOT

UNCOMFORTABLY COLD

FIGURE 3

-

75°

THERMOSTAT

74°

73°

FIGURE 2

FIGURE 4

7

Page 8

OPERATION

COMMON SENSE

Please read the following before firing your furnace. It is

most important that you follow these suggestions and

limitations in order to maintain your warranty and guar

antee the long life of your furnace.

NOTE: Smoke detectors and fire extinguishers should

always be a part of your equipment.

This furnace is an airtight unit designed to burn 6-8

hours per load of wood or coal. If the furnace is being

fired hot constantly with full flames and operating at

only 2-4 hour burn cycles, it may be over fired. Your

home heating needs may be too great for the size of

furnace you have purchased. Your furnace can be dam

aged if fired at extremely high temperatures.

Forced firing or abuse can be detected upon inspection

AND WILL VOID YOUR WARRANTY.

DANGER:

RISK OF FIRE OR EXPLOSION. DO NOT BURN GARBAGE, GASOLINE, DRAIN OIL, OR OTHER FLAMMABLE LIQUIDS. FAILURE TO HEED MAY RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

! IF YOU HAVE CHIMNEY FIRE !

Meyer Mfg. Corp. recommends the following actions:

1. Shut any doors and air inlet dampers and draft con

trol. This should take no longer than a few seconds.

CLOSED

2. Alert everyone in the house.

3. Call the fire department.

NOTE: Emptying a large box of baking soda will slow

down the fire in your Woodchuck.

Keeping your chimney and stove pipe clean is the best

insurance against chimney fires.

-

MANUAL DRAFT

! IMPORTANT !

OPERATION PROCEDURE IN THE

EVENT OF POWER FAILURE:

Your Woodchuck can operate and produce heat without

electric power. This is one of the features built into every Woodchuck.

The following steps should be taken in the event of an

electrical power failure:

-

DANGER:

NEVER USE CHEMICALS OR FLUIDS SUCH AS

GASOLINE, CHARCOAL LIGHTER FLUID, DRAIN

OIL, FUEL OIL OR KEROSINE TO LIGHT A FIRE IN

YOUR WOODCHUCK. FAILURE TO HEED MAY RE

SULT IN SERIOUS PERSONAL INJURY OR DEATH.

CAUTION:

·

RISK OF FIRE

·

DO NOT OPERATE WITH FUEL LOADING OR

ASH REMOVAL DOORS OPEN.

·

DO NOT STORE FUEL OR OTHER COMBUSTI

BLE MATERIAL WITHIN MARKED INSTALLATION

CLEARANCES.

·

INSPECT AND CLEAN FLUES AND CHIMNEY

REGULARLY.

·

UNDER CERTAIN CONDITIONS OF USE, CREO

SOTE BUILDUP MAY OCCUR RAPIDLY.

·

WAIT 10 SEC. ON FIRST LATCH BEFORE RE

FUELING.

·

LOAD FUEL CAREFULLY OR DAMAGE MAY RE

SULT.

-

-

-

-

1. Locate all heating duct dampers

damper), if any, to open position.

2. Turn manual draft controls to this position.

Ash door should never be used

in power failure.

3. Remove filter box service access cover, allowing

cooler air to move hot air through the furnace, cooling

the plenum and the house hot air duct system.

If power fails, to avoid product damage, close manual

draft completely. Forced draft and natural draft are pre

set.

In the event of a runaway fire, close all drafts. Close

smoke damper halfway.

(not smoke pipe

CLOSED

MANUAL DRAFT

-

8

Page 9

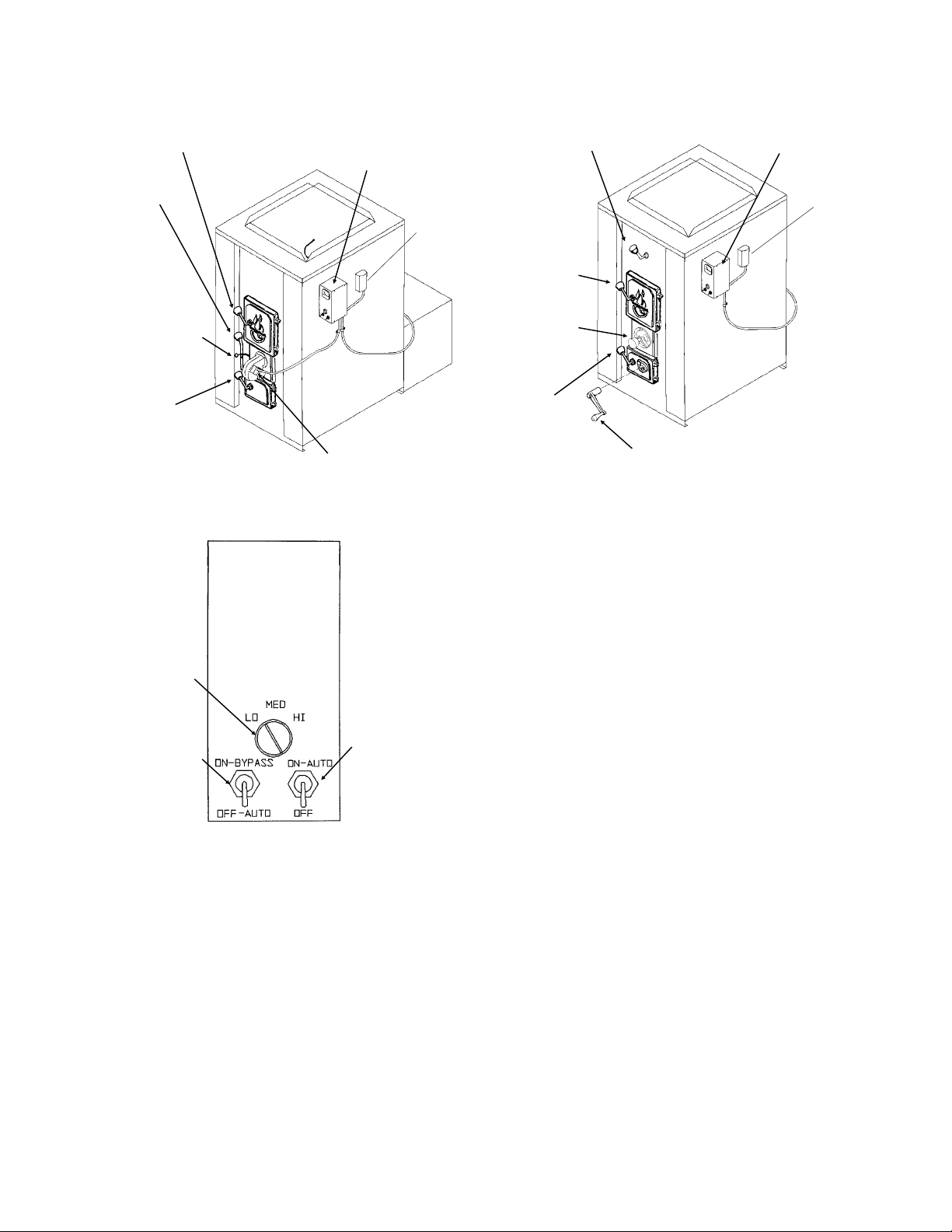

SHAKER

GRATE

DOUBLE LATCH

LOADING DOOR

COMFORT

CONTROL CENTER

FAN/LIMIT

HEAT EXCHANGER

CONTROL ROD

DOUBLE LATCH

LOADING DOOR

COMFORT

CONTROL CENTER

FAN/LIMIT

DRAFT CHANNEL

SELECTOR - 80/20

COMBUSTION AIR

RATIO CONTROL

MODELS

ASH DOOR

2900/4000

FORCED DRAFT

BLOWER

FIGURE 5 WOODCHUCK CONTROLS

CIRCULATING

BLOWER

DRAFT BLOWER

LO-LIMIT BYPASS

DRAFT BLOWER

MANUAL SWITCH

FIGURE 6 COMFORT CONTROL CENTER

OPERATING YOUR WOODCHUCK

FURNACE

STARTUP

Never leave ash pan in unit. Use only when cleaning

out ashes.

MANUAL DRAFT

(Forced Draft Is

Optional)

ASH DOOR

SHAKER GRATE CRANK.

SHAKER GRATES ARE OPTIONAL

MODEL 526

NOTE: All models are equipped with a “low limit” which

will not allow the auto draft to operate when the unit is

not warm. To start auto draft, turn Lo-Limit toggle switch

on comfort control center to “On”, figure 6.

Now you are ready to light a fire.

BURNING WOOD IN YOUR WOODCHUCK

1. Adjust draft channel selector, figure 5, to appropriate

fuel setting on model 2900/4000. On Model 526 with

manual draft, open it. Place several pieces of crumpled

paper in the center of your Woodchuck. Criss-cross a

couple of handfuls of dry kindling wood 3/4" thickness,

then several small dry pieces of firewood. Ignite the pa

per and close the door. Do not attempt to open the door

immediately after igniting the fire. There could be a

flame flash out.

2. It will take 5-10 minutes for the fire to establish itself.

Once you have some good red hot burning embers,

add larger pieces of wood. All chimneys and hookups

are different. After 3-4 fires, you’ll find out how your unit

works for the best starting.

-

First thing is to check that your main blower and draft

blower are in proper working order before lighting a fire.

To check main blower, push button on fan/limit control

for manual override testing. When finished, reset to au

tomatic position, figure 5. Next, turn thermostat upstairs

to high temperature so draft blower turns on.

3. After about 30-40 minutes you can adjust the draft

according to your needs. Adjust smoke pipe damper ac

cording to your needs also.

-

NOTE: On airtight units, the burning time is controlled

mostly by the draft controls on the furnace, contrary to

9

-

Page 10

the old type of pot belly stoves where the smoke pipe

damper controlled the burning time.

NOTE: With new steel, there is a small amount of oil or

dirt on the metal and you may smell an odor. Provide

adequate ventilating to home during the first operation.

Your new Woodchuck is capable of putting out many

BTU’s, so treat it with respect. Don’t fully load your fur

nace or open all drafts fully until you have become thor

oughly familiar with the operation of the furnace.

NOTE: A full load does not always give the best results

for your needs.

4. When loading your Woodchuck with existing hot

coals, rake red hot embers over grates evenly. Put a

few small pieces of wood on the coals first, then

load-up.

5. If you have the automatic draft control, turn low limit

by-pass switch to “On”. Turn thermostat up to activate

auto draft and proceed as with manual draft. Once the

unit is warmed up you can turn the low limit by-pass

switch to “OFF”. This will allow the auto draft to shut off

if the unit runs out of fuel while you are gone.

CAUTION:

WAIT 10 SECONDS ON FIRST LATCH BEFORE REFUELING. OPENING LOADING DOOR RAPIDLY CAN

CAUSE A FLAME TO FLASH OUT THE DOOR. THIS

OCCURS WHEN THERE IS UNBURNT FUEL AND A

LARGE AMOUNT OF GASES ON TOP OF THE FIREBOX. WHEN THE DOOR IS OPEN, OXYGEN IS COM

BINED WITH GASES AND IGNITES. USE CAUTION

WHEN OPENING LOADING DOOR.

HELPFUL HINTS

Adjust the draft to the proper setting for your home

needs. The chimney, hookups, and kind of wood will

also be a factor.

Your Woodchuck is capable of holding very large logs.

DO NOT try to add a log that is larger than you can

easily place in the furnace. You will get the best effi

ciency when you add only the amount of wood needed

fora6to8hour burn.

mometer at the rear of the furnace on the smoke pipe

where it connects to the collar on the back of the

Woodchuck. 300-400 degrees should be maintained

when the Woodchuck is operating in the burn cycle with

the forced draft blower running to eliminate a creosote

build up. (If the unit has a manual draft or a natural

draft, monitor the flue temperature when the drafts are

in the open position). Depending on the weather, you

may not need a full load of wood for a good over night

burn. You will get best efficiency when you add only the

amount of wood needed until the next time you are

available to load.

Always try to place the logs so air can flow between

them -this will enhance combustion considerably.

ASH REMOVAL

When burning wood, run your poker over top of the

grate to be sure grate slots are clear of burnt fuel. This

should be done every morning when there is just a bed

of hot coals.

CAUTION

NEVER LET ASHES BUILD-UP TO GRATE LEVEL.

THIS WILL GREATLY REDUCE THE LIFE SPAN OF

YOUR GRATE.

Wood ash is useful as a fertilizer, particularly because

of its potassium content. Ashes will also decrease the

acidity of garden soil.

-

·

KEEP ASH PAN OUT OF UNIT DURING OPERA

TION. ASH PAN CAN GET VERY HOT.

·

ASH CAN MUST BE PLACED ON A

NONCOMBUSTIBLE SURFACE.

·

NEVER USE ANYTHING BUT AN AIR TIGHT

METAL CONTAINER TO DUMP YOUR ASHES IN.

EVERY YEAR MANY FIRES ARE CAUSED BY

EMPTYING ASHES INTO CARDBOARD BOXES

OR PAPER BAGS.

·

PROVEN FACT- SMALL RED EMBERS BURIED

IN ASH CANS STAY RED HOT FOR DAYS.

-

ASHES ARE A GOOD THERMAL INSULATOR

AND KEEP ENOUGH OXYGEN AWAY SO THE

EMBERS DO NOT BURN OUT.

CAUTION

-

In the spring and fall, the weather is mild, which will al

low you to burn very large loads of wood for long peri

ods of time and hence accumulate very large amounts

of creosote. KEY: Stack temperature should be

300°F-400°F for good burning. An external flue temper

ature thermometer (Woodchuck part #08-0084) is in

cluded in the owner’s manual package for monitoring

stack temperature. Install the flue temperature ther

-

-

-

-

-

10

Page 11

BURNING COAL IN YOUR WOOD

-

CHUCK

Never attempt to burn coal without a shaker grate.

Shaker grates are standard on Models 2900 and 4000

but optional on Model 526.

A coal fire should not be poked or broken up as this

tends to bring ash to the surface of the coal bed where it

may fuse. If the ash fuses, clinkers will form. It may be

necessary to remove all unburned material and ash from

the firebox to remove clinkers. These should be re

moved with gloves or tongs, and as always, put into a

metallic air-tight container.

-

A barometric draft control in the smoke pipe must be

used when burning coal.

CAUTION:

UNSAFE TO LOAD COAL ABOVE TOP OF FIRE BRICK.

STARTING A COAL FIRE

Open all draft controls on your Woodchuck.

Build a fire using dry wood kindling and establish a bed

of coals. Add several small shovels of coal over the

wood coals. After the coal fire is established and spread

throughout the firebox, add larger amounts of coal to

build up the coal bed. Gently shake the grate until live

coals fall into the ash pan area. Allow your Woodchuck

to operate with drafts open for approximately 15 minutes

or until fresh coal ignites. When the coal is properly ignited, adjust the drafts accordingly. Check the fire periodically to be sure it is spreading through the coal bed.

RECHARGING

Gently shake grates down. Open drafts and establish a

good flow of primary air below the grates. When recharging, fresh coal tends to give off large quantities of

volatile gas. This gas may accumulate and possibly ig

nite causing a backpuff. To reduce back-puffing, open

the fire door to the first safety latch position for 15-20

seconds before opening fully. Spread fresh coal evenly

over existing coal, leaving some hot coals exposed in

the center of the firebox. Be careful not to smother your

existing coals. Never allow coal to build up above the

top of the firebrick. When blue flame creeps up between

the coals, drafts may be adjusted to maintain burn level.

If the coal fire dies down before recharging, a fresh sup

ply of kindling may have to be added.

BANKING

Banking allows you to recharge in such a manner as to

retain a hot coal bed throughout the night. Approxi

mately an hour before retiring for the night, push the

coals to the rear of the firebox with the coal tapered

down in the front. Add a new layer of coal. Always leave

some hot coals exposed in the front. This allows for

more coal to be added to the firebox.

BITUMINOUS RECHARGING

Because bituminous coal has a higher percent of sul

phur and lower percent of fixed carbon than anthracite,

recharging should be as follows:

Gently shake down grates, with drafts open and a good

flow of primary air entering below the grates. Push the

hot coals to the rear of the fire box and position fresh

coal on the grate in front of the banked coal. As the

fresh coal begins to burn, wood may be added to the top

of the coal.

NOTE: Woodchuck recommends coal 1 inch to 3 inches

in diameter. Ashes may be sifted through a mesh screen

to reclaim particles of unburned coal.

HELPFUL HINTS

Burning coal will provide a lesson in patience. Take the

time necessary to experiment and understand the operation of your Woodchuck wood/coal furnace.

Too much draft air will cause clinkering of coal and will

waste heat up the chimney. Shut draft down to as low a

point as you can and still heat your home.

-

1. NEVER stand in front of loading door when opening

it. Stand to the side.

2. NEVER completely cover the live fire with fresh coal.

Always leave a generous area of burning coal at the top

of the fire and at the rear.

3. Always keep the ash pit clean.

If the fire goes out or does not hold overnight look for:

-

1. Poor draft.

2. Incorrect damper settings.

3. Improper firing methods for coal being used.

4. More combustion air needed.

5. Coal not sized to furnace. We recommend 1" to 3" di

ameter pieces of coal.

-

6. Ashes, if allowed to accumulate in the ash pit, will not

allow the required air for combustion. Keep ash pit

clean.

-

-

11

Page 12

ASH REMOVAL

Ash should always be put into an air-tight, metal con

tainer.

CAUTION

KEEP ASH PAN OUT OF UNIT DURING OPERA

·

TION. ASH PAN CAN GET VERY HOT.

ASH PAN MUST BE PLACED ON A

·

NONCOMBUSTIBLE SURFACE.

NEVER USE ANYTHING BUT AN AIR TIGHT

·

METAL CONTAINER TO DUMP YOUR ASHES IN.

EVERY YEAR MANY FIRES ARE CAUSED BY

EMPTYING ASHES INTO CARDBOARD BOXES

OR PAPER BAGS.

PROVEN FACT- SMALL RED EMBERS BURIED

·

IN ASH CANS STAY RED HOT FOR DAYS.

ASHES ARE A GOOD THERMAL INSULATOR

AND KEEP ENOUGH OXYGEN AWAY SO THE

EMBERS DO NOT BURN OUT.

MAINTENANCE

Coal firing produces much more ash than wood. These

ashes must be removed often (possibly daily) in order

to avoid piling up too closely to the grates. Removal of

the coal ash will prevent warpage and damage to

grates, and allow passage of primary air to the coal

bed.

Unlike wood ash, coal ash cannot be used as fertilizer.

All coal contains small amounts of dangerous elements.

It is therefore essential that your coal ash be disposed

of in municipally designated areas.

WARNING:

DISCONNECT APPLIANCE FROM ELECTRICAL

SUPPLY BEFORE SERVICING UNIT. FAILURE TO

HEED MAY RESULT IN SERIOUS PERSONAL INJURY

OR DEATH.

Keep chimney and smoke pipe clean by cleaning at least

twice during a heating season. Keeping your chimney

and stove pipes clean is the best insurance against

chimney fires.

If you clean your own chimney and stovepipe, Meyer

Manufacturing Corp. recommends purchasing the same

equipment professionals use. Brushes are available in

enough sizes and shapes to snuggly fit inside any com

mon flue.

Replace any cracked or deteriorated firebrick. This will

prolong the life expectancy of the firebox.

Check door gasket and replace as needed.

Oil blowers every 6 months of use. (SAE 10 motor oil re

quired.)

OPTIONAL CATALYTIC COMBUSTOR

FOR MODELS 2900/4000

NOTE: Optional catalyst not recommended for Model

2900/4000 with 6" flue adapter. Smoke spillage may occur out of door when refueling.

Even with complete combustion there is a small amount

of residue. Eventually enough will collect on the

combustor to interfere with its operation. Therefore it is

necessary to clean it periodically. To clean the

combustor simply remove from unit and run tap water

through it until no sign of residue remains. The

combustor simply slides up into the exhaust pipe stub

which protrudes down into the firebox. There are three

rods on the combustor which engage slots in the pipe

and then turn slightly to lock in place. These rods are not

symmetrical so observe their orientation when you re

move it. Two rods are welded at 90° and they point to

ward the rear of the firebox.

NOTCHES IN EXHAUST

PIPE

-

-

-

Keep ash pit clean especially when burning coal.

Turn on your regular furnace once every month to keep

it tuned up and limber.

CATALYTIC ELEMENT

RODS ON RETAINER

OPTIONAL CATALYTIC

COMBUSTOR

12

Page 13

TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

1. Main blower vibrating

when in use.

2. Main blower continues to

run.

3. Main blower won’t turn

on.

4. Draft blower staying on. Wall thermostat bad, check by turning temp. to

5. Draft blower not turning

on. NOTE: Be sure switch

on blower is on.

6. Smell an odor from the

first fire in the furnace.

7. Not getting heat in the

home.

8. Flames coming out the

door when loading.

Loose Allen screw on squirrel cage.

Bad motor bearings.

Weights on squirrel cage wheel moved in ship

ment.

Manual control turned on (fan/limit control). Check fan/limit control switch. Push

Defective fan/limit control.

Defective 3-speed blower switch.

Defective circulation blower motor.

60° then check if draft blower is running.

Short in thermostat wire.

Home not getting heat needed to satisfy wall

thermostat.

Switch blower to the off position. Bad wall Thermostat; check by turning it up to 80° and if the

draft blower does not turn on, replace thermostat.

Lo limit bypass on “off”.

New steel, small amounts of residue on the

steel.

Bad weld, if smell continues for two weeks of

burning.

Unit may be too small for your home; check

specification chart.

Improper insulation in home allowing heat to

escape.

Improper hookup to furnace.

Ducting not sized properly for unit.

Excessive amount of gases on top of the fire

box and igniting when given oxygen from open

door. NOTE: This is one of your Woodchuck

safety features built into every unit with a dou

ble latch system.

Large amounts of unburned wood. Try to load when fire is at its lowest

Tighten Allen screw, be sure squirrel

cage did not move to one side or the

other.

Return blower to your local dealer

for a replacement.

Try to adjust it yourself or return

blower for replacement.

for manual, pull for auto. If in auto

position, replace fan/limit control.

Replace.

Replace.

Replace.

Replace wall thermostat.

Check all wiring again.

Check on spec’s chart to be sure

your unit is large enough for your

home. Be sure installation is proper:

check with your local heating man.

Replace thermostat.

When starting up it is necessary to

turn toggle switch on front of comfort

control center to “on” until unit

warms up.

This will disappear in a matter of

hours.

Contact dealer immediately.

Replace with a larger unit or have

regular furnace help.

Reinsulate!

Check installation drawings and/or

consult your local heating man.

-

point, but have enough embers left

for a good start again. NOTE: Only

you will know this time after some

experience with your unit and instal

lation.

-

13

Page 14

PROBLEM POSSIBLE CAUSE SOLUTION

9. Excessive amounts of

smoke coming out loading

door when loading.

10. Puffing of smoke

through draft control.

Improper draft.

Chimney cap too close to top of chimney.

Too long of run of smoke pipe from Woodchuck

to chimney.

Improper draft.

Down draft on chimney.

Measure with draft gauge-should

have .04 to .06 water column.

Relocate.

Relocate Woodchuck closer to

chimney.

Check draft with gauge. Should be

.04 to .06 water column.

Check for cold spots on chimney

or obstruction outside chimney.

Trees or other buildings.

Plugged chimney.

Check with mirror in clean-out

door or send cleaning brush down

chimney. Check stovepipe con

nections.

11. Excessive dirt build-up

around air vent in home.

12. Improper seal around

door.

Too much smoke escaping out of loading door

when loading.

Bad weld in fire box of unit.

No return air ducting.

Door rope not sealing on door frame.

Check problem No. 9.

Call dealer immediately.

Install return air duct.

Check door rope so that all parts

of door frame are sealed, espe

cially corners.

Loose door from shipment.

Simply bend door latch in to

tighten door seal.

13. Excessive creosote

build-up.

A reminder, whatever kind of

fuel you burn, there is some

kind of residue build-up on

the furnace and chimney.

Same with wood no matter

how good the conditions.

The use of wet, frozen, or unseasoned wood.

The use of soft wood, particularly those of high resin

content such as plywood or blandex with glue.

Poor natural draft or an obstruction in the stove

pipe or chimney flue.

Too long of burning times.

Inadequate amount of oxygen supplied to the

combustion chamber

If you have to use wet wood, make

loads smaller and burn them hotter.

Avoid using if possible.

Measure draft with gauge. Should

have a minimum of .04-.06 water

columns of draft.

Smaller and hotter fires.

Adjust draft for hotter fires or in

some homes, it has been determined there was not enough in the

basement due to such an air-tight

home. We recommend 4" round

hole to the outside with a screen

on to keep varmints out.

Low fire or flue gas temperatures.

Smaller loads of wood and hotter

fire. Stack temps. should maintain

minimum 300° to 400°.

Uninsulated stovepipe or chimney flues, espe

cially if construction is exterior to the house.

-

Never use uninsulated pipe for

chimneys installed on the outside

of the house, INSULATE!

Air leaks in the stove pipe or chimney.

Check chimney from top to bot

tom. NOTE: Creosote is a tarry liq

uid or solid coming from distillation

of wood during the combustion

process. The heavier buildups, the

greater chance of a chimney fire.

NOTE: No matter how seasoned

the wood, no matter how good the

draft, you always will get a small

amount of soot buildup. Should be

cleaned before winter firing and

during mid-winter’s firing.

-

-

-

-

14

Page 15

INSTALLATION

GENERAL REQUIREMENTS

CAUTION:

EQUIPMENT MUST BE INSTALLED BY A QUALIFIED

HEATING PERSON.

CAUTION:

ONLY “CLASS A” ALL-FUEL OR SOLID FUEL CHIM

NEYS INTENDED FOR USE WITH YOUR WOOD

CHUCK SHOULD BE USED.

FIRST AND ABOVE ALL is safety for you and your

family.

-

-

MUST USE: Class A Masonry or ULC listed, manufac

tured Class A All Fuels Chimney.

RECOMMENDED SIZE: Rectangular 8"x12" or Round

8".

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE. The Woodchuck is

to be used in conjunction with a listed gas or oil fired

furnace or as a central furnace.

ELECTRICAL SUPPLY: 115 volts, 60HZ, 1 Phase,

less than 12 amps.

Install system with 0.2 static pressure.

Flue setting .06 W.C. Max to .04 W.C. Min.

Wood or coal related fires are caused almost exclu

sively by installation, operation or maintenance errors;

but not by unsafe equipment.

IMPORTANT: Check with your local state and federal

codes on installation at your local fire department.

PLACEMENT AND MINIMUM CLEAR

ANCES

-

-

-

CAUTION:

FURNACE MUST BE INSTALLED ON A NON-COM

BUSTIBLE FLOOR OR 3/8" THICK FIREPROOF MILL

BOARD OR EQUIVALENT.

Locating your unit is very important for proper draft and

most efficient heating possible. See figure 7.

-

-

FIGURE 7 LOCATING THE WOODCHUCK

15

Page 16

THE CAP SHOULD BE SUCH THAT IT HELPS TO PREVENT

DOWNDRAFT WHILE PROVIDING ADEQUATE EXHAUST

DRAFT.

TOP OF CHIMNEY MUST BE AT LEAST 2’ HIGHER THAN PEAK

OR HIGHEST PORTION OF ROOF WITHIN 10’ HORIZONTALLY.

ALSO SEE FIGURE 9.

A CHIMNEY WHICH RISES WITHIN HOUSE IS BETTER

INSULATED THAN A CHIMNEY WHICH IS LOCATED OUTSIDE

THE HOUSE AND IS EXPOSED TO WEATHER.

THE CHIMNEY FLUE MUST HAVE A CROSS SECTIONAL AREA

AT LEAST EQUAL TO OR LARGER THAN THAT OF THE

STOVES FLUE COLLAR; BUT NO MORE THAN TWICE THAT

AREA.

MIN. 3’ FROM TOP OF CHIMNEY TO POINT AT

WHICH IT PASSES THROUGH THE ROOF

RECOMMENDED MIN. HEIGHT

APPROX. 20’

THE CHIMNEY THIMBLE SHOULD BE CONSTRUCTED OF

FIRE CLAY AND SHOULD HAVE AN INSIDE DIAMETER WHICH

IS NOMINALLY EQUAL TO THE OUTSIDE DIAMETER OF THE

SMOKE PIPE TO ASSURE A REASONABLY AIR TIGHT FIT.

THE THIMBLE MUST NOT EXCEED BEYOND THE FLUE

LINING.

FLUE SHOULD BE OF CONSTANT CROSS

SECTIONAL AREA THROUGHOUT ITS LENGTH

CLEANOUT DOOR SHOULD BE PROVIDED AND IT MUST

HAVE AN AIRTIGHT FIT. IT SHOULD NOT BE LEFT OPEN

FOR ANY LENGTH OF TIME WHEN STOVE IS IN

OPERATION

FIGURE 8 TYPICAL CHIMNEY CHECKLIST

16

Page 17

Your unit should be place on a non-combustible floor or

3/8" thick fireproof millboard or equivalent which ex

tends at least 8" from the sides and rear and extends

24" from the front. Leave a minimum clearance of 36" in

front of your unit. This is for safe, easy loading and

cleaning of your unit.

Also be sure to allow enough room at the rear of the

Woodchuck for installation of the circulating blower and

filter box.

which can ignite and cause severe damage to any

chimney. MAKE SURE YOUR WOODCHUCK IS IN

STALLED INTO A PROPER CHIMNEY.

For maximum safety and efficiency never install the

Woodchuck furnace into the same chimney serving an

other appliance.

A typical chimney checklist of requirements is depicted

on figure 8.

-

-

If using your unit as an add-on, 6" minimum clearance

is required from your present furnace.

One very important step in locating your wood/coal fur

nace is how much distance you will be from your new or

existing chimney. The unit should be installed as close

to the chimney as possible with a minimum of elbows

(no more than 2) and no more than 6 feet horizontally

with ½" rise per foot.

CHIMNEY INSTALLATION

It is extremely important that your Woodchuck furnace

be installed into a CLASS A CHIMNEY ONLY. These

chimneys consist of a flue-lined masonry chimney or

an approved Class A All Fuel factory built metal type.

Any other installation constitutes a fire hazard, as wood

and coal burning units have stack temperatures as

much as 300° to 1000° and may also deposit creosote

10’ MIN.

2’ MIN.

The Model 526 furnace is equipped with a 6" flue collar

having 28 sq. in. of exhaust area. Models 2900 and 4000

have an 8" flue collar having 50 sq. in. of exhaust area.

When connecting the furnace to the chimney maintain a

chimney flue section giving these minimum areas or

larger but not exceeding twice this area. Some common

sizes that are acceptable are 8" round, 10" round, or

8"x12" rectangular. All Woodchuck furnaces must be in

stalled into a chimney developing a minimum of .04 W.C.

to a maximum of .06 W.C. inches of draft. To maintain

this range of draft, a barometric damper should be in

stalled (see pgs. 18-20) on each unit when the draft from

the chimney is capable of exceeding .06 W.C. inches of

draft.

Insufficient draft can contribute to smoke spillage when

the loading door is opened and to rapid creosote accumulation. Excessive draft can cause high flue gas temperature, loss of overall efficiency and effect the degree

of control the operator can exert on the unit.

3’ MIN.

2’ MIN.

-

-

APPROVED CHIMNEY

6" OR 7" PIPE FOR

MODEL 526

8" PIPE FOR

MODELS

2900/4000

SIDE VIEW

APPROVED

CHIMNEY

STOVE PIPE

DAMPER

DAMPER

FRONT VIEW

FIGURE 9 CHIMNEY/ROOF CLEARANCE

TYPICAL STOVE PIPE INSTALLATION

17

Page 18

When using approved factory built metal chimneys, you

must have at least 2" of clearance when going through

a wall or next to a wall. A typical factory chimney instal

lation is shown on figure 9.

INSTALLING YOUR WOODCHUCK

Most of the Woodchuck furnace is factory assembled.

The factory assembly should be located as detailed in

the PLACEMENT AND MINIMUM CLEARANCES sec

tion and on figure 7.

Remaining assembly will consist of mounting the con

trols, draft and circulating blowers, filter box if used, and

electrical connection. These details will be provided af

ter stove pipe and air duct installation.

STOVE PIPE INSTALLATION

Install your Wood/Coal unit as close to the chimney as

possible with a minimum of elbows. We recommend no

more than two elbows. The maximum horizontal run

should not exceed 6 feet with a ½" rise per foot. The

pipe should maintain a ½" rise per foot and NEVER be

installed closer than 18" from combustibles. Exceeding

these recommendations normally represents creosote

build-up, a smoking furnace, or one with poor draft.

When connecting stove pipe, all joints should be secured with at least three #10 sheet metal screws.

NOTE: If it is absolutely necessary to make a run

greater than 6 feet (not recommended), use extra support brackets every 3 ft.

The connection to the wood furnace’s collar must also

be more than just a snug fit. Drill holes through the

Woodchuck’s collar and secure with sheet metal

screws. Mark each connection for cleaning. This will

prevent frustration when matching up your hole pattern

again.

DAMPERS IN STOVE PIPES:

A manual damper may be installed at a safe convenient

place between the barometric damper and the chimney.

In the event of chimney fire, it can quickly be closed

reducing draft to the chimney. See figure 10.

SUGGESTED TYPE

DAMPER

INSTALLATION OF A BAROMETRIC DRAFT

Some codes and NFPA require draft regulators in the

chimney connector of wood or coal furnaces and boil

ers, and manufacturers recommend their use with some

stoves. There is some doubt among wood heat experts

as to whether use of barometric draft regulators is wise.

Draft regulators limit the draft-the suction pulling air into

the appliance. A pivoted, counter-balanced flap is

pulled open by the draft when the draft reaches a criti

cal amount (figure 10). This permits air to enter the

chimney, thus preventing the draft in the appliance from

rising any higher.

Use of draft regulators with oil-fired equipment is com

mon. One objective is to keep the oil flame from being

blown out by excessive draft. This is more an annoy

ance than a safety problem since most oil burners have

primary safety controls which stop the fuel flow into the

burner whenever the flame goes out, and modern

flame-retention burner design makes draft regulation al

most unnecessary for this objective.

A second objective is to limit the amount of air passing

through the system in order to maintain high heat transfer efficiency. Another desirable consequence is a decrease in peak chimney temperatures due to the added

air entering through the regulator.

High draft does not blow out the flames but fans them in

wood and coal burning equipment. An especially hot

fire can result. Control of the fire may be difficult, particularly if the wood burner is not airtight. Energy efficiencies may be adversely affected, and chimney fires may

be ignited. A barometric draft regulator can alleviate

these problems by limiting the flow of combustion air

into the appliance and by adding cooling air to the hot

flue gases.

However the cooling air may result in more creosote

accumulation, and if a chimney fire does start, it will be

more intense because of the draft regulator. Large

flows of air into the regulator will fan the fire in the

chimney. Thus the net effect of barometric draft

regulators is unclear-they help in some aspects, and

hurt in others. Note, though, that if a chimney is clean

so that chimney fires are impossible, a draft regulator

does no harm, and does help limit the intensity of the

fire in the appliance, and it helps prevent the flue gases

in the chimney from getting too hot. Barometric draft

regulators are recommended by JFPA for hand fired

thermostatically controlled solid fuel furnaces.

-

-

-

-

-

AIR HOLES

18

Page 19

MANUAL DAMPER MAY BE

INSTALLED BETWEEN BAROMETRIC

DAMPER AND CHIMNEY

With no draft in chimney, regulator

is closed, no air gets in.

Moderate suction in chimney pulls regulator open

enough to maintain desired draft for appliance.

FIGURE 10 A BAROMETRIC DRAFT REGULA

TOR AND ITS INTENDED EFFECT

AIR DUCT INSTALLATION

SPECIAL AIR FLOW CONSIDERATIONS FOR

WOOD/COAL FURNACES

With Wood/Coal furnaces, a special concern is preventing wood joists and flooring close to the hot air

ducts and plenum from overheating. A fire hazard is

created by the hot air flow circulating through ducts not

designed for such high temperatures. Most Wood/Coal

furnaces produce much hotter air than oil or gas fired

units. So most clearances from the existing ducts and

plenum are usually inadequate with a supplemental

Wood/Coal furnace installation.

When installing the air duct, follow recommended

clearances shown in figure 11.

The plenum on the Woodchuck should be 20"x23" and

no less than 18" high while maintaining a minimum of

18" clearance to the ceiling or other combustible mate

rial. In a power outage situation, excessive heat

buildup at the plenum top may be dangerous, so make

sure clearances are maintained. For the Model 4000

allow at least 4" from ceiling to plenum.

-

Excessive suction in chimney pulls regulator further

open, allowing substantial air into chimney connector.

of 600 ft/min to 1000 ft/min at the registers. NEVER

supply less than 150 sq. in. of heated air outlet area.

Cold air returns must be at least equal in size to the

heated air outlets and preferably 10% larger. Every

Woodchuck furnace MUST be installed with a cold air return.

ADD-ON INSTALLATIONS

Before installing your Woodchuck furnace, consult

your furnace man and local state building codes to de

termine if your furnace will accept an add-on applica

tion. Some small furnaces and especially counter-flow

furnaces may not be used in add-on installations.

Once it has been determined that your existing fur

nace will accept an add-on installation, we recommend

a parallel installation, with direct (ducted) feed of re

turn air to the Wood/Coal furnace, see figure 12. The

back flow prevent damper assures that when either

unit is operating by itself, the hot air will flow into the

home, and not flow back through the other furnace.

Figure 13 shows a central installation.

-

-

-

-

The ducts, fittings, grilles and registers should be

sized so that the total external static pressure does not

exceed .02 W.C. inches while developing air velocities

We do not recommend supplemental wood furnace

installations with series connection. These types of

installation are not advisable in spite of their simplicity,

see figure 14.

19

Page 20

FIGURE 11 HOT AIR DUCT CLEARANCE REQUIREMENTS

FIGURE 12 PARALLEL ADD-ON INSTALLATION

WOODCHUCK FINAL ASSEMBLY

OPTIONAL SHAKER GRATE INSTALLATION

FOR MODEL 526

1. Remove standard grates from firebox. Assemble com

plete shaker grate kit outside of unit. Figure 16.

FIGURE 13 CENTRAL ADD-ON INSTALLATION

2. Assemble the left front bar (different from right front bar,

has shorter extension shaft at front) to a rear bar. Slide a

gear onto the front shaft.

3. Set this assembly into the front frame first and then into

-

the rear frame.

20

Page 21

4. Assemble the right front bar to a rear bar. Slide a gear

onto the front shaft, aligning it to engage the gear on the

left bar. Place the front bar onto the front frame and then

setting the rear bar onto the rear frame.

5. Place rear retainer in place, then the center and the

front retainers. Place all four bolts through retainers and

frame. Secure with locknuts. To prevent binding, it is ad

visable to snug the locknuts but do not over tighten.

6. Try moving the shaker grate bars with the handle.

NOTE: Both bars in normal position should be flat. If not,

one or the other gear is not aligned correctly.

7. To install the assembly into the unit, place the front

end of the assembled grate on the loading door lower

frame. The grate should be the upside down position.

Slide the grate (front end first) into the firebox allowing

the front end to lower into the hearth area. Once the

back end of the grate has cleared the door frame, “flip” it

over toward the rear of the unit. If necessary, reach into

the ash pit door and pull the front of the grate forward

until it lodges into place.

INSTALL SHAKER GRATE HANDLE,

MODEL 2900 ONLY

-

1. Open the door ash door. Slide the shaker grate handle

through the opening in the side of the door frame and

guide it through the actuator arm and into the receiving

boss on the opposite side of the frame.

2. Secure handle to actuator with 1/4x1-1/2 bolt and nut.

See figure 15.

SHAKER GRATE HANDLE

ACTUATOR ARM

RECEIVING BOSS

1/4x1-1/2 BOLT

FIGURE 14 POOR INSTALLATIONS

ALIGN HOLES

ASH DOOR FRAME

FIGURE 15 INSTALL SHAKER GRATE HANDLE

21

Page 22

REAR BAR

RETAINER

CENTER

RETAINER

RETAINER

LEFT FRONT BAR

RIGHT FRONT BAR

(NOTE LONG SHAFT ON

FRONT)

HANDLEREAR FRAME

GEARSLOCKNUTS

FRONT FRAME

FIGURE 16 INSTALL OPTIONAL SHAKER GRATE FOR MODEL 526

INSTALL FIREBRICK

Place firebrick into unit as follows:

1. Place two longer bricks with bevel cuts against the

rear wall of the firebox. See figure 17.

2. Place remaining two bricks with bevel cuts against

the front wall of firebox.

3. Place rectangular brick along side walls of firebrick as

illustrated. If Rectangular bricks are two different widths,

then an equal number of each will go on both sides of

firebox.

INSTALL OPTIONAL CATALYTIC

COMBUSTOR (MODEL 2900/4000)

NOTE: Optional catalyst not recommended with 6" flue

adapter. Smoke spillage may occur out of door when

refueling.

RECTANGULAR

BRICKS ON

SIDES

RECTANGULAR

BRICKS ON SIDES

BEVEL CUT BRICKS

FRONT & BACK

MODELS 2900/4000

BEVEL CUT BRICKS

FRONT & BACK

Greater efficiency can be obtained when burning wood

by use of a catalytic combustor. In addition, it will de

crease the accumulation of creosote and diminish the

possibility of a chimney fire.

-

MODEL 526

FIGURE 17 INSTALL FIREBRICK

22

Page 23

The pyrolysis of wood produces certain substances

which will not burn unless the temperature in the firebox

reaches 1000°F or higher. Under normal conditions

these temperatures are not attained and these sub

stances simply escape up the chimney as wasted energy

and can form deposits in the chimney. By forcing these

unburned substances to come into contact with a cata

lyst, we can cause them to burn at much lower tempera

tures that are easily attainable during normal operation.

Installation and removal of the combustor is simple, the

element fits inside a retainer. The retainer fits inside the

furnace exhaust pipe which extends down into the fire

box. The assembled combustor slides up into the ex

haust pipe stub which protrudes down into the firebox.

There are three rods on the retainer which engage slots

in the pipe and then turn slightly to lock in place. These

rods are not symmetrical. Two rods are welded together

to form a 90° angle. This angle points toward the rear of

the firebox.

-

1/4 LOCKNUT

-

-

DO NOT REMOVE

KNOCKOUT

MANUAL DRAFT

CONTROL

-

-

1/4x1-1/2 BOLT

FIGURE 19 INSTALL MANUAL DRAFT-MODEL 526

SLOTS IN EXHAUST PIPE

CATALYTIC ELEMENT

RODS ON RETAINER

FIGURE 18 INSTALL OPTIONAL CATALYTIC

COMBUSTOR (MODEL 2900/4000)

ASSEMBLE MANUAL DRAFT

MODEL 526 ONLY

Using a 1/4x1-1/2 bolt and locknut, mount manual draft

control onto the draft channel, figure 19. If you are going

to install optional forced draft, disregard. Do not tighten

too tight to damper draft adjustment, but not too loose to

let more air in than required. DO NOT remove knockout

on draft channel. Locknut can be held with wrench in

serted through air opening.

INSTALL COMFORT CONTROL CENTER

AND FORCED DRAFT BLOWER

1. Install all knobs to control levers and door handles.

See figure 20.

2. The comfort control center is factory wired to the

fan/limit control and the forced draft blower. It has a

prewired flexible conduit for connection to the circulating

blower.

3. If you have optional temperature gauge on your con

trol, then strip ½" of insulation from the two leads of ther

mocouple wire protruding through the rectangular

opening on the furnace side. Connect these leads to the

terminals on the temperature gauge of the control. IM

PORTANT: Remove the wire ground clip from the termi

nals of the gauge and connect White wire to + terminal

and Red wire to - terminal. See figure 22.

4. Mount the control to the side of the furnace with four

#10 sheet metal screws.

5. Remove the knockout section of the draft channel on

model 526 by striking sharply with a hammer. Be careful

so you do not damage the mechanism inside the chan

nel and directly behind the knock-out. DO NOT allow the

knock-out to fall inside the draft channel.

6. Align the forced draft blower outlet flange over the

knockout and secure with three #10 sheet metal screws.

-

7. Secure conduit to furnace side using conduit clamps

and #10 sheet metal screws.

-

-

-

-

-

23

Page 24

INSTALL ALL CONTROL

AND HANDLE KNOBS

KNOCKOUT IN DRAFT

CHANNEL REMOVED

FORCED DRAFT

BLOWER

THERMOCOUPLE WIRE

COMFORT CONTROL CENTER

FAN/LIMIT CONTROL

SECURE CONDUIT WITH

CONDUIT CLAMPS AND

#10 SHEET METAL SCREW

PRE-WIRED FLEXIBLE CONDUIT

TO CIRCULATING BLOWER

FIGURE 20 INSTALL COMFORT CONTROL

CENTER AND FORCED DRAFT BLOWER

INSTALL CIRCULATING BLOWER

The flanges on the circulating blower simply slide be

hind the angle mounts welded to the rear of the furnace.

Slide in from the top side, figure 21.

INSTALL FILTER BOX

The filter box is standard on Model 526. Installation in

structions are included with Model 526 filter box.

1. The filter box can be installed with the filter on either

side. The access door will fit the opening either side and

the handle should face forward.

2. Find two factory shipped support angles. Force sup

port angle sides without tabs into the groove of the

mounting strip on both rear sides of the furnace. Posi

tion at correct height to accept filter box, figure 21.

3. With filter box set against back of furnace, bend

down the tabs on the support angles so they lock be

hind the flanges of the top and bottom panels of the

box.

4. Install the access door. Install filter not supplied

and install a cold air return system to the filter box fil

ter side opening.

-

5. Route flexible conduit from comfort control through

hole in top panel and to box connector on blower

connection box. Connect wires to blower motor by

joining wires of the same color.

FEED MOTOR

-

White White/Purple

Red Red

-

Blue Blue

Black Black

-

-

24

Page 25

SLIDE FLANGES OF

CIRCULATING BLOWER

BEHIND ANGLES ON BACK

OF FURNACE

FILTER (NOT

SUPPLIED)

ACCESS DOOR

ELECTRICAL

CONNECTION BOX

FORCE FLANGE OF SUPPORT

ANGLE INTO GROOVE ON FURNACE

MOUNTING STRIP

HOLE FOR

CONDUIT

FILTER

ANGLES

GROOVE IN

FURNACE

MOUNTING STRIP,

BOTH SIDES

SUPPORT ANGLE

BEND TABS ON SUPPORT ANGLE

OVER, BEHIND FLANGE ON FILTER

BOX, TOP & BOTTOM

FIGURE 21 INSTALL CIRCULATING BLOWER AND FILTER

ELECTRICAL HOOKUP (FIGURE 22)

former in the comfort control. These connections have

been routed to a terminal strip on the outside of the

1. If you have an optional temperature gauge to monitor

comfort control box for convenient connection.

heat exchanger temperature in your comfort control

center, then the thermocouple wires must be connected

to the gauge when installing the control. See figure 20.

IMPORTANT: Remove the wire ground clip from the ter

minals of the gauge and connect White wire to + termi

nal and Red wire to - terminal. See figure 22.

4. The circulating blower limit control is factory wired to

the comfort control center. Jumper removed, normal fan

limit control settings are 160°F ON, and 110°F OFF.

-

-

5. Route 110VAC power through conduit from your

power supply to the comfort control center box. Route

through box connector provided and connect hot (L

2. A prewired conduit is connected to the comfort con

trol center for the circulating blower. The opposite end is

to be connected in the junction box on the blower motor.

Connect like colored wires. Secure conduit to junction

box with box connector.

BLACK, Neutral to WHITE and ground to GREEN as

shown on figure 22. You must provide a power discon

nect in the power supply line to your furnace which is

within sight of the Woodchuck and not more than 30

feet away. Your circuit breaker at the power supply may

3. The comfort control is factory wired to the forced draft

meet these requirements.

motor (optional on Model 526). If you have the forced

draft, locate a wall thermostat in the desired location of

you house and run #18 thermostat wire (not furnished)

from this thermostat to R and G terminals of the trans

-

25

)to

1

-

Page 26

WARNING:

ELECTRICITY CAN KILL, SHOCK, OR BURN. DISCONNECT AND LOCKOUT POWER SOURCE BEFORE

SERVICING OR INSTALLING ELECTRICAL COMPONENTS. FAILURE TO HEED MAY RESULT IN SERIOUS

PERSONAL INJURY OR DEATH.

CAUTION:

ALL WIRING MUST MEET LOCAL, STATE AND NATIONAL CODES AND BE INSTALLED BY A QUALIFIED

ELECTRICIAN.

W

R

FIGURE 22 ELECTRICAL WIRING DIAGRAM

26

Page 27

REPAIR PARTS

BASIC UNIT FOR MODEL 526

KEY NO. PART NO. DESCRIPTION

1 01-0526 Welded Assembly

2 03-5262 Shroud - Right Side

3 03-5263 Shroud - Left Side

4 03-5261 Shroud - Top

5 08-0005 Circulation Blower

6 06-1001 Ash Pan

7 02-5261 Fuel Door

8 02-5262 Ash Door

9 06-1014 Door Knob

10 06-5261 Fuel Door Gasket

11 06-5262 Ash Door Gasket

12 06-0200 1/4 Door Pin

13 05-0004 Handle Access Cover

14 801-2520-1.5Z 1/4x1-1/2 Bolt

KEY NO. PART NO. DESCRIPTION

15 06-0215 Spring

16 814-2520-Z 1/4 Lock Nut

17 05-0002 Small Grate

18 05-0001 Large Grate

19 07-5263 Front Brick Kit (2 pc.)

20 07-5262 Rear Brick Kit (2 pc.)

21 07-5261 Side Brick Kit (18 pc.)

22 07-5260 Complete Brick Kit

23 01-0526-19 Heat Exchanger Gate

24 03-5264 Z-Lock 25-1/2"

25 06-5263 Heat Exchanger Rod

26 05-0005 Manual Draft Butterfly

27 06-0221 Stainless Steel Cotter Pin

27

Page 28

BASIC UNIT FOR MODEL 2900

KEY NO. PART NO. DESCRIPTION

1 01-2900 Welded Assembly

2 03-2901 Shroud - Top

3 03-2904 Shroud - Front

4 03-2902 Shroud - Right Side

5 03-2903 Shroud - Left Side

6 05-2908 Shaker Handle

7 06-1001 Ash Pan

8 06-1013 80/20 Selector Knob

9 06-0200 1/4" Door Pin

10 06-2903 Ash Door Gasket

11 02-2902 Ash Door

12 06-1014 Handle Knob (Large)

KEY NO. PART NO. DESCRIPTION

13 02-2901 Fuel Door

14 06-2902 Fuel Door Gasket

15 07-2901 Side Brick Kit (4 pc.)

16 07-2902 Rear Brick Kit (2 pc.)

17 07-2903 Front Brick Kit (2 pc.)

18 07-2900 Complete Brick Kit

19 06-2907 Insulation - Front

20 06-2906 Insulation - Side

21 08-0005 Circulation Blower

22 03-2905 Z-Lock 28-1/2"

23 03-2906 Z-Lock 44-3/4"

28

Page 29

BASIC UNIT FOR MODEL 4000

KEY NO. PART NO. DESCRIPTION

1 01-4000 Welded Assembly

2 03-4001 Shroud - Top

3 03-2904 Shroud - Front

4 03-4003 Shroud - Left Side

5 03-4002 Shroud - Right Side

6 06-4001 Insulation - Side

7 06-2907 Insulation - Front

8 08-0005 Circulation Blower

9 06-1014 Handle Knob (Large)

10 06-1013 80/20 Selector Knob

11 06-1001 Ash Pan

KEY NO. PART NO. DESCRIPTION

12 06-0200 Door Pin

13 02-2901 Fuel Door

14 06-2902 Fuel Door Gasket

15 02-2902 Ash Door

16 06-2903 Ash Door Gasket

17 07-4003 Front Brick Kit (2 pc.)

18 07-4002 Rear Brick Kit (2 pc.)

19 07-4001 Side Brick Kit (4 pc.)

20 07-4000 Complete Brick Kit

21 03-4004 Z-Lock 34-1/4"

22 03-4005 Z-Lock 48"

29

Page 30

#05-5260-OPTIONAL SHAKER GRATE FOR MODEL 526

KEY NO. PART NO. DESCRIPTION

1 801-2520-1.25Z 1-1/2x1/4 Bolt

2 05-5265 End Retainer (S-5)

3 05-5266 Center Retainer (S-6)

4 05-5268 Rear Bar, Female (S-3)

5 05-5263 Front Bar, w/Extension (S-2-1)

6 05-5262 Front Bar, Male (S-2)

7 05-5264 Gears (S-4)

8 05-5267 Handle (S-7)

9 05-5261 Front Frame (S-1)

10 814-2520-Z 1/4 Lock Nut

#05-2900 SHAKER GRATE FOR

MODELS 2900/4000

KEY NO. PART NO. DESCRIPTION

1 05-2902 Side Rail (W-9)

2 05-2903 End Rail (W-10)

3 05-2904 Shaker Bar (CC-130)

4 05-2905 Shaker Rail (WC-2900)

05-4001 Shaker Rail (WC-4000)

5 05-2906 Sleeve (WC-2900)

05-4003 Sleeve (WC-4000)

6 05-2908 Handle (WC-2900) E423

05-2907 Handle (WC-4000)

7 06-1014 Knob

8 801-2520-1.5Z 1/4x1-1/2 Bolt

9 814-2520-Z 1/4 Lock Nut

10 05-2901 Linkage

4

KEY NO. PART NO. DESCRIPTION

526 2900/4000

1 04-2900-6 04-2900-6 Door

2 04-5260-7 04-2900-7 Cabinet Assy.

3 NA 04-2905 Mounting Cleat

4 04-5260 04-2900 Complete Filter

Box

FILTER BOX

30

Page 31

CIRCULATING BLOWER

#08-0100

COMFORT CONTROL

DRAFT BLOWER

9

Wiring Decal,

See Next

Page.

2 COVER

(not shown)

#08-0090 COMPLETE BLOWER ASSY.

KEY NO. PART NO. DESCRIPTION

1 08-0001 Motor

2 08-0002 Capacitor

3 08-0005 Blower Assembly (no motor)

4 08-0048 Electrical Connection Box

5 08-0004 Capacitor Boot

6 08-0003 Capacitor Bracket

7 08-0049 Electrical Box Cover

8 08-0005-2 Large Motor Mount Bracket

9 08-0005-3 Short Motor Mount Bracket

10 08-0005-4 Motor Clamps

KEY NO. PART NO. DESCRIPTION

1 08-0100-1 Box Enclosure

2 08-0100-3 Cover

3 08-0029 Therm-O-Disc

4 08-0017 Fan Relay Center

5 08-0026 3 Speed Switch

6 08-0089 Switch Toggle

7 08-0106 Terminal Strip

8 08-0015 Fan Limit Control

9 462900-8 Wiring Decal

10 08-0006 60 CFM Draft Blower

11 08-0084 Flue Temperature Gauge

31

Page 32

46-2900-8 Wiring Diagram

32

Page 33

PERSONAL DATA INFORMATION FOR FUTURE

REFERENCE

Model No. Of Unit

Serial No. Of Unit

Dealer Name

Address

Phone

Equipment Options

Filter Box

q

Shaker Grate

q

Domestic Coil

q

Date Of Purchase

Date Of Installation

Name Of Installer

Address

Phone

33

Page 34

This Page Intentionally Blank

34

Page 35

LIMITED WARRANTY

What is covered:

Meyer Manufacturing Corporation warrants to the original owner only, all parts in

this model Woodchuck solid fuel appliance to be free from defects in material and

workmanship.

For how long:

For a period of one (1) year (from date of purchase) of normal use.

Additional Coverage:

In addition, Meyer Manufacturing Corporation separately warrants the firebox for

an additional five (5) years on a prorated basis. Proration will begin with the 13th

month of ownership.

Exclusions:

The firebrick and grates which are expendable and replaceable parts as well as

cosmetic changes due to normal operation are not covered.

What the Customer must do: